Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58 results about "Polyvinyl alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This medication is used to relieve dry, irritated eyes.

Solid-type filter stick formed by granular assembling and preparation method thereof

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

High-strength and high-modulus polyvinyl alcohol fiber and melt spinning method of high-strength and high-modulus polyvinyl alcohol fiber

InactiveCN102776597AHigh strengthMeet toughnessFilament forming substance formingArtificial filament washing/dryingAlcoholPolymer science

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

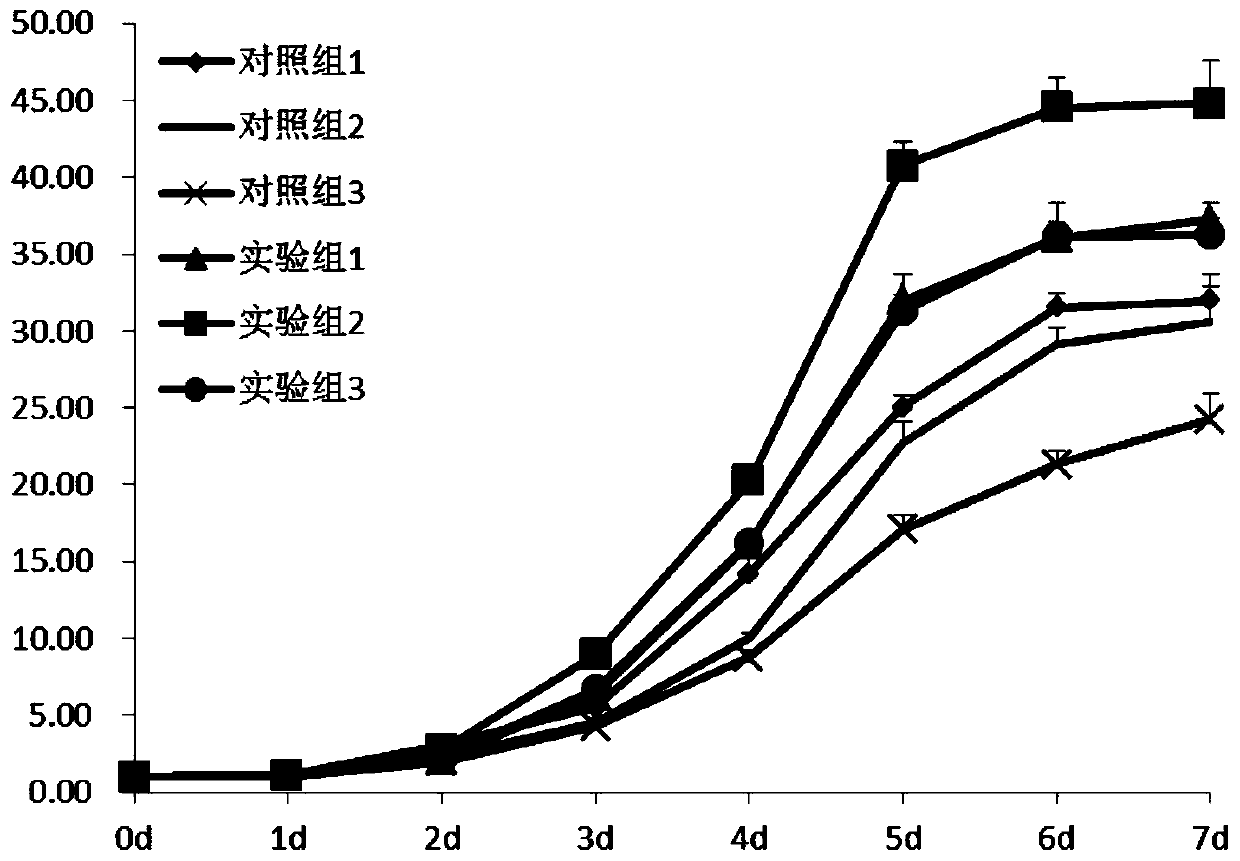

Serum-free culture medium, preparation method thereof and culture method of mesenchymal stem cells

ActiveCN110923196AImprove proliferative abilityImprove performanceCulture processSkeletal/connective tissue cellsPolyvinyl alcoholHydrocortisone

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

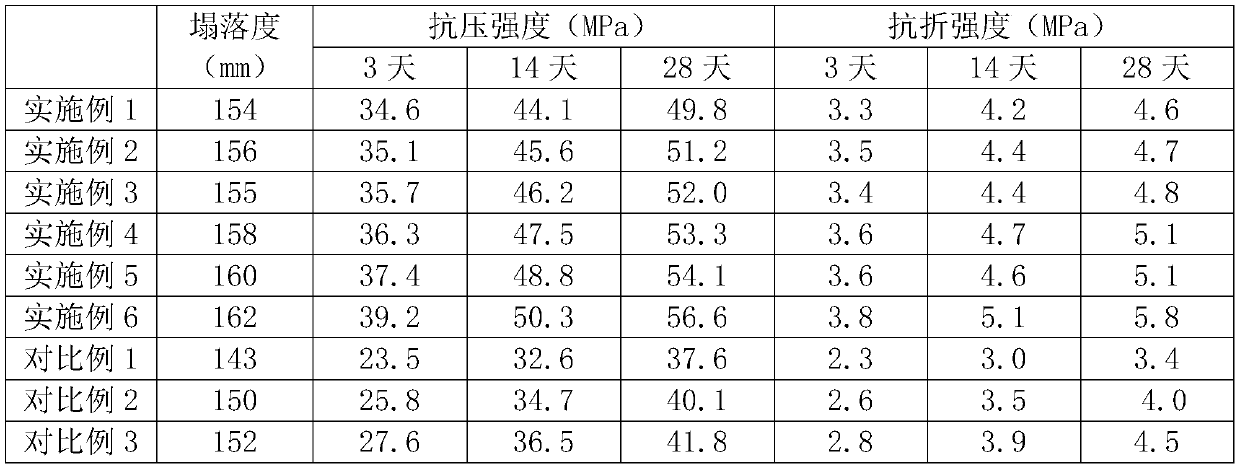

Recycled concrete and preparation method thereof

Owner:陕西金基石新型建材有限公司

Thermoplastic polymer composition and molded article

InactiveUS20130122289A1Excellent in flexibility propertyImprove mechanical propertiesNon-fibrous pulp additionNon-macromolecular adhesive additivesPolyvinyl alcoholGlass transition

Owner:KURARAY CO LTD

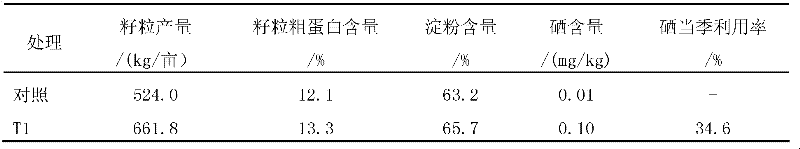

Selenium-containing coating agent for sustained release fertilizer special for selenium-rich agricultural products and preparation method for selenium-containing coating agent

ActiveCN102503669AIncrease profitMeet the needs of the whole growth periodFertilizer mixturesEpoxyPolyvinyl alcohol

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

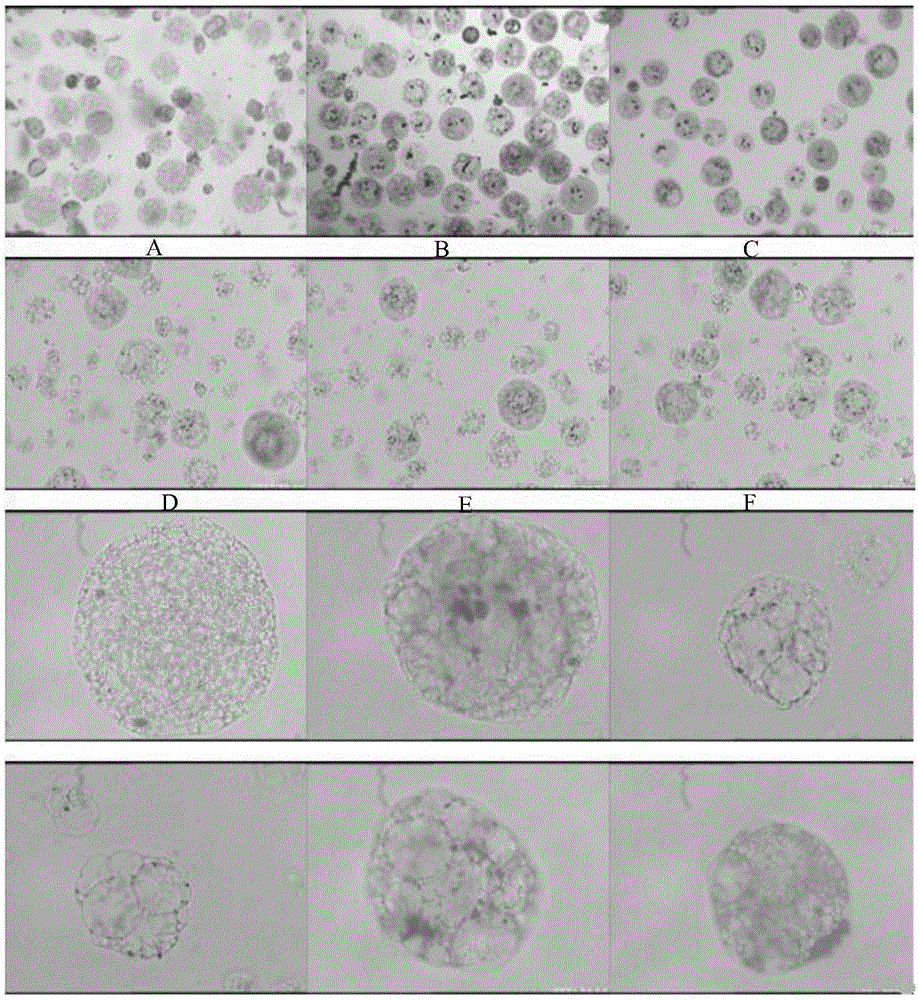

Three-dimensional wrinkle polylactic acid microballoons and preparation method and uses thereof

InactiveCN105273216AAchieve transformationLarge specific surface areaTissue cultureLiquid separationCell adhesionMicrosphere

Owner:JIANGSU UNIV

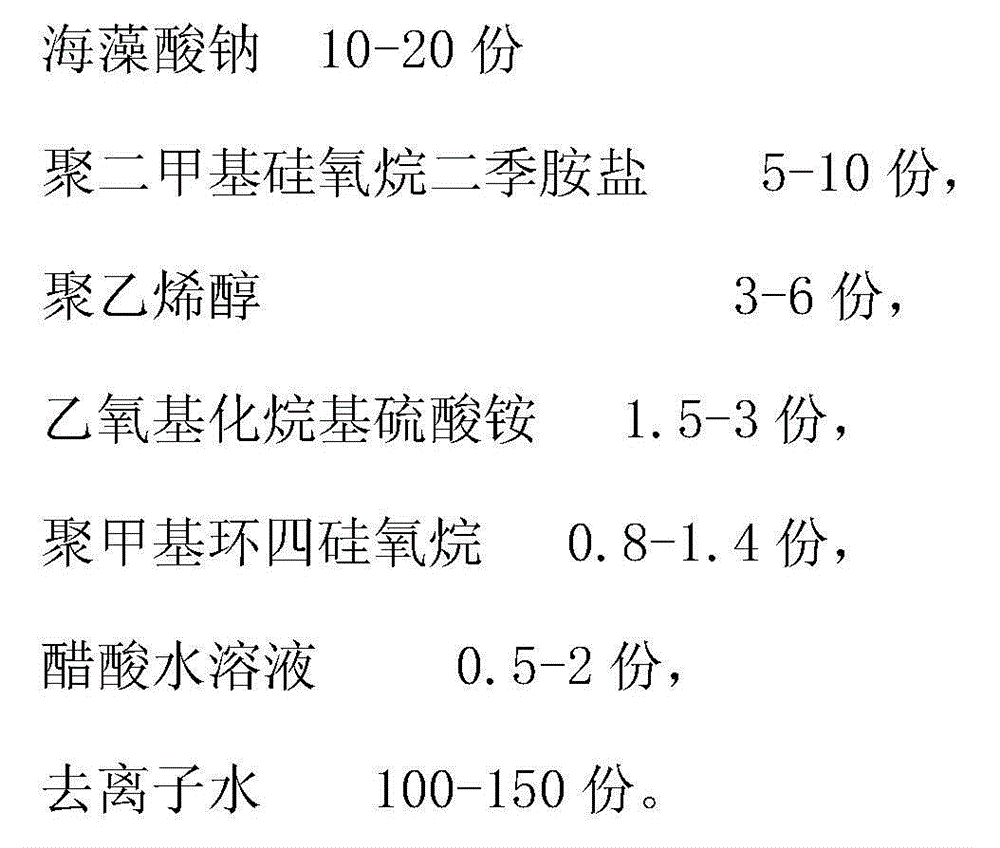

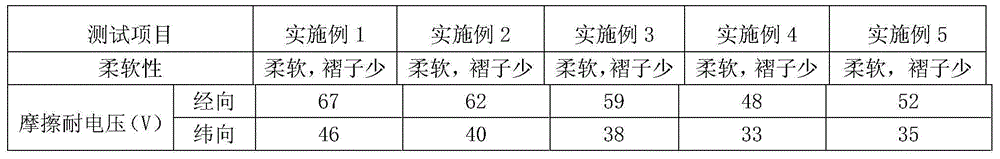

Novel electrostatic removal agent for textile materials and preparation method of novel electrostatic removal agent

InactiveCN104532572AEasy to dissolve and disperseImprove stabilityFibre treatmentAcetic acidPolyvinyl alcohol

Owner:HUZHOU LINGHU ZHONGZHAO JINHUI SILK WEAVING FACTORY

Sodium bentonite processing agent for blue-green algae and preparation method thereof

InactiveCN104495960AFast gatheringQuick gather salvageBiocideDisinfectantsSodium BentoniteEutrophication

A sodium bentonite processing agent for blue-green algae is prepared from the following raw materials in parts by weight: 10-20 parts of serpentine, 40-45 parts of sodium-base bentonite, 2-3 parts of magnesium chloride, 8-13 parts of calcium chloride, 15-20 parts of potassium ferrate(VI), 12-16 parts of equisetum hyemale, 13-16 parts of pericarpium granati, 3-5 parts of polymaleic acid, 3-4 parts of sodium pyrophosphate, 2-3 parts of urea, 3-5 parts of anhydrous sodium sulfate, 3-5 parts of boric acid, 4-6 parts of polyvinyl alcohol, proper amount of water, and 3-4 parts of an adsorption auxiliary agent. By adding potassium ferrate(VI), the processing agent for blue-green algae has synergic effects of oxidation, adsorption, flocculating, precipitation, sterilization, disinfection, decoloring and deodoring, also does not generate any toxic and harmful substances, is capable of increasing water dissolved-oxygen content, has good removal effects on ammonia nitrogen, nitrites and algae in water, and is used to remove fulvic acid and suspensions in water and eutrophication phenomenon in fresh water. The processing agent for blue-green algae is good in dispersing suspending property and good in adsorption property, and can help to rapidly aggregate and salvage blue-green algae.

Owner:WUHU XIANGRONG FOOD

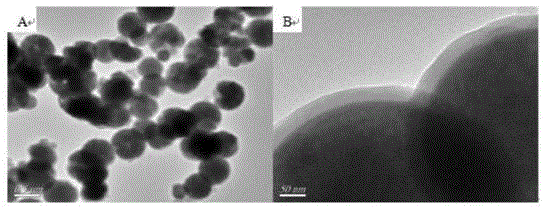

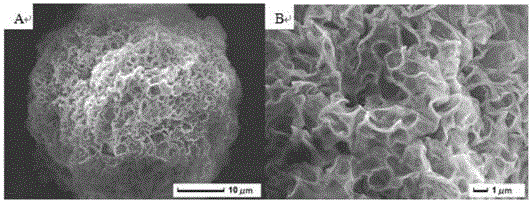

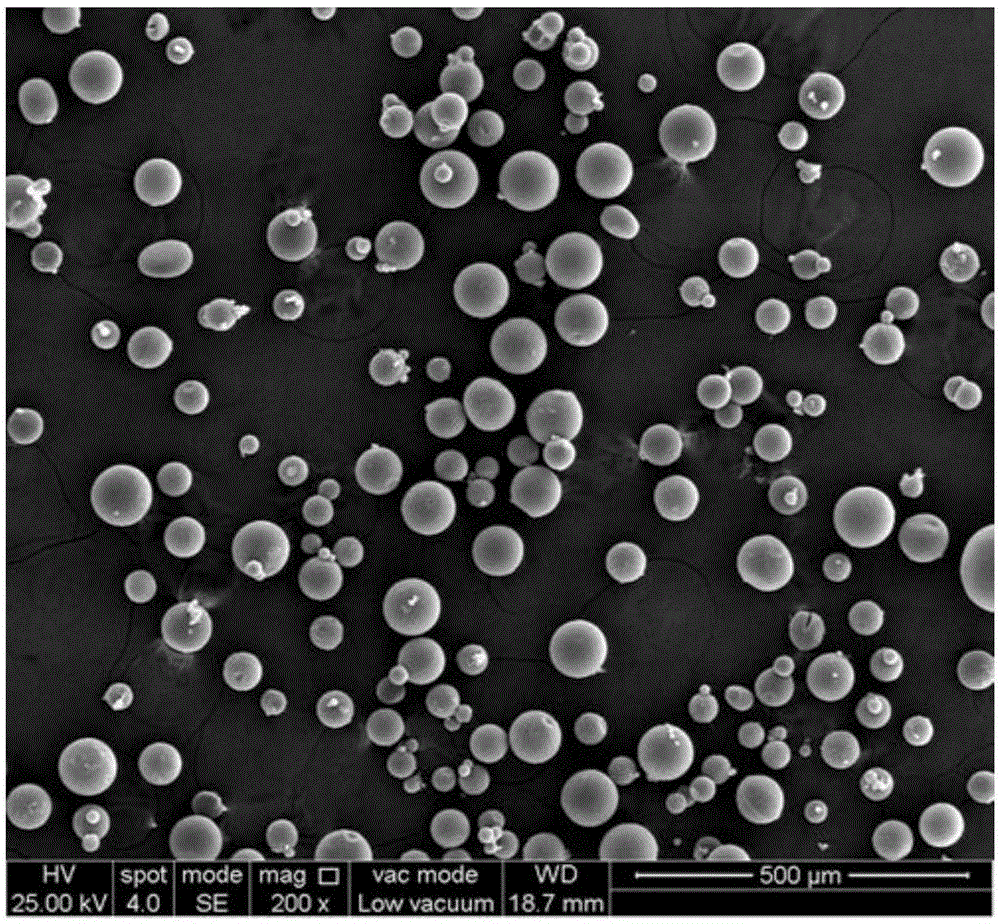

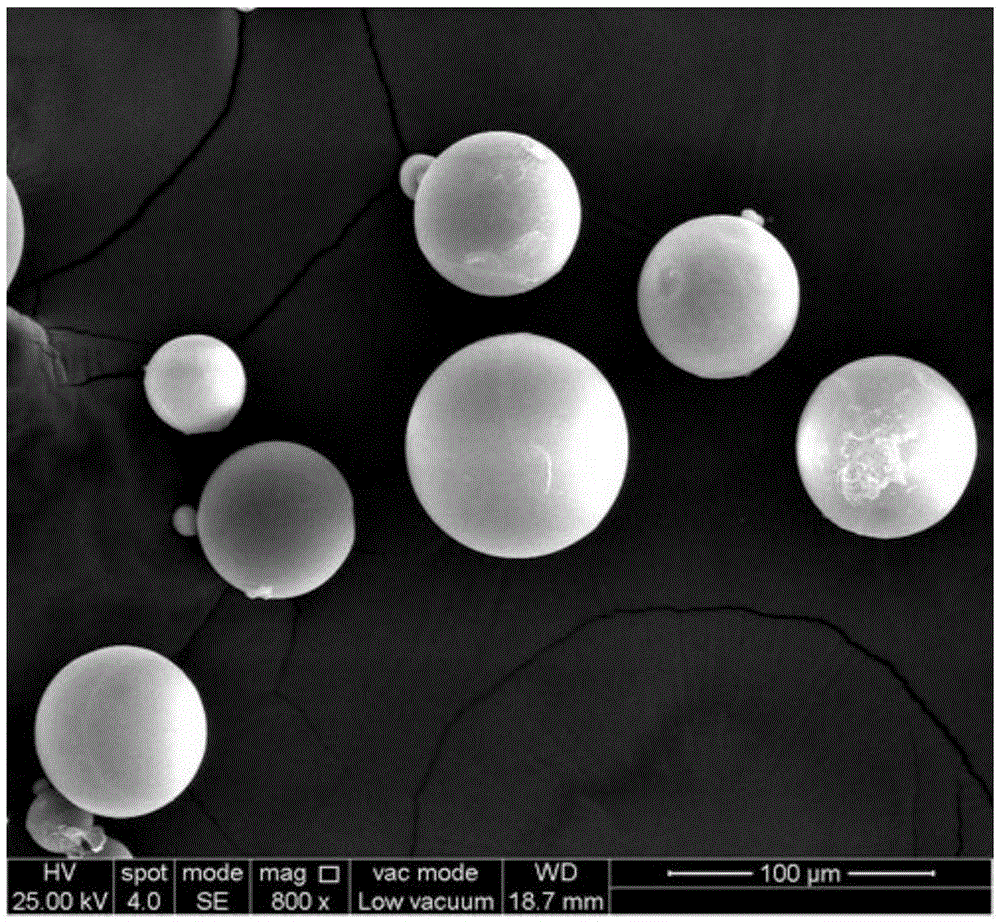

Preparation method for polyvinyl alcohol/silicon dioxide composite microspheres

ActiveCN105344334AGood dispersionSpherical RegularityOther chemical processesMicrospherePolyvinyl alcohol

Owner:CHINA UNIV OF MINING & TECH

Calcium carbonate compound type flame-retardant foaming agent

Owner:新建特阔漂整(南通)有限公司

Aqueous porcelain imitating coating material

Owner:NANTONG XINGYU PAINT

Waterproof reinforced composite and preparation method thereof

The invention discloses a waterproof reinforced composite and a preparation method thereof. The waterproof reinforced composite is prepared from the following raw materials in parts by weight: 60-90 parts of epoxy resin modified polyurethane emulsion, 15-30 parts of organic silicon styrene-acrylic emulsion, 10-30 parts of methyl methacrylate, 10-20 parts of polyacrylate, 2-4 parts of N-hydroxymethyl acrylamide, 6-12 parts of oxide-coated titanium dioxide, 10-30 parts of composite filler, 3-8 parts of silane coupling agent, 3-6 parts of propanediol butyl ether, 3-6 parts of diethylene glycol monobutyl ether, 5-10 parts of sodium polyphosphate, 4-8 parts of polyvinyl butyral, 2-5 parts of urea-isobutyraldehyde-formaldehyde resin, 0.3-0.6 part of sodium perfluorous nonenoxybenzene sulfonate,0.4-0.9 part of polypropylene wax emulsion, 0.3-0.7 part of polyether modified polysiloxane, 0.5-1 part of hydroxypropyl methyl cellulose, 1-3 parts of epoxy phosphate ester, 1-5 parts of compound antiaging agent and 10-20 parts of water.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

Weather-resistant impact-resistant waterproof plugging material with stable quality and its preparation method

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

Curved lenses configued to decode three-dimensional content

Owner:SCHLUMBERGER TECH CORP

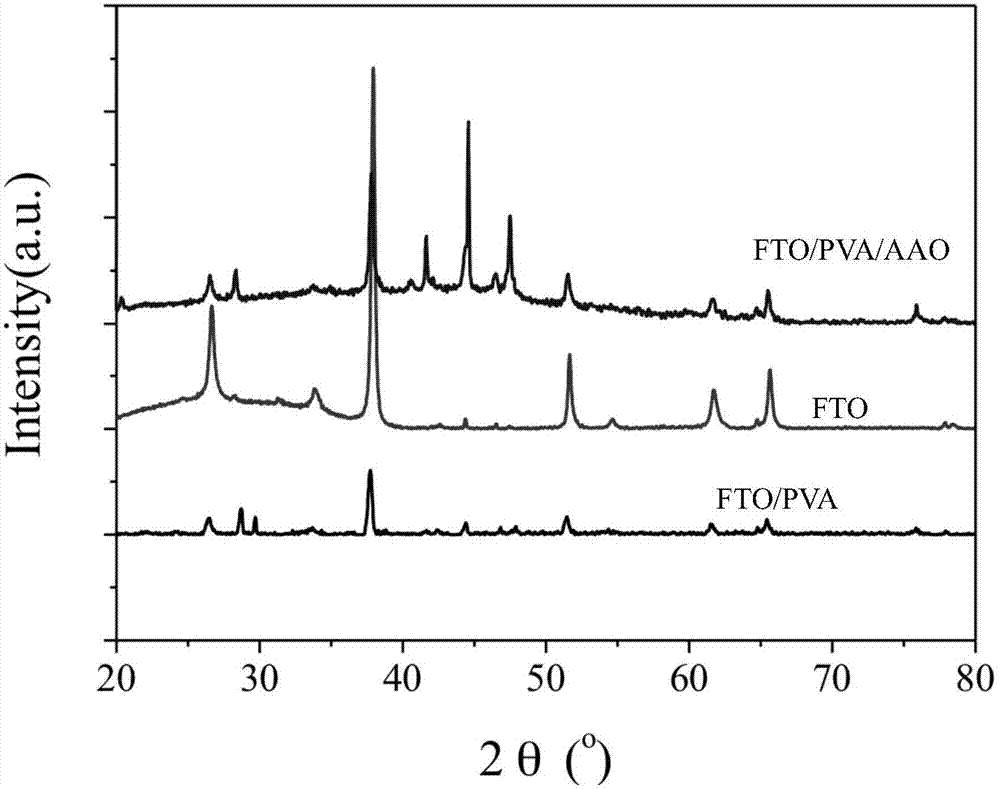

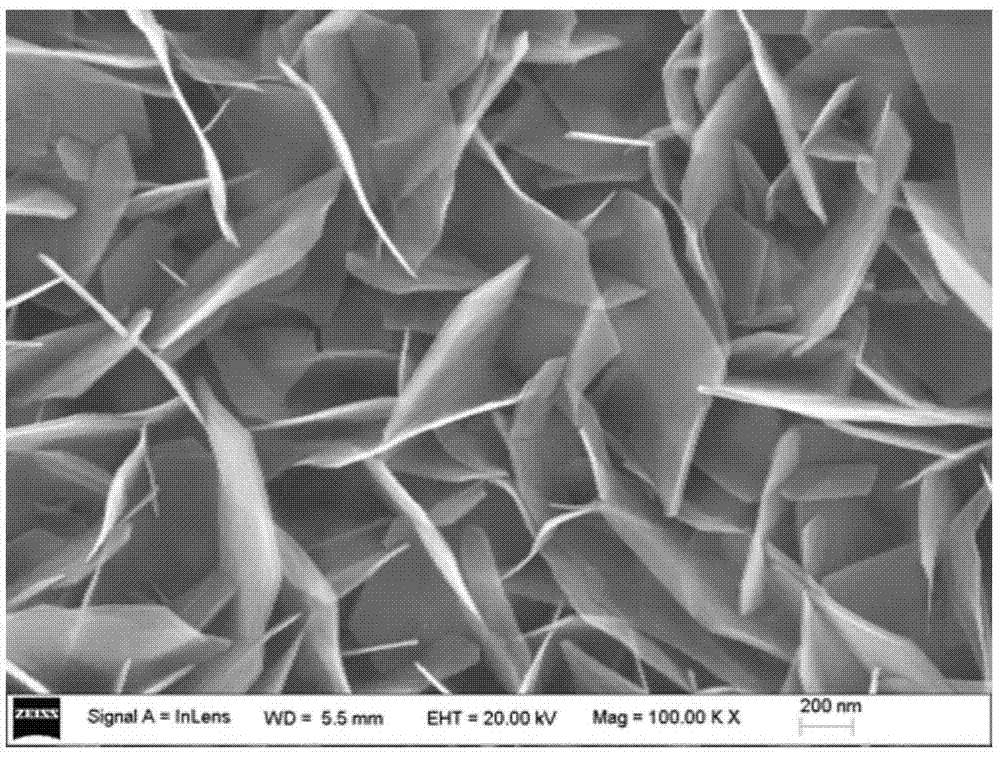

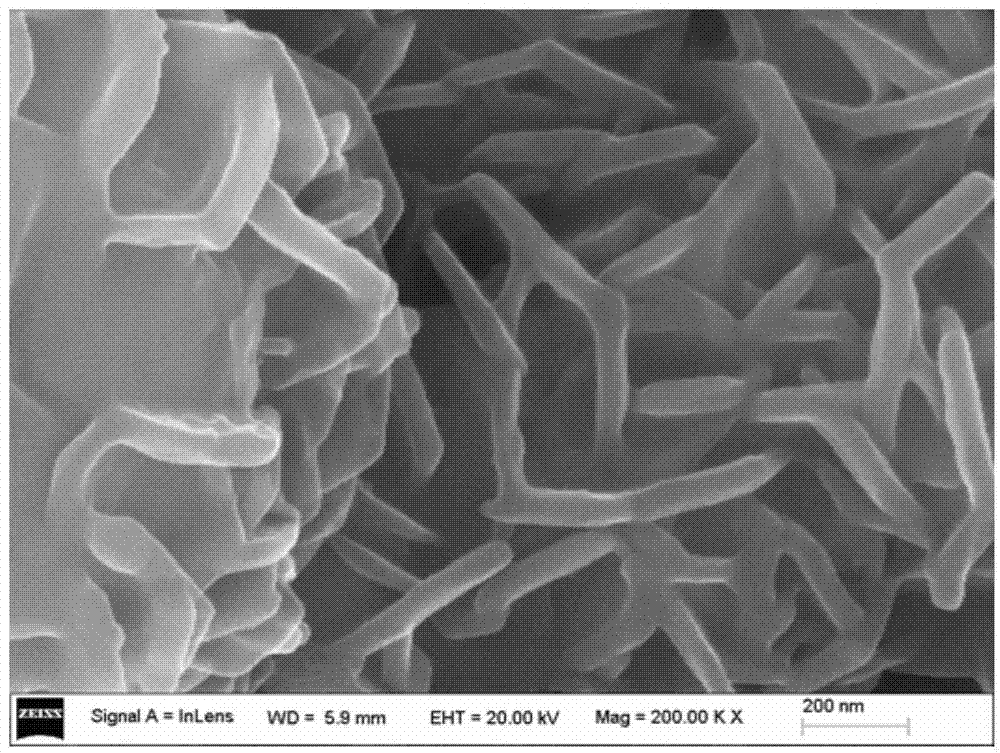

Method for preparing flowerlike nanometer cobalt by using anodised aluminum template, and product of same

ActiveCN104846411AThe method is simple and fastMild reaction conditionsNanotechnologyAdhesivePolyvinyl alcohol

Owner:BEIHANG UNIV

Anti-flaming thermal-insulation environmentally-friendly polymeric foaming material and method for producing the same

InactiveCN102516710ALow thermal conductivityImprove insulation effectPolymer sciencePolyvinyl alcohol

The invention discloses an anti-flaming thermal-insulation environmentally friendly polymeric foaming material and a method for producing the material. The method comprises the following steps: preparing a urea resin foam adhesive by successively adding 37 % of formaldehyde, polyvinyl alcohol and glycerin in a reaction kettle and stirring to heat up and then adding urea, hexamethylene tetramine, stabilizer and thiourea, preparing a foaming agent by firstly adding water in a stirring tank, successively adding nekal and nonylphenol polyoxylethylene ether with stirring, heating up for completely dissolving, and then adding phosphoric acid, glycerin and sodium phosphate, uniformly stirring until completely dissolving, and discharging and packaging, and preparing a foamed product by taking the urea resin adhesive, urea and the foaming agent, mixing and stirring uniformly, putting in a foaming machine to foam, and carrying out foaming, extrusion molding, drying and packaging. The invention can be widely applied in thermal insulation of building facilities, thermal insulation of venue decoration, shock absorption, replacement of benzene plate flexible package without anti-flaming property, and the like.

Owner:王喆

Impact-resistant composite insulating material and preparing method thereof

The invention discloses an impact-resistant composite insulating material and a preparing method thereof. The insulating material is prepared from 4-10 parts of polyimide resin, 3-6 parts of glass fibers, 5-12 parts of bisphenol-S epoxy resin, 5-15 parts of polycarbonate, 4-8 parts of dodecyl acrylate, 3-7 parts of dodecanol polyethenoxy ether, 2-5 parts of ethylene bis-oleamide, 3-6 parts of styrylphenol polyoxyethylene ether, 4-10 parts of phenolic epoxy vinyl ester resin and 2-5 parts of polyvinyl cinnamate. The preparing method includes the following steps that 1, the components are thrown into a high-speed mixer to be mixed; 2, the insulating material mixture mixed evenly is taken out of the high-speed mixer and extruded through a double-screw extruder; 3, the material extruded in the step 2 is granulated, and the impact-resistant composite insulating material is obtained after the granulated material is cooled to normal temperature.

Owner:SUZHOU YIXINYUAN PHOTOELECTRIC TECH

Thin-film capacitor housing heat dissipation coating and preparation method thereof

A thin-film capacitor housing heat dissipation coating is prepared from, by mass, 35 parts of resol, 3 parts of gelatin, 5 parts of glycidyl methacrylate, 3 parts of sodium dodecyl benzene sulfonate, 3 parts of gloss oil, 5 parts of dimethyl dicarbonate, 3 parts of olive oil, 3 parts of colored glaze carbylic acid, 3 parts of olive oil, 3 parts of graphene, 5 parts of pigment, 50 parts of distilled water, 3 parts of benzoyl paeoniflorin, 3 parts of sodium hypochlorite, 5 parts of a modifying agent, 3 parts of calcium carbonate, 3 parts of glacial acetic acid, 3 parts of magic acid, 5 parts of polyester resin, 3 parts of potassium dihydrogen phosphate, 1 part of sodium phosphate, 3 parts of aluminum silicate, 3 parts of imidazole, 3 parts of cohesive soil, 3 parts of polyvinyl alcohol and 3 parts of sodium borohydride. The modifying agent is added in a traditional formula to perform modification processing, the coating coated on a capacitor housing can effectively guide capacitor inside temperature rising due to work to the housing and convert heat into infrared radiation waves, and the working voltage of a capacitor can be also in a stable state in addition to prolonging of the service life of the capacitor.

Owner:HUAIAN SHENGYU ELECTRONICS

Tomato fertilizer containing rich nucleic acid and preparation method of tomato fertilizer

InactiveCN106007932AImprove water holding capacityImprove stabilityCalcareous fertilisersAlkali orthophosphate fertiliserHeavy metal chelationPolyvinyl alcohol

The invention discloses a tomato fertilizer containing rich nucleic acid. The tomato fertilizer is prepared from raw materials in parts by weight as follows: 200-210 parts of rice straw, 20-21 parts of kaoline, 10-11 parts of urea, 10-11 parts of furnace dust, 5-6 parts of hawthorn seeds, 7-8 parts of nucleic acid wastewater, 0.3-0.4 parts of ammonium polyphosphate, 0.1-0.2 parts of a urease inhibitor, 1-2 parts of gypsum powder, 1-2 parts of amino acid powder, 15-16 parts of polyvinyl alcohol, 1-1.1 parts of tea polyphenol, 1-1.1 parts of carbon nanotubes, 1.2-1.3 parts of beta-cyclodextrine and 800-810 parts of 28% ammonia water. Amino groups are introduced to biomass charcoal prepared from the rice straw and can be chelated with heavy metal, the heavy metal adsorption capability is improved, and the pollution influence of the heavy metal on soil and the environment is reduced. The carbon nanotubes are added to a film coating liquid, the mechanical strength of a film can be improved, and added tea polyphenol can improve the slow-release property of the film; besides, the tomato fertilizer contains rich nucleic acid, the activity of tomatoes can be enhanced, decaying of the tomatoes is delayed, and the yield is increased.

Owner:ANHUI YONGGUAN AGRI TECH CO LTD

Preparation method for in-situ forming of hexagonal phosphorspath coating on surface of titanium-based nanotube

ActiveCN108070900APolycrystalline material growthFrom normal temperature solutionsAnodic oxidationPolyvinyl alcohol

Owner:TAIYUAN UNIV OF TECH

Oil-absorbing decontamination agent and preparation method and application thereof

ActiveCN105949372AStop the spreadEasy to recycleOther chemical processesPolyvinyl alcoholMethacrylate methyl

The invention discloses an oil-absorbing decontamination agent. The oil-absorbing decontamination agent is prepared by, by weight, 100 parts of organic monomer and styrene, 1-5 parts of polyvinyl alcohol, 2-10 parts of hollow glass beads, 1-3 parts of initiator, 1-5 parts of crosslinking agent and 1000-3000 parts of water, wherein the mass ratio of organic monomer to styrene is 5-7:5-7; the organic monomer is methyl methacrylate, octadecyl methacrylate or butyl acrylate. The oil-absorbing decontamination agent has the advantages that the oil-absorbing decontamination agent can condense oil to allow the oil to form solid jelly, the diffusion of spilled oil can be prevented effectively, and the oil-absorbing decontamination agent can float on the water surface for a long time before oil absorbing and is easy to recycle and fish.

Owner:CHINESE PEOPLES ARMED POLICE FORCE ACAD

Bamboo plywood and preparing method thereof

ActiveCN107310001AEasy to spreadImprove permeabilityWood treatment detailsReed/straw treatmentPolyvinyl alcoholDiluent

Owner:SHENZHEN ART DECORATION ENG CO LTD

Peel-off mudpack for balancing sebum and removing blackhead

InactiveCN107648086AStrong sebum absorption abilityGuaranteed flexibilityCosmetic preparationsToilet preparationsBlackheadsPolyvinyl alcohol

The invention relates to the field of skin beauty, in particular to a peel-off mudpack for balancing sebum and removing blackhead, and a preparation method thereof. The peel-off mudpack for balancingsebum and removing blackhead provided by the invention is prepared from sebum-balancing components and blackhead-removing components, wherein the sebum-balancing components comprise volcanic mud, marine mud and kaolin; the blackhead-removing components comprise polyvinyl alcohol and corn starch. The peel-off mudpack provided by the invention realizes double care on balancing sebum and removing blackhead through a peel-off mudpack way, and is moderate and non-irritating to face skins and eyes.

Owner:NOX BELLCOW COSMETICS CO LTD

Environment-friendly plastic material and preparation method thereof

The invention discloses an environment-friendly plastic material and a preparation method thereof. The preparation method comprises the following steps that 1, ball milling is performed on calcium sulfate and magnesium oxide through a ball mill, the ball milling time is 3-5 h, and the ratio of grinding media to the materials is 20:1-30:1; 2, 12-20 parts of polyamide-1010, 5-10 parts of polycarbonate, 4-9 parts of alkyd resin, 4-8 parts of polyvinyl alcohol, 3-8 parts of calcium sulfate, 4-10 parts of magnesium oxide, 2-6 parts of polytrimethylene terephthalate, 3-8 parts of tetrafluoroethylene-hexafluoropropylene copolymer, 2-6 parts of polybutyl methacrylate and 4-10 parts of polyparahydroxybenzoic acid are weighed by weight, all the components are extruded inside a double-screw extruder, and the extruded components are the environment-friendly plastic material. The obtained plastic material effectively overcomes the defects that the tensile strength and the elongation at break of the conventional plastic material are low, and the mechanical performance of the plastic material is improved.

Owner:SUZHOU SHURUI ENVIRONMENTAL PROTECTION TECH CO LTD

Organic silicon electronic potting adhesive for PCB circuit board with stable dielectric insulation performance

InactiveCN106634810AHigh tensile strengthHigh hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesDielectricAdhesive

The invention discloses an organic silicon electronic potting adhesive for a PCB circuit board with stable dielectric insulation performance. The organic silicon electronic potting adhesive is prepared from the following raw materials in parts by weight: 40 to 50 parts of vinyl-terminated silicone oil-1, 50 to 60 parts of vinyl-terminated silicone oil-2, 0.38 to 0.5 part of 12% of a platinum catalyst, 0.02 to 0.04 part of acetenyl cyclohexanol, 25 to 30 parts of vinyl silicon resin, 14.8 to 16.8 parts of 1-allyloxy-2,3-epoxypropane, 23 to 25 parts of 1,3,5,7-tetramethyl cyclotetrasiloxane, 2.7 to 3.6 parts of a silane coupling agent A171, an appropriate amount of silicon-containing silicon oil, 2.6 to 3 parts of mica powder, 1.8 to 3 parts of porcelain powder, 0.2 to 0.3 part of dimethyl silicone polymer, 4.6 to 5 parts of carboxylated latex, 1.1 to 1.6 parts of polyvinyl alcohol and an appropriate amount of deionized water. The potting adhesive disclosed by the invention has high heat conduction, dielectric insulation, impact resistance and adhesive performance, is high in fluidity, and is extremely suitable for potting electronic products.

Owner:TONGLING ONBOLE PCB CO LTD

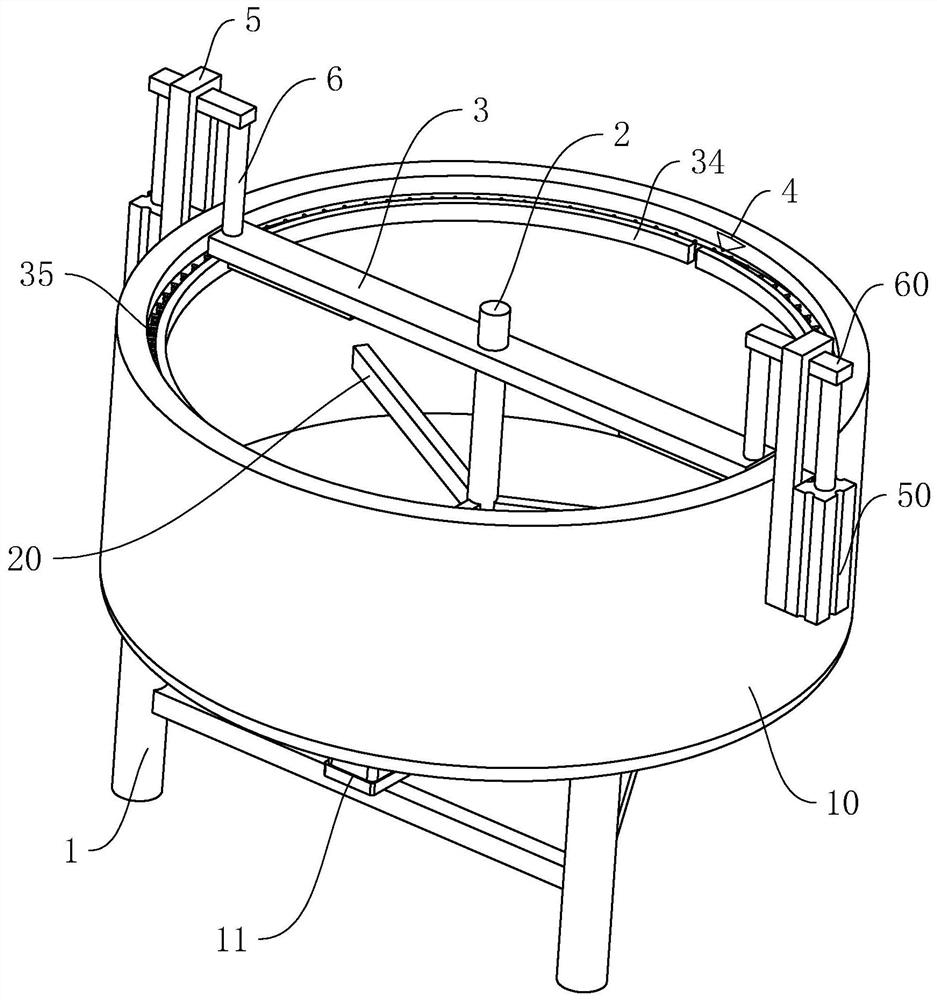

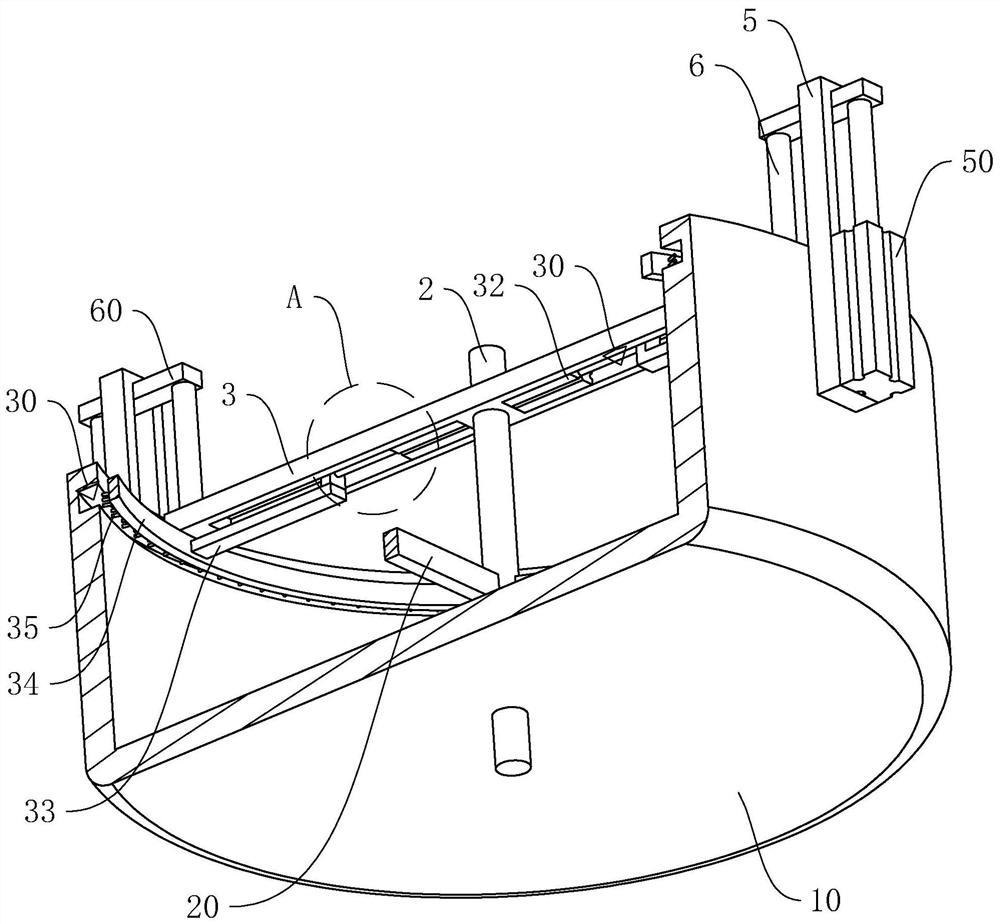

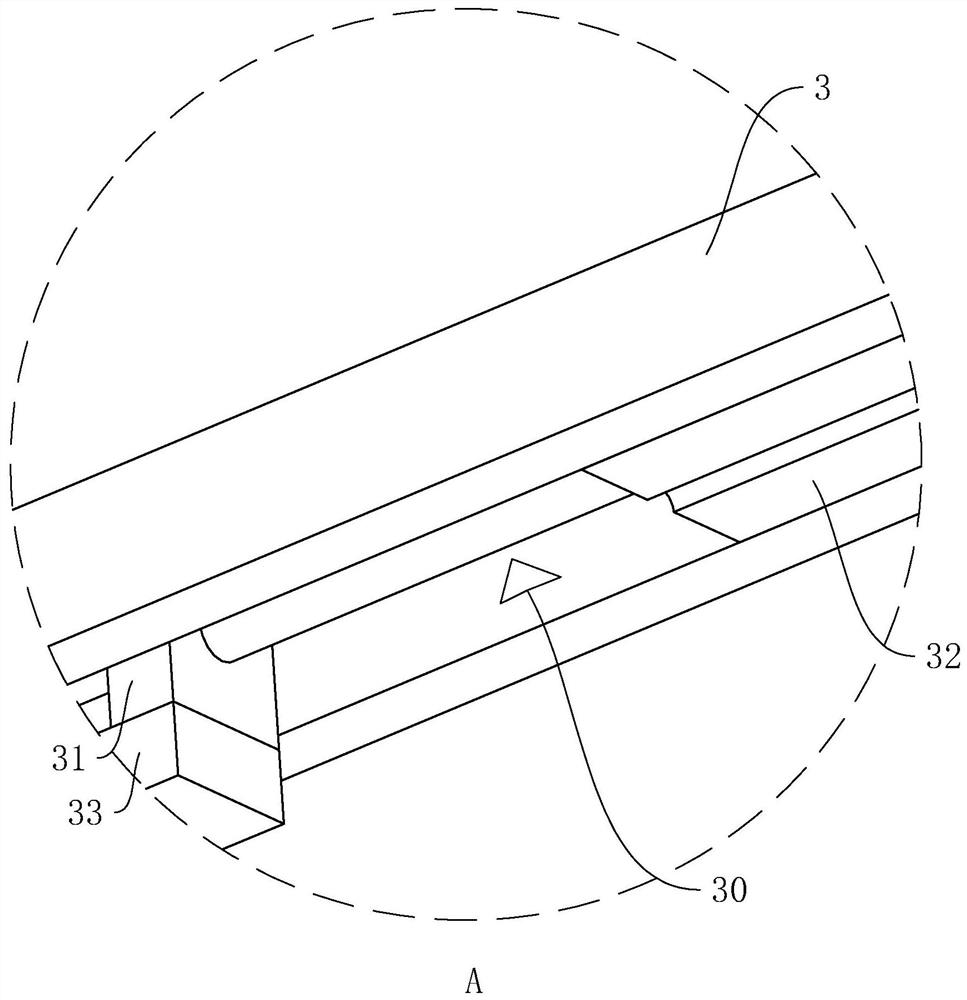

High-ductility concrete as well as preparation method and equipment thereof

Owner:佛山市高明明建混凝土配送有限公司

Degradable capacitor plastic shell and preparation method thereof

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

Zirconium boride contained fused quartz ceramic material and preparation method thereof

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap