Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "Fuel gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fuel gas is any one of a number of fuels that under ordinary conditions are gaseous. Many fuel gases are composed of hydrocarbons (such as methane, biogas or propane), hydrogen, carbon monoxide, or mixtures thereof. Such gases are sources of potential heat energy or light energy that can be readily transmitted and distributed through pipes from the point of origin directly to the place of consumption.

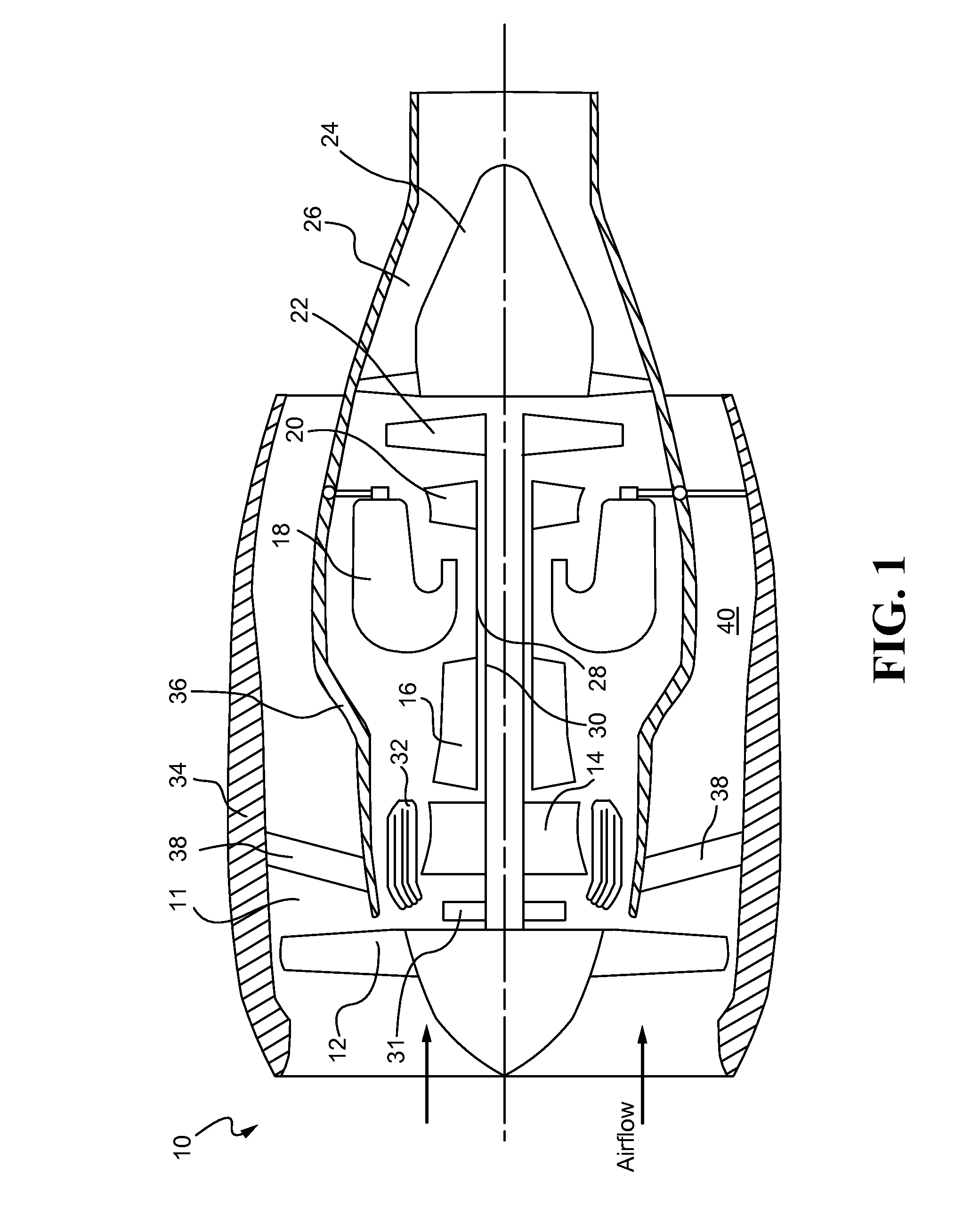

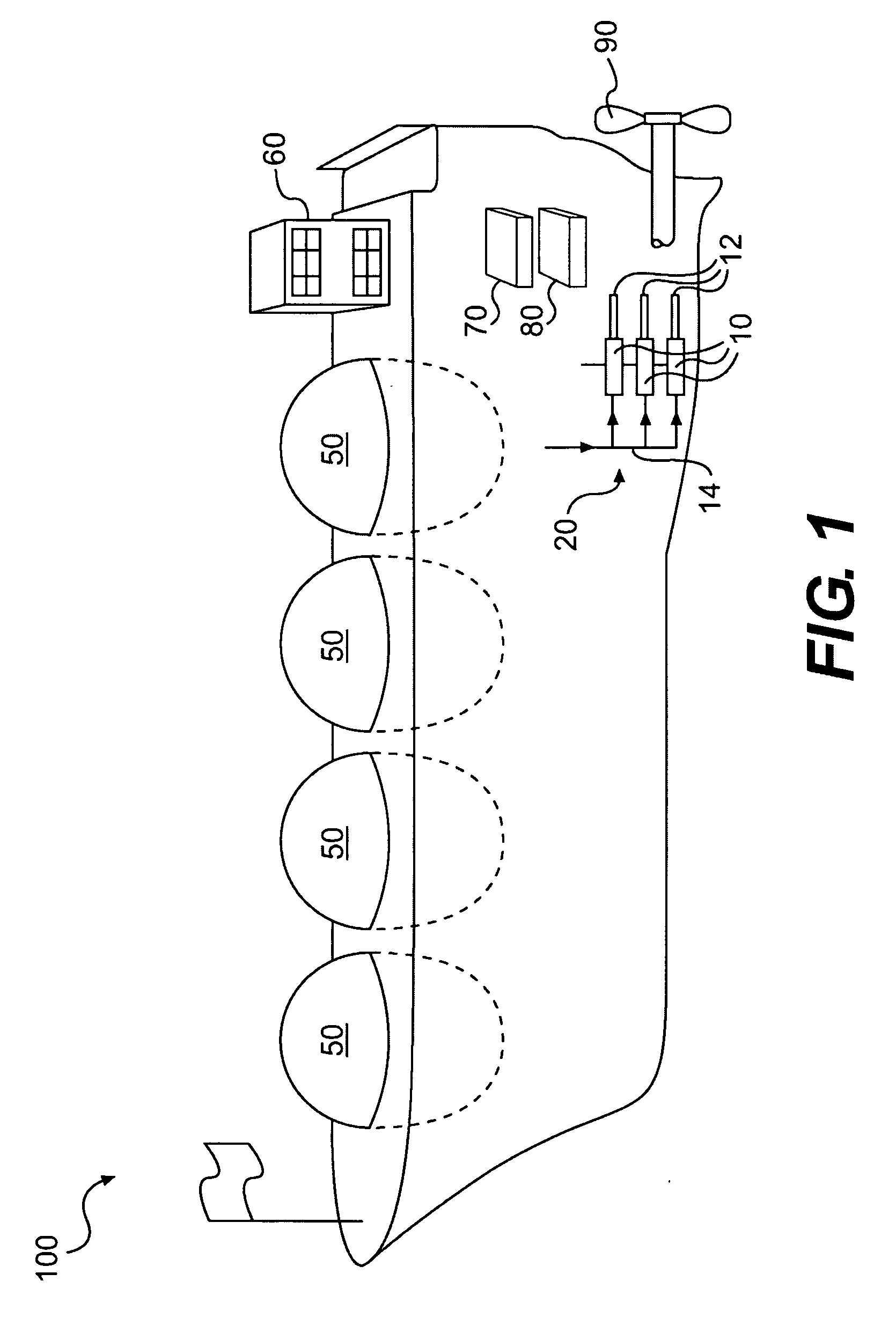

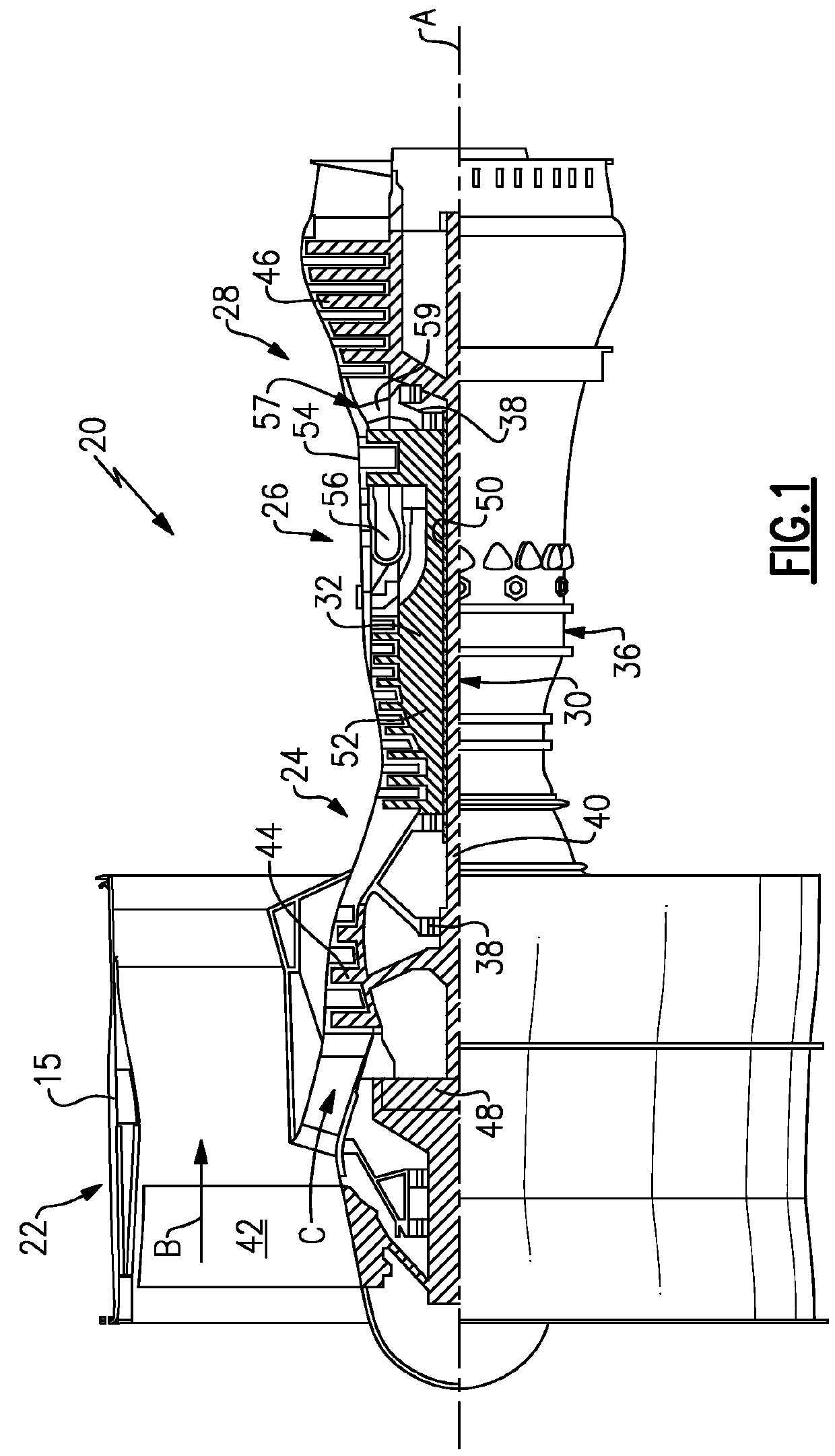

Method of chilling inlet air for gas turbines

InactiveUS20050056023A1Lower the average temperature of the chilling waterLower inlet temperatureClimate change adaptationEvaporators/condensersPower stationCooling coil

A method for cooling inlet air to a gas turbine is provided. For example, a method is described including passing inlet air through a cooling coil that includes an opening for receiving the inlet air and that is operably connected to a gas turbine power plant. The gas turbine power plant may include at least one gas turbine, and at least one gas turbine inlet which receives the inlet air. The method may further include passing circulating water through a water chiller at a first flow rate to reduce the temperature of the circulating water, the water chiller including a conduit through which the circulating water is capable of passing and passing the circulating water having the first flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air. Additionally, the method may include reducing the flow rate of the circulating water passing through the water chiller, passing the circulating water through a water chiller at a second flow rate to reduce the temperature of the circulating water, the second flow rate being lower than the first flow rate, and passing the circulating water having the second flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air.

Owner:TAS ENERGY +1

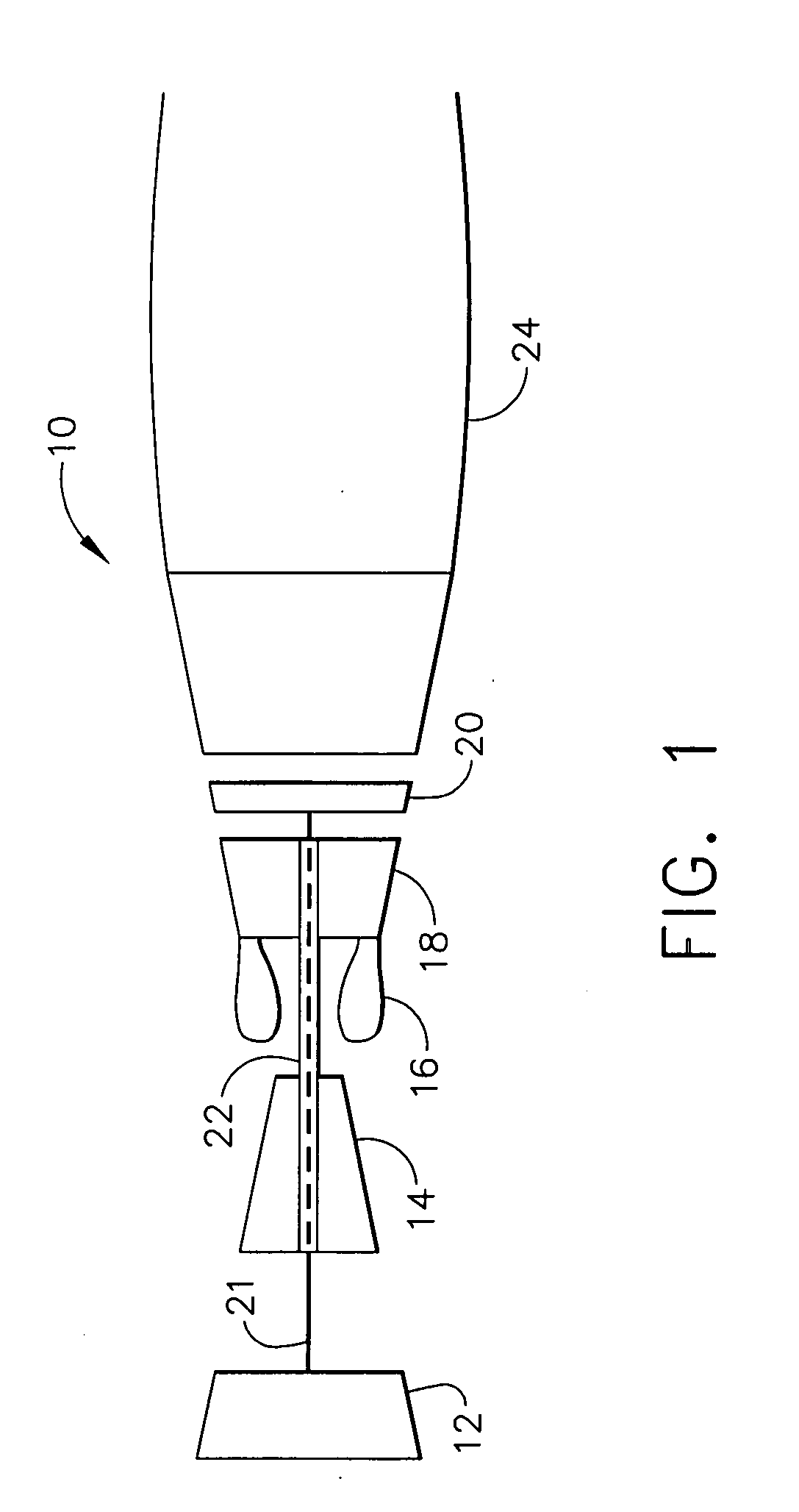

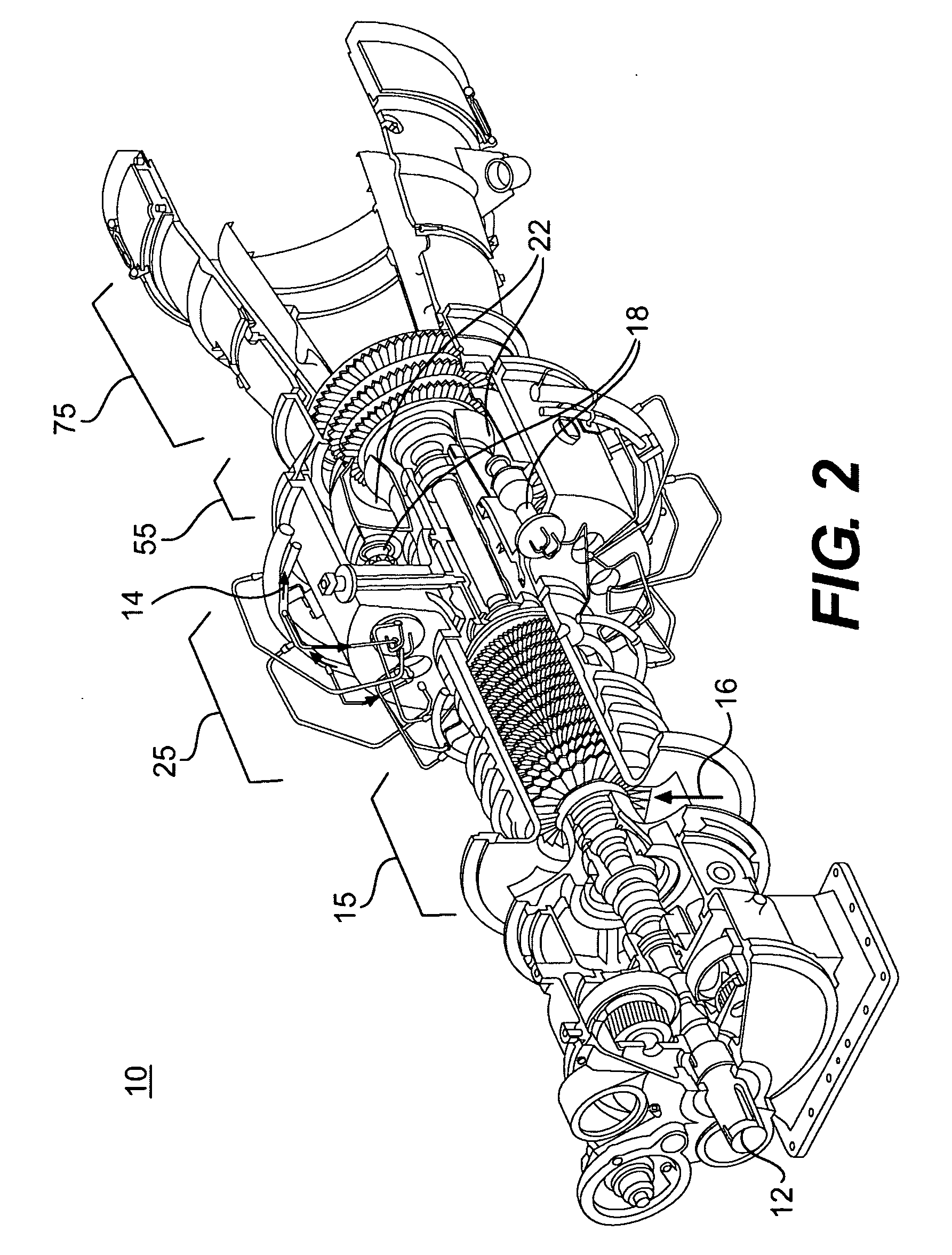

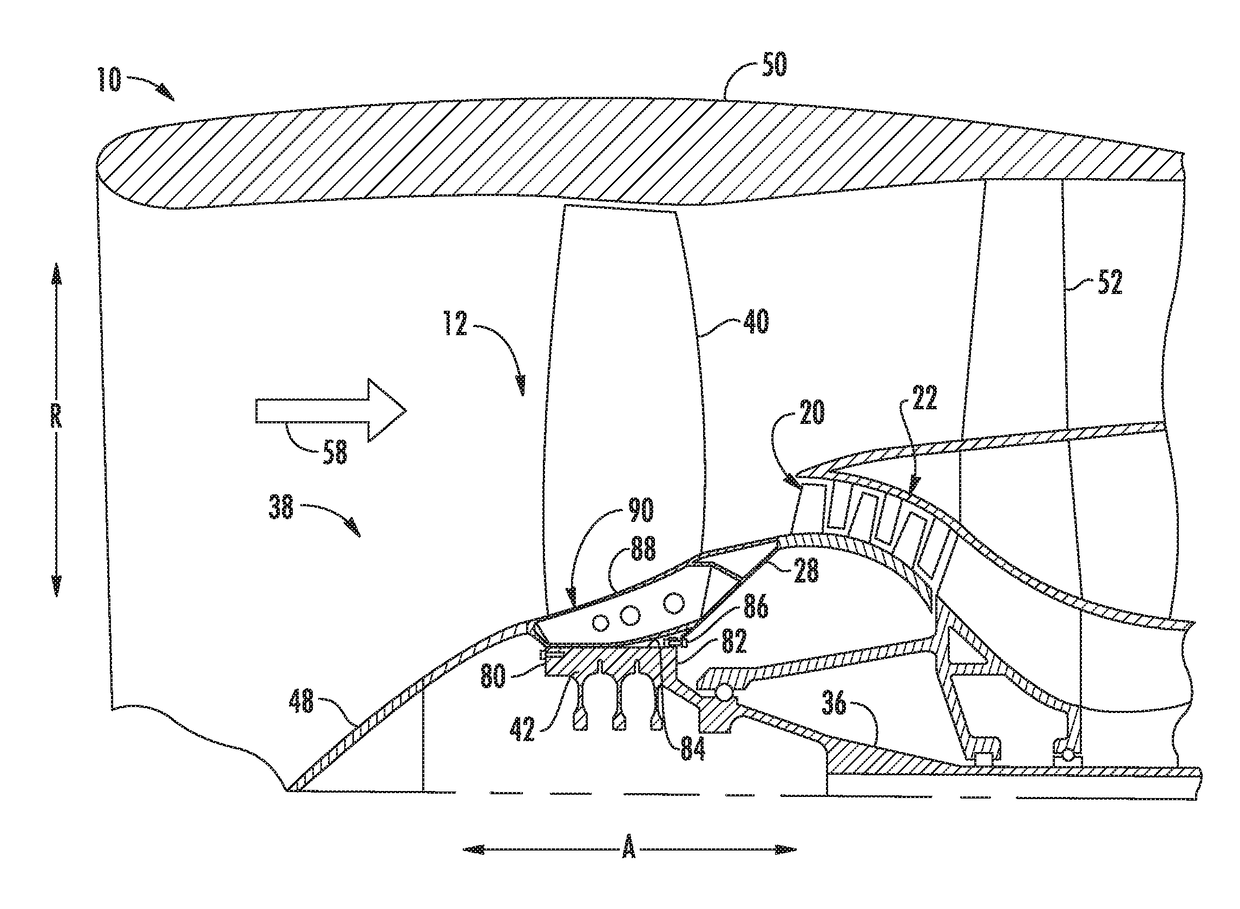

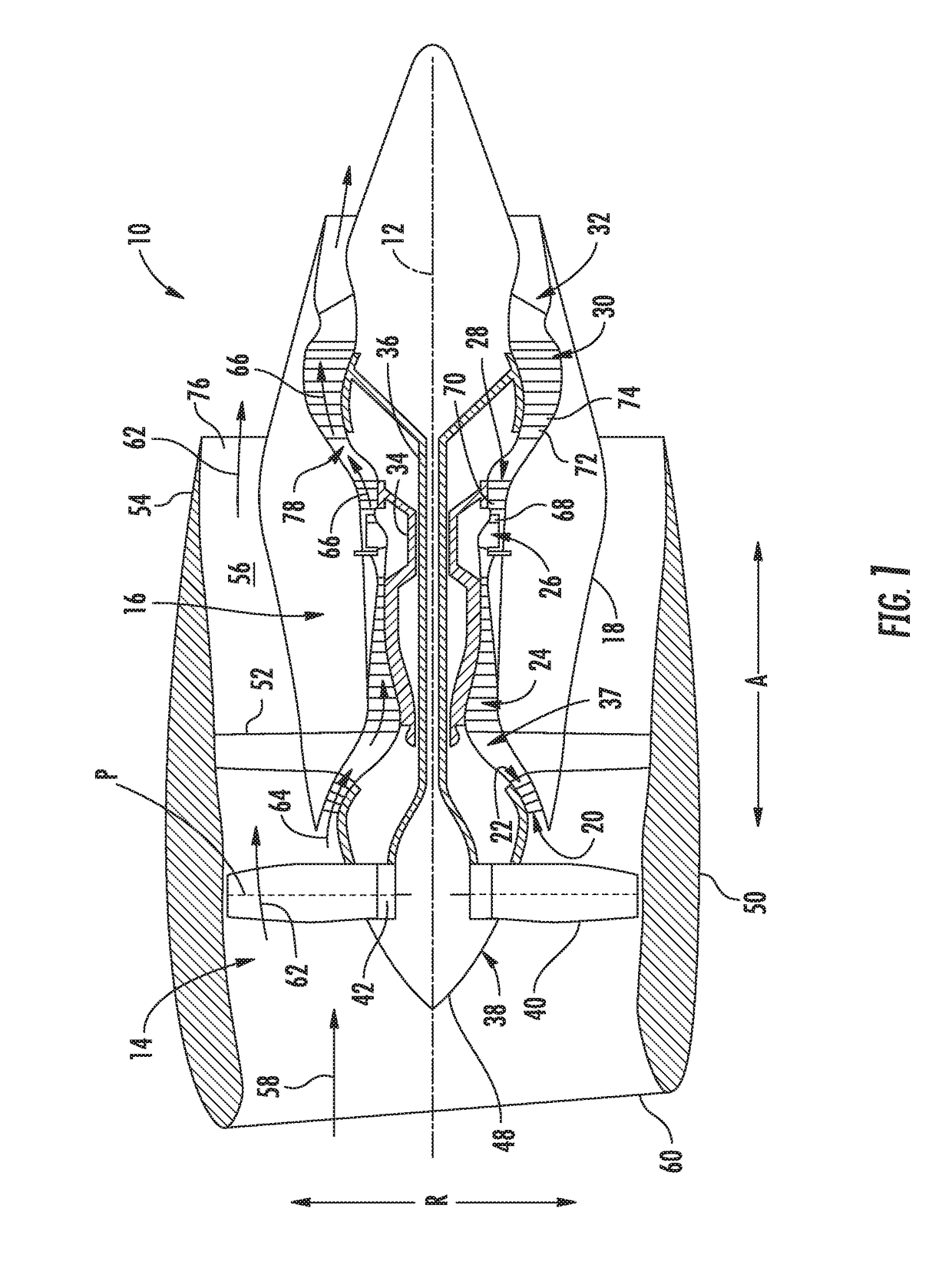

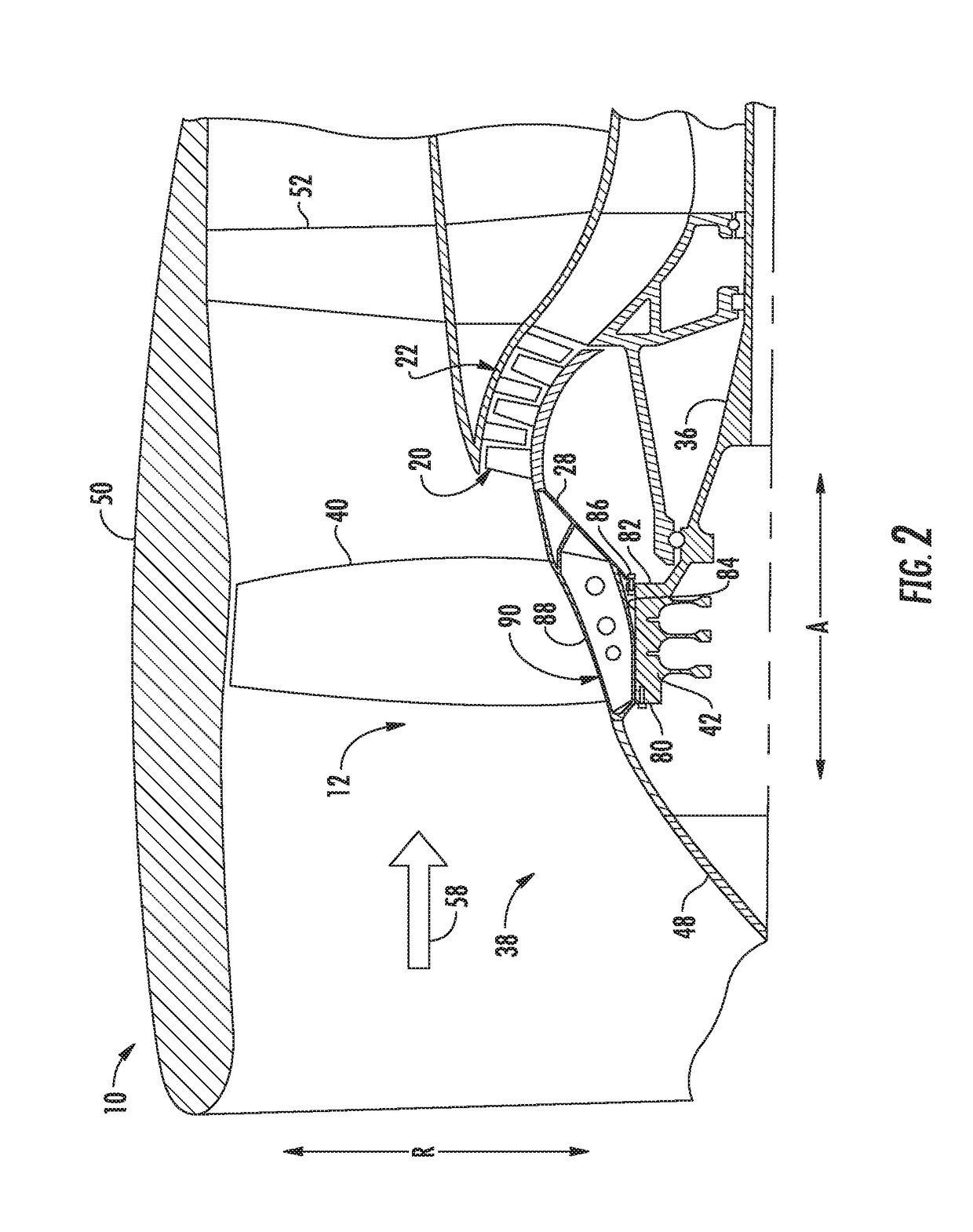

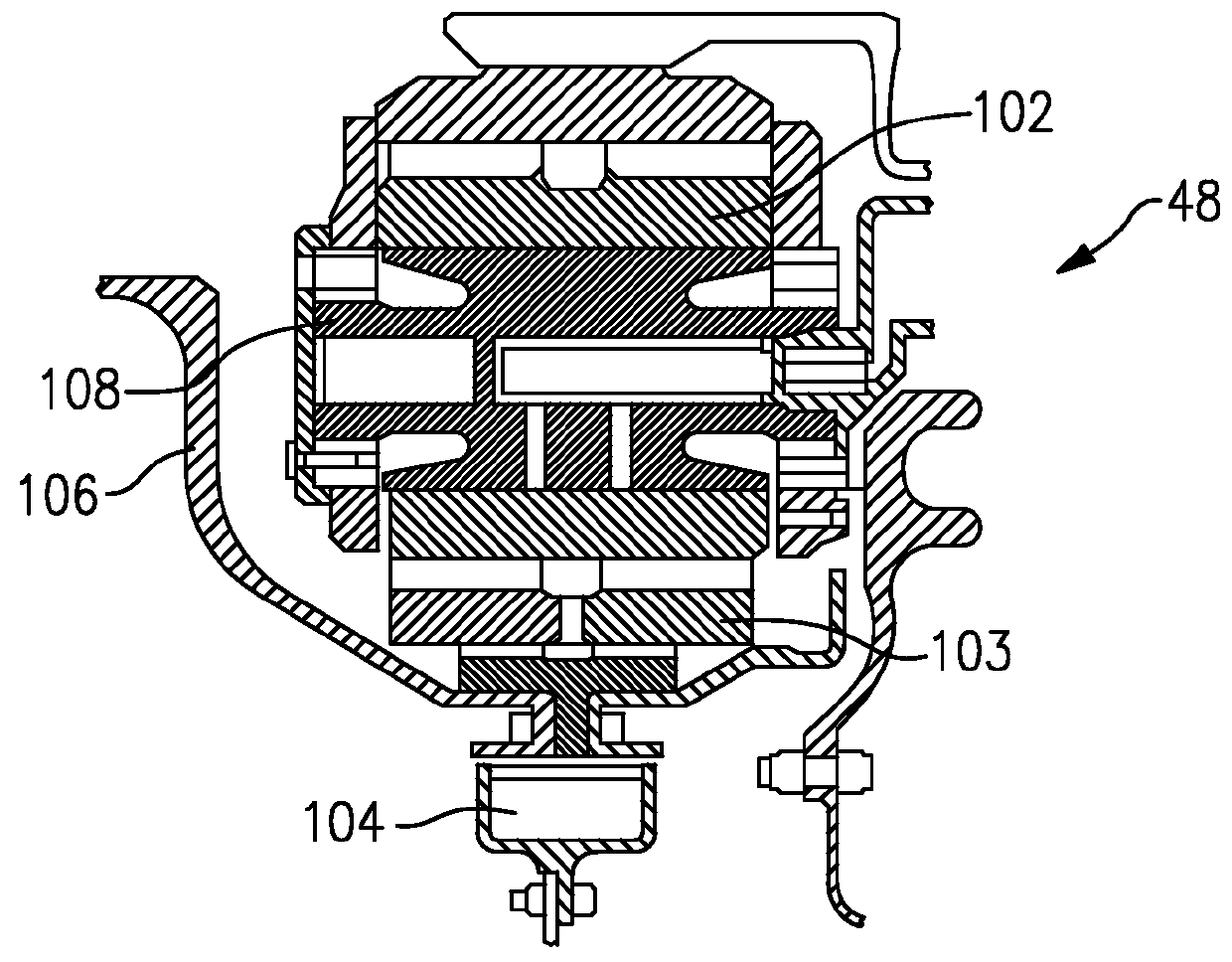

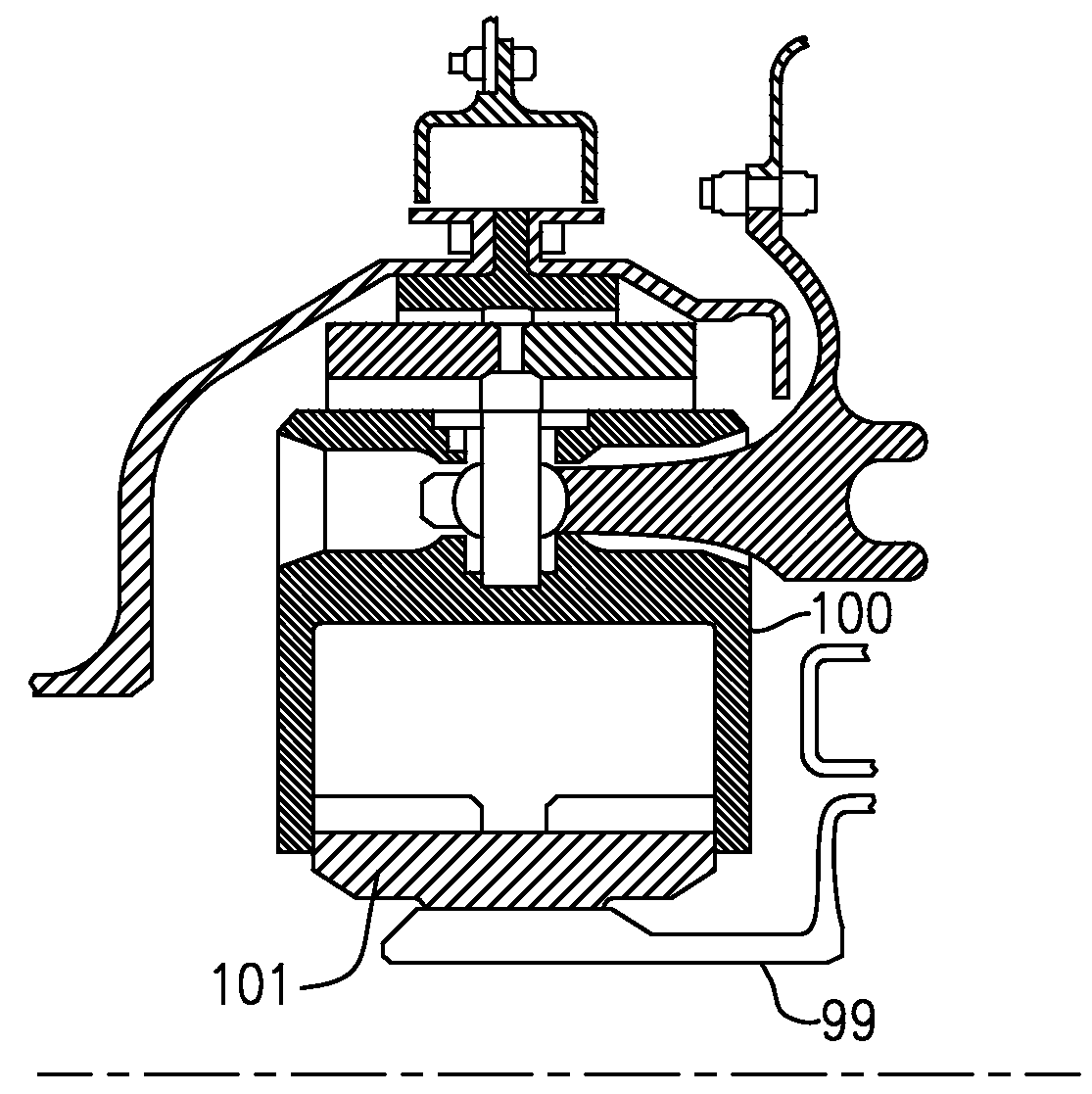

System for damping vibration in a gas turbine engine

InactiveUS20120180500A1Reduce vibrationContinuous combustion chamberEngine fuctionsTurbineGas turbines

Owner:GENERAL ELECTRIC CO

Directional pyrolysis method of combustible wastes

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

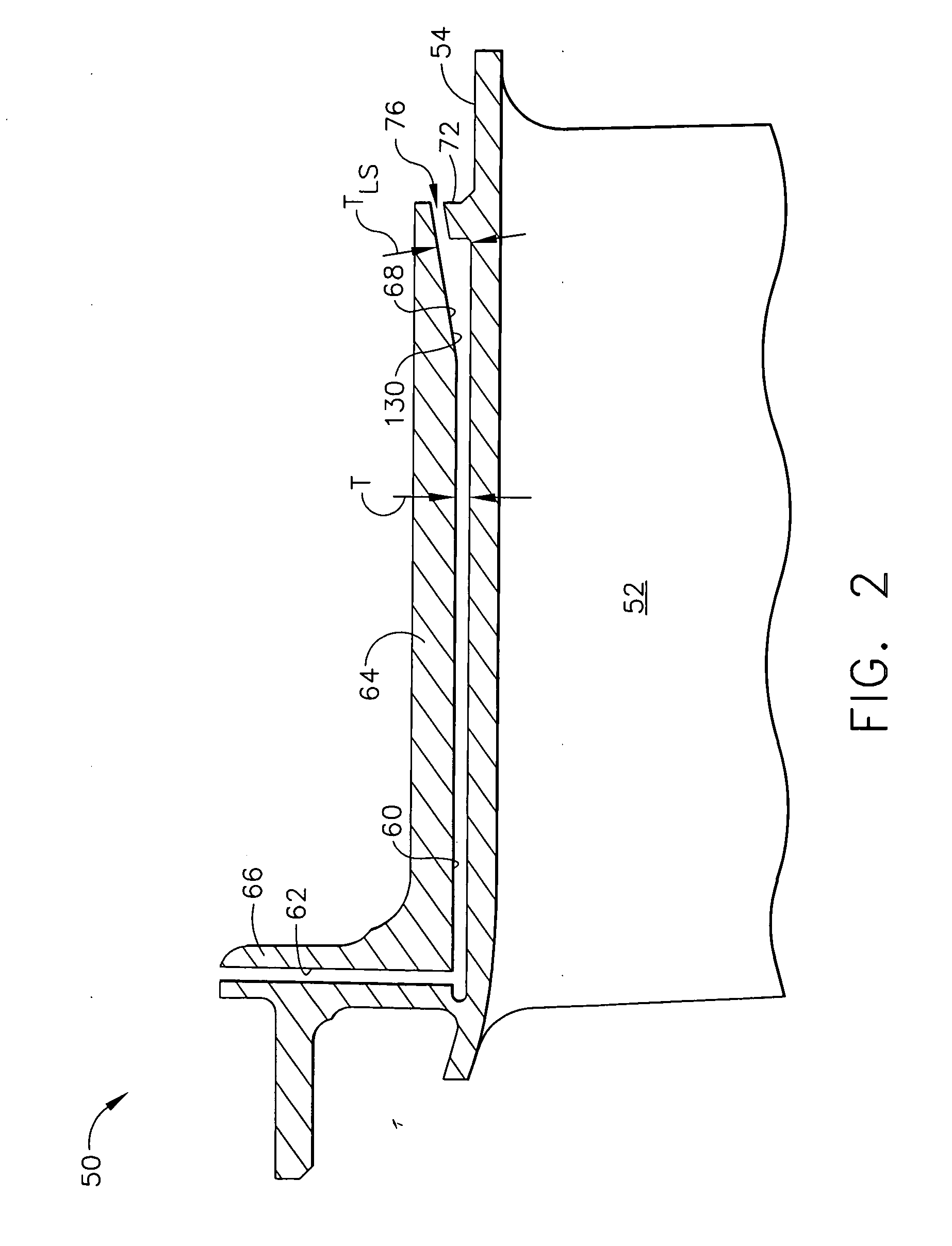

Apparatus and method for cooling a turbine airfoil arrangement in a gas turbine engine

A turbine airfoil arrangement for a gas turbine engine includes an airfoil having an inlet and an exit, the inlet configured to receive a cooling gas flow operable to cool at least part of an other airfoil; and a passage disposed in the airfoil and fluidly coupled to the inlet and the exit, the exit being configured to pass at least some of the cooling gas flow to the other airfoil.

Owner:ROLLS ROYCE CORP

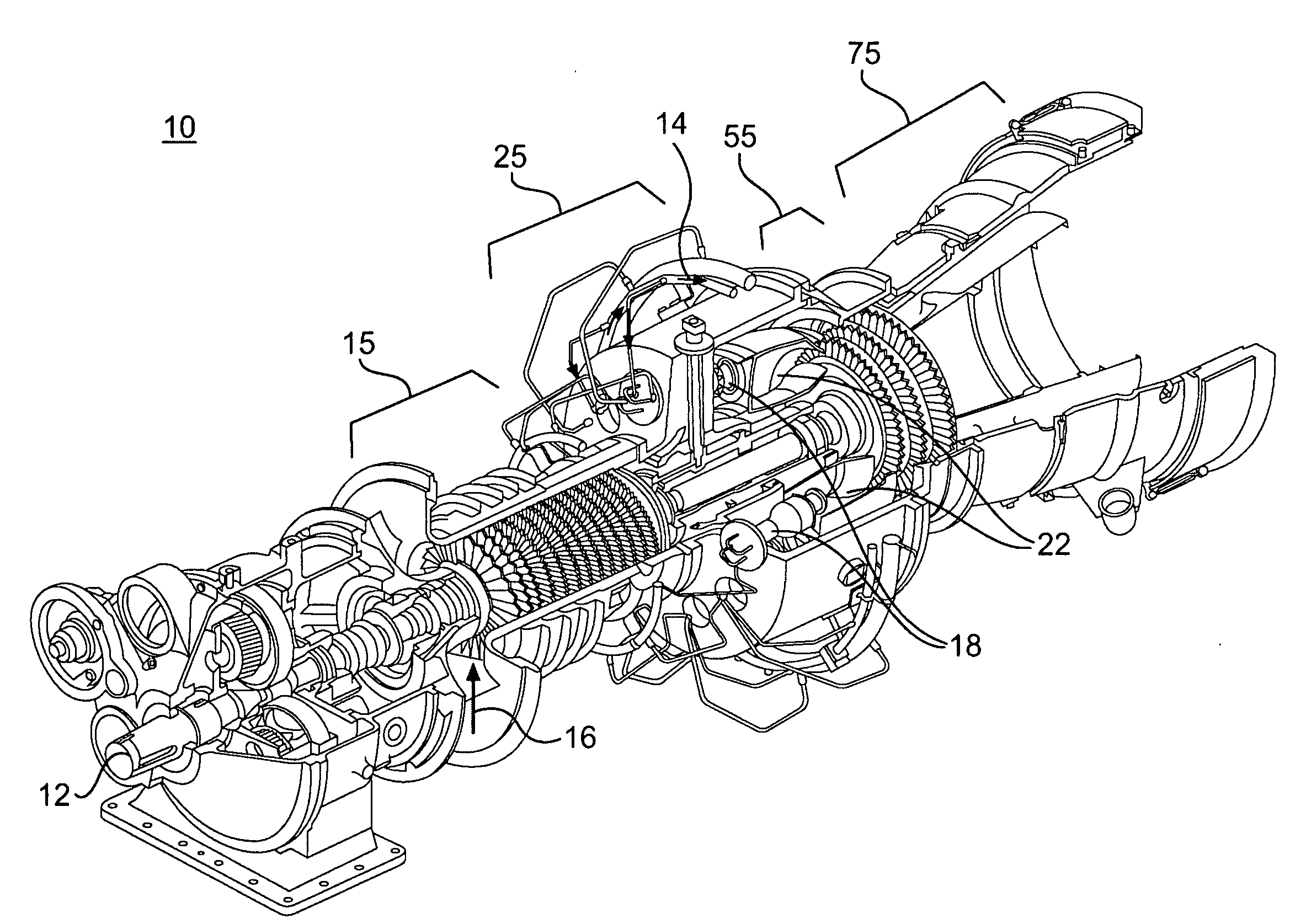

Apparatus and process for testing an industrial gas turbine engine and components thereof

ActiveUS20140053641A1Gas-turbine engine testingJet-propulsion engine testingIndustrial gasEngineering

A system and a process for testing a gas turbine engine or component thereof, especially for a large aero gas turbine engine, and for a process for testing a large industrial gas turbine engine that requires large flow capacity and pressure ratios. The system and process may include the use of a large compressed air storage reservoir to provide compressed air to the testing system. Further, the system and process may also include the use of a pre-heating system, which may include a heater and a heat exchange device, to warm the compressed air from the compressed air storage reservoir to a temperature suitable to simulate normal operating conditions of the gas turbine engine or component thereof.

Owner:FLORIDA TURBINE TECH

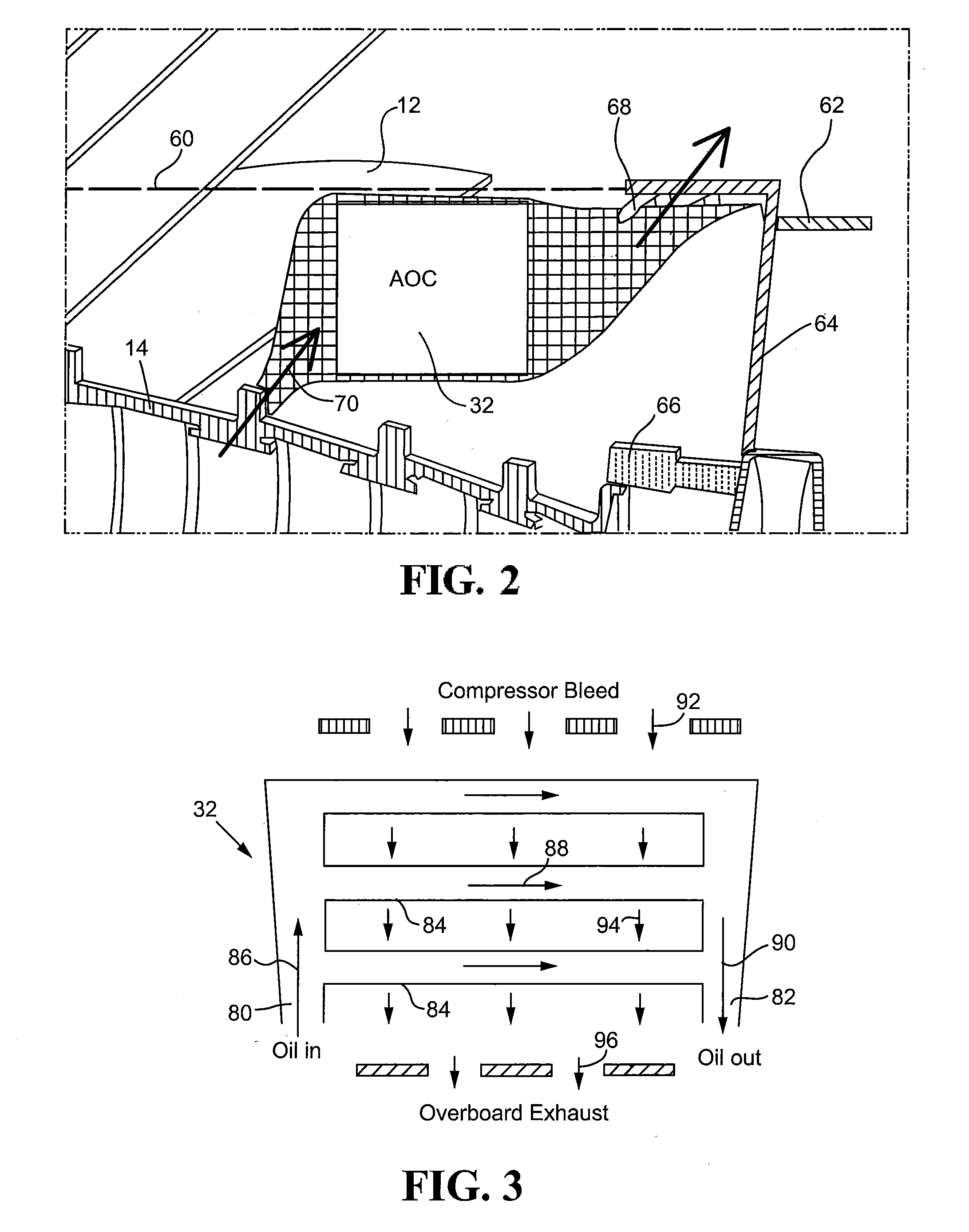

Low Profile Compressor Bleed Air-Oil Coolers

Owner:RAYTHEON TECH CORP

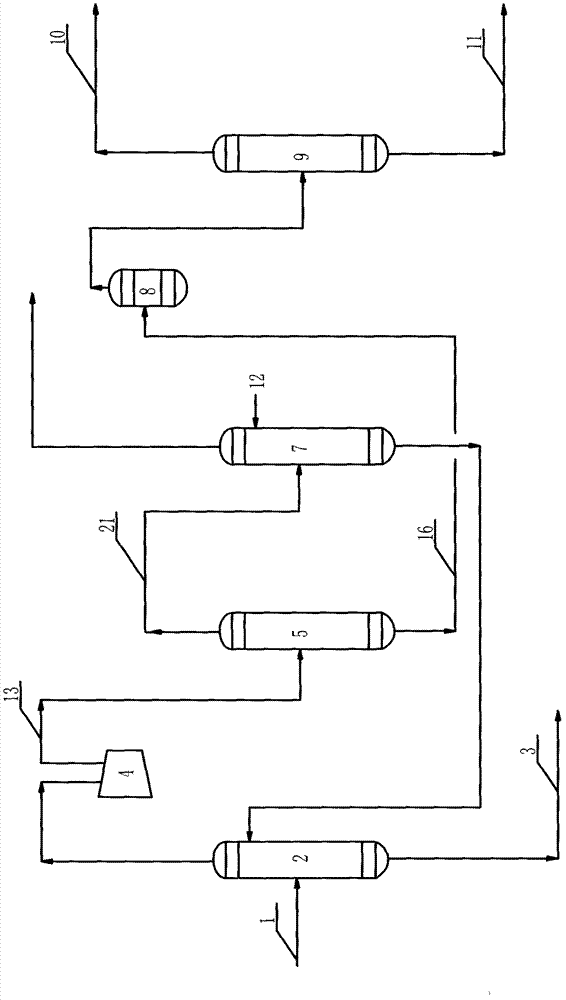

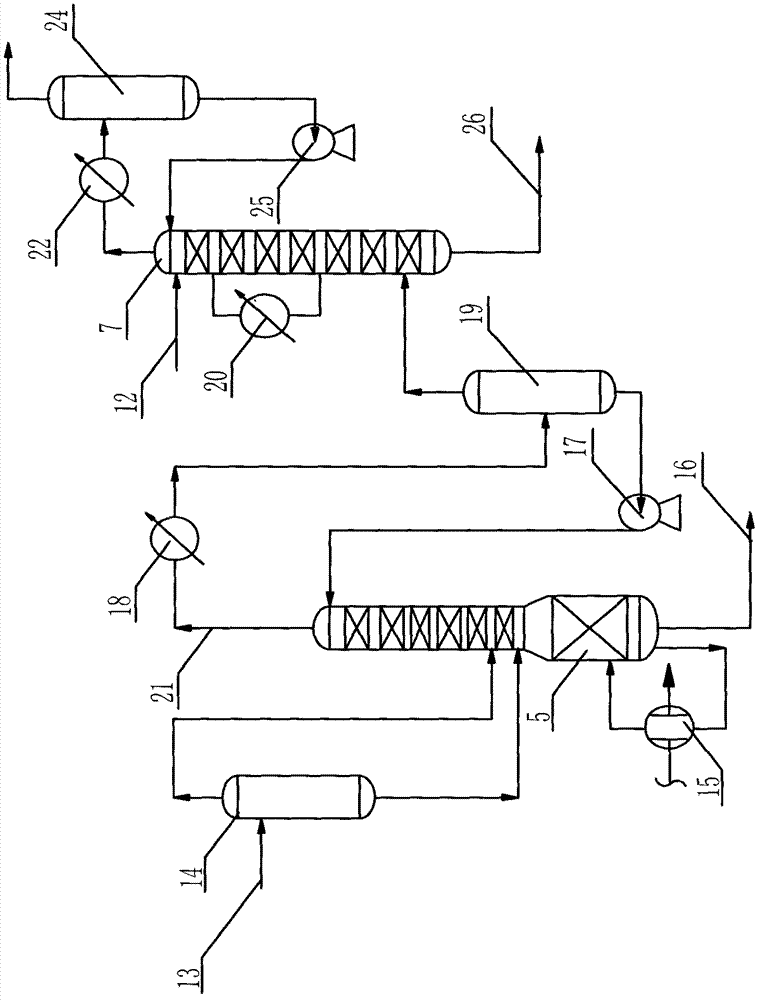

Method for separating low-carbon olefin gas

ActiveCN103242123ALow powerLow operating pressureDistillation purification/separationEthylene productionGas phaseDistillation

Owner:CHINA PETROLEUM & CHEM CORP +1

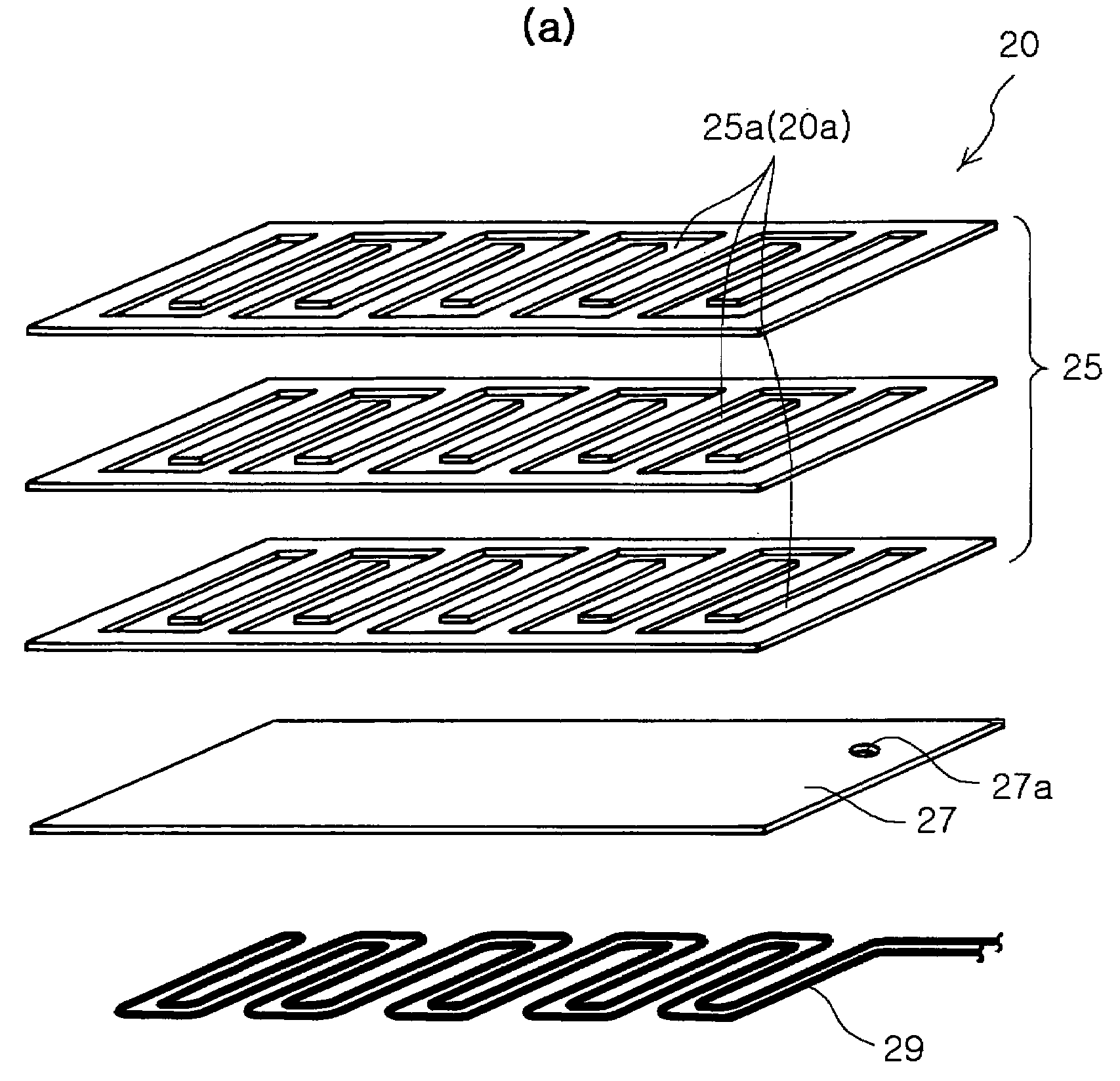

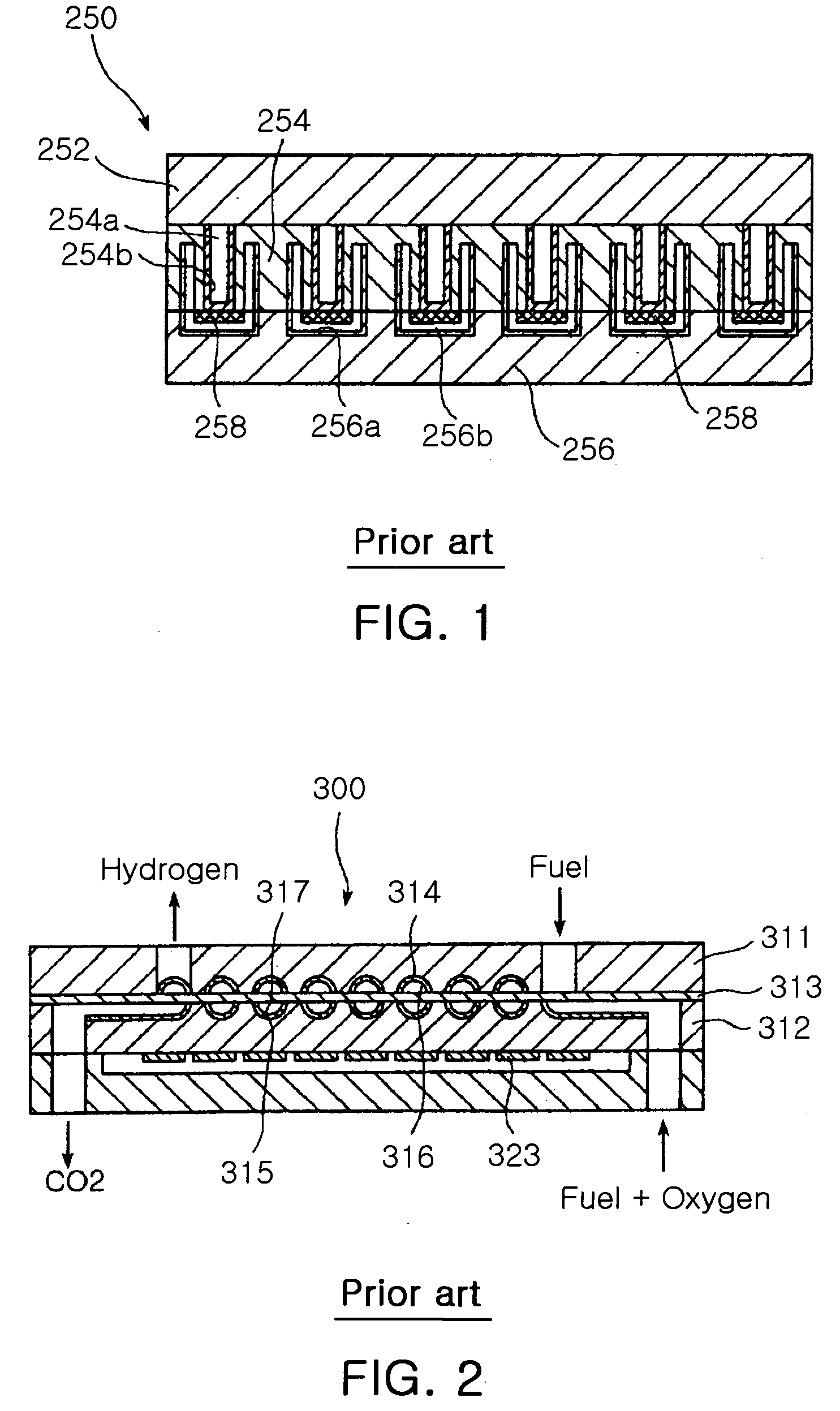

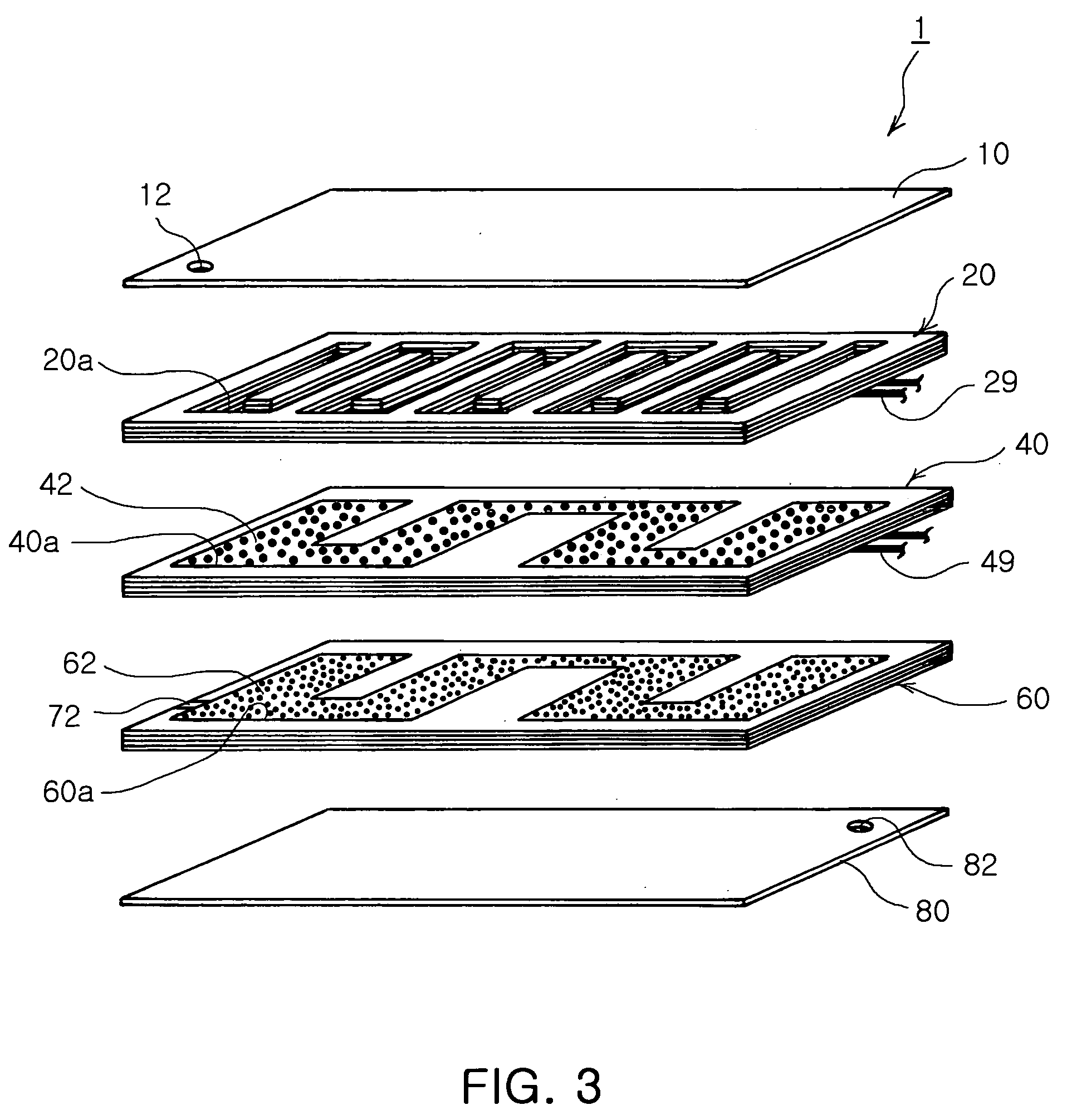

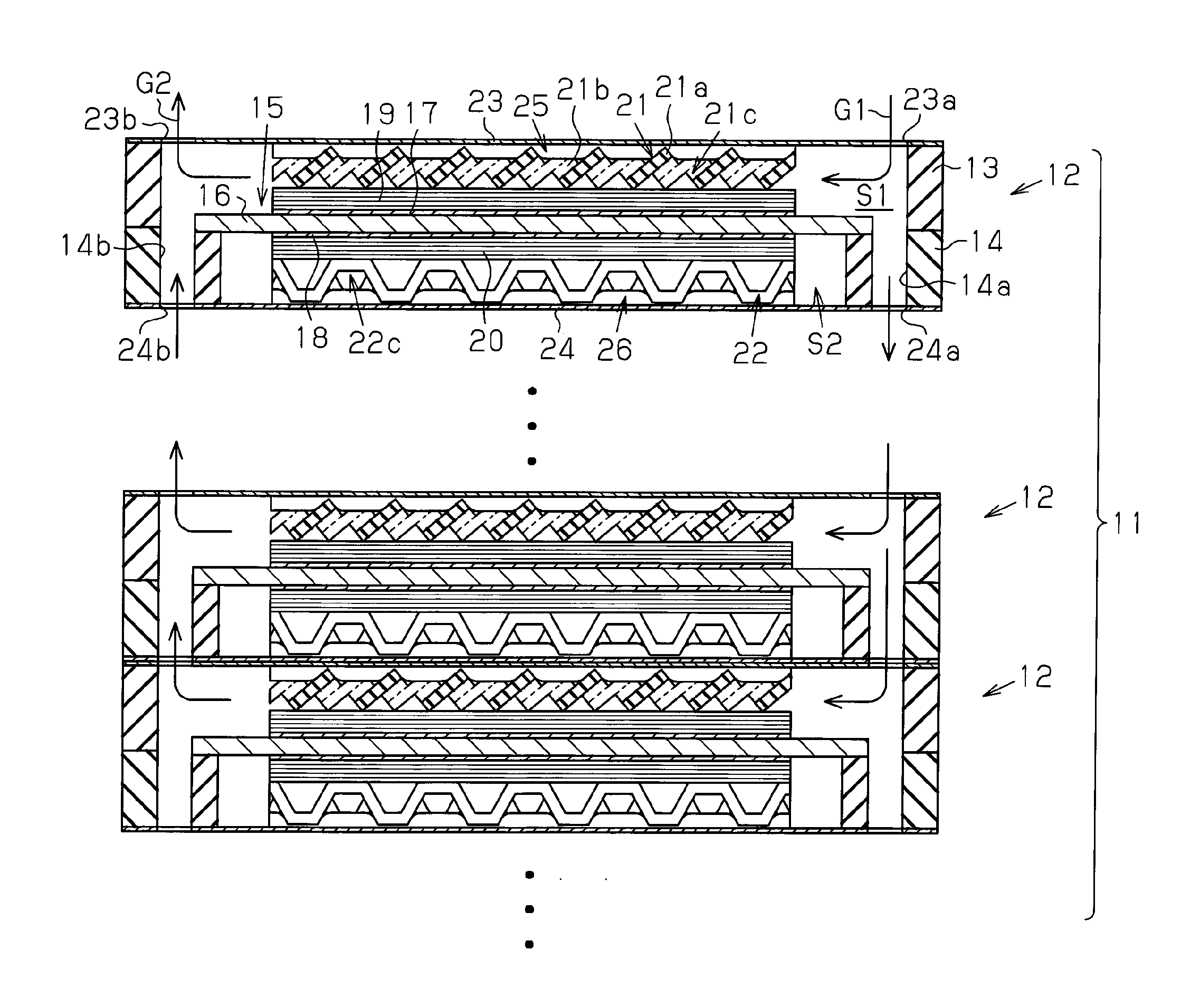

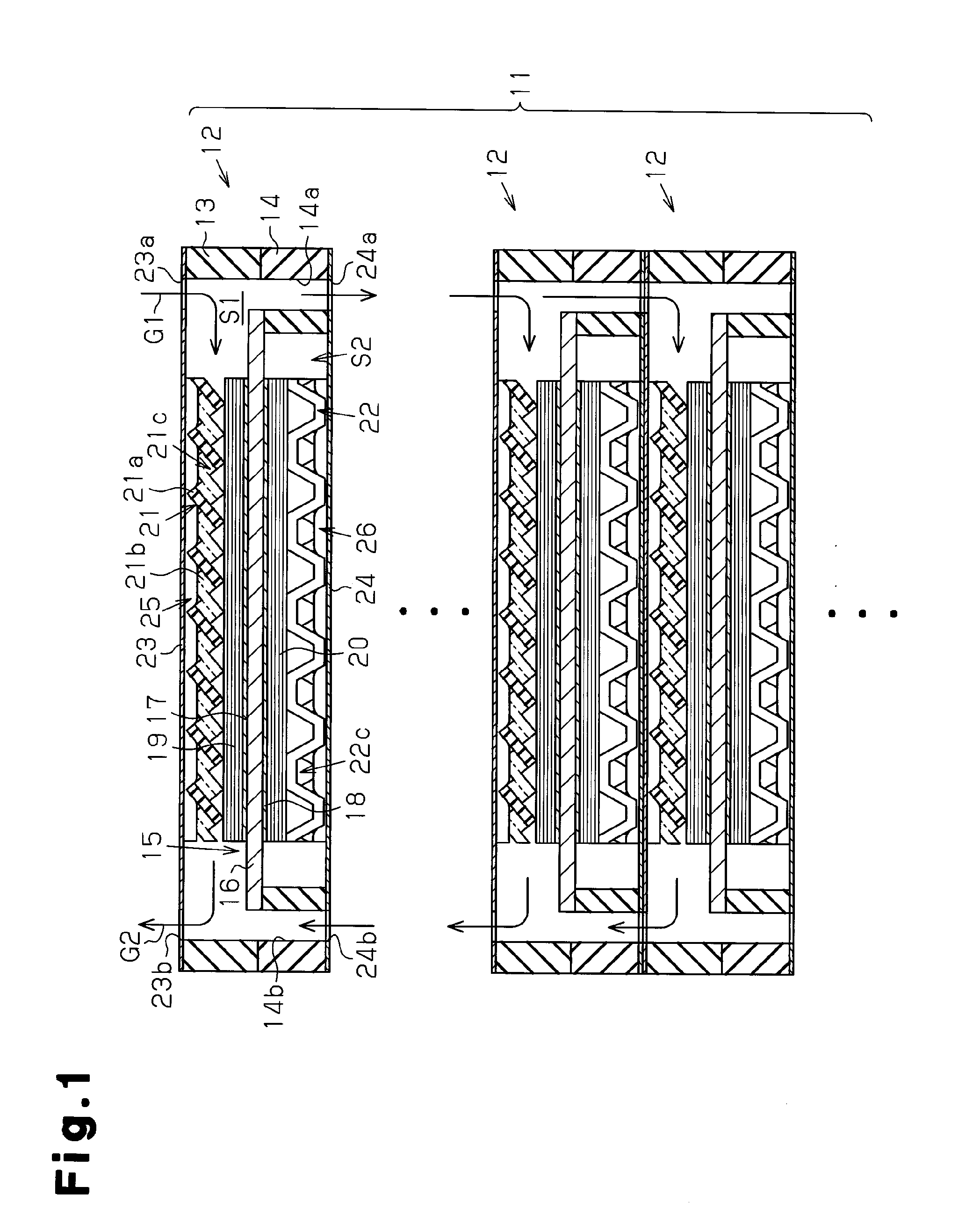

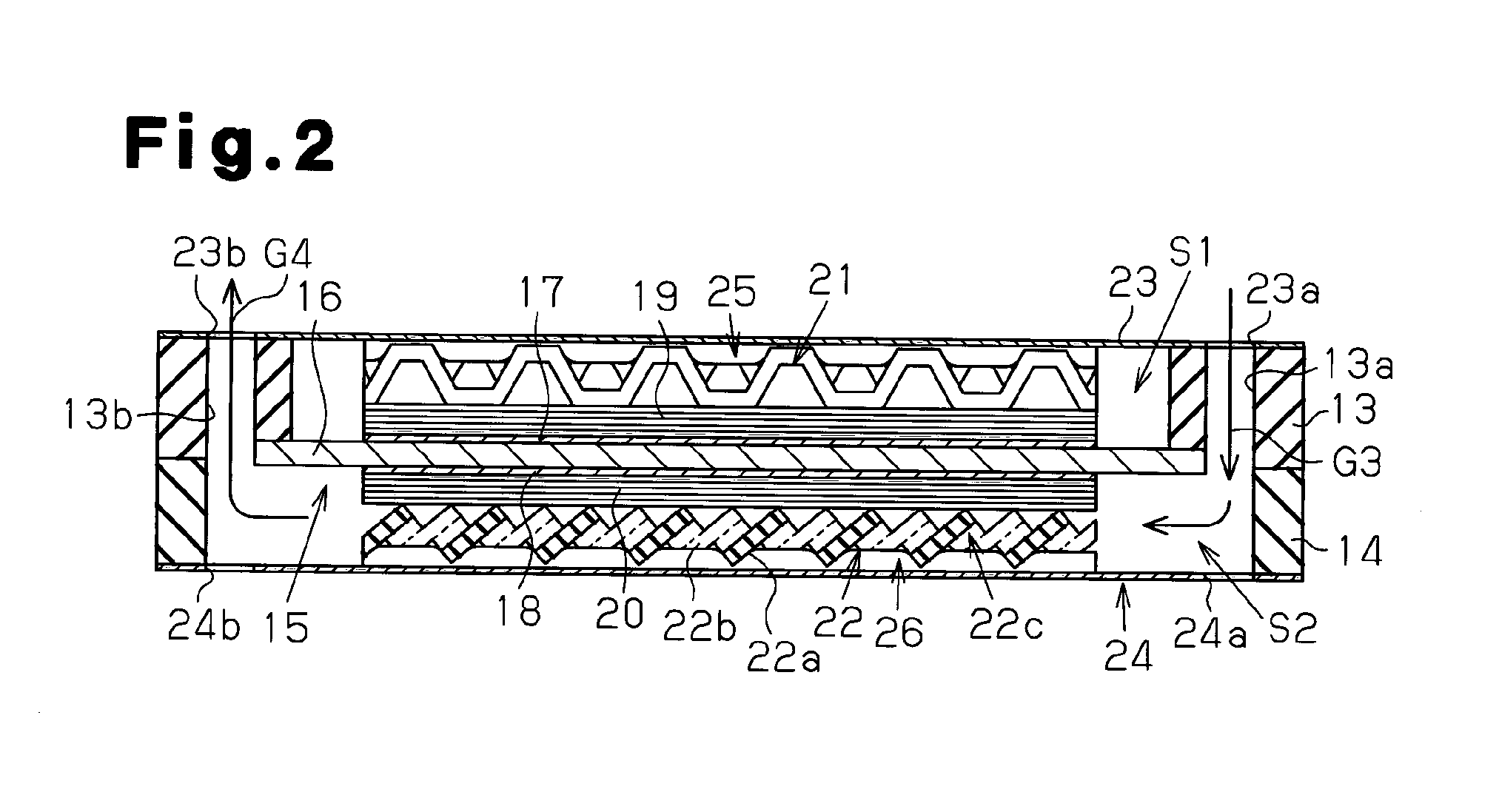

Multi-layer ceramic substrate reforming apparatus and manufacturing method therefor

InactiveUS20070154367A1Guaranteed uptimeSmall and thin and light-weight structureHydrogenChemical/physical/physico-chemical microreactorsHydrogenEngineering

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Methods and apparatus for assembling gas turbine engine stator assemblies

Owner:GENERAL ELECTRIC CO

Engine with intake air temperature control system

Owner:SOLAR TURBINES

Pulverization-free, dampness-resistant, coke tar-free biomass gasification oven preventing burning out

InactiveCN101240904AWide variety of sourcesWon't clogProductsDomestic stoves or rangesBiomass gasifierOxygen

Owner:沈桀

Low modulus insert for a component of a gas turbine engine

Owner:GENERAL ELECTRIC CO

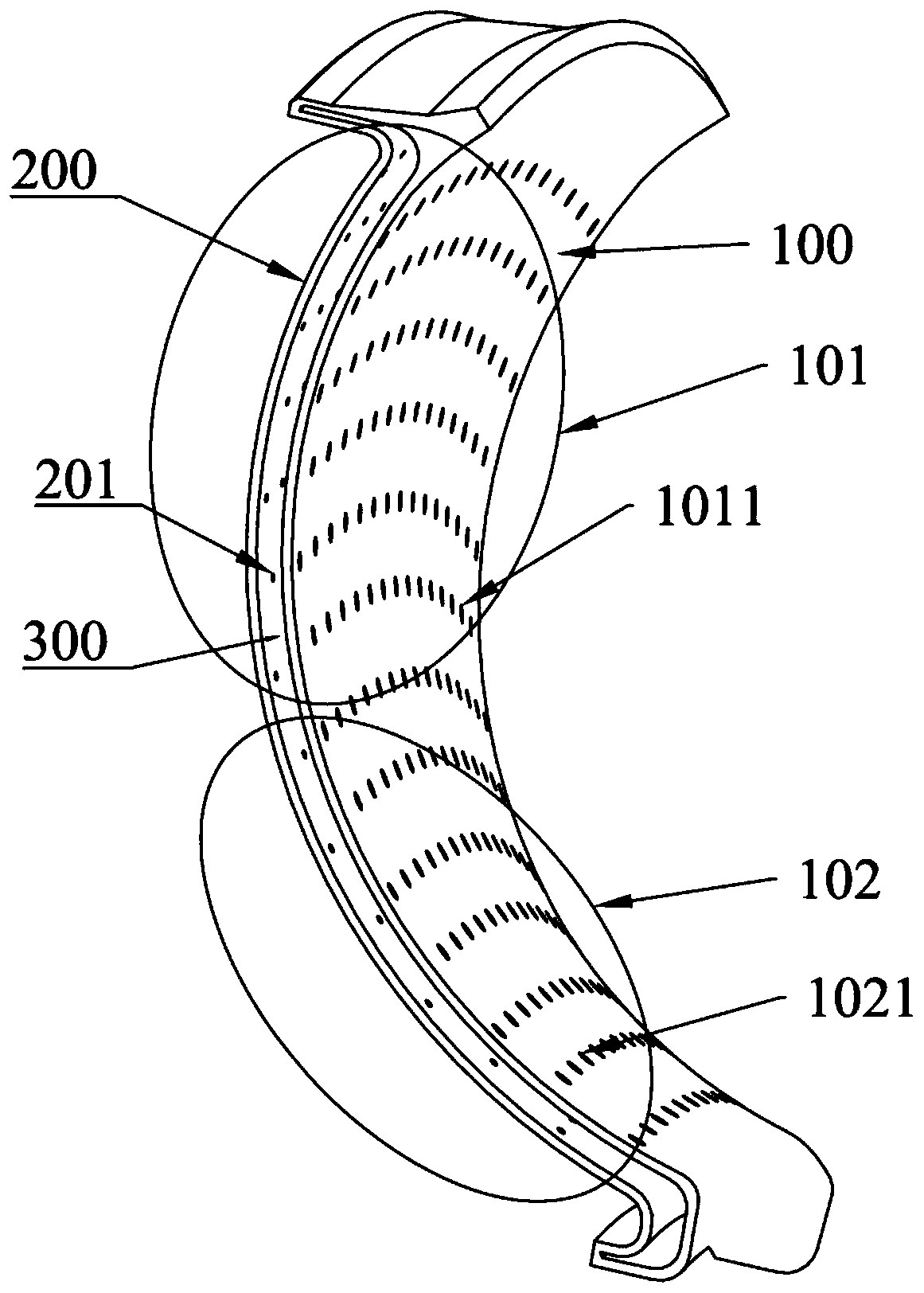

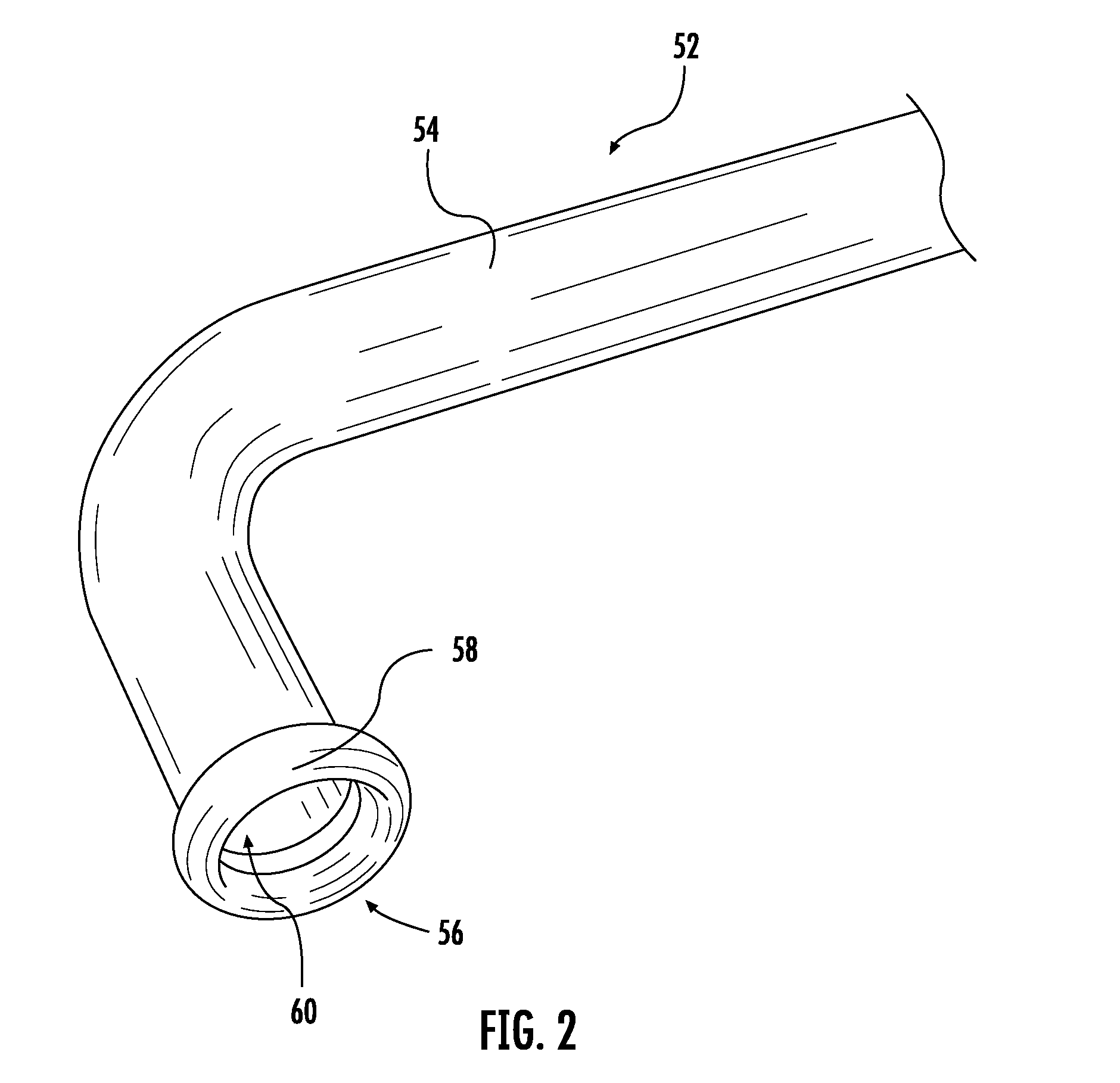

Reverse flow combustor and double-wall elbow structure thereof

ActiveCN109974033AReduce peak wall temperatureHigh strengthContinuous combustion chamberCombustorCombustion chamber

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

System for providing protection from reactive oxygen species

Owner:KRASBERG ALAN

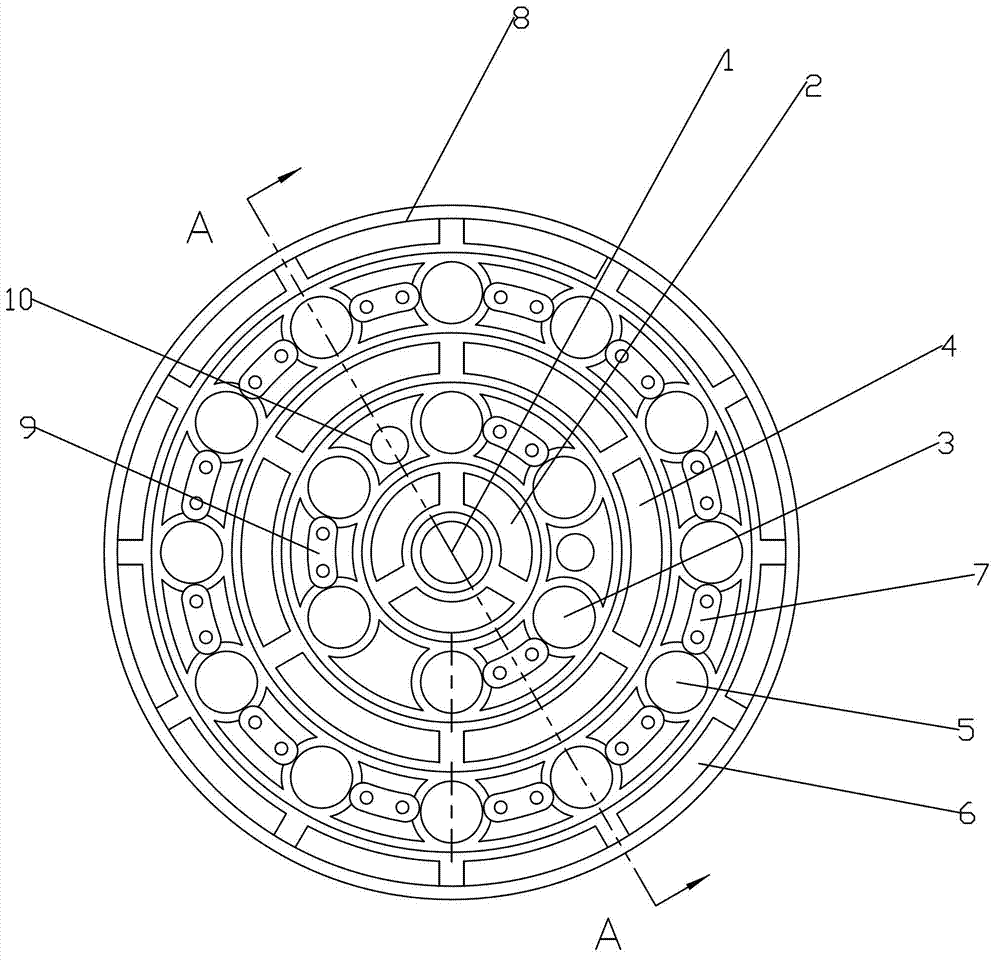

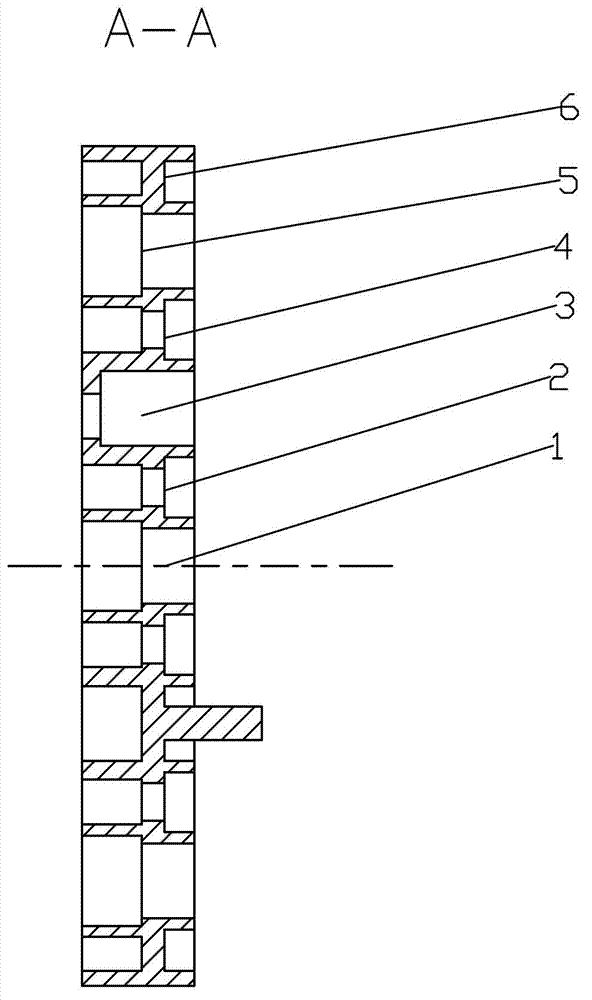

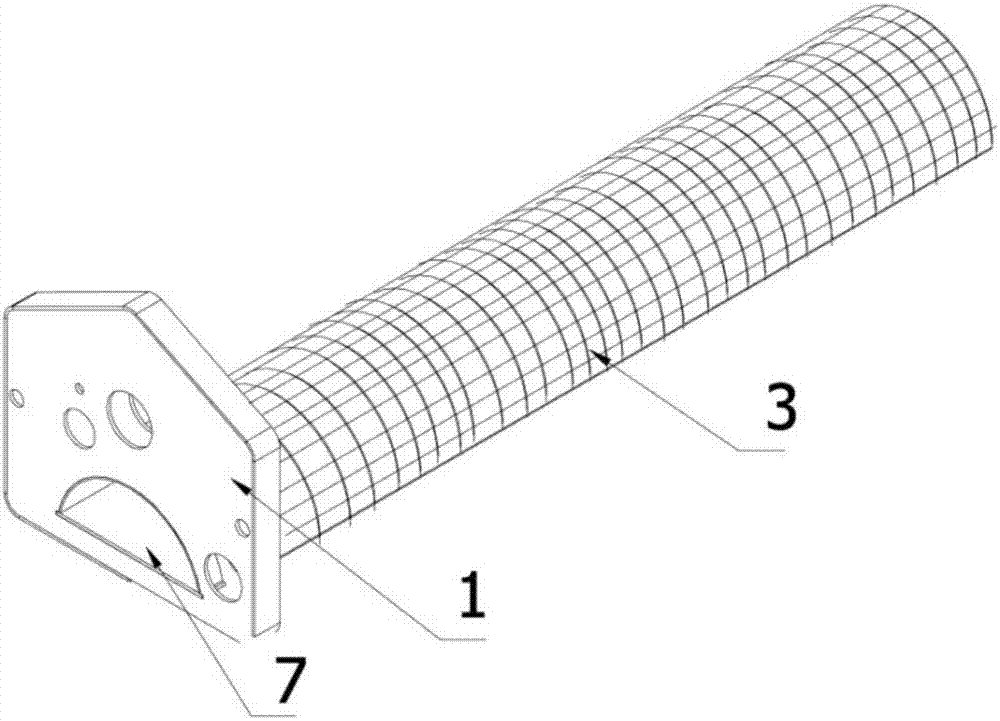

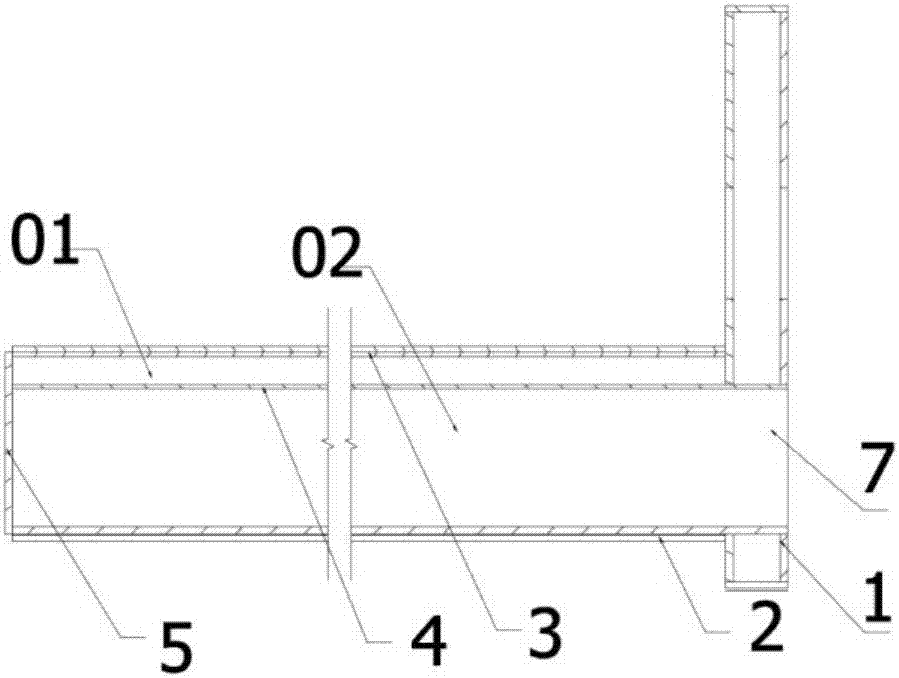

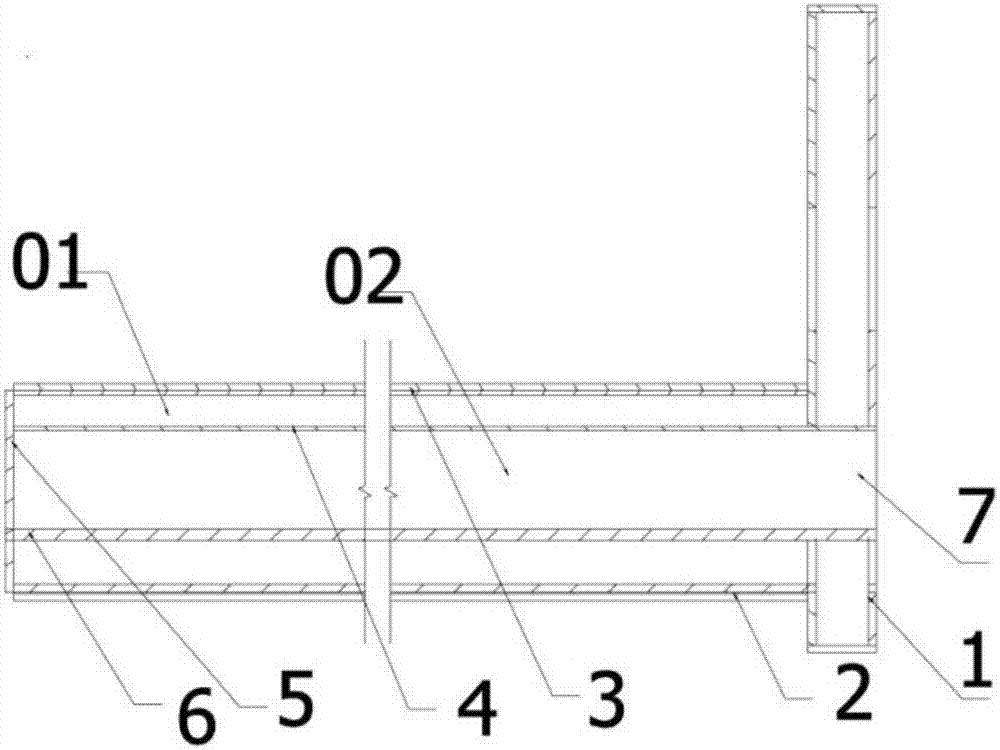

Low-NOx combustor suitable for various low-heat-value/low-pressure fuel gases

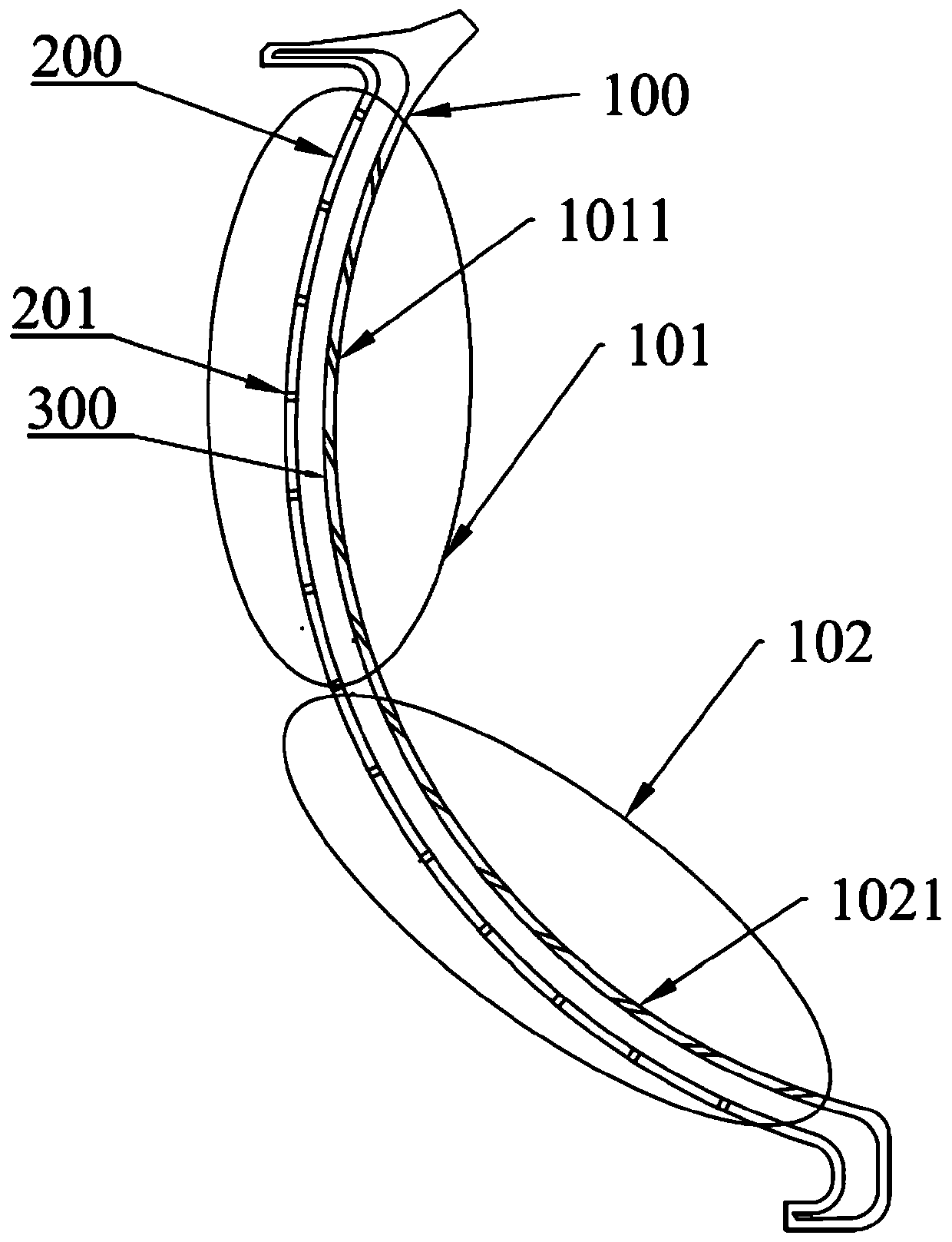

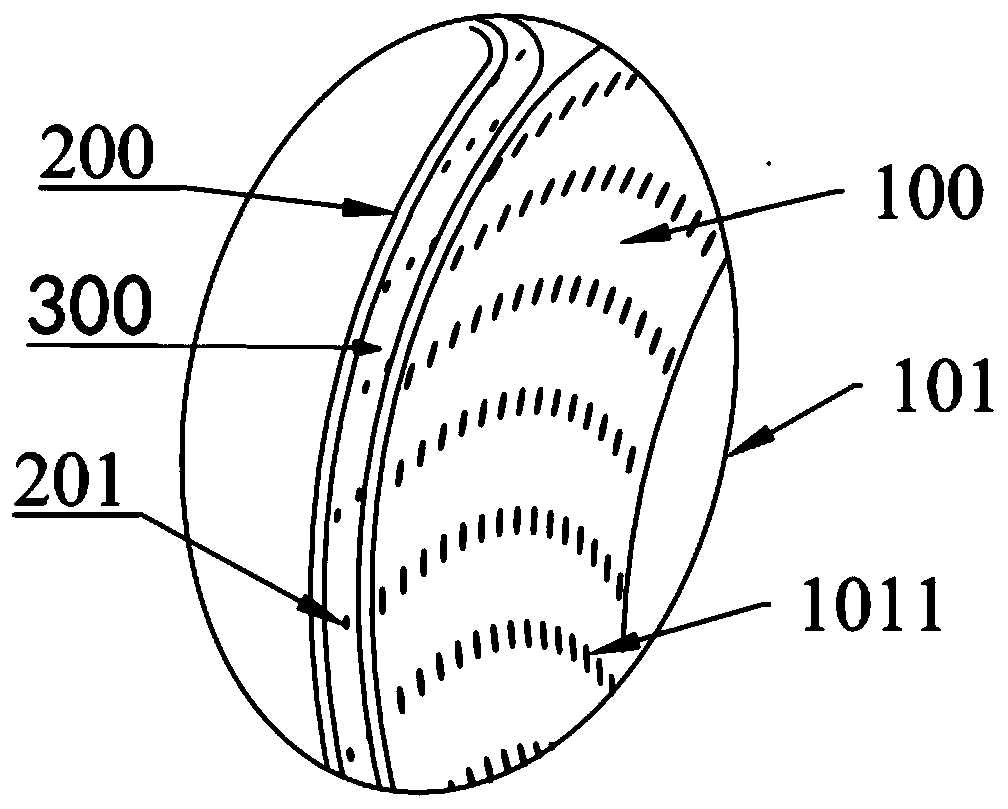

The invention belongs to the technical field of industrial combustors, and discloses a low-NOx combustor suitable for various low-heat-value / low-pressure fuel gases for solving the technical problem about how to further reduce the NOx emission of combustors. The low-NOx combustor is characterized in that a center air pipe, an inner pipe, an outer pipe, an outer sleeve and a throat are sequentially and coaxially arranged from inside to outside; a first combustion air channel is formed between the center air pipe and the inner pipe, and the upper end of the first combustion air channel is fixedly connected with a first swirler; a fuel gas channel is formed between the inner pipe and the outer pipe, and the upper end of the fuel gas channel is provided with a plurality of inward center fuel gas nozzles and a plurality of outward center fuel gas nozzles in a circular-ring uniform distribution manner; a second combustion air channel is formed between the outer pipe and the outer sleeve, and the end of the second combustion air channel is fixedly connected with a second swirler; and a third combustion air channel is formed between the outer sleeve and the throat. By the combination of a dense-dilute combustion method and a staged combustion manner, flames can be relatively stable, the intensity of dense combustion is improved, and an extremely strong reduction atmosphere is formed for restraining NOx generation. The low-NOx combustor is suitable for various low-heat-value / low-pressure fuel gases.

Owner:SHANGHAI WISEBOND TECH

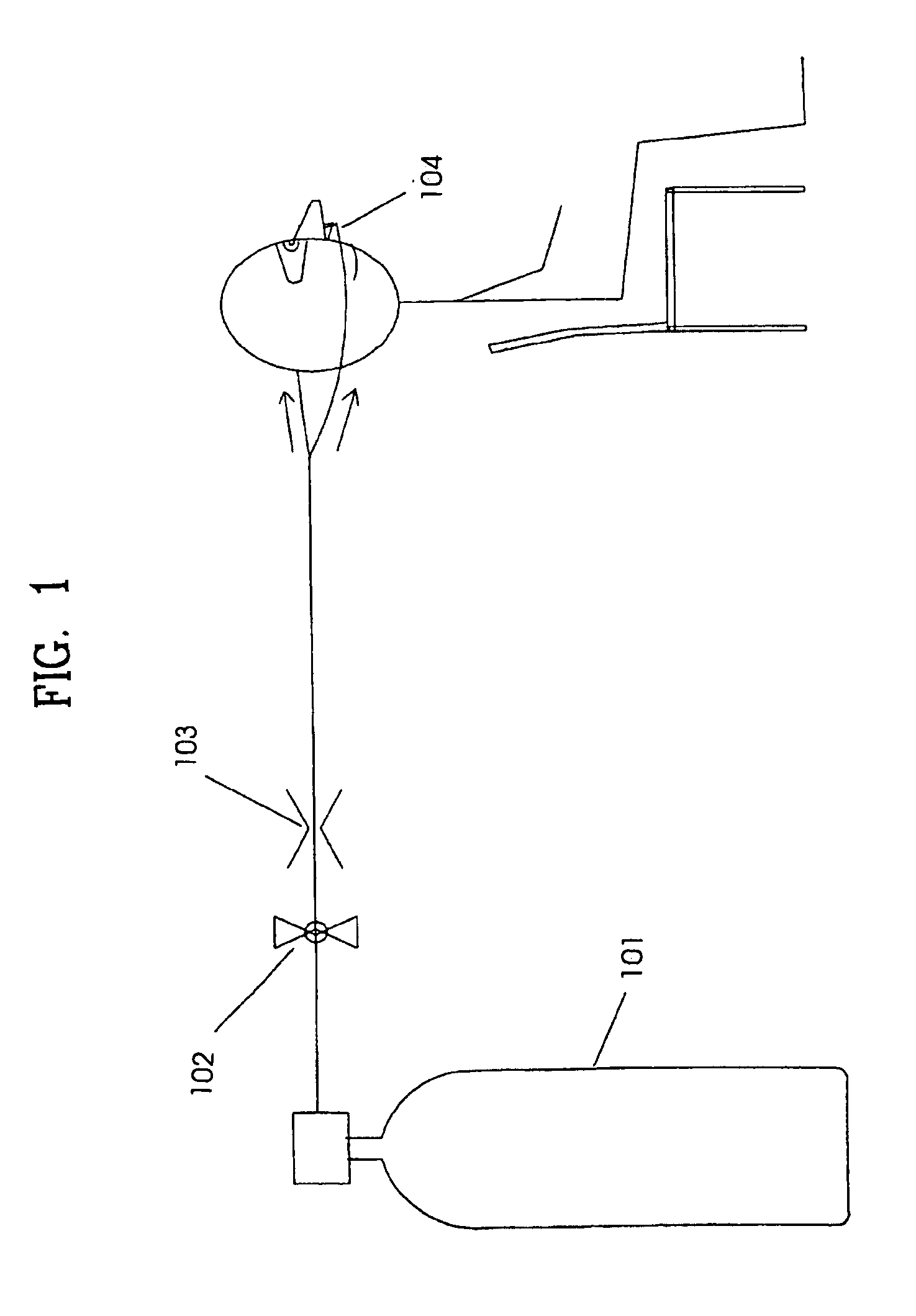

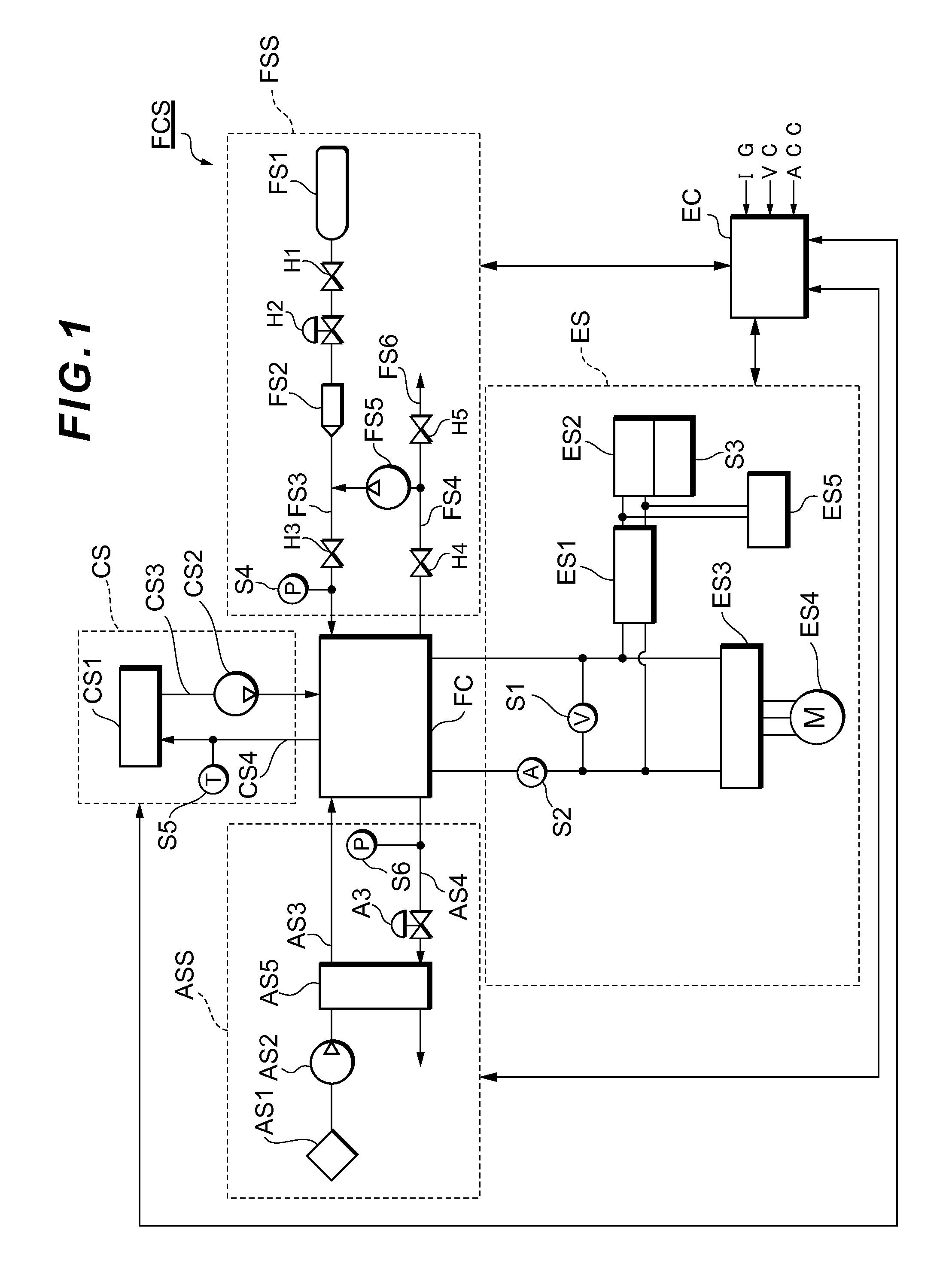

Fuel Cell System

InactiveUS20080008913A1Increased durabilityImprove reliabilityFuel cells groupingFuel cell auxillariesElectricityExhaust valve

The disclosure describes fuel cell systems including a fuel cell stack that generates electricity, an exhaust valve that externally vents a fuel gas from a fuel chamber of the fuel cell stack, and a controller that computes an estimated time to replace an oxidant gas in at least the fuel chamber with a newly supplied fuel gas, wherein at a time of starting-up the fuel cell system the controller maintains the exhaust valve in an open position for the estimated time. In some embodiments, the controller computes the estimated time as a summation of a first time T1 measured from the fuel cell start-up time to a time when contents of a supply conduit are replaced with fuel gas, a second time T2 measured from the when contents of a supply conduit are replaced with fuel gas to a time when contents of the fuel chamber are replaced with fuel gas, and a third time T3 measured from time when contents of the fuel chamber are replaced with fuel gas to a time when contents of the exhaust conduit are replaced with fuel gas. The disclosure further describes methods of operating a fuel cell system, particularly during fuel cell start-up.

Owner:NISSAN MOTOR CO LTD

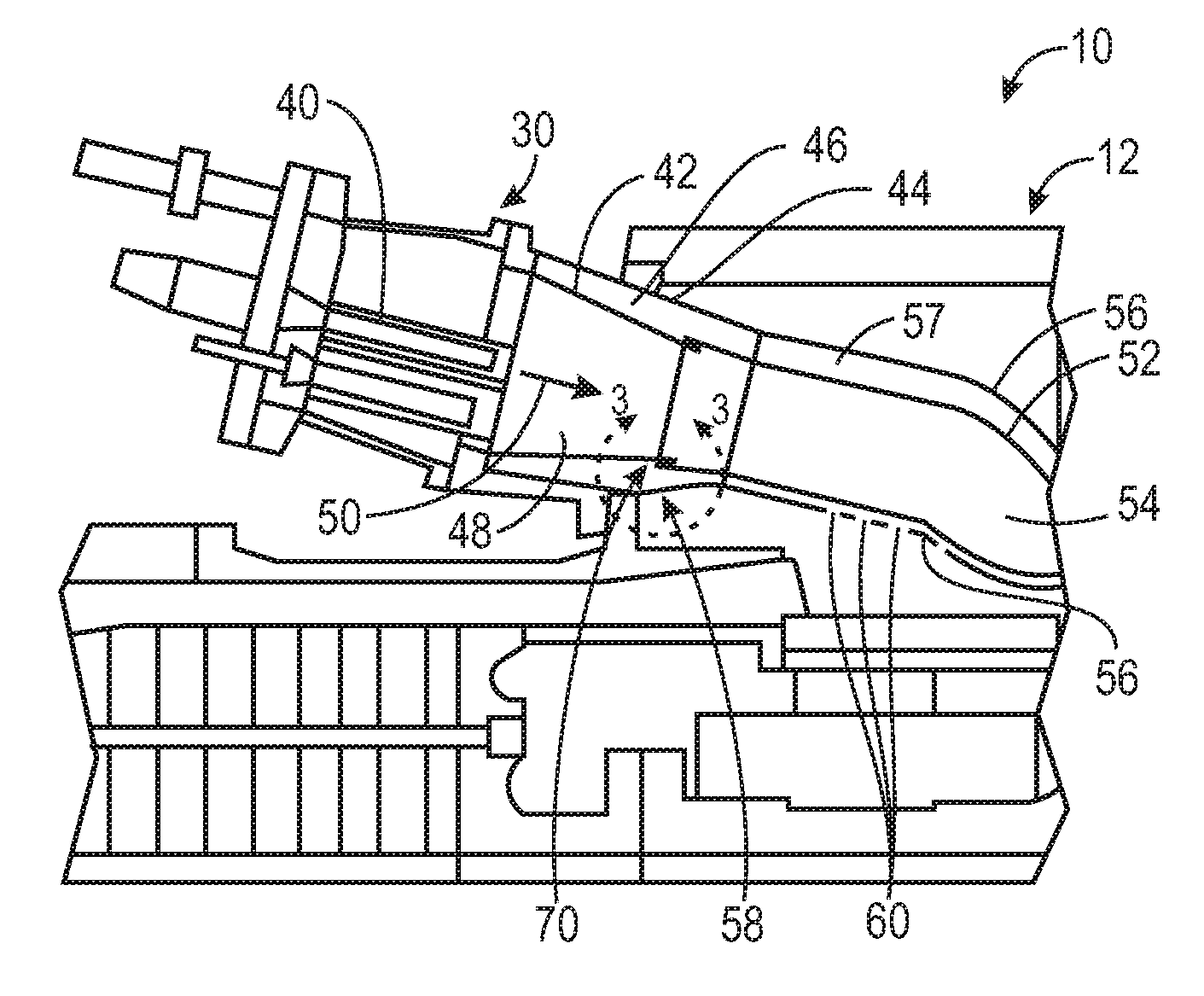

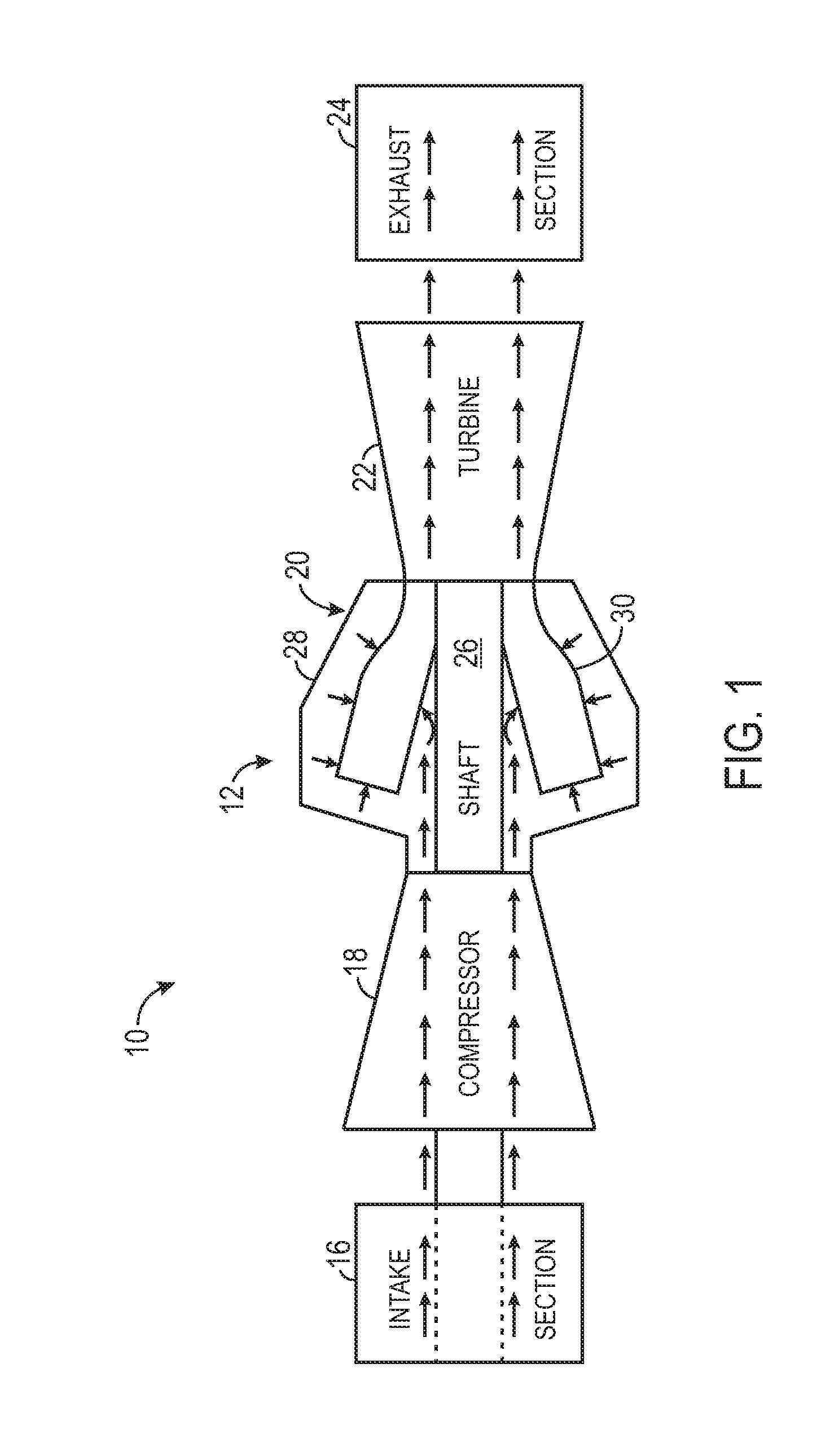

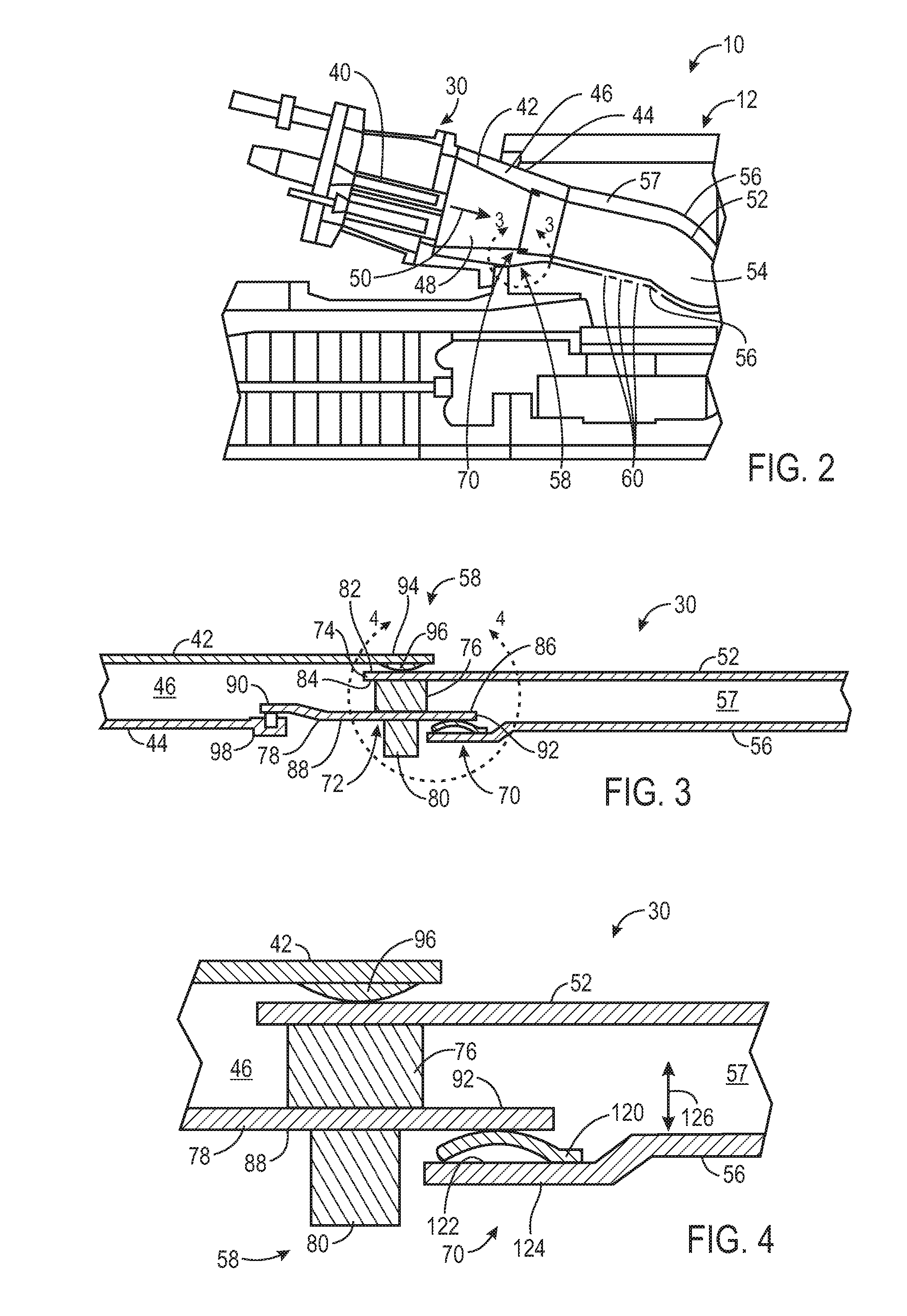

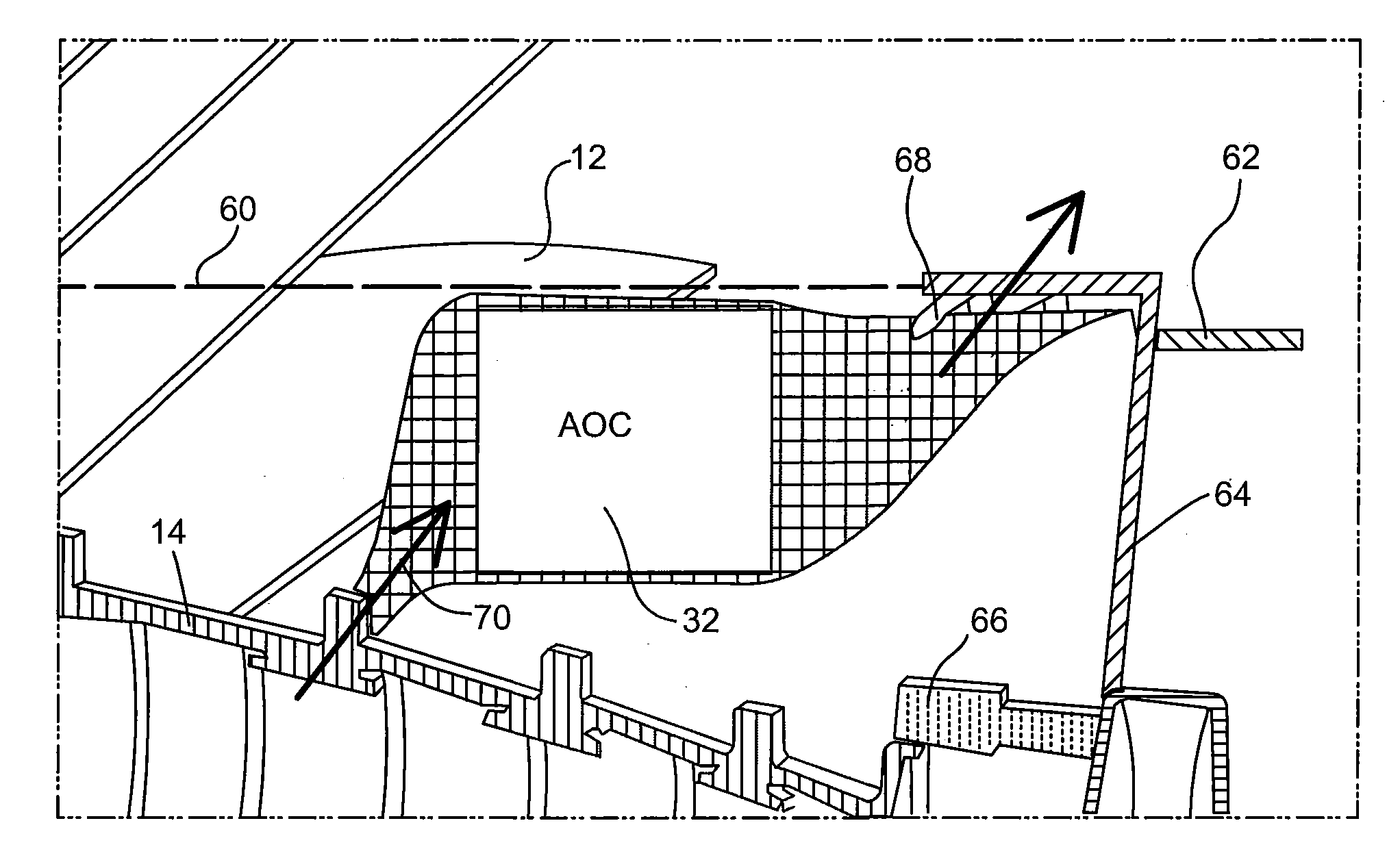

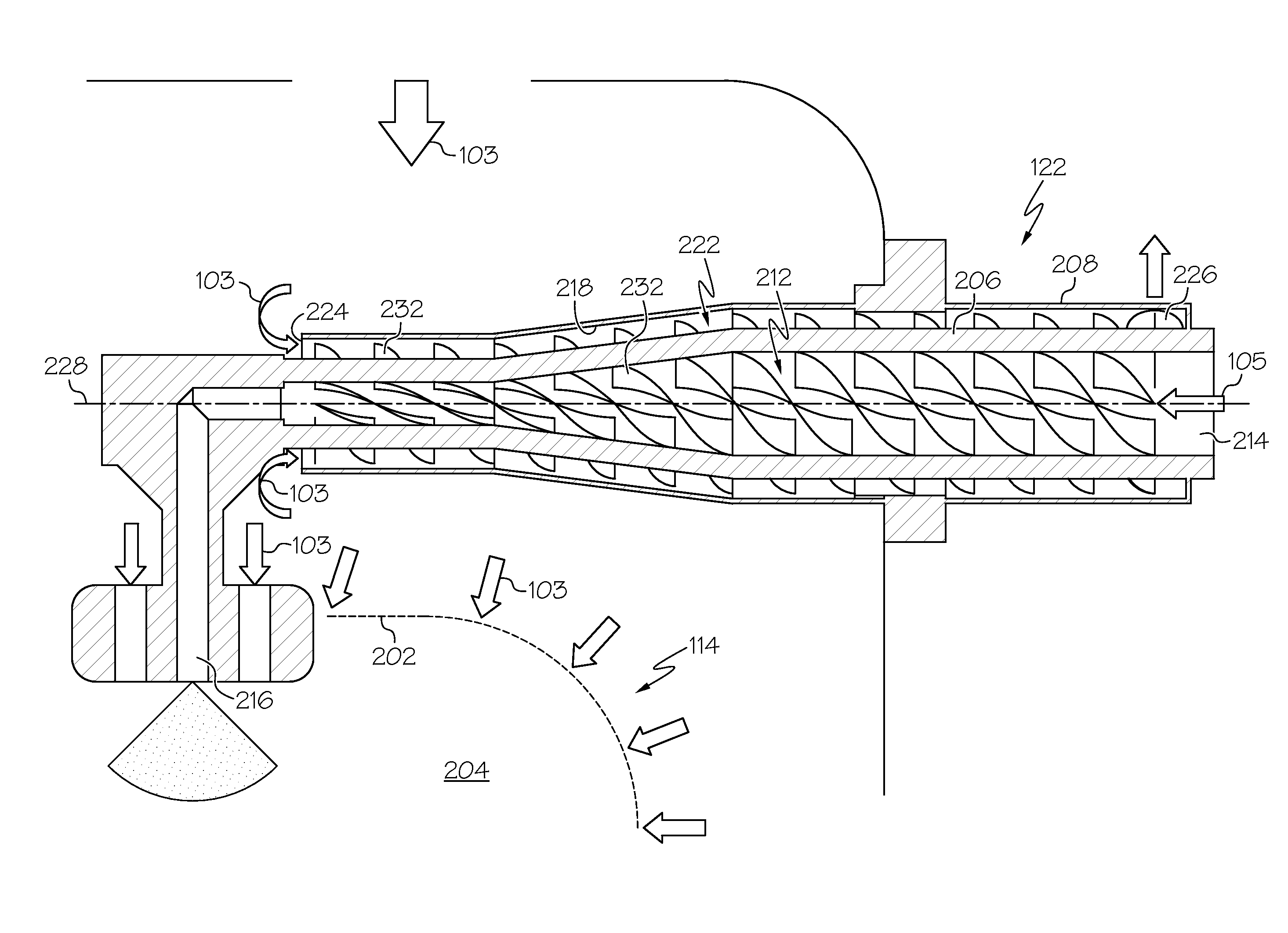

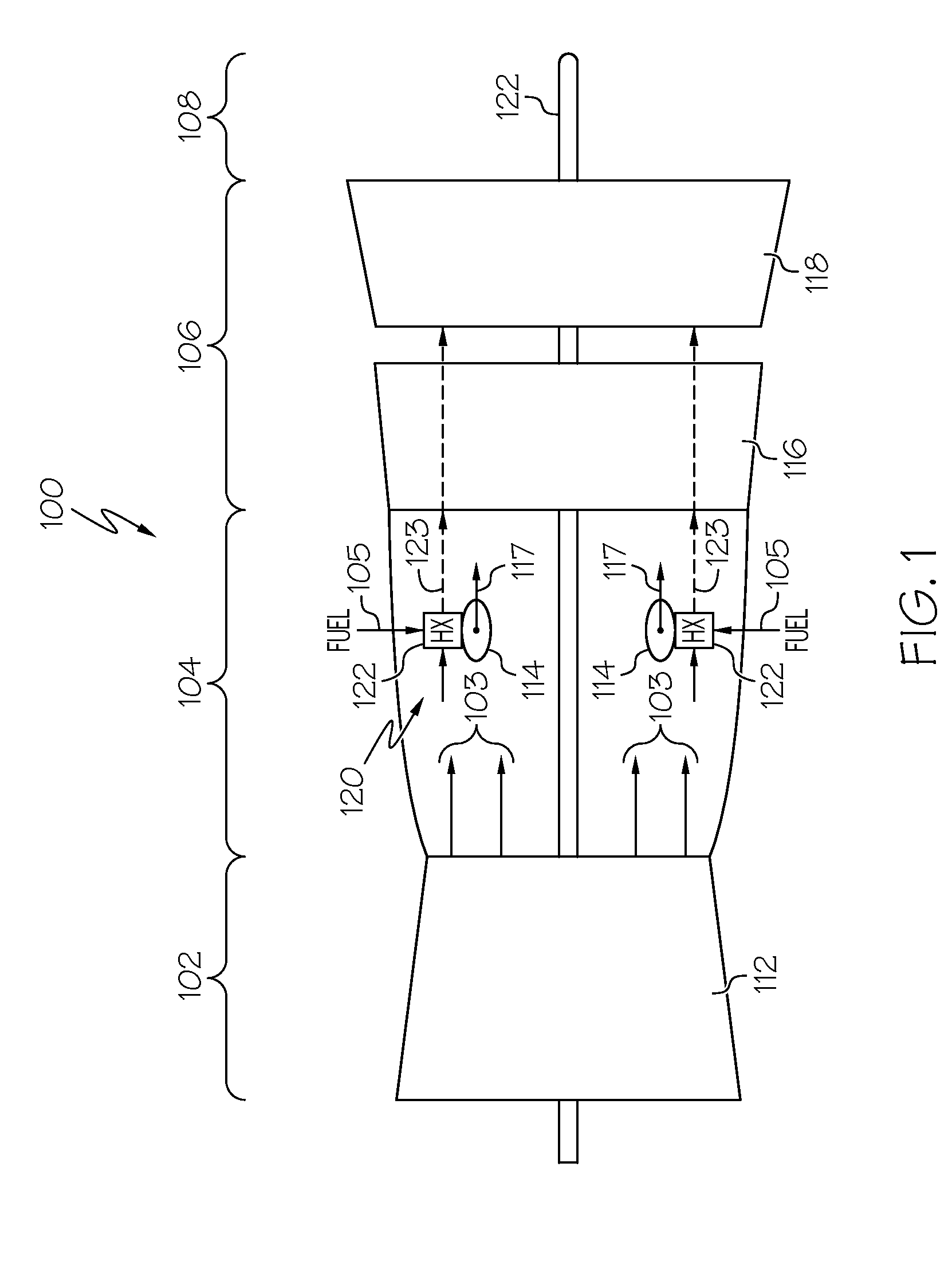

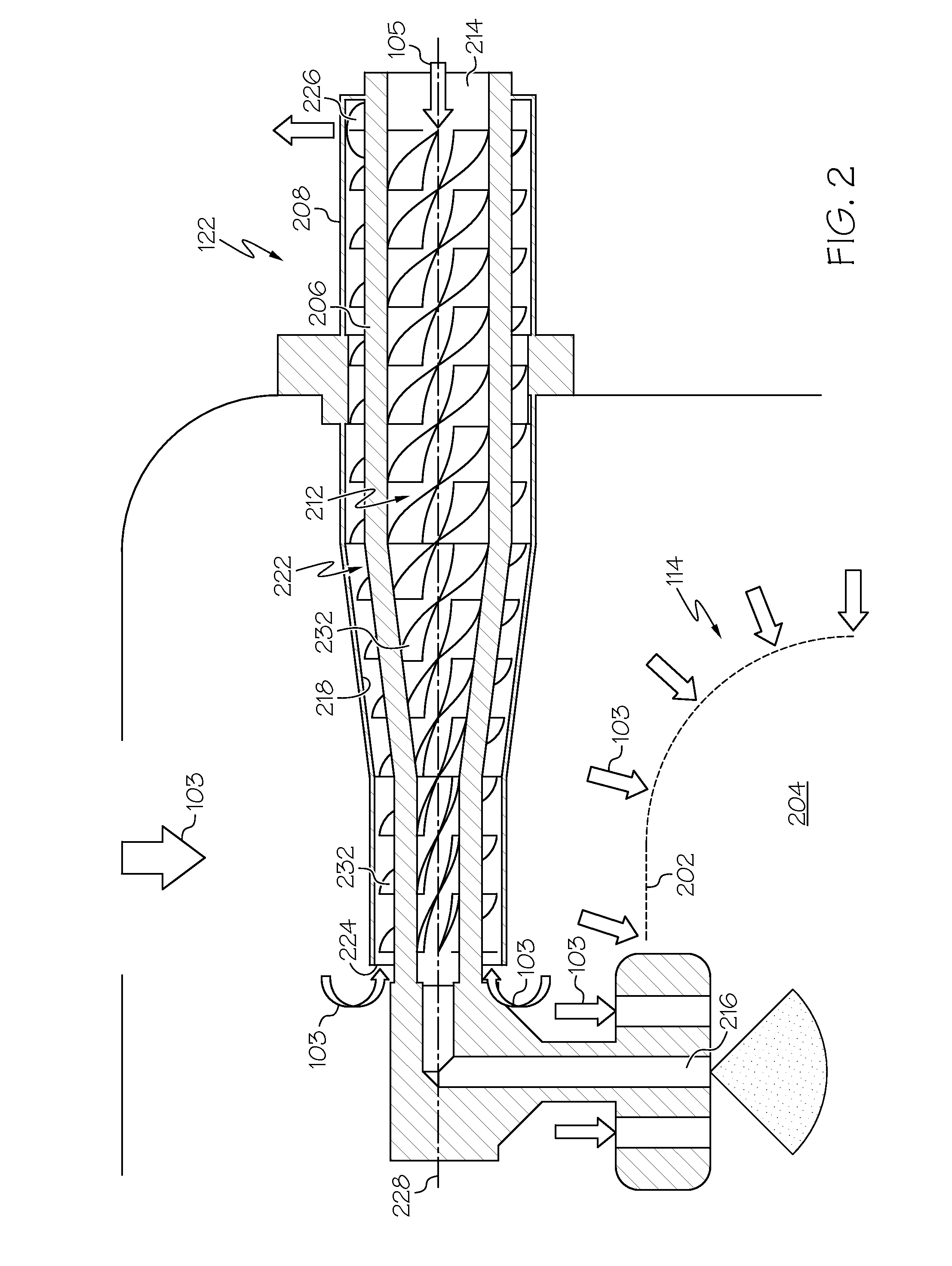

Gas turbine engine fuel cooled cooling air heat exchanger

ActiveUS20160290290A1SFC also risesReduce trafficBurnersContinuous combustion chamberTurbineGas turbines

Owner:HONEYWELL INT INC

Flow guiding disc of group injection flow complemented-burning type gas burner

Owner:嘉善创越知识产权服务有限公司

Fuel cell

InactiveUS20120009498A1Complex structureLow costFuel cells groupingCell component detailsCross-linkFuel cells

A fuel cell is provided with a separator that supports an electrolyte / electrode assembly sandwiched therebetween. The separator is provided with: first and second fuel gas supply parts in the center of which fuel gas supply holes are formed; first and second cross-link parts connected to the first and second fuel gas supply parts; and first and second surrounding support parts connected to the first and second cross-link parts. Each first surrounding support part is provided with a set of fuel gas exhaust passages that discharge fuel gas that has gone through a fuel gas passage and been used. The cross-sectional areas of the fuel gas exhaust passages are larger on the downstream sides than on the upstream sides, in terms of the direction of fuel gas flow.

Owner:HONDA MOTOR CO LTD

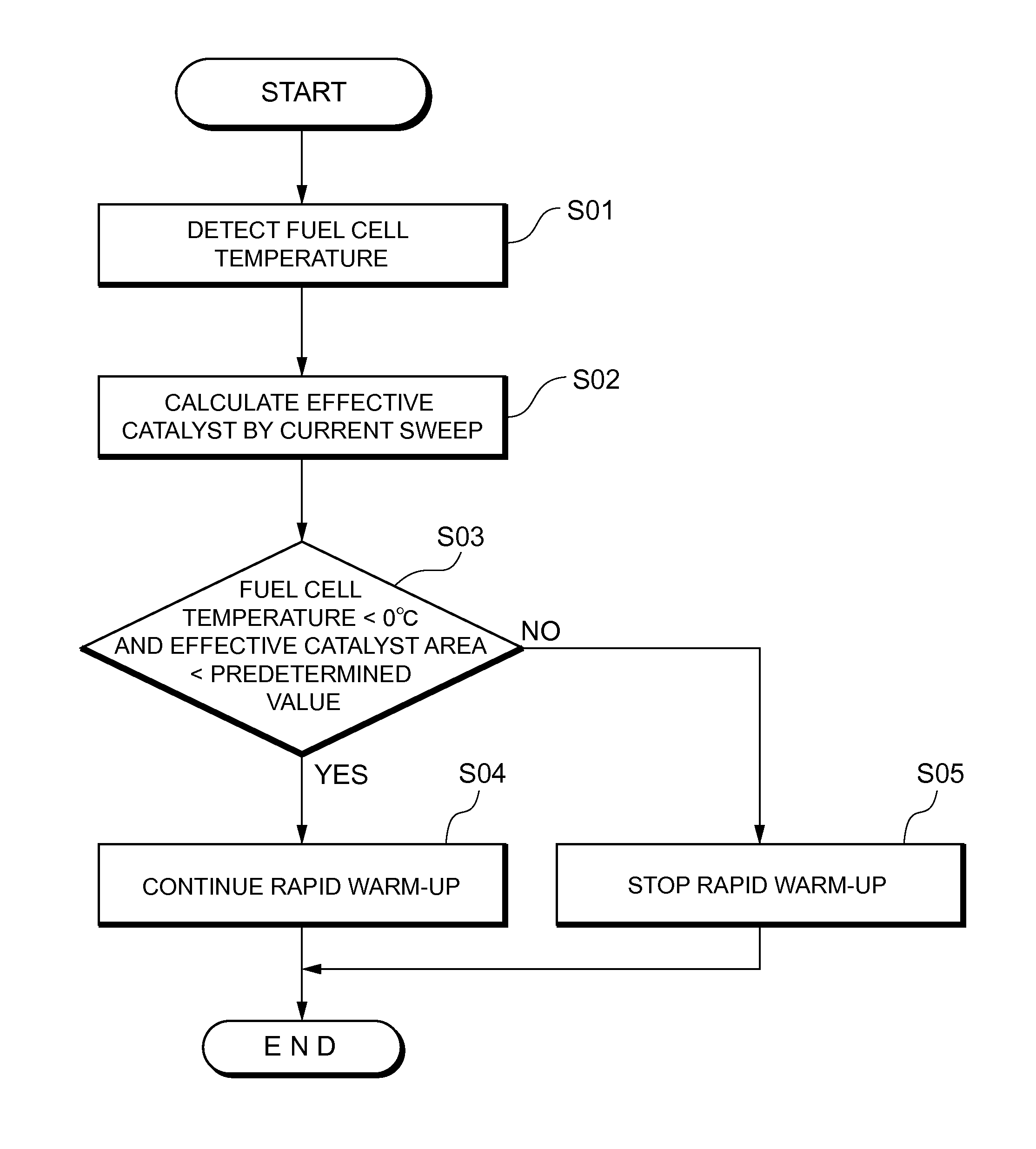

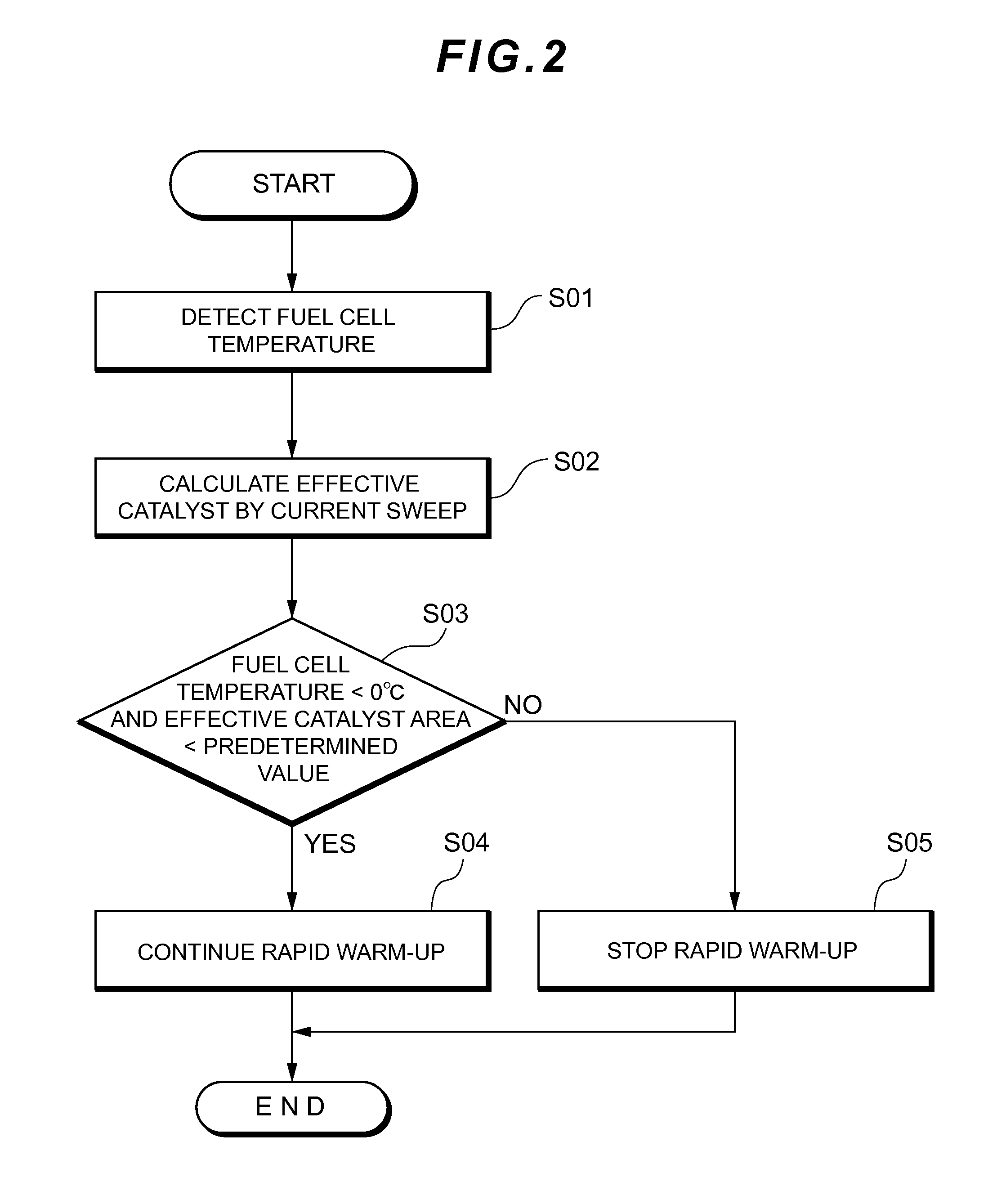

Fuel cell system

ActiveUS8092947B1Find exactlyFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsCurrent voltage

Owner:TOYOTA JIDOSHA KK

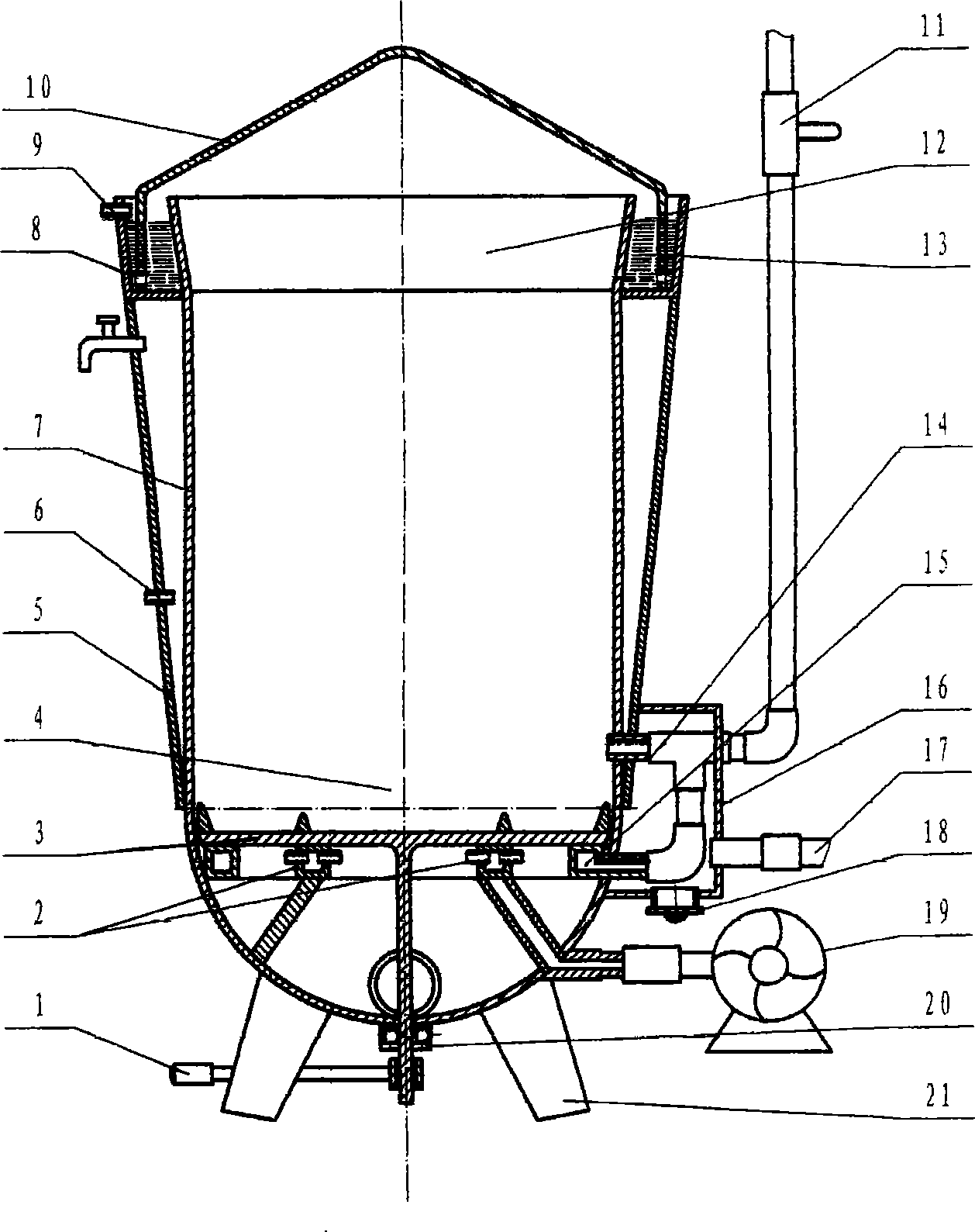

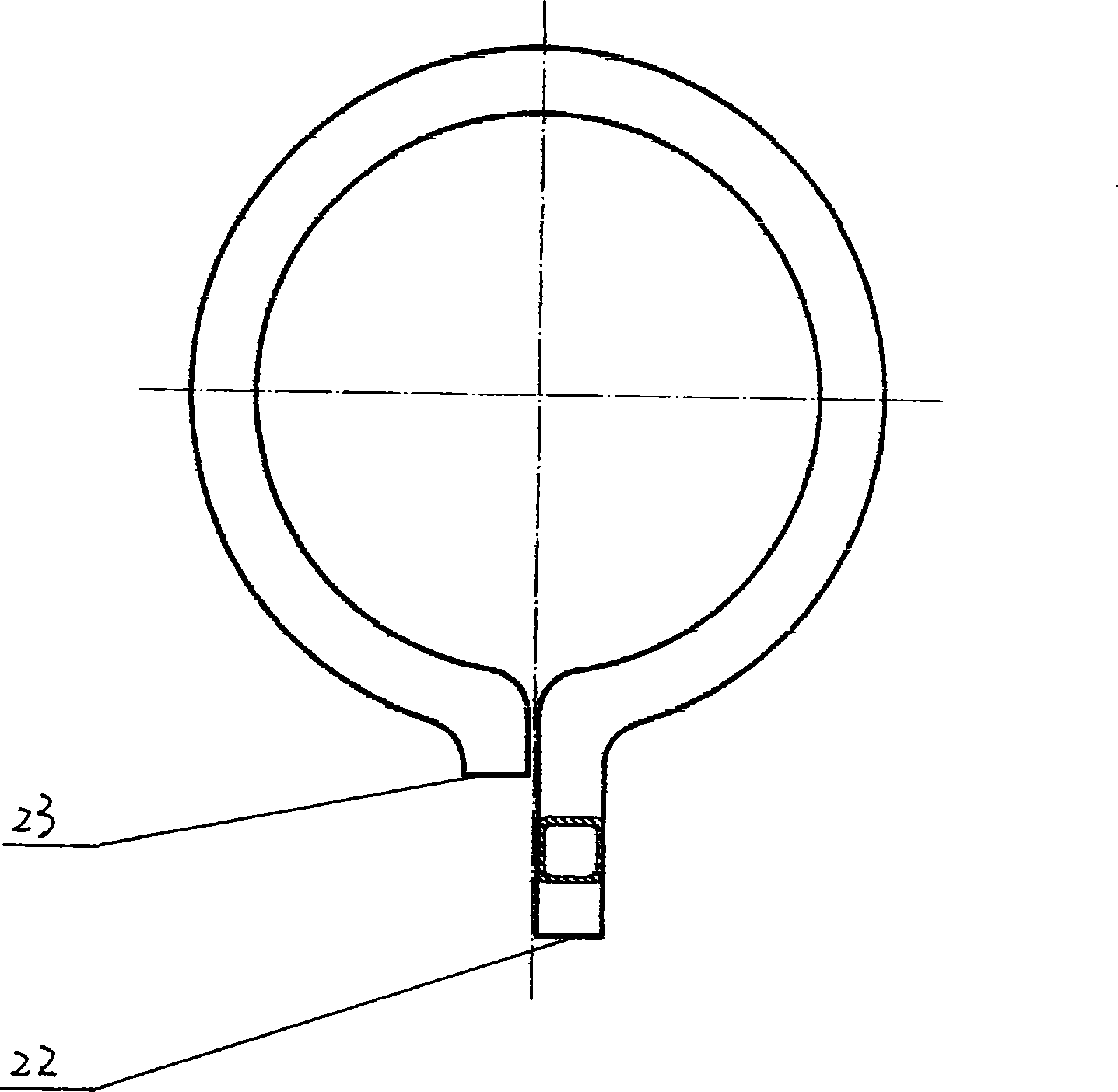

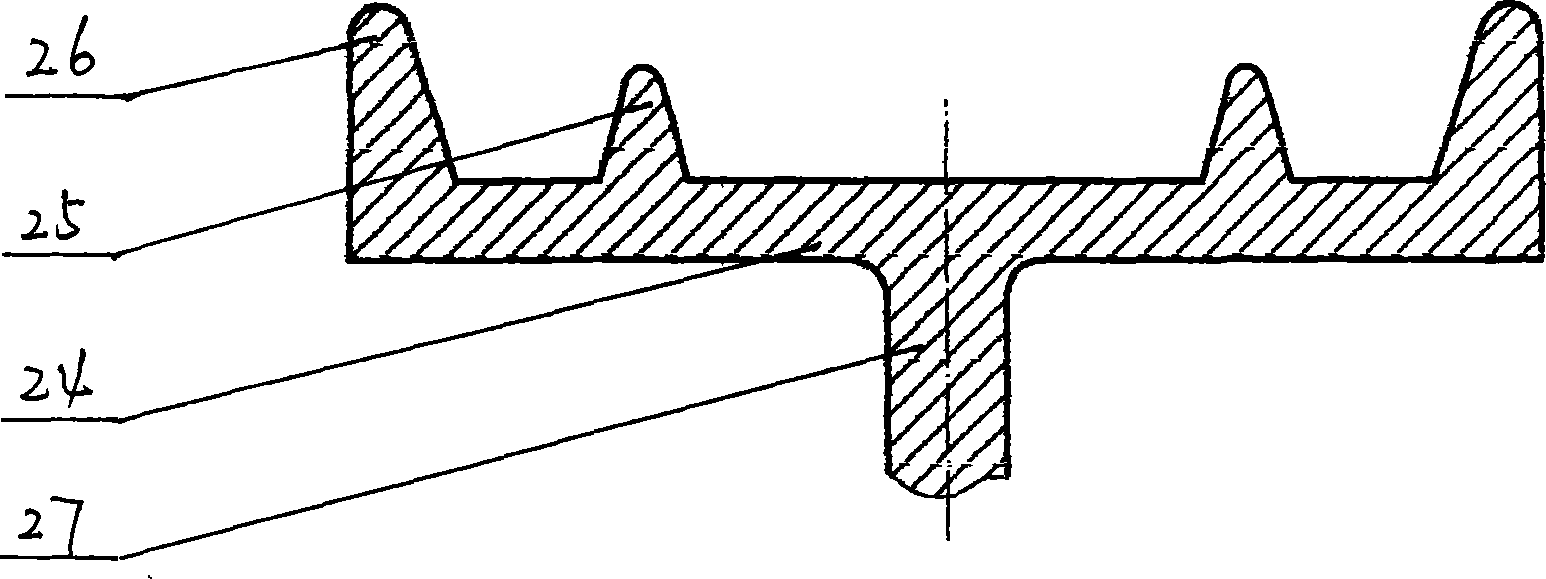

Slag removal machine of waste pyrolysis gasifier

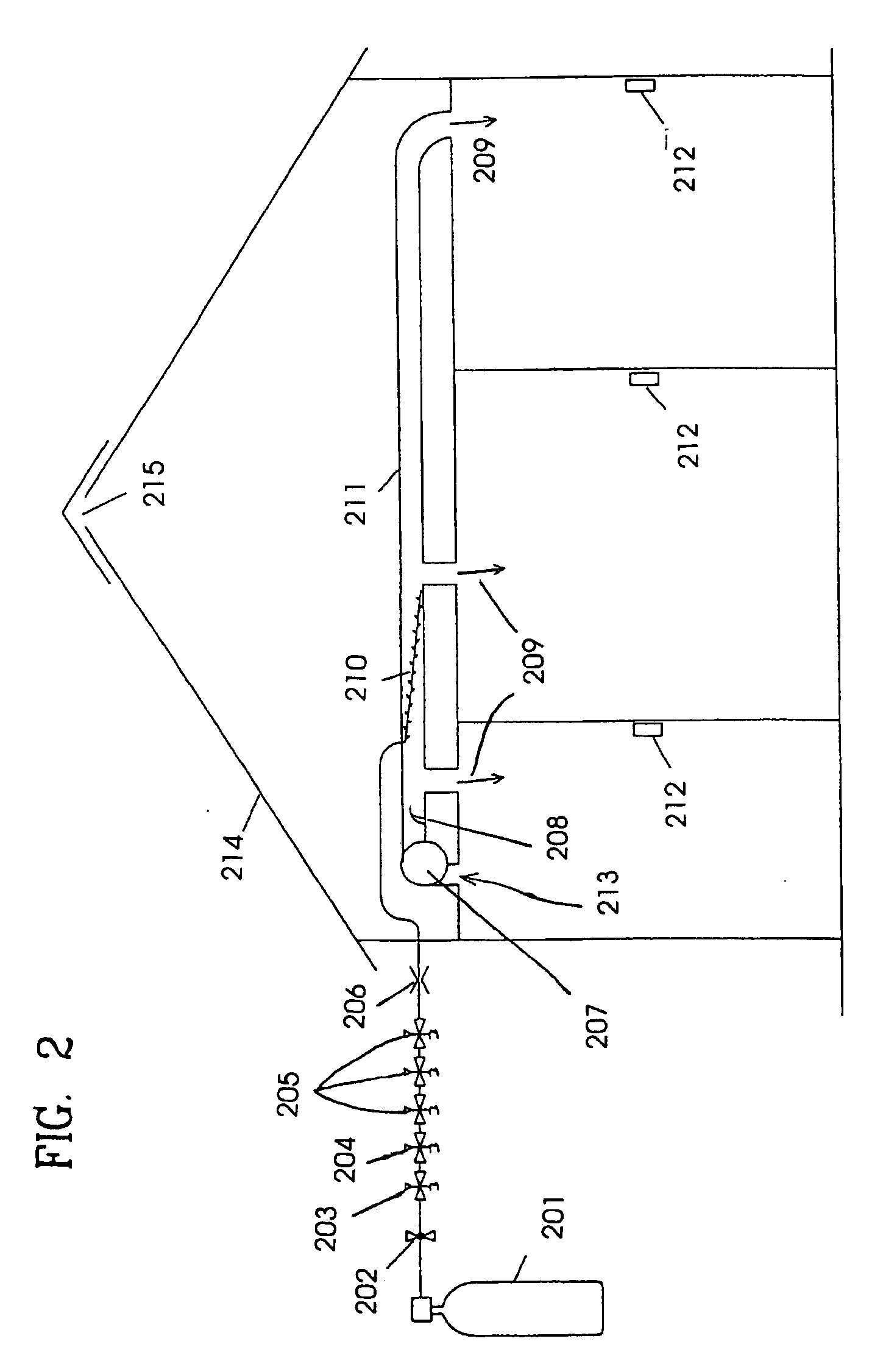

The invention discloses a slag removal machine of a waste pyrolysis gasifier. The slag removal machine structurally comprises a furnace body, a material conveying pipe, a pushing machine, a feeding hopper, a fuel gas outlet, a hot air inlet and a slag removing mechanism, wherein the material conveying pipe is arranged at the top end of the left side of the furnace body, the pushing machine is arranged at the left end of the conveying pipe, the upper surface of the conveying pipe is connected with the feeding hopper, the fuel gas outlet is formed in the right side of the upper portion of the furnace body, and the hot air inlet is formed in the right side of the lower portion of the furnace body. The gasifier has the beneficial effects that a wiper and a scraper are arranged on the two sides of a rotating column, a motor drives the rotating column to rotate, a cutter is installed on the scraper so as to to scrape slag on the inner wall, the slag can fall into a material receiving disc, the inner wall is wiped through a cleaning brush on the wiper after the slag is scrapped, a ball pushing device and a stirring device are arranged inside the rotating column, a stirring rod can control balls in a rolling way, and the scraper and the wiper can be controlled to be stretched by changing the movement of the balls so as to adapt to furnace bodies with different sizes.

Owner:QUANZHOU TONGTONG ELECTRONIC EQUIP CO LTD

Upper-air-intake dual-ring combustor

PendingCN111486456AReduce the effect of temperature riseImprove temperature measurement accuracyDomestic stoves or rangesCooking fumes removalCombustorEngineering

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Geared gas turbine engine with oil deaerator and air removal

Owner:RAYTHEON TECH CORP

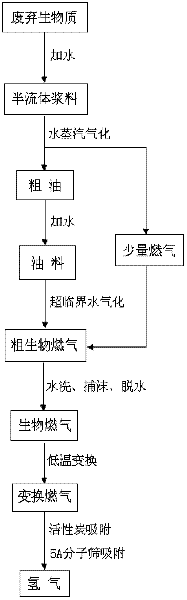

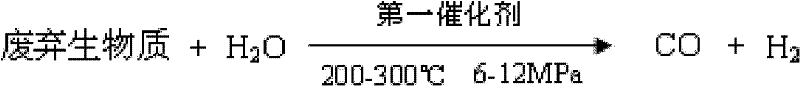

Method for preparing hydrogen by utilizing waste biomass

InactiveCN102653393AReduce pollutionReduce manufacturing costHydrogen separation using solid contactCombustible gas catalytic treatmentRare-earth elementWater vapor

Owner:北京雷恩新材料科技有限公司

Power generation cell for fuel battery

InactiveUS20110159399A1Increased durabilityImprove voltage stabilityFuel cell auxillariesSolid electrolyte fuel cellsElectrolyteFuel gas

Owner:TOYOTA SHATAI KK

Combustion apparatus and gas turbine engine

InactiveUS20140144143A1Increase supplyEliminate cavitiesContinuous combustion chamberGas turbine plantsCombustion chamberEngineering

Owner:SIEMENS AG

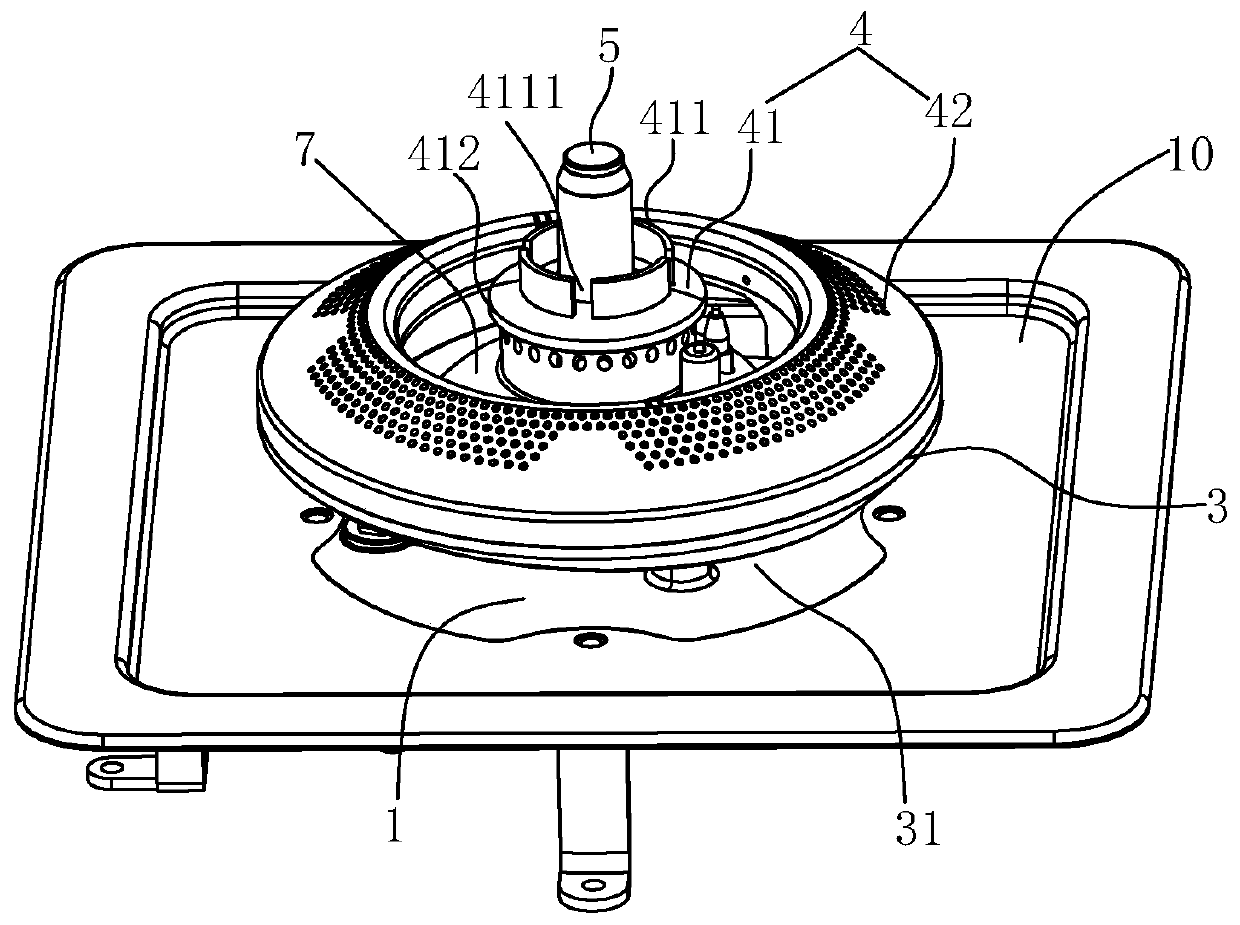

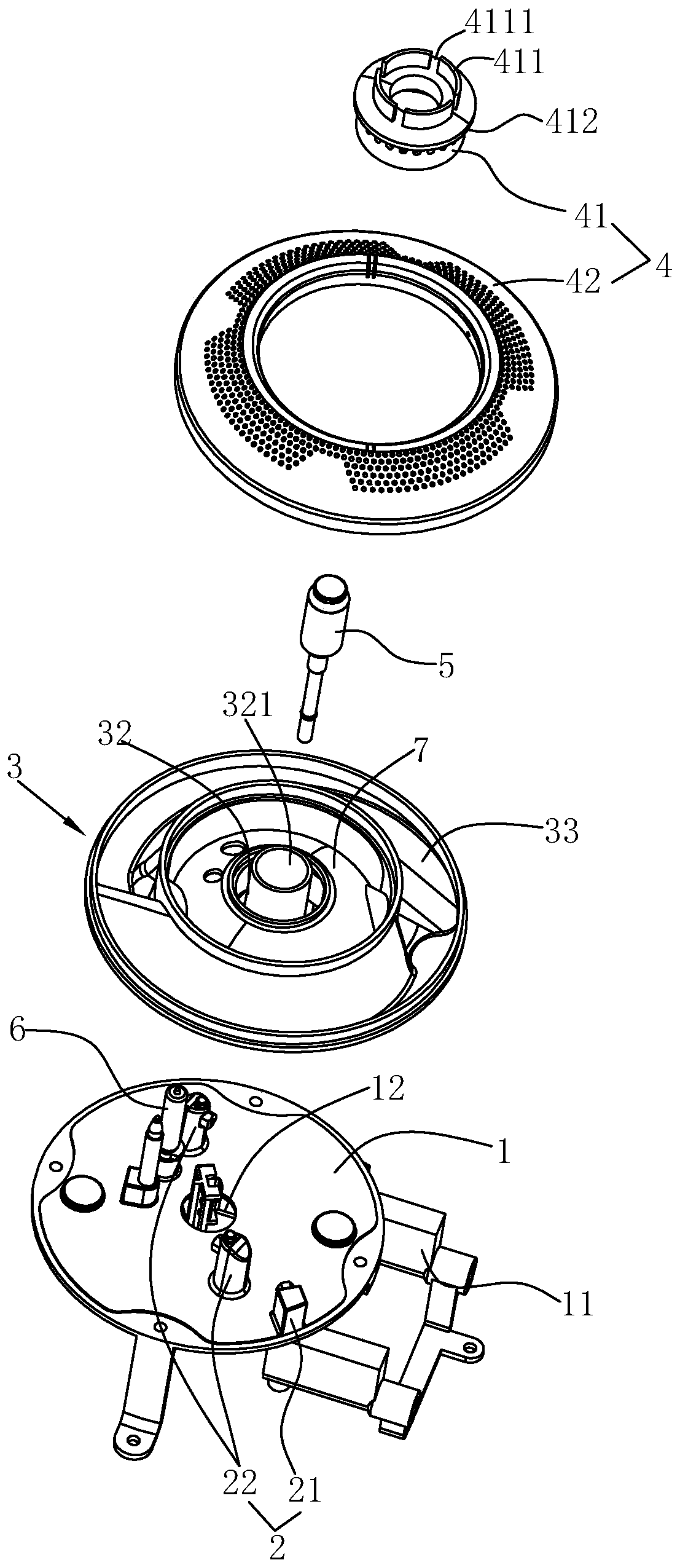

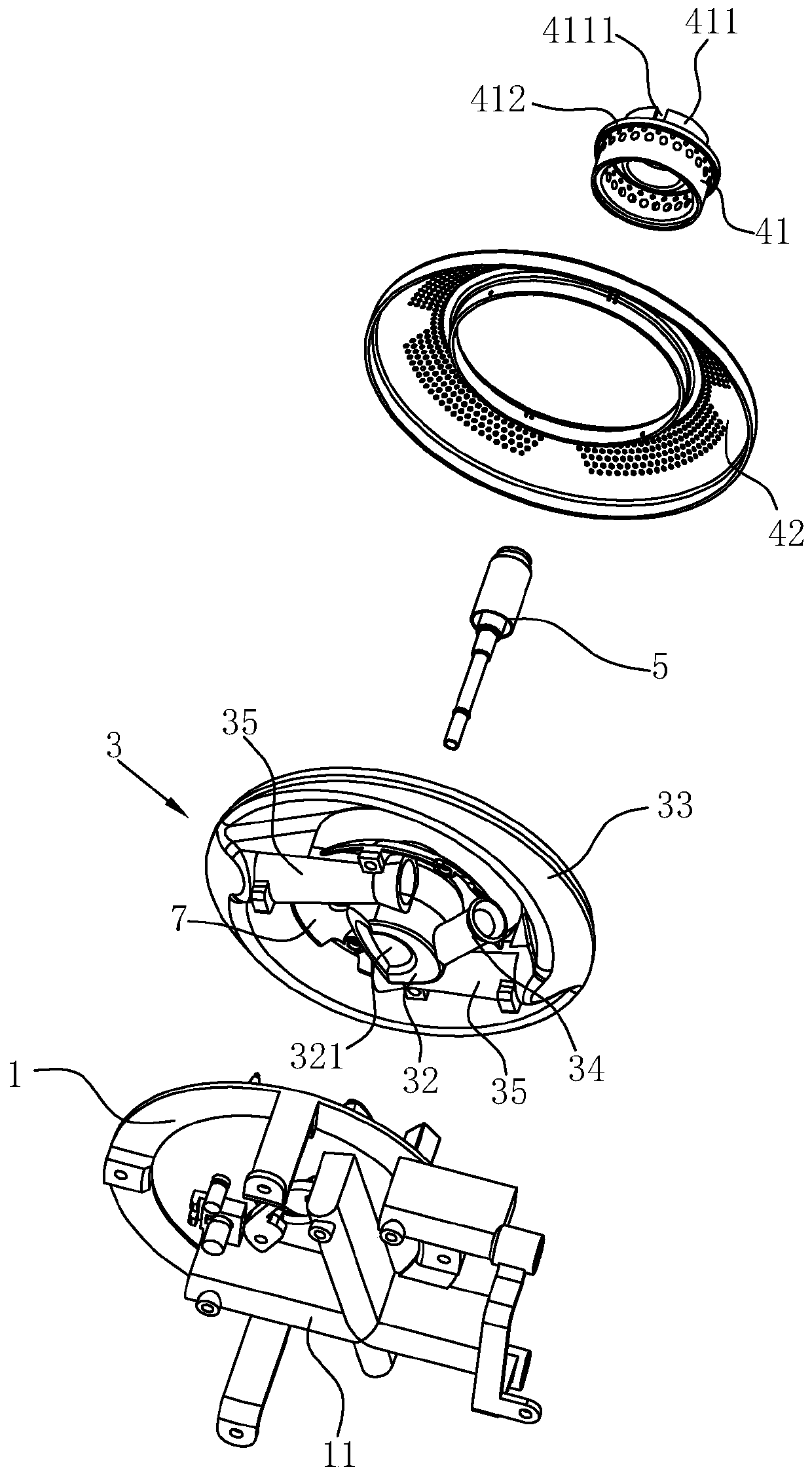

Gas burner and gas stove

PendingCN107091476AGuaranteed service lifeUniform energy supplyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsEngineering

Owner:YANTAI ZHONGDE ENVIRONMENTAL PROTECTION EQUIPTECH

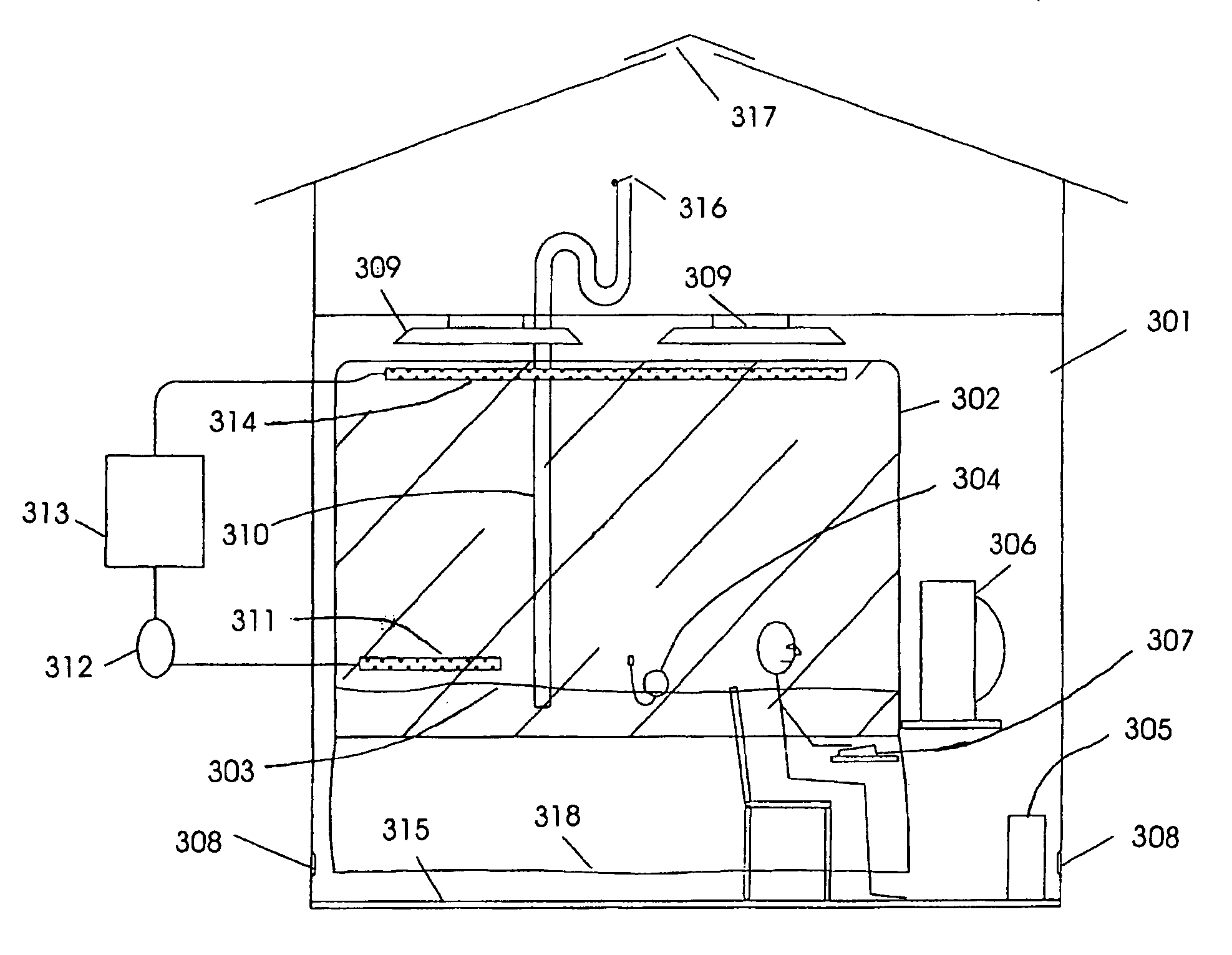

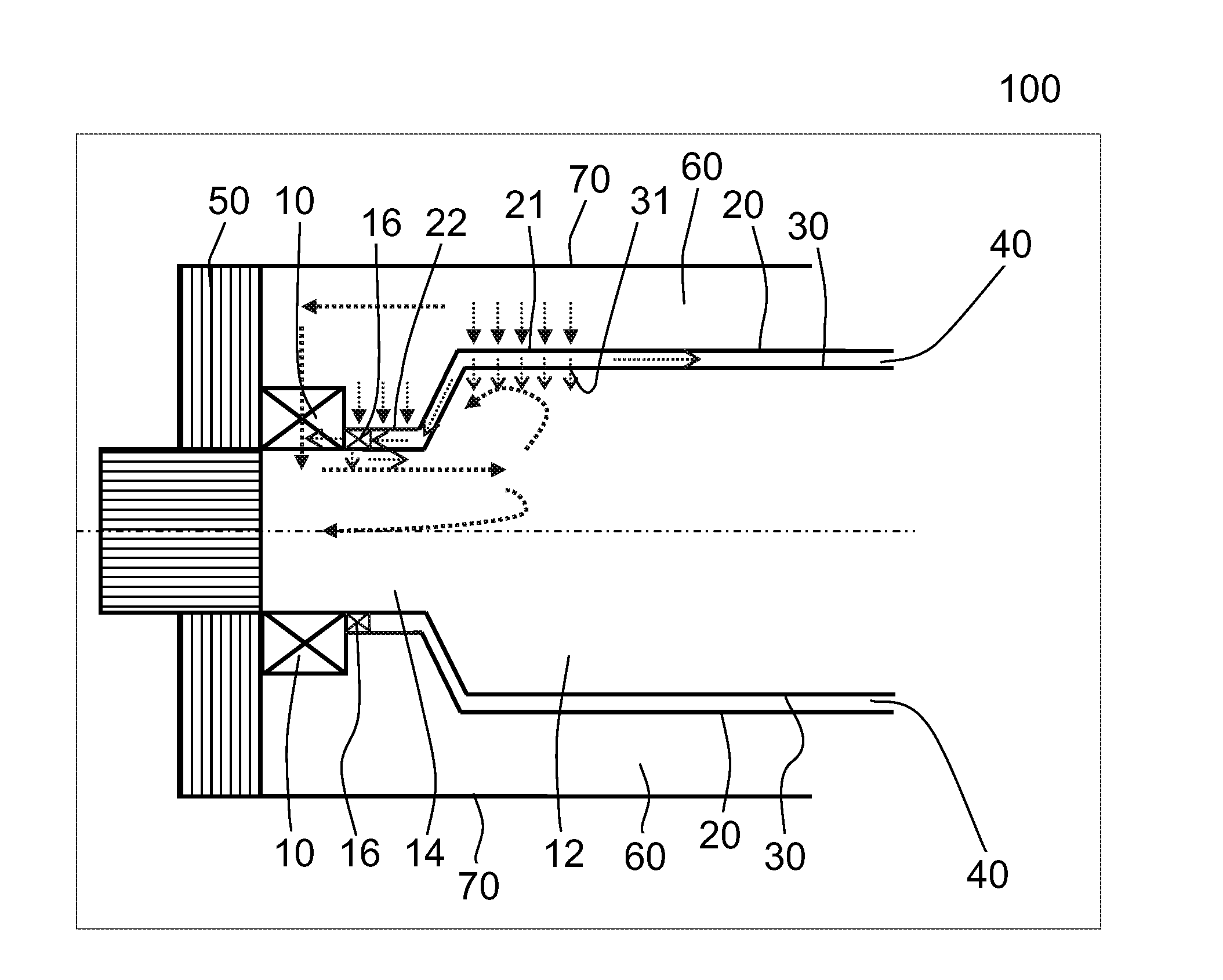

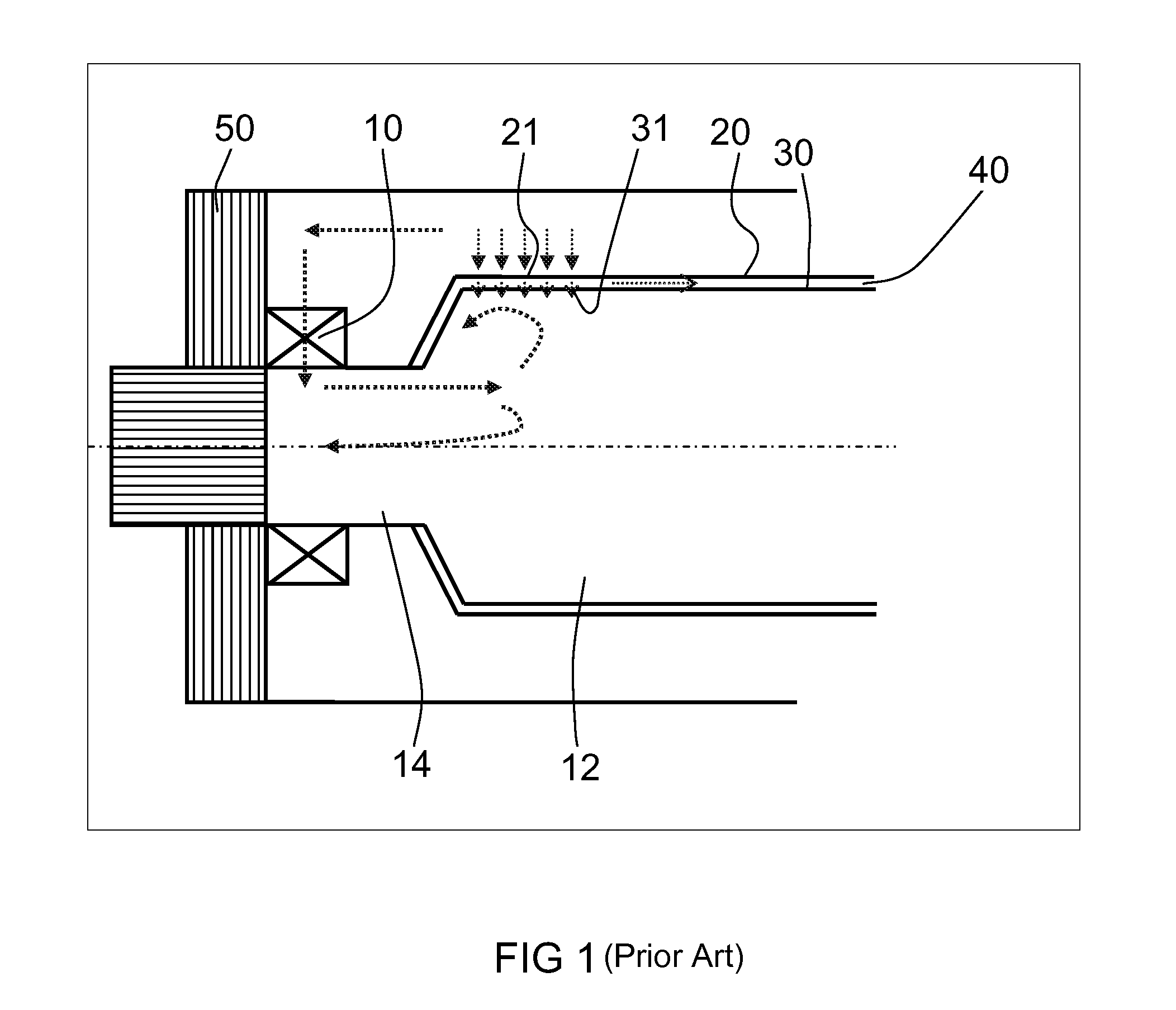

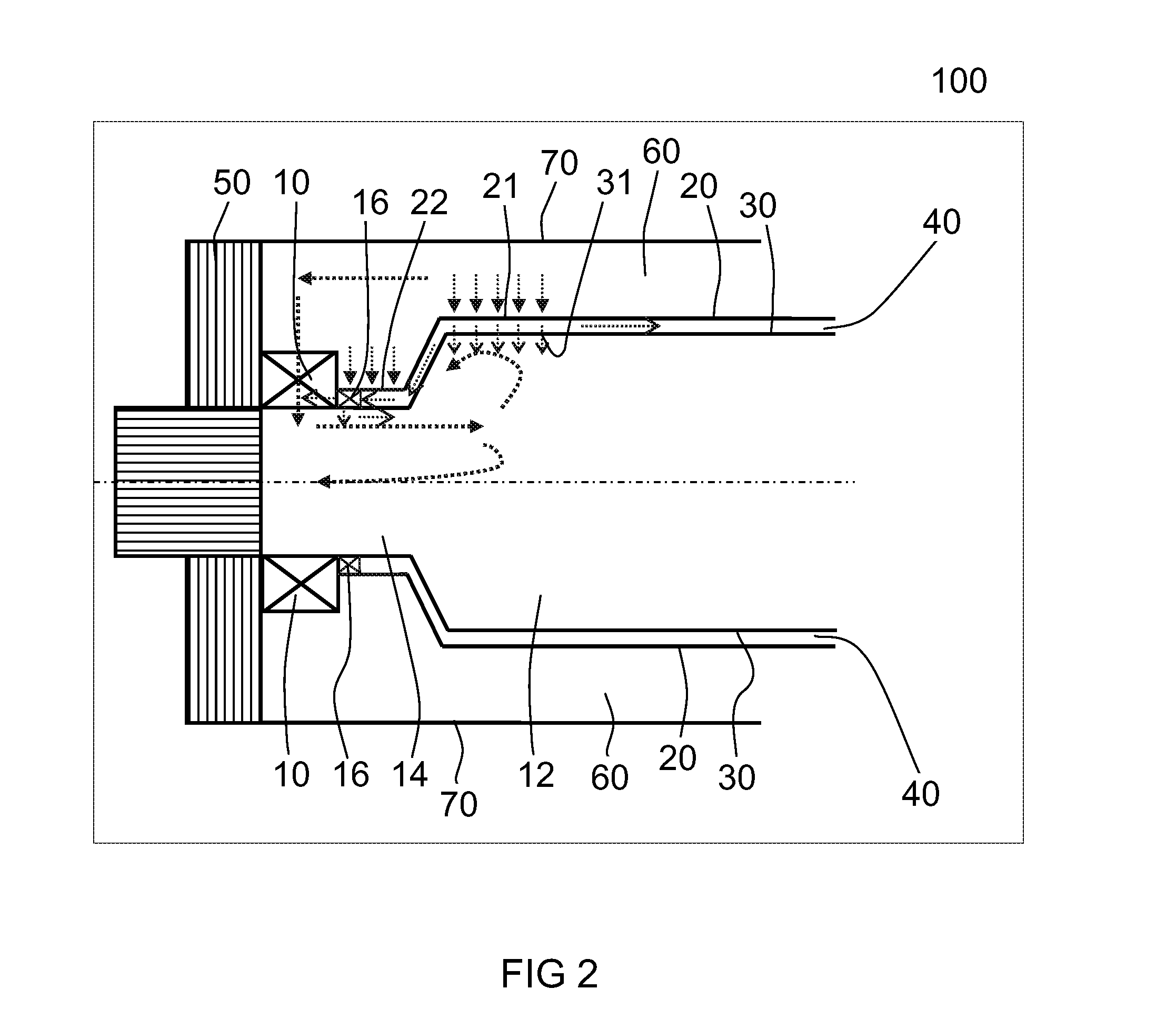

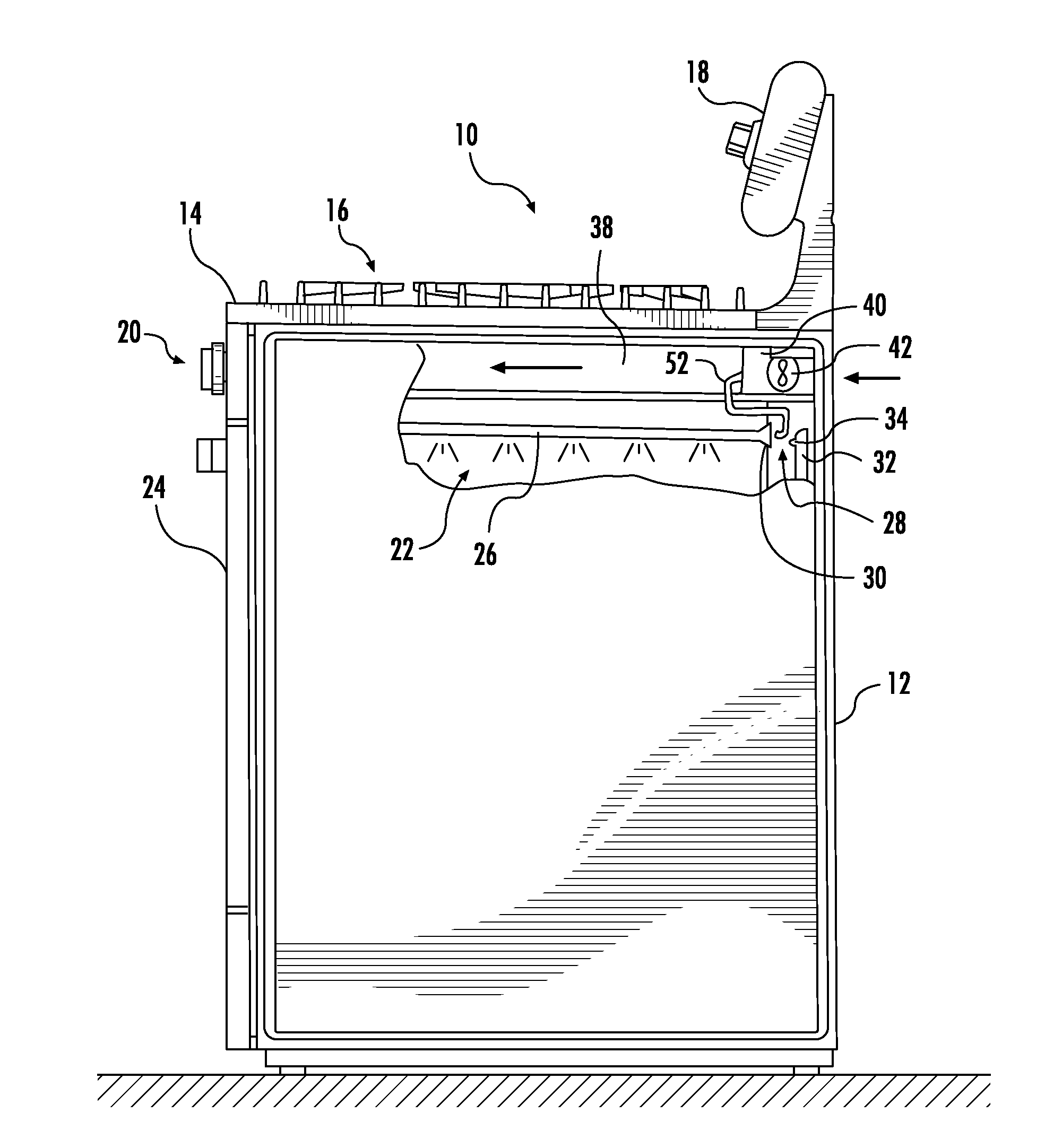

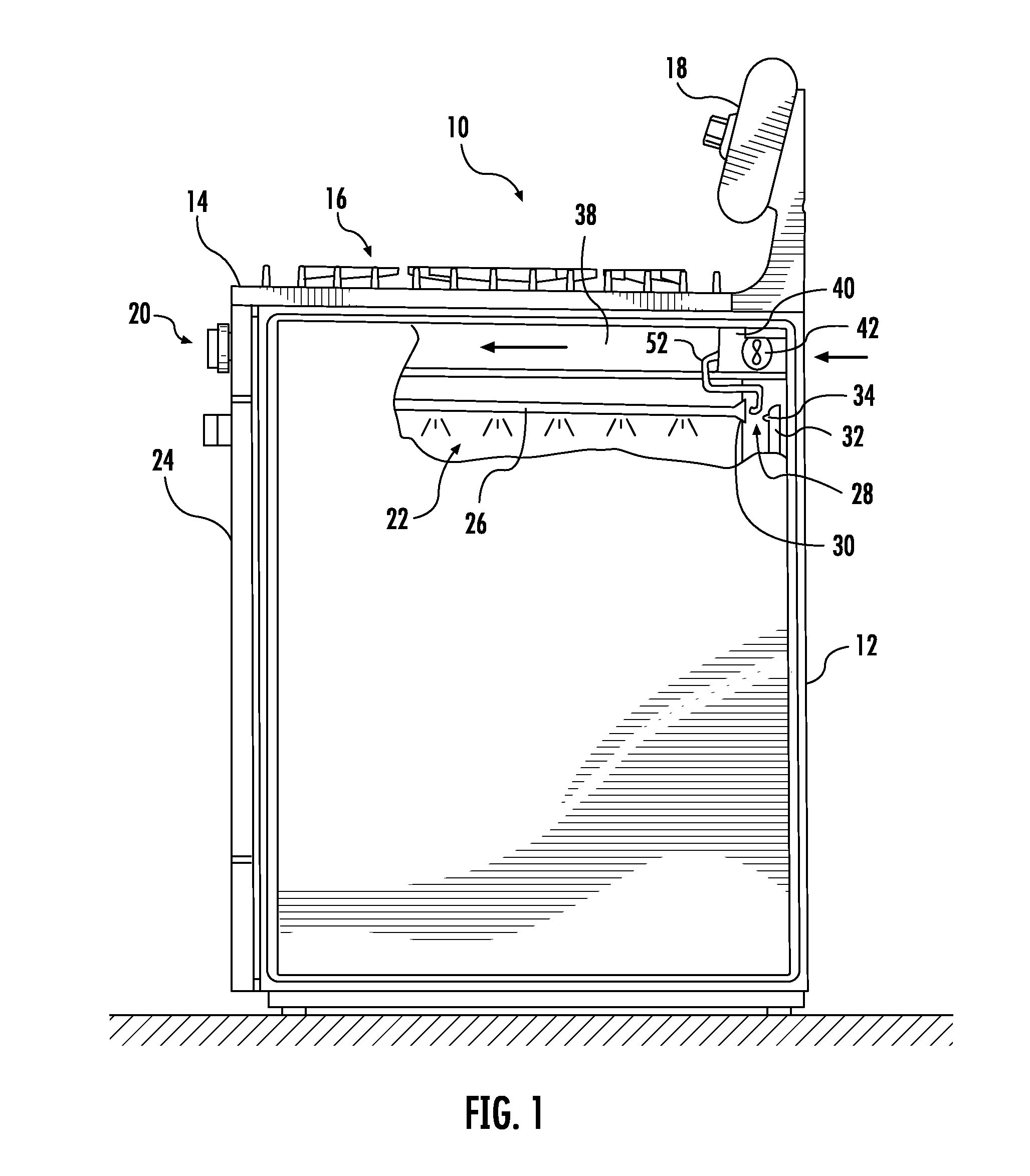

Home appliance with supplemental combustion air supply apparatus

ActiveUS20140305424A1Increasing burner efficiencyImprove efficiencyAir supply regulationDomestic stoves or rangesThermodynamicsCombustor

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Jet engine

Owner:朴德春

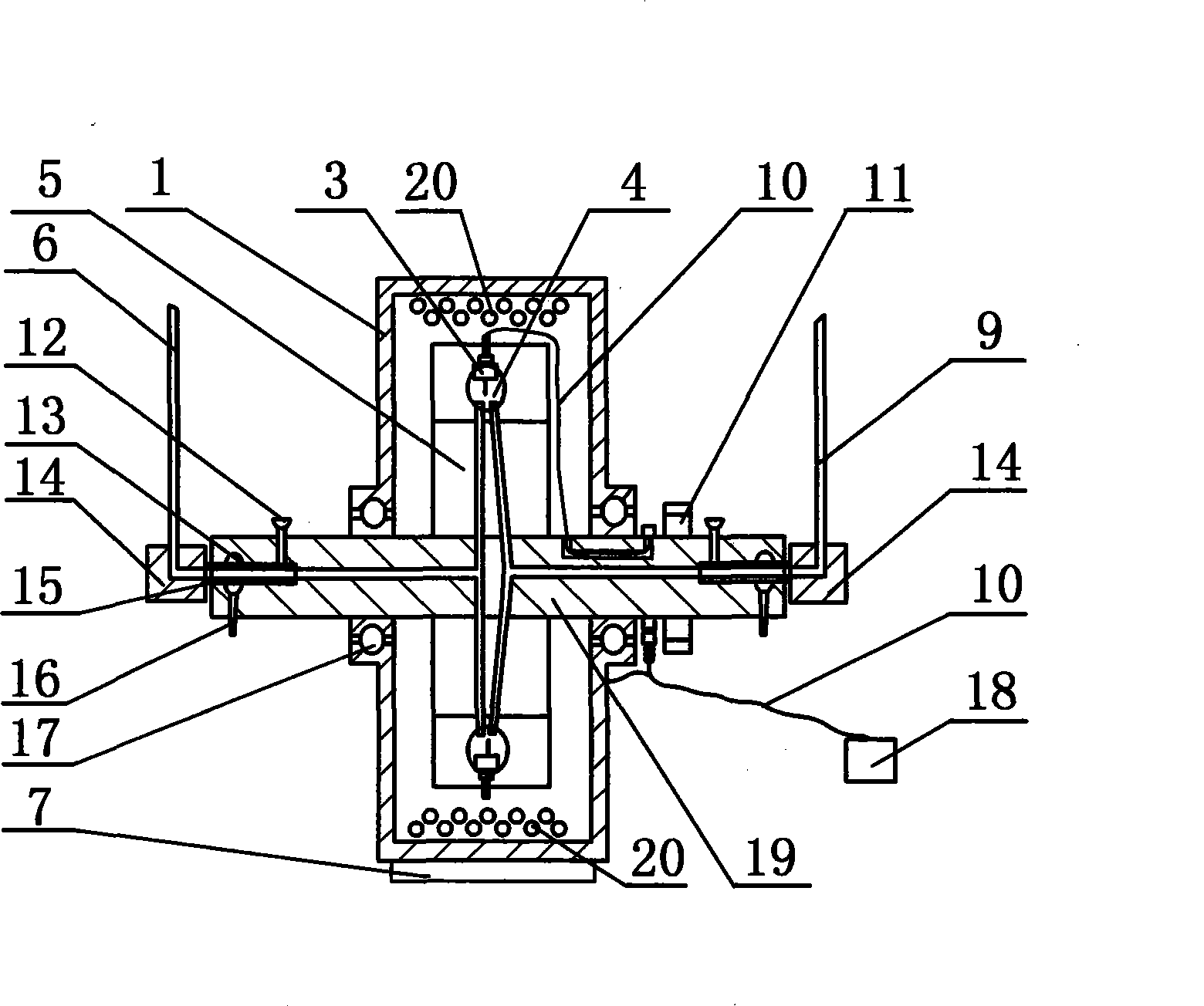

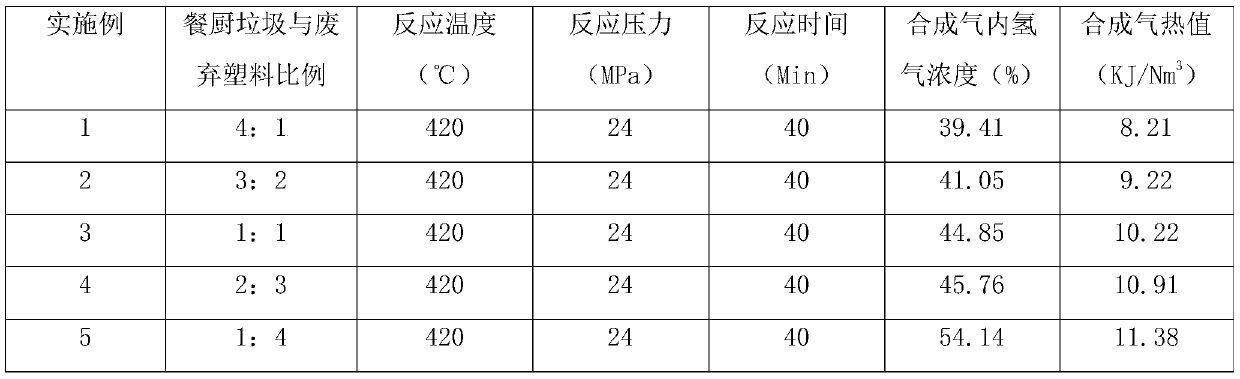

Combined method for treating kitchen waste and waste plastics to prepare hydrogen-rich fuel gas

InactiveCN110643392AEasy to handleIncrease the concentration of hydrogenGaseous fuelsGasification processes detailsSyngasAir pump

Owner:ZHEJIANG UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap