Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

150 results about "Machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machines employ power to achieve desired forces and movement. A machine has a power source and actuators that generate forces and movement, and a system of mechanisms that shape the actuator input to achieve a specific application of output forces and movement. Modern machines often include computers and sensors that monitor performance and plan movement, and are called mechanical systems. The meaning of the word "machine" is traced by the Oxford English Dictionary to an independently functioning structure and by Merriam-Webster Dictionary to something that has been constructed. This includes human design into the meaning of machine. The adjective "mechanical" refers to skill in the practical application of an art or science, as well as relating to or caused by movement, physical forces, properties or agents such as is dealt with by mechanics. Similarly Merriam-Webster Dictionary defines "mechanical" as relating to machinery or tools. Power flow through a machine provides a way to understand the performance of devices ranging from levers and gear trains to automobiles and robotic systems.

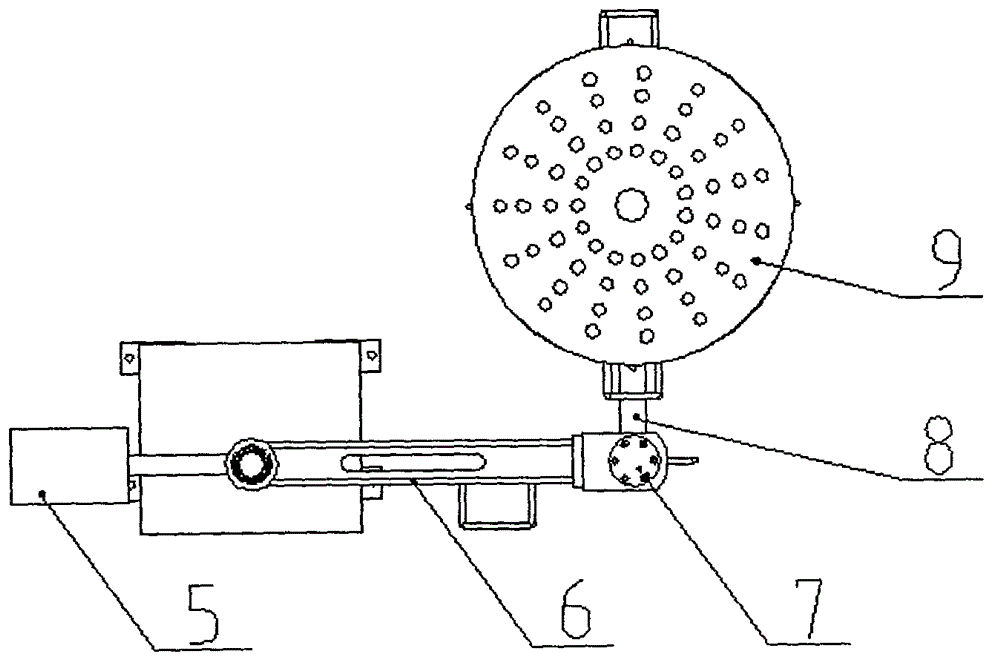

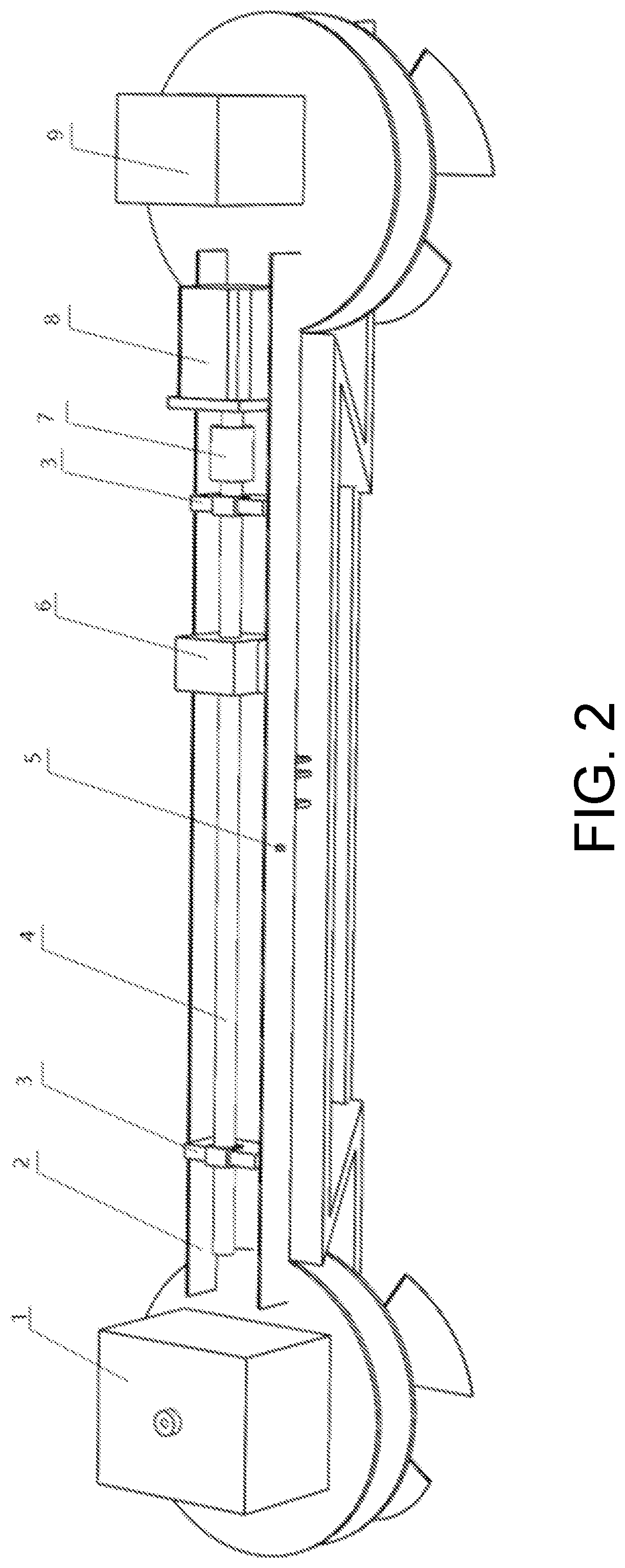

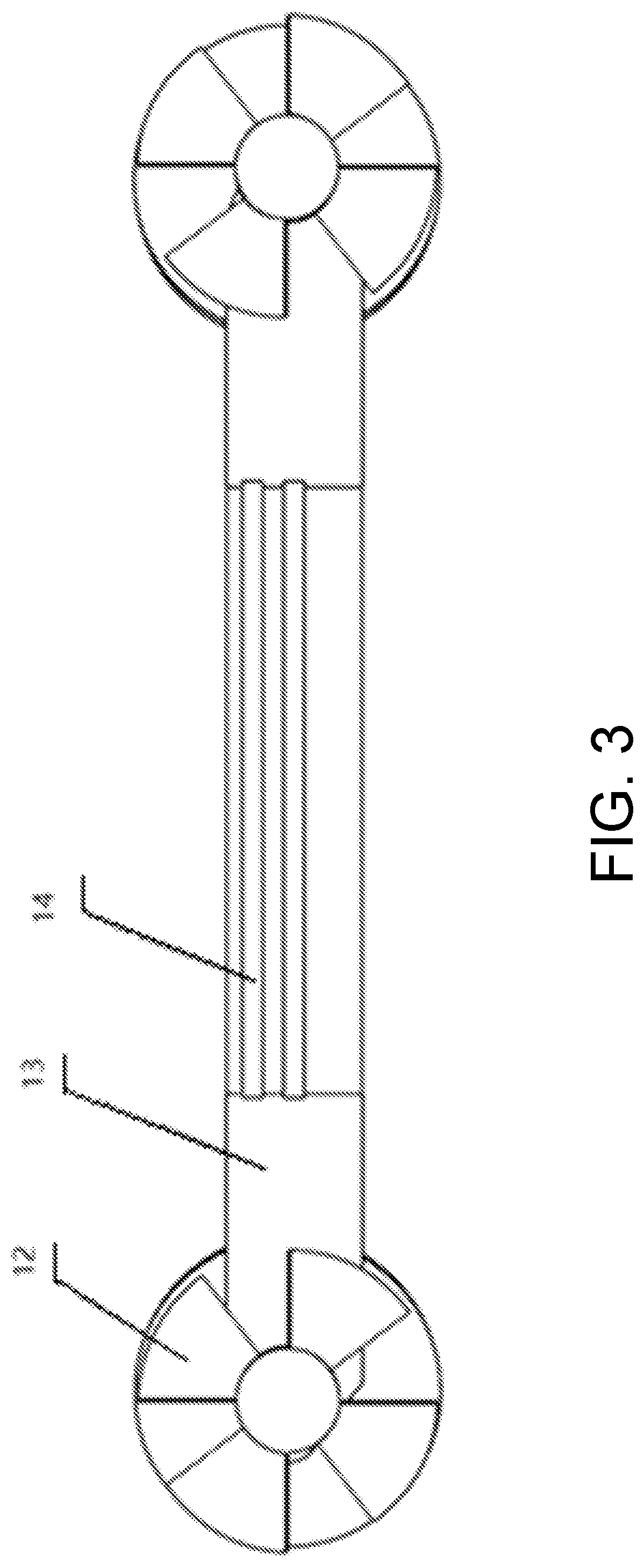

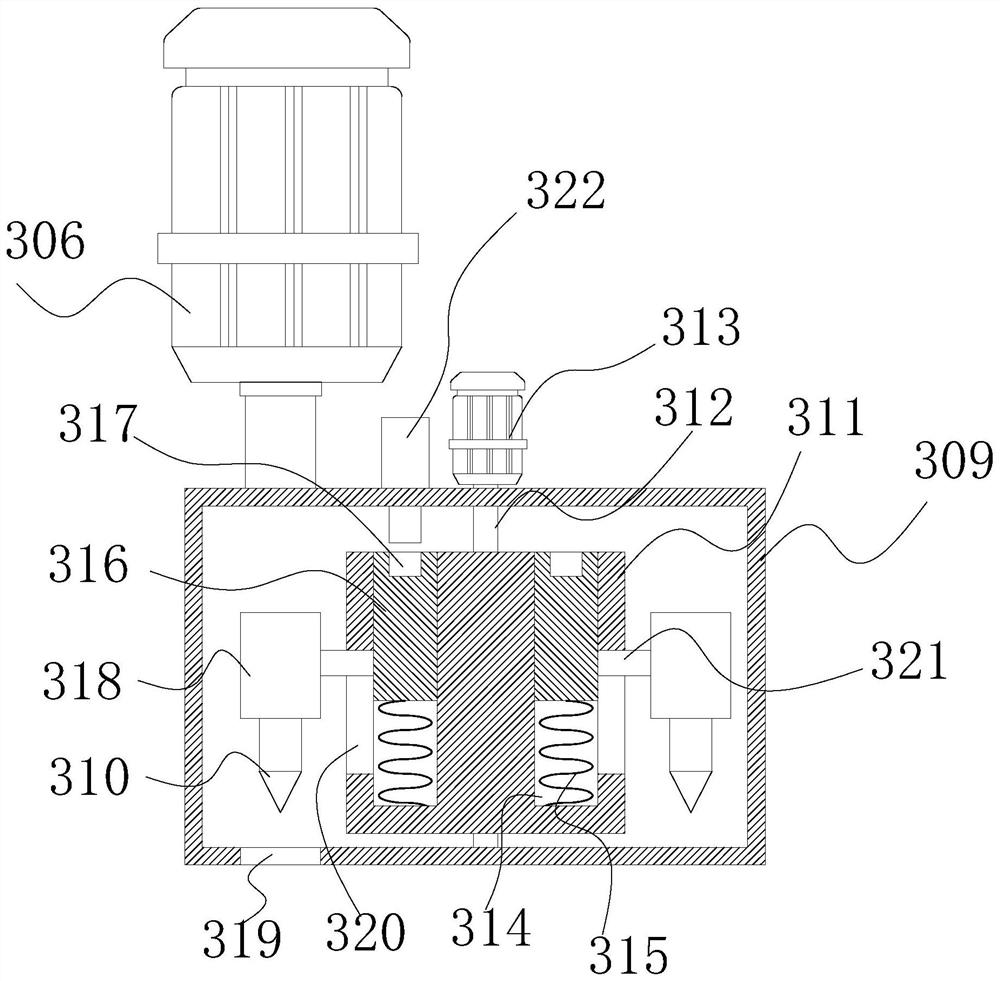

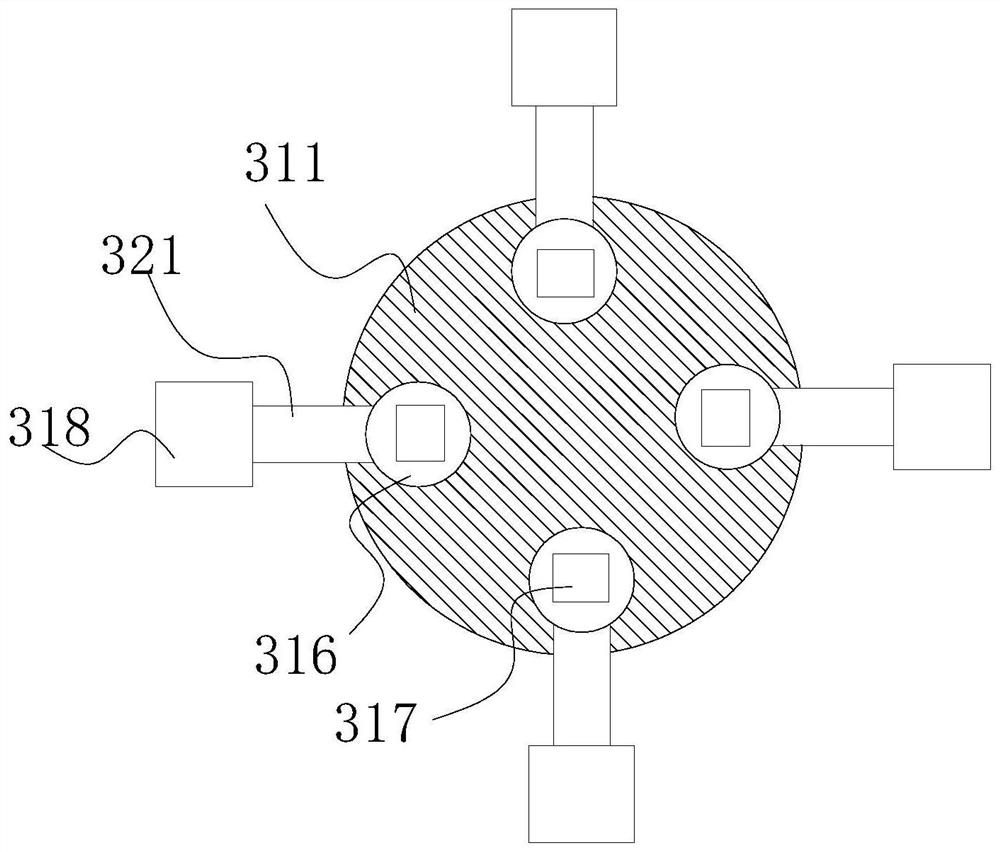

Punching and grooving device for manufacturing small wood vehicle wheels

InactiveCN111070340AImprove work efficiencyStationary drilling machinesMulti-purpose machinesMachineAutomotive engineering

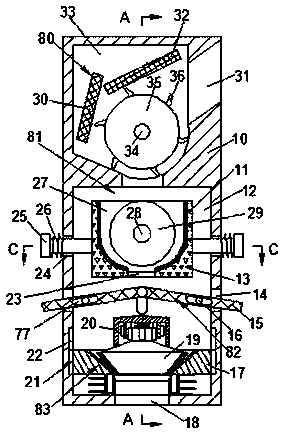

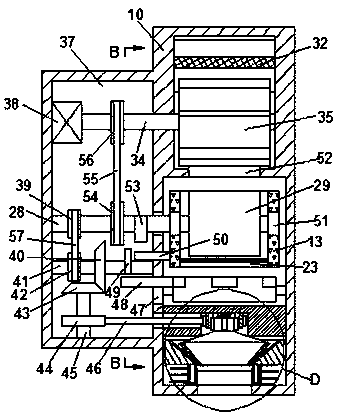

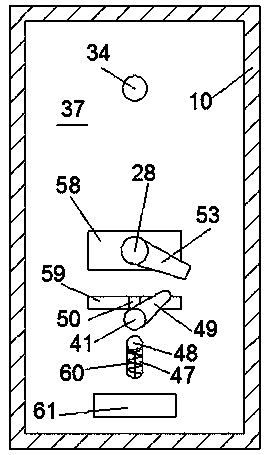

The invention relates to a punching and grooving device, in particular to a punching and grooving device for manufacturing small wood vehicle wheels. The technical objective is to design and provide the punching and grooving device for manufacturing the small wood vehicle wheels which is capable of simultaneously punching and grooving the wood vehicle wheels, convenient to operate and high in working efficiency, and is capable of collecting the punched and grooved wood vehicle wheels. The punching and grooving device for manufacturing the small wood vehicle wheels comprises a base, a rotatingshaft, a circular frame and the like, wherein the rotating shaft is rotationally connected to the middle of the top of the base, the rotating shaft is connected with the base through a bearing seat, and the circular frame capable of placing the wood vehicle wheels is fixedly connected to the top end of the rotating shaft. According to the punching and grooving device for manufacturing the small wood vehicle wheels, the proper number of wood vehicle wheels are put into the circular frame to be fixed by a clamping mechanism, a punching machine is started, a pushing plate is pushed to move downwards, the punching machine can punch the wood vehicle wheels, a grooving ring grooves the wood vehicle wheels, and the situation that a punching tool does not need to be taken by a human hand to punchthe wood vehicle wheels, and then a grooving tool is replaced for grooving is avoided, so that the working efficiency is high.

Owner:龙立明

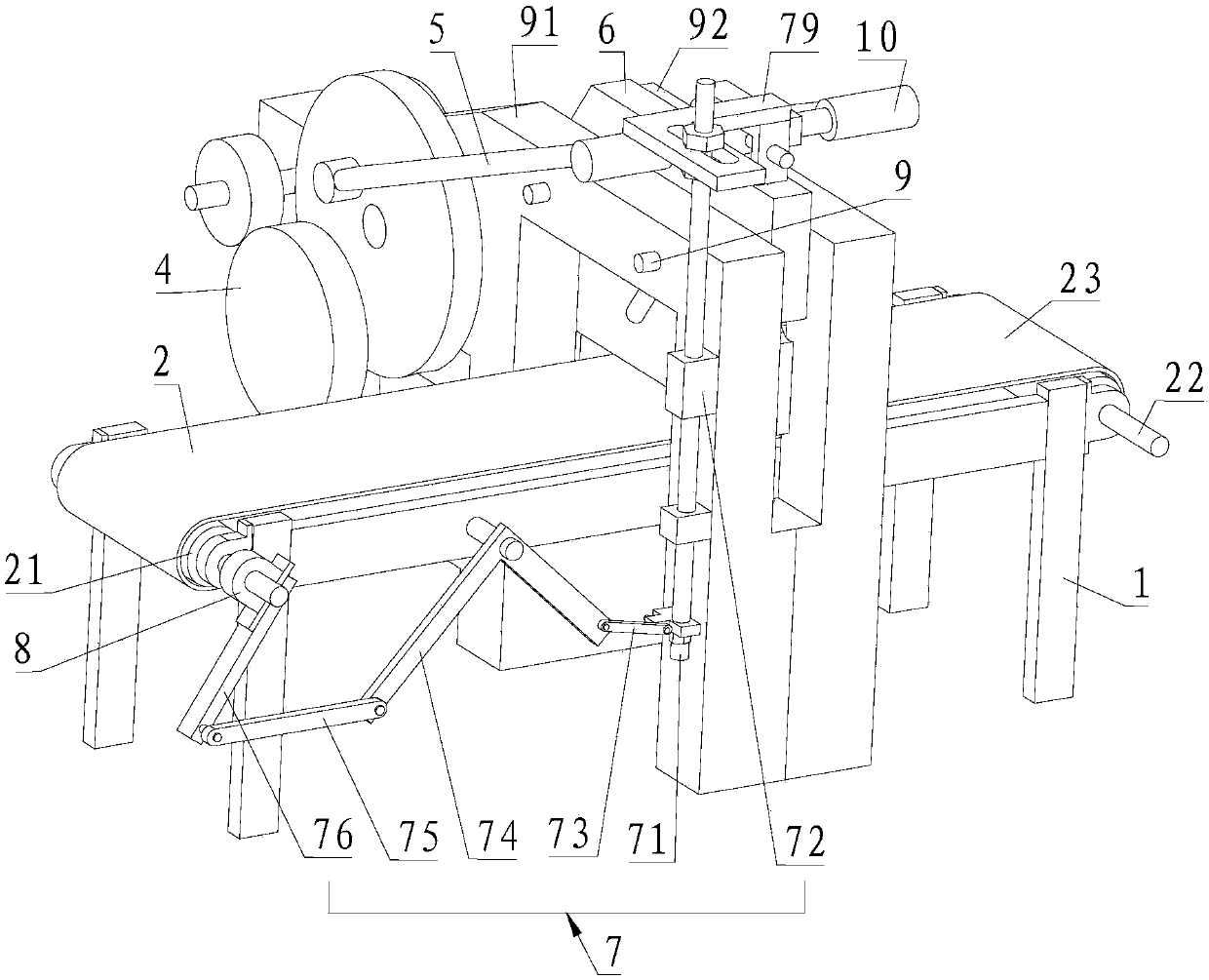

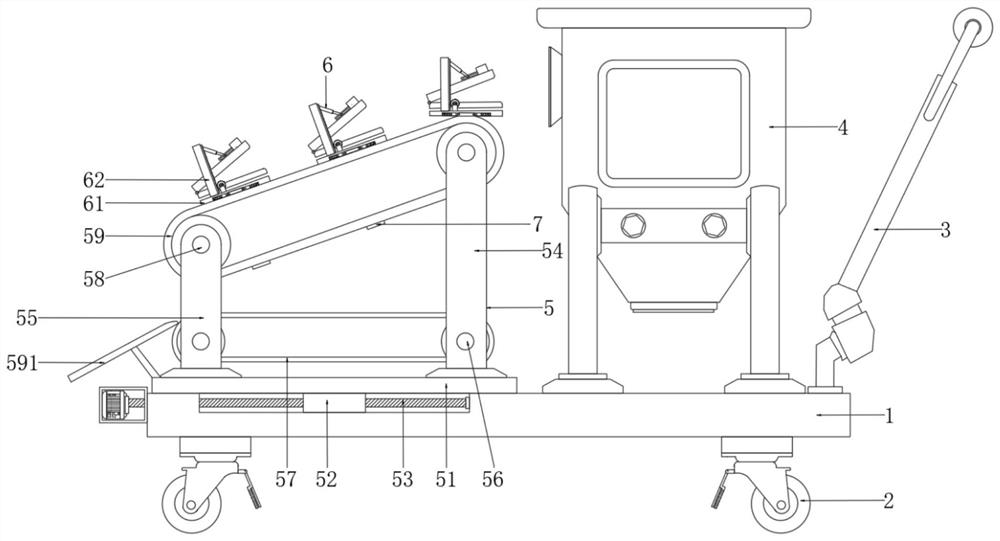

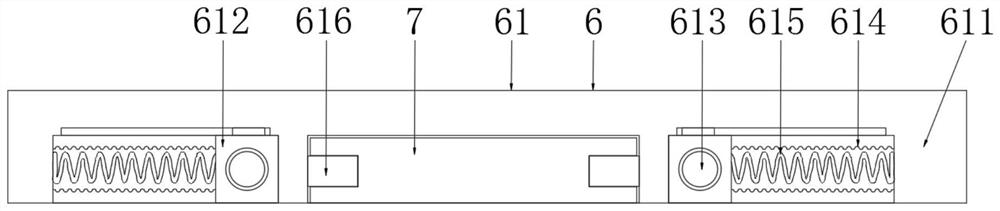

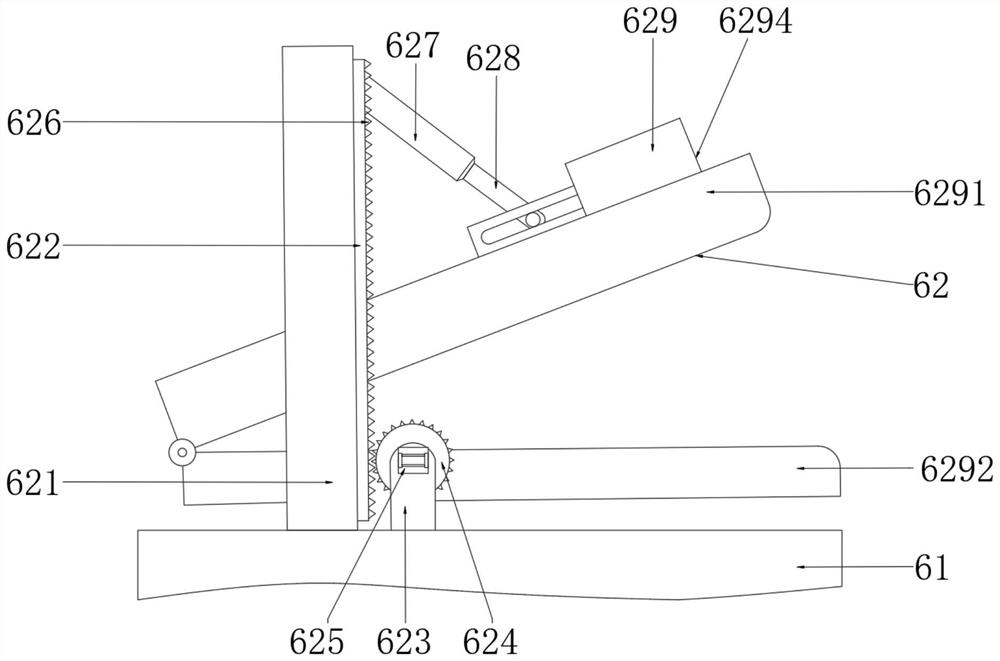

Telescopic belt conveyor changeable in amplitude and direction

ActiveCN106966116AFunction increaseExtended working hoursConveyorsLogistics managementClassical mechanics

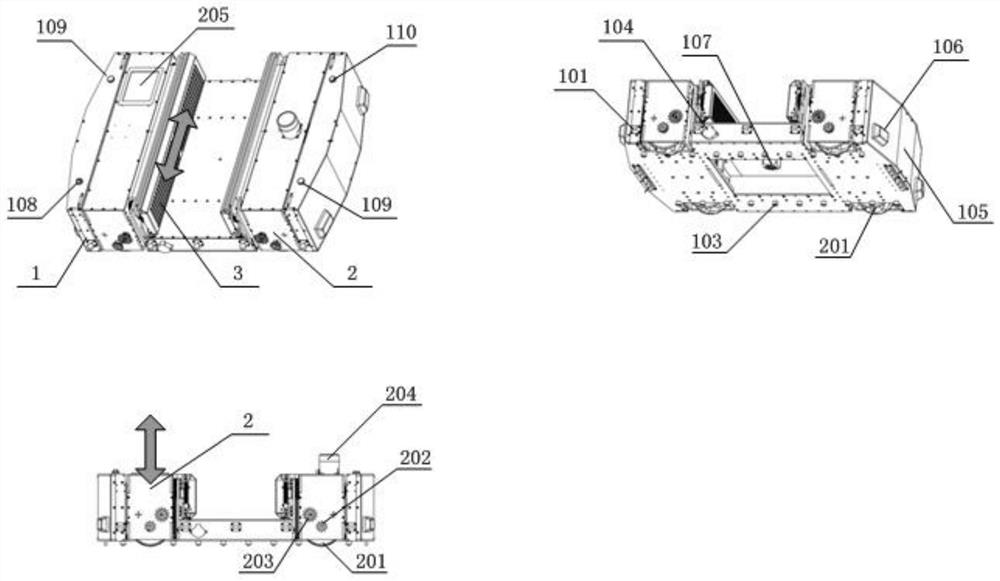

The invention discloses a telescopic belt conveyor changeable in amplitude and direction, and relates to the field of logistics transportation cargo handling mechanical equipment. The telescopic belt conveyor is composed of a three-section two-stage telescopic belt conveyor body with a telescopic function, an amplitude change mechanism with tilting and amplitude change functions, and a swing rotating mechanism with swing rotating and direction change functions. According to the telescopic belt conveyor changeable in amplitude and direction, a sleeved telescopic machine frame structure is adopted, and the elongation and shortening function, the tilting and amplitude change functions and the swing rotating and direction change functions of the belt conveyor are added by additionally arranging the amplitude change mechanism and the swing rotating mechanism; the conveying range is widened, along with conducting of the loading, unloading and conveying processes, under the condition that loading and unloading places of materials are changed, the conveying distance, height and direction are adjusted by driving and controlling a telescopic mechanism, the amplitude change mechanism and a direction change mechanism, and thus, the telescopic belt conveyor can adapt to change of the loading and unloading places; cargoes are directly delivered to the destination through only one time of loading and unloading, manual auxiliary carrying is reduced, the labor intensity is relieved, the operation time is shortened, the loading and unloading efficiency is improved, and the loading and unloading carrying cost is reduced; and the working environment and the labor condition are effectively improved, and the effect that loading and unloading transport is economical, rapid, convenient and safe is ensured.

Owner:XIANGYANG ZHONGLIANG ENG MASCH CO LTD

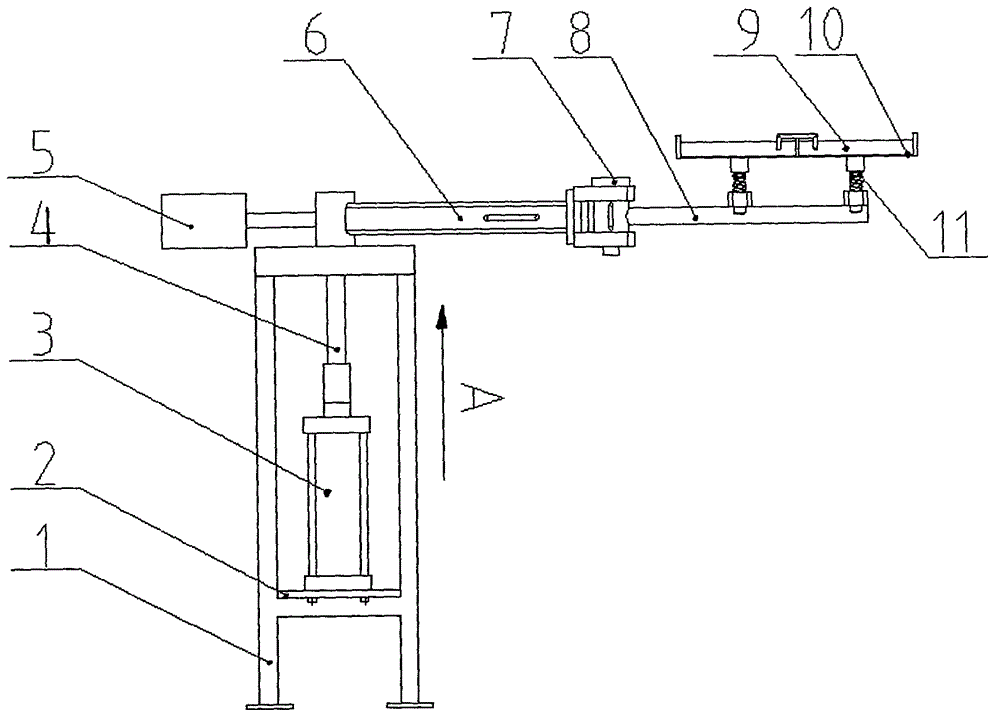

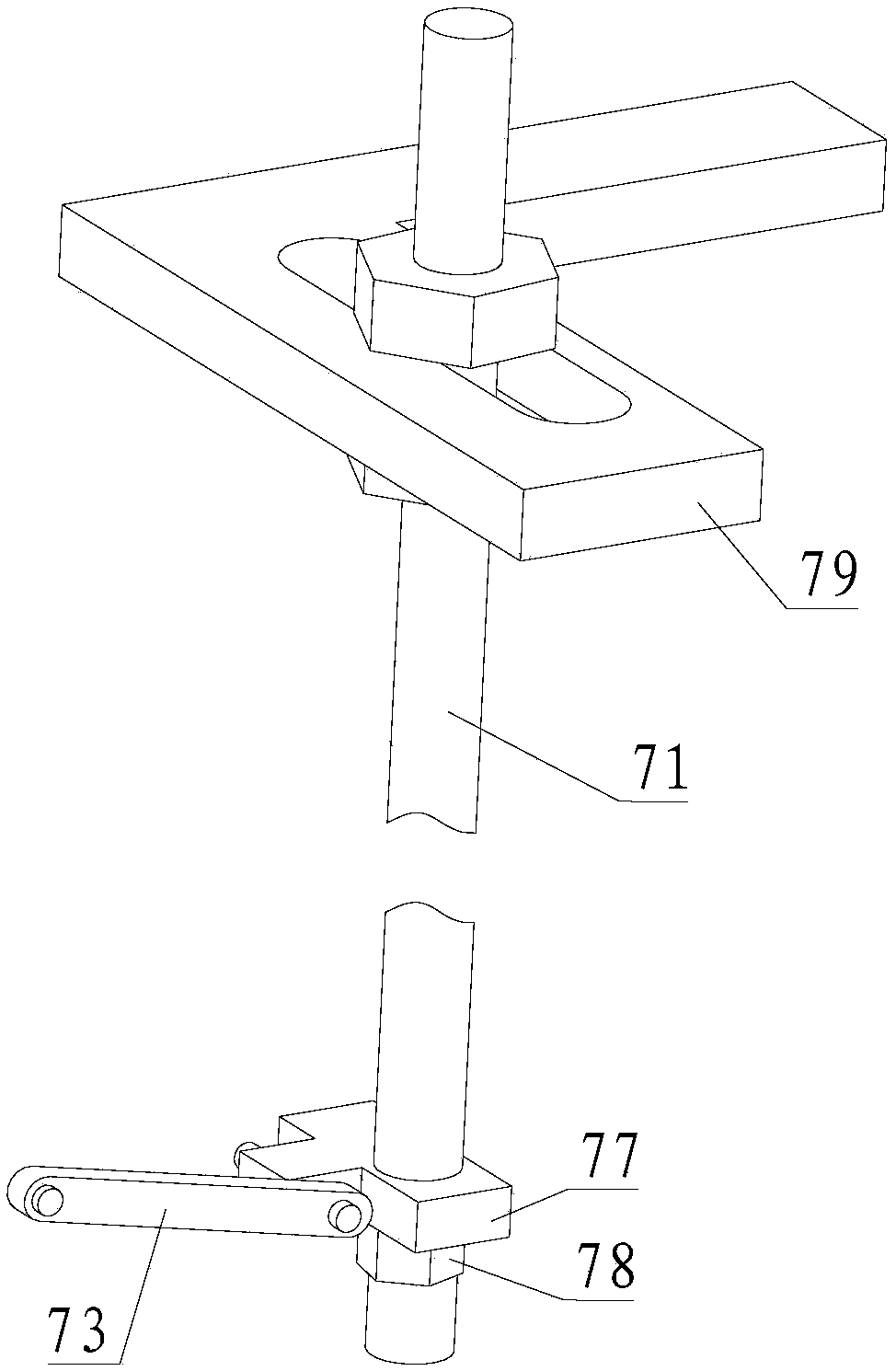

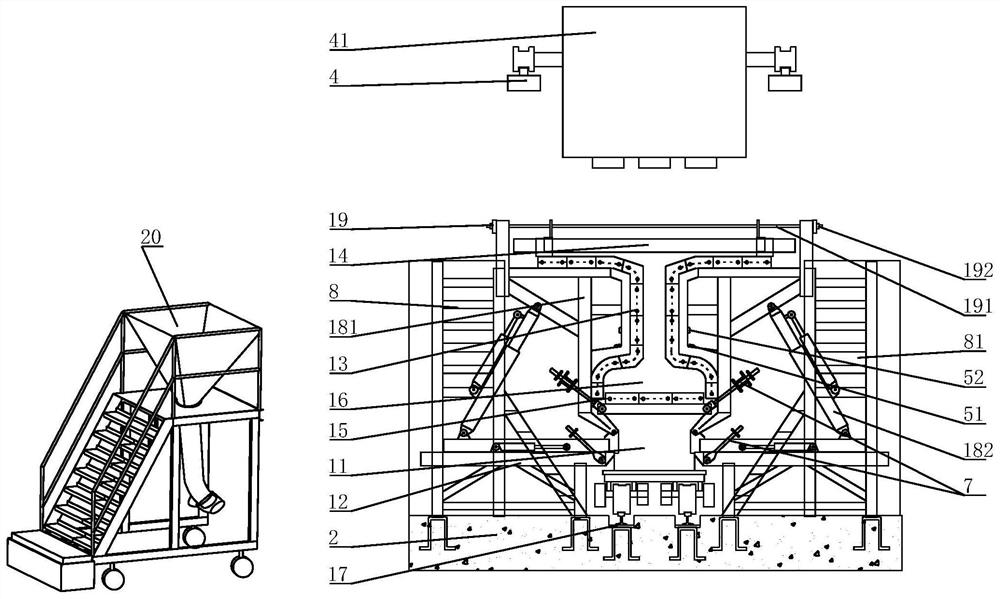

Automatic cast receiving method for rollover casting machine and receiving mechanical arm thereof

InactiveCN102873314AEasy to install and debugReduce manufacturing costProgramme-controlled manipulatorRotational axisManipulator

The invention relates to an automatic cast receiving method for a rollover casting machine. The method comprises the following steps of: after casting and mold opening of the casting machine, firstly rotating a mechanical arm comprising a main arm and an auxiliary arm to extend into the interior of the rollover casting machine, and aligning a disc on the auxiliary arm with a cast in position; then controlling a driving device to drive the mechanical arm to automatically rise and receiving the cast by the disc, and then controlling the driving device to drive the mechanical arm to automatically fall, and rotating the mechanical arm outward to automatically take out the cast. The adopted mechanical arm is characterized in that the driving device is mounted on a base; the driving device is connected with the main arm by a transmission rod; one end of the main arm is connected with a balancing block, and the other end is connected with the auxiliary arm by a rotating shaft; and a tray is mounted to the tail end of the auxiliary arm. The automatic cast receiving method for the rollover casting machine provided by the invention has the beneficial effect that installation and debugging are convenient, the manufacturing cost is low, the production efficiency is obviously improved, the labor intensity is effectively lowered, and potential safety hazard is eliminated.

Owner:WENZHOU RUIMING IND

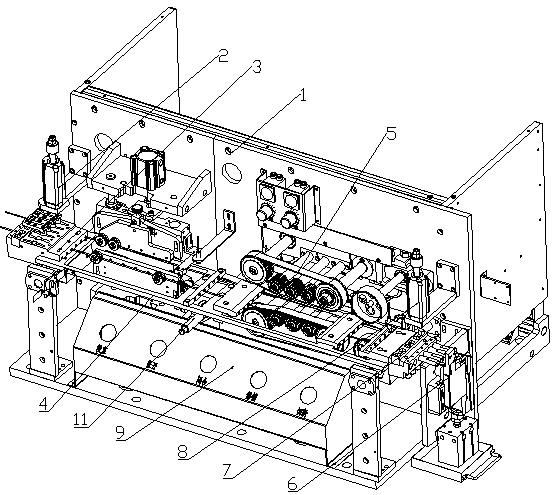

Tool changing trolley and PCB drilling and milling machine

PendingCN111586974AEasy to recycleRealize unmannedInsulating layers/substrates workingRobot handMachine

The invention belongs to the technical field of PCB processing, and discloses a tool changing trolley which comprises a trolley body, at least two layers of supporting plates arranged in the trolley body in a sliding manner, a tool box placing plate mounted on the supporting plate and sliding along with the supporting plate, a tool box fixed on the toolbox placing plate and used for placing a tool, and a manipulator arranged on the trolley body and used for taking and placing the toolbox. According to the tool changing trolley, at least two layers of supporting plates are arranged, so that atleast two layers of tool boxes can be placed, multi-layer placement of tools is achieved, the tool placing number is increased, and the working efficiency of the tool changing trolley is improved. Theinvention further provides a PCB drilling and milling machine with the tool changing trolley, unmanned, intelligent and flexible tool changing procedures can be achieved, a movable tool holder is matched with the tool changing trolley, tools can be changed while machining is conducted, the equipment utilization rate is increased, and recovery and grinding management of the tools are facilitated.

Owner:SUZHOU VEGA TECH CO LTD

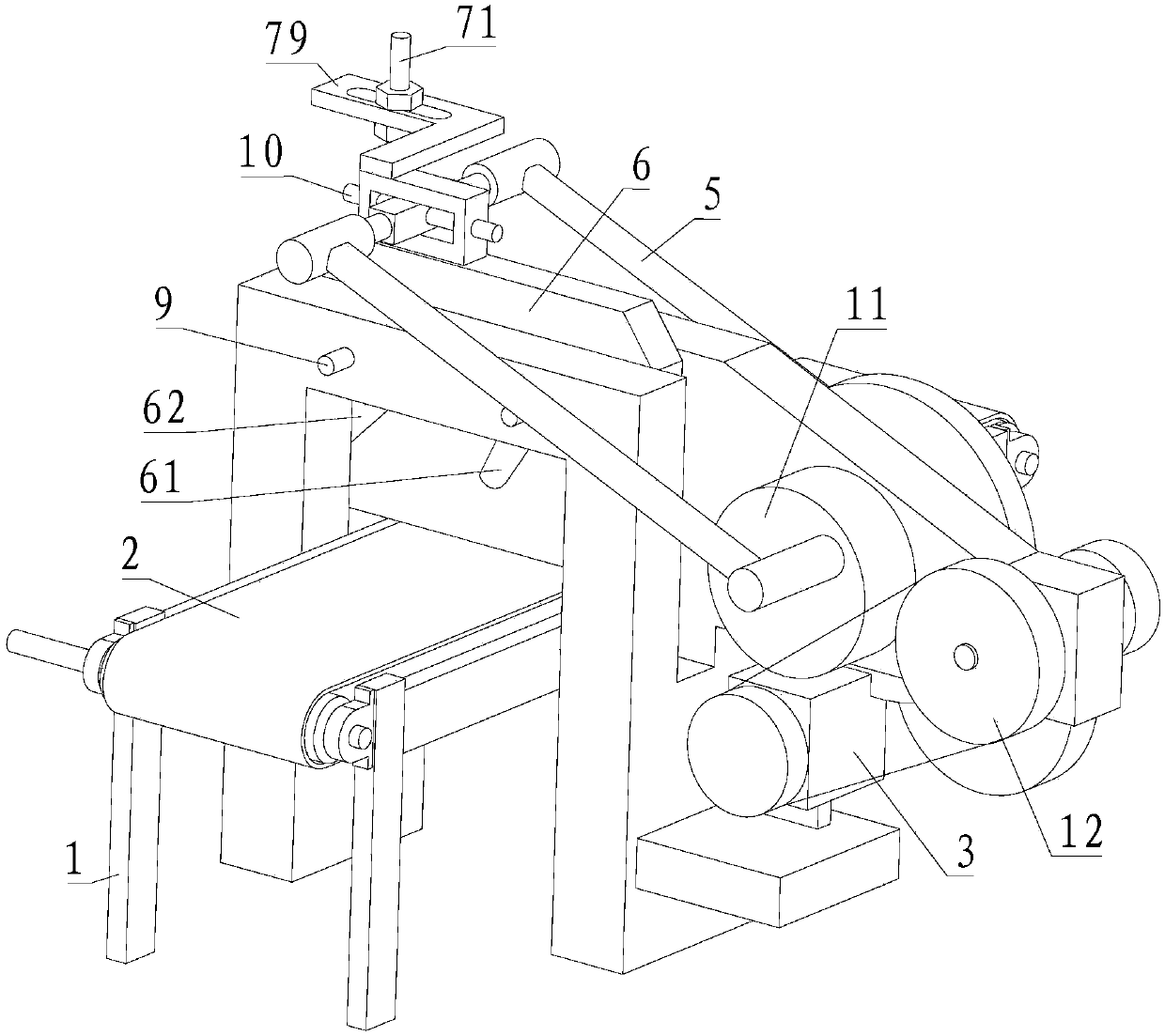

Film cutting device

PendingCN107792707AReasonable and stable structureSimple system structureConveyorsArticle deliveryEngineeringGear drive

The invention provides a film cutting device comprising a machine frame and a conveyer belt assembly. The conveyer belt assembly comprises a first rolling shaft, a second rolling shaft and a conveyerbelt. The conveyer belt is connected to the first rolling shaft and the second rolling shaft in a sleeving manner. The film cutting device further comprises a motor, a gear transmission assembly, pullrods, a cutter, a connection rod mechanism and a one-way bearing. An output shaft of the motor is connected with the input end of the gear transmission assembly. One end of each pull rod is rotationally connected with the gear transmission assembly in an eccentric manner. The other end of each pull rod is rotationally connected with the upper end of the cutter. The cutter is located above the conveyer belt. The input end of the connection rod mechanism is connected with the upper end of the cutter. The output end is connected with the first rolling shaft through the one-way bearing. The motoris fixed to the machine frame. The motor drives the cutter to move up and down through the gear transmission assembly and the pull rods, the first rolling shaft is driven to conduct intermittent rotation through the connection rod mechanism and the one-way bearing, and the two actions of film cutting and feeding are achieved. The film cutting device is simple in system and saves energy.

Owner:王友炎

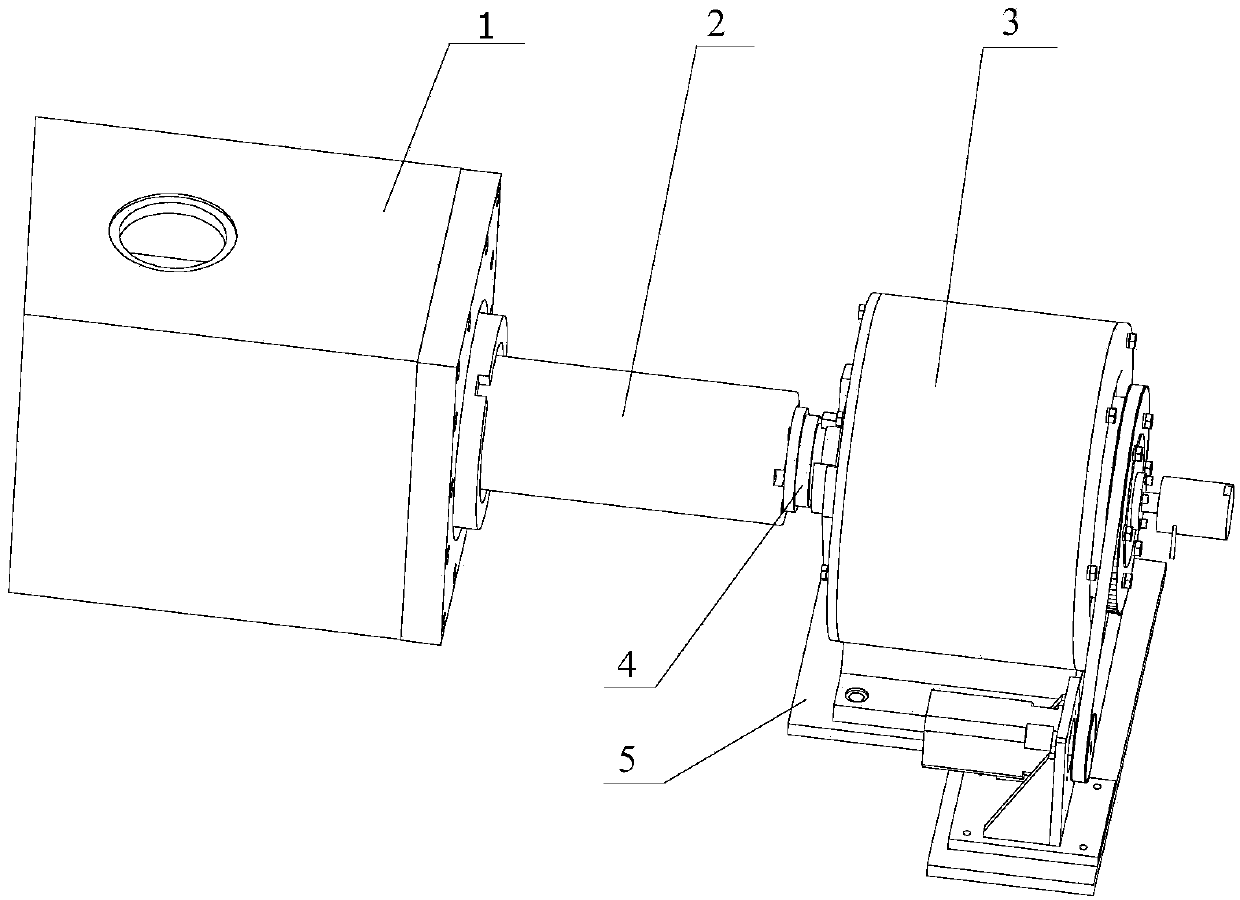

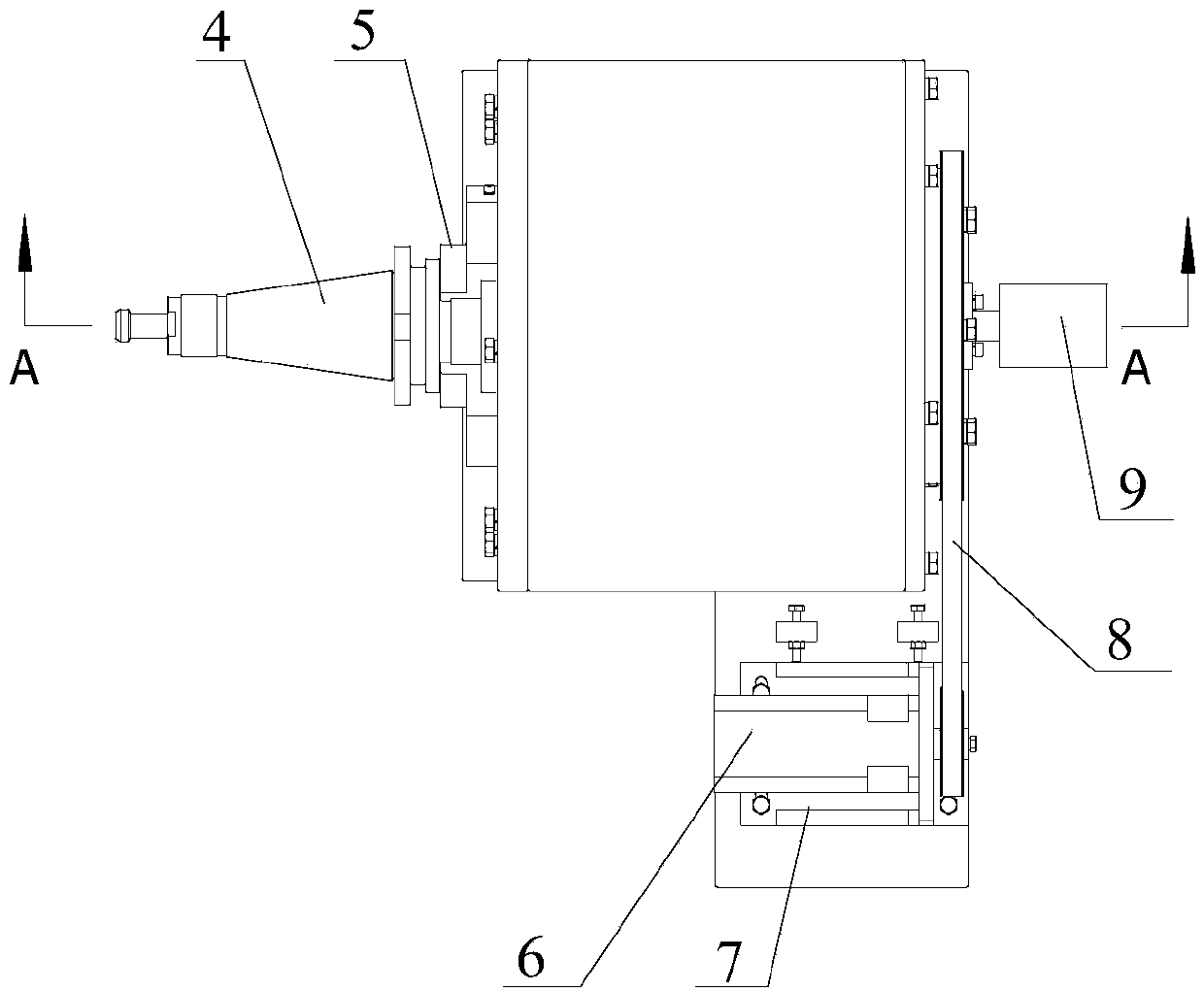

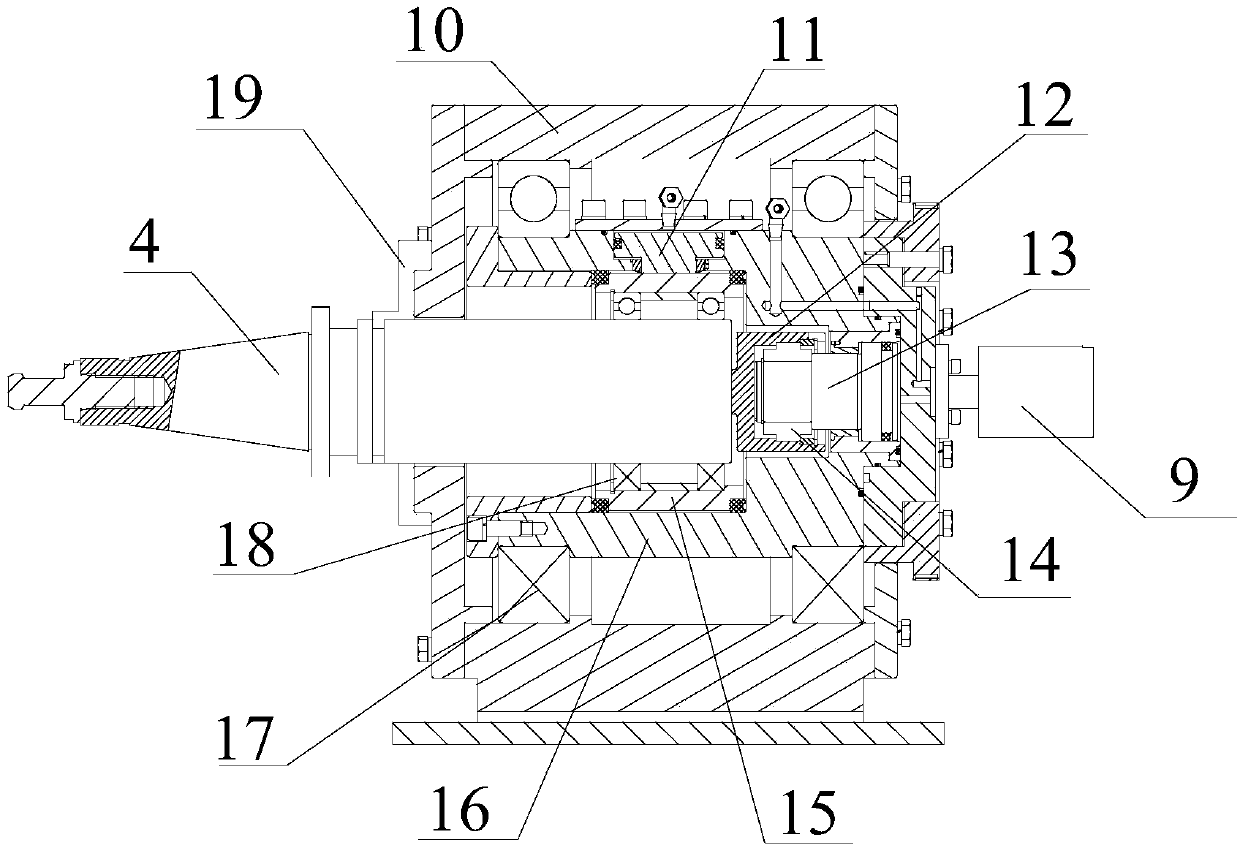

Machine tool cutting force simulation loading device

ActiveCN103737431AHigh simulationSimple structureProgramme controlMeasurement/indication equipmentsNumerical controlHydraulic cylinder

Owner:通用技术齐齐哈尔二机床有限责任公司

Automatic cutting, grinding and polishing machine for PCB

InactiveCN107378707AAccurate cutting positionImprove processing efficiencyGrinding feed controlGrinding machinesVertical planeWorkspace

The invention provides an automatic cutting, grinding and polishing machine for a PCB. The automatic cutting, grinding and polishing machine comprises a machine body, a working region, a clamping jaw, an action executing unit and a control panel, wherein the machine body is provided with a horizontal plane and a vertical plane which is perpendicular to the horizontal plane and is positioned at one side of the horizontal plane; the working region is arranged on the horizontal plane, and comprises a polishing disc, a grinding disc, a cutting disc and a laser aligning device; the action executing unit is arranged on the vertical plane, and the clamping jaw is connected with the action executing unit and is driven by the action executing unit to move in the vertical plane; and the control panel is arranged on the machine body and is positioned at one side of the working region. The automatic cutting, grinding and polishing machine for the PCB provided by the invention can realize advanced determining as well as automatic continuous cutting, grinding and polishing treatment of the PCB, is accurate in cutting position, is high in processing efficiency, is good in continuity, and sufficiently meets the needs, on product structure checking, of a laboratory of the PCB.

Owner:KUNSHAN HUANSHENG ELECTRONICS CO LTD

Improved plate turnover machine with quick turnover function

PendingCN113060519ASafe and reliable actionThe rotating structure is reasonable and effectiveConveyor partsRotational axisElectric machine

The invention belongs to the technical field of plate processing, and particularly relates to an improved plate turnover machine with a rapid turnover function. According to the improved plate turnover machine, through arrangement of a rotating shaft, a rotating plate, a motor pressing unit and an elastic plate unit on a driving motor, the purposes that plates are turned over quickly and stably, and are not prone to collide and damage are achieved. The improved plate turnover machine has the advantages that a rotating structure for plate turnover is reasonable and effective, and the plate clamping type rotating turnover action is safe and reliable; the plate is not prone to damage, and a plate pushing feeding and discharging structure is simple and efficient; the mode that an elastic plate unit is pressed to store energy firstly and then assists in pushing out the plate is flexible and ingenious, and the overall plate feeding and discharging structure is rapid, labor-saving, stable and accurate; and the whole turning plate structure is stable and compact, flexible, adjustable, energy-saving and economical.

Owner:ZHEJIANG YASHA DECORATION

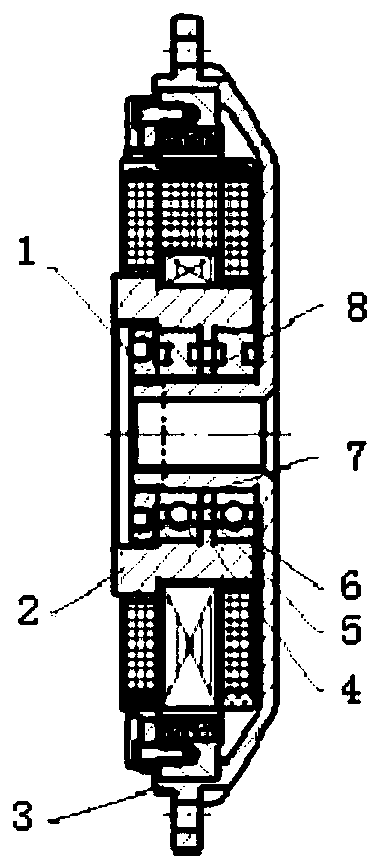

Double-screw compression and expansion all-in-one machine for fuel cell

ActiveCN112746958ASolve the problem of low recycling powerReduce speedRotary piston pumpsRotary piston liquid enginesFuel cellsElectric machine

The invention discloses a double-screw compression and expansion all-in-one machine for a fuel cell. According to the all-in-one machine, high-pressure orifices are formed in positions close to the middle of a machine body, and low-pressure orifices are formed in the two ends of the machine body; a female rotor of a compressor and a male rotor of an expander are coaxially connected and fixed, a male rotor of the compressor and a female rotor of the expander are also connected through a rotor shaft, the male rotor of the compressor is fixed to the rotor shaft, and the female rotor of the expander and the rotor shaft are in clearance fit and slide mutually; and the low-pressure side of the expander is connected with a motor. According to the all-in-one machine, the number of bearings is reduced, the size, weight and cost are lowered, the rotating speed of the expander is effectively lowered by the rotor gear ratio, and flow matching of the compressor and the expander is realized; and meanwhile, the load of the bearings is effectively lowered through the stress balance effect of the compressor rotors and the expander rotors, the power loss of the bearings is reduced, and the problem that the recovery work is little when the expander is at a low load is solved.

Owner:XI AN JIAOTONG UNIV

Natural stone crushing and grinding equipment

InactiveCN111389567ASimple and fast operationReduce manufacturing costSievingScreeningCrushed stoneStructural engineering

Owner:杭州瑞芳容科技有限公司

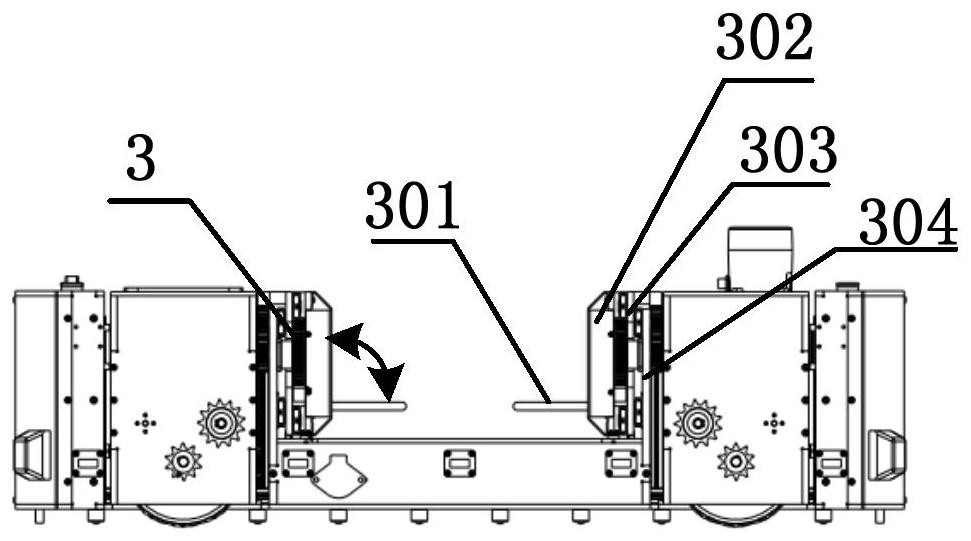

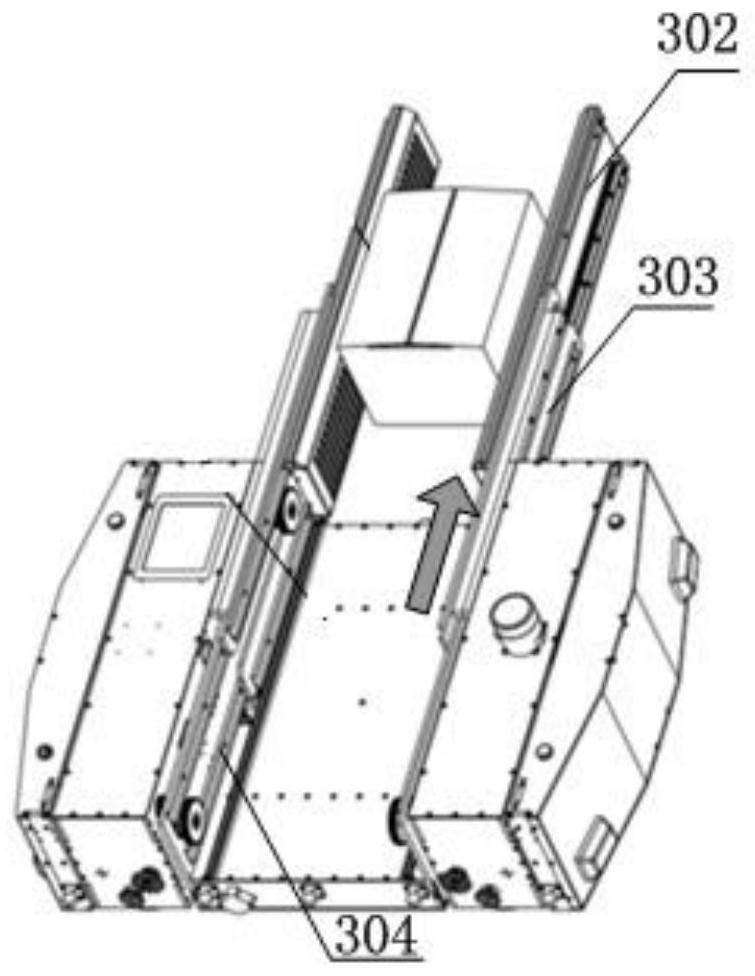

3D sorting logistics robot

ActiveCN112009926ATaking care of transportationIncrease working spaceStorage devicesLogistics managementStructural engineering

Owner:SHANGHAI AEROSPACE SYST ENG INST

Cutting device with deformation protective structure and for hydraulic power oil tank processing

ActiveCN111702250ASolve the problem of untidyImprove stabilityMetal sawing devicesMetal sawing accessoriesStructural engineeringProcess engineering

The invention discloses a cutting device with a deformation protective structure and for hydraulic power oil tank processing. The cutting device comprises a device main body, the device main body comprises a supporting column, a supporting plate is fixedly connected to the top end of the supporting column, side plates are correspondingly connected to the left and right sides of the supporting plate, a top plate is fixedly connected between the two groups of side plates, a hydraulic push rod is fixedly connected to the bottom end of the top plate, a cutting machine is fixedly connected to the bottom end of the hydraulic push rod, a trolley is movably connected to the right side of the supporting column, a transmission mechanism is arranged on the left side of the hydraulic push rod, a clamping mechanism is arranged on the upper part of the supporting plate, an extruding mechanism is arranged in the supporting plate, a pushing mechanism is arranged in the supporting plate, and a transport mechanism is arranged on the right side of the supporting plate. According to the cutting device, the stability during cutting and the accuracy of cutting of the device are improved, a metal plate after cutting can be directly dropped into the trolley, and convenience is provided for manual collection.

Owner:HUNAN YONGSHENG HYDRAULIC TECH CO LTD

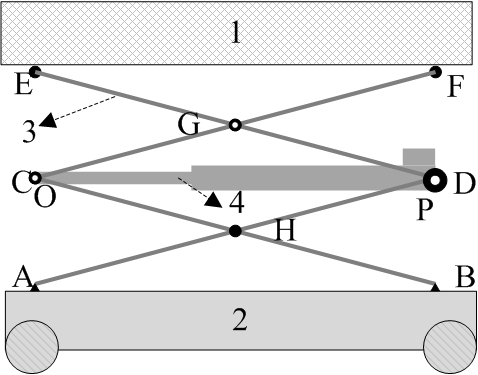

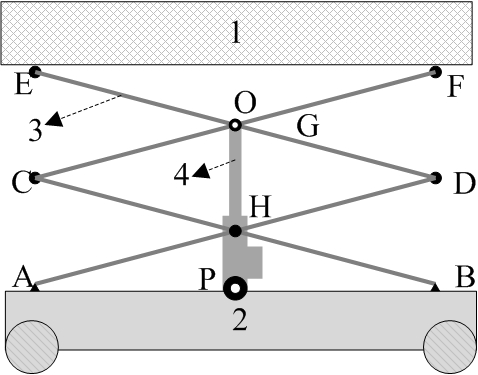

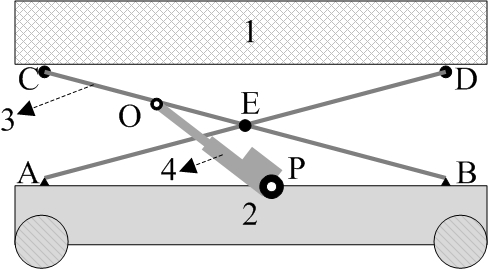

Full-electric scissor type aerial work platform

InactiveCN112850595ASolve UtilizationAddress riskSafety devices for lifting equipmentsSteering angleElectrical battery

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD

Intelligent ore crushing device with automatic adjusting function

ActiveCN113499819AWith automatic adjustment functionAutomatically adjusts the rotation rateSievingScreeningFrequency changerElectric machine

The invention discloses an intelligent ore crushing device with an automatic adjusting function. The intelligent ore crushing device comprises a machine body, a frequency converter and gravity sensors, a feeding opening is fixedly formed in the upper portion of the machine body, a forward and reverse motor is installed on the left side of the feeding opening, a second sliding groove is formed in the inner surface of the feeding opening, an opening is formed in the upper portion of the machine body, a driving motor is installed on the left side of the machine body, the output end of the driving motor is connected with a crushing roller on the upper portion in the machine body, and a second open groove is formed in the surface of the right side of the machine body. According to the intelligent ore crushing device with the automatic adjusting function, the feeding quantity can be detected through a feeding gravity detection device formed by the froward and reverse motor in the feeding opening and the gravity sensors on the surfaces of material separation plates, through cooperation with use of the frequency converter installed on the surface of the output end of the driving motor, the device can automatically adjust the rotating speed of the crushing roller driven by the driving motor conveniently by combining the material feeding quantity with use of the frequency converter, and then the ore crushing effect is improved.

Owner:SHANDONG JIUCHANG HEAVY IND TECH

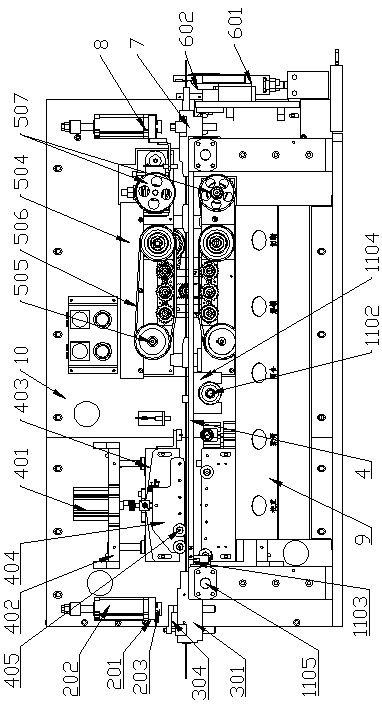

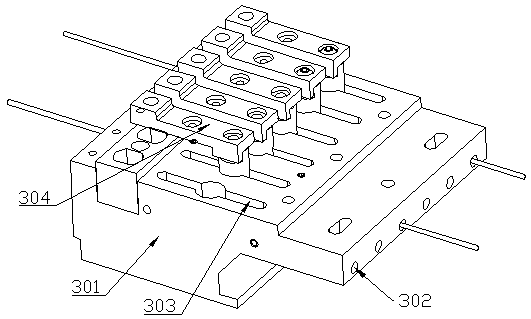

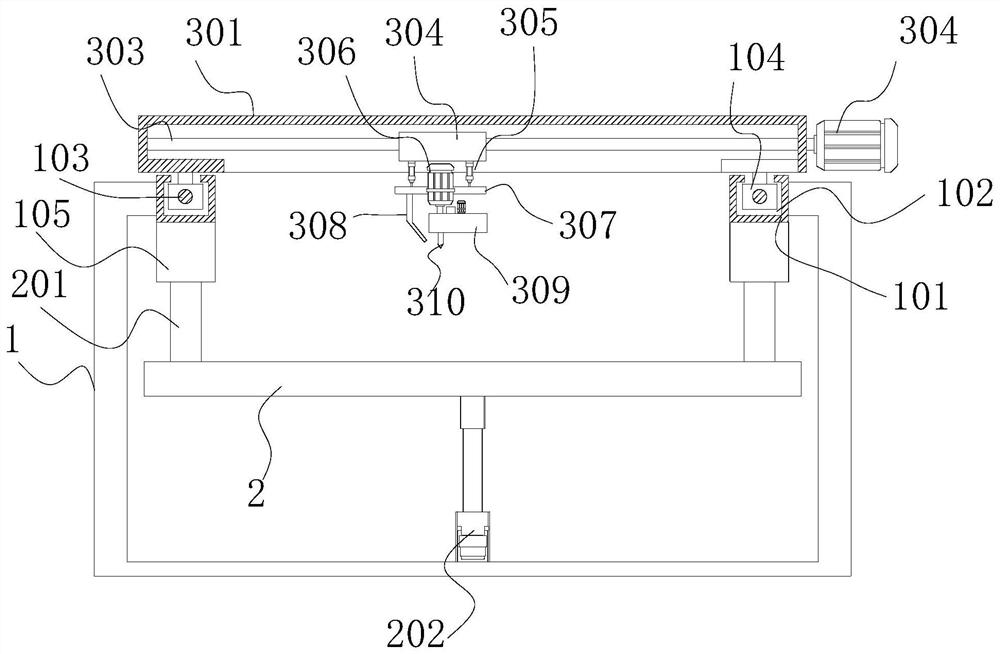

Supporting plate feeding system of numerical-control scraping rolling machine

InactiveCN112476011AAssisted movementReduce the impact of movementFeeding apparatusMaintainance and safety accessoriesGear wheelControl engineering

The invention relates to the technical field of oil cylinder machining, and discloses a supporting plate feeding system of a numerical-control scraping rolling machine. The supporting plate feeding system comprises a rack, wherein guide rails are fixedly mounted on the left side and the right side of the top end of the rack, fixed frames are movably mounted at the top ends of the guide rails, andracks are fixedly mounted at the ends, close to each other, of the two guide rails; and fixed seats are fixedly mounted on sides of the back surfaces of the fixed frames. According to the supporting plate feeding system of the numerical-control scraping rolling machine disclosed by the invention, the bottom ends of the output shafts of servo motors are fixedly sleeved with the gears, the racks arearranged on the side surfaces of the guide rails and connected to the gears in a meshed mode; and when the fixed frames need to be moved, the gears at the bottom ends of the servo motors can be driven to rotate at the moment by starting the servo motors; the gears can be driven by the racks to move relative to the guide rails and drive the fixed frames to move relative to the guide rails, so thatthe influence of sliding friction on movement of the fixed frames is reduced, and therefore, the advantage of assisting movement of the fixed frames is achieved.

Owner:LOUDI DINGLI HYDRAULIC TECH CO LTD

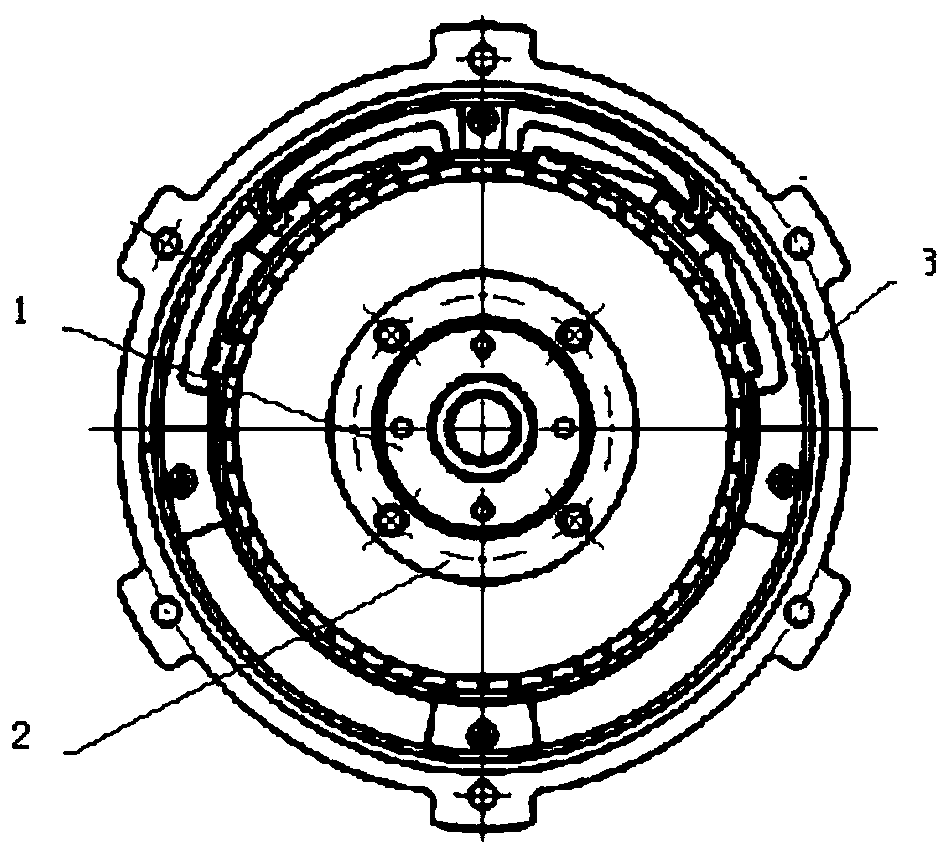

Bearing preload adjusting and locking structure for a small and special electrical machine and implementation method

ActiveCN110867984ARealize imposingRealize mass productionMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMachine

Owner:TIANJIN NAVIGATION INSTR RES INST

Adjustable wheel track axle with independent wheel angle control for an agricultural vehicle

A system to simultaneously adjust a wheel track axle width and a steering angle of an agricultural vehicle made of: an at least two variable axle assemblies, each one of the variable axle assemblies connected to a wheel set of the agricultural vehicle is provided. During the wheel track axle adjustment process of a variable wheel track axle machine the angle of each wheel is “toed-in” or toed-our depending on wheel track extension or retraction. When the wheel track axle of the machine is being extended, all wheels are commanded to “toe-out” 3 degrees to aid in the extension and reduce external forces on the wheel and axle system. When the wheel track axle of the machine is being retracted, all wheels are commanded to “toe-out” 3 degrees to aid in the retraction and reduce external forces on the wheel and axle system. Once the wheel track axle adjustment is complete all wheels return to 0 degrees for normal operation.

Owner:RBR ENTERPRISE LLC

Adaptive balancing mechanism of dual-head cement trowelling machine and adjusting method thereof

ActiveUS20210254291A1Easy to driveEasy to operateBuilding constructionsRoads maintainenceDynamic balanceControl engineering

Owner:JIANGSU UNIV

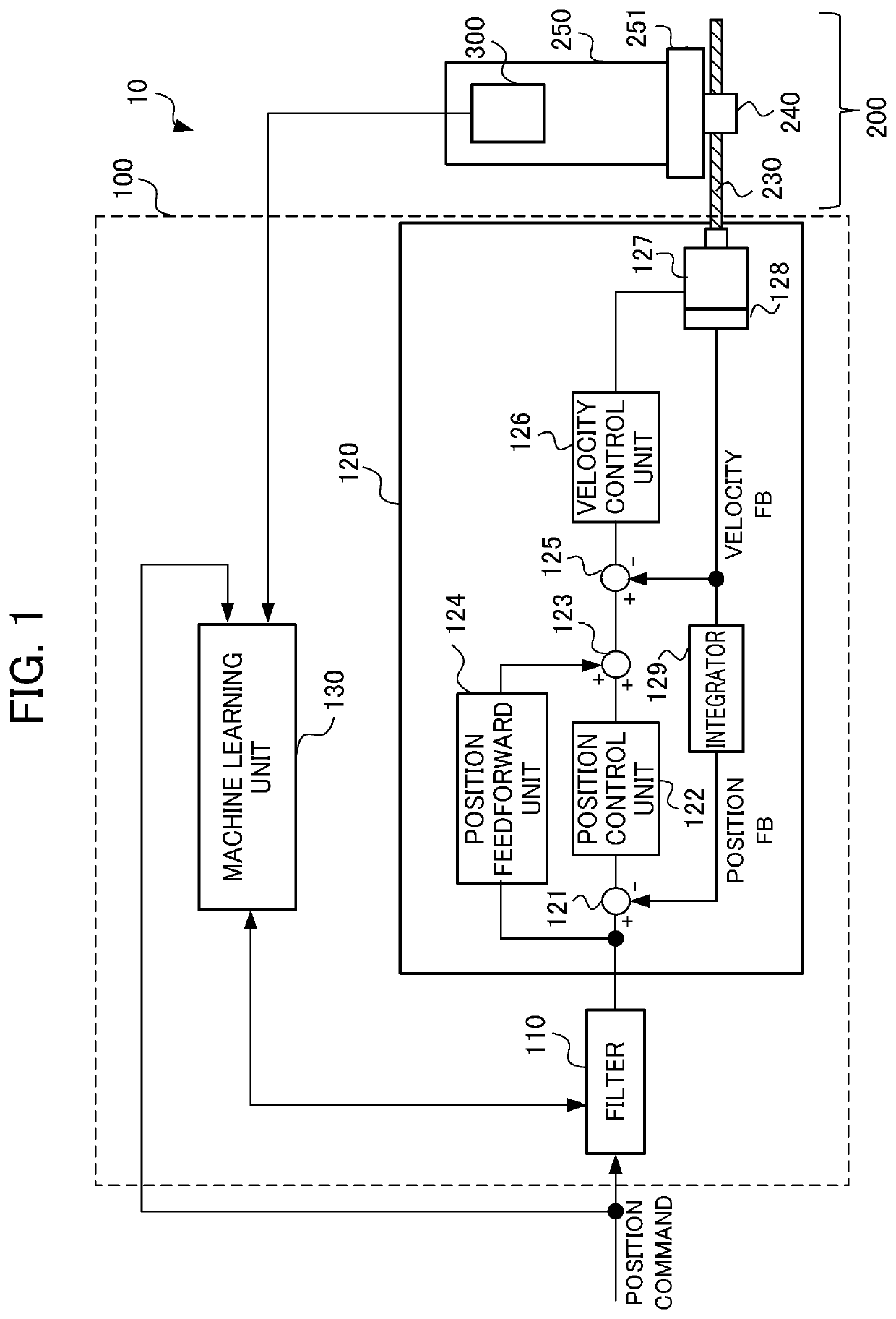

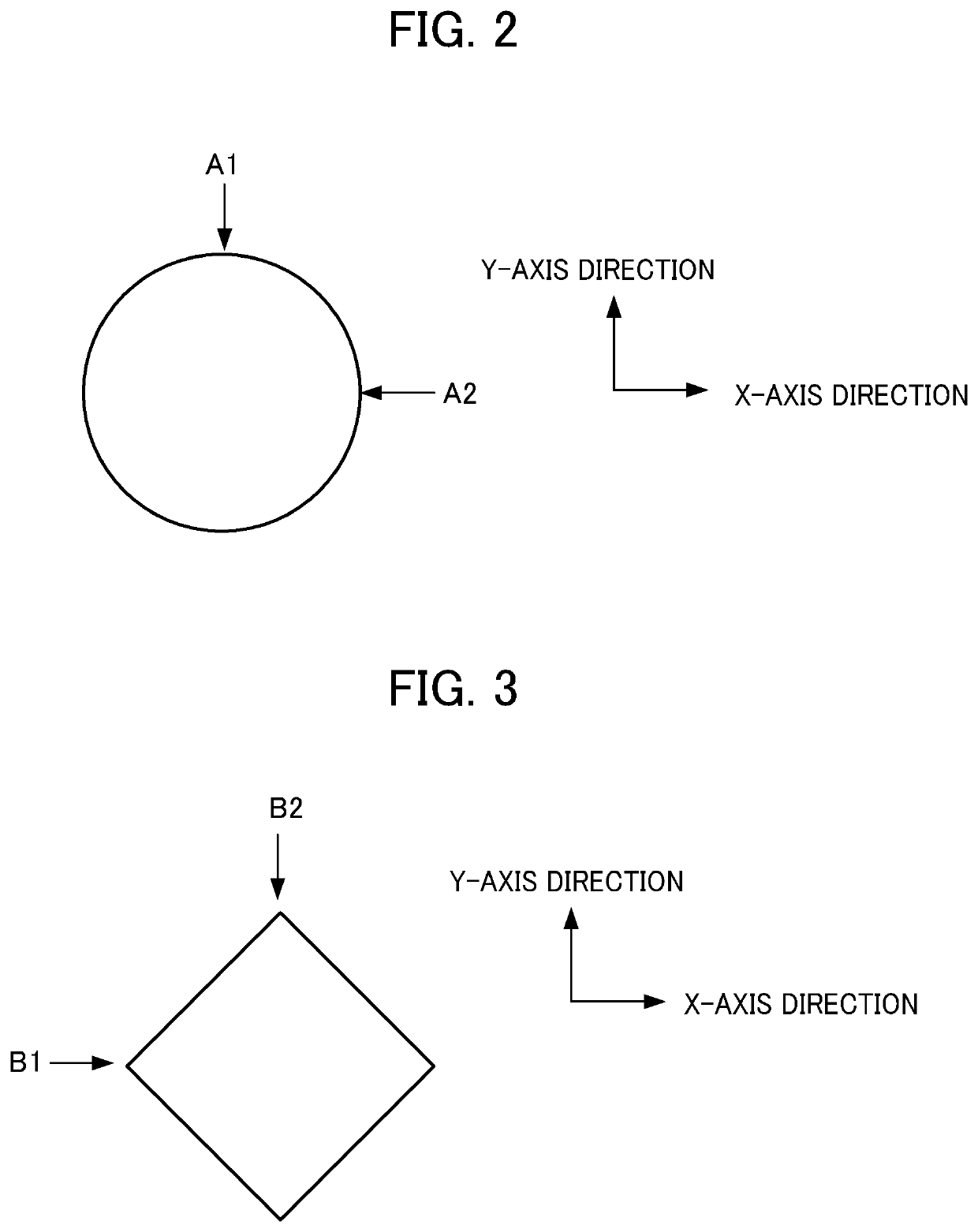

Machine learning device, control system, and machine learning method

ActiveUS20200073343A1Low costImprove reliabilityElectric motor controlSoftware algorithm controlControl systemControl engineering

Owner:FANUC LTD

Cutter error compensation method and device and computer equipment

ActiveCN111077845AReduce interventionHigh precisionProgramme controlComputer controlControl engineeringMachine

The invention provides a cutter error compensation method and device, computer equipment and a computer storage medium. The cutter error compensation method is used for compensating the error of a cutter of an edge milling machine, and the method comprises the steps: measuring a cutter of the edge milling machine, and obtaining the diameter of the cutter; processing a linear path in a test processing area by using a cutter, and obtaining a first starting point coordinate and a first ending point coordinate of the linear path; acquiring the width of a linear path, a second starting point coordinate and a second ending point coordinate in the test processing area by using a CCD sensor; and determining a cutter compensation value according to the diameter, the width of the linear path, the first starting point coordinate, the first ending point coordinate, the second starting point coordinate and the second ending point coordinate, and performing error compensation on the cutter by utilizing the compensation value. According to the cutter error compensation method, manual intervention on cutter error compensation can be reduced, the error probability is reduced, and the cutter error compensation precision is improved.

Owner:SUZHOU VEGA TECH CO LTD

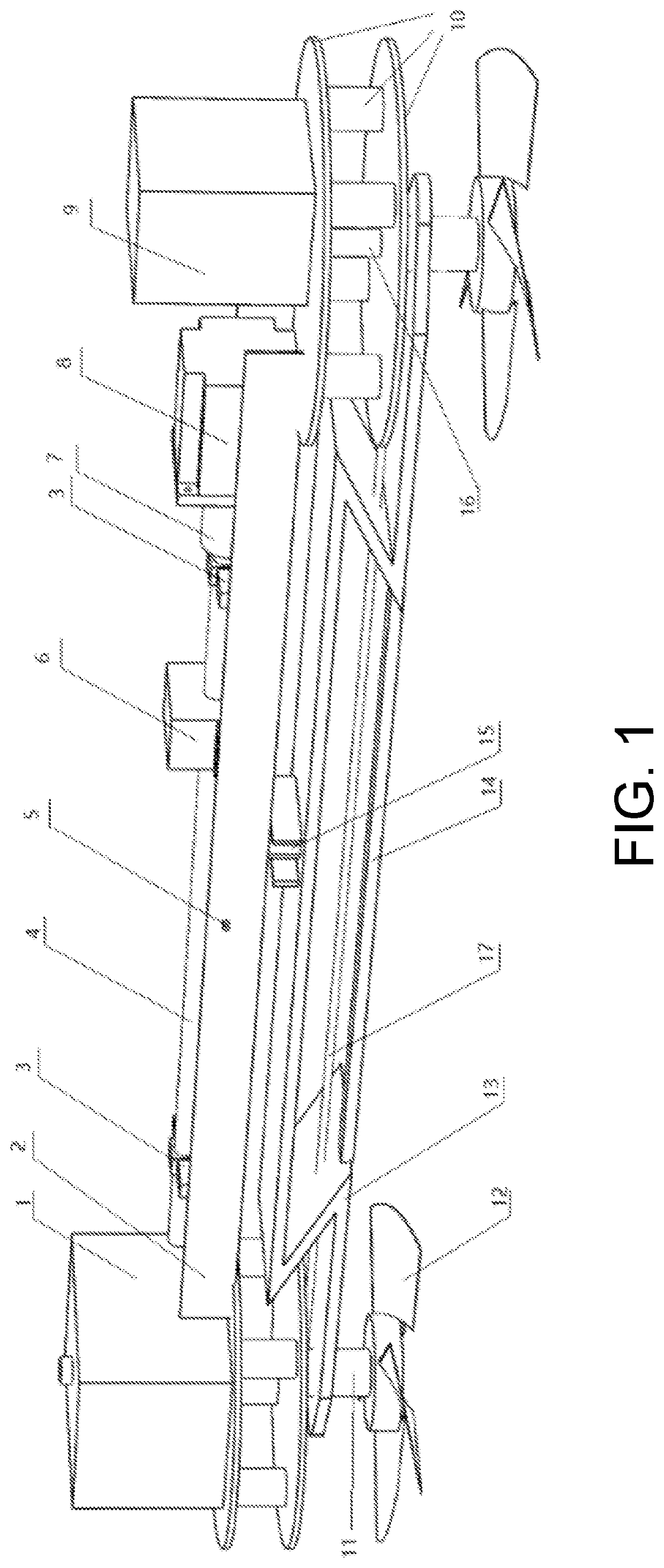

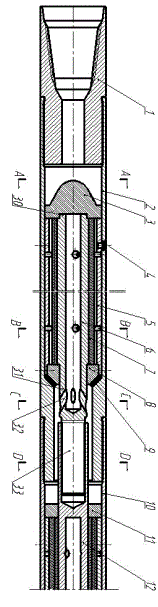

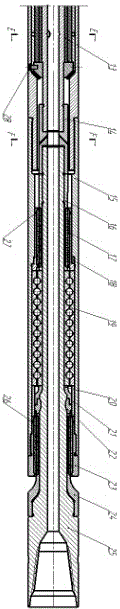

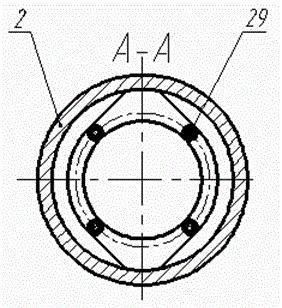

Coaxial all-metal cam stator and rotor underground dynamical drilling tool

Owner:XI'AN PETROLEUM UNIVERSITY

Pressing and flattening device for bag making machine

ActiveCN105109103AMeet production needsCompact structureContainer making machineryEngineeringMachine

The invention relates to a pressing and flattening device for a bag making machine. The pressing and flattening device for the bag making machine is characterized in that the pressing and flattening device comprises two single-edge shaping mechanisms which are mounted on a support. The two single-edge shaping mechanisms are of the same structure and are oppositely and symmetrically arranged. Each single-edge shaping mechanism comprises a sliding block, a connecting rod, a spring, a shaft, a bearing and a flattening wheel, wherein the sliding block is mounted in a long groove in the support and can move leftwards and rightwards, and the upper end of the connecting rod is connected with the sliding block; the rear end of the shaft is mounted at the lower end of the connecting rod through a hinge shaft, the shaft can rotate around the hinge shaft, and the flattening wheel is mounted on the shaft through a bearing support; the upper end of the spring is connected to the connecting rod, and the lower end of the spring is tightly pressed on the shaft. The pressing and flattening device for the bag making machine is compact in structure, convenient to operate, highly adjustable and capable of meeting the requirements for producing packaging bags of dimensions, improving working efficiency, relieving labor intensity and guaranteeing product quality.

Owner:WUXI KING MO MACHINERY

Horizontal-type horizontal moving multi-wire feeding device

Owner:HEBI HAICHANG SPECIAL EQUIP

Tenon-and-mortise connection machine

InactiveCN107415017ARealize automatic tenonRealize mortise and tenon operationDovetailed workStructural engineeringMachine

The invention provides a tenon-and-mortise connection machine. The tenon-and-mortise connection machine comprises a mounting rack, two push plates, a profiling mold, a lever and a driving part. The two push plates are mounted on the mounting rack in a sliding mode and oppositely arranged in a spaced mode. The profiling mold comprises an inner profiling mold body and two outer profiling mold bodies. The inner profiling mold body is detachably mounted on the mounting rack; the two outer profiling mold bodies are detachably mounted on the two push plates correspondingly; a tenon-and-mortise connection area for achieving tenon-and-mortise connection of workpieces is defined by the inner profiling mold body and the two outer profiling mold bodies jointly; one end of the lever is connected with the two push plates, and the other end of the lever is connected with the driving part; and the driving part is mounted on the mounting rack to push the lever, so that the two push plates and the two outer profiling mold bodies move in the opposite directions to perform tenon-and-mortise connection operation. By means of the tenon-and-mortise connection machine, automatic tenon-and-mortise connection of the workpieces is achieved, and the production efficiency is improved.

Owner:GUANGXI GUILIN HUAHAI HOUSEWARES CO LTD

Efficient threshing machine with conveying mechanism for agricultural machinery and using method

Owner:湖南怡田美农业科技有限公司

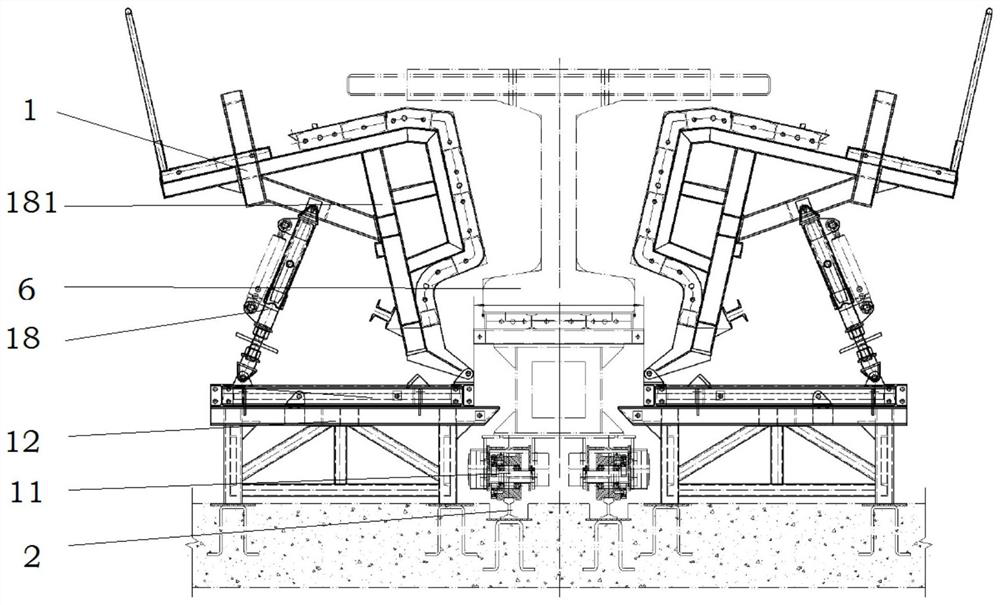

Pouring system and method for automatic prefabricated T beam

PendingCN111702948AStable structureIncrease productivityDischarging arrangementFeeding arrangmentsT-beamButt joint

Owner:安徽省路港工程有限责任公司

Elevator counterweight guide rail guidance stroke measurement device based on sensor technology

ActiveCN111362088AImprove the level of inspection scienceSolve the difficulty of measurementElevatorsLaser rangingRemote control

The invention discloses an elevator counterweight guide rail guidance stroke measurement device based on the sensor technology. The device comprises a measurement robot and a remote control box. The distance between the machine body of the measurement robot and a guidance surface of a guide rail is measured in real time through a Hall sensor on the robot. The distance between the top of the counterweight guide rail and an elevator counterweight side oil cup is measured through a laser distance sensor. Then the guide rail guidance stroke of when a buffer is completely compressed by an elevatoris measured. According to the elevator counterweight guide rail guidance stroke measurement device based on the sensor technology, a method is high in measurement accuracy and quick in measurement, the problem that it is difficult to measure the guide rail guidance stroke is solved, the measurement accuracy of the guide rail guidance stroke is greatly improved, the checking science level of a checking mechanism is improved as well, and powerful technology support is provided for guaranteeing elevator operation security.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

Tightening machine capable of automatically correcting position of bottom plate of sewing machine shell

InactiveCN113182829AIncrease productivityAvoid assembly errorsMetal working apparatusPush and pullReciprocating motion

The invention relates to a tightening machine capable of automatically correcting the position of a bottom plate of a sewing machine shell. The tightening machine is characterized in that the tightening machine comprises a rack and a fixture for positioning and clamping the machine shell and the bottom plate; the rack is provided with a floating mechanism for positioning the position of the bottom plate, a tightening mechanism for assembling the machine shell and the bottom plate, a material pushing and pulling device for driving a workpiece to reciprocate between a feeding station and a tightening station, a measuring device for measuring the position of the bottom plate of the machine shell and a driving device for adjusting the position of the machine shell; the driving device is used for driving the machine shell fixture to adjust the position of the machine shell according to a measured value of the measuring device; and the floating device is used for converting the positioning reference of the fixture into the assembling reference of the tightening mechanism. The reference is converted through the floating device, and the positioning reference sum of the fixture is converted into the assembling positioning reference. Compared with an existing manual assembly mode, the production efficiency is greatly improved, meanwhile, assembly errors are avoided, and large-scale production can be achieved; and moreover, parts with different sizes can be used, and the universality is good.

Owner:DONGFENG EQUIP MFG CO LTD

Auxiliary device for furniture production

InactiveCN111923154AEasy to replaceFast punchingStationary drilling machinesMulti-purpose machinesElectric machineryMachine

Owner:安徽钜将家具制造有限公司

Oil conveying pipeline shaping machine

The invention provides an oil conveying pipeline shaping machine and relates to the technical field of bent pipe machining. The oil conveying pipeline shaping machine comprises a fixing part, a pushing part, an inclined plate pressing part, thermal deformation assemblies, a driving assembly, a shaping part and a grinding control part and has the beneficial technical effects that a port of a pipeline can be closed, and the left end of the pipeline is pressed into a closed cross-shaped pattern. The pushing part is connected to the middle of the fixing part in a matched mode, the inclined plate pressing part is arranged at one end of the fixing part, the four thermal deformation assemblies are evenly arranged on the inclined plate pressing part in a surrounding mode, the driving assembly is fixedly connected to the other end of the fixing part, the shaping part is connected to the driving assembly in a matched mode, and the grinding control part is arranged on the shaping part, and the grinding control part drives the shaping part to rotate.

Owner:金爱兰

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap