Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water resistance may refer to: . The WR mark on a wristwatch indicating its ability to withstand exposure to water; The IP code on a mechanical or electrical enclosure indicating its ability to resist the ingress of water; Wet strength, a measure of the strength of paper when wet; Waterproofing, making objects or structures resist the ingress of water under specified conditions

Thin film and thin film laminate comprising the same

InactiveUS20090233083A1Maintain good propertiesExcellent gas barrier performanceRecord carriersSynthetic resin layered productsHeat resistancePliability

Owner:TOMOEGAWA CO LTD

Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

ActiveCN102030857AGood adhesionImprove water resistanceMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsCross-linkPolymer science

The invention relates to a vinyl acetate-ethylene copolymer emulsion as an electrostatic spinning adhesive and a synthesis method thereof. Organic peroxides and zinc formaldehyde sulfate are taken as an initiator; vinyl acetate, ethylene, acrylic ester monomers and cross-linking monomer N-hydroxymethyl acrylamide are taken as comonomers; a nonionic emulsifier, and the synthetic emulsion and the protective colloid of an amphoteric emulsifier are matched to be taken as an emulsification system; and the copolymer emulsion is prepared through emulsion polymerization. Compared with the VAE (vinyl acetate-ethylene) emulsion prepared by the conventional preparation method, the product in the invention has the advantages of good water resistance, strong adhesion on low-surface-energy materials (polyethylene, polypropylene and the like), fine grain and the like. The vinyl acetate-ethylene copolymer emulsion is suitable for being as the adhesive to be applied to the field of the electrostatic spinning in textile industry and the fields of waterproofing and packaging.

Owner:CHINA PETROCHEMICAL CORP +1

Transparent thermal insulation coating material system for glass substrate

InactiveCN102942841AInstant cureReduce energy consumptionPolyurea/polyurethane coatingsEpoxy resin coatingsThermal insulationUltraviolet lights

The present invention discloses a transparent thermal insulation coating material system for a glass substrate. The coating material system is a double layer coating material system formed by a separately-prepared primary coating and a separately-prepared surface coating, wherein the surface coating is coated on the primary coating, the primary coating comprises the following components, by mass, 0.05-3 parts of a silicane coupling agent or a titanate coupling agent, 0.2-5 parts of a hydrolysis catalyst, and 95-99 parts of a solvent, and the surface coating comprises the following components, by mass, 50-80 parts of a light curable resin, 5-35 parts of an active diluent, 1-8 parts of a photoinitiator, 5-35 parts of an antimony tin oxide nanometer thermal insulation powder slurry or an indium tin oxide nanometer thermal insulation powder slurry, 100-140 parts of an inert diluent, and 0.01-0.15 part of a leveling agent. With the coating material system, a film can be formed through a conventional film forming method, and the film layer can be cured within a few seconds after ultraviolet light irradiation. In addition, the coating material system has characteristics of high hardness, excellent adhesion and excellent water resistance.

Owner:刘志钊 +1

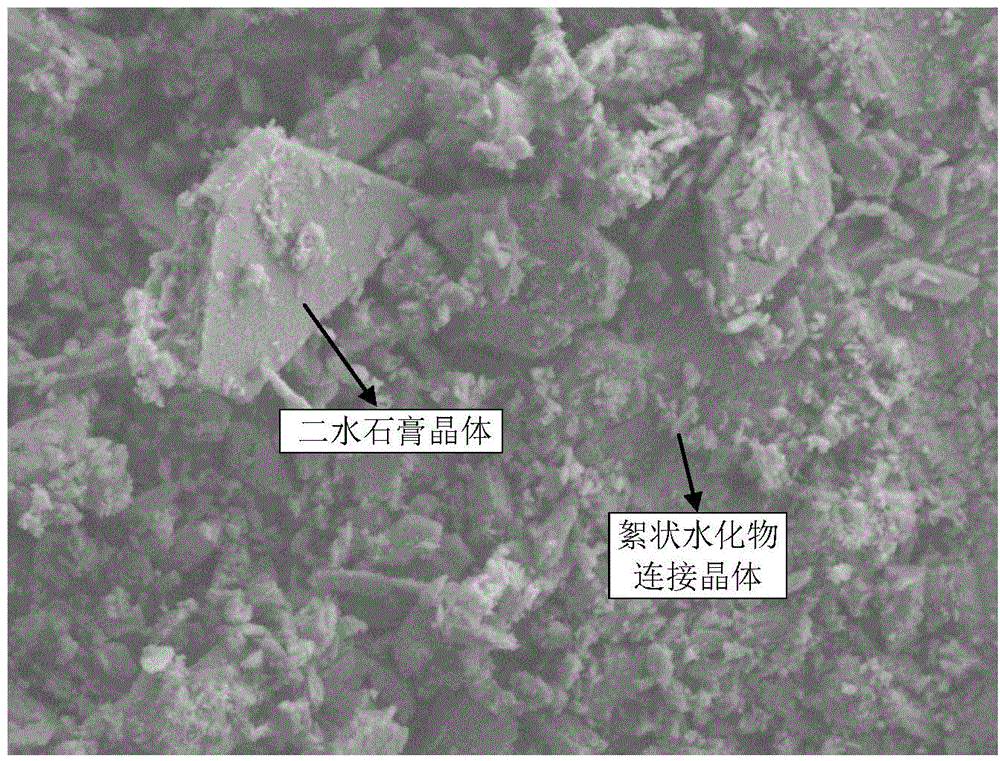

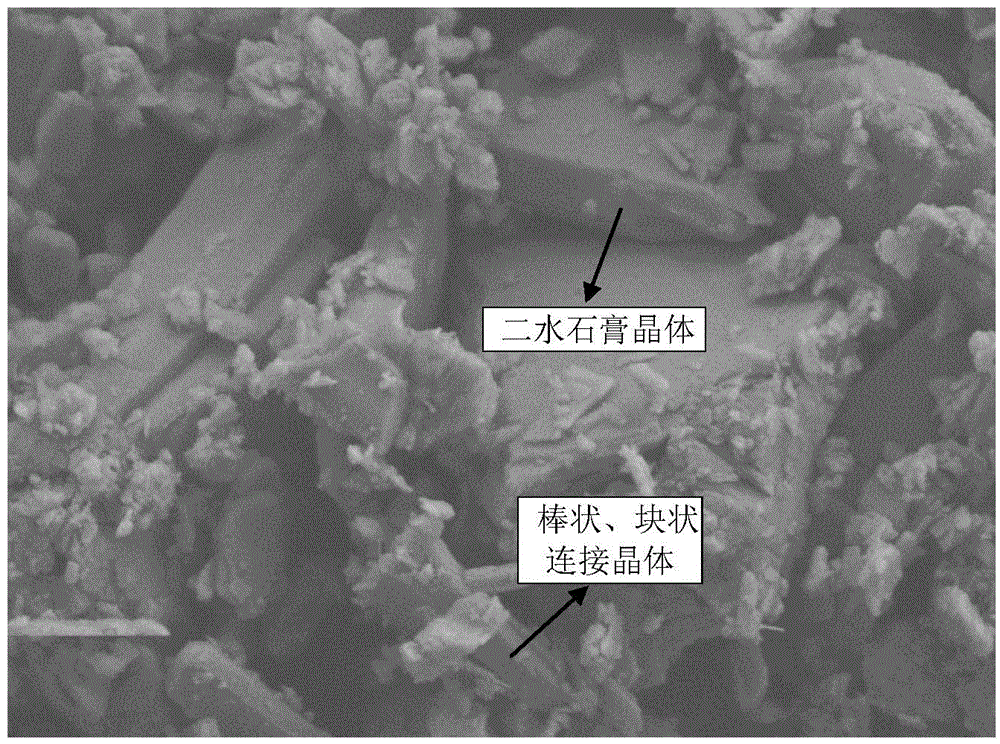

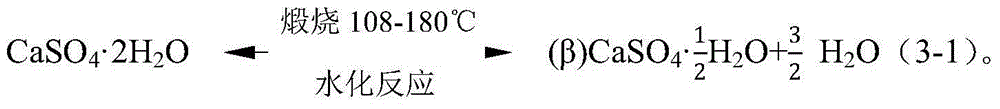

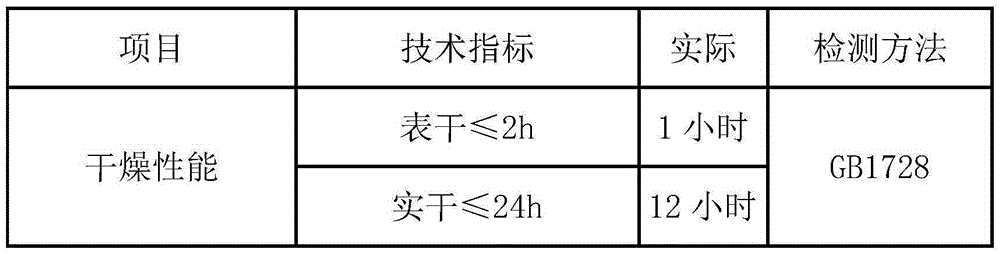

Modified phosphogypsum highway subgrade filler and preparation method thereof

Owner:WUHAN HUAZHONG UNIV OF SCI & TECH TESTING TECH CO LTD +1

Propping agent for resin coating film and preparation method thereof

InactiveCN102899019AImprove water resistanceImproves breakage resistanceFluid removalBreakage rateResin coating

The invention discloses a propping agent for a resin coating film and a preparation method thereof. The propping agent comprises an aggregate, a resin, a curing agent and a dispersing agent, wherein the dosage of the resin is 1%-10% of the weight of the aggregate; the dosage of the curing agent is 0.5%-5% of the weight of the aggregate; and the dosage of the dispersing agent is 0.2%-2% of the weight of the aggregate. The propping agent for the resin coating film provided by the invention has the functions of allowing oil gas to smoothly penetrate and preventing water from penetrating through the propping agent, so that the separating effect of oil gas and water is enhanced by the functions and the oil extraction cost is lowered; due to the excellent hydrophobic property of the resin film, the propping agent has excellent water resistance, the anti-breaking capability of the propping agent is increased and the long-term flow-guiding effect is good; a triple film coating technology is adopted by the invention and the calcium stearate is taken as a dispersing agent, so that the quality is greatly increased, the yield is increased to above 80%, the cost is greatly lowered and the production efficiency is increased; and the preparation method provided by the invention is simple, the product yield is high and the breakage rate of the product is obviously reduced.

Owner:YIXING TENGFEI OIL FRACTARING PROPPANT

Colored continuous-phase silicone-acrylic emulsion reactable with protective glue and preparation method thereof

Owner:中山市巴德富化工科技有限公司

Good-weather and water resistance water-based alkyd resin

Owner:深圳海德新材料科技有限公司

Fluorine-containing aqueous coating composition

InactiveCN1738878AGood chemical resistanceImprove water resistancePolyurea/polyurethane coatingsWater dispersibleSolvent

A fluorine-containing aqueous coating composition composed of (A) an aqueous emulsion of a functional group-containing fluororesin obtained by dispersing, in water, a fluoroolefin copolymer having a functional group that is obtained through solution polymerization and (B) a water-dispersible unblocked isocyanate compound is disclosed. The fluororesin aqueous coating composition can be cured at ordinary temperature, and a coating formed therefrom is excellent in chemical resistance, water resistance, solvent resistance, contamination resistance, hardness, weathering resistance and durability.

Owner:DAIKIN IND LTD

High-temperature iron-based zeolite molecular sieve honeycomb type denitration catalyst and preparation method thereof

ActiveCN107519926AEvenly dispersedSimple preparation processMolecular sieve catalystsDispersed particle separationFerrous saltsStearic acid

Owner:VALIANT CO LTD

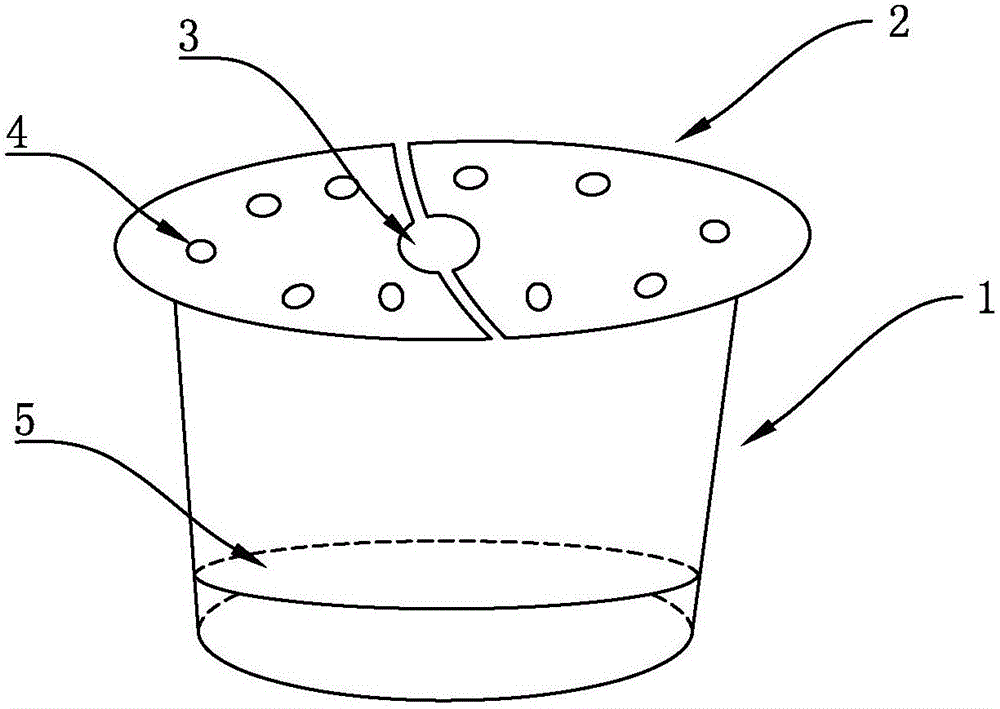

Plant cultivation bowl and production method thereof

InactiveCN106718286AGuaranteed nutritionLess nutrient lossGrowth substratesCulture mediaDiseaseNutrient solution

Owner:WEIFANG YOURONG IND

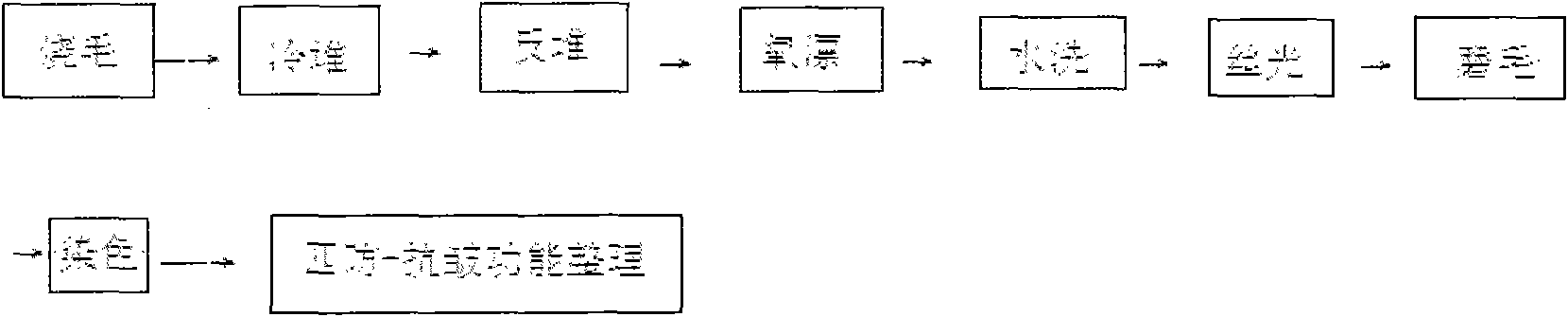

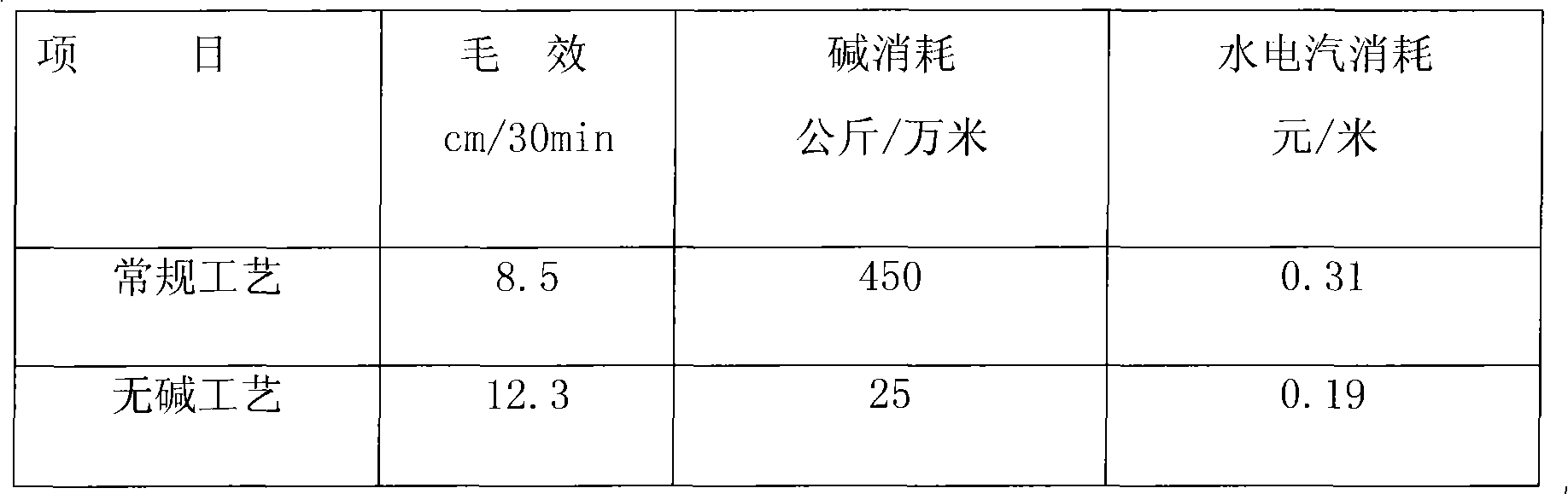

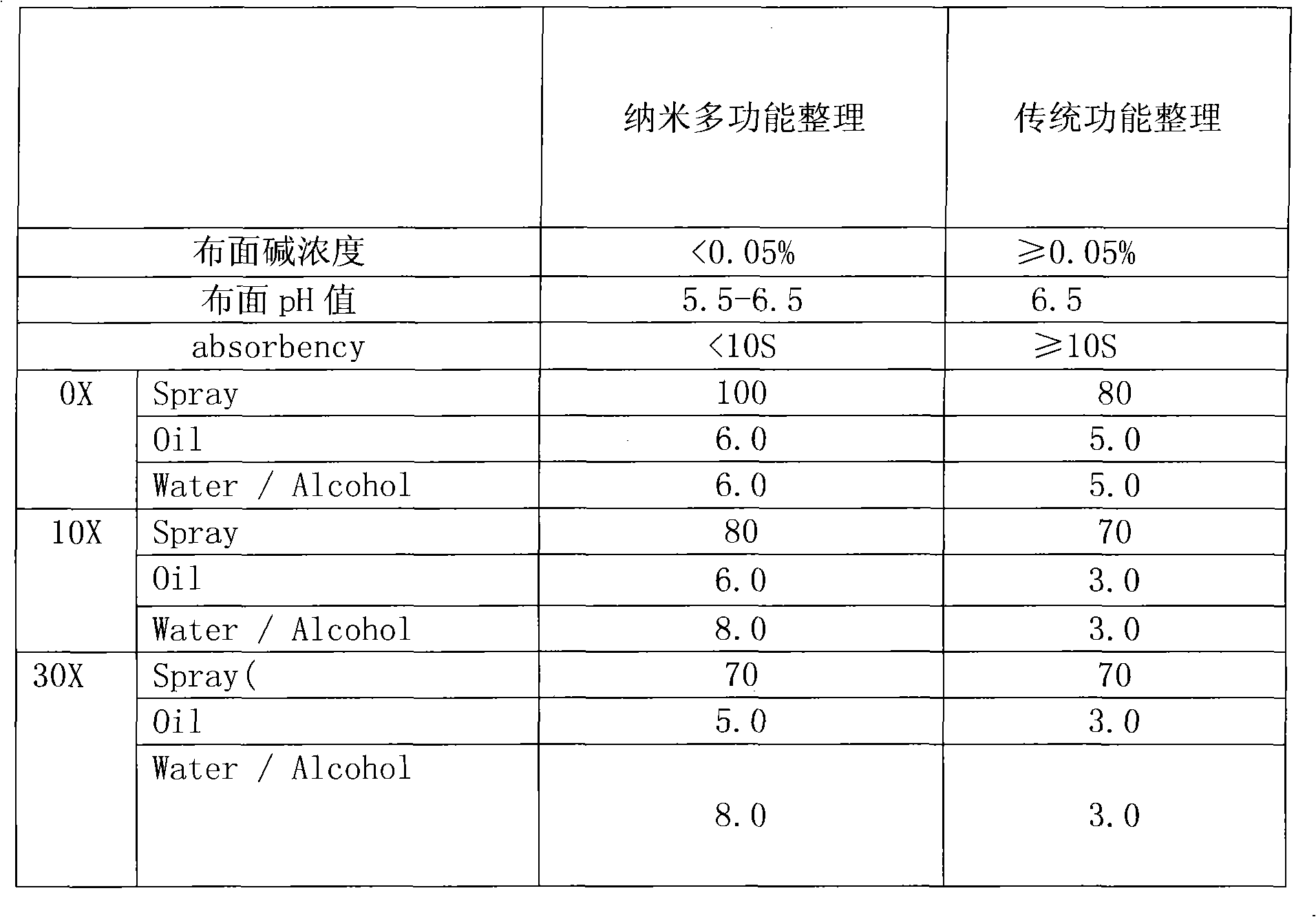

Dyeing and finishing technology of nano multifunctional fabric

InactiveCN102071578ARetain good propertiesRetain propertiesBiochemical fibre treatmentBleaching apparatusSide effectAdditional values

Owner:SUNTEX

Novel magnesium oxysulfate cement-based fireproof coating and preparation and application methods thereof

Owner:UNIV OF SCI & TECH LIAONING

Ink set for inkjet recording, recording method, and colored material produced using the ink set

InactiveUS20130328979A1Convenient lightingIncrease resistanceMeasurement apparatus componentsDuplicating/marking methodsOrganic solventWater soluble

An ink set for inkjet recording, which has excellent water resistance and light resistance in the hue range of yellow-orange-magenta. The ink set includes two-color ink compositions, i.e., a) a magenta ink composition and b) an yellow ink composition, each of which includes a dye, water and a water-soluble organic solvent, wherein the magenta ink composition a) contains a compound produced by sulfonating a compound represented by the formula (1), a salt of the compound, or a mixture thereof as a coloring agent.

Owner:NIPPON KAYAKU CO LTD

Composite waterproof nano-fiber fabric

InactiveCN105291519AImprove waterproof performanceLower surface energySynthetic resin layered productsClothingsFiberNanofiber

The invention relates to composite waterproof nano-fiber fabric. The composite waterproof nano-fiber fabric comprises a fabric layer and is characterized in that a waterproof fiber layer is arranged on the upper surface of the fabric layer, the waterproof fiber layer is composed of warps and wefts in an interweaving mode, the warps are fluorine-containing polymer nano fibers, and the wefts are chemical fiber filaments. The composite waterproof nano-fiber fabric is excellent in water resistance and capable of effectively maintaining the dryness and comfort of clothes.

Owner:SUZHOU MINGSHENG CHEM FIBER CO LTD

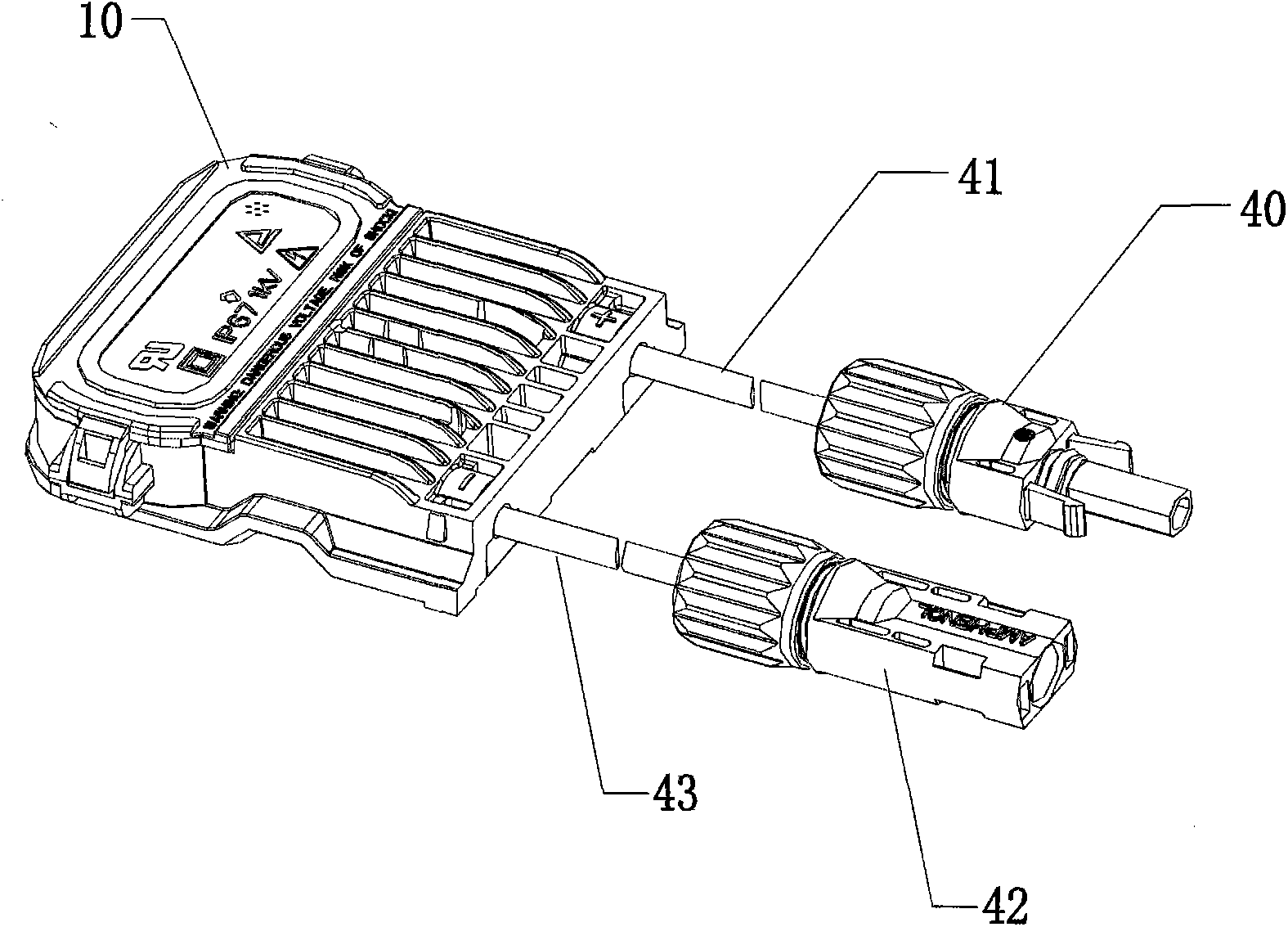

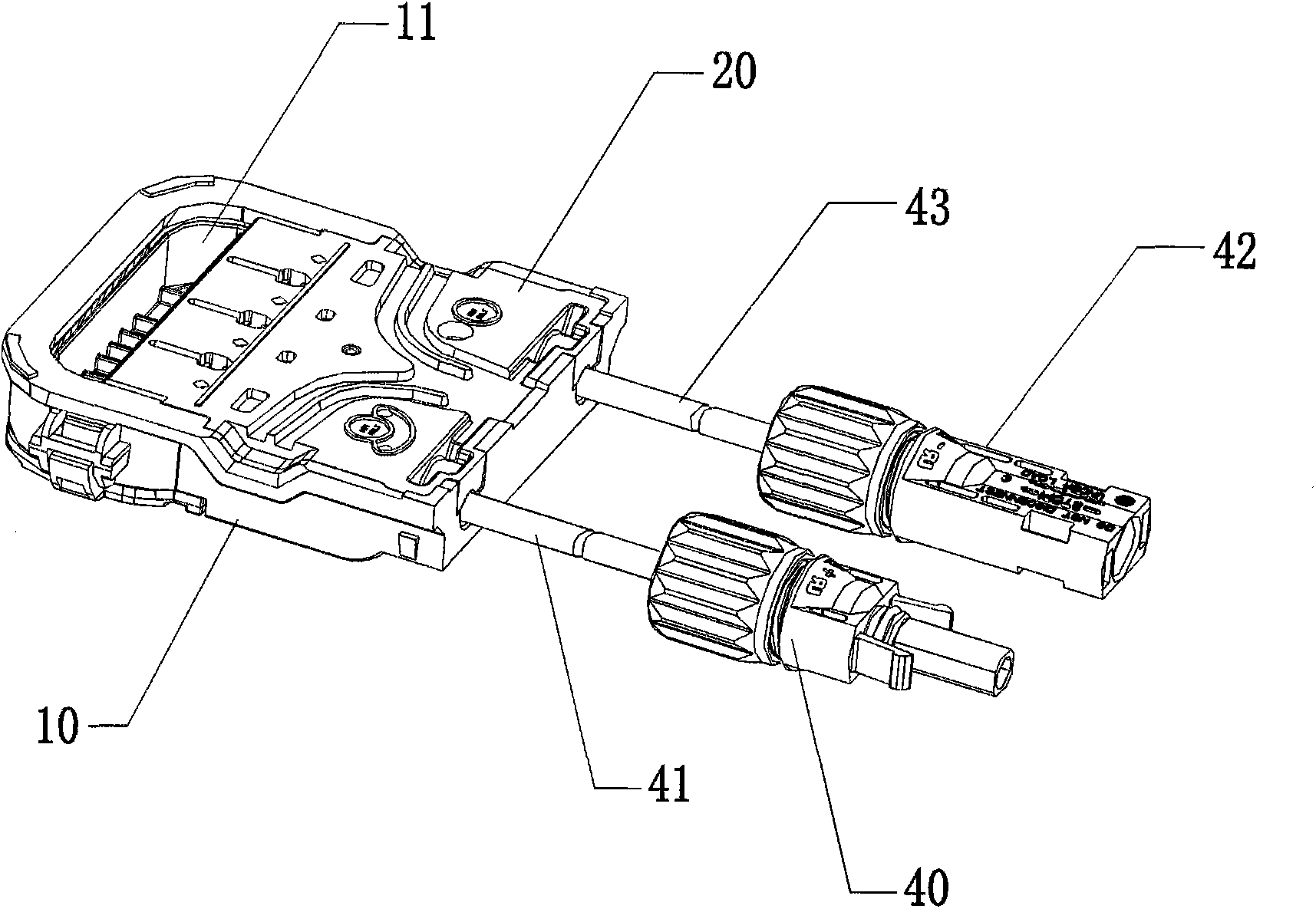

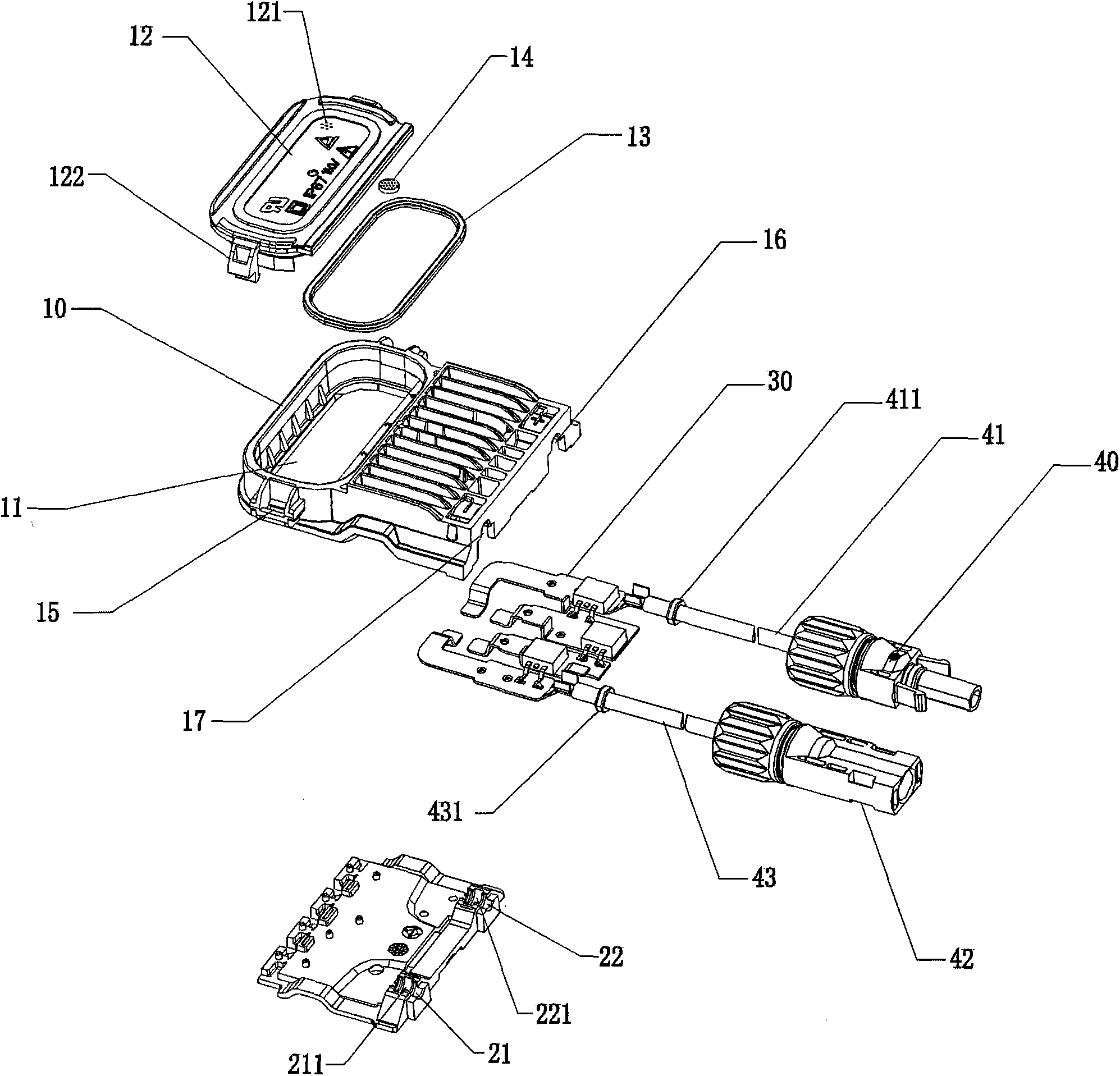

Waterproof and ventilating structure of solar junction box

InactiveCN103413853ANot prone to performance degradation issuesAvoid enteringClimate change adaptationPhotovoltaic energy generationEnvironment effectWater vapor

Owner:AMPHENOL TECH (SHENZHEN) LTD CO LTD

UV wax oil and preparation method thereof

InactiveCN110079198AIncrease productivityHigh coating hardnessWax coatingsAntifouling/underwater paintsVegetable oilUltraviolet

The invention discloses UV (ultraviolet) wax oil which comprises the following raw materials in percentage by mass: 40-60% of vegetable oil modified epoxy acrylate, 10-20% of Chinese wood oil, 5-10% of rosin, 5-10% of paraffin, 2-6% of beewax, 3-7% of palm wax, 3-6% of photoinitiator, 0.5-2% of assistant and 10-20% of wear-proof powder. The raw materials are combined together organically, so thatthe UV wax oil can be used for roller coating or rubbing coating and produced on a production line; and the production efficiency is greatly improved. The UV wax oil is free from VOC (volatile organiccompound) emission, belongs to an environment-friendly product, is high in film hardness, good in wear resistance, water resistance and fouling resistance, high in adaptability and low in productioncost, and can completely substitute the traditional common wax oil; the high-quality UV wax oil can be prepared through a series of operation of material preparation, ester addition, addition of the oil, the wax, the rosin and the like, re-charging, inspection and packaging; intensive mixing of the raw materials is facilitated; the raw materials are made full use of; and the production quality ofthe UV wax oil is improved.

Owner:YOUCAI (SHANDONG) ENVIRONMENTAL PROTECTION TECH CO LTD

Manufacturing method of bamboo spring bracket and application thereof

InactiveCN109227826AReduce usageReduce production processWood working apparatusCane mechanical workingCarbonizationEngineering

Owner:NANJING FORESTRY UNIV

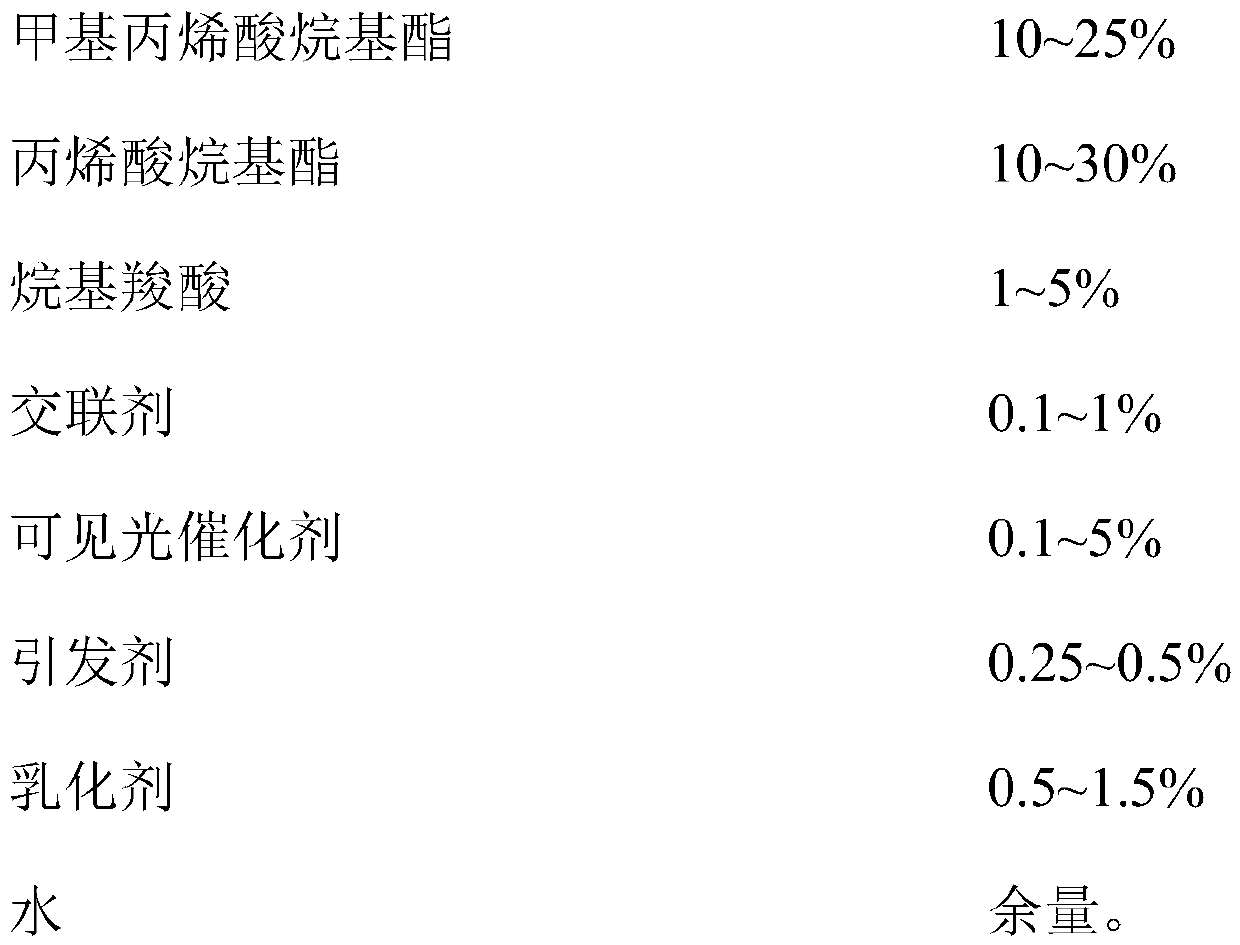

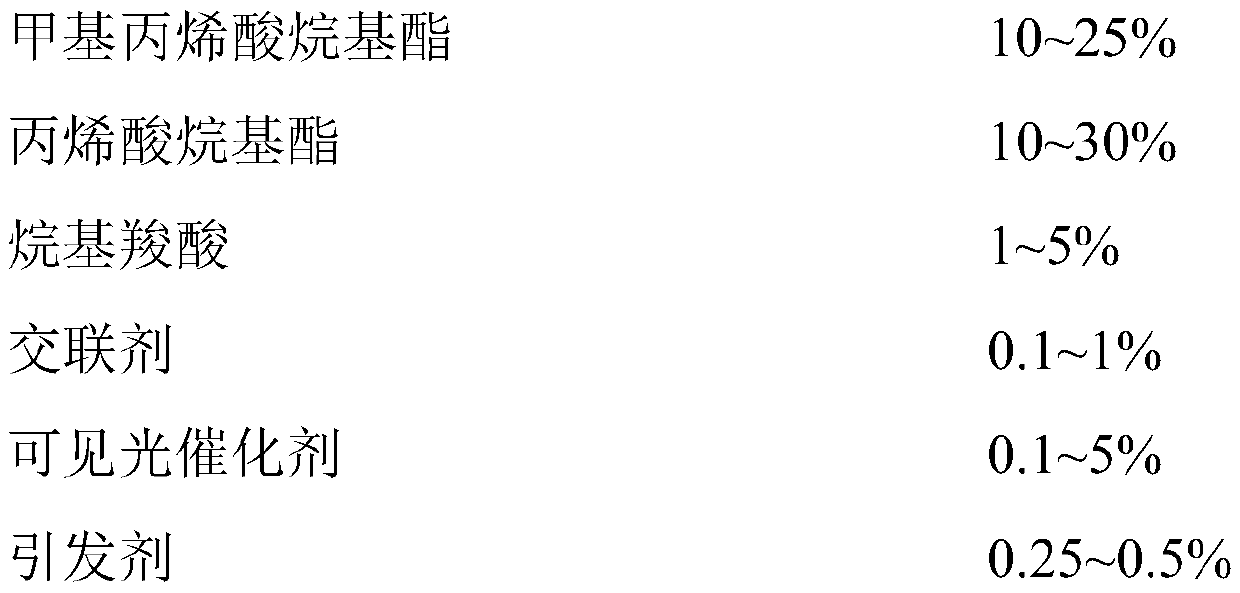

Aqueous acrylic resin which can degrade formaldehyde by using visible light and preparation method of aqueous acrylic resin

Owner:KUNMING UNIV OF SCI & TECH

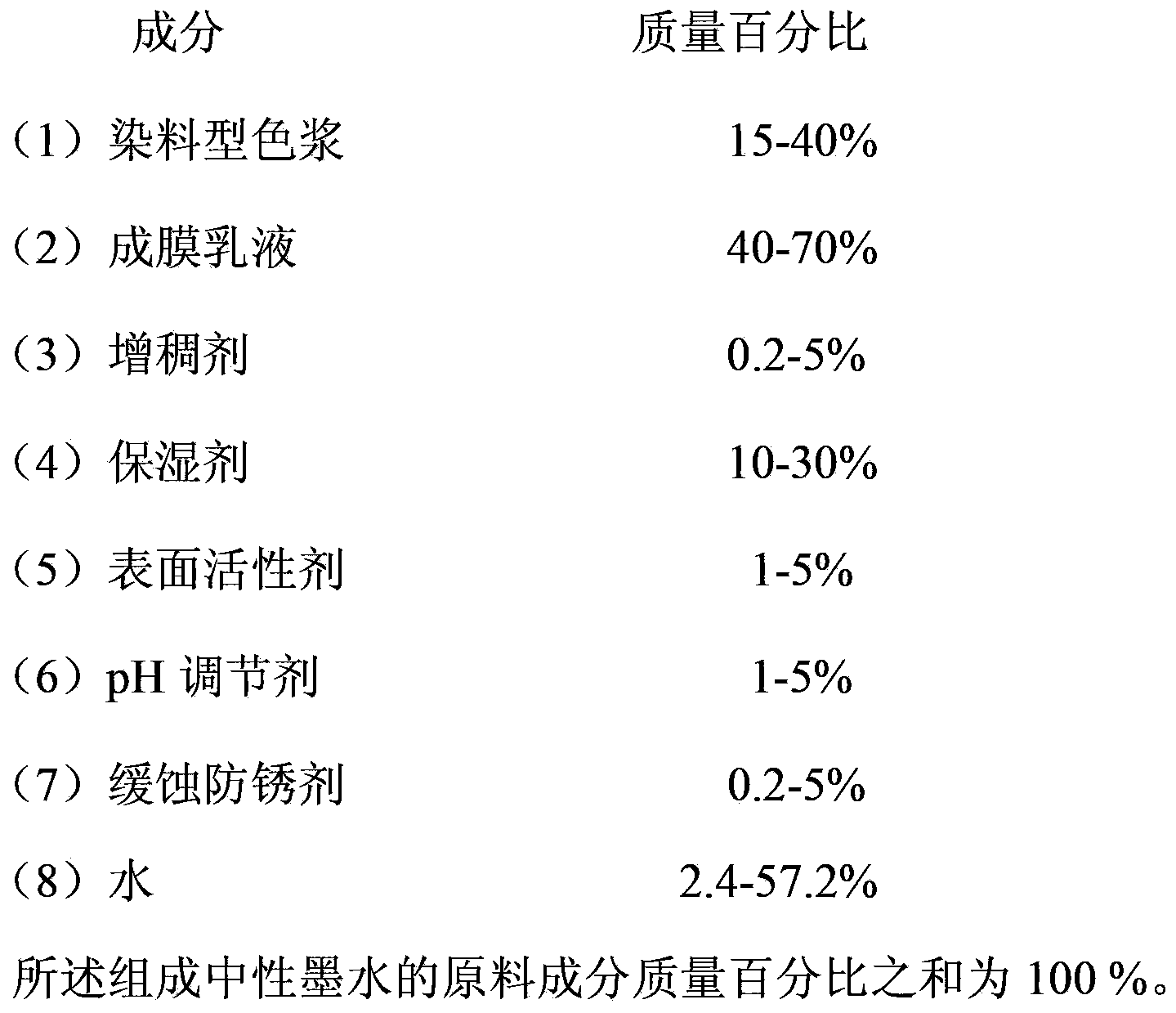

Dye-type neutral ink and preparation method thereof

Owner:DALIAN UNIV OF TECH

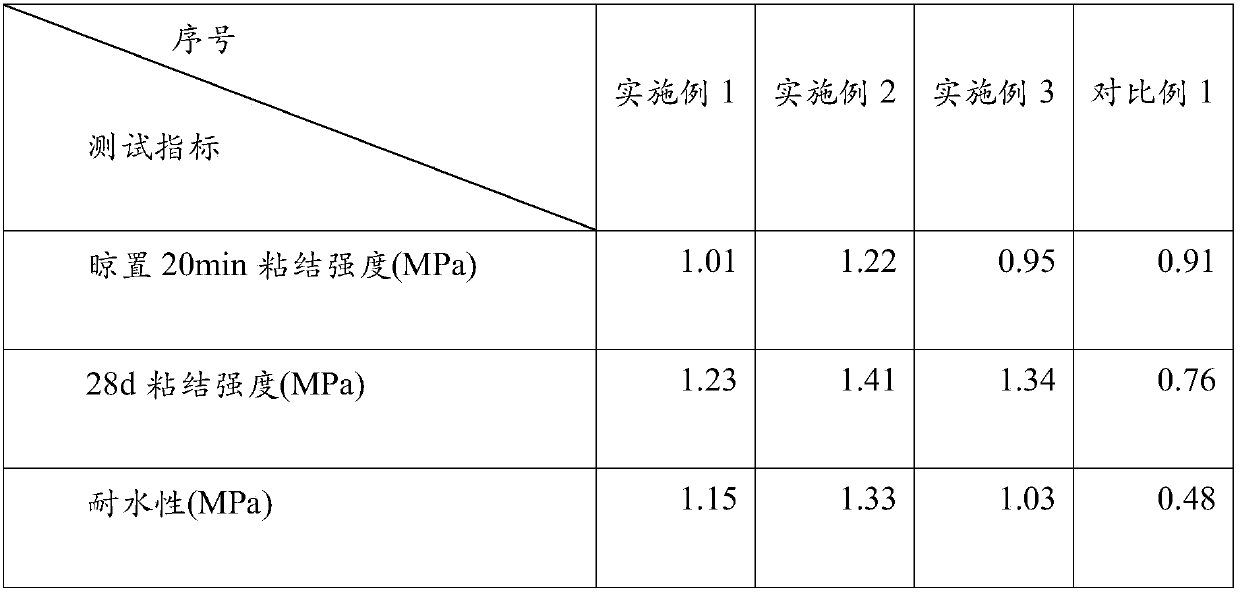

Polymer bonding mortar and preparation method thereof

The invention discloses a polymer bonding mortar and a preparation method of the polymer bonding mortar. The bonding mortar uses a modified redispersible powder to replace the traditional sizing material, the redispersible powder modified by paraffin and micron sized silica aerogel is better in water resistance and dispersibility, the bonding strength between the redispersible powder and an aggregate is stronger, in addition, a certain amount of aramid pulp and activated carbon powder are added as the aggregate, the degree of compacting of the mortar and the internal permeability of the mortar are improved, the bonding speed of the mortar is accelerated, the uneven hydration is avoided, the solidified mortar is excellent in anti-permeability, an introduced water retention particle is a long-acting reversible product, the water retaining property of the mortar is effectively improved, and the comprehensive performance of the mortar are further improved. The prepared bonding mortar is green and environmentally friendly, is economical and efficient, and has a prominent application advantage in an external wall insulation system.

Owner:HEFEI SHENZHOU CONSTR GRP CO LTD

Environmental-friendly water-resistance high-strength ceramic gum and preparation method

Owner:WUHAN UNIV OF SCI & TECH

Fireproof blocking plate

InactiveCN104070714AAvoid warpingGuaranteed compression performanceLayered productsNon toxicityFire resistance

The invention provides a fireproof blocking plate. The fireproof blocking plate consists of a main material, a frame layer reinforcing material, a light material, a modifier and water, wherein the main material consists of magnesium chloride and magnesium oxide; the frame layer reinforcing material consists of glass fibers; the light material consists of vermiculite and perlite; the modifier consists of hydrochloric acid. The fireproof blocking plate has the advantages of being manufactured by scientifically mixing and pressing a plurality of incombustible materials; the fireproof blocking plate has the fire resistance and the characteristics of long incombustible time in fire, high mechanical strength, strong explosion resistance, water resistance, oil resistance, chemical corrosion resistance, non-toxicity and the like; meanwhile, the fireproof blocking plate does not deform when the highest temperature of the flame reaches 1000 DEG C in a combustion test of inorganic fire barriers; all the indexes of the fireproof blocking plate meet the specified requirements of GB23864-2009; the combustion property can reach the standard of grade A (incombustible) in the regulations of GB8624.

Owner:TIANJIN ANSHENGDA FIREPROOF MATERIAL CO LTD

Coating process of outer surface of sculpture

InactiveCN105921387APrevent metal oxidationSufficient adhesionPretreated surfacesSpecial surfacesWeather resistanceSurface roughness

Owner:NANJING CHENGUANG ART ENG CO LTD

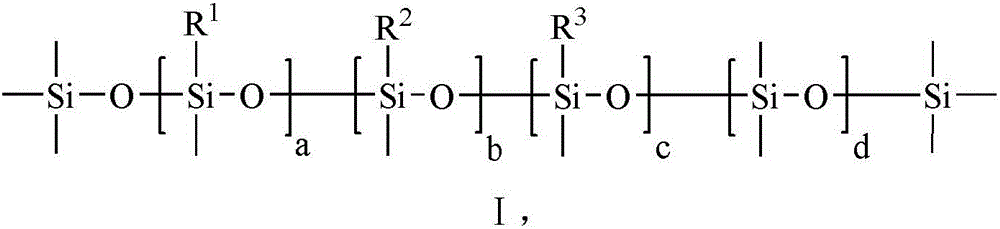

Rosin modified silicon wax and preparing method thereof

Owner:太仓中化环保化工有限公司

High-temperature-resistant insulation material applied to power equipment and preparation method of high-temperature-resistant insulation material

InactiveCN107189167AGood mechanical propertiesImprove insulation performancePlastic/resin/waxes insulatorsEpoxyAlkali free

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

An adhesive used for moisture-proof fiberboards

InactiveCN106554737AShort curing timeImprove waterproof and water resistanceNon-macromolecular adhesive additivesStarch adhesivesAdhesiveMoisture

Owner:SHIFANG MIDEE WOOD IND

Concealer with toning ability, water resistance and makeup blurring resistance

InactiveCN106511129AGood concealerImmediate whitening effect is obviousCosmetic preparationsMake-upSkin colorComposition B

The invention discloses a concealer with toning ability, water resistance and makeup blurring resistance. The concealer comprises a composition A and a composition B. In use, the composition A is smeared at first and then the composition B is smeared onto the composition A. The two different compositions, i.e., the composition A and the composition B, are employed, and different amounts of the composition A and the composition B are separately and successively smeared for concealing according to different skin colors of users. Compared with traditional concealers, the concealer provided by the invention has the advantages of easiness in smearing, good concealing effect and obvious whitening effect, so the concealer is the first choice for ladies enamored of beauty.

Owner:张二伟

Waterborne fireproof paint and preparation method thereof

ActiveCN107641387ALong fire resistanceReduce manufacturing costFireproof paintsCarvacryl acetateStabilizing Agents

Owner:山东七维新材料有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap