Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Liquid waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid waste can be defined as such Liquids as wastewater, fats, oils or grease (FOG), used oil, liquids, solids, gases, or sludges and hazardous household liquids.

Comprehensive recycling treatment method of waste rare-earth fluorescent lamp

ActiveCN103627906AShort processReduce recycling costsProcess efficiency improvementLiquid wasteEconomic benefits

The invention discloses a comprehensive recycling treatment method of a waste rare-earth fluorescent lamp, which comprises the steps that S1, waste fluorescent powder, a waste glass tube and mercury-containing waste liquid are separated and recycled from the waste rare-earth fluorescent lamp; S2, the waste fluorescent powder is roasted; an obtained roasted ore is leached; a leaching solution and a leaching residue are obtained; S3, the leaching solution is subjected to extraction, reverse extraction and separation; alumina and rare-earth oxide are obtained; and S4, the leaching residue is subjected to digestion, extraction and purification; and a strontium-containing product is obtained. The waste rare-earth fluorescent lamp is separated, the obtained waste fluorescent powder and the obtained mercury-containing waste liquid are comprehensively recycled respectively by technologies of roasting, leaching, extraction, reverse extraction and the like, and then secondary valuable resources such as alumina, various rare-earth oxide and the strontium-containing product are comprehensively recycled from the waste fluorescent powder. The method is short in technological process and low in recycling cost, solves the problems of stockpiling, environmental pollution and the like caused by the industrial waste rare-earth fluorescent lamp, and has certain economic benefits and industrial significance.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Dry recycling technology for MOX fuel pellet waste

ActiveCN106782736AHigh recovery rateShort recycling processRadioactive decontaminationLiquid wasteCombustion

The invention belongs to the field of nuclear fuel. In order to solve the problem that an MOX fuel pellet waste wet recycling technology has many defects, the invention provides a dry recycling technology for MOX fuel pellet waste. The technology comprises the following steps of 1, burning MOX fuel pellet waste; 2, crushing by using a crusher; 3, screening; 4, ball milling; and 5 recycling. According to the technology provided by the invention, powdering of the MOX fuel pellet waste is achieved by crushing-ball milling technologies, so that the technology is fundamentally different from a dry recycling technology for UO2 fuel pellet waste using an oxidized crushing technology. Practical application shows that the MOX fuel pellet waste wet recycling technology provided by the invention has the advantages of high recycling rate, short recycling technical process, high in speed, simple in equipment, low in cost, and being free from generating radioactive liquid waste, and can be recycled in an MOX combustion manufacturer; the recycled power has similar sintering performance with the common MOX raw material powder, and can be mixed with common raw materials for preparing MOX fuel pellets.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

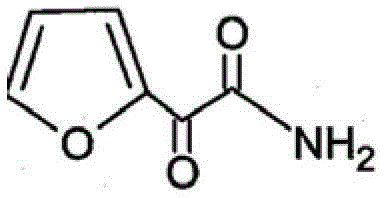

Method for improving yield of synthesized 2-furanyloxoacetic acid

Owner:JIANGSU QINGQUAN CHEM CO LTD +1

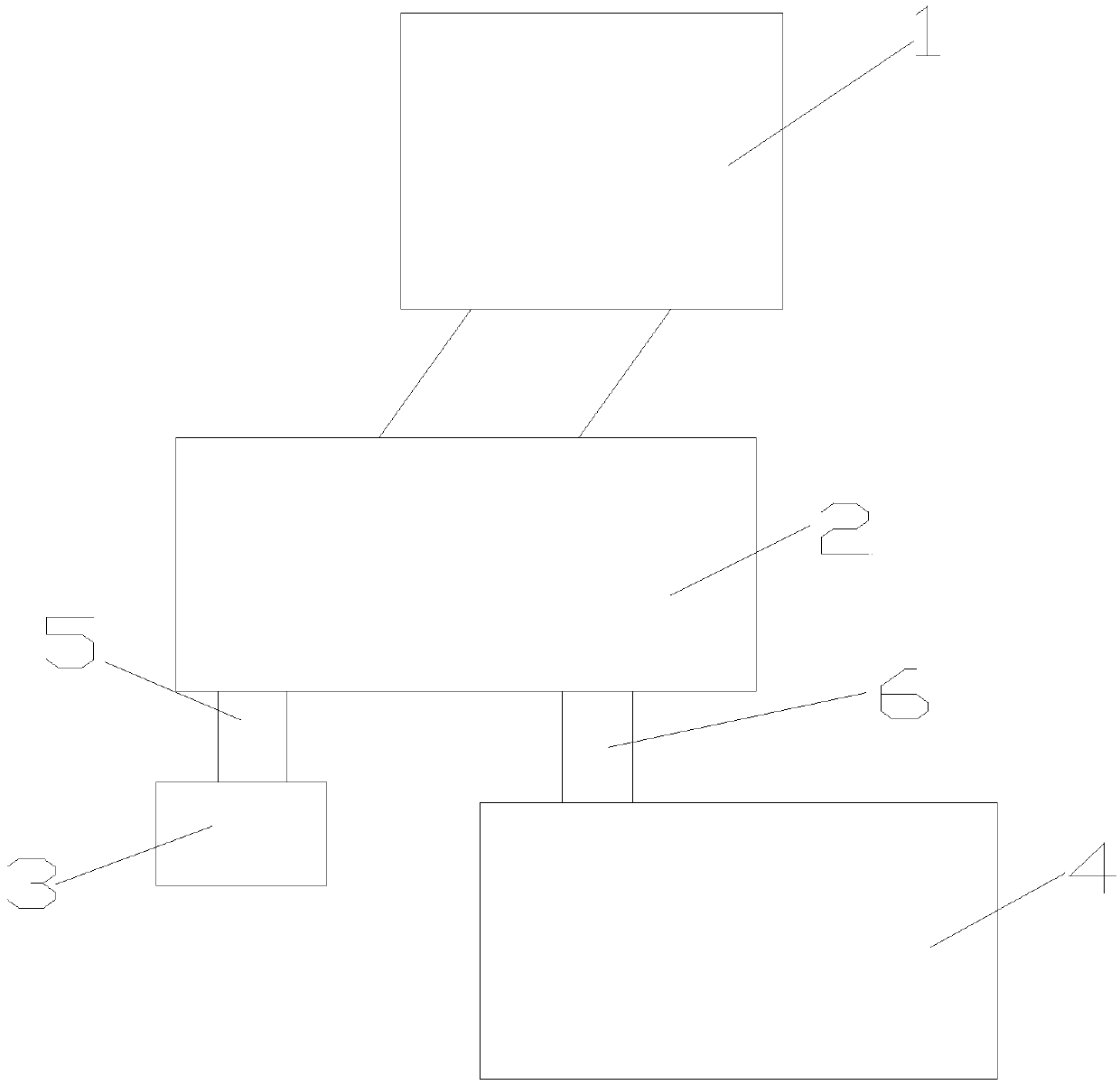

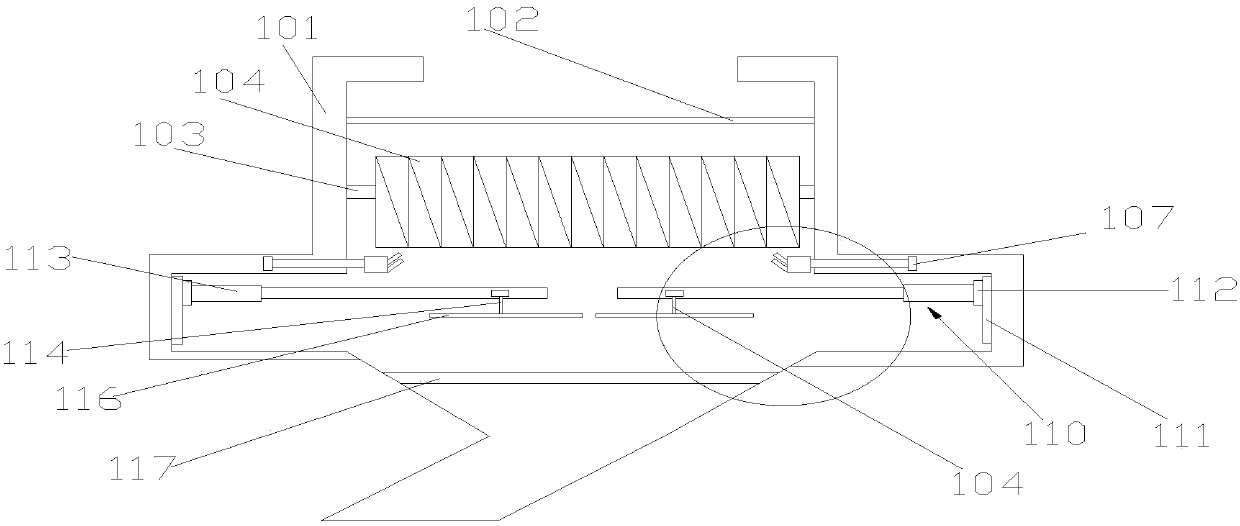

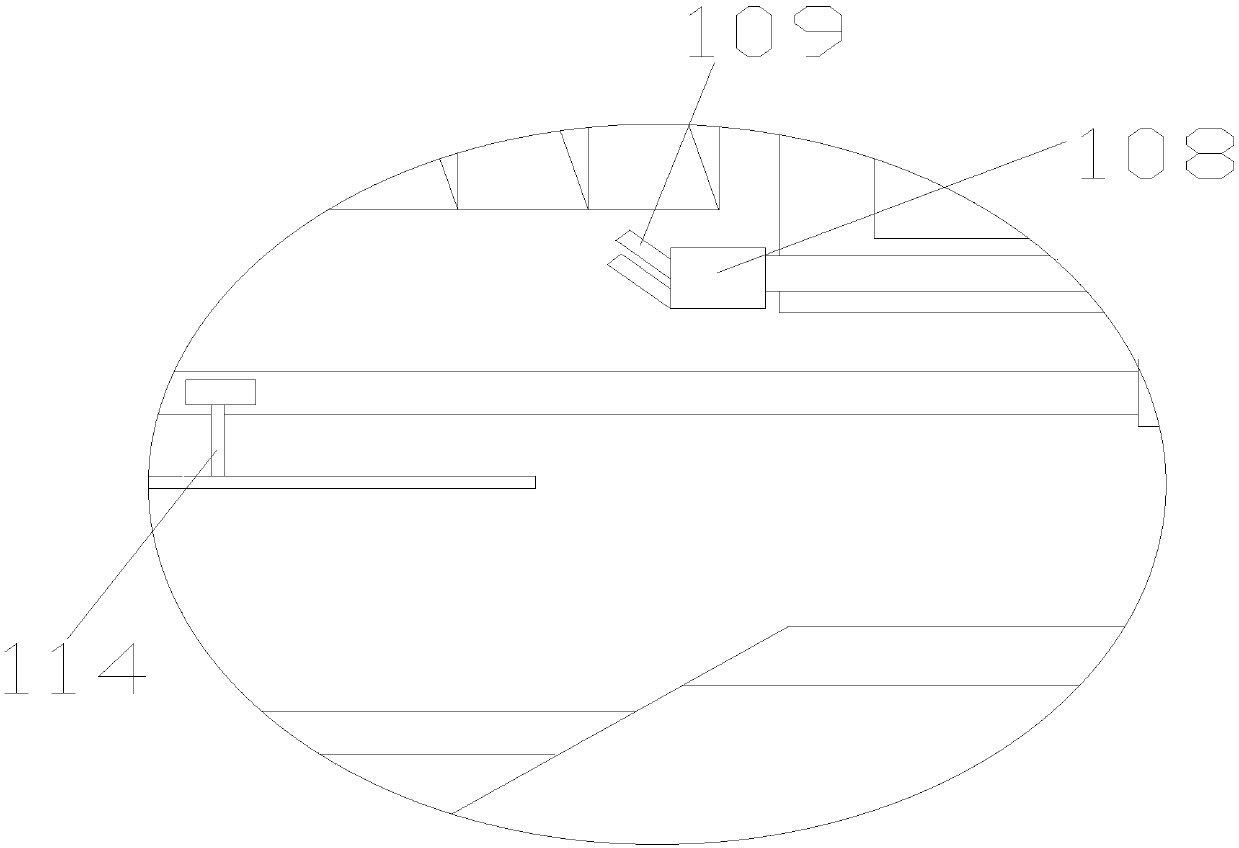

Treatment equipment for kitchen waste

Owner:SUZHOU MEIJIESHENG ENVIRONMENTAL PROTECTION ENG CO LTD

Nuclear power plant solid waste processing system

The invention provides a nuclear power plant solid waste processing system. The nuclear power plant solid waste processing system comprises a carrier, a cement tank, a lime tank, a waste liquid measuring tank, a waste resin measuring tank, a stirrer, a conveyor and a waste barrel, wherein the cement tank, the lime tank, the waste liquid measuring tank, the waste resin measuring tank, the stirrer, the conveyor and the waste barrel are arranged on the carrier, the cement tank is used for containing cement, the lime tank is used for containing lime, the waste liquid measuring tank is used for quantitatively containing waste liquid, the waste resin measuring tank is used for quantitatively containing waste resin, the stirrer is used for stirring and mixing cement, lime and waste resin with waste liquid to form a mixture, the conveyor is used for conveying cement and lime into the stirrer, and the waste barrel is used for containing the mixture. The discharge port of the cement tank and the discharge port of the lime tank are communicated with the feed port of the conveyor, the discharge port of the conveyor is communicated with the feed port of the stirrer, and the waste liquid measuring tank and the waste resin measuring tank are communicated with the feed port of the stirrer. The nuclear power plant solid waste processing system has the advantages of being convenient to move and improving the utilization rate.

Owner:中广核工程有限公司 +1

Treatment method of chemical copper plating waste liquid

InactiveCN106957077ANo pollution in the processLow costWater contaminantsWaste water treatment from metallurgical processLiquid wasteProduction rate

Owner:GUILIN UNIV OF ELECTRONIC TECH

Cable cleaning device

ActiveCN108405441ACleaning using toolsDrying machines with progressive movementsLiquid wasteEngineering

The invention provides a cable cleaning device which comprises a cleaning tank, a cleaning part in the cleaning tank, a liquid waste pool located below the cleaning tank, and a cable inlet formed in the side face of the cleaning tank. The cleaning part comprises cleaning devices arranged in the cleaning tank and spraying devices connected with a water tank. The cleaning devices comprise mounting seats arranged on the inner walls of the side faces of the cleaning tank and connected with a cleaning liquid tank, supporting devices and cleaning wheels. Cleaning grooves sunken towards the centers of the cleaning wheels are formed in the cleaning wheels, and cleaning sponge layers are arranged on the cleaning grooves. According to the cable cleaning device, a cable is cooled through the sprayingdevices, the cable is wetted preliminarily, the mounting seats connected with the cleaning liquid tank provide cleaning liquid for cable cleaning when the cable passes through the cleaning wheels, the cable is sufficiently cleaned when passing through the cleaning grooves with the cleaning sponge layers, the service life of the cable is prolonged, and the manpower cost is reduced.

Owner:LONGYOU COUNTY POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD

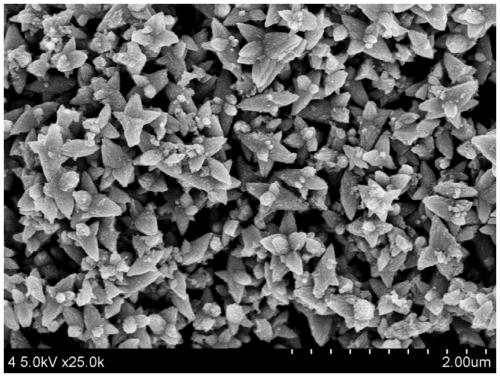

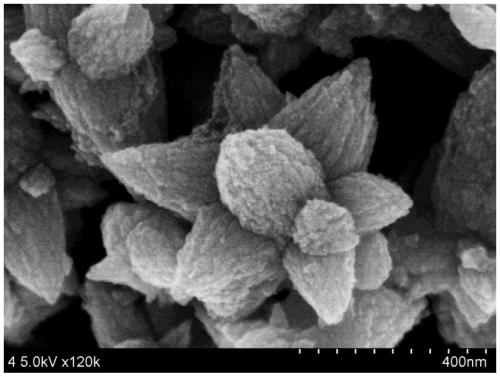

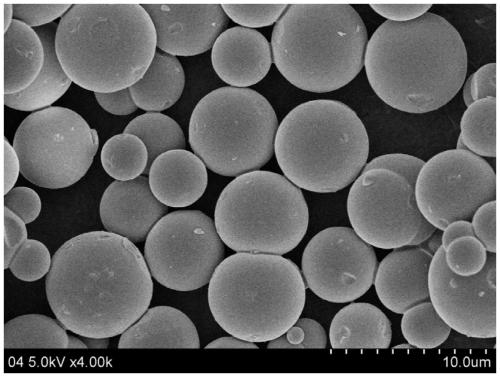

Preparation method and application of Ag2Se/GO nano material with micro-flower structure

InactiveCN109806891AImprove catalytic performanceImprove photocatalytic performancePhysical/chemical process catalystsWater/sewage treatment by irradiationLiquid wasteWastewater

Owner:DONGHUA UNIV

Device and method for carrying out low-concentration SO2 smoke desulfurization through alkaline waste liquid

The invention discloses a device and method for carrying out low-concentration SO2 smoke desulfurization through alkaline waste liquid. The device mainly comprises a SO2 smoke absorption tower, an electric mist precipitator, an active ore pulp buffer tank, an active ore pulp absorption-liquid buffer tank, a waste electrolyte buffer tank, a waste electrolyte circulating trough and a tail smoke discharging chimney. Acid gas SO2 in the smelting smoke is absorbed two times through alkaline ingredients in active ore pulp, and then the acid gas SO2 in the smelting smoke is further absorbed through alkaline ingredients in waste electrolytes; meanwhile, ore dust in the smelting smoke is removed, the two kinds of waste alkali liquid including the active ore pulp and the waste electrolytes are greatly used, the technological process is simple, running is reliable, the desulfurization effect is remarkable, investment is low, the floor area is small, operation is easy, desulfurization of the huge amount of low-concentration SO2 smoke can be completed only through low cost, the raw material cost of the desulfurization process is reduced, new waste can not be generated, and the aims that through treatment, environment-friendly collected SO2 meets the standard and economy reaches the standard are achieved in the mode that waste is controlled through waste.

Owner:金川集团镍钴有限公司

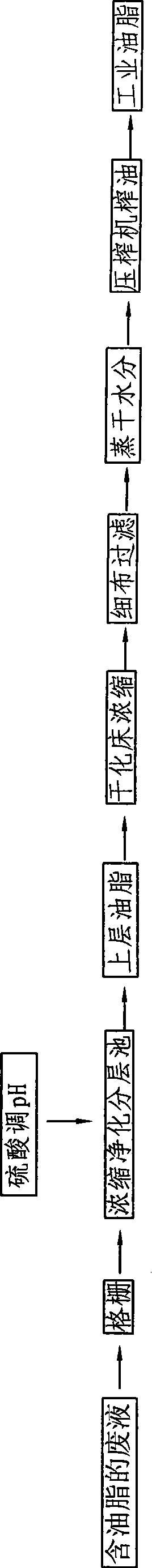

Process for extracting commercial grease by tanning lipid-containing waste liquor

InactiveCN101497847AReduce difficultyWide range of usesFatty oils/acids recovery from wasteFatty substance recoveryLiquid wasteTerra firma

Owner:张勇

Treatment system and method for mixed waste liquid of drilling wastewater and fracturing flowback fluid

InactiveCN110078251AAchieve re-useWell mixedWater contaminantsScale removal and water softeningLiquid wasteIon exchange

Owner:PETROCHINA CO LTD

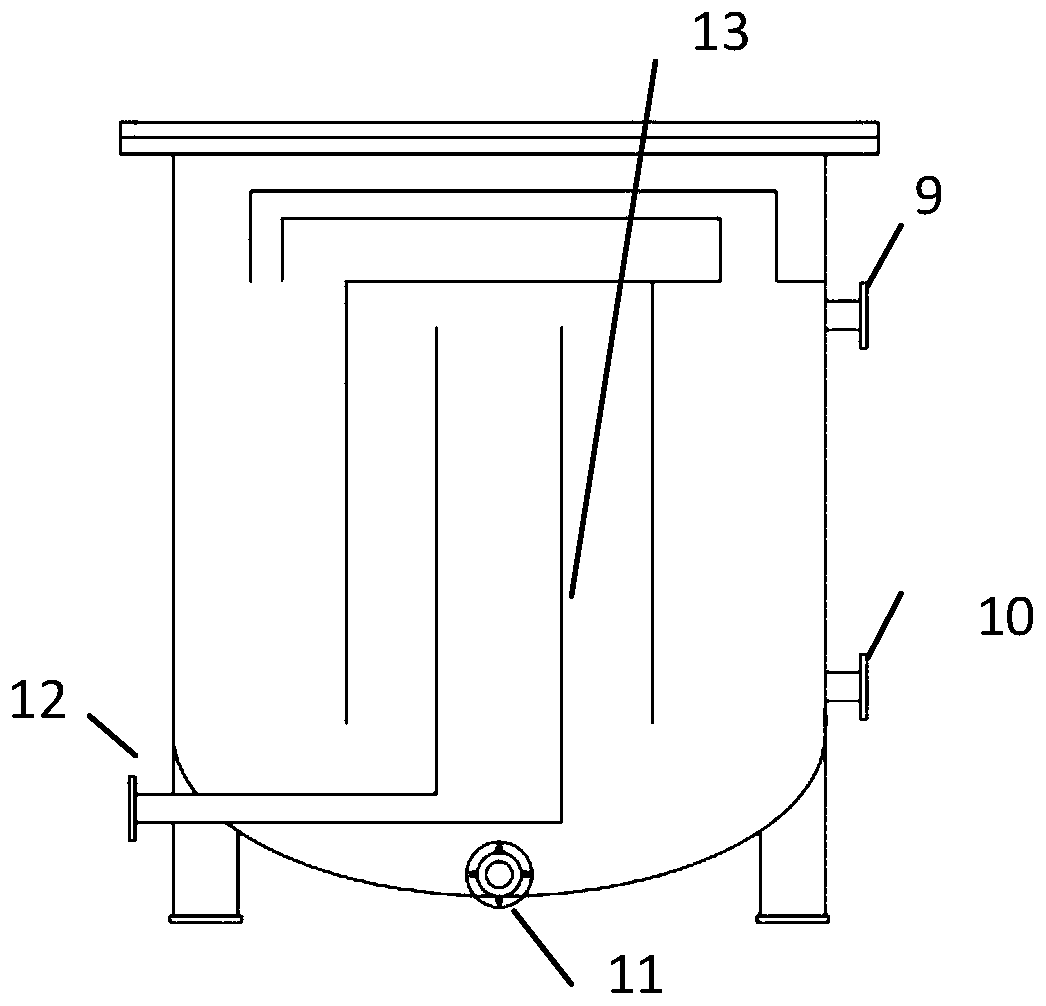

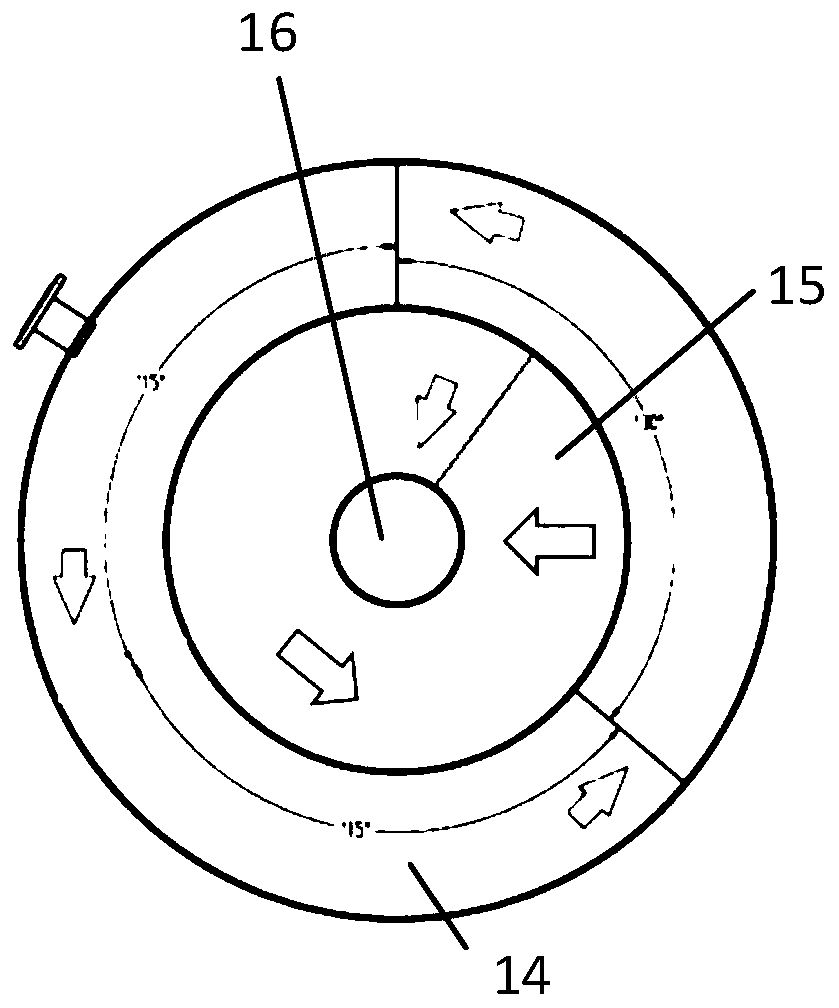

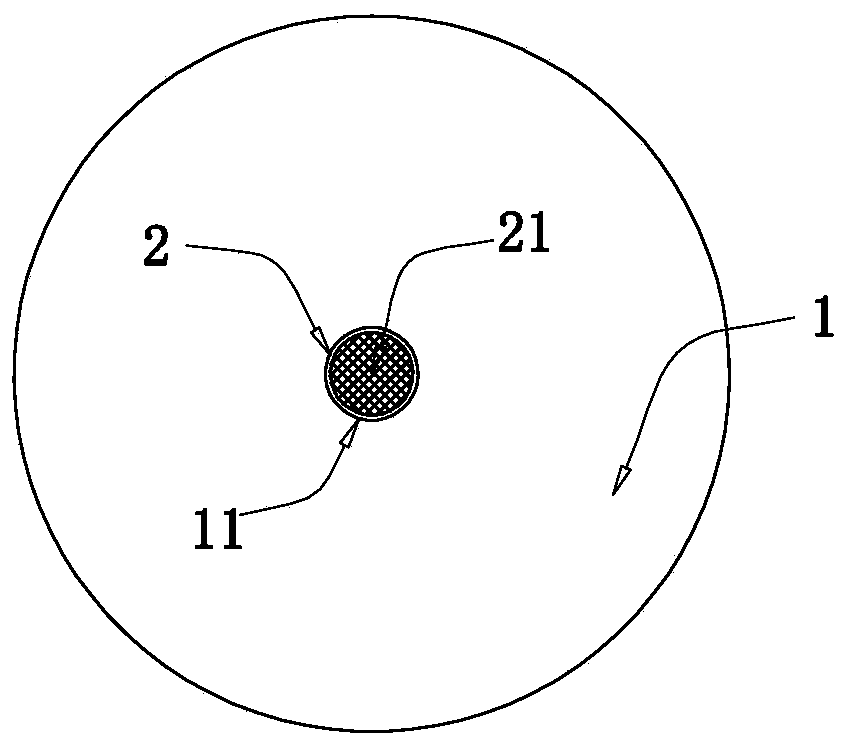

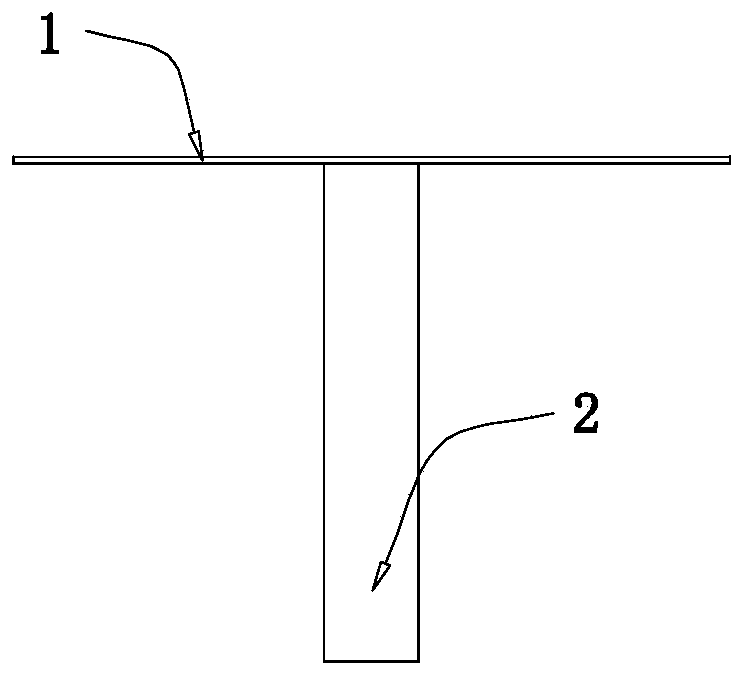

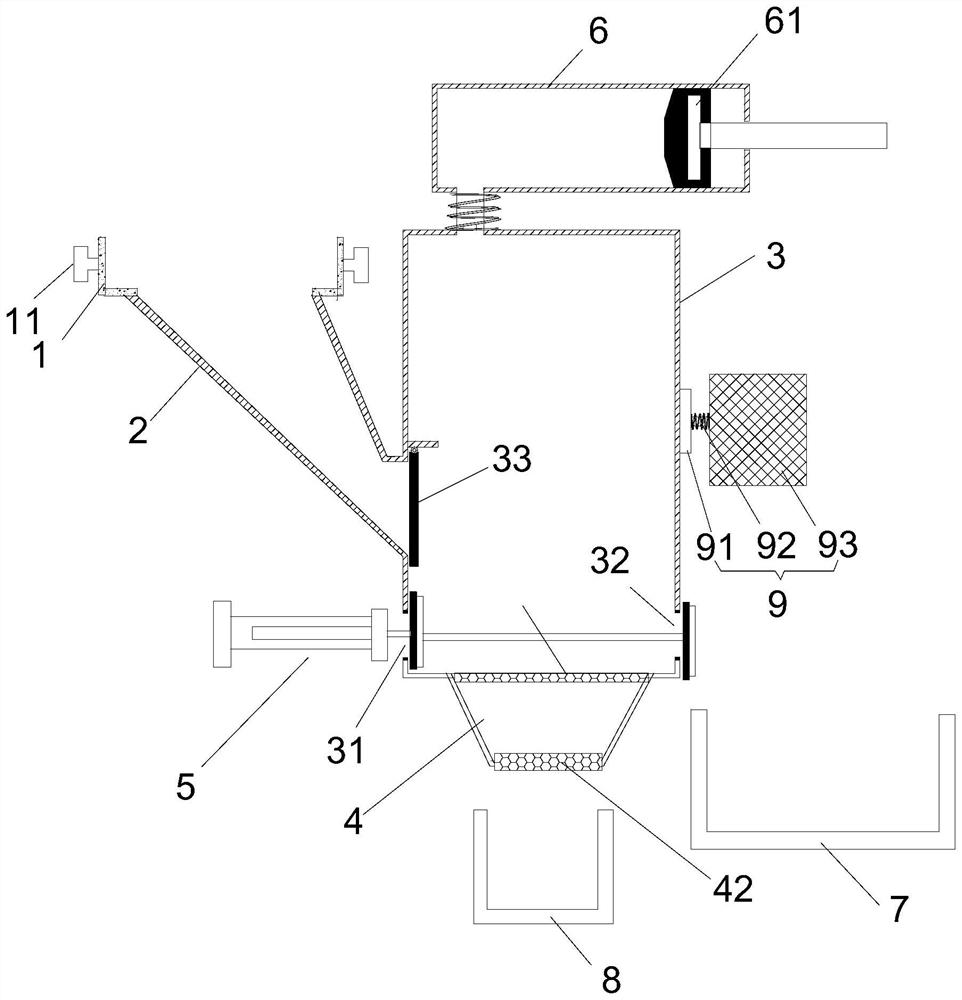

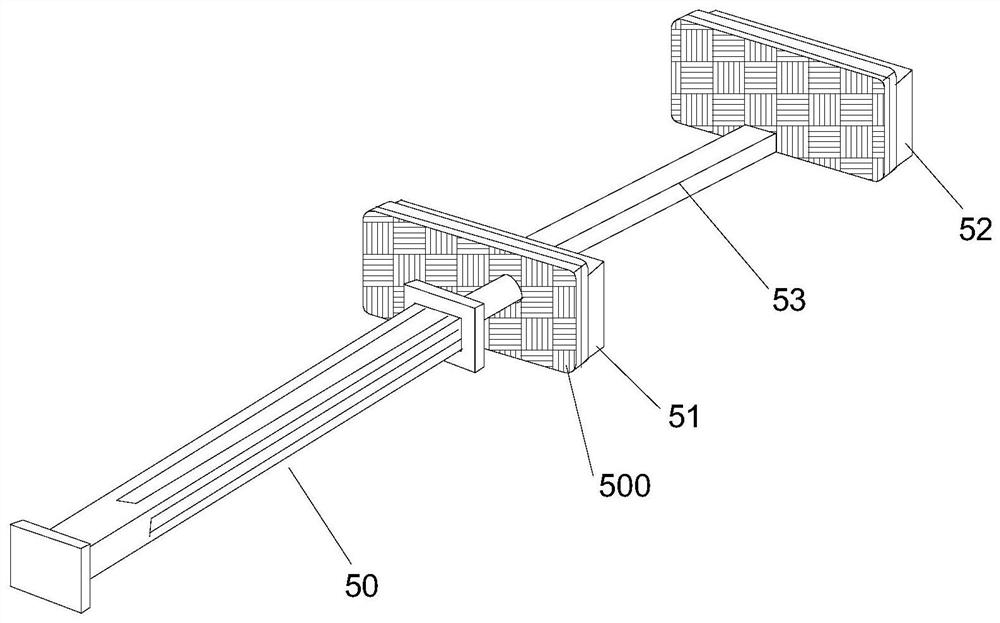

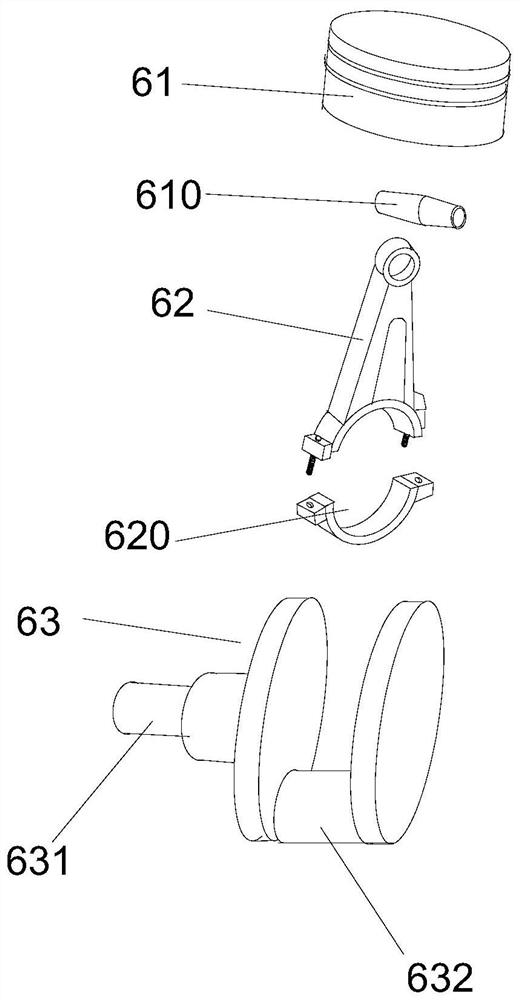

Medical liquid waste and solid waste collecting device

Owner:SHANDONG PROVINCIAL HOSPITAL

Method for producing saline alkali soil conditioning agent through reconstituted tobacco concentrated waste liquor

InactiveCN105777422AIncrease valueLow costCalcareous fertilisersExcrement fertilisersLiquid wasteAlkali soil

The invention discloses a method for producing a saline alkali soil conditioning agent through reconstituted tobacco concentrated waste liquor.Paper-making reconstituted tobacco waste liquor is obtained for filtering separation, a liquid phase portion is fed into concentration equipment to be subjected to low-temperature vacuum concentration, the solid content of the concentrate is 40-55%, 65-85% of the concentrate, 15-35% of an organic matter carrier and 2-6% of a microbial agent are mixed, blended and mixed to be uniform, and low-temperature drying is performed to till the water content reaches 18-22%, and drying is performed after granulation is performed till the water content is lower than 14%.According to the method, the waste liquor can become available resources, waste materials are changed into things of value, the soil conditioning agent can be obtained to improve soil, and economic benefits of a reconstituted tobacco enterprise can be improved.

Owner:YUNNAN FUFA BIOTECH CO LTD

Efficient machining waste recycling device for numerical control machine tool

InactiveCN112476033AEasy to separateMaintainance and safety accessoriesNumerical controlLiquid waste

Owner:ANHUI JIANGJI HEAVY DUTY CNC MACHINE TOOL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap