Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104results about "Other printing apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

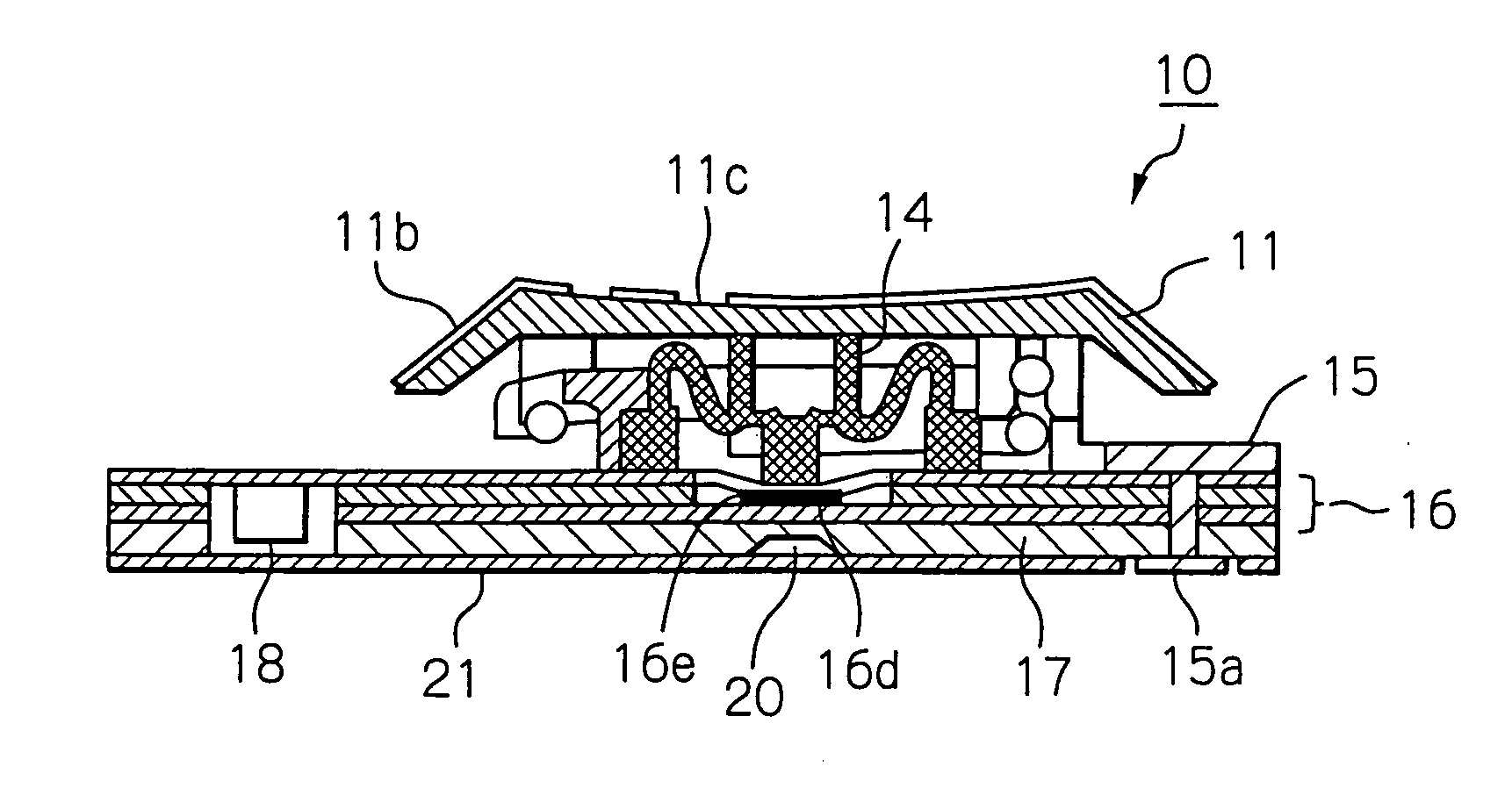

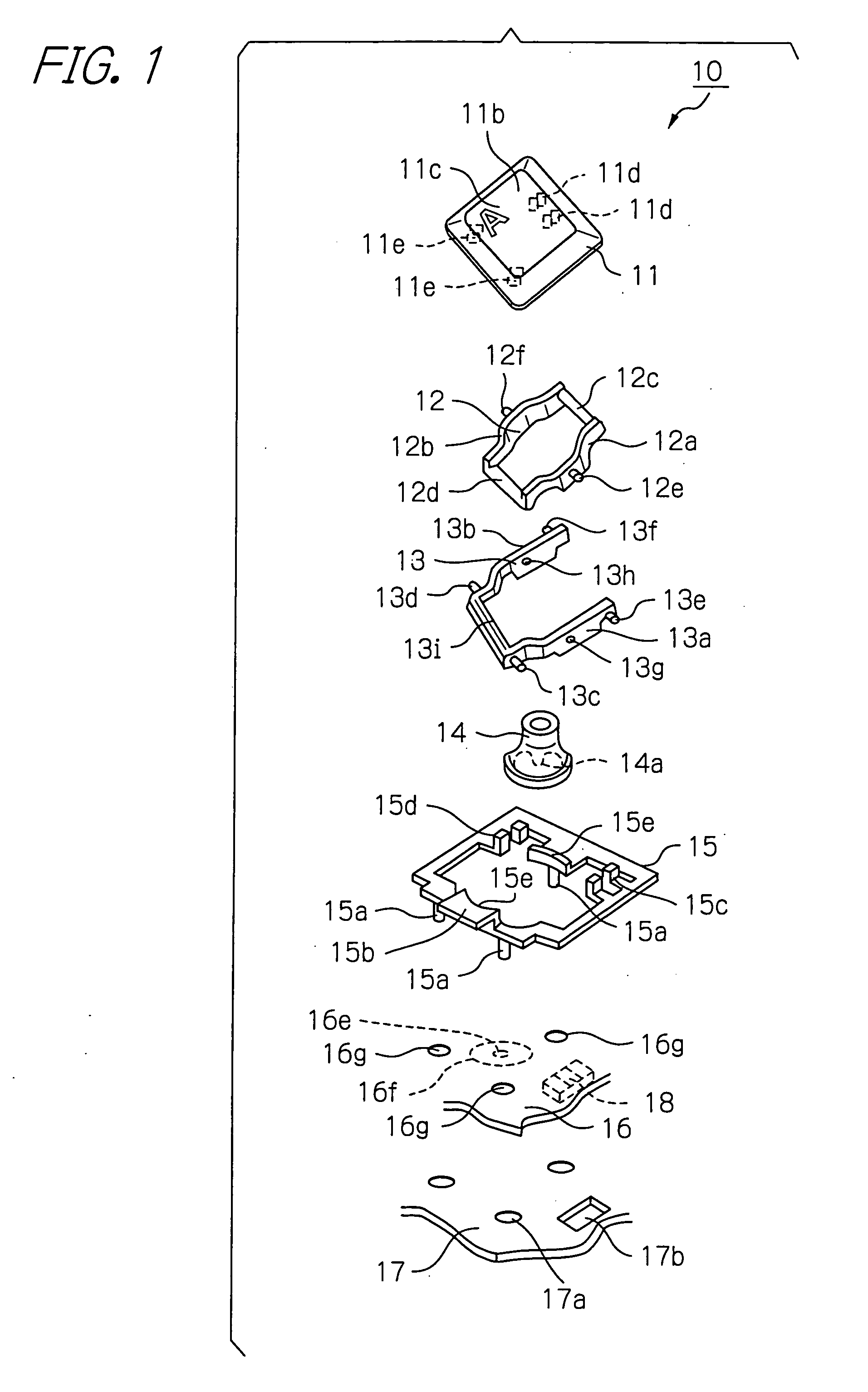

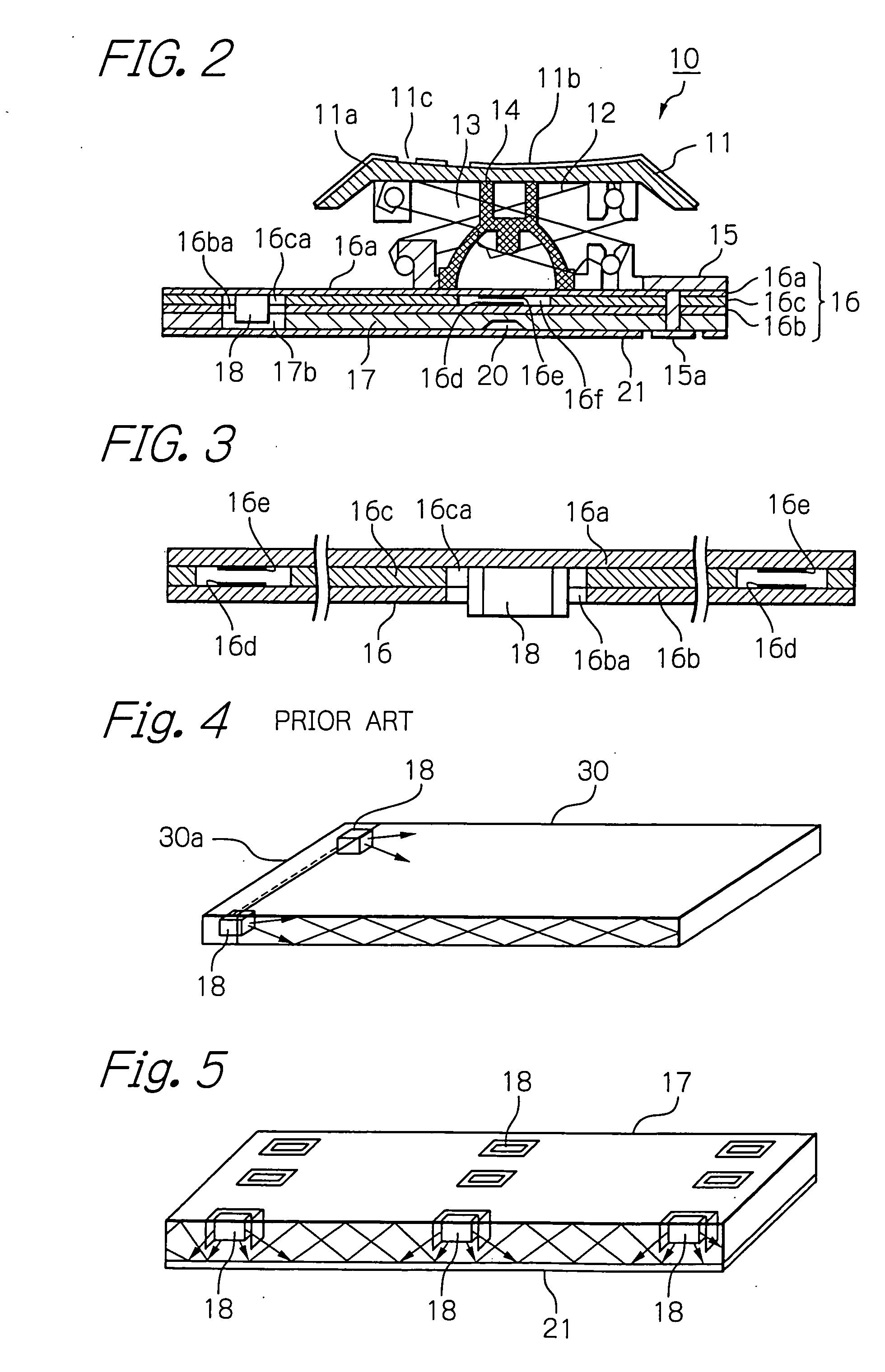

Key switch arrangement having an illuminating function

InactiveUS20090103964A1Reduce the overall heightLow costEmergency actuatorsContact mechanismsEngineeringKey switch

Owner:OKI ELECTRIC IND CO LTD

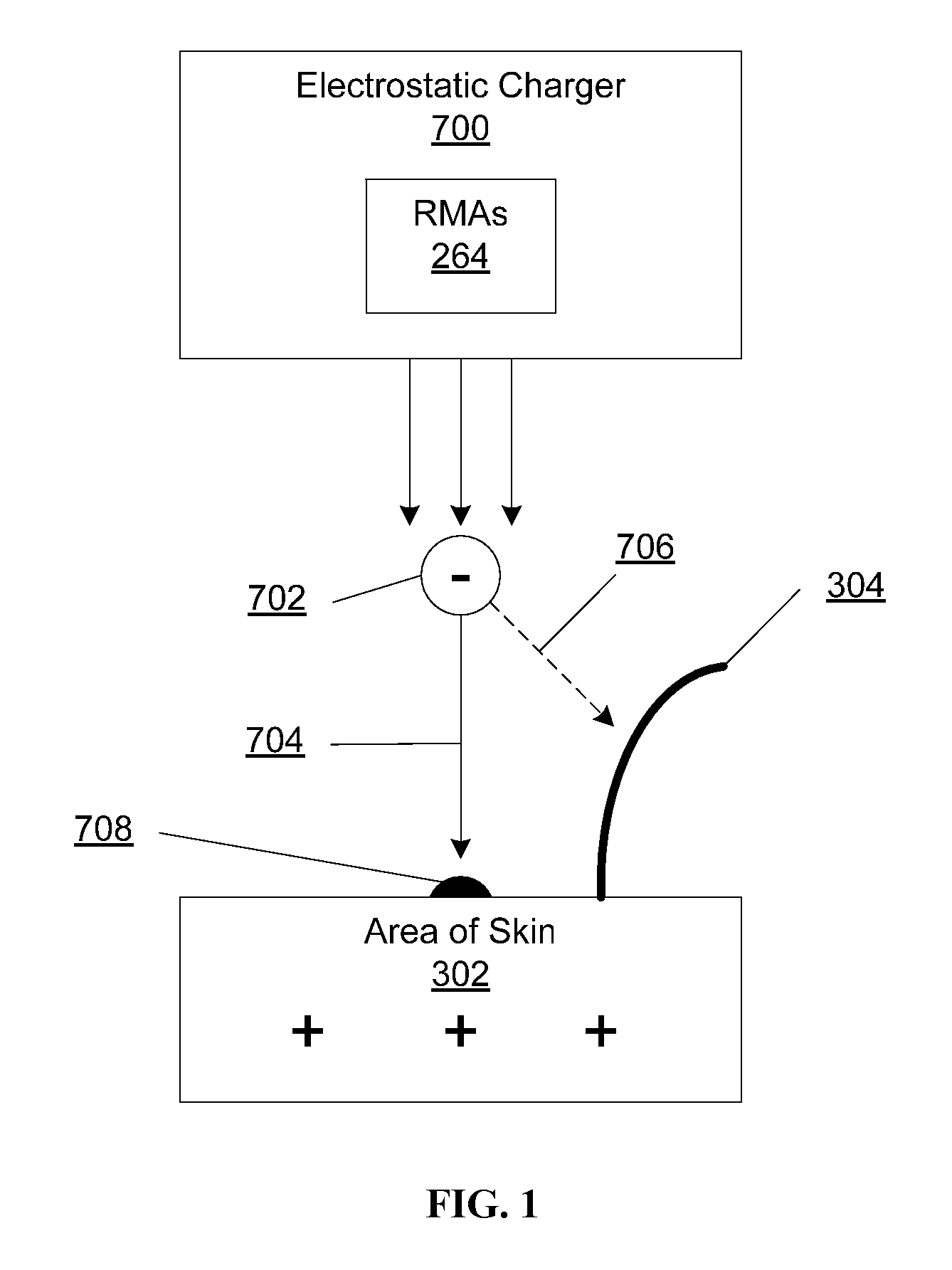

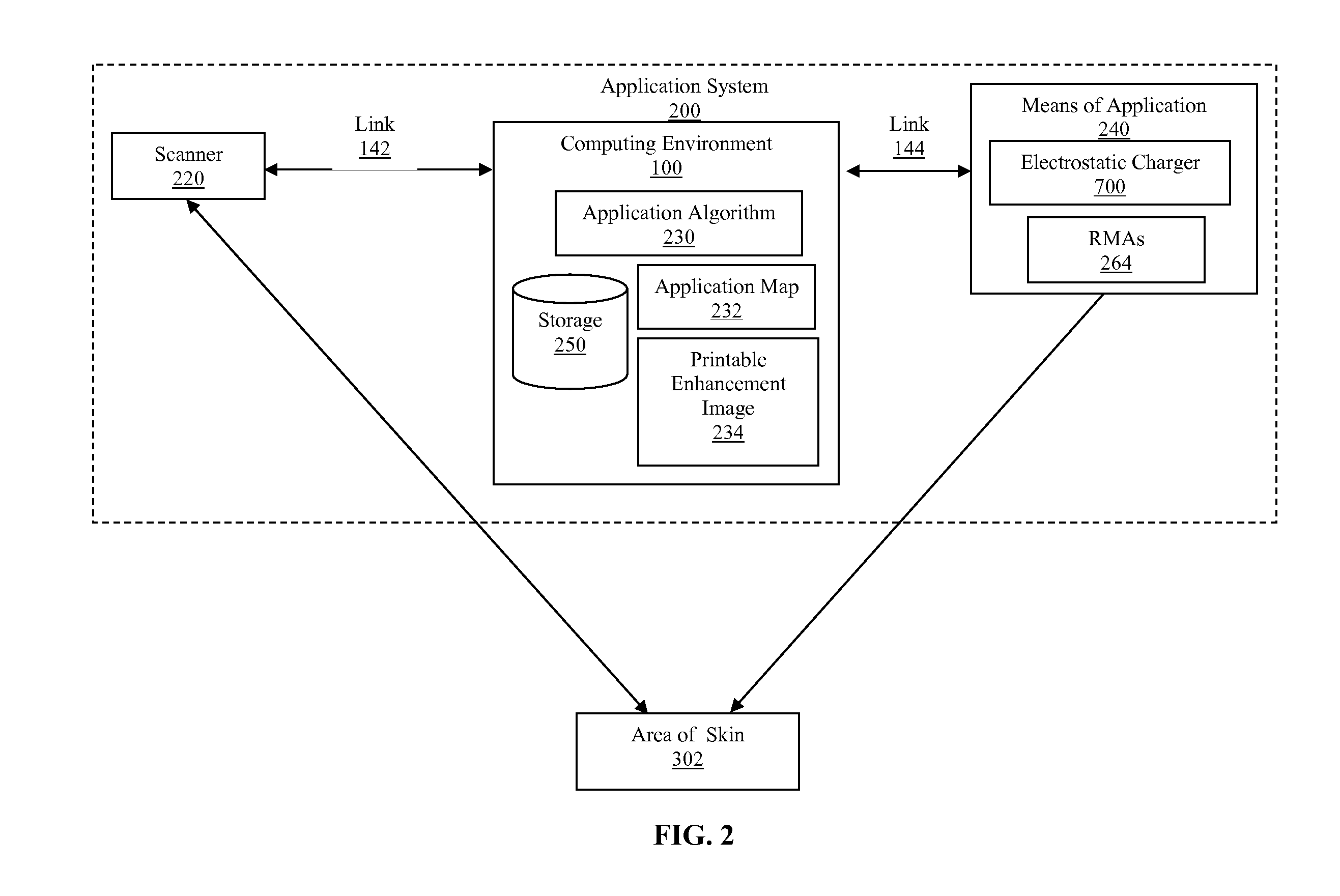

System and method for applying a reflectance modifying agent electrostatically to improve the visual attractiveness of human skin

ActiveUS20080194971A1Enhanced surface irregularityTypewritersMedical applicatorsComputer control systemHuman skin

Owner:TCMS TRANSPARENT BEAUTY LLC

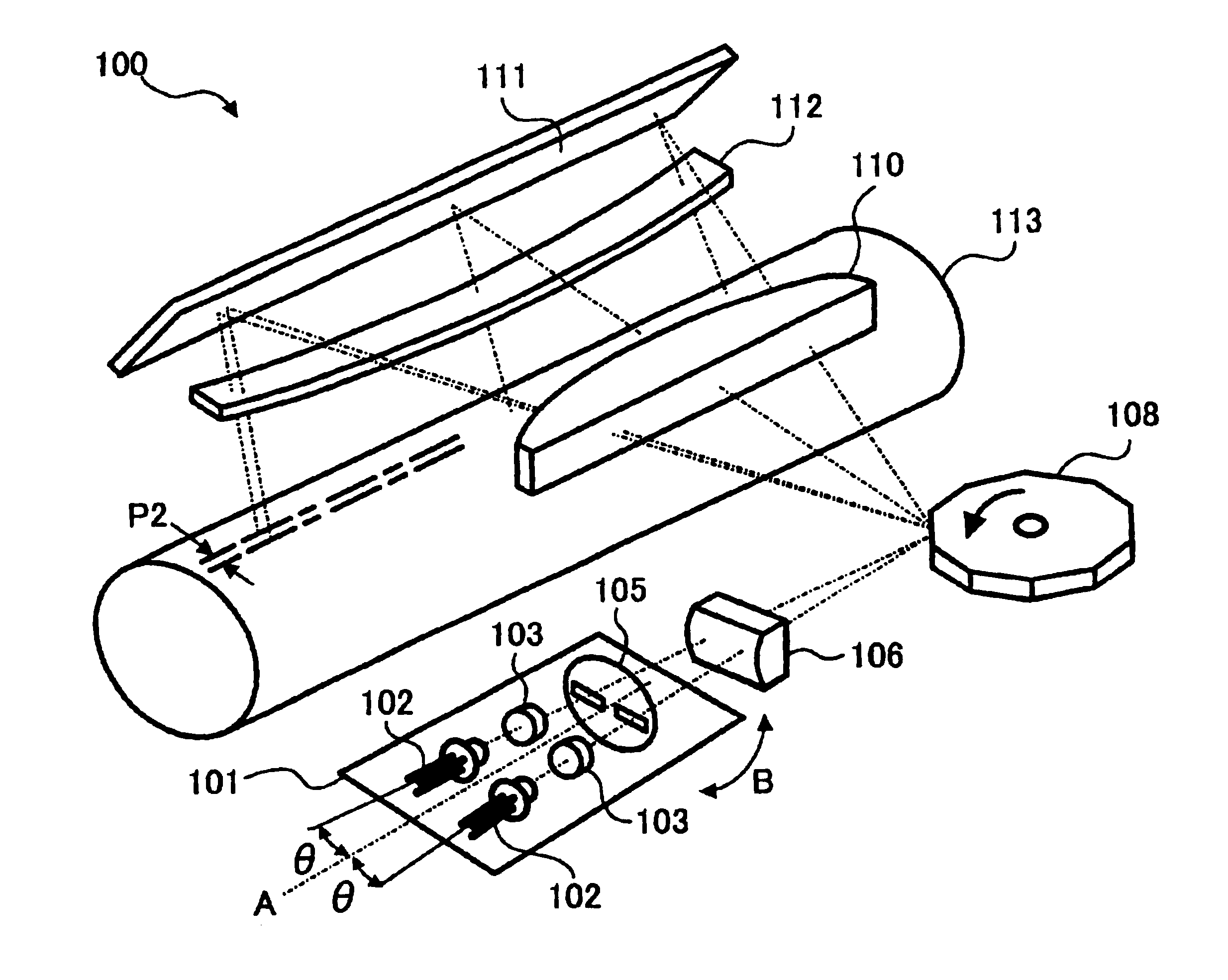

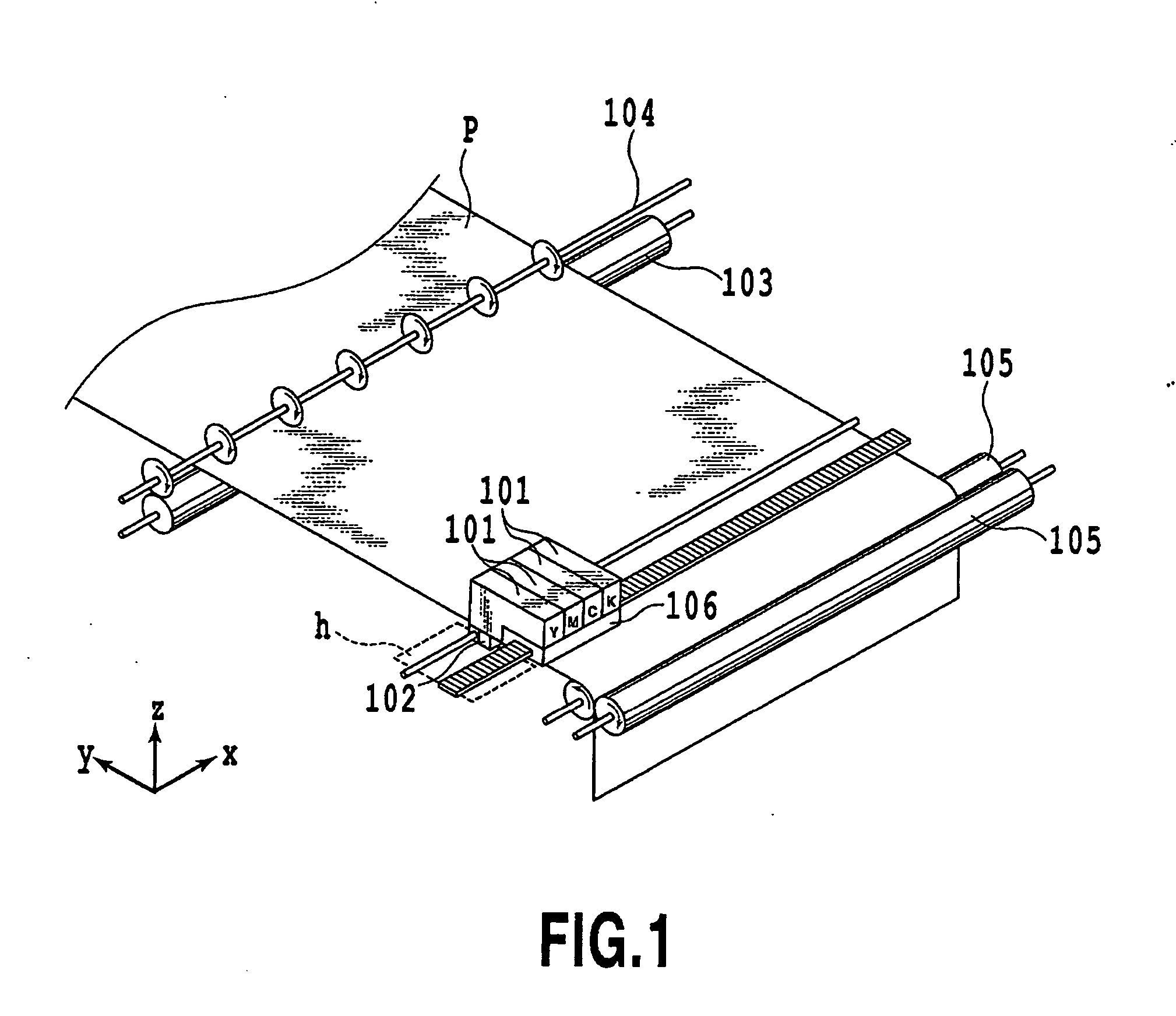

Method and apparatus for multi-beam optical scanning capable of effectively adjusting a scanning line pitch

Owner:RICOH KK

Recording apparatus and method of controlling air releasing valve in drying section of the recording apparatus

Owner:SEIKO EPSON CORP

Systems for the prevention or treatment of carpal tunnel syndrome

InactiveUS6852067B2Eliminate pressurePrevent and relieve symptomSubsonic/sonic/ultrasonic wave measurementGymnastic exercisingElectricityCTS - Carpal tunnel syndrome

Apparatuses and methods for preventing and / or treating carpal tunnel syndrome are disclosed. One such apparatus comprises a splint for wearing on a portion of an upper extremity of an individual, a warning mechanism carried by the splint and a switch mechanism carried by the splint and electrically coupled to the warning mechanism. The switch mechanism is operable to activate the warning mechanism upon extension or flexion of the hand beyond a predetermined range of motion and thereby alert the user of such undesirable motion of the hand.

Owner:NEUROSPECTRUM

System and method for monitoring program code

A method, apparatus, and system are provided for monitoring of system resources. According to one embodiment, a monitor server may be used to monitor system resources, to collect monitoring data associated with the resources, and to provide the monitoring data to a destination. The monitor server may include a Java Management Extensions (JMX)-based monitor server. Further, a managed bean server having a registry of managed beans may be coupled with the monitor server to facilitate the monitor server to monitor the resources.

Owner:SAP AG

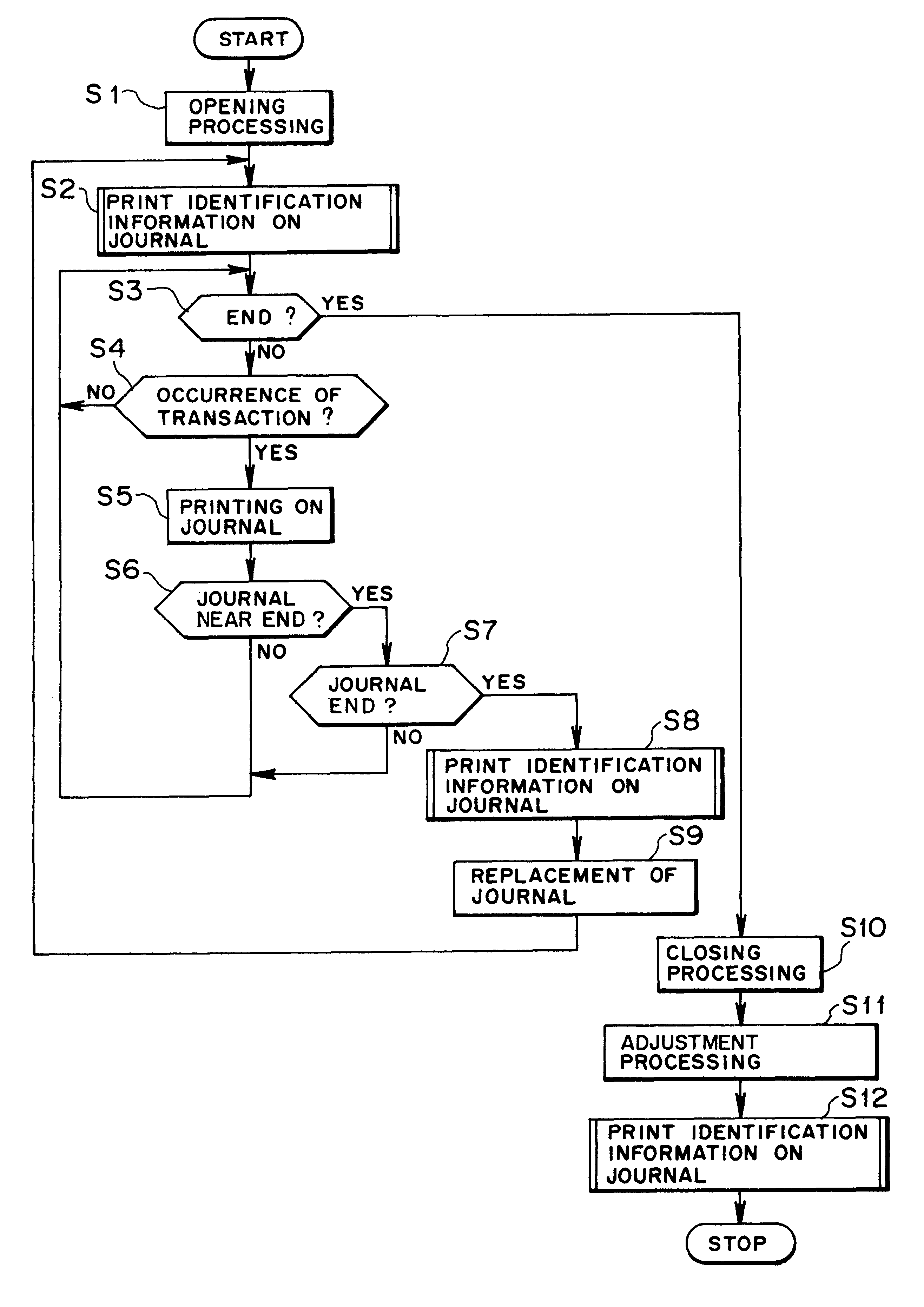

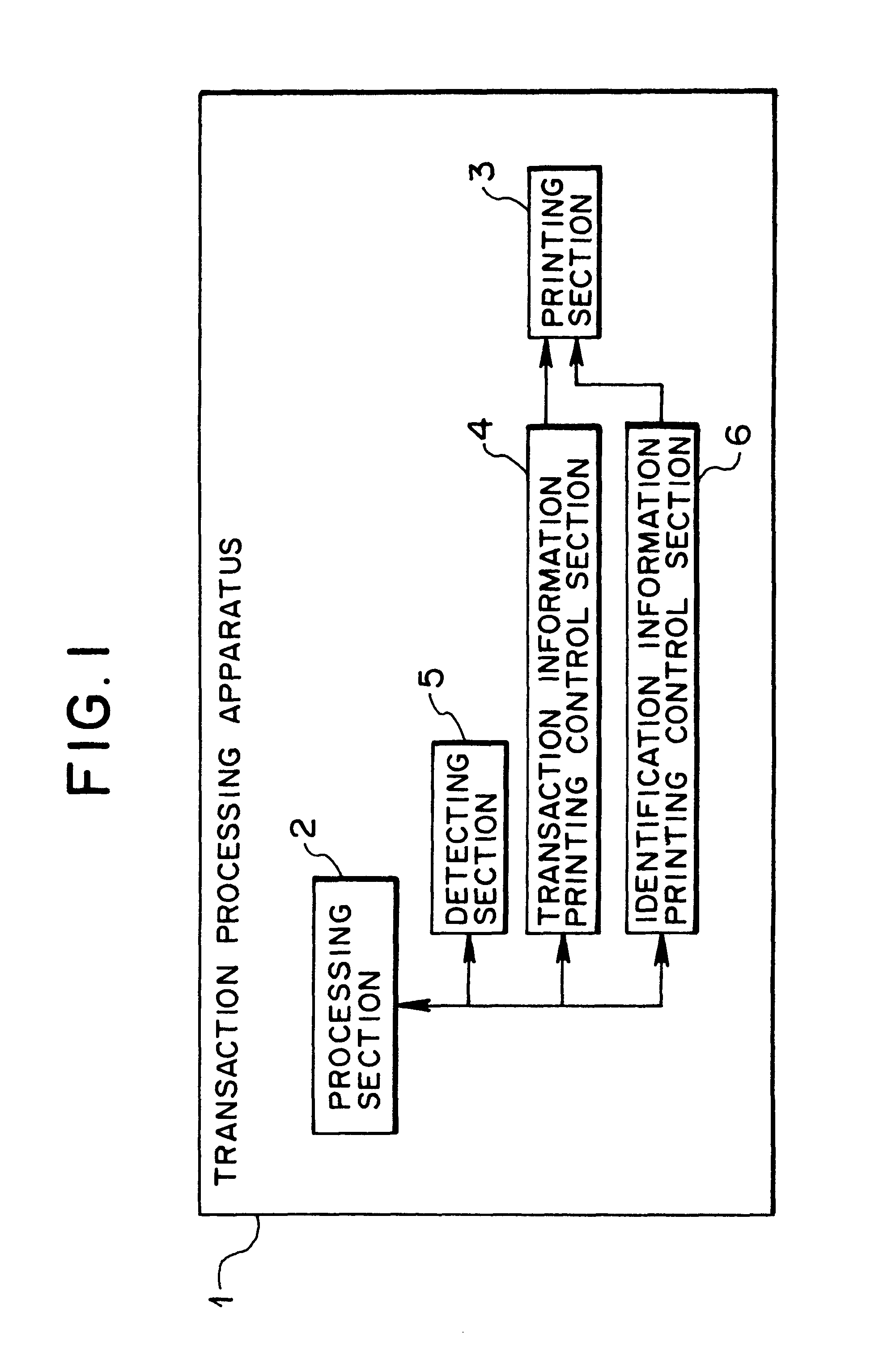

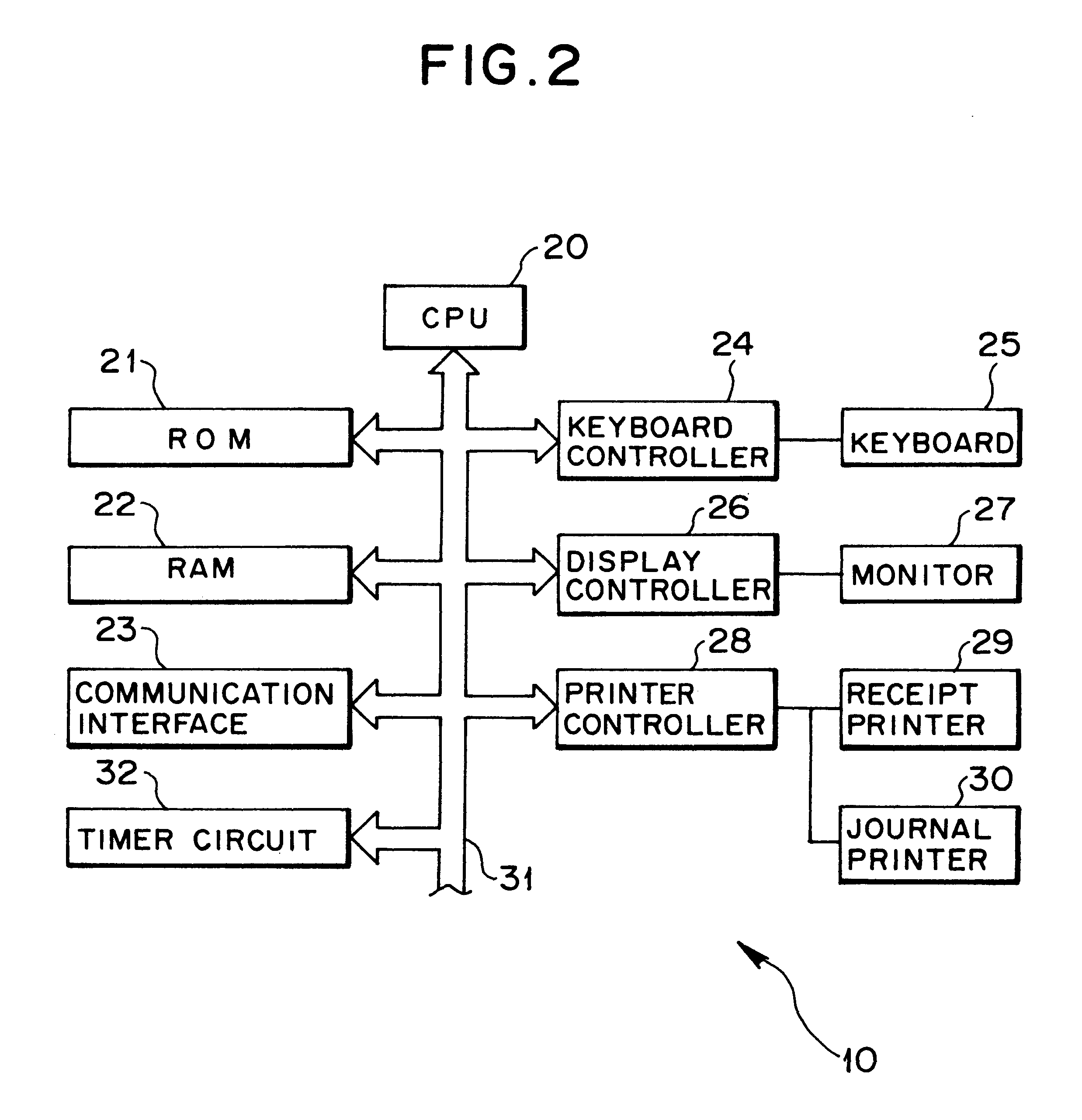

Journal form managing method, transaction processing apparatus, and transaction record journal form

InactiveUS6721613B1Shorten the timeReduce laborCoin countersPayment architectureTransaction dataDatabase

Owner:FUJITSU LTD

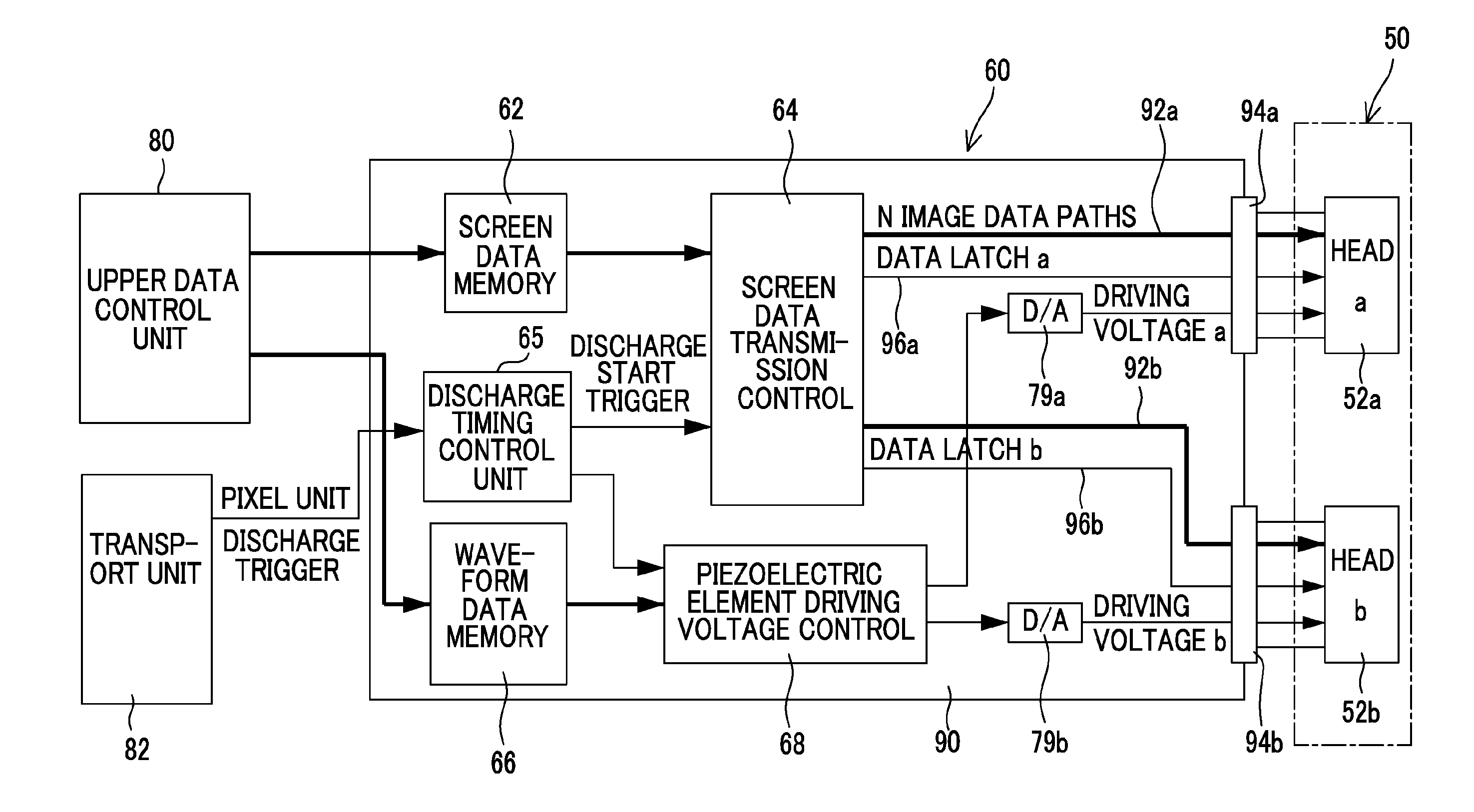

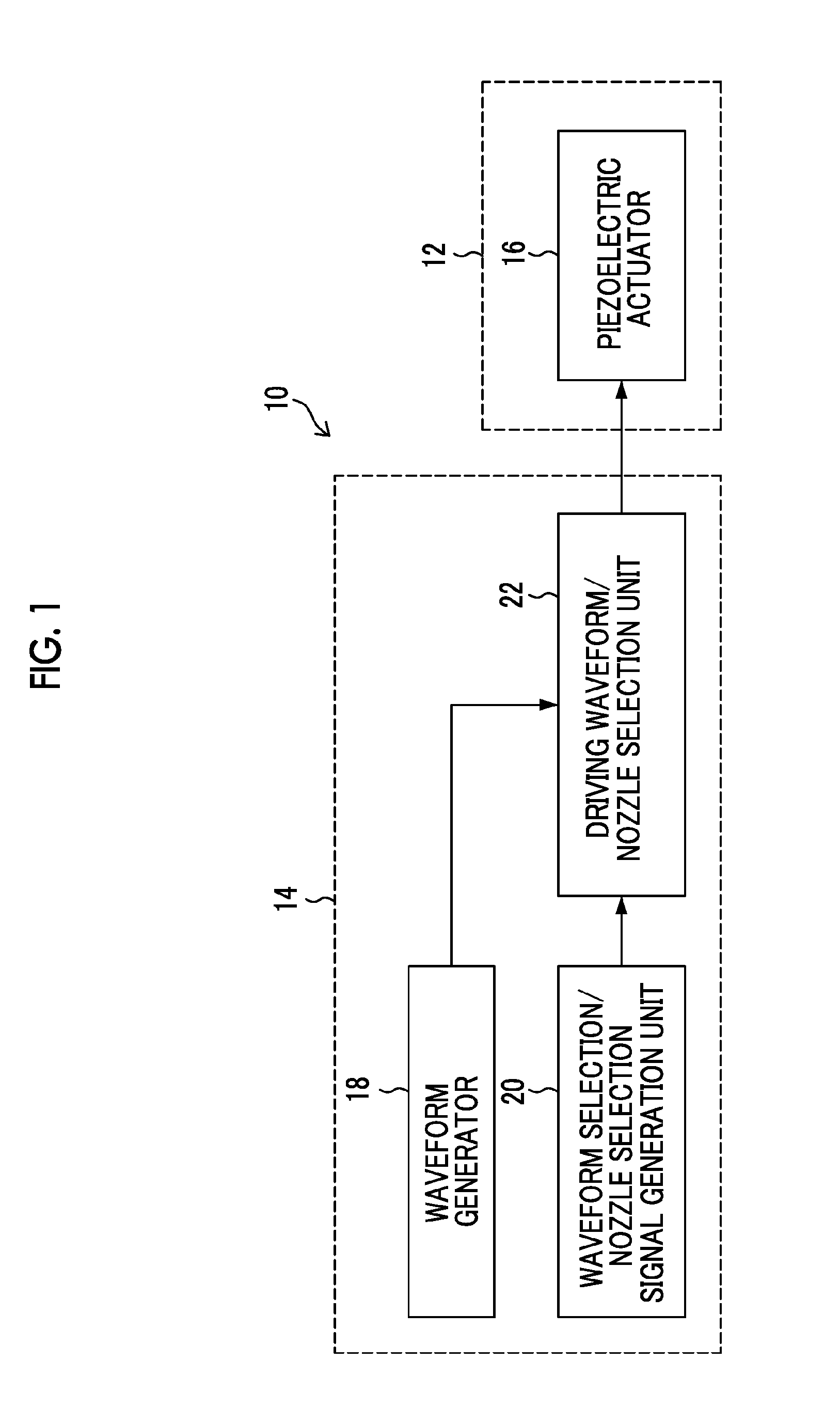

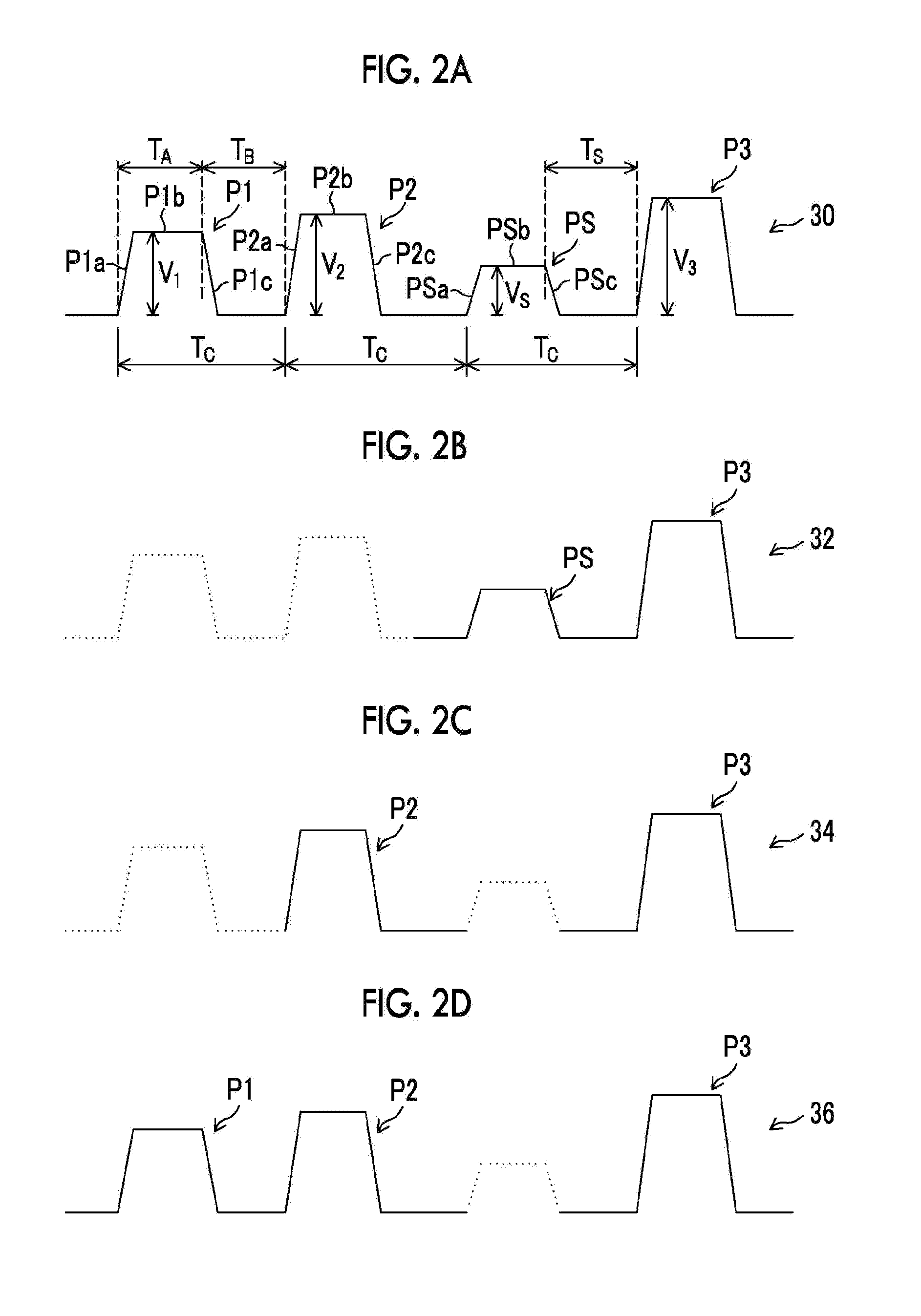

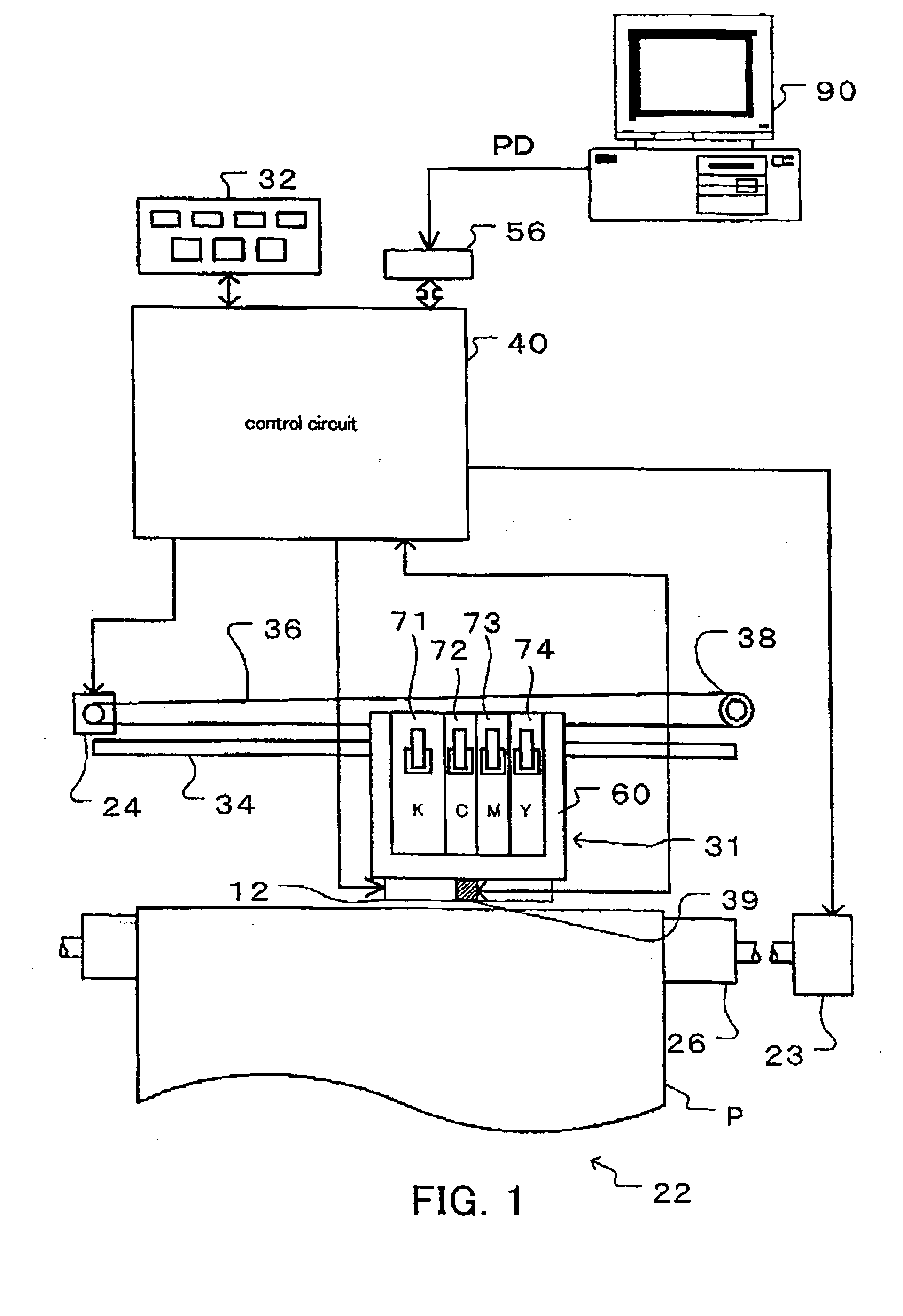

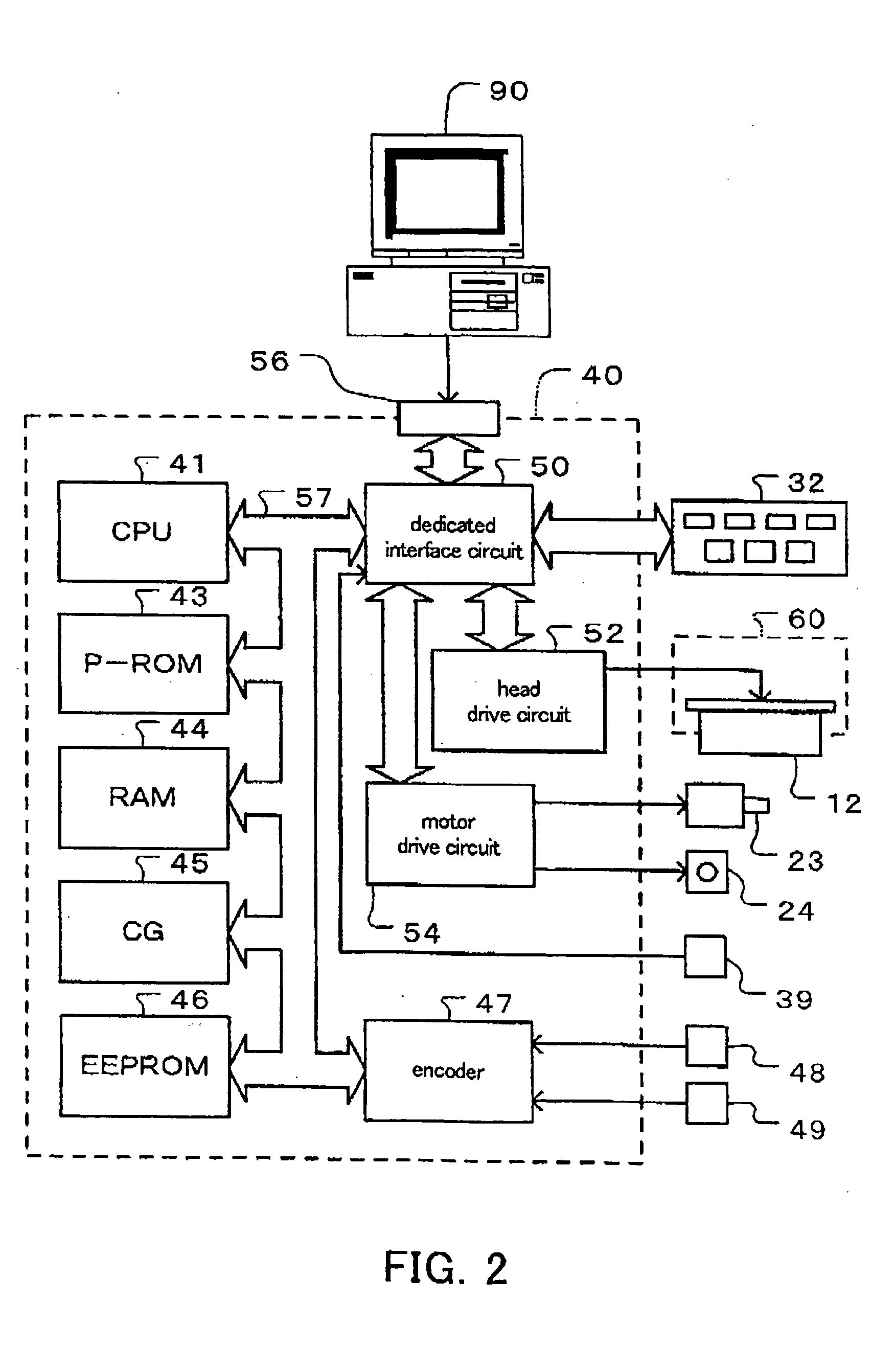

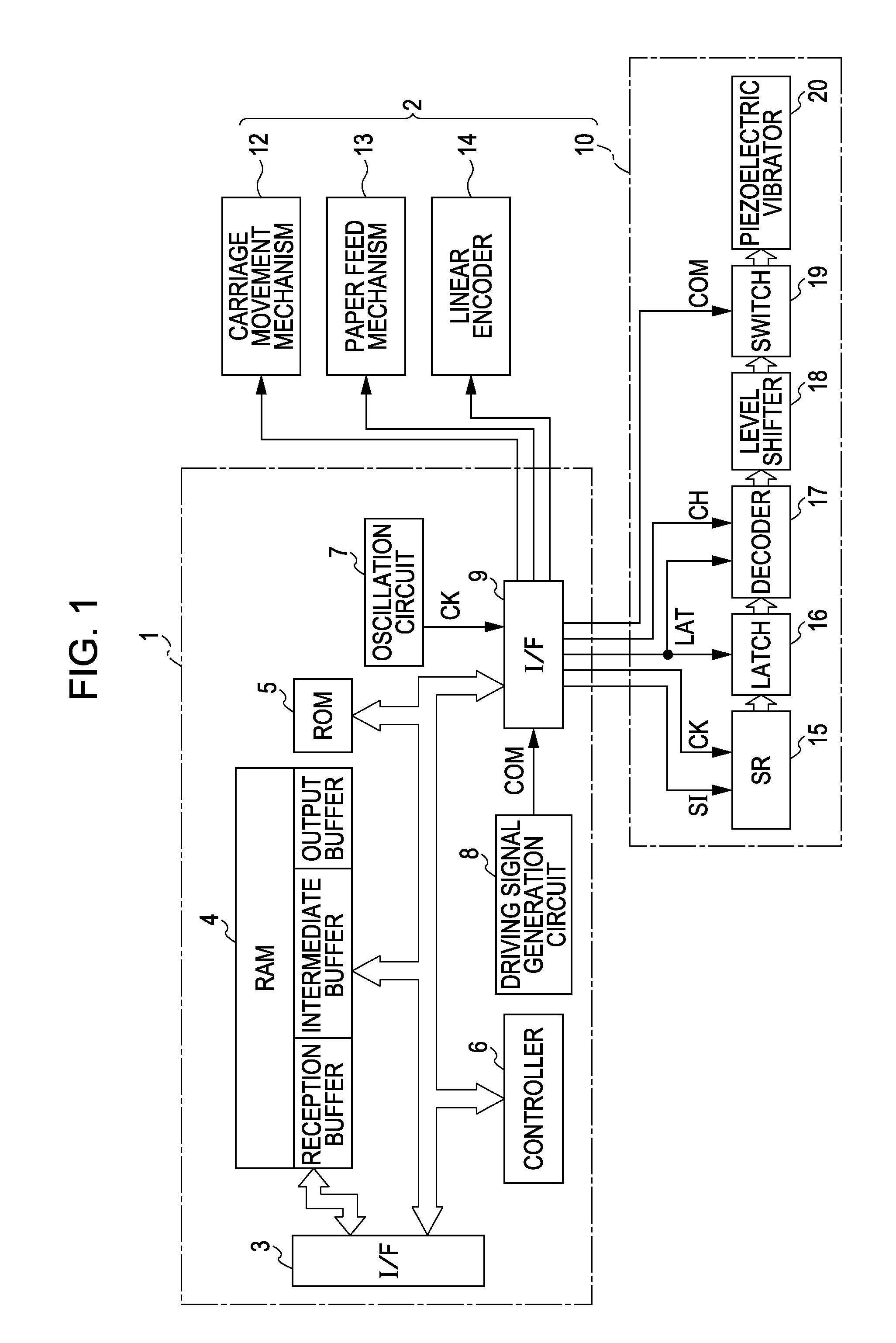

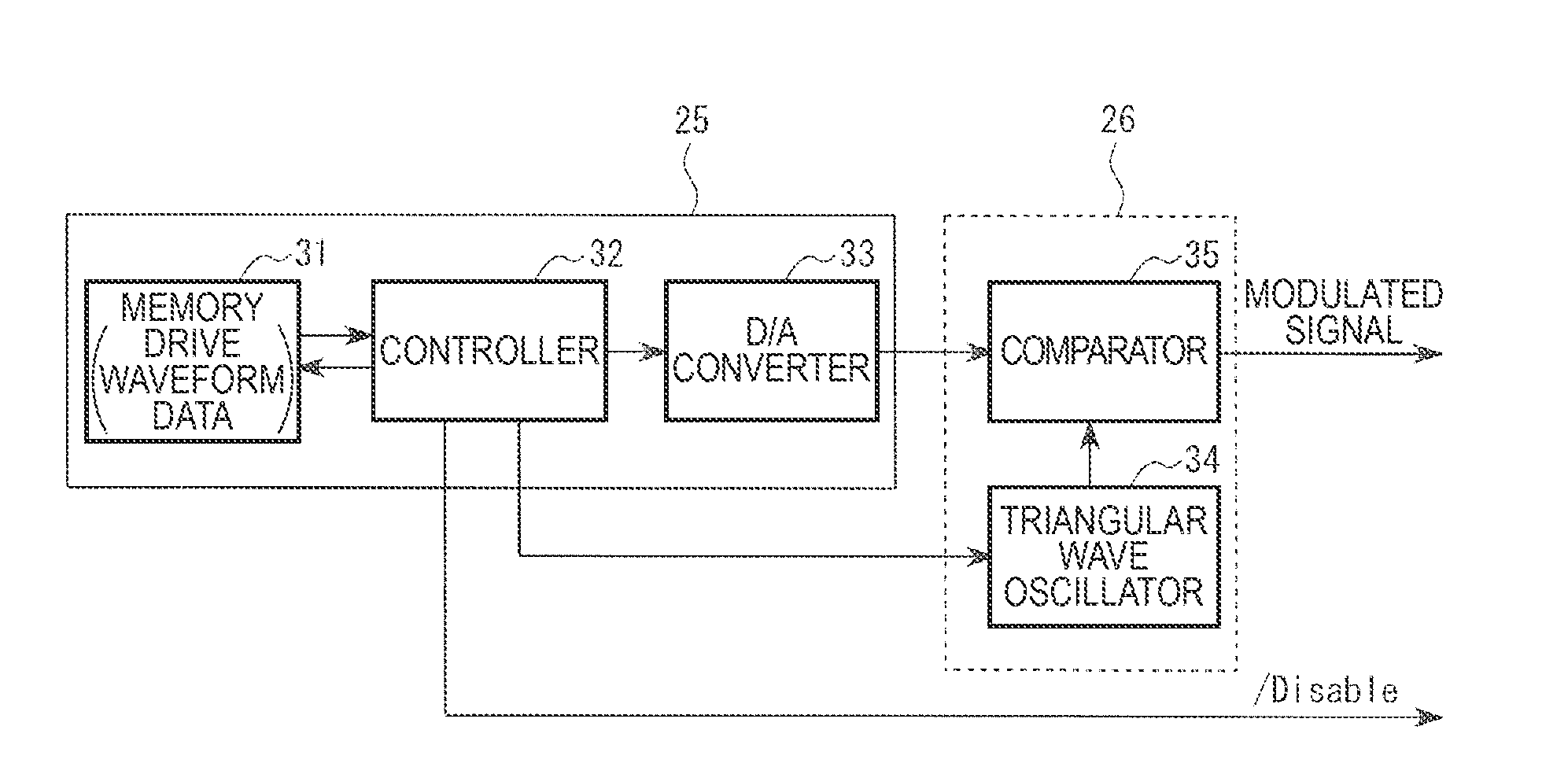

Device and method for driving liquid discharge head, liquid discharge apparatus, and ink-jet apparatus

ActiveUS20130083106A1Accurate landing positionImprove picture qualityInking apparatusOther printing apparatusElectrical and Electronics engineeringEnergy analysis

Owner:FUJIFILM CORP

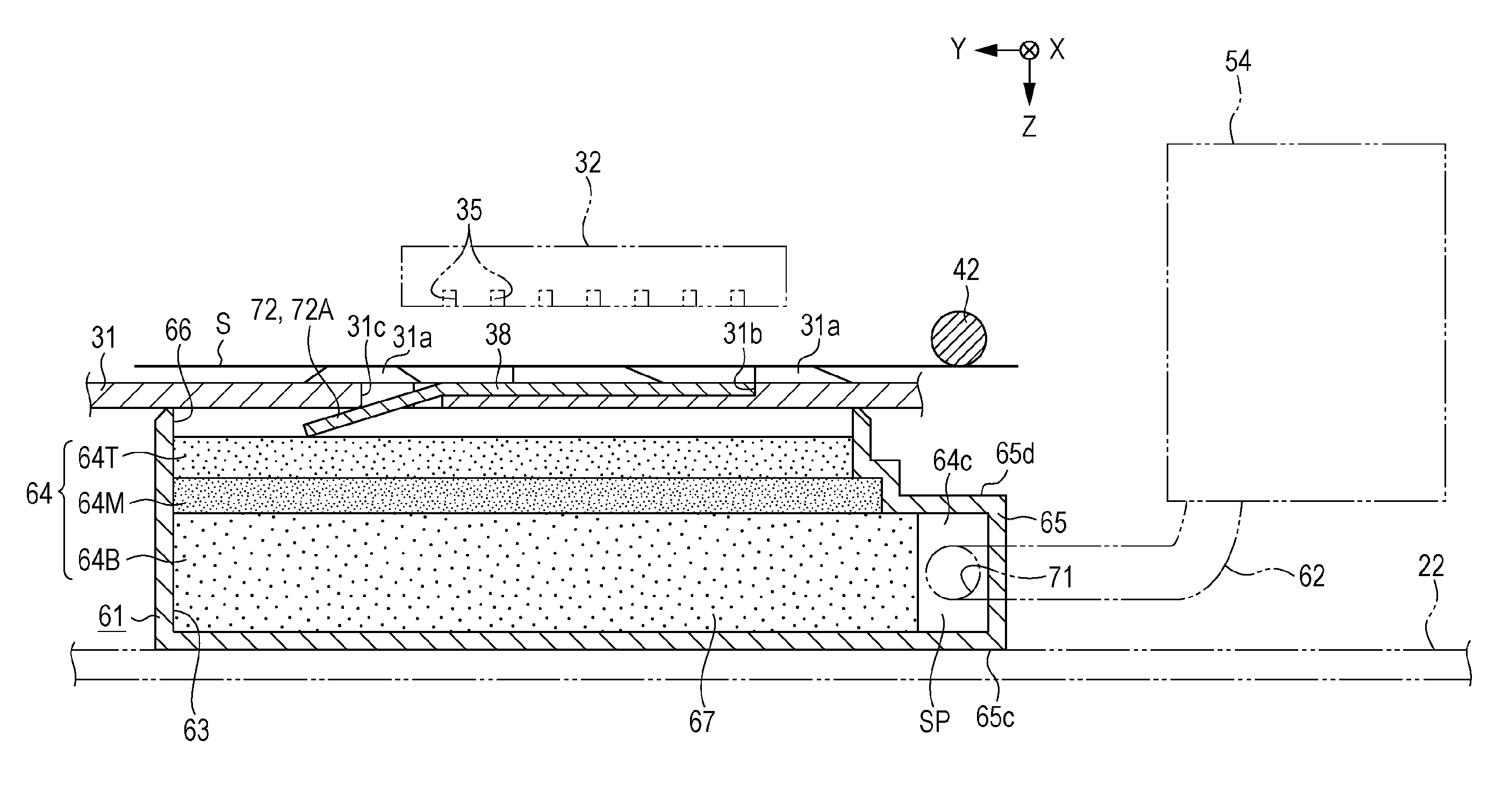

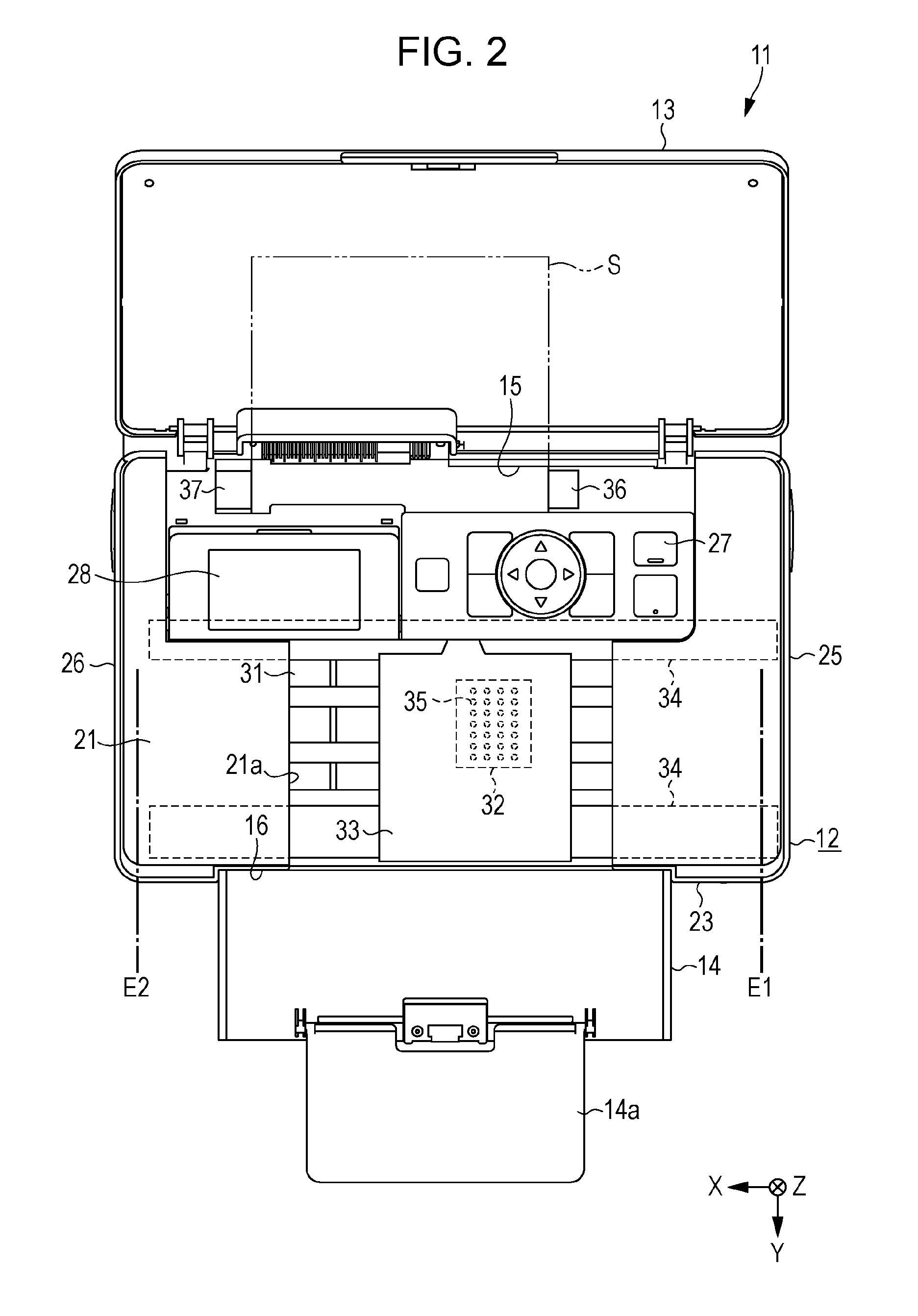

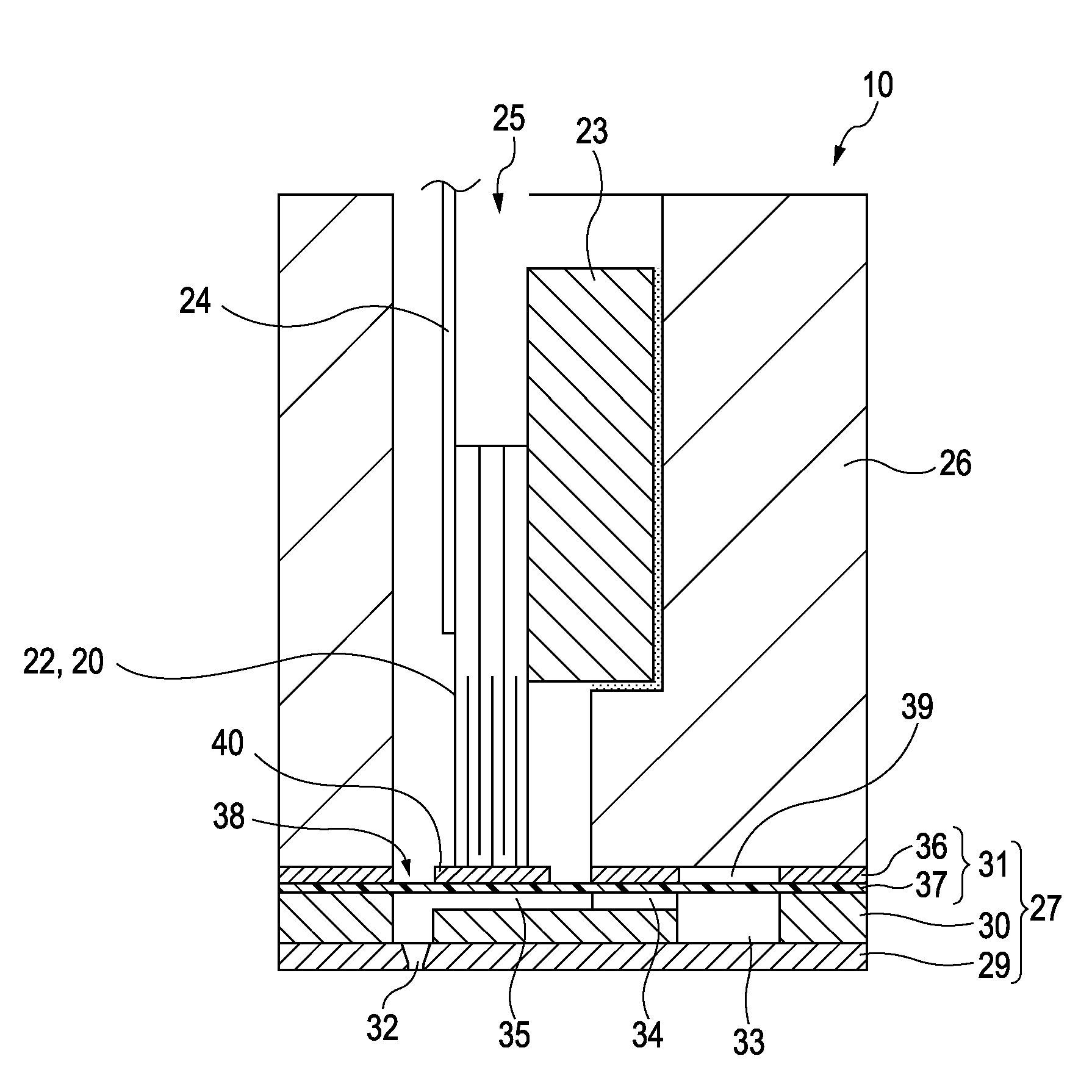

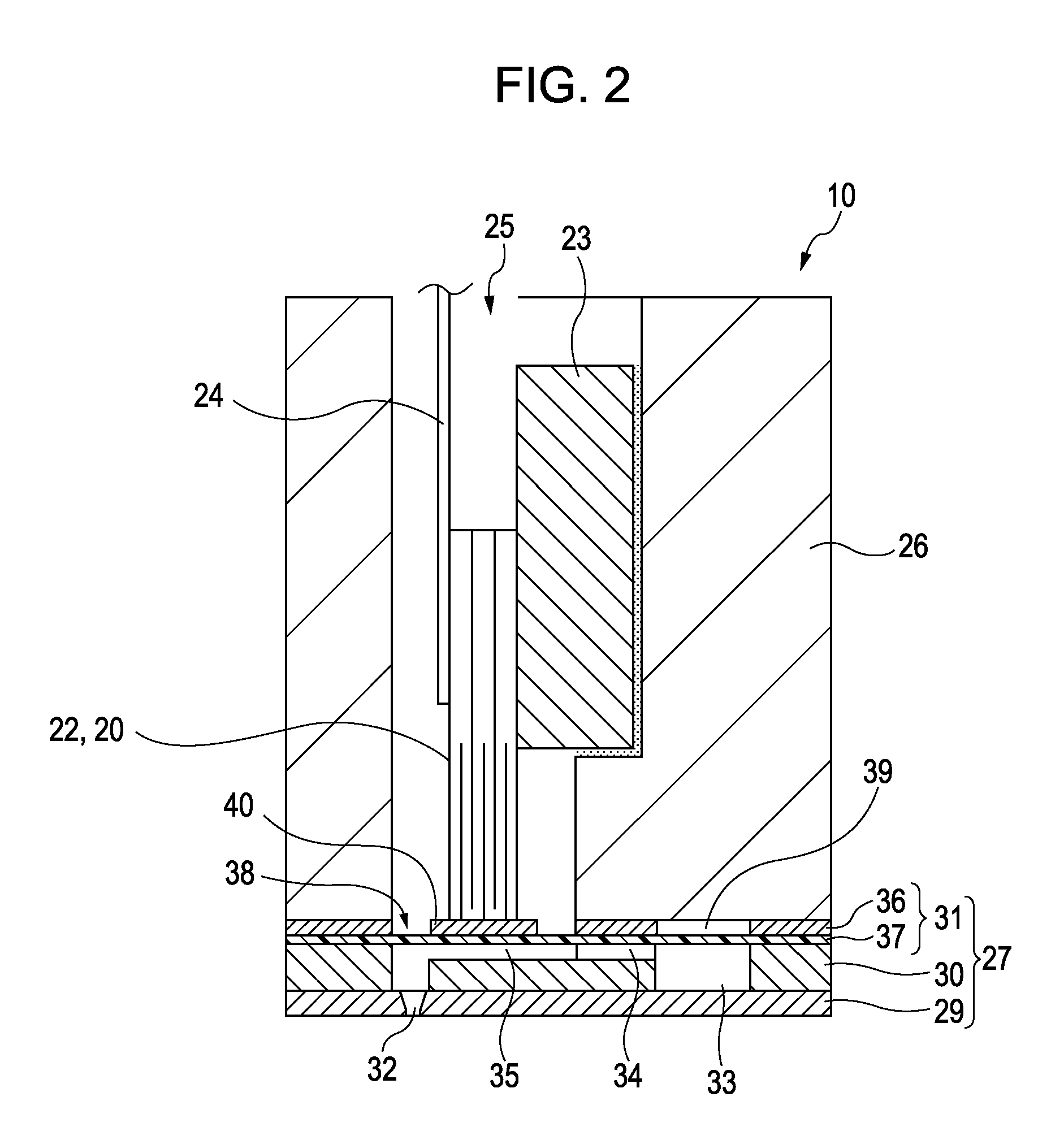

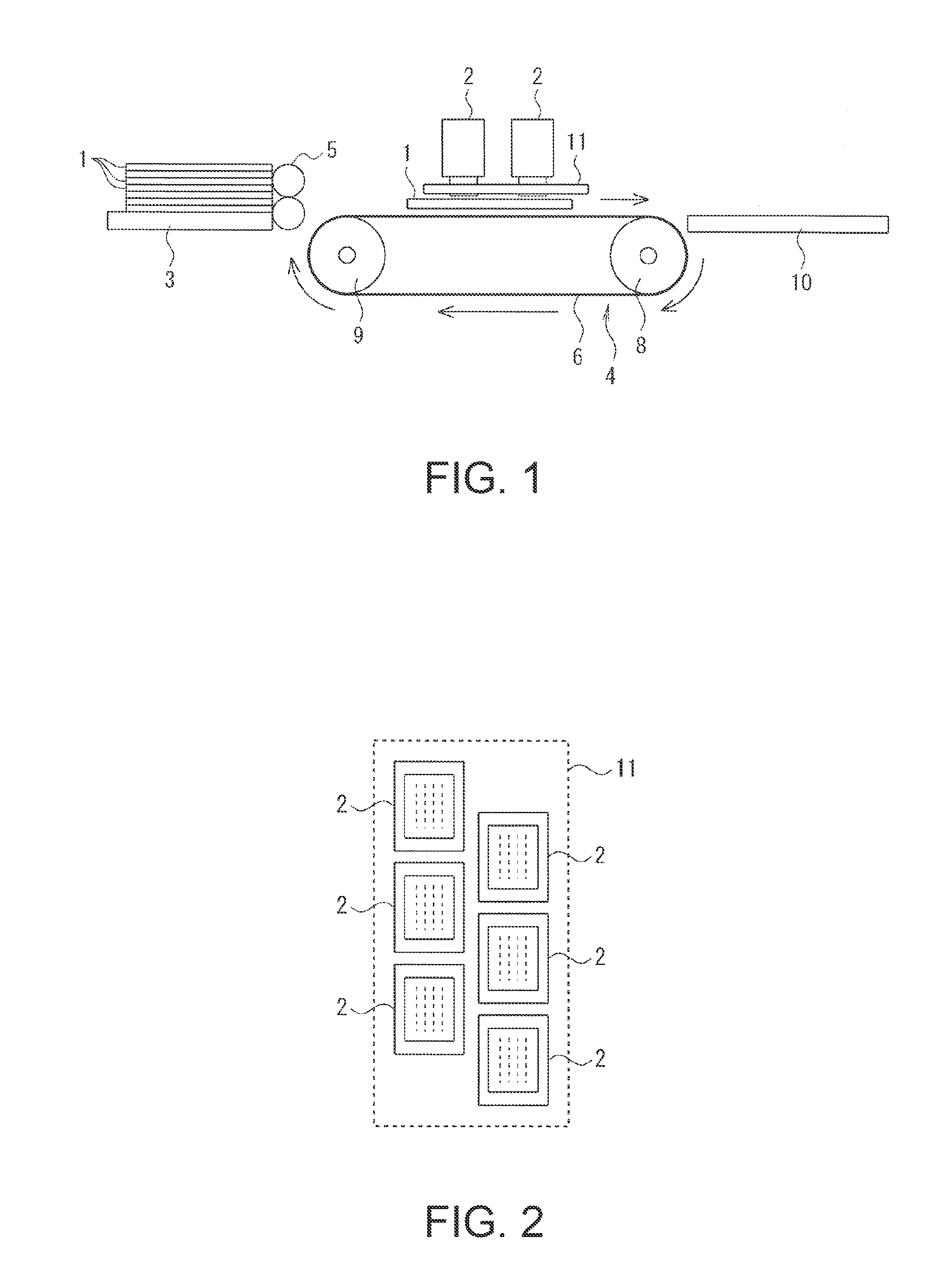

Liquid ejecting apparatus

ActiveUS20150336386A1Shorten the flow pathSuppress enlargementOther printing apparatusEngineeringWaste management

Owner:SEIKO EPSON CORP

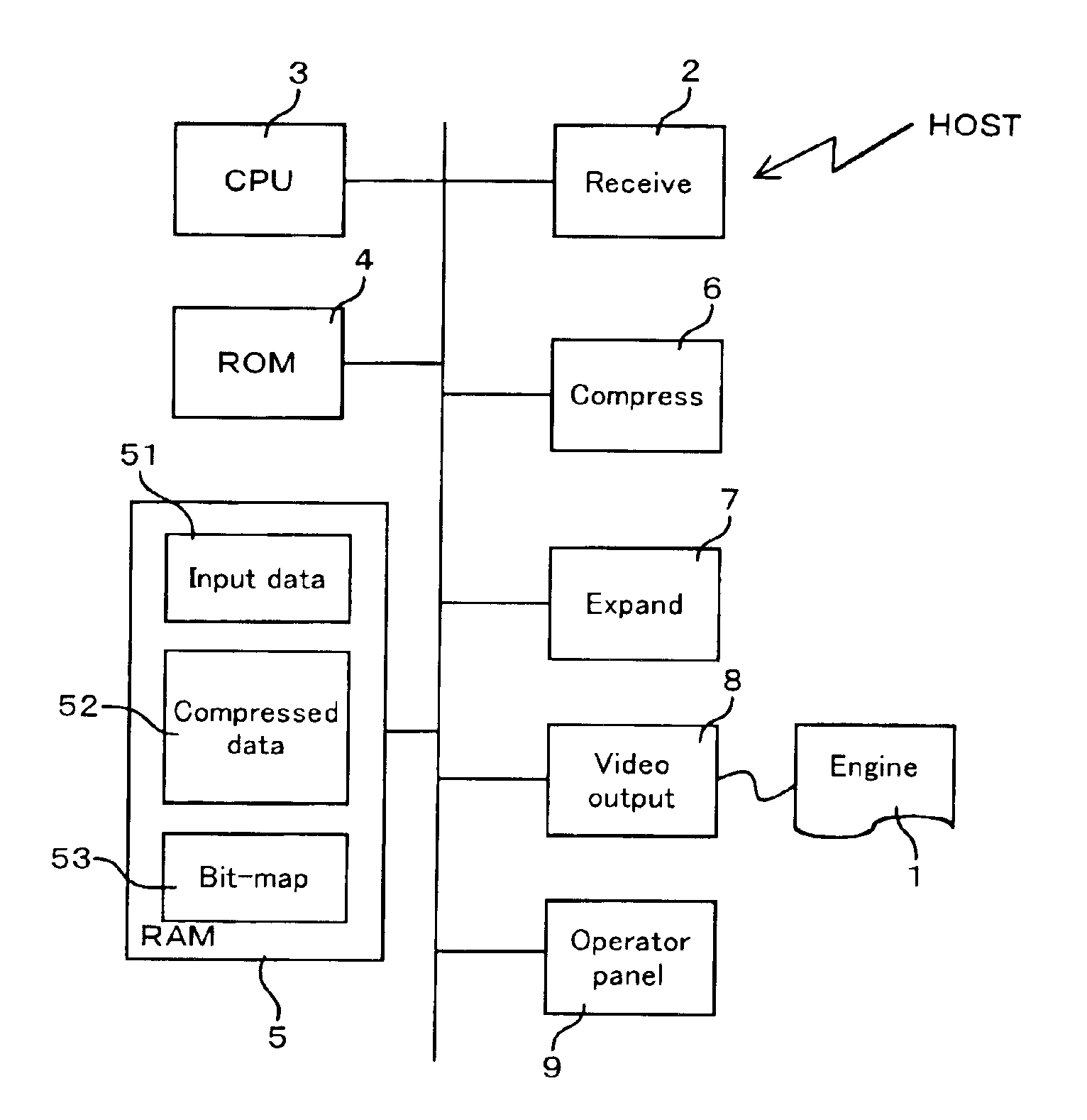

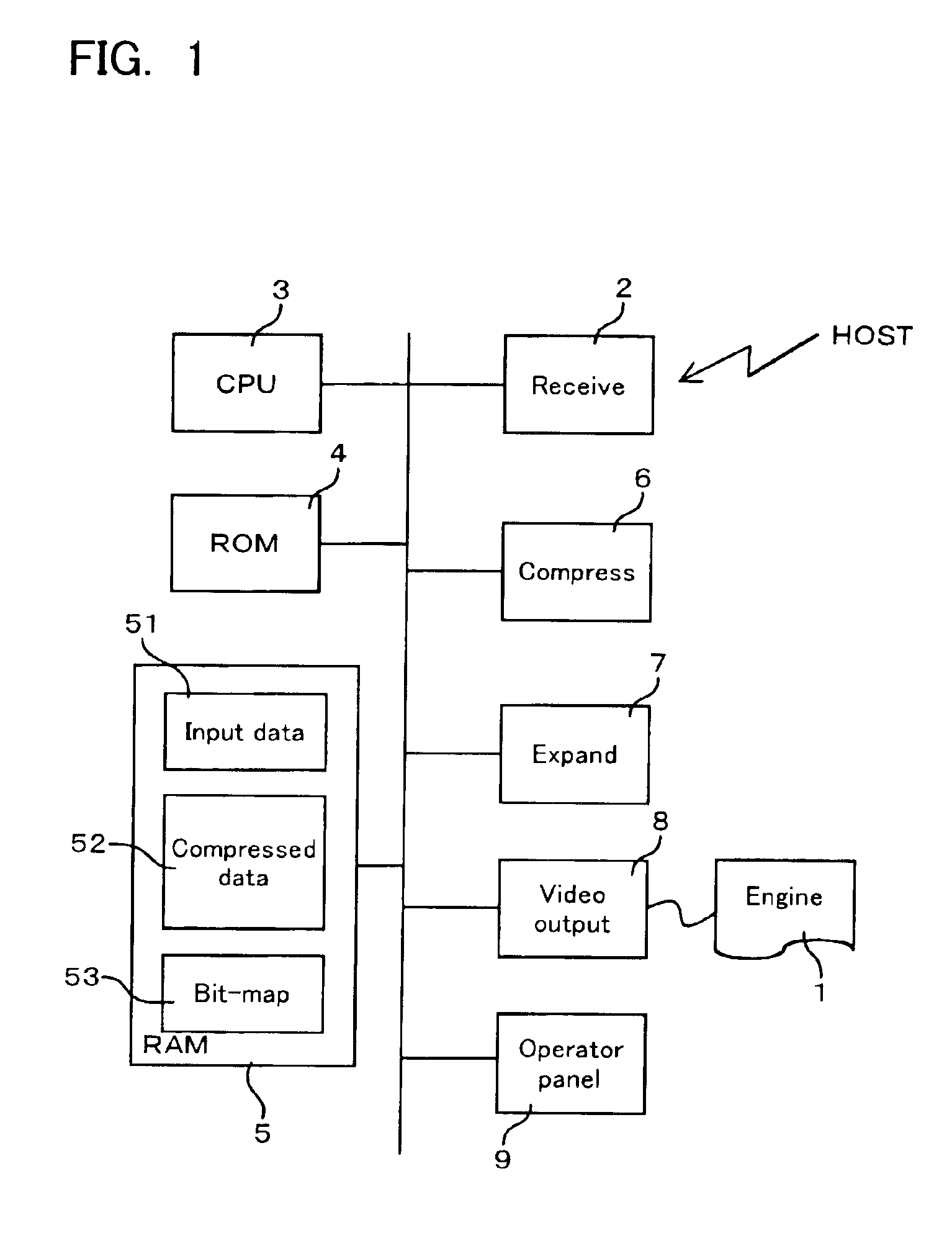

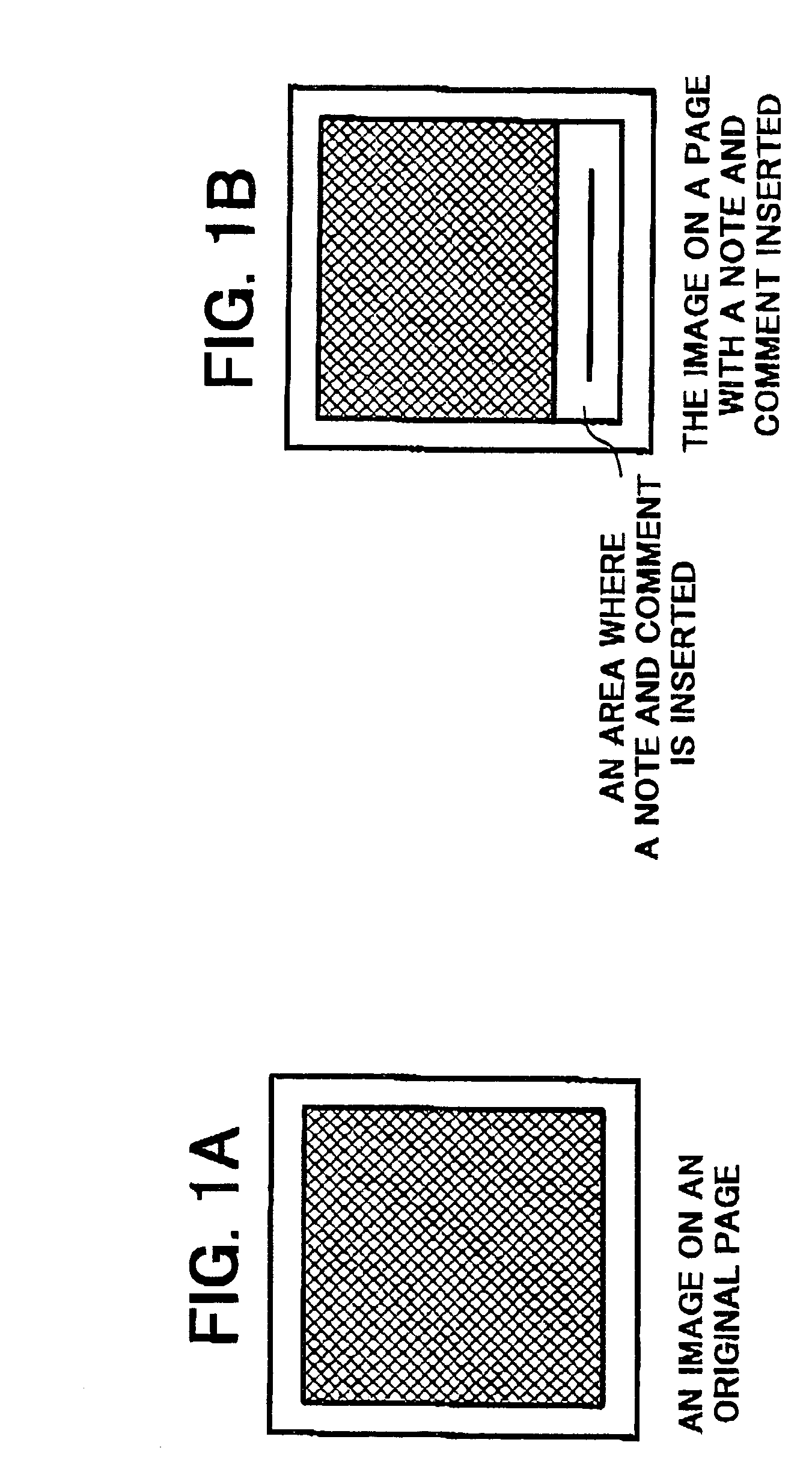

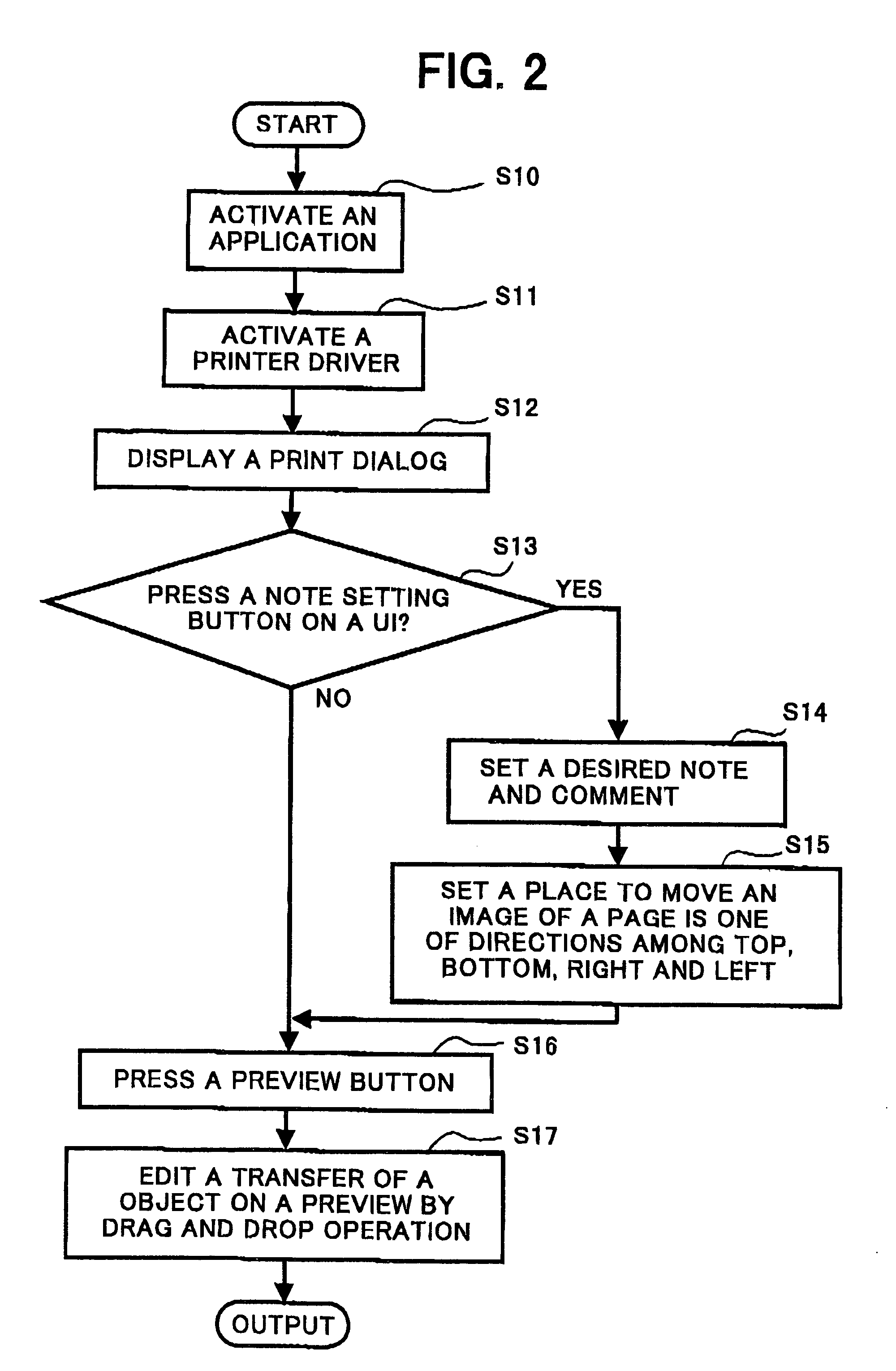

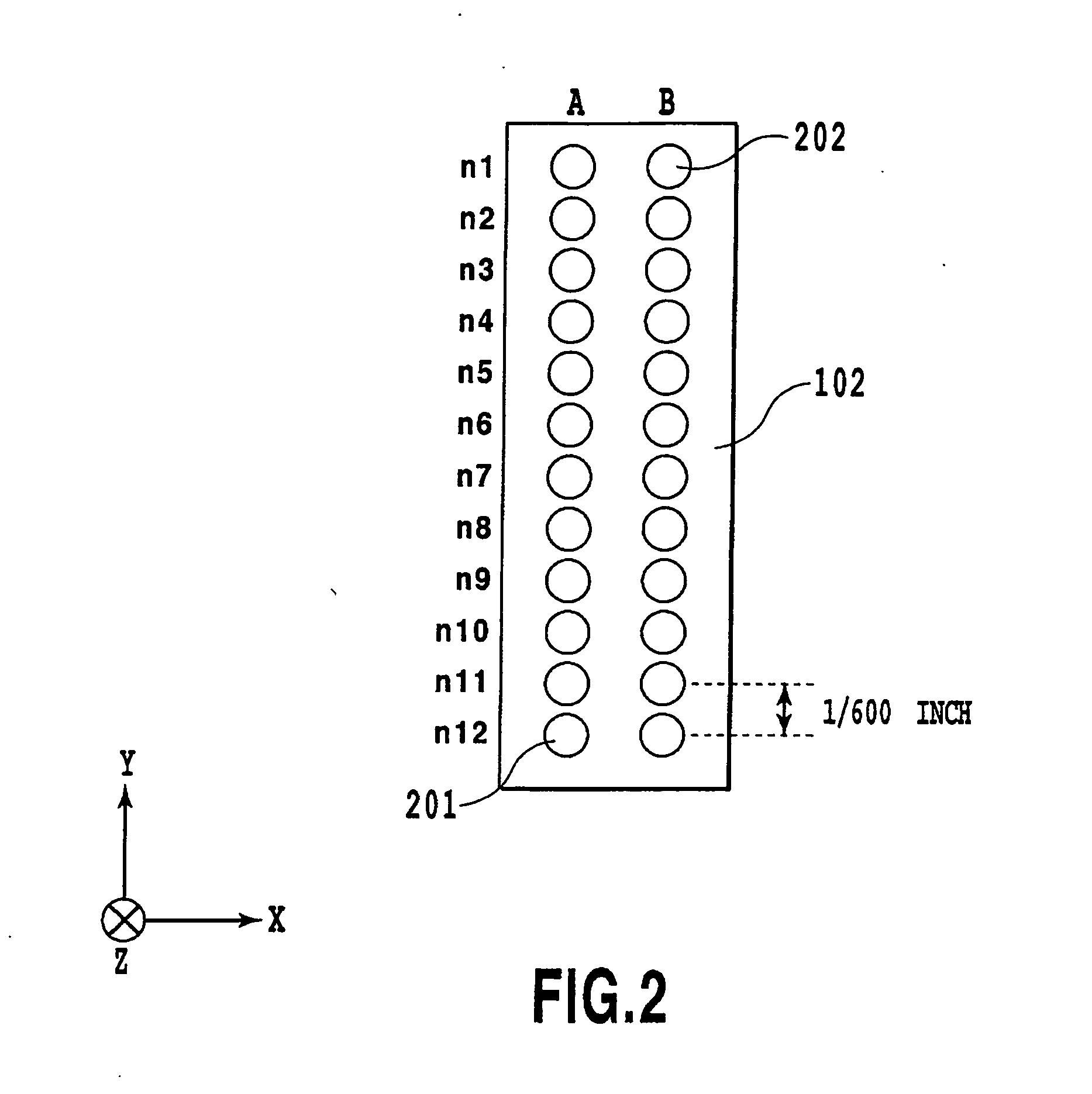

Page printer and page printer control method

InactiveUS6906822B1Digitally marking record carriersVisual presentation using printersComputer graphics (images)Image resolution

Owner:FUJIFILM BUSINESS INNOVATION CORP

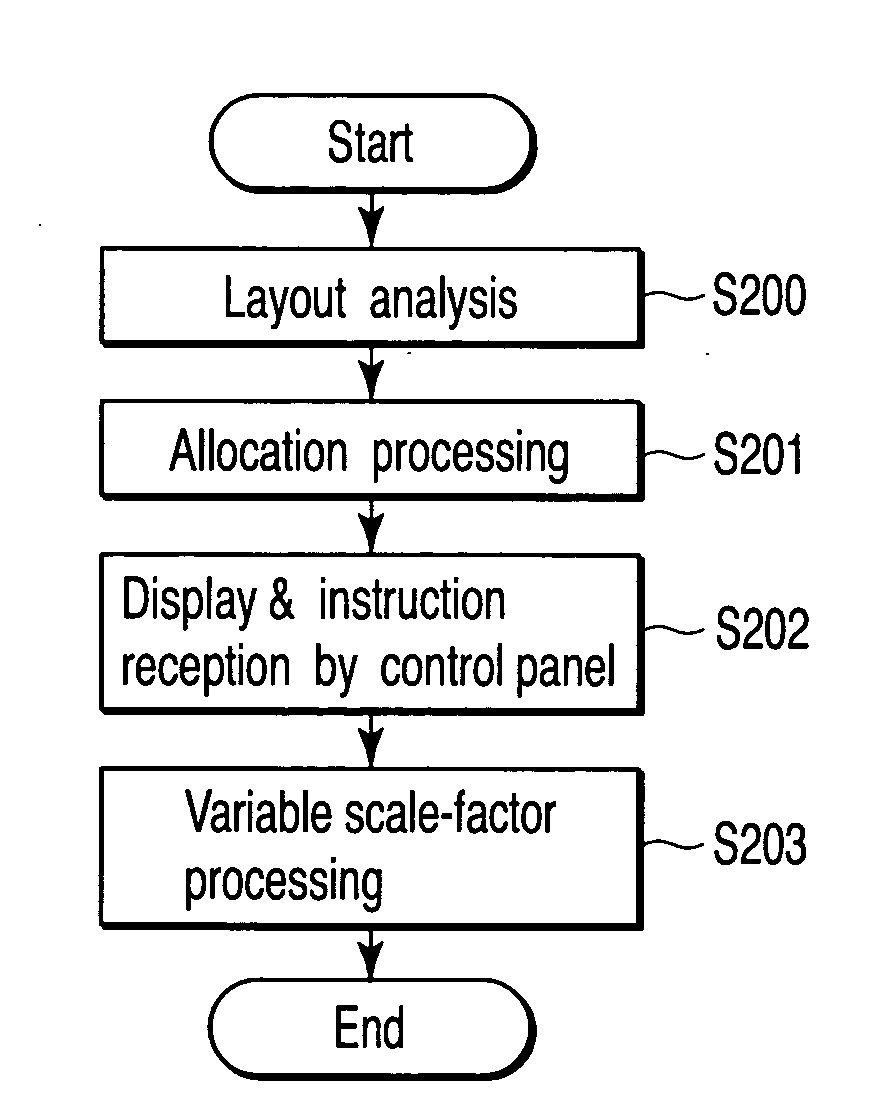

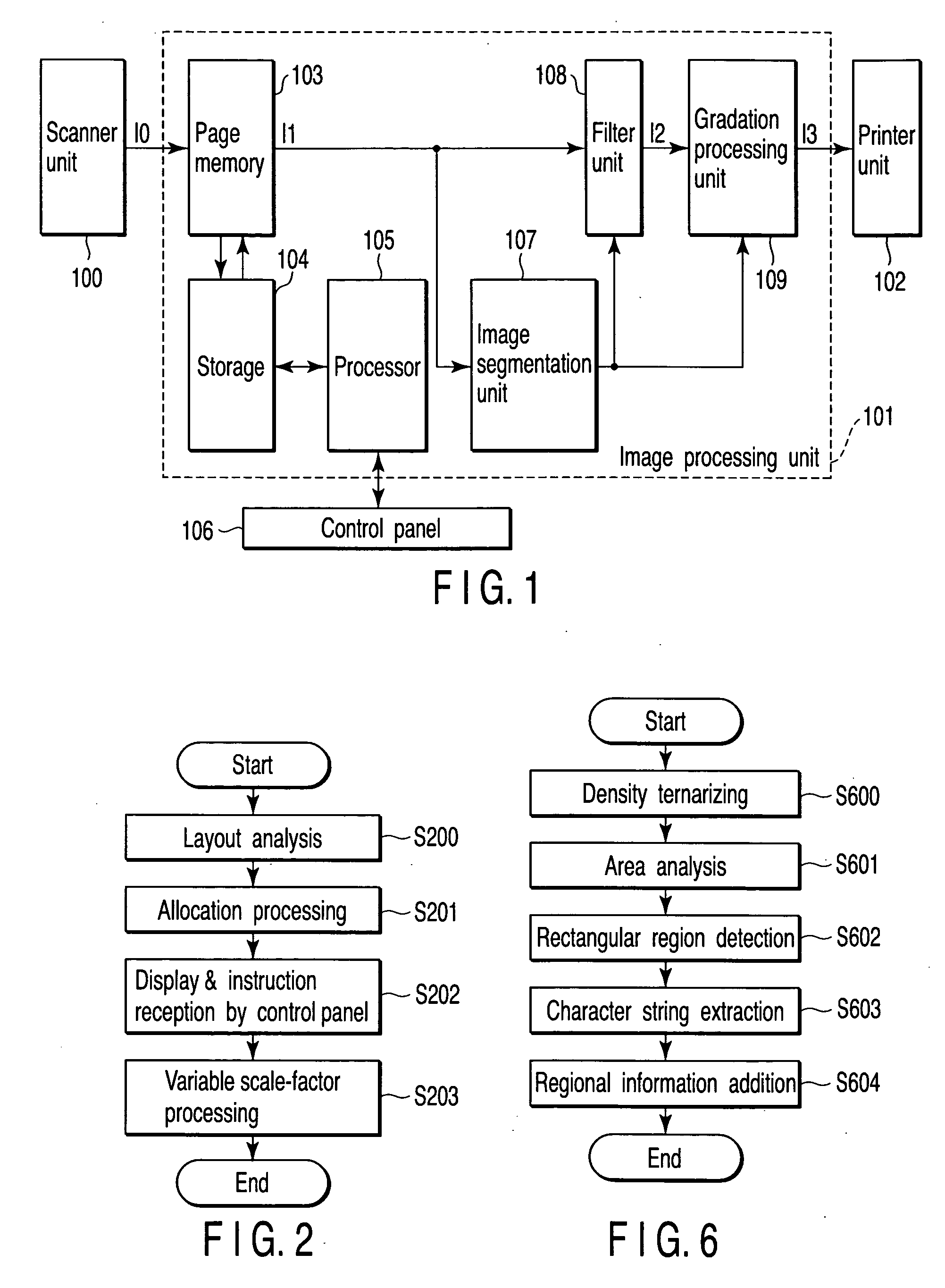

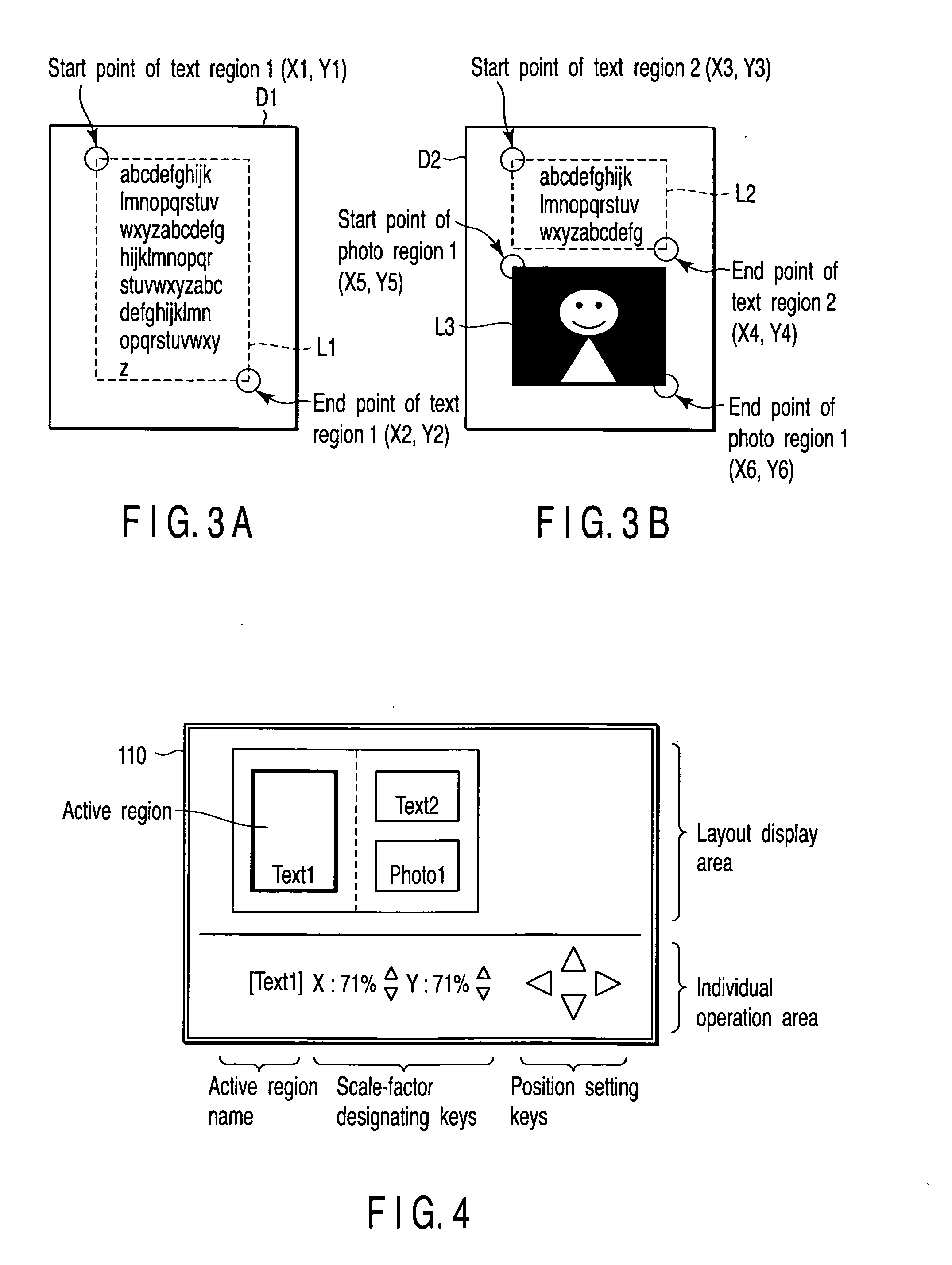

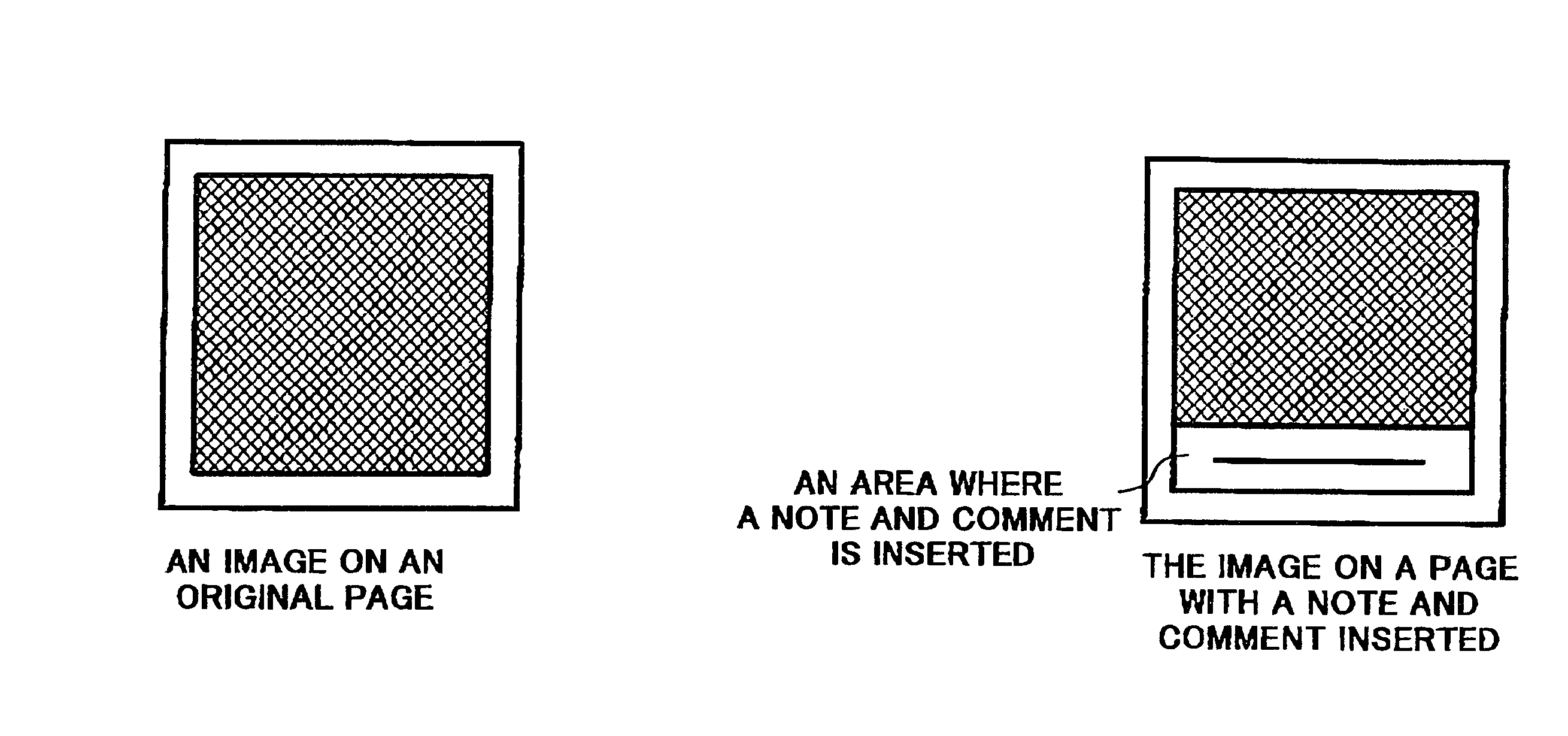

Image processing apparatus

InactiveUS20050207675A1Prevent textCharacter and pattern recognitionVisual presentationImaging processingPaper document

Owner:KK TOSHIBA +1

Mobile phone cover glass main printing technology

Owner:广东星弛光电科技有限公司

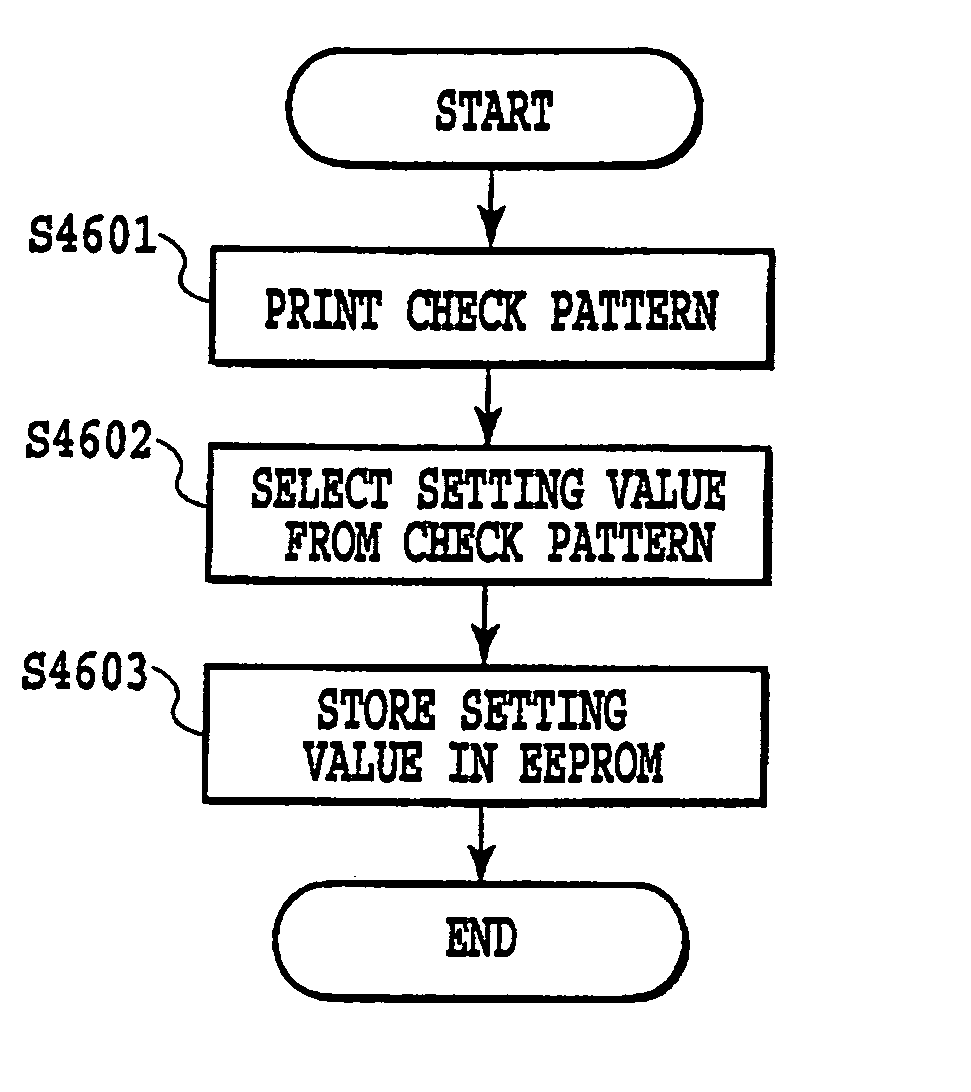

Printing method, printing apparatus, and storage medium

Owner:SEIKO EPSON CORP

Printing apparatus and method of adjusting printing position

ActiveUS20070013726A1Image deterioration is suppressedImage deterioration is complexlySpacing mechanismsOther printing apparatusAdverse effectElectrical and Electronics engineering

Owner:CANON KK

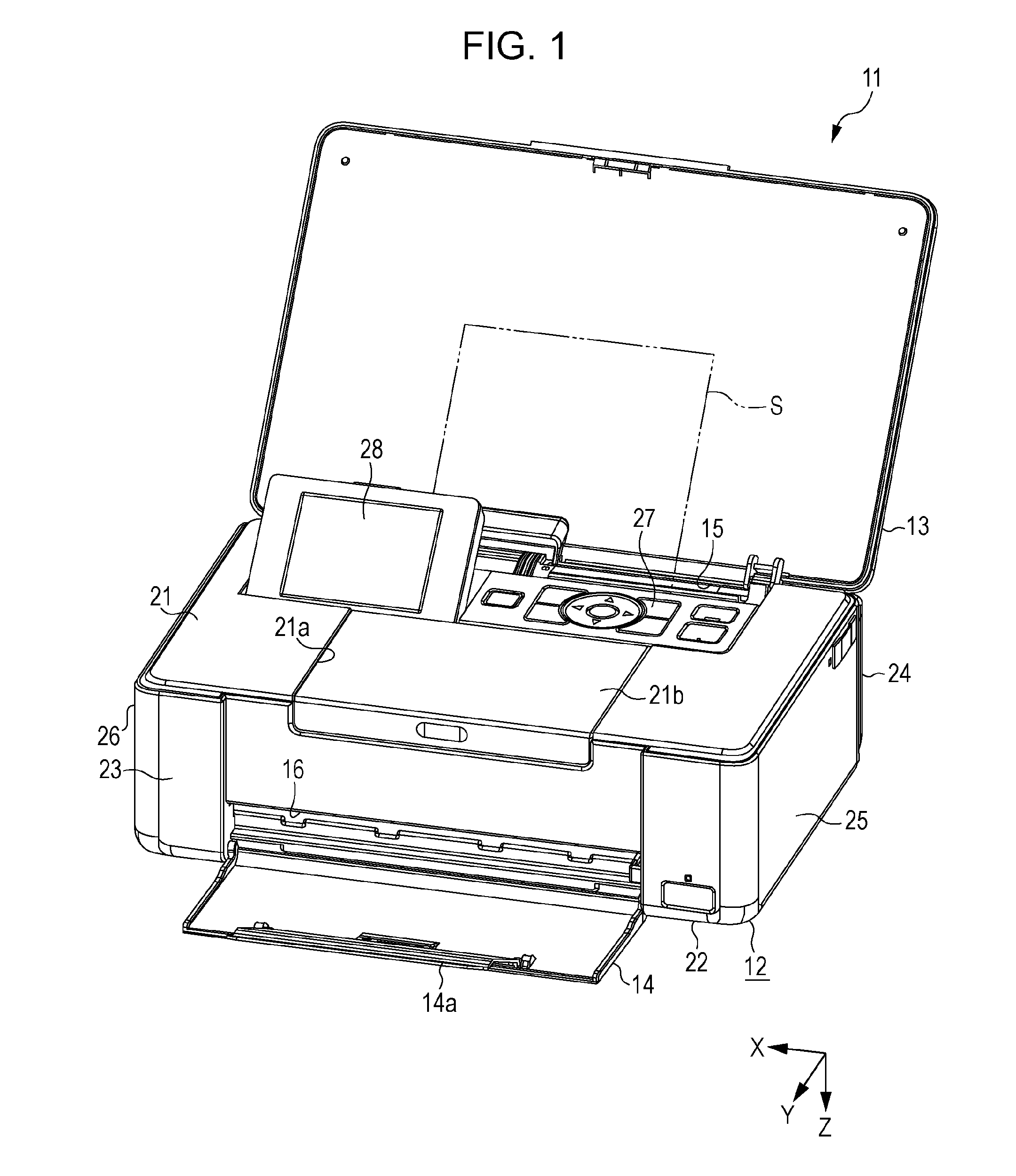

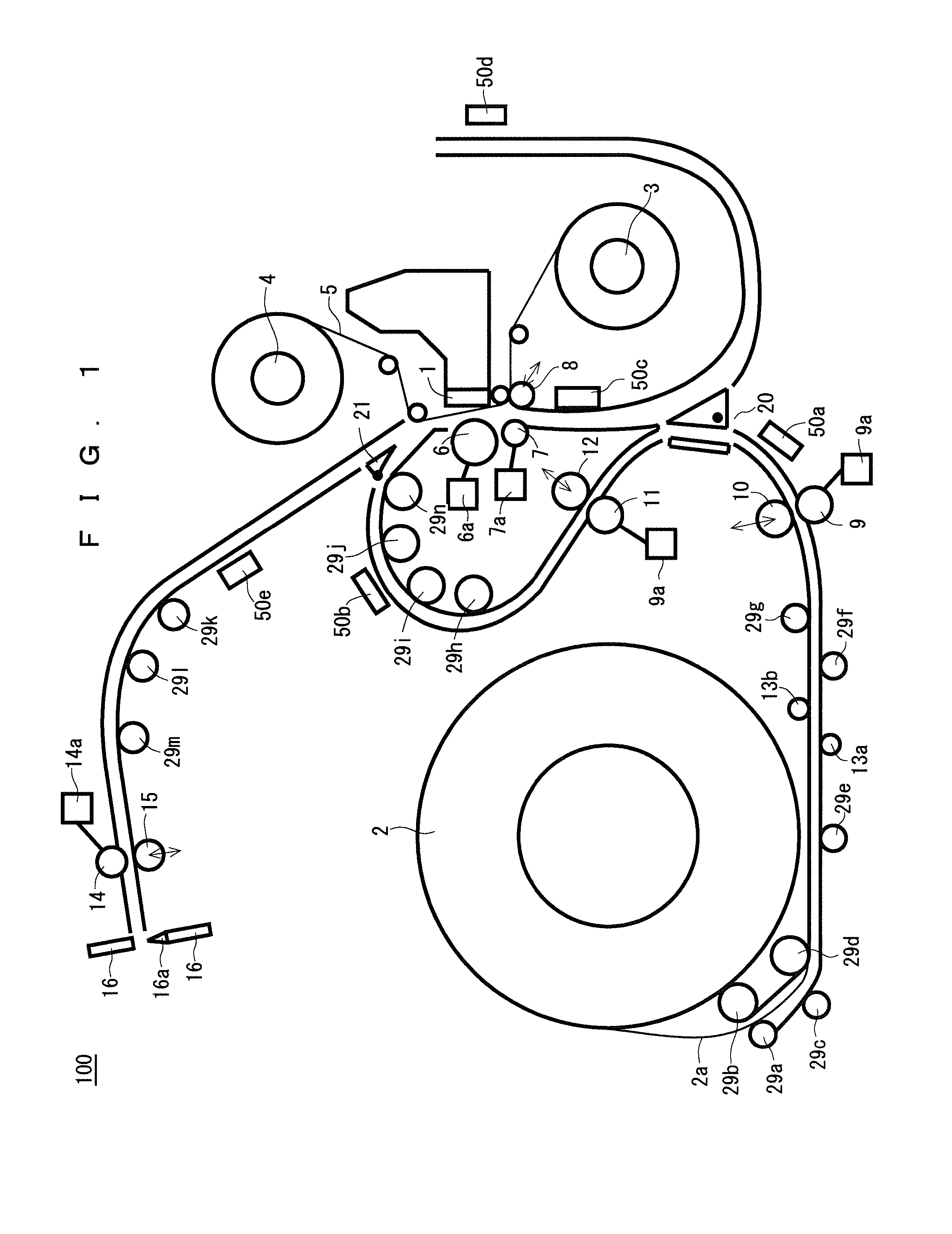

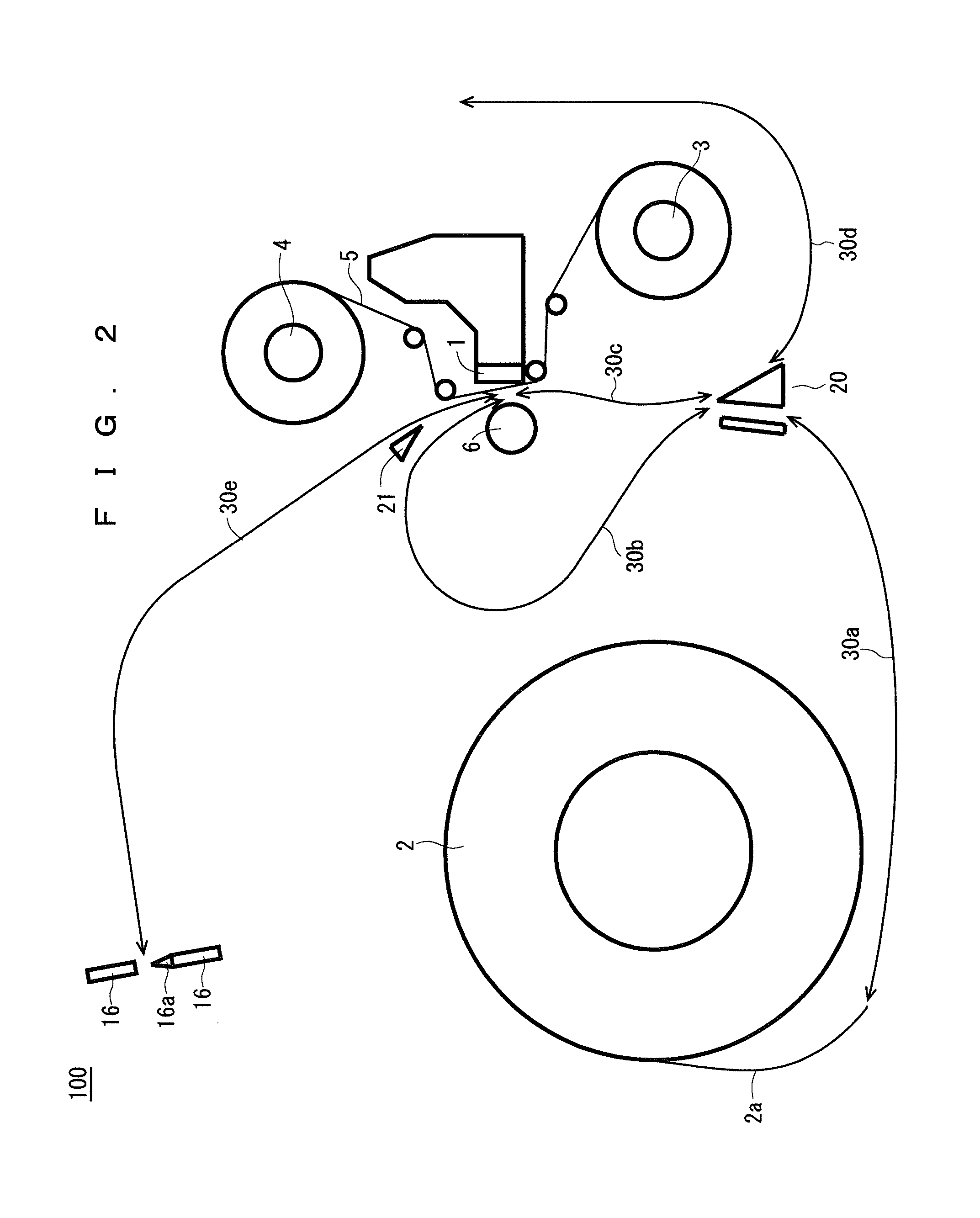

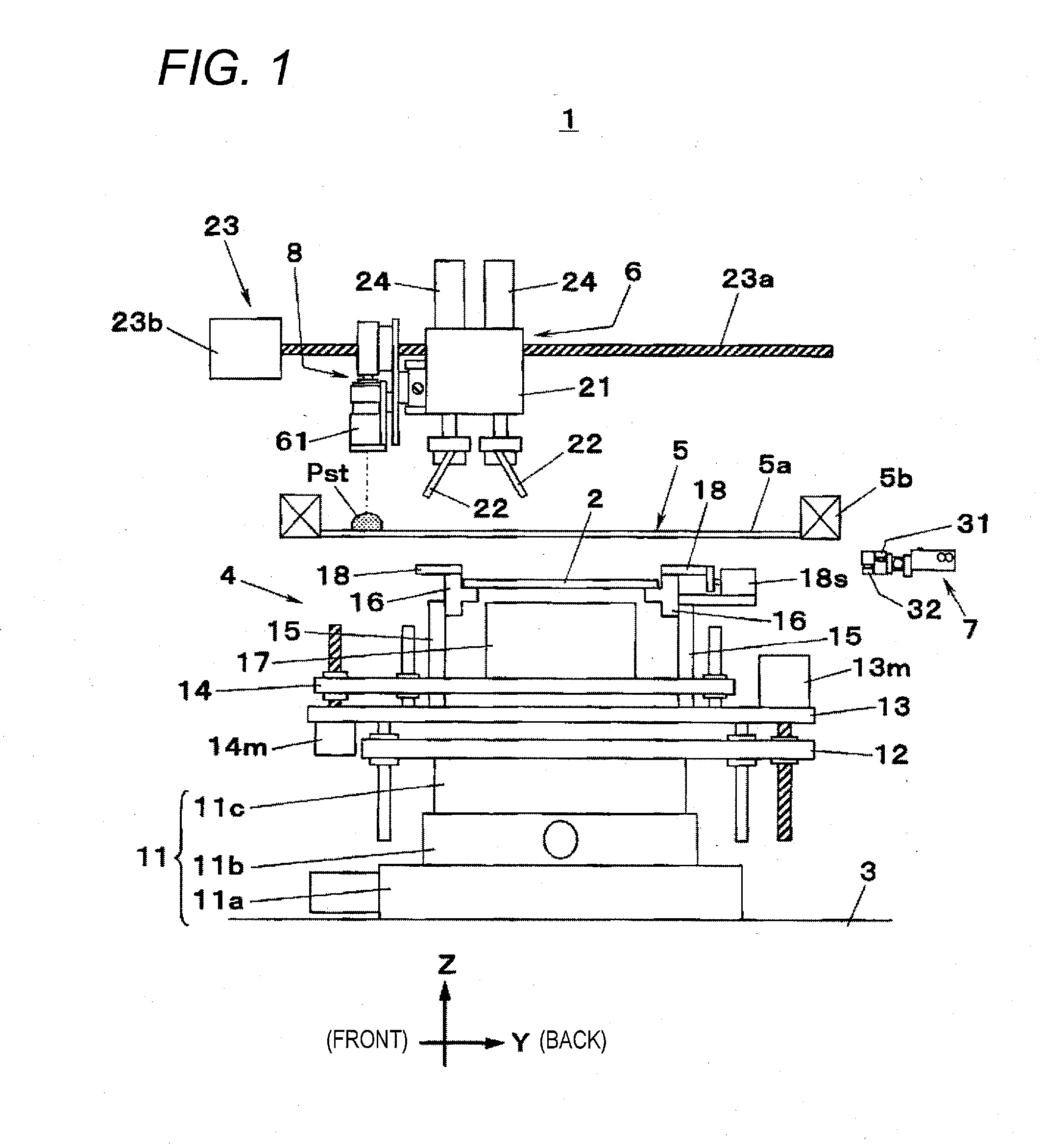

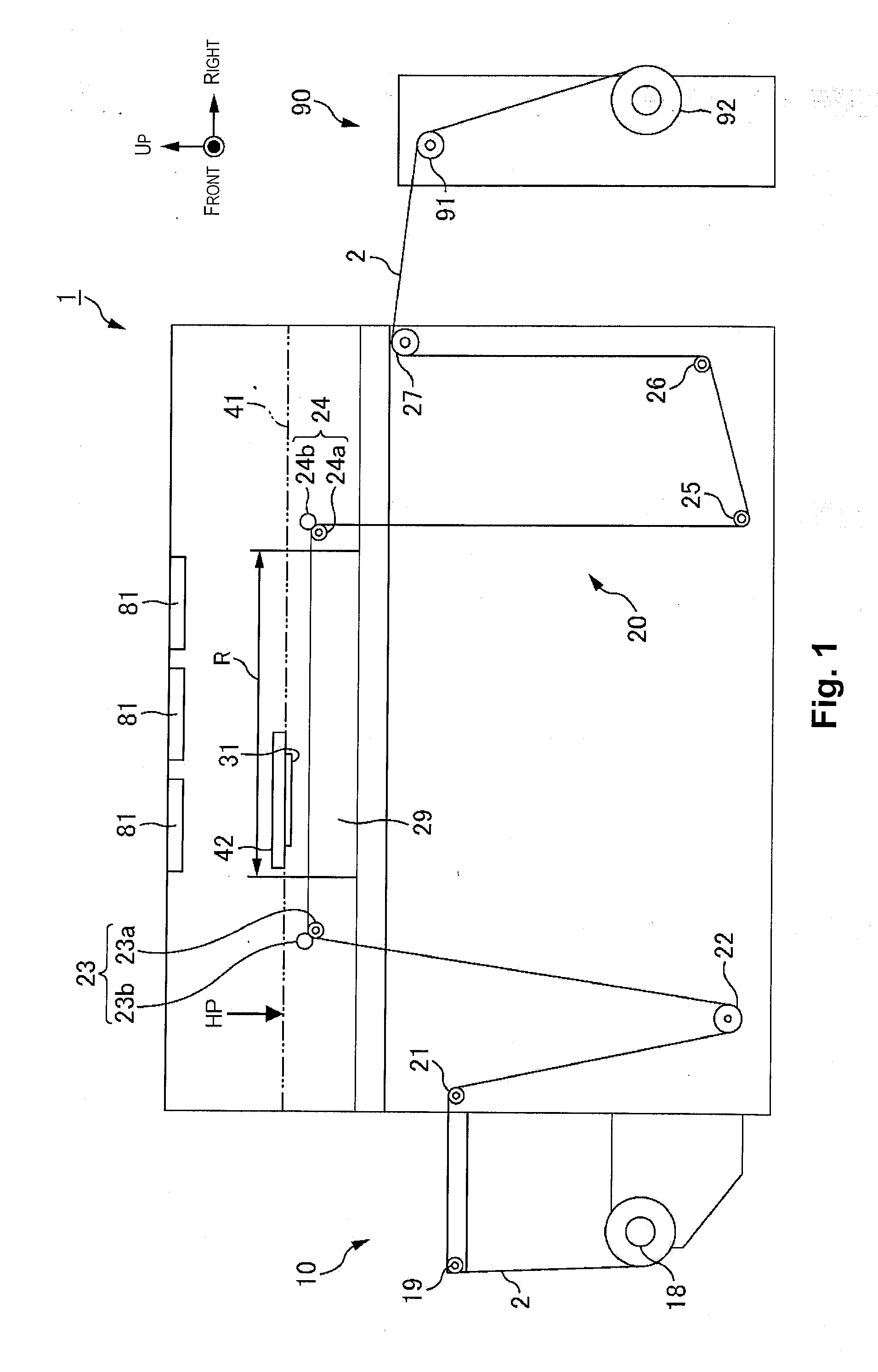

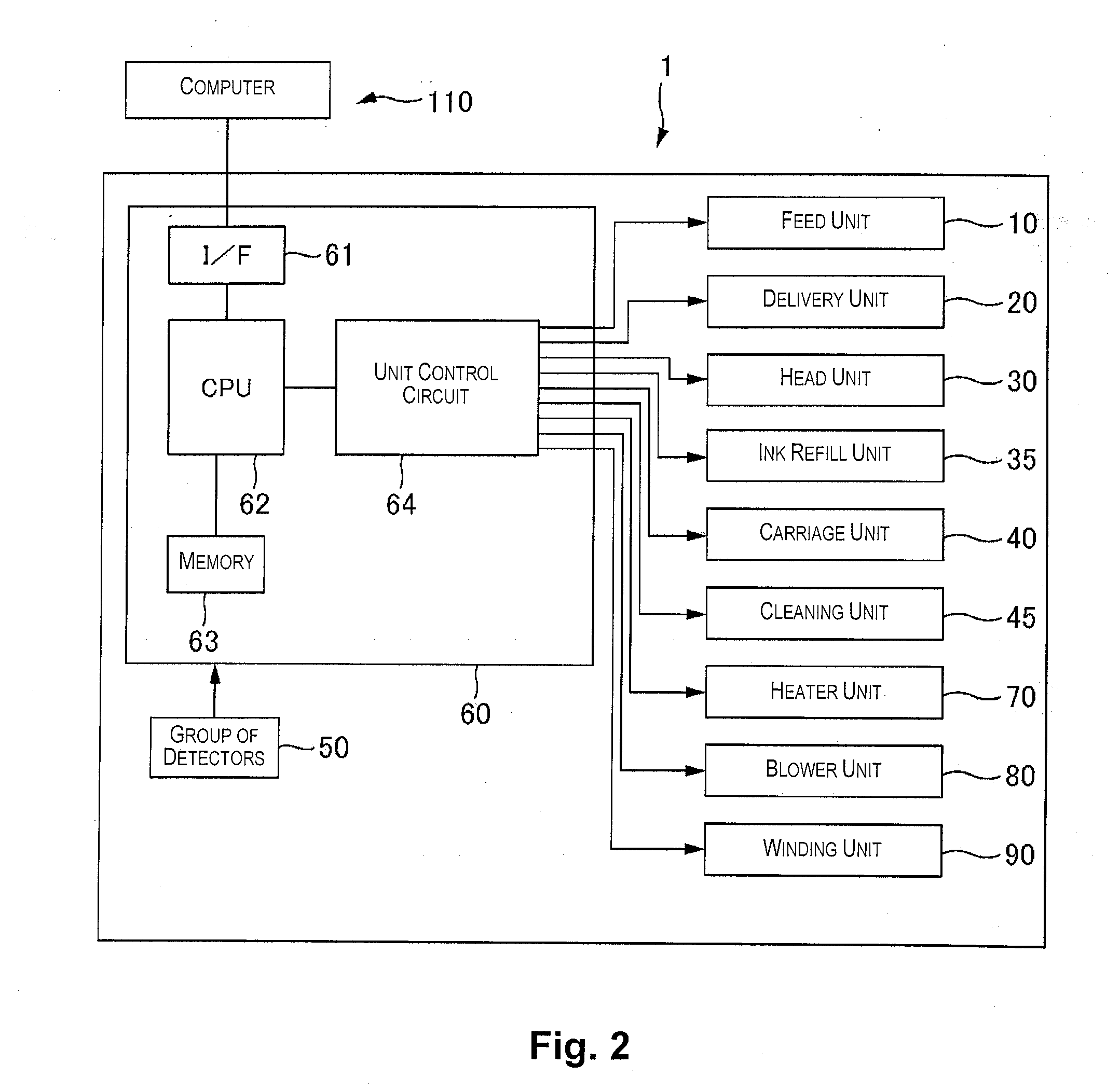

Recording apparatus

InactiveUS20100180784A1Easy to operateIncrease in sizeOther printing apparatusOffice printingEngineeringRecording media

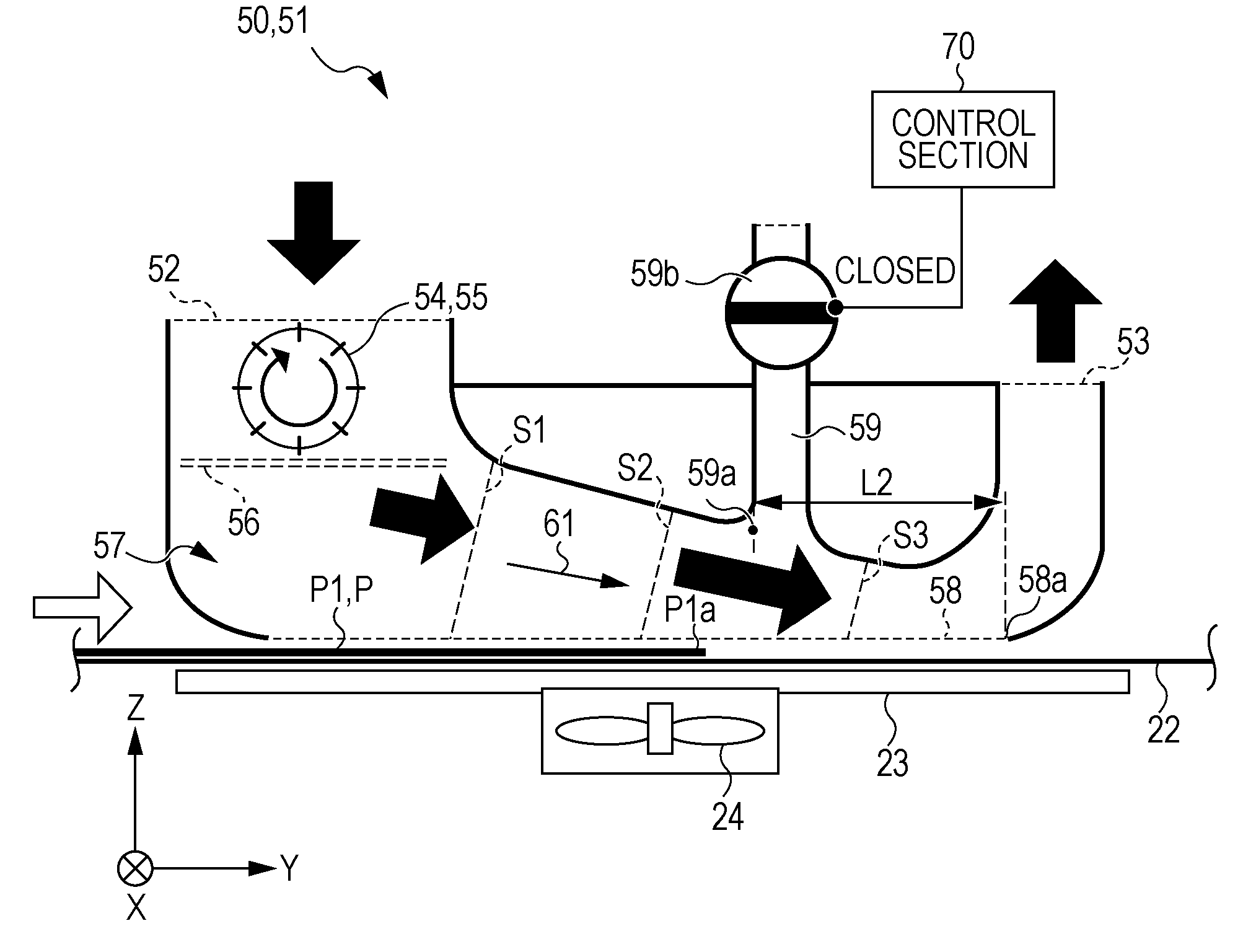

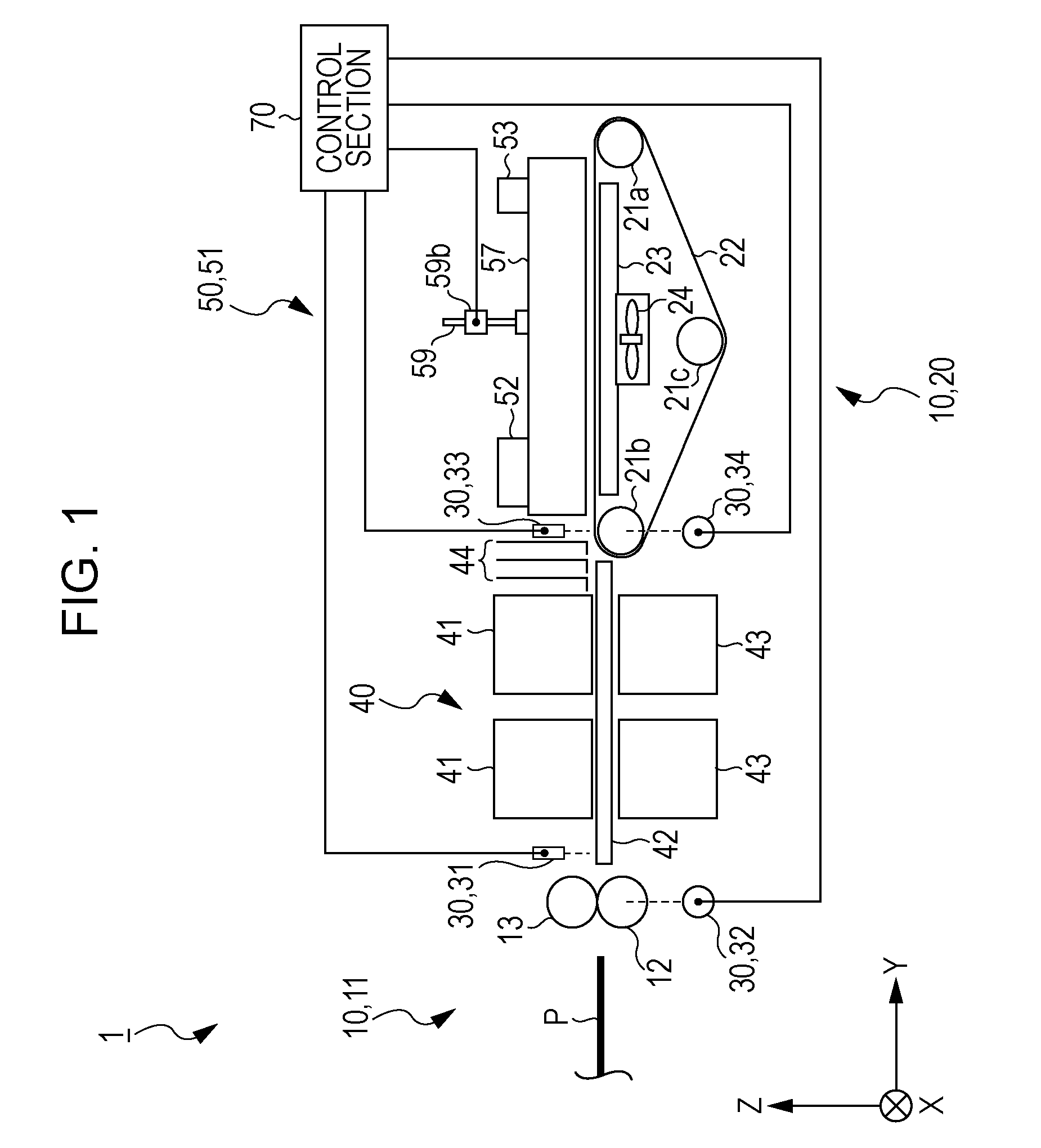

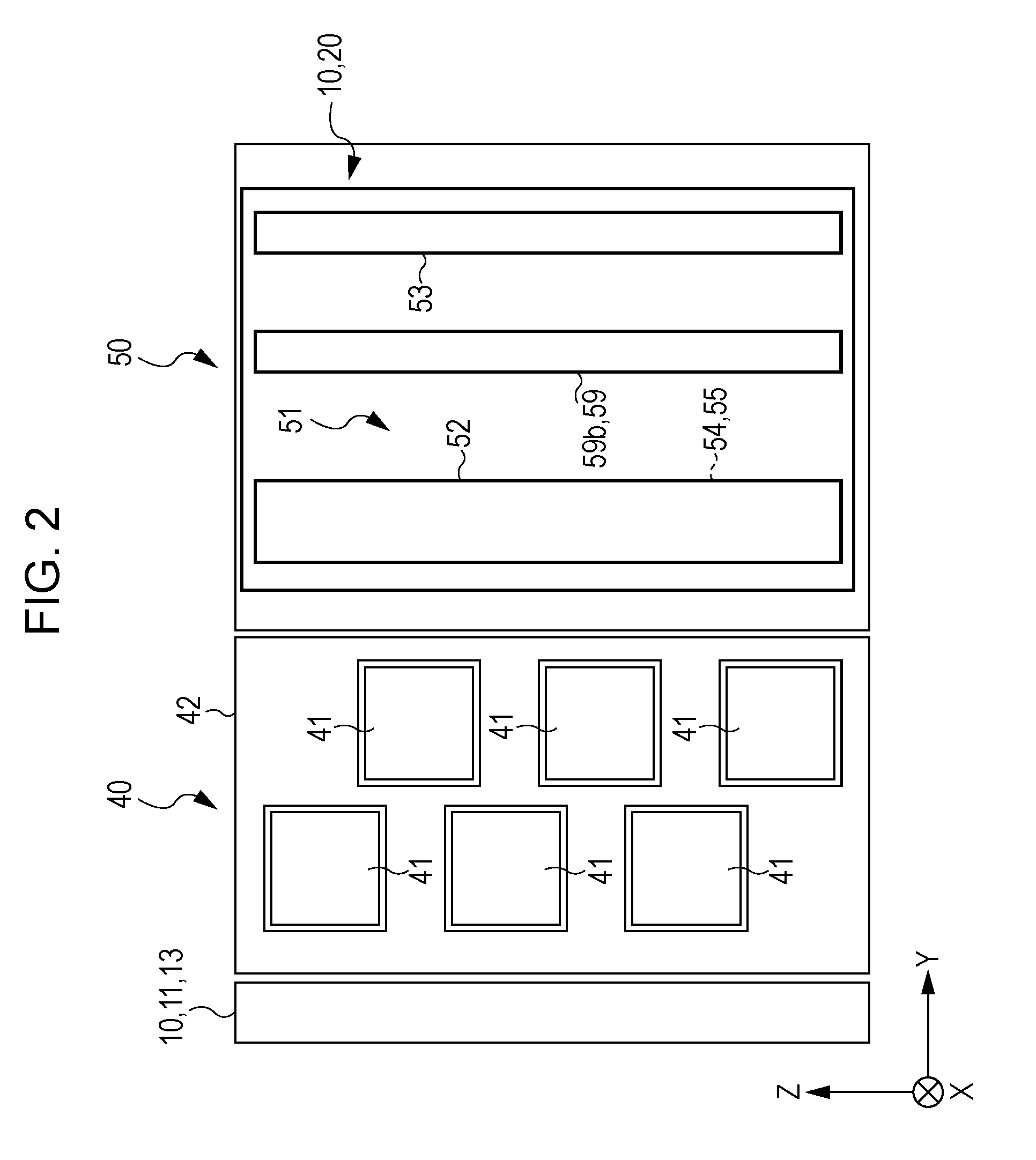

A recording apparatus includes: a recording unit that performs a recording operation on a recording medium; a transport unit that transports the recording medium; and a drying unit that promotes drying of the recording medium by ejecting gas to the recording medium. The drying unit includes a main passage through which the gas flows on a surface of the recording medium along the transport direction of the recording medium, and a sub-passage that merges with the main passage and extends in a direction crossing the surface of the recording medium when merging with the main passage.

Owner:SEIKO EPSON CORP

Liquid ejecting apparatus and control method of the same

Owner:SEIKO EPSON CORP

Fluid ejection device and fluid ejection printer

Owner:SEIKO EPSON CORP

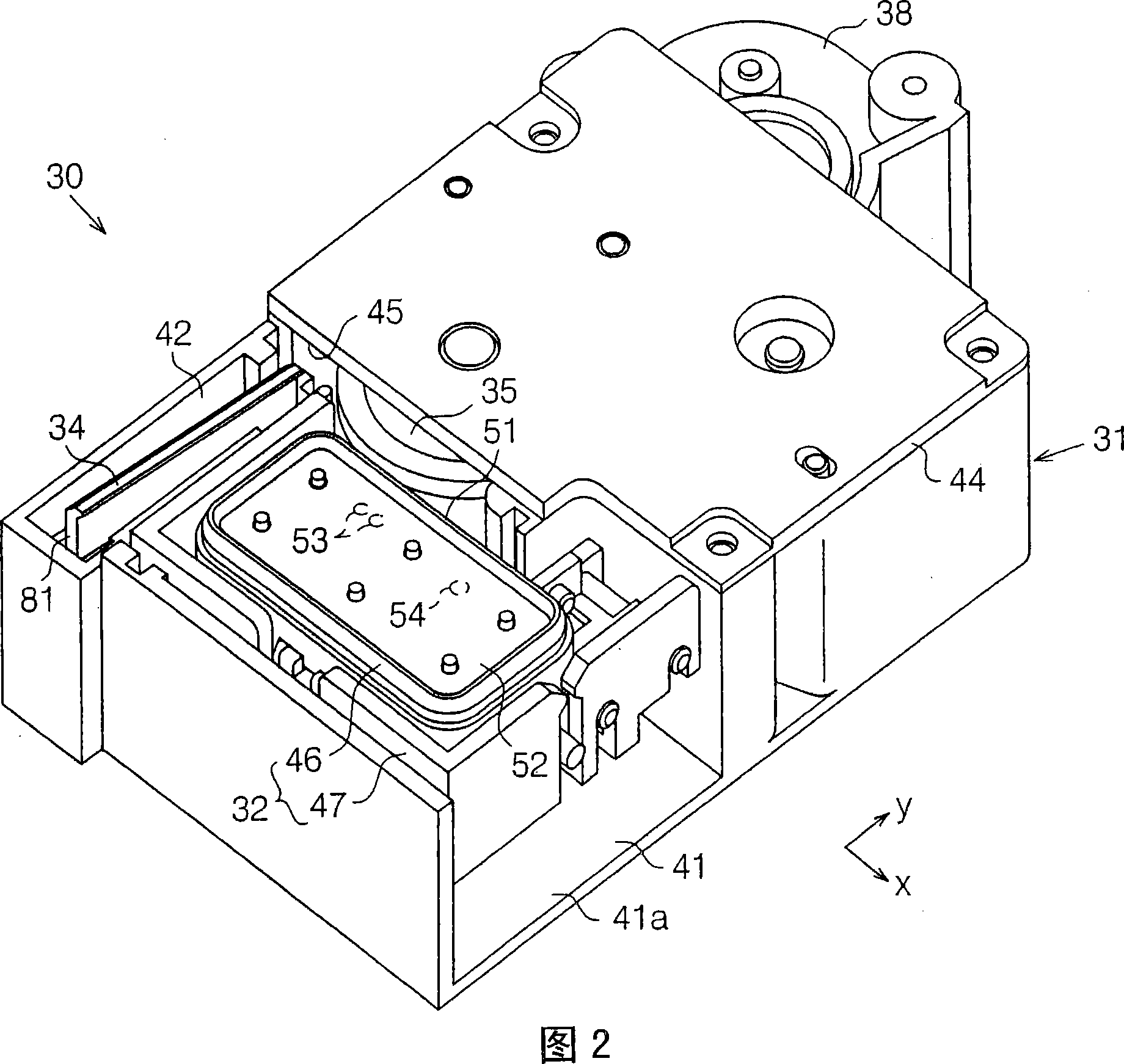

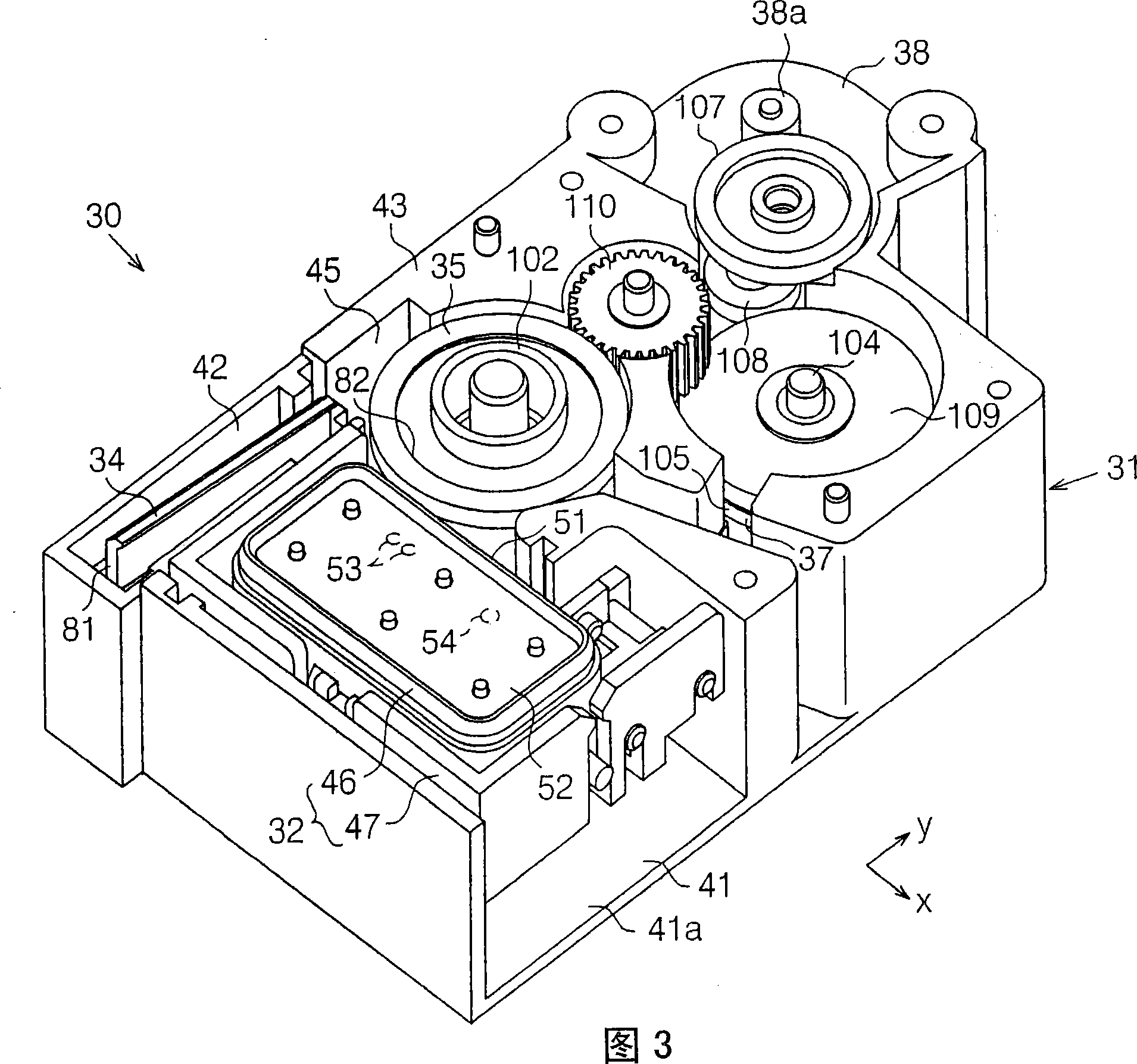

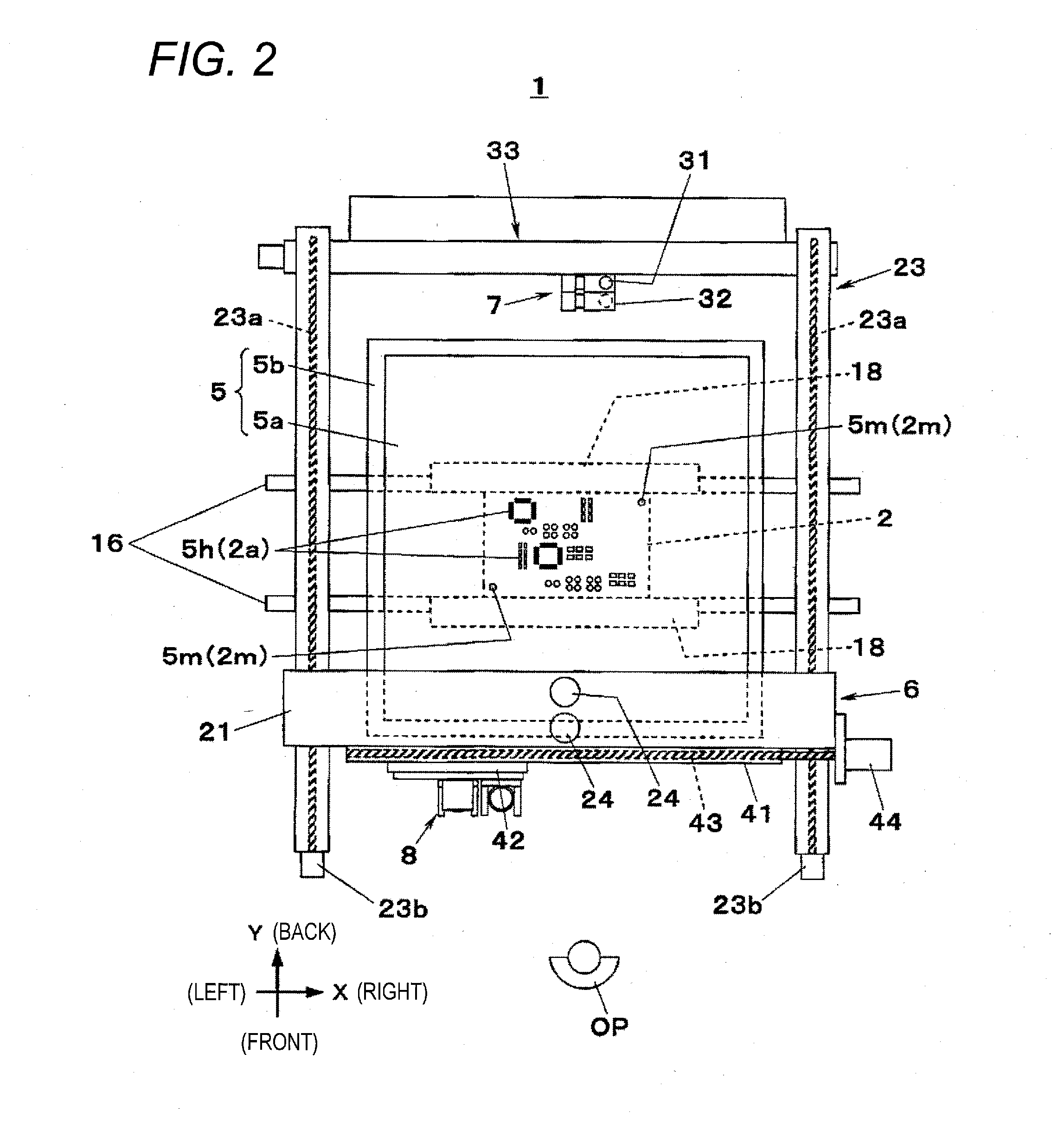

Rotor, drive converting apparatus, cleaning apparatus, wiping apparatus, and liquid ejection apparatus

A nozzle protecting device 30 of an ink jet type recording apparatus has a cap 46 which covers nozzles of a recording head and a cap support member 47 which is connected to the cap 45 via a spring member 80. The distance between the cap 46 and the cap support member 47 can be changed by elastic deformation of the spring member 80. A vent hole 54 is formed in the cap 46. A valve seat 56 which covers the terminal portion of the vent hole 54 is provided. A valve body 58 is rotatably attached to the lower portion of the cap 46. The valve body 58 selectively abuts on and parts from the valve seat 56 in accordance with the distance between the cap 46 and the cap support member 47. As a result, the inside of the cap 46 is opened and closed to air via the vent hole 54.

Owner:SEIKO EPSON CORP

Validation of consumables

Owner:DYMO (BVBA)

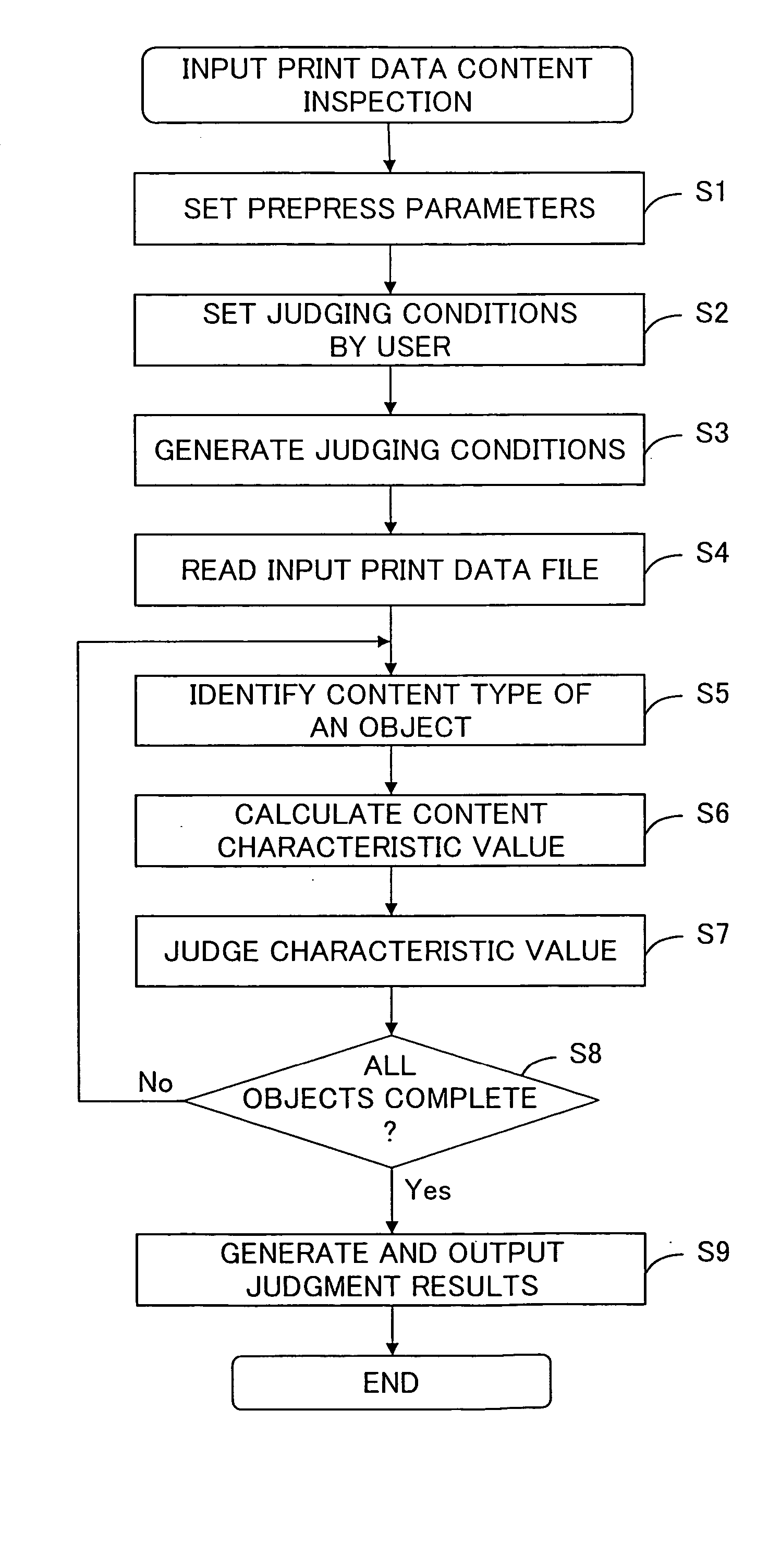

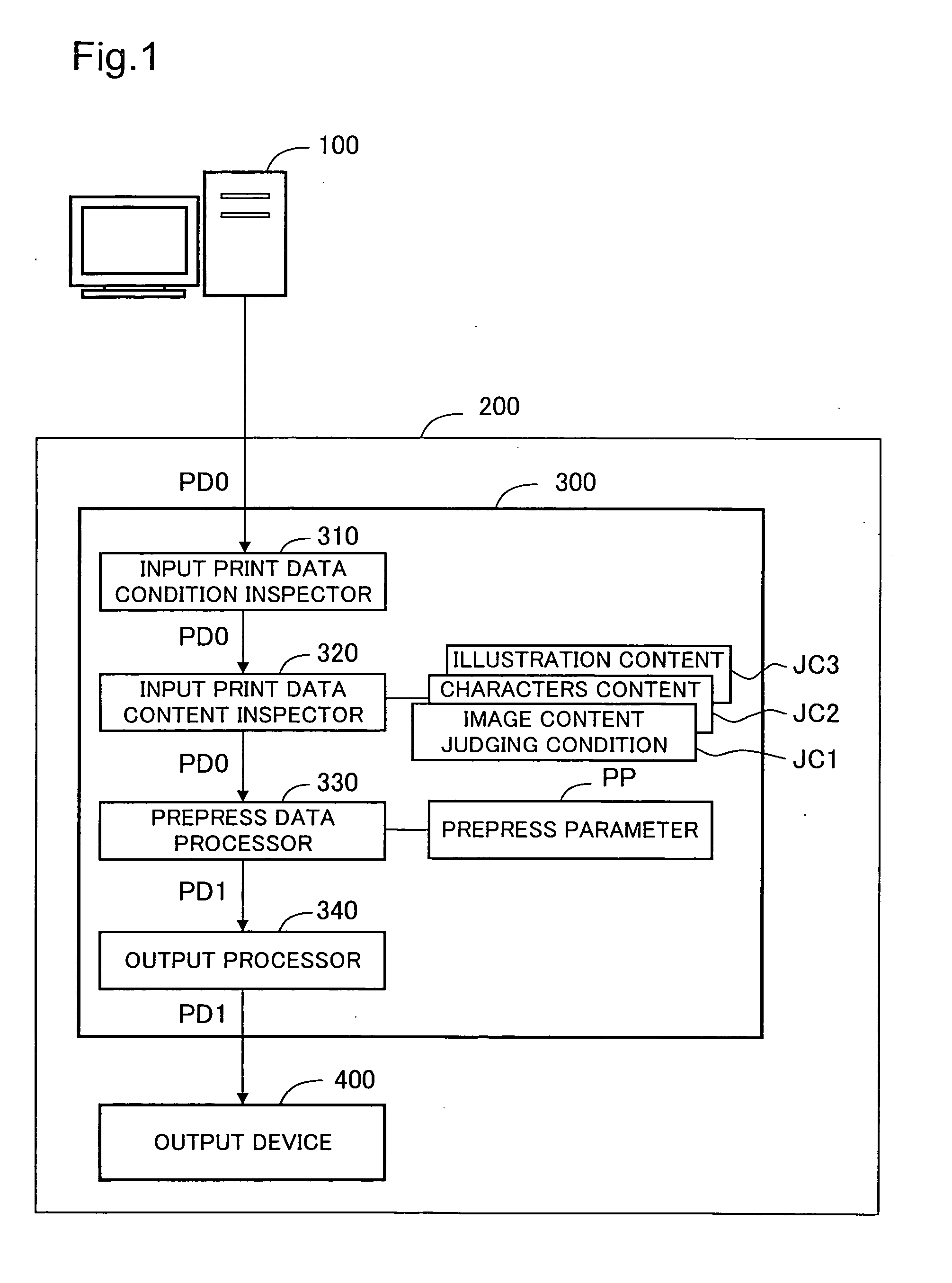

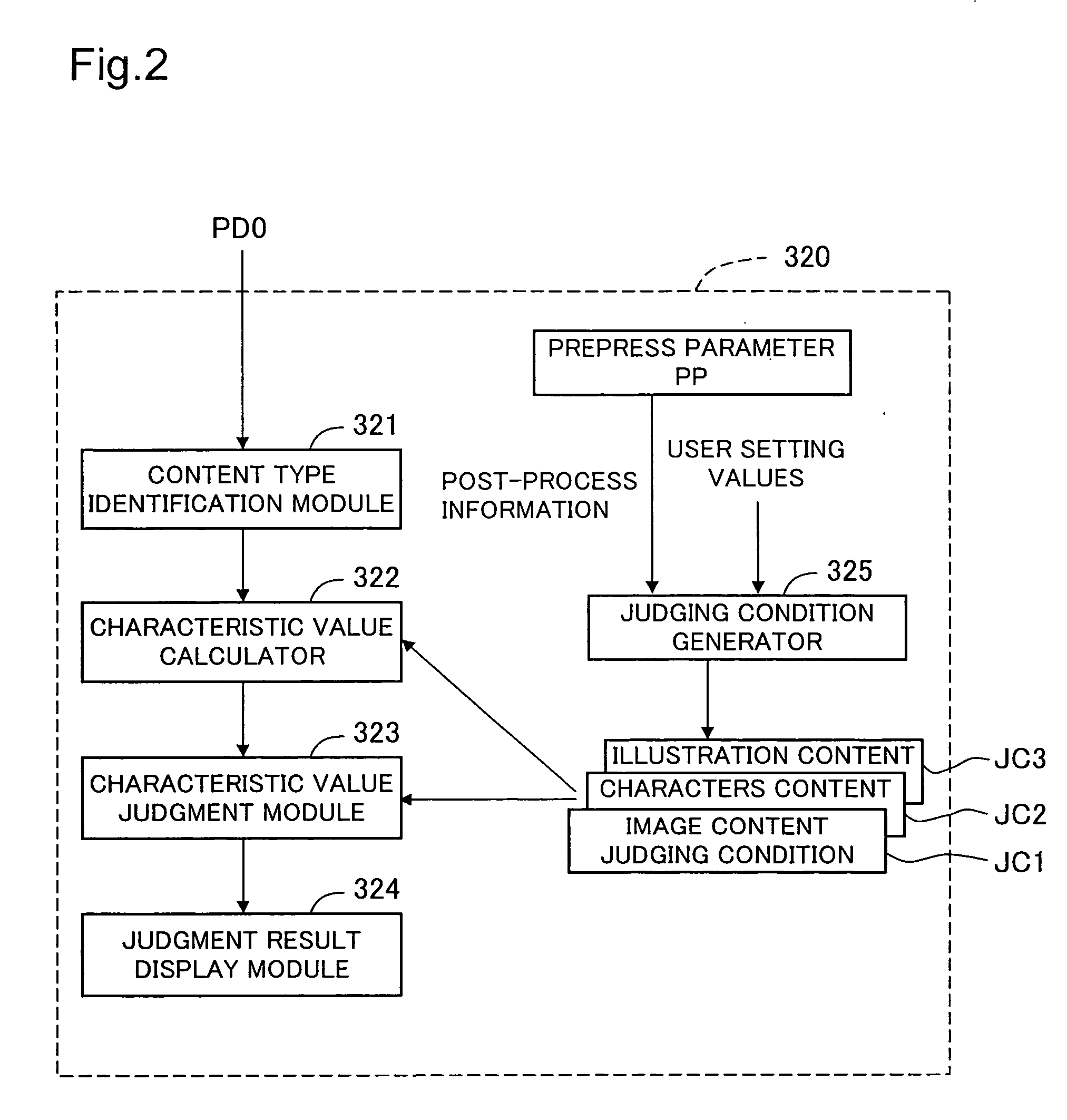

Content inspection for input print data file

InactiveUS20050060639A1Good reproducibilityOther printing apparatusSpecial data processing applicationsData fileContent type

Owner:DAINIPPON SCREEN MTG CO LTD

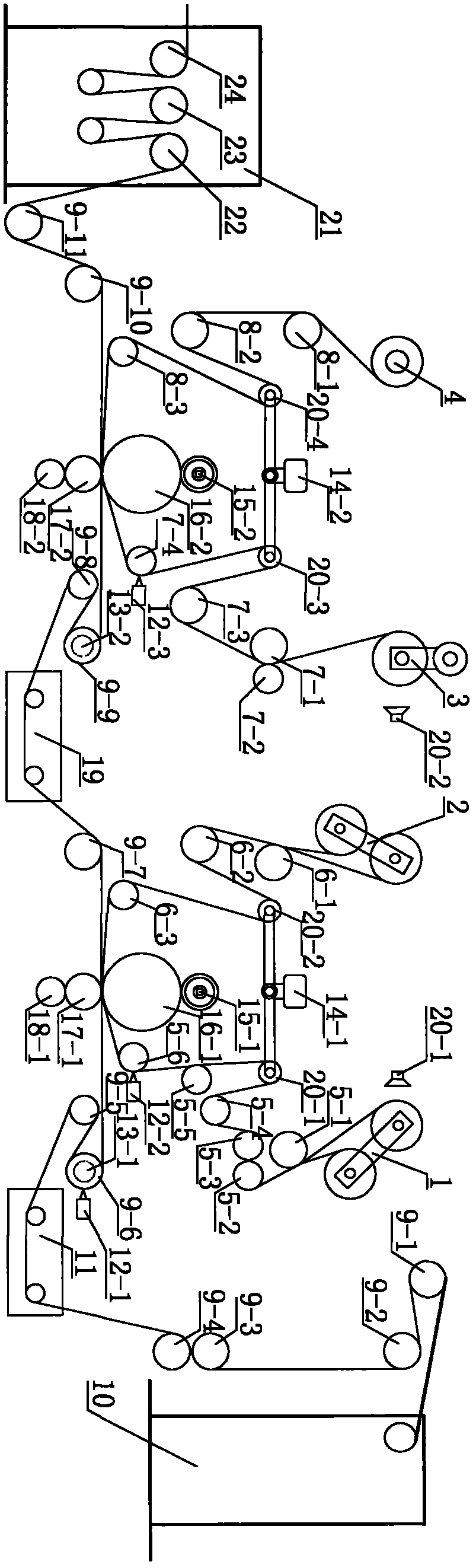

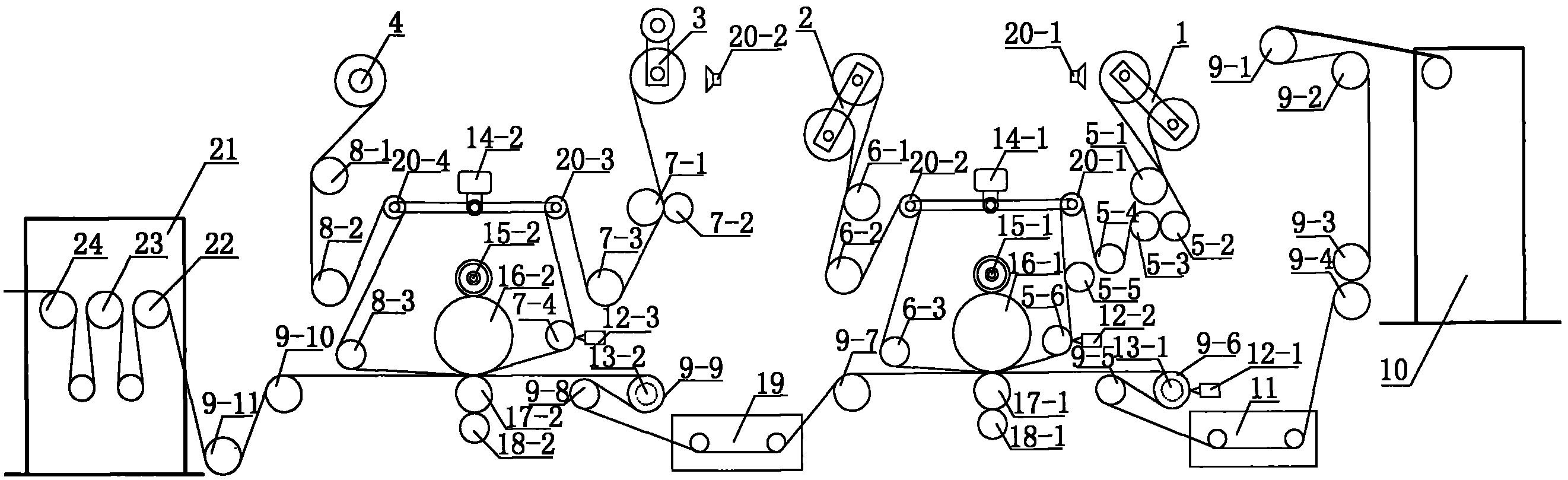

One-step forming method for online hot stamping and concave-convex die cutting of web gravure printing

Owner:TONGXIANG PRINTING

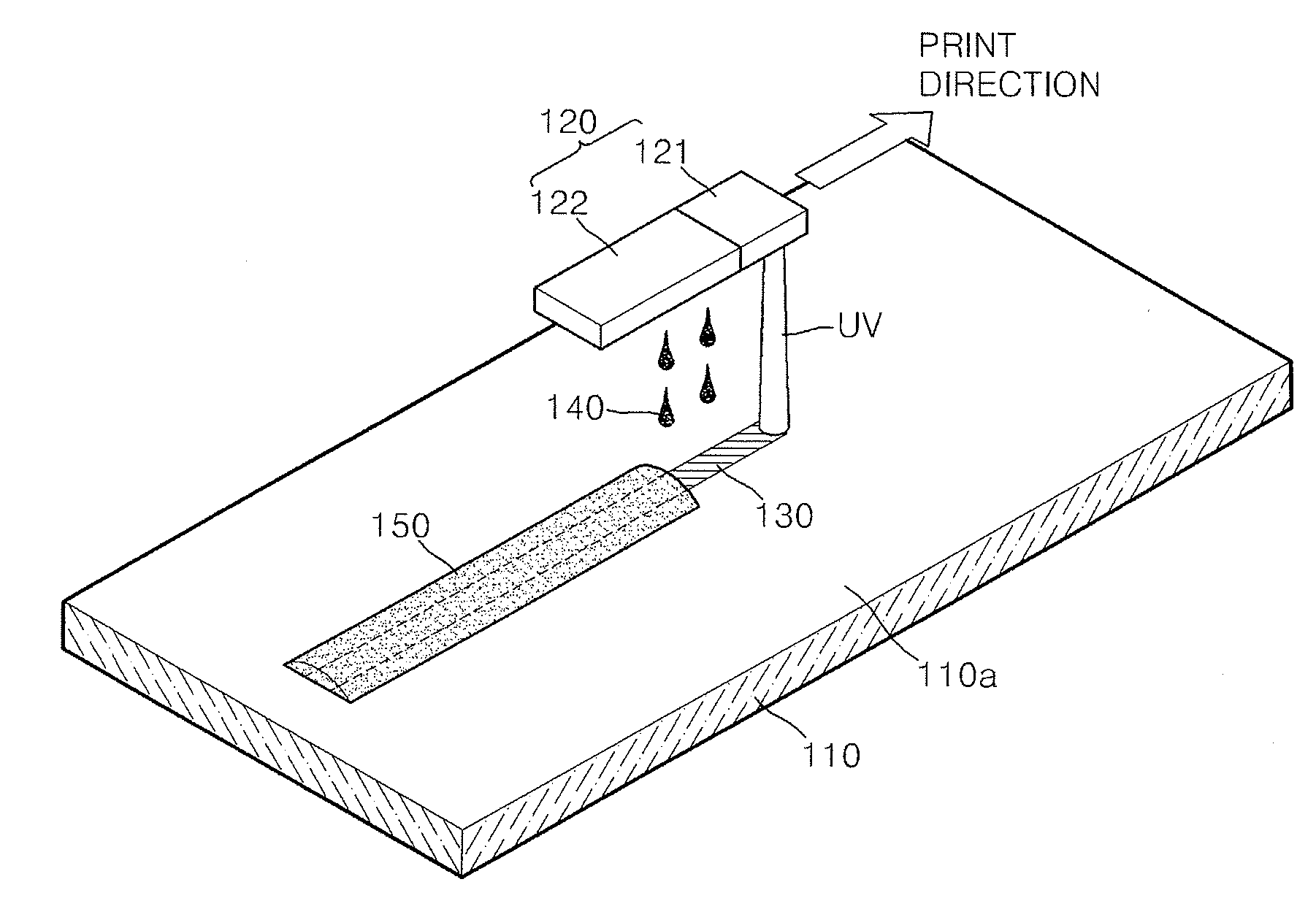

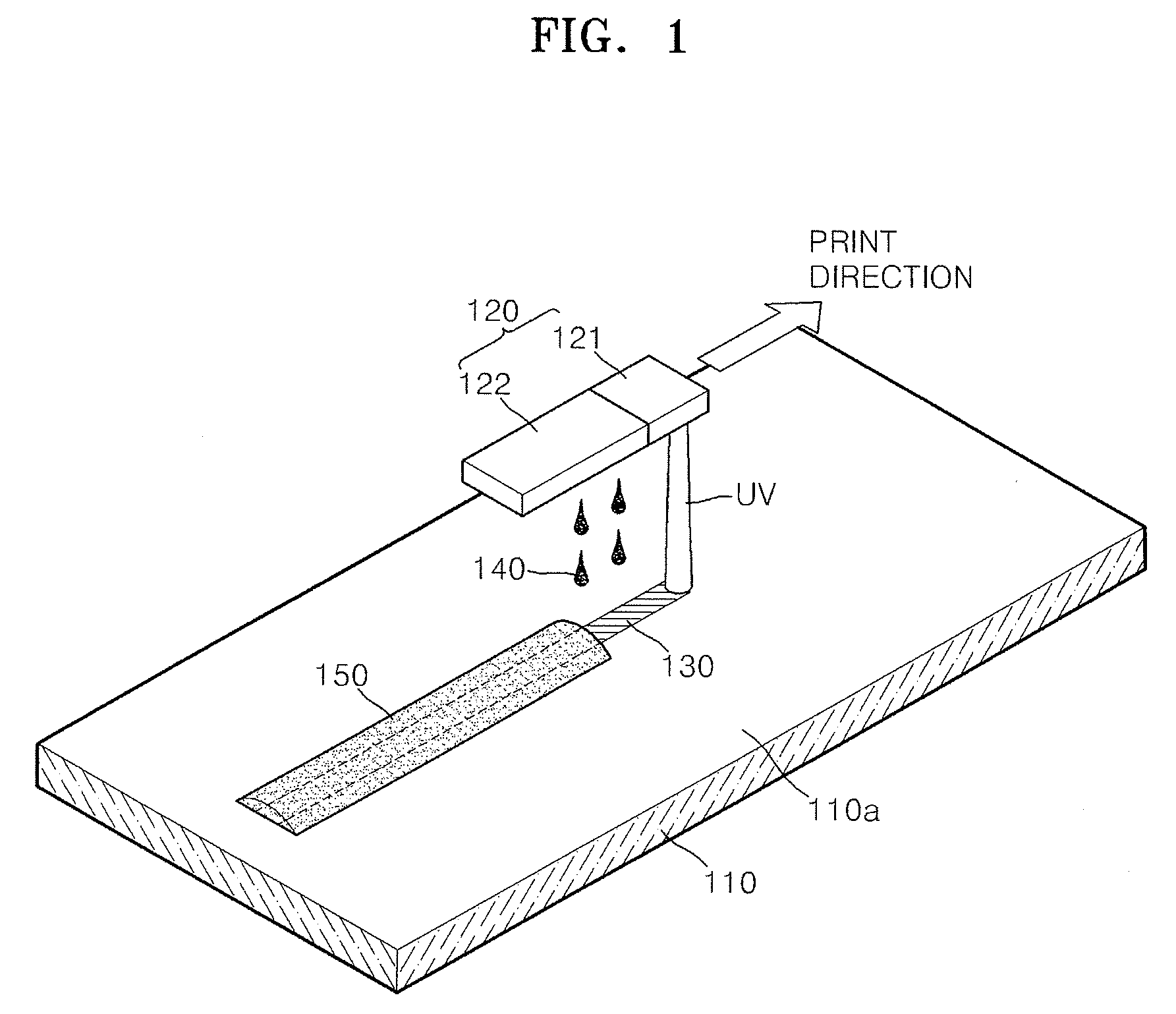

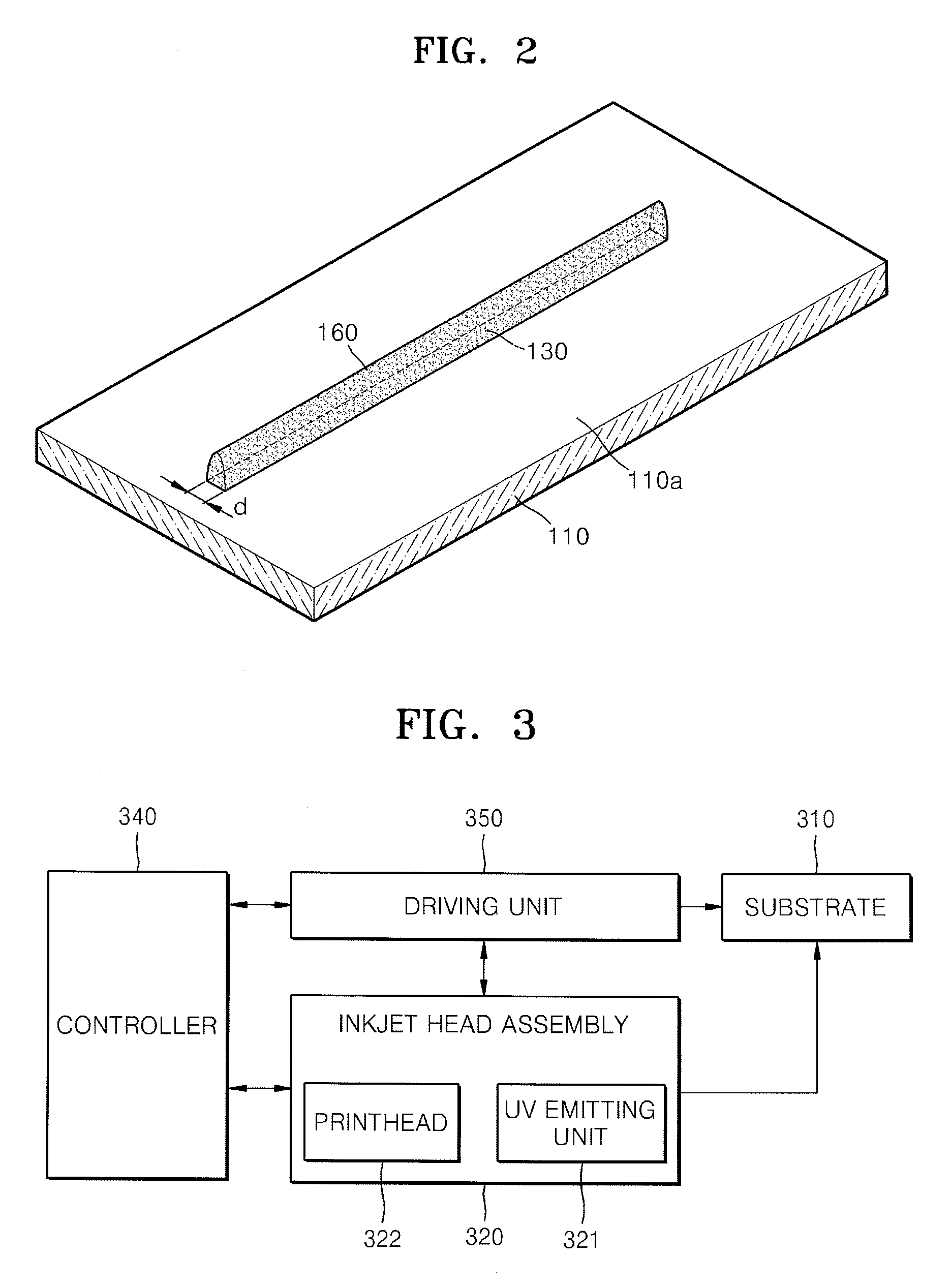

Inkjet head assembly and printing apparatus and method using the same

Owner:SAMSUNG DISPLAY CO LTD

Thermal printer

ActiveUS9108436B1Simple configurationTypewritersOther printing apparatusEngineeringMechanical engineering

Owner:MITSUBISHI ELECTRIC CORP

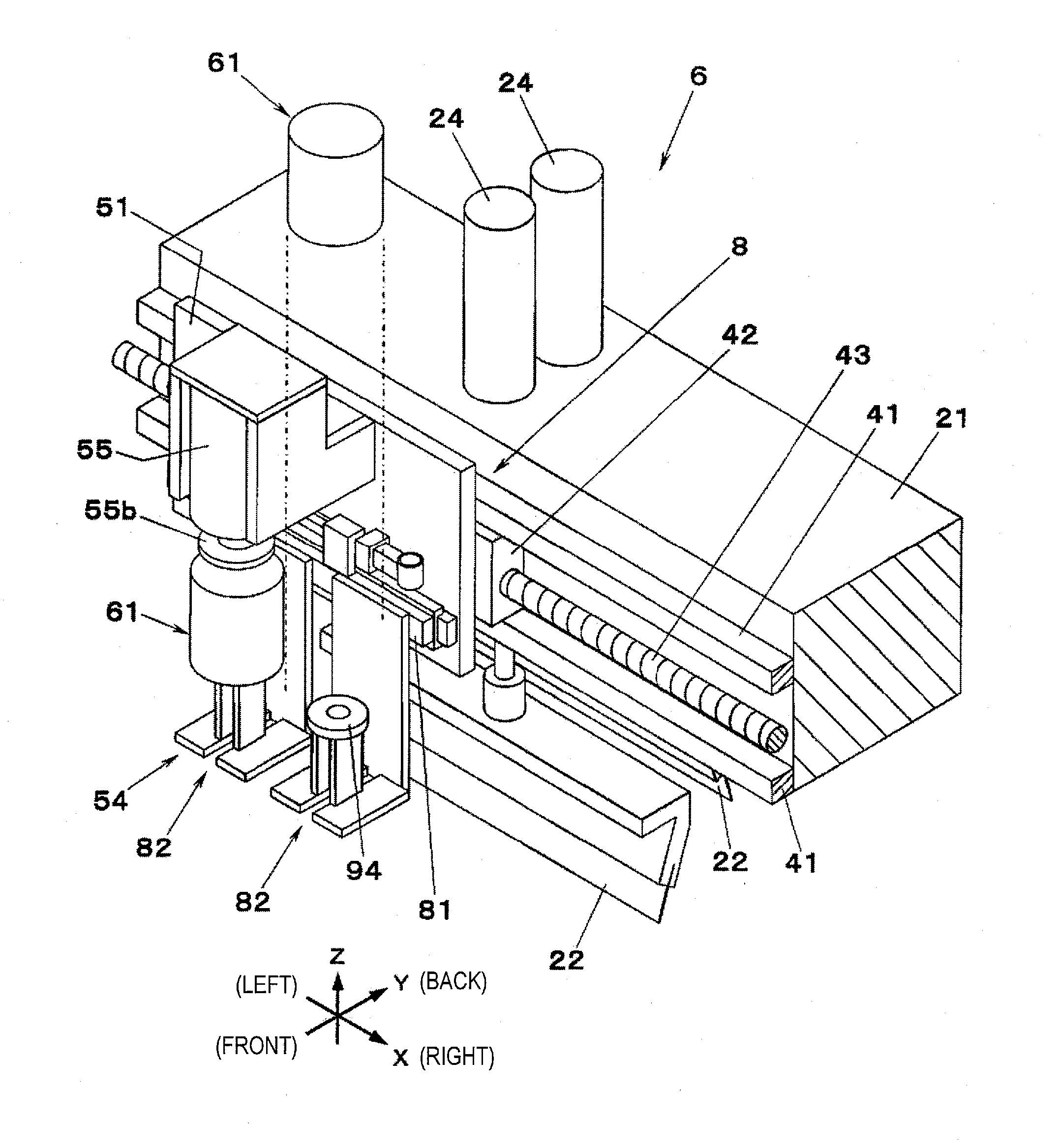

Paste supply apparatus, screen printing machine, paste supply method and screen printing method

ActiveUS20140366754A1Improve work efficiencyInking apparatusLiquid surface applicatorsScreen printingEngineering

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

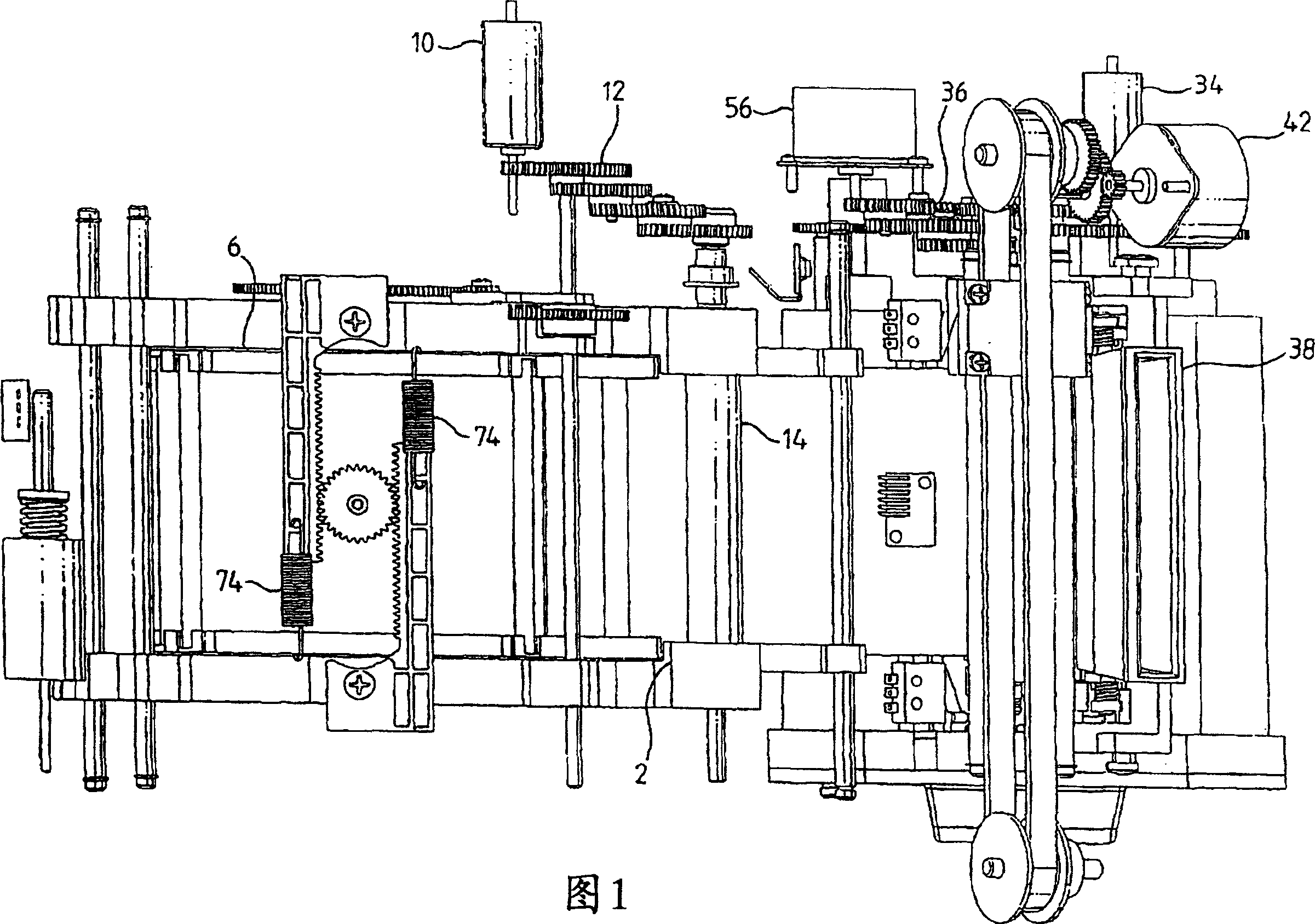

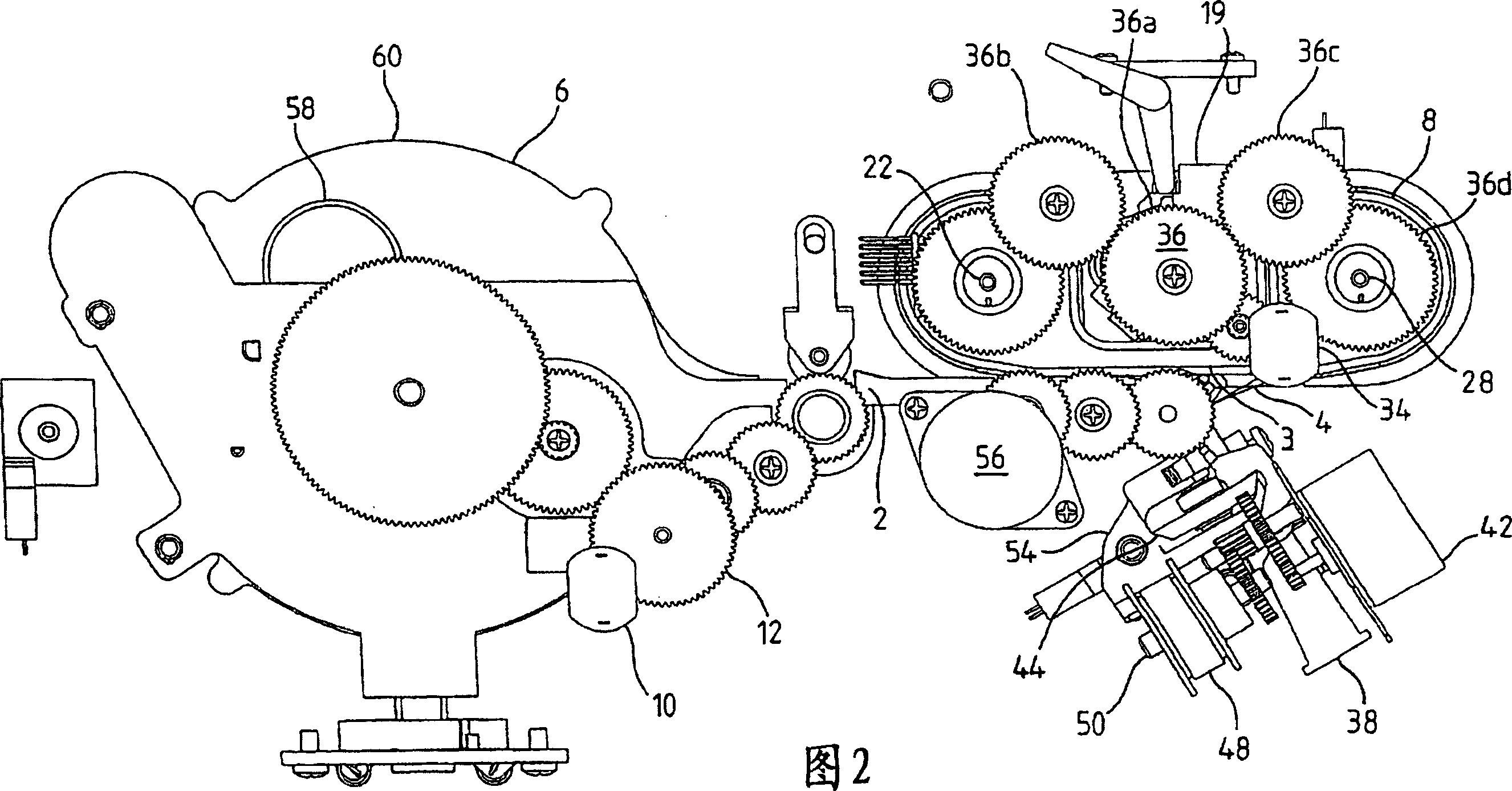

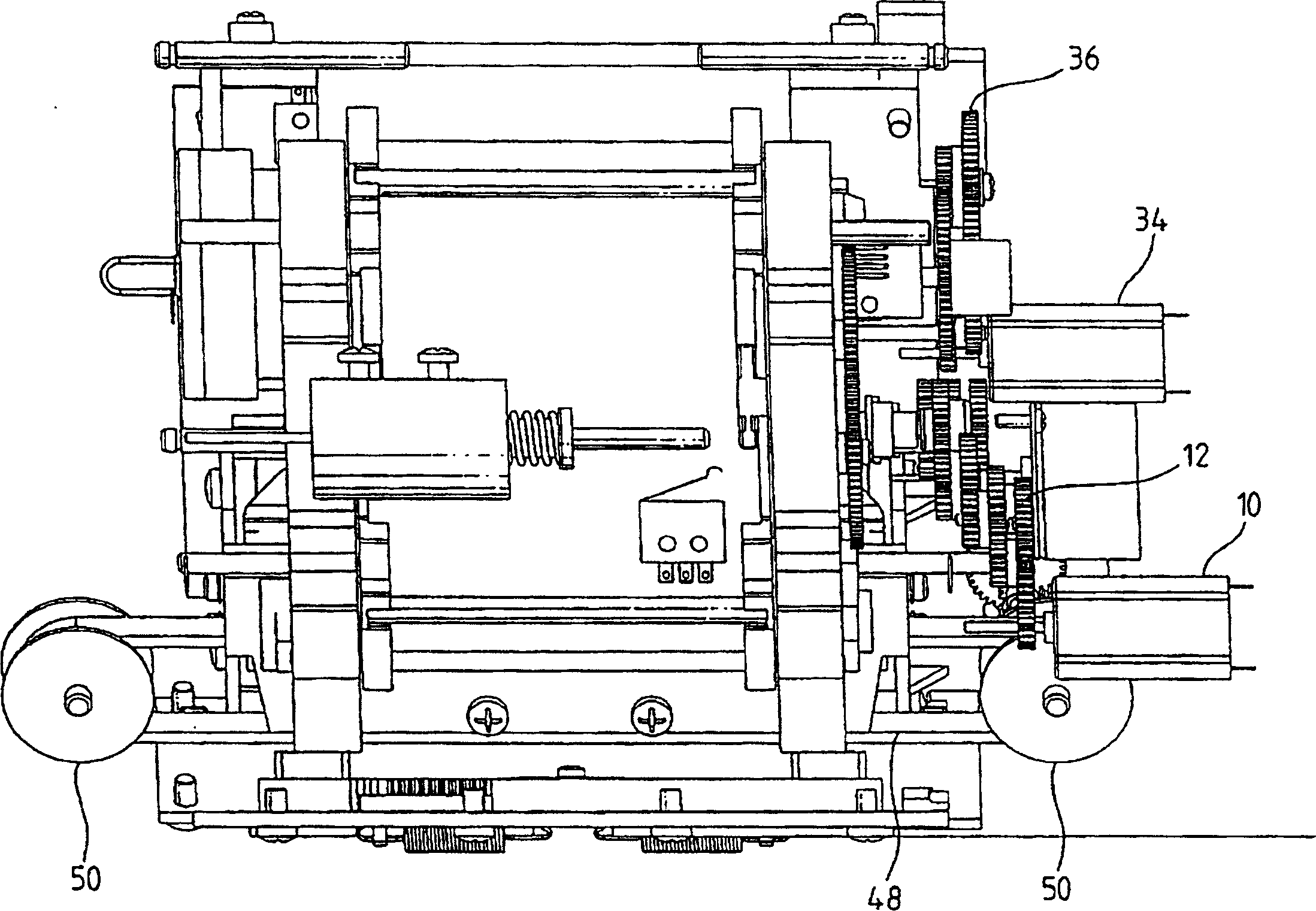

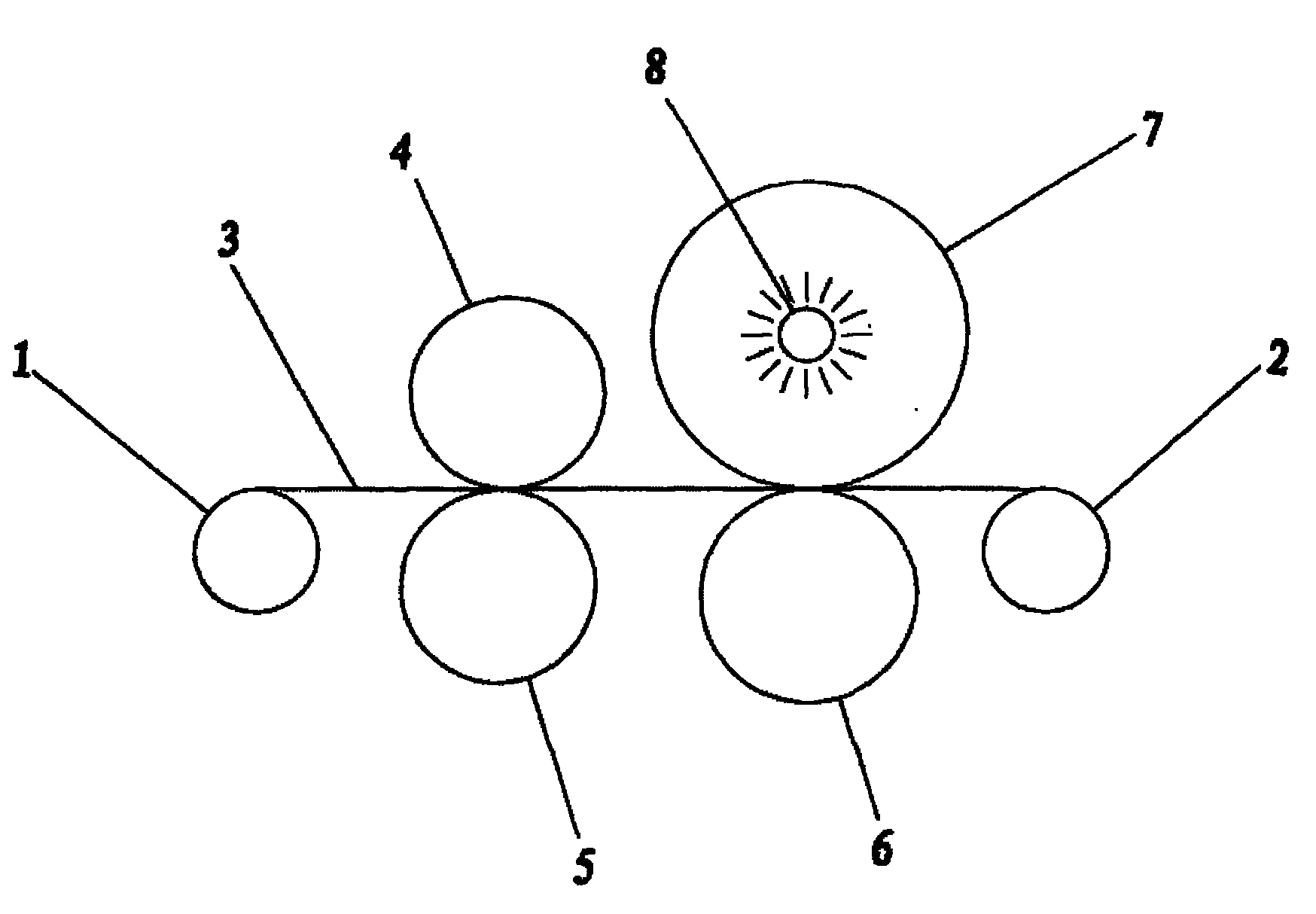

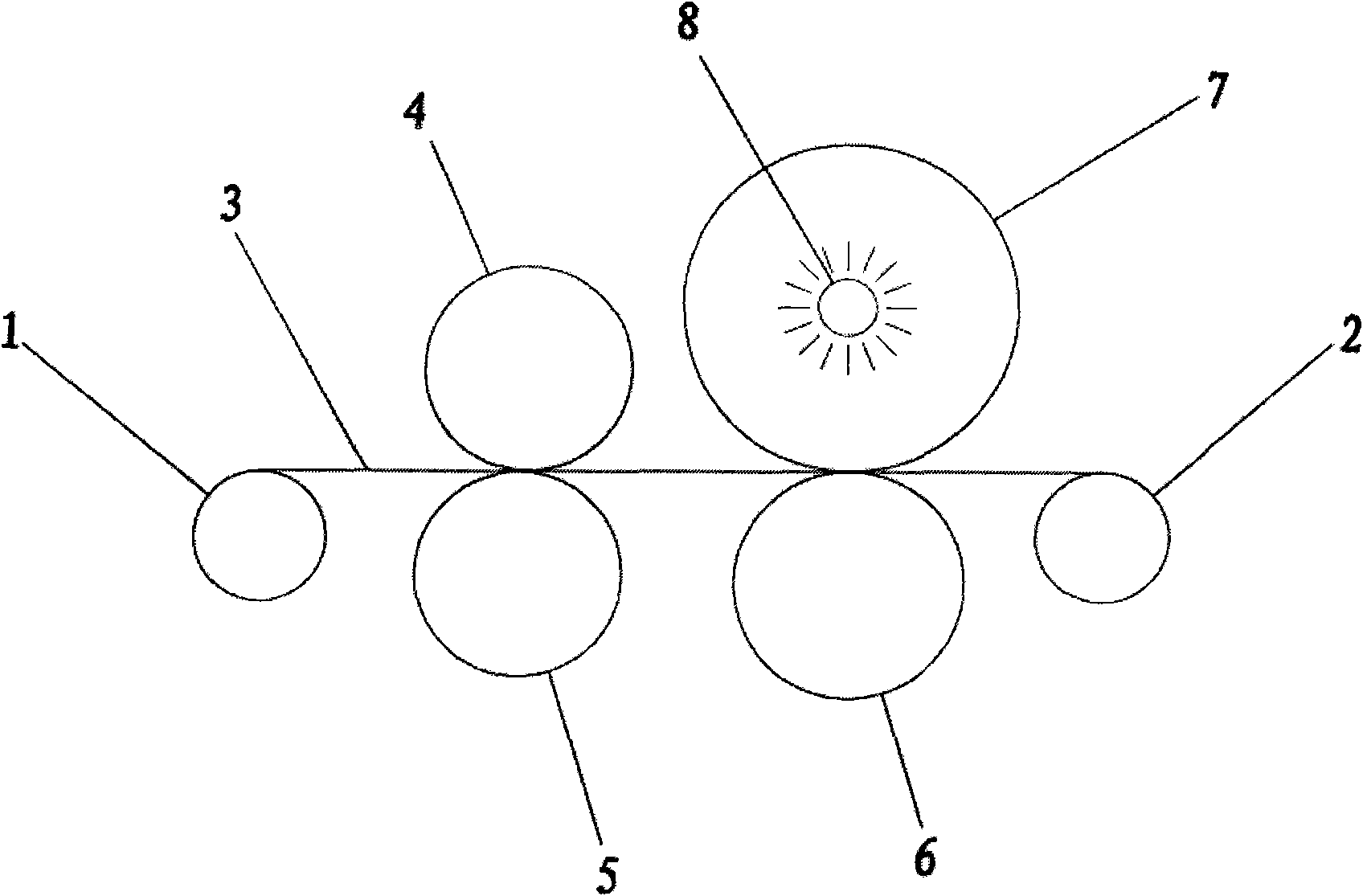

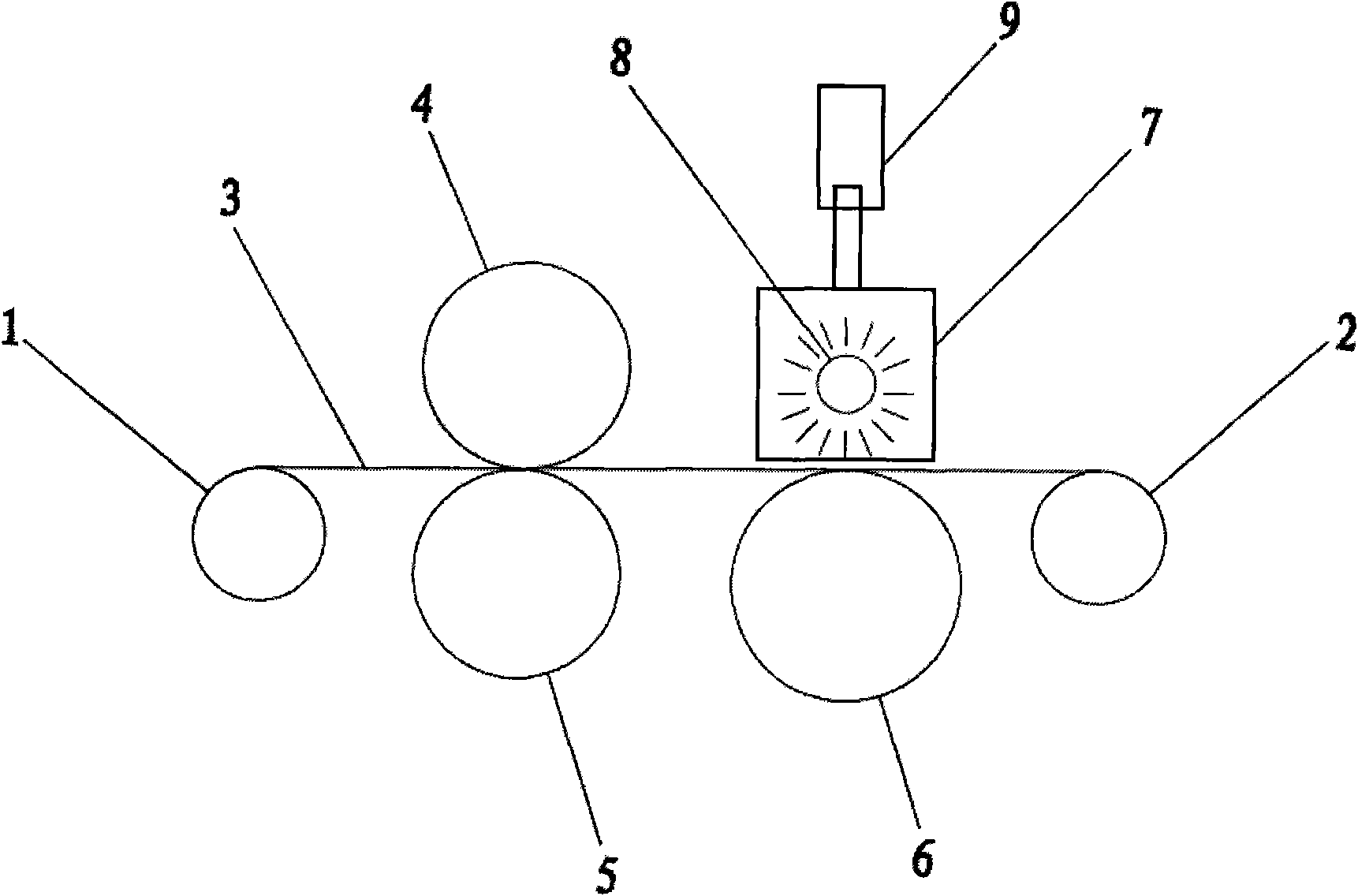

Heat transfer printing printer

ActiveCN106926588AAvoid wastingReduce printing costsOther printing apparatusSeparated statePaper tape

A heat transfer printing printer comprises a machine base, a printing rubber roller, a printing head bracket, a printing head, a thermal transfer ribbon mechanism, a paper supplying trough, a paper dividing mechanism and a paper feeding mechanism. A lifting mechanism is additionally arranged, first fastening pieces are directly mounted on the power output end of the lifting mechanism, and the lifting mechanism drives the first fastening pieces to lift and drop, so that the printing head and the printing rubber roller are in a closed state or a separation state; meanwhile, a take-up gear and a drive gear are in a meshing state or a separation state; and in the separation state, winding of a thermal transfer ribbon is suspended, so that thermal transfer ribbon waste caused by thermal transfer ribbon empty winding at the time of printing blank data is avoided, the thermal transfer ribbon is saved by a large margin, and printing cost is reduced. Limit partition boards and limit adjustment mechanisms are arranged on the two sides of a paper feeding belt and paper feeding pinch rollers, when the printing head is locally damaged and needs to change the printing position, the positions of the limit partition boards are changed by adjusting the limit adjustment mechanisms of the corresponding limit partition boards, so that the printing head can still print normally under the condition of local damage, and the printing cost is reduced.

Owner:SHANTOU HIGH TECH ZONE JUSHENG TECH CO LTD

Method and device for obtaining holographic patterns and printing machine with same

InactiveCN101797850AShorten the timePrevent fallingRotary pressesOther printing apparatusEngineeringPrinting press

Owner:BROTECH GRAPHIC

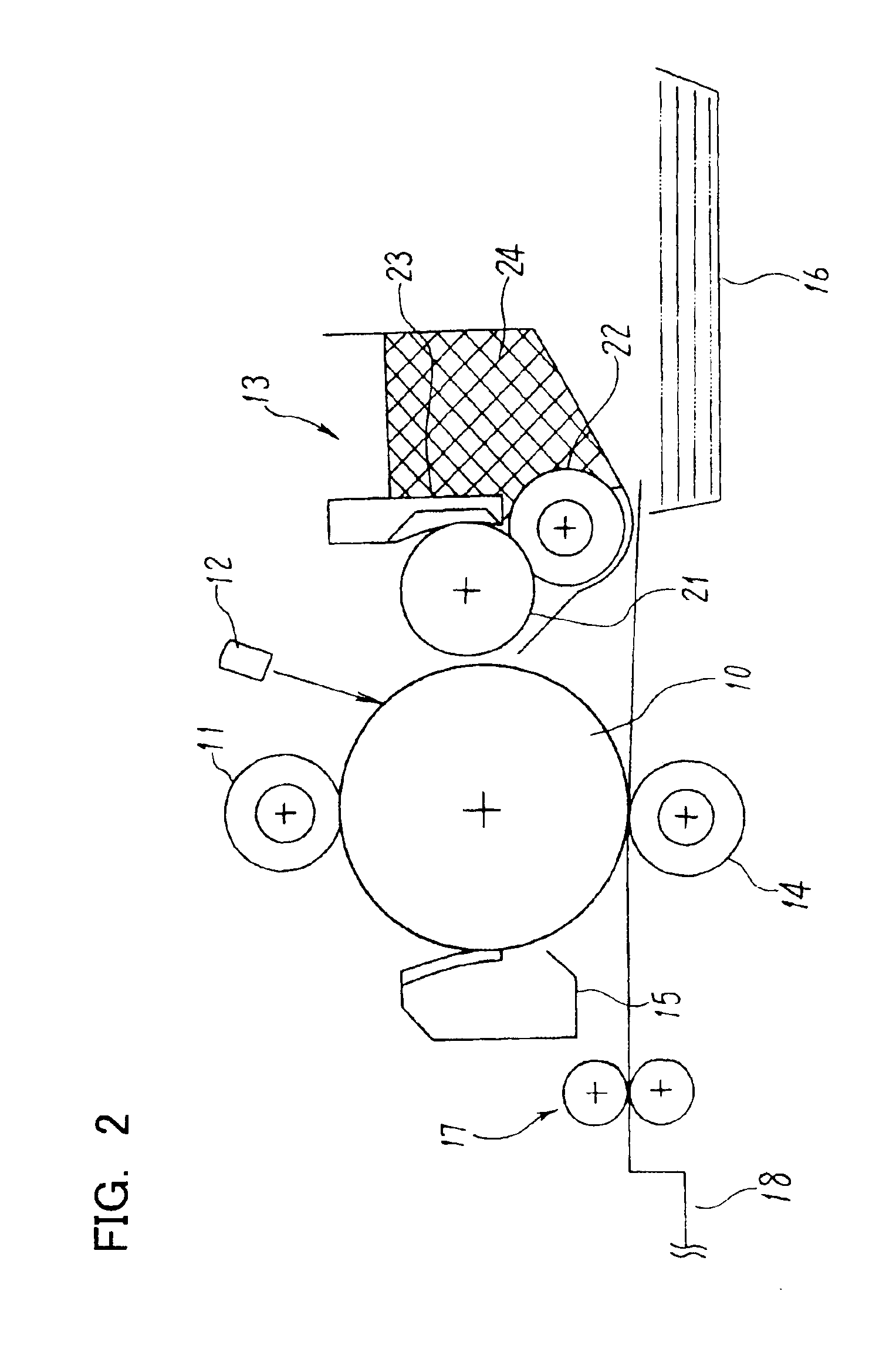

Image forming device and method

InactiveUS7167269B2Large document imageSmall capacity work memoryDigitally marking record carriersVisual presentation using printersOut of memoryImage formation

A device for printing a document, such as an HTML document, in which data to be incorporated into an output image can be described in the form of reference to an outside source, the device being capable of smooth printing a large document using a small memory. A document structural information manager creates document structural information which describes a structure of document elements, based on a result of analysis on an HTML document carried out by a document analyzer. During asynchronous downloading of substantial data of each document element, should work memory shortage occur, a memory manager unloads substantial data of a document element with a latter order at which to be incorporated into an output among those in the work memory, and saves the unloaded substantial data in an HDD. Thereafter, when data becomes no longer necessary as a result of being printed, the memory manager deletes the data from the work memory and reloads data saved in the HDD back to the work memory.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Liquid-discharging device, liquid stirring method, and liquid filling method

Owner:SEIKO EPSON CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap