Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about "Plastic recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite plastic materials produced from waste materials and method of producing same

InactiveUS7022751B2Plastic recyclingConductive materialFibre reinforcementFiber-reinforced composite

Owner:ROYAL GRP TECH LTD

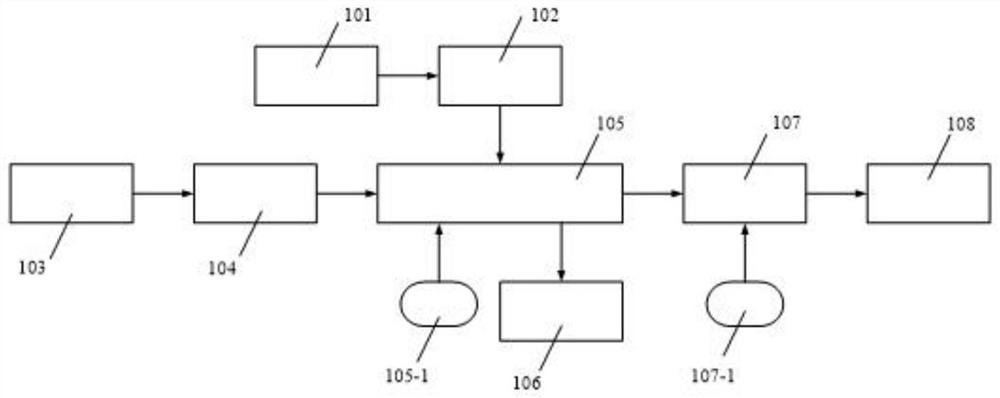

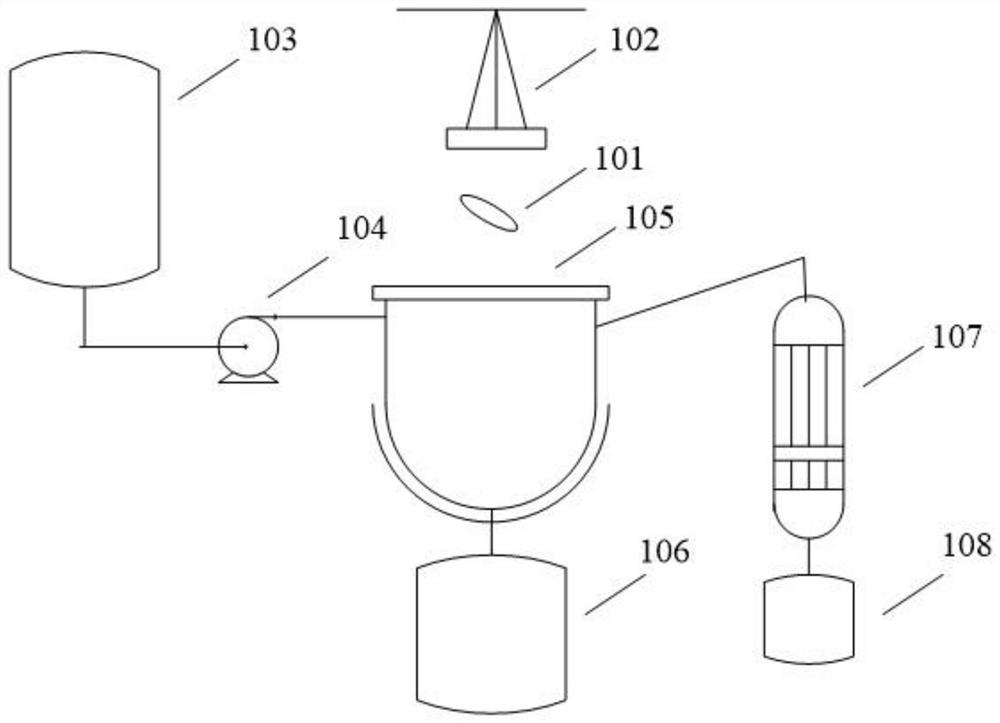

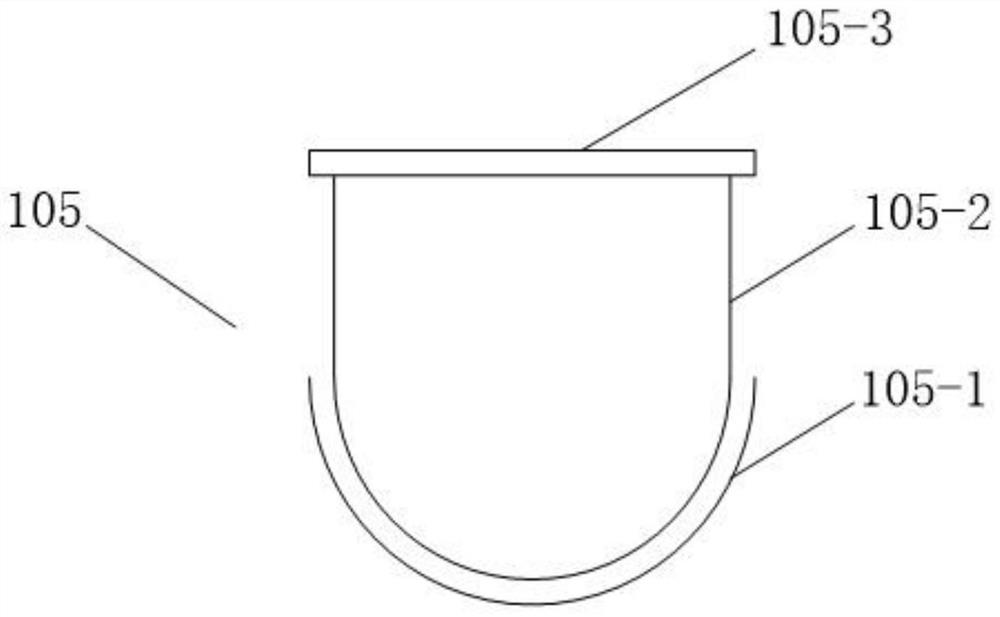

Separation settling tank

Owner:GENOX RECYCLING TECH

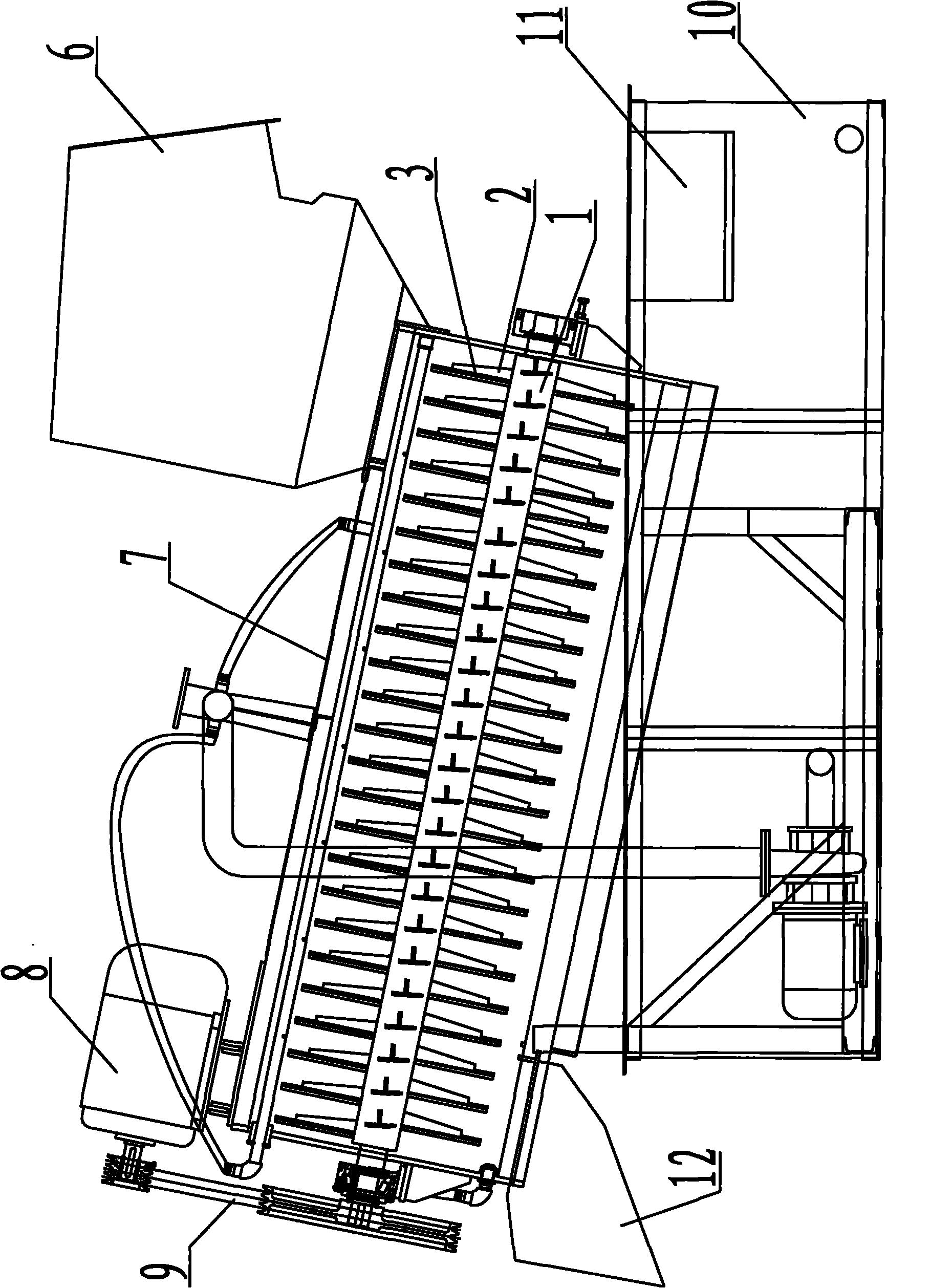

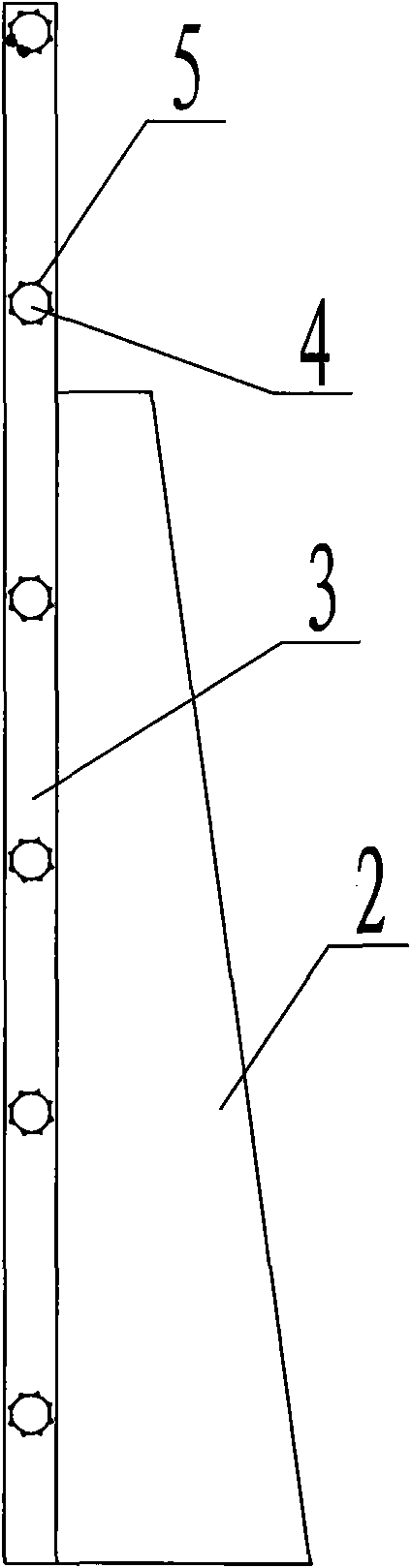

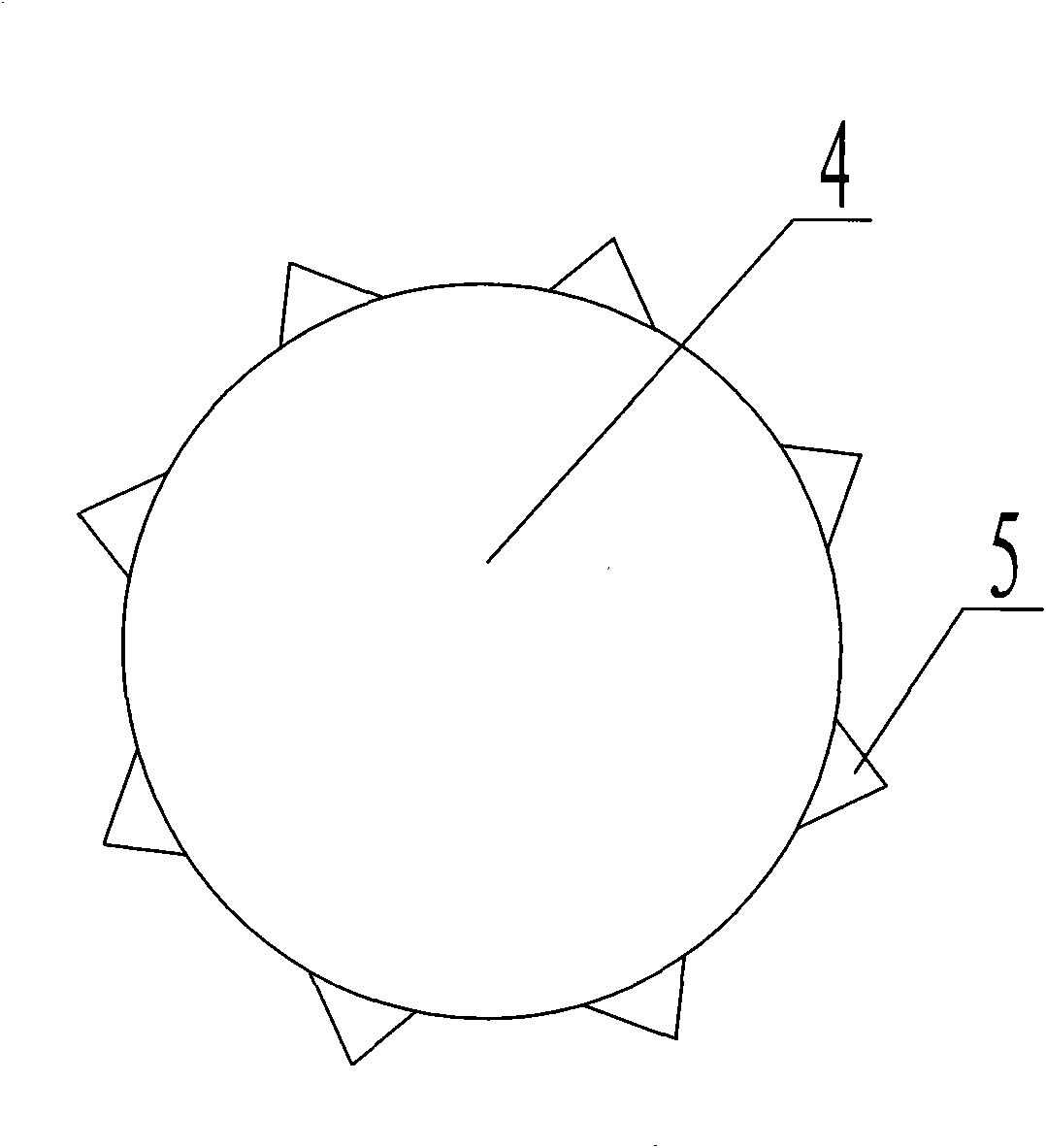

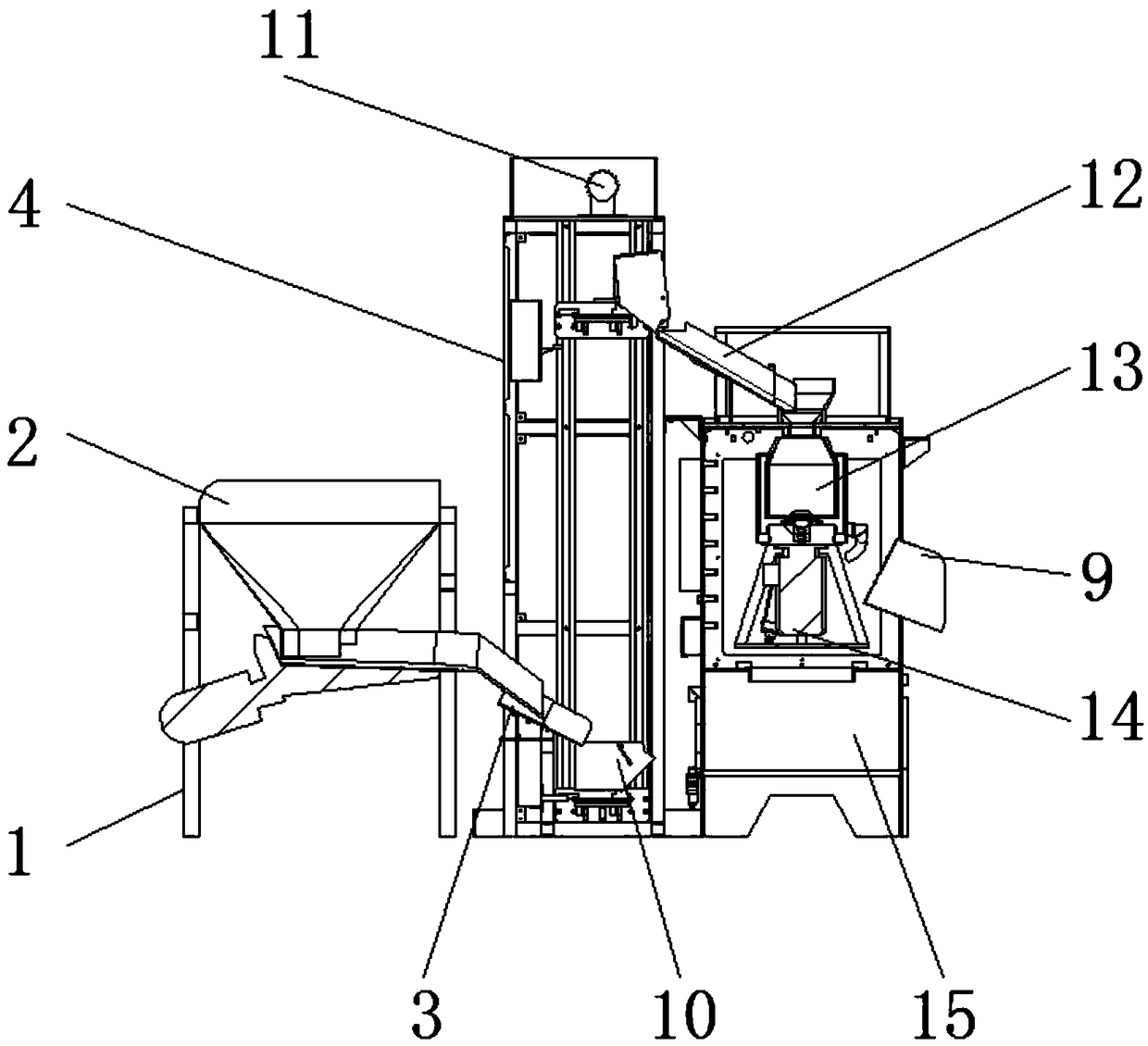

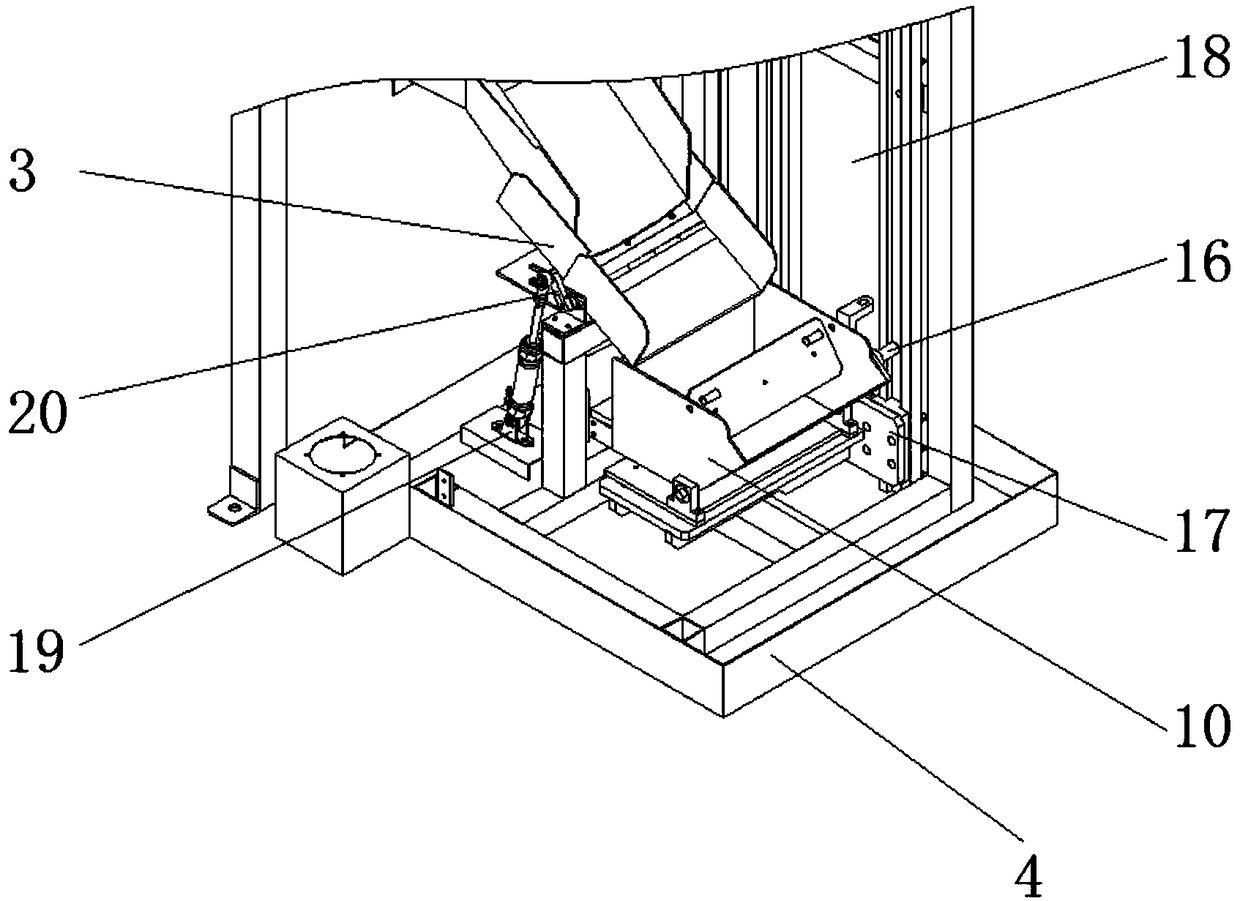

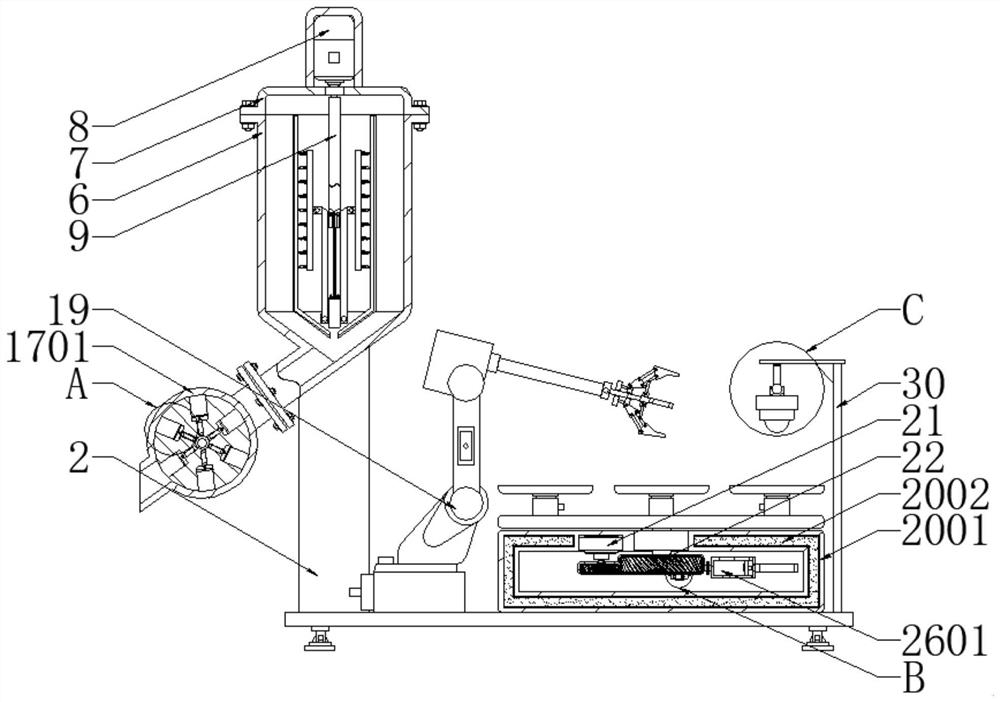

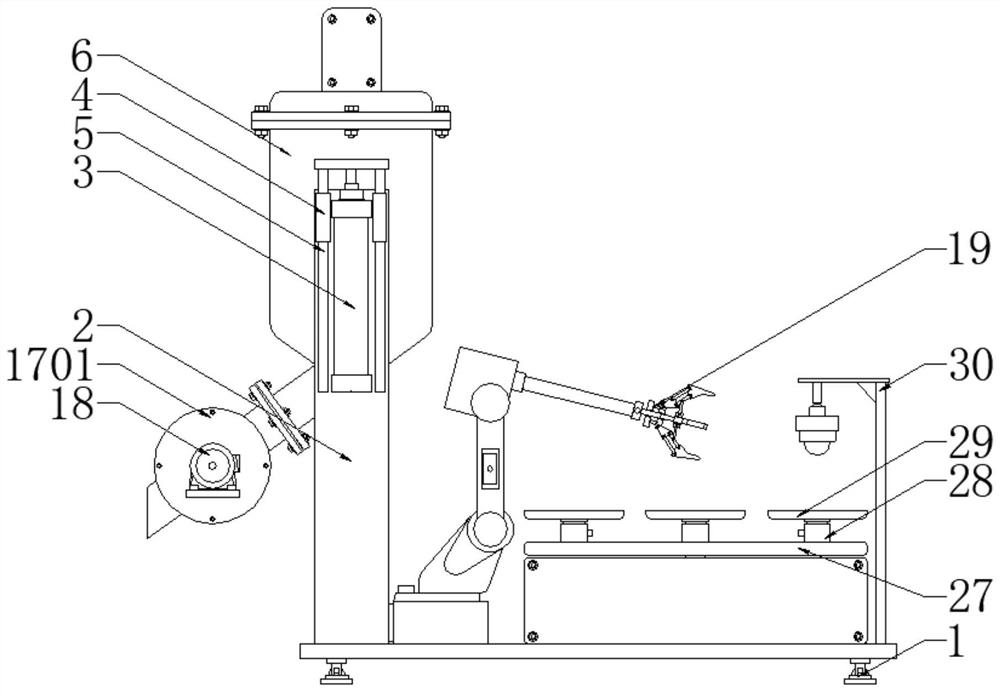

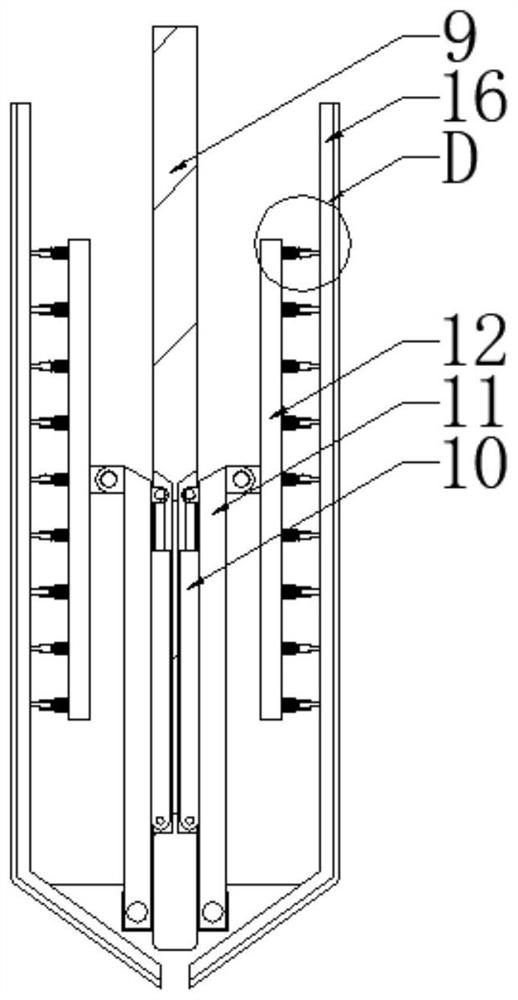

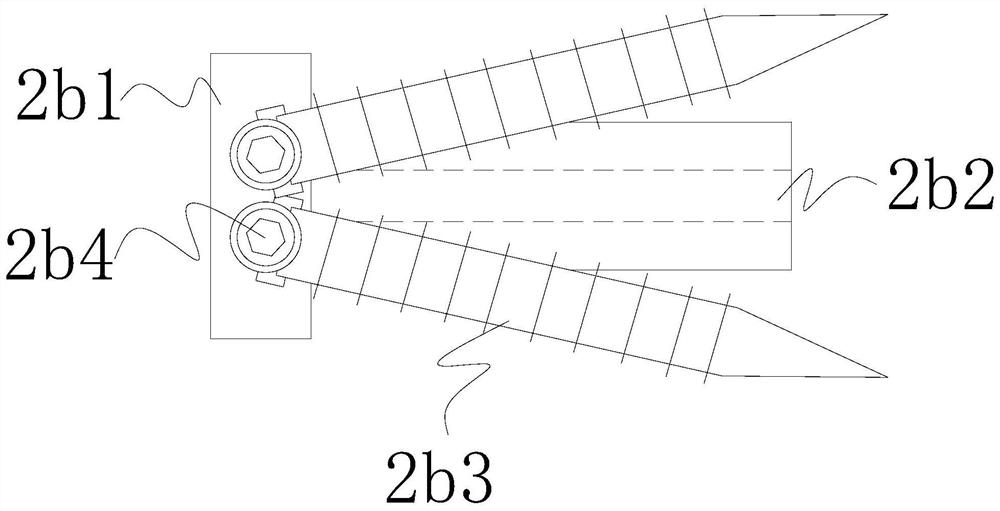

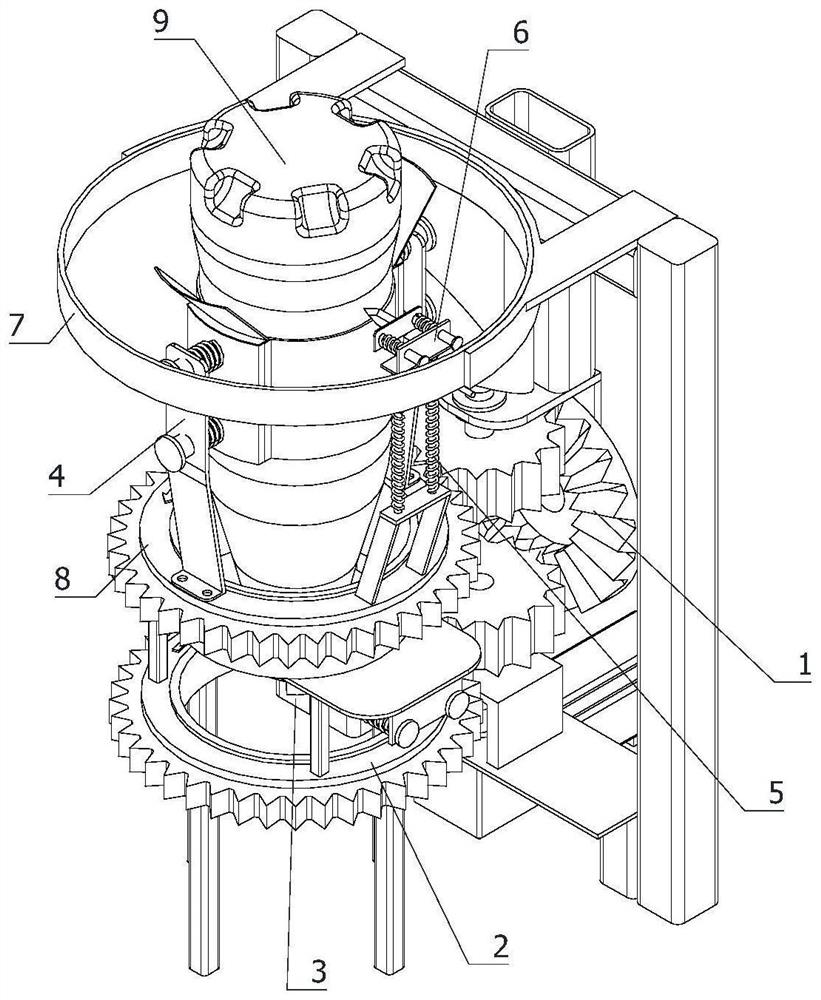

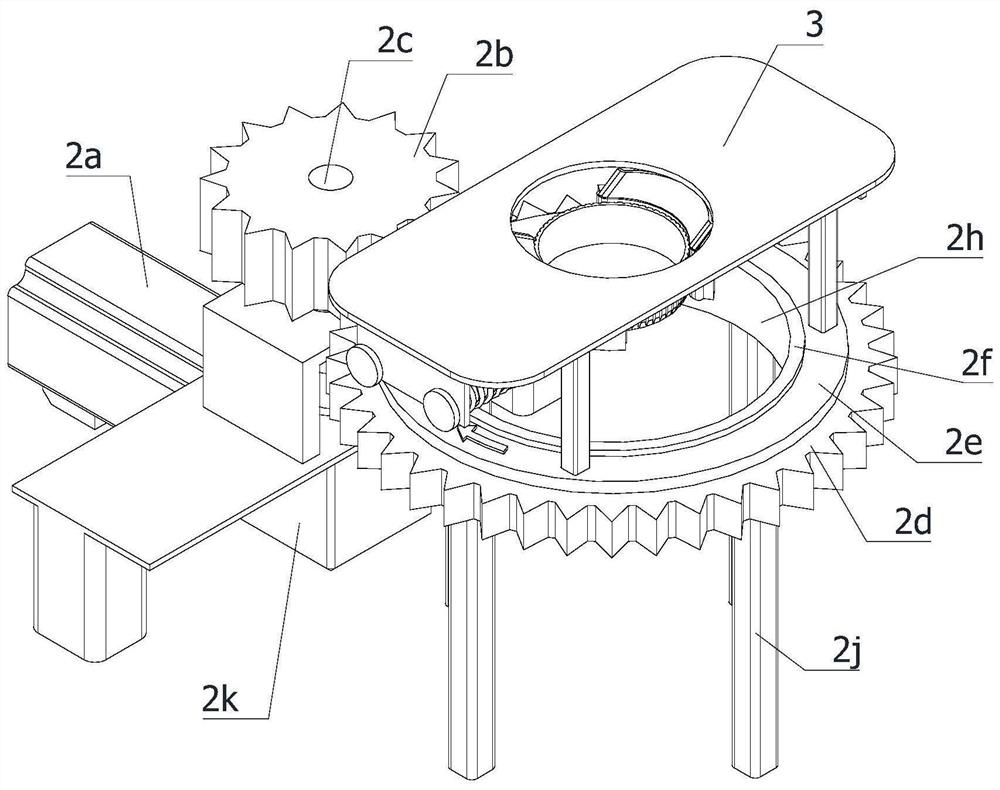

Comprehensive treating device for disassembling old shoes and recycling useful materials in old shoes

InactiveCN108453953ASolve problems that are difficult to recycle efficientlyEasy to recycleGas current separationPlastic recyclingResource utilizationEngineering

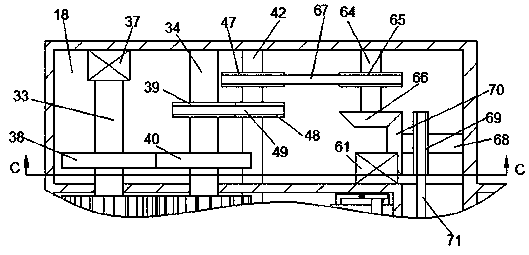

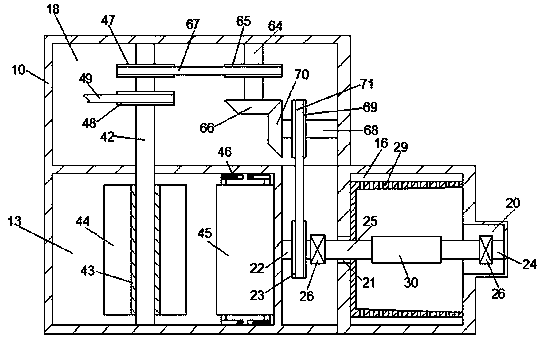

The invention relates to a comprehensive treating device for disassembling oil shoes and recycling useful materials in the old shoes. The comprehensive treating device comprises a coarse smashing module, a fine smashing module and a screening and separation module, wherein in the coarse smashing module, a plurality of saw blades are evenly arranged on two shafts and can perform opposite meshed high-speed rotation to coarsely smash the oil shoes; in the fine smashing module, four roller wheels are arranged in a cavity body regularly, two groovy rollers with the same inner diameter can achieve primary fine smashing on the old shoes through opposite meshed differential-speed rotation, two polishing rollers with the different inner diameters and two groovy rollers with the different inner diameters can achieve secondary fine smashing on the old shoes through opposite meshed equal-speed rotation, the screening and separating module can utilize an air blower to blow air to layer different masses of old shoe particles in the cavity body, and then the old shoe particles are classified and recycled. The comprehensive treating device disclosed by the invention can effectively smash waste shoes, the sizes of the smashed particles can be set as an adjustable mode according to need, the smashed materials can be screened and collected according to different masses, a resource utilization rate is improved, and environmental pollution caused by directly incinerating or burying the old shoes and resource waste are reduced.

Owner:WUHAN UNIV OF TECH

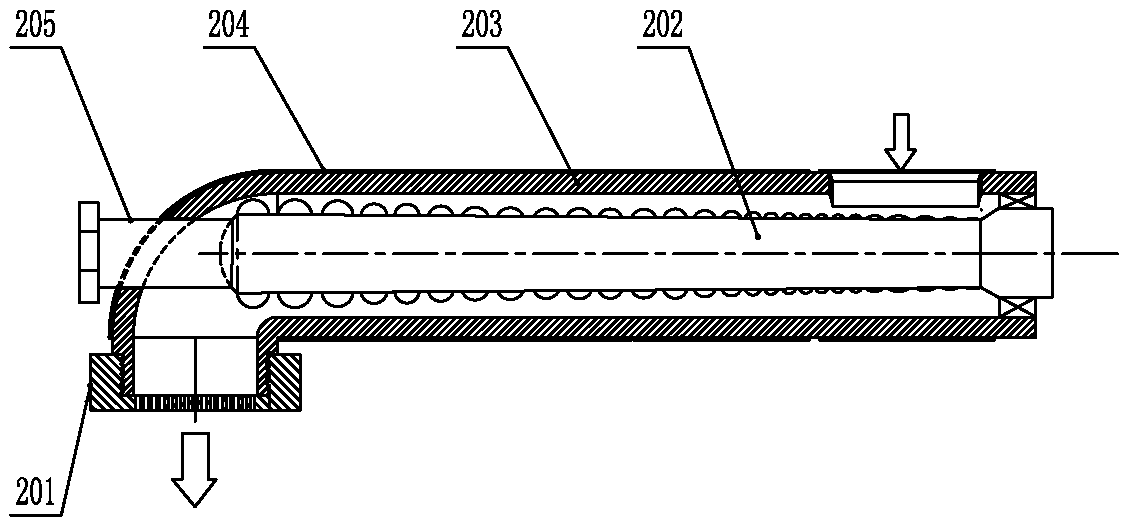

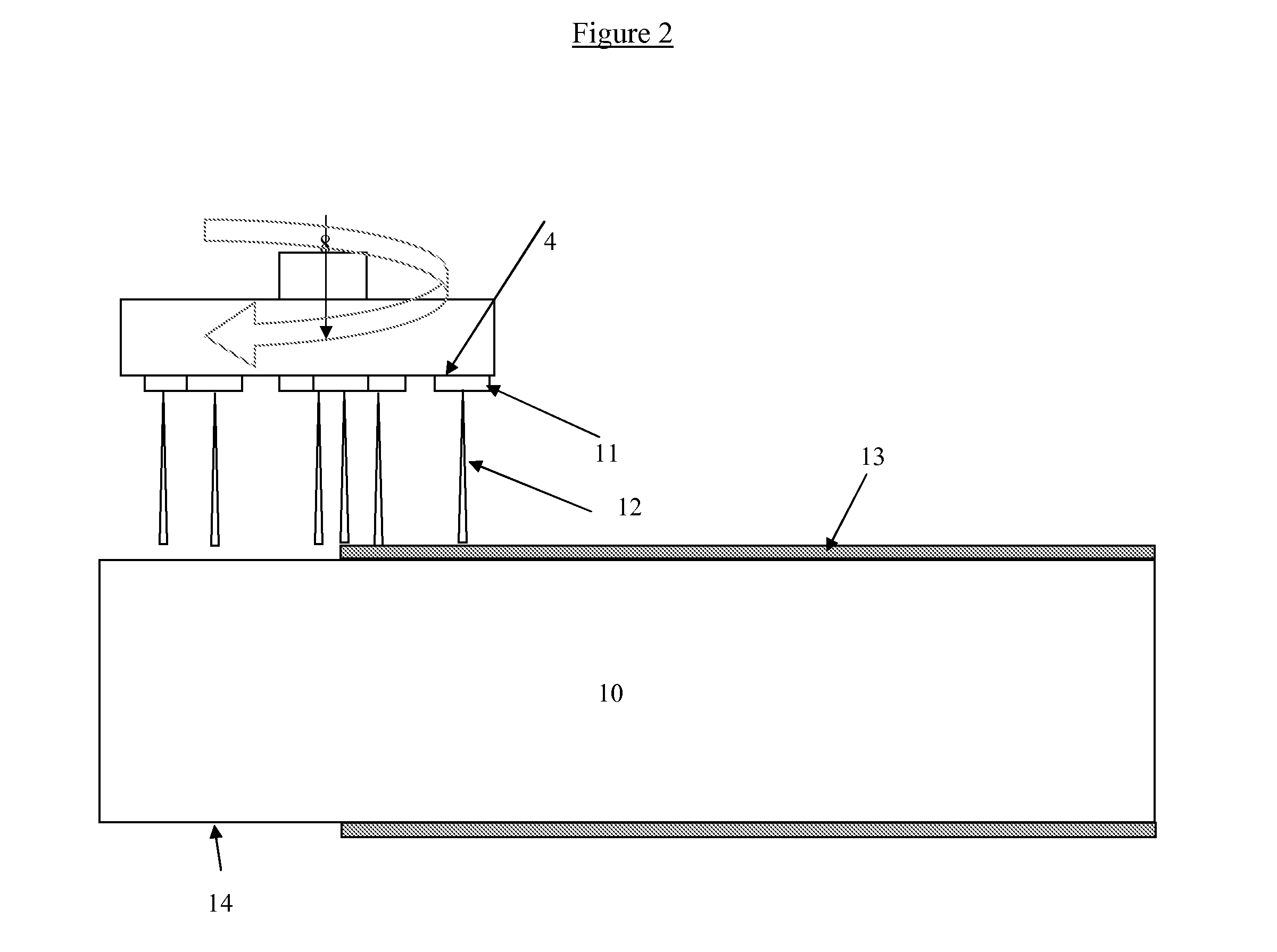

Orbiting wire accumulator

InactiveUS20050247261A1Easy to collectLiquid surface applicatorsPlastic recyclingEngineeringElectric wire

A wire accumulator is used in wire manufacturing such as wire insulation lines or bare wire manufacturing. Wire collection on an accumulator allows the wire manufacturing process to continue even during basket switching. The orbiting motion of such accumulator produces controlled wire collection pattern formation, where in the preferred instance the geometric pattern is the pedal lay pattern.

Owner:NIEHOFF ENDEX NORTH AMERICA

Crushing and sorting device for waste battery

InactiveCN111054499ASimple and fast operationReduce manufacturing costPlastic recyclingReclaiming serviceable partsProcess engineeringMechanical engineering

Owner:PUJIANG CIFANG ENVIRONMENTAL PROTECTION TECH CO LTD

Recycling and regeneration device for FDM printing waste

Owner:NINGXIA KOCEL MOLD

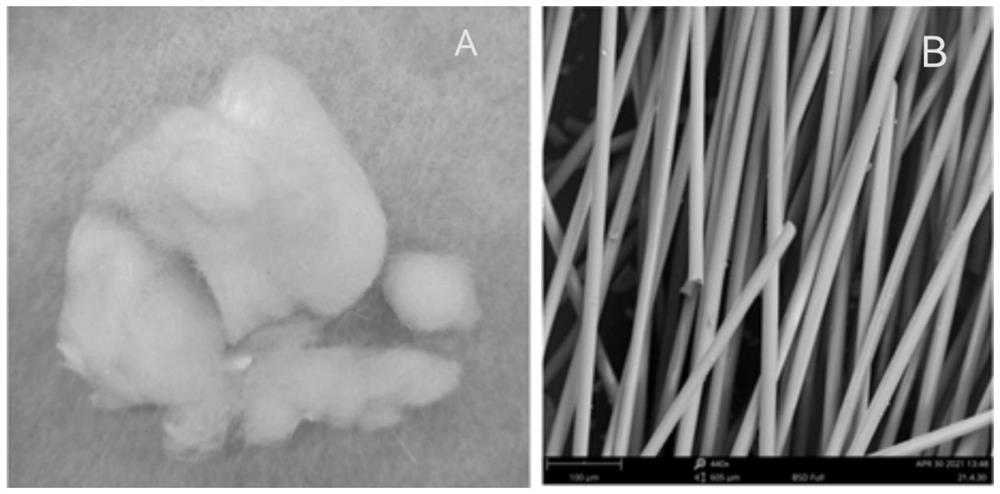

Separation method of waste polyphenylene sulfide and polytetrafluoroethylene blended dust settling pockets

The invention relates to a separation method of waste polyphenylene sulfide and polytetrafluoroethylene blended dust settling pockets. The separation method comprises the steps that the waste polyphenylene sulfide and polytetrafluoroethylene blended dust settling pockets are firstly smashed, then the smashed mixed materials are added into a separating medium with the density between the density of polyphenylene sulfide and the density of polytetrafluoroethylene for centrifugal separation, blended fabric is smashed according to the different densities of two fibers, and the aim of recycling polyphenylene sulfide and polytetrafluoroethylene in the waste dust settling pockets is achieved through centrifugal separation. The purity of polyphenylene sulfide materials obtained after separation reaches 97% or above, the purity of polytetrafluoroethylene materials reaches 91% or above, the material separation purity is high, the separation effect is good, and the recycling value is high.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

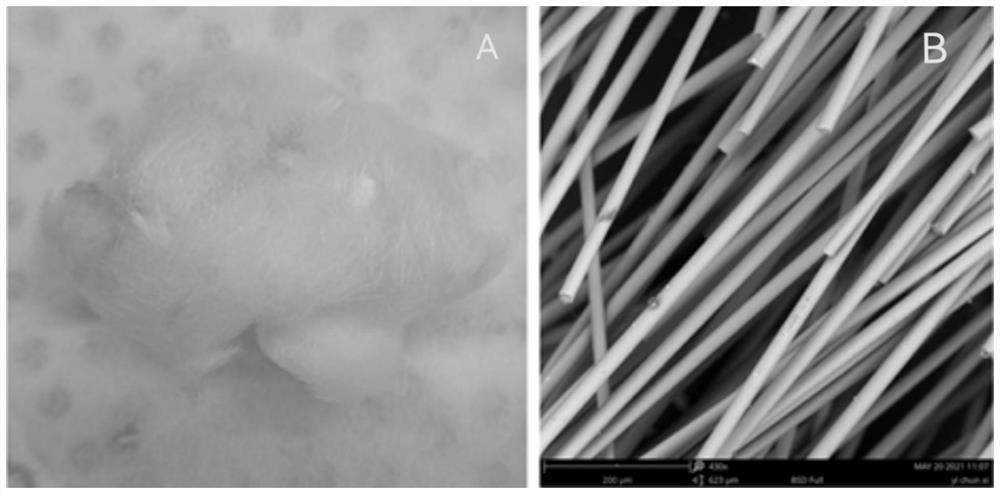

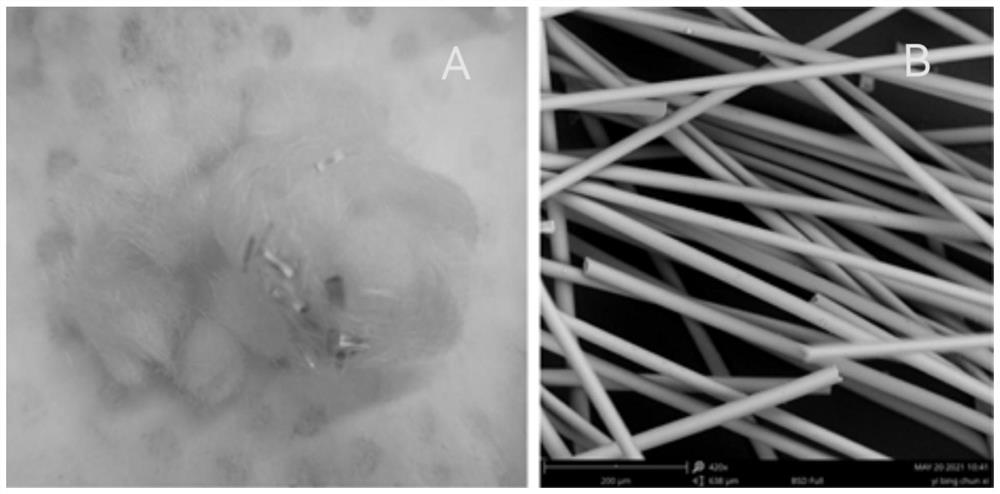

Recycling method of epoxy resin composite material, obtained glass fiber and application of glass fiber

Owner:GUANGDONG POWER GRID CO LTD +1

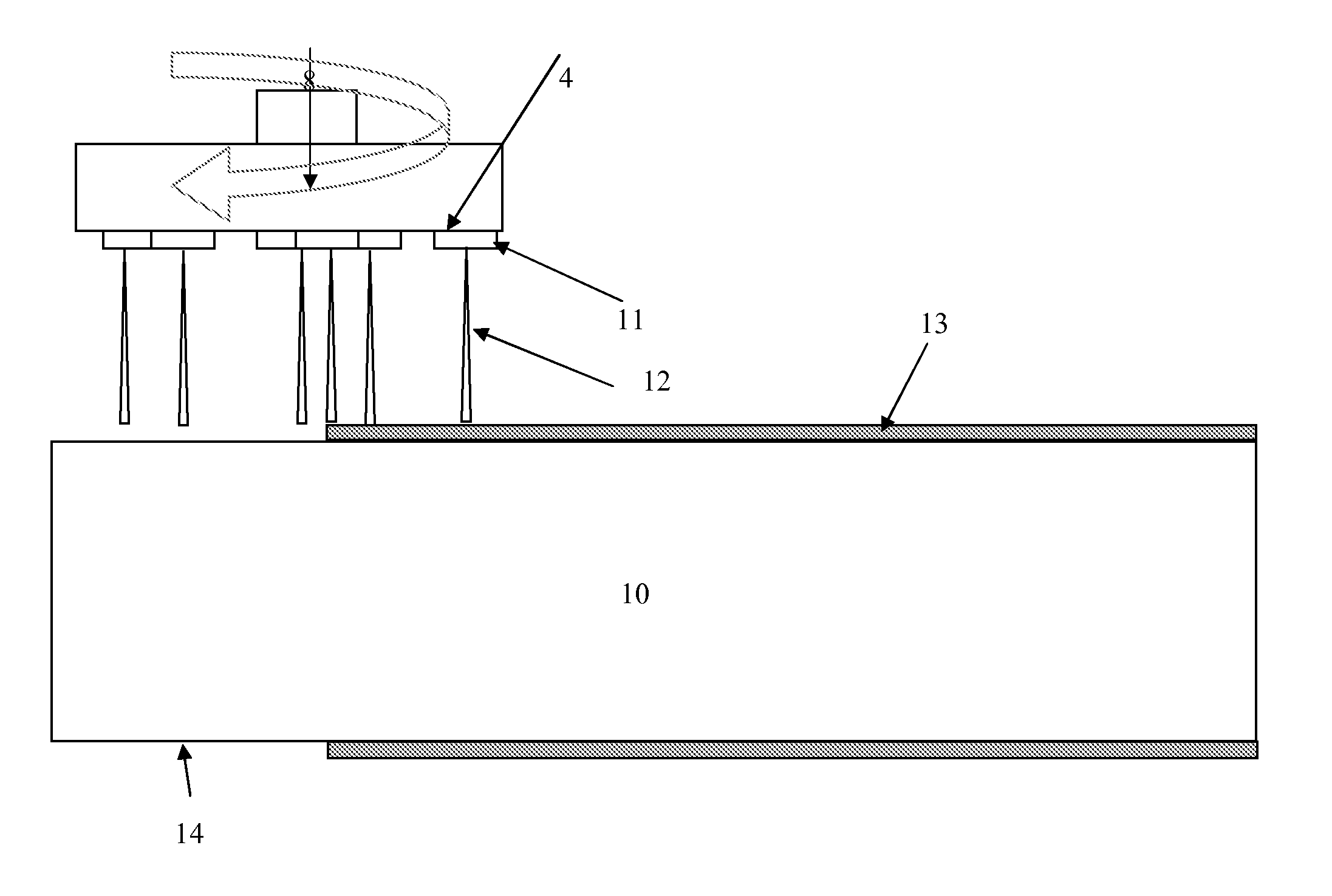

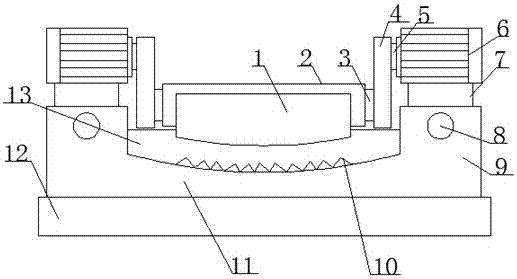

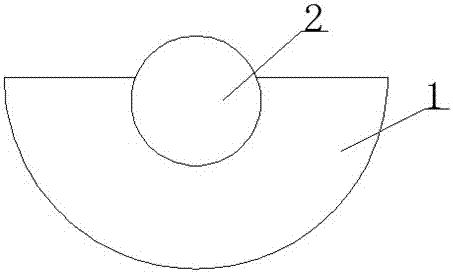

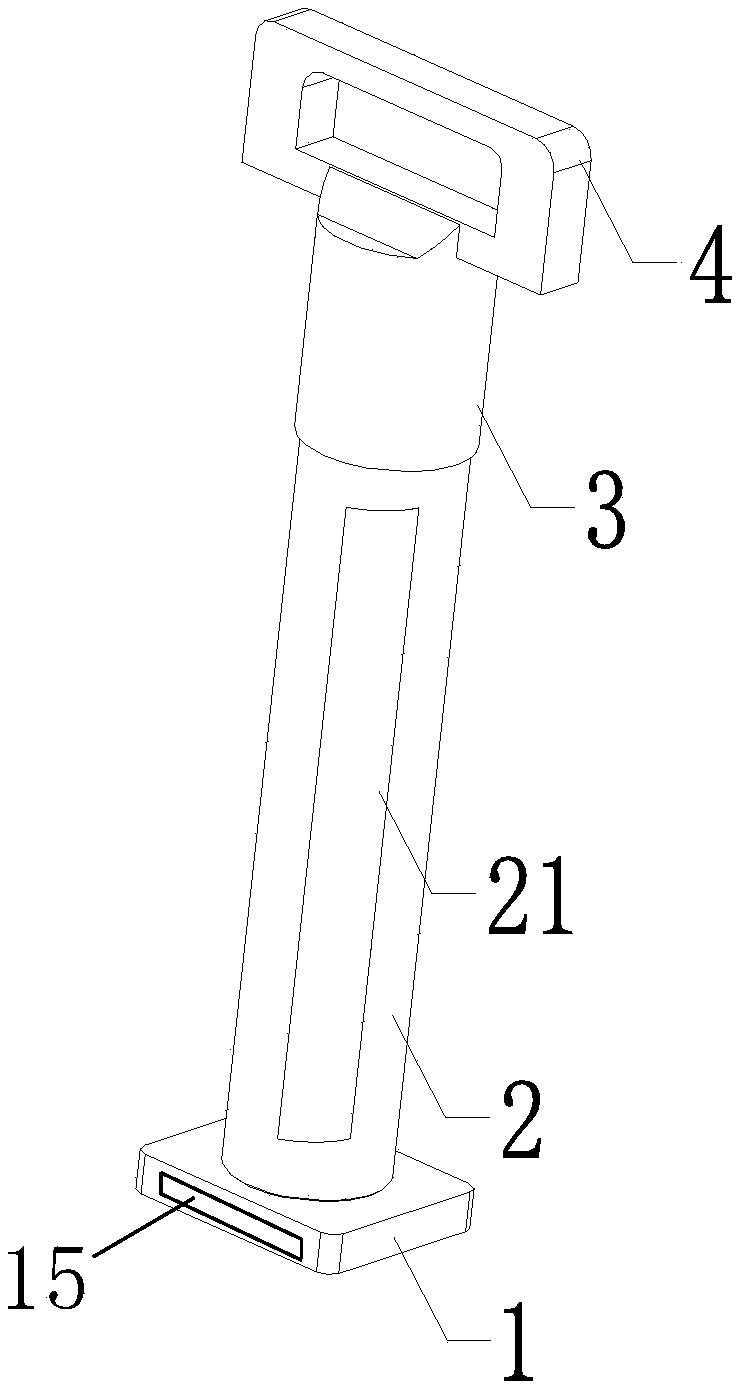

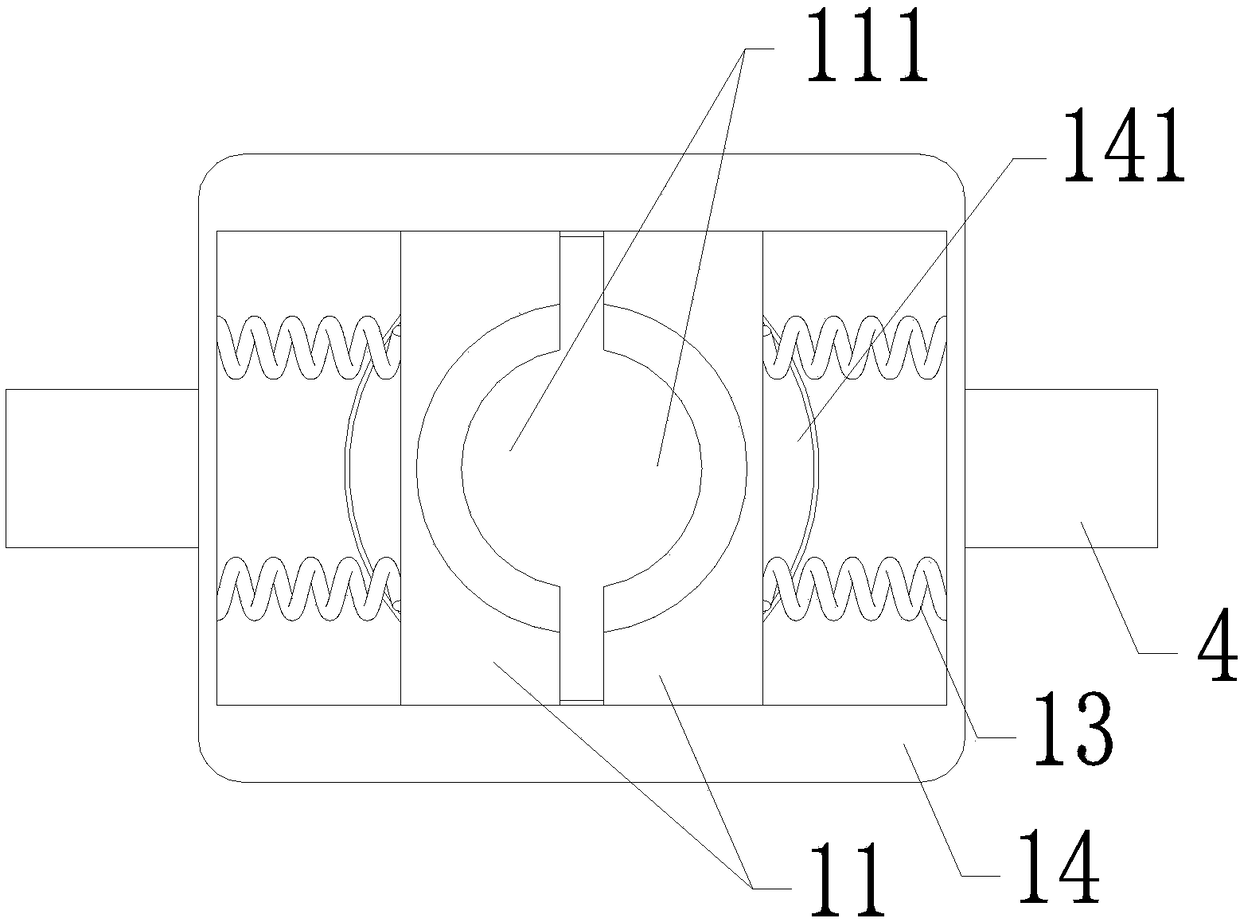

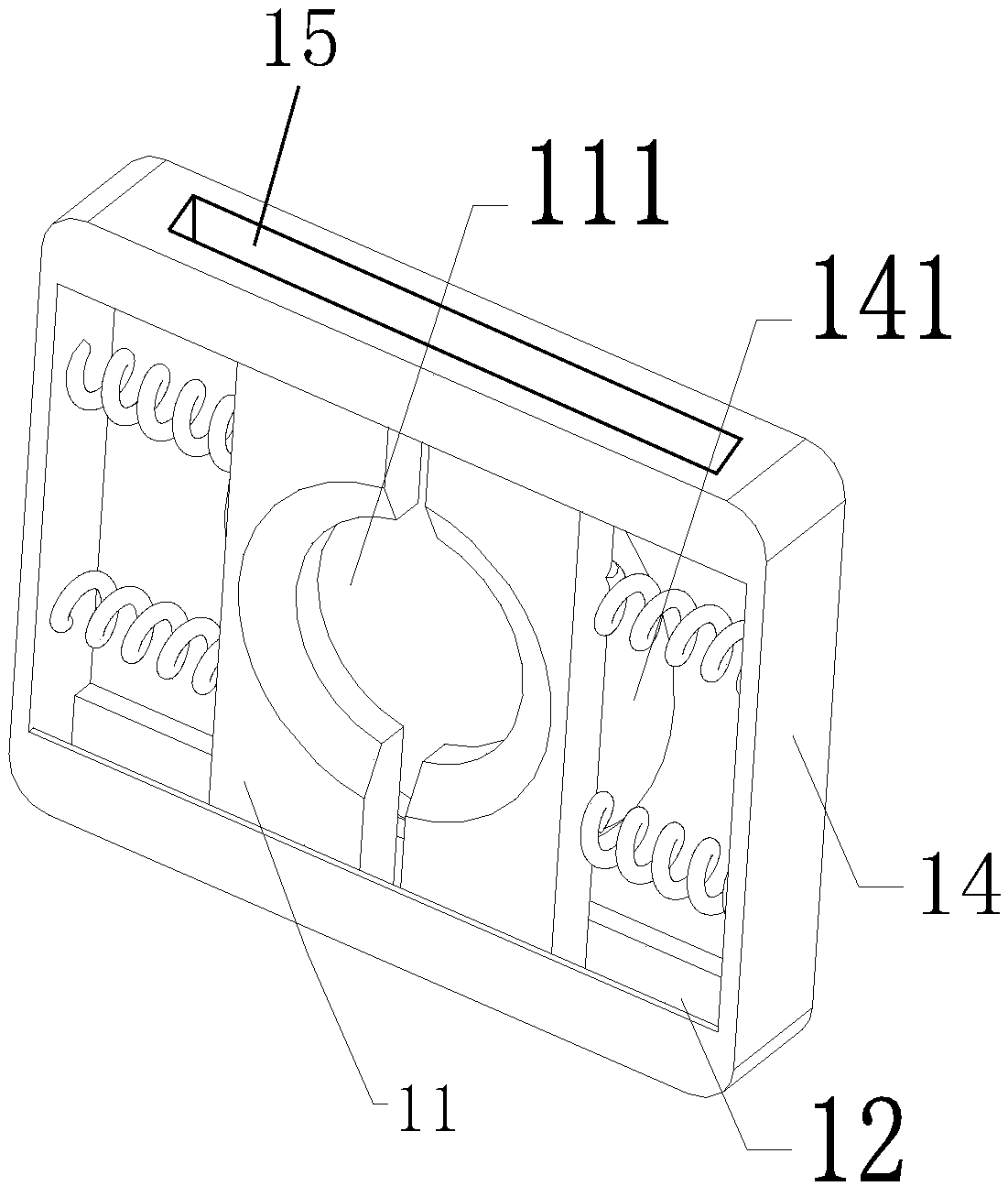

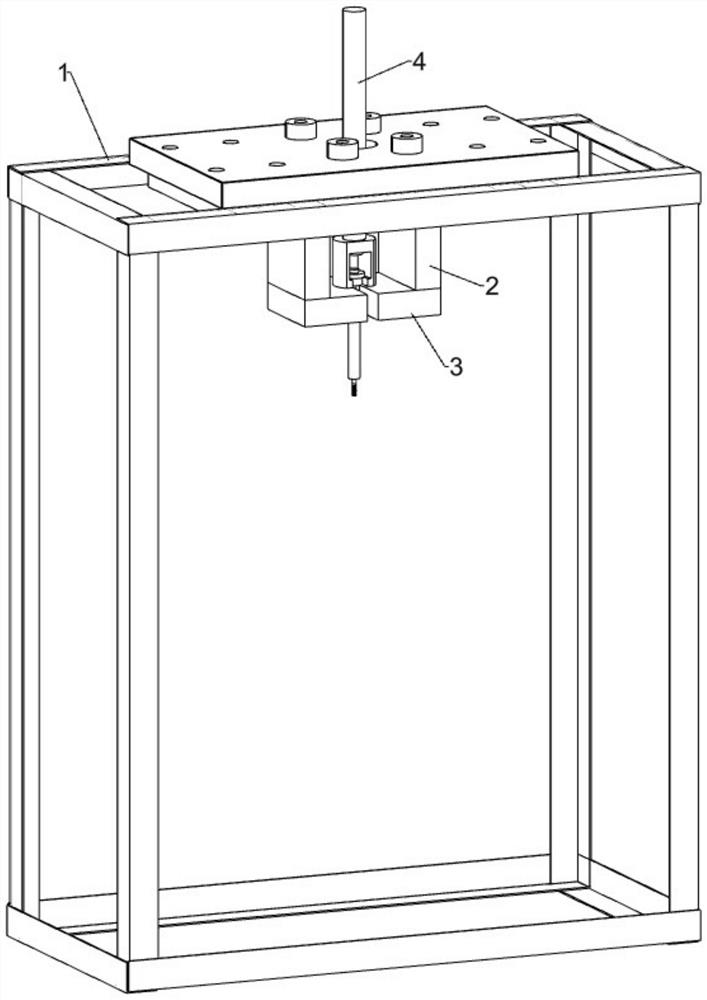

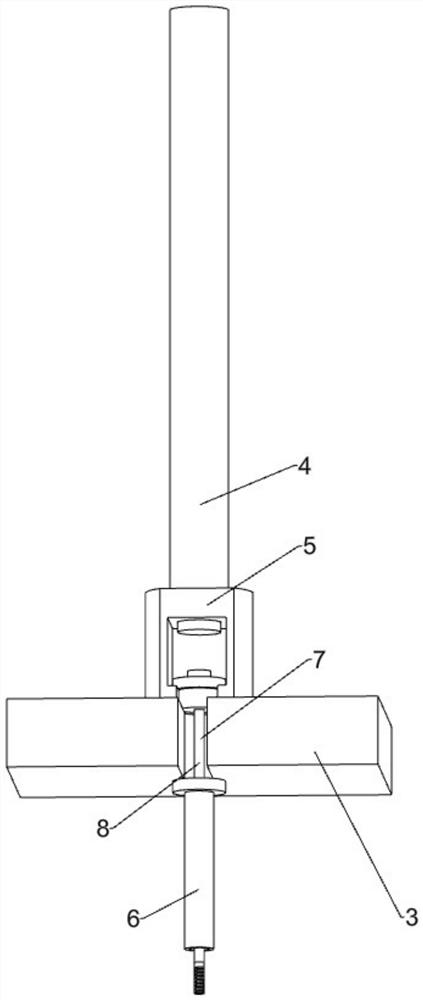

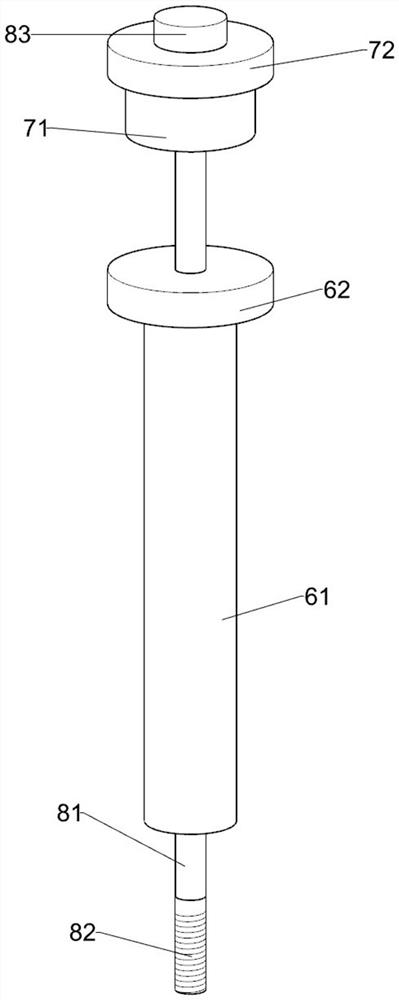

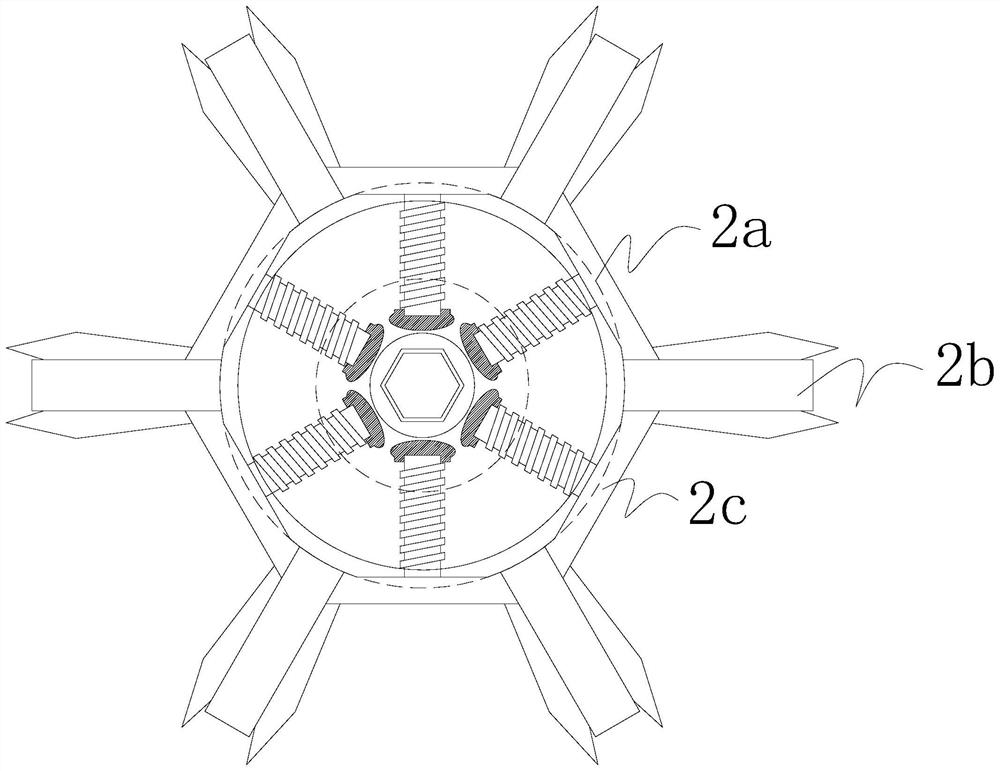

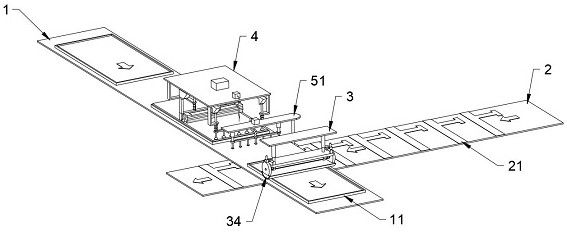

Plastic part processing mechanism

ActiveCN112873392ARealize moving forwardImprove adaptabilityGrinding drivesPlastic recyclingStructural engineeringMechanical engineering

The invention discloses a plastic part processing mechanism, and belongs to the field of rubber part processing. The plastic part processing mechanism comprises a bending frame, wherein the bending frame is fixedly provided with four ground feet, the ground feet are uniformly arranged at the bottom end of the bending frame, the lower part of the side wall of the bending frame is provided with a passing opening and a pushing opening, the side wall of the bending frame is provided with an inclined plate pushing frame, the upper end and the lower end of the inclined plate pushing frame are fixedly connected with the side wall of the bending frame through compression springs correspondingly, and a plane shaft seat is fixedly installed at the top end of the bending frame. The plastic part processing mechanism can realize automatic blanking of plastic parts.

Owner:SHANGRAO MEIYUDA OPTICAL INSTR CO LTD

Stripping device in plastic bottle label stripping machine

InactiveCN102101328AEasy to separateSimple structurePlastic recyclingEngineeringElectrical and Electronics engineering

Owner:ZHANG JIAGANG BAIXIONG KLIMENS MACHINERY

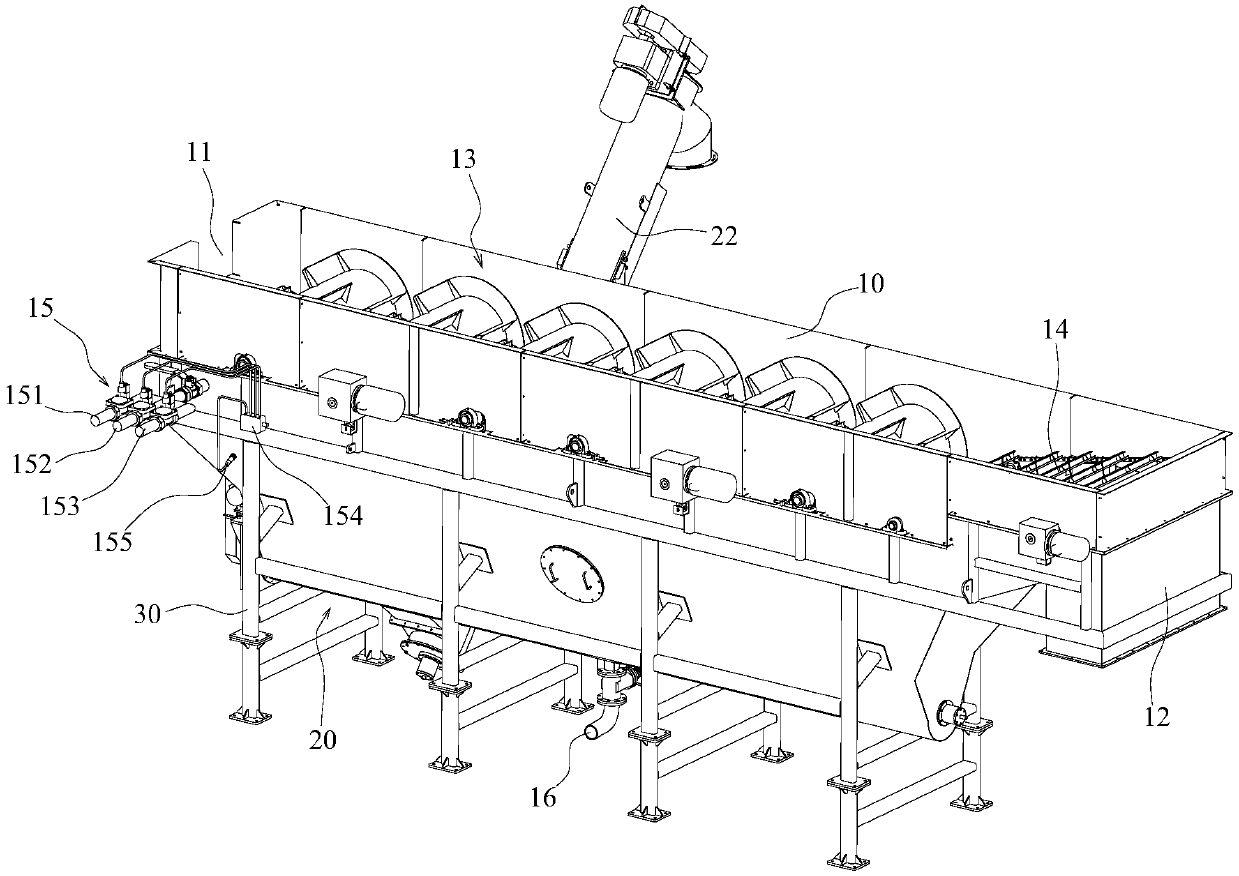

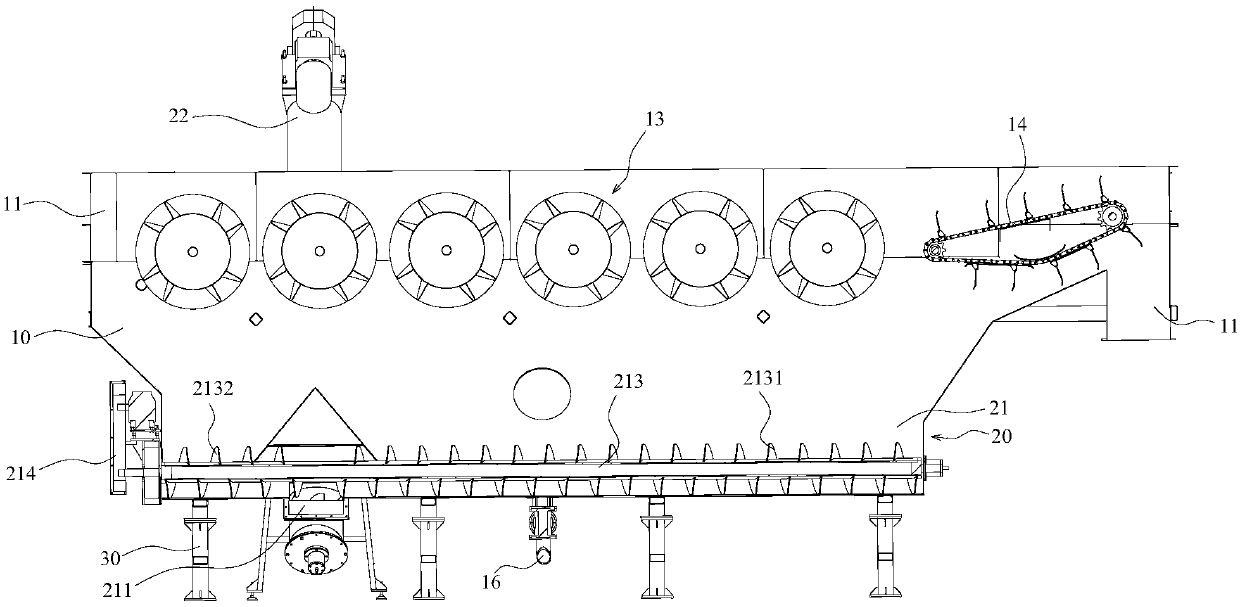

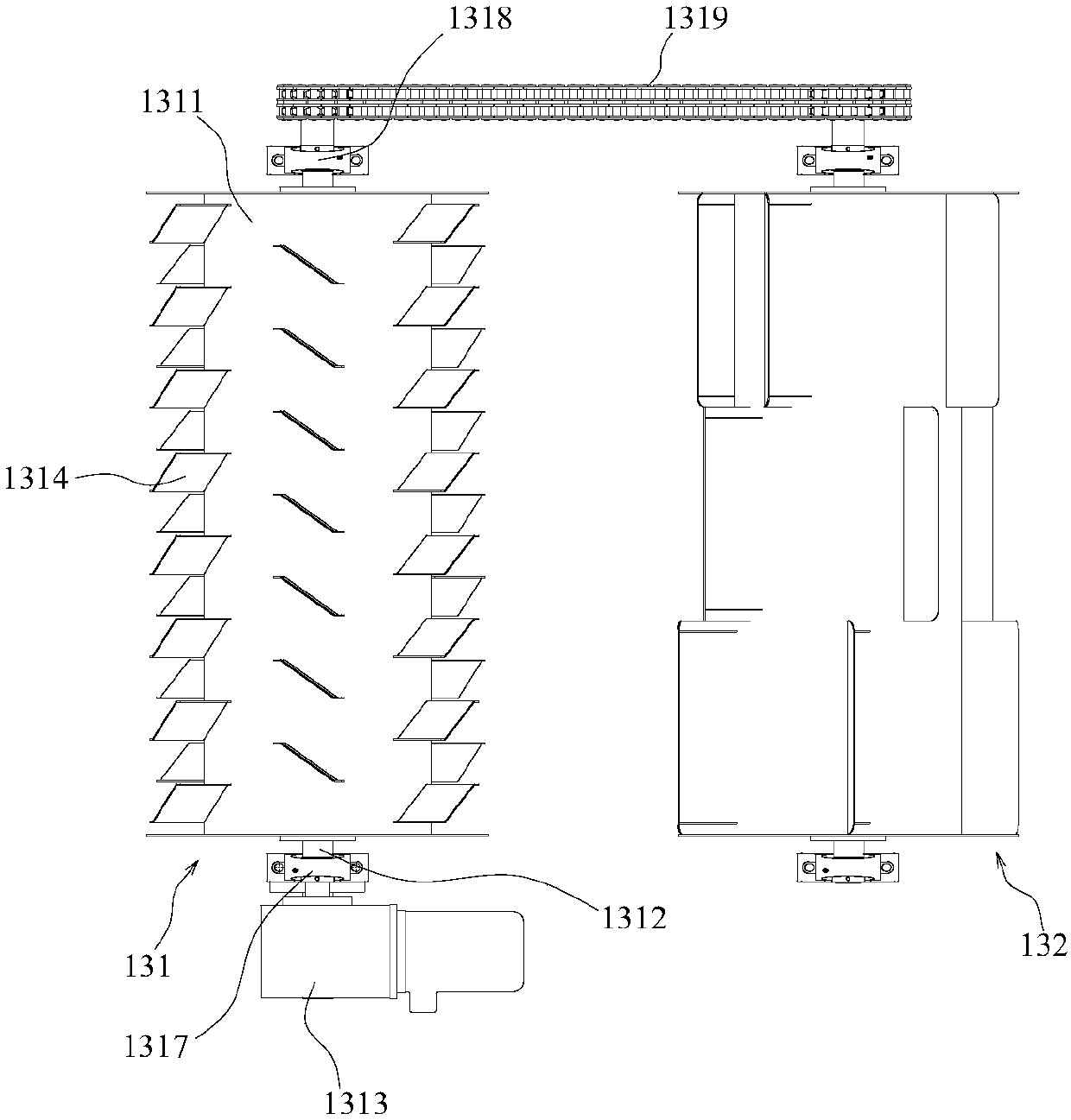

Centralized cleaning device with heating function

ActiveCN109013625ABlock fallIncrease spaceDrying solid materials without heatPlastic recyclingEngineeringMechanical engineering

Owner:高嘉智能设备(嘉兴)股份有限公司

Process for removing a composite coating present on the surface of a gas cartridge

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

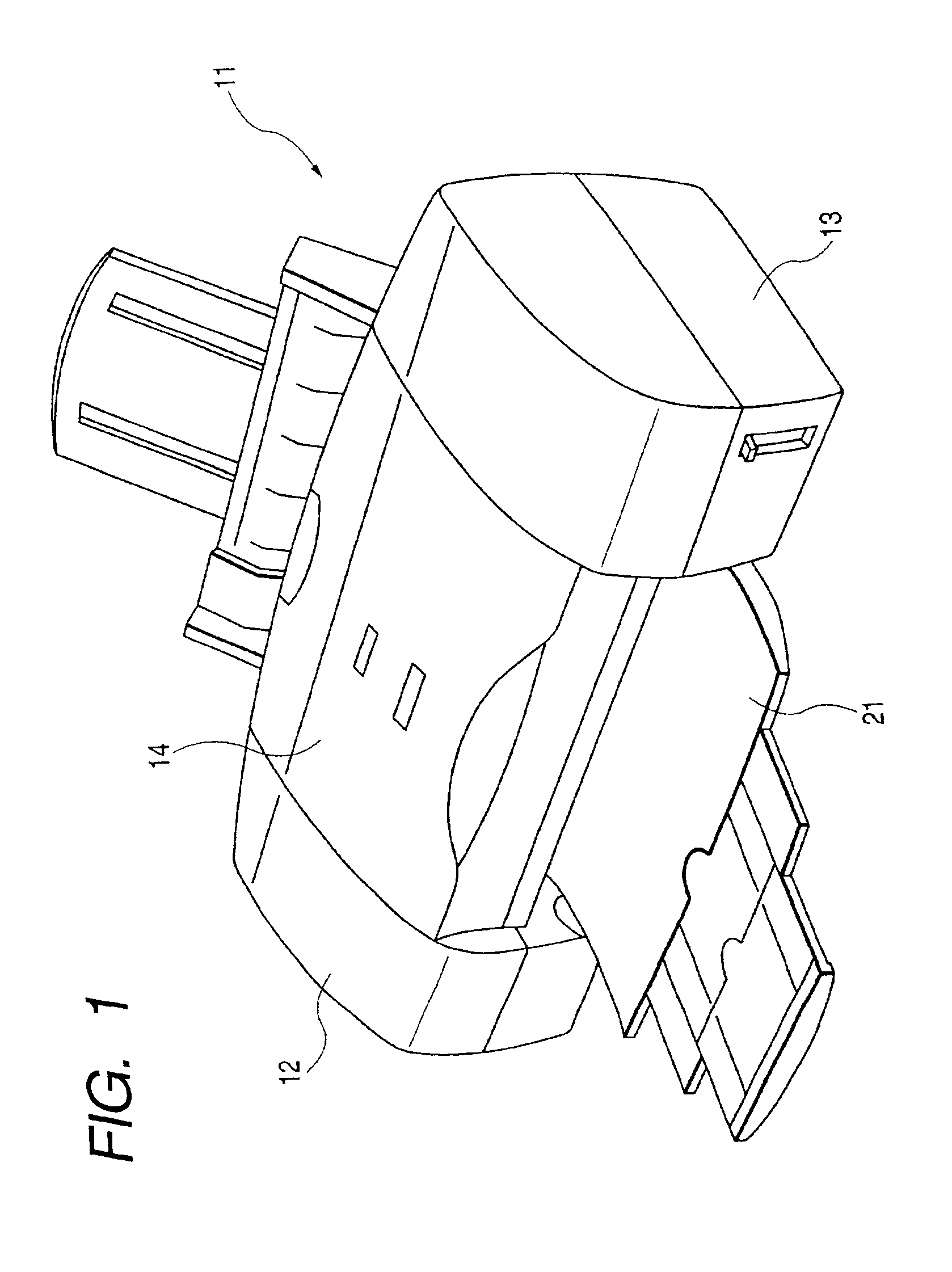

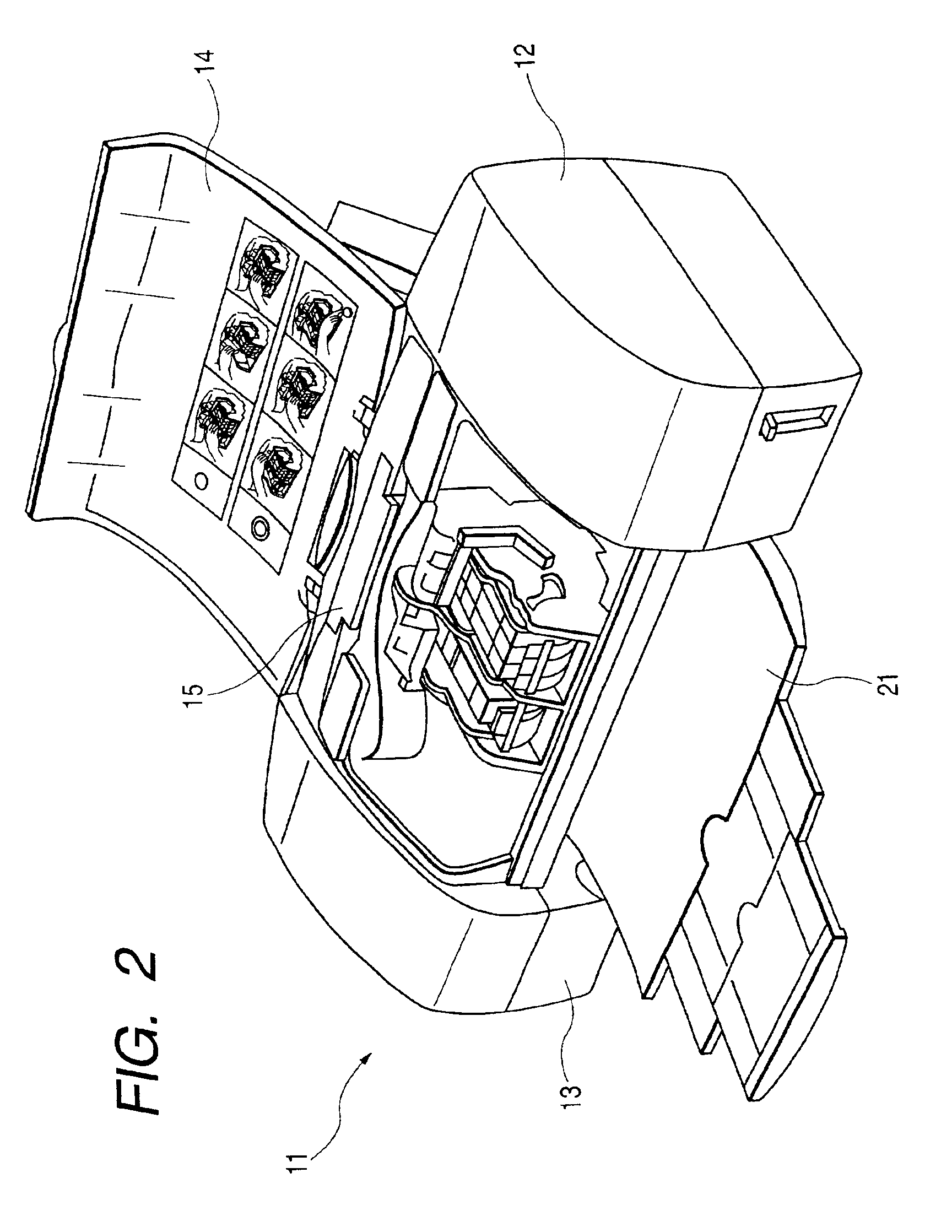

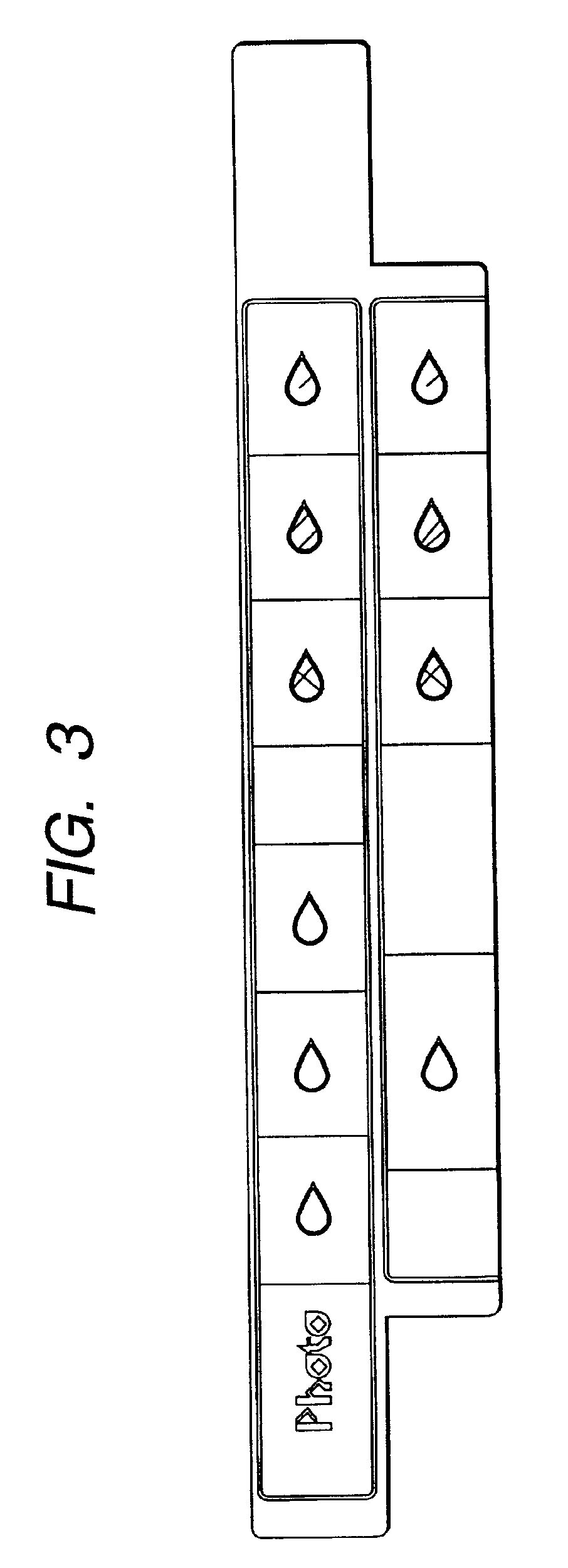

Recycled ABS resin, recycled ABS alloy resin and production process of ABS alloy resin

InactiveUS6881368B2Improve defectsMaintain good propertiesOther chemical processesPlastic recyclingAlloyInjection molding machine

Owner:CANON KK

Recycling method for plastic films

Owner:邹贝尔

Crushing device for waste plastic and working method thereof

InactiveCN111497074AEfficient crushingEasy to crushPlastic recyclingMechanical material recoveryHeating oilElectric machinery

Owner:界首市亚鑫塑业科技有限公司

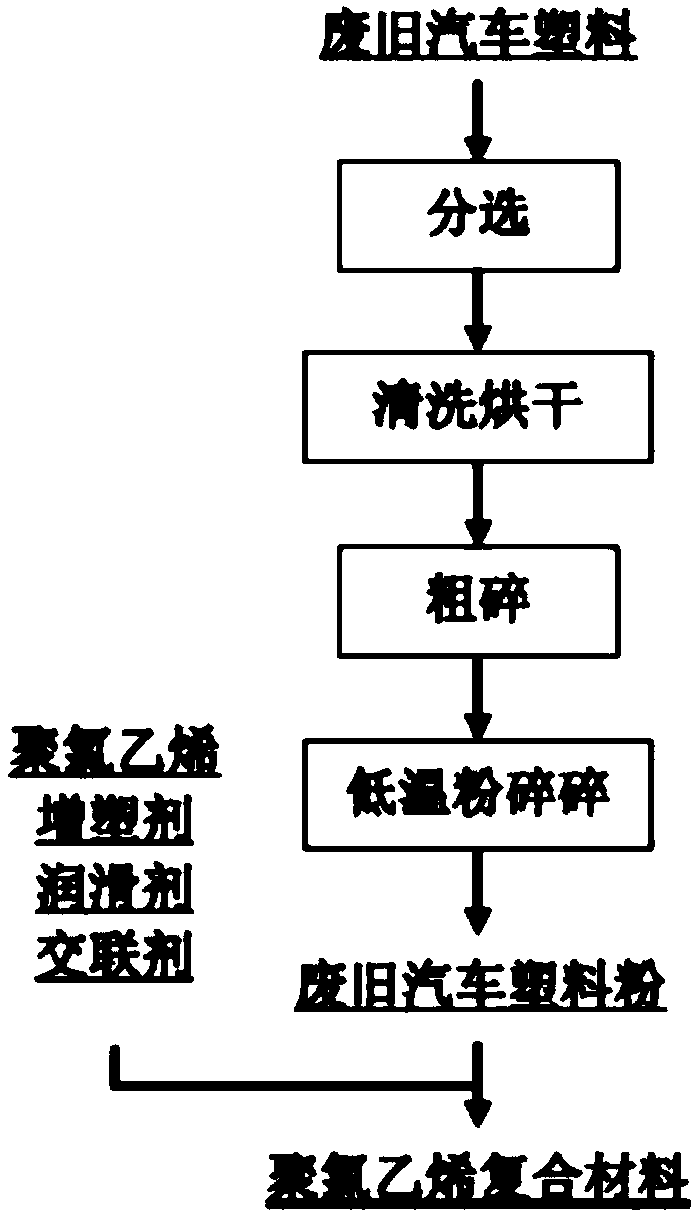

Polyvinyl chloride composite material realizing reutilization of waste plastic and preparation method thereof

InactiveCN108659377ALow costImprove mechanical propertiesPlastic recyclingMechanical material recoveryPlasticizerPolyvinyl chloride

Owner:湖北天霖新材料有限公司

Environment-friendly recycling device for hospital

The invention discloses an environment-friendly recycling device for a hospital. The environment-friendly recycling device for the hospital comprises a sleeve, a bottom plate, a second controller anda first controller; a containing tank is arranged over the sleeve, an installing substrate is installed in the containing tank, a collecting cylinder is installed over the installing substrate, and acollecting tank is arranged over the collecting cylinder; and the bottom plate is fixedly installed on one side of the upper portion of the sleeve, a servo motor is installed on one side of the upperportion of the bottom plate, a rotating shaft is fixedly installed at the driving end of the servo motor, a closing cover is fixedly installed on the rotating shaft, an installing tank is arranged onthe side, close to the sleeve, of the closing cover, a compression plate is slidably installed in the installing tank, and two first electric hydraulic pushing rods are symmetrically and fixedly installed at the bottom of the installing tank. According to the environment-friendly recycling device for the hospital, the problem that the collecting cylinder is cleaned frequently when medical personnel collect plastic infusion bottles is solved, work of the medical personnel is convenient, the maintenance period of the collecting cylinder is prolonged, the practicability is high, and meanwhile energy conservation and environment protection are achieved.

Owner:冯松伟

Odorless high-strength regenerated rubber

Owner:四川省隆昌海燕橡胶有限公司

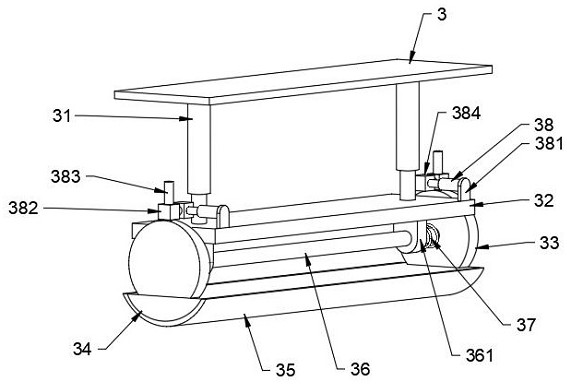

Quick rolling device for plastic recycling

InactiveCN107571428AHeight adjustableEasy to roll in batchesPlastic recyclingEngineeringMechanical engineering

Owner:南京华域云脑信息科技有限公司

Automatic material taking and discharging mechanism of metal powder injection molding machine

ActiveCN114570928AEfficient cleaning structureWith structureSubsonic/sonic/ultrasonic wave measurementPlastic recyclingEngineeringMachine

Owner:扬州钰能精密机械科技有限公司

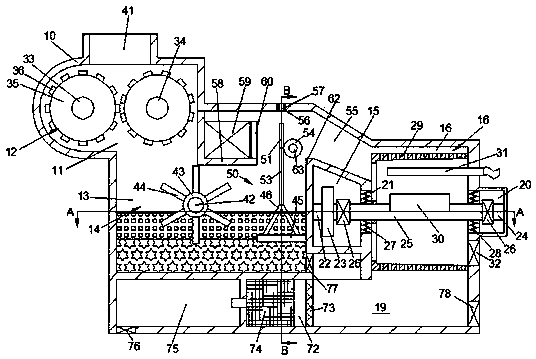

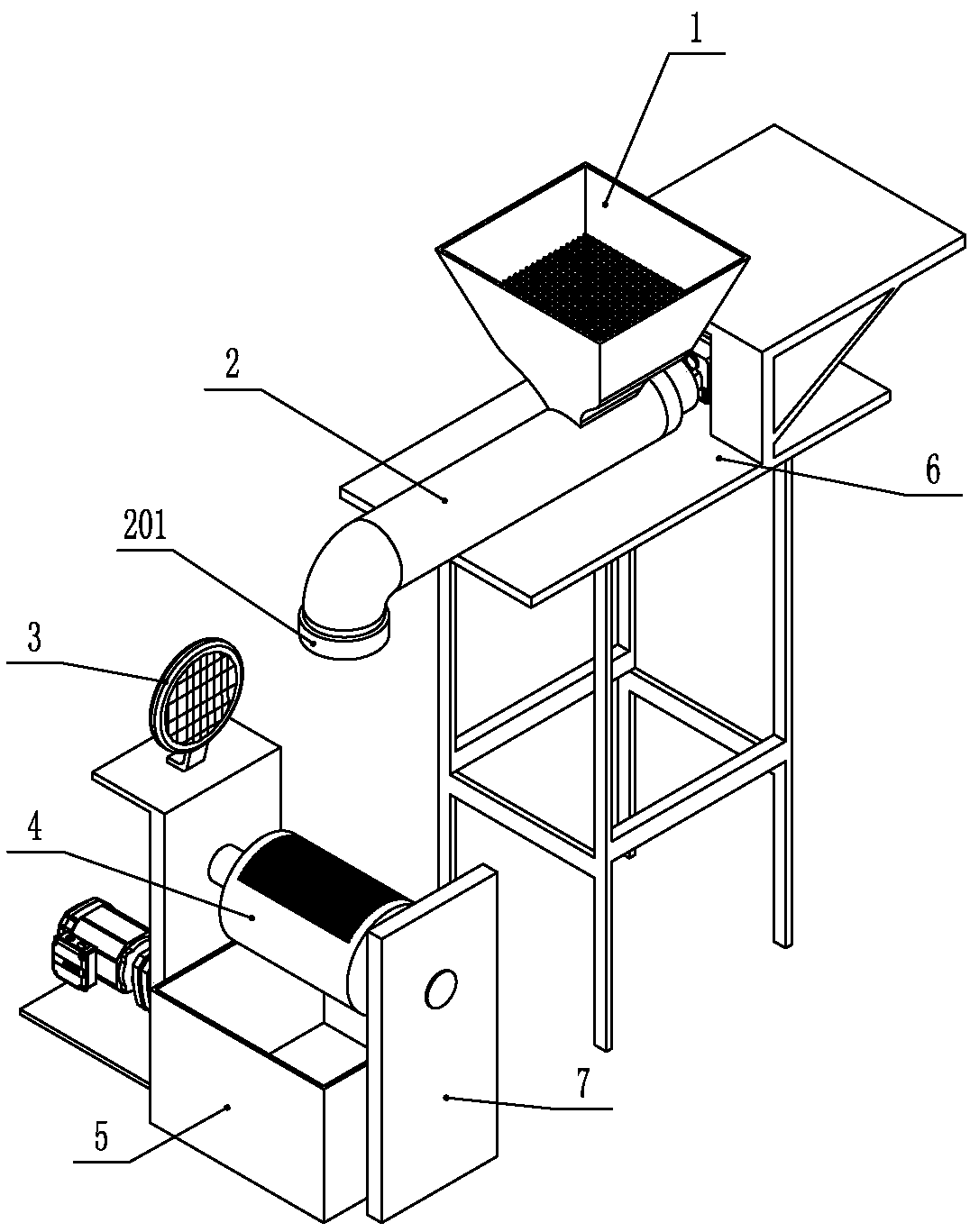

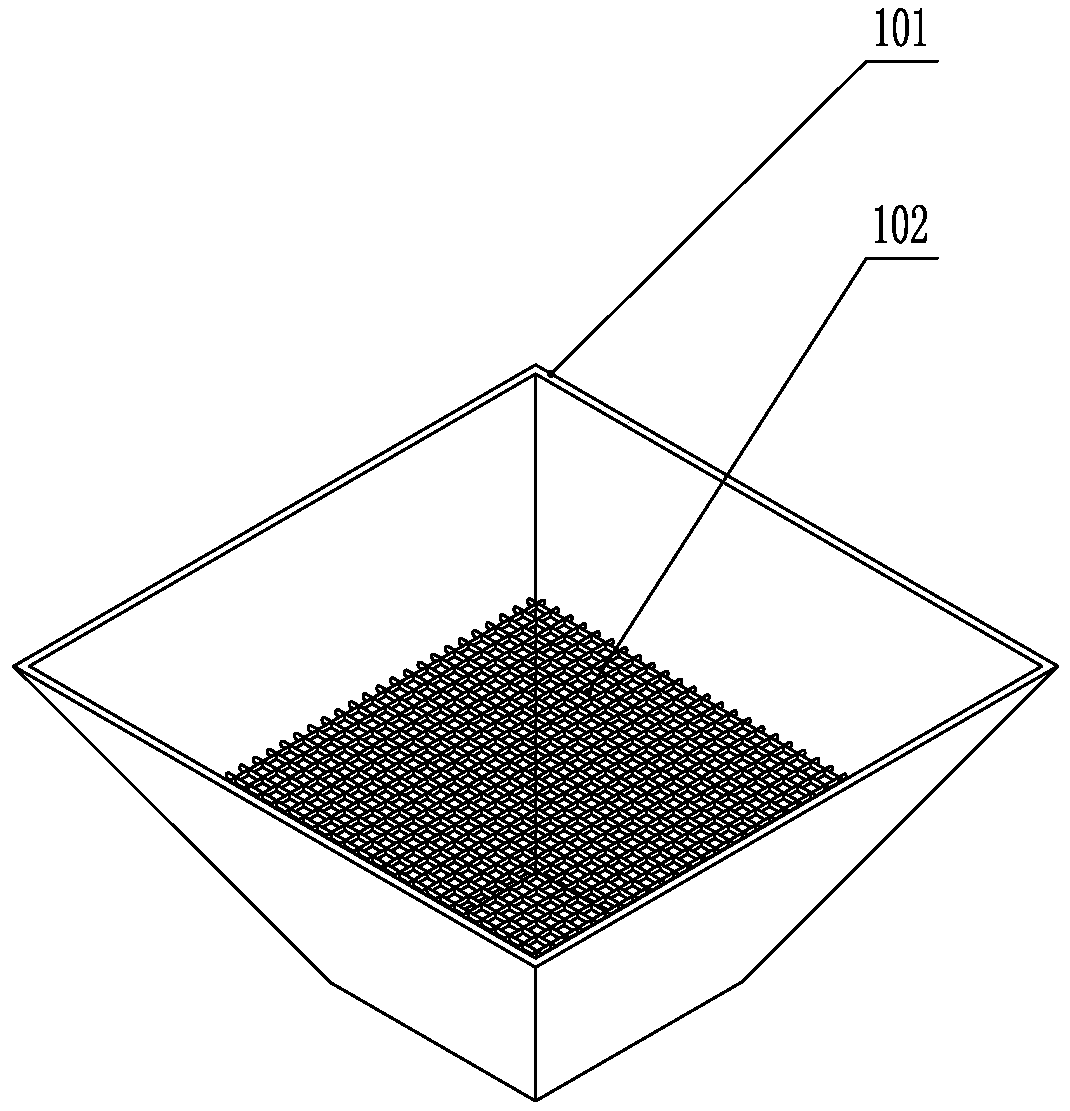

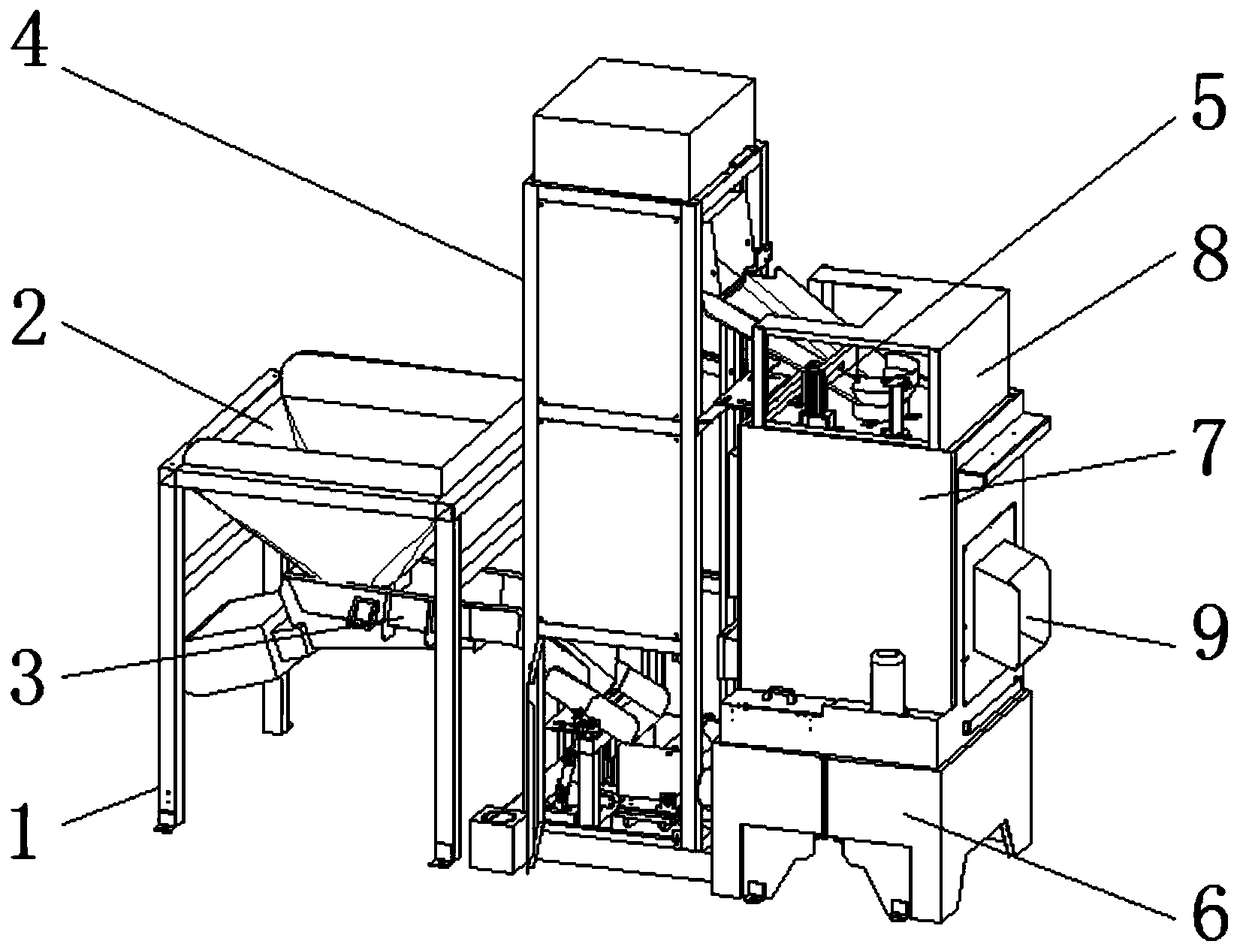

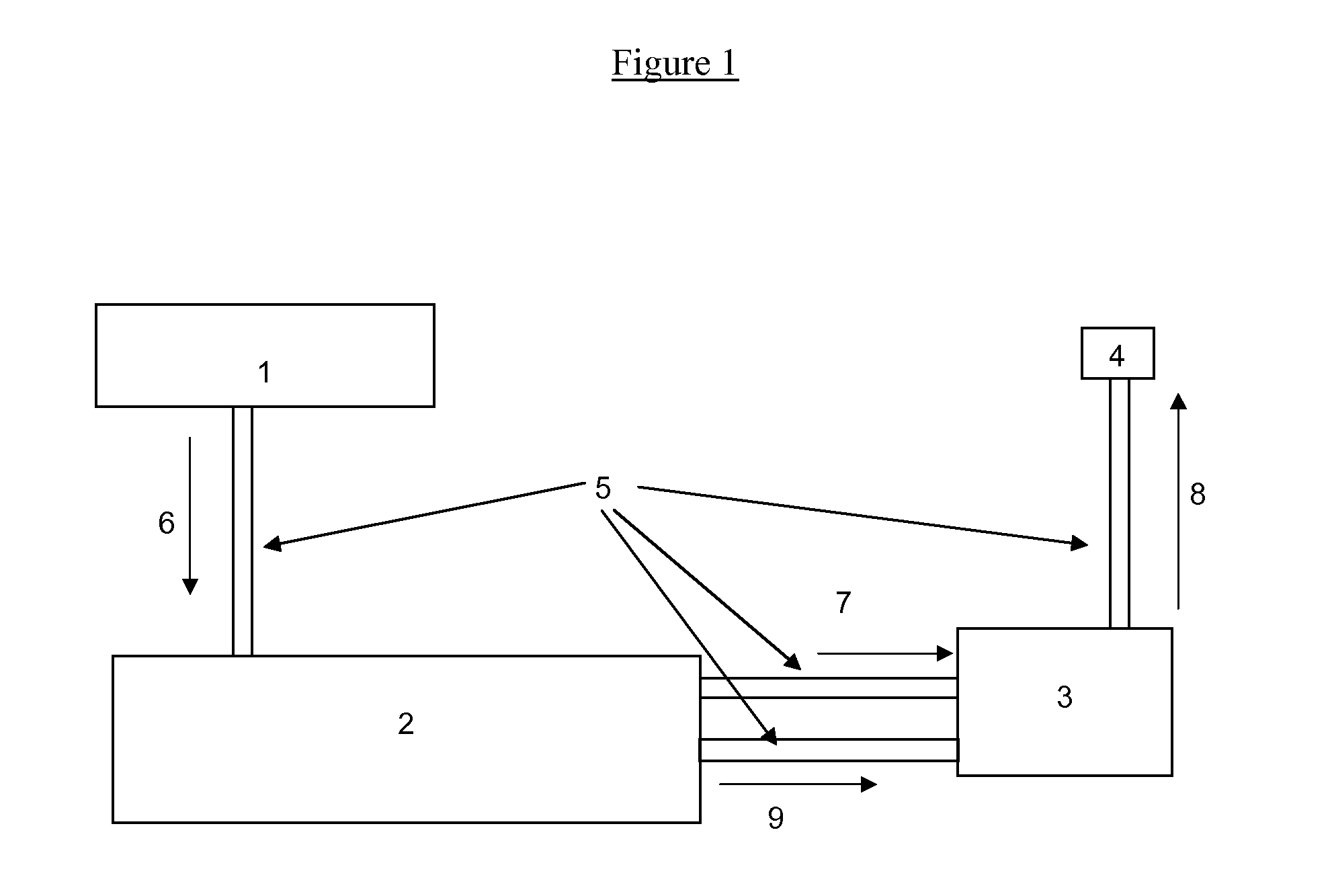

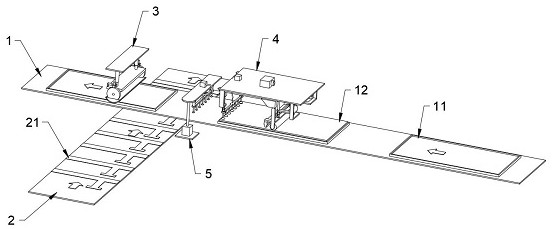

Energy-saving waste plastic crushing and cleaning system and implementing method thereof

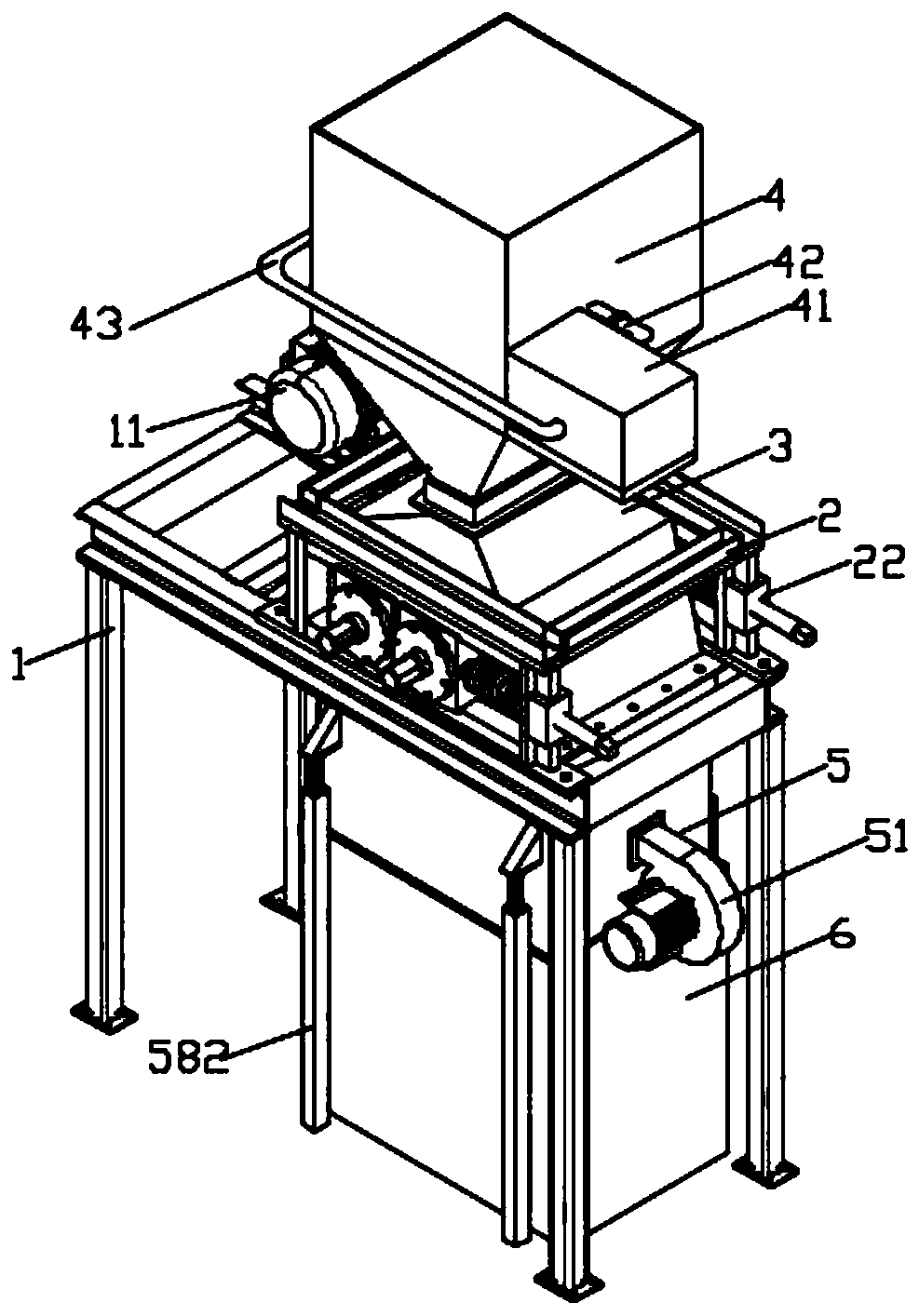

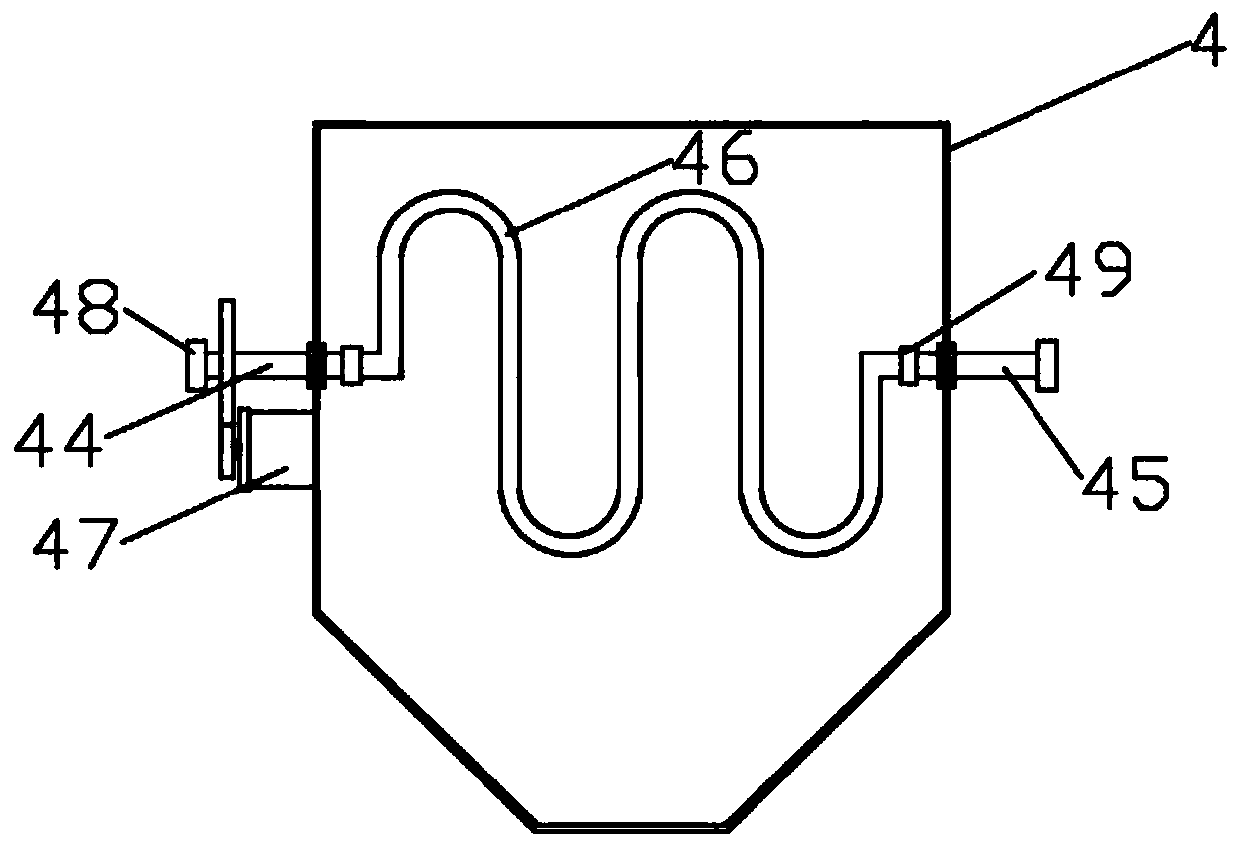

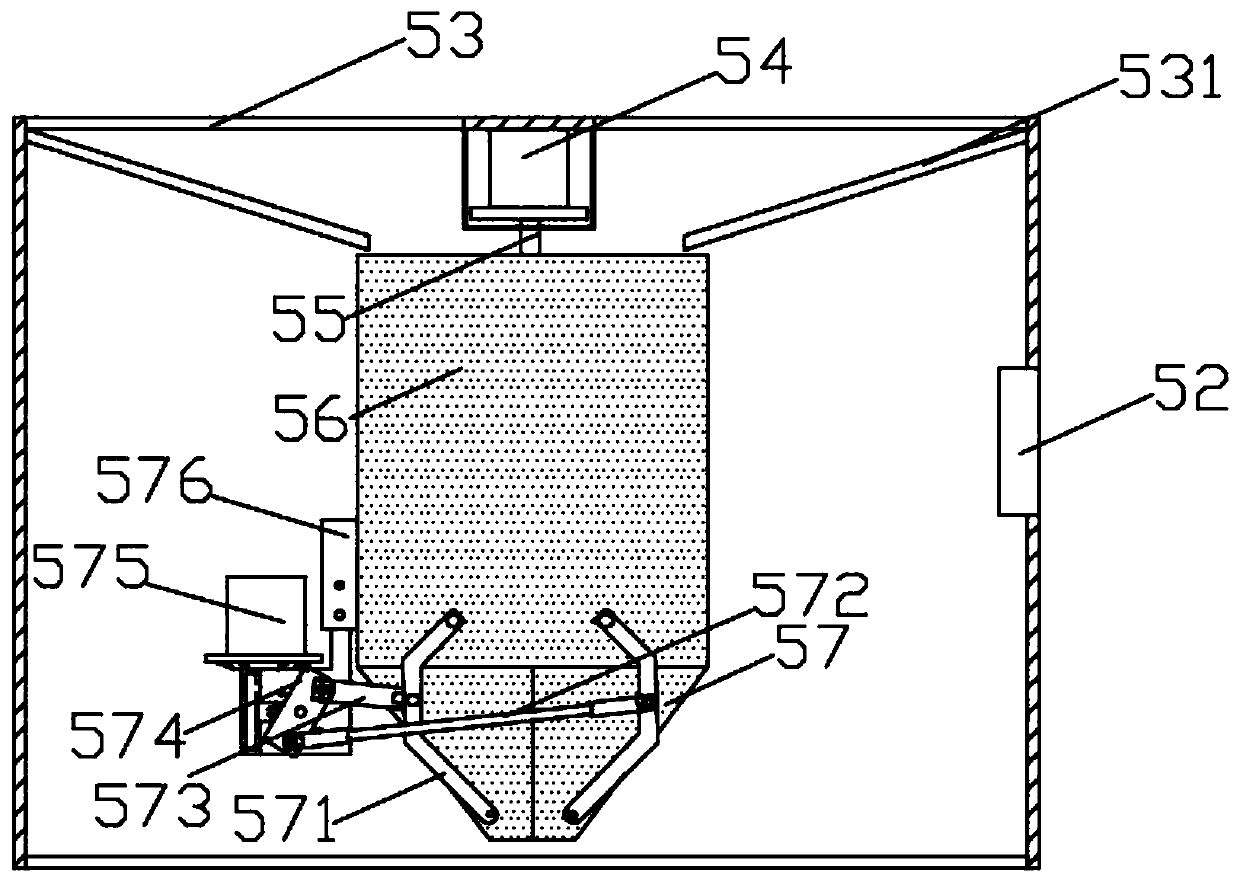

ActiveCN104227872AAchieve brokenAchieve batchPlastic recyclingMechanical material recoveryWater cyclingPolystyrene

The invention discloses an energy-saving waste plastic crushing and cleaning system and an implementing method thereof. The energy-saving waste plastic crushing and cleaning system and the implementing method thereof can solve the problem that existing cleaning devices cannot clean waste plastics in batches and are low in impurity removal rate. The energy-saving waste plastic crushing and cleaning system comprises a crusher, a first rinsing tank, a desalted water recycling device, a second rinsing tank, an environment-friendly material processing system and a sediment processing system, wherein the first rinsing pool is connected with the discharging port of the crusher and provided with rinsing liquor, which is formed by mixing sodium chloride, calcium chloride and water and is at a salinity of 15-25; the desalted water recycling device is communicated with the first rinsing pool; the second rinsing pool is communicated with the first rinsing pool and provided with rinsing liquor, which is formed by mixing sodium chloride, calcium chloride and water and is at a salinity of 7-8; the environment-friendly material processing system and the sediment processing system are communicated with the second rinsing pool. The energy-saving waste plastic crushing and cleaning system is reasonable in design, convenient to operate, high in automation degree, capable of stably cleaning PS (polystyrene) or ABS (acrylonitrile butadiene styrene) waste plastics, high in impurity removal rate and capable of cleaning environment-friendly materials and non-environment-friendly materials simultaneously.

Owner:SICHUAN PLASTIC GOLD TECH CO LTD

Plastic product and hardware recovery device and operation method thereof

ActiveCN113263661APlastic recyclingProcess efficiency improvementEmbedded systemElectrical and Electronics engineering

Owner:江西远翔塑胶有限公司

Rubber crushing recycling machine

InactiveCN112171966AAvoid bouncingRealize staggered cuttingPlastic recyclingMechanical material recoveryRotational axisHot melt

Owner:庄佳敏

Plastic bottle recycling equipment

Owner:汉中格伯莱彻环保新材料有限公司

Light guide plate FPC assembling device in mobile phone backlight plate processing process

Owner:JINGJIANG YONGSHENG OPTOELECTRONICS TECH

ACM thermoplastic vulcanized rubber and preparation method and application thereof

Owner:浙江科普特新材料有限公司

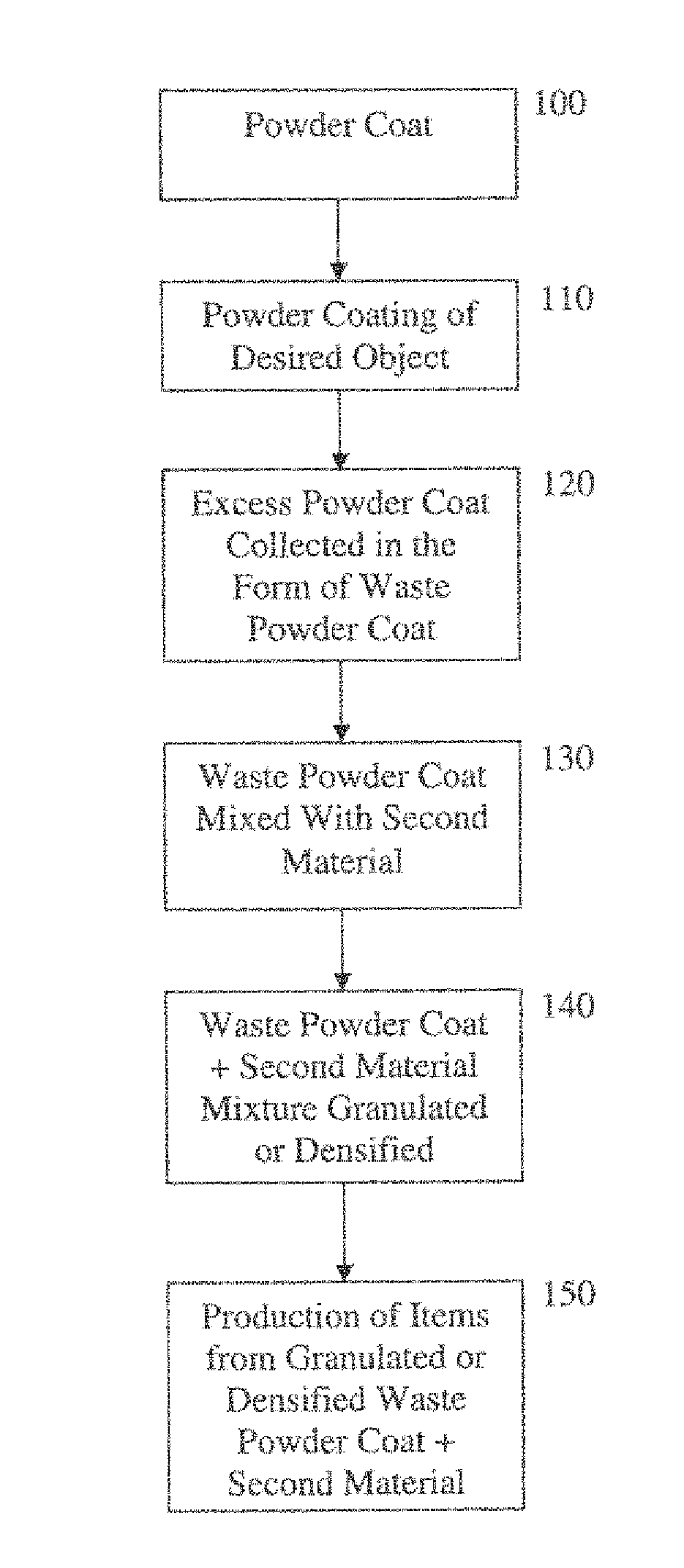

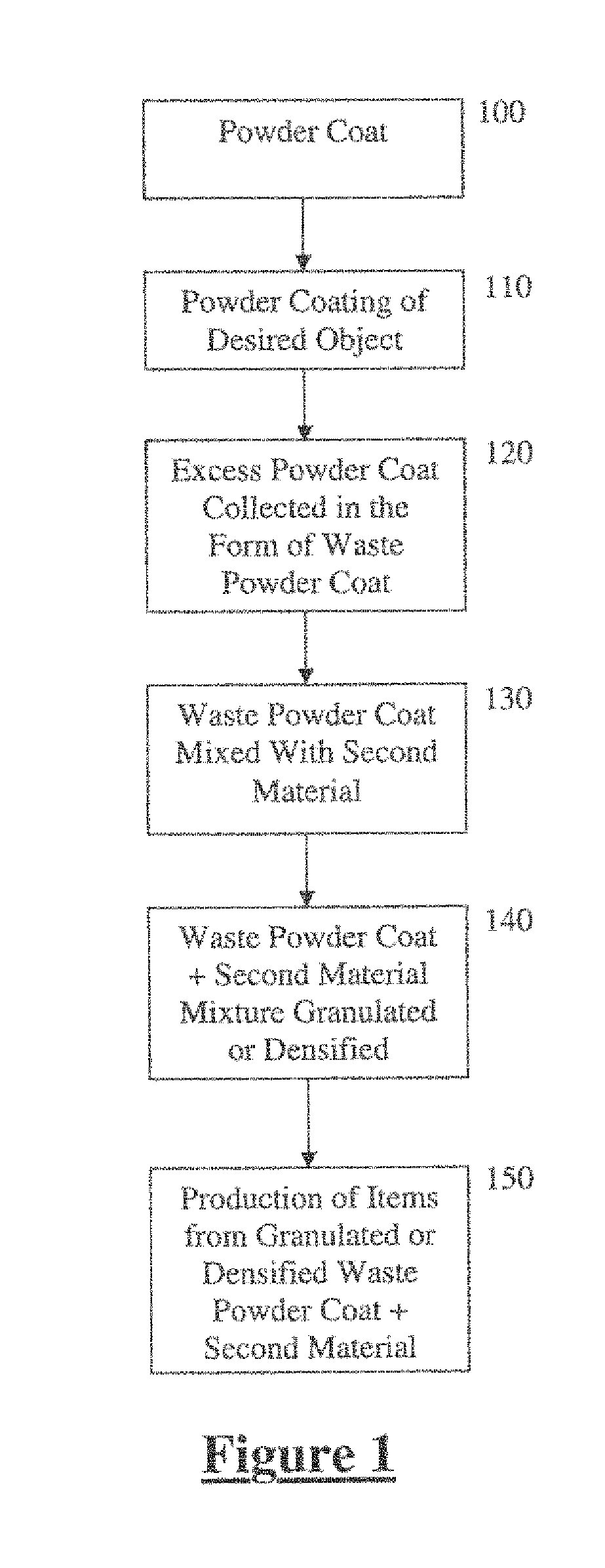

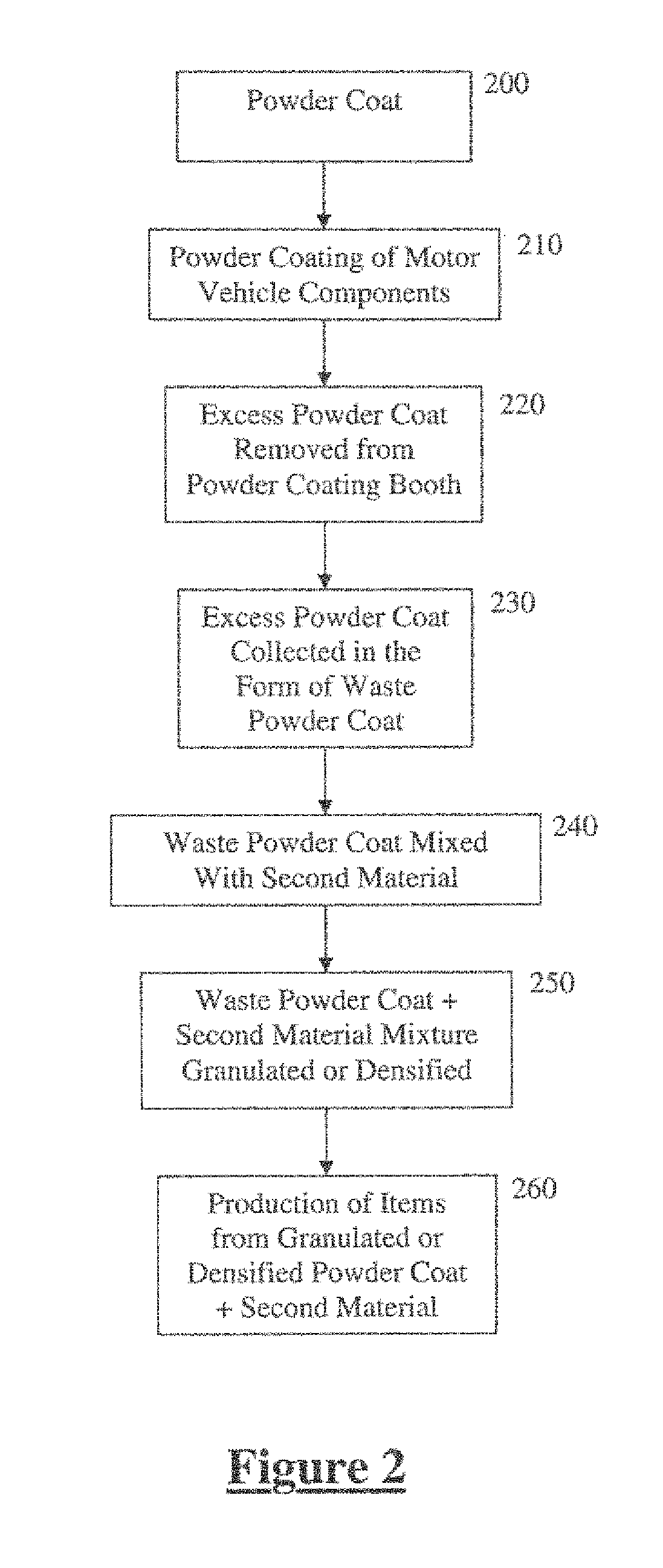

Process of recycling powder coat material and component made thereof

Owner:GREEN PLANET INVESTMENTS

Method for fully recycling and reproducing waste drip irrigation belts and waste greenhouse films

PendingCN114211640AQuality improvementOutstanding reproduction effectPlastic recyclingMechanical material recoveryBlow moldingMasterbatch

The invention relates to a waste drip irrigation tape and waste greenhouse film total recovery and reproduction method, and relates to the technical field of waste drip irrigation tape and waste greenhouse film resource recovery and reutilization, and the method comprises the following steps: waste material cleaning: putting waste drip irrigation tapes and waste greenhouse films into a cleaning pool for full cleaning; waste material drying, wherein the cleaned waste drip irrigation tape and the cleaned waste greenhouse film are dried; the waste materials are cut up, wherein the dried waste drip irrigation belts and the dried waste greenhouse films are cut up; mixing the raw materials: fully mixing the chopped waste materials with the new plastic material and the dyeing master batch; granulation: adding the mixed raw materials into an extruder for extrusion granulation; and film forming: performing blow molding and film forming on the raw material particles to finish reproduction of the waste materials. The waste drip irrigation tape and the waste greenhouse film can be utilized to the maximum extent, and the produced product is good in performance and good in application effect.

Owner:NINGXIA YURUN AGRI WATER SAVING IRRIGATION MFG CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap