Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about "Equalizing valves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

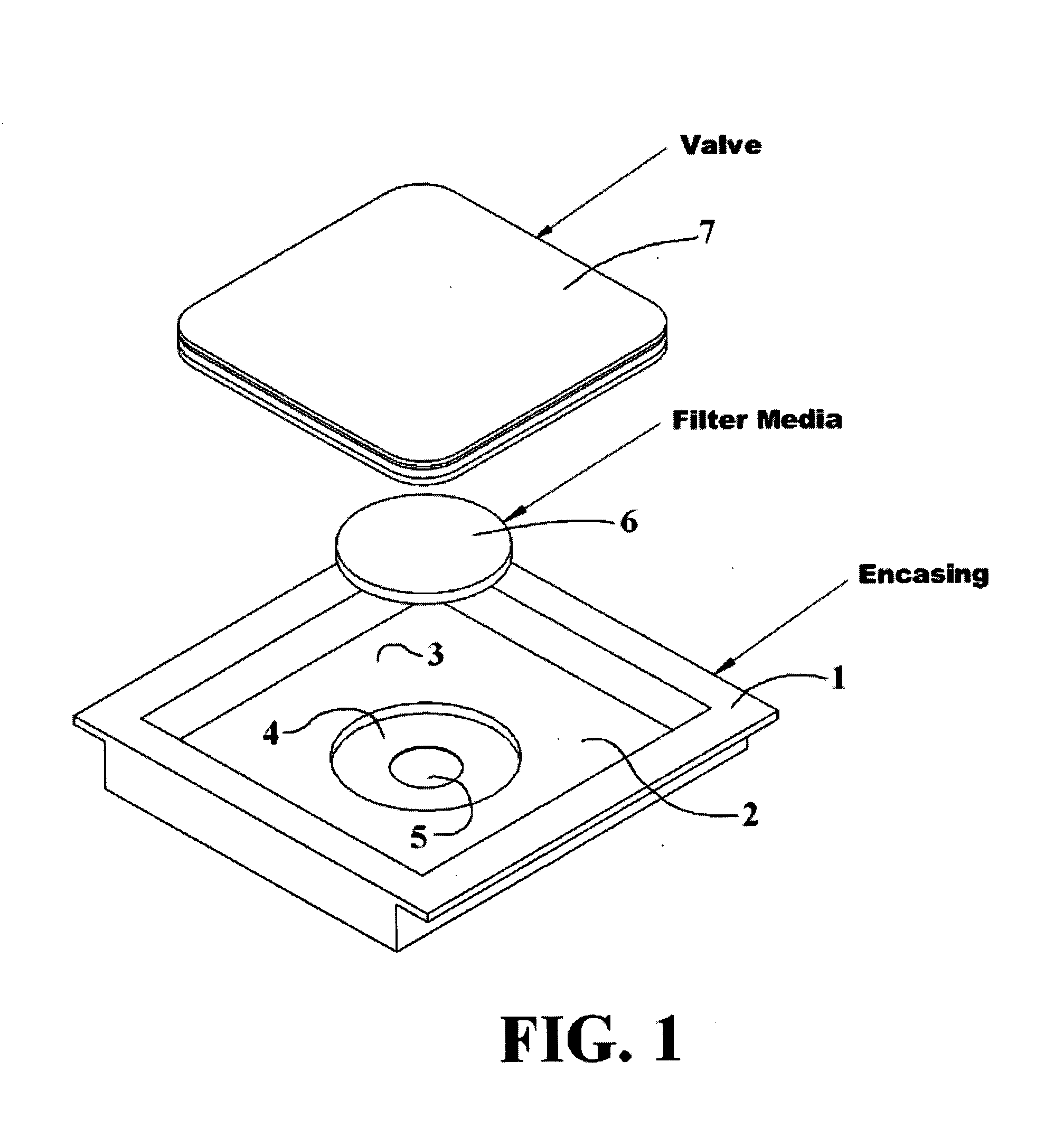

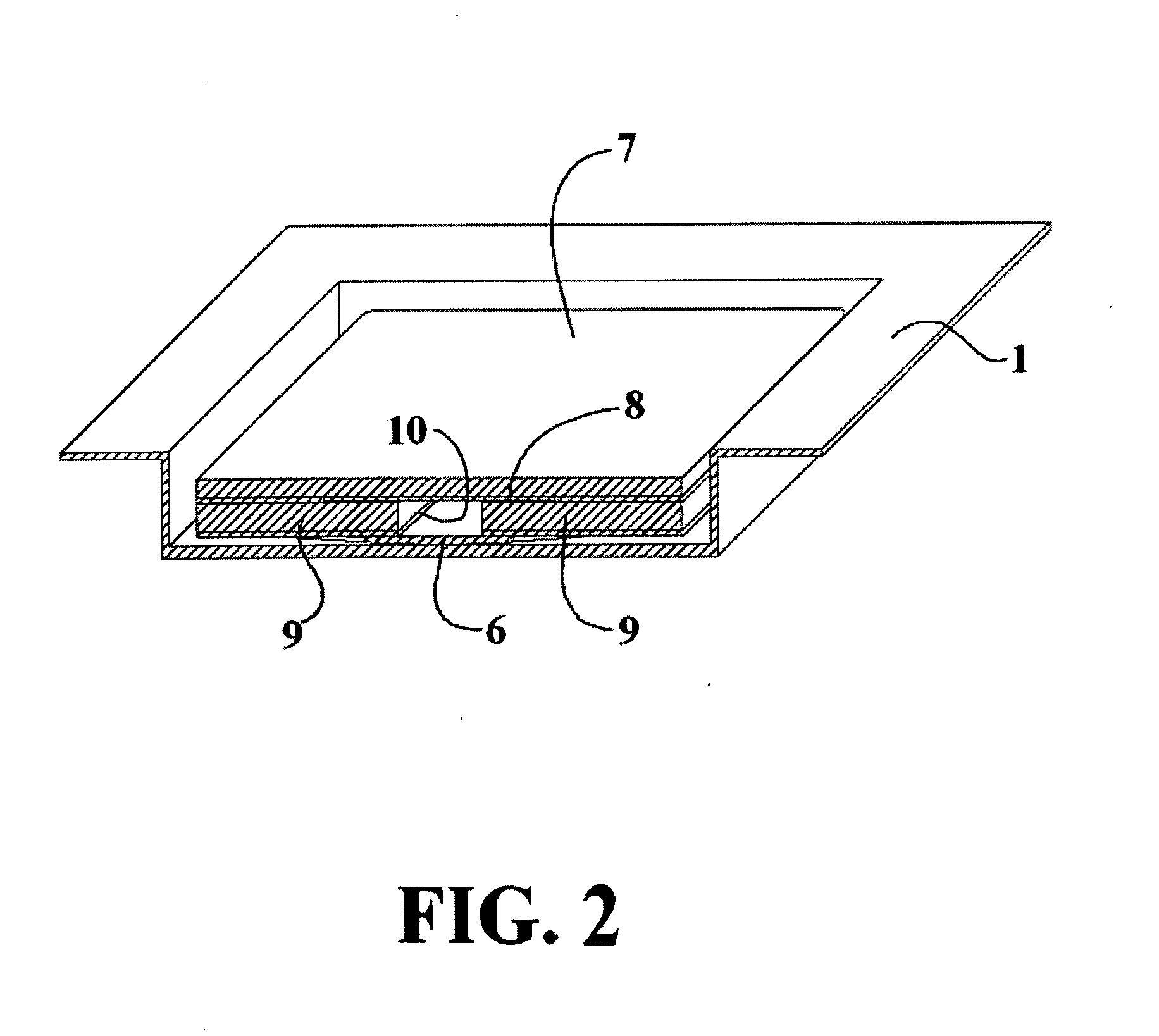

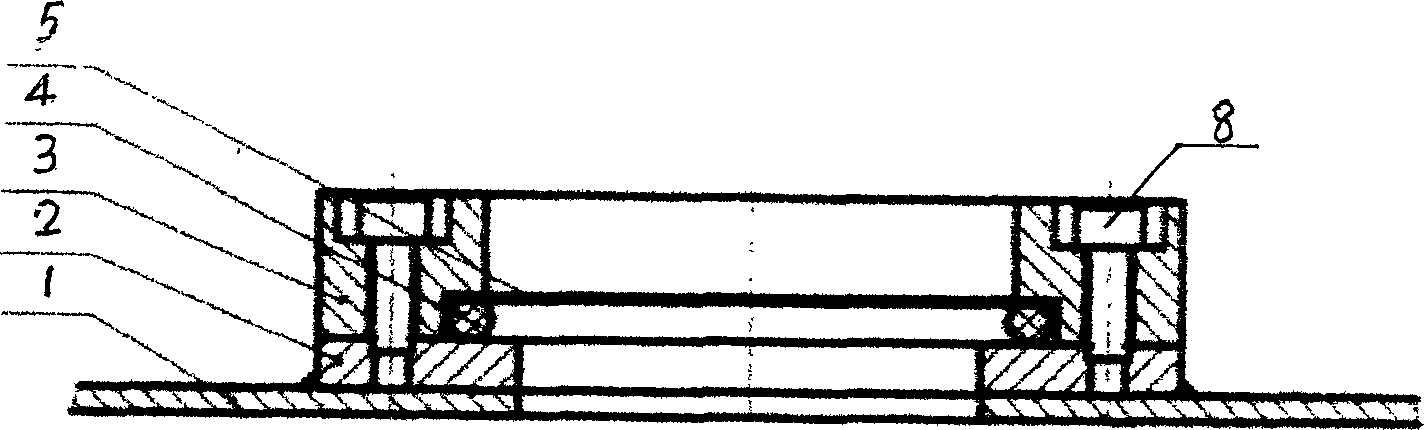

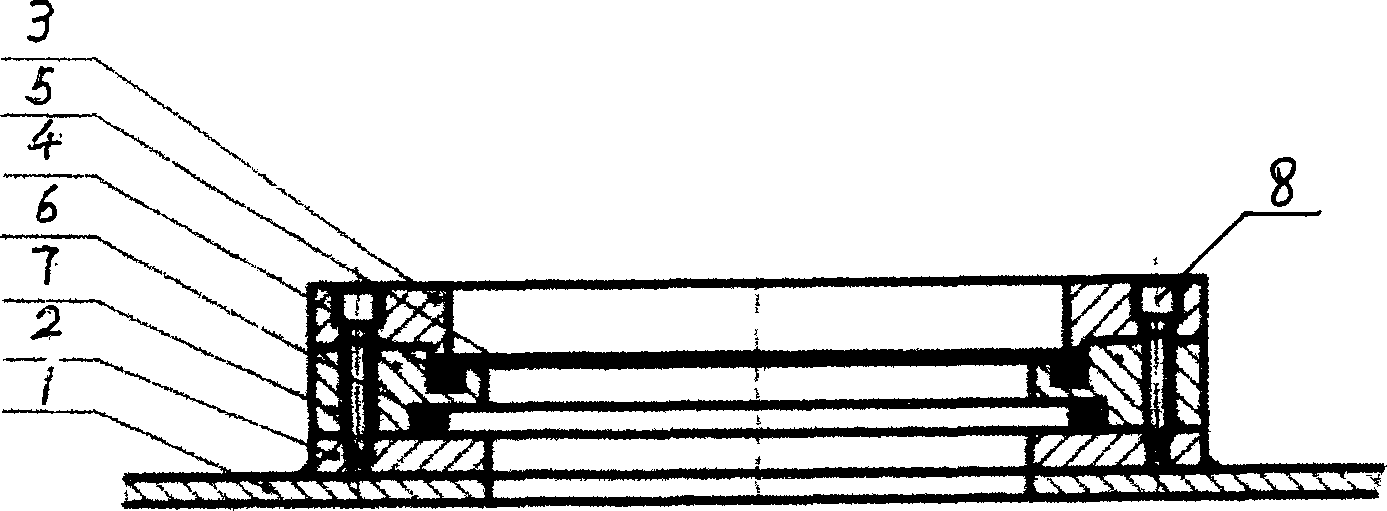

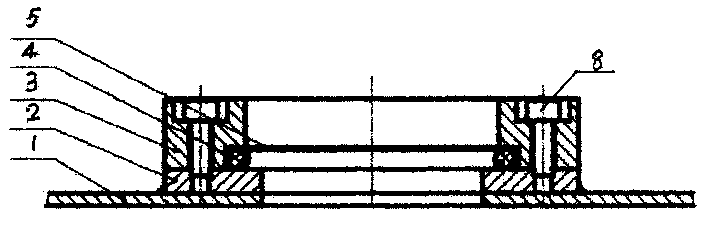

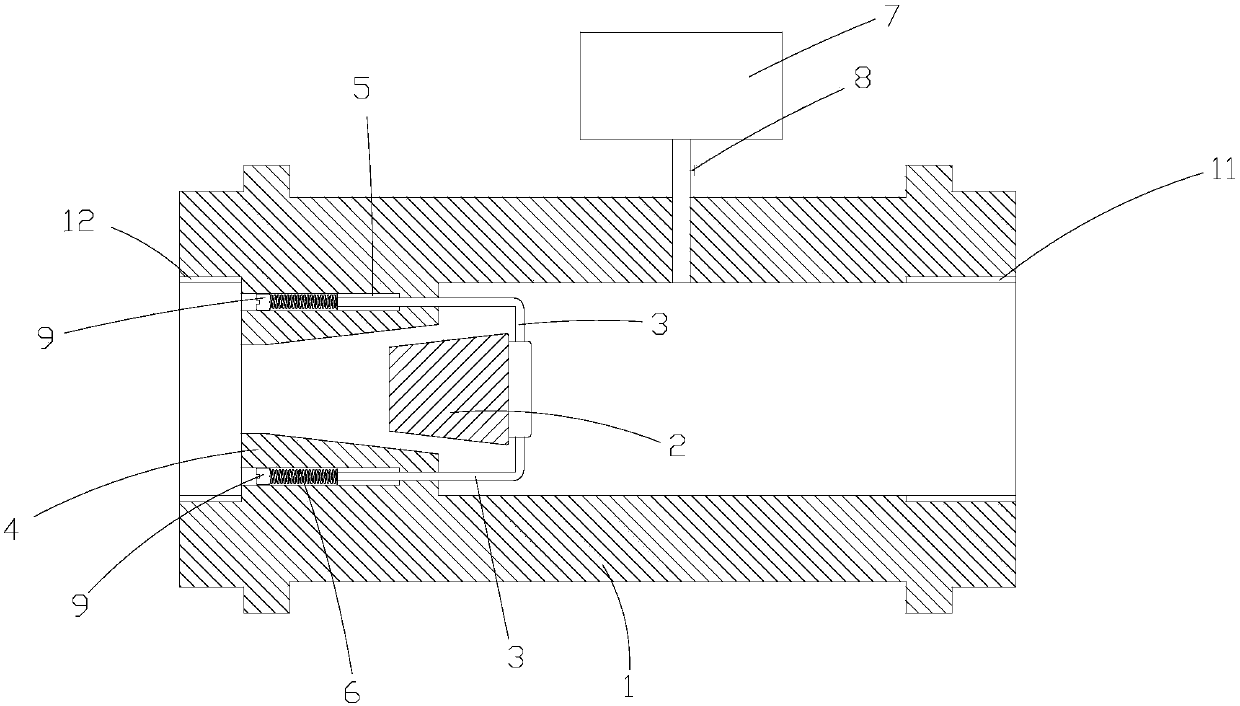

Micropumps with passive check valves

Owner:WATERS TECH CORP

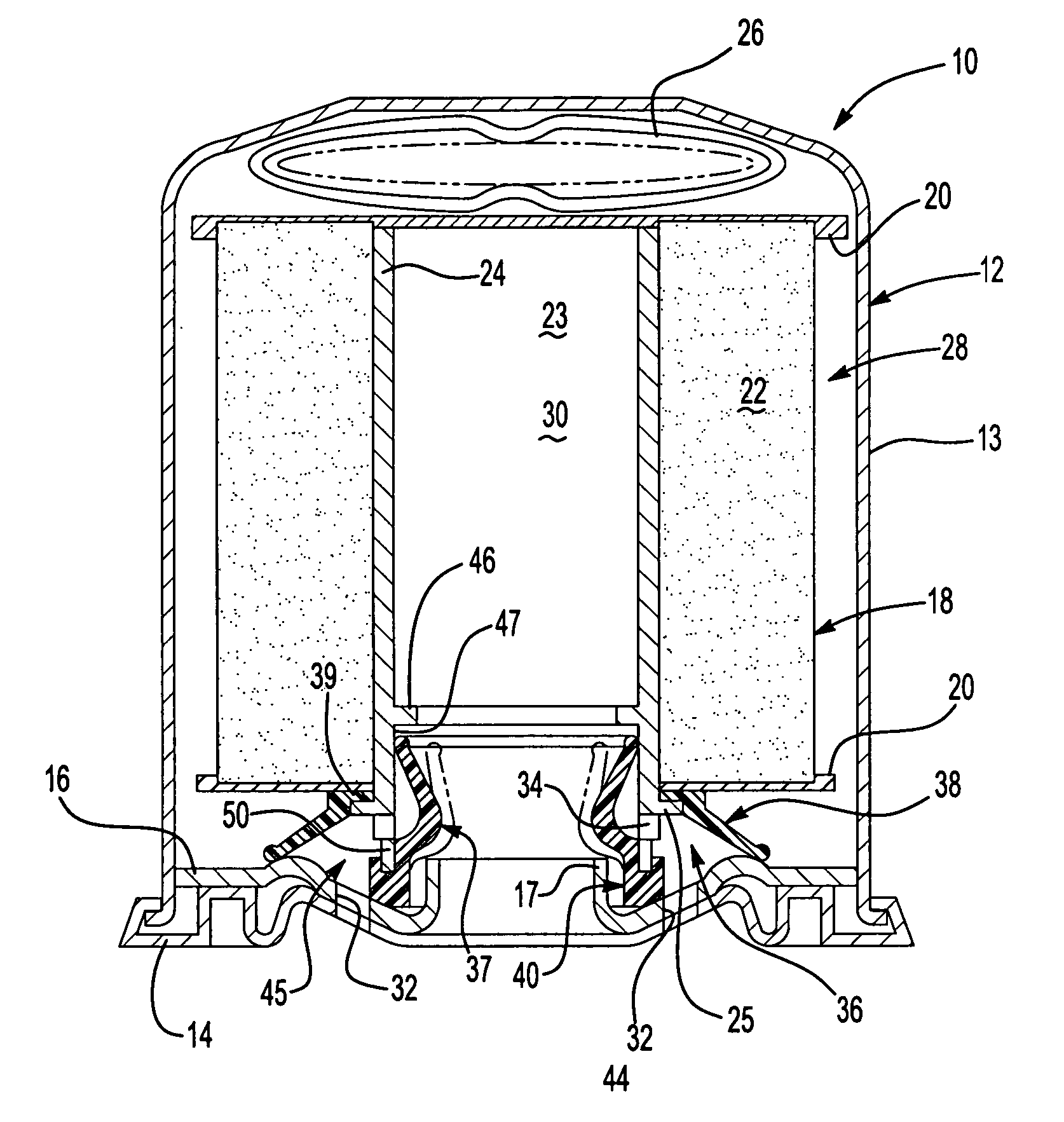

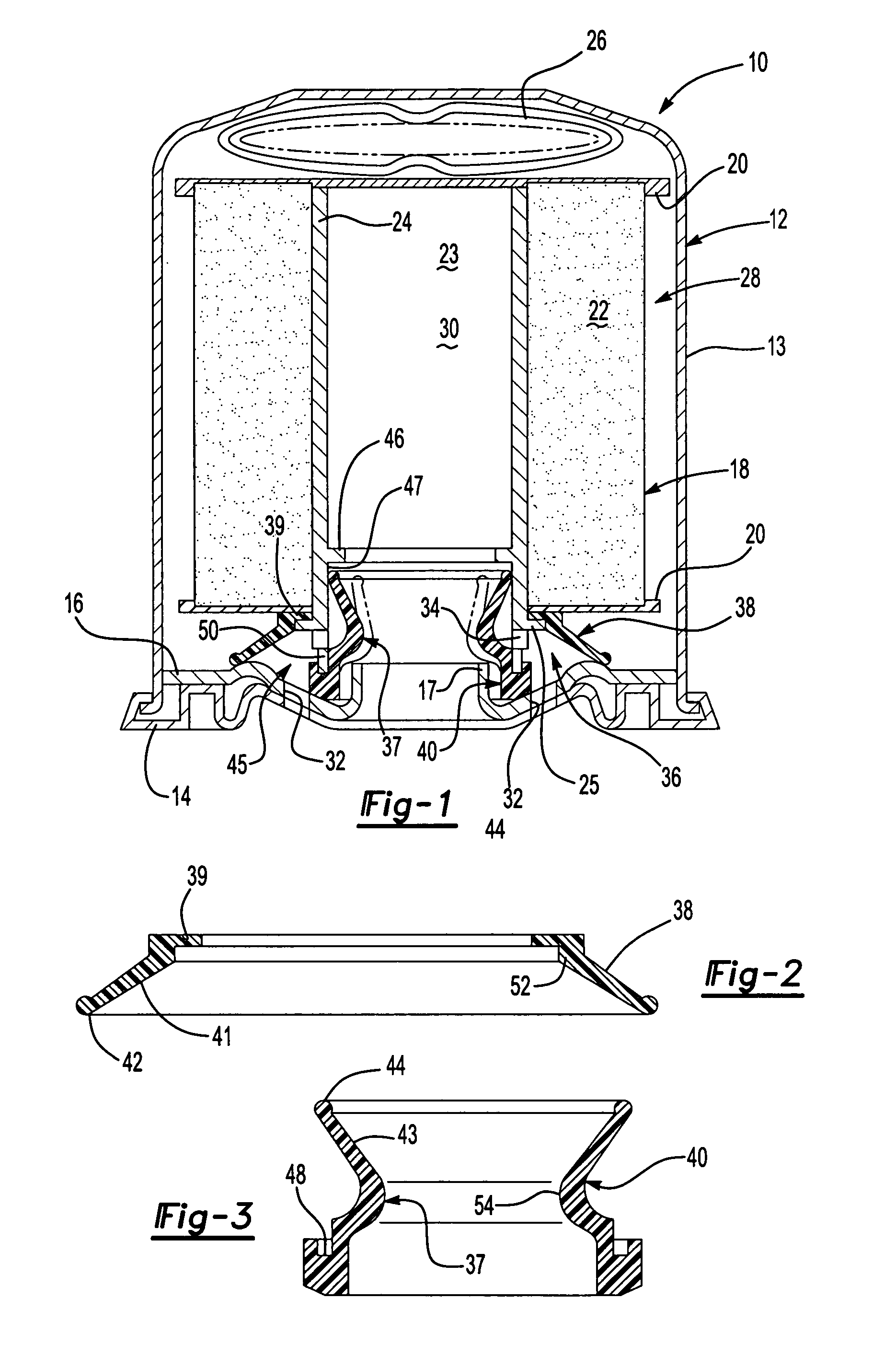

Two piece elastomer relief and anti-drain back valves for filter

InactiveUS20050161378A1Reduce in quantityEliminate the problemSettling tanks feed/dischargeEqualizing valvesElastomerDifferential pressure

Owner:PUROLATOR ADVANCED FILTRATION

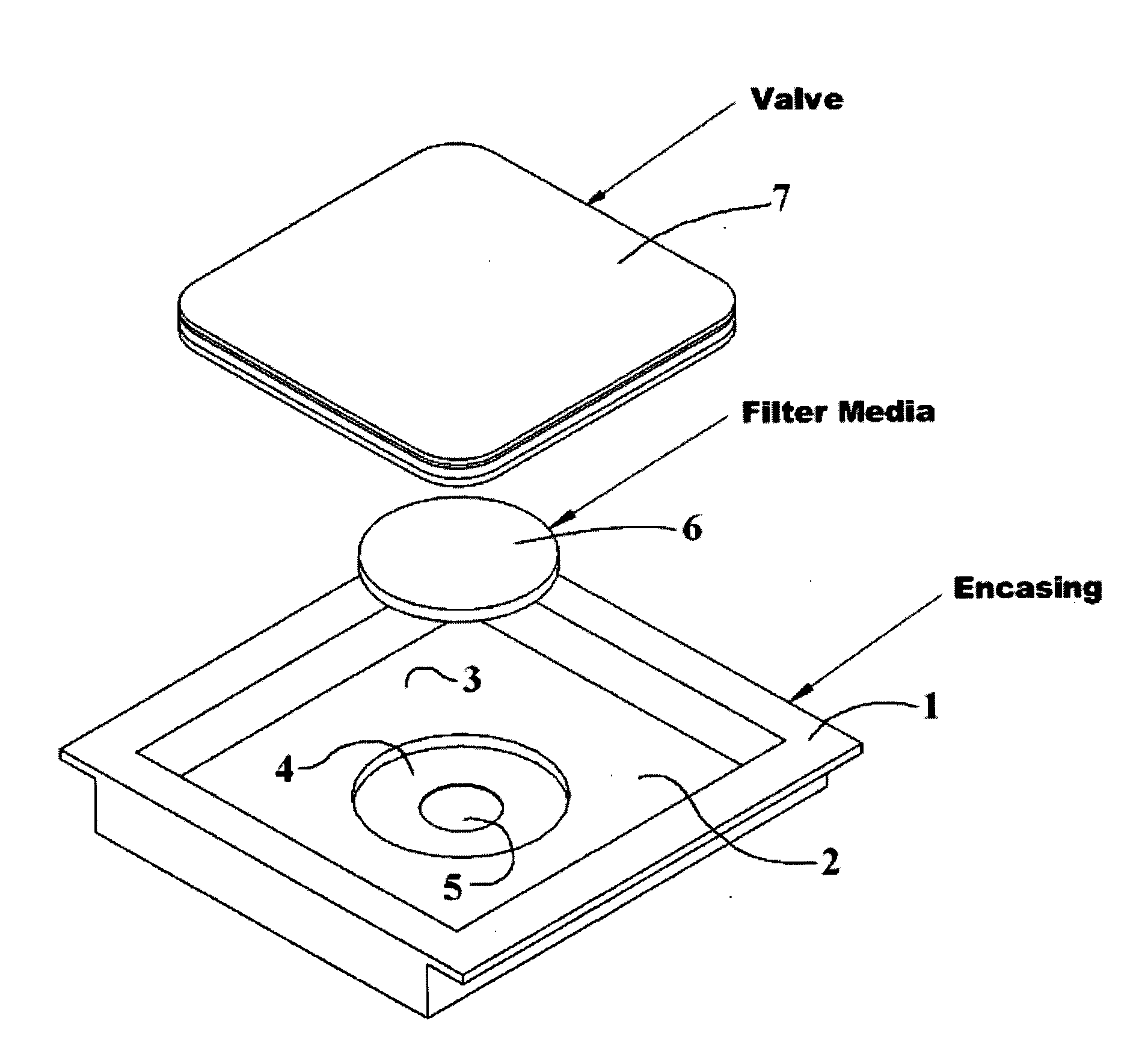

Interior-mountable pressure relief valve

Owner:PLITEK

Pressure relief device

A pressure relief device having a housing including an inlet, an outlet, and an inner wall defining a bore connecting the inlet and the outlet. The inlet is in communication with a fluid under pressure in a pressure vessel. The bore includes an inlet portion extending from the inlet toward the outlet, and an outlet portion extending from the outlet toward the inlet. The bore also includes a tapered portion connecting the inlet portion and the outlet portion. The inlet portion has a diameter which is less than the outlet portion's diameter. A plug is located in the bore and movable from a closed position, in which flow of fluid through the bore is blocked, to an open position, in which flow of the fluid through the bore is permitted in response to a pressure differential between the inlet and the outlet.

Owner:WESTPORT FUEL SYST CANADA INC

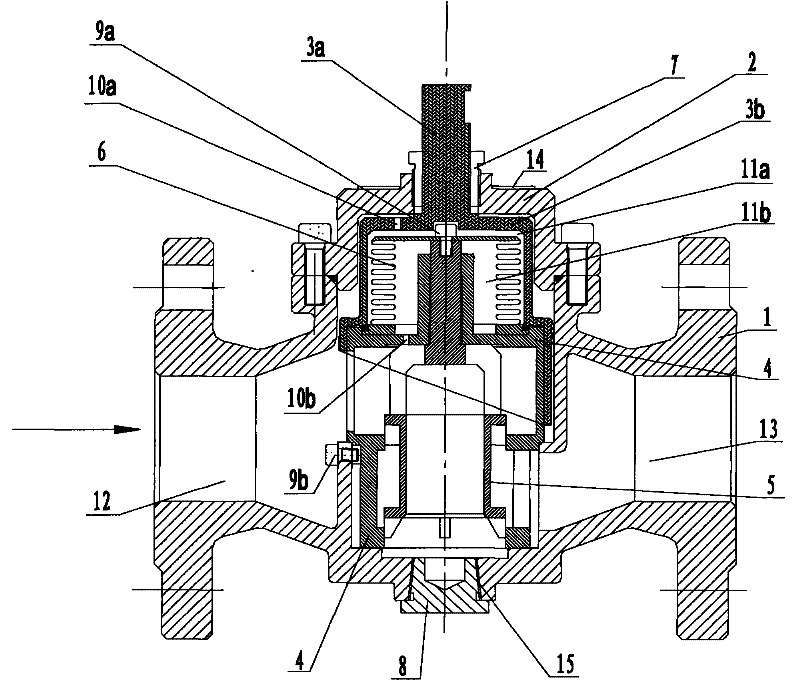

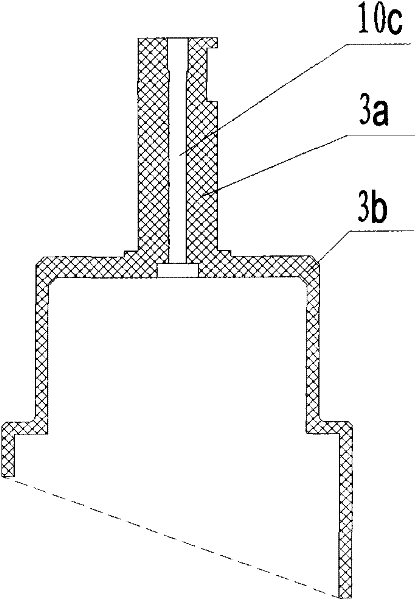

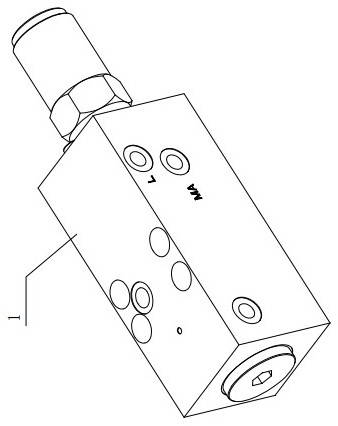

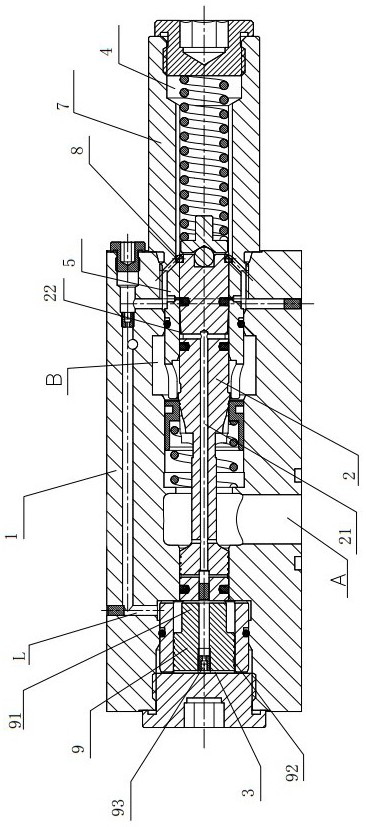

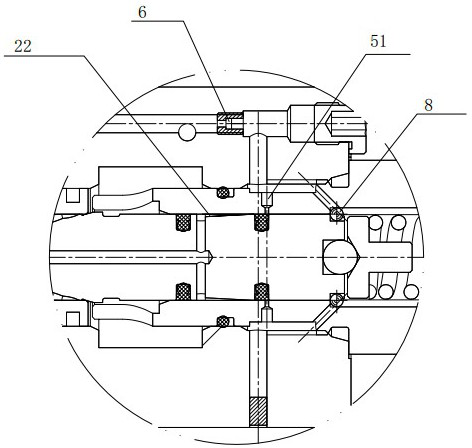

Multi-functional constant flow control valve

InactiveCN102162539ARealize on-site disassemblyRealize online sewageEqualizing valvesSafety valvesAutomatic controlDifferential pressure

Owner:北京天箭星节能技术有限公司 +1

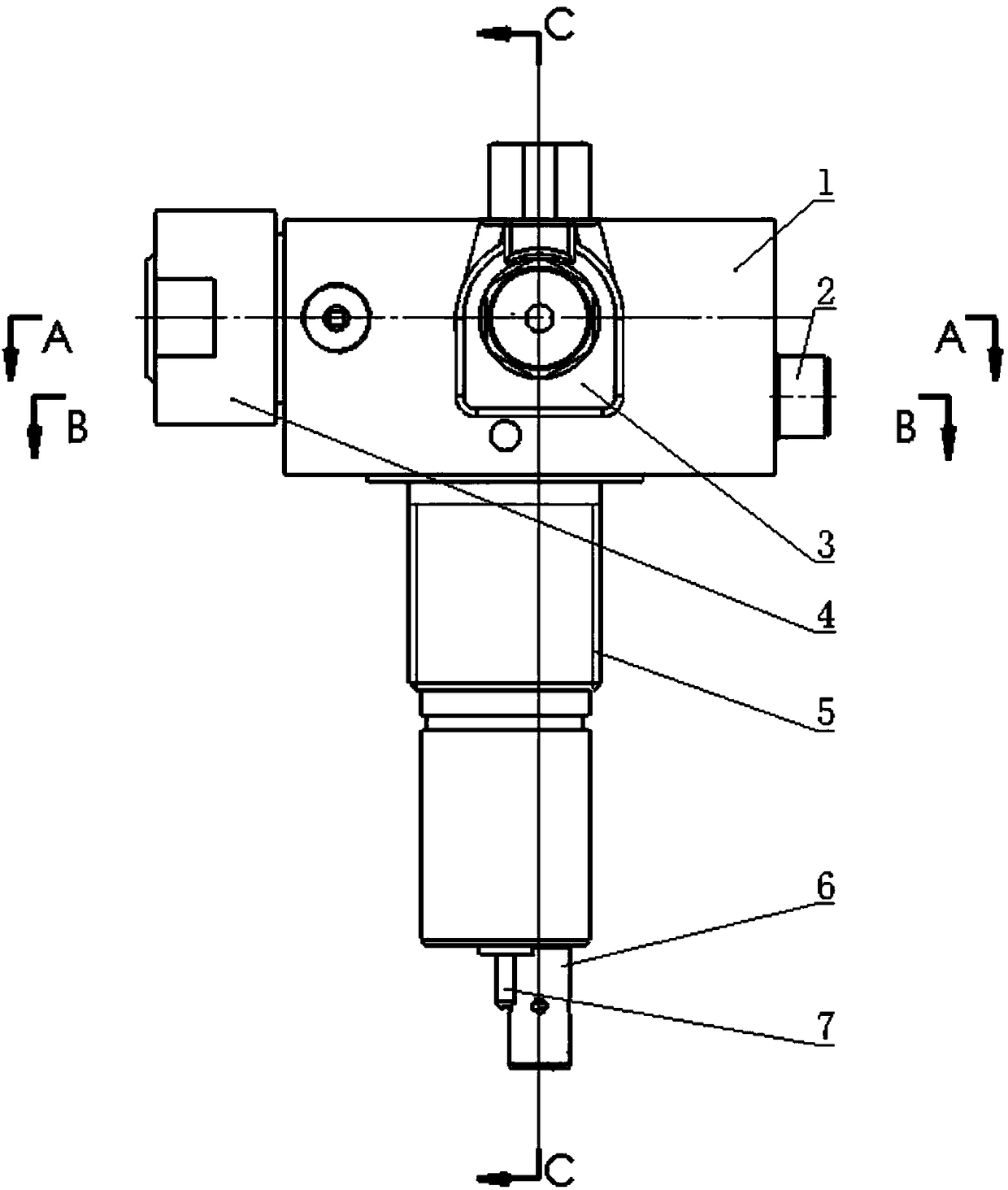

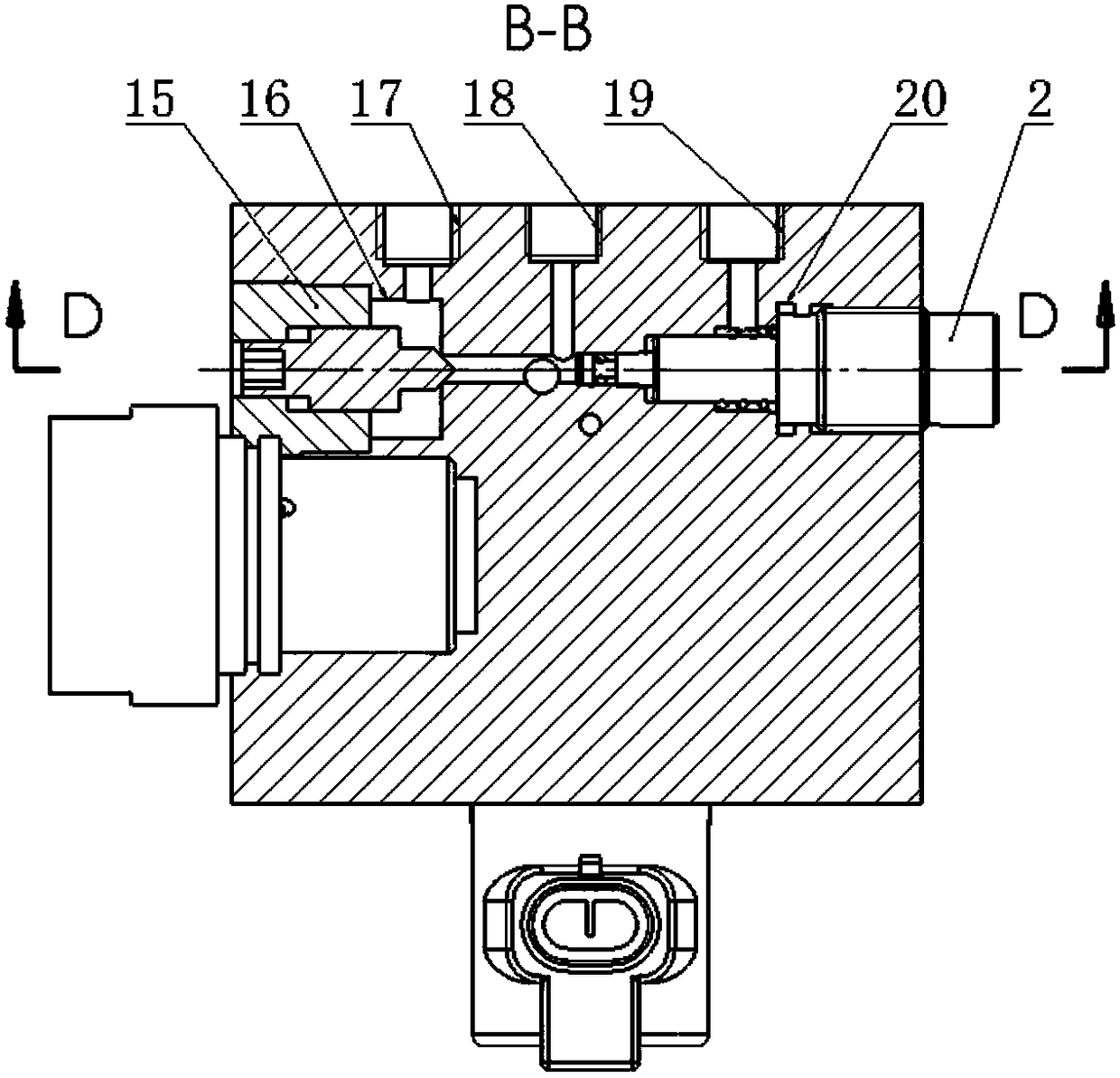

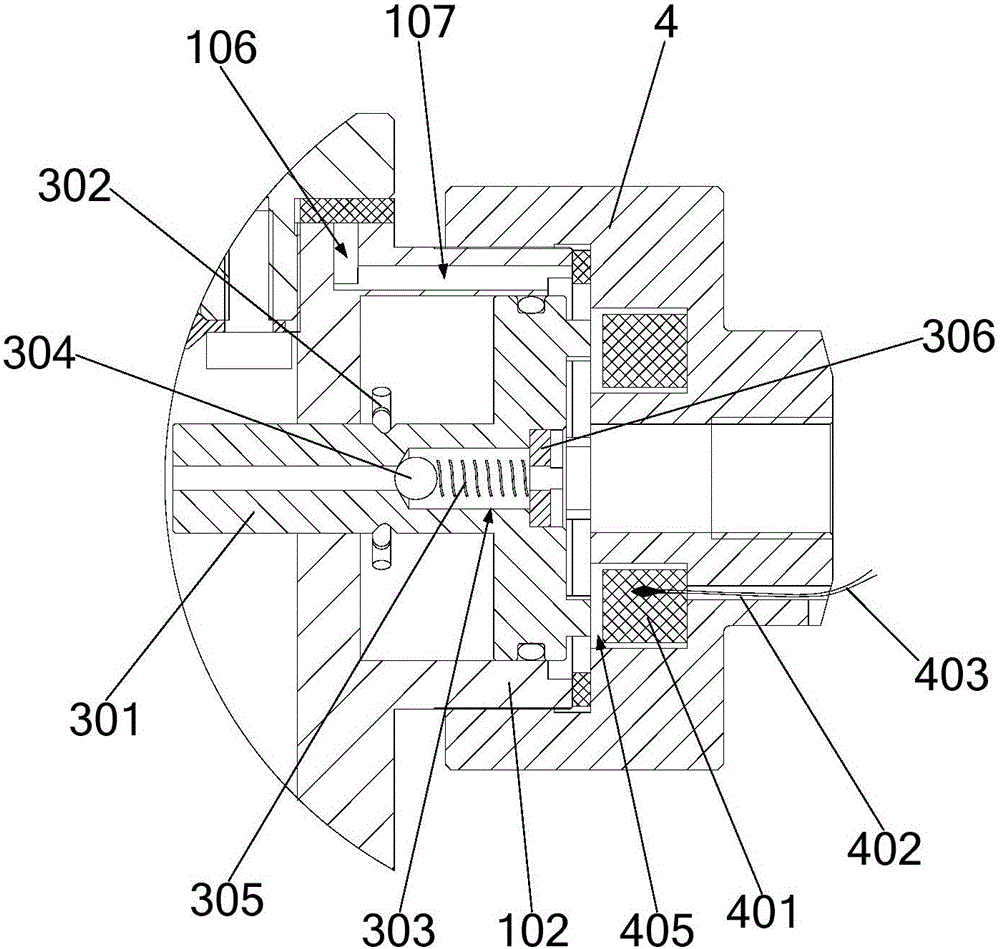

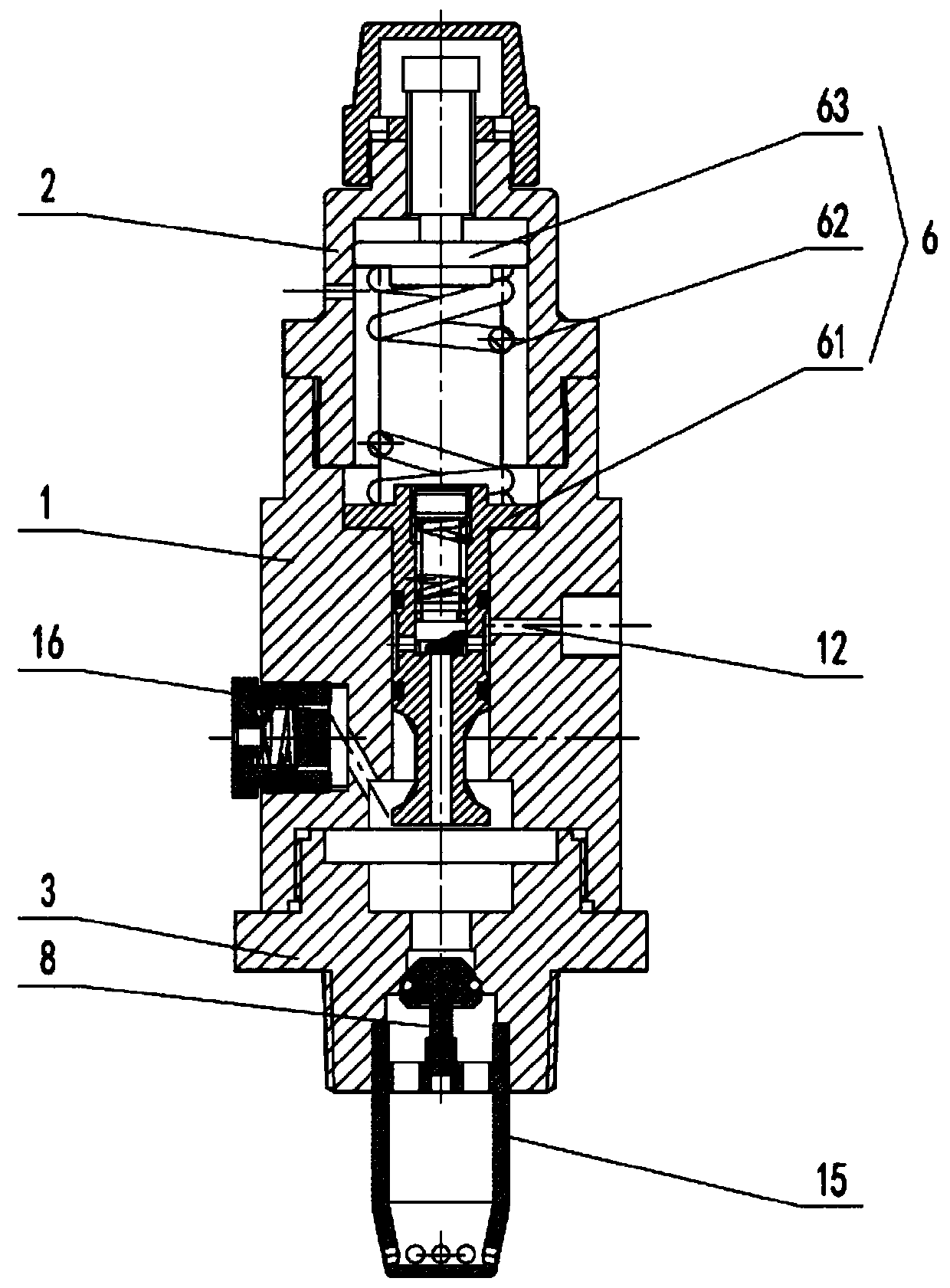

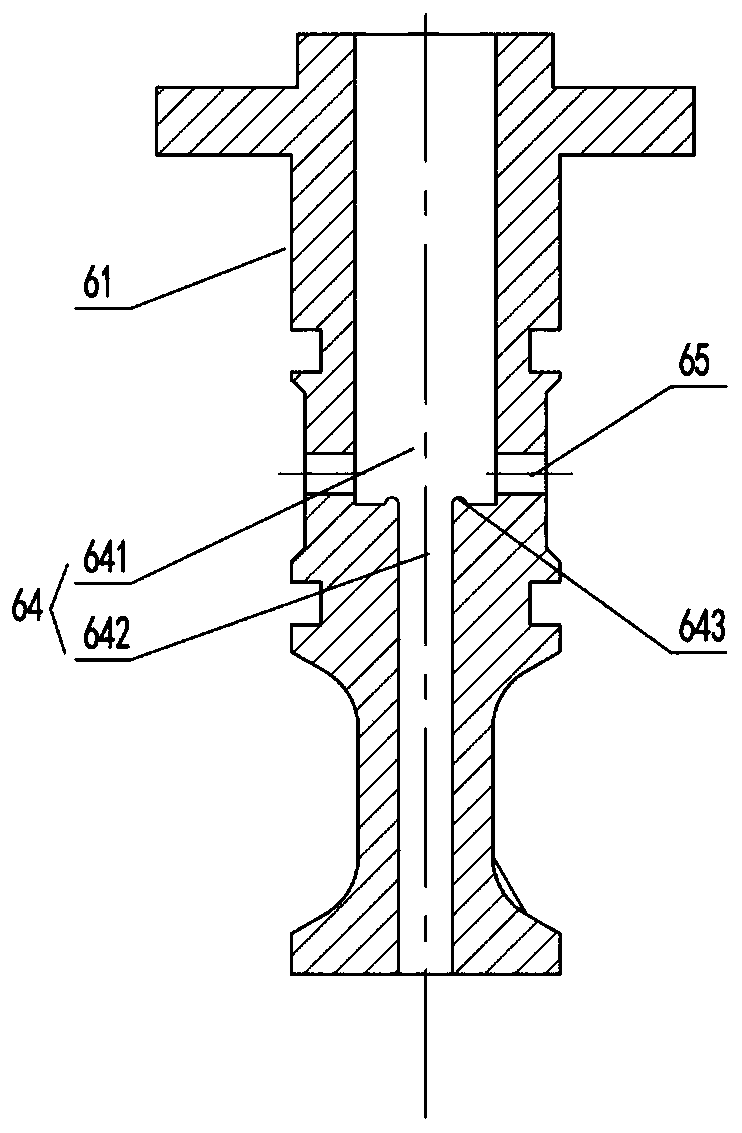

Ultrahigh-pressure hydrogen electromagnetic valve having pressure relief function and applied to vehicle

PendingCN108278395AExtended service lifeGuaranteed stabilityOperating means/releasing devices for valvesEqualizing valvesHydrogenUltra high pressure

Owner:DANYANG FEILUN GAS VALVE

Pilot-operated type overflow valve with pressure resisting function

InactiveCN106382401AValve members for absorbing fluid energyEqualizing valvesVALVE PORTRemote control

Owner:GUANGXI OUXUN TECH SERVICE CO LTD

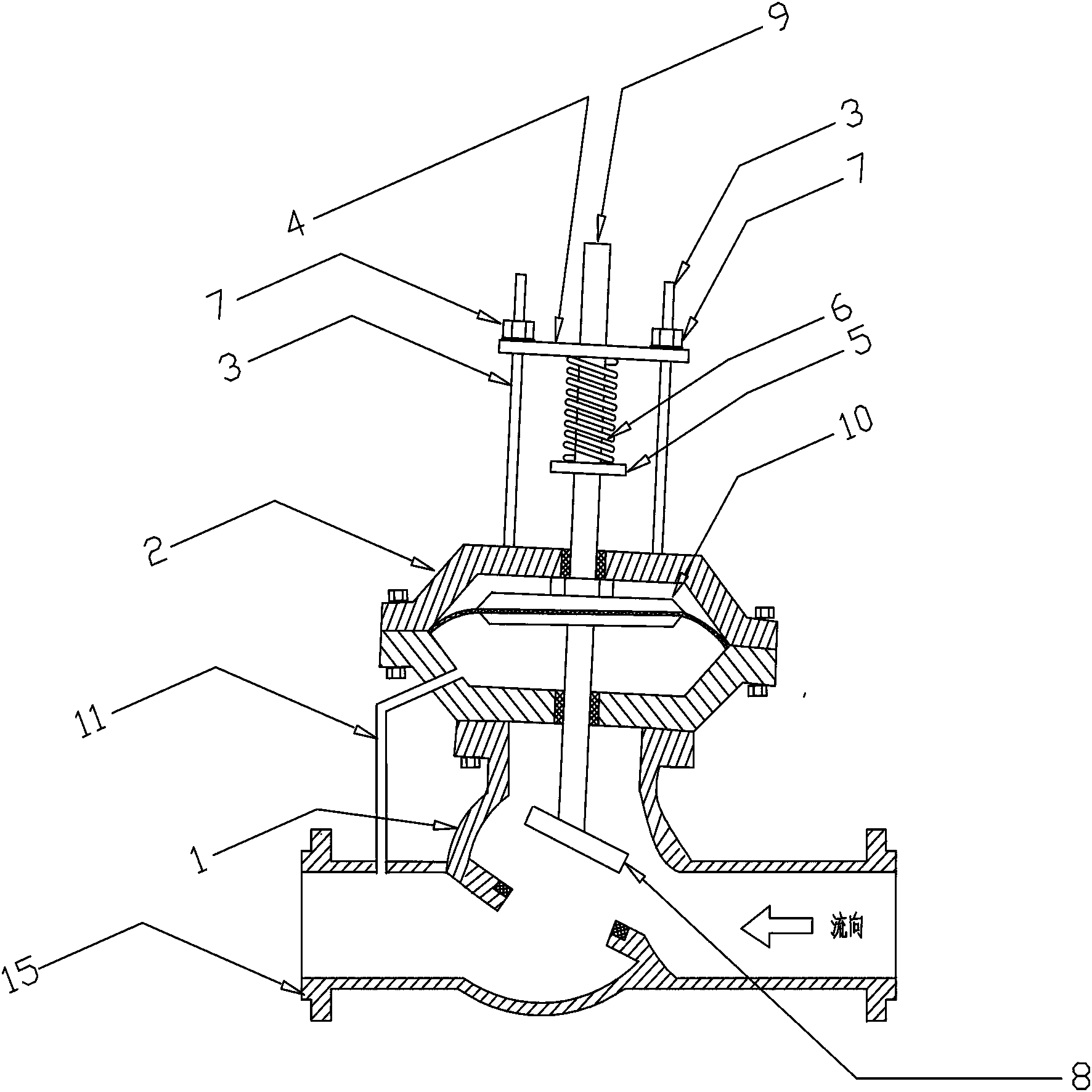

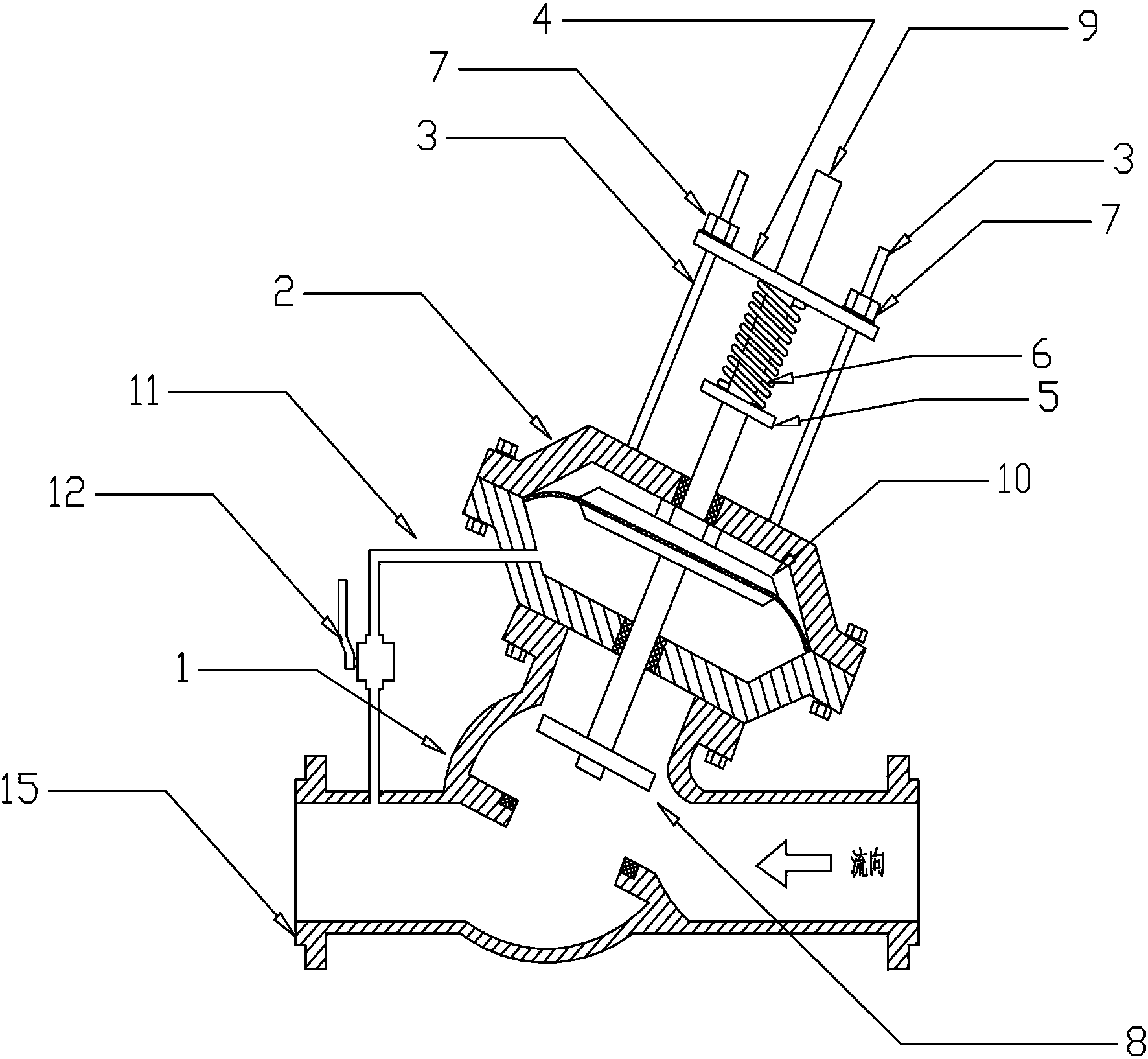

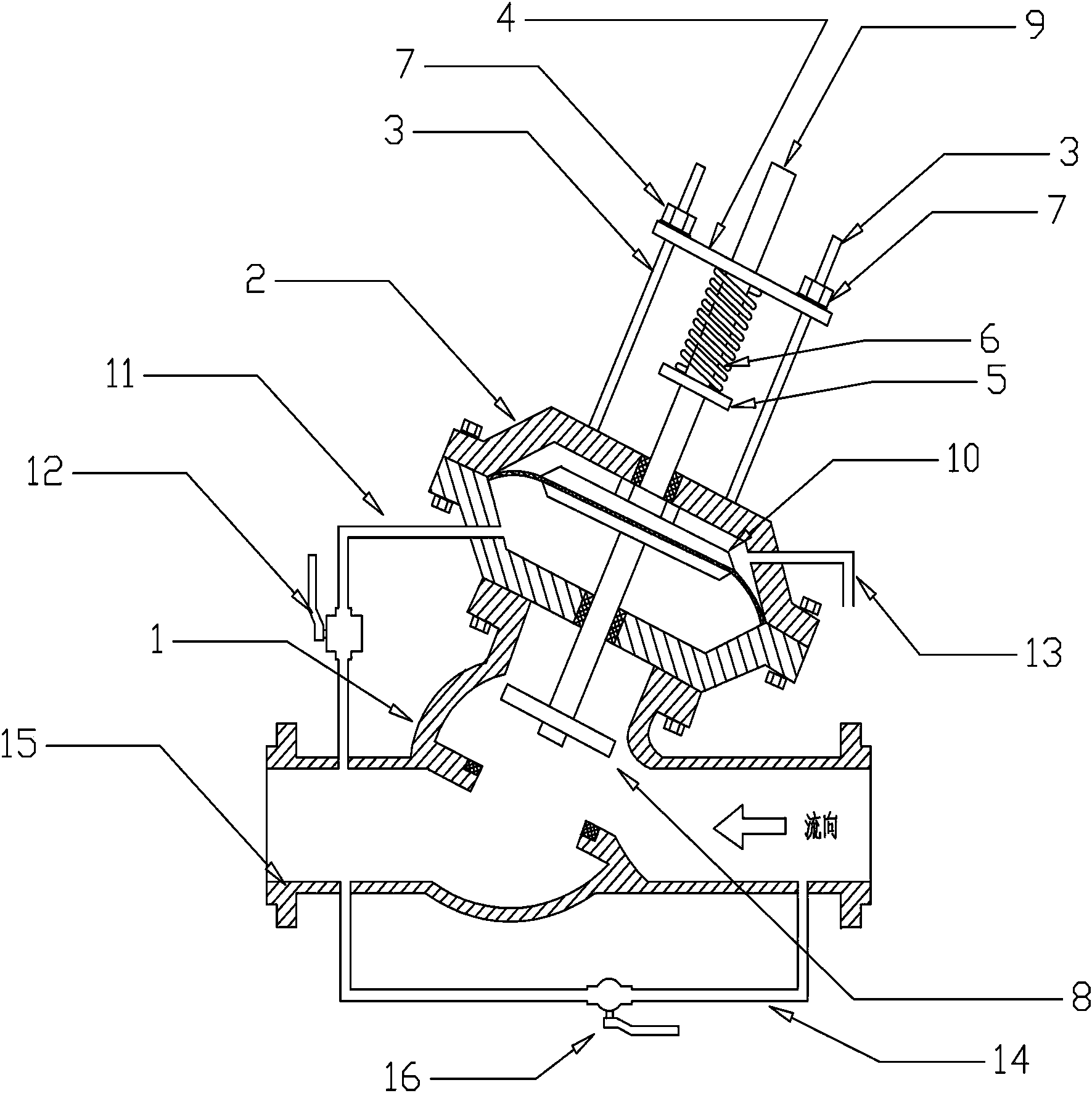

Pipe bursting shutoff valve

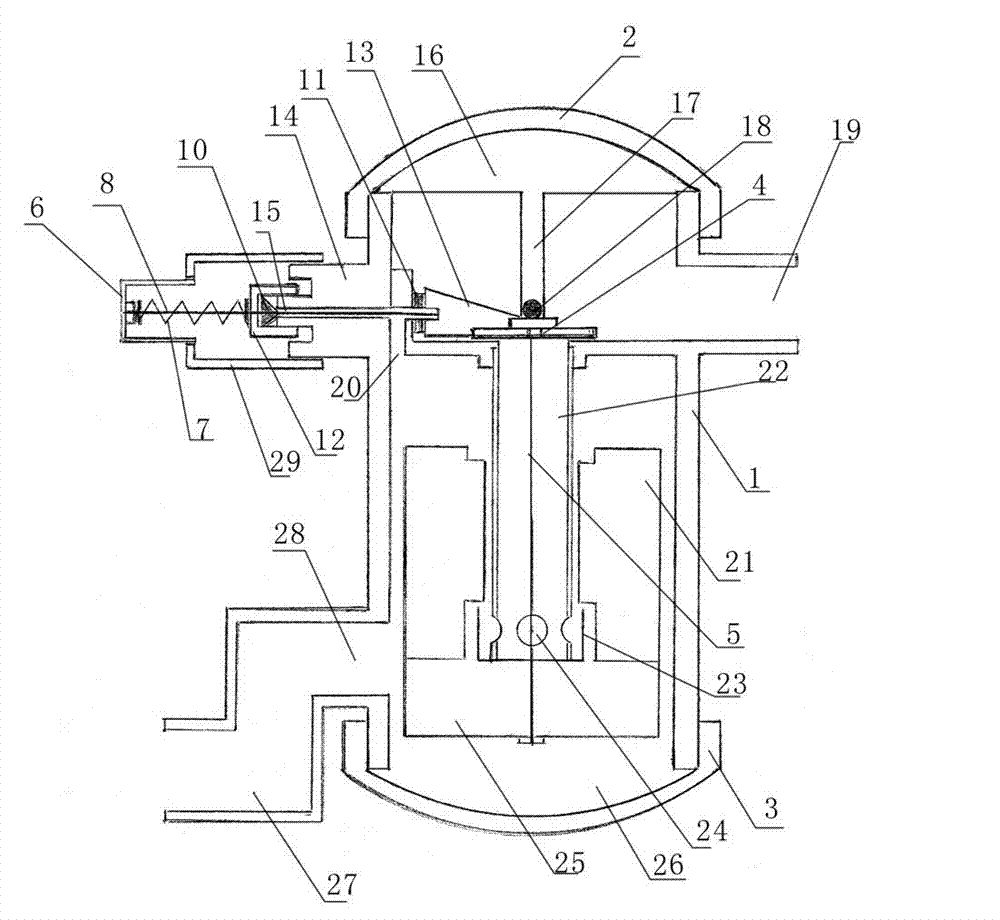

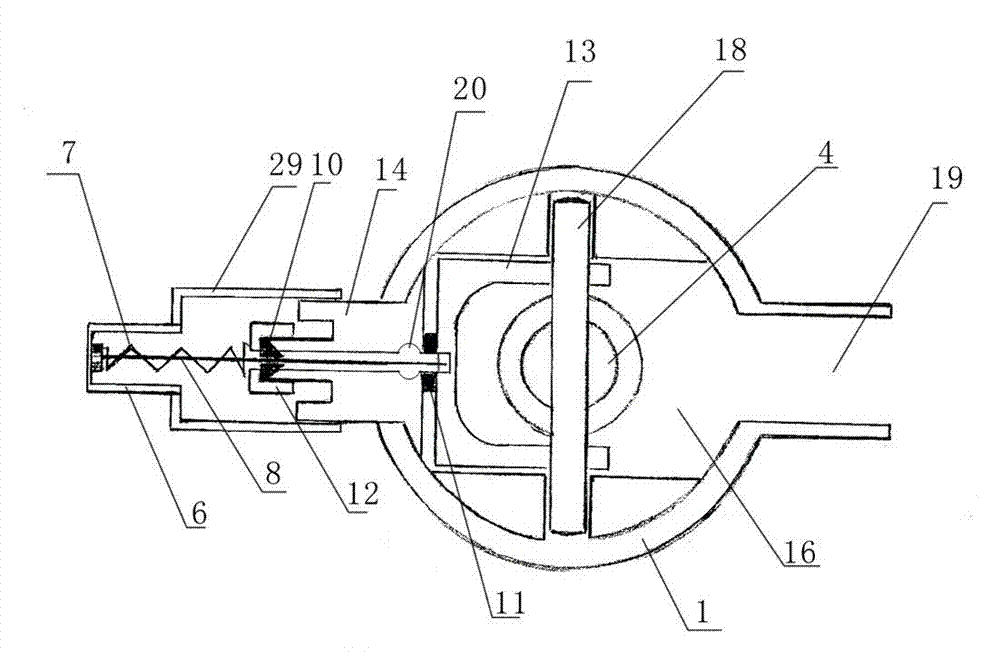

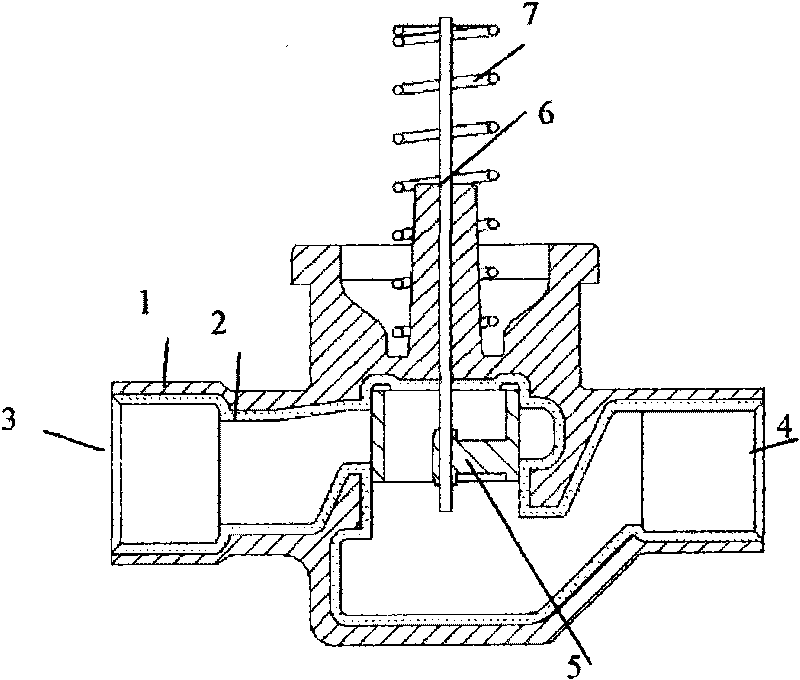

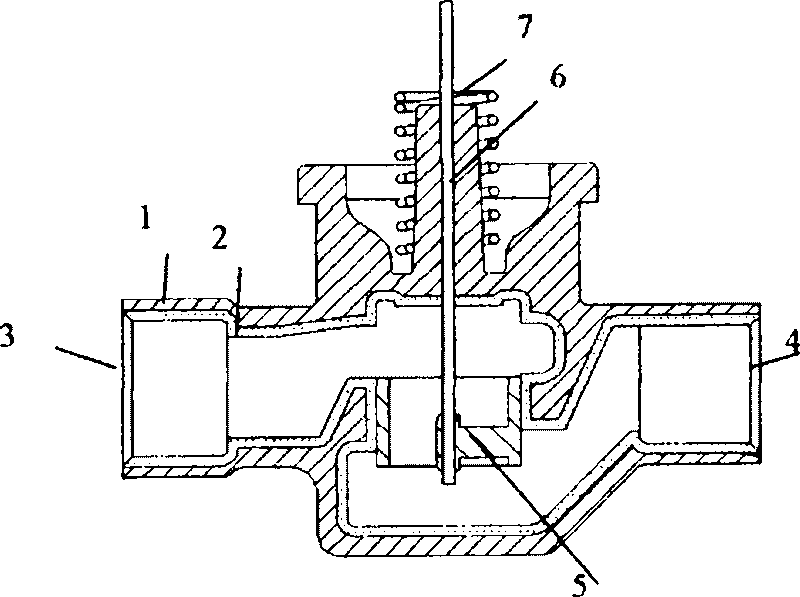

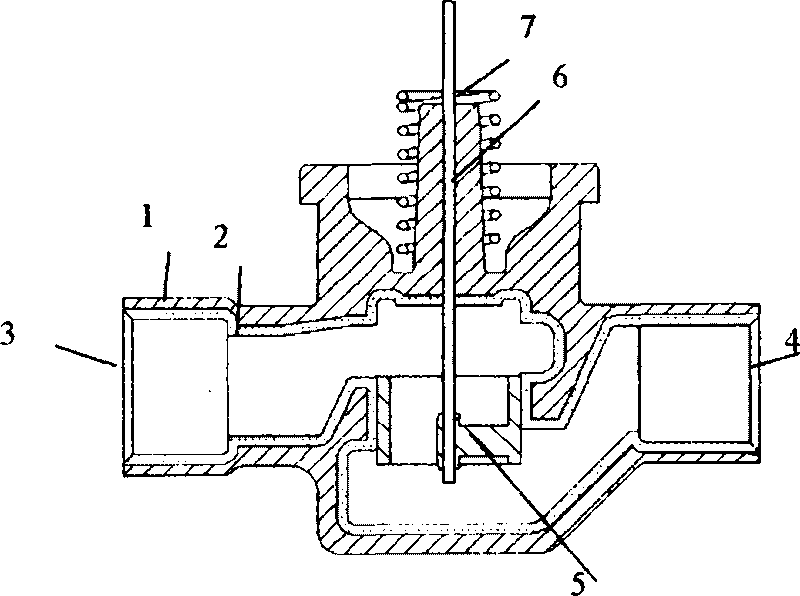

A pipe bursting shutoff valve comprises a valve body which is arranged on a pipe body and communicated with the inner portion of the pipe body. The pipe bursting shutoff valve further comprises a control cavity, a valve shaft, a first elastic component, a diaphragm piston and a valve disc, the first elastic component, the diaphragm piston and the valve disc are arranged on the valve shaft in sequence, the control cavity is connected with the valve body, the valve shaft penetrates through the control cavity to enter the valve body, the diaphragm piston is arranged inside the control cavity, the control cavity is in rigid connection with the diaphragm piston, the control cavity is divided into an independent upper chamber and an independent lower chamber, the valve disc is arranged inside the valve body, the lower chamber is communicated with the pipe body through a lower chamber through pipe, the first elastic component can drive the valve shaft to move along the central line of the valve shaft after being stressed and deformed, and the movement of the valve shaft can enable the diaphragm piston to be deformed in the control cavity to change the size of the upper chamber and the size of the lower chamber, and meanwhile can drive the valve disc to move in the valve body and the pipe body. The pipe bursting shutoff valve has the advantages of being capable of adapting to the normal change of pressure in a pipeline and being mounted by adopting any angle.

Owner:CHINA THREE GORGES CORPORATION

Flow Rate Safety Valve

ActiveUS20180128392A1Improve sealingImprove mobilityCheck valvesEqualizing valvesEngineeringSafety valve

Owner:YUHUAN JIANGLIN PLUMBING HOSE & PARTS

Dropping type safety decompression device

InactiveCN1514156AHigh sealing requirementsEasy to prepareEqualizing valvesSafety valvesUpper limbEngineering

Owner:DALIAN UNIV OF TECH

Throttling device

Owner:甘肃腾越电子科技有限公司

Convenient faucet

Owner:单祥海

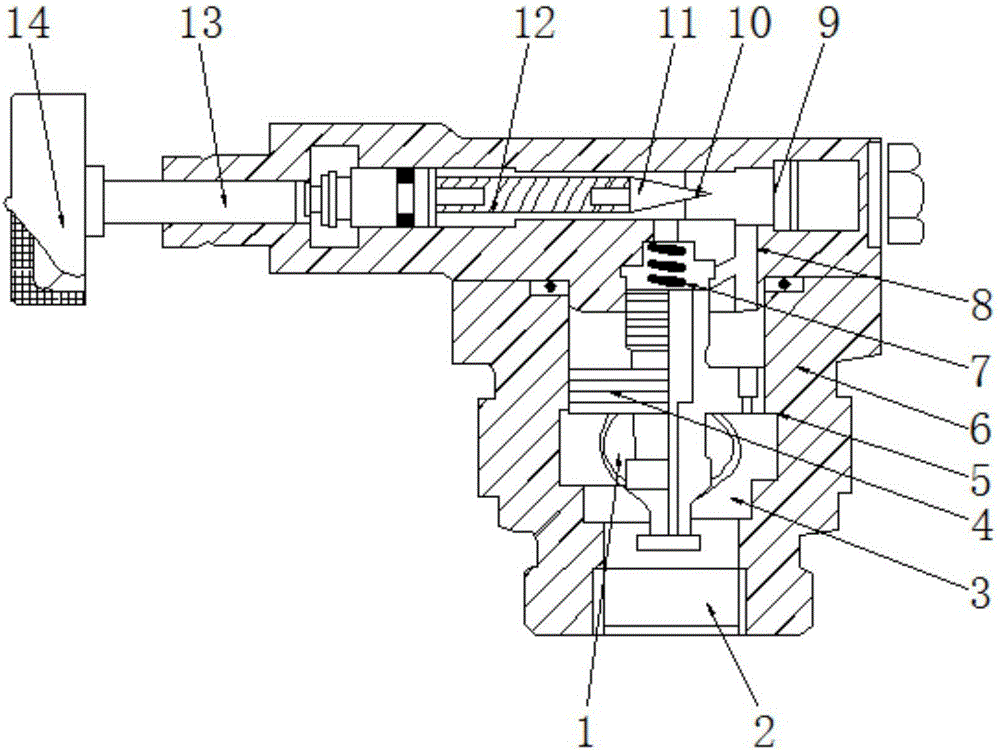

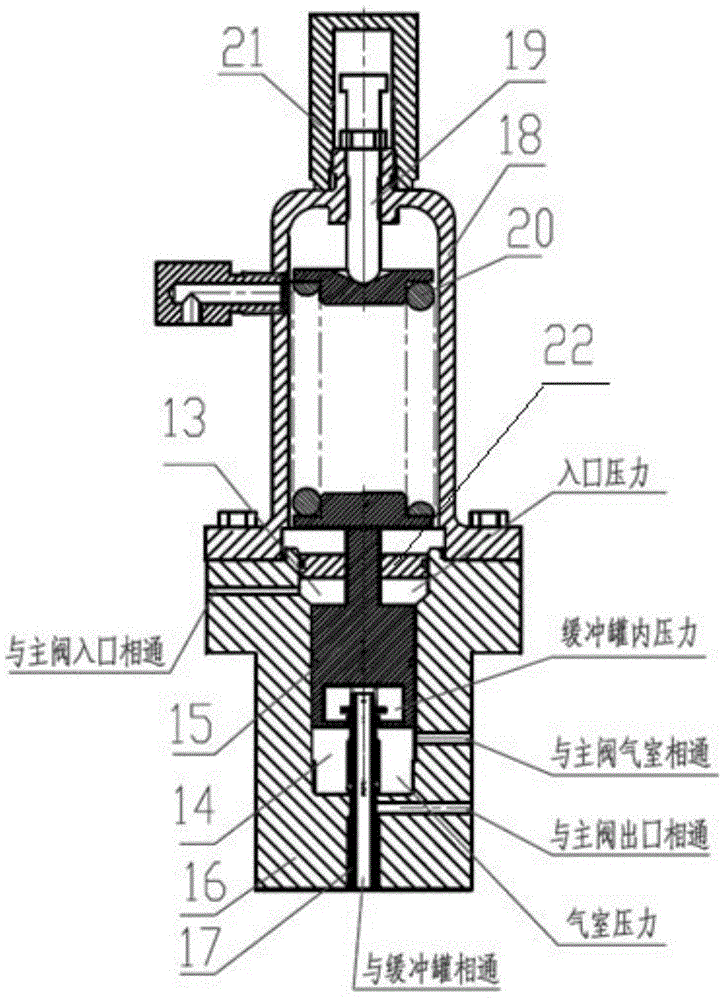

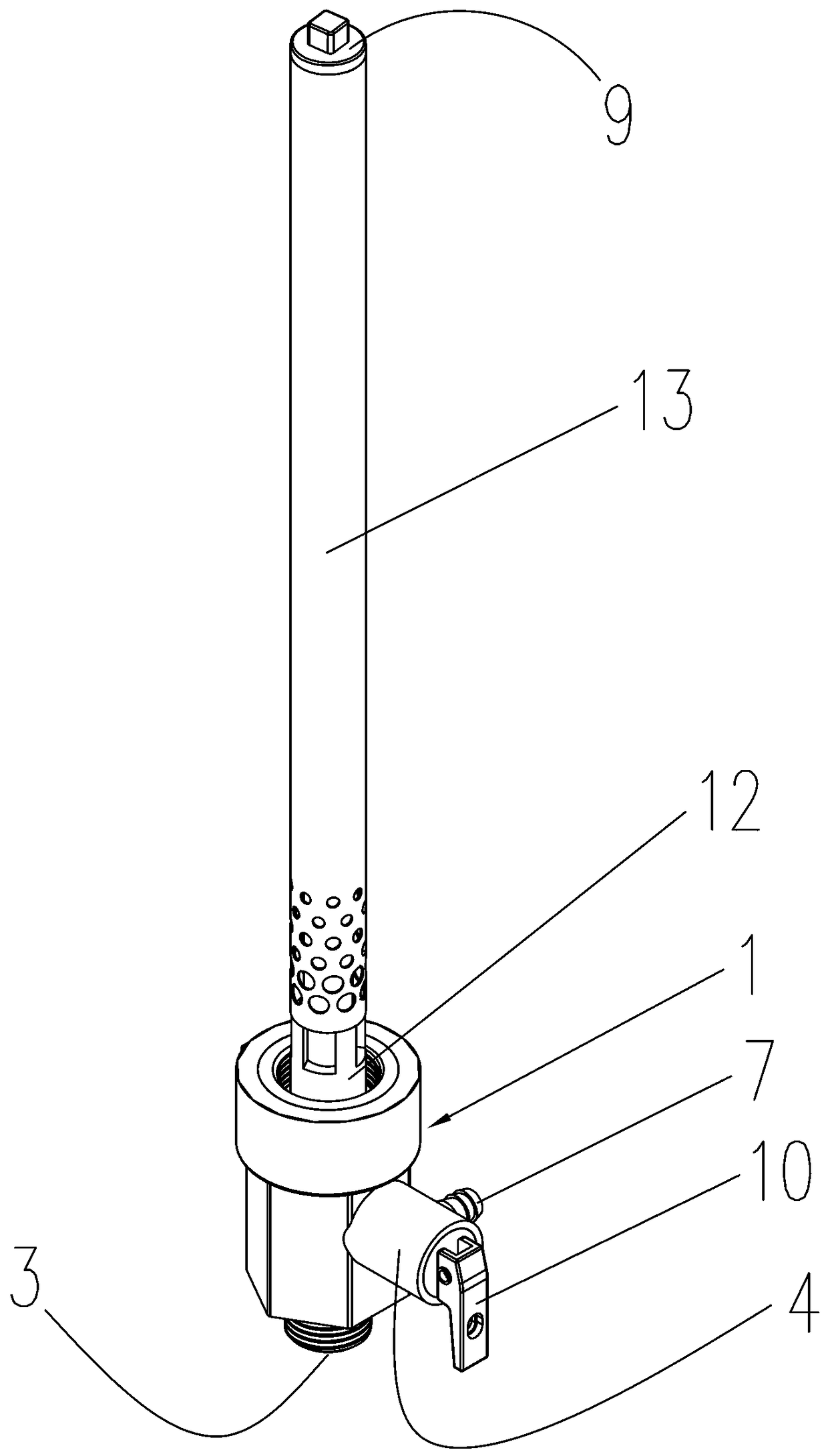

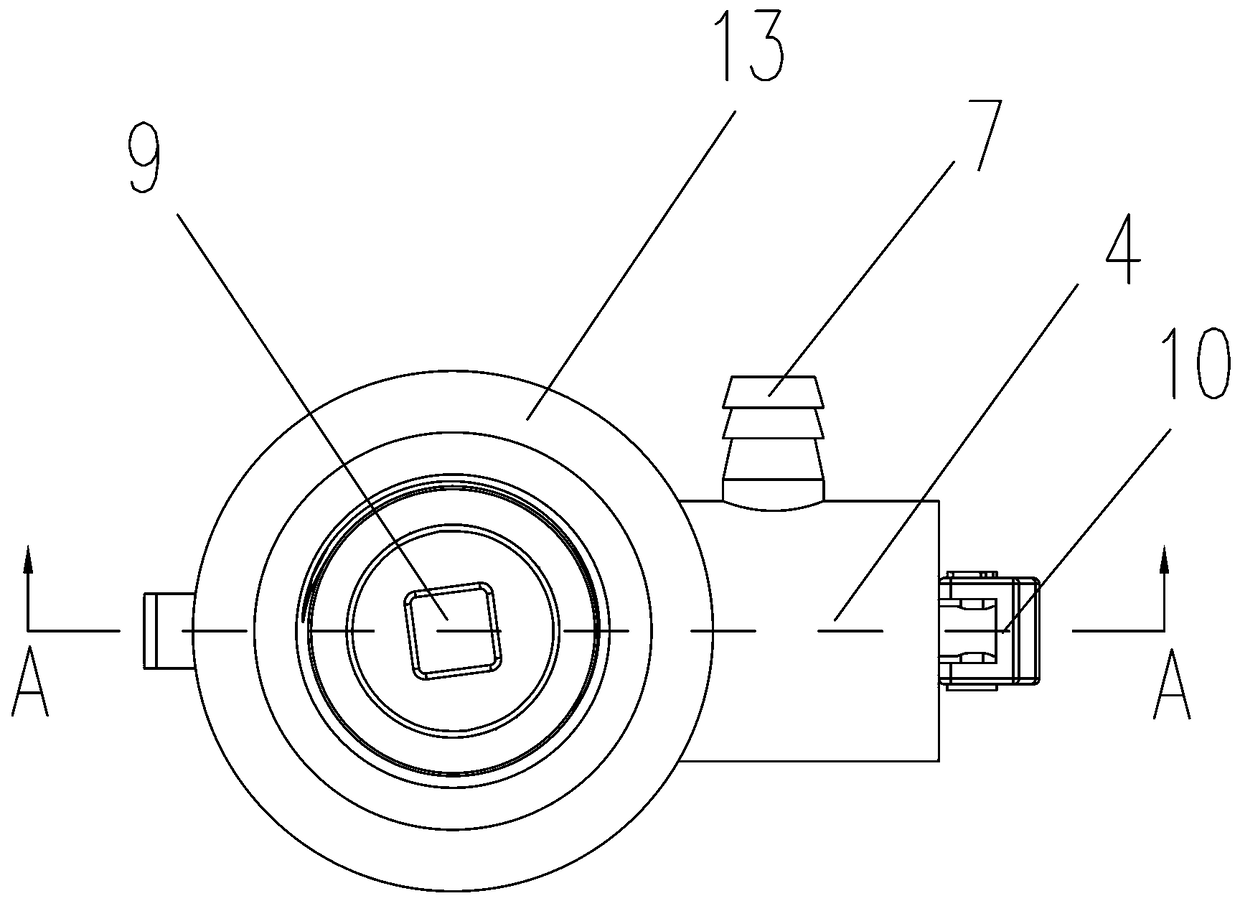

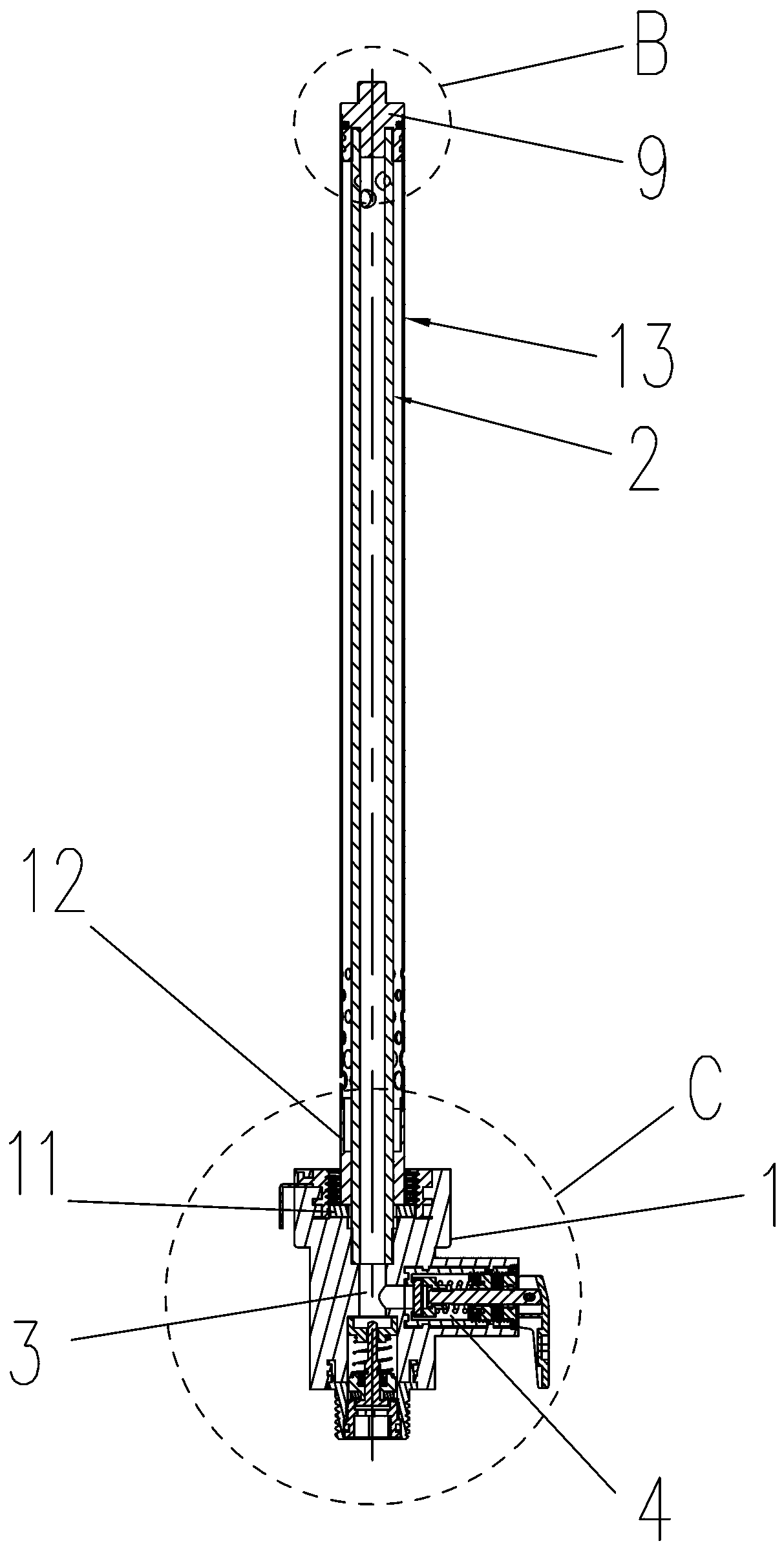

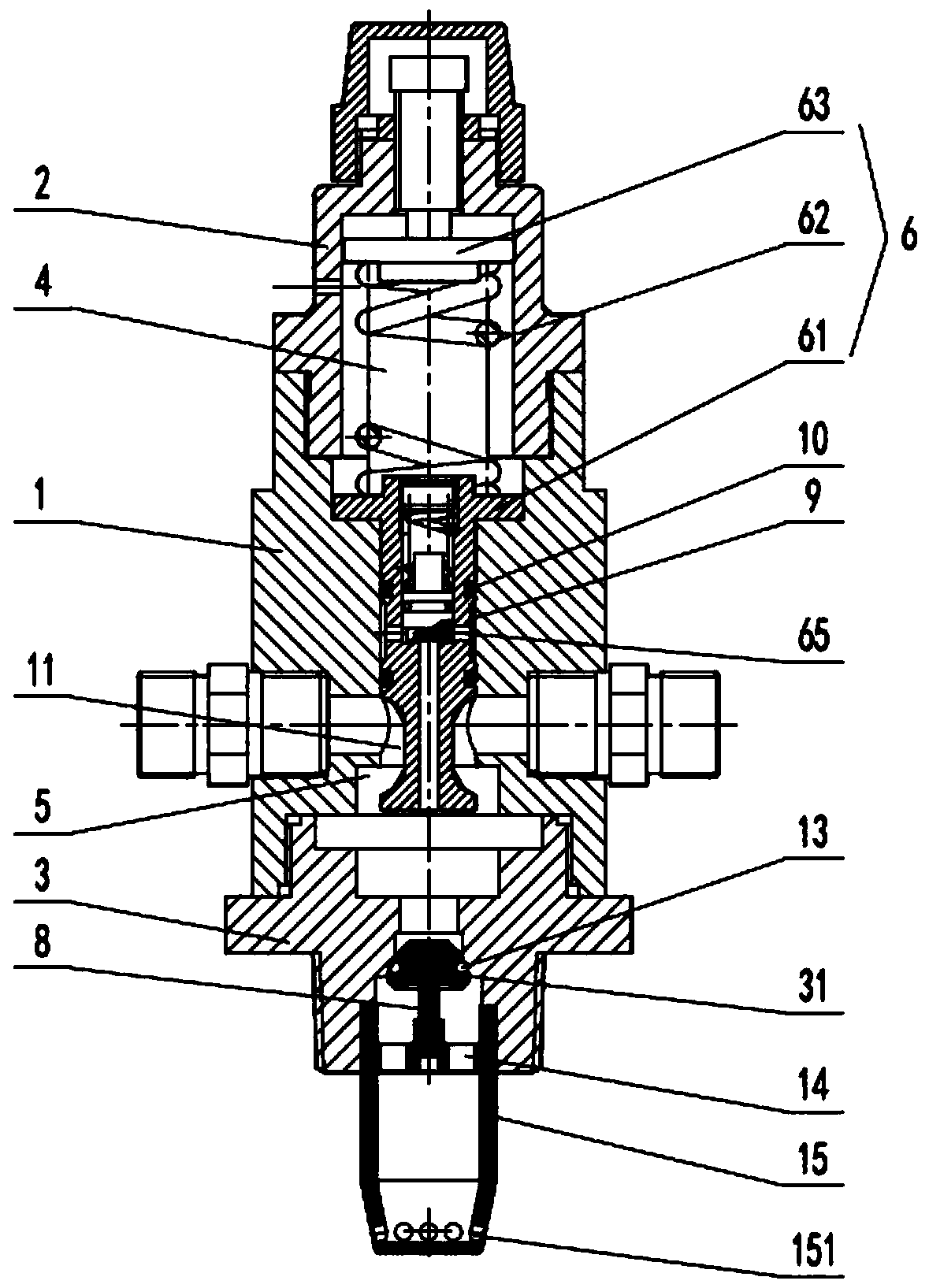

Pilot operated safety valve with independent gas source control

ActiveCN104358917AOperating means/releasing devices for valvesEqualizing valvesEngineeringCheck valve

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

Safe pressure relieving and anti-creeping device for water heater

PendingCN108980429ALow thermal conductivityPlay a security functionFluid heatersEqualizing valvesInternal pressureElectricity

Owner:蒋琪峰

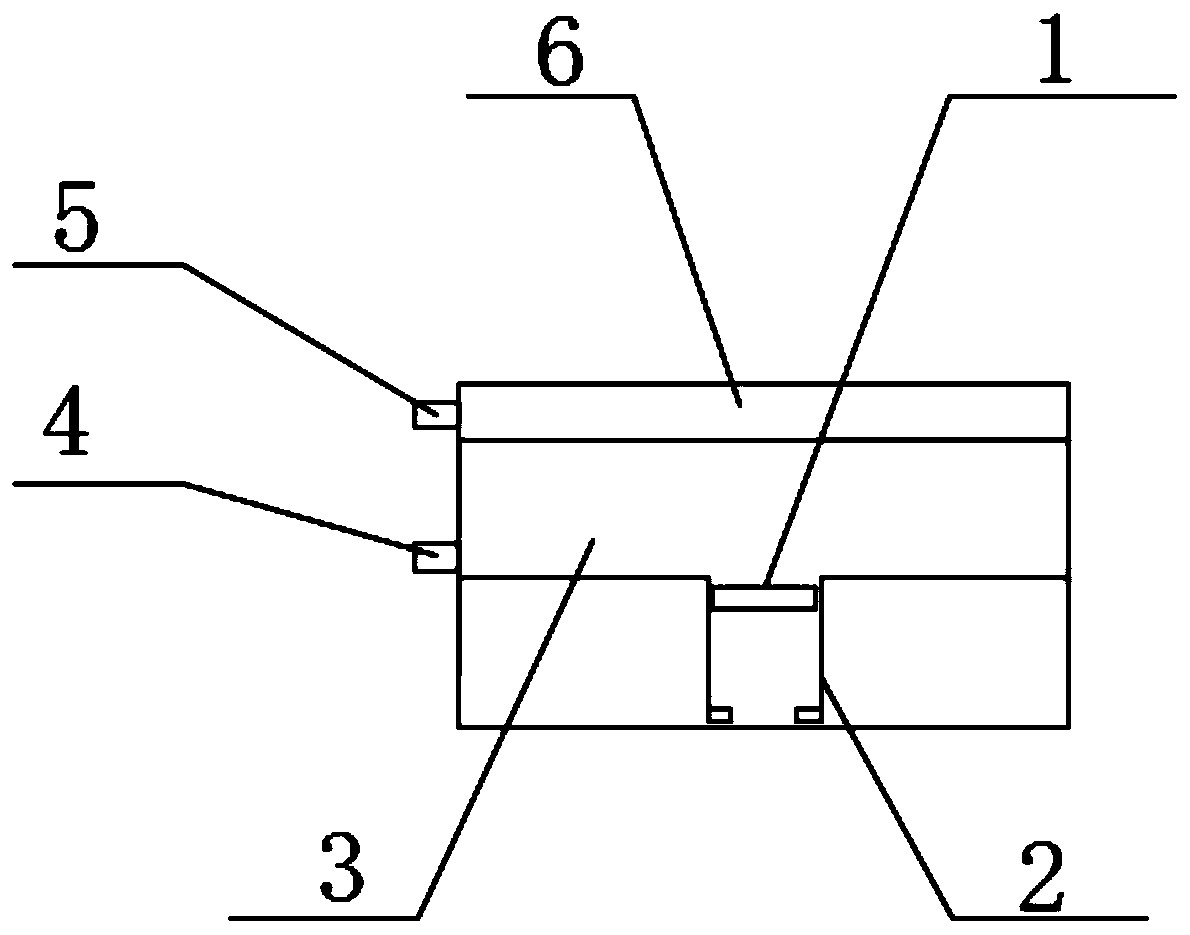

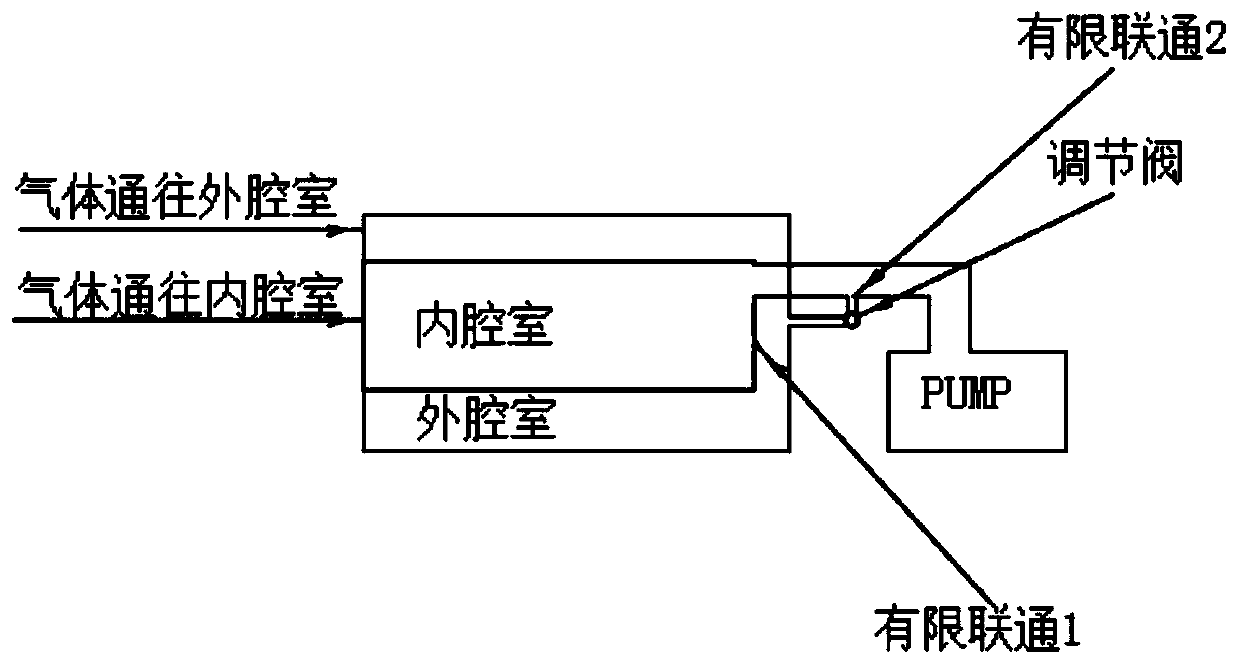

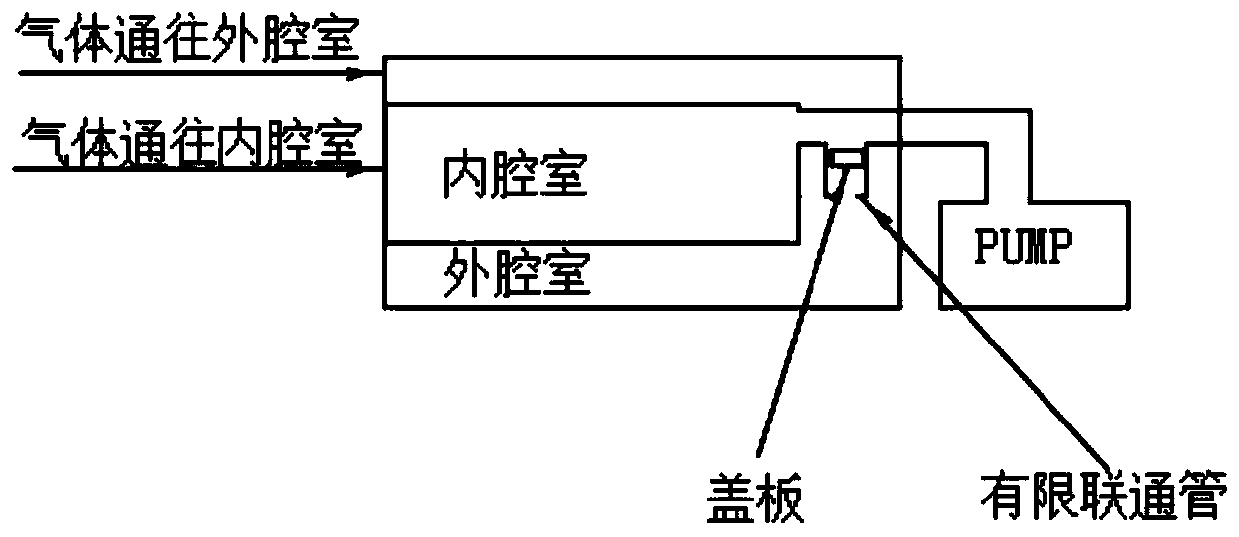

Vacuum pressure adjusting device

PendingCN111396610ASemiconductor/solid-state device manufacturingEqualizing valvesPhysicsVacuum pressure

Owner:艾华(无锡)半导体科技有限公司

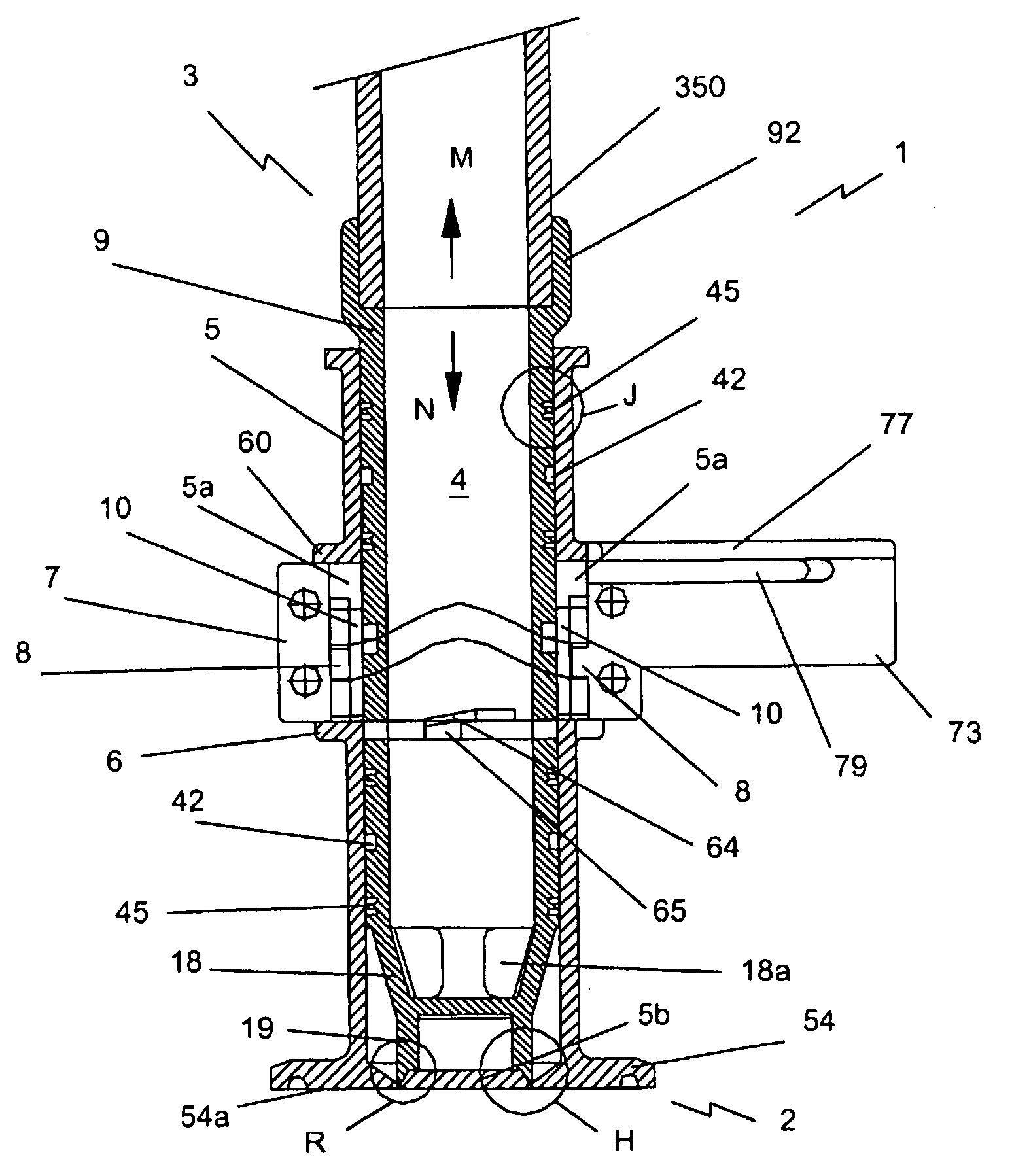

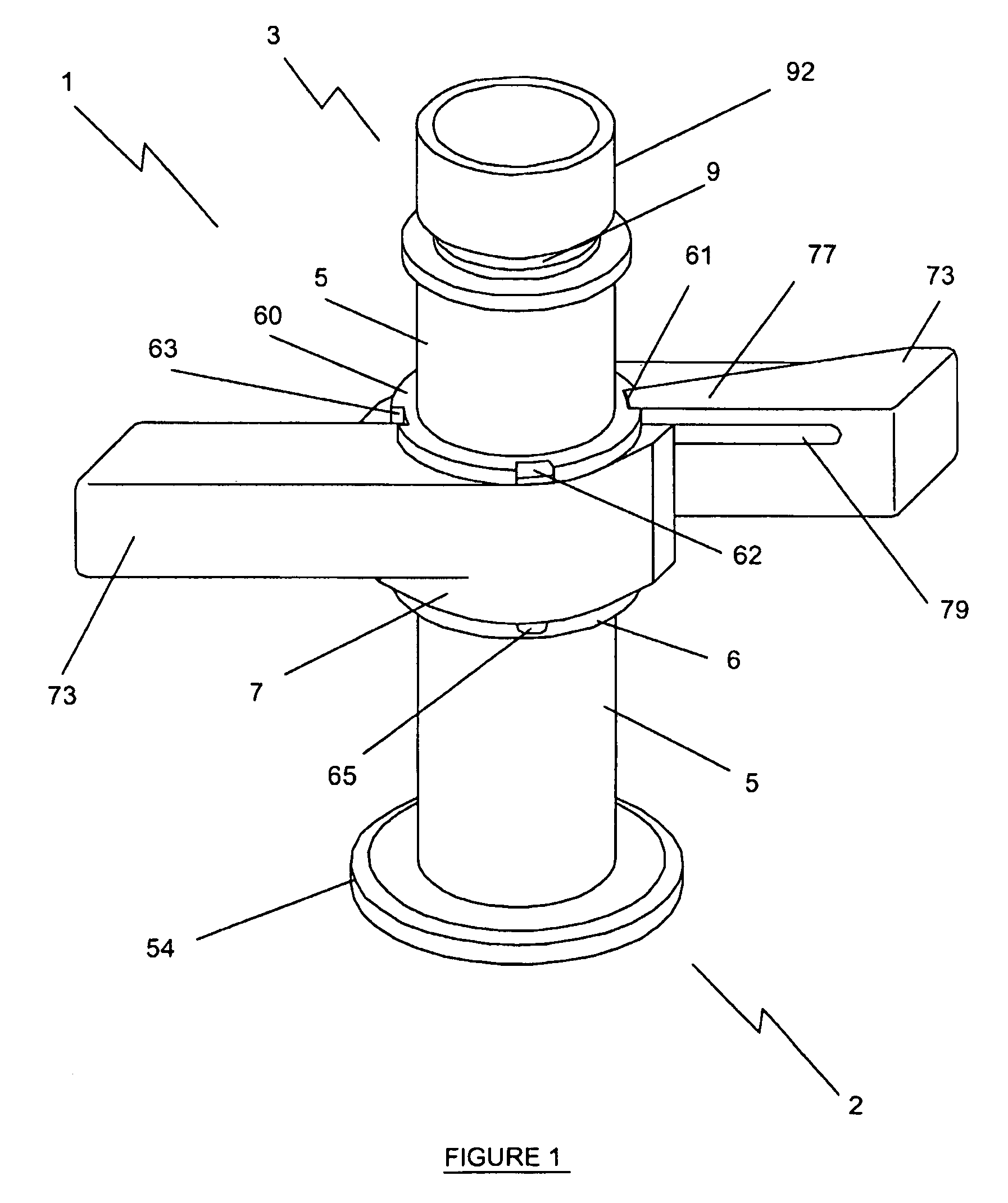

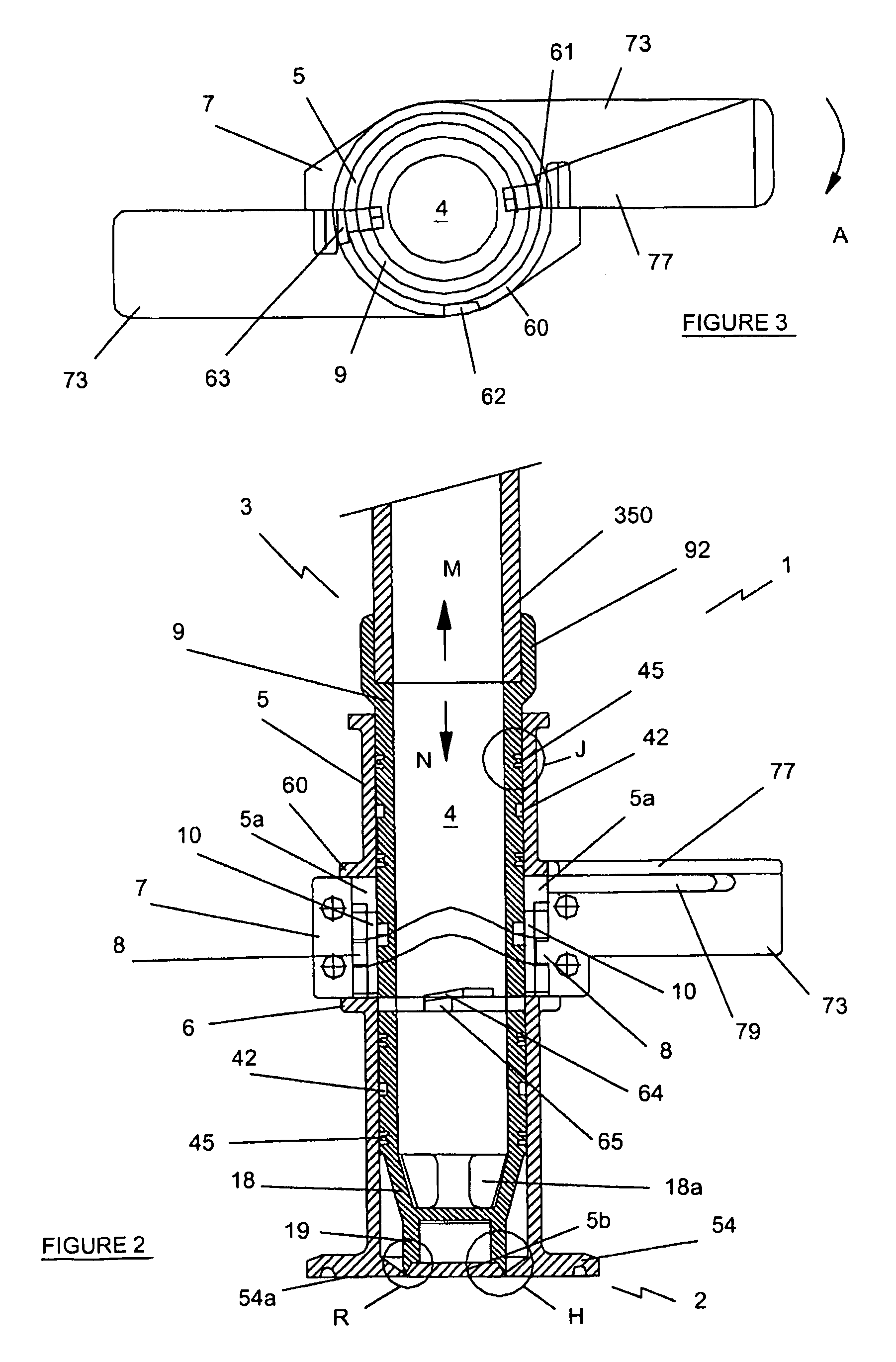

Valve

InactiveUS7766029B2Quicker and easy separationReduce riskOperating means/releasing devices for valvesPlungersDownstream processingCam

Owner:GL TOOL & MFG

Gas extinguishing agent container valve

Owner:XIAN XINZHU FIRE & RESCUE EQUIP

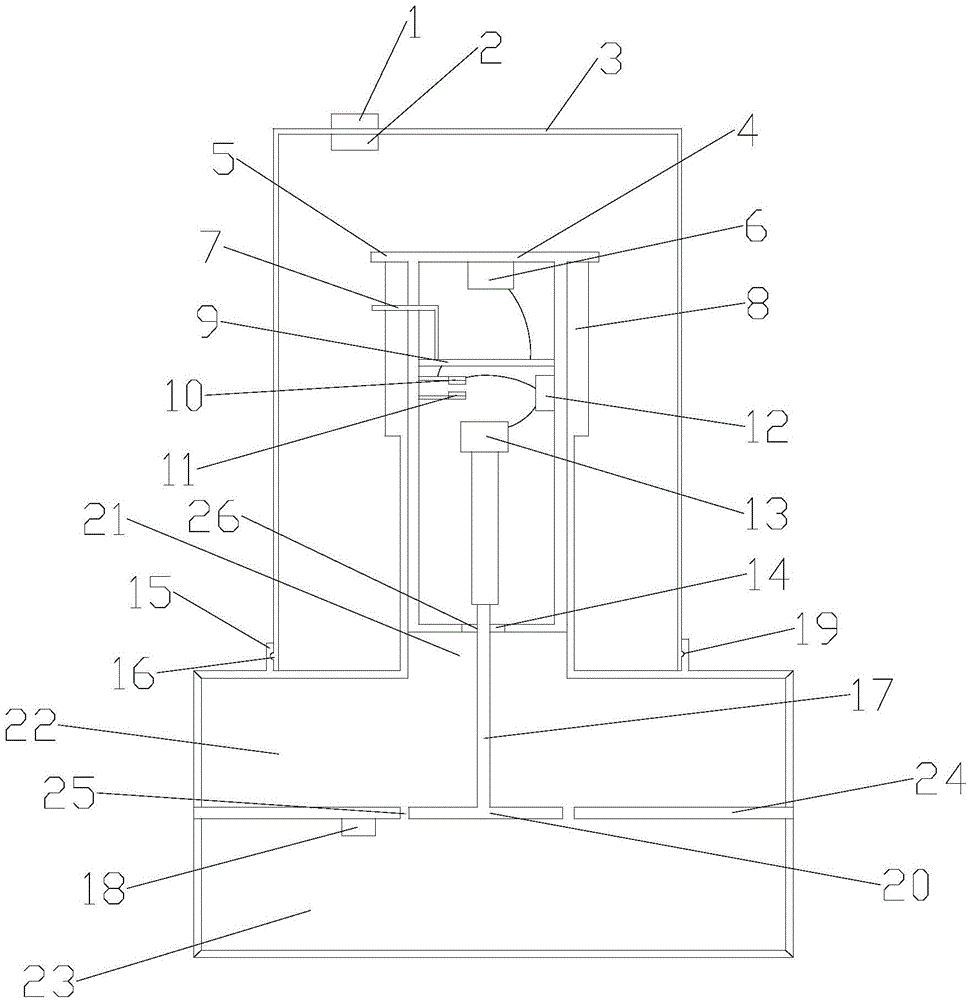

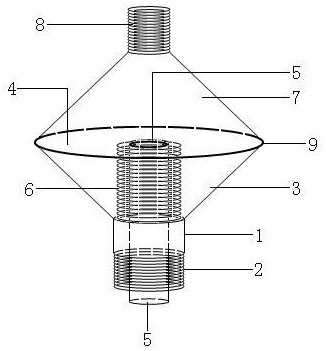

Water cutting protector

InactiveCN102777643ALow costEasy to useEqualizing valvesSafety valvesEnvironmental geologyStructural engineering

The invention relates to an automatic water cutting protector. The automatic water cutting protector comprises a cylindrical valve body, an upper valve cover, a lower valve cover, a plugging, a connecting rod, a buoy unit and a rest button unit, wherein the top of the cylindrical valve body is in threaded connection with the upper valve cover; the bottom of the cylindrical valve body is in threaded connection with the lower valve cover; the cylindrical valve body is internally provided with a partition plate, and the partition plate is used for dividing the interior of the cylindrical valve body into an upper water cavity and a lower water cavity; the upper end of the exterior of the cylindrical valve body is provided with a water inlet, the water inlet is communicated with the upper water cavity, and the lower end of the exterior of the cylindrical valve body is provided with a water outlet; and the water outlet is communicated with the lower water cavity, and the buoy unit is arranged in the lower water cavity. The automatic water cutting protector provided by the invention has the advantages that the cost is cheap, the use is convenient, the structure is compact, the property is reliable, and the service life is long.

Owner:洪博华

Small pressure release valve

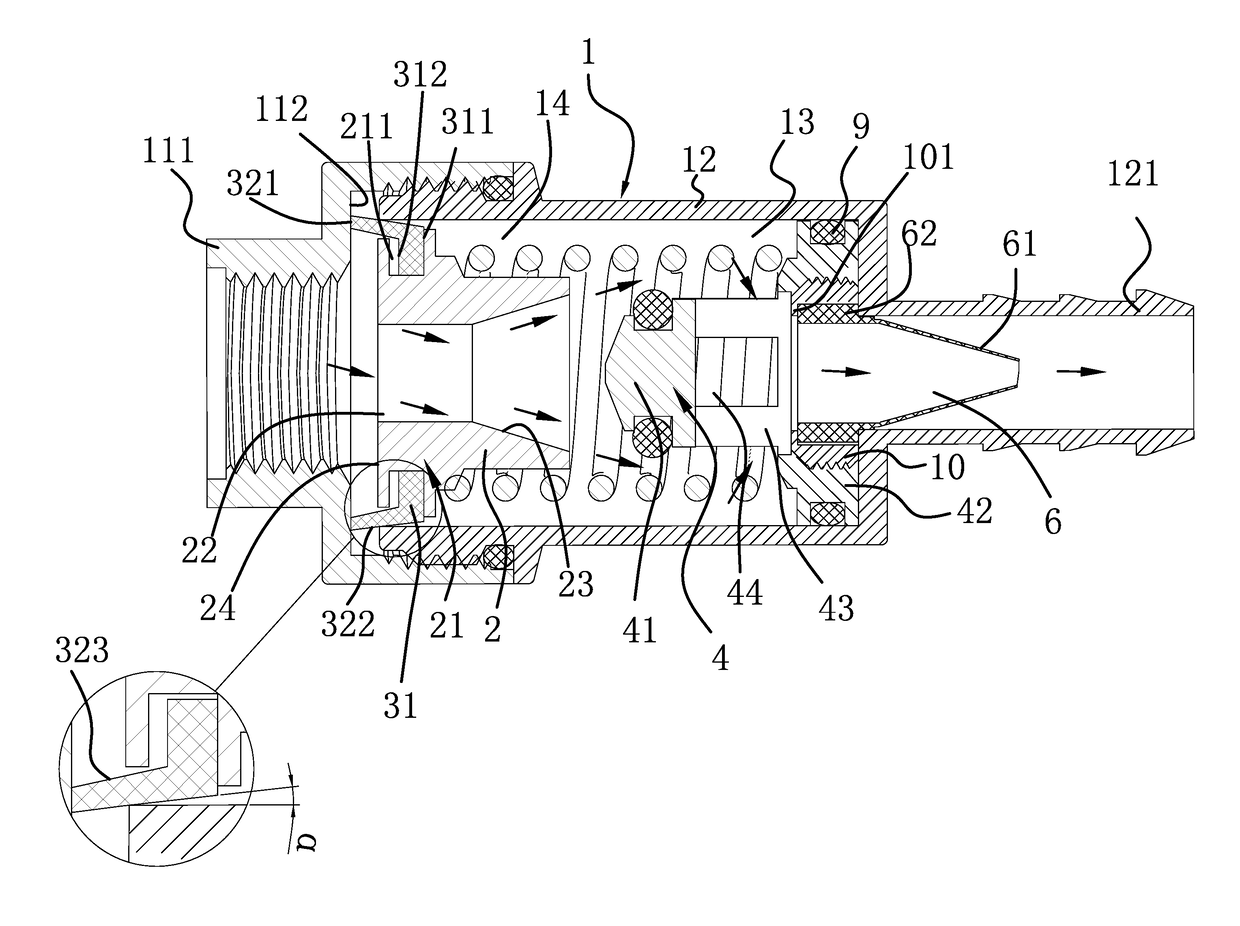

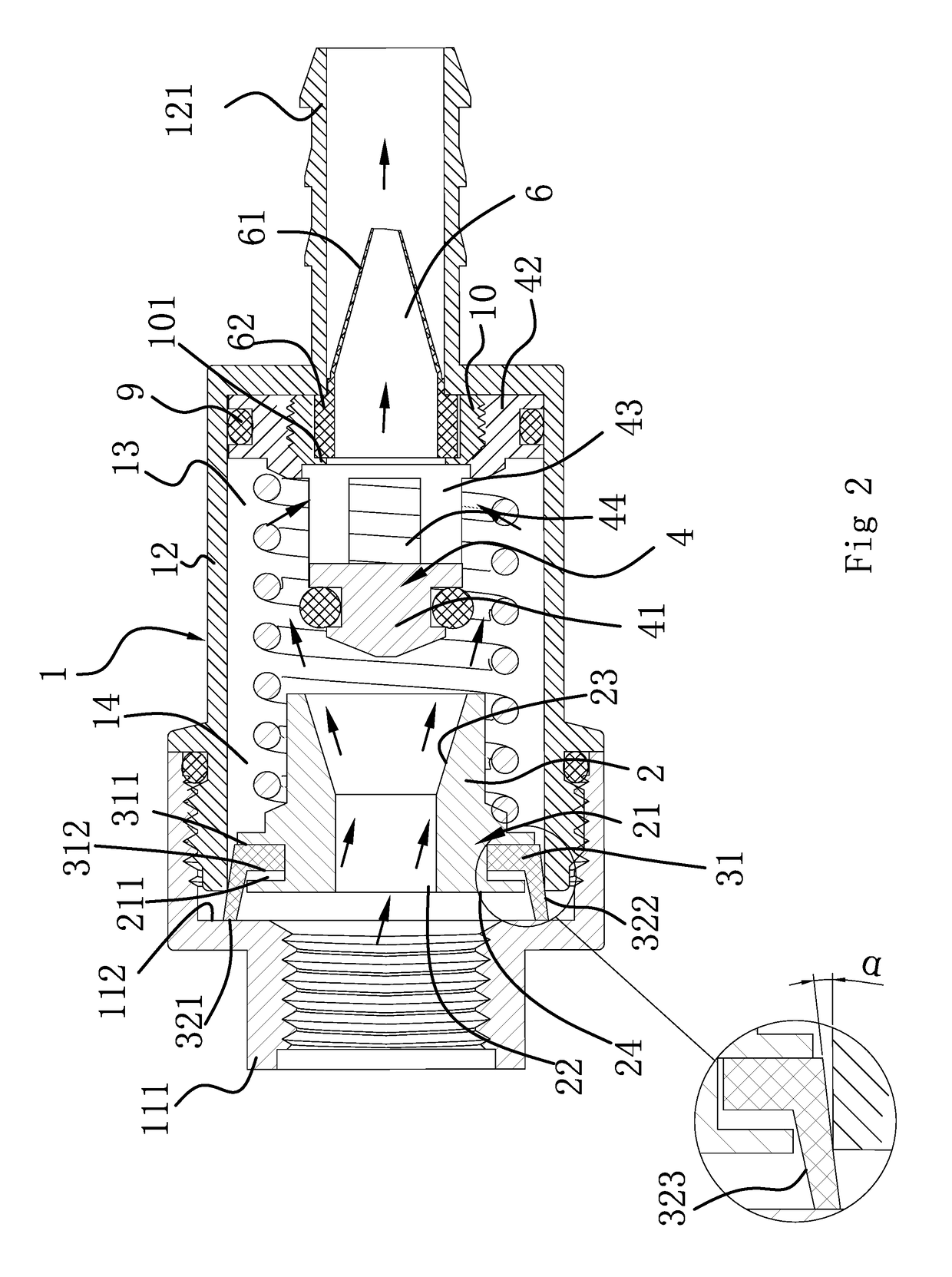

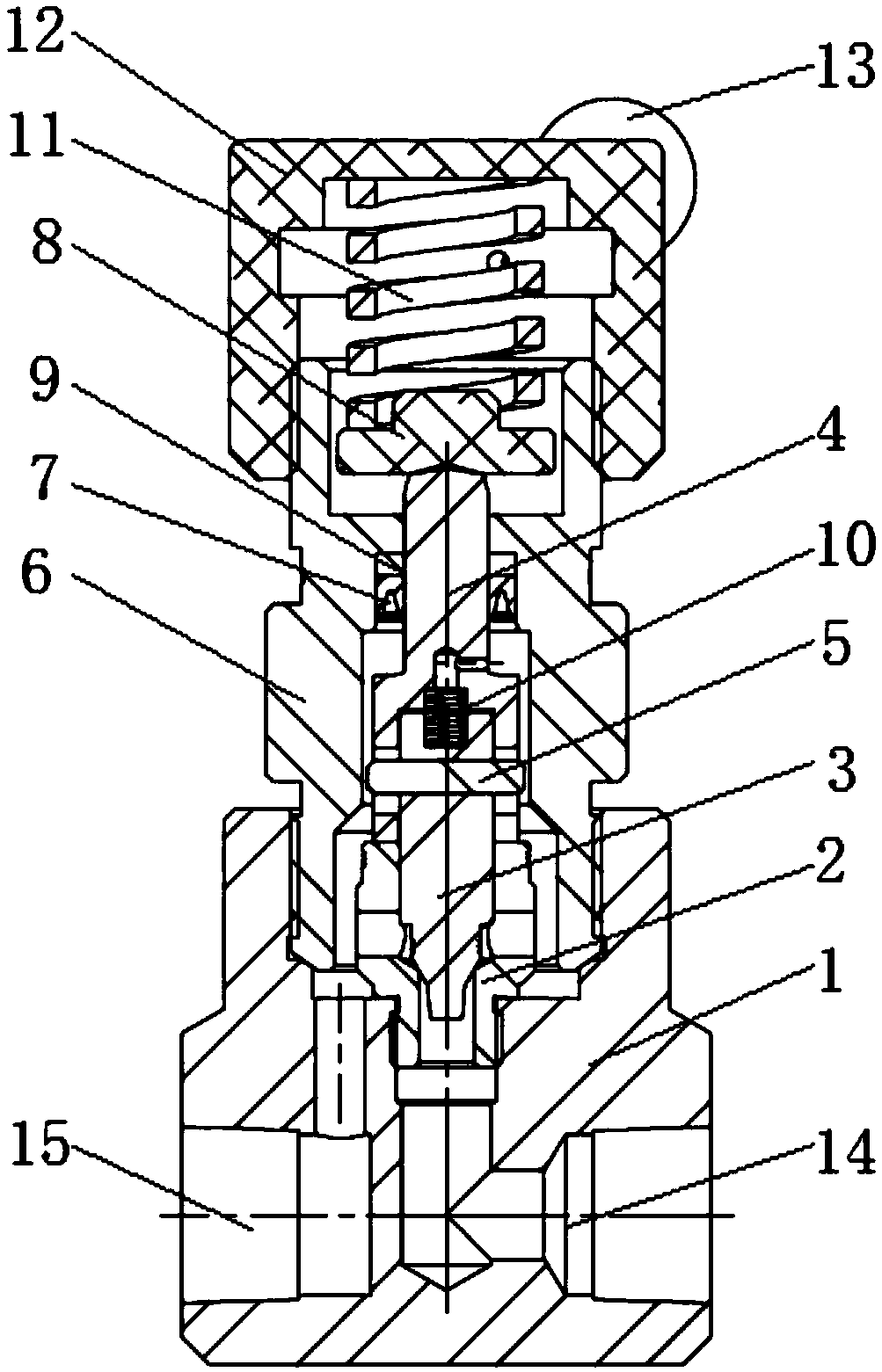

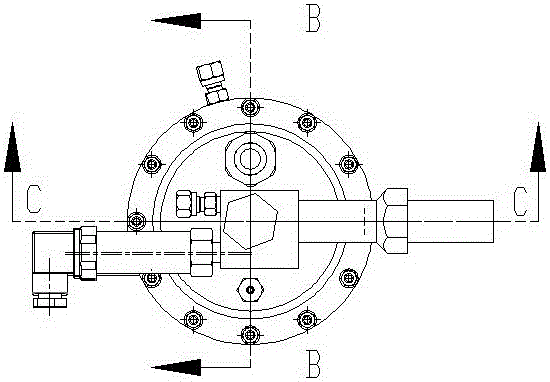

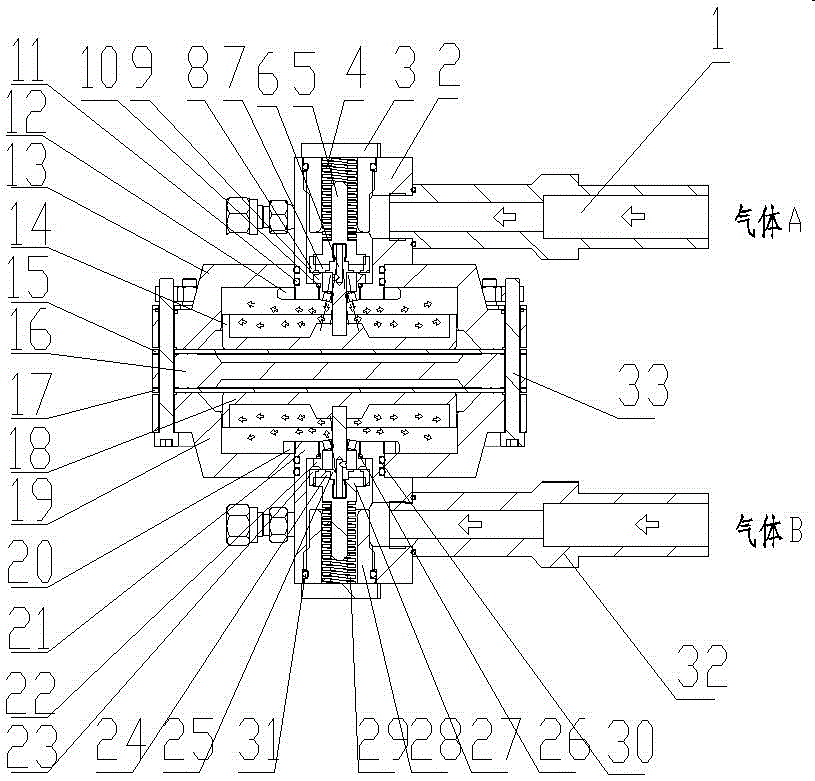

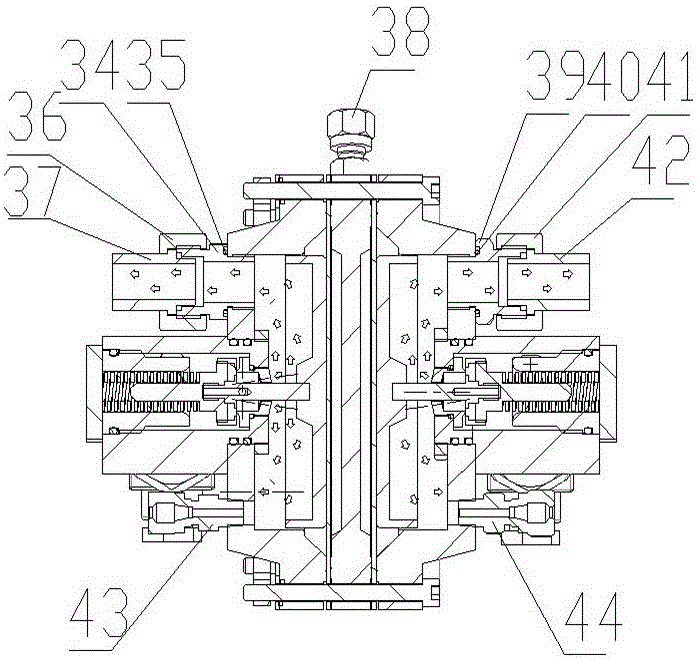

PendingCN113446420AGuaranteed tightnessRealize self-relieving functionSpindle sealingsEqualizing valvesEngineeringPhysics

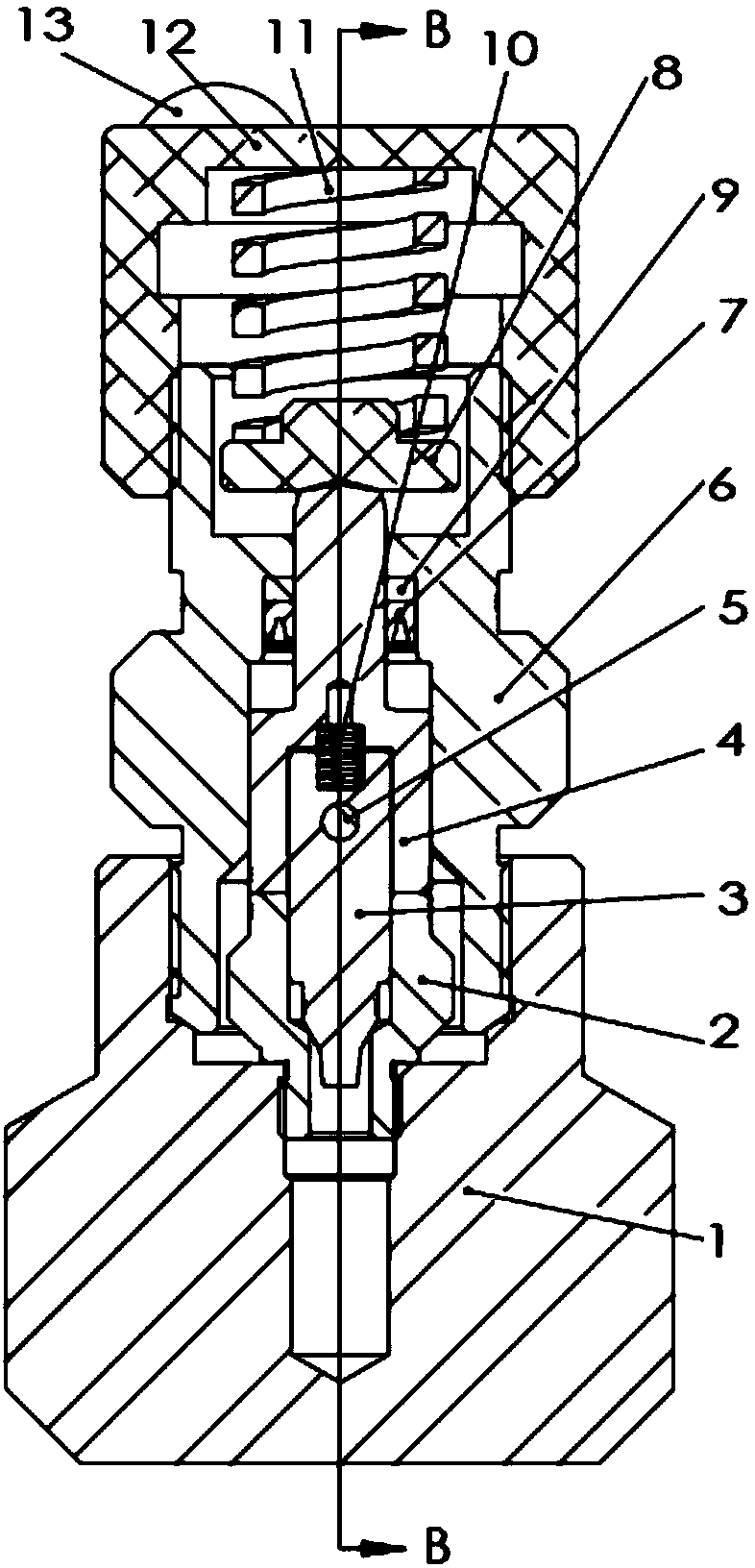

The invention discloses a small pressure release valve. The small pressure release valve comprises a valve body, a valve rod, a spring and a pre-compression force adjusting nut, the valve rod is arranged in the valve body, the valve rod is sleeved with the spring, the pre-compression force adjusting nut is connected to the rear end of the valve rod in a threaded mode, the two ends of the spring abut against the step face of the inner wall of the valve body and the pre-compression force adjusting nut respectively in a contact mode, an O-shaped sealing ring is fixed to the front end of the valve rod and makes contact with the inner wall of the valve body in an abutting mode to achieve sealing of the pressure release valve, during pressure release, the valve rod drives the O-shaped sealing ring on the valve rod and the pre-compression force adjusting nut to move leftwards, the O-shaped sealing ring is separated from the inner wall of the valve body, and an inner cavity of the valve body is opened to achieve pressure release operation. The small pressure release valve overcomes the defects of an existing pressure release valve, is simple in structure and convenient to mount and dismount, adopts double sealing, is good in sealing performance, adopts the pre-compression force adjusting nut to adjust the pressure release force, is flexible in pressure adjustment, and can be used independently or used in cooperation with other devices.

Owner:THE 40TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Composite material for balance valve

InactiveCN105422939AImprove stabilityHigh adjustment accuracyEqualizing valvesSafety valvesMaterials science

Owner:WUXI FUMEI LIGHT ALLOY TECH

Pressure-reducing pressure-stabilizing and constant-pressure starting valve for fire fighting

PendingCN109973692AGuaranteed sealing performanceNo malfunctionCheck valvesEqualizing valvesEngineeringLow leakage

Owner:万升消防科技有限公司

Automatic alarm room temperature on-off control valve

Owner:天津市金超利达科技有限公司

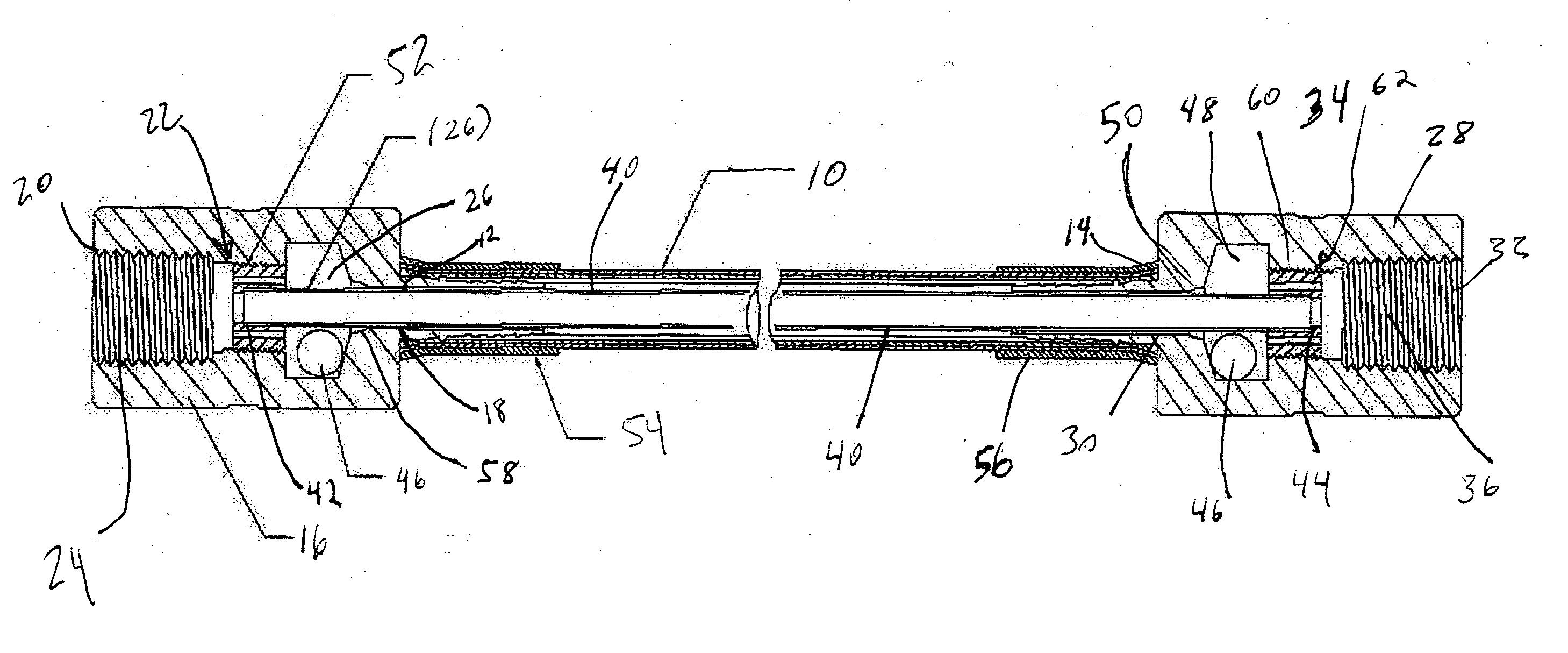

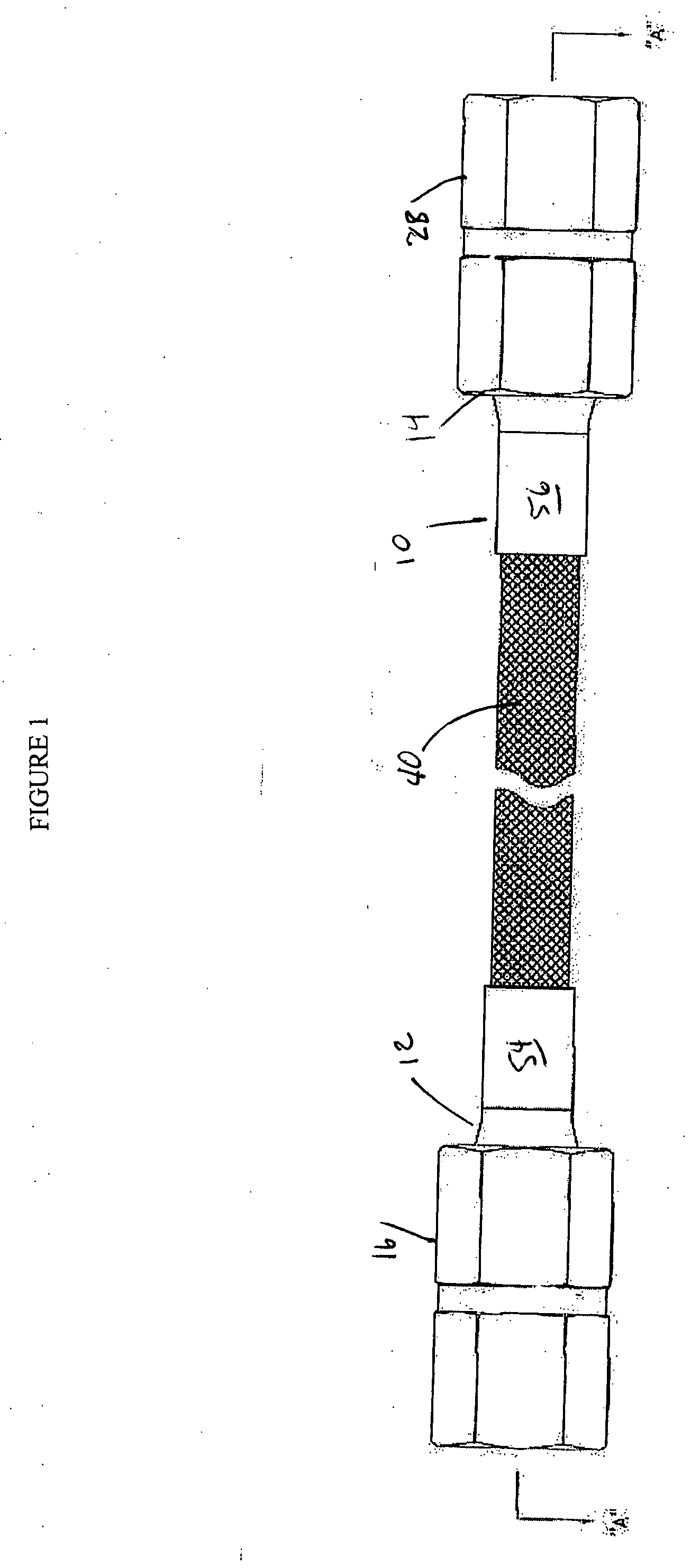

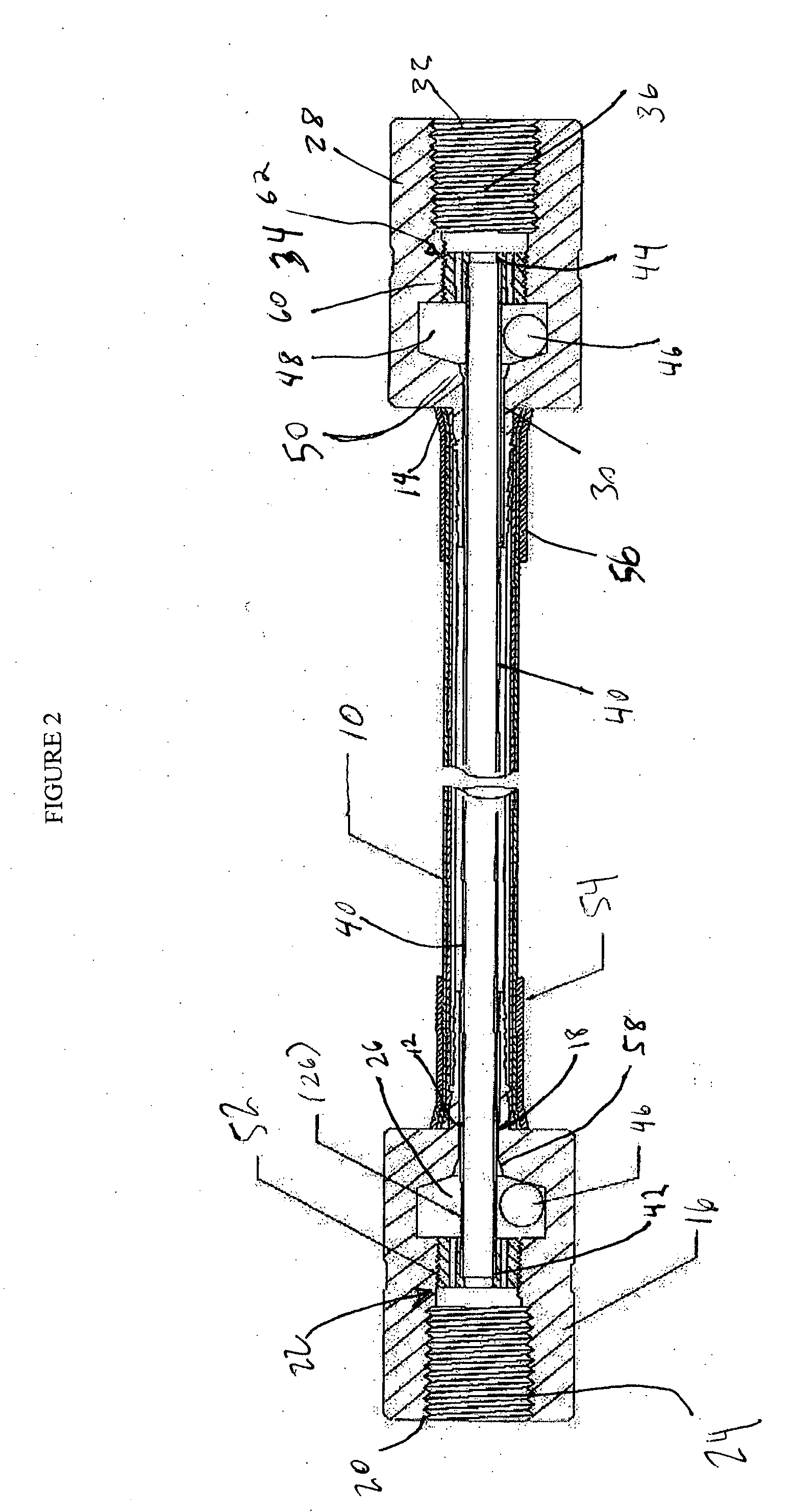

Safety system hose

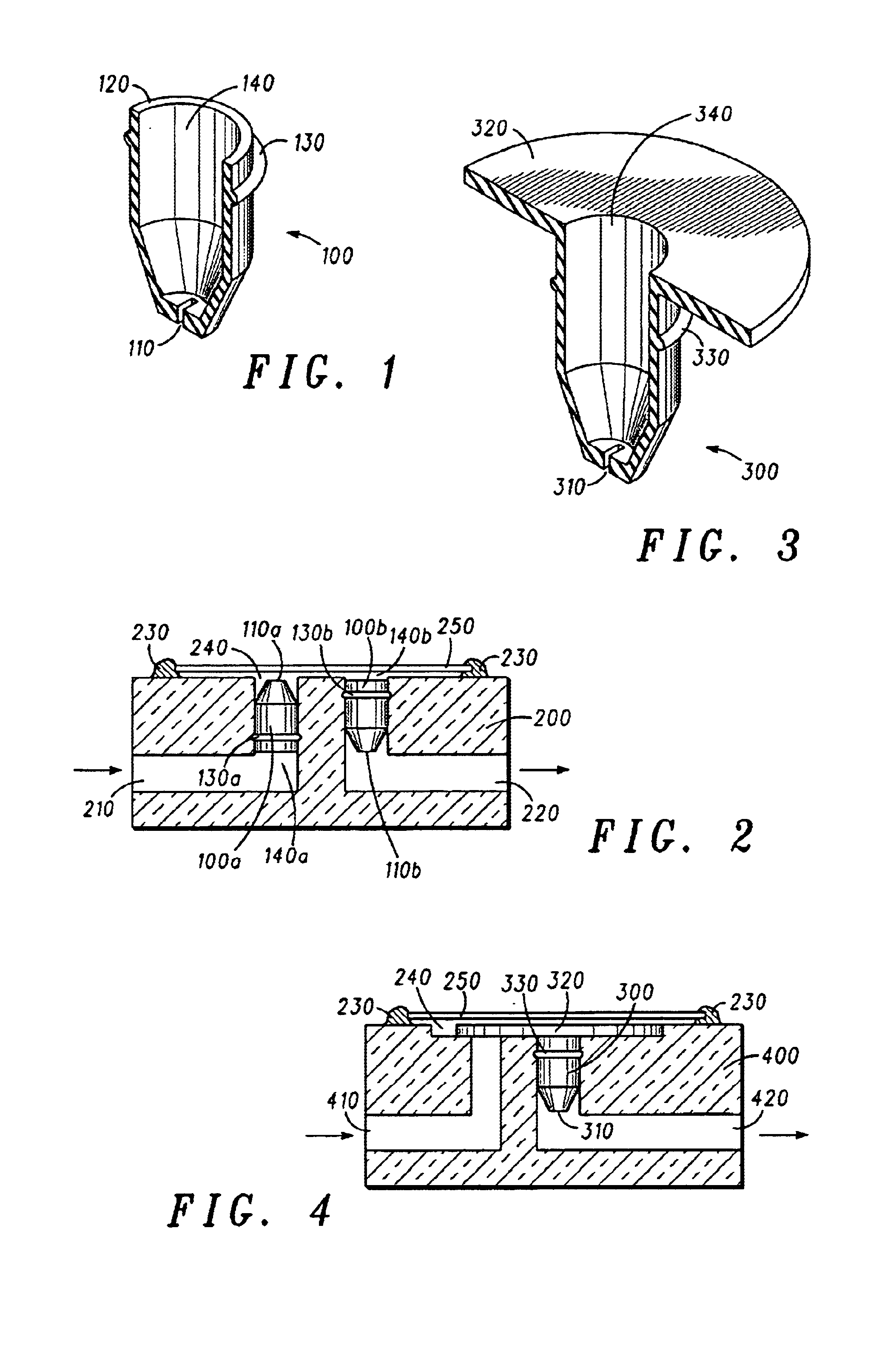

A safety system for a fluid conduit having: a hose; a first housing connected to the hose with an internal cavity having a first connection point and a first check ball opening cavity; a second housing connected to the hose with an internal cavity having a second connection point and a second check ball opening cavity; a perforated retention tube positioned longitudinally within the hose and in communication with the first connection point and the second connection point; a first check device contained within the first check ball opening cavity and interposed between the perforated retention tube and the first check ball opening cavity; and a second check device contained within the second check ball opening cavity and interposed between the perforated retention tube and the second check ball opening cavity.

Owner:GOLDSTEIN JEFFREY

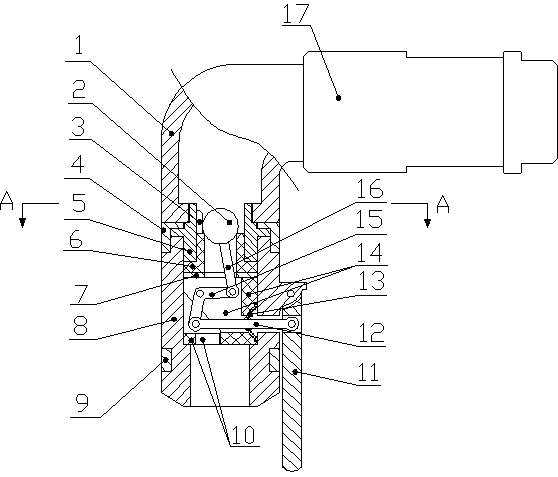

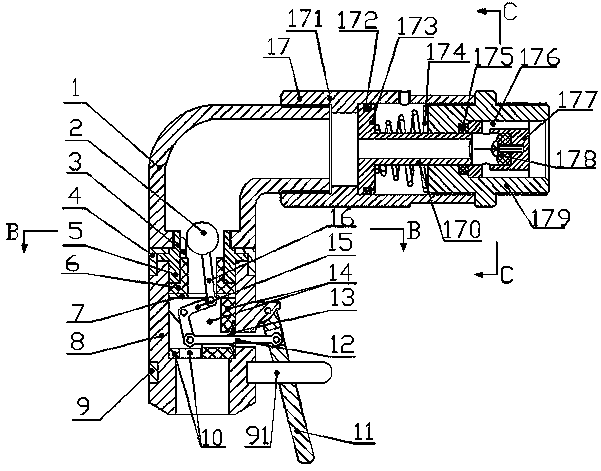

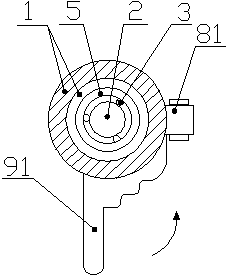

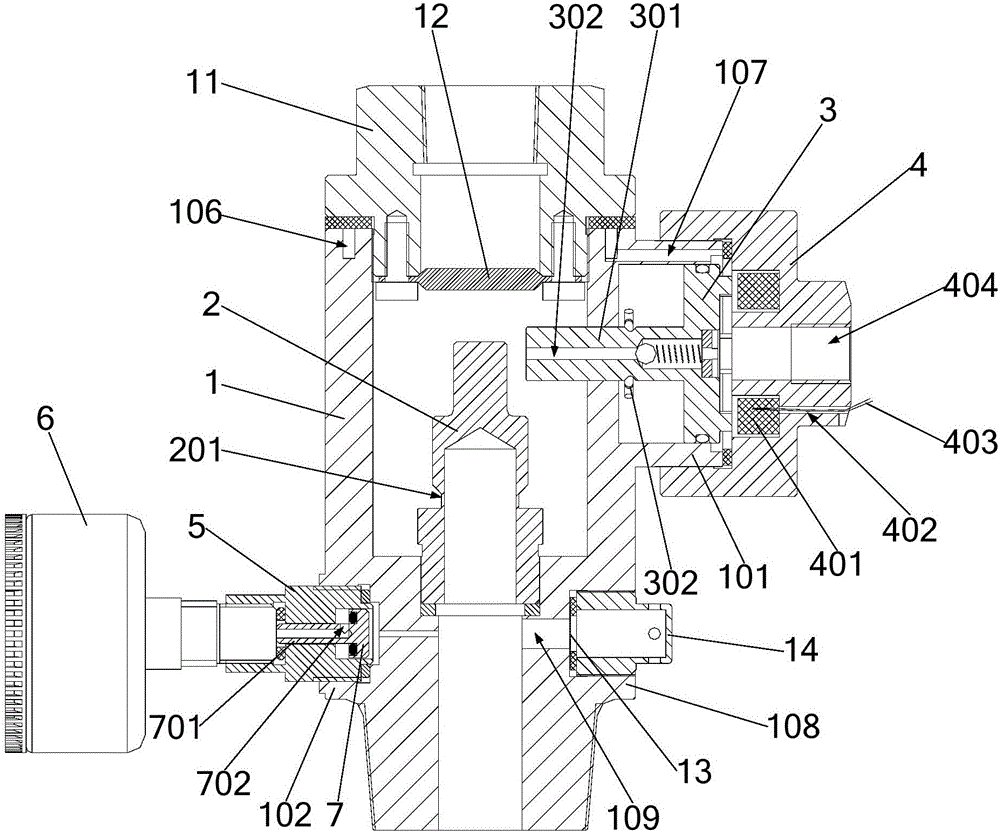

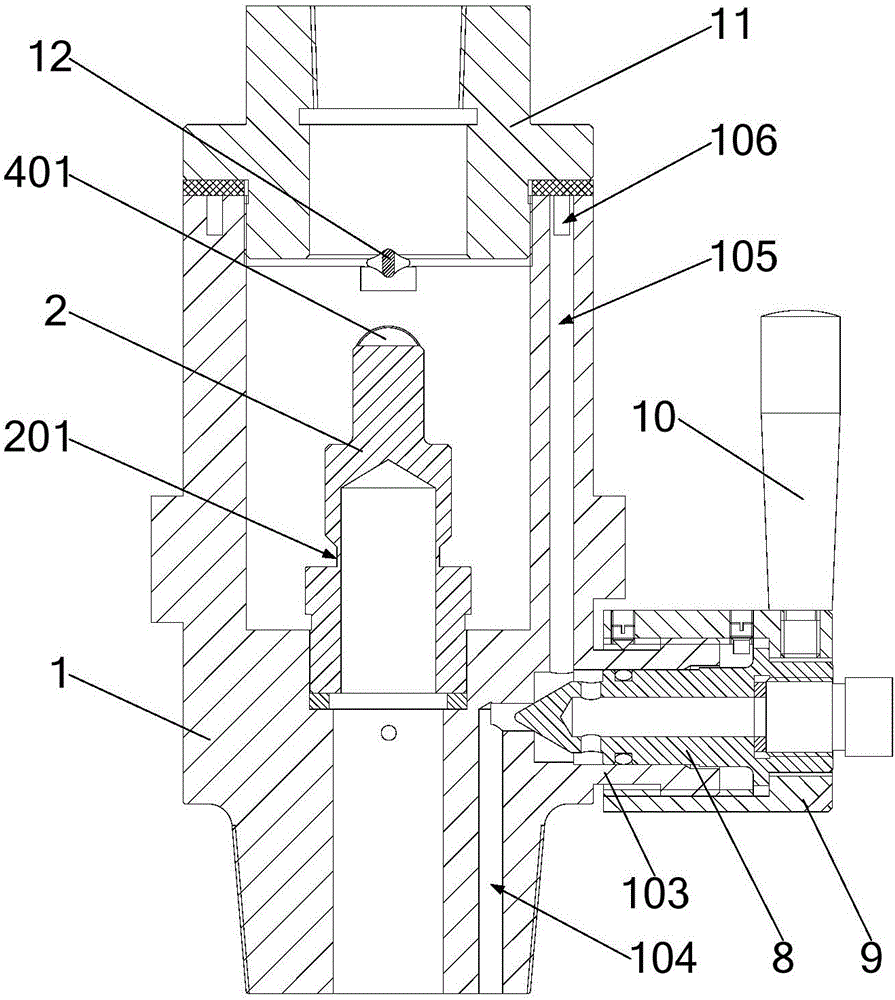

Mechanical drive control type flow regulating valve

Owner:SICHUAN AVIATION IND CHUANXI MACHINE

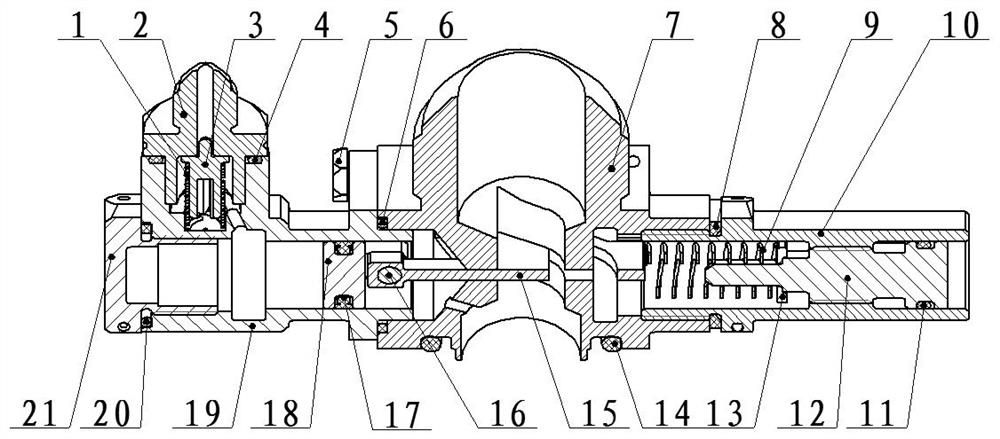

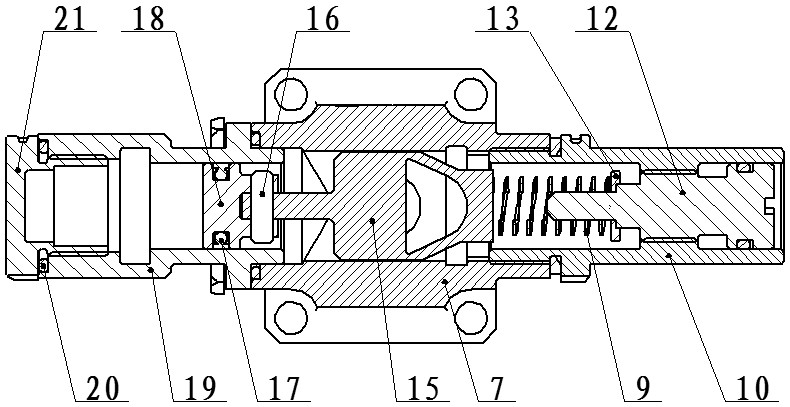

Composite flow valve

InactiveCN101737512AMeet pressure flow requirementsMeet the needs of high operating temperatureCheck valvesEqualizing valvesFluid intakeWorking temperature

Owner:重庆启蓝科技有限公司

Double-damping high-pressure back pressure valve without diaphragm

Owner:MILTON ROY IND SHANGHAI

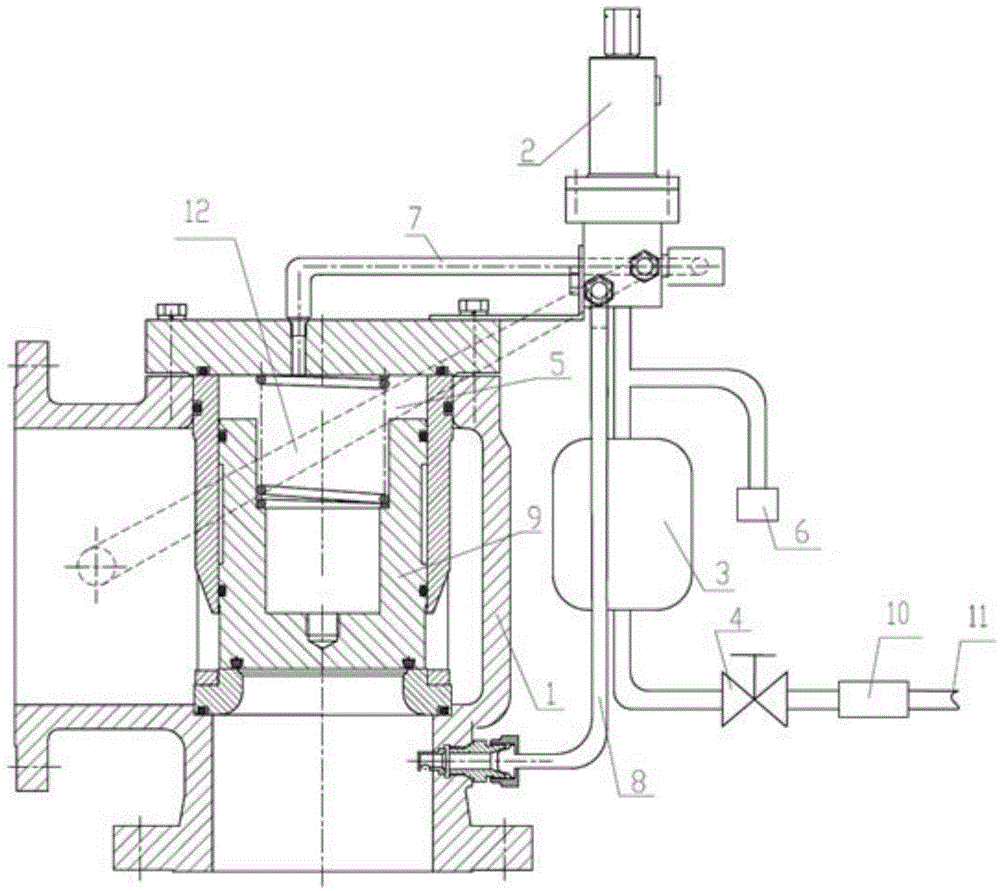

High-pressure balance valve for proportioning cabinet

Owner:JINAN HUAXIN AUTOMATION ENG

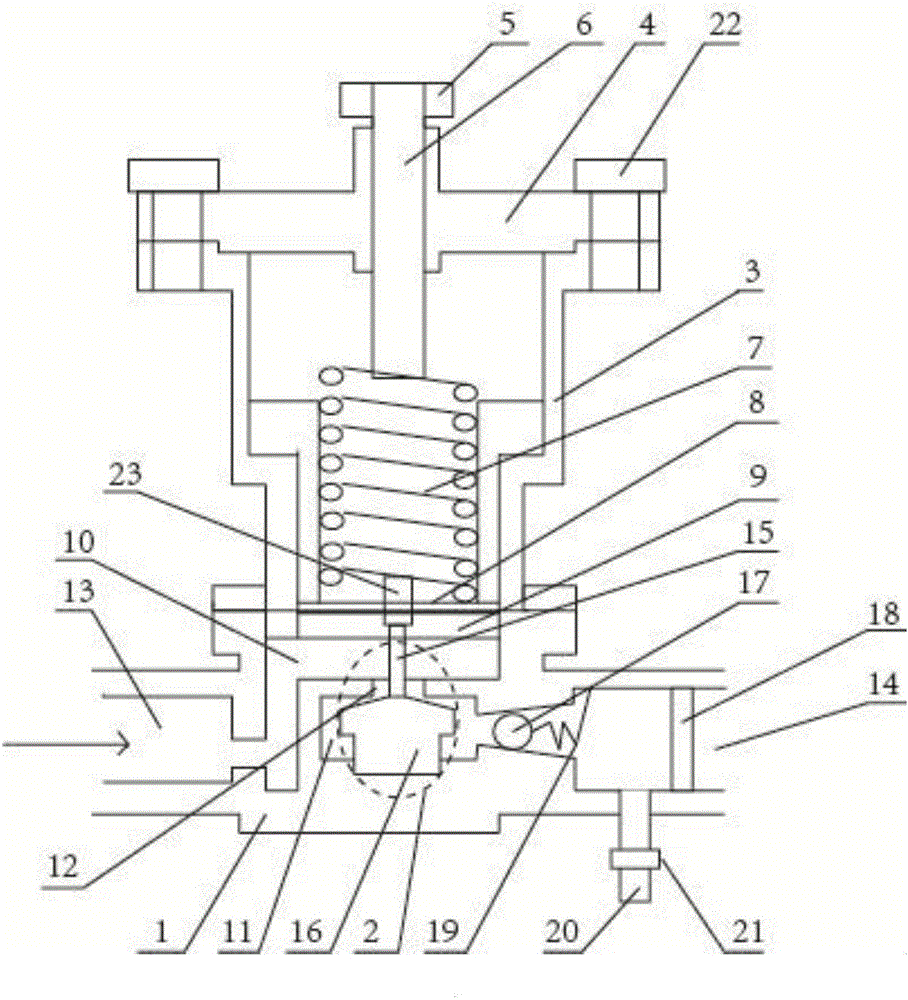

Load compensation balance valve

PendingCN111664136ASmooth movementReliable actionServomotor componentsServomotorsSpring forceEngineering

Owner:SHENGBANG GRP +3

Pressure reducing valve

Owner:TIANJIN SHOUFA TECH CO LTD

High-sensitivity pressure-limiting air valve of truck air pump

Owner:房县启扬工贸有限责任公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap