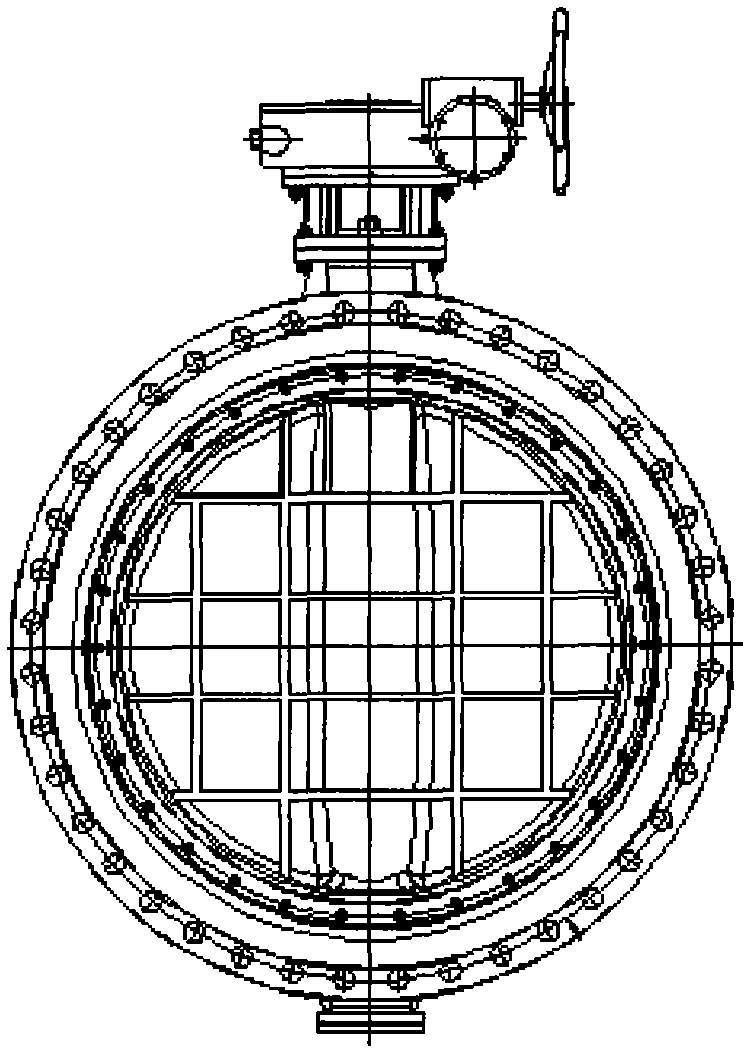

Eccentric two-way sealing butterfly valve

A two-way sealing, eccentric technology, applied in the direction of lift valve, valve details, valve device, etc., can solve problems such as butterfly valve leakage, and achieve the effect of preventing valve leakage, alleviating excessive deformation, and convenient replacement of floating valve seat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is an improvement based on the structural defects of the existing butterfly valve. According to the necessary requirements for sealing, a floating sealing valve seat is added, and the fluid pushes the floating valve seat to generate a specific pressure greater than the minimum sealing pressure so that the two directions of the butterfly valve All can be sealed.

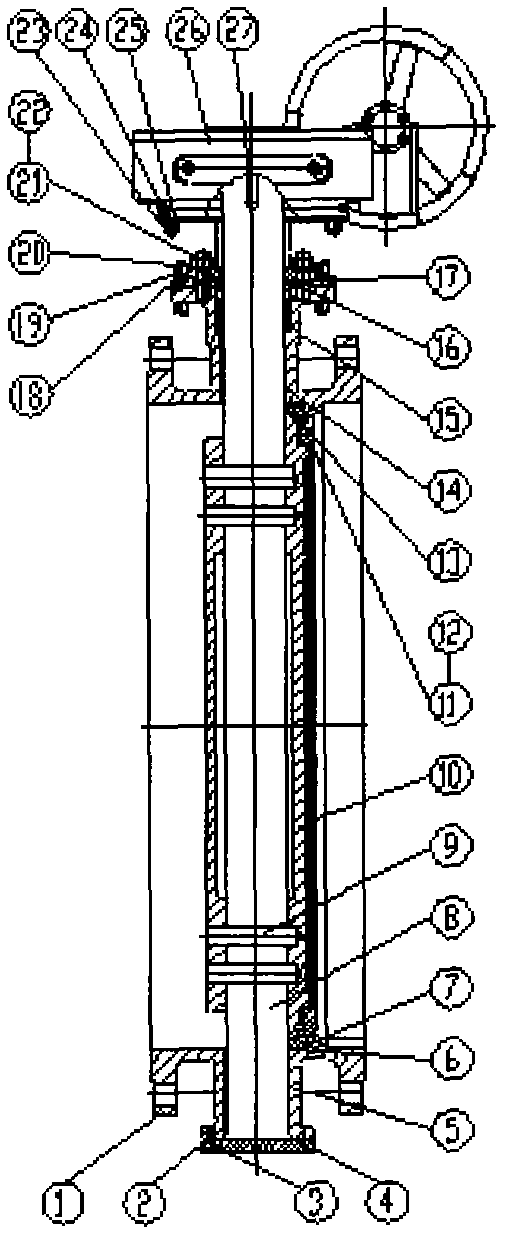

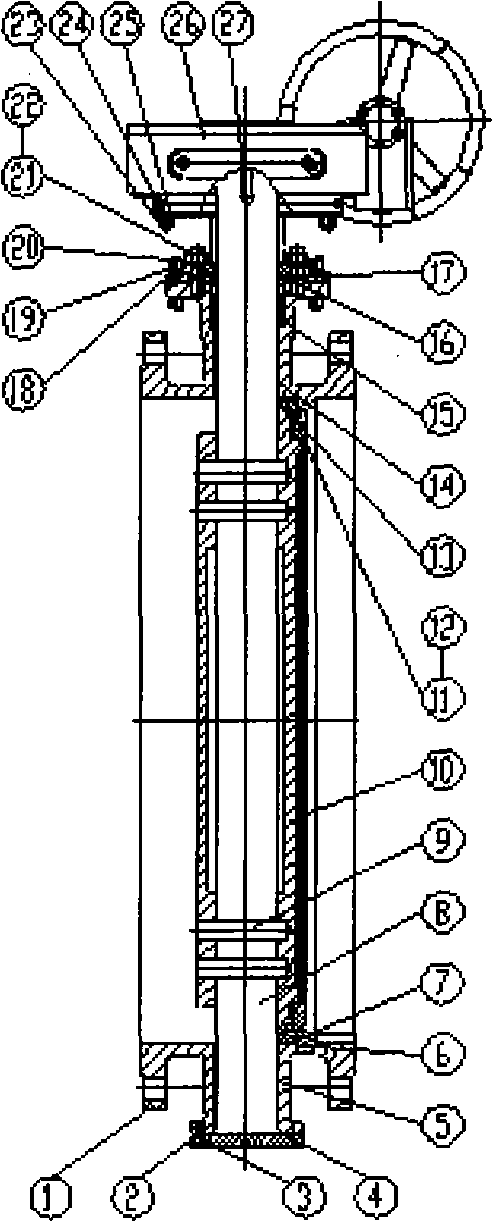

[0025] attached figure 2 It is the left side view of the present invention, as shown in the figure, the torque input to the worm gear device 26 (also can be other such as electric device, hydraulic device or handle, etc.) drives the valve stem 8 to rotate through the key 27, and the valve stem torque passes through the cylindrical pin 9 Drive the butterfly plate 10 and multi-layer sealing ring 13 (the multi-layer sealing ring 13 is fixed on the butterfly plate 10 through the hexagon socket head screw 12 and the pressure plate ring 11) to rotate, and the multi-layer sealing ring 13 gradually

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap