Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Foaming agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A foaming agent is a material that facilitates formation of foam such as a surfactant or a blowing agent. A surfactant, when present in small amounts, reduces surface tension of a liquid (reduces the work needed to create the foam) or increases its colloidal stability by inhibiting coalescence of bubbles. A blowing agent is a gas that forms the gaseous part of the foam.

Small pore diameter silicone rubber sponge and preparation method thereof

The invention discloses small pore diameter silicone rubber sponge and a preparation method thereof and relates to the field of processing of high polymer materials. The small pore diameter silicone rubber sponge comprises the following components in parts by weight: a component A: 100 parts of liquid organic silicone rubber; a component B: 3-8 parts of hydrogen-containing silicone oil; a component C: 0.5-10 parts of an emulsifier; a component D: 2-4 parts of a catalyst; a component E: 1-2 parts of an inhibitor; and a component F: 0-35 parts of a silicon resin. An emulsion dispersion mode is adopted, the dispersion phase size is small, and the silicone rubber sponge prepared by the method has the characteristics of bubble dispersion uniformity, small pore diameter and controllable density; and moreover, water serves as a foaming agent, and the sponge has the advantage of environment friendliness. The silicone rubber sponge material prepared by the method can serve as shock absorption, insulating, sound insulation and heat insulation materials.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Methods for purifying and stabilizing hydrofluoroolefins and hydrochlorofluoroolefins

Owner:ARKEMA INC

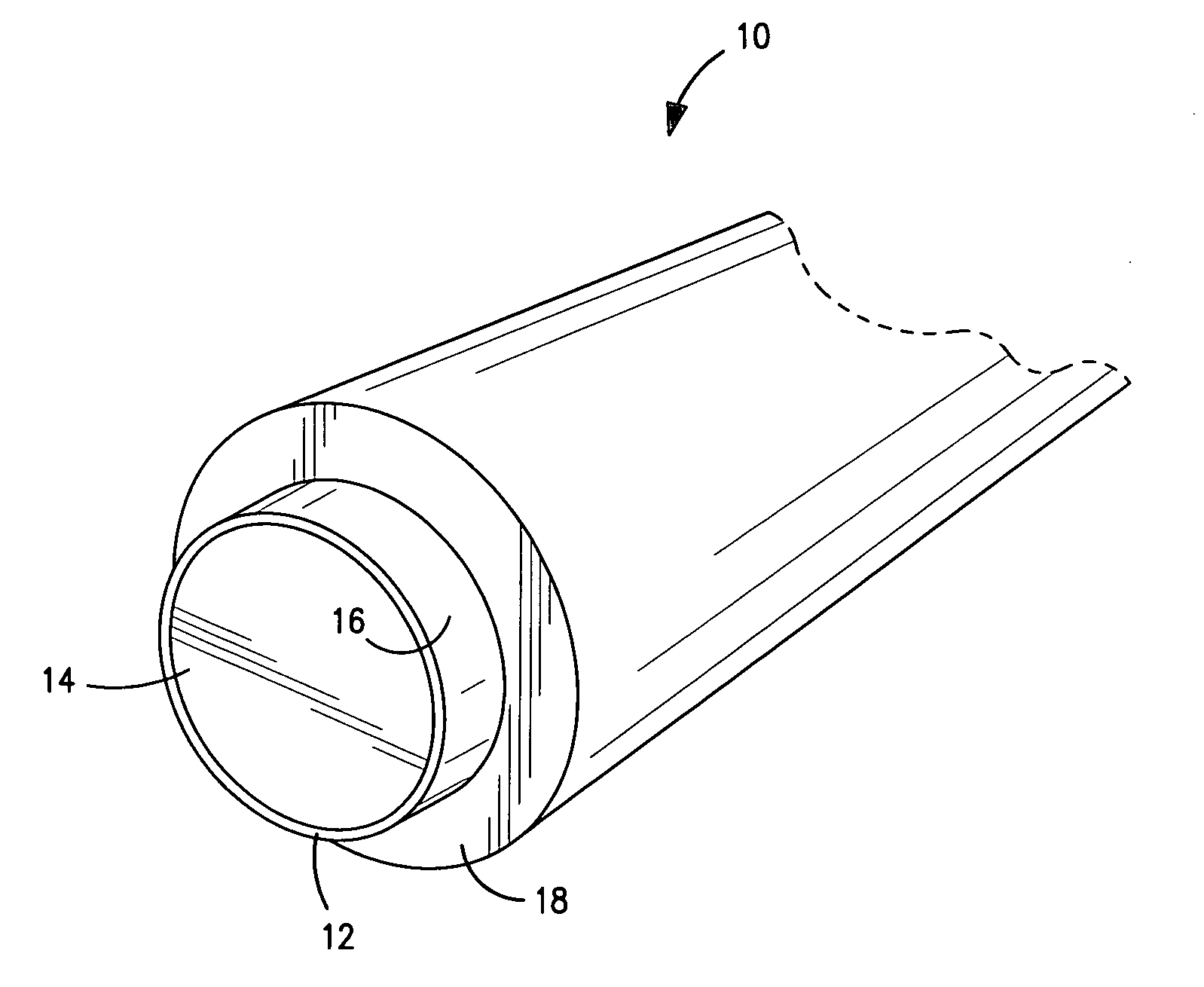

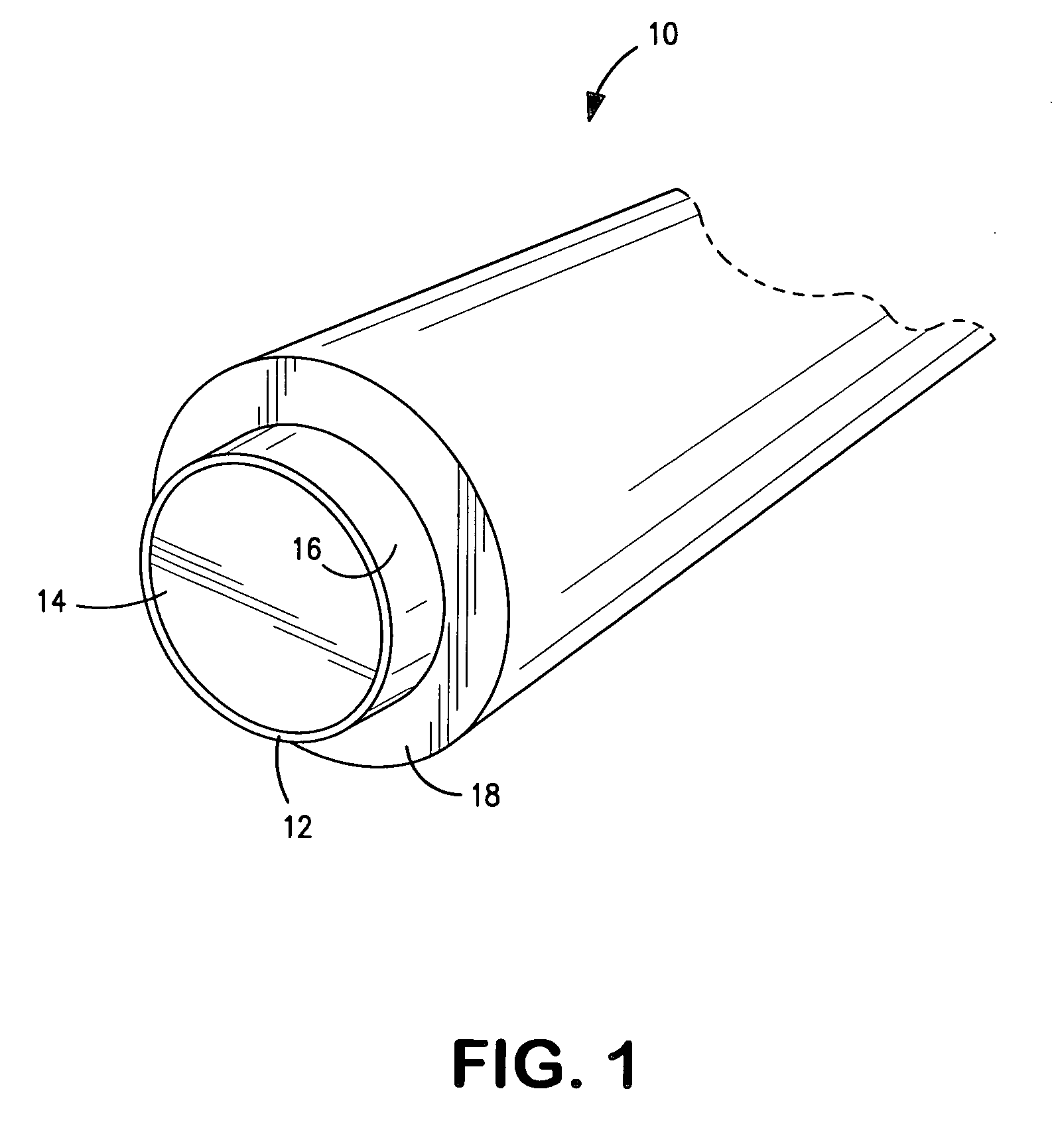

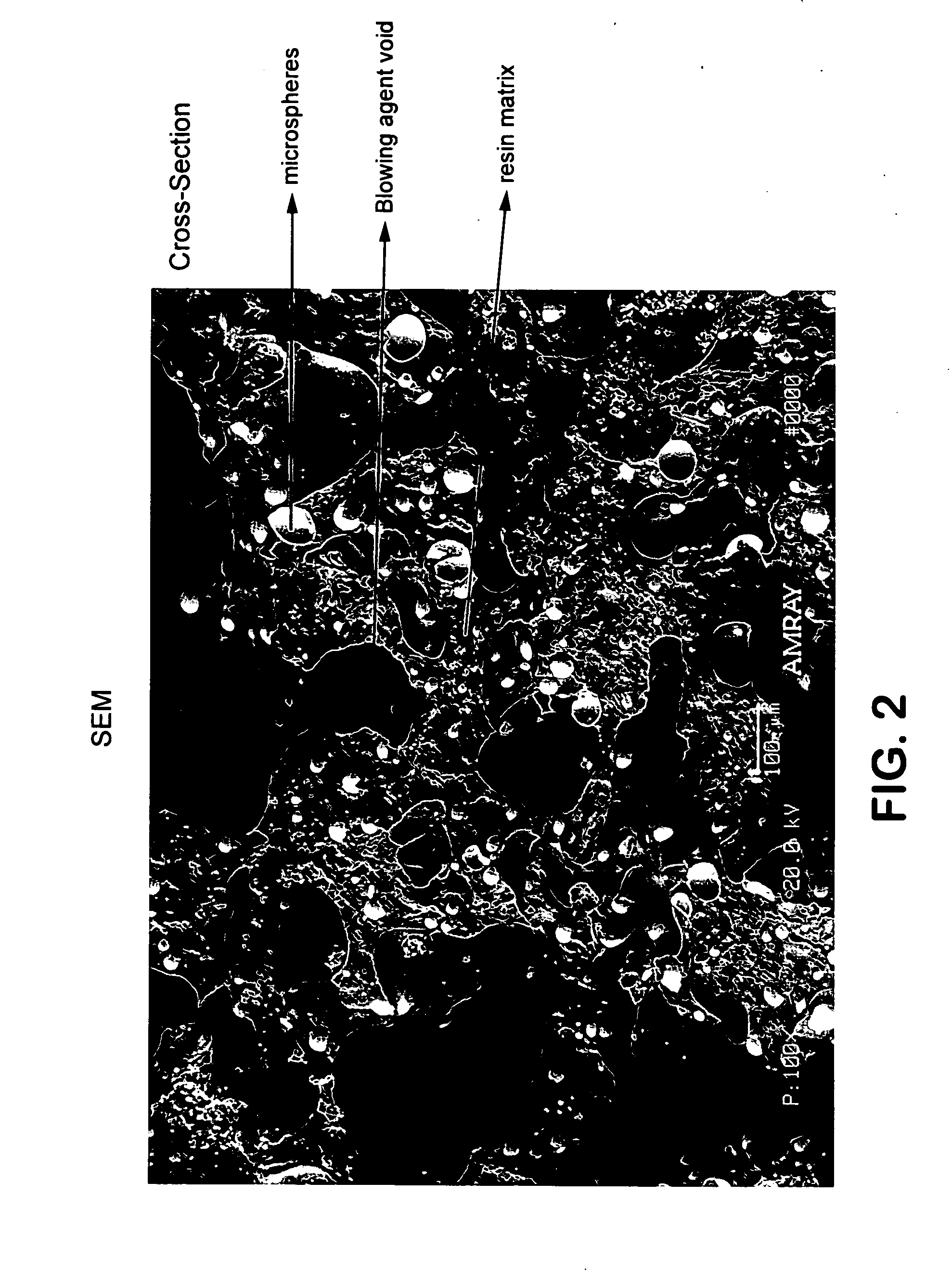

Syntactic Foam Compositions, Pipelines Insulated with Same, and Method

InactiveUS20110017340A1Improve thermal insulation propertiesIncrease buoyancyThermal insulationSolid waste managementEpoxyFoaming agent

Owner:CABOT CORP

Multi-purpose strippable acrylate adhesive microporous material and preparation method thereof

ActiveCN102925084AEasy to peelIncrease elasticityFilm/foil adhesivesEster polymer adhesivesPolymer scienceFoaming agent

Owner:HARBIN INST OF TECH

HDPE(high-density polyethylene) membrane composited by high foaming of LDPE(Low-Density Polyethylene) and preparation method of HDPE membrane

ActiveCN104401076AHigh mechanical strengthImprove performanceSynthetic resin layered productsLaminationLow-density polyethyleneFoaming agent

The invention discloses an HDPE(high-density polyethylene) membrane composited by high foaming of LDPE(Low-Density Polyethylene) and a preparation method of the membrane. The HDPE membrane composited by the high foaming of the LDPE comprises the HDPE membrane, wherein a sheet layer formed by the high foaming of the LDPE is arranged on the surface of the HDPE membrane, and a PE(Poly Ethylene) bonding layer is arranged between the HDPE membrane and the sheet layer; the sheet layer consists of the following components in percentage by weight: 95% of the LDPE, 3.5% of a nucleating agent, 1.39% of a foaming agent, 0.1% of an antisbrinking agent and 0.01% of an auxiliary addition agent. Compared with the prior art, the HDPE membrane composited by the high foaming of the LDPE is a novel environmental-friendly packaging material with high buffering capacity and shock resistant capacity, the membrane has the advantages that the flexibleness and the buffering capacity are good, the heat conductivity is low, the heat-shielding performance is excellent, the membrane does not pollute the environment, and the membrane belongs to the materials capable of being recycled.

Owner:SUZHOU JIUDING

Wear resistant sole material

InactiveCN103483677ADoes not affect elasticityDoes not affect resilienceSolesEnvironmental resistanceFoaming agent

The invention relates to a wear resistant sole material. The wear resistant sole material comprises, by weight, 35-45 parts of EVA, 4-8 parts of styrene butadiene rubber, 1-8 parts of butadiene rubber, 1-4 parts of a vulcanizing agent, 2-5 parts of a reinforcing agent, 1-4 parts of an activator, 1-4 parts of an accelerant and 0.5-3 parts of a foaming agent. The wear resistant material greatly improves the wear resistance of a sole without influencing the elasticity, the resilience, the portability or the like of the sole, and also has the advantages of non-toxicity, no pollution, safety and environmental protection.

Owner:KUNSHAN CHUNBAI PRECISE HARDWARE CO LTD

Combined fatigue resistant pad and manufacturing method thereof

InactiveCN101292833AReduce manufacturing costEffective protectionLayered productsDomestic articlesFoaming agentPolyvinyl chloride

Owner:TAICANG ALL MATS PLASTIC IND

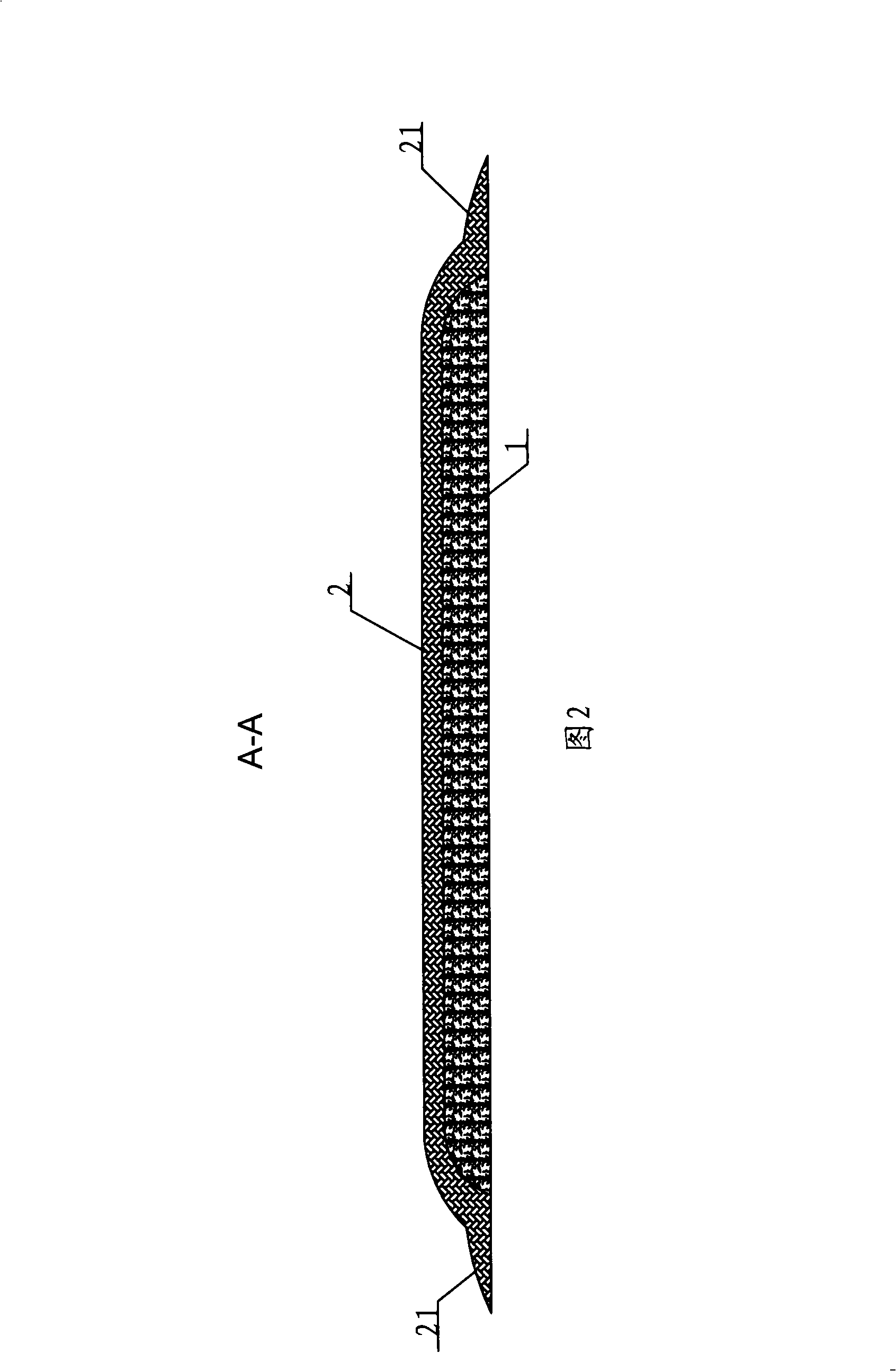

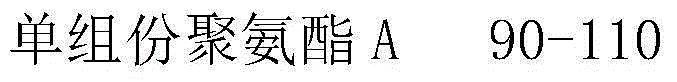

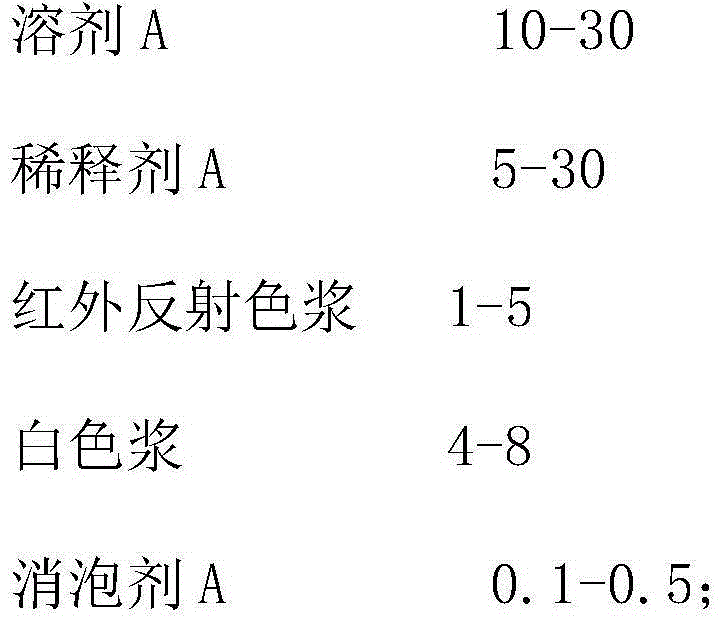

Infrared stealth textile coating fabric

ActiveCN105034523ALow infrared reflectanceImprove stealth performanceSynthetic resin layered productsCross-linkPolymer science

Owner:CTA HI TECH TEXTILES

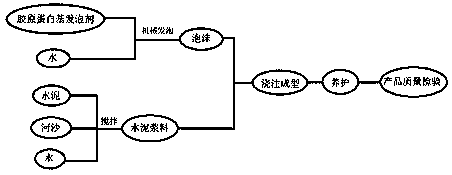

Low-density foaming cement and preparation method thereof

The invention discloses a low-density foaming cement, which comprises the following components in parts by weight: 60 to 120 parts of cement, 0.3 to 1.0 part of coagulant, 0.4 to 1.0 part of foam stabilizer, 0.5 to 1.2 parts of water reducer, 9 to 14 parts of foaming agent, 0.2 to 0.5 part of fiber, and 25 to 50 parts of water. The invention also discloses a preparation method of the low-density foaming cement. The low-density foaming cement is prepared through the following steps: evenly stirring dry powder, adding water to prepare cement slurry, adding a foaming agent under rapid stirring, casting to mould, and carrying out natural maintenance; and has the advantages of low dry density and low thermal conduction coefficient.

Owner:GUANGDONG JIANKE CONSTR CONSULTING CO LTD

Thermal insulation material and preparation method thereof

InactiveCN107721451AEvenly dispersedEffective control of cell stabilityConstruction materialCeramicwareFoaming agentPolymer science

The invention discloses a thermal insulation material and a preparation method thereof. The thermal insulation material comprises a cement-based block skeleton and graphene modified polystyrene, wherein the cement-based block skeleton comprises multiple cavities; the multiple cavities are filled with graphene modified polystyrene; and graphene modified polystyrene is formed by performing melt extrusion on graphene and polystyrene resin according to a weight ratio of 1:(1-5) in the multiple cavities in the presence of an alkane foaming agent. According to the thermal insulation material disclosed by the invention, the strength and thermal insulation property are further improved.

Owner:ZHONGJING ECO IND CO LTD

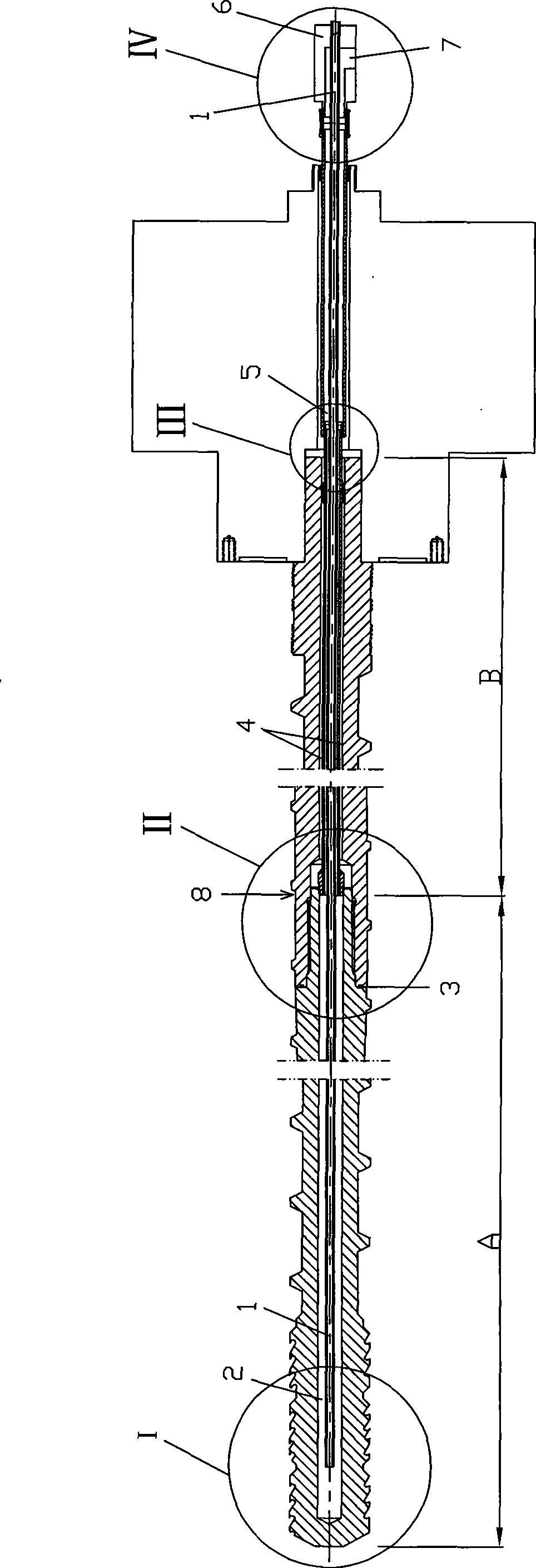

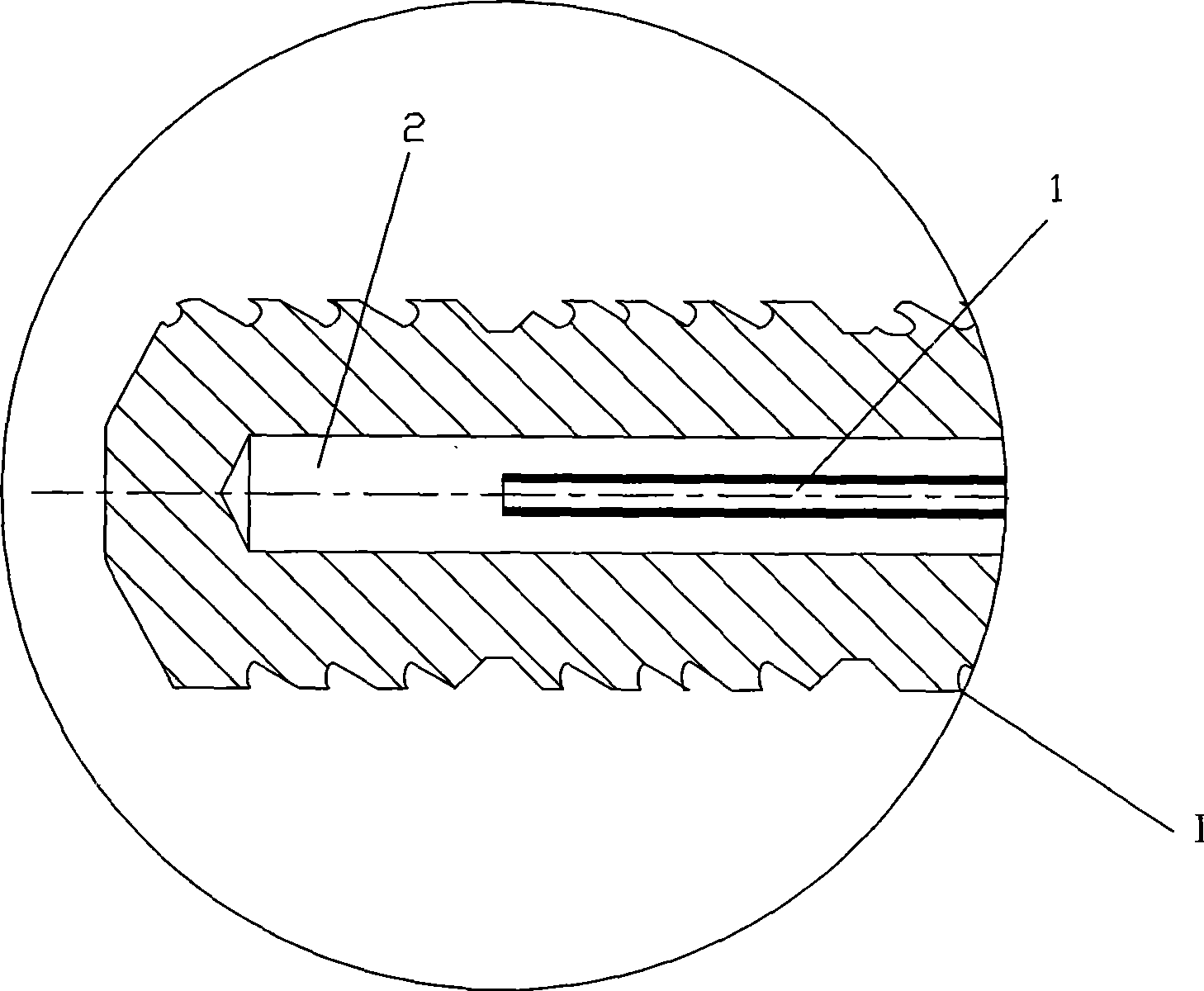

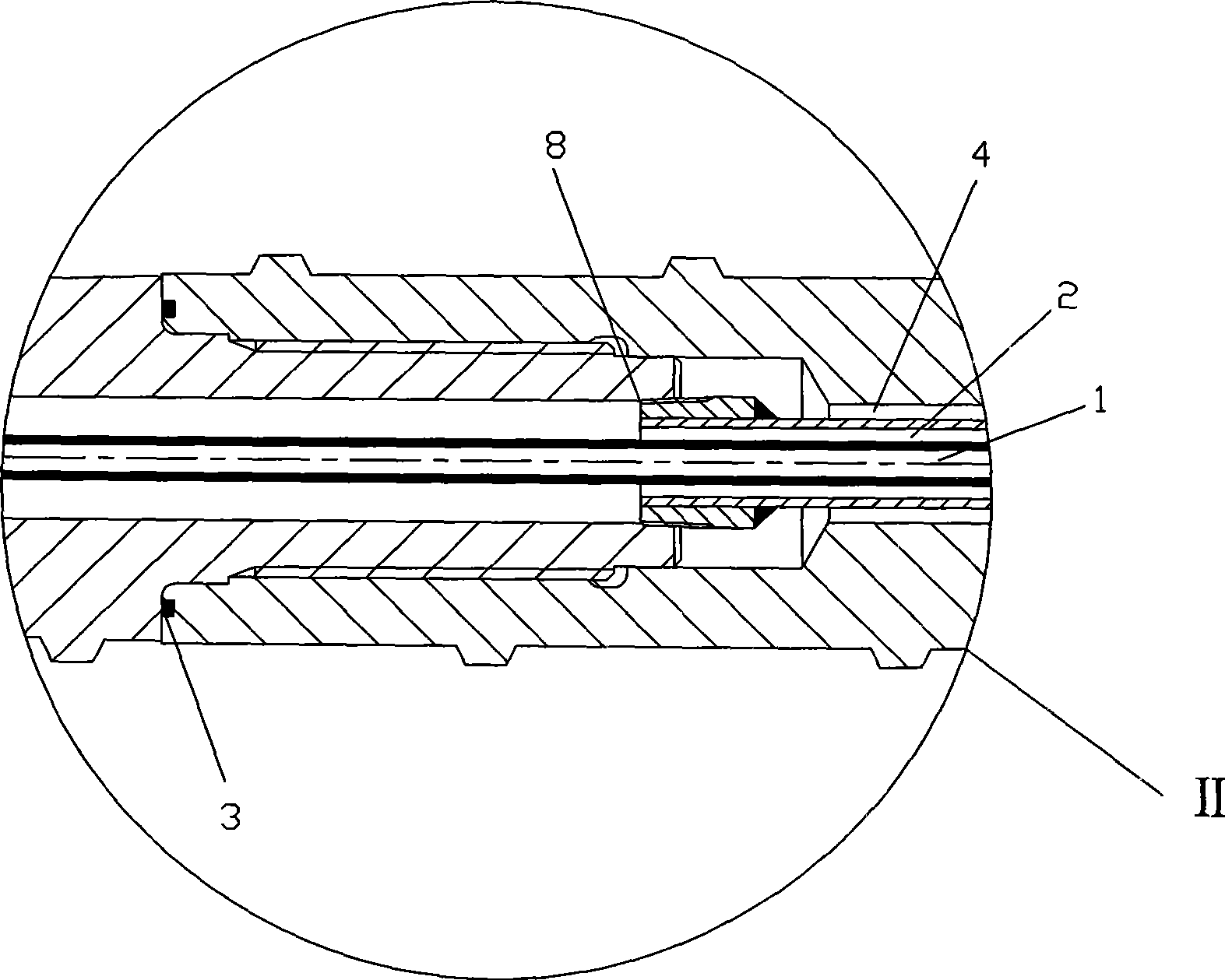

Screw rod of EPE/EPS single-screw rod foam extrusion machine with constant temperature oil for cooling forepart inner wall

InactiveCN101480841AIncrease elasticitySatisfy the processing technology requirements of subsection coolingFoaming agentReturn channel

Owner:罗承绪

Calcium carbonate compound type flame-retardant foaming agent

Owner:新建特阔漂整(南通)有限公司

High-strength concrete formula and preparation method of high-strength concrete formula

InactiveCN102690126AHigh strengthImprove penetration resistanceCeramicwareHigh strength concreteLevel structure

The invention discloses a high-strength concrete formula. The high-strength concrete formula is characterized by comprising the following constituents by weight: 20-40% of cement, 3-5% of pulverized coal ash, 30-50% of fine aggregate, 20-40% of coarse aggregate, 3-5% of plant protein foaming agent, 1-10% of water reducer and 1-10% of water. Above materials are mixed and uniformly stirred to obtain the concrete. The concrete disclosed by the invention has the advantages of fewer holes in interior of the concrete, compact microstructure and meso-level structure and excellent anti-permeability performance by mutual interaction of various ingredients, so that the high-performance concrete is good in durability, and the strength can be up to over 280MPa.

Owner:LANGFANG RONGSHENG CONCRETE

Method for preparing foam glass with high foaming rate by utilizing lead-free high-barium abandoned lamp tube

InactiveCN106630649AHigh foaming rateLow melting pointGlass shaping apparatusFoaming agentSodium phosphates

The invention discloses a method for preparing foam glass with a high foaming rate by utilizing a lead-free high-barium abandoned lamp tube and belongs to the field of foam glass. The method comprises the following steps: carrying out ball milling on the lead-free high-barium abandoned lamp tube to form a glass powder raw material; feeding foaming agents, namely manganese dioxide and calcium carbonate, a fluxing agent, namely sodium fluorosilicate, and a stabilizer, namely sodium phosphate into a ball mill to be subjected to ball milling; feeding mixture obtained through ball milling into a high-temperature-resistant mould, preheating for 15-20 minutes at the temperature of 400-430 DEG C, then heating up to 800-820 DEG C, and carrying out heat preservation for 20-30 minutes; then cooling to 500-550 DEG C, annealing, and carrying out heat preservation for 35-40 minutes; and finally carrying out furnace cooling to room temperature. The prepared foam glass is uniform in pore diameter, closed pores are formed mainly, the average pore diameter reaches about 4.2mm, the density is 0.58g / cm<3>, the compressive strength is 3.78MPa, the performance is excellent, and the application standard of the foam glass can be met.

Owner:YANGZHOU UNIV

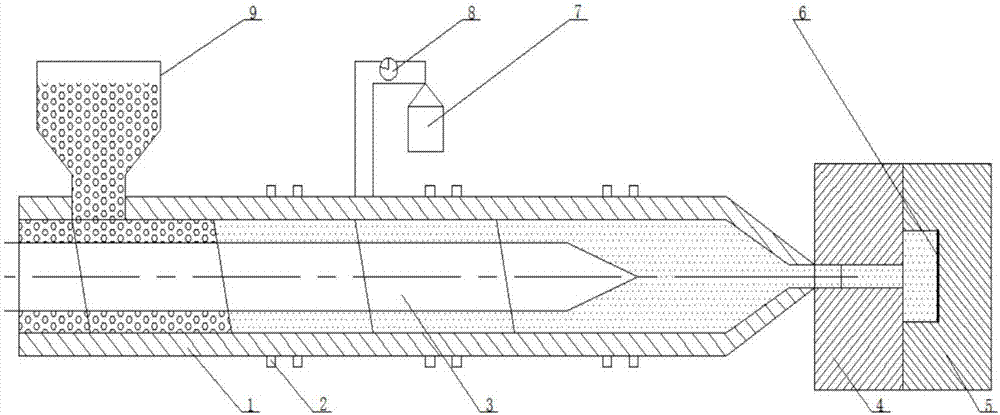

Microcellular foaming and in-mold decoration composite molding device with composite foaming agents and microcellular foaming and in-mold decoration composite molding method

InactiveCN107379388AImprove foaming efficiencyImprove surface qualityCoatingsFoaming agentGas cylinder

Owner:WUHAN UNIV OF TECH

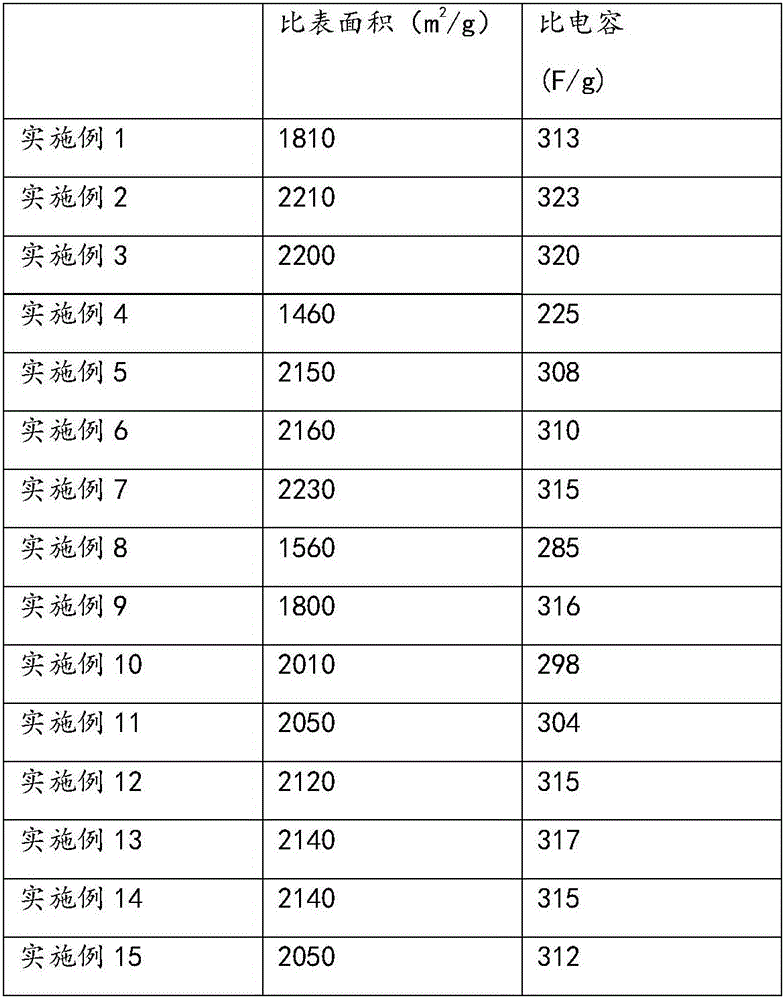

Graphene-based hierarchical pore capacitor carbon and preparation method thereof as well as capacitor

InactiveCN106467299ACurl suppressionSuppress stackingHybrid capacitor electrodesGrapheneCross-linkPorosity

Owner:山东圣泉新能源科技有限公司

Foaming-ceramic heat insulating board and preparing method thereof

InactiveCN105503238ALow thermal conductivityHigh compressive and flexural strengthCeramicwarePorosityPotassium

Owner:韩功篑

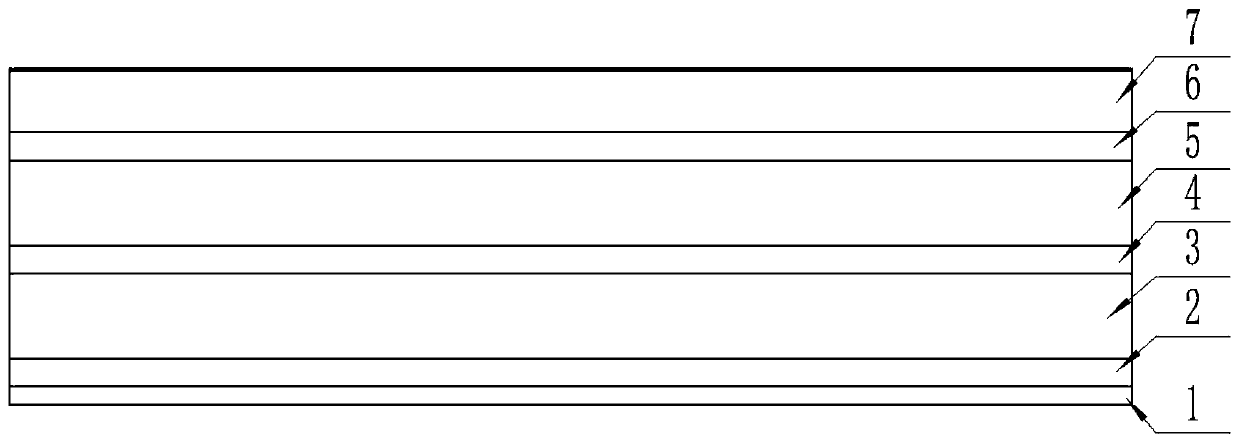

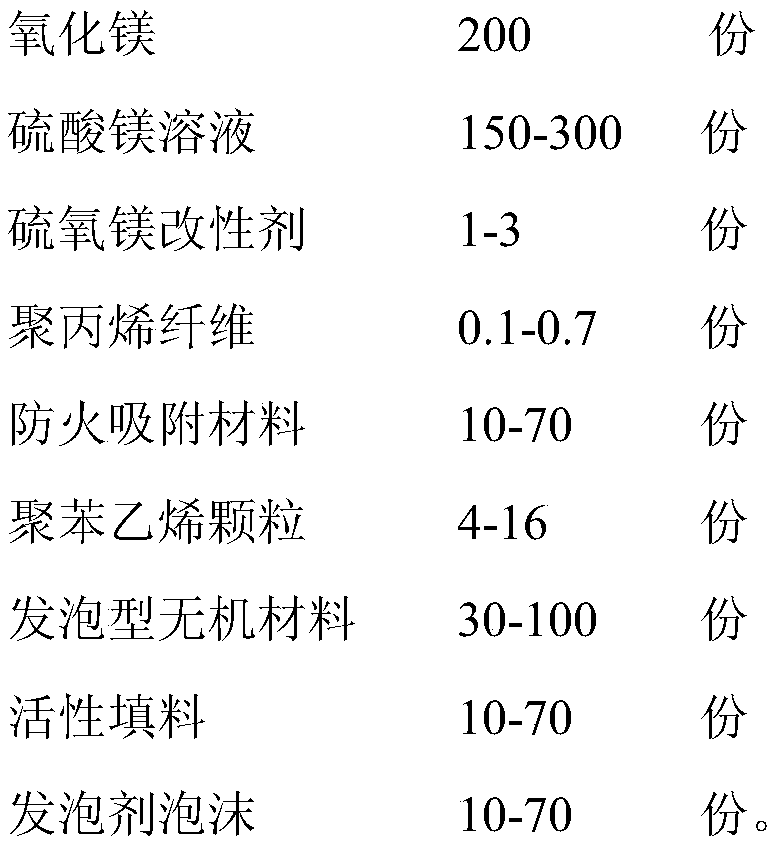

Novel magnesium oxysulfate cement-based fireproof coating and preparation and application methods thereof

Owner:UNIV OF SCI & TECH LIAONING

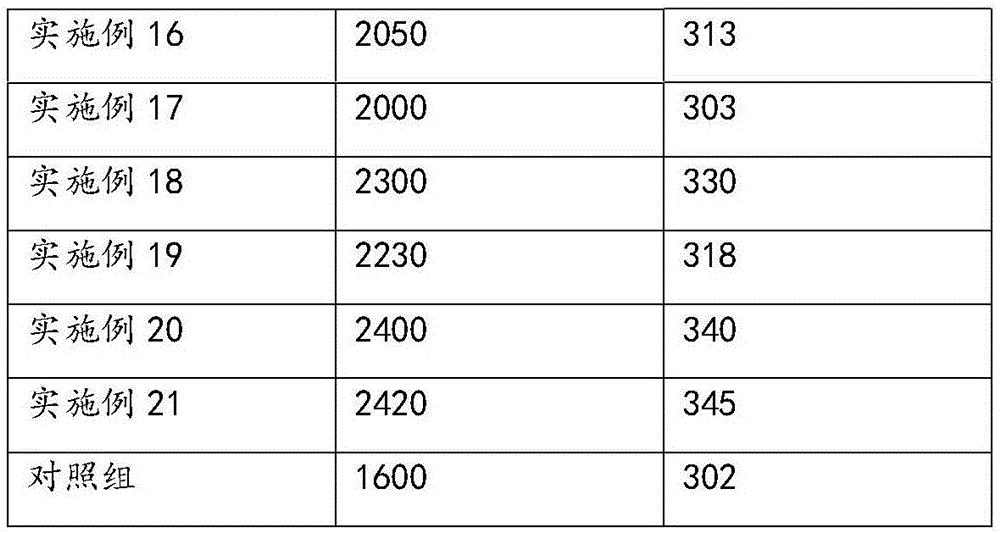

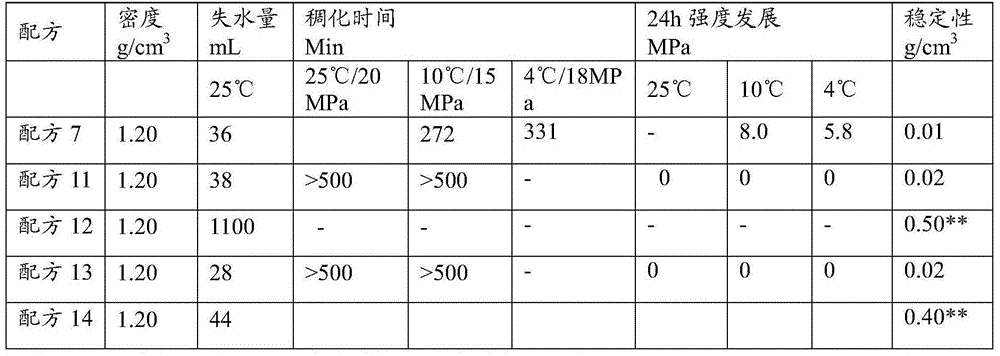

Early strength foam cement slurry for well cementation

ActiveCN104946220AAdjustable densityFast development of low temperature strengthDrilling compositionCeramicwareCement slurryFoaming agent

The invention discloses early strength foam cement slurry for well cementation. The early strength foam cement slurry comprises the following components in parts by mass: 100 parts of sulphoaluminate cement, 4-12 parts of a foaming agent, 2-7 parts of a foam stabilizer, 1-3 parts of a retarder, 3-5 parts of a fluid loss agent and 30-40 parts of water. The early strength foam cement slurry provided by the invention has the advantages that the density can be adjusted within 0.55-1.40 g / cm<3>; the low-temperature strength is rapidly developed; the early strength foam cement slurry is applicable to the cementation of an oil-gas well of which the bottom-hole temperature is 4-25 DEG C.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

Decomposable environmentally-friendly heat-insulation packaging bag

Owner:桐城市人和包装有限公司

Fireproof anti-abrasion rubber shoe sole material and preparation method thereof

InactiveCN109354817AImprove wear resistanceGood mechanical propertiesSolesPolymer scienceMechanical property

Owner:JINJIANG XINQIMEI SHOES MATERIAL DEV

Environment-friendly composite alkaline foam cleaning agent and preparation method thereof

ActiveCN110079402AShort preparation timeImprove cleaning efficiencyInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsFoaming agentHalf-life

Owner:陕西汉隆清洁科技有限公司

Anti-flaming thermal-insulation environmentally-friendly polymeric foaming material and method for producing the same

InactiveCN102516710ALow thermal conductivityImprove insulation effectPolymer sciencePolyvinyl alcohol

The invention discloses an anti-flaming thermal-insulation environmentally friendly polymeric foaming material and a method for producing the material. The method comprises the following steps: preparing a urea resin foam adhesive by successively adding 37 % of formaldehyde, polyvinyl alcohol and glycerin in a reaction kettle and stirring to heat up and then adding urea, hexamethylene tetramine, stabilizer and thiourea, preparing a foaming agent by firstly adding water in a stirring tank, successively adding nekal and nonylphenol polyoxylethylene ether with stirring, heating up for completely dissolving, and then adding phosphoric acid, glycerin and sodium phosphate, uniformly stirring until completely dissolving, and discharging and packaging, and preparing a foamed product by taking the urea resin adhesive, urea and the foaming agent, mixing and stirring uniformly, putting in a foaming machine to foam, and carrying out foaming, extrusion molding, drying and packaging. The invention can be widely applied in thermal insulation of building facilities, thermal insulation of venue decoration, shock absorption, replacement of benzene plate flexible package without anti-flaming property, and the like.

Owner:王喆

Ultrahigh-foaming amount polyurethane foaming agent

Owner:GUNUO TIANJIN IND

Light sandwich paperless gypsum board containing high-temperature phosphogypsum as well as preparation method and application thereof

ActiveCN111268987ANot easy to moldLight weightLaminationLamination apparatusFiberglass meshGlass fiber

The invention discloses a light sandwich paperless gypsum board containing high-temperature phosphogypsum. The paperless gypsum board is prepared from the following raw materials in parts by weight: 10-20 parts of high-temperature phosphogypsum, 80-90 parts of high-strength alpha-phosphogypsum, 3-10 parts of lime, 3-10 parts of heavy calcium carbonate, 1-3 parts of glass fiber gridding cloth, 0.05-1 part of a composite foaming agent and 0.01-0.1 part of a composite foam stabilizer. According to the invention, the core layer takes high-temperature phosphogypsum and high-strength alpha-phosphogypsum as main raw materials for the first time, and lime and coarse whiting inorganic powder are doped to serve as filler; by means of the idea of foaming by introducing a foaming agent and a foam stabilizer, a layered cast-in-place method, a combined pouring method and an integral assembly method after layered manufacturing are adopted for preparation. The production process is simplified, dryingis easy, the prepared paperless gypsum board is not prone to mildewing, the strength of a core layer is 0.6 MPa or above, the volume weight is smaller than 550 kg / m3, the volume weight of a paperlessgypsum board wall is reduced, and the heat preservation performance of the paperless gypsum board wall is improved.

Owner:GUIZHOU KAILIN PHOSPHOGYPSUM INTEGRATION UTILIZATION

Fireproof door core and preparing method thereof

InactiveCN107082617AImprove fire resistanceGood heat insulationFireproof doorsCeramicwareFiberZinc borate

Owner:合肥市旺友门窗有限公司

Method for preparing magnesia-based lightweight aggregates by foaming method

Owner:UNIV OF SCI & TECH LIAONING

Special unsaturated polyester resin adhesive for quartz stone sheet material

InactiveCN106753148AImprove impact toughnessHigh bonding strengthNon-macromolecular adhesive additivesGas phasePhosphine oxide

The invention discloses a special unsaturated polyester resin adhesive for a quartz stone sheet material. The special unsaturated polyester resin adhesive is prepared from the following raw materials: unsaturated polyester resin, acrylic acid-2-hydroxyethyl ester, pentaerythritol triacrylate, 2-methyl-1-(4-methylthiophenyl)-2-morpholinyl-1-acetone, biphenyl-(2,4,6-trimethylbenzoyl)phosphine oxide, a flatting agent, a de-foaming agent, a silane coupling agent, gas-phase silicon dioxide, glass microsphere and modified aluminum hydroxide. The special unsaturated polyester resin adhesive for the quartz stone sheet material, provided by the invention, has high binding performance, good impacting toughness and excellent flame-retarding performance.

Owner:ANHUI AIDIBEI BIOLOGICAL CO LTD

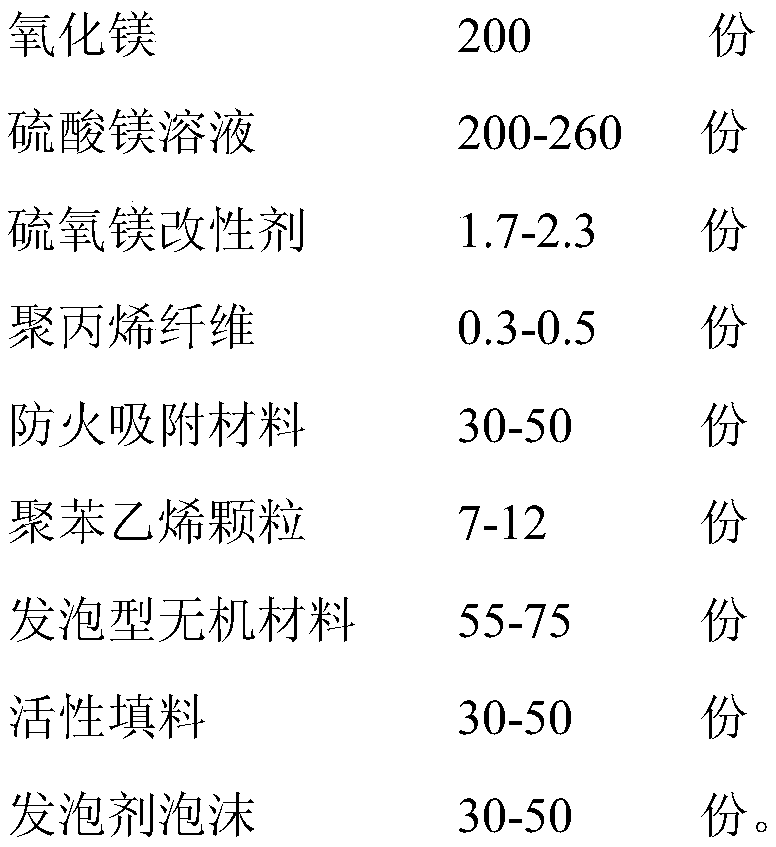

Heat-preservation sound-insulation magnesium oxysulfate fireproof material applied to wallboard and preparation method thereof

InactiveCN110294619ALow densityEasy to carryGlass/slag layered productsFoaming agentVolumetric Mass Density

Owner:常州布鲁科技有限公司

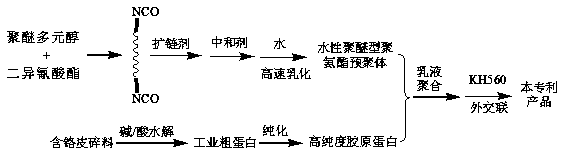

Preparation method of waterborne polyurethane modified collagen-based concrete foaming agent

Owner:QILU UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap