Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108results about "Pretreated surfaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

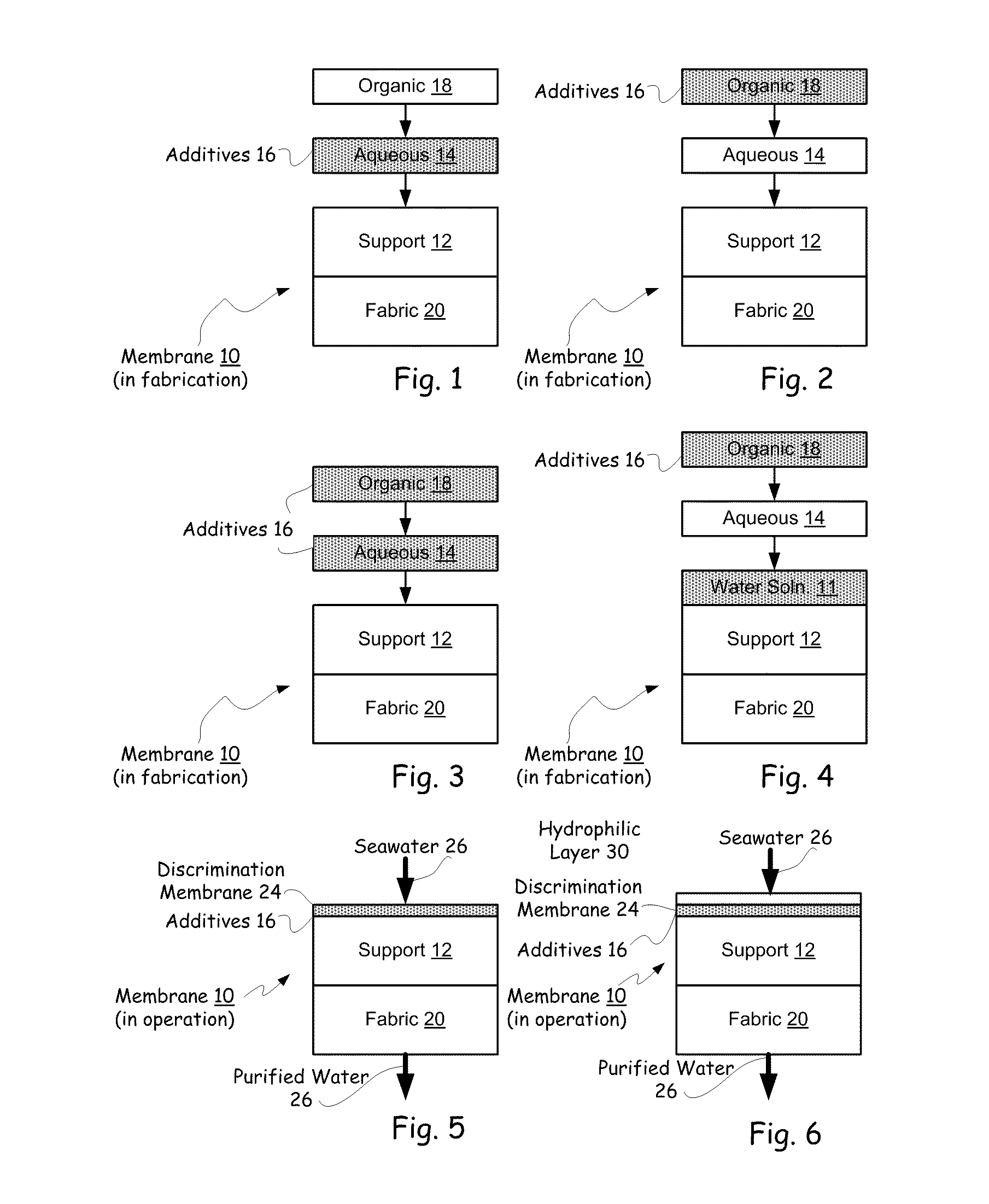

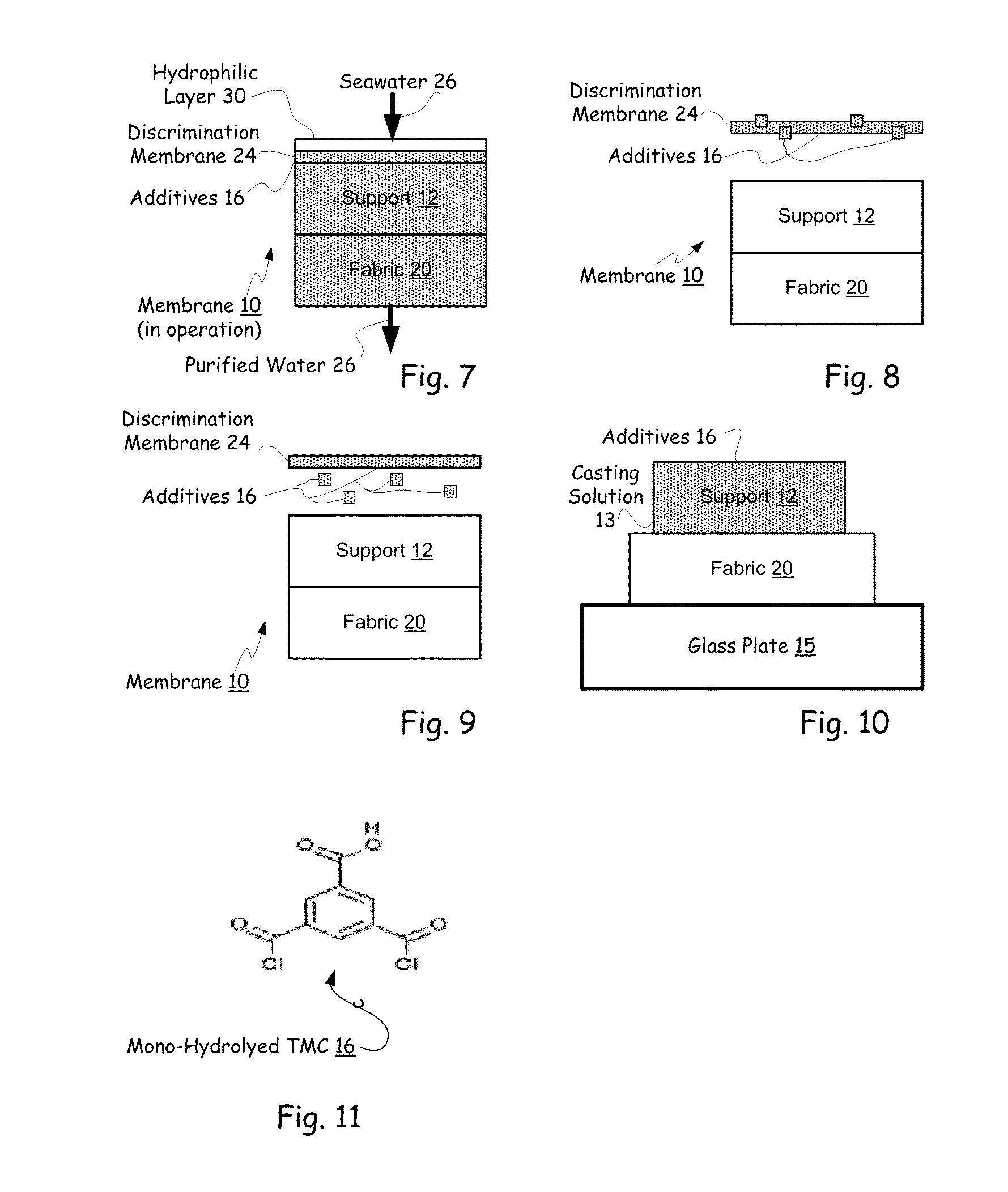

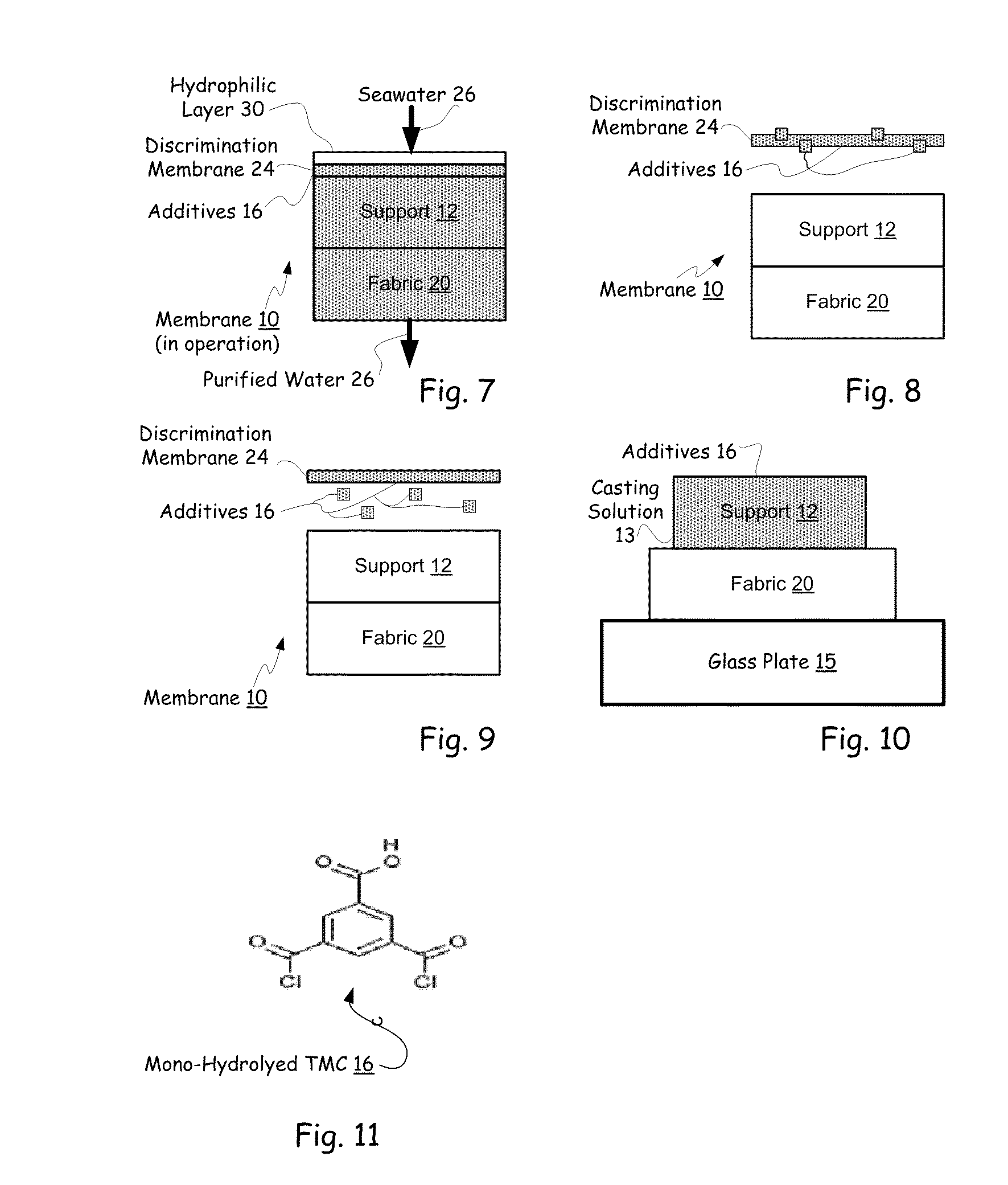

Hybrid tfc ro membranes with nitrogen additives

ActiveUS20110005997A1Increase fluxIncreased rejectionMembranesPretreated surfacesChloramine BAlkaline earth metal

Owner:NANOH2O

Method for treating a solid material to make it hydrophobic, material obtained and uses

InactiveUS6342268B1Simple and rapid and methodWater-repelling agents additionOther chemical processesChemical structureProduct gas

A solid material is treated, the chemical structure of which defines reactive protogenic hydrophillic functions accessible to gases, by applying at least one gas stream (3) onto at least one microdispersion (5) of at least one grafting reagent RX produced on the solid material, R being a hydrophobic group, X being chosen so that HX is volatile under normal conditions, R and X being chosen so that the reaction of RX on the hydrophillic functions produces covalent grafting of the hydrophobic group R with formation of the compound HX, it being possible for the reaction to be carried out in a solid / gas heterogeneous medium on all the reactive hydrophillic functions accessible to gases and only on these. The invention extends to the hydrophobic solid material obtained, and is applicable to the obtaining of natural or artificial fibrous or inorganic structures impermeable to water and to aqueous solutions and / or absorbing fats.

Owner:BT3 TECH

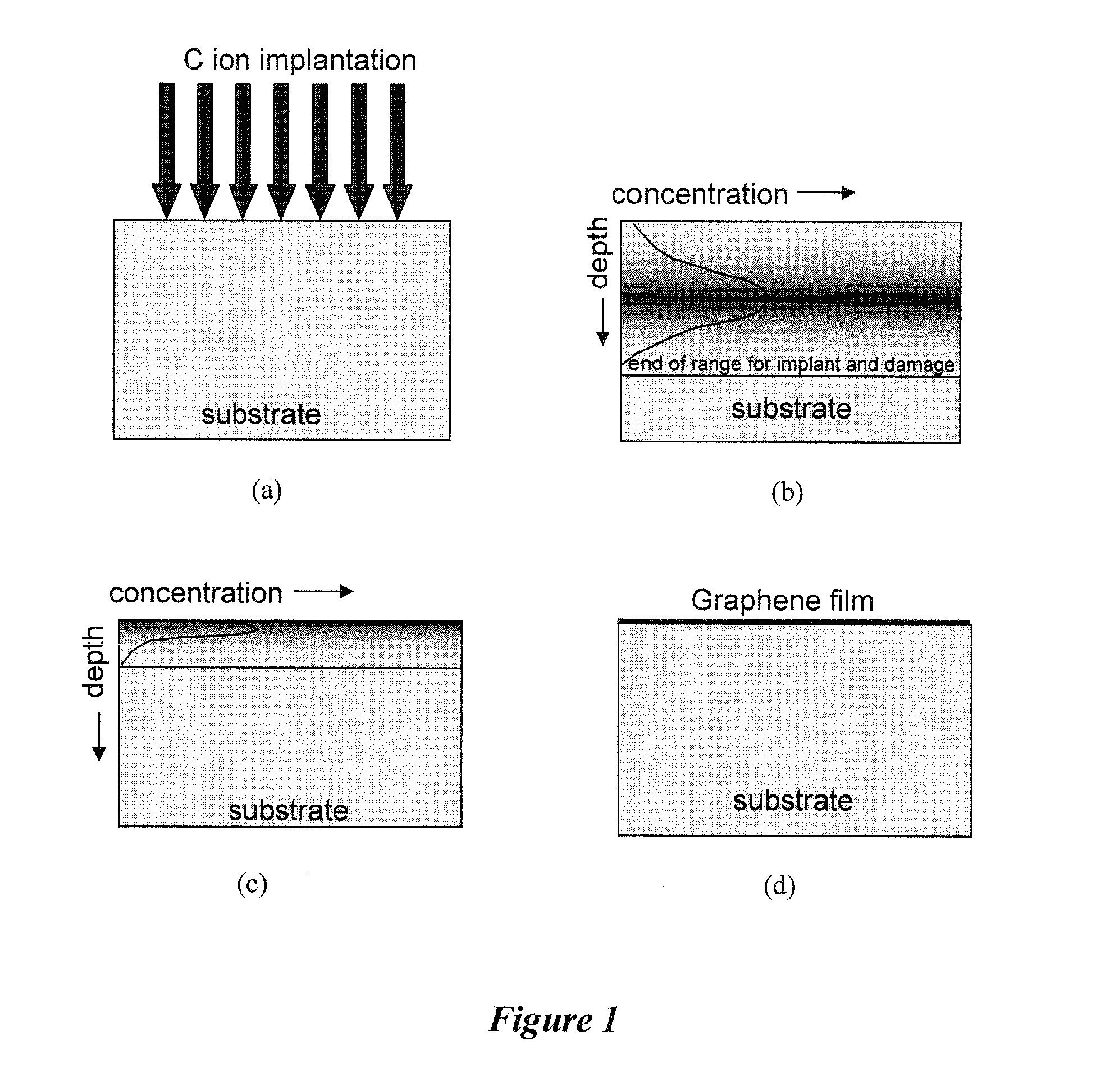

Graphene processing for device and sensor applications

Owner:UNIV OF FLORIDA RES FOUNDATION INC

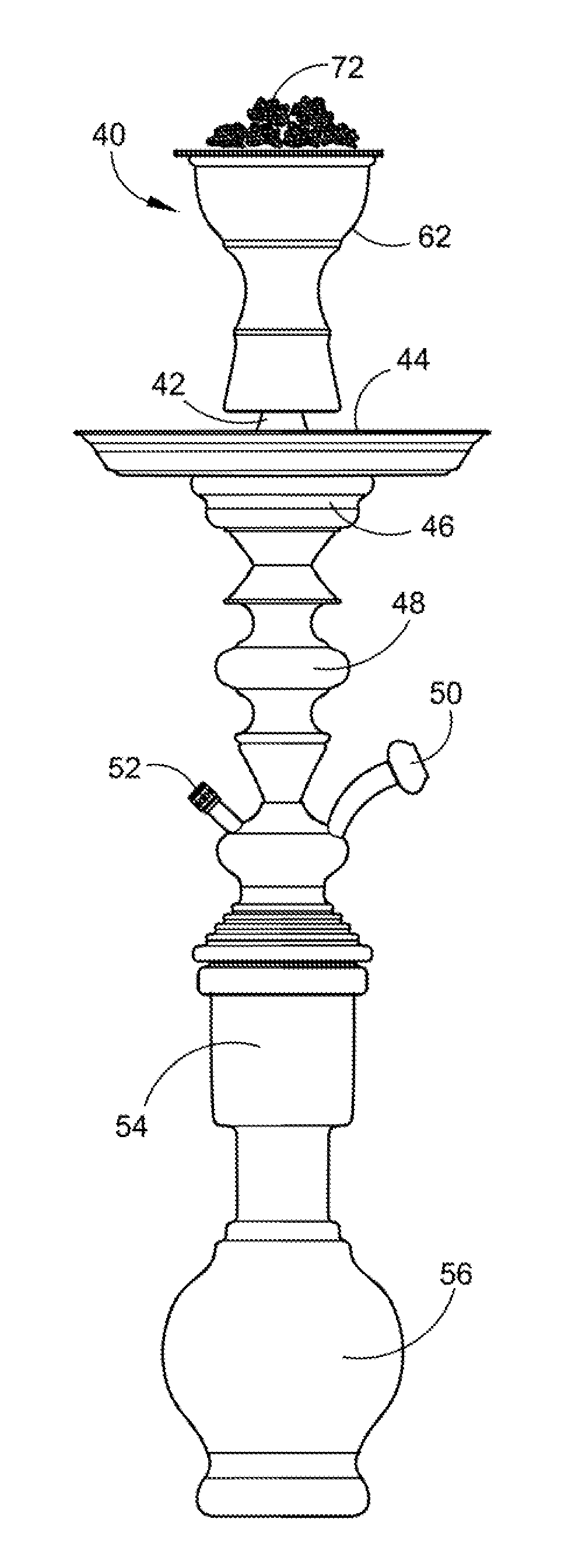

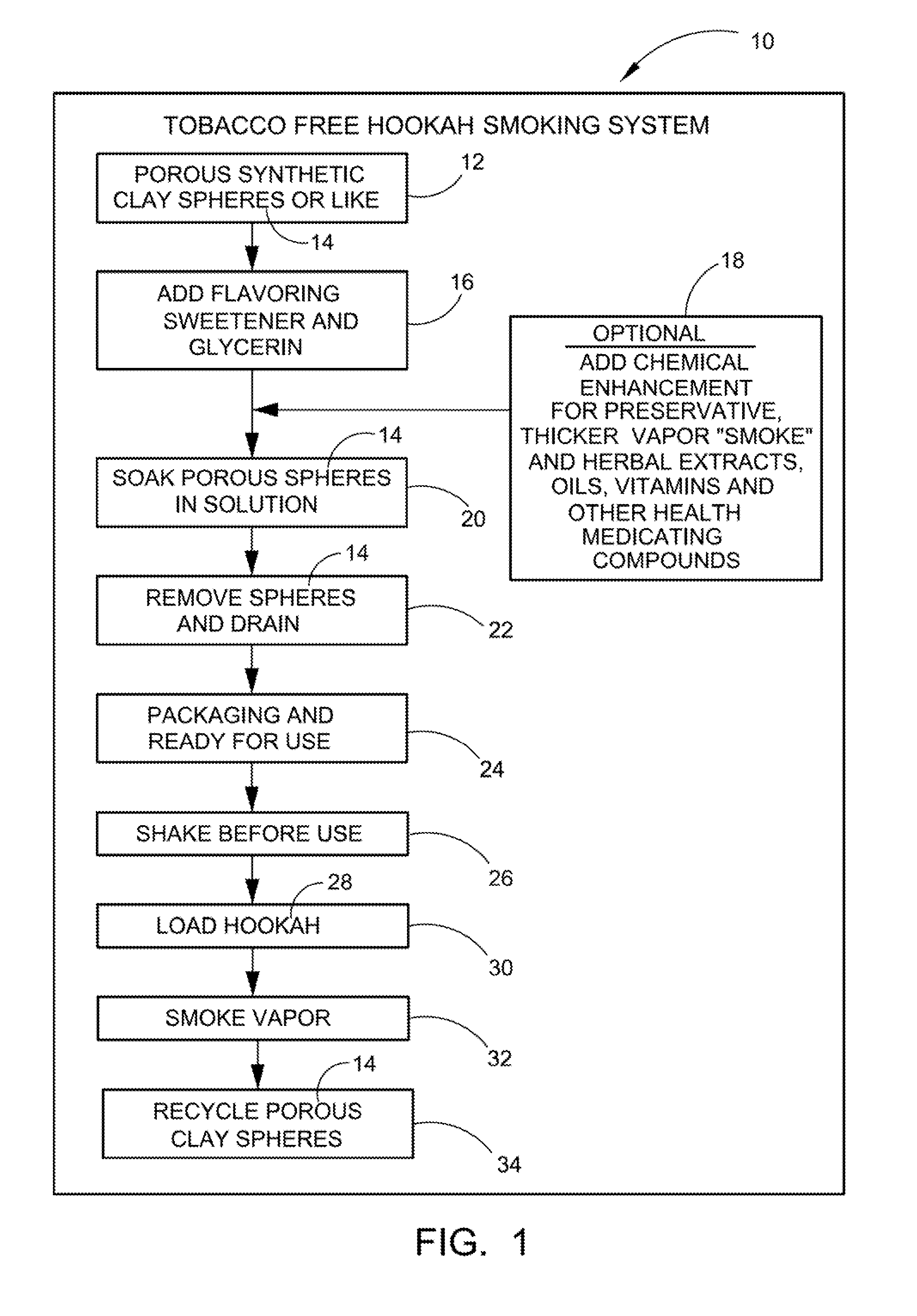

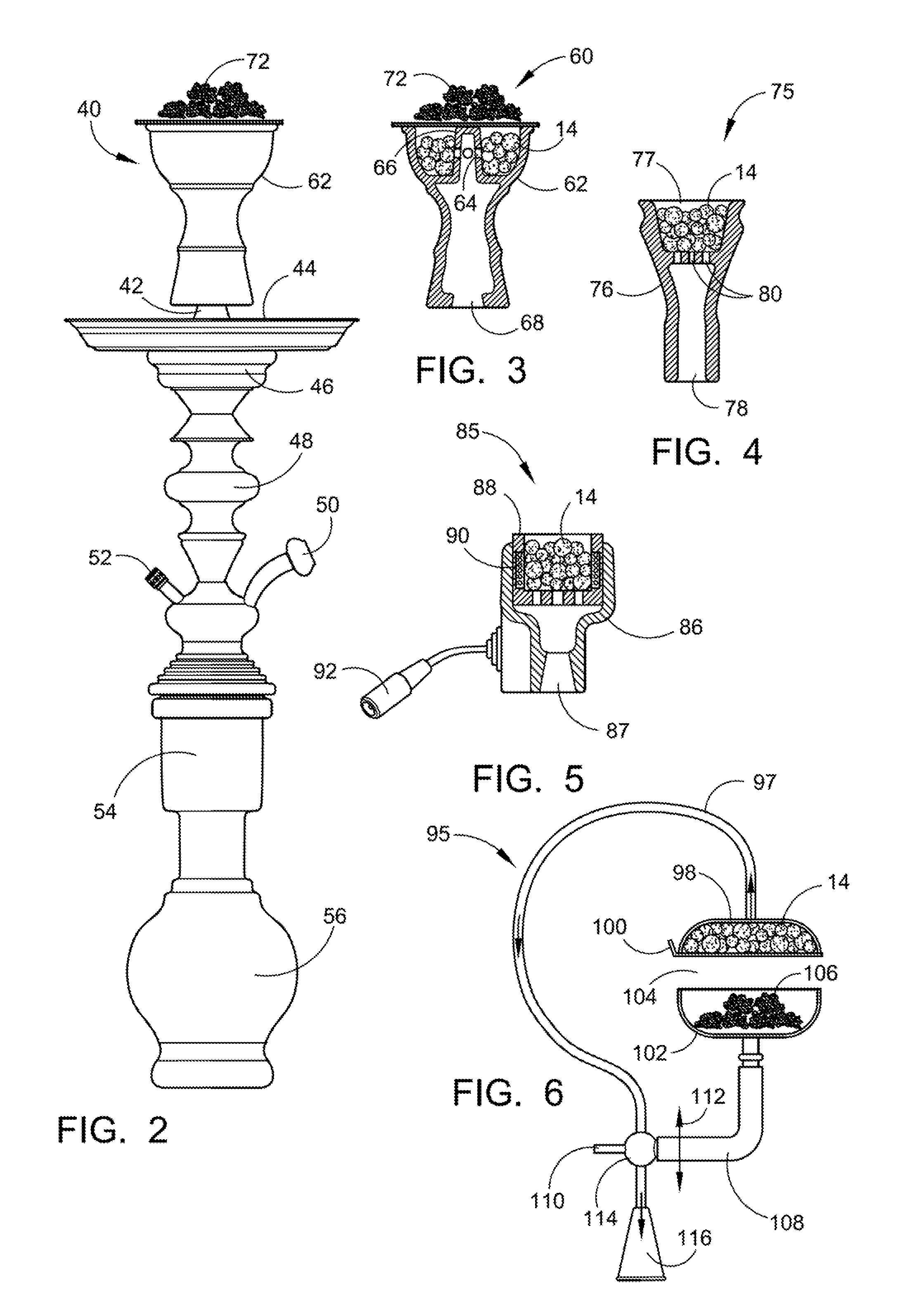

Tobacco free hookah smoking system

Owner:BEDROCK HLDG TRUST 2012

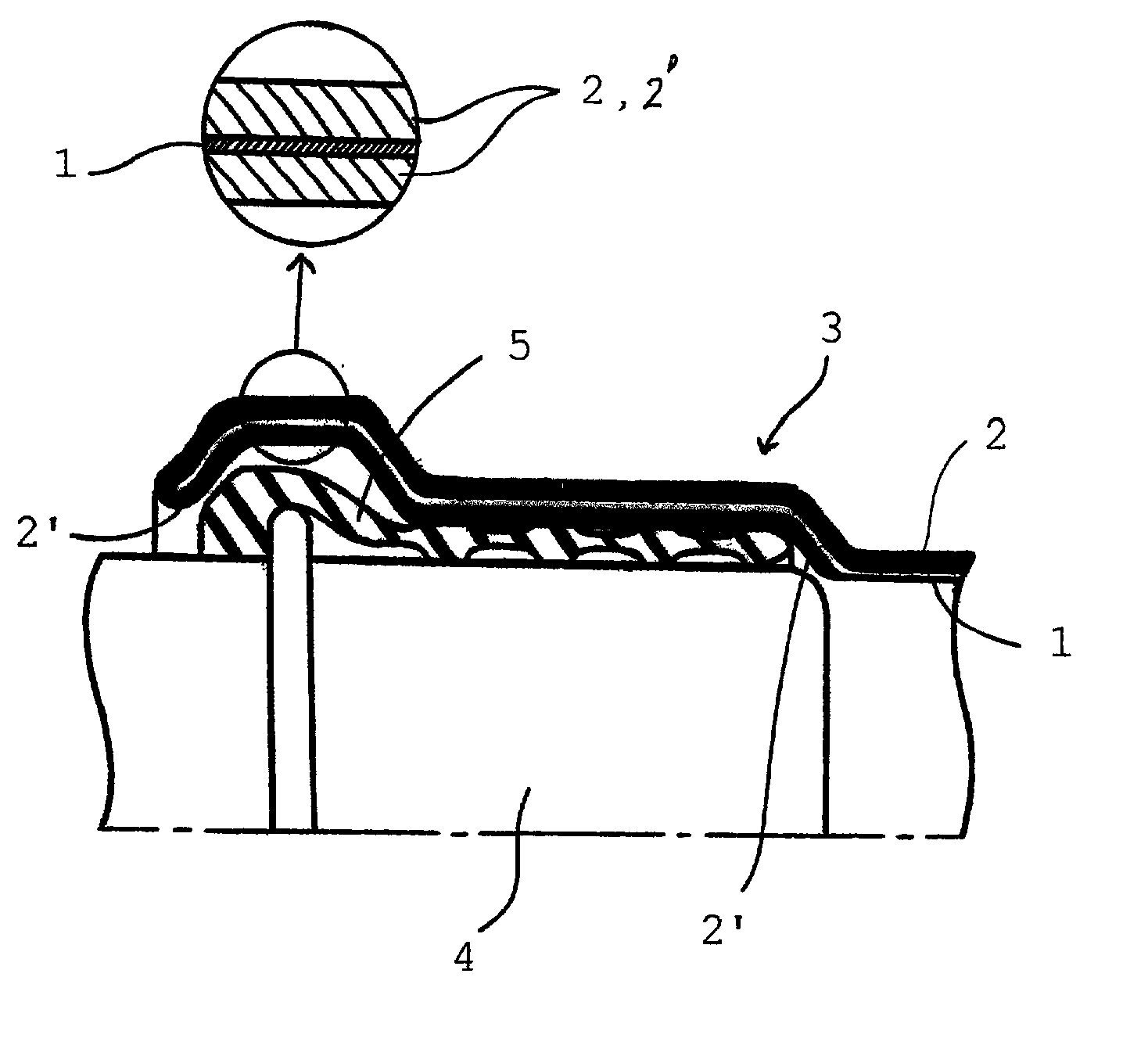

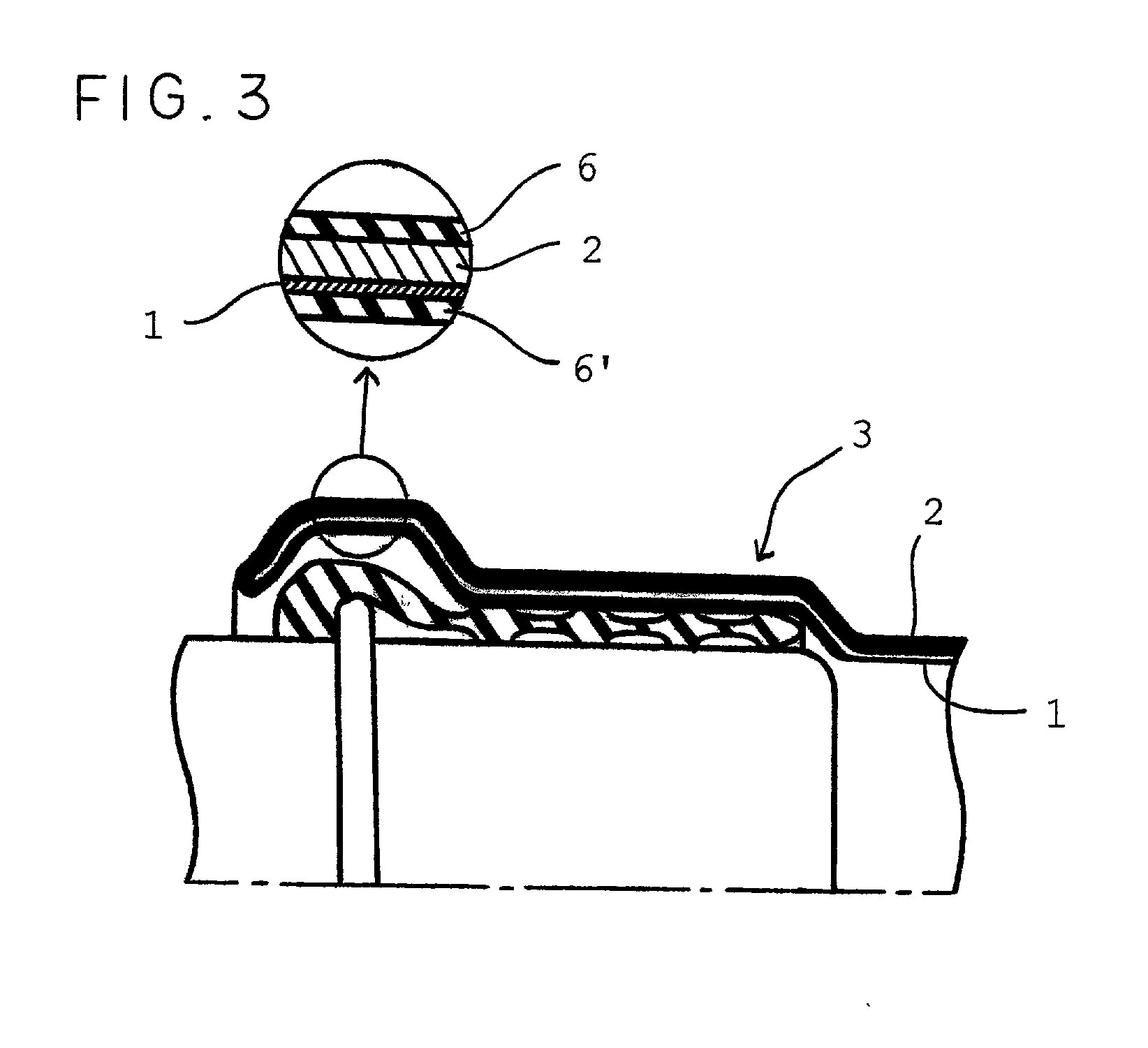

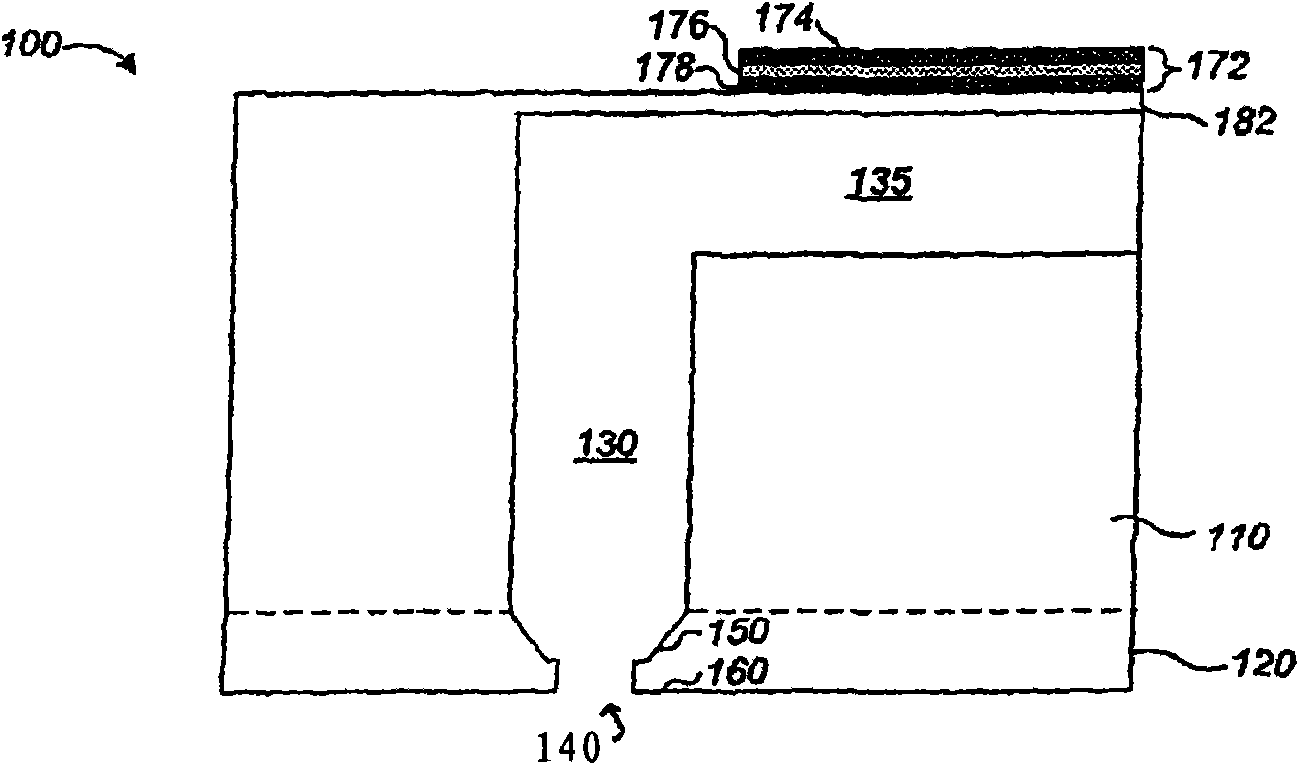

Device for arraying biomolecules and for monitoring cell motility in real-time

The invention relates to devices, devices for arraying biomolecules, including cells, methods for arraying biomolecules, assays for monitoring cellular movement, and systems for monitoring cellular movement. The devices include a support; a first layer configured to be placed in fluid-tight contact with the support, the first layer having an upper surface and defining a pattern of micro-orifices, each micro-orifice of the pattern of micro-orifices having walls and defining a micro-region on the support when the first layer is placed in fluid-tight contact with the support such that the walls of said each micro-orifice and the micro-region on the support together define a micro-well; and a second layer configured to be placed in fluid-tight contact with the upper surface of the first layer, the second layer defining a pattern of macro-orifices, each macro-orifice of the pattern of macro-orifices having walls and defining a macro-region when the first layer is placed in fluid-tight contact with the support and the second layer is placed in fluid-tight contact with the first layer such that the walls of the macro-orifice and the macro-region together define a macro-well.

Owner:SURFACE LOGIX INC

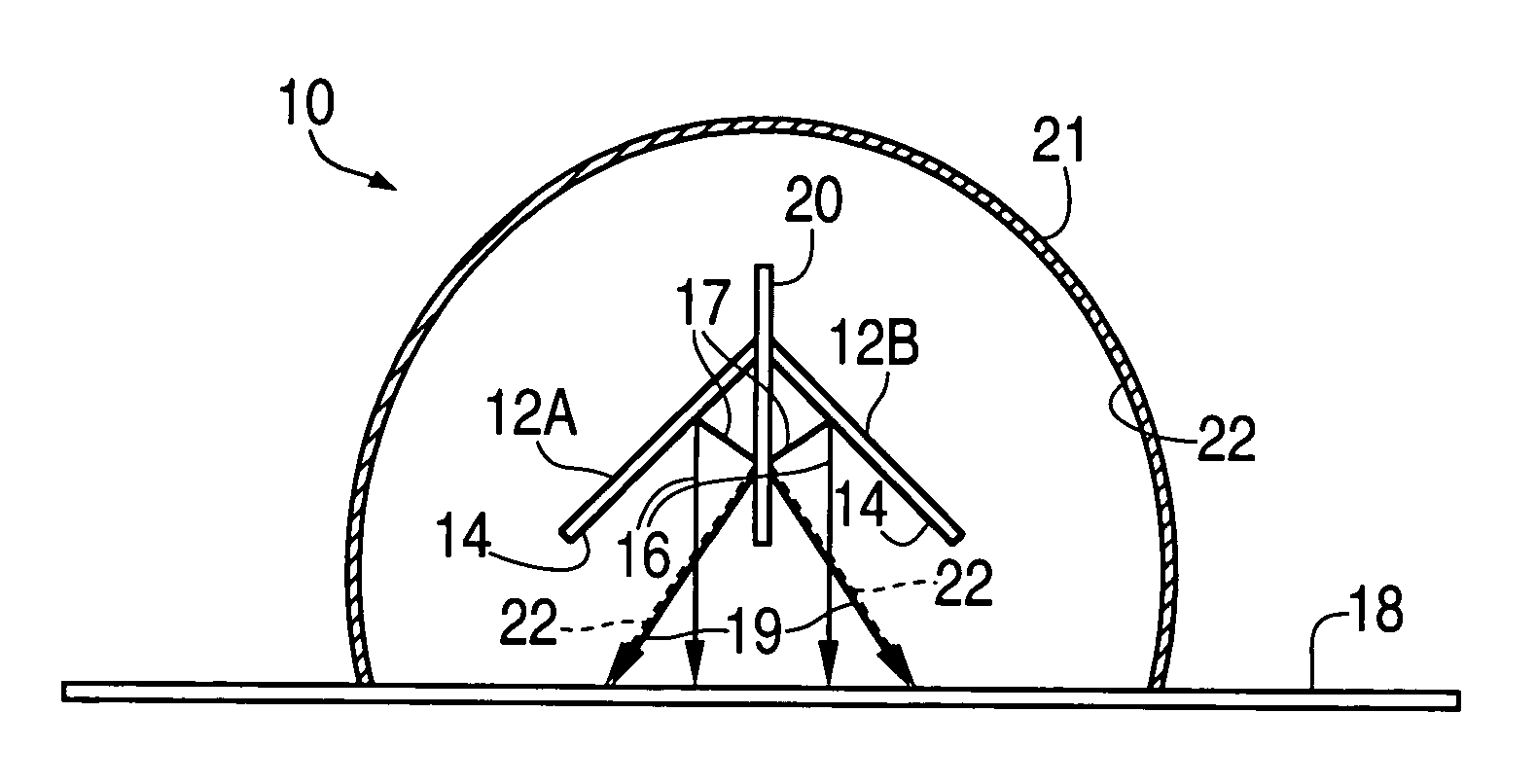

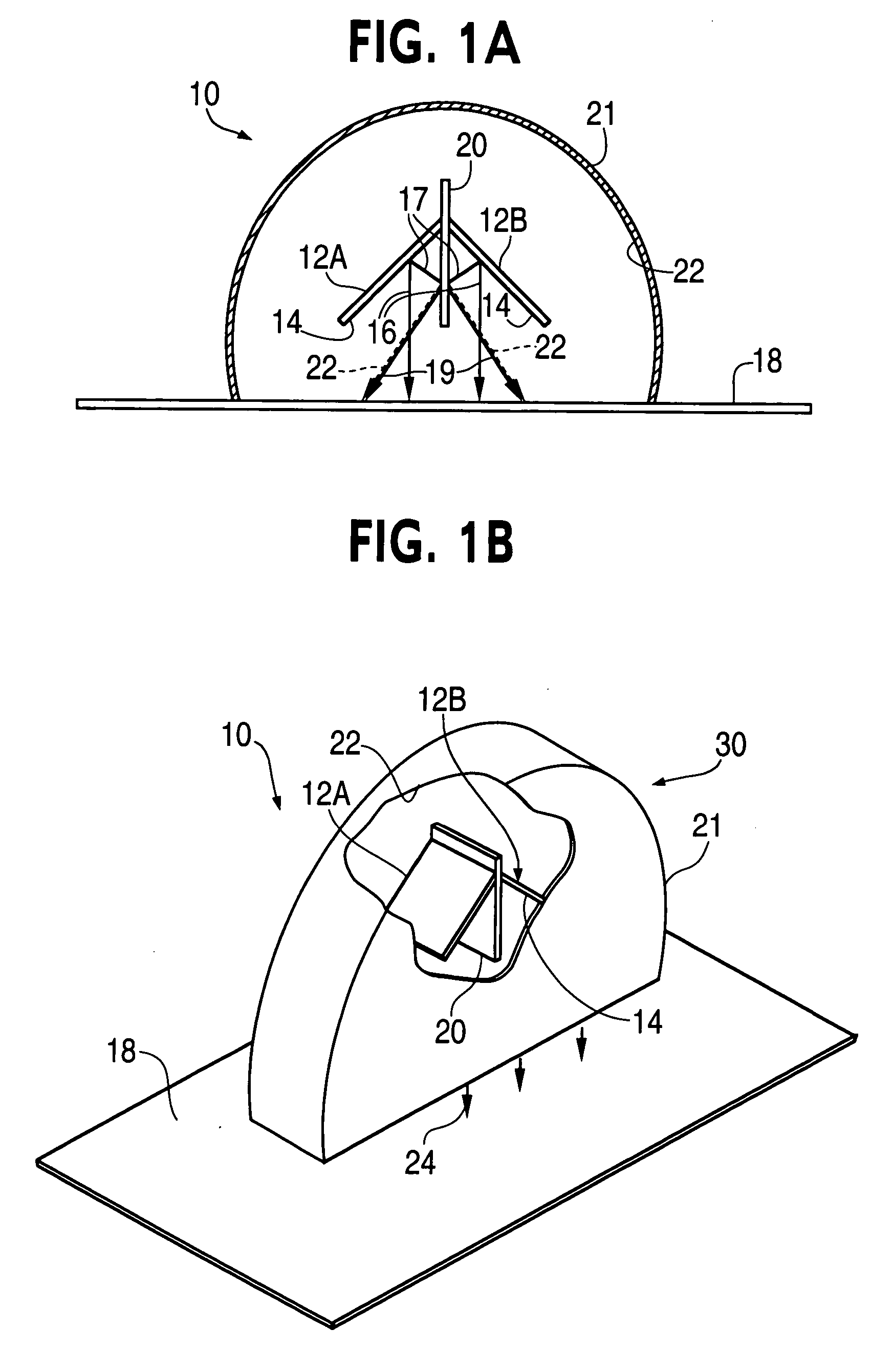

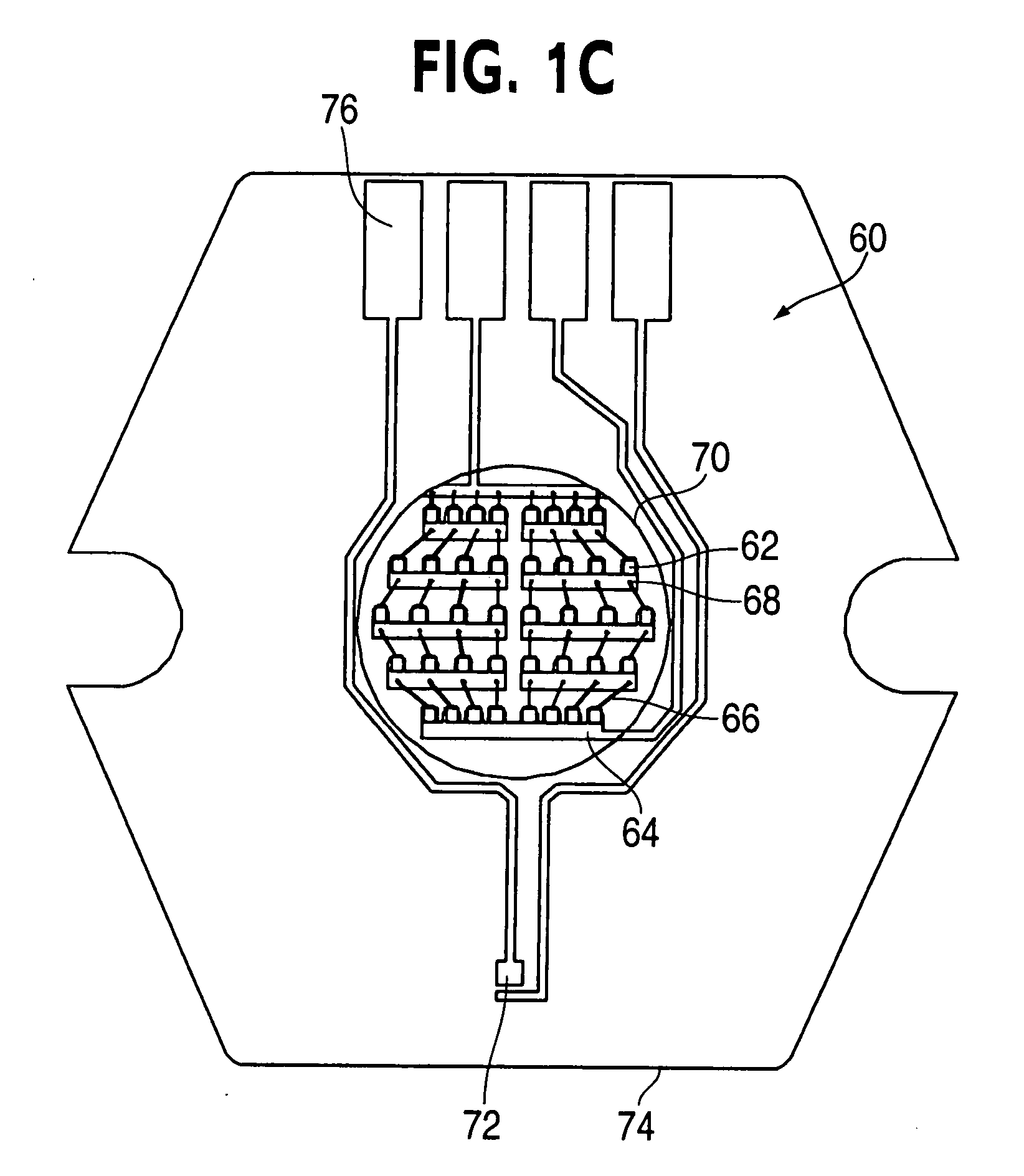

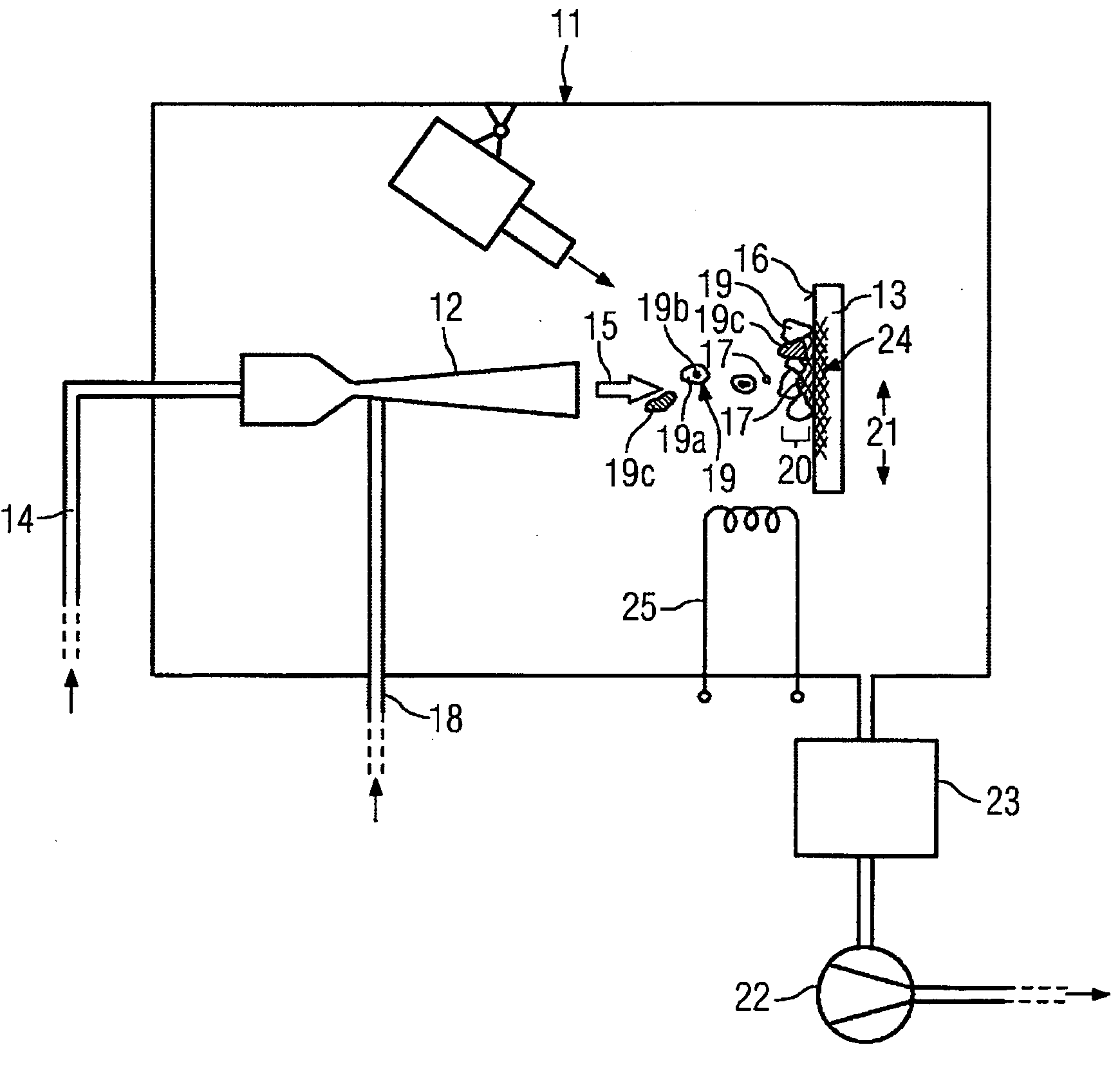

Solid-state light sources for curing and surface modification

InactiveUS20060274421A1Improve stabilityExtended service lifePoint-like light sourcePretreated surfacesMultiwavelength spectroscopyLight beam

Owner:HERAEUS NOBLELIGHT AMERICA

Apparatus and method for plasma treating and dispensing an adhesive/sealant onto a part

InactiveUS20060172081A1Minimal timeLow costMovable spraying apparatusPretreated surfacesAdhesiveSealant

Owner:NORDSON CORP

Method for Producing Ceramic Layers

InactiveUS20090202732A1Efficient methodReduce internal stressPretreated surfacesPressure inorganic powder coatingHeat sensitiveProduct gas

Owner:SIEMENS AG

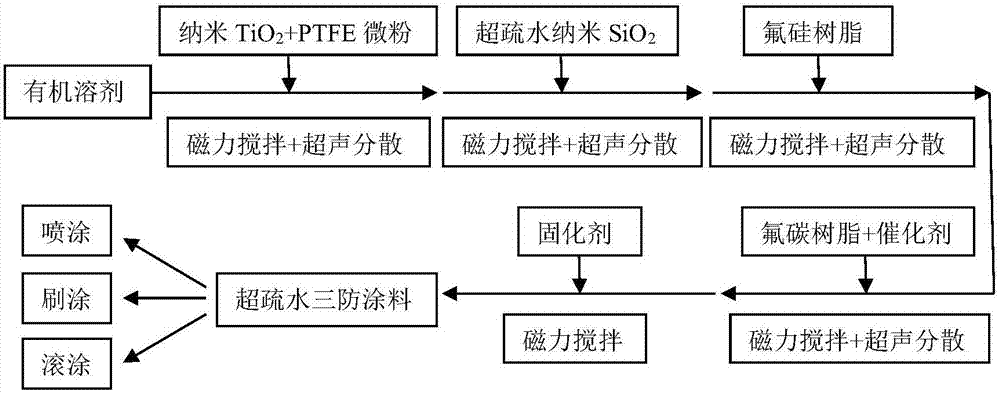

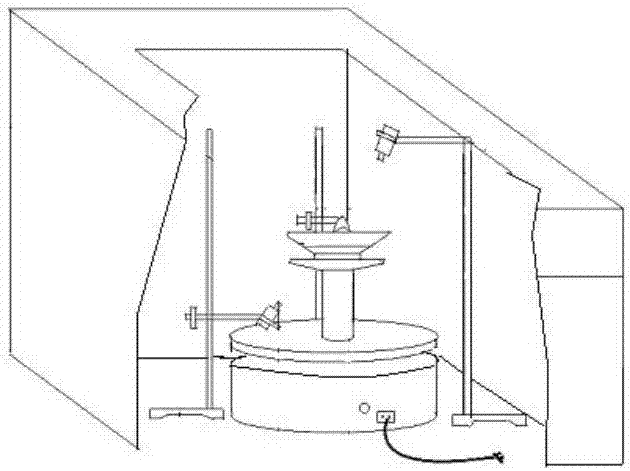

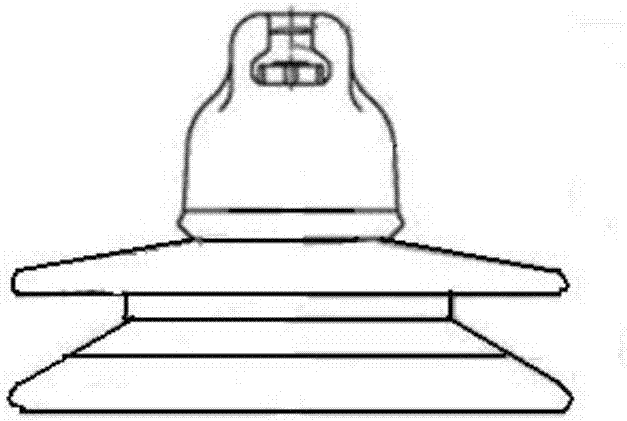

Super-hydrophobic conformal coating, and preparation method and application method thereof

Owner:昆明理工大电力工程技术有限公司

Method for metallizing ceramic surface and method for connecting ceramic with aluminum

ActiveUS20120121896A1Hot-dipping/immersion processesSoldering apparatusMicrometerAlloy thin film

A process for metalizing a ceramic surface or attaching a ceramic to a metal is provided. The process may comprise: immersing the ceramic into an aluminum or aluminum alloy melt, making the ceramic move or stay still relative to the melt to adhere the melt to the ceramic; and then removing the ceramic from the melt to unaffectedly cool the film adhered thereto. The process can attach an aluminum or aluminum alloy thin film having a thickness of several to tens of micrometers on a ceramic surface. The thin film is formed by solidification, and does not have microscopic faults such as oxide film inclusions or pores, therefore having proper physical of mechanical properties of aluminum. Ceramics or a ceramic and a metal can be brazed via the surface metalizing film, the bonding strength of their interface can over the strength of aluminum itself.This invention discloses a process for metalizing the surface of a ceramic and a process for attaching a ceramic to a metal. A process for attaching an aluminum or aluminum alloy thin film to a ceramic surface comprises the steps of: immersing a ceramic surface to be metalized into a aluminum or aluminum alloy melt, and making the ceramic move or stay still relative to the melt to adhere the melt of the aluminum or aluminum alloy to the metalizing surface of the ceramic; and then removing the metalizing surface of the ceramic from the melt to unaffectedly cool the aluminum or aluminum alloy liquid film adhered thereto to obtain a ceramic having the aluminum or aluminum alloy thin film attached to the surface. The process to attaching aluminum or aluminum alloy thin film on the surface of a ceramic of the present invention can attach an aluminum or aluminum alloy thin film having a thickness of several micrometers to tens of micrometers on the surface of a ceramic. The thin film is formed by the solidification of the aluminum of aluminum alloy liquid film attached on the surface of a ceramic, and it does not have the microscopic faults such as oxide film inclusions or pores, therefore having the proper physical of mechanical properties of aluminum. Ceramics or a ceramic and a metal can be brazed via the surface metalizing film, the bonding strength of their interface can over the strength of aluminum itself.

Owner:TSINGHUA UNIV

Method of Producing Optical Film and Anti-Reflection Film Optical Film, Anti-Reflection Film, Polarizing Plate and Image Display Device Comprising Same

InactiveUS20070247711A1Improve scratch resistanceSufficient anti-reflection propertyPretreated surfacesPolarising elementsLength waveWavelength range

Owner:FUJIFILM CORP

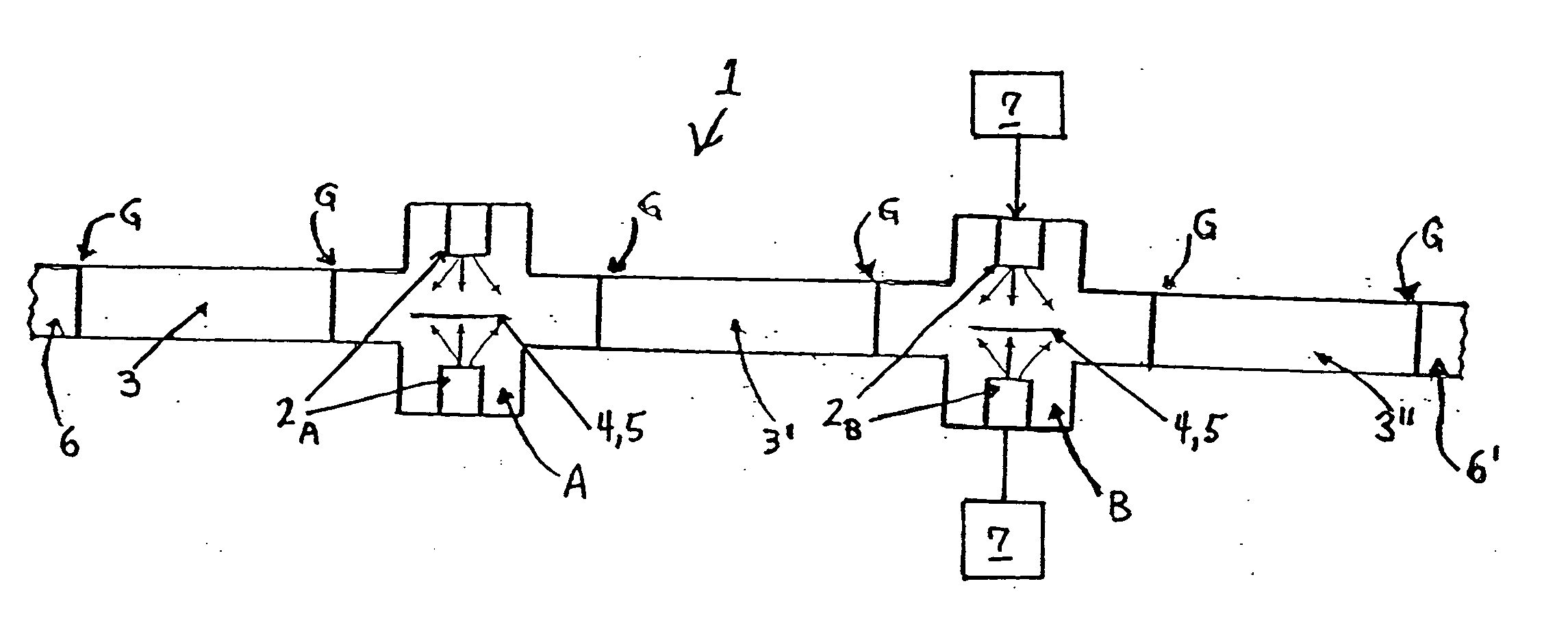

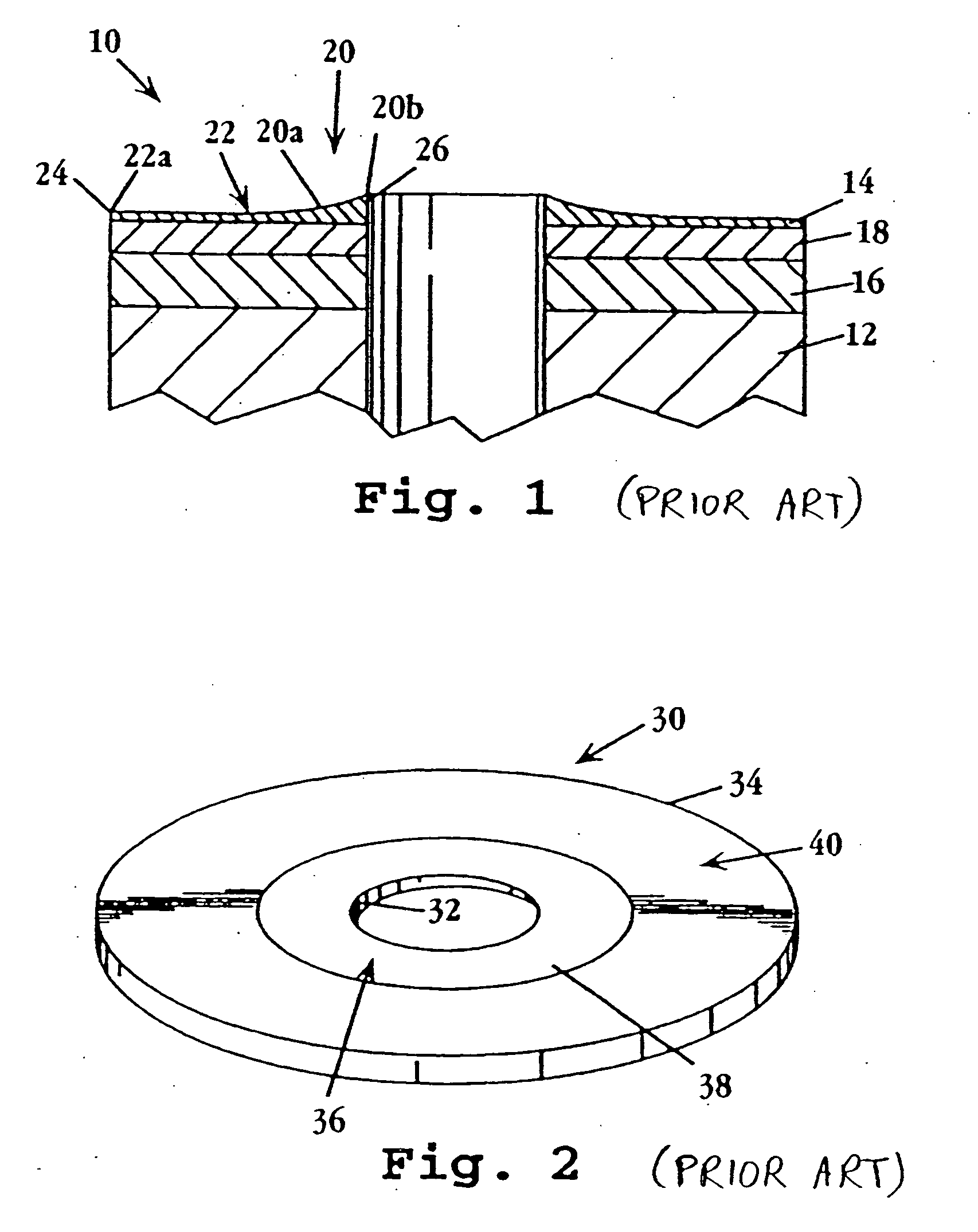

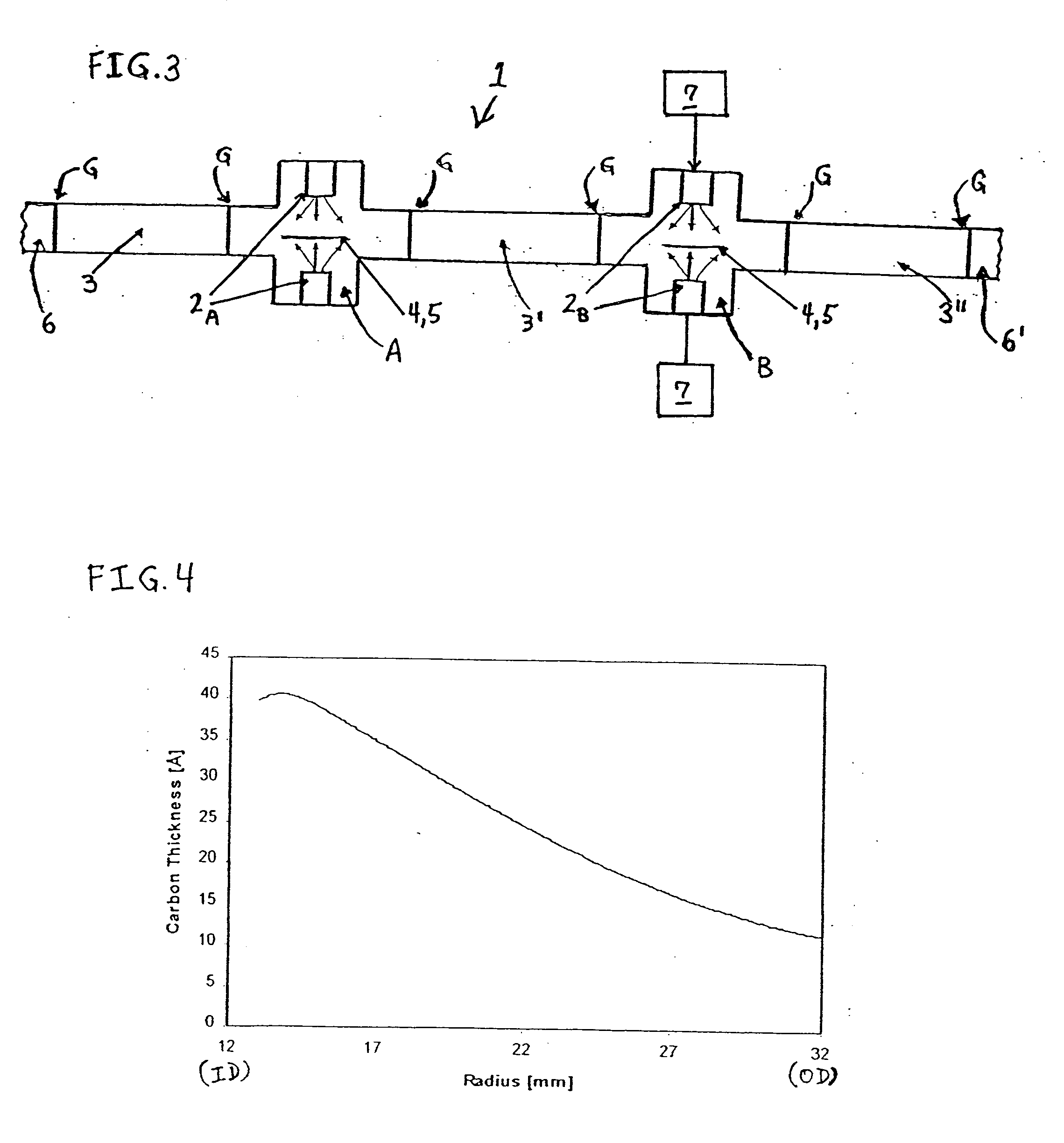

Thickness gradient protective overcoat layers by filtered cathodic arc deposition

InactiveUS20050249983A1Simple methodApparatus is enlargedCellsProtective coatings for layersCathodic arc depositionMaterials science

Owner:SEAGATE TECH LLC

Particle coating

Owner:SCHERING PLOUGH HEALTHCARE PRODUCTS INC

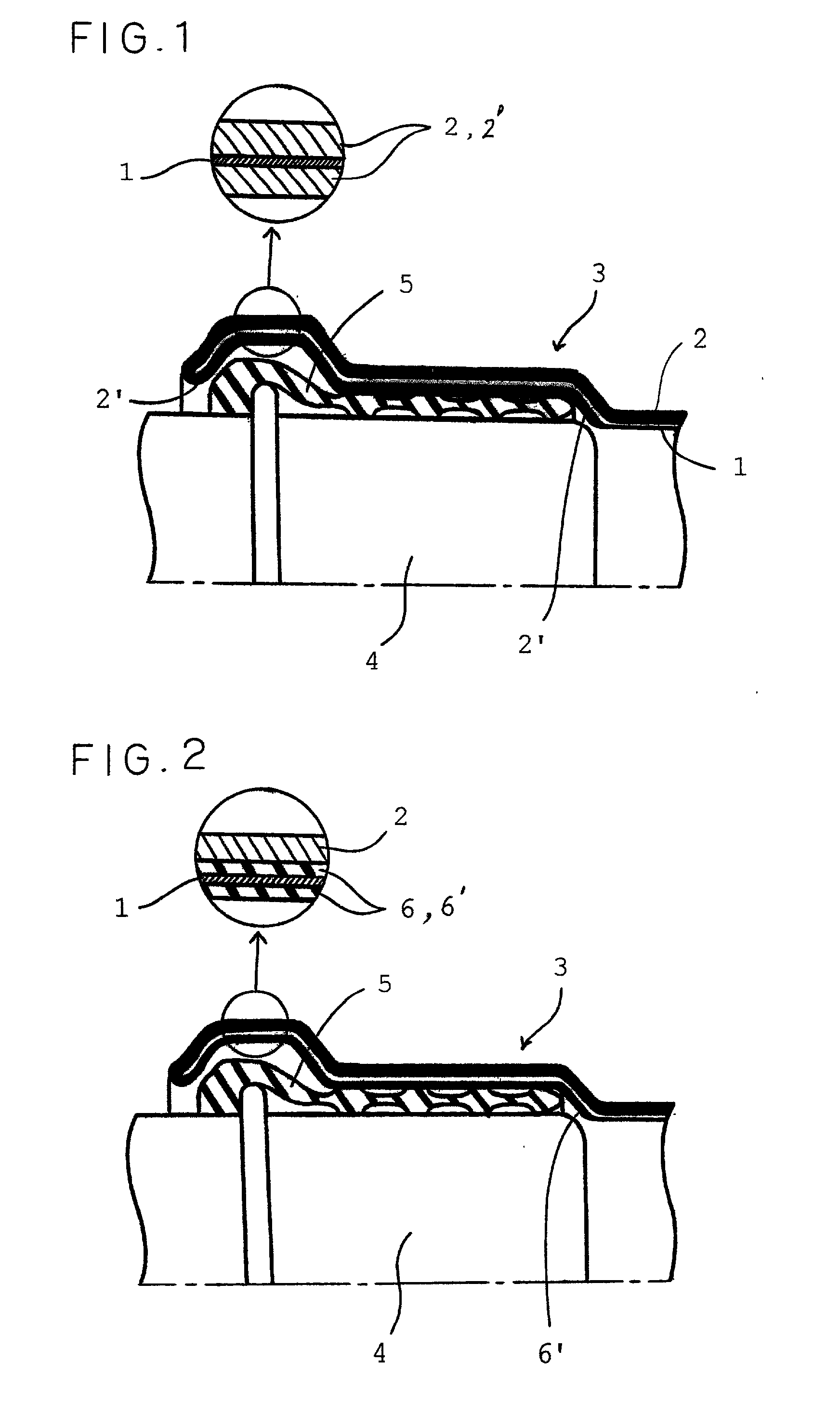

Metal-composite hose and a process for manufacturing the same

Owner:TOKAI RUBBER IND LTD

Novel uhmwpe fiber and method to produce

Owner:HONEYWELL INT INC

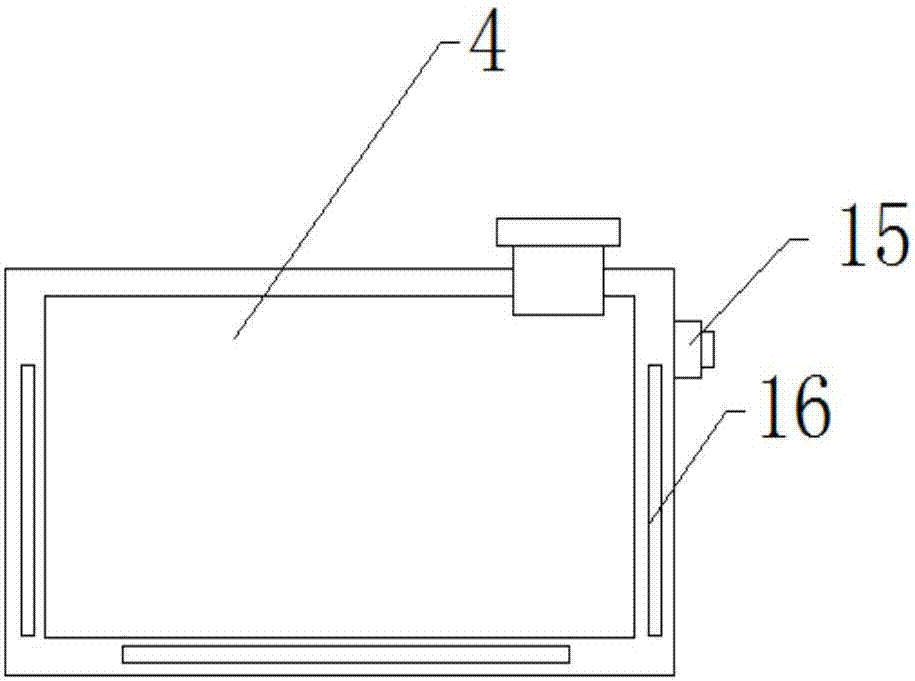

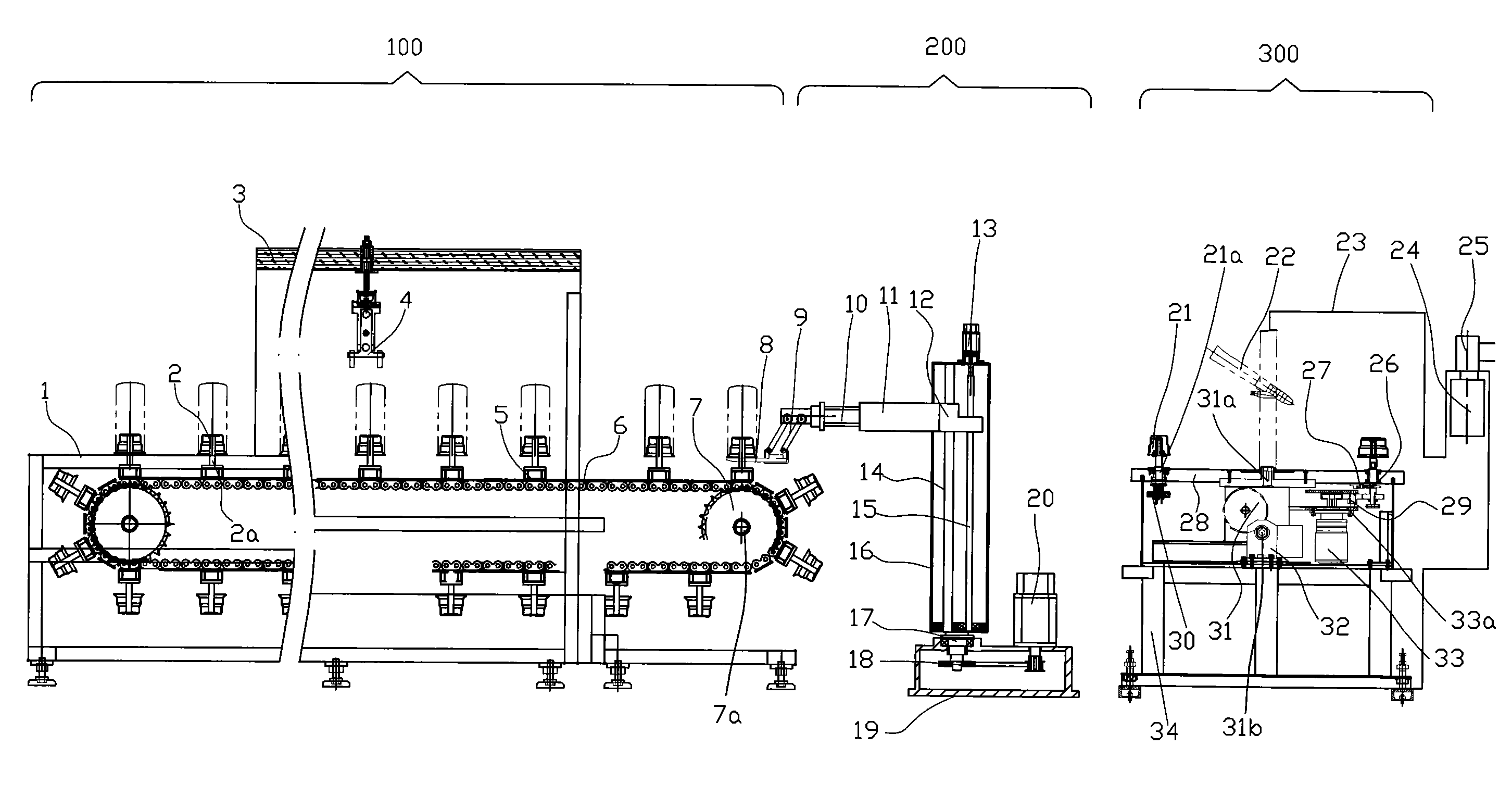

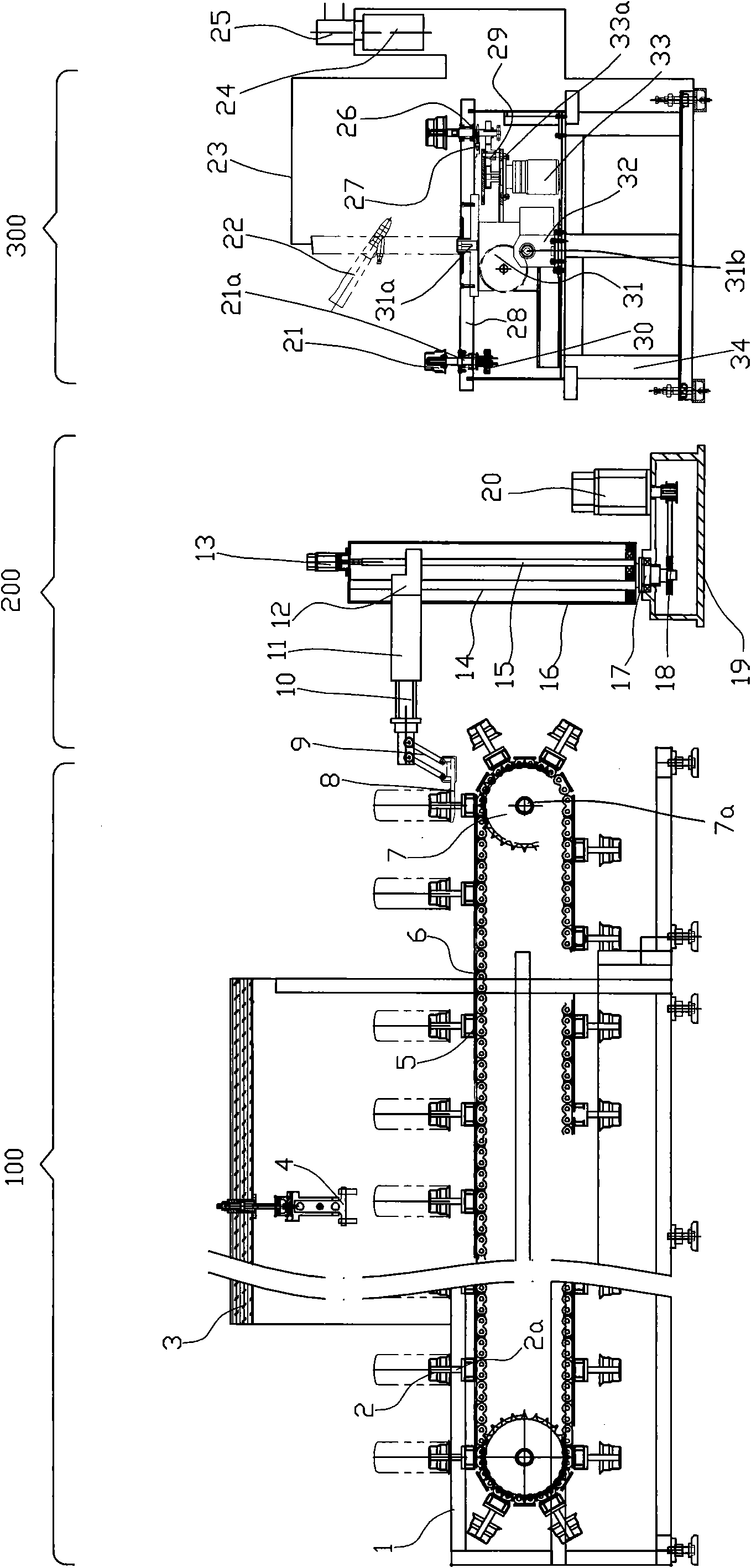

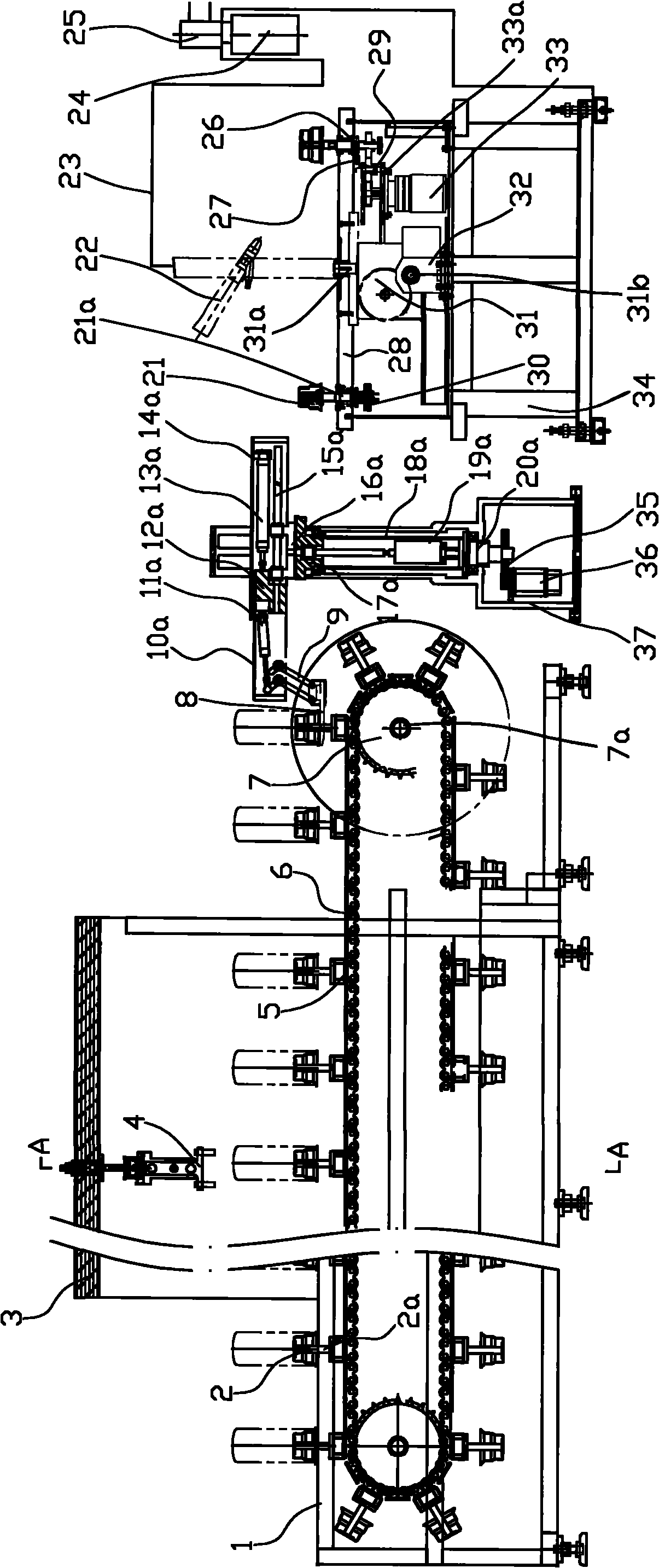

Plate glue spreading device

Owner:LIANGXI HAOXING IND DESIGN OFFICE

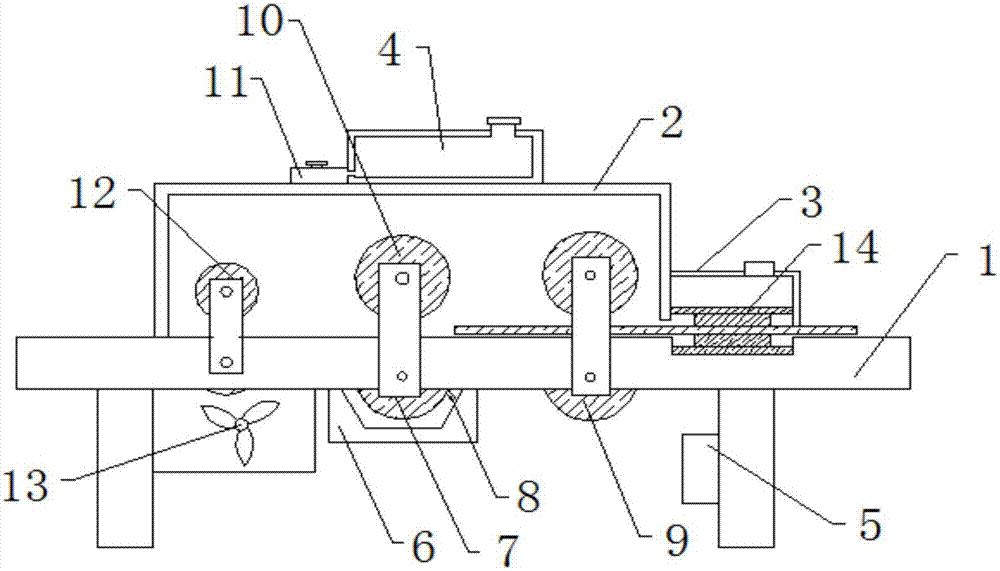

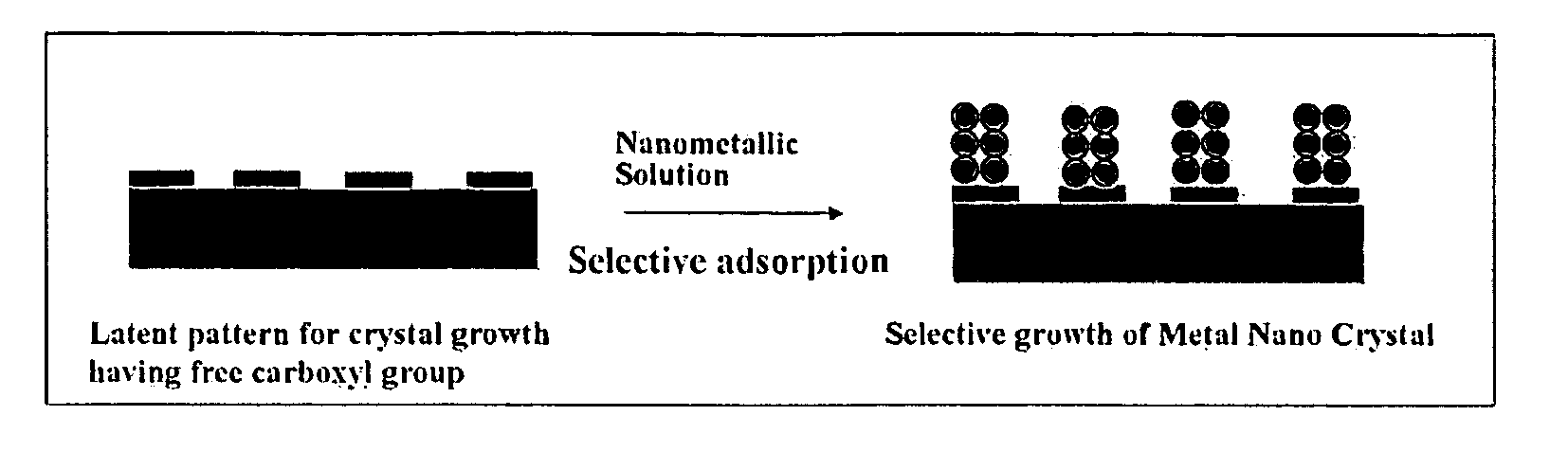

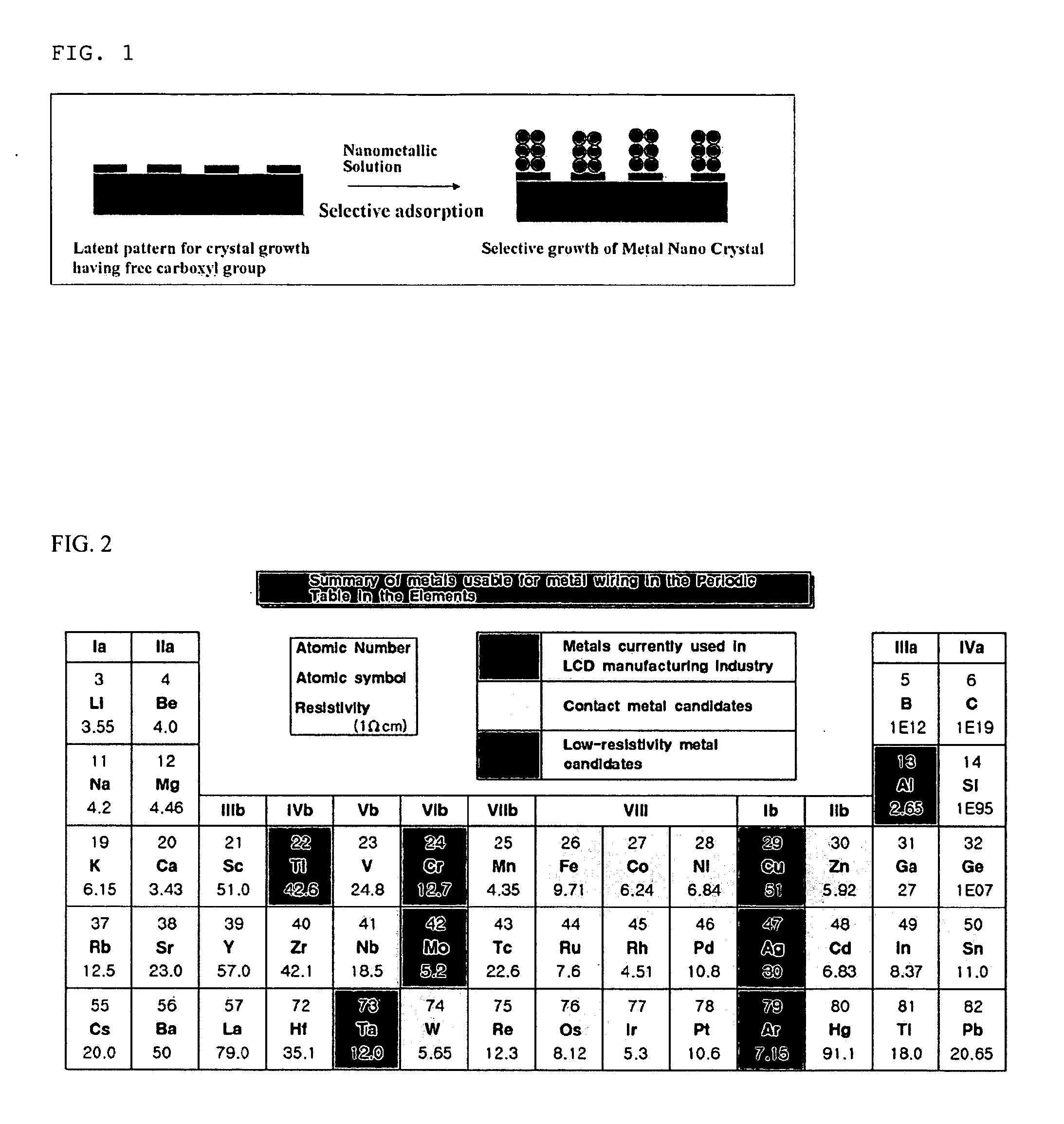

Method for forming metal pattern by using metal nanocrystals

ActiveUS20060110686A1Superior in metal wiring propertyRadiation applicationsPretreated surfacesFlat panel displayLight exposure

Owner:SAMSUNG ELECTRONICS CO LTD

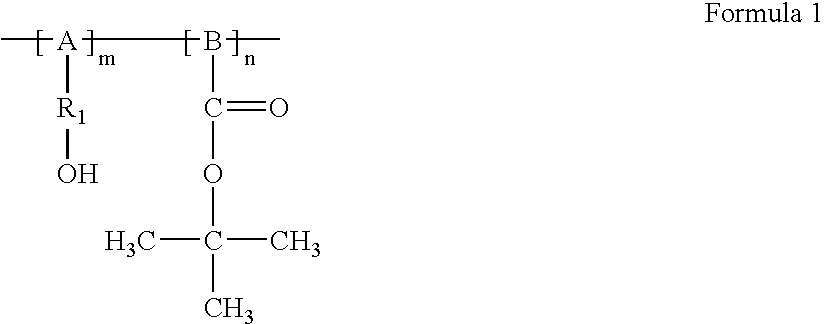

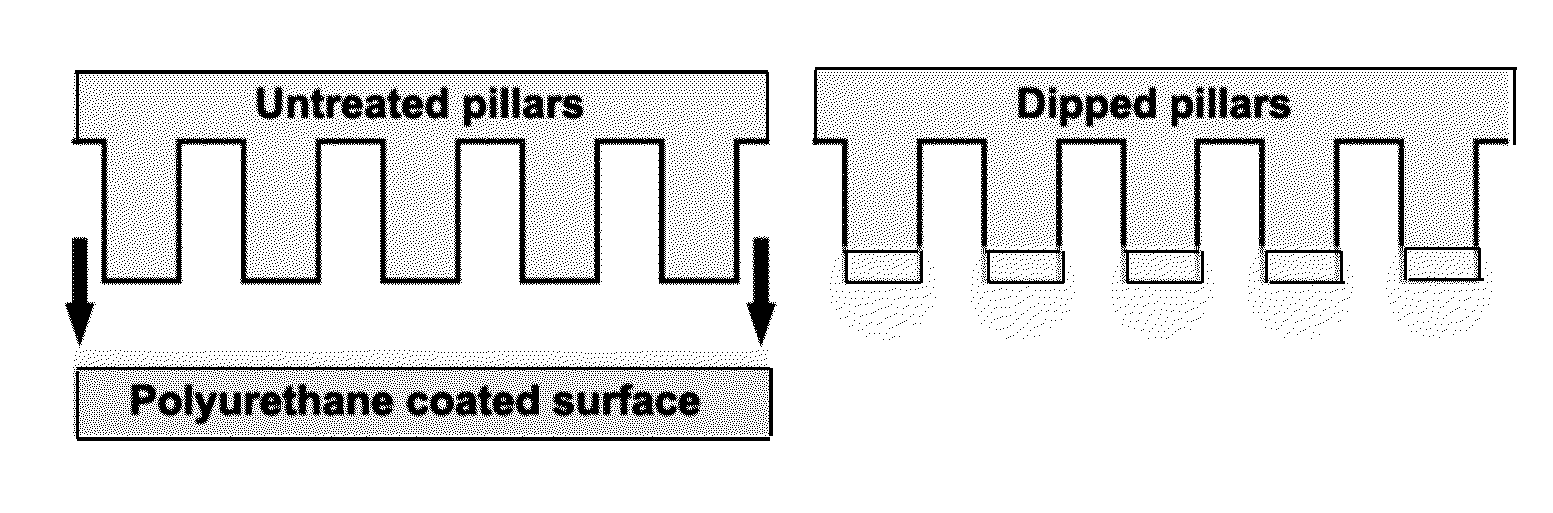

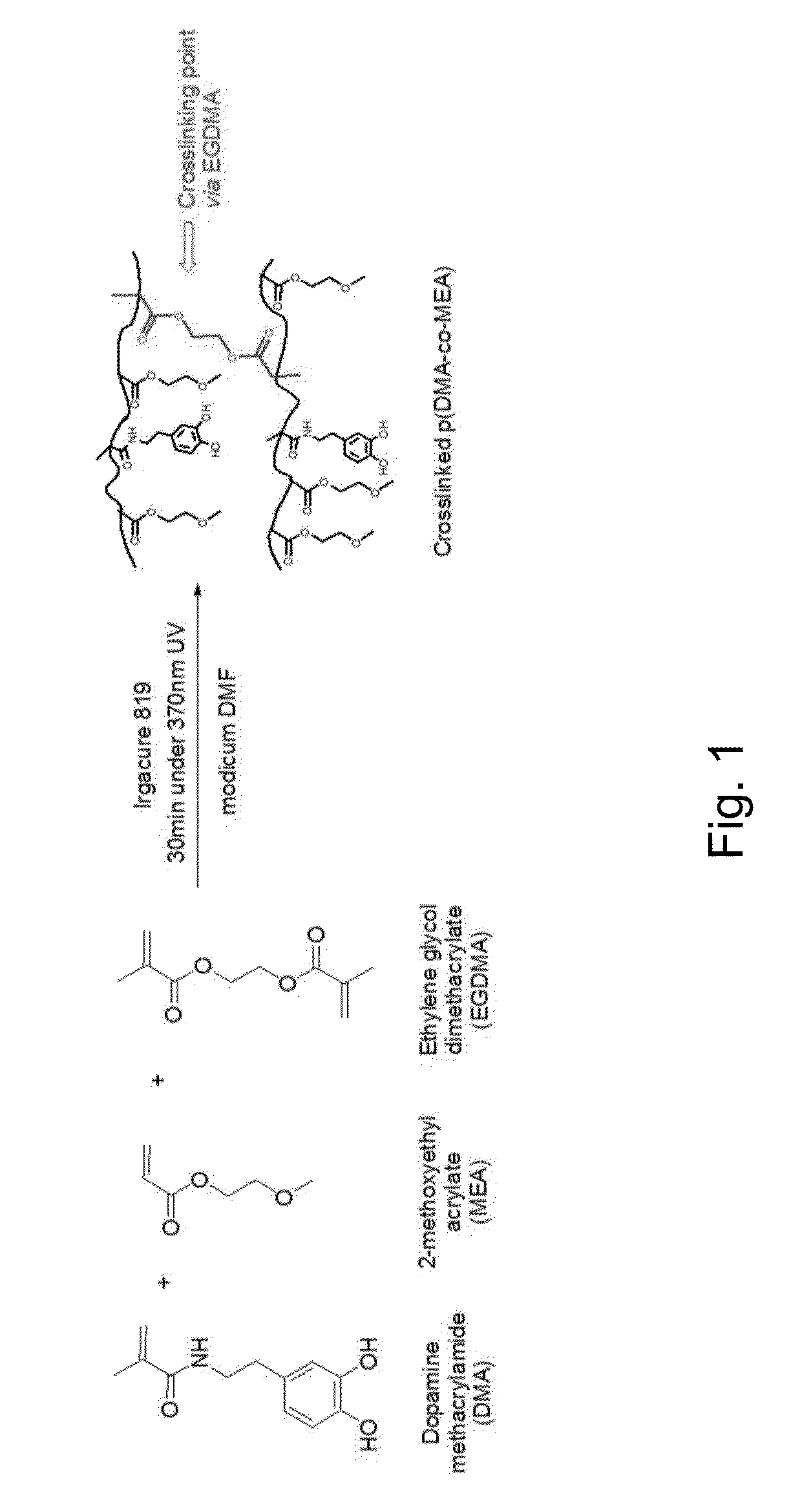

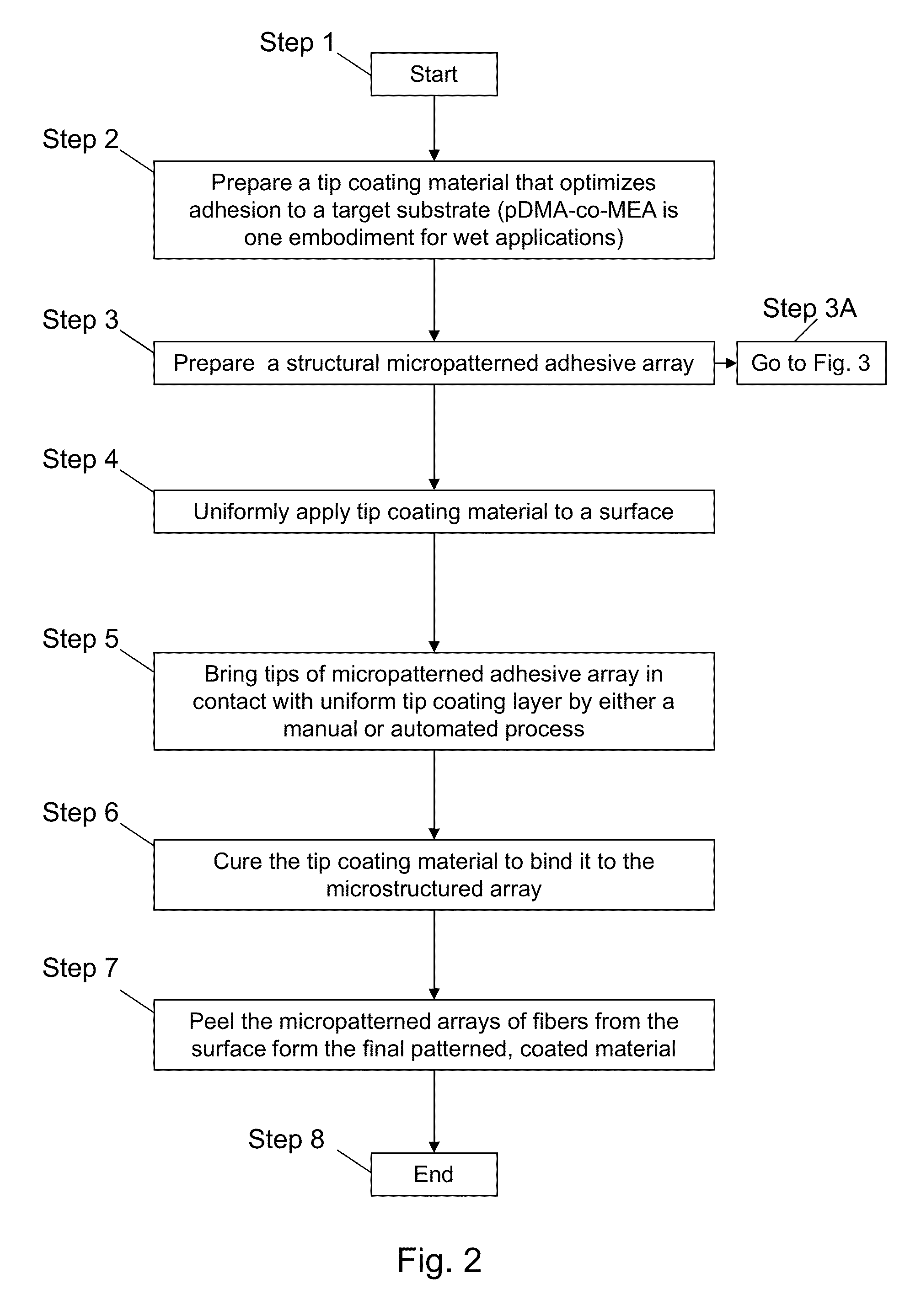

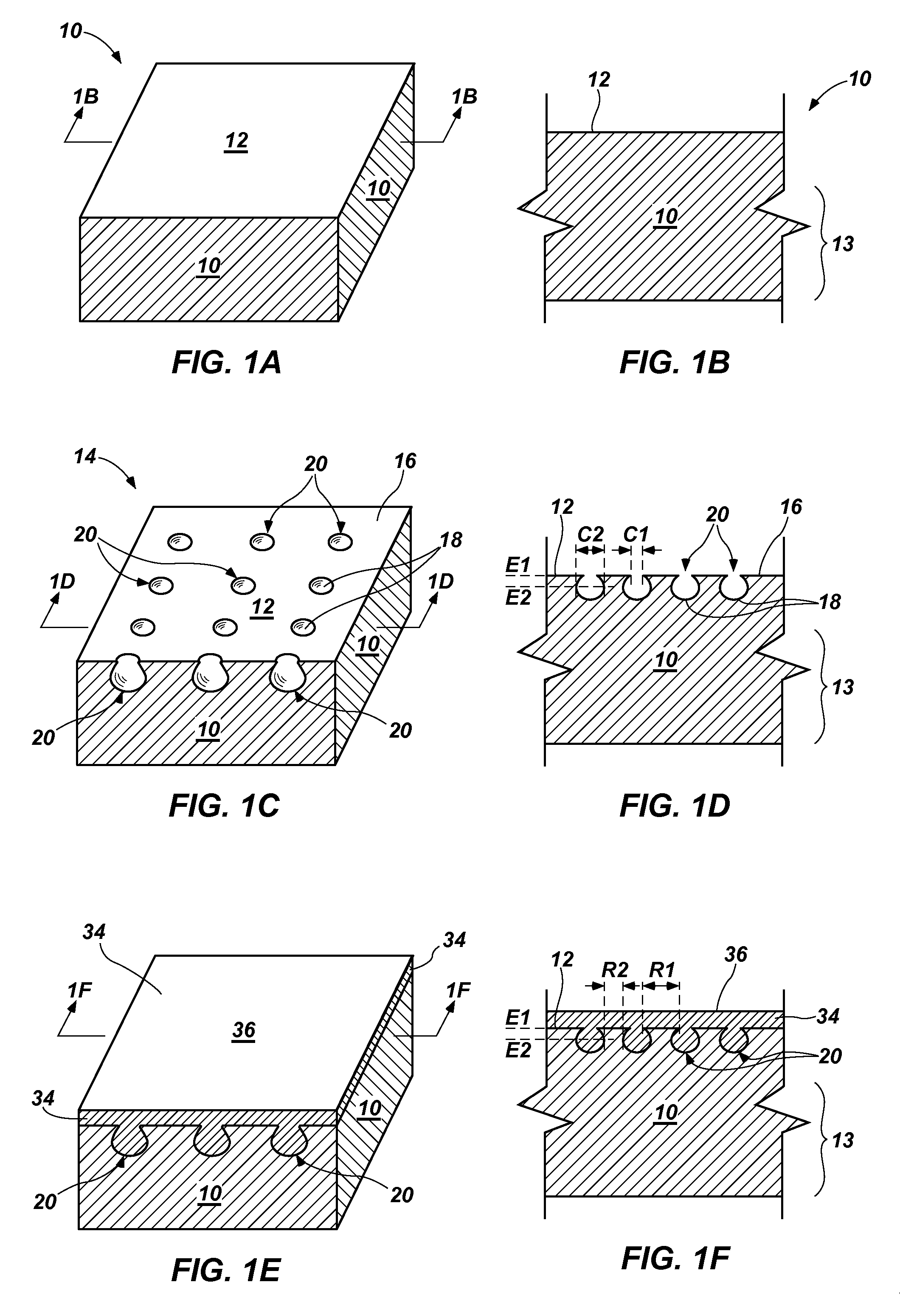

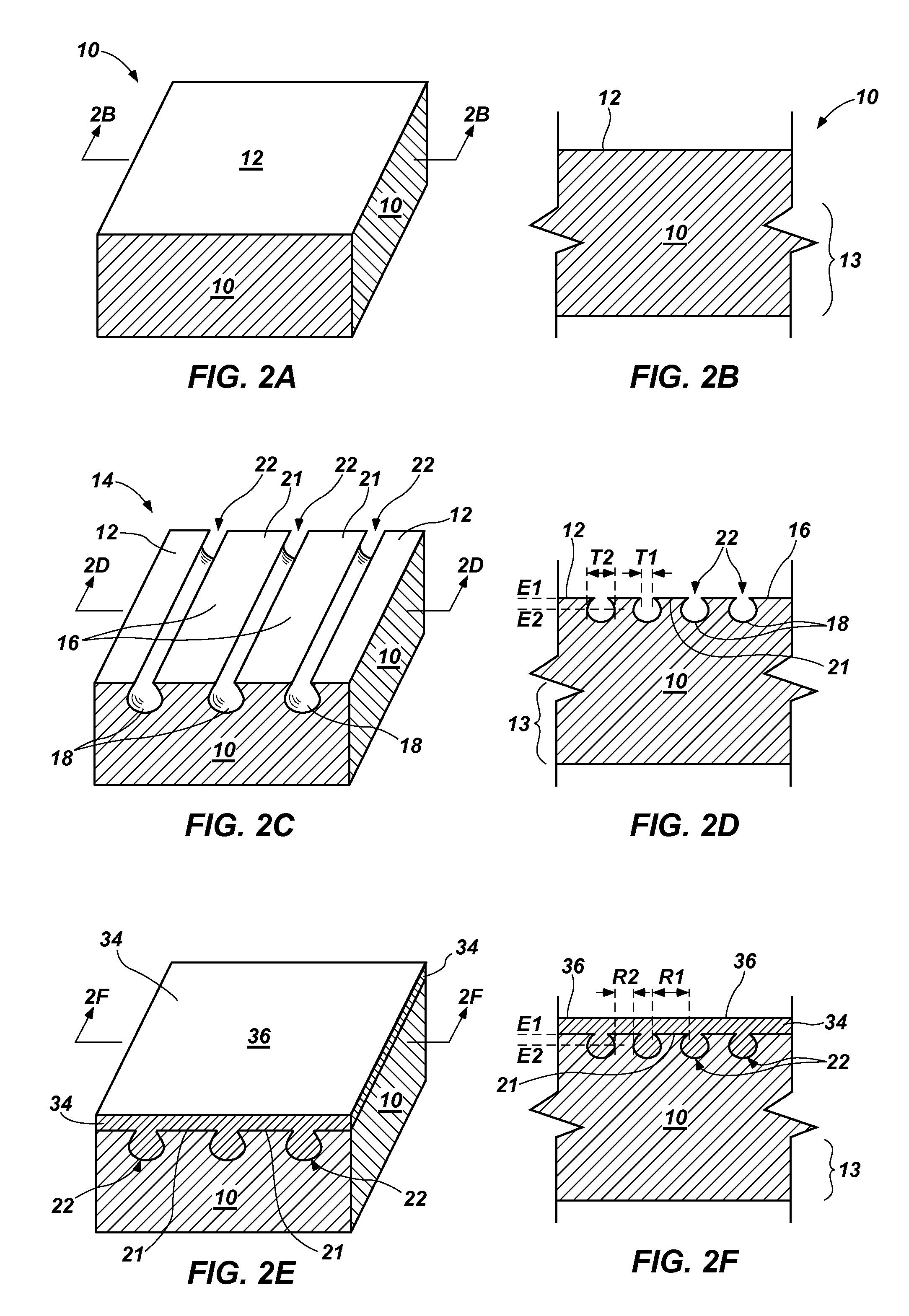

Micro-fiber arrays with tip coating and transfer method for preparing same

ActiveUS20130183481A1Performance deteriorationLayered productsPretreated surfacesMicron scaleElastomer

Owner:CARNEGIE MELLON UNIV CENT FOR TECH TRANSFER & ENTERPRISE CREATION

Powder spraying curing automatic production line of case of rotary filter

Owner:BENGBU HAOYE FILTER

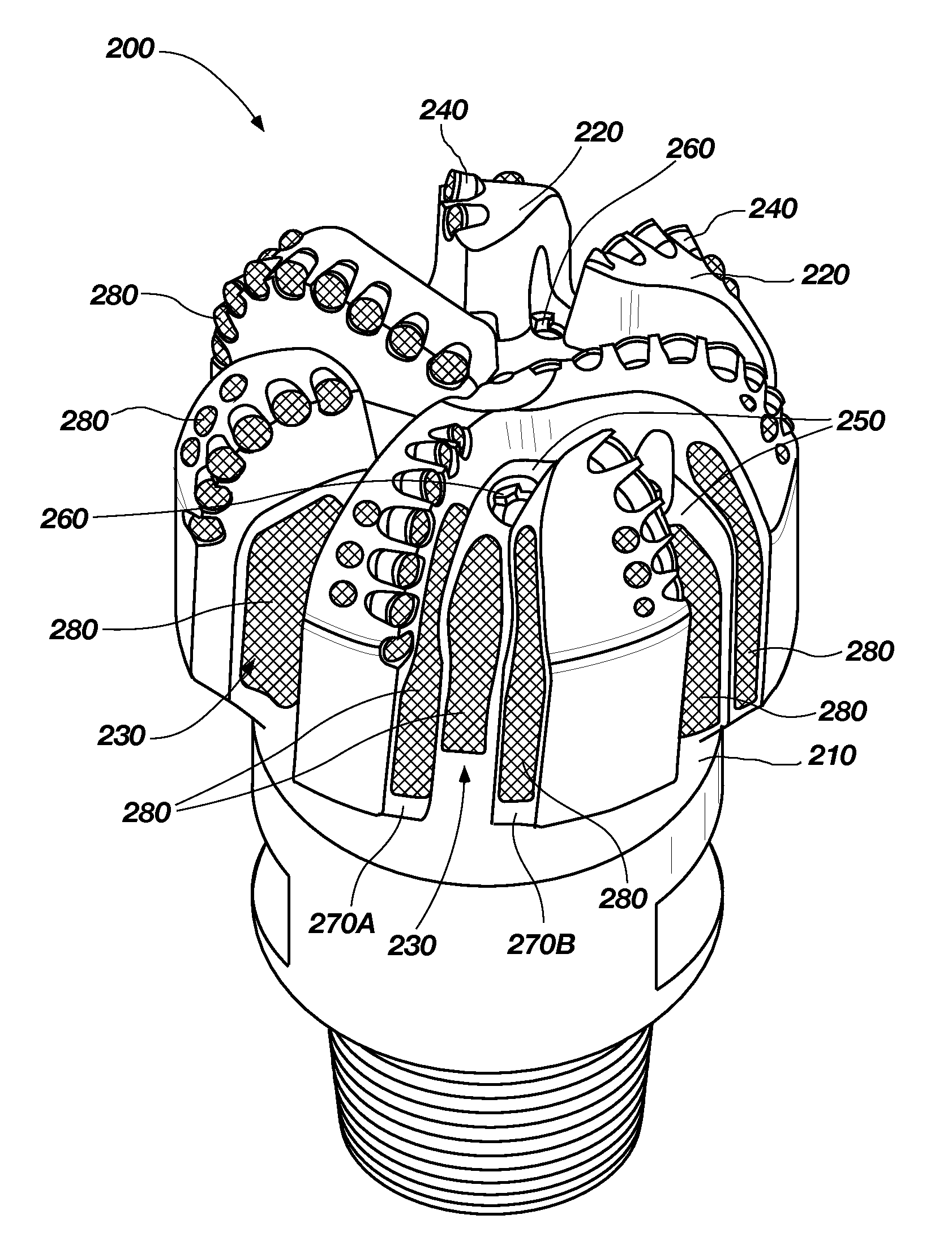

Methods of coating wellbore tools and components having such coatings

Owner:BAKER HUGHES INC

Method for producing resin porous membrane with adhesive layer, resin porous membrane with adhesive layer, and filter member

Owner:NITTO DENKO CORP

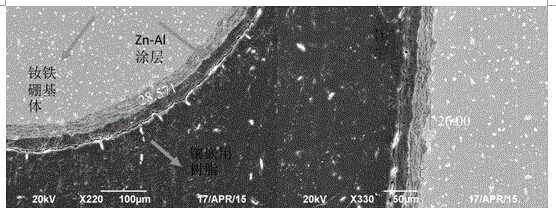

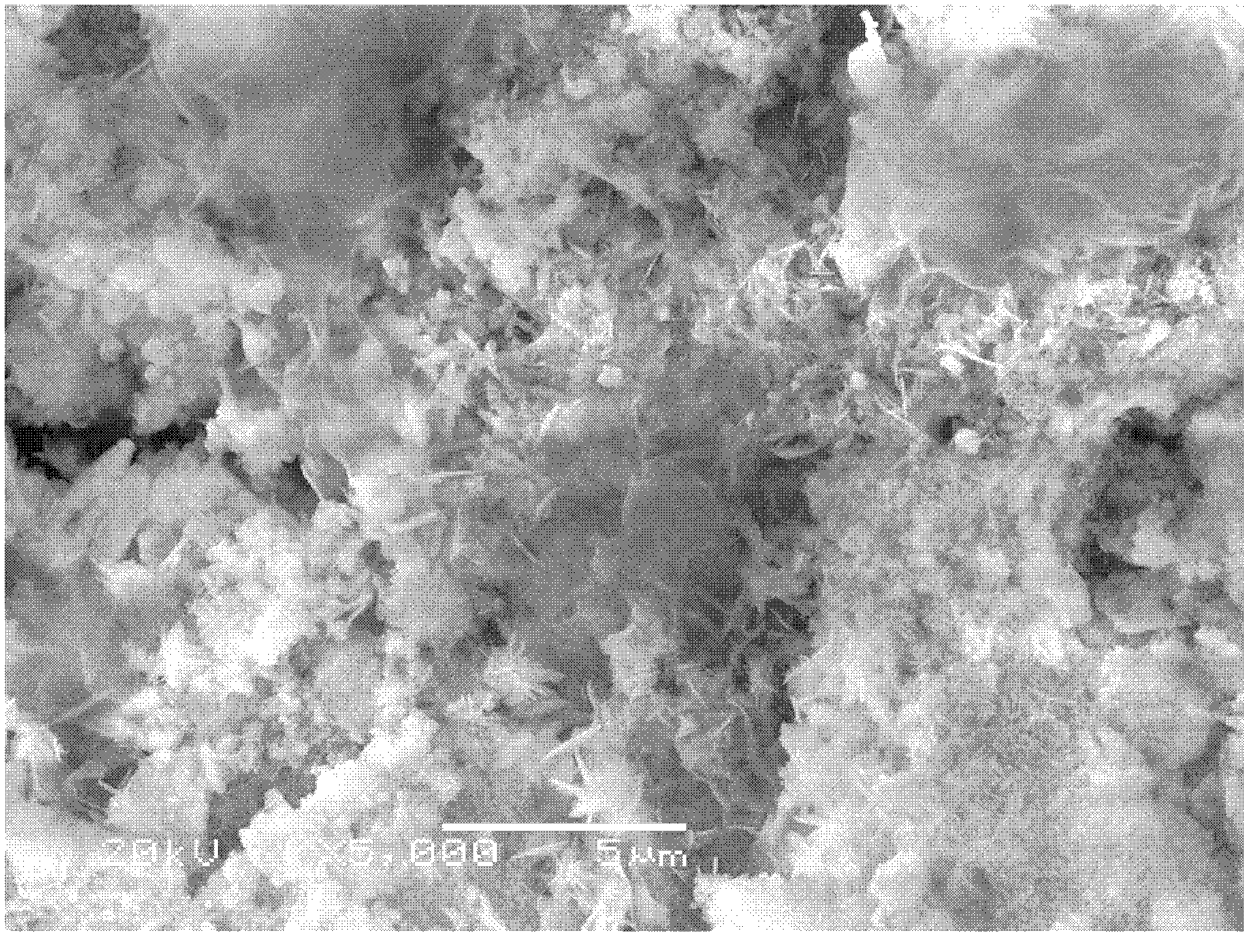

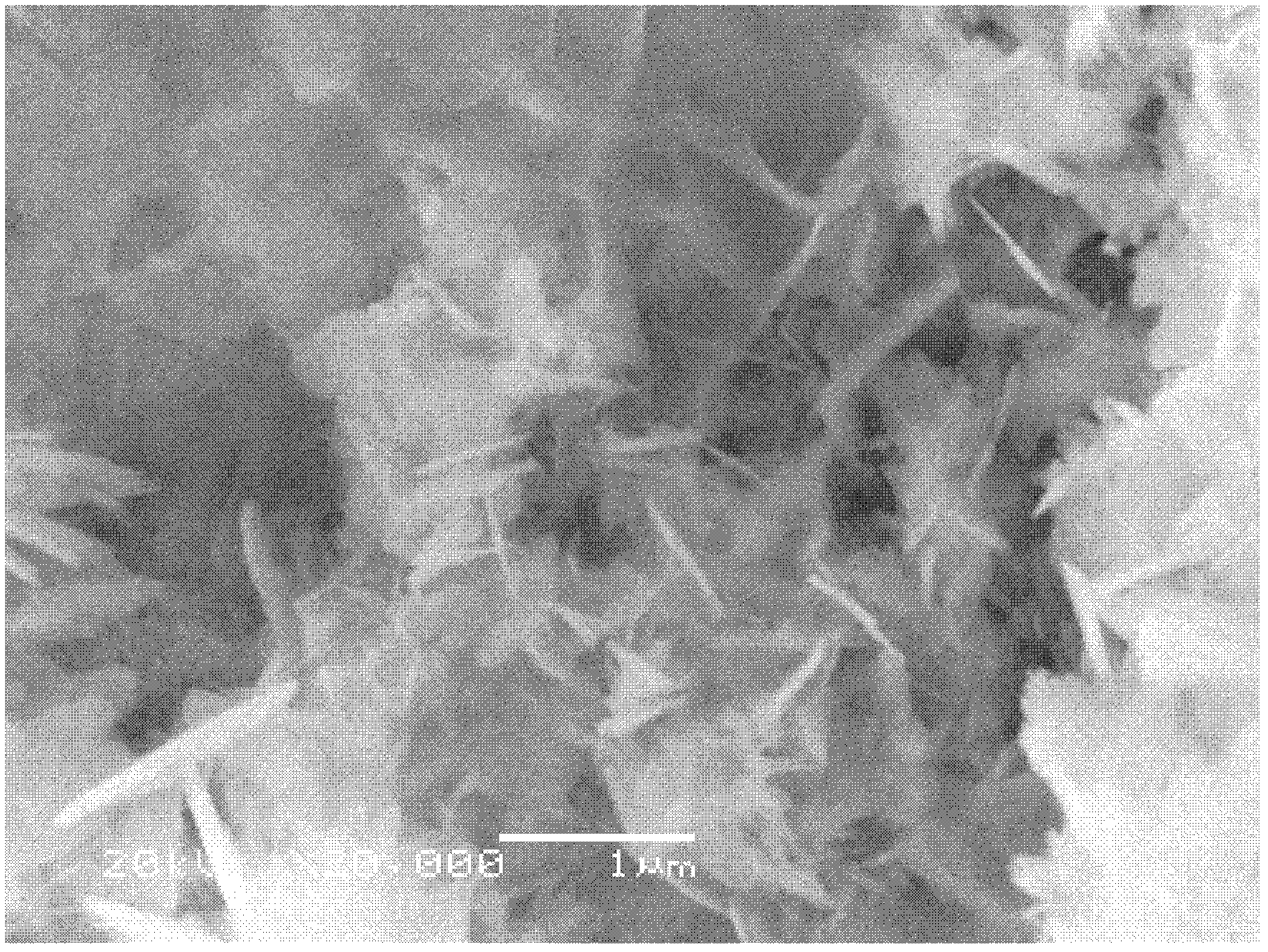

Zinc-aluminum coating enhanced with particles in micro-nano sizes and production method of zinc-aluminum coating

InactiveCN104984889AImprove mechanical propertiesImprove scratch resistancePretreated surfacesSpecial surfacesMicro nanoSilicon oxide

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

Method for preparing super-hydrophobic green film on magnesium alloy substrate

Owner:DALIAN UNIV OF TECH

Systems and methods for enhancing mobility of atomic or molecular species on a substrate at reduced bulk temperature using acoustic waves, and structures formed using same

ActiveUS20140199550A1Improve mobilityReduce the temperatureRadiation applicationsVacuum evaporation coatingChemical physicsAcoustic wave

Under one aspect of the present invention, a method for enhancing mobility of an atomic or molecular species on a substrate may include exposing a first region of a substrate to an atomic or molecular species that forms a molecular bond with the substrate in the first region; directing a laser pulse to a second region of the substrate so as to generate an acoustic wave in the second region, the acoustic wave having spatial and temporal characteristics selected to alter the molecular bond; and transmitting the acoustic wave from the second region to the first region, the acoustic wave altering the molecular bond between the substrate and the atomic or molecular species to enhance mobility of the atomic or molecular species on the substrate in the first region.

Owner:THE AEROSPACE CORPORATION

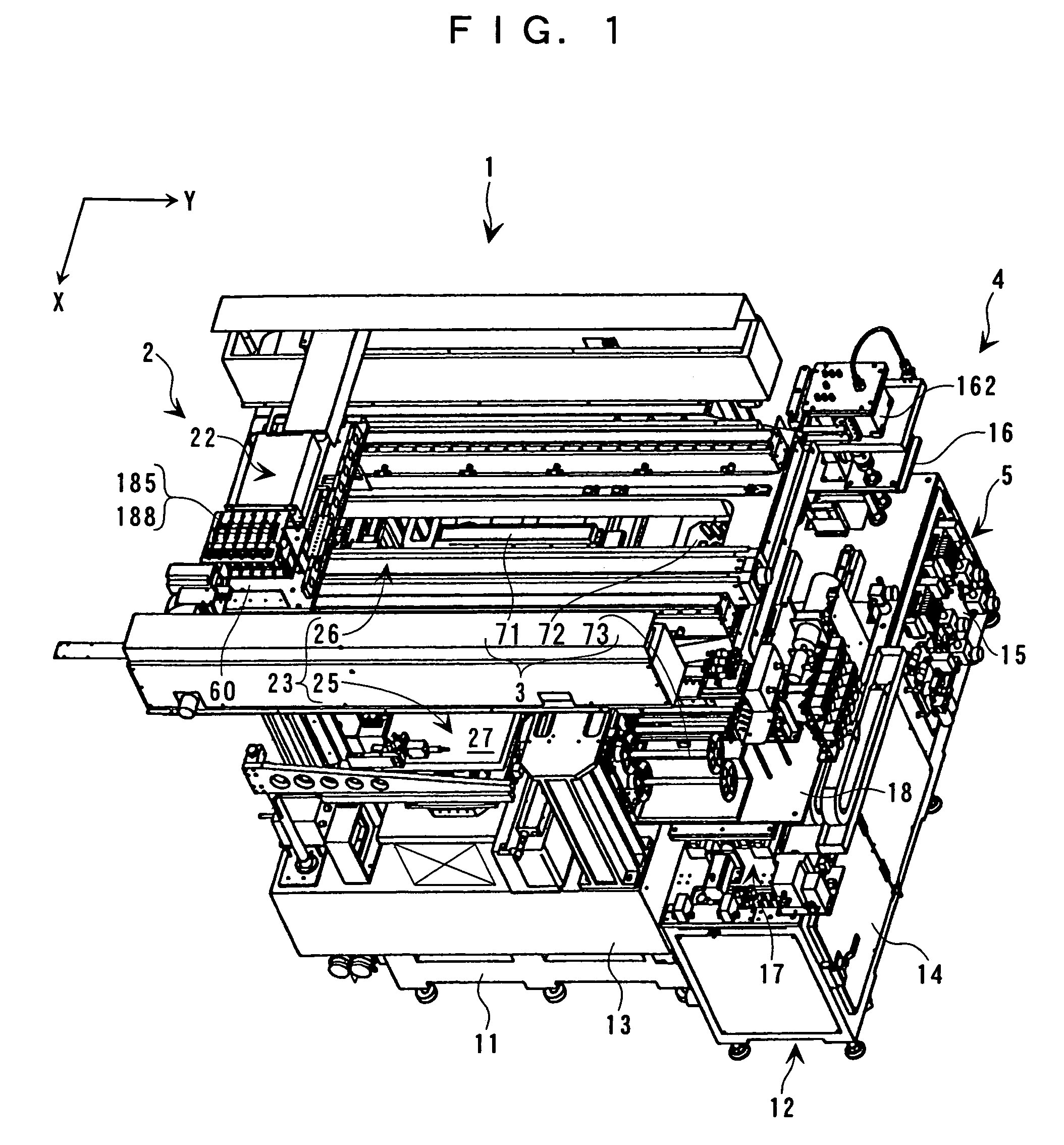

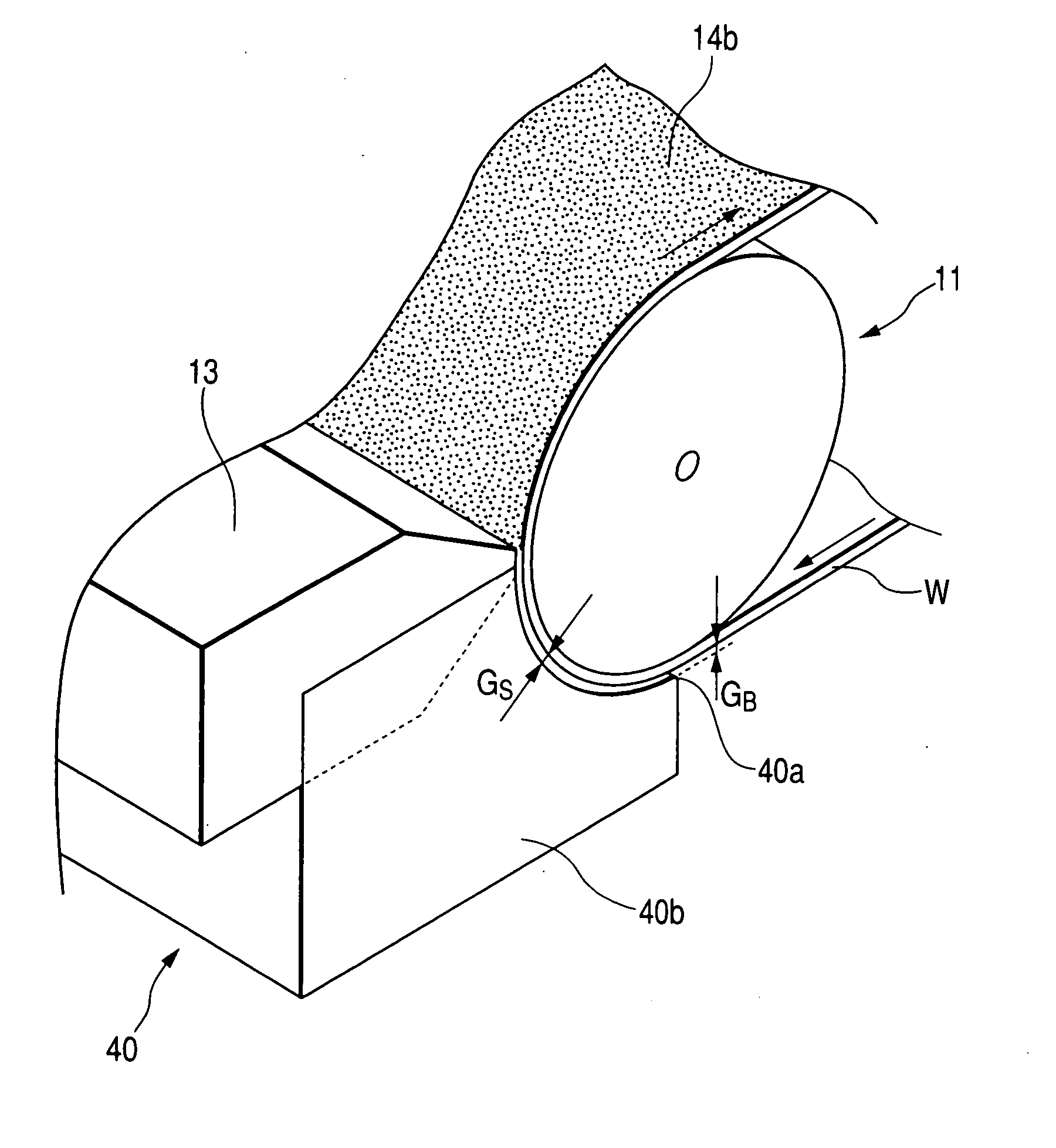

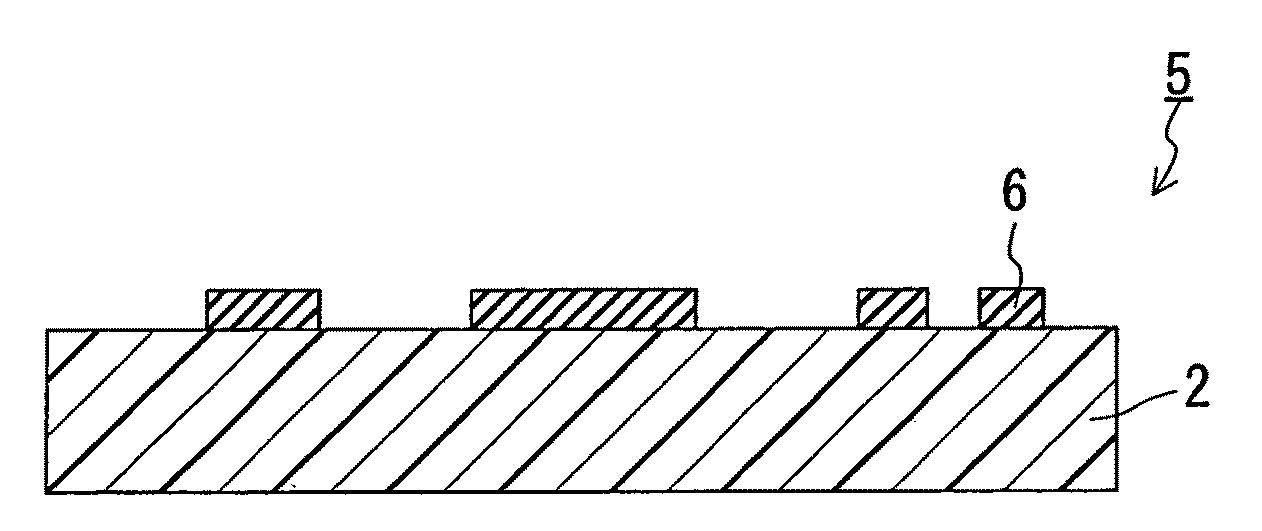

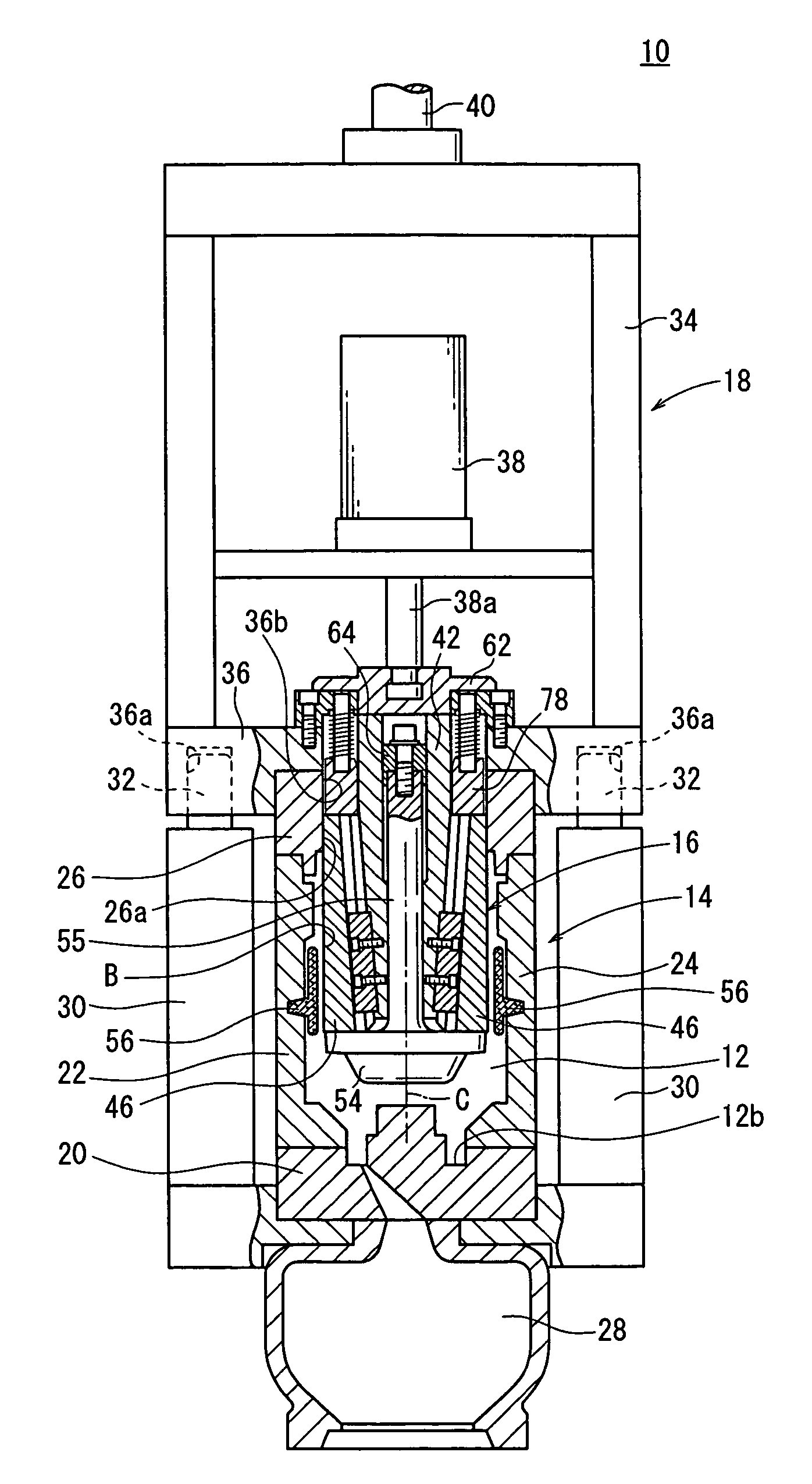

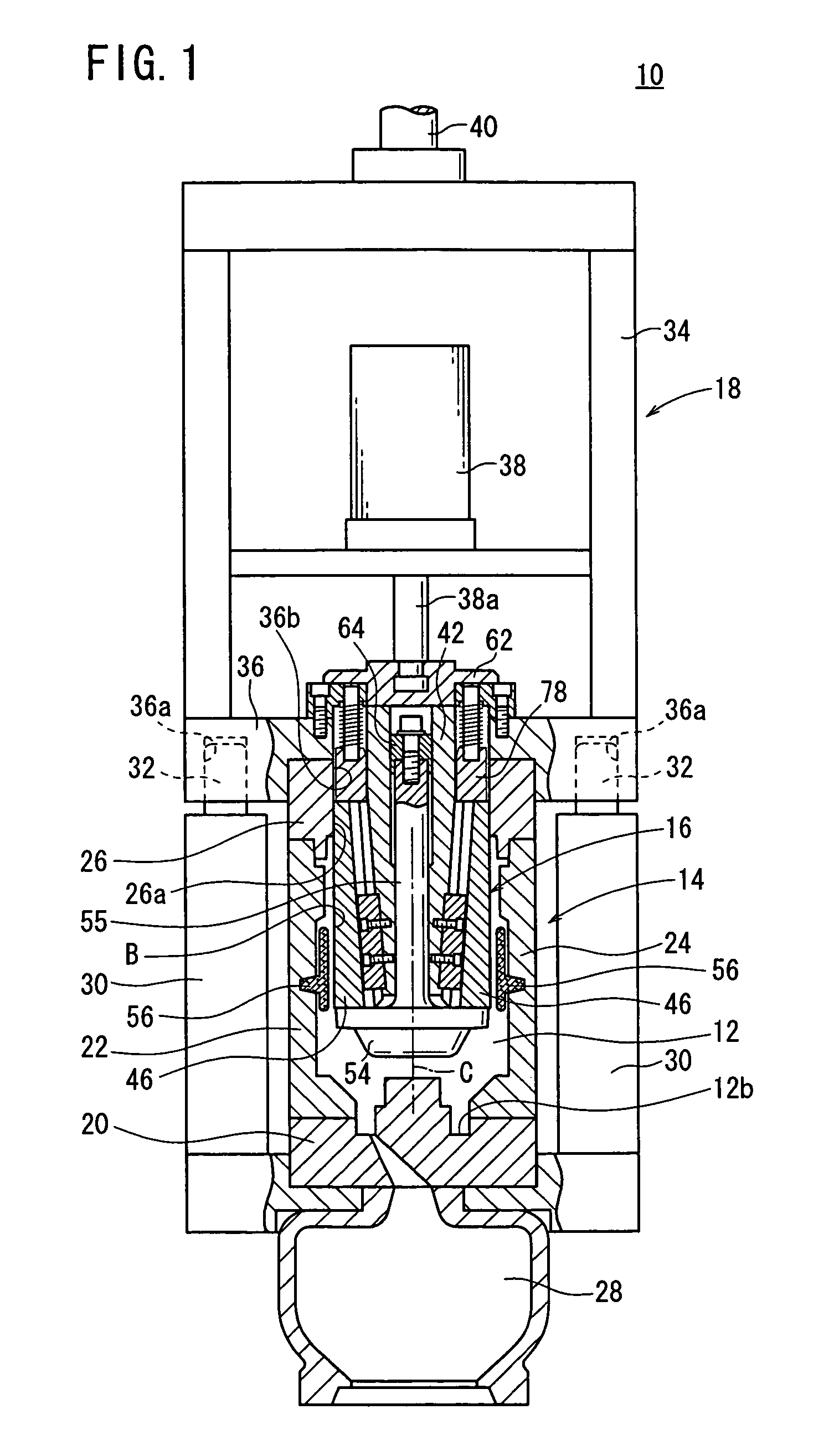

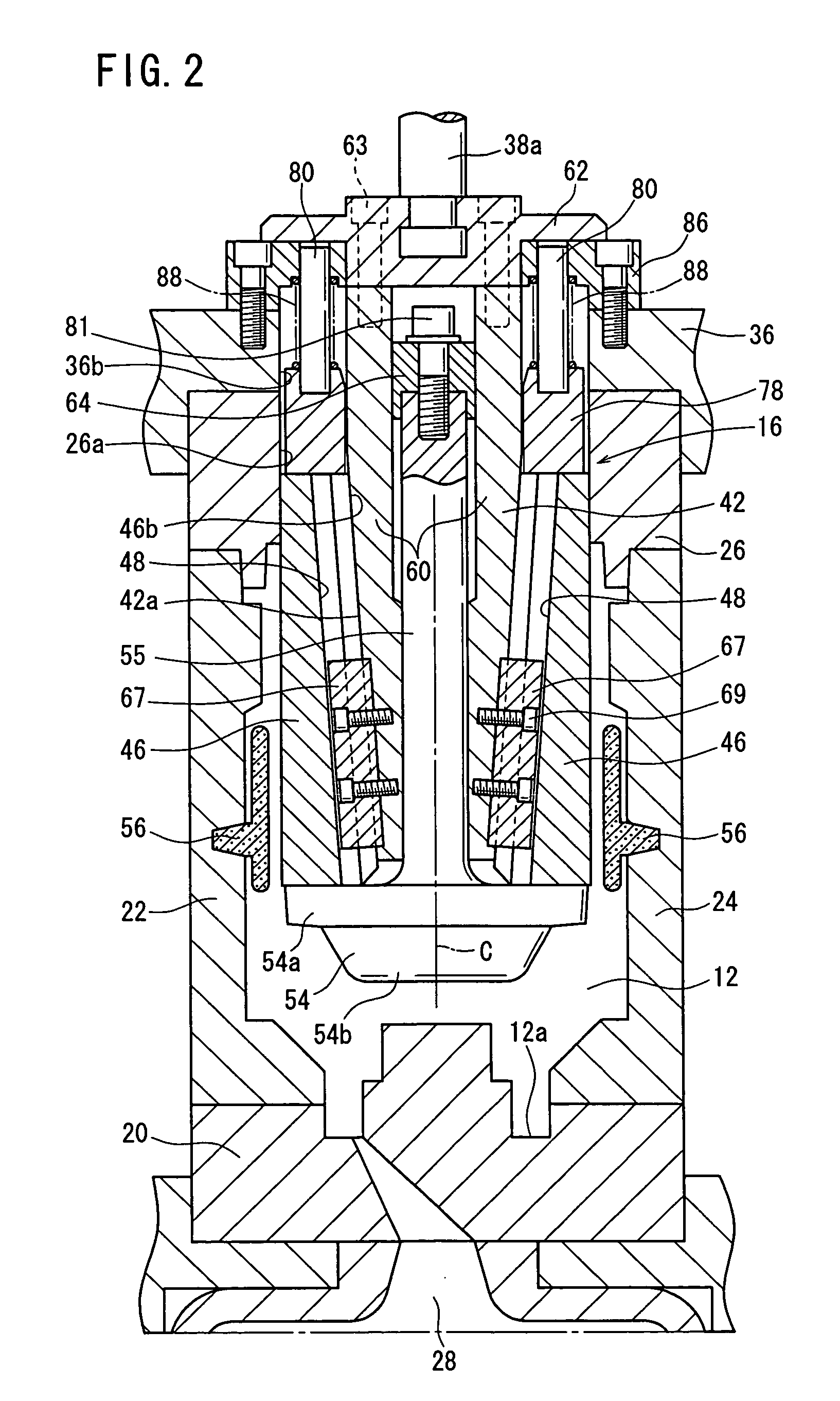

Mold Device and Method of Manufacturing Cylinder Block

InactiveUS20080274289A1Quality improvementSmall amount of materialCylinder headsPretreated surfacesPush outCylinder block

Owner:HONDA MOTOR CO LTD

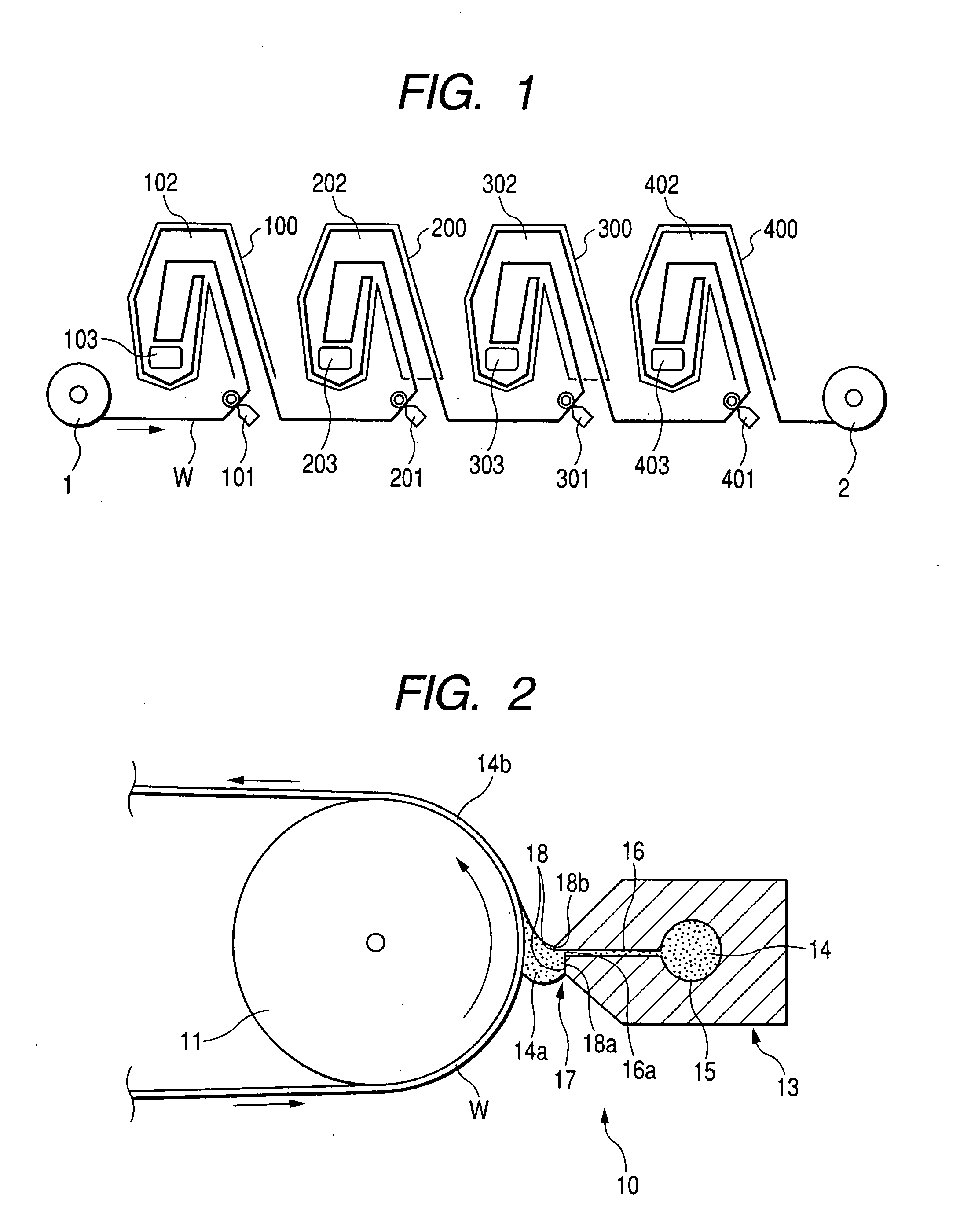

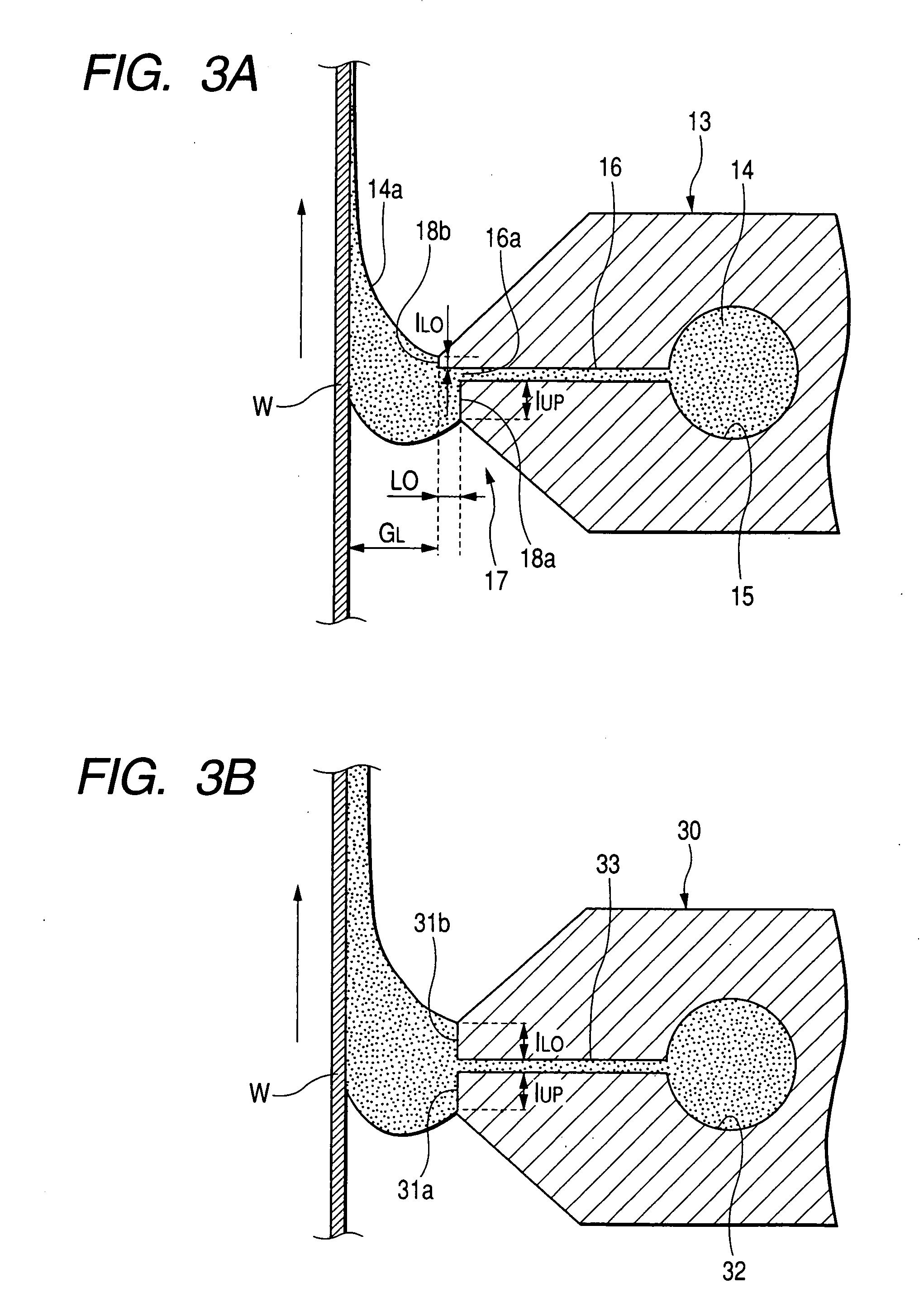

Method for manufacturing long laminated polarizing plate and long laminated polarizing plate

It is an object of the invention to provide a method for manufacturing a long laminated polarizing plate having a long polarizing coating formed by coating directly on a long retardation film and to provide such a long laminated polarizing plate. The present invention relates to a method for manufacturing a long laminated polarizing plate comprising a long retardation film having a slow axis in its longitudinal direction and a long polarizing coating placed on the retardation film and having an absorption axis or a transmission axis in an in-plane direction at an angle of 25 to 65° to the slow axis direction of the long retardation film.

Owner:NITTO DENKO CORP

Reactive surface coating having chemical decontamination and biocidal properties

ActiveUS20140287154A1Reduce and limit amountHigh activityBiocideAntifouling/underwater paintsBiochemical engineeringEnvironmental engineering

Reactive compositions are provided, having biocidal and chemical decontamination / neutralization properties, comprising a hygroscopic polymer and an active, which are useful in a variety of commercial, healthcare and military applications and a wide variety of contaminants, including without limitation chemical and biological warfare agents. The reactive compositions are renewable or rechargeable after use by exposure to an additional application of the active and do not require removal, disposal or replacement of the originally applied composition. Methods for preparing and applying the reactive compositions are disclosed.

Owner:AMERICAN STERILIZER CO +1

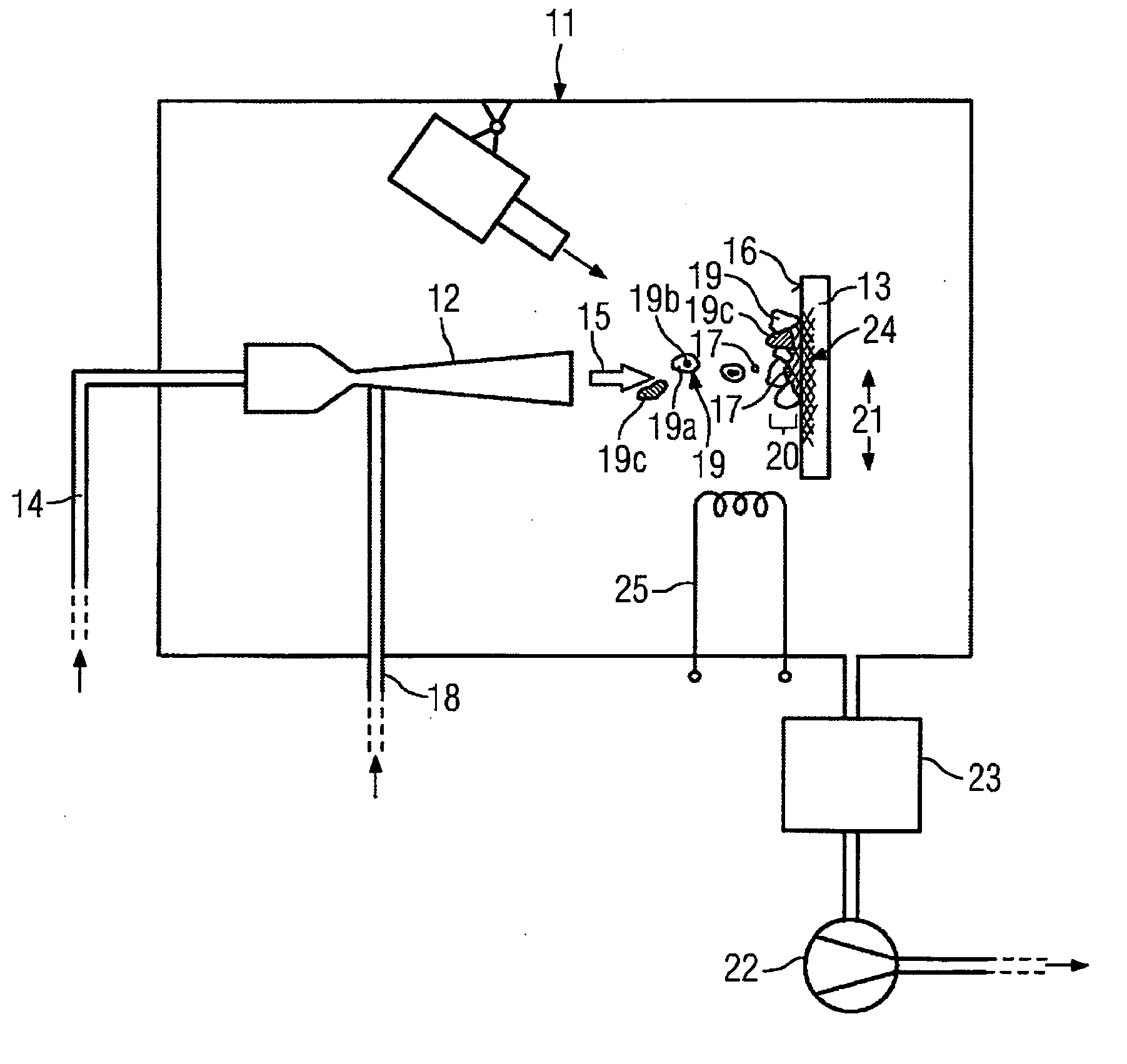

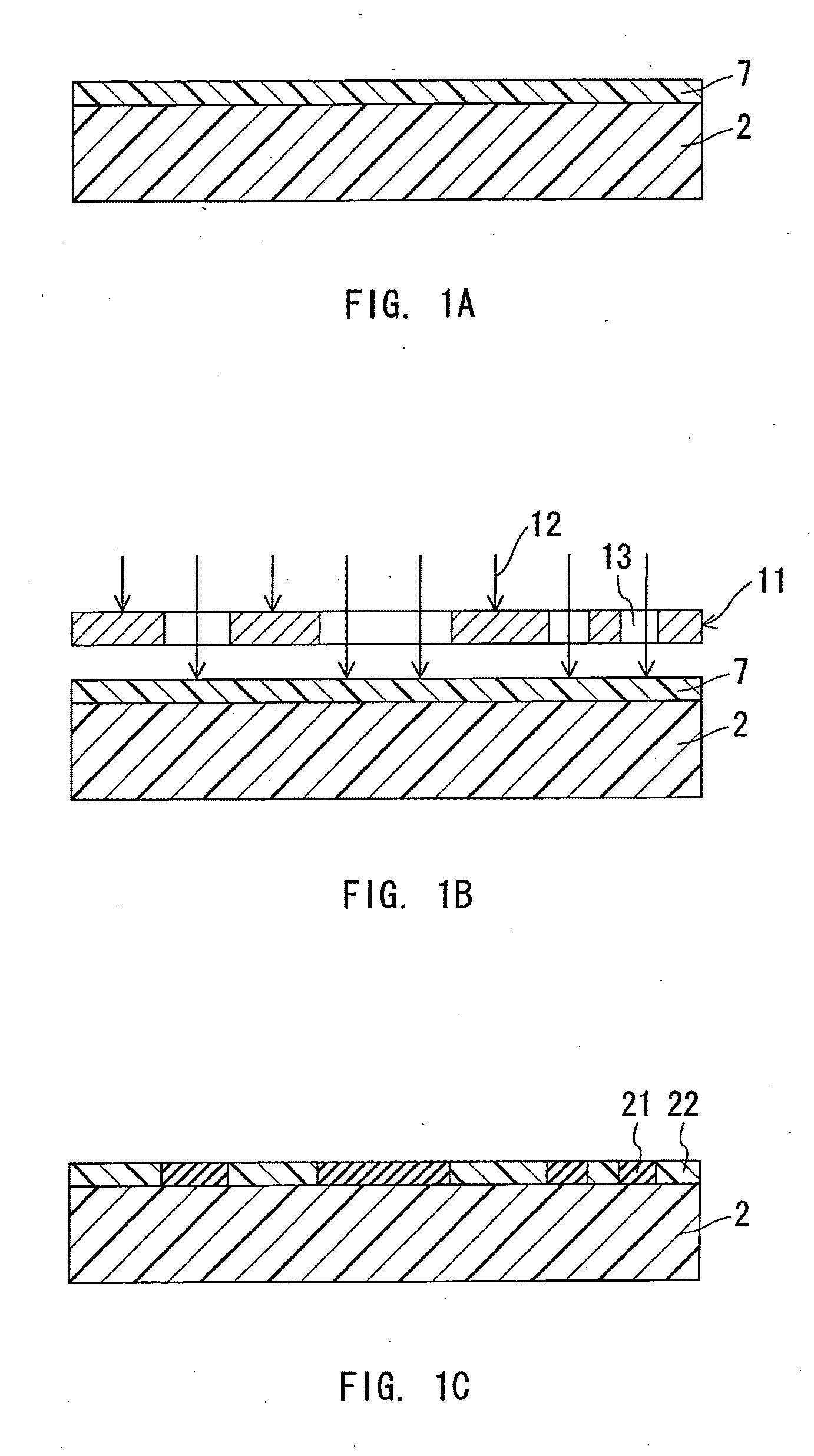

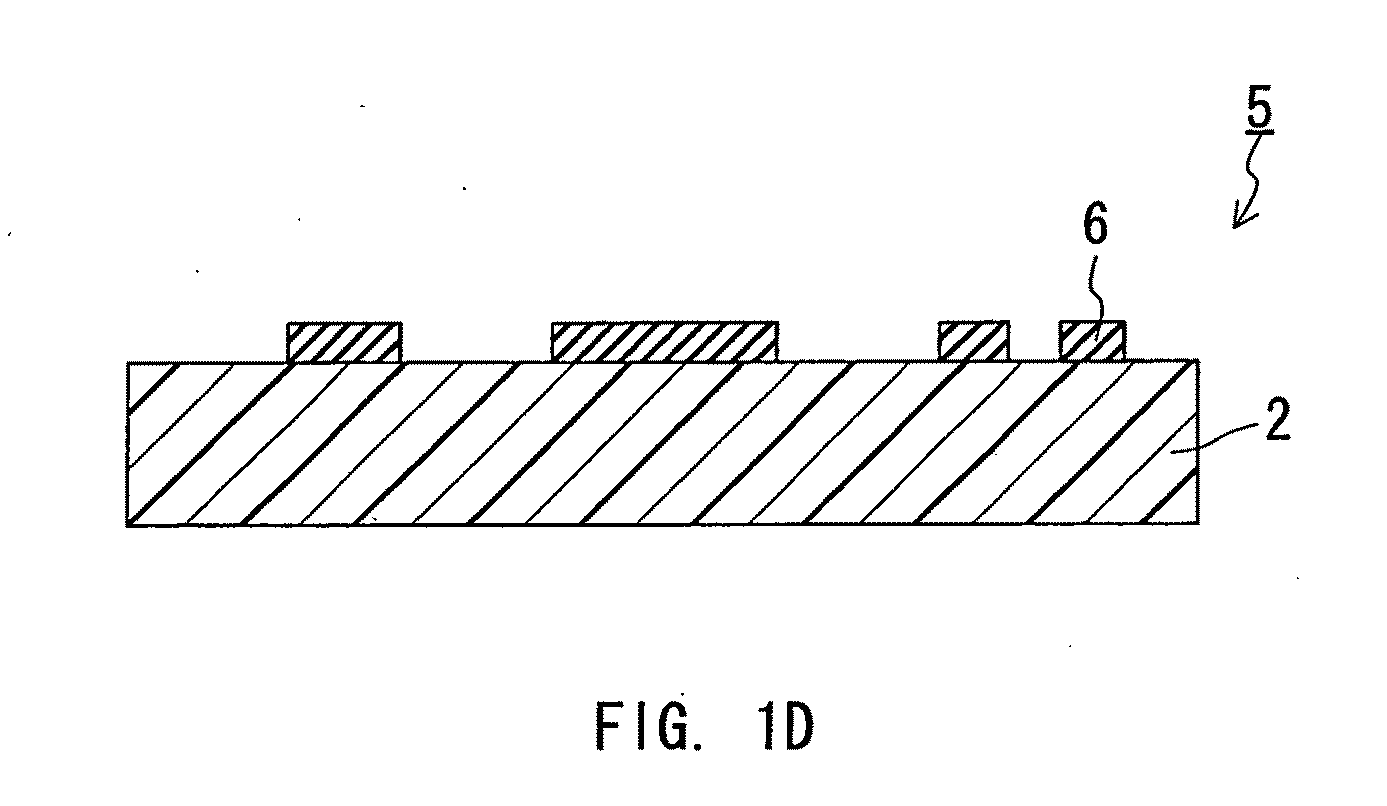

Substrate processing apparatus and substrate processing method

ActiveUS20170213725A1Efficiently formedShort timeSolid-state devicesPretreated surfacesProduct gasEngineering

A substrate processing apparatus comprises: a first solidifier and a second solidifier. The first solidifier solidifies a liquid to be solidified adhering to a front surface of a substrate by supplying a liquid refrigerant to a back surface of the substrate at a first position. The second solidifier solidifies the liquid to be solidified by at least one of a first cooling mechanism and a second cooling mechanism. The first cooling mechanism cools the liquid to be solidified by supplying a gas refrigerant toward the substrate at a second position more distant from a center of rotation of the substrate in a radial direction than the first position. The second cooling mechanism cools the liquid to be solidified by bringing a processing surface into contact with the liquid to be solidified at the second position.

Owner:DAINIPPON SCREEN MTG CO LTD

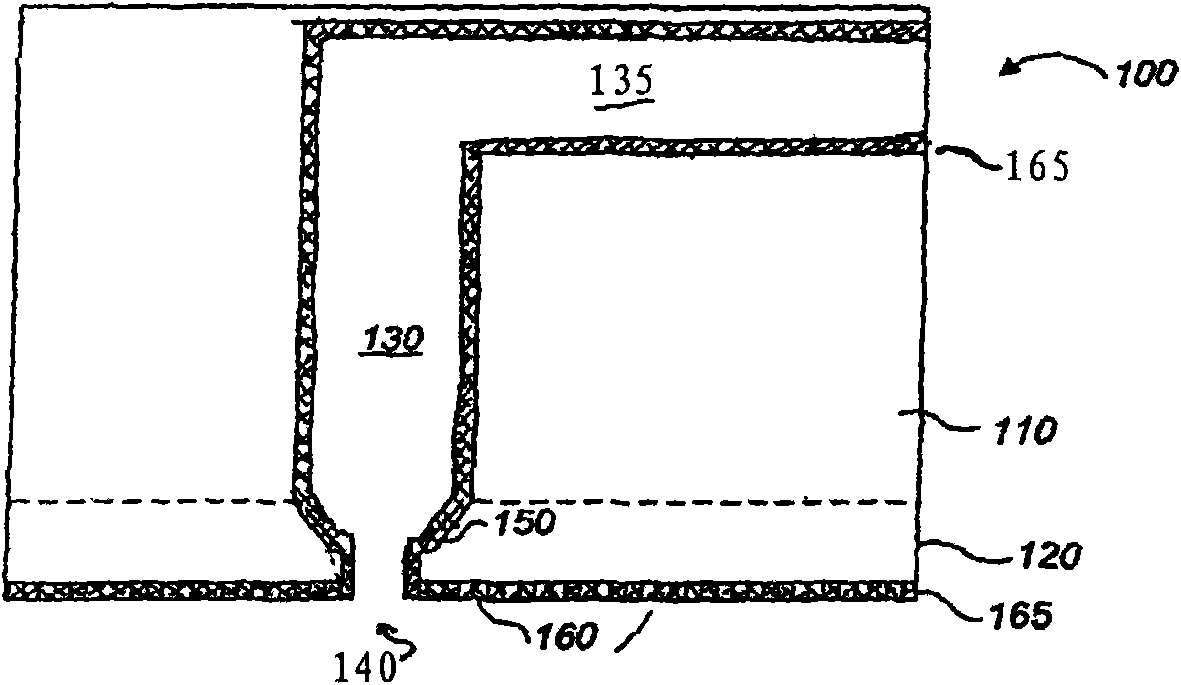

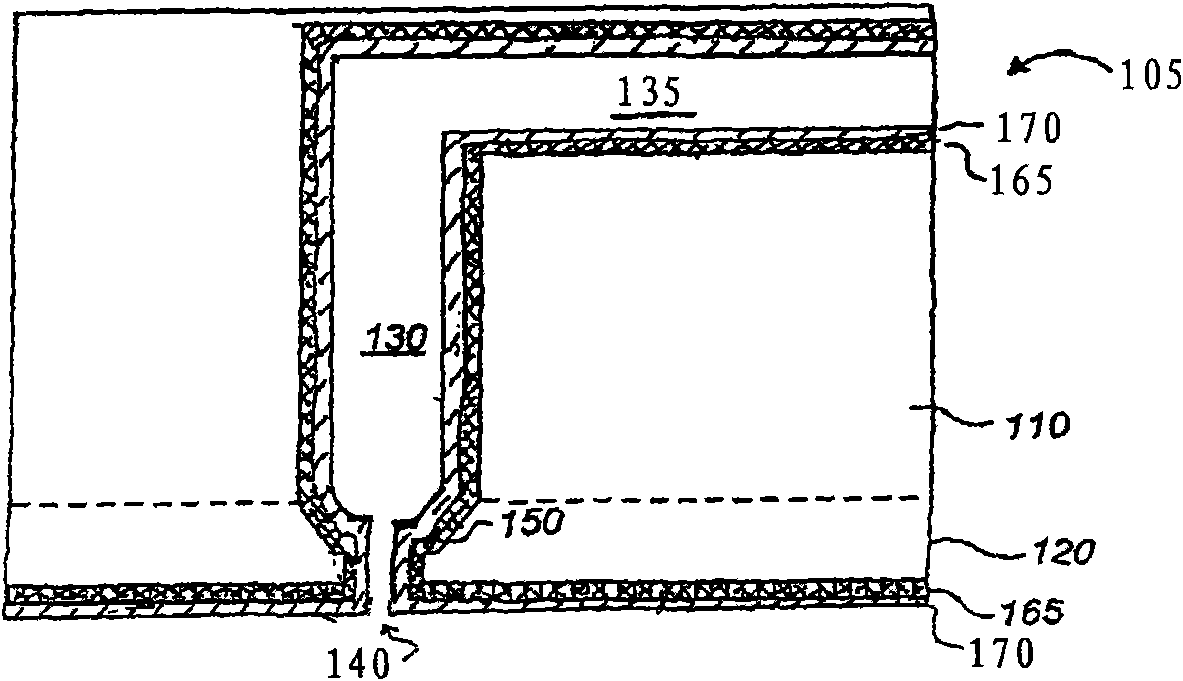

Non-wetting coating on a fluid ejector

Owner:FUJIFILM DIMATIX

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap