Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84 results about "Flue gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flue gas is the gas exiting to the atmosphere via a flue, which is a pipe or channel for conveying exhaust gases from a fireplace, oven, furnace, boiler or steam generator. Quite often, the flue gas refers to the combustion exhaust gas produced at power plants. Its composition depends on what is being burned, but it will usually consist of mostly nitrogen (typically more than two-thirds) derived from the combustion of air, carbon dioxide (CO2), and water vapor as well as excess oxygen (also derived from the combustion air). It further contains a small percentage of a number of pollutants, such as particulate matter (like soot), carbon monoxide, nitrogen oxides, and sulfur oxides.

Preparation method of polylactic acid strand filtering rod capable of lowering flue-gas temperature and reducing suction resistance

ActiveCN108523216AImprove the taste of smokingReduce the temperatureTobacco treatmentCigar manufactureFlue gasEngineering

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

Check fire valve for flue

Owner:韩文强

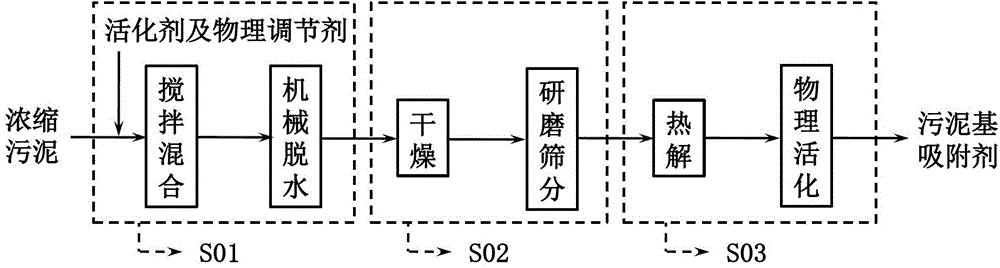

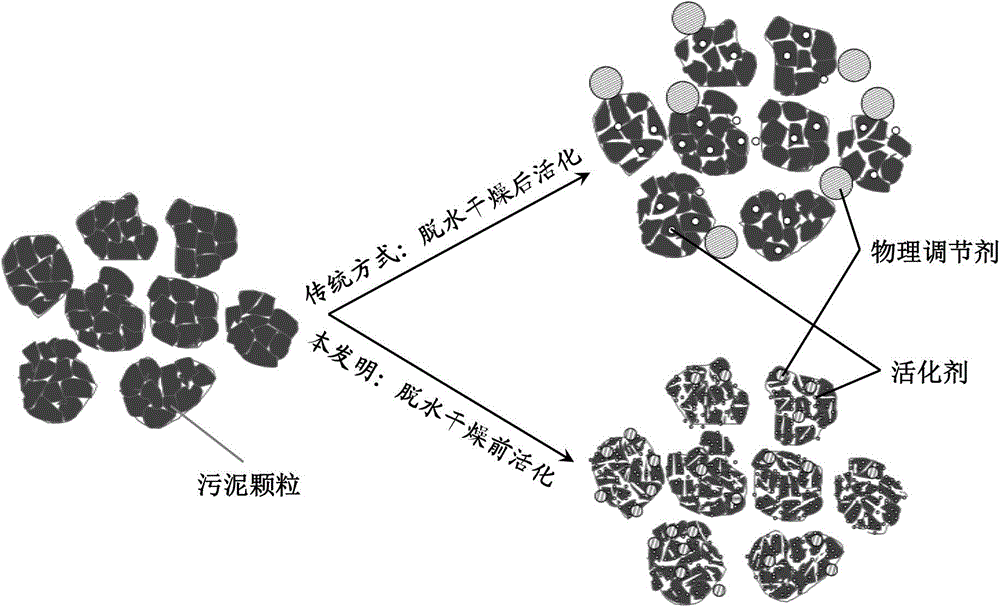

Sludge-based adsorbent used for desulfurization and demercuration of flue-gas and preparation method thereof

ActiveCN102745879AHigh porosityHigh adsorption activitySludge treatment by de-watering/drying/thickeningOther chemical processesSludge cakePhysical conditioning

Owner:HUAZHONG UNIV OF SCI & TECH

Technique for producing energy-saving sintering brick by silt

InactiveCN101265077AHigh porosityImprove thermal insulationCeramic materials productionClaywaresPorosityBrick

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

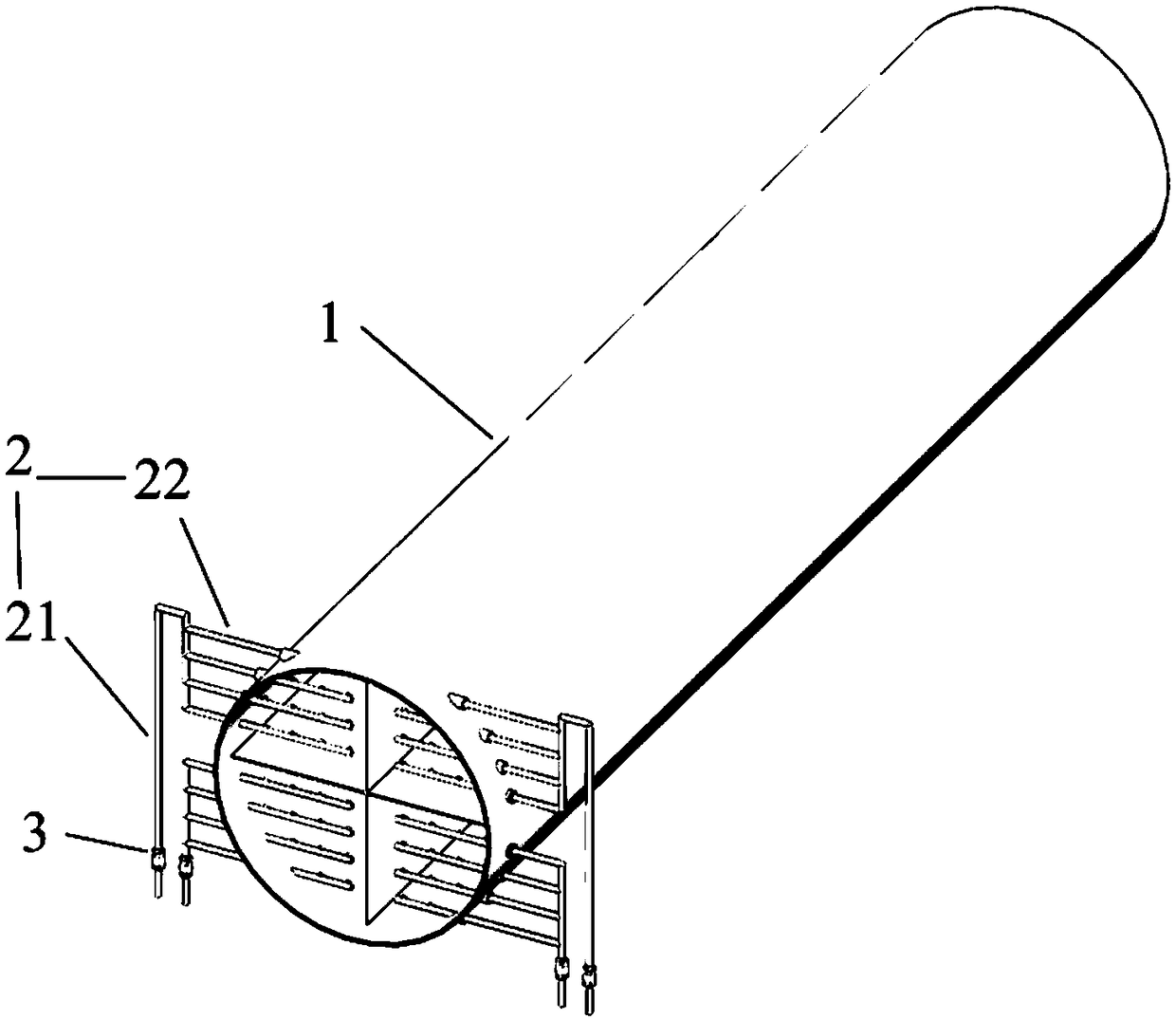

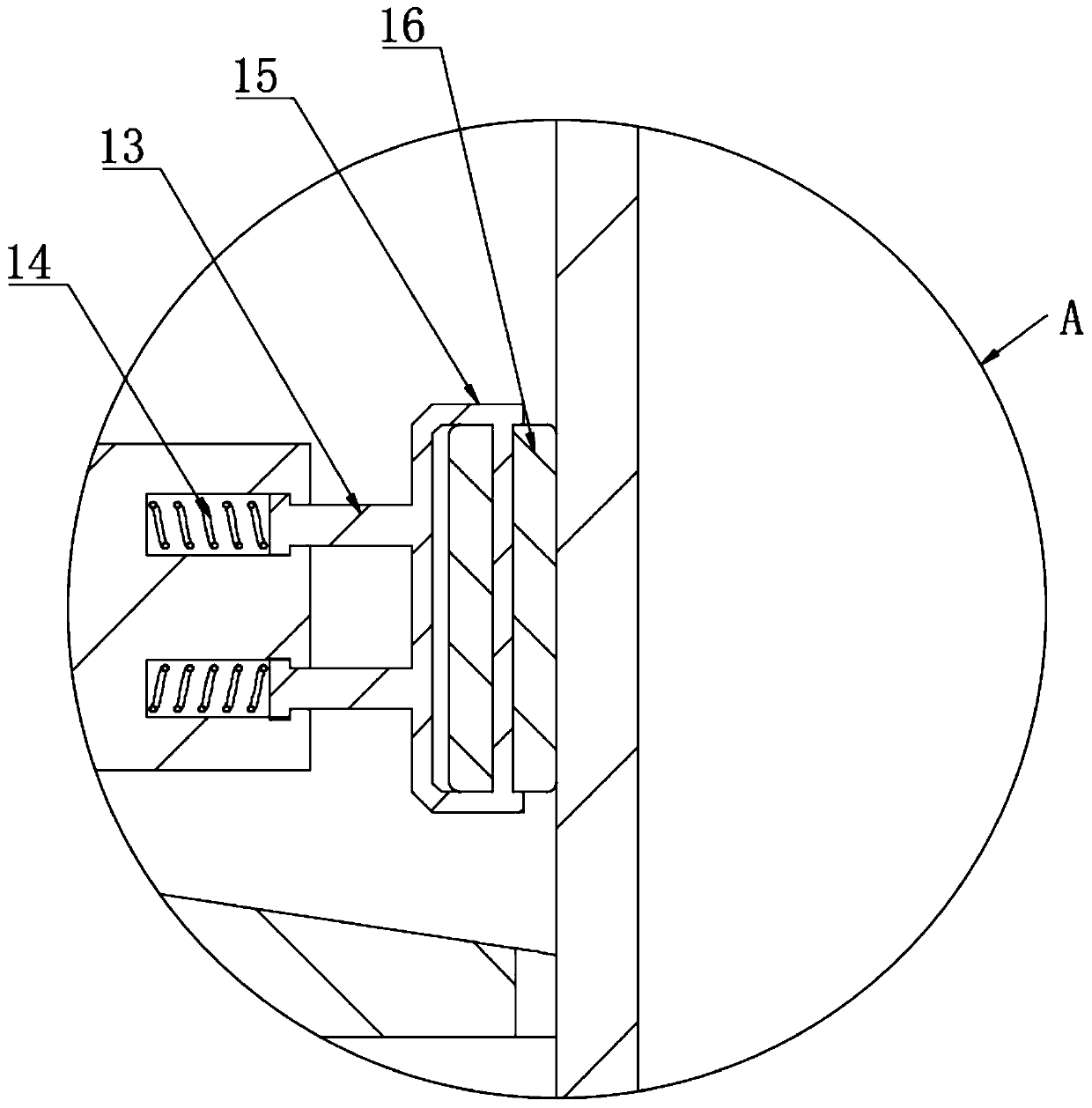

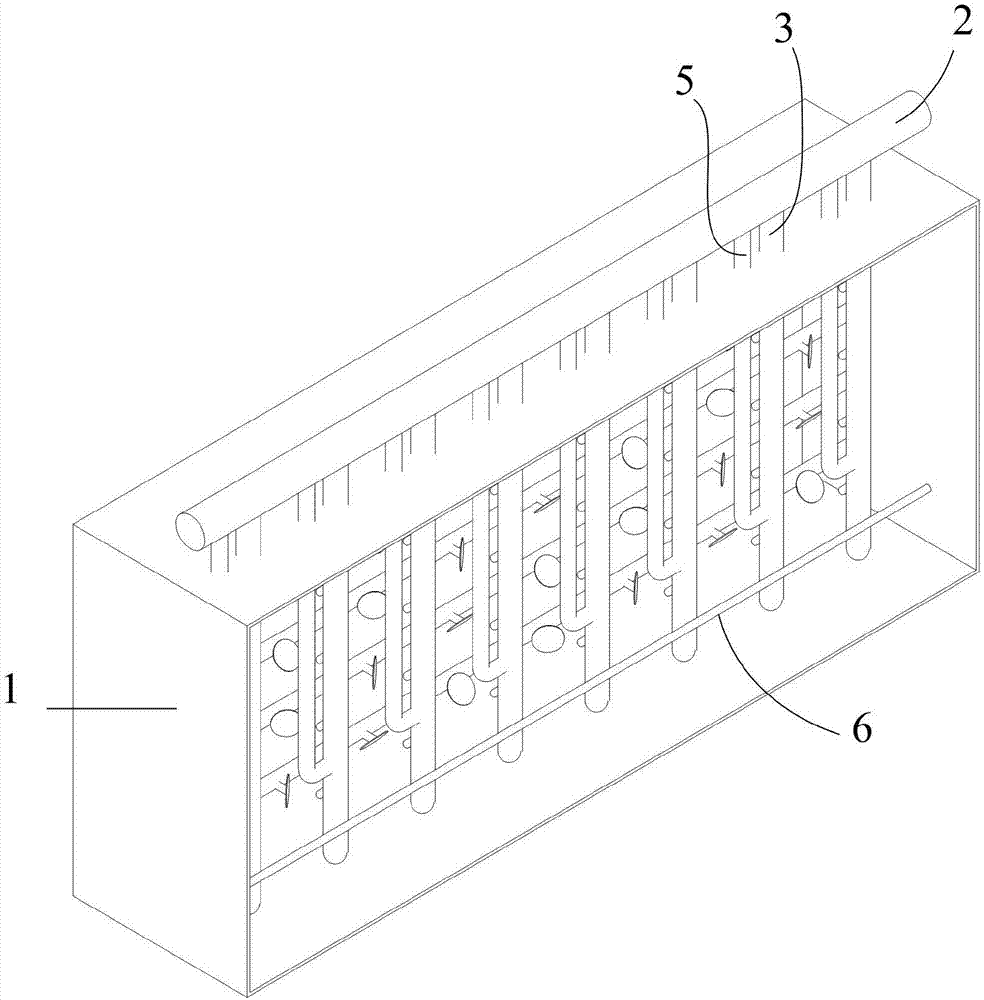

Zoning oxidation ozone distributor, and arrangement mode and applications thereof

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

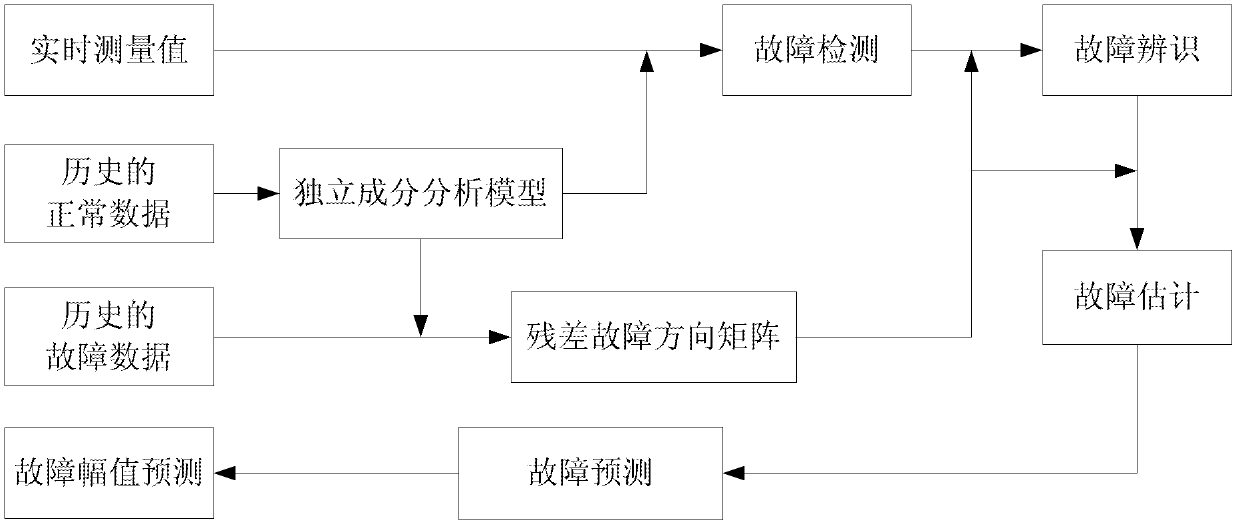

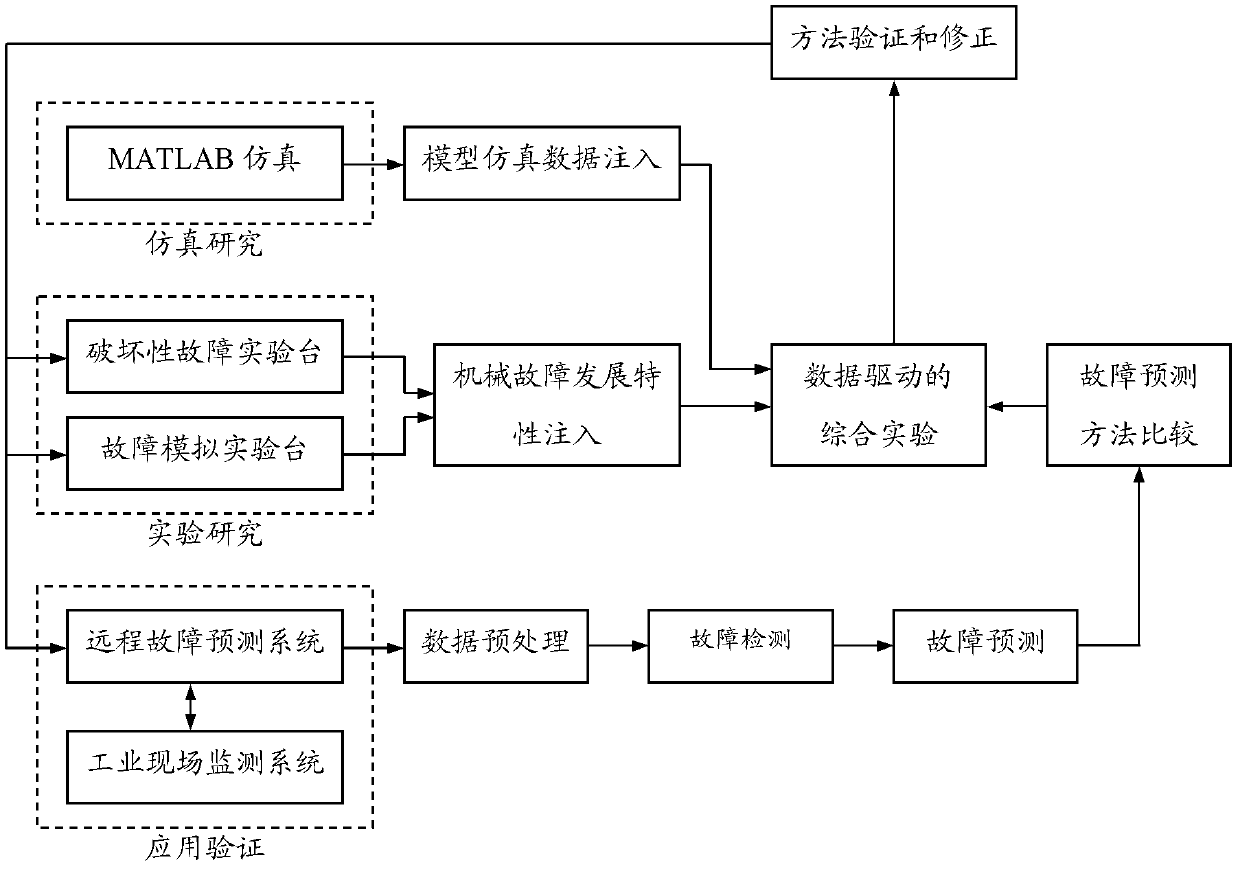

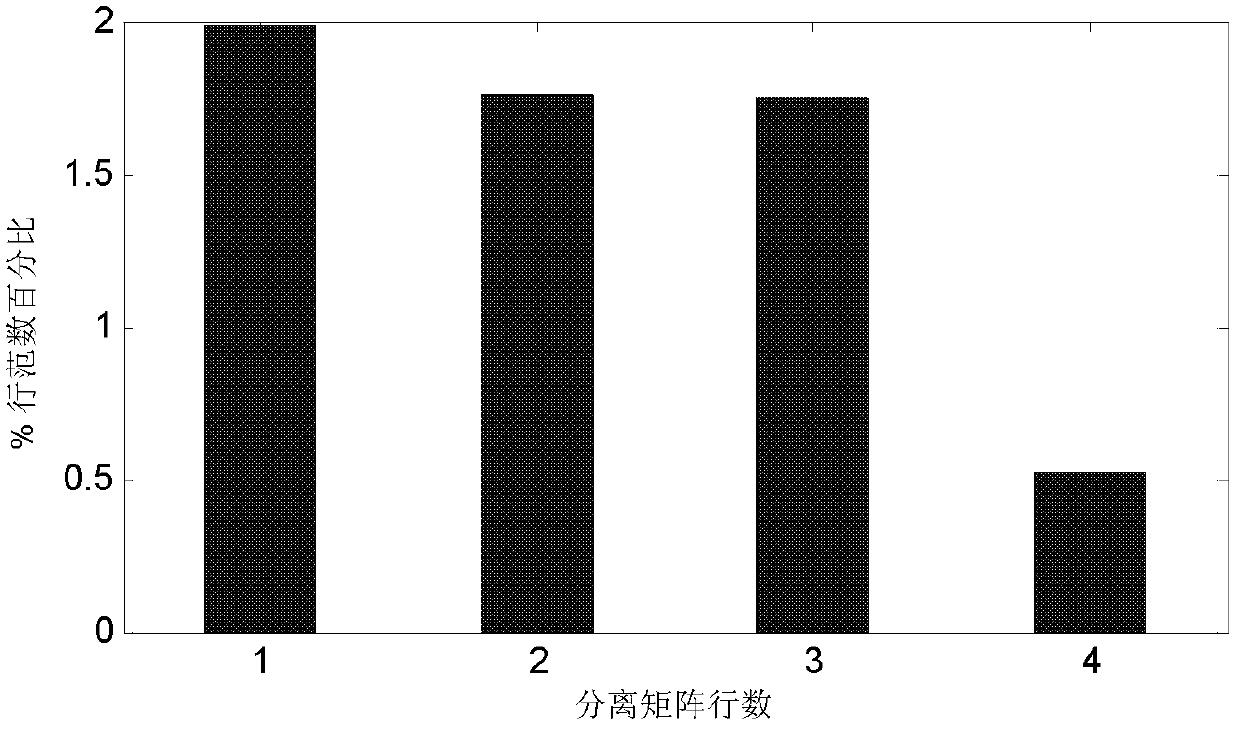

Failure prediction method based on ICA reconstruction

ActiveCN102539192ASolve the problem of not being able to utilize multi-dimensional effective dataImprove forecast accuracySubsonic/sonic/ultrasonic wave measurementStructural/machines measurementReal-time dataAlgorithm

Owner:BEIJING INFORMATION SCI & TECH UNIV

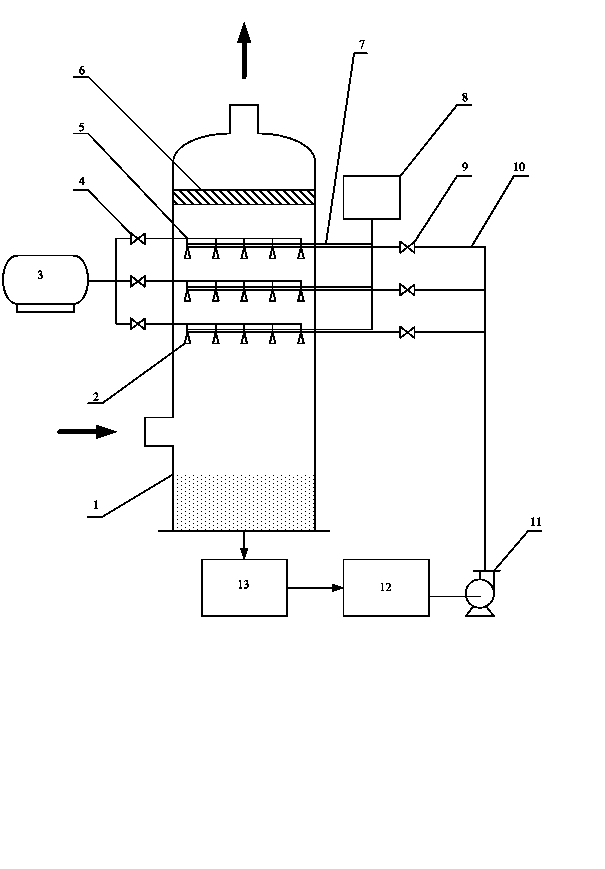

Method for synchronously removing sulfur dioxide and fine particles in smoke through electrical charge and mist spray

InactiveCN104162486ADispersed particle separationExternal electric electrostatic seperatorSulfur dioxideFlue gas

Owner:SHANGHAI SANQING ENVIRONMENTAL PROTECTION TECH

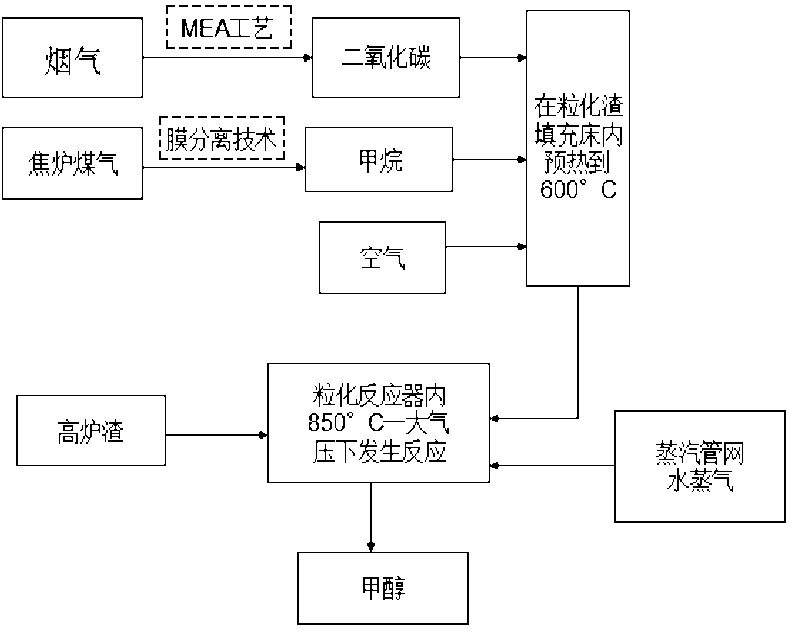

Method for preparing methanol by sensible heat of blast furnace slag

InactiveCN103304372AAlleviate or even eliminate the problem of carbon depositionEmission reductionPreparation by oxidation reactionsChemical industrySlagEnergy recovery

Owner:NORTHEASTERN UNIV

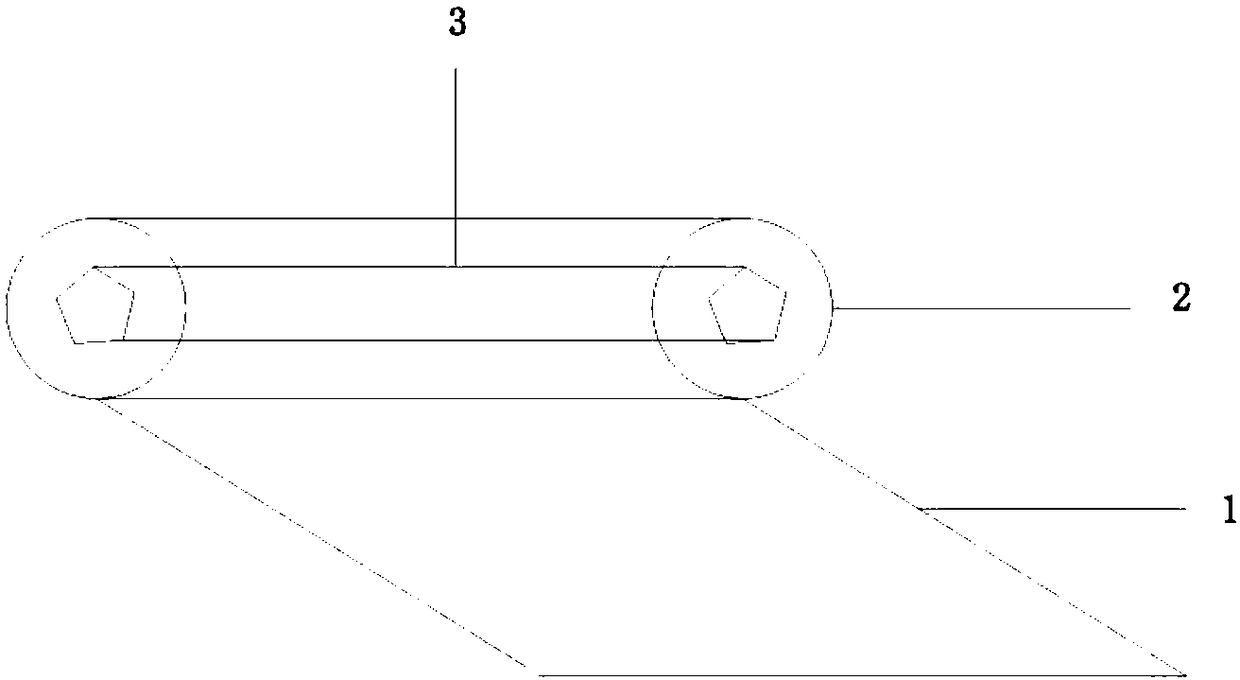

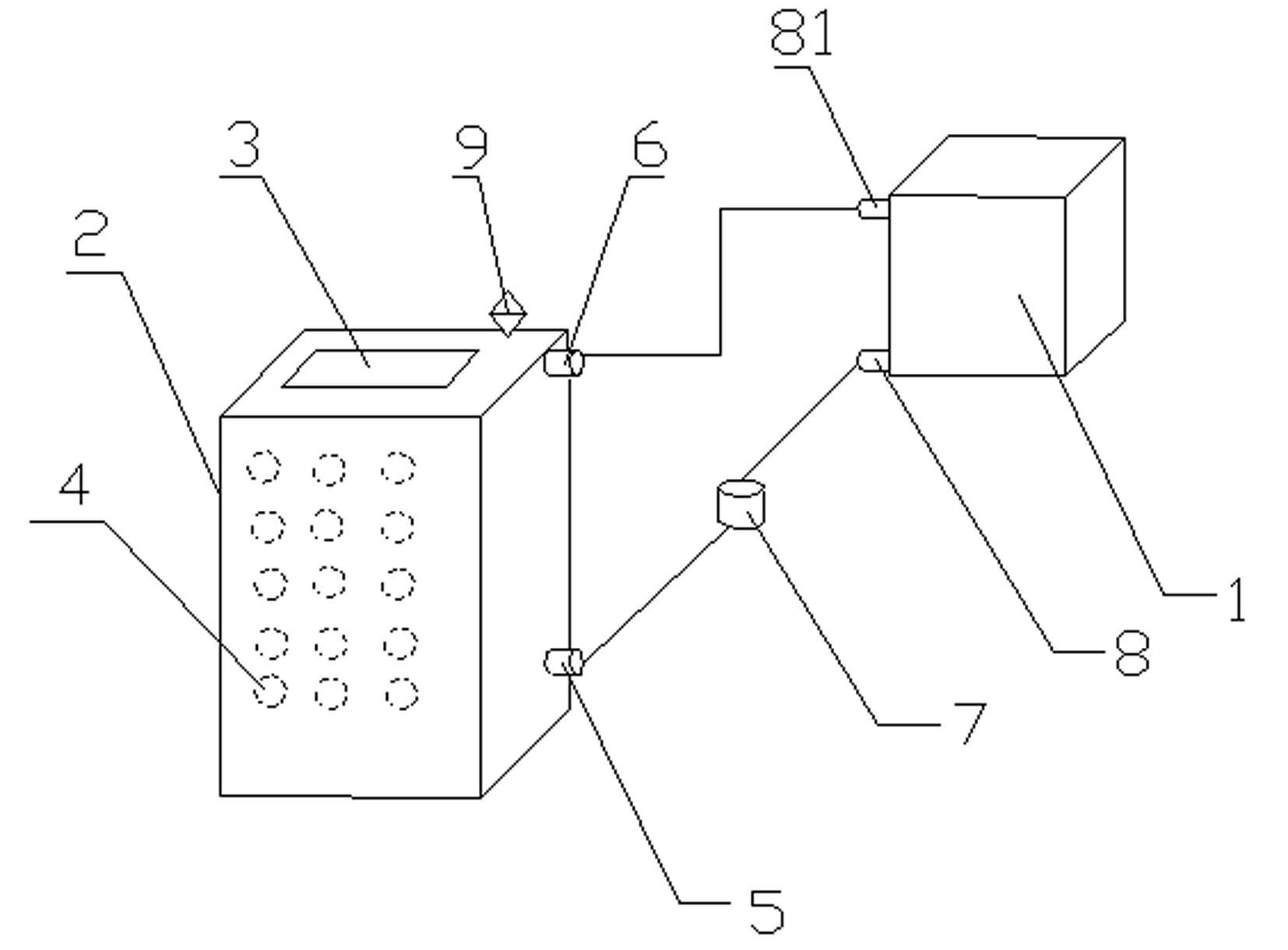

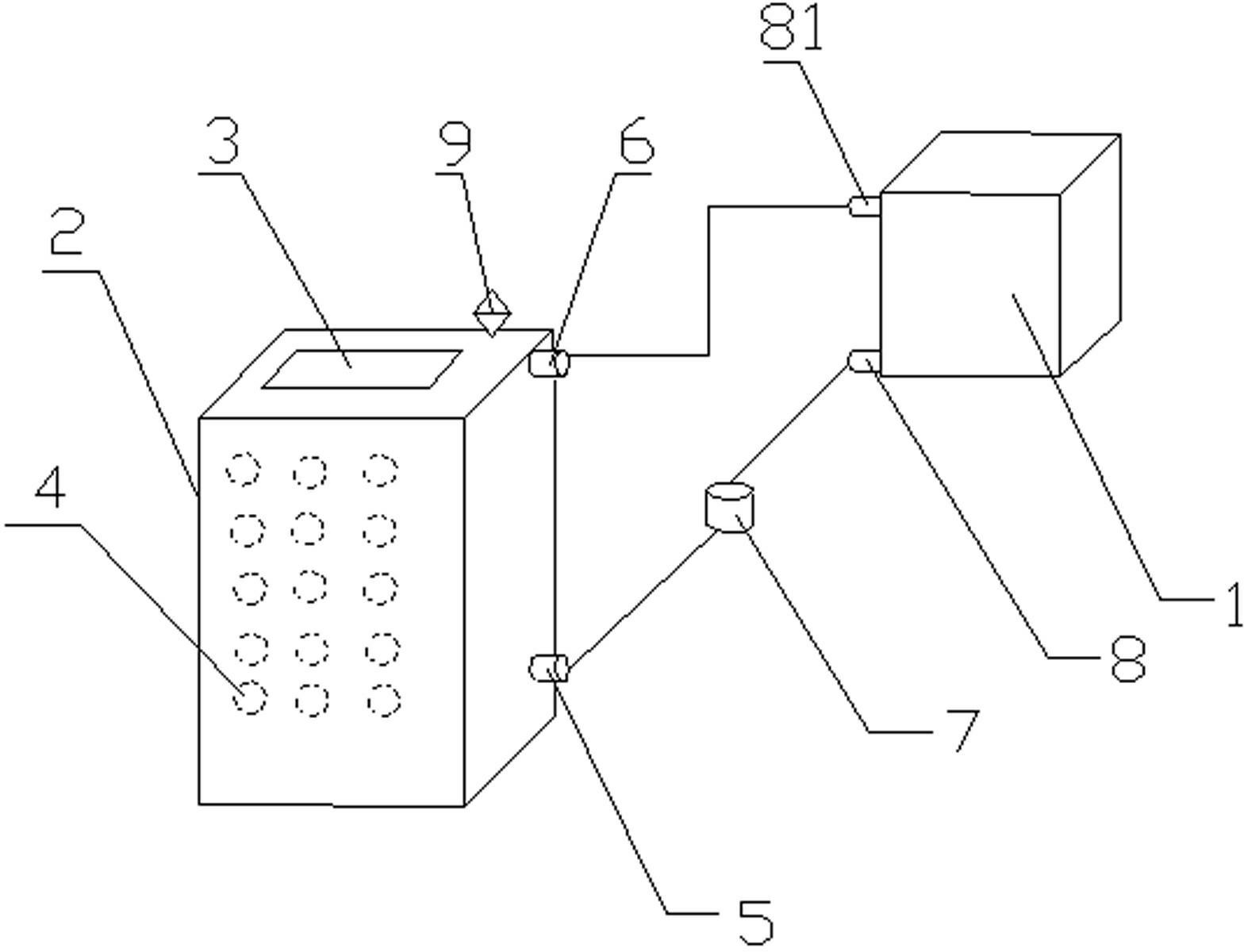

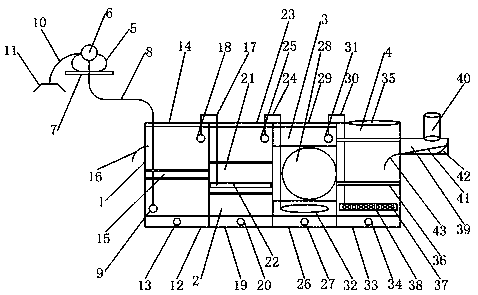

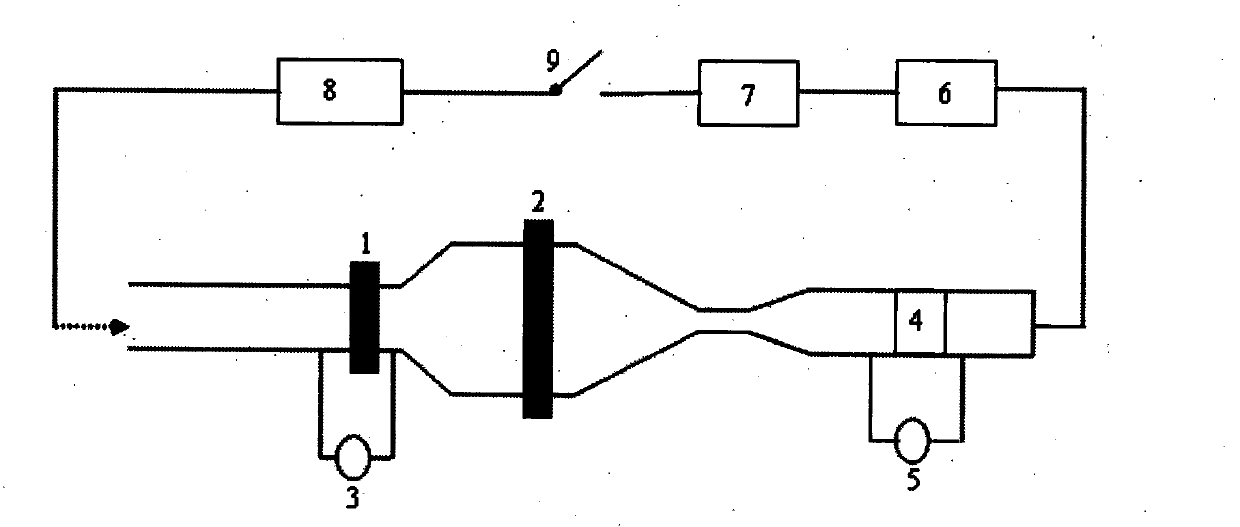

Acquisition system for collecting particles of different particle size discharged by fire coal

InactiveCN103323292AEasy to carryGood effectWithdrawing sample devicesPreparing sample for investigationParticulatesCombustion

The invention relates to an acquisition system for collecting particles of different particle size discharged by fire coal. The acquisition system comprises a flue gas collecting box, a flue gas pipeline, a slide plate with wheels, a civil coal-fired furnace, a blower, a frequency converter, a condenser tube, a temperature sensor, a MCI sampler and a MOUDI sampler. The flue gas collecting box, the flue gas pipeline and the slide plate with wheels are made of stainless steel; the civil coal-fired furnace is put inside the flue gas collecting box; the blower can blow air into the flue gas collecting box to dilute flue gas and provide oxygen for combustion; and the particles in the air are filtered by a filter cloth of 120 meshes at the blower air inlet. The apparatus in the invention avoids the defects that original particles in the air cannot be purified to enter the acquisition system, dilution multiple of fire coal flue gas cannot be calculated and flue gas temperature cannot be adjusted, the original apparatus is not convenient for carrying and condensation enters into sampler flue gas etc. The experiment result shows that the effect of collecting particles of different particle size that are discharged by fire coal is obvious and the sampling operation is simple.

Owner:SHANGHAI UNIV

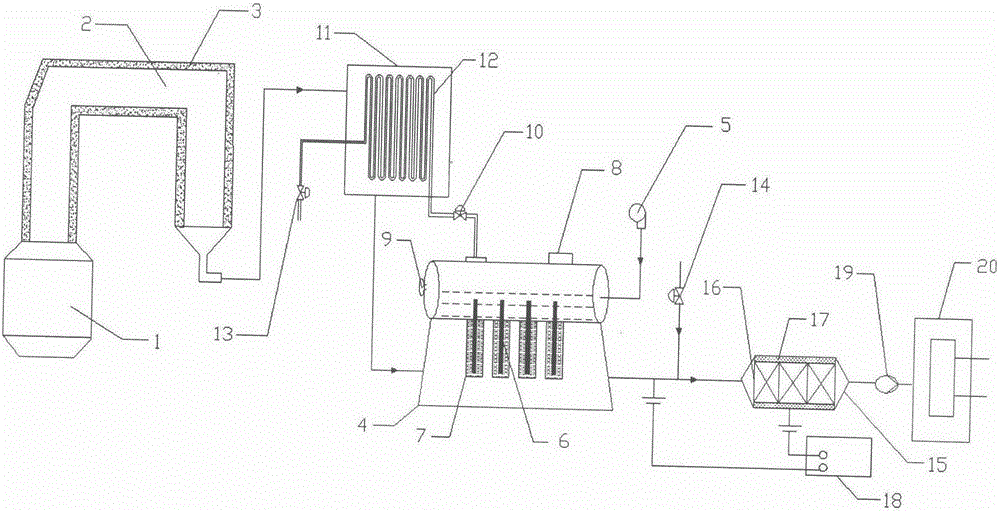

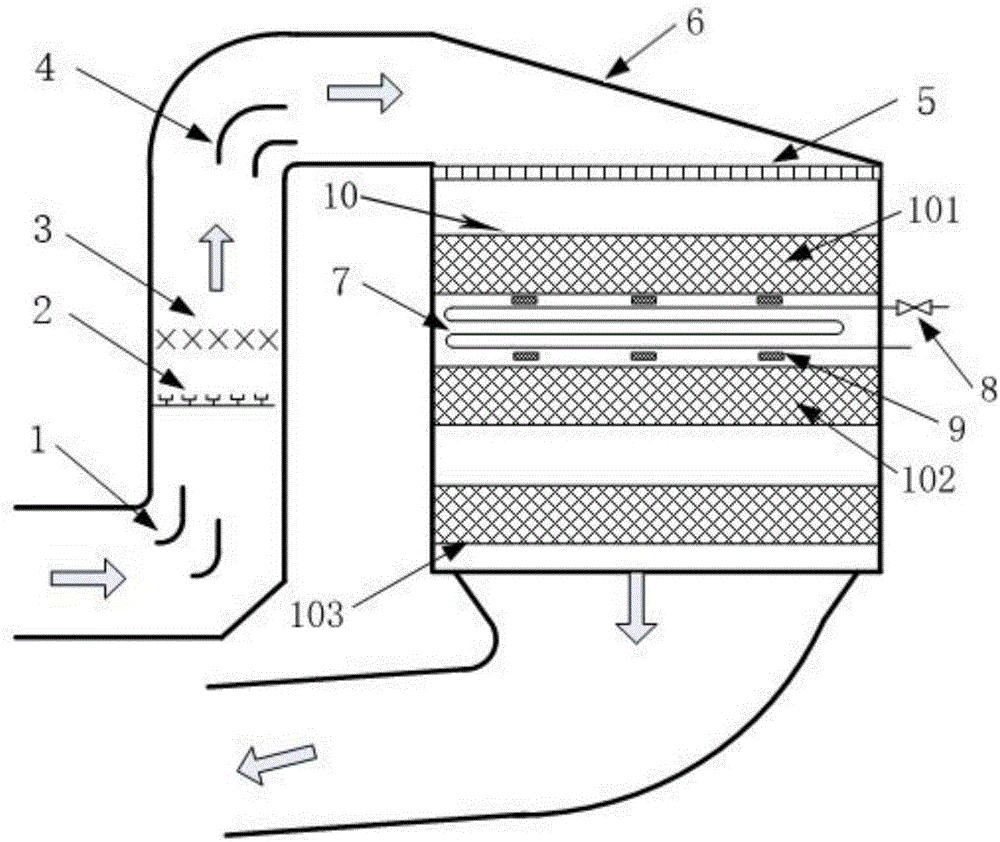

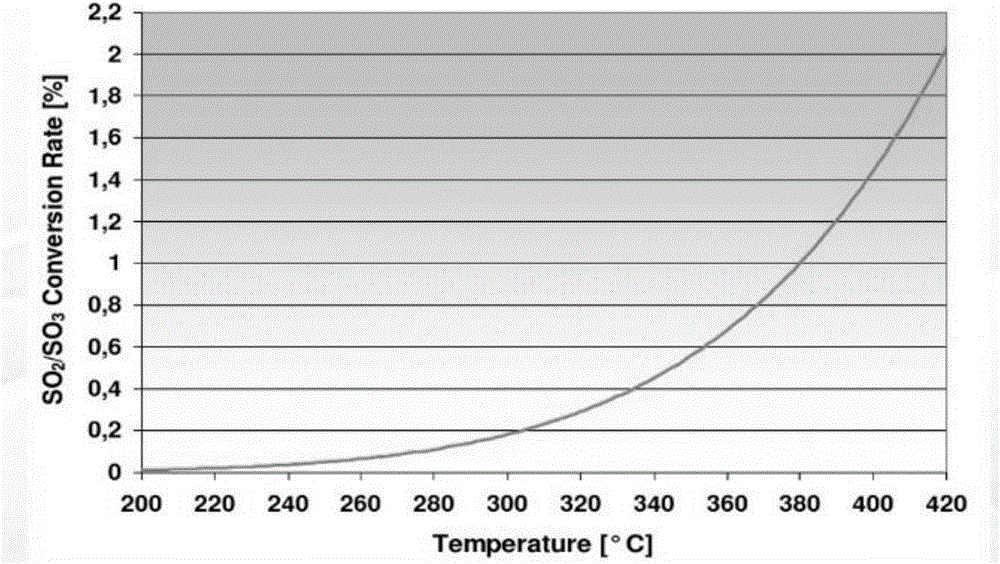

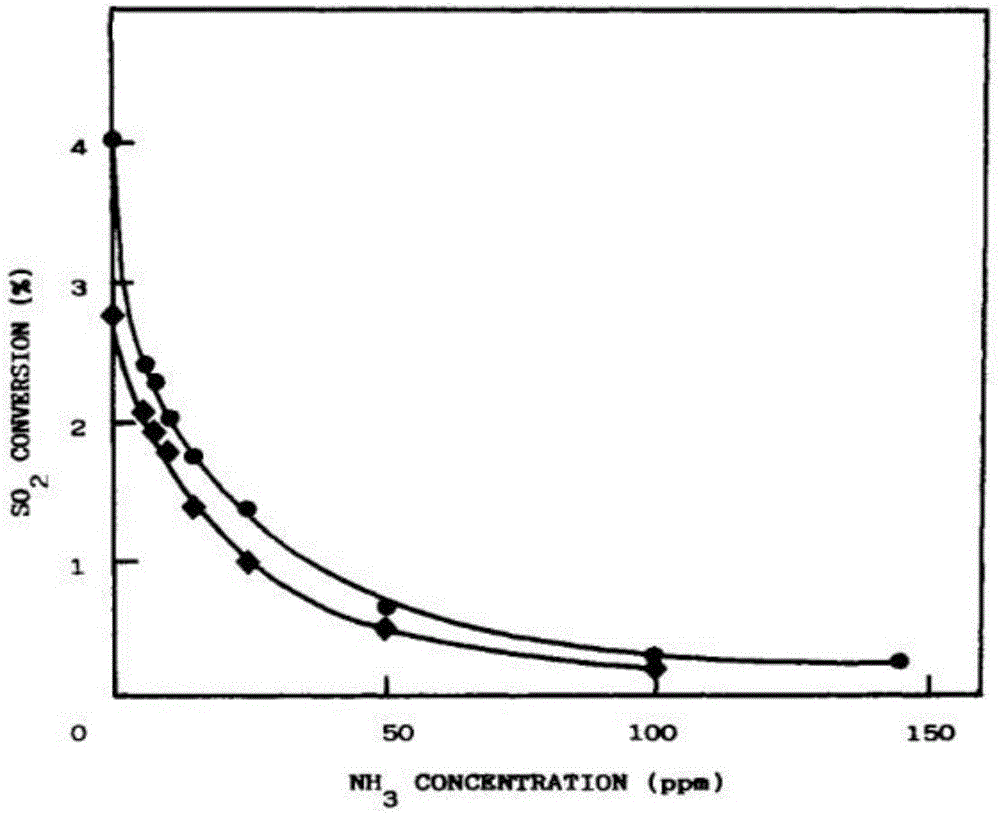

SCR denitration system with low SO2/SO3 conversion rate

InactiveCN106178950AReasonable structureEasy to installDispersed particle separationFlue gasEngineering

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Method for controlling discharge of dioxins in burning process using sulfurous iron ore

Owner:ZHEJIANG UNIV

Hydrogen-peroxide high-efficiency utilization method and apparatus for desulphurization and denitration of low-temperature flue gas

InactiveCN106853328AIncrease profitReduce usageDispersed particle separationAir quality improvementFlue gasPhysical chemistry

The invention provides a hydrogen-peroxide high-efficiency utilization method and apparatus for desulphurization and denitration of low-temperature flue gas. According to the method, hydrogen peroxide is fed in the form of gas in the process of desulphurization and denitration of low-temperature flue gas via hydrogen peroxide. The apparatus comprises a hydrogen peroxide storage tank, a feed pump, a flue and an absorbing tower. The apparatus is characterized in that hydrogen peroxide is converted to a gaseous state after treatment by a device for feeding liquid hydrogen peroxide after direct heating and vaporization of liquid hydrogen peroxide, or a device for feeding hydrogen peroxide after bubbling of hot carrying gas in hydrogen peroxide, or a device for feeding hydrogen peroxide carried by hot carrying gas or a device for feeding atomized hydrogen peroxide carried by hot carrying gas; the gaseous hydrogen peroxide then enters the flue; and the gaseous hydrogen peroxide and hydroxyl radicals therein are used for desulphurization and denitration reactions. The method and apparatus provided by the invention changes a conventional liquid-gas mixed reaction into a gas-gas mixed reaction. Compared with liquid hydrogen peroxide, more hydroxyl radicals can be produced through decomposition in the process of vaporization of hydrogen peroxide, so the utilization rate of hydrogen peroxide and the removal rate of NOx are improved, and the usage amount of hydrogen peroxide is reduced.

Owner:UNIV OF JINAN

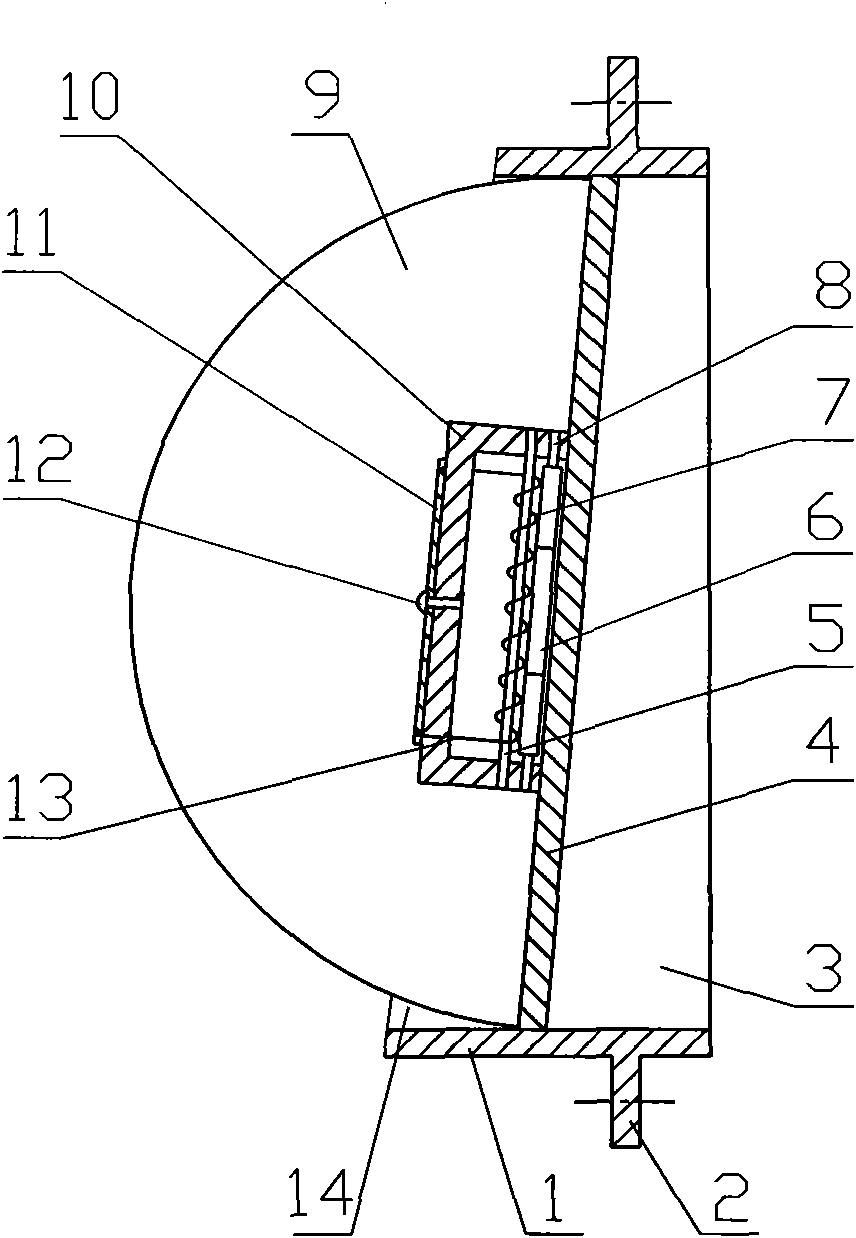

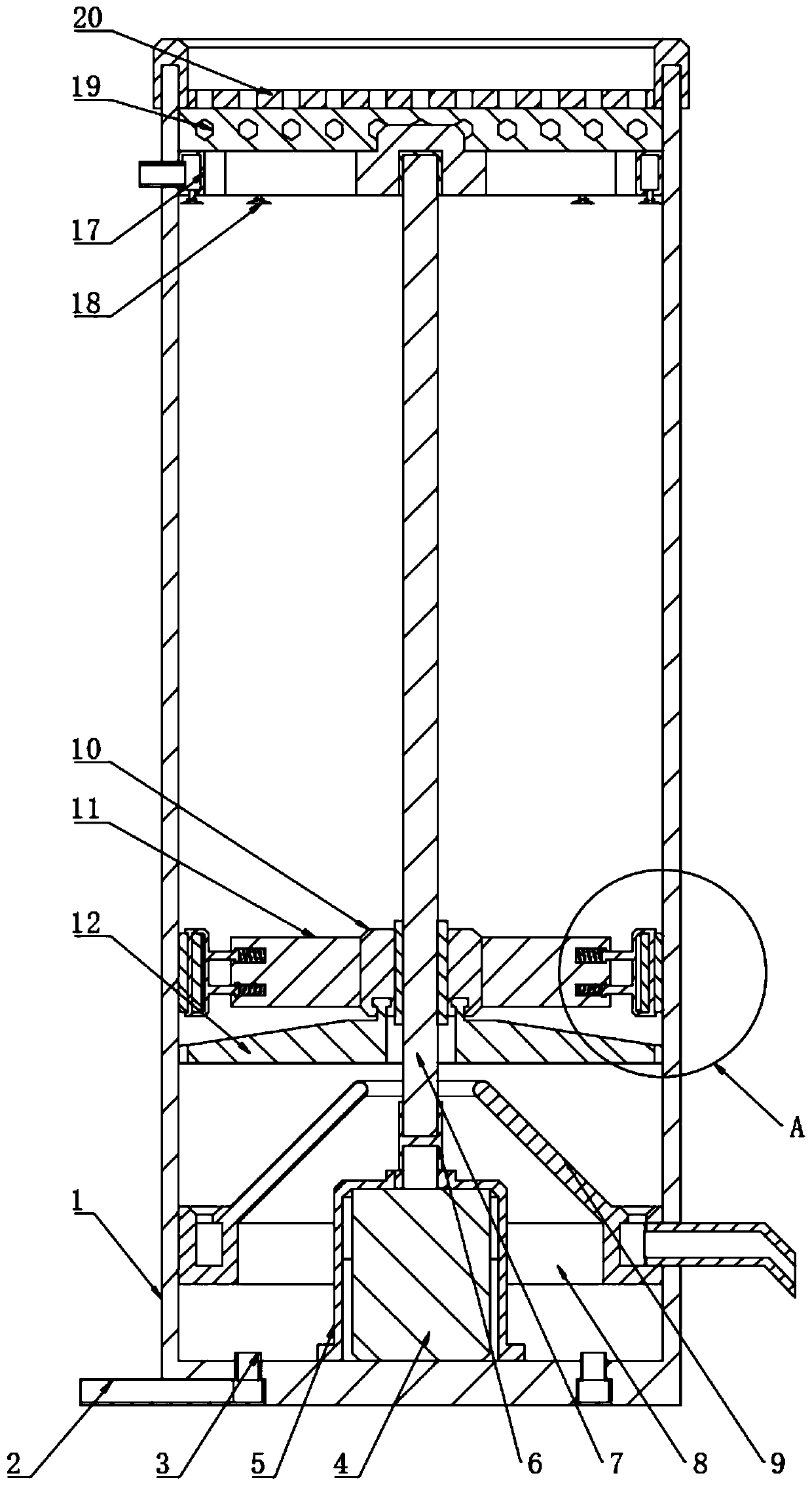

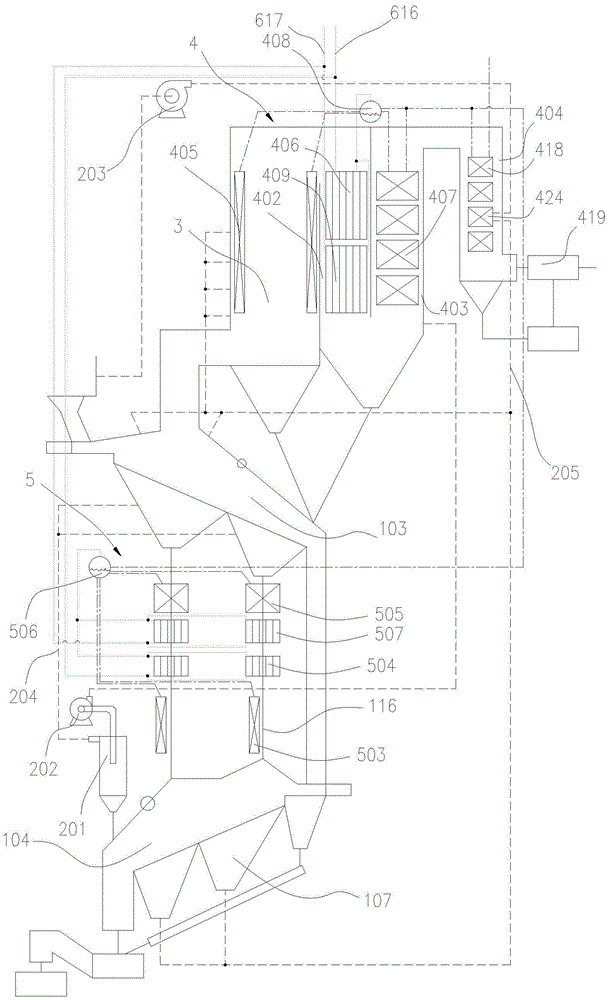

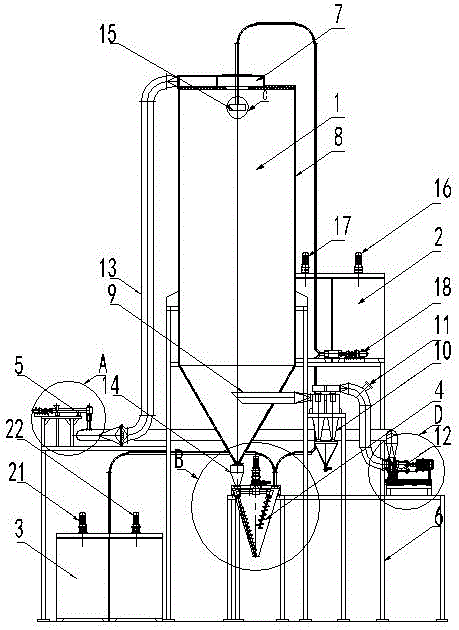

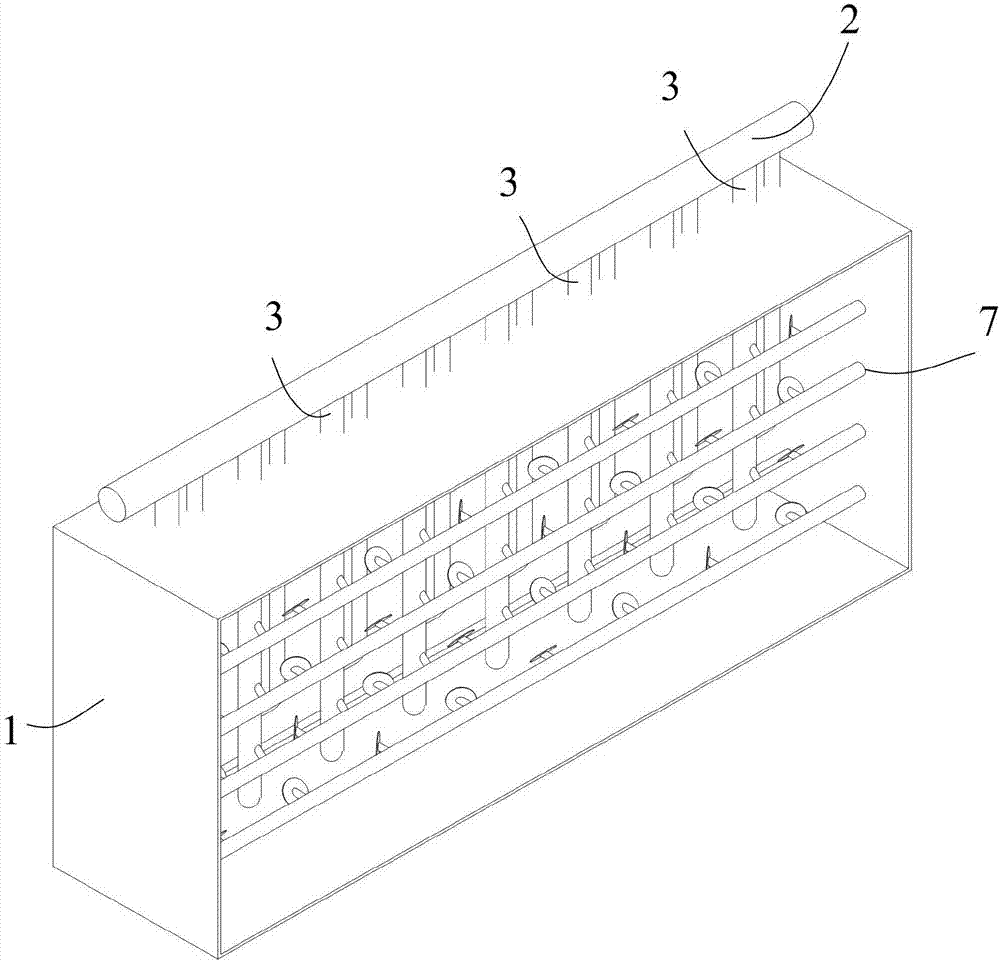

Complete equipment for denitration method in boiler

InactiveCN107626205AHigh yieldAvoid extra supplyLighting and heating apparatusDispersed particle separationBoiler furnaceFlue gas

The invention belongs to the field of environment-friendly equipment and particularly relates to complete equipment for a denitration method in a boiler. The complete equipment comprises an ammonia gas generating device, a gas mixing device and a catalyst cage. The yield of a target product ammonia gas is increased by using the ammonia gas generating device arranged in the boiler and high-temperature polymerized urea in the boiler, extra supply of energy is avoided and energy consumption is reduced; by arranging the gas mixing device, the ammonia gas overflows from a plurality of opening holesin the wall of an ammonia gas mixing pipe and is sufficiently mixed with NOx in high-temperature flue gas in a sleeve pipe; by arranging the catalyst cage, the ammonia gas and the NOx which are uniformly mixed repeatedly react under the action of high temperature and a catalyst, so that the denitration efficiency is greatly improved. The equipment disclosed by the invention has the advantages ofsimple structure, energy consumption conservation, greenness, environment friendliness and suitability for industrial denitration.

Owner:YANCHENG JISHENGDA ENVIRONMENTAL PROTECTION ENG CO LTD

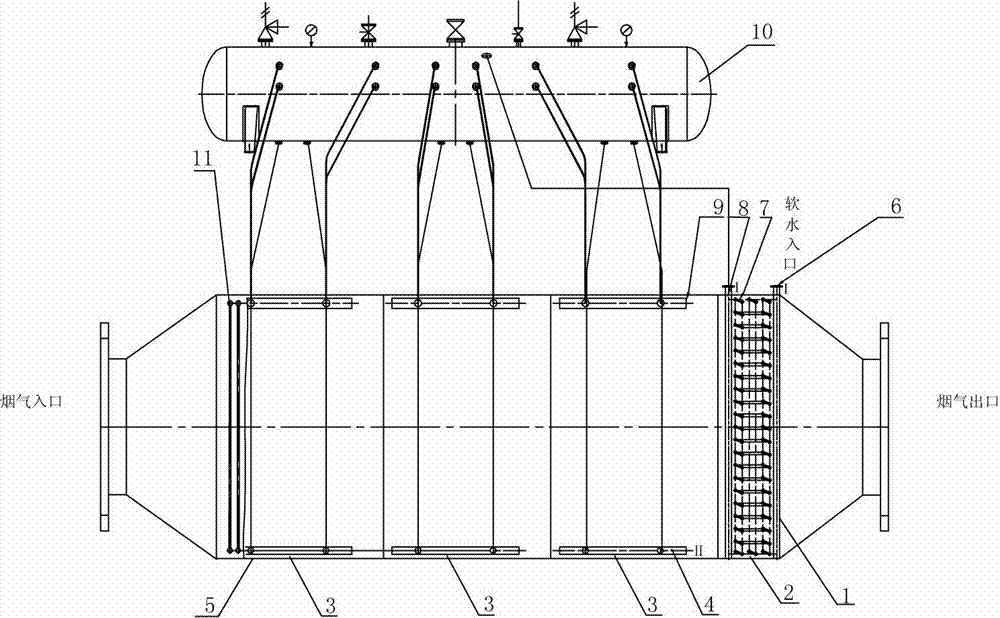

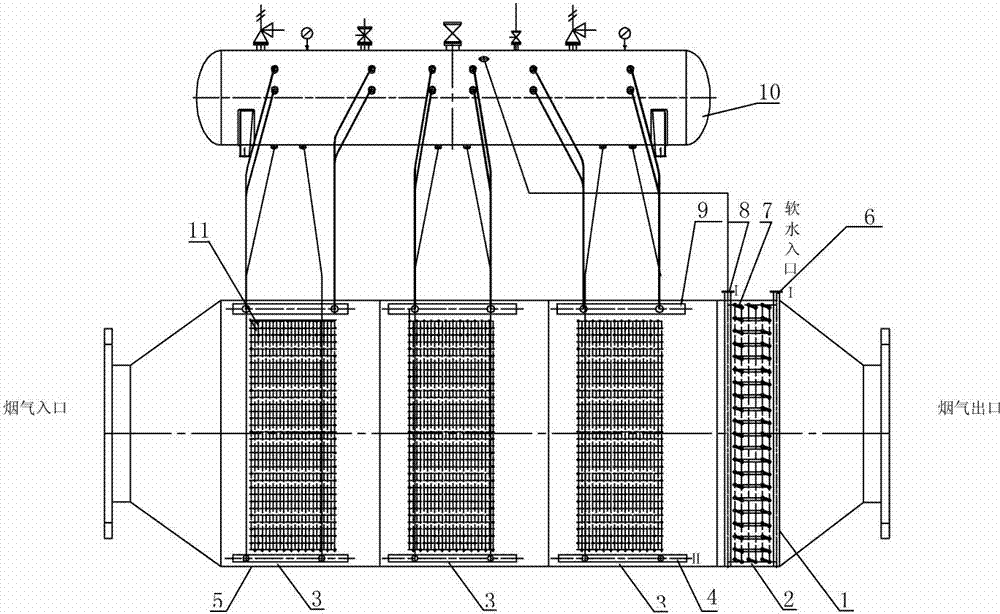

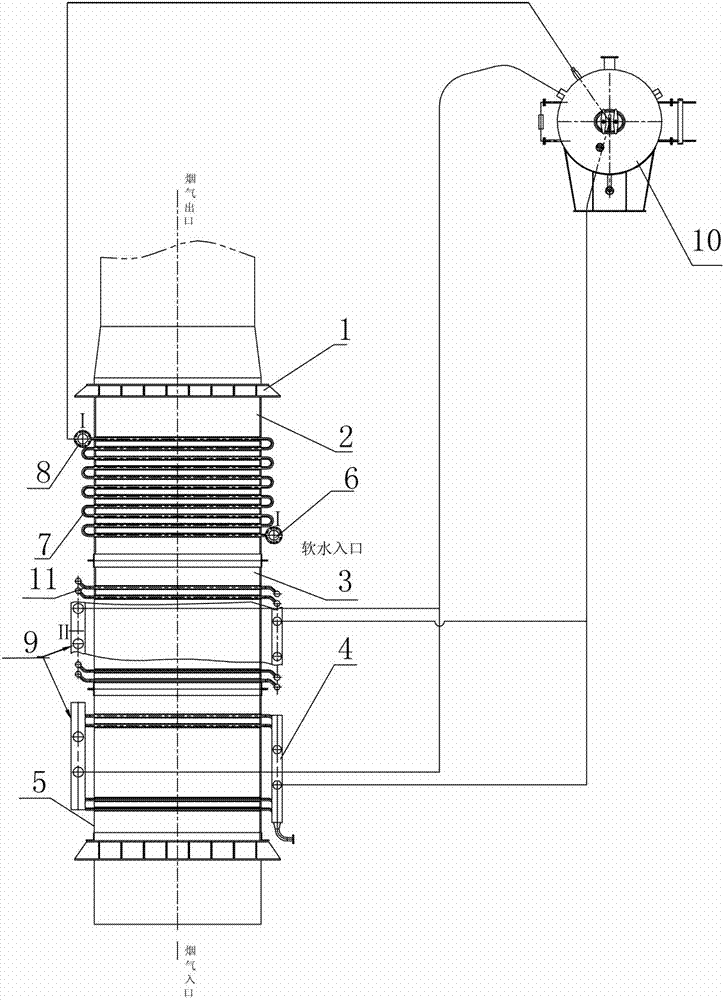

Radial heat tube-ordinary heat exchange tube combined type waste heat recovery device for flue tail gases

InactiveCN103292305ALower exhaust gas temperatureAvoid corrosionSteam generation using hot heat carriersFlue gasExhaust fumes

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP +1

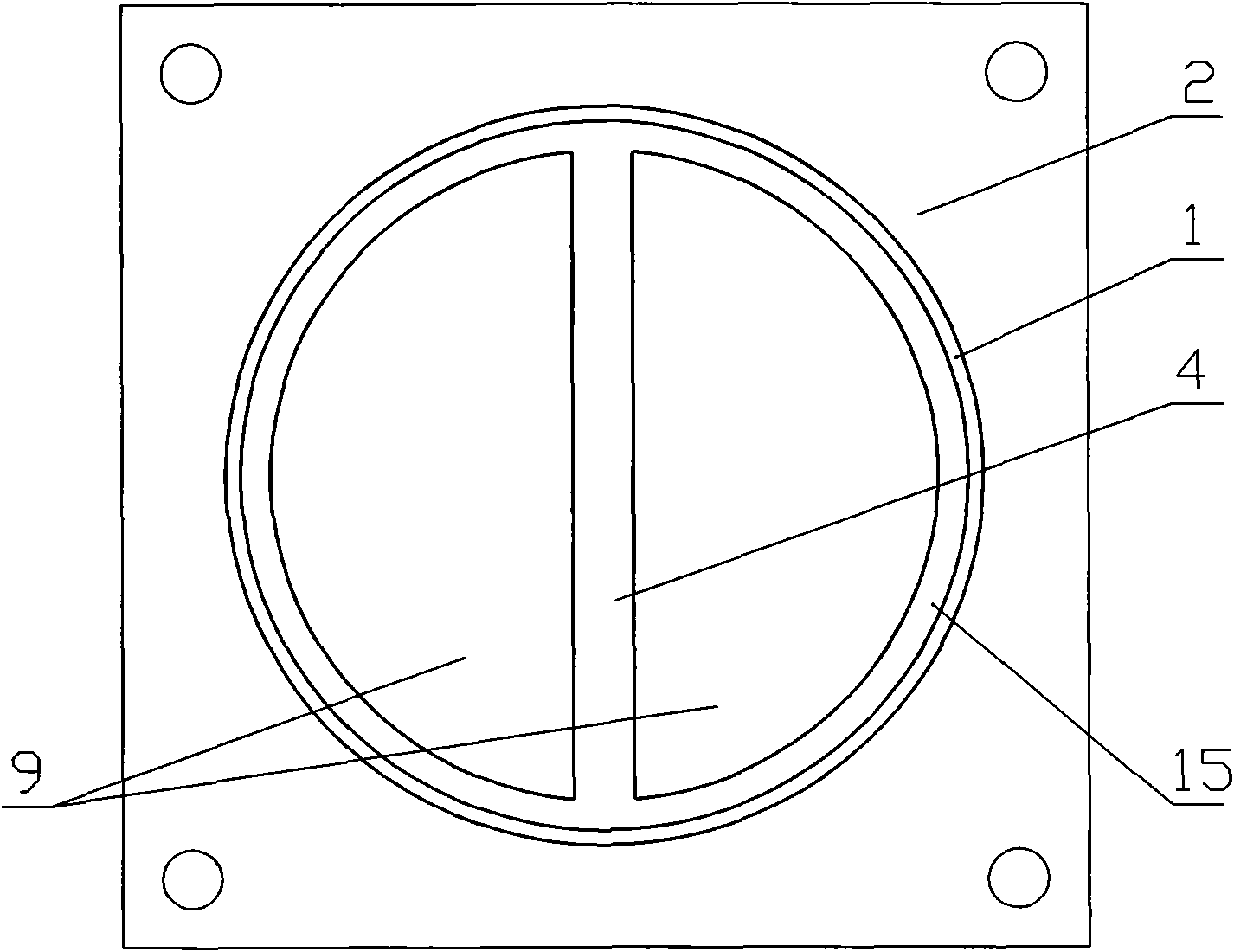

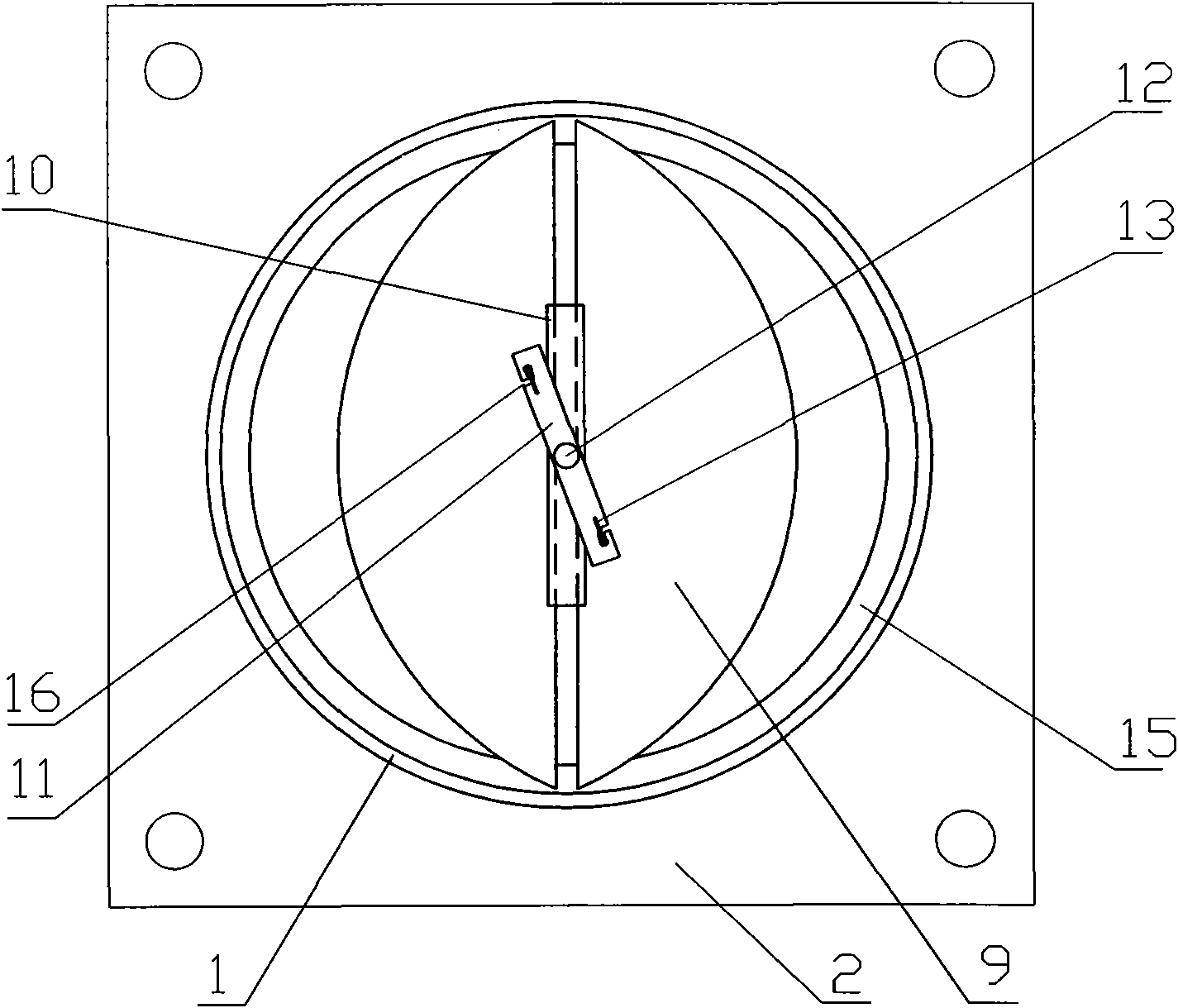

Flue gas desulfurization and denitration system and method

The invention discloses a flue gas desulfurization and denitration system and method, and belongs to the technical field of flue gas processing. The system comprises a pre-deduster, a rotating spray desulfurization and denitration system, an induced draft fan and a chimney, a circulating fluidized bed desulfurization system is arranged between the rotating spray desulfurization and denitration system and the induced draft fan, and a flue gas mixing axial adjustment damper is arranged between the rotating spray desulfurization and denitration system and the circulating fluidized bed desulfurization system; the system further comprises a booster conveying fan, a material conveying pump I and a material conveying pump II. Accordingly, the rotating spray desulfurization and denitration systemand the circulating fluidized bed desulfurization system are combined, step-by-step desulfurization and denitration on flue gas are achieved, and the desulfurization and denitration efficiency is high; due to step-by-step desulfurization and denitration, the system and method can be applied to desulfurization and denitration processing of the flue gas high in sulfur content and nitrate content, and the application range is high.

Owner:NANJING SHIBO ENVIRONMENTAL PROTECTION TECH CO LTD

Flue gas white smoke removal equipment for intelligent production factory of rubber plant

Owner:山东保蓝环保有限公司

Boiler waste heat recovery device

InactiveCN102287805ARealize secondary recycling and reuseRaise the water temperatureFluid heatersCombustion technology mitigationWaste heat recovery unitFlue gas

Owner:PENGLAI HUIYANG FOOD

Dual-layer mechanical grate type garbage gasifying incinerator and dual-boiler power generation system thereof

ActiveCN105465793AImprove insulation effectPrevent leakageMachines/enginesIncinerator apparatusCycloneCombustion chamber

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Special preparation device for boiler flue gas desulfurization tower repairing agent

ActiveCN106079100AAvoid pollutionReduce investmentMixing operation control apparatusPretreatment controlFluidized bedFlue gas

Owner:桐乡市金琪塑料包装有限公司

Desulfurization wastewater zero discharging system and method based on waste heat reuse under low-load working condition

PendingCN107973475AIncrease temperatureSolve the problem of incomplete evaporationGas treatmentLighting and heating apparatusFlue gasEvaporation

Owner:DATANG ENVIRONMENT IND GRP

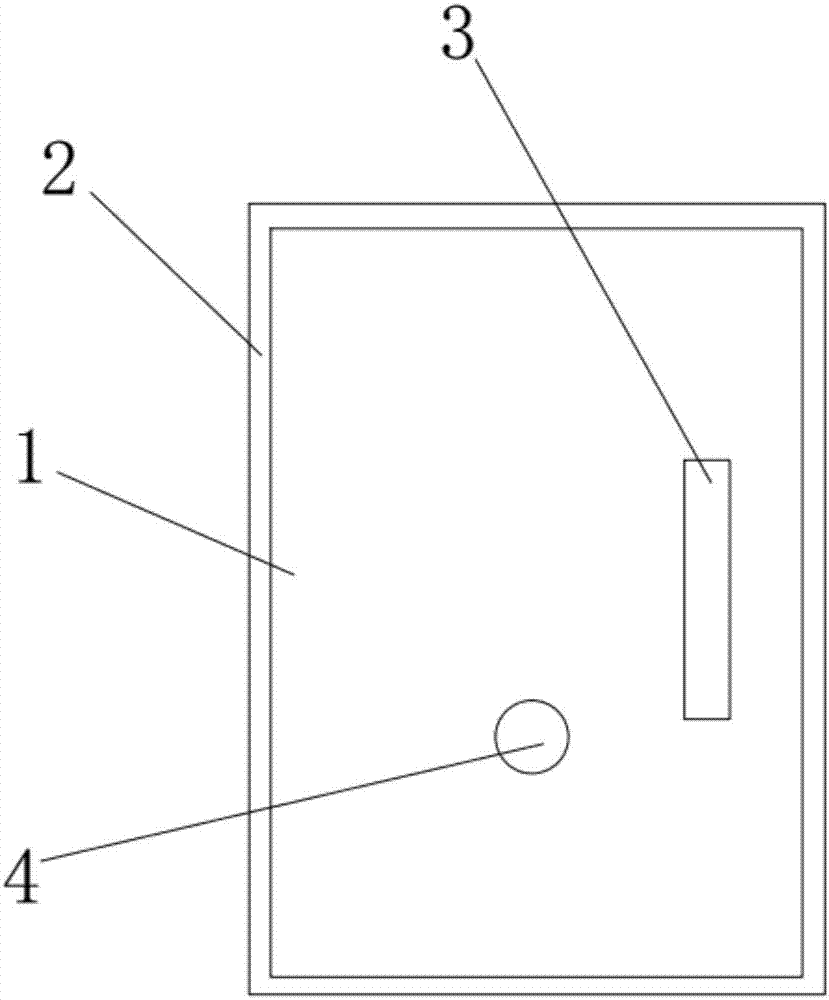

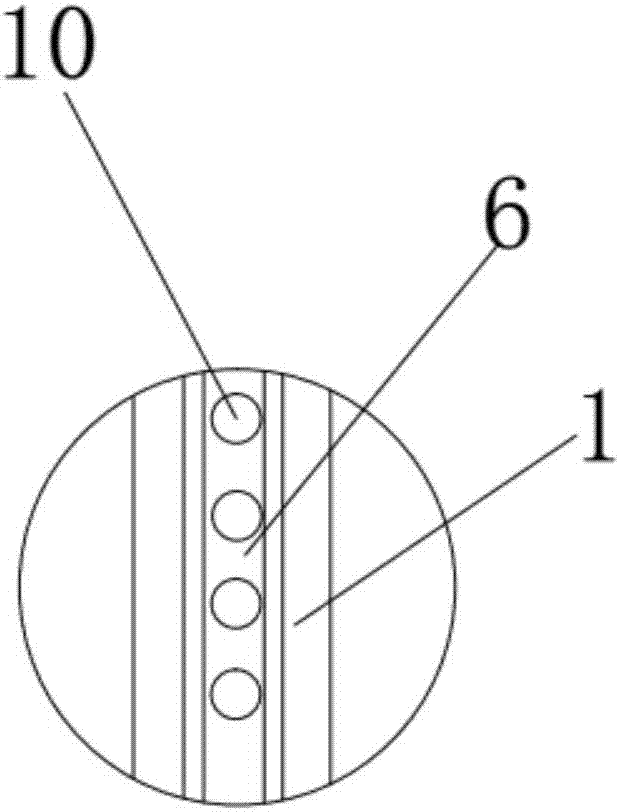

Fireproof door with smoke-proof function

Owner:TIANJIN LONGJIA SPECIAL DOOR & WINDOW

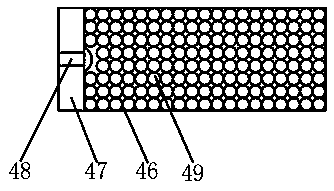

Flue gas desulfurizing, denitrating and dedusting device

InactiveCN110141963AImprove the efficiency of desulfurization treatmentImprove purification efficiencyCombination devicesActivated carbonFiber

Owner:新昌县以琳环保科技有限公司

High-heat-storage-density open type heat absorption heating system

ActiveCN112944726AImprove the grade of industrial waste heatReduce the temperatureHeat pumpsClimate change adaptationFlue gasCooling coil

The invention discloses a high-heat-storage-density open type heat absorption heating system. The system comprises an open type absorber, a cooler, an evaporator / condenser and a closed type absorber. The open type absorber communicates with high-humidity flue gas, a solution and a cooling water pipe are arranged in the cooler, a solution outlet of the open type absorber is connected to a solution inlet of the cooler and a solution inlet of the closed type absorber, and a solution outlet of the cooler is connected to a solution spraying end of the open type absorber; condensed water and a cooling coil pipe are arranged in the evaporator / condenser, and the top of the evaporator / condenser is connected to the closed type absorber through a steam pipe; and a to-be-heated water pipe and a solution spraying device are arranged in the closed type absorber, the solution spraying device is arranged above the to-be-heated water pipe, and an outlet of the to-be-heated water pipe is connected to a heat supply tail end. The system has the heat storage function and the heat heating function, meanwhile, due to the fact that the closed type absorber plays a role in increasing the heat output temperature, the open type absorber remarkably reduces the solution temperature through multi-stage cooling, and the high latent heat recovery rate can be obtained.

Owner:ZHEJIANG SCI-TECH UNIV

Ozone static mixing device

Owner:中瑞工程设计院有限公司

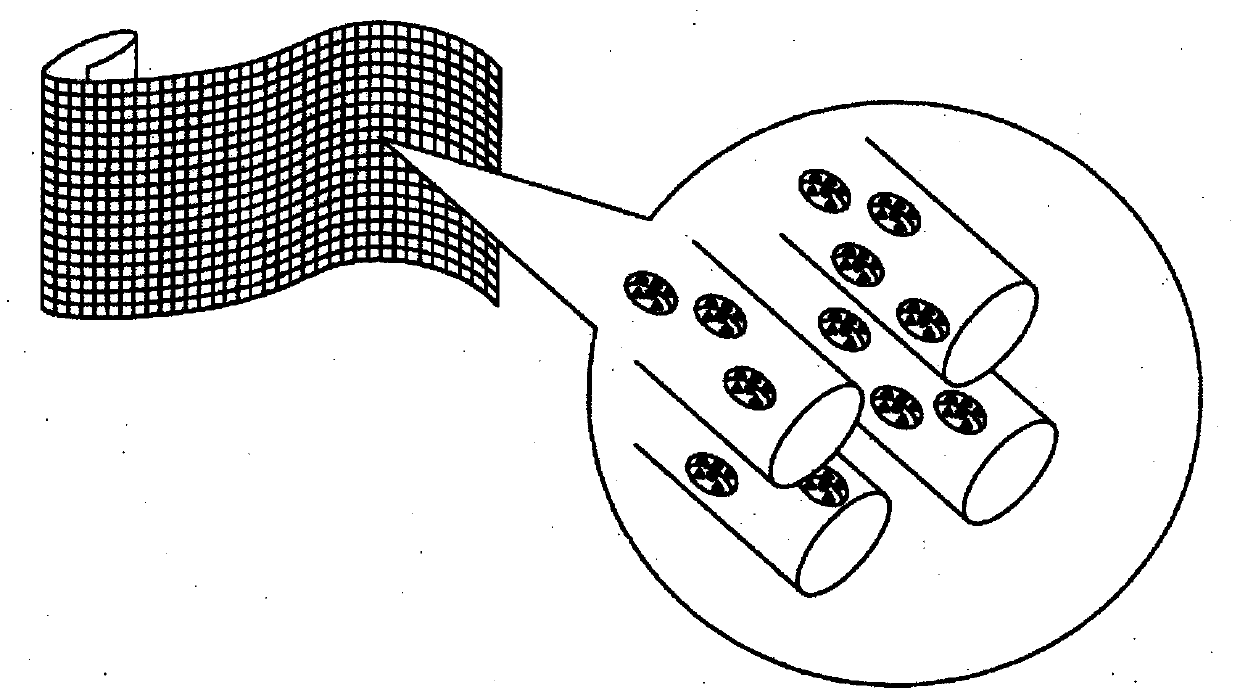

Honeycomb denitration catalyst with water resistance and preparation method therefor

InactiveCN105413678AHigh mechanical strengthExtended service lifeGas treatmentDispersed particle separationPtru catalystFlue gas

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Burner

A burner operating with flameless combustion, comprising a system for sucking the recycling flue gases directly from the combustion chamber by means of an ejector (1) fed with the comburent, a heat exchange system positioned between the recycling flue gases and the comburent, a system for injecting the fuel directly into the recycling flue gases, the latter comprising or not comprising the comburent with formation of a mixture of fuel-recycling flue gases-comburent in the zone around the outlet of the comburent ejector and following introduction of the mixture into the combustion chamber.

Owner:SOFINTER

Preparation method of catalyst for simultaneously removing NO and fine particles in coal-fired flue gas

Owner:DONGHUA UNIV

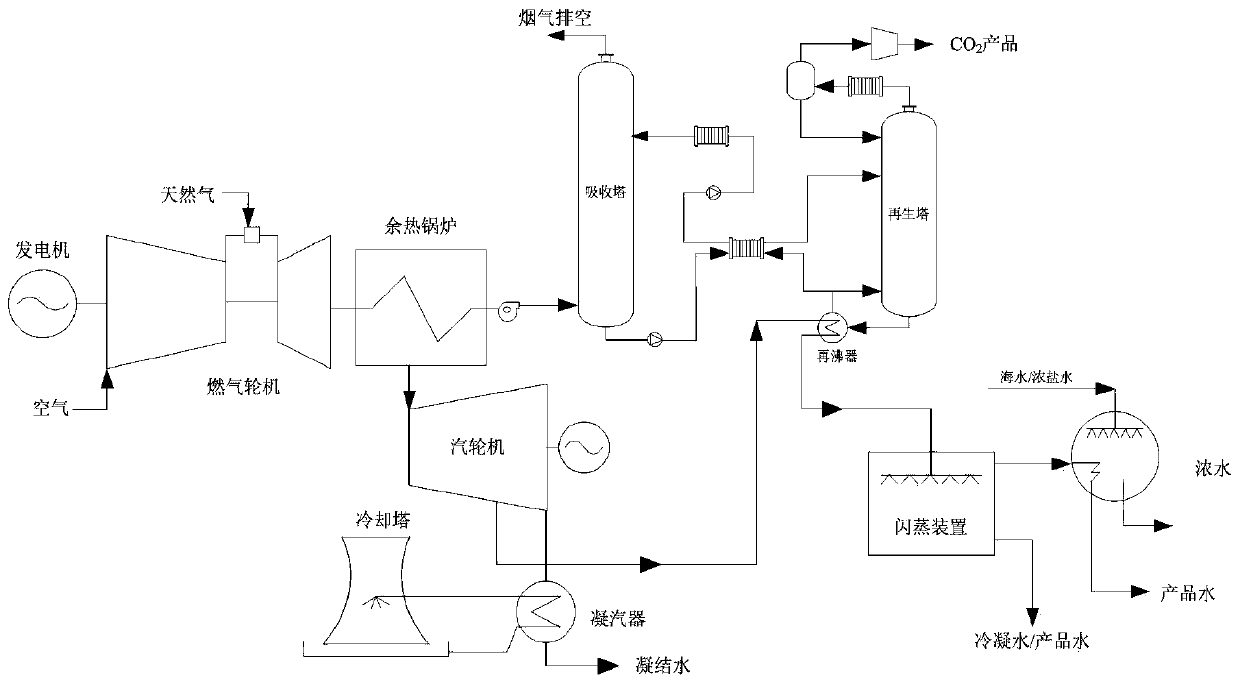

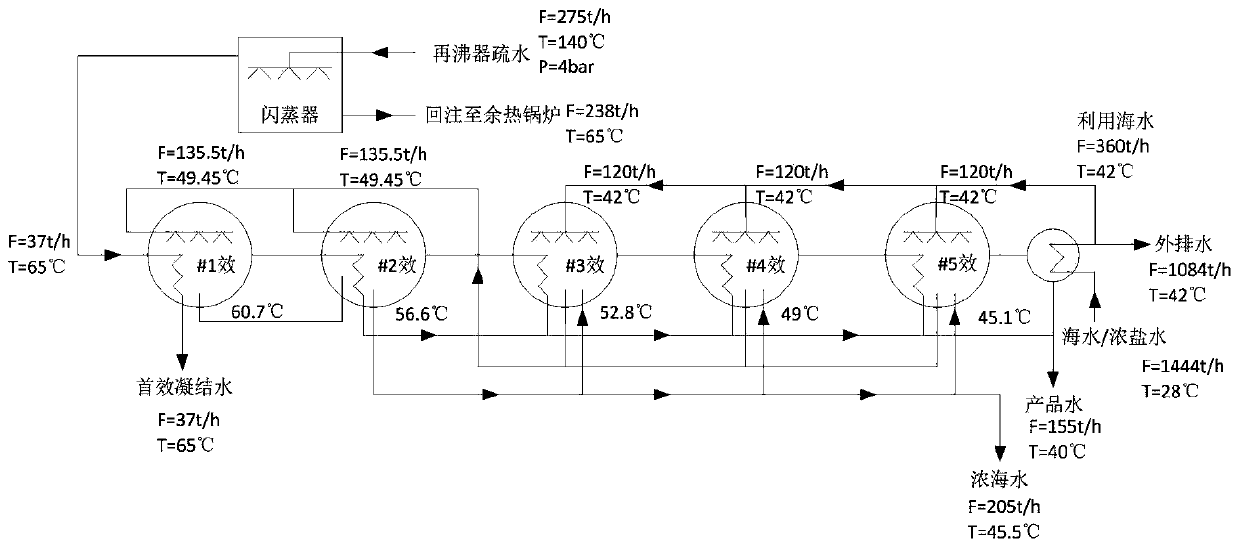

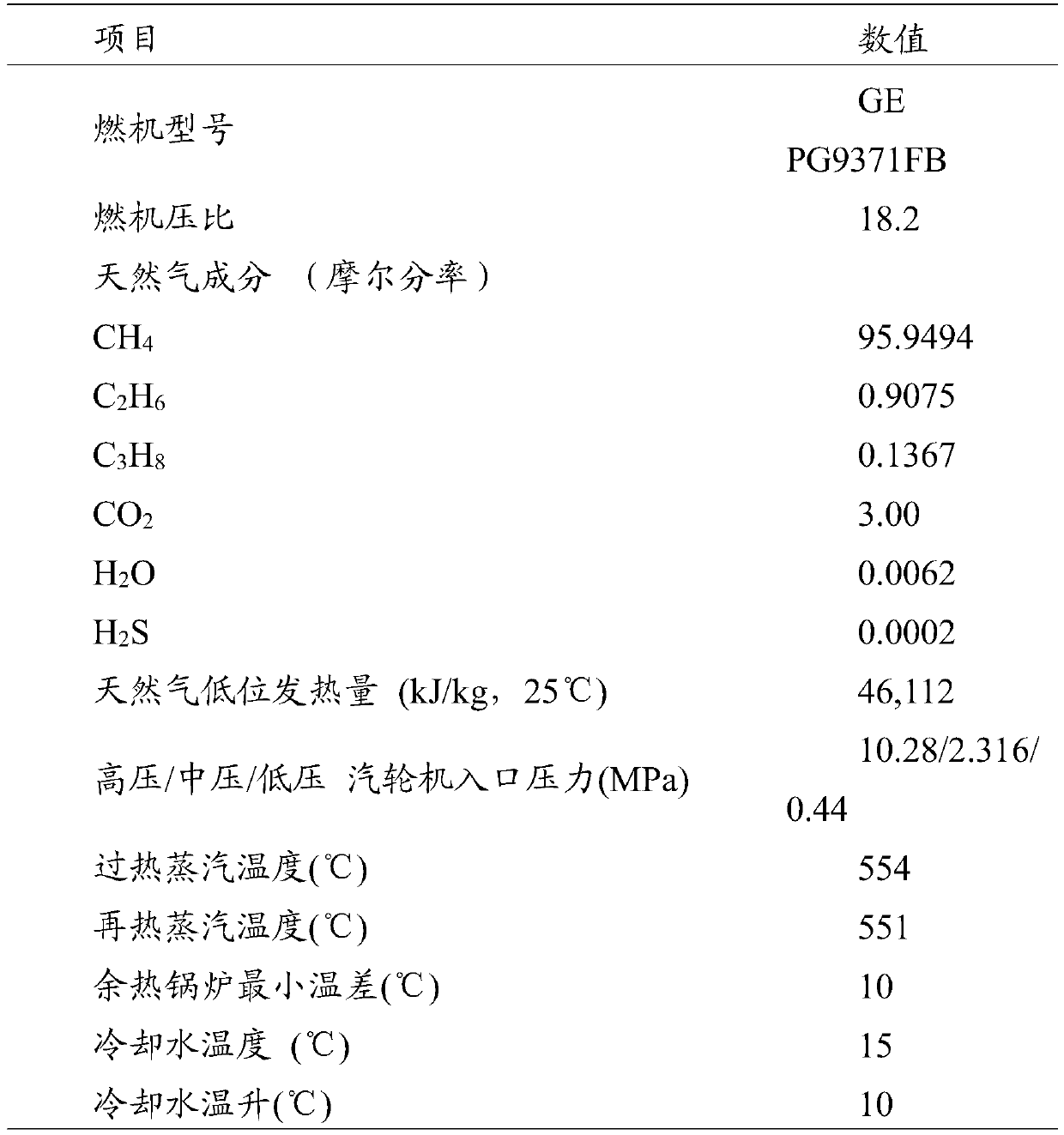

Steam waste heat gradient utilization system for carbon capture absorbent regeneration system

InactiveCN111420516AReduce the temperatureMake full use of waste heatDispersed particle separationSteam useReboilerWater circulation

Owner:北京中冶设备研究设计总院有限公司

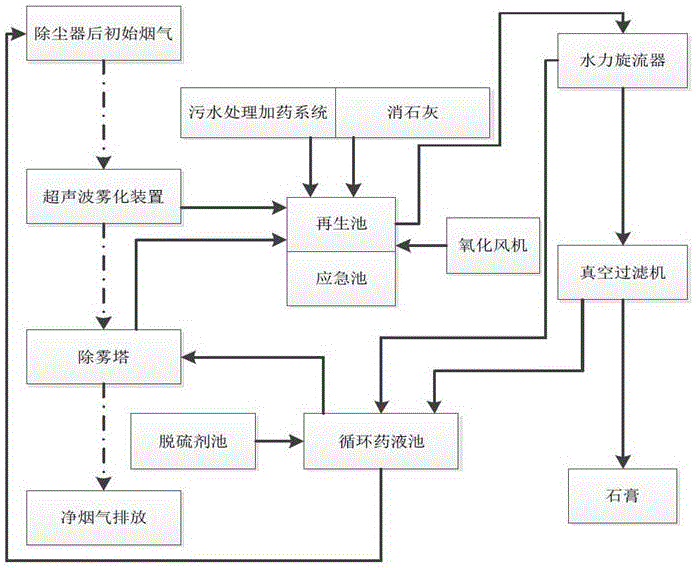

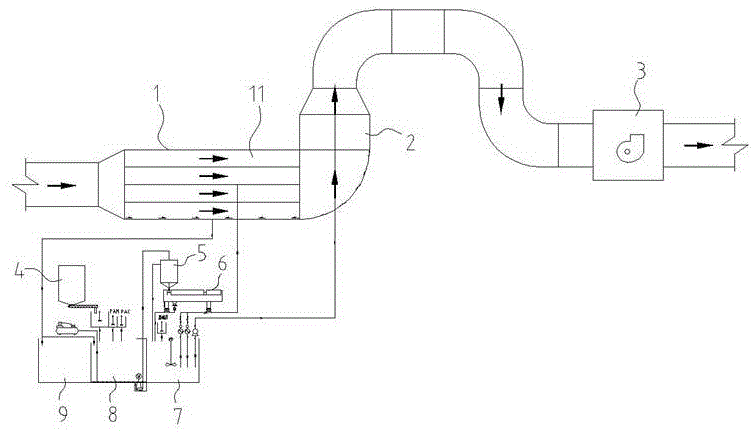

Thermal power plant ultrasonic atomization desulfurization-dust removal-ammonia escape prevention integrated system

InactiveCN107433115ALow concentration of sulfur dioxideReduce dust contentCombination devicesGas treatmentAutomatic controlEngineering

Owner:陈佐会

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap