Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Butt joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A butt joint is a technique in which two pieces of material are joined by simply placing their ends together without any special shaping. The name 'butt joint' comes from the way the material is joined together. The butt joint is the simplest joint to make since it merely involves cutting the wood to the appropriate length and butting them together. It is also the weakest because unless some form of reinforcement is used (see below) it relies upon glue alone to hold it together. Because the orientation of the wood usually presents only one end to long grain gluing surface, the resulting joint is inherently weak.

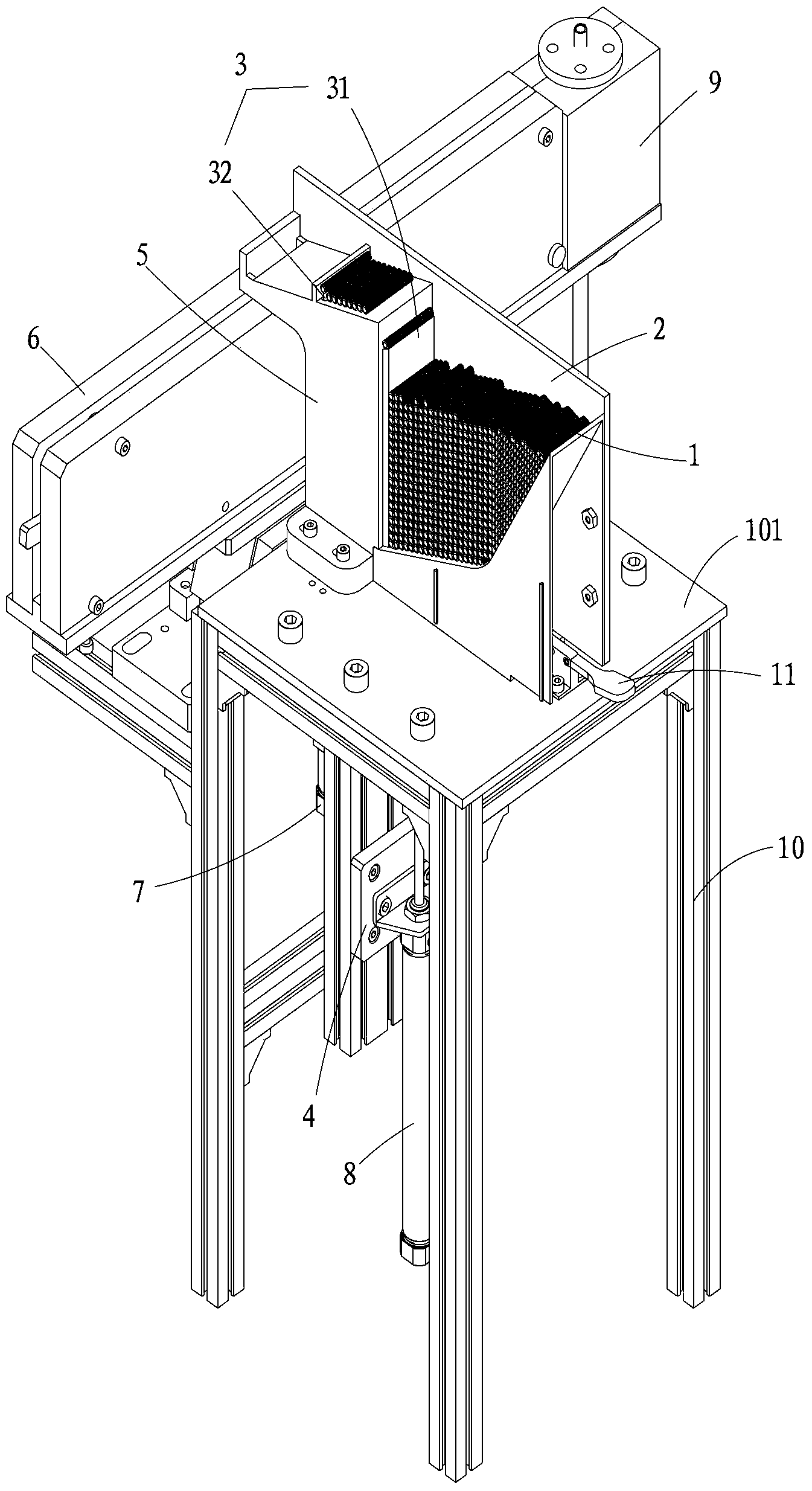

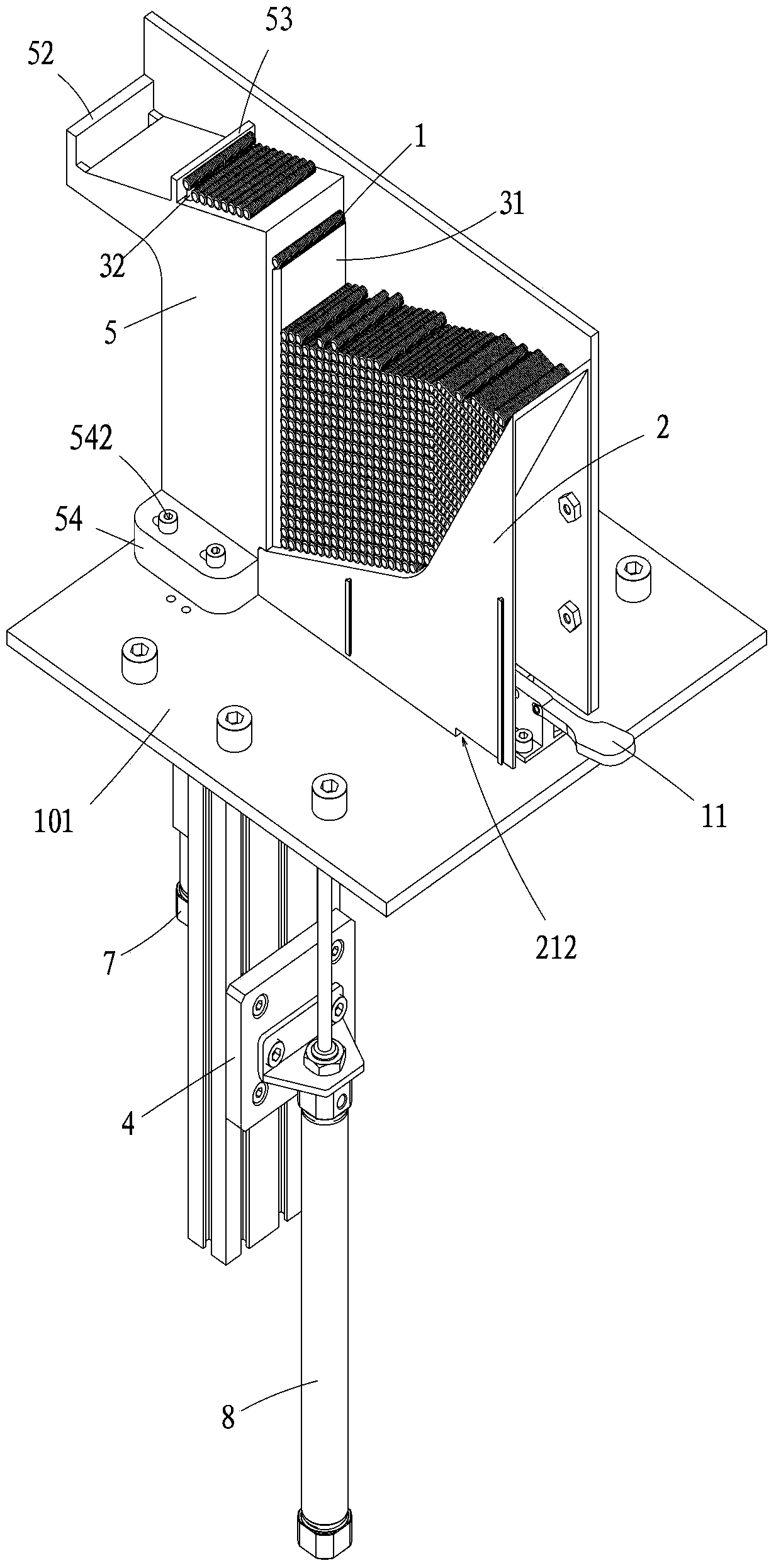

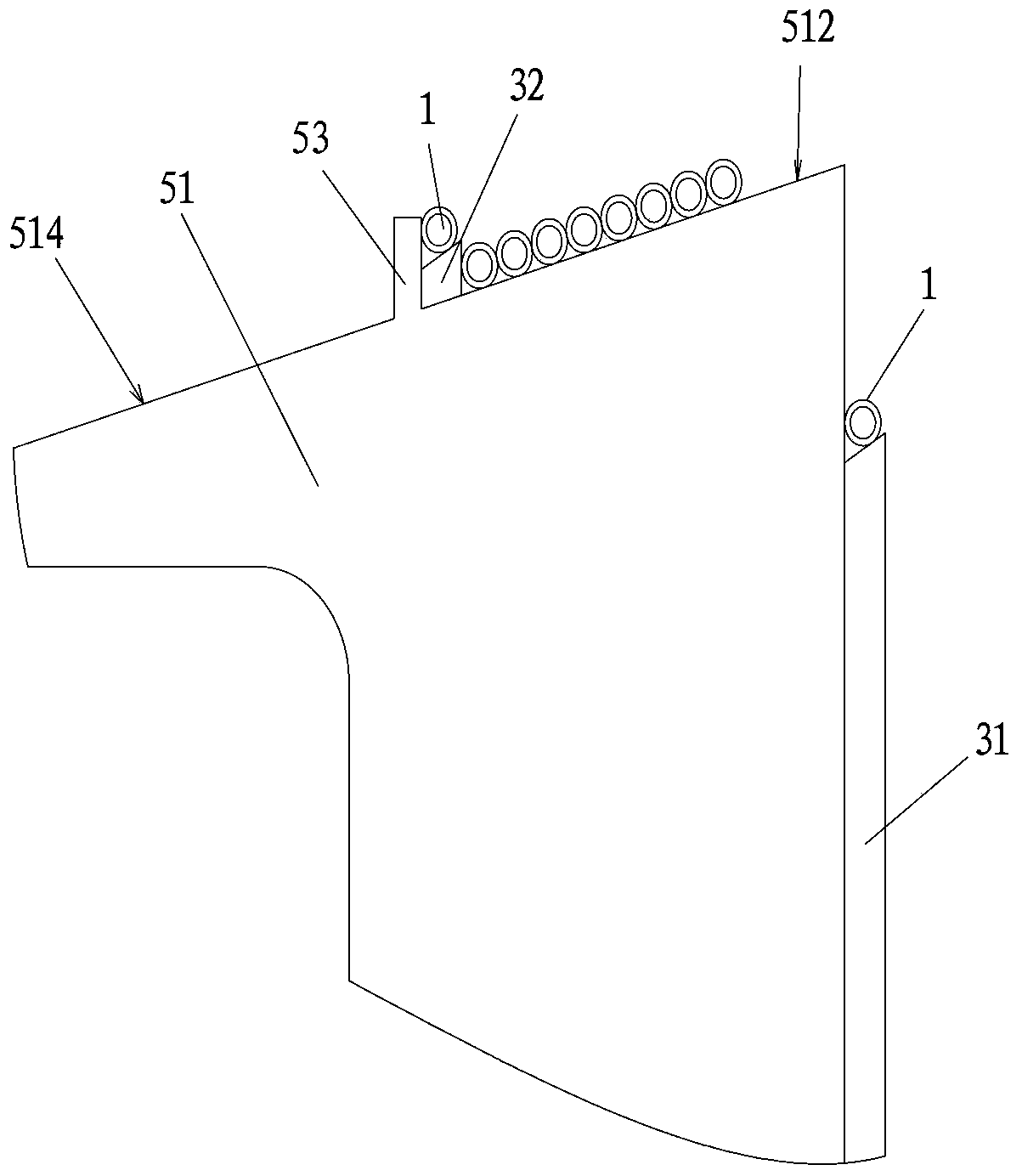

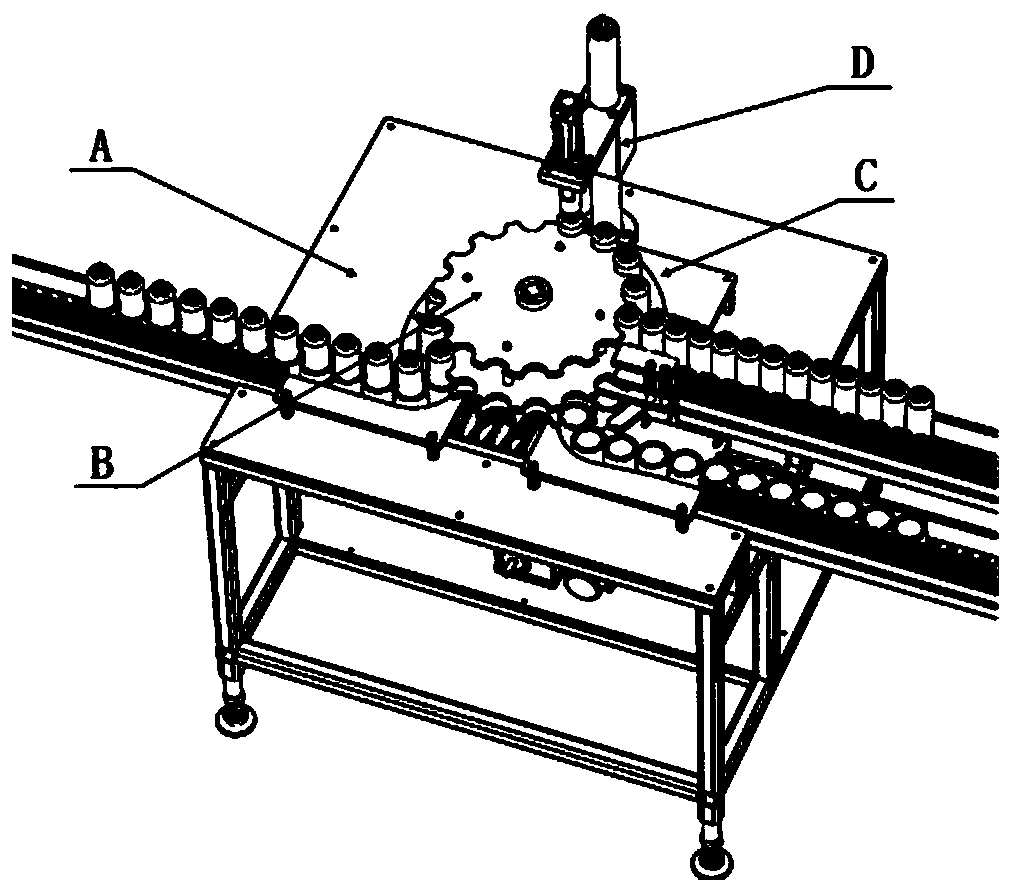

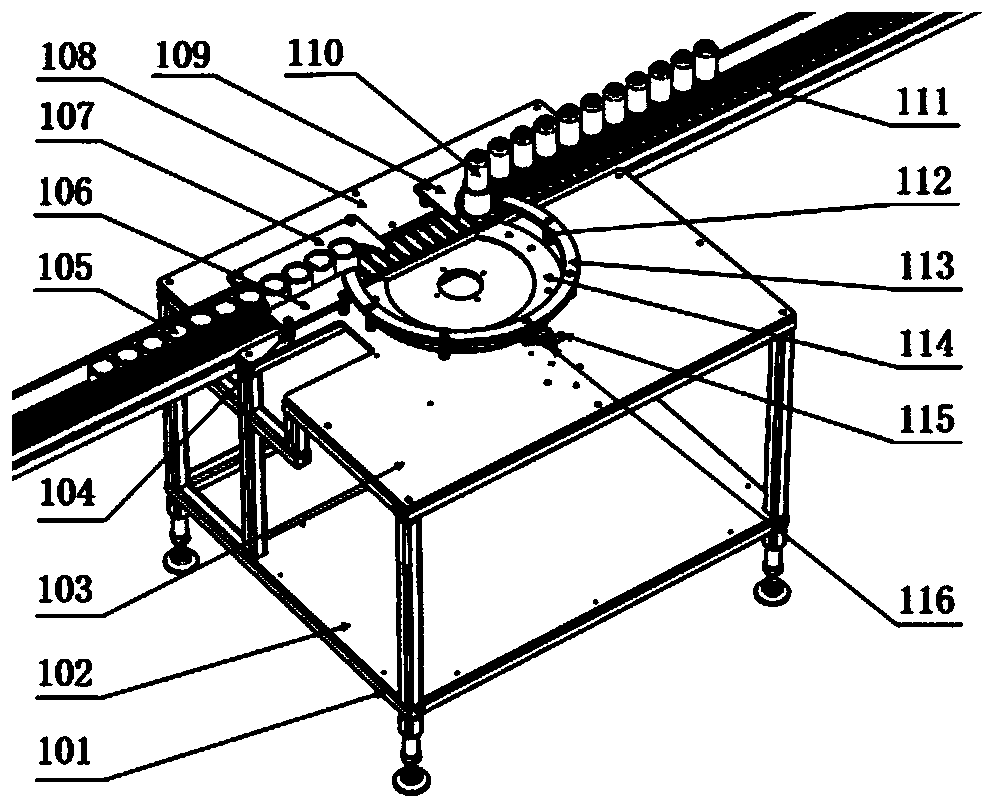

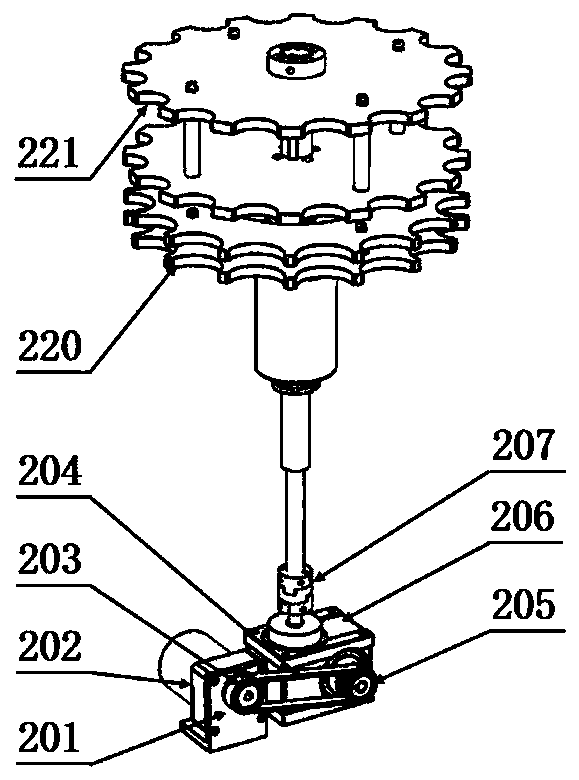

Automatic screw rod feeding device

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Network transmission method for TCP/IP protocol based on Windows

ActiveCN103873474AConfirm sizeResolve separation and receive in its entiretyTransmissionButt jointSoftware development

The invention belongs to the field of software development and design, and particularly relates to a network transmission method for a TCP / IP protocol based on Windows. The method comprises the following steps that (1), the operating system function of an inner core layer is called by an application layer; (2), the application layer is in butt joint with the inner core layer; (3), signals of a network port are detected by the inner core layer; (4), data transmission is carried out. Few threads can be used for processing a large number of client connections in the connection processing process by adopting an AcceptEx asynchronous connecting mechanism. Meanwhile, burdens of the I / O operation are greatly relieved through the mode of separating a data receiving thread (an I / O work thread) and a data processing thread (a worker thread) in the data transmission process, and the problem of large concurrent connection processing blocking is solved.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

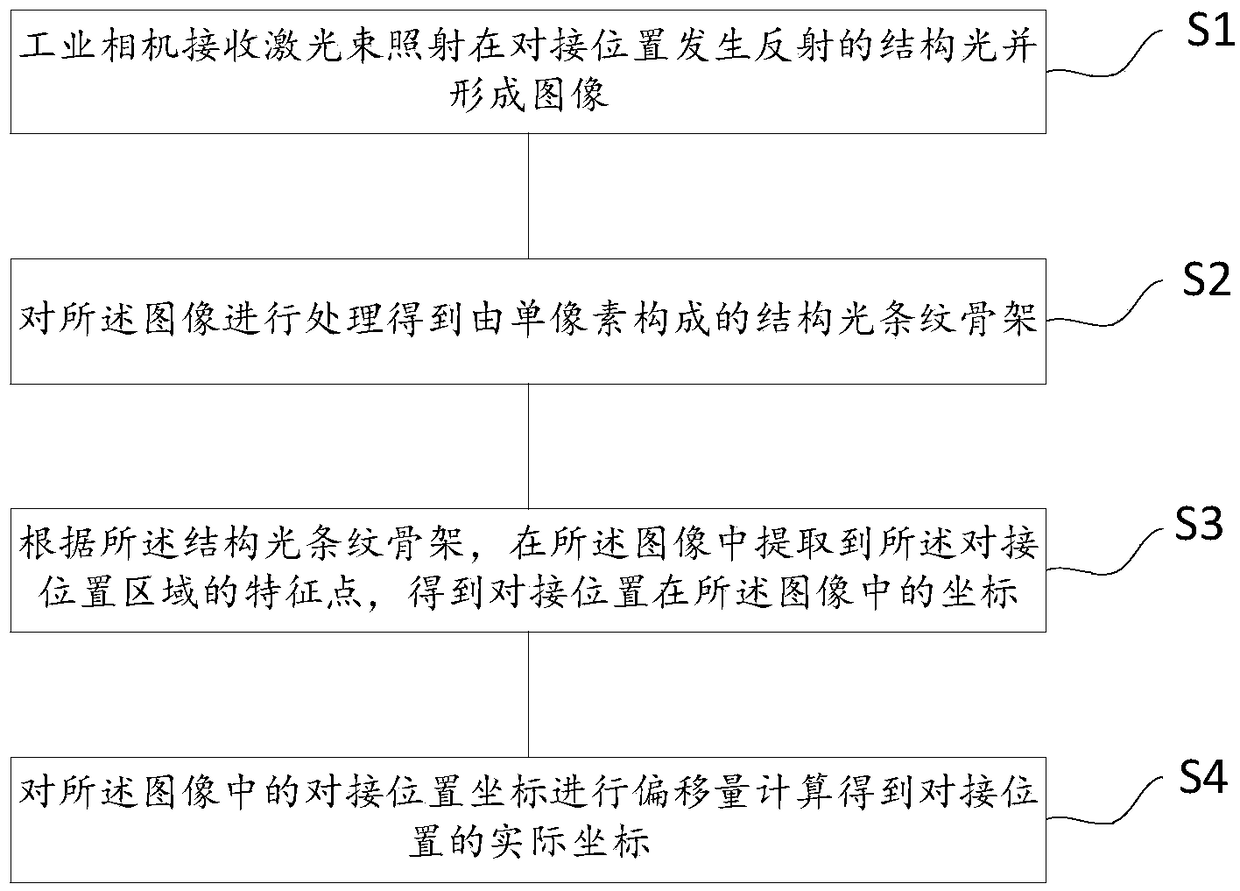

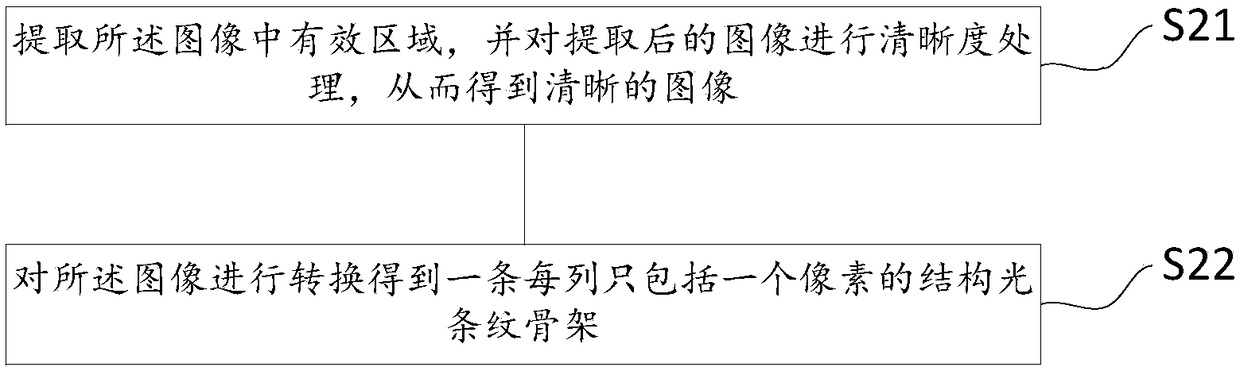

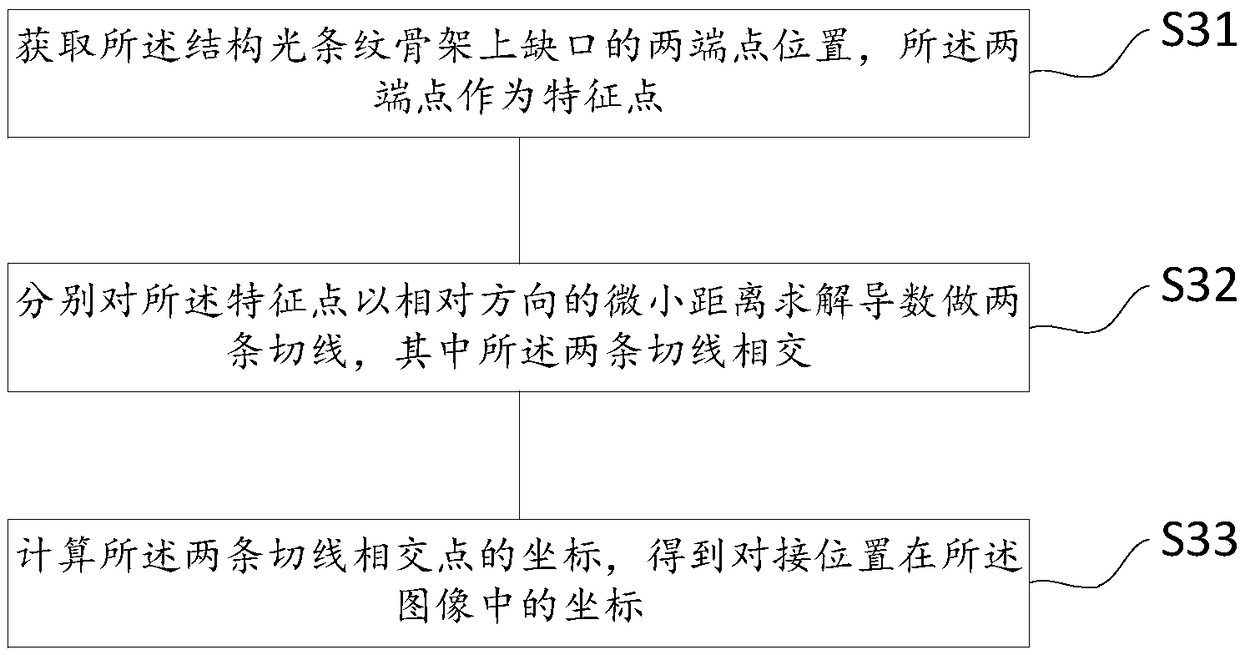

Welding line positioning method and system applied to welding line positioning

InactiveCN109202284AFix inaccurate positioningHigh positioning accuracyLaser beam welding apparatusButt jointEngineering

Owner:HANS LASER TECH IND GRP CO LTD +1

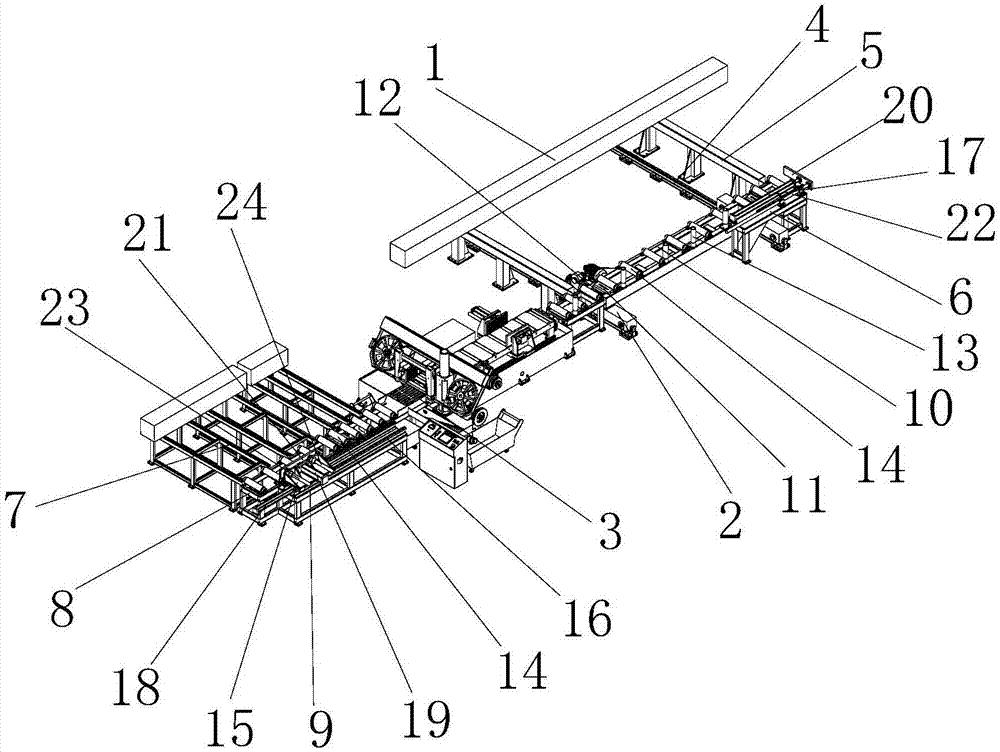

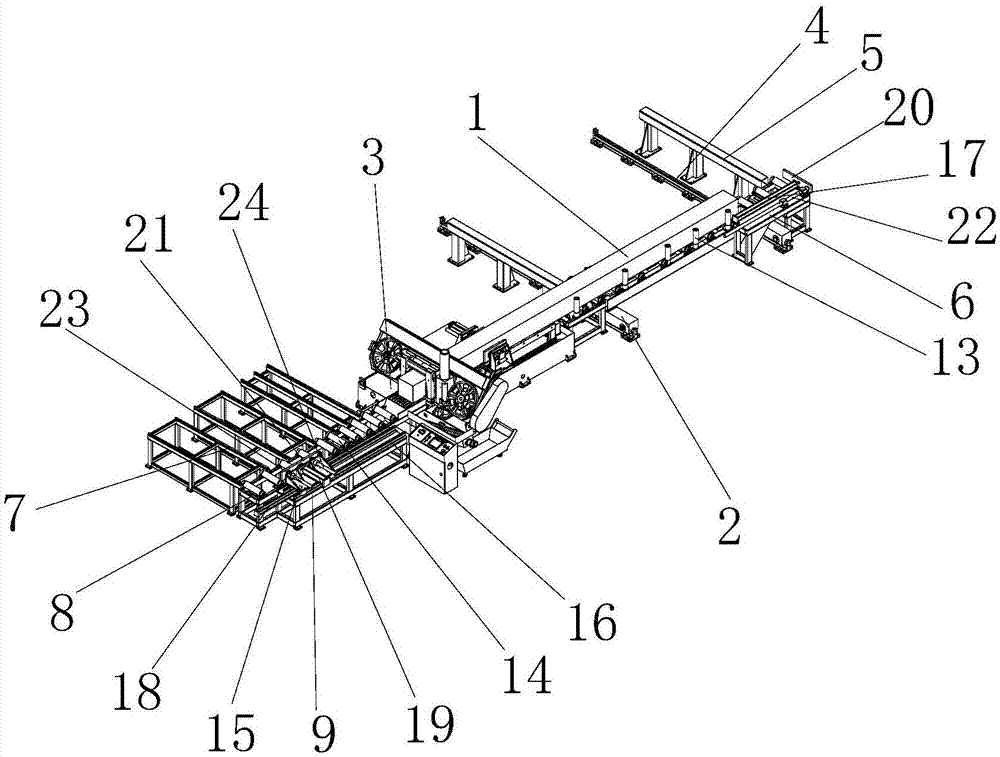

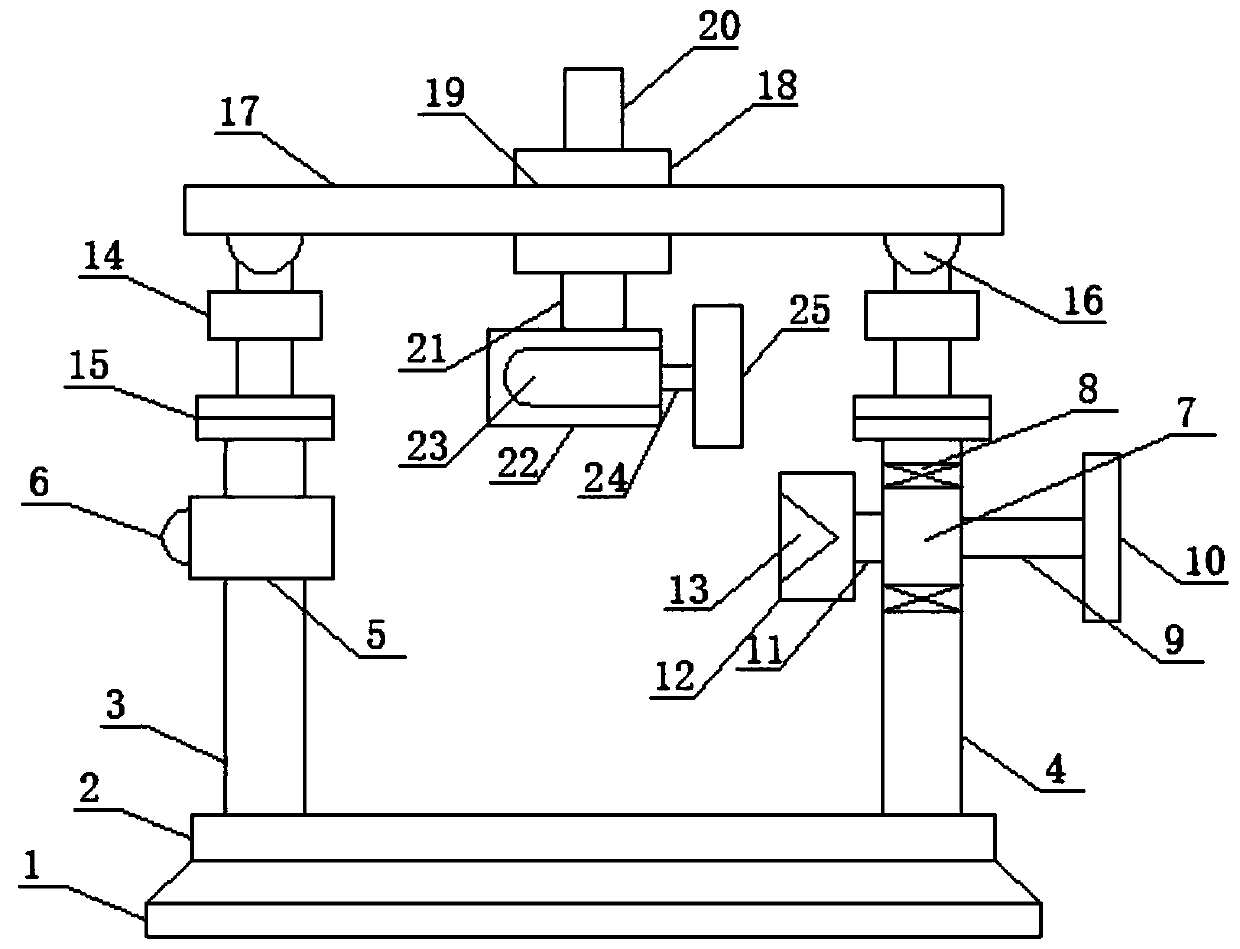

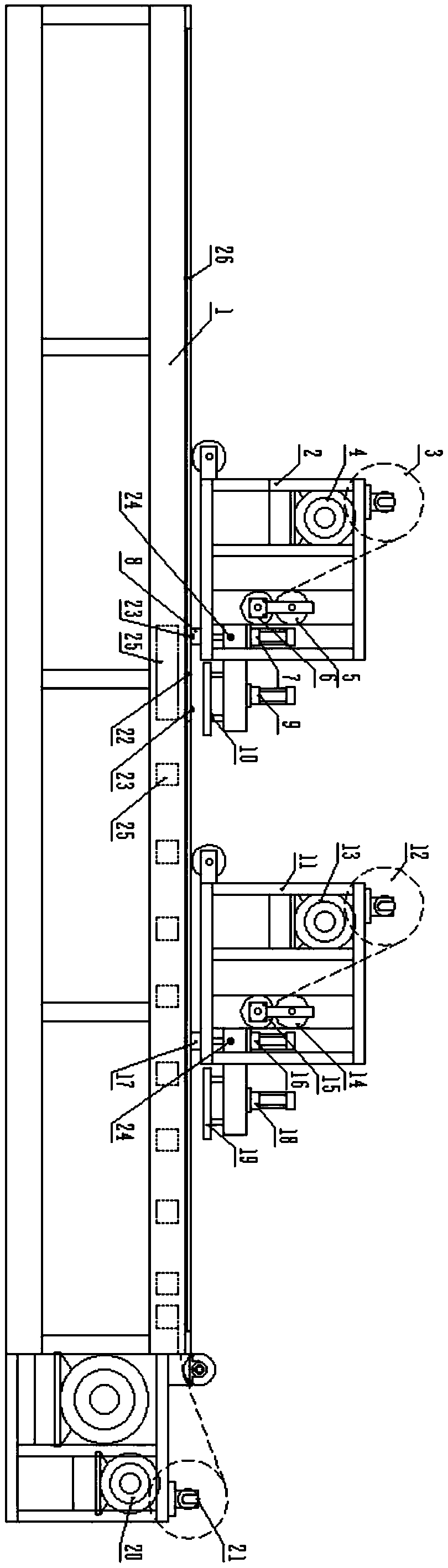

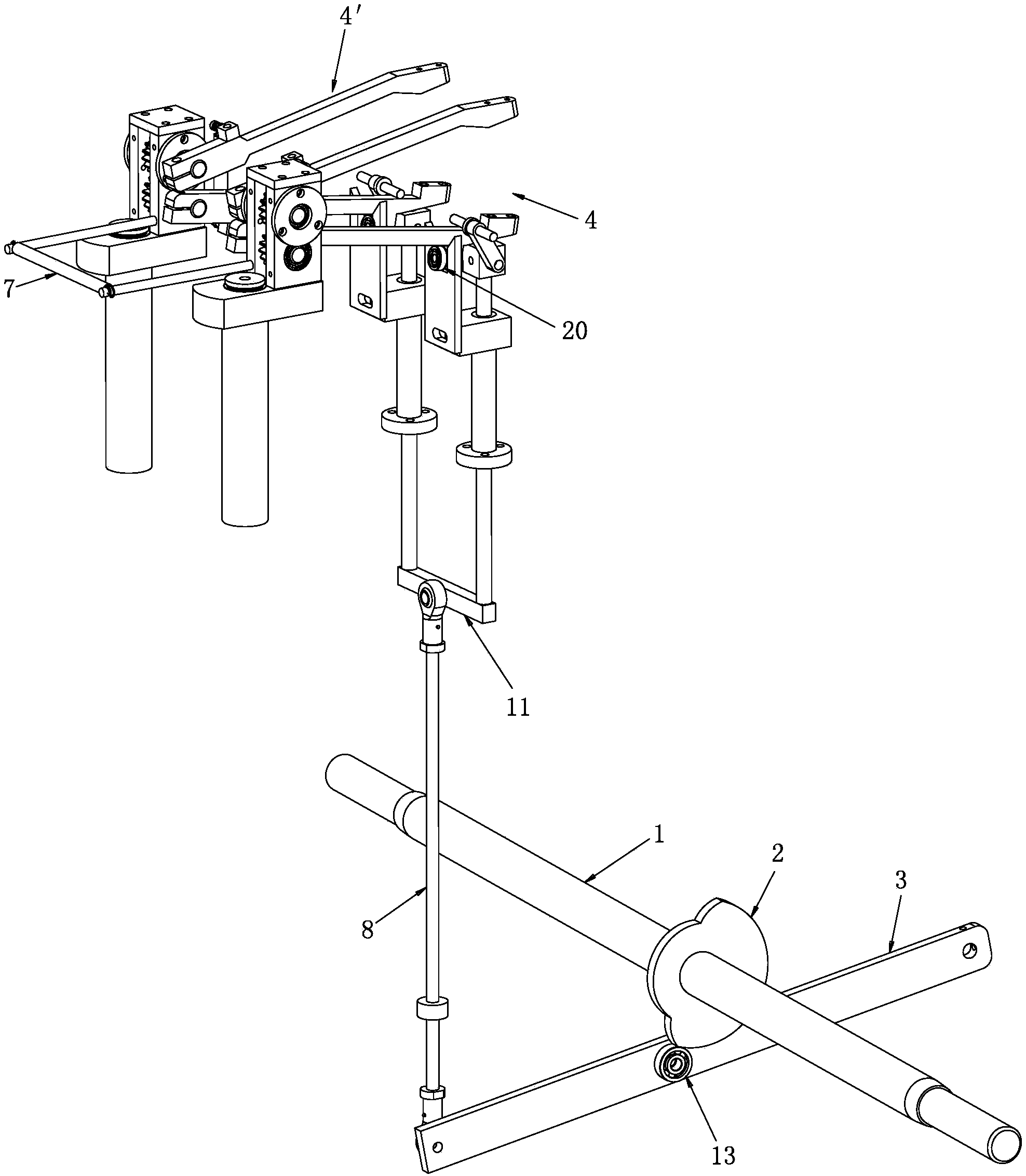

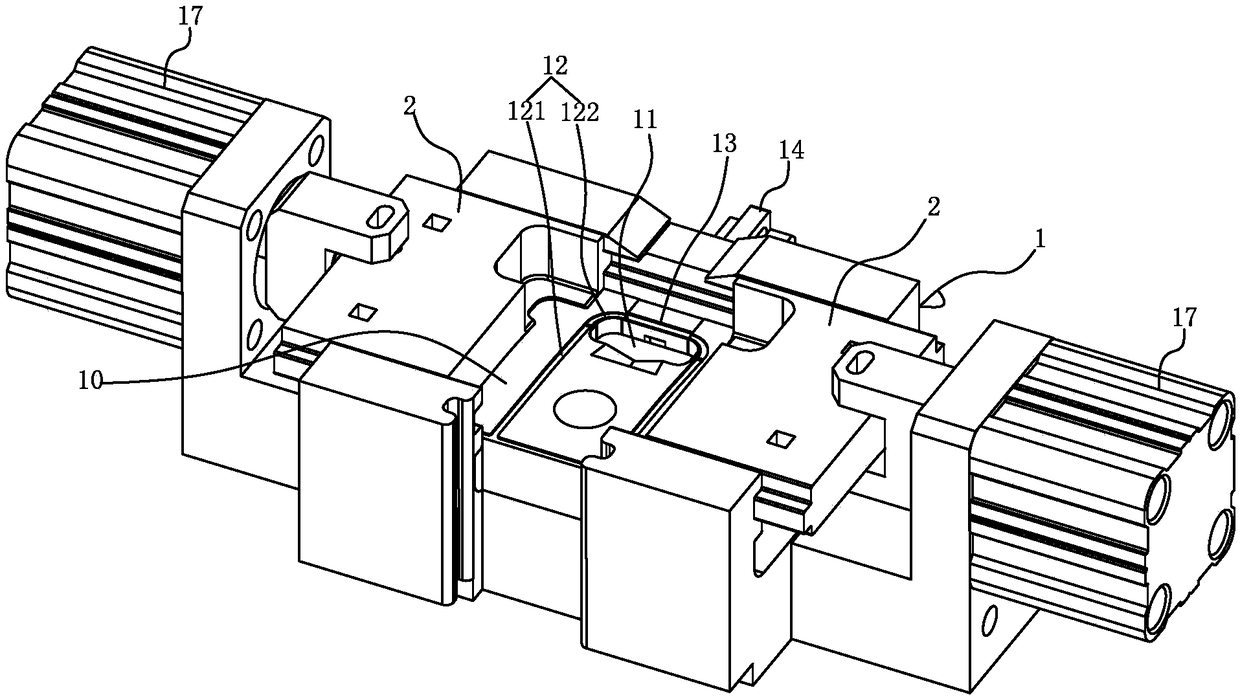

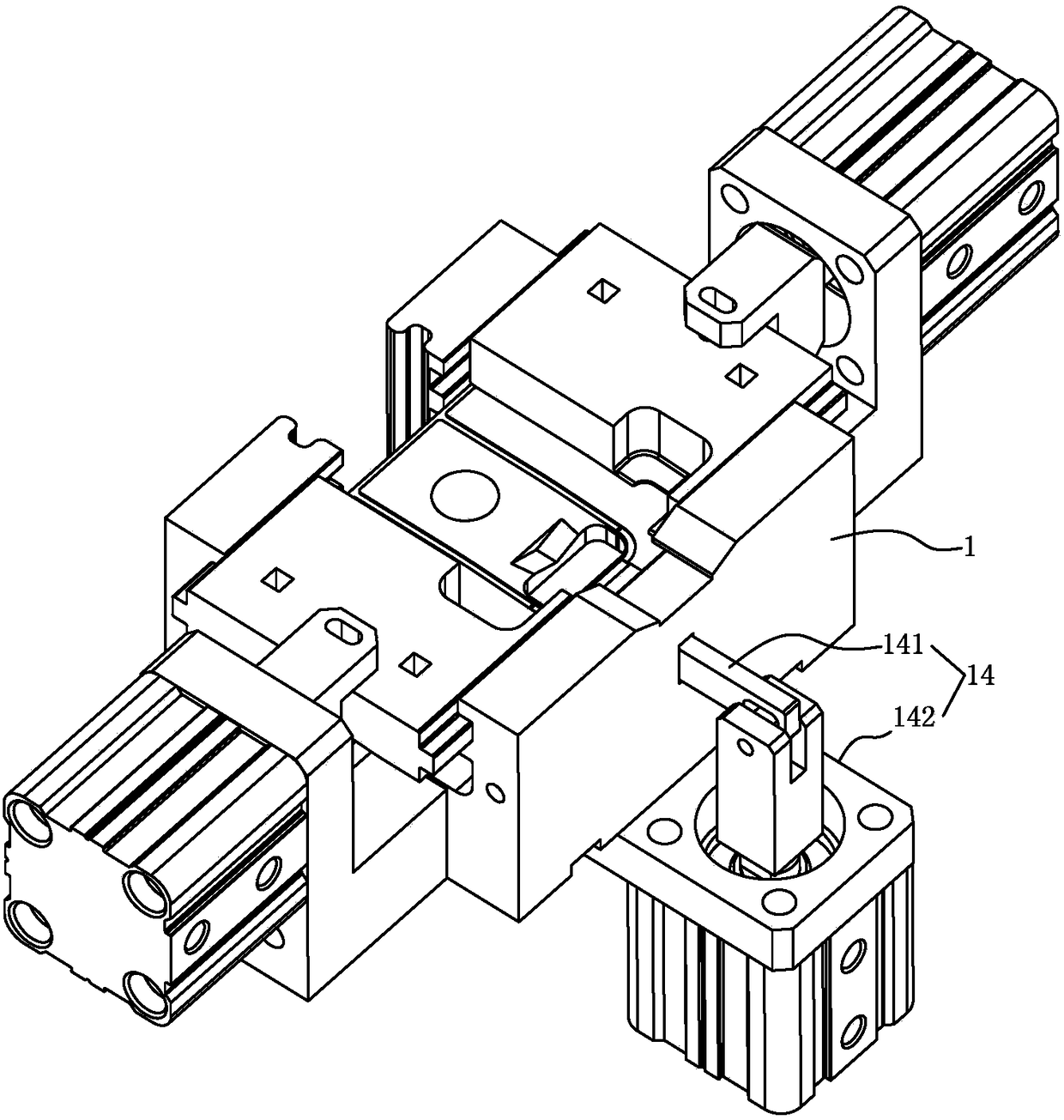

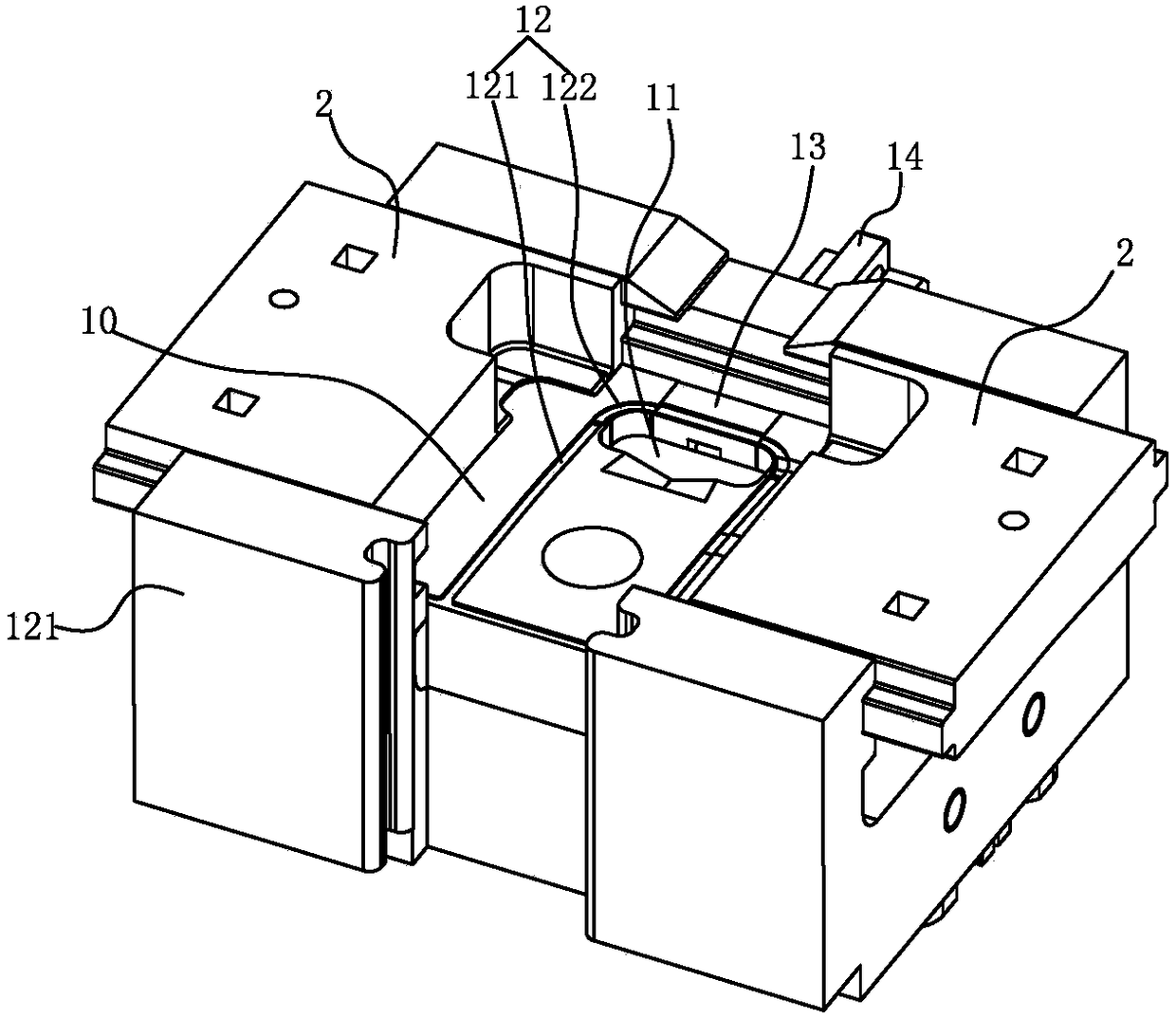

Punch line and material pushing and positioning device thereof

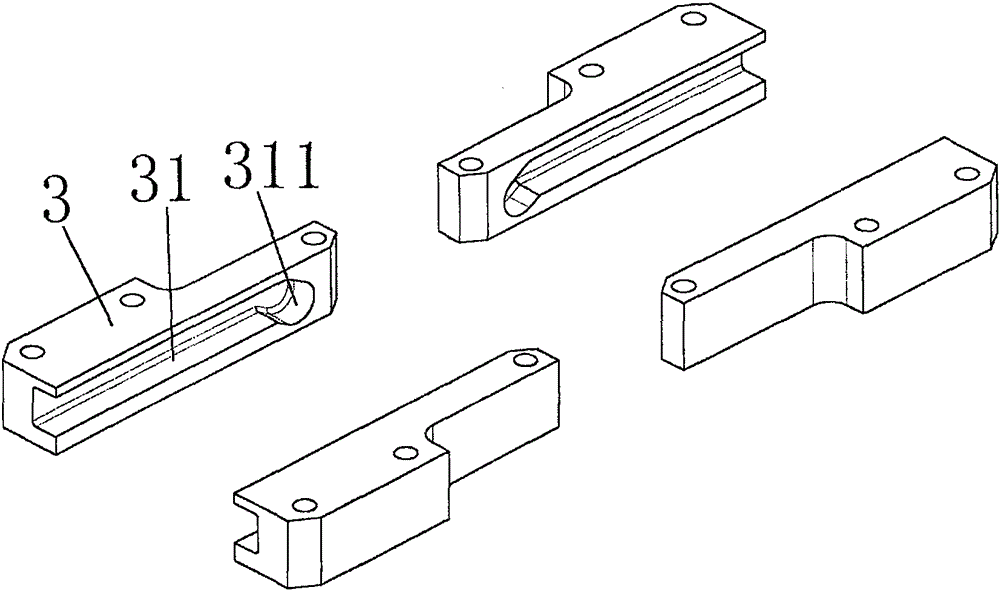

InactiveCN104722669AImprove connection convenienceMetal-working feeding devicesPositioning devicesButt jointEngineering

The invention discloses a punch line and a material pushing and positioning device thereof. The material pushing and positioning device comprises an installation seat, a material pushing seat, a material pushing plate, a straight connecting rod, a bent connecting rod, a telescopic cylinder connecting rod and a telescopic cylinder, wherein one end of the installation seat is rotationally connected with the material pushing seat, and the other end of the installation seat is connected with a fixed part of the telescopic cylinder; the material pushing plate in butt joint with a blank is installed at the upper end of the material pushing seat, the lower end of the material pushing seat is rotationally connected with a first end of the straight connecting rod, and a second end of the straight connecting rod is rotationally connected with the lower end of the bent connecting rod; the corner of the bent connecting rod is rotationally connected with the installation seat, the upper end of the bent connecting rod is rotationally connected with the upper end of the telescopic cylinder connecting rod, and the lower end of the telescopic cylinder connecting rod is fixedly connected with a telescopic part of the telescopic cylinder; all rotary shafts are parallel. In this way, the material pushing and positioning device can realize automatic feeding and positioning of blank materials, thereby improving the efficiency of punching production and the automation degree of the punch line, relieving the labor intensity of workers, and guaranteeing the production safety of workers.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

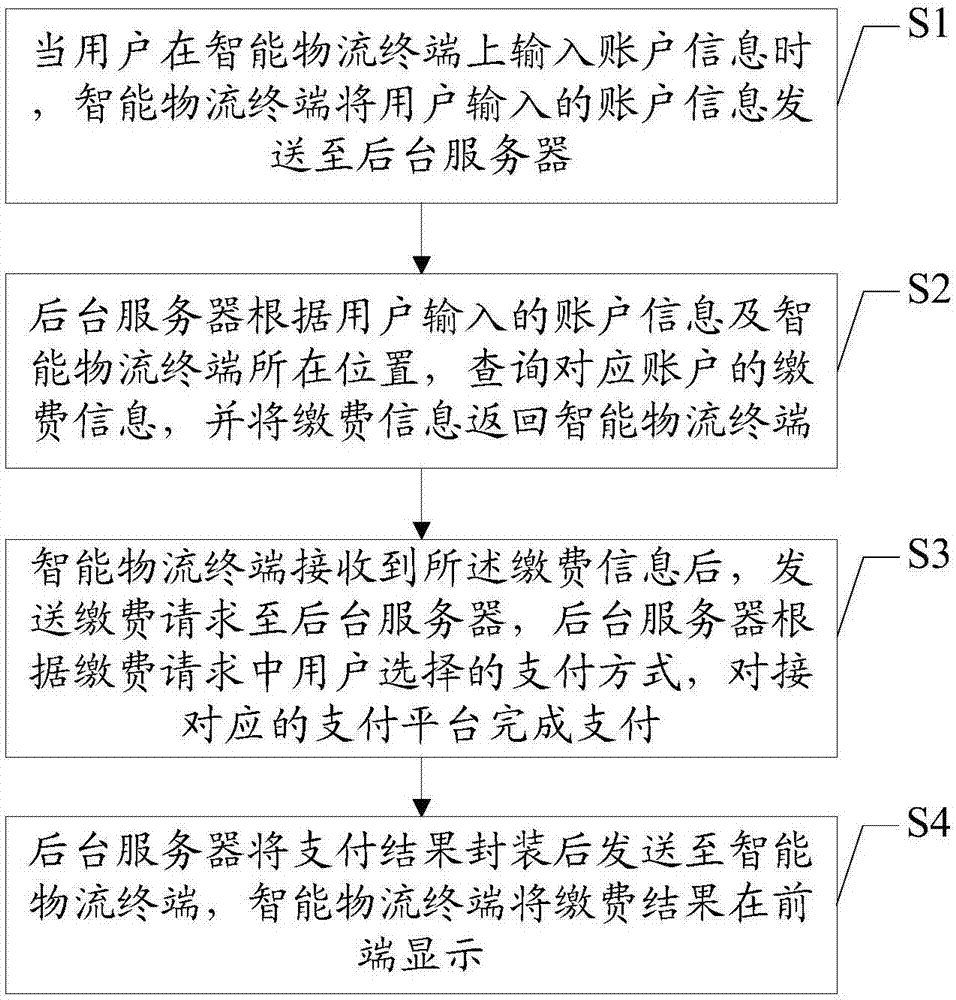

Cost collection method based on intelligent logistics terminal and system thereof

InactiveCN107516198APayment architectureApparatus for meter-controlled dispensingPayment orderButt joint

Owner:SHENZHEN HIVE BOX TECHNOLOGY CO LTD

Press fitting device for aerosol tank and universal base

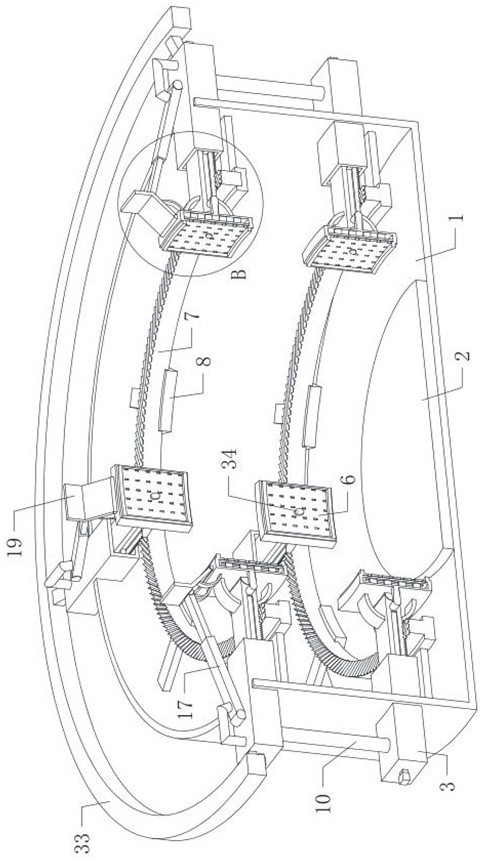

PendingCN109732321ASimultaneous pressingDoes not affect the beatMetal working apparatusProduction lineButt joint

Owner:YANGZHOU MEIDA FILLING MACHINERY

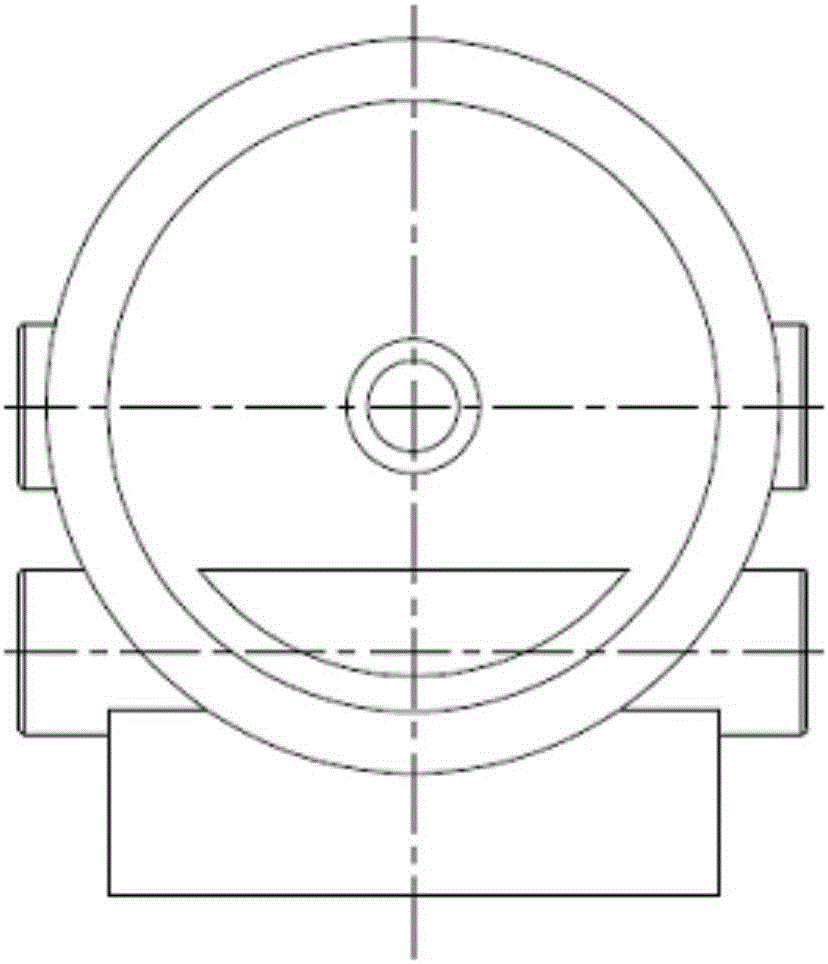

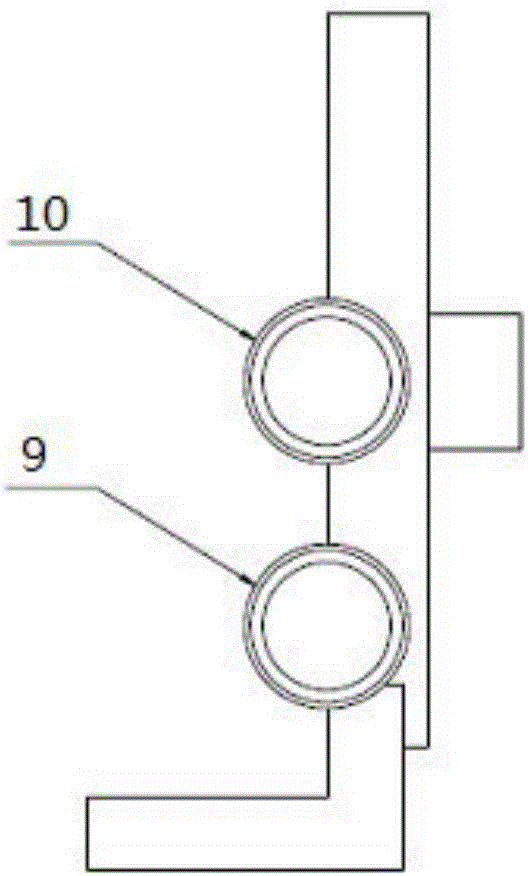

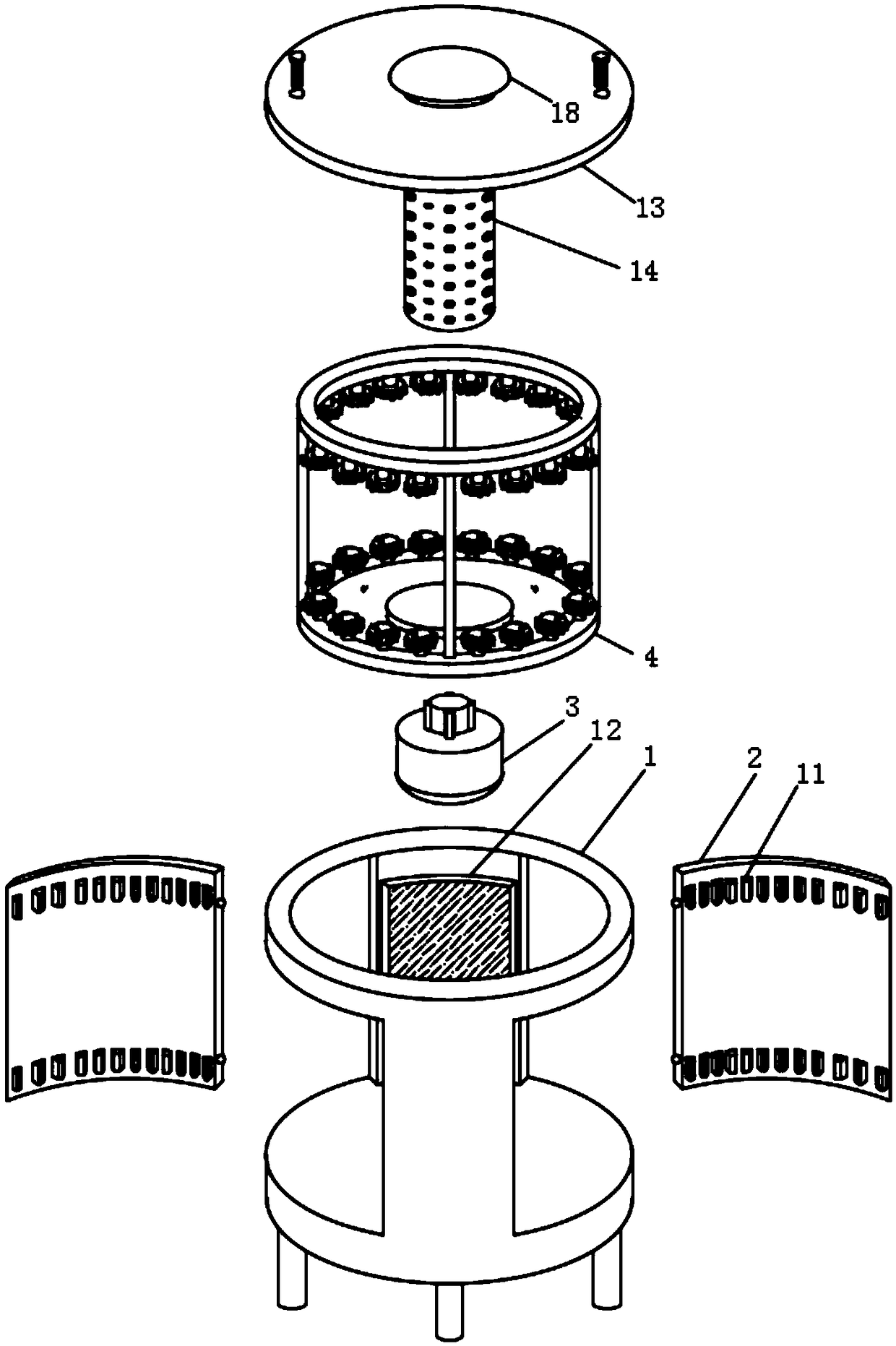

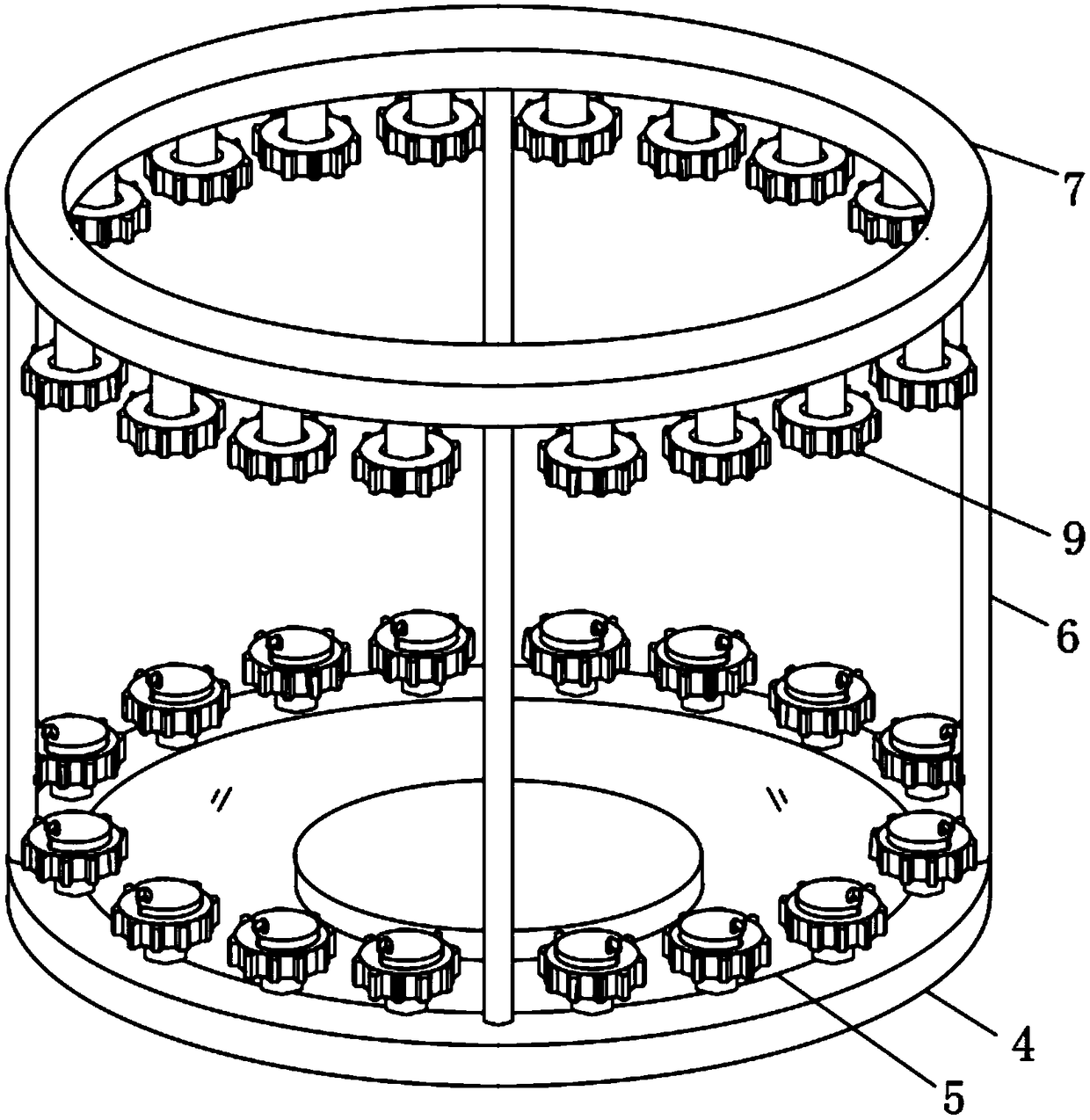

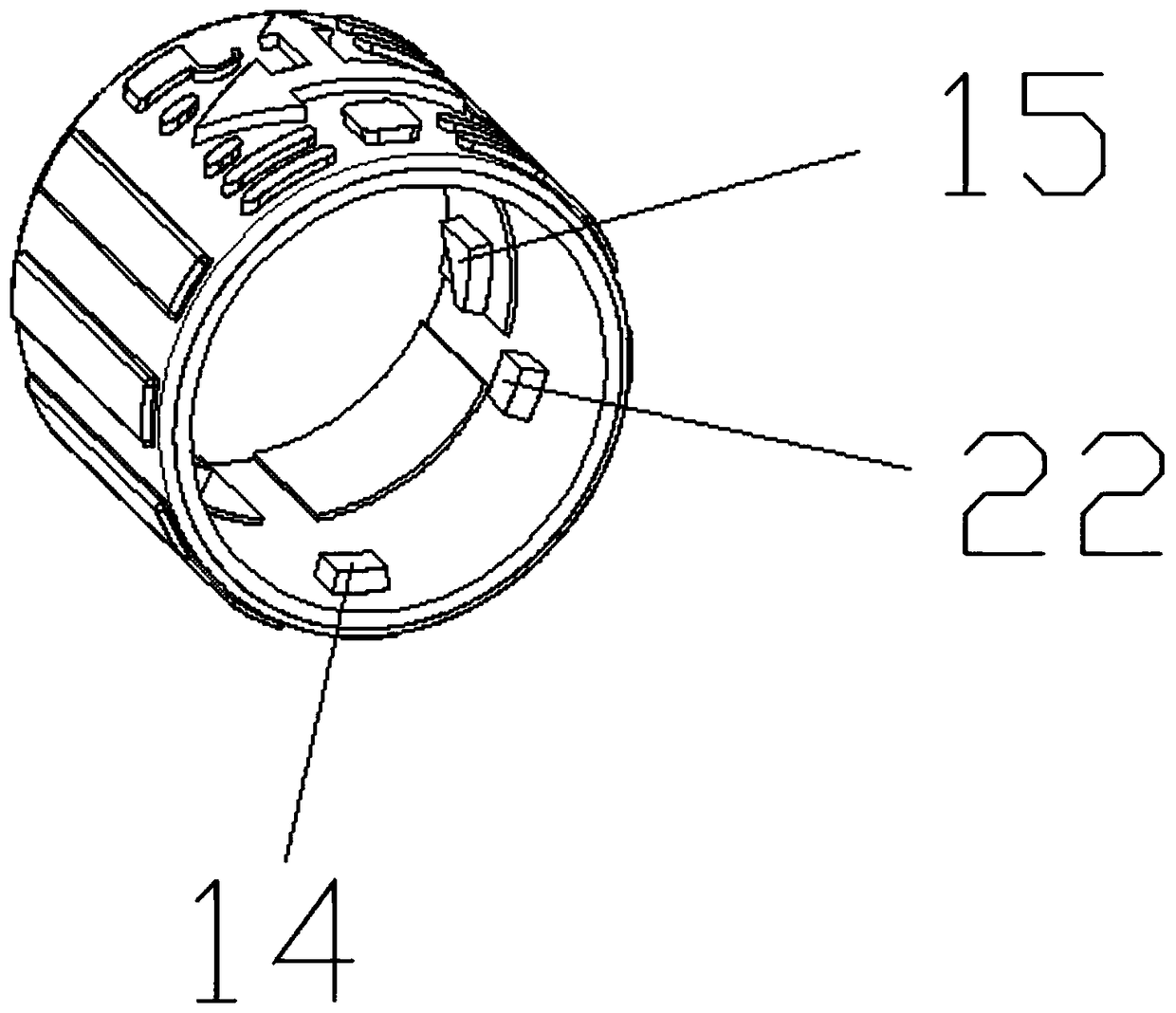

Universal rotary-assembly type oil product filter with filter element replaceable function and automatic water drainage function

InactiveCN105697204AAchieve the purpose of reusingSmall sizeMachines/enginesLiquid fuel feedersButt jointWater level

Owner:XIAN TIANHOU FILTRATION TECH

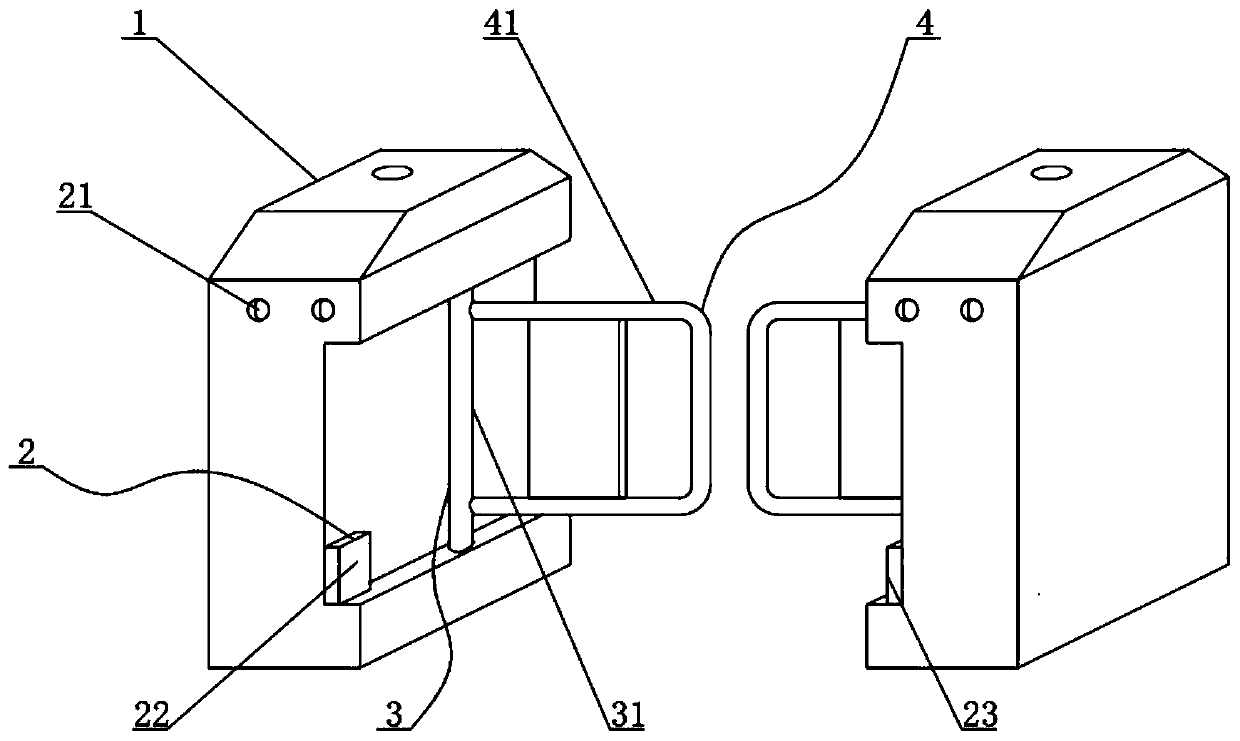

Tensile fixture

InactiveCN109142043AClamp firmlyPrevent slippageMaterial strength using tensile/compressive forcesButt jointRebar

Owner:LIUZHOU RAILWAY VOCATIONAL TECHN COLLEGE

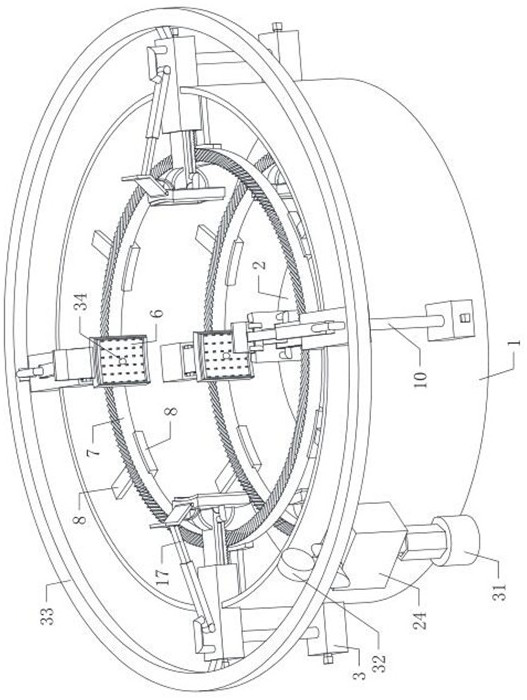

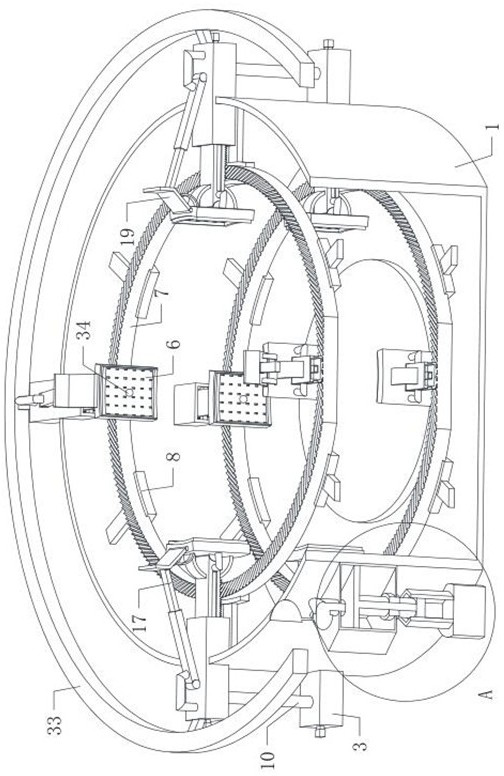

Pot body welding clamping tool

PendingCN113814638AEasy to moveConsistent extrusion strengthWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

Owner:诸城市众工机械有限公司

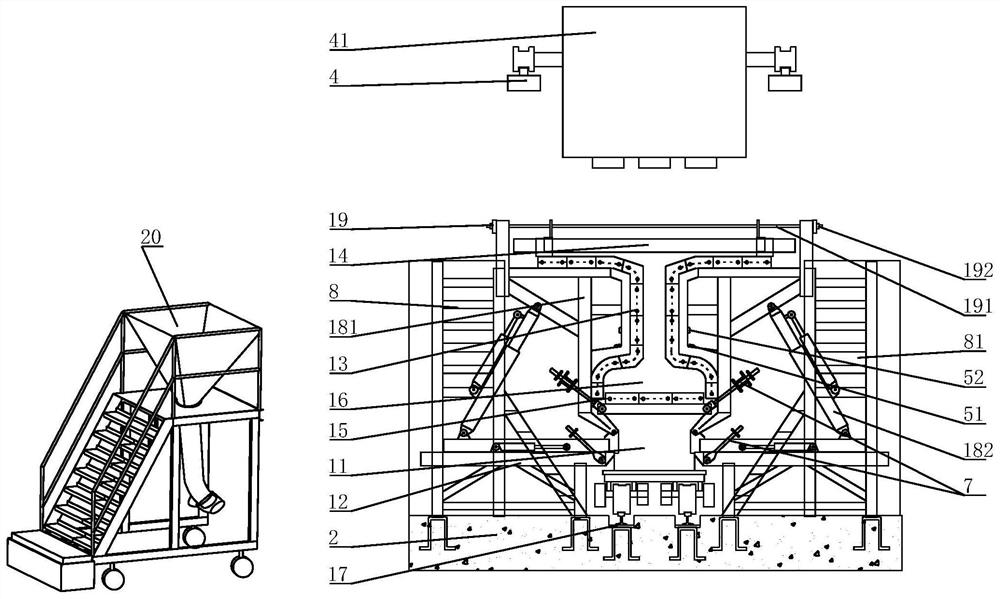

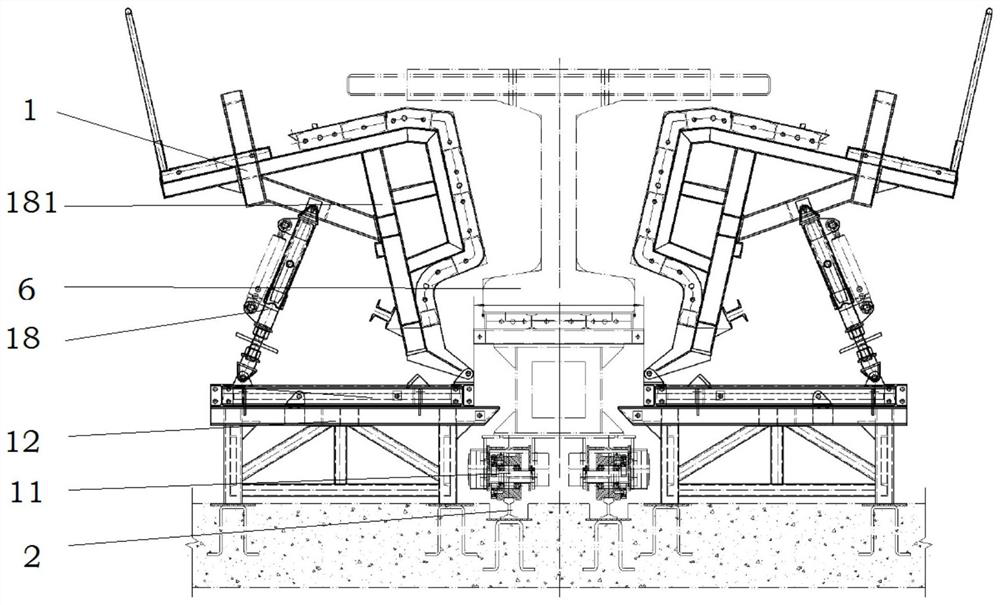

Pouring system and method for automatic prefabricated T beam

PendingCN111702948AStable structureIncrease productivityDischarging arrangementFeeding arrangmentsT-beamButt joint

Owner:安徽省路港工程有限责任公司

High-intensity high-speed informationization manned spacecraft manufactured by new graphene materials

InactiveCN102745344AHigh hardnessImprove conductivityArtificial satellitesSecondary cellsRe entryNew energy

Owner:WUXI TONGCHUN NEW ENERGY TECH

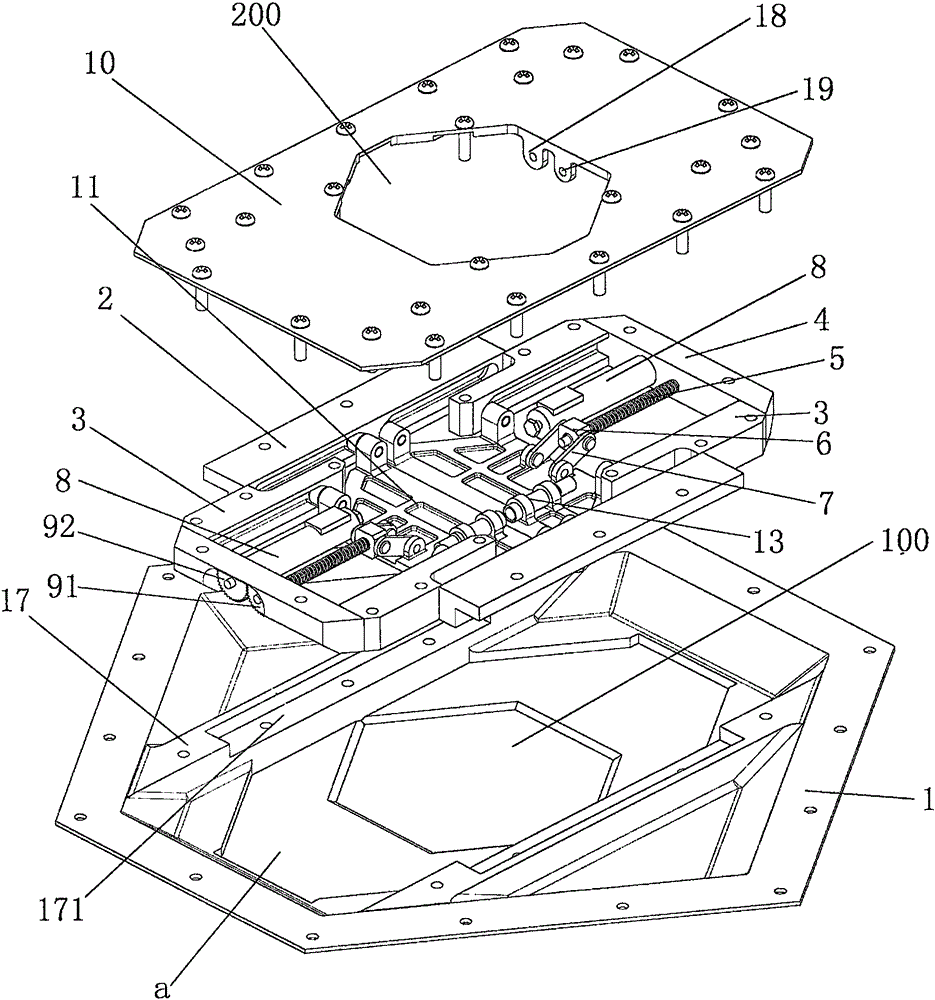

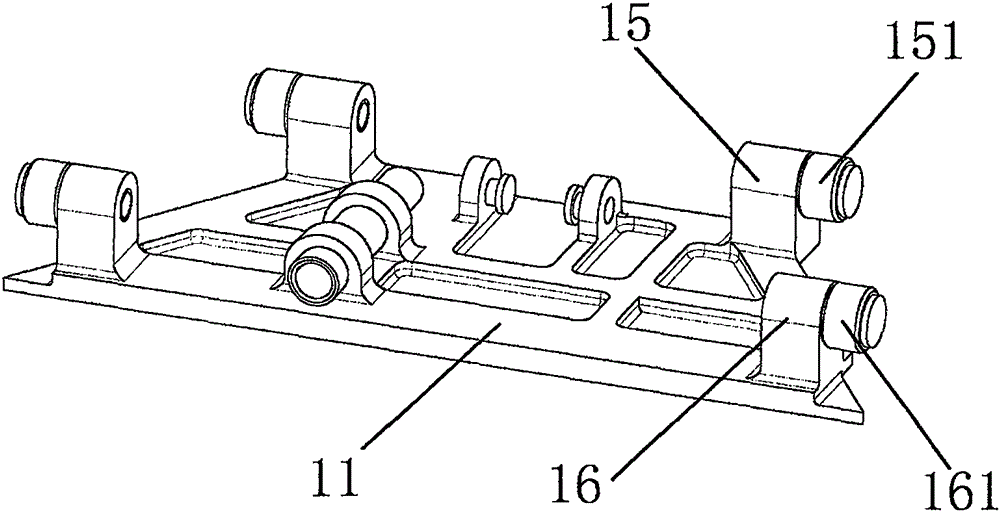

Self-adaptive resetting adjustable flexible supporting mechanism

Owner:航天科工哈尔滨风华有限公司

Multi-joint cotton packaging film connection equipment and application thereof

Owner:山东莱芜新甫冠龙塑料机械有限公司

Motor-driven sealing mechanism for aircraft external hanging point

Owner:NORTHWESTERN POLYTECHNICAL UNIV

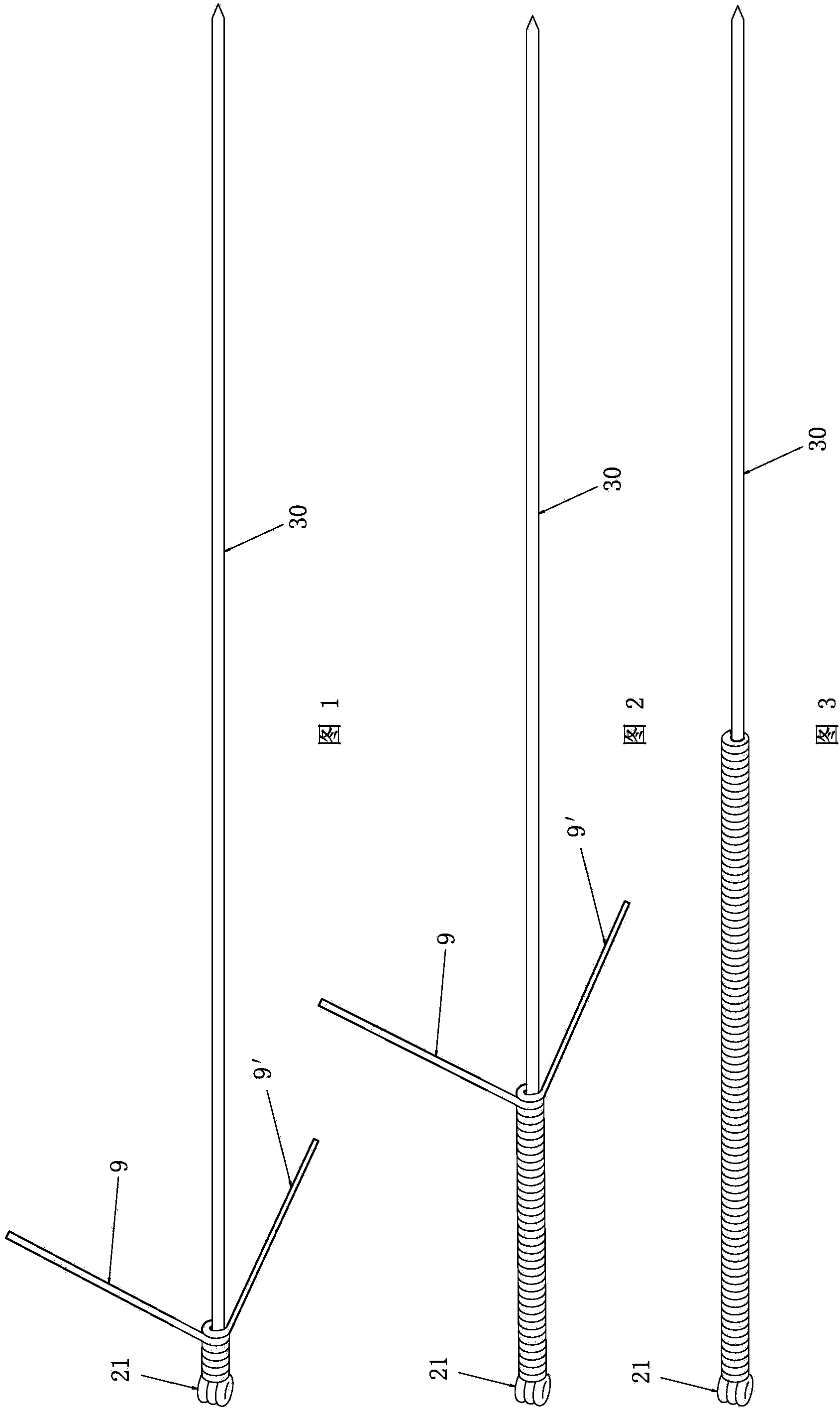

Metal wire clamping mechanism of acupuncture needle automatic handle winding machine

Owner:SUZHOU MEDICAL SUPPLY FACTORY CO LTD

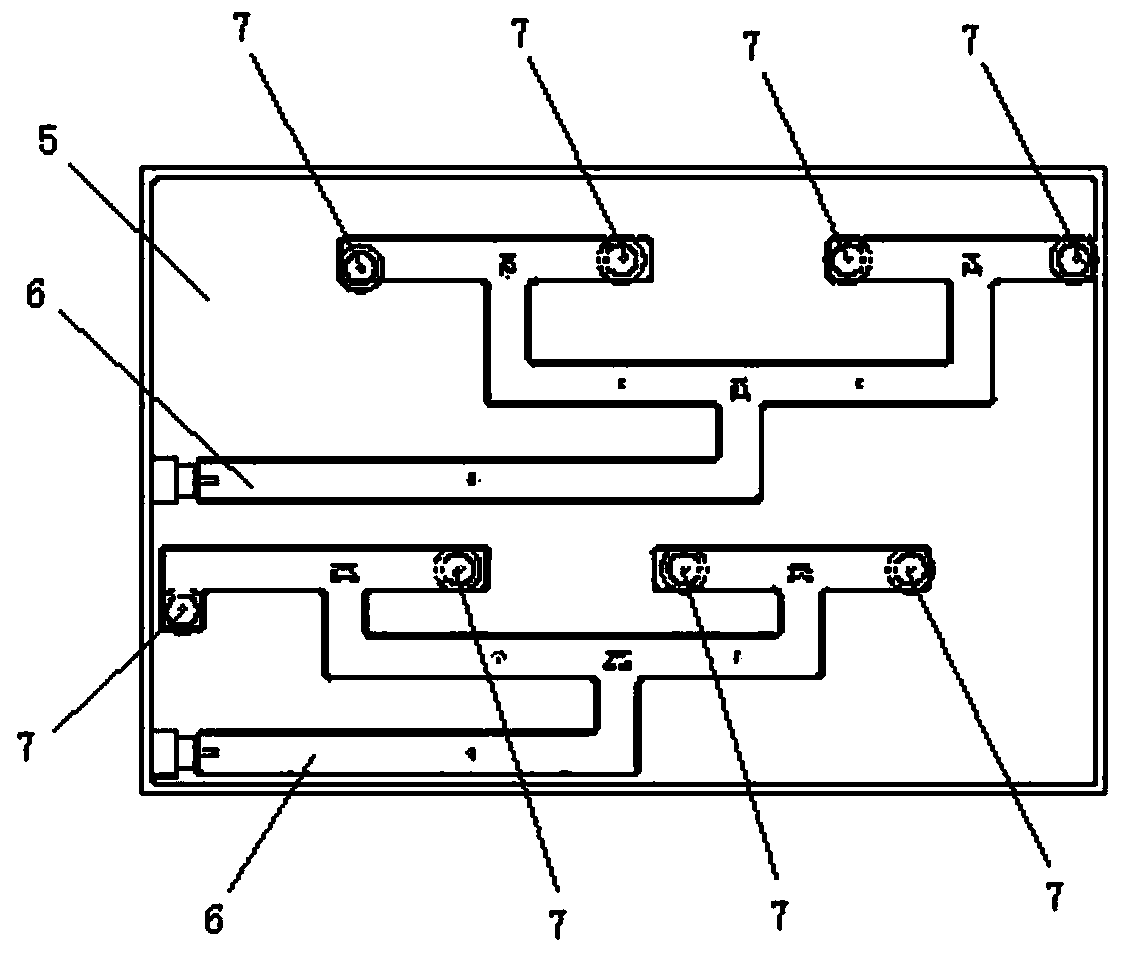

Fresh air intelligent control system and control method thereof

ActiveCN107120807AExtended service lifeLow costLighting and heating apparatusSpace heating and ventilation safety systemsCommunication interfaceAutomatic control

The invention discloses a fresh air intelligent control system and a control method thereof. The system comprises a fresh air controller and an intelligent housing system, and the fresh air controller is in communication connection with the intelligent housing system through a wireless module, a radio frequency communication module or an RS485 communication interface; and the fresh air controller comprises a PM2.5 sensor, a CO2 sensor, a temperature and humidity sensor and an MCU arranged in the fresh air controller, and the PM2.5 sensor, the CO2 sensor and the temperature and humidity sensor are electrically connected with the MCU to achieve signal and data transmission. The fresh air intelligent control system is elaborate in design and simple in structure; and by means of the fresh air intelligent control system, a fresh air system is an intelligent control system which can conduct scientific automatic control and can be in real-time butt joint with intelligent housing. By means of the air intelligent control system, the service life of a fresh air controller is greatly prolonged, cost is reduced, and application and popularization in the industry are achieved.

Owner:SUZHOU BAYAIR PURIFYING SCI & TECH CO LTD

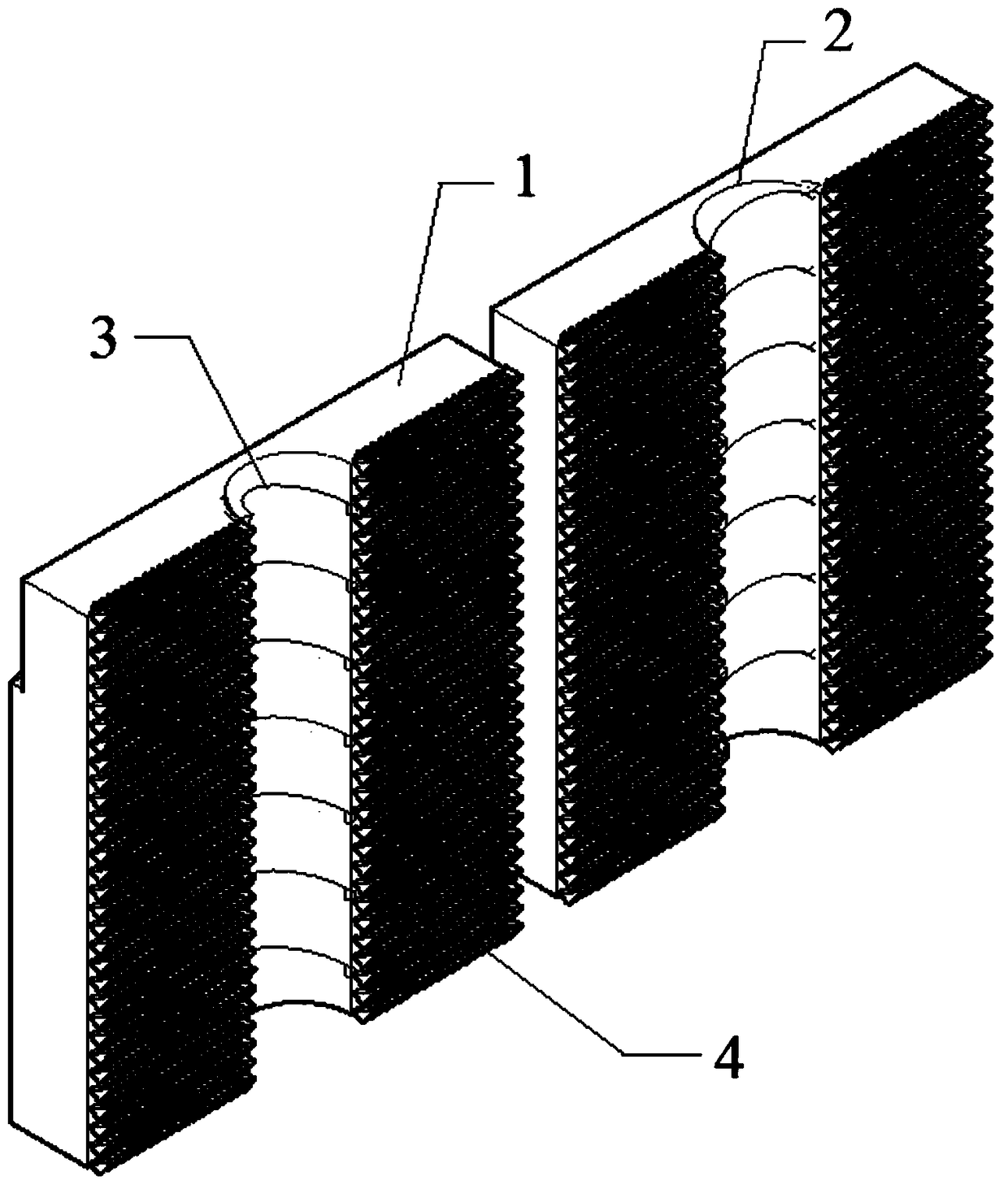

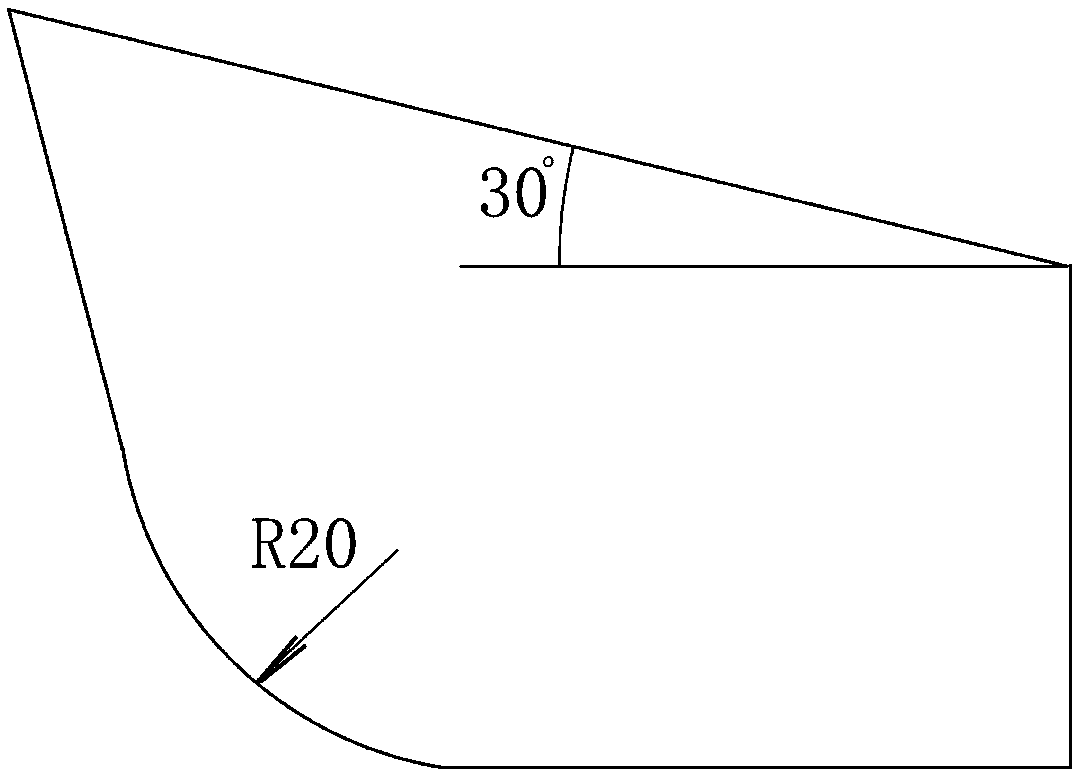

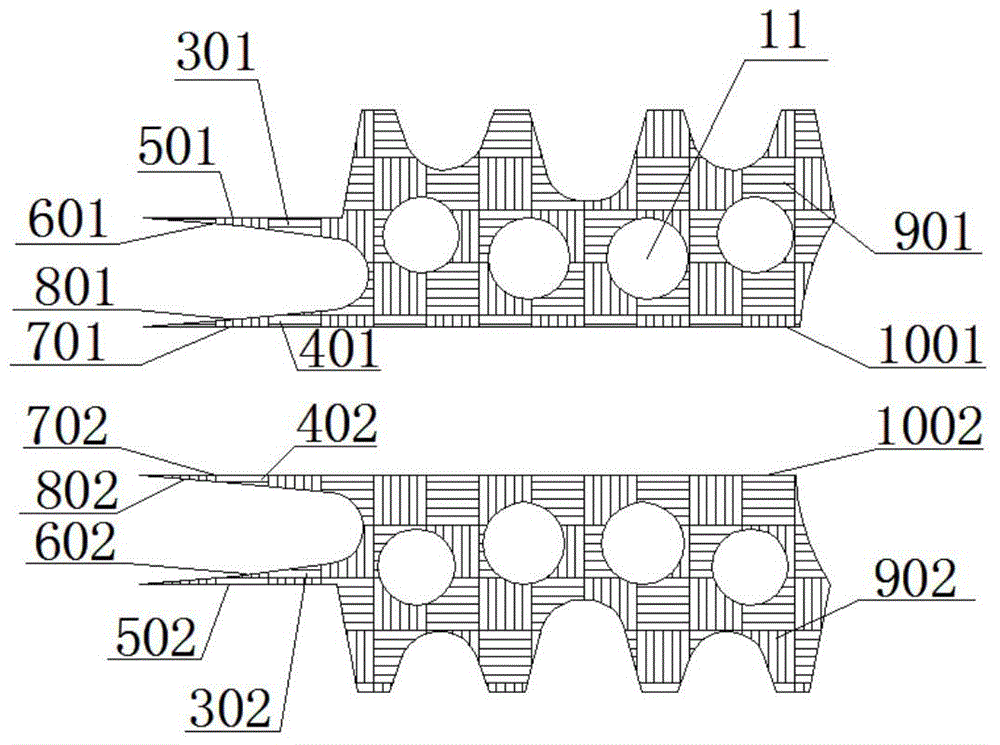

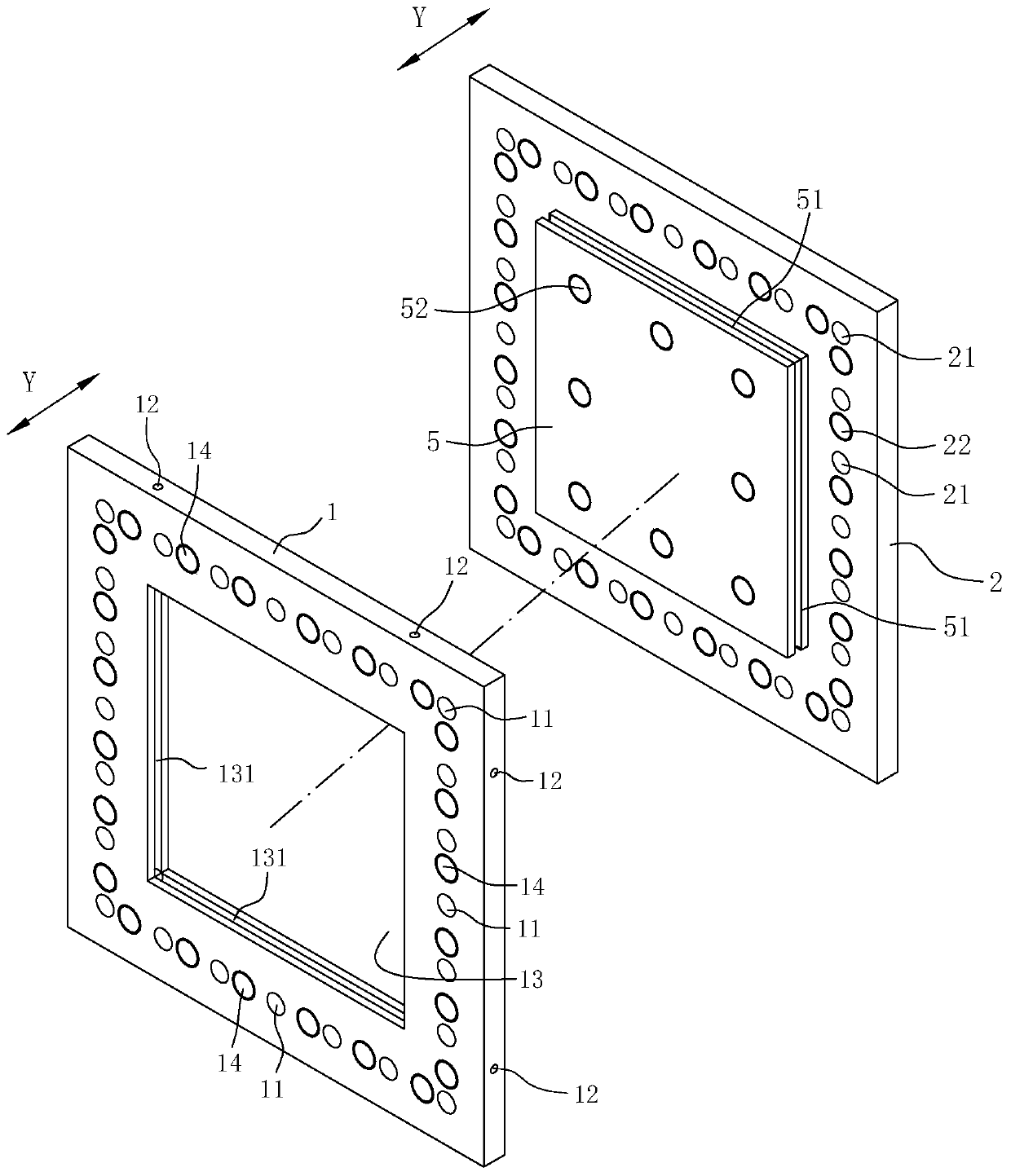

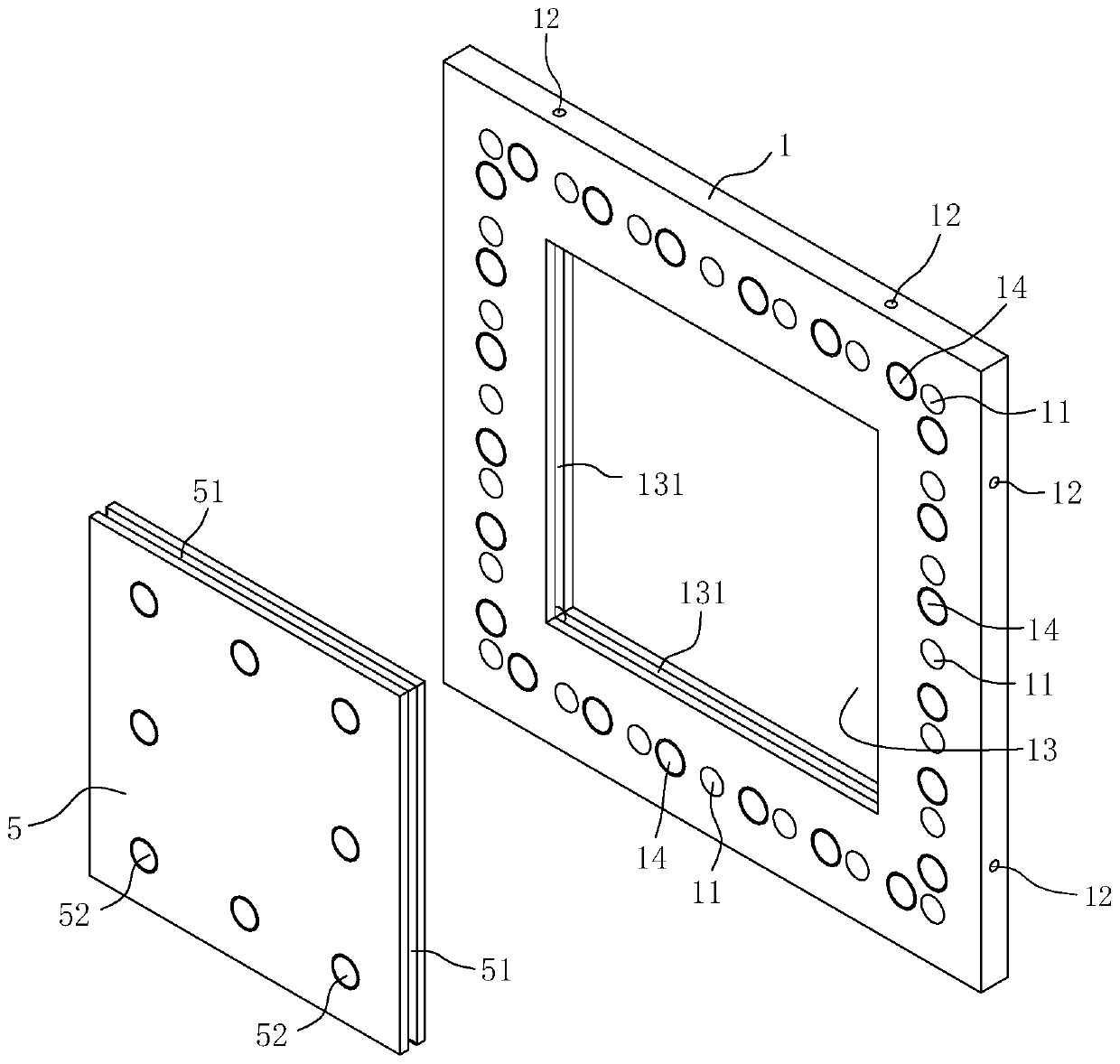

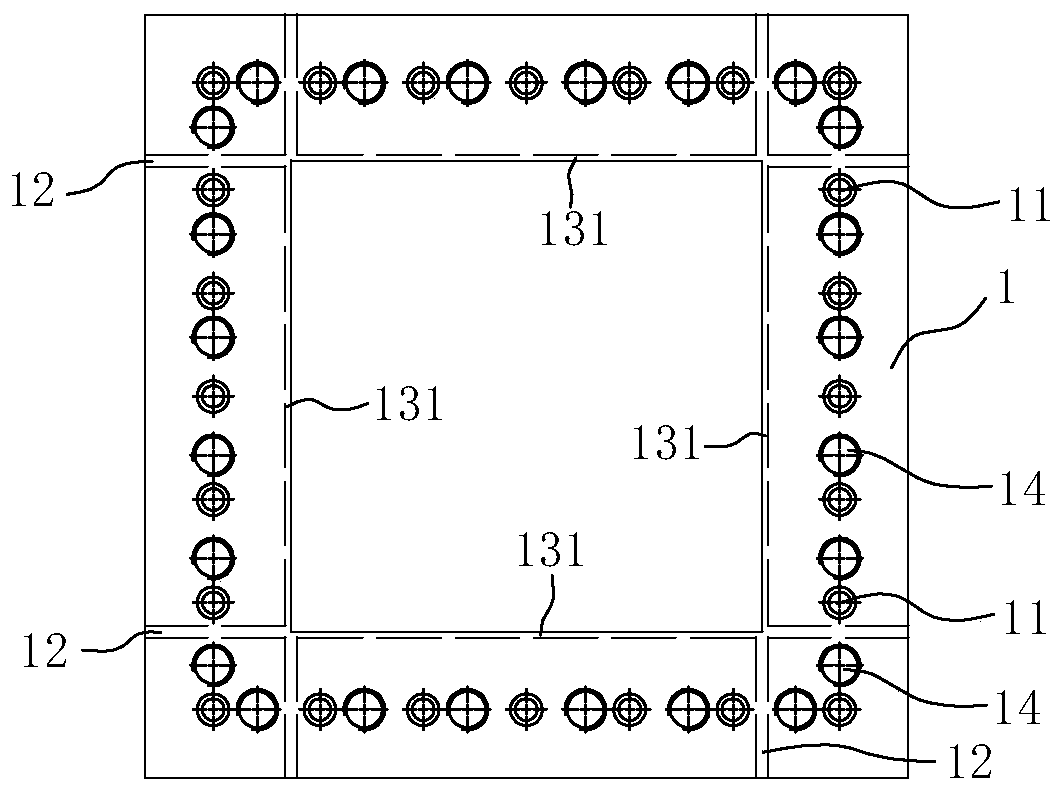

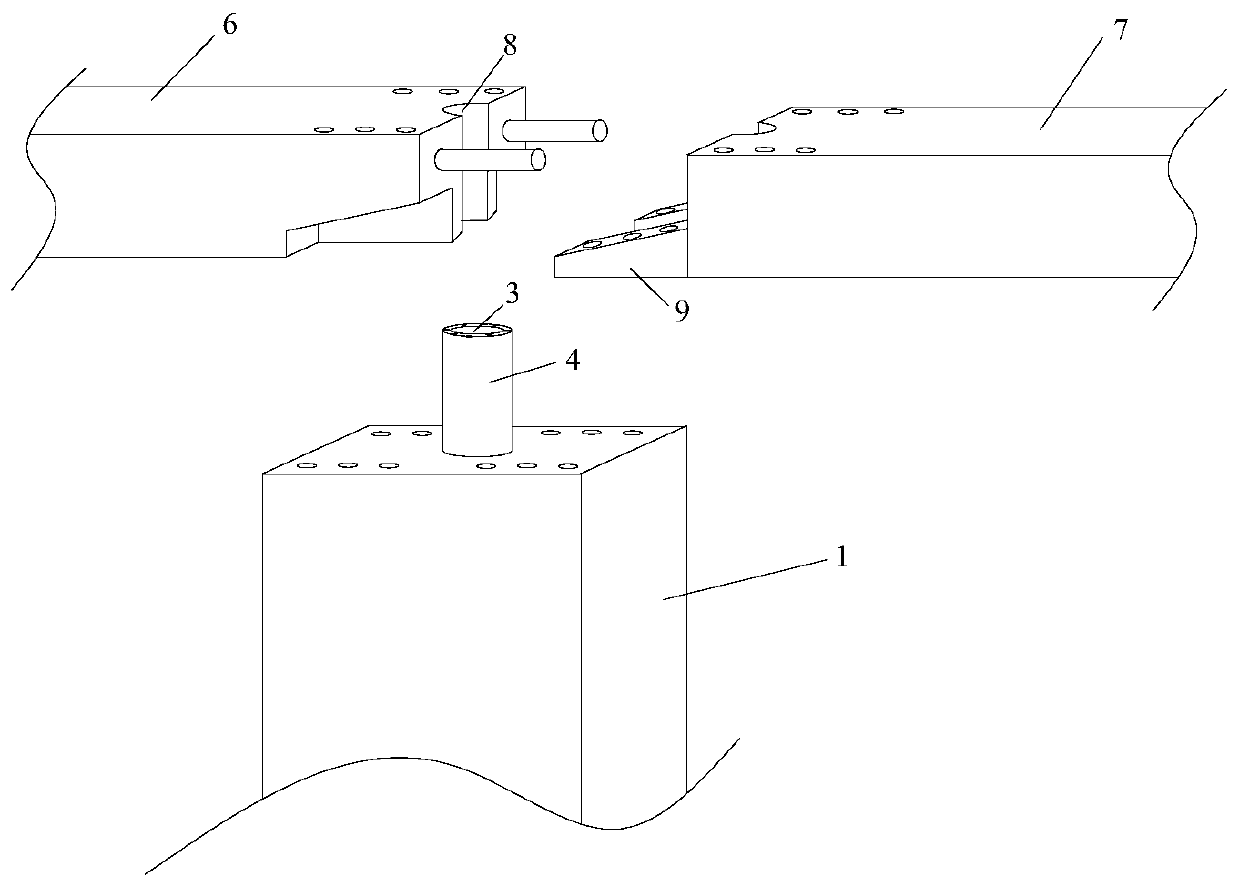

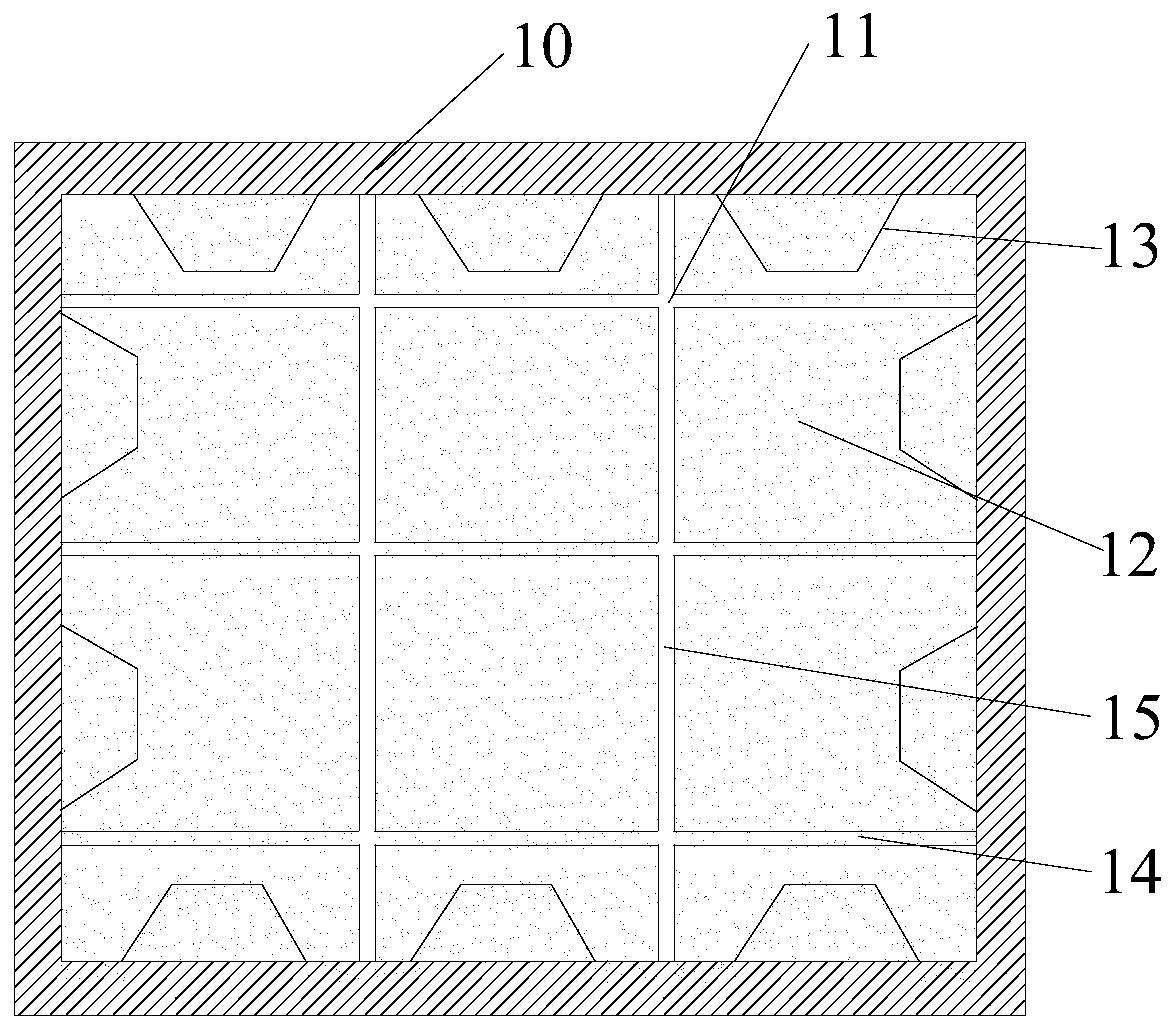

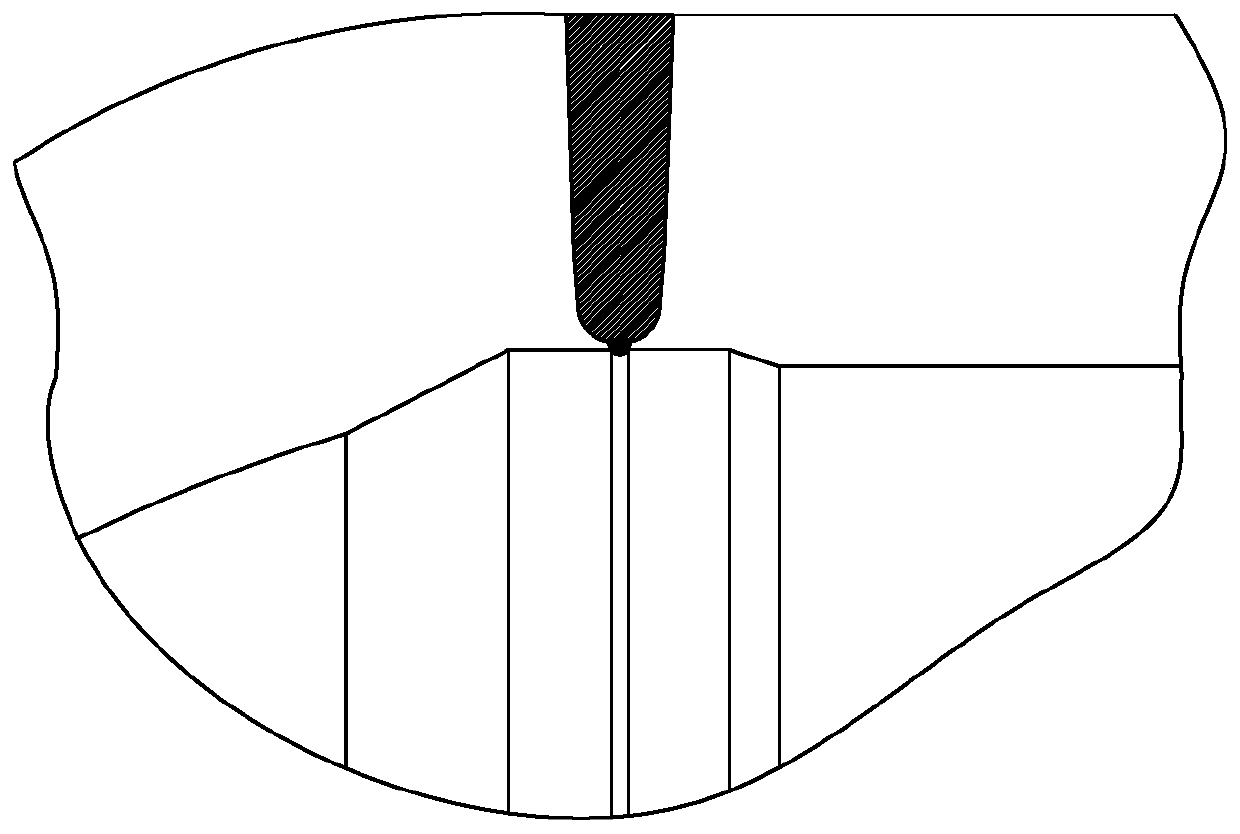

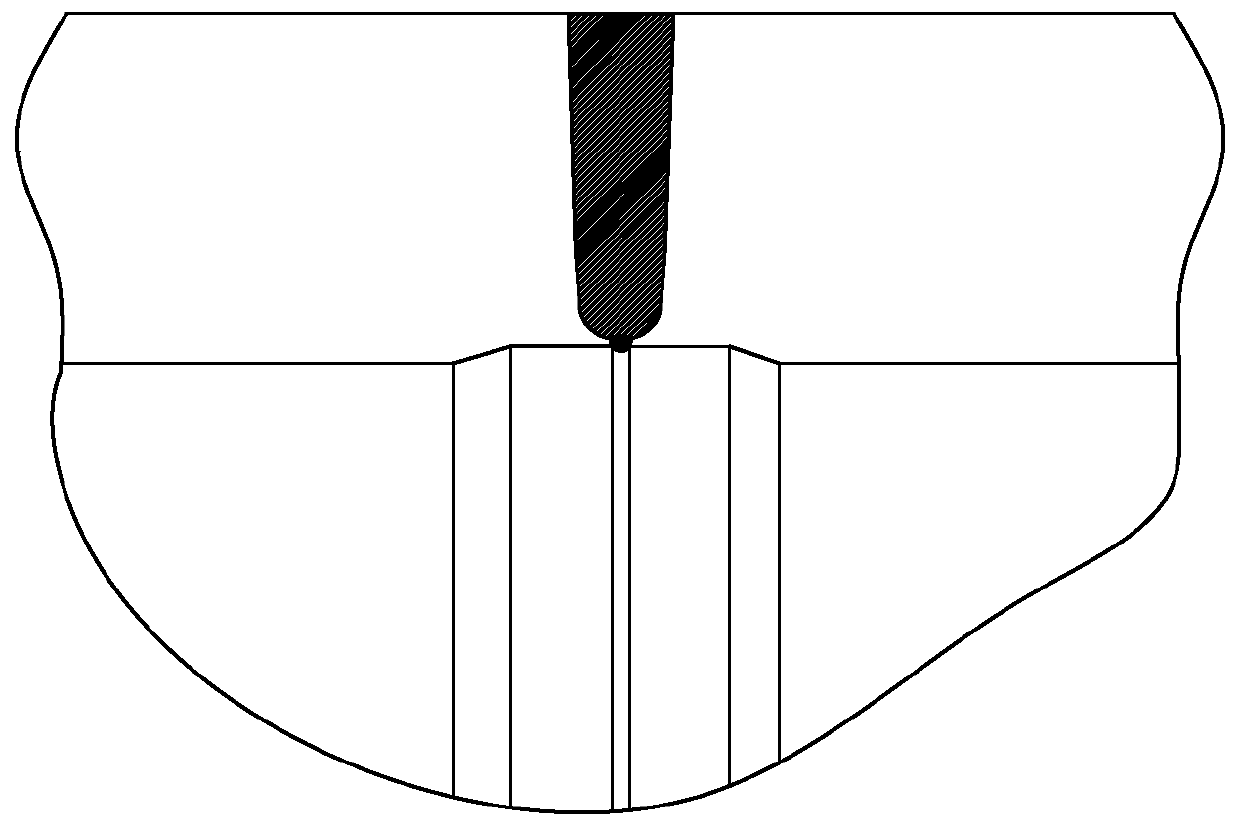

Butt joint structure of fabricated prefabricated columns and prefabricated beams and butt joint construction method of butt joint structure

ActiveCN111042334ALimit relative displacementImprove stabilityStrutsPillarsButt jointIndustrial engineering

Owner:XINJIANG AGRI UNIV

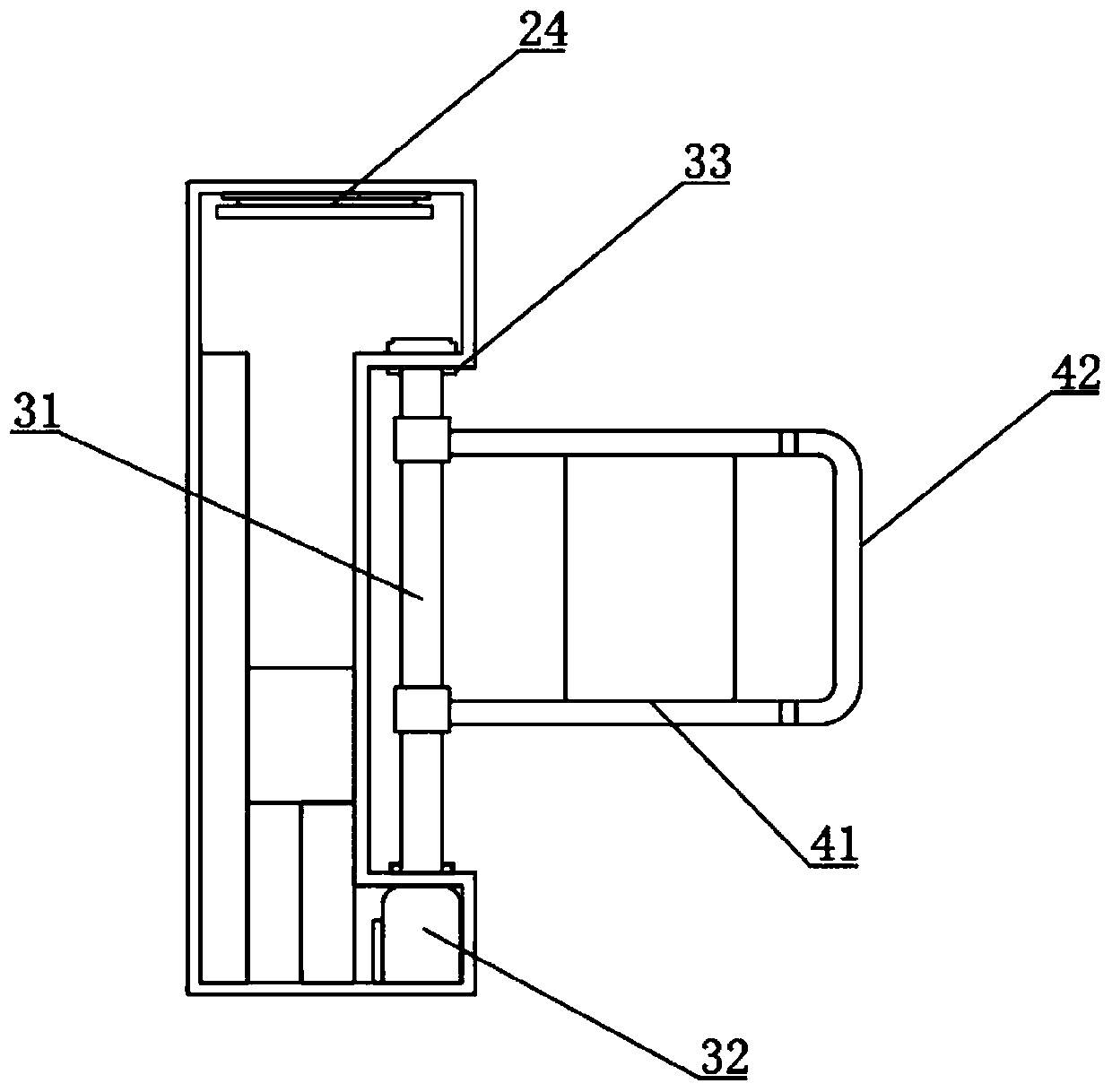

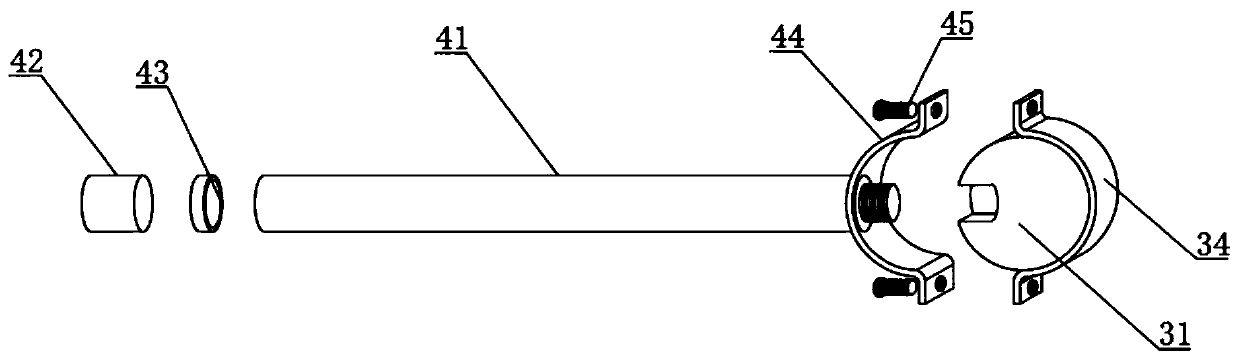

Swing gate with infrared protection function

PendingCN110396955AUse adaptationThe disassembly process is simple and convenientTraffic restrictionsDrive shaftButt joint

Owner:溧阳大唐智能化工程有限公司

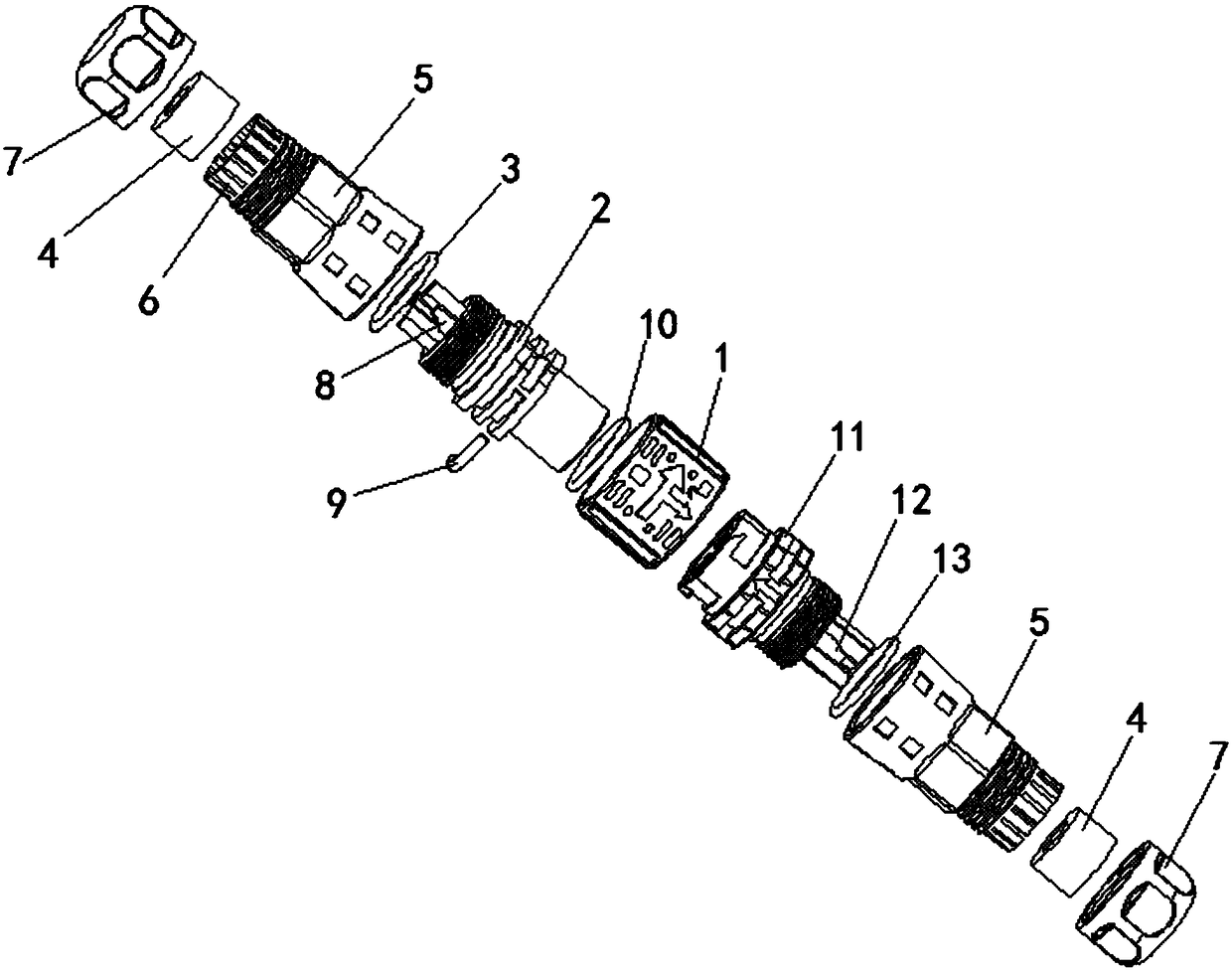

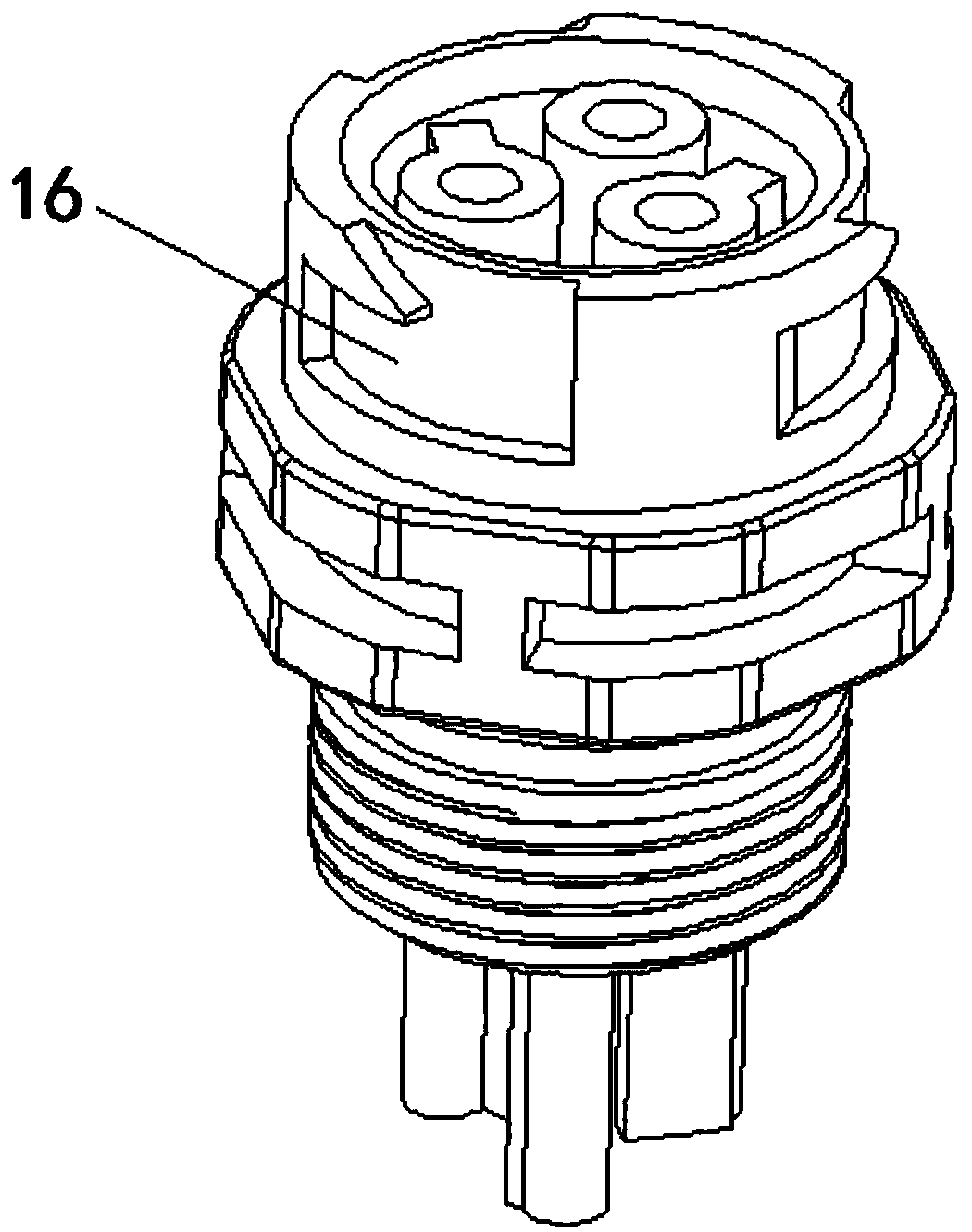

Self-locking waterproof connector

PendingCN108988003AEasy to assembleAvoid deformationTwo-part coupling devicesCouplings bases/casesButt jointEngineering

Owner:深圳澳华电气股份有限公司

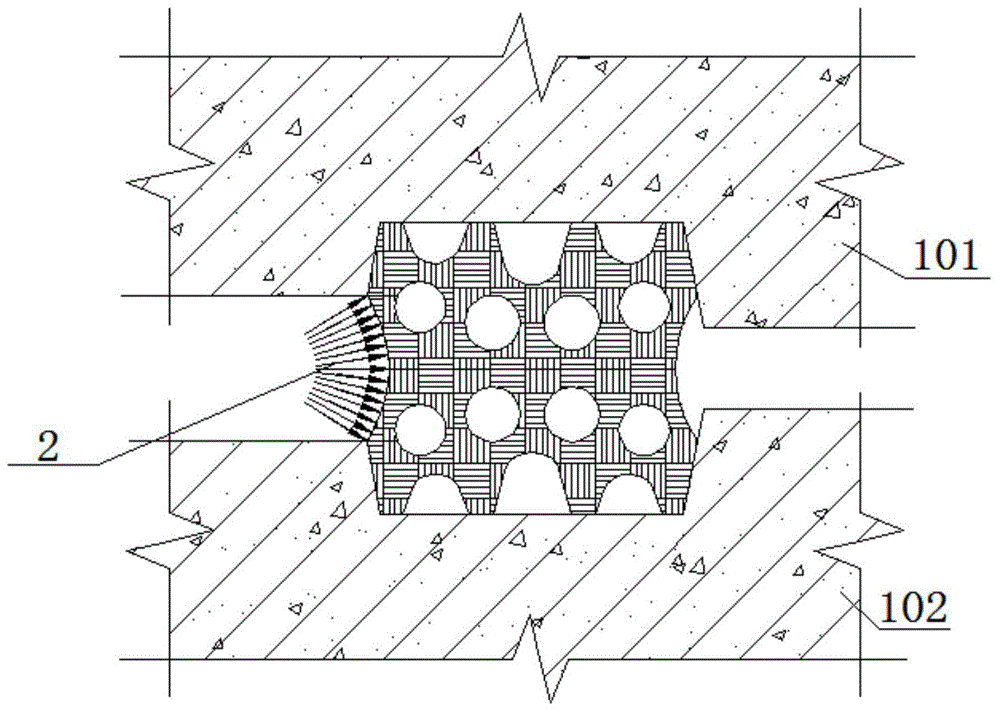

A cable wrapping intermediate joint and a manufacturing process thereof

PendingCN109245022AImprove electrical performanceGuaranteed uptimeCable junctionsApparatus for joining/termination cablesElectrical conductorButt joint

The invention provides a cable wrapping intermediate joint and a manufacturing process thereof, which are used for butt joint of two sections of three-core or single-core cables. The wrapping intermediate joint includes the connector wrapping connecting each single-phase cable, and the protective wrapping all the connectors; A tap wrap includes a pressure nozzle connected with a conductor core ofthat same-phase cable, a stress cone sleeved on the cable, a wound limiting step, a semi-conductive tape layer, an insulating tape layer, a tap shield layer, a copper mesh layer, a single-phase cablemetal shield tape, a PVC layer and a single-phase cable waterproof layer; The protective wrapping package comprises a binding layer, a cable metal shielding tape, a cable waterproof layer and a cablearmor layer from the inside to the outside. The winding intermediate joint of the invention can achieve the purposes of good connection, reliable insulation, good sealing performance, high mechanicalstrength, simple structure and convenient fabrication and installation of the conductor core of the cable, can ensure the safety and stability of the cable operation and obtain good economic benefits, and therefore has great popularization and application value.

Owner:SHANGHAI G&W ELECTRIC LTD

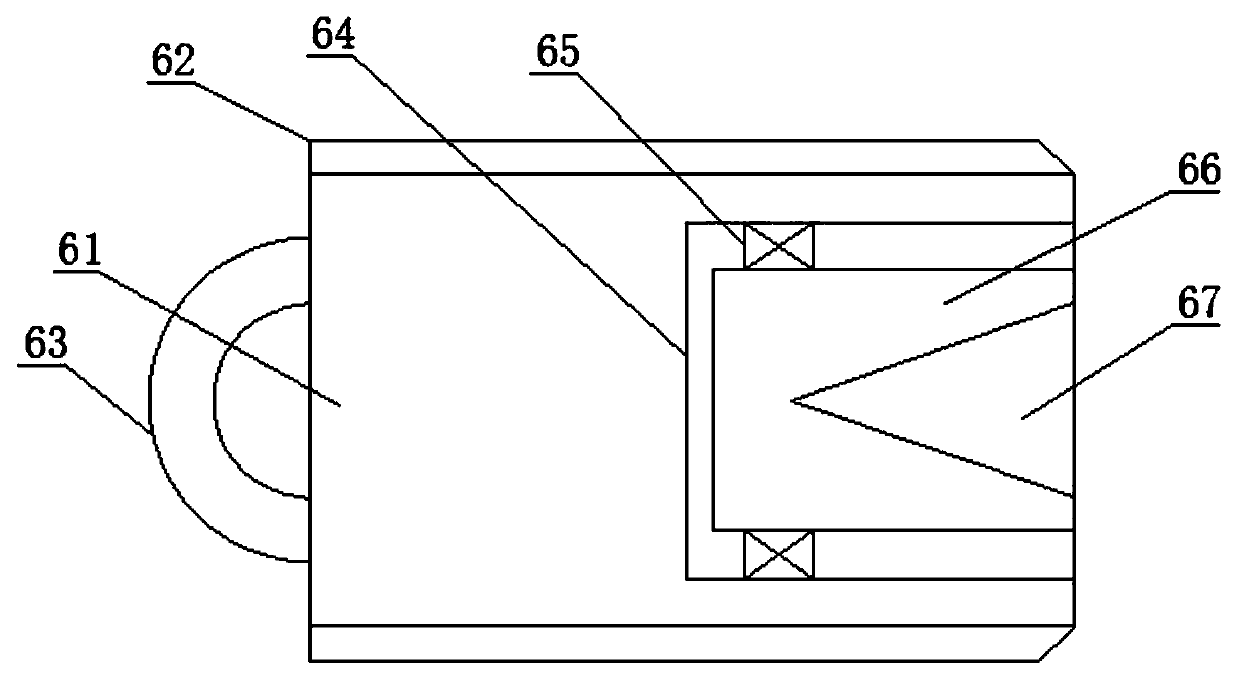

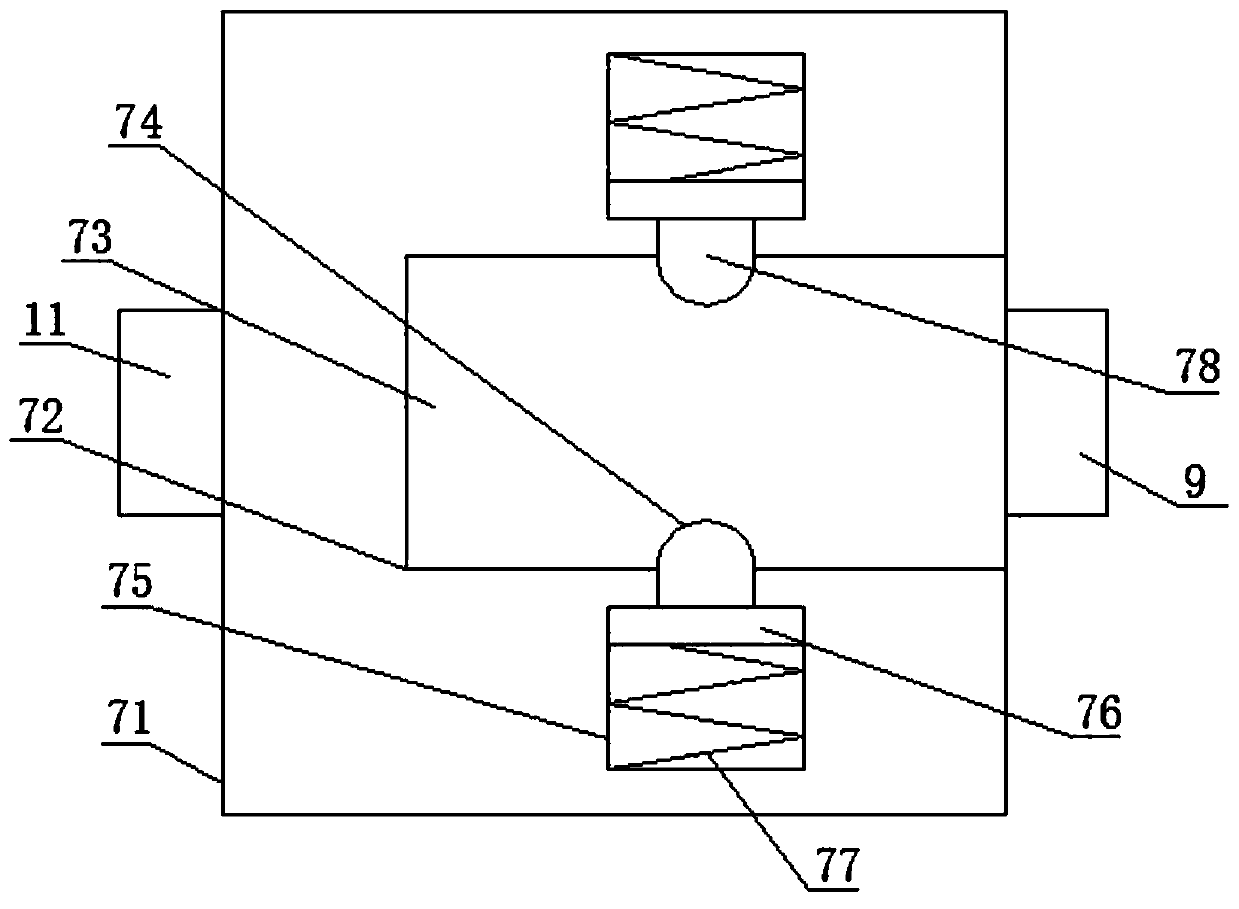

Circulation system and method for atmosphere protecting four-push-plate furnace

The invention discloses a circulation system for an atmosphere protecting four-push-plate furnace. The circulation system comprises the four-push-plate furnace, wherein an inlet-outlet of the four-push-plate furnace is provided with a transition cabin, the transition cabin is in butt joint with a cleaning cabin, and the cleaning cabin comprises four push plate positions arranged in a two-row two-column mode. A transverse conveying platform comprises four push plate positions arranged in parallel, and a temporary storage platform comprises two push plate positions arranged in parallel. The invention further correspondingly discloses a circulation method. The method comprises the steps that S01, push plates are pushed into the temporary storage platform from a conveying roller line; S02, push plates on the temporary storage platform and push plates on the transverse conveying platform are simultaneously pushed into the cleaning cabin; S03, the push plates in the cleaning cabin are pushed into the transition cabin to make the four push plates in the transition cabin arranged in parallel and are simultaneously pushed into the four-push-plate furnace; S04, the four push plates in the four-push-plate furnace are pushed out and pushed into the transition cabin at an outlet and then are pushed into the cleaning cabin, and finally the push plates in the cleaning cabin are pushed out and pushed to the conveying roller line. Both the circulation system and the circulation method have the advantages of improving the production efficiency and the like.

Owner:HUNAN SEMICORE THERMAL INTELLIGENT EQUIP CO LTD

Microwave transceiving channel assembly

InactiveCN109873655AReduce volumeGuaranteed Isolation IndexTransmissionLocal oscillator signalMicrowave

Owner:西安茂德通讯科技有限公司

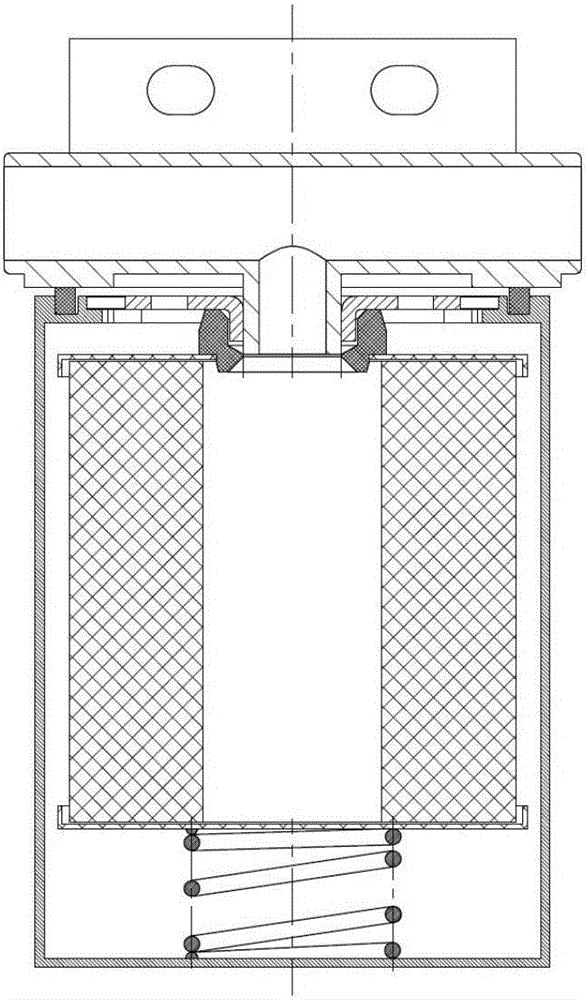

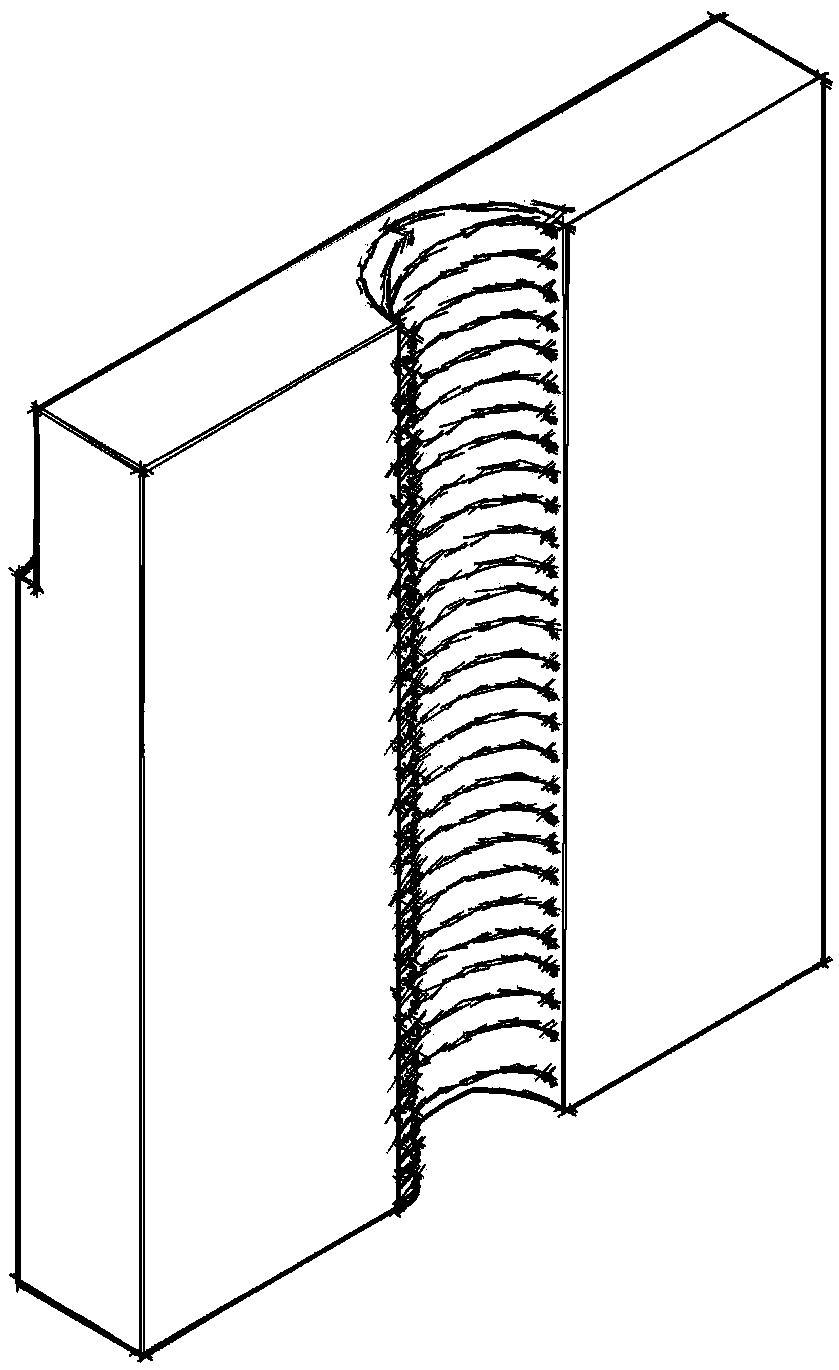

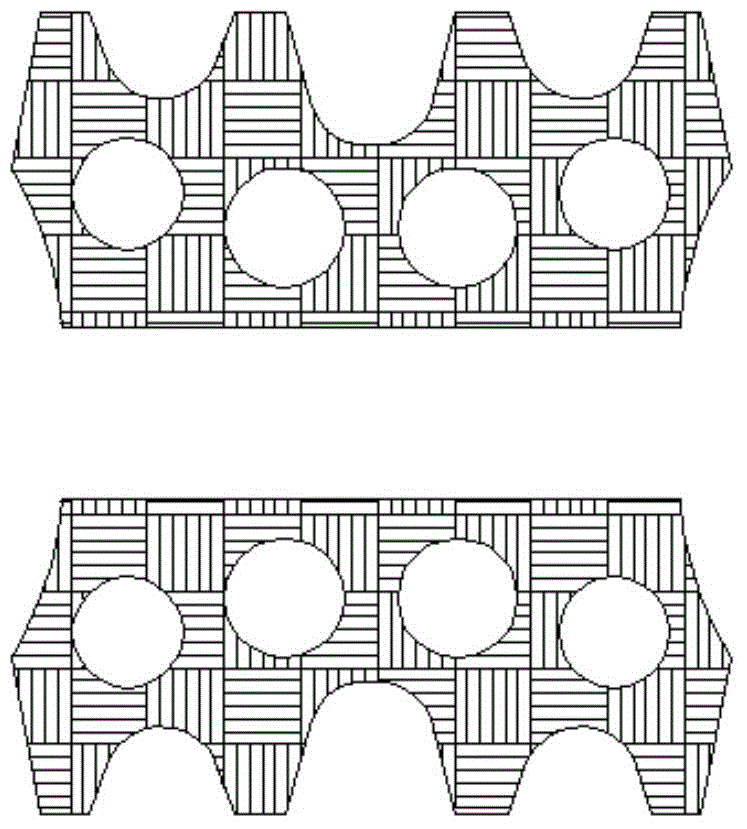

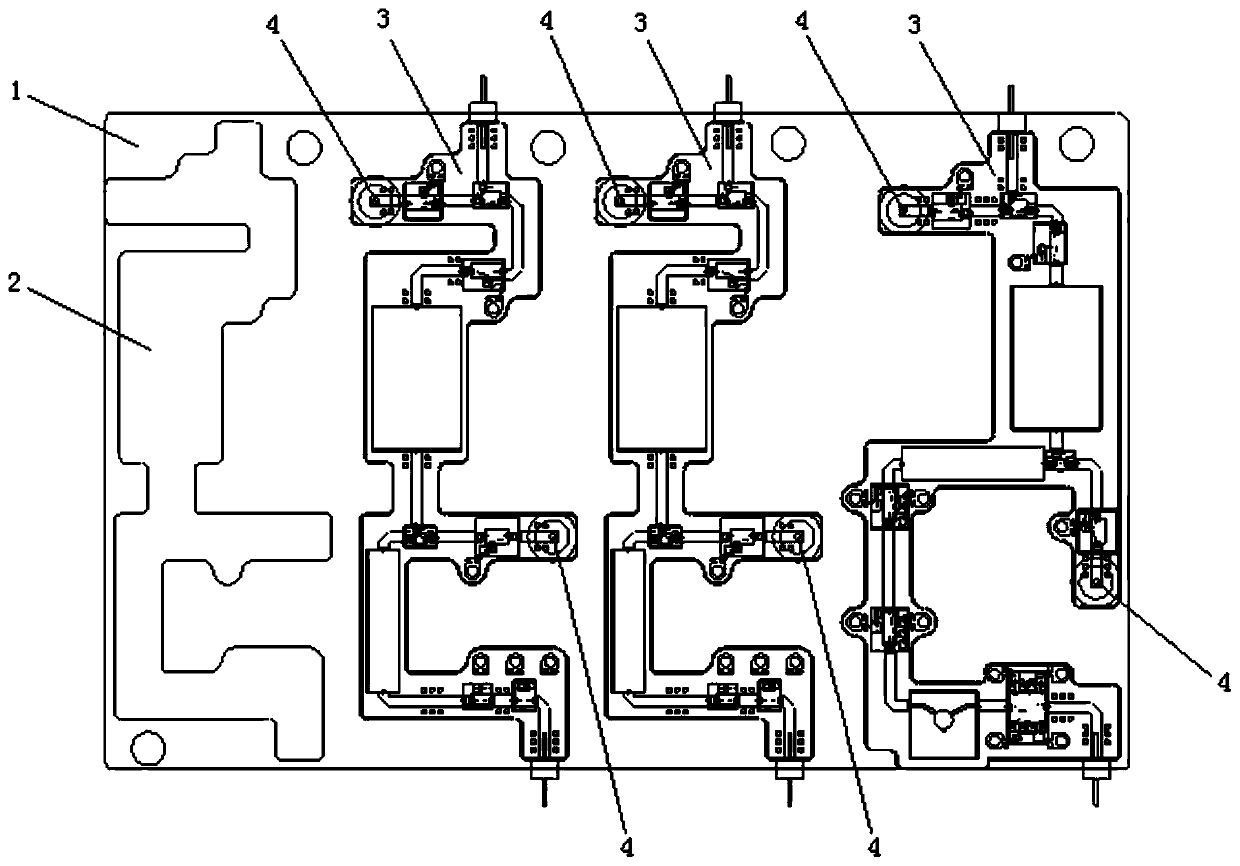

Filter extrusion forming winding module

PendingCN108417383AProduction reachedLow costImpedence networksCoils manufactureInlet channelButt joint

Owner:东莞市拿创机电科技有限公司

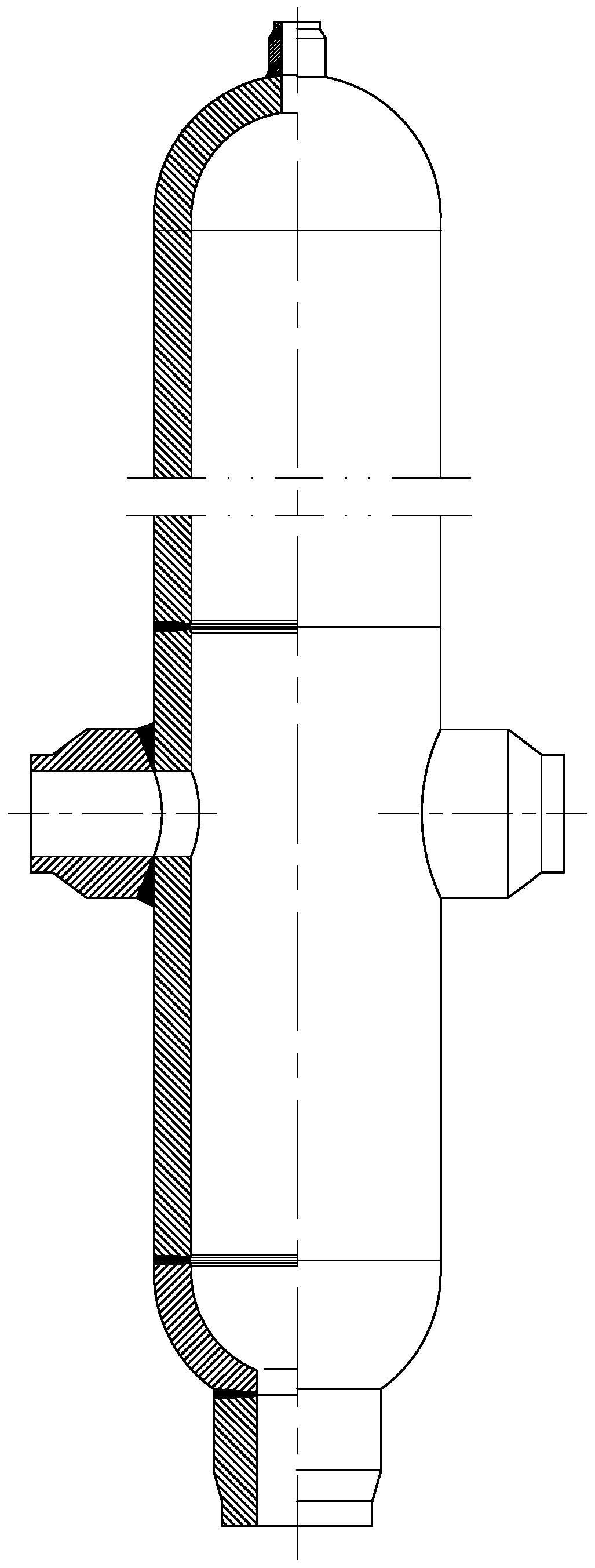

Water storage tank circular seam structure and manufacturing method thereof

ActiveCN109945155AReduce consumptionReduce the positive deviation of wall thicknessSteam boilersSteam boilers componentsManufacturing technologyPower station

Owner:HARBIN BOILER

Underframe of steel bridge frame

InactiveCN109894788AStructural connection is stableEasy to connectWelding/cutting auxillary devicesAuxillary welding devicesButt jointSupport plane

The invention relates to an underframe of steel bridge frame. The underframe comprises a supporting frame supporting the lower end face of the steel bridge frame, and the supporting frame comprises aplurality of parallel cross beams and a plurality of parallel vertical beams. The cross beams and the vertical beams re perpendicular, and sliding grooves in sliding connection with the vertical beamsare formed in the cross beams. Supporting columns in butt joint with the ground are arranged at the intersections of the cross beams and the vertical beams. The underframe is stable in overall structure connection, and the large steel bridge frame can be supported; and due to the fact that the vertical beams penetrate through the cross beams, the connecting mode is simple, the cross beams and thevertical beams can be transported to the site to be constructed, and the transportation efficiency can be improved by transporting the cross beams and the vertical beams separately.

Owner:SHENZHEN LIANTIAN STEEL STRUCTURE BRIDGE ENG CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap