Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Valve seat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The valve seat in an internal combustion gasoline or diesel engine is the surface against which an intake or an exhaust valve rests during the portion of the engine operating cycle when that valve is closed. The valve seat is a critical component of an engine in that if it is improperly positioned, oriented, or formed during manufacture, valve leakage will occur which will adversely affect the engine compression ratio and therefore the engine efficiency, performance (engine power and engine torque), exhaust emissions, and engine life.

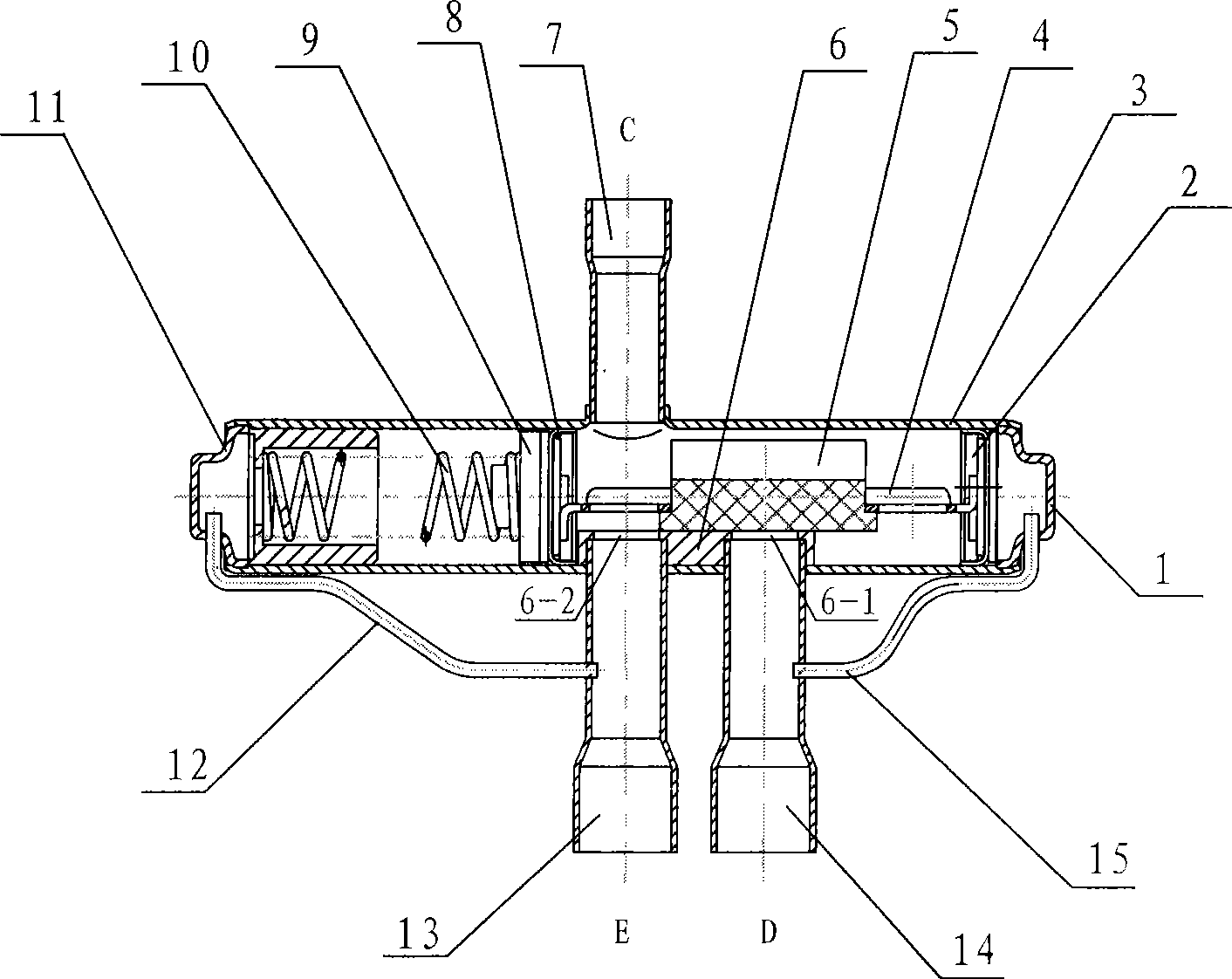

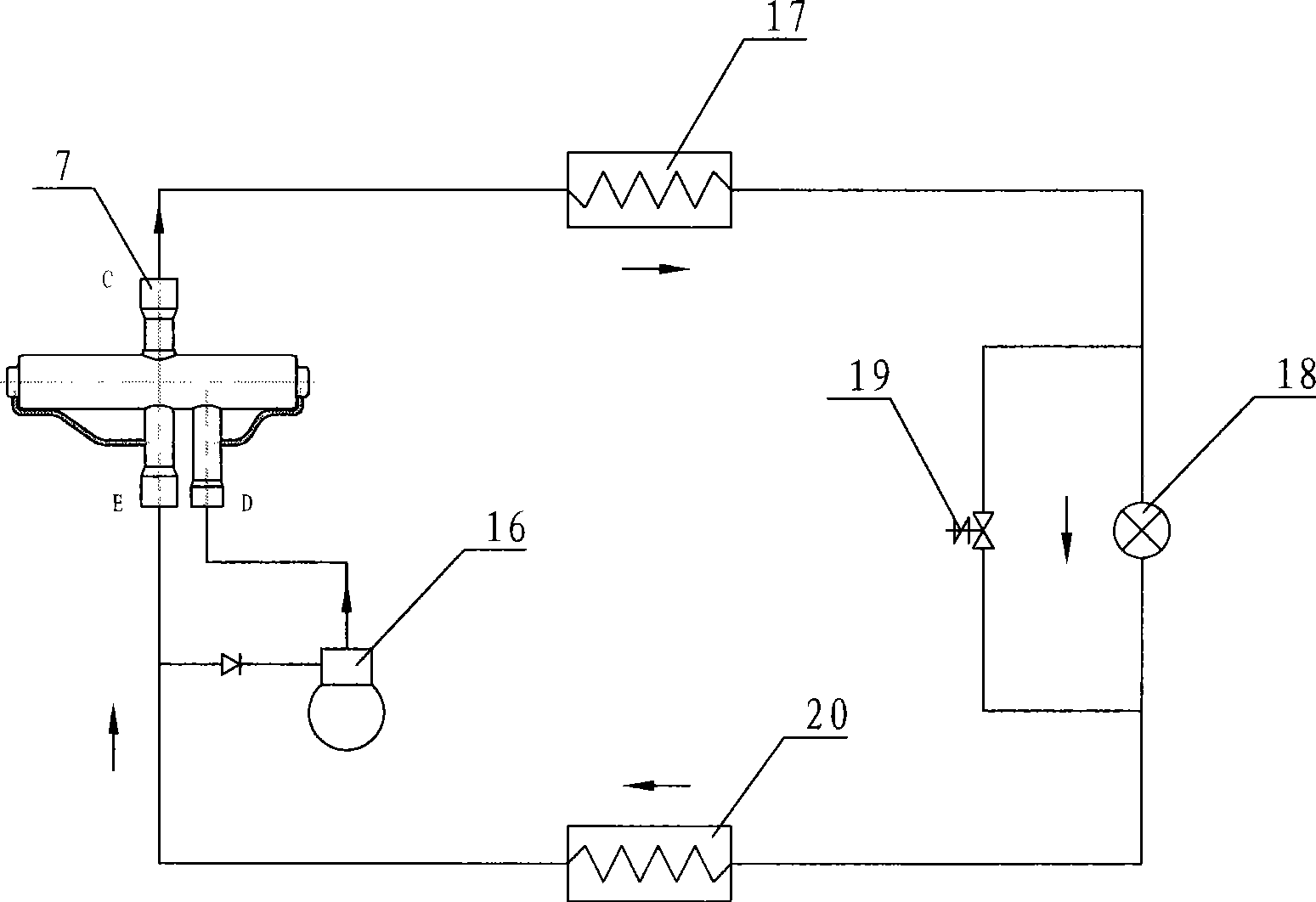

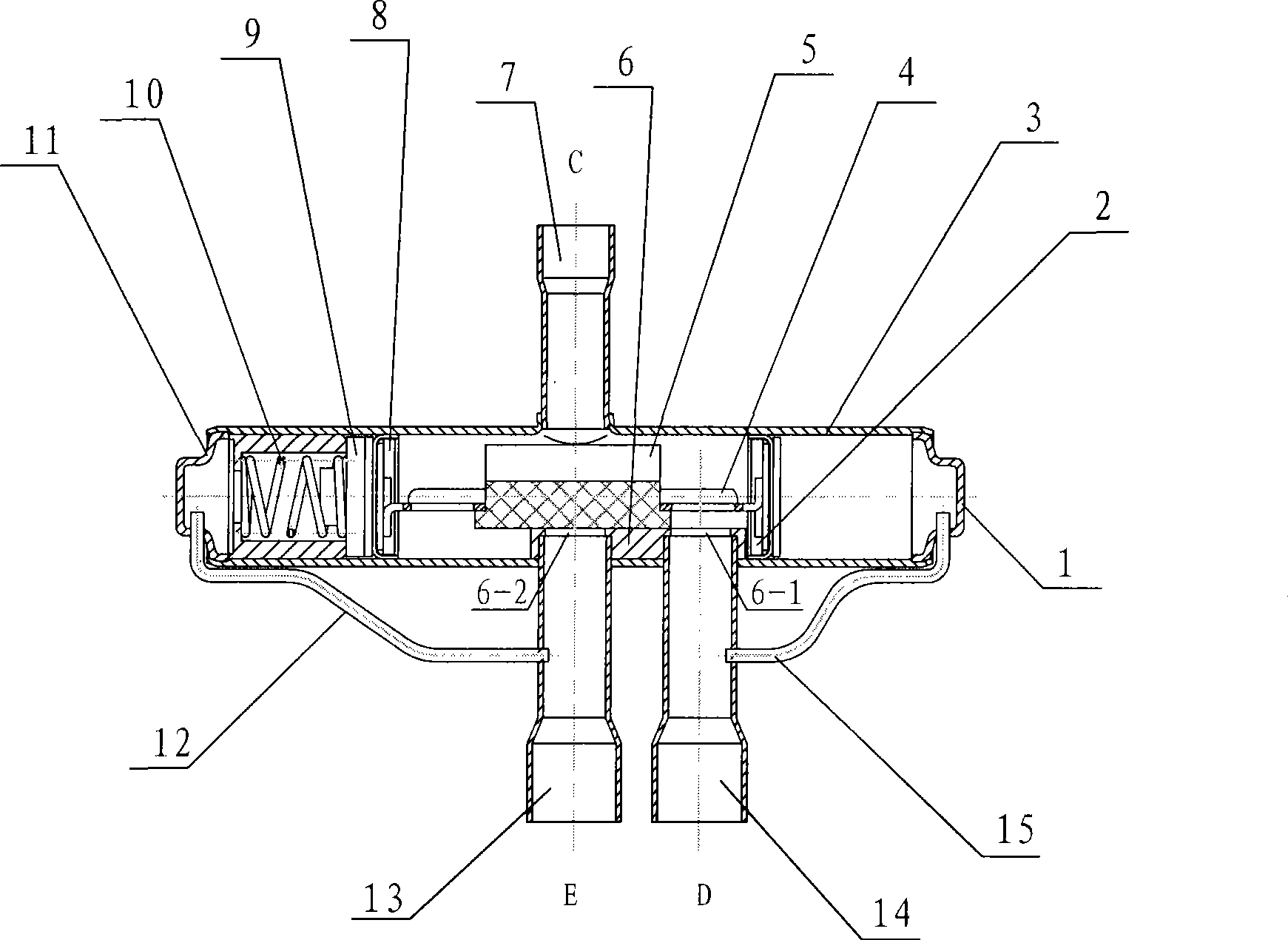

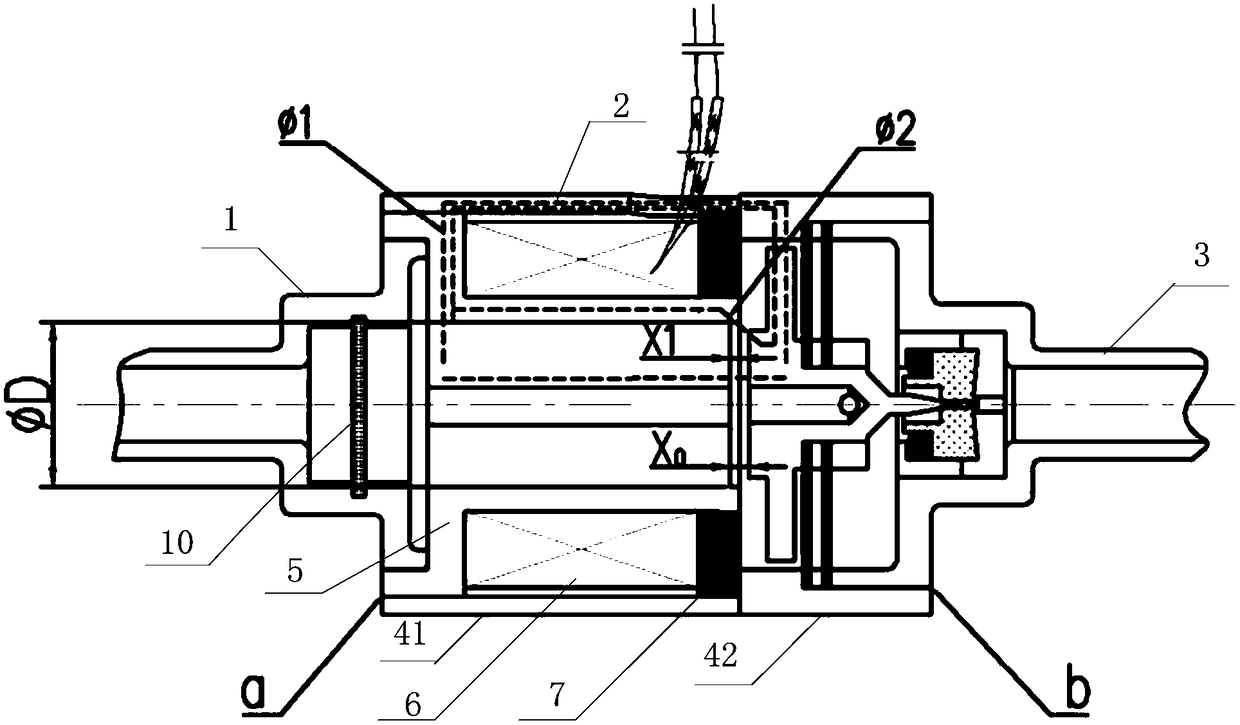

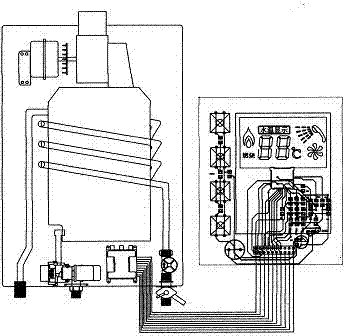

Self-powering three-way change valve

InactiveCN101424465AGuarantee stabilityEnsure reliabilityFluid circulation arrangementEngineeringHigh pressure

Owner:ZHEJIANG CHUNHUI INTELLIGENT CONTROL

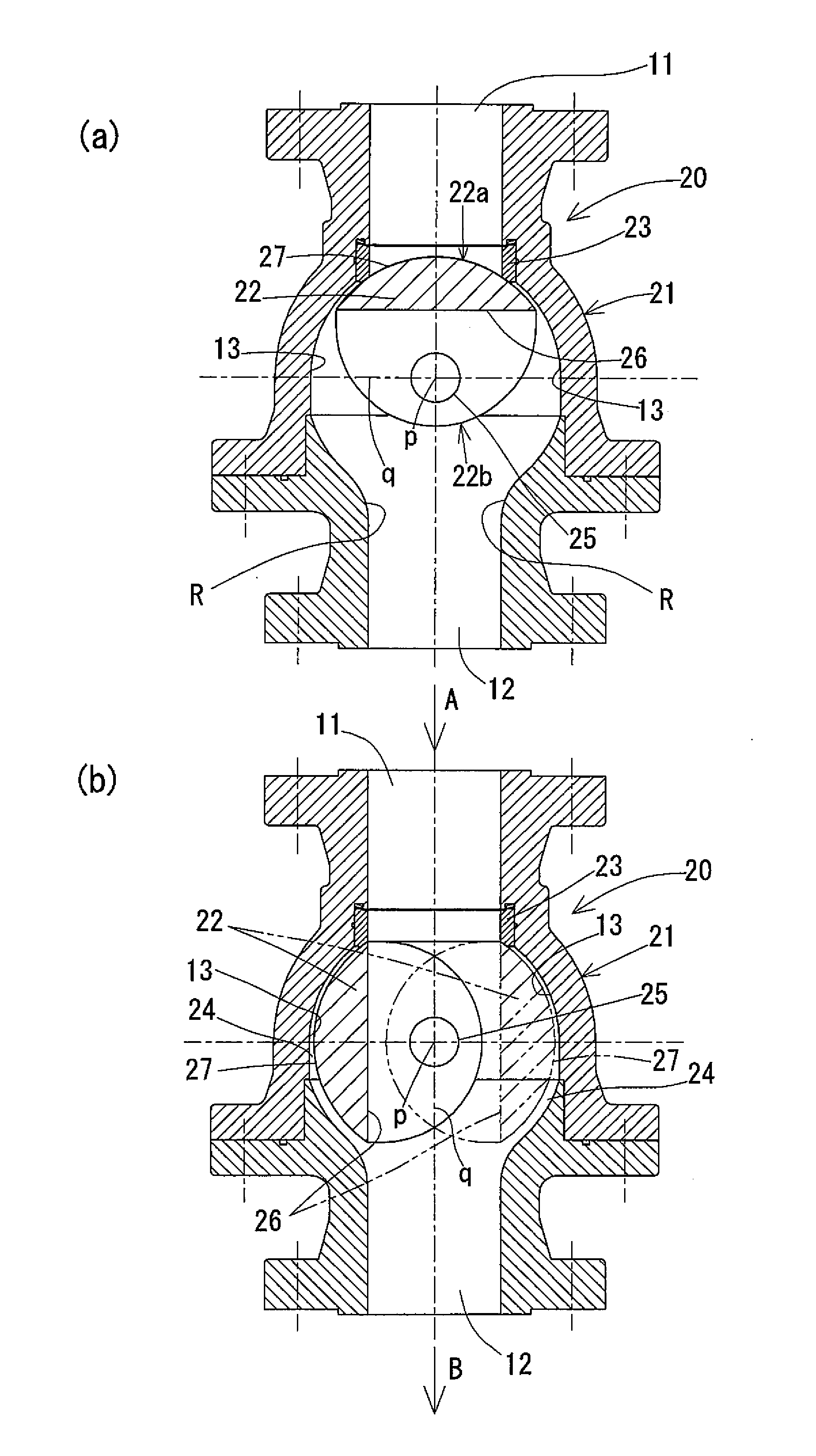

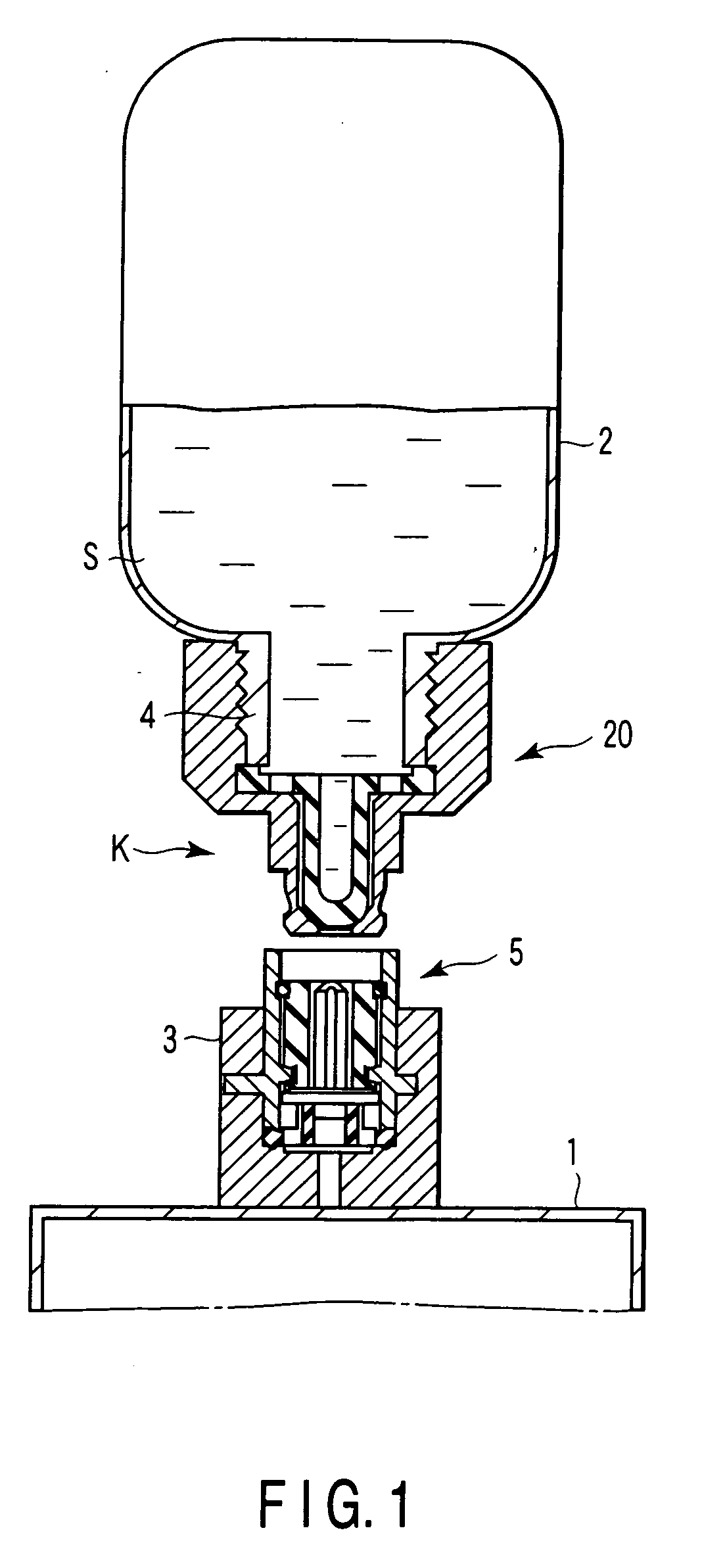

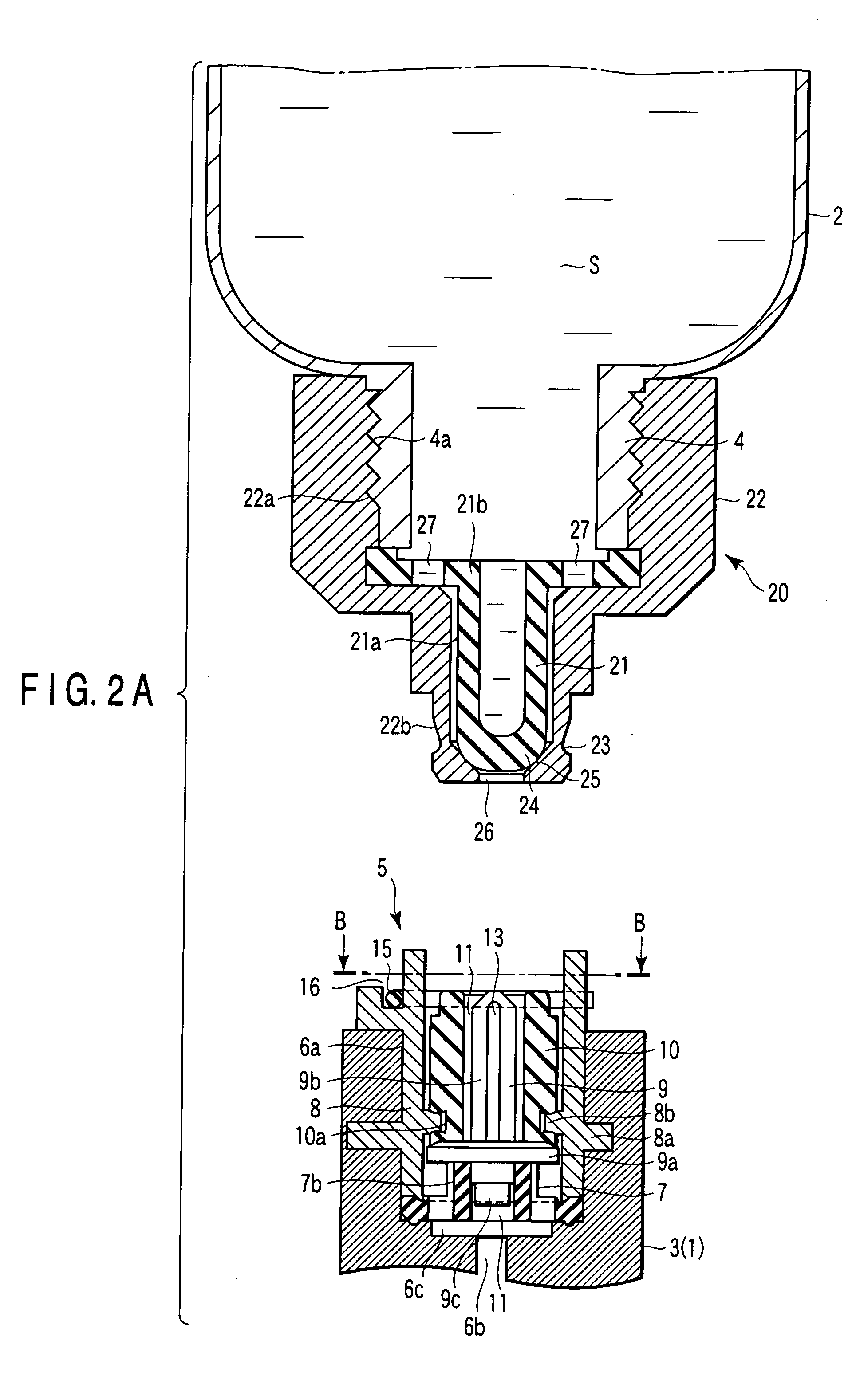

Four-way switching valve

InactiveUS6860294B2Operating means/releasing devices for valvesAir-treating devicesSolenoid valveReciprocating motion

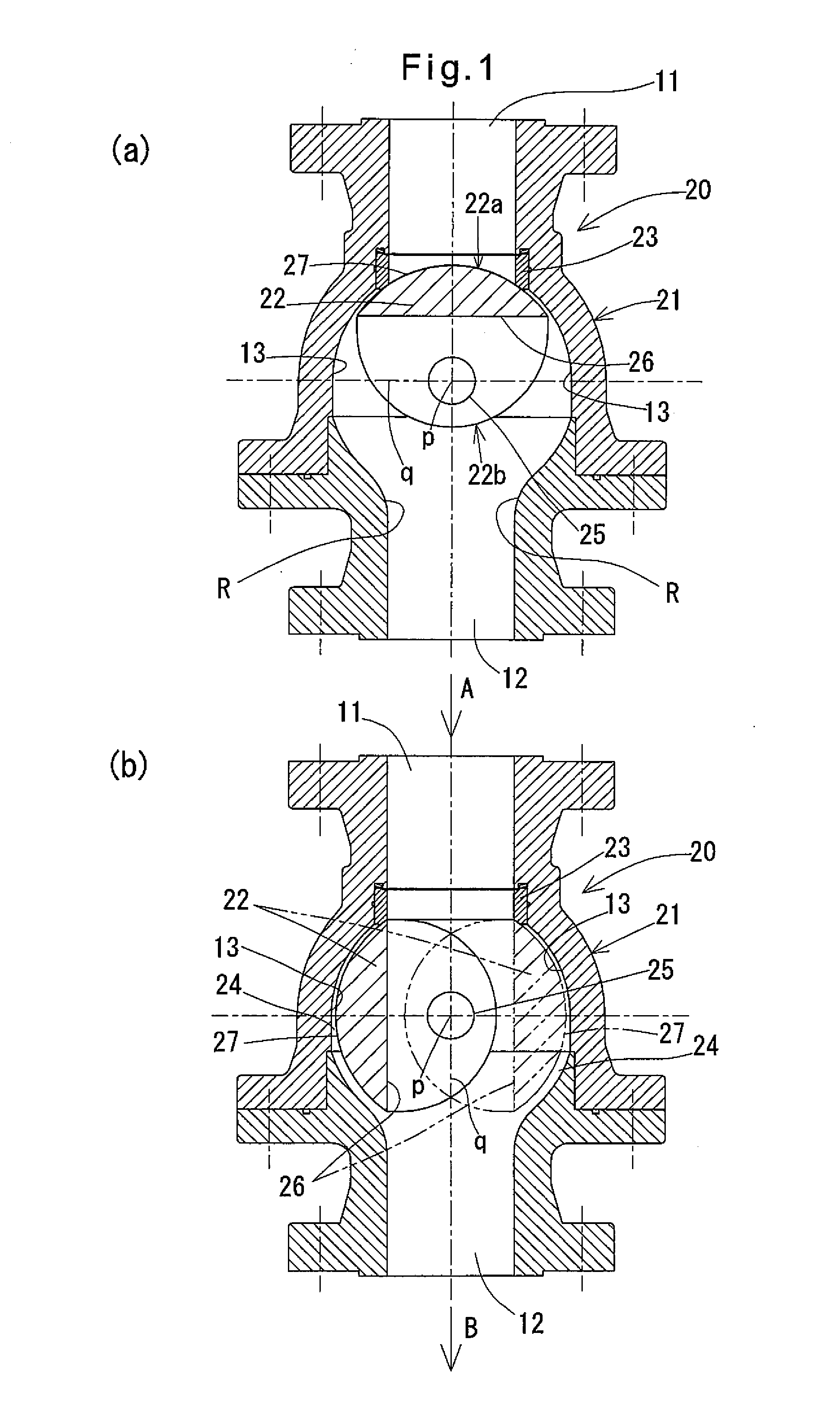

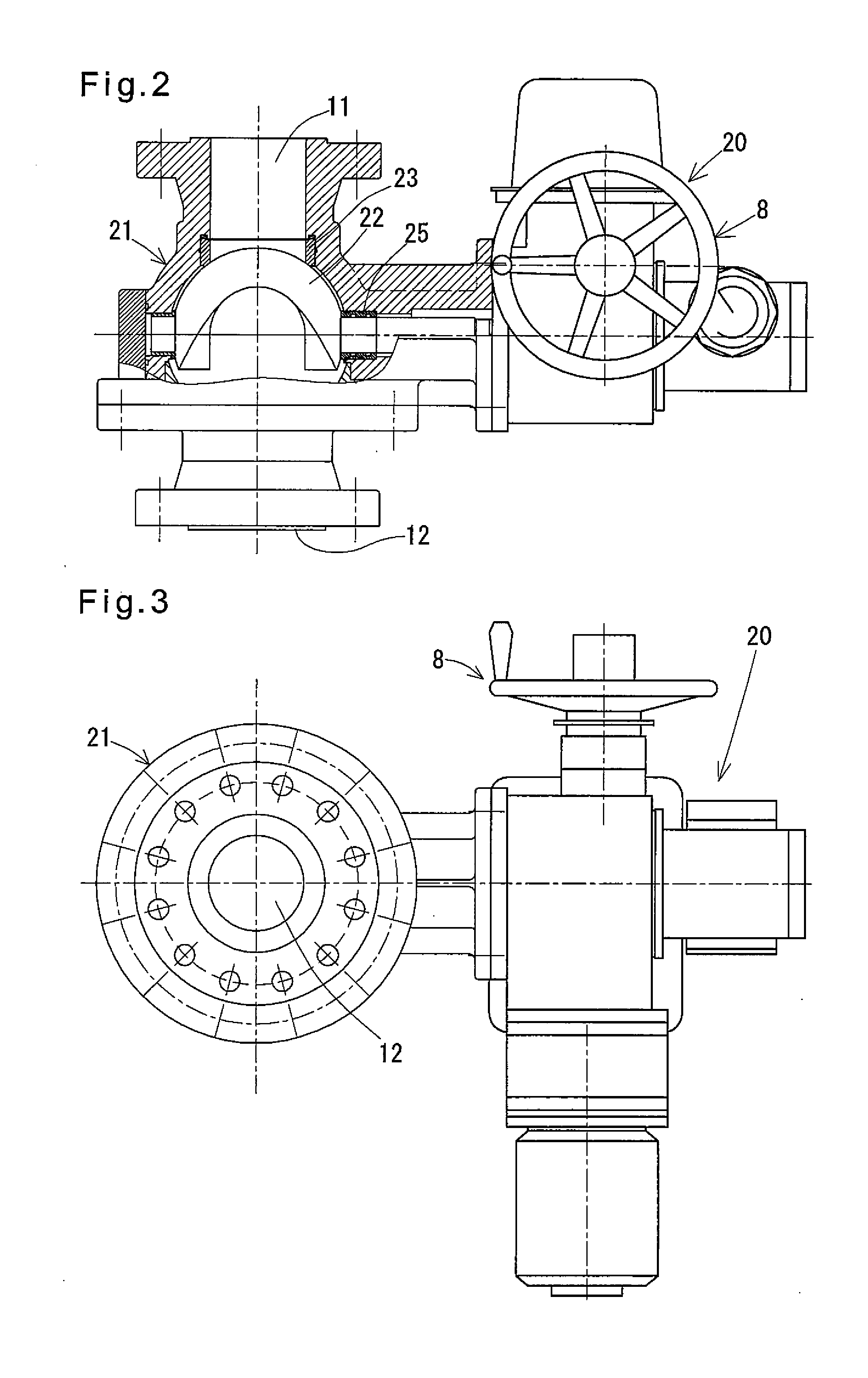

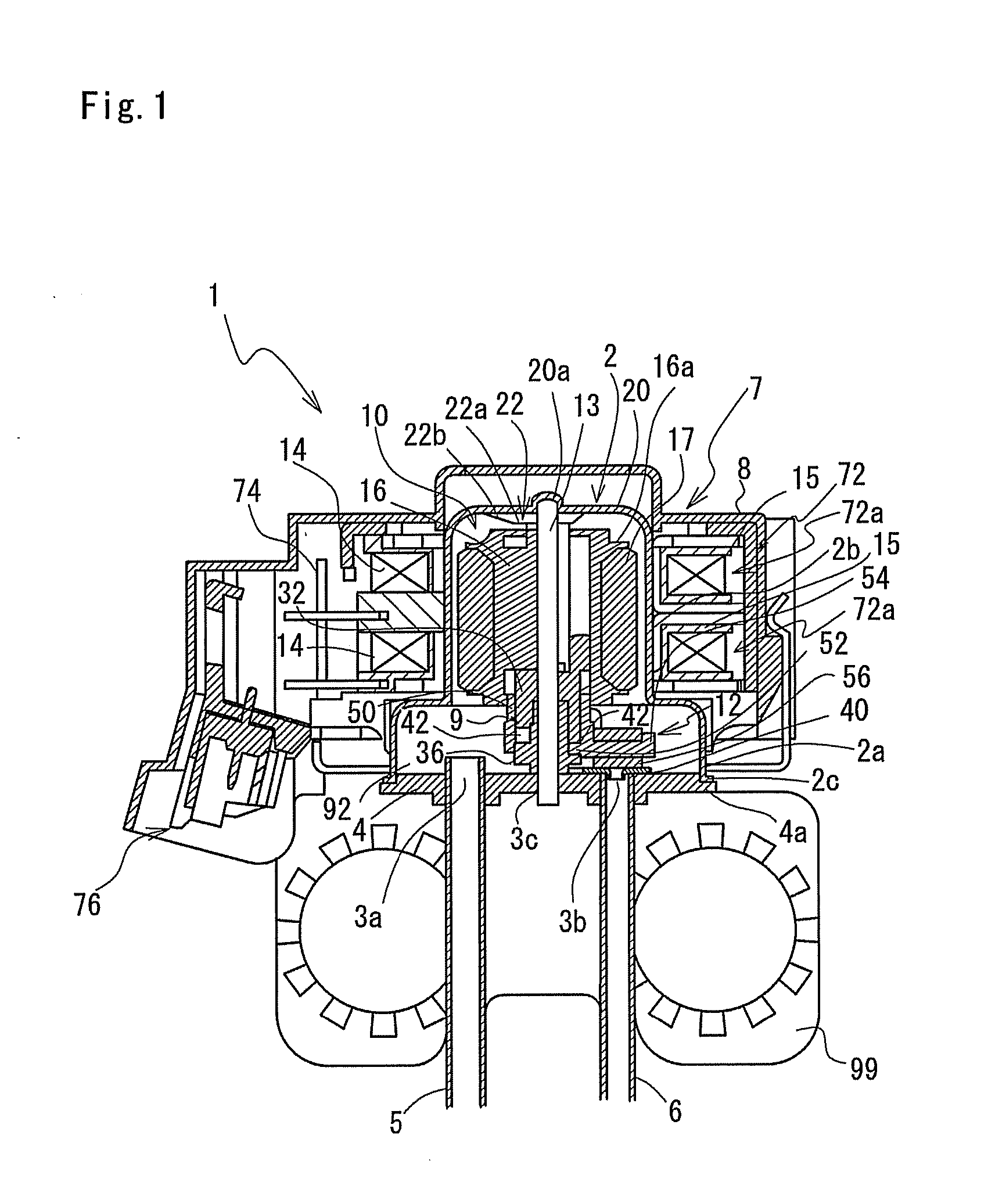

To provide a four-way solenoid valve having a three-way solenoid valve of which non-concentricity between a valve element and a valve hole is small, if any. A core of a three-way solenoid is integrally formed with a refrigerant passage extending axially therethrough, an annular projection forming a valve seat, and a guide for guiding reciprocating motion of a needle forming a valve element. A plug closing a cylinder of a body to define the pressure control chamber is also integrally formed with a valve seat and a guide for guiding reciprocating motion of a needle forming a valve element associated with the valve seat. This causes the needles to be seated on the valve seats associated therewith in respective states guided by the guides substantially concentric with the valve holes, which makes it possible to impart sufficient sealing properties to the valve portions when each valve is closed.

Owner:TGK

Valve for powder

InactiveUS20120037833A1Withstand high feed pressureSimple structurePlug valvesBulk conveyorsSpherical formValve seat

Owner:MITSUI ENG & SHIPBUILD CO LTD

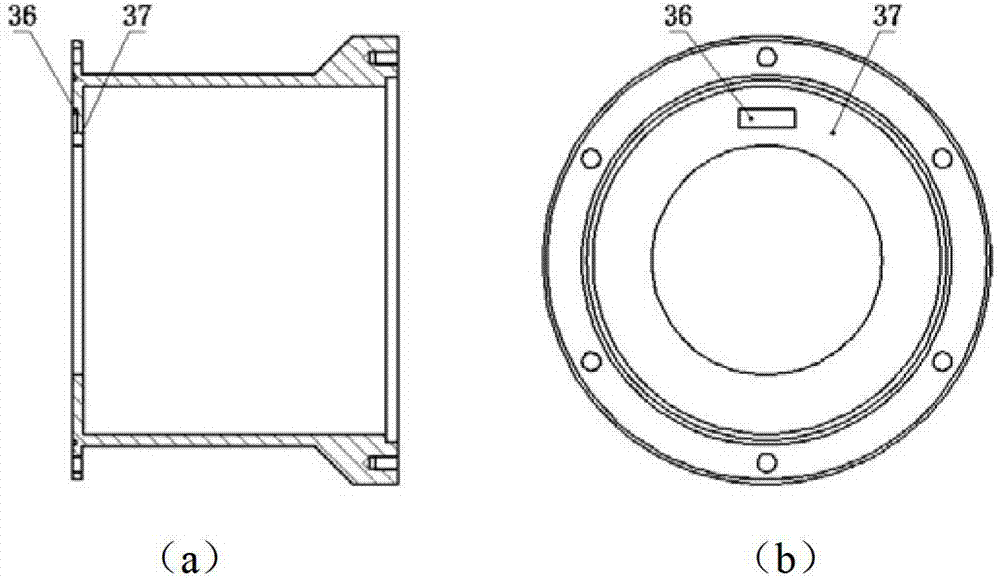

Integrated Dewar applied to linear pulse tube refrigerator and method for manufacturing integrated Dewar

InactiveCN103245120AAvoid axial forceCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorEngineering

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Ceramic valve element with drinking water control function

The invention discloses a ceramic valve element with a drinking water control function. The ceramic valve element is formed in the manner that a rotating base is arranged in a valve shell in an assembled manner, a linking block, a movable valve block and a fixed valve block which are sequentially overlapped are arranged below the rotating base, a valve rod upwards extending out of the valve shell is arranged in the rotating base in pivoted manner, a stirring part at the bottom end of the valve rod and the linking block are embedded, the movable valve block is embedded through the linking block, and the movable valve block is driven by the linking block to move horizontally or rotate through the operation of the valve rod; by means of the change of the position corresponding relation between the movable valve block and the fixed valve block, a tap is controlled to allow water to flow or stop water flowing, or the mixing proportion of cold water and hot water and the output water flow are changed, and internal members such as the fixed valve block, the movable valve block, the linking block and the rotating base are stopped from dropping out through combination of a valve seat below the valve shell. The ceramic valve element can control use of tap water and drinking water, and the complexity of the whole structure is effectively simplified.

Owner:SHANGHAI GEAR PLASTIC

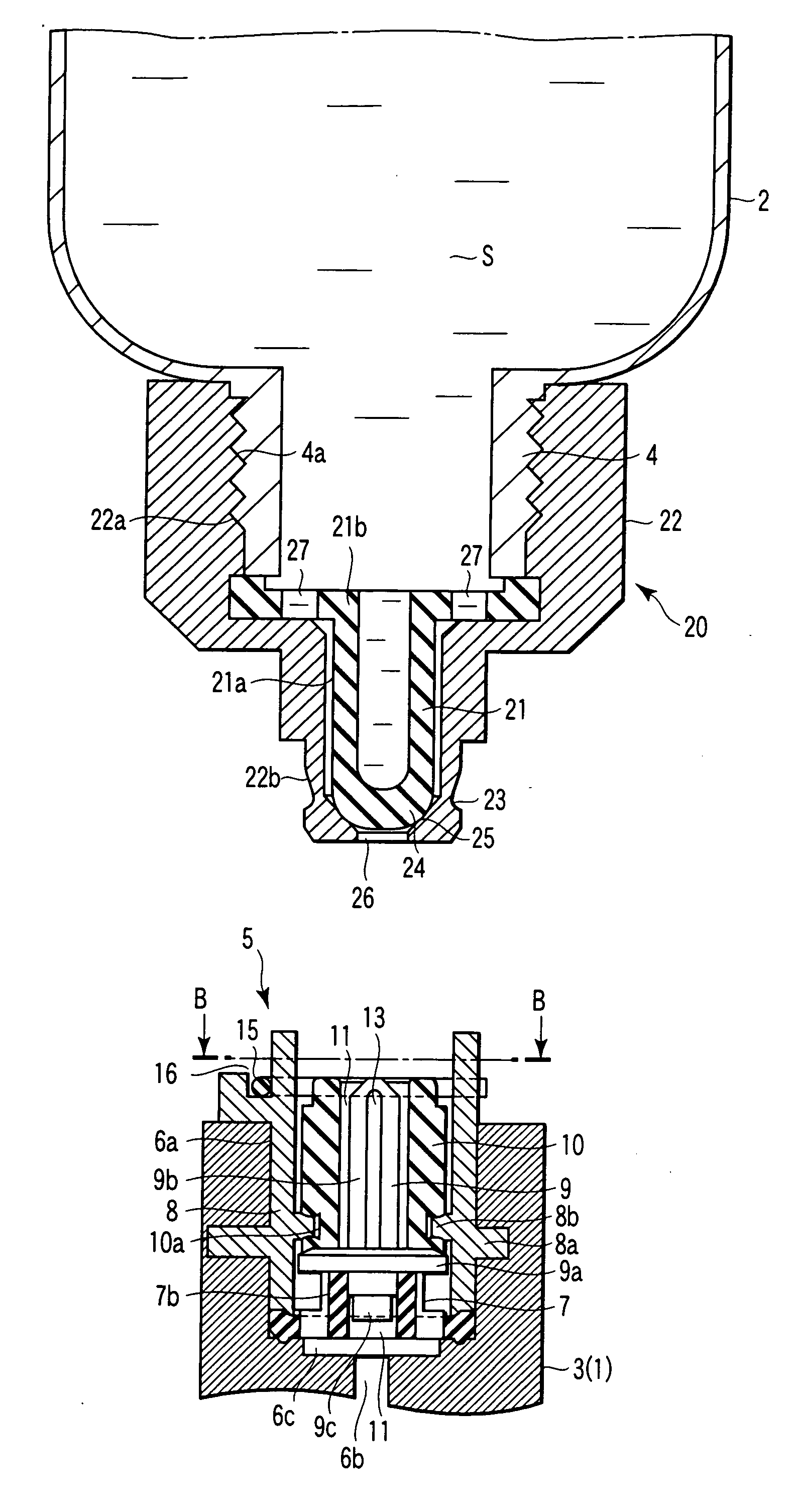

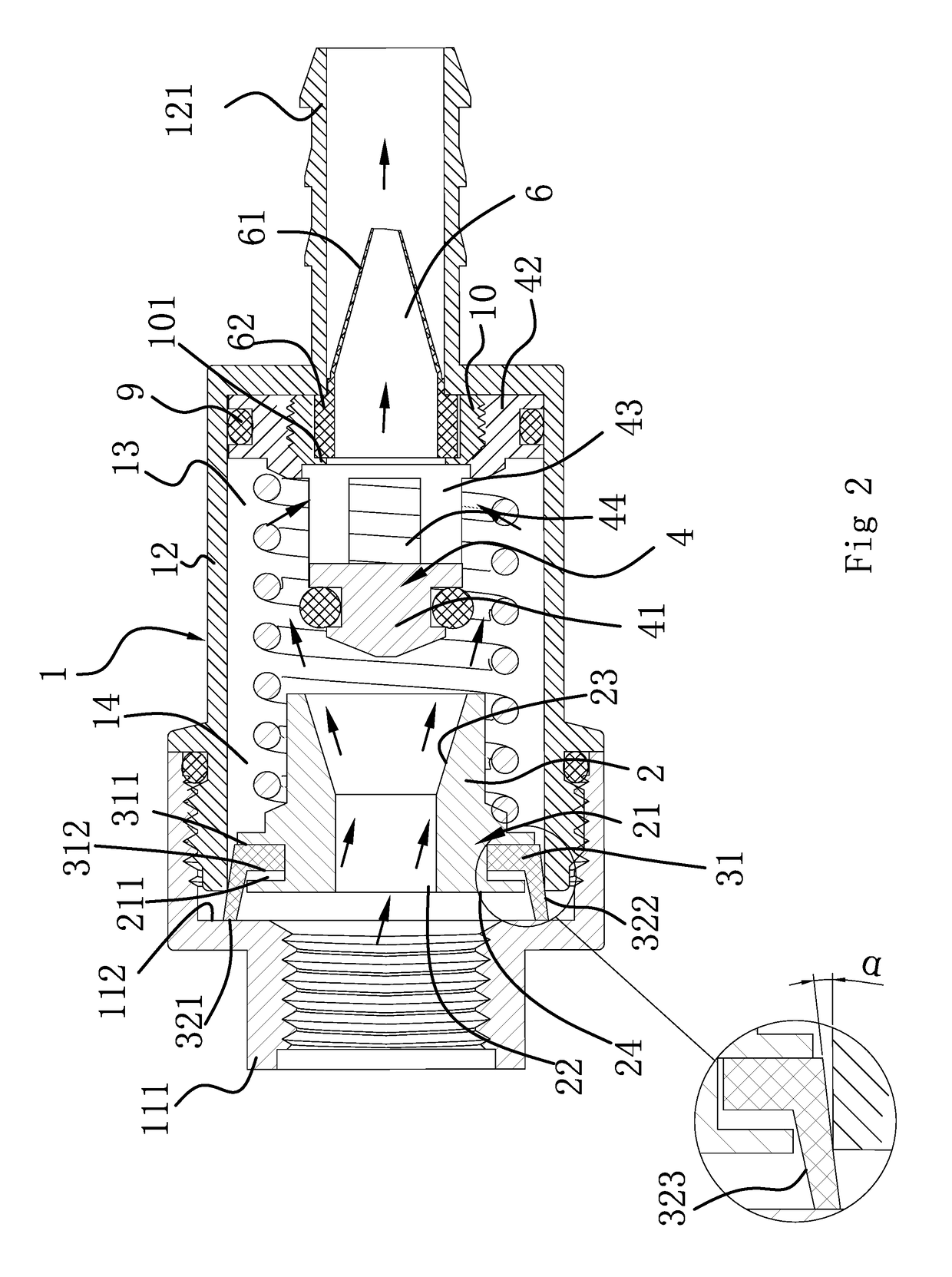

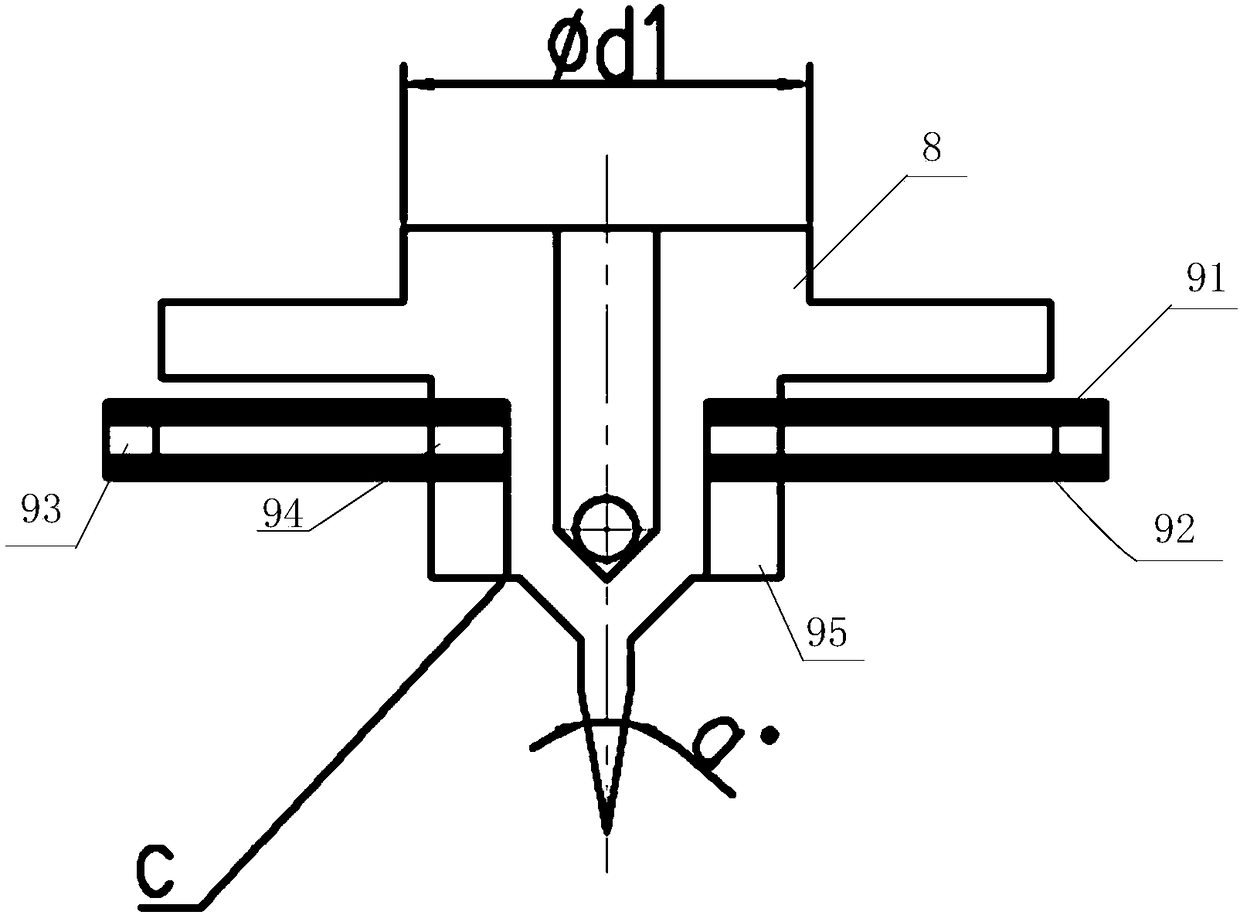

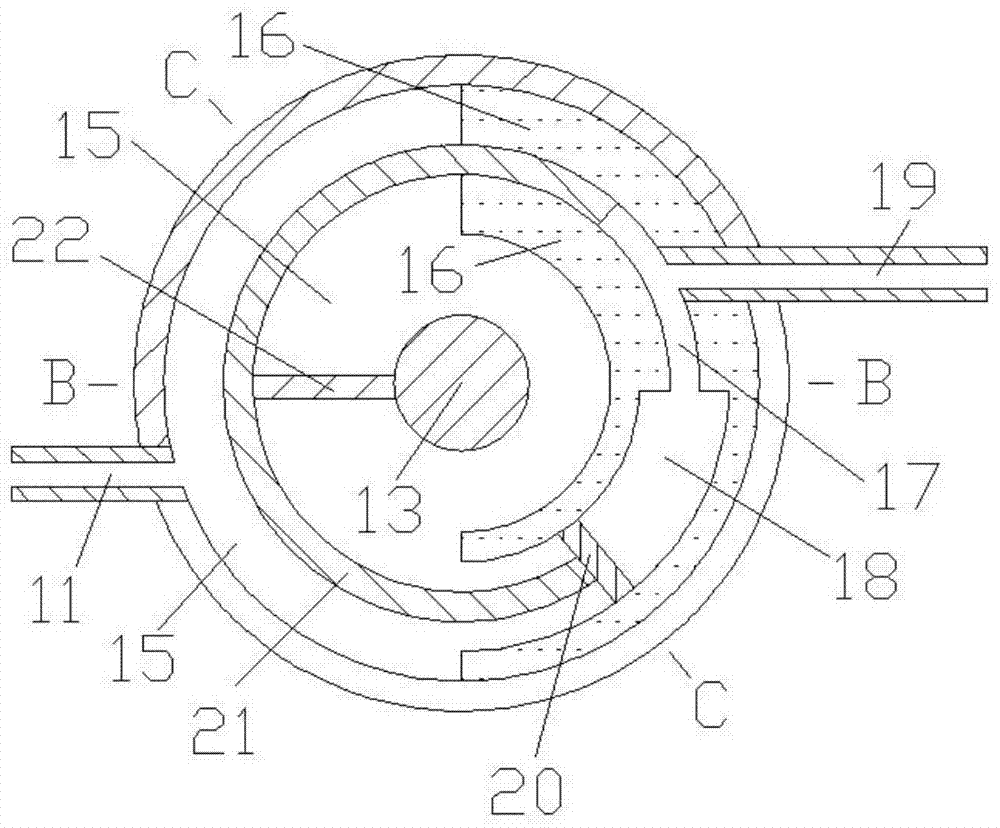

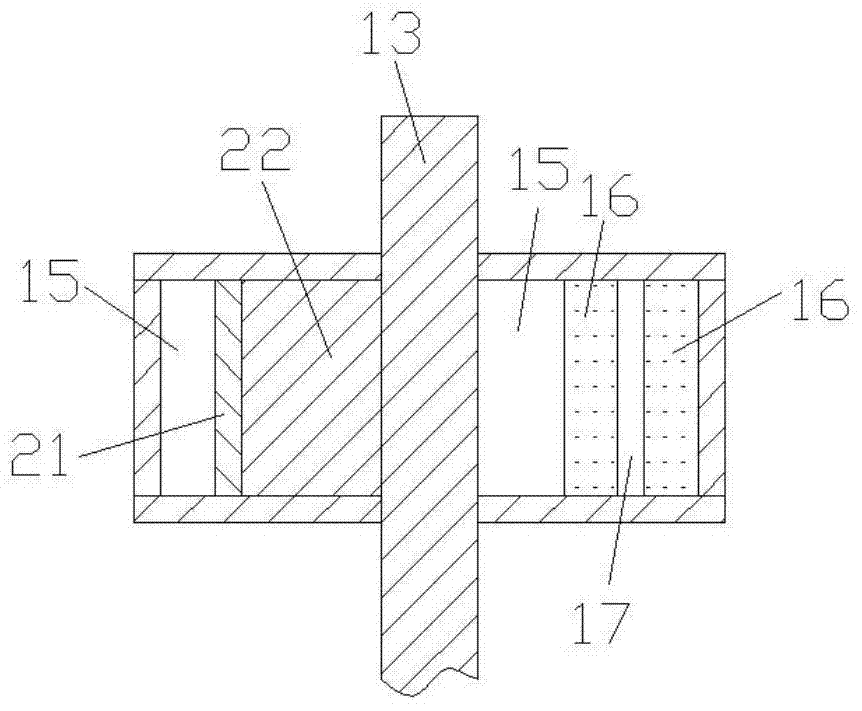

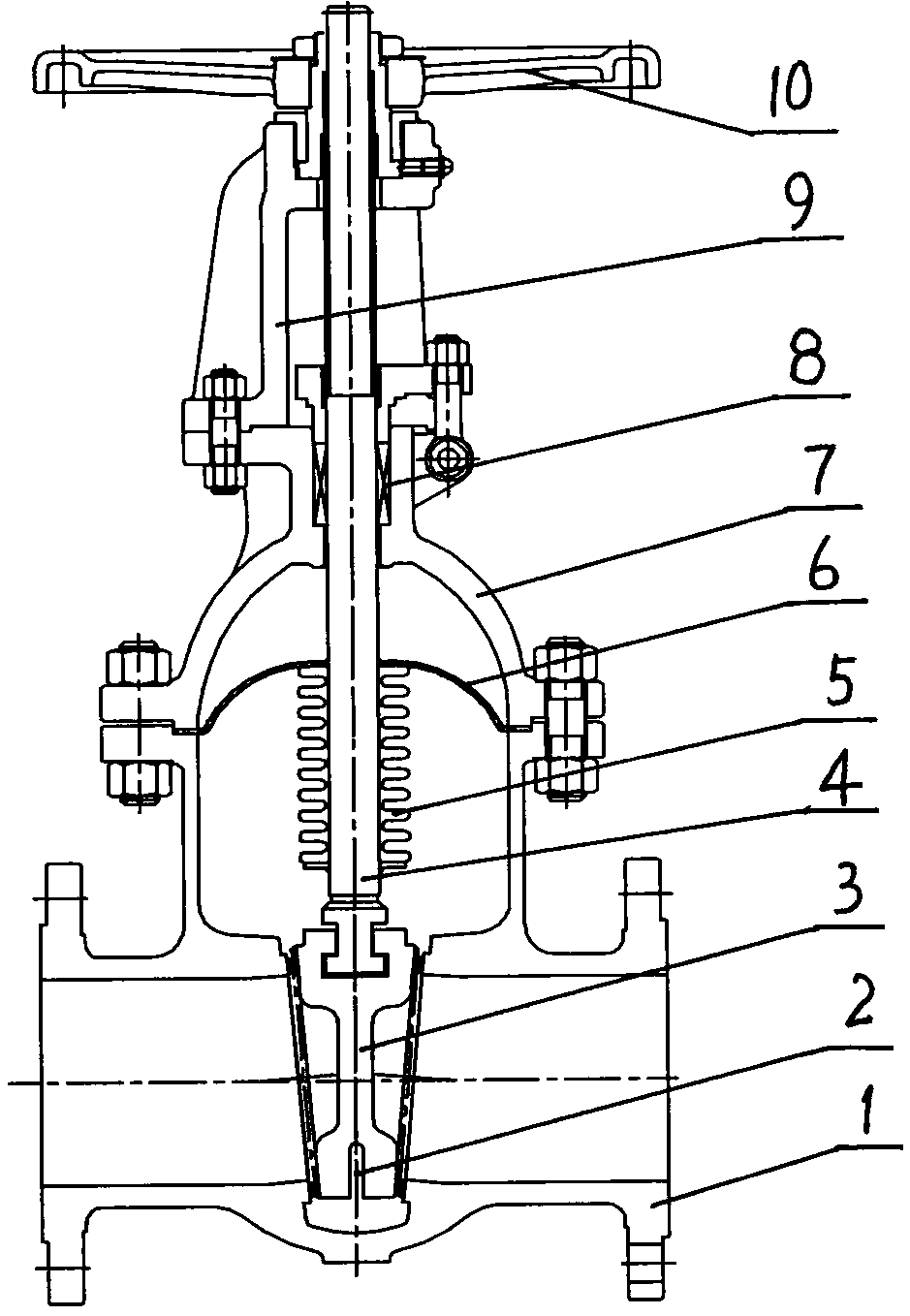

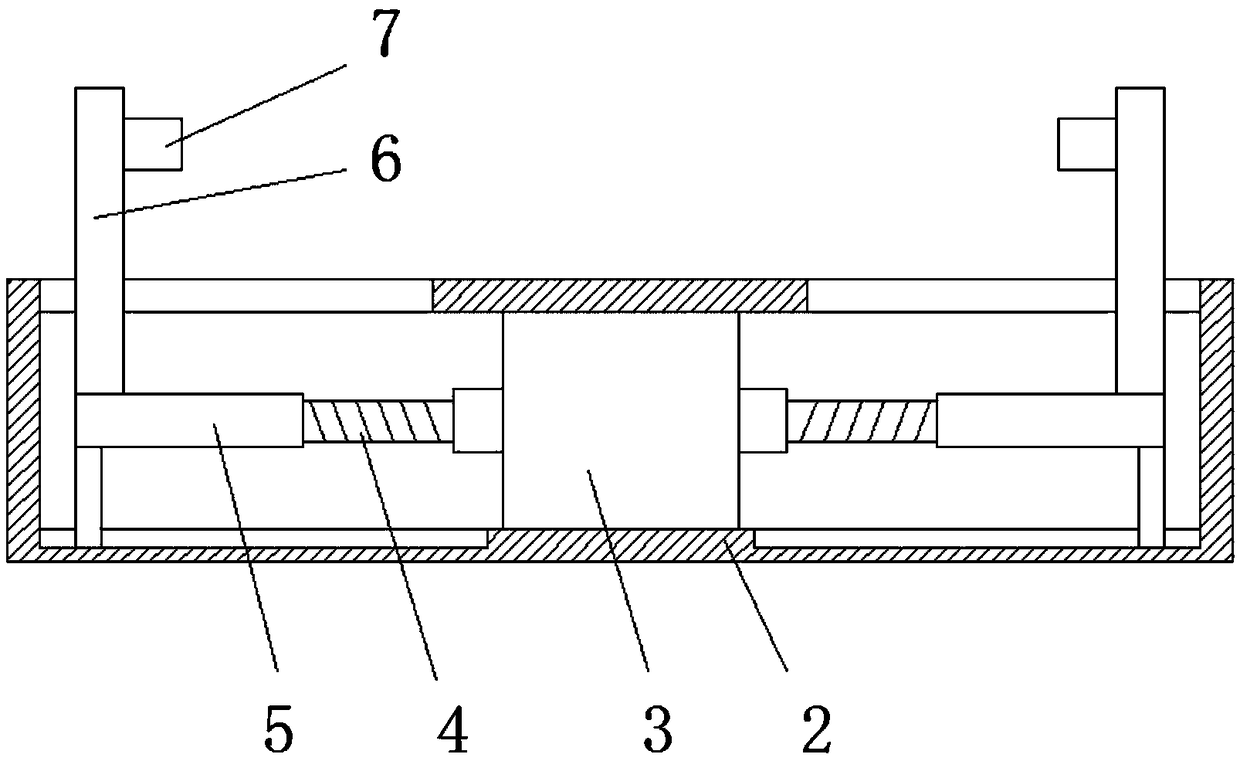

Valve core for four-way switching valve and four-way switching valve thereof

InactiveCN101644347AEasy to moveHigh mechanical strengthMultiple way valvesSlide valveValve seatPhysics

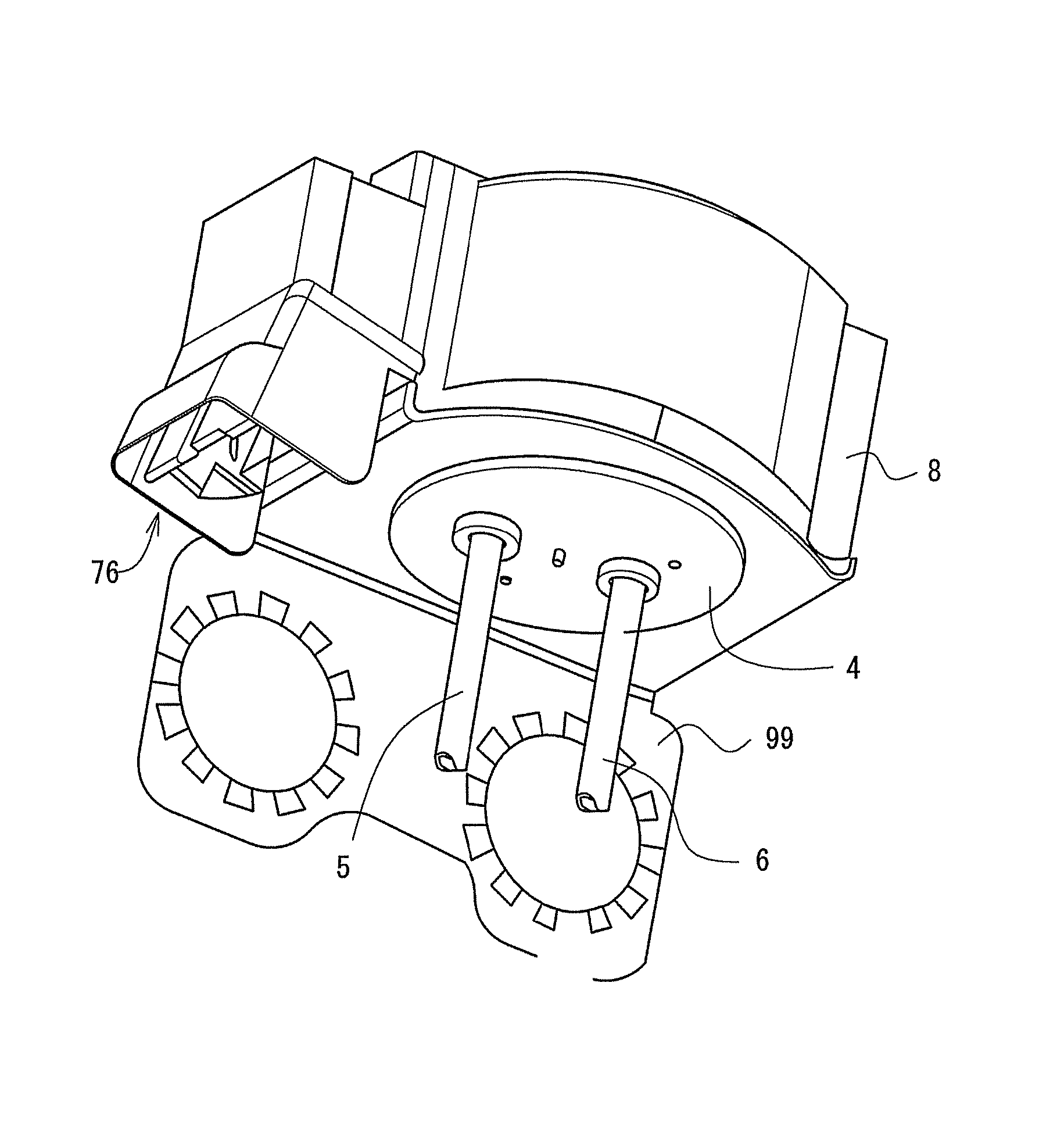

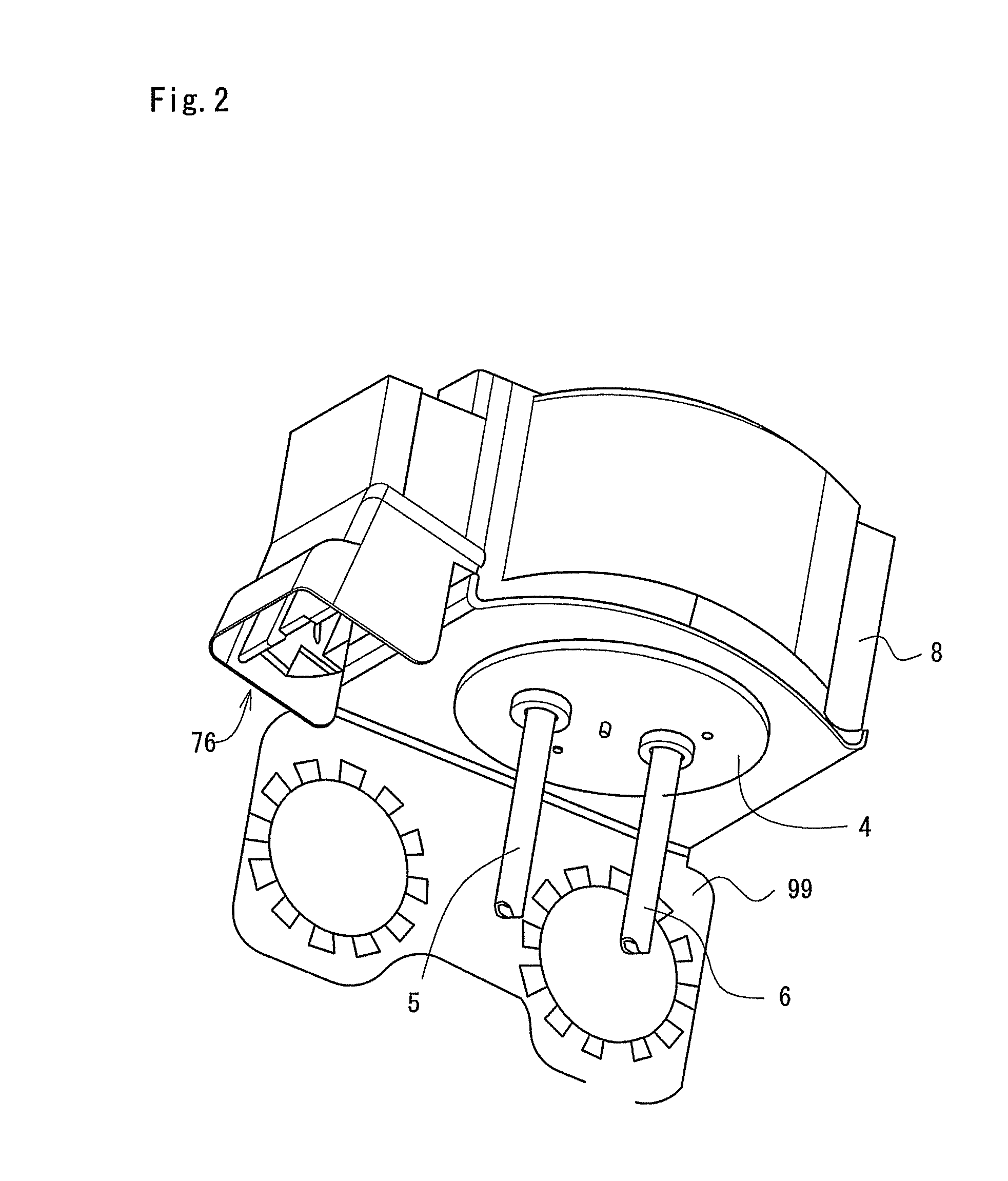

The present invention provides a valve core for a four-way switching valve, which can ensure smooth fluid movement in the valve core and can improve mechanical strength. The four-way switching valve (2) comprises the following components: a valve body (3) with a closed space; a first pipe (5) connected with one side of the valve body (3); a second pipe (7) connected with the other side of the valve body (3); a third pipe (11) and a fourth pipe (12) which are separated by the second pipe (7) and configured adjacently with two sides; a valve seat (16) which is provided in the valve body (3) andis provided with an opening communicated with each pipe; and a valve core (1) which is slidably configured to the valve seat (16). Through the sliding of the valve core (1), the communication state between the first pipe (5) and the third pipe (11) or between the first pipe (5) and the fourth pipe (12) is selectively switched. The valve core (1) comprises the following components: a supporting rod (1d) which is configured to penetrate an opening end face part (1j) adjacently with the opening end face part (1j) of a bowl-shaped body (1c); and a flange part (projected part) (1k) which is formedintegrally with the a main body (1c) at the position of the of the opening end face part (1j) that is next to the main body (1c). The flange part (1k) projects to a position that is next to the innerwall surface (3c) of the valve body (3) from the outer surface of the main body (1c) along the axial direction of the supporting rod (1d).

Owner:FUJIKOKI MFG CO LTD

Coupler

InactiveUS20060065312A1Easy to operateImprove reliabilityValve arrangementsReactant parameters controlInjection portEngineering

Owner:KK TOSHIBA

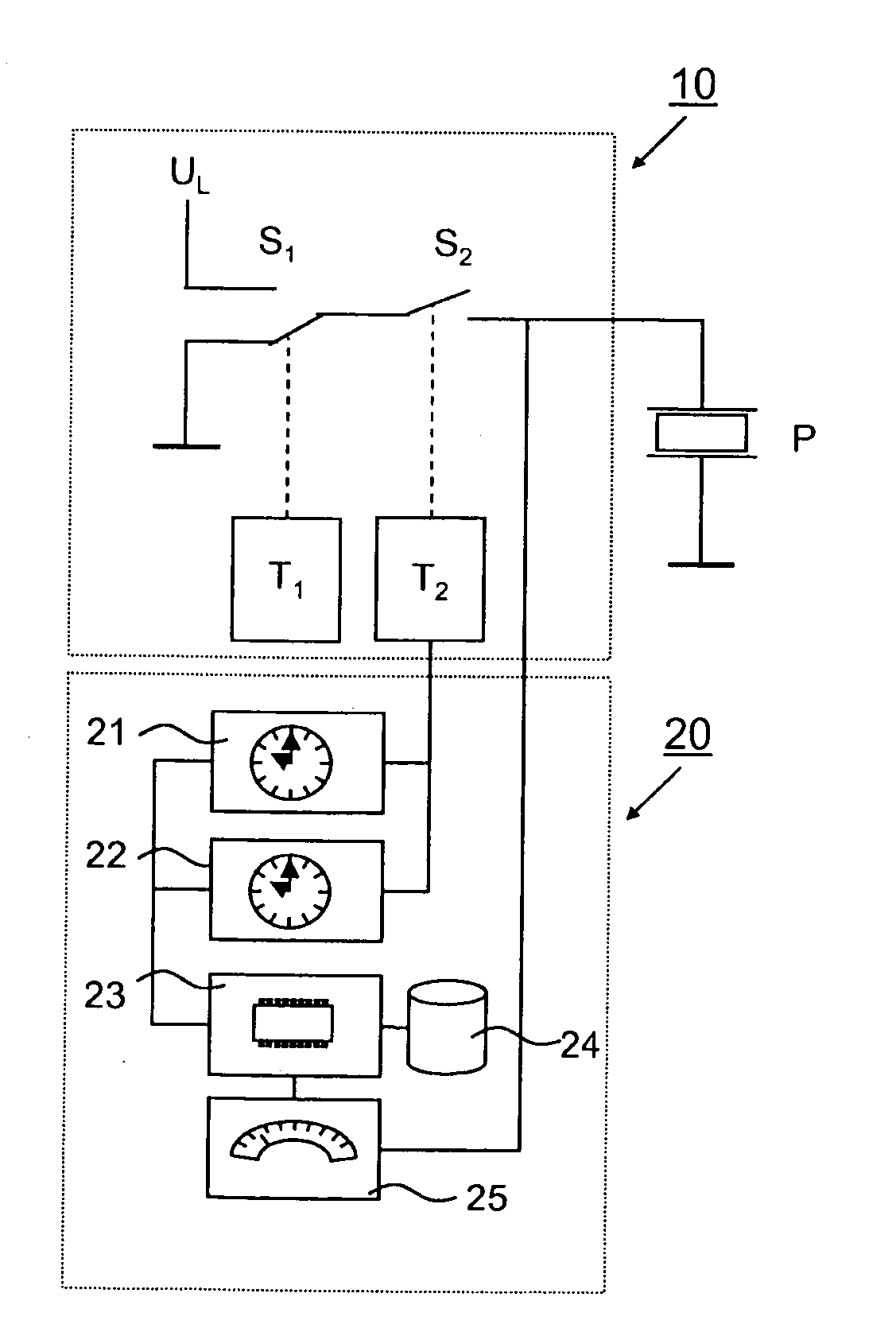

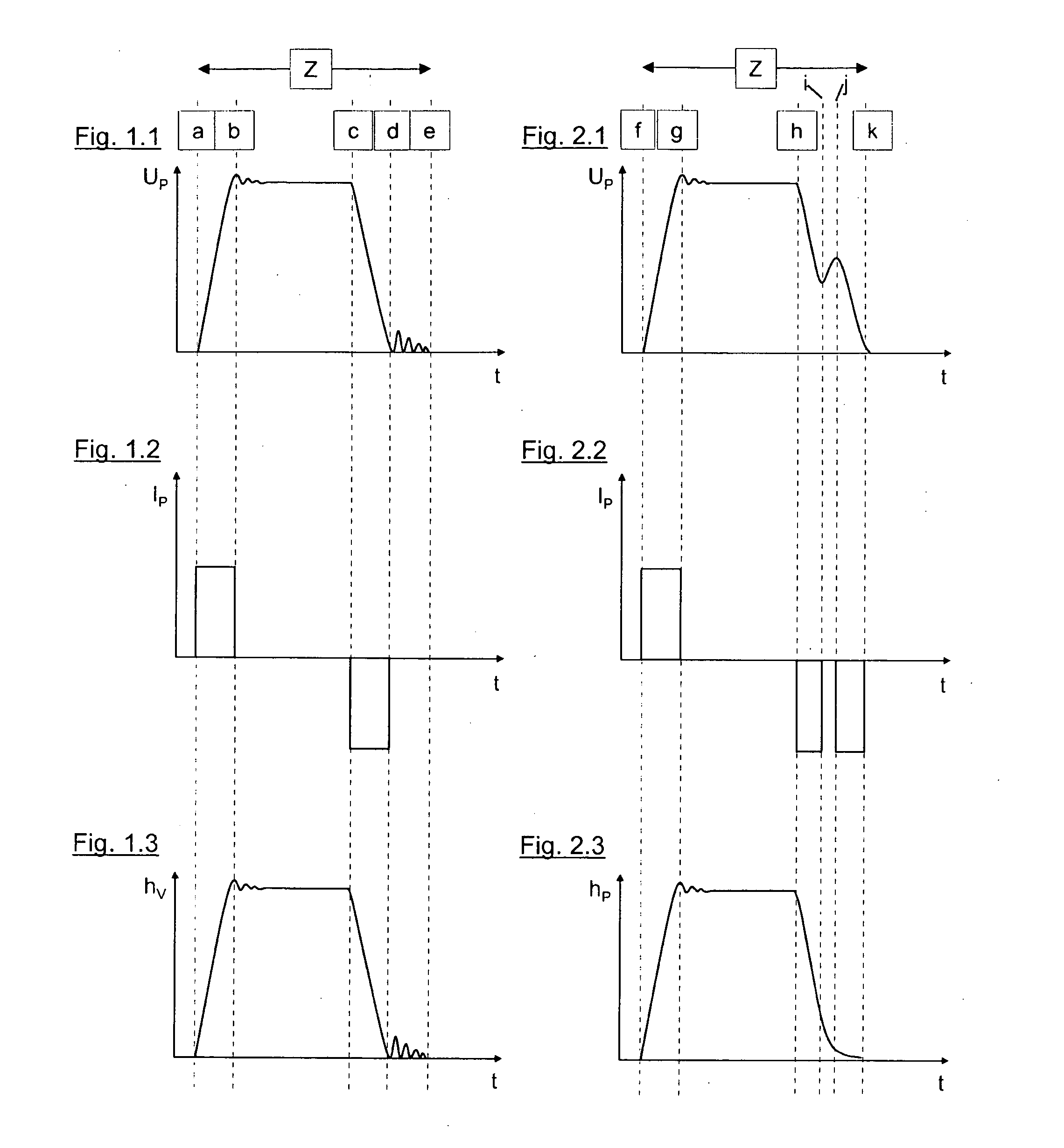

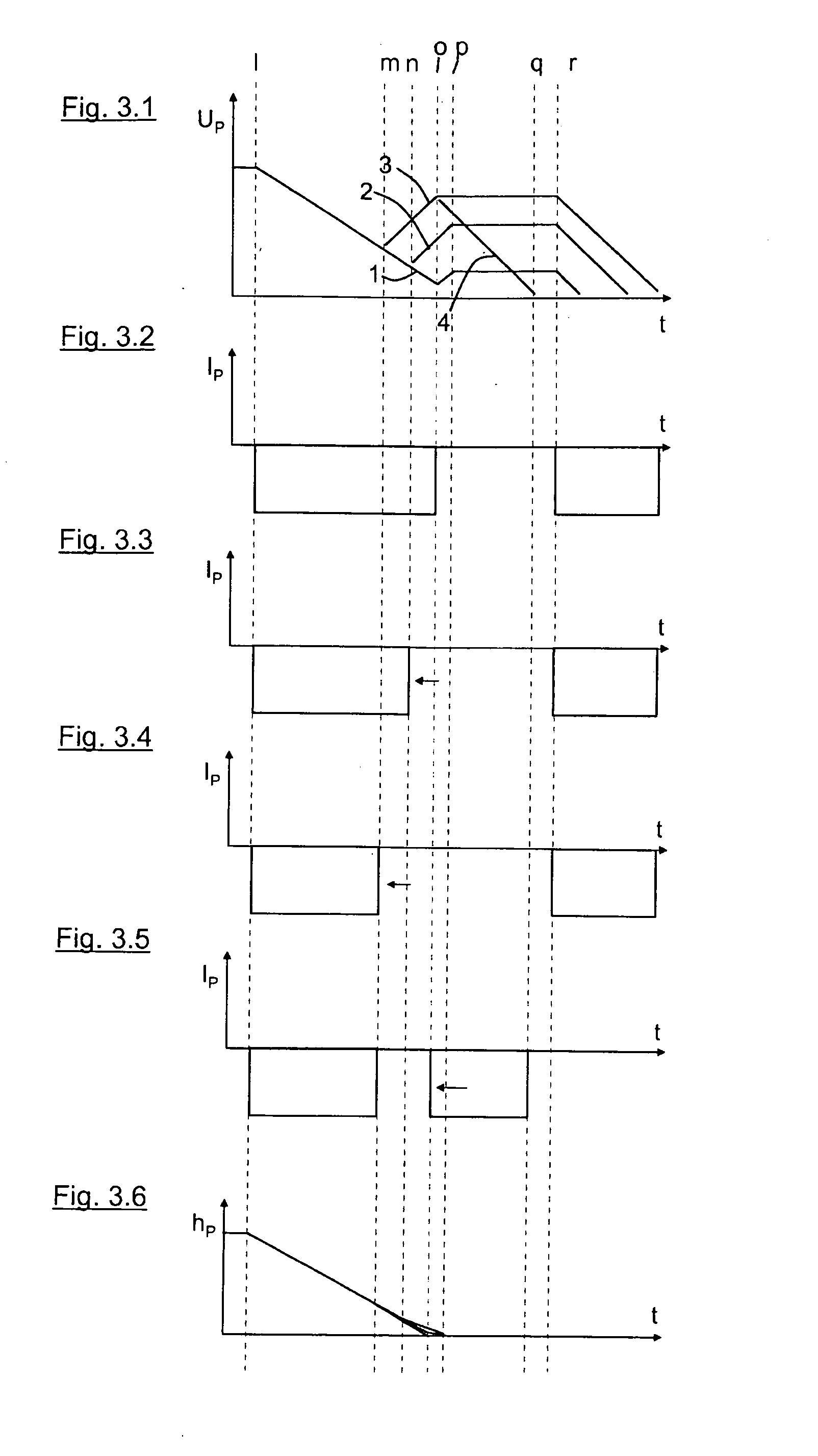

Method for bounce suppression of a valve switched by a piezo actuator

InactiveUS20110042594A1Enhance resilienceElectrical controlOperating means/releasing devices for valvesElectricityPiezoelectric actuators

Owner:ROBERT BOSCH GMBH

Flow Rate Safety Valve

ActiveUS20180128392A1Improve sealingImprove mobilityCheck valvesEqualizing valvesEngineeringSafety valve

Owner:YUHUAN JIANGLIN PLUMBING HOSE & PARTS

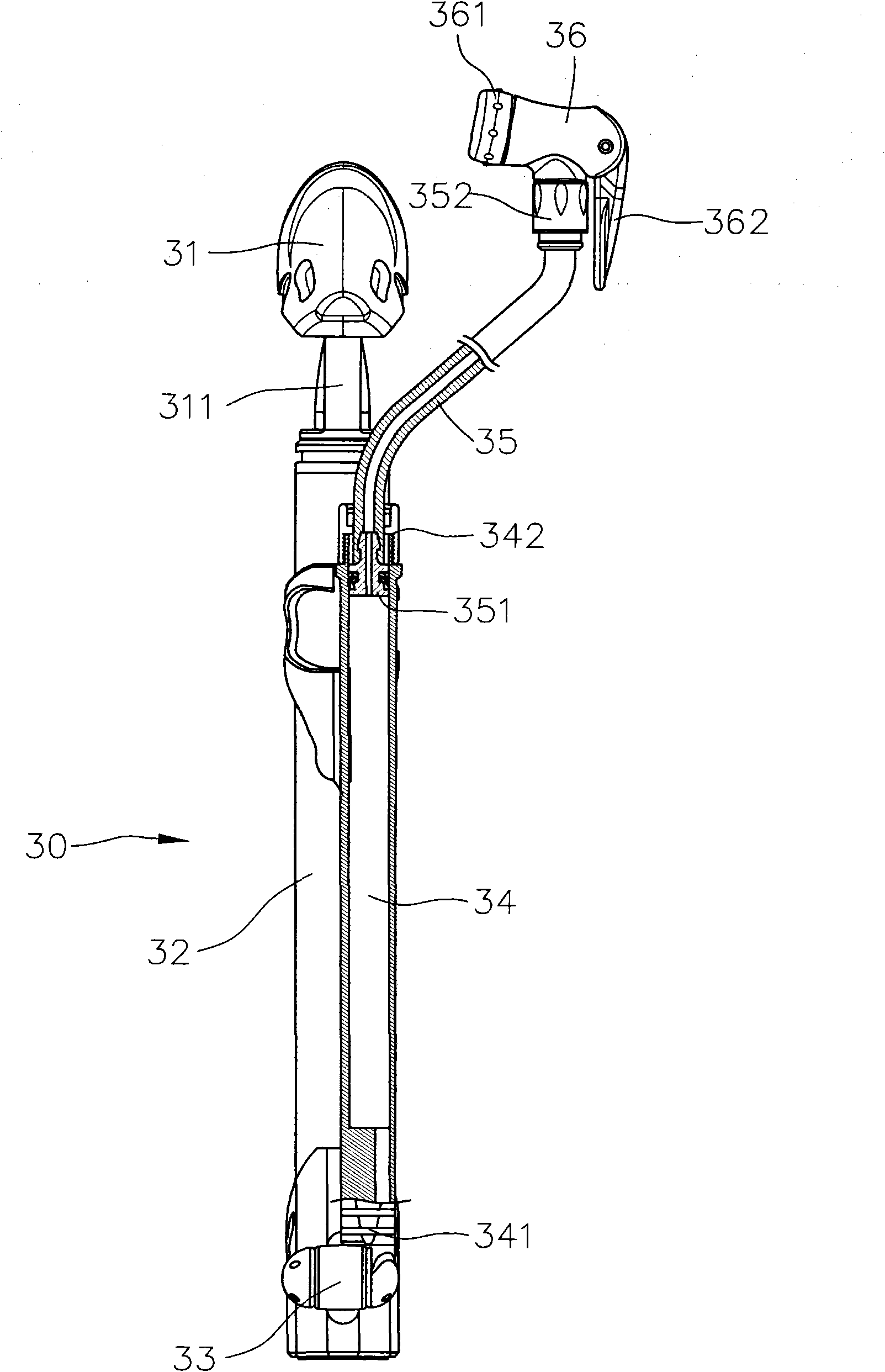

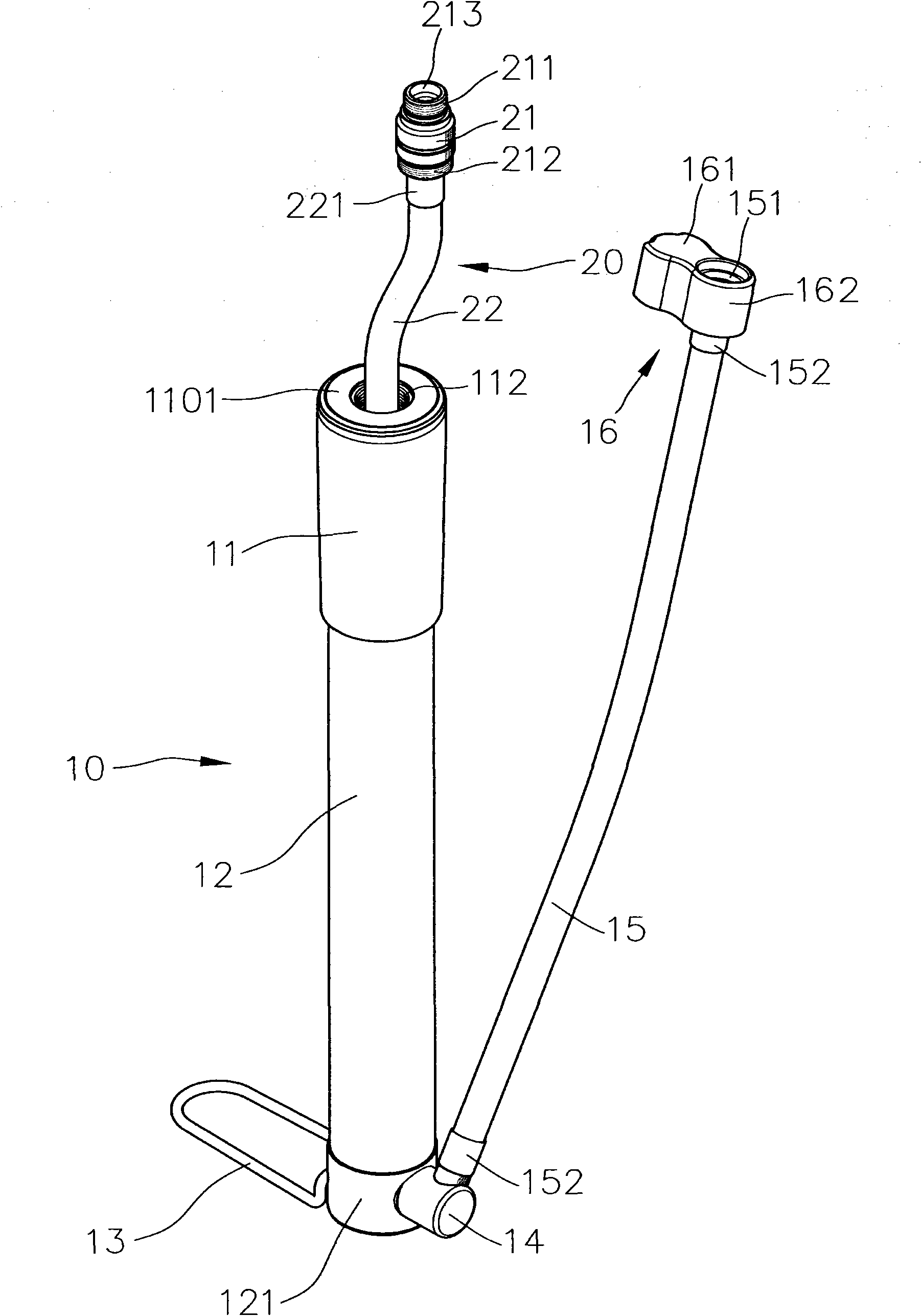

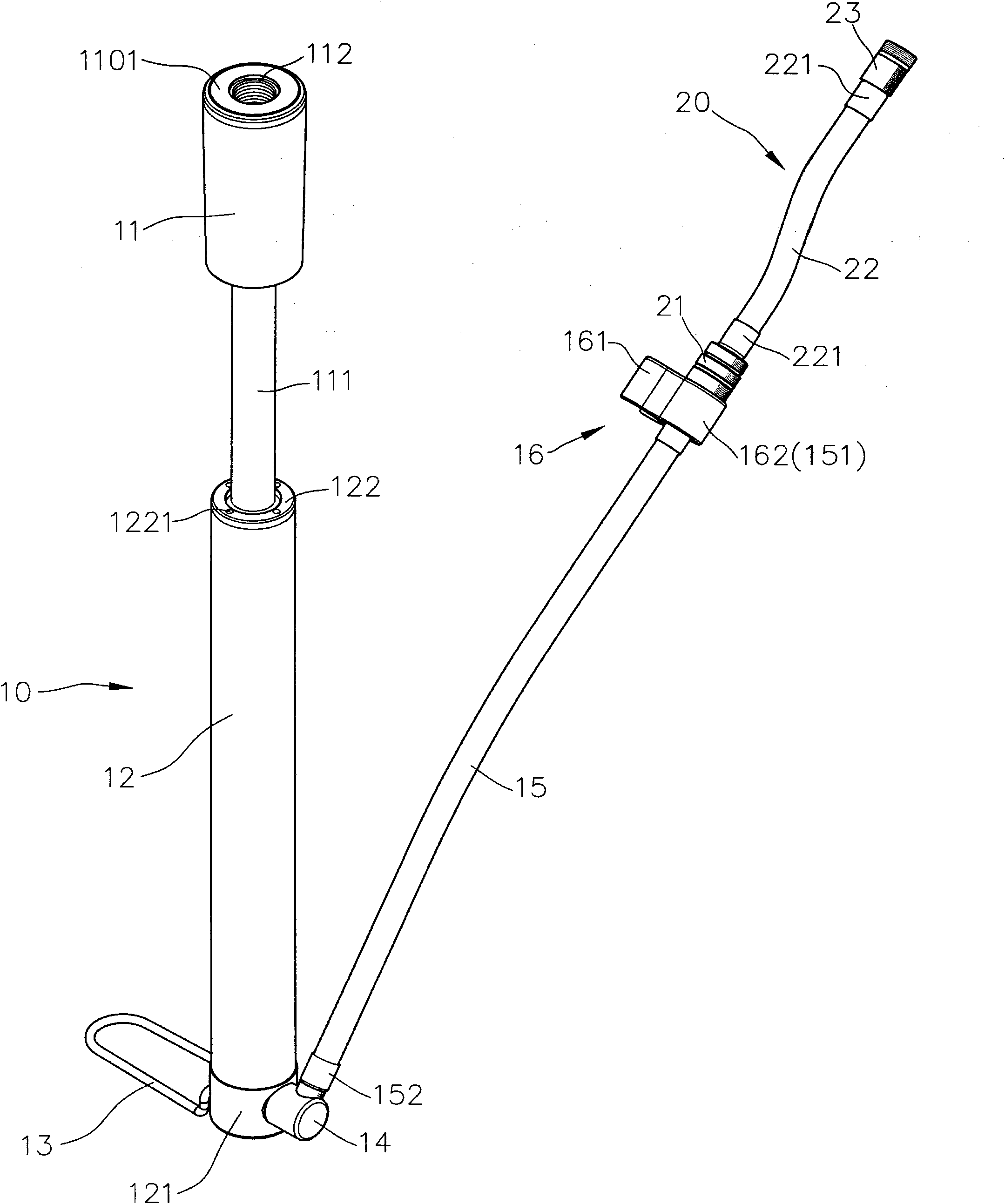

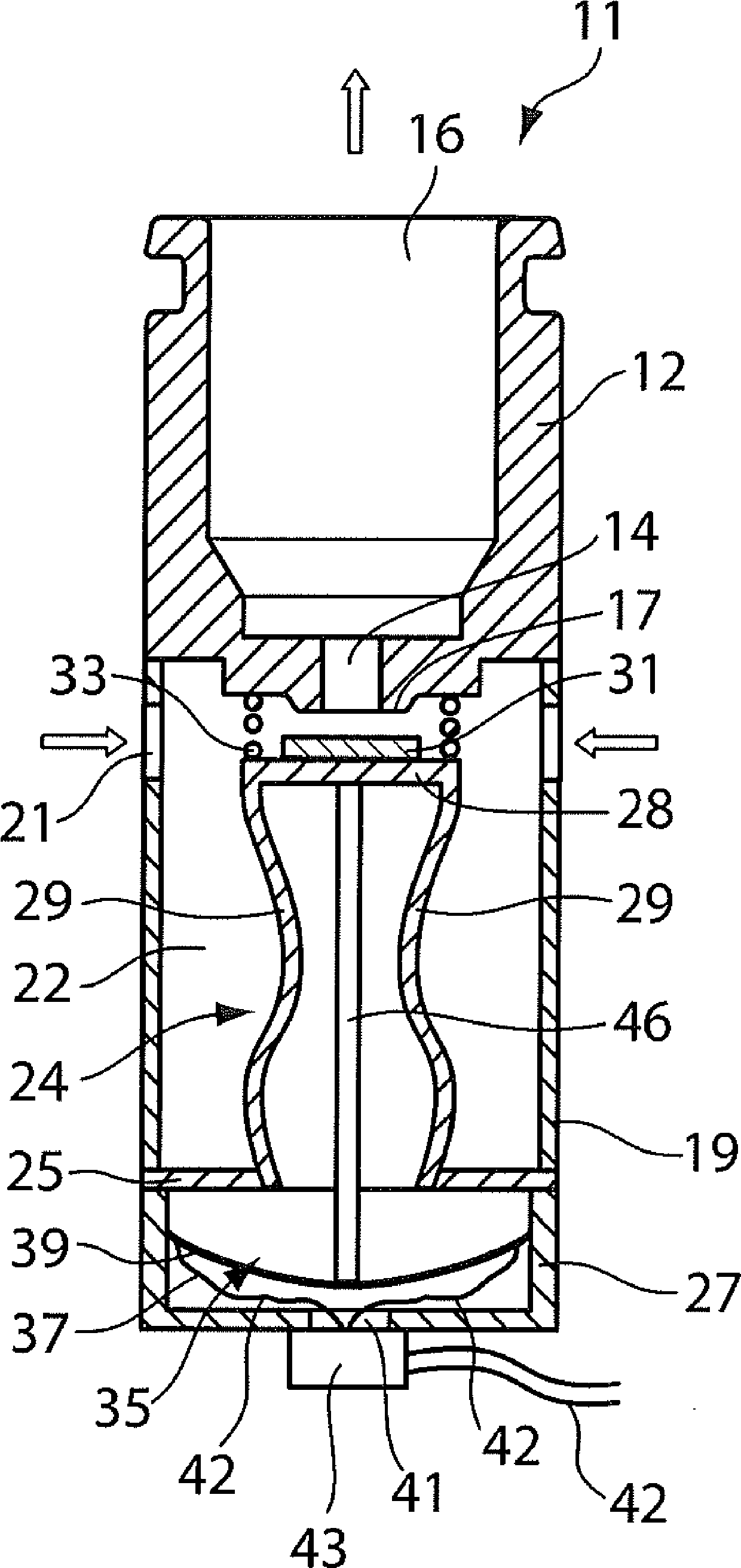

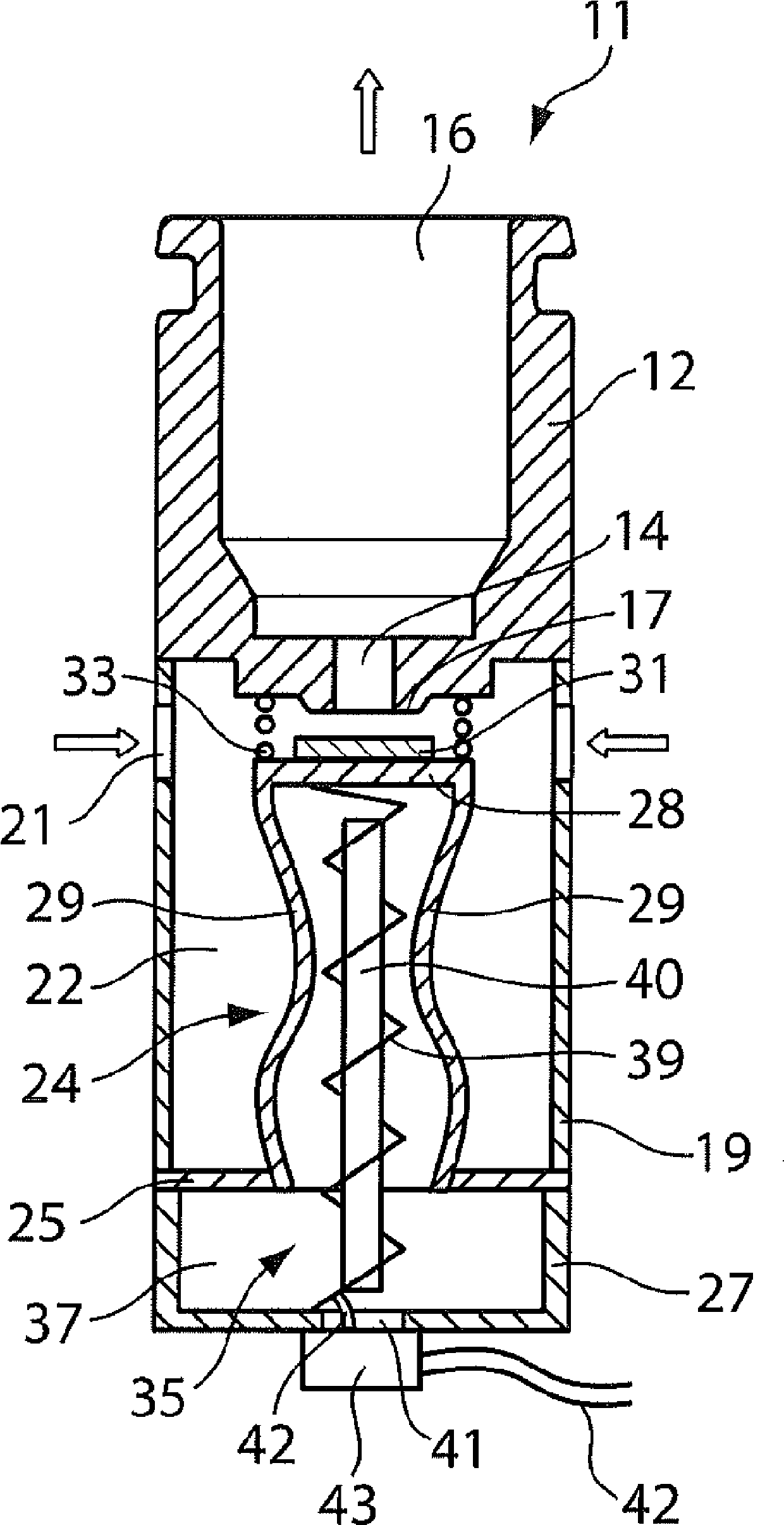

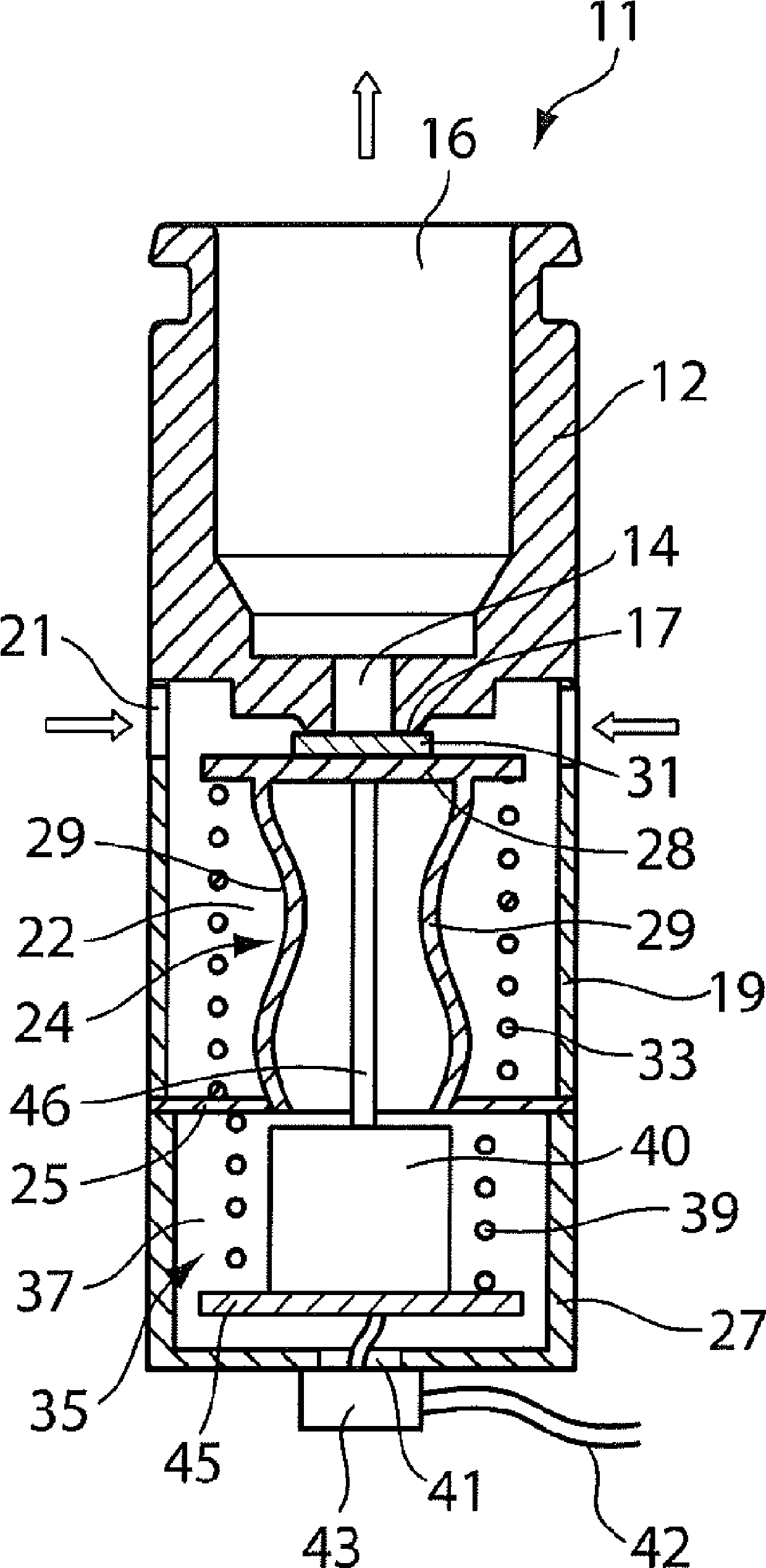

Inflator structure

Owner:黄英哲 +1

Gas plug valve assembly

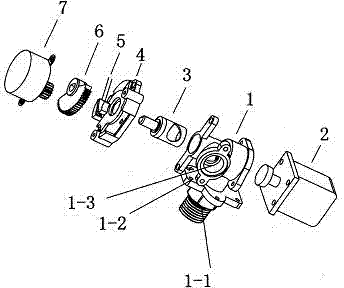

InactiveCN103115160ACompact structureEasy to processPlug valvesOperating means/releasing devices for valvesMagnetic valveEngineering

The invention provides a gas plug valve assembly. The gas plug valve assembly comprises a plug valve and a magnetic valve. The plug valve comprises a valve body, a valve seat, a valve core, a switch shaft, a braking wheel and a valve needle. The magnetic valve comprises a type cavity and a thimble. A first spring is installed on the thimble. The magnetic valve is pushed by the first spring in an opening mode. A second spring is installed on the thimble. The braking wheel is a camshaft. A buffering spring is added in pushing the magnetic valve, thus the safe opening of the magnetic valve is achieved. Service life of the magnetic valve can be prolonged at the same time when the damage rate of the magnetic valve is reduced. Function reliability of the gas plug valve assembly is improved.

Owner:HUBEI IND & SCI & TECH CO LTD XUNDA GRP

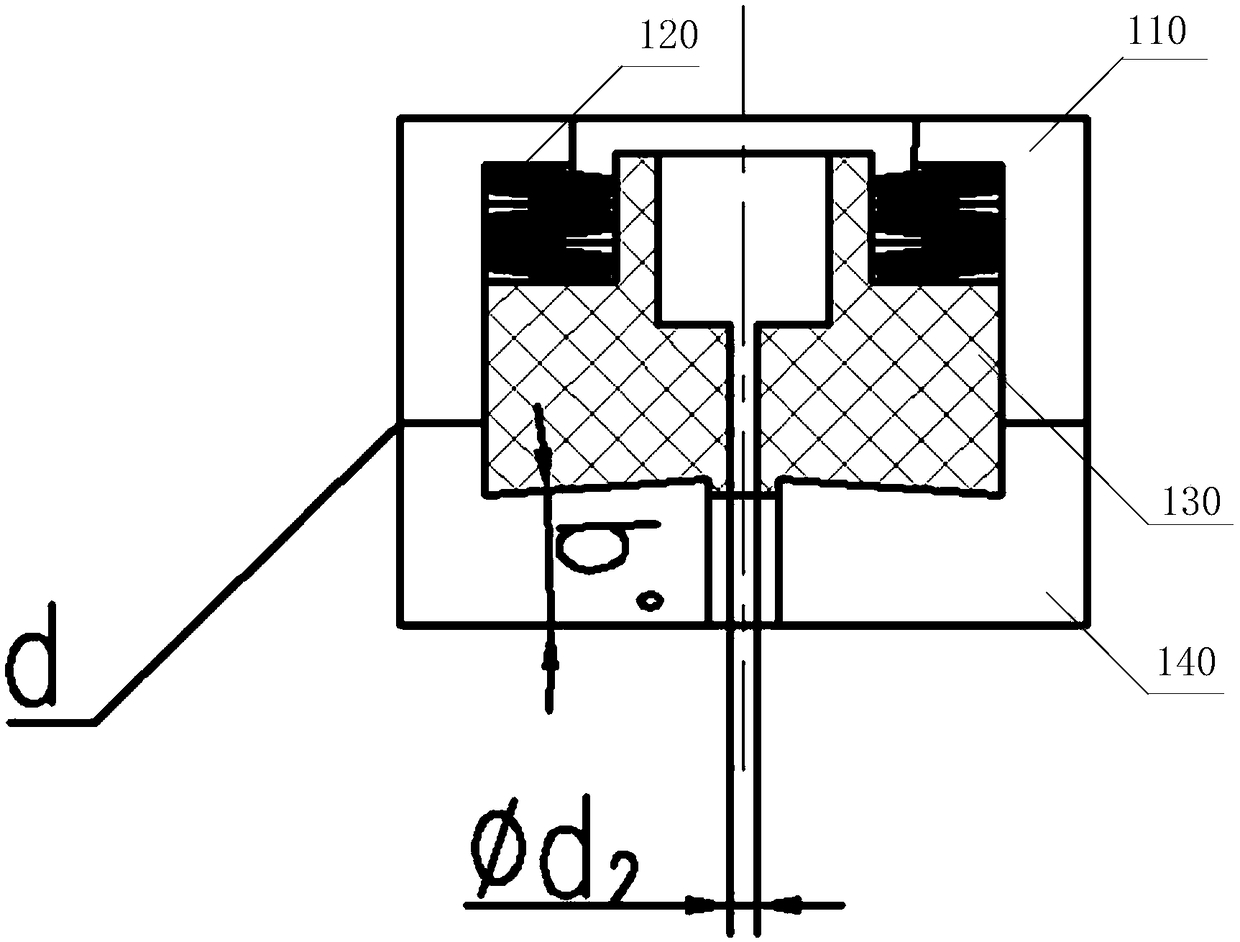

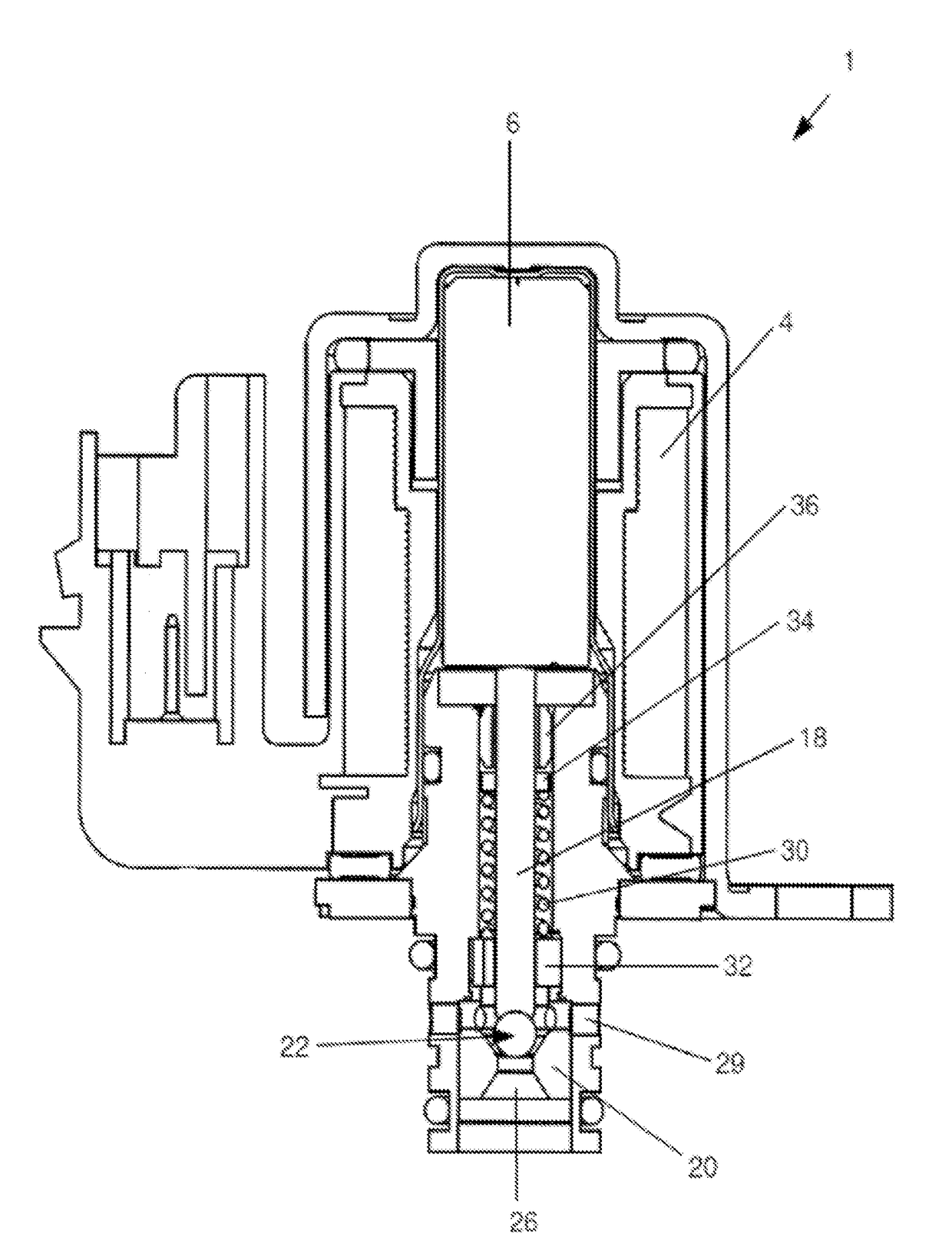

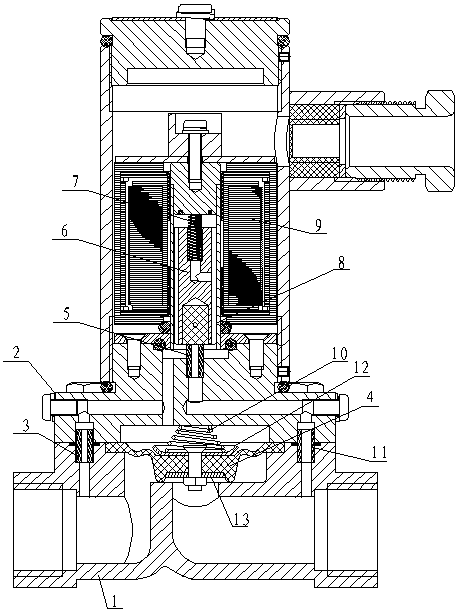

Micro-flow accurate control type proportional electromagnetic valve

ActiveCN108413106AWork reliablyAchieving a continuous proportional linear relationshipOperating means/releasing devices for valvesElectricityElectromagnetic valve

Owner:BEIJING INST OF CONTROL ENG

Turbine front-and-back pressure difference control type low-pressure circulating system

InactiveCN103573396ATaking into account low and medium speed conditionsReasonable designInternal combustion piston enginesDetonationGas compressor

Owner:刘洪涛

High pressure valve and integrated valve group

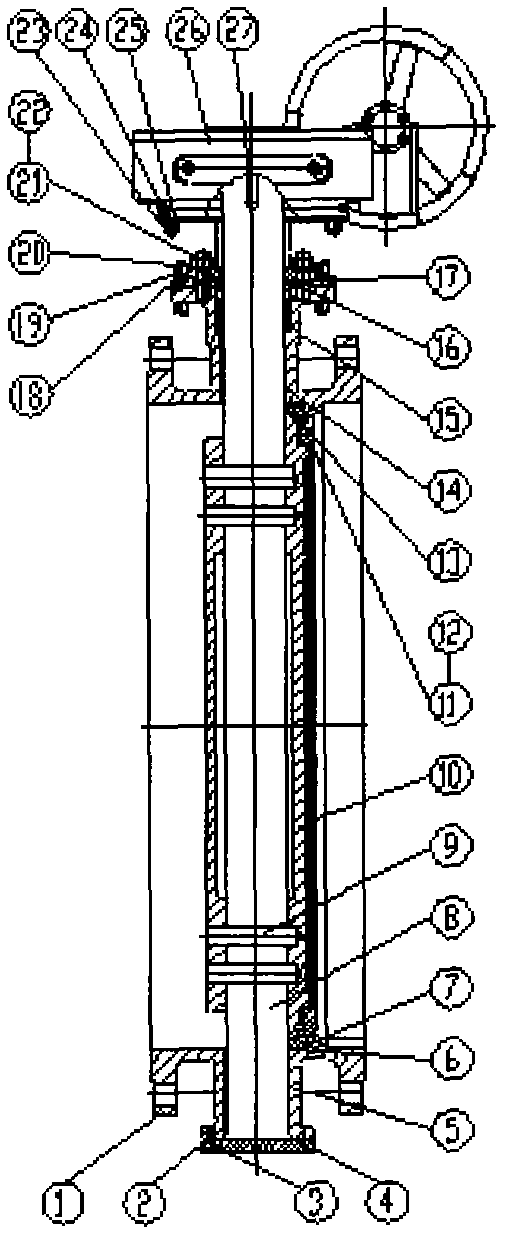

InactiveCN109253301ASmall diameterIncrease the cost of useOperating means/releasing devices for valvesValve housingsEngineeringValve stem

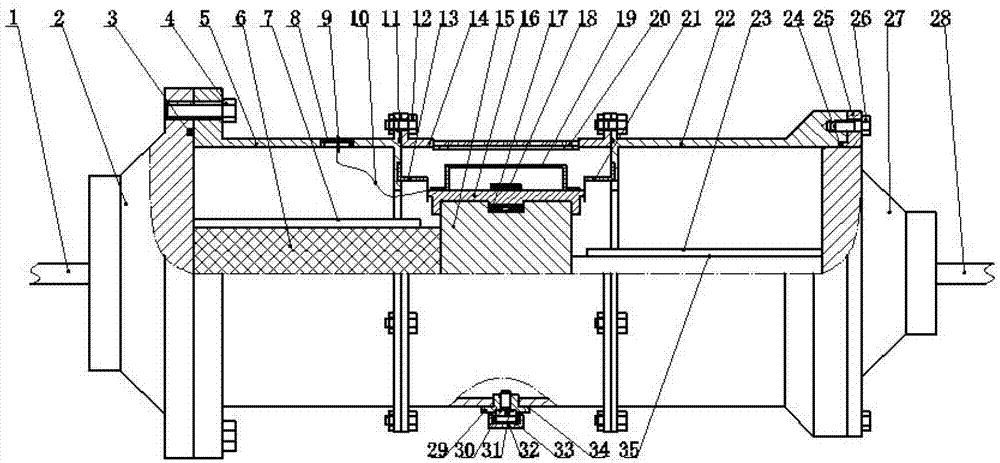

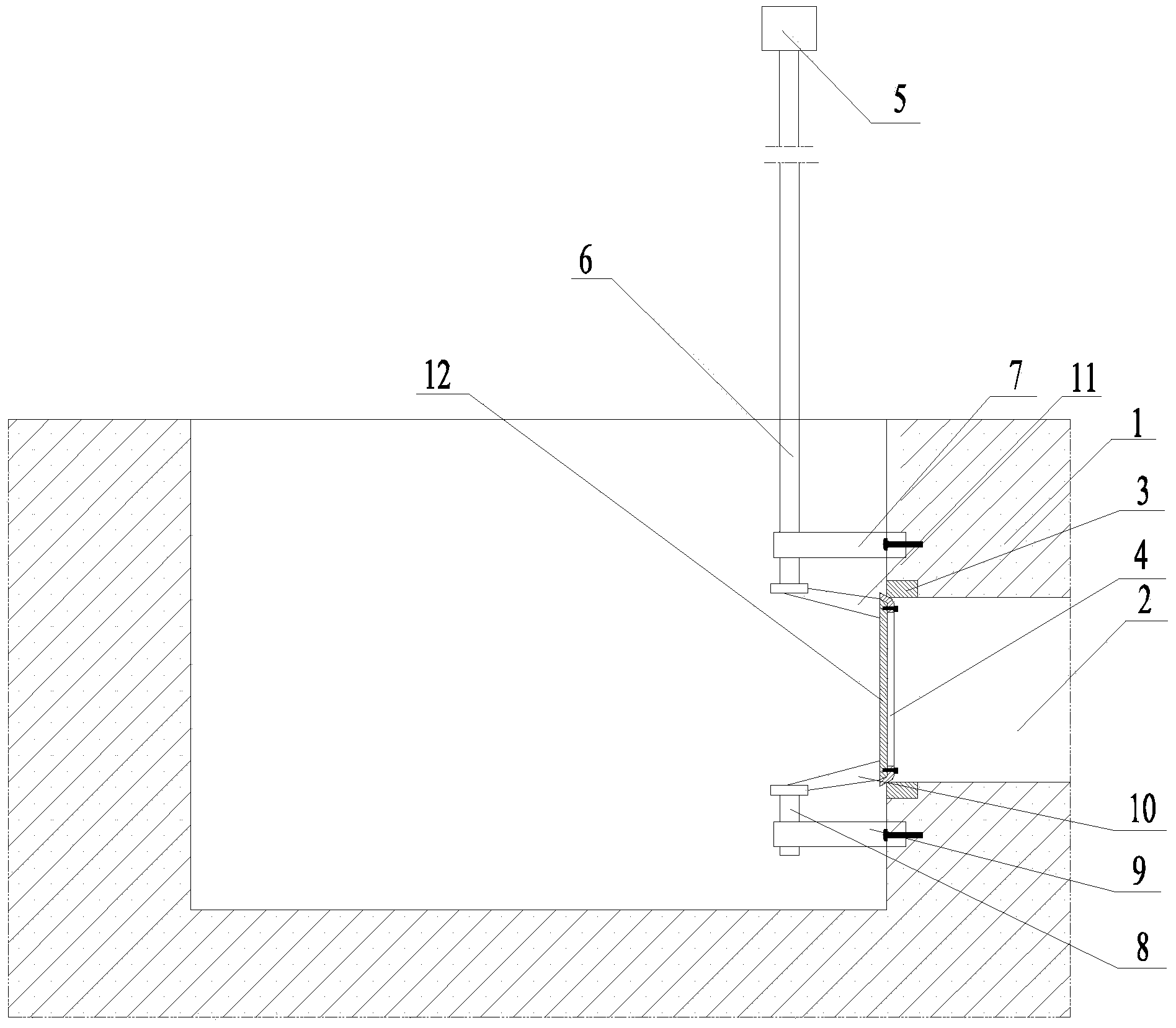

The invention provides a high pressure valve and an integrated valve group. The upper portion of a valve body of the high pressure valve is provided with a cylinder, and a piston rod of the cylinder is connected with a sealing valve stem in the valve body and drives the sealing valve stem to rise or fall in the valve body; an input port is formed in the upper portion of a sealing gasket in the valve body, an output port is formed in the lower portion of the sealing gasket, in use, the input port and the output port of the high pressure valve are respectively connected with an input section andan output section of a pipeline, the sealing valve stem is controlled to rise or fall by the cylinder to achieve break-over and cut-off of the pipeline, the integrated valve group includes an integrated base and a plurality of high pressure valve bodies disposed on the integrated base, during use, an inlet in the integrated base is connected to the input section of the pipeline, output ports of each high pressure valve body in an integrated valve seat are connected with an output mechanism, each high pressure valve body is opened or closed according to the demand to achieve the circulation and cut-off of high pressure fluid in different pipelines, the structure is simple, the disassembly and assembly are convenient, the valve does not need to be manually opened or closed during use, and the safety is high.

Owner:ULVAC ORIENT CHENGDU

Assembly of pressure adjustable and anti oil pumping cylinder cap and cowling

A cylinder housing assembly being able to regulate pressure and prevent oil from fleeing includes setting pressure regulating valve under pressure indicating valve in valve cavity of engine oil pressure indicating valve on housing body; forming pressure regulating valve by valve seat, valve core, spring and nut; setting oil inlet hole on housing body between two valves and oil discharging hole at bottom side of housing body; as well as setting an oil baffle outside of oil discharging hole on housing.

Owner:JIANGSU NONGHUA WISDOM AGRICULTURAL SCIENCE AND TECHNOLOGY CO LTD +1

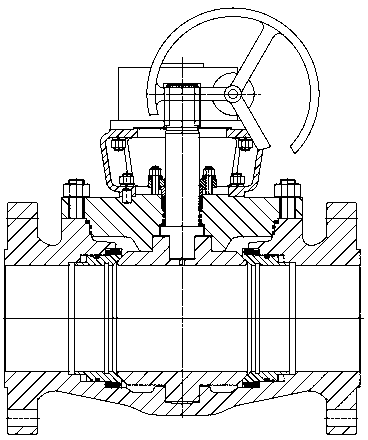

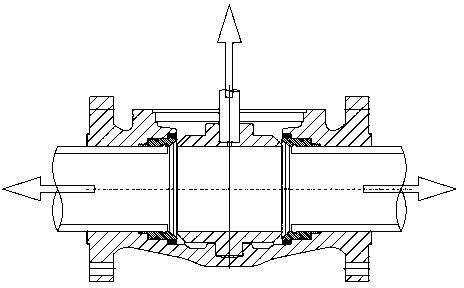

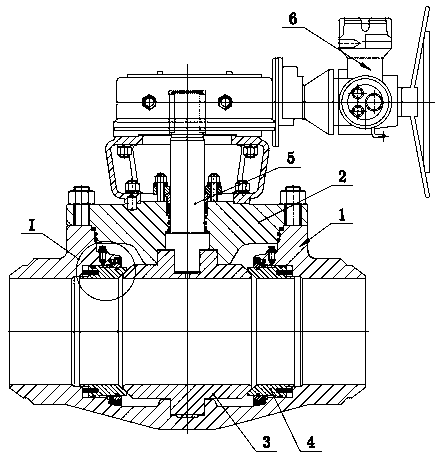

Top assembling type ball valve capable of achieving on-line disassembly and assembly

Owner:CHAODA VALVE GRP

Variable damping valve

PendingCN113685569AFlow adjustableOperating means/releasing devices for valvesSpringsStructural engineeringMechanics

Owner:JINTAN PUCHEN ELECTRONICS

Valve element opening/closing device

InactiveUS20080029724A1Easy to useAvoid damageOperating means/releasing devices for valvesCentre of rotationEngineering

Owner:SANKYO SEIKI MFG CO LTD

Eccentric two-way sealing butterfly valve

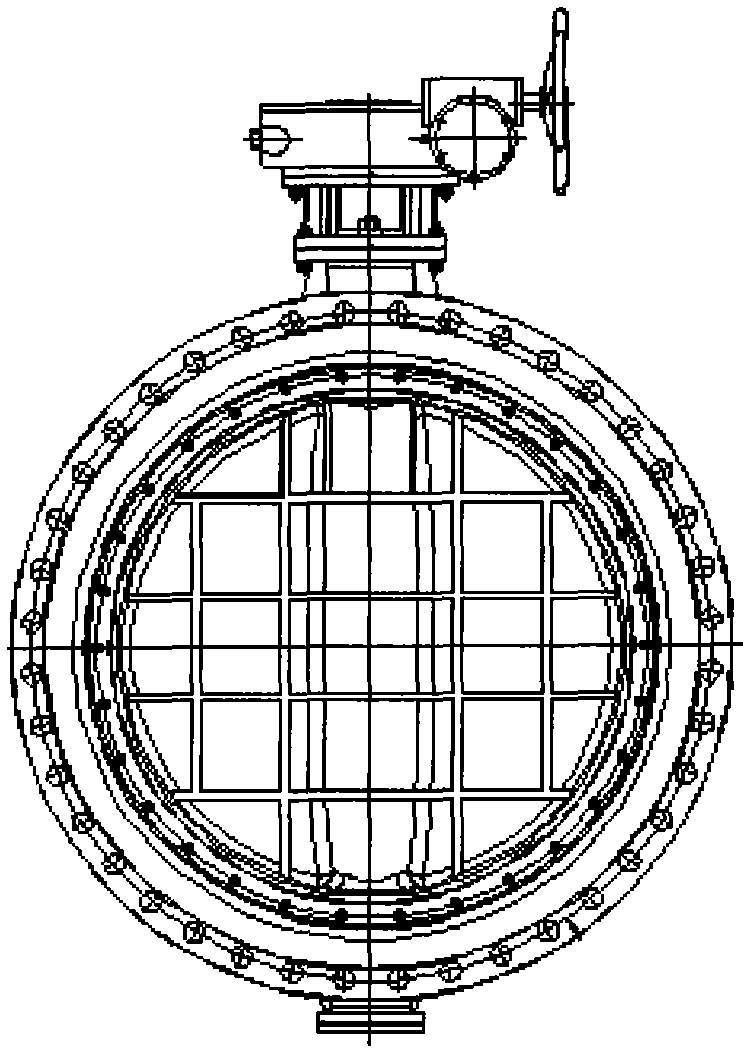

InactiveCN101988590AAchieving tightnessPrevent backflowOperating means/releasing devices for valvesLift valveEngineeringButterfly valve

Owner:JIANGSU SUWEI VALVE

Gate valve

InactiveCN107940089AAchieve leakPrevent high temperature swellingSpindle sealingsSlide valveEngineeringGate valve

Owner:郑立新

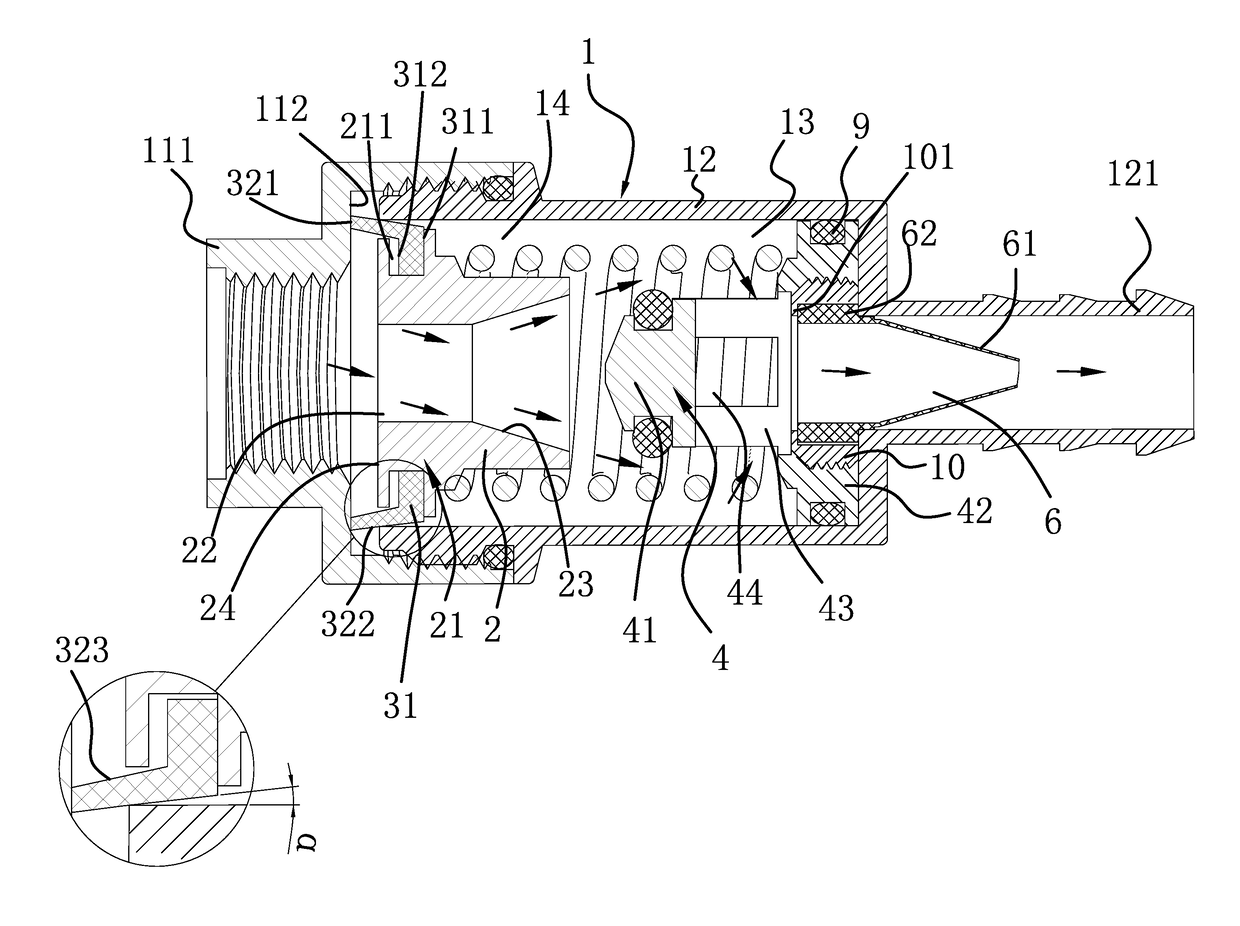

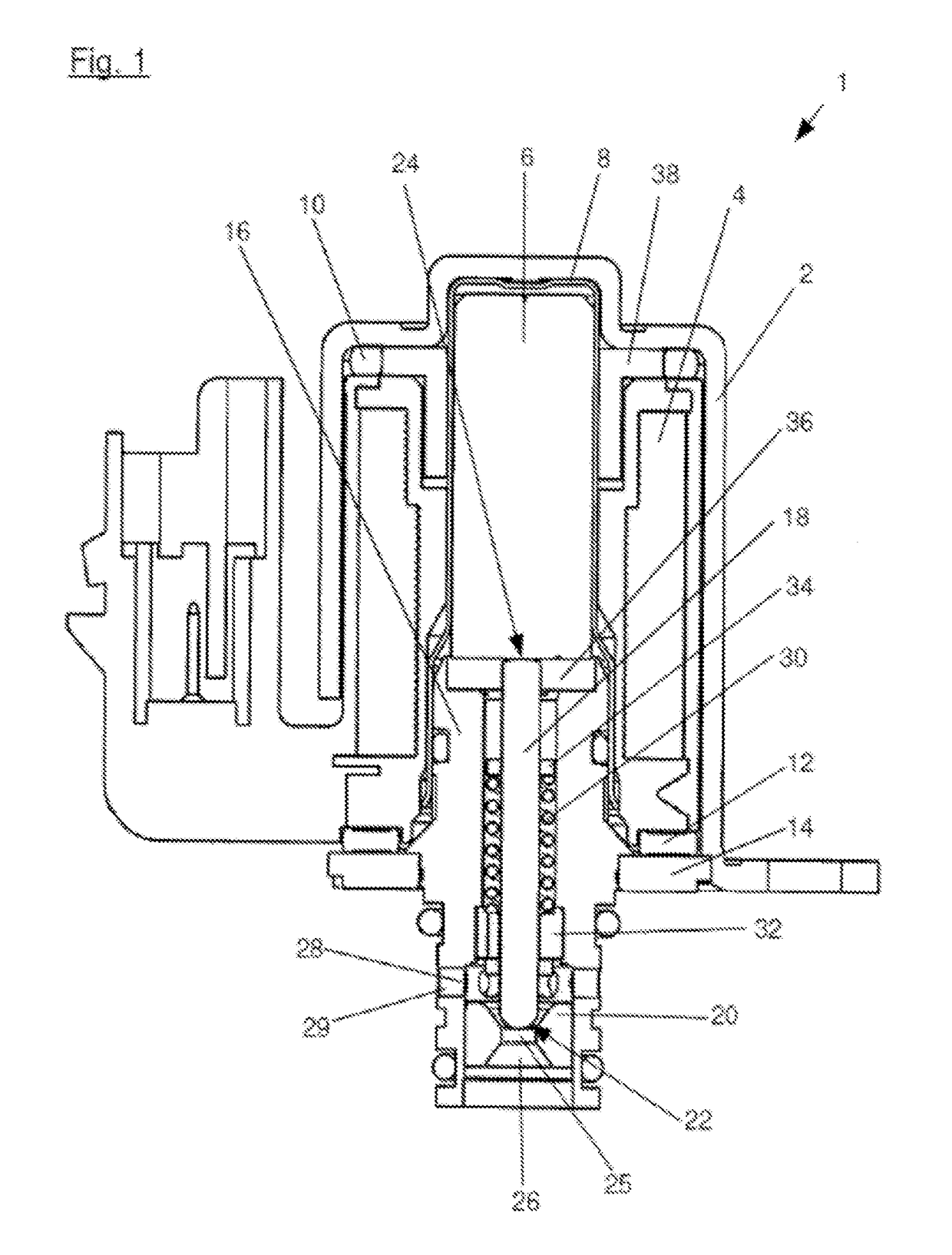

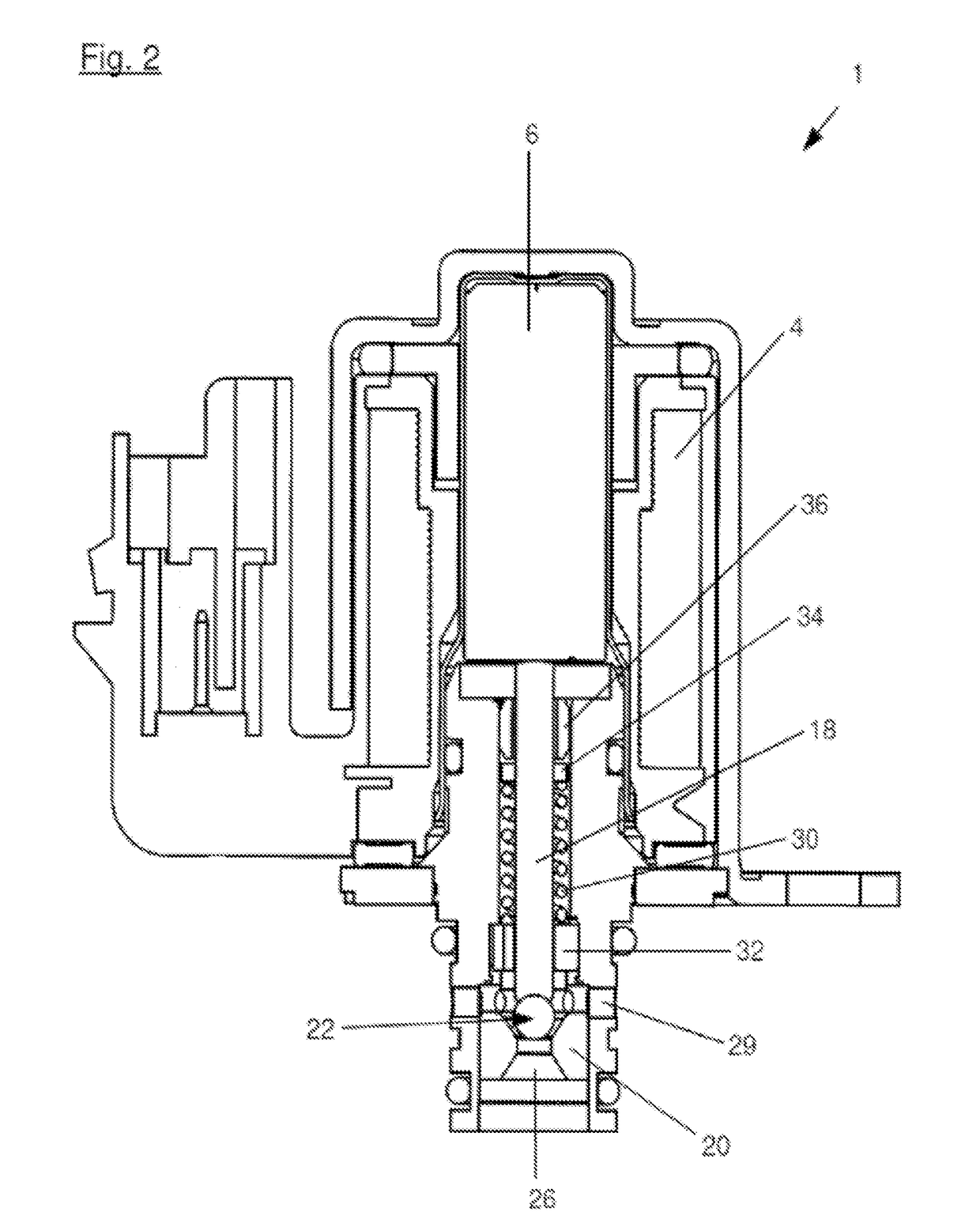

Volume Flow-Regulated Seat Valve

InactiveUS20180112789A1Operating means/releasing devices for valvesInternal combustion piston enginesEngineeringMotorized vehicle

Owner:KENDRION VILLINGEN GMBH

Automatic hard alloy welding tool for valve seat

Owner:盐城市景盛石化机械有限公司

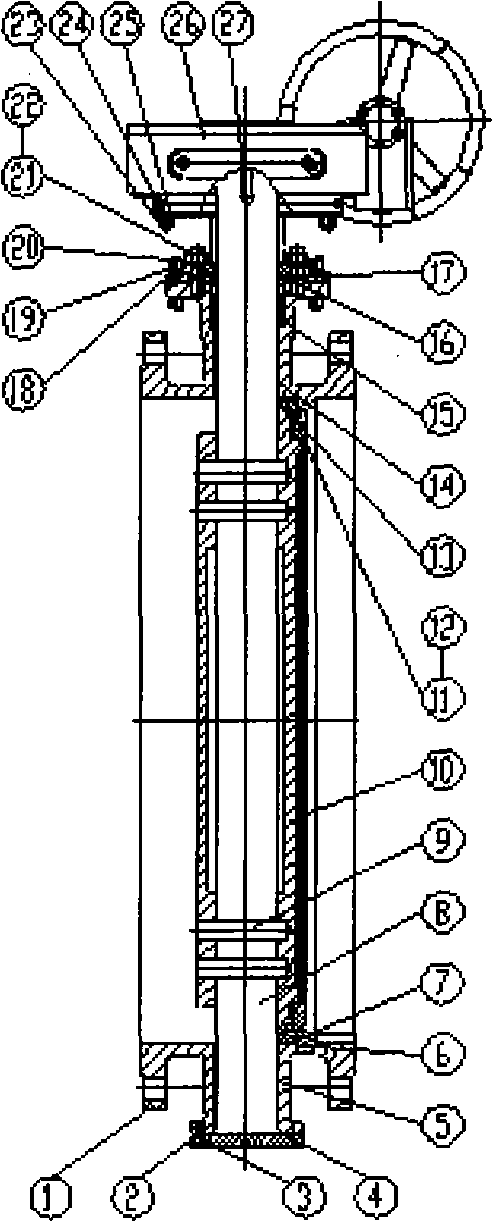

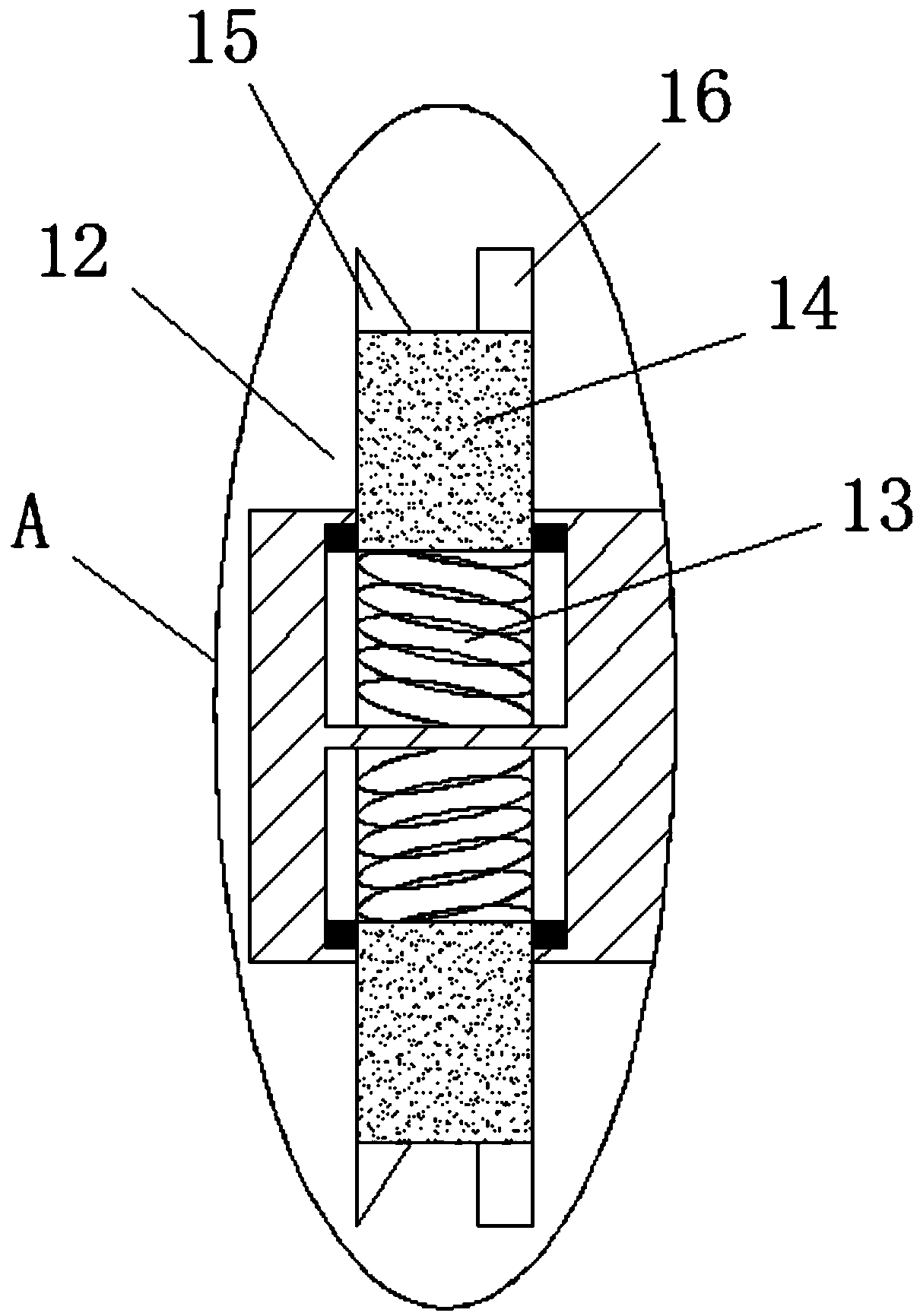

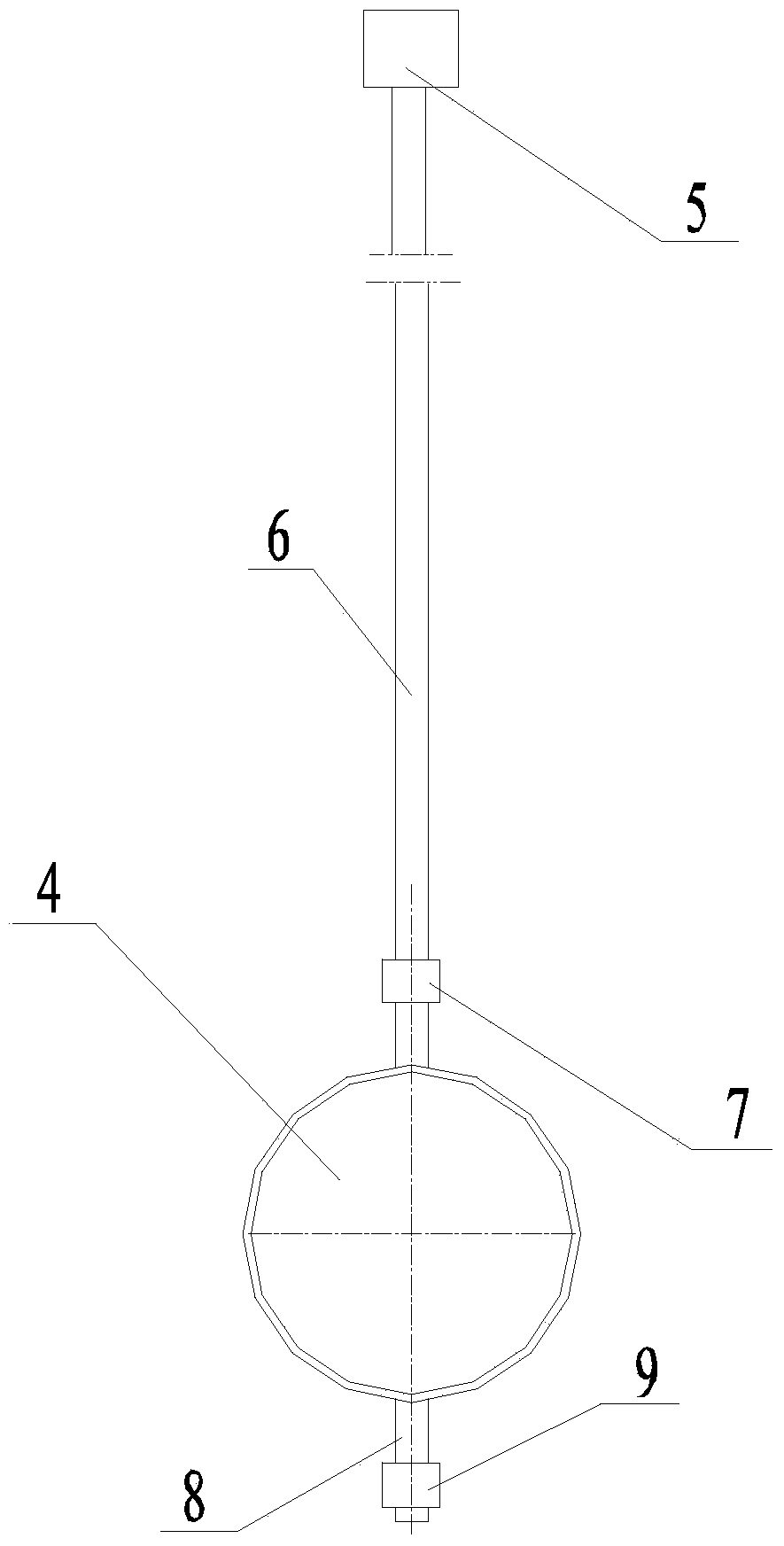

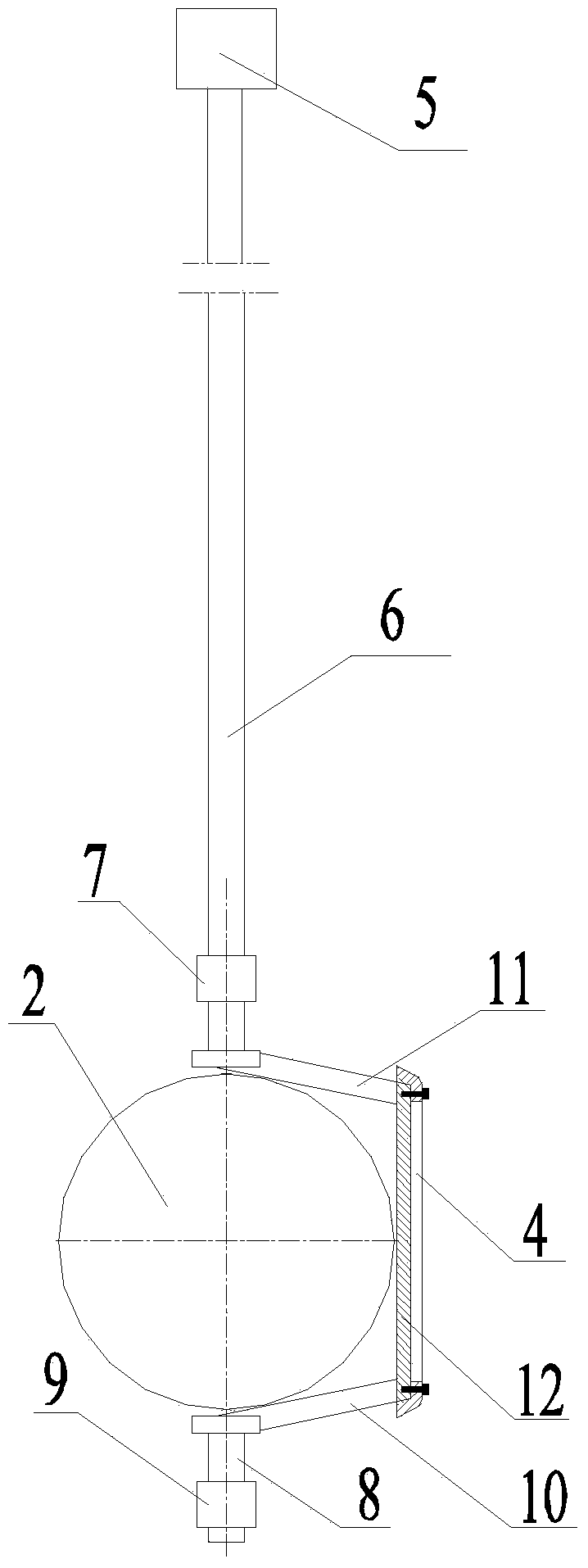

Valve seat automatic compensation one-way valve structure

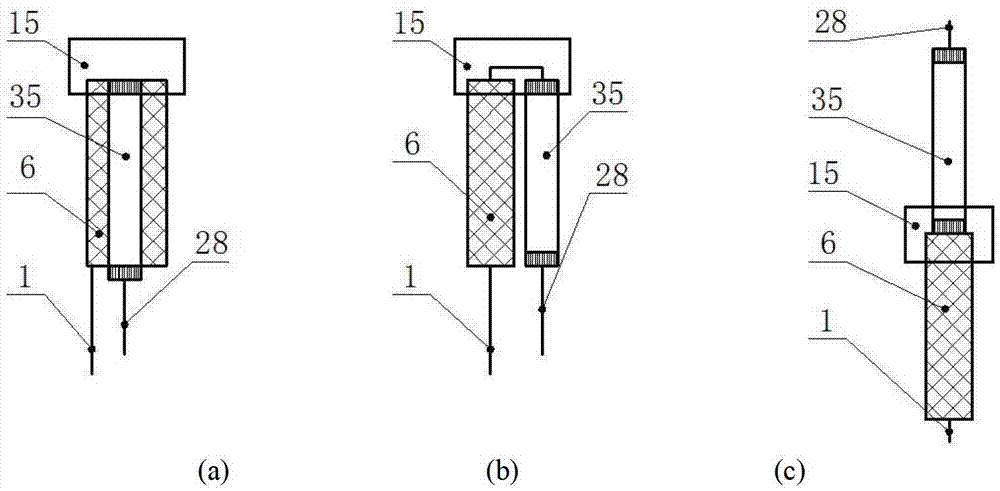

The invention relates to a valve seat automatic compensation one-way valve structure. The valve seat automatic compensation one-way valve structure comprises a valve body (3), an automatic adjusting valve seat mounted in the valve body (3) to move up and down and a valve ball (4) placed on the automatic adjusting valve seat. Compared with the prior art, when inlet pressure is difference, the position height of a valve seat is automatically adjusted, then the maximum lift height of the valve ball is adjusted, quite stable flow is kept, and when a diaphragm moves towards the diaphragm oil side protection disc, impacting to the protection disc and the influence on the drive end are reduced.

Owner:MILTON ROY IND SHANGHAI

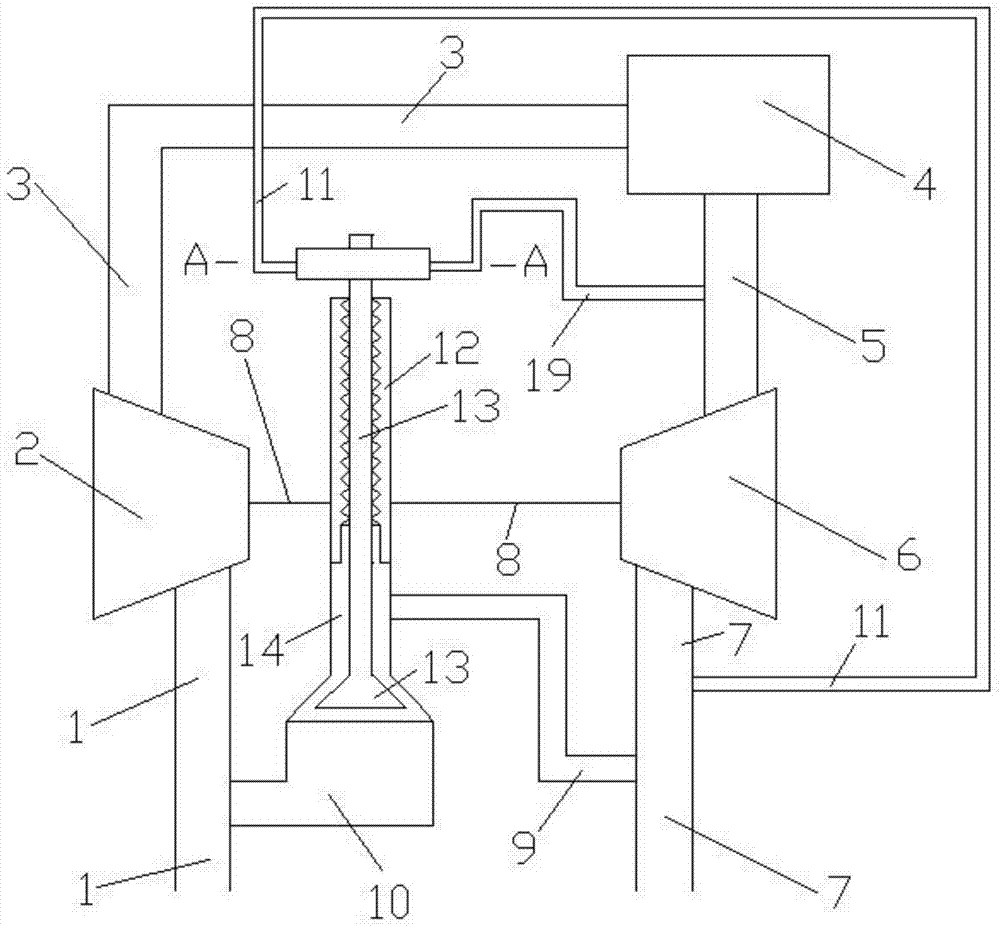

Numerical control proportional valve

InactiveCN104747779AReduce volumeOperating means/releasing devices for valvesNumerical controlEngineering

Owner:朱殿臣

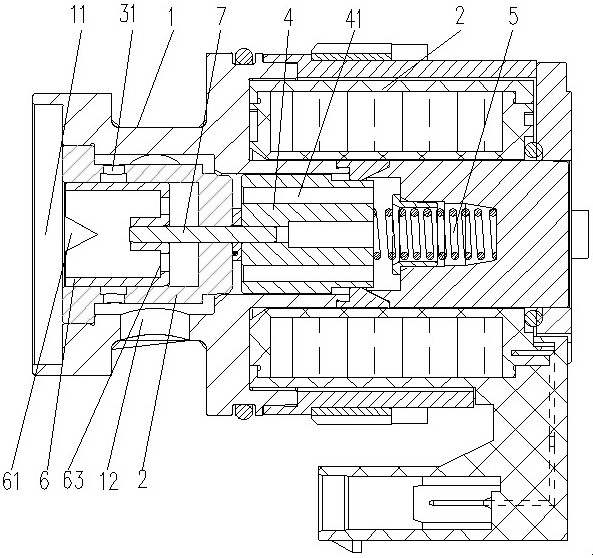

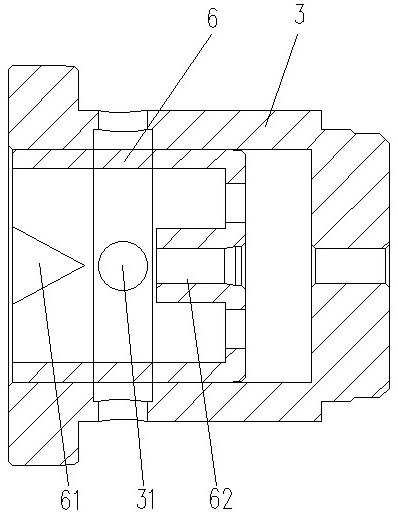

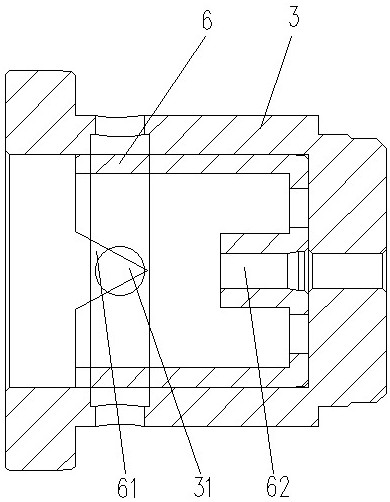

Electric control plug valve

ActiveCN107255173BSmall opening and closing torqueImprove sealingPlug valvesElectrical controlElectric control

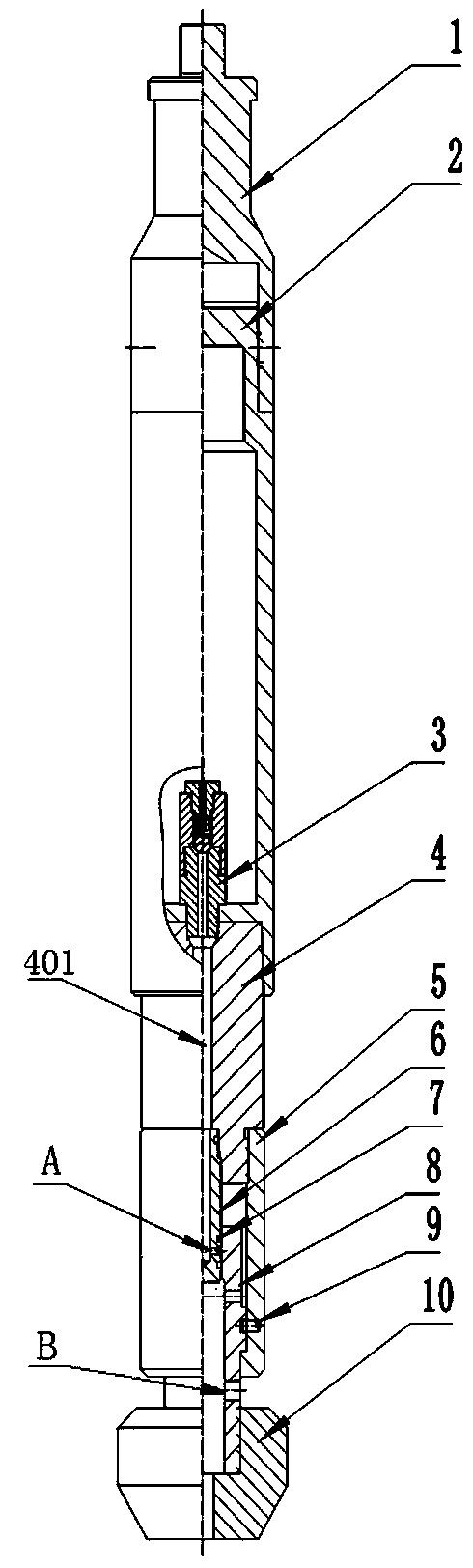

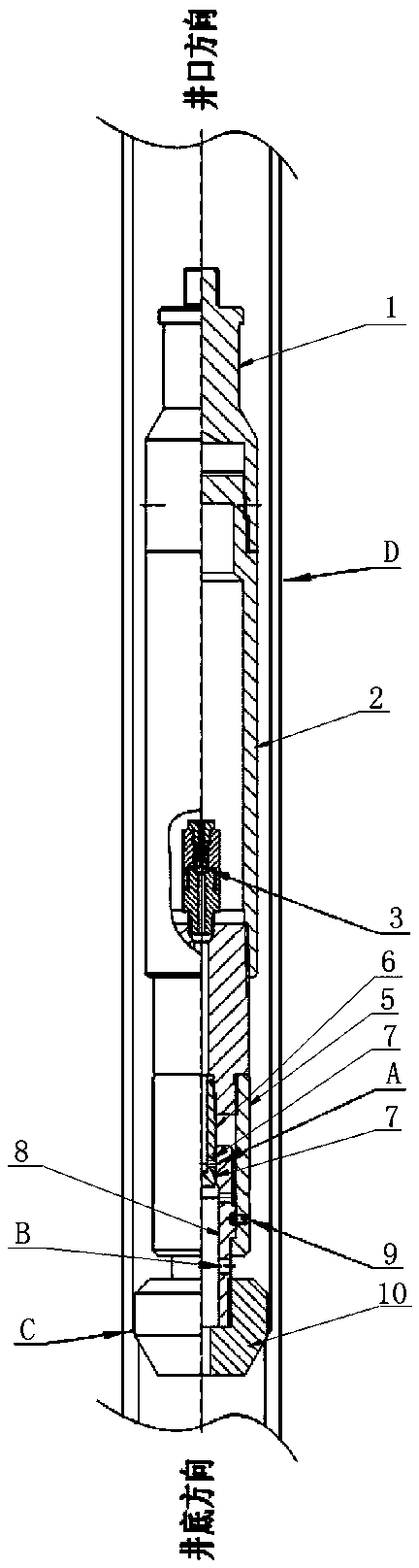

The invention relates to an electric control cock valve comprising a valve body, a cock body and a valve rod. The electric control cock valve is mainly characterized in that a valve seat is mounted in an annular cavity in the outer side of an inlet-outlet channel of the valve body in a motive seal mode; a pressure control cavity is formed between the back face of the valve seat and the bottom face of the annular cavity and connected with a pressure control mechanism through a pressure channel; the pressure control mechanism is composed of a piston control mechanism and an electrical control circuit; under control of the pressure control mechanism, the negative pressure is generated in the pressure control cavity when the valve is opened or closed, and the valve seat is made to contract into the pressure control cavity; and after the valve is opened or closed in place, the pressure is injected into the pressure control cavity, and the valve seat is pushed out of the pressure control cavity to be in compressed seal fit with the cock body. The electric control cock valve has the characteristics of small open-close torque, reliable sealing performance, long service life of a product, high using pressure and the like, and is applied to the high-pressure medium working condition.

Owner:YONGJIA XINCHENG TECH SERVICE CO LTD

A cutting ball valve

InactiveCN107514480AFlexible opening and closingOpen and close quicklyPlug valvesOperating means/releasing devices for valvesEngineeringValve seat

The invention discloses a cut-off ball valve, comprising: a valve body, a valve seat, a valve stem and a valve core, the valve body is a side-mounted valve body, a valve seat and a valve core are installed in the valve body, and the valve seat is installed in the valve body Between the valve core and the valve seat, the cross-sectional shape of the valve seat is "<", the bottom of the valve stem passes through the top of the valve body and is installed on the top of the valve core, the top of the valve body is fixedly installed with a bracket, and the top of the bracket is installed with an actuator. The actuator is fixedly connected with the valve stem, and the actuator is a pneumatic actuator. The technical purpose of the present invention is to provide a shut-off ball valve with fast opening and more reliable sealing. This shut-off ball valve can quickly cut off the medium in the pipeline, thereby ensuring the safety of production, and has floating sealing performance.

Owner:CHENGDU DESHANNENG TECH CO LTD

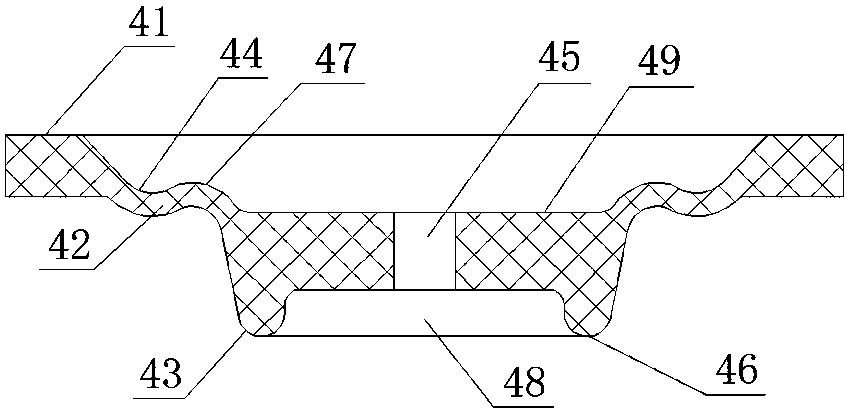

Membrane pad type solenoid valve

InactiveCN108458129AExtended service lifeGood flexibilityDiaphragm valvesOperating means/releasing devices for valvesSolenoid valveBody positions

Owner:SUZHOU ZHONGKUANG SANJIE TECH

Shut-off valve for liquid and gaseous media

ActiveCN104781597AReduce weightKeep reaction timeOperating means/releasing devices for valvesLiquid stateShape-memory alloy

Owner:OTTO EGELHOF

Vertical cutting plugging device

Owner:WUHAN SHENGYU DRAINING SYST

Underground liquid sampling tool

Owner:HUNAN VICTOR PETROTECH SERVICE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap