Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124 results about "Aluminium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. It is a silvery-white, soft, non-magnetic and ductile metal in the boron group. By mass, aluminium makes up about 8% of the Earth's crust; it is the third most abundant element after oxygen and silicon and the most abundant metal in the crust, though it is less common in the mantle below. The chief ore of aluminium is bauxite. Aluminium metal is highly reactive, such that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.

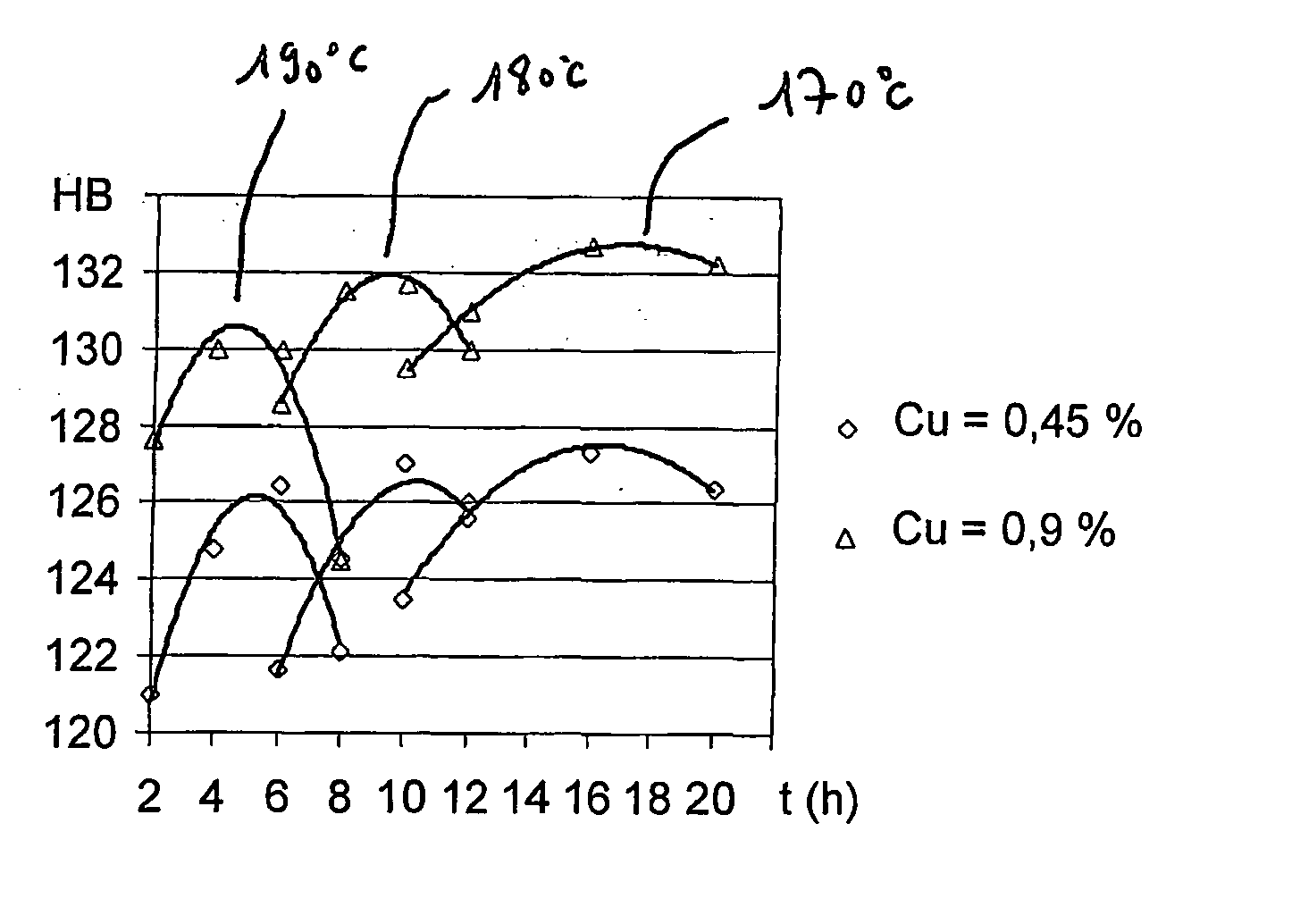

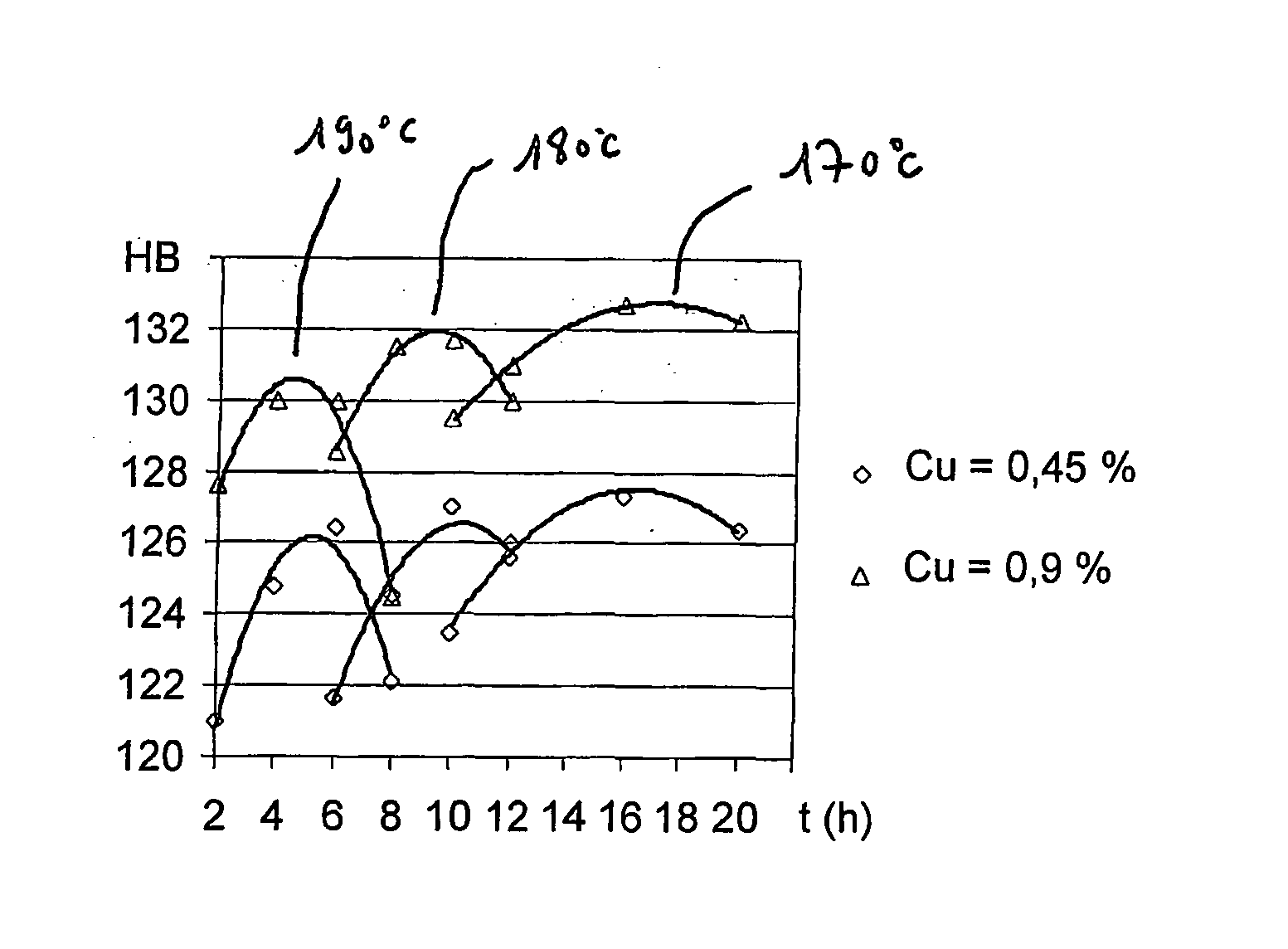

Safety component moulded in a1-si alloy

Owner:ALUMINUM PECHINEY

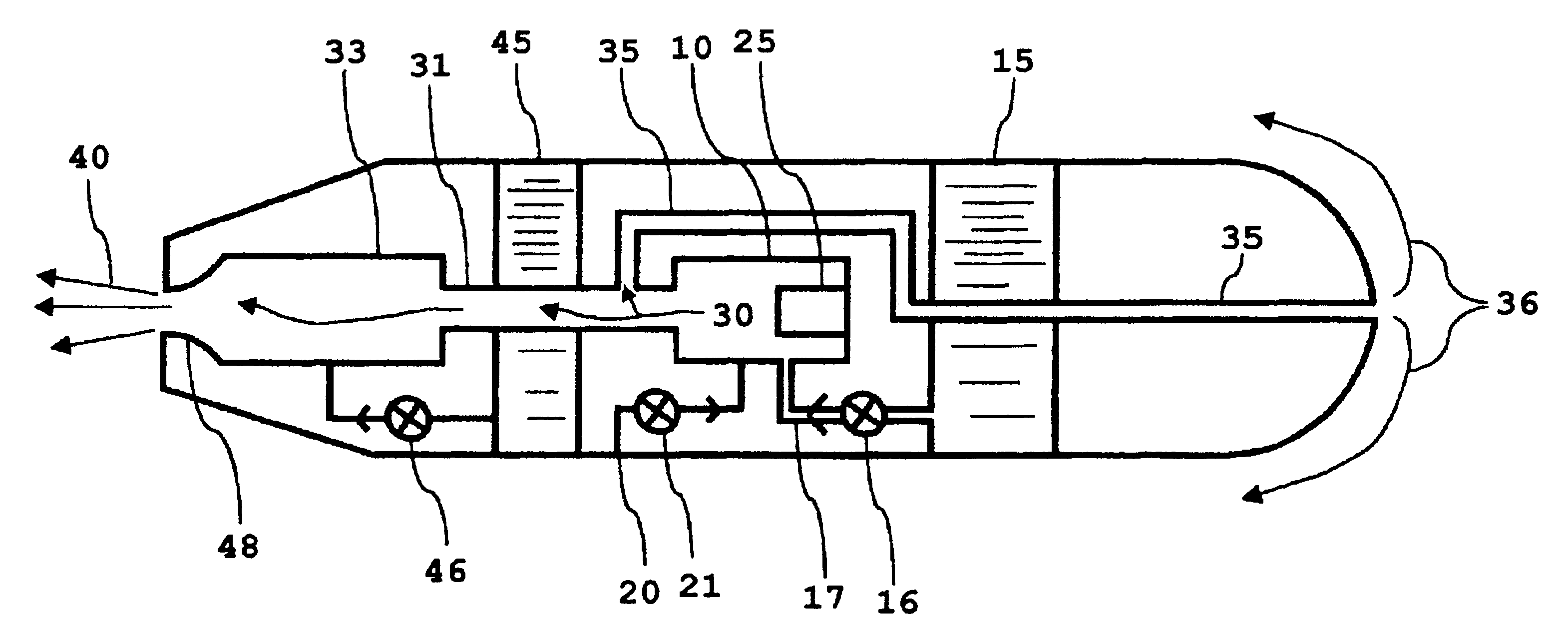

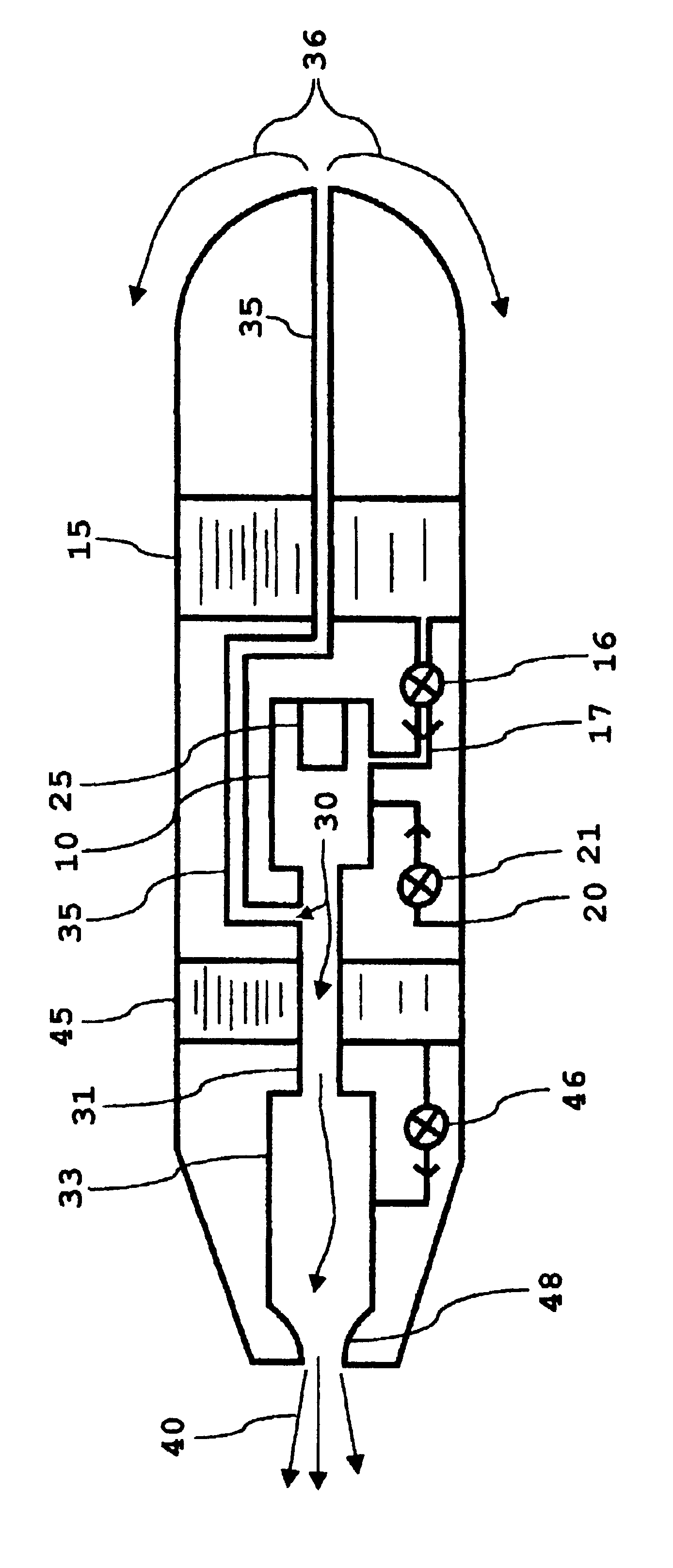

Gas generating process for propulsion and hydrogen production

InactiveUS6849247B1Reduce the temperatureProducing energyLoomsHydrogen productionMetallic materialsSlurry

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

A production method for copper-coated aluminum material

InactiveCN101123129AAvoid high temperature oxidationAvoid lubricationCable/conductor manufactureCelsius DegreeMaterials science

Owner:丹阳市中信化工电器设备有限公司

Deformed Al-Mn series alloy and preparing process thereof

Owner:ZHENGZHOU UNIV

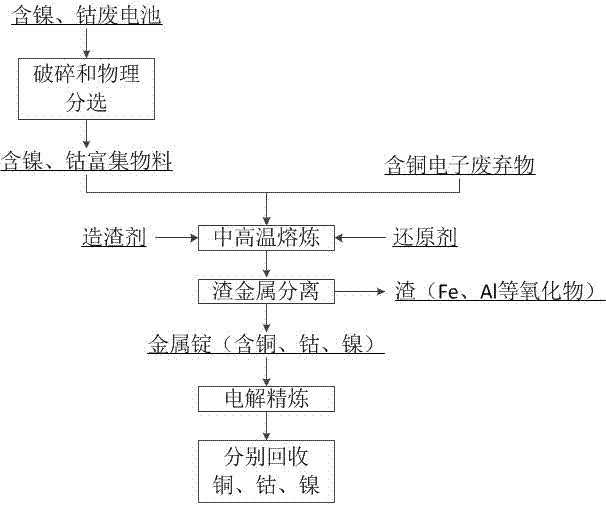

Synergetic metal recycling method for nickel and cobalt containing waste batteries and copper containing electronic waste

InactiveCN107012332AHigh purityAvoid efficiencyPhotography auxillary processesWaste accumulators reclaimingElectrolysisElectrical battery

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

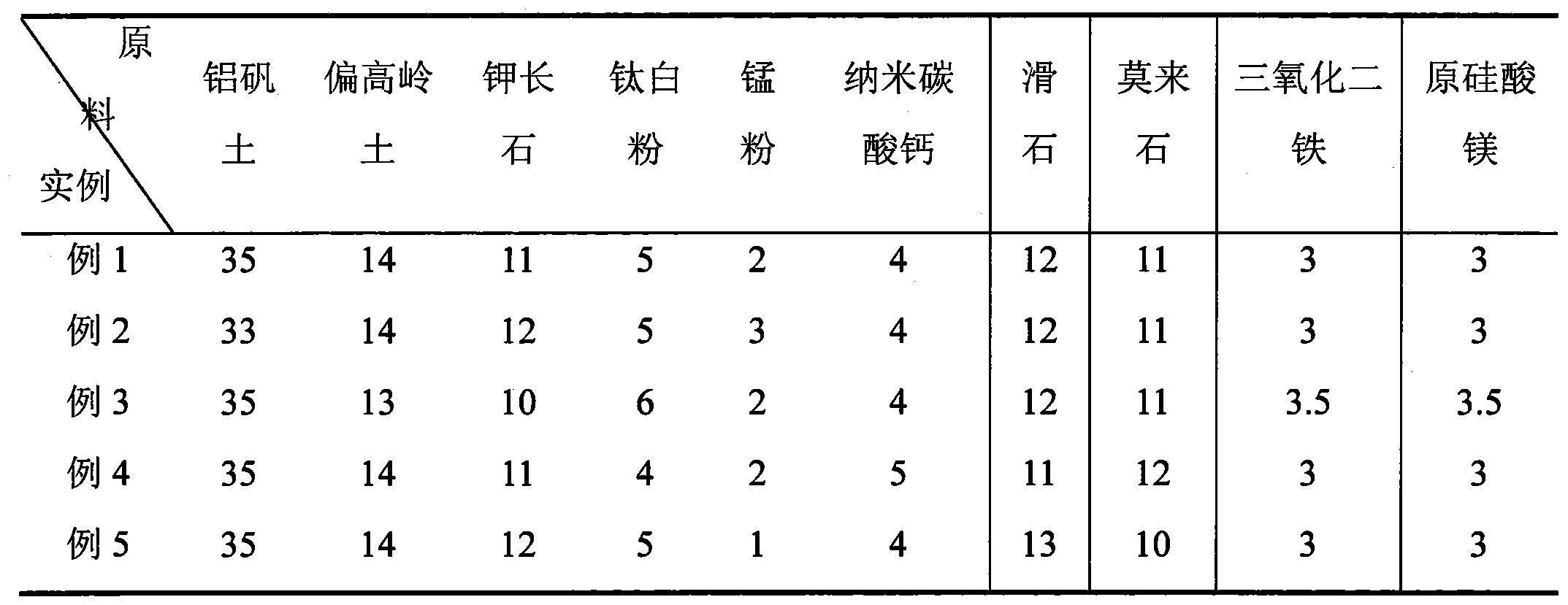

Castable for blast-furnace tapping channel and preparation method thereof

Owner:JIANGSU REFUTA NEW MATERIALS CO LTD

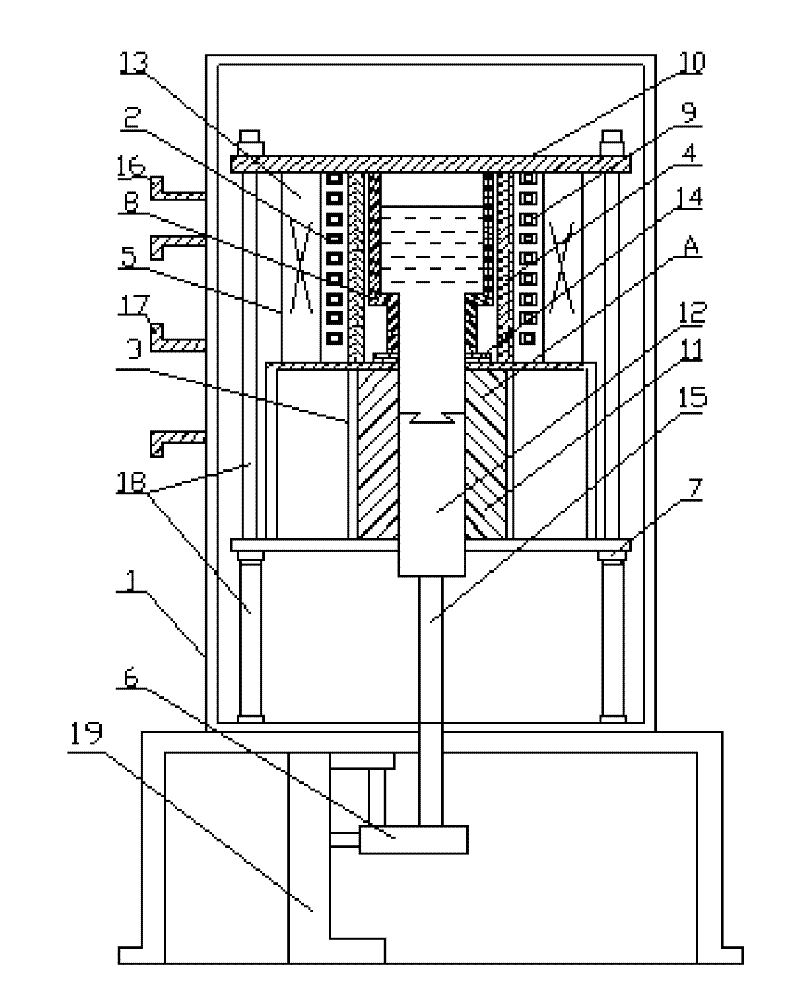

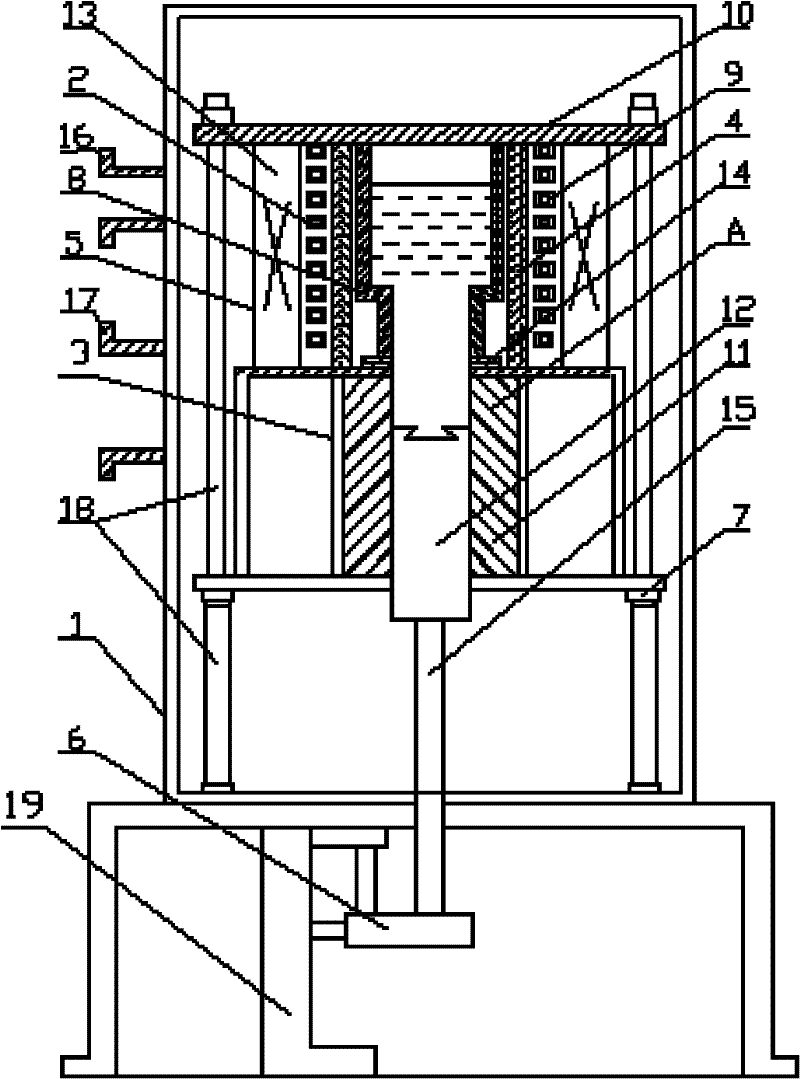

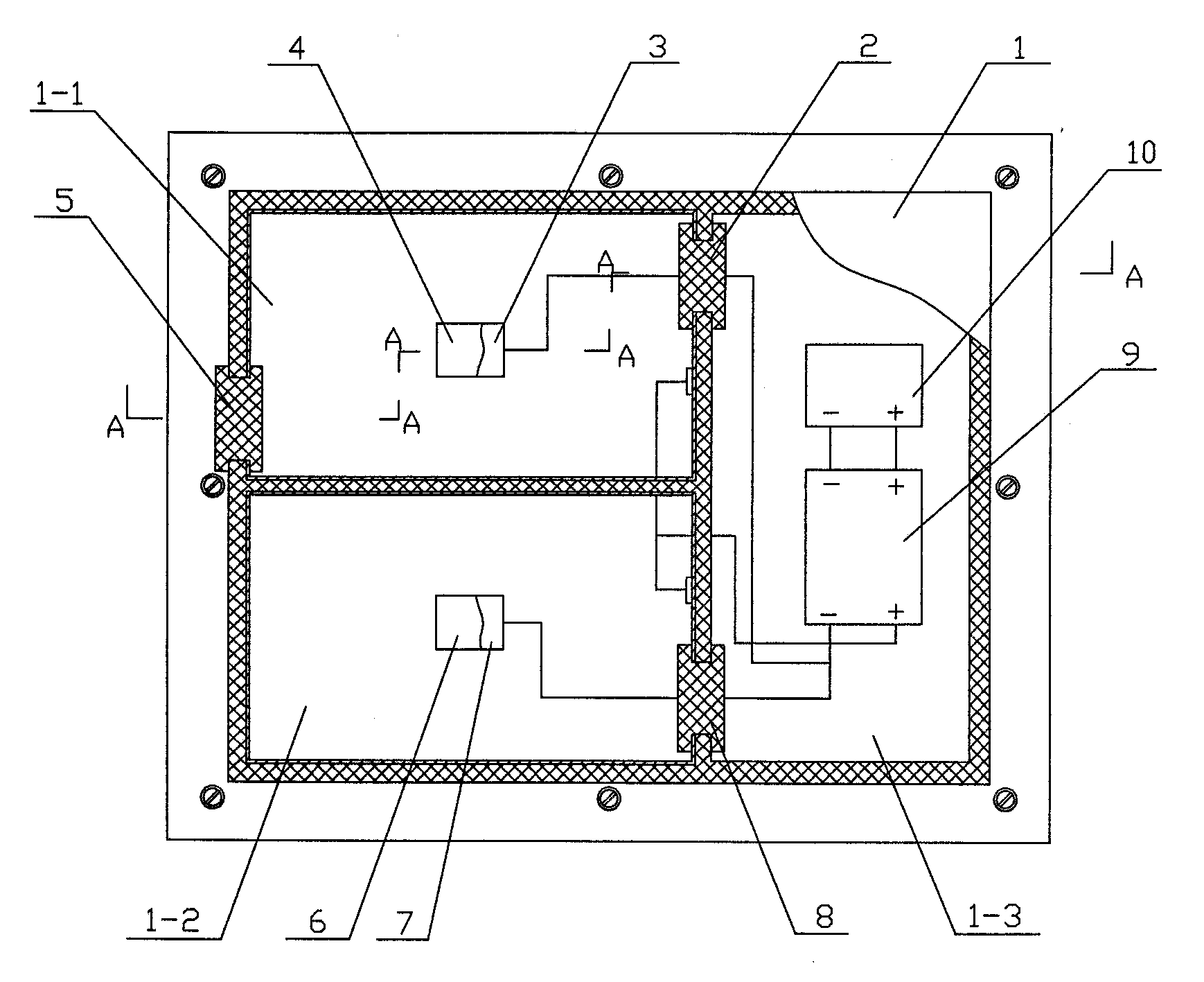

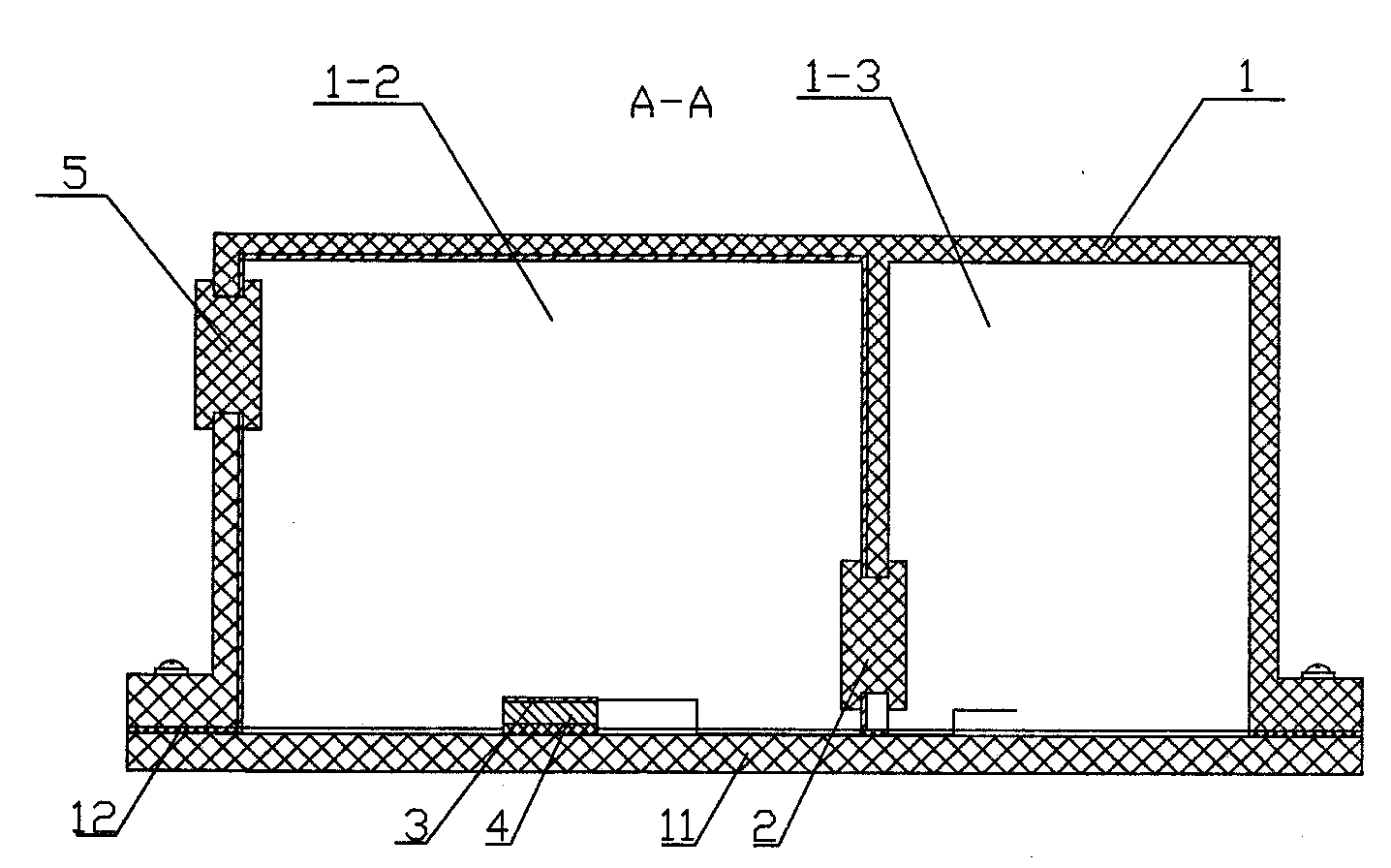

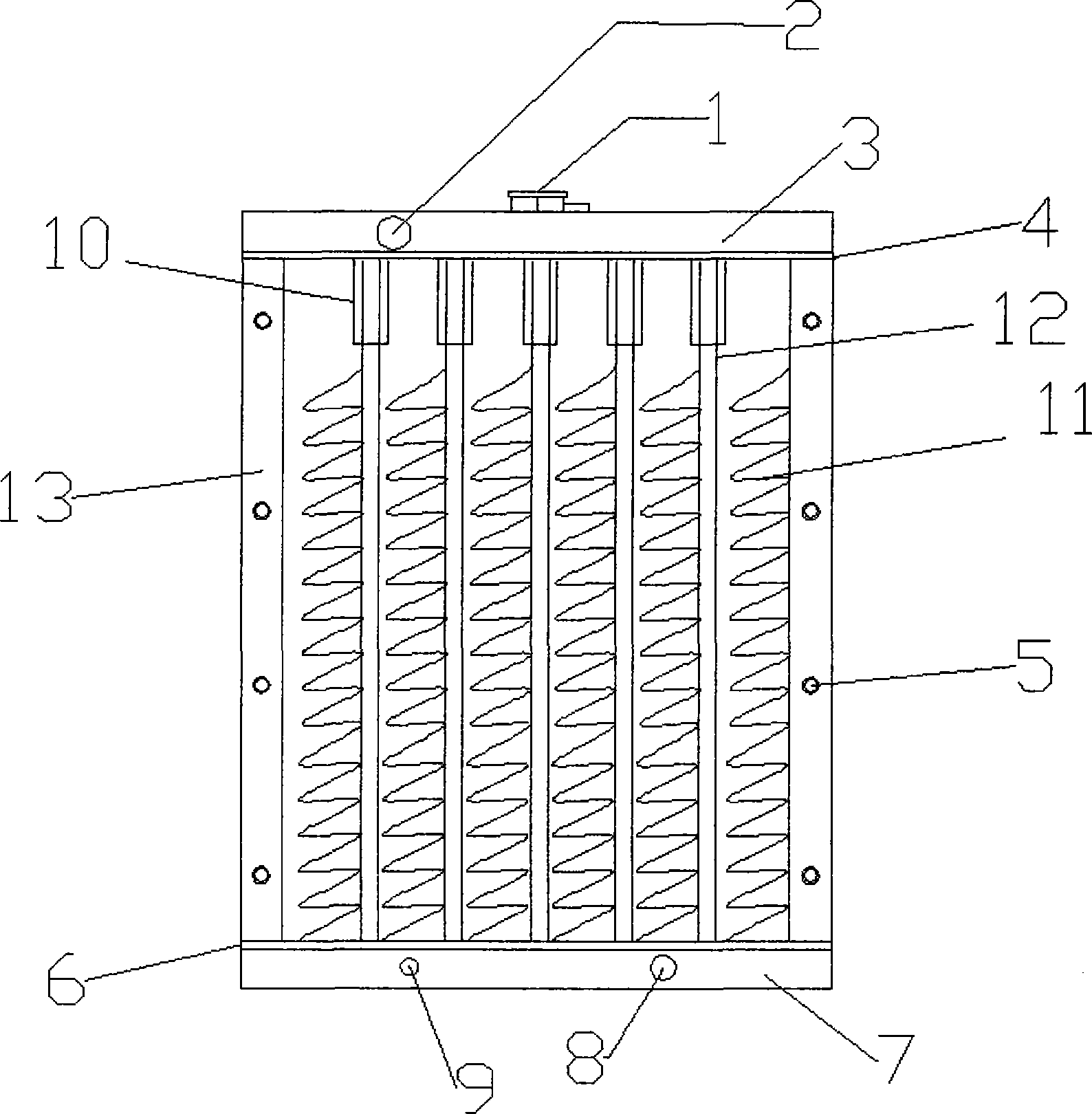

Vacuum purifying device of high-purity aluminium

Owner:SHANGHAI JIAO TONG UNIV

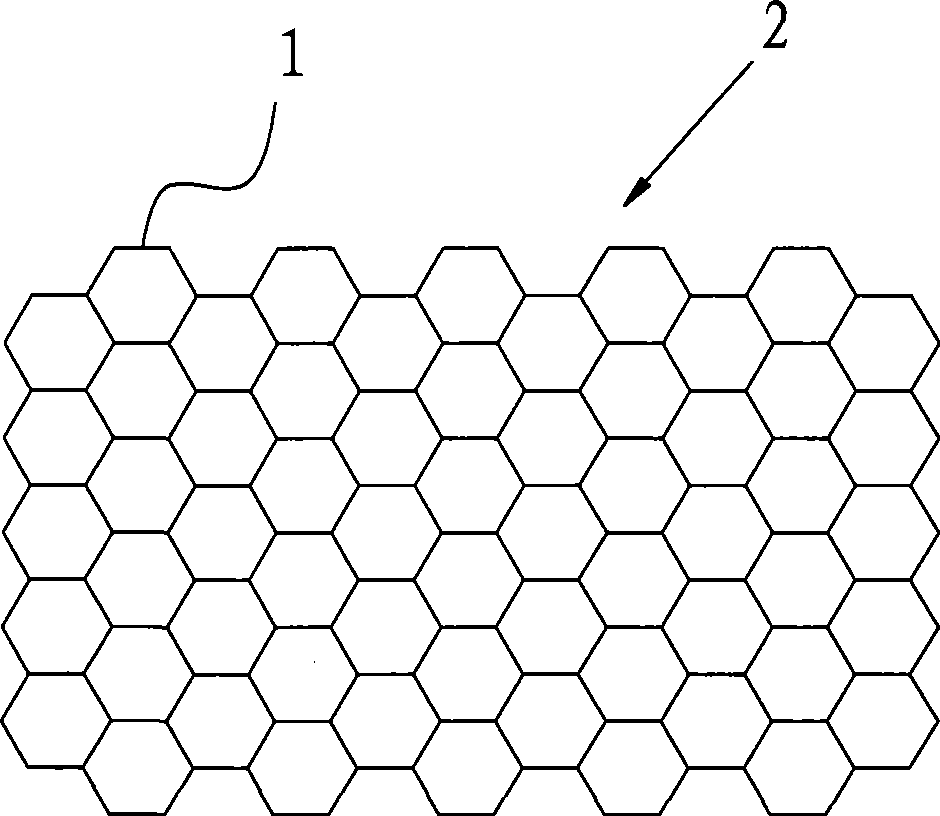

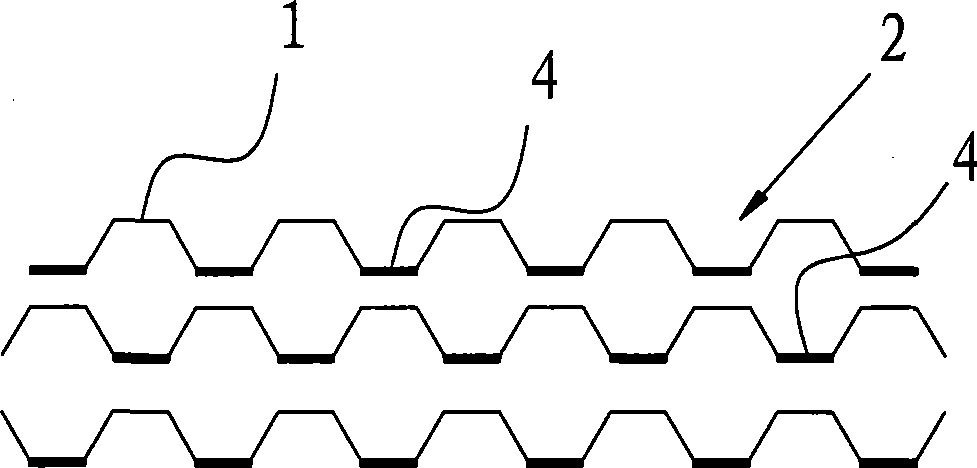

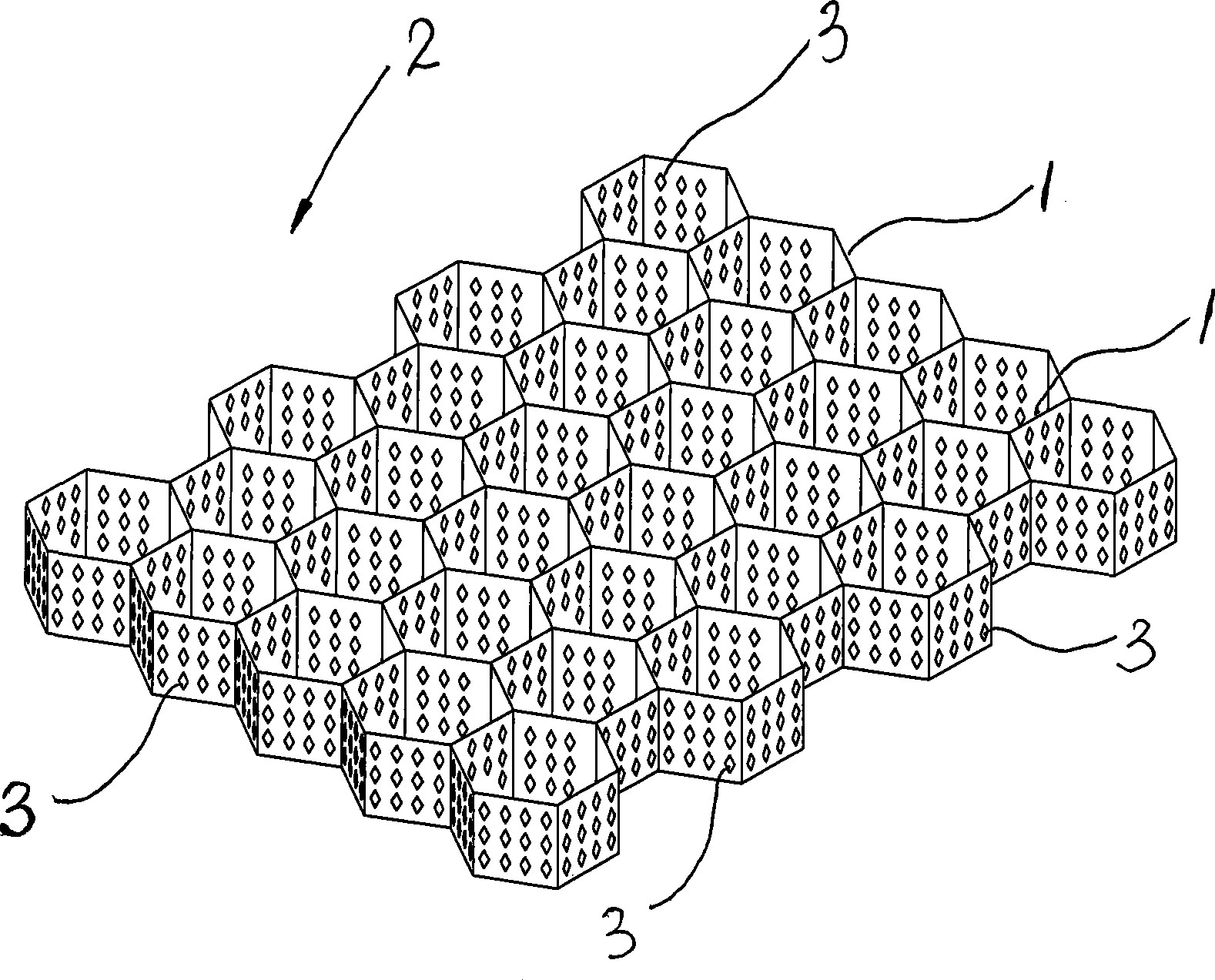

High intensity lightweight honeycomb core and production method thereof

Owner:苏州航通蜂窝科技有限公司

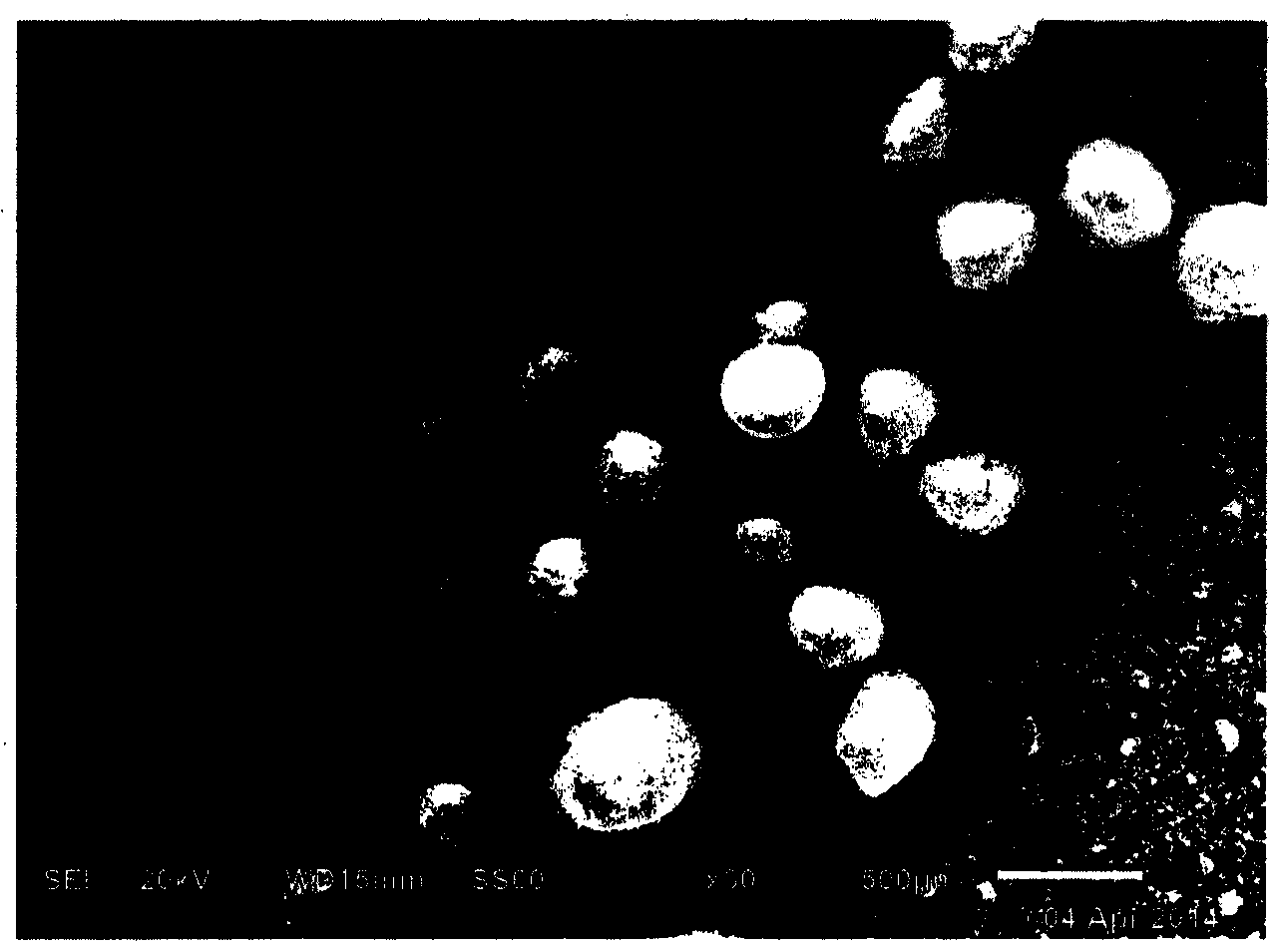

New low-density high-intensity ceramsite fracturing propping agent and preparation method thereof

ActiveCN104099082AAppropriate dispersionEnhancement effect is goodFluid removalDrilling compositionMagnesium orthosilicateExpanded clay aggregate

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

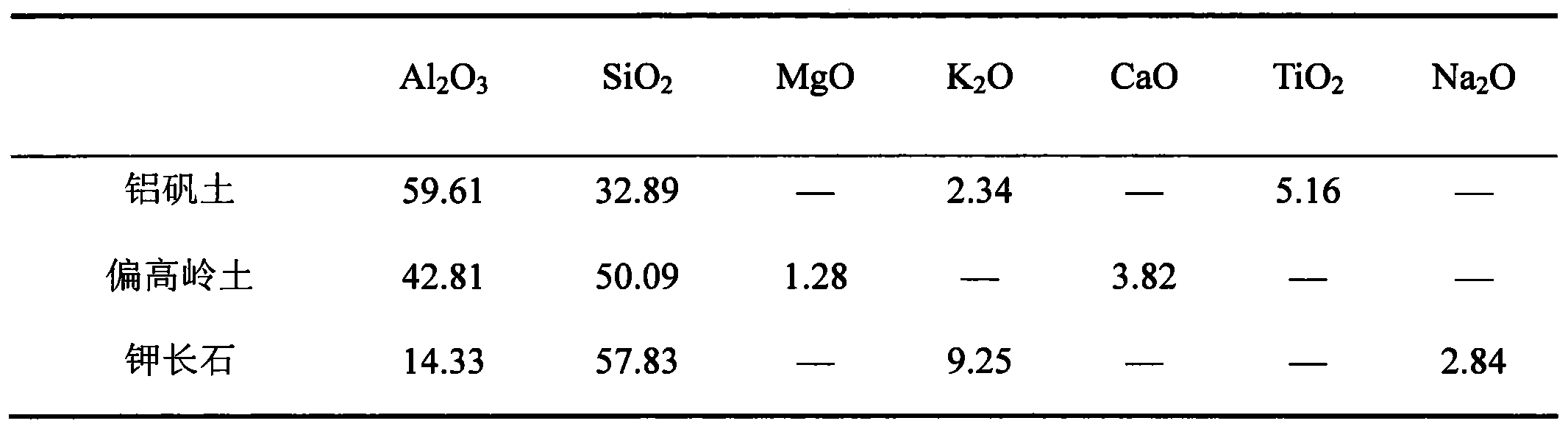

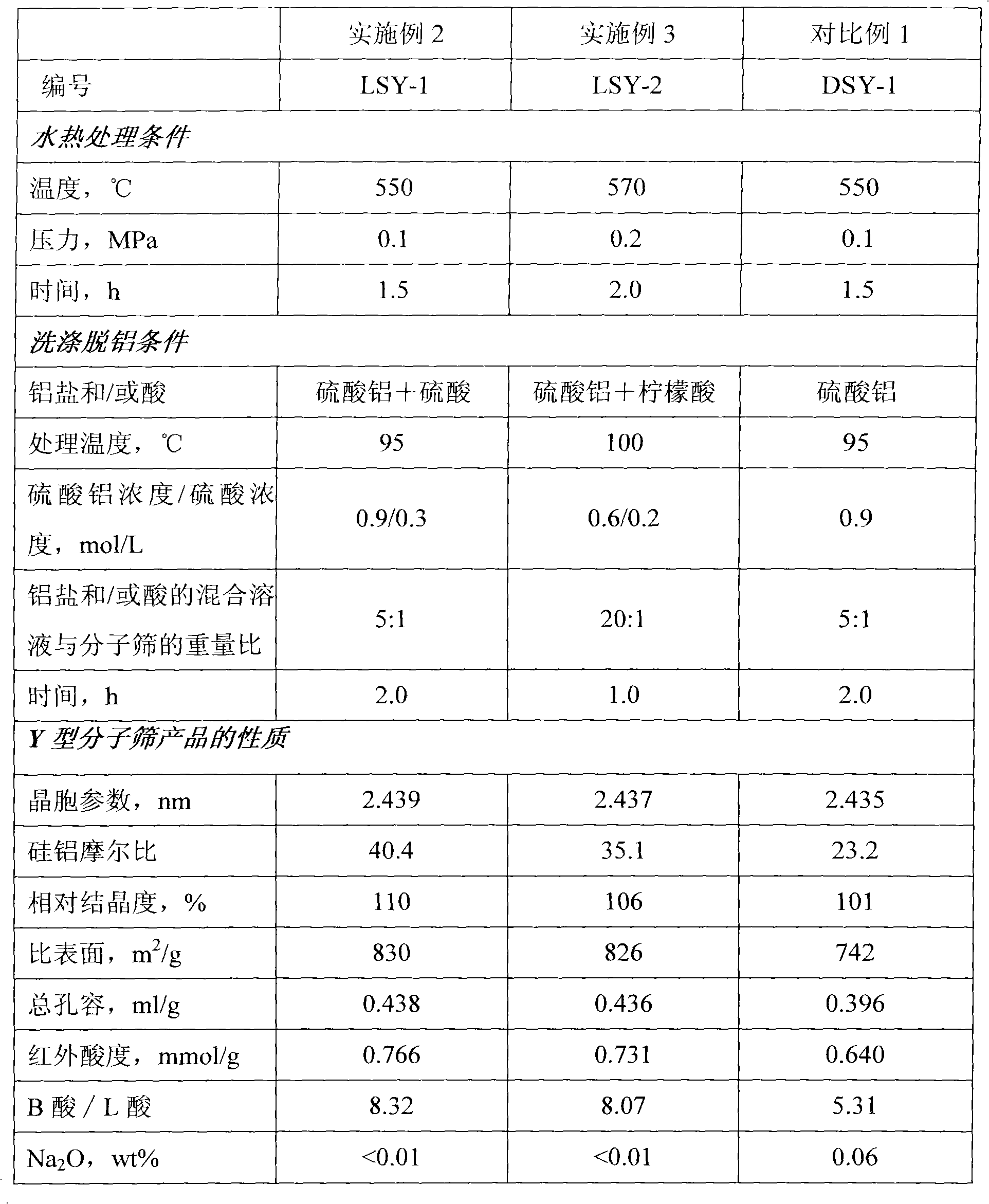

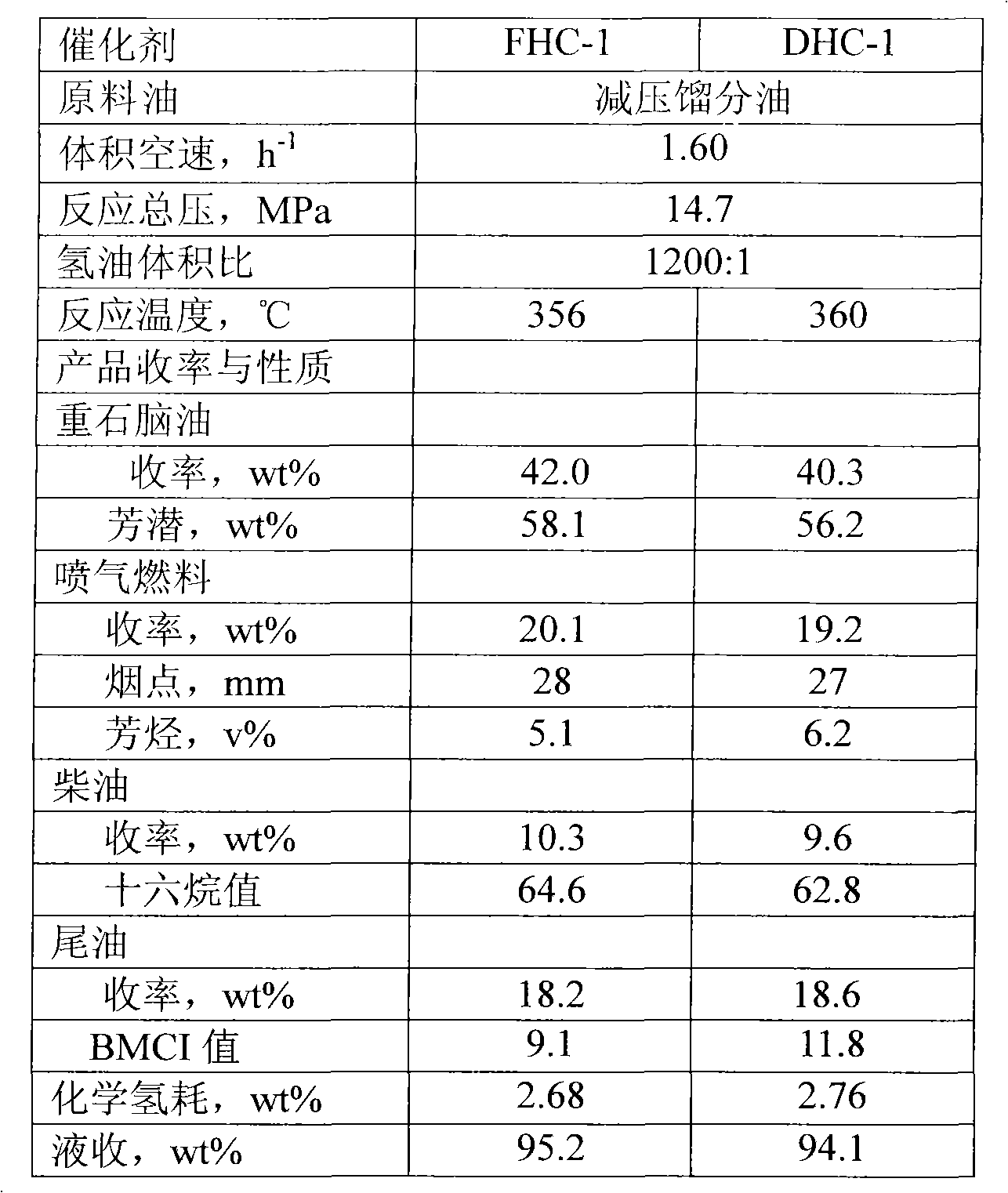

Y-type molecular sieve-containing hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618347AHigh ratio of silicon to aluminumLarger than surfaceCatalyst carriersMolecular sieve catalystsCrystallinityCell parameter

Owner:CHINA PETROLEUM & CHEM CORP +1

Copper and iron compound honeycomb coating type denitrification catalyst as well as preparation method and application thereof

InactiveCN109499607AImprove thermal stabilityImprove anti-sulfur poisoning performanceMolecular sieve catalystsDispersed particle separationIon exchangeVacuum coating

Owner:VALIANT CO LTD

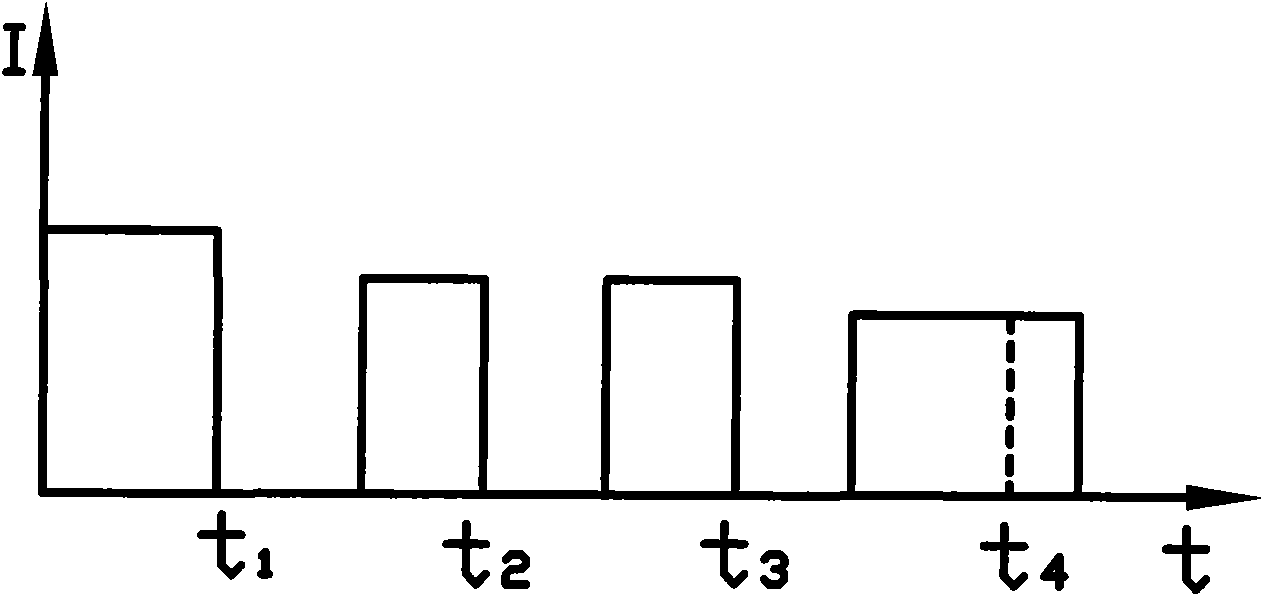

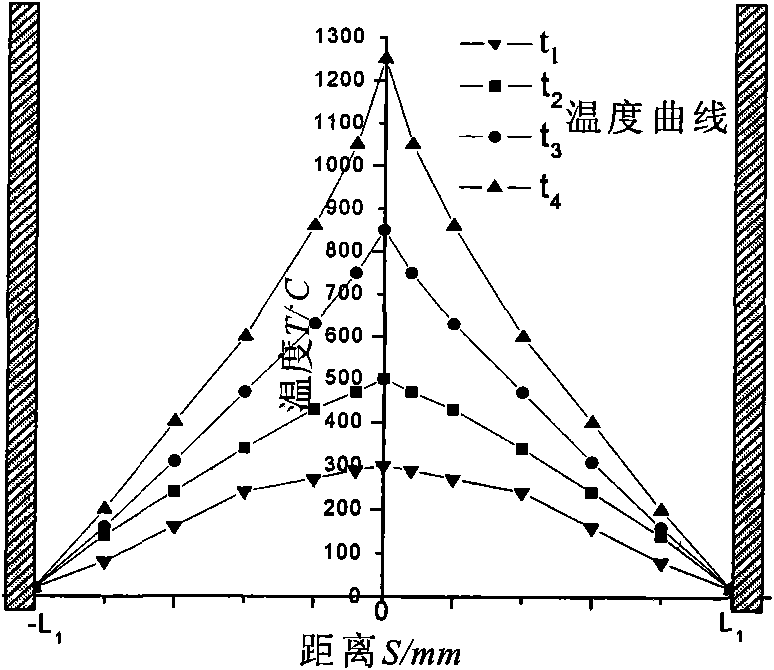

Butt welding method of small caliber metallic resistances

ActiveCN101596643ALess heat productionReduce the impactResistance welding apparatusButt weldingEngineering

Owner:BEIJING UNIV OF TECH

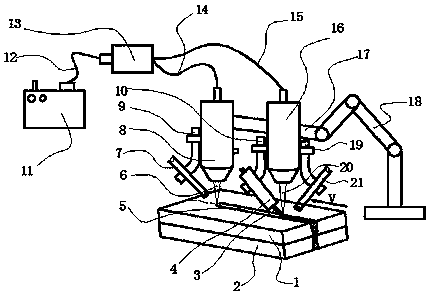

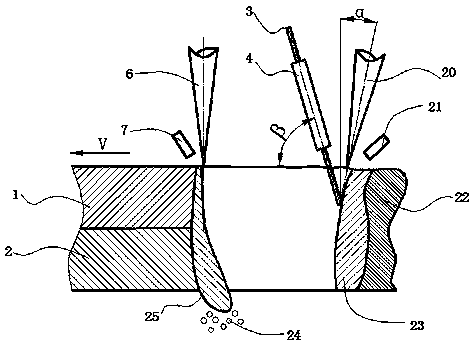

Car steel-aluminum splicing joint welding method and system

InactiveCN107971650AImprove connection strengthIncrease binding areaWelding/soldering/cutting articlesWelding apparatusLaser cuttingEngineering

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Solar film battery assembly for architecture

InactiveCN101510567AStable working environmentStrong penetrating powerGlass/slag layered productsCoatingsThermal insulationEngineering

The invention relates to a solar energy thin-film battery component applied to architecture; the solar energy thin-film battery component consists of a conducting-film glass layer, a thin-film battery layer, an aluminum-film layer, an EVA layer, a float glass layer and a hollow glass layer in sequence from top to bottom; spacing bars are arranged at two ends between the float glass layer and the hollow glass layer and separate the float glass layer from the hollow glass layer to form a hollow cavity; a LOW-E film layer is arranged at either of the upper side and the lower side of the hollow cavity; from the external side of one spacing bar to the lateral side of the float glass layer, a junction box with diodes is arranged; and an electrode is led out respectively from the conducting-film glass layer and the aluminum-film layer, then the two electrodes are connected with the circuit inside the junction box. Compared with the prior art, the solar energy thin-film battery component is combined with the architecture and provided with an energy-saving coated film, a hollow structure and the junction box convenient for building installation, and has the advantages of environmentally-friendly power generation with solar energy, energy conservation and heat insulation of buildings, thermal insulation, sound insulation and no deposition of dew and frost.

Owner:HIMIN CLEAN ENERGY HLDG

Fouling resistant spark plug

InactiveUS20130300278A1Sparking plugsVitrificationCelsius Degree

Owner:FRAM GROUP IP +1

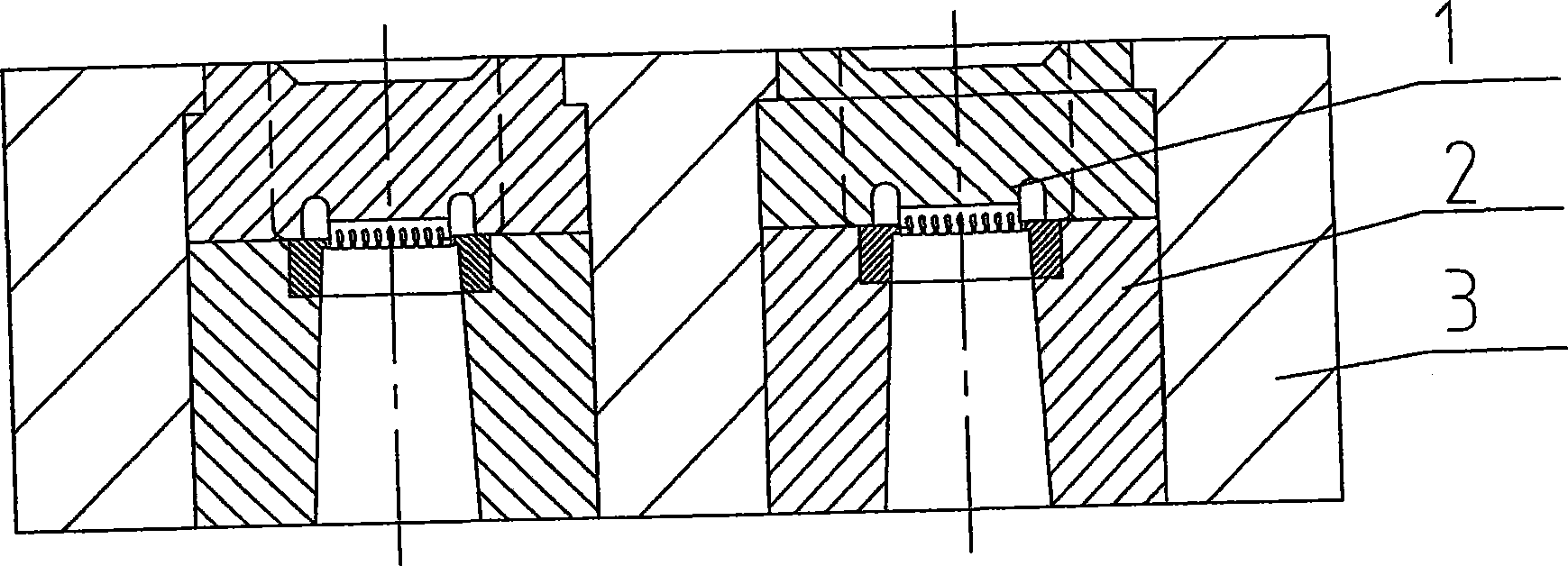

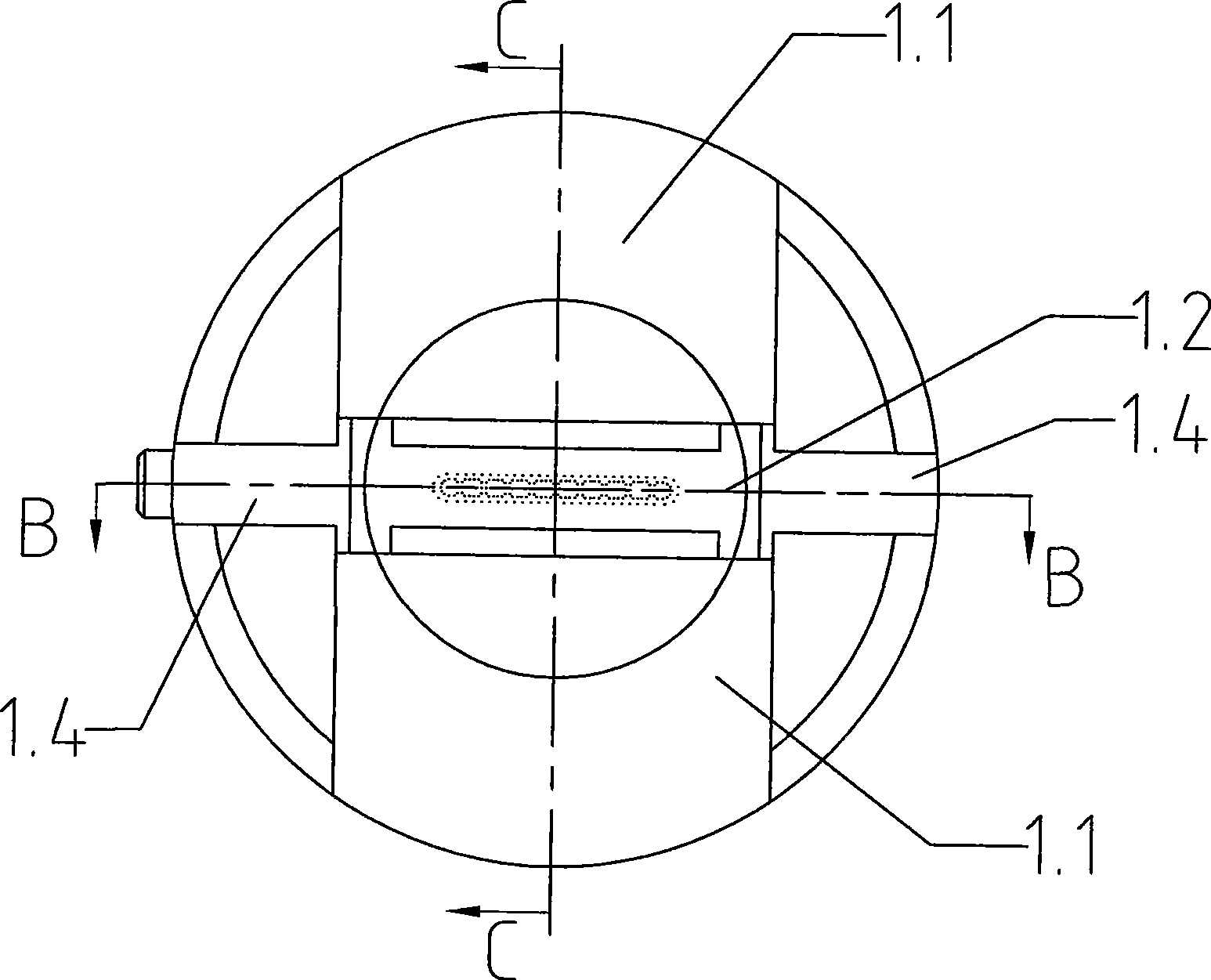

Extruded aluminium section die for vehicle condenser tube

Owner:JIANGYIN GIANSUN MOLD

Sintered bearing and manufacturing method for same

InactiveUS20150064045A1Increase production capacityLow costTransportation and packagingShaftsAluminiumSurface layer

Owner:NTN CORP

Photocatalyst film and method for manufacturing the same

InactiveUS20080004175A1Suppress generationAvoid chain reactionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationActive layerHydrolysis

Owner:FUJIFILM CORP

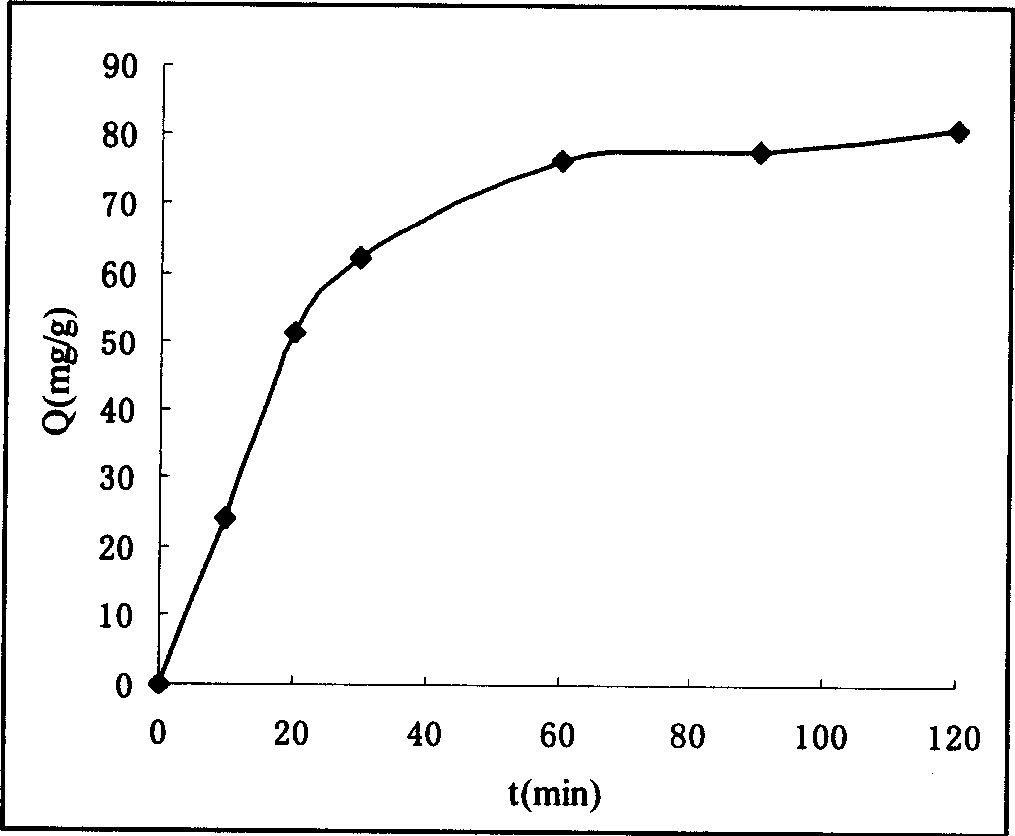

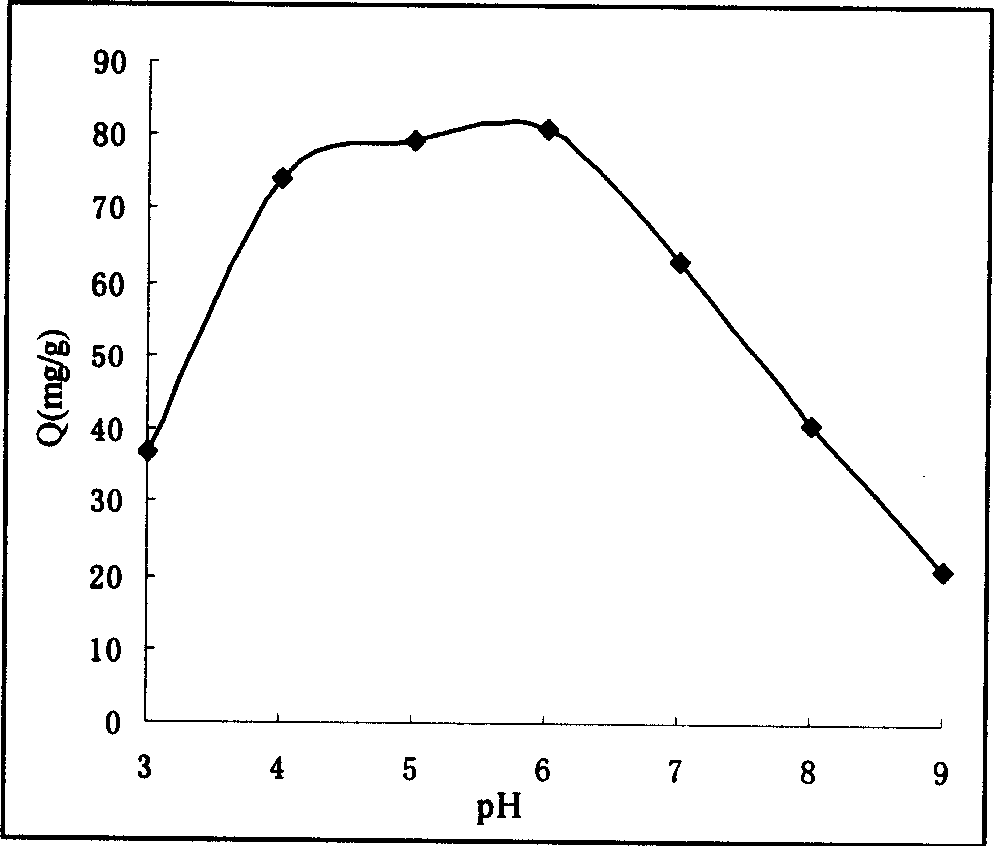

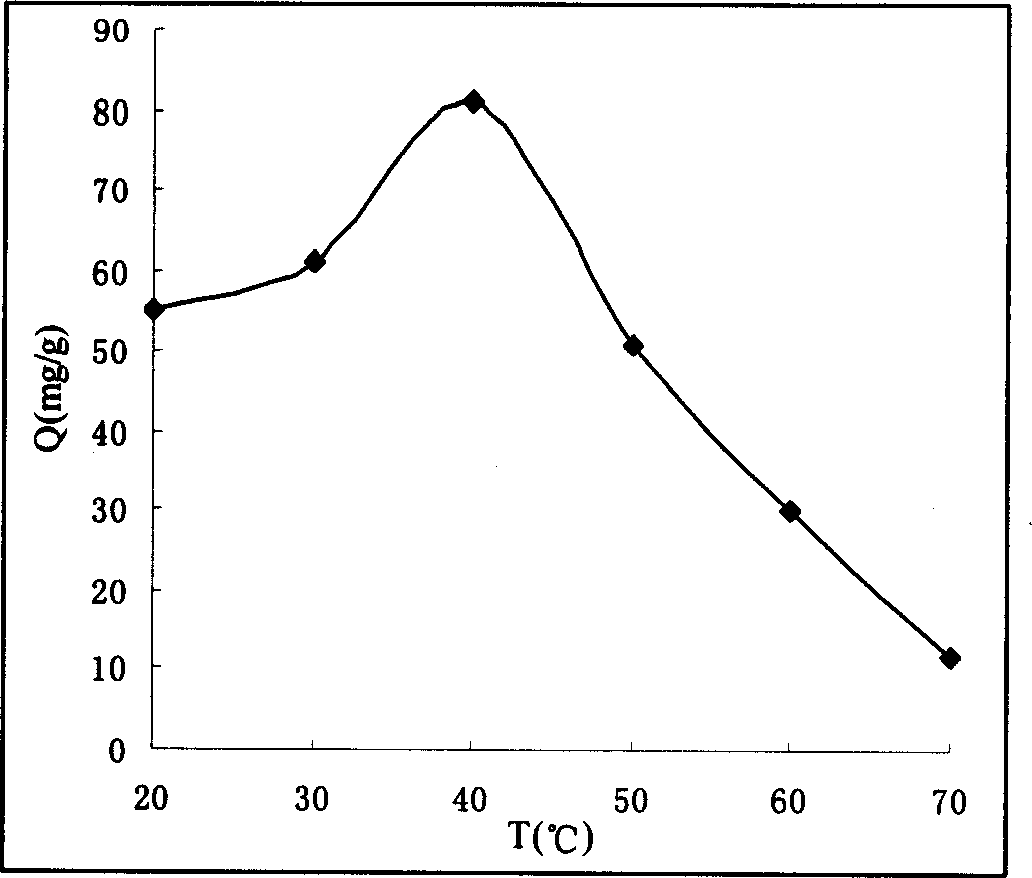

Use of zinc magnesium aluminium ternary hydrotalcite calcining matter in hexavalent chromium of adsorbed water

InactiveCN1736942AEasy to recycleImprove adsorption capacityWater/sewage treatment by sorptionHydrotalciteZinc

Owner:ZHEJIANG UNIV OF TECH

Device and method for measuring concentration of <222>Rn and <220>Rn synchronously by adopting electrostatic collection and solid nuclear track

ActiveCN103983999ASimple and reliable measurement processThe calculation method is simple and reliableRadiation intensity measurementMeasurement deviceEtching

Owner:HENGYANG NORMAL UNIV

Aluminum base alloy containing boron and manufacturing method thereof

InactiveUS7125515B2Evenly distributedNuclear energy generationCasting safety devicesBoron containingAlloy

Owner:KOBE STEEL LTD

Method for tempering high temperature slag and mineral cotton production method

Owner:CHINA JINGBLUE BEIJING ENVIRONMENTAL ENG CO LTD

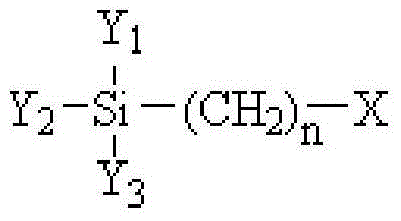

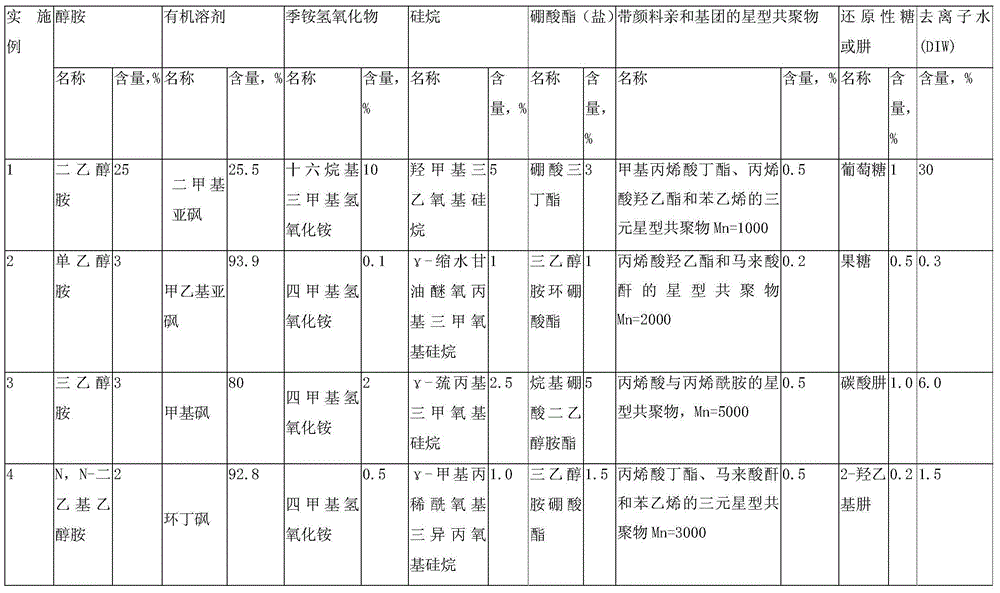

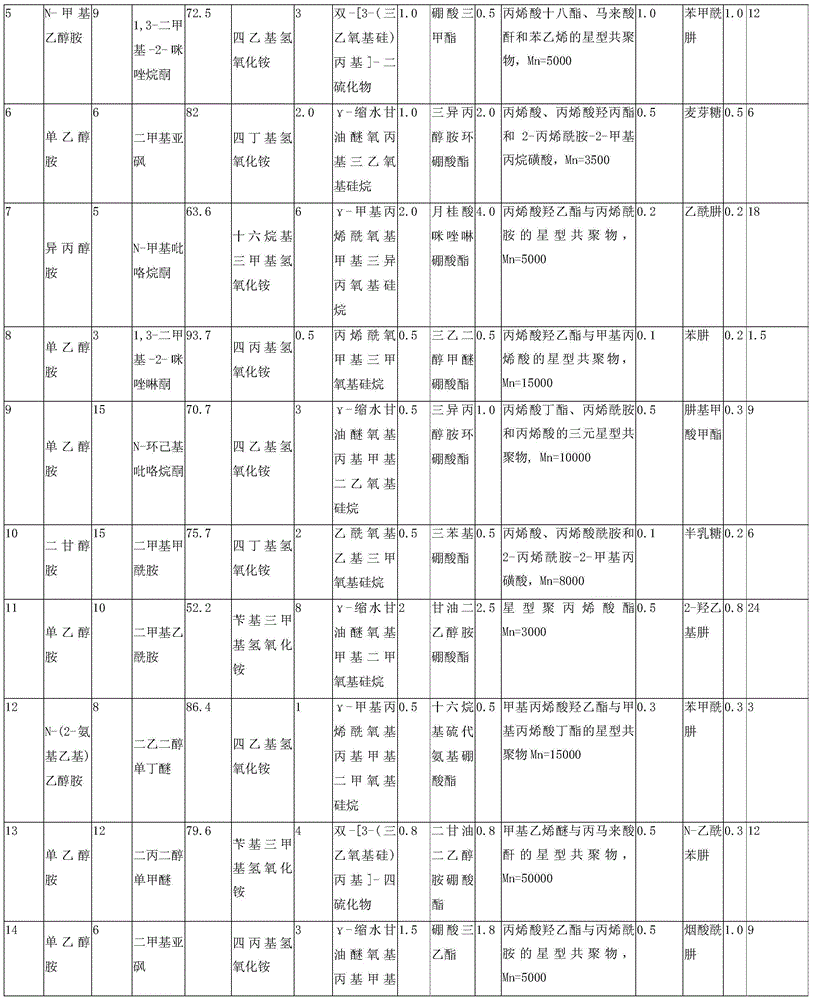

Photoresist cleaning fluid

InactiveCN105527802AEfficient removalLarge operating windowPhotosensitive material processingSilanesSolvent

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

Positive electrode for nonaqueous electrolyte secondary battery and nonaqueous electrolyte secondary battery

ActiveUS20170187036A1InhibitionWithout deteriorating battery characteristicFinal product manufactureElectrode carriers/collectorsLithiumInorganic particle

The positive electrode as an embodiment includes a positive electrode current collector mainly composed of aluminum, a positive electrode mixture layer containing a lithium-containing transition metal oxide and disposed above the positive electrode current collector, and a protective layer disposed between the positive electrode current collector and the positive electrode mixture layer. The protective layer contains inorganic particles, an electro-conductive material, and a binding material; is mainly composed of the inorganic particles; and is disposed on the positive electrode current collector to cover the positive electrode current collector in approximately the entire area where the positive electrode mixture layer is disposed and at least a part of the exposed portion of the positive electrode current collector where the positive electrode mixture layer is not disposed on the surface of the positive electrode current collector.

Owner:PANASONIC CORP

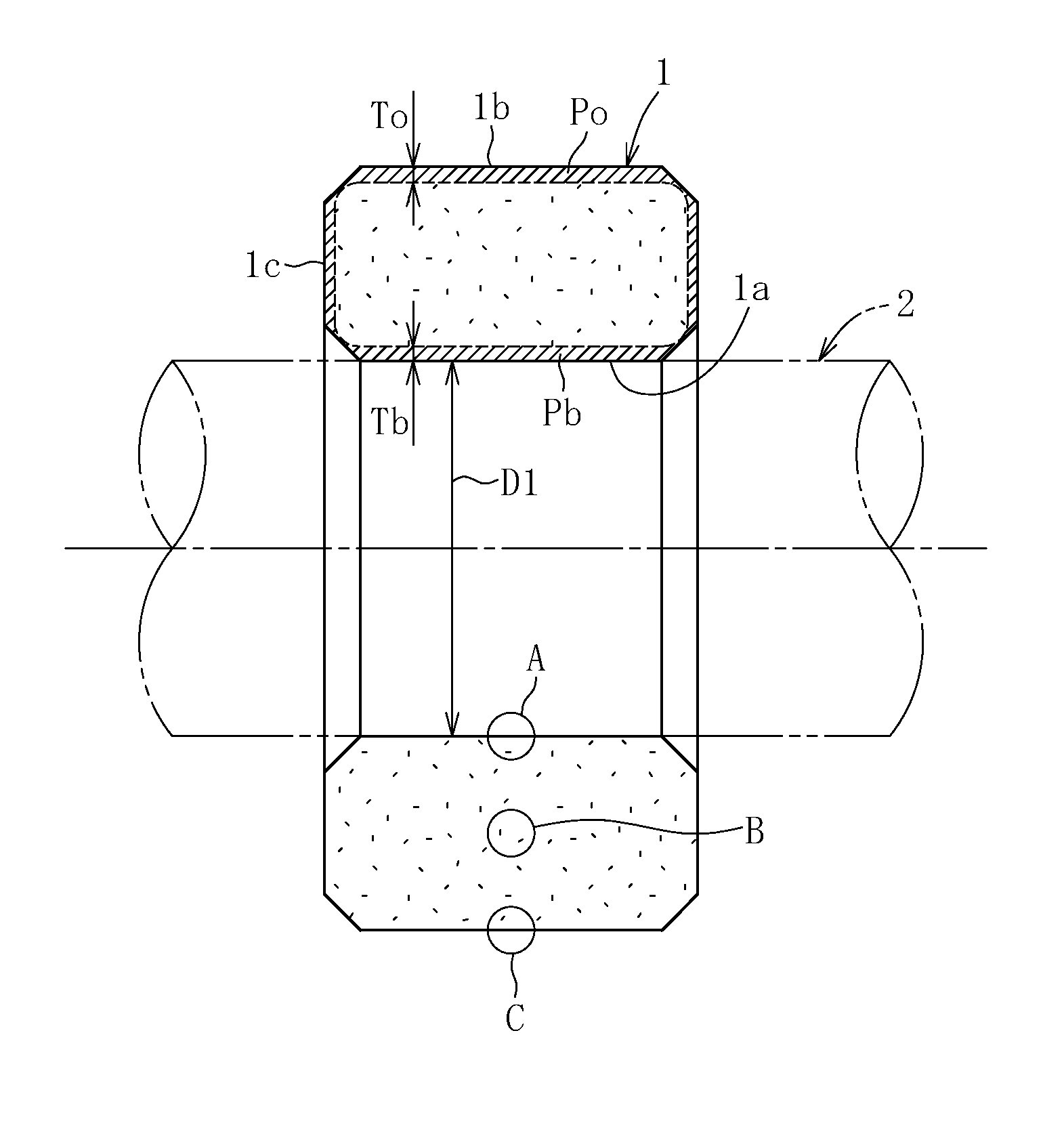

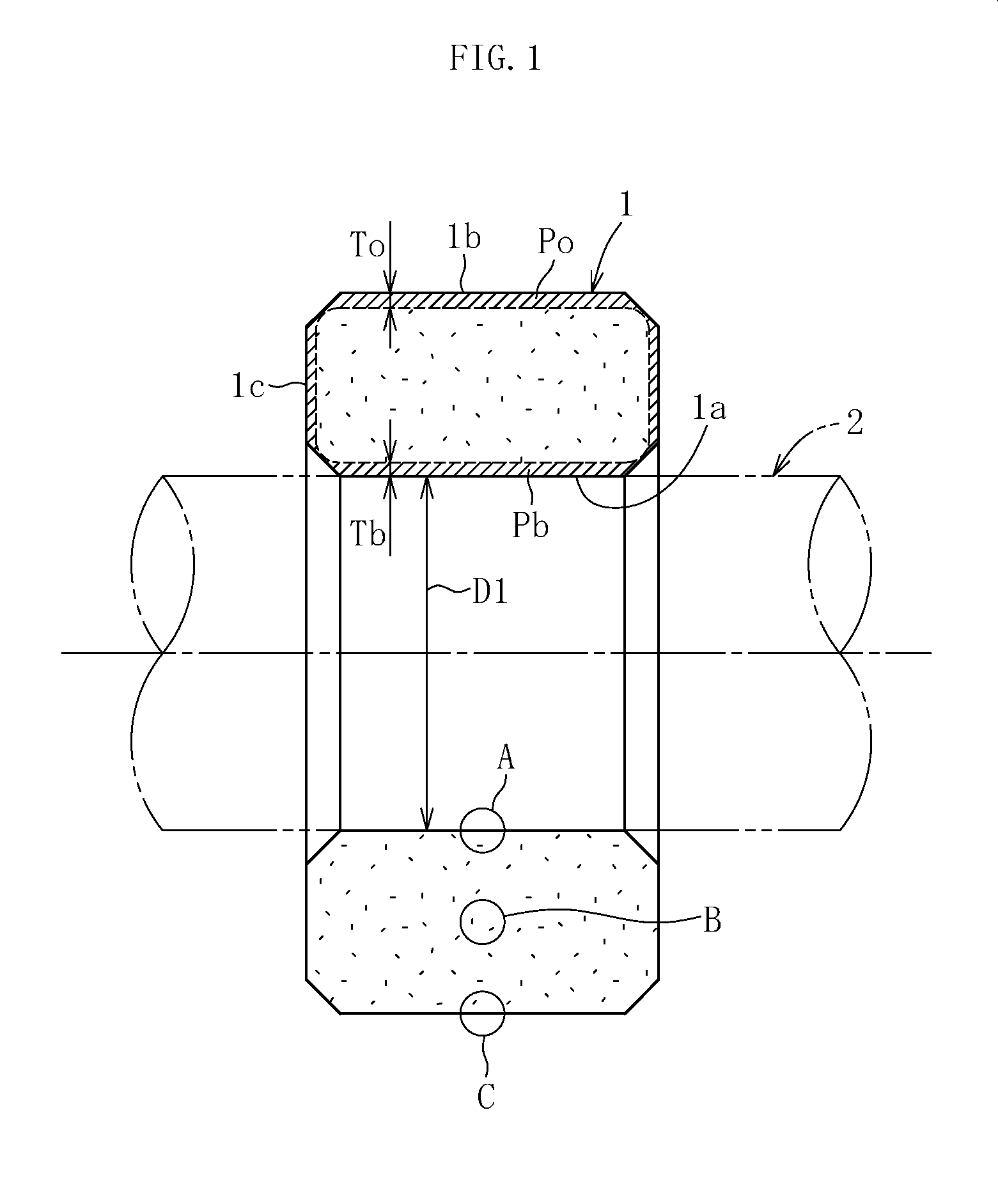

Valve body manufacturing method

The invention discloses a valve body manufacturing method. The valve body manufacturing method includes the following steps that firstly, raw metal materials are subjected to hot melting and extrusion forming to form long-strip-shaped profiles; secondly, the profiles are cut into a plurality of blanks, wherein the blanks are matched with valve bodies in shape and are slightly larger than the valve bodies; and thirdly, the blanks are ground and drilled to obtain the valve bodies. According to the manufacturing method, due to the fact that the profile forming step can be performed in most of existing profile production plants in a concentrated mode, and valve body manufacturers only need to perform cold machining such as cutting, grinding and drilling on the profiles without additionally arranging heat treatment equipment, the equipment and production cost is reduced, production efficiency is improved, meanwhile, pollution and energy consumption are reduced, and energy conservation and environment protection are archived; besides, due to the fact that existing professional profile production plants have large profile production equipment, raw metal materials such as aviation aluminum with better performance can be adopted for manufacturing the profiles, the performance of the valve bodies can be effectively improved, and the market competitiveness of enterprises can be effectively improved.

Owner:ZHONGSHAN XIANGFENG GAS APPLIANCE WARE

Air-added brick and preparation method thereof

Owner:明光市凯旋新型建材厂

Concrete expansive agent

Owner:王嘉文

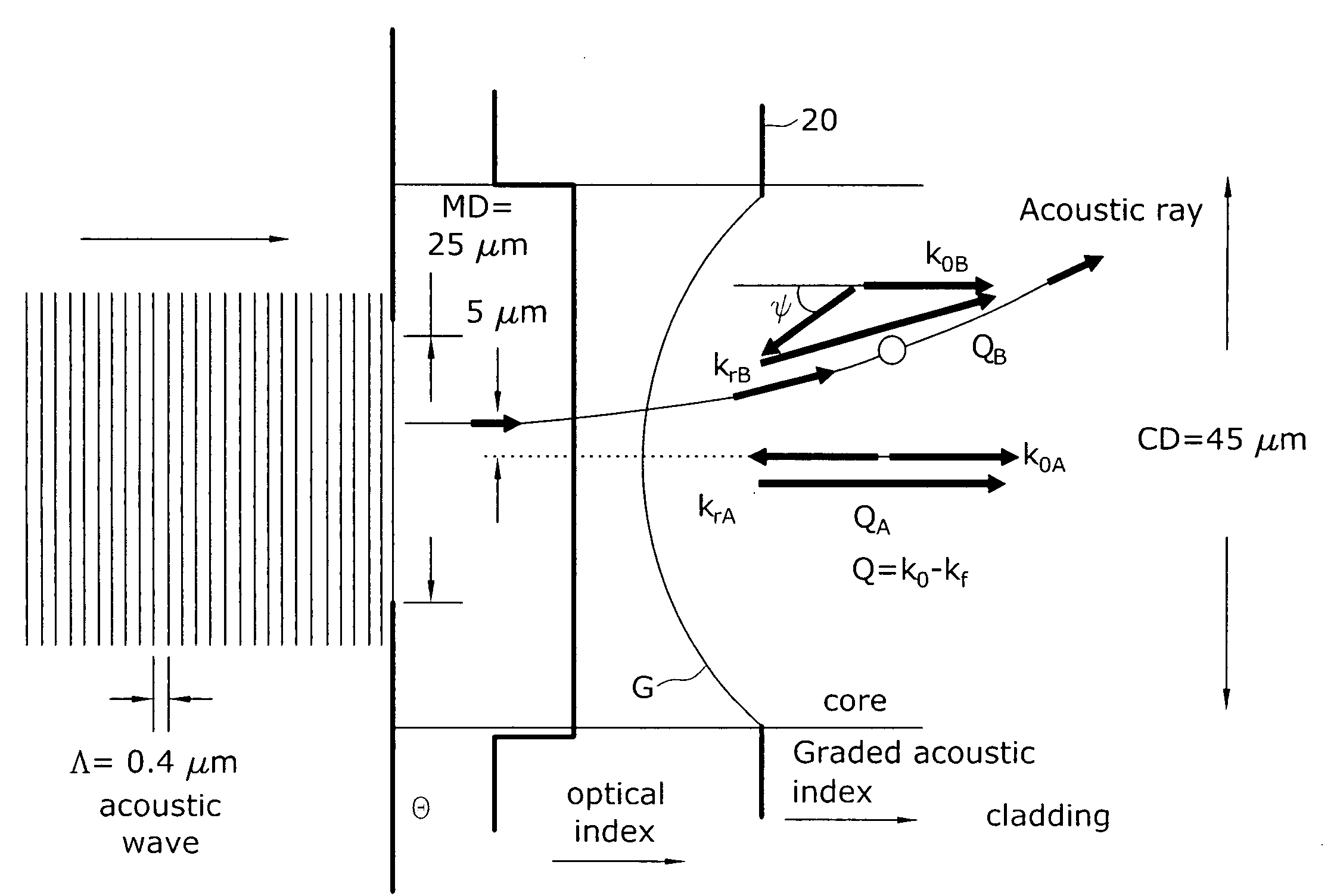

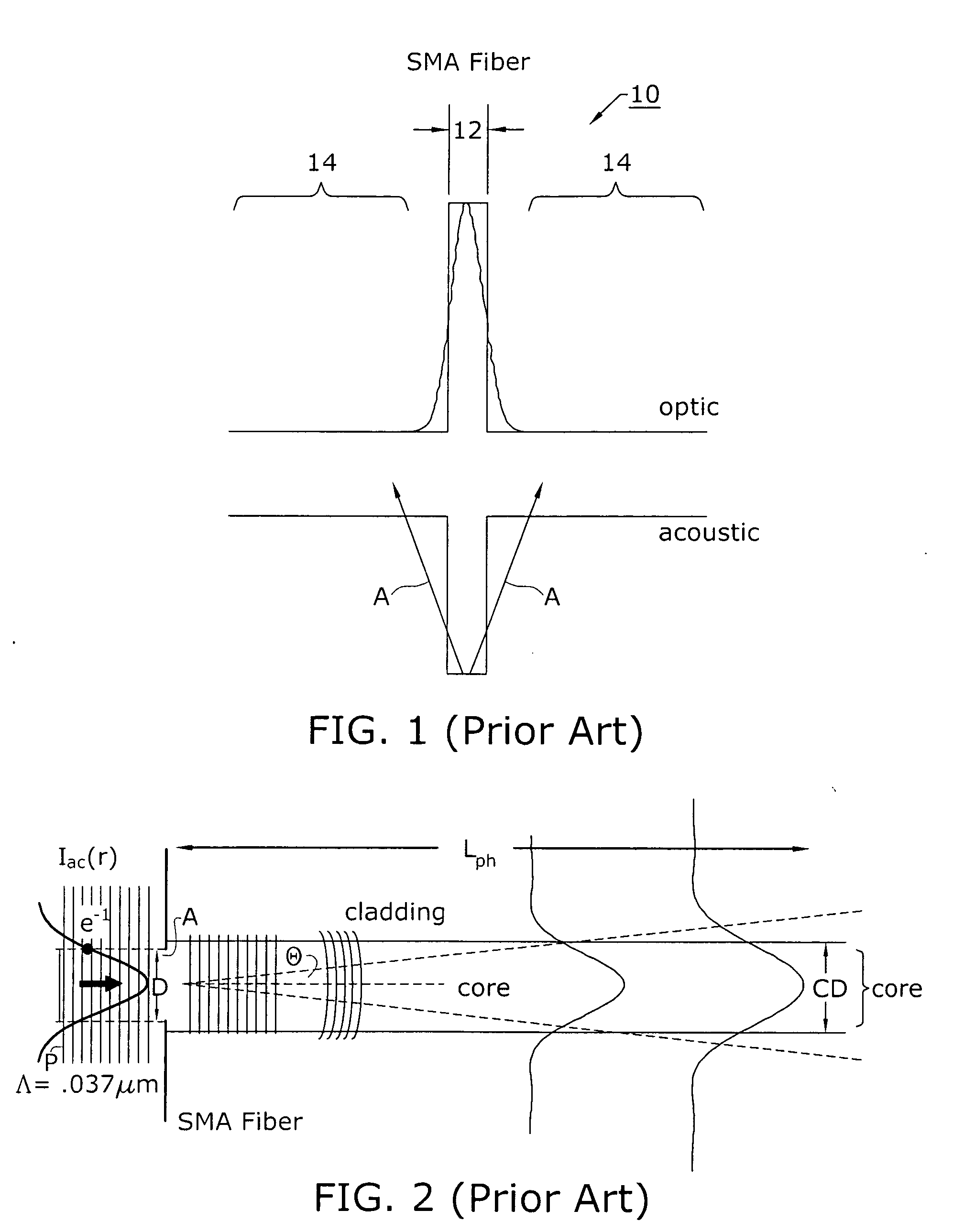

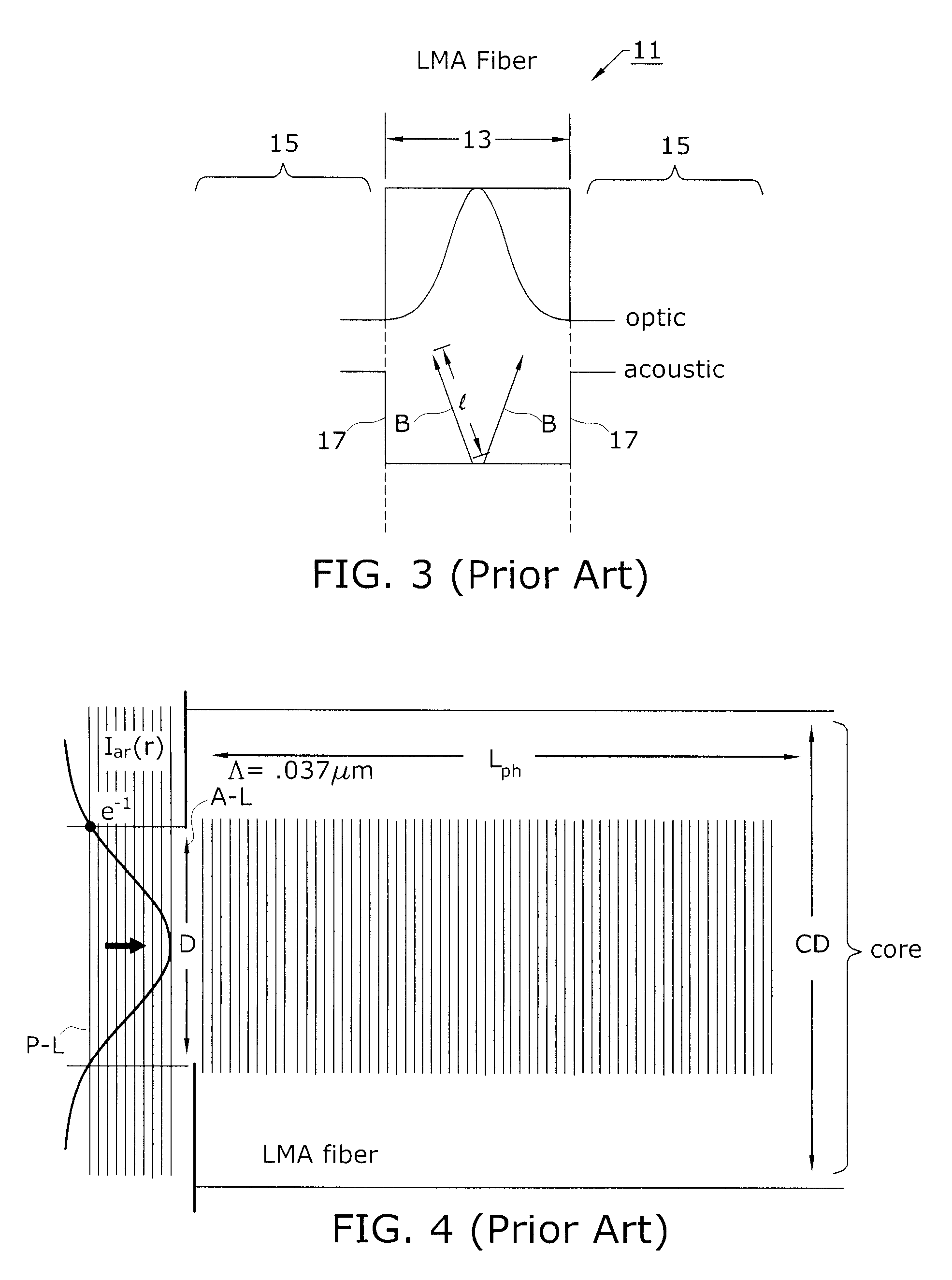

Large mode area fiber amplifiers with reduced stimulated brillouin scattering

ActiveUS20090116800A1Large mode areaLaser detailsOptical fibre with graded refractive index core/claddingPhononAluminium

Owner:OFS FITEL LLC

Reinforcing pipe sleeve and clamping sleeve for automobile radiator and intercooler, and use method

ActiveCN103382878AExtended service lifeReduce replacement rateInternal combustion piston enginesEngine cooling apparatusEngineeringIntercooler

Owner:李冬根

Beauxite applied pipeline transportation method

InactiveCN1730363AImprove working environmentSave engineering investmentBulk conveyorsWorking environmentEngineering

Owner:GUIYANG AL-MG DESIGN & RES INST

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap