Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "Vinyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vinyl acetate is an organic compound with the formula CH₃CO₂CH=CH₂. This colorless liquid is the precursor to polyvinyl acetate, an important industrial polymer.

Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

ActiveCN102030857AGood adhesionImprove water resistanceMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsCross-linkPolymer science

The invention relates to a vinyl acetate-ethylene copolymer emulsion as an electrostatic spinning adhesive and a synthesis method thereof. Organic peroxides and zinc formaldehyde sulfate are taken as an initiator; vinyl acetate, ethylene, acrylic ester monomers and cross-linking monomer N-hydroxymethyl acrylamide are taken as comonomers; a nonionic emulsifier, and the synthetic emulsion and the protective colloid of an amphoteric emulsifier are matched to be taken as an emulsification system; and the copolymer emulsion is prepared through emulsion polymerization. Compared with the VAE (vinyl acetate-ethylene) emulsion prepared by the conventional preparation method, the product in the invention has the advantages of good water resistance, strong adhesion on low-surface-energy materials (polyethylene, polypropylene and the like), fine grain and the like. The vinyl acetate-ethylene copolymer emulsion is suitable for being as the adhesive to be applied to the field of the electrostatic spinning in textile industry and the fields of waterproofing and packaging.

Owner:CHINA PETROCHEMICAL CORP +1

Preparation of highly water-soluble polyvinyl alcohol

Owner:SICHUAN UNIV

Ink resin composite used for plastic gravure printing and preparation method thereof

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Method for preparing chloroprene rubber adhesive agent

InactiveCN101781538APromote environmental protectionHigh affinitySolesGraft polymer adhesivesPolymer scienceBenzoyl peroxide

Owner:NANTONG GUANGTAI BIOCHEM PROD

Antibacterial finishing agent, antibacterial yarn and preparation method and application of antibacterial yarn

InactiveCN107217481AHas antibacterial propertiesPrevent mildewBiochemical fibre treatmentGrip property fibresYarnWater based

Owner:湖南莎丽袜业股份有限公司 +1

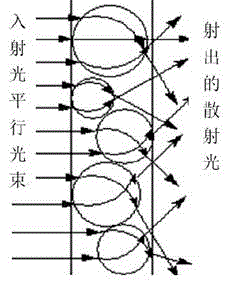

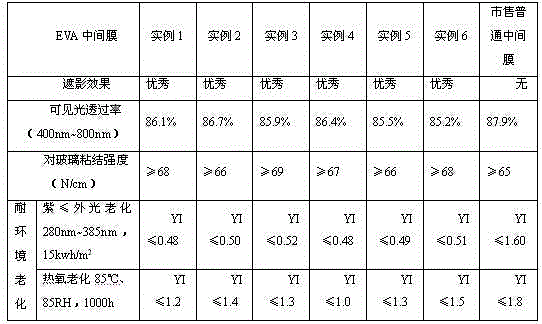

Laminated glass intermediate film with shielding capacity and high transparency as well as preparation method thereof

InactiveCN104098828AAchieve light transmissionAchieve the optical effect of shadingPolymer scienceCross linker

Owner:NANJING KIN YONG FA PLASTIC MFG

Nontoxic degradable plastic

Owner:青岛海蓝海洋复合功能材料科技有限公司

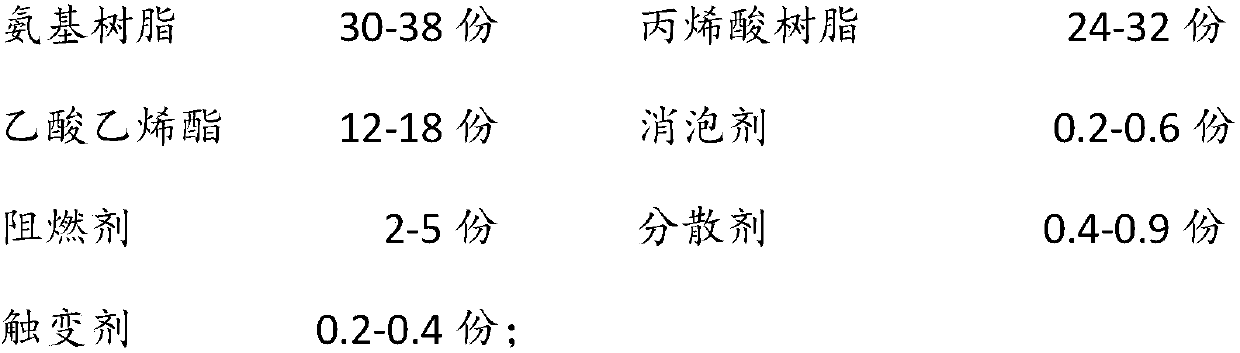

Flame-retardant finish paint for furniture

InactiveCN107629661AImprove flame retardant performanceStrong impact resistanceFireproof paintsPolyurea/polyurethane coatingsAcrylic resinLacquer

Owner:佛山市三水区白坭镇巨财红木厂

Waterborne fireproof paint and preparation method thereof

ActiveCN107641387ALong fire resistanceReduce manufacturing costFireproof paintsCarvacryl acetateStabilizing Agents

Owner:山东七维新材料有限公司

Graphene/fluorine-silicon self-crosslinking resin composite heavy-duty anti-corrosion finish paint and preparation method thereof

PendingCN110642970AAvoid the disadvantages of easy reunionEvenly dispersedAnti-corrosive paintsEthyleneglycol monobutyl etherIn situ polymerization

The invention relates to graphene / fluorine-silicon self-crosslinking resin composite heavy-duty anti-corrosion finish paint and preparation thereof. The finish paint is prepared from the following rawmaterials in parts by weight through in-situ polymerization: 30 to 40 parts of hydroxyethyl allyl ether, 50 to 60 parts of vinyl acetate, 25 to 35 parts of undecylenic acid, 10 to 20 parts of ethylene glycol monobutyl ether, 8 to 10 parts of vinyl siloxane, 50 to 60 parts of chlorotrifluoroethylene CTFE, 4 to 20 parts of graphene oxide, 125 to 150 parts of a solvent and 5 to 6 parts of an initiator. A graphene fluorine-silicon self-crosslinking resin composite is prepared by performing in-situ polymerization on a part of free double bonds of graphene oxide and an olefin monomer, namely, dispersing graphene in a polymer monomer for monomer-monomer polymerization and monomer-graphene-monomer polymerization. The preparation process is simple; the graphene oxide is uniformly dispersed in theresin and is firmly combined with the resin; and the defect that the graphene is easy to agglomerate is avoided. After the finish paint is cured, interface strength is improved, so the corrosion resistance of the graphene paint is improved.

Owner:CP NANOMATERIALS RES CENT (DALIAN) CO LTD

Setting agent used after wool stretch and refinement

InactiveCN106702736AGuaranteed stabilityImprove oxidation efficiencyAnimal fibresPolystyreneButanone

Owner:HUZHOU PINCHUANG INCUBATOR

Technology for coating inside woven bag by using polyether glycol composition

InactiveCN102978946AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingIsocyanate compoundEngineering

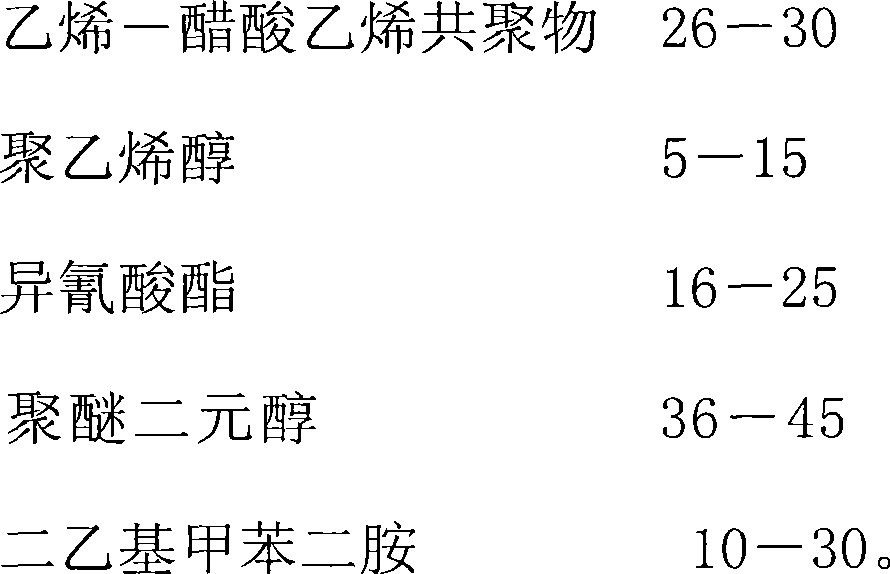

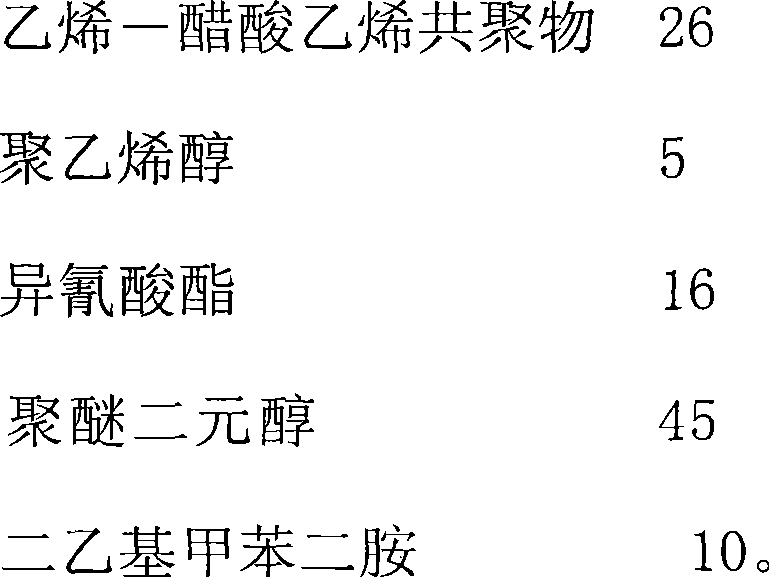

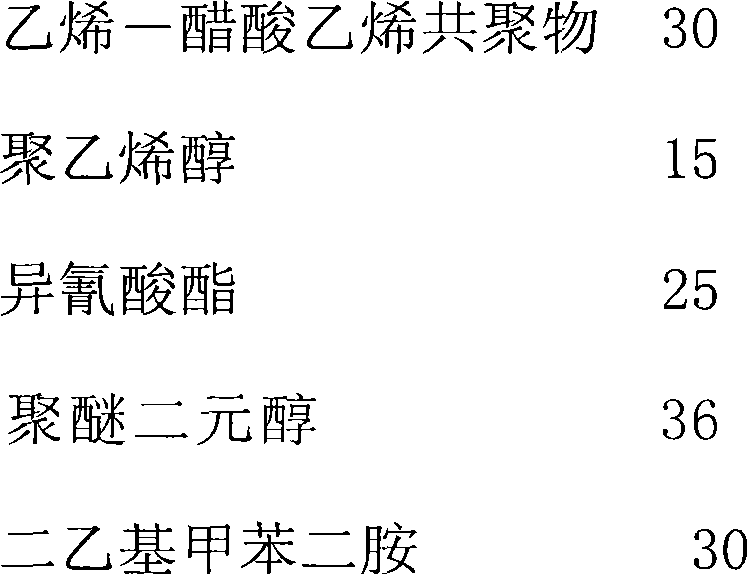

The invention discloses a technology for coating inside a woven bag by using a polyether glycol composition. The technology comprises the following steps of: firstly, weaving a cylindrical fiber woven layer by using warps and wefts, both of which are made of fiber materials, on a circular weaving machine, then, spraying the coating prepared on site to the inner side of the woven layer to form a liner, and drying to obtain an inside-sprayed woven bag product, wherein the coating comprises the following components in parts by weight: 26-30 parts of ethylene-vinyl acetate copolymer, 5-15 parts of polyvinyl alcohol, 16-25 parts of isocyanate, 36-45 parts of polyether glycol, and 10-30 parts of diethyl toluenediamine.

Owner:QINGDAO PENGHAI SOFT CO LTD

Nano water-based paint imitating electroplated coating and preparation method thereof

InactiveCN112358802AGood effectIncrease brightnessAnti-corrosive paintsPolyurea/polyurethane coatingsEmulsionSlurry

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Halogen-free low-smoke cable material for ship and ocean engineering cables

The invention belongs to the technical field of compositions of high-molecular compounds, and discloses a halogen-free low-smoke cable material for a ship and ocean engineering cable. The flame-retardant EVA rubber material is prepared from 35-45 parts of ethylene-vinyl acetate resin, 20-25 parts of EVA rubber material, 15-18 parts of carbon fiber, 7-8 parts of filler, 7-8 parts of ceramic powder, 4-6 parts of halogen-free flame retardant, 3-6 parts of lubricating oil, 2-4 parts of processing aid, 2-4 parts of antioxidant and 1-3 parts of compatilizer. The cable material solves the problem that the existing cable material is light in weight, so that the mechanical strength of the cable material is complemented due to the proportion of the raw materials, and the service life of the prepared cable is short.

Owner:CHONGQING EASTFUL ELECTRIC WIRE & CABLE CO LTD

Low-odor and low-VOC environment-friendly latex paint and preparation method thereof

InactiveCN110776790AImprove performanceImprove antibacterial functionAntifouling/underwater paintsPaints with biocidesAntibacterial propertyNanotube

Owner:NIPPON PAINT CHENGDU

Hot-melt optical adhesive with ultraviolet blocking function and preparation method thereof

ActiveCN113604178AAggregation is stableFix compatibility issuesGraft polymer adhesivesMeth-Formate

Owner:SHENZHEN GAOREN ELECTRONICS NEW MATERIAL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap