Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49 results about "Toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In materials science and metallurgy, toughness is the ability of a material to absorb energy and plastically deform without fracturing. One definition of material toughness is the amount of energy per unit volume that a material can absorb before rupturing. It is also defined as a material's resistance to fracture when stressed.

Preparation method of superfine fiber high-imitation grain synthetic leather

ActiveCN102304858AImprove protectionImprove breathabilityLamination ancillary operationsSynthetic resin layered productsLow-density polyethylenePolymer science

The invention discloses a preparation method of superfine fiber high-imitation grain synthetic leather. The preparation method comprises the following steps of: spinning sea-island composite fibers by utilizing nylon 6 and low-density polythene as raw materials, manufacturing non-woven fabric by utilizing the sea-island composite fibers, coating one surface of the non-woven fabric by utilizing high-solid-concentration polyurethane slurry, infiltrating the non-woven fabric by utilizing low-solid-concentration polyurethane slurry, enabling the non-woven fabric to pass through an aqueous solution of dimethylformamide after infiltrating, solidifying polyurethane and forming a cellular structure to obtain synthetic leather semi-finished products, enabling the synthetic leather semi-finished products to pass through methylbenzene to separate sea-component low-density polythene out of the sea-island fibers, peeling off the sea-island composite fibers to be superfine fibers, washing away methylbenzene through boiling water, and drying to obtain the superfine fiber high-imitation grain synthetic leather. The product manufactured by the method disclosed by the invention has the advantages of strong gradient, abundant hand feeling, fine and smooth surface wrinkles and strong toughness after being bent, and has the beneficial effects on aspects of pollution reduction, animal protection, ecological protection and the like.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

3D printing modified polyamino acid material and preparation method thereof

Owner:INST OF CHEM CHINESE ACAD OF SCI

Thick steel board

Owner:KOBE STEEL LTD

Material and method used for TA2/0Cr18Ni9Ti welded by high-entropy effect

InactiveCN102676904AImprove performanceSimple preparation stepsWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceAlloy

The invention discloses a high-entropy interlayer alloy, which comprises the following components in atomic percentage: 5-10% of Ti, 5-10% of Fe, 25-30% of Al, 15-20% of Ni, 30-35% of Cu and 5-10% of Cr. The invention also discloses a method for welding TA2 / 0Cr18Ni9Ti by the high-entropy effect, which comprises the following steps that: high-entropy interlayer alloy is placed between the two plates to be welded, the high-entropy interlayer alloy is in a foil folding structure, and the high-entropy interlayer alloy and local parent metal are subjected to heat fusing by an interface resistor ina resistance spot welding mode, so that the high performance welding of TA2 / 0Cr18Ni9Ti can be realized. According to the method and the high-entropy interlayer alloy of the method, which are disclosed by the invention, the high-entropy interlayer alloy has the advantages of favorable strength, toughness and corrosion resistance, is easy to process and form and is convenient to weld and assembly. The preparation method has the advantages of simple step and low manufacture cost and is convenient to popularize.

Owner:XIAN UNIV OF TECH

Ultrahigh-toughness concrete and a preparing method thereof

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

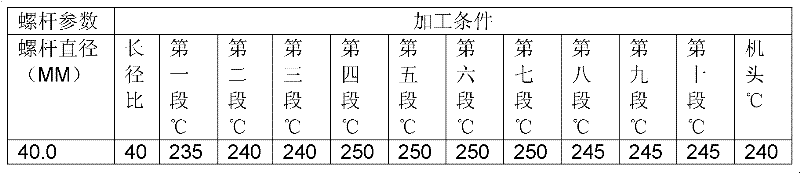

High-toughness high temperature-resistant modified PVC pipe

InactiveCN105440481AImprove toughnessImprove high temperature resistanceAcrylonitrileMaterials science

The invention discloses a high-toughness high temperature-resistant modified PVC pipe. The high-toughness high temperature-resistant modified PVC pipe comprises the following raw materials by weight: 80 to 120 parts of PVC resin, 30 to 60 parts of chlorinated polyethylene, 40 to 80 parts of liquid butadiene-acrylonitrile rubber, 10 to 30 parts of polyurethane elastomer, 2 to 8 parts of modified nanometer calcium carbonate, 1 to 5 parts of kaolin, 2 to 6 parts of fly ash, 4 to 8 parts of glass beads, 4 to 8 parts of glass fiber, 1 to 6 parts of titanium dioxide, 3 to 9 parts of PE wax, 2 to 5 parts of methyl methacrylate, 4 to 8 parts of acrylate, 1 to 5 parts of a heatproof modifier and 2 to 6 parts of a coupling agent. The PVC pipe provided by the invention has excellent toughness and high temperature resistance.

Owner:NINGGUO CITY GAOXIN PIPE CO LTD

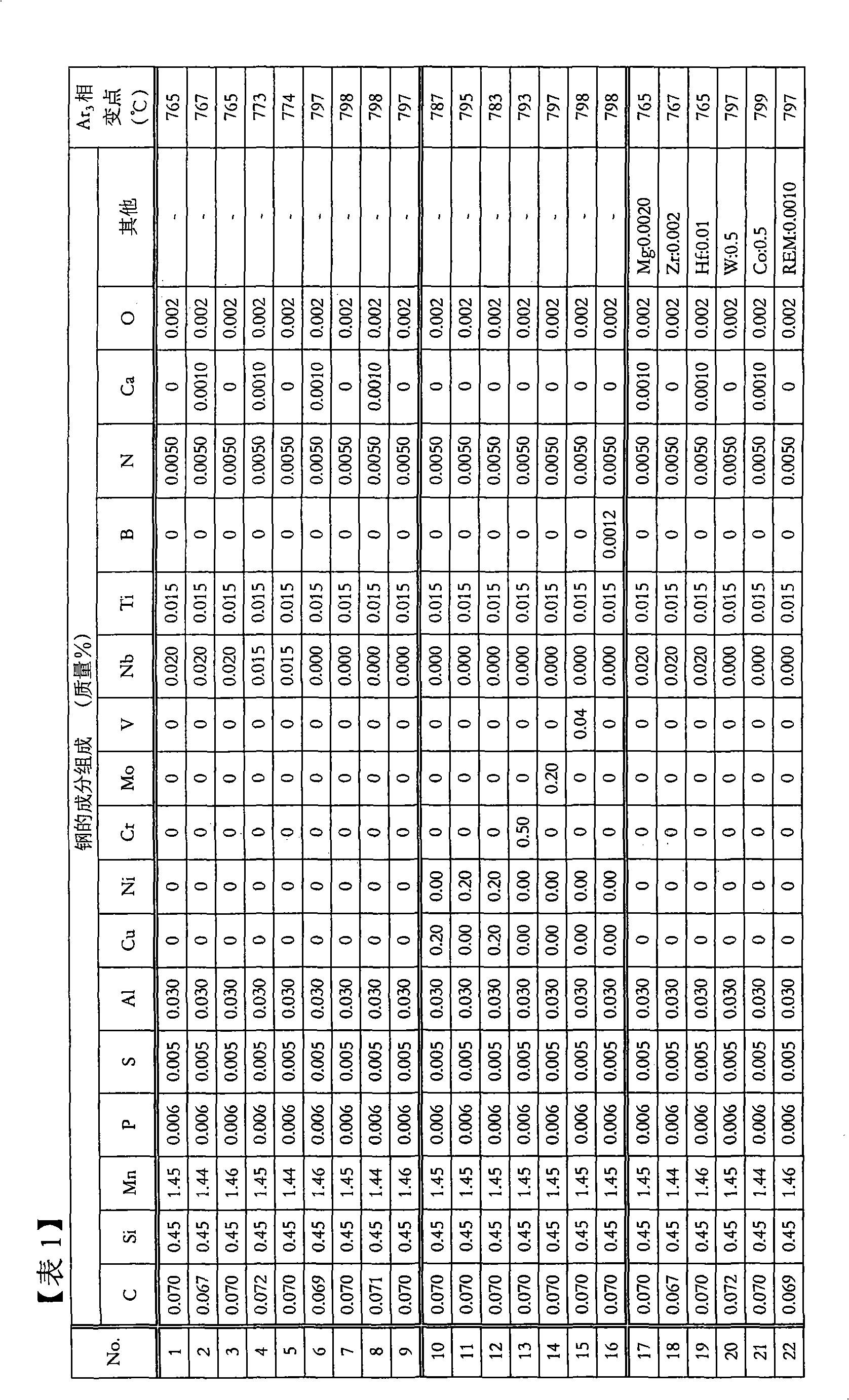

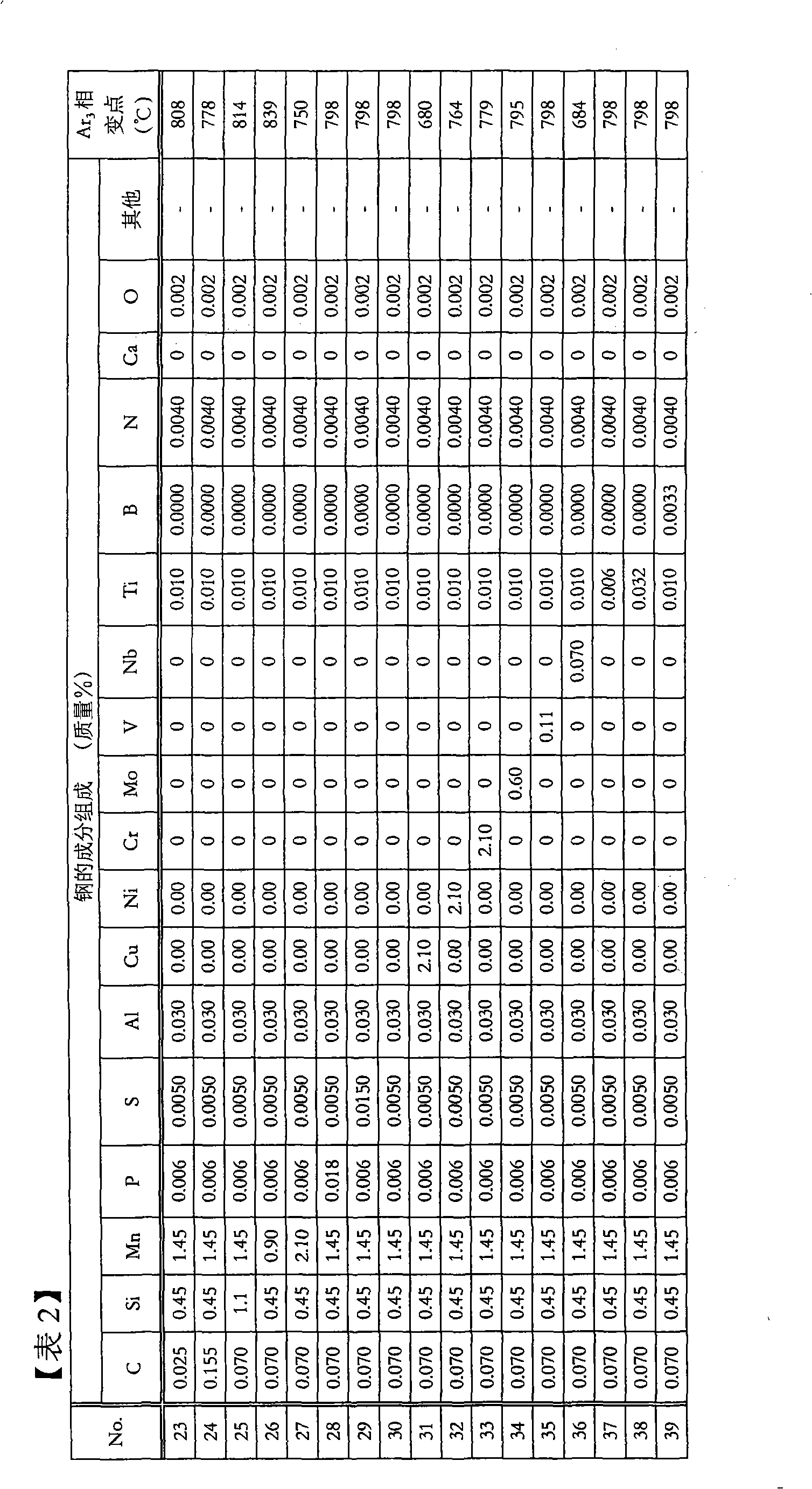

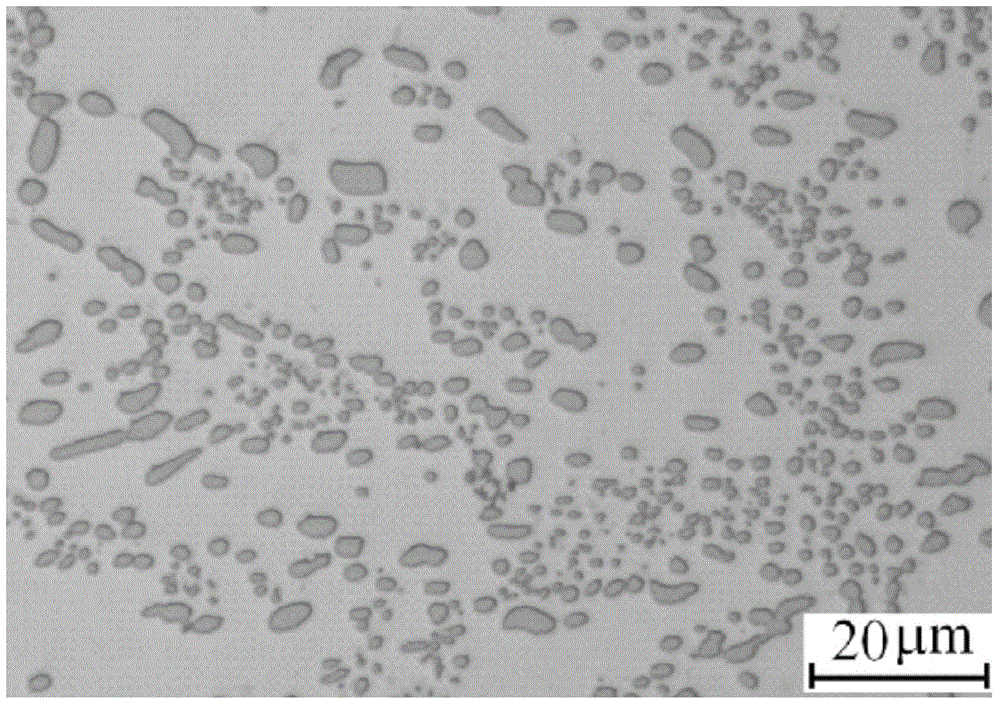

Hot-rolled steel strip for high strength electric resistance welding pipe and manufacturing method thereof

InactiveUS7501030B2Low costIncreasing costFurnace typesWelding/cutting media/materialsElectrical resistance and conductanceSolderability

A hot-rolled steel strip having superior low temperature toughness and weldability, which is suitably used as a starting material for high strength electric resistance welding pipe, is provided at a low cost without constructing new production facilities and increasing cost. The hot-rolled steel strip is low carbon steel containing at least one of about 0.5.% or less of Cu, about 0.5% or less of Ni, and about 0.5% or less of Mo, wherein Pcm represented by the following equation (1) is 0.17 or less:Pcm=(% C)+(% Si) / 30+((% Mn)+(% Cu)) / 20+(% Ni) / 60+(% Mo) / 7+(% V) / 10 Equation (1),(where (% M) indicates the content of element M on a mass percent basis), and the balance includes Fe and incidental impurities. In addition, in the entire microstructure, the ratio of bainitic ferrite, which is a primary phase, is controlled to be about 95 percent by volume or more.

Owner:JFE STEEL CORP

High-strength environment-friendly composite board and preparation method thereof

InactiveCN104690805AHigh strengthImprove toughnessNon-macromolecular adhesive additivesProtein adhesivesEnvironmental resistanceFiber

Owner:安徽忠盛新型装饰材料有限公司

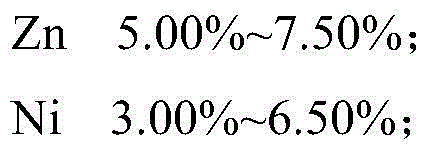

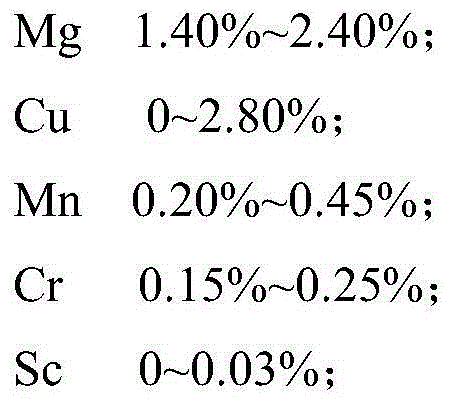

Preparation method of high-strength cast aluminum alloy

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

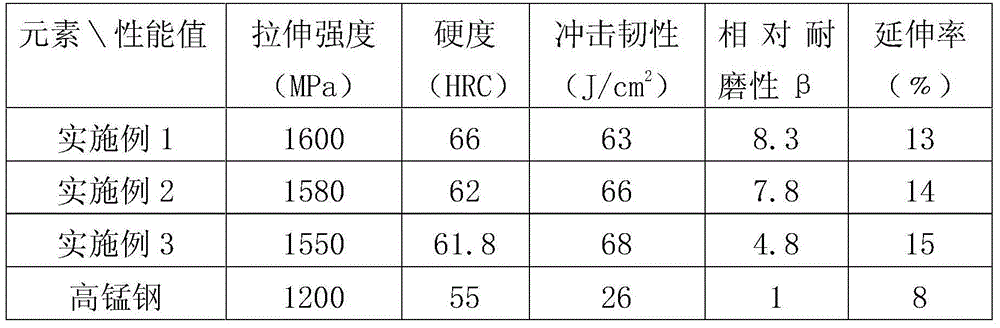

Boron-bearing chromium molybdenum nickel wear-resistant alloy and preparation method thereof

Owner:GUANGXI UNIV

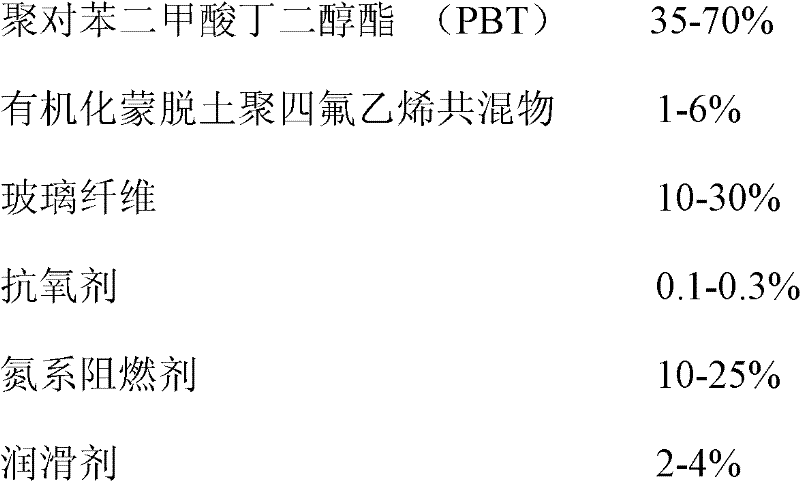

Halogen-free flame-retardant polybutylene terephthalate PBT (polybutylece terephthalate) composite material and preparation method thereof

ActiveCN102391624APhenomenon that limits floating fibersExcellent surface finishPolytetramethylene terephthalateAlkali free

Owner:LONGJAR SHANGHAI IND

Low-cost high-strength steel plate for engineering machinery, and production method thereof

Owner:HEBEI IRON AND STEEL

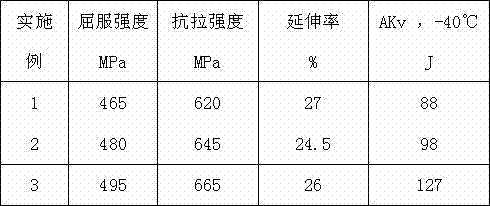

High-performance bridge steel with yield strength not smaller than 500 MPa and preparation method and application of high-performance bridge steel

The invention belongs to the technical field of metallurgy, and particularly relates to high-performance bridge steel with the yield strength not smaller than 500 MPa and a preparation method and application of the high-performance bridge steel. The bridge steel is prepared from the following components: 0.03% to 0.06% of C, 0.10% to 0.25% of Si, 1.30% to 1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, 0.010% to 0.040% of Als, 0.25% to 0.45% of Cr, 0.05% to 0.20% of Mo, 0.20% to 0.30% of Cu, 0.25% to 0.40% of Ni, 0.030% to 0.040% of Nb, 0.010% to 0.040% of Ti and the balance Fe and impurities. According to the high-performance bridge steel with the yield strength not smaller than 500 MPa and the preparation method and application of the high-performance bridge steel, microalloying design is adopted, a TMCP technology is matched, precious elements are reduced, the structure is fine and uniform, and a prepared steel plate has high toughness, a low yield ratio, weather resistance, weldability and the anti-fatigue performance.

Owner:SD STEEL RIZHAO CO LTD

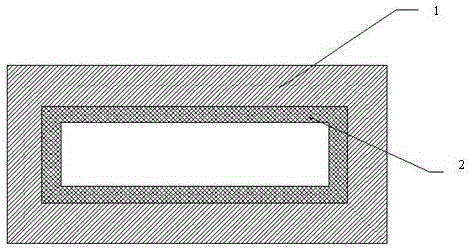

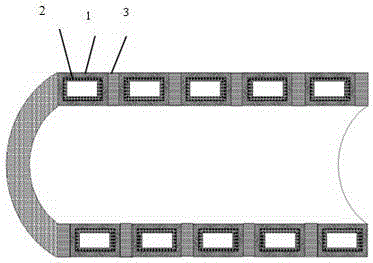

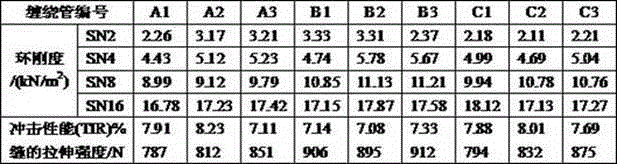

Winding pipe with fiber reinforced polypropylene (FRPP) reinforced hollow-structure wall and machining process for winding pipe

Owner:HUBEI KINGBULL PIPE IND

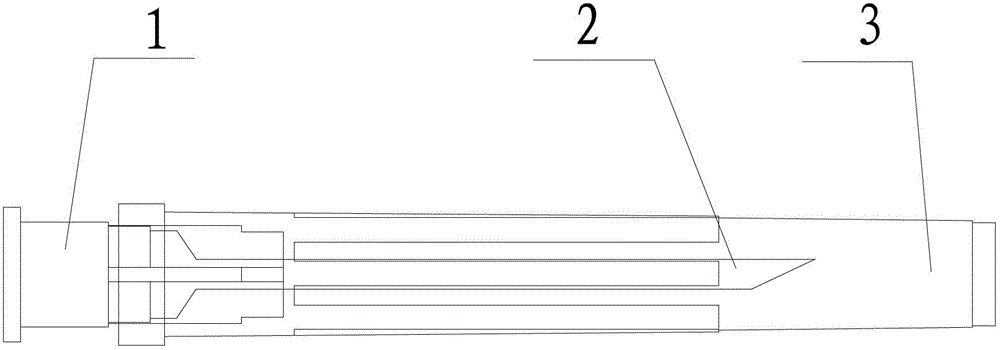

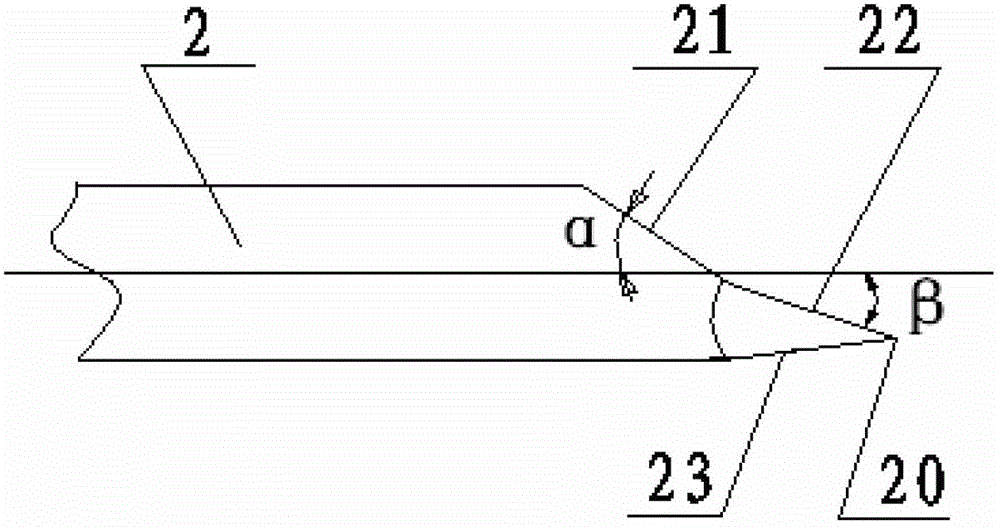

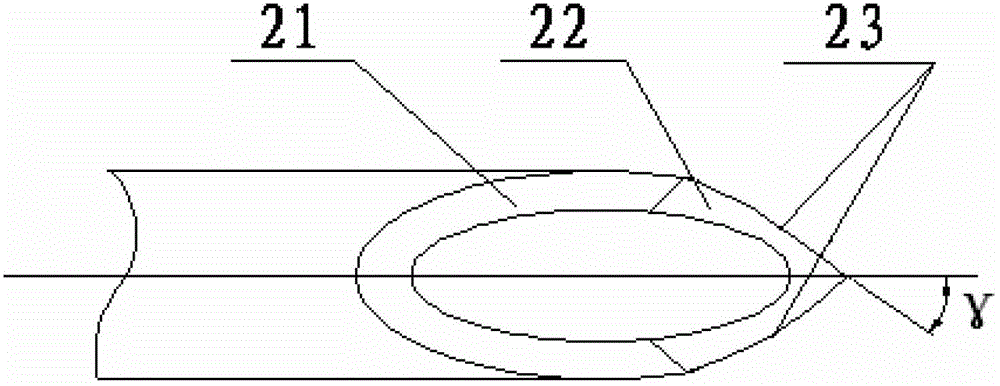

Disposable medical syringe needle

InactiveCN102716531AMeet production requirementsEasy to processInfusion needlesDiseaseInjection moulding

Owner:侯李明

Preparation method of special coating resin composition for polyethylene

ActiveCN102863670AImprove melt strengthLow shrinkageNon-macromolecular adhesive additivesFilm/foil adhesivesLow-density polyethylenePeroxide

Owner:PETROCHINA CO LTD

Heat treatment process for lowering yield ratio of ultra-high-strength marine steel

Owner:SUQIAN NANGANG JINXIN STEEL ROLLING CO LTD

High-rigidity and high-toughness resin material for clothing buttons

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

Low-aging sensitivity hot rolled plate with high strength and toughness and manufacturing method thereof

InactiveCN103757548AAddress uneven performanceSolve the costManufacturing convertersChemical compositionSmelting process

Owner:ANGANG STEEL CO LTD

High-efficiency filter sheets for air microfiltration membrane filters

InactiveCN108031209AHigh mechanical strengthIncreased mechanical toughnessDispersed particle filtrationFiltration separationPolyvinyl chlorideFilter effect

The present invention relates to a high-efficiency filter sheet for air microfiltration membrane filters. The high-efficiency filter sheet comprises a polyvinyl chloride fiber layer and a polytetrafluoroethylene fiber layer, wherein fiber filaments in the polyvinyl chloride fiber layer and the polytetrafluoroethylene fiber layer are respectively in a unidirectional arrangement, and an included angle between the fiber filaments in the polyvinyl chloride fiber layer and the fiber filaments in the polytetrafluoroethylene fiber layer is 60-65 DEG. According to the high-efficiency filter sheet, a double layer combination of the polyvinyl chloride fiber layer and the polytetrafluoroethylene fiber layer is used, and a specific angle between the fiber filaments is set, so that windage resistance and filtering effect of the filter sheet are improved; the introduced polytetrafluoroethylene fiber layer has superhigh mechanical strength and structural toughness, so that vibration caused by strongwind can be effectively suppressed, and airflow in a dust collection chamber of a vacuum cleaner is stabilized; and a filling layer is additively arranged, so that the filtering effect of the filter sheet is further improved.

Owner:SUZHOU QINGRUI AIR SYST

Cracking-resistant iron-base powder metallurgy material used for valve and preparation method of cracking-resistant iron-base powder metallurgy material

The invention discloses a cracking-resistant iron-base powder metallurgy material used for a valve. The cracking-resistant iron-base powder metallurgy material used for the valve is prepared from the following raw materials in parts by weight: 0.2-0.4 part of stearic acid boron, 3-4 parts of aluminum nickel alloy powder, 3-4 parts of nickeling silicon carbide crystal whisker, 3-4 parts of TiO2, 1-1.5 parts of fumed silica, 0.4-0.6 part of palm wax, 1-2.6 parts of nanometer boron fiber, 1-1.5 parts of cordierite powder, 2-2.6 parts of aluminium titanate, 0.3-0.4 part of silane coupling agent kh-550, a proper quantity of 1% sodium carbonate solution, a proper quantity of water, 2.5-3.5 parts of sodium hypophosphite, 0.4-0.6 part of polyethylene glycol, 30-35 parts of 2mMol / L copper sulphate solution, 2-3 parts of wetting accessory ingredient and 77-82 parts of iron powder. The nanometer boron fiber and the nickeling silicon carbide crystal whisker are added into the valve material to increase compatibility and prevent cracking while the toughness, the heat resistance and the impact strength resistance of valve materials are increased.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Domestic ceramic with high toughness, and production method thereof

Owner:福建省德化县嘉威陶瓷有限公司

Calcium sulfate whisker/styrene-butadiene latex composite foaming material and preparation method thereof

ActiveCN108841060AImprove performanceImprove mechanical propertiesMechanical propertyButadiene-styrene rubber

The invention discloses a calcium sulfate whisker / styrene-butadiene latex composite foaming material and a preparation method thereof. Raw materials preparing the calcium sulfate whisker / styrene-butadiene latex composite foaming material comprise, in parts by weight: 50 to 70 parts of styrene-butadiene latex, 8 to 20 parts of natural rubber latex, 5 to 20 parts of modified calcium sulfate whiskers, 0.5 to 4 parts of a modified glass fiber, 2 to 6 parts of talcum powder, 0.02 to 0.15 part of calcium chloride, 2 to 6 parts of zinc oxide, 3 to 8 parts of liquid soap and 0.5 to 3 parts of benzoylperoxide, wherein the solid content of the styrene-butadiene latex is 55 to 68 percent. The calcium sulfate whisker / styrene-butadiene latex composite foaming material prepared by the method is low indensity, light in weight, high in bearing capacity, excellent in mechanical property such as breaking elongation and toughness and high in resilience performance; furthermore, the preparation method is simple, and the preparation process is easy to operate; a product is high in size stability.

Owner:RUIAN SAIBAO LATEX TECH CO LTD

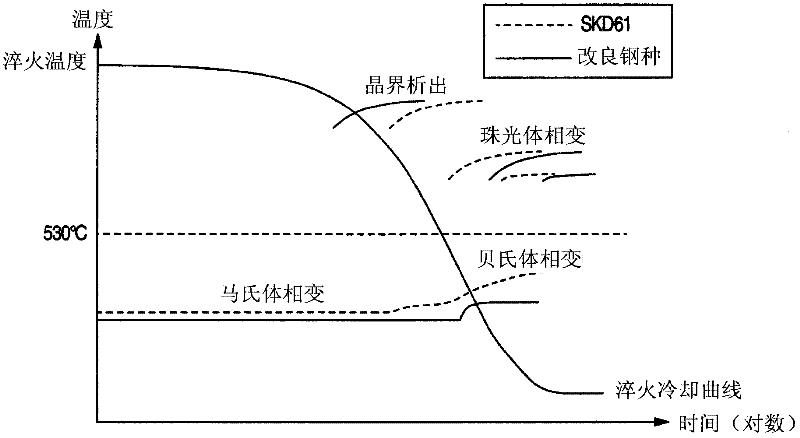

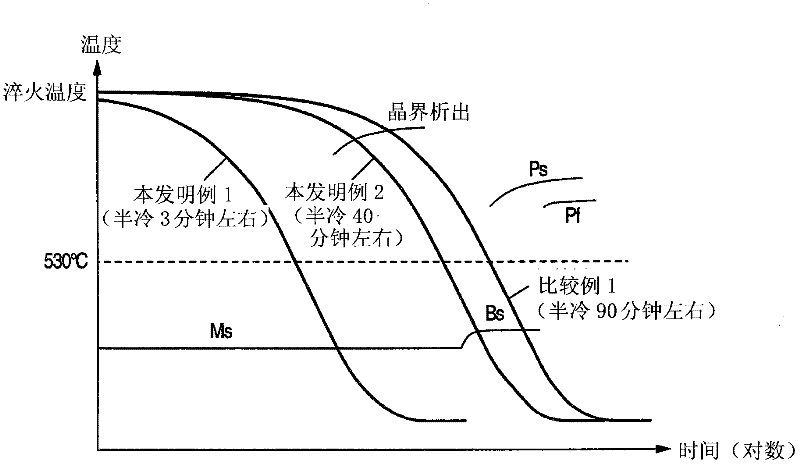

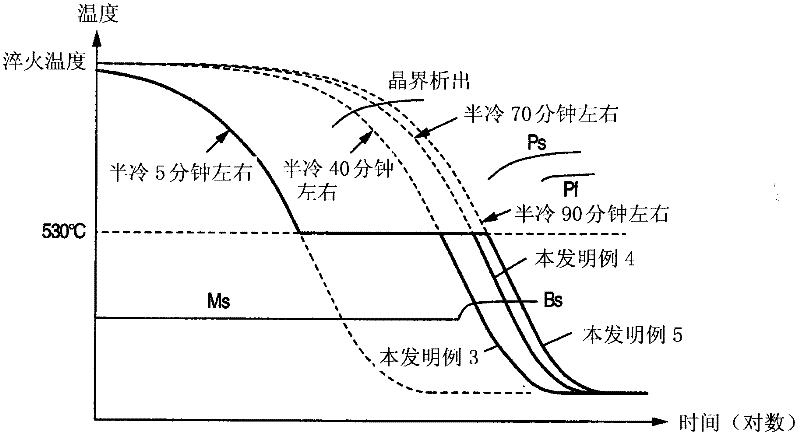

Steel quenching method

Owner:HITACHI METALS LTD

Double-layer intermediate transition welding method for titanium steel composite plate

InactiveCN113145994AReduce brittlenessSimple designWelding/cutting media/materialsSoldering mediaTitanium coatingButt welding

The invention relates to a double-layer intermediate transition welding method for a titanium steel composite plate. The method comprises the following steps: when the titanium steel composite plate consisting of a TA1 or TA2 titanium coating with the thickness of more than 1.0 mm and low-carbon steel with the thickness of more than 5.0 mm is subjected to butt welding, pure copper and pure nickel are adopted as an intermediate transition layer at the interface of the low-carbon steel and the titanium coating for welding. The method has the advantages that a titanium-nickel compound is used for replacing a ferrotitanium compound, the brittleness of the compound is reduced, and the structural toughness is improved. The welding method adopts a manual easy-to-operate method, and is flexible to use, stable in process and good in portability. The material of the middle layer is selected from common pure copper and pure nickel metal in the market, the cost of the material of the middle layer is greatly reduced, and the applicability is high.

Owner:ANGANG STEEL CO LTD

Wave-absorbing breathable environment-friendly molding and preparation method thereof

InactiveCN107324688AImprove the performance of anti-electromagnetic radiationEffective absorptionSolid waste managementBuilding constructionsFiberPolyester

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

High-toughness anti-cracking rubber material for sealing ring and method for preparing same

InactiveCN106398002ANot easy to wear offExcellent abrasion resistanceRubber materialGlycidyl methacrylate

Owner:岳承华

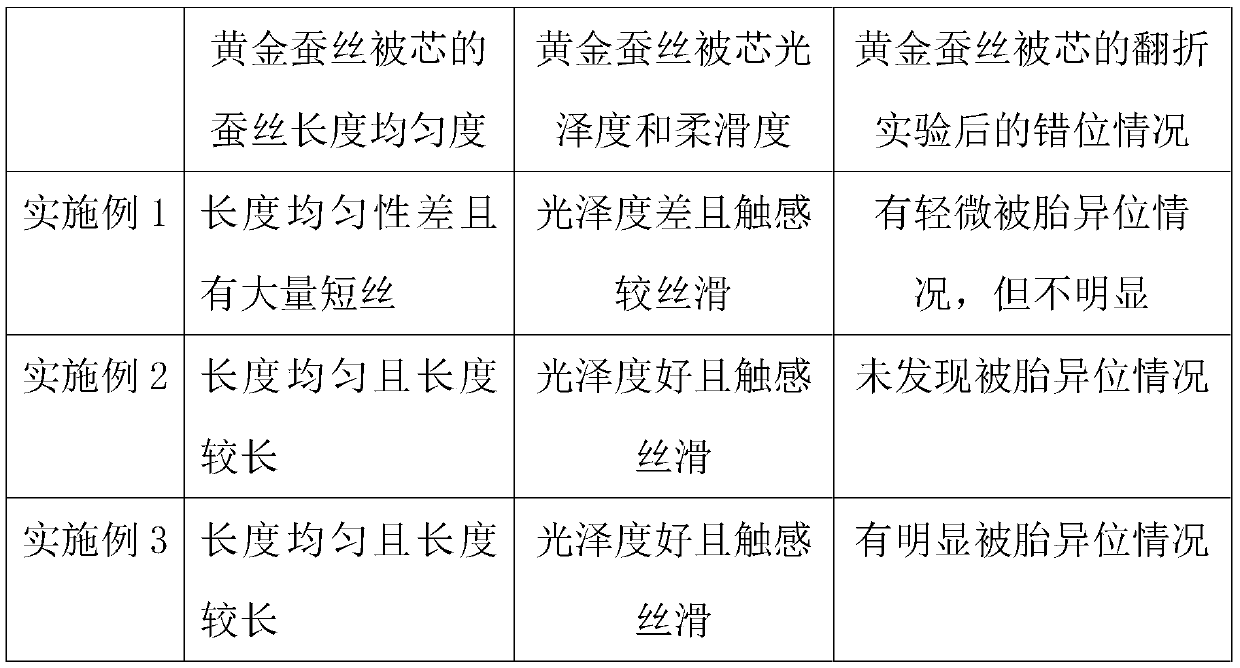

Making process of gold silk skin-nourishing quilt

InactiveCN110257924AFull penetrationAffect glossBed linenSilk cocoons cleaning/classifyingToughnessPermeation

Owner:江苏缔凡蚕丝科技创意园有限公司

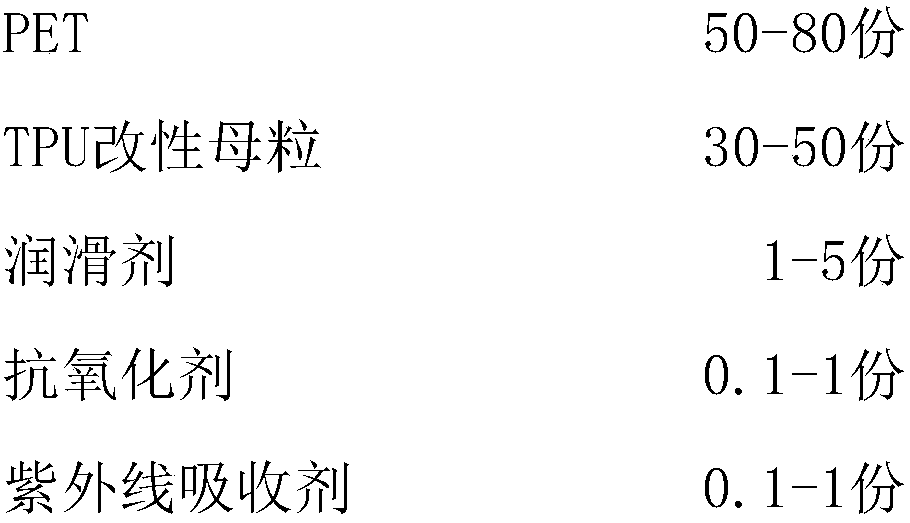

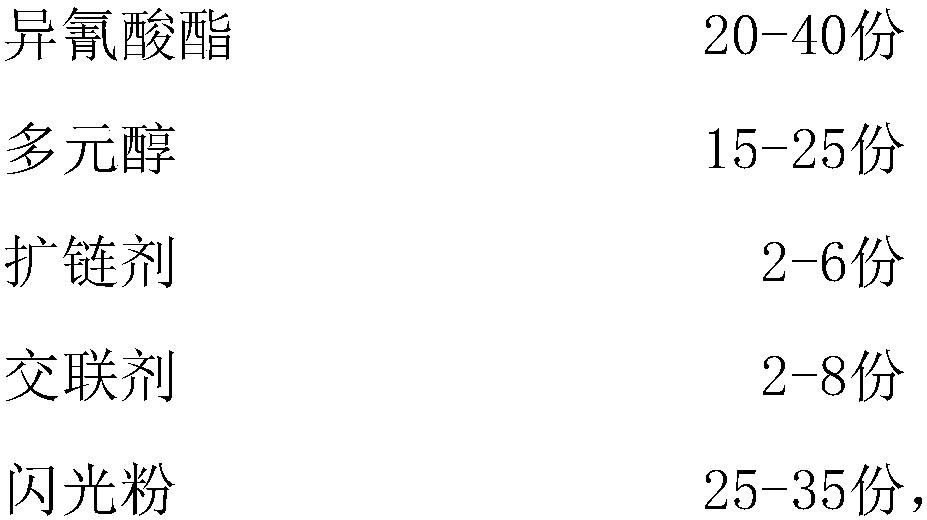

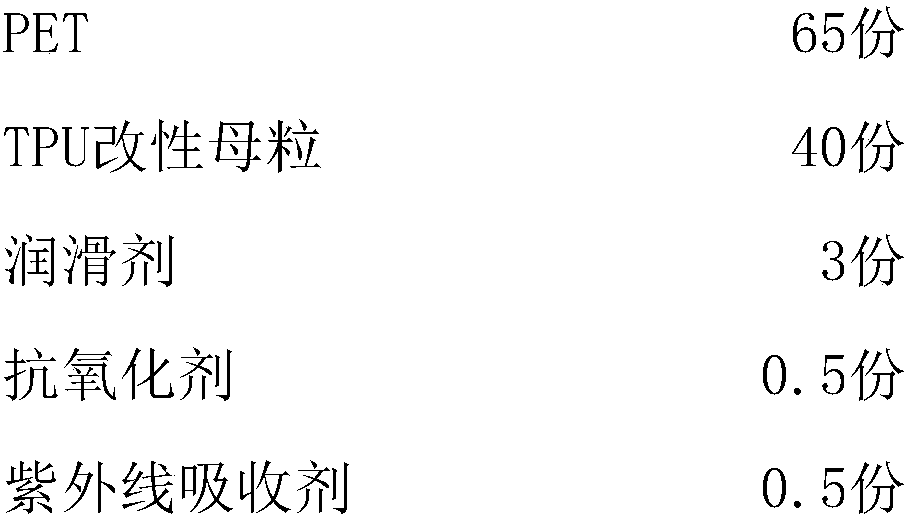

Transparent flashing polyester chain tooth, preparation method and zip fastener

Owner:东莞市瑞翔新型材料科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap