Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

20 results about "Exhaust valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

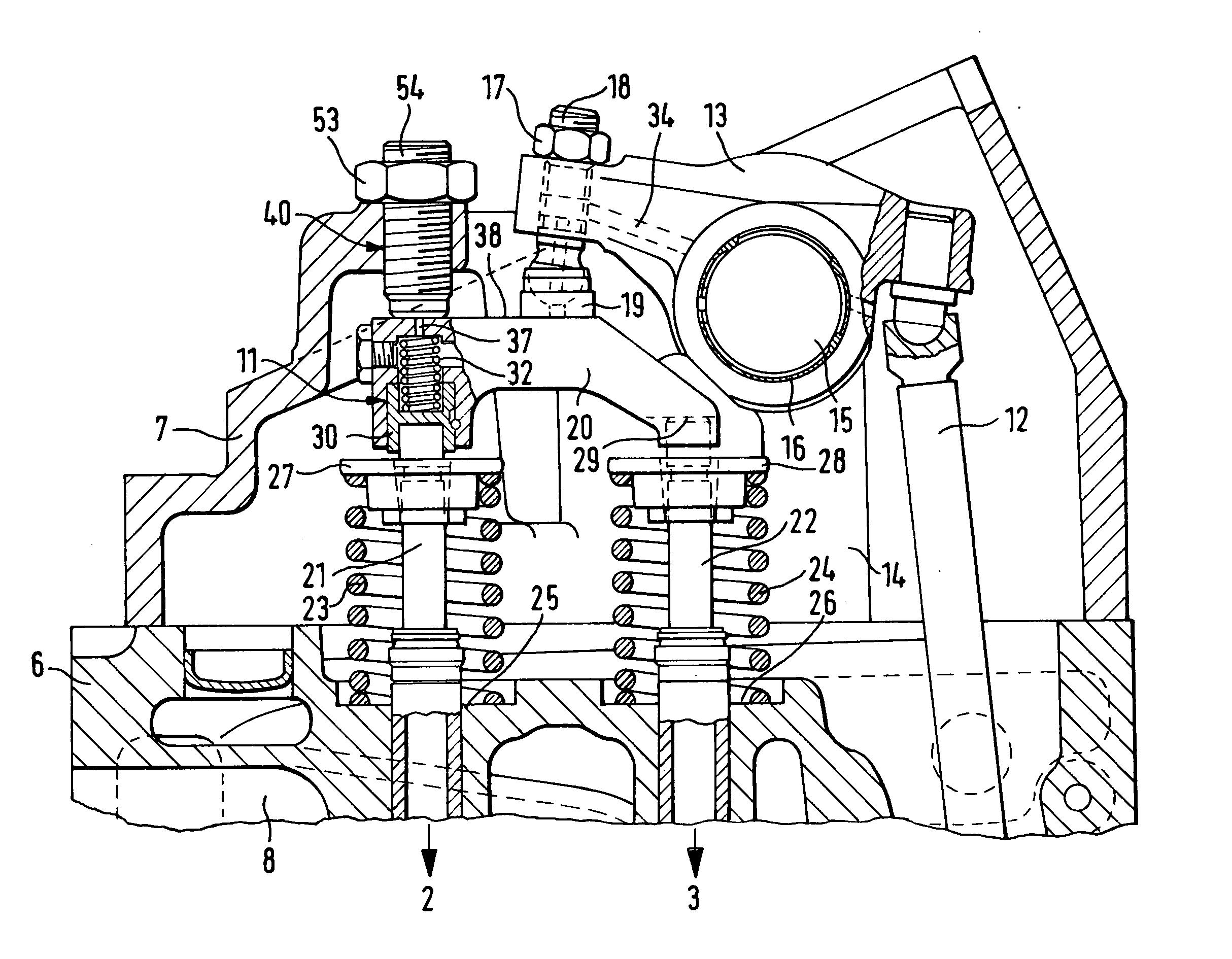

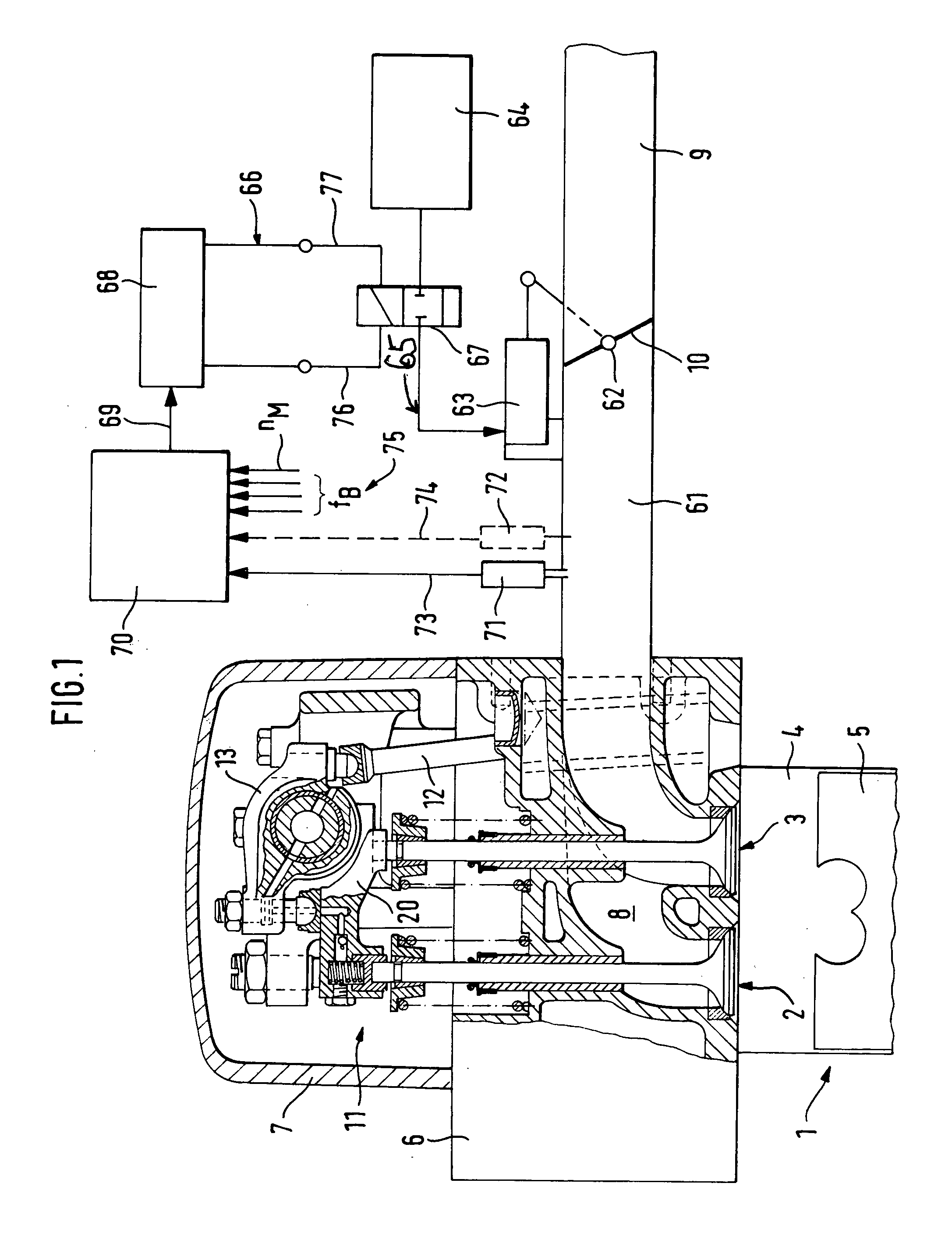

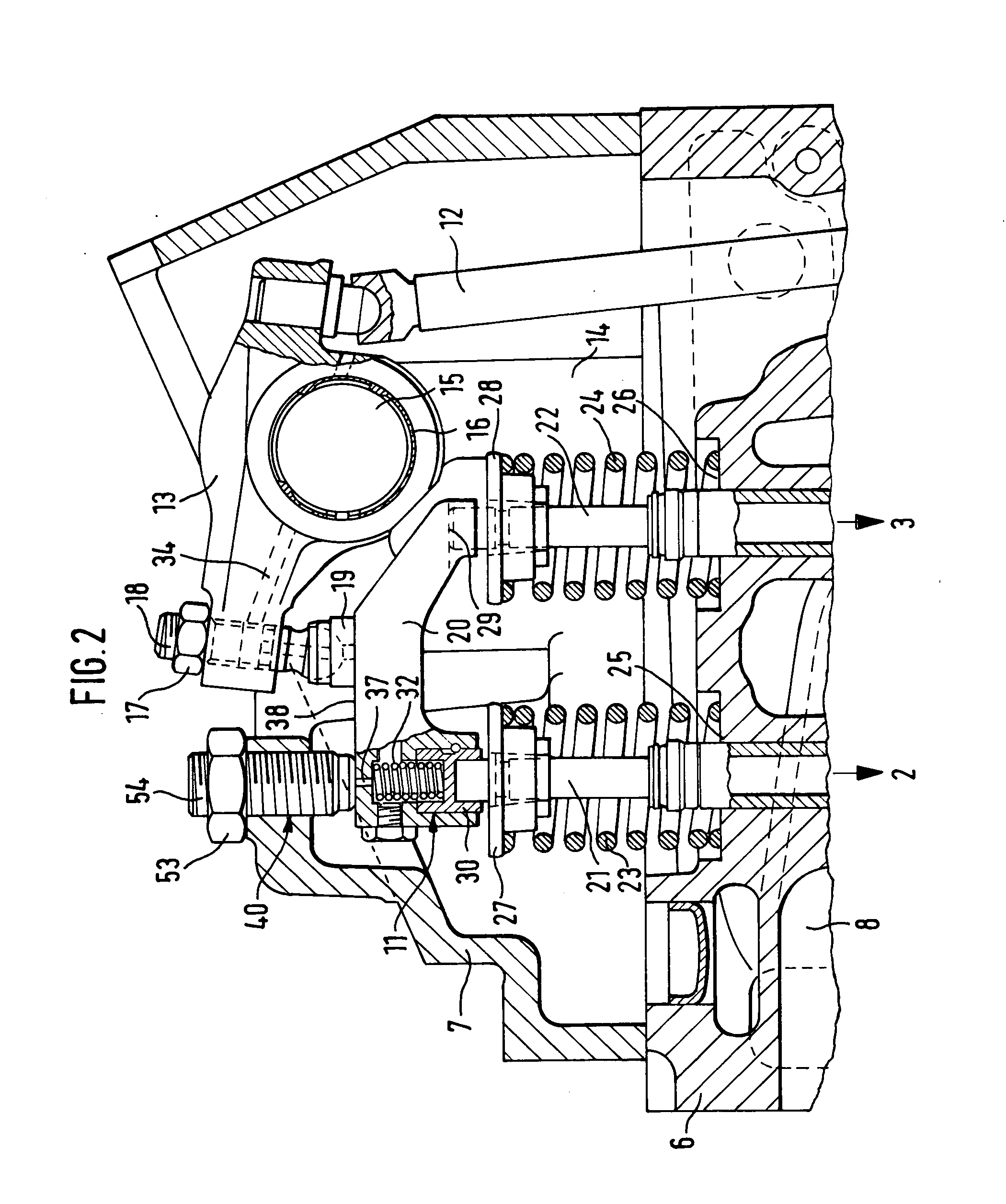

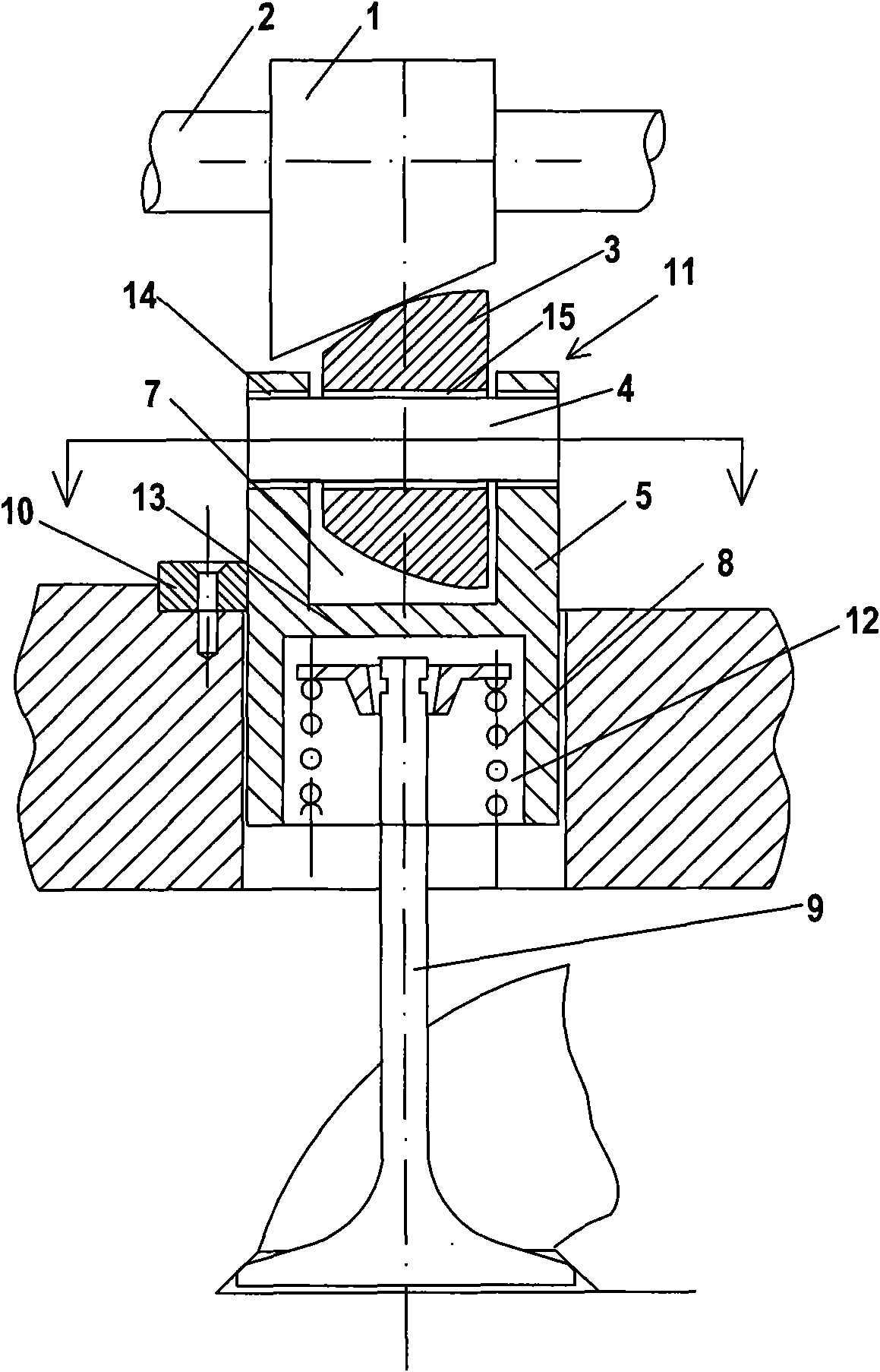

Engine air brake device for a 4-stroke reciprocating piston internal combustion engine

ActiveUS20050087170A1Low costHigh engine braking outputValve arrangementsExhaust apparatusExhaust valveEngineering

Owner:MAN NUTZFAHRZEUGE AG

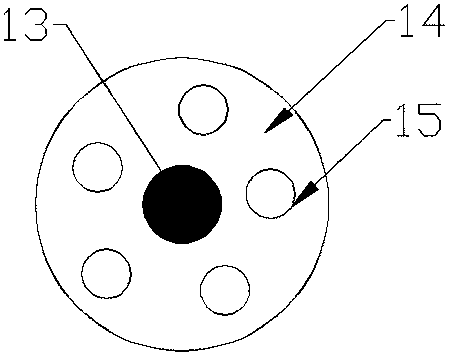

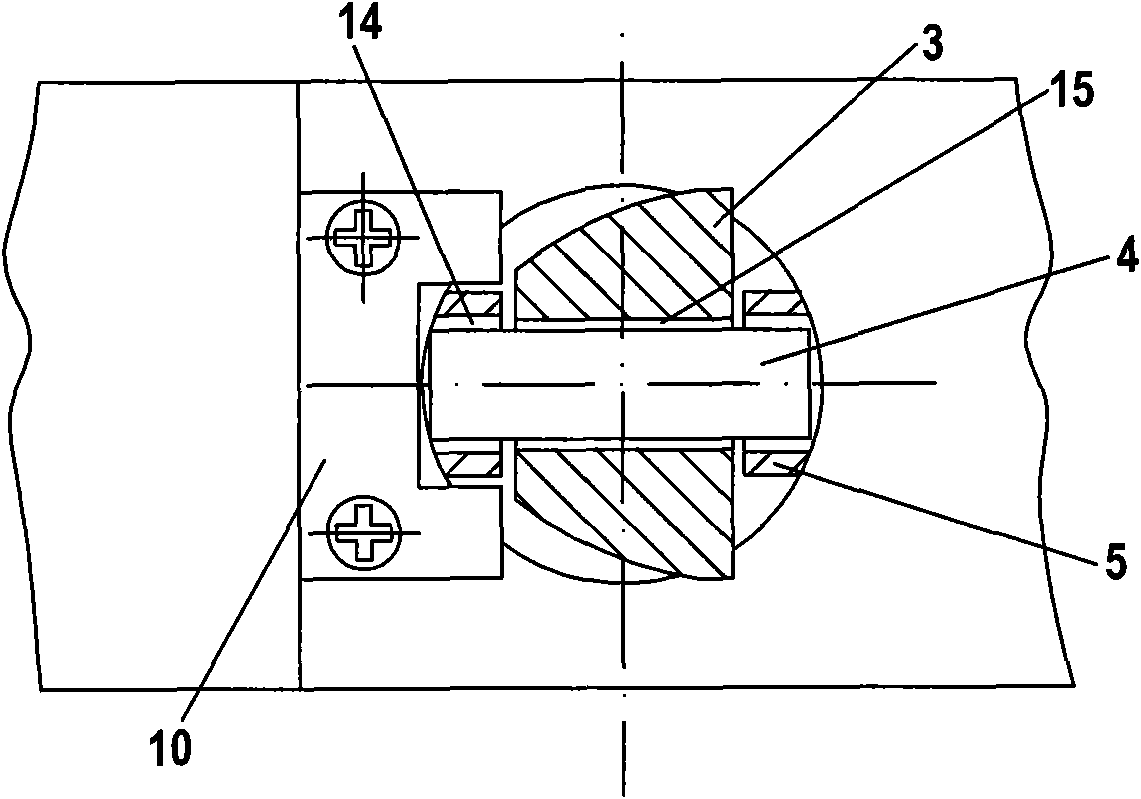

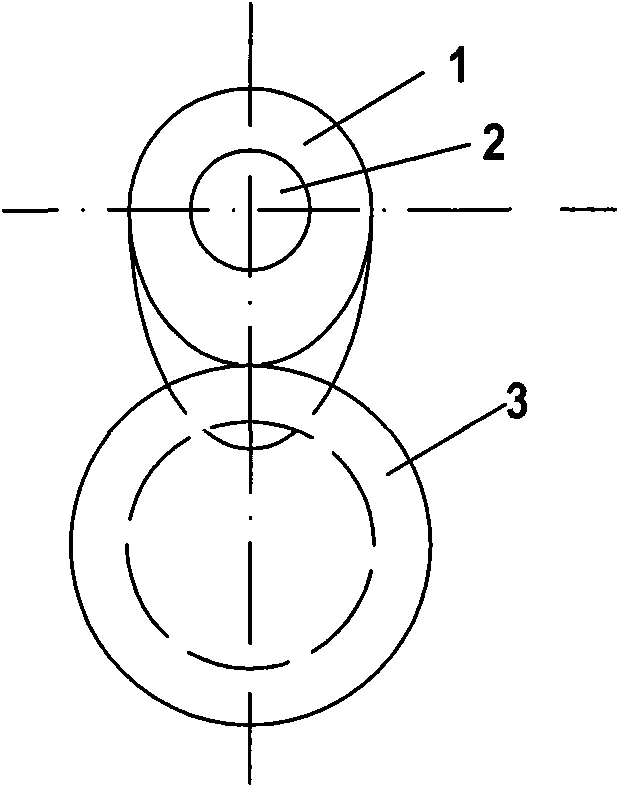

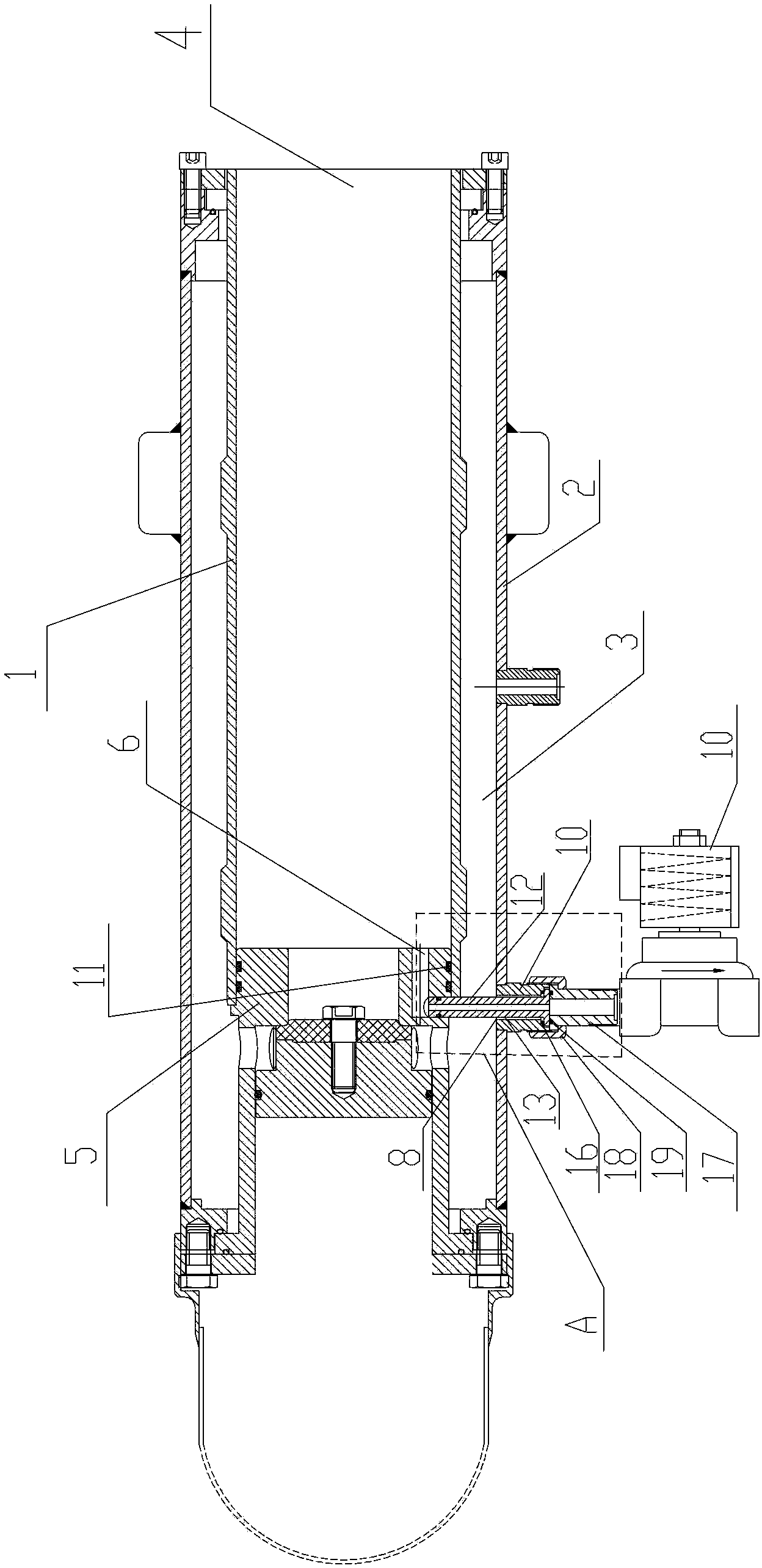

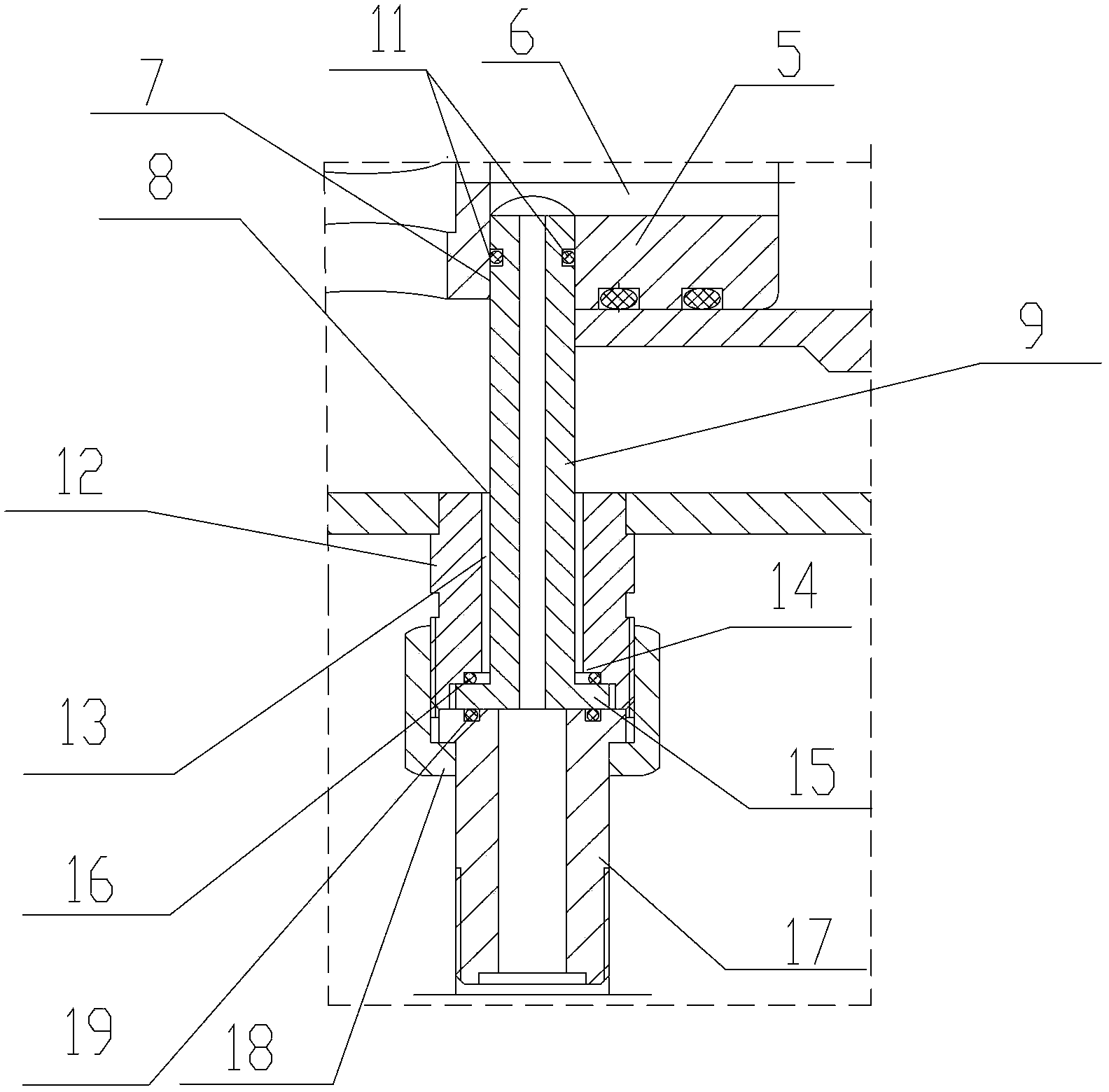

Compression braking device of four-stroke cycle internal combustion engine

ActiveCN101526018AAchieve the purpose of brake assistIncrease stiffnessValve arrangementsOutput powerExhaust valveSpring force

The invention provides a compression braking device of a four-stroke cycle internal combustion engine. A control valve mechanism (13) and a clearance compensation mechanism (23) with the compensated clearance being the lift range of a braking projection are installed in parallel on one end of an amounting elephant feet of a rocker (3); a clearance compensation mechanism (11) with the compensated clearance being the lift range of a valve clearance is arranged in the midpoint of the connecting positions of an exhaust valve bridge (5) and two exhaust valves (6); the elephant feet (24) are coaxially connected below the lower end of the previous clearance compensation mechanism (23); the upper end of the next clearance compensation mechanism (11) is always in contact with the lower ends of the elephant feet; and the spring force of the clearance compensation mechanism is smaller than braking oil pressure and larger than dead weight of the elephant feet. Compared with the prior art, the compression braking device improves the reliability and the balance of a valve actuating mechanism, simplifies the structure, reduces the processing difficulty of the rocker, improves the rigidity of the rocker, and improves the accuracy and operability of the adjustment of the valve clearance. In addition, when the engine compresses and brakes, the two exhaust valves can be opened at the same time, thereby improving the braking effect of the engine.

Owner:ZHEJIANG LIMING INTELLIGENT MFG CO LTD

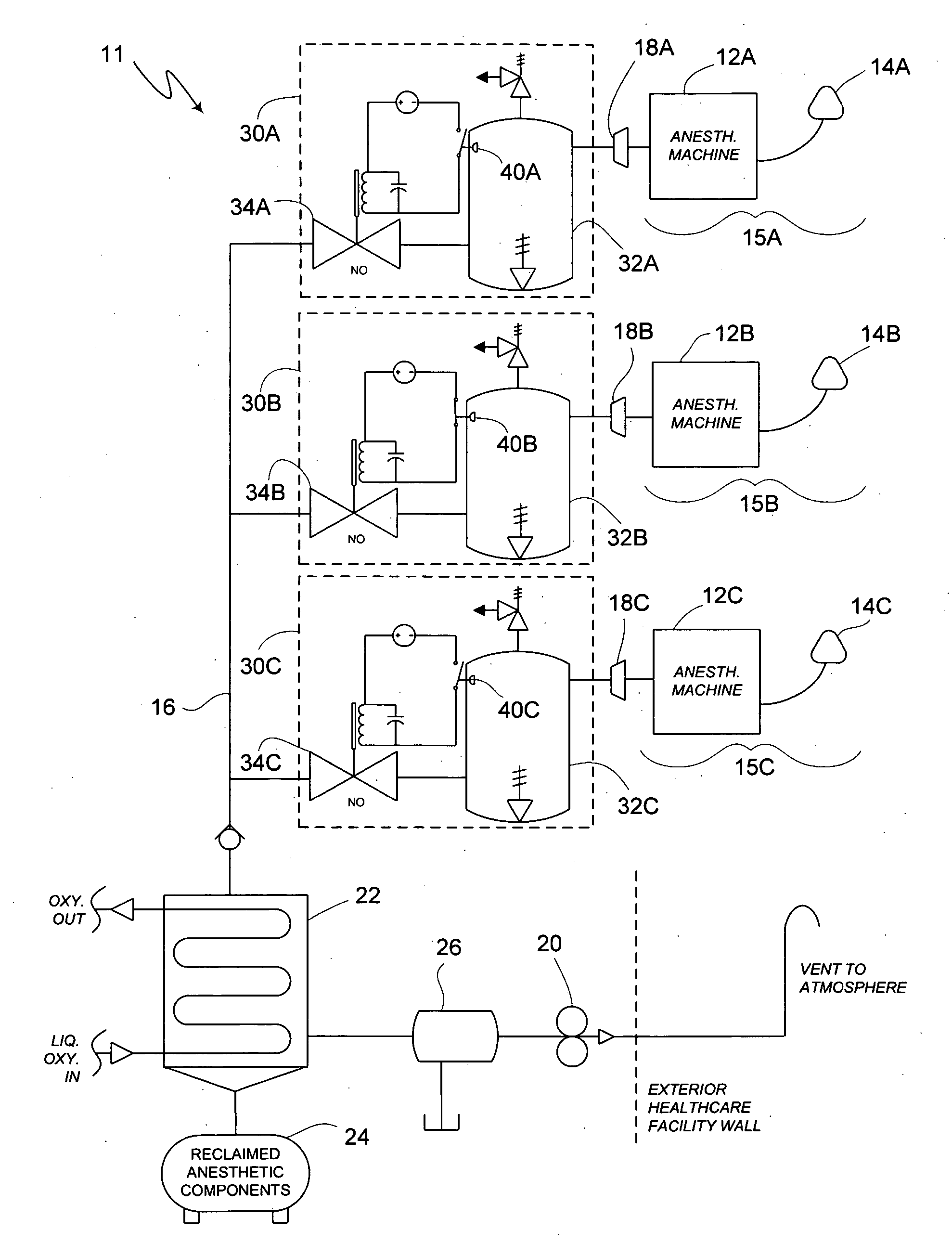

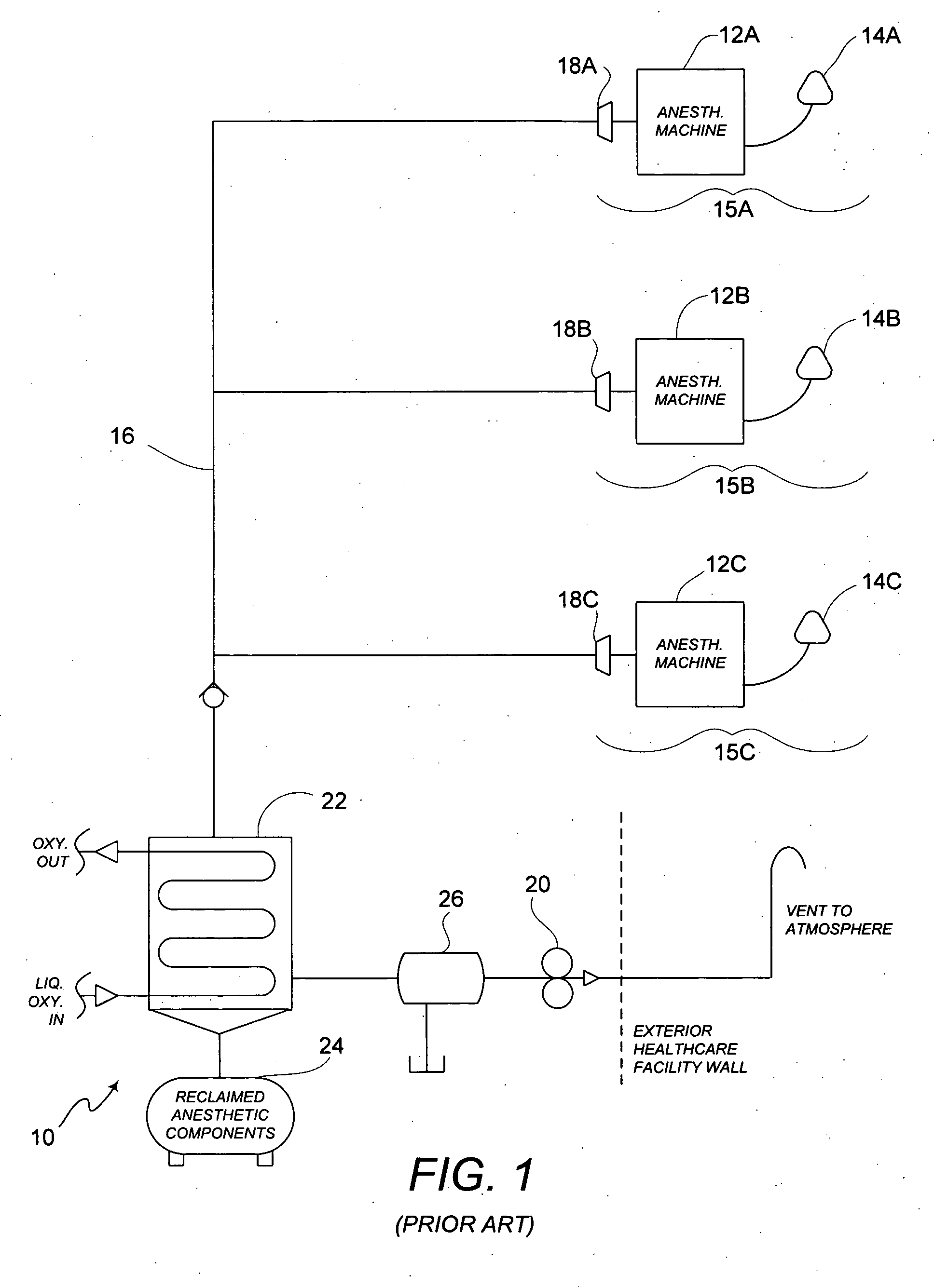

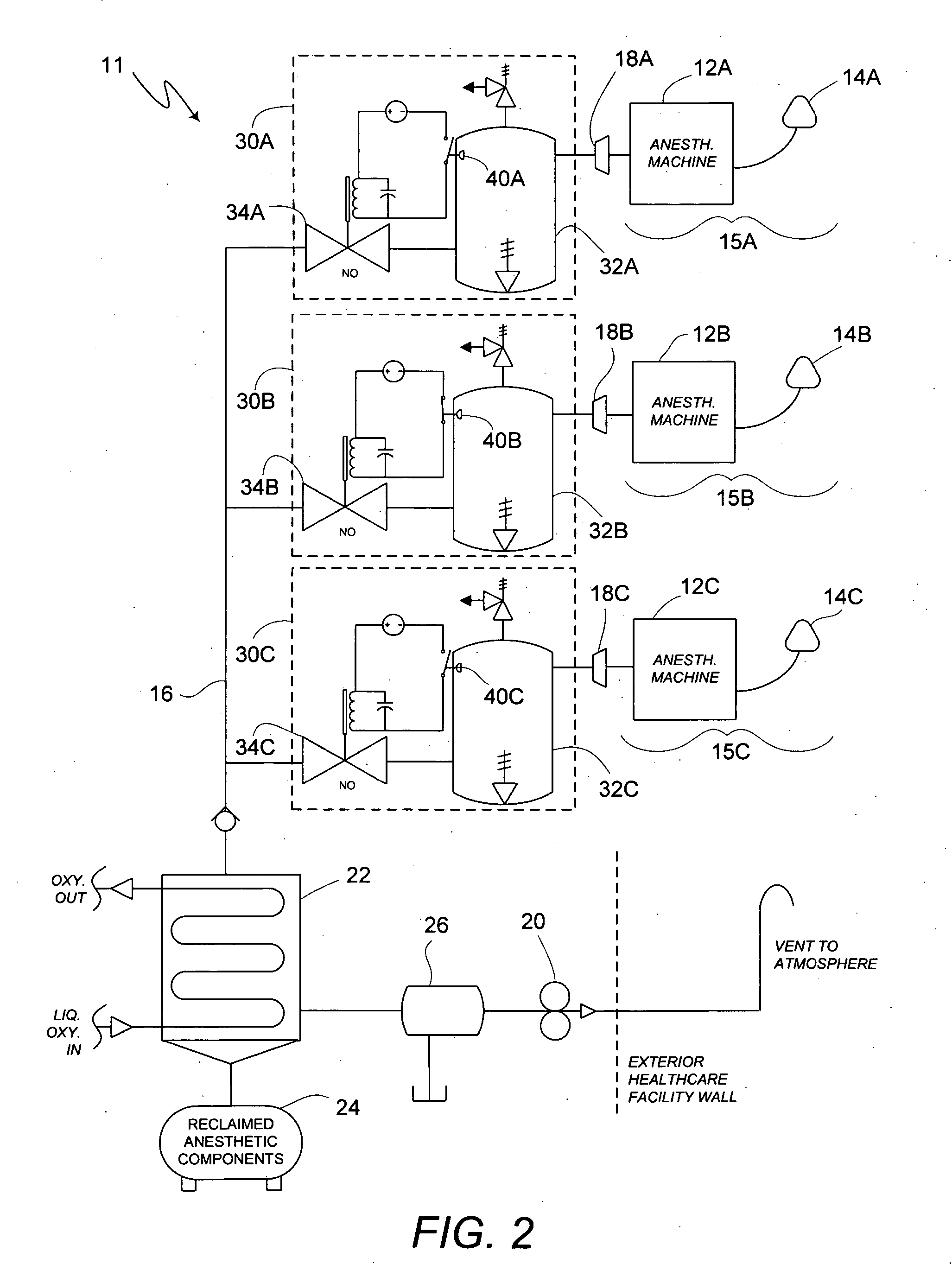

Method of low flow anesthetic gas scavenging and dynamic collection apparatus therefor

Owner:ANESTHETIC GAS RECHAMATION LLC

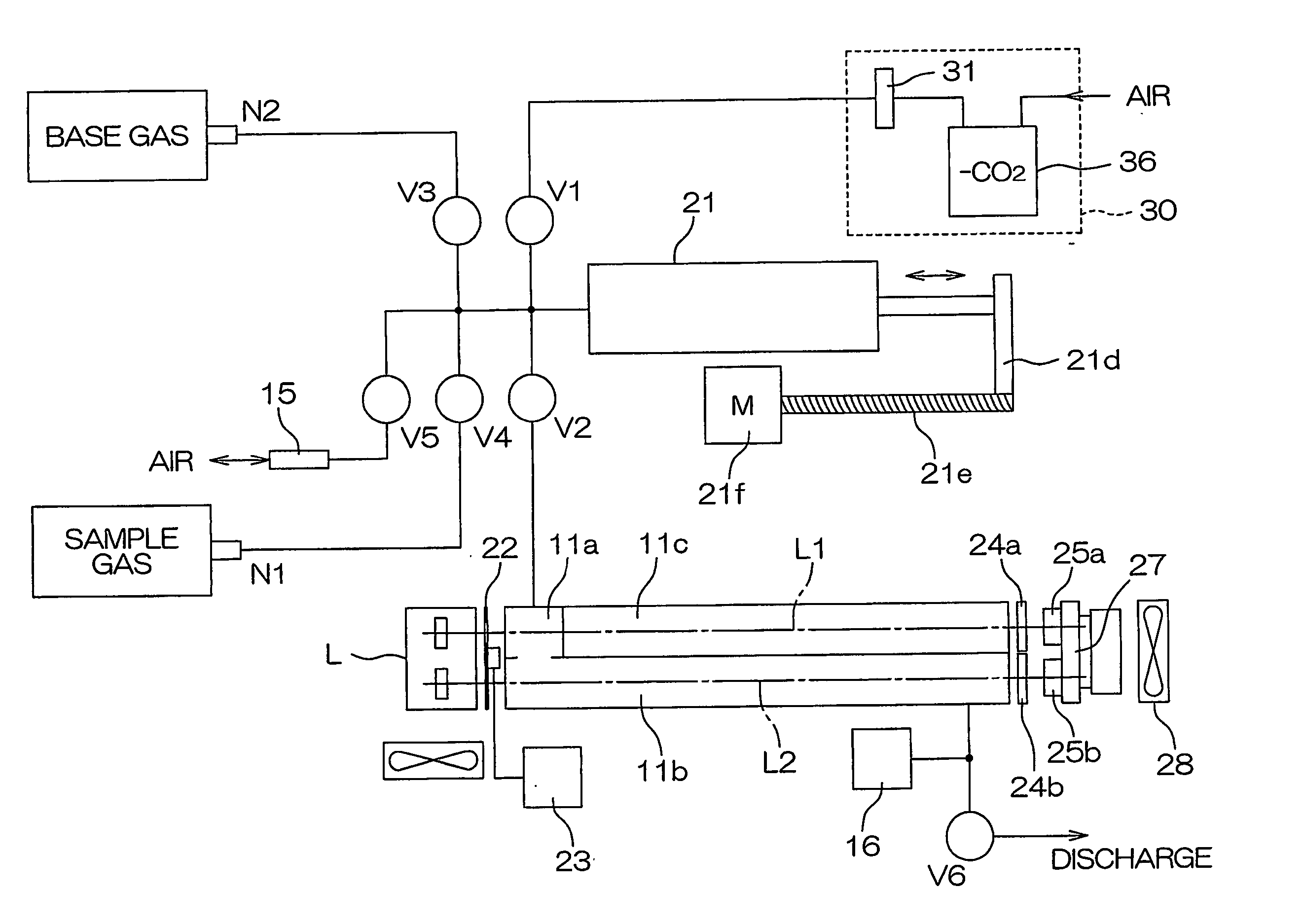

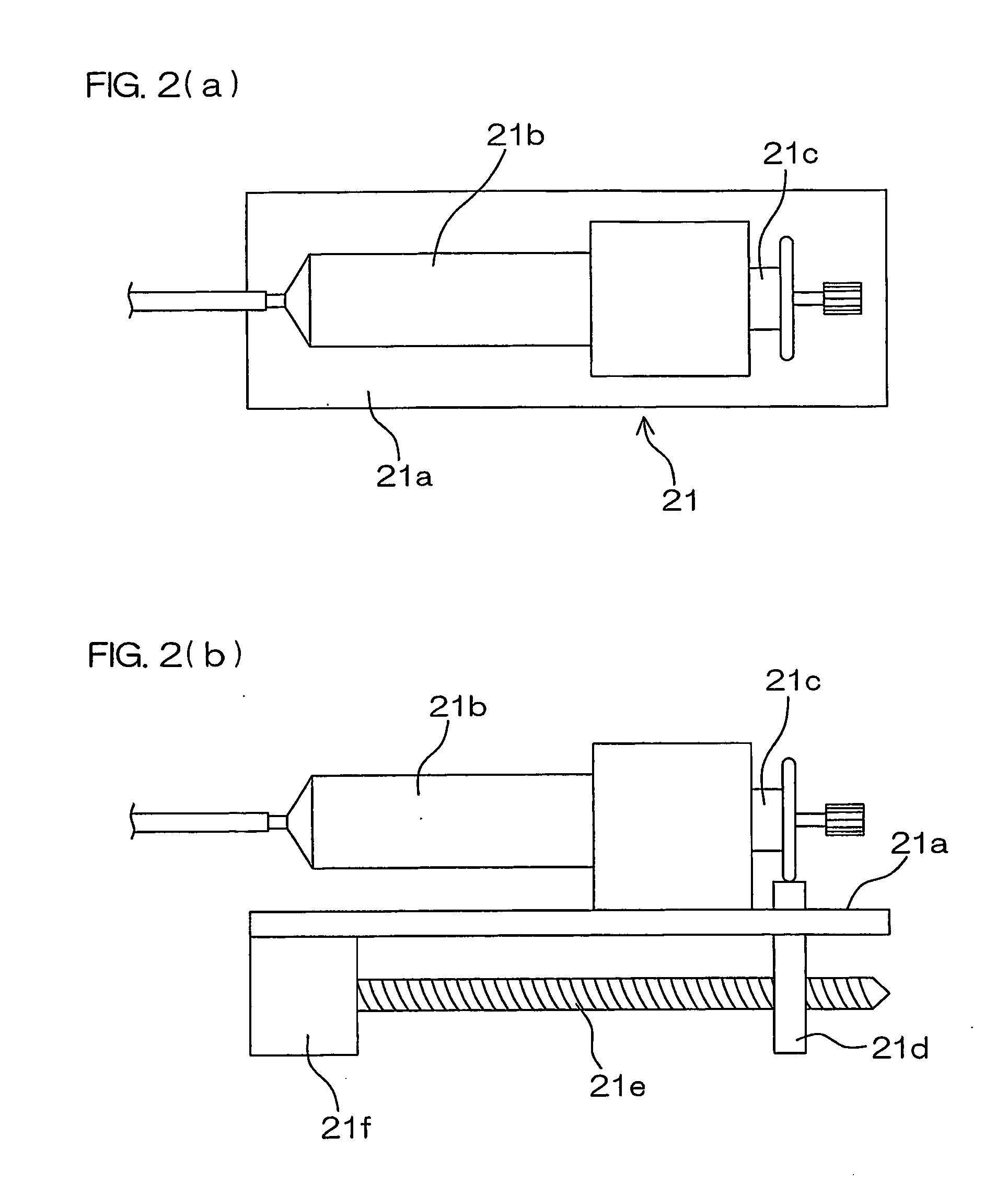

Gas injection amount determining method method in isotope gas analysis, and, isotype gas analyzing and measuring method and apparatus

ActiveUS20070077167A1Improve precisionGood reproducibilityWeather/light/corrosion resistanceWithdrawing sample devicesGas analysisExhaust valve

Owner:OTSUKA PHARM CO LTD

Fuel Cell System

InactiveUS20080008913A1Increased durabilityImprove reliabilityFuel cells groupingFuel cell auxillariesElectricityExhaust valve

The disclosure describes fuel cell systems including a fuel cell stack that generates electricity, an exhaust valve that externally vents a fuel gas from a fuel chamber of the fuel cell stack, and a controller that computes an estimated time to replace an oxidant gas in at least the fuel chamber with a newly supplied fuel gas, wherein at a time of starting-up the fuel cell system the controller maintains the exhaust valve in an open position for the estimated time. In some embodiments, the controller computes the estimated time as a summation of a first time T1 measured from the fuel cell start-up time to a time when contents of a supply conduit are replaced with fuel gas, a second time T2 measured from the when contents of a supply conduit are replaced with fuel gas to a time when contents of the fuel chamber are replaced with fuel gas, and a third time T3 measured from time when contents of the fuel chamber are replaced with fuel gas to a time when contents of the exhaust conduit are replaced with fuel gas. The disclosure further describes methods of operating a fuel cell system, particularly during fuel cell start-up.

Owner:NISSAN MOTOR CO LTD

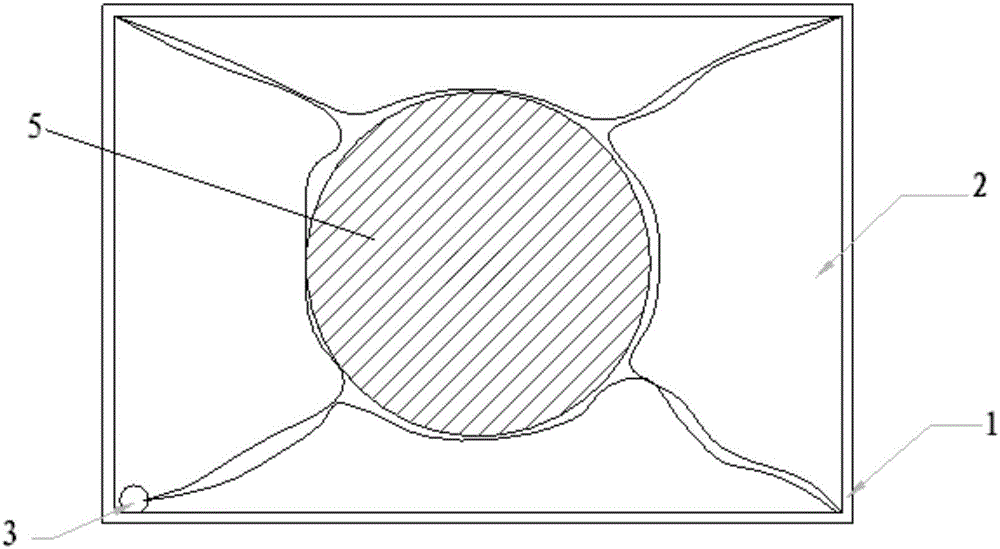

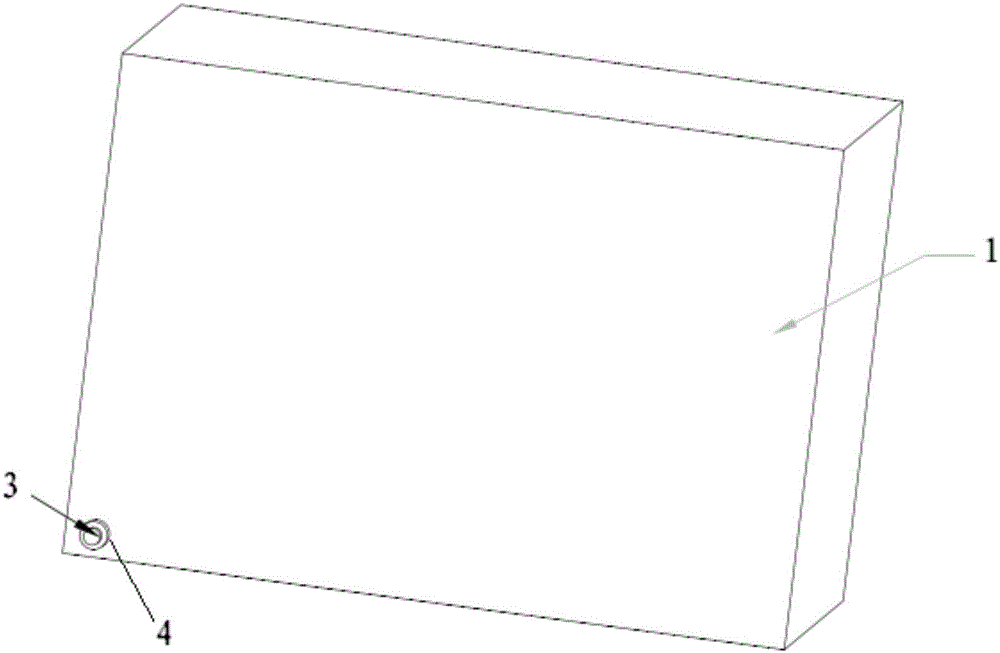

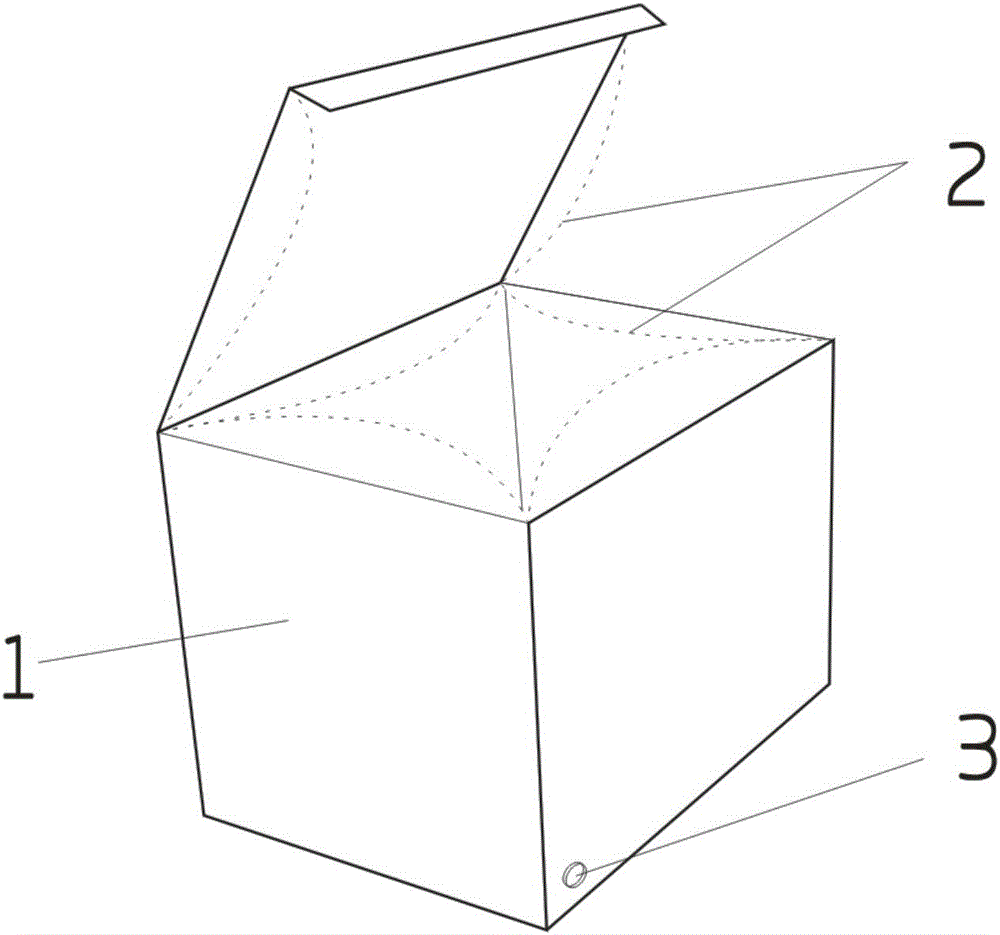

Novel buffer packaging box

InactiveCN106429008AInsufficient improvementLow costContainers to prevent mechanical damageInternal fittingsExhaust valveCarton

Owner:潘宏毅

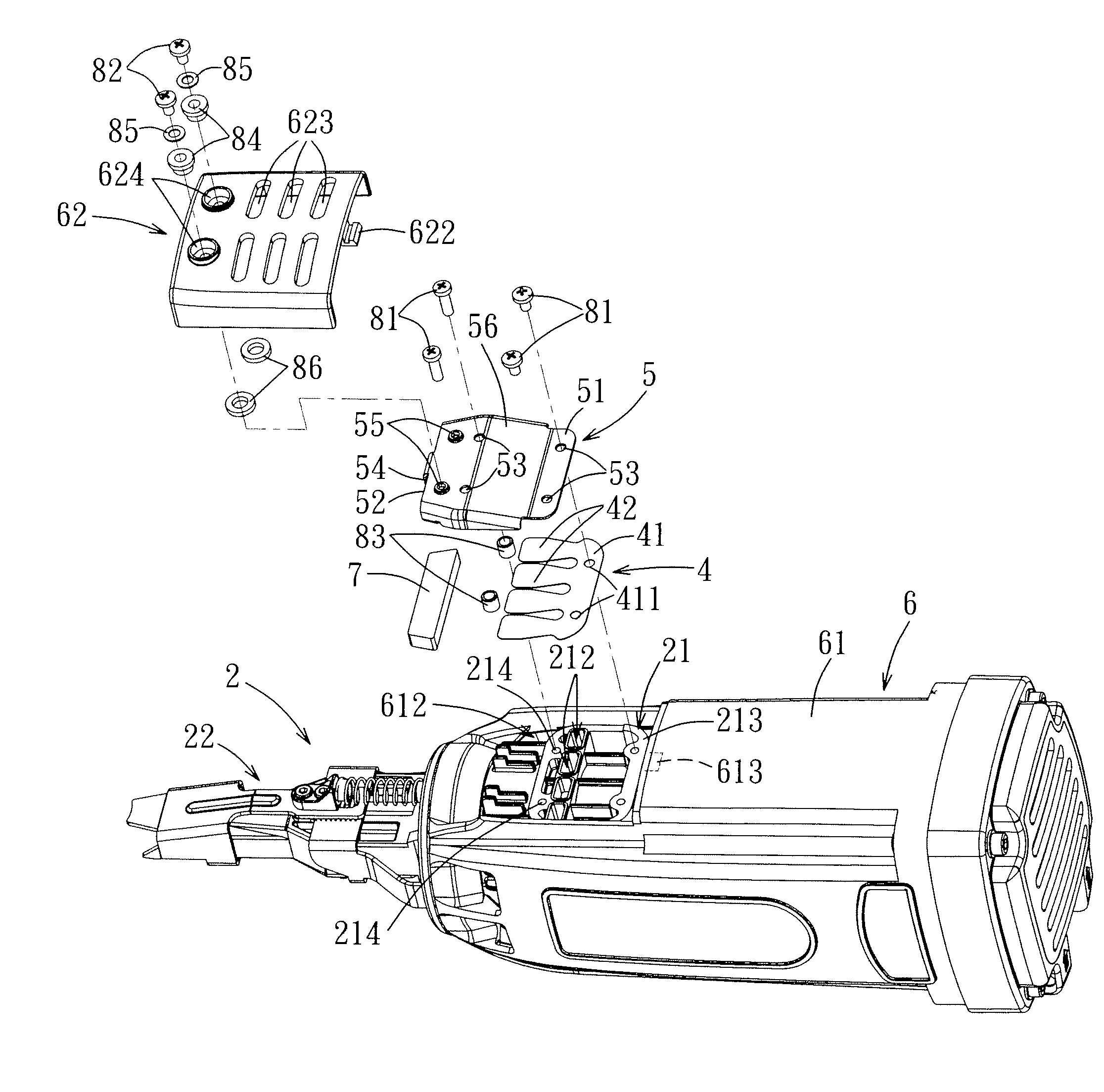

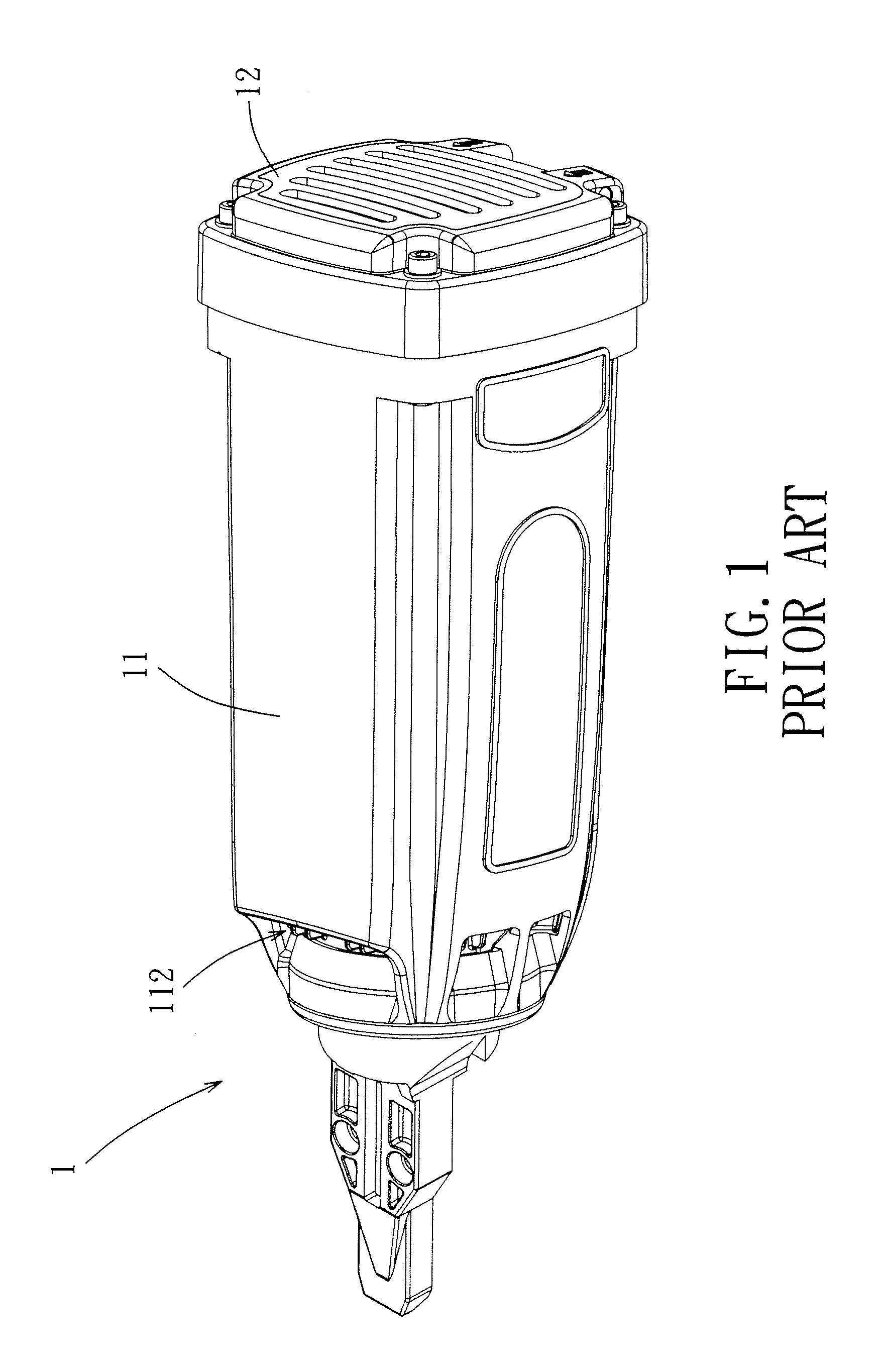

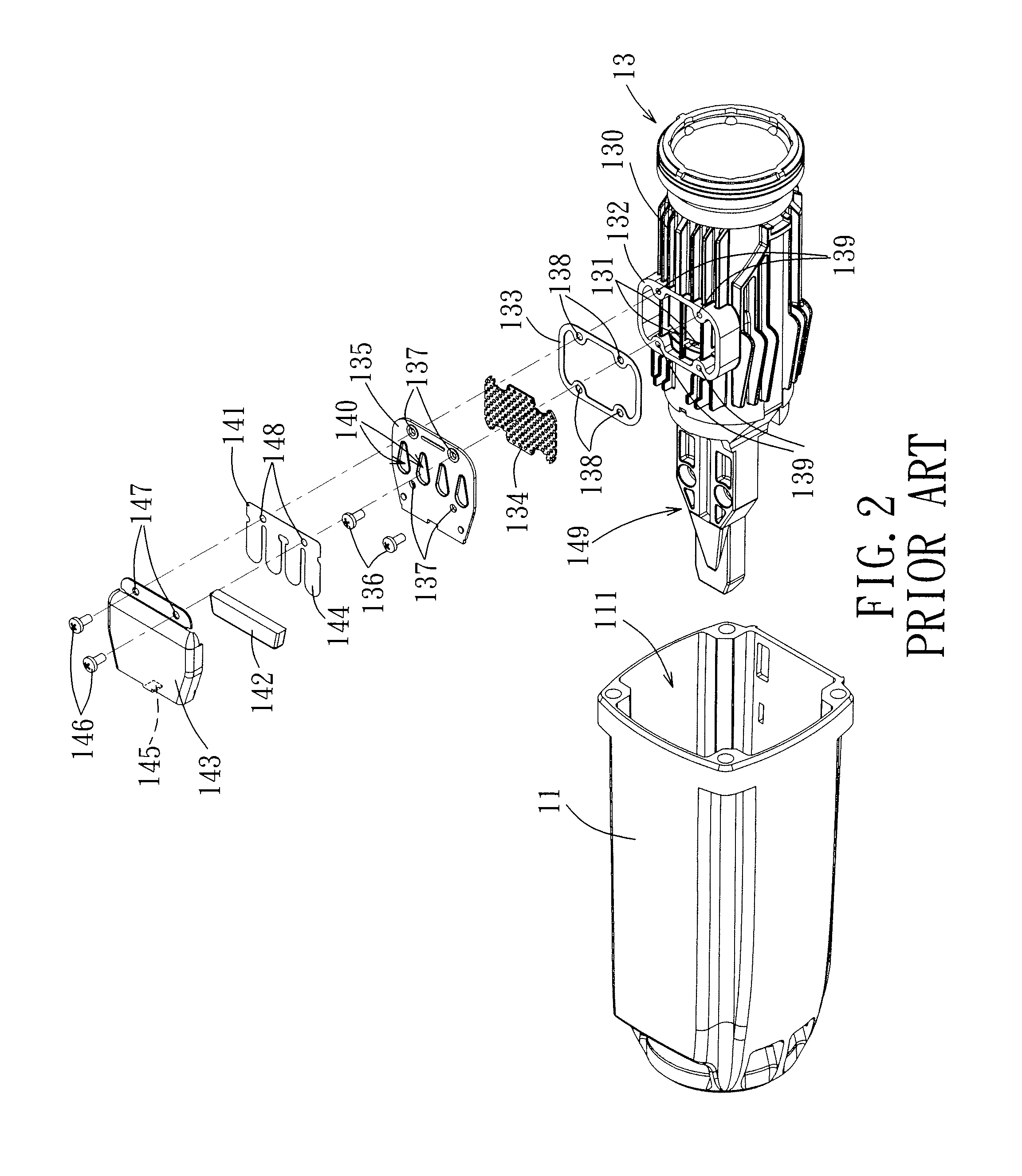

Combustion Nailing Tool

Owner:ZHU YIMIN

Low-temperature stretching testing system and testing method

Owner:SOUTHWESTERN INST OF PHYSICS

Intake and exhaust valve raceway and intake and exhaust valve assembly of engine

ActiveCN106282783AReduce wearSolve the problem of gap exceptionMachines/enginesLift valveExhaust valveHeat resistance

The invention relates to an intake and exhaust valve raceway and intake and exhaust valve assembly of an engine. The intake and exhaust valve raceway and intake and exhaust valve assembly comprises an intake valve raceway of the engine and an intake valve matched with the intake valve raceway and an exhaust valve raceway and an exhaust valve matched with the exhaust valve raceway; the intake and exhaust valve raceways contain materials of Ni-Co-Mo-Cr and are manufactured by adopting a powder metallurgy technique; the main contents of the intake valve are Cr-Si-Mn-P or Cr-Mn-Ni-N; the main contents of the exhaust valve are Cr-Mn-Ni-Nb-W, or bead welding is performed on the disc part of the exhaust valve with the materials of Cr-W-Ni-Fe-Mo; and the problem of mechanical tappet clearance abnormity of the natural gas engine is solved by lowering abrasion loss between the intake valve raceway and the intake valve as well as abrasion loss between the exhaust valve raceway and the exhaust valve. According to the intake and exhaust valve raceway and intake and exhaust valve assembly, abrasion-resistance, heat-resistance and radial crushing strength of the intake valve raceway and the exhaust valve raceway are improved; and quality problems of valve clearance abnormity and the like caused by abnormal abrasion and deformation between the intake valve raceway and the intake valve as well as between the exhaust valve raceway and the exhaust valve are solved.

Owner:SMAPOW ENGINE

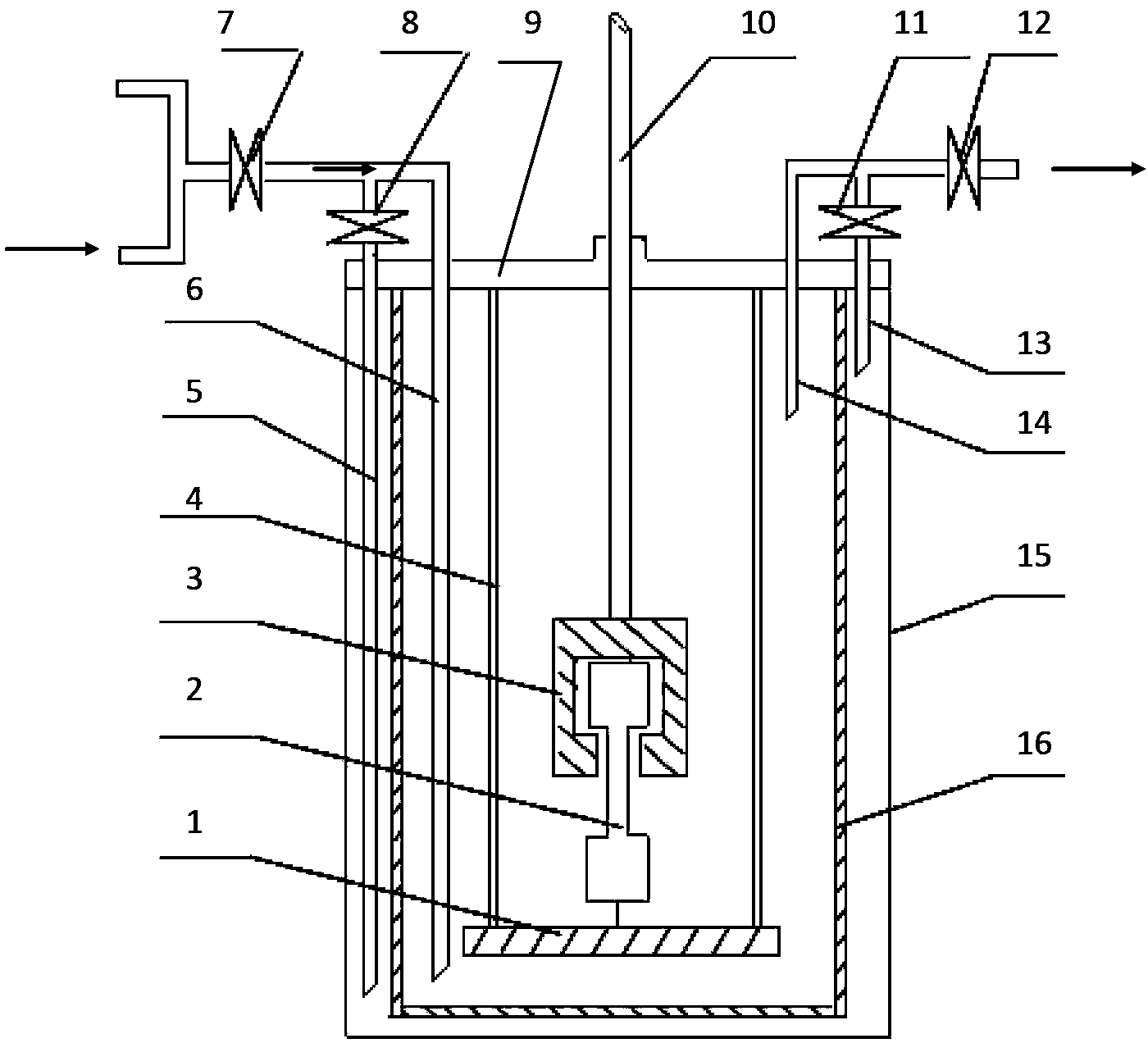

Waste heat utilization system of electric heating steam generator

PendingCN112626819AAchieve recyclingShorten heating timeHand ironTextiles and paperExhaust valveThermodynamics

The invention relates to the field of steam equipment in the garment processing industry, and in particular relates to a waste heat recovery system of an electric heating steam generator. The waste heat recovery system comprises an electric heating steam generator body, a water supply pipe, a first water pump, a steam outlet pipe, a steam exhaust pipe, an exhaust valve and a heat preservation water storage tank, wherein the electric heating steam generator body comprises a box body, an inner container and a heater; the inner container is arranged in the box body; the heater is arranged in the inner container; and the water supply pipe is sequentially connected with the heat preservation water storage tank, the first water pump and the inner container; one end of the steam outlet pipe is connected with the inner container, and the other end of the steam outlet pipe is connected with an ironing device; one end of the steam exhaust pipe is connected with a steam iron, and the other end is in communication with the heat preservation water storage tank; and the exhaust valve is arranged on the top wall of the heat preservation water storage tank. The system has the effect of reducing resource waste.

Owner:SHAANXI MEIGE GARMENT CO LTD

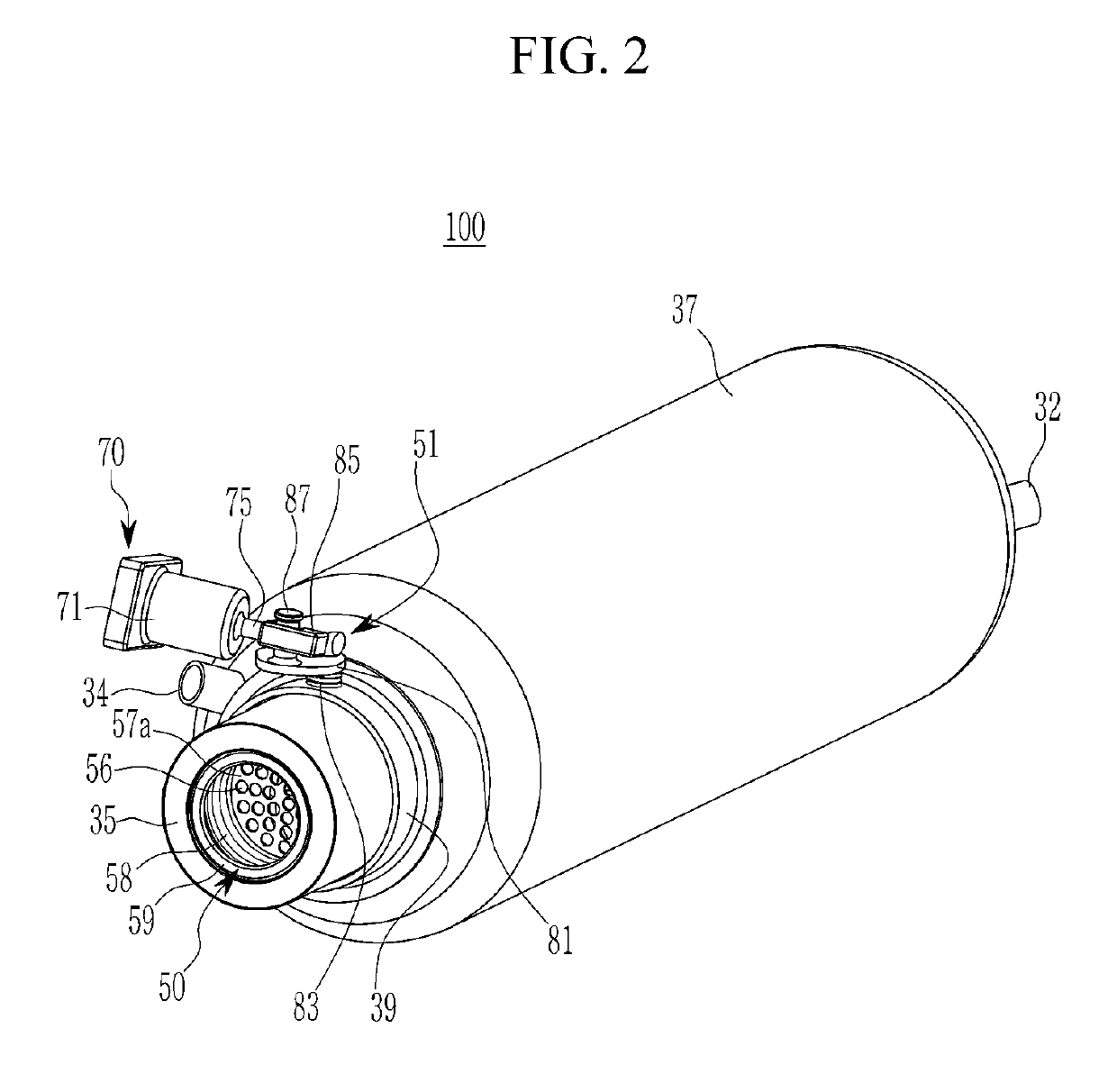

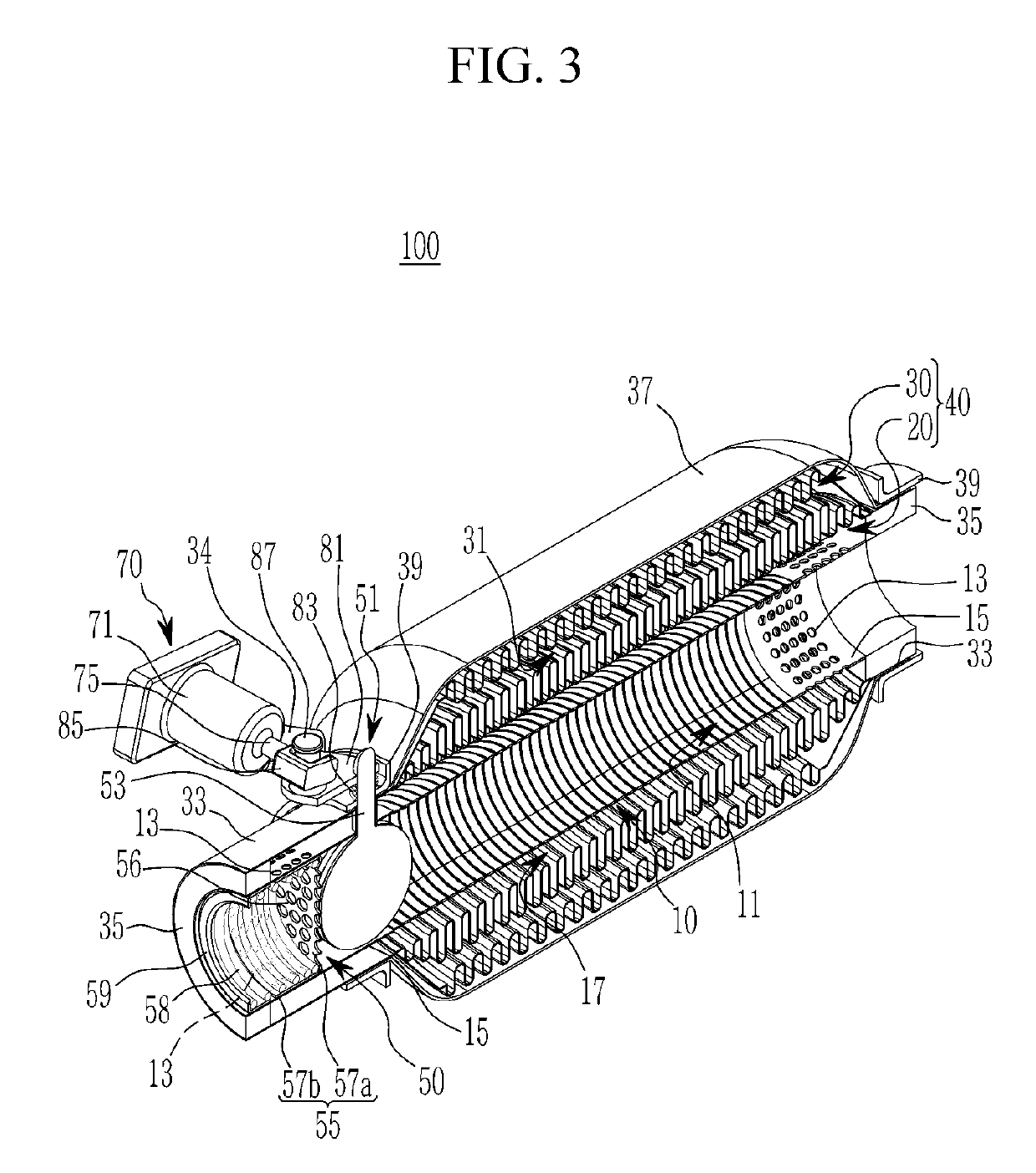

Exhaust heat recovery apparatus

ActiveUS20190128169A1Improve heating efficiencyInternal combustion piston enginesSilencing apparatusExhaust valveExhaust fumes

Owner:HYUNDAI MOTOR CO LTD +1

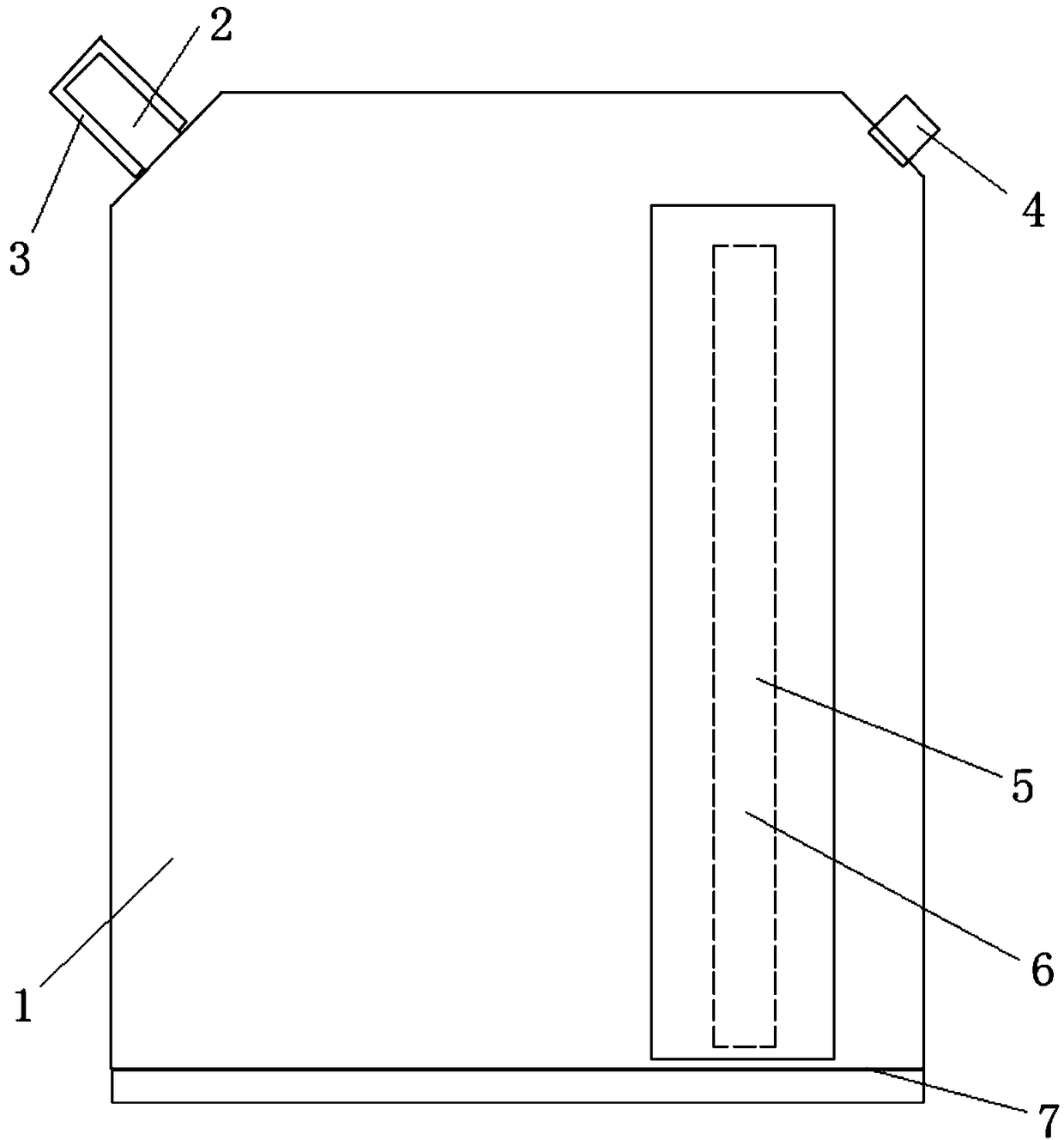

Damp-proof bag

Owner:江门市君扬五金塑料制品有限公司

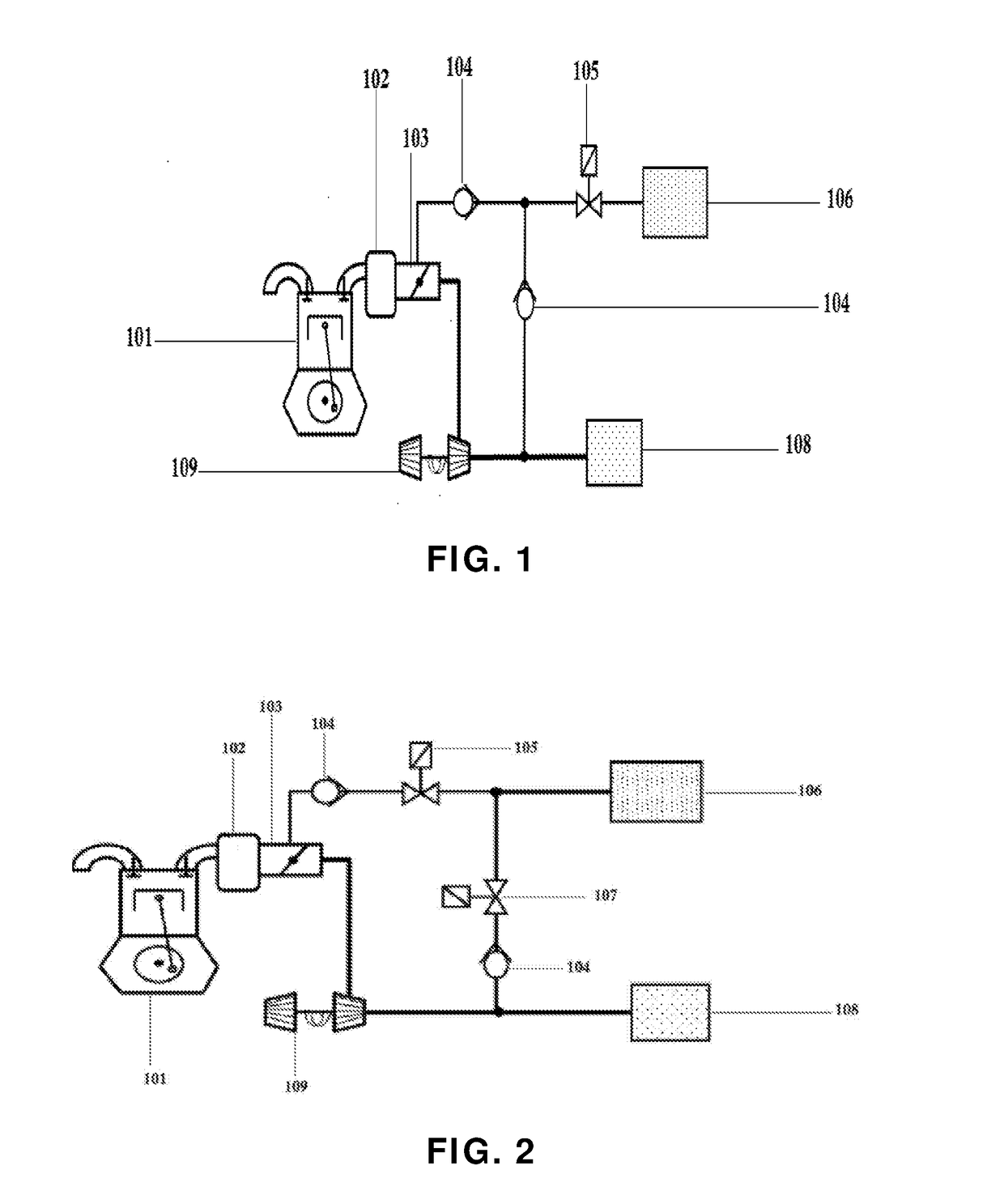

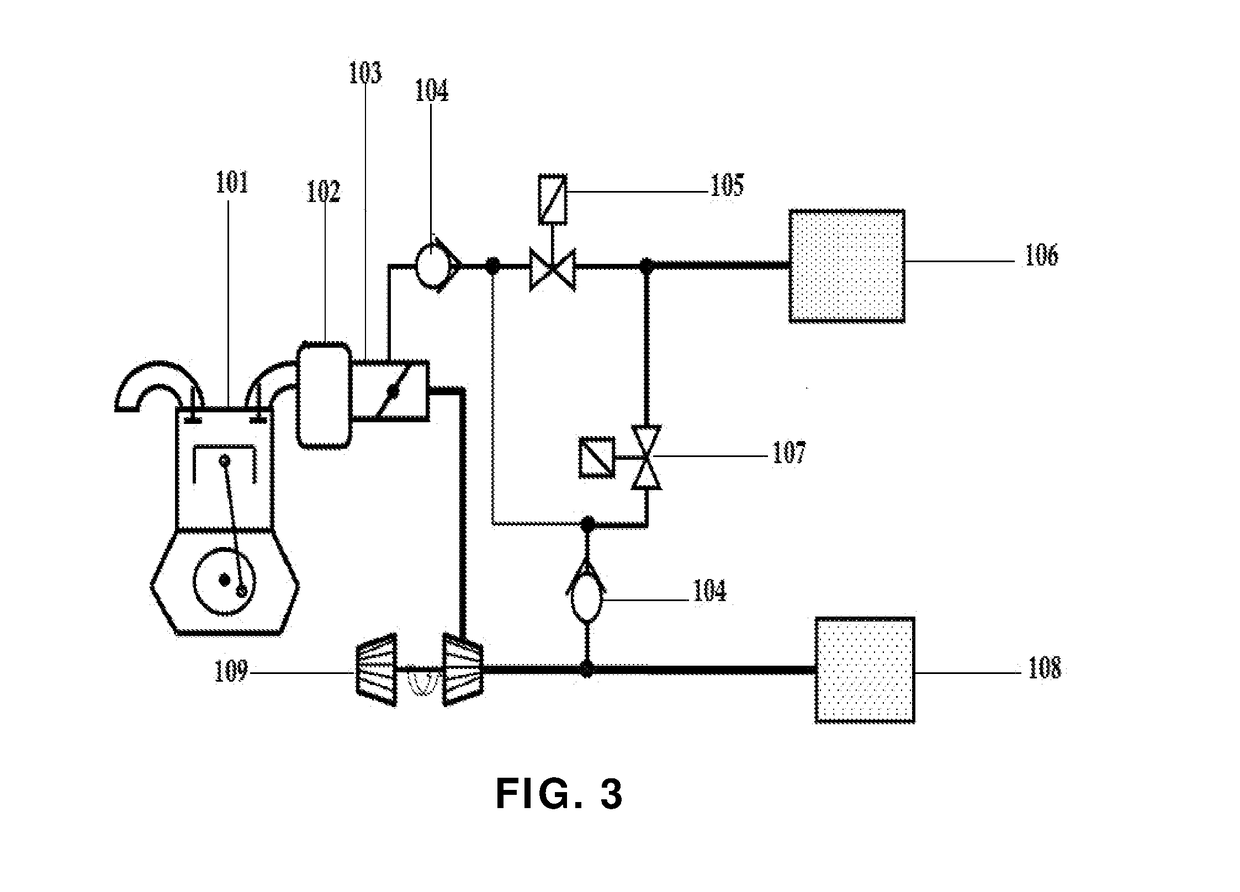

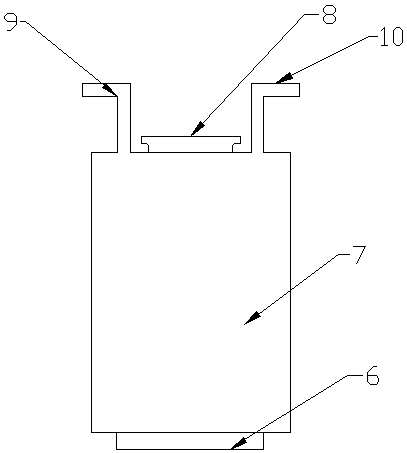

A dual path dual purge valve system and valve assembly for turbo boosted engine

ActiveUS20180372238A1Reduce forceCost efficientElectrical controlOperating means/releasing devices for valvesExhaust valveSolenoid valve

Owner:PADMINI VNA MECHATRONICS PVT LTD

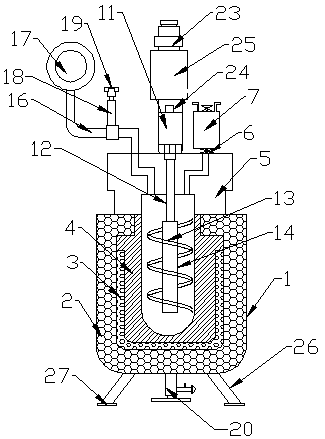

In-situ polymerization reactor

PendingCN107774220AWell mixedSolve the shortcomings of insufficient axial mixingChemical/physical/physico-chemical stationary reactorsFeed devicesExhaust valveIn situ polymerization

Owner:JIANGSU RUIMEIFU IND

Device for controlling air inlet valve and air outlet valve of internal combustion engine

InactiveCN101782006ALarge adjustment rangeSmooth runningValve arrangementsMachines/enginesExhaust valveExternal combustion engine

Owner:杨鲁川

Gas gun with projectile body filling and exhausting structure

Owner:北京北机机电工业有限责任公司

Air ventilation purifier and ventilation filtering technical method

PendingCN109751701AGuaranteed ventilation effectLow costLighting and heating apparatusSpace heating and ventilation detailsExhaust valveEngineering

The invention discloses an air ventilation purifier and a ventilation filtering technical method. The air ventilation purifier comprises a preliminary filtering net, an air intake pipe, an air internal and external circulation switching valve; a filtering device comprises a U-shaped filtering cylinder, a U-shaped filtering element, an air ventilator, an intelligent switching controller and an airoutlet pipe; and an exhausting device comprises an air exhausting pipe, an air exhausting valve and an air exhauster. One end of the air intake pipe communicates with the outdoor air, and the other end of the air intake pipe is connected to an indoor air purifier; the exhausting pipe is arranged at the place of the farthest distance from an opposite angle of a port of the indoor air outlet pipe; two ends of the air exhausting pipe correspondingly communicate with the outdoor air and indoor air; and when the air ventilation purifier is started, the outdoor air enters the U-shaped filtering cylinder through the air intake pipe, the outdoor air is filtered by the U-shaped filtering element and enters the room through the air outlet pipe, the outdoor air is breathed by people when flowing indoors and then discharged outdoors through the air exhausting pipe. The principle of the purifier is that the outdoor air is purified and then introduced indoors for air exchange, and the defect that atraditional air purifier can only filter air but not replace the indoor air is solved.

Owner:周先明

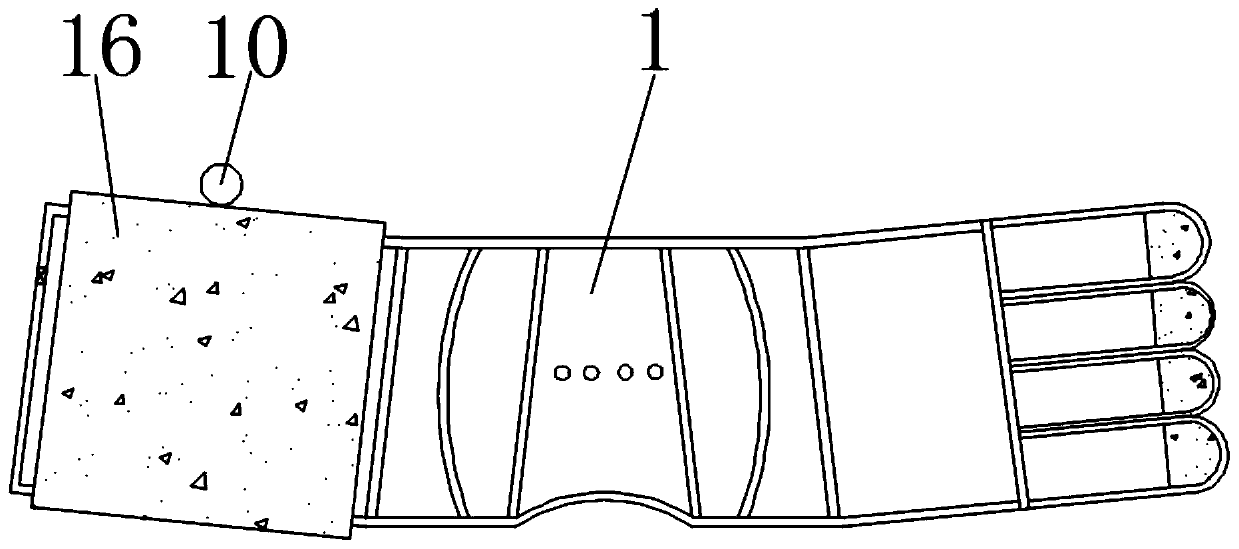

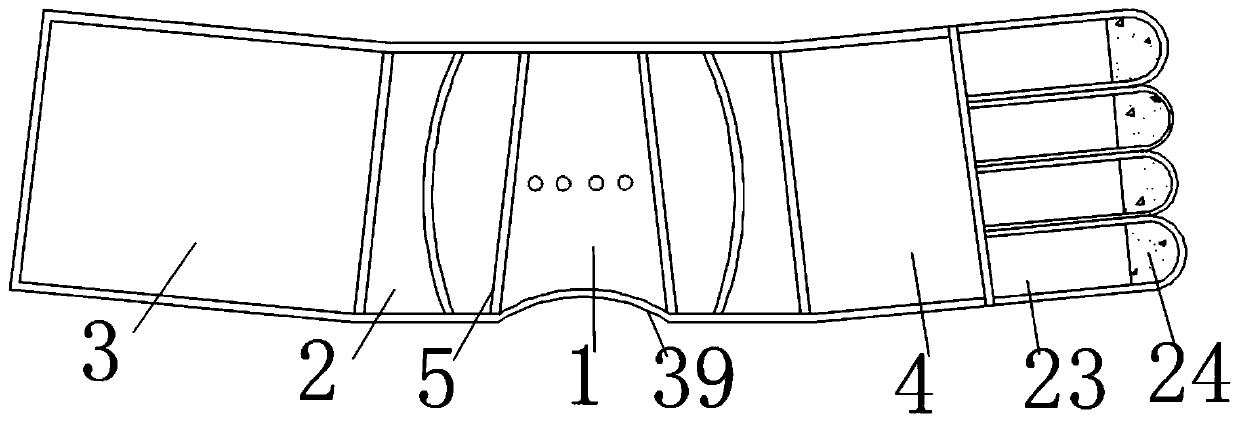

Pressurizing bellyband device for gynaecology and obstetrics

ActiveCN111568618AReduce the numberReduce the frequency of washing the abdominal beltMedical scienceExhaust valveEngineering

Owner:刘艳春

Exhaust valve assembly and engine

The invention discloses an exhaust valve assembly and an engine. The exhaust valve assembly comprises an exhaust valve body and an exhaust valve guide pipe; the exhaust valve body comprises an exhaust valve rod part extending in the axial direction and an exhaust valve head part arranged at one end of the exhaust valve rod part; the exhaust valve guide pipe is used for being fixedly installed on a cylinder cover of the engine; the exhaust valve guide pipe is provided with a guide channel penetrating in the axial direction; the guide channel is used for allowing the exhaust valve rod portion to be movably inserted; and the guide channel is provided with a waste containing section close to the exhaust valve head portion and a guide section away from the exhaust valve head portion, and the inner diameter of the guide channel in the waste containing section is larger than that of the guide section. In this way, the waste containing gap between the waste containing section and the exhaust valve rod part is larger than the gap between the guide section and the exhaust valve rod part, when the exhaust valve body moves close to the exhaust valve guide pipe, the waste containing gap can allow the exhaust valve rod part with hard particles attached to the periphery to penetrate through, and therefore the exhaust valve rod part and the exhaust valve guide pipe cannot be clamped, and normal operation of the engine is ensured.

Owner:DONGFENG LIUZHOU MOTOR

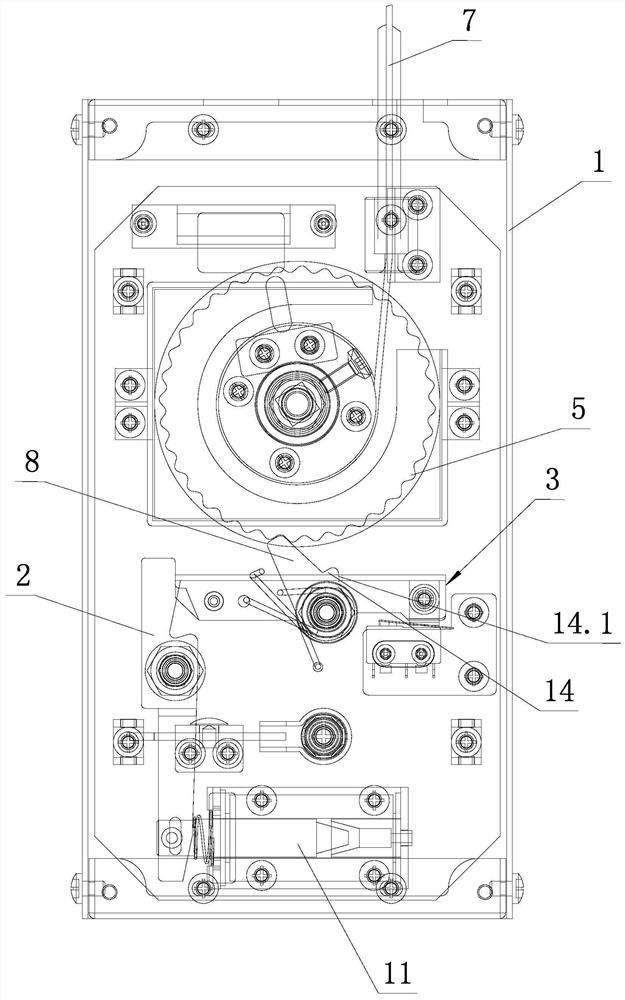

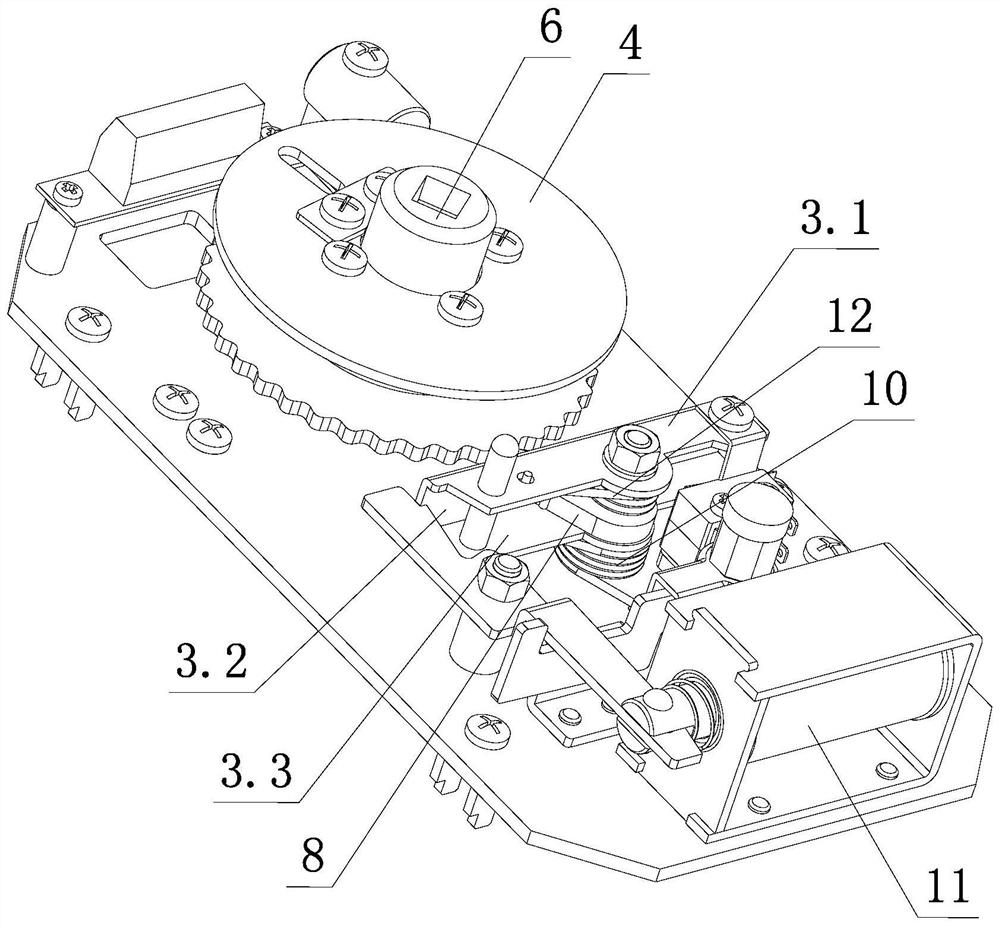

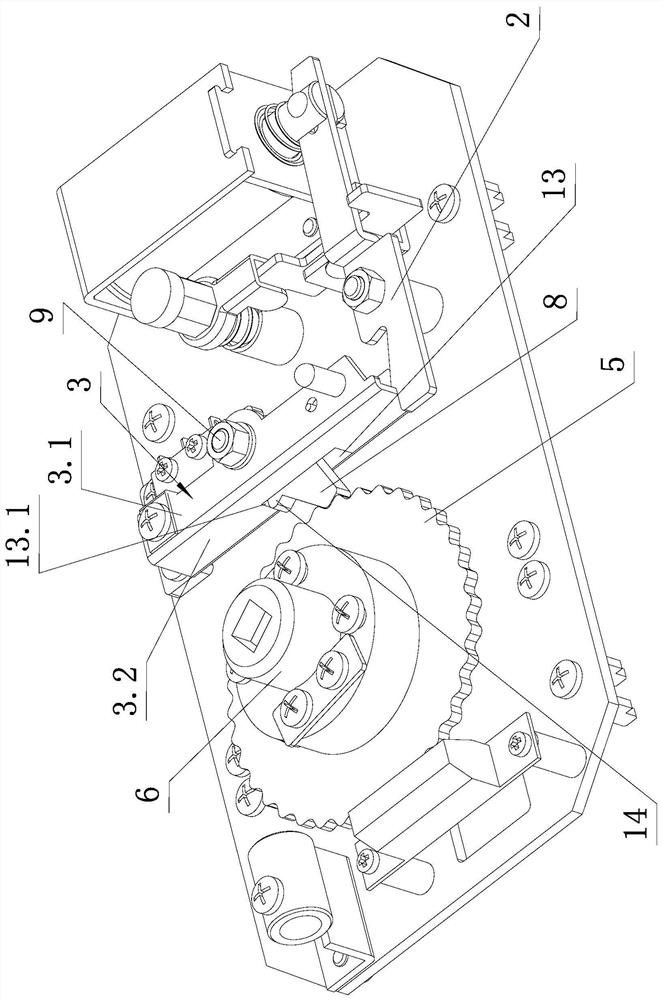

Remote executing mechanism of smoke exhaust valve

PendingCN113719655ALow failure rateReduce frictionOperating means/releasing devices for valvesRatchetExhaust valve

Owner:NINGBO DONGLING PLUMB & AIR CONDITIONING PARTS & ACCESSORIES

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap