Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Elastomer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An elastomer is a polymer with viscoelasticity (i.e., both viscosity and elasticity) and has very weak intermolecular forces, generally low Young's modulus and high failure strain compared with other materials. The term, a portmanteau of elastic polymer, is often used interchangeably with rubber, although the latter is preferred when referring to vulcanisates. Each of the monomers which link to form the polymer is usually a compound of several elements among carbon, hydrogen, oxygen and silicon. Elastomers are amorphous polymers maintained above their glass transition temperature, so that considerable molecular reconformation, without breaking of covalent bonds, is feasible. At ambient temperatures, such rubbers are thus relatively soft (E ≈ 3 MPa) and deformable. Their primary uses are for seals, adhesives and molded flexible parts. Application areas for different types of rubber are manifold and cover segments as diverse as tires, soles for shoes, and damping and insulating elements. The importance of these rubbers can be judged from the fact that global revenues are forecast to rise to US$56 billion in 2020.

Composition, apparatus, kit and method and uses thereof

A curable composition for use in wound care comprising, apportioned between at least one Part A and at least one Part B: one or more alkenyl-group containing polymers (i) having at least one alkenyl group or moiety per molecule, one or more SiH-containing polymers (ii) having at least one Si—H unit per molecule; and a catalyst (iii) for curing by addition of alkenyl-containing polymer (i) to SiH-containing polymer (ii), Part A and Part B independently having viscosity at 23° C. in the range 5-300 Pa·s, preferably 10-100 Pa s, at a shearing rate of 10 s−1, and when combined in one Part having cure time at 23° C. in the range from 0.5 min to 25 min, wherein when dispensed into a location about a wound dressing, said wound dressing overlying a wound site and skin thereabout, said dispensing being so as to intimately contact and overlie an edge of said dressing and skin about said edge, the composition cures in contact with said edge and skin at 32° C. to an elastomer exhibiting zero or low tack at a time in the range from 0.5 to less than 30 minutes, apparatus for use with said composition comprising dispensing apparatus or wound dressing, a kit comprising the same, and methods of dispensing and curing the same and of using the same in sealing a wound dressing and in treating a wound site of a human in need thereof.

Owner:SMITH & NEPHEW PLC

Solid implant

Owner:KU DAVID N

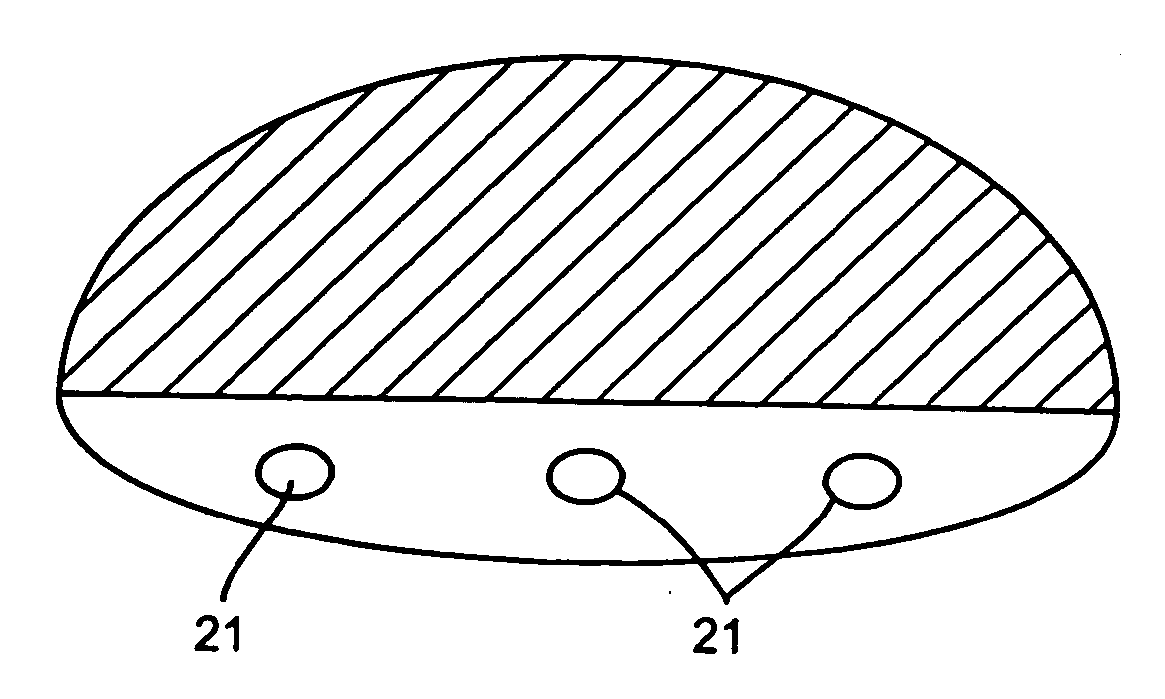

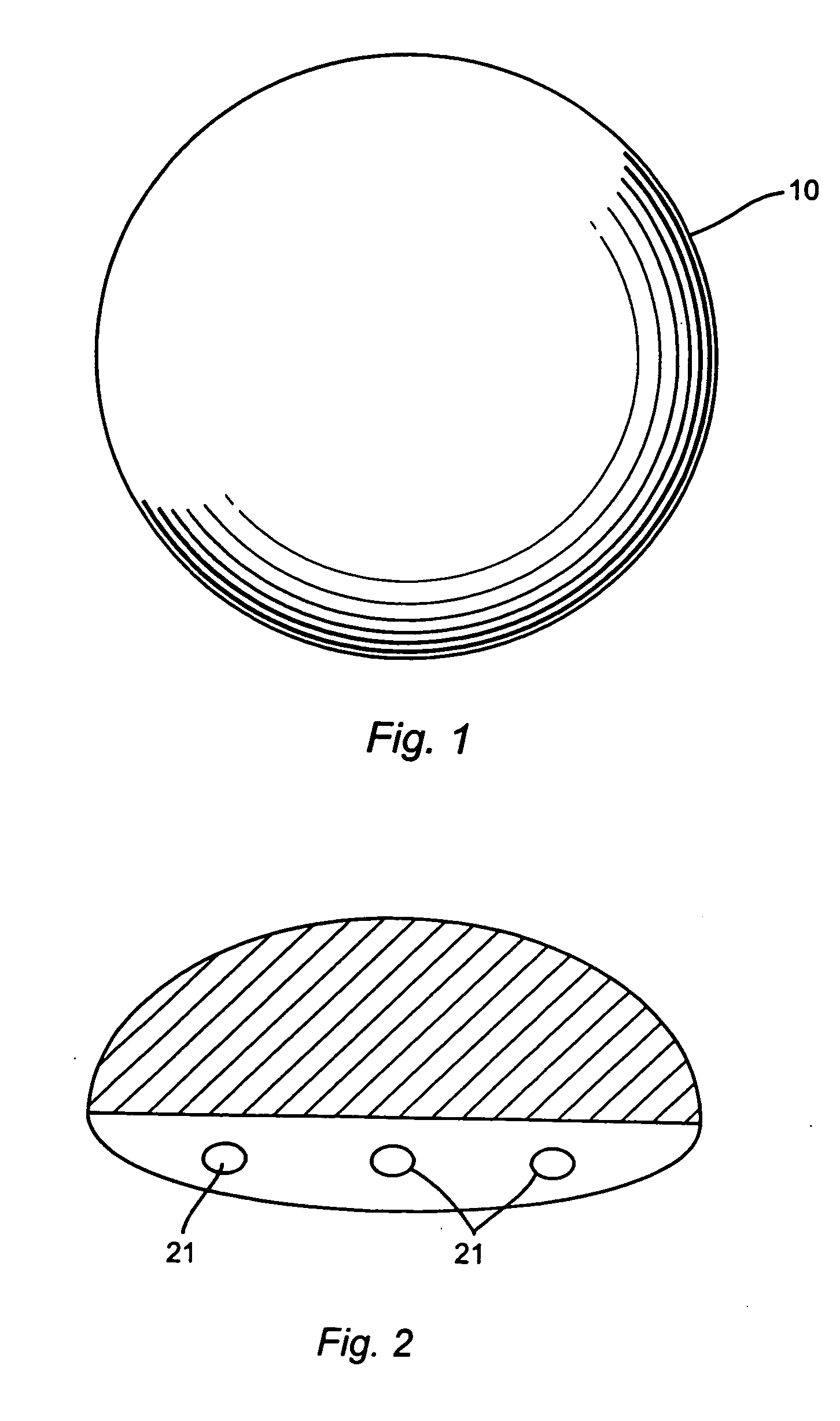

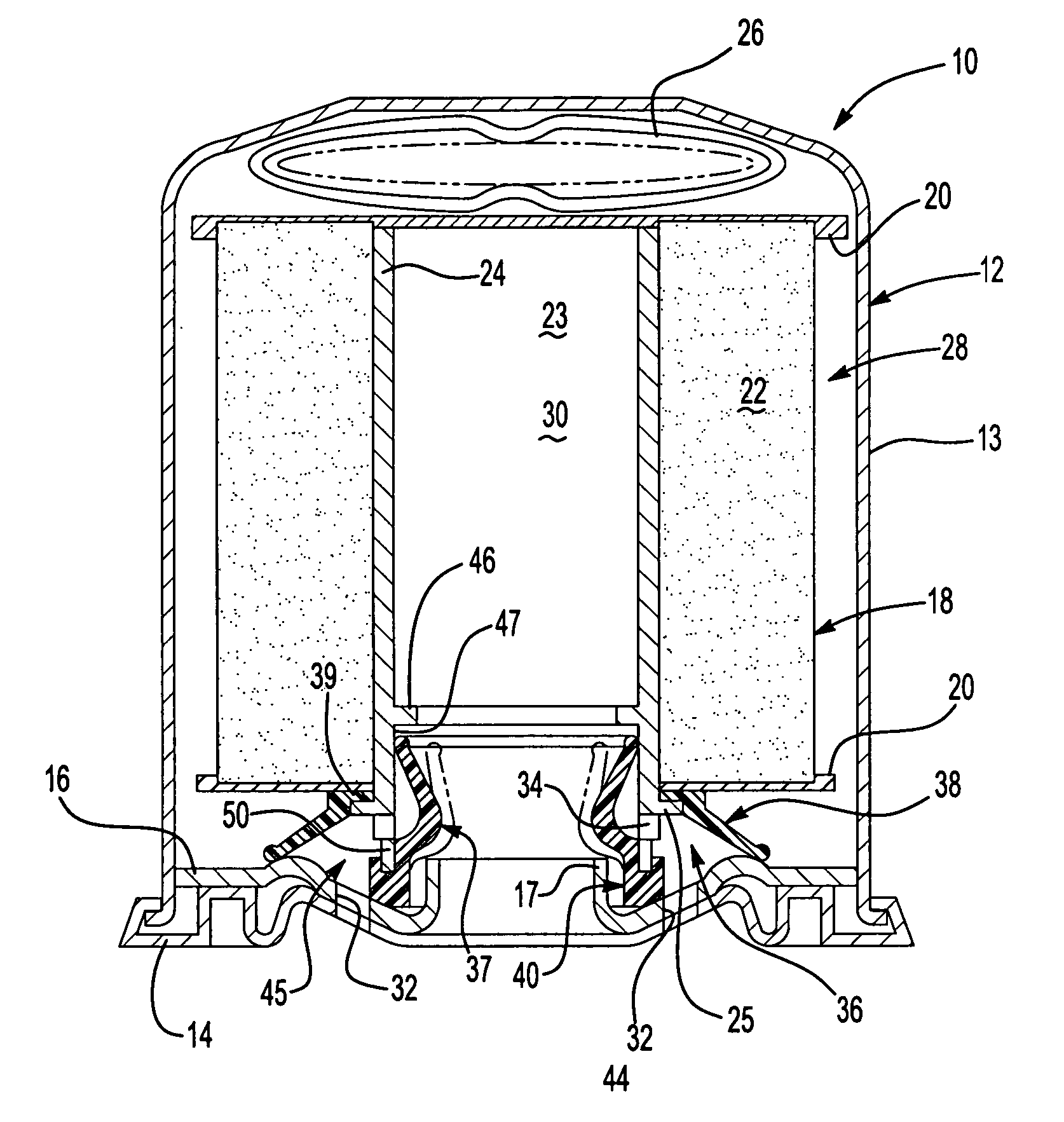

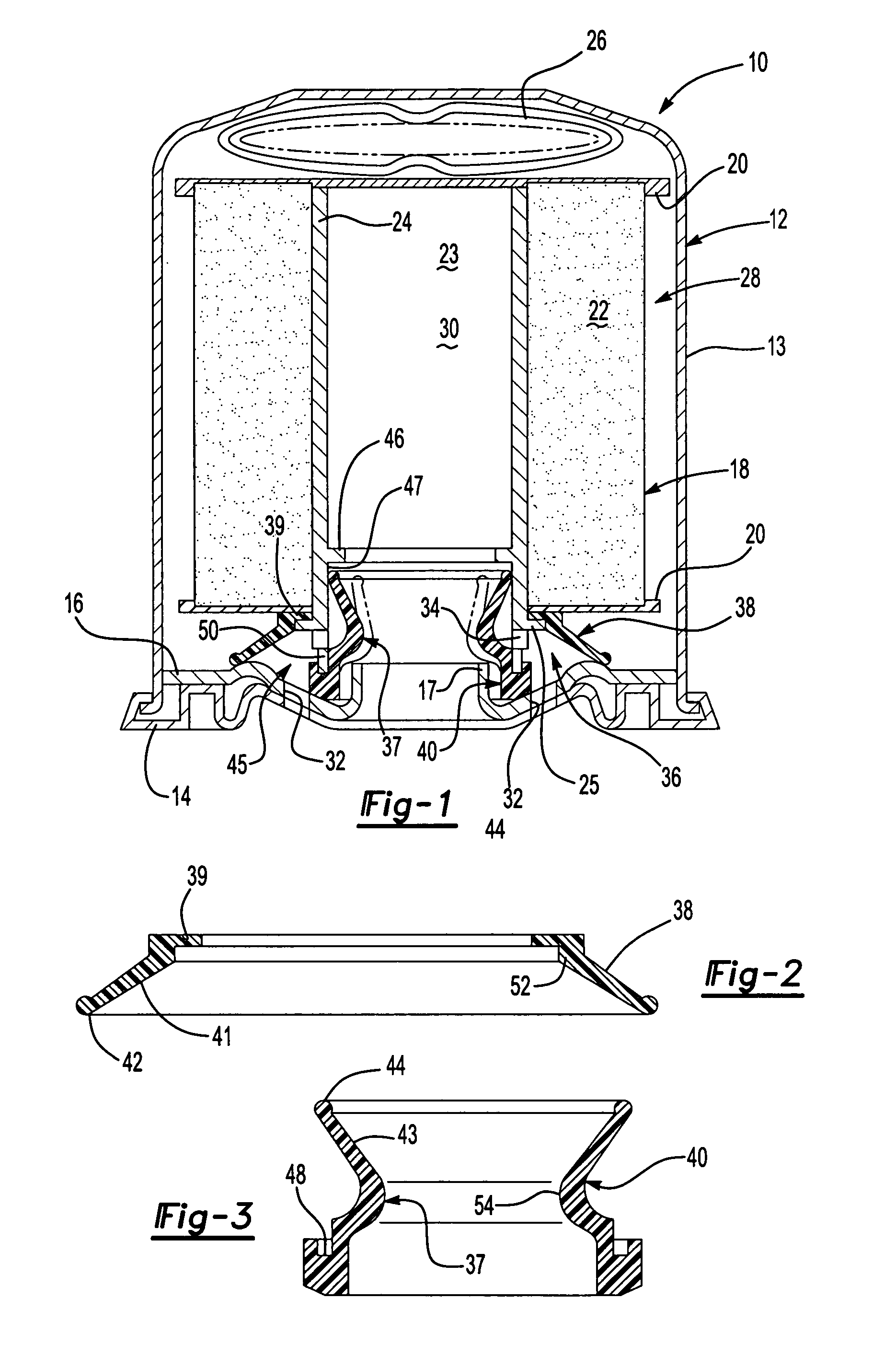

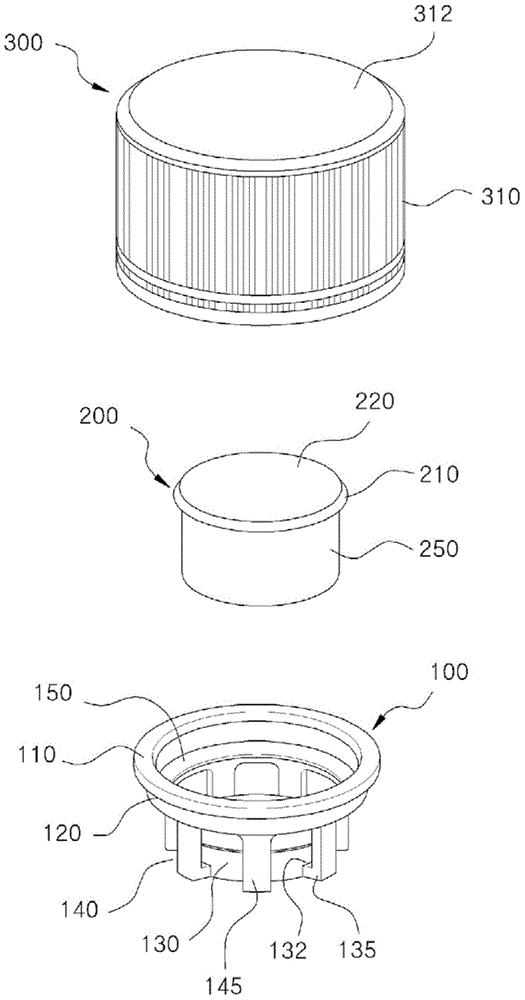

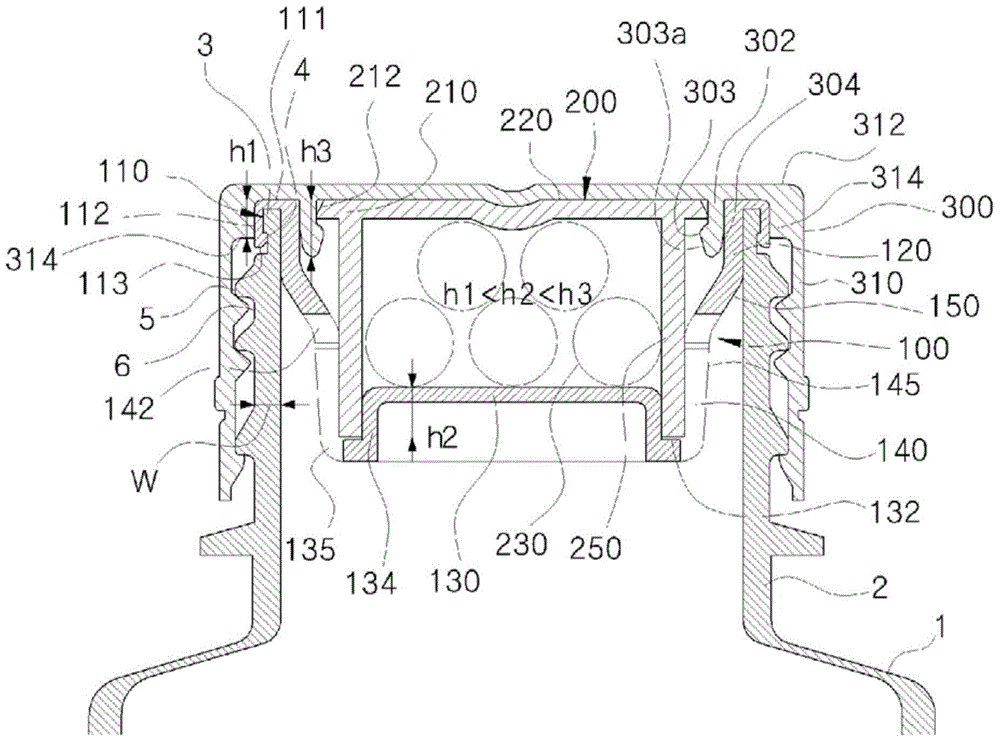

Two piece elastomer relief and anti-drain back valves for filter

InactiveUS20050161378A1Reduce in quantityEliminate the problemSettling tanks feed/dischargeEqualizing valvesElastomerDifferential pressure

Owner:PUROLATOR ADVANCED FILTRATION

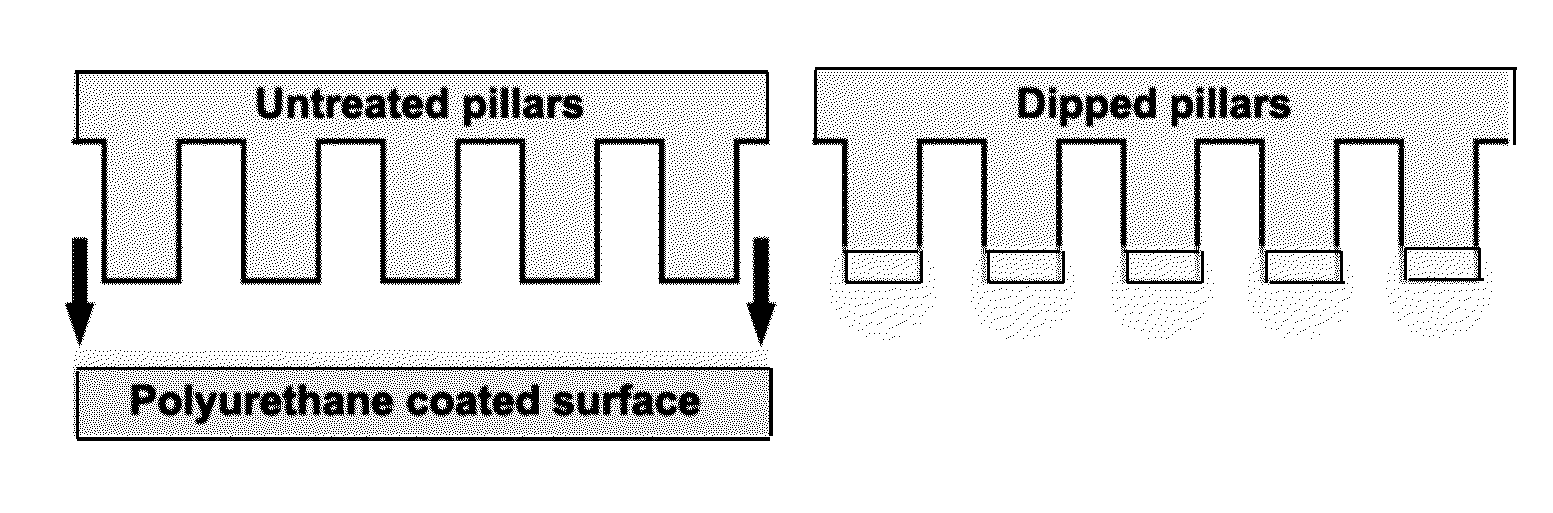

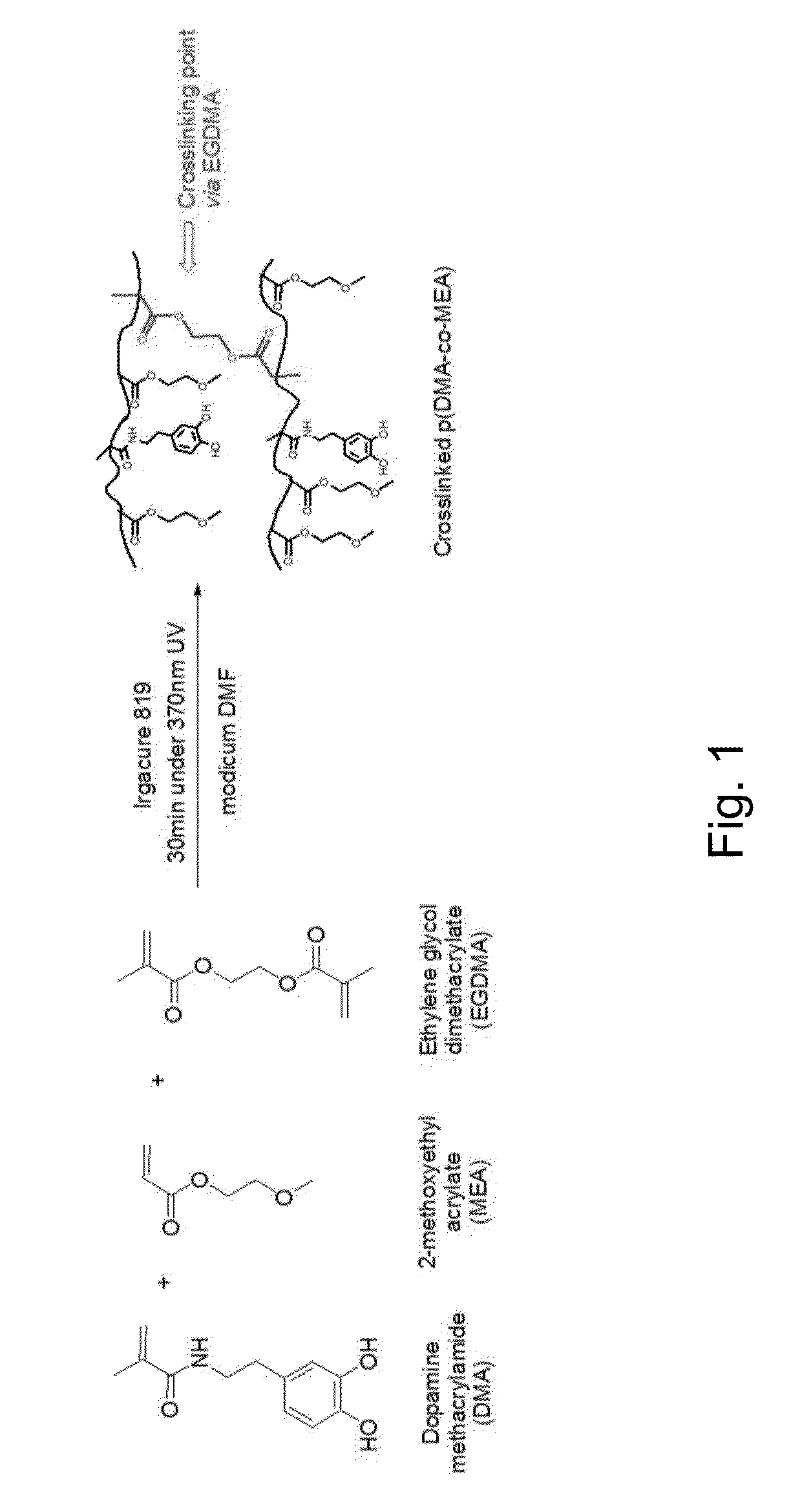

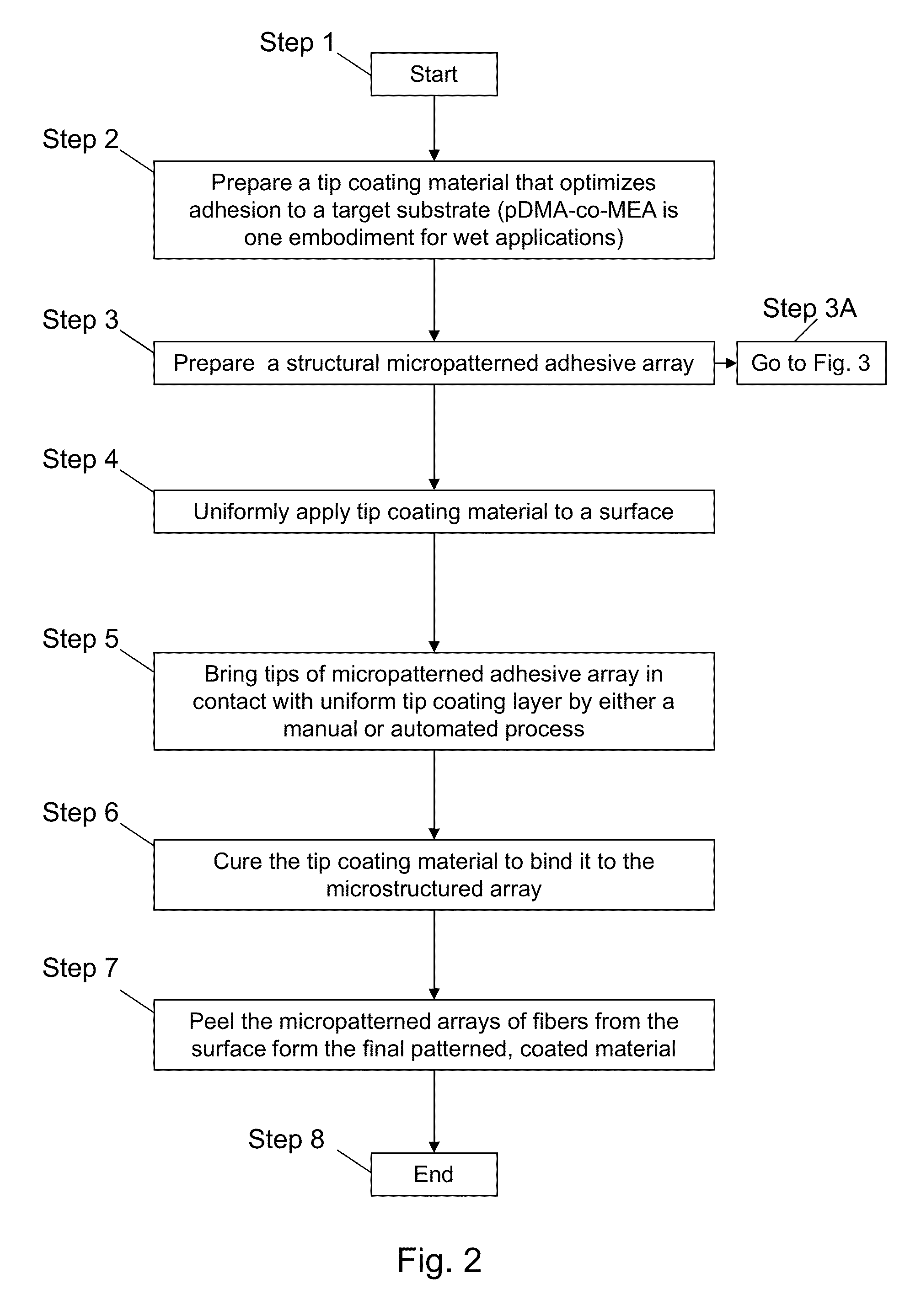

Micro-fiber arrays with tip coating and transfer method for preparing same

ActiveUS20130183481A1Performance deteriorationLayered productsPretreated surfacesMicron scaleElastomer

Owner:CARNEGIE MELLON UNIV CENT FOR TECH TRANSFER & ENTERPRISE CREATION

Reinforced polyethylene glycol terephthalate-modified material and preparation method thereof

InactiveCN101875759AImprove low temperature resistanceImprove creep resistanceGlass fiberThermoplastic

The invention discloses a reinforced polyethylene glycol terephthalate-modified material and a preparation method thereof. The reinforced polyethylene glycol terephthalate-modified material comprises the following components in part by weight: 100 parts of polyethylene glycol terephthalate, 30 to 50 parts of glass fibers, 6 to 10 parts of flexibilizer, 0.5 to 1 part of antioxygen, 3 to 6 parts of compound nucleating agent and 10 to 15 parts of elastomer SEBS. The reinforced polyethylene glycol terephthalate-modified material has high low temperature resistance and creep resistance and can be used in place of the conventional thermoplastic ethylene-propylene diene methylene dynamically vulcanized elastomer to make frame seals and other parts and reduce use cost of the materials. A new application field of the modifying polyethylene glycol terephthalate is opened, the conventional thermoplastic ethylene-propylene diene methylene dynamically vulcanized elastomer can be replaced by the material, and the use cost of the material is reduced greatly.

Owner:SHENZHEN KEJU NEW MATERIAL

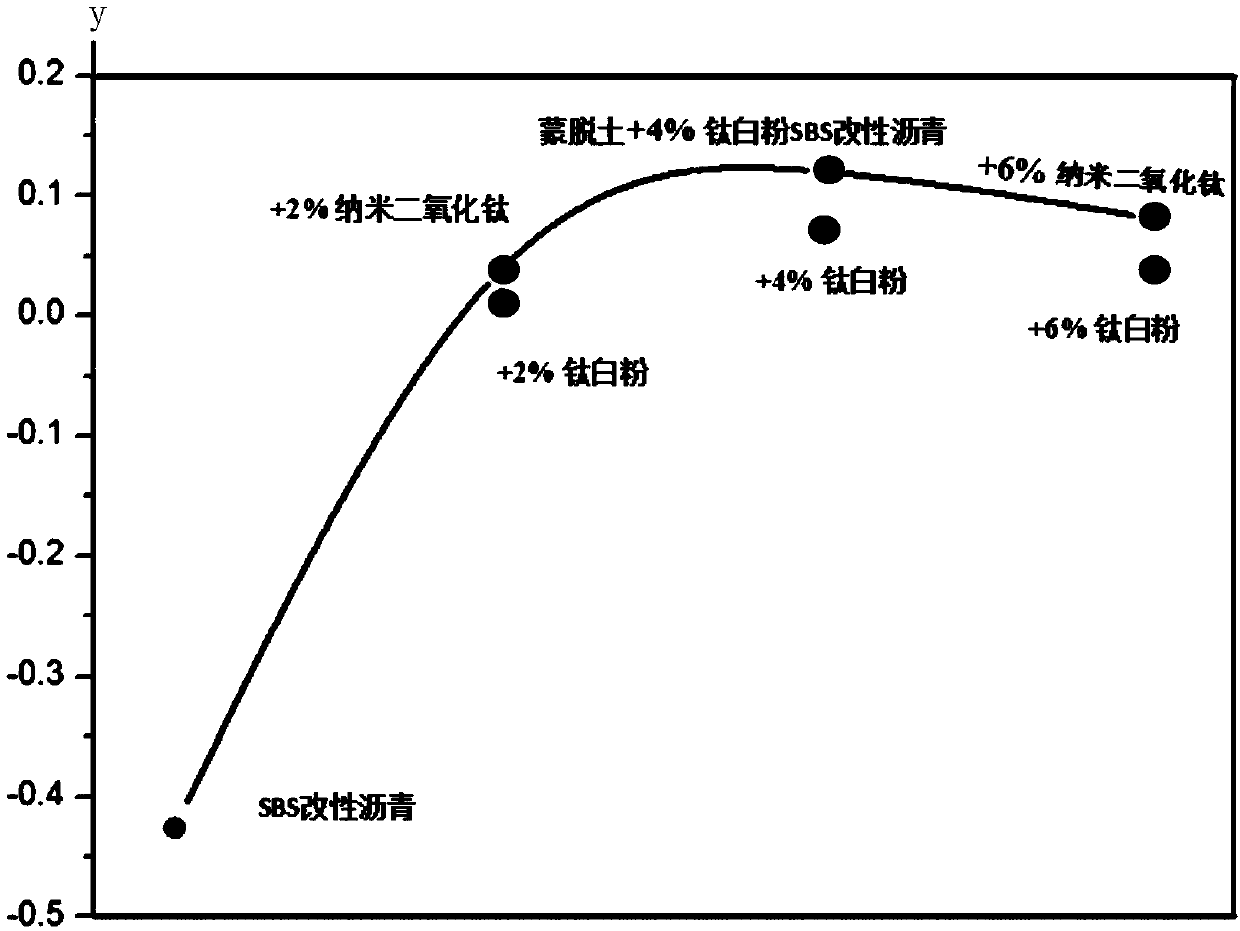

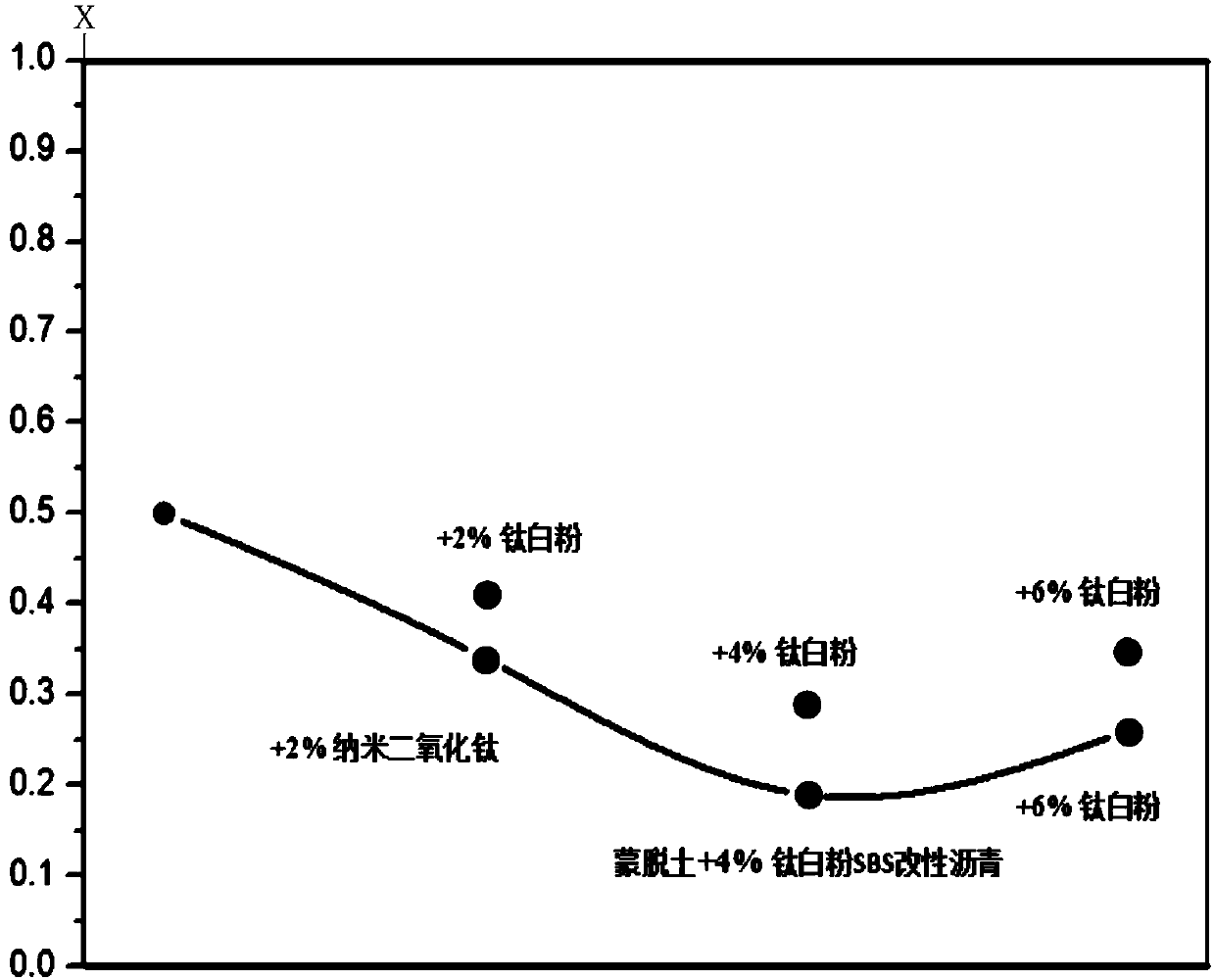

Preparation method of durable modified asphalt

Owner:宁夏路桥工程股份有限公司

Polyamide toughening agent as well as preparation method and use thereof

InactiveCN104177825AImprove impact resistanceImprove low temperature impact resistanceElastomerPolyolefin

The invention provides a polyamide toughening agent as well as a preparation method and use thereof. The polyamide toughening agent is mainly prepared from the following raw materials in parts by weight: 50-95 parts of an ethylene-octene copolymer elastomer, 0.5-2.5 parts of a grafting monomer, 5-50 parts of polyolefin, 0.05-0.5 part of an initiator and 5-20 parts of polyamide. The toughening agent provided by the invention is simple in preparation method, have good mechanical property and low-temperature impact toughness when being used for toughening the polyamide, and can be widely applied to modification of polyamide materials in the fields of inner and outer decorative parts of automobiles, electric tools, rail bases, transformers, oil tubes and the like.

Owner:DONGGUAN CALVIN PLASTIC & TECH

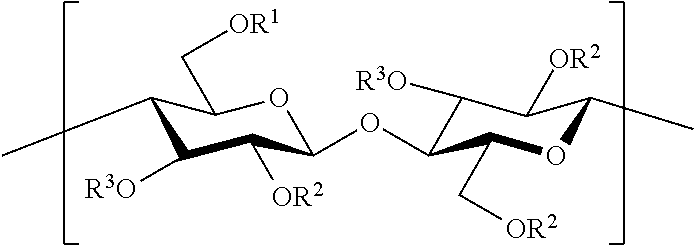

Process for dispersing cellulose esters into elastomeric compositions

Owner:EASTMAN CHEM CO

Intermediate transfer belt, image forming apparatus, and method for producing intermediate transfer belt

InactiveUS20120201578A1Excellent toner releasabilityImprove transfer rateElectrographic process apparatusElastomerLatent image

Owner:RICOH KK

High-rigidity and high-toughness resin material for clothing buttons

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

Container cap for enabling granules and contents of container to be taken simultaneously

ActiveCN105164022AClosure with auxillary devicesContainers with multiple articlesEngineeringElastomer

Owner:JCTECH

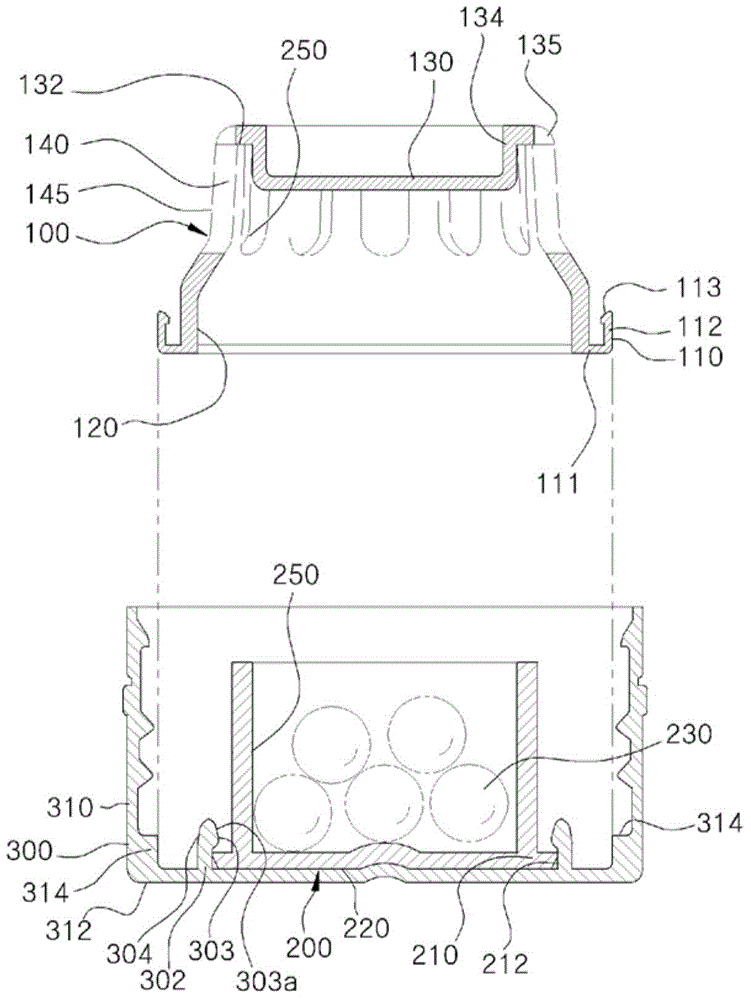

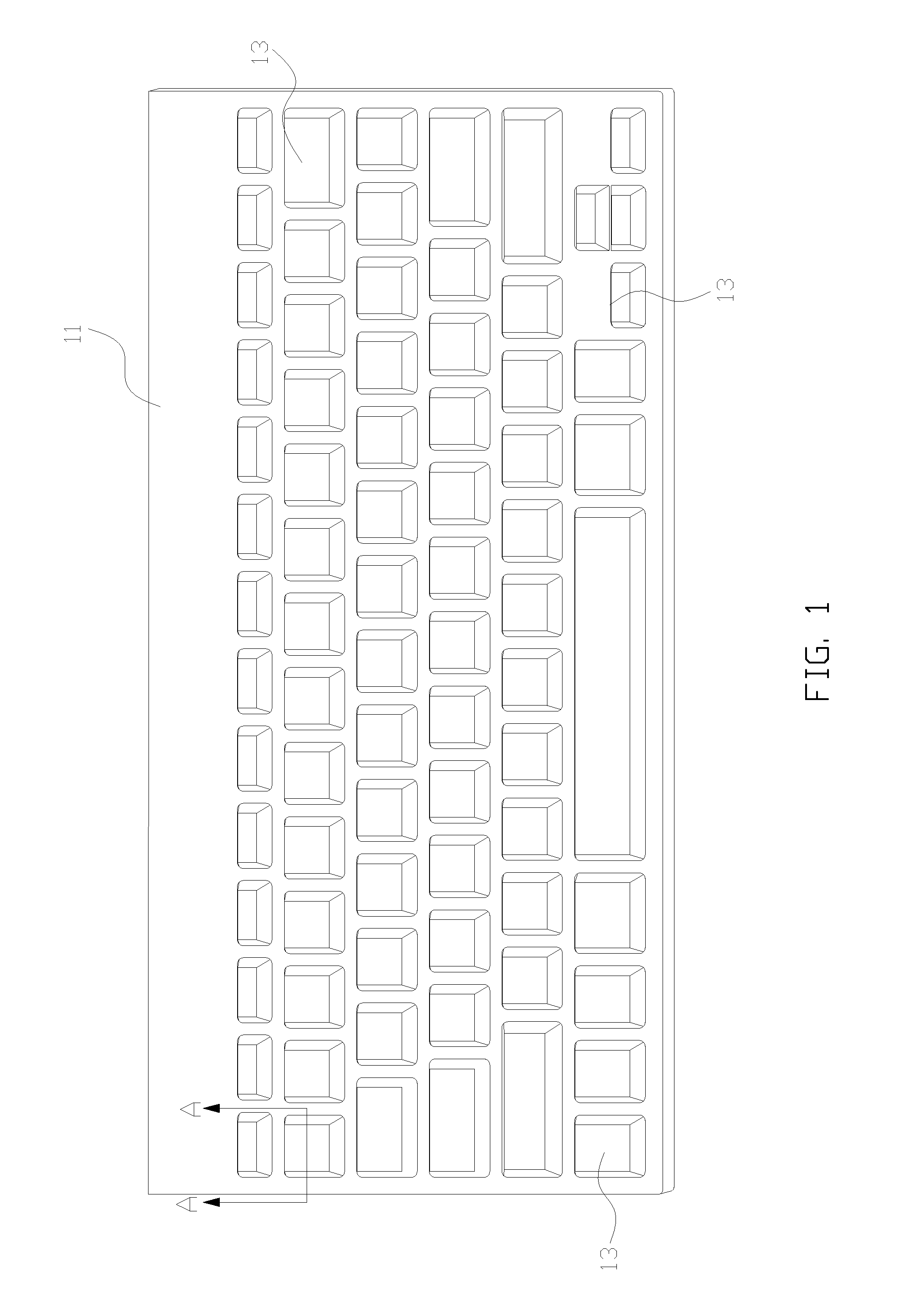

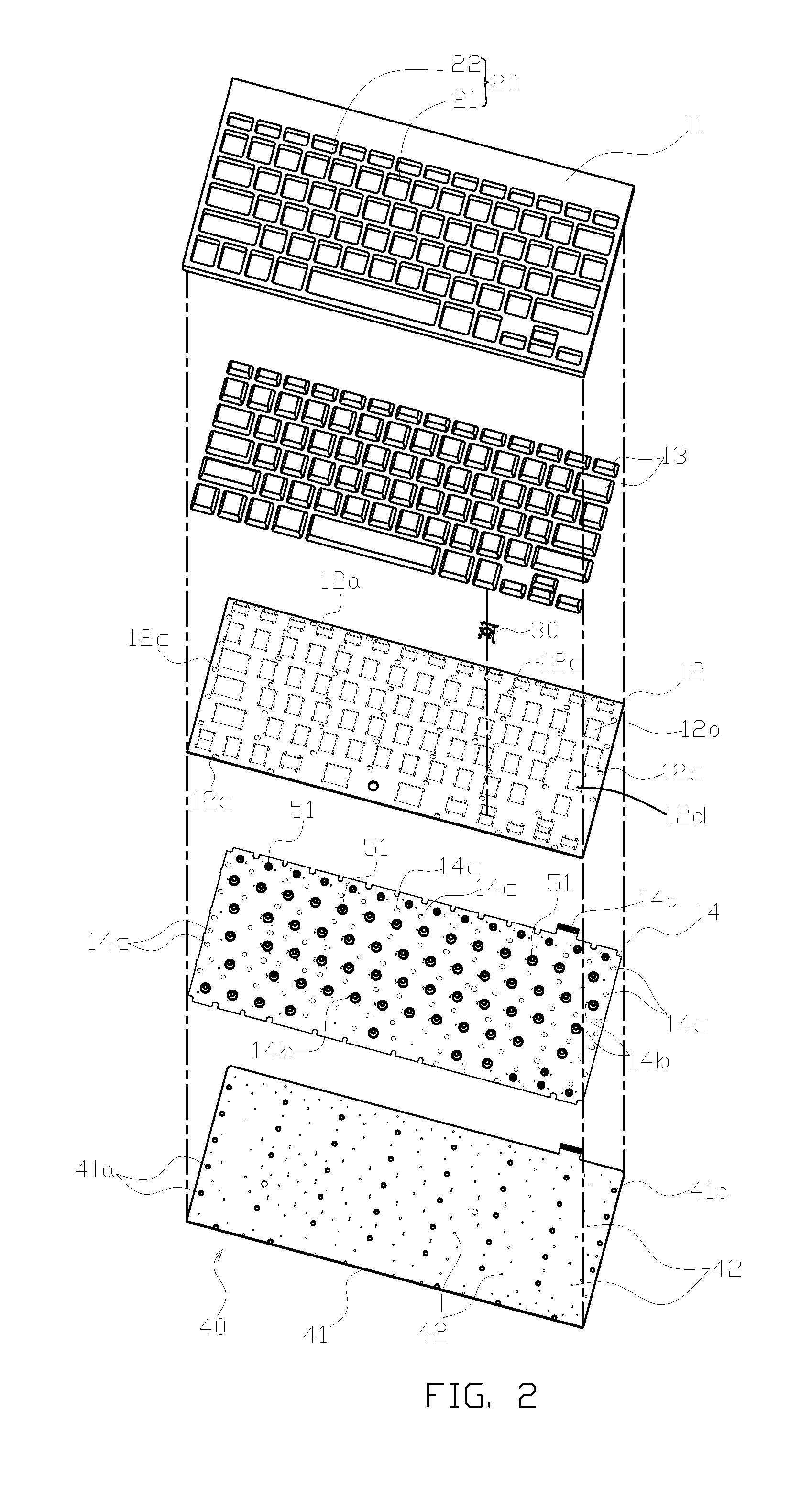

Keyboard

InactiveUS20130208440A1Reduce thicknessInput/output for user-computer interactionMeasurement apparatus componentsElastomerLight beam

Owner:ZHANG WENYU

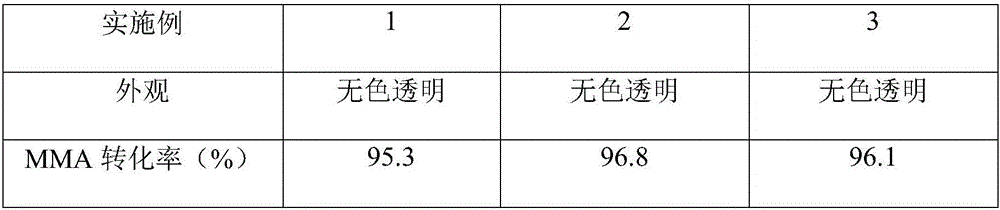

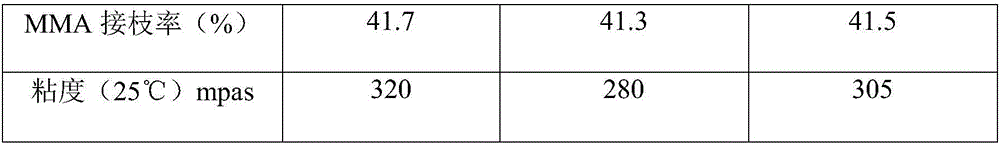

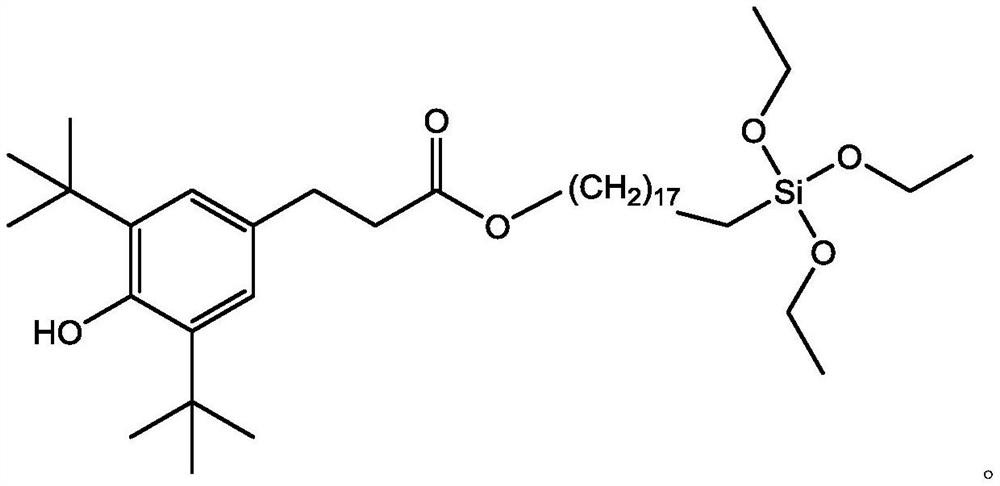

SBS grafted odor-removing mattress spraying glue and preparation method thereof

ActiveCN107177332AIncrease forceReduce the numberMacromolecular adhesive additivesGraft polymer adhesivesElastomerMethyl isobutyl ketone

Owner:佛山市东方树新材料科技有限公司

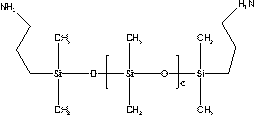

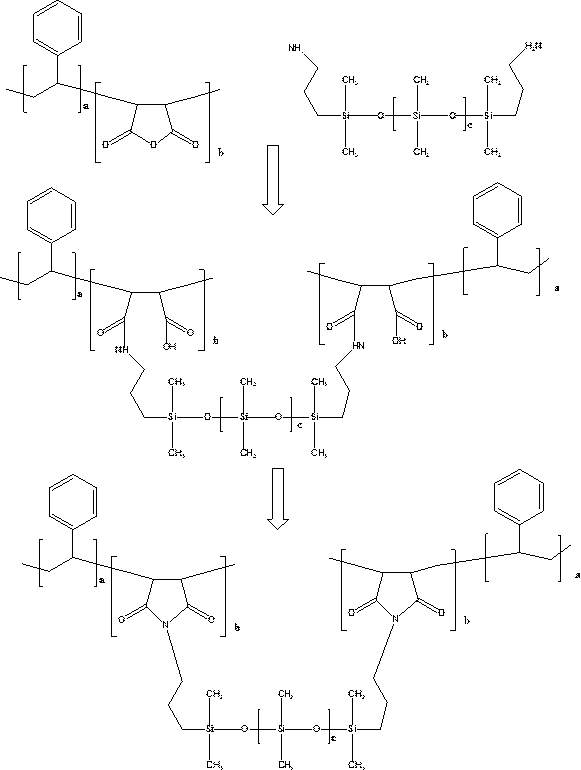

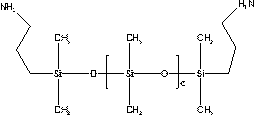

Synthesis of end amino silicone oil modified stryenemaleic anhydride copolymer

InactiveCN109337085AFlexible structure adjustmentControl Molecular Weight DistributionElastomerPolyolefin

Owner:YANTAI DARBOND TECH

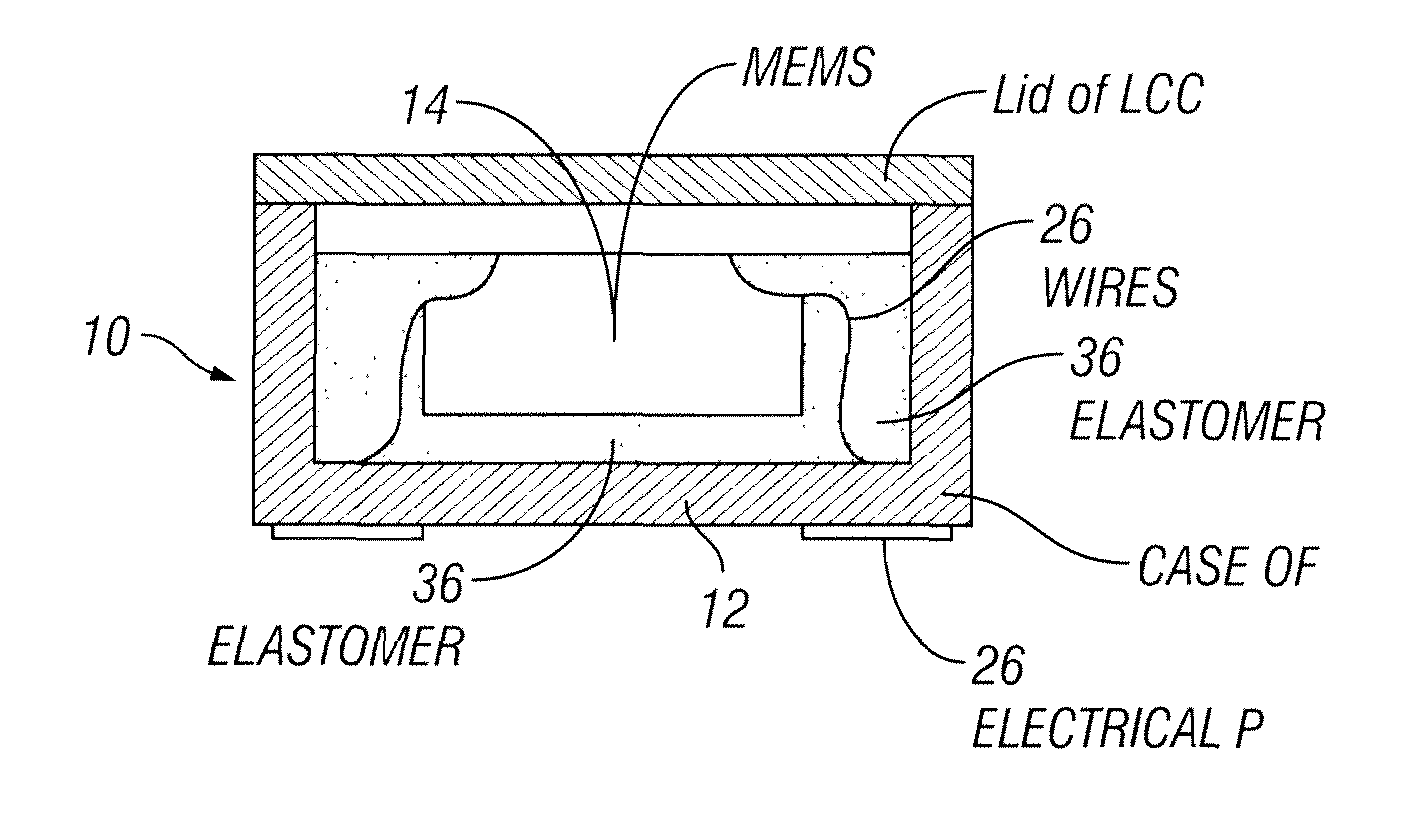

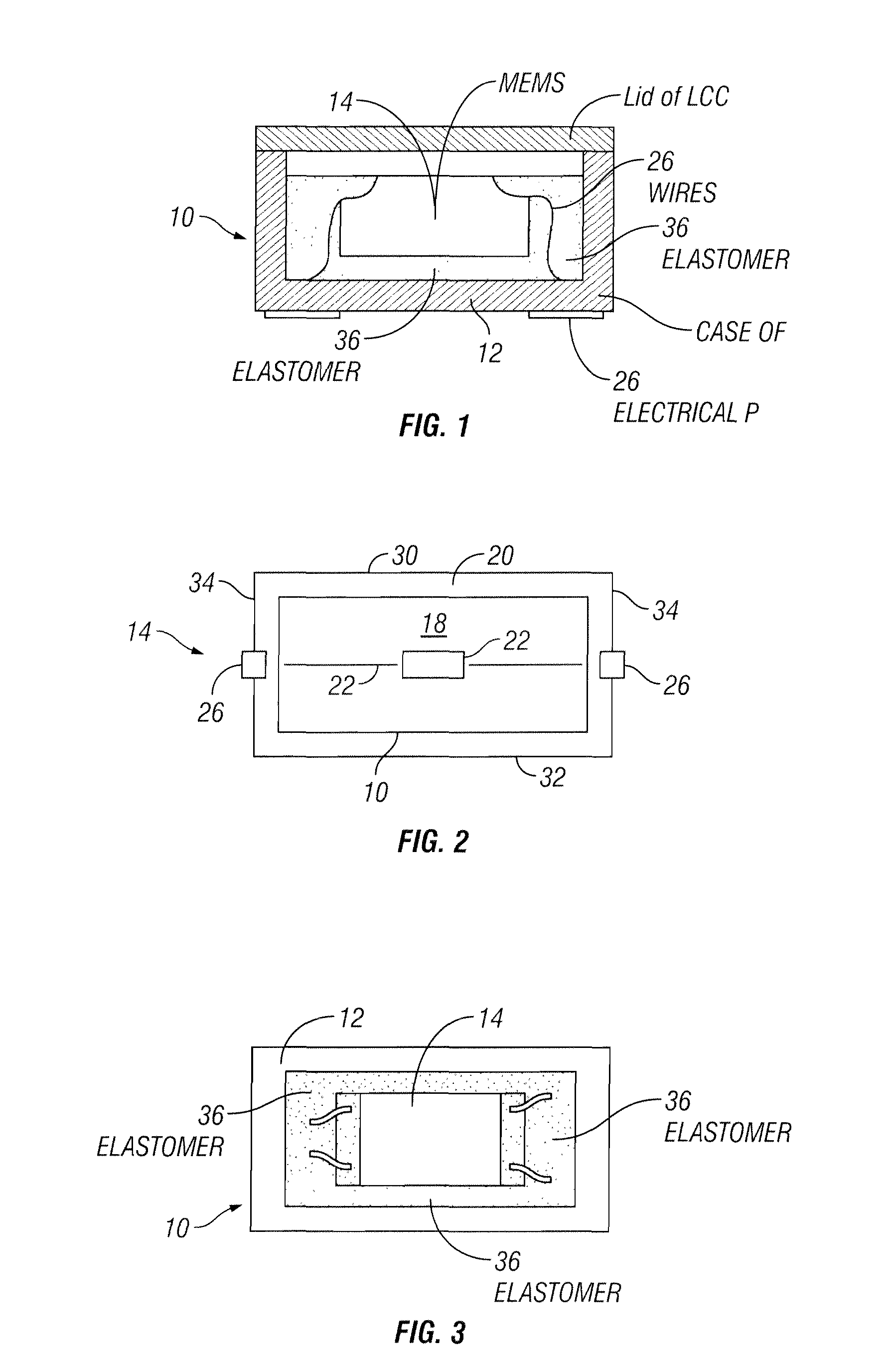

Shock Resistant Mounting for High G Shock Accelerometer

InactiveUS20120085170A1High G shockLow case strain sensitivityAcceleration measurement using interia forcesSpeed/acceleration/shock instrument detailsElastomerAccelerometer

Owner:MEGGITT ORANGE COUNTY

Process for the simultaneous extraction of lignin and silica from biomass and elastomer reinforced with a mixture of lignin and silica

The invention relates to a process for the simultaneous extraction of lignin and silica from lignocellulosic plant material, characterized in that it comprises the steps of:a) fractionating the lignocellulosic plant material in the presence of an acid solution, so as to obtain a solid fraction comprising cellulose, residual lignin and silica;b) extracting simultaneously lignin and silica from the solid fraction obtained in step a) with a basic solution, at a pH between 10 and 13 and at a temperature between 70° C. and 90° C., so as to obtain a liquid phase comprising lignin and silica, and a solid phase;c) separating the liquid phase and of the solid phase obtained in step b),d) coprecipitating a mixture of lignin and silica comprised in the liquid phase, at a pH between 5 and 6.

Owner:CIE IND DE LA MATIERE VEGETALE

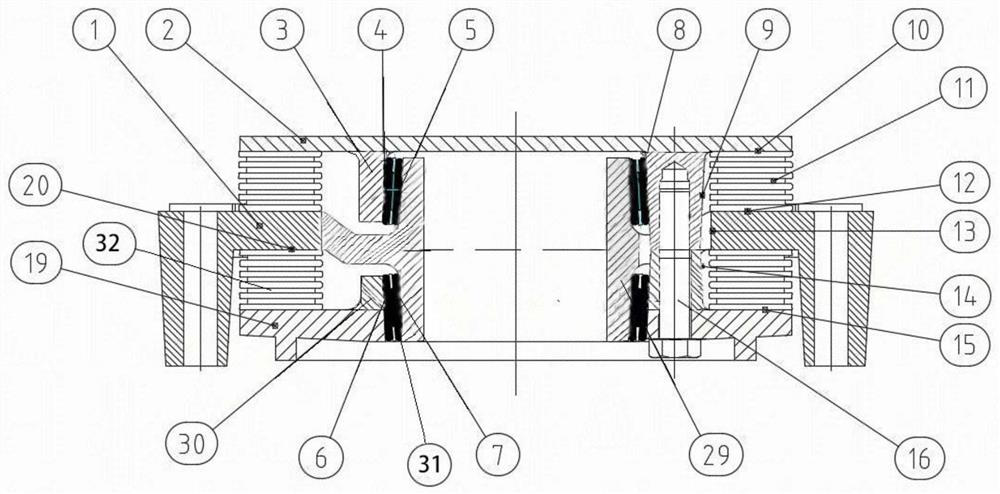

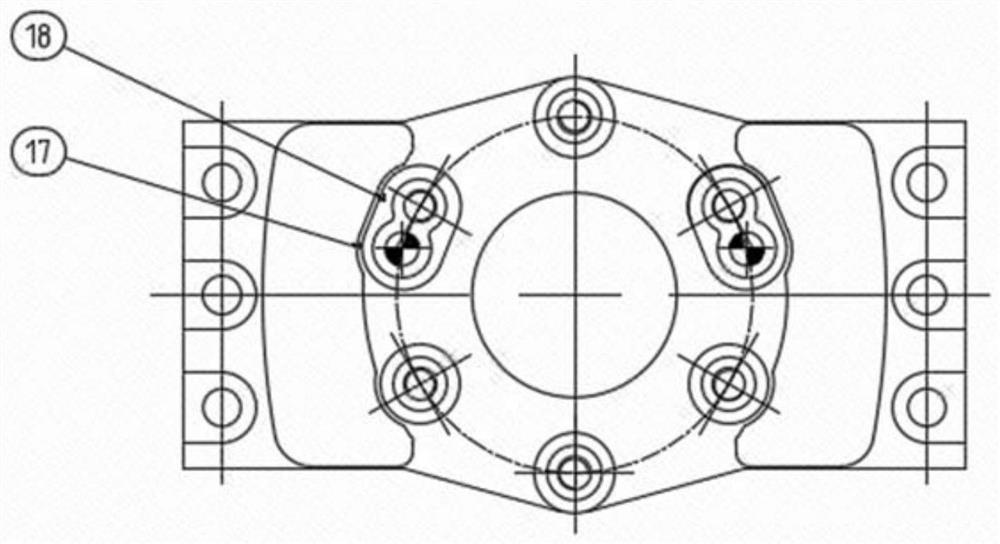

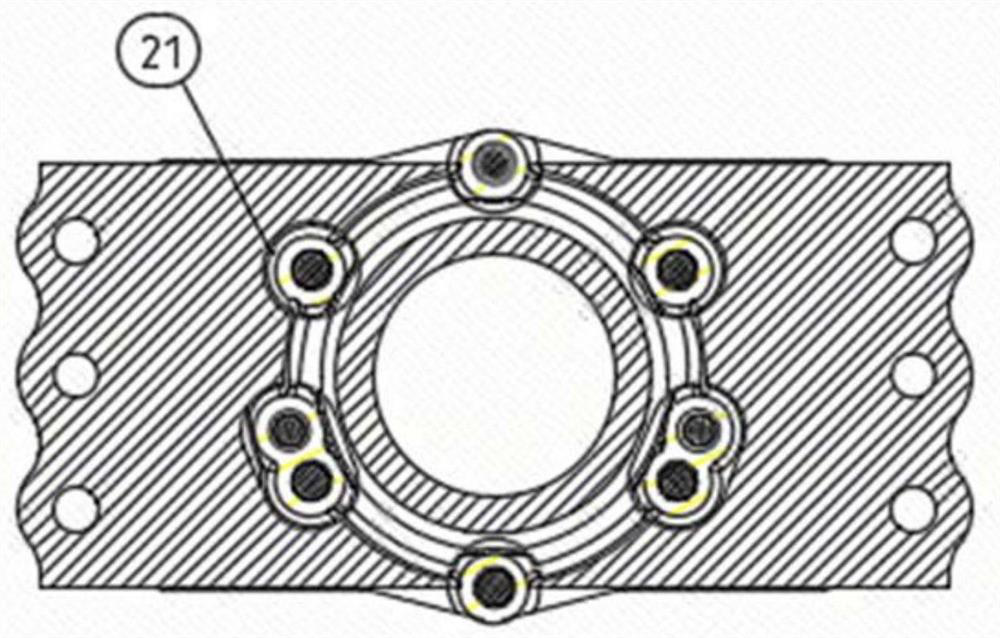

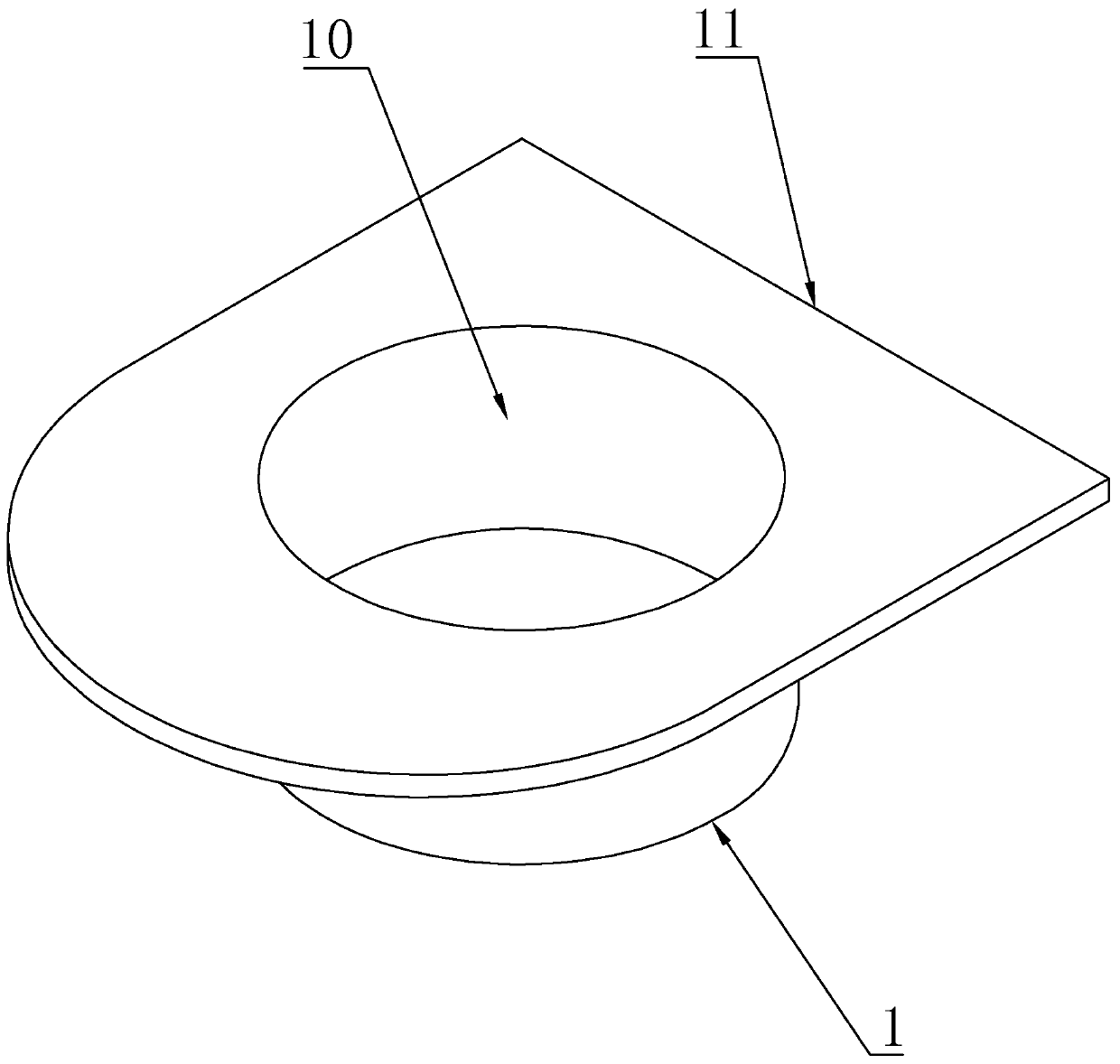

Elastomer strip design for torsional vibration dampers and torsional vibration dampers having same

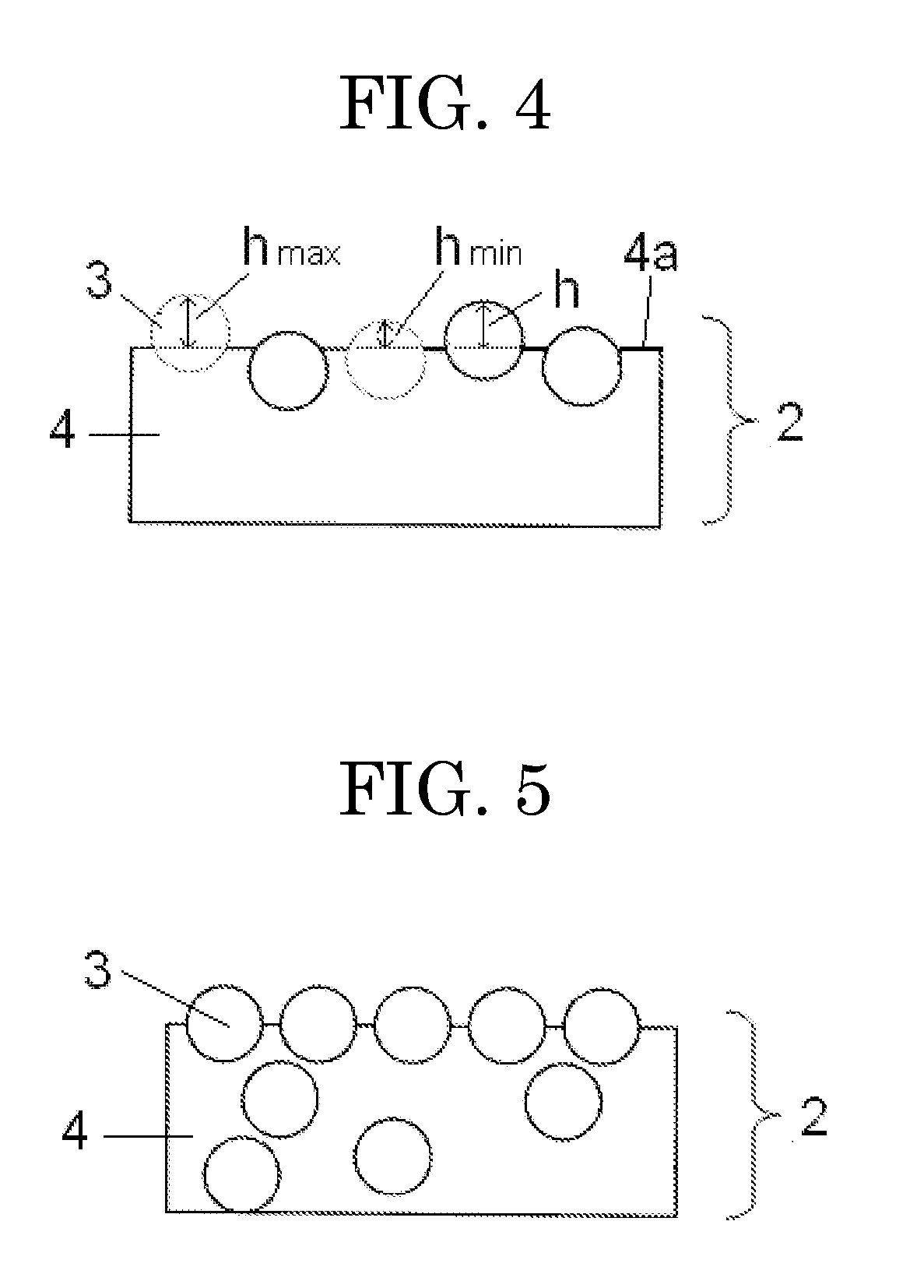

InactiveCN107208691AIncreased slip torque capacityImprove fatigue lifeSpringsShaftsElastomerTransverse plane

Elastomer members for a torsional vibration damper, methods of making the same, and torsional vibration dampers having the elastomer members are disclosed. The elastomer members have a first major surface and an opposing second major surface with opposing side joining the first major surface to the second major surface, have a median sagittal plane extending parallel to the first major surface and the second major surface, and a transverse plane perpendicular to the median sagittal plane. In a cross-sectional geometry in a plane bisecting the median sagittal plane and the transverse plane, a thickness of the elastomer member changes along the median sagittal plane in a direction parallel to the transverse plane with a first thickness at both opposing sides and a second thickness at the transverse plane, where the second thickness is greater than the first thicknesses.

Owner:DAYCO IP HLDG

Automobile side wall cavity sound absorption cotton and preparation method thereof

The invention relates to the field of automobile accessories, in particular to automobile side wall cavity sound absorption cotton and a preparation method thereof. The sound absorption cotton comprises an outer bag made of an elastomer, and the outer bag is filled with crushed cotton and is sealed. The outer bag is made of the elastomer and filled with the crushed cotton, and the path of noise and vibration transmission can be blocked; meanwhile, due to the internal material porous structure, certain sound absorption performance is achieved, and the sound absorption cotton can be freely installed, is flexible in design and can be used for sealing cavities in various automobile bodies; additional assembly is not needed, and the sound absorption cotton can be directly placed in the cavitiesin the automobile bodies.

Owner:WENZHOUSHI HUANQIU AUTO-LINER CO LTD

Cement nanometer toughening agent for natural gas well cementation

Owner:CNPC BOHAI DRILLING ENG

Composition comprising a semi-crystalline vdf polymer and a fluorinated thermoplastic elastomer block copolymer

InactiveUS20200095415A1Improved resistance to stainingEasy to adjustInsulatorsElastomerPolymer science

Owner:SOLVAY SOLEXIS

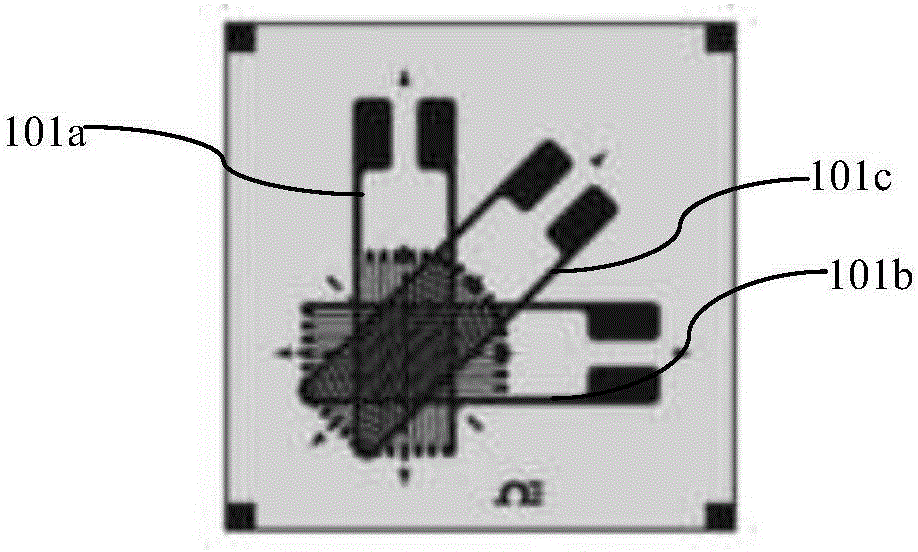

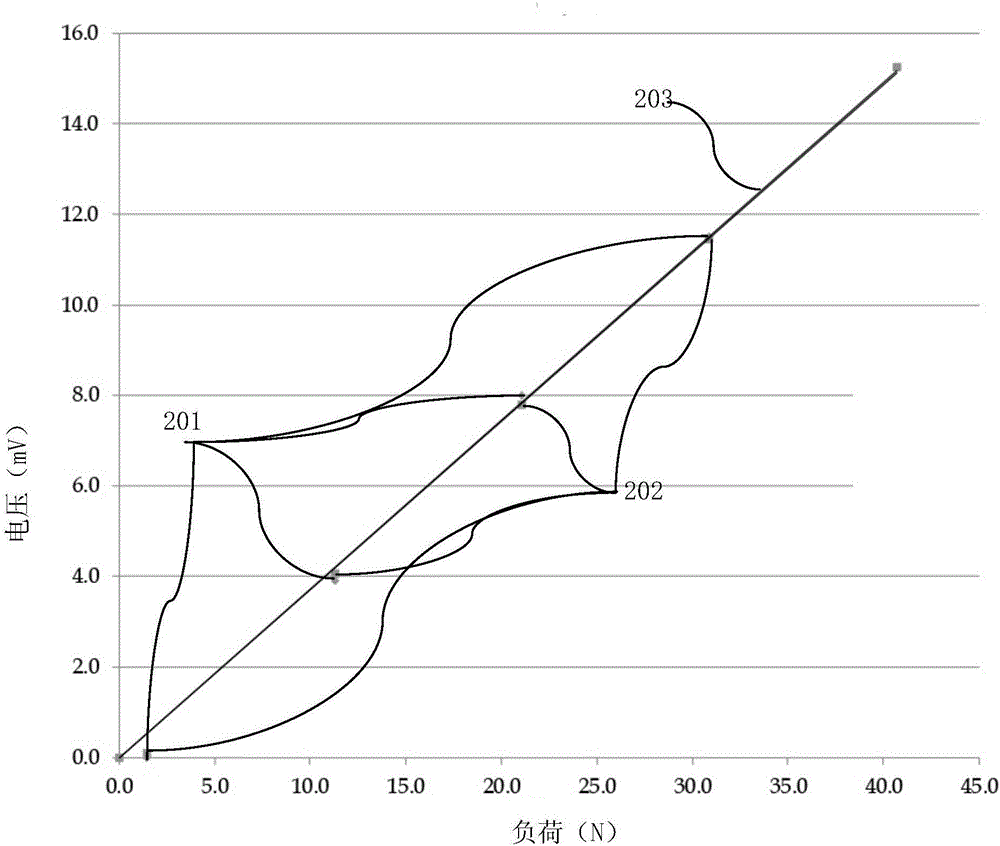

Load cell

ActiveUS20180106690A1High resolutionImprove signal-to-noise ratioForce measurement by permanent gauge deformationForce measurement by measuring optical property variationRelative displacementElastomer

Owner:TAIYO YUDEN KK

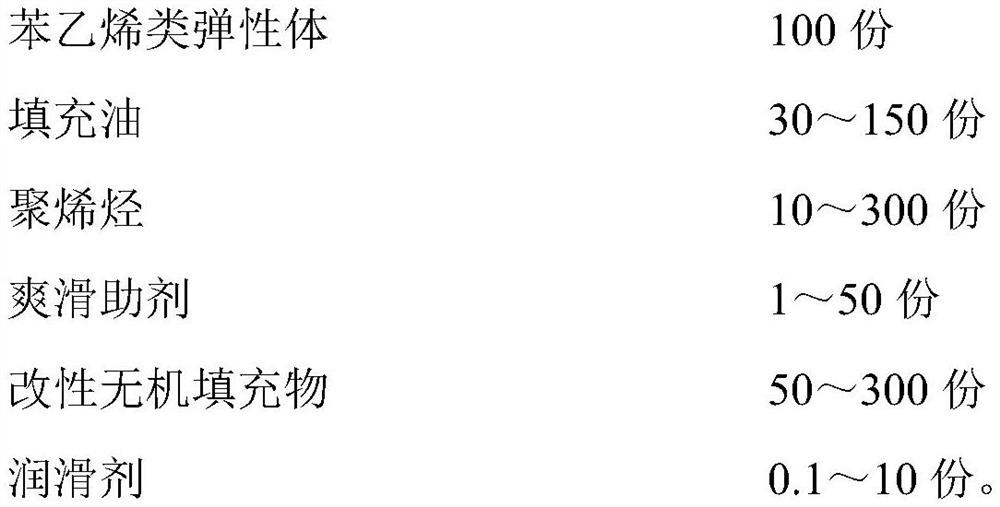

High-filling scratch-resistant extrusion-grade thermoplastic elastomer material and preparation method thereof

Owner:NANTONG POLYMAX ELASTOMER TECH

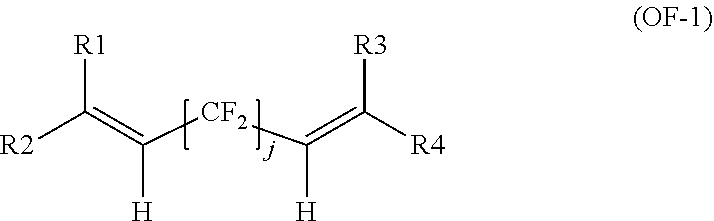

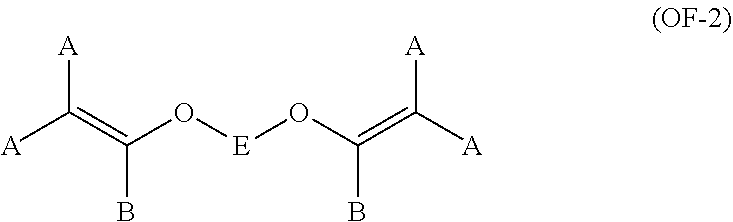

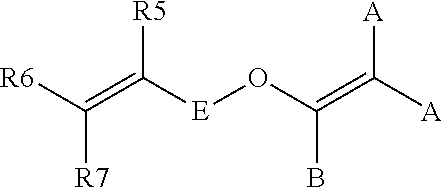

Functionalized elastomer

The present invention is directed to a stereoregular functionalized elastomer represented by poly(M1 co M2), wherein the functionalized elastomer comprises a microstructure selected from the group consisting of microstructures having at least 90 percent by weight of monomer residues in trans 1,4-configuration, and microstructures having at least 80 percent by weight of monomer residues in cis 1,4-configuration; wherein M1 is selected from the group consisting of isoprene and 1,3-butadiene; and M2 is of formula 4wherein R6 is a covalent bond, phenylene, a linear or branched alkane diyl group containing 1 to 10 carbon atoms, or a combination of one or more phenylene groups and one or more linear or branched alkane diyl groups containing 1 to 10 carbon atoms; R7 is hydrogen or a linear or branched alkyl group containing 1 to 10 carbon atoms; X1 is selected from formulas 5 and 6wherein R8 and R9 are independently trialkylsilyl, phenyl or a linear or branched alkyl group containing 1 to 10 carbon atoms, or one of R8 and R9 is hydrogen and the other is phenyl or a linear or branched alkyl group containing 1 to 10 carbon atoms, or R8 and R9 taken together with the nitrogen atom represent a nitrogen containing heterocyclic group containing from 4 to 12 carbon atoms; and X2 is a sulfur atom or a structure of formula 7 or 8wherein when X2 is of formula 8, the S atom of formula 8 is adjacent to the phenyl ring of formula 6 and the N atom of formula 8 is adjacent to R6.

Owner:THE GOODYEAR TIRE & RUBBER CO

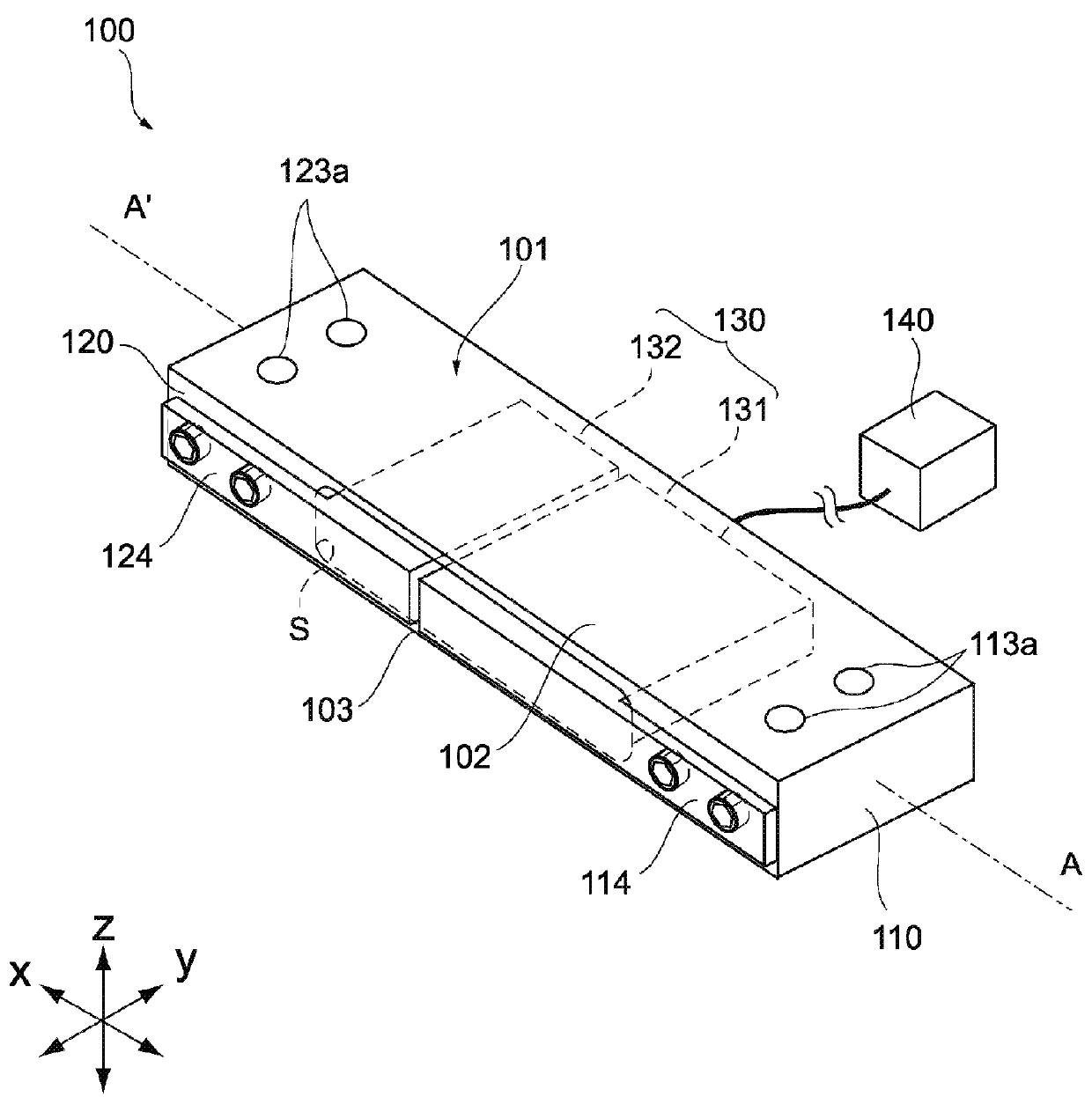

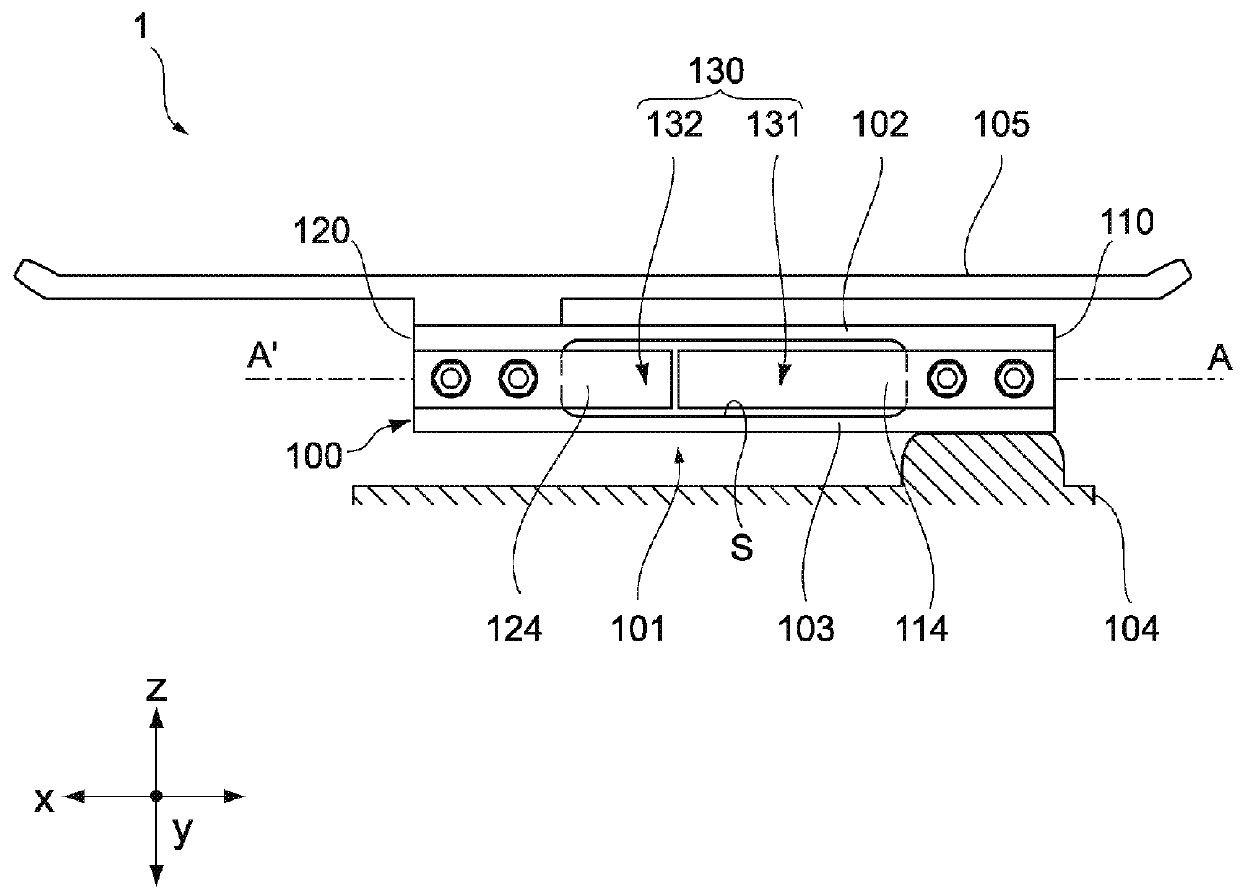

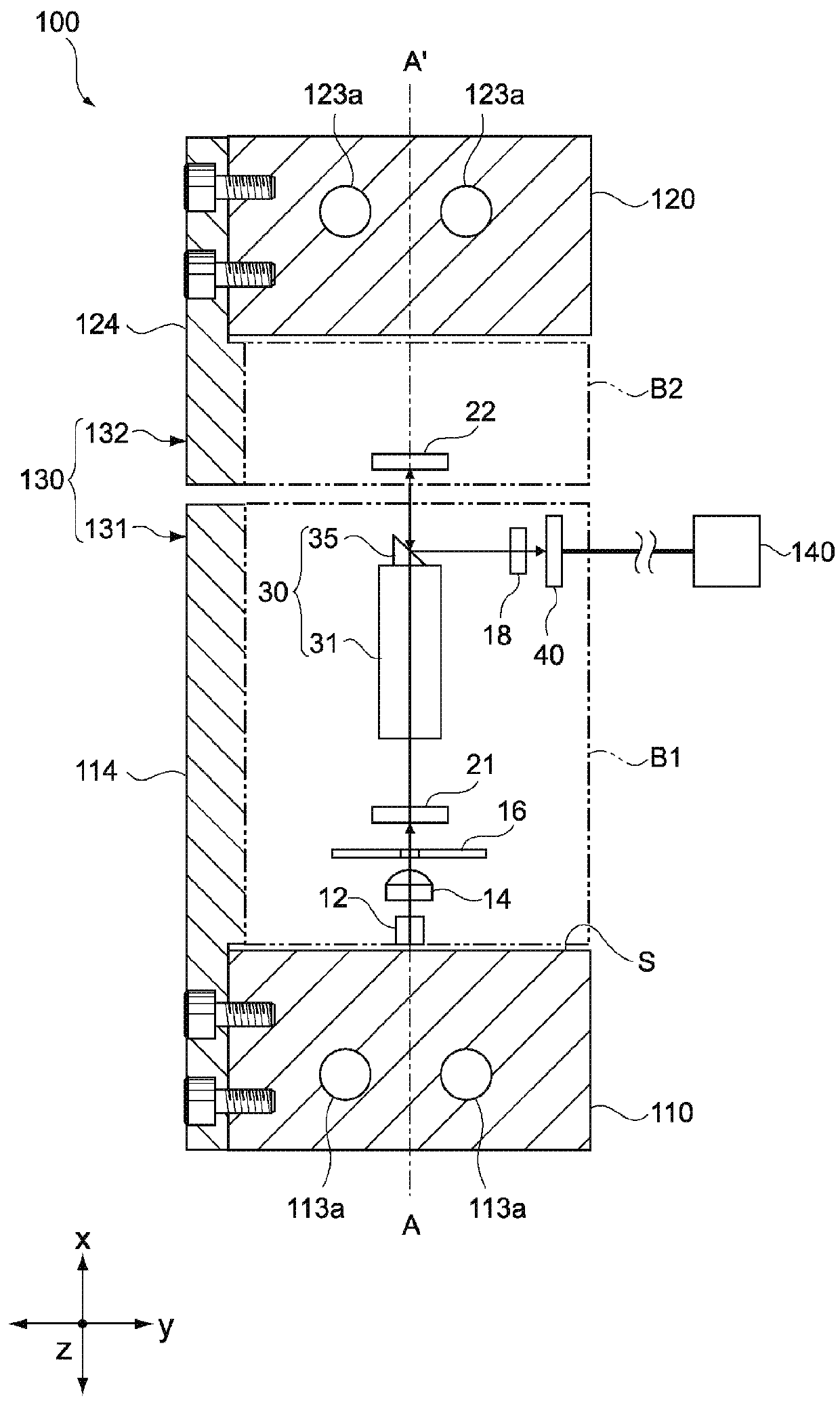

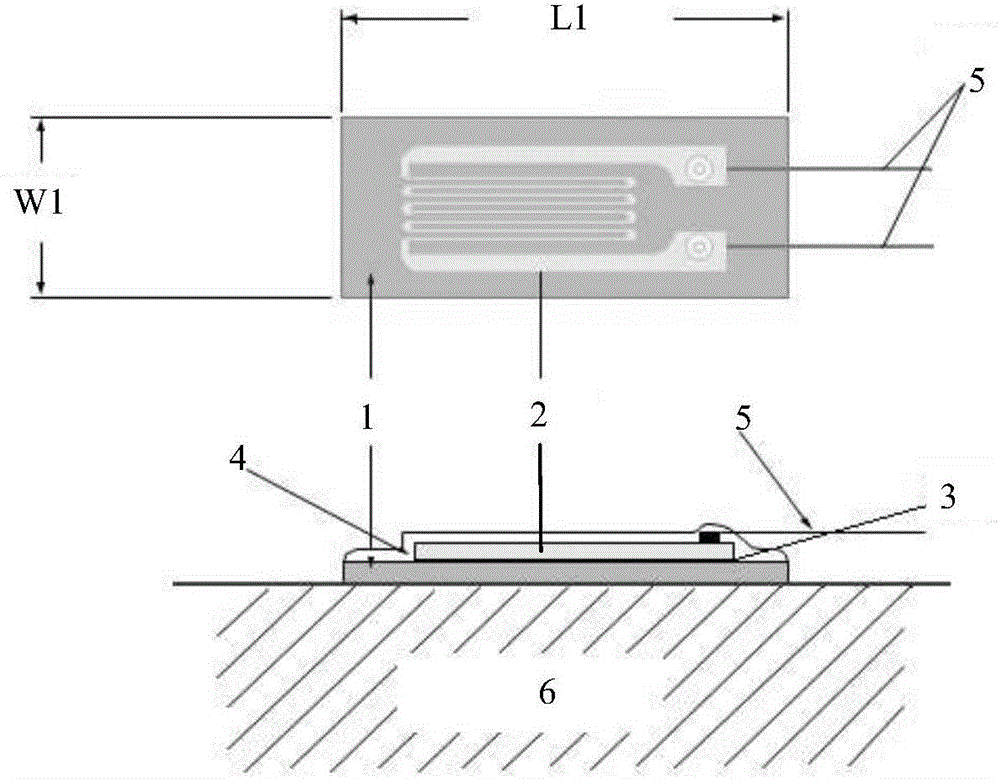

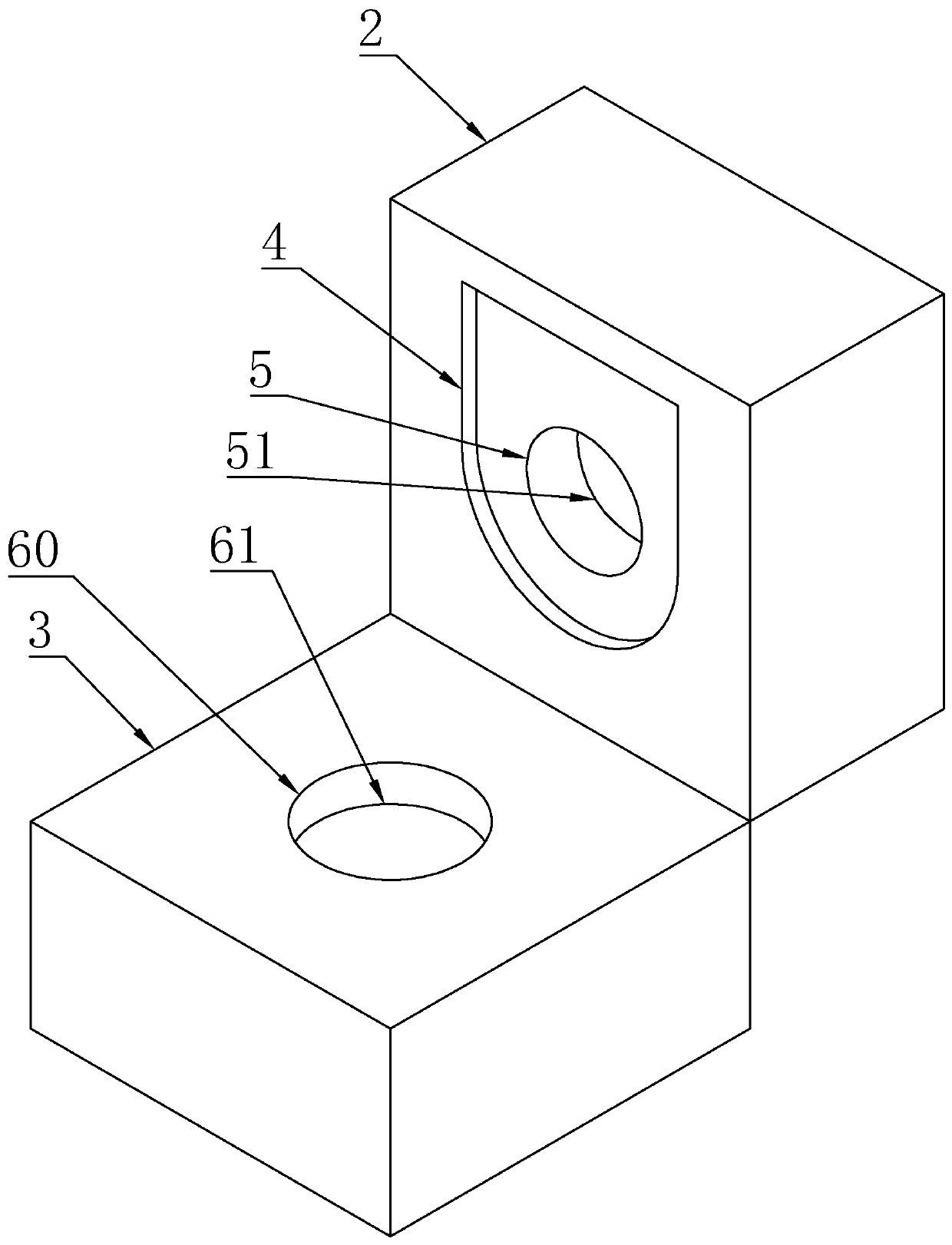

Deformation measuring device

InactiveCN106768215AHigh precisionGood repeatabilityWeighing apparatus using elastically-deformable membersElastomerAcoustics

Owner:SHANGHAI YAMATO SCALE

Polyether-organosilicon composite nylon elastomer and preparation method thereof

Owner:SHANDONG DONGCHEN ENG PLASTIC

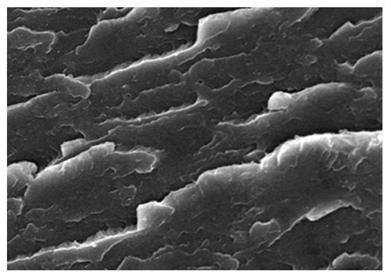

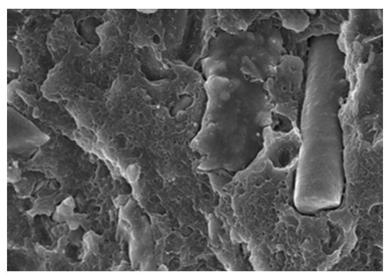

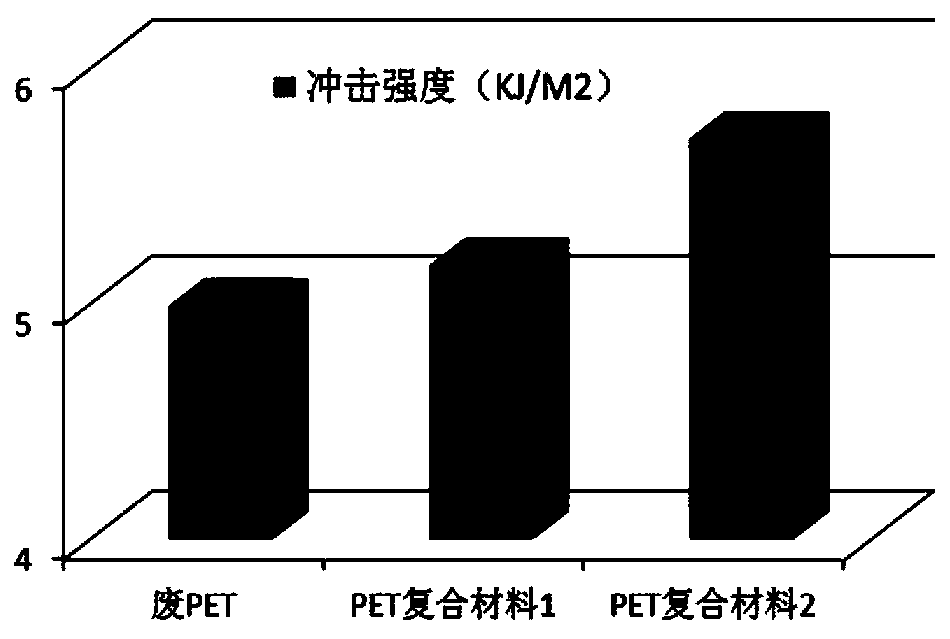

Waste PET composite material

ActiveCN109651776AOvercoming the problem of insufficient impact strengthImprove rigidityElastomerPolyolefin

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

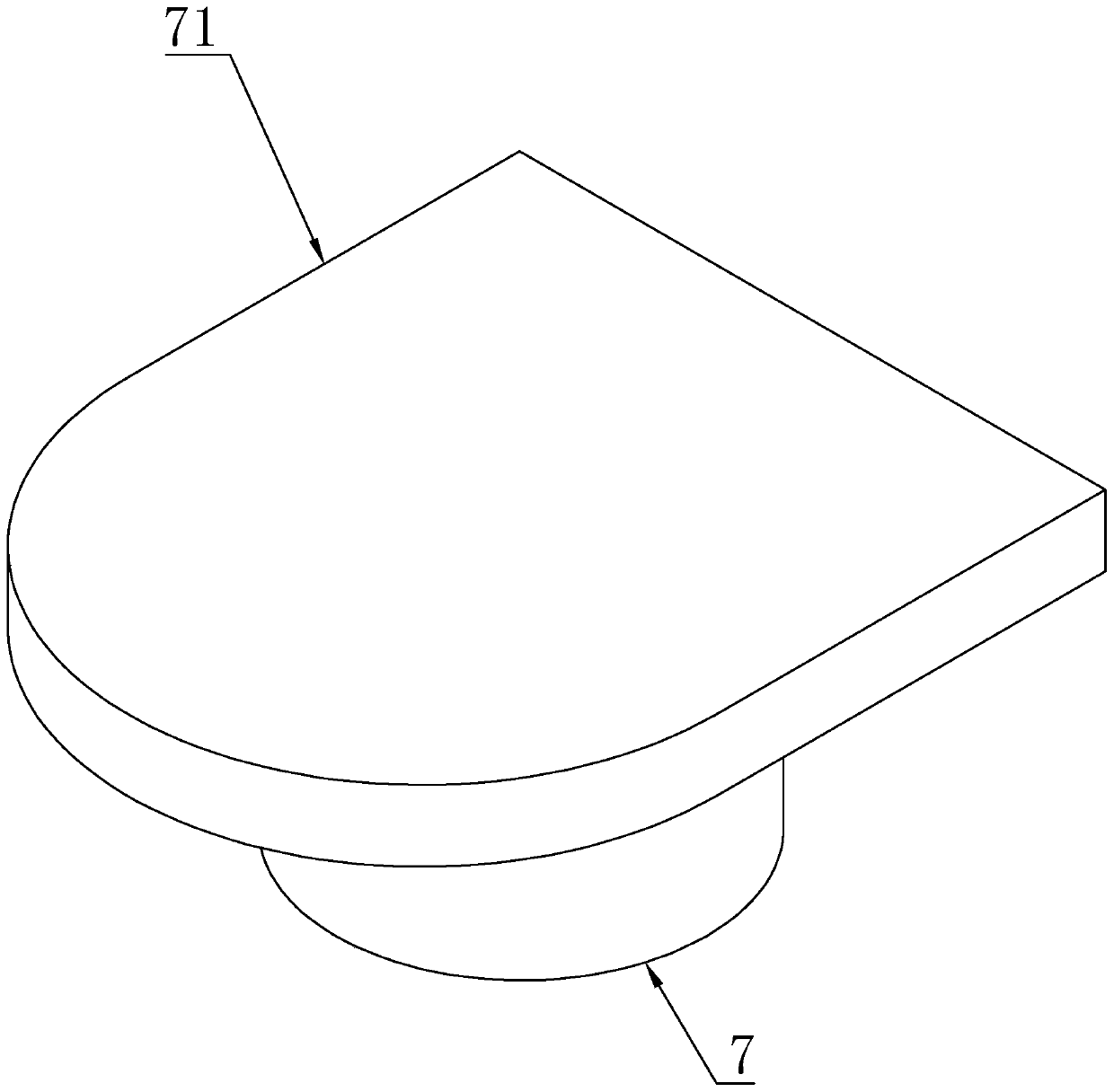

Double-conical-surface flexible supporting device

ActiveCN113858437AEliminate rotational errorsImprove stabilityCement mixing apparatusElastomerEngineering

Owner:SHAANXI FAST AUTO DRIVE GROUP CO LTD

Sole assembly and mold thereof, shoe comprising sole assembly and manufacturing method of shoe

Owner:浙江盖瑞莉娃文化科技有限公司

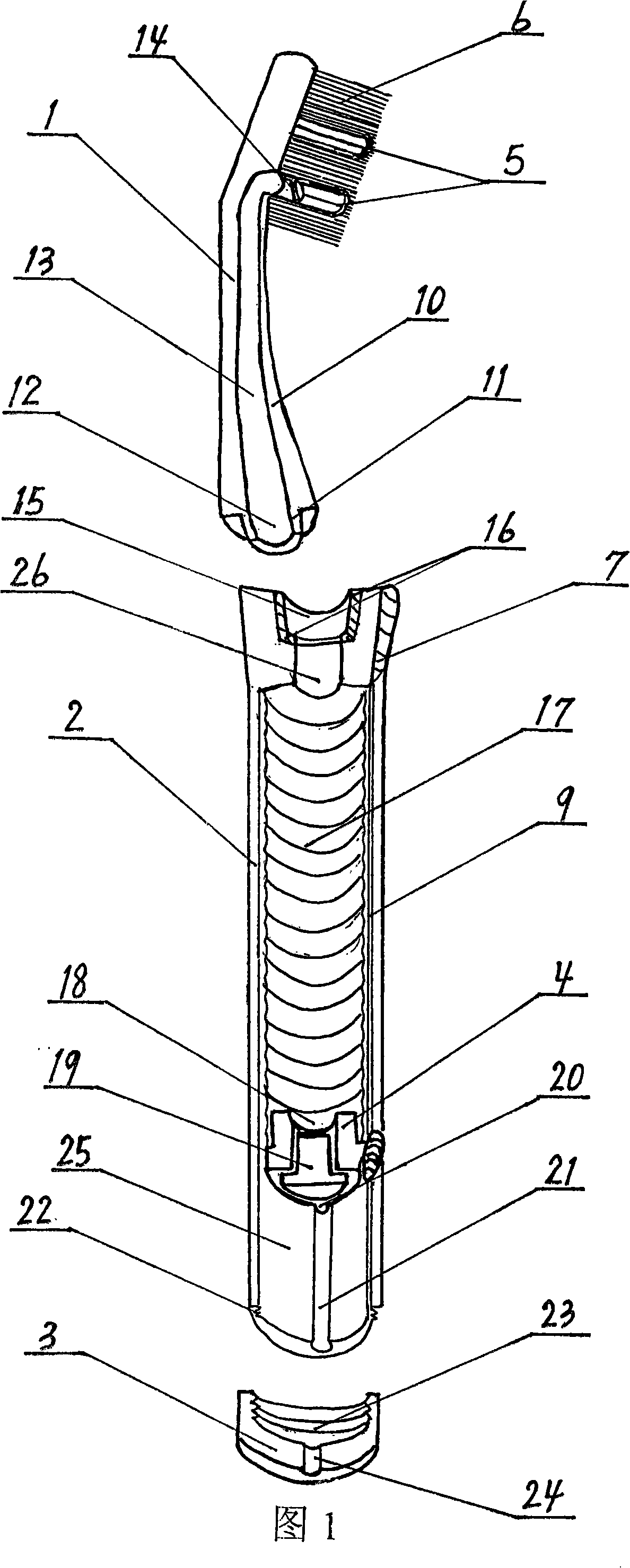

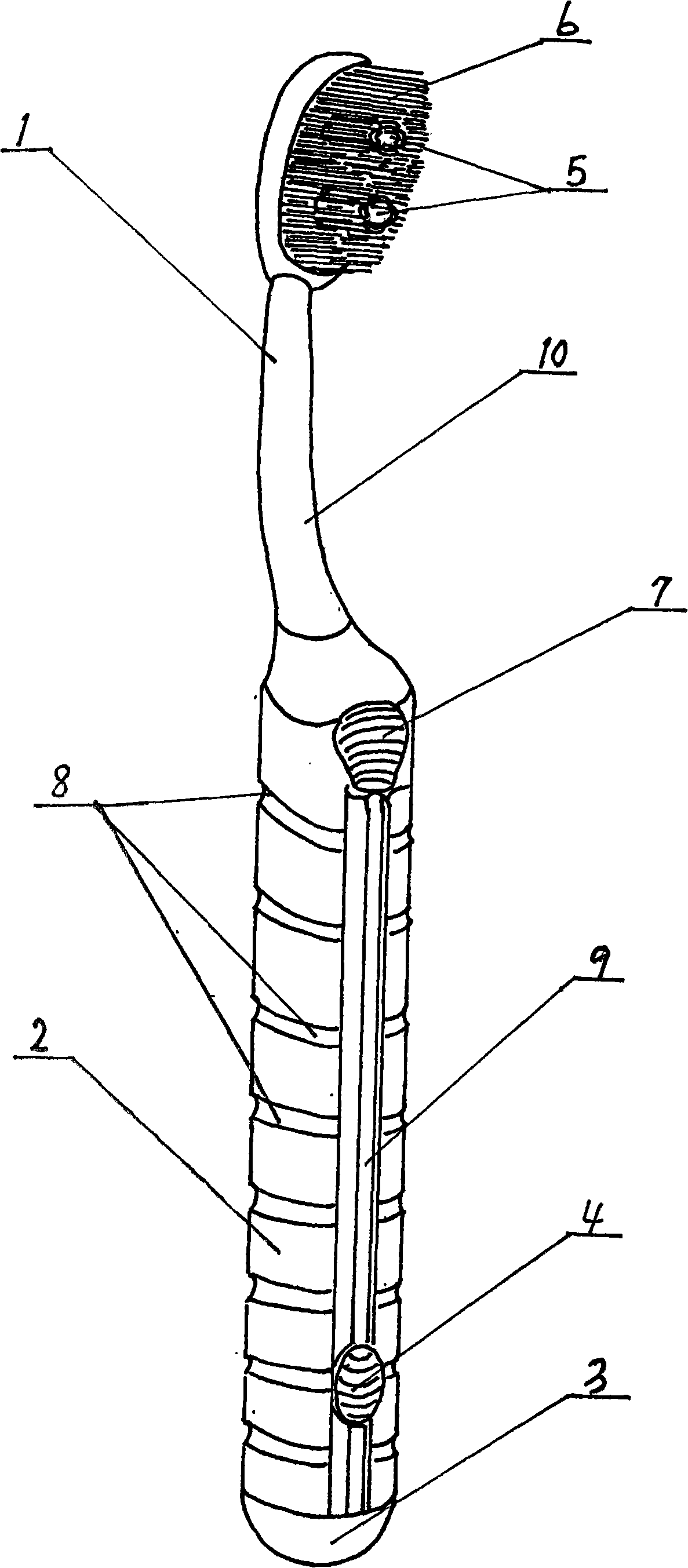

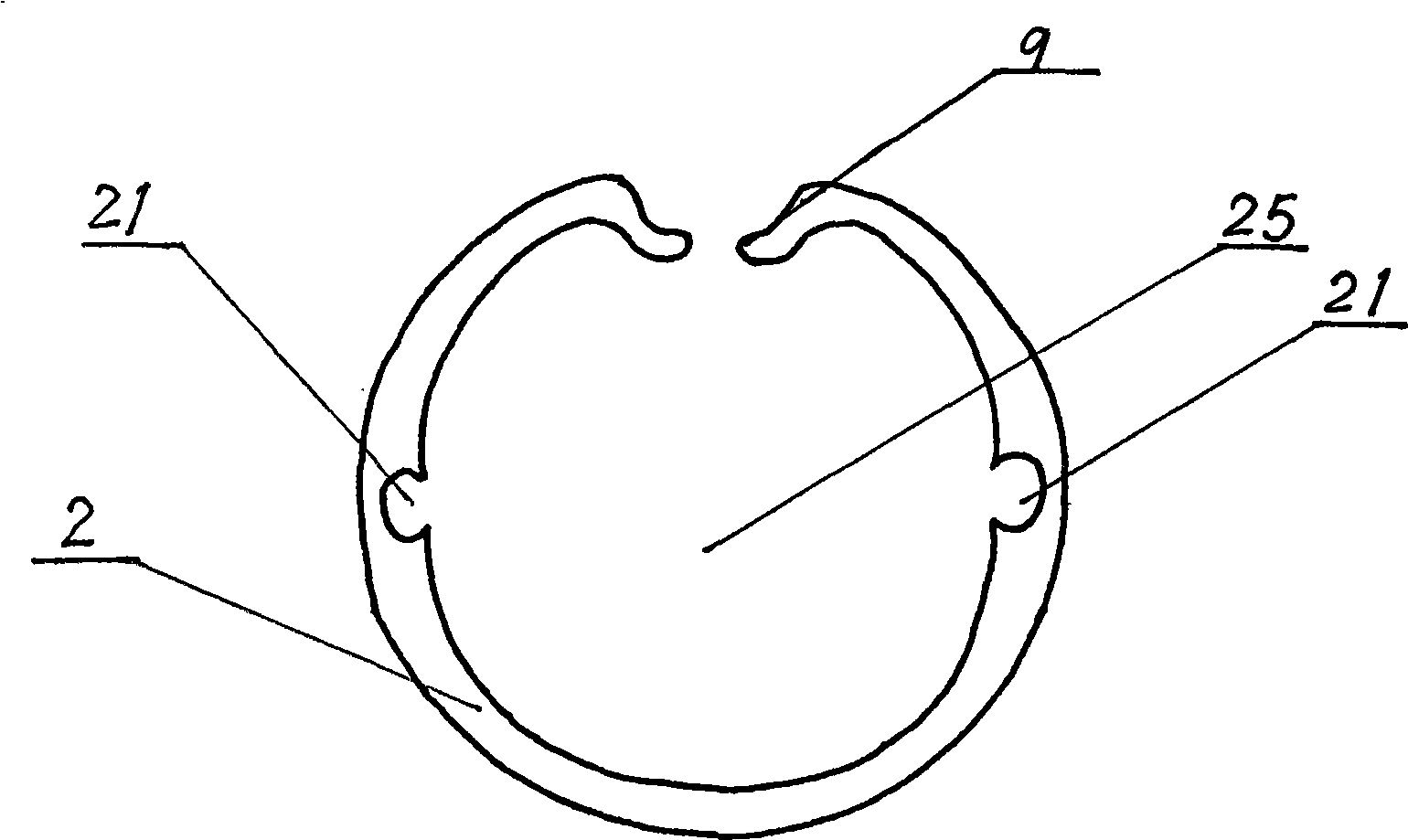

An aortic infusion tube with an elastic hemostatic ring

The invention relates to an aortic perfusion tube with an elastic hemostatic ring, belonging to the technical field of medical instruments. The aortic perfusion tube with an elastic hemostatic ring comprises an aortic perfusion tube body, a fixing ring, an elastomer and a flexible compression ring. The fixing ring is sleeved on the aortic perfusion tube body and fixed with the aortic perfusion tube body. The flexible pressing ring is sleeved on the aortic perfusion tube body and connected with the fixing ring through an elastomer. When the elastomer is deformed, the flexible pressing ring is movable on the aortic perfusion tube body. As the flexible pressure re has elasticity, the aortic perfusion tube with the elastic hemostatic ring of the invention can be naturally adhere to and pressedon the arterial wall without adjusting the position, and the arterial wall is compressed to prevent blood leakage around the intubation when the aortic perfusion tube is used.

Owner:DALIAN CORVIVO MEDICAL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap