Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81 results about "Spray nozzle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A spray nozzle is a precision device that facilitates dispersion of liquid into a spray. Nozzles are used for three purposes: to distribute a liquid over an area, to increase liquid surface area, and create impact force on a solid surface. A wide variety of spray nozzle applications use a number of spray characteristics to describe the spray.

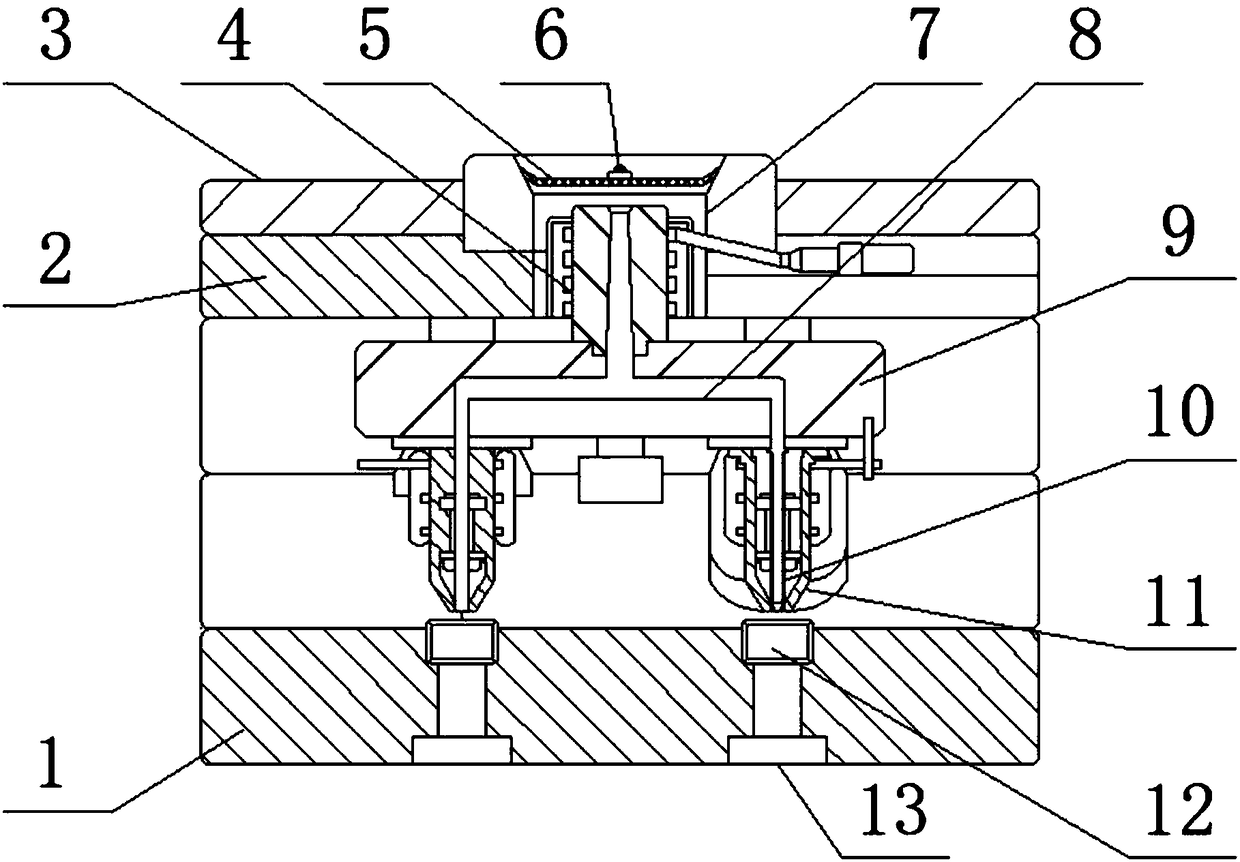

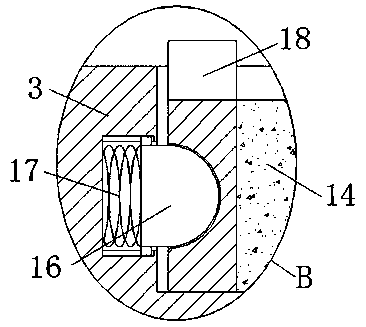

Multifunctional sprinkler structure

ActiveUS7255291B1Accurate operationEqually distributedMovable spraying apparatusSpray nozzlesImpellerWater discharge

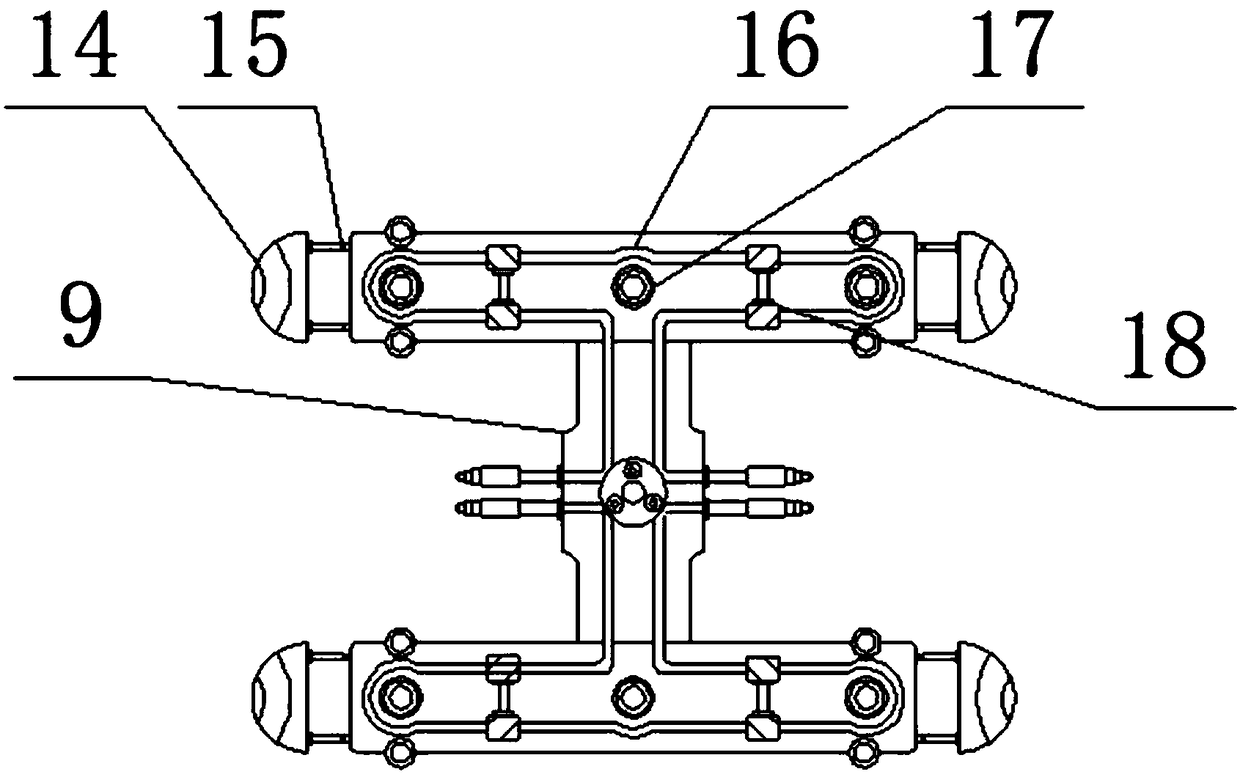

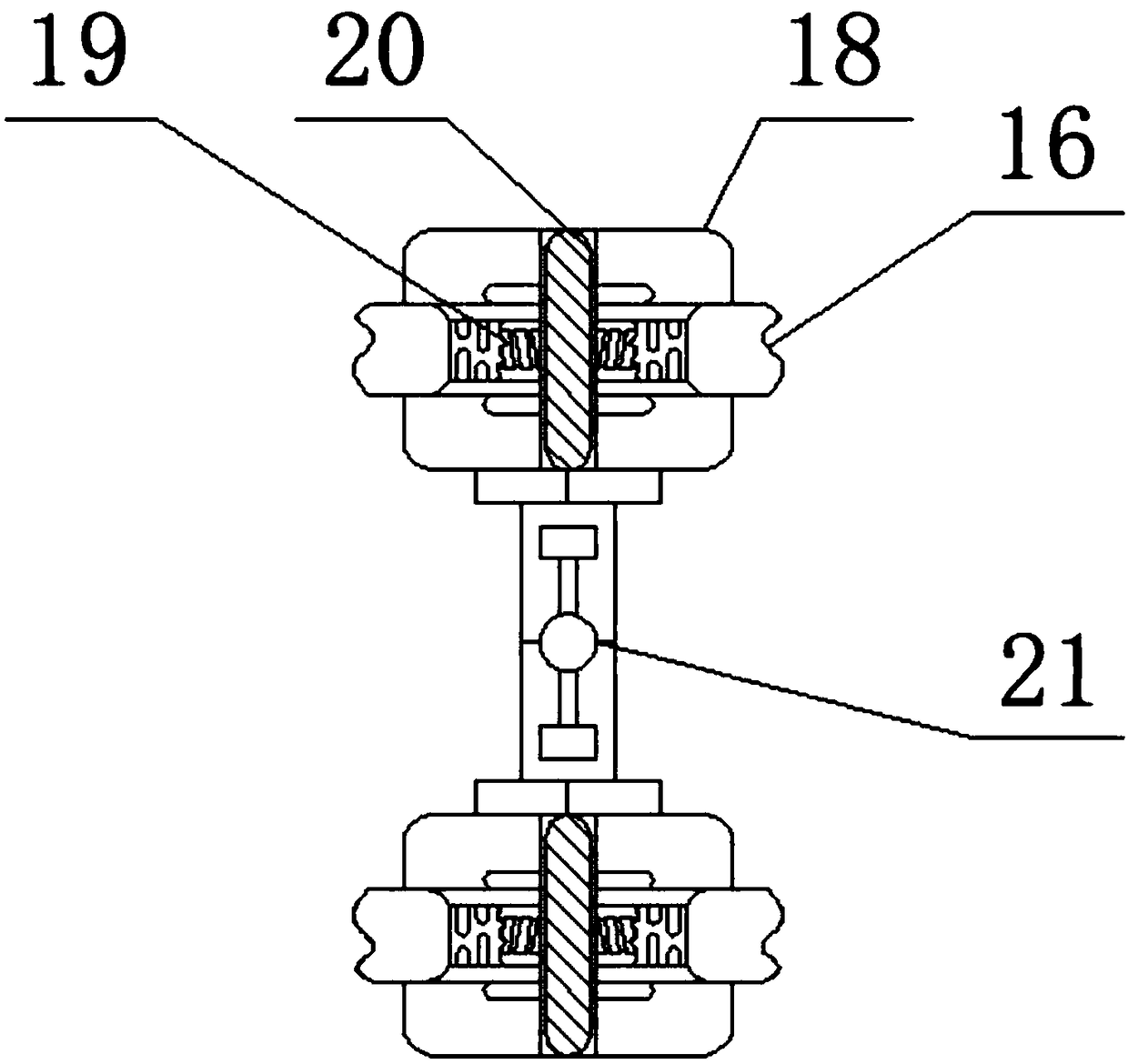

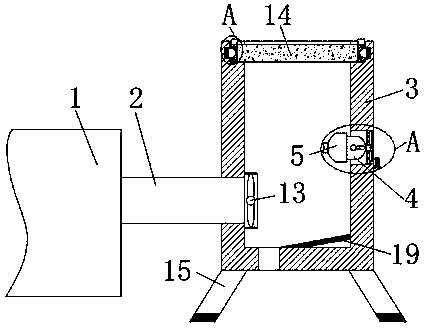

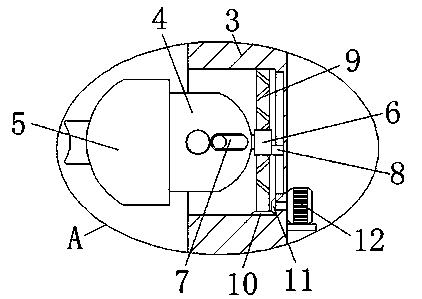

A multifunctional sprinkler structure comprises a water motor having an outlet seat and a top cover mounted to a top-end side, and two adjusting seats and a water supply seat assembled onto a bottom-end side. The bottom-end side of the water motor has a guide groove with a restrictive hole for the extension of a switch shaft there-through. The outlet seat has a water-discharge chamber with multiple barriers extending thereon corresponding to an impeller of the water motor, and an oblique-extending central guide port matching to a spray nozzle having multiple water-guiding ribs obliquely extending towards the same direction therein. Therefore, the barriers of the outlet seat and the water-guiding ribs of the spray nozzle are utilized to correspond to the direction of the water flow so that the water discharge can be easily switched to eject either in more direct and forceful column-like spray or in more expanding spray.

Owner:YUAN MEI CORP

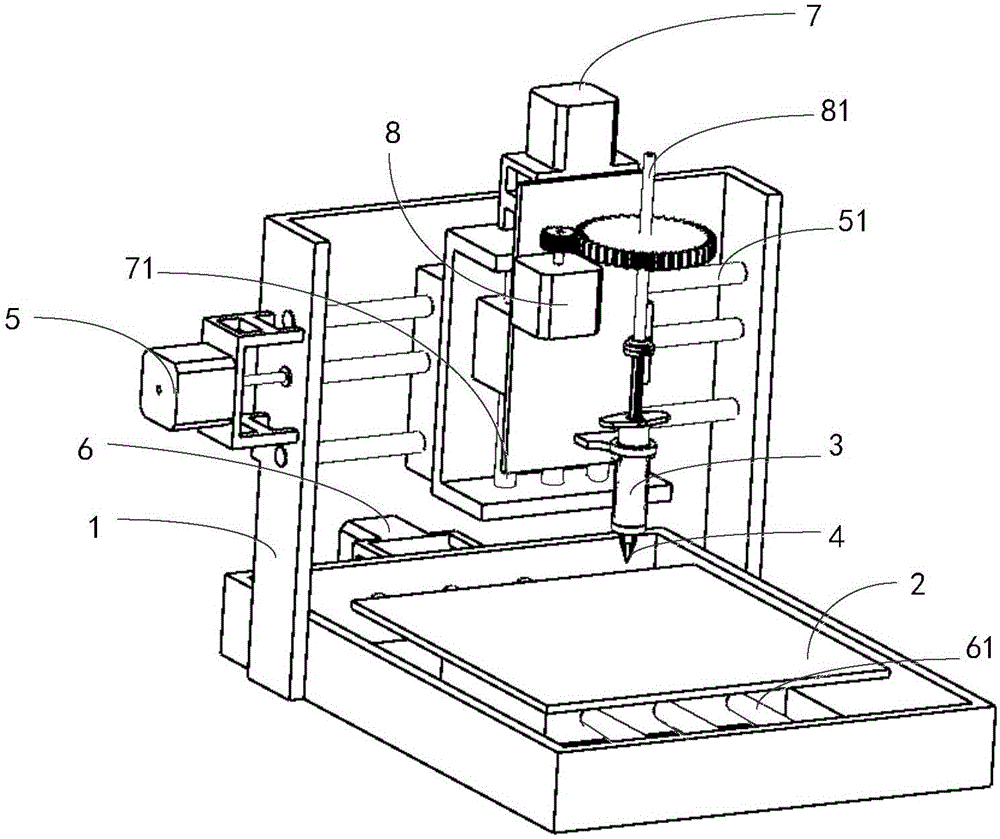

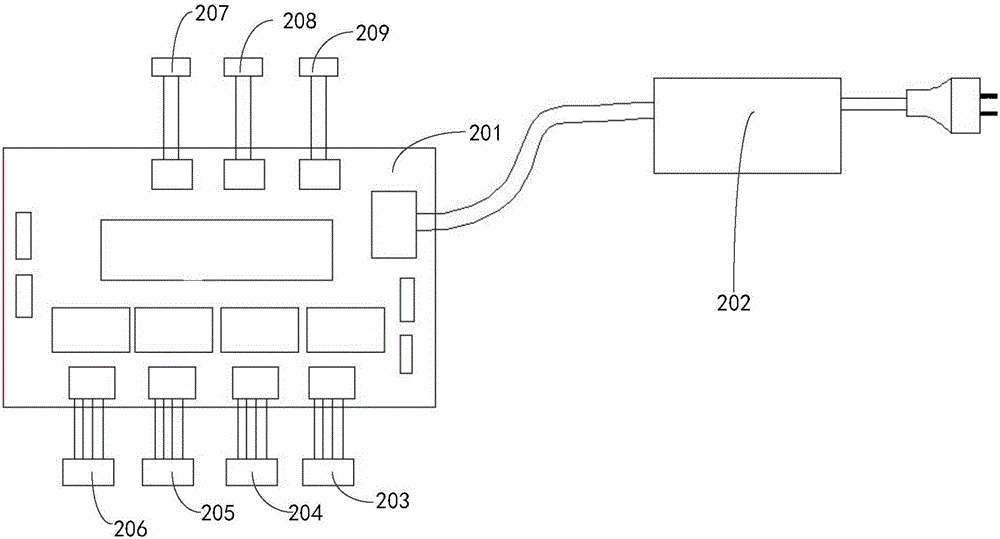

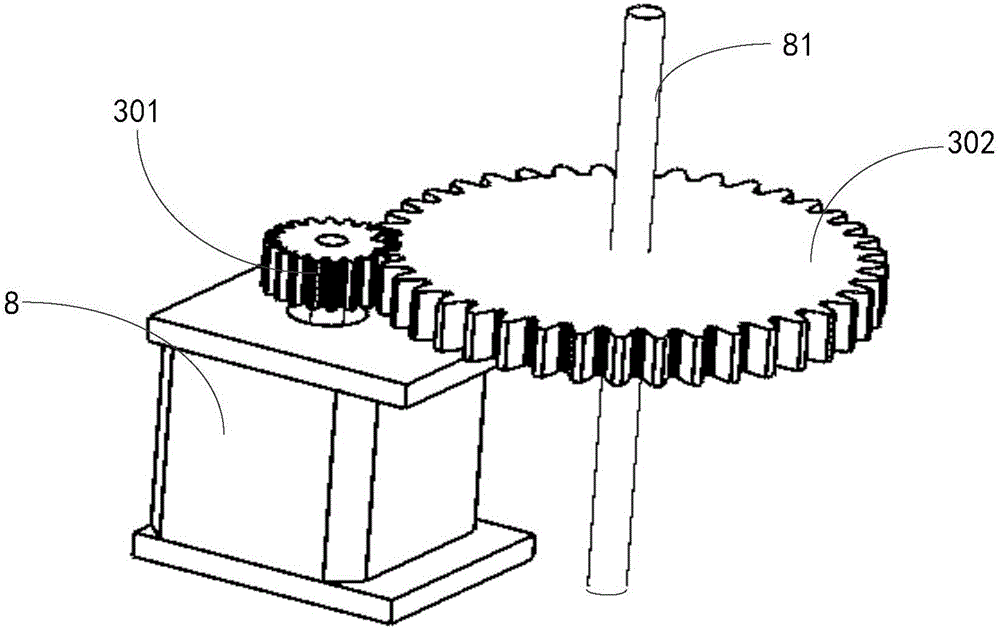

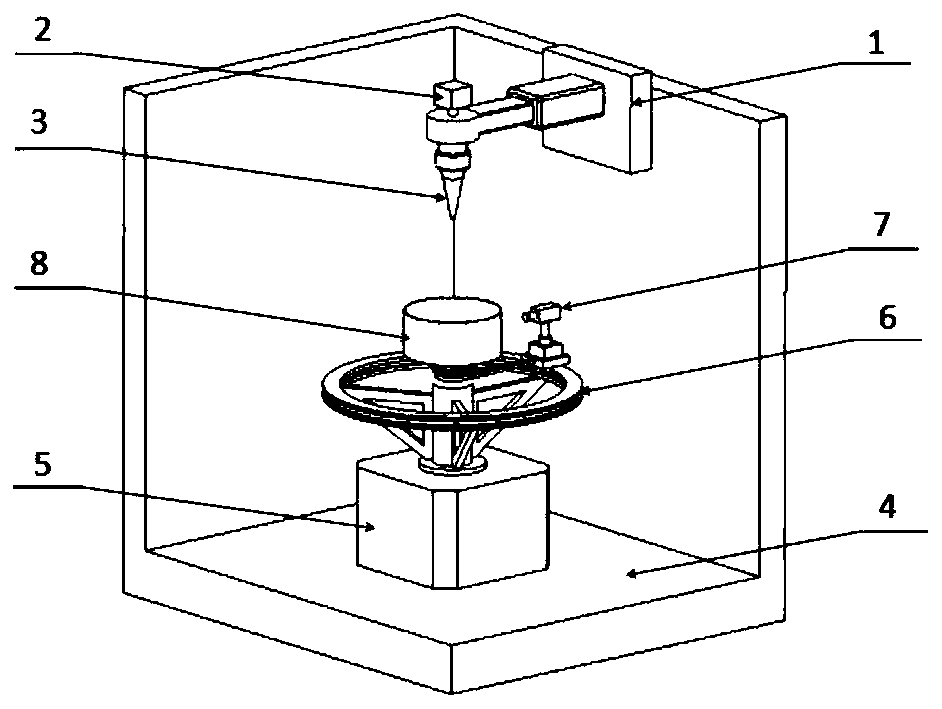

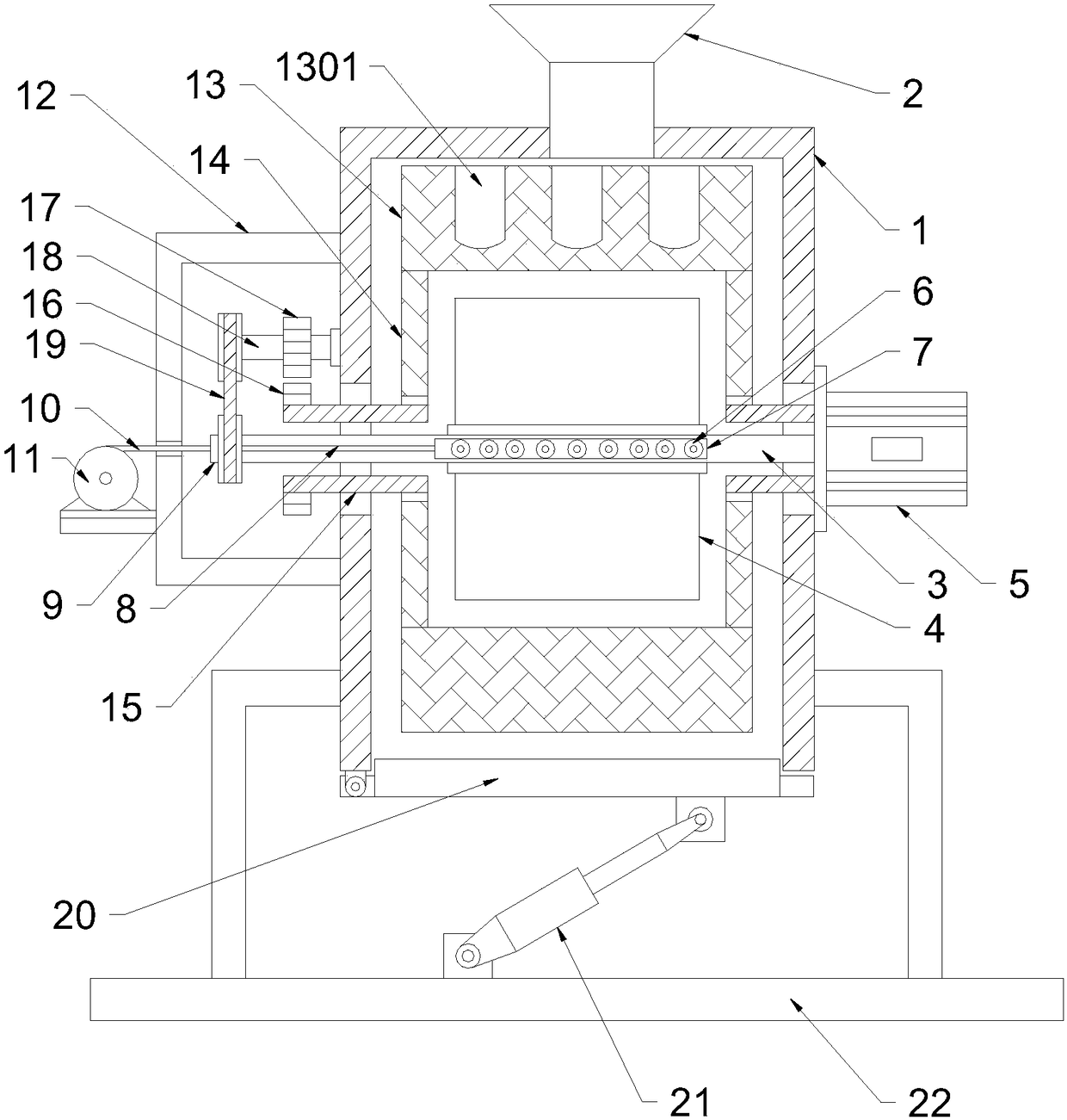

Three-dimensional printer, three-dimensional printing method and preparation method for metal slurry

InactiveCN105108152AGuaranteed printing accuracySimple structureAdditive manufacturing apparatusSpray nozzleSlurry

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

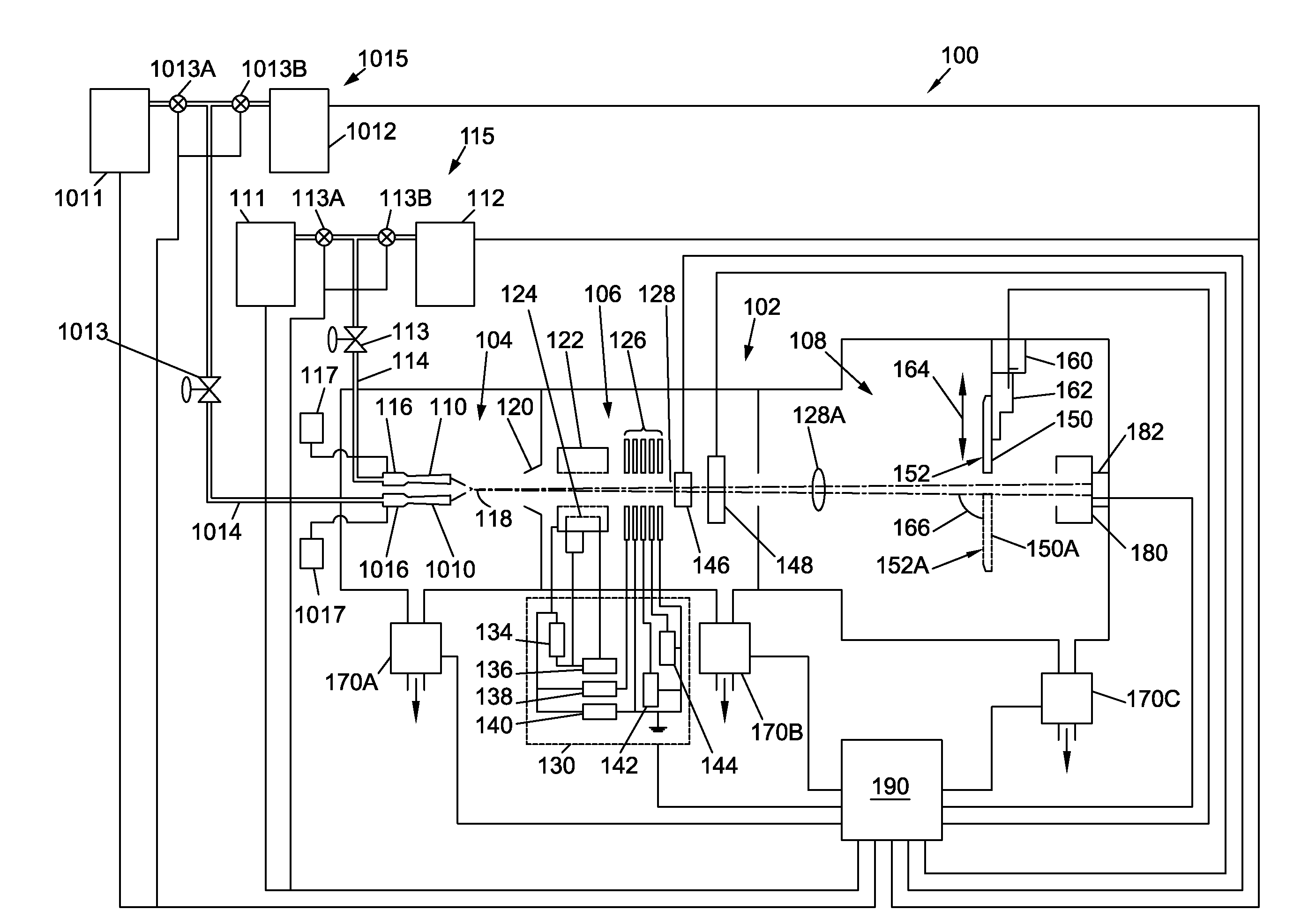

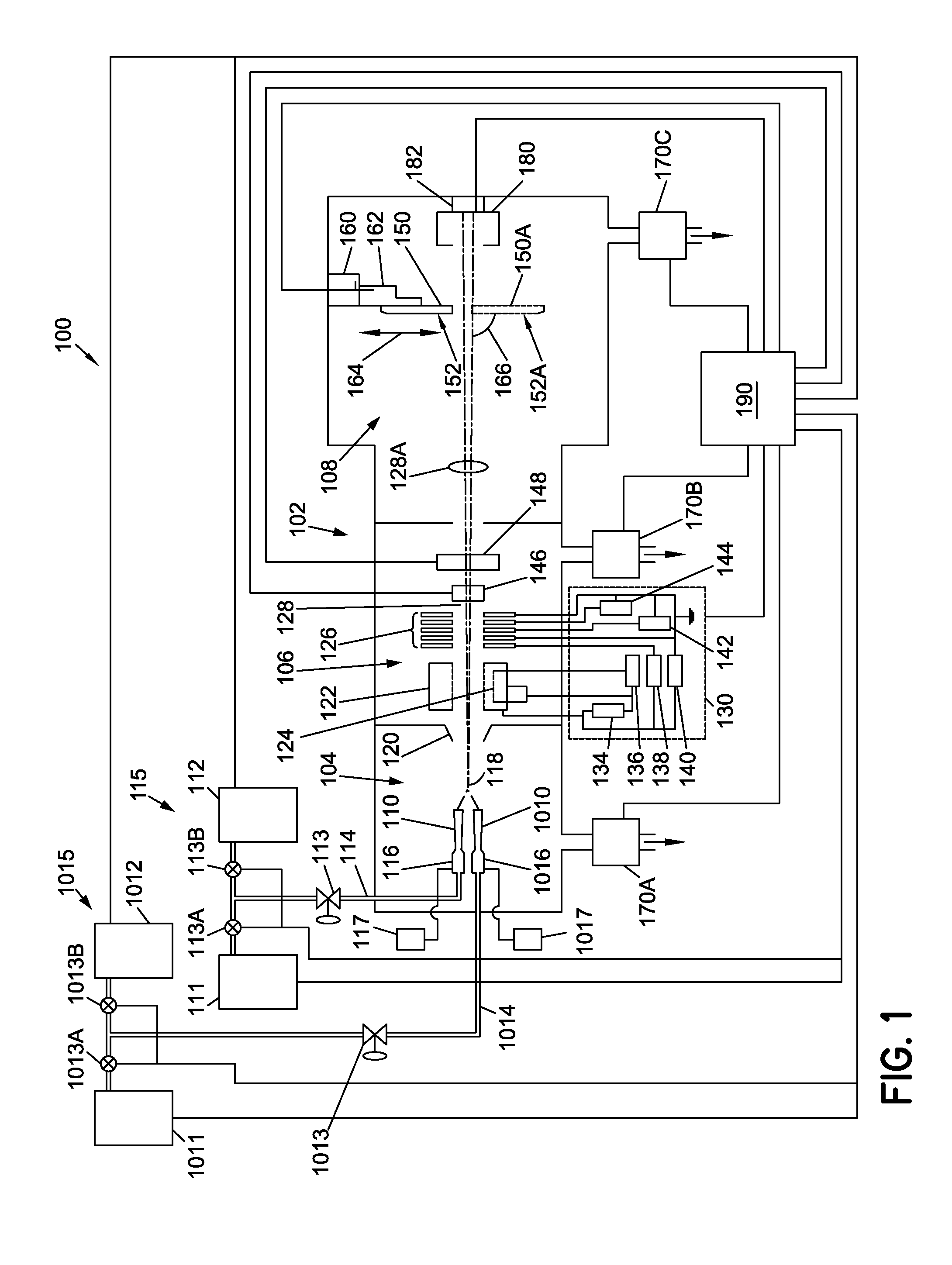

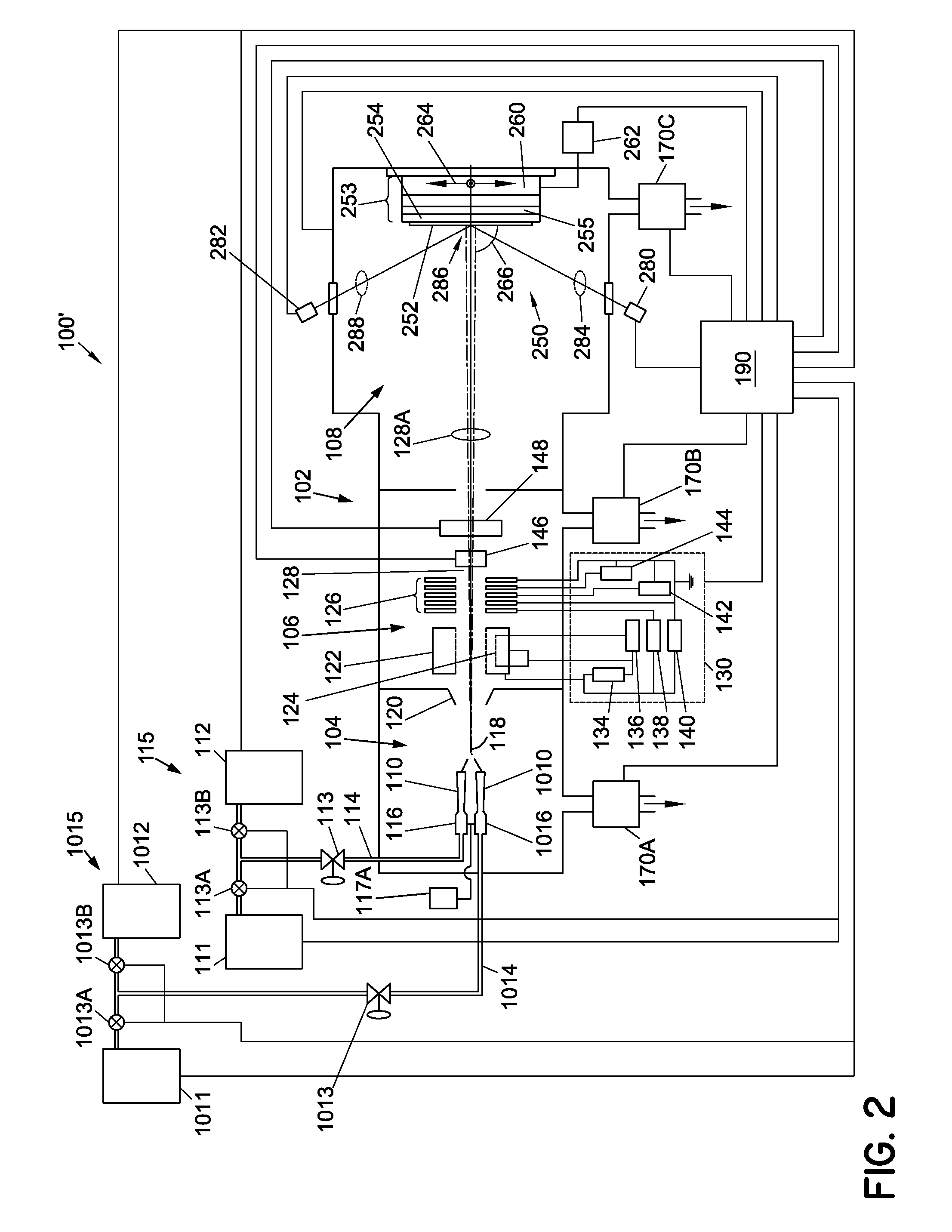

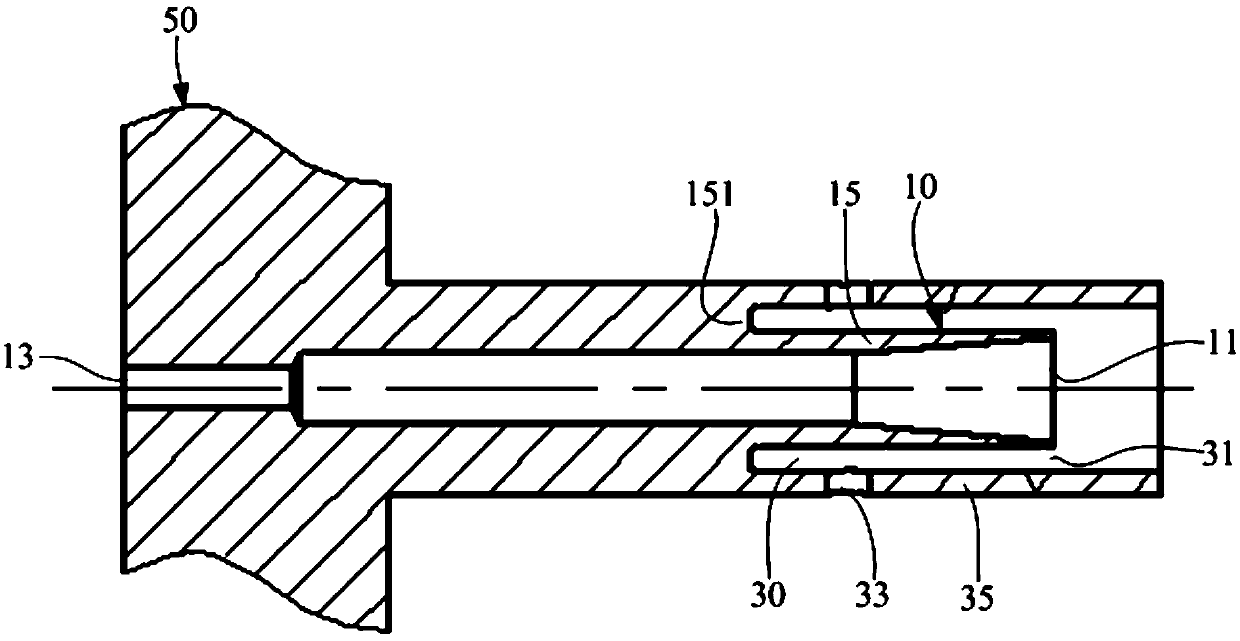

Gas cluster ion beam system with cleaning apparatus

ActiveUS20110272593A1Easy to cleanElectric discharge tubesSemiconductor/solid-state device manufacturingGas cluster ion beamSpray nozzle

Owner:TEL EPION

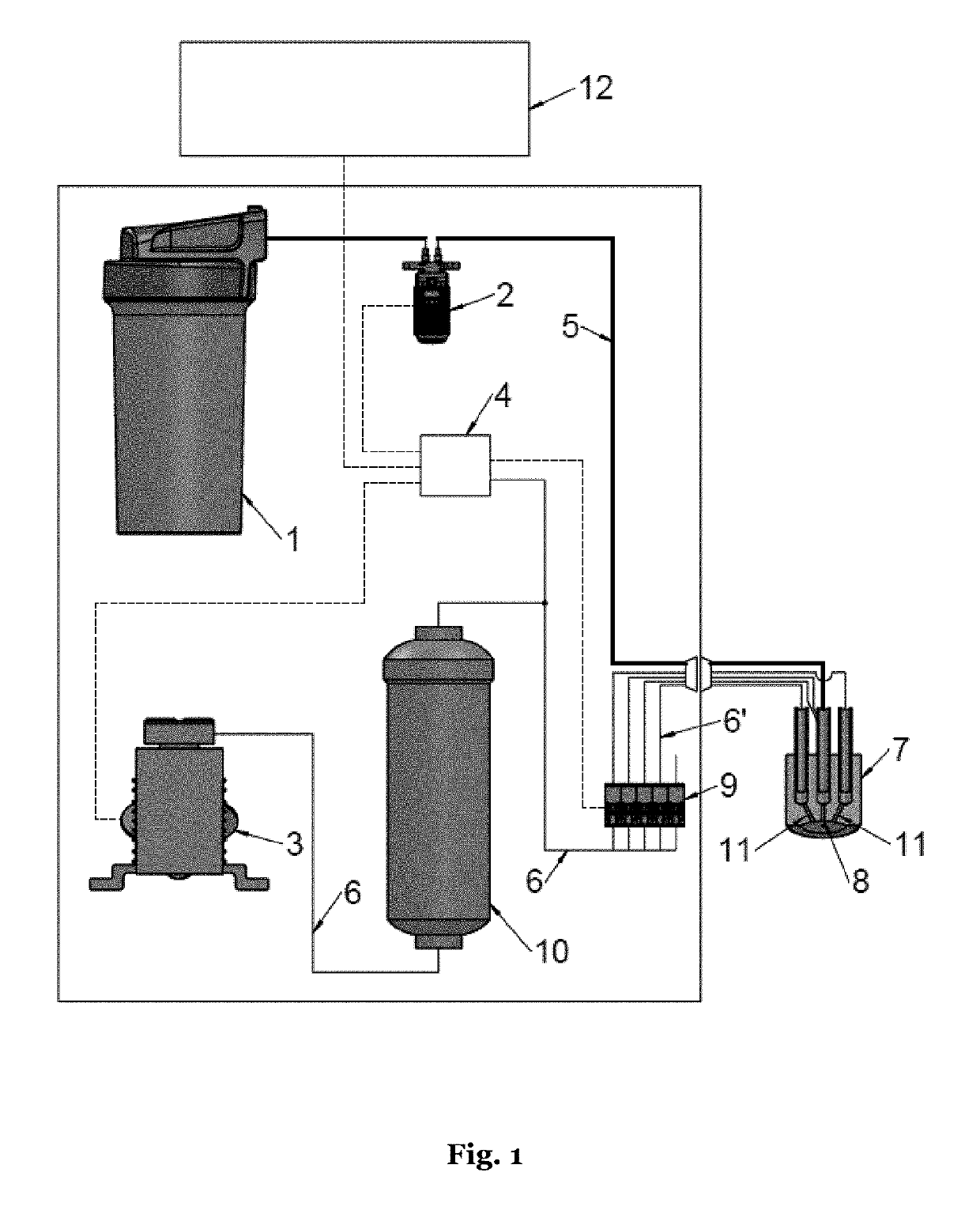

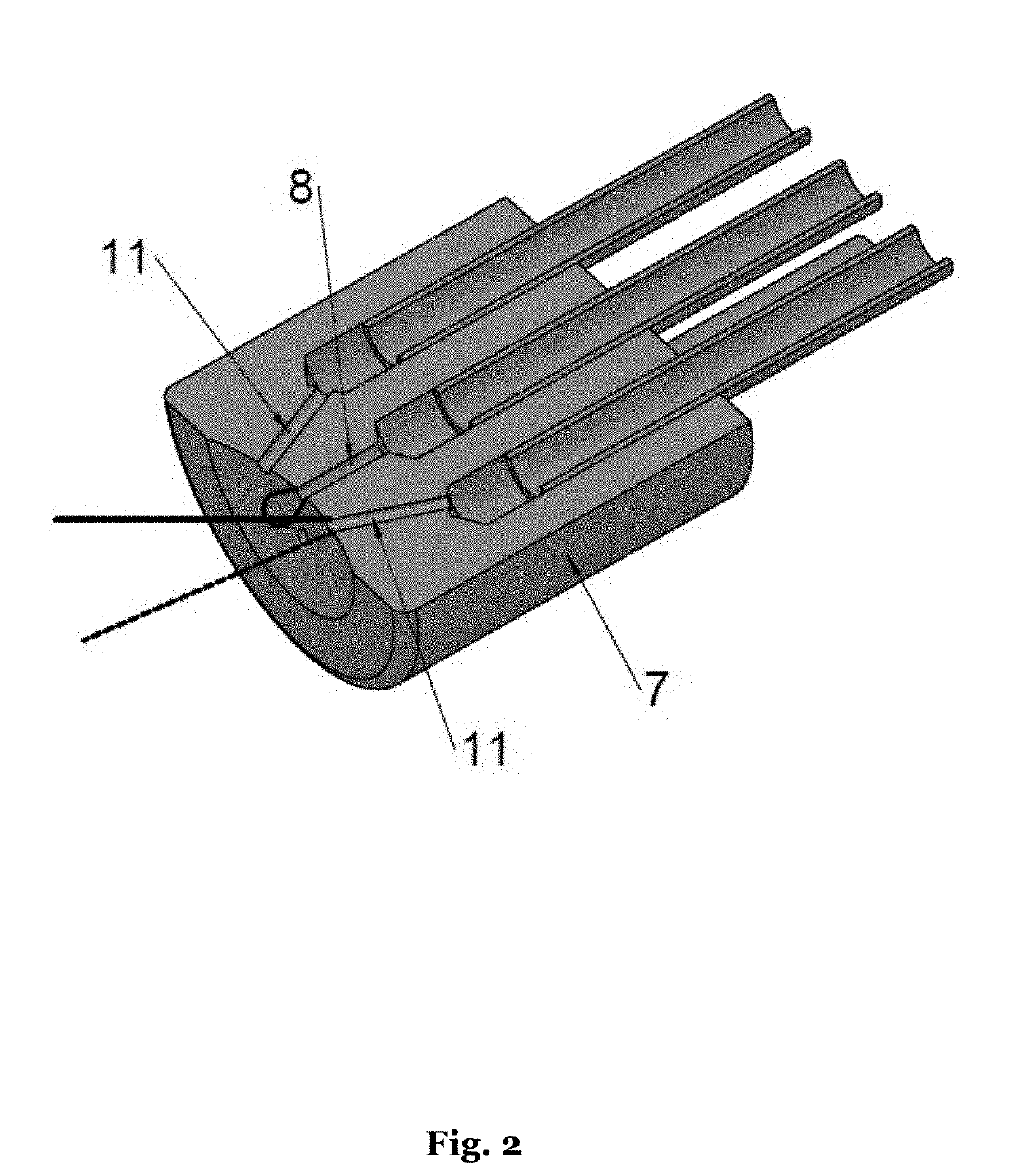

Micro-pulsed liquid spray for cooling

Owner:FOTONA D O O

Manufacturing Method of Antimicrobial Fiber Using Nano Silver Powder

InactiveUS20090214771A1Good antimicrobialHigh bactericidal activityLiquid surface applicatorsCoatingsSolventSpray nozzle

Owner:SHIN HYUNKYUNG +1

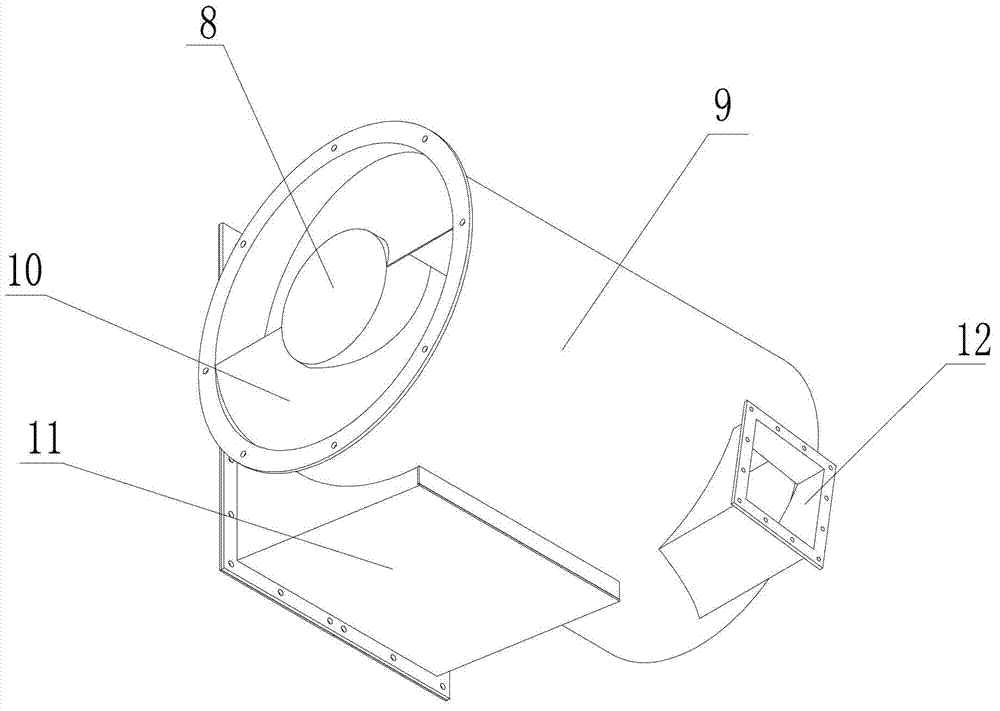

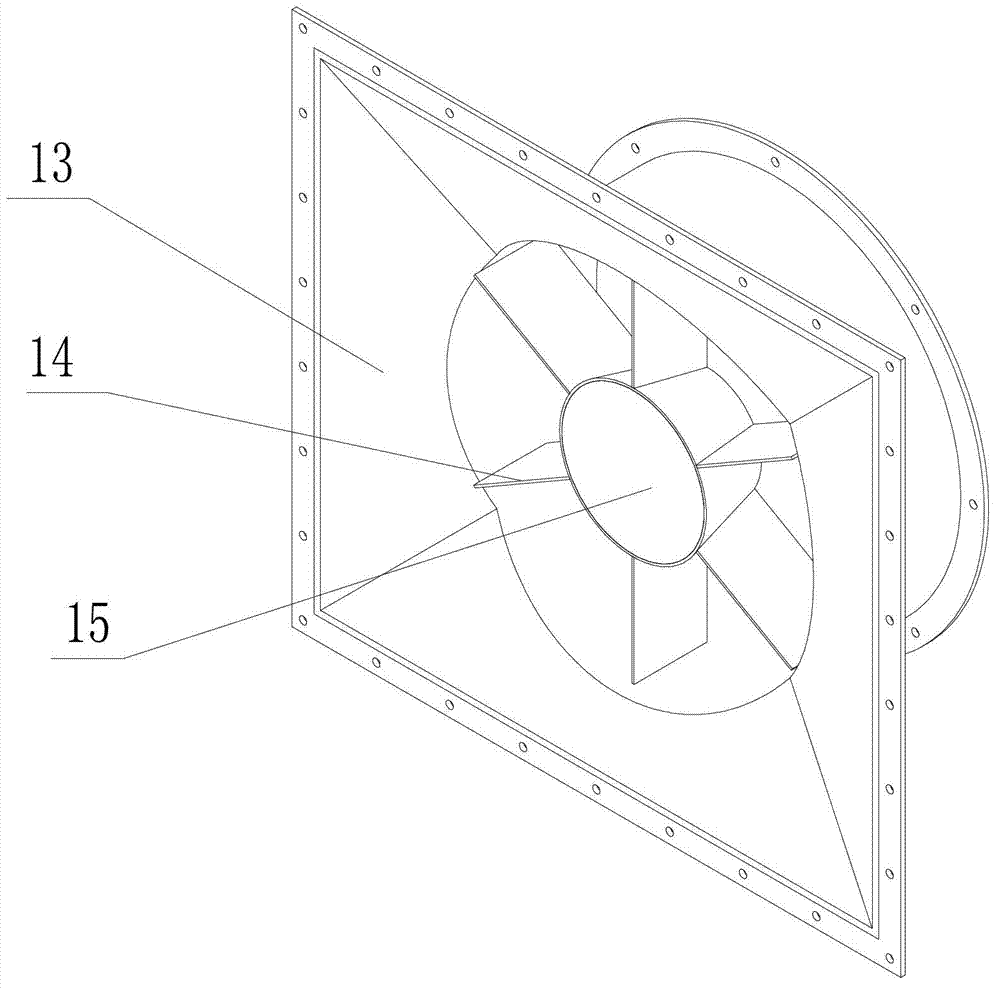

Device and Method for Admixing Liquids into Flowable Bulk Material

ActiveUS20080144425A1High energyEfficient mixingMixing/kneading structural elementsFlow mixersSpray nozzleImpact area

A device for admixing a liquid into flowable dry materials has a housing with a mixing chamber having an inner wall with an impact area and an exit opening at a bottom end of the mixing chamber. Dry material is supplied from above into the mixing chamber and falls downwardly toward the impact area in front of the inner wall of the mixing chamber and exits through the exit opening. A nozzle generates a pressurized high-speed jet of a liquid impacting on the inner wall of the mixing chamber in the impact area and wetting the dry material with the liquid as the jet passes through the dry material and impacts against the inner wall. An opening inside the housing is provided for supplying liquid and pasty additives, wherein the opening is directed toward an area of the mixing chamber between the nozzle and the impact area.

Owner:DIERKS & SOHNE GMBH & CO KG

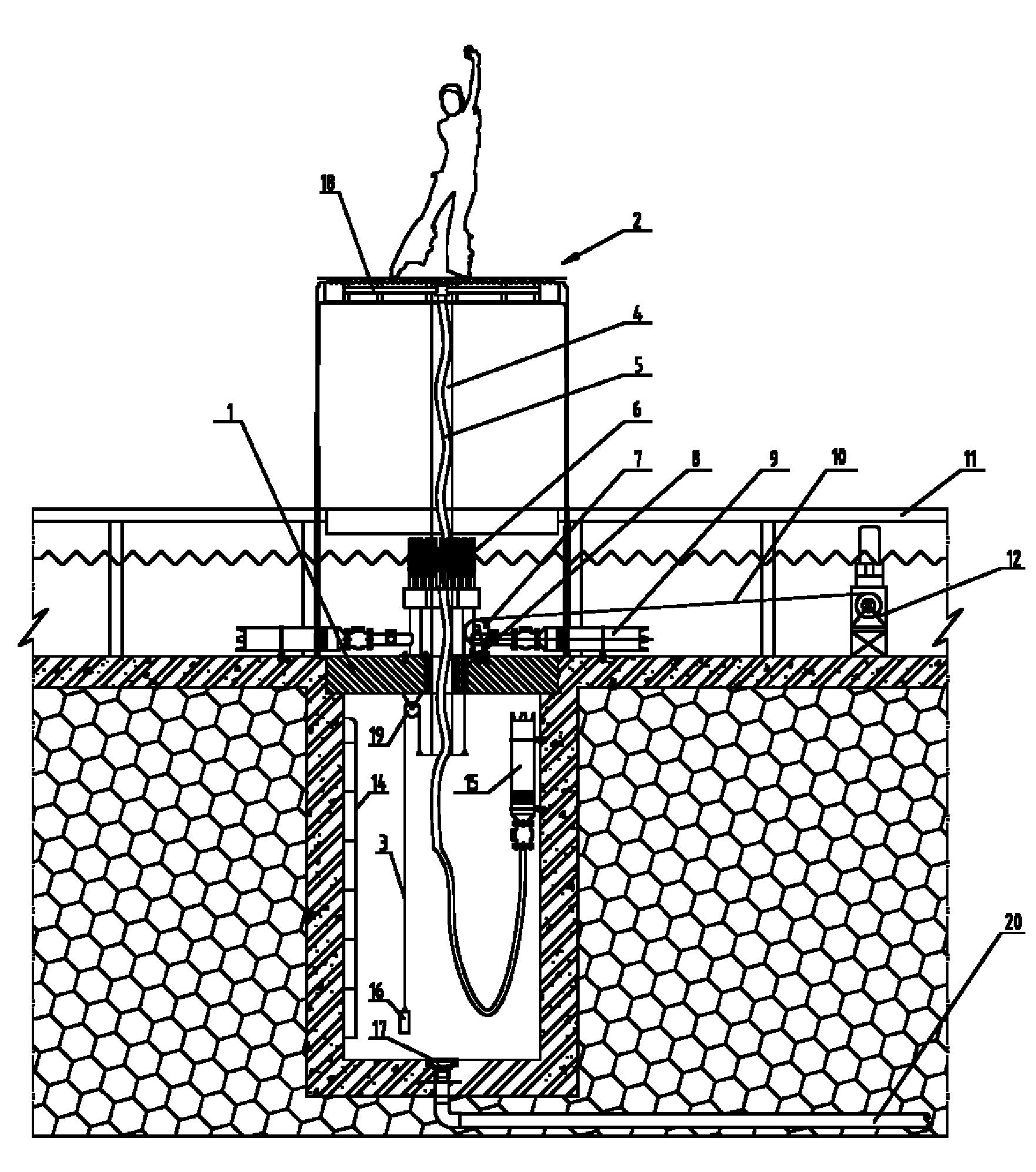

Elevating fountain stage

ActiveCN102031881AEnhance dynamic look and feelPracticalLiquid spraying apparatusTheatresWater flowSpray nozzle

Owner:东莞市环宇文化科技有限公司

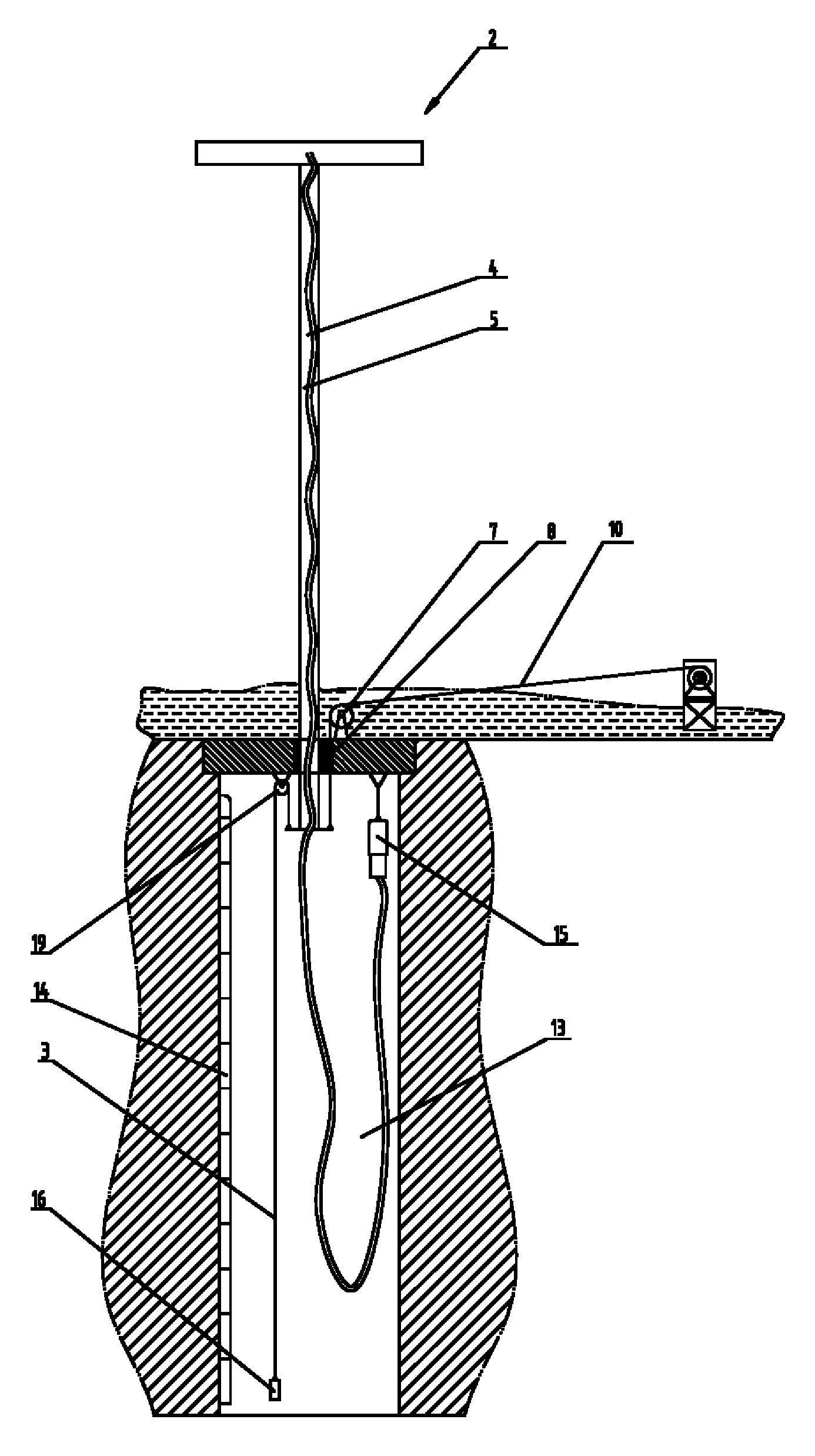

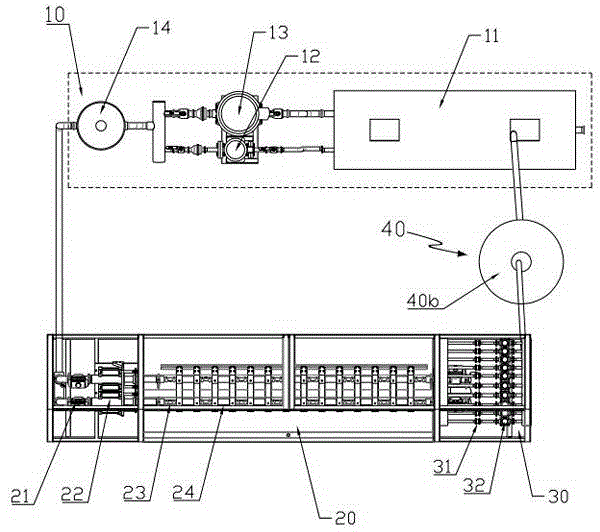

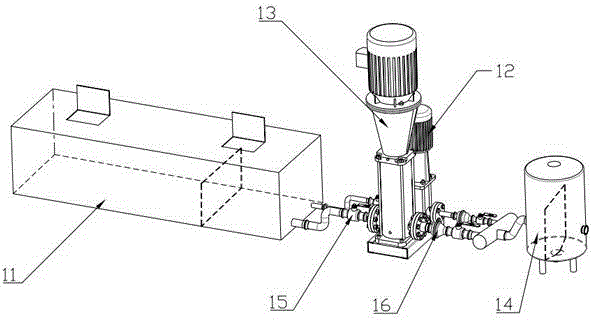

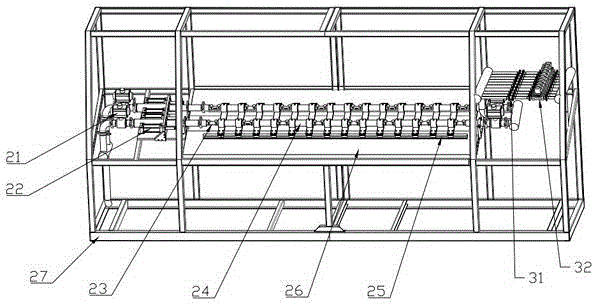

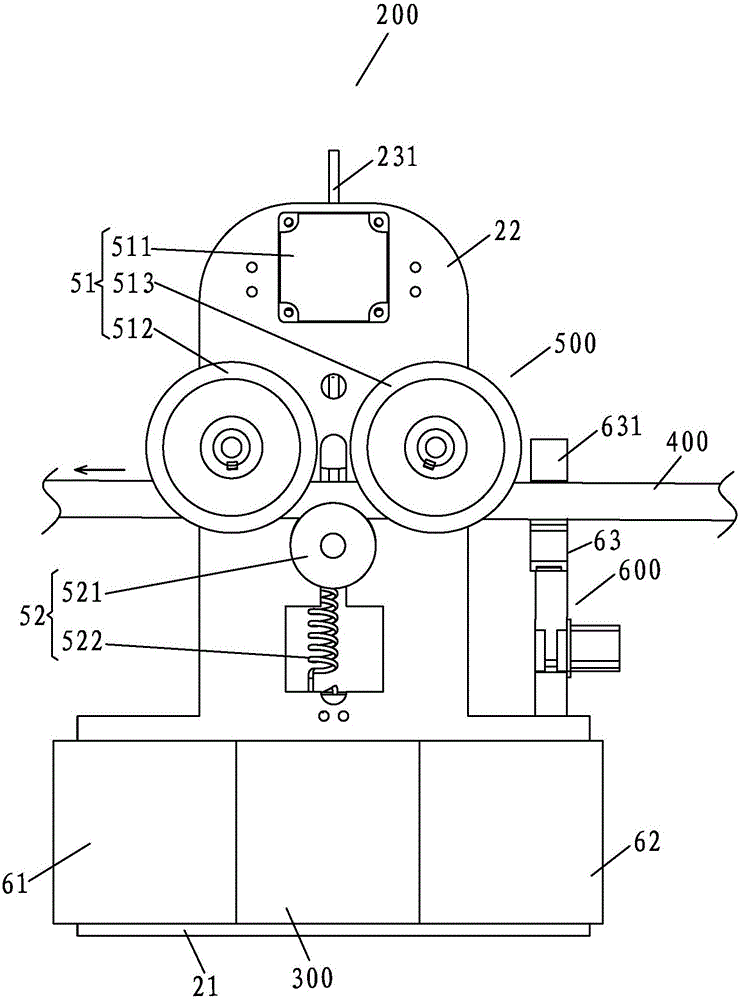

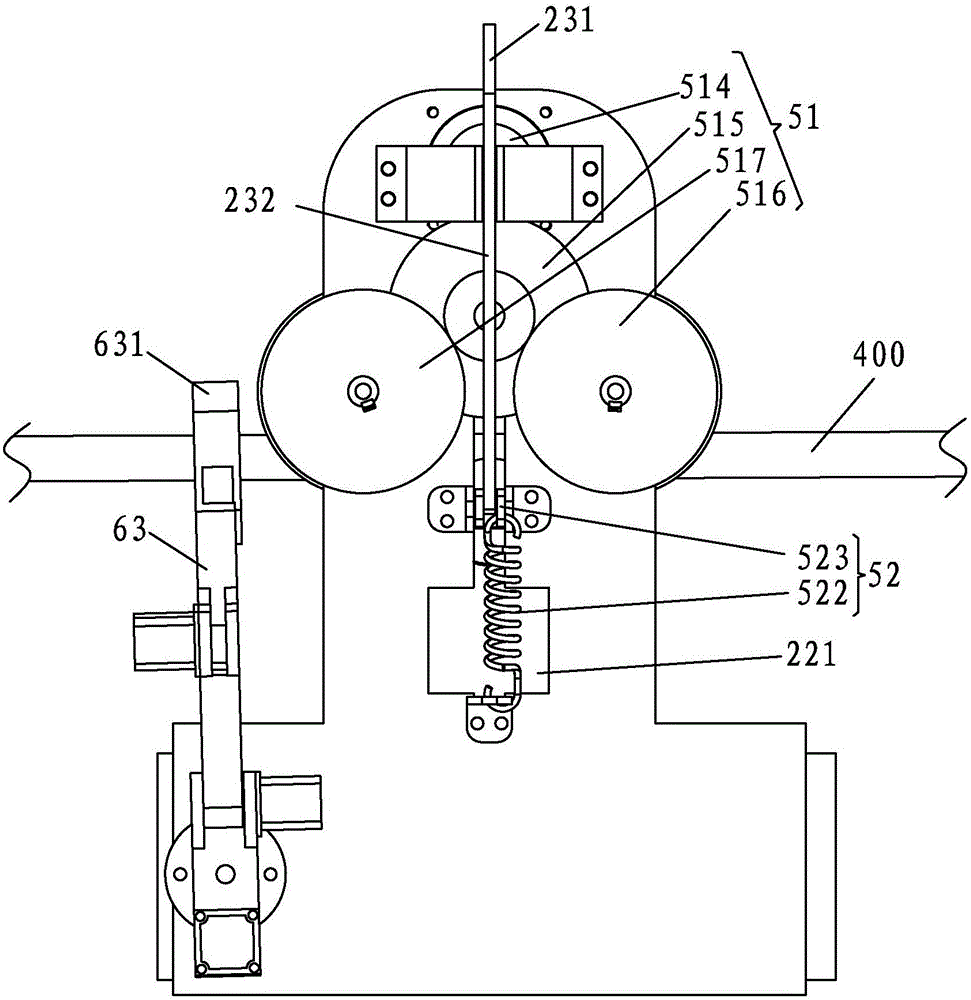

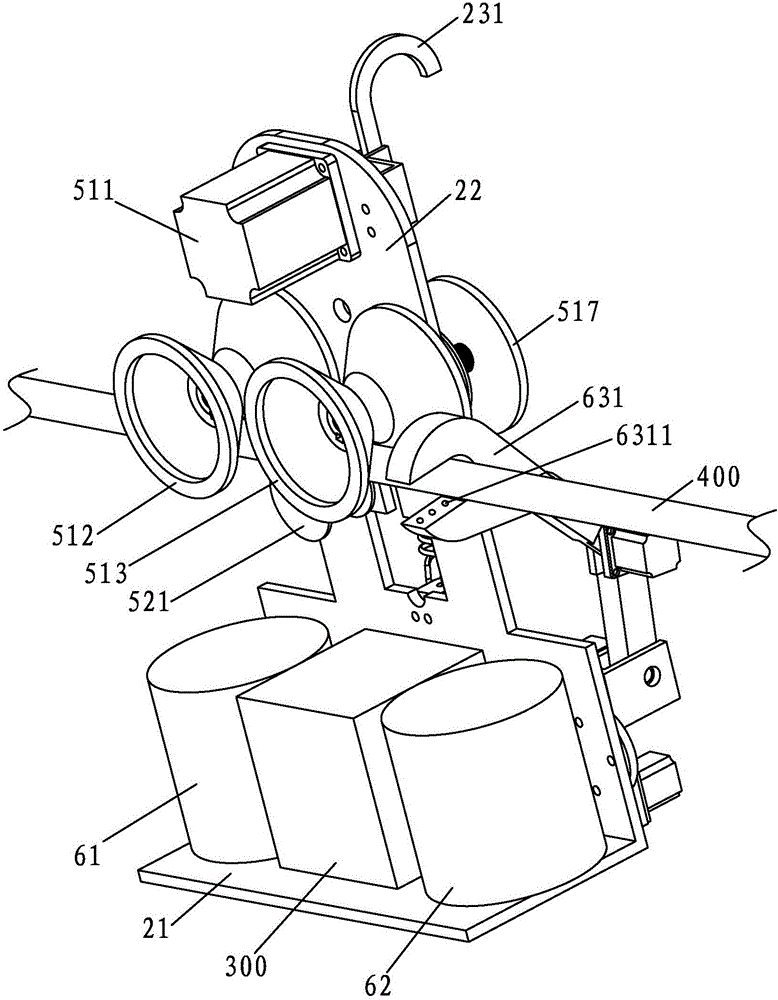

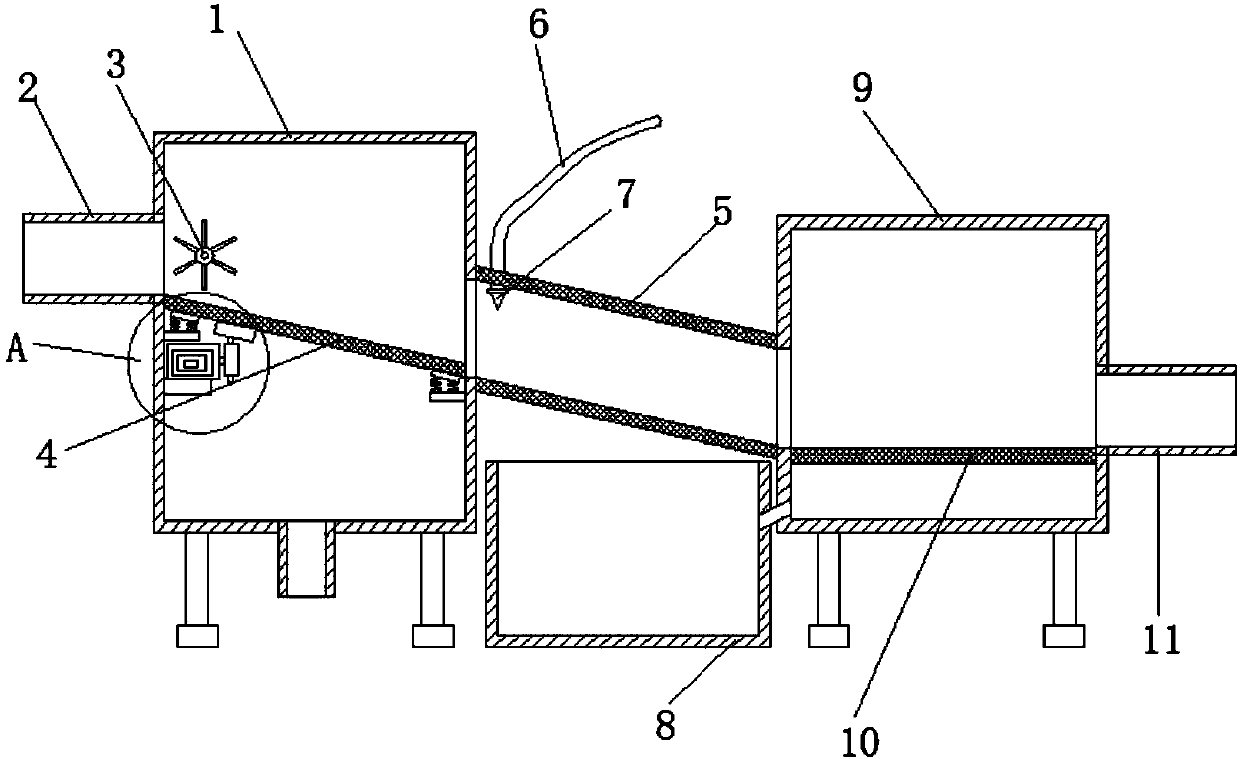

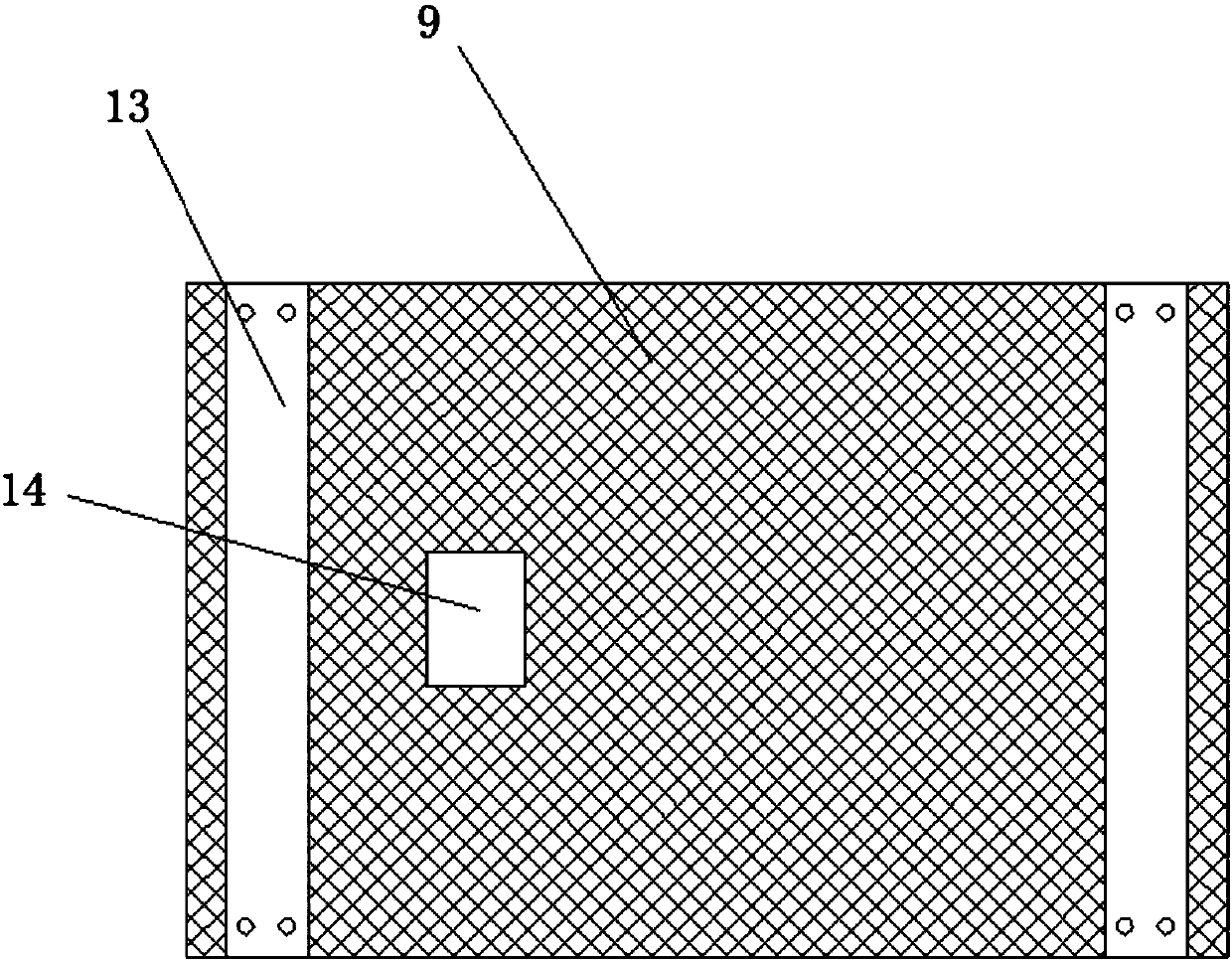

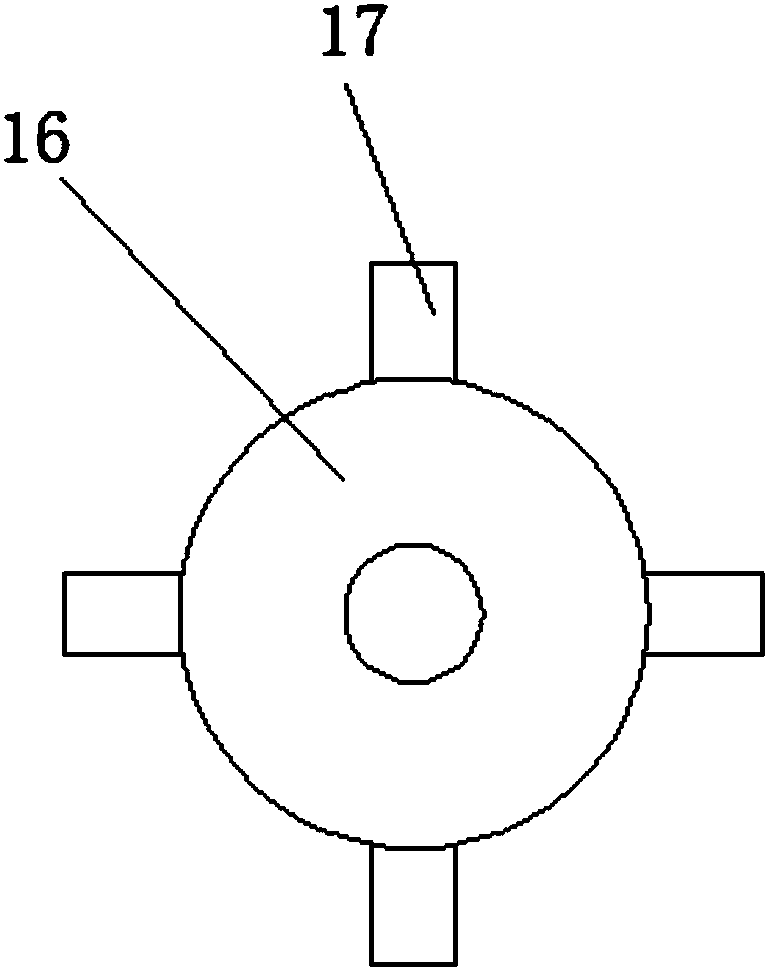

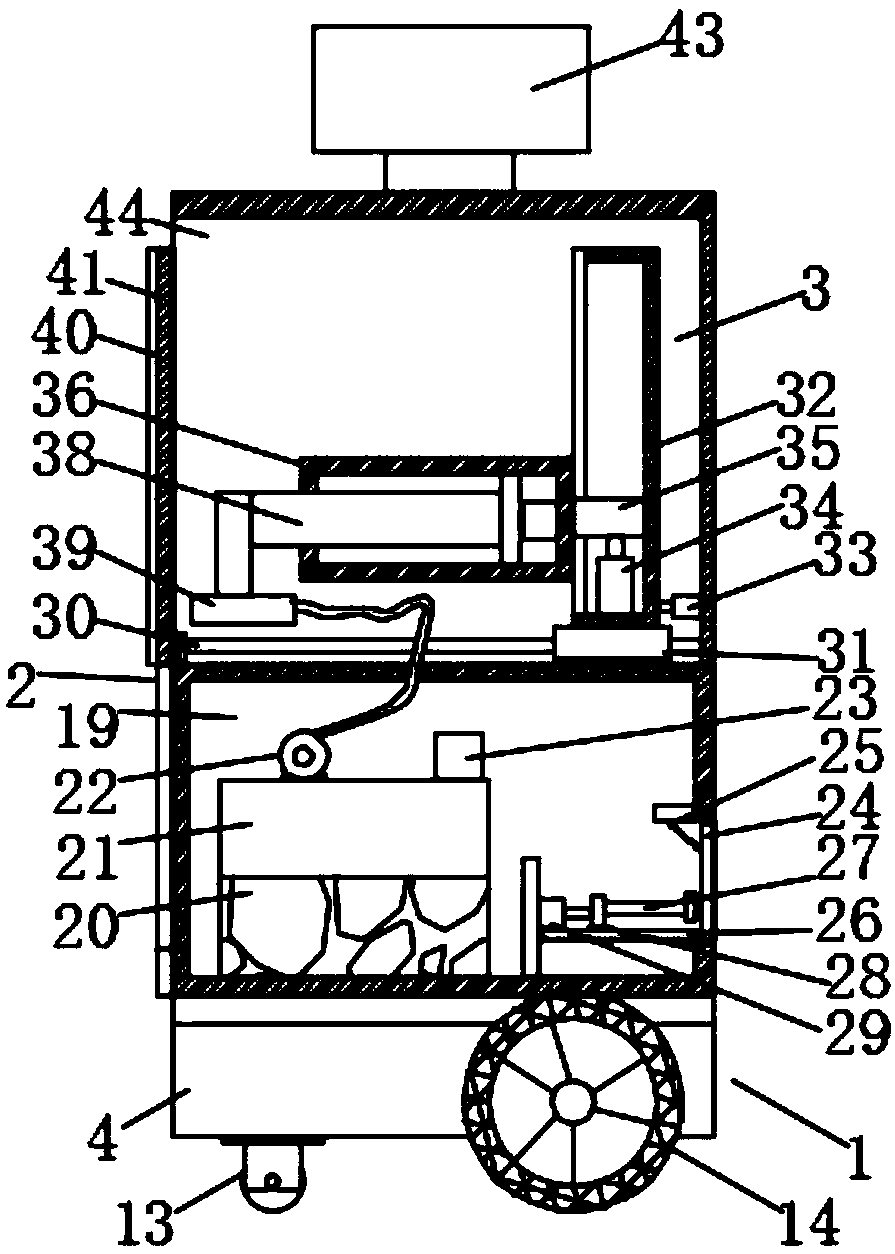

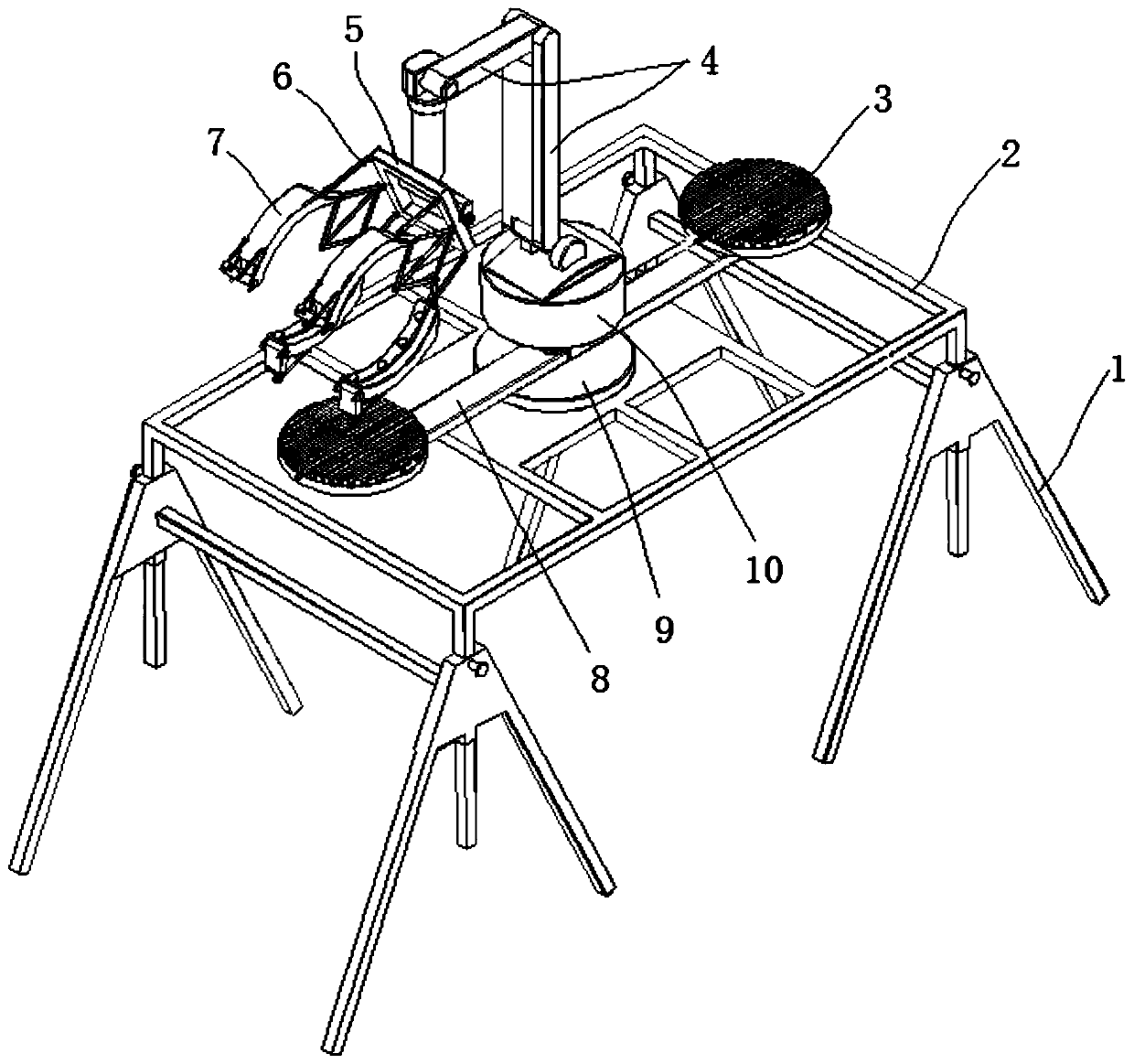

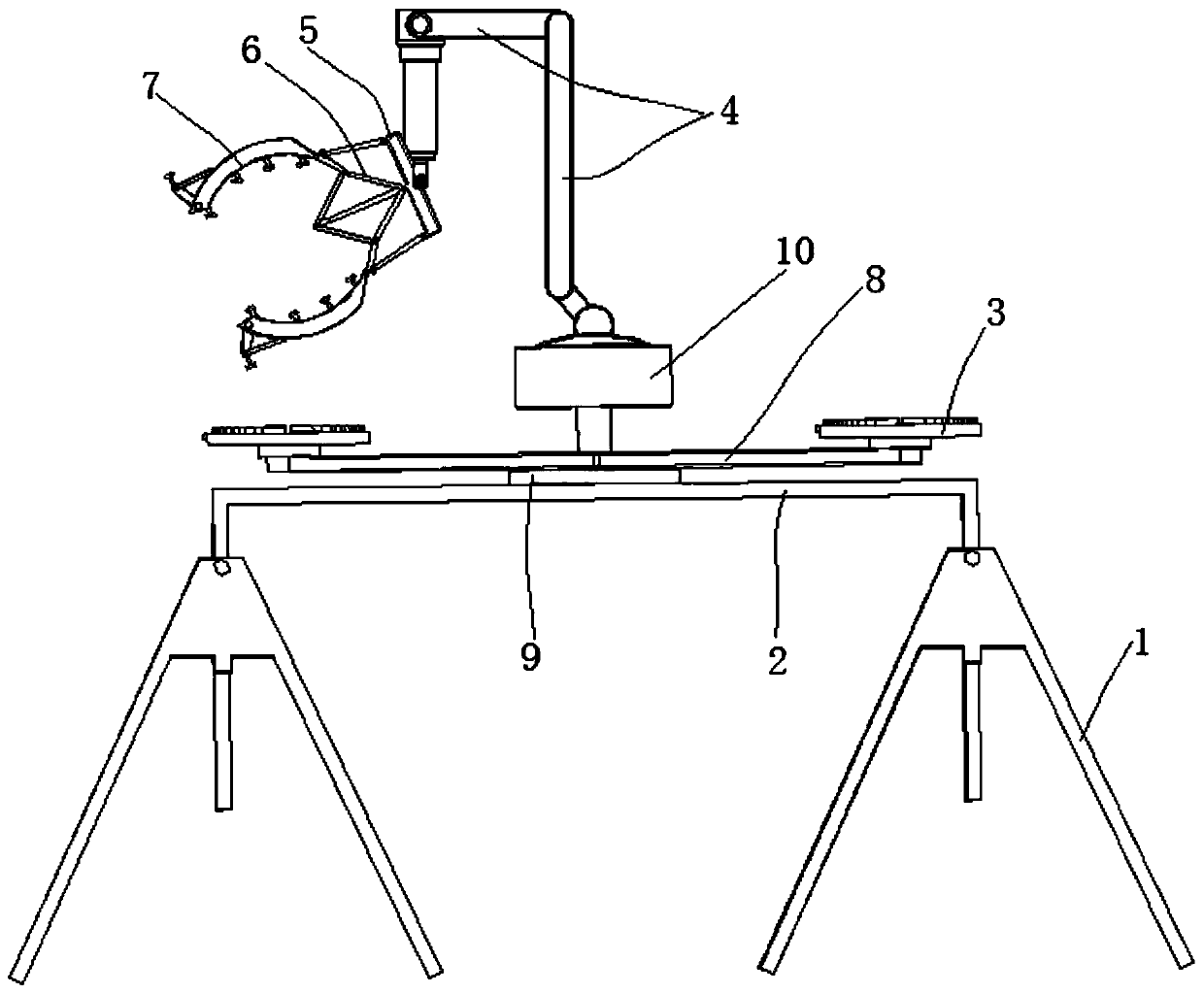

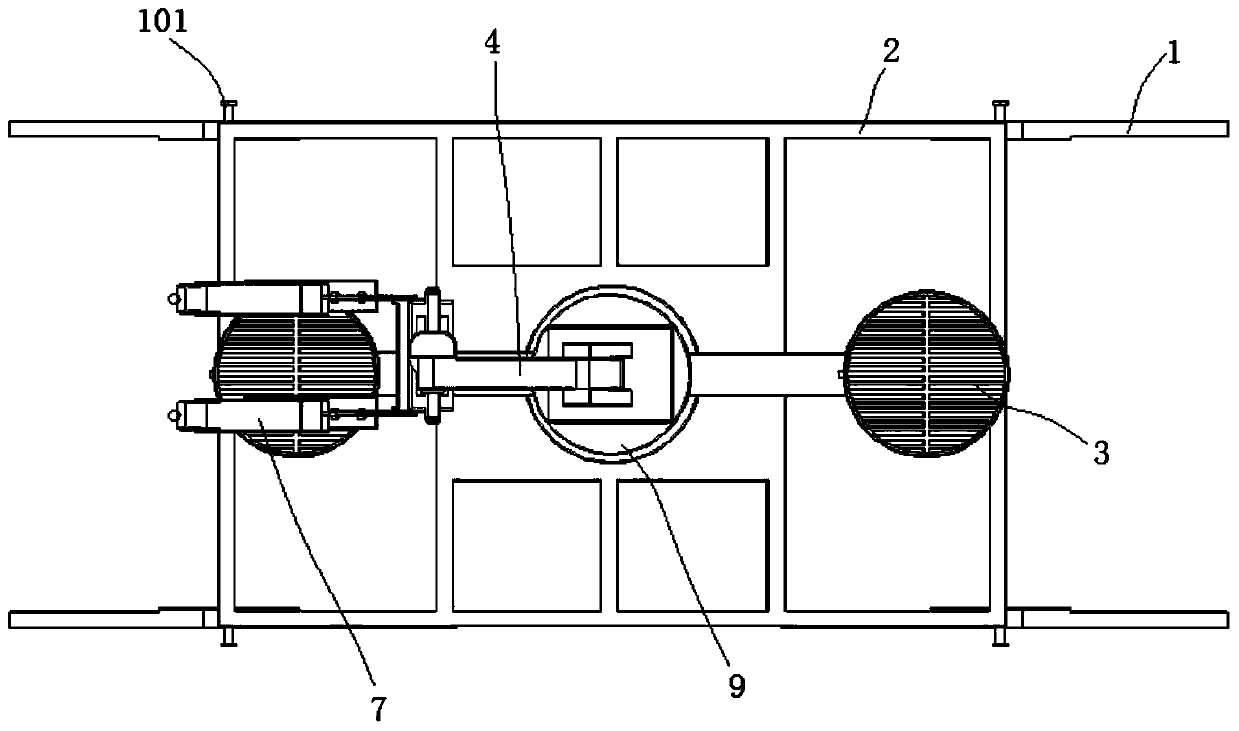

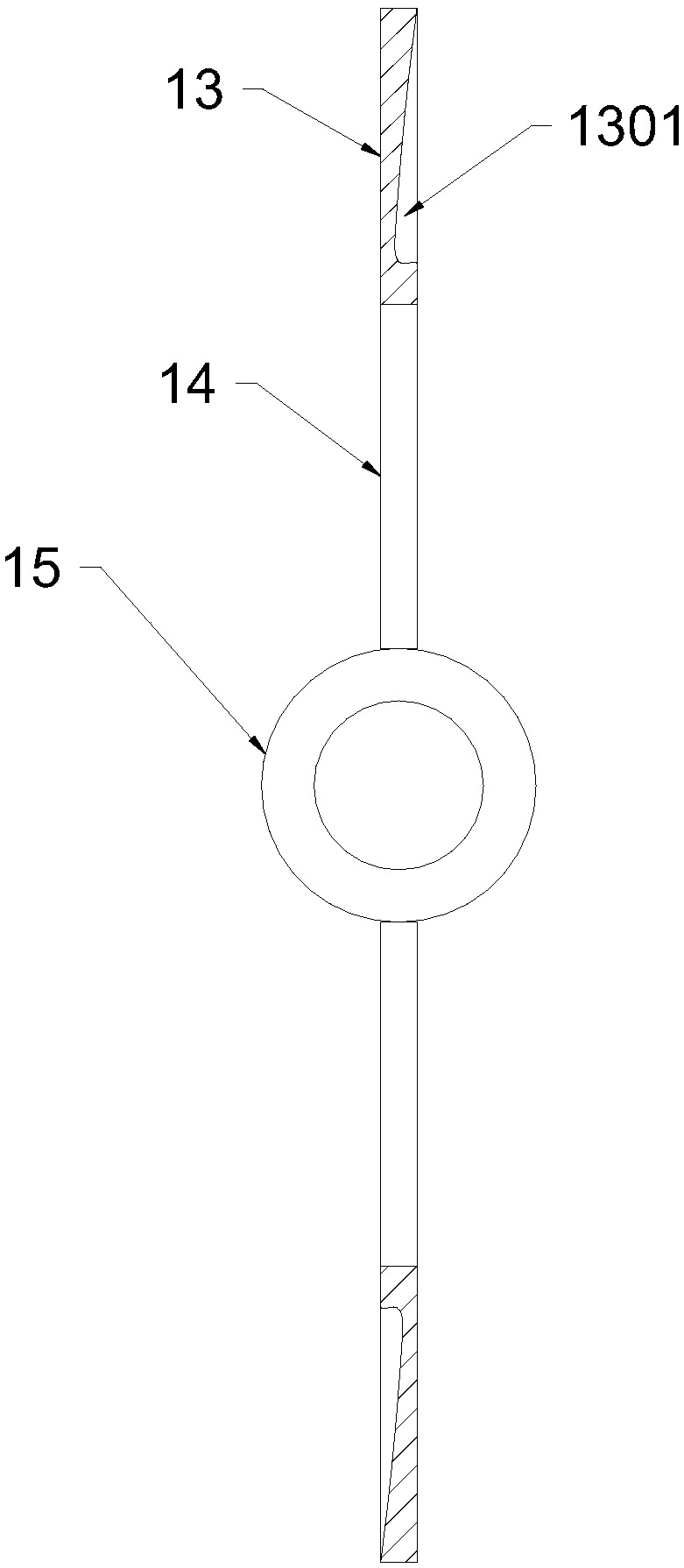

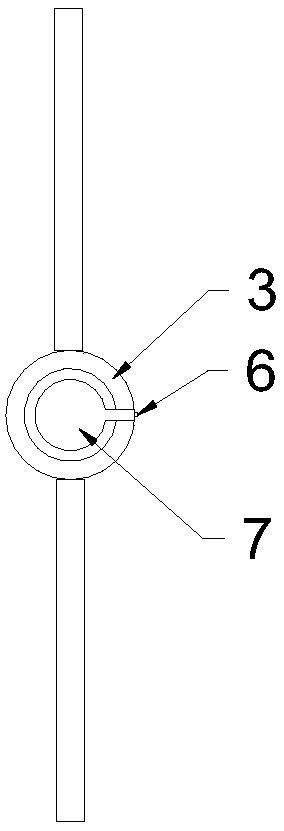

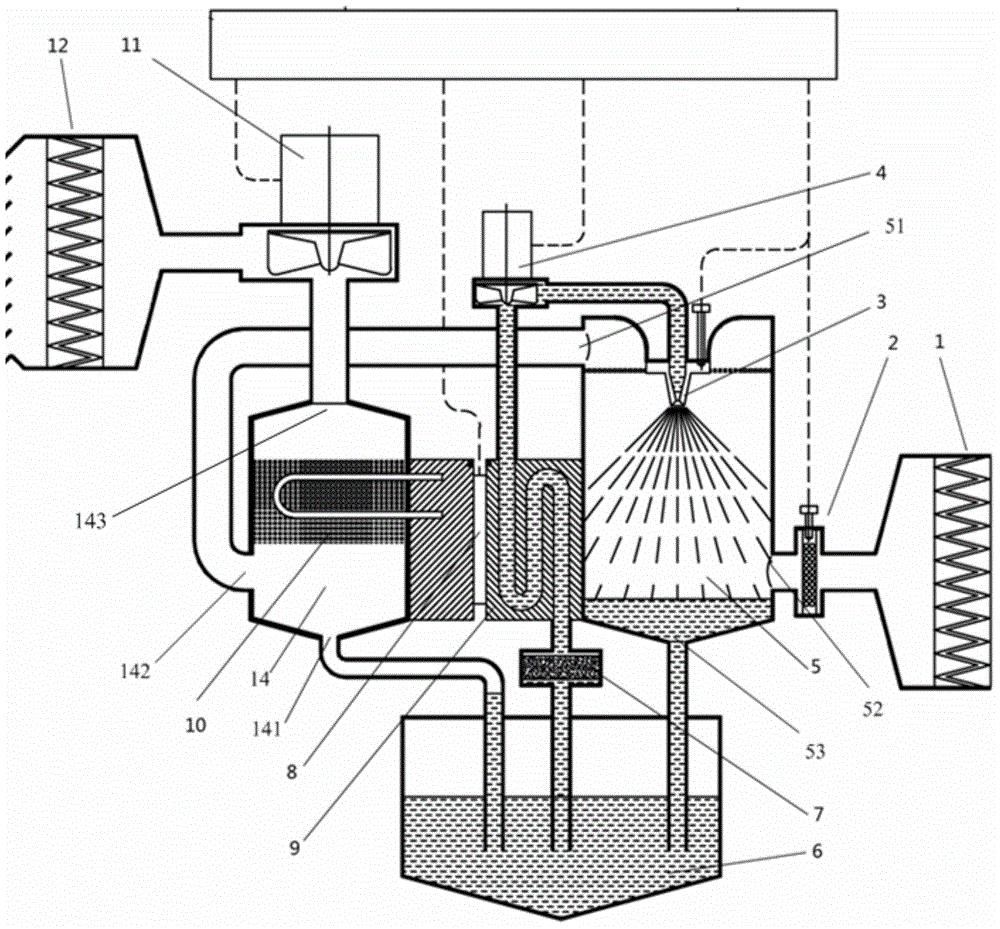

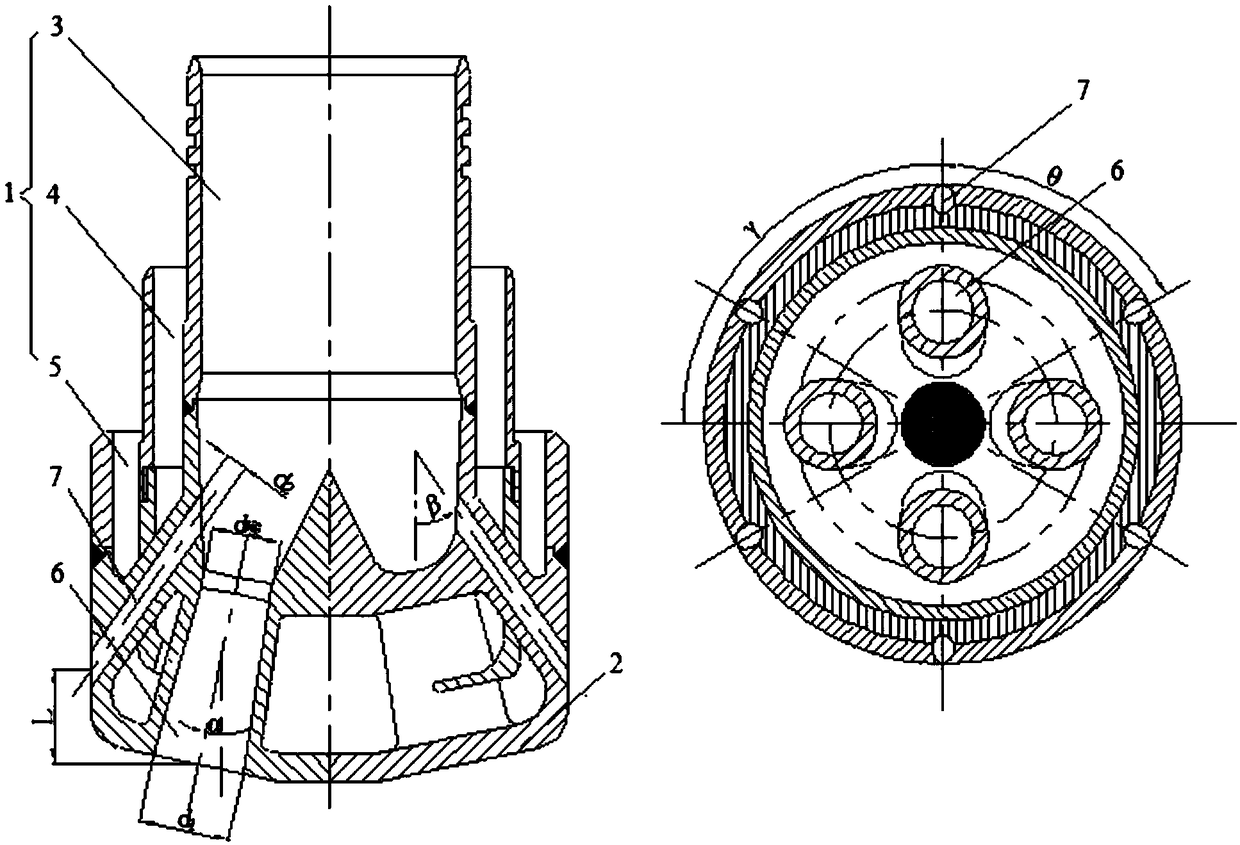

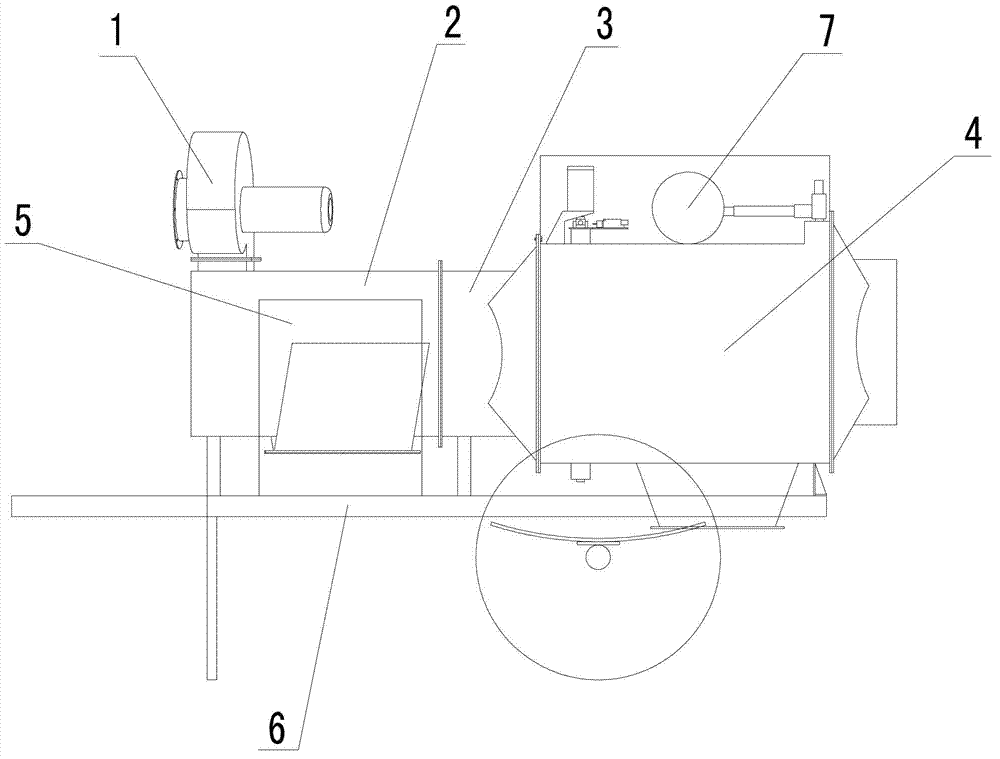

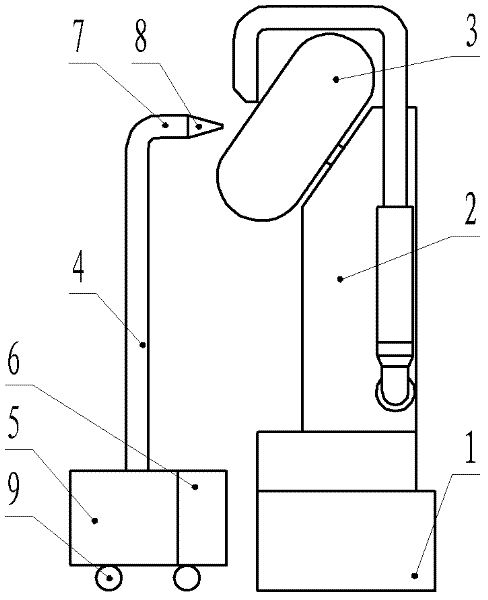

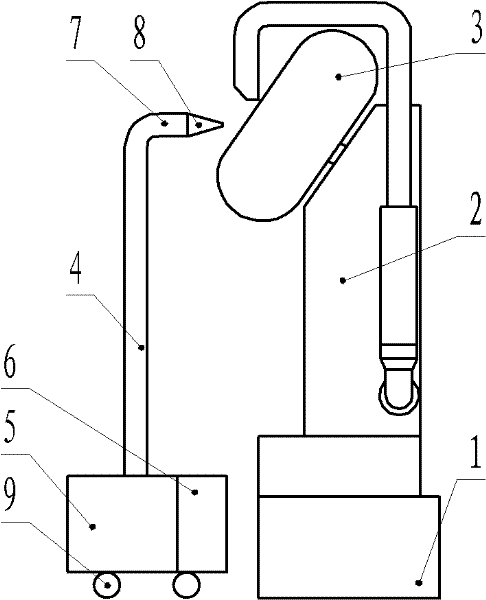

Automatic spraying robot for overhead transmission line

The invention discloses an automatic spraying robot for an overhead transmission line. The automatic spraying robot for the overhead transmission line comprises a control system and a mobile machine body; a power supply, a travelling system and a spraying system are arranged on the mobile machine body; the spraying system comprises an air pressure tank, an insulating paint barrel and a spraying head; the spraying head is designed as a mechanical arm; the paw of the mechanical arm is provided with a closed accommodating cavity; an insulating paint in the insulating paint barrel is conveyed into the closed accommodating cavity through pressure; a spraying nozzle of the spraying head is arranged on the paw of the mechanical arm and is arranged in a manner of surrounding the overhead transmission line in the radial direction. When the automatic spraying robot for the overhead transmission line works, the paw of the mechanical arm is circularly arranged at the periphery of the overhead transmission line under the control of the control system, troubles caused by manual sleeving and mounting are avoided, the situation of locking is avoided, and the automation degree and the work reliability are high. Moreover, in case that the spraying head fails and cannot spray, the power supply of the overhead transmission line is not required to be cut off, and the mechanical arm is only required to be controlled to leave the overhead transmission line and then the spraying head is maintained; the automatic spraying robot for the overhead transmission line is convenient to use and does not influence power production.

Owner:QUANZHOU ZHIYONGDA ELECTRIC

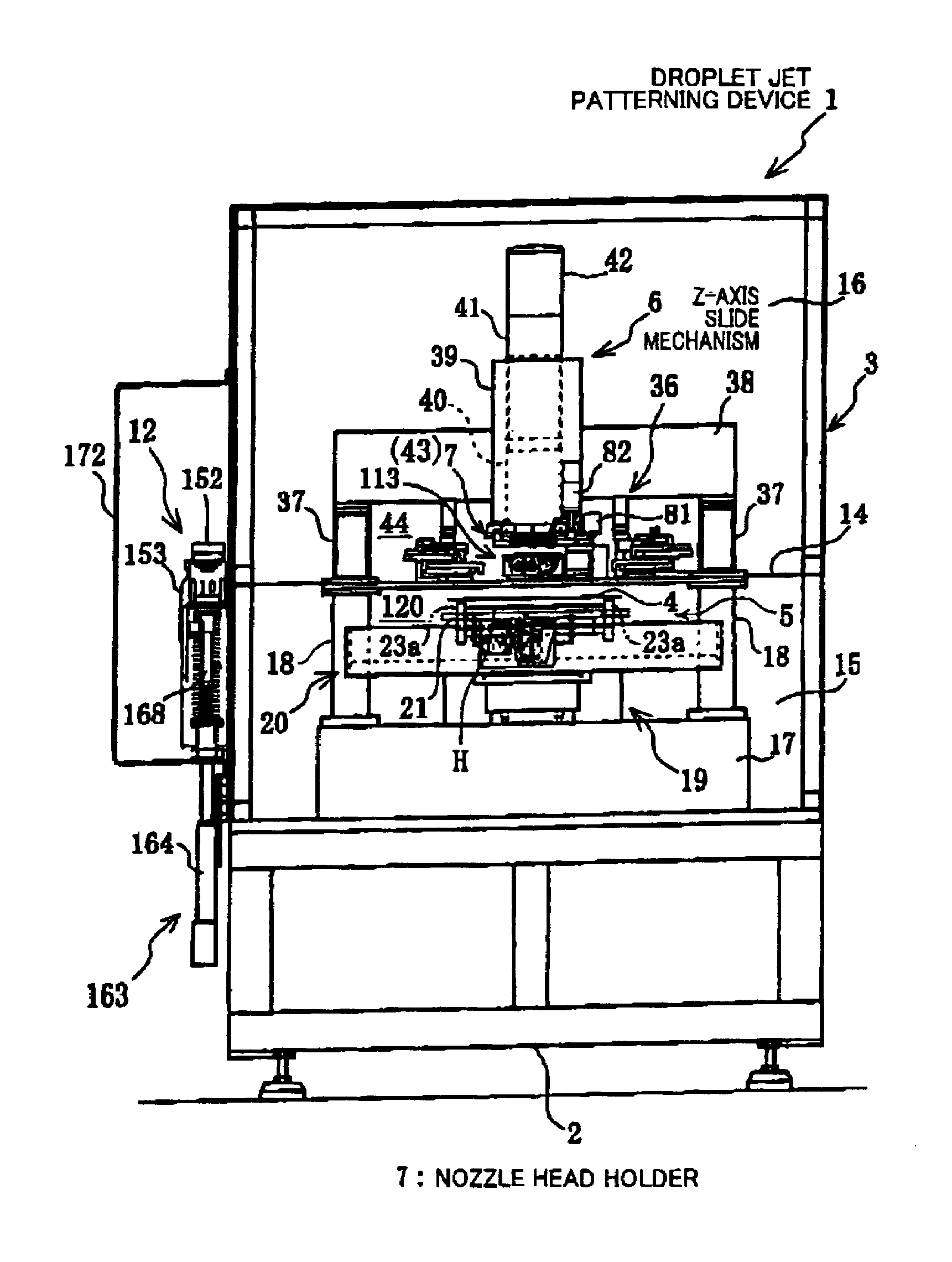

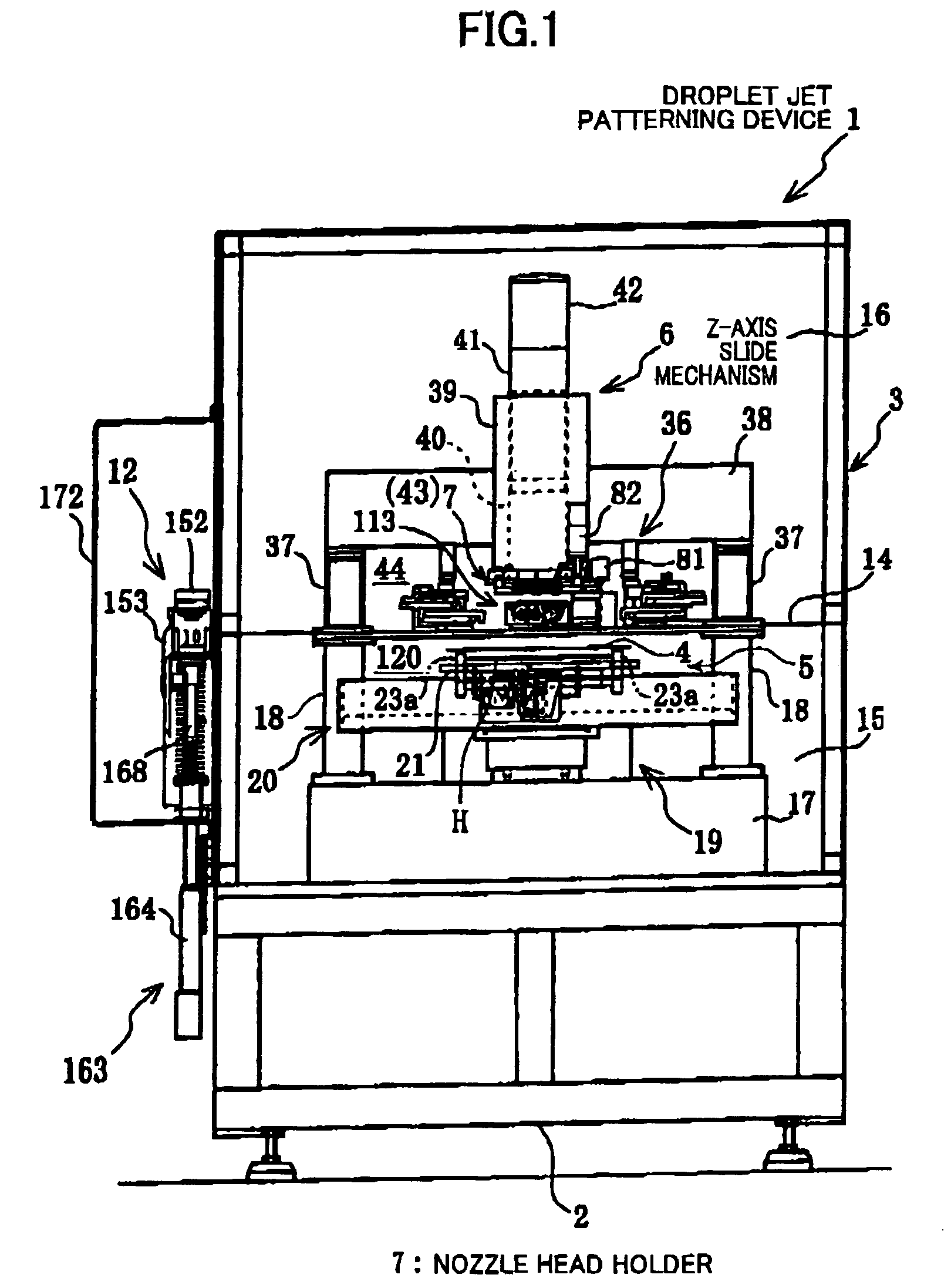

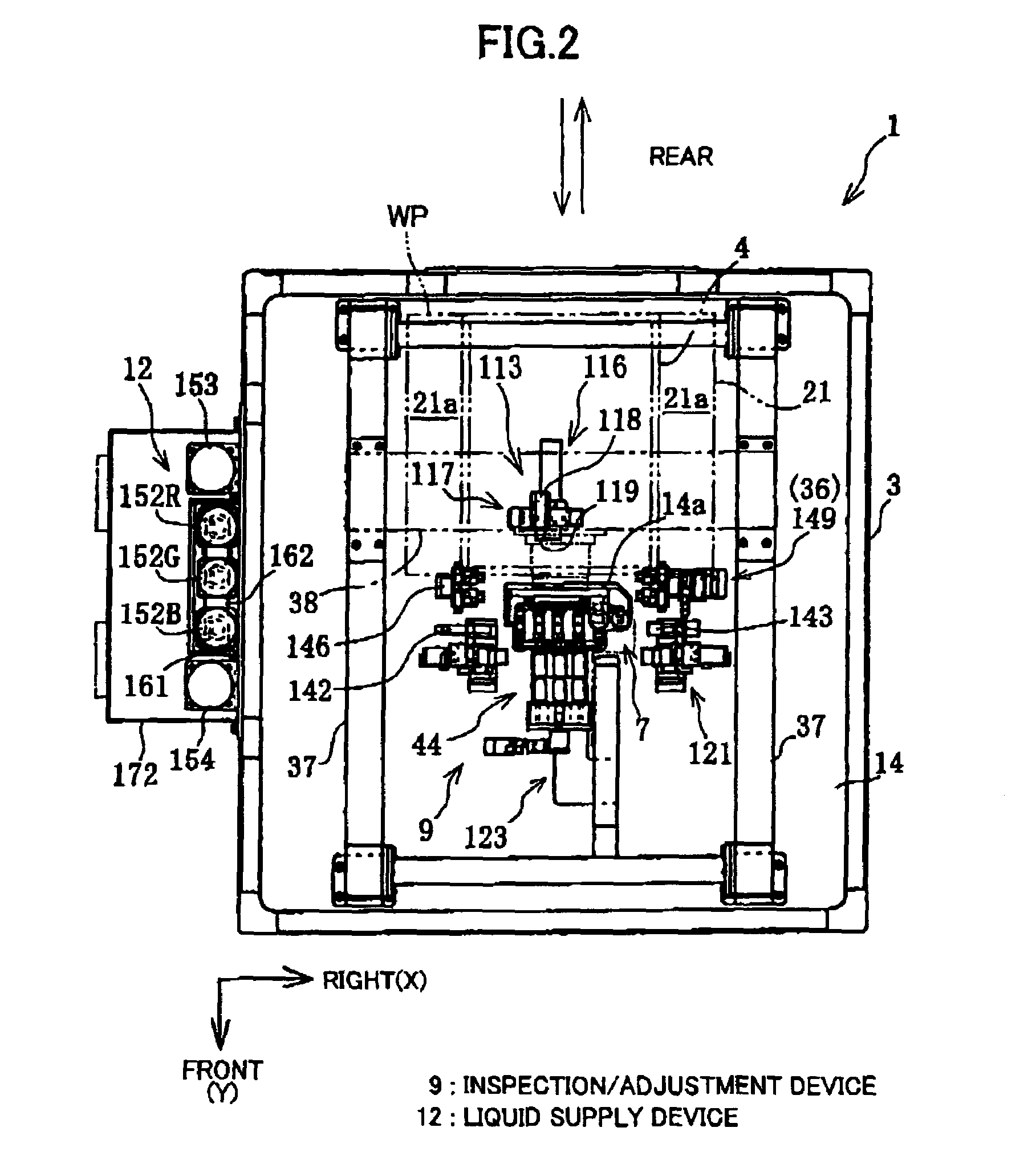

Nozzle head, nozzle head holder, and droplet jet patterning device

InactiveUS7008482B2Data processing is simpleEasy to controlLiquid surface applicatorsMovable spraying apparatusSpray nozzleEngineering

Owner:BROTHER KOGYO KK

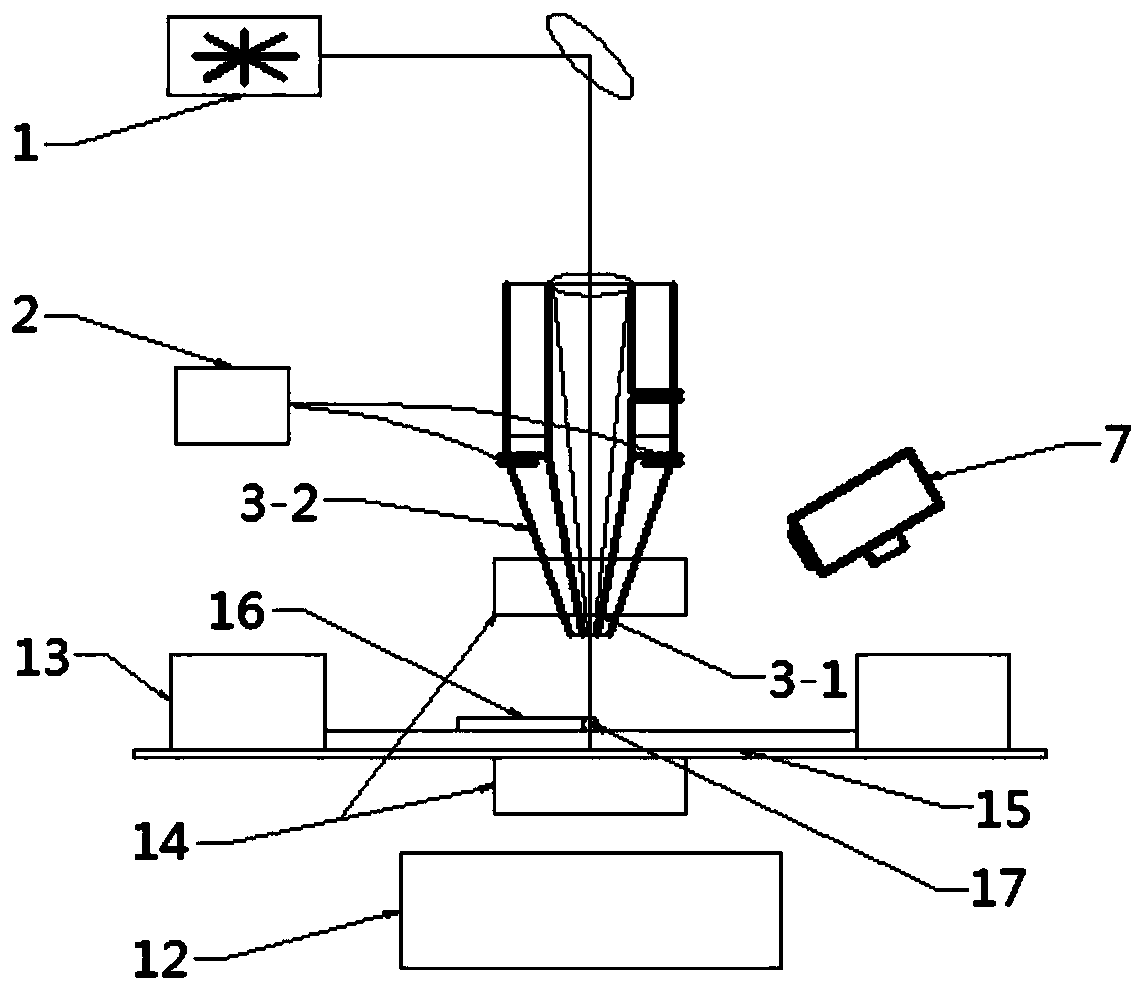

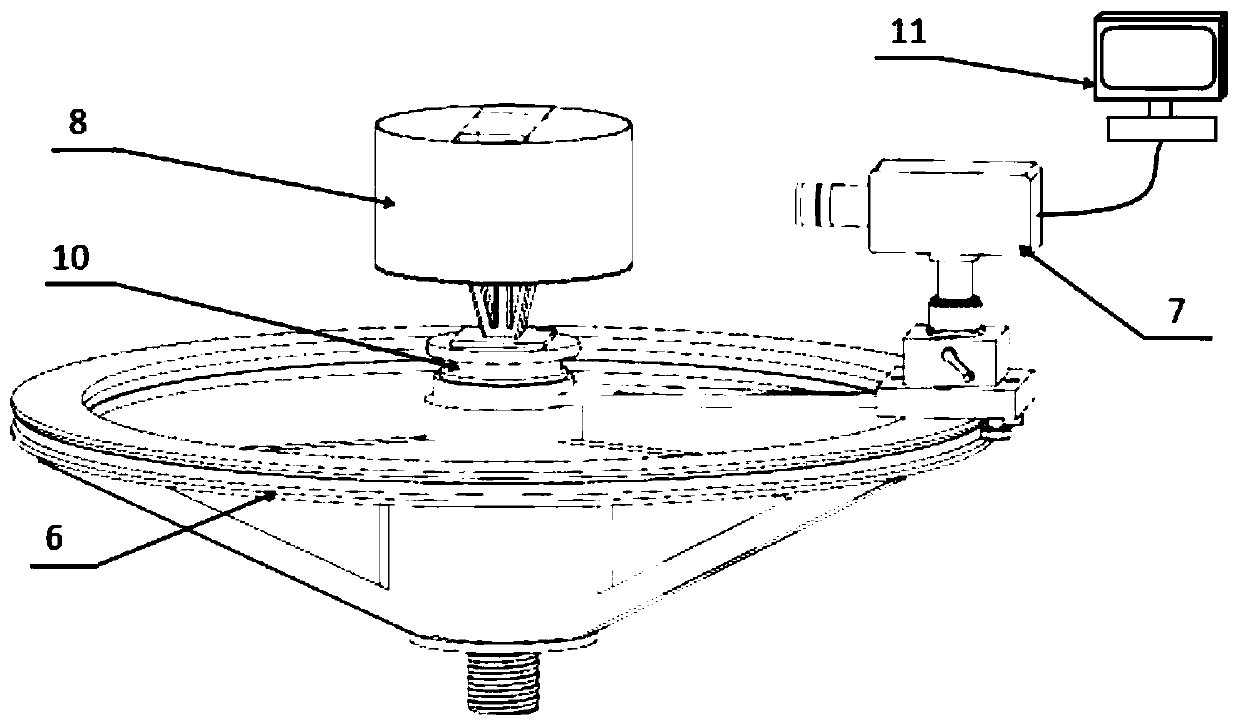

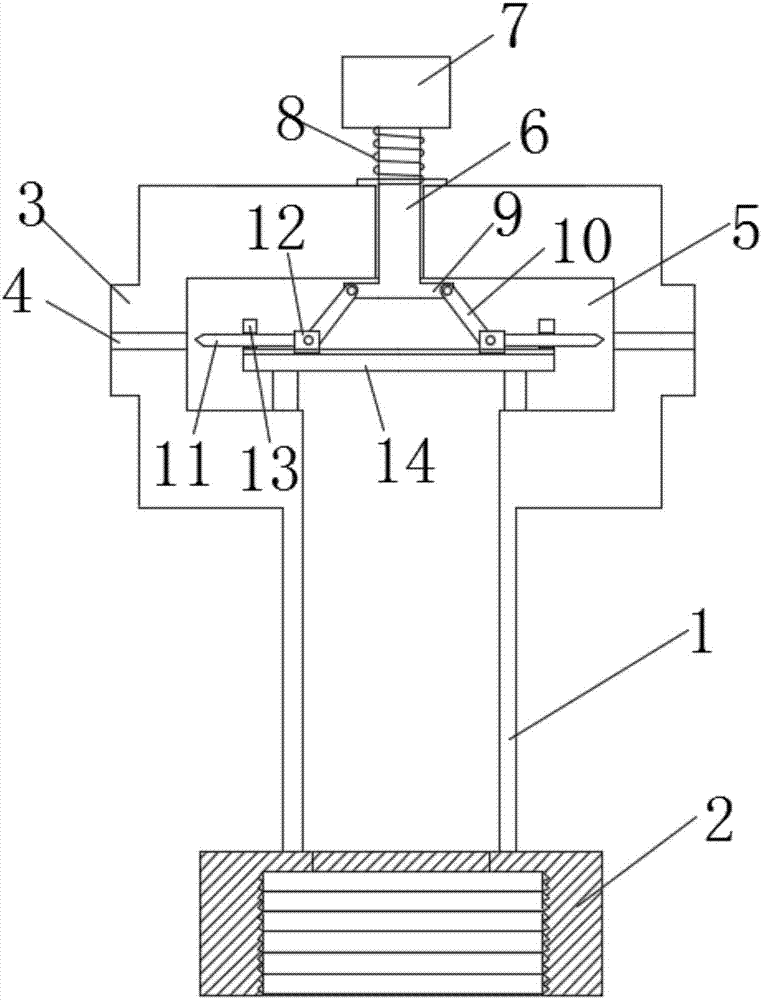

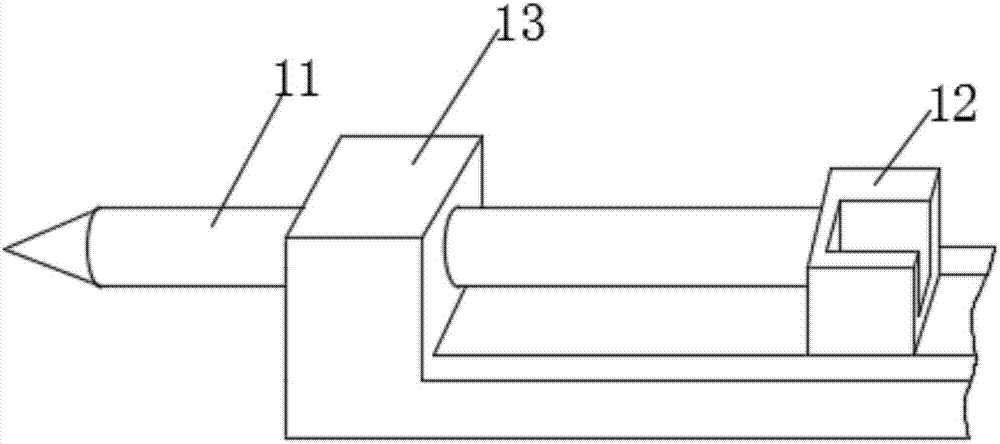

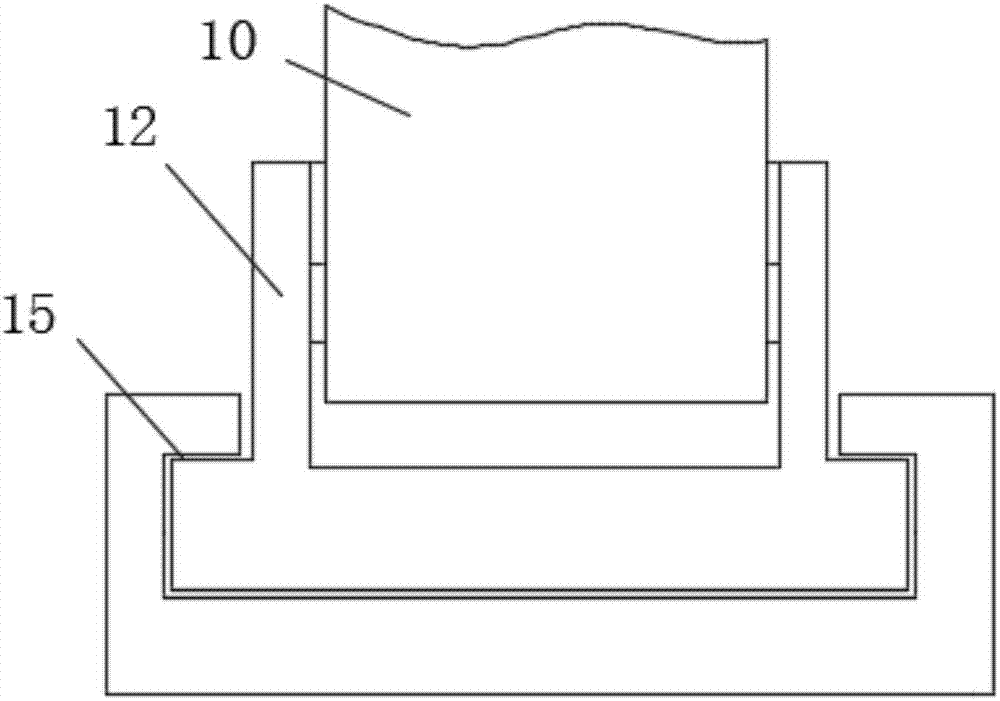

Adjustable magnetic field coupling and ultrasonic-assisted laser additive manufacturing and monitoring device

InactiveCN110280904AWide range motion captureComprehensive perspectiveLaser beam welding apparatusUltrasonic assistedLaser Nozzle

Owner:JIANGSU UNIV

Anti-blocking spray nozzle for drop irrigation

Owner:重庆七棵树农业技术服务有限公司

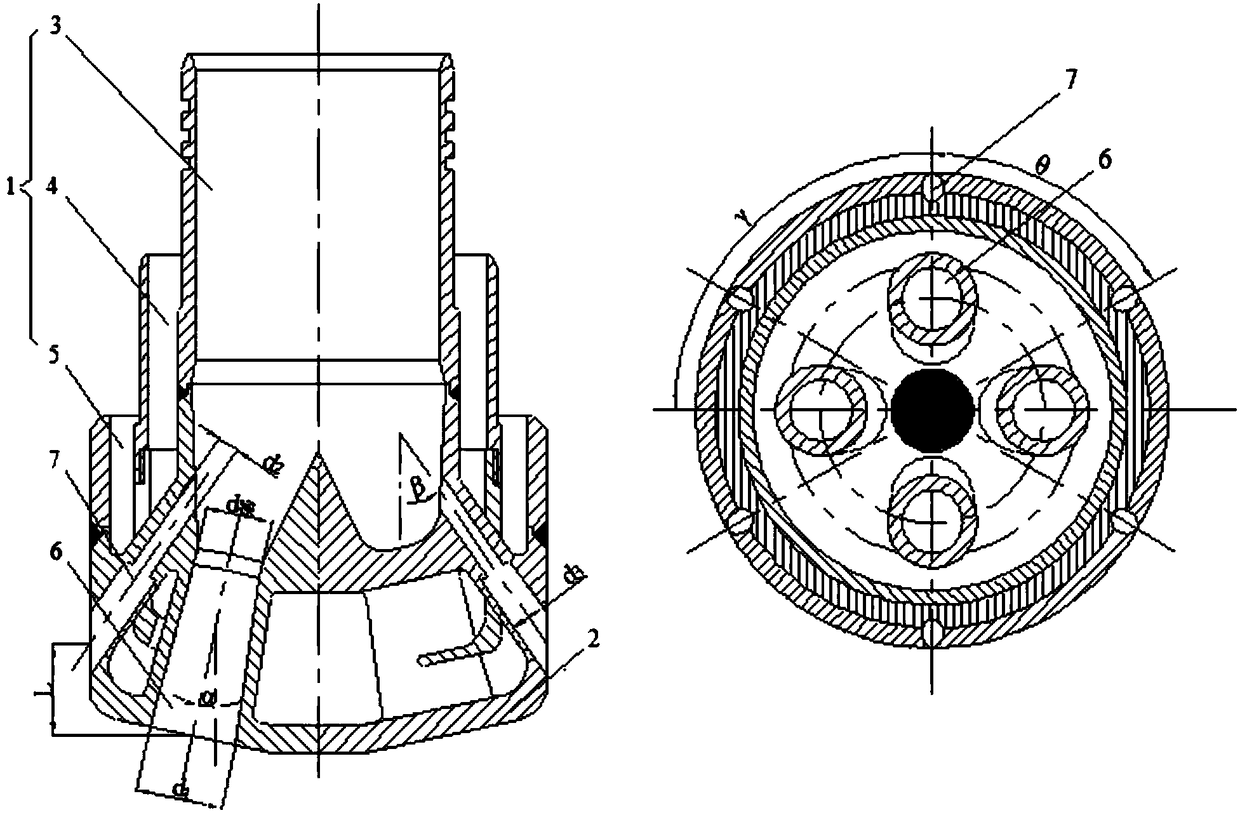

Low-NOx combustor suitable for various low-heat-value/low-pressure fuel gases

The invention belongs to the technical field of industrial combustors, and discloses a low-NOx combustor suitable for various low-heat-value / low-pressure fuel gases for solving the technical problem about how to further reduce the NOx emission of combustors. The low-NOx combustor is characterized in that a center air pipe, an inner pipe, an outer pipe, an outer sleeve and a throat are sequentially and coaxially arranged from inside to outside; a first combustion air channel is formed between the center air pipe and the inner pipe, and the upper end of the first combustion air channel is fixedly connected with a first swirler; a fuel gas channel is formed between the inner pipe and the outer pipe, and the upper end of the fuel gas channel is provided with a plurality of inward center fuel gas nozzles and a plurality of outward center fuel gas nozzles in a circular-ring uniform distribution manner; a second combustion air channel is formed between the outer pipe and the outer sleeve, and the end of the second combustion air channel is fixedly connected with a second swirler; and a third combustion air channel is formed between the outer sleeve and the throat. By the combination of a dense-dilute combustion method and a staged combustion manner, flames can be relatively stable, the intensity of dense combustion is improved, and an extremely strong reduction atmosphere is formed for restraining NOx generation. The low-NOx combustor is suitable for various low-heat-value / low-pressure fuel gases.

Owner:SHANGHAI WISEBOND TECH

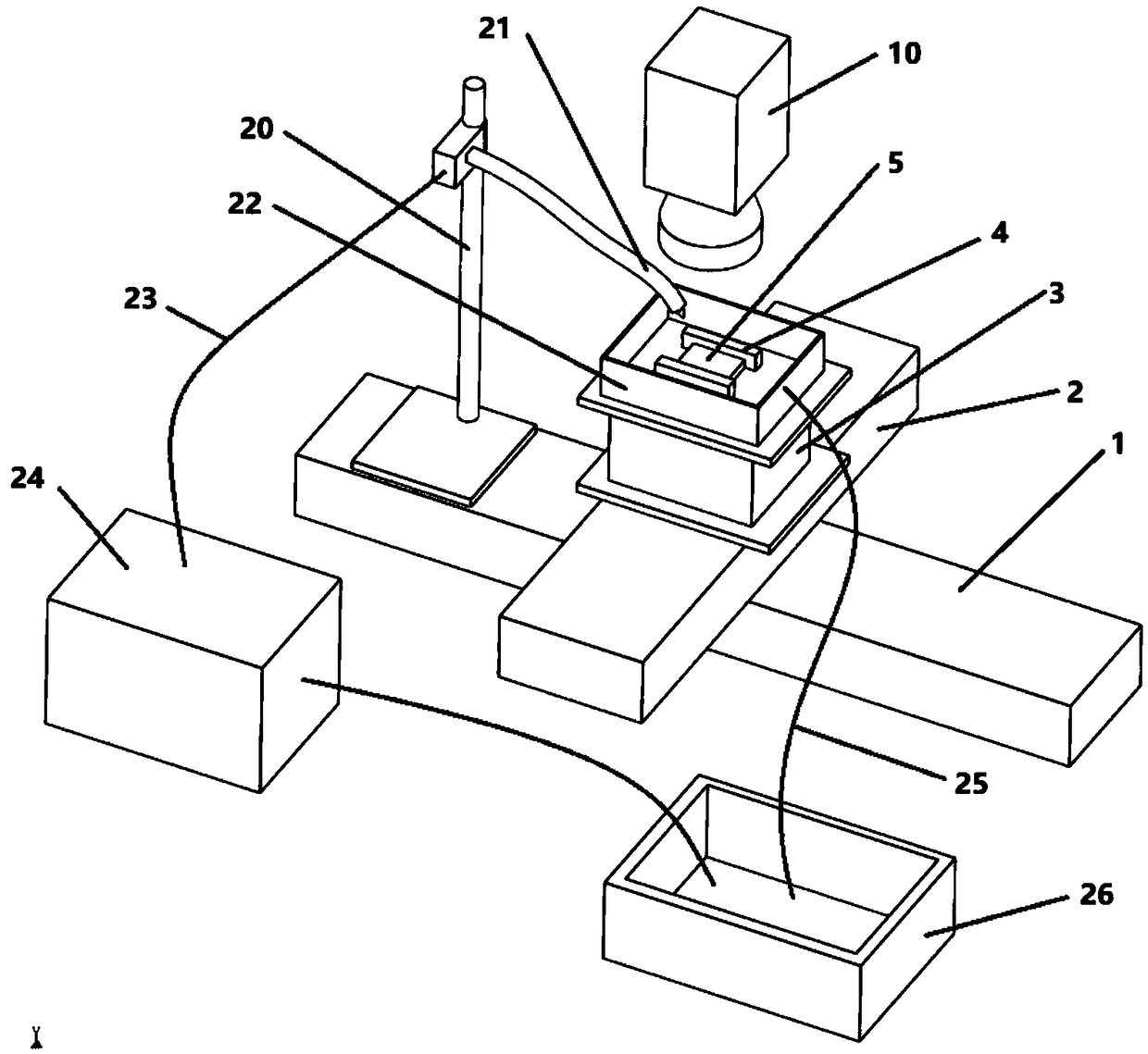

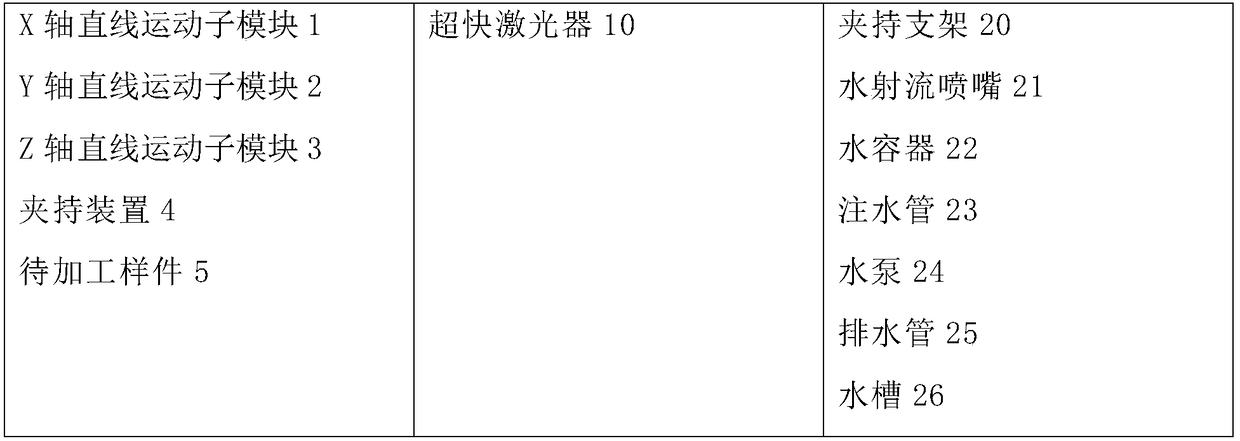

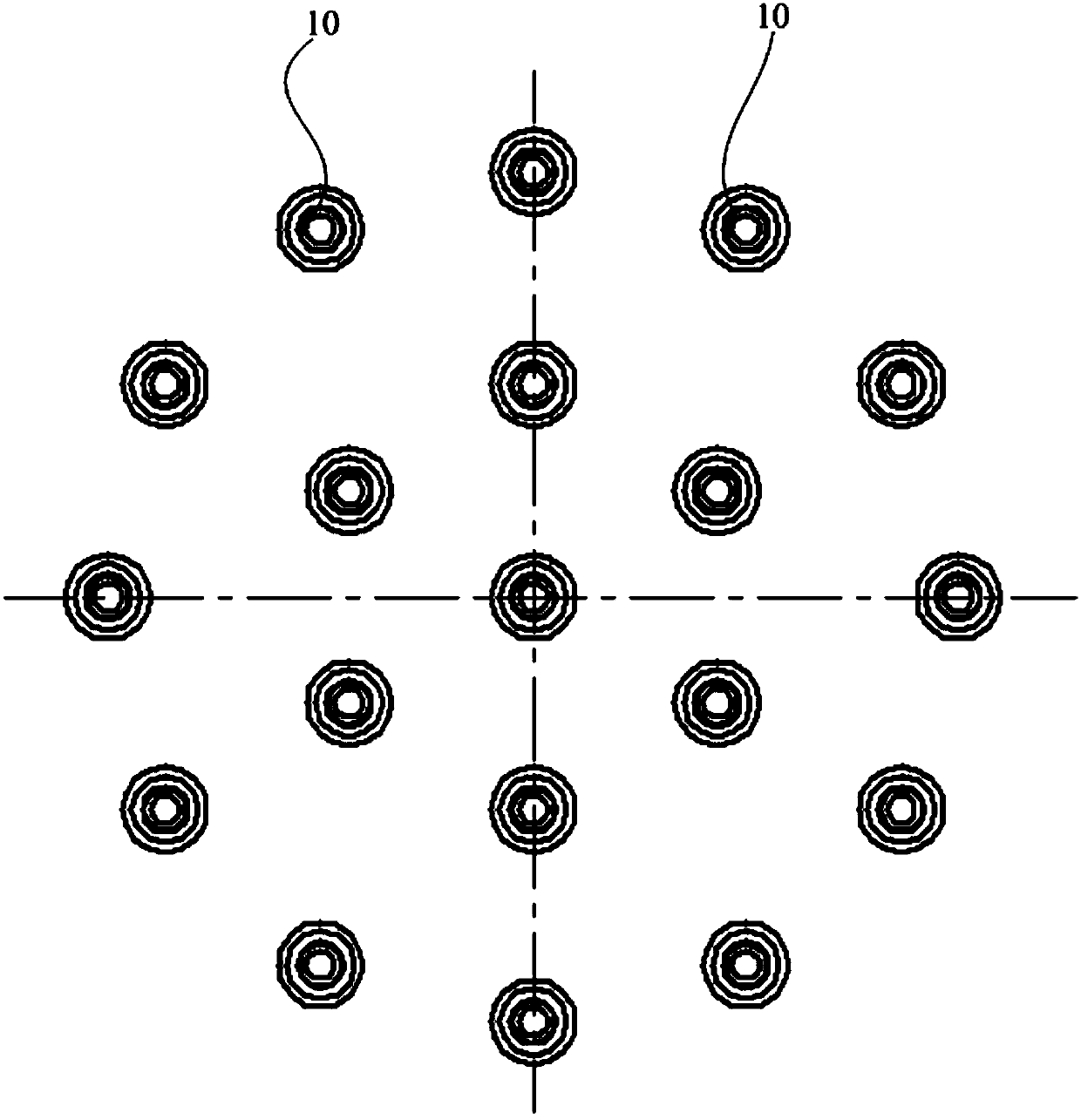

Device and method for conducting superfast laser machining of air film hole in water jet environment

Owner:SHANGHAI JIAO TONG UNIV

Rocket engine injection structure, injection device, rocket engine and rocket

InactiveCN109653902ASituations to Avoid WeldsReduce the use of weldingRocket engine plantsSpray nozzleInjection device

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

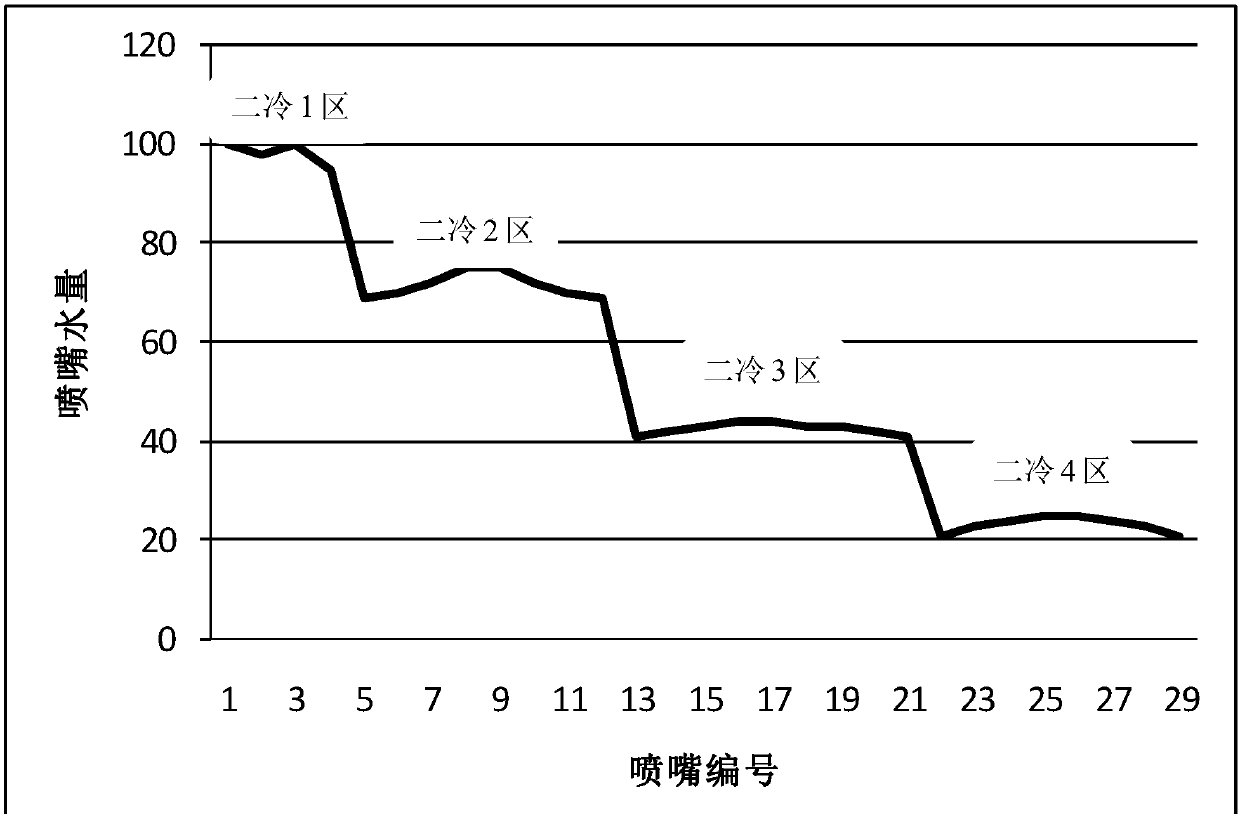

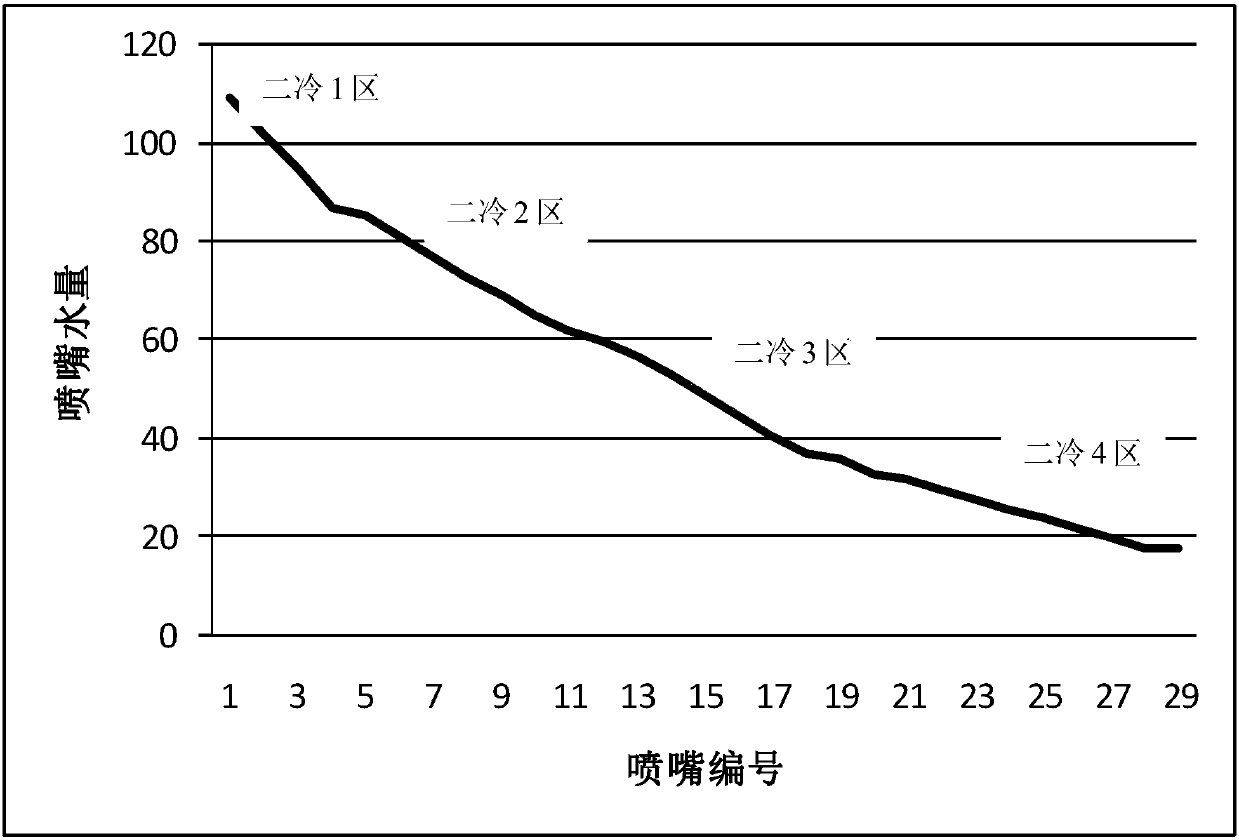

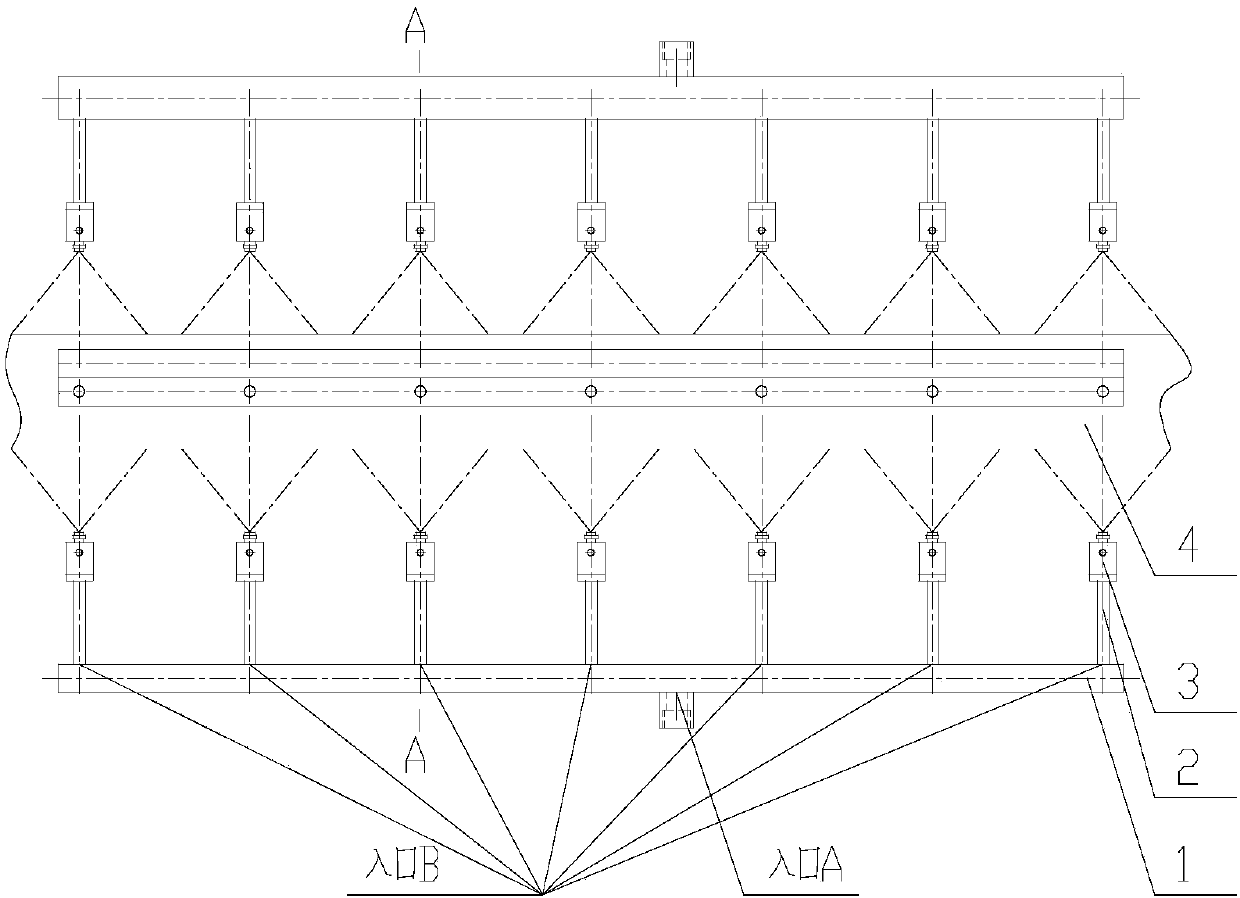

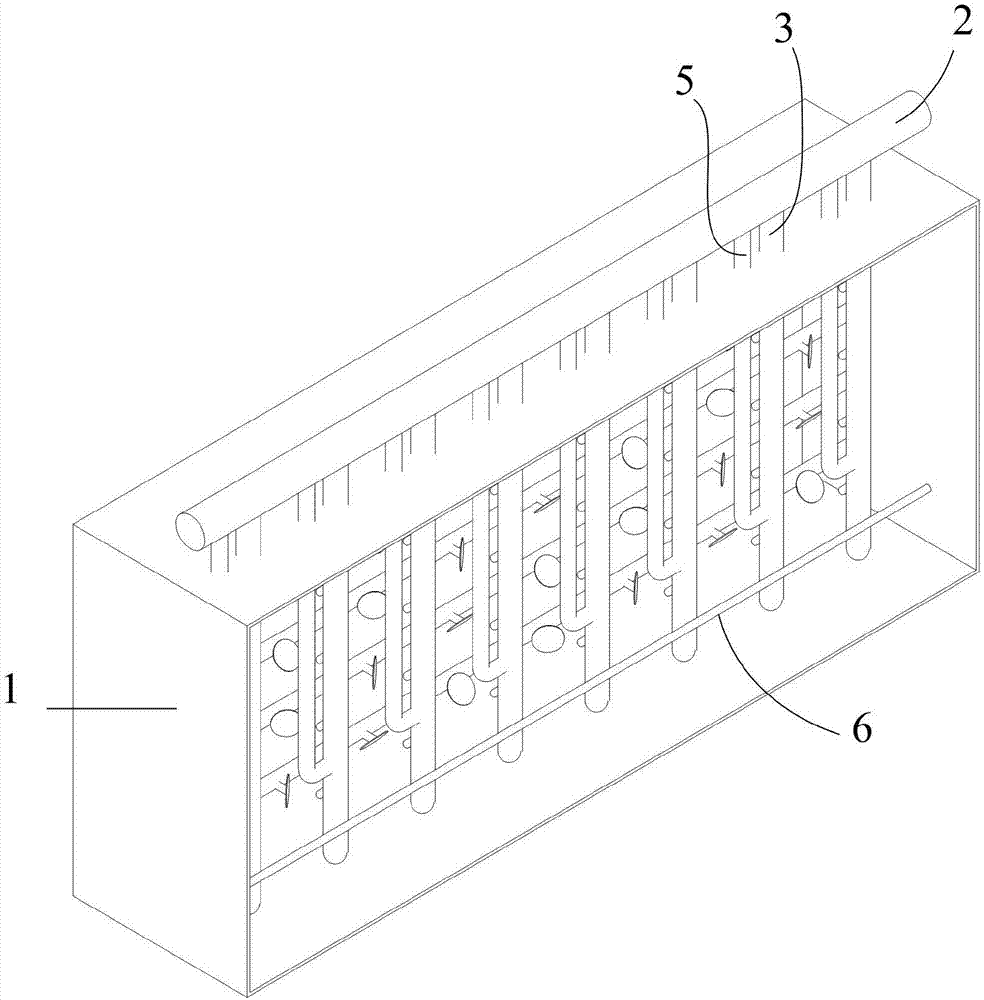

Secondary cooling method and device for continuous casting machine

PendingCN107737896AControl and regulate outflow flowImprove cooling uniformityThermodynamicsSpray nozzle

Owner:CISDI ENG CO LTD +1

Straw impurity removing device

Owner:咸丰隆态生物科技有限公司

Vacuum cleaner and suction piece assembly thereof

InactiveCN1138500CReduce structural weightImprove maneuverabilitySuction nozzlesImpellerSpray nozzle

A suction piece and a vacuum cleaner using the same where in the suction piece is provided with impeller adapted to be rotated by a sunction force, brushes or scrapers spirally mounted to the whole or part of the impeller and adapted to come into contact with a surface being cleaned, a rotary brush coaxial with the impeller and adapted to rotate together therewith, and there is not provided any partition or the like between the impeller and the rotary brush where by the suction piece is made small-sized, lightweight and quiet.

Owner:HITACHI LTD

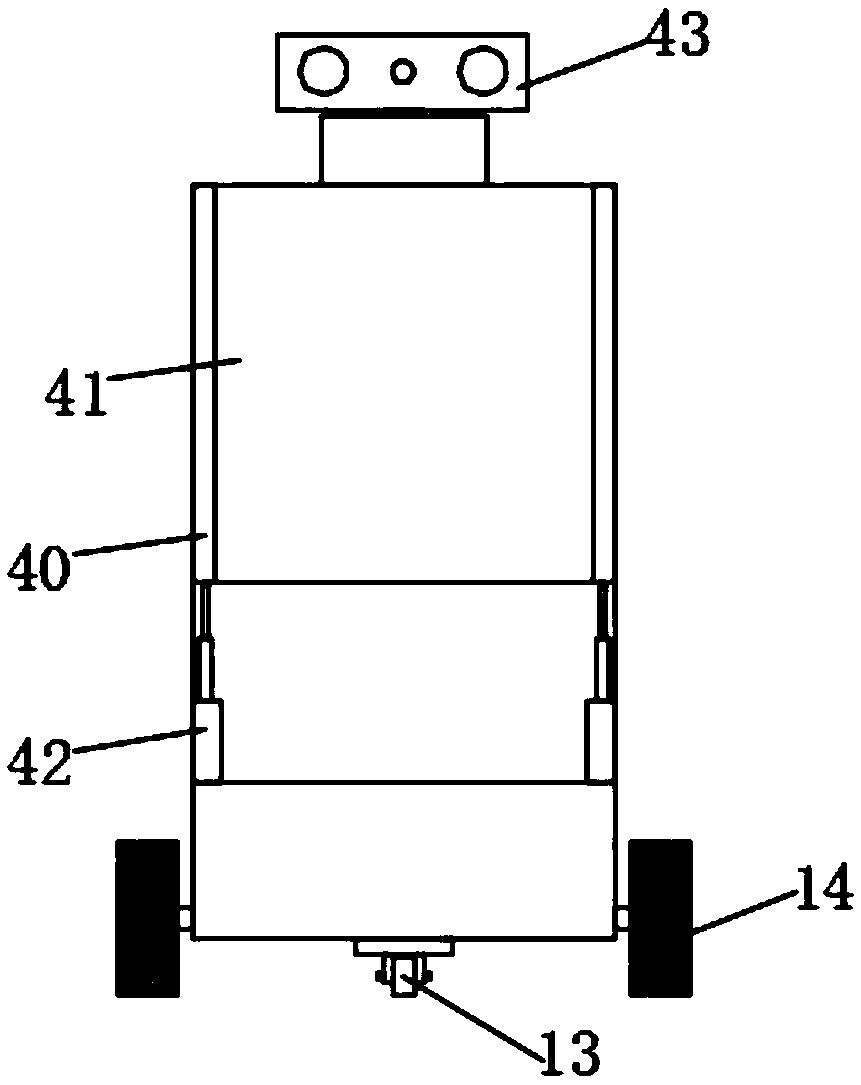

Intelligent robot that can return to charge

ActiveCN108972588AEasy to moveEasy to self-applyMedical atomisersManipulatorSteering wheelBack burns

Owner:付小芹

Industrial painting robot with regulating function

Owner:NANJING YUZHI INTELLIGENT TECH CO LTD

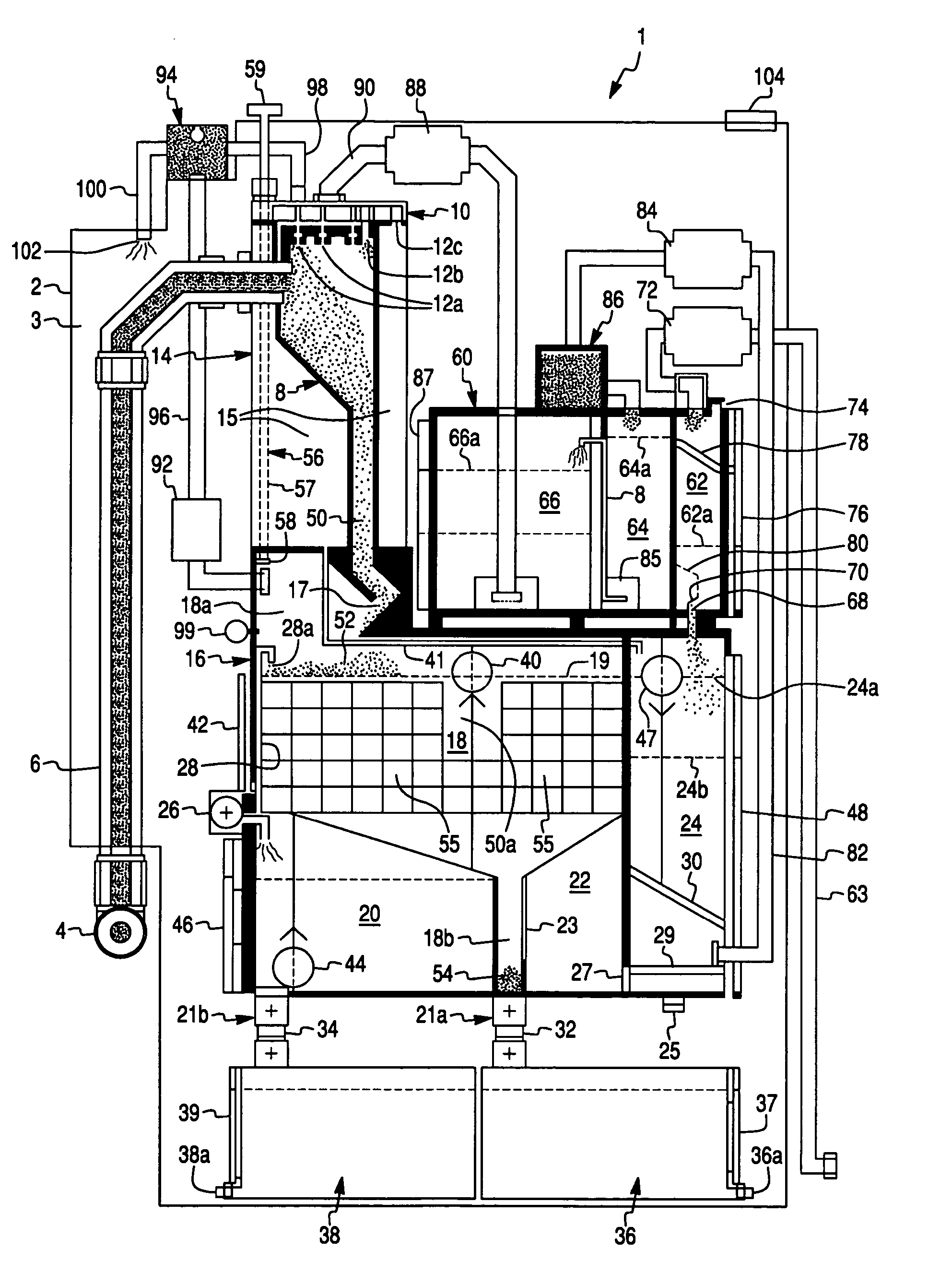

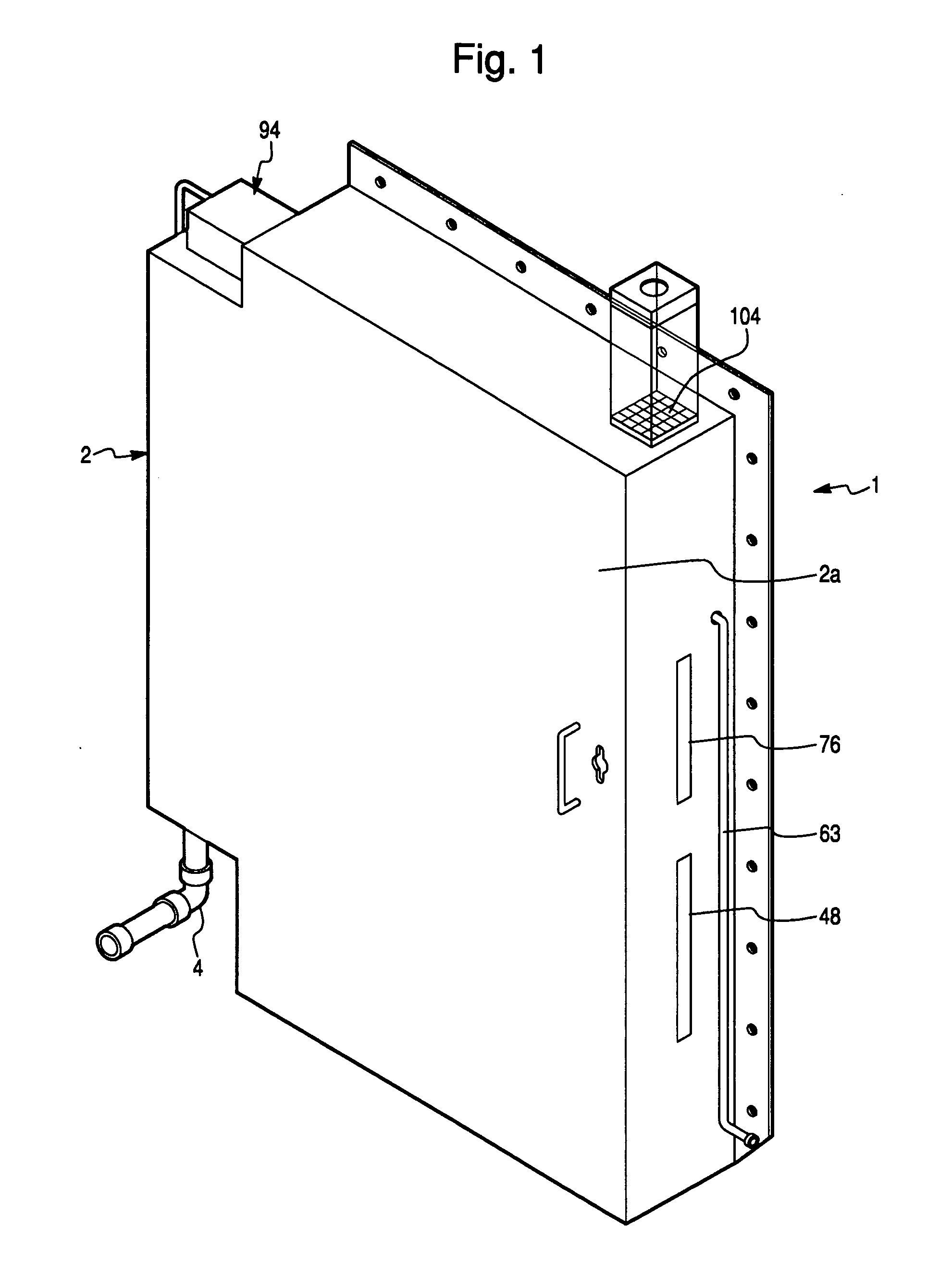

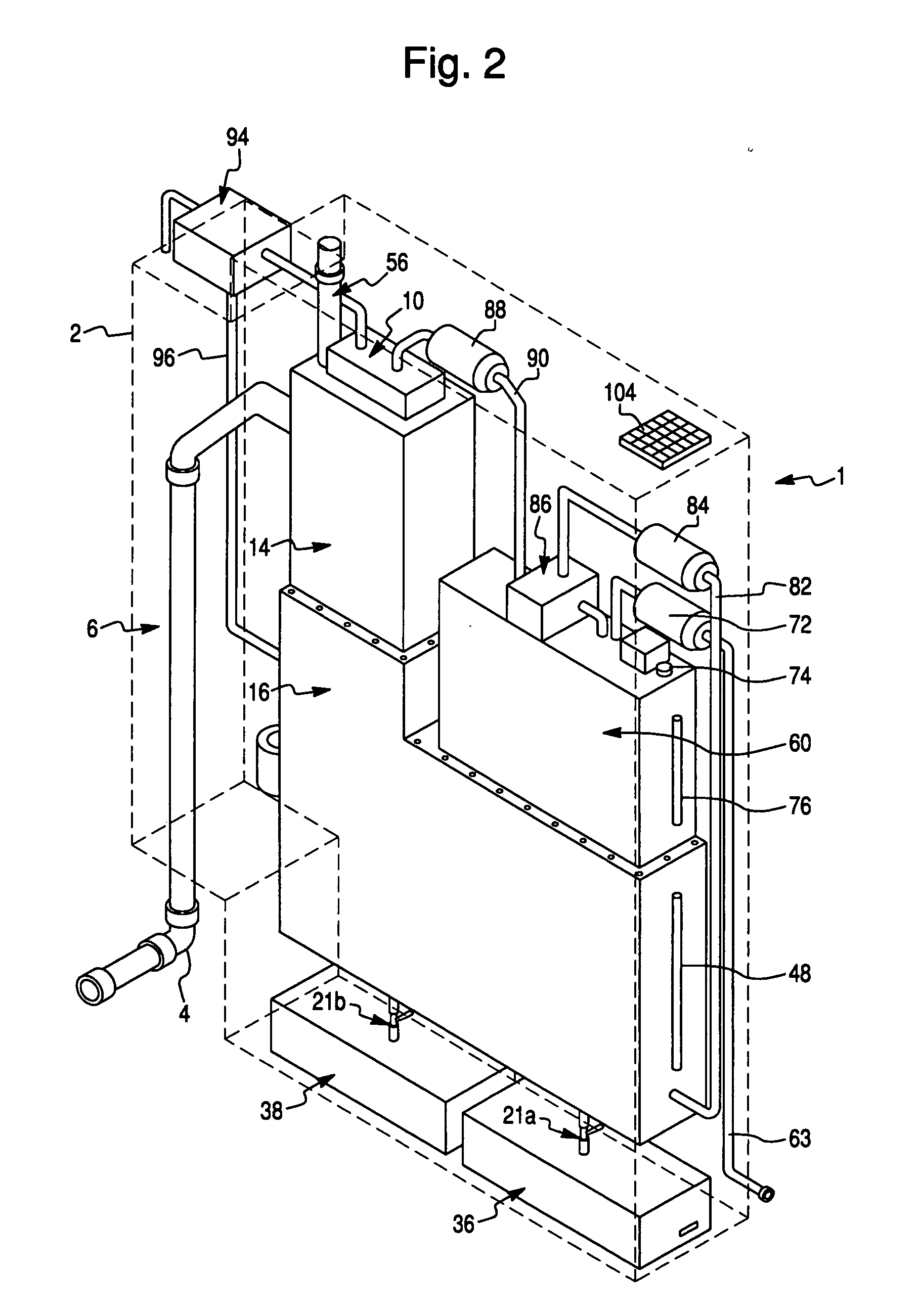

Exhaust gas purifying system

InactiveUS20050138922A1Liquid degasificationInternal combustion piston enginesCombustionSpray nozzle

Owner:BONCODIN FRANZ B

Feed uniform stirring device with drying function

Owner:自贡正邦农牧科技有限公司

Electrostatic water mist air purification device

Owner:SHENZHEN CYTOROLA BIOMEDICAL TECH CO LTD

Single-flow-channel secondary combustion oxygen lance capable of improving scrap ratio of converter and application method of single-flow-channel secondary combustion oxygen lance

PendingCN108977620AHigh desulfurization rateIncrease the amount of steel scrap into the furnaceManufacturing convertersProcess efficiency improvementCombustionSpray nozzle

Owner:NORTHEASTERN UNIV

Centrifugal pulse dust collector

Owner:CHENGDU YUNLONG TECH

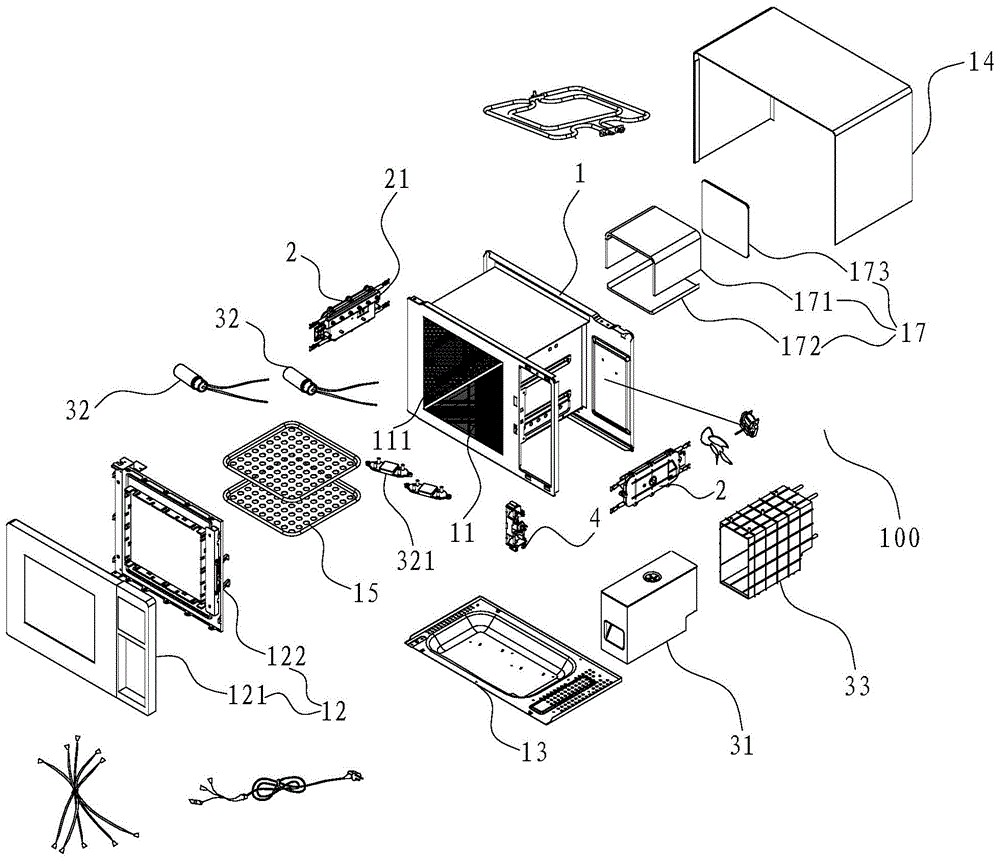

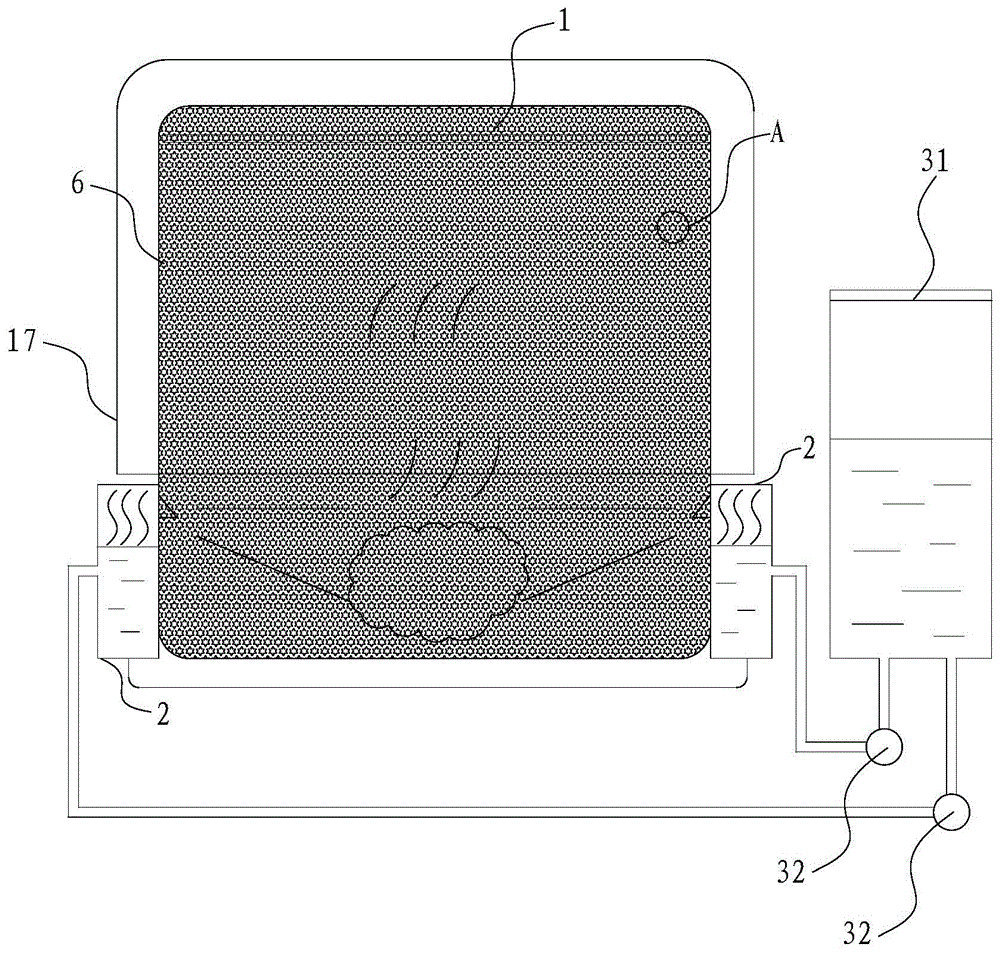

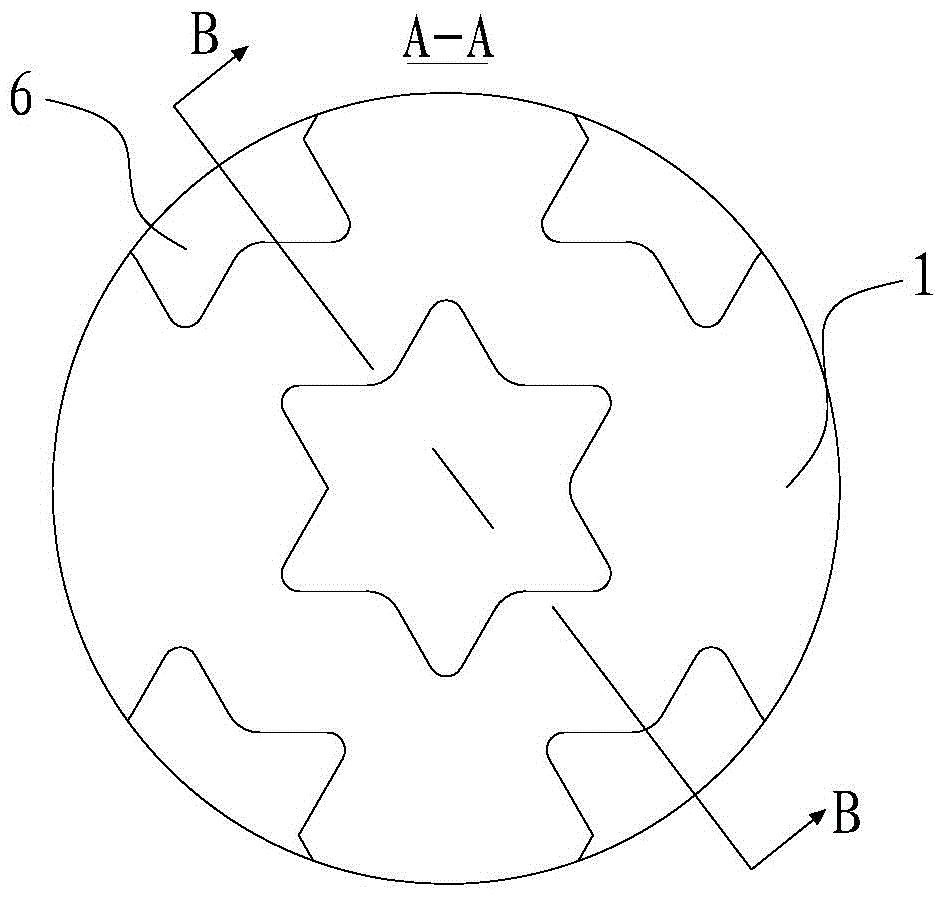

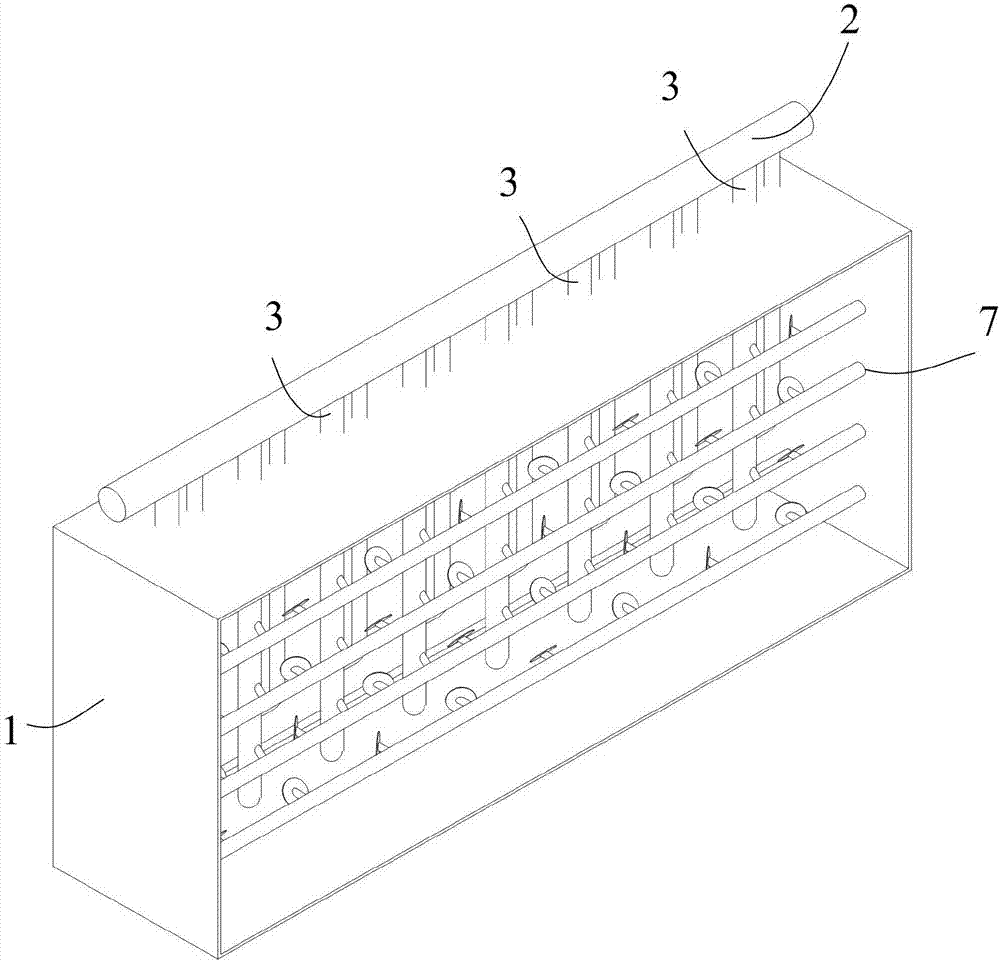

Steam cooking utensil

Owner:MIDEA GRP CO LTD +1

Ozone static mixing device

Owner:中瑞工程设计院有限公司

Chufa-type sugarcoating machine

InactiveCN102406550AReduce dosageUniform weight and thicknessPharmaceutical product form changeSpray nozzleEngineering

Owner:上海新亚药业邗江有限公司

Hot runner mold with multipoint hot gate

Owner:江门市荣兴达科技有限公司

Spraying deodorization device for garbage station

Owner:扬州市国翔智慧机电设备有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap