Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Crusher" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated. Crushing is the process of transferring a force amplified by mechanical advantage through a material made of molecules that bond together more strongly, and resist deformation more, than those in the material being crushed do. Crushing devices hold material between two parallel or tangent solid surfaces, and apply sufficient force to bring the surfaces together to generate enough energy within the material being crushed so that its molecules separate from (fracturing), or change alignment in relation to (deformation), each other. The earliest crushers were hand-held stones, where the weight of the stone provided a boost to muscle power, used against a stone anvil. Querns and mortars are types of these crushing devices.

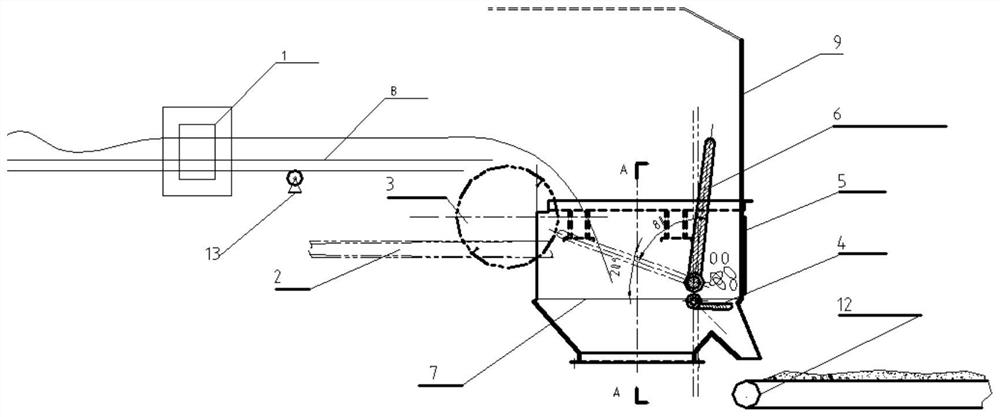

Air separation device and method of garbage

InactiveCN101823019AObvious superiorityImprove sorting efficiencyGas current separationWet separationAir volumeMagnetic separator

Owner:BEIJING HAOHAI TIANJI TECH +1

Double layer crusher

ActiveCN104759336AGuaranteed uptimeExtended service lifeWood working apparatusGrain treatmentsEngineeringCrusher

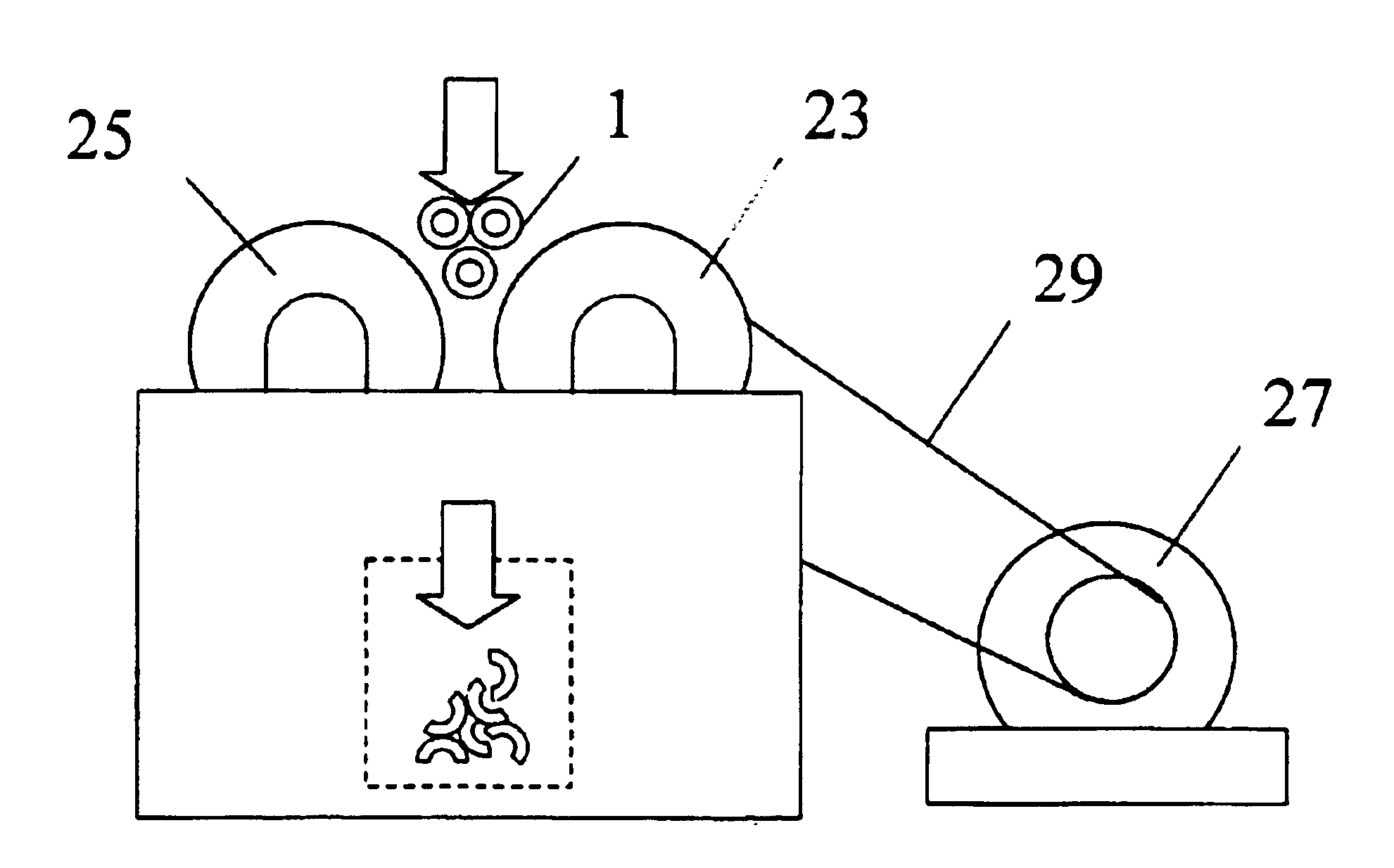

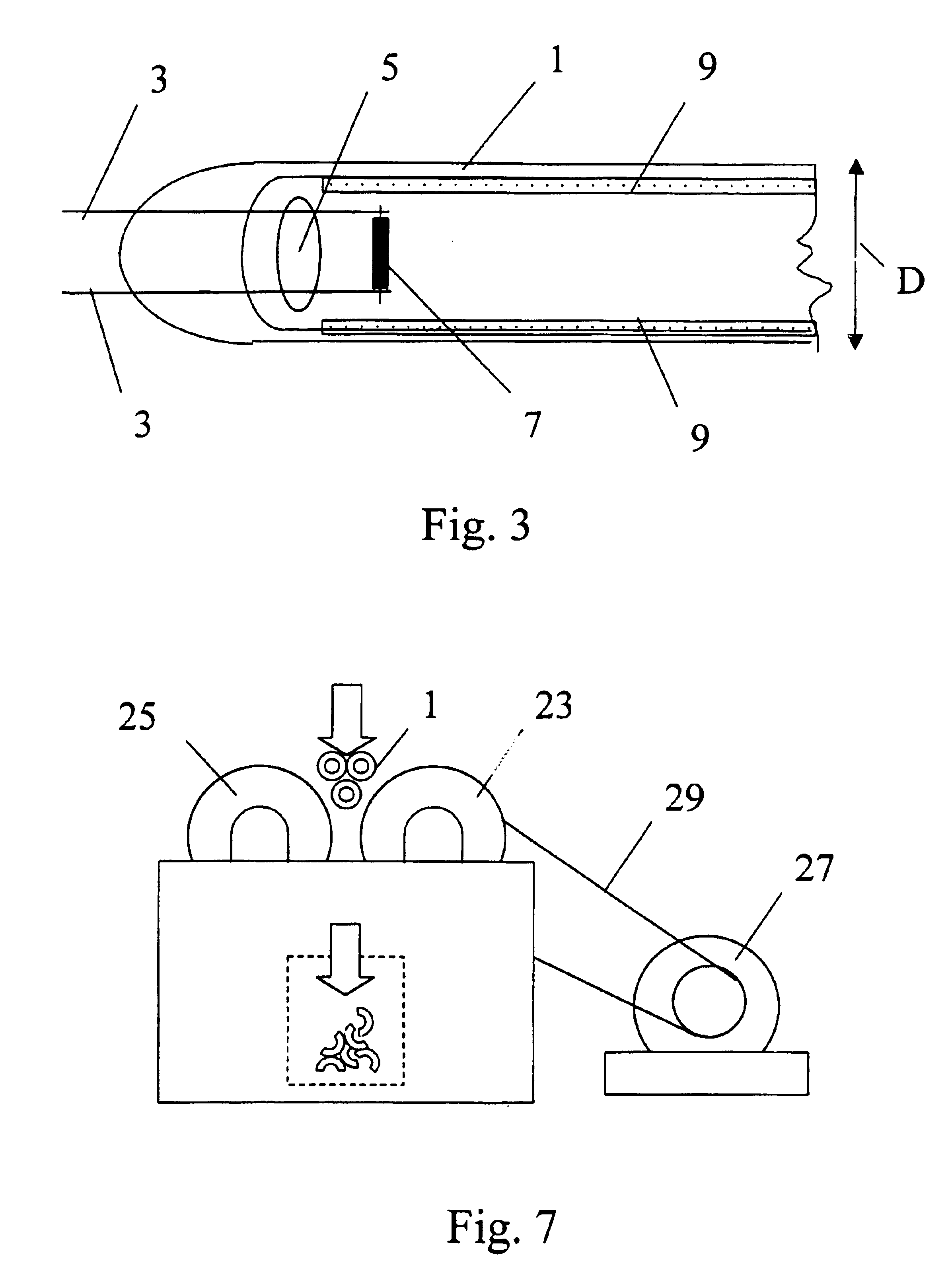

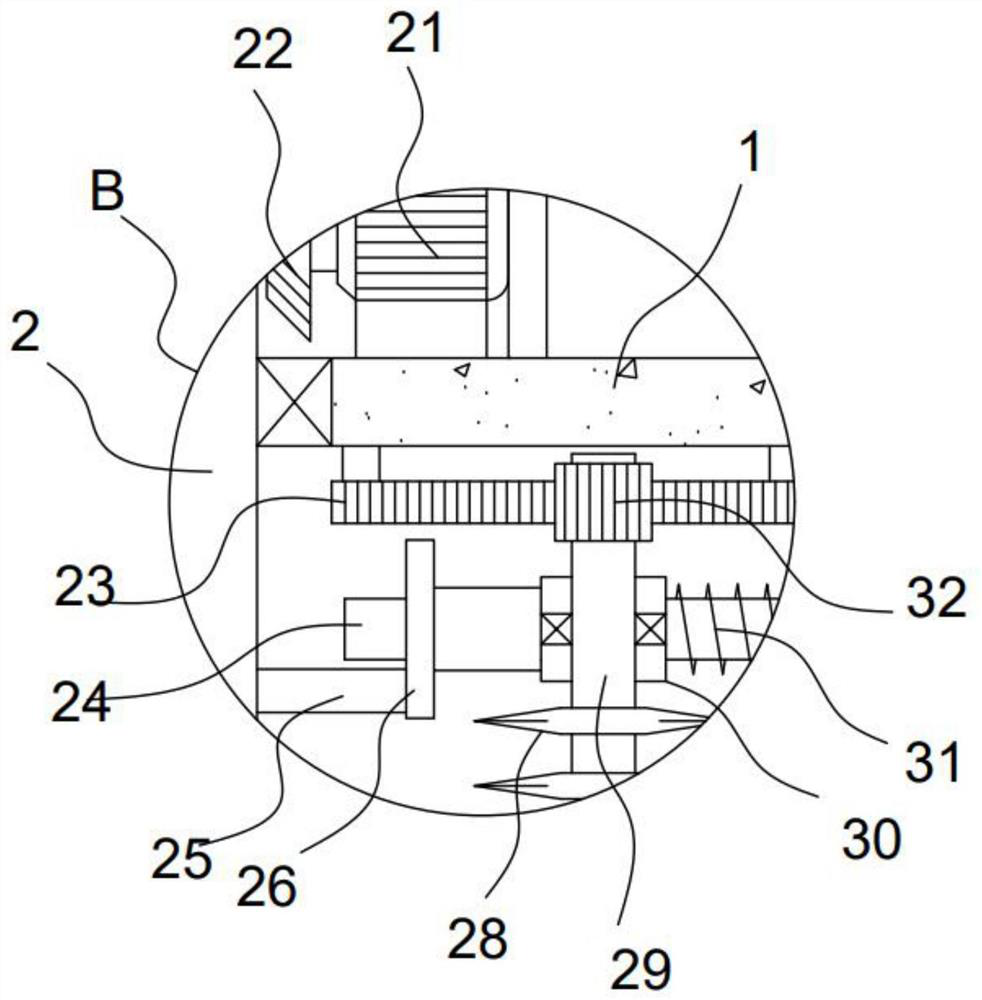

The invention discloses a double layer crusher. A smashing chamber is fixed on a main body of a machine base; a crushing chamber is arranged above the smashing chamber; a feeding opening is formed in the top part of the crushing chamber; a discharging opening is formed in the lower part of the smashing chamber; an rolling cutter rotor assembly is used for smashing wood bars and cutting long bars to small blocks; a centrifugal hammer sheet rotor assembly is used for smashing the small blocks; the inner spaces of the crushing chamber and the smashing chamber are mutually communicated; a screen and a strong magnet device are arranged between the two chambers from up to bottom in sequence. The double layer crusher adopts a unique two-in-one mode; by integrating cutting and smashing functions, the double layer crusher can meet market demands, the cost is lowered and the efficiency is increased.

Owner:SHANDONG YULONG MASCH CO LTD

Automatic crawler type mobile integrated crusher

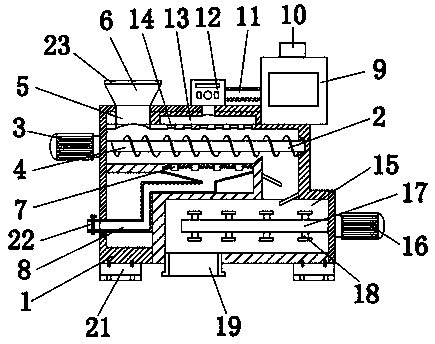

The invention discloses an automatic crawler type mobile integrated crusher. The automatic crawler type mobile integrated crusher comprises a charge long-arm excavating device, a walking device, a power device, a crushing device, a magnetic separating device, a discharging device, and a charge wide-opening ground shovel, wherein the charge wide-opening ground shovel is connected with the crushing device via a charge conveying belt; the walking device is also fixedly provided with a rotary chassis; the charge long-arm excavating device, the power device, the crushing device and the magnetic separating device are all fixedly installed on the rotary chassis. According to the invention, charging equipment and a mobile crusher are integrated; materials are directly put into the crusher via the charge conveying belt by the charge wide-opening ground shovel, so that a charge hopper is omitted; the charge long-arm excavating device, the power device, the crushing device and the magnetic separating device are all fixedly installed on the rotary chassis, so that charging and crushing are integrated, and the crusher can be used rotationally, and the crusher has the technical effects of energy conservation, environment protection, high efficiency and use flexibility.

Owner:SHENZHEN ZHONGCHENG GREEN BUILDING TECH +1

Multifunctional organic/inorganic compound fertilizer and preparation method thereof

Owner:山东华粮生物工程集团股份有限公司

Dry recycling technology for MOX fuel pellet waste

ActiveCN106782736AHigh recovery rateShort recycling processRadioactive decontaminationLiquid wasteCombustion

The invention belongs to the field of nuclear fuel. In order to solve the problem that an MOX fuel pellet waste wet recycling technology has many defects, the invention provides a dry recycling technology for MOX fuel pellet waste. The technology comprises the following steps of 1, burning MOX fuel pellet waste; 2, crushing by using a crusher; 3, screening; 4, ball milling; and 5 recycling. According to the technology provided by the invention, powdering of the MOX fuel pellet waste is achieved by crushing-ball milling technologies, so that the technology is fundamentally different from a dry recycling technology for UO2 fuel pellet waste using an oxidized crushing technology. Practical application shows that the MOX fuel pellet waste wet recycling technology provided by the invention has the advantages of high recycling rate, short recycling technical process, high in speed, simple in equipment, low in cost, and being free from generating radioactive liquid waste, and can be recycled in an MOX combustion manufacturer; the recycled power has similar sintering performance with the common MOX raw material powder, and can be mixed with common raw materials for preparing MOX fuel pellets.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for recovering fluorescent material from faulty glass bodies of discharge lamps

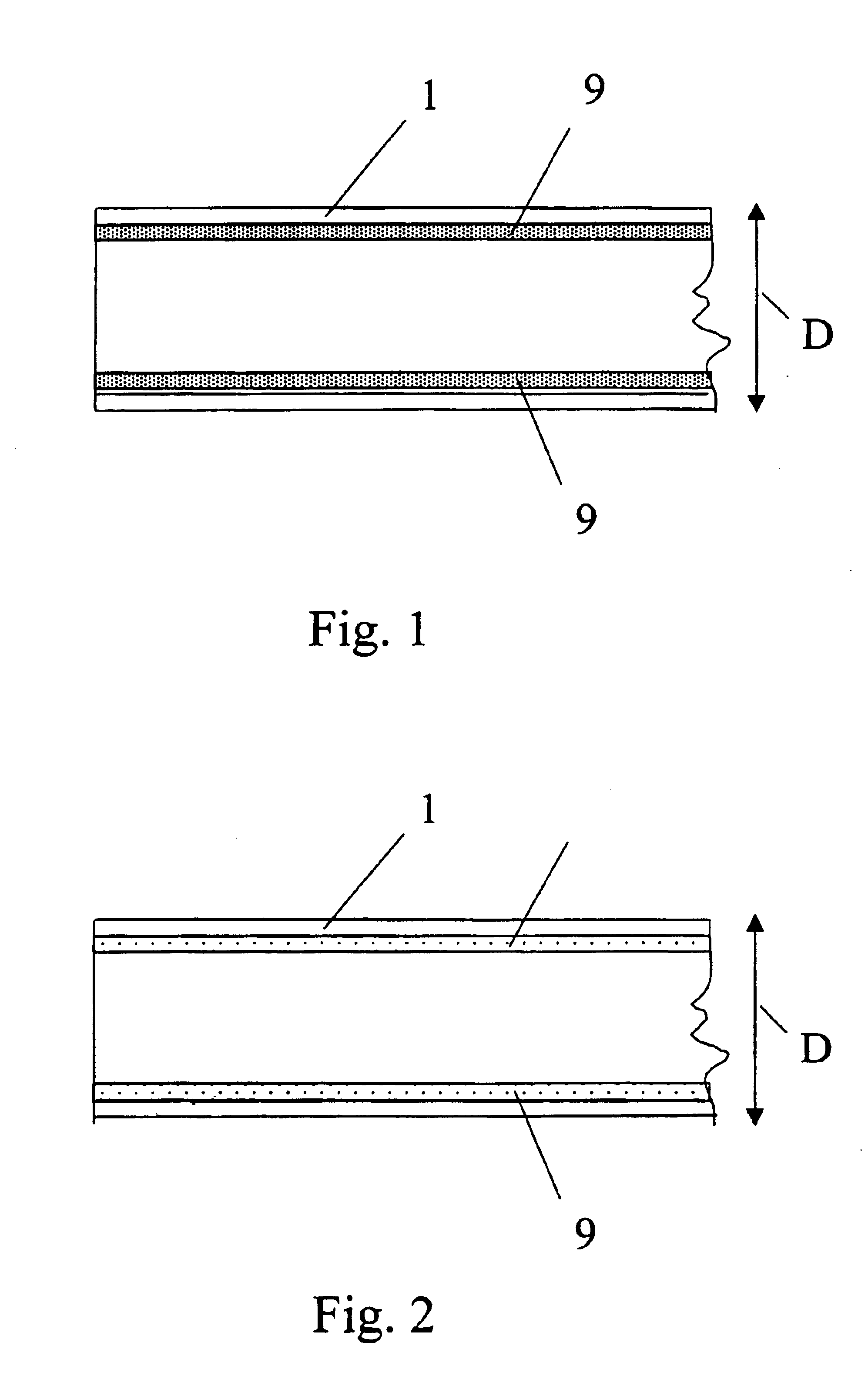

InactiveUS6869327B2Efficiently good resultEasy to separateDischarge tube luminescnet screensLamp detailsGlass particleCrusher

Owner:GENERAL ELECTRIC CO

Method and system for treating human excrement

InactiveCN108218480AAvoid pollutionLimit churnBio-organic fraction processingClimate change adaptationHuman wasteLiquid storage tank

The invention discloses a method for treating human excrement. The method comprises the steps as follows: (1) a liquid in the human excrement is discharged into an original liquid storage tank, and solids are dehydrated; (2) solids obtained after dehydration treatment in the step (1) are subjected to aerobic fermentation after being crushed; (3) secondary fermentation is performed; (4) materials obtained after the secondary fermentation are used as solid fertilizer. The invention also discloses a system adopting the method. The system comprises impurity removal equipment A, a dewatering deviceA, the original liquid storage tank, a crusher A, a distributor A, a full-closed fermentation tank A, an oxygen generator and the like. The method and the system for treating the human excrement havethe advantages as follows: a complete production process is provided for recycling of human excrement, a scheme is provided for urban emission reduction and sewage treatment plant pressure reduction,waste can be reused, and sustainable development can be realized really.

Owner:石伟

Concrete crushing and recycling device

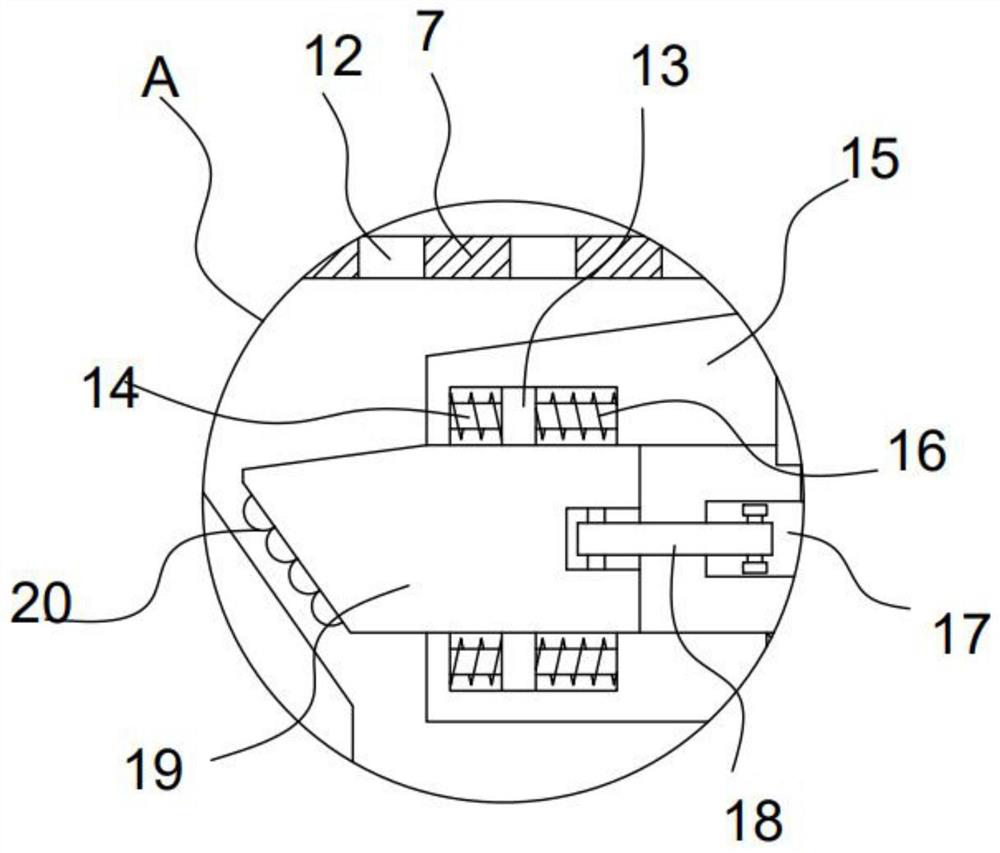

ActiveCN112495476APrevent looseningReal-time adjustmentSievingSolid waste managementEnvironmental engineeringCrusher

The invention discloses a concrete crushing and recycling device. The concrete crushing and recycling device comprises a crushing mechanism, a dust channel and a mud generating mechanism, wherein thedust channel is formed in one side of the crushing mechanism; and the mud generating mechanism is arranged on one side of the dust channel. According to the concrete crushing and recycling device, a crushing roller adjusting mechanism is additionally arranged, and the distance between crushing rollers can be adjusted in real time according to concrete of different sizes, so that the crushing effect is better, jamming is prevented, and the crushing efficiency is improved; and dust generated in the crushing process is collected and made to form mud under the action of an atomization spraying mechanism, and the mud is discharged under the combined action of a mud settling mechanism and a discharge box, so that the dust is effectively controlled, and the environmental pollution is prevented; and meanwhile, the dust can be reprocessed and reutilized, so that raw materials are saved, and waste is prevented.

Owner:GUI ZHOU CHANG TONG DIAN LI XIAN LU QI CAI YOU XIAN GONG SI

Beauxite applied pipeline transportation method

InactiveCN1730363AImprove working environmentSave engineering investmentBulk conveyorsWorking environmentEngineering

Owner:GUIYANG AL-MG DESIGN & RES INST

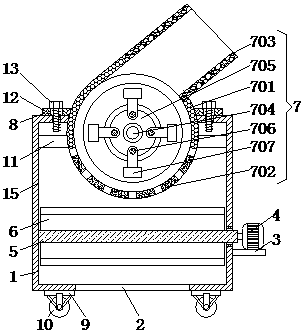

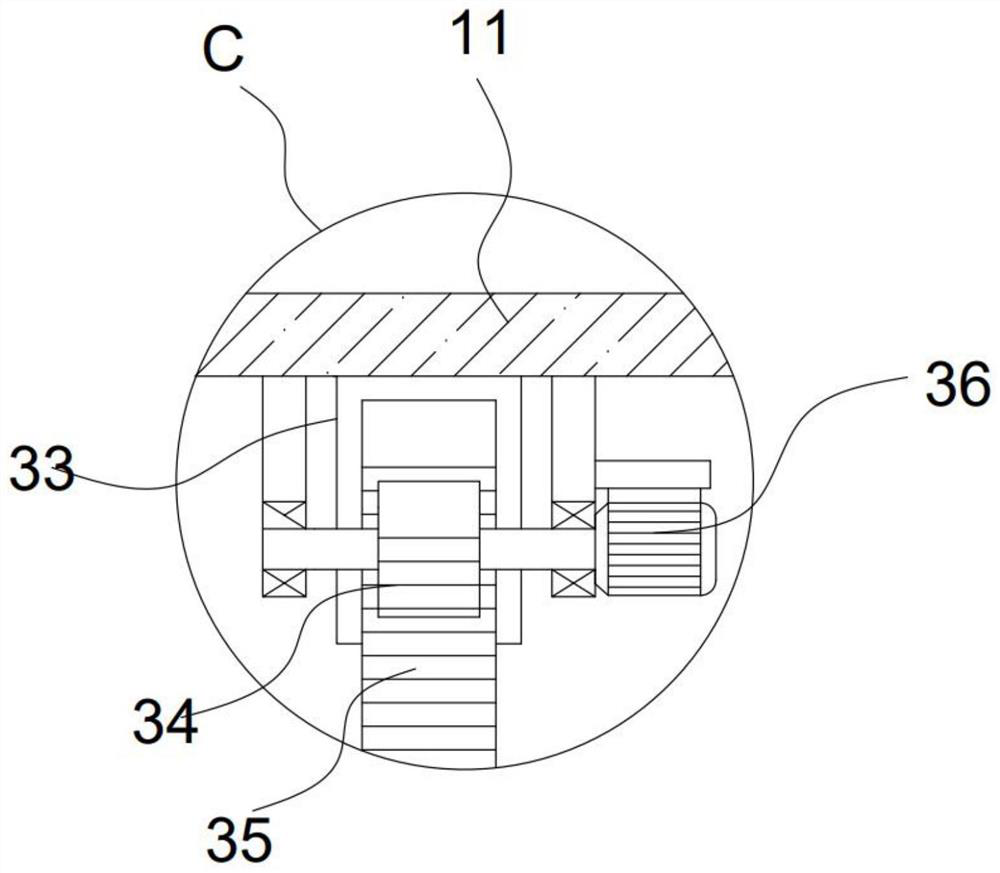

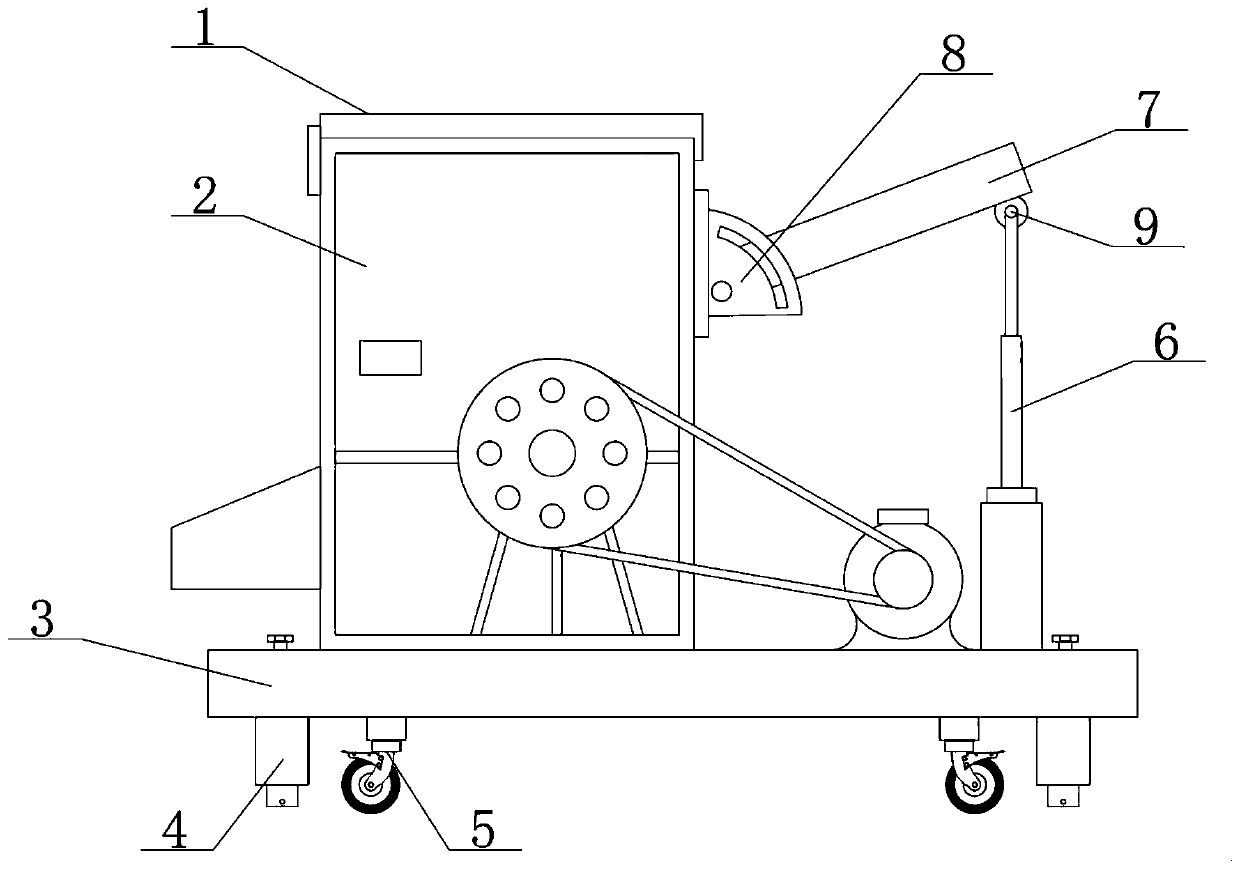

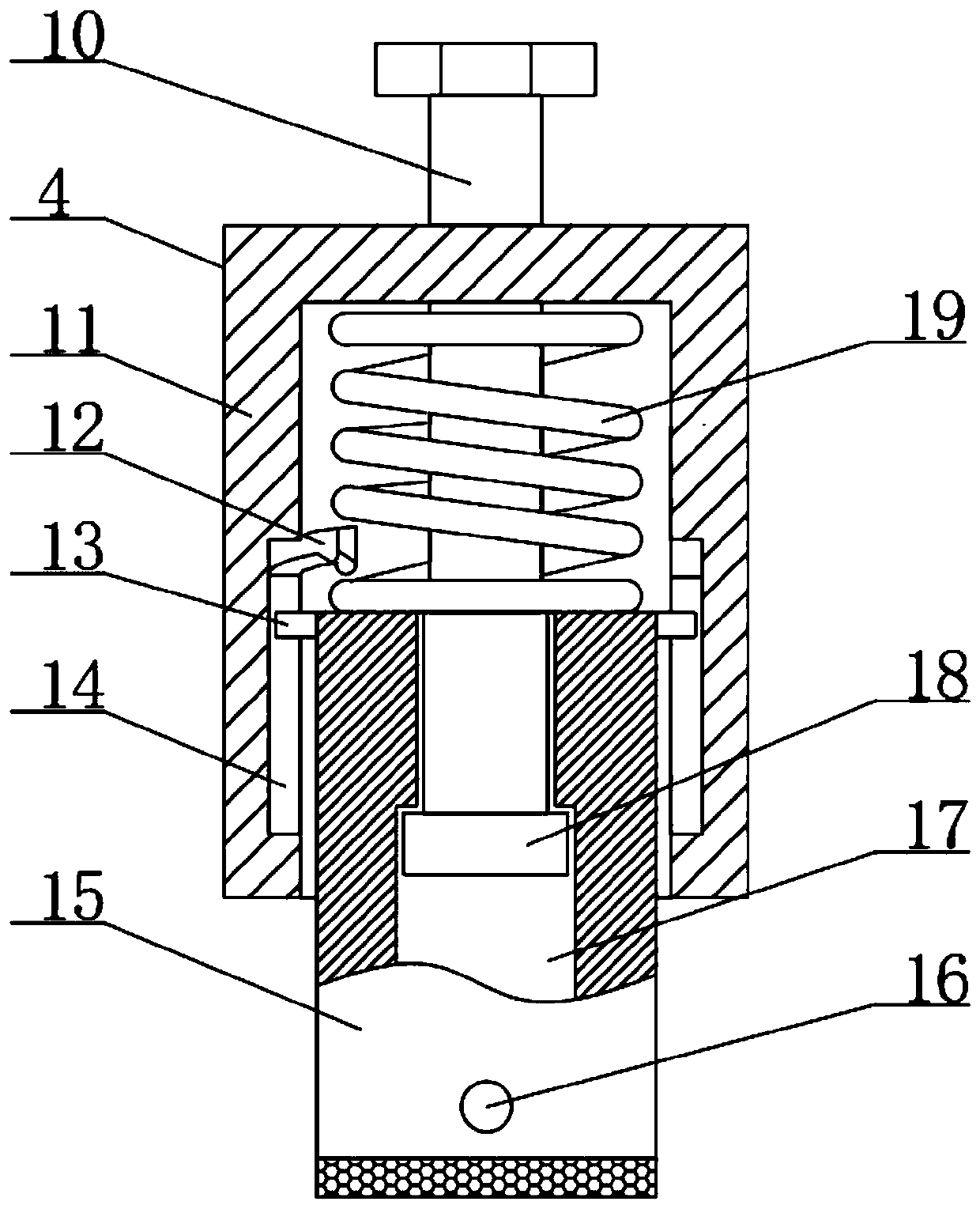

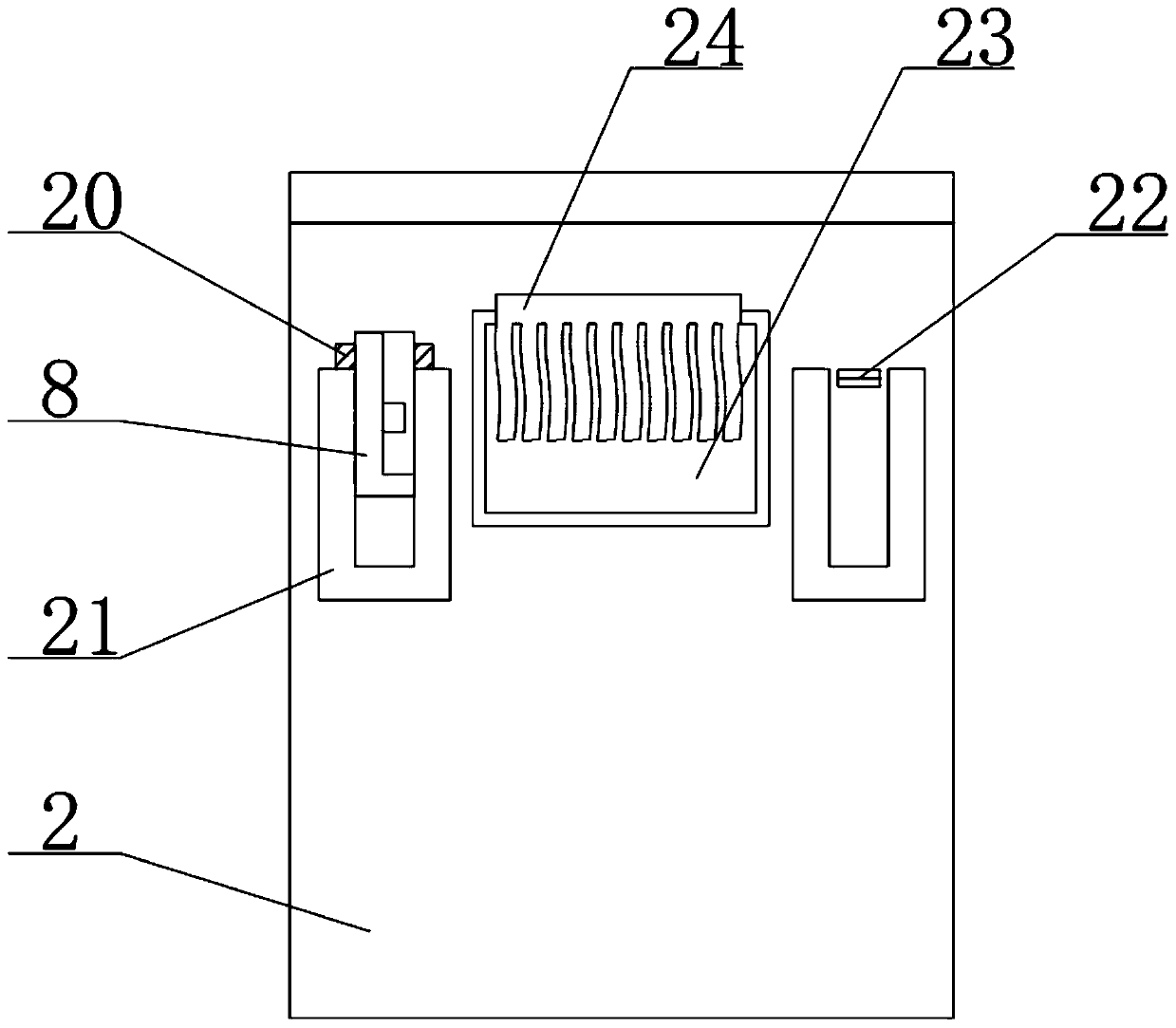

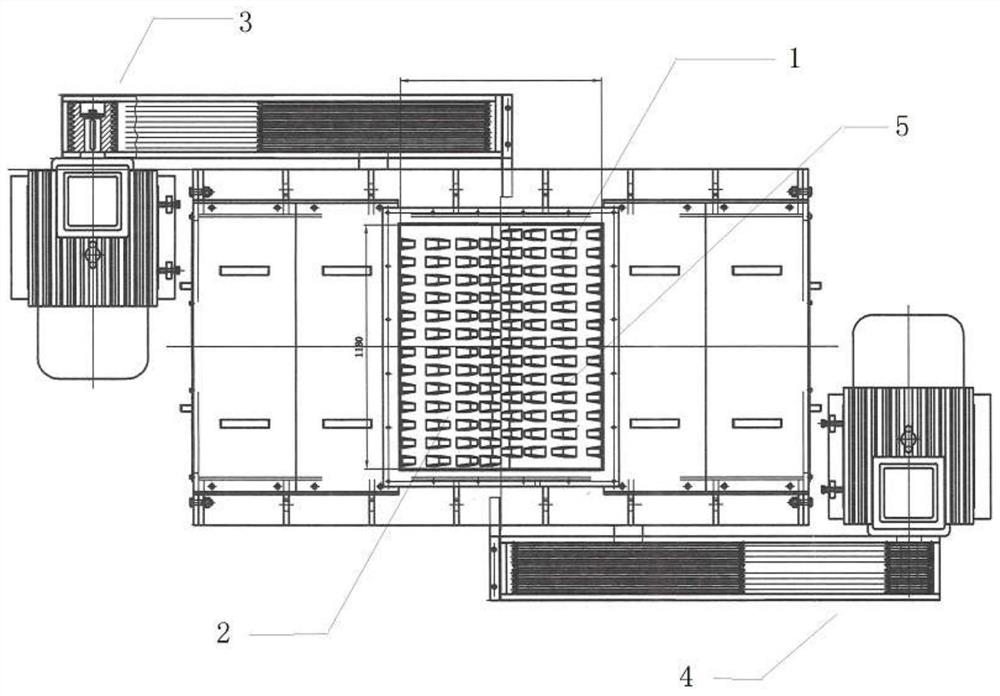

Crushing device for producing moulded coal

The invention provides a crushing device for producing moulded coal. The crushing device comprises a crushing mechanism, a vibration mechanism and a coarse material recycling mechanism. The crushing mechanism comprises a crushing machine body, a crushing motor and a scraper motor. The lower end of the crushing mechanism is provided with the vibration mechanism which is a vibration screen. The interior of the vibration screen is provided with screen cloth with the particle size being 3 mm, the upper portion of the vibration screen is provided with a coarse material outlet, and the lower portion of the vibration screen is provided with a discharge outlet. The coarse material recycling mechanism comprises a receiving hopper, an air cylinder and a telescopic rod, wherein the receiving hopper is arranged at the lower end of the coarse material outlet, and the air cylinder is arranged on a fixed rod and connected with a moving rod; the moving rod is in axial connection with the telescopic rod, and an air cylinder switch is connected to the air cylinder; and the bottom of the receiving hopper is provided with a slide plate and a slipway matched with the slide plate. The crushing device for producing the moulded coal has the beneficial effects that by arranging the coarse material recycling mechanism, not only can continuous operation of a production line be ensured, but also coarse materials can be recycled through recrushing, and coal dust can be prevented from flying through a hopper cover.

Owner:TIANJIN BEIFANG YULIANG TECH

Construction stone crusher

PendingCN108499670AIncrease mutual contactPrevent flying outCleaning using liquidsGrain treatmentsArchitectural engineeringCrusher

Owner:夏怡

Hammer crusher for ore mining

Owner:李广辉

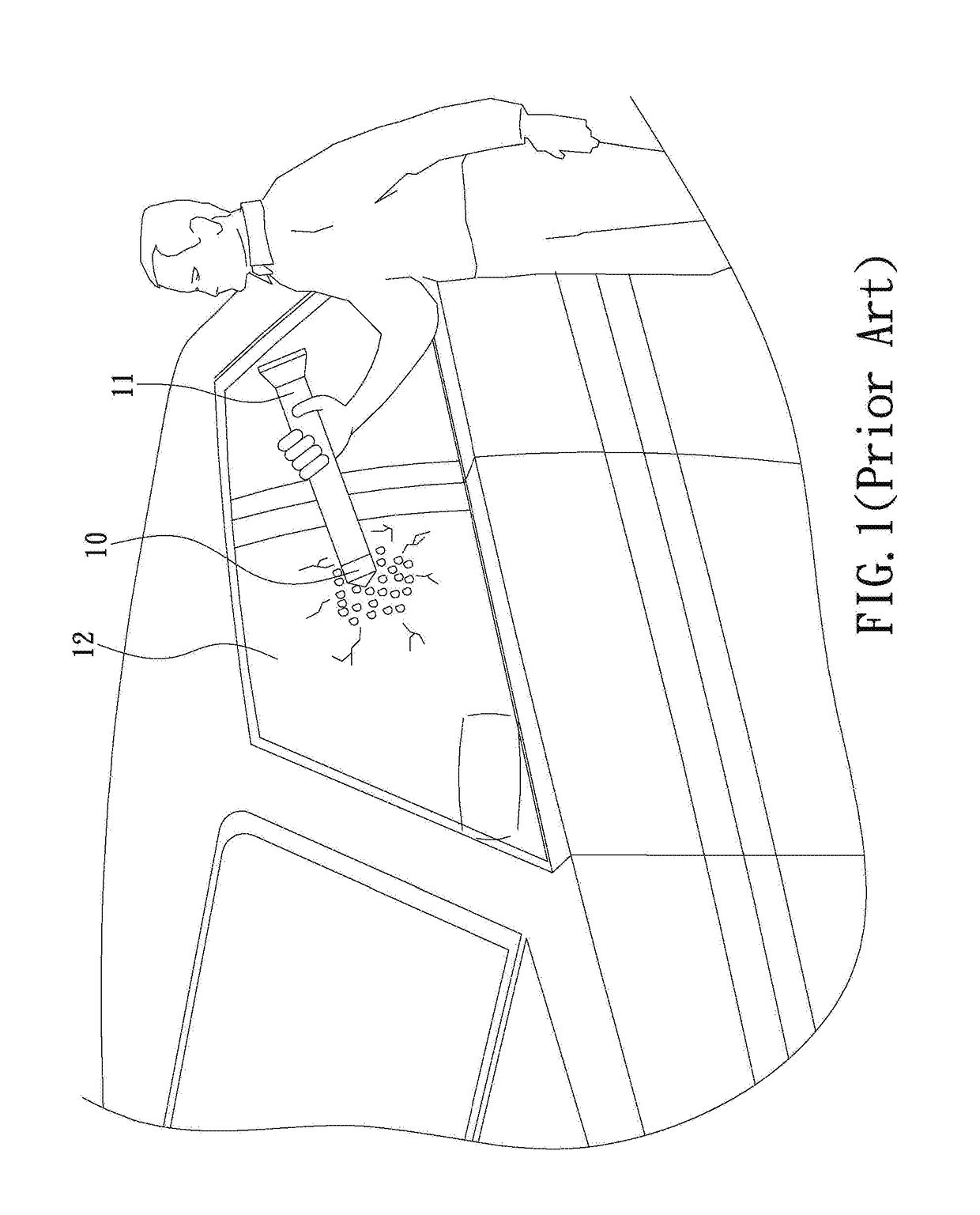

Removal method of outdoor hanging steps

InactiveCN112727147AReduce demandNo drop phenomenonBuilding repairsBridge strengtheningArchitectural engineeringCrusher

Owner:ZHEJIANG YIJIAN CONSTR GROUP

Method for extracting chitosan from oyster shells

The invention discloses a method for extracting chitosan from oyster shells. The method includes the steps of firstly, using clean water to clean waste oyster shells to remove silt and impurities on the surfaces of the oyster shells; secondly, drying and crushing the oyster shells obtained in the first step to obtain oyster shell powder; thirdly, sequentially performing low-temperature freezing and low-temperature lyophilization, and then using liquid nitrogen as the grinding medium to perform low-temperature crushing under the temperature from minus 80 DEG C to minus 120 DEG C by using an ultralow-temperature crusher; fourthly, adding purified water into materials obtained in the third step, evenly mixing, and processing in a high-pressure homogenizing machine; fifthly, performing acid treatment, to be more specific, soaking materials obtained in the fourth step into diluted hydrochloric acid, washing until neutrality is achieved, centrifuging, and drying to obtain chitin; sixthly, performing deacetylation, and drying to obtain the chitosan. The method has the advantages that the whole working procedure time is shortened, black impurities in the intermediate working procedure are avoided, and the obtained chitosan is pure white.

Owner:GUANGXI HUANZHU MARINE BIOLOGICAL TECH CO LTD

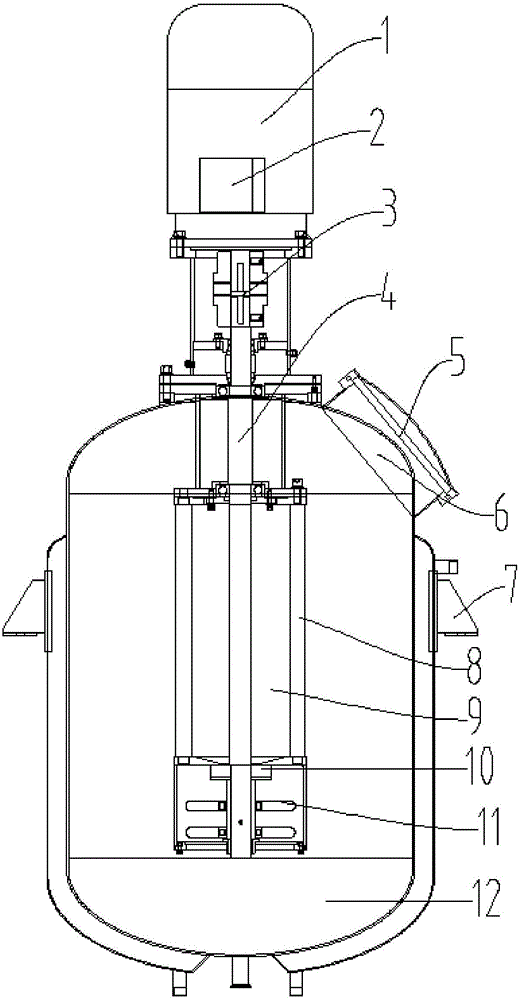

Raw material pretreatment device for hydrogen purification

InactiveCN113210089ARealize the rotary shredding effectImprove chopping effectGrain treatmentsReciprocating motionStructural engineering

Owner:WUHU MEDIUM HYDROGEN NEW ENERGY TECH CO LTD

Method for preparing coarse granularity chromium carbide powder

ActiveCN108046259AMeet wear resistanceCorrosiveCarbon compoundsChemical industryAdhesiveWear resistant

Owner:锦州市金属材料研究所

Quick-dismounted crushing device for high-purity fused quartz production

PendingCN110116042AEasy to moveMobile does not affectNon-rotating vibration suppressionGrain treatmentsMaterial resourcesEngineering

Owner:新沂市引河石英材料有限公司

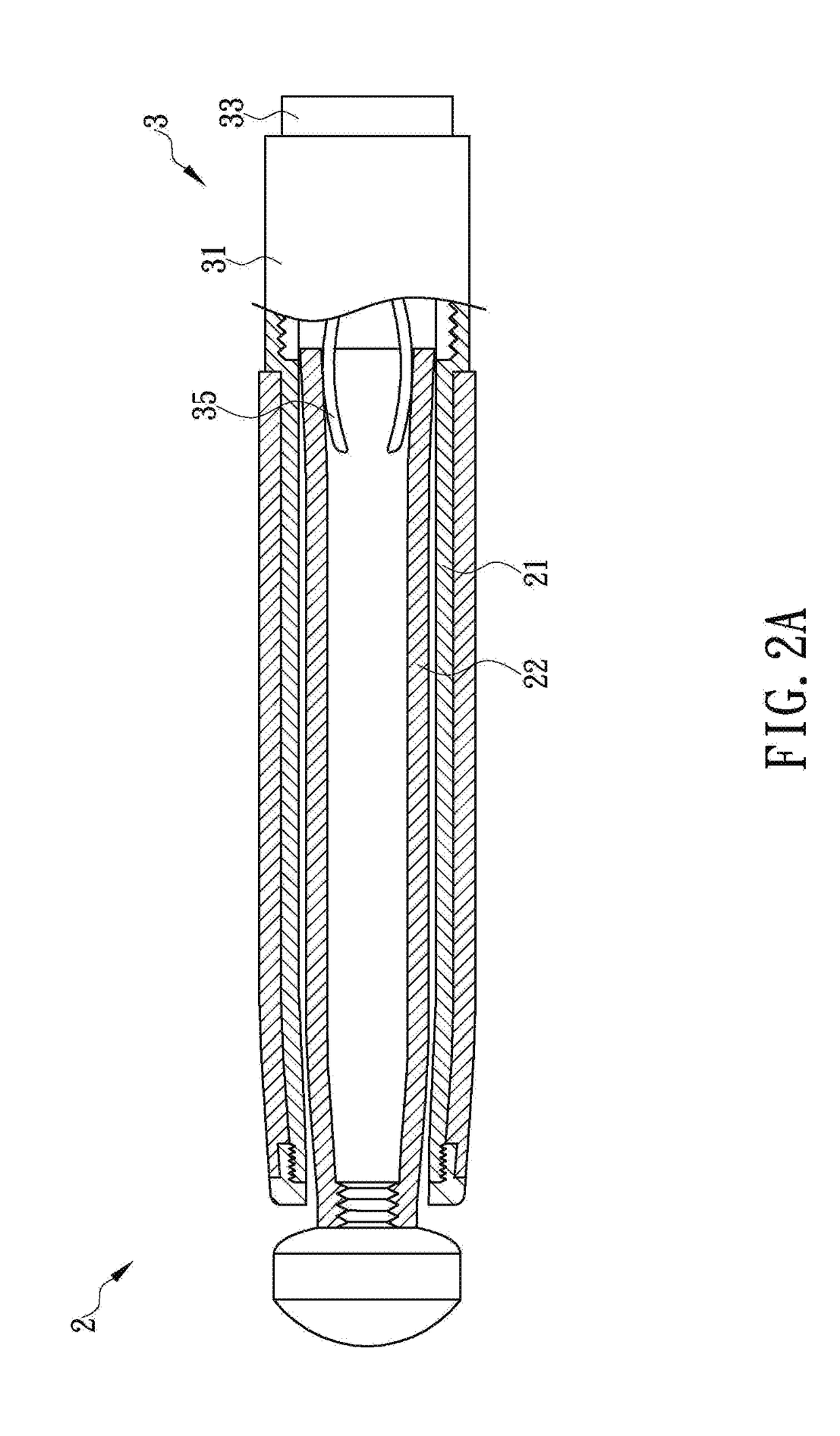

Expandable baton structure with hidden smasher at rear end of handle and hidden smasher thereof

Owner:LEE YUAN TE

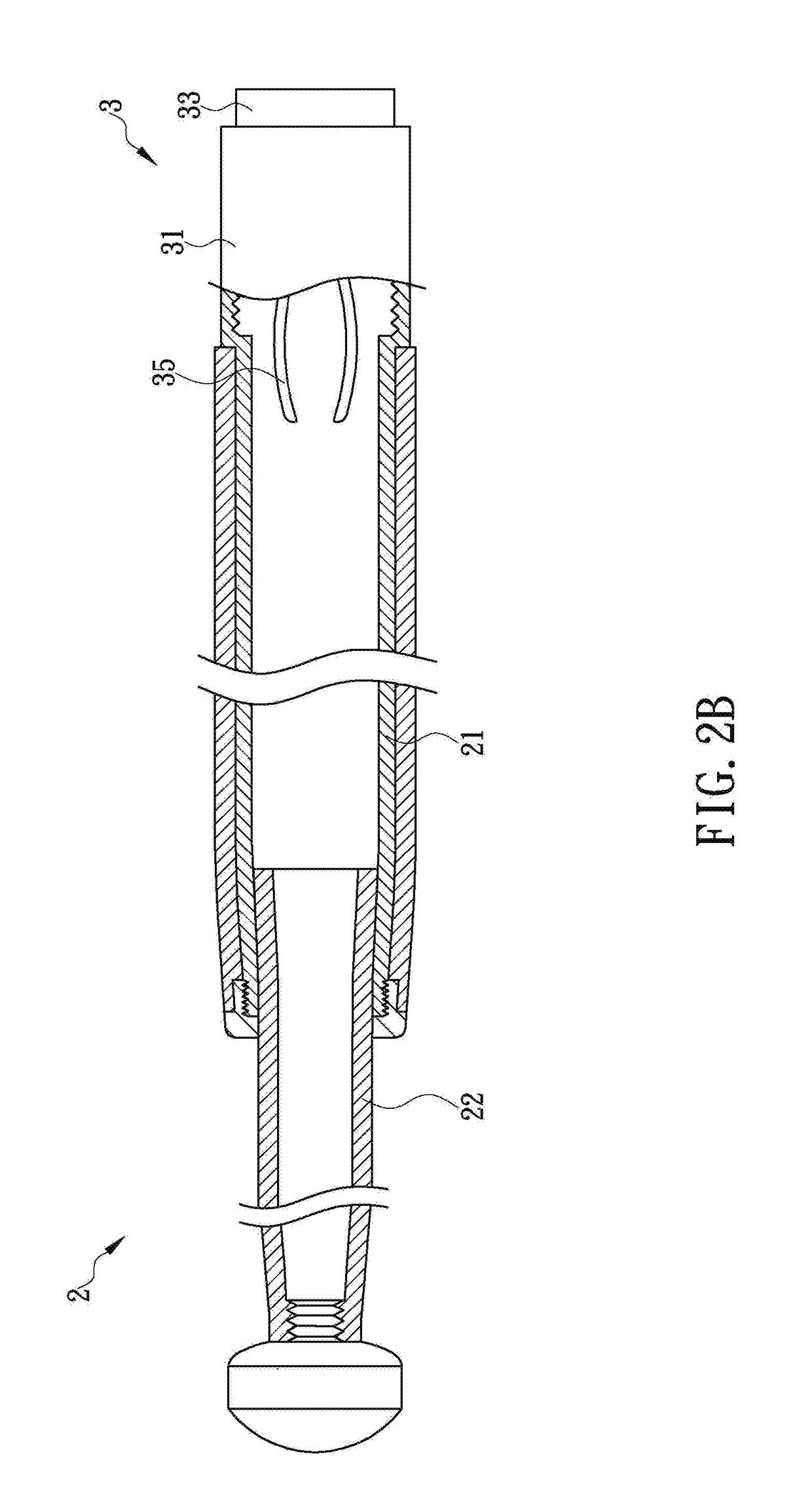

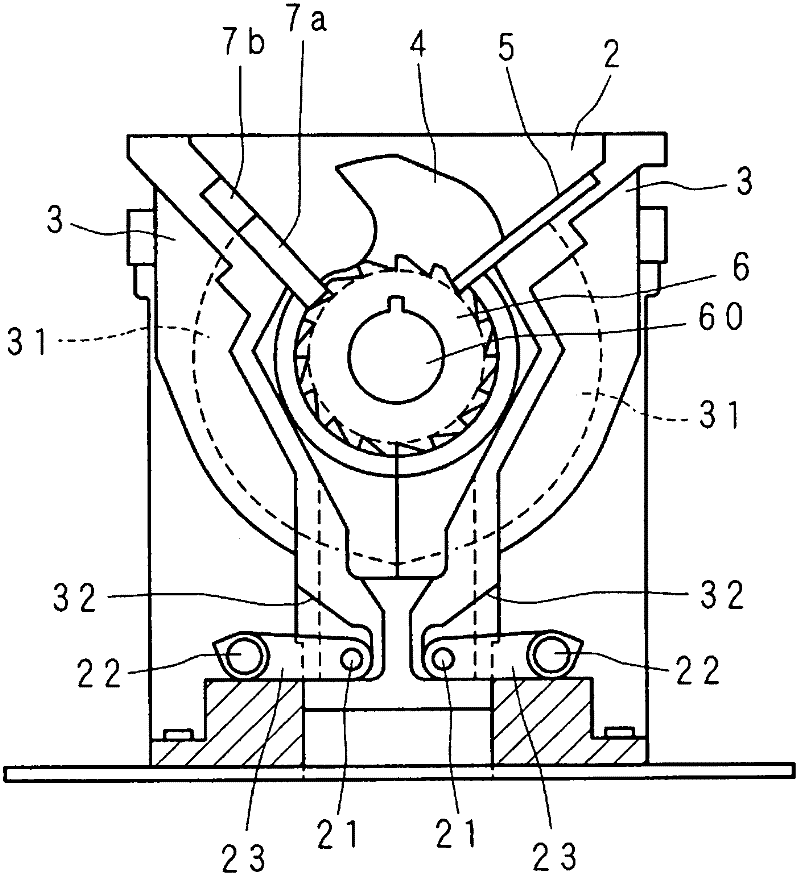

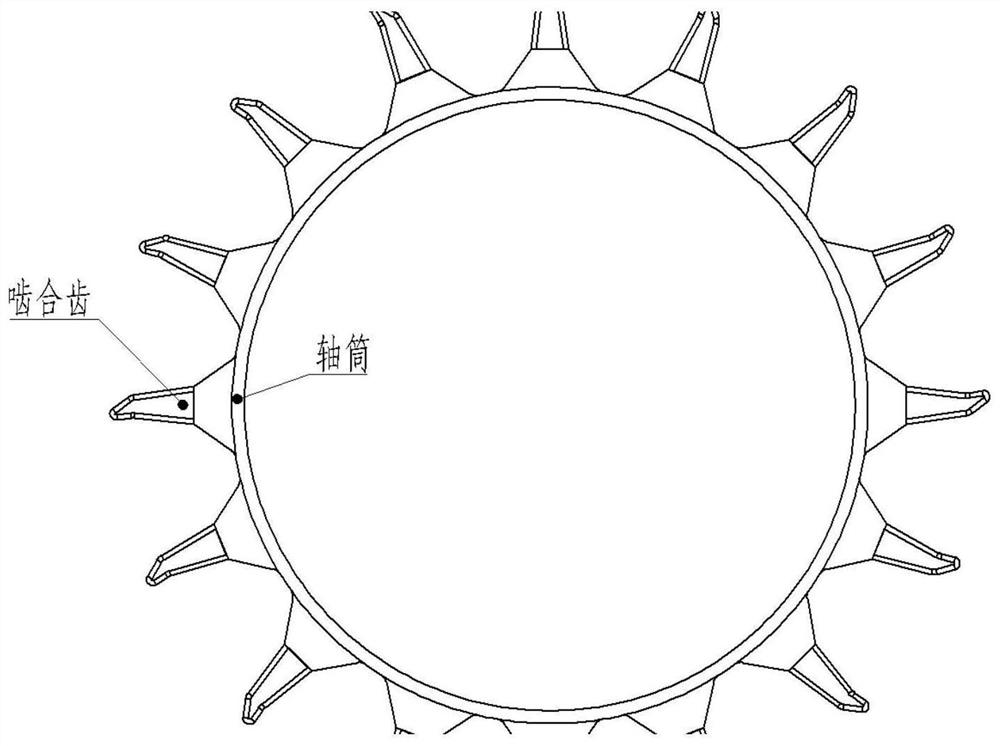

Crusher

InactiveCN102227264AEasy to openReduce manufacturing costGrain treatmentsManufacturing cost reductionEngineering

Owner:MATSUI MFG

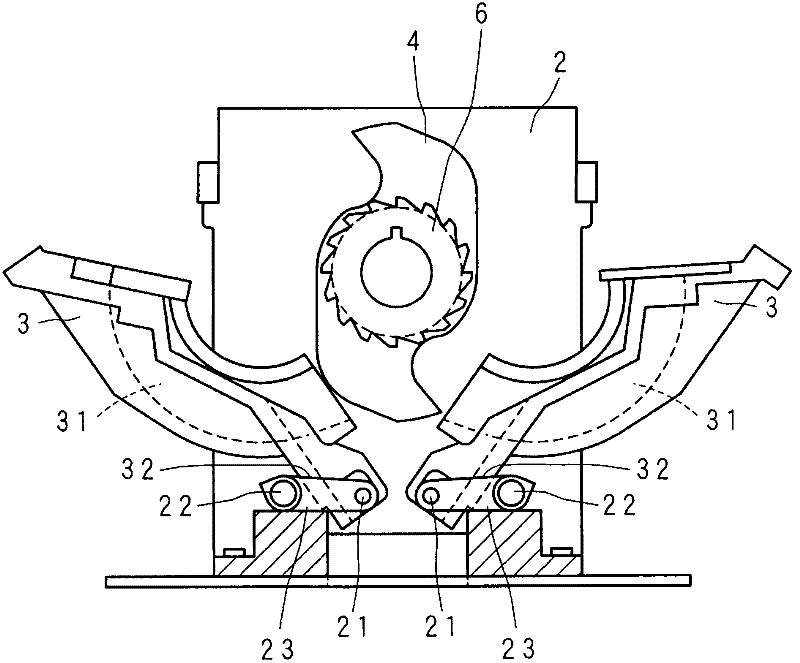

Energy-saving waste plastic crushing and cleaning system and implementing method thereof

ActiveCN104227872AAchieve brokenAchieve batchPlastic recyclingMechanical material recoveryWater cyclingPolystyrene

The invention discloses an energy-saving waste plastic crushing and cleaning system and an implementing method thereof. The energy-saving waste plastic crushing and cleaning system and the implementing method thereof can solve the problem that existing cleaning devices cannot clean waste plastics in batches and are low in impurity removal rate. The energy-saving waste plastic crushing and cleaning system comprises a crusher, a first rinsing tank, a desalted water recycling device, a second rinsing tank, an environment-friendly material processing system and a sediment processing system, wherein the first rinsing pool is connected with the discharging port of the crusher and provided with rinsing liquor, which is formed by mixing sodium chloride, calcium chloride and water and is at a salinity of 15-25; the desalted water recycling device is communicated with the first rinsing pool; the second rinsing pool is communicated with the first rinsing pool and provided with rinsing liquor, which is formed by mixing sodium chloride, calcium chloride and water and is at a salinity of 7-8; the environment-friendly material processing system and the sediment processing system are communicated with the second rinsing pool. The energy-saving waste plastic crushing and cleaning system is reasonable in design, convenient to operate, high in automation degree, capable of stably cleaning PS (polystyrene) or ABS (acrylonitrile butadiene styrene) waste plastics, high in impurity removal rate and capable of cleaning environment-friendly materials and non-environment-friendly materials simultaneously.

Owner:SICHUAN PLASTIC GOLD TECH CO LTD

Bag breaking machine for crushing decoration garbage

ActiveCN112478345AImprove crushing efficiencyEasy to cutCoatingsUnpacking by cuttingStructural engineeringCrusher

Owner:NANJING FUYUAN RESOURCES UTILIZATION CO LTD

Automated drug component content detector for medicine production

ActiveCN105974149AAvoid influenceImprove accuracyMaterial weighingBiochemical engineeringWater storage tank

Owner:SUZHOU CANCERCELL BIOTECH

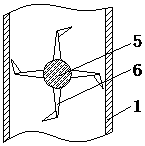

Method for mounting and adjusting hammer crusher

InactiveCN103510536AGuaranteed installation accuracyReduce running vibrationFoundation engineeringButtressFree state

Owner:洛阳天信矿山机械制造有限公司

Safety logic control device for crushing and conveying of limestone

Owner:娄卡奔新能源科技发展(上海)有限公司

Peanut shell smashing machine

A peanut shell grinder, comprising a grinder body, a hopper is arranged above the grinder body, a rotating shaft is clamped at both ends of the grinder body through bearings, and a crushing roller is sleeved on the outer wall of the rotating shaft, One end of the pulverizer body is fixed with a motor through a fixing frame, and a filter plate is inserted under the pulverizer body, and one end of the filter plate is connected to a clamping plate through a connecting rod. A distribution bin is arranged below, and a discharge port is arranged below the distribution bin. The device has a groove on the outer wall of the pulverizer body for use with the filter plate, and the height of the groove is consistent with the thickness of the filter plate, so that the filter plate can be clamped under the inside of the pulverizer body, which is convenient for installation and disassembly. It is regularly cleaned and replaced to prevent clogging of the filter plate after long-term use, and to improve the crushing efficiency of the device.

Owner:LICHUAN LONGXIANG BIOTECHNOLOGY CO LTD

Movable jaw plate of jaw crusher

Owner:西部黄金克拉玛依哈图金矿有限责任公司

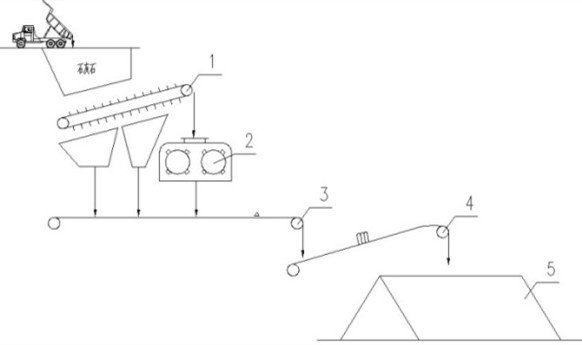

Municipal household garbage treatment system

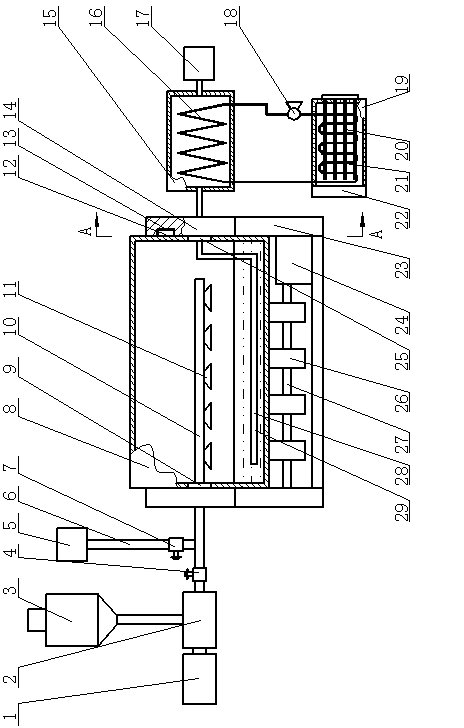

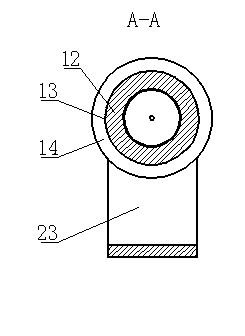

InactiveCN105499253AHarmlessRealize resourcesSolid waste disposalHazardous substanceThermal insulation

The invention discloses a municipal household garbage treatment system which is provided with a bag breaker (1), a belt conveyor (2), a four-axis crusher (4), a vertical type spiral gas floater (5), a dissolved air floater (6), a solid-liquid separator (7), sewage purifying equipment (8) and a garbage treatment station house (10). According to the technical scheme adopted by the invention, municipal household garbage treatment system can be used for deeply treating the municipal household garbage, so that harmful gas in the garbage can be decomposed, harmful substances in the garbage also can be diluted, and part of the substances are floated and circulated, and therefore, labor intensity in a treatment process is greatly reduced, and man power and material resources are greatly saved; the garbage is used as a production raw material, organic substances and inorganic substances in the garbage are separated and are reasonably utilized to produce organic fertilizers and building block materials; and the white pollutants are used for building thermal-insulation materials, so that harmless and recycling treatment of the garbage is realized.

Owner:ANHUI JIHONG ENVIRONMENTAL PROTECTION TECH CO LTD

Lees multi-meat oil aroma sauce

InactiveCN106858540AGood color and fragranceMeet urban and rural marketsFood sciencePiper nigrum L.Flavor

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

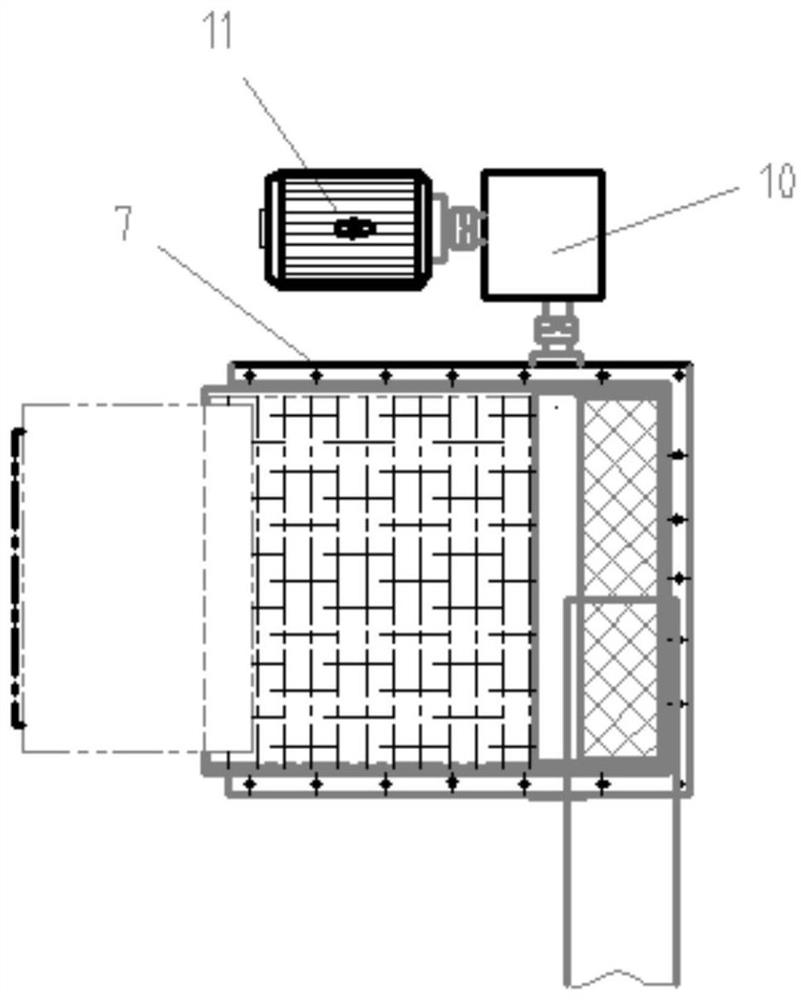

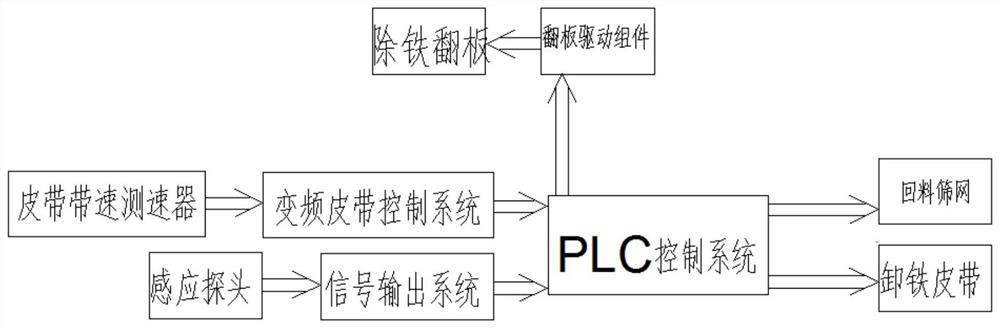

Metal detecting and sorting-out system

PendingCN111774327AAvoid damageRealize the detection functionMagnetic separationSortingIron removalEngineering

Owner:江苏扬联磁电科技有限公司

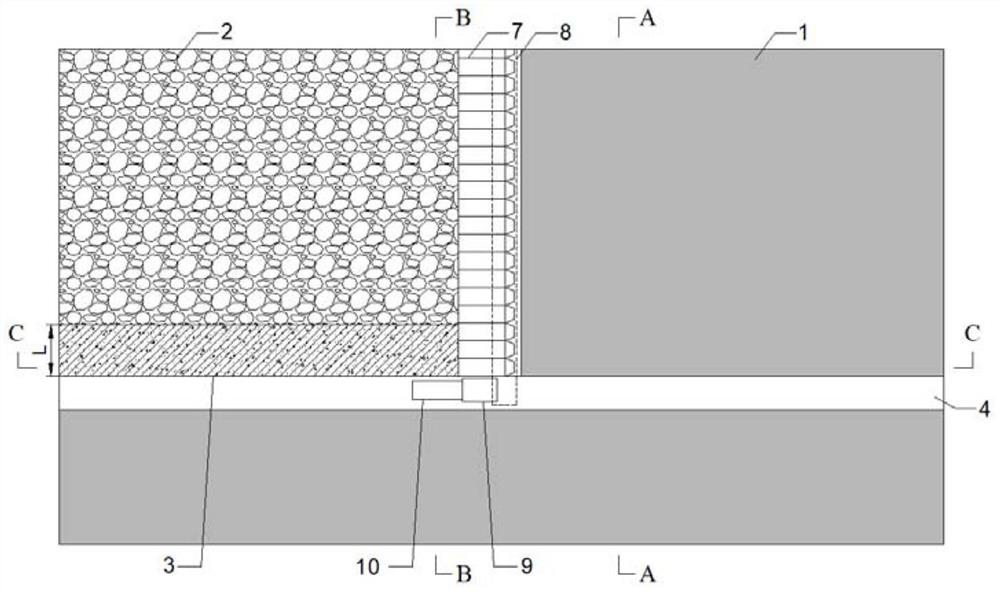

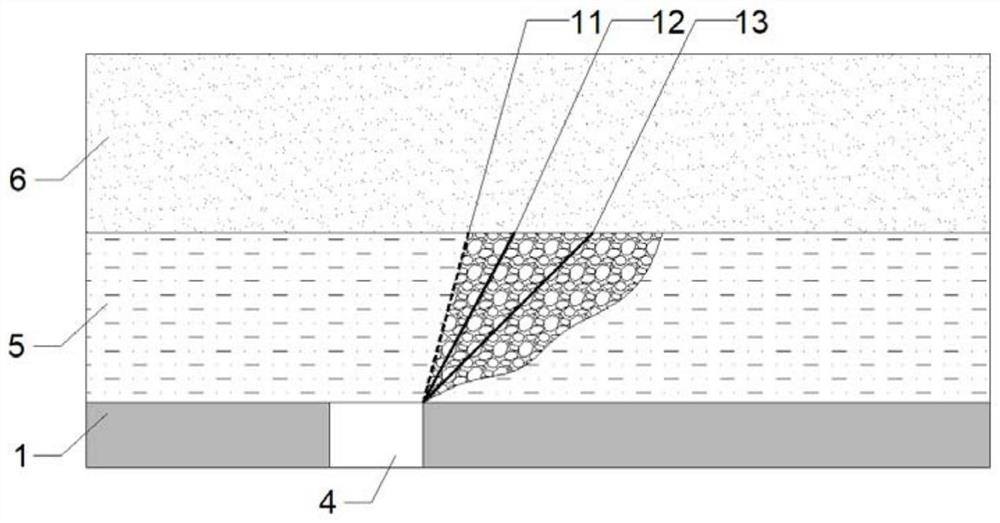

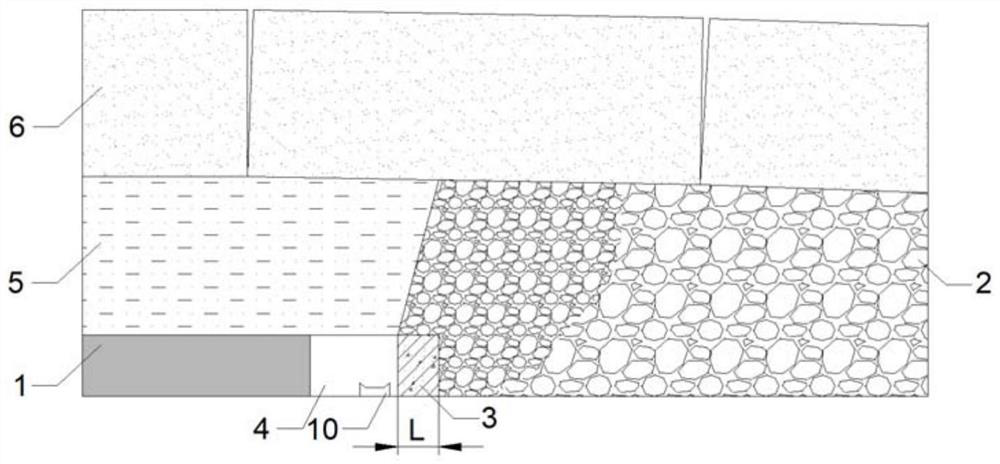

Method for protecting roadway under top-cutting gob-side entry retaining of coal seam containing dirt band

InactiveCN114517676ADoes not affect normal productionDo not reduce the width of the laneMining devicesUnderground chambersSpontaneous combustionMining engineering

Owner:ZAOZHUANG UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap