Method of, and apparatus for, filling liquid droplet ejection head with function liquid; liquid droplet ejection apparatus; electrooptic device; method of manufacturing electrooptic device; and electronic apparatus

a technology of function liquid and which is applied in the field of filling the liquid droplet ejection head of the ink jet system with a function liquid, can solve the problems of poor ejection from the nozzle, wasteful consumption of expensive function liquid, and air bubbles that cannot be easily discharged toward the nozzle by the liquid feeding under positive pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082]With reference to the accompanying drawings, a description will now be made about the method of, and an apparatus for, filling a liquid droplet ejection head with a function liquid, and a liquid droplet ejection apparatus. This liquid droplet ejection apparatus is to be built into a line of manufacturing a flat panel display such as an organic electroluminescence (EL) device, or the like. An image (or picture) drawing is made with an ink jet system by selectively ejecting from a liquid droplet ejection apparatus a function liquid such as a filter material, an emitting material, or the like, toward a substrate (workpiece). A predetermined film forming part is thus formed on the substrate.

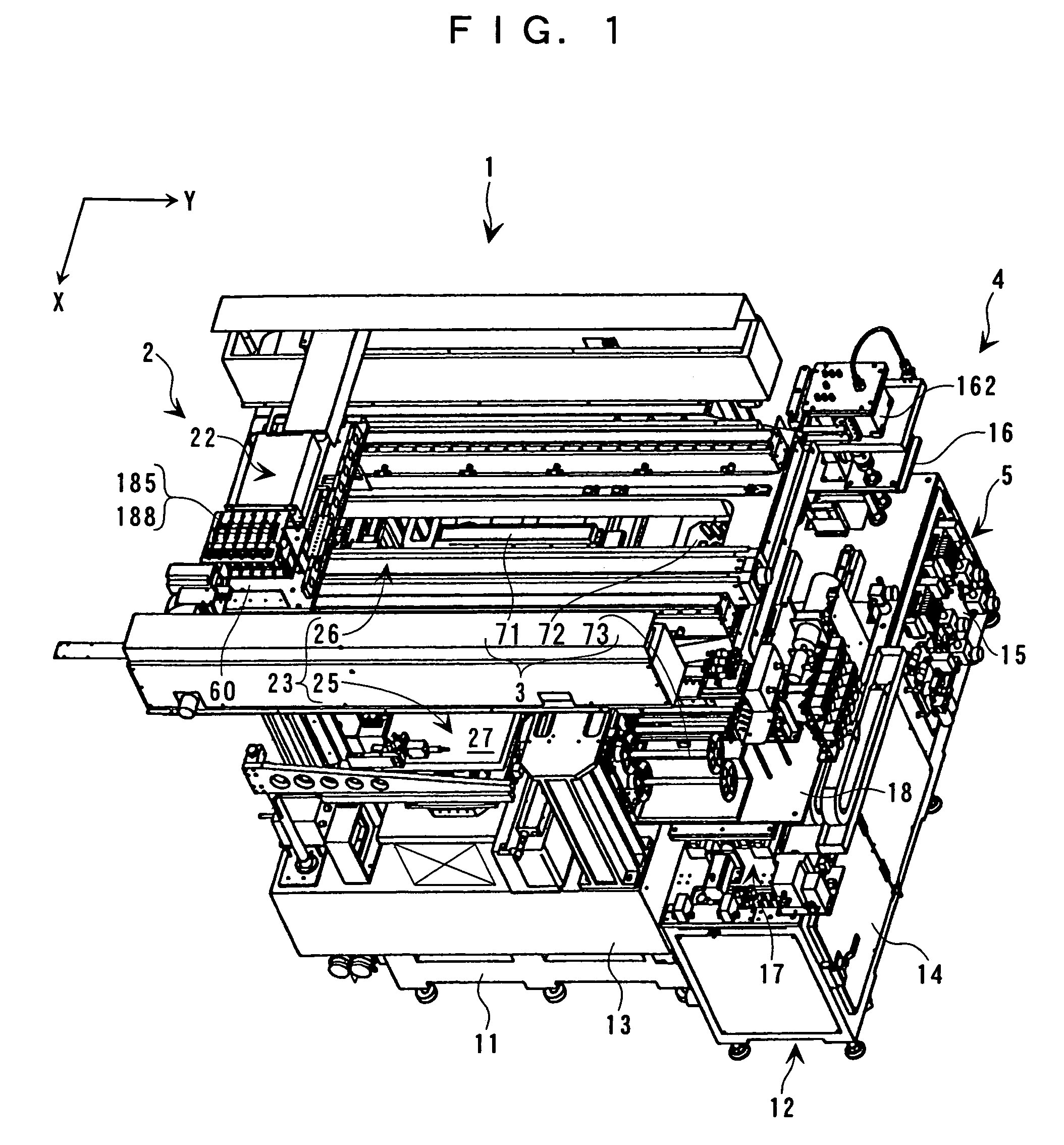

[0083]As shown in FIGS. 1 through 4, the liquid droplet ejection apparatus 1 is made up of: ejecting means 2 which has liquid droplet ejection heads 20 as shown in FIGS. 6A and 6B and which ejects function liquids; maintenance means 3 which performs maintenance work of the liquid droplet ejection

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap