Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Torsional vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Torsional vibration is angular vibration of an object—commonly a shaft along its axis of rotation. Torsional vibration is often a concern in power transmission systems using rotating shafts or couplings where it can cause failures if not controlled. A second effect of torsional vibrations applies to passenger cars. Torsional vibrations can lead to seat vibrations or noise at certain speeds. Both reduce the comfort.

Torsional vibration damper

Owner:ZF FRIEDRICHSHAFEN AG

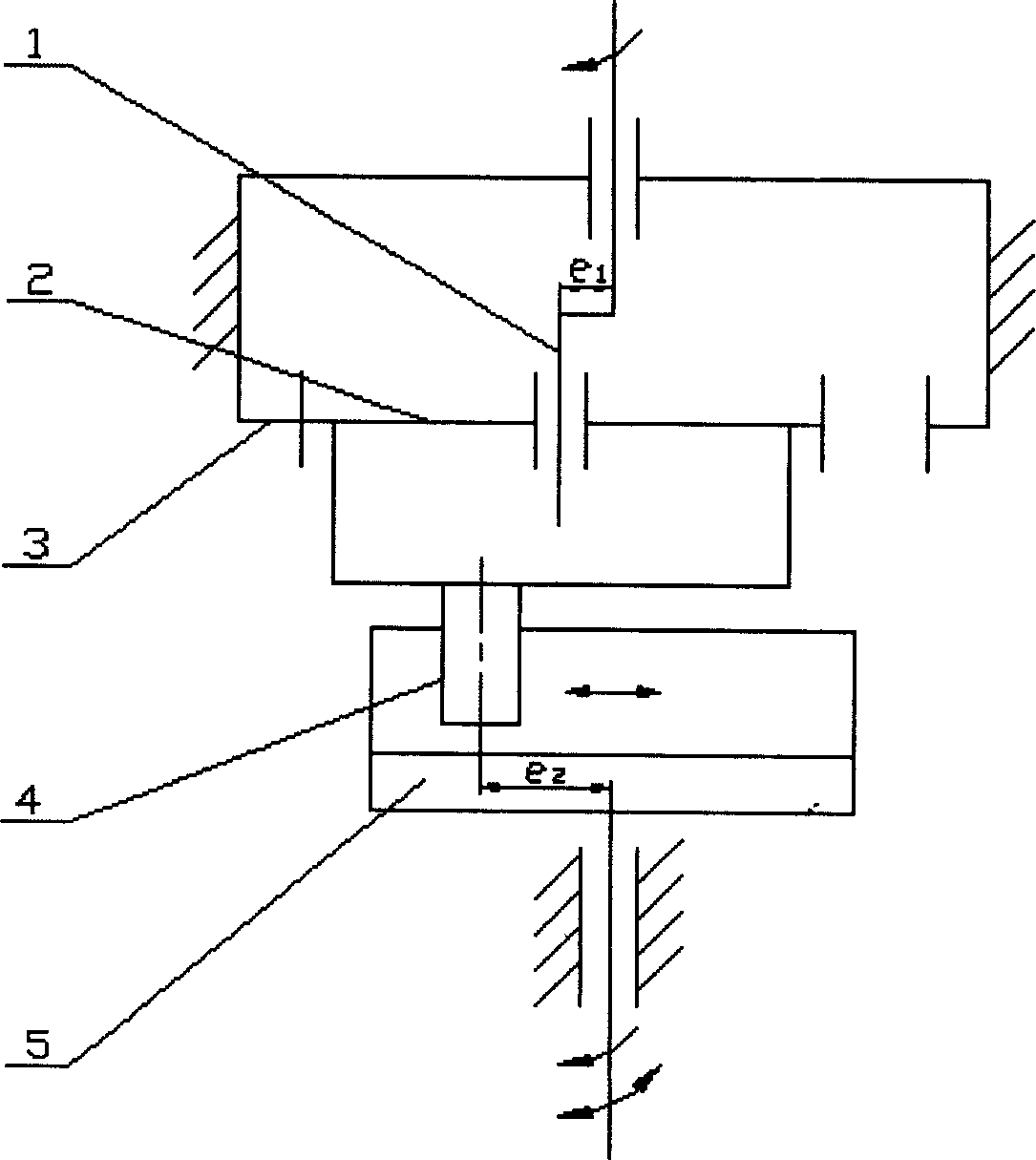

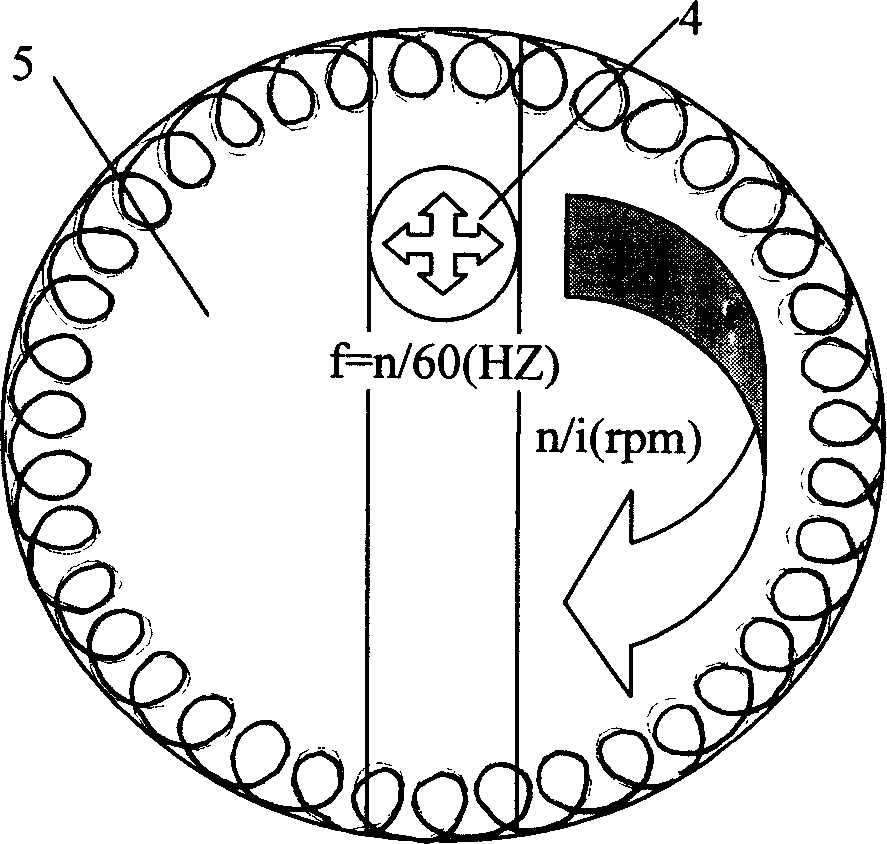

Rotation and torsional vibration compound movement mechanism based on planetary drive with small teeth difference

InactiveCN1632347ACompact structureEasy to assembleRevolution surface grinding machinesToothed gearingsLow speedRadius of gyration

Owner:XIAN UNIV OF TECH

Improved DOB and torque high-pass filter based elasticity connection transmission system torsional oscillation inhibiting method

InactiveCN105915138AEnhanced inhibitory effectGood dynamic follow performanceElectronic commutation motor controlVector control systemsElectric machineBand-pass filter

The invention discloses an improved DOB and torque high-pass filter based elasticity connection transmission system torsional oscillation inhibiting method which comprises the following steps: measuring the rotation speed of a motor and in the process of speed measurement, adding a low-pass filter; using measured torque current and rotation speed measured value to observe obtained torque through the improved DOB; multiplying torque current by a current torque ratio coefficient to obtain a magnetic torque added by what is obtained through the multiplying of the rotation speed measured value by a motor inertia in the observer and subtracted by what is obtained through the multiplying of the rotation speed measured value by a motor inertia after a second low pass filter; and taking the obtained torque observed by an improved DOB as electromagnet torque feedback amount through the high pass filter and feedback gain which goes back to a system to finely tune the electromagnet torque and achieves the effect of torsional oscillation inhibiting. The method can better balance the effect of torsional oscillation inhibiting and dynamic following performance, which effectively inhibits noises in rotation speed measurement. The method further does not have high requirements on model parameters, nor is sensitive about the change in load inertia. With high reliability, the method can be easily performed.

Owner:SHANGHAI UNIV

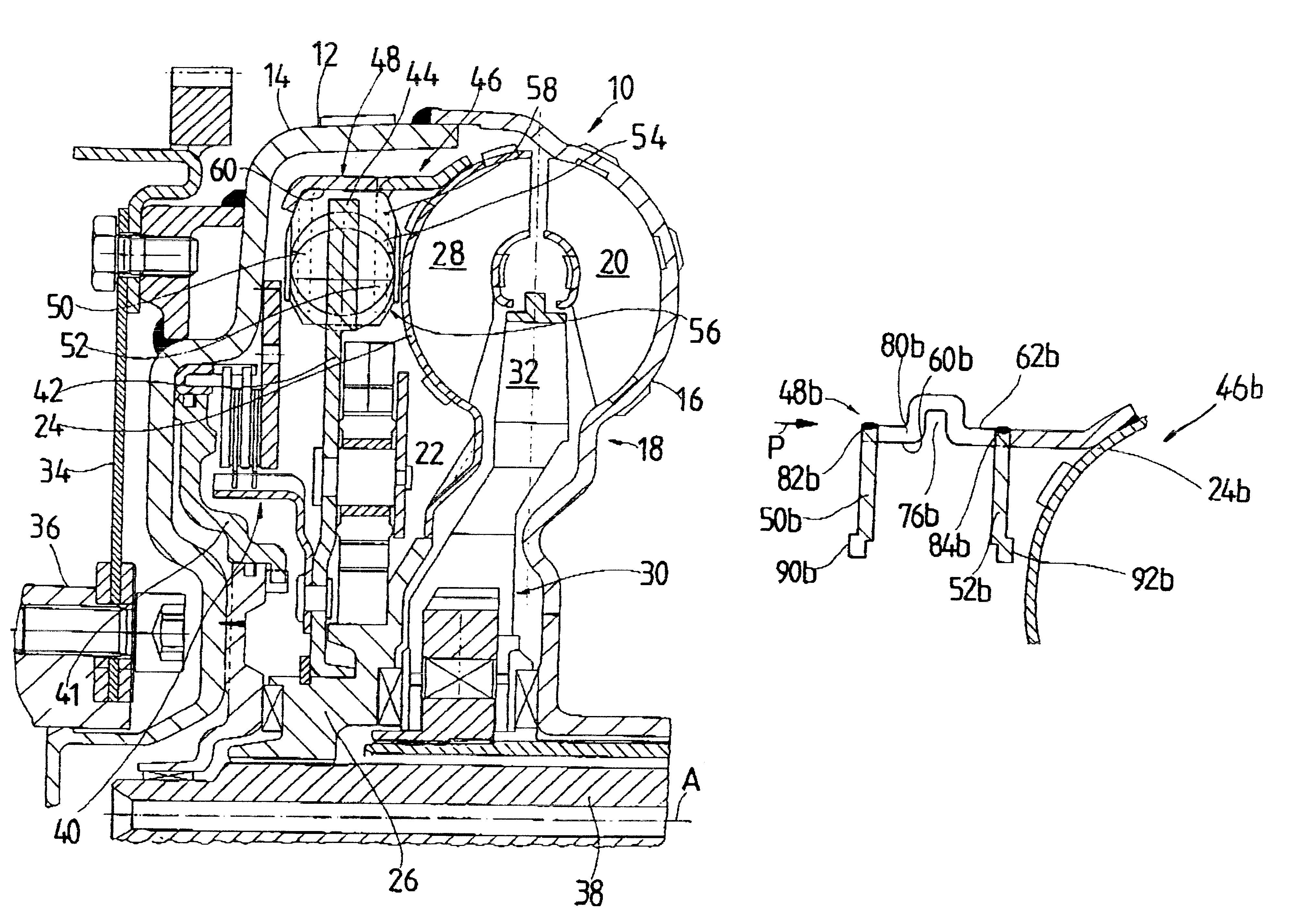

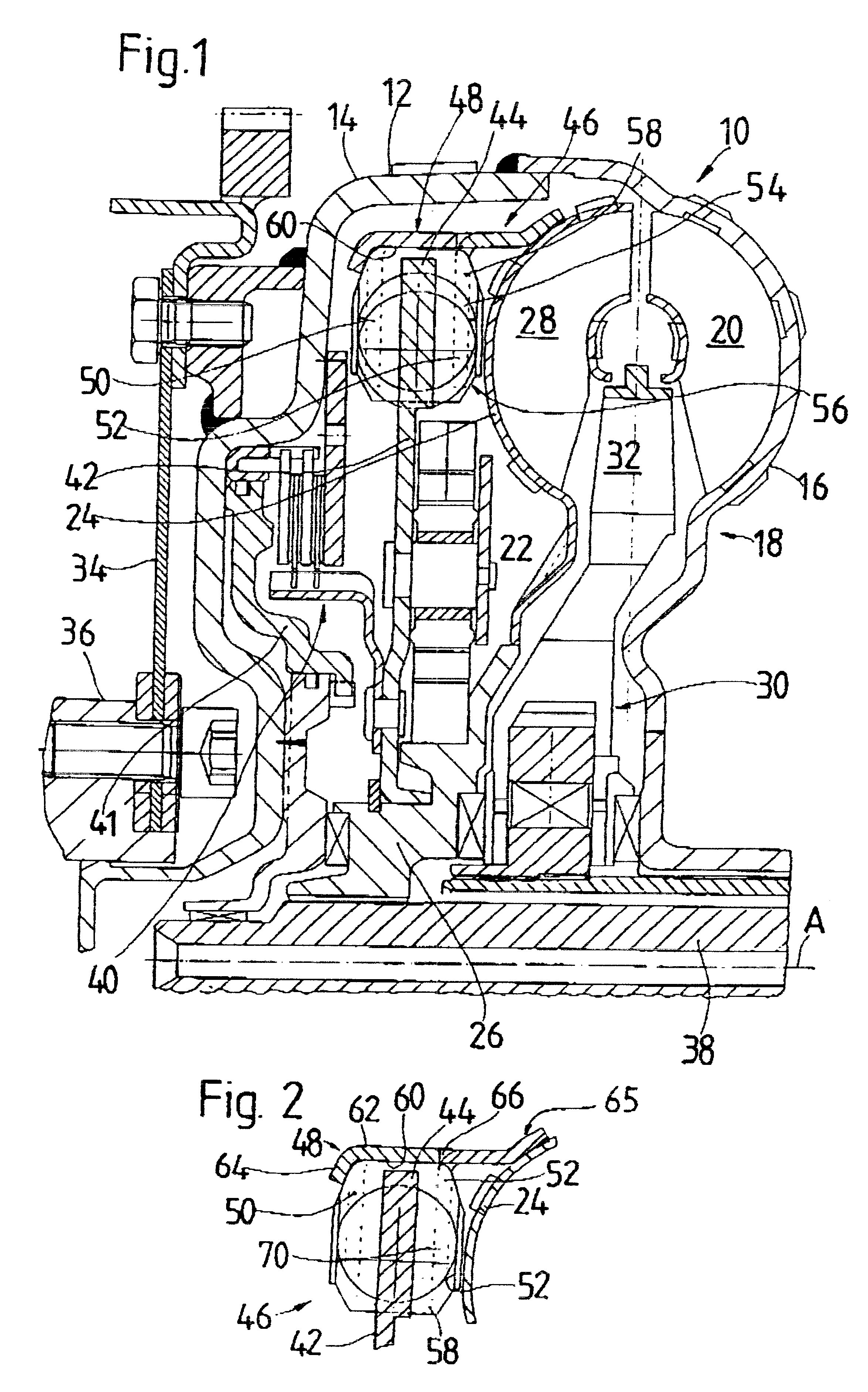

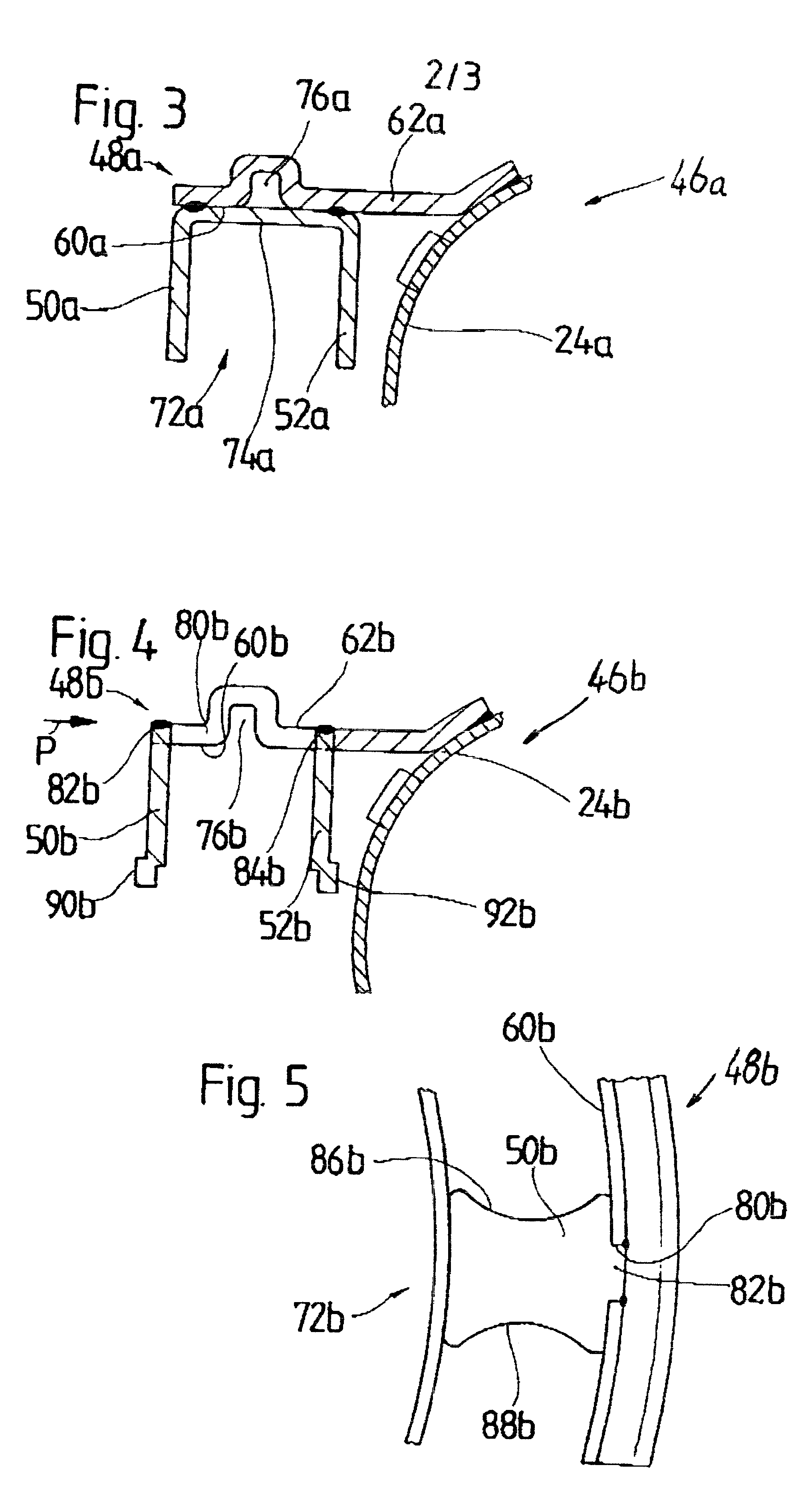

Elastomer strip design for torsional vibration dampers and torsional vibration dampers having same

InactiveCN107208691AIncreased slip torque capacityImprove fatigue lifeSpringsShaftsElastomerTransverse plane

Elastomer members for a torsional vibration damper, methods of making the same, and torsional vibration dampers having the elastomer members are disclosed. The elastomer members have a first major surface and an opposing second major surface with opposing side joining the first major surface to the second major surface, have a median sagittal plane extending parallel to the first major surface and the second major surface, and a transverse plane perpendicular to the median sagittal plane. In a cross-sectional geometry in a plane bisecting the median sagittal plane and the transverse plane, a thickness of the elastomer member changes along the median sagittal plane in a direction parallel to the transverse plane with a first thickness at both opposing sides and a second thickness at the transverse plane, where the second thickness is greater than the first thicknesses.

Owner:DAYCO IP HLDG

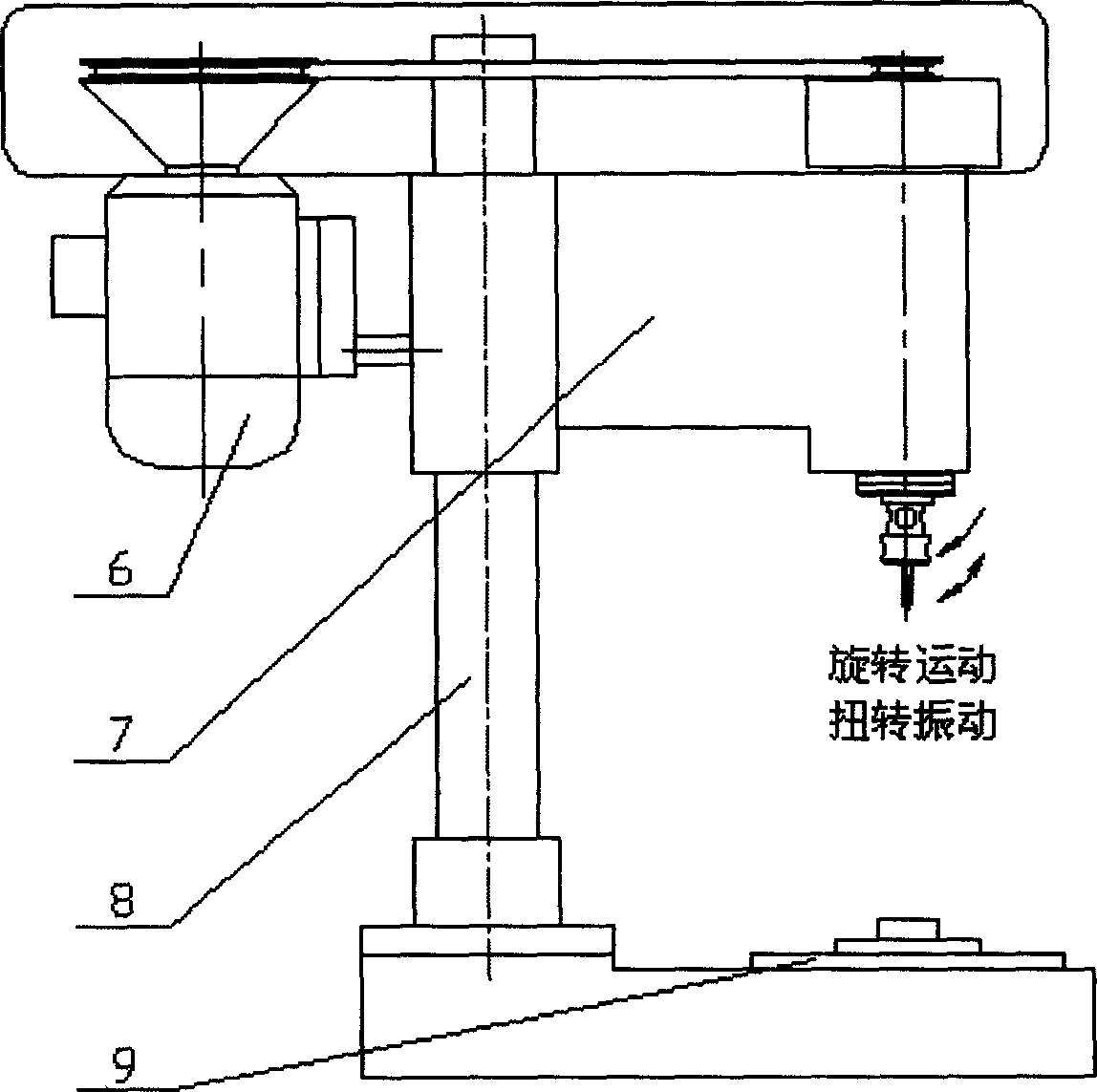

Torsional vibration sandwich-type beam-slab composite excitation ultrasonic motor, and drive platform and drive method thereof

InactiveCN105262366AOverall machine output performance improvementGuaranteed uptimePiezoelectric/electrostriction/magnetostriction machinesElastomerBall bearing

The invention discloses a torsional vibration sandwich-type beam-slab composite excitation ultrasonic motor, and a drive platform and a drive method thereof and aims at solving the technical problem that the ultrasonic motor which individually adopts a beam structure or disk structure elastomer is not ideal in overall output performance and the like. The torsional vibration sandwich-type beam-slab composite excitation ultrasonic motor comprises a fixed base, a first elastomer, a second elastomer, a rotating body, keys, a thrust ball bearing, a belleville spring, a nut and an output shaft, wherein the first elastomer is in a beam structure; the second elastomer is in a slab structure; a d<15> excitation mode is adopted by an annular piezoelectric ceramic piece; an excitation electric signal in an ultrasonic frequency band is applied to the piezoelectric ceramic piece; the first elastomer and the second elastomer are excited to generate torsional and flexural vibration modes respectively; a drive traveling wave is generated to form drive friction force by superposing and coupling of the vibration modes; and movement outputs in positive and reverse two directions are achieved. The torsional vibration sandwich-type beam-slab composite excitation ultrasonic motor has the technical advantages of high output power, stable motor operation, wide application range and the like, and has a wide application prospect in the technical fields of precision driving and micro positioning.

Owner:CHANGCHUN UNIV OF TECH

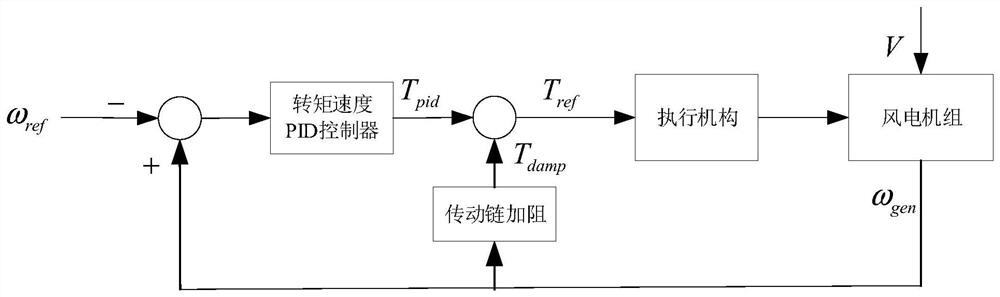

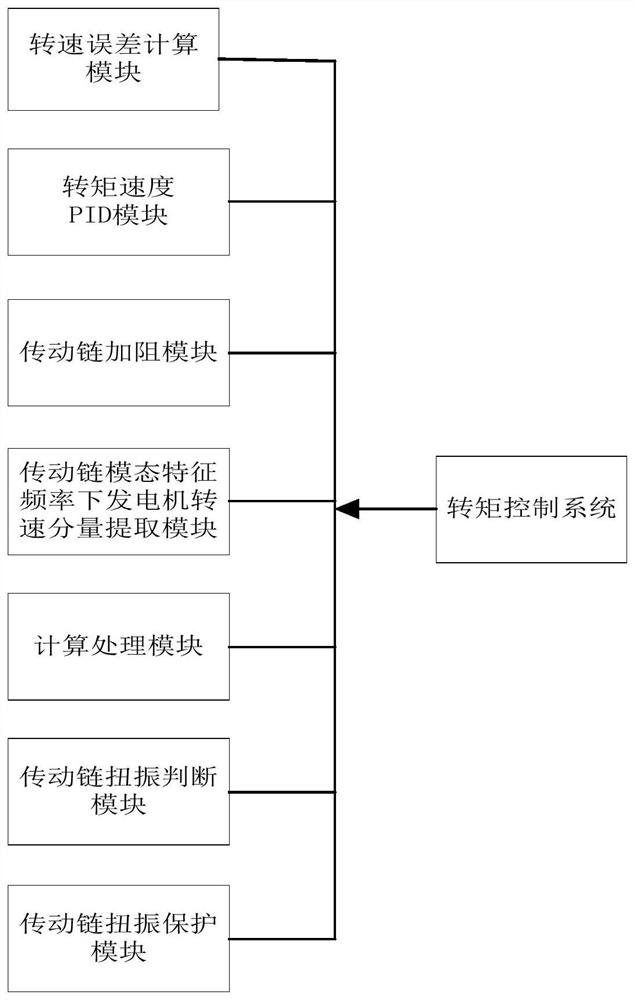

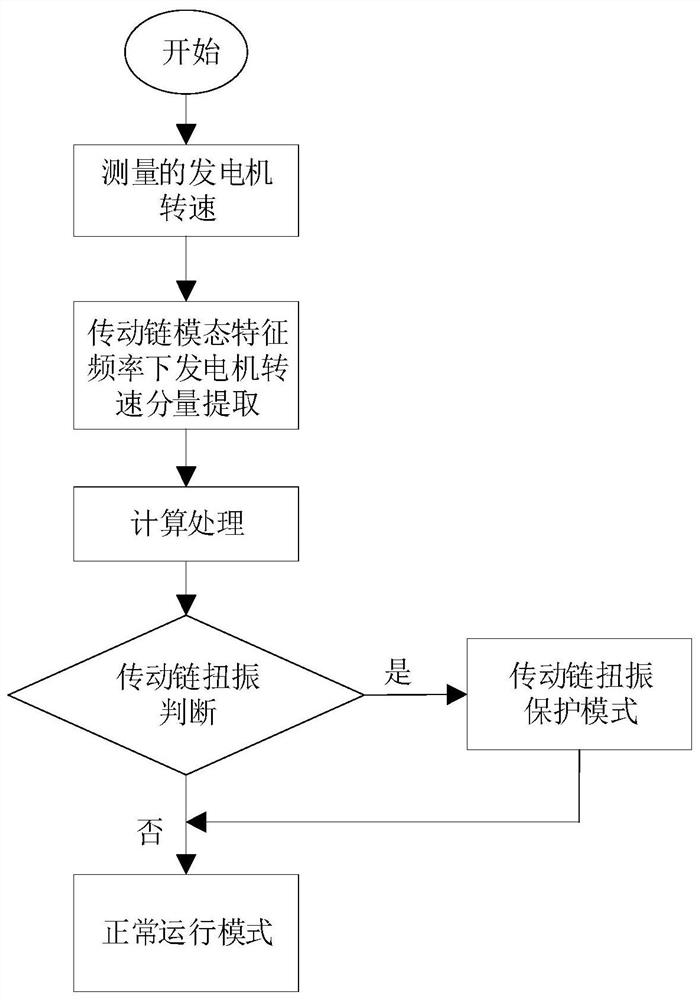

Torsional vibration protection method and system for transmission chain of wind generating set

PendingCN114576100AIdentify torsional vibrationsAvoid torsional vibrationWind motor controlMachines/enginesLogical operationsTorsional vibration

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap