Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about "Shafts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

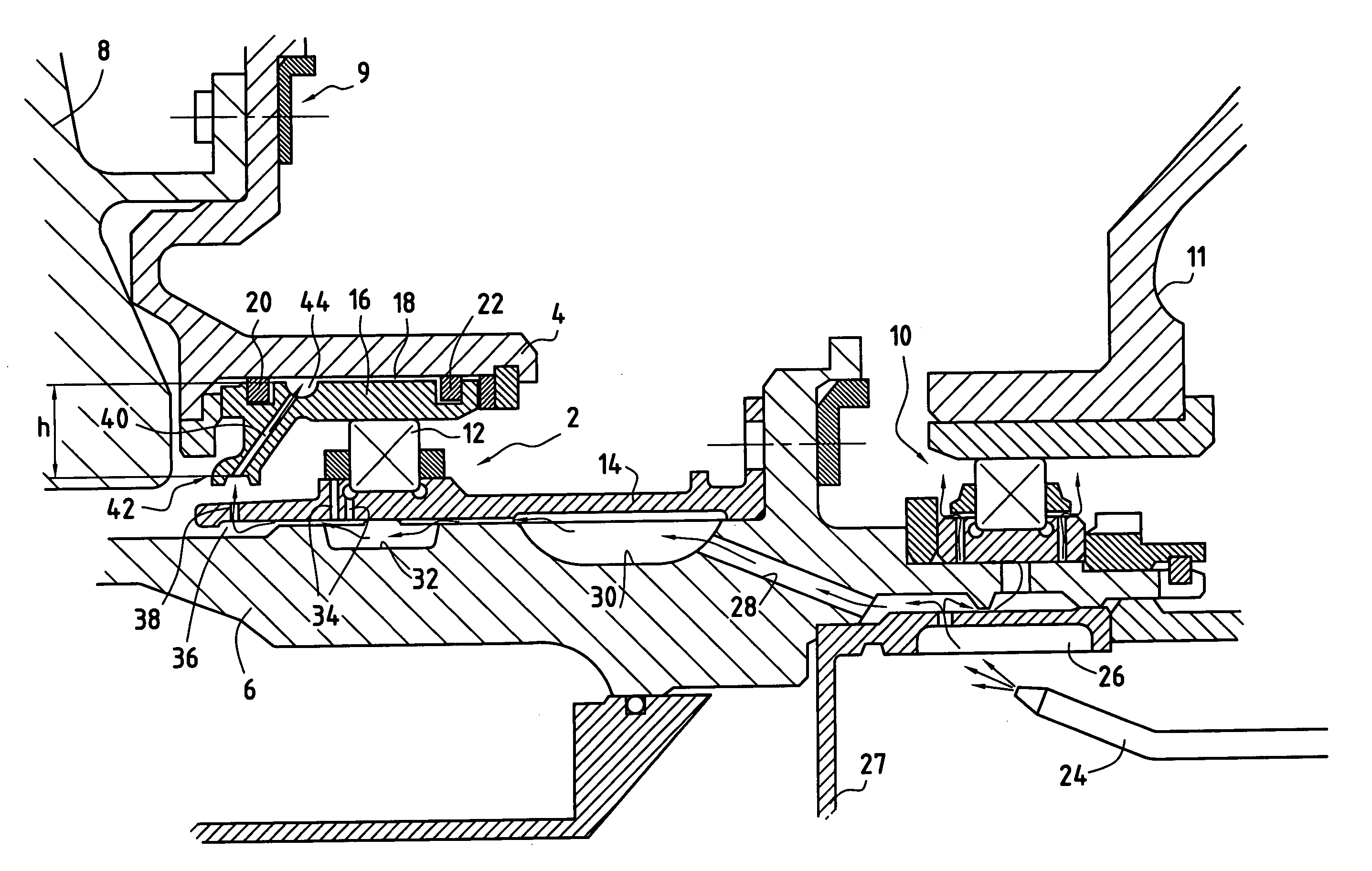

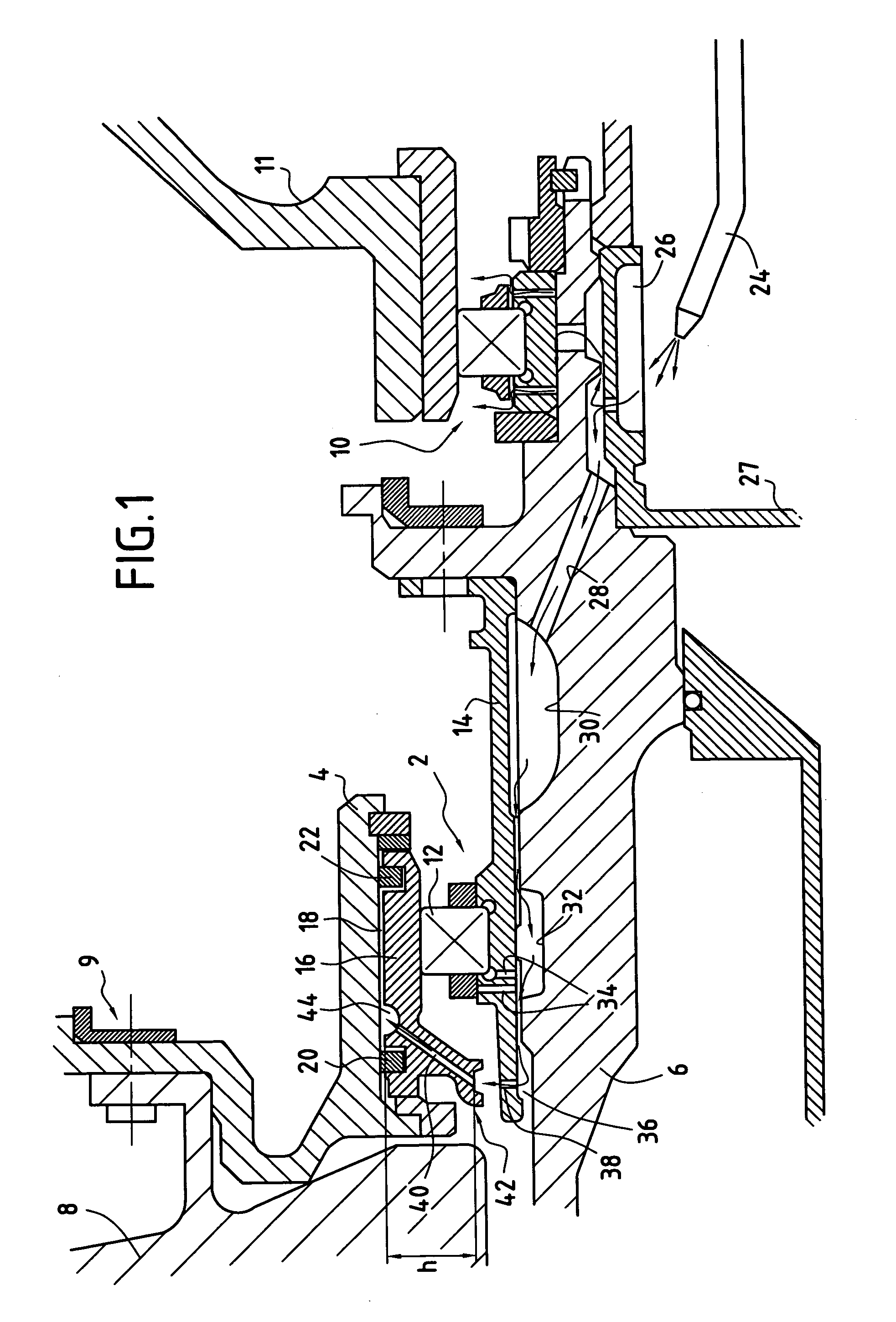

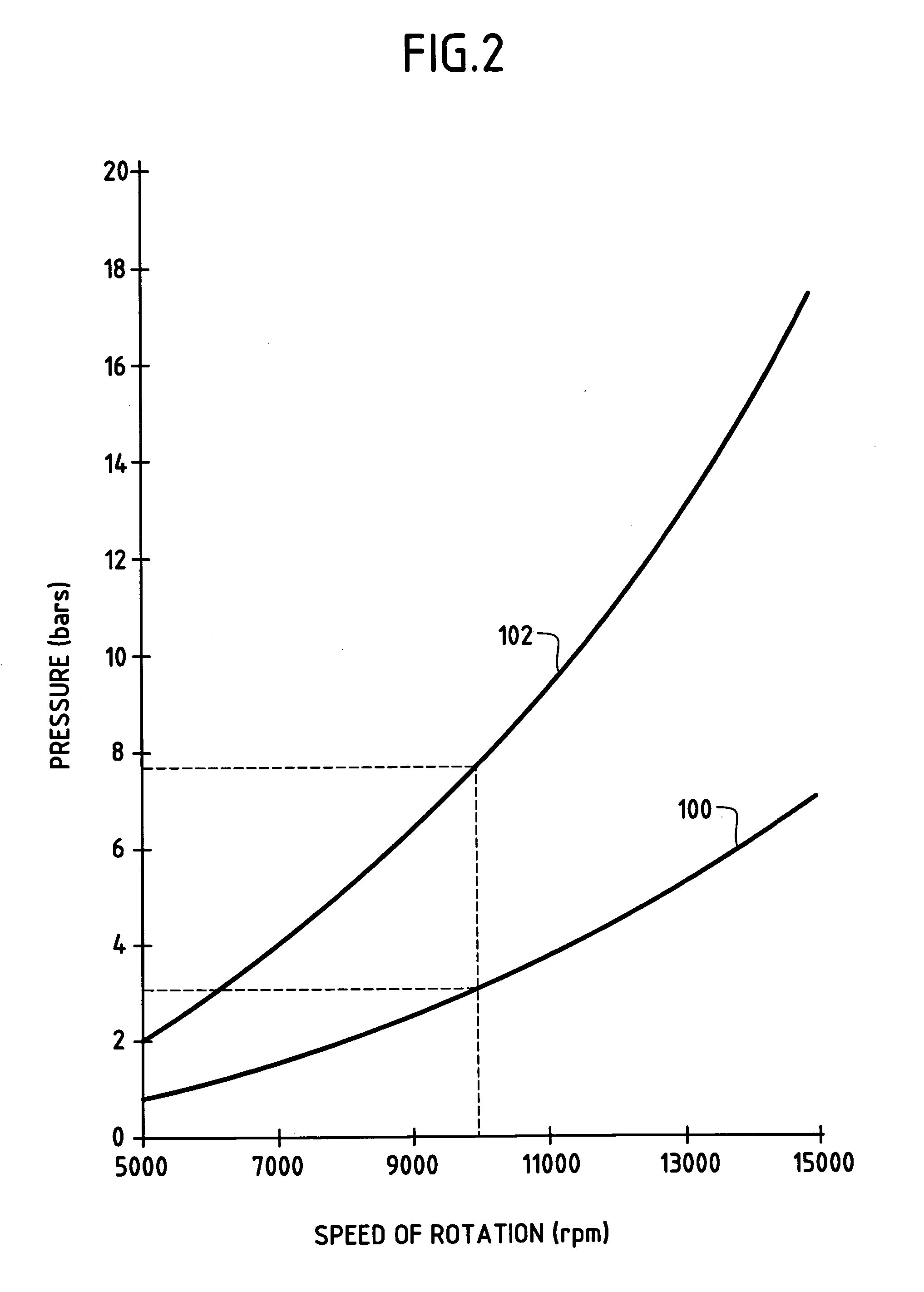

Oil-damped rolling bearing

ActiveUS20040062460A1Mitigate such drawbackRoller bearingsPump componentsRolling-element bearingEngineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

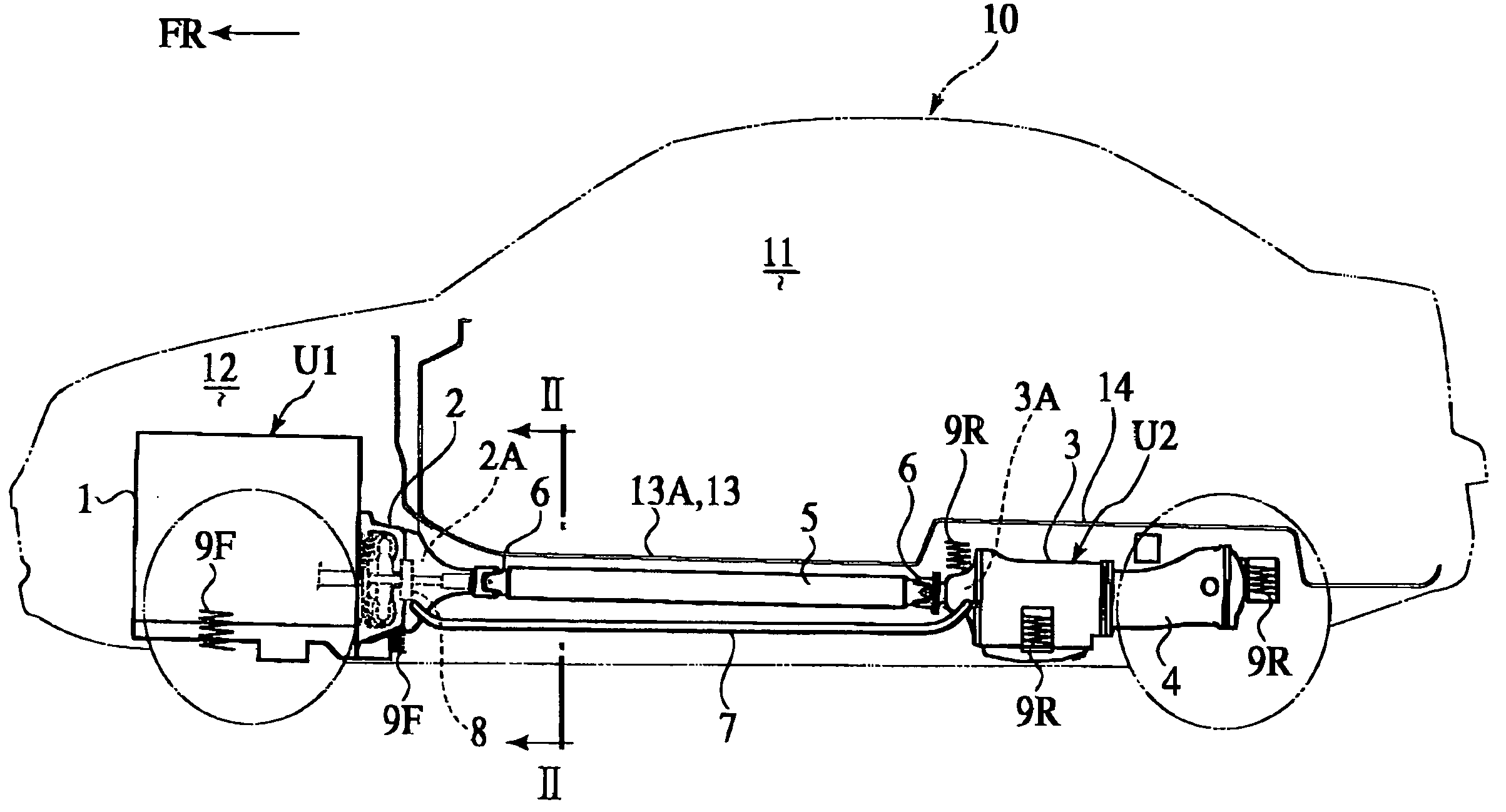

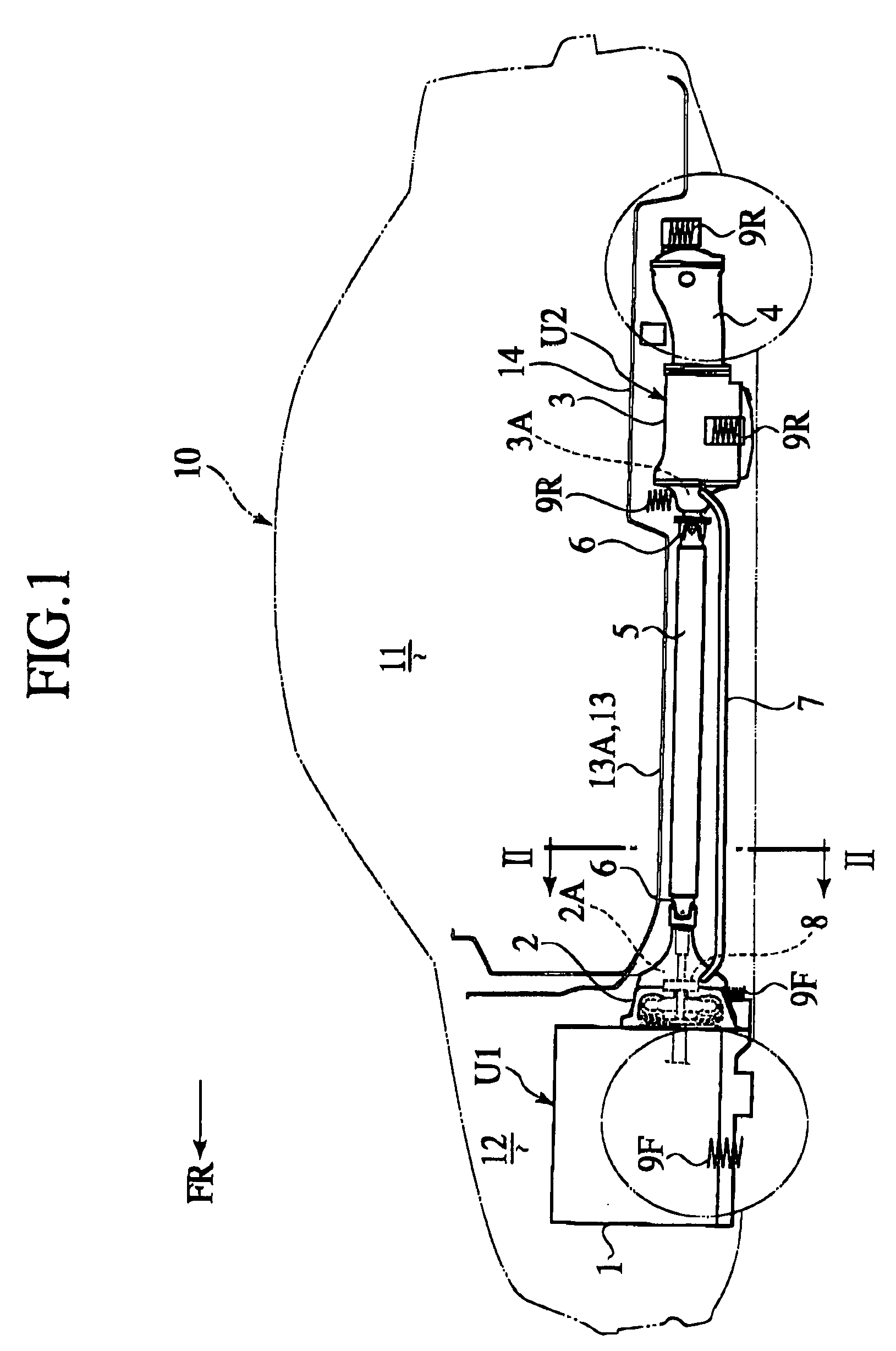

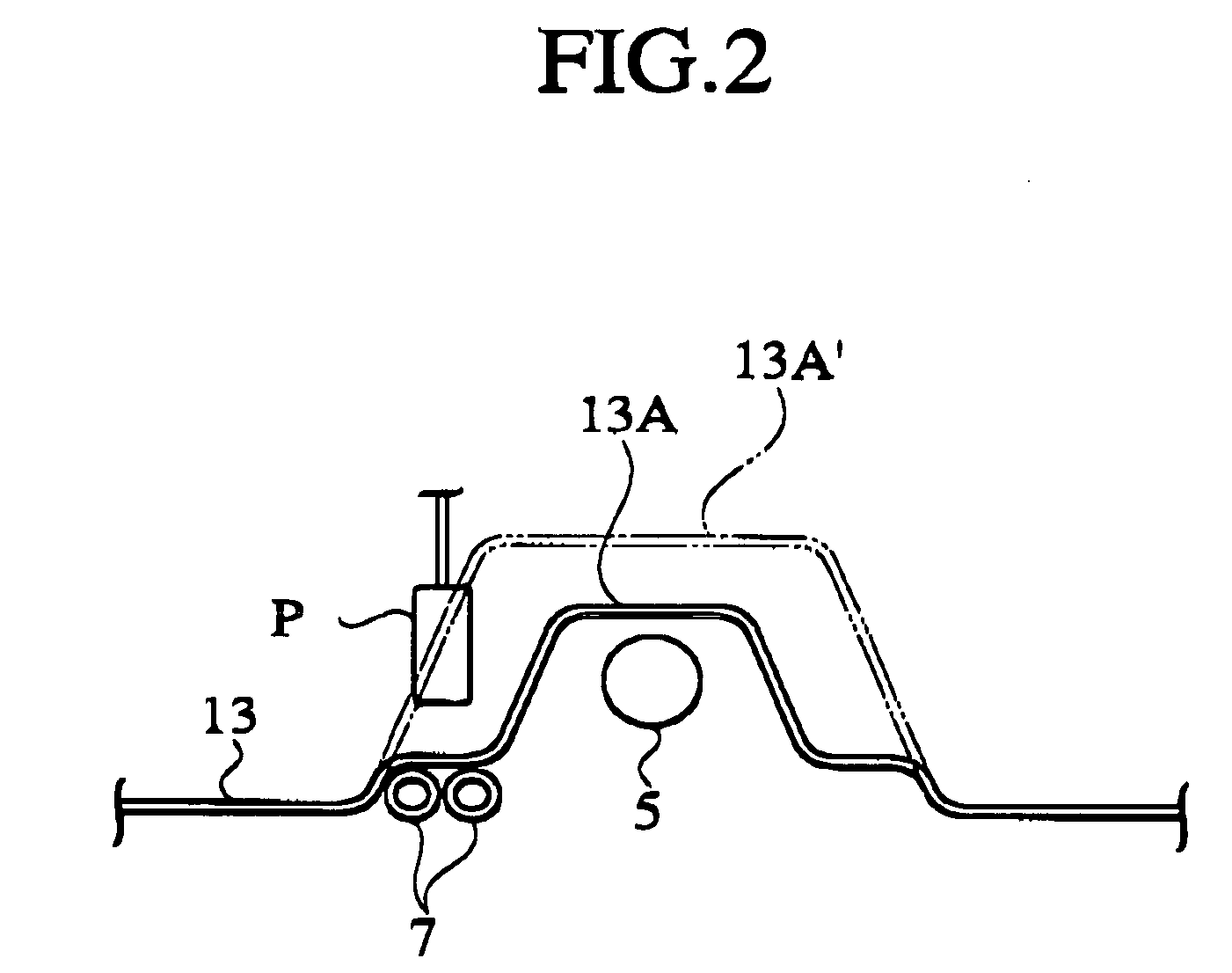

Vehicle drive system

InactiveUS20050061573A1Minimize occurrenceHeavy weightGearboxesShaftsAutomotive engineeringTorque converter

Owner:NISSAN MOTOR CO LTD

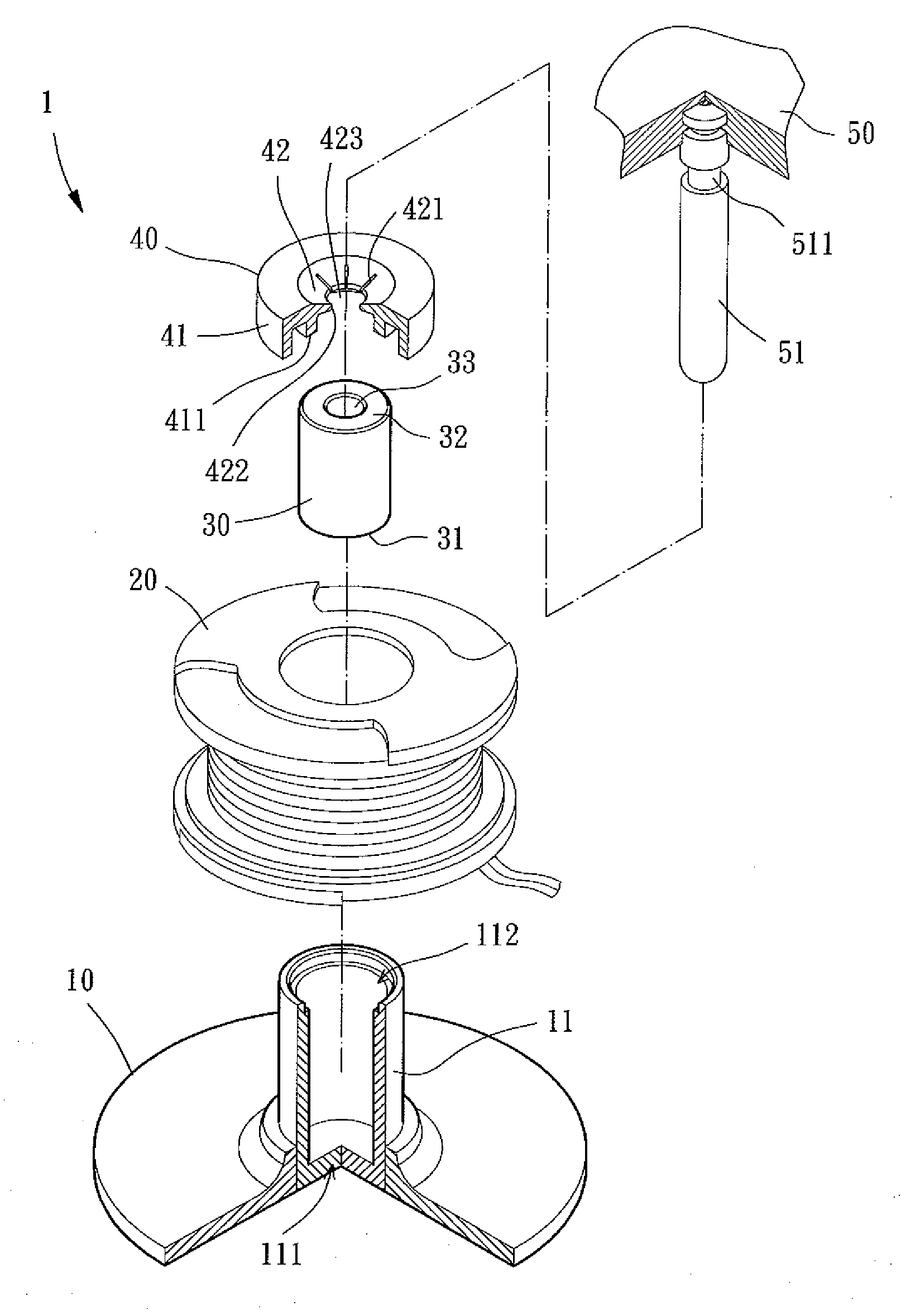

Motor

InactiveUS20050035670A1Reduce noiseExtended service lifePump componentsMagnetic circuitPhysicsMagnetic structure

Owner:DELTA ELECTRONICS INC

Motor

InactiveUS20100127588A1Prevent disengagementMagnetic circuit rotating partsPump componentsEngineeringSingle component

Owner:SUNONWEALTH ELECTRIC MACHINE IND

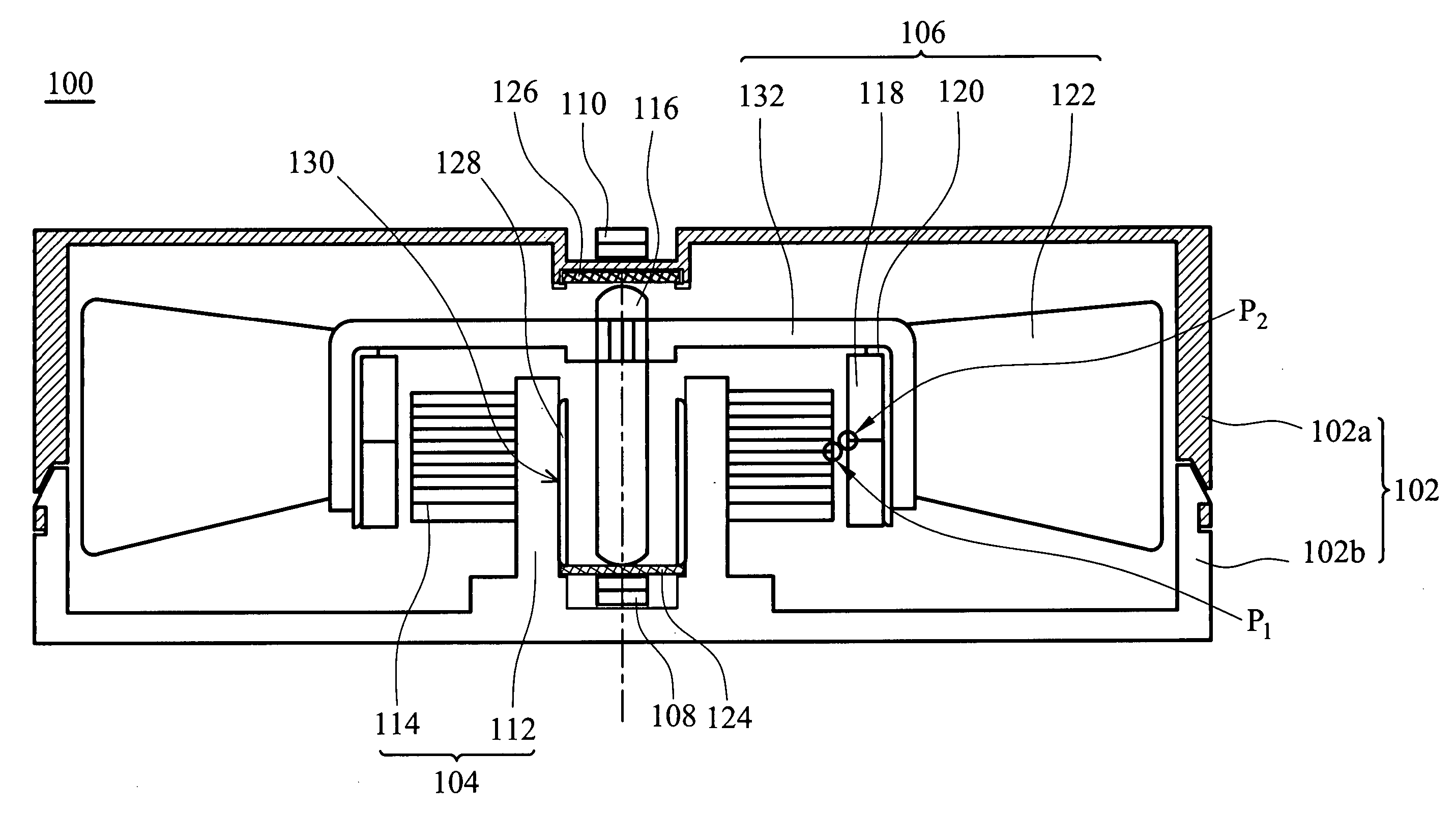

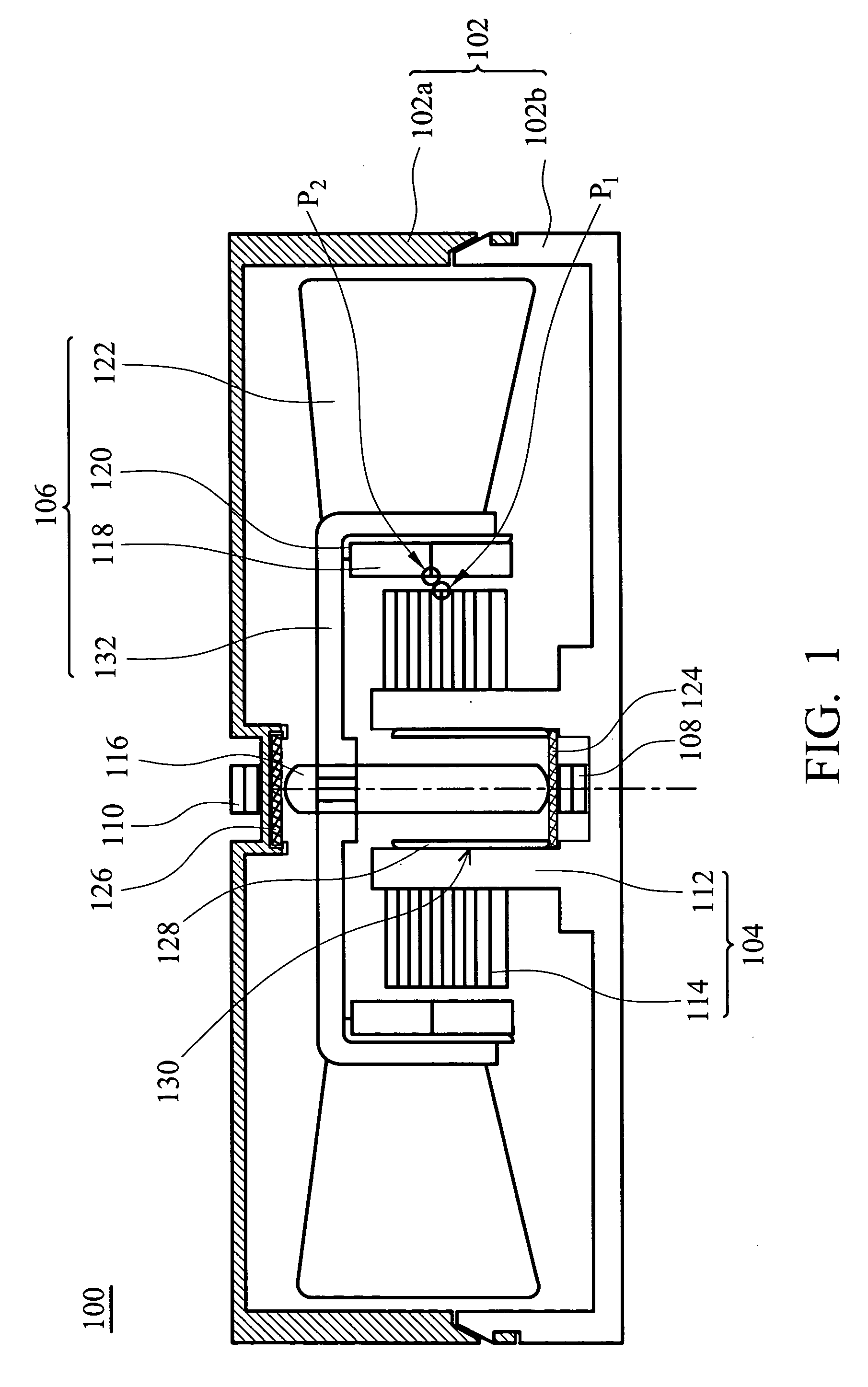

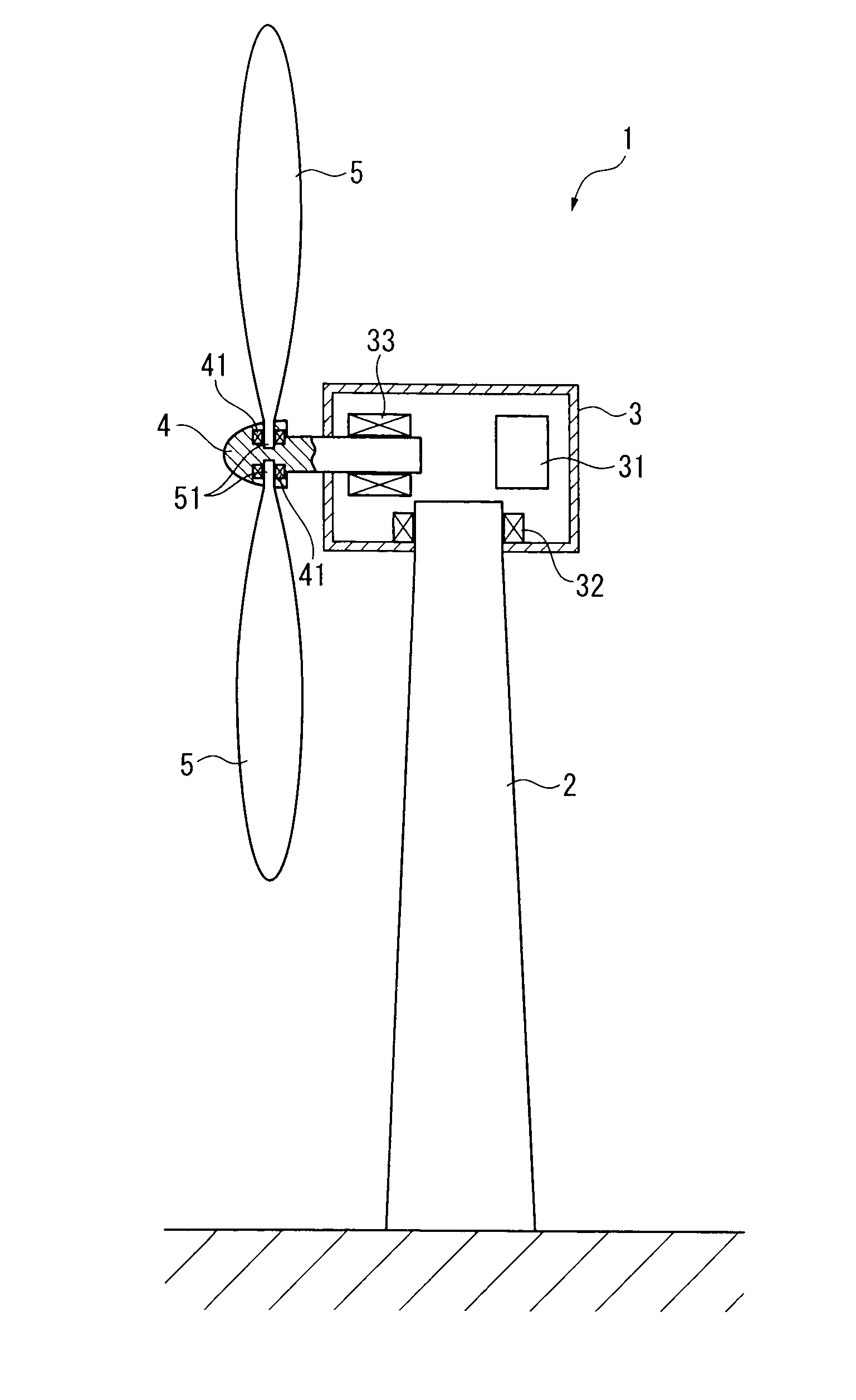

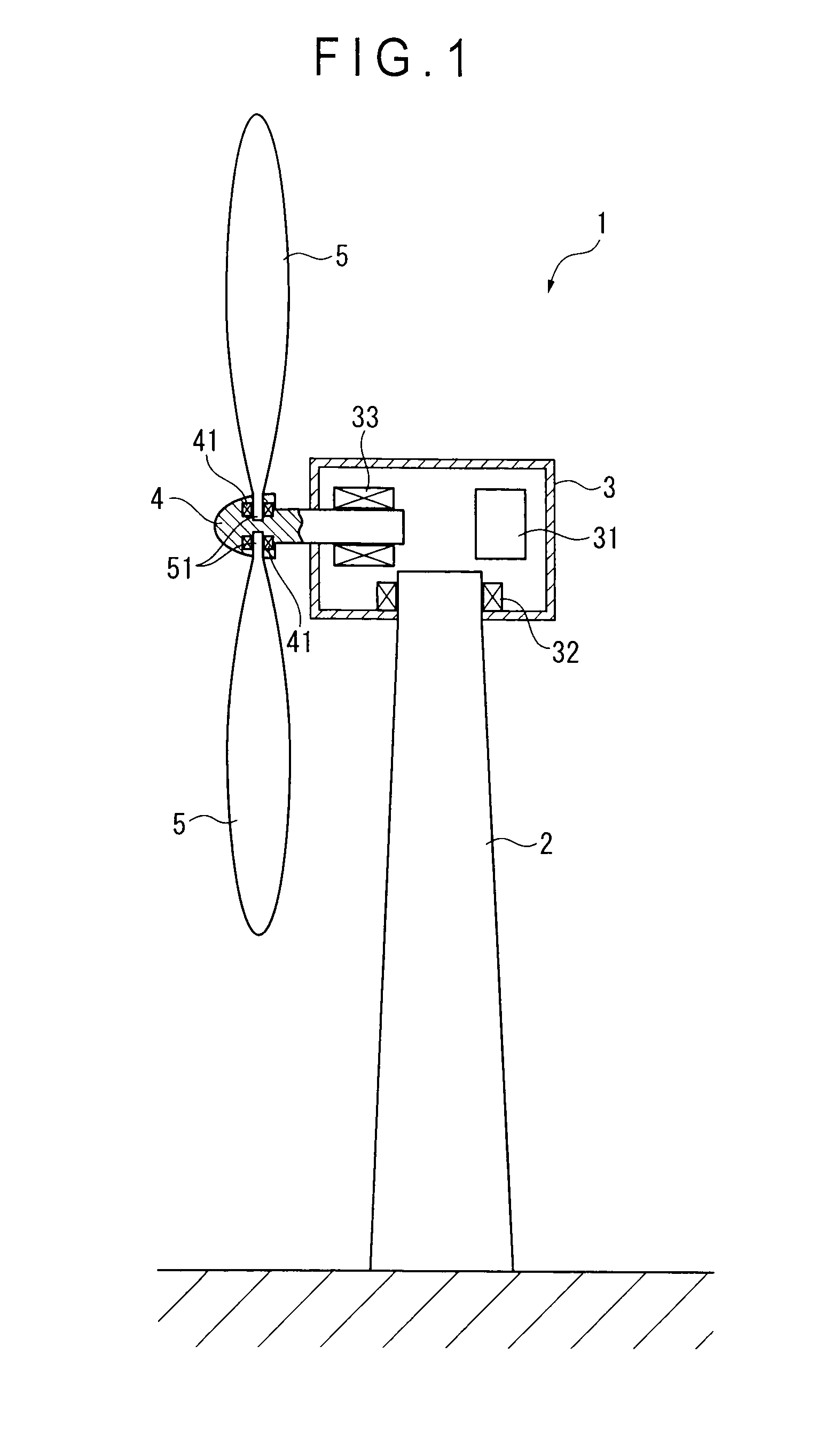

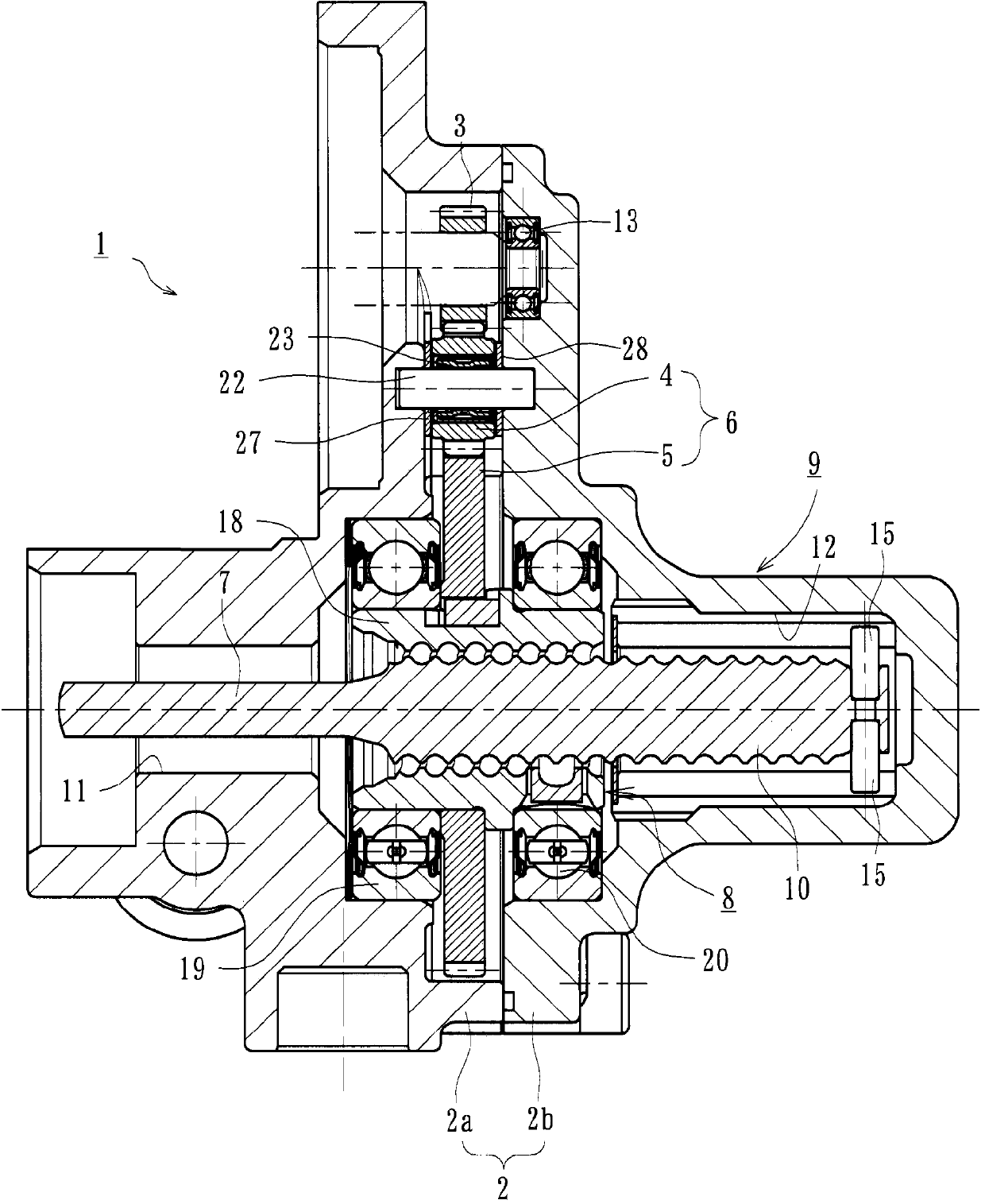

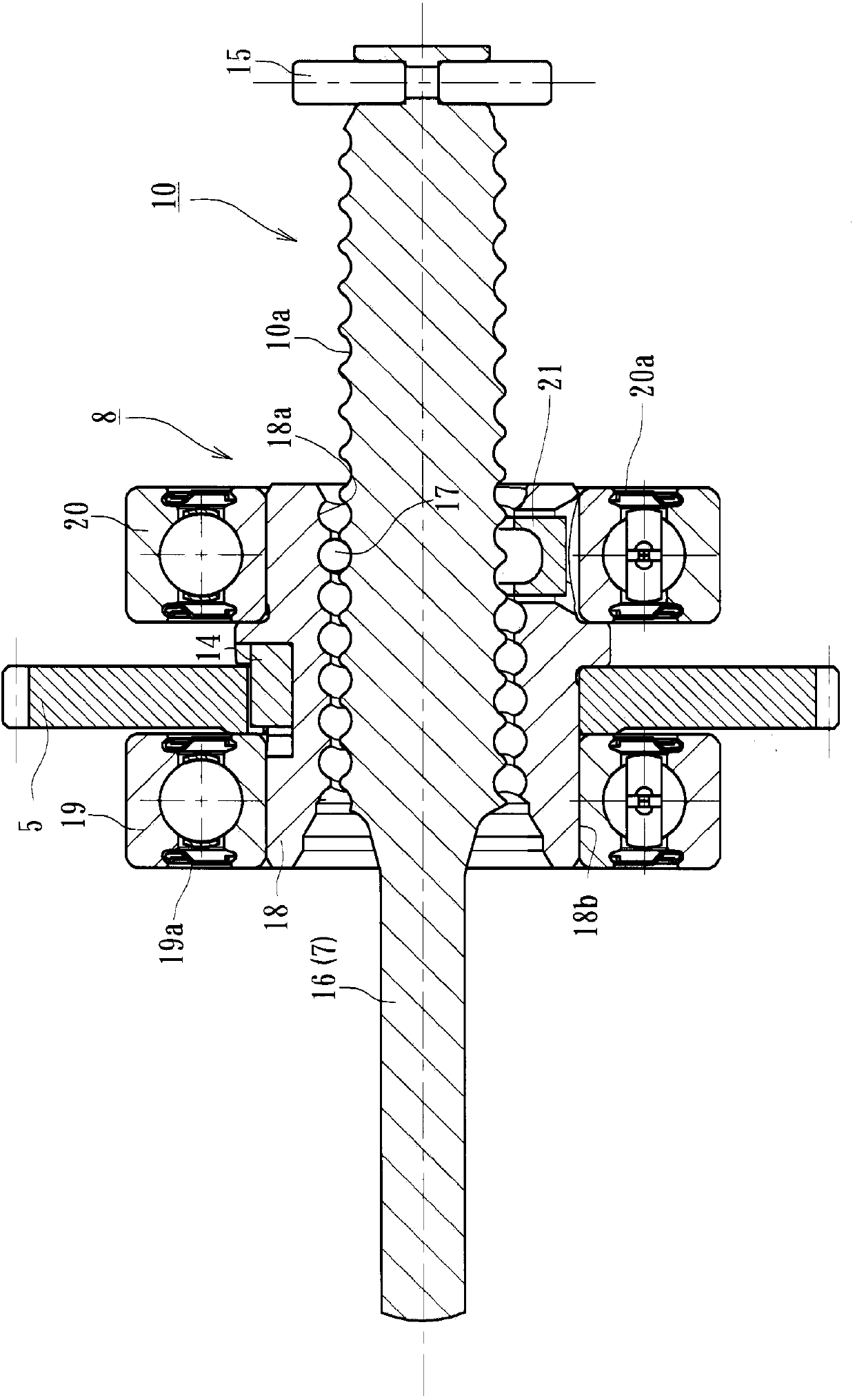

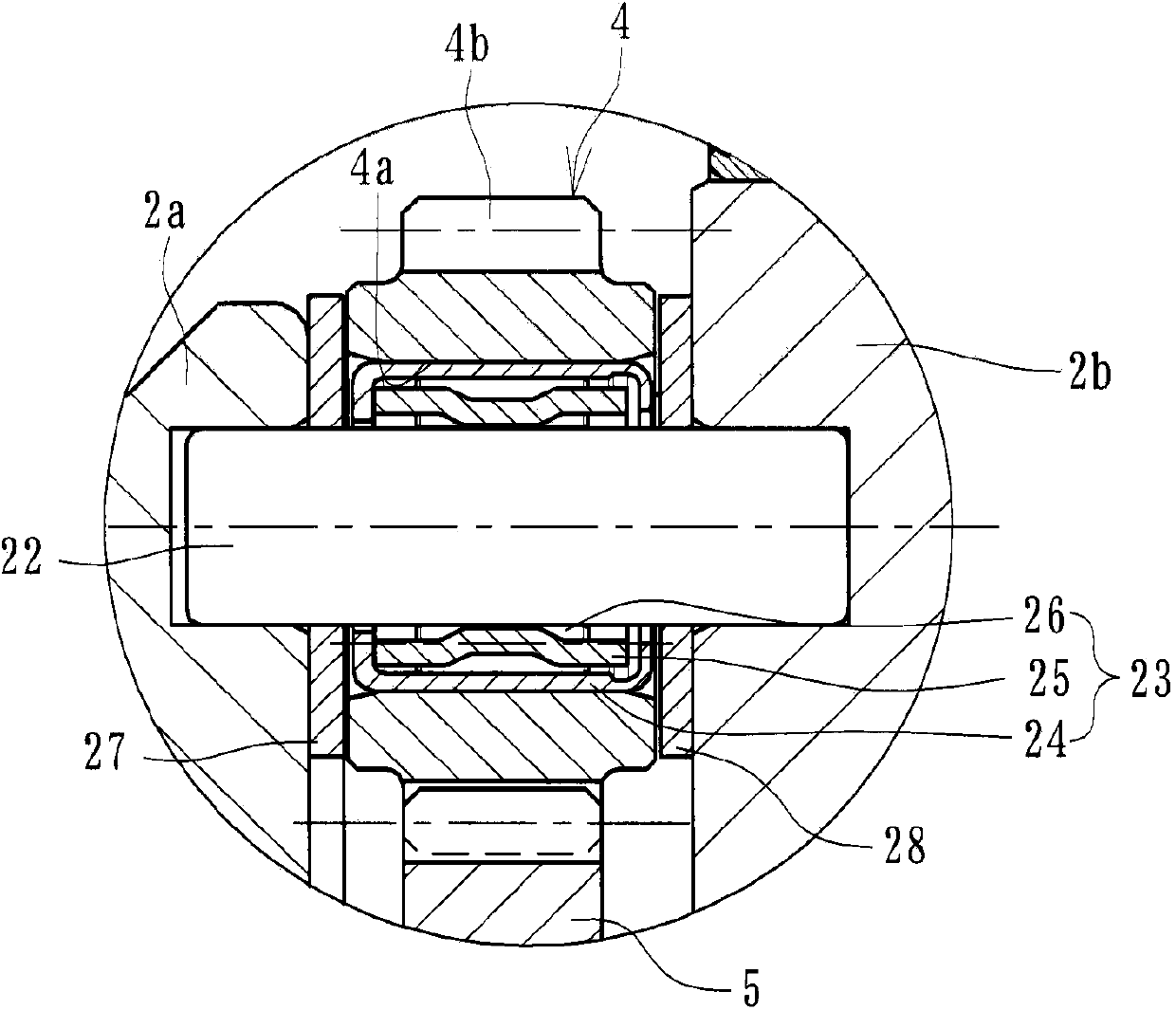

In-wheel actuator and in-wheel assembly comprising the same

An in-wheel assembly is provided, and the in-wheel assembly includes an in-wheel actuator and a wheel. The in-wheel actuator includes a driving motor; a decelerator which is disposed inside the driving motor and configured to reduce a rotational speed of the driving motor; and a hollow shaft which is disposed inside the driving motor and configured to transfer a rotational force of the driving motor to the decelerator, which is accommodated in a hollow of the hollow shaft, and circulates fluid inside of the driving motor with respect to a surface of the decelerator when driven to rotate by the driving motor. The wheel accommodates the in-wheel actuator and receives a rotational speed reduced by the decelerator to rotate.

Owner:SAMSUNG ELECTRONICS CO LTD

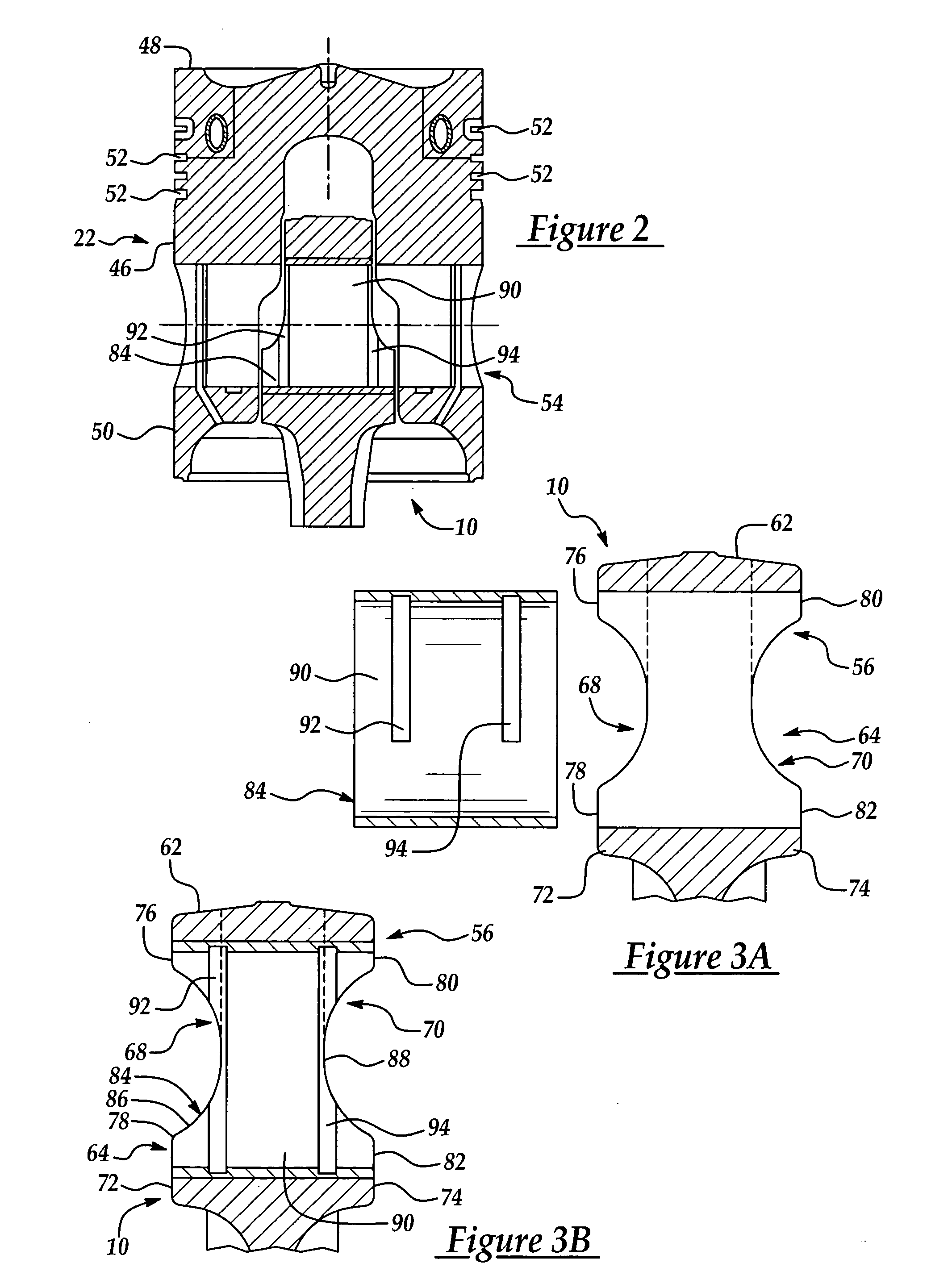

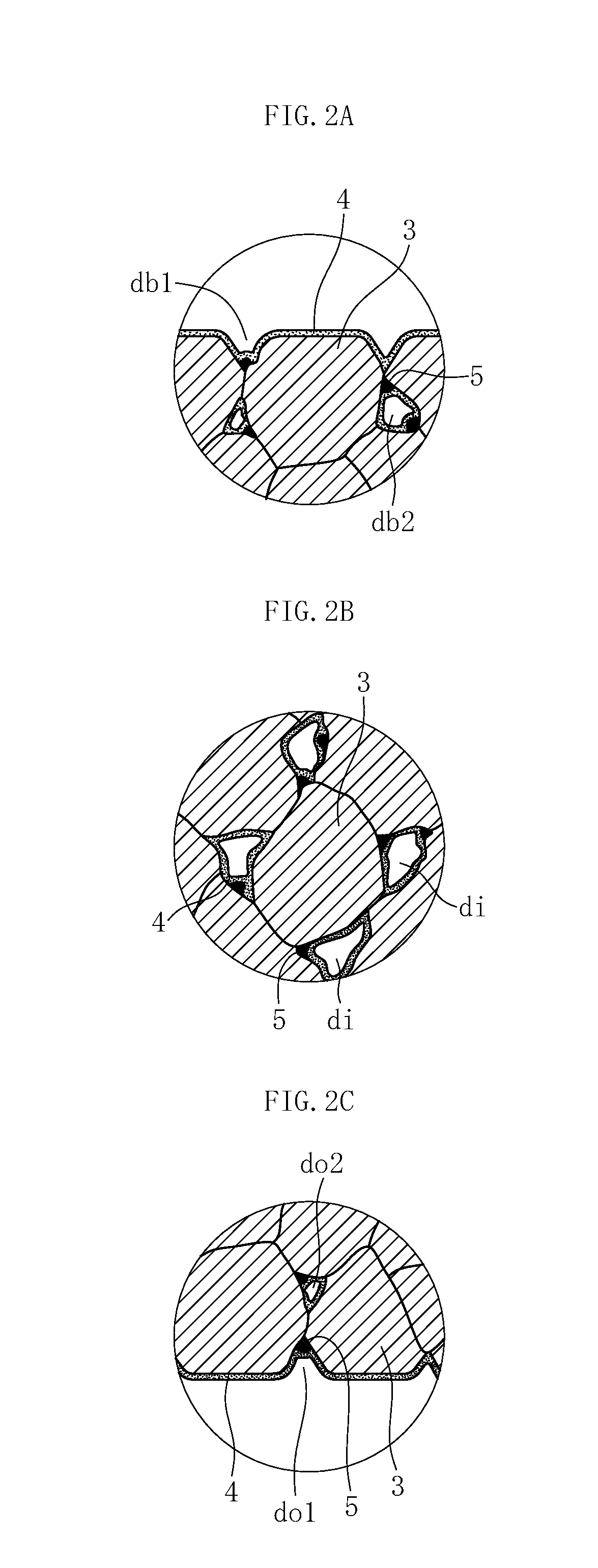

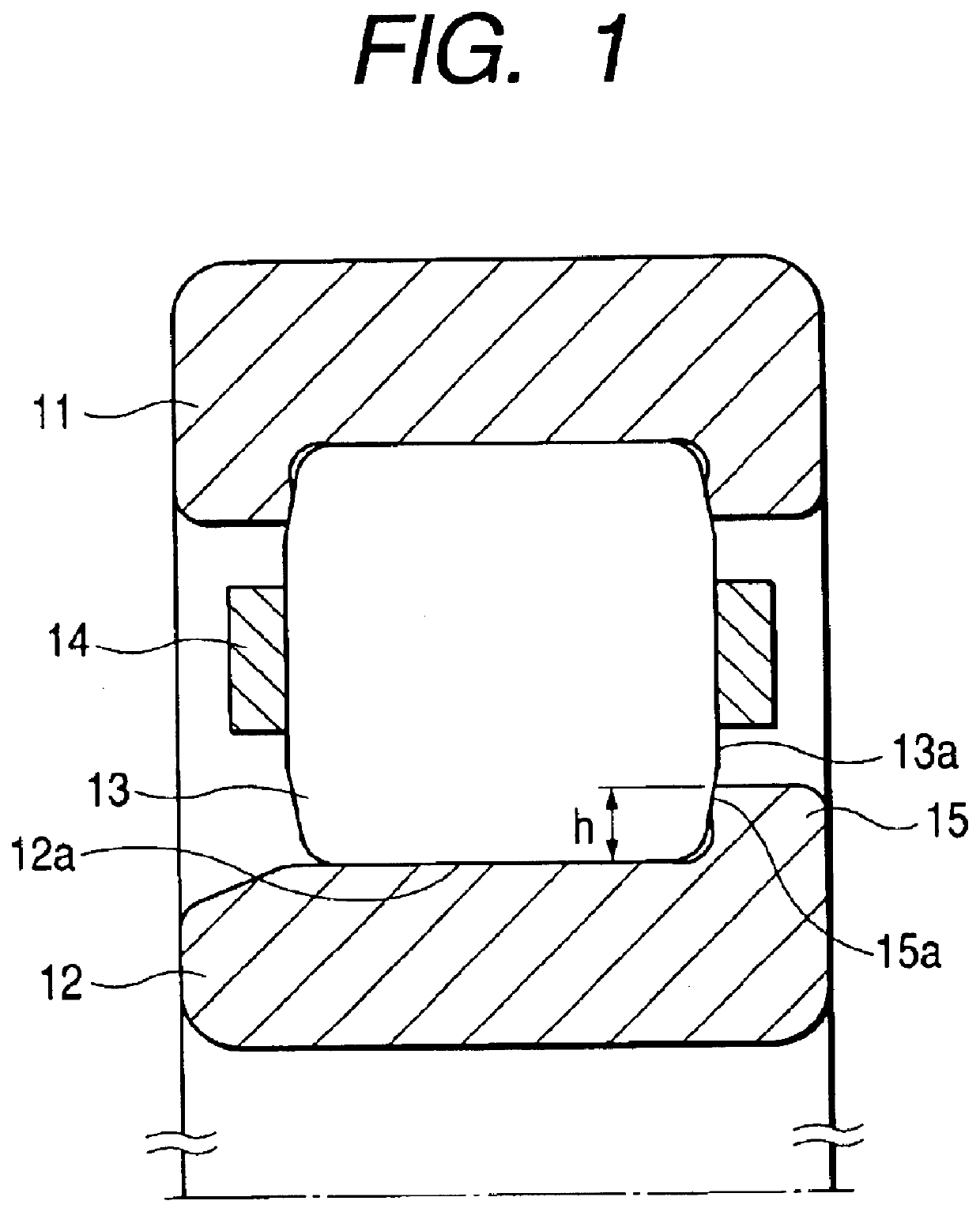

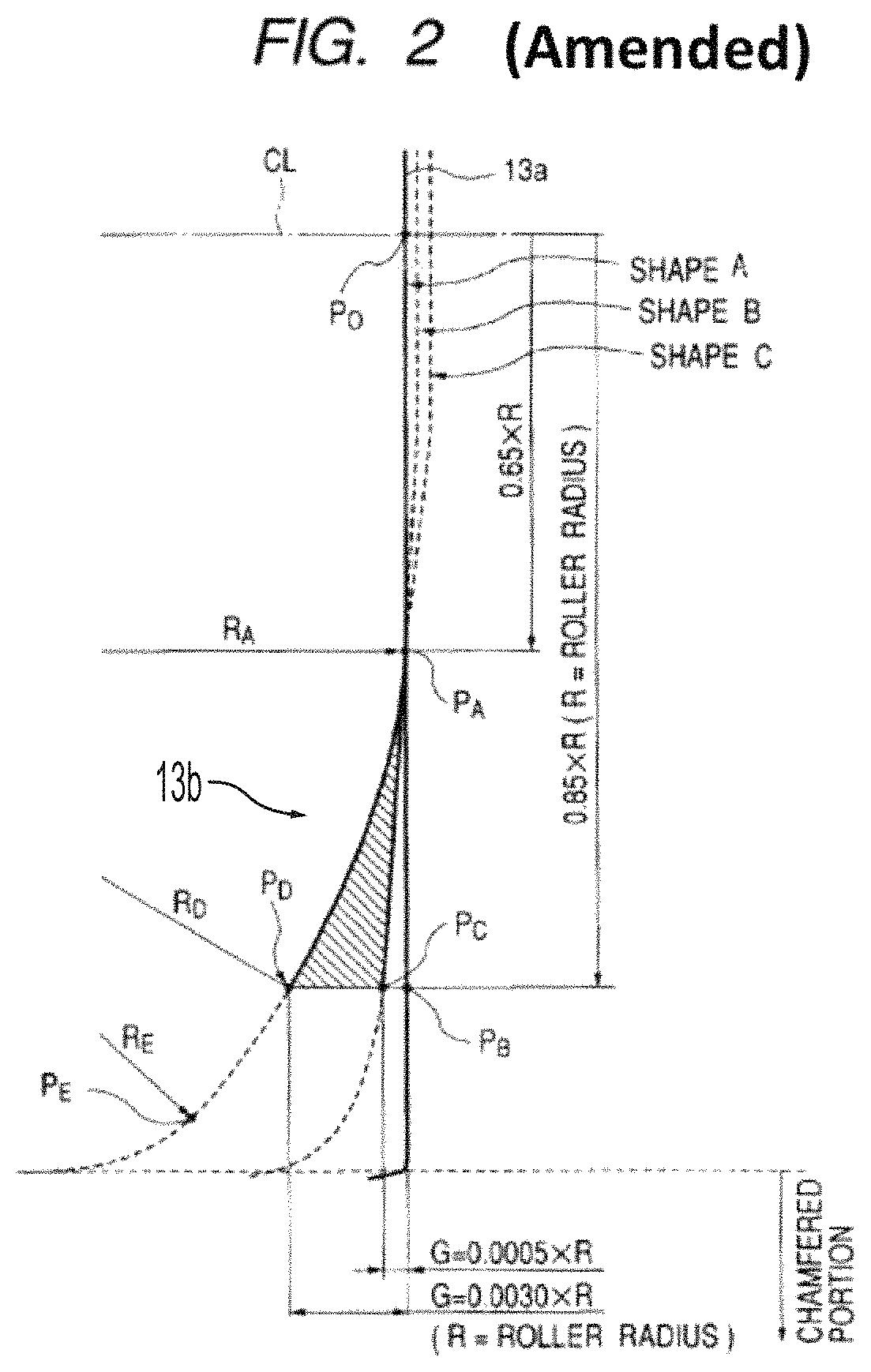

Tapered roller bearing

ActiveUS20050213861A1Reduce rotational torqueSimple processRoller bearingsHubsCircular coneEngineering

A tapered roller bearing comprises an outer race, an inner race, a plurality of tapered rollers, and a cage. A small-diameter end portion of the inner race is formed with a small flange portion for limiting axial movement of the tapered rollers and a cylindrical portion which has a less diameter than the small flange portion and is connected to an axial outer end of the small flange portion. The cage is formed at a small-diameter end portion thereof with a bent portion which is bent inward in a radial direction. A small-diameter end portion of the cage has a bent portion which is faced to an outer surface of the cylindrical portion of the inner race with a predetermined clearance therefrom such that a labyrinth is created between the cage and the inner race.

Owner:JTEKT CORP

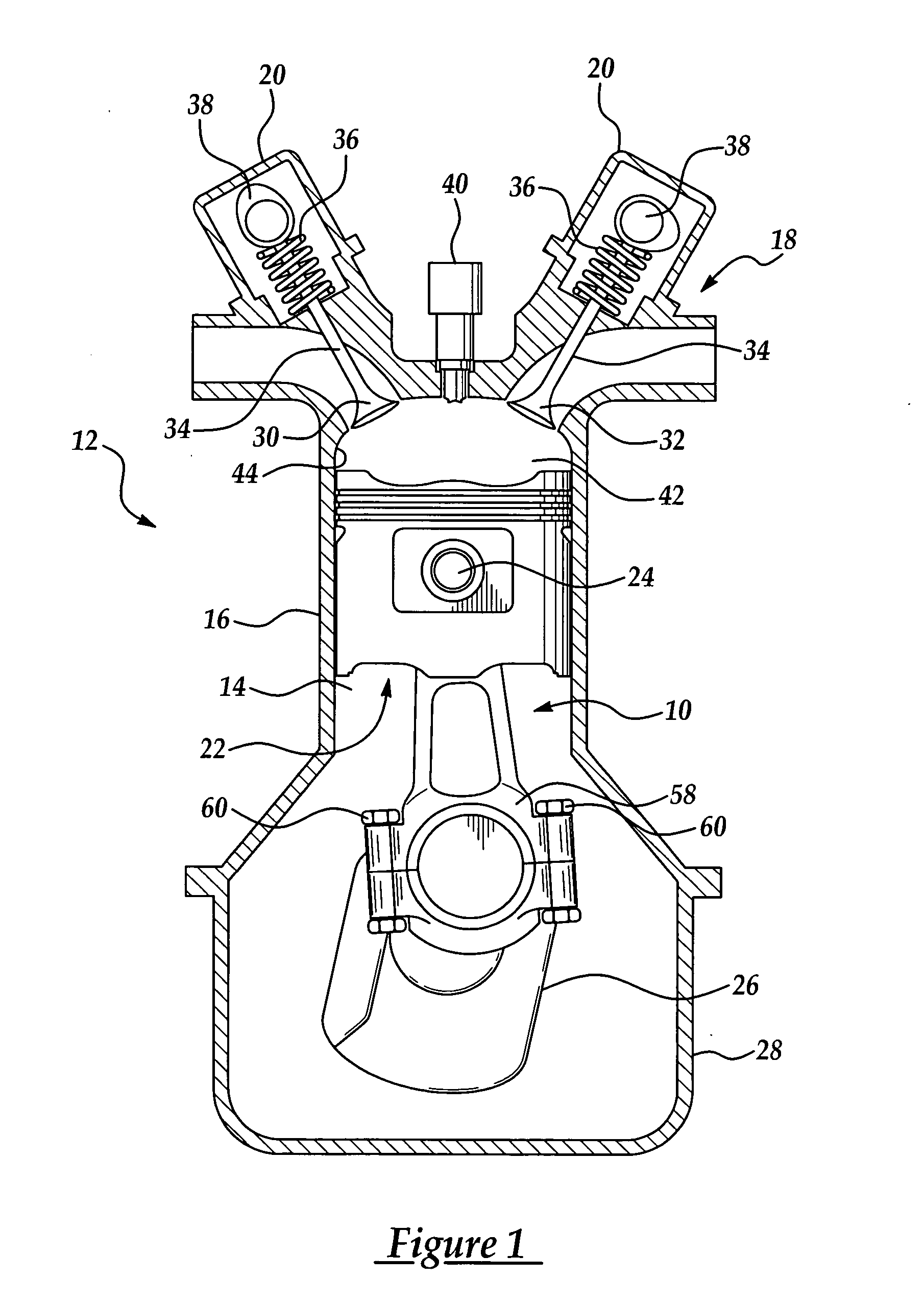

Connecting rod assembly for an internal combustion engine and method of manufacturing same

InactiveUS20060101939A1Simplify the manufacturing processReduce widthConnecting rod bearingsConnecting rodsEngineeringInternal combustion engine

Owner:MAHLE IND

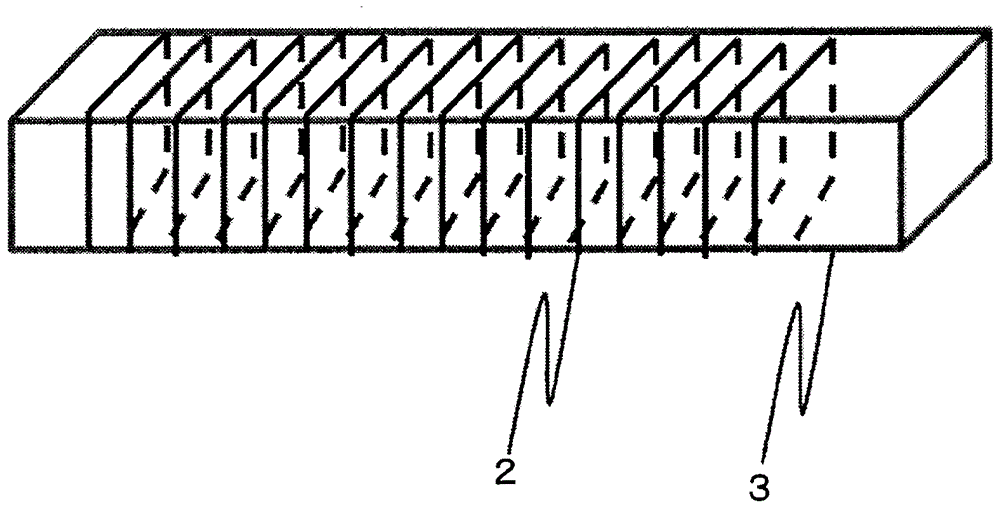

Sintered bearing and manufacturing method for same

InactiveUS20150064045A1Increase production capacityLow costTransportation and packagingShaftsAluminiumSurface layer

Owner:NTN CORP

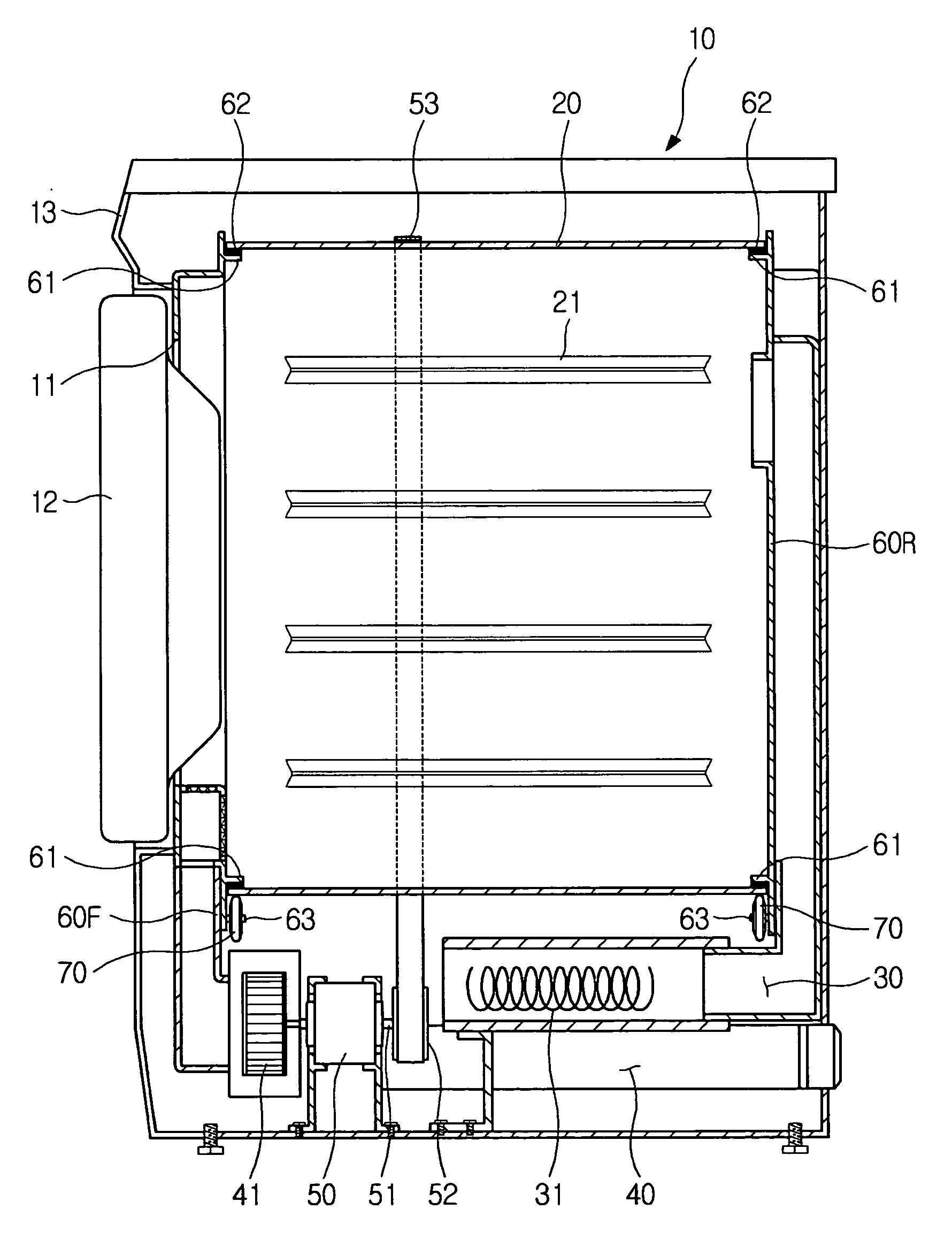

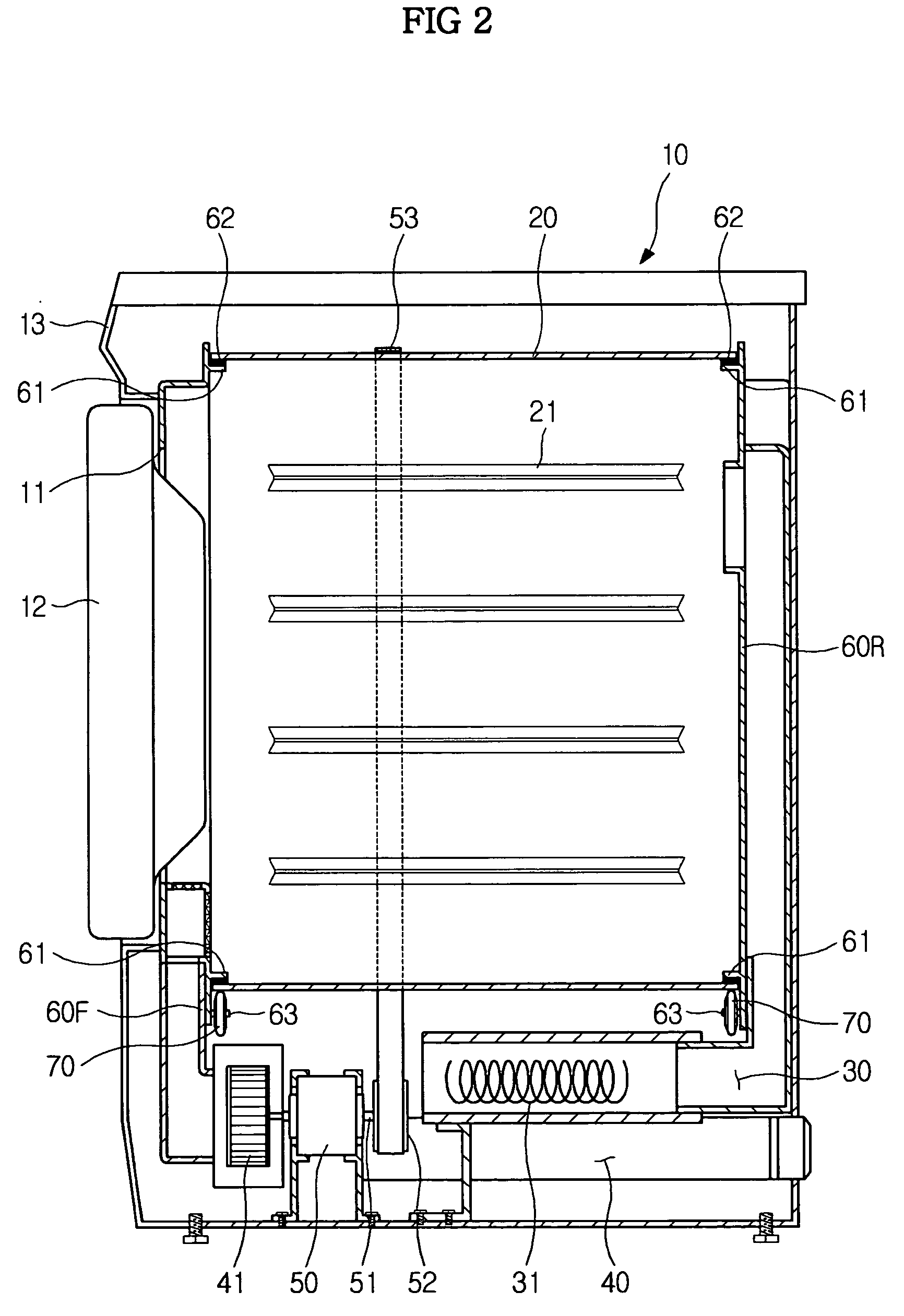

Roller and clothes drying apparatus provided with the same

InactiveUS20050097772A1Improve impact absorption performanceTextile treatmentShaftsEngineeringHardness

Owner:SAMSUNG ELECTRONICS CO LTD

Grease composition

InactiveUS20120098269A1Long life-timeSuppressing bearing wearPump componentsAdditivesBase oilViscosity

Owner:IDEMITSU KOSAN CO LTD

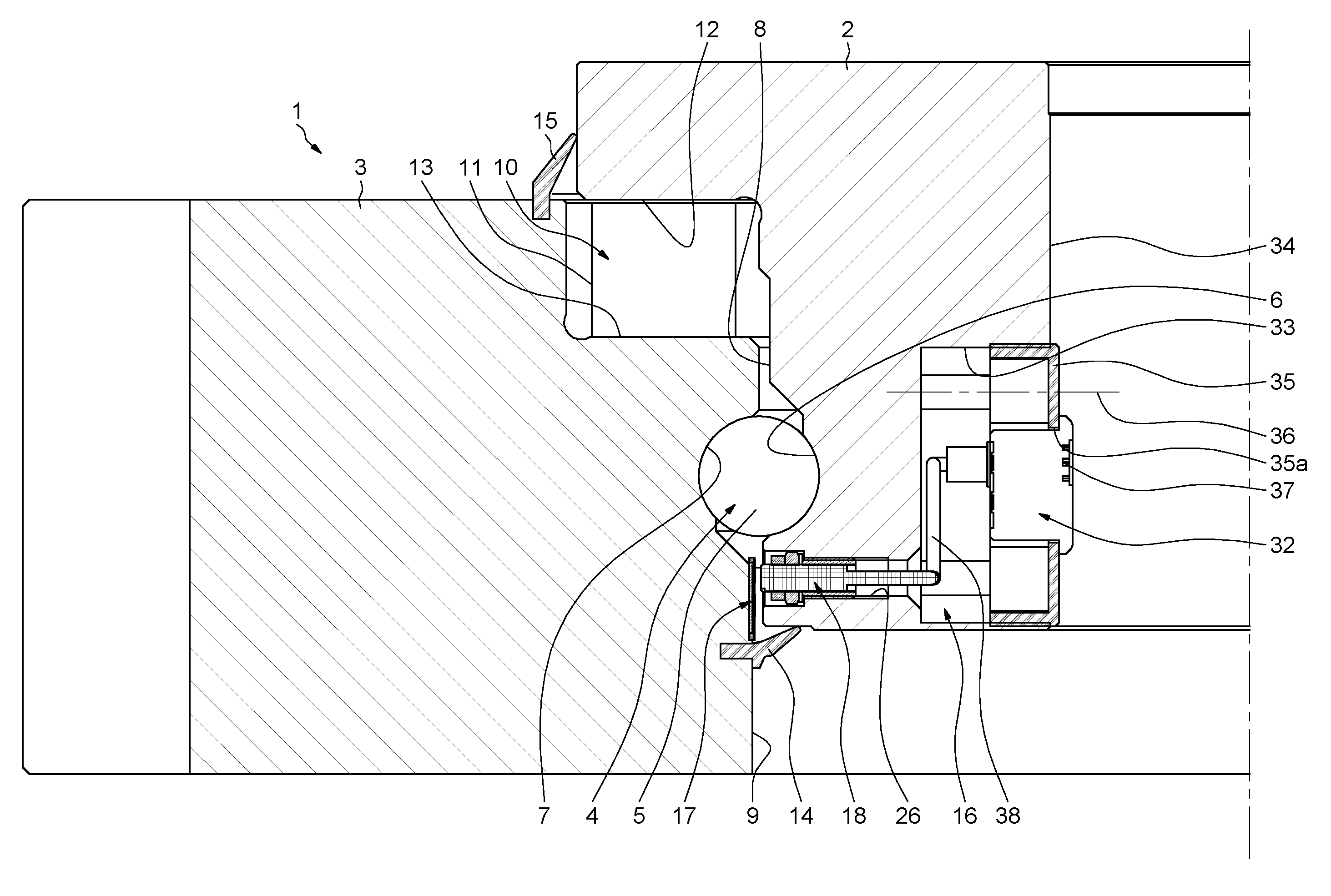

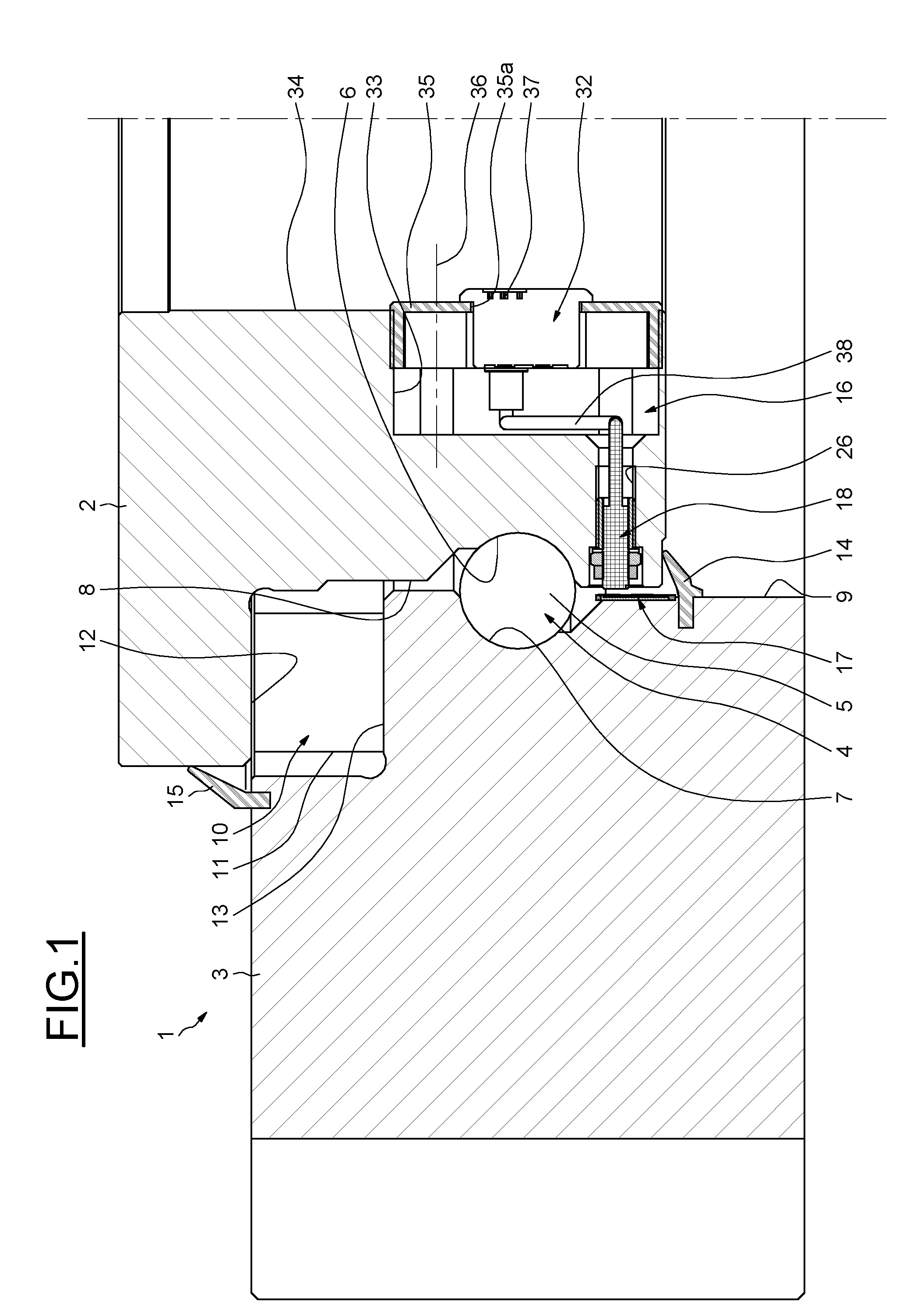

Door handle assembly for a vehicle

ActiveUS8904835B2Improve reliabilityMechanical deflection device is inexpensiveAnti-theft cycle devicesShaftsEngineeringElectrical and Electronics engineering

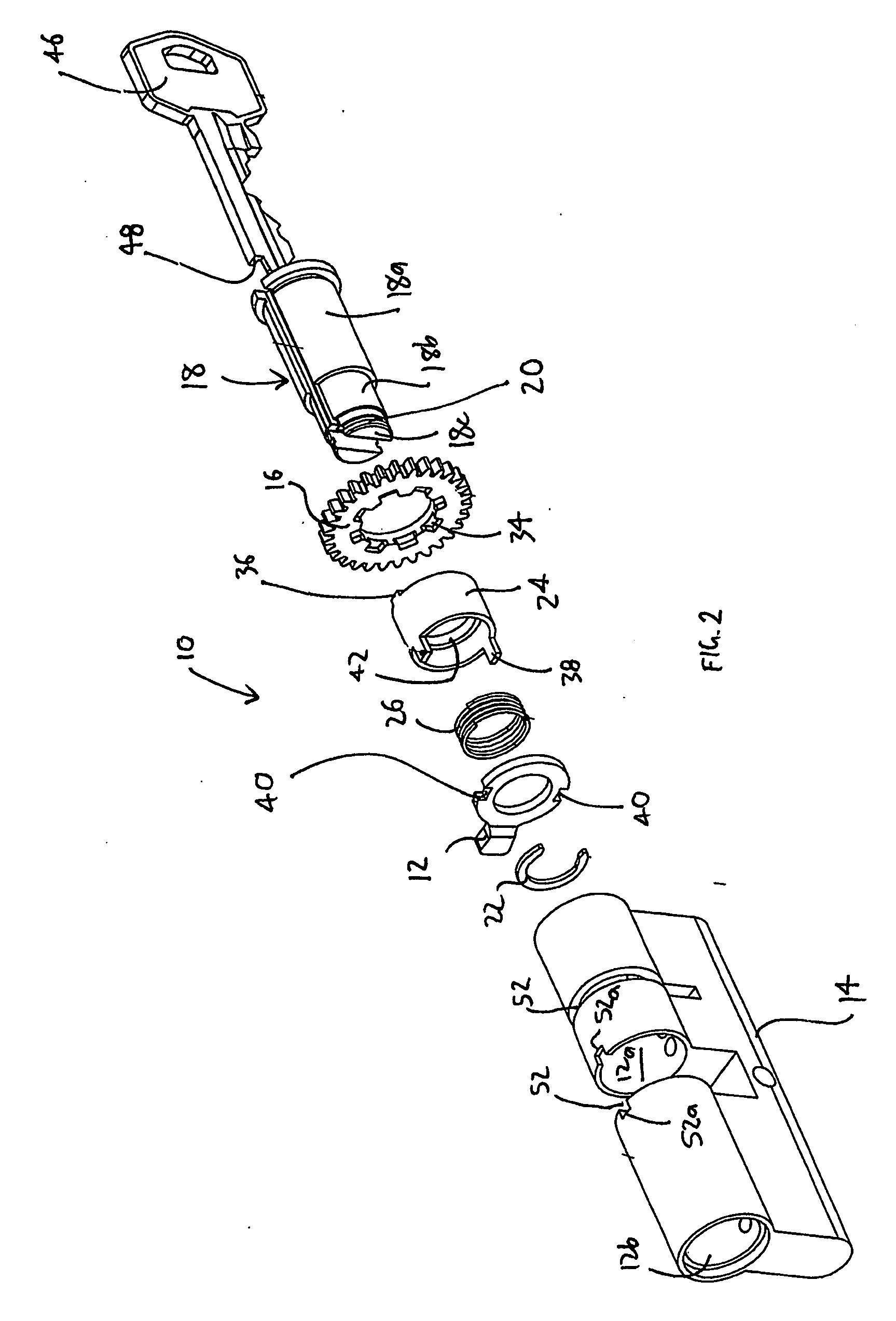

Door handle assembly (1) for a vehicle, including a door handle (2) for actuating a door lock (6), which can be moved by external power from a level rest position to an exposed operative position, and a lock cylinder (3) placed adjacent to the door handle (2) for locking and unlocking the door lock (6). The lock cylinder (3) can be covered by a cover plate (4) which, when actuated by hand, exposes the lock cylinder (3) and allows switch of the door handle (2) from the rest position to the operative position.

Owner:AUDI AG

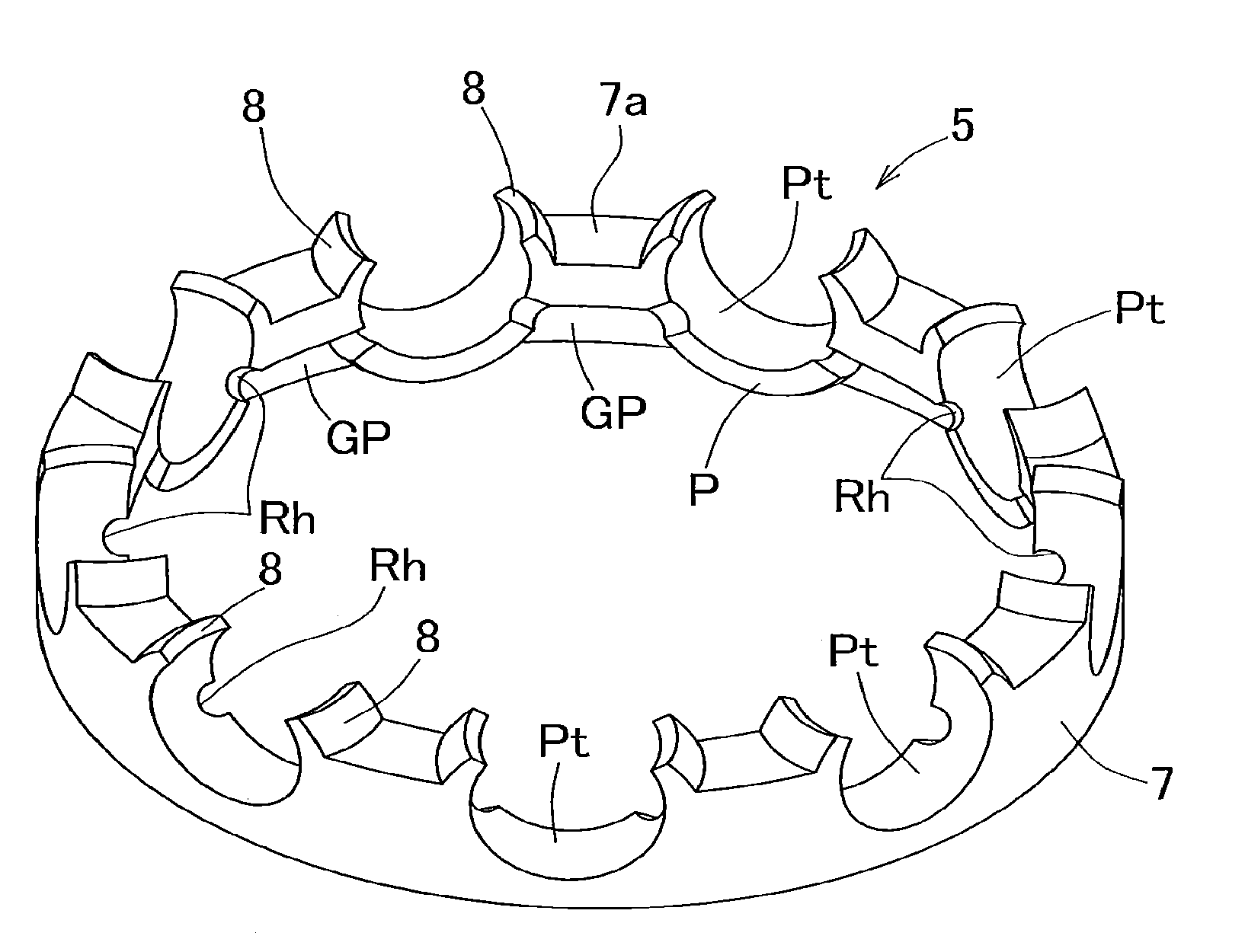

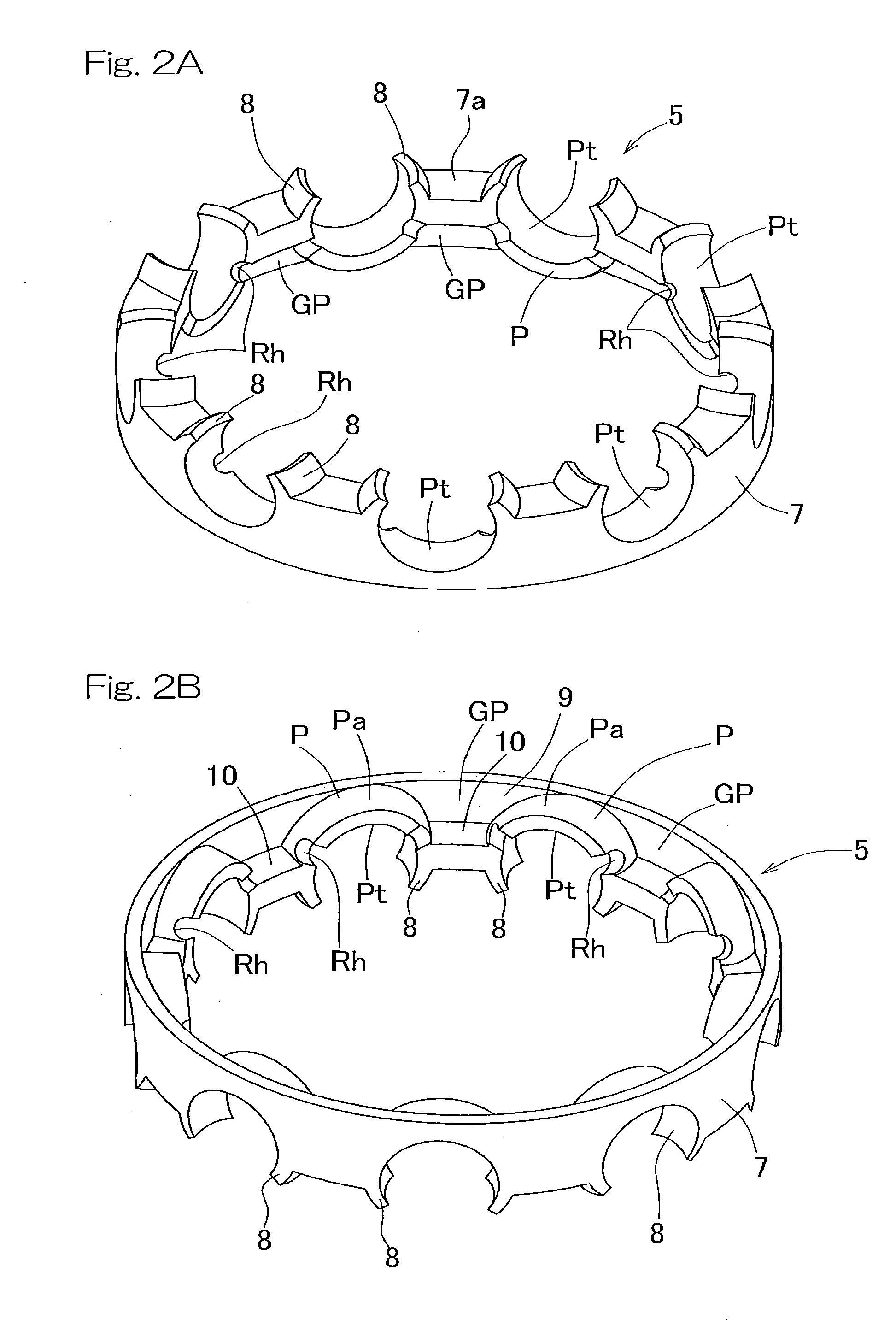

Rolling bearing and crown-shaped retainer

Owner:NTN CORP

Rolling knuckle bearing

InactiveCN106015325AIncreased tolerable angular deviationReduce frictionRolling contact bearingsShaftsRolling resistanceEngineering

Owner:ZHEJIANG UNIV

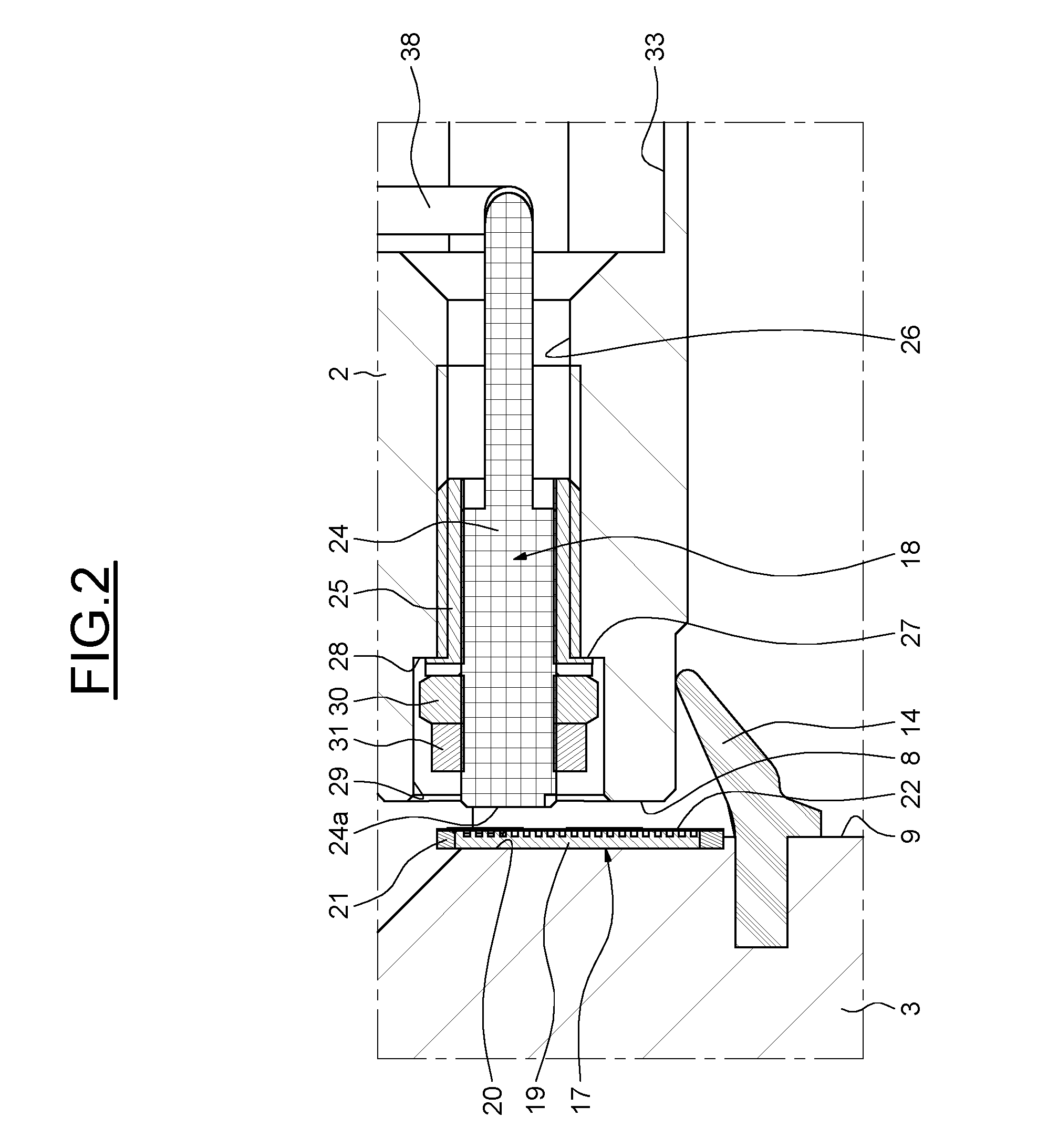

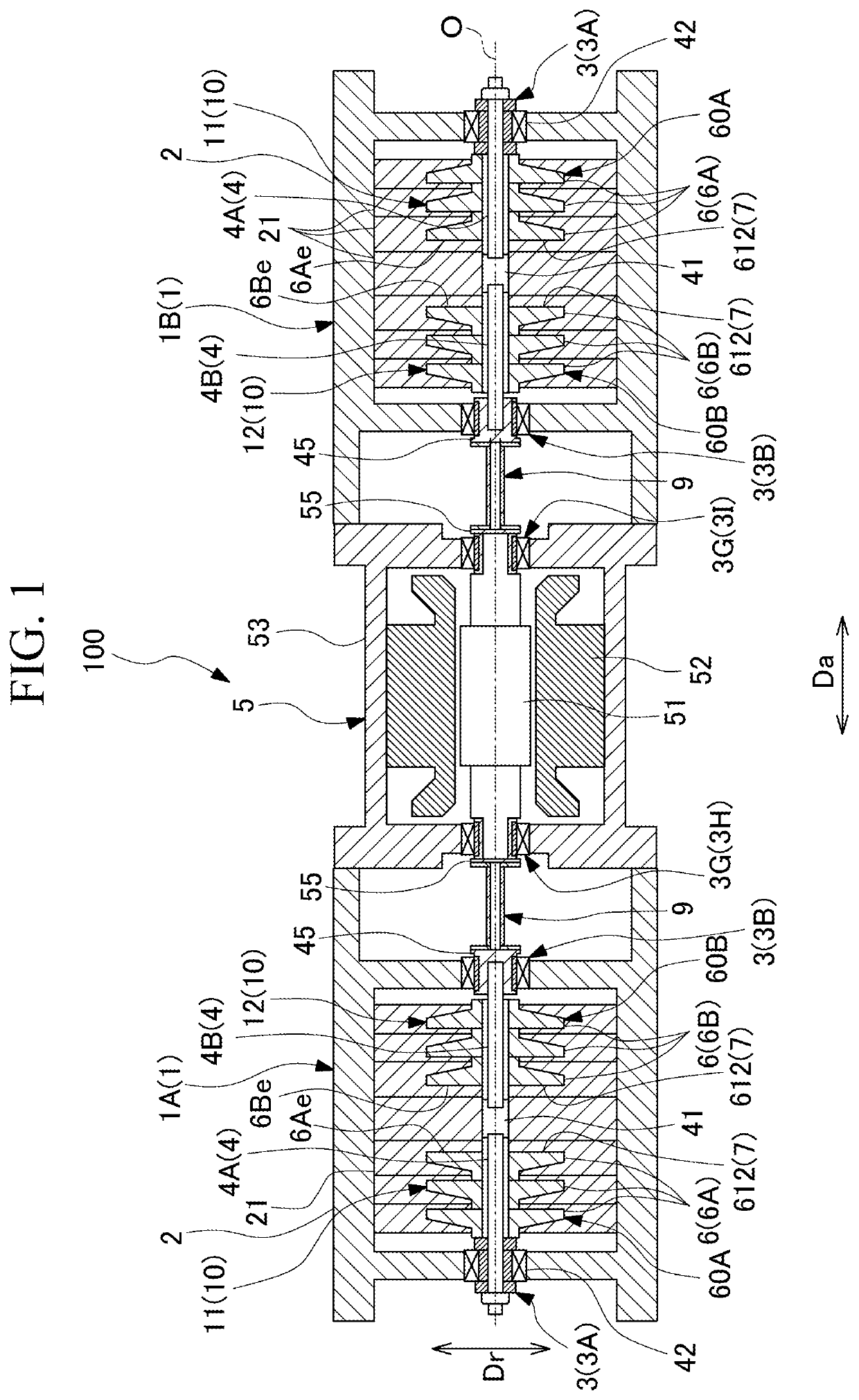

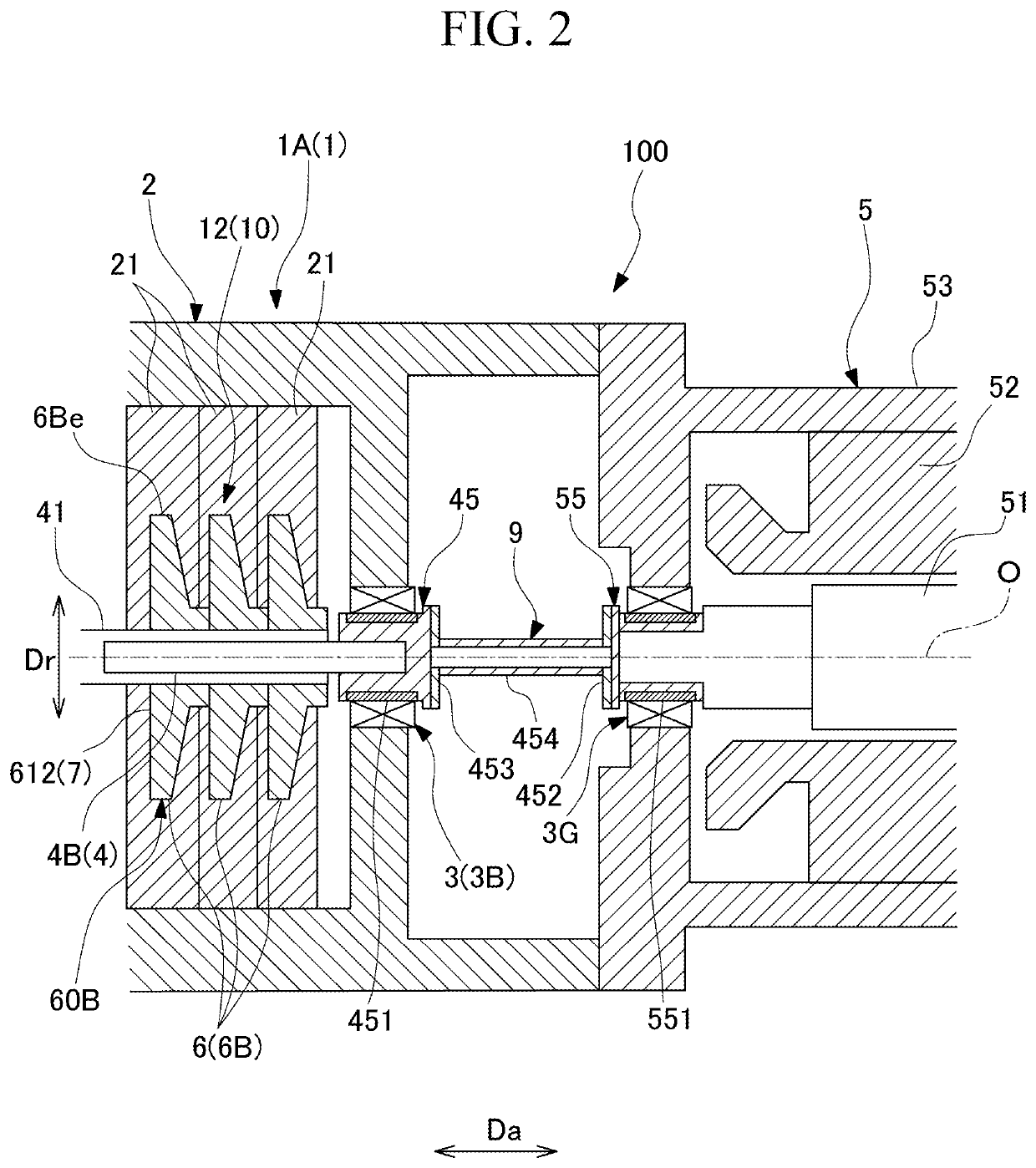

Electric linear actuator

Owner:NTN CORP

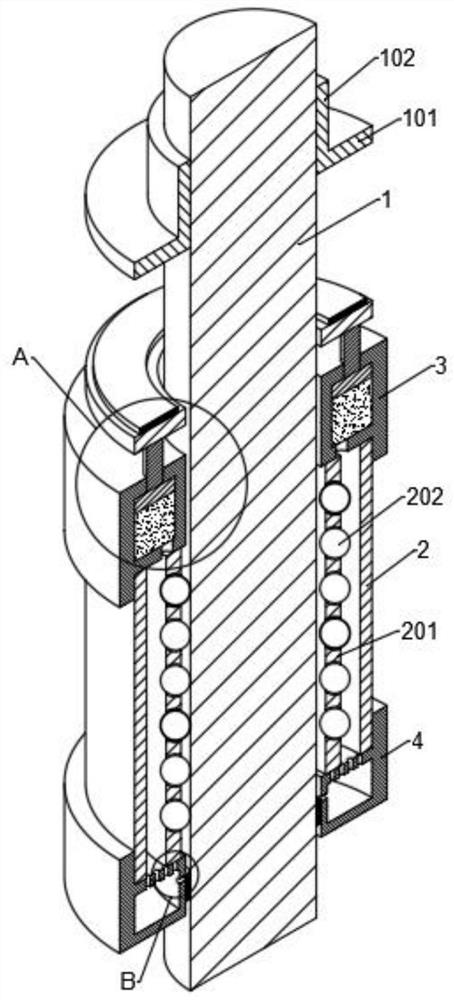

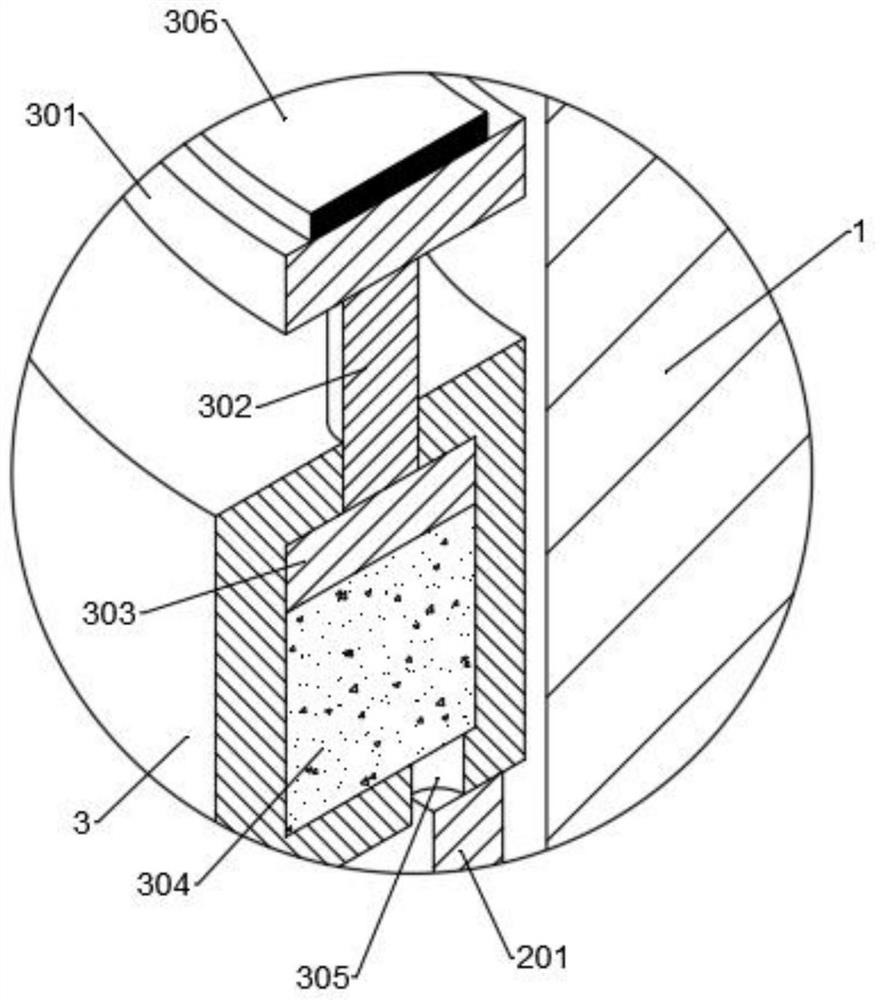

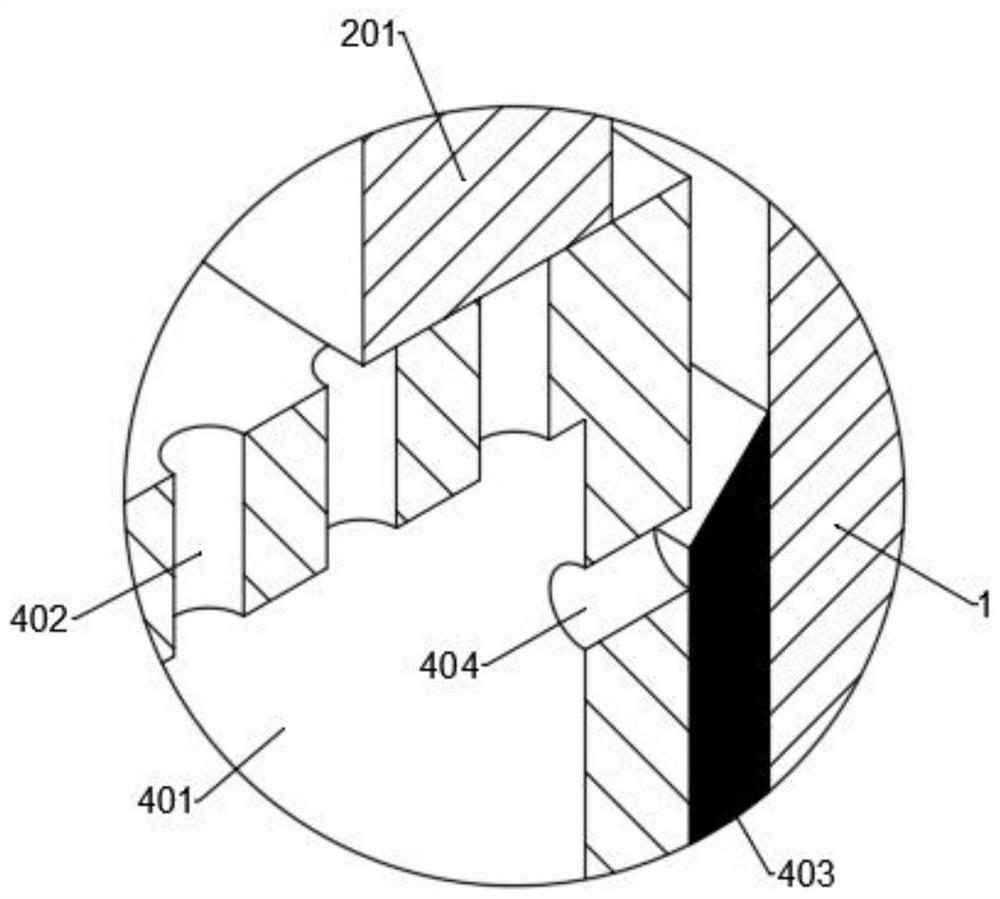

Two-shaft acoustic motor

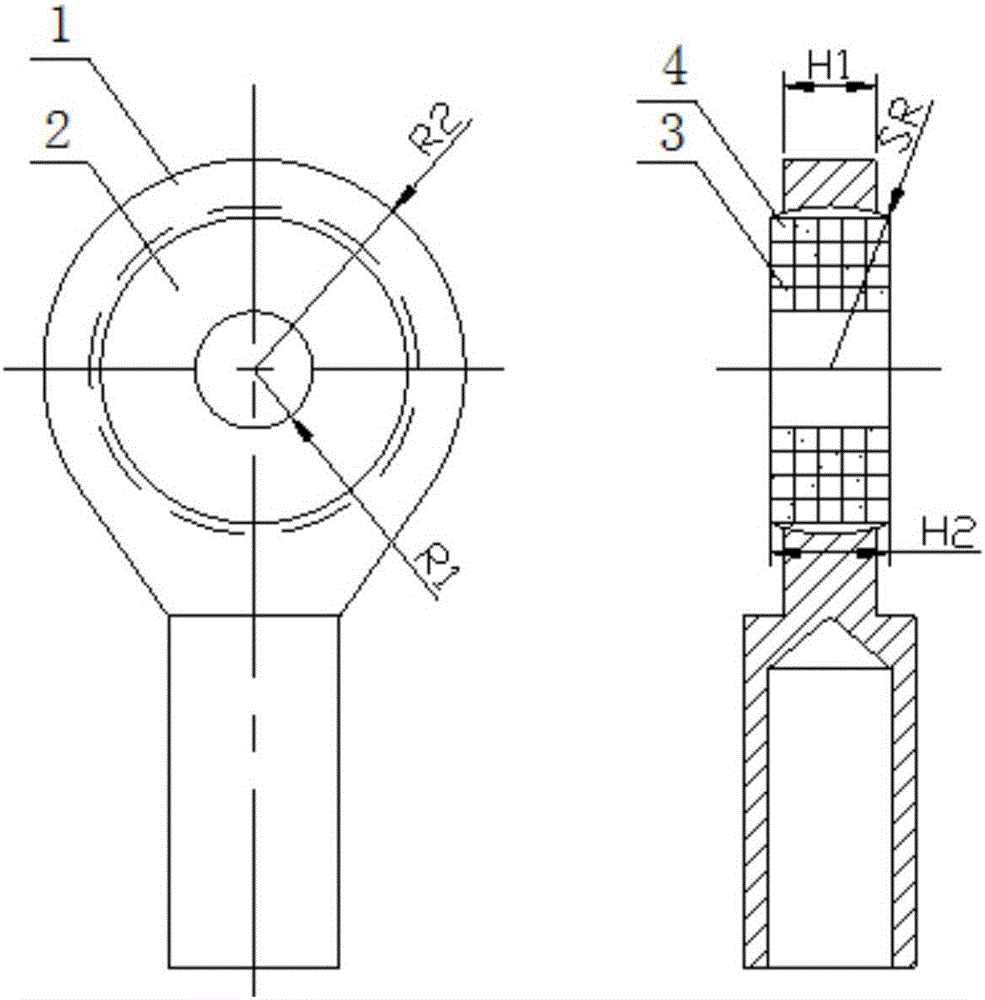

PendingCN110798014ASimple structureSolve common production problemsShaftsMechanical energy handlingElectric machineMotor shaft

The invention relates to the technical field of acoustic motor, and discloses a two-shaft acoustic motor. The two-shaft acoustic motor includes a motor, a motor shaft and a toothbrush matching shaft.The toothbrush matching shaft includes a shaft head, a shaft journal and a shaft body which are successively connected end to end. A first end face of the toothbrush matching shaft is located at the shaft head, and the second end face of the toothbrush matching shaft is located at the shaft body; the shaft head has a first cross section, a second cross section, a third cross section and a fourth cross section in the axial direction; the side wall of the shaft journal is provided with a first groove, a second groove and a third groove; and the shaft body is provided with blind holes. The structure of the whole motor is simple. For different customers, through setting and cooperative use of the toothbrush matching shaft, the acoustic motor and the motor shaft, different shafts are used for the junction part between the motor shaft and the toothbrush head, thus bringing great convenience for the processing of the central shaft of an electric toothbrush and the general production of the motor, reducing the production cost of the electric toothbrush and solving the general production problem of motors in the prior art.

Owner:ANHUI MIBEI ELECTRONIC TECH CO LTD

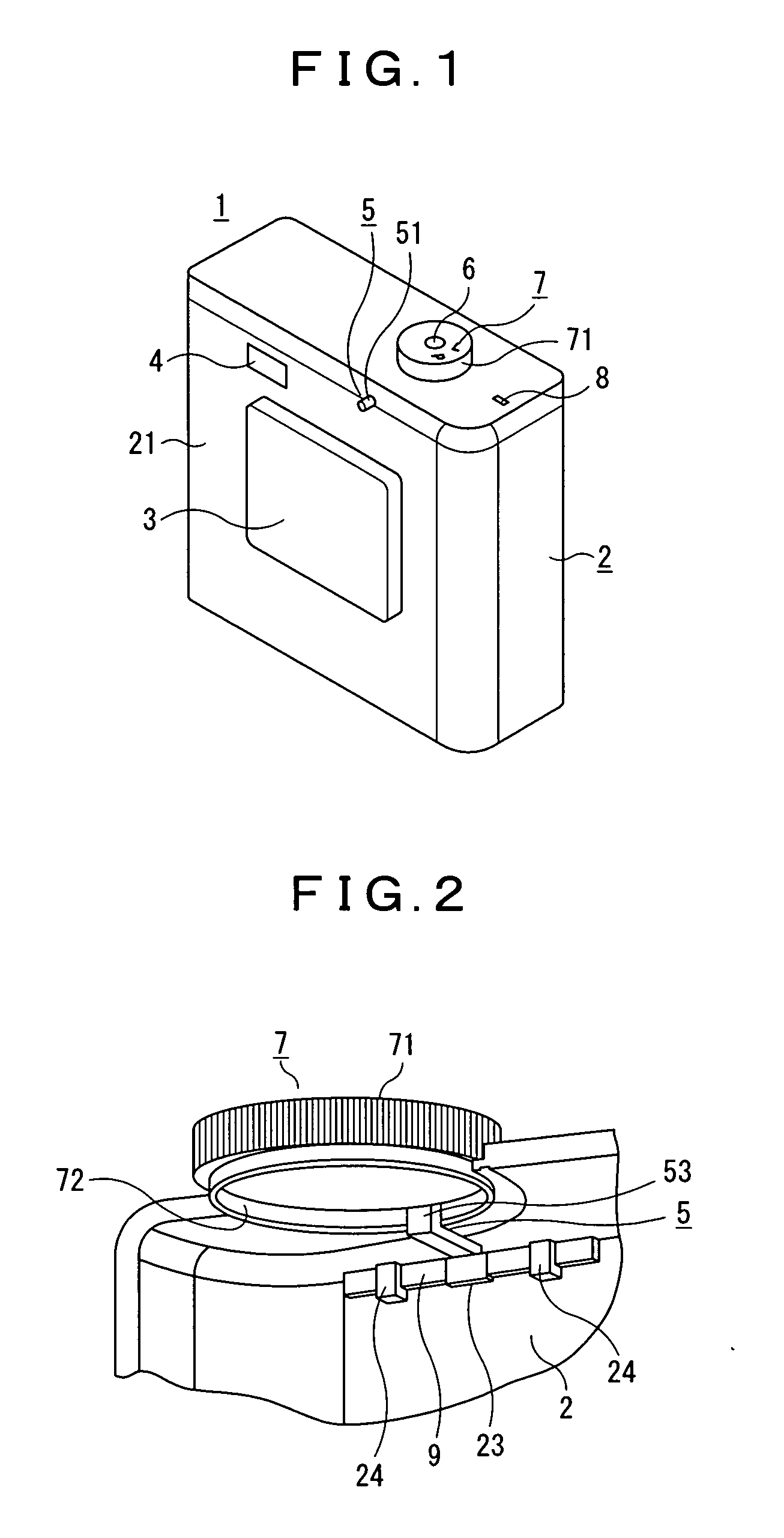

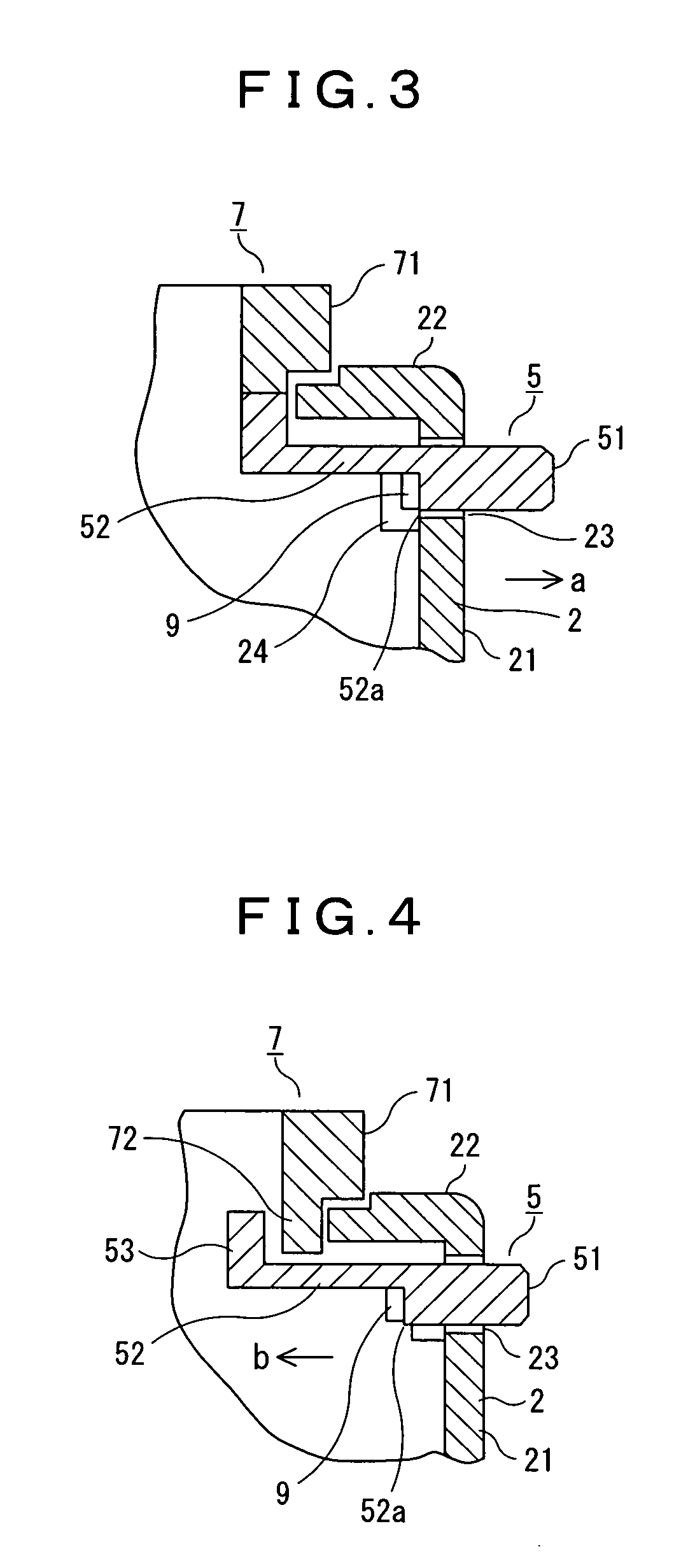

Camera

Owner:FUNAI ELECTRIC CO LTD

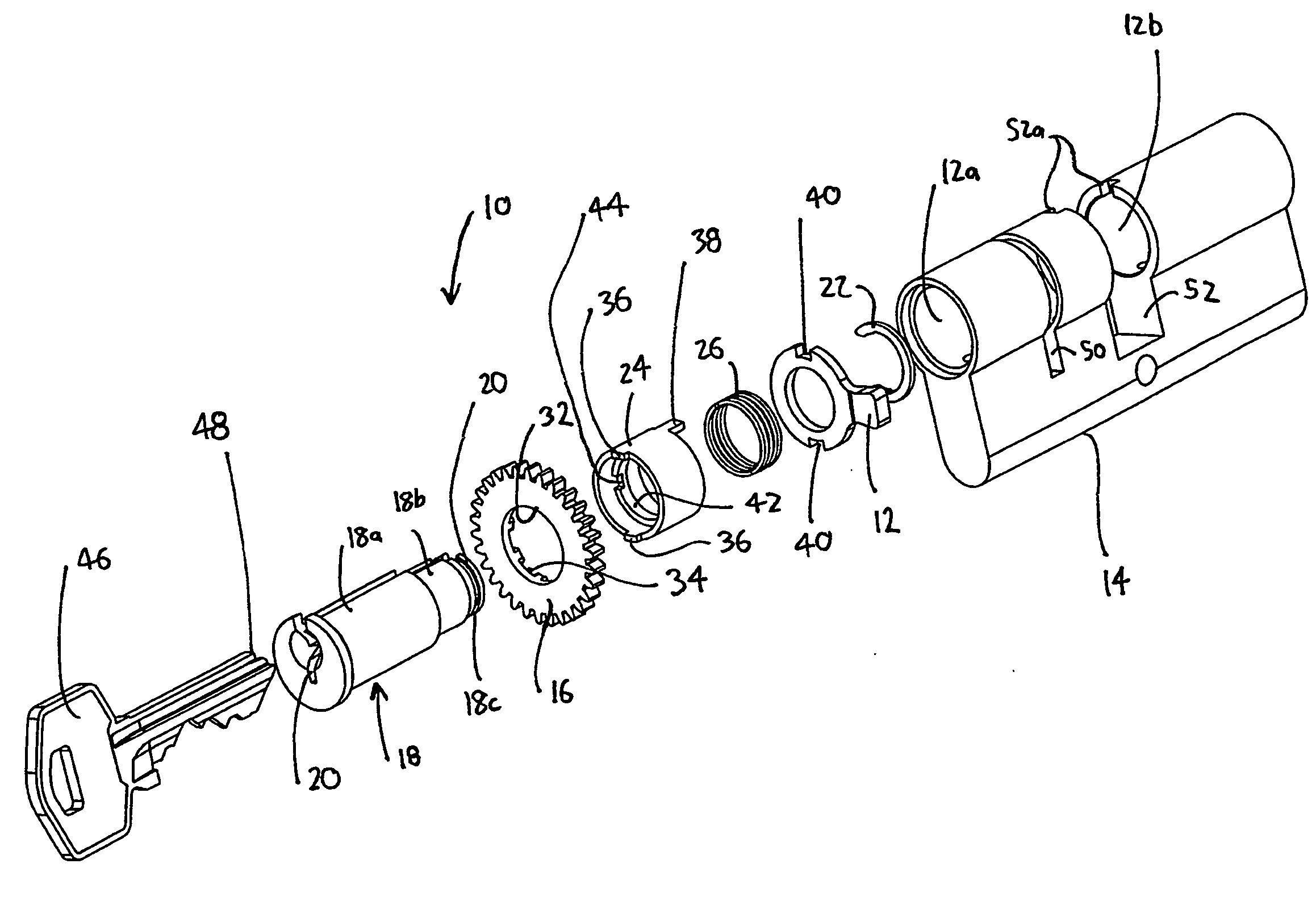

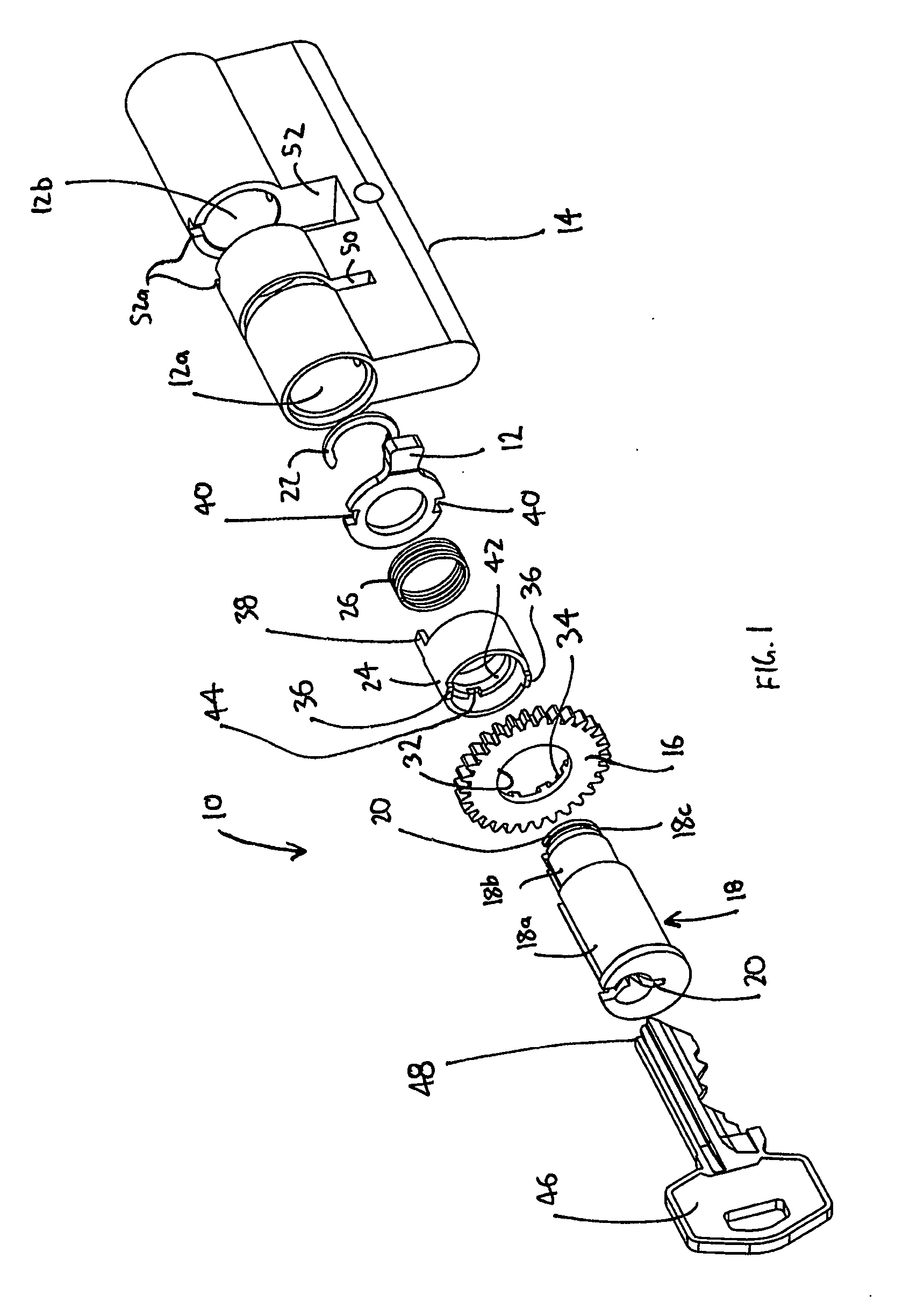

Lock Assembly

Owner:GAINSBOROUGH HARDWARE INDS

Elastomer strip design for torsional vibration dampers and torsional vibration dampers having same

InactiveCN107208691AIncreased slip torque capacityImprove fatigue lifeSpringsShaftsElastomerTransverse plane

Elastomer members for a torsional vibration damper, methods of making the same, and torsional vibration dampers having the elastomer members are disclosed. The elastomer members have a first major surface and an opposing second major surface with opposing side joining the first major surface to the second major surface, have a median sagittal plane extending parallel to the first major surface and the second major surface, and a transverse plane perpendicular to the median sagittal plane. In a cross-sectional geometry in a plane bisecting the median sagittal plane and the transverse plane, a thickness of the elastomer member changes along the median sagittal plane in a direction parallel to the transverse plane with a first thickness at both opposing sides and a second thickness at the transverse plane, where the second thickness is greater than the first thicknesses.

Owner:DAYCO IP HLDG

Miniature ball bushing guide assembly

Owner:东莞市创宇模具配件有限公司

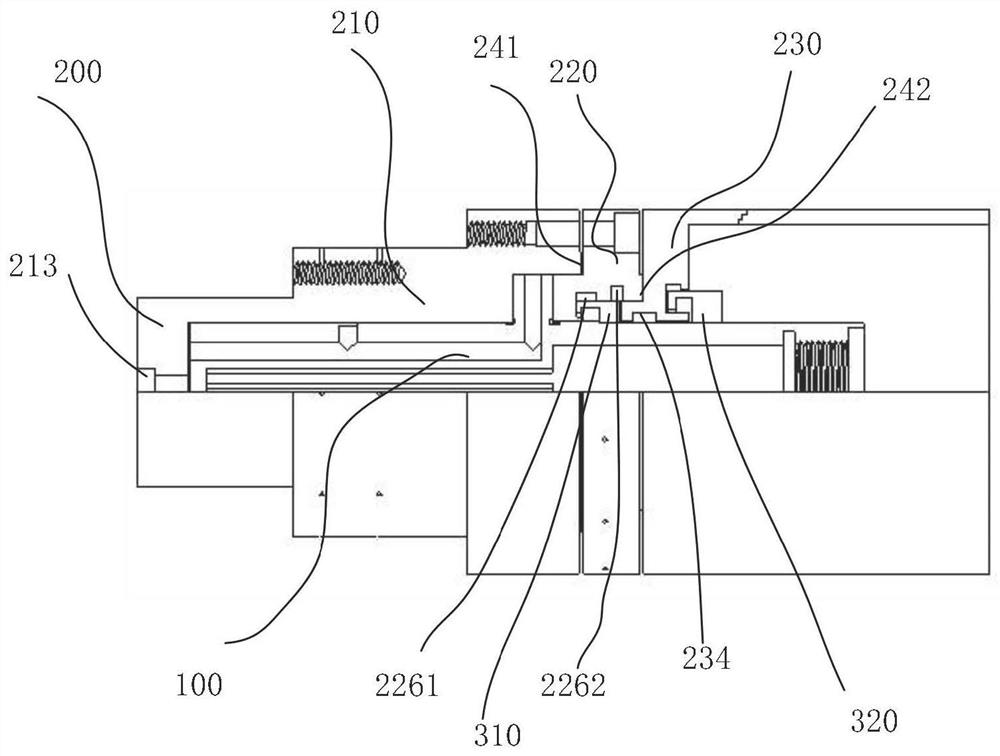

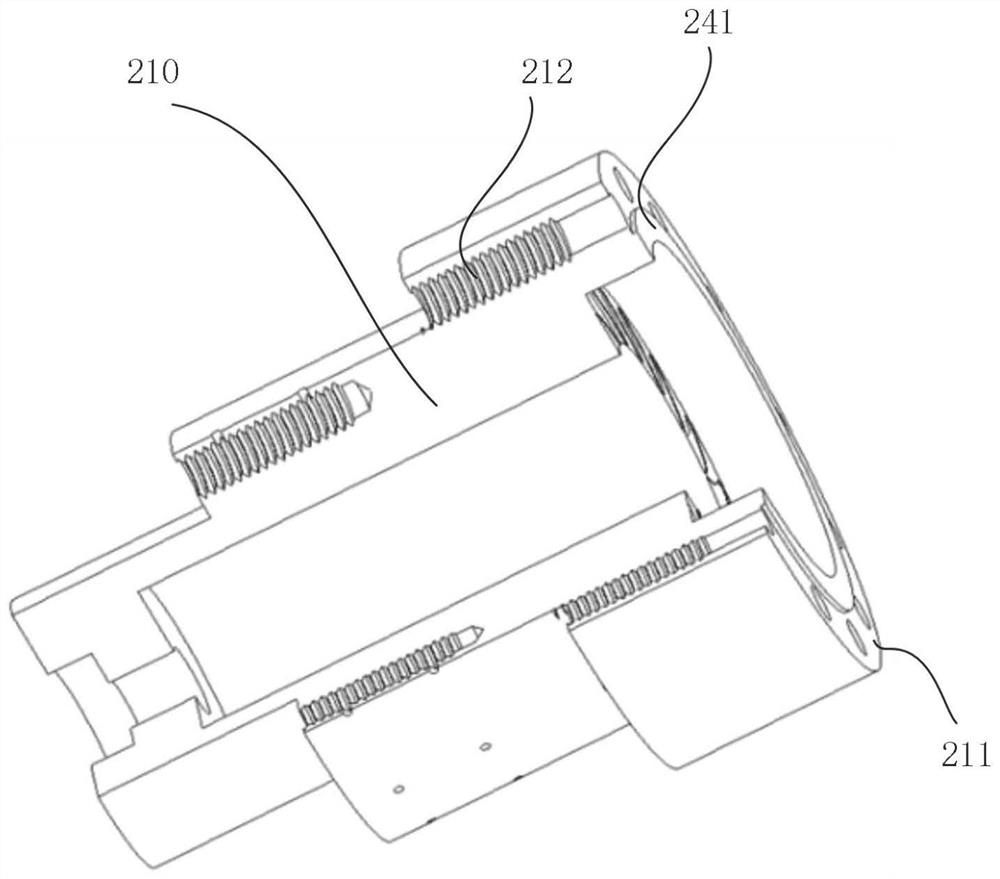

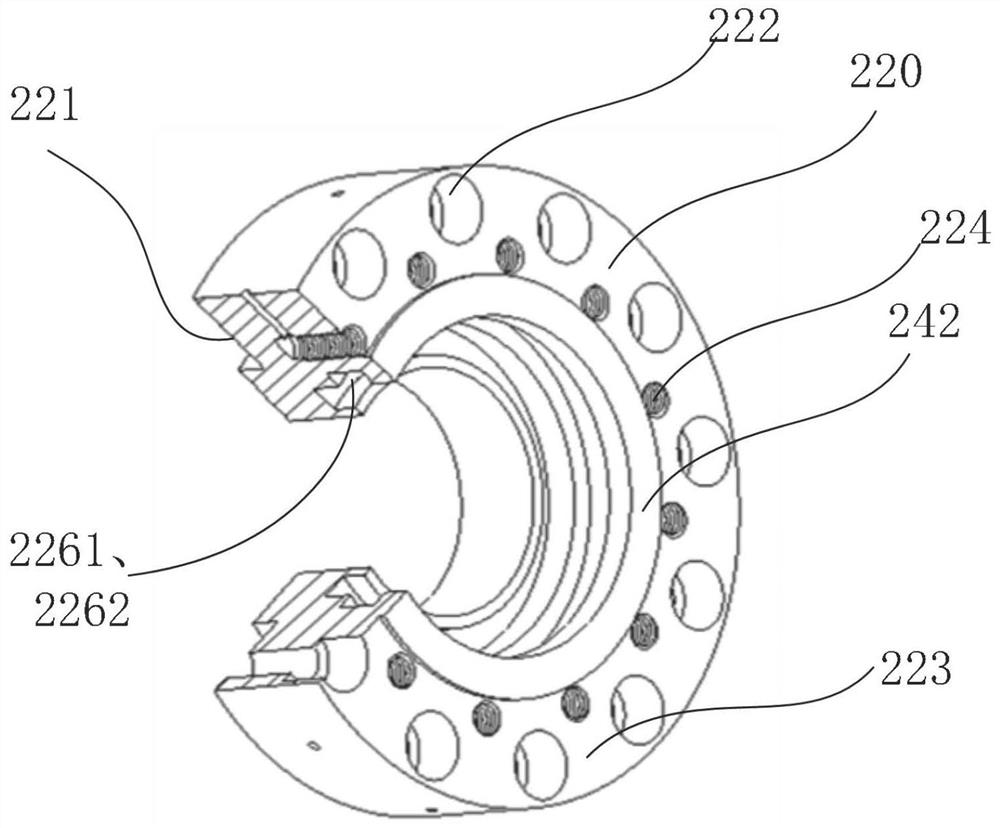

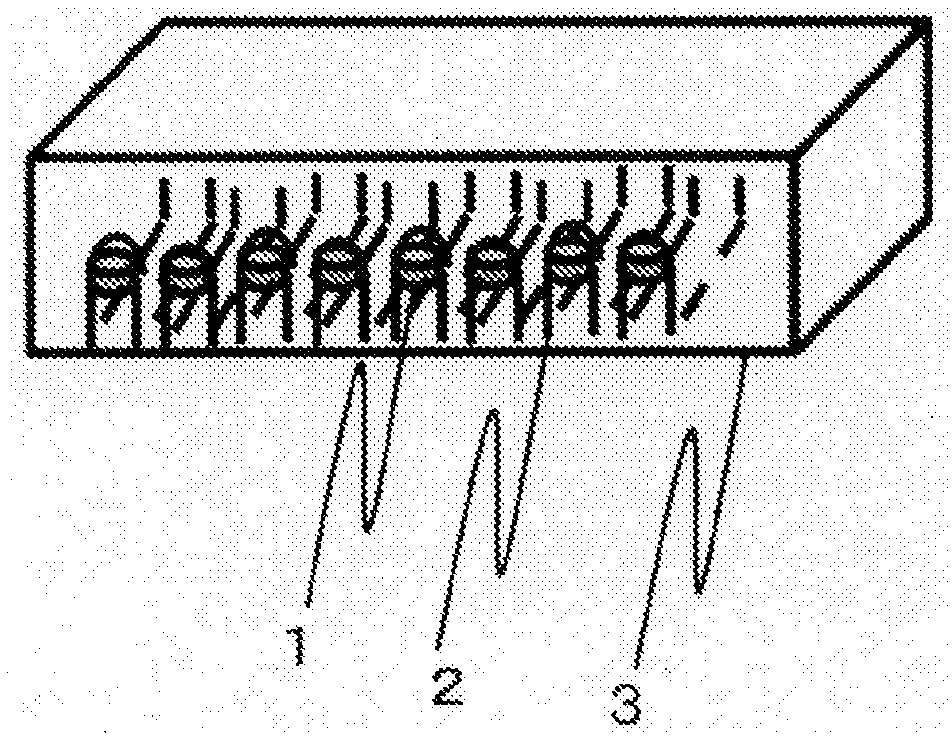

Ball socket machining device for inner ring of socket curved groove ball bearing

InactiveCN111069671AShorten the timeHigh indexing accuracyPrecision positioning equipmentShaftsBall bearingMilling cutter

The utility model discloses a ball socket machining device for an inner ring of a socket curved groove ball bearing, and belongs to the field of mechanical engineering. In order to overcome the defects of low working efficiency, large workload, incapability of effectively ensuring the precision and the like of ball socket machining of the inner ring of the socket curved groove ball bearing. The machining device comprises a base, a rapid clamping device, a set of ball socket milling devices arranged in the circumferential direction, a set of indexing precision control blocks and a feeding precision control mechanism and the like; and an air cylinder is used for independent feeding, and a motor is used for driving a spherical milling cutter to conduct independent milling. The machining device for the inner ring of the socket curved groove ball bearing has the following advantages that (1) a plurality of ball sockets can be machined at the same time at a time, and time is saved; (2) the indexing precision of the ball sockets is improved by using a movable positioning block; and (3) the feeding power of the air cylinder is flexible force, so that the impact of the milling cutter can beavoided.

Owner:NORTHWEST A & F UNIV

Liquid metal sliding bearing, X-ray tube and CT scanning device

Owner:北京智束科技有限公司

High-temperature-resisting knuckle bearing for actuator

InactiveCN106321626AGuaranteed StrengthReduce structural weightShaftsRotary machine partsStress strengthHafnium

Owner:BEIJING POWER MACHINERY INST

Compressor system

ActiveUS20210207607A1Improve rotor dynamicIncrease rotation speedYielding couplingPump componentsImpellerRotational axis

Owner:MITSUBISHI HEAVY INDUSTIES COMPRESSOR CORP

Dual taper steering column lock bolt

InactiveUS20050109073A1Improve the unlocking processEasy to unlockBuilding locksShaftsSteering columnEngineering

The invention provides a locking pin for a steering column lock assembly. The locking pin includes a dual taper defined by the first and second truncated cone portions. The first truncated cone portion narrows at a first angle and the second truncated cone portion narrows at a second angle, wherein the first and second angles are different from one another. The second angle can be less than the first angle. The dual taper of the locking pin reduces the likelihood that extreme tortion will not induce camming forces urging the locking pin out of engagement with a locking plate connected to the steering shaft.

Owner:DELPHI TECH INC

Double shunting reducer and transmission shaft thereof

The embodiment of the invention discloses a transmission shaft of the double shunting reducer, which comprises a ring groove arranged on the transmission shaft, a radial hole arranged in the ring groove and an axial hole communicated with the radial hole. A gear positioned on the transmission shaft of the double shunting reducer provided by the embodiment of the invention is fixed on the position where the ring groove is located by interference fit; high-pressure oil enters into the radial hole through the axial hole and then flows into the ring groove; after the ring groove is filled with the high-pressure oil, the gear is isolated from the transmission shaft under the action of oil pressure, the transmission shaft is adjusted to be in a synchromesh position with the other gear; after the adjustment, the injection of the high-pressure oil stops so as to recovery the interference fit of the gear and the transmission shaft. The embodiment of the invention solves the problem that the gears on two transmission shafts at the same level are not synchronously meshed with the gears at the adjacent level. The embodiment of the invention also discloses a double shunting reducer with the above transmission shaft.

Owner:WORLD TRANSMISSION TECH TIANJIN SHARE LTD

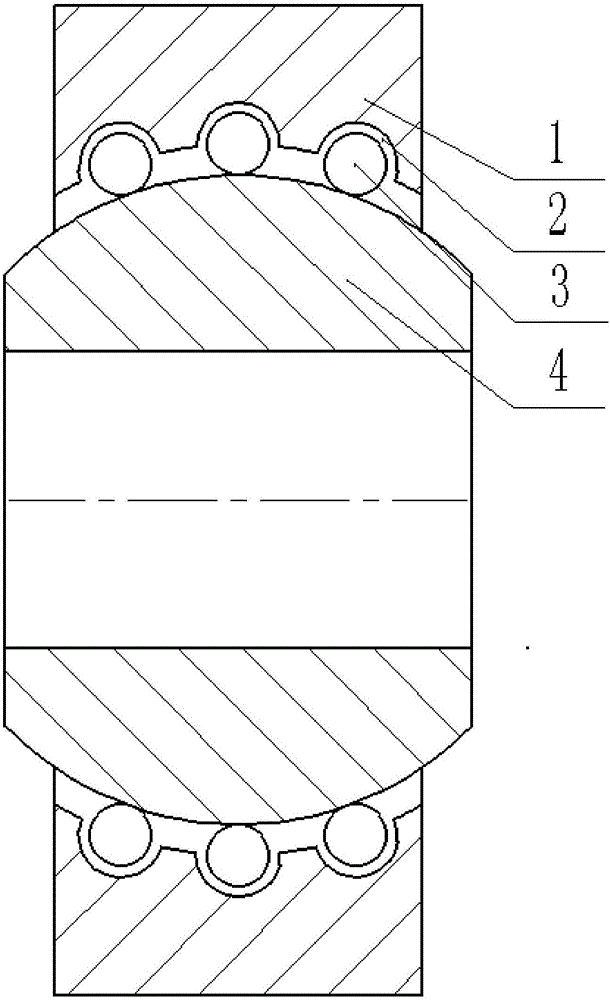

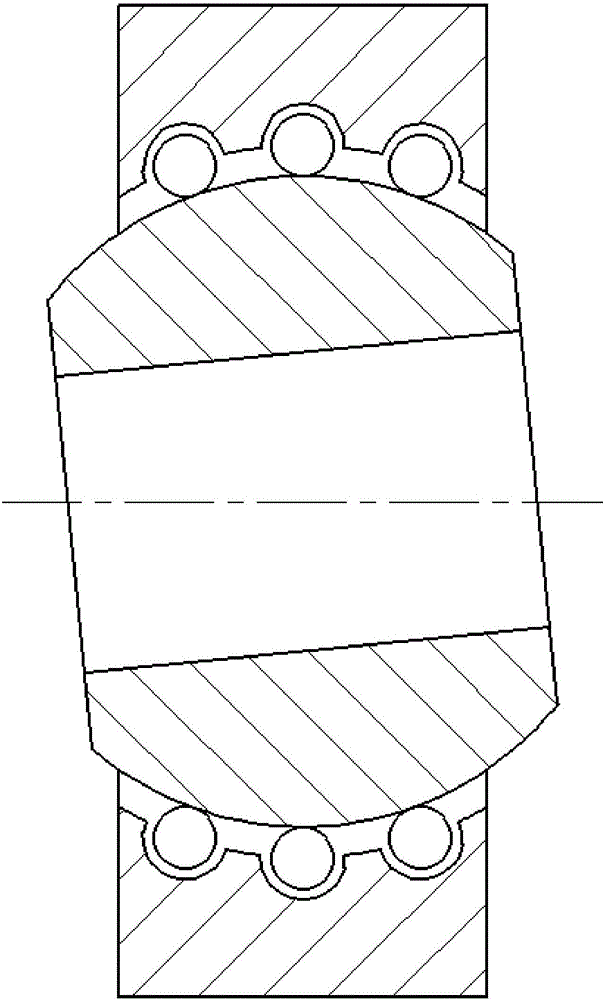

Roller bearing

InactiveUSRE48586E1Convenient introductionEasy to touchRoller bearingsShaftsEngineeringRoller bearing

Owner:NSK LTD

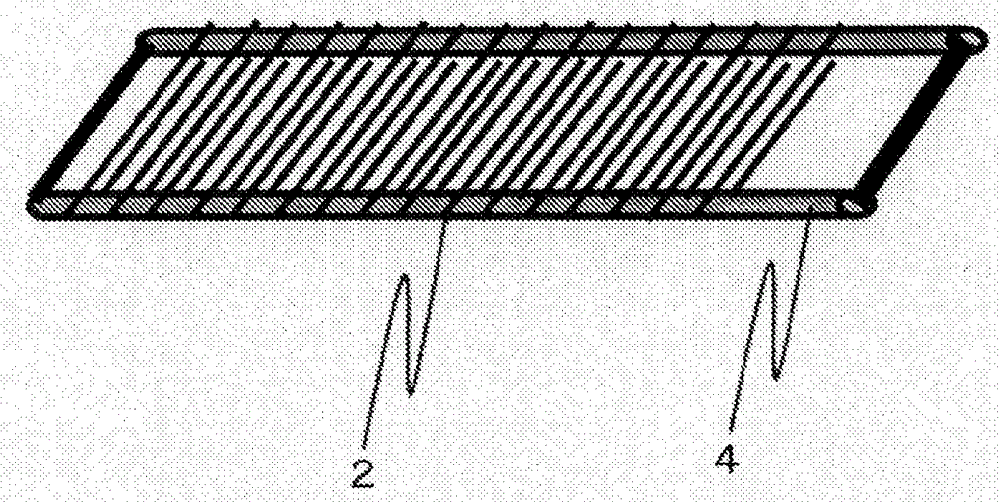

Low-friction sliding material and low-friction pressurizing member for toner fixing devices

Owner:TORAY IND INC

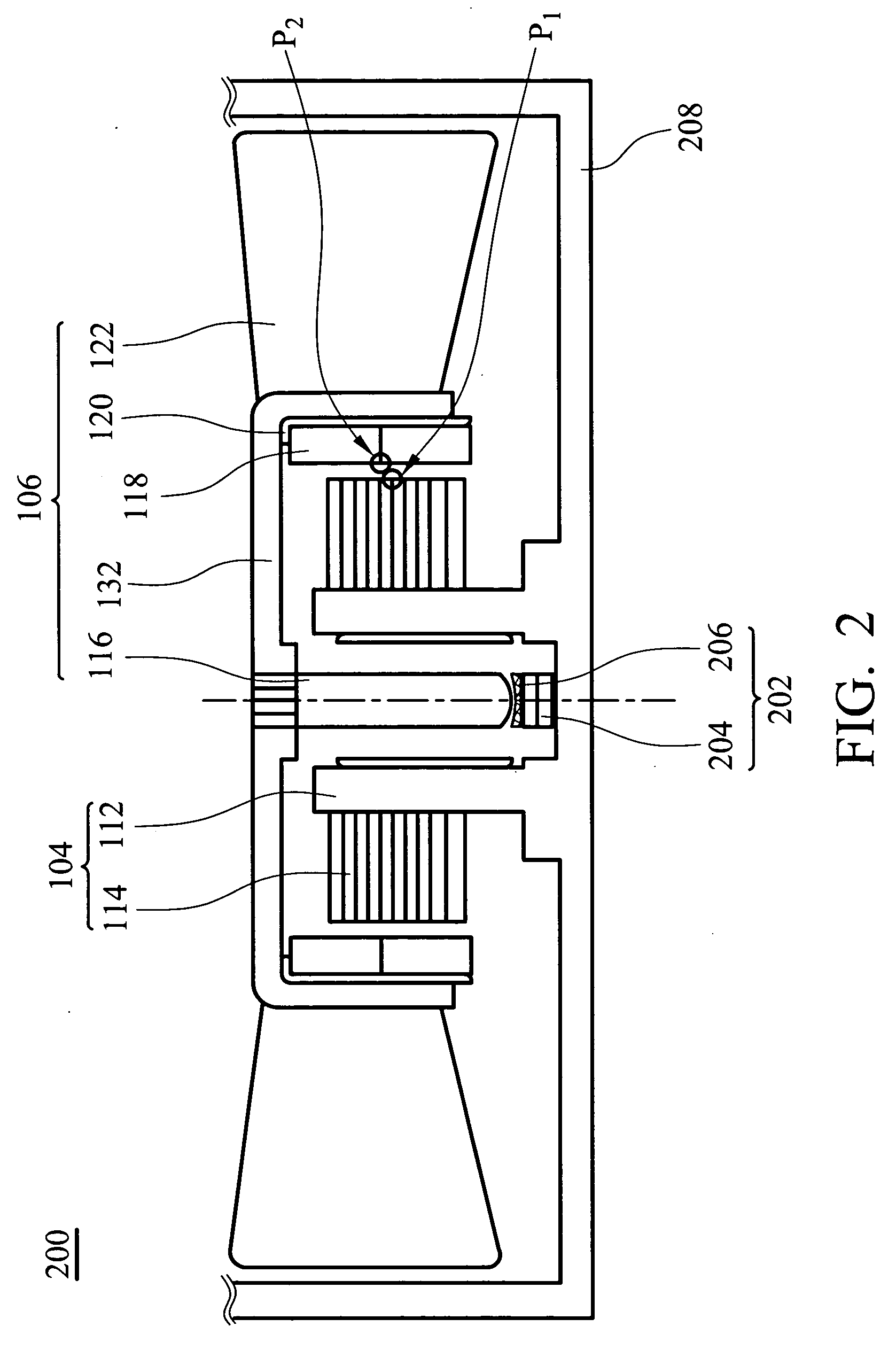

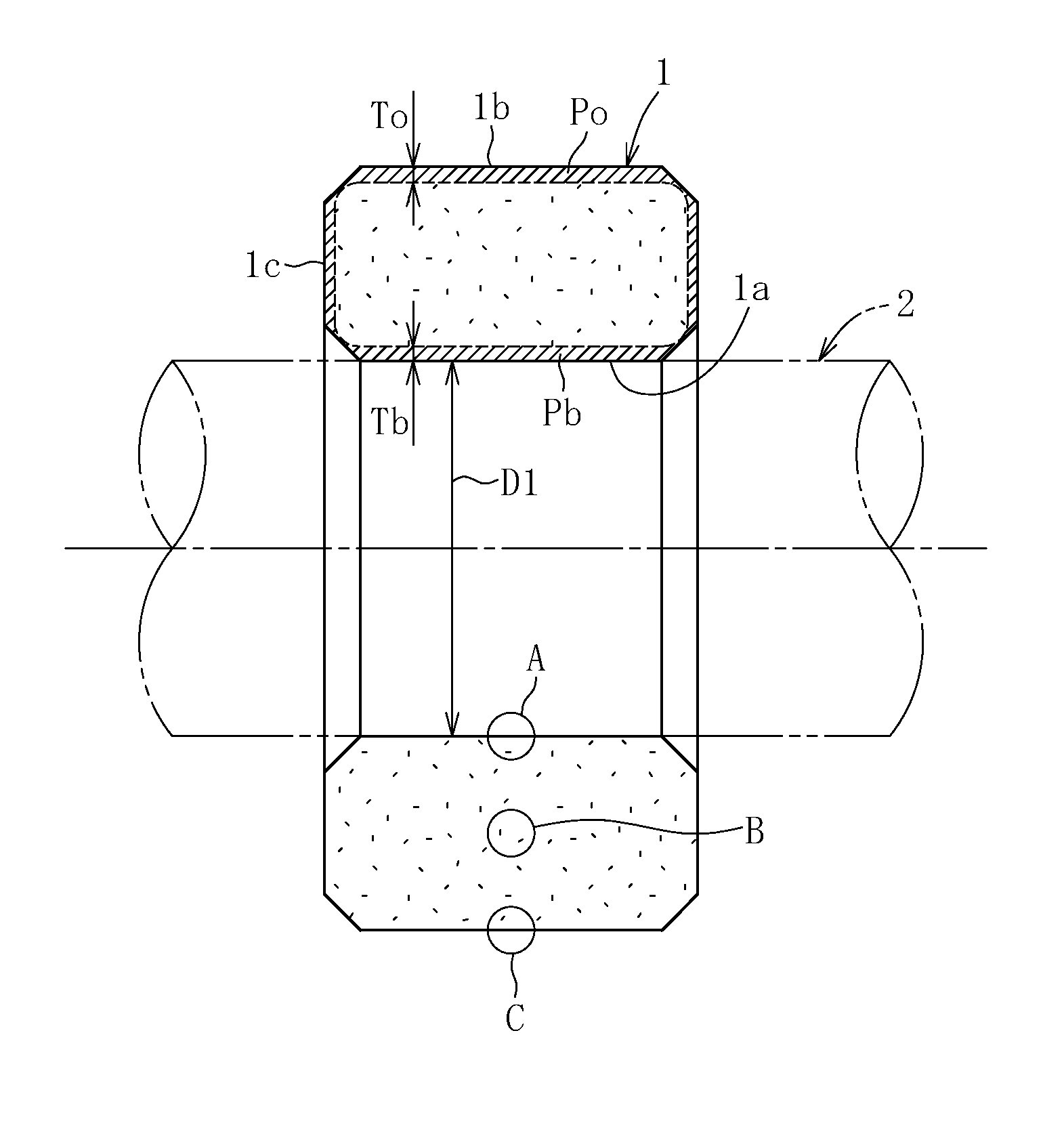

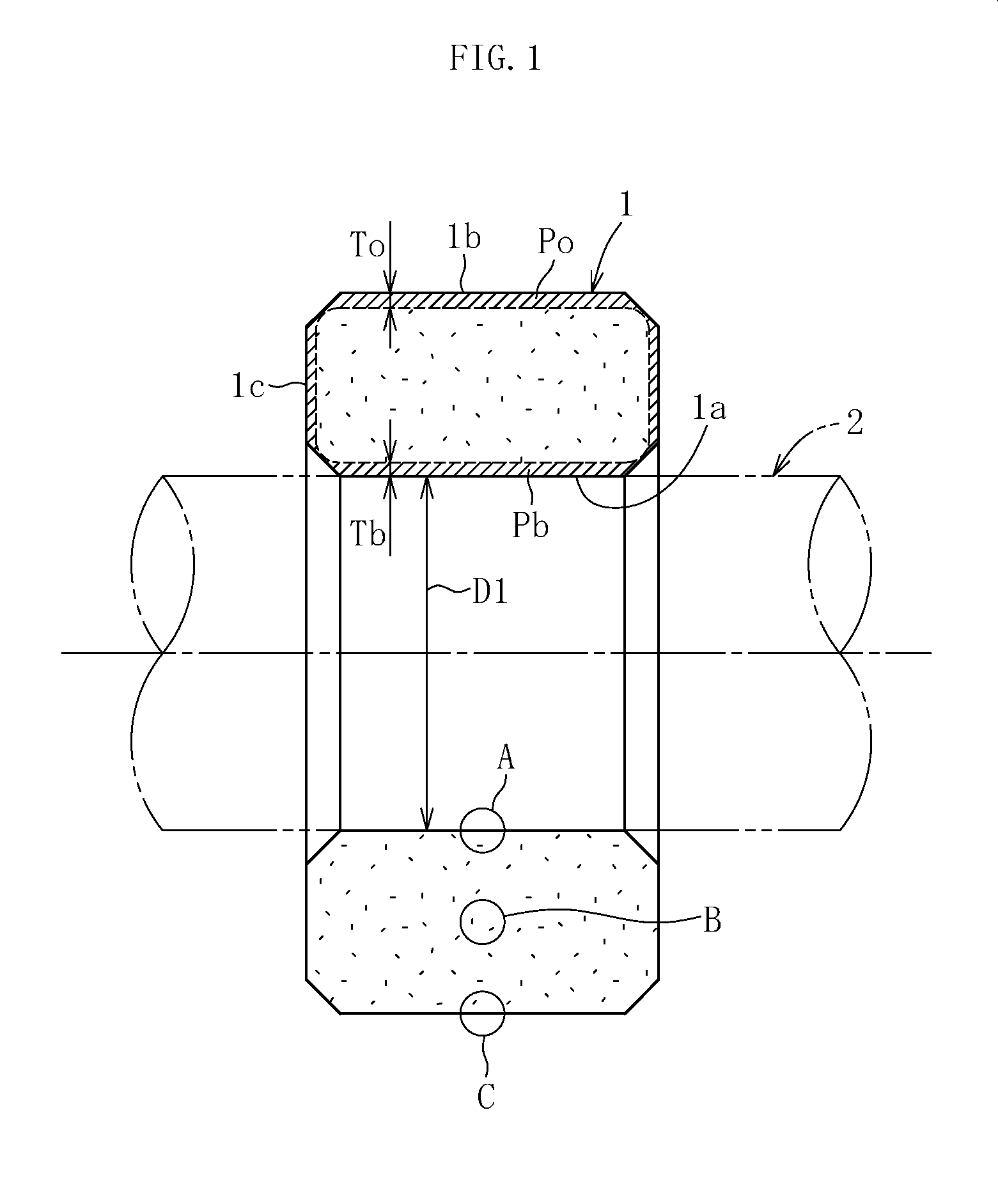

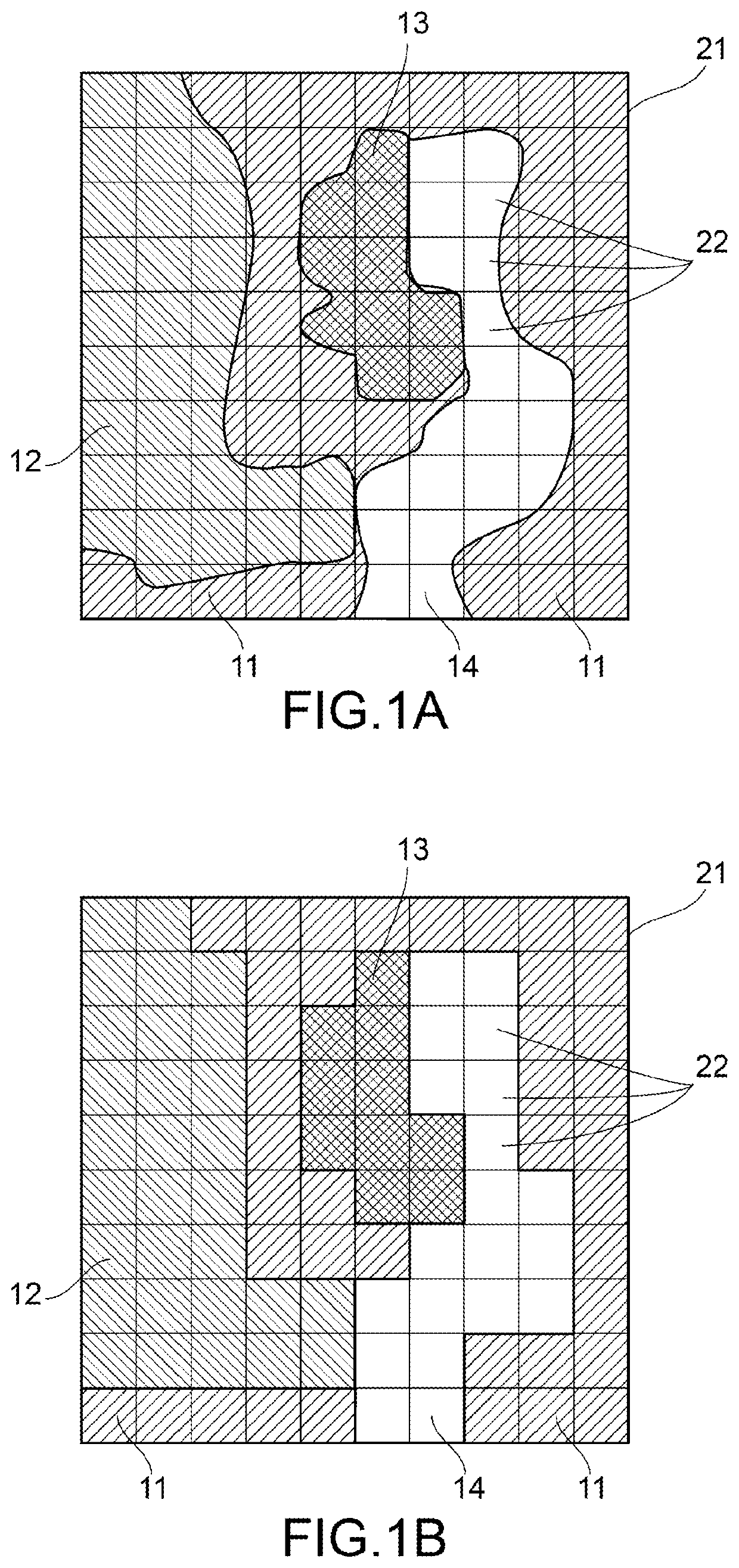

Fluid dynamic pressure bearing device, spindle motor provided with the fluid dynamic pressure bearing device, and recording disk drive device

InactiveUS7661882B2Promote generationRapid fluctuationShaftsRecord information storageRefluxEngineering

A fluid dynamic pressure bearing device includes a shaft member (5) and a bearing member (41), at least one of the shaft member or the bearing member being rotatable with respect to the other. A shaft member-side annular member (13) is fixed with respect to the shaft member. The shaft member-side annular member includes a large-diameter rim portion and a small-diameter outer circumferential surface portion. A bearing member-side annular member (14) is fixed with respect to the bearing member. The bearing member-side annular member includes an inner circumferential large-diameter step portion, and a small-diameter inner circumferential surface portion. A plurality of convex surface portions are formed either on a surface of the inner circumferential large-diameter step portion facing the large-diameter rim portion of the shaft member-side annular member, or on a surface of the large-diameter rim portion of the shaft member-side annular member facing a surface of the inner circumferential large-diameter step portion. A reflux groove (17) surrounds the convex surface portions.

Owner:MINEBEAMITSUMI INC

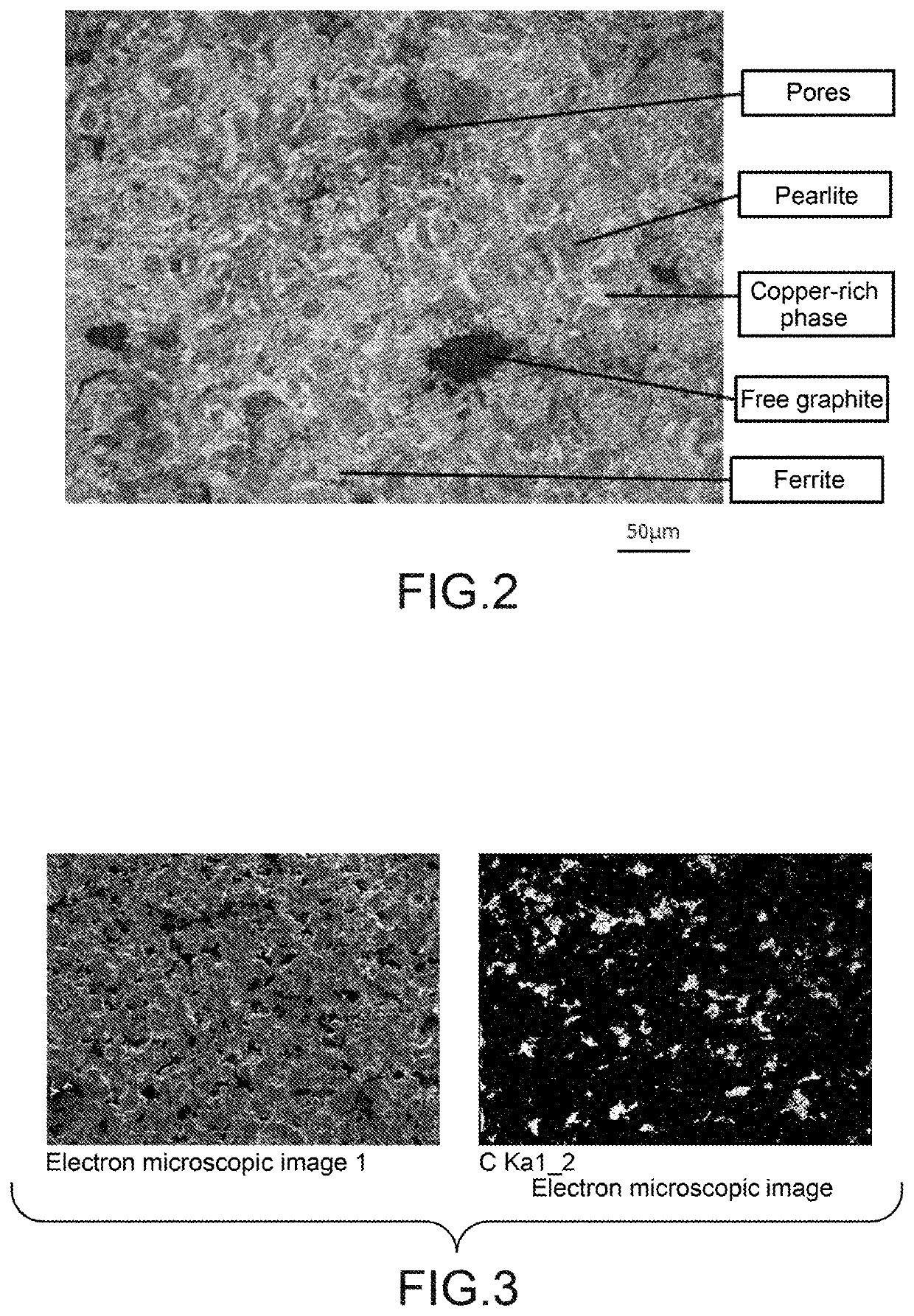

Sintered oil-impregnated bearing

ActiveUS20200180032A1High cost performanceExcellent wear resistance performanceTransportation and packagingShaftsPearliteBearing surface

Owner:DIAMET CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap