Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

219results about "Grain treatments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

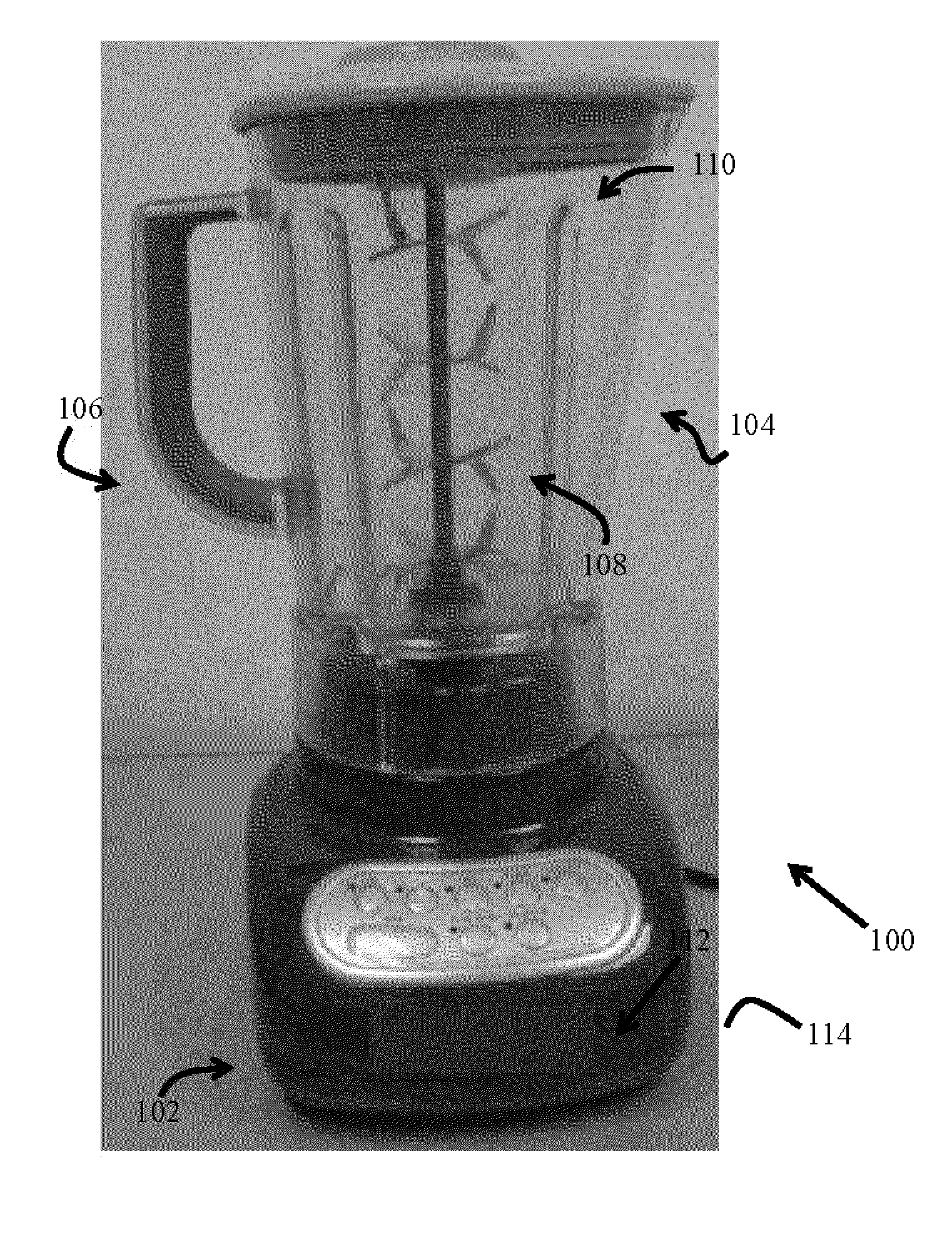

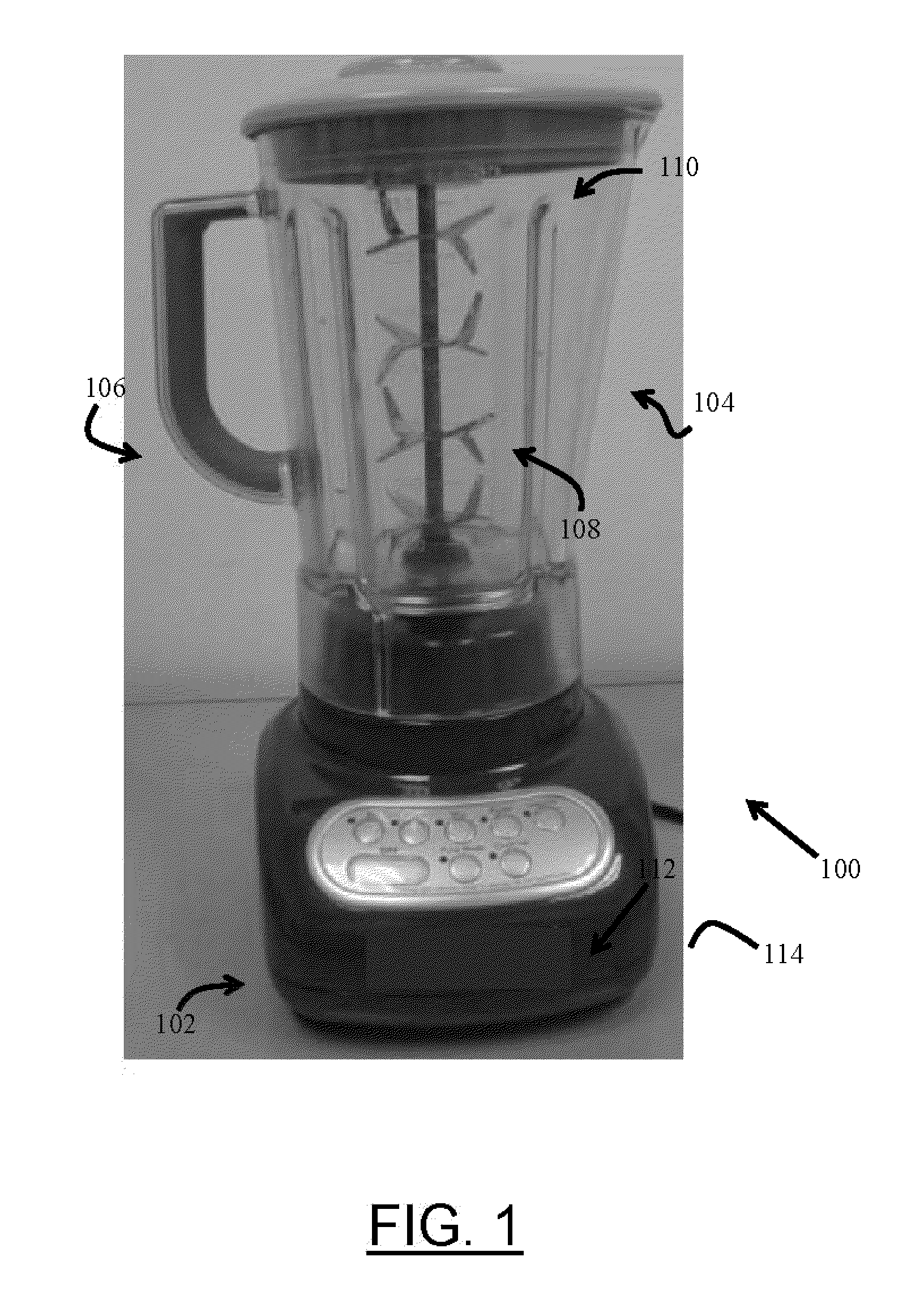

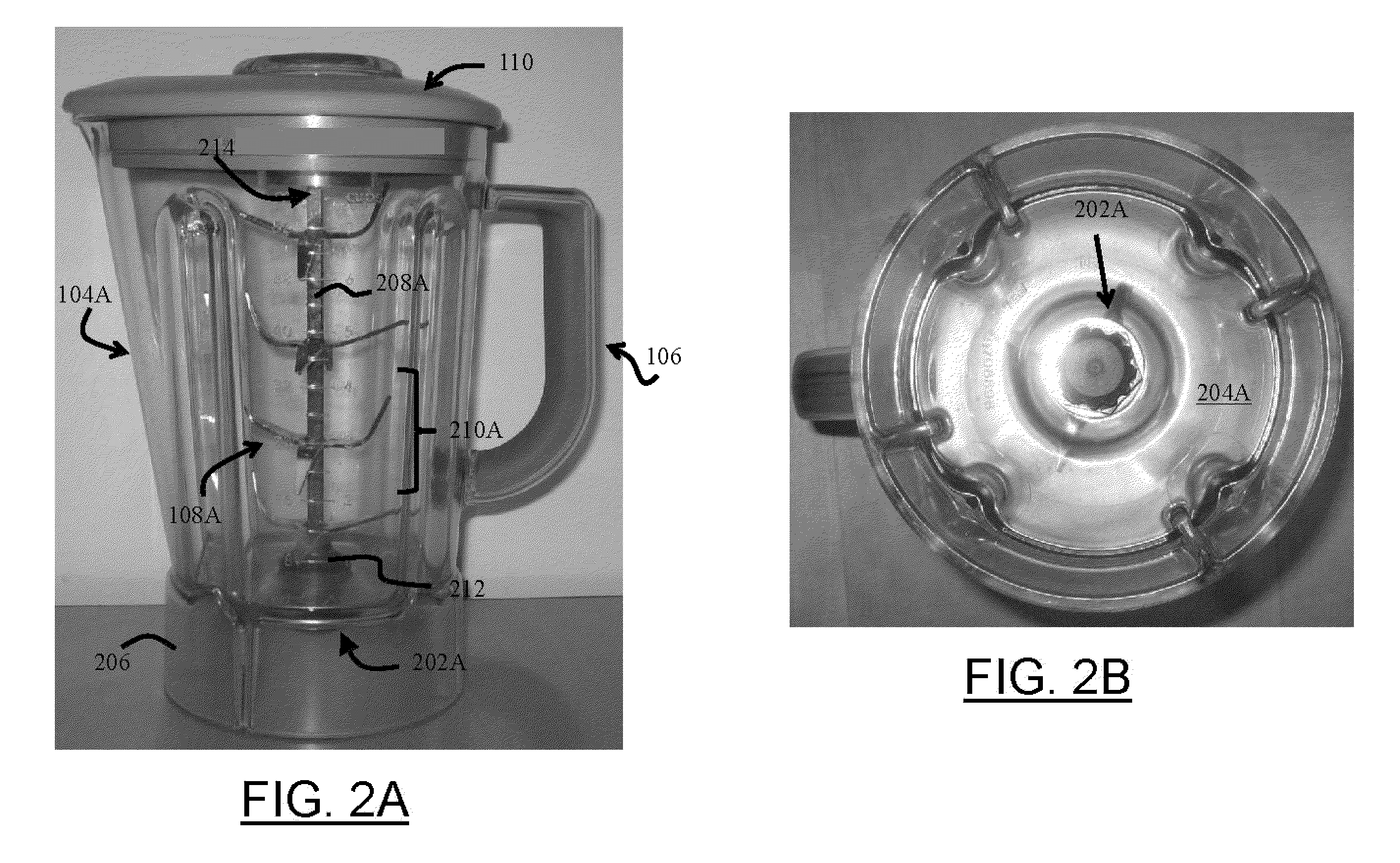

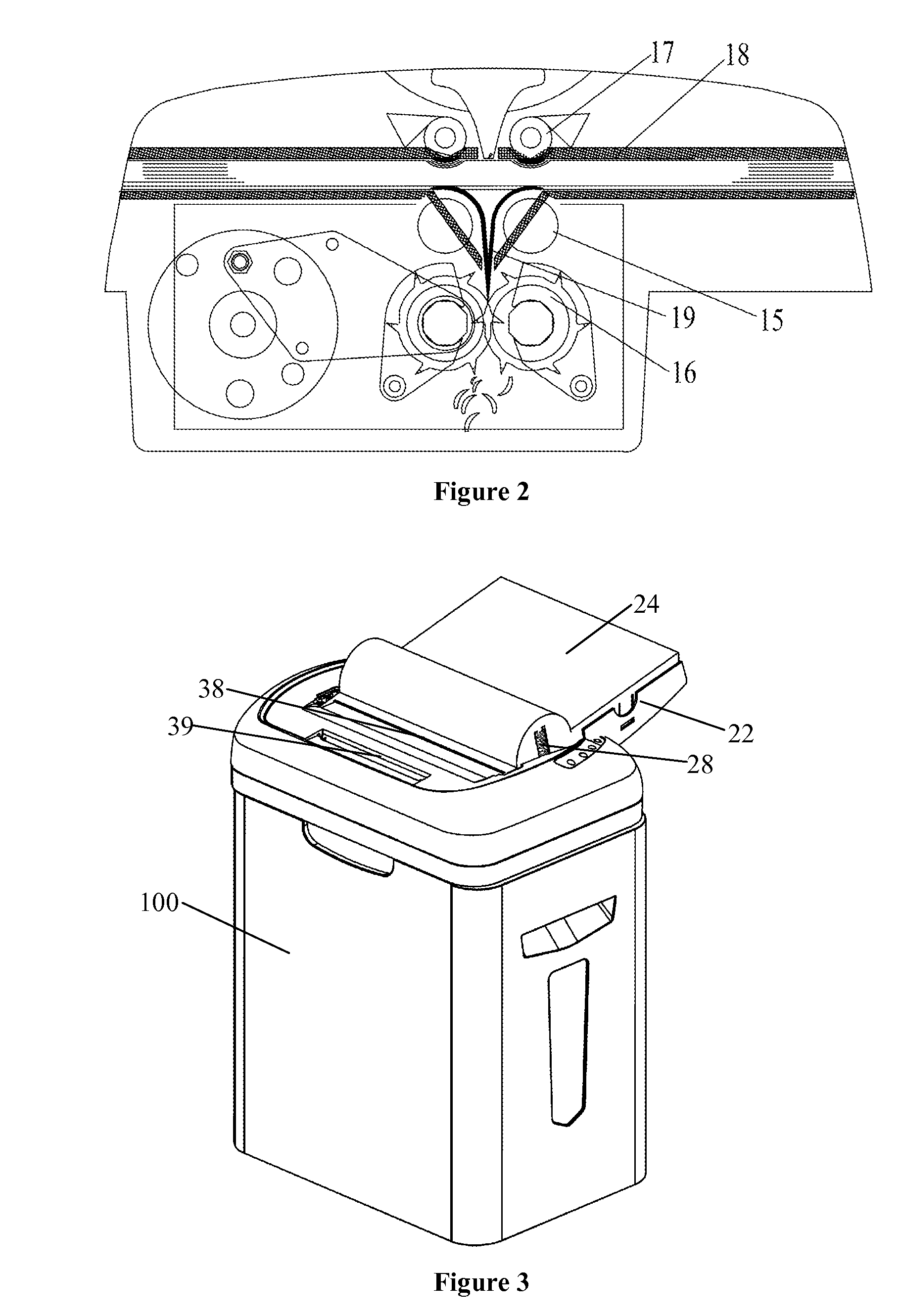

Blender and food processor device

Owner:CARRIERE MARK C

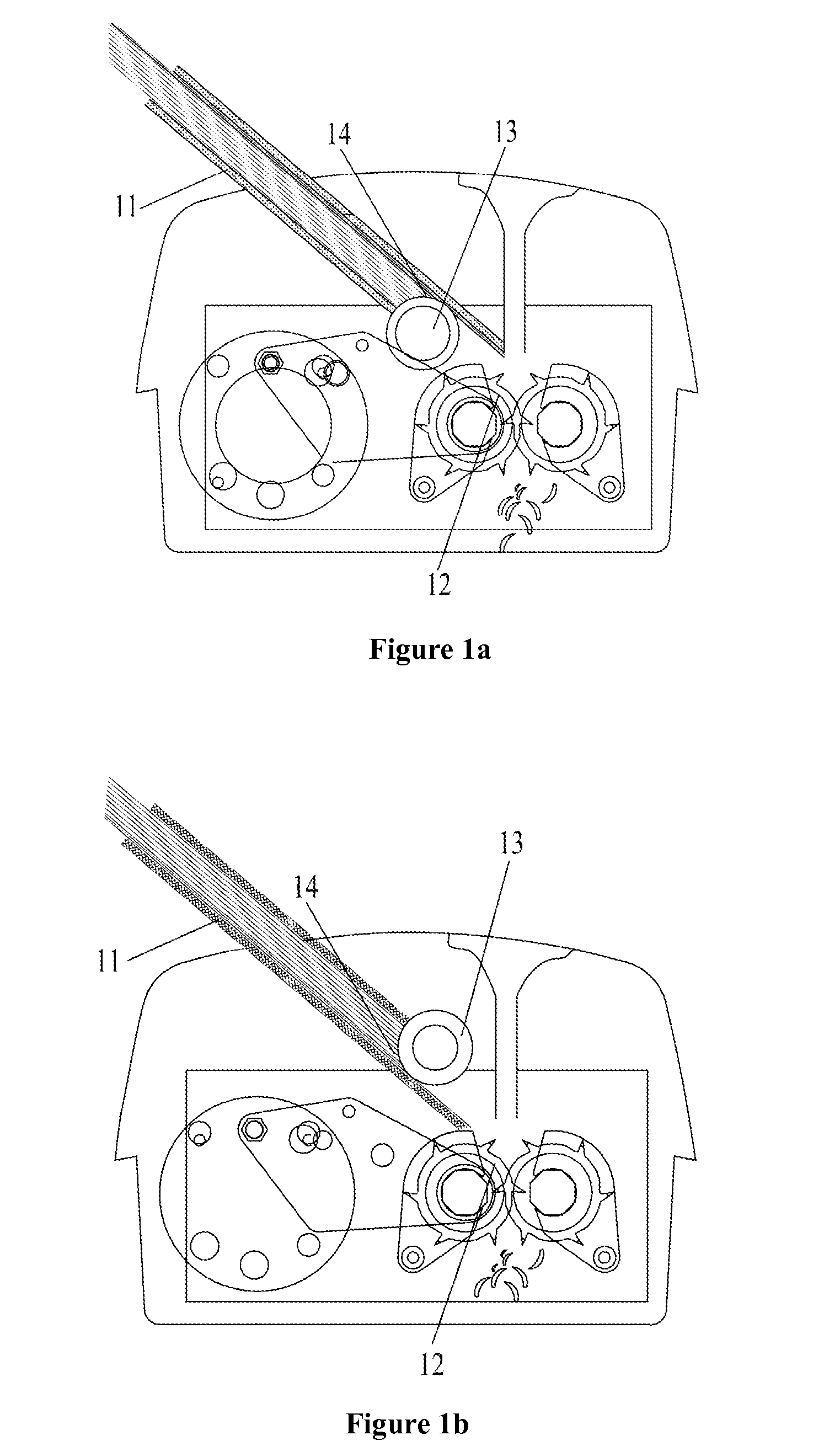

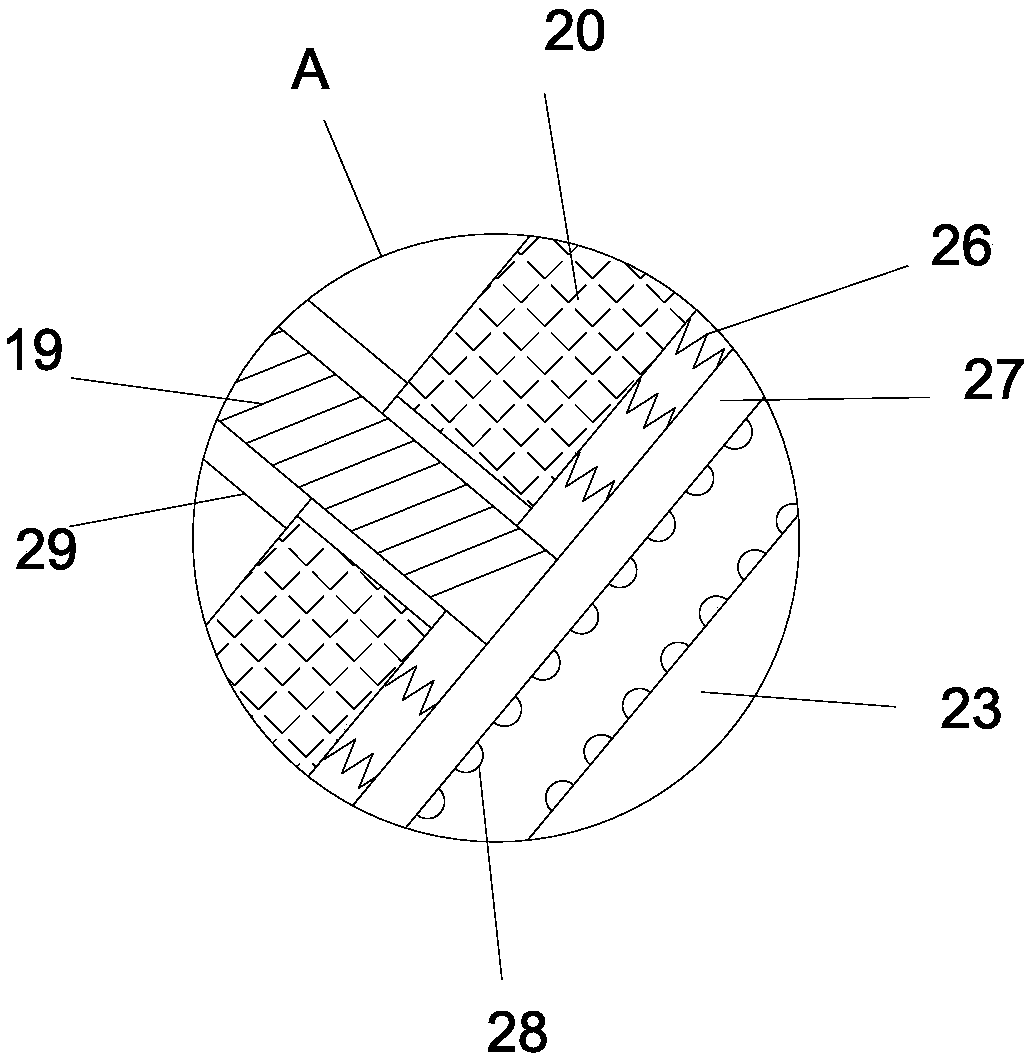

Automatic shredder without choosing the number of paper to be shredded

Owner:AURORA OFFICE EQUIP

Eccentric rotary cone type stone crushing device for mineral processing

Owner:浙江燕思志网络科技有限公司

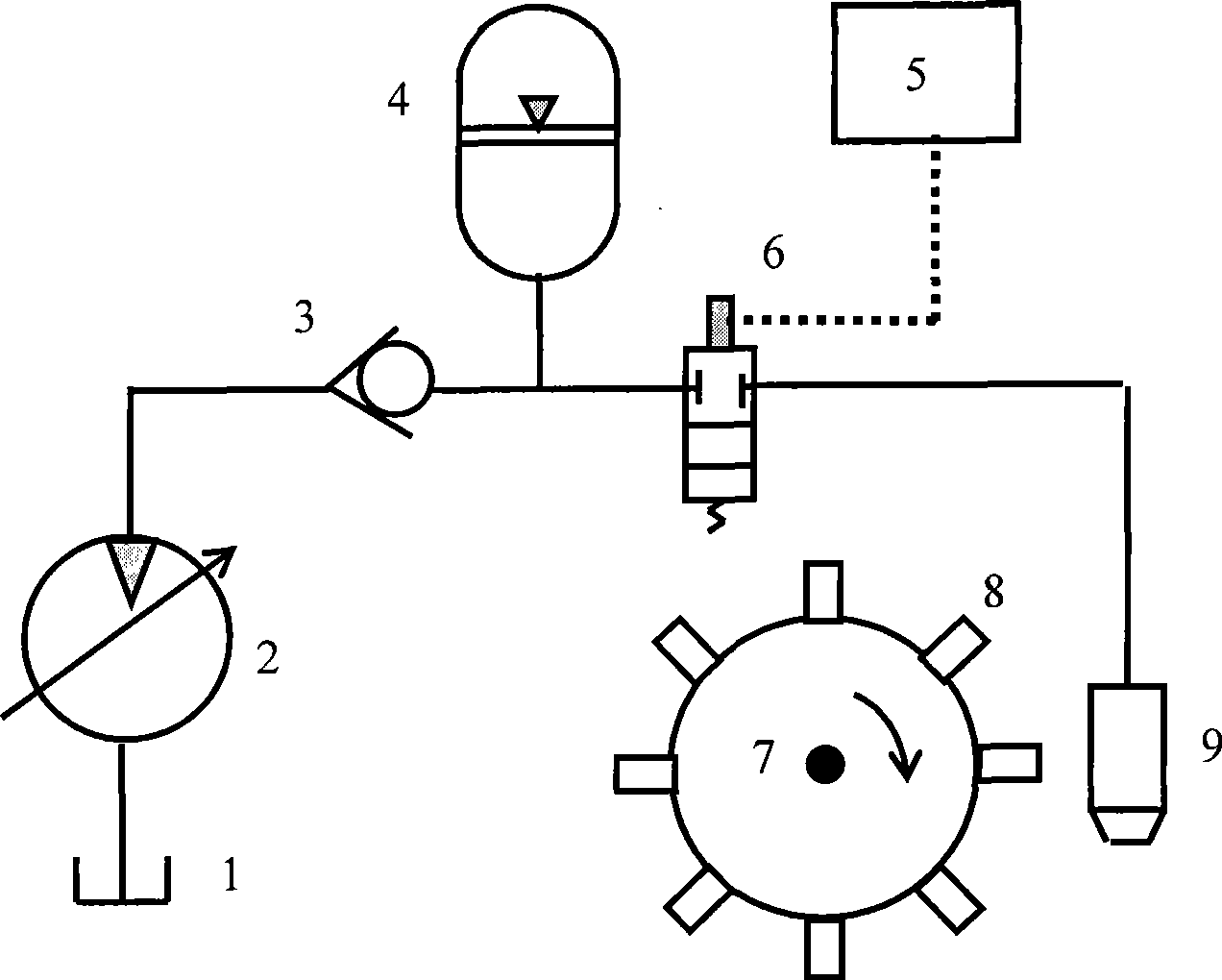

Method for producing rare earth ion doped yttrium aluminum garnet nano phosphor powder

InactiveCN101602944AImprove uniformityOvercoming phenomena such as reunionLiquid spraying apparatusGrain treatmentsHigh concentrationRare-earth element

The invention discloses a method for producing a rare earth ion doped yttrium aluminum garnet nano phosphor powder. The general formula of the nano powder is (Y1-xLnx)3Al5O12, wherein Ln is one of rare earth elements Ce and Eu, x is more than or equal to 0.0 and less than or equal to 0.1, mixed solution of nitrates or acetates of Al, Y and Ln is used as a mother liquor of salt, and mixed solution of NH4HCO3 and NH3.H2O is used as solution of compound precipitator; the ammonia water is used for adjusting the pH value of the solution of compound precipitator to 10; and the mother liquor of salt undergoes ultrasonic atomization and then is sprayed in the solution of compound precipitator which is continuously stirred, and after complete reaction, the mixed solution if filtered, washed, dried, repeatedly ball-milled and calcined to obtain uniform and dispersed rare earth ion doped YAG nano phosphor powder. The method has the advantages that the produced nano phosphor powder is uniform and dispersed, the granularity is small (between 50 and 70 nanometers), and the generated phase is unitary; and the high-concentration uniform doping of the rare earth ions is realized, so that the rare earth ion doped yttrium aluminum garnet nano phosphor powder can be obtained in high efficiency.

Owner:NINGBO UNIV

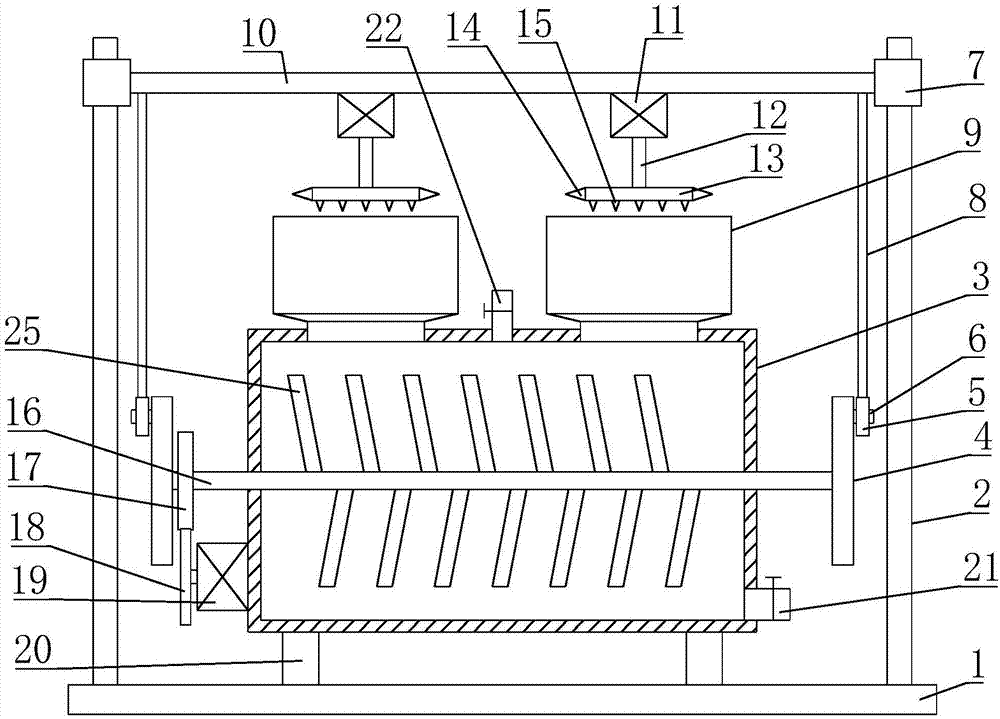

Slurry stirring device for coated fabric production

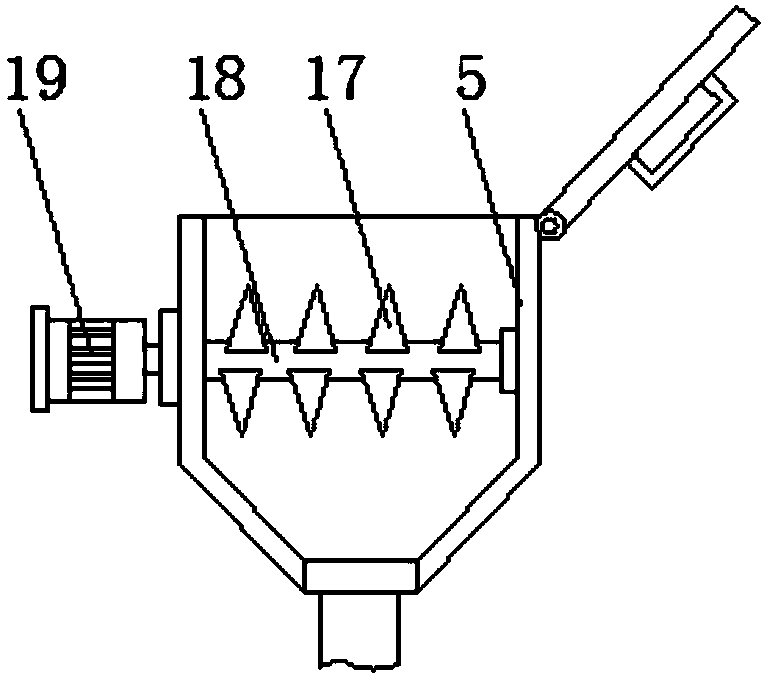

PendingCN108607463AStir wellEffective crushing and refiningRotary stirring mixersTransportation and packagingPulp and paper industryReducer

Owner:浙江唐艺织物整理有限公司

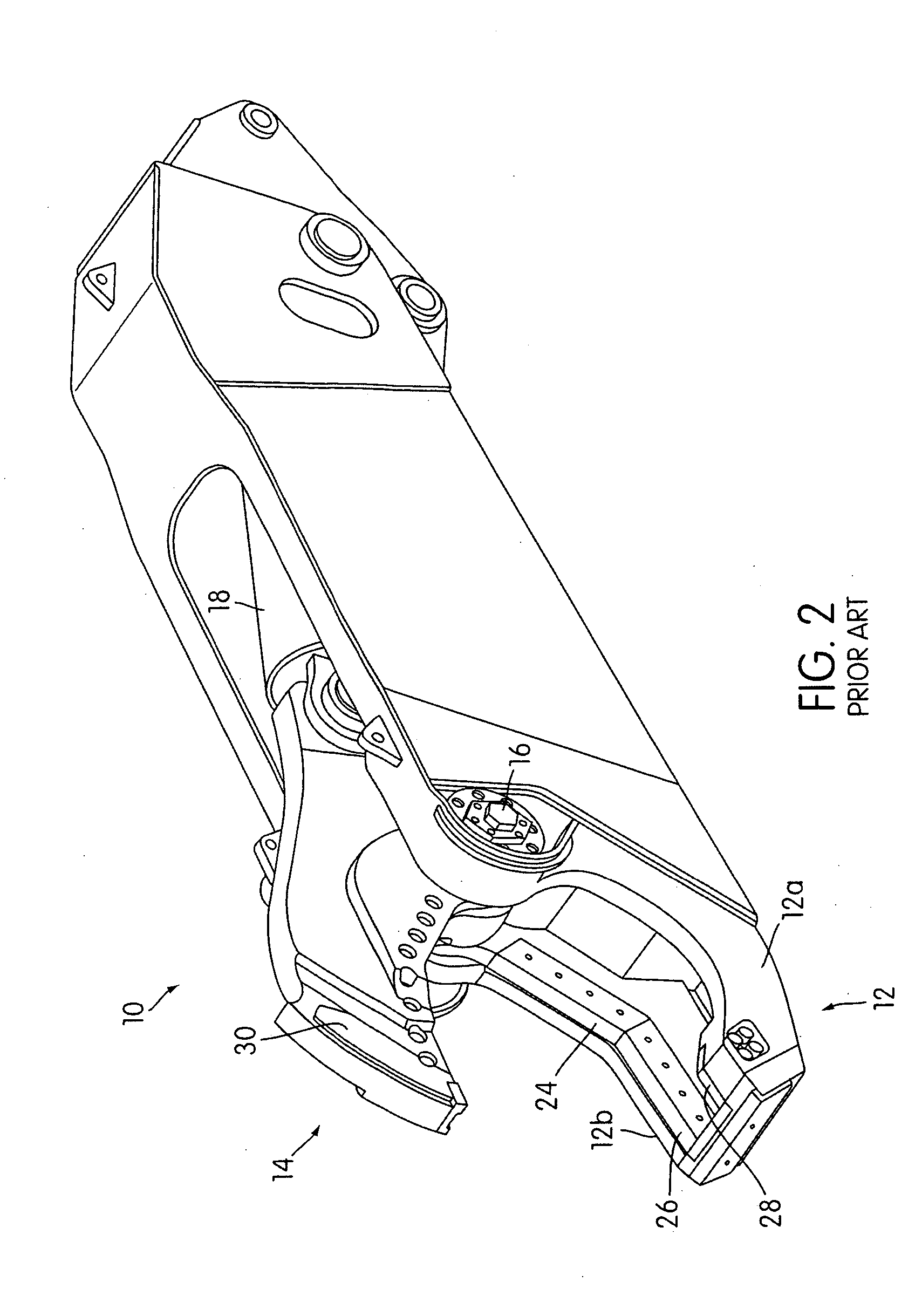

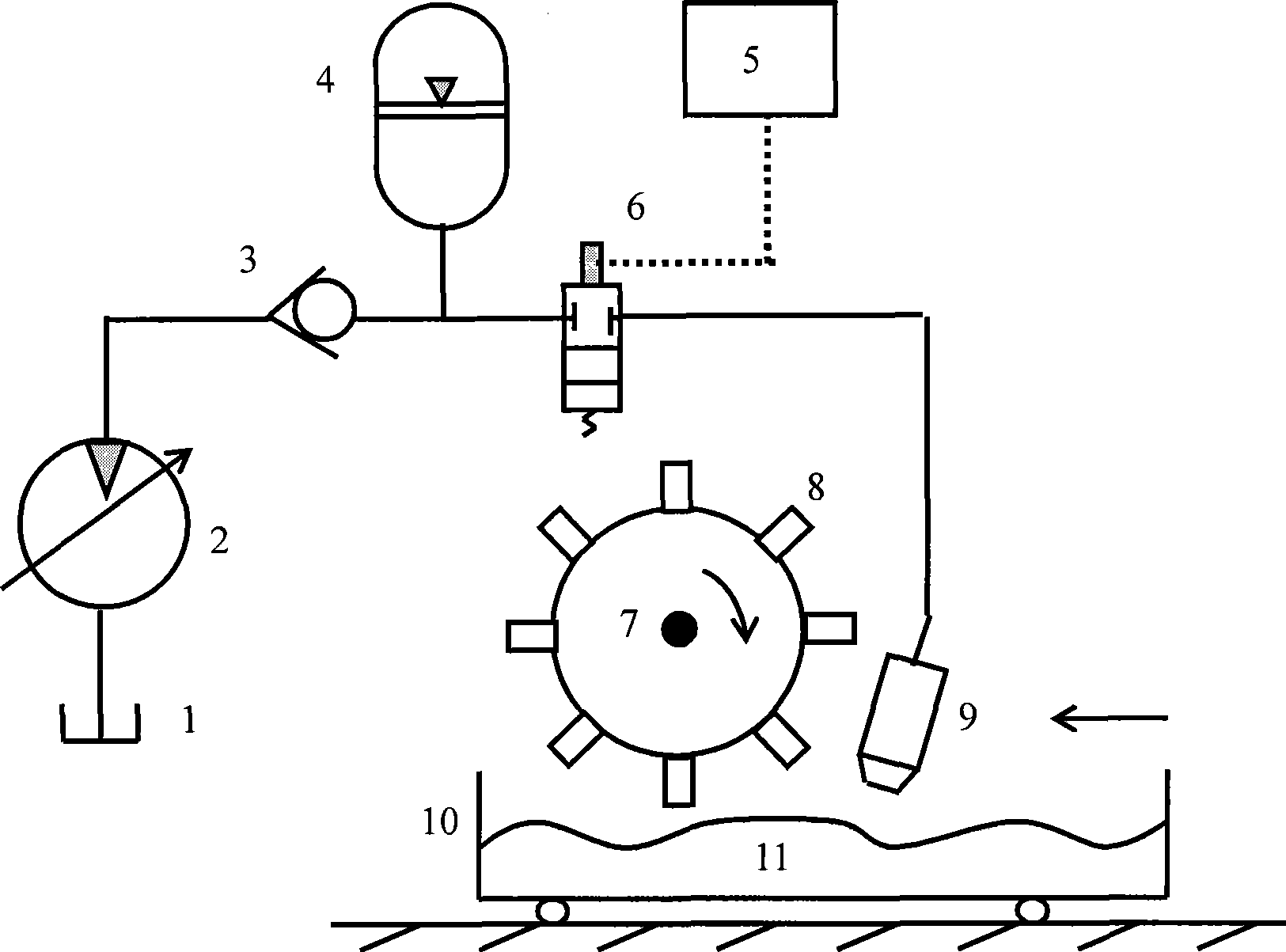

Lubricating system for material-processing shears

Owner:STANLEY WORKS THE

Installation construction method of large coal pulverizer

ActiveCN103816983ANo pollutionReduce construction costsFoundation engineeringGrain treatmentsSocial benefitsCoal

The invention discloses an installation construction method of a large coal pulverizer. The method comprises the following steps: 1, carrying out basic inspection and acceptance; 2, unpacking and inspecting an apparatus; 3, paying off a line; 4, installing an anchor bolt; 5, installing an apparatus pedestal; 6, installing a main bearing pedestal; 7, installing a main bearing; 8, installing a rotation portion; 9, installing a transmission portion; 10, installing a cylinder lining board and a feeding and discharging port lining board; 11, installing a gear cover and other accessories; and 12, carrying out test driving. The installation construction method allows an apparatus body and transmission mechanisms to be assembled on the ground, integral hoisting is carried out after the assembling of the apparatus body and the transmission mechanisms, and local adjustment is carried out to solve a series of problems of need of the arrangement of a full framing scaffolding on the apparatus, long use time of large tonnage cranes, low installation precision and the like are solved, and good economic and social benefits are realized.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

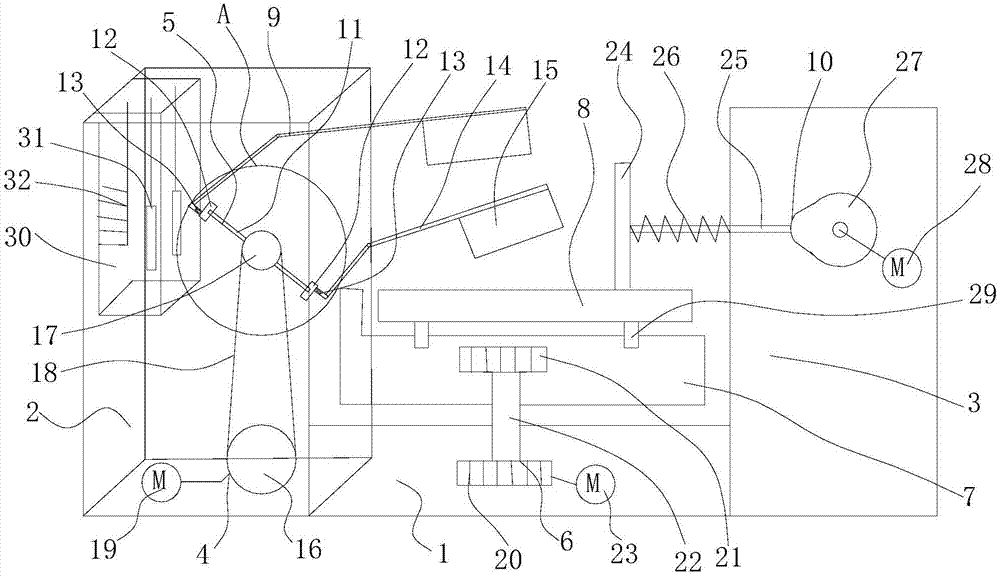

Imitated artificial meat chopping machine

InactiveCN107335510AGuaranteed tasteRealize automatic meat turningGrain treatmentsEngineeringRocker arm

Owner:SOUTH CHINA UNIV OF TECH

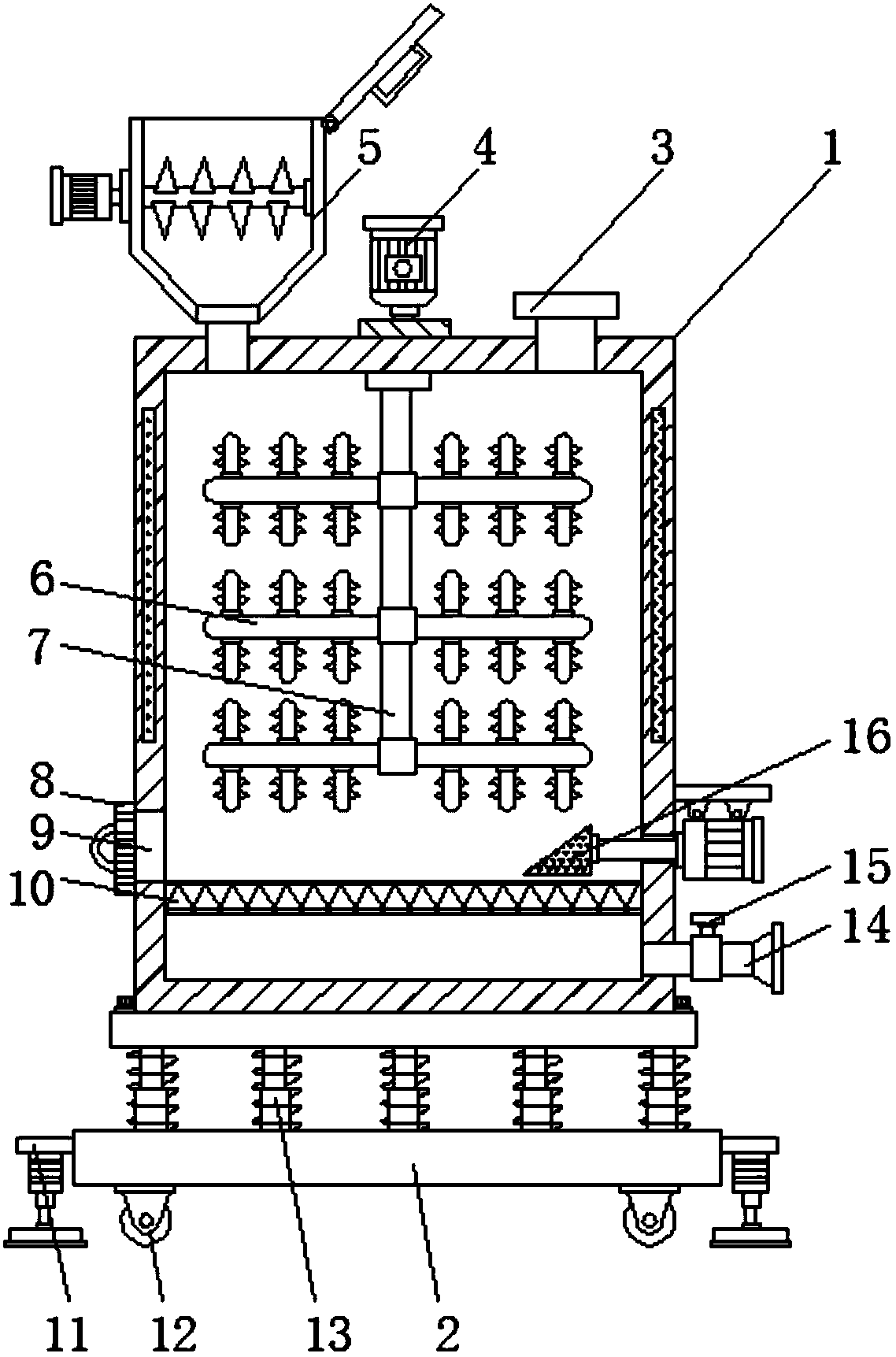

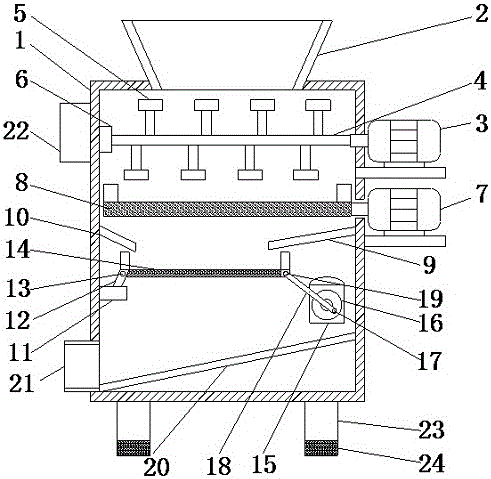

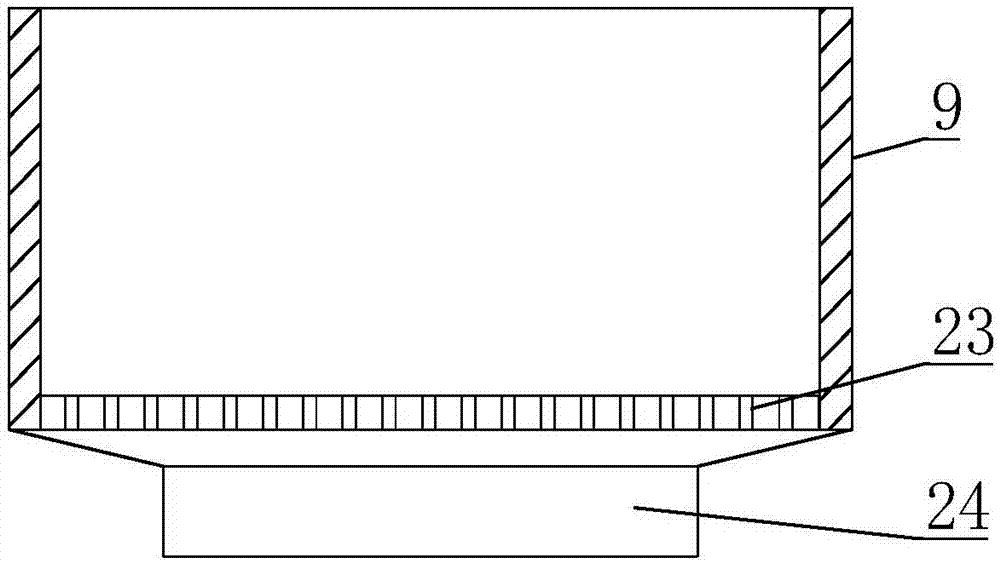

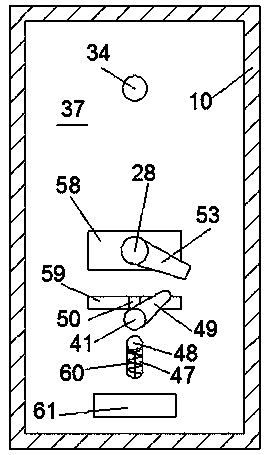

Construction sand screening machine

InactiveCN106540782ASolve the inefficiency of screeningPrevent leakageGrain treatmentsSieveScreening effect

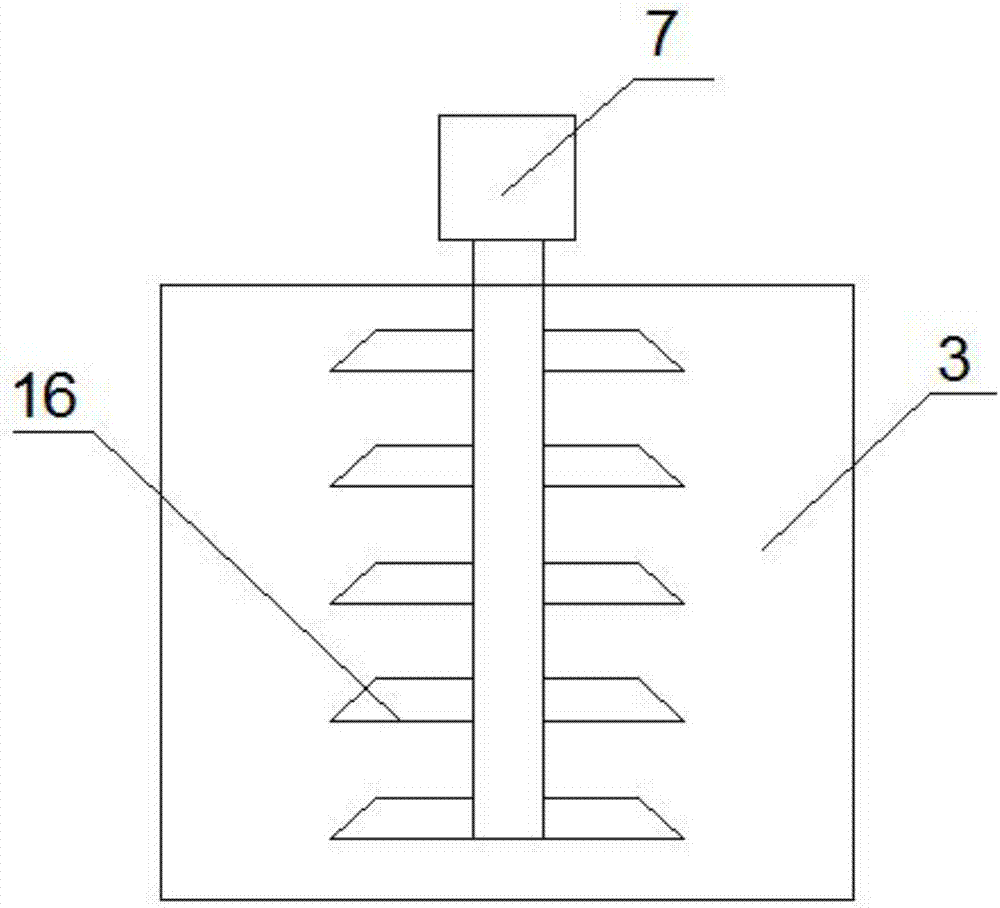

The invention discloses a construction sand screening machine which comprises a machine body. The top of the machine body communicates with a feed hopper. A first motor is fixedly mounted at the top of the right side of the machine body. The output end of the first motor penetrates through the machine body and extends into the machine body to be fixedly connected with a rotary shaft. Stirring rods are fixedly mounted on the surface of the rotary shaft. A bearing is movably connected with the left side of the rotary shaft. The left side of the bearing is fixedly connected with the left side of the inner wall of the machine body. A second motor is fixedly mounted on the portion, under the first motor, of the right side of the machine body. According to the construction sand screening machine, the leakage problem when sand falls to a secondary sieve from a primary sieve can be effectively avoided through a first baffle and a second baffle, screening can be effectively conducted through cooperation of the secondary sieve, a disc and a third motor, the screening effect of the coarse sand and the fine sand can be better through arrangement of the primary sieve and the secondary sieve, and therefore the problem of low screening efficiency is solved.

Owner:林志城

Method and device for pulverizing deep-sea cobalt crust

Owner:深圳市中南大学产学研基地有限公司

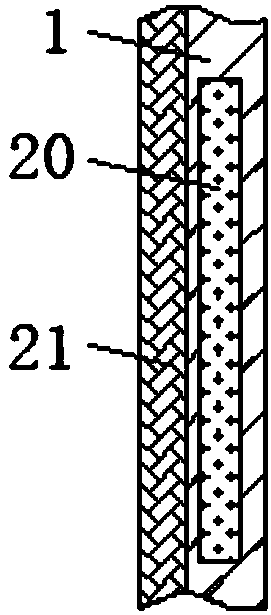

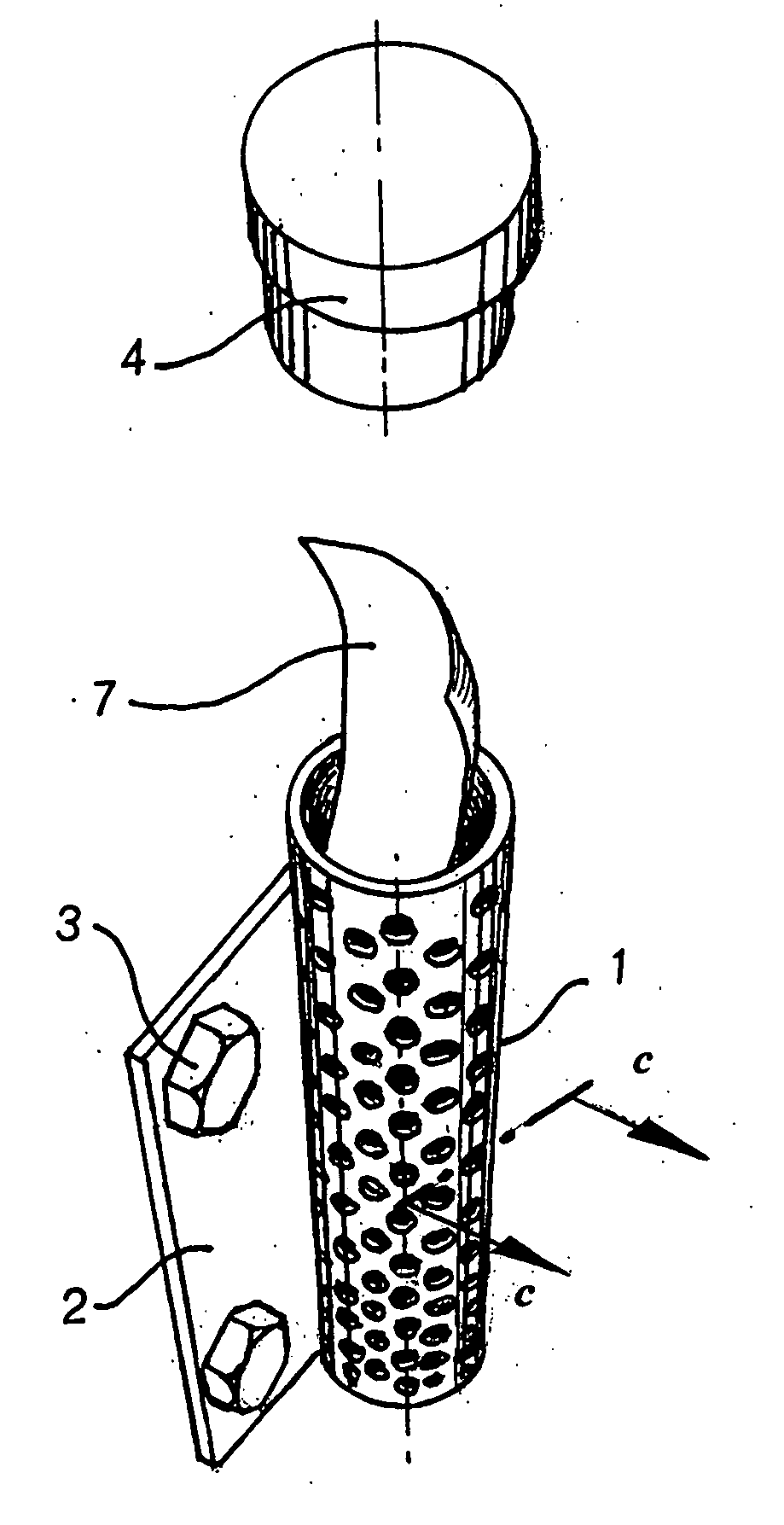

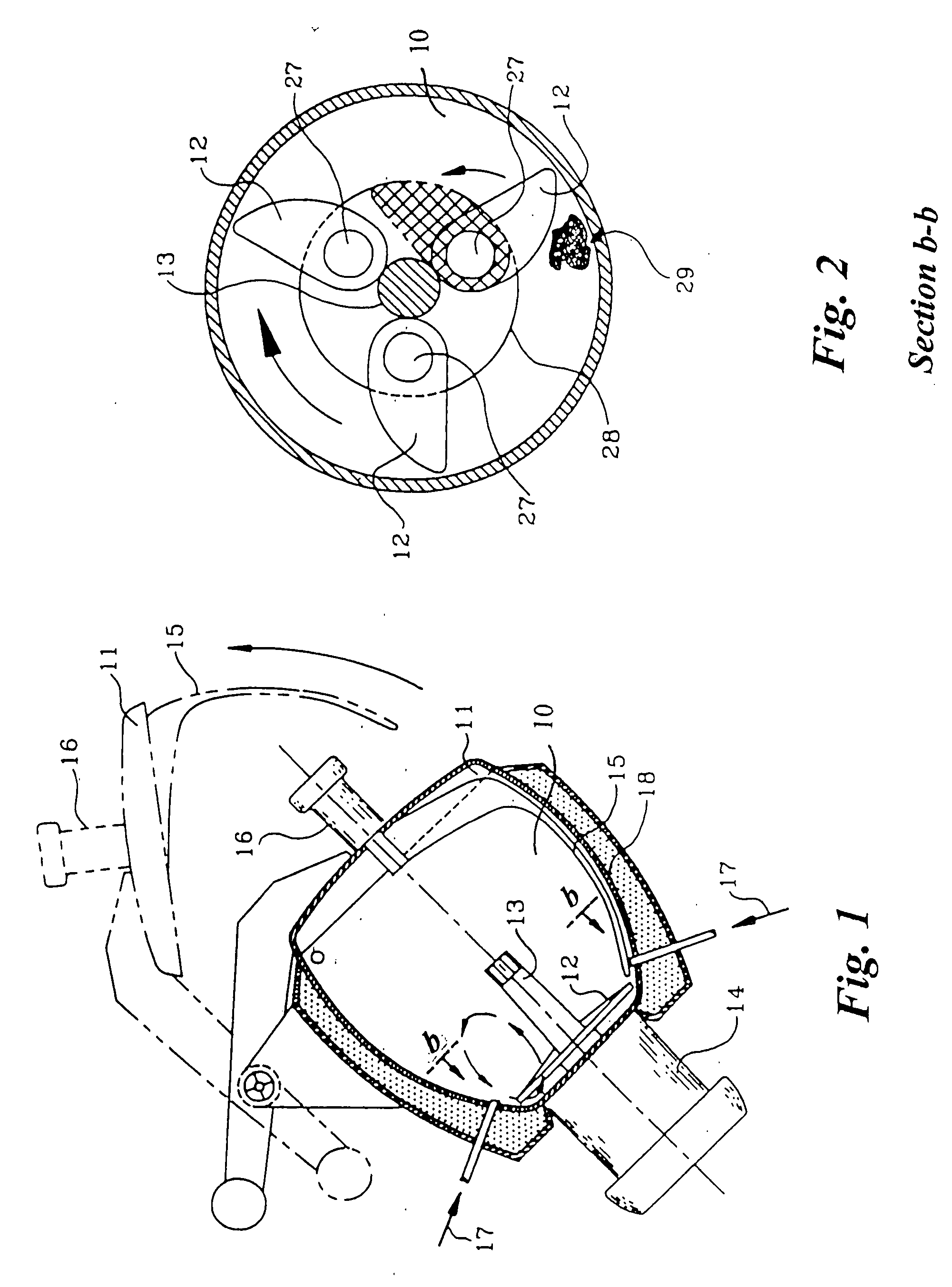

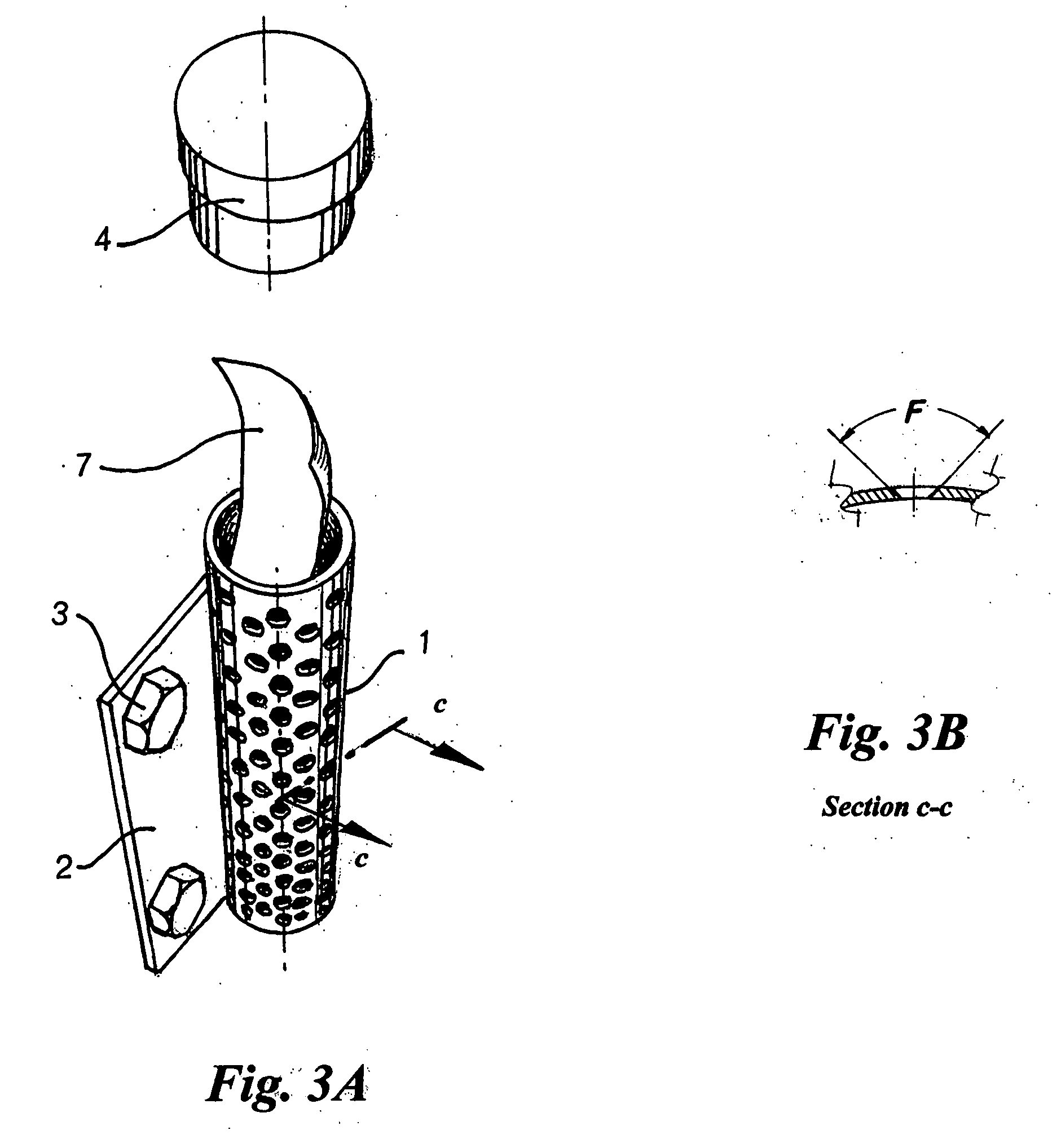

Safeguard for bio-indicators in medical waste autoclaves

InactiveUS20080063580A1Effective protectionReduced violent agitationMedical waste disposalGrain treatmentsInternal rotationBiomedical engineering

Owner:VON LERSNER WOLF A

Double layer crusher

ActiveCN104759336AGuaranteed uptimeExtended service lifeWood working apparatusGrain treatmentsEngineeringCrusher

The invention discloses a double layer crusher. A smashing chamber is fixed on a main body of a machine base; a crushing chamber is arranged above the smashing chamber; a feeding opening is formed in the top part of the crushing chamber; a discharging opening is formed in the lower part of the smashing chamber; an rolling cutter rotor assembly is used for smashing wood bars and cutting long bars to small blocks; a centrifugal hammer sheet rotor assembly is used for smashing the small blocks; the inner spaces of the crushing chamber and the smashing chamber are mutually communicated; a screen and a strong magnet device are arranged between the two chambers from up to bottom in sequence. The double layer crusher adopts a unique two-in-one mode; by integrating cutting and smashing functions, the double layer crusher can meet market demands, the cost is lowered and the efficiency is increased.

Owner:SHANDONG YULONG MASCH CO LTD

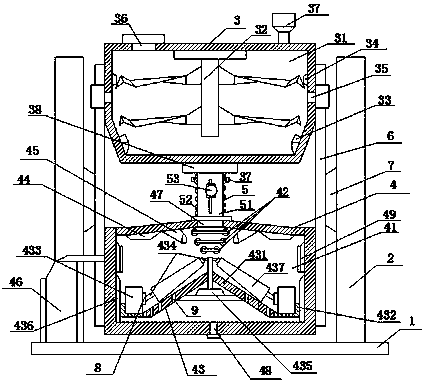

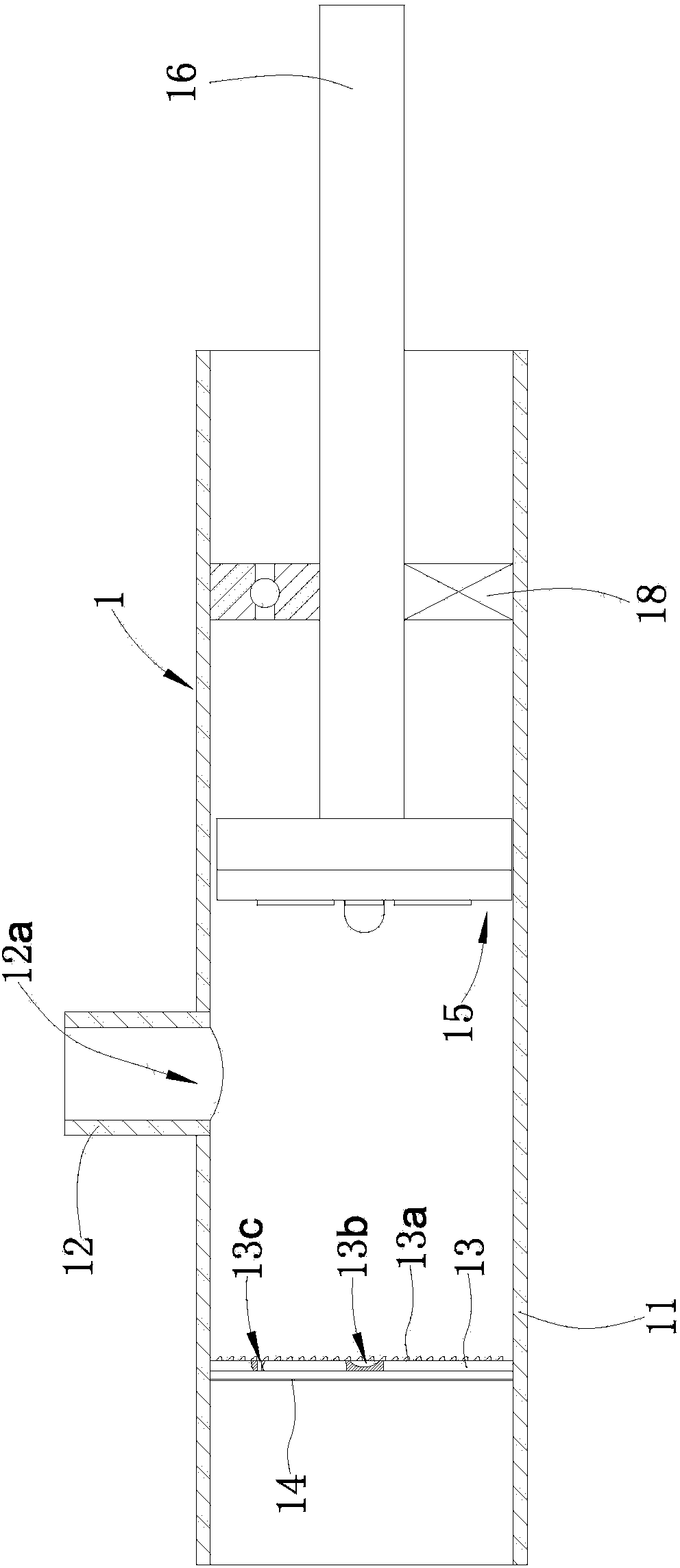

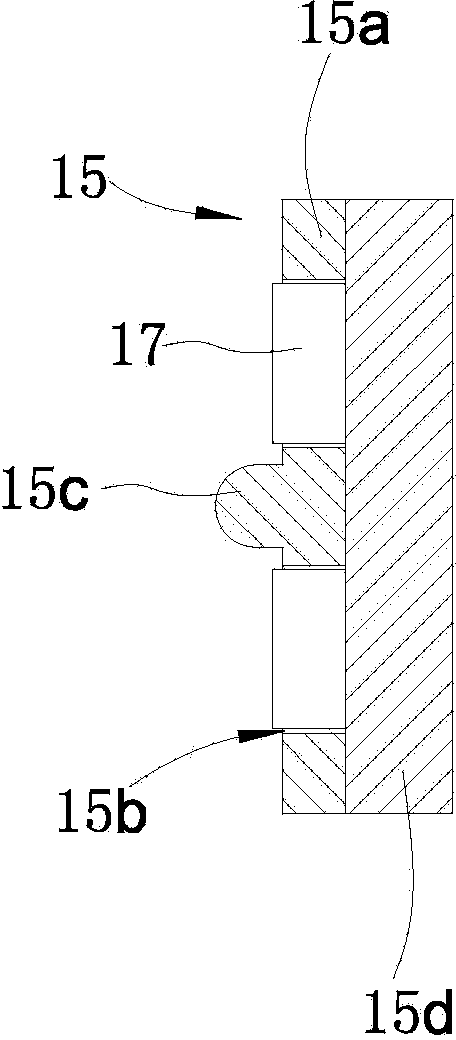

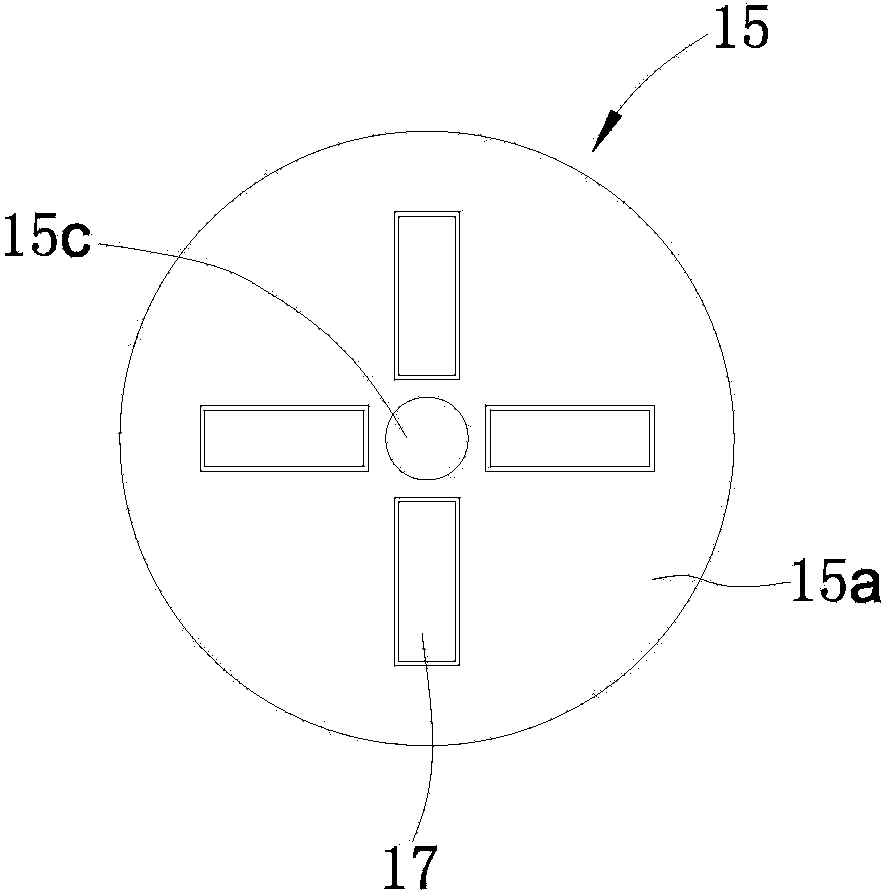

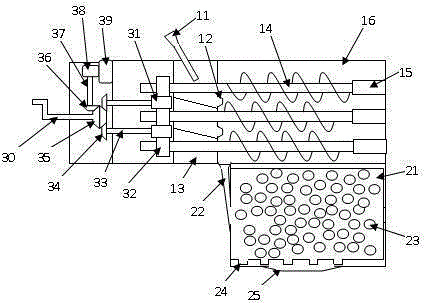

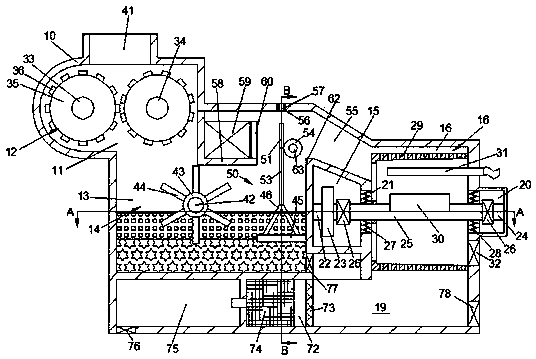

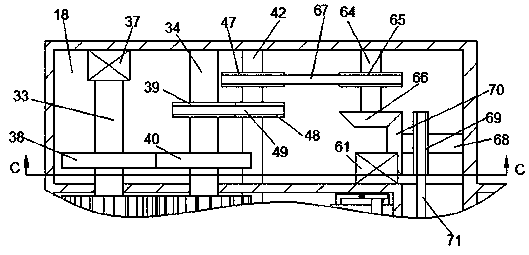

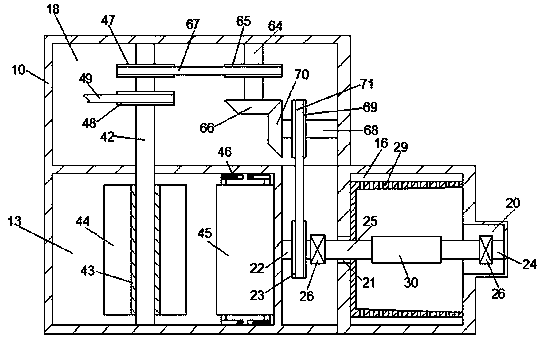

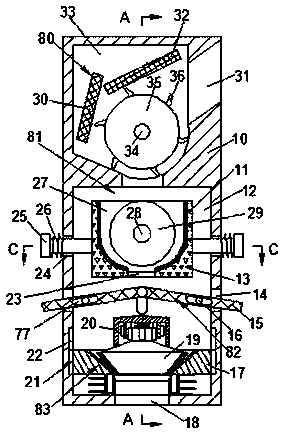

Automatic crawler type mobile integrated crusher

The invention discloses an automatic crawler type mobile integrated crusher. The automatic crawler type mobile integrated crusher comprises a charge long-arm excavating device, a walking device, a power device, a crushing device, a magnetic separating device, a discharging device, and a charge wide-opening ground shovel, wherein the charge wide-opening ground shovel is connected with the crushing device via a charge conveying belt; the walking device is also fixedly provided with a rotary chassis; the charge long-arm excavating device, the power device, the crushing device and the magnetic separating device are all fixedly installed on the rotary chassis. According to the invention, charging equipment and a mobile crusher are integrated; materials are directly put into the crusher via the charge conveying belt by the charge wide-opening ground shovel, so that a charge hopper is omitted; the charge long-arm excavating device, the power device, the crushing device and the magnetic separating device are all fixedly installed on the rotary chassis, so that charging and crushing are integrated, and the crusher can be used rotationally, and the crusher has the technical effects of energy conservation, environment protection, high efficiency and use flexibility.

Owner:SHENZHEN ZHONGCHENG GREEN BUILDING TECH +1

Efficient bone powder preparing system and using method

PendingCN107552202AIncrease productivityImprove product qualityGrain treatmentsProcess specificationUltrasonic vibration

Owner:郑州中技联创环境技术有限公司

Multi-stage efficient stone breaking device

Owner:六安市金安区一元通包装设计中心(普通合伙)

Agricultural caking granular fertilizer dissolving-mixing device

InactiveCN107570038AImprove solubilityEasy accessRotary stirring mixersGrain treatmentsAgricultural engineeringFertilizer

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

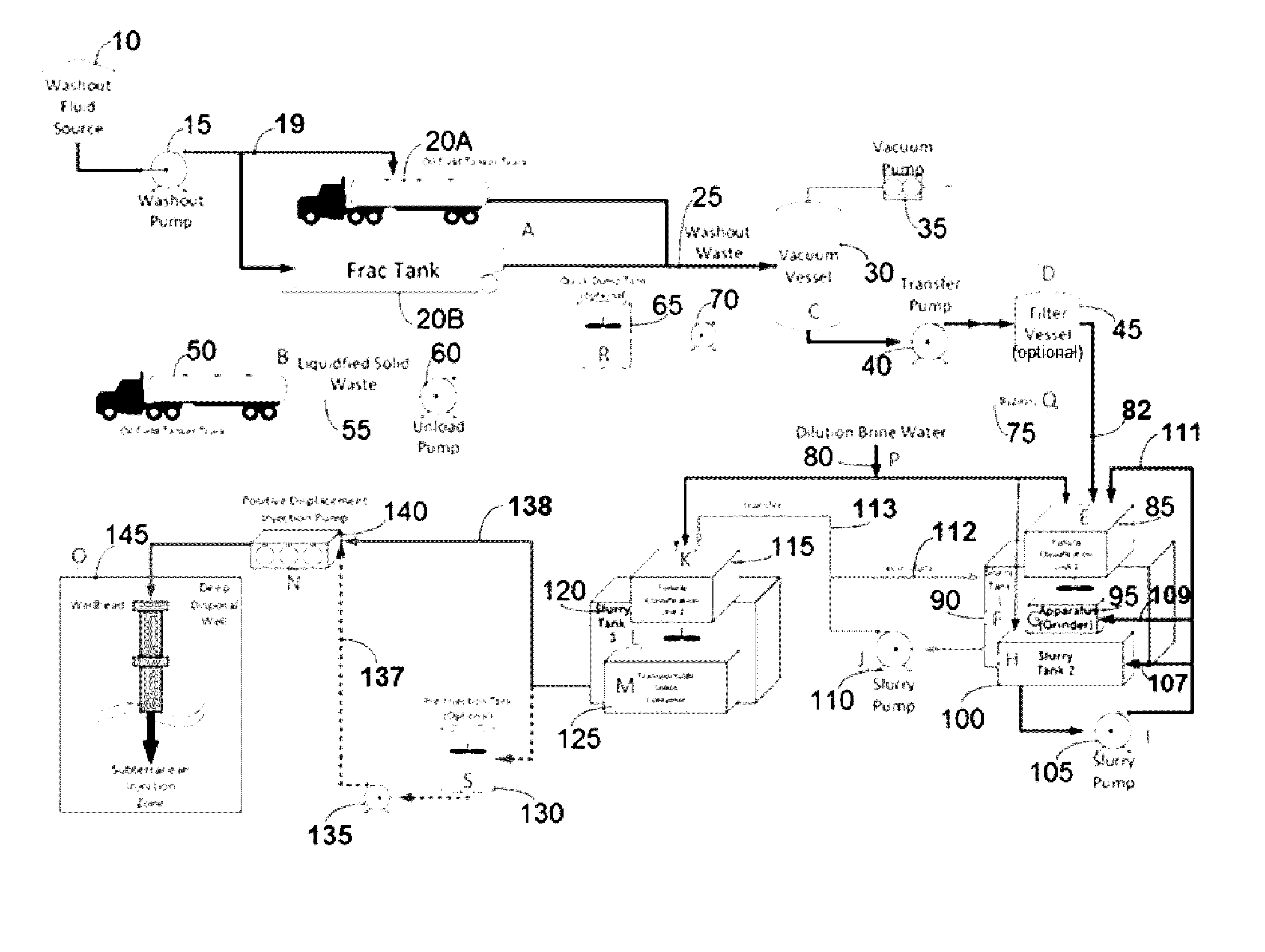

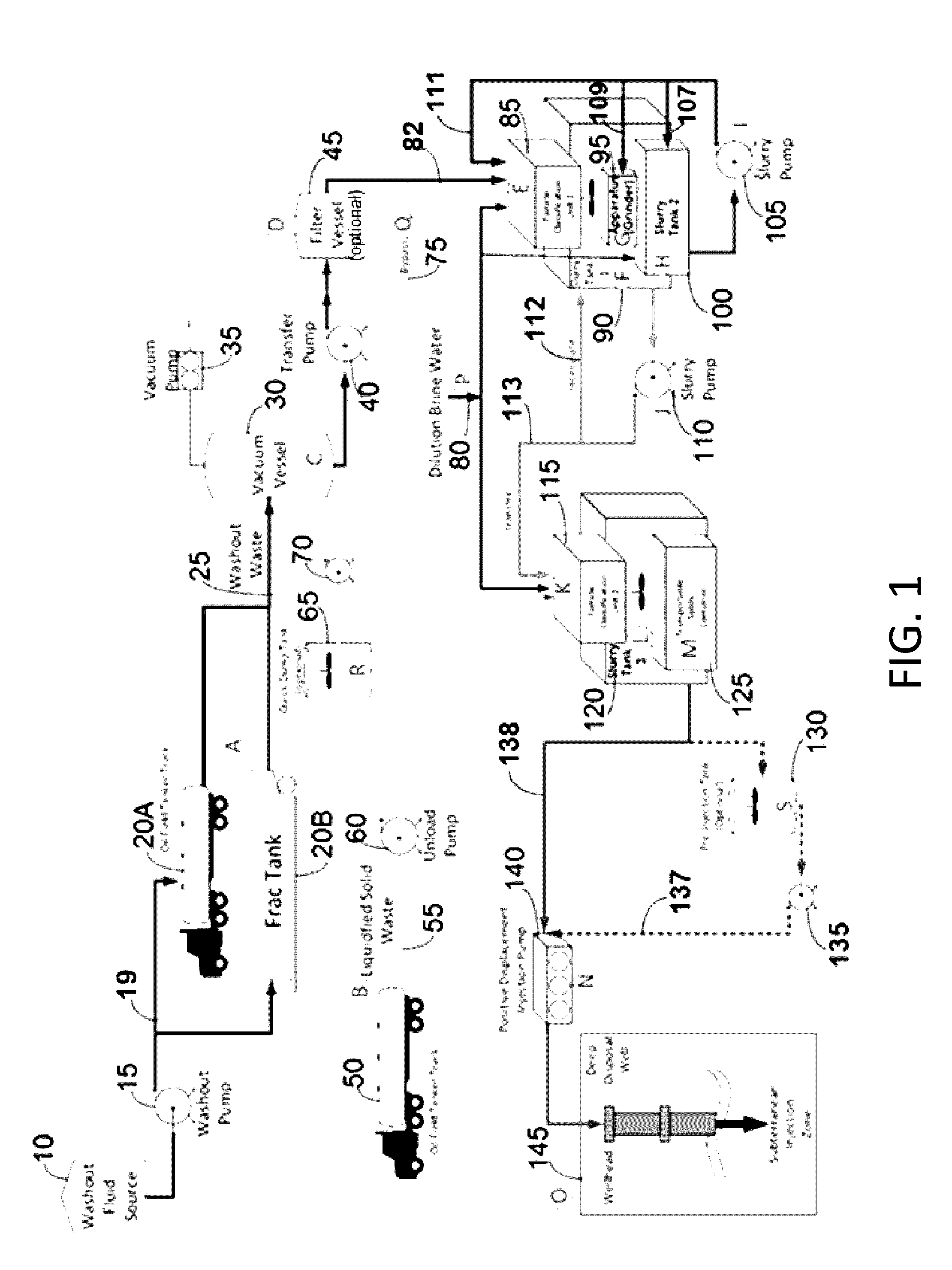

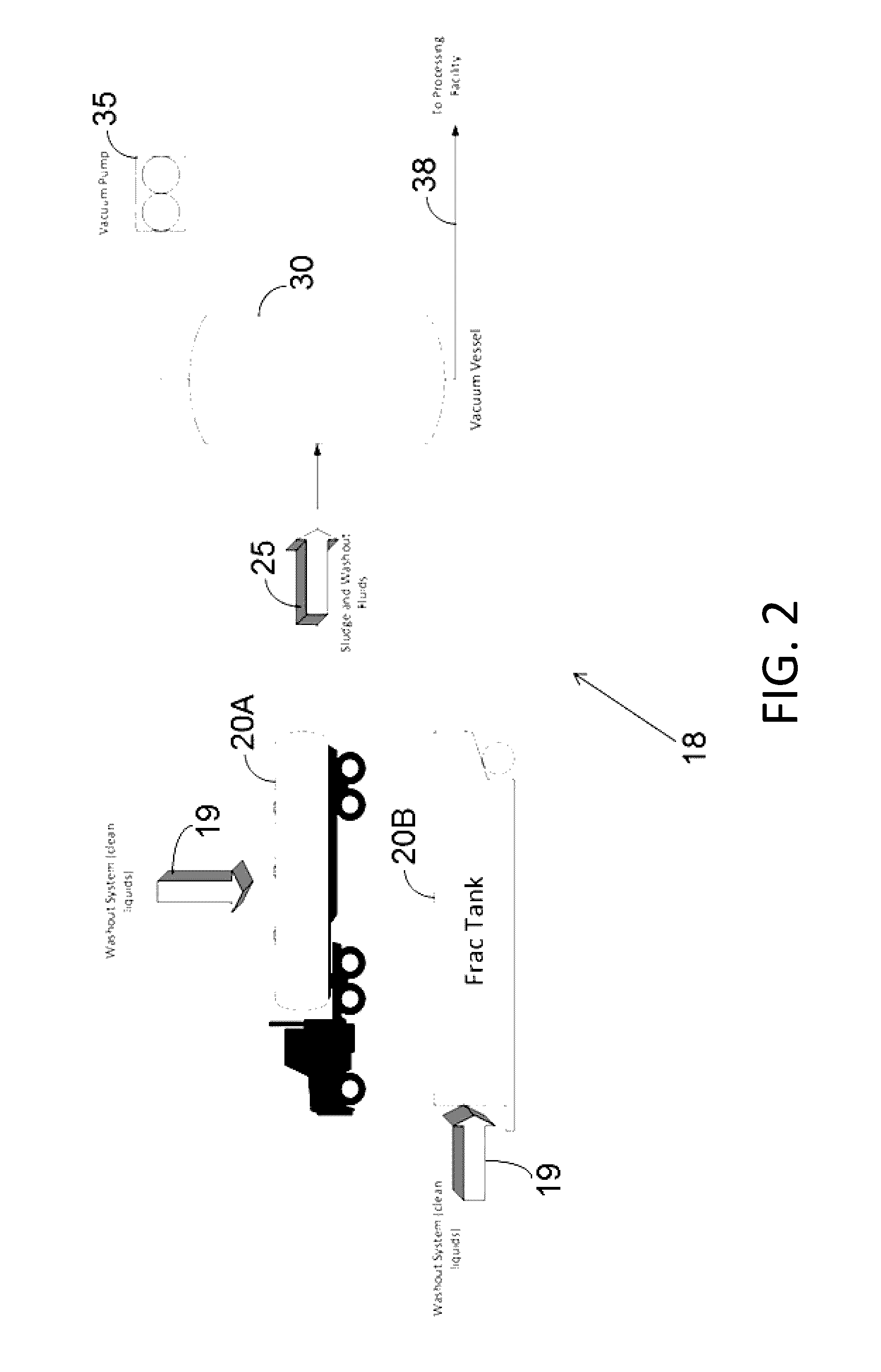

Systems and methods for oil field solid waste processing for re-injection

Owner:NGL WATER SOLUTIONS PERMIAN LLC

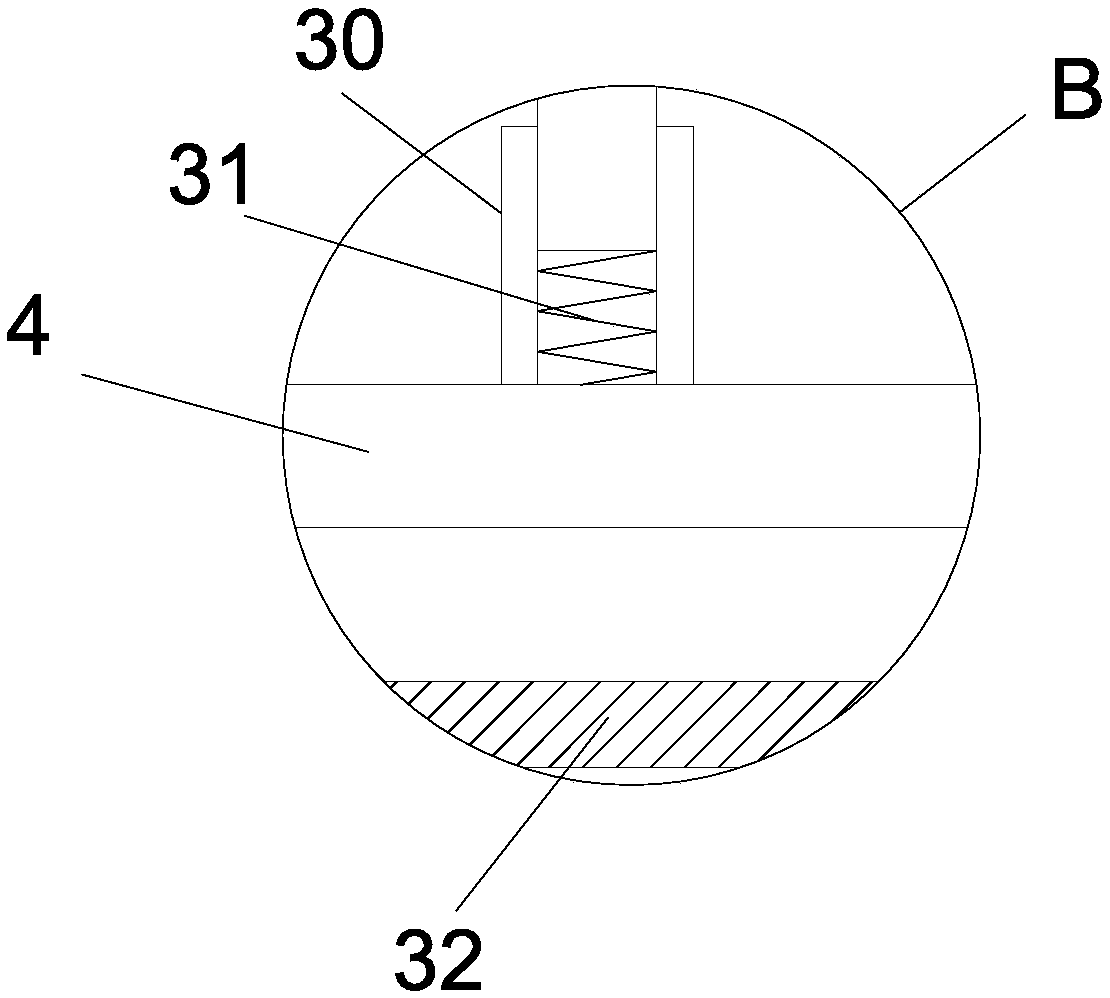

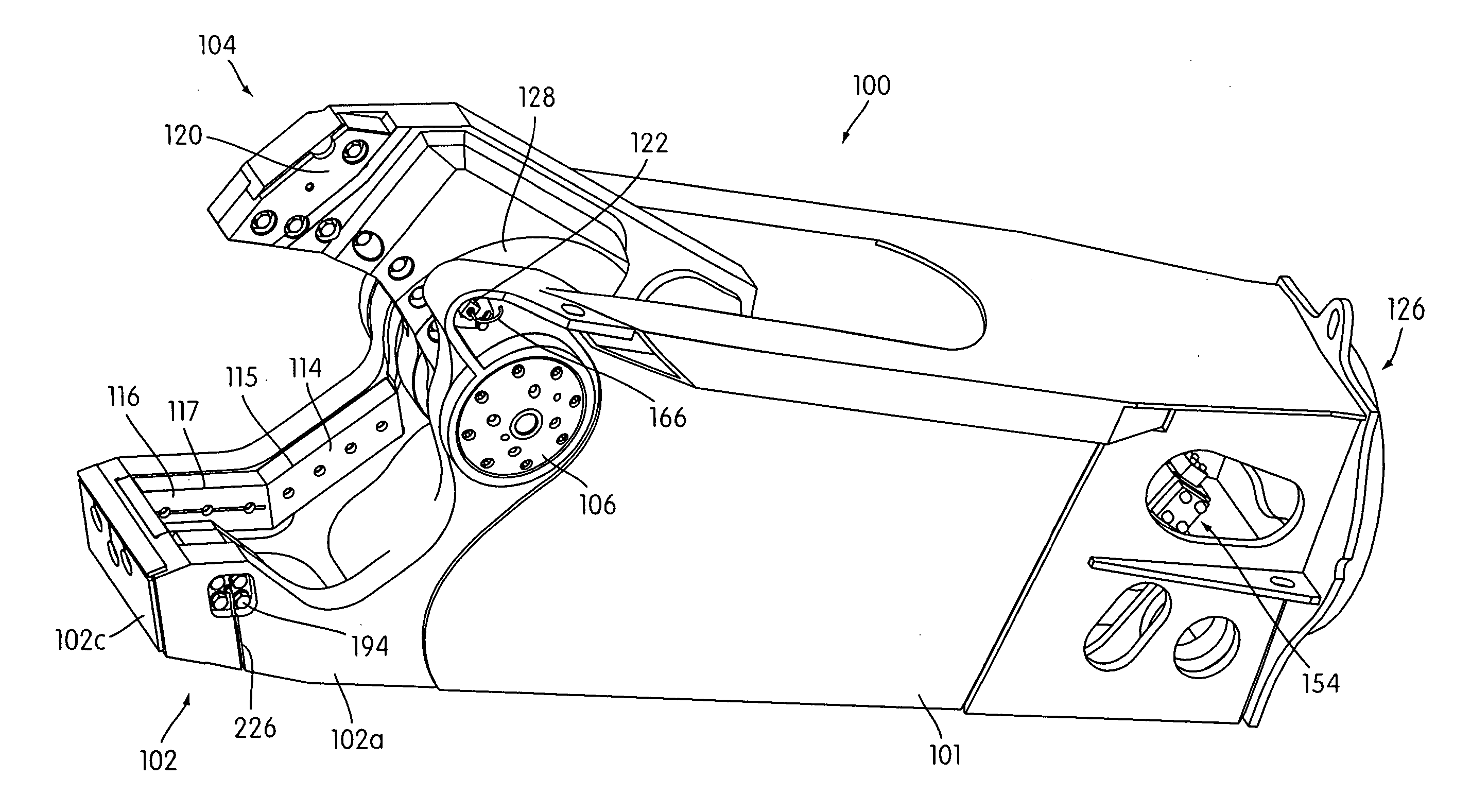

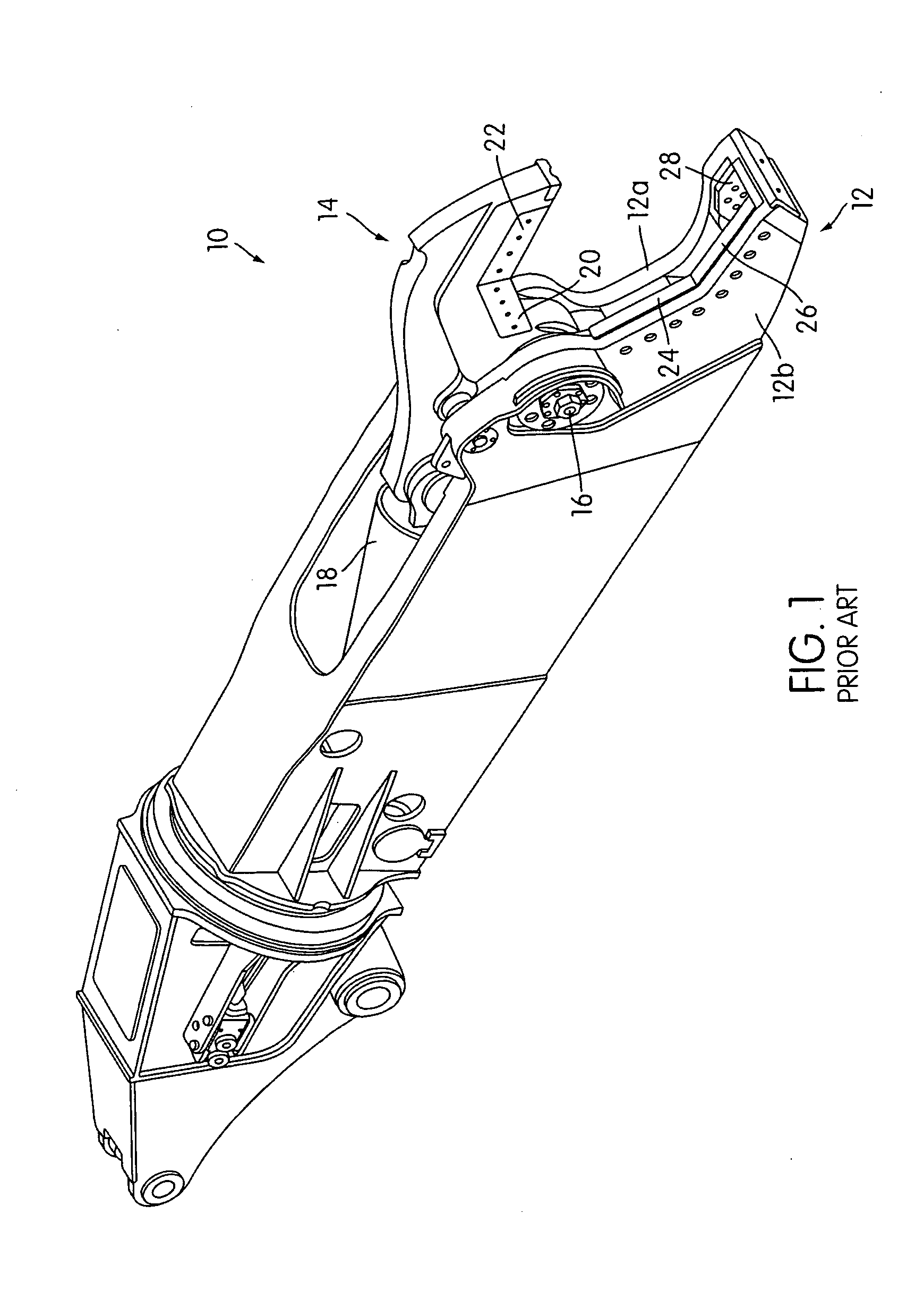

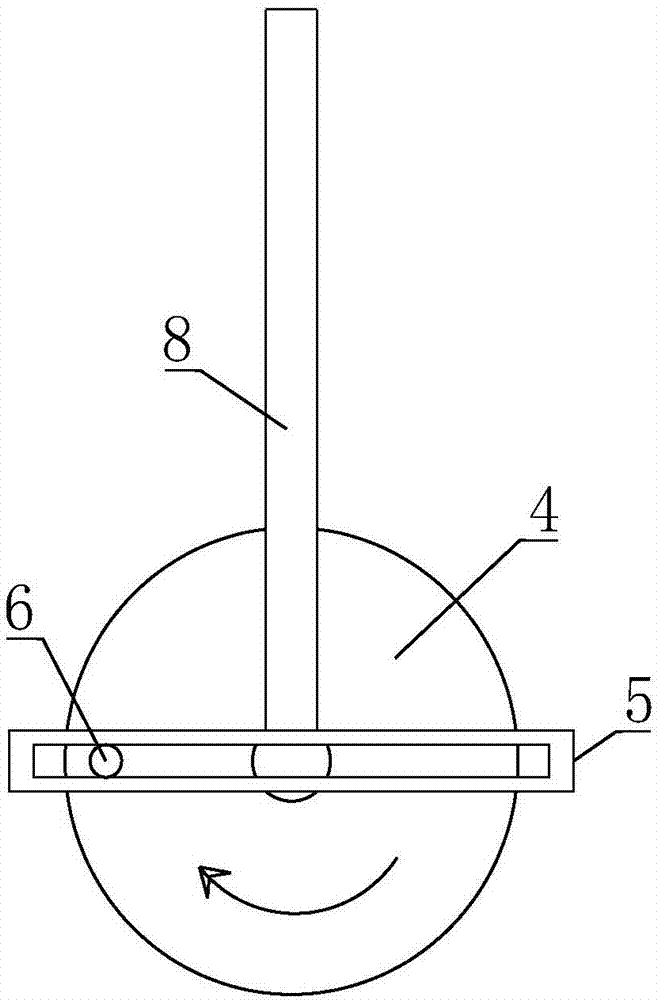

Stump grinder cutting system

Embodiments provide a cutting system for the stump grinder including a cutting assembly configured to be coupled to a wheel on the stump grinder. The cutting assembly may include a mounting block and a cutting block. The mounting block may be disposed in a pocket of the wheel that extends inward from a circumferential outer edge of the wheel. The cutting block may be coupled to the mounting block. The cutting block may have a continuous cutting edge that extends from a first side of the wheel to a second side of the wheel around a circumferential outer edge of the wheel.

Owner:CAIRNS KEITH

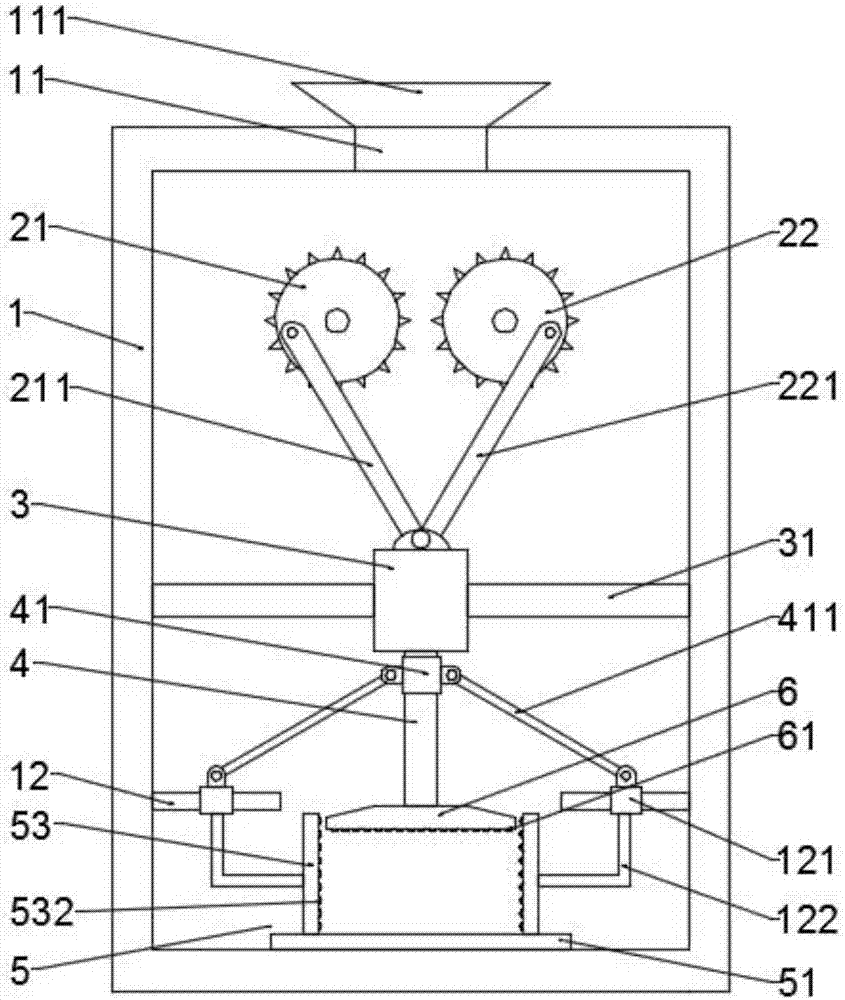

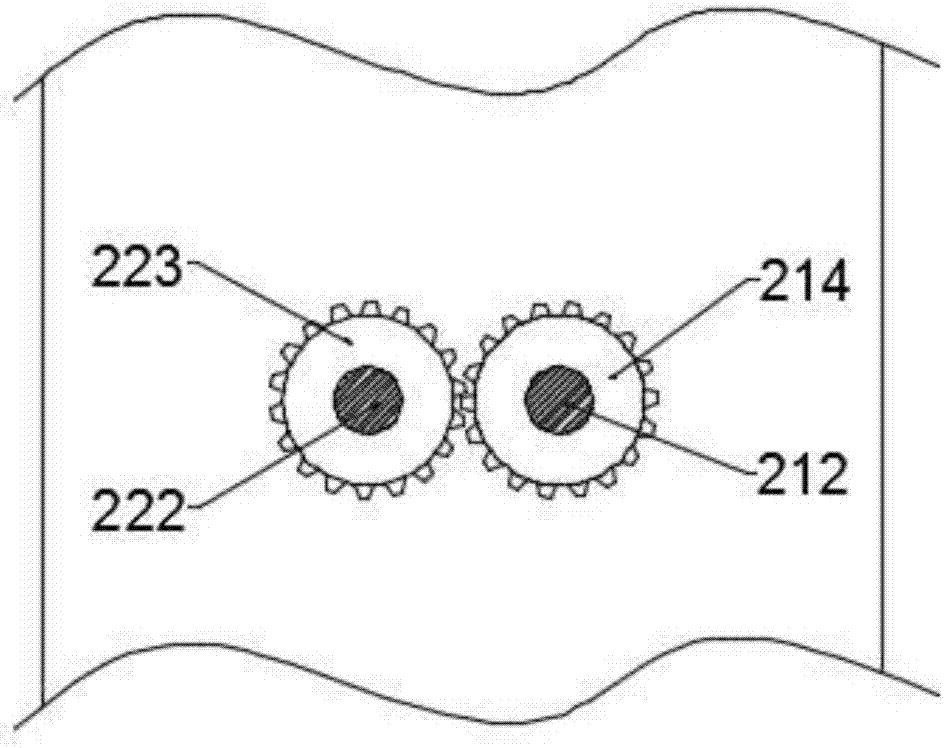

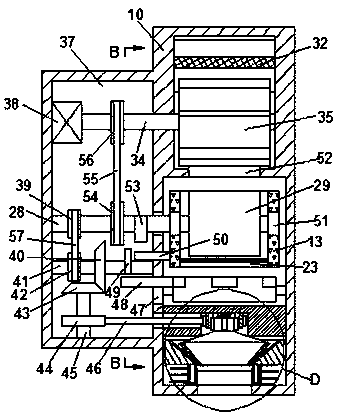

Double-crushing type civil paper shredder

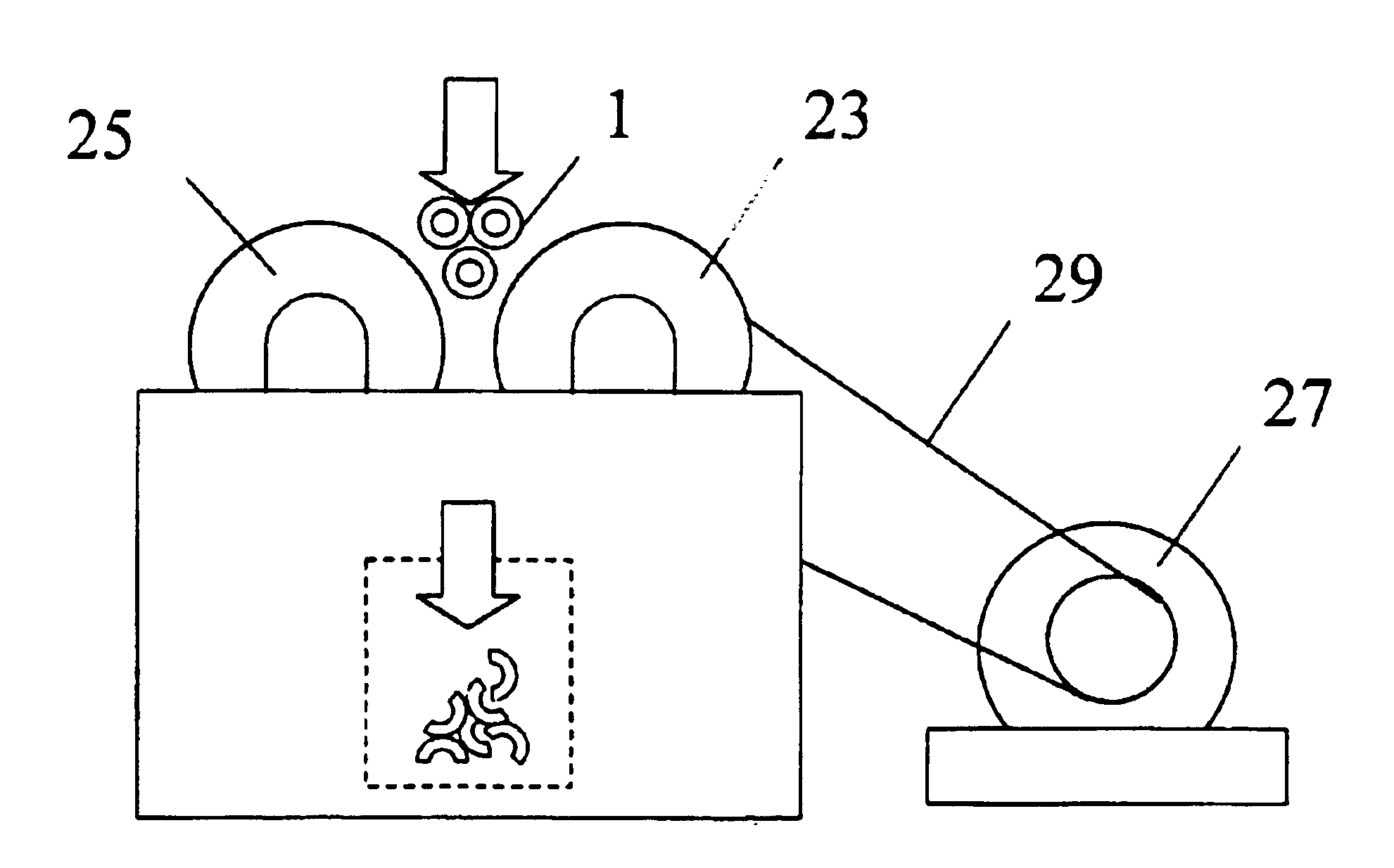

InactiveCN108654779AReduce the number of installationsImprove confidentialityGrain treatmentsGear wheelPulp and paper industry

The invention discloses a double-crushing type civil paper shredder. The double-crushing type civil paper shredder comprises a paper shredder body, a paper inlet is formed in the top end of the papershredder body, two rubber roller shafts are movably arranged in the positions, located at the lower end of the paper inlet, in the paper shredder body, two paper shredding hobs are movably arranged atthe lower ends of the two rubber roller shafts correspondingly, a center shaft of one paper shredding hob is fixedly connected with the driving end of a motor, a driving gear is fixedly arranged on the outer side of the driving end of the motor, and a transmission gear is movably meshed on the driving gear. According to the double-crushing type civil paper shredder, waste paper is preliminarily crushed by the two paper shredding hobs which roll oppositely, one paper shredding hob is driven by the motor, the other paper shredding hob can freely rotate, furthermore, one rubber roller shaft is driven to rotate through a gear transmission structure, and the other rubber roller shaft can freely rotate, so that the number of the motors to be installed is reduced; and when the waste paper crushed by the paper shredding hobs enters a secondary crushing box, secondary crushing is carried out on preliminarily crushed paper strips by a high-speed rotating crushing device.

Owner:MINNAN INST OF SCI & TECH

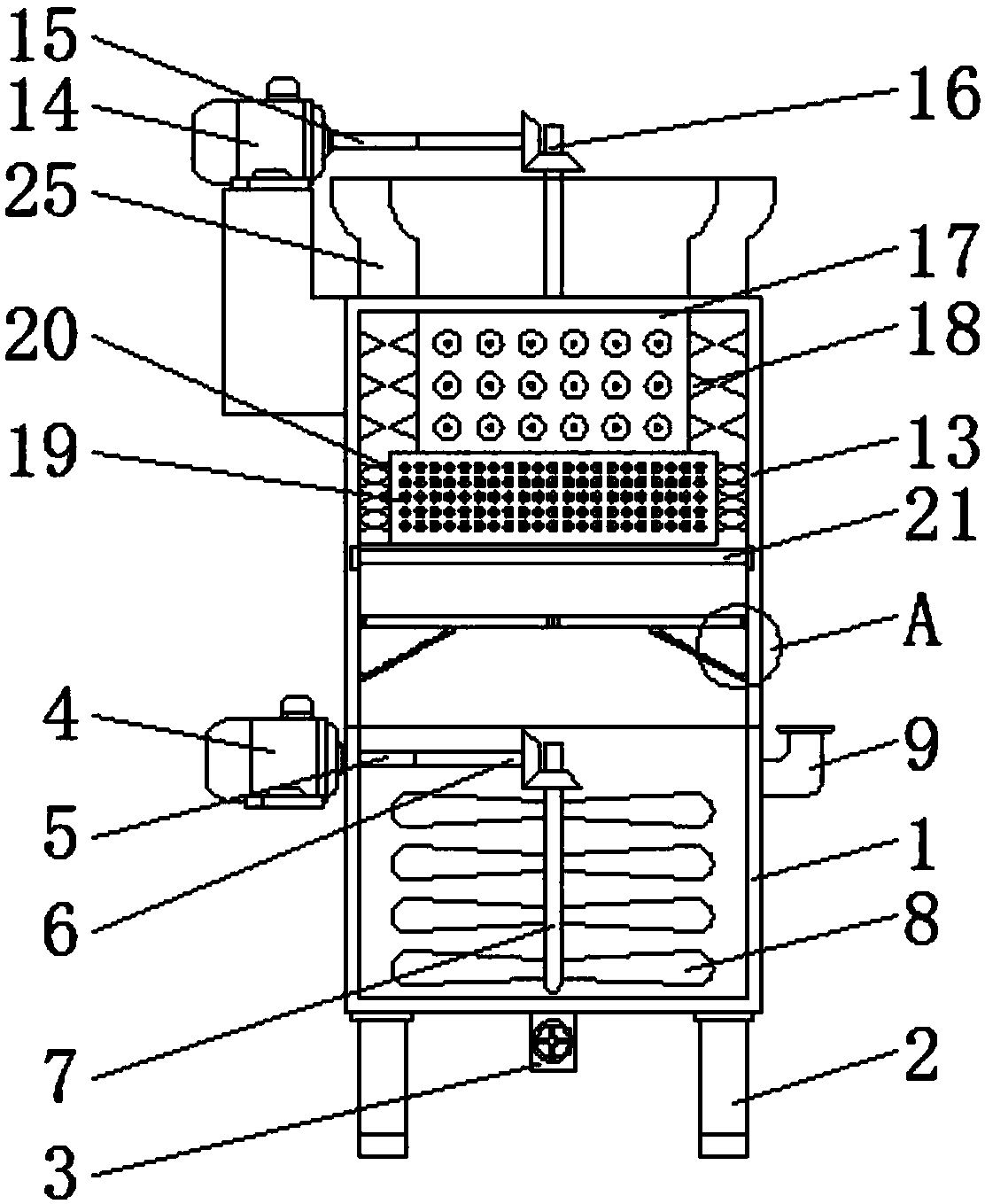

Building waste residue treatment device

InactiveCN111790477AAvoid damageImprove screening efficiencySievingScreeningWinding machineElectric machine

The invention discloses a building waste residue treatment device, and belongs to the technical field of building waste residue treatment tools. The building waste residue treatment device comprises ascreening device and a crushing device, wherein the screening device is arranged above the crushing device, the screening device is used for separating waste residues with different sizes, the crushing device is prevented from being damaged due to the fact that part of waste residues are too large in size and too hard, and the crushing device is used for crushing small waste residues; and the screening device comprises a screening shell, a screening net, a steel wire, a winding machine, a winding motor, a left side plate and a right side plate, after the screening net screens small waste residues in the waste residues, the winding machine is driven to rotate through work of the winding motor, the steel wire is lengthened, and the screening net is driven to turn over downwards, large wasteresidues left on the screening net are discharged, a part of overlarge and hard building waste residues are prevented from damaging the crushing device to a certain extent, and the service life of the crushing device is prolonged.

Owner:过蕊

Straw crushing and grinding device and operation method thereof

Owner:合肥荣电环境电器有限公司

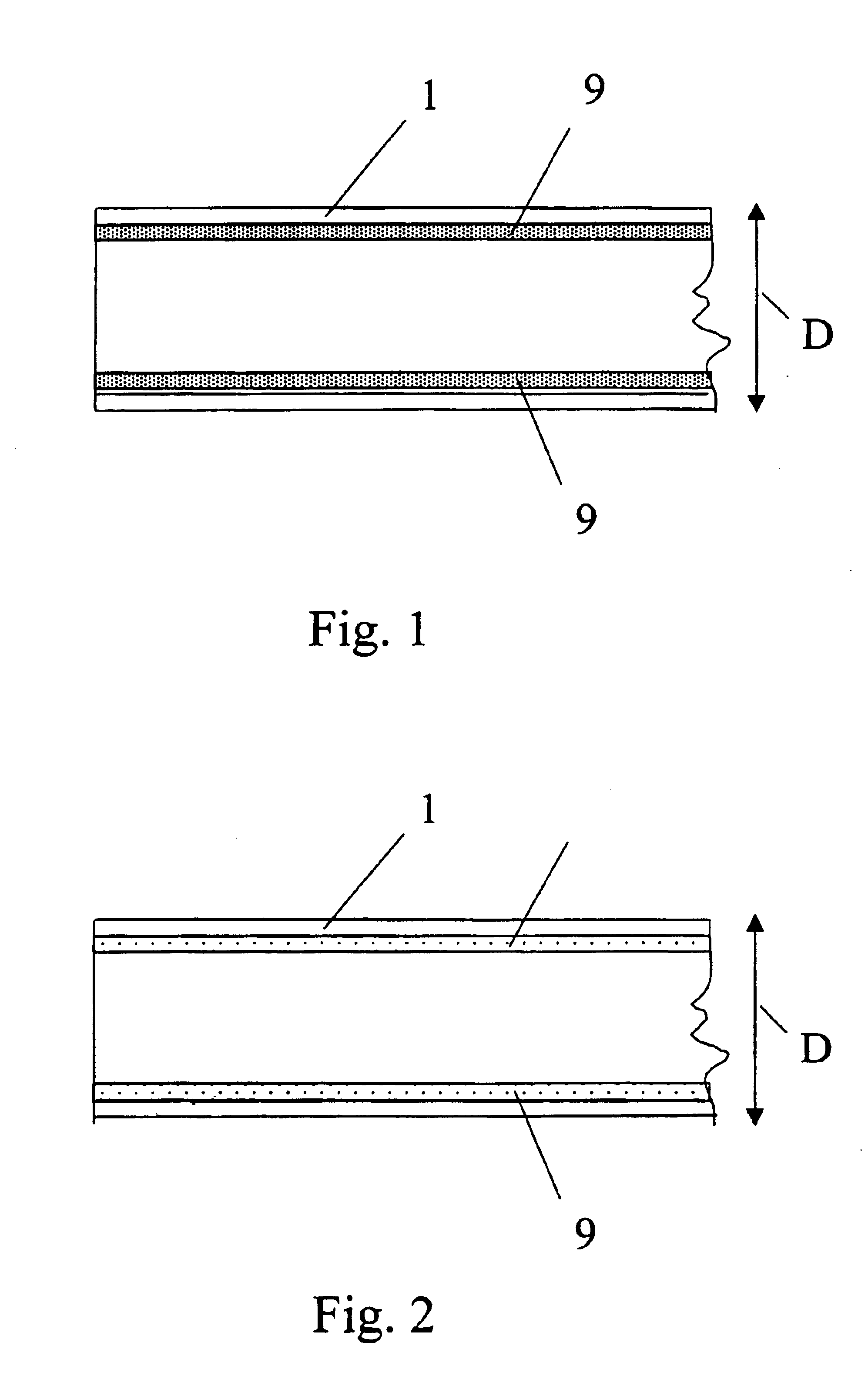

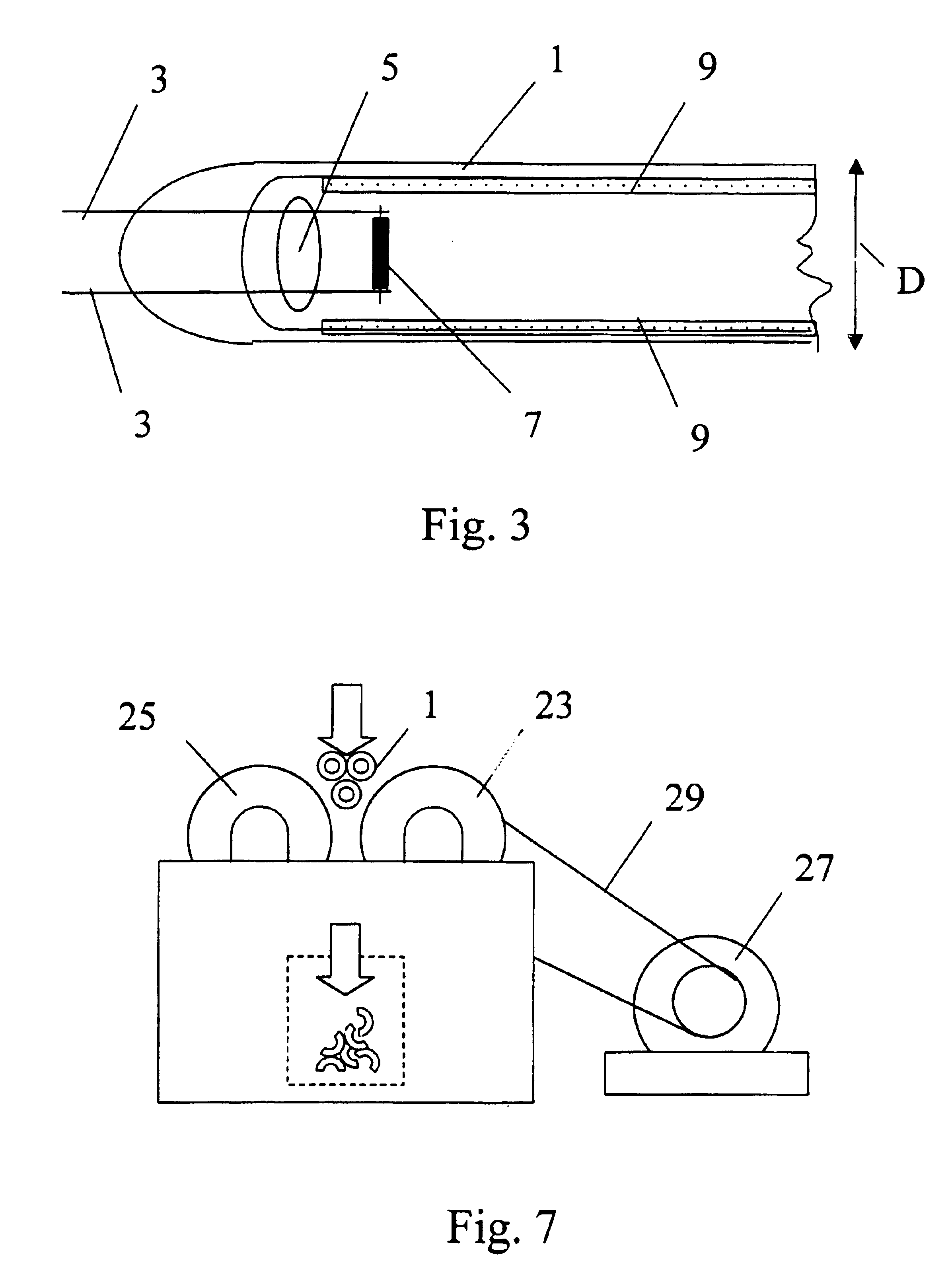

Method for recovering fluorescent material from faulty glass bodies of discharge lamps

InactiveUS6869327B2Efficiently good resultEasy to separateDischarge tube luminescnet screensLamp detailsGlass particleCrusher

Owner:GENERAL ELECTRIC CO

Concrete crushing and recycling device

ActiveCN112495476APrevent looseningReal-time adjustmentSievingSolid waste managementEnvironmental engineeringCrusher

The invention discloses a concrete crushing and recycling device. The concrete crushing and recycling device comprises a crushing mechanism, a dust channel and a mud generating mechanism, wherein thedust channel is formed in one side of the crushing mechanism; and the mud generating mechanism is arranged on one side of the dust channel. According to the concrete crushing and recycling device, a crushing roller adjusting mechanism is additionally arranged, and the distance between crushing rollers can be adjusted in real time according to concrete of different sizes, so that the crushing effect is better, jamming is prevented, and the crushing efficiency is improved; and dust generated in the crushing process is collected and made to form mud under the action of an atomization spraying mechanism, and the mud is discharged under the combined action of a mud settling mechanism and a discharge box, so that the dust is effectively controlled, and the environmental pollution is prevented; and meanwhile, the dust can be reprocessed and reutilized, so that raw materials are saved, and waste is prevented.

Owner:GUI ZHOU CHANG TONG DIAN LI XIAN LU QI CAI YOU XIAN GONG SI

Grinding filter component and bone slurry machine

Owner:润桐(苏州)技术服务有限公司

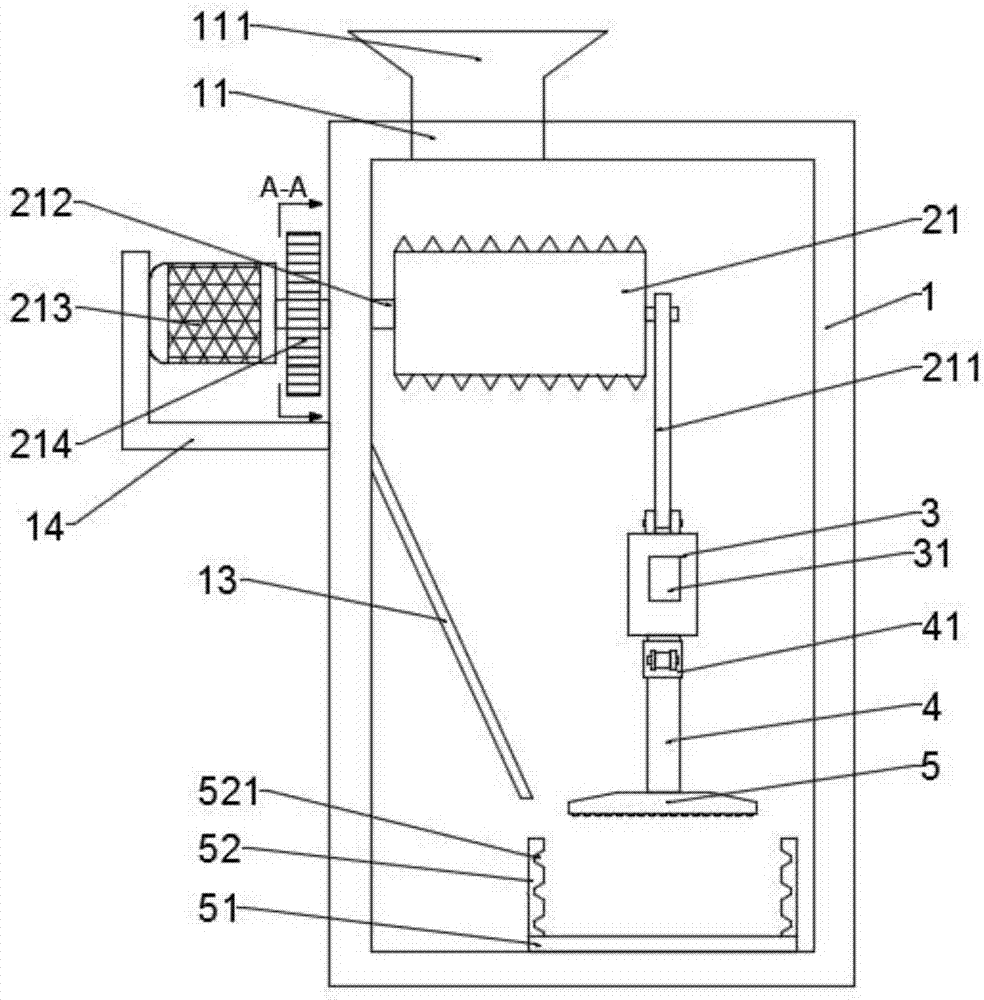

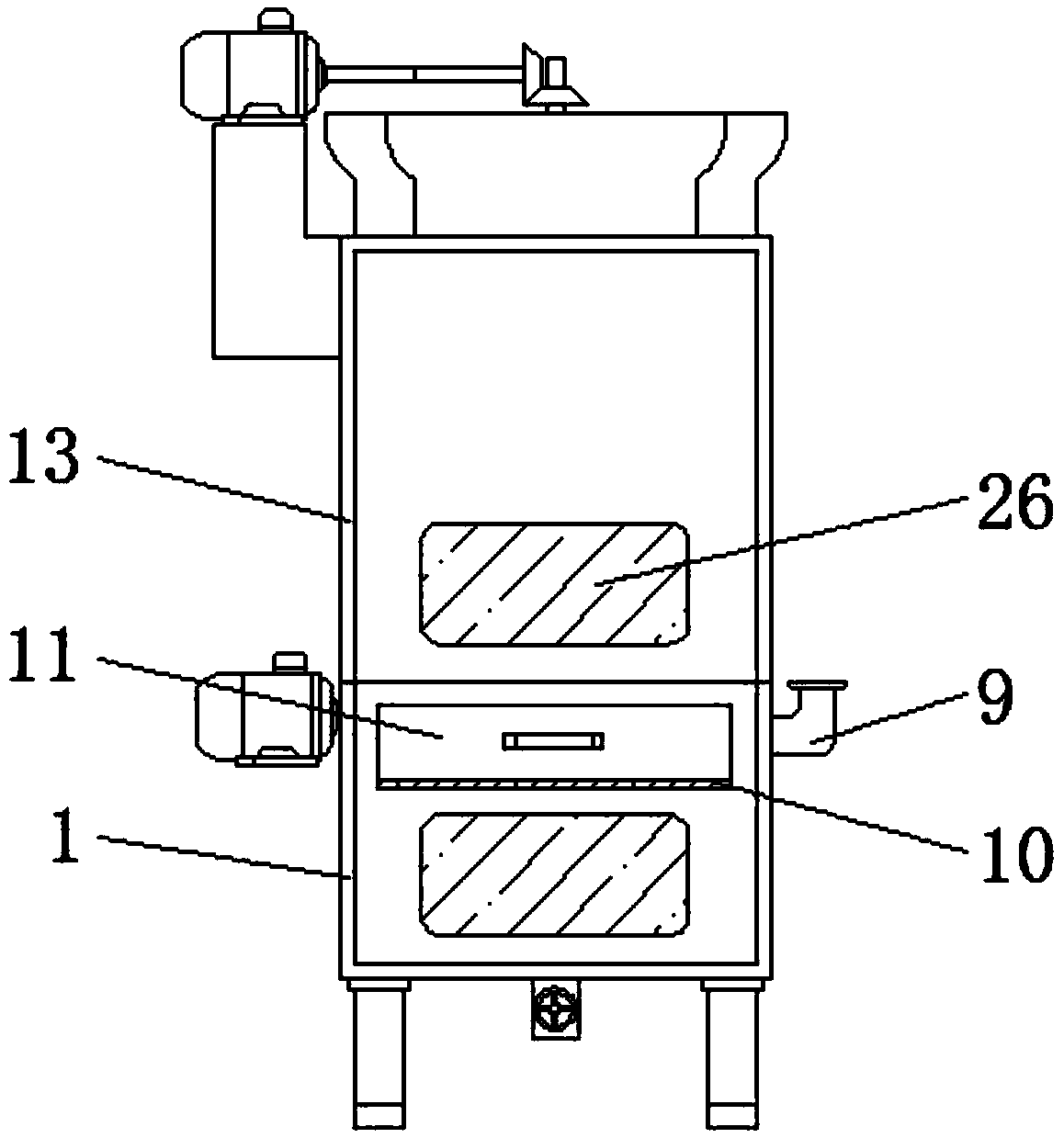

Drug breaking and grinding device

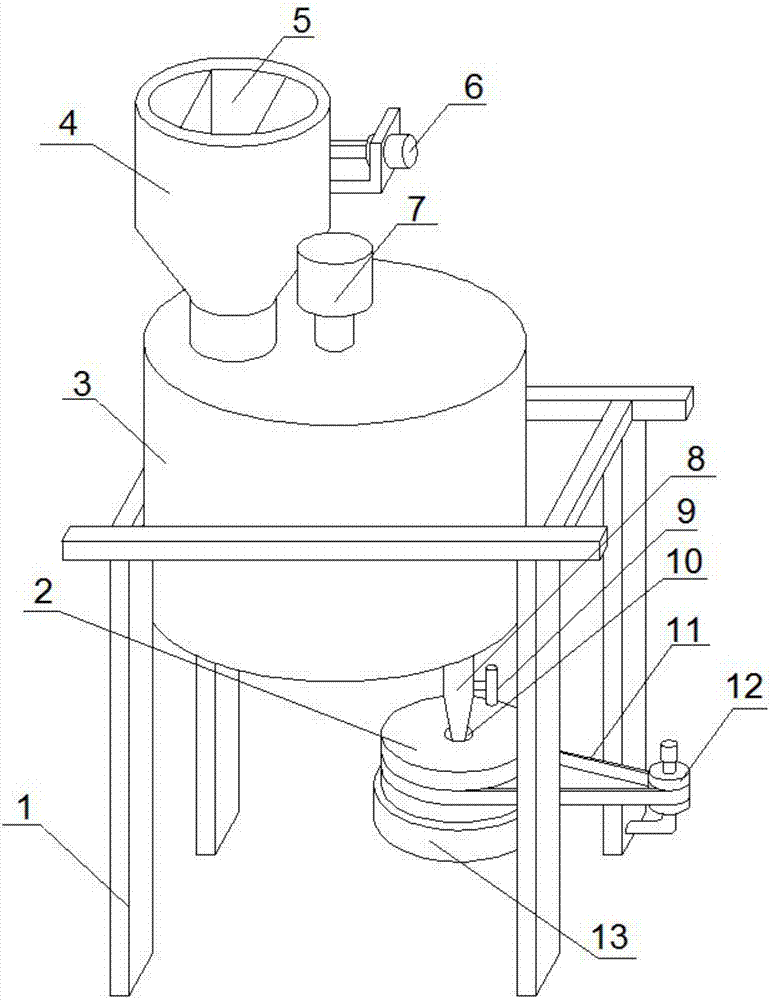

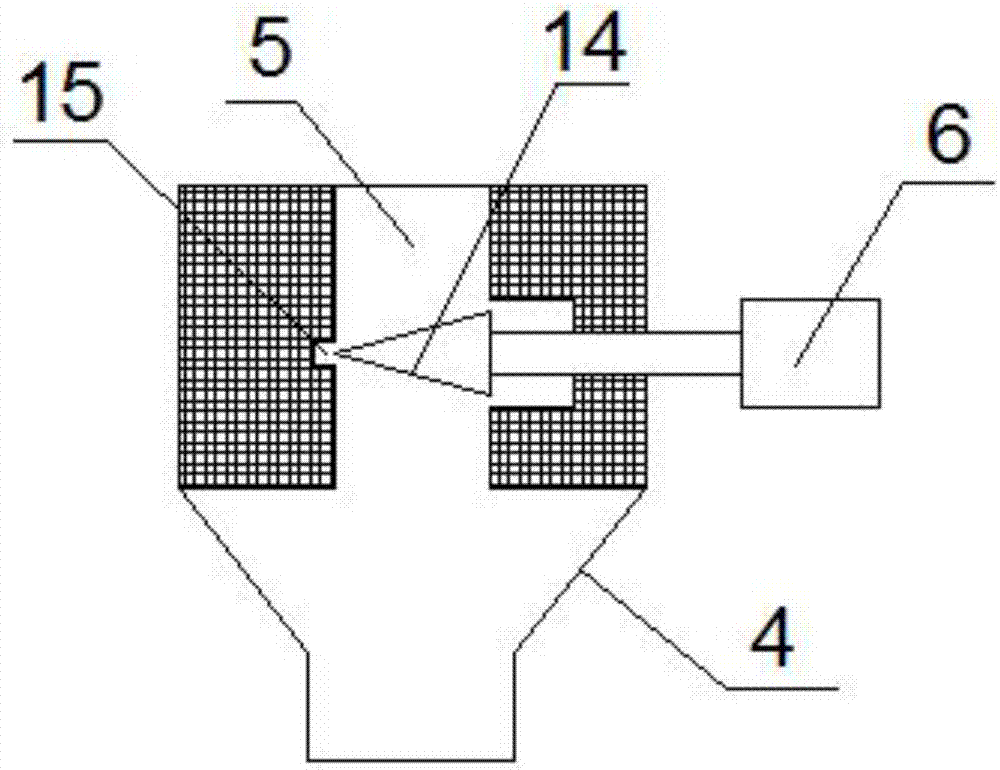

InactiveCN106733109AIncrease grinding rateImprove grinding effectFurnace typesGrain treatmentsDrugTransmission system

The invention relates to a drug breaking and grinding device which comprises a breaking system, a grinding system and a power and transmission system. Through the improvement and reasonable arrangement of the various components, breaking and grinding are separated, so that the working efficiency is improved. In addition, with the creative adoption of the grinding system in which grinding balls are matched with a grinding internal barrel and a grinding external barrel, the grinding efficiency and the product quality are improved.

Owner:王宝林

Crushing and sorting device for waste battery

InactiveCN111054499ASimple and fast operationReduce manufacturing costPlastic recyclingReclaiming serviceable partsProcess engineeringMechanical engineering

Owner:PUJIANG CIFANG ENVIRONMENTAL PROTECTION TECH CO LTD

Vertical metal smelting device for alloy steel forging and casting

The invention discloses a vertical metal smelting device for alloy steel forging and casting. The vertical metal smelting device for alloy steel forging and casting comprises a high-temperature-resistant shell, wherein a first connector and a second connector are arranged in the middle of a connecting pipe; clamping slots are symmetrically formed in the outer sides of the first connector and the second connector; a filter screen is jointly arranged in the first connector and the second connector; an outer seal ring is jointly arranged on the outer sides of the first connector and the second connector; clamping blocks corresponding to the clamping slots are arranged on the inner side of the outer seal ring; and an inner seal ring corresponding to the filter screen is arranged on the inner side of the outer seal ring. According to the vertical metal smelting device for alloy steel forging and casting provided by the invention, through arranging the filter screen, metal particles in smokedust can be prevented from being discharged to cause the resource waste; and in addition, through taking off the outer seal ring and the inner seal ring on the outer sides of the first connector andthe second connector, the filter screen can be conveniently taken out so as to be conveniently cleaned and prevented from being blocked.

Owner:NANTONG JUXING CASTING & FORGING CO LTD

Natural stone crushing and grinding equipment

InactiveCN111389567ASimple and fast operationReduce manufacturing costSievingScreeningCrushed stoneStructural engineering

Owner:杭州瑞芳容科技有限公司

Crushing and mixing integrated device for recycling construction waste concrete

InactiveCN108654768AEasy to crushEasy to reprocess and recycleMixing operation control apparatusPretreatment controlEngineeringBevel gear

Owner:WUHU TIANMENG INFORMATION TECH CO LTD

High-quality ceramic stone machining system

InactiveCN107913778AAvoid unmanageable problemsImprove product qualityMagnetic separationGrain treatmentsIron removalStone particle

The invention discloses a high-quality ceramic stone machining system. The high-quality ceramic stone machining system comprises a slurry inlet pipe, a grinding mechanism for grinding slurry, a filtering mechanism for filtering the slurry, a drying mechanism for drying ceramic stone particles, and an iron removal mechanism for removing iron in the ceramic stone particles. The high-quality ceramicstone machining system has the beneficial effects that the slurry can be subjected to adsorbing impurity removal after being dried and formed, iron scraps in the slurry are reduced, and the problem that due to the fact that impurity removal is carried out before an overall process, the iron scraps mixed in the work process cannot be treated is avoided; the product quality is improved, a continuousproduction mode of grinding, filtering and screening, drying and iron removing can be formed, and machining efficiency is greatly improved; and the overall structure is simple, and very good market generalization performance is achieved.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap