Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about "Inks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

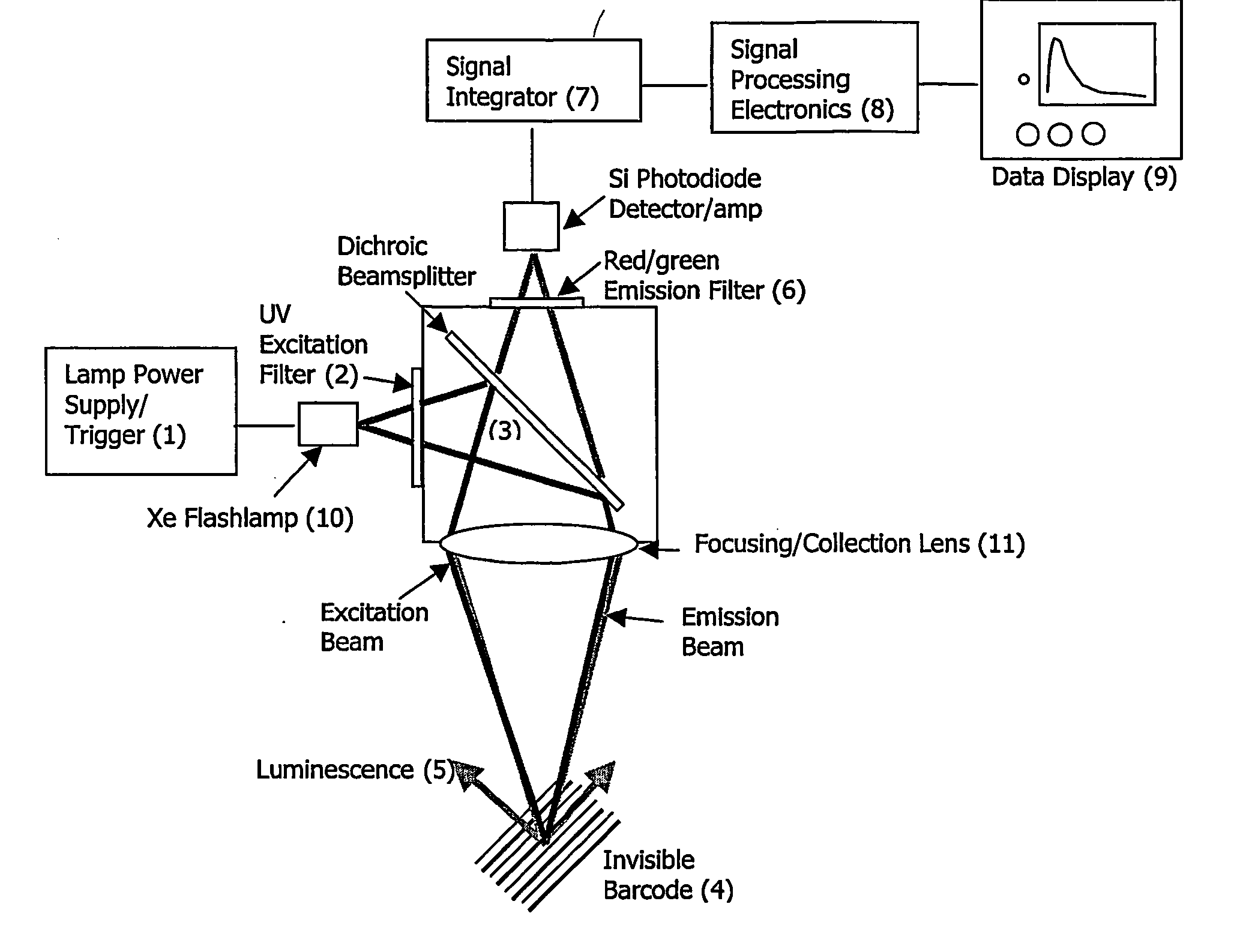

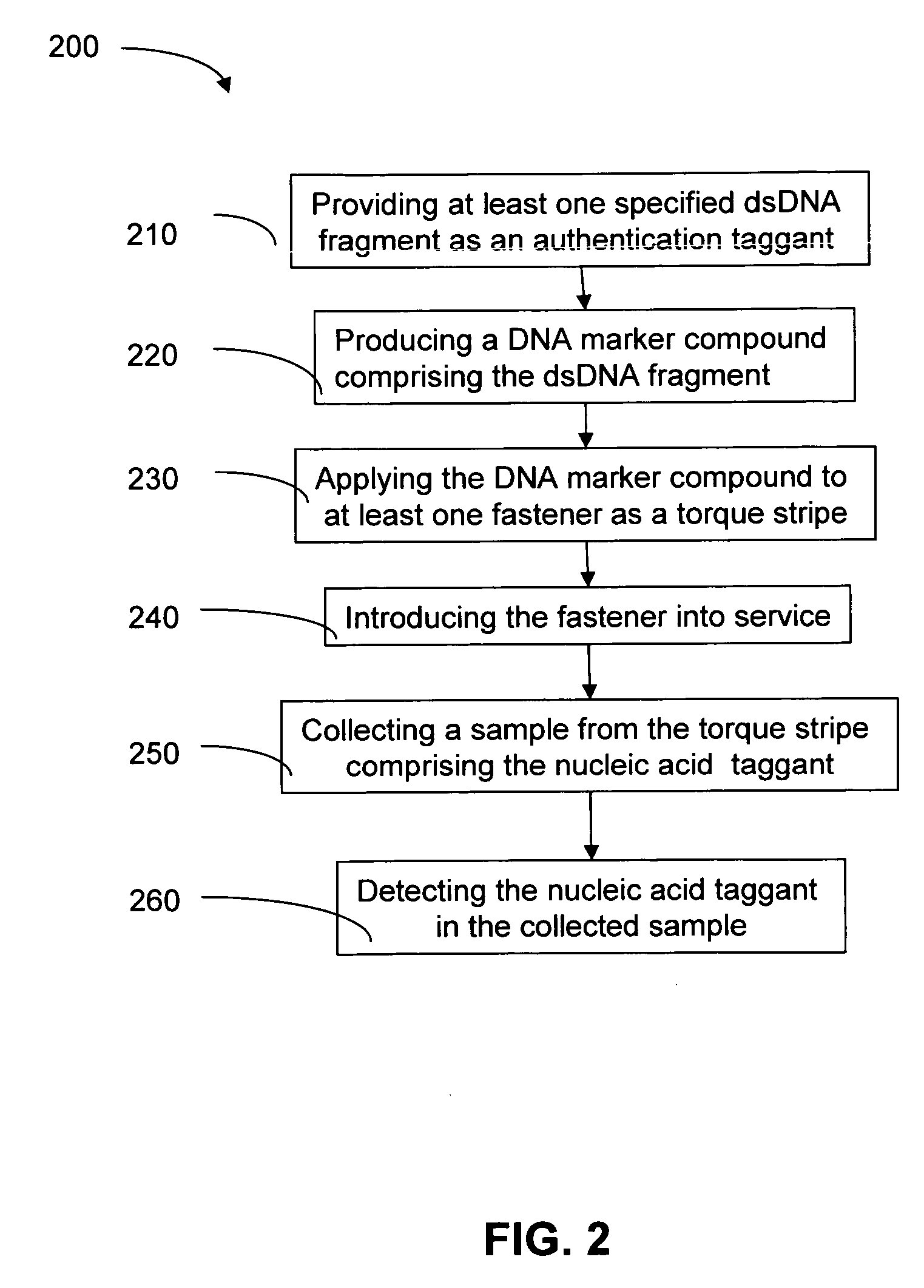

System and methods for product and document authentication

Owner:JONES GUILFORD II +2

Ink jet ink containing polyurethane dispersant

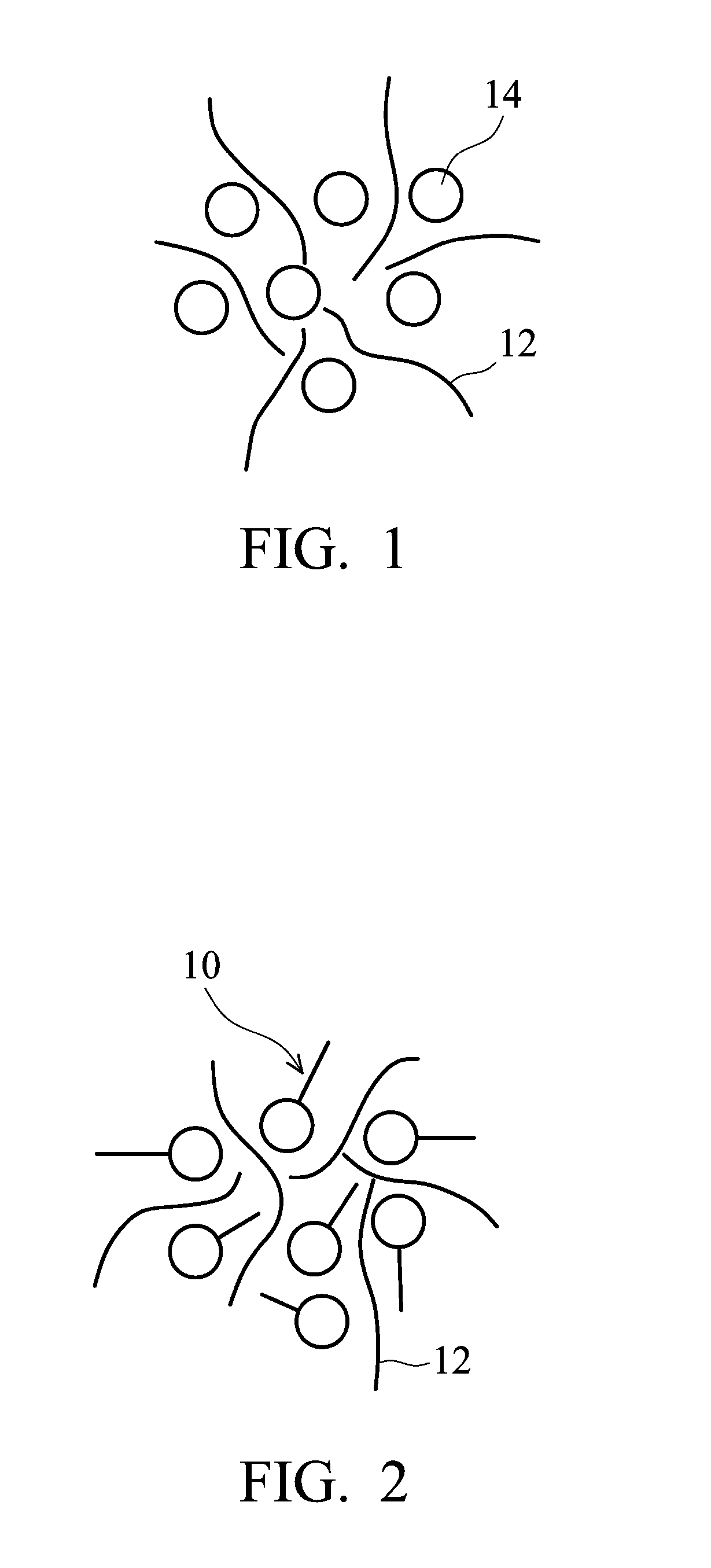

InactiveUS6136890AResistance to agglomerationResistance to flocculationDuplicating/marking methodsInksPolymer chemistryPigment

Owner:3M INNOVATIVE PROPERTIES CO

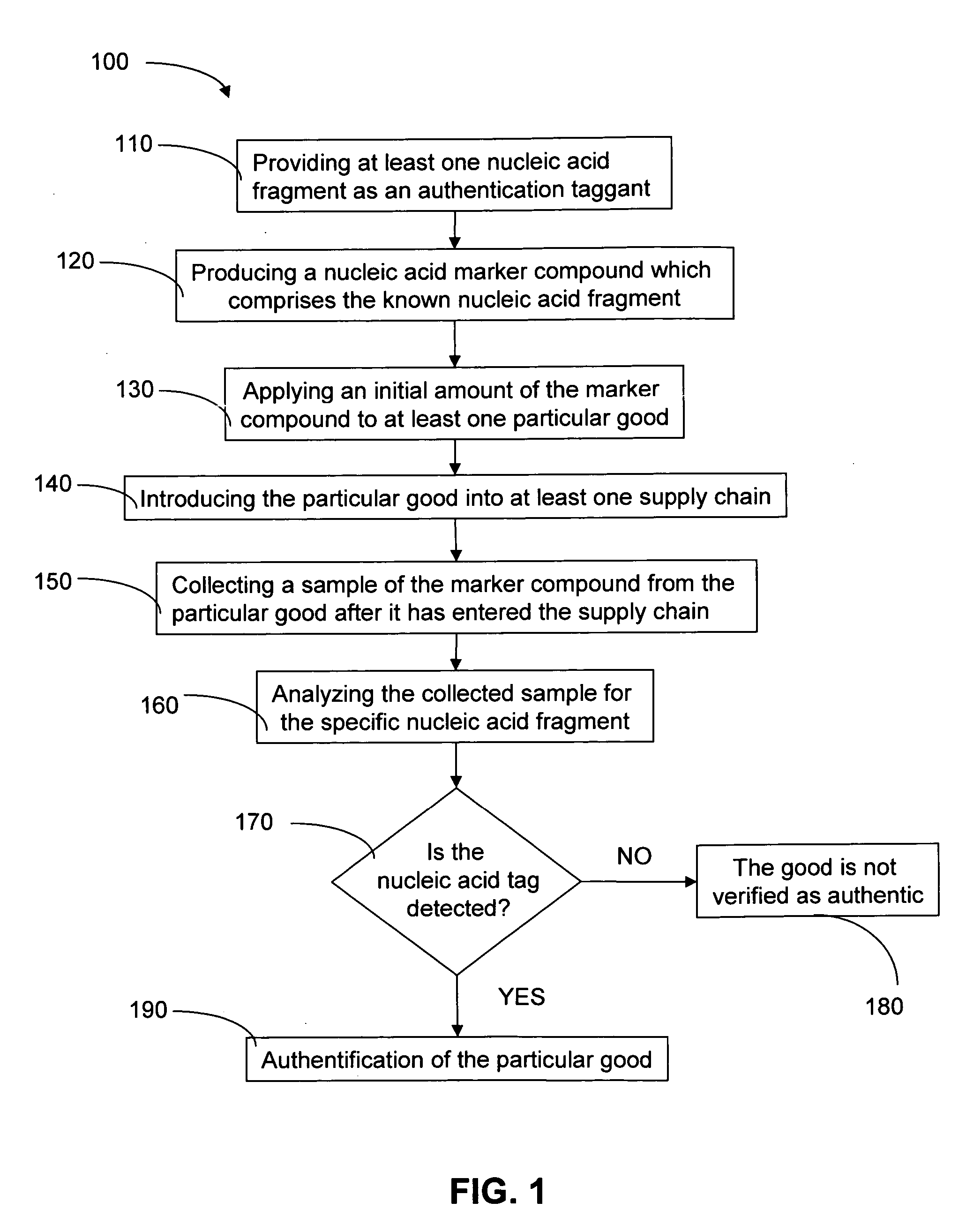

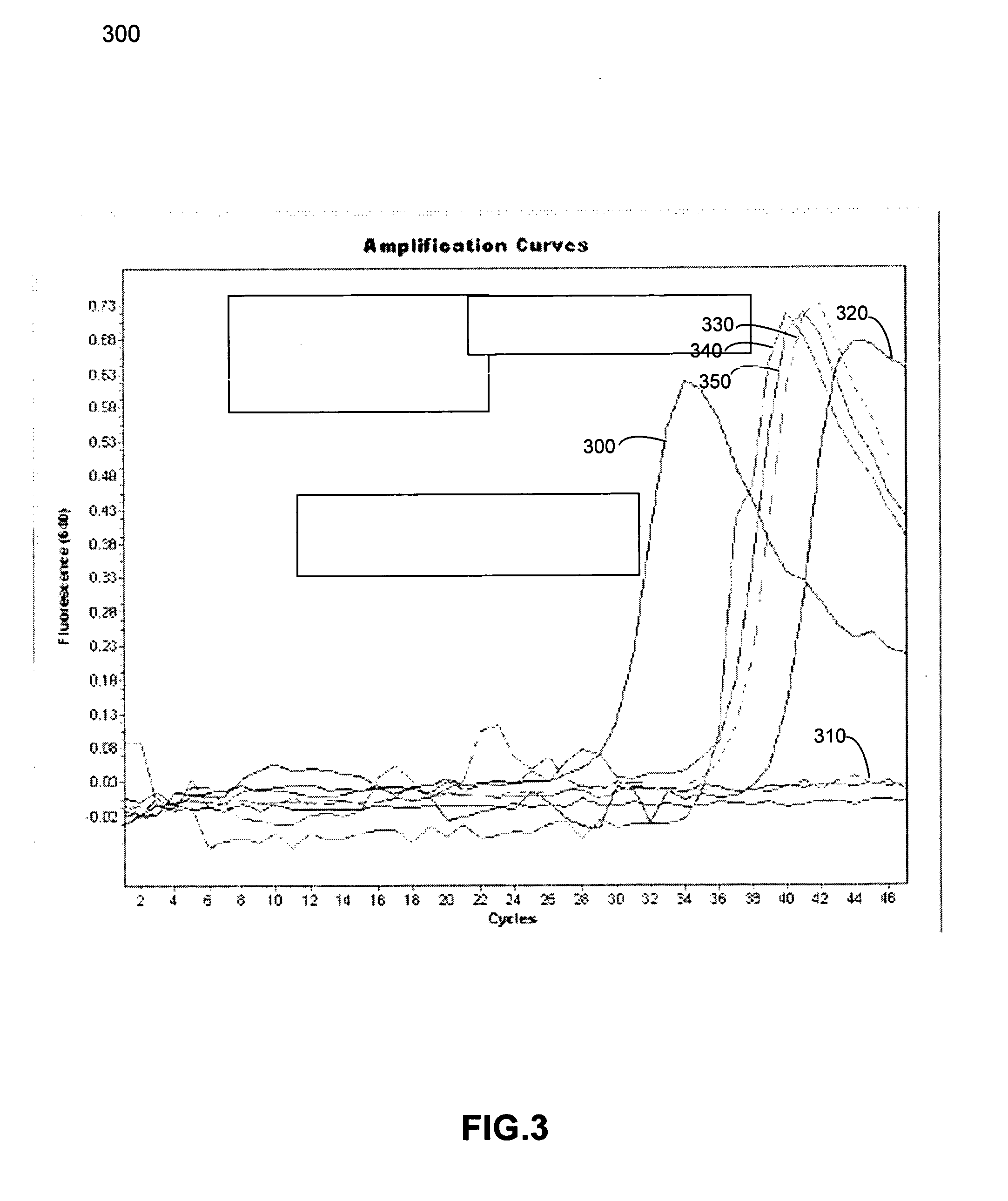

System and method for authenticating multiple components associated with a particular product

InactiveUS20070048761A1Speed up QA/QC operationMicrobiological testing/measurementInksChemistryNucleic acid

Owner:APDN INC

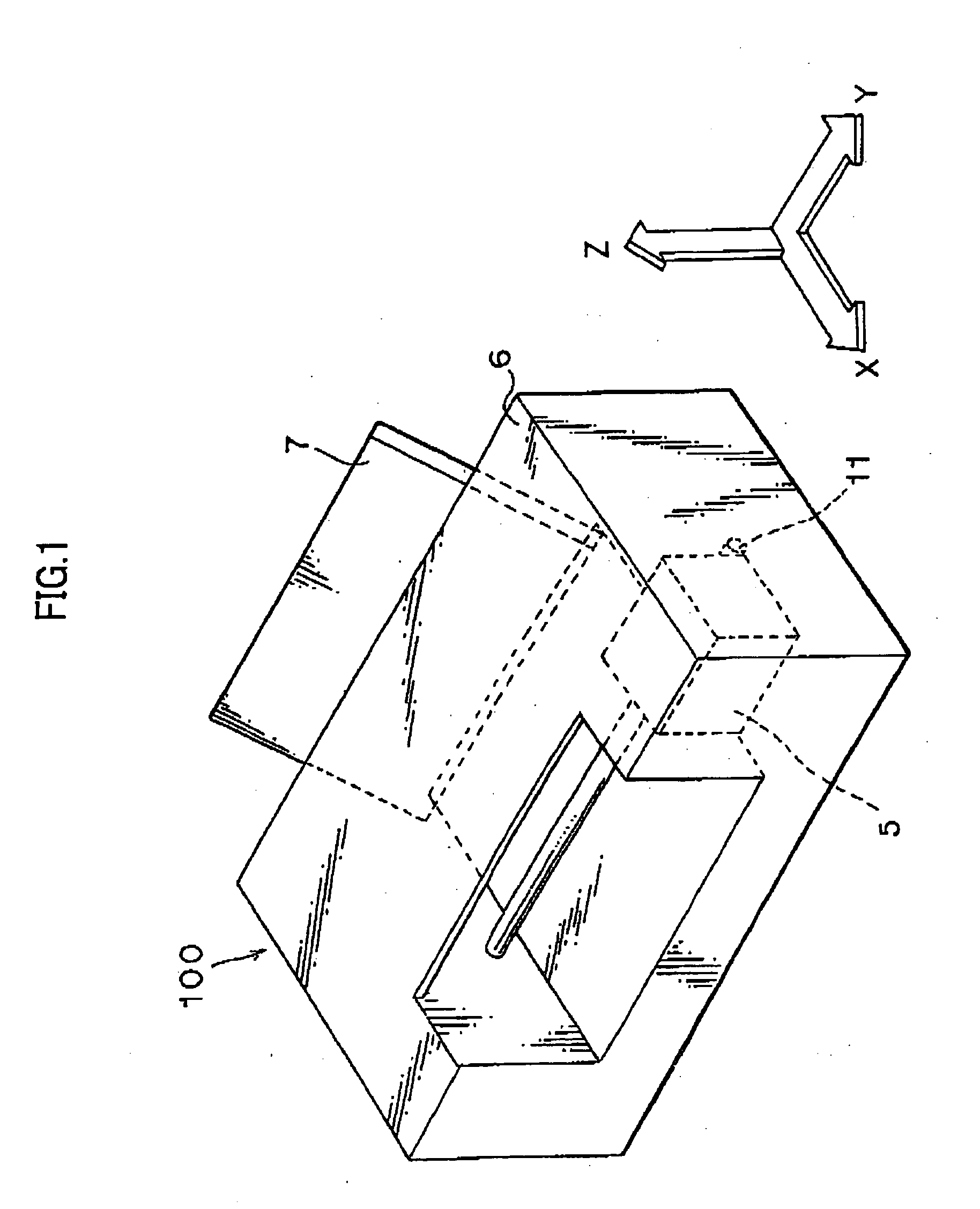

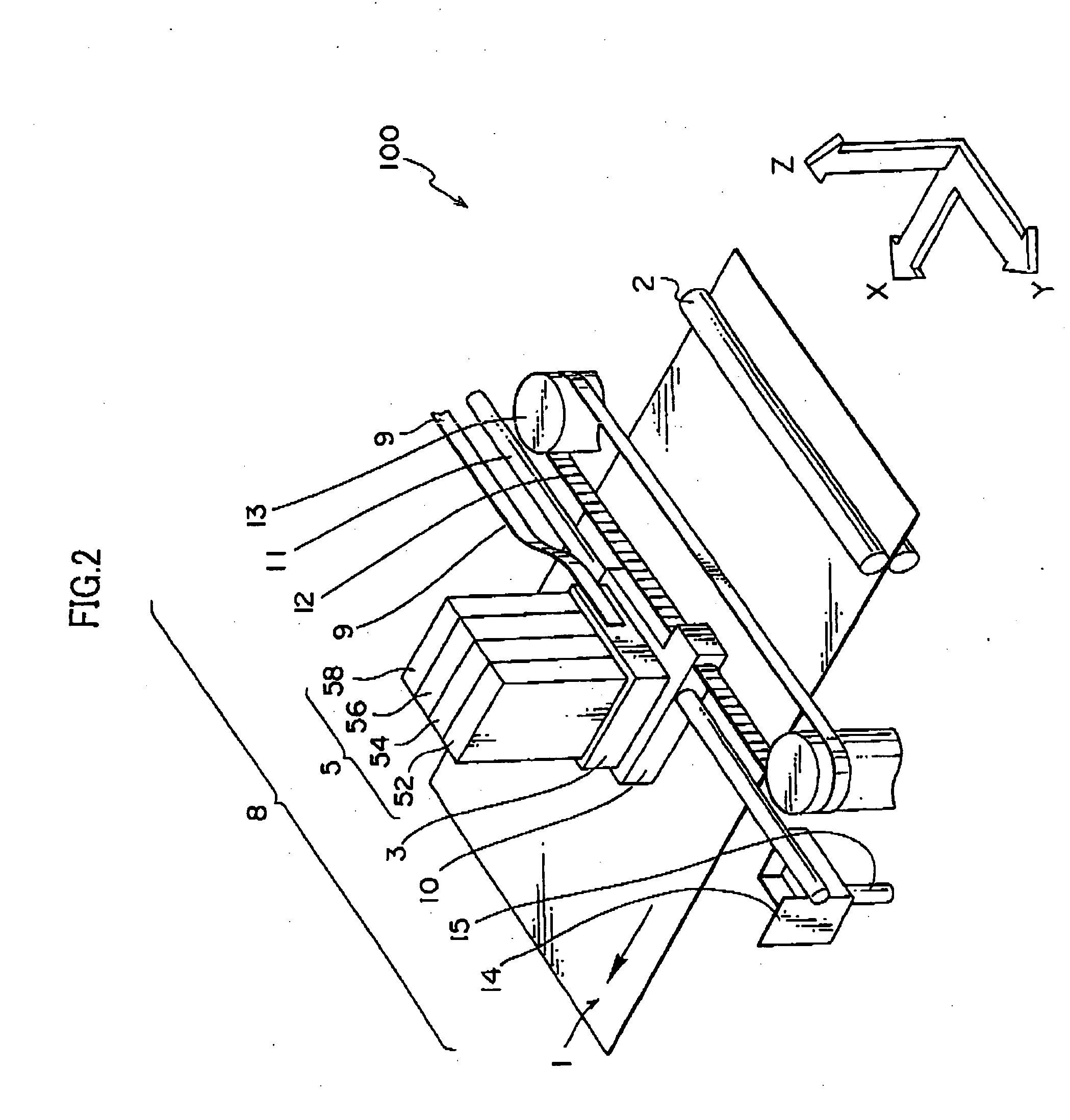

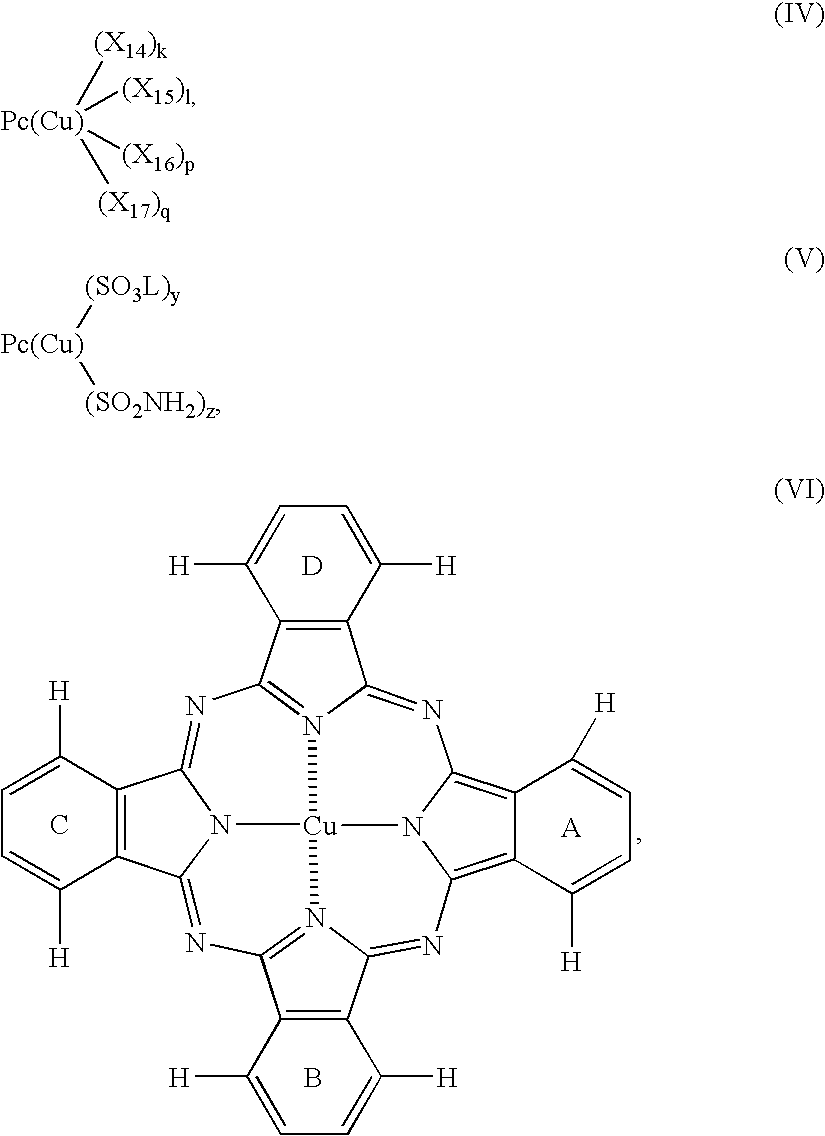

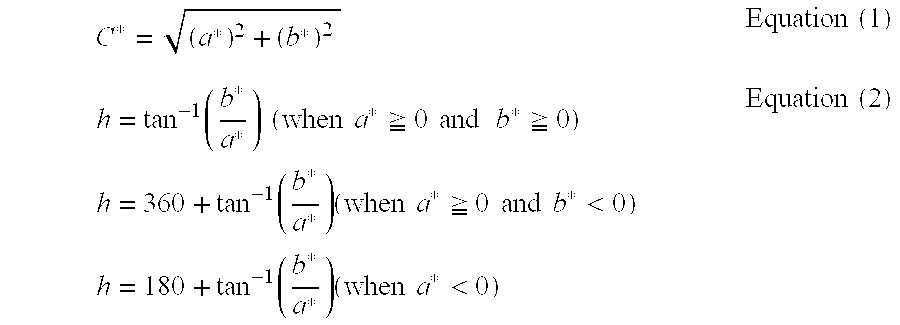

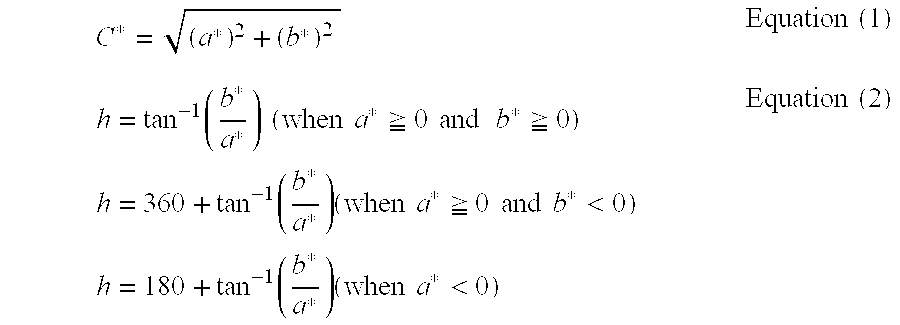

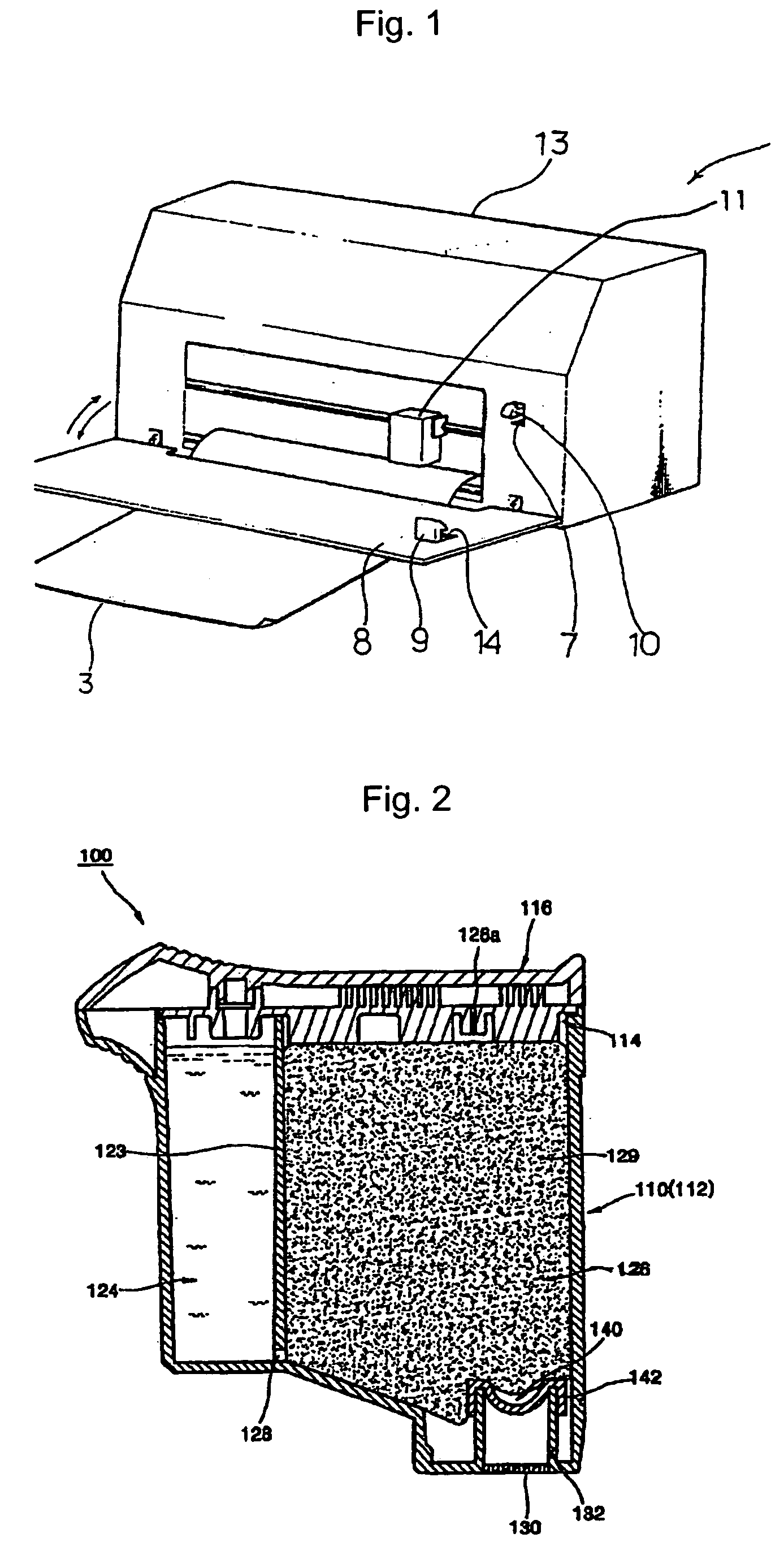

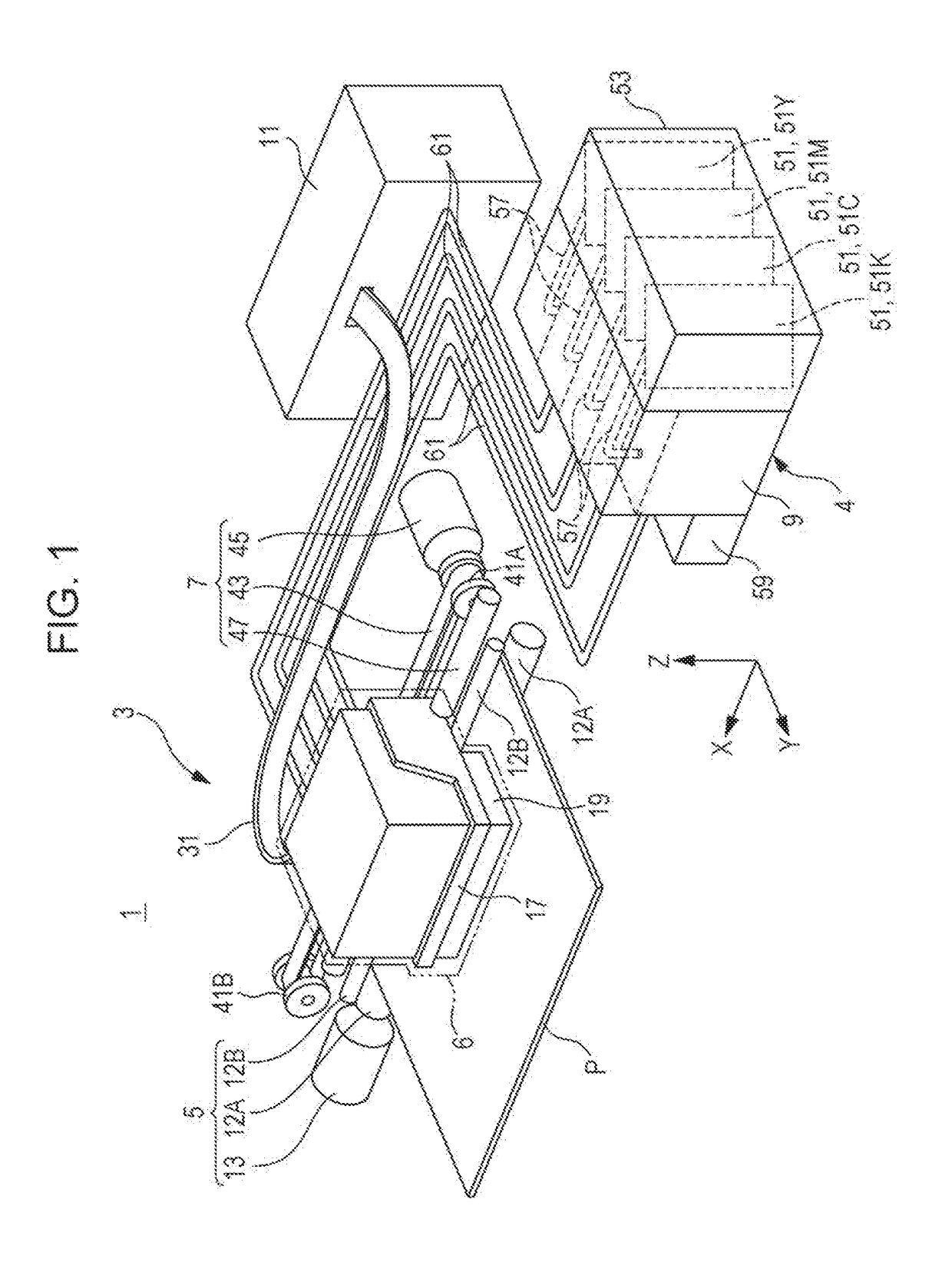

Ink set for ink-jet recording, ink-jet recording method and ink-jet recording apparatus

InactiveUS20050012796A1Measurement apparatus componentsDuplicating/marking methodsWater solubleSolvent

Owner:FUJIFILM BUSINESS INNOVATION CORP

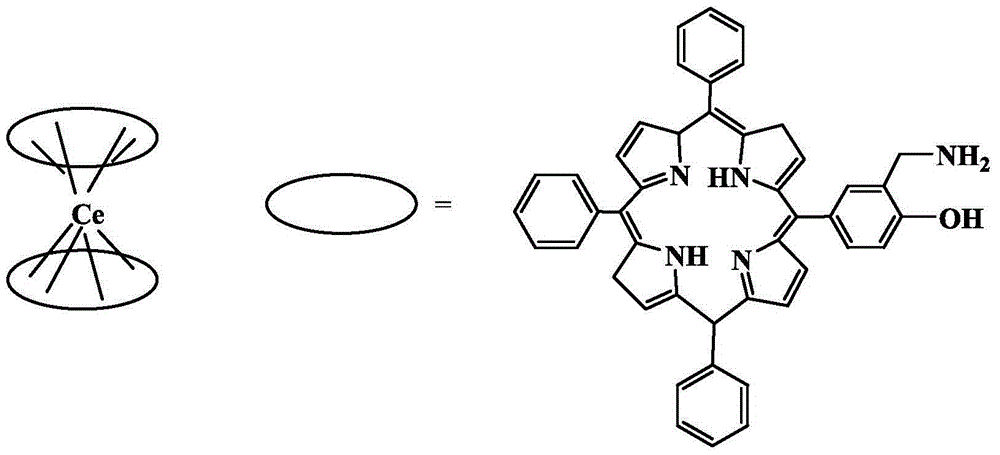

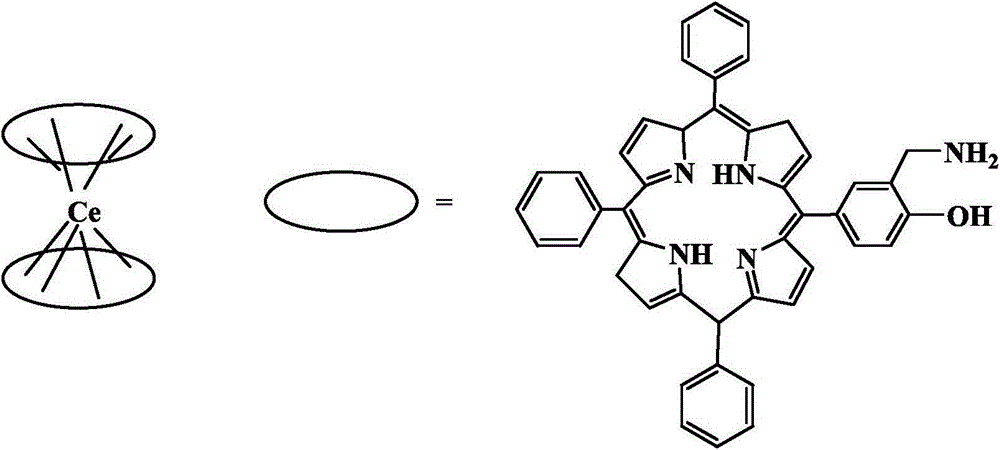

Water-soluble double-layer sandwich-type Ce metalloporphyrin complex and application of complex in microcontact printing technique

ActiveCN104447820AHigh resolutionSmooth responseInksGroup 3/13 element organic compoundsWater solublePolymer substrate

The invention relates to a water-soluble double-layer sandwich-type Ce metalloporphyrin complex and application of the water-soluble double-layer sandwich-type Ce metalloporphyrin complex in a microcontact printing technique. Metal patterns are prepared on the surface of a polymer substrate commonly used in the electronics industry by taking bis(5-(4'-hydroxy-3'-aminomethylphenyl)-10,15,20-triphenyl porphyrin) complexed Ce aqueous solution as microcontact printing ink, and a new thought is provided for the microcontact printing industry.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Water-Based Ink Set For Ink-Jet Recording

ActiveUS20070186812A1Improves not recovery performanceImprove the problemDuplicating/marking methodsInksWater basedMagenta

Owner:BROTHER KOGYO KK

High abrasion-proof PU printing ink for silicon rubber surface

Owner:东莞市贝特利新材料有限公司

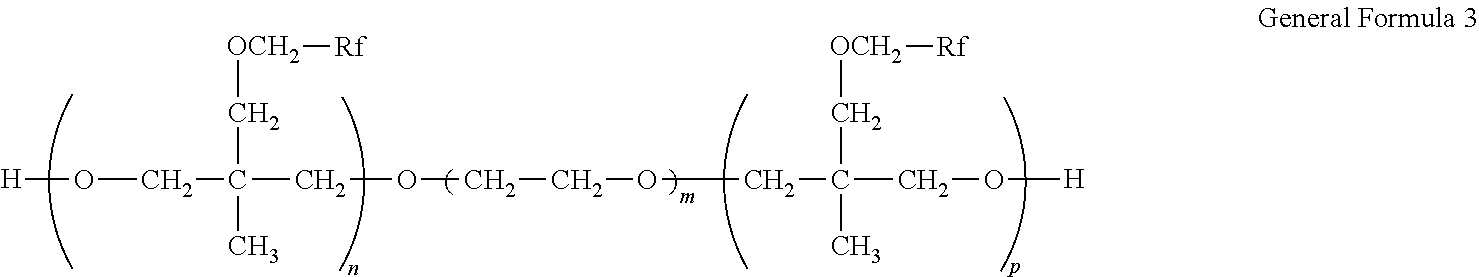

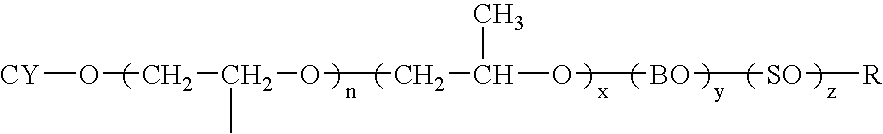

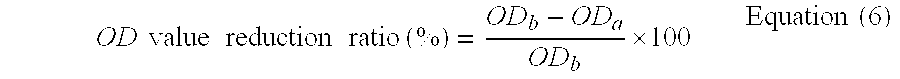

Inkjet recording ink set and ink cartridge, and recording device, image forming method, and image-formed article using such ink set

ActiveUS20120242741A1Desirable image densityImprove image qualityDuplicating/marking methodsInksPolymer scienceSURFACTANT BLEND

Owner:RICOH KK

Infrared Reflecting Black Pigment, Paint and Resin Composition

InactiveUS20080134941A1Good infrared reflection performanceGood blacknessMaterial nanotechnologyPigmenting treatmentLength waveCopper

Owner:TODA IND

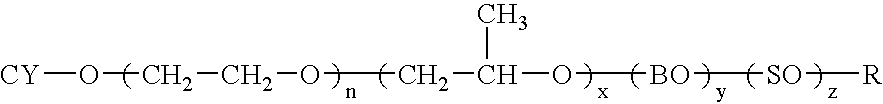

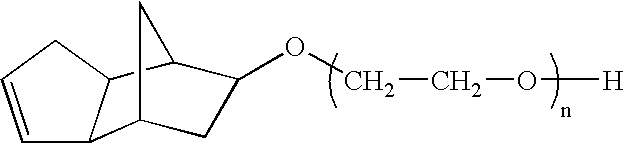

Dispersions containing alkoxylates of alicyclic polycyclic compounds

Owner:ETHOX CHEM LLC

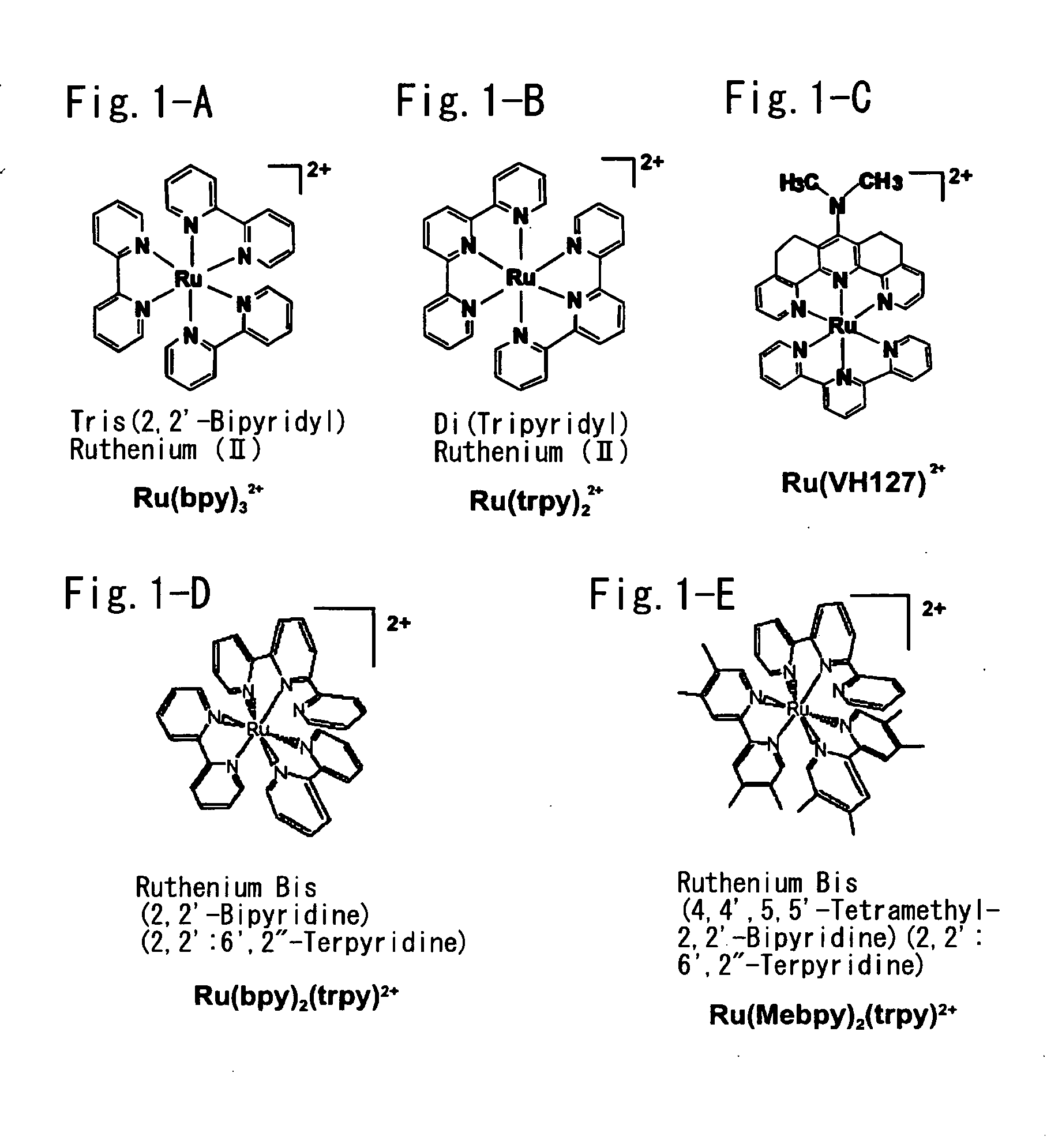

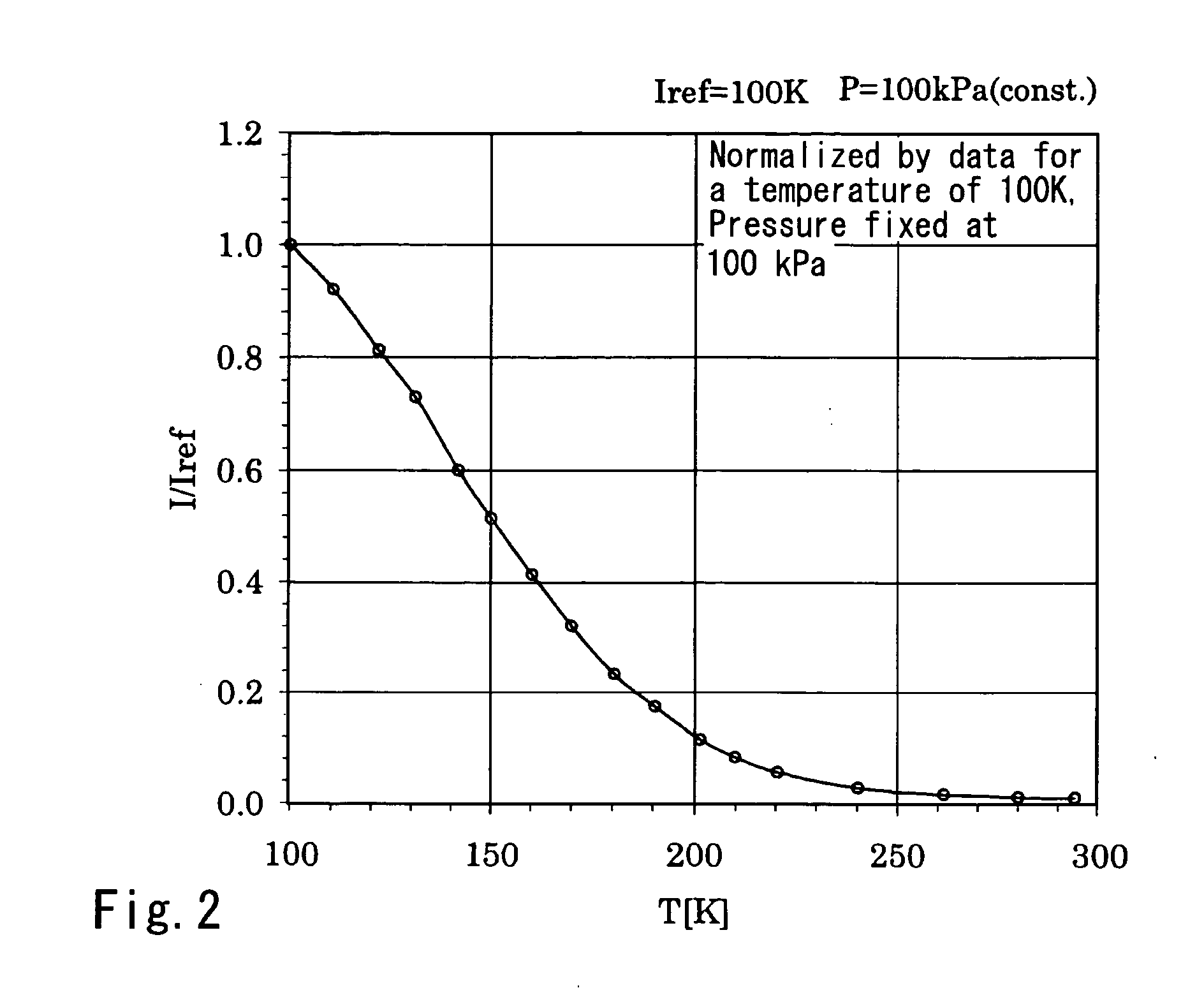

Temperature sensitive paint for low-temperature use

InactiveUS20050040368A1High luminous intensityLarge variation in light emission intensityAnalysis using chemical indicatorsLuminescent paintsSolubilityLuminous intensity

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

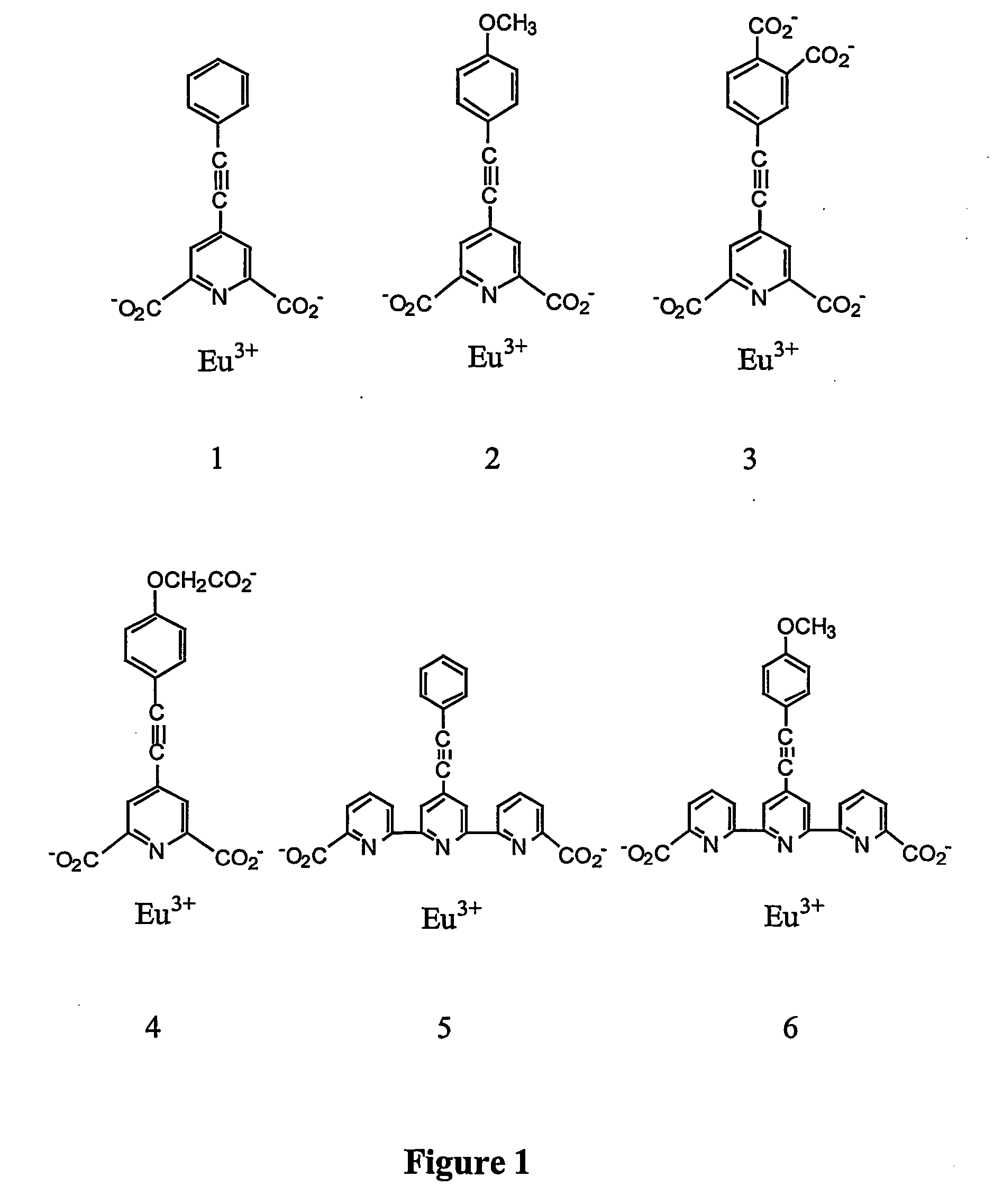

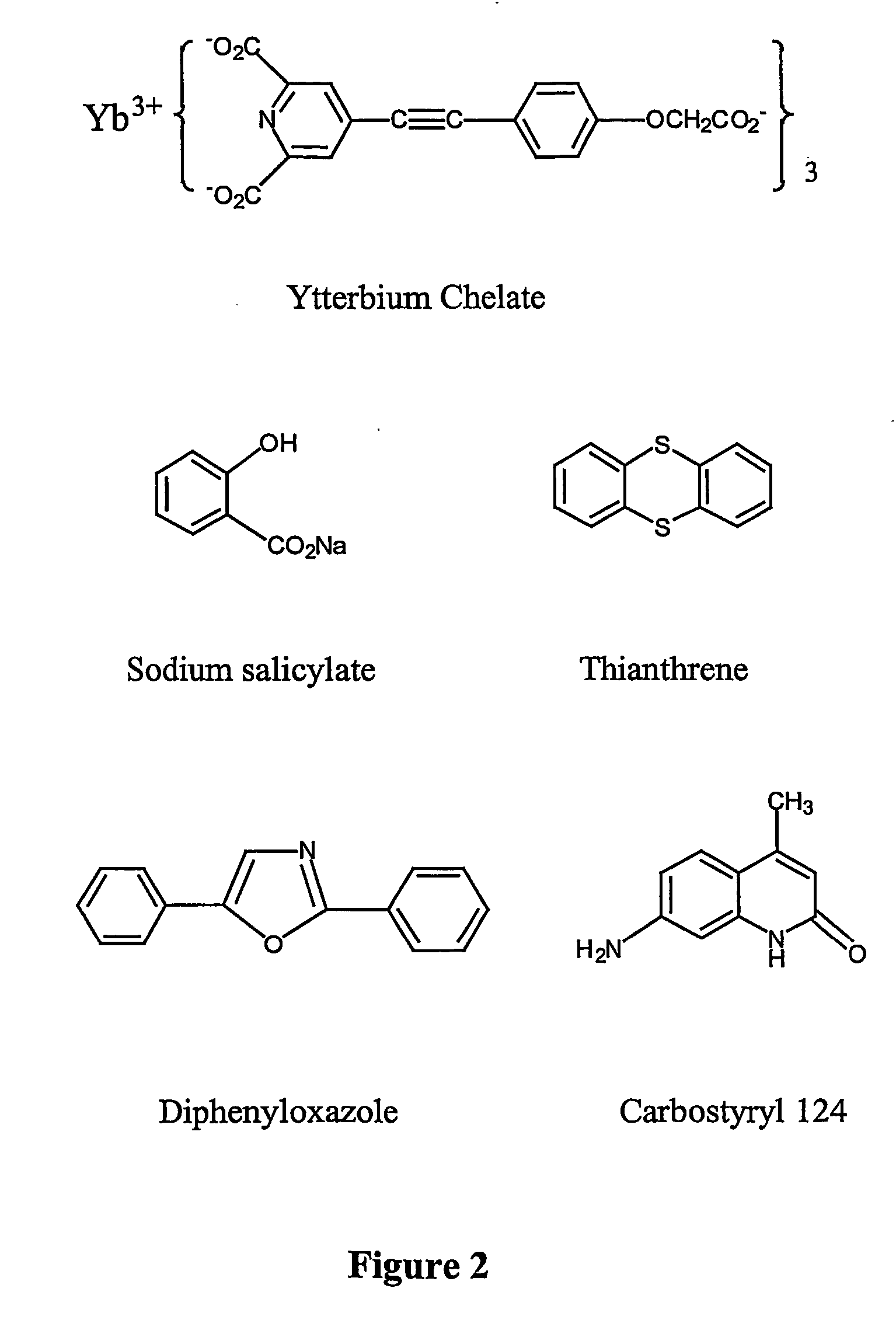

Fluorescent image-printed article and fluorescent ink

ActiveUS20060063036A1Improve security levelOther printing matterDuplicating/marking methodsFluorescenceRare earth

Owner:KK TOSHIBA

Low Dielectric Loss Power Cable Sheaths Comprising High Pressure Polyolefins Free of Silane Functionality

Power cables that comprise a sheath layer, e.g., an insulation layer, are produced from a mixture of a high pressure polyolefin free of silane functionality, e.g., high pressure low density polyethylene, and a polyether polyol of which at least 50 percent of its molecules comprise no more than a single hydroxyl functionality. Preferably, the power cable is a medium or high voltage power cable, and the polyolefin is crosslinked as the sheath layer is fabricated and / or subsequent to the fabrication of the sheath layer.

Owner:DOW GLOBAL TECH LLC

Aqueous graphene-based electric-conducting ink and preparation method thereof

The invention relates to aqueous graphene-based electric-conducting ink, which comprises: 1-15% of an aqueous resin, 30-90% of a graphene-based composite slurry, 0.5-3% of a first auxiliary agent and5-10% of a solvent, wherein the graphene-based composite slurry comprises graphene micro-sheets, carbon nano-tubes, nano-scale superconducting carbon black, a diluent and a second auxiliary agent, anda mass ratio of the graphene to the carbon nano-tubes to the nano-scale superconducting carbon black is (3-10):(0.5-5):(0.1-4). The aqueous graphene-based electric-conducting ink of the invention isstable in performance, environmentally friendly, efficient and extremely low in resistance value, and can replace the existing solvent-based ink products on the market. The invention also relates to apreparation method of the aqueous graphene-based electric-conducting ink.

Owner:NINGBO MORSH TECH

Ink resin composite used for plastic gravure printing and preparation method thereof

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Water-based ink set for ink-jet recording and ink-jet recording method

InactiveUS20070046750A1Reduce graininessExcellent gas resistanceMeasurement apparatus componentsDuplicating/marking methodsWater basedHigh density

Owner:BROTHER KOGYO KK

Ink composition for inkjet recording

InactiveUS20080066644A1Eject evenlyDecreasing amountInksPrintingElectrical and Electronics engineering

Owner:SAMSUNG ELECTRONICS CO LTD

Thermal vanishing ink

Owner:王勇

Formulation of inks containing ceramic nanoparticles

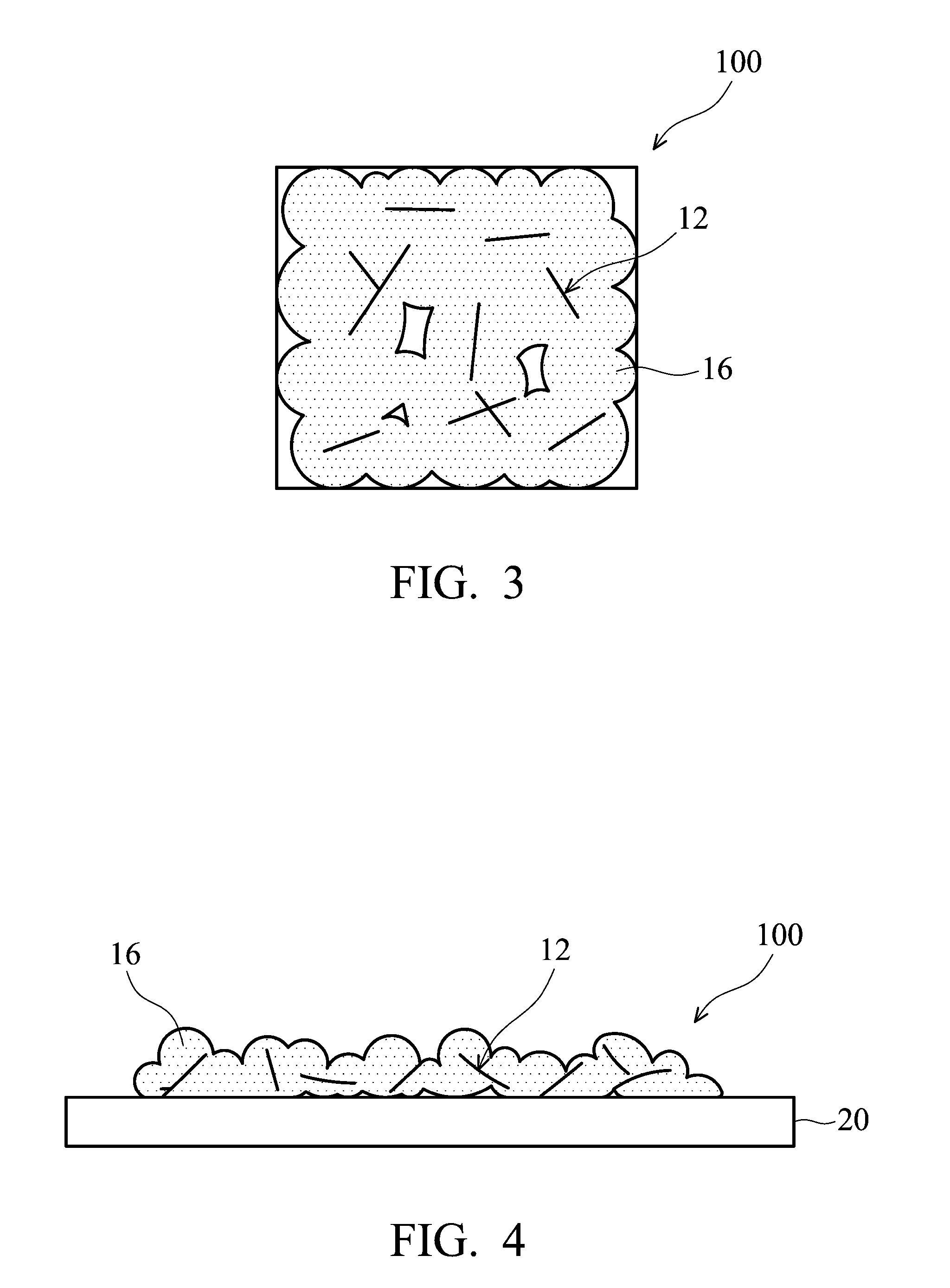

InactiveUS20150152239A1Facilitate redispersionImprove wettabilityMaterial nanotechnologyNanostructure manufactureNanoparticleSolvent

Owner:ABENGOA SOLAR NEW TECH SA

Edible printing ink

Owner:苏州凹凸彩印厂

Temperature change ink for printing drink label

InactiveCN102241917ANo pollutionPlay anti-counterfeiting functionStampsInksOrganic solventAcrylic resin

Owner:LETONG CHEM CO LTD

Electrically conductive composition and fabrication method thereof

ActiveUS20110101283A1Electric discharge heatingRadiation applicationsConductive polymerConductive materials

Owner:IND TECH RES INST

Method for printing double smooth surfaces at one time and matting agent for printing ink

Owner:JIANGSU JIN JIA NEW PACKAGING MATERIALS CO LTD

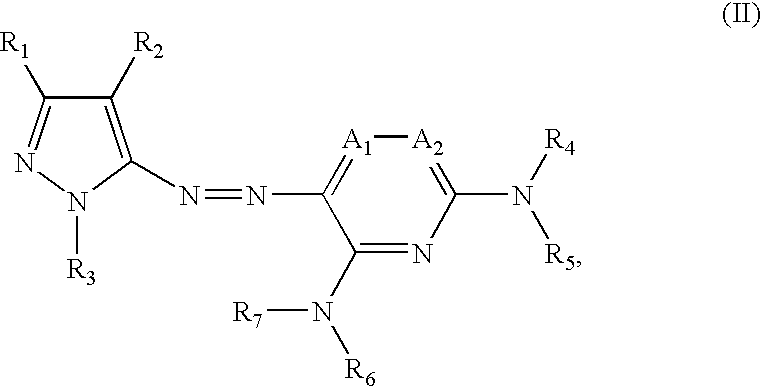

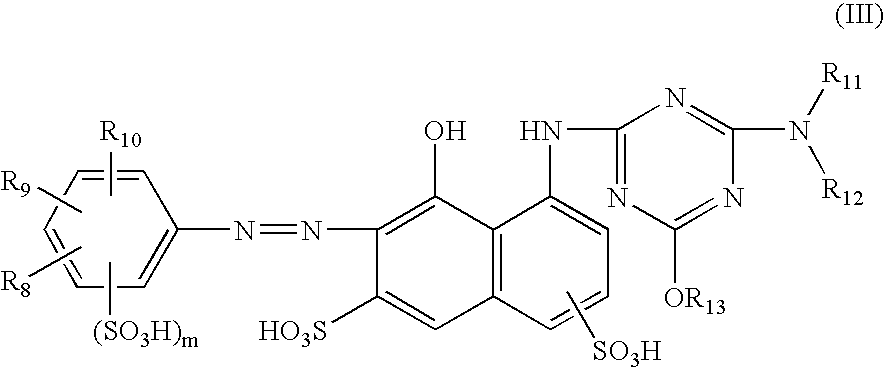

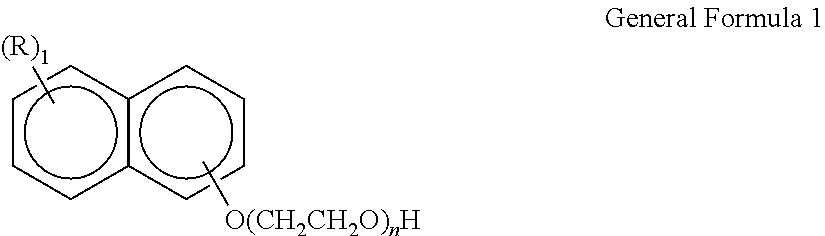

Ink set for inkjet recording, recording method, and colored material produced using the ink set

InactiveUS20130328979A1Convenient lightingIncrease resistanceMeasurement apparatus componentsDuplicating/marking methodsOrganic solventWater soluble

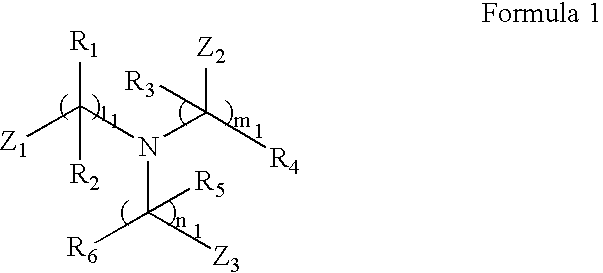

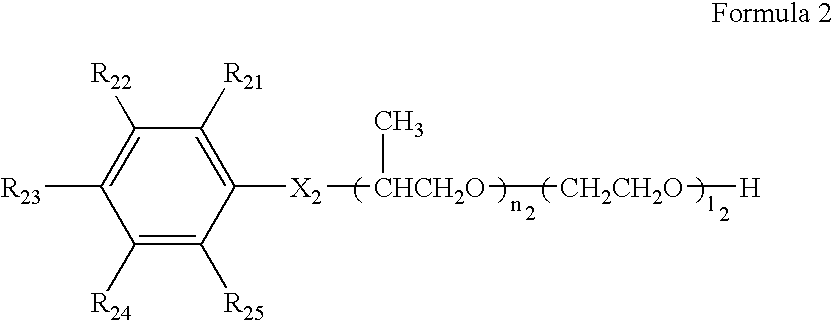

An ink set for inkjet recording, which has excellent water resistance and light resistance in the hue range of yellow-orange-magenta. The ink set includes two-color ink compositions, i.e., a) a magenta ink composition and b) an yellow ink composition, each of which includes a dye, water and a water-soluble organic solvent, wherein the magenta ink composition a) contains a compound produced by sulfonating a compound represented by the formula (1), a salt of the compound, or a mixture thereof as a coloring agent.

Owner:NIPPON KAYAKU CO LTD

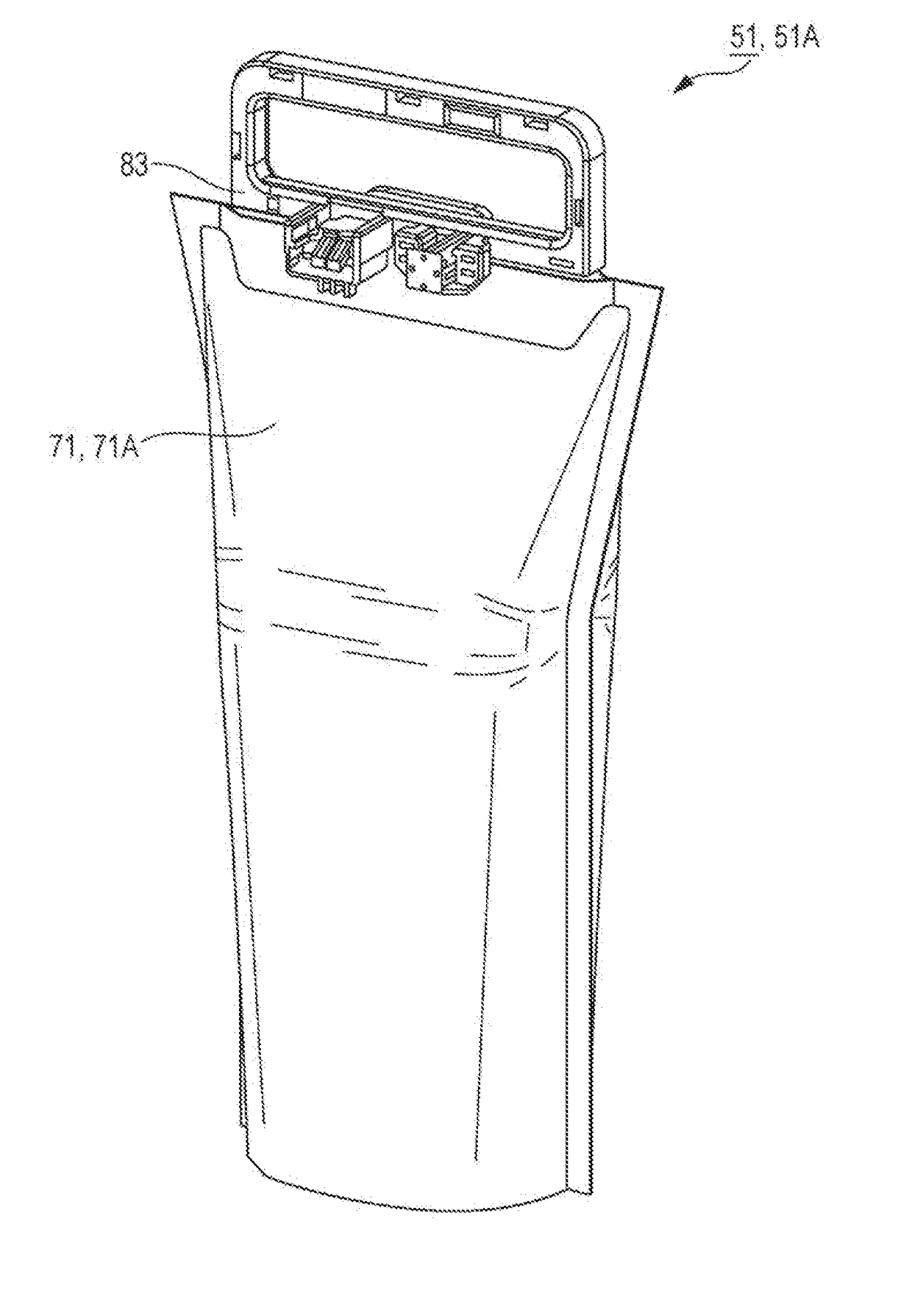

Ink composition and container

Owner:SEIKO EPSON CORP

Microcapsule Type Thermochromic Pigment and Preparation Method and Use Thereof, Thermochromic Ink and Use Thereof

The disclosure provides a microcapsule type thermochromic pigment and a preparation method and use thereof, and a thermochromic ink and use thereof. The microcapsule type thermochromic pigment provided by the disclosure includes a core material and a wall material wrapping the core material, wherein the core material includes the following components: a leuco dye, a developer and stearic acid 2-[4-(phenylmethoxy)phenyl]ethyl ester, and the wall material is self-emulsifying polyurethane or self-emulsifying epoxy resin.

Owner:WUHAN ZHONGKE ADVANCED MATERIAL TECH CO LTD

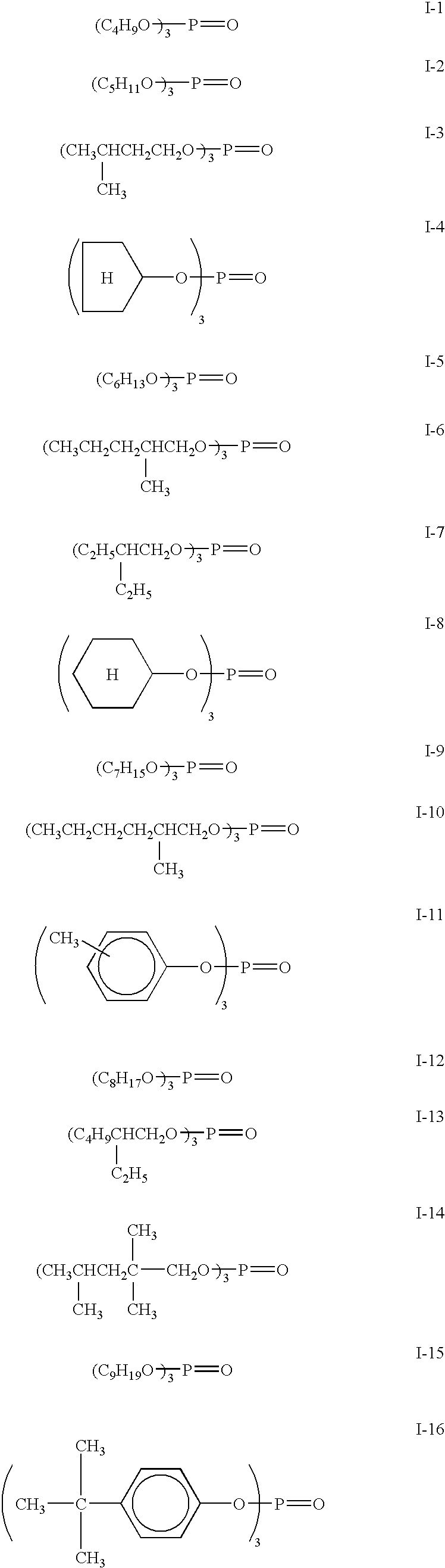

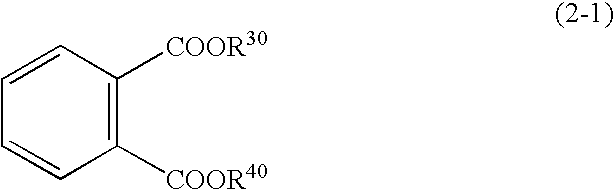

Ink composition

InactiveUS20060213391A1Shrinkage factorPromote wettingDuplicating/marking methodsInksPlasticizerPhosphate

Owner:FUJIFILM CORP +1

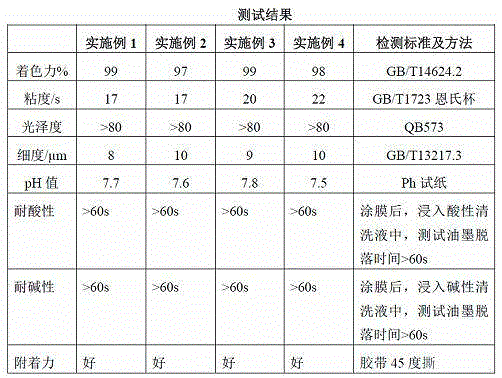

Colorful acid and alkali resistant laser printing ink and preparation method thereof

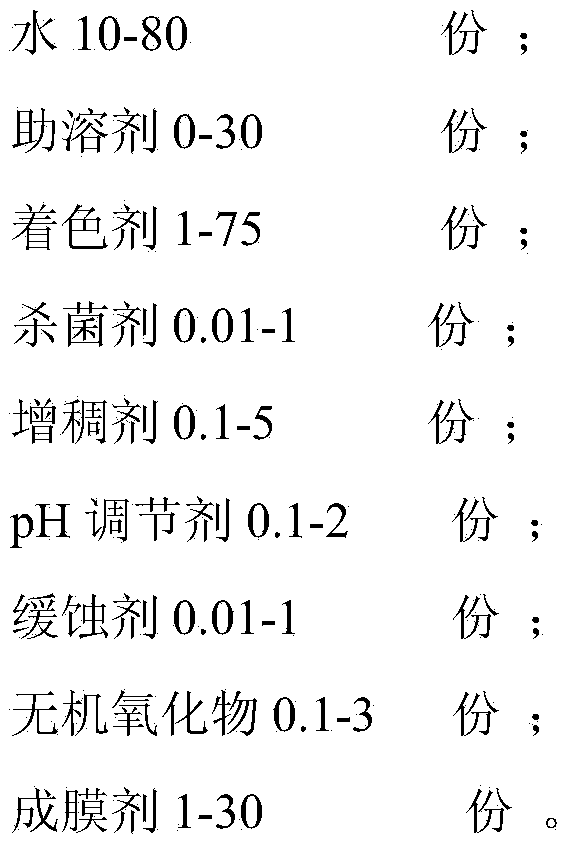

InactiveCN104403412AGood acid and alkali resistanceOvercome the disadvantage that it is easy to produce depletion when mixed with acid and alkaliInksChemistryPrinting ink

The invention discloses a colorful acid and alkali resistant laser printing ink and a preparation method thereof. The printing ink is composed of the following components in parts by weight: 0 to 30 parts of butanone, 10 to 30 parts of isopropanol, 2 to 6 parts of curing agent, 10 to 15 parts of pigment, and 10 to 30 parts of glycidyl ether epoxy resin. The glycidyl ether epoxy resin is adopted to produce the printing ink, aliphatic polyamine is further chosen as the curing agent, the acid and alkali resistant performance of the printing ink is strengthened through optimizing the formula, thus the shortage that the colorful laser printing ink is lost when being mixed with acid and alkali is overcome, moreover, the color of the laser printing product is more abundant, and the patterns are more clear.

Owner:深圳市天意通防伪包装材料有限公司

Preparation method of organic tin-free chlorine ether resin

Owner:HANGZHOU ELECTROCHEM GROUP

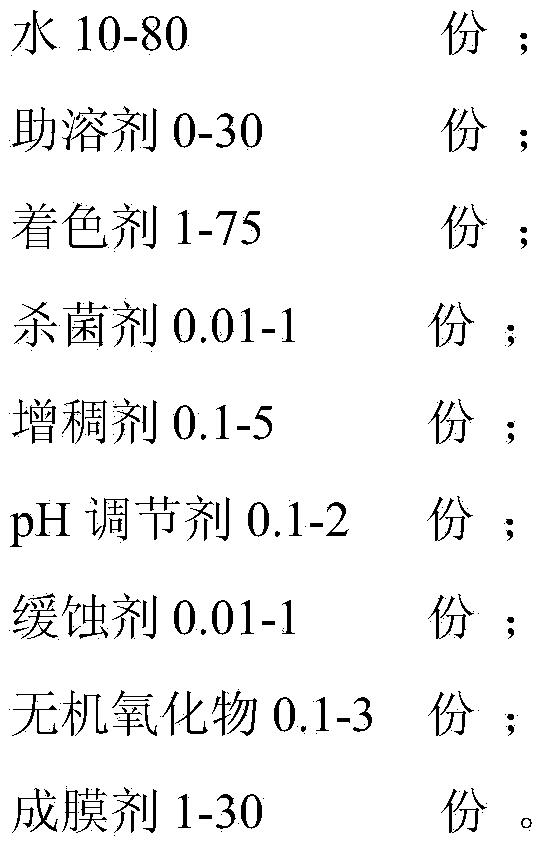

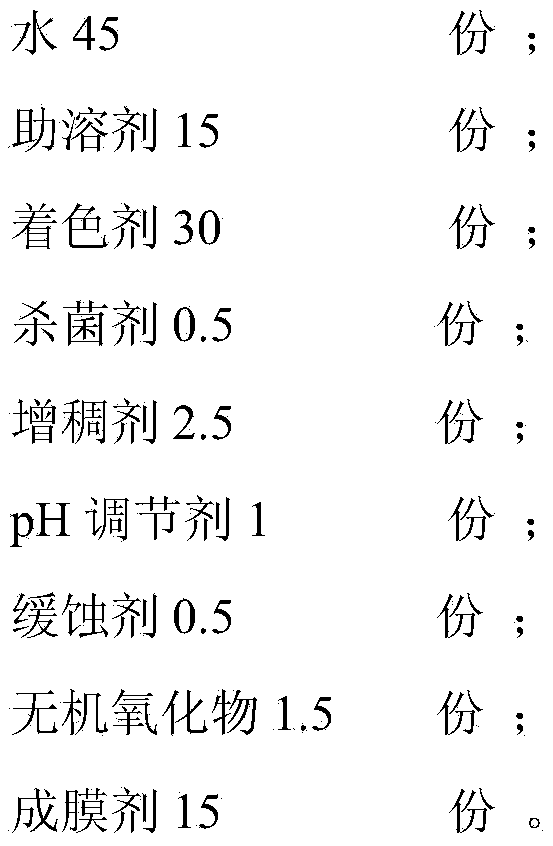

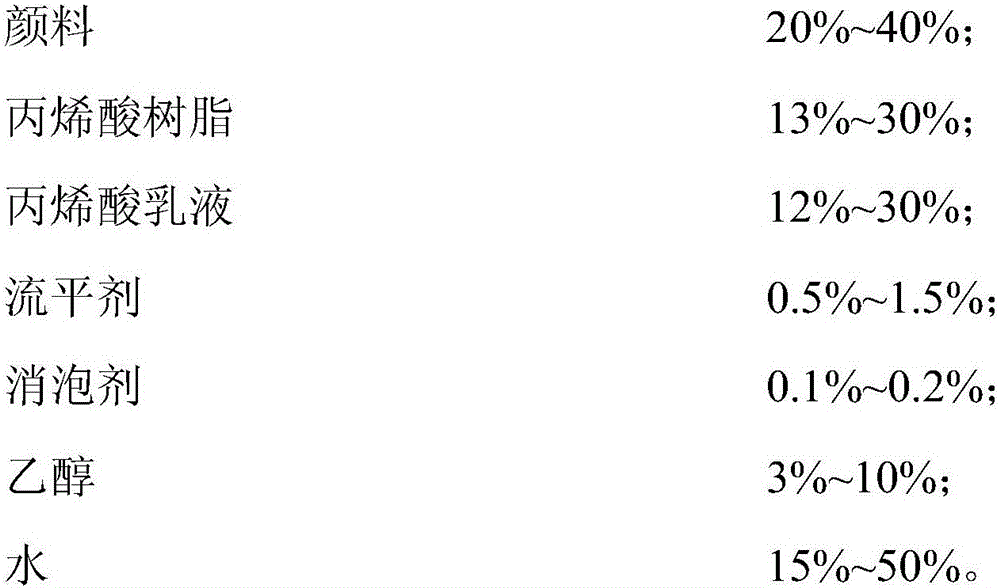

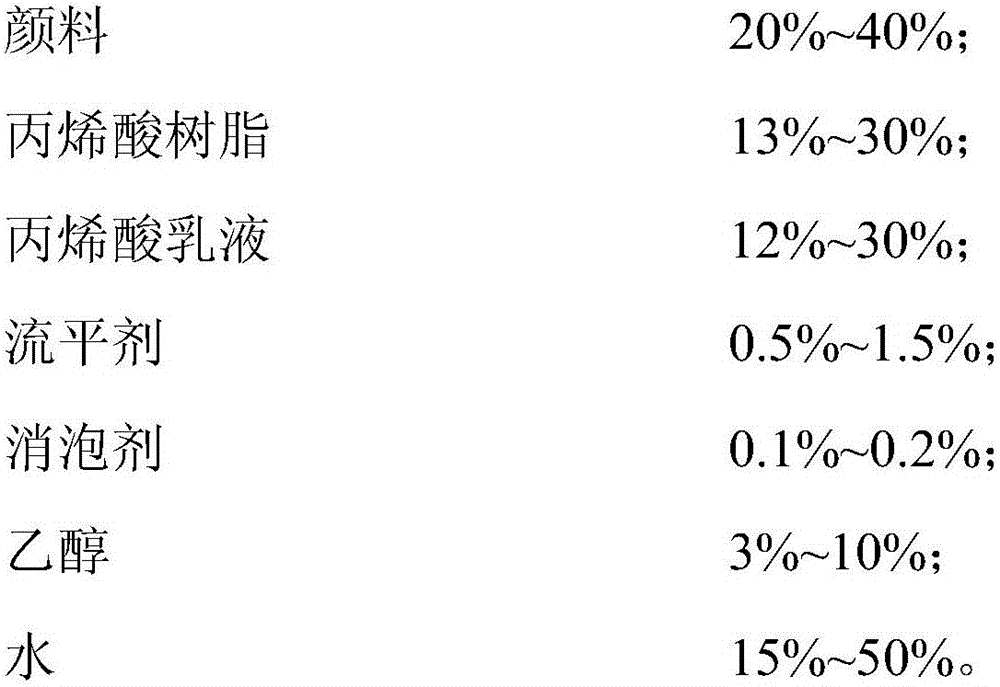

Waterborne printing ink for food package printing and preparation method of printing ink

Owner:JINAN UNIVERSITY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap