Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about "Solid waste management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

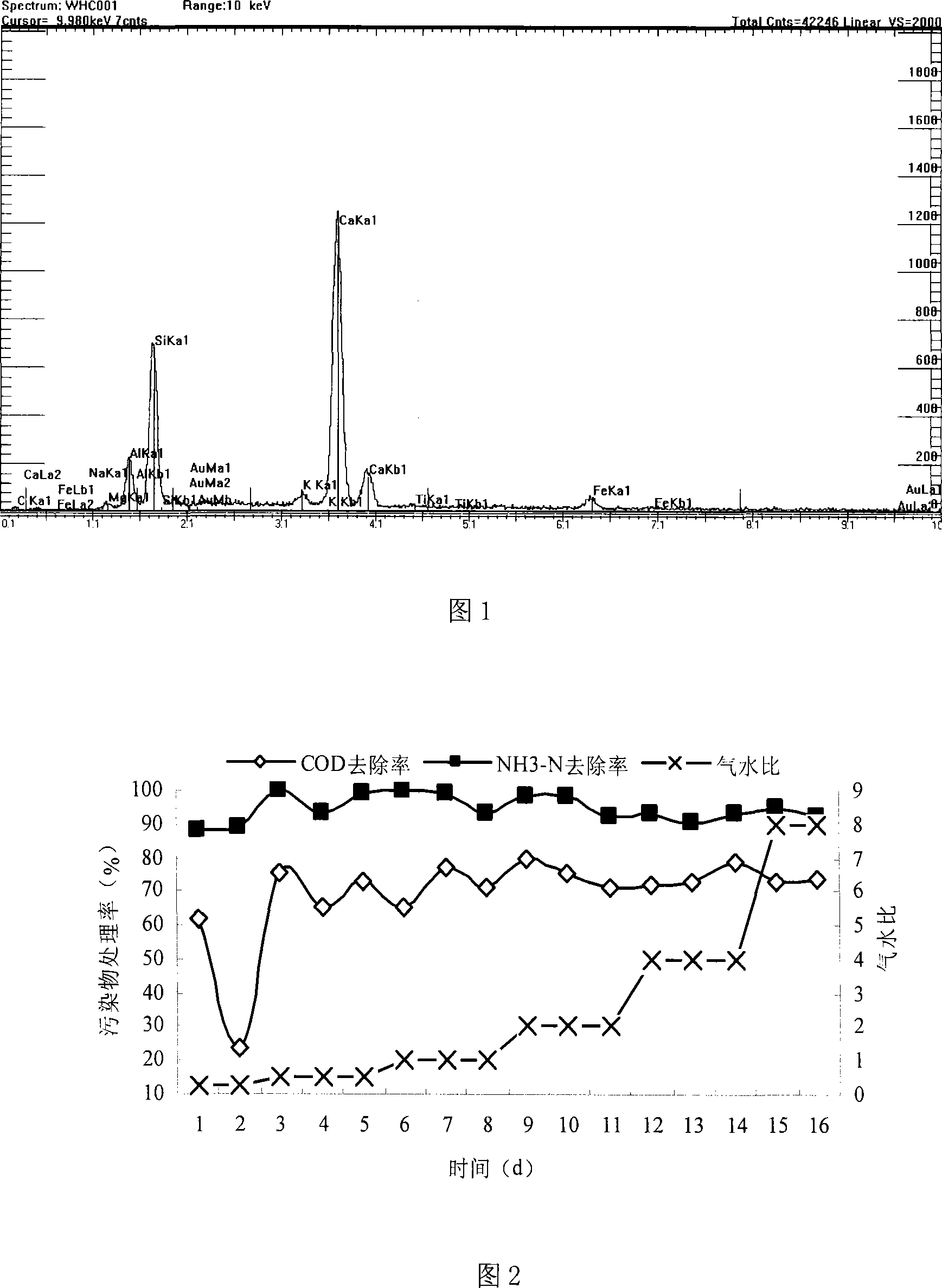

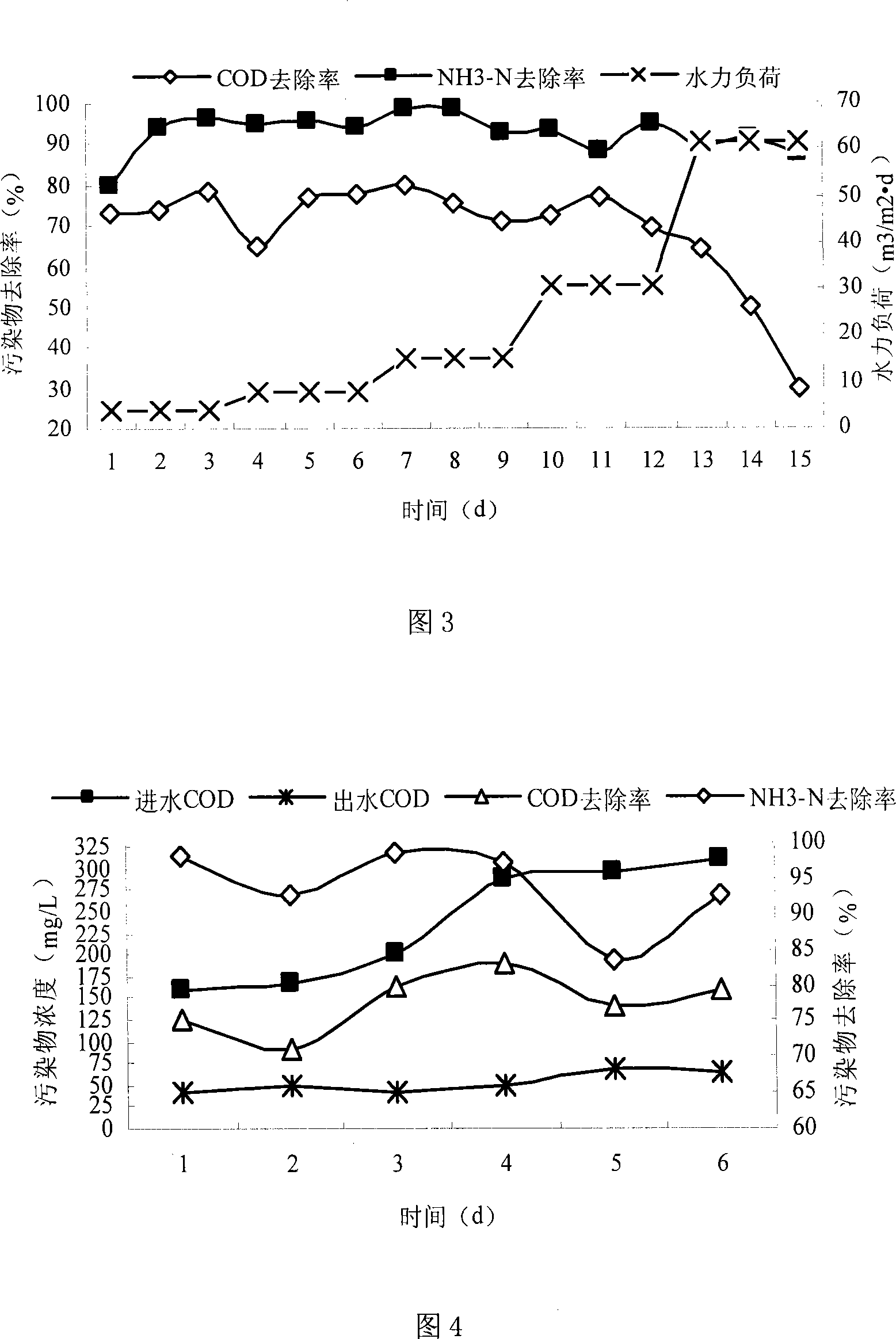

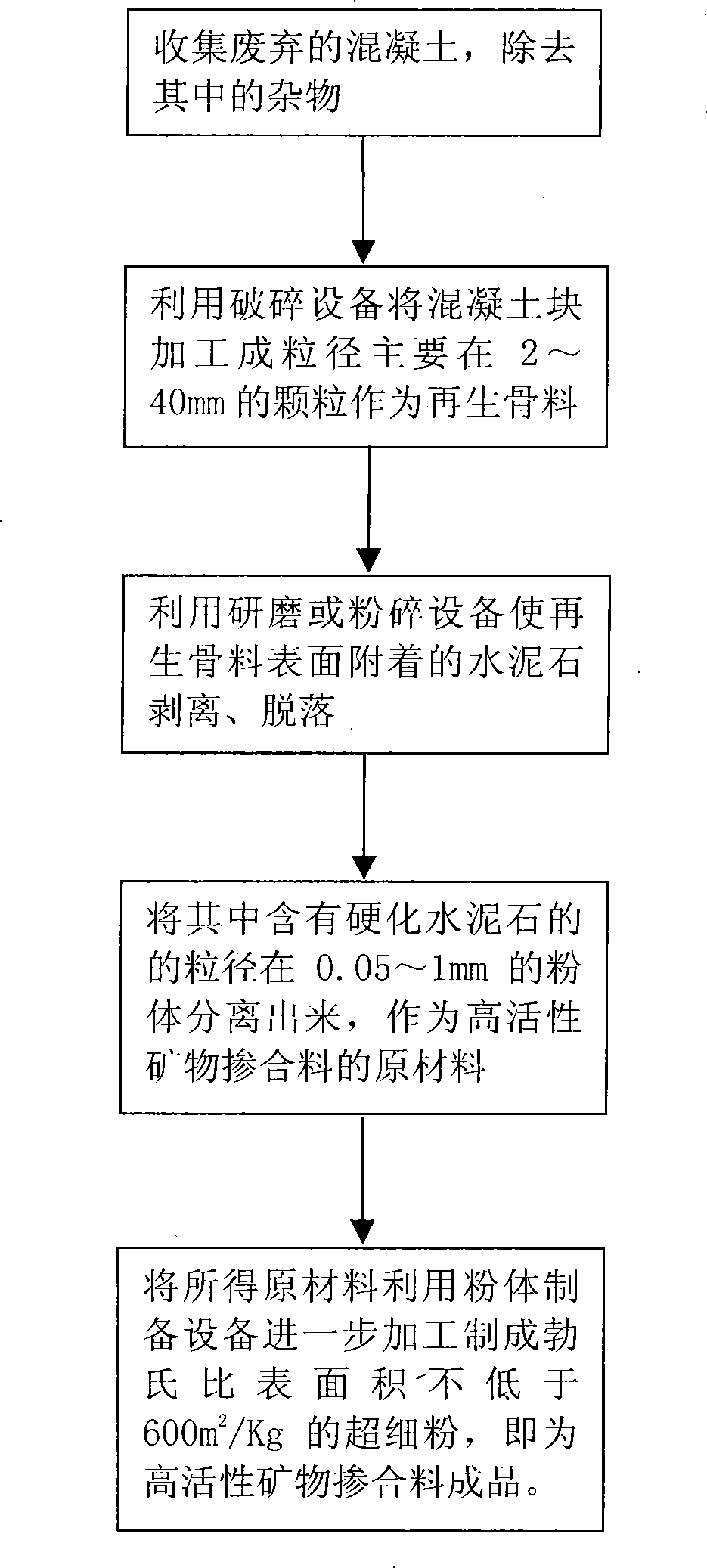

Biological aerated filter filtering material for treating sewage and preparation method thereof

Owner:LANZHOU UNIVERSITY

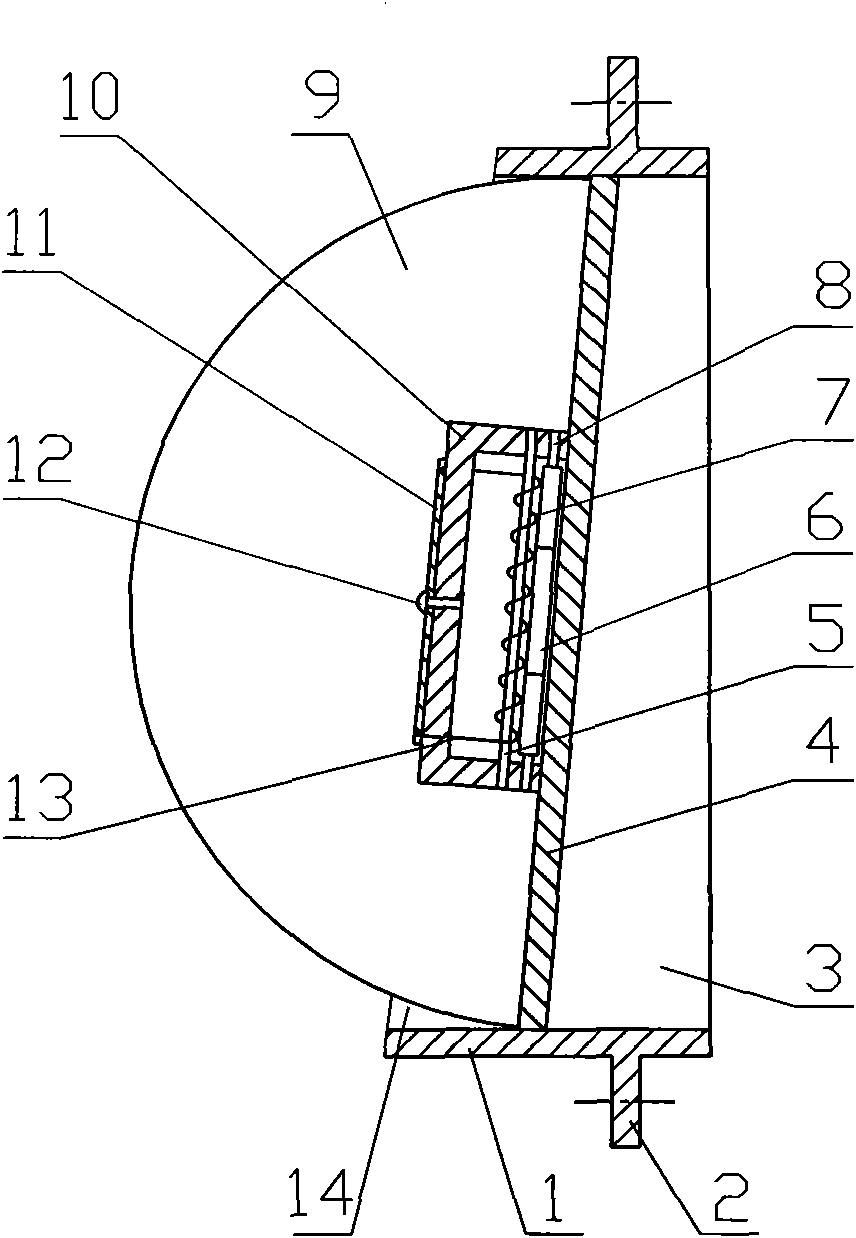

Method for manufacturing high-activity mineral blending material and application thereof

InactiveCN101244906AIncrease 3d intensityReduce water consumptionSolid waste managementPrice ratioCement paste

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

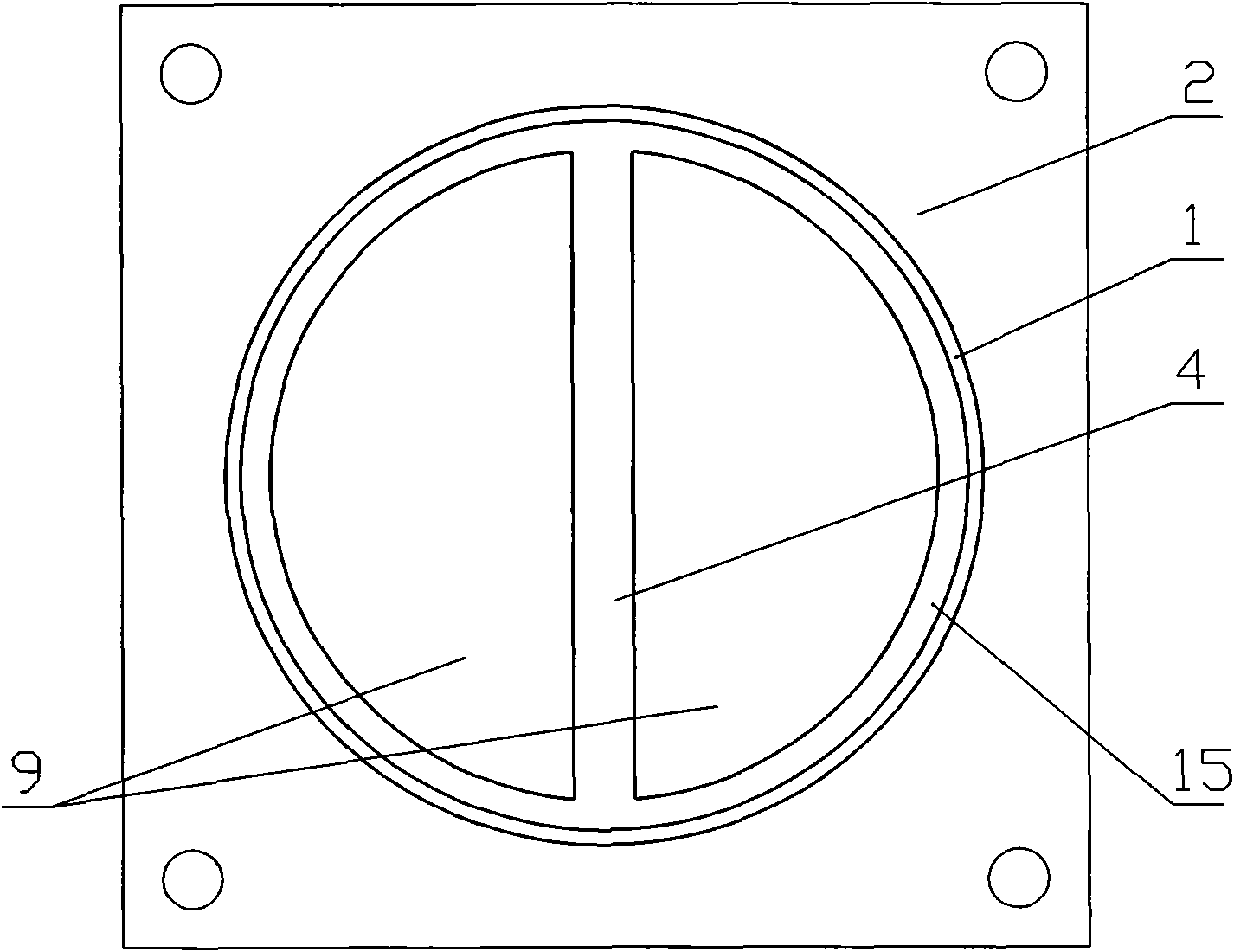

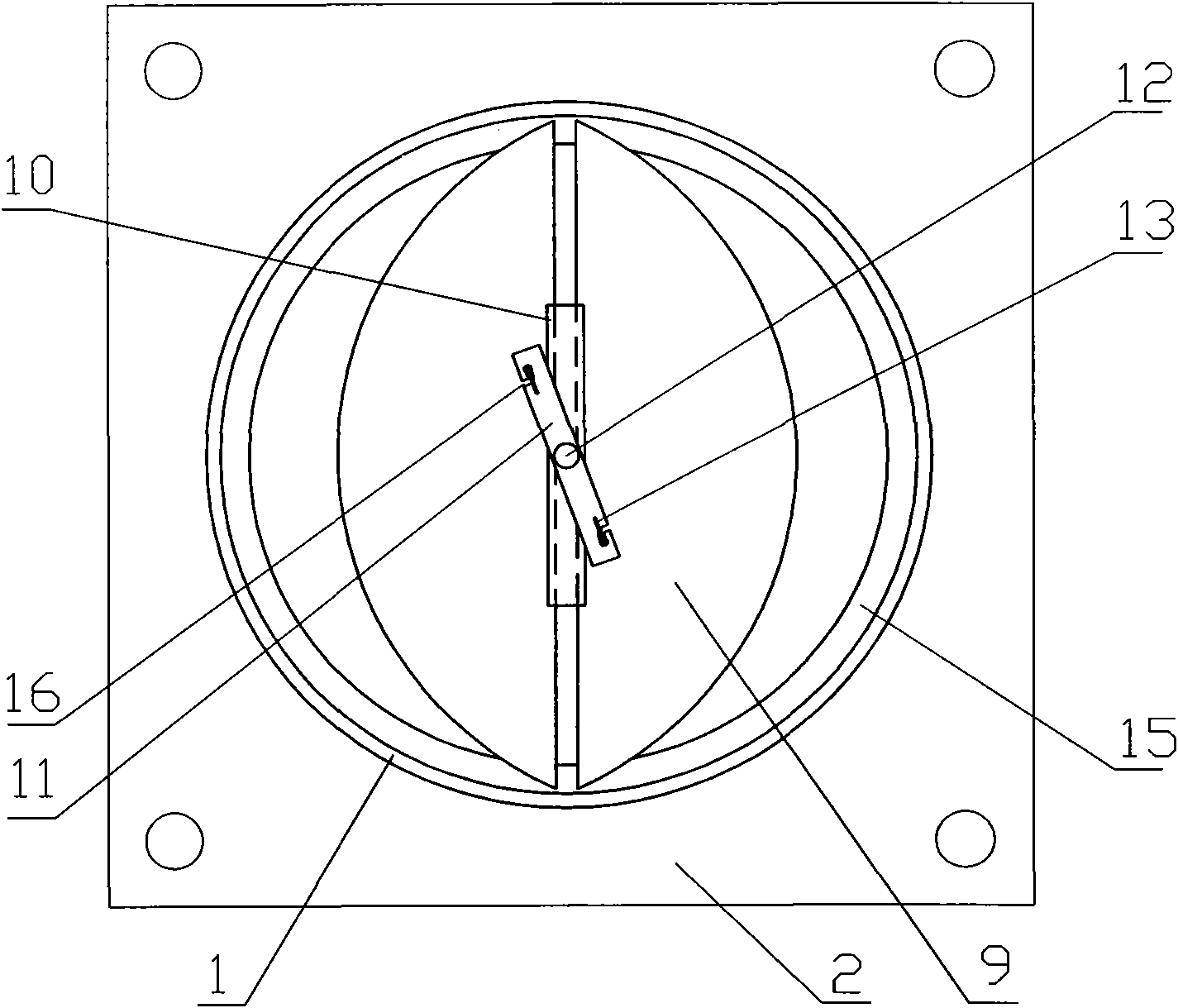

Check fire valve for flue

Owner:韩文强

Method for preparing vegetation form cellular concrete

InactiveCN101318795AEasy to prepareEasy to operateSolid waste managementCeramicwareGas phaseAgglutination

Owner:SOUTH CHINA UNIV OF TECH

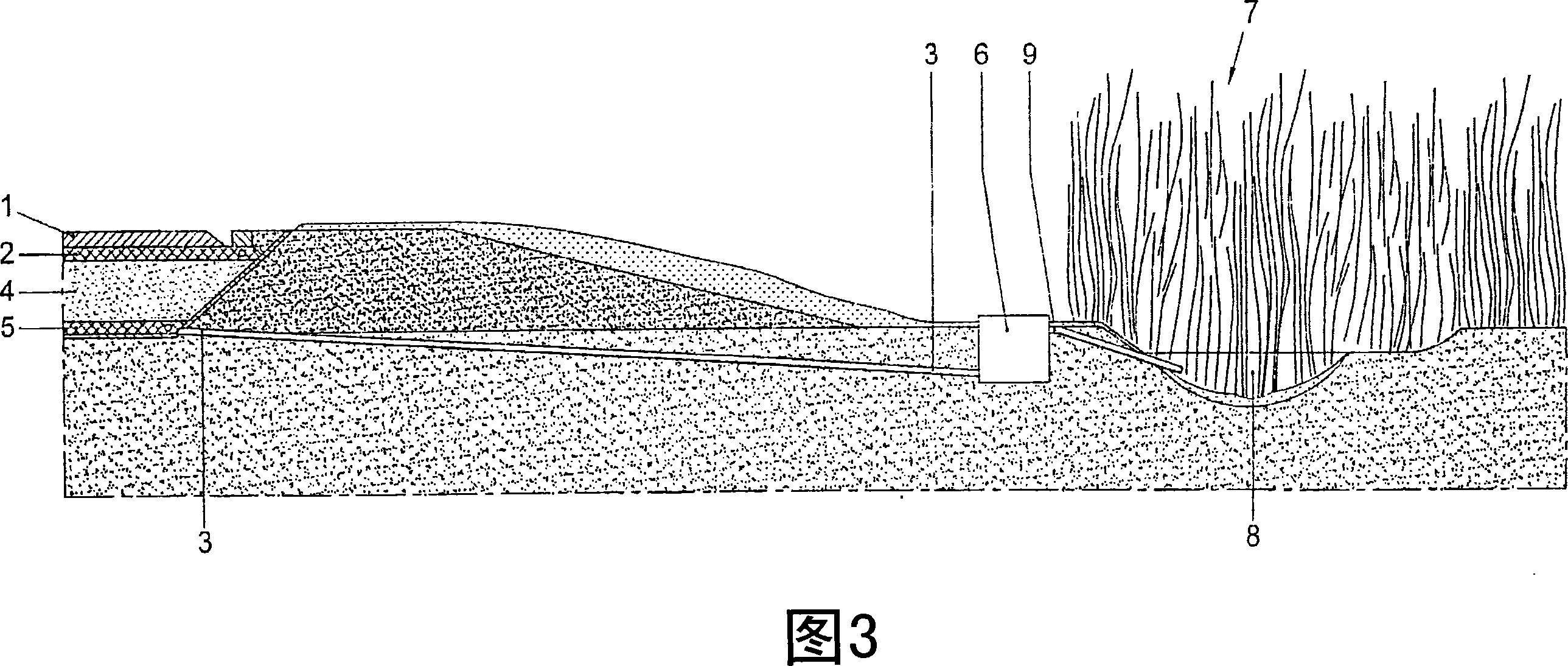

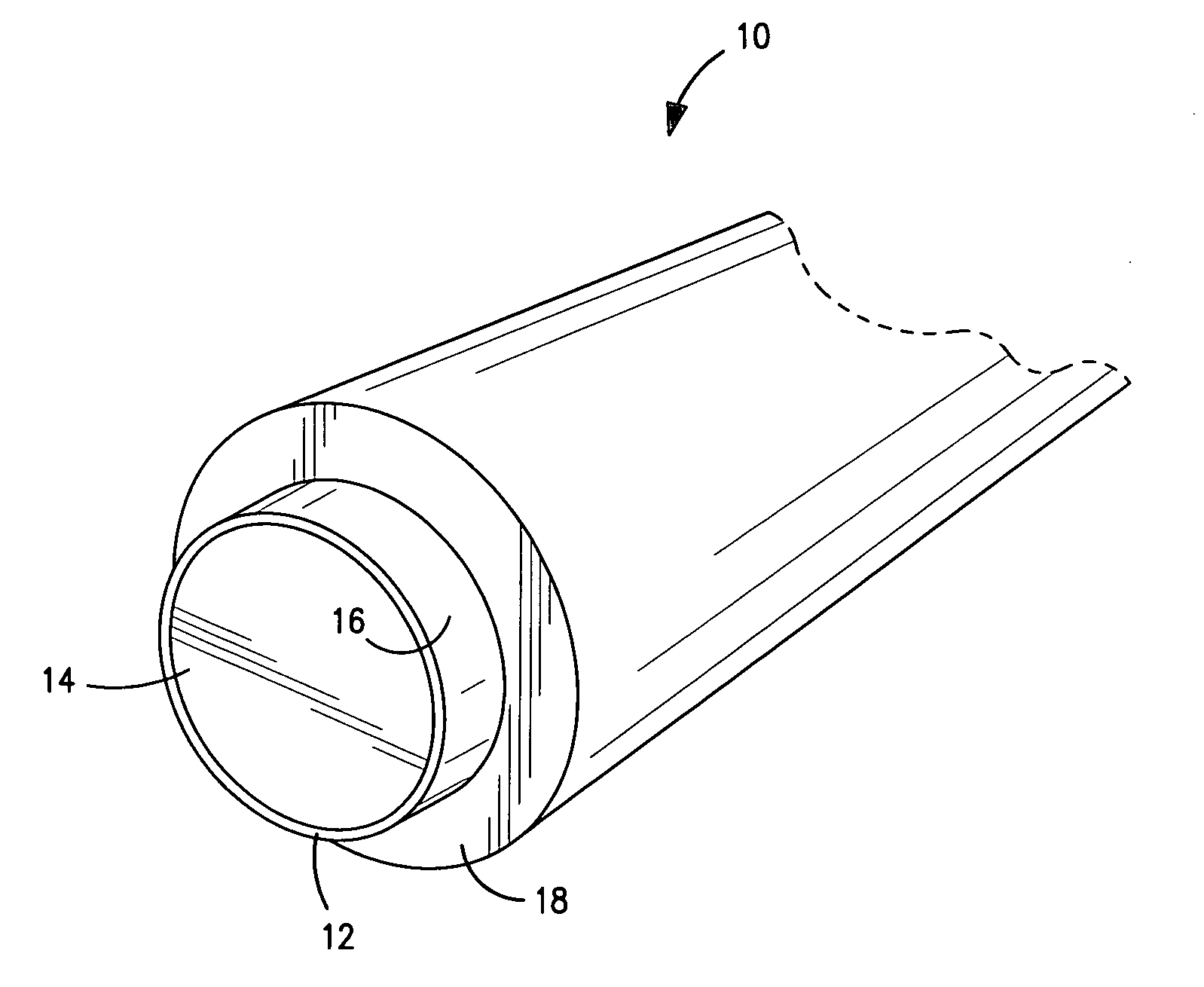

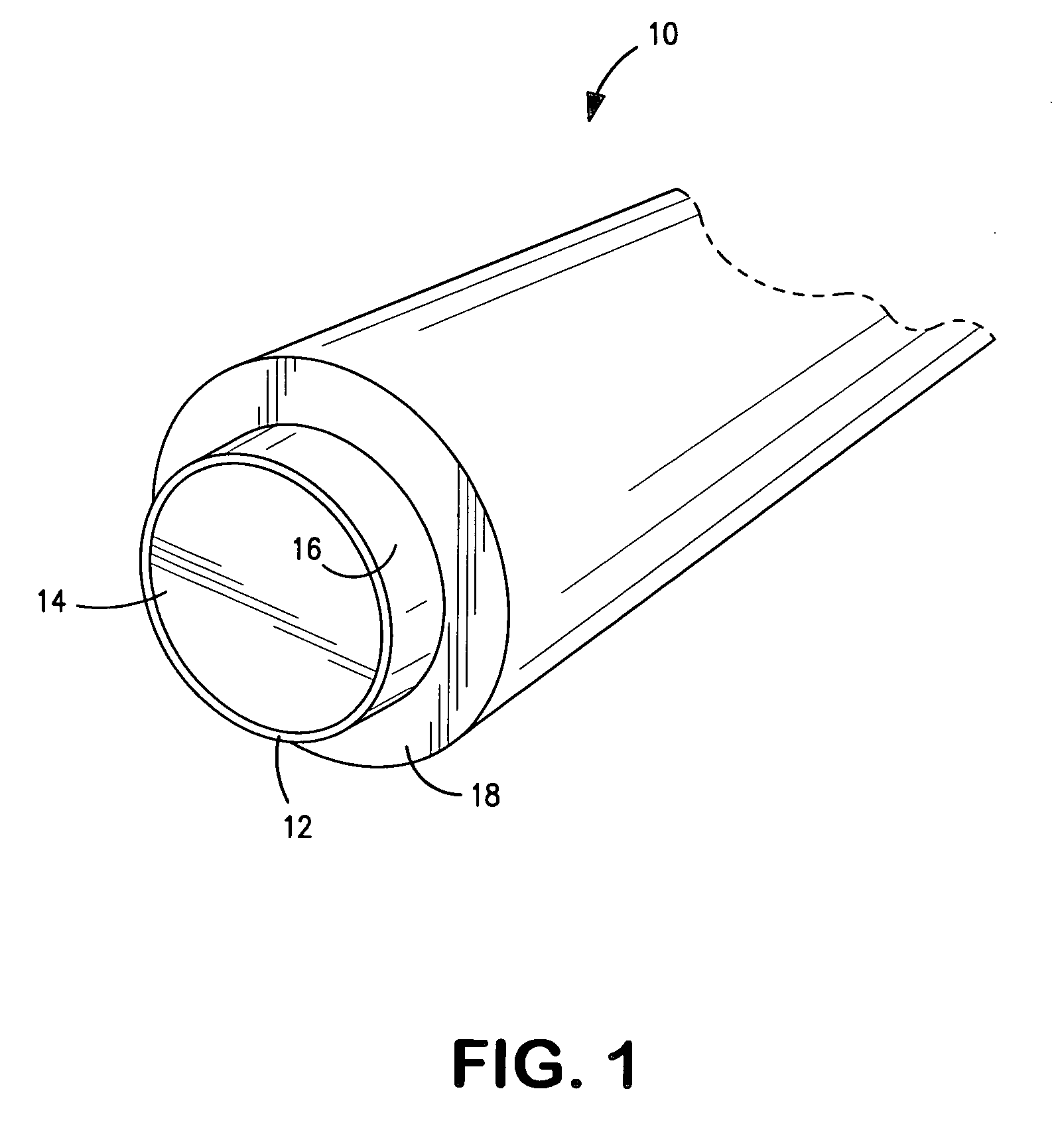

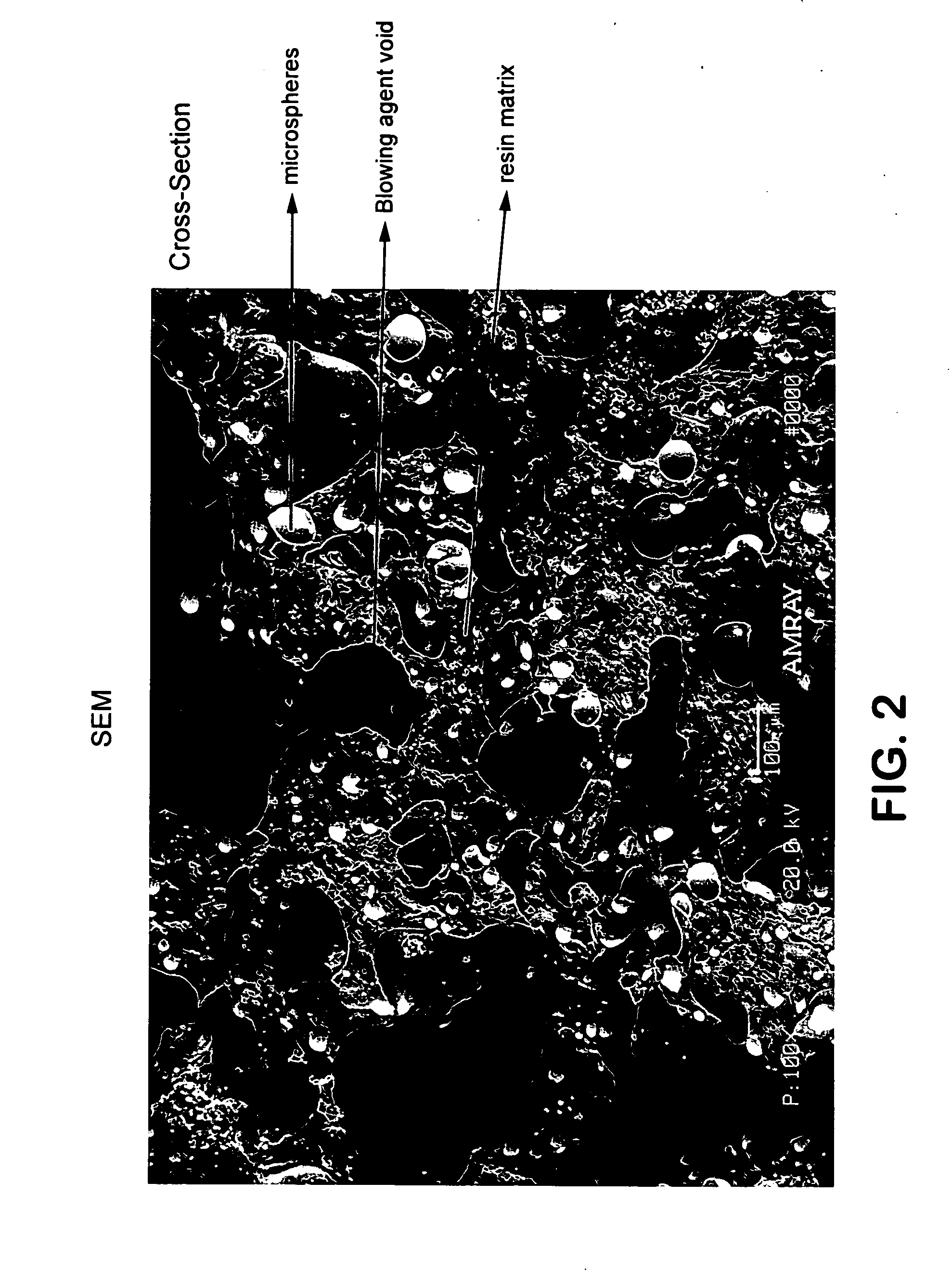

Syntactic Foam Compositions, Pipelines Insulated with Same, and Method

InactiveUS20110017340A1Improve thermal insulation propertiesIncrease buoyancyThermal insulationSolid waste managementEpoxyFoaming agent

Owner:CABOT CORP

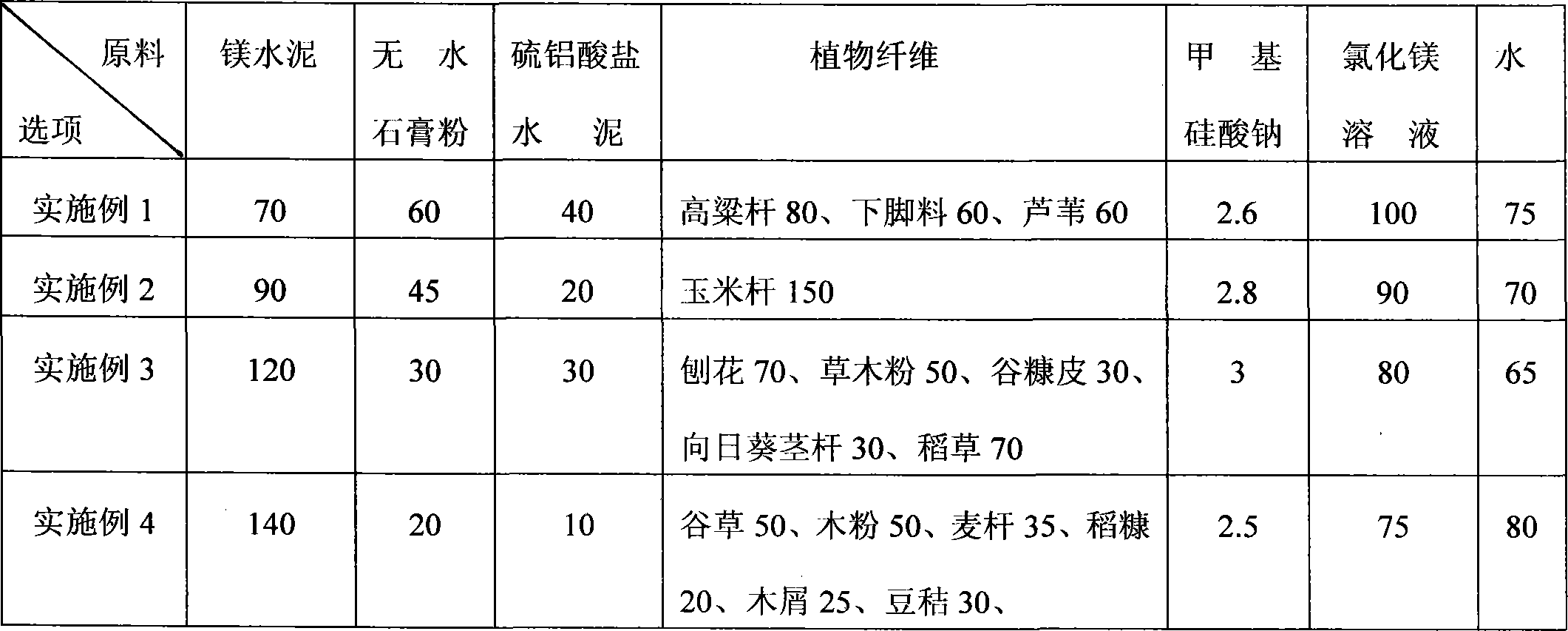

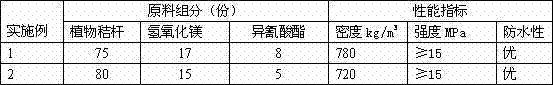

Magnesium-calcium pyrophyte pressed-fibre board and method of manufacturing the same

InactiveCN101172825AObvious beneficial effectGood effectSolid waste managementWeather resistancePlant fibre

Owner:谢涛

High-temperature resistant heat insulating material using vermiculite as main raw material and method for manufacturing same

InactiveCN101560087ASolve the strength problemSolve temperature problemsSolid waste managementMixing operation control apparatusPhosphateVolumetric Mass Density

Owner:佛山市冠富贸易有限公司 +1

Down hole impacting rotary jetting mixing pile construction technology and device

ActiveCN106996105ASimple structureNo need to disassembleSolid waste managementBulkheads/pilesArchitectural engineeringHigh pressure

The invention provides a down hole impacting rotary jetting mixing pile construction technology and device. The down hole impacting rotary jetting mixing pile construction device includes a drill rod, a down hole impacting device arranged at the bottom end of the drill rod, a mixing device connected to the lateral side of the drill rod or the down hole impacting device, and a nozzle arranged on the lateral side of the down hole impacting device. A communicating high-pressure air passageway is arranged among the drill rod, the nozzle and the down hole impacting device. The above down hole impacting rotary jetting mixing pile is adopted in the down hole impacting rotary jetting mixing pile construction technology. By means of the down hole impacting rotary jetting mixing pile construction technology and device, the stratum adaptability is high, and pollution and influences of industrial production to the environment are reduced.

Owner:BEIJING RONGCHUANG GEOTECHNICAL ENG CO LTD

Method for making bricks by using construction wastes

The invention discloses a method for making bricks by using construction wastes. The bricks are characterized by comprising the following raw materials: 30-57 parts of crushed aggregates of construction wastes of which the metal particles are removed and the diameter is small than 14mm, 20-40 parts of coal gangue particles, 10-15 parts of phosphate slag with the particle diameter being less than 1mm, 8-15 parts of cement, 0.6-0.8 part of quick lime, 3-18 parts of pulverized fuel ash, 0.01-0.025 part of a hydroxyl silicon sealed curing agent, 8-12 parts of water and 0.1-0.2 part of sodium silicate. The crushed aggregates of construction wastes can be dismantled materials of old buildings or wastes of novel buildings, and an anti-freezing agent or an anti-freezing chlorine salt can be added into the raw materials. The method has the advantages that the proportioning is simple, the energy is renewable, the environment is protected, and the wastes are utilized.

Owner:HEFEI BAOLI ENVIRONMENTAL PROTECTION TECH

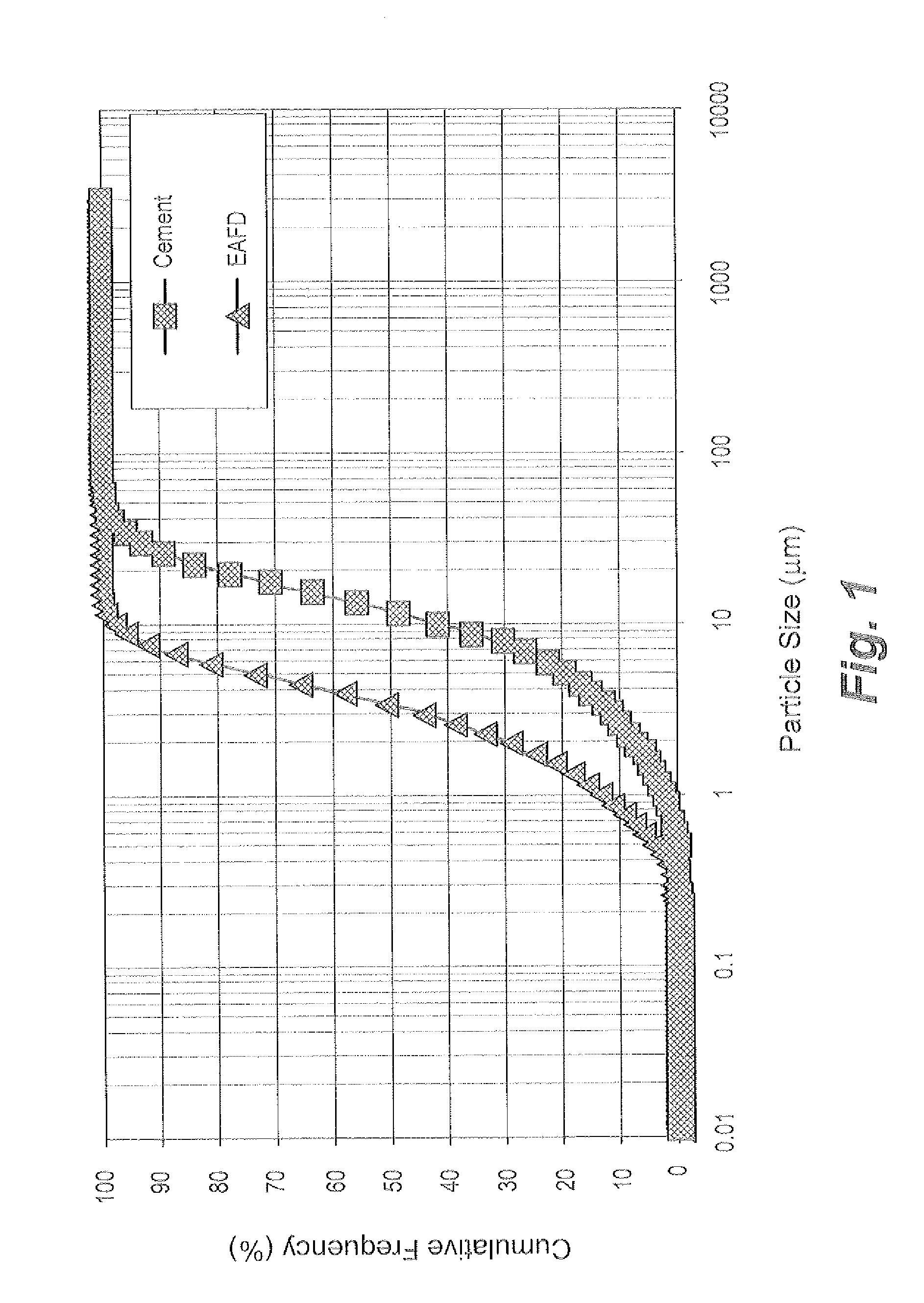

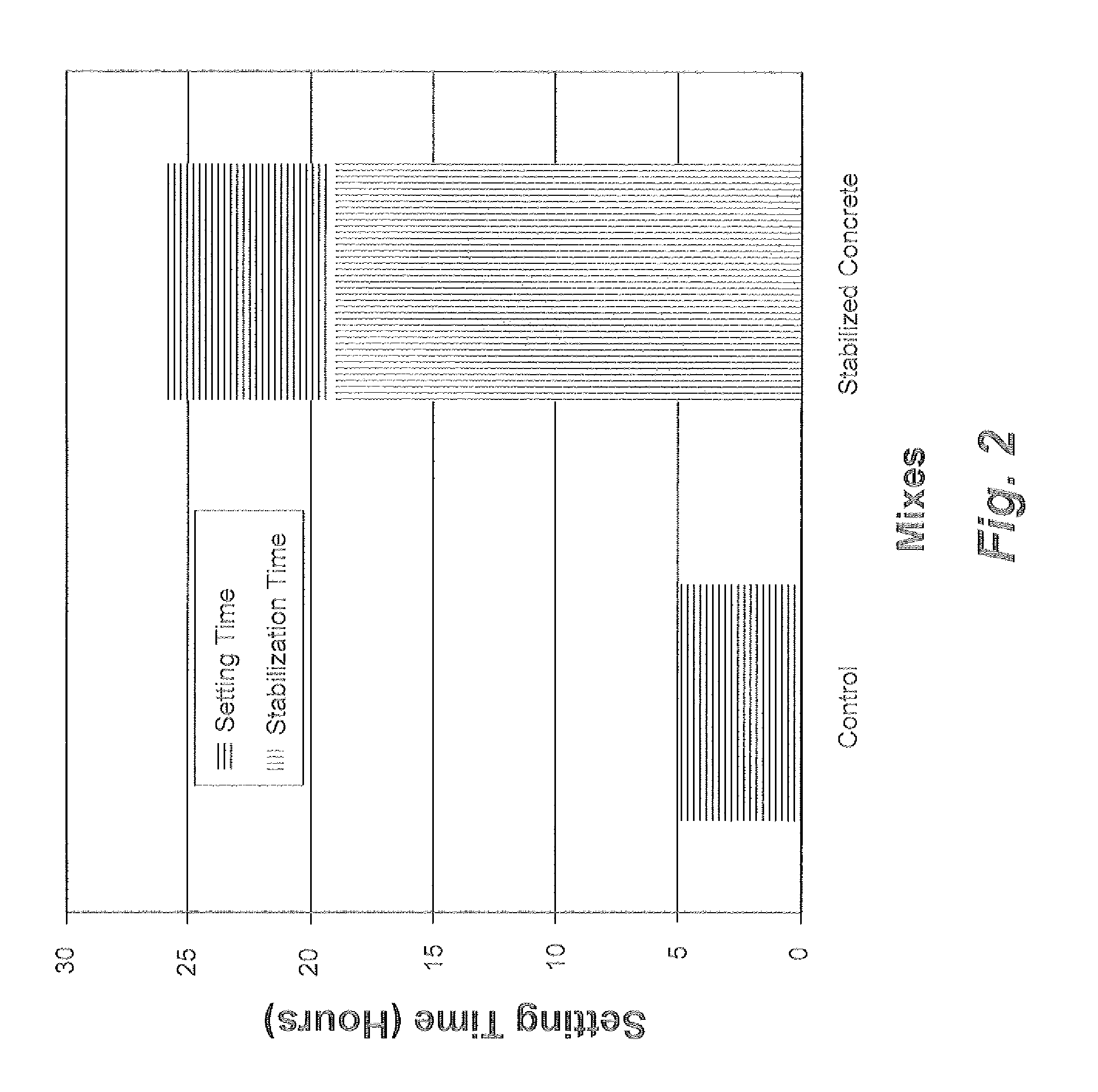

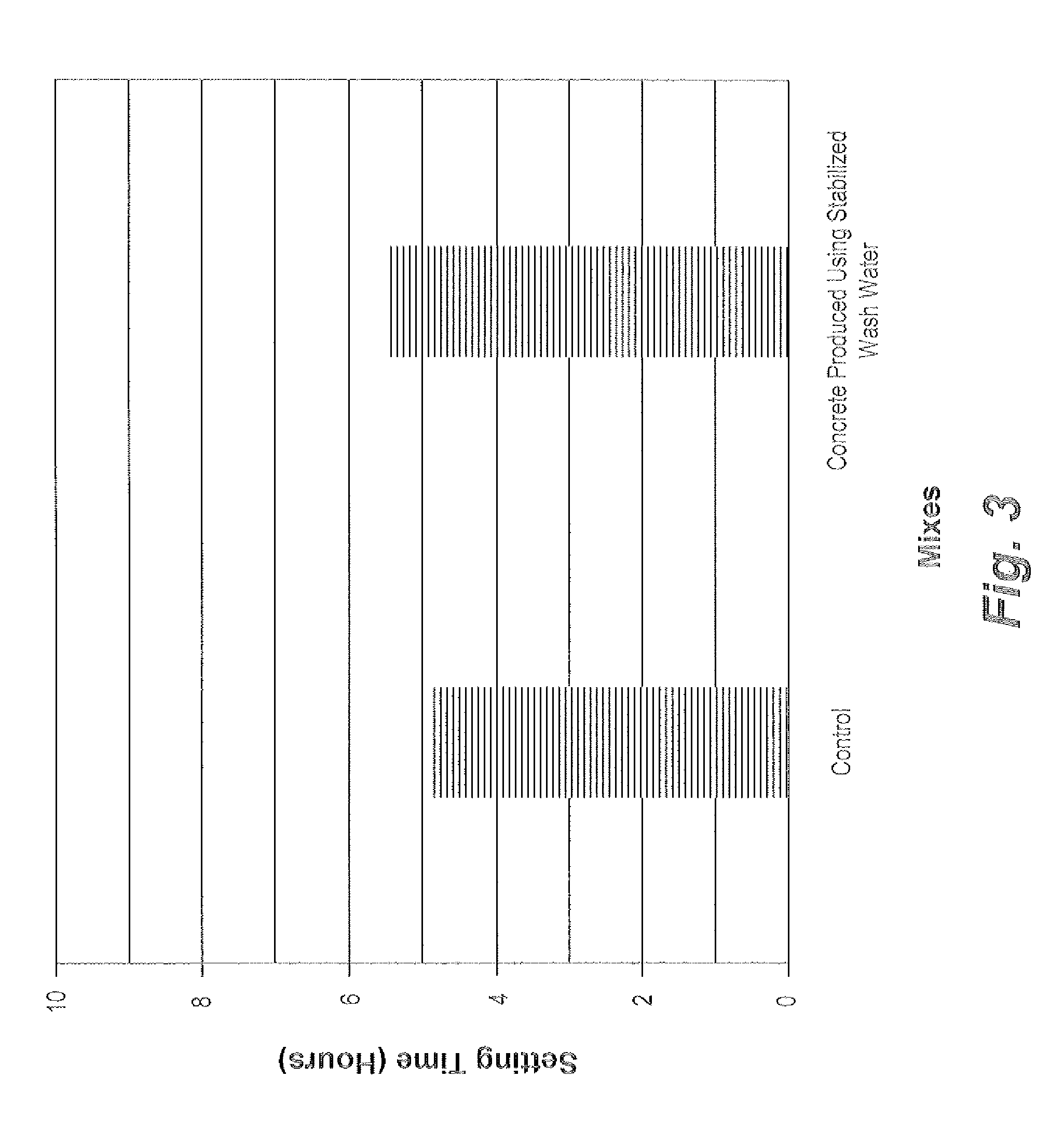

Eafd stabilizer for returned concrete and mixer drum wash water

ActiveUS20120049399A1Readily apparentSolid waste managementTransportation and packagingStabilizing AgentsMaterials science

Owner:KING SAUD UNIVERSITY

Integral utilization treatment method for aerating concrete waste material

InactiveCN101215110AHigh activityImprove performanceSolid waste managementCeramicwareBall millGypsum

Owner:HOHAI UNIV

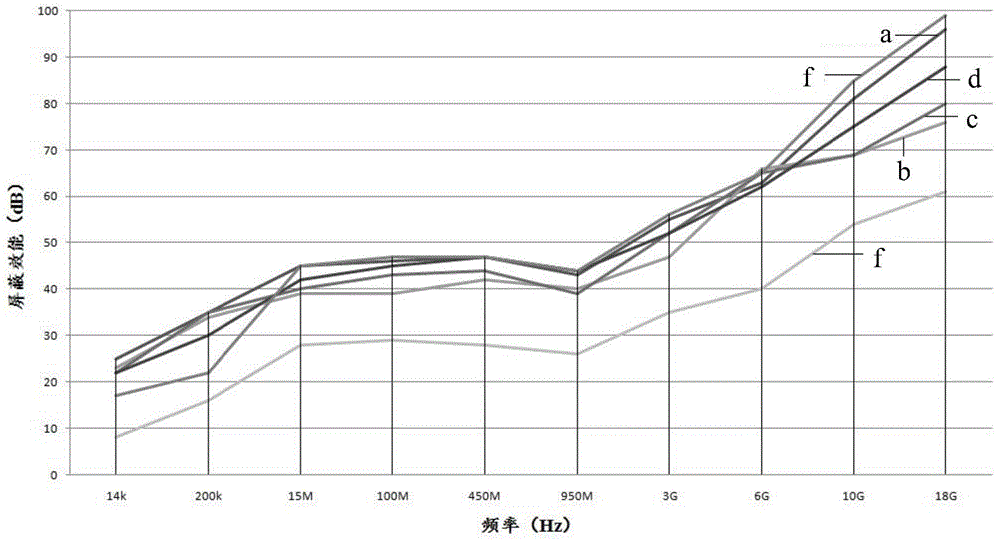

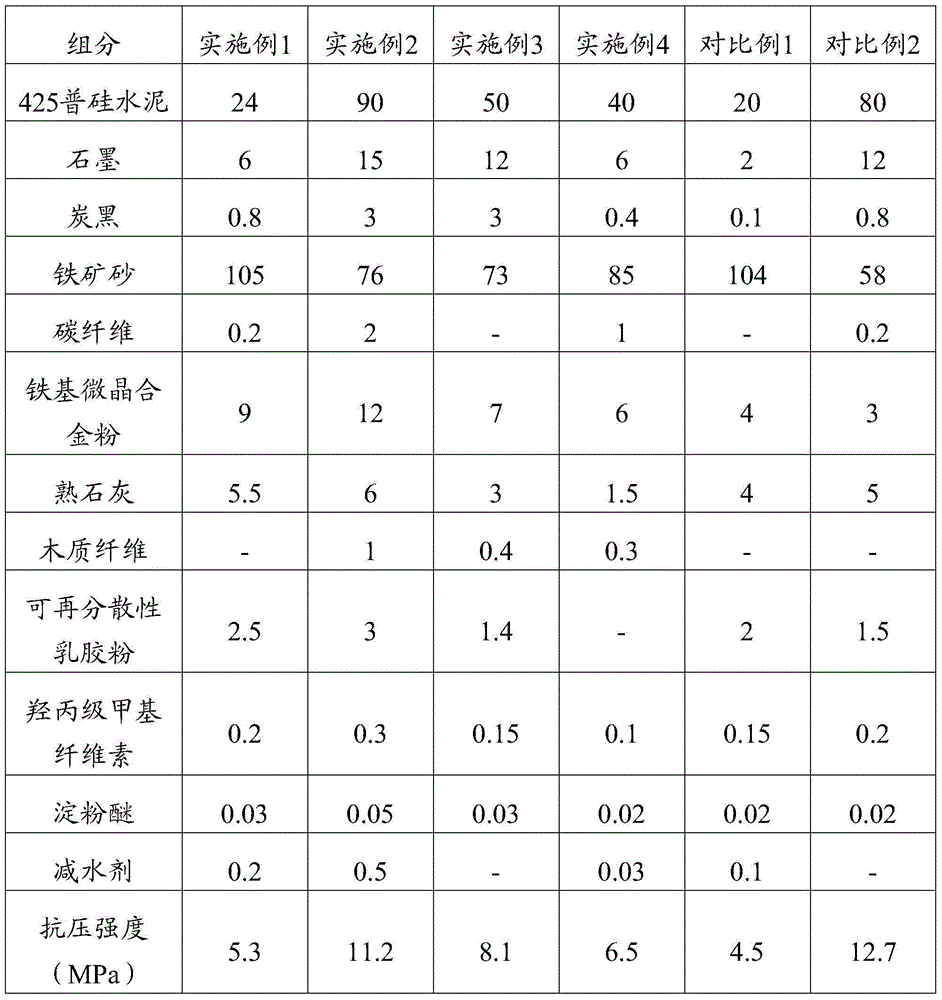

Cement mortar

Owner:ANFANG HI TECH ELECTROMAGNETIC SAFETY TECHN BEIJING

Concrete crushing and recycling device

ActiveCN112495476APrevent looseningReal-time adjustmentSievingSolid waste managementEnvironmental engineeringCrusher

The invention discloses a concrete crushing and recycling device. The concrete crushing and recycling device comprises a crushing mechanism, a dust channel and a mud generating mechanism, wherein thedust channel is formed in one side of the crushing mechanism; and the mud generating mechanism is arranged on one side of the dust channel. According to the concrete crushing and recycling device, a crushing roller adjusting mechanism is additionally arranged, and the distance between crushing rollers can be adjusted in real time according to concrete of different sizes, so that the crushing effect is better, jamming is prevented, and the crushing efficiency is improved; and dust generated in the crushing process is collected and made to form mud under the action of an atomization spraying mechanism, and the mud is discharged under the combined action of a mud settling mechanism and a discharge box, so that the dust is effectively controlled, and the environmental pollution is prevented; and meanwhile, the dust can be reprocessed and reutilized, so that raw materials are saved, and waste is prevented.

Owner:GUI ZHOU CHANG TONG DIAN LI XIAN LU QI CAI YOU XIAN GONG SI

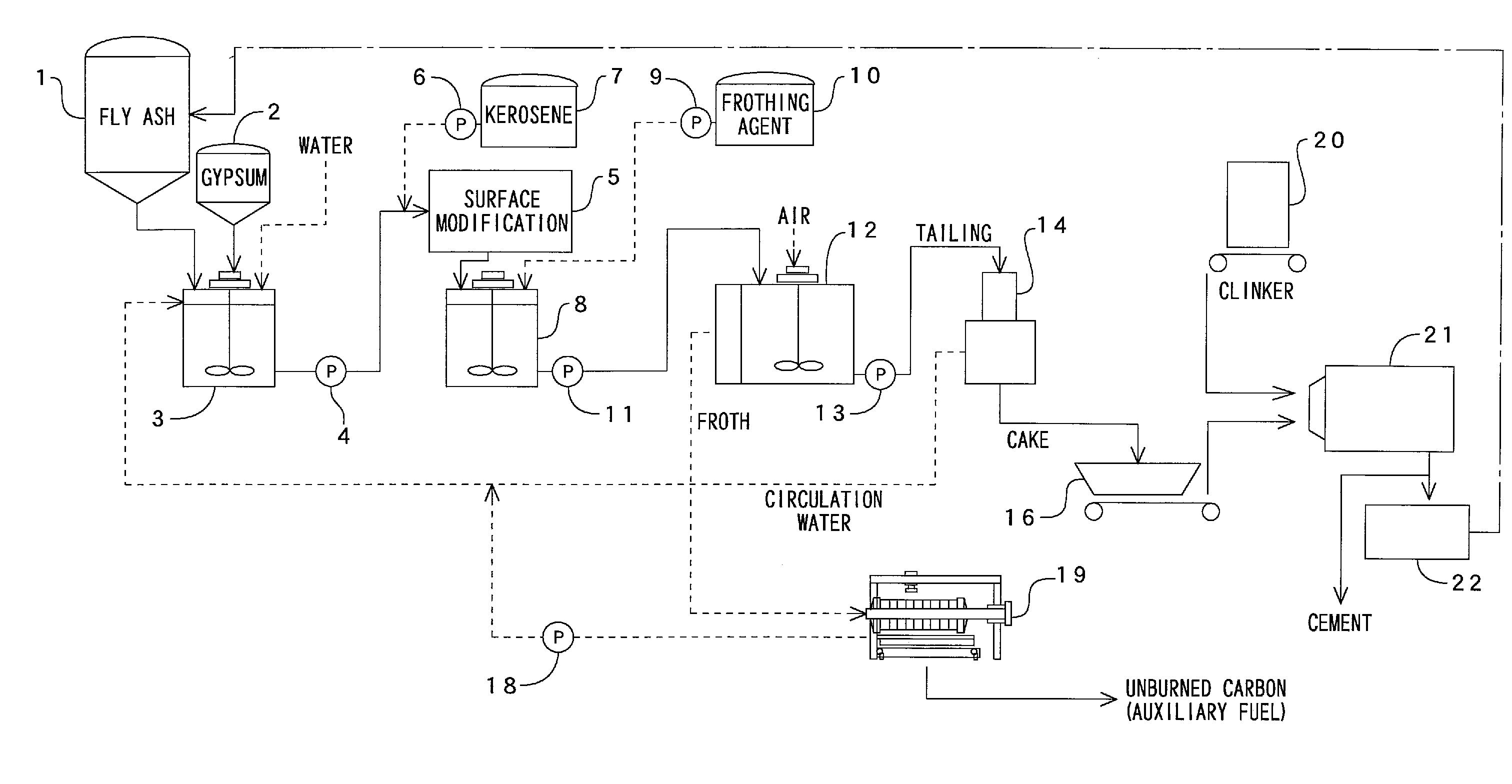

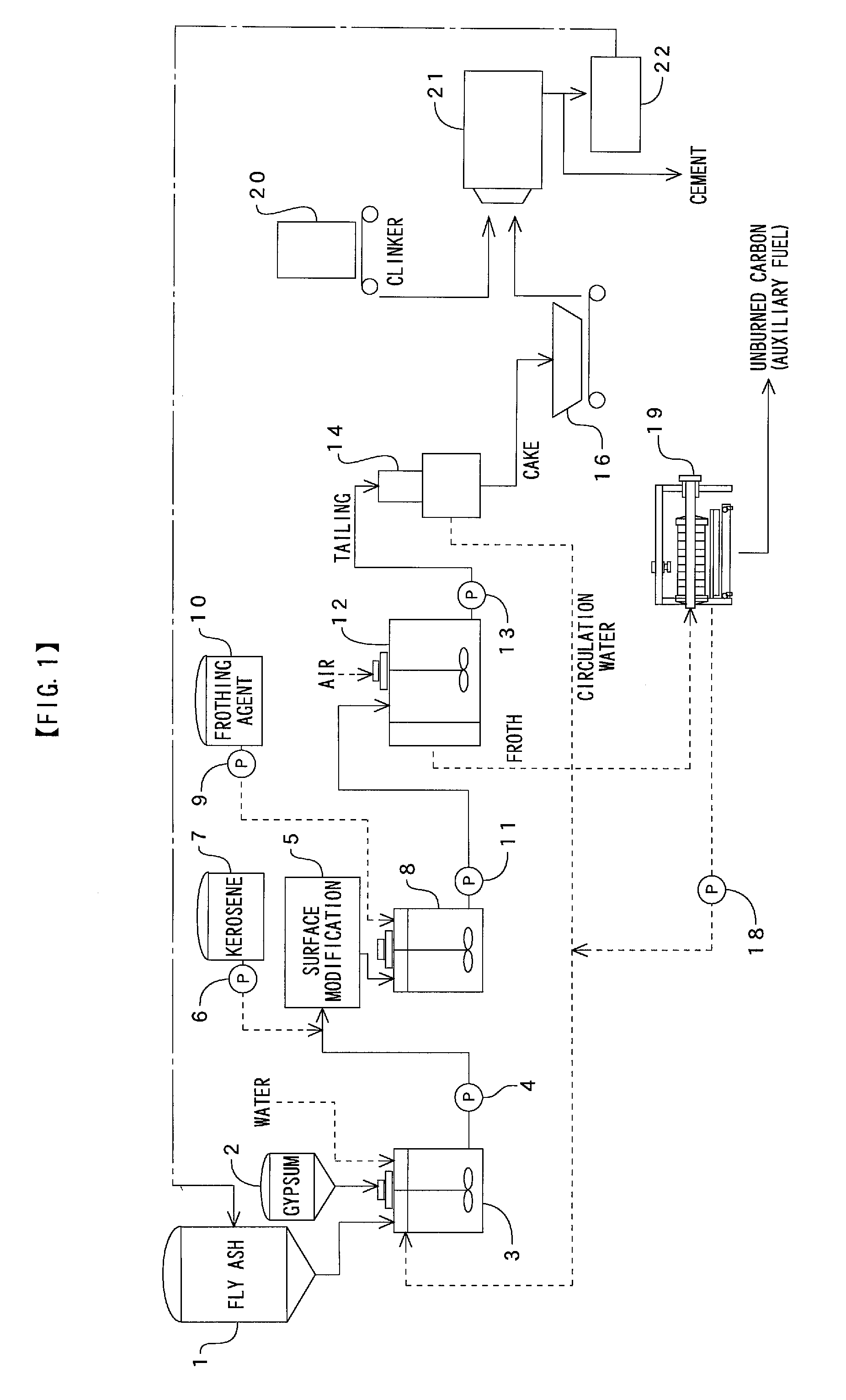

Cement manufacturing apparatus and method

InactiveUS20100011995A1Increase the number ofSolid waste managementMixing operation control apparatusManufactured apparatusCement manufacturing

Owner:TAIHEIYO CEMENT CORP

Grinding aid material for improving fluidity of fly ash, and use method thereof

Owner:WUHAN HUAXUAN HIGH TECH

Anti-cracking impervious concrete

Owner:中建西部建设西南有限公司 +1

Fungicidal and Parasiticidal Fire-Retardant Powder

InactiveUS20130274347A1Improve air qualityMinimizes fume emissionBiocideSolid waste managementNatural fiberFire retardant

Owner:SOLVAY SA

Inorganic fireproof thermal insulation plate and preparation method thereof

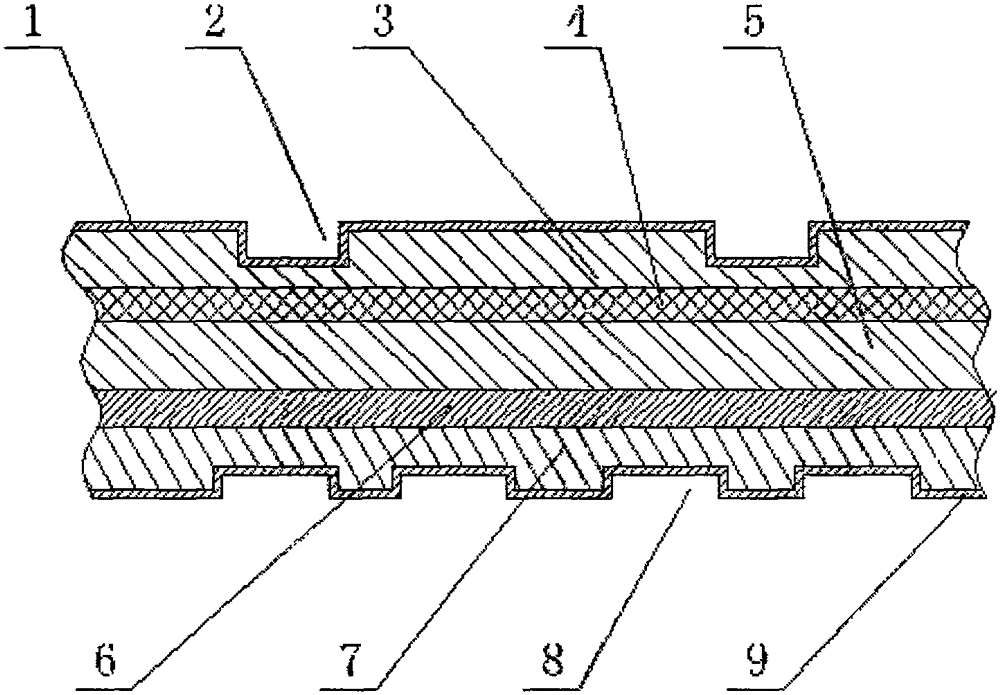

InactiveCN105239681AGood thermal insulation performanceLow thermal conductivitySolid waste managementCeramic shaping apparatusHollow corePerlite

The invention discloses an inorganic fireproof thermal insulation plate and a preparation method thereof. The inorganic fireproof thermal insulation plate is characterized by comprising a hollow ceramic bead surface layer, a fiberglass gridding cloth layer, an expanded perlite composite layer, a fiberglass gridding cloth layer and a hollow ceramic bead bottom layer in sequence from top to bottom. A pit slot is formed in the hollow ceramic bead surface layer; and a groove is formed in the hollow ceramic bead bottom layer. Non-woven fabric layers are respectively arranged on the hollow ceramic bead surface layer and the hollow ceramic bead bottom layer. The hollow ceramic bead surface layer and the hollow ceramic bead bottom layer are made of hollow ceramic bead slurry; and the expanded perlite composite layer is made of expanded perlite composite layer slurry. The preparation method comprises the following steps of preparing the hollow ceramic bead bottom layer, flatly laying the fiberglass gridding cloth layer, preparing the expanded perlite composite layer, flatly laying the fiberglass gridding cloth layer, preparing the hollow ceramic bead surface layer, compacting and molding these layers, and demolding and curing these layers. The invention is advantaged in that the thermal insulation performance of the inorganic fireproof thermal insulation plate is good, the heat conductivity coefficient of the inorganic fireproof thermal insulation plate is low, flame retardant grade and fireproofing grade of the inorganic fireproof thermal insulation plate are high, the inorganic fireproof thermal insulation plate is green and environment-friendly, and the integral compressive strength of the inorganic fireproof thermal insulation plate is greatly enhanced and so on.

Owner:张琳

Interfacial agent for binding vitrified tiles and construction method thereof

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Solid waste-based baking-free environment-friendly hollow brick and preparation method thereof

Owner:SHANDONG UNIV +1

Wave-absorbing breathable environment-friendly molding and preparation method thereof

InactiveCN107324688AImprove the performance of anti-electromagnetic radiationEffective absorptionSolid waste managementBuilding constructionsFiberPolyester

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Autoclaved lime sand brick and production method thereof

InactiveCN104098312AStable expansion coefficientOvercome problemsSolid waste managementBrickMolding machine

The present invention discloses an autoclaved lime sand brick and a production method thereof, and solves the problems that in the prior art lime sand brick production cycle is long, the intensity is not high, the discrete degree is great and the like; the autoclaved lime sand brick is characterized in that: on the traditional basis of green sand and quick lime, a right amount stone chip is added, the quick lime is crushed, then the quick lime, the green sand and the stone chip are firstly mixed with water in an ash mixing machine, after 2.5 ~ 3 hours of hopper type digestion, secondary stirring is performed to make caking in the mixture broken and loose, the mixture is sent by a conveying system into a turntable type molding machine for pressing into green bricks, the pressed green bricks are sent by a traction machine into an autoclave for high temperature and high pressure autoclaving to produce the autoclaved lime sand brick with the strength more than 2 times of that of national standard of ordinary standard bricks.

Owner:HUANGGANG TONGKAI BUILDING MATERIALS CO LTD

Plant fiber fireproofing silencing plate

Owner:GUANGDONG YIXIN HOUSEHOLD MATERIALS GROUP CO LTD

Basalt fiber air-entrained partition board

PendingCN105924041ALow fiber densityLow thermal conductivitySolid waste managementCeramic shaping apparatusHydroxypropylmethyl celluloseMethyl cellulose

The invention discloses a basalt fiber air-entrained partition board, prepared from the following raw materials: glyceryl monooleate, isocyanic acid octadecyl ester, boiled wood oil, white oil, polyacrylamide, glycosyl-acidamide modified polysiloxane, tetrabutyl ammonium bromide, basalt fibers, hydroxypropyl methyl cellulose, trehalose, sodium carbonate, fly ash fibers, polysiloxane sealant, cement, ceramsite, steel slag, sand, a concrete water reducer, a foaming agent, polystyrene, and an appropriate amount of water. The partition board prepared according to the invention has the advantages of light weight, uniform porosity, high strength, good thermal insulation property, good fireproof performance, simple and convenient construction and installation, space saving, good sound insulation, and durability.

Owner:安徽惠明建材科技发展有限公司

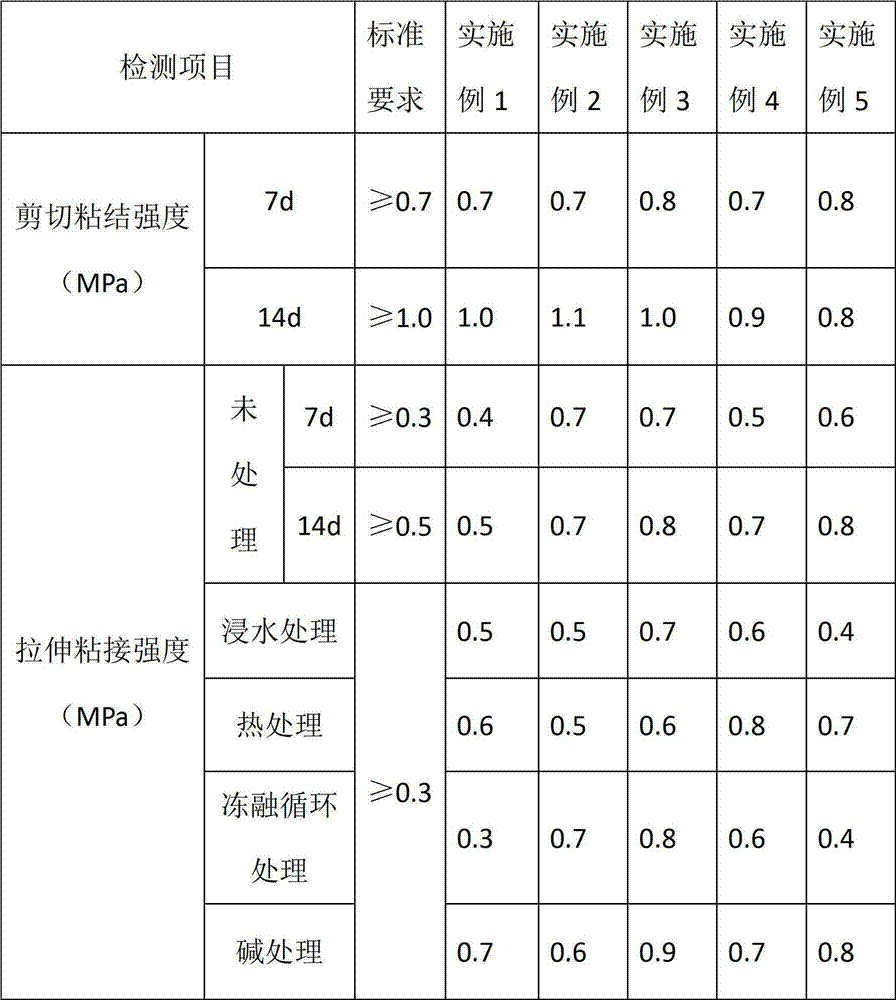

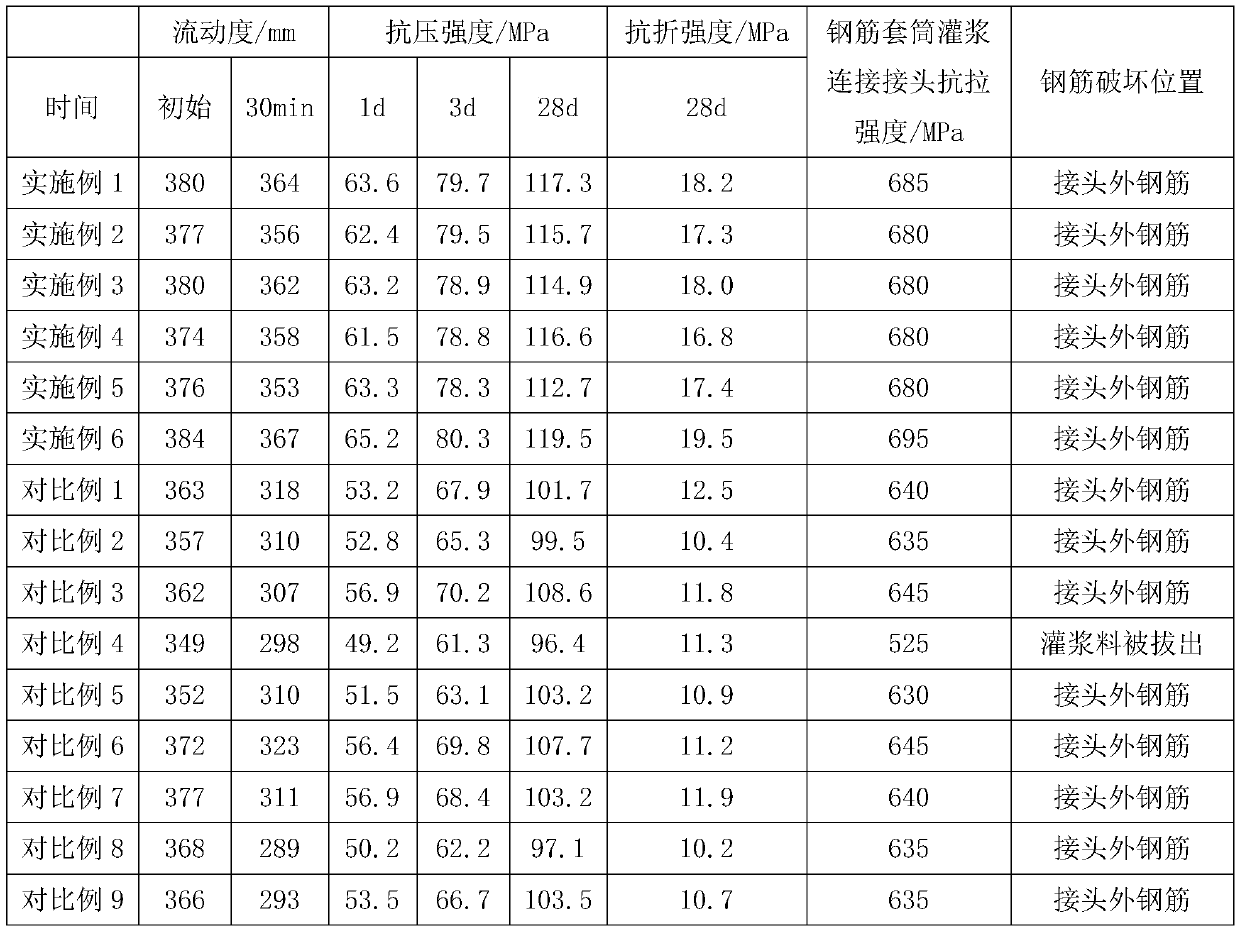

Sleeve grouting material for steel bar connection of prefabricated building

ActiveCN111517729AHigh mechanical strengthGood fluiditySolid waste managementFiberArchitectural engineering

Owner:SHENYANG JIANZHU UNIVERSITY

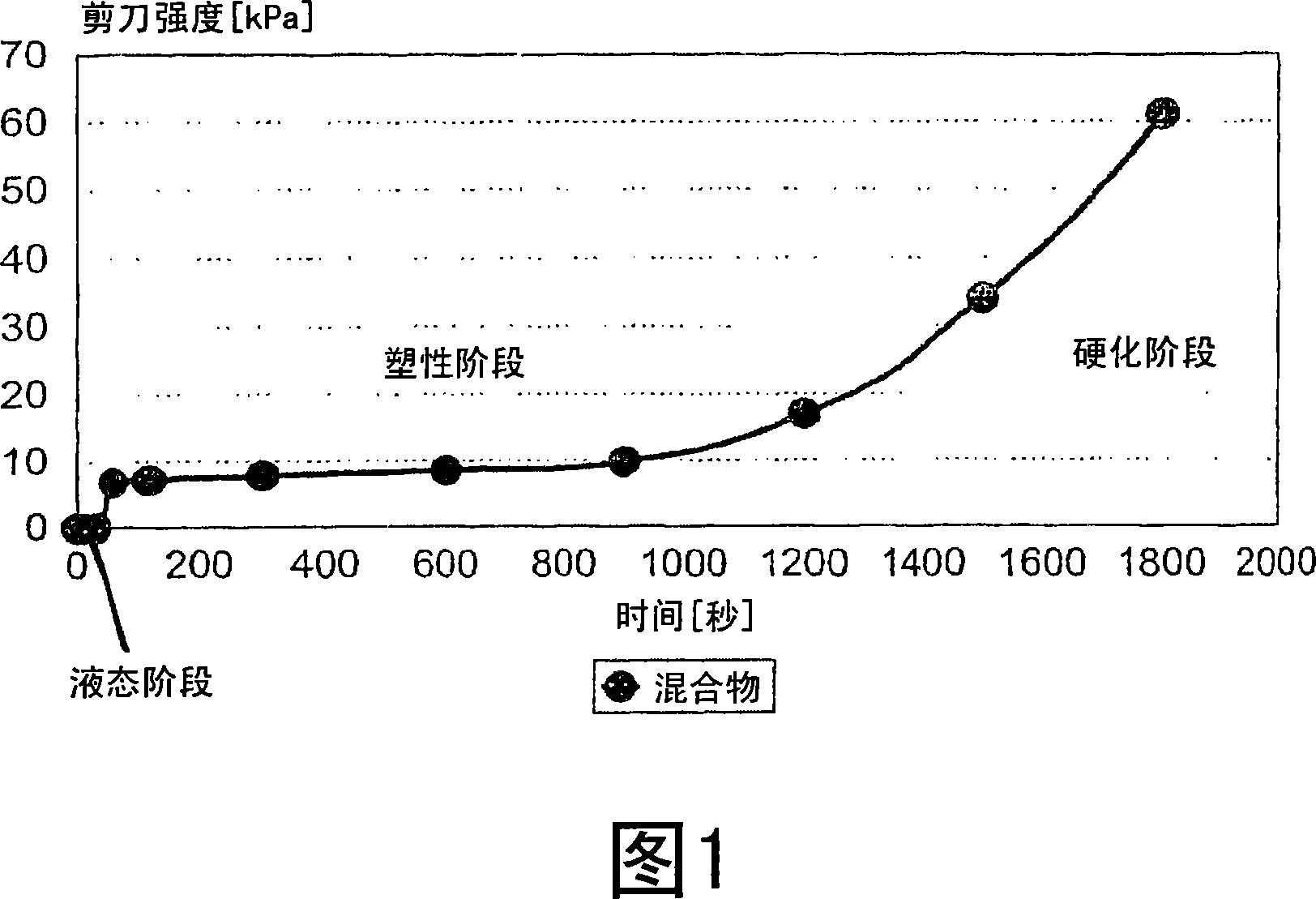

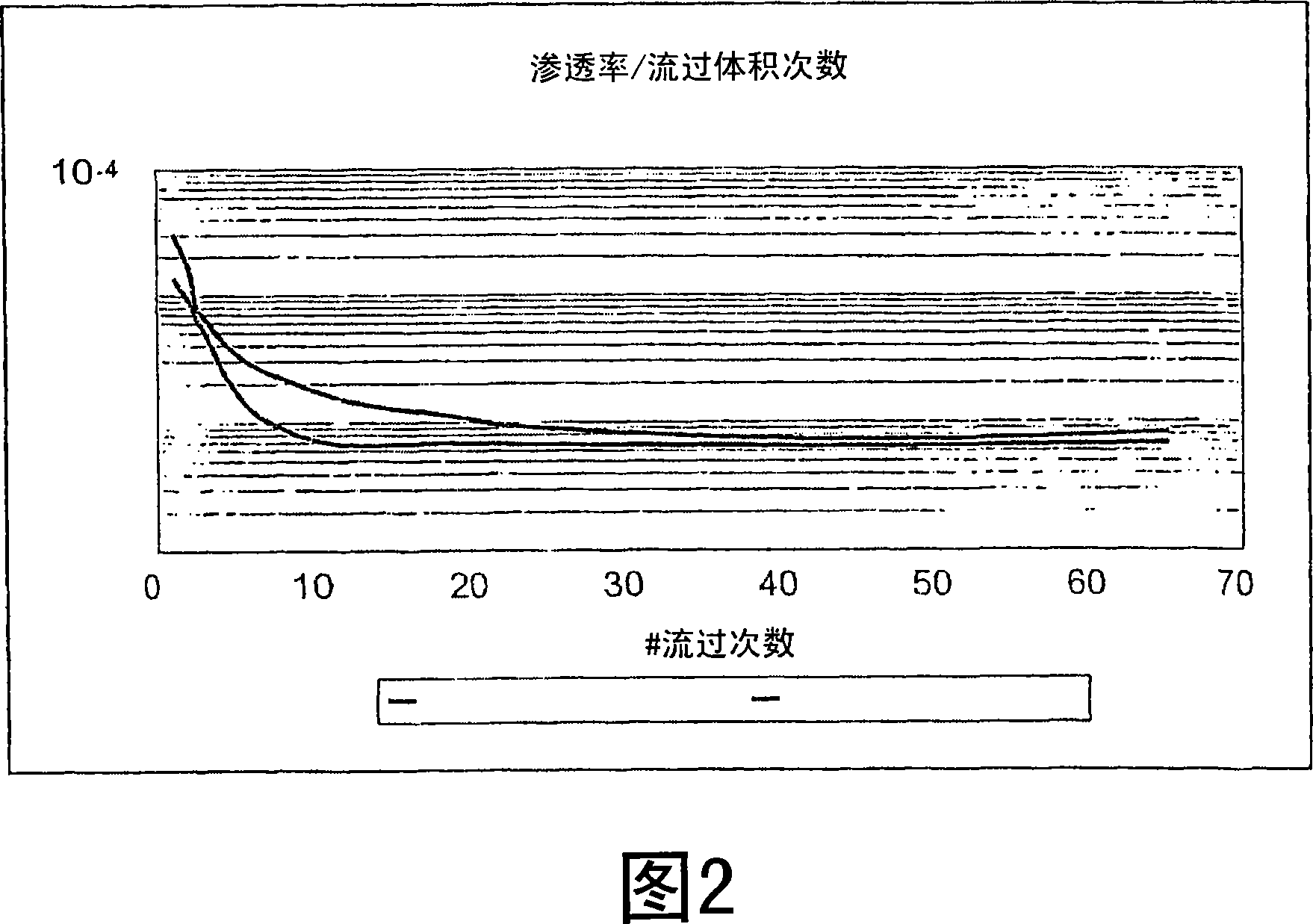

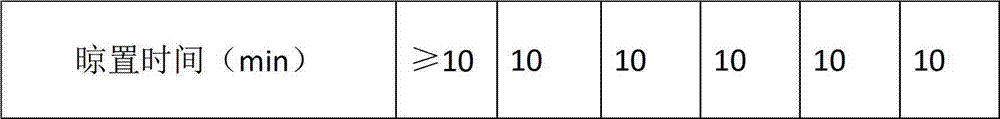

Toad deep disease trenchless repair method based on foam geopolymer

InactiveCN112358245AReduce accumulationReduce the burden onSolid waste managementCement productionArchitectural engineeringGeopolymer

The invention discloses a road deep disease trenchless repair method based on a foam geopolymer. The road deep disease trenchless repair method comprises a road deep disease trenchless repair construction process and a corresponding foam geopolymer repair material. The trenchless repair construction process for the deep road diseases comprises a large-hole and small-hole spaced grouting method, main diseases are repaired by compacting, splitting and grouting large holes from bottom to top, and fine diseases are repaired by permeating small holes from top to bottom. The situation that waste iscaused by excessive grouting during single grouting, and some small cracks and holes are not effectively filled can be effectively avoided. The invention also provides a foamed geopolymer grouting material for road grouting reinforcement, the grouting material is divided into a component A and a component B, and has the characteristics of low density, high strength, good durability and no shrinkage after being cured, the density can reach 600-700kg / m<3>, and the 7-day compressive strength can reach 10-12MPa.

Owner:HUNAN COMM RES INST CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap