Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108 results about "Product gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Product gas meaning, product gas definition | English Cobuild dictionary. product. 1 n-count A product is something that is produced and sold in large quantities, often as a result of a manufacturing process.

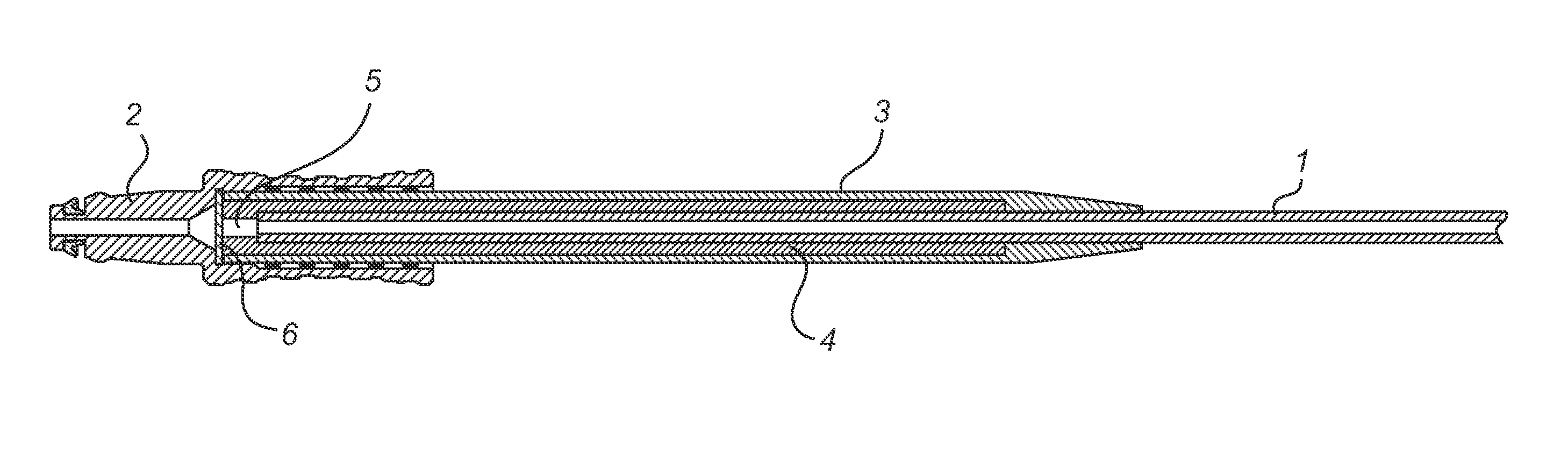

Gas sampling line

ActiveUS20110237969A1Improve accuracyReduce distortion problemsDispersed particle separationRespiratory organ evaluationGas analysisPolyethylene oxide

Owner:JPMORGAN CHASE BANK NA

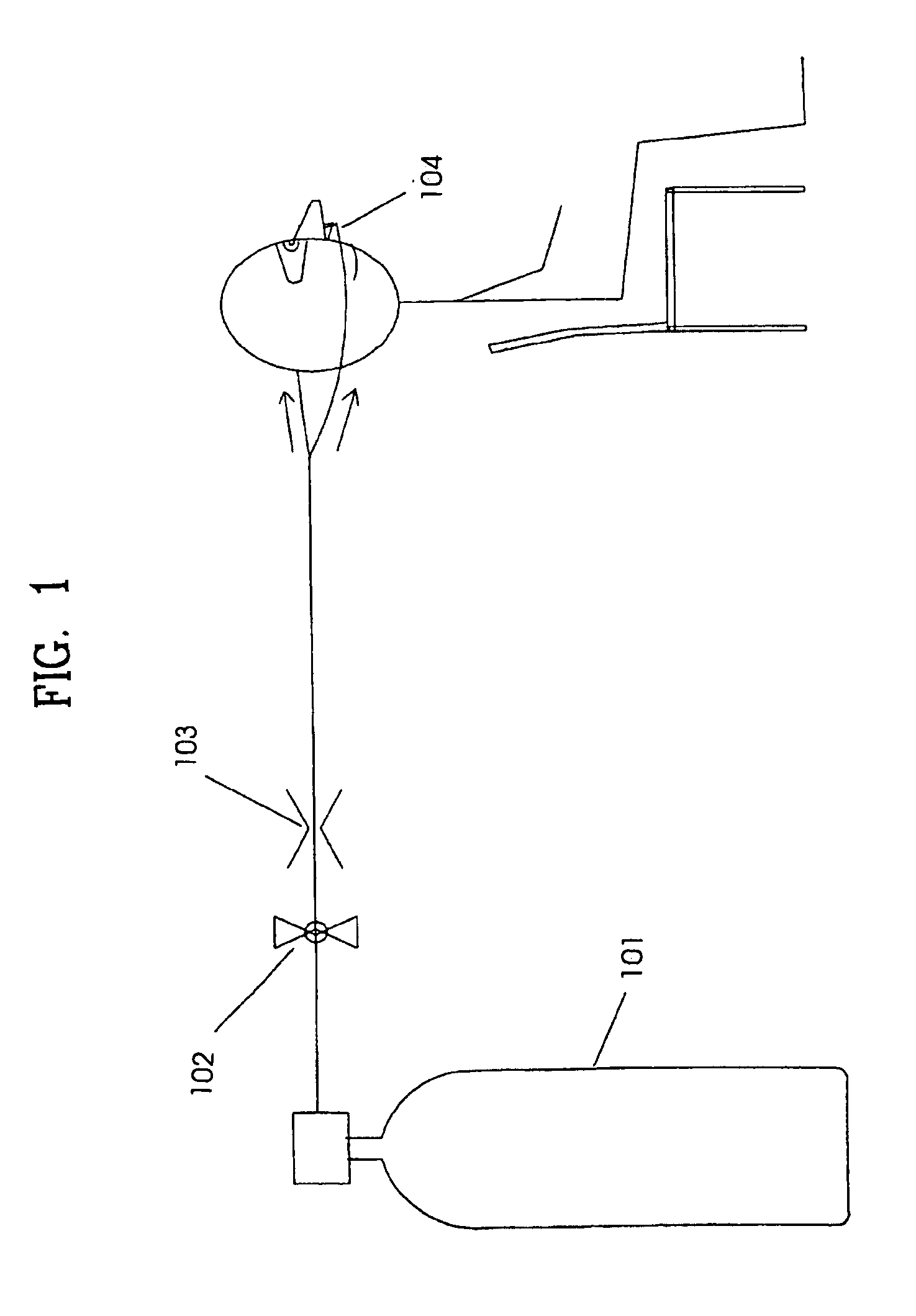

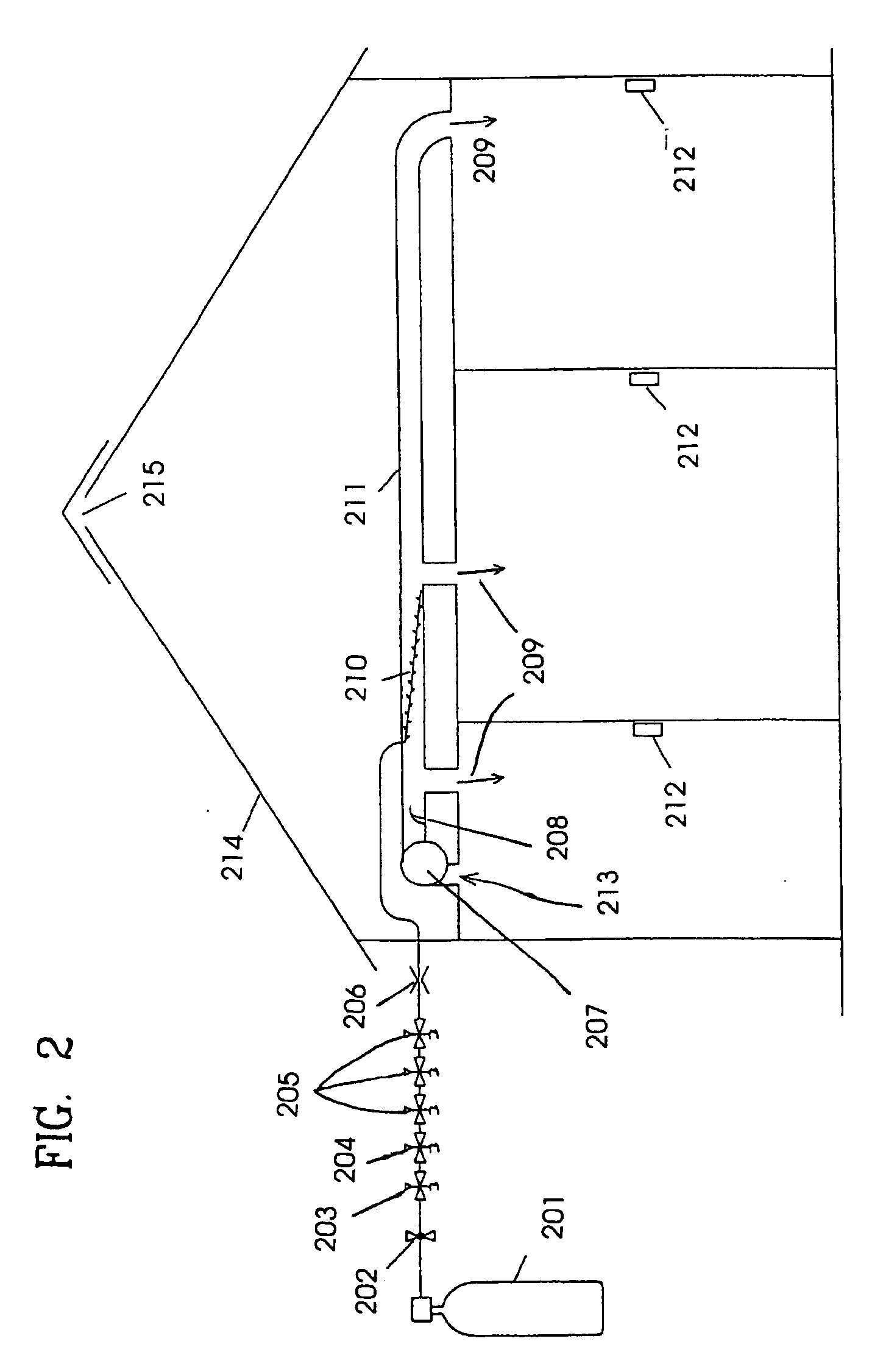

Method for treating a solid material to make it hydrophobic, material obtained and uses

InactiveUS6342268B1Simple and rapid and methodWater-repelling agents additionOther chemical processesChemical structureProduct gas

A solid material is treated, the chemical structure of which defines reactive protogenic hydrophillic functions accessible to gases, by applying at least one gas stream (3) onto at least one microdispersion (5) of at least one grafting reagent RX produced on the solid material, R being a hydrophobic group, X being chosen so that HX is volatile under normal conditions, R and X being chosen so that the reaction of RX on the hydrophillic functions produces covalent grafting of the hydrophobic group R with formation of the compound HX, it being possible for the reaction to be carried out in a solid / gas heterogeneous medium on all the reactive hydrophillic functions accessible to gases and only on these. The invention extends to the hydrophobic solid material obtained, and is applicable to the obtaining of natural or artificial fibrous or inorganic structures impermeable to water and to aqueous solutions and / or absorbing fats.

Owner:BT3 TECH

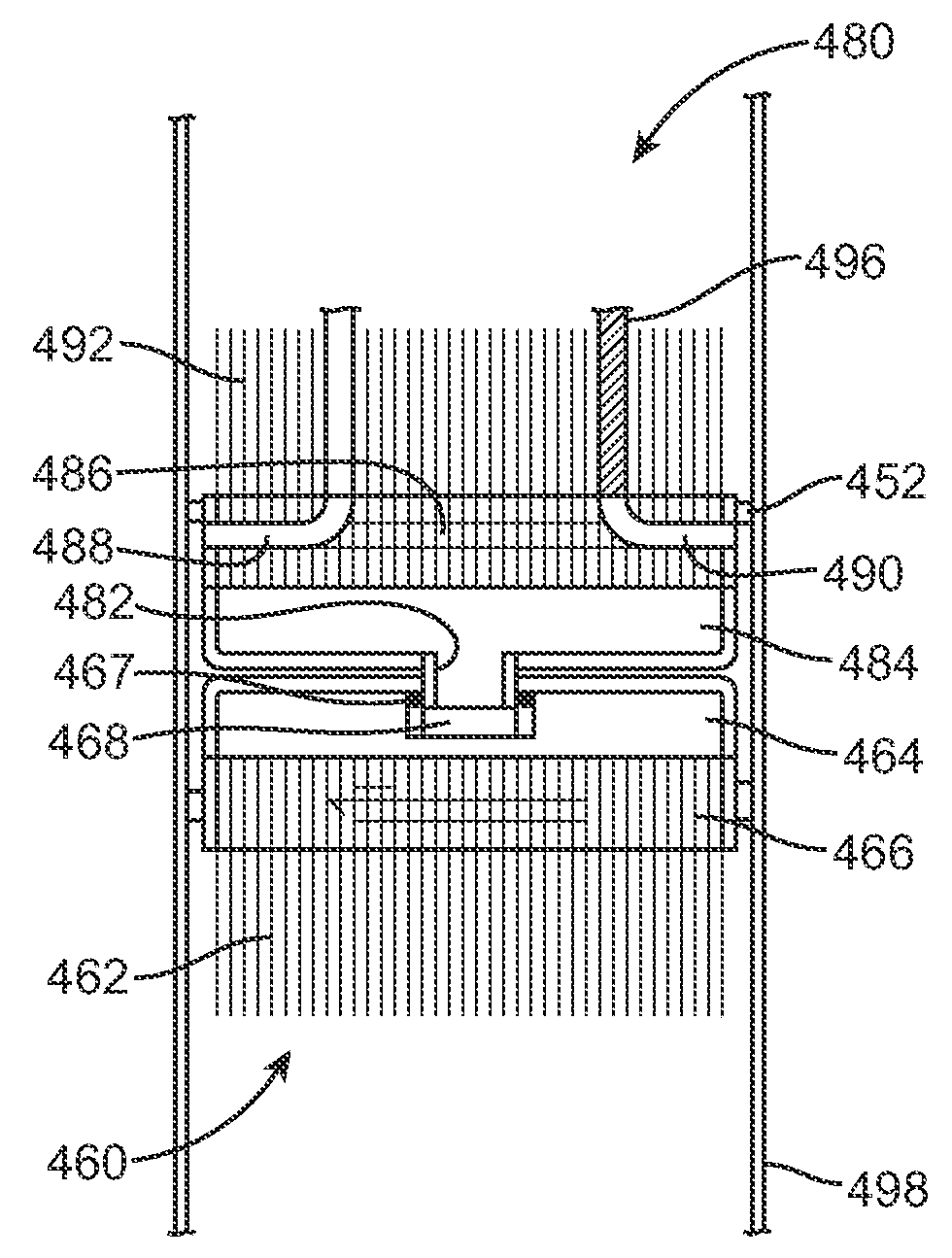

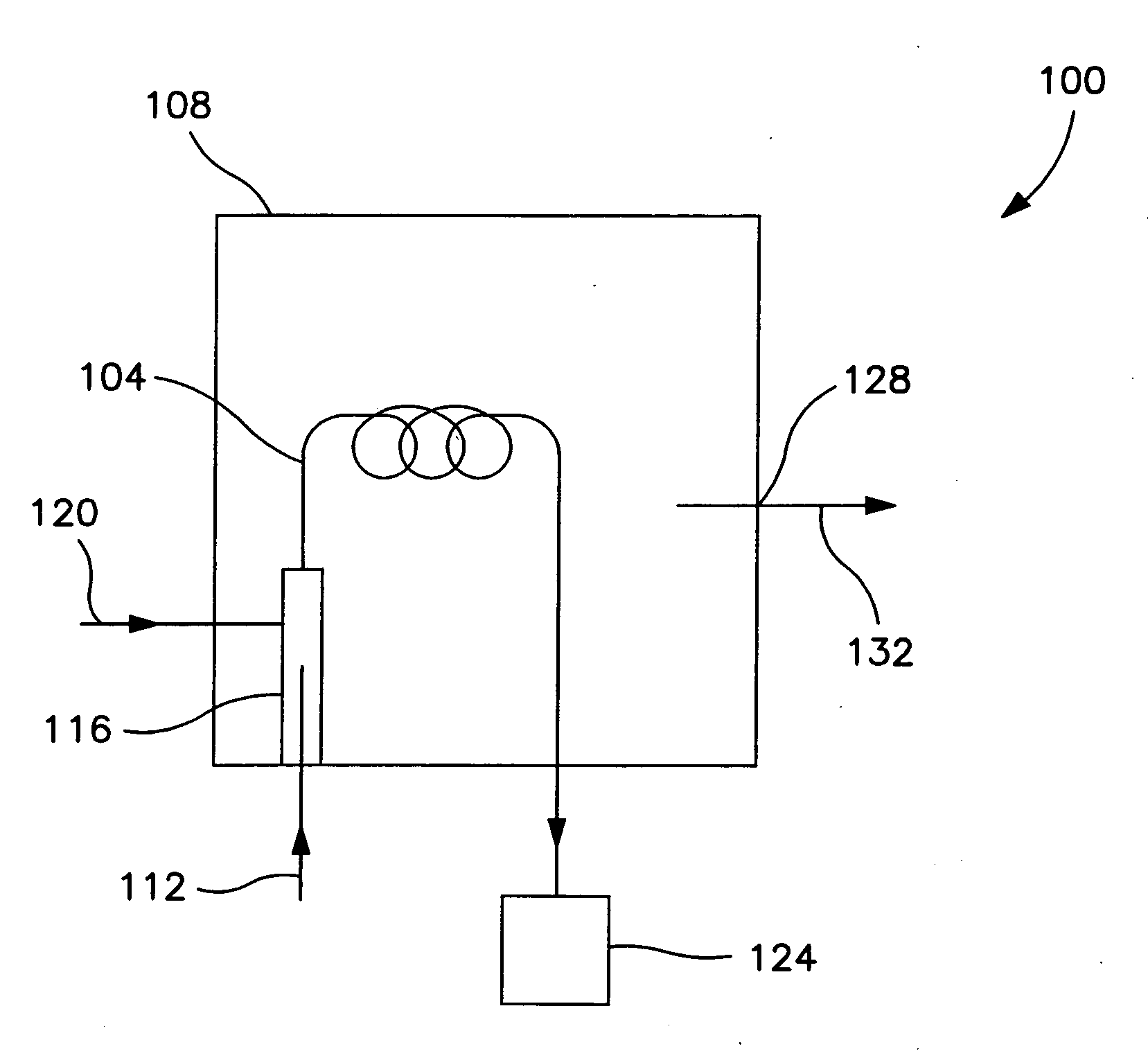

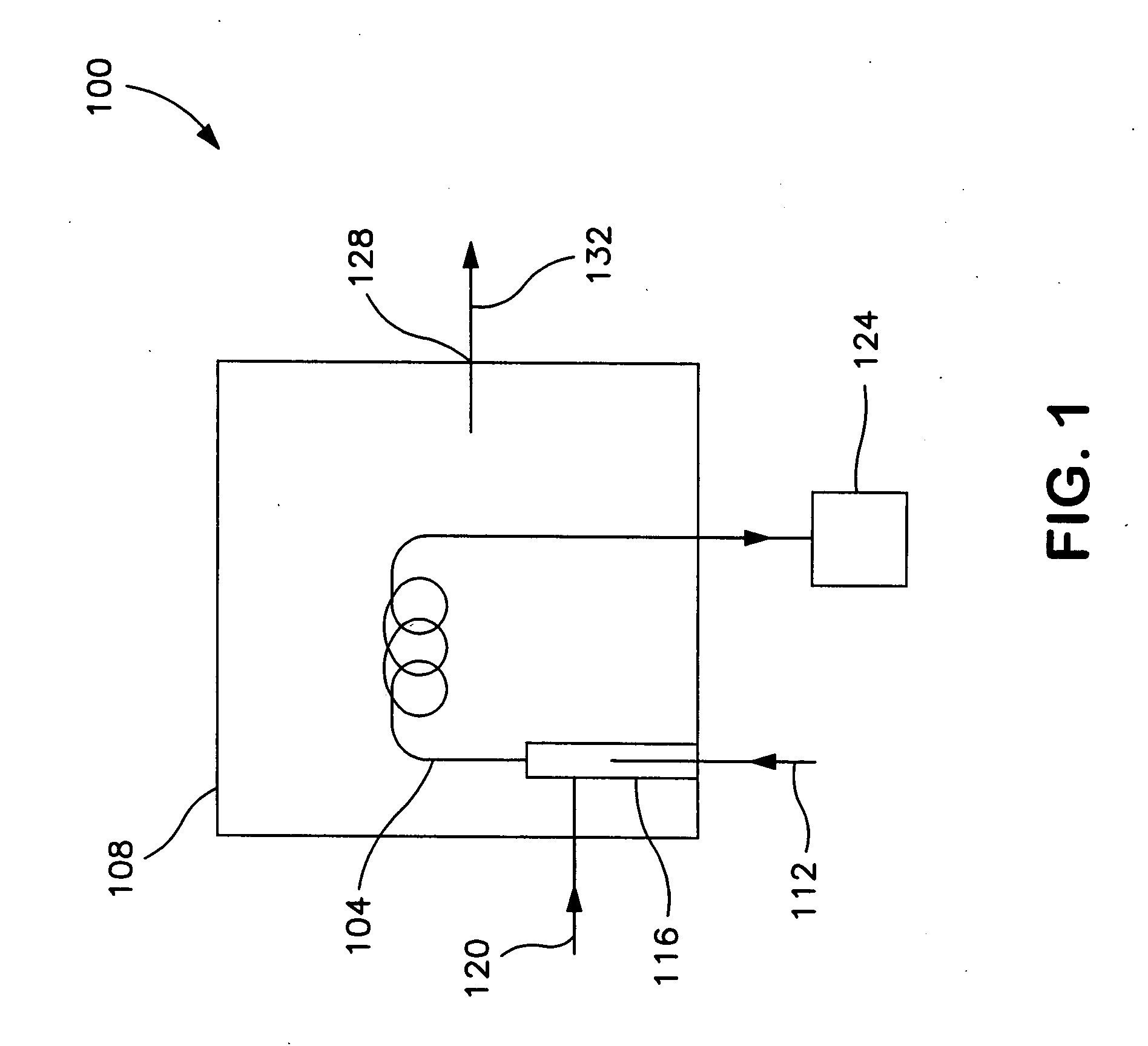

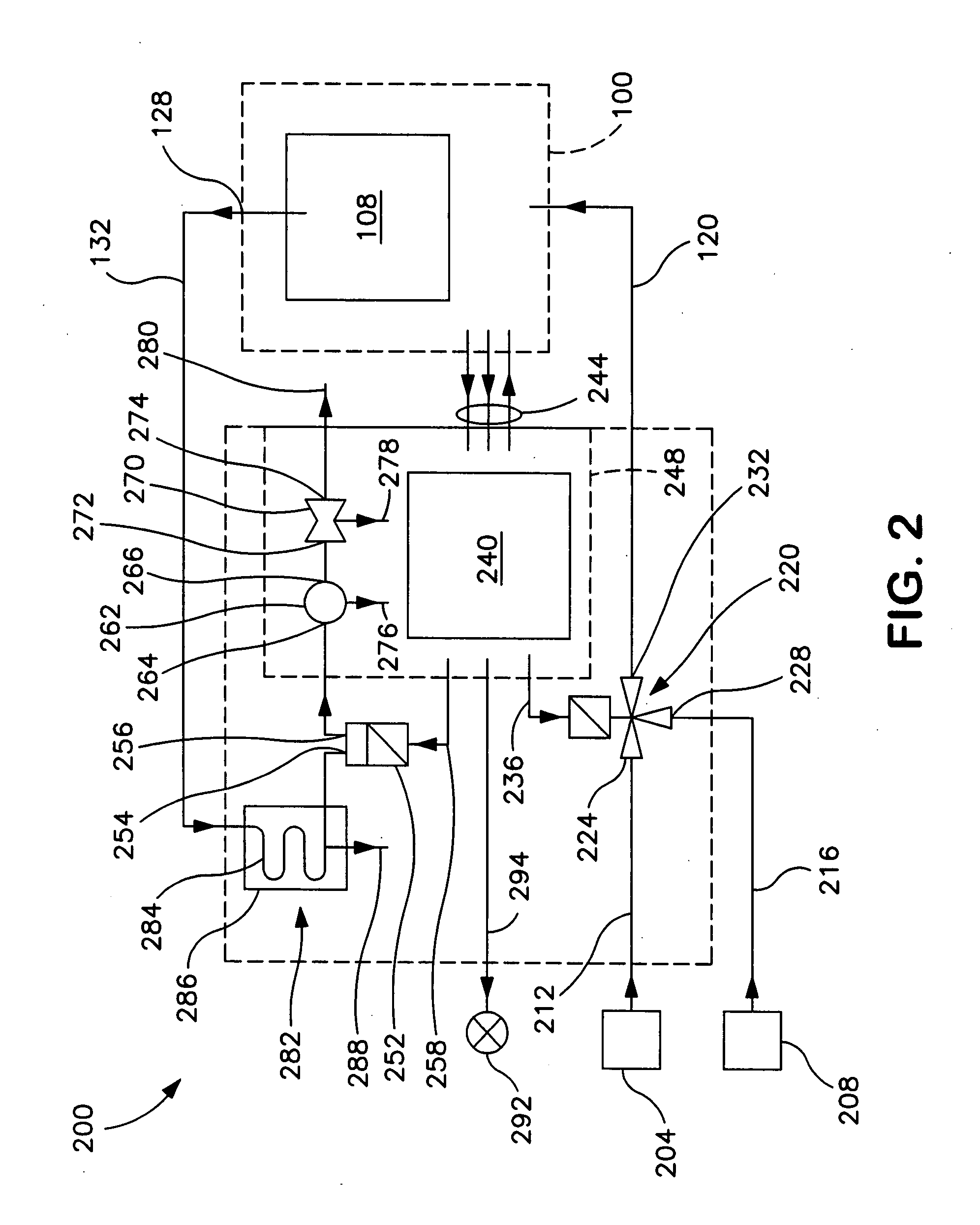

Portable oxygen concentrator with a docking station

Disclosed is an oxygen supply system comprising a portable oxygen concentrator for providing oxygen-rich product gas to a patient. The oxygen concentrator contains a rechargeable power source. A docking station is provided to receive the oxygen concentrator. The docking station provides electric power to operate the oxygen concentrator while it is docked and recharges the rechargeable power source.

Owner:VBOX

Gas generating process for propulsion and hydrogen production

InactiveUS6849247B1Reduce the temperatureProducing energyLoomsHydrogen productionMetallic materialsSlurry

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

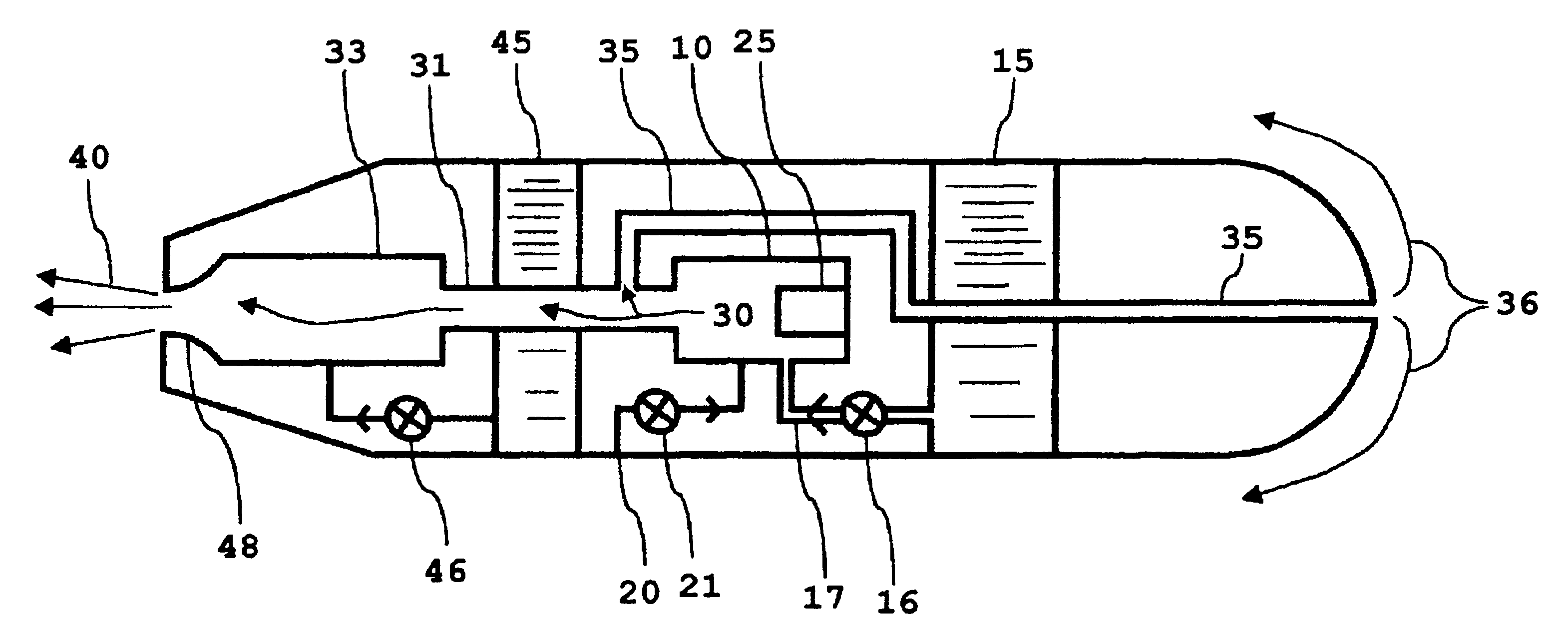

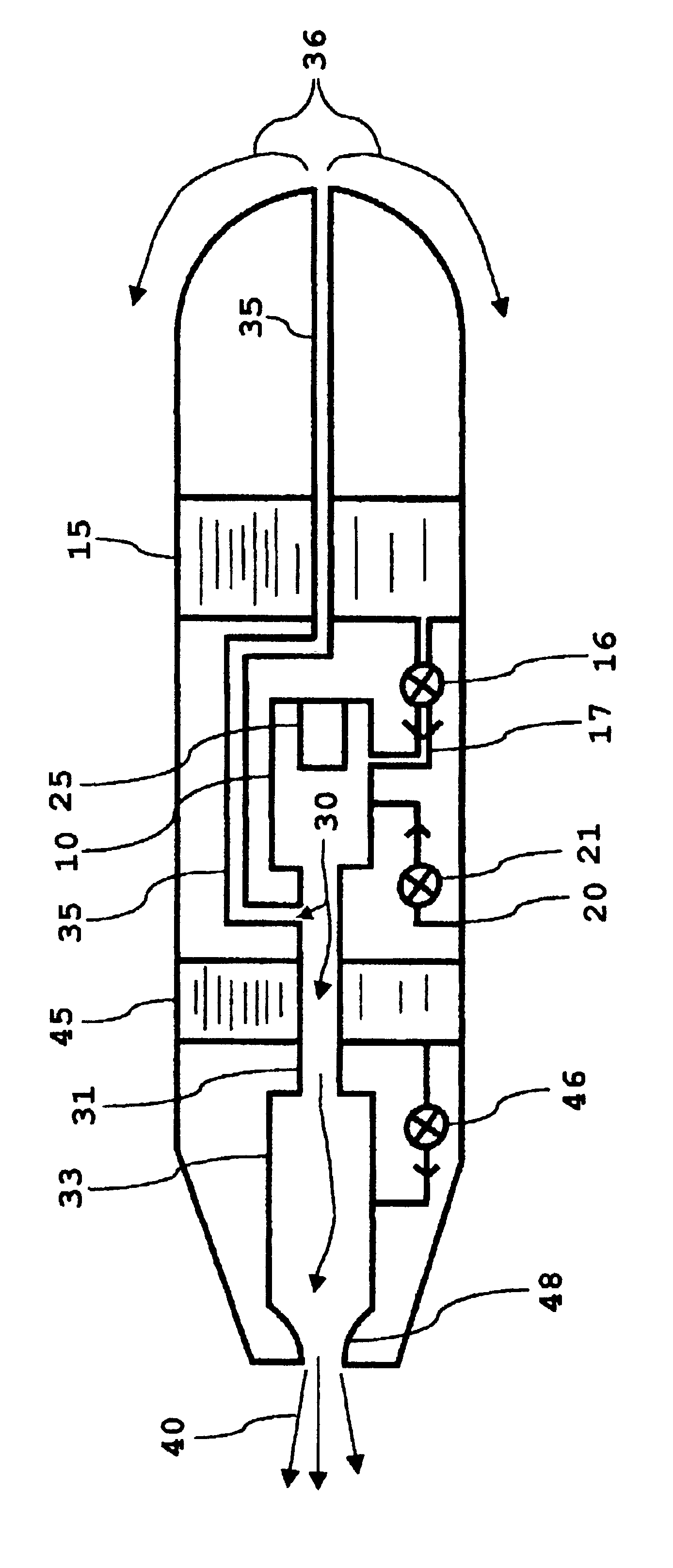

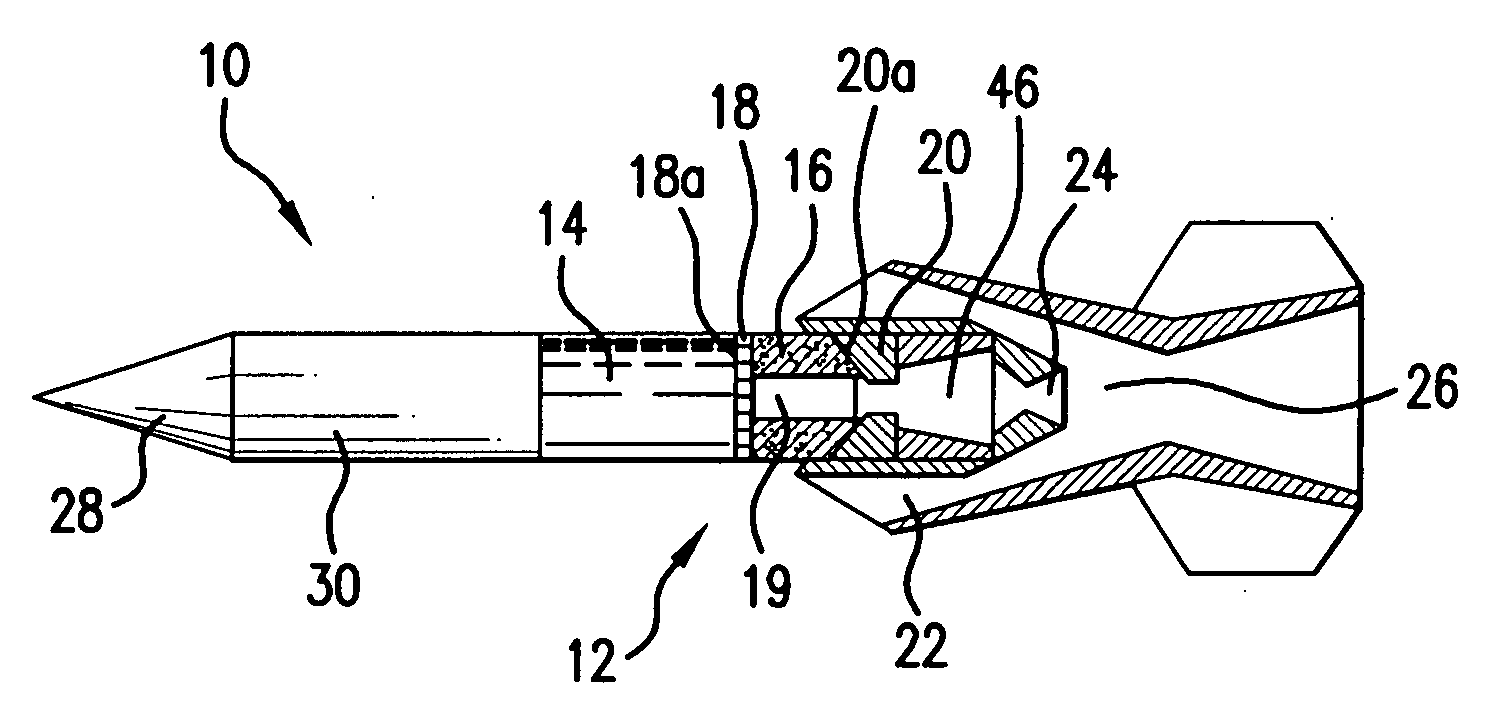

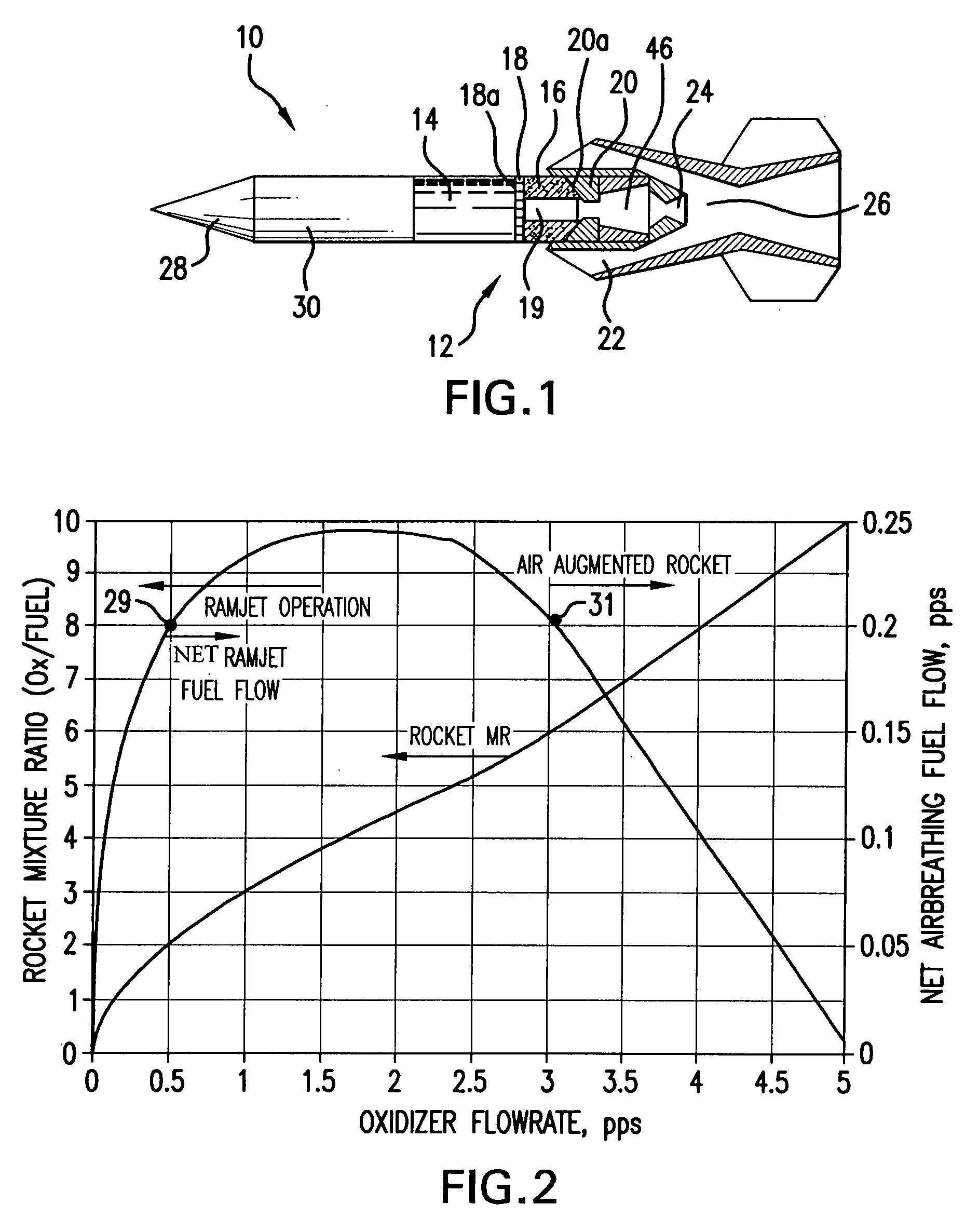

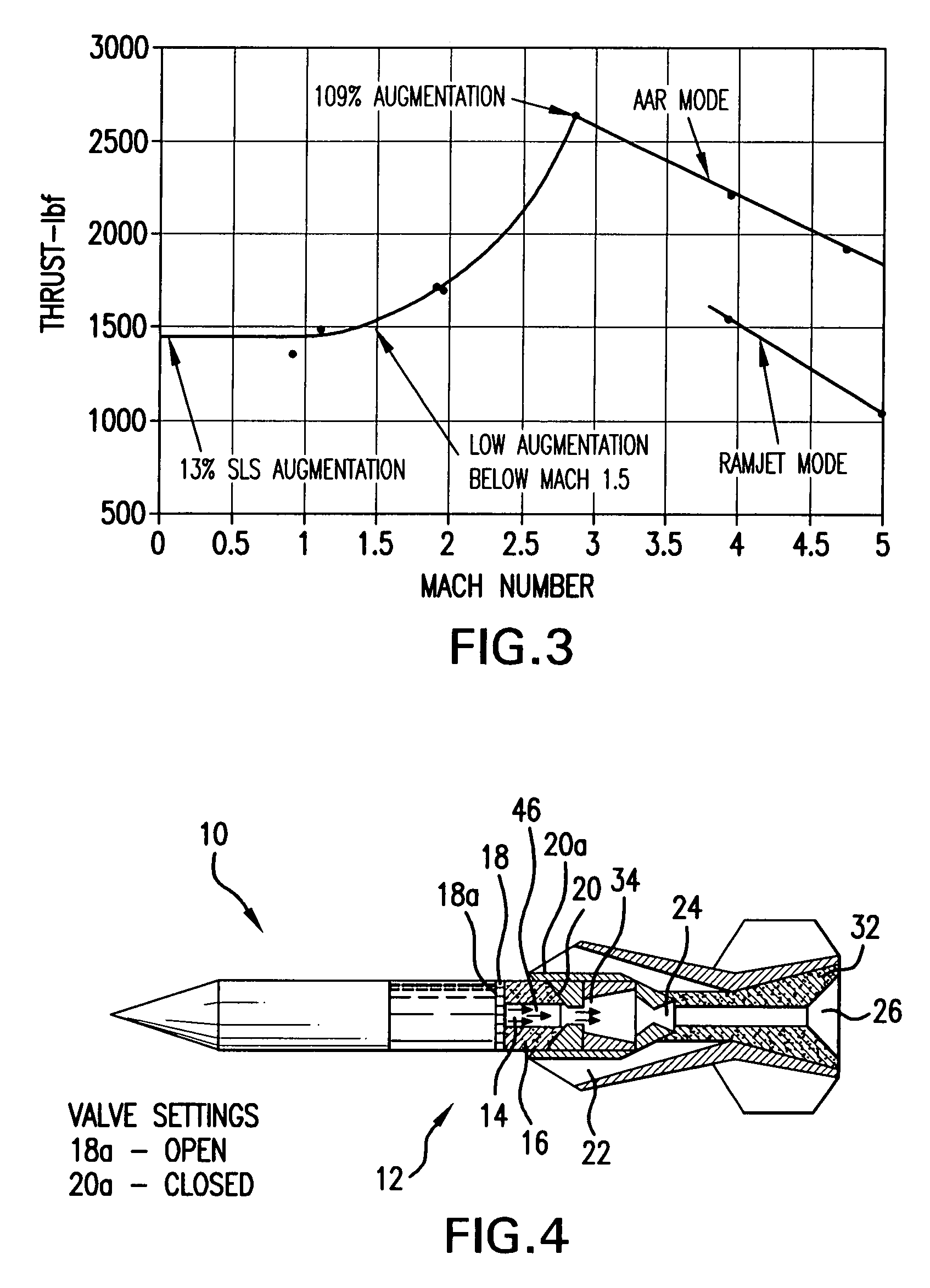

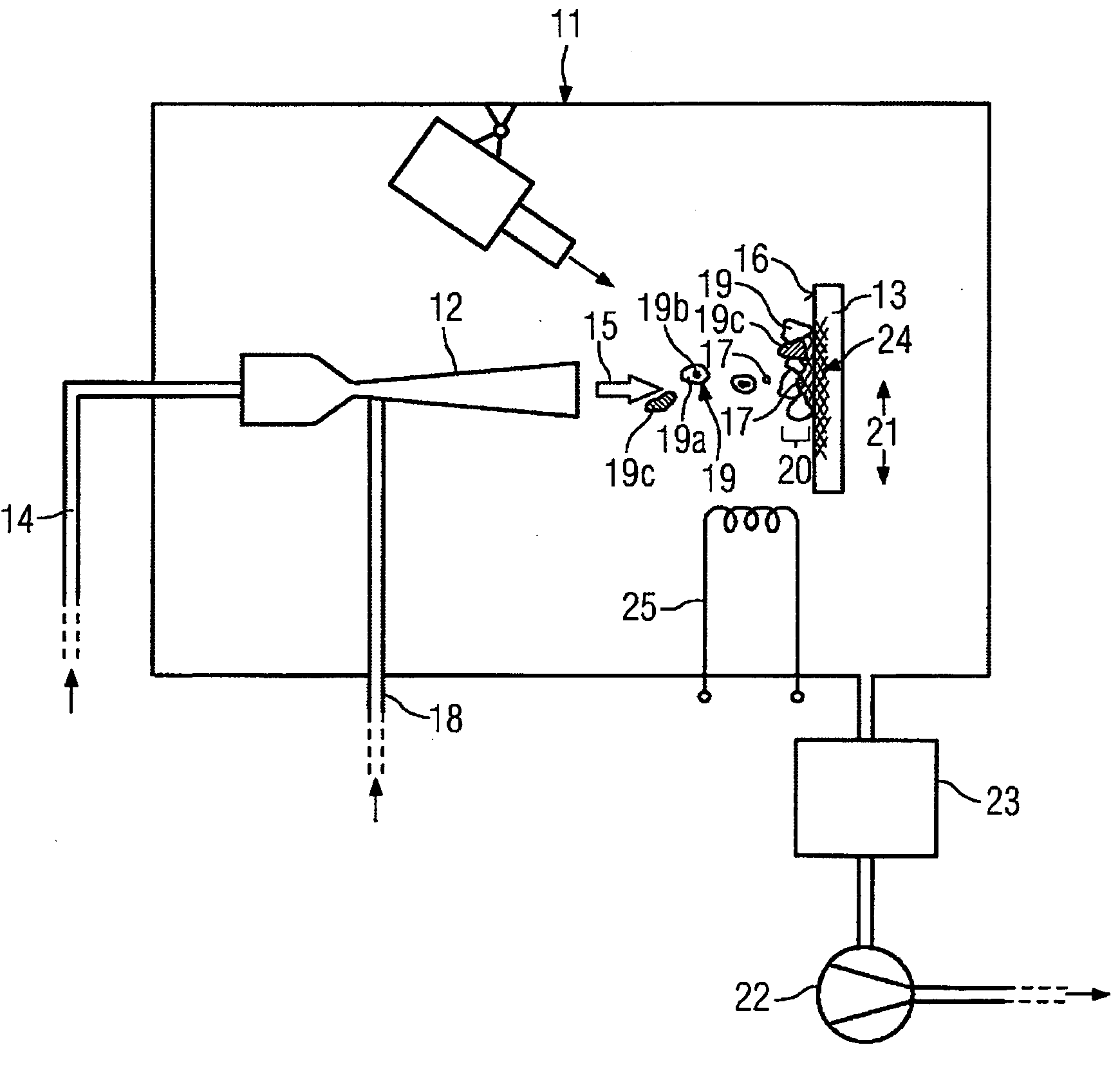

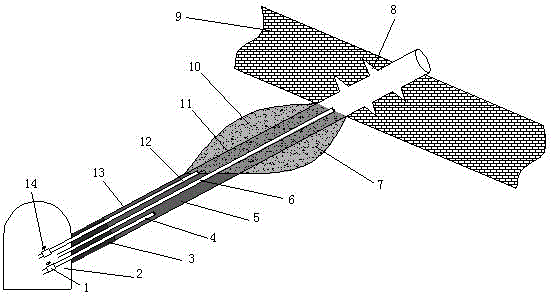

Combined cycle missile engine system

Owner:AEROJET ROCKETDYNE INC

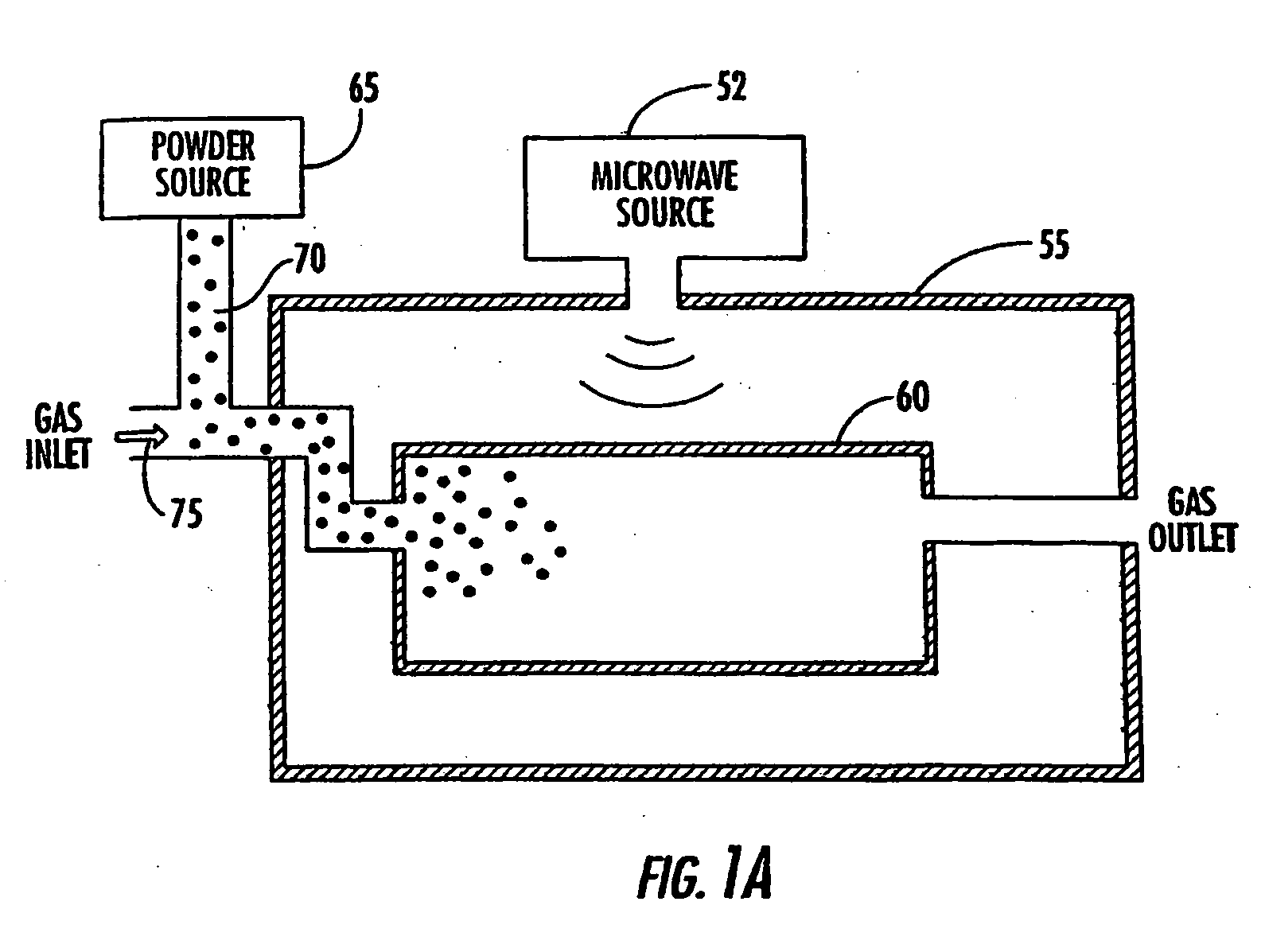

Method for Producing Ceramic Layers

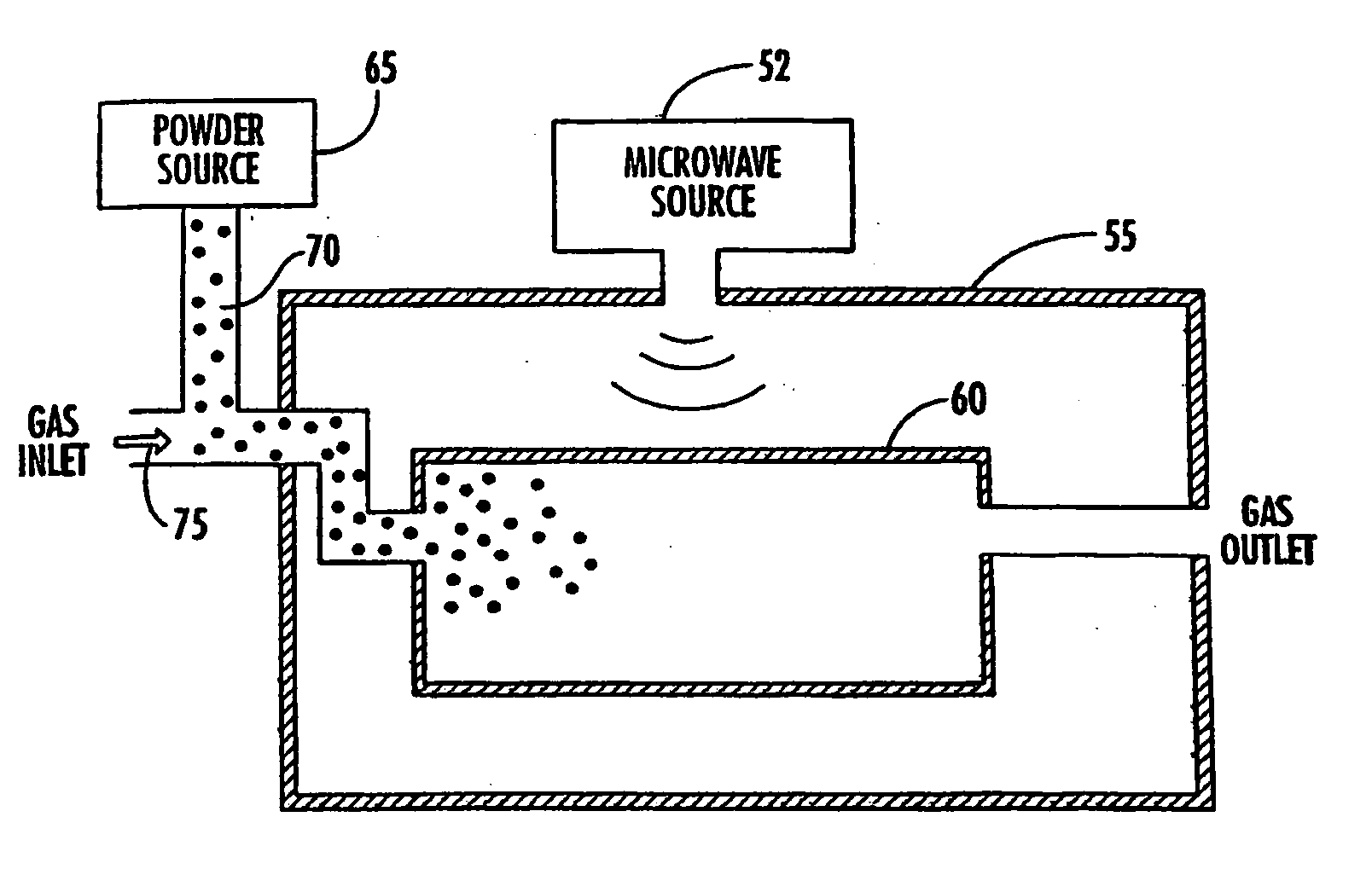

InactiveUS20090202732A1Efficient methodReduce internal stressPretreated surfacesPressure inorganic powder coatingHeat sensitiveProduct gas

Owner:SIEMENS AG

Technical method and schedule for preparation of foam carbon material used asphalt as raw material

Owner:DALIAN UNIV OF TECH

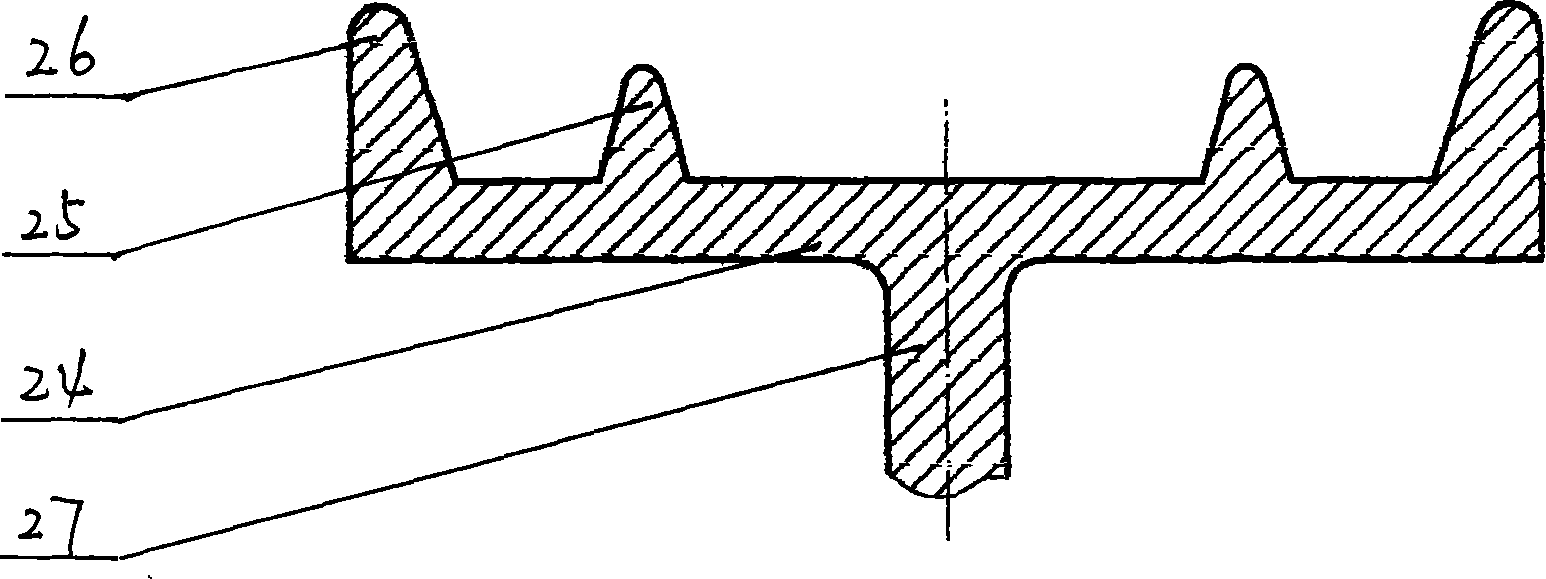

Solid-oxide-fuel-cell cathode gas flow field plate and preparation method thereof

ActiveCN104253280AEfficient use ofFully contactedFinal product manufactureCollectors/separatorsIsosceles trapezoidFuel cells

The invention discloses a solid-oxide-fuel-cell cathode gas flow field plate which is used to uniformly distribute an oxidation gas and collect cathode current. The cathode gas flow field plate is formed by multiple tooth-shaped ripple blocks which are in parallel connection and have same dimension, each tooth-shaped ripple block is formed by two tooth-shaped ripple strips (3 and 4) which are in parallel arrayed connection after being staggered at a distance (7), each tooth-shaped ripple strip (3 and 4) is formed by multiple flat-top bosses (2) and flat plates (1) which are in alternate connection, each flat-top boss (2) has a tooth-shaped contour, the flat plates (1) are connected with the root parts of the flat-top bosses (2) to form tooth-shaped ripples, and the cross section of each flat-top boss (2) has a shape same to the shape of an isosceles trapezoid without a bottom edge. The cathode gas flow field plate of a fuel cell is capable of overcoming the problems that a conventional flow field is large in gas pressure reduction and low in fuel utilization rate. By employing a roll forming technology for preparing the flow field plate, the flow field plate is simple in technology, can be precisely formed and high in product qualified rate.

Owner:HUAZHONG UNIV OF SCI & TECH

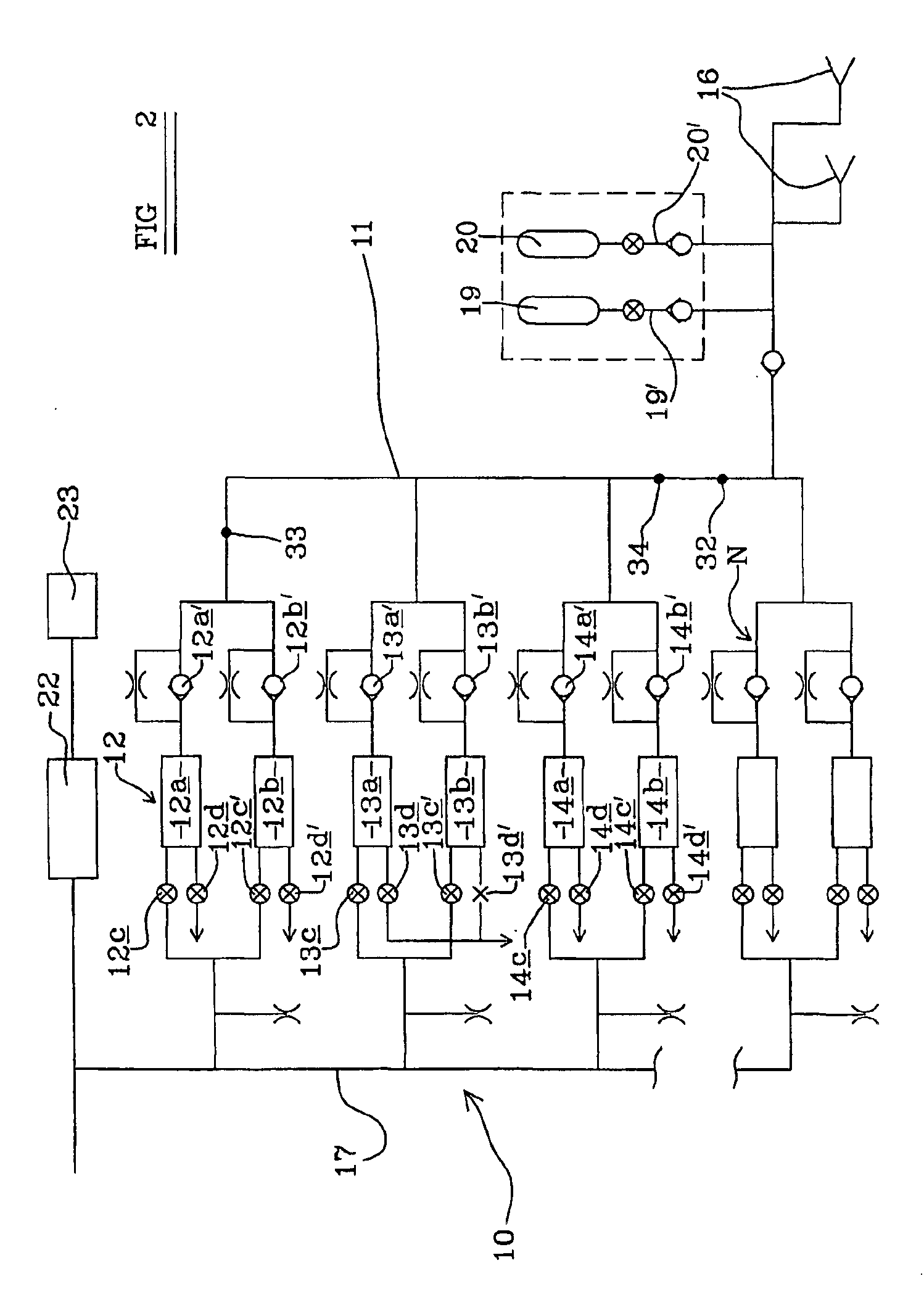

Plasma-assisted processing in a manufacturing line

InactiveUS20060081567A1Arc welding apparatusSemiconductor/solid-state device manufacturingProduct gasManufacturing line

Owner:BTU INTERNATIONAL

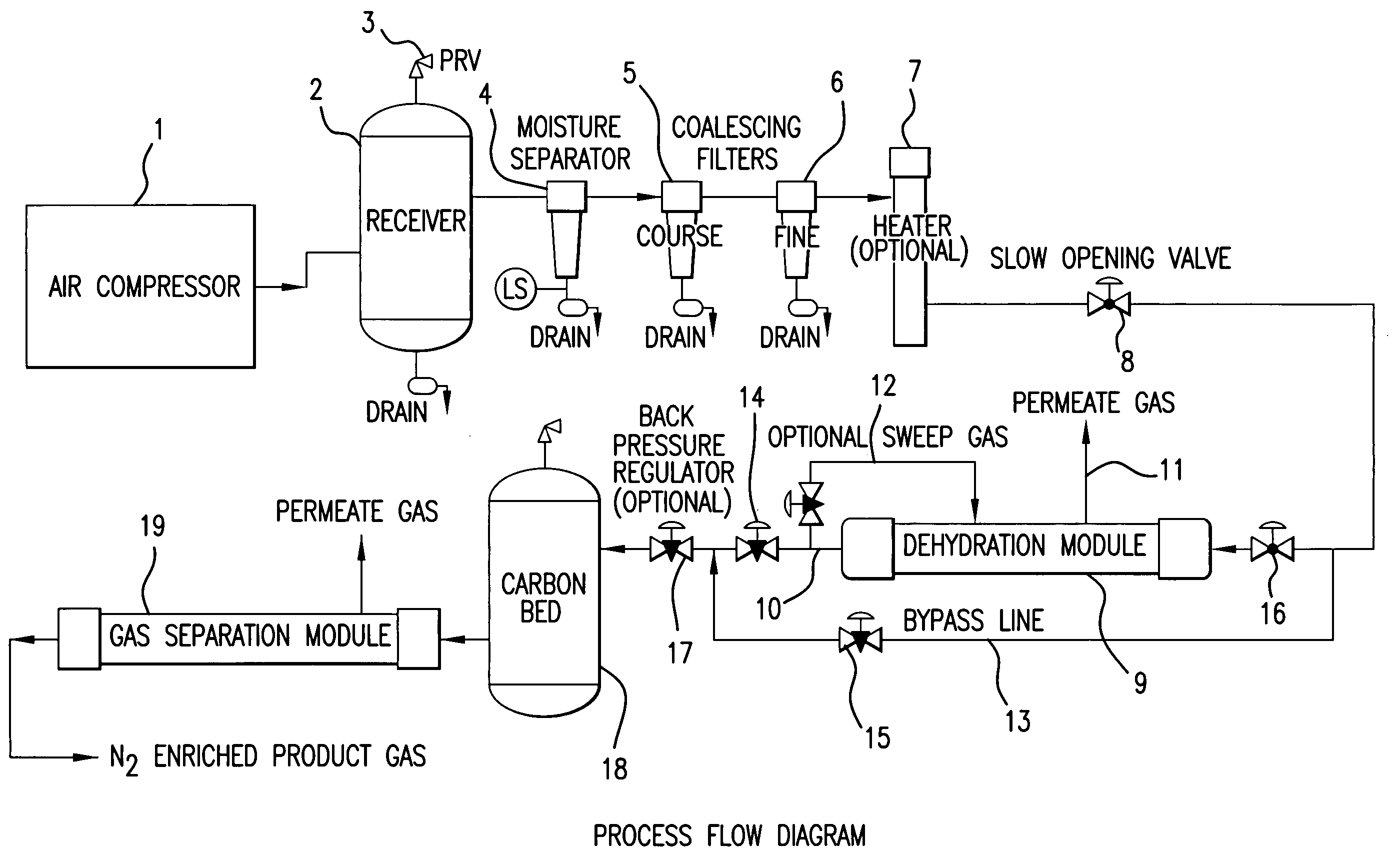

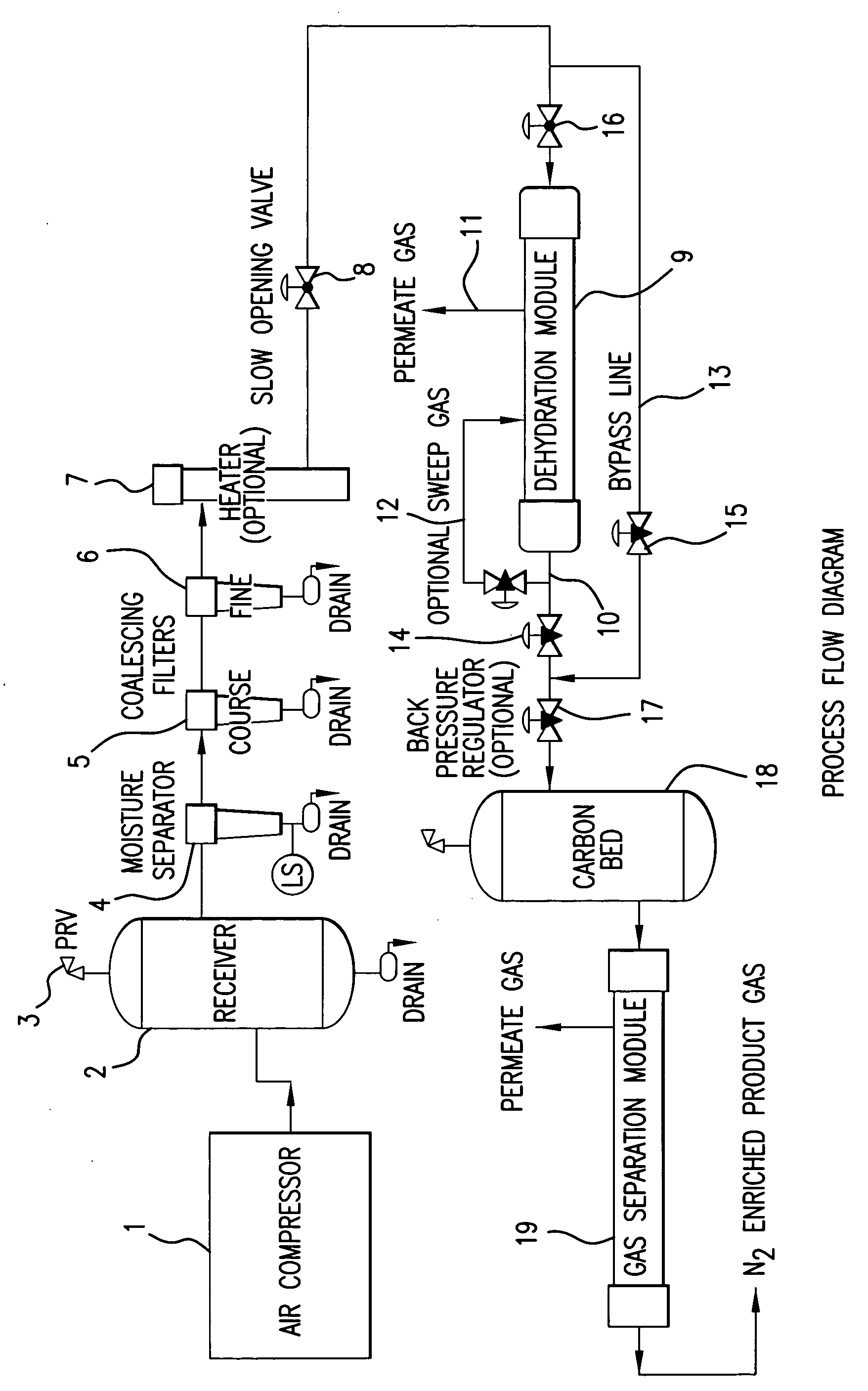

Air separation system using dehydration membrane for pretreatment of compressed air

Owner:GENERON IGS

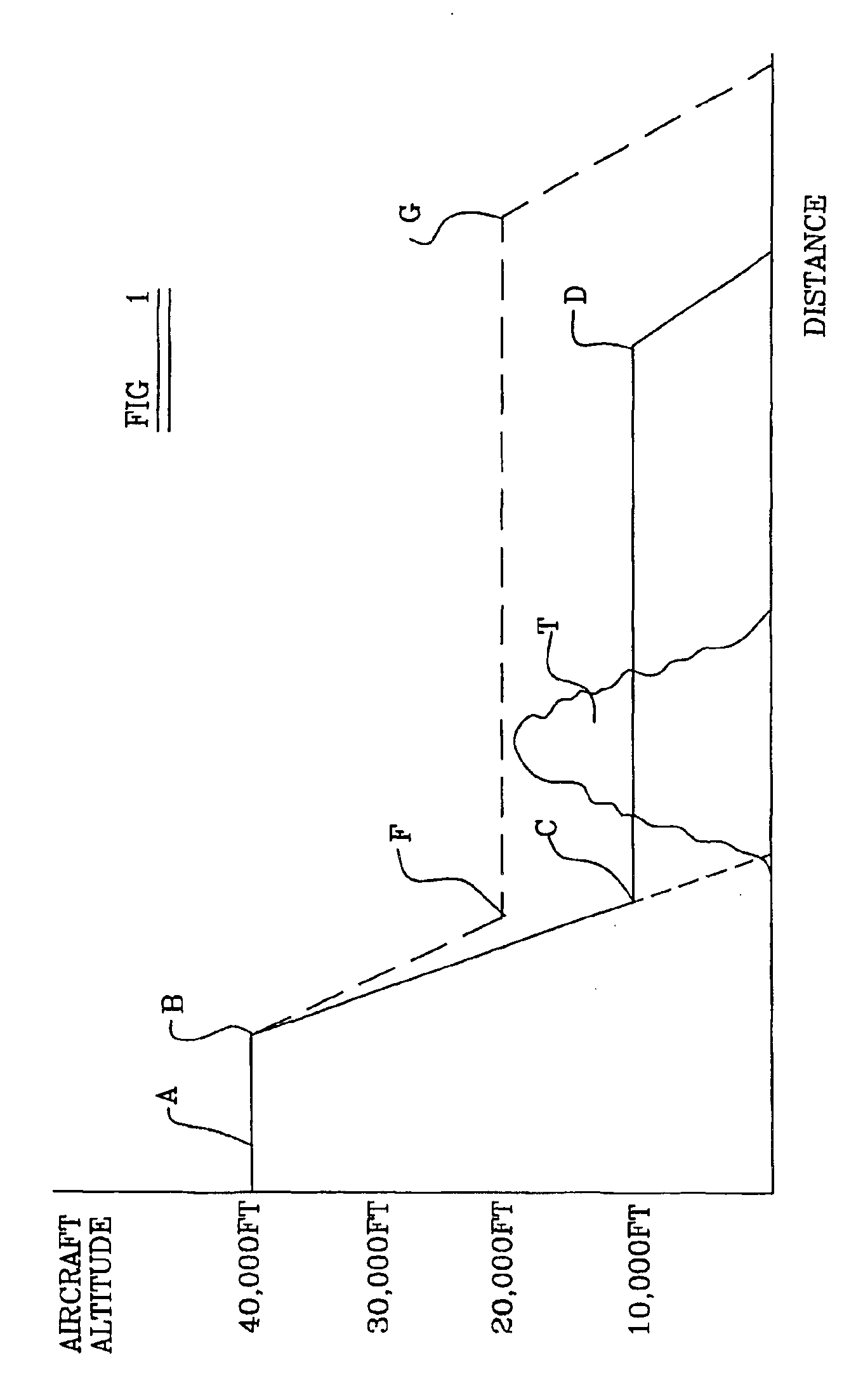

Compressed gas energy storage and release system

A compressed gas energy storage and release (CGESR) system and method. The system has a gas compressor, a container for storing compressed gas, a pressure engine, and an underground high temperature region. Conduits connect the gas compressor, the container and the pressure engine. The compressed gas drives the pressure engine. An electrical power generating means is operatively connected to said pressure engine to generate electricity. The system further comprises a means to heat at least a portion of one of the conduits utilizing heat from the underground high temperature region to heat the compressed gas therein prior to driving the pressure engine.

Owner:DE CHABRIS ANDREW MARKS

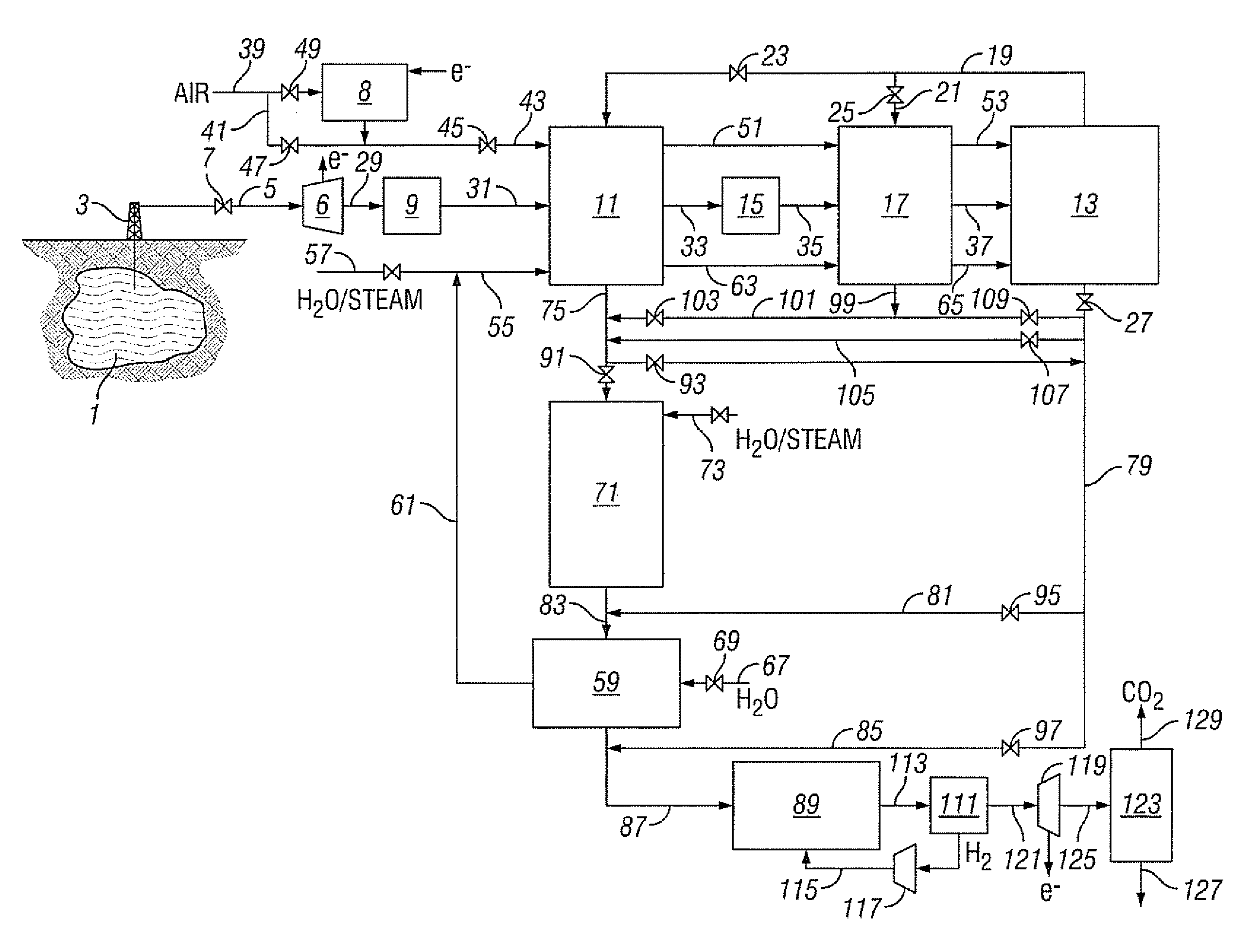

Method for recovering a natural gas contaminated with high levels of co2

Owner:SHELL OIL CO

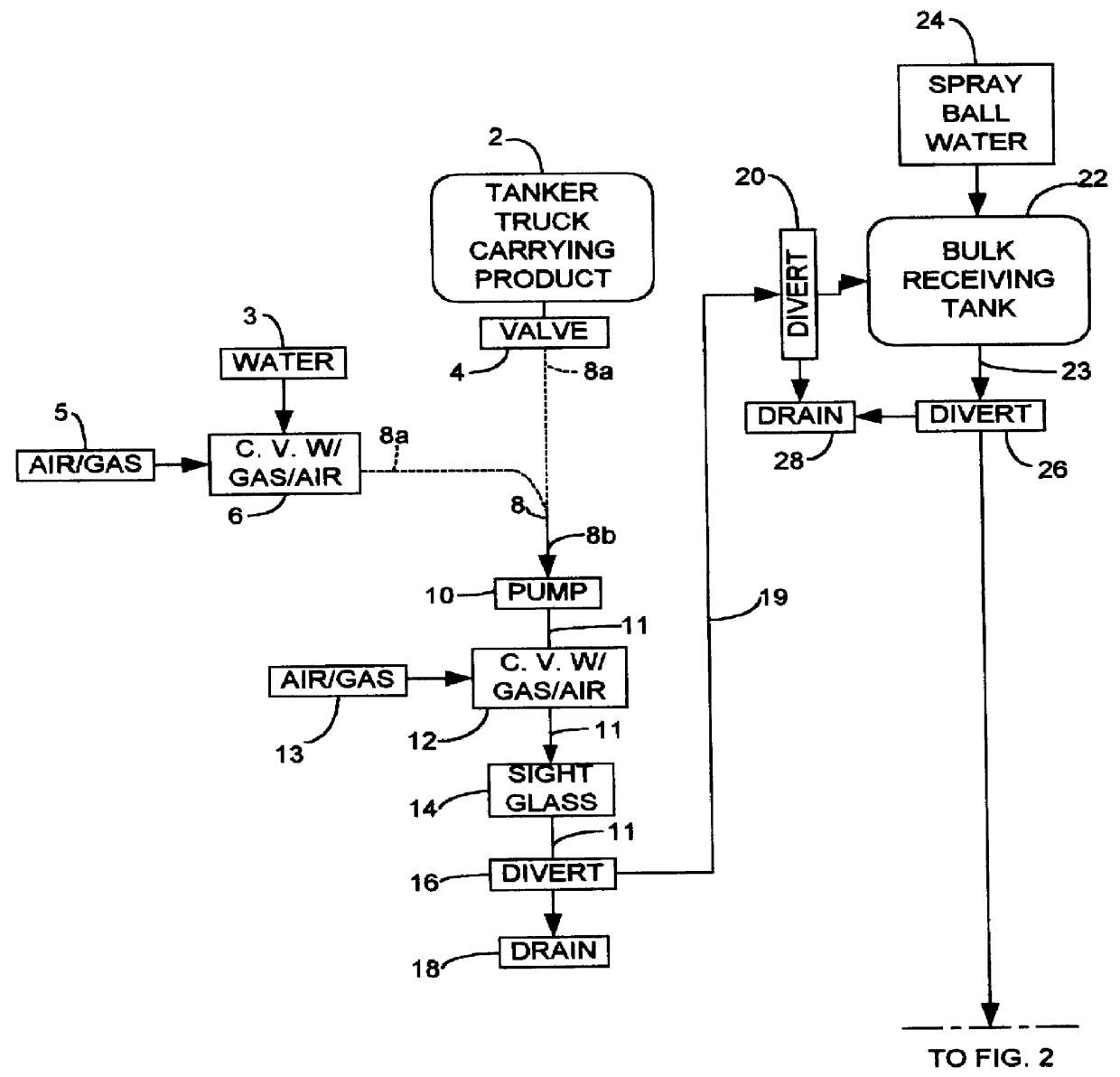

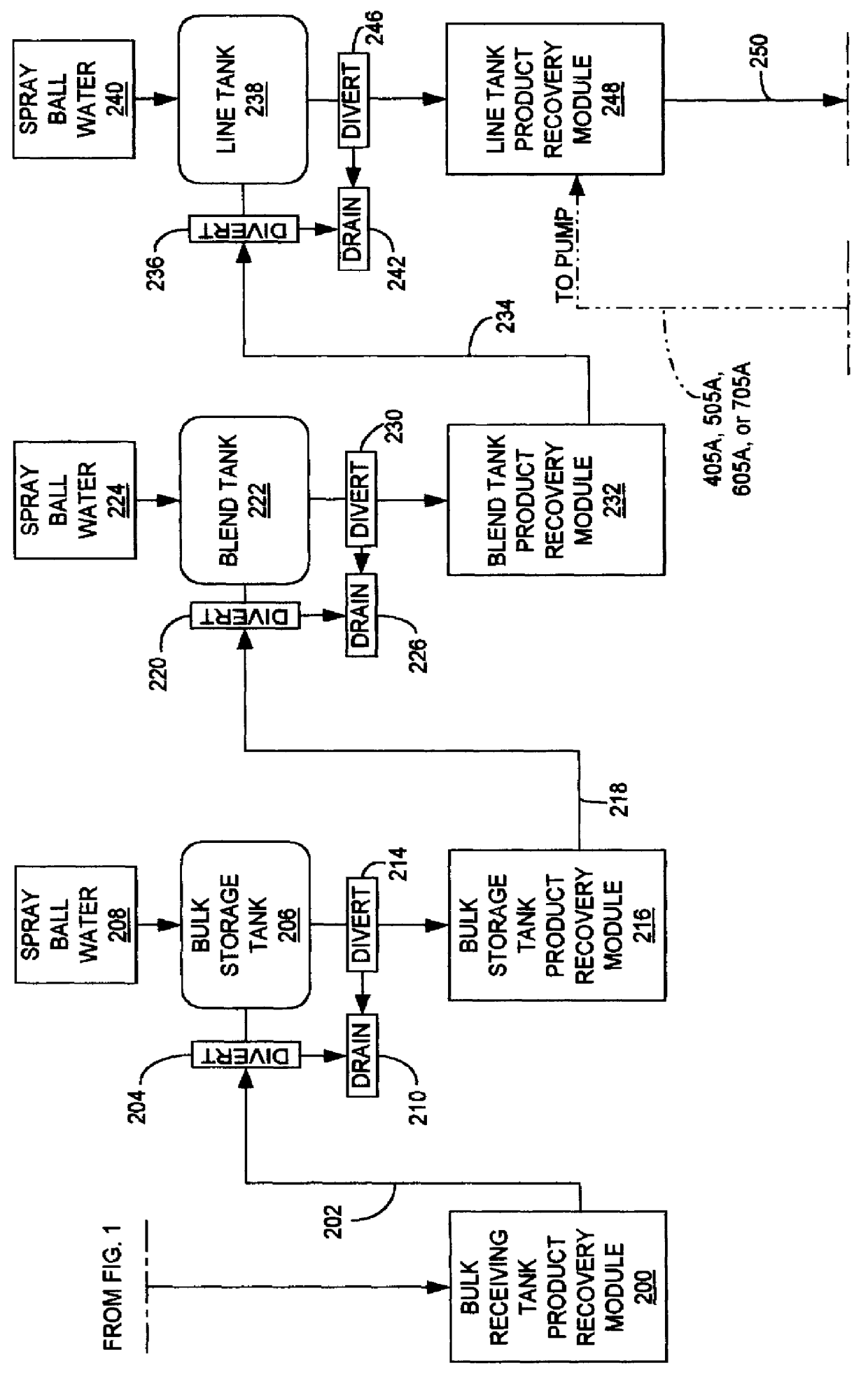

Method and apparatus for a product recovery system

Owner:KIHOLM INDS

Method for degrading malodorous gas by coupling biotrickling filter with dielectric barrier discharge

ActiveCN104128083AIncrease concentrationEasy to handleDispersed particle separationAir quality improvementProduct gasEnvironmental engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

Efficient molding core production method for water glass sand blowing hardening

InactiveCN105665646ASolve the overblowing problemReduce the amount addedFoundry mouldsFoundry coresAmorphous siliconProduct gas

The invention discloses a high-efficiency core-making method for blowing and hardening water glass sand. The original sand, water glass for casting and non-crystalline silicon oxide are mixed by a sand mixer to obtain a core sand mixture, and then the mold-making The core sand mixture is filled into the mold by a core shooter or manually, and the CO blowing is used to 2 CO 2 The gas is blown into the cavity of the mold for blowing hardening, the blowing pressure is 0.1-0.4Mpa, the blowing time is 5-200s, and CO blowing 2 After the gas is finished, replace the compressed air, blow the compressed air into the mold cavity, the blowing pressure is 0.1-0.4Mpa, blow the compressed air for 10-200s, and the mold is ejected after the blowing is completed. The present invention can solve the problem of water glass sand blowing CO 2 The overblowing problem of the method can be solved, and the added amount of water glass can be reduced by more than 50%, and the mechanical properties of the manufactured core can be significantly improved at the same time.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

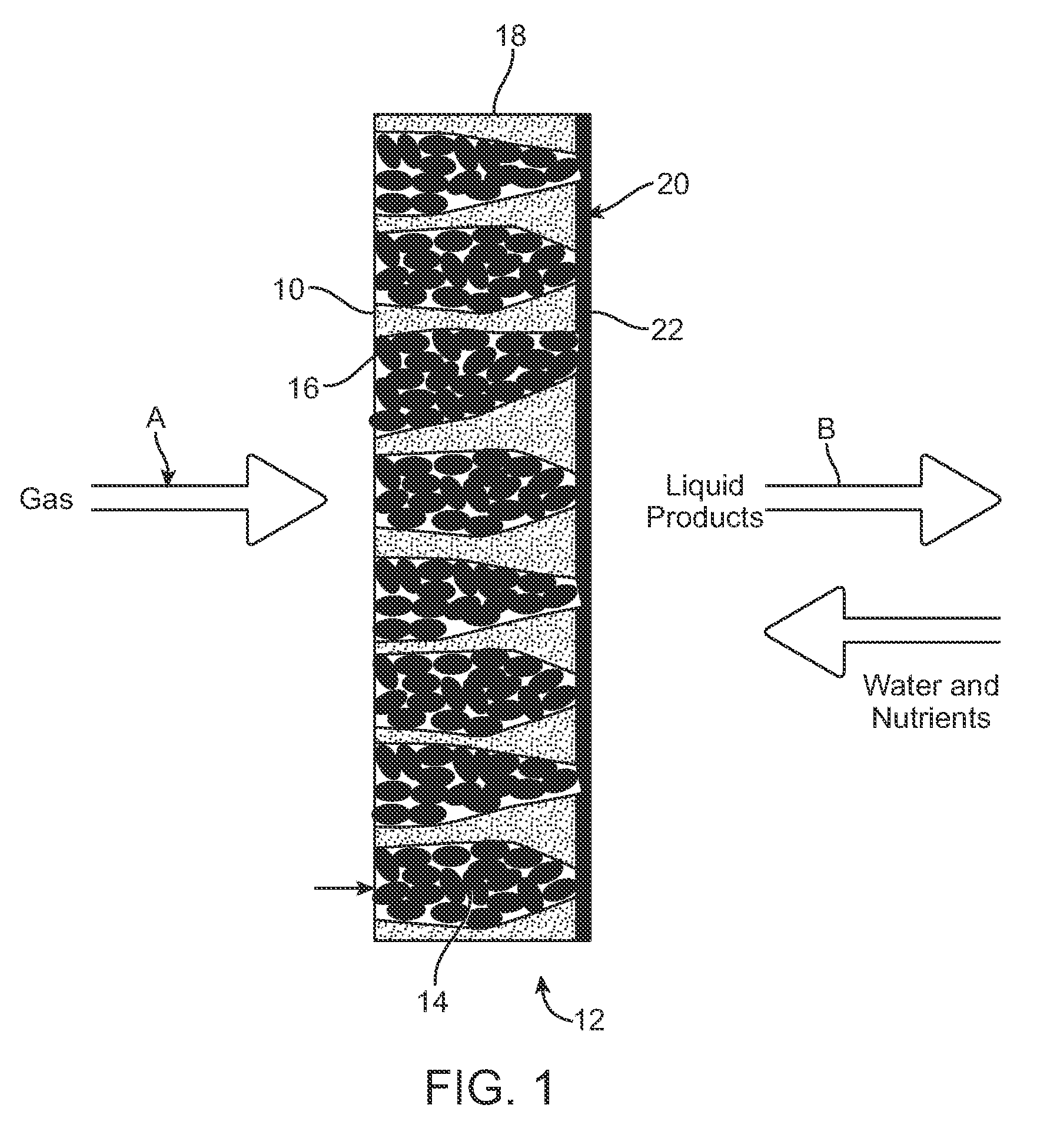

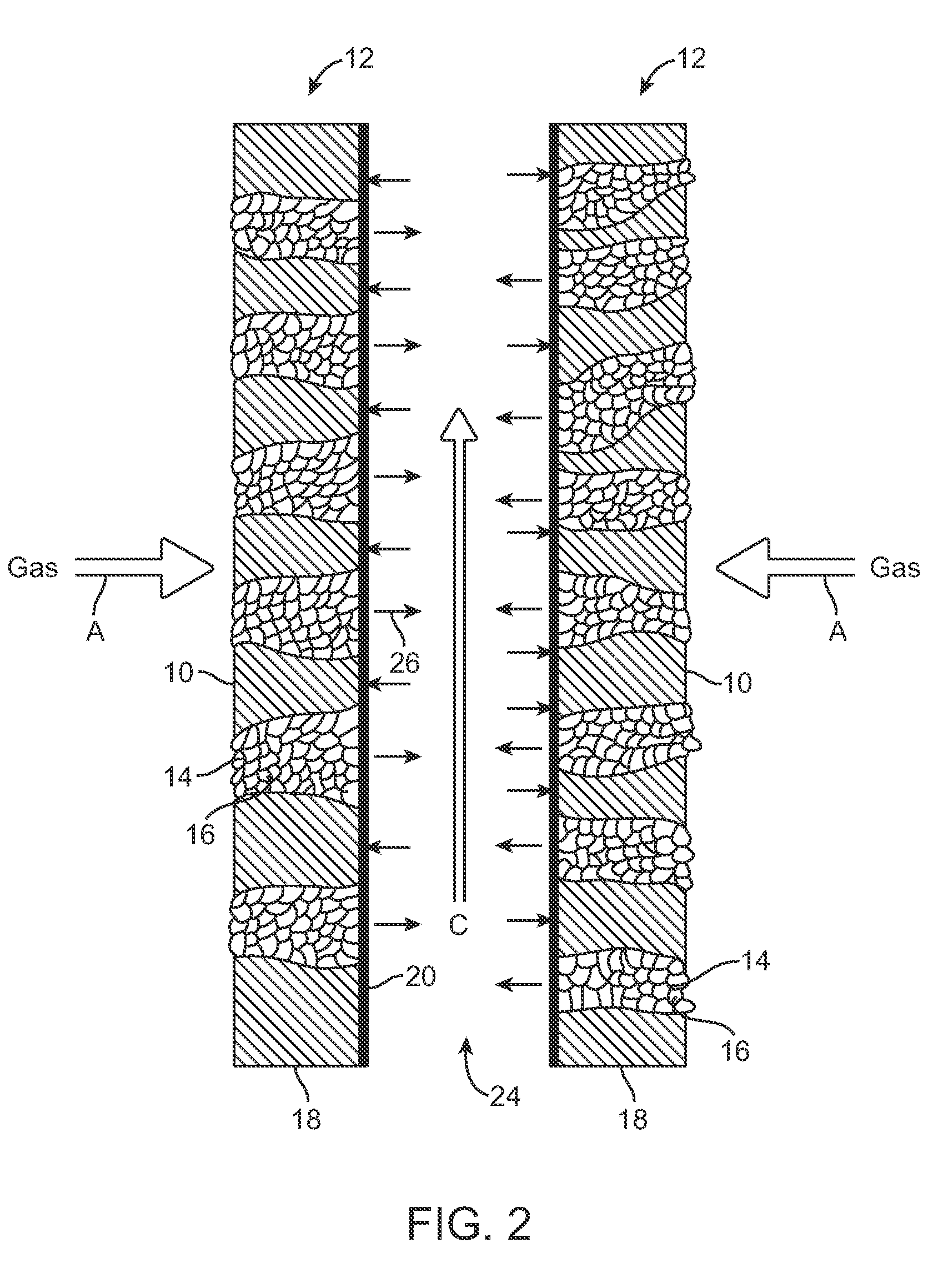

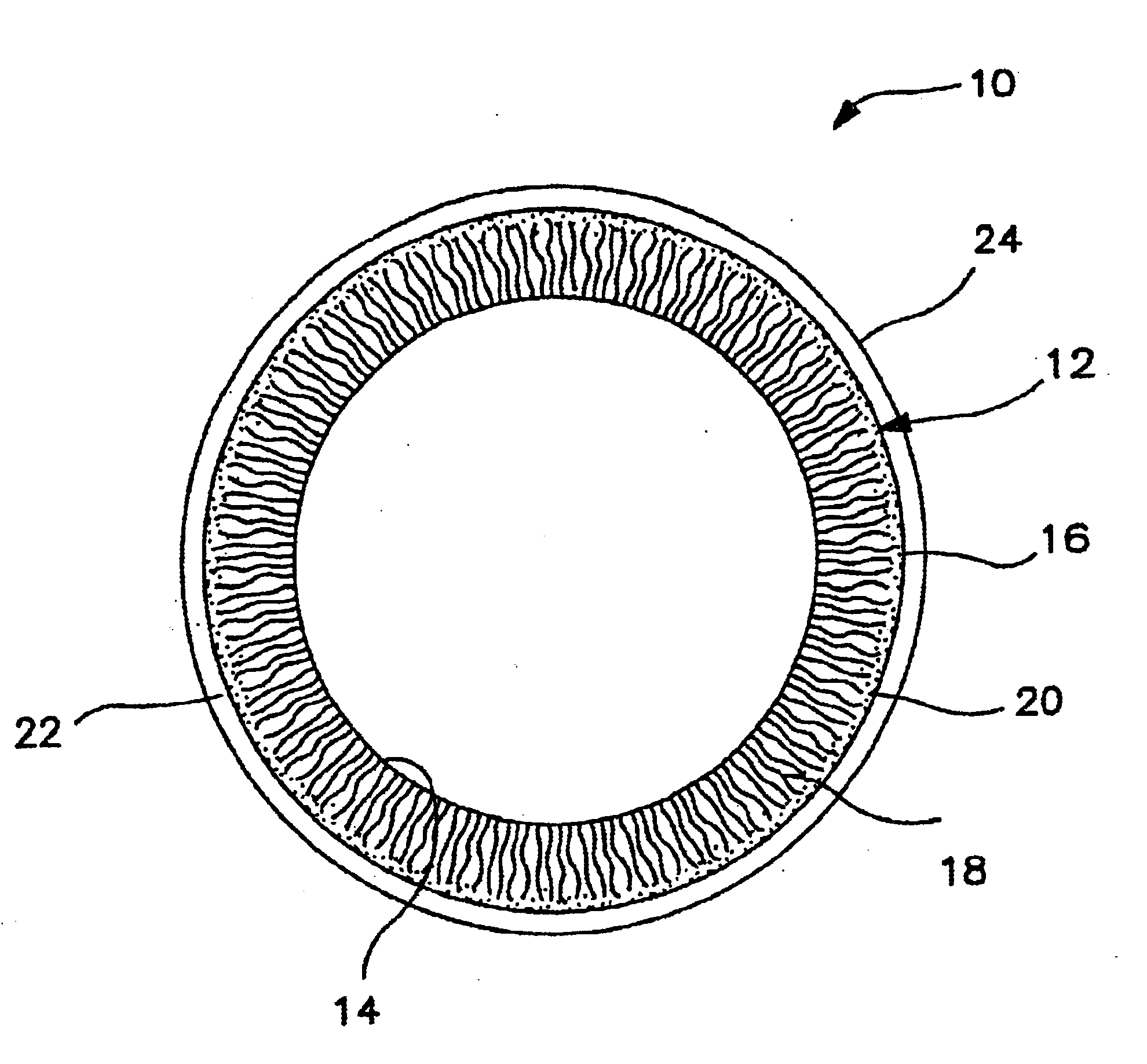

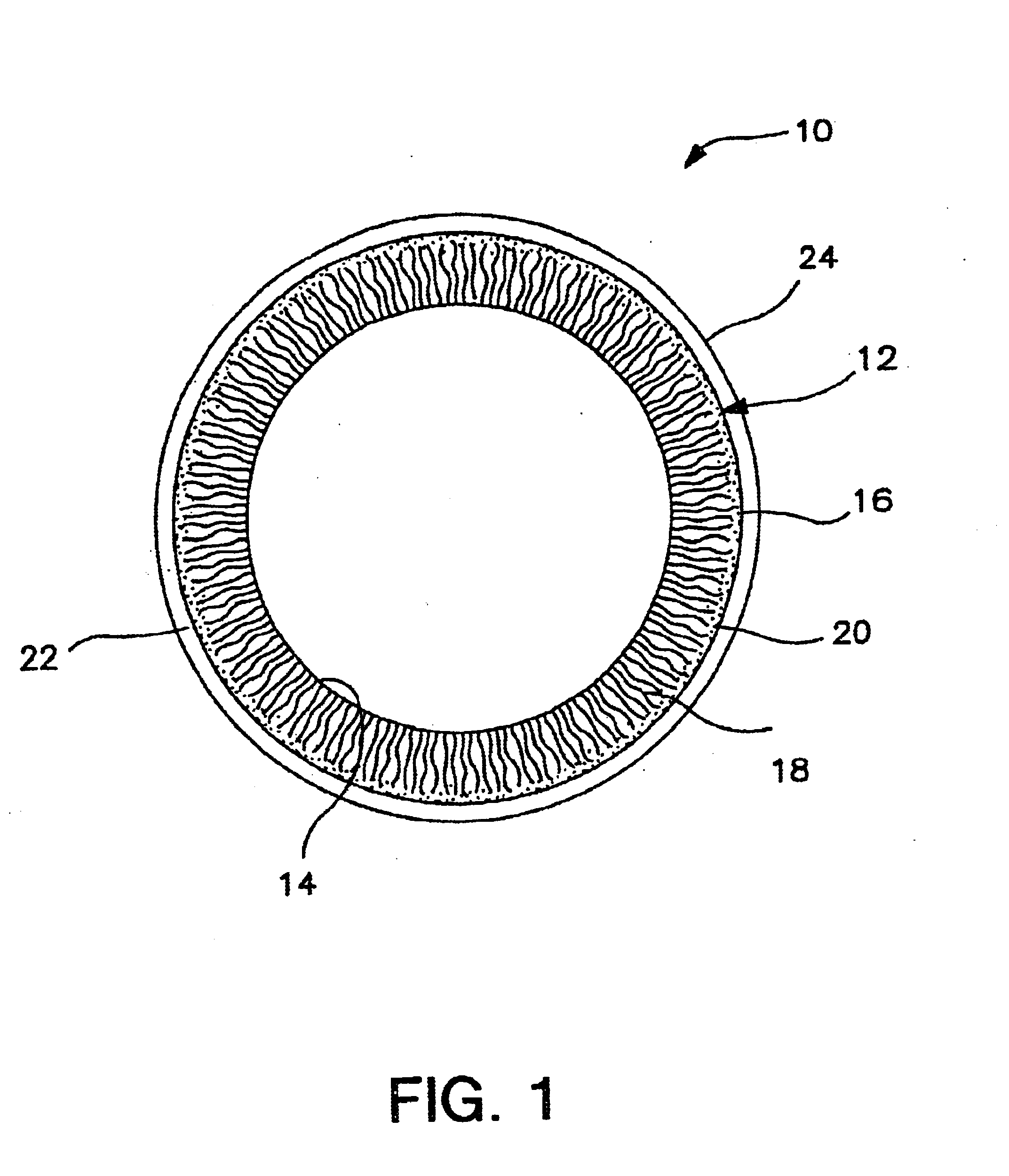

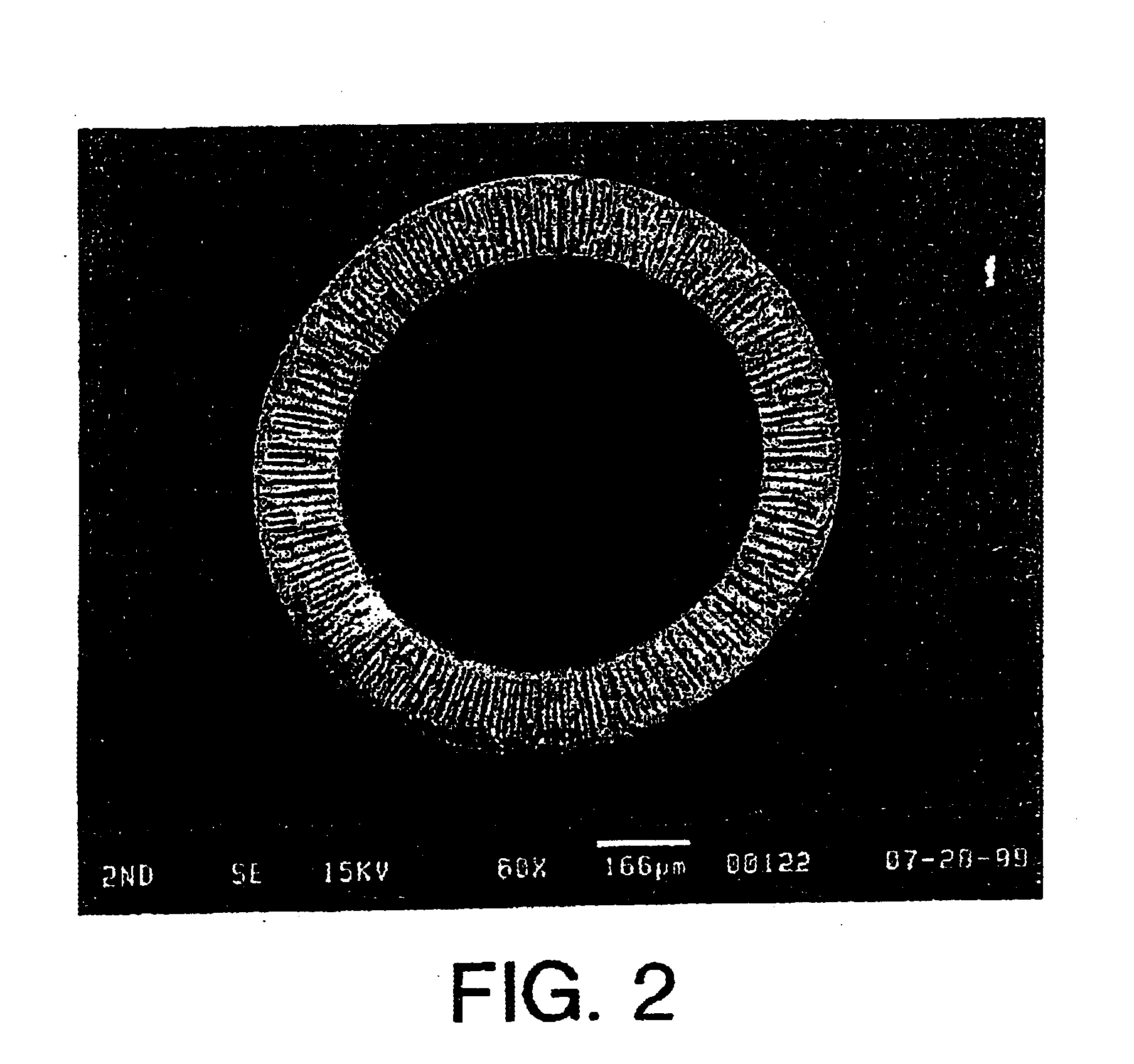

Stacked Array Bioreactor for Conversion of Syngas Components to Liquid Products

InactiveUS20090215153A1Promote and controlLess permeabilityBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid productFiber

Owner:SYNATA BIO INC

Catalyst for oxidative dehydrogenation of raw materials containing CO (carbon monoxide) gas

InactiveCN102649055ACarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsLoss rateAdditive ingredient

The invention relates to a catalyst for oxidative dehydrogenation of raw materials containing CO (carbon monoxide) gas, which mainly solves the technical problems in the prior art that the hydrogen removal rate is low, and the loss rate of CO is high. The catalyst comprises a carrier, an active component and an accessory ingredient in percentage by weight: (a) the active component which is selected from at least one of platinum metals, and has the dosage being 0.003-2 percent of the weight of the catalyst in a metering manner of a simple substance; (b) the accessory ingredient which is selected from at least one of Pr, Nd, Cs and Ba, and has the dosage being 0.005-15 percent of the weight of the catalyst in a metering manner of a simple substance; and (c) 84-99.5 percent of carrier, wherein the carrier is selected from a compound type carrier of aluminum oxide and silicon oxide, and the weight ratio of the aluminum oxide to the silicon oxide is 0.01-100:1. According to the technical scheme, the problems are better solved, and the catalyst can be applied in industrial production of oxidative dehydrogenation of raw materials containing the CO gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas detection system and method

An example of a gas detection system includes a gas chromatograph oven, a gas detector, a sample gas moving device, and a flow detector. An example of a method for detecting gas includes flowing a sample gas from the oven, determining whether the flow rate equals or is less than a minimum, and determining whether the concentration of a first gas of the sample gas, such as a combustible gas, equals or exceeds a maximum. If either the flow rate or the concentration indicates an error condition or is out of bounds, an alarm response is initiated. The alarm response may include shutting off the flow of the first gas to the oven, and flowing a second gas, such as a safe gas, to the oven.

Owner:BRUKER DALTONIK GMBH & CO KG

Gas-saving gas supercharger for secondary utilizing driving gas

Owner:DALIAN MARITIME UNIVERSITY

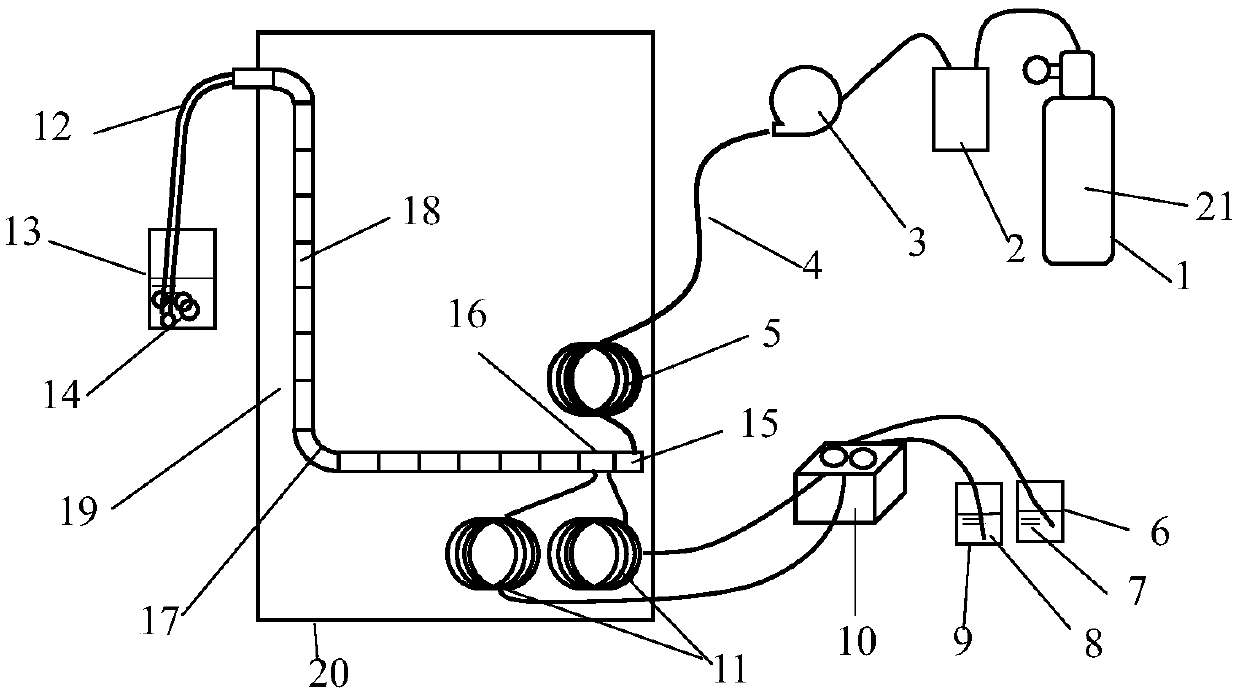

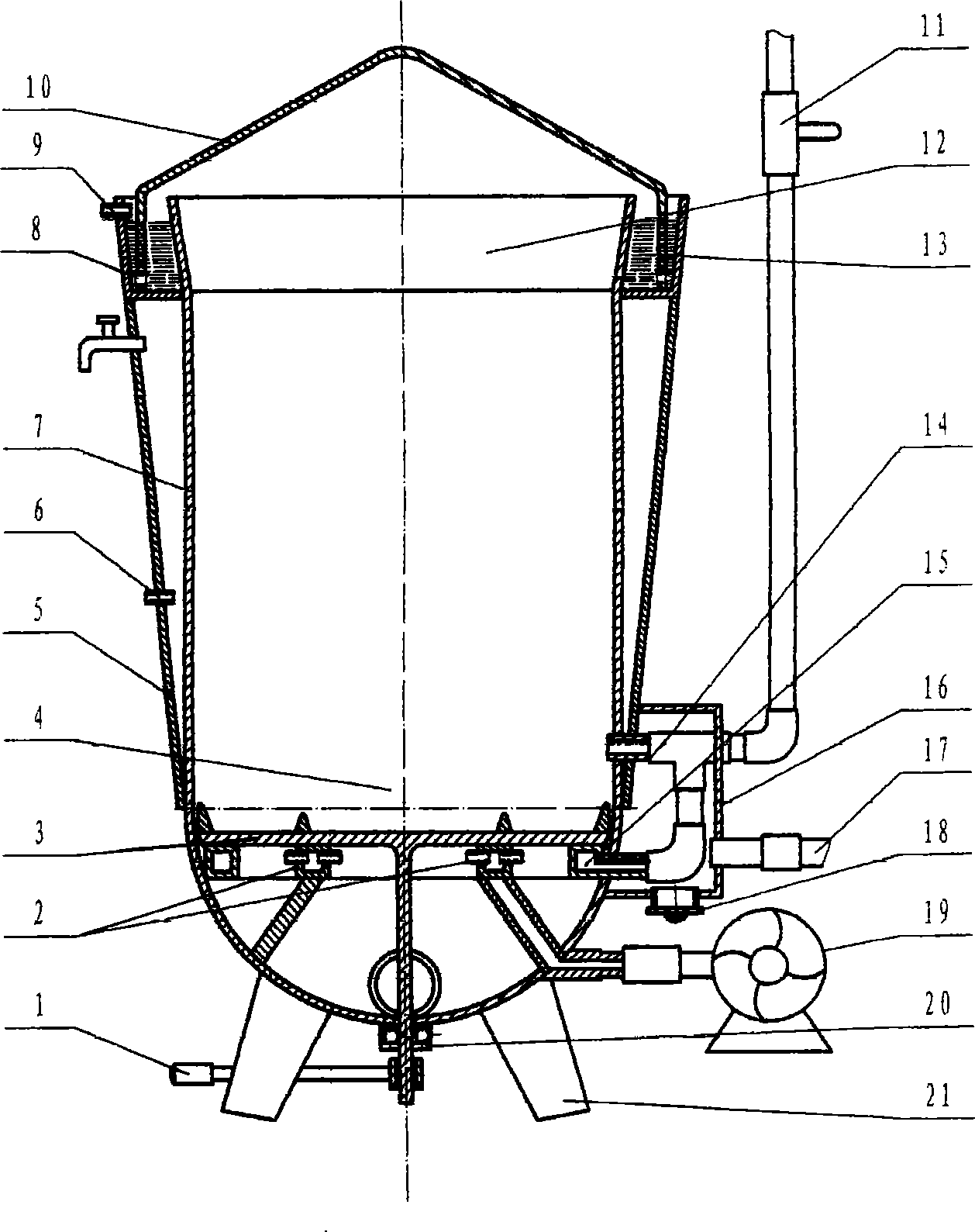

Experiment device for evaporating scaling risk of water production gas well shaft and method

ActiveCN108843314AEvaluation of foulingAssessing the risk of cloggingSurveySection planeCollection system

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

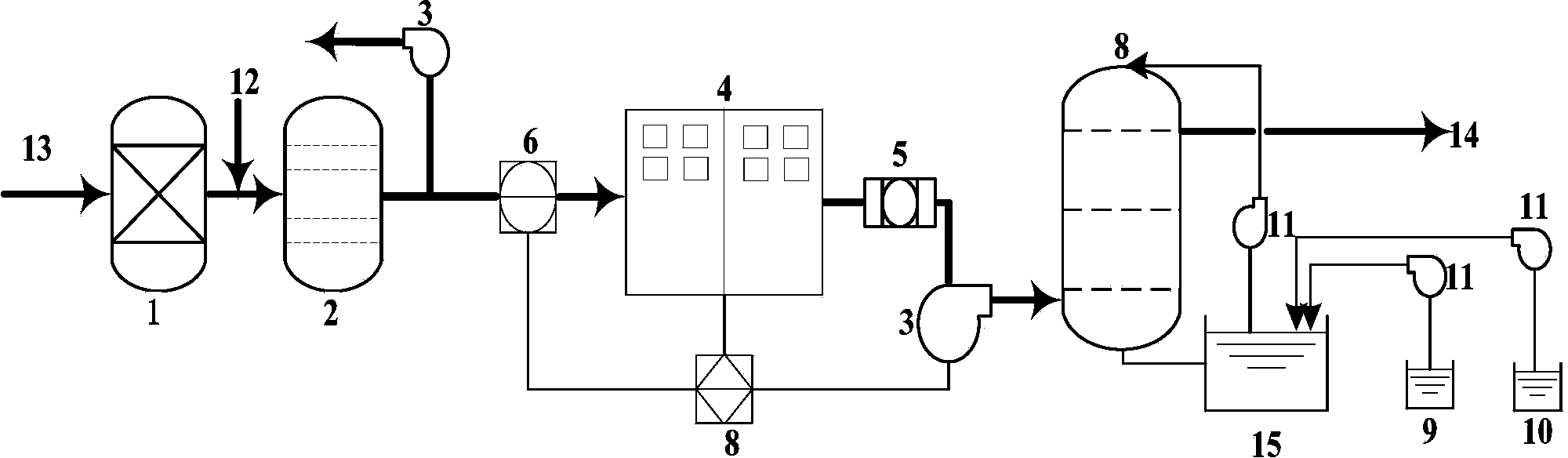

Industrial gas purification dust removal equipment

InactiveCN106731372ASimple structureEasy to useHuman health protectionCombination devicesParticulatesHEPA

The invention discloses industrial gas purification dust removal equipment, which comprises an air inlet pipeline, a cyclone separation tower, an electrostatic dust removal tower, a spraying tower, an activated carbon adsorption device and an air outlet pipeline, wherein the air inlet pipeline is arranged on an air inlet of the cyclone separation tower; a first centrifugal fan is arranged on the air inlet pipeline; an air outlet of the cyclone separation tower is connected with the air inlet of the cyclone separation tower; the air outlet of the cyclone separation tower communicates with an air inlet of the electrostatic dust removal tower; an HEPA (high efficiency particulate air) filtering net is arranged inside a pipeline for connecting the cyclone separation tower and the electrostatic dust removal tower; an air outlet of the electrostatic dust removal tower communicates with an air inlet of the spraying tower. The industrial gas purification dust removal equipment has the advantages that the structure is simple; the use is convenient; effective purification and dust removal can be performed on industrial waste gas; the purification effect is good; in addition, the environment pollution can be reduced; a protection effect is achieved on environment; meanwhile, industrial dust can be removed, so that the work environment of workers is more comfortable and healthy.

Owner:HEFEI QIFEI INFORMATION TECH CO LTD

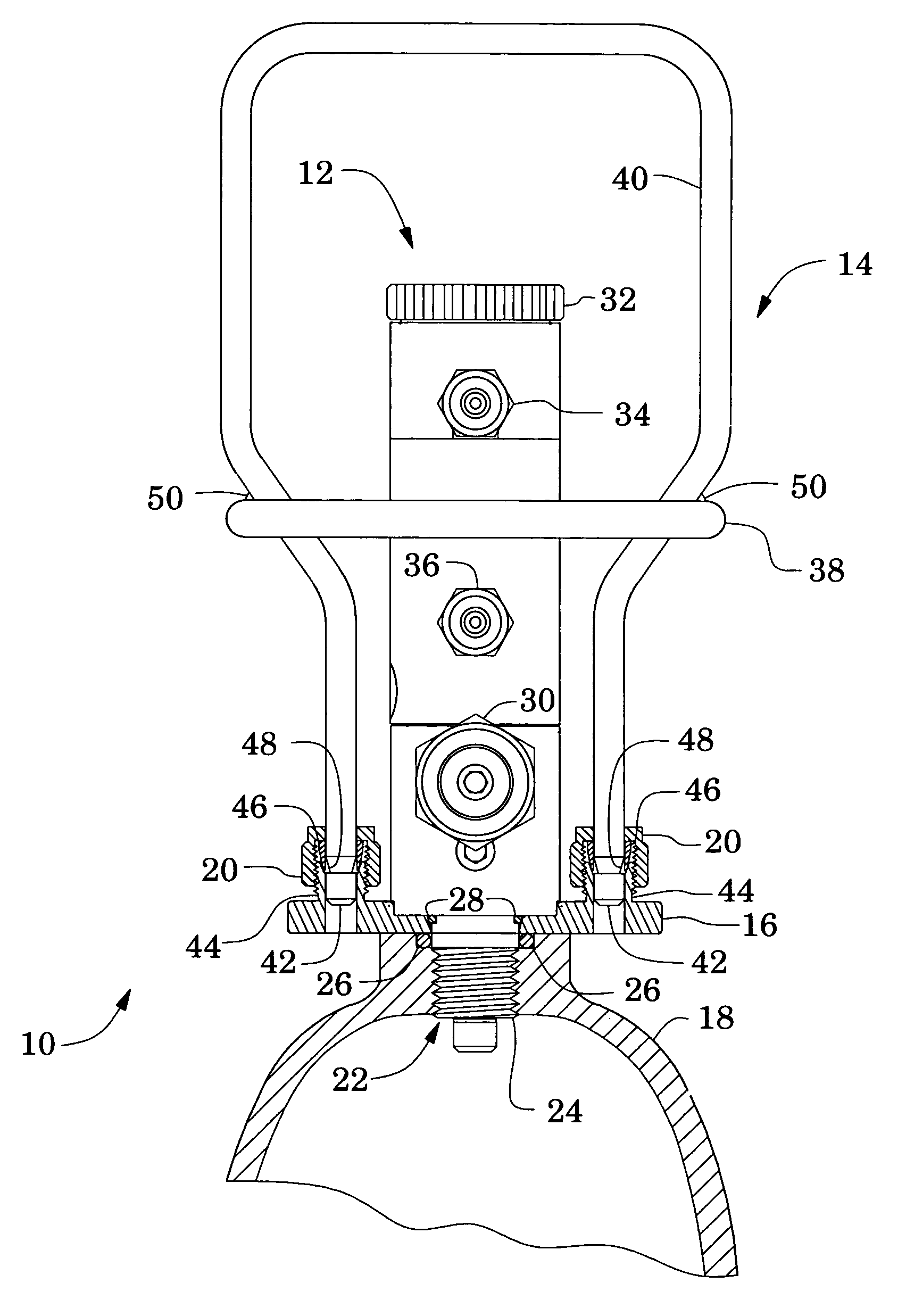

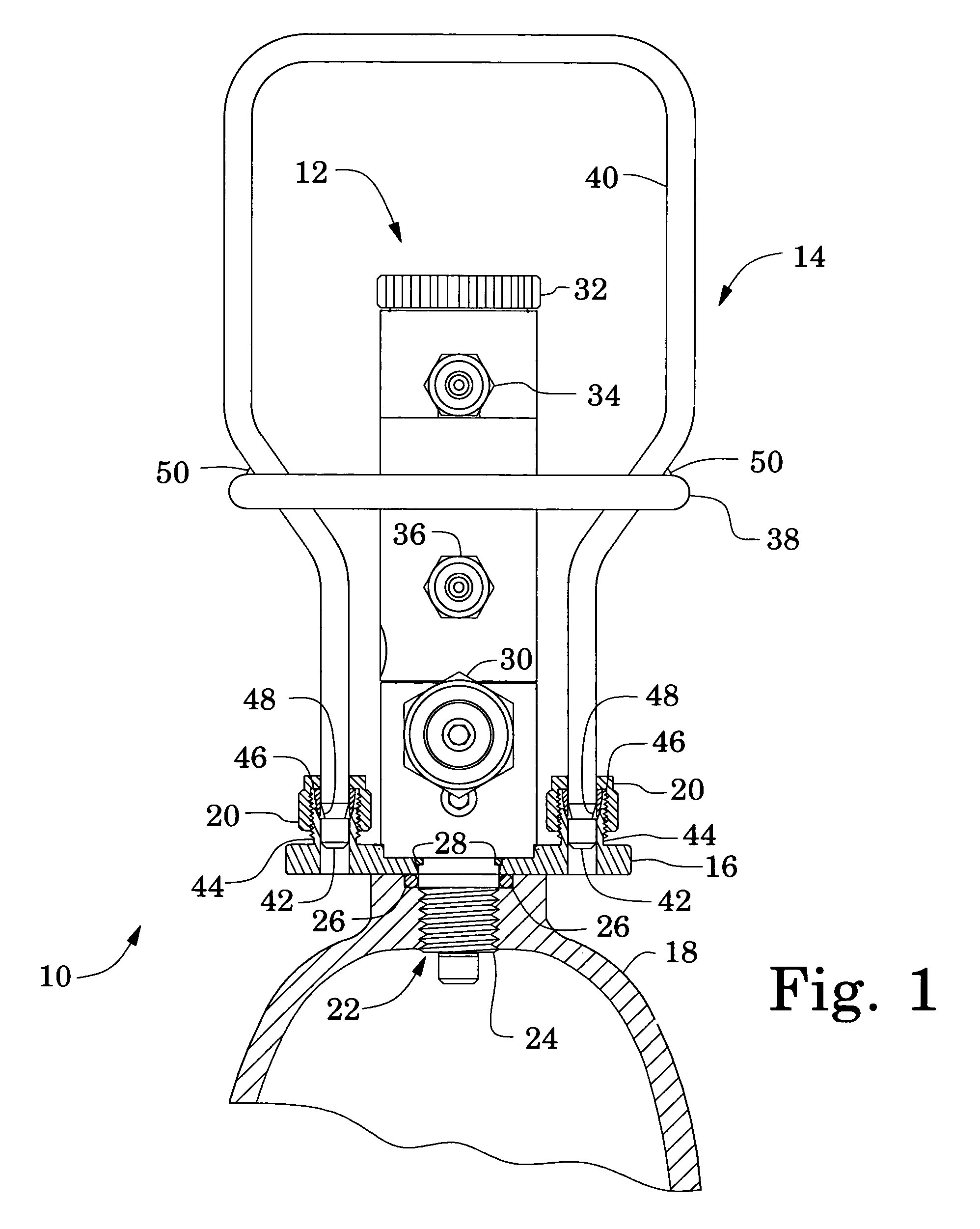

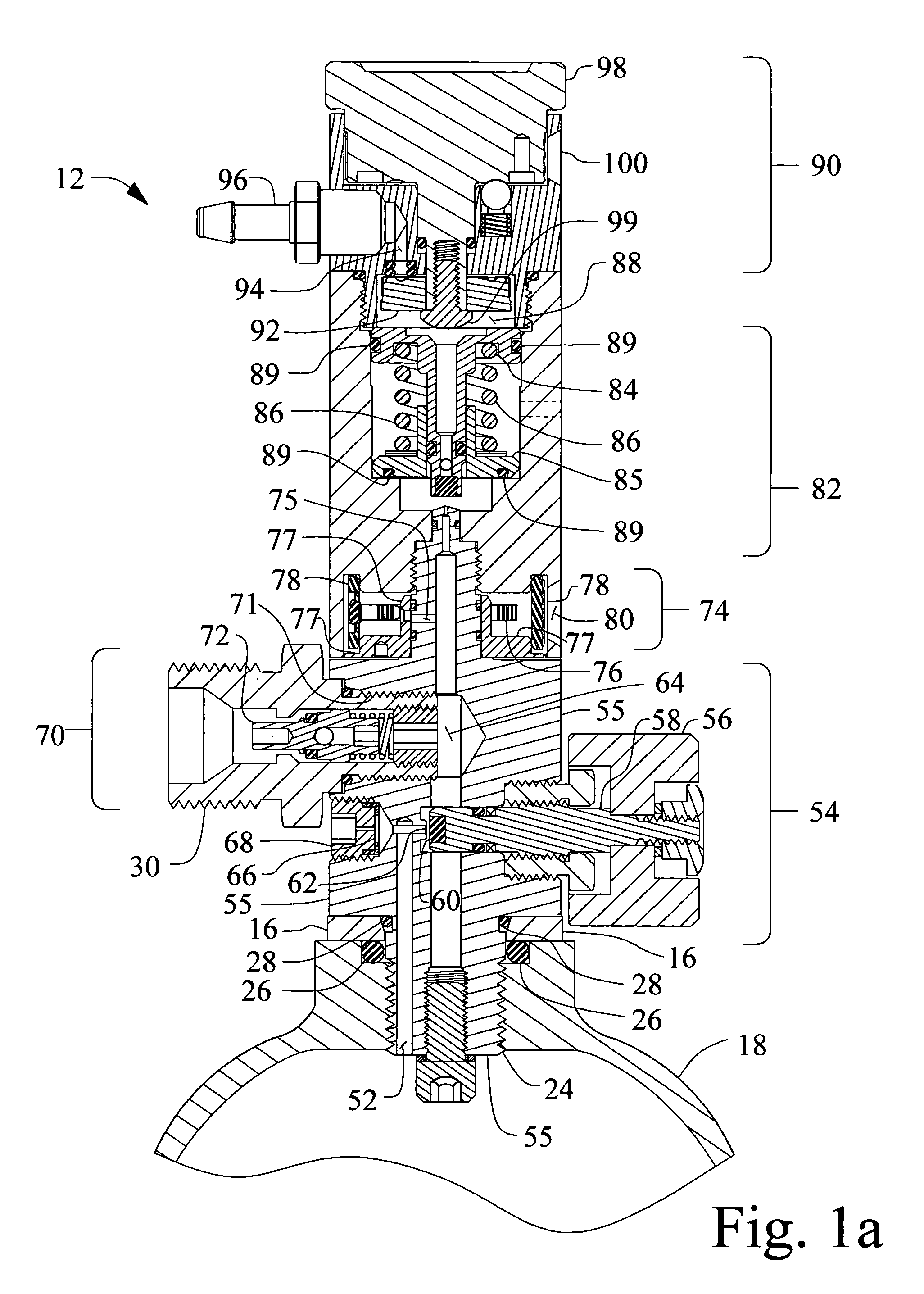

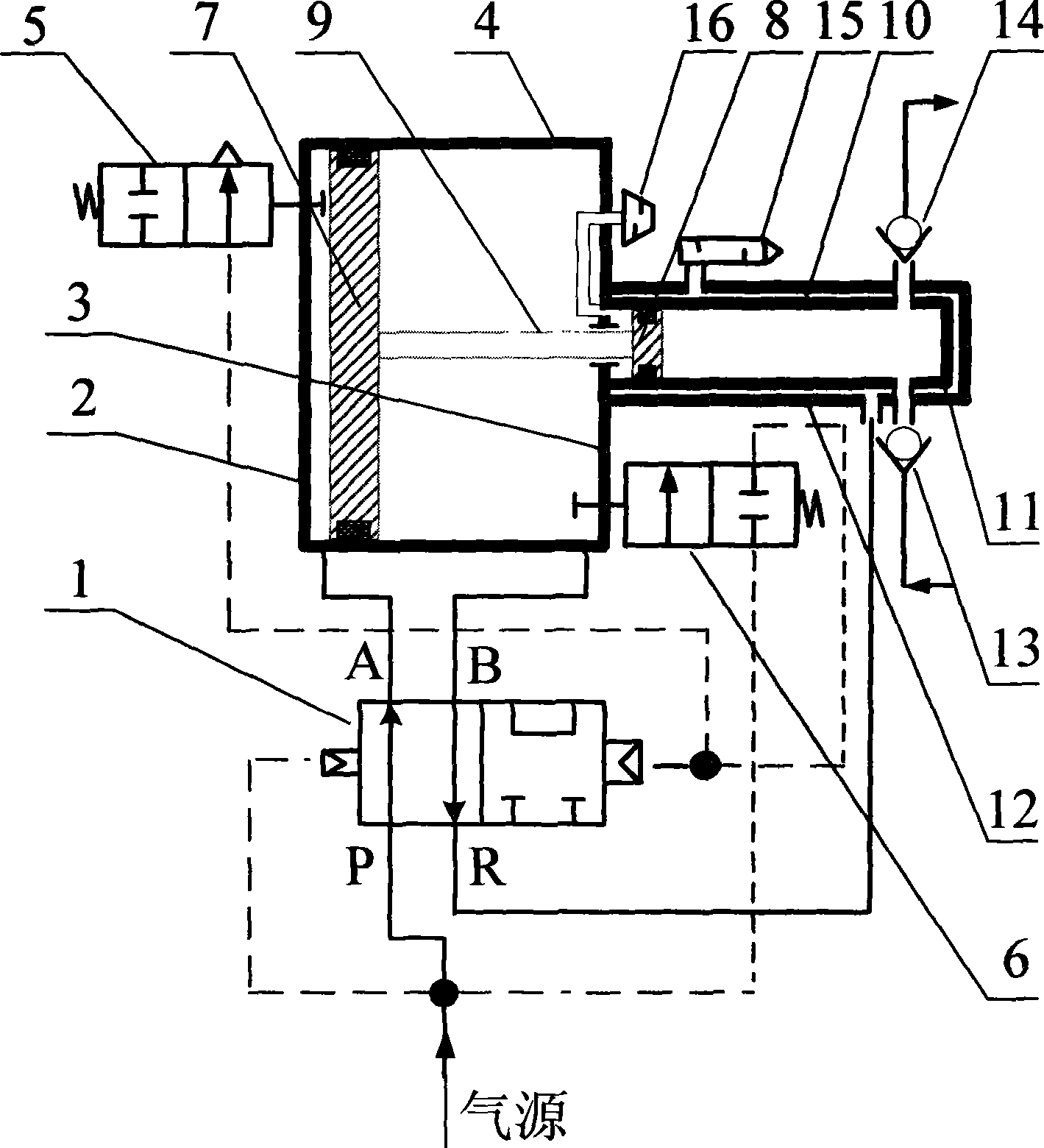

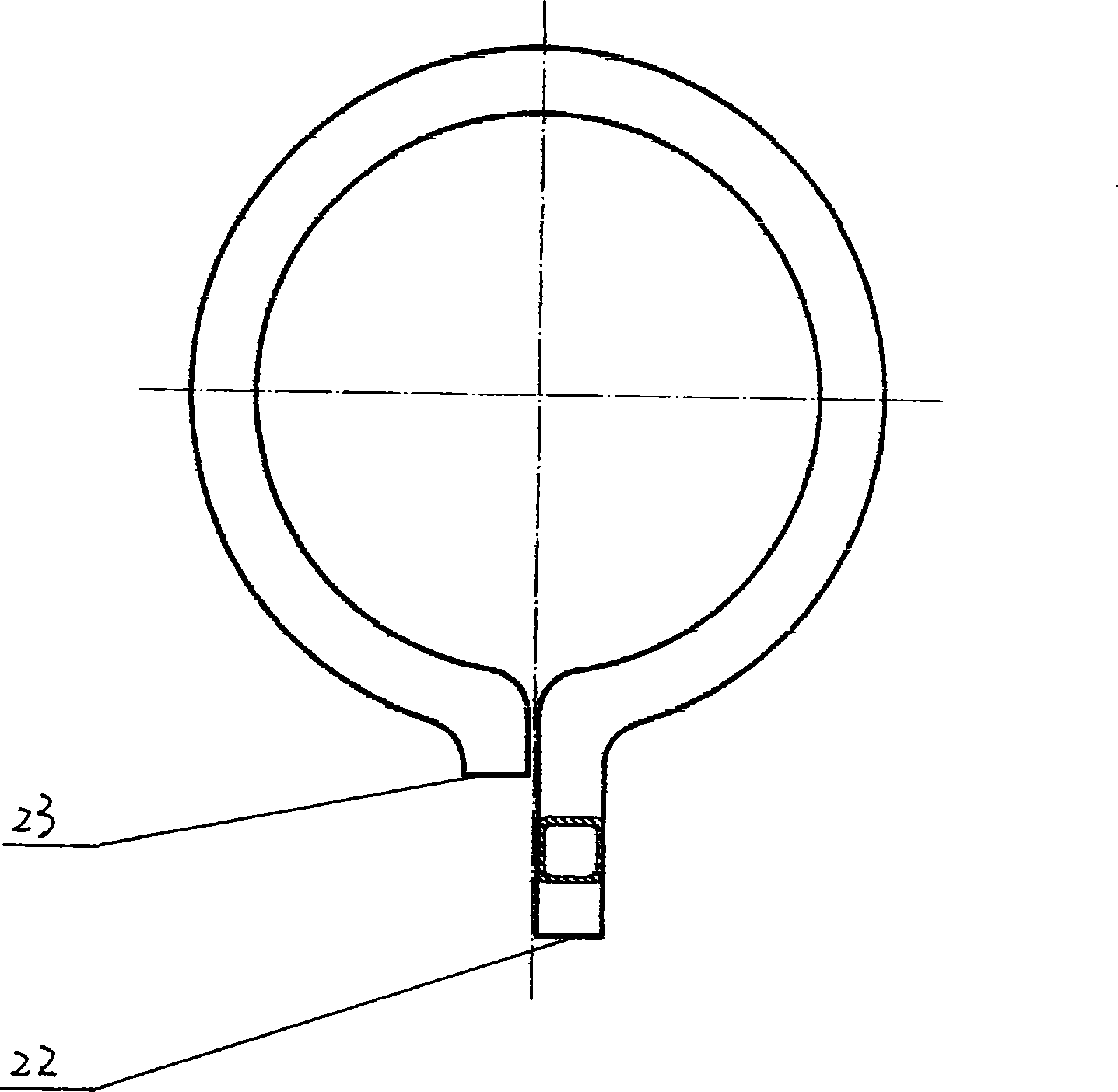

Method for fracturing coal seam by employing high-pressure gas

ActiveCN104405358ASolve the problem of air leakageGuaranteed gas pressureFluid removalSealing/packingParticulatesProduct gas

Owner:TAIYUAN UNIV OF TECH

Engine with intake air temperature control system

Owner:SOLAR TURBINES

Pulverization-free, dampness-resistant, coke tar-free biomass gasification oven preventing burning out

InactiveCN101240904AWide variety of sourcesWon't clogProductsDomestic stoves or rangesBiomass gasifierOxygen

Owner:沈桀

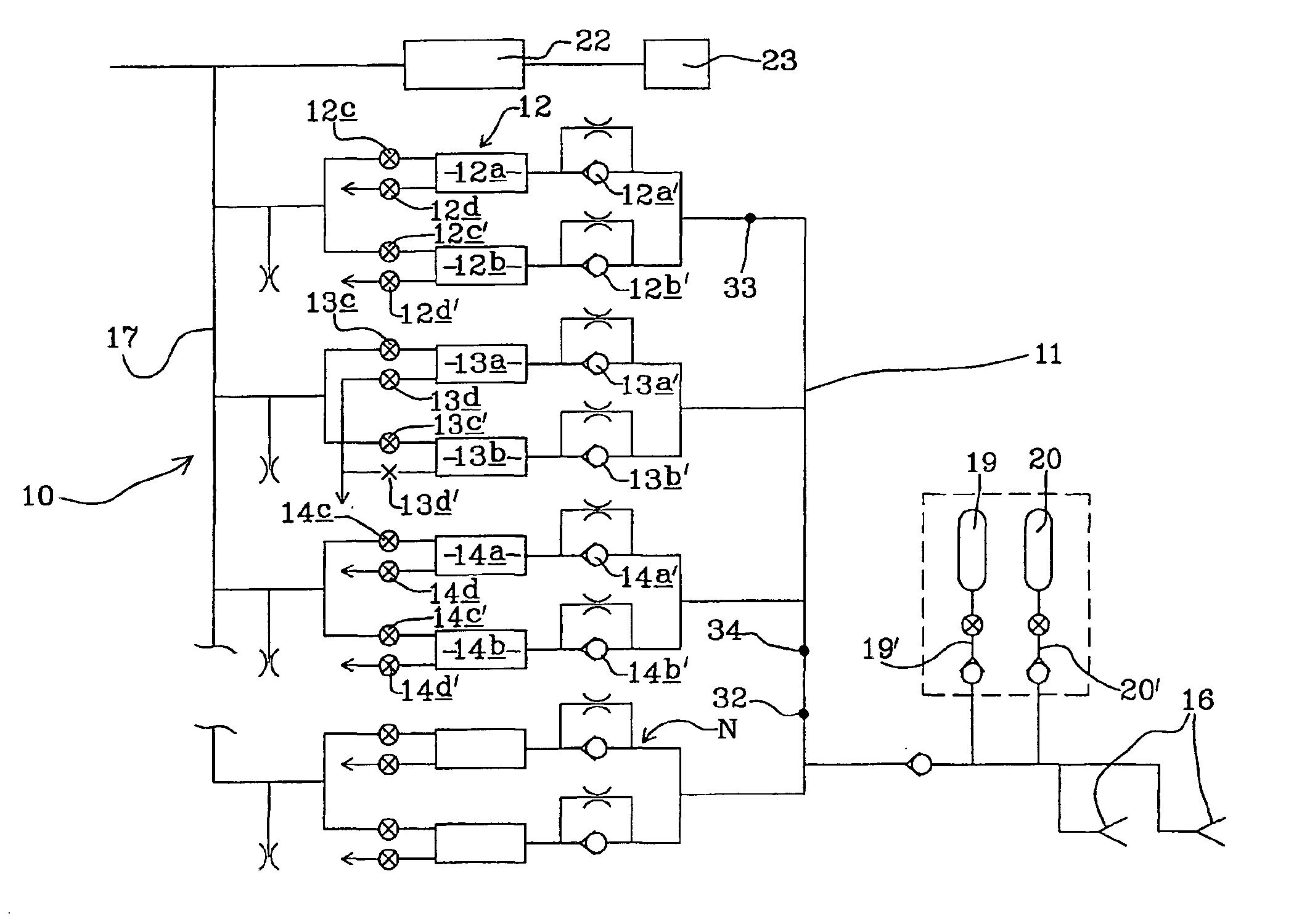

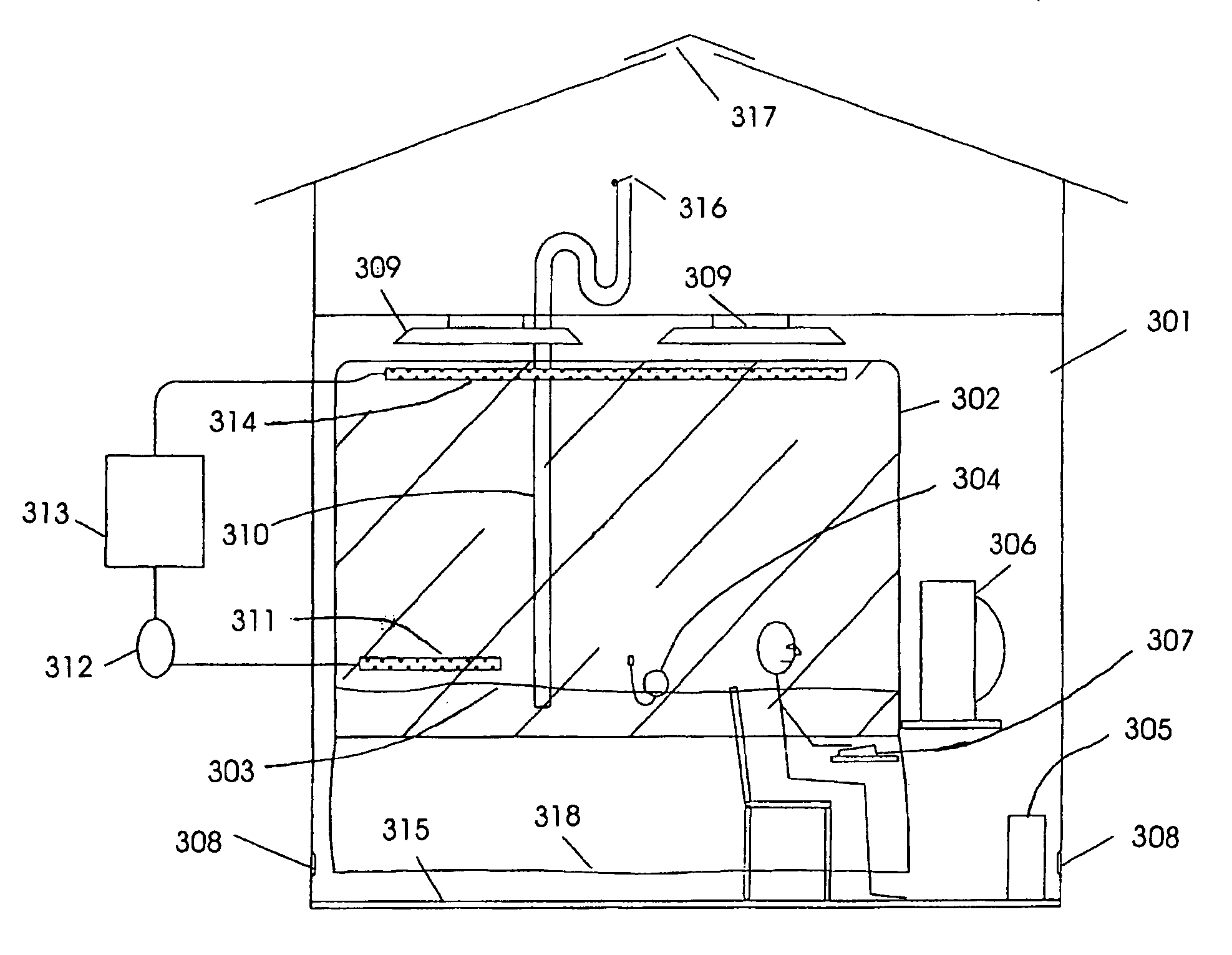

Life support system

InactiveUS6846347B2Reduce weightImprove securityDispersed particle filtrationAir-treatment apparatus arrangementsBreathing gasProduct gas

Owner:HONEYWELL NORMALAIR GARRETT HLDG

Method of preparing composite gas separation membranes from perfluoropolymers

InactiveUS6923846B2Enhances membrane productivityImproved gas permeation characteristicSemi-permeable membranesFibre treatmentFiberProduct gas

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Method for preparing lignose chitosan reaction film

Owner:NORTHEAST FORESTRY UNIVERSITY +2

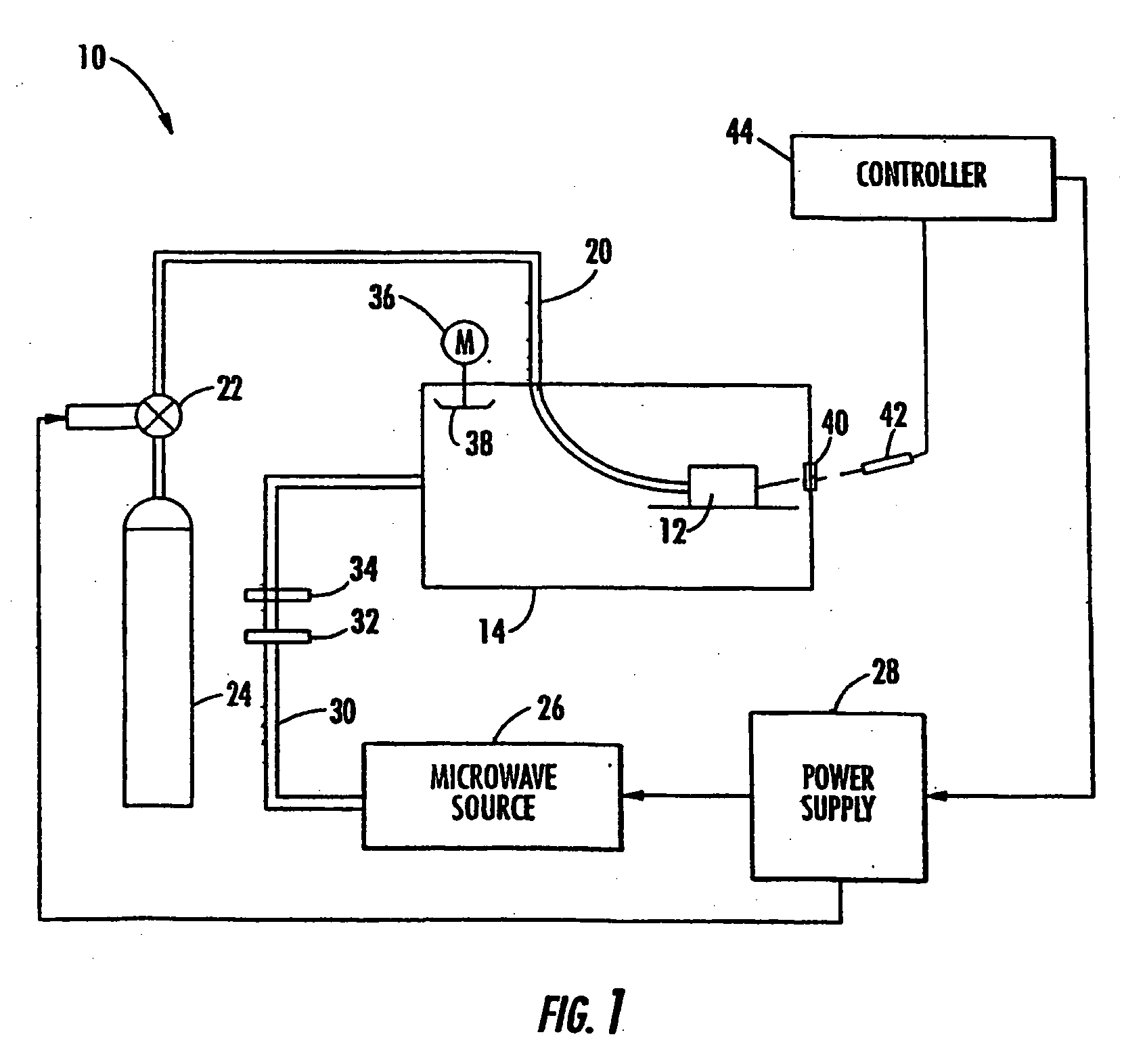

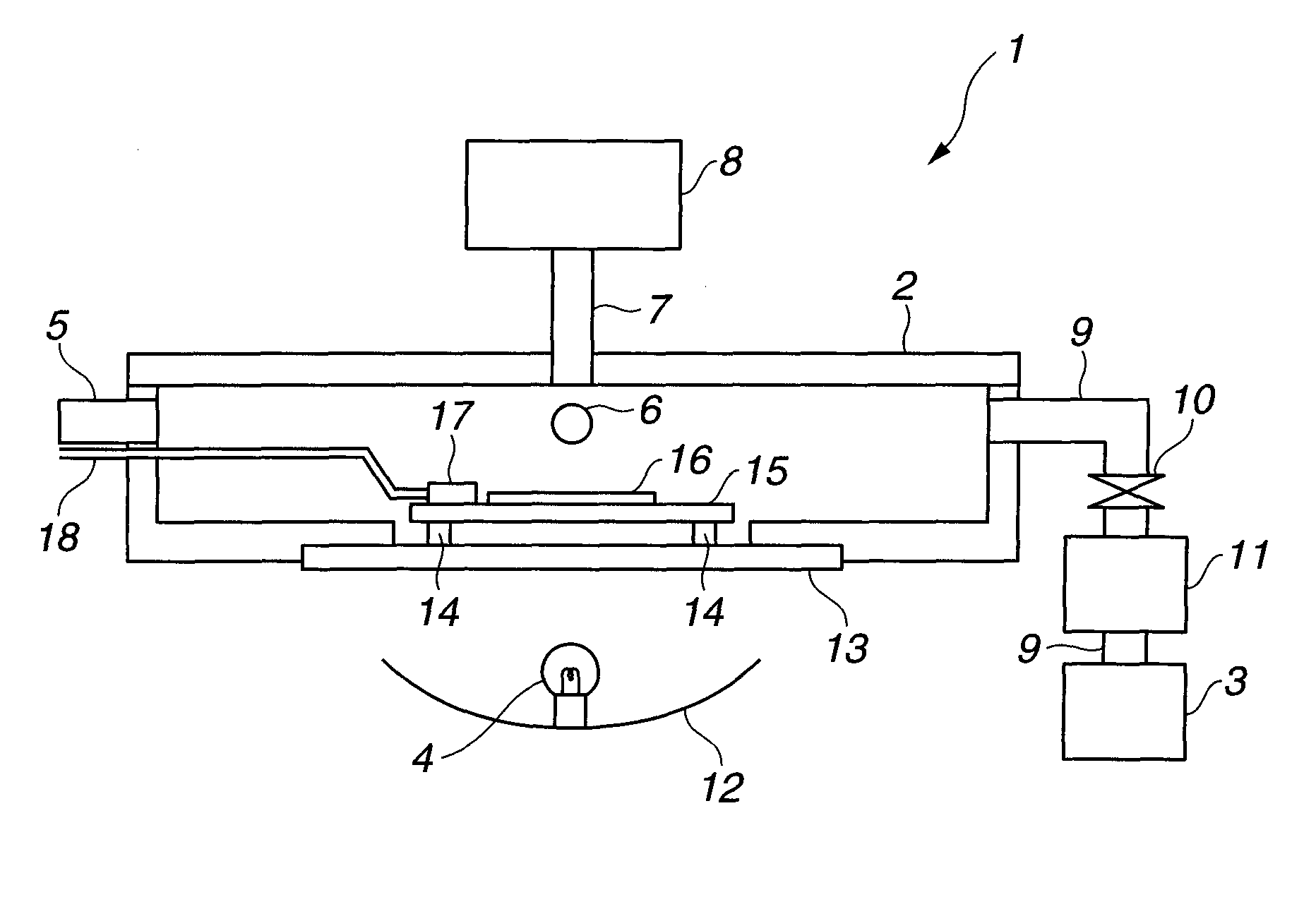

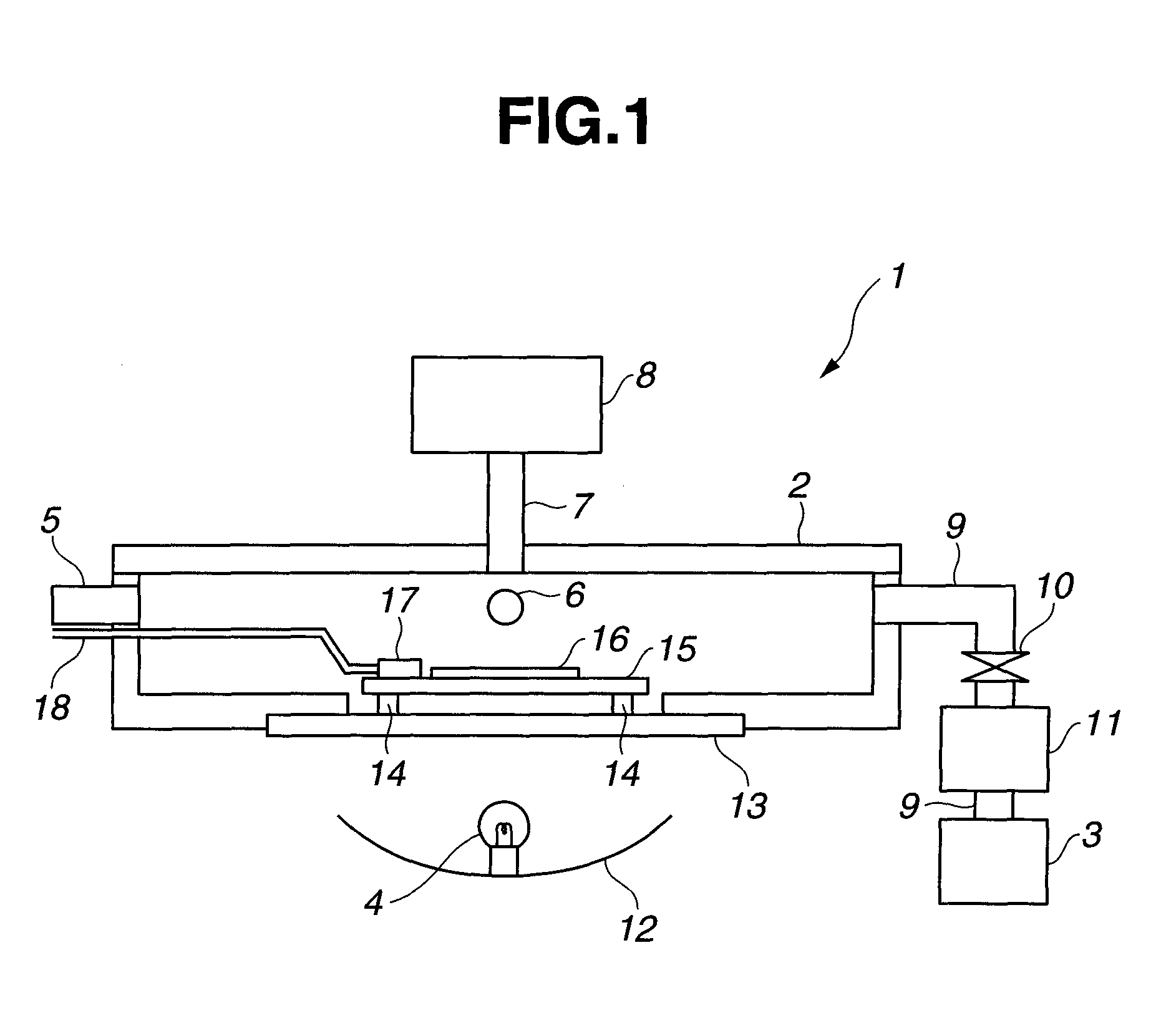

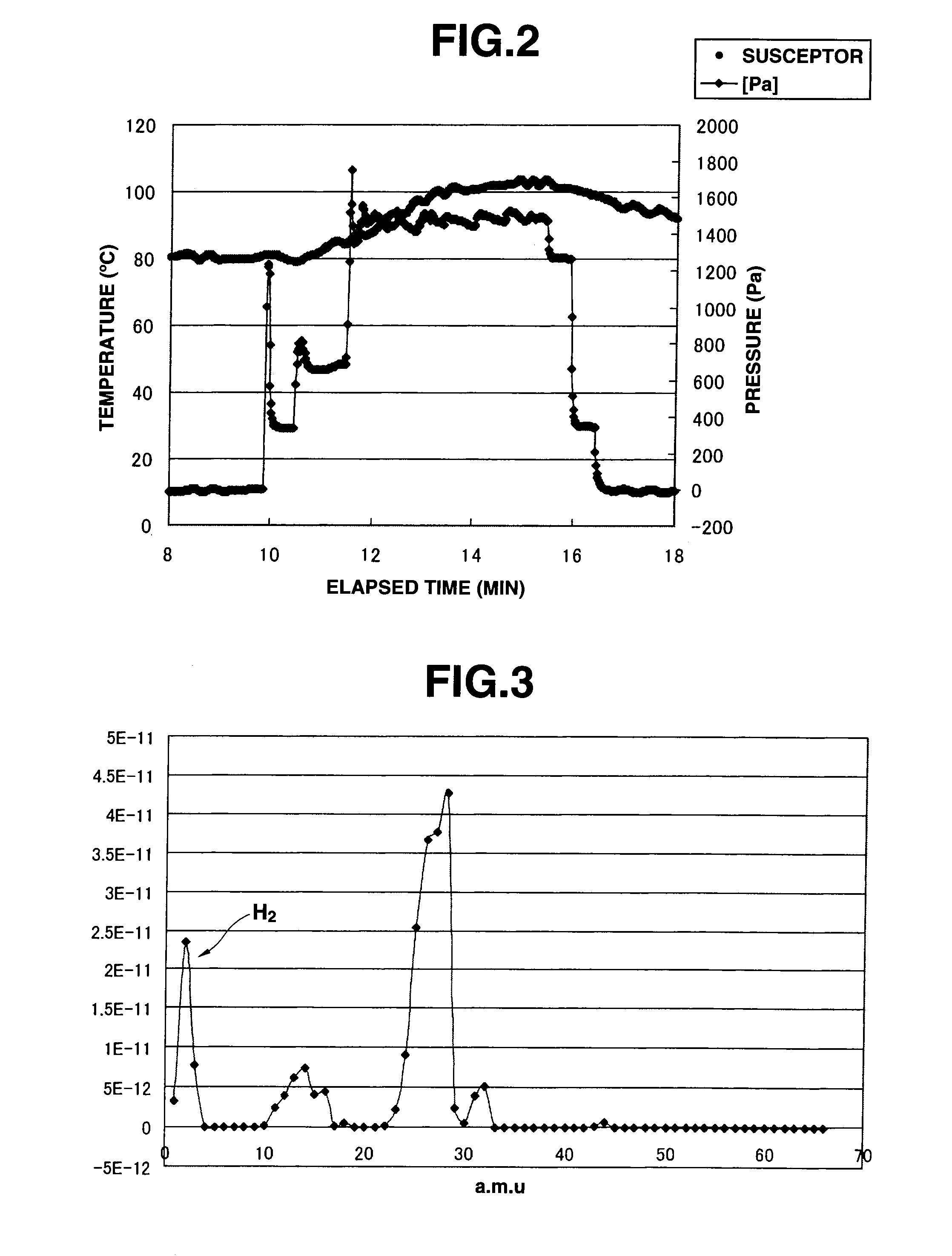

Method of removing resist and apparatus therefor

ActiveUS20100139708A1Easy to moveLow vapor pressureDecorative surface effectsHollow article cleaningResistSusceptor

Owner:MEIDENSHA ELECTRIC MFG CO LTD

System for providing protection from reactive oxygen species

Owner:KRASBERG ALAN

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap