Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Roasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Roasting is a process of heating of sulfide ore to a high temperature in presence of air. It is a step of the processing of certain ores. More specifically, roasting is a metallurgical process involving gas–solid reactions at elevated temperatures with the goal of purifying the metal component(s). Often before roasting, the ore has already been partially purified, e.g. by froth flotation. The concentrate is mixed with other materials to facilitate the process. The technology is useful but is also a serious source of air pollution.

Far infrared Nixing pottery product and preparation method thereof

The invention discloses a far infrared Nixing pottery product and a preparation method thereof. The far infrared Nixing pottery finished product, far infrared Nixing pottery powder and far infrared Nixing pottery slurry is prepared by adding the metal oxides Cr2O3, MgO, MnO2 and ZrO2 and other compounds serving as auxiliary raw materials into Nixing pottery which is made in Qinzhou, Guangxi, and has the advantages of more cheap chemical components, high content and high quality and serves as a main raw material and roasting the mixture at the temperature of between 1,000 and 1,200 DEG C in a high-temperature electric furnace or a high-temperature roasting furnace or a high-temperature burning kiln according to the pottery. The far infrared Nixing pottery product transmits a far infrared ray with the wavelength of 6 to 23 mu m at the normal temperature and can be applied to the industry, medical care and living goods in the fields such as medical care, energy conservation and environment protection, building materials, heat insulating materials, water quality improvement, paper making plastic, fiber weaving, food preservation, food roasting, wine making industry, pharmaceutical industry and the like. The preparation method has the advantages of simple process, low energy consumption, low cost, high benefit and good product quality.

Owner:李建洪

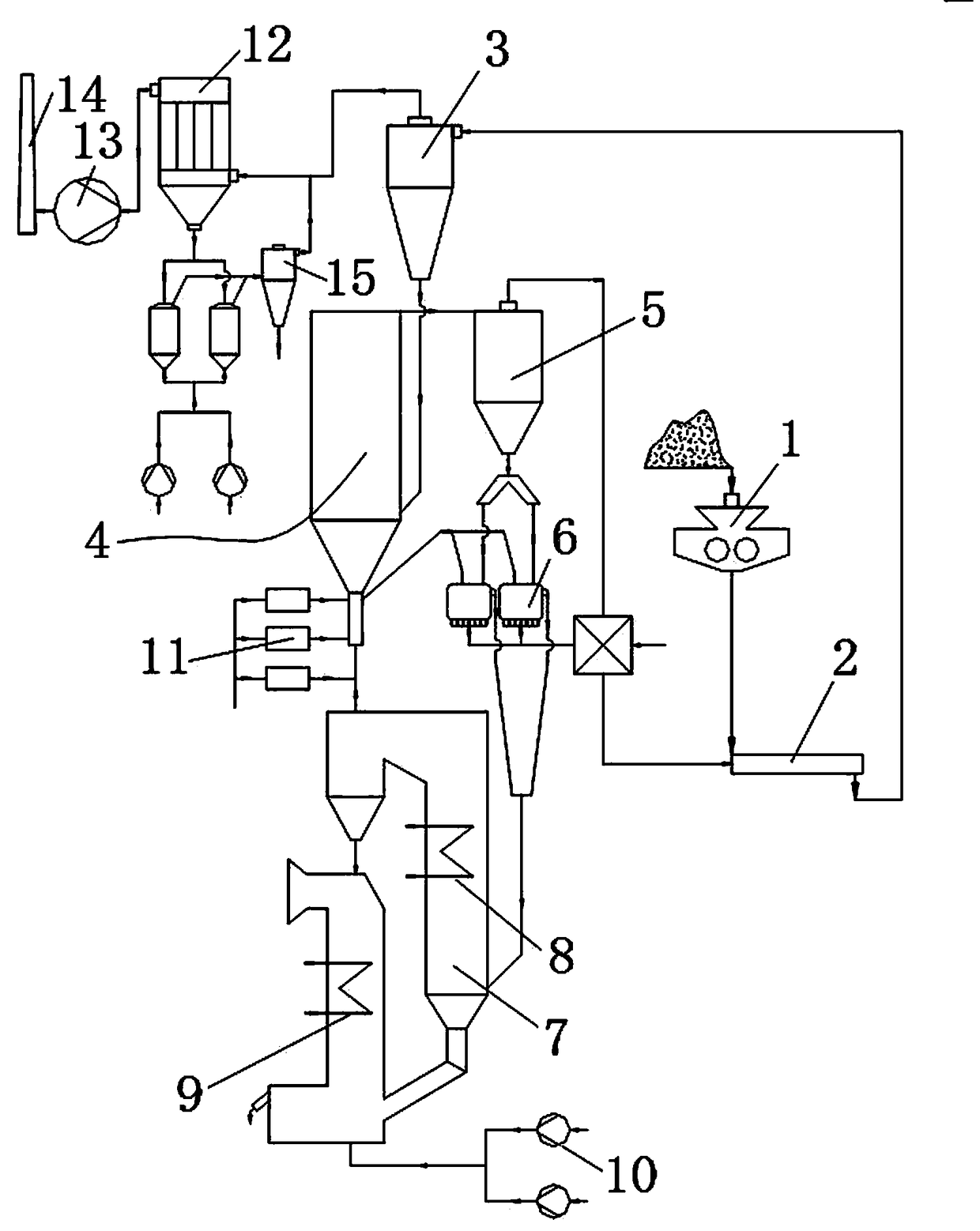

Refractory iron ore dry grinding-suspension roasting integration technology and device

ActiveCN108823400AReduce energy consumptionReasonable useHuman health protectionGrain treatmentsSuperheaterBall mill

The invention provides a refractory iron ore dry grinding-suspension roasting integration technology and device. The refractory iron ore dry grinding-suspension roasting integration technology comprises the following steps of: breaking powder iron ores by a roller press, carrying out ore grinding by a dry-type ball grinder or the roller press, fluidifying to generate fine powder gas-solid two phase flow, then introducing the fine powder gas-solid two phase flow to a raw material cyclone collector for gas-solid separation in a suspension magnetic roasting technology, introducing middle-temperature flue gas discharged by the suspension magnetic roasting technology to a dry-type ore grinding technology for fluidifying, separating to obtain iron ore powder, carrying out oxidizing roasting on iron ore powder in a suspension magnetizing roasting main furnace, preheating coal gas to 450-500 DEG C by using burnt gas discharged by the oxidizing roasting in the suspension magnetizing roasting main furnace, entering a magnetizing roasting furnace so as to carry out iron ore reducing roasting, carrying out indirect heat exchanger cooling on roasted ore produced after reducing coasting to obtain roasting ore with the relatively high magnetism by using a suspended bed supercharger and a fluidized bed. The refractory iron ore dry grinding-suspension roasting integration technology has short technological process, does not consume water, consumes little coal gas, is low in cost, reduces the carbon emission, improves environments and improves economic benefits.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Full-tooth continuous quenching method for slewing bearing

PendingCN114317906AHigh hardnessImprove mechanical propertiesFurnace typesIncreasing energy efficiencyRare-earth elementKerosene

Owner:安徽省宁国顺昌机械有限公司

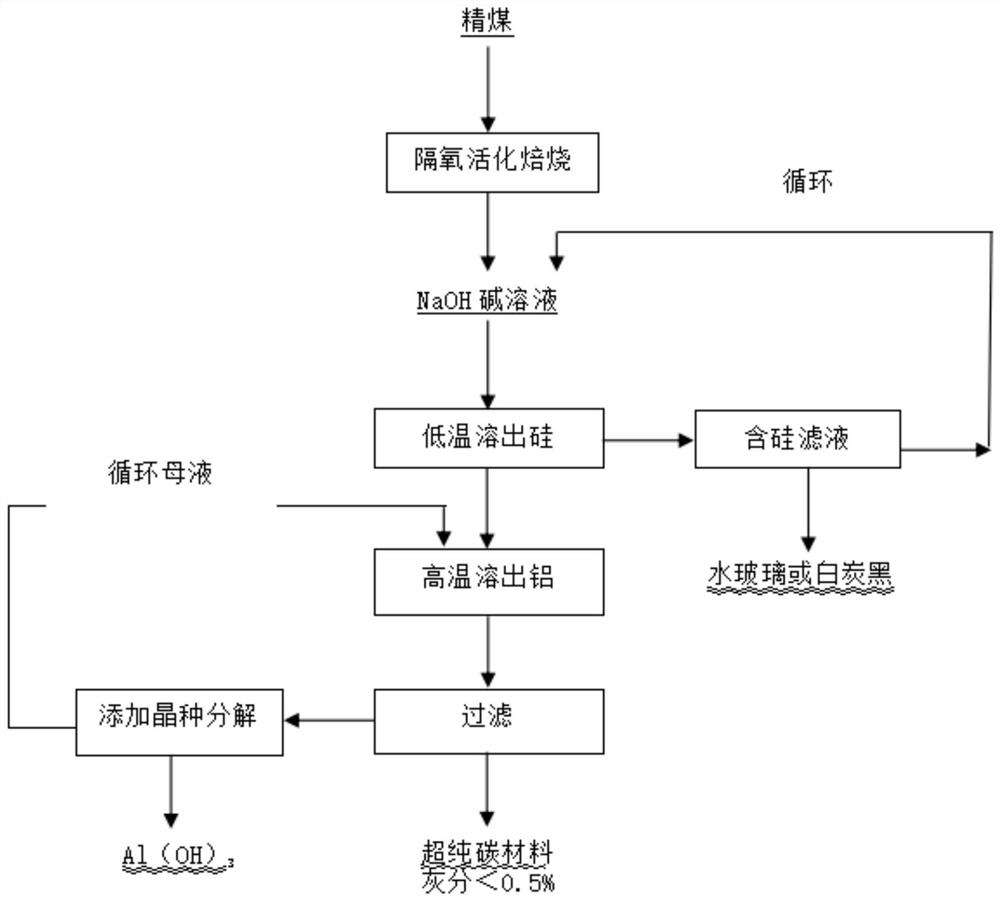

Chemical purification method for preparing ultralow ash content coal from clean coal

ActiveCN114317061ARealize recycling of resourcesAchieve recyclingSilicaSolid fuelsResource recoverySodium aluminate

Owner:HUAYANG NEW MATERIAL TECH GRP CO LT

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap