Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about "Lift valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LED array driving apparatus and backlight driving apparatus using the same

InactiveUS20060175986A1Uniform colorUniform luminanceStatic indicating devicesElectroluminescent light sourcesDriving currentFeedback controller

The present invention relates to an LED array driving apparatus and a backlight driving apparatus using the same which enables regulation of analogue and PWM dimming for each channel and LED of a backlight, thereby allowing uniform luminance and color in all regions of backlight. The invention converts power with a constant voltage regulator to provide PWM pulse type power to the LED array having a plurality of LEDs connected in series. It regulates the on / off interval of the constant voltage regulator via a PWM dimmer to adjust the duty ratio of the PWM pulse. Further, it regulates the level of the driving current detected at the LED array via the feedback controller and analogue dimmer to apply to the constant voltage regulator by feedback process, thus regulating the amplitude of the PWM pulse.

Owner:SAMSUNG ELECTRONICS CO LTD

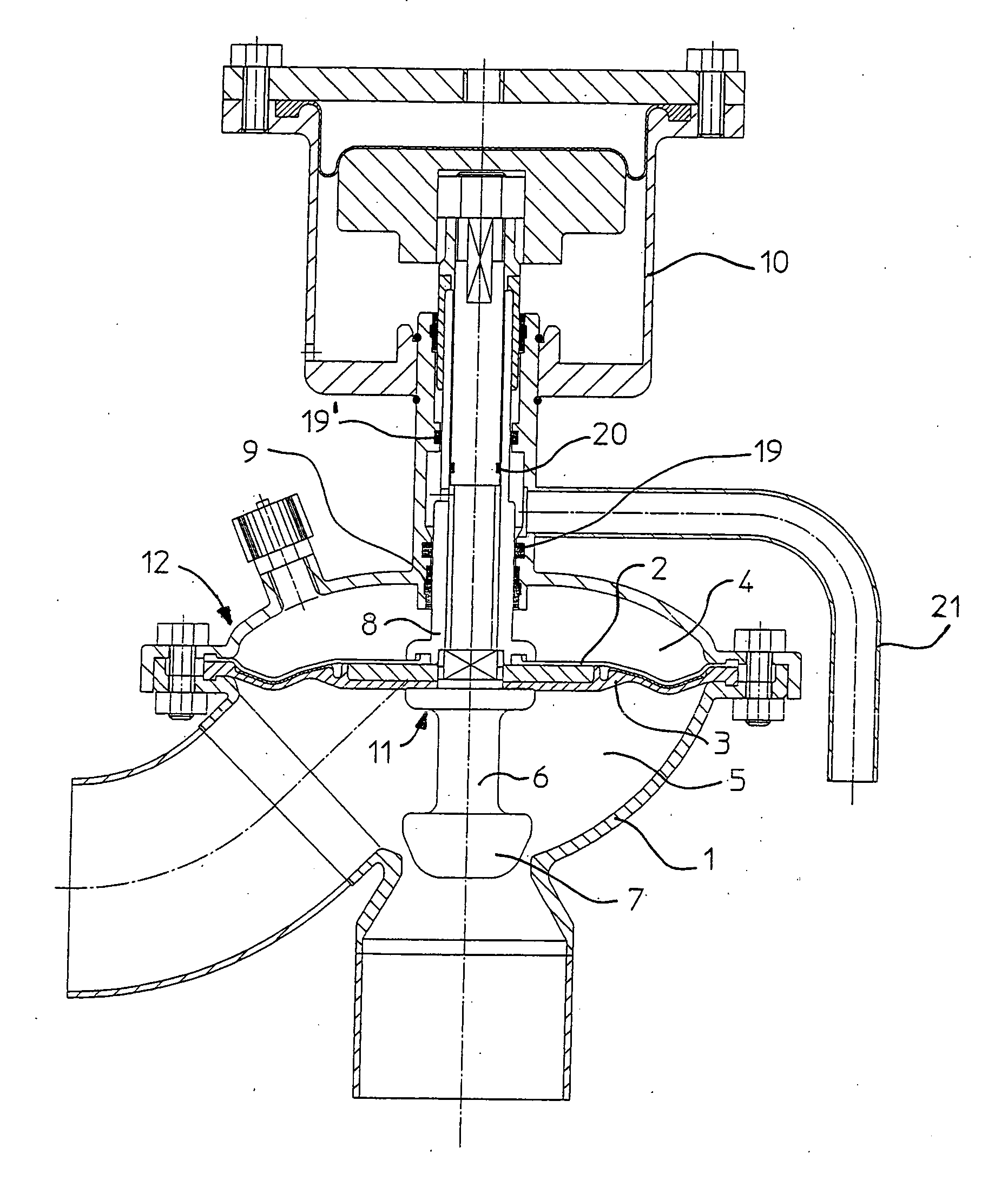

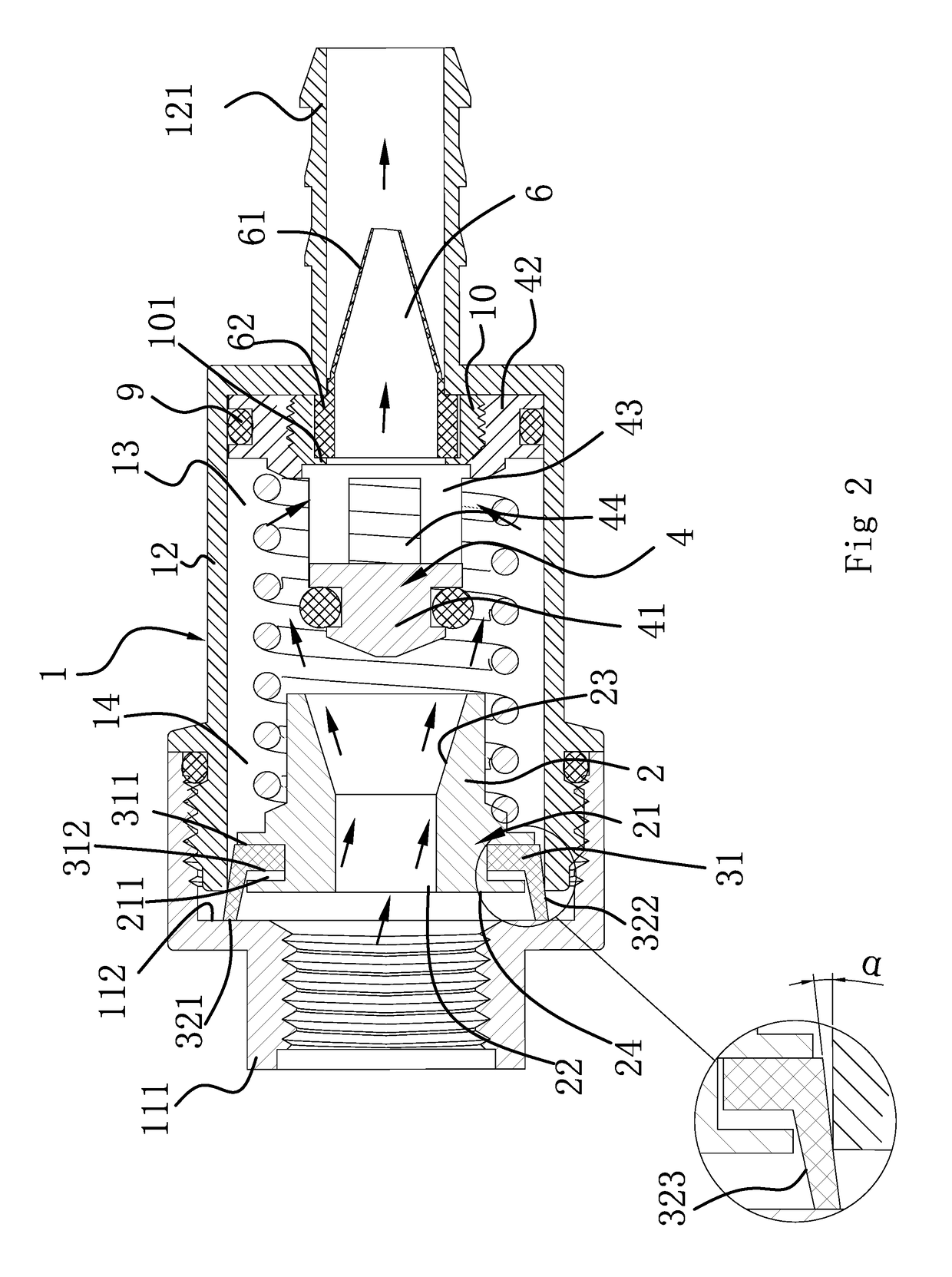

Fuel injector for internal combustion engine and corresponding method of manufacture

ActiveUS20070289578A1Contained costDrawback can be obviatedOperating means/releasing devices for valvesSpray nozzlesComing outBobbin

Owner:C R F SOC CONSORLILE PER AZIONI

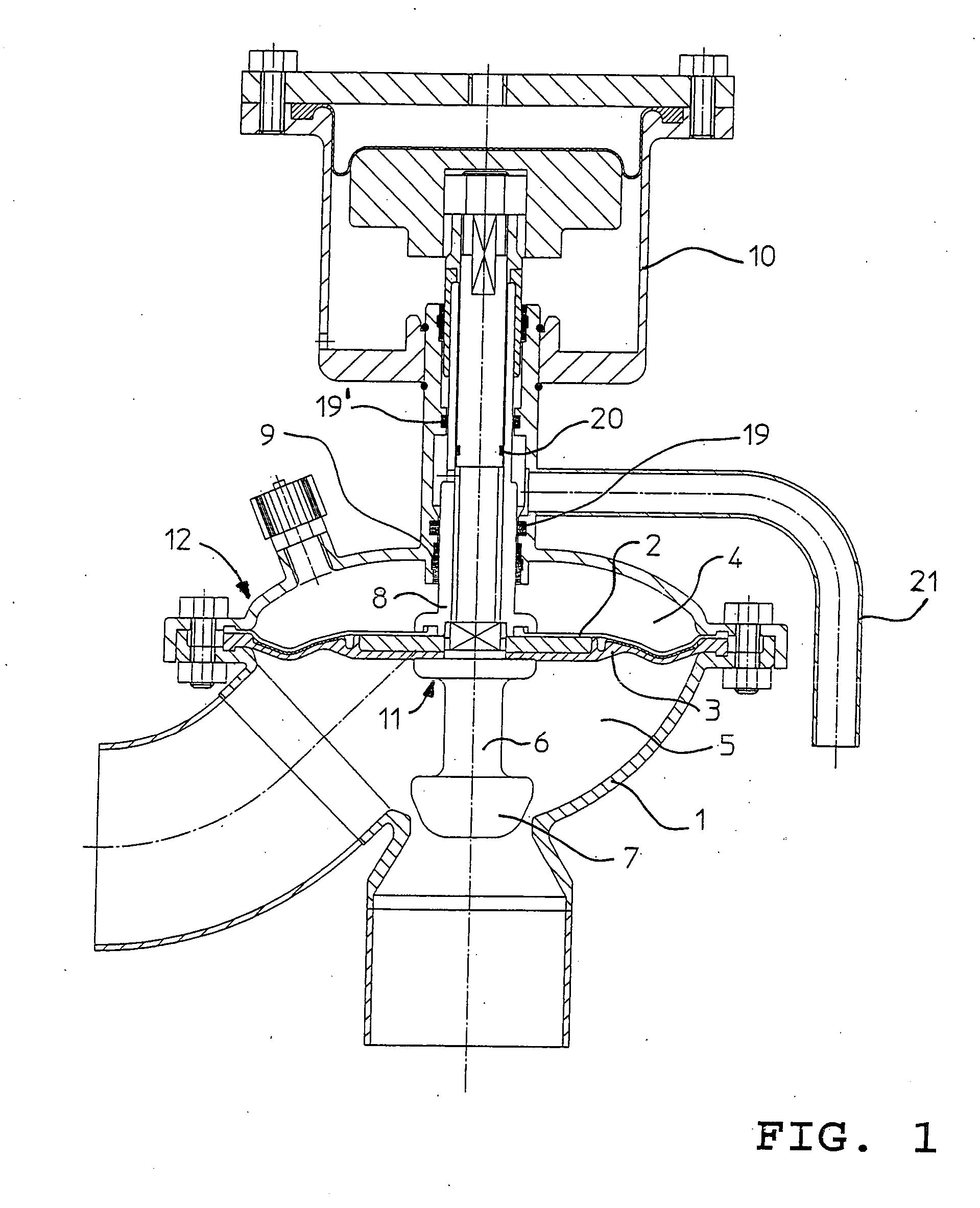

Food and beverage industry membrane valve structure

ActiveUS20060273206A1Easy constructionReduce the numberSpindle sealingsOperating means/releasing devices for valvesTrademarkEngineering

Owner:APV ROSISTA

Variable valve system of internal combustion engine and control method thereof

InactiveUS20060052216A1Inhibit deteriorationGearing controlEngine controllersExternal combustion engineInternal combustion engine

A valve characteristic changing mechanism is supplied with oil discharged from an electric oil pump in addition to oil discharged from a mechanical oil pump that is driven by an operation of an internal combustion engine. Driving of the electric oil pump is controlled such that a work rate of the electric oil pump increases as a temperature of the oil supplied to the valve characteristic changing mechanism increases, or as a viscosity of the oil is reduced.

Owner:TOYOTA JIDOSHA KK

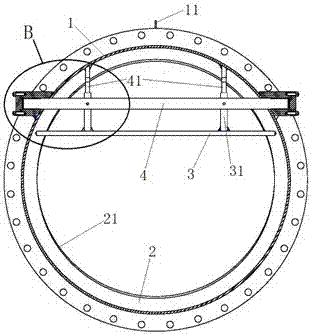

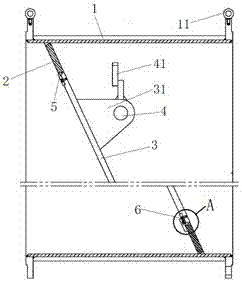

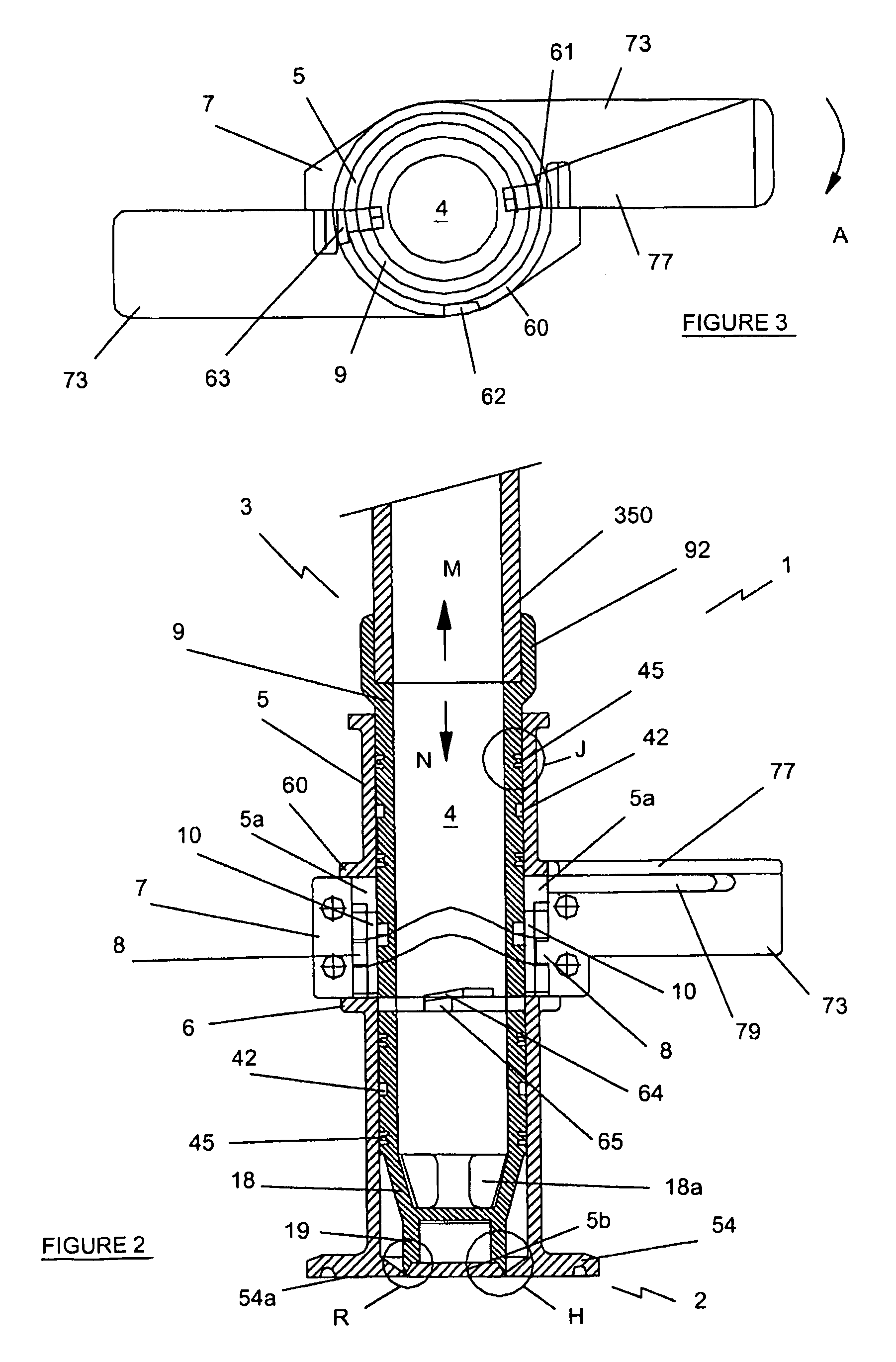

Low Torque, High Flow and Tight Sealing Tube Butterfly Valve

A butterfly valve including a valve body having a passage, a valve shaft assembly, a valve plate, and a tube that is friction fit inside the passage is provided. The valve shaft assembly includes a first shaft portion and a second shaft portion. The first and second shaft portions are in opposing spaced relation with the valve plate disposed therebetween. The valve plate has a flange such that when the butterfly valve is in the closed position a seal is formed with the tube, which is disposed within the fluid flow passage. The valve plate has lip extending from a portion of the valve plate that is radially outward from the circumference of the tube. The lip acts to reduce flow induced torque experienced while the valve plate is actuated from the closed to the open position.

Owner:WOODWARD GOVERNOR CO

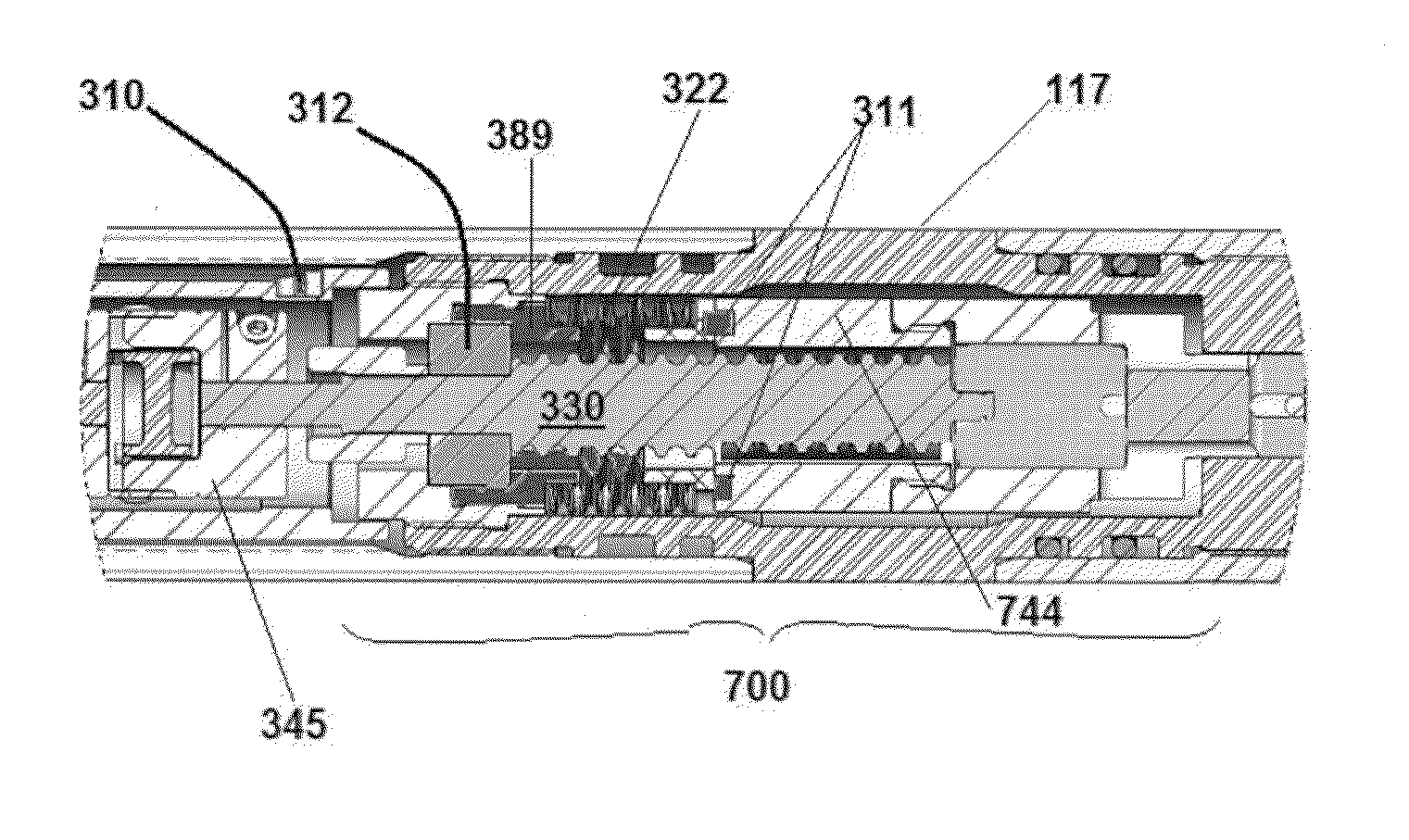

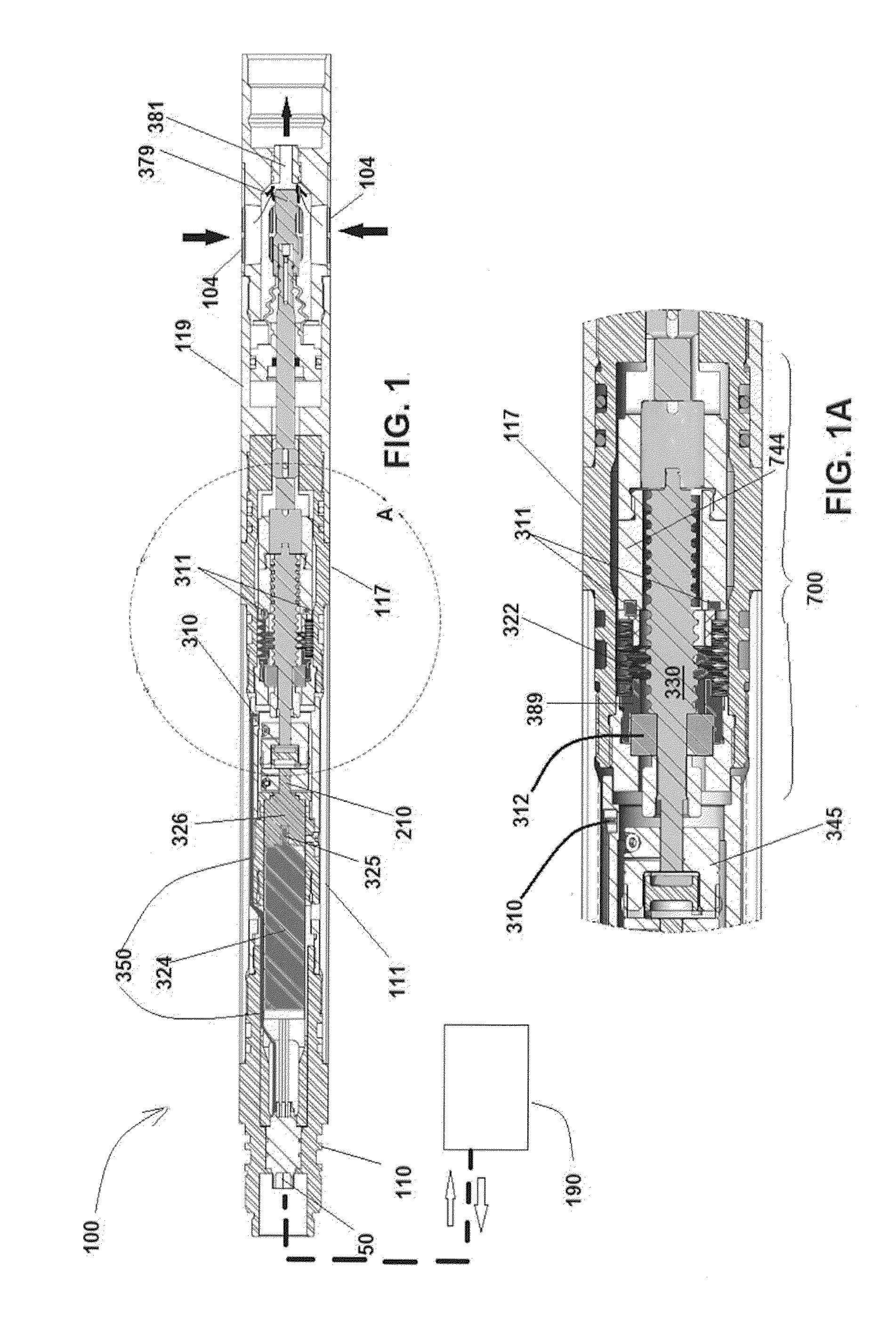

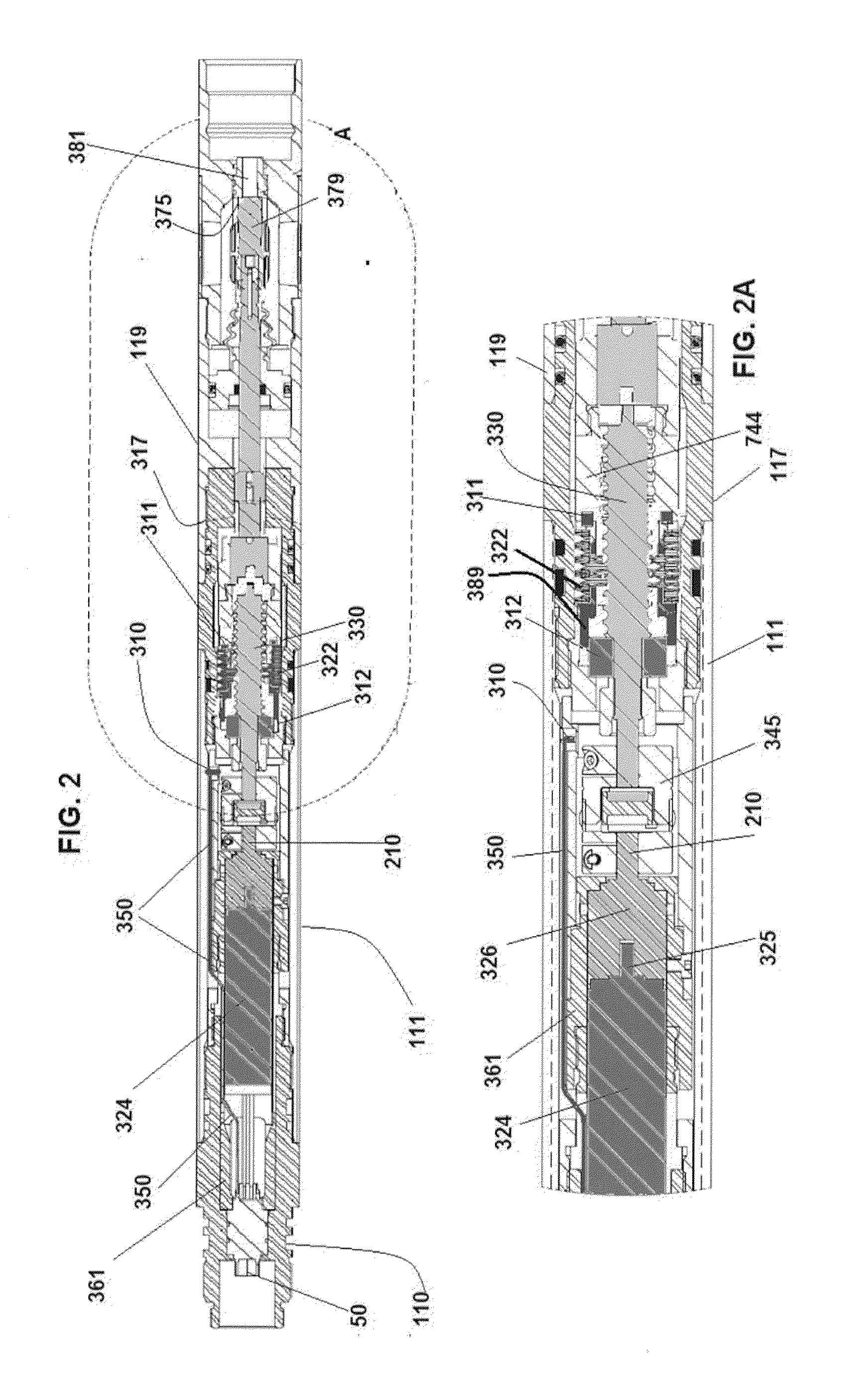

Mud pulser with poppet valve, having linear displacement determination means

ActiveUS20160208953A1Slow changeReduce non-linearityOperating means/releasing devices for valvesSurveyServo actuatorEngineering

Owner:VERTEX DOWNHOLE TECH INC

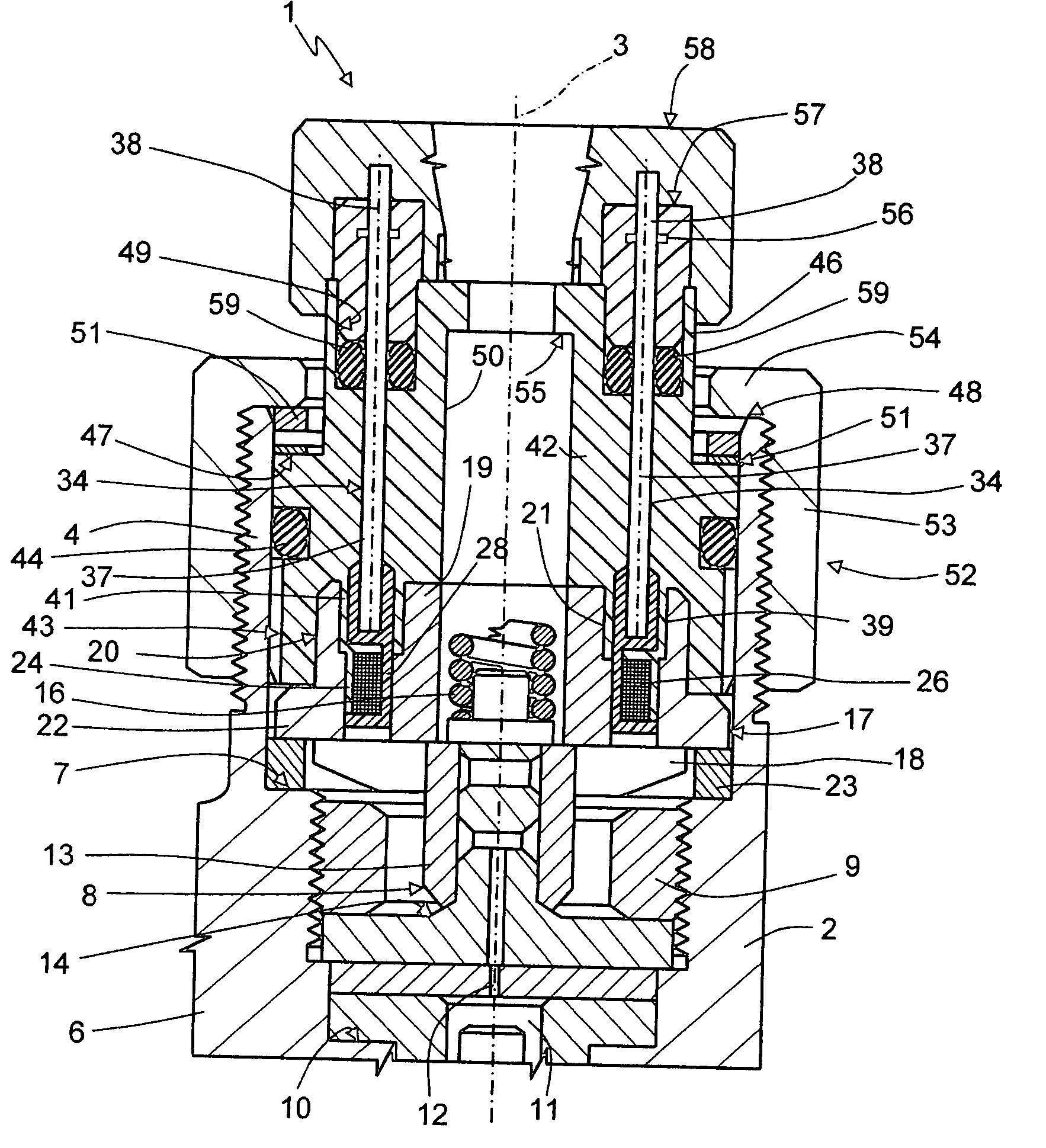

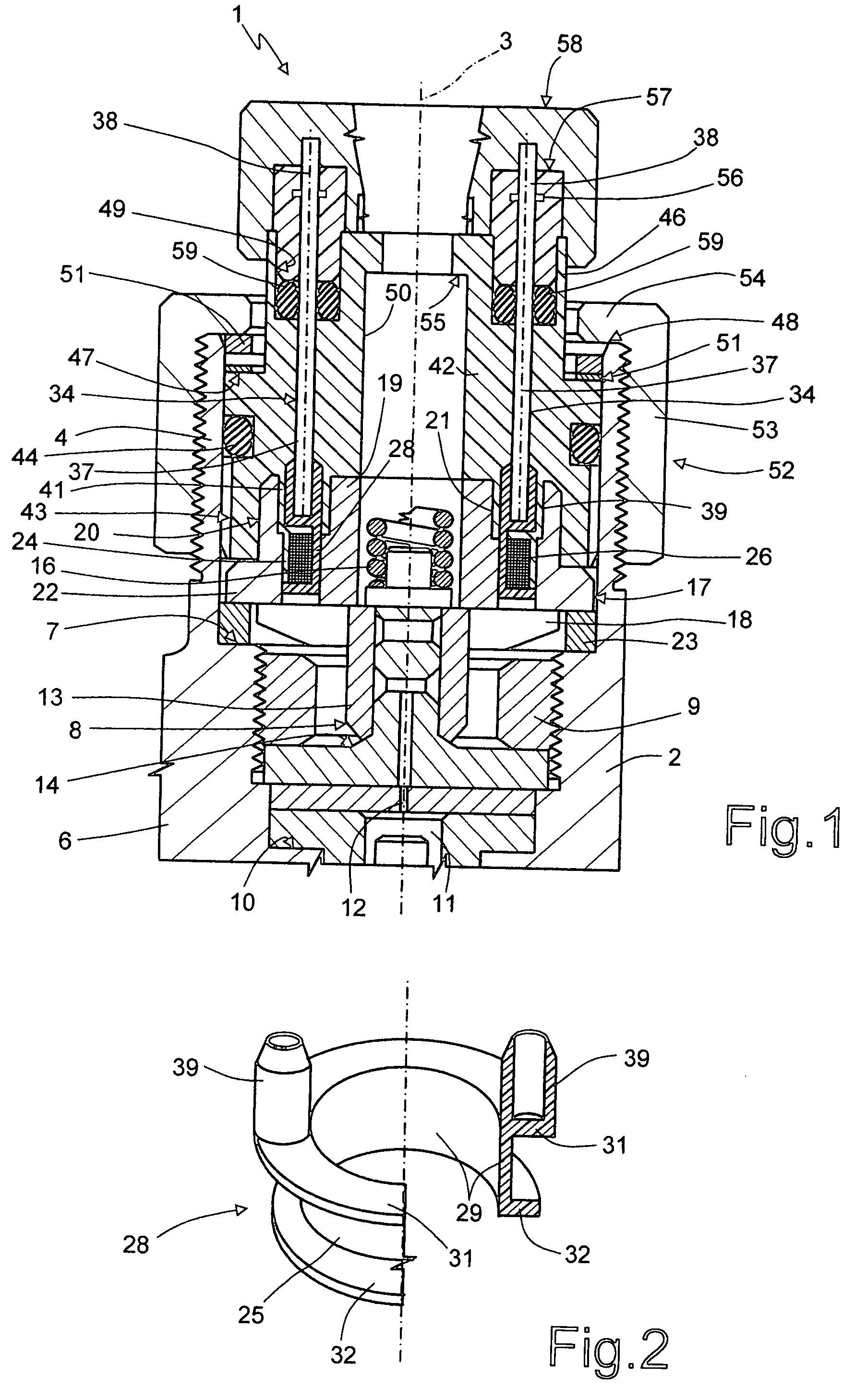

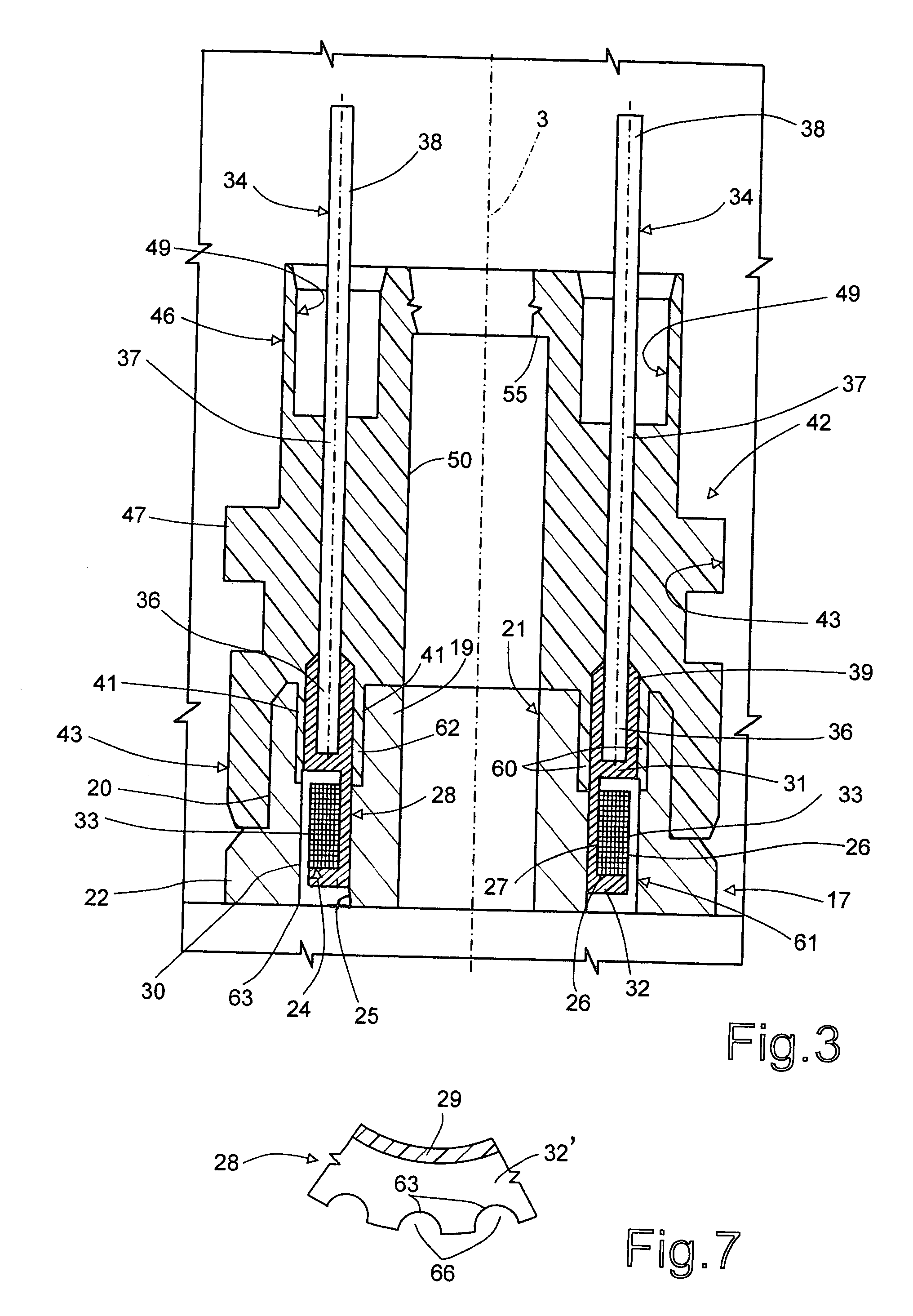

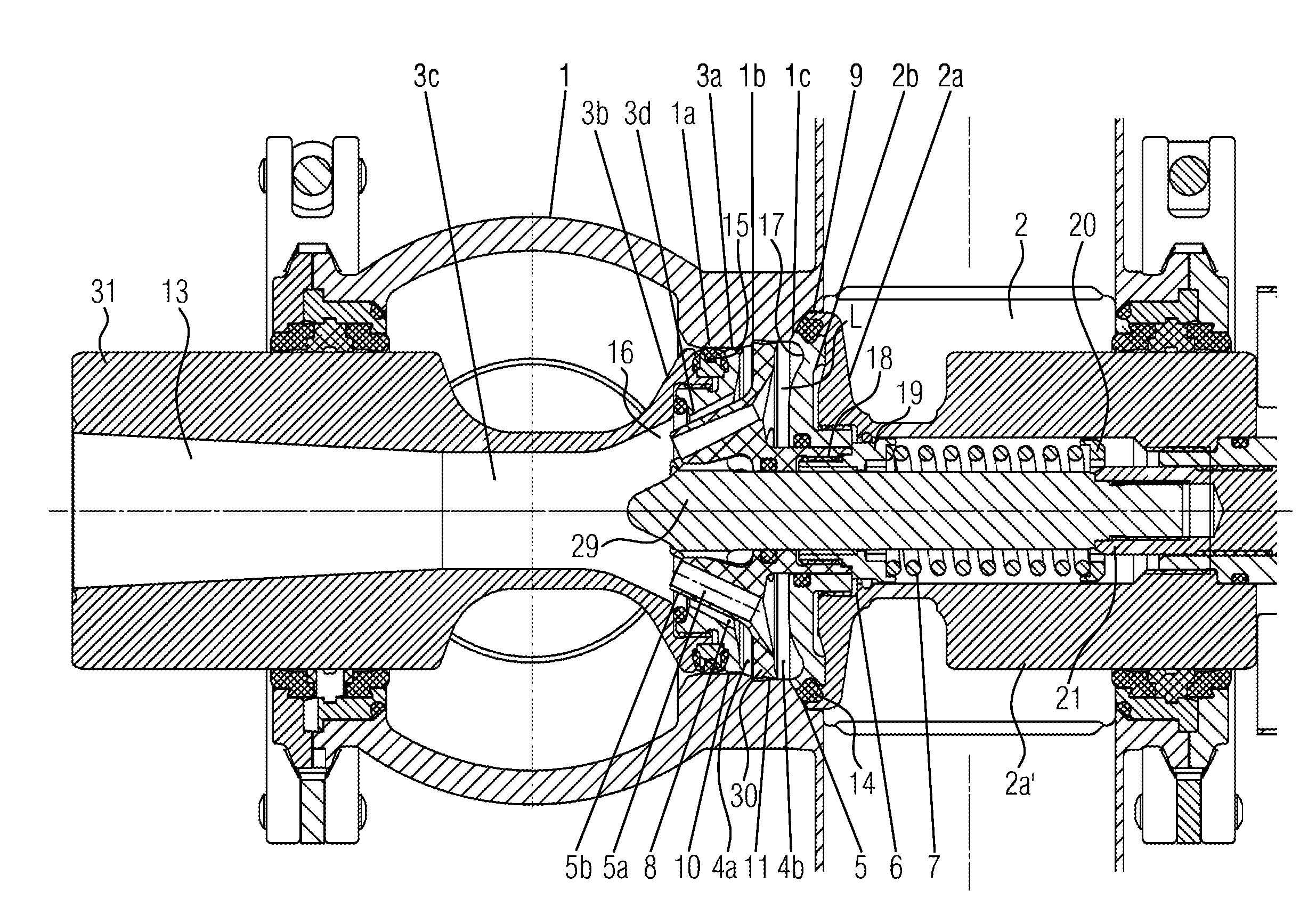

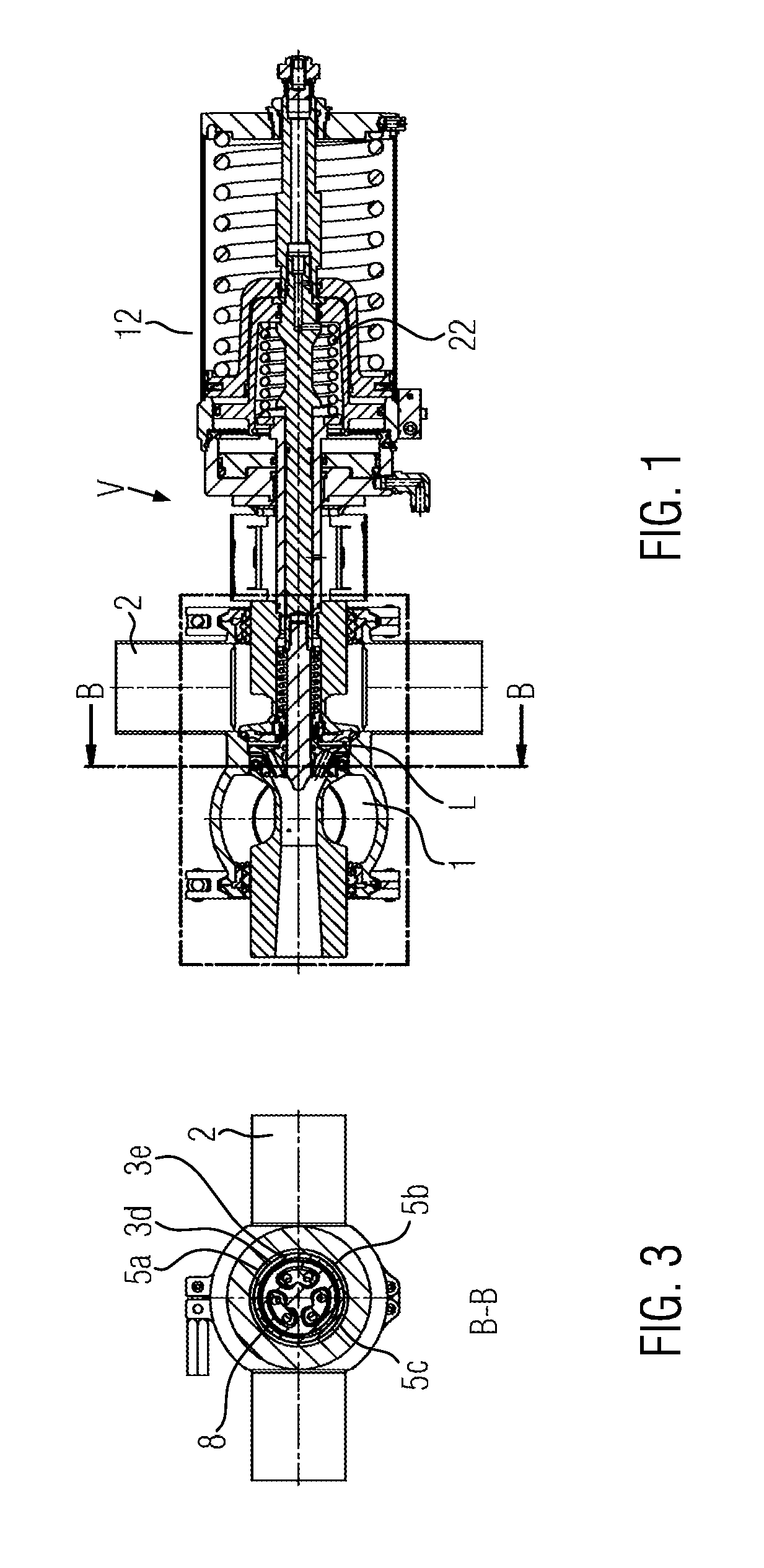

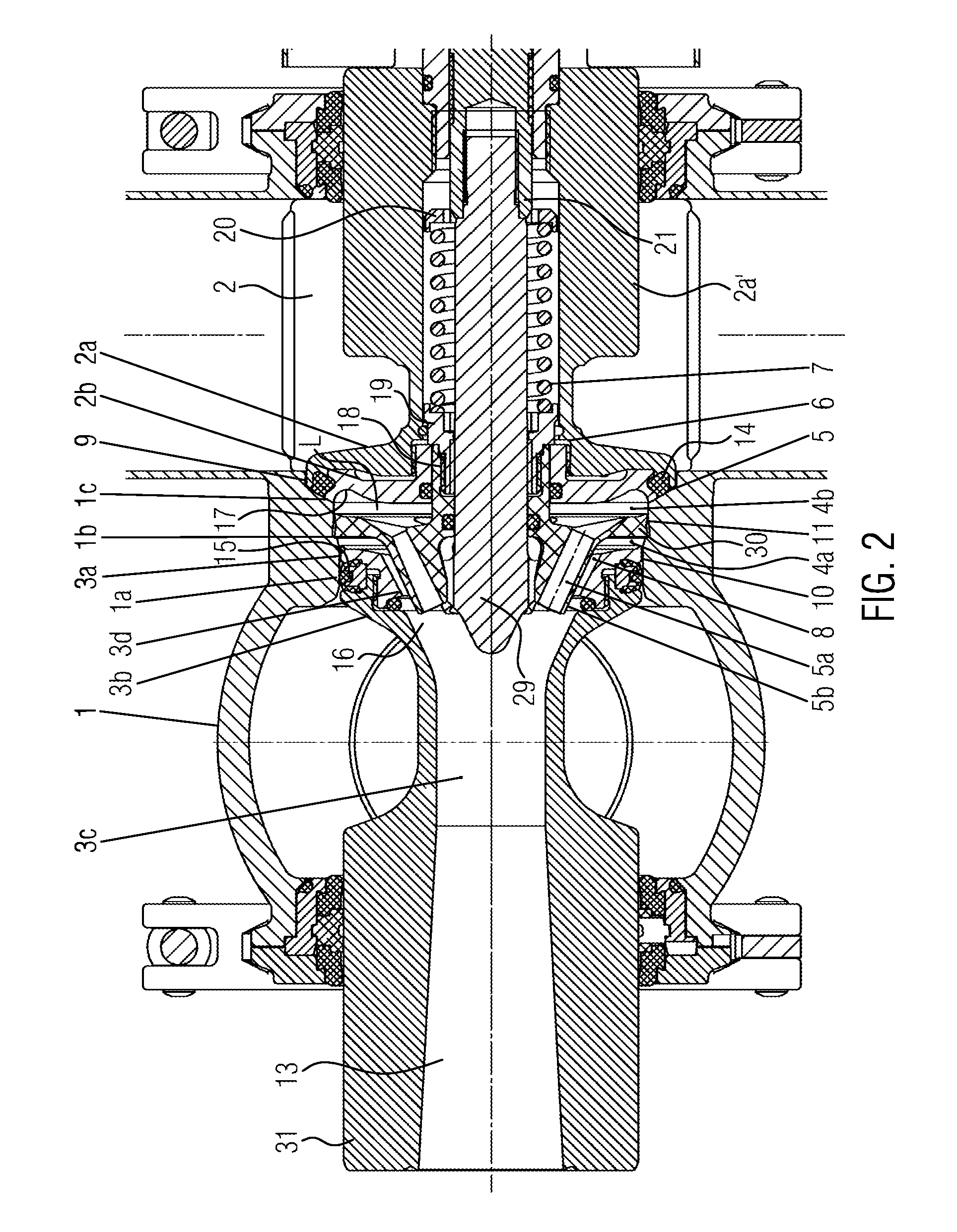

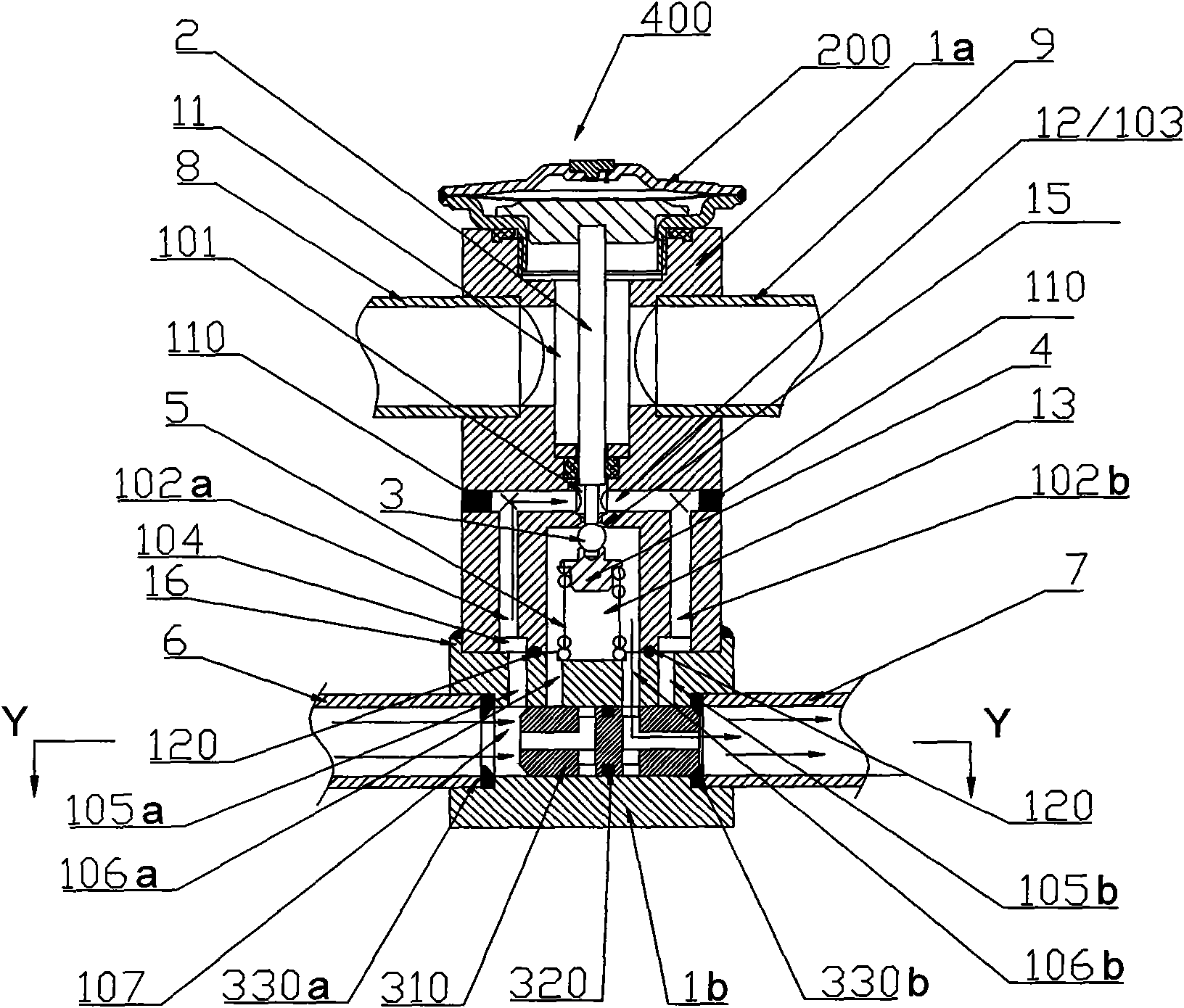

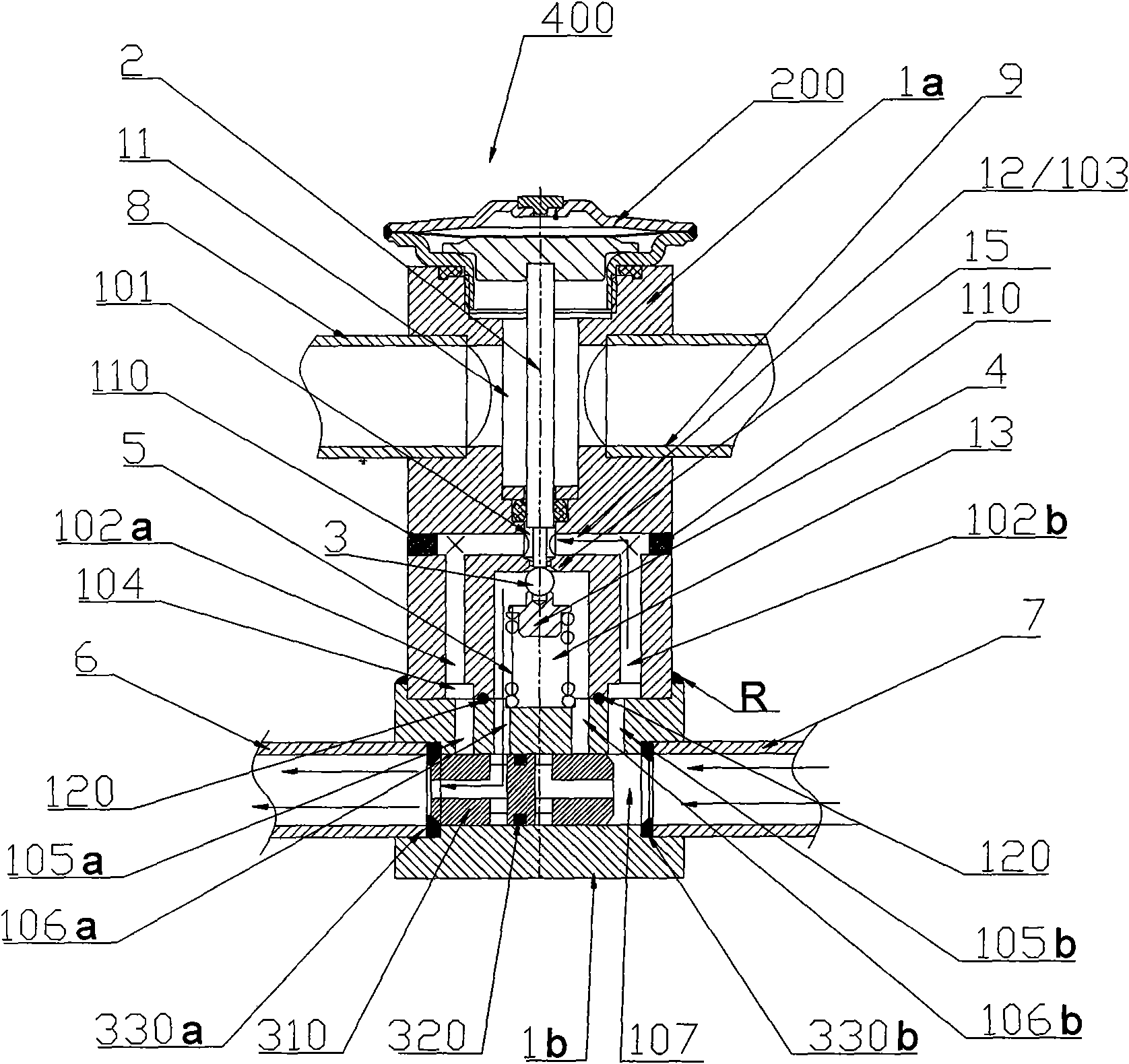

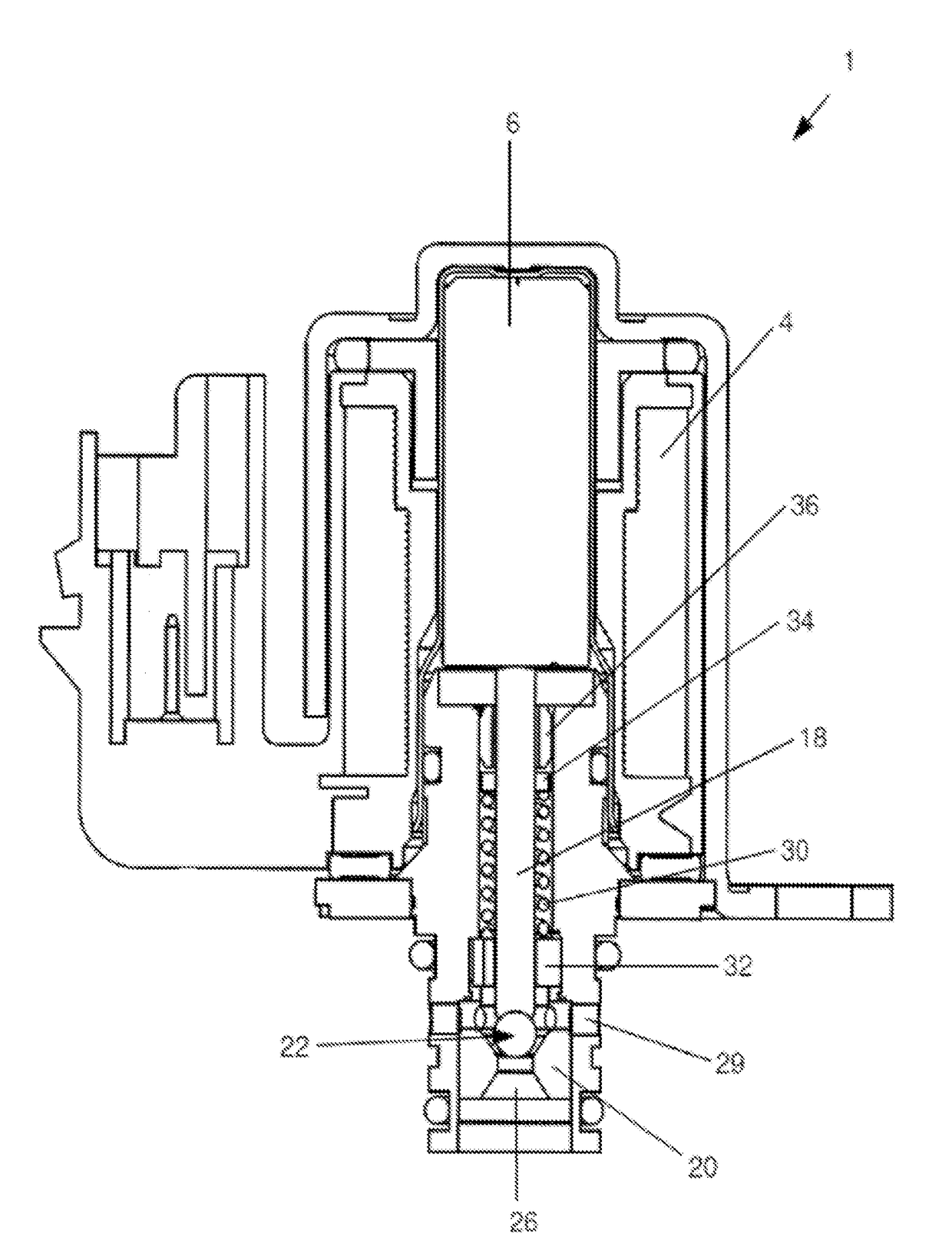

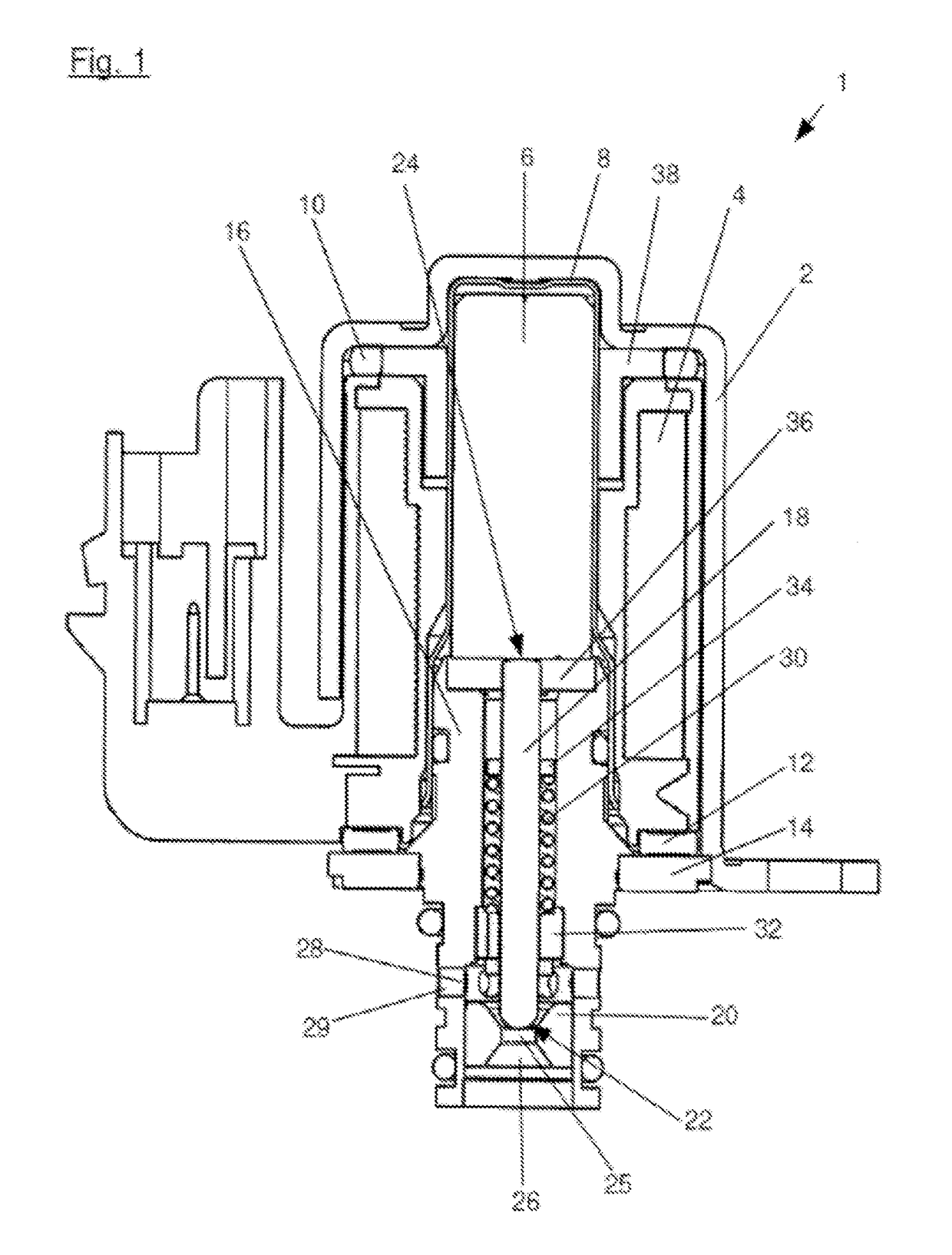

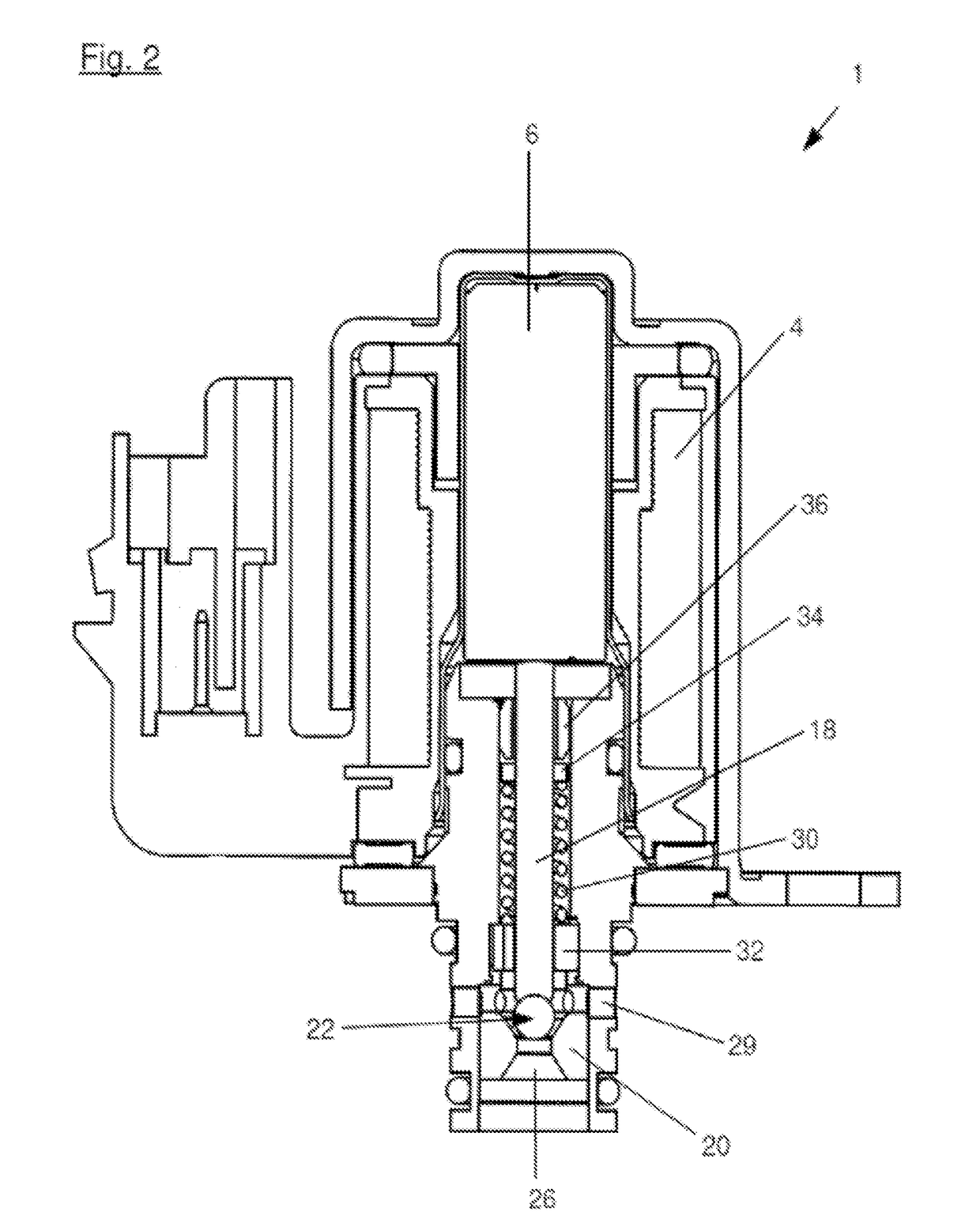

Double seat valve

ActiveUS20170037974A1Undesired splashing effect is avoidedOptimizationLift valveThin material handlingLow leakageEngineering

Owner:EVOGUARD GMBH

Flow Rate Safety Valve

ActiveUS20180128392A1Improve sealingImprove mobilityCheck valvesEqualizing valvesEngineeringSafety valve

Owner:YUHUAN JIANGLIN PLUMBING HOSE & PARTS

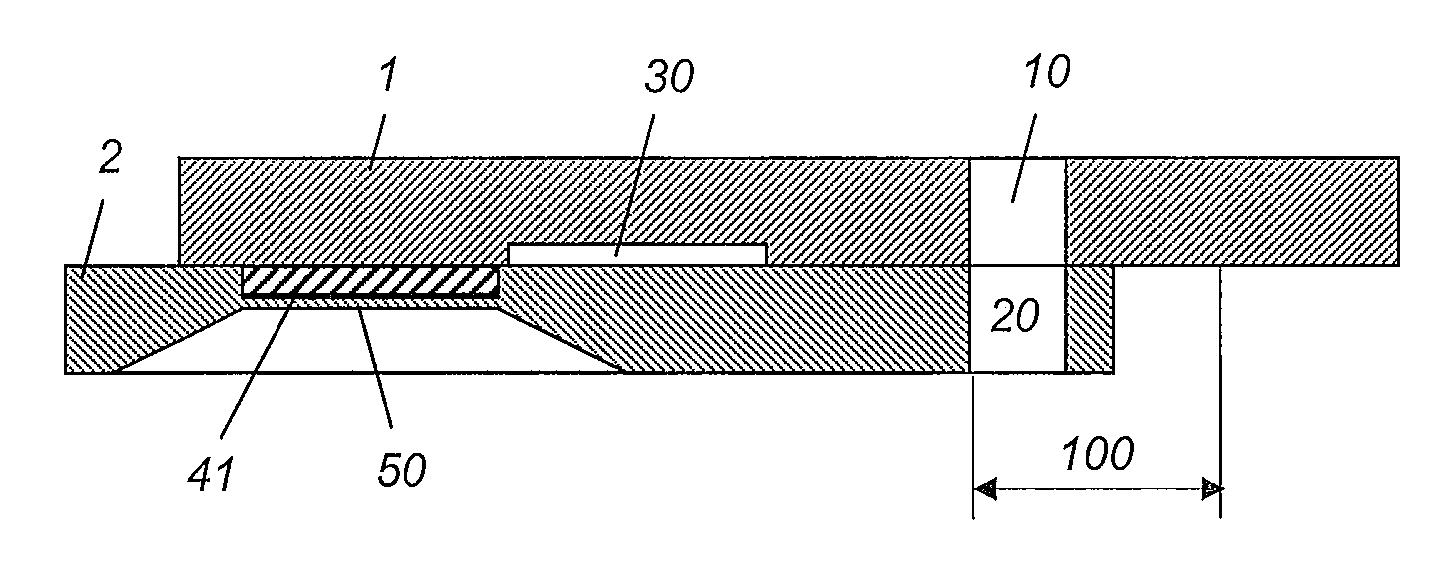

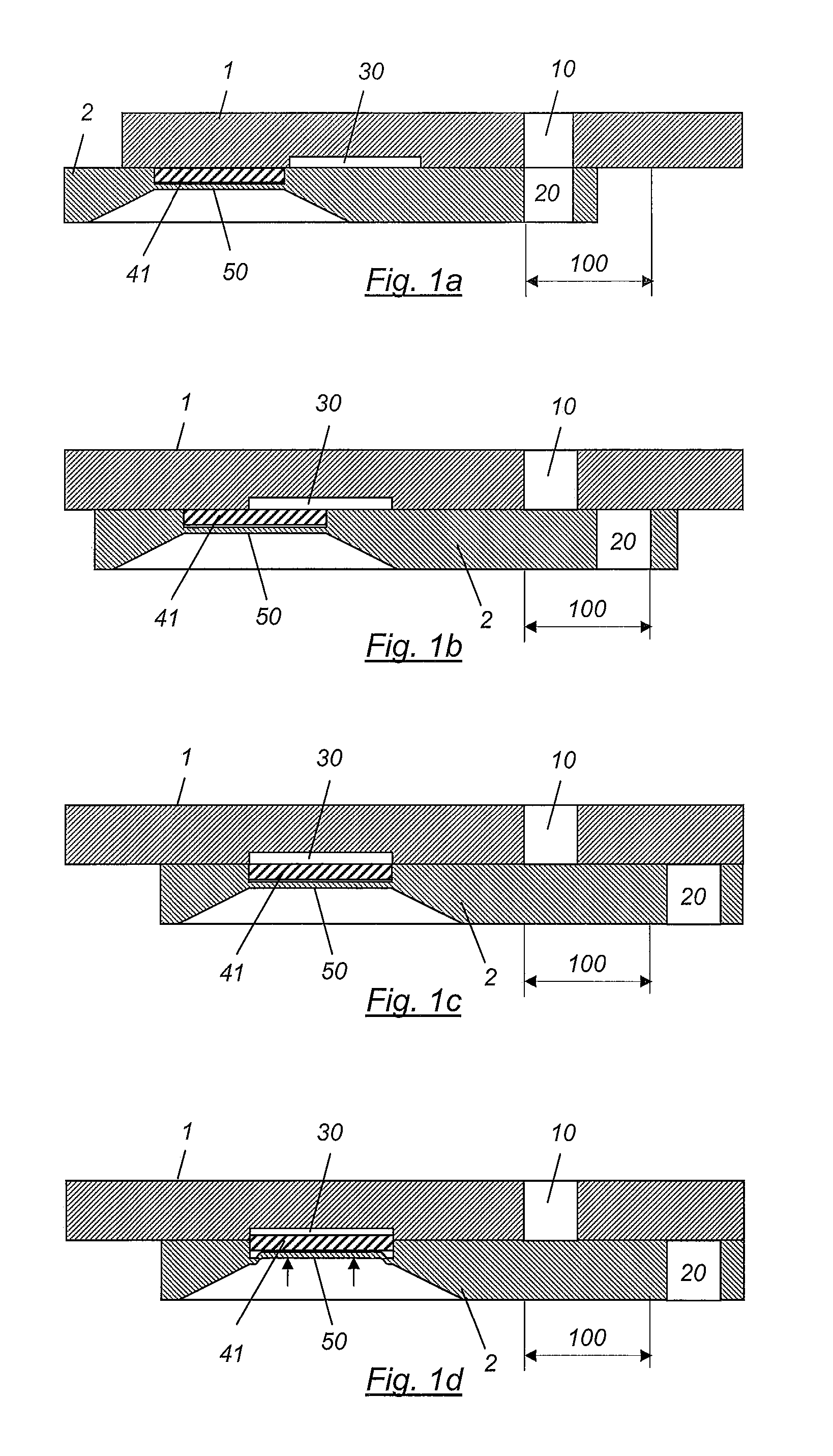

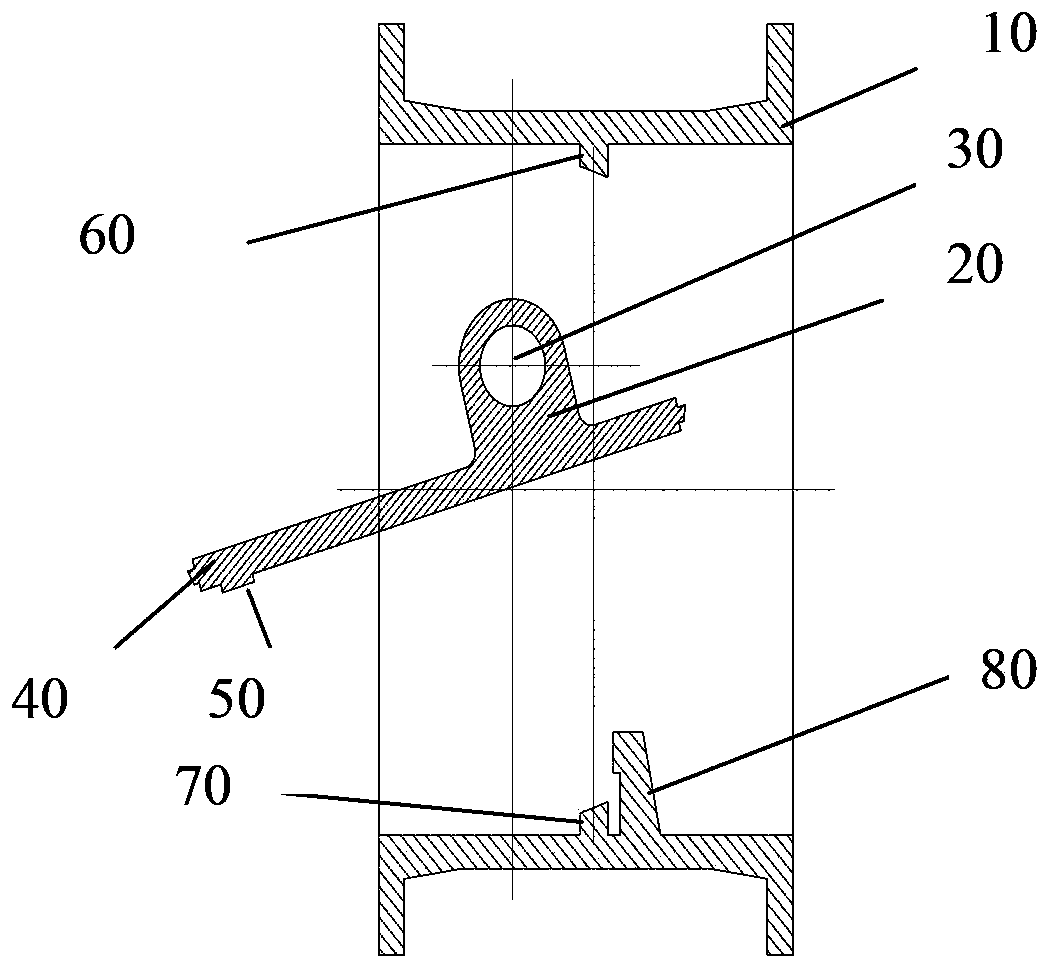

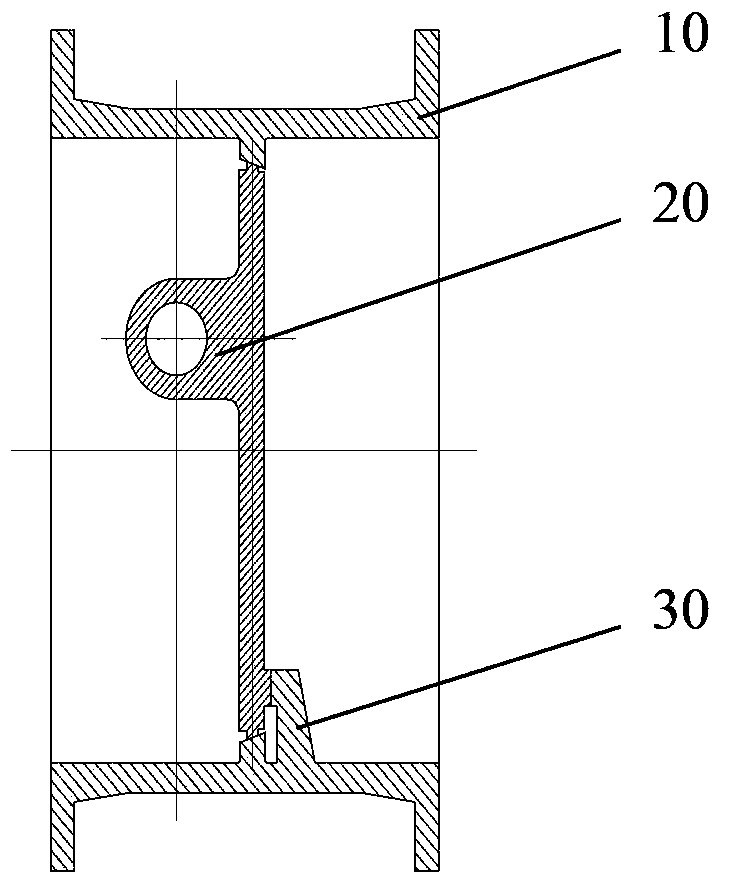

Valve core

The seal member 30 is held between first and second flanges 22 and 24 in the valve core 10, and a locking projection 26 is connected in a combination of a recessed portion and a projected portion between the first and second flanges 22 and 24 and the seal member 30 while the locking projection 26 is caught by the seal member 30. Thus, deformation of the seal member 30 in diameter is controlled. The seal member 30 is moved to the first and second flanges 22 and 24 side in a fixed state when the valve core 10 is opened even though the seal member 30 is stuck on an inner periphery of a core mounting hole 52. Thus, separation of the seal member 30 is prevented.

Owner:PACIFIC INDUSTRIAL CO LTD

Thermal expansion valve

InactiveCN101988585AAvoid shakingAvoid throttling differencesOperating means/releasing devices for valvesValve members for absorbing fluid energyThermal expansionEngineering

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

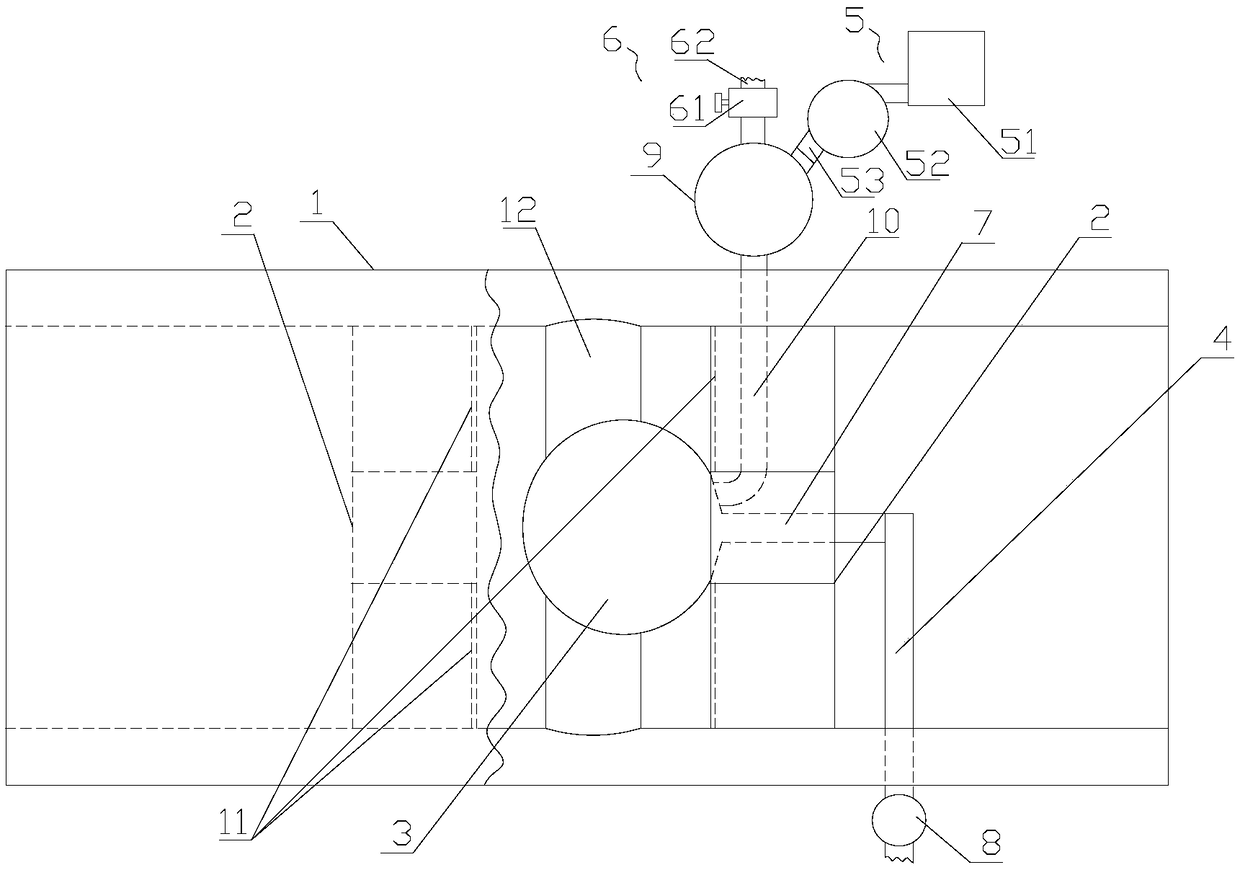

Vacuum chamber negative pressure adjusting device and method for using same

Owner:GUANGDONG SHENGYI SCI TECH

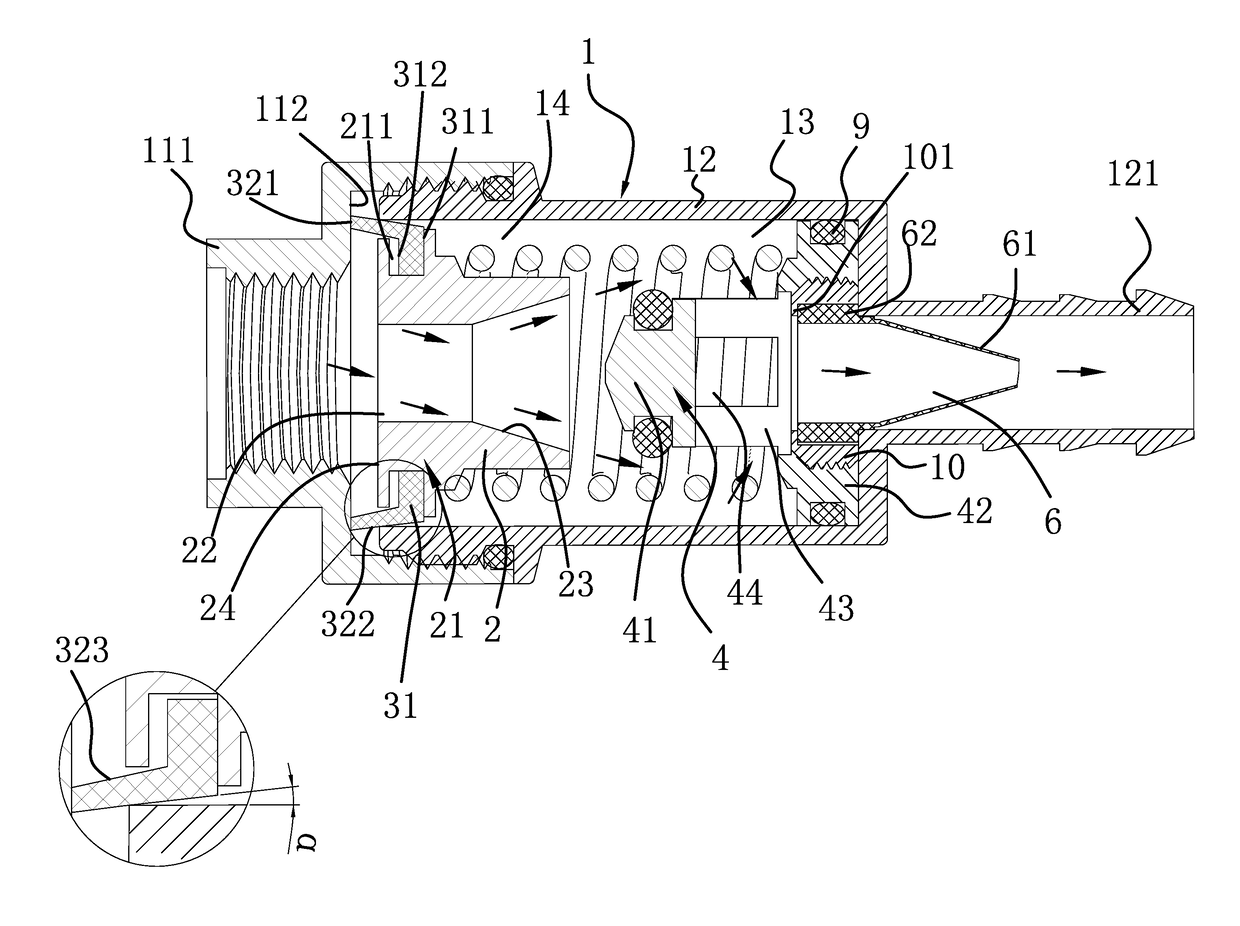

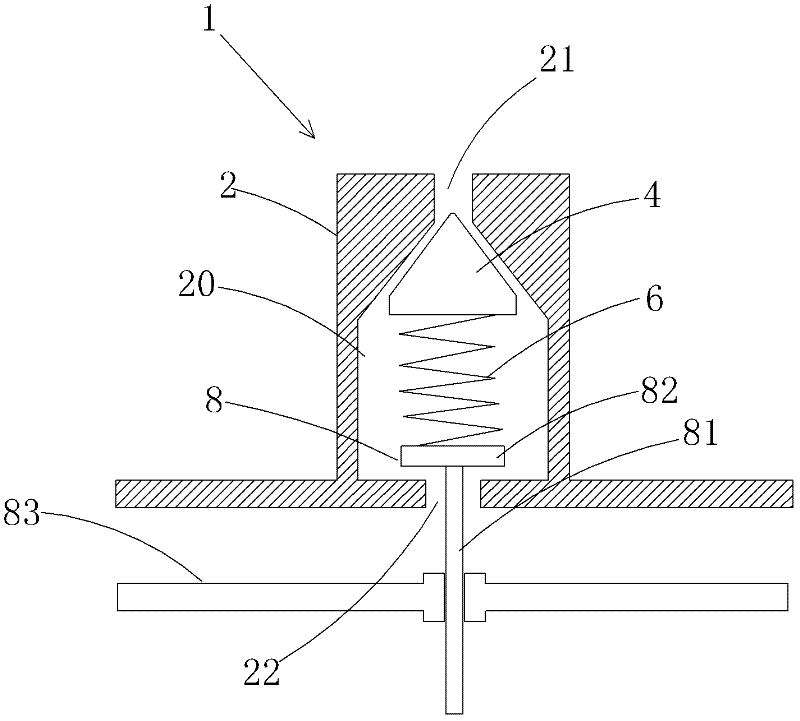

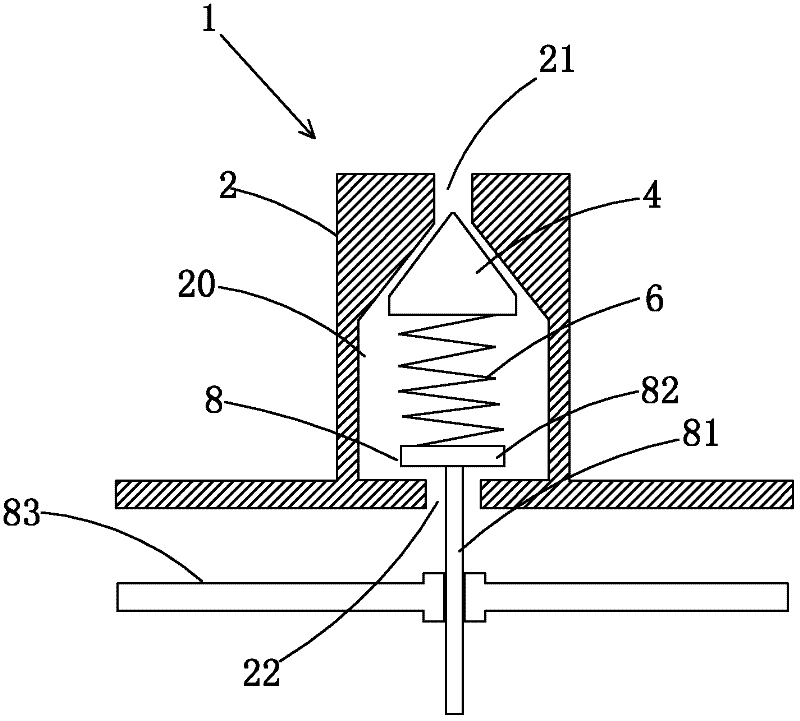

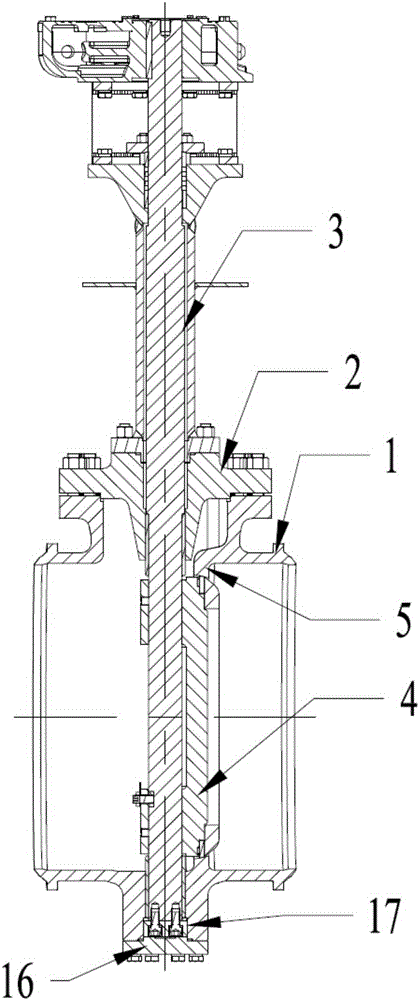

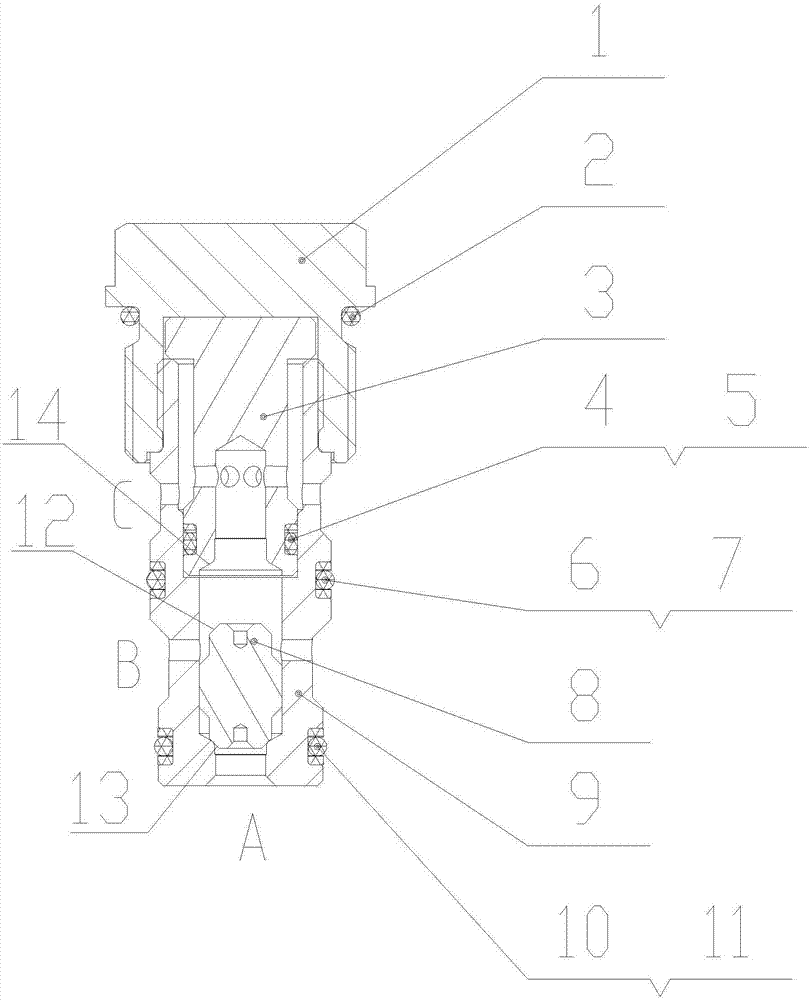

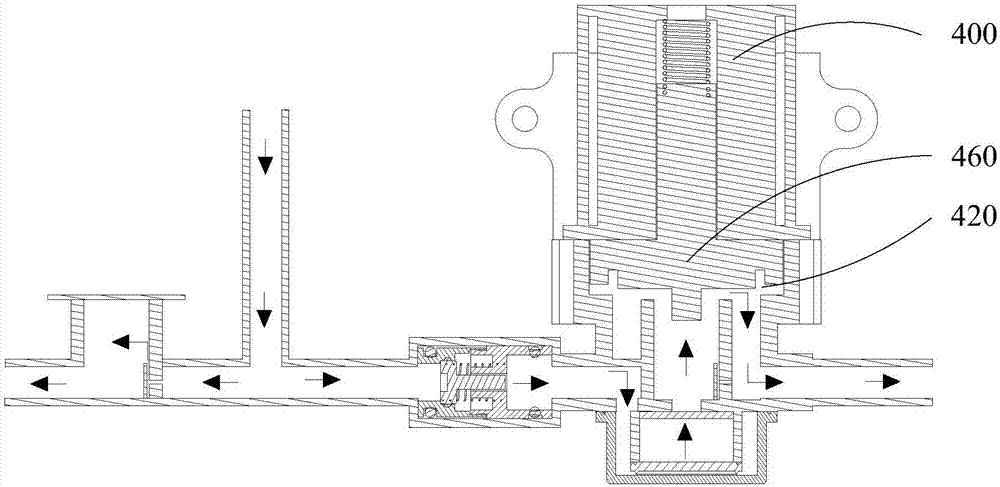

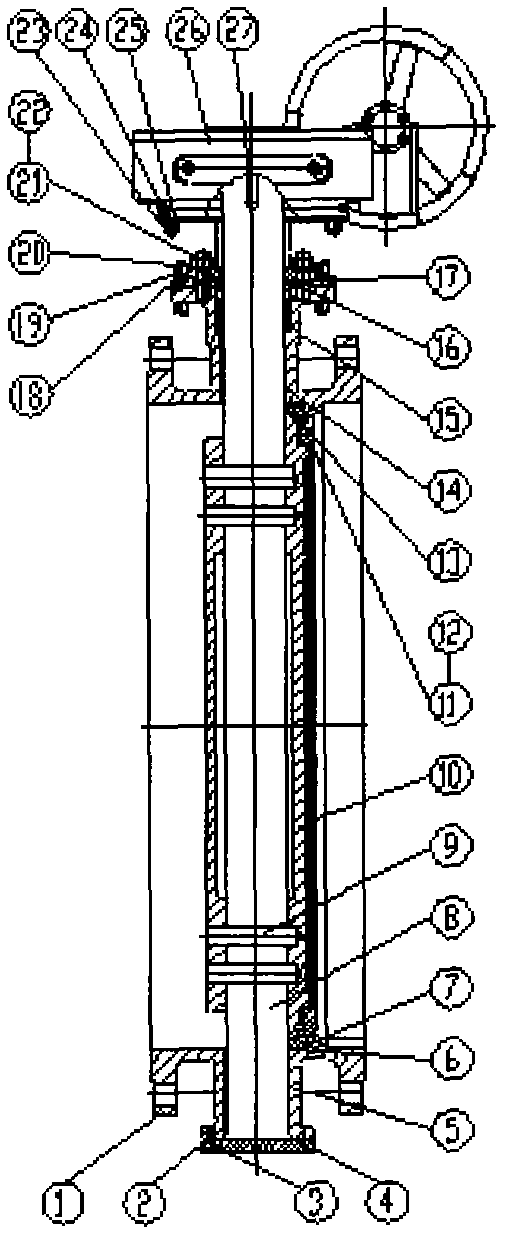

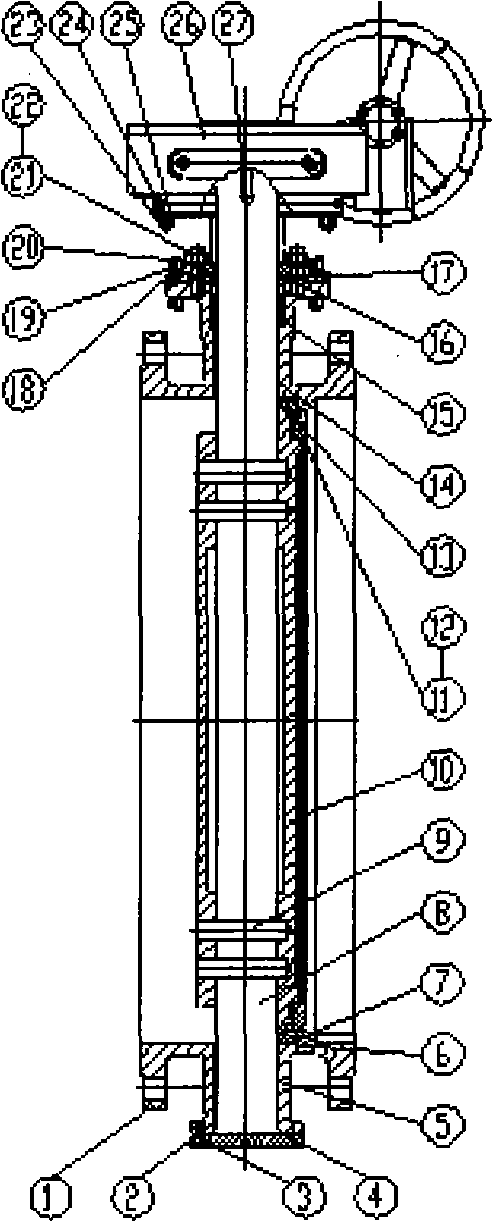

Internally debuggable constant-temperature valve having adjustable KV value

The invention discloses an internally debuggable constant-temperature valve having an adjustable KV value. The internally debuggable constant-temperature valve comprises a valve body, a valve seat, avalve deck, a linkage rod, a piston, a reset spring, a guiding cap, a nut and an adjusting column, wherein an inner cavity with a polygonal cross section is formed in the valve deck, an opening of theinner cavity is downward, the guiding cap is arranged in the cavity and is provided with a third through hole extending in the vertical direction, the guiding cap abuts against the upper end the reset spring, the linkage rod upwards extends out of the third through hole, the nut is arranged in the inner cavity, the outer cross section of the nut is matched with the cross section of the inner cavity, the nut can be vertically move in the inner cavity, a threaded end matched with the nut is arranged at the lower end of the adjusting column, and the upper end of the adjusting column upwards extends out of a second through hole. According to the internally debuggable constant-temperature valve having the adjustable KV value, due to the fact that the rotation of the nut is limited, extension of the adjusting column extending out of the nut can be adjusted by screwing the adjusting column, accordingly the length of the linkage rod extending into the valve body is changed, and the internallydebuggable constant-temperature valve is simple in structure, lower in production cost and more convenient to implement.

Owner:CHINA AEROSPACE CONSTR GROUP

Sleeve Valve with Permanent End Position

Owner:ARCHER OILTOOLS

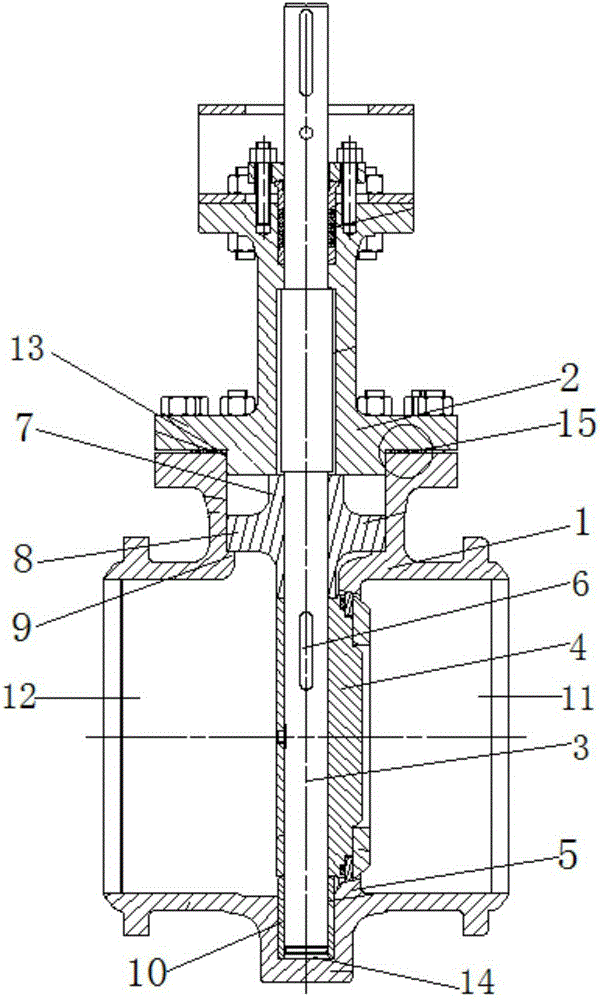

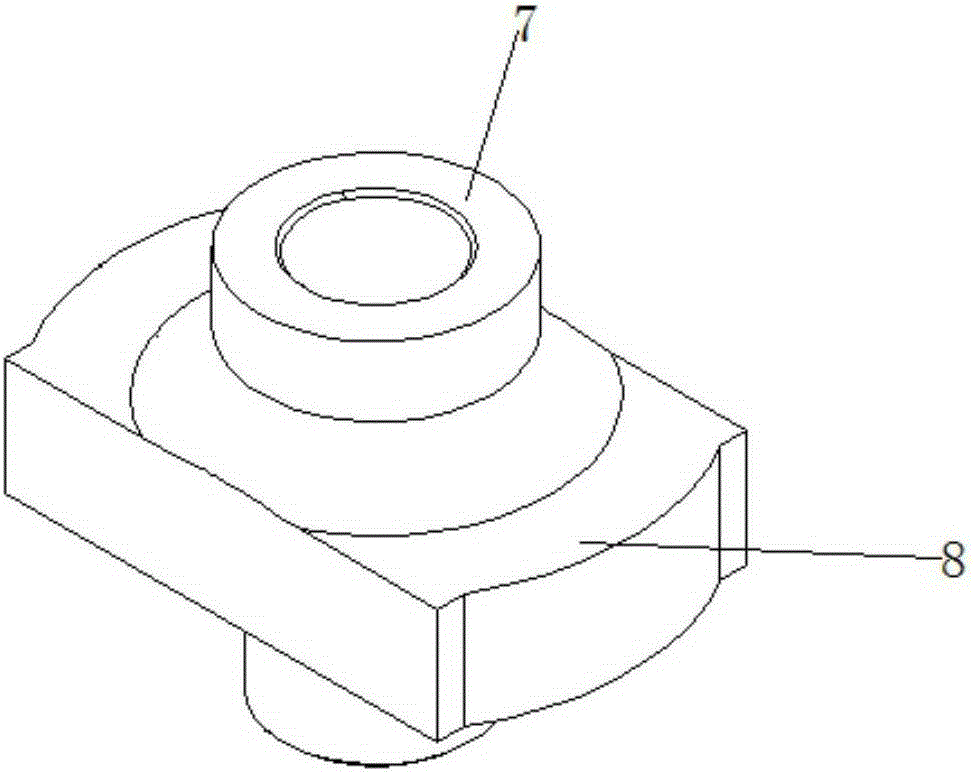

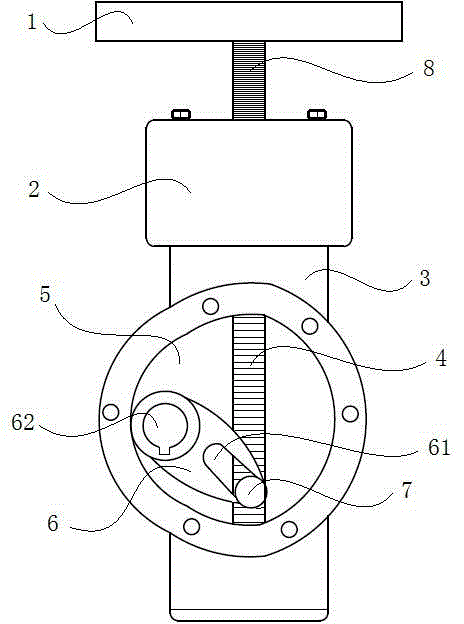

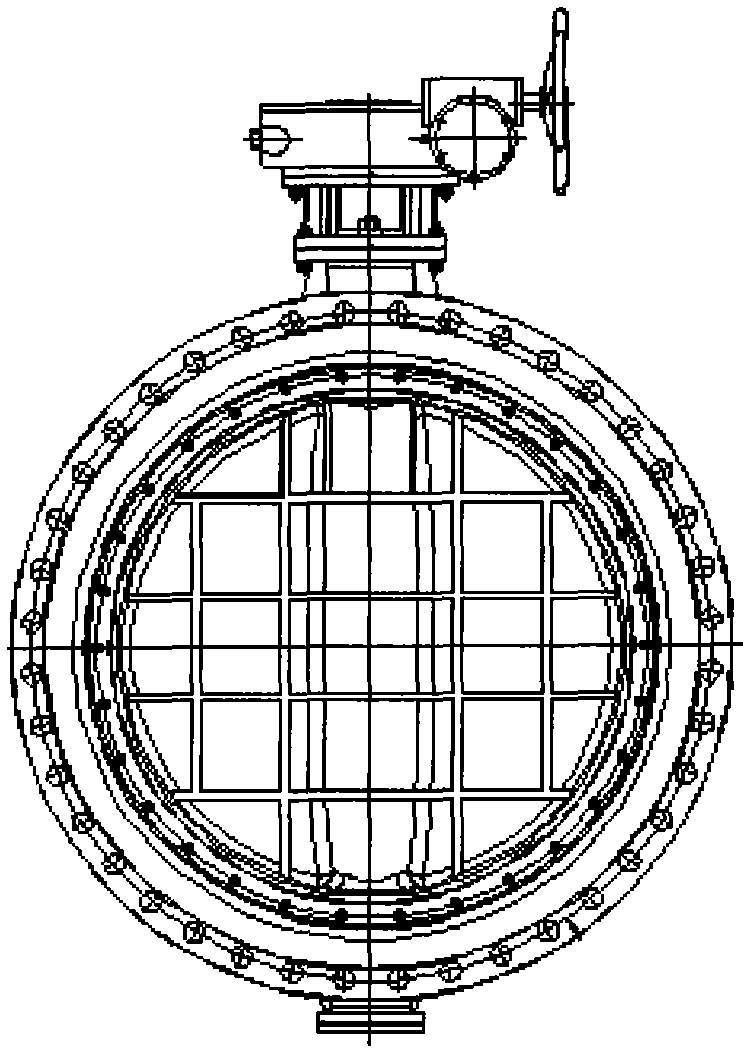

Upper mounting type butterfly valve

Owner:NEWAY VALVE SUZHOU

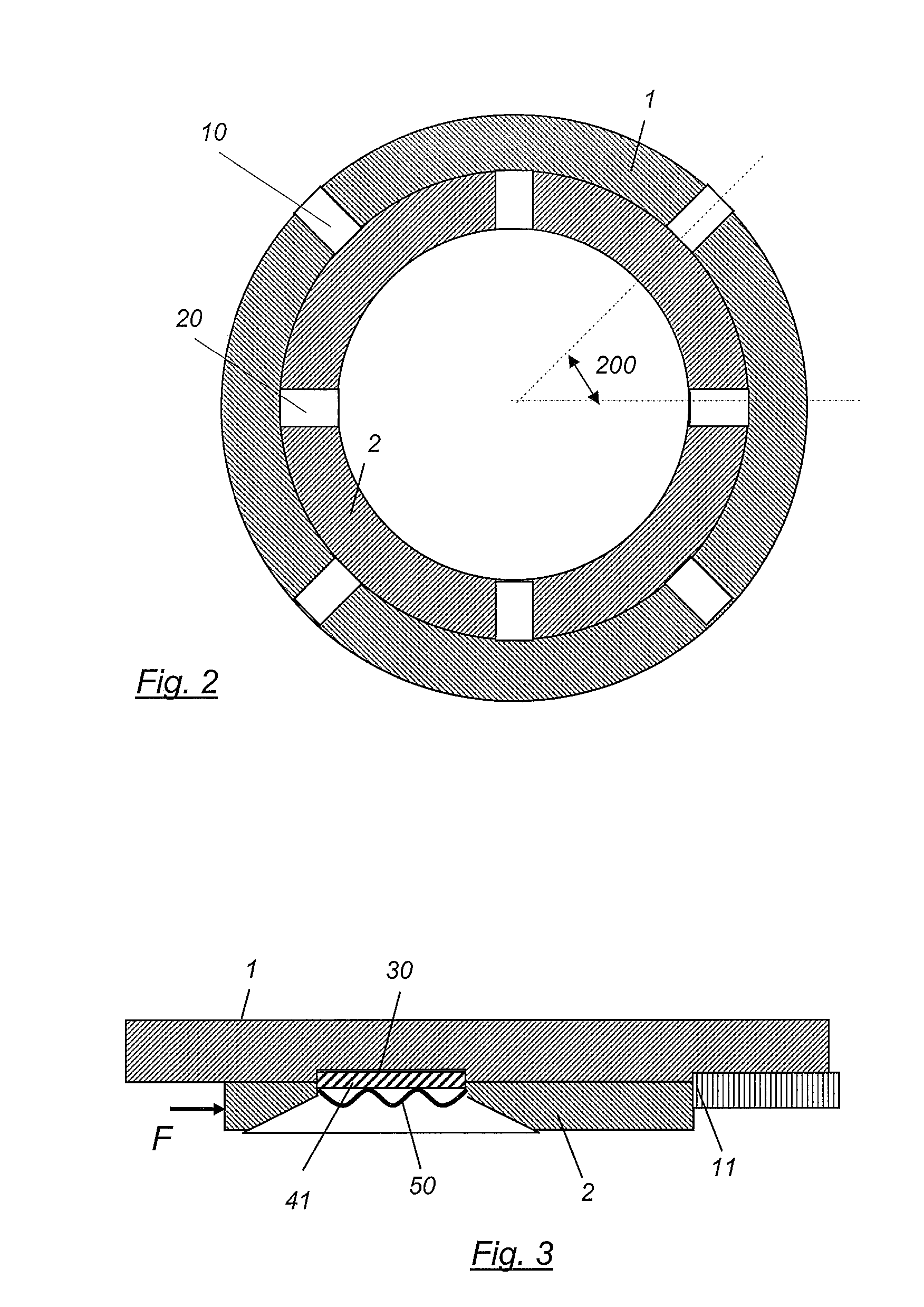

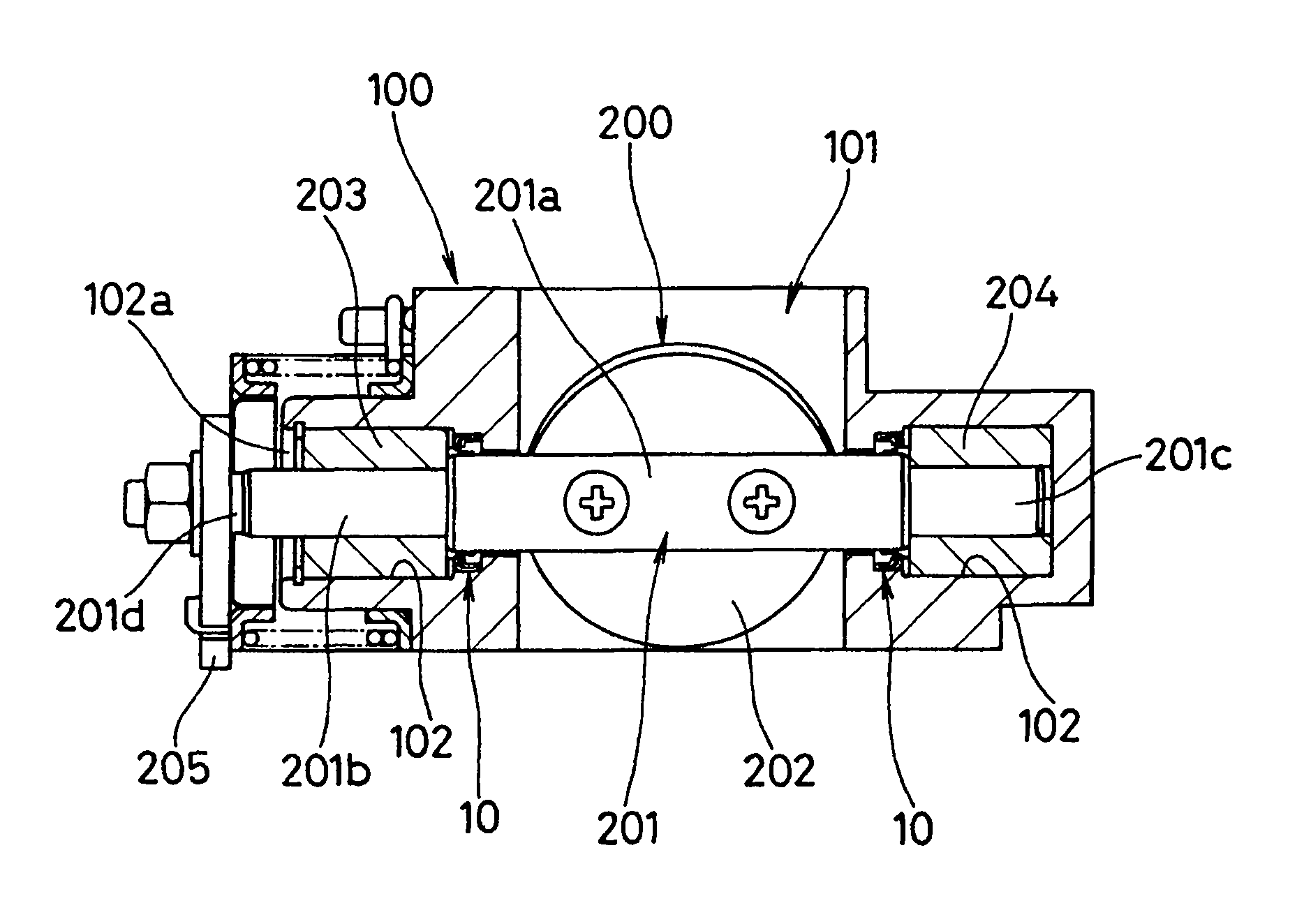

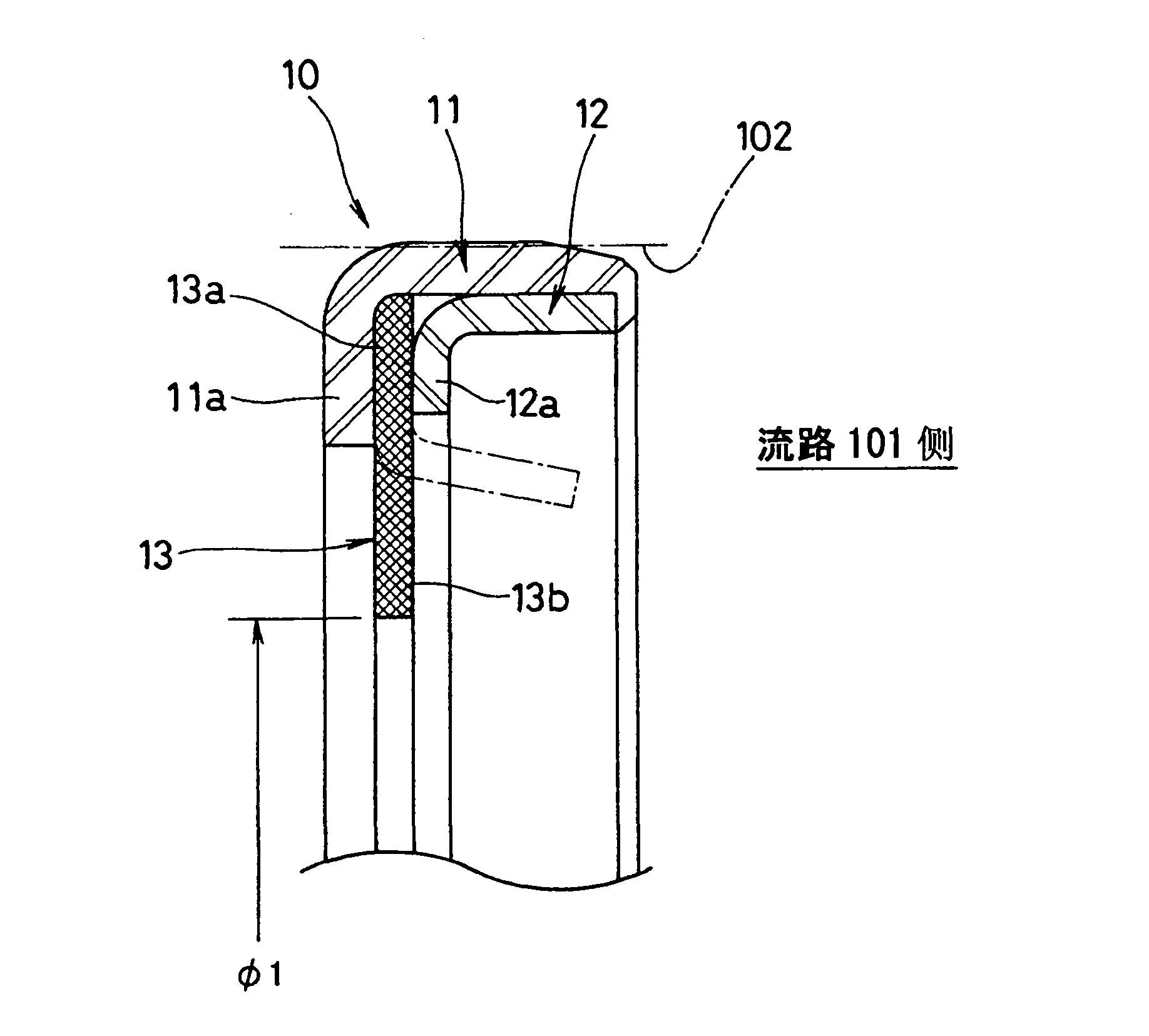

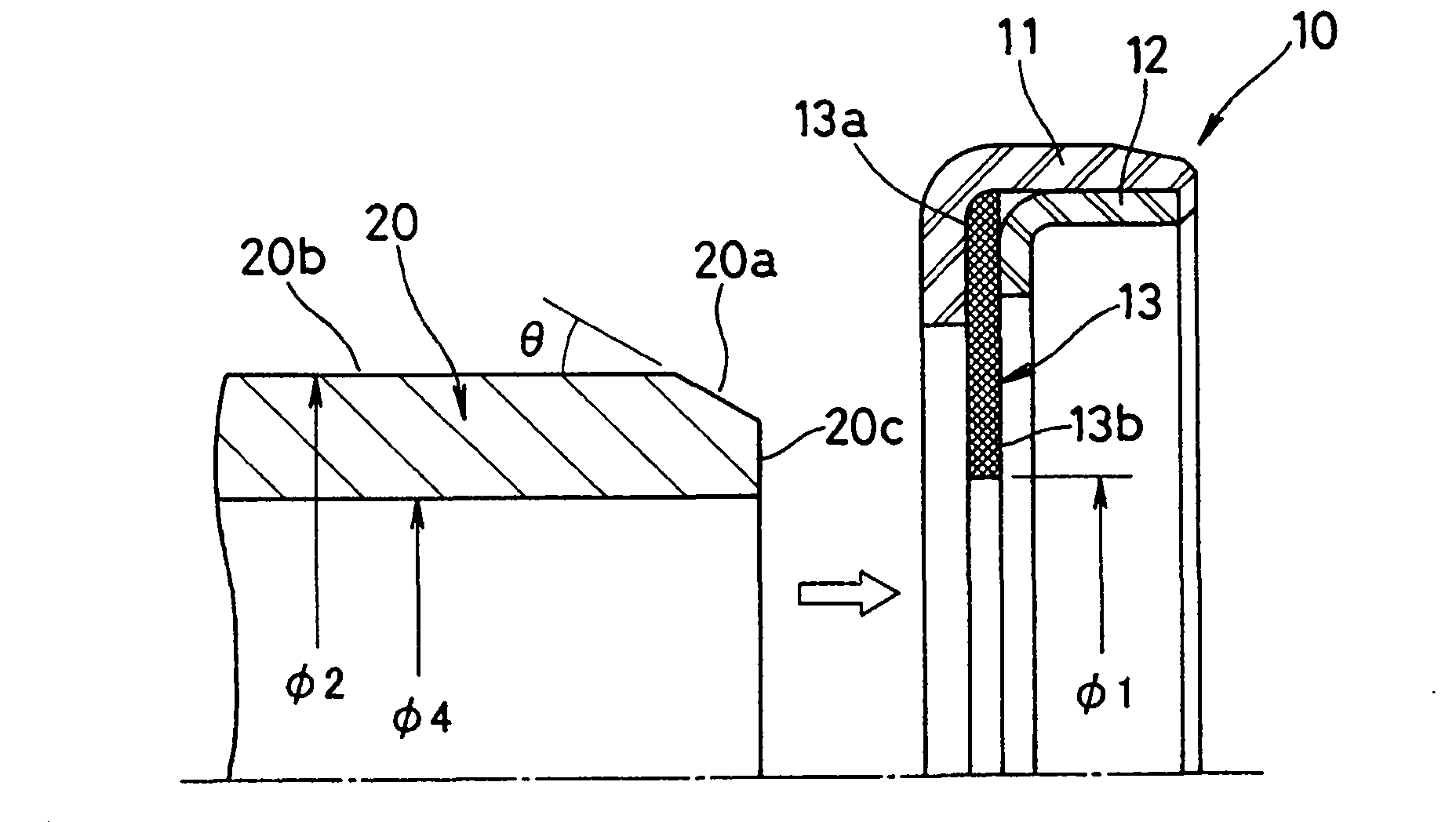

Sealing device and method of mounting same

ActiveCN102144116ALarge initial interferenceImprove sealingEngine sealsNon-fuel substance addition to fuelCircular discButterfly valve

Owner:NOK CORP

Low pressure drop check valve

InactiveCN107289157ASimple structureCompact structureCheck valvesLift valveVertical planeEngineering

Owner:SHANGHAI ZHONGHANG VALVE CO LTD

Intake and exhaust valve raceway and intake and exhaust valve assembly of engine

ActiveCN106282783AReduce wearSolve the problem of gap exceptionMachines/enginesLift valveExhaust valveHeat resistance

The invention relates to an intake and exhaust valve raceway and intake and exhaust valve assembly of an engine. The intake and exhaust valve raceway and intake and exhaust valve assembly comprises an intake valve raceway of the engine and an intake valve matched with the intake valve raceway and an exhaust valve raceway and an exhaust valve matched with the exhaust valve raceway; the intake and exhaust valve raceways contain materials of Ni-Co-Mo-Cr and are manufactured by adopting a powder metallurgy technique; the main contents of the intake valve are Cr-Si-Mn-P or Cr-Mn-Ni-N; the main contents of the exhaust valve are Cr-Mn-Ni-Nb-W, or bead welding is performed on the disc part of the exhaust valve with the materials of Cr-W-Ni-Fe-Mo; and the problem of mechanical tappet clearance abnormity of the natural gas engine is solved by lowering abrasion loss between the intake valve raceway and the intake valve as well as abrasion loss between the exhaust valve raceway and the exhaust valve. According to the intake and exhaust valve raceway and intake and exhaust valve assembly, abrasion-resistance, heat-resistance and radial crushing strength of the intake valve raceway and the exhaust valve raceway are improved; and quality problems of valve clearance abnormity and the like caused by abnormal abrasion and deformation between the intake valve raceway and the intake valve as well as between the exhaust valve raceway and the exhaust valve are solved.

Owner:SMAPOW ENGINE

Automatic water-saving faucet

Owner:张庆柳

Switch assembly of synthetic liquid fuel range

InactiveCN101435597ACompact structureFlexible structureDomestic stoves or rangesLighting and heating apparatusEngineeringLiquid fuel

Owner:张世贵

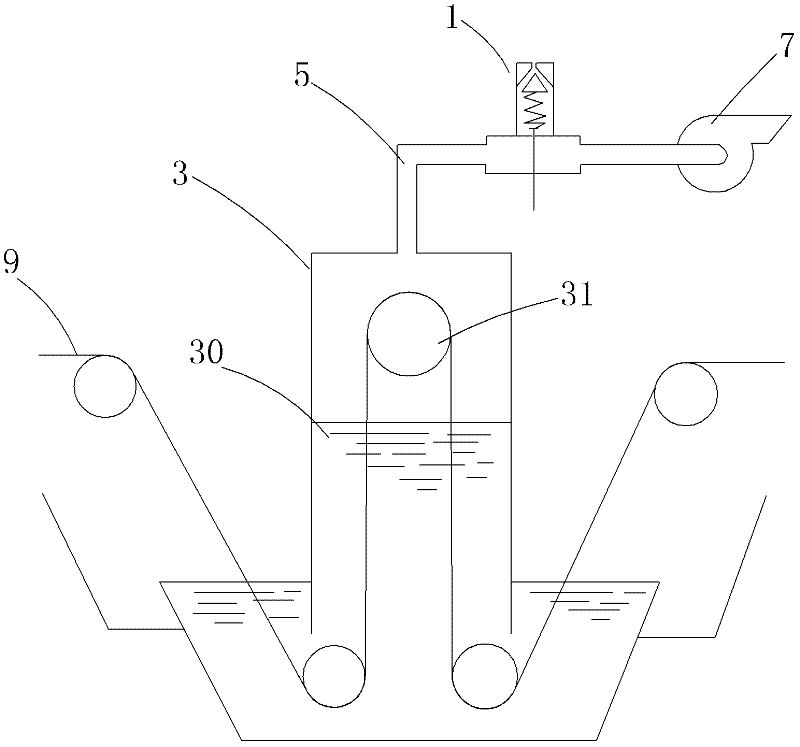

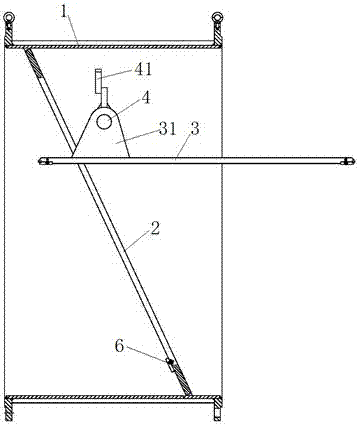

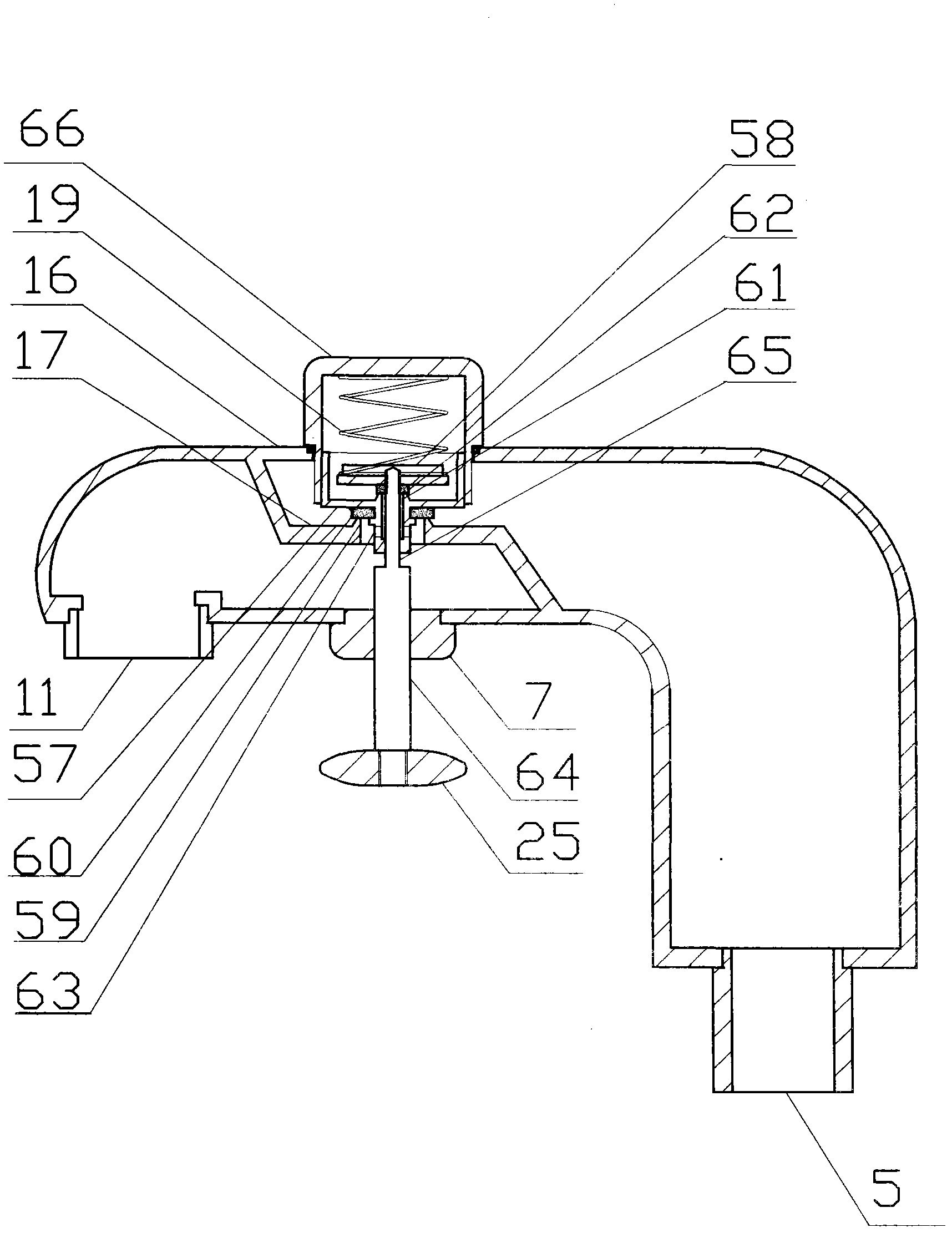

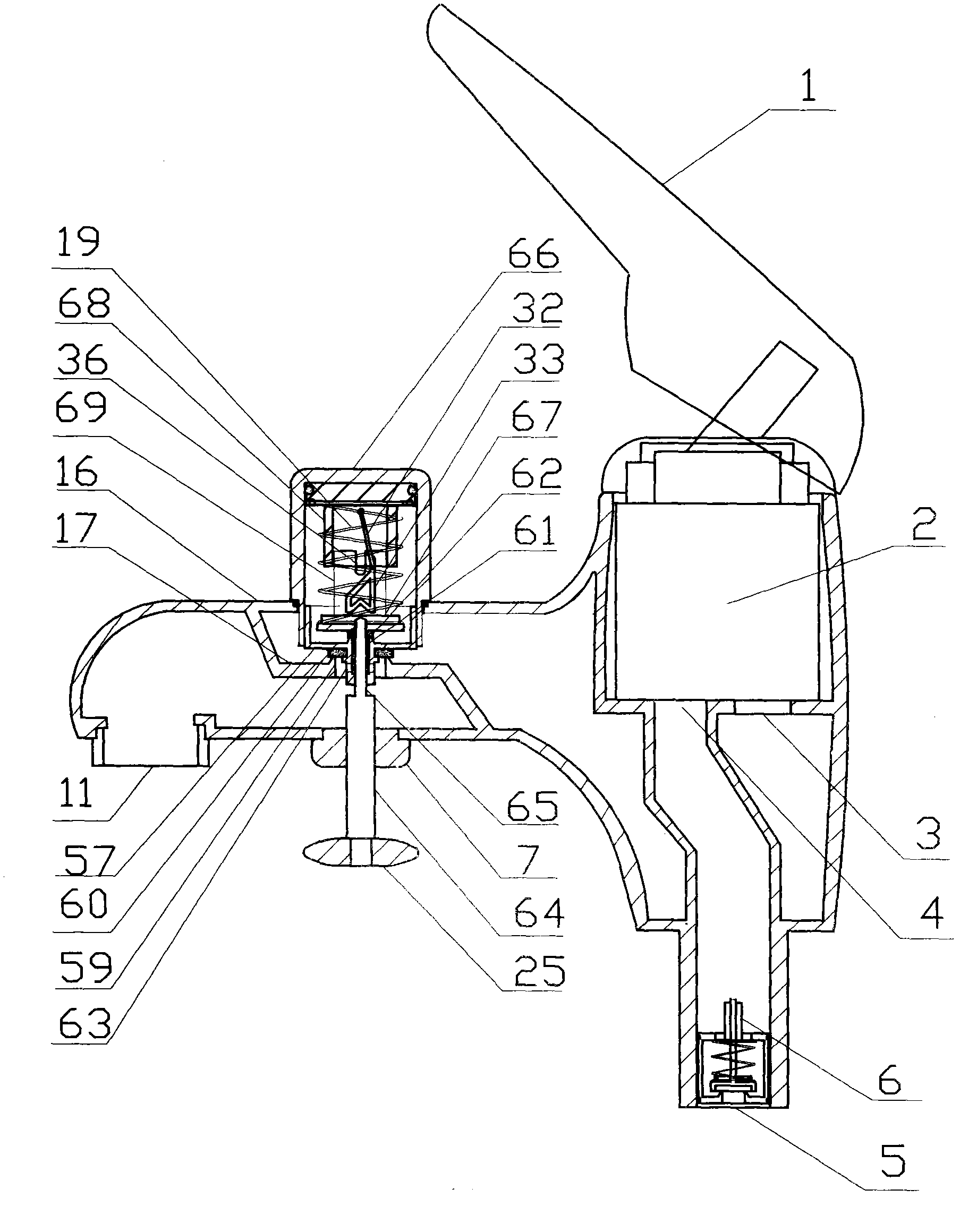

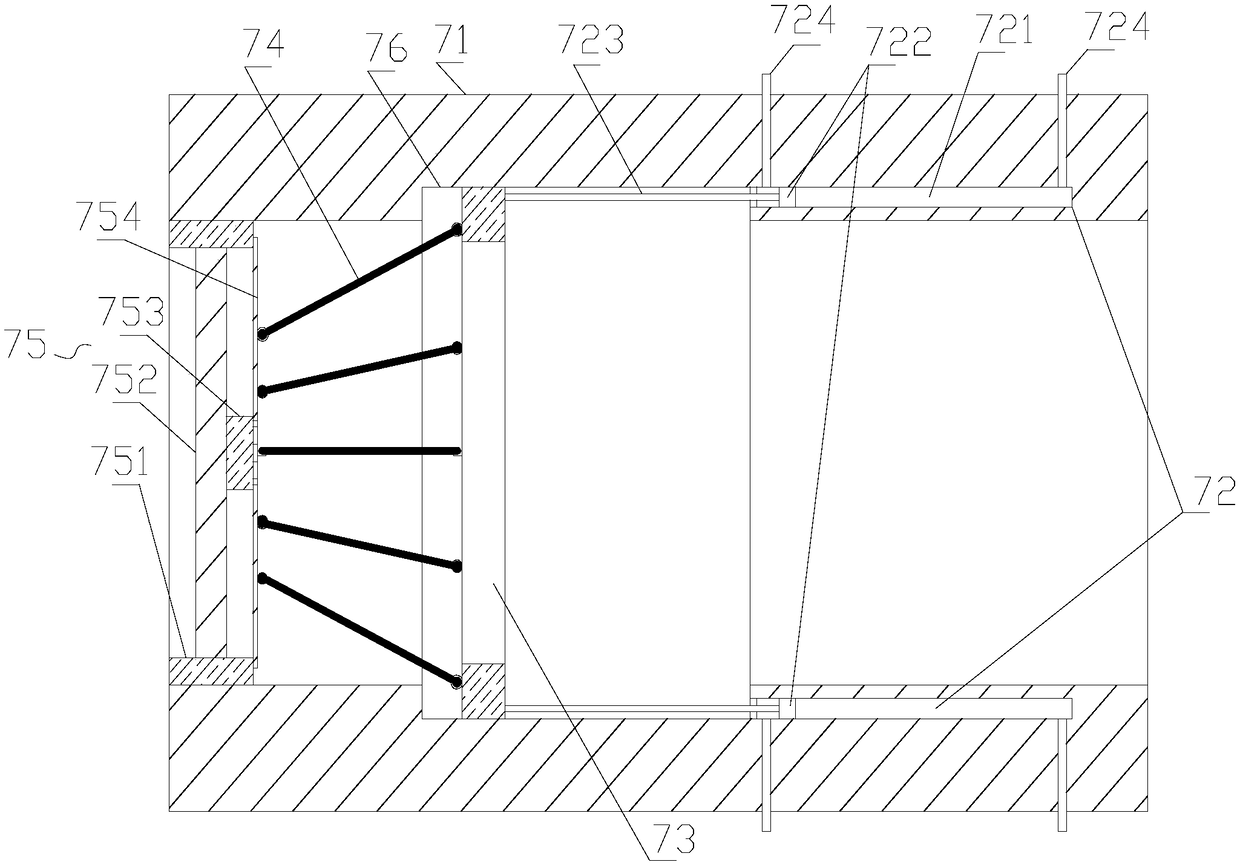

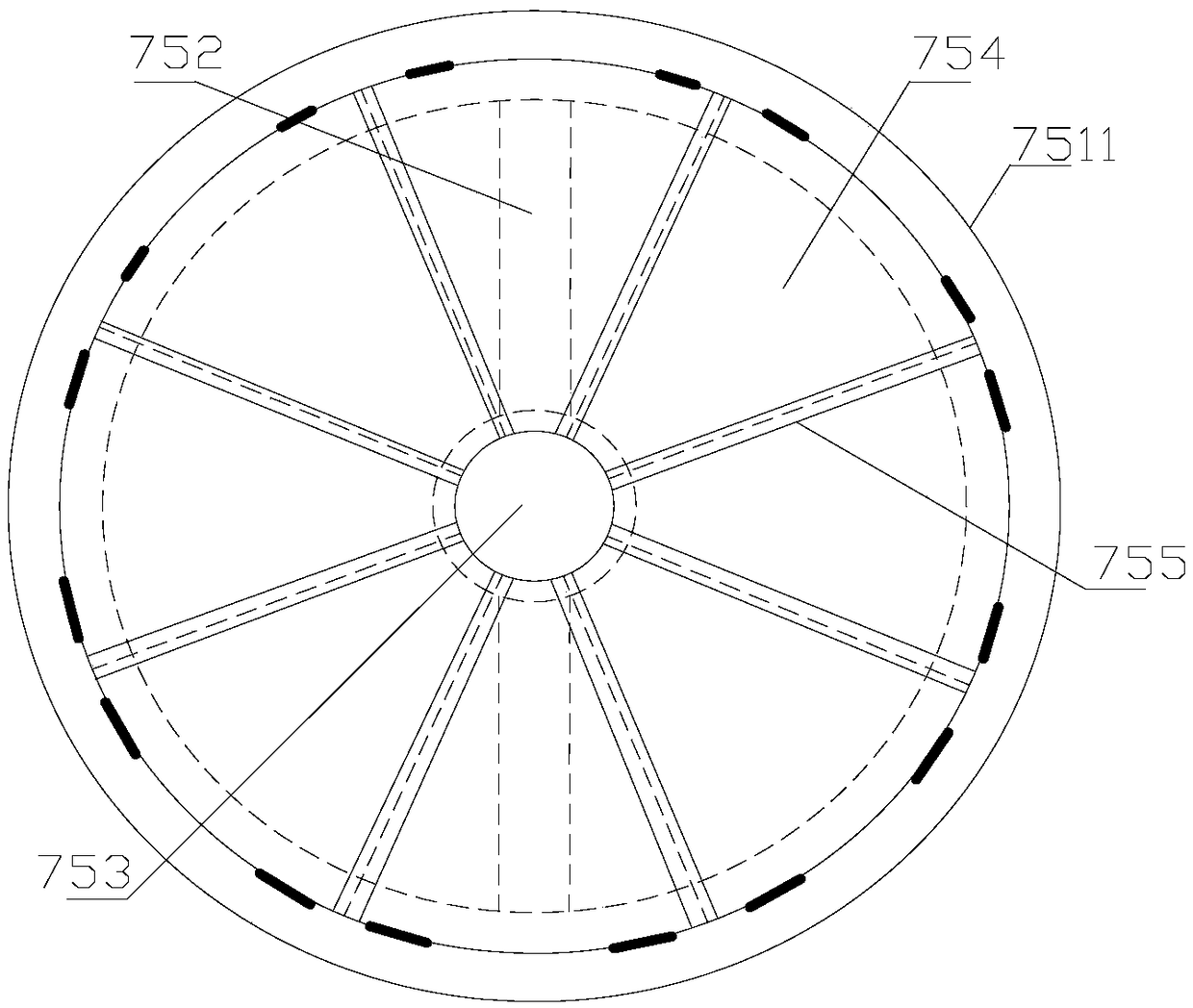

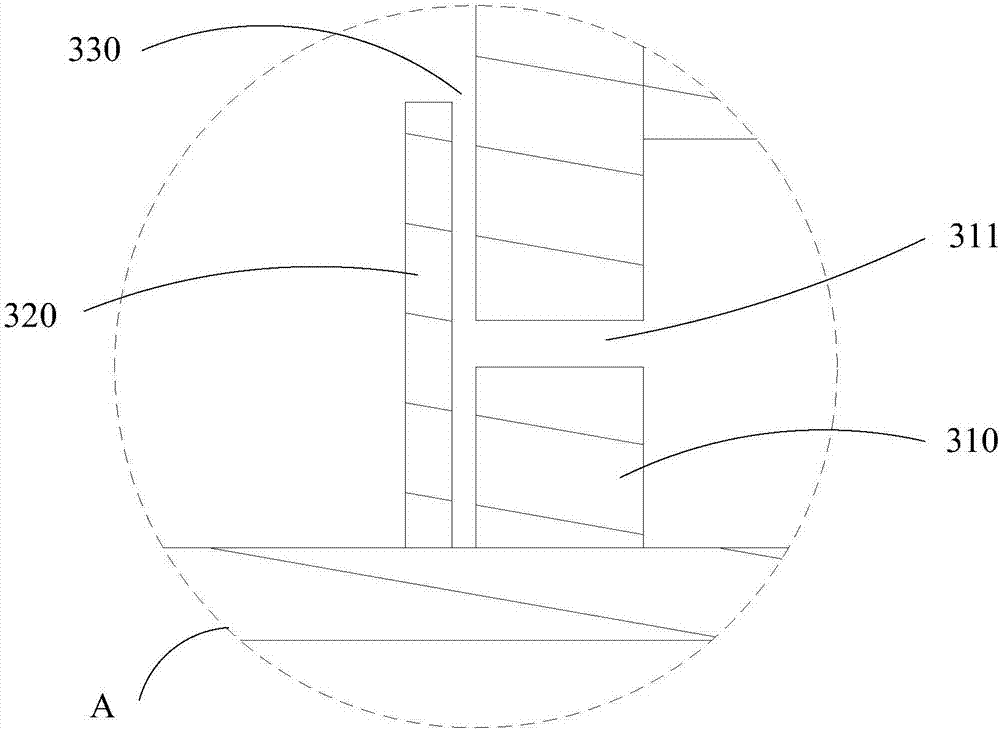

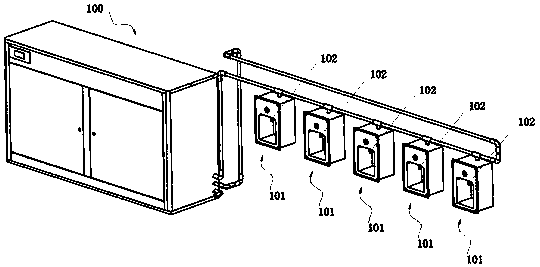

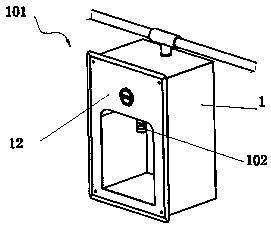

Vacuum slit valve

The invention relates to a vacuum slit valve which comprises a valve body. The valve body is provided with a channel for conveying a strip, and a vacuum accommodating cavity is disposed in the valve body. A valve body assembly and a valve plate assembly are placed in the vacuum accommodating cavity, and an executor connected with the valve plate assembly is arranged outside the valve body assembly. The valve body assembly is provided with a channel for conveying the strip, and the channel arranged on the valve body assembly is communicated with the channel arranged on the valve body, an included angle between the sealing surface of the valve body assembly and the working direction of the strip is 10-45 degrees, and at least one compressible sealing element surrounds a channel outlet of the sealing surface of the valve body assembly. An included angle between the sealing surface of the valve plate assembly and the working direction of the strip is 10-45 degrees, and the sealing surface of the valve plate assembly is provided with compressible sealing elements corresponding to the sealing elements on the sealing surface of the valve body assembly. According to the vacuum slit valve, under the conditions that the strip is not damaged, vacuum sealing of different vacuum chamber parts is achieved.

Owner:XIAORUI VACUUM EQUIP (JIAXING) CO LTD

Shifting fork type butterfly valve driver

Owner:JIANGSU ZHONGQIANG INTERNAL COMBUSTION ENGINE FITTINGS

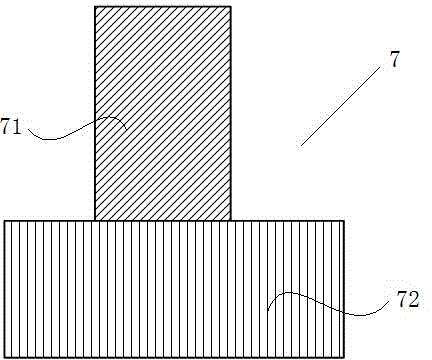

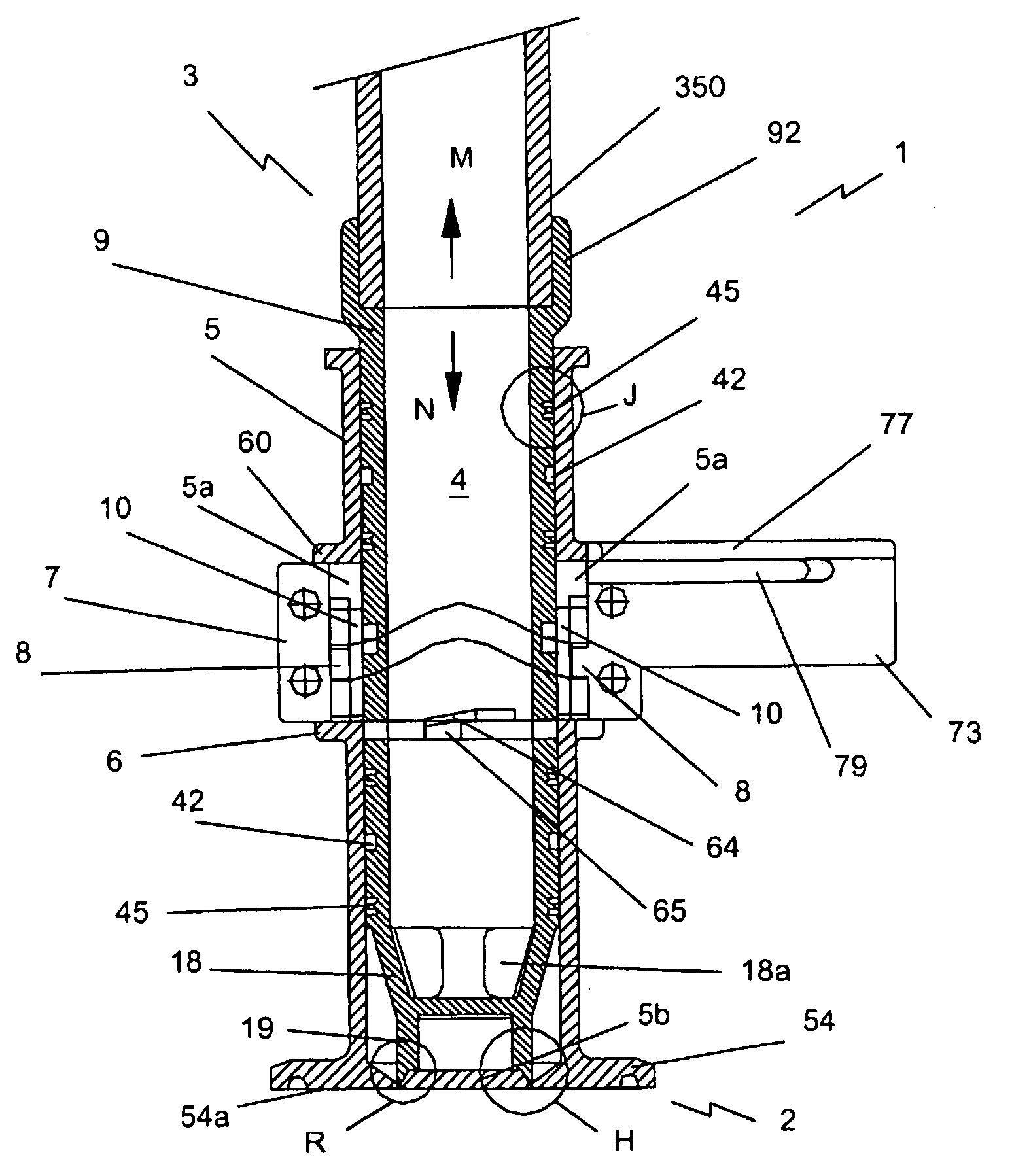

Valve

InactiveUS7766029B2Quicker and easy separationReduce riskOperating means/releasing devices for valvesPlungersDownstream processingCam

Owner:GL TOOL & MFG

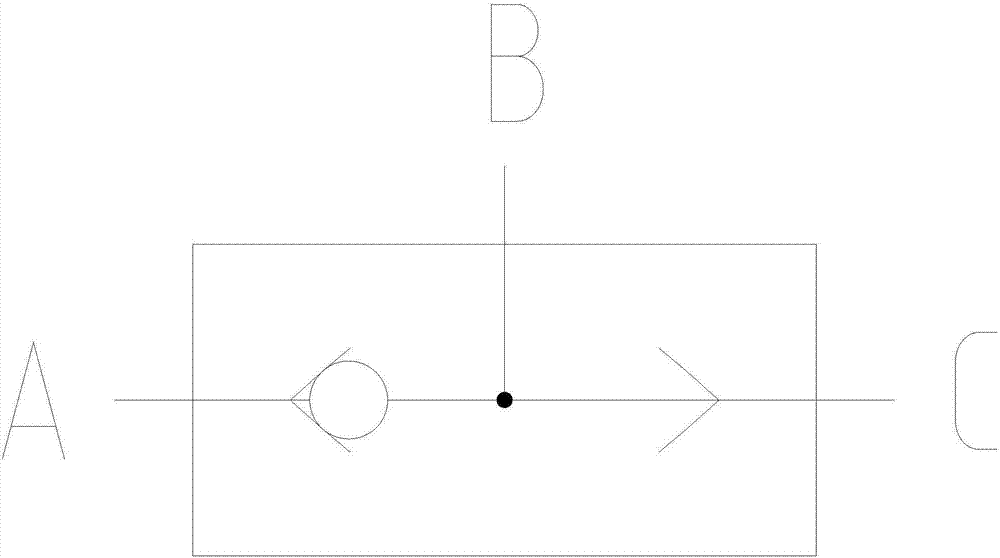

Shuttle valve, hydraulic system and mechanical equipment

Owner:HUNAN KAIENLI HYDRAULIC MACHINERY MFG CO LTD

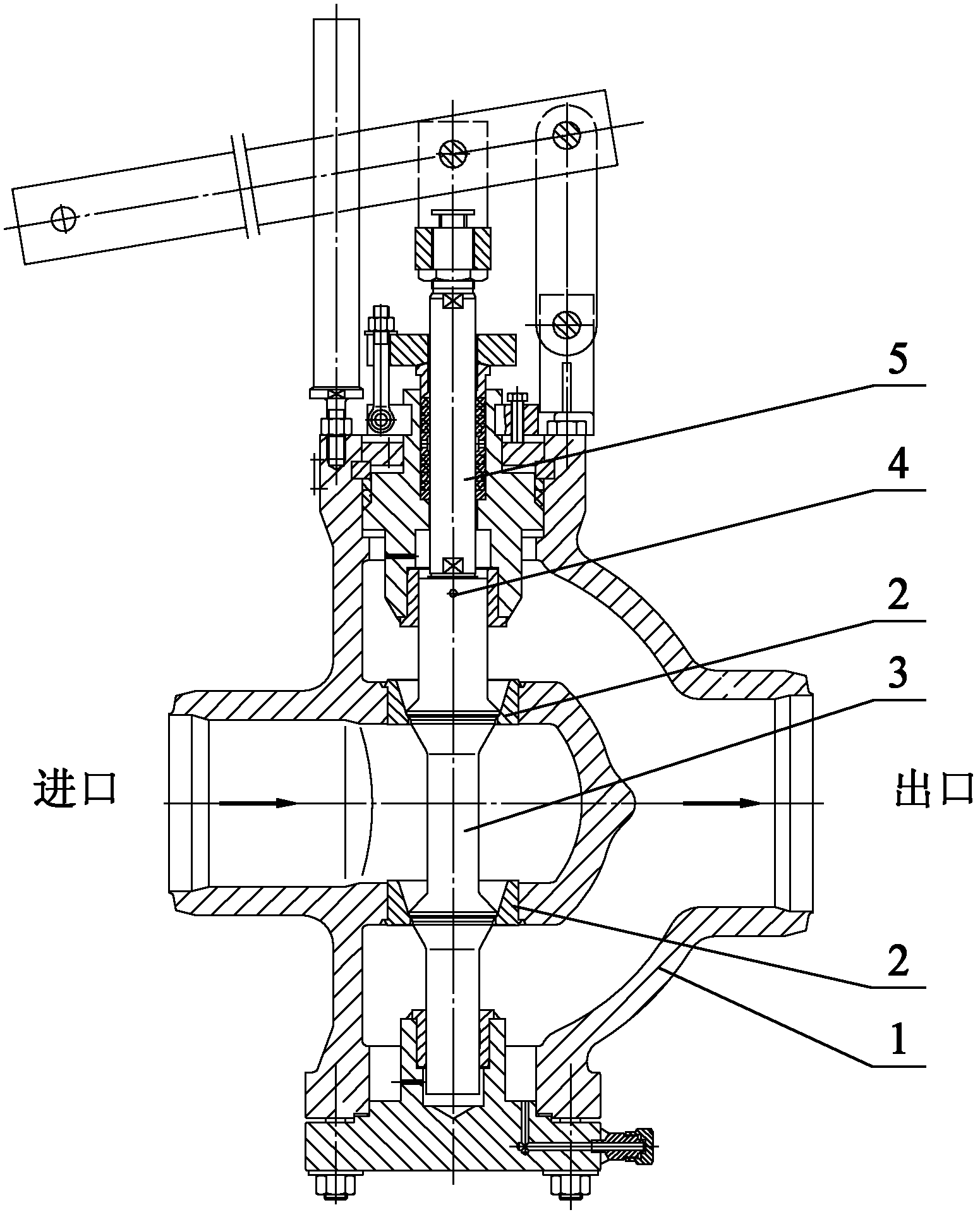

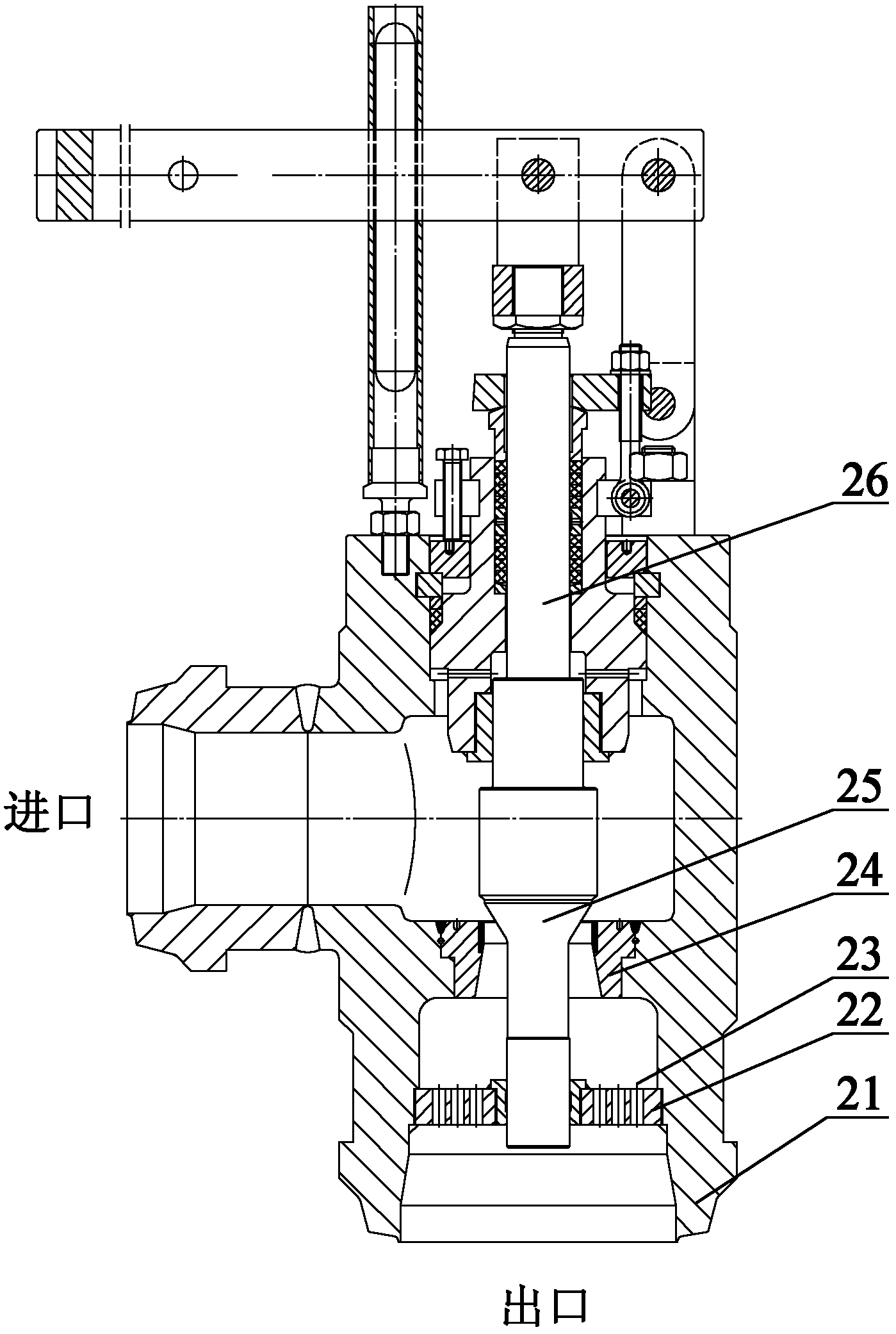

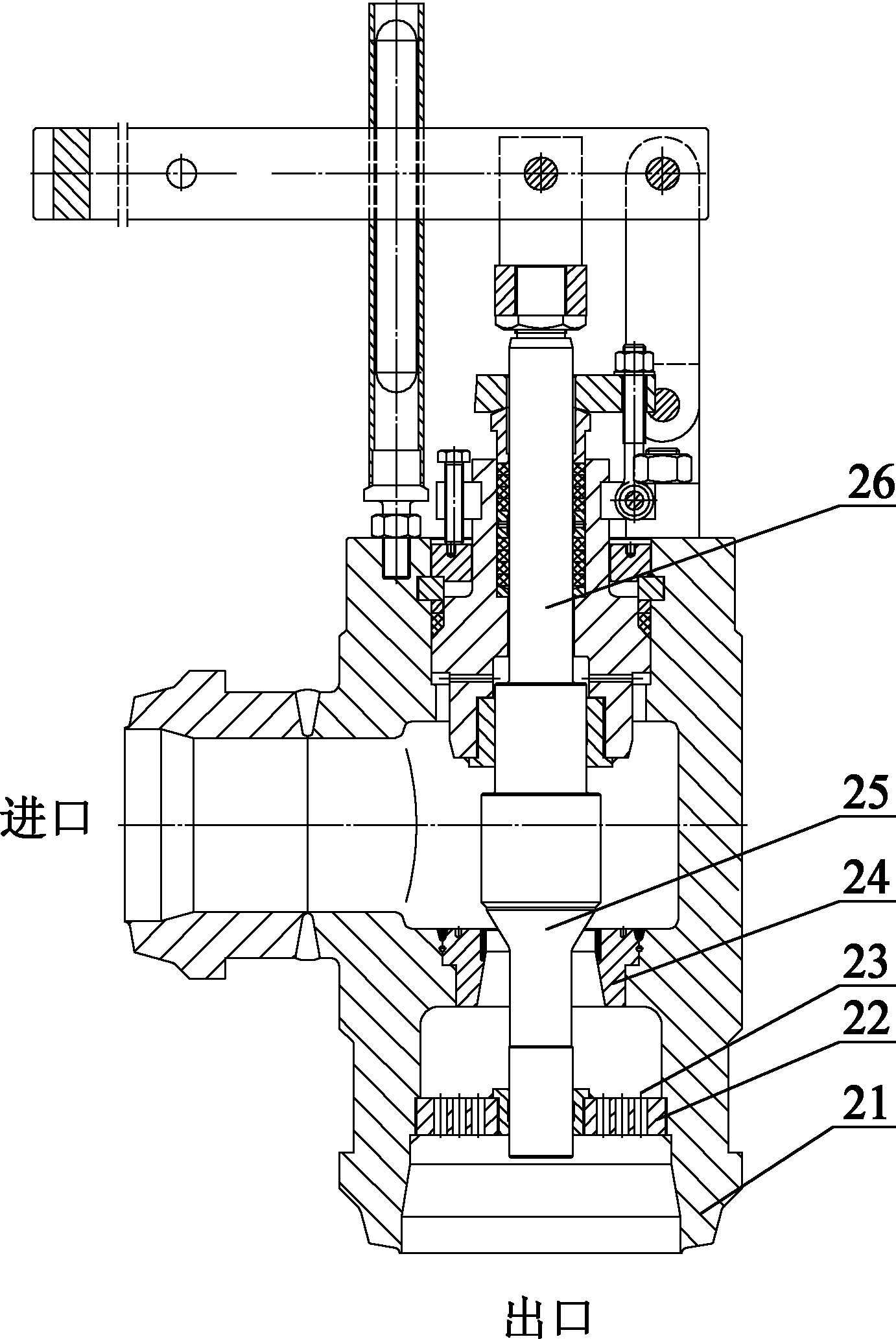

Pressure reducing valve and temperature-reducing and pressure-reducing device

Owner:HANGZHOU WORLDWISE VALVE

Capsule type water quantity adjusting device with discharge door device with large opening degree

ActiveCN109442060AWide openAvoid wear and tearDiaphragm valvesOperating means/releasing devices for valvesNatural materialBall valve

Owner:山东高新创达科技创业服务有限公司

Check valve allowing external adjustment of closing positions of valve plate

InactiveCN103383013AAvoid disassemblyExtended service lifeCheck valvesLift valveEngineeringCheck valve

Owner:BENSV VALVE CO LTD

Waste water valve, and reverse osmosis water purifier

ActiveCN107998888ASimple waterwaySimple structureReverse osmosisWater/sewage treatment bu osmosis/dialysisReverse osmosisWater purification filter

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

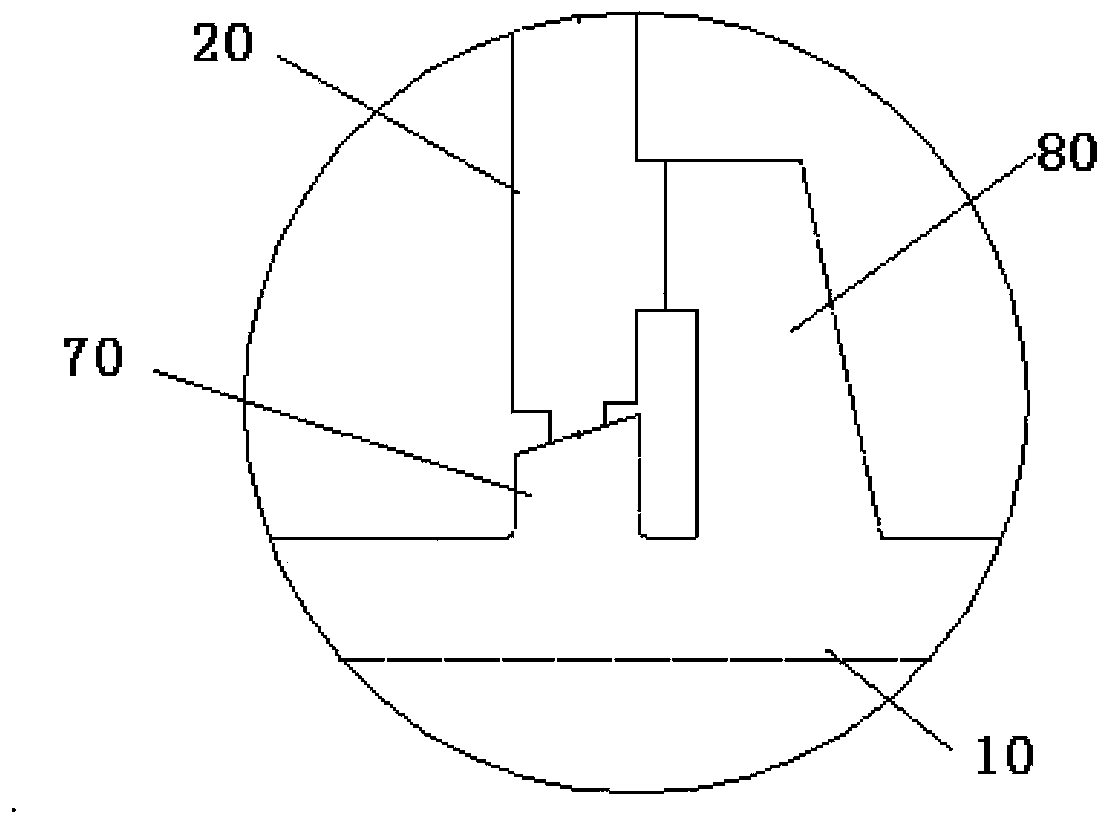

Eccentric two-way sealing butterfly valve

InactiveCN101988590AAchieving tightnessPrevent backflowOperating means/releasing devices for valvesLift valveEngineeringButterfly valve

Owner:JIANGSU SUWEI VALVE

Water dispenser for jail

Owner:中山市全众饮水设备有限公司

Volume Flow-Regulated Seat Valve

InactiveUS20180112789A1Operating means/releasing devices for valvesInternal combustion piston enginesEngineeringMotorized vehicle

Owner:KENDRION VILLINGEN GMBH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap