Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about "Webs handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

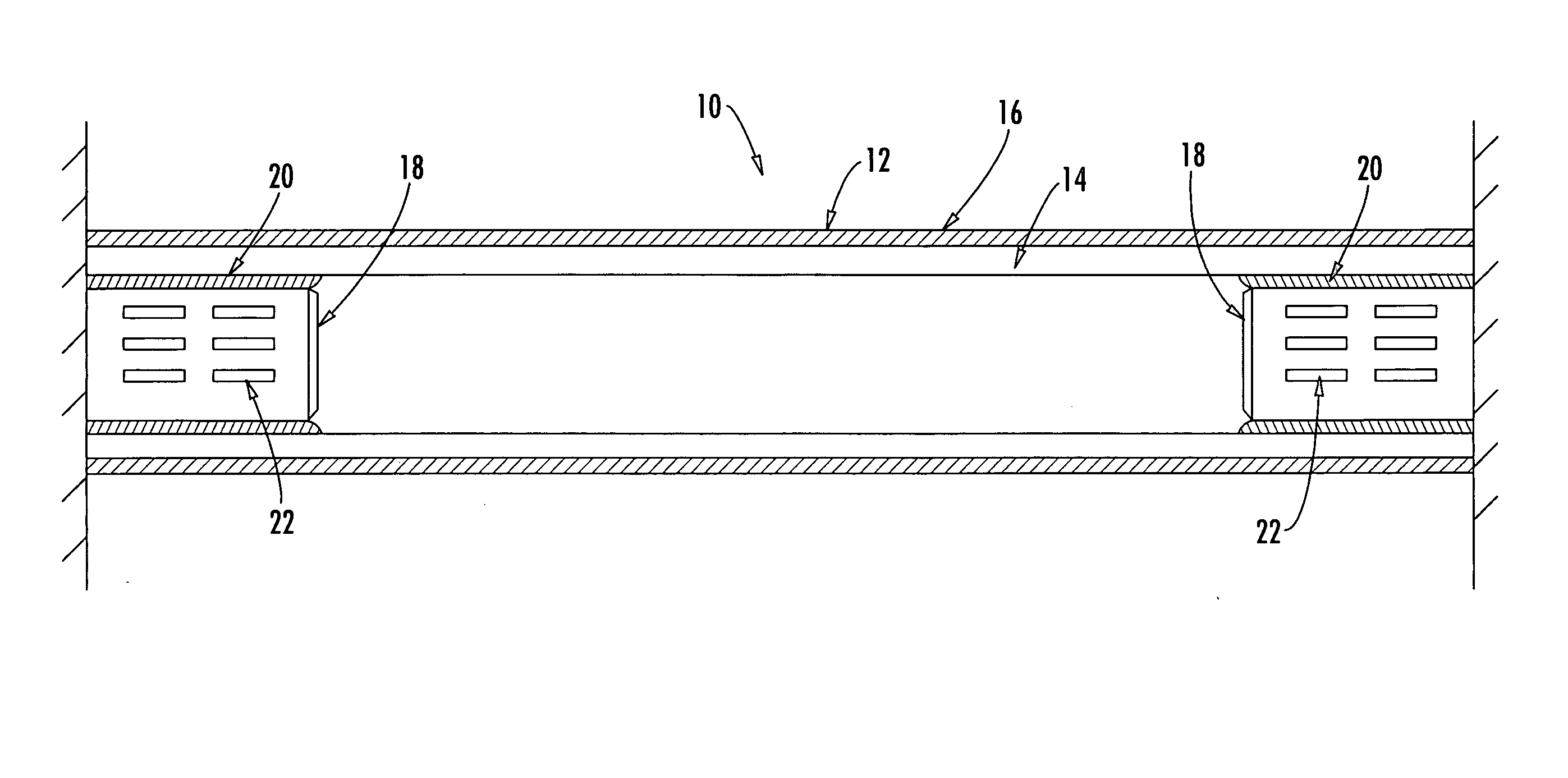

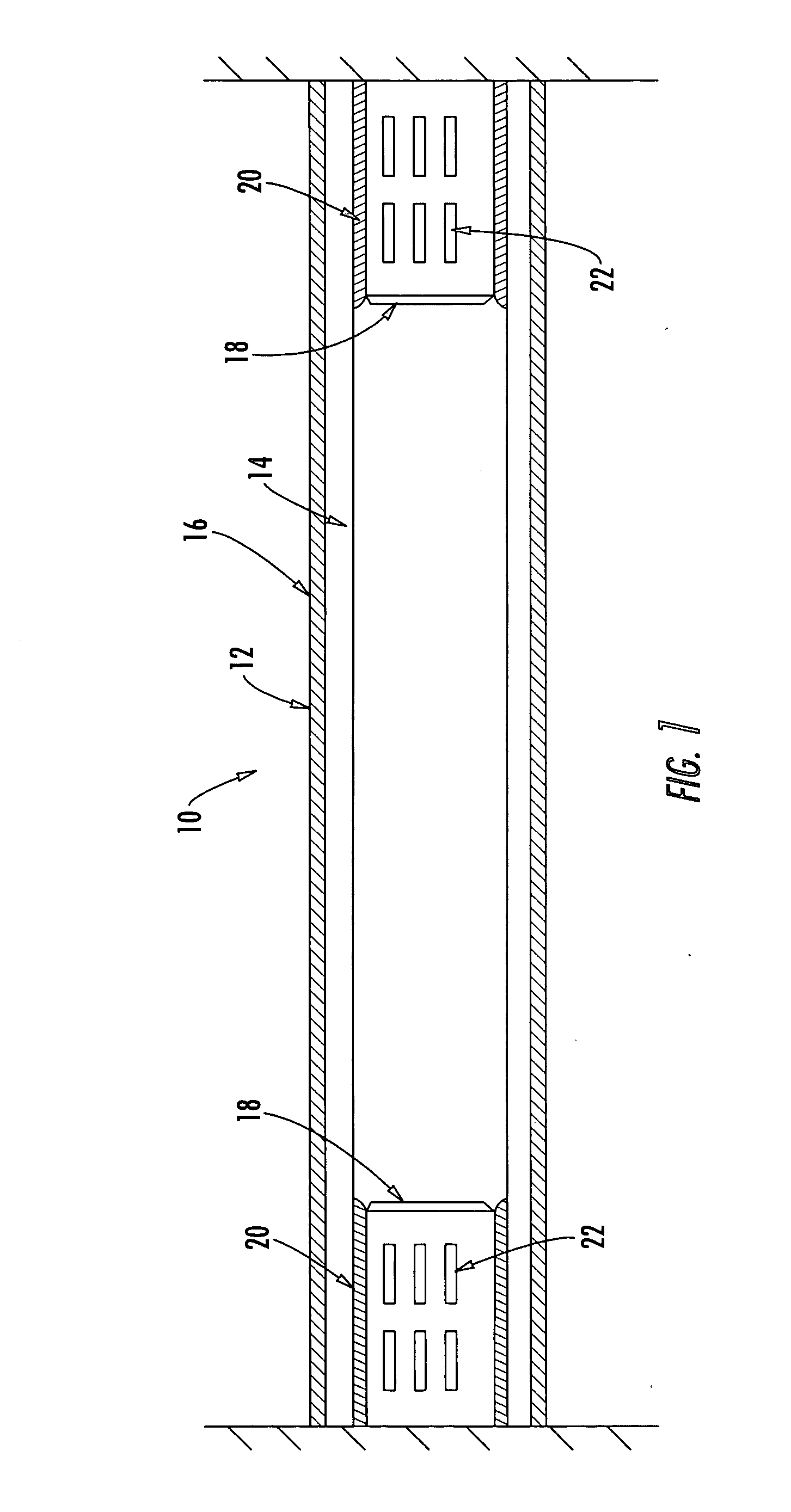

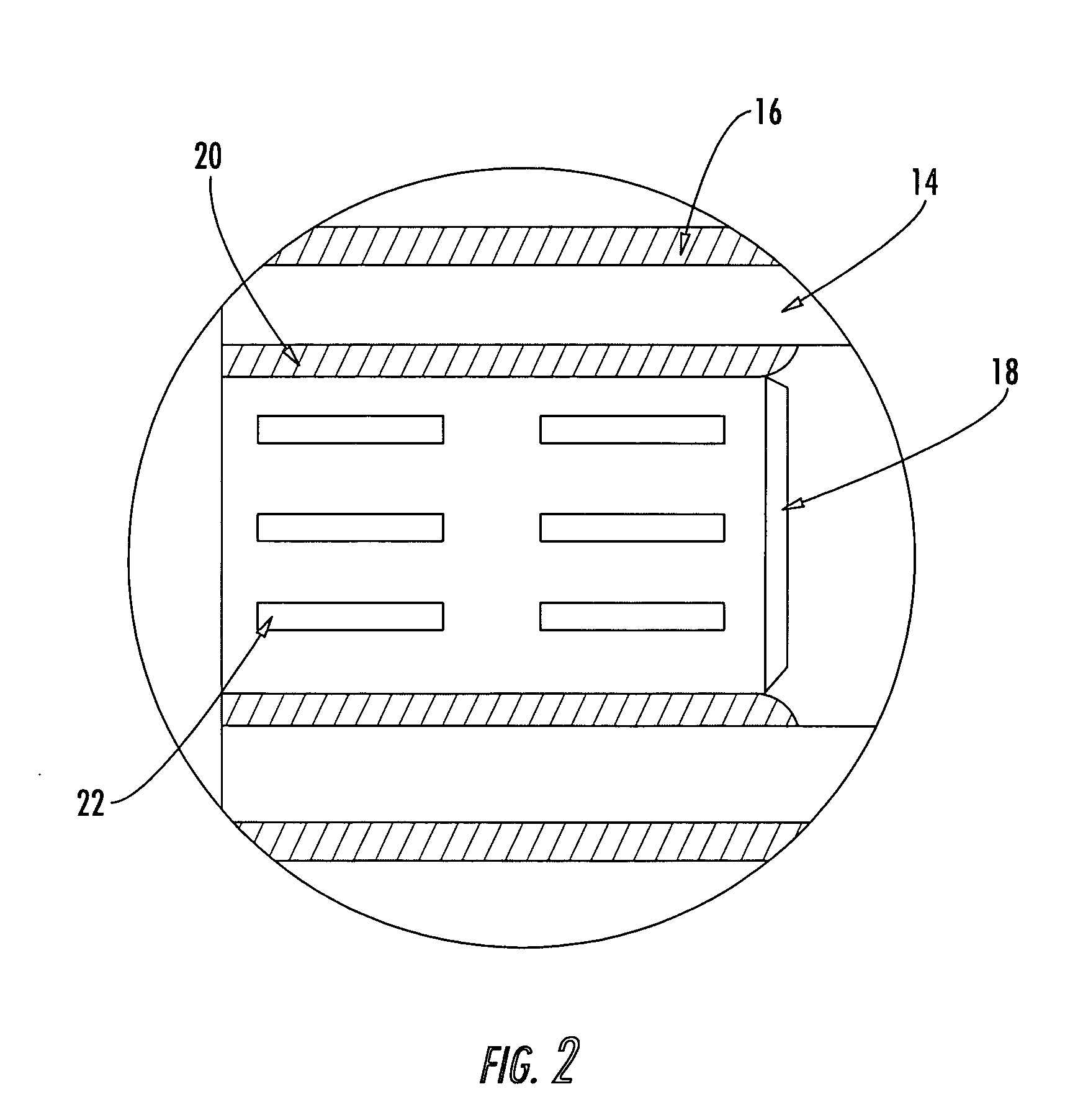

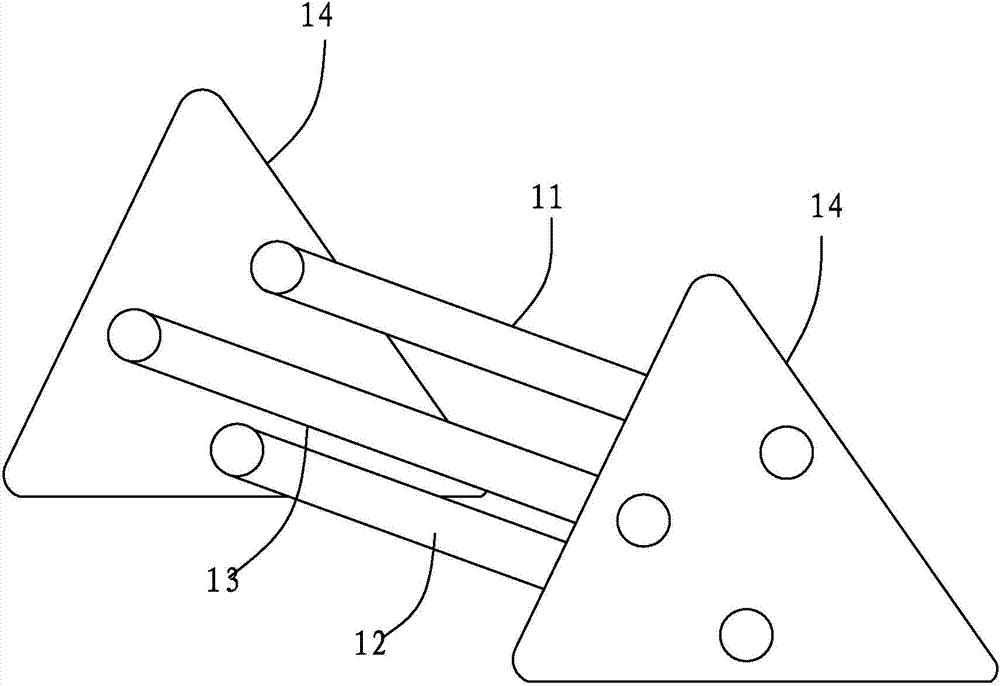

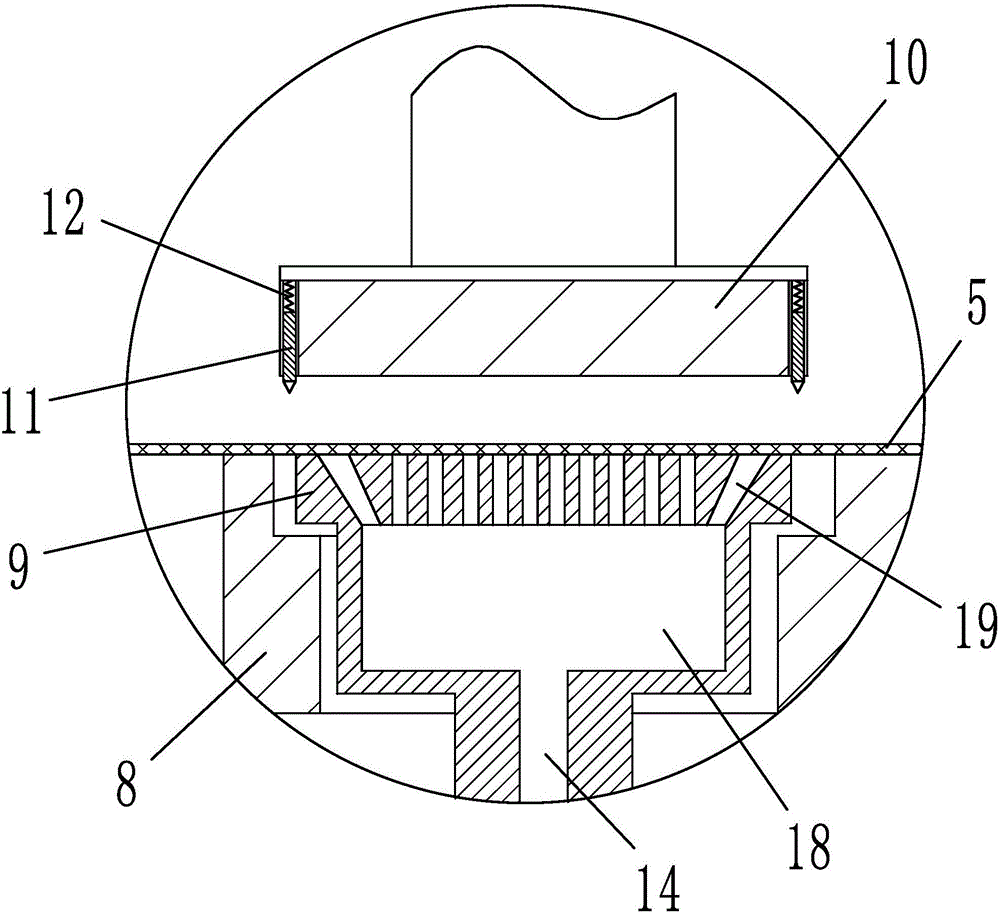

Winding core and associated method

InactiveUS20050184191A1Improved gripping surfaceIncreased chuck factorWebs handlingEngineeringMechanical engineering

Owner:SONOCO DEV INC

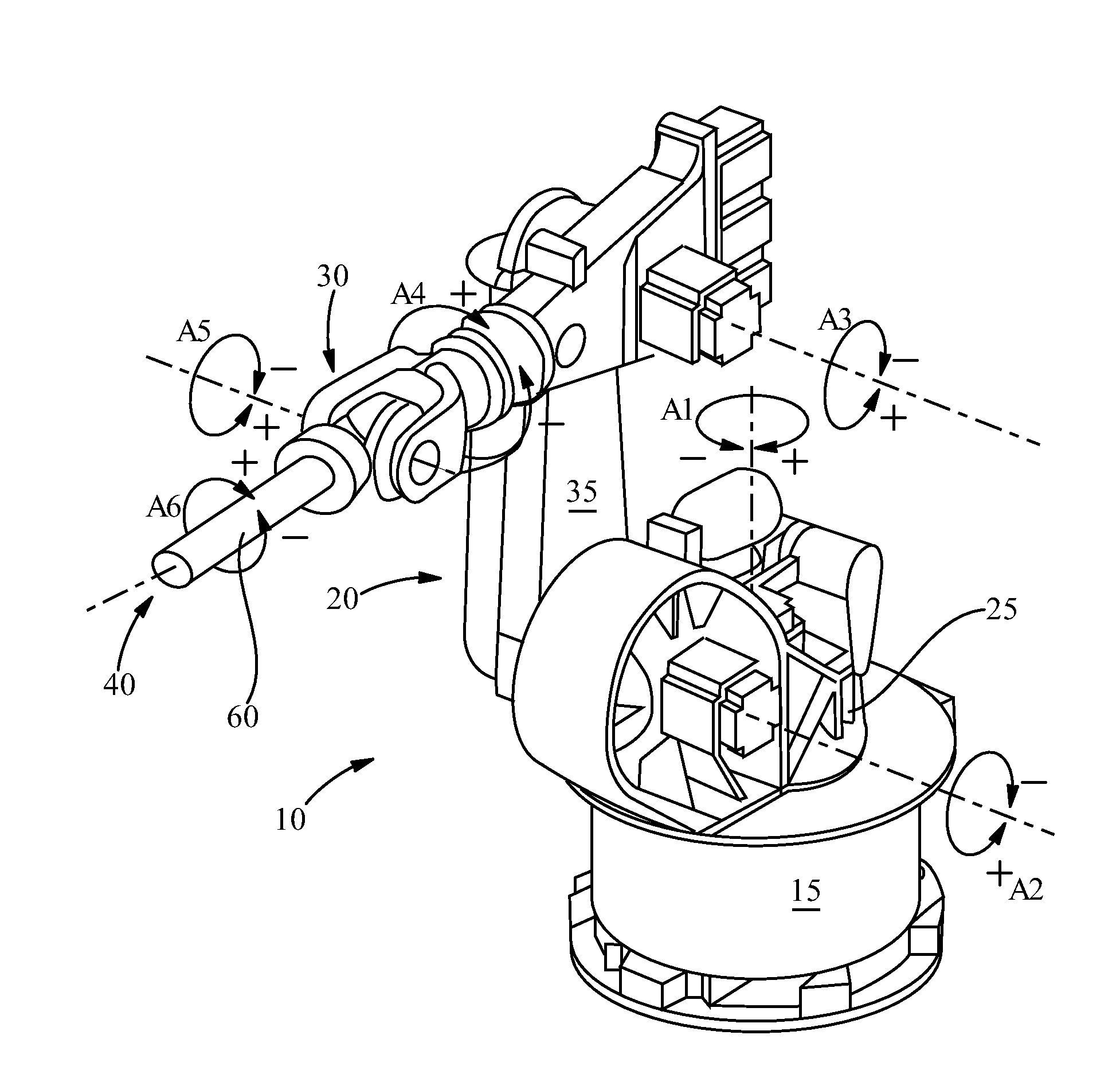

Web material unwind apparatus

Owner:THE PROCTER & GAMBLE COMPANY

Adhesive tape, carrier tape connecting thin film, carrier tape connecting method and connected carrier tape

InactiveCN103131343AEasy alignmentPrevent reduction in work efficiencyAdhesive processesPressure sensitive film/foil adhesivesUltimate tensile strengthTears

The invention relates to an adhesive tape, a carrier tape connecting thin film, a carrier tape connecting method and a connected carrier tape. The invention relates to an adhesive tape which is characterized in that a face of a substrate is provided with an adhesive layer. Tear-resisting strength in a first direction of the face and tear-resisting strength in the second direction which is perpendicular to the first direction are characterized in that when the tear-resisting strength in the second direction is 1, the tear-resisting strength in the first direction is less than 0.75.

Owner:NITTO DENKO CORP +1

Thermal printer

ActiveUS9108436B1Simple configurationTypewritersOther printing apparatusEngineeringMechanical engineering

Owner:MITSUBISHI ELECTRIC CORP

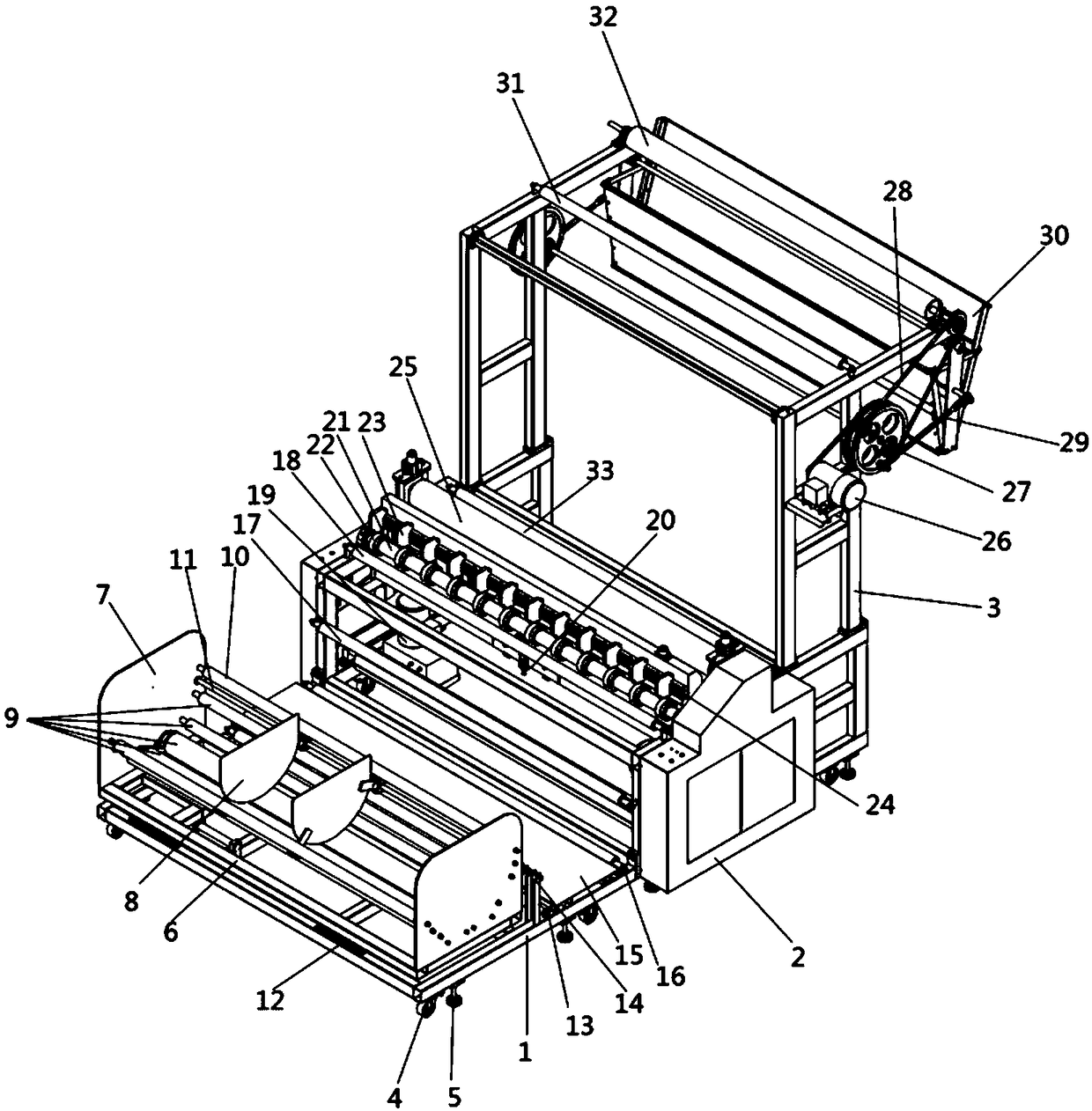

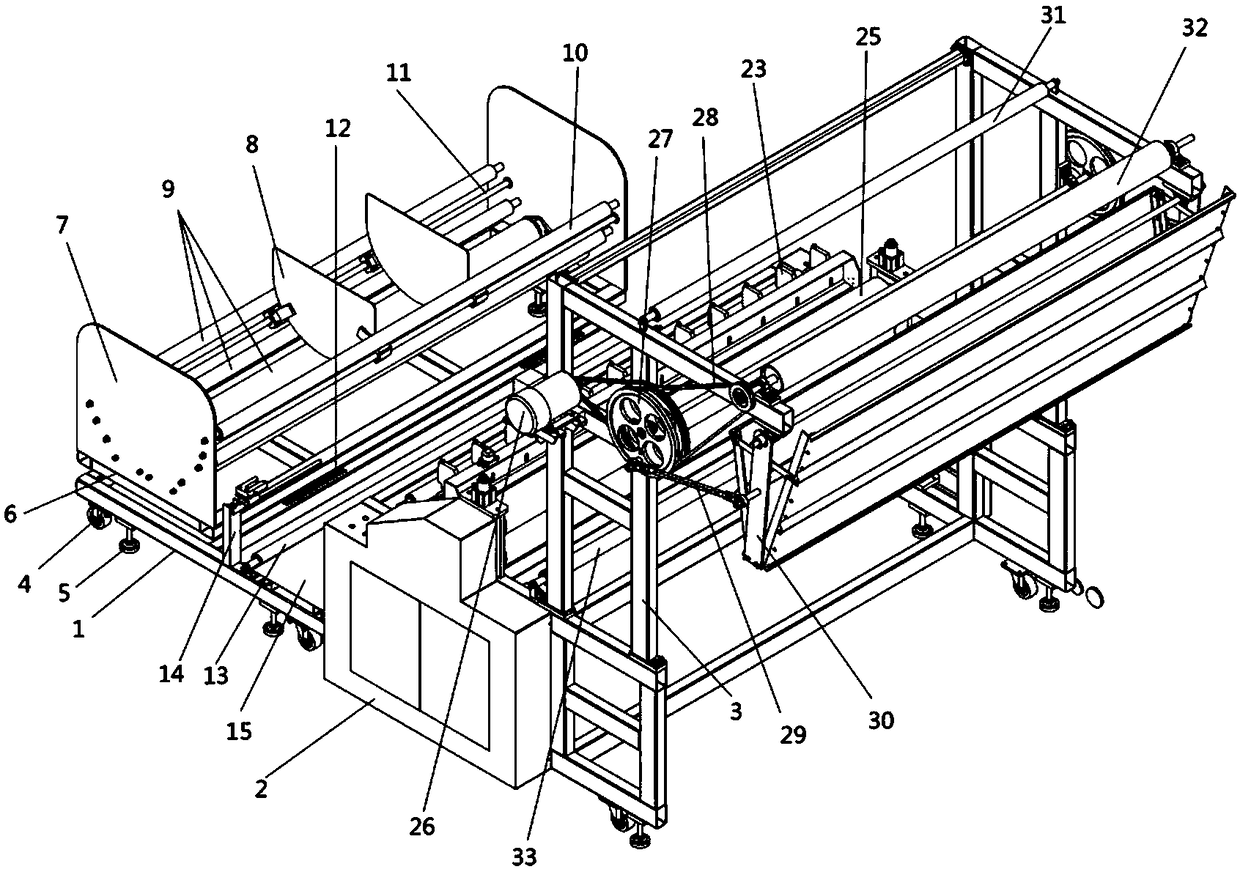

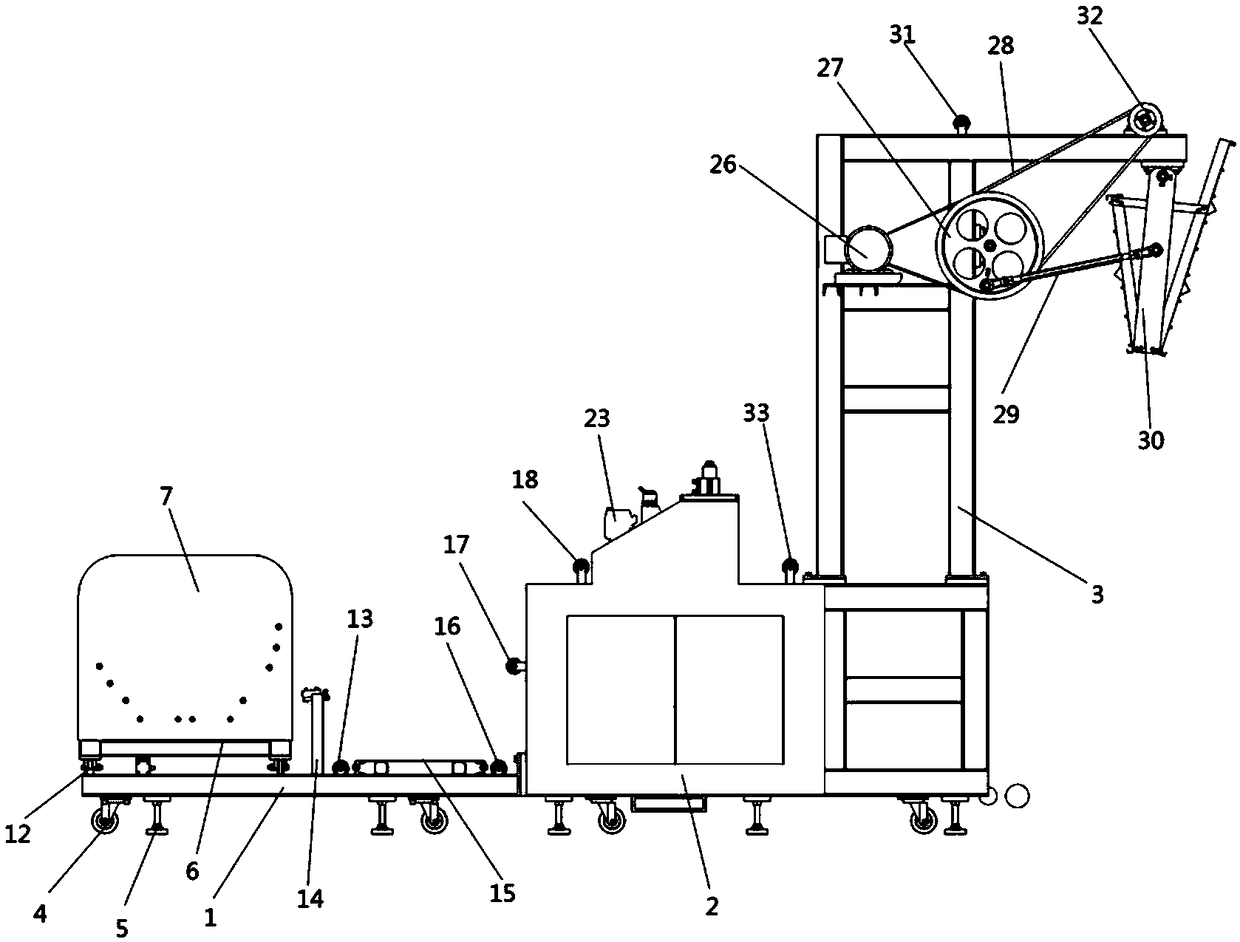

Cloth winding machine for cloth processing production

Owner:安徽富贵服饰有限公司

Cloth guiding device

Owner:佛山市顺德彩辉纺织集团有限公司

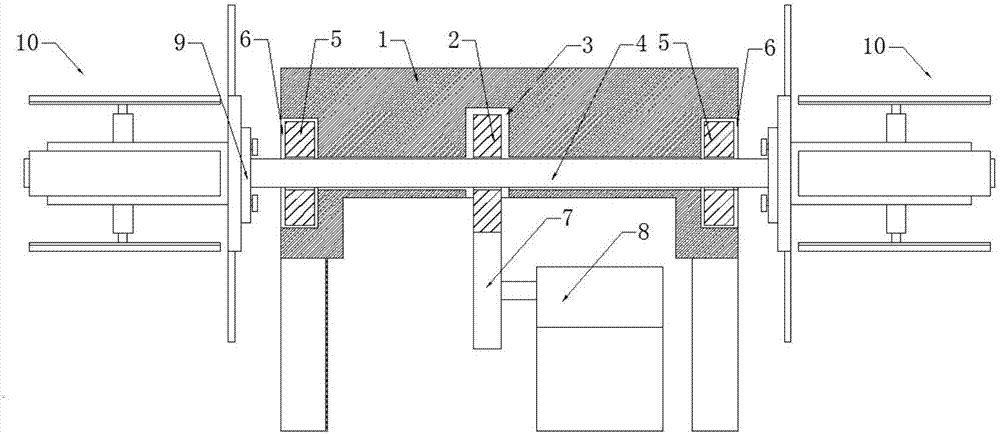

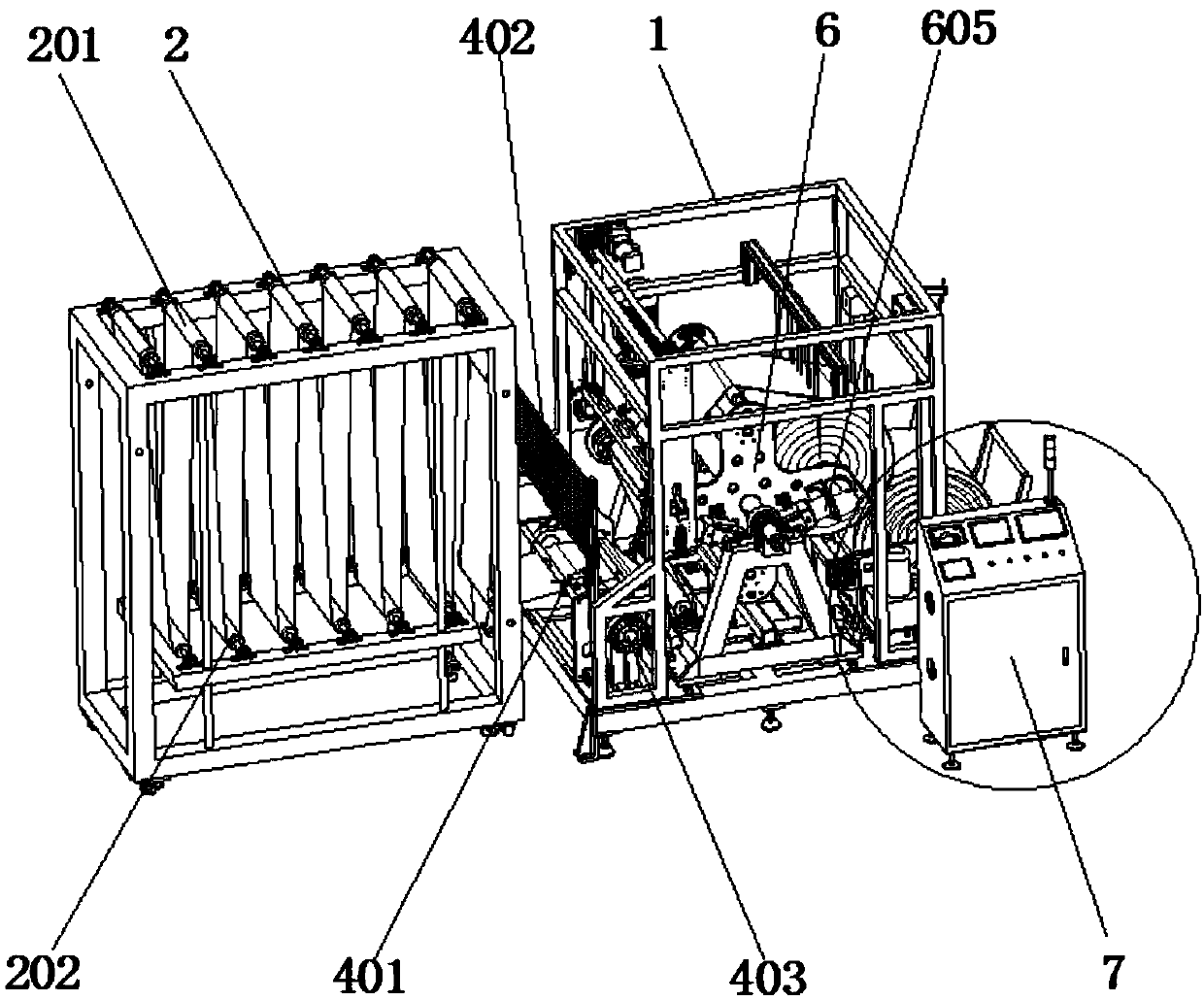

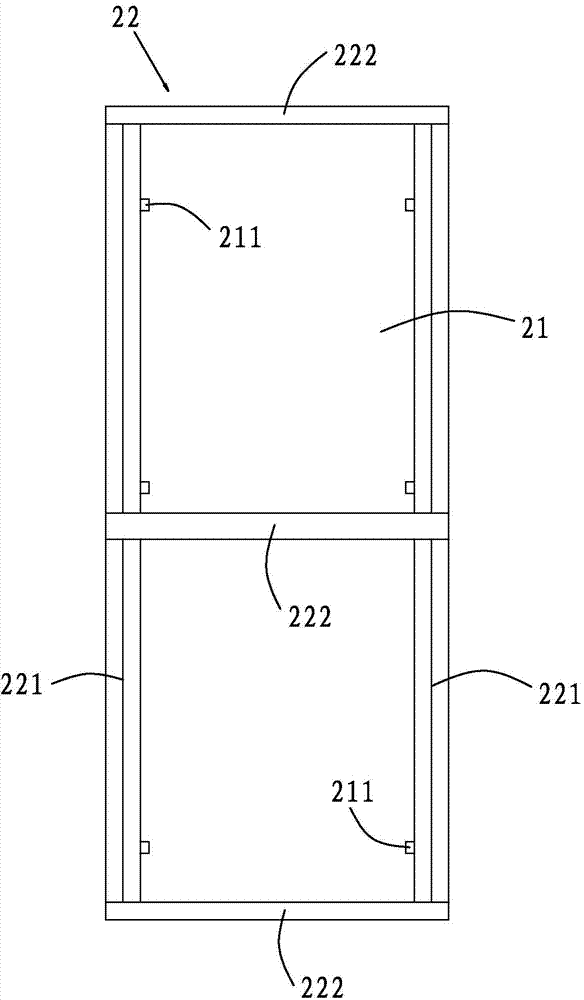

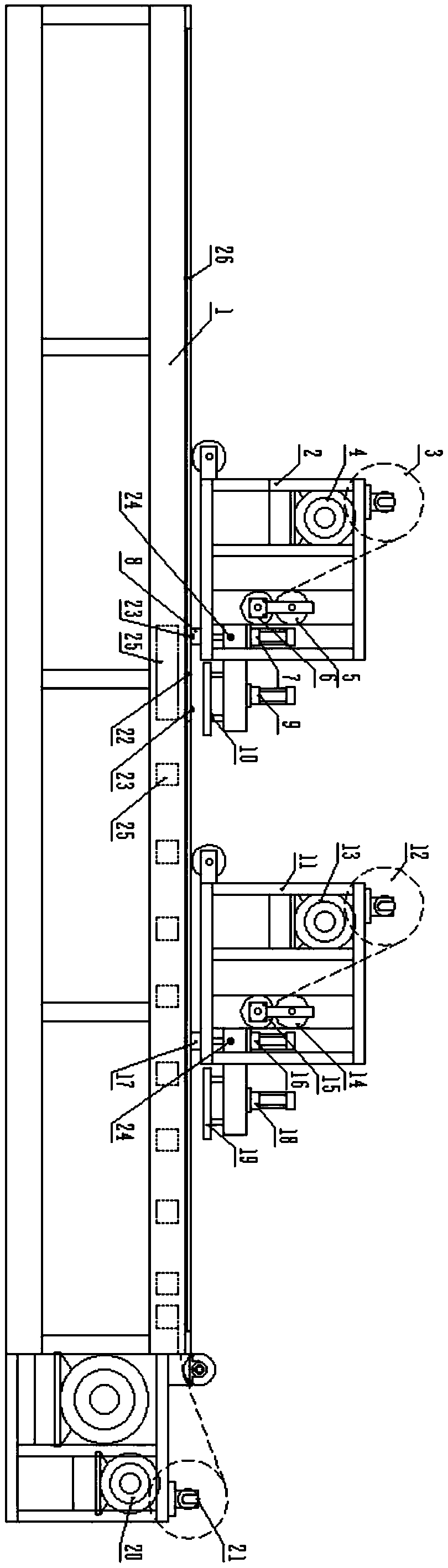

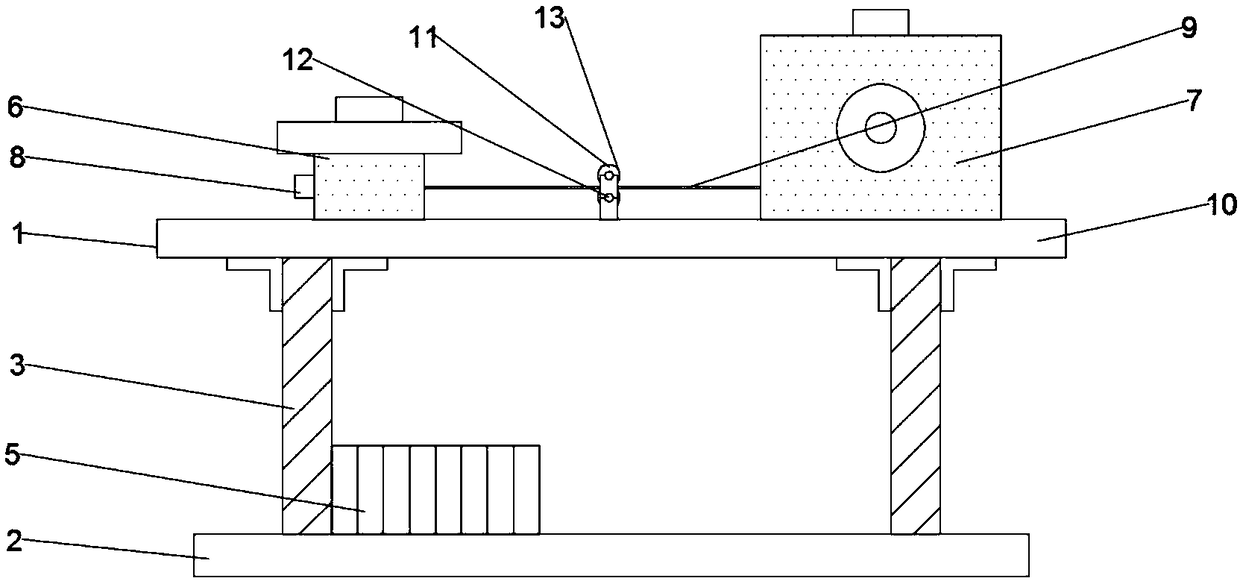

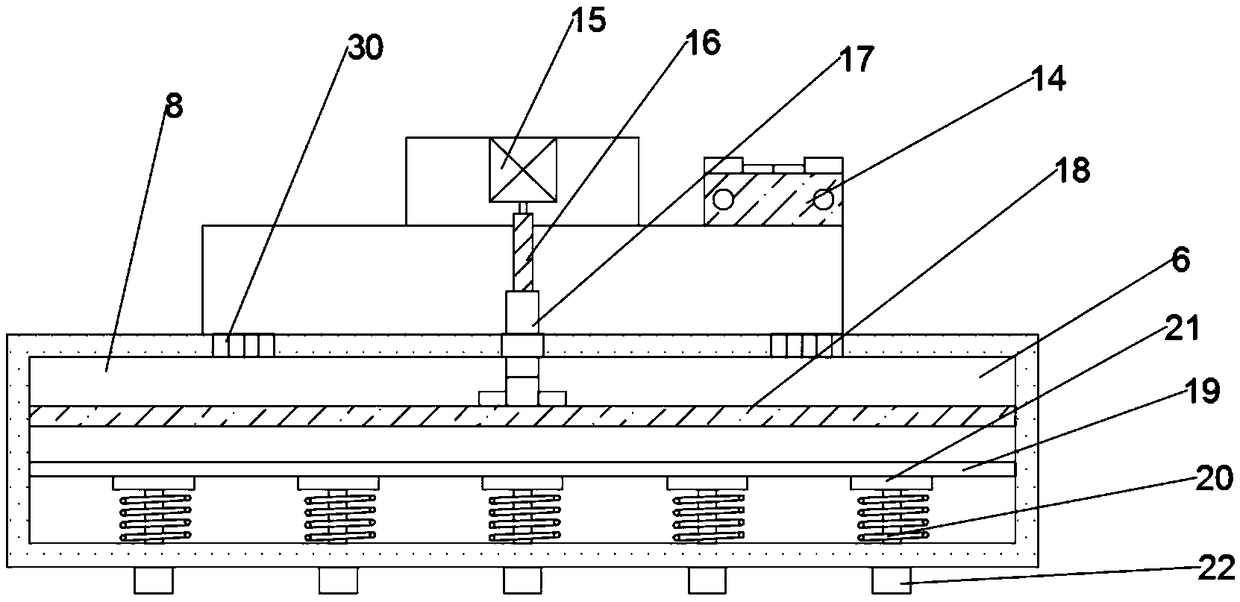

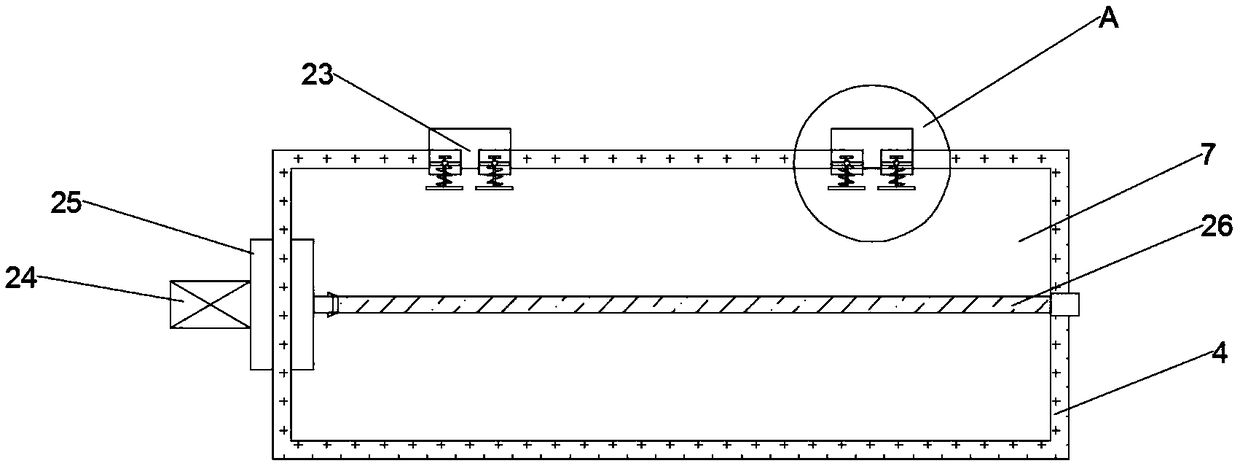

Non-woven fabric winding and cropping combined device

InactiveCN108622695AAchieve reductionIncrease productivityWebs handlingEngineeringMechanical engineering

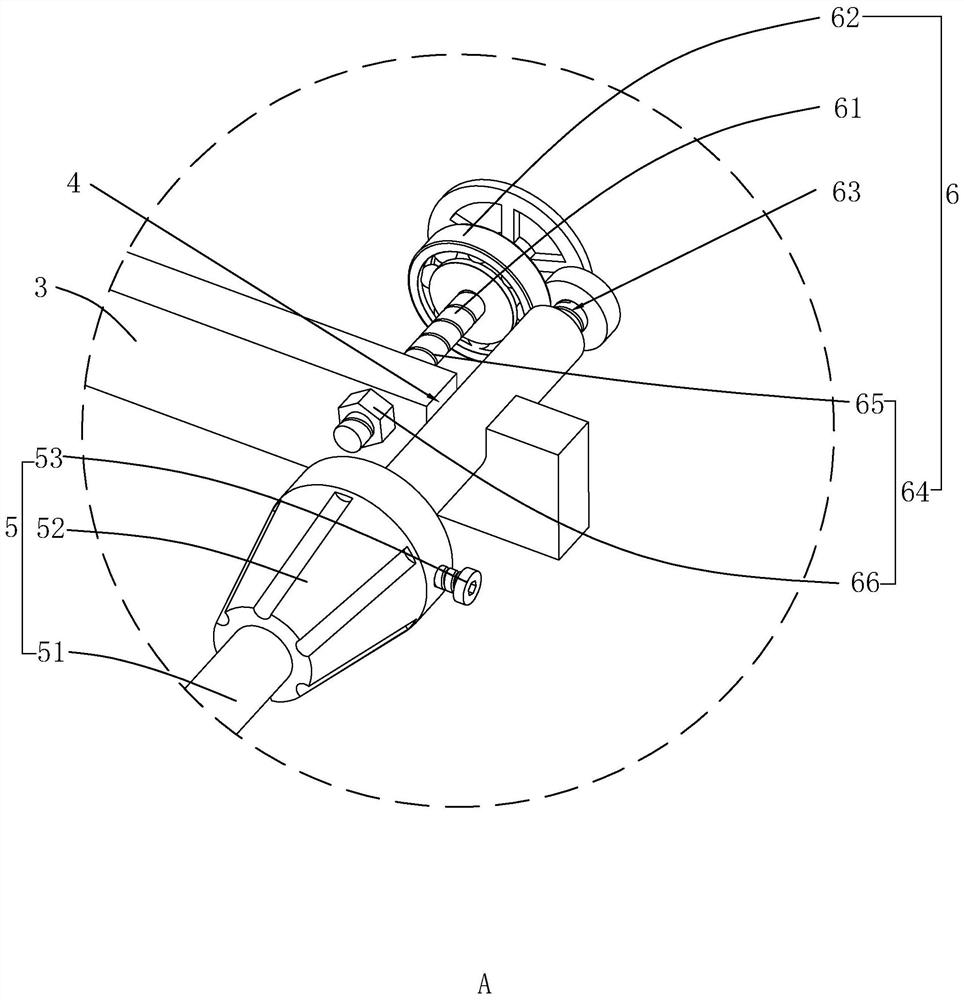

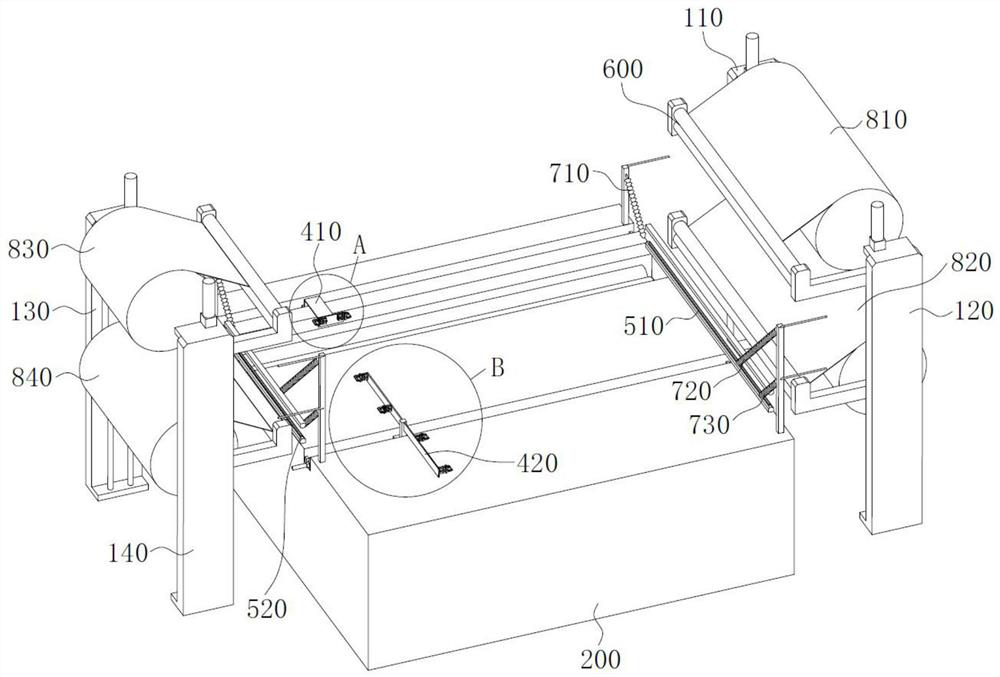

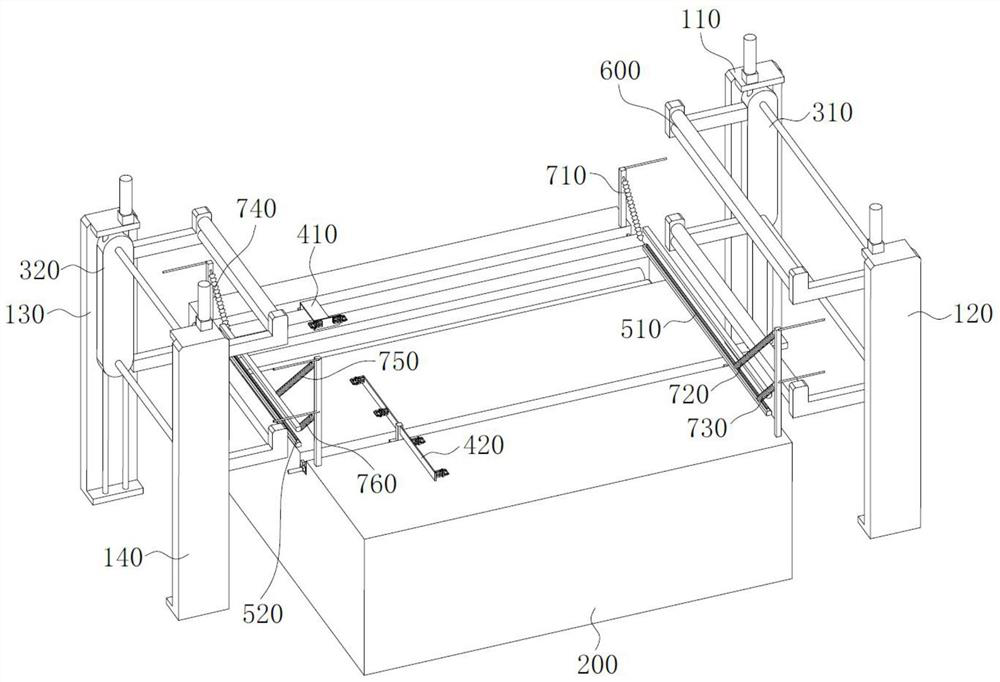

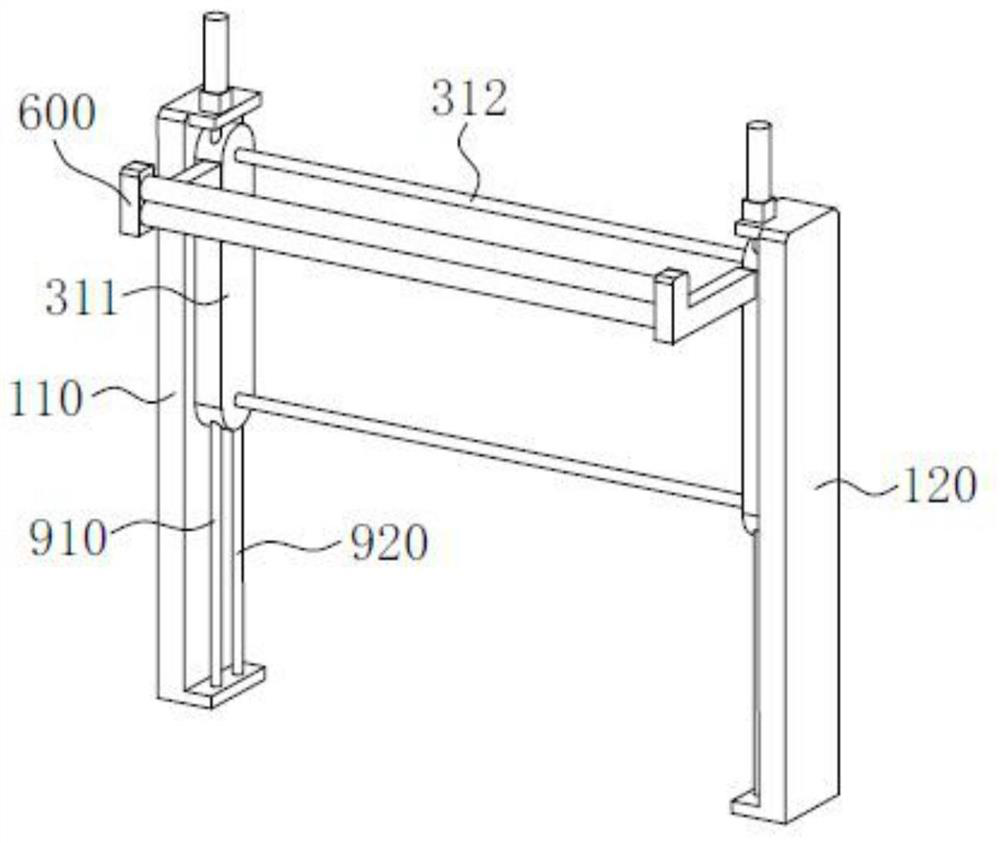

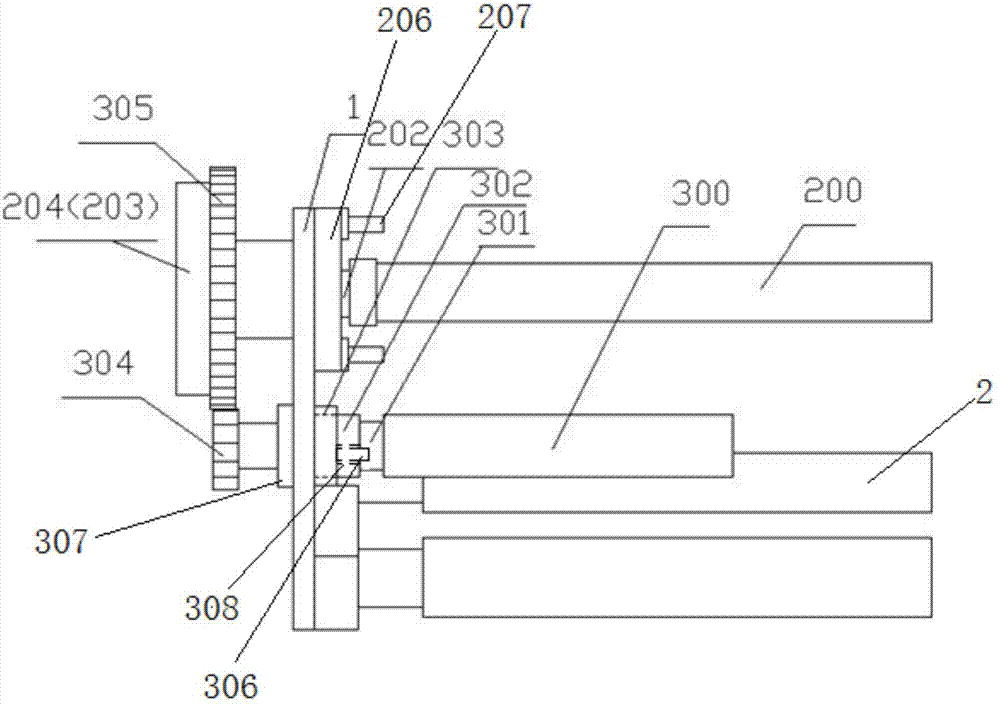

The invention relates to a non-woven fabric winding and cropping combined device. The non-woven fabric winding and cropping combined device comprises winding equipment and cropping equipment which coordinate with each other. The winding equipment comprises a supporting frame. The cropping equipment comprises a material carrying assembly and a cropping assembly, wherein the material carrying assembly comprises a roll shaft frame and a plurality of first tension adjusting rollers, the roll shaft frame is installed on the supporting frame and extends towards one side of the supporting frame, andthe multiple tension adjusting rollers are rotationally installed on the roll shaft frame; and the cropping assembly comprises a supporting vertical plate, an abutting roller, a plurality of second tension adjusting rollers, an extending plate and a plurality of sets of cropping cutters, the supporting vertical plate is arranged on one side of the material carrying assembly and corresponds to theroll shaft frame, the abutting roller is installed on the side face of the supporting vertical plate and is perpendicular to the supporting vertical plate, the multiple second tension adjusting rollers are installed on the side face of the supporting vertical plate and located between the abutting roller and the roll shaft frame, the extending plate is installed on the side face of the supportingvertical plate and located over the abutting roller, and the multiple cropping cutter sets are arranged on the side face of the extending plate in a lifting manner and are arranged at intervals. The non-woven fabric winding and cropping combined device can wind non-woven fabric and crop the non-woven fabric in the length direction, and the production efficiency of the non-woven fabric is advantageously improved.

Owner:YANCHENG YUECHENG NON WOVEN FABRICS CO LTD

Strip steel feeding device for motor stator and rotor production

Owner:当涂县华胜电子元件制造厂

Laminating device for LCM and screen

PendingCN109808972AHigh degree of automationImprove bonding efficiencyArticle unpackingWebs handlingEngineeringManipulator

Owner:深圳双十科技股份有限公司

Mulch applicator

PendingCN110053343ARealize collectionRealize the effect of automatic laminationLaminationLamination apparatusFixed framePulp and paper industry

Owner:温州光明印刷机械有限公司

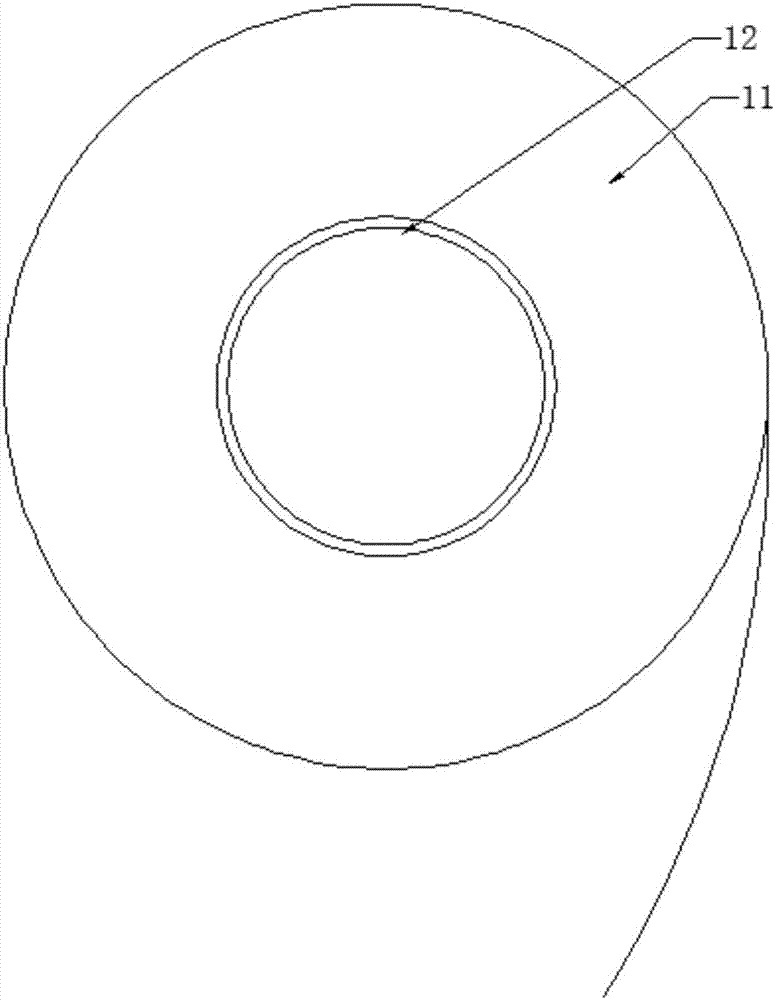

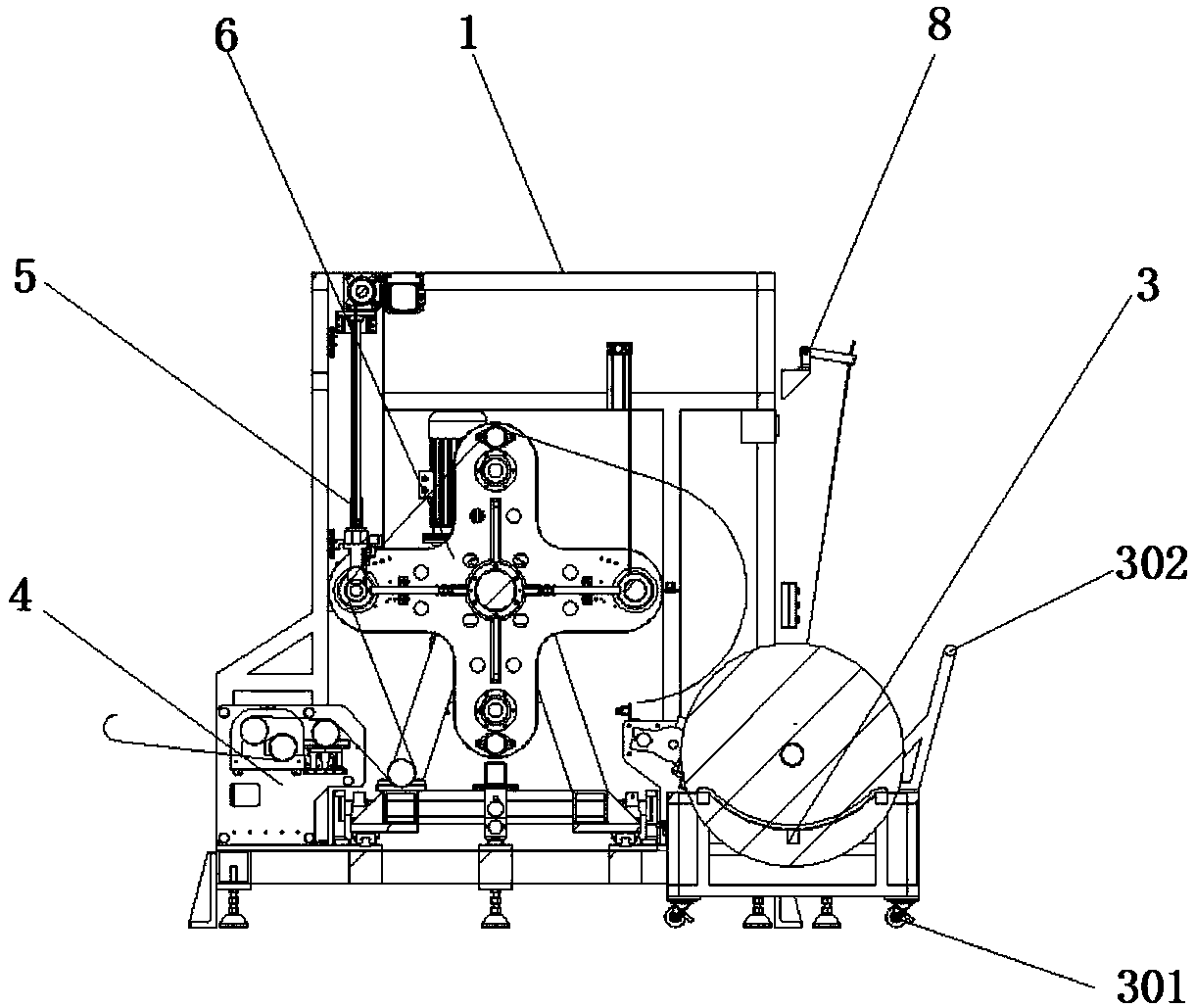

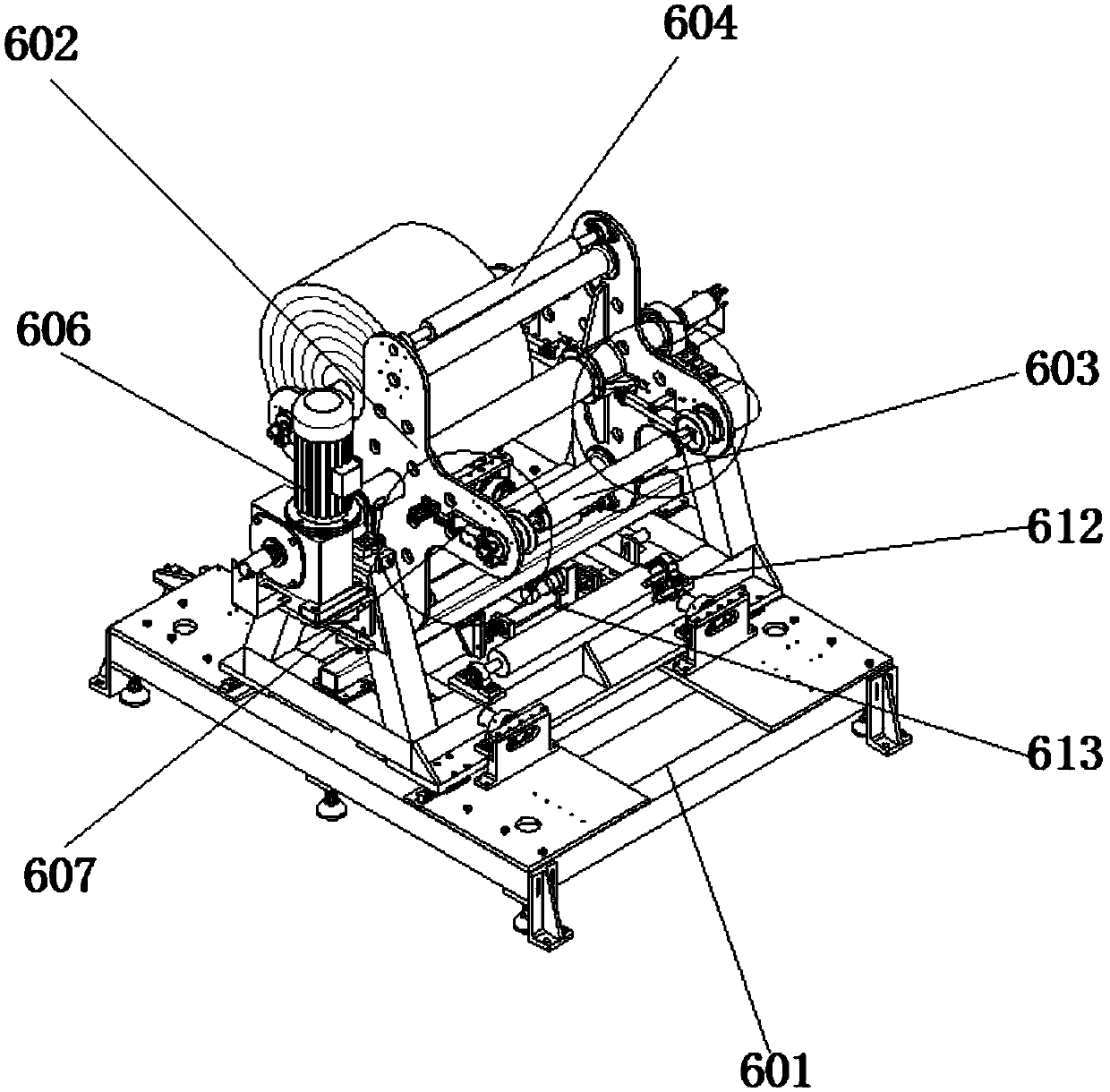

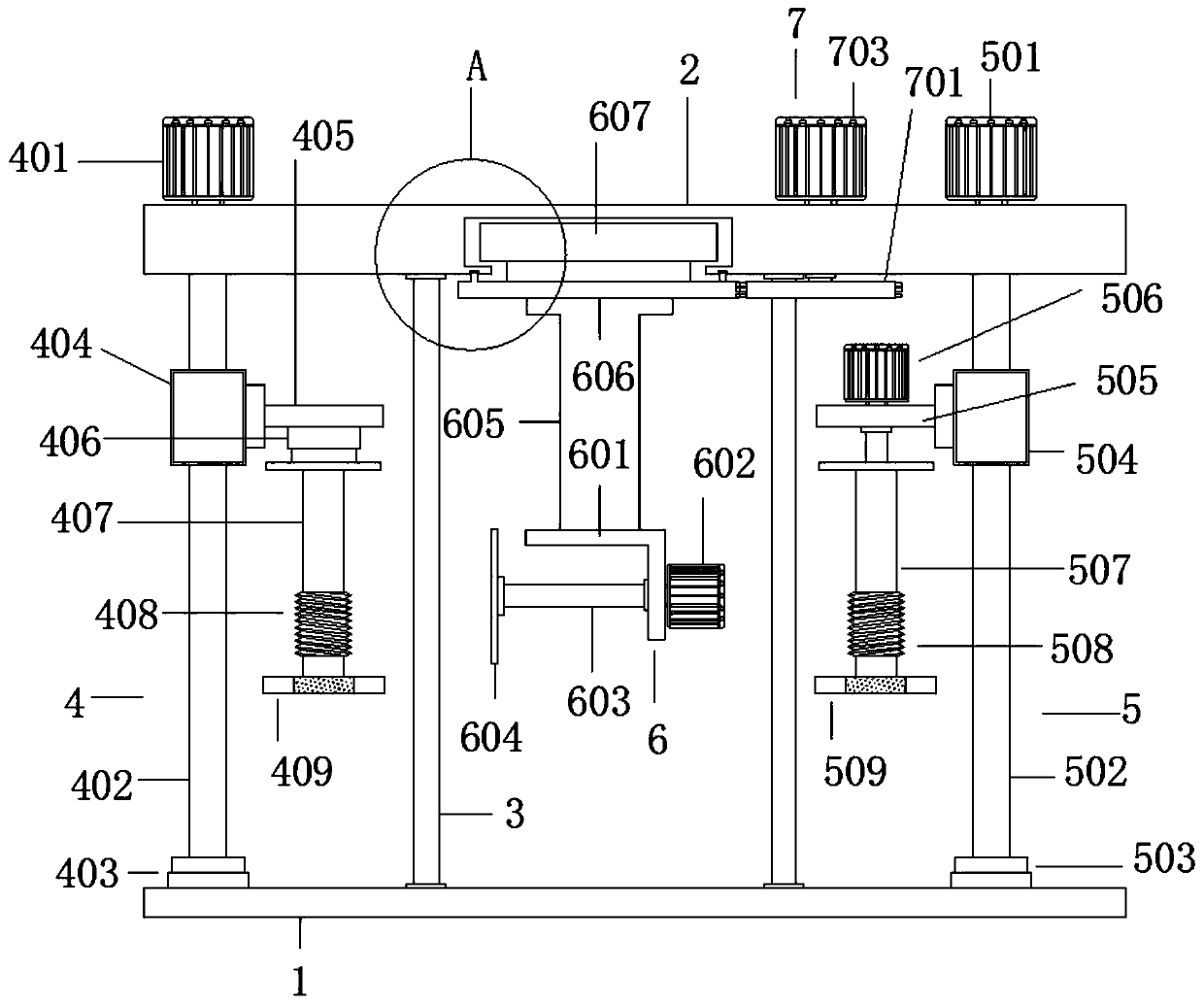

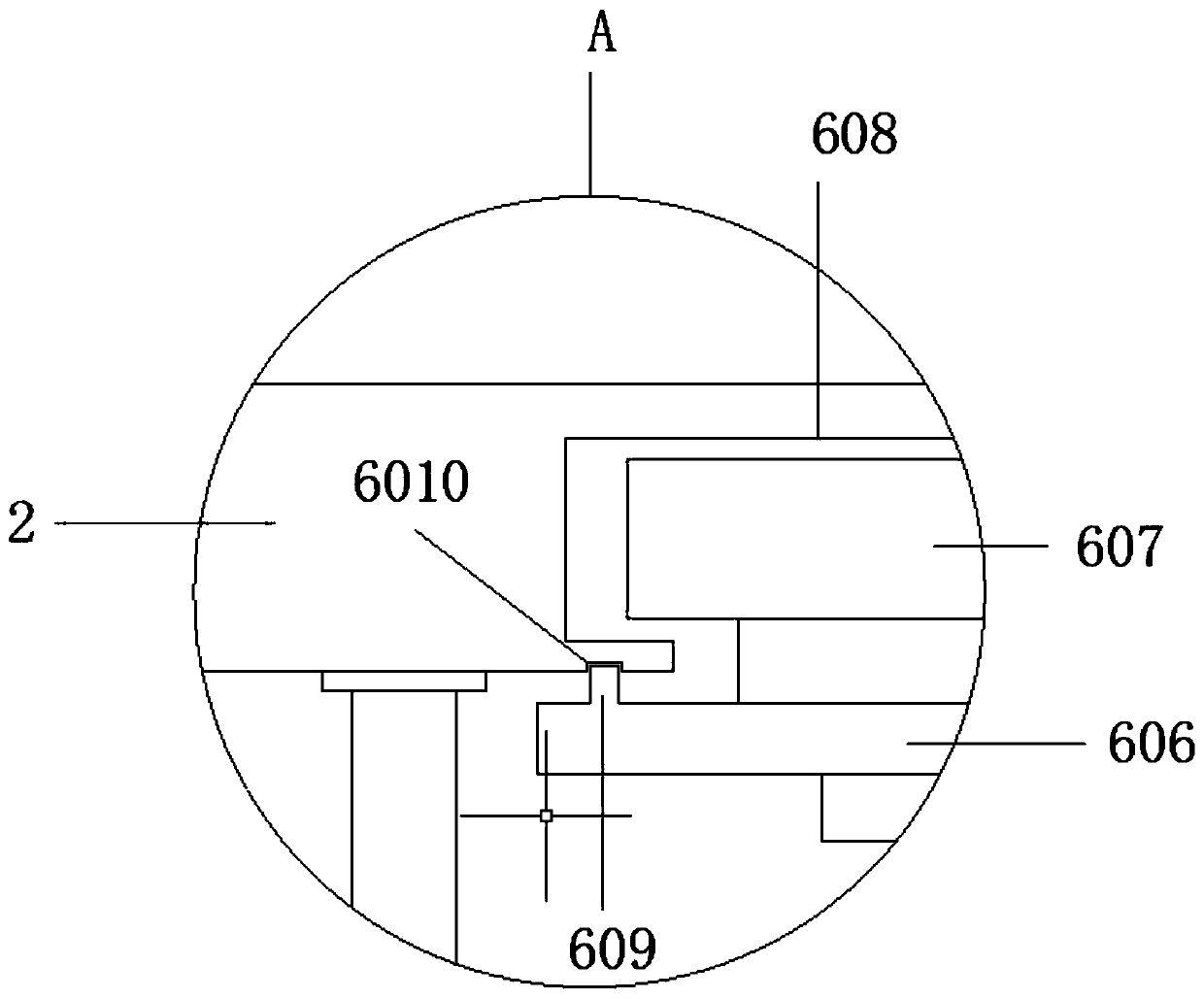

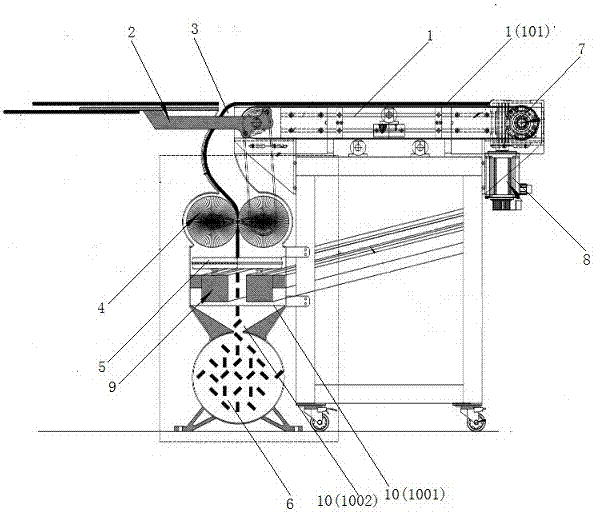

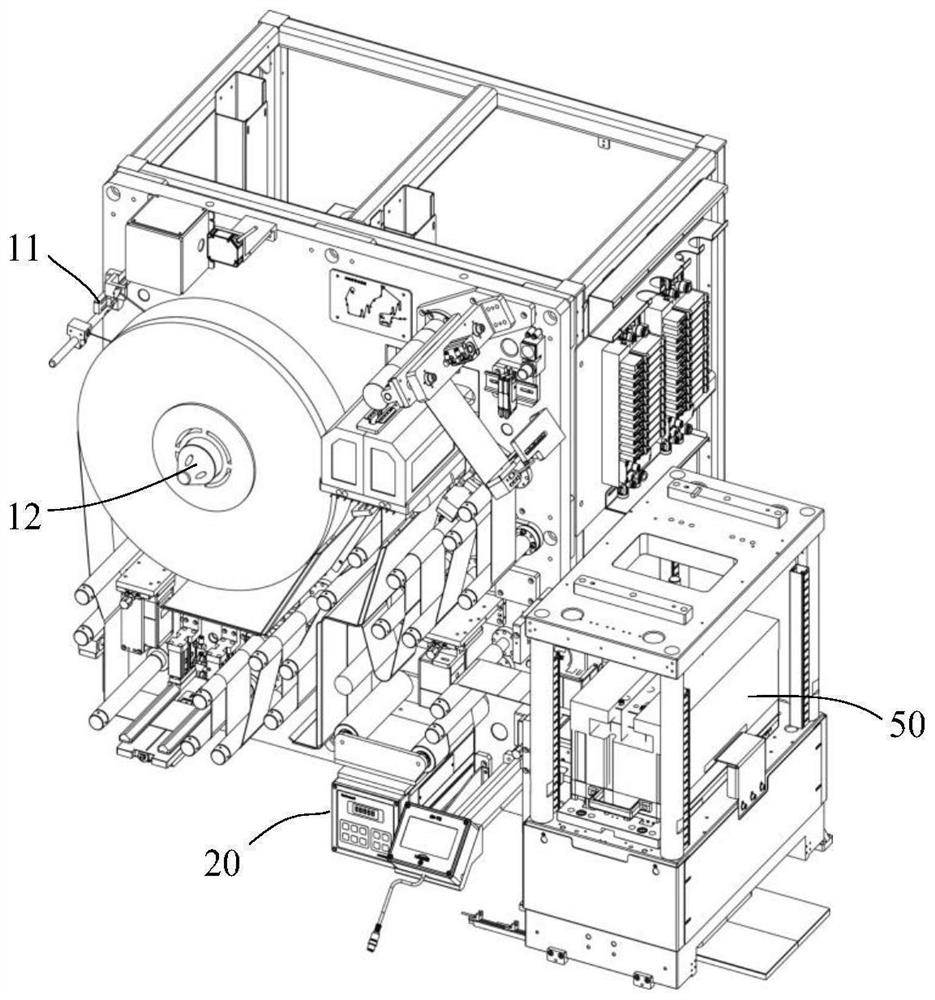

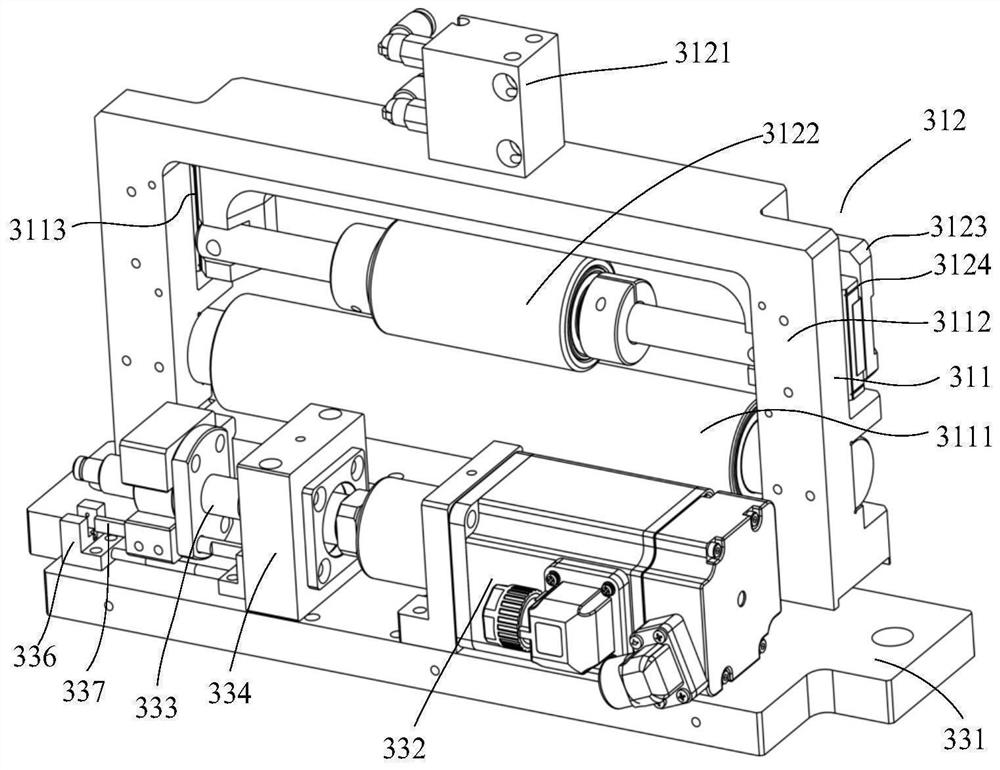

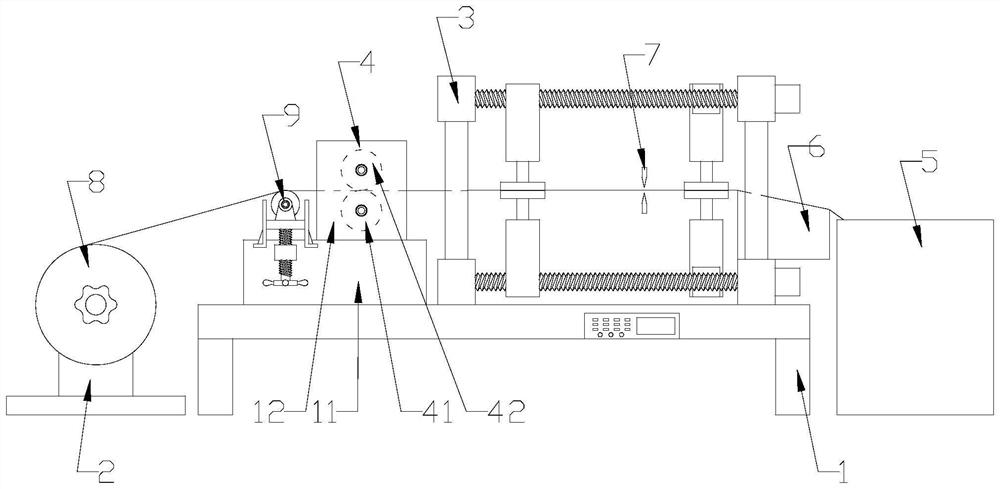

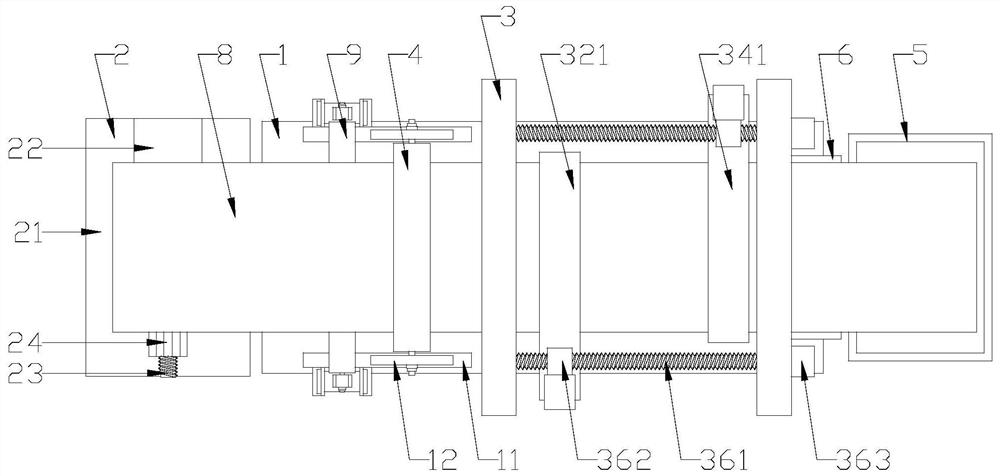

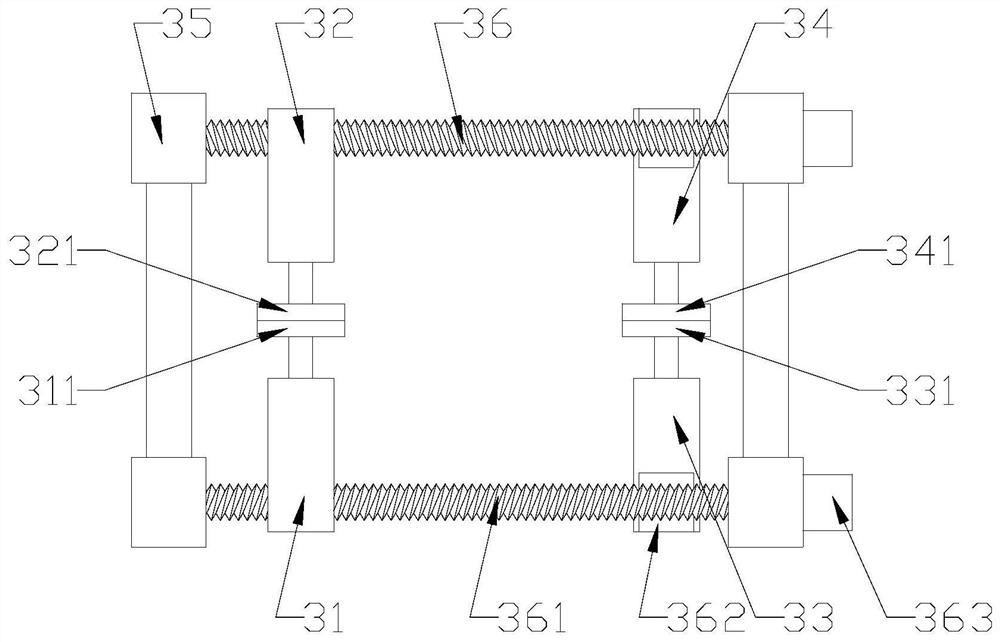

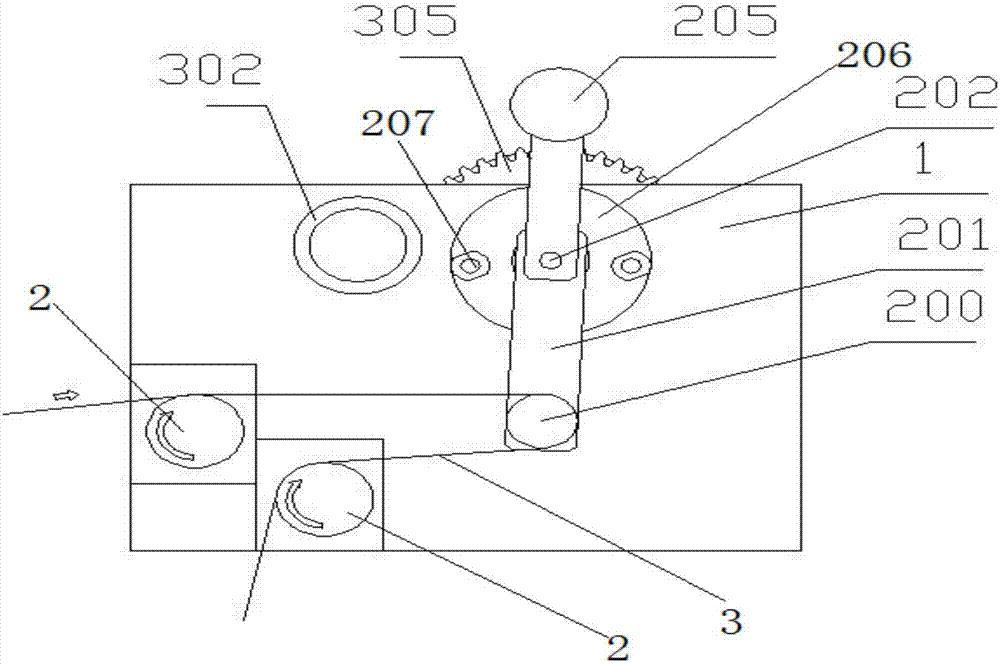

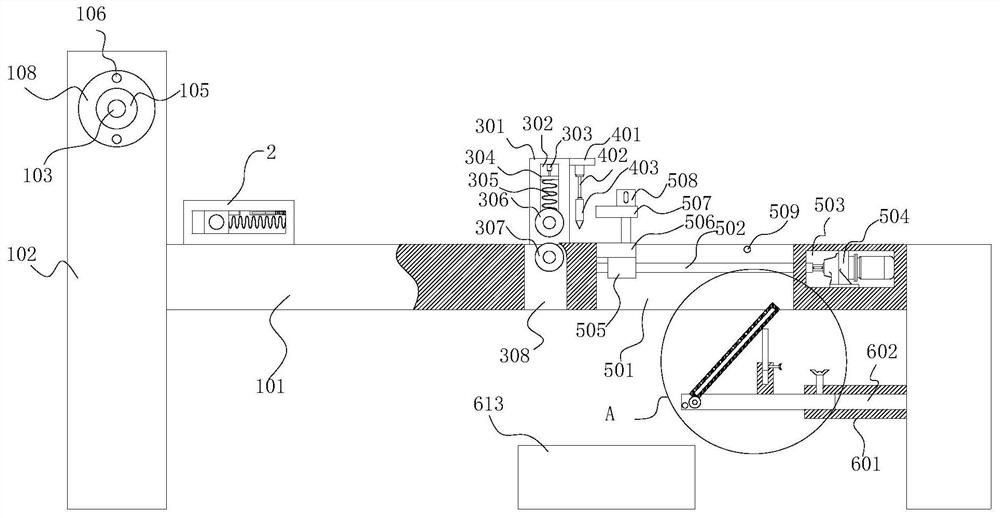

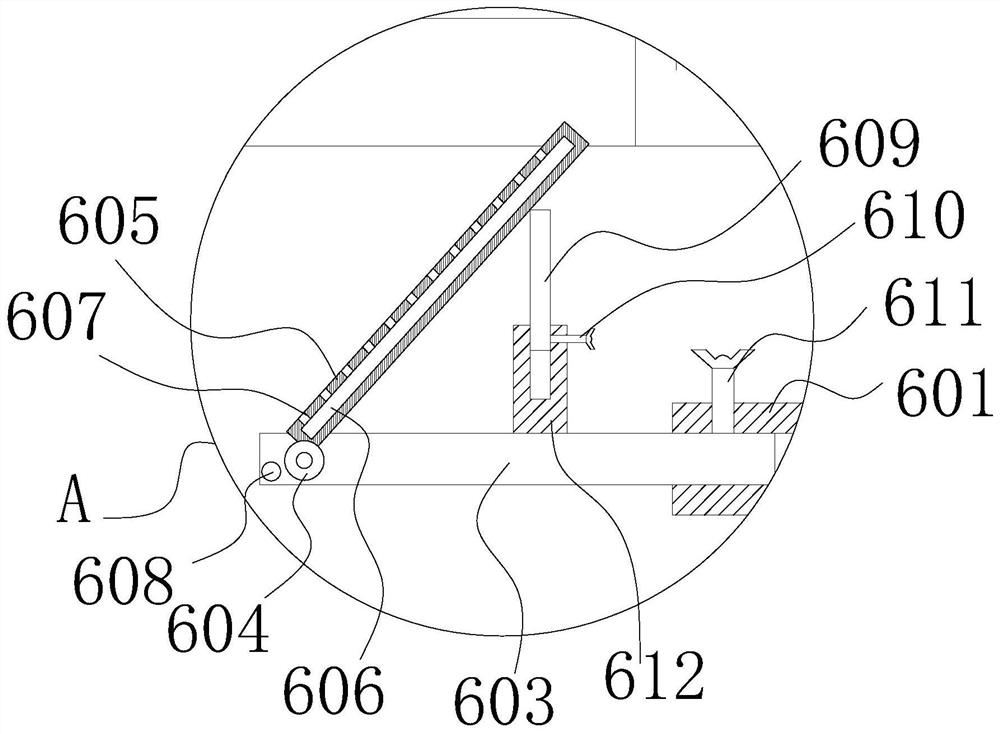

Automatic aluminum foil winding machine

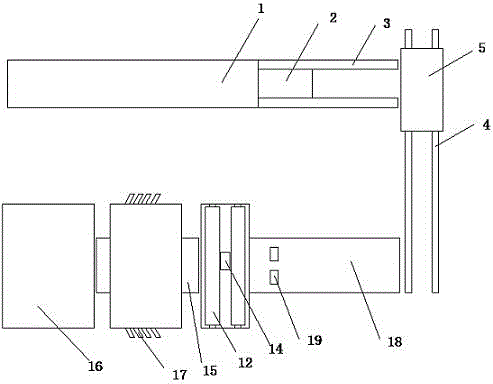

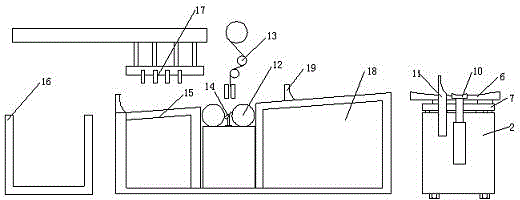

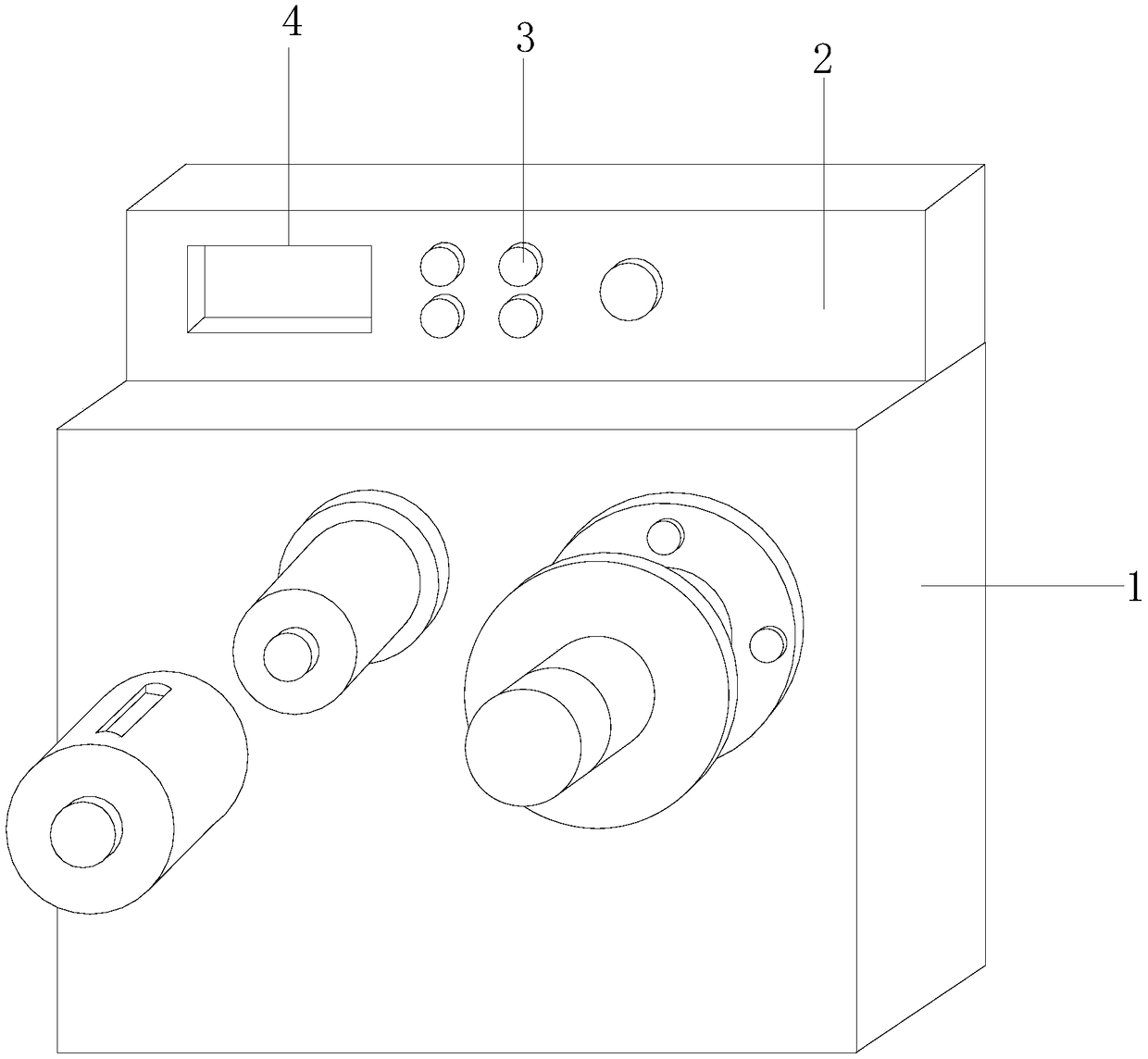

The invention discloses an automatic aluminum foil winding machine. The machine comprises a machine frame, a feeding mechanism, a discharging mechanism and an operation box, wherein the feeding mechanism, the discharging mechanism and the operation box can be detached from the machine frame; the feeding mechanism and the discharging mechanism are arranged at the front end and the rear end of the machine frame respectively; the machine frame is provided with a tension control mechanism, a cutting mechanism and a turnover large rotary plate mechanism; the tension control mechanism is arranged atthe front end of the machine frame and is matched with the feeding mechanism for feeding; the turnover large rotary plate mechanism is arranged between the tension control mechanism and the discharging mechanism; and the cutting mechanism is arranged between the tension control mechanism and the turnover large rotary plate mechanism and is located above the turnover large rotary plate mechanism.According to the automatic aluminum foil winding machine, the tension force can be flexibly controlled, and the winding position can be flexibly adjusted.

Owner:DONGGUAN XINLIANGDIAN AUTOMATION EQUIP TECH

Cutting device for aluminum box adhesive tape processing

ActiveCN110282481AEasy to installEfficient cuttingArticle deliveryWebs handlingEngineeringMechanical engineering

Owner:福建友谊胶粘带集团有限公司

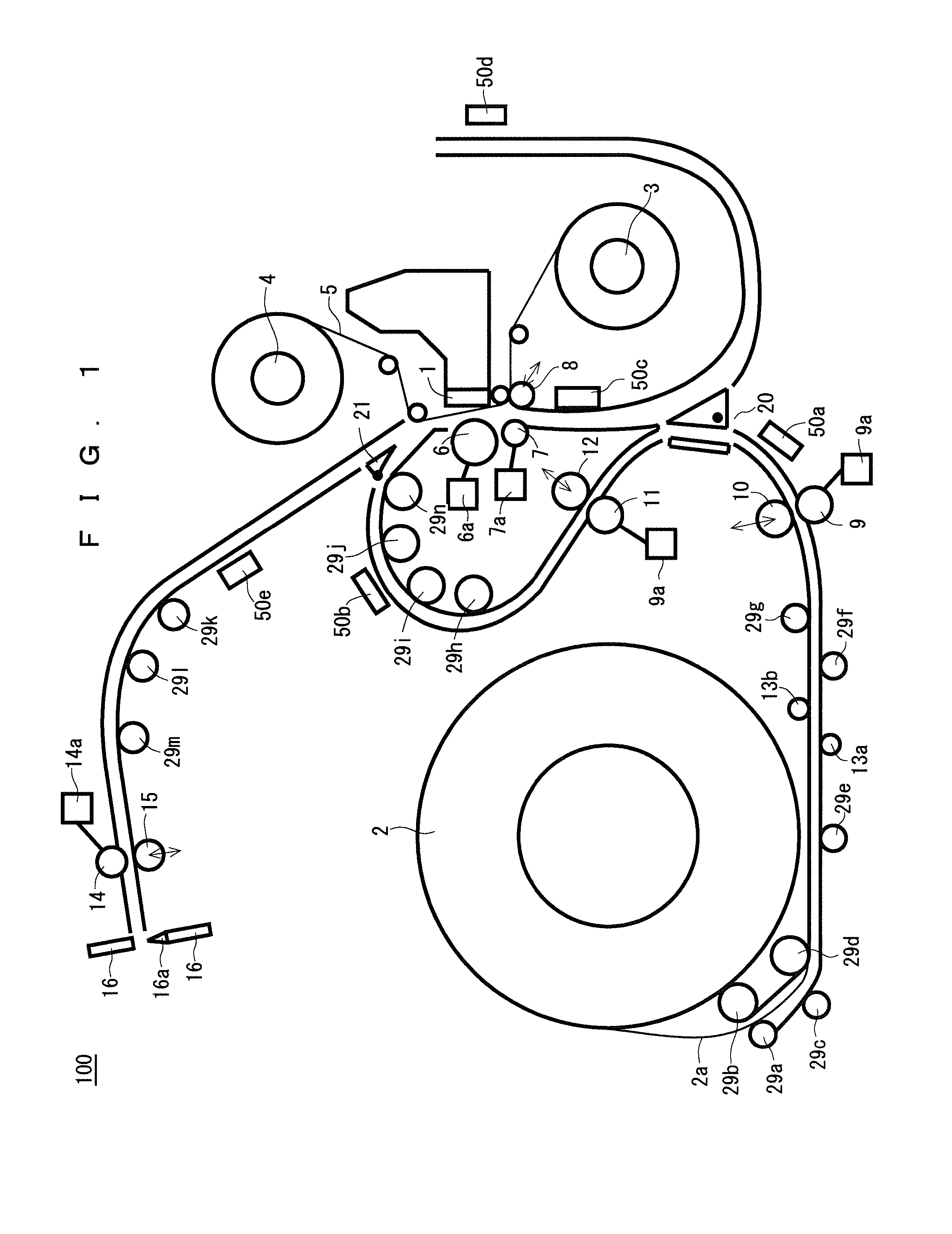

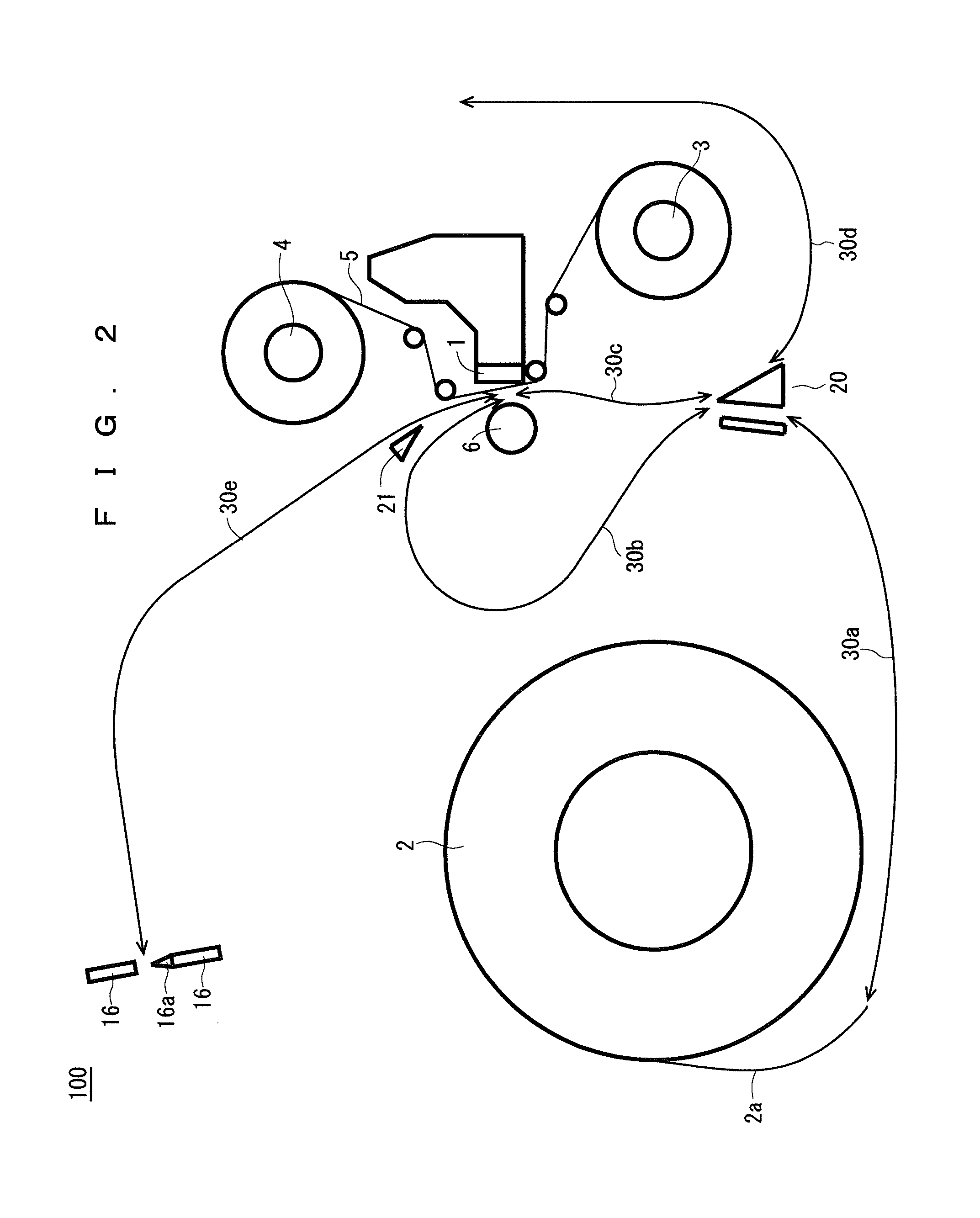

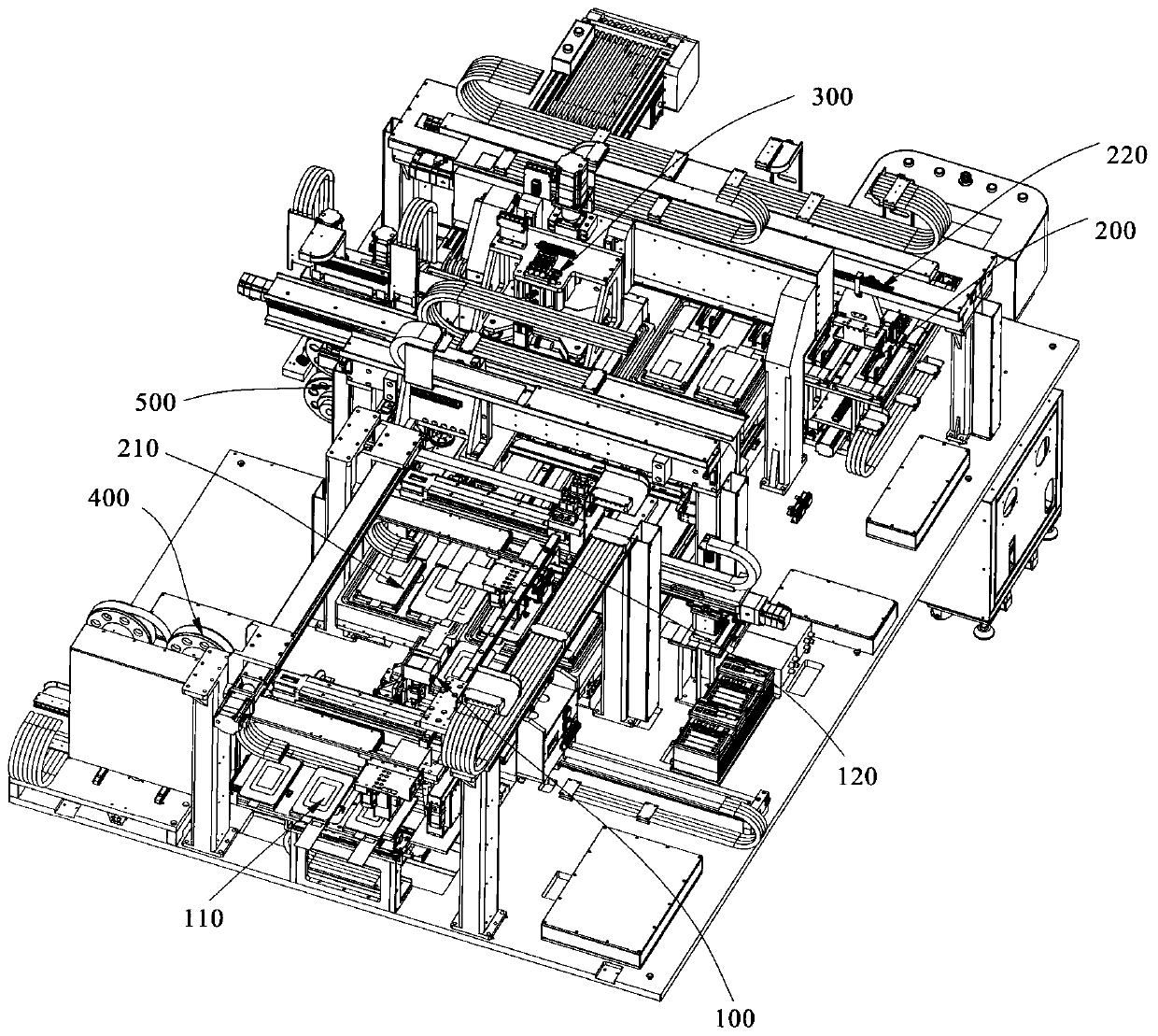

Production line and production process for conveying and packaging of homogenous rolled plastic flooring

ActiveCN104691814AEnsure safetyReduce the difficulty of packagingPaper article packagingMechanical conveyorsProduction lineEngineering

Owner:北新弹性地板有限公司

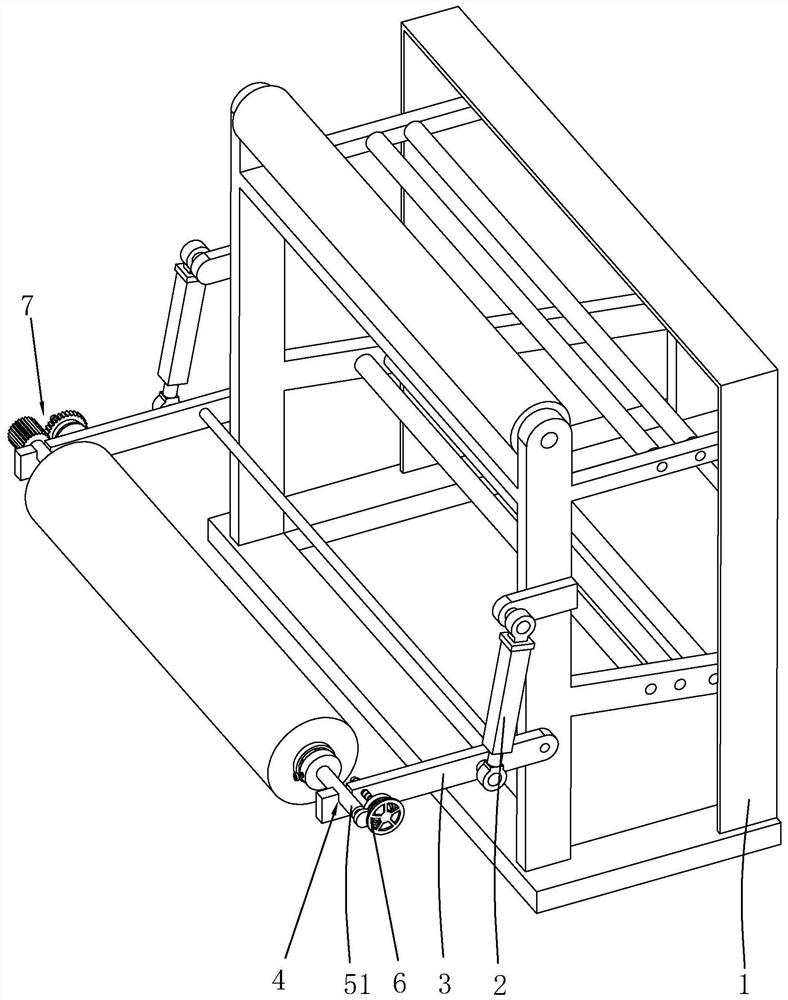

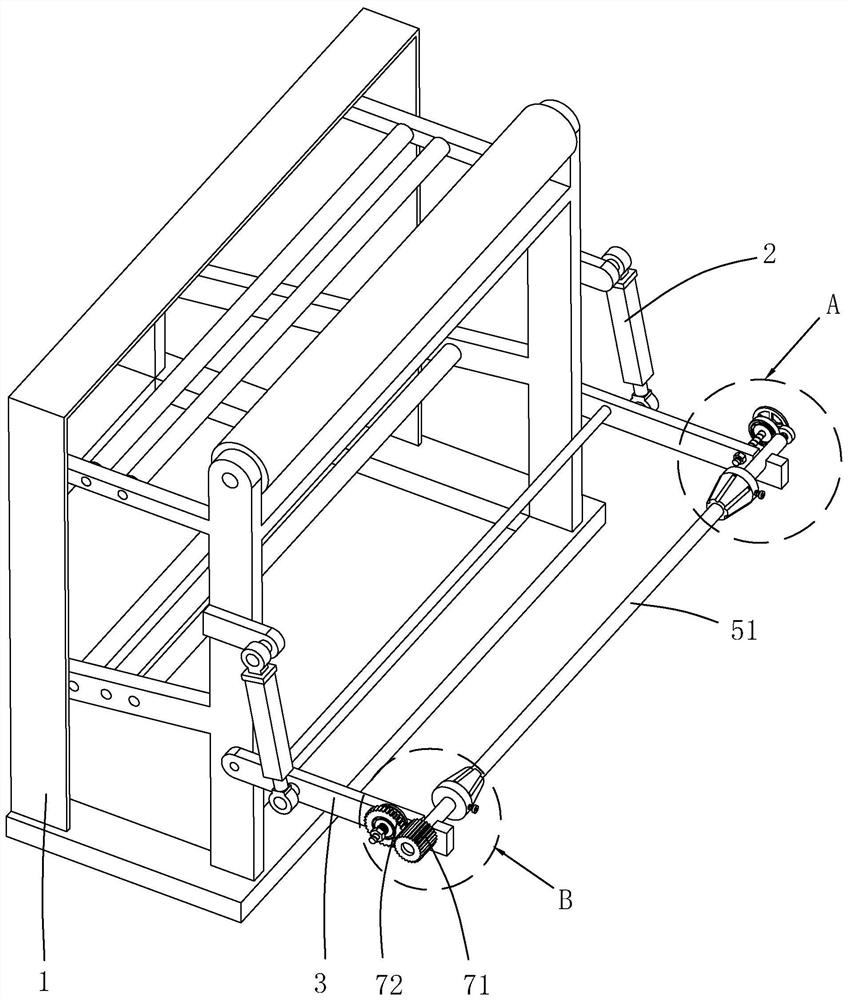

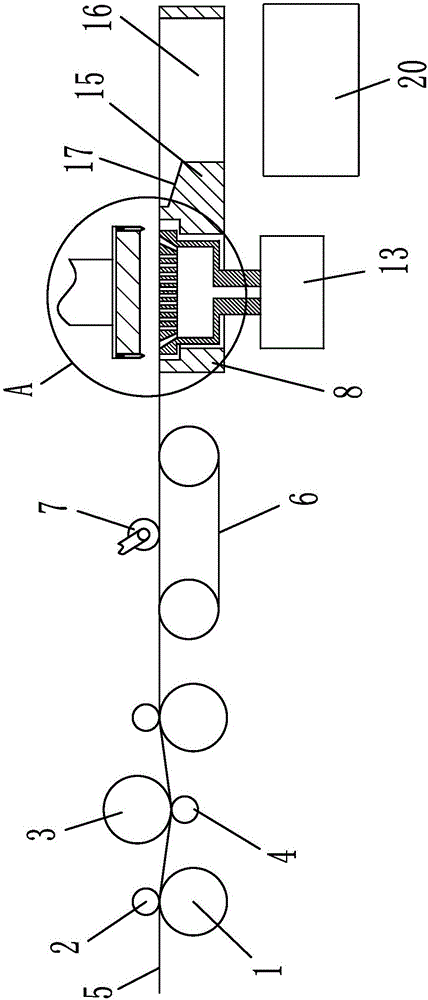

Production system for soft foam die-cutting piece with large foaming holes

ActiveCN112573269AReduce contact areaAvoid bad strippingPackagingWebs handlingPunchingIndustrial engineering

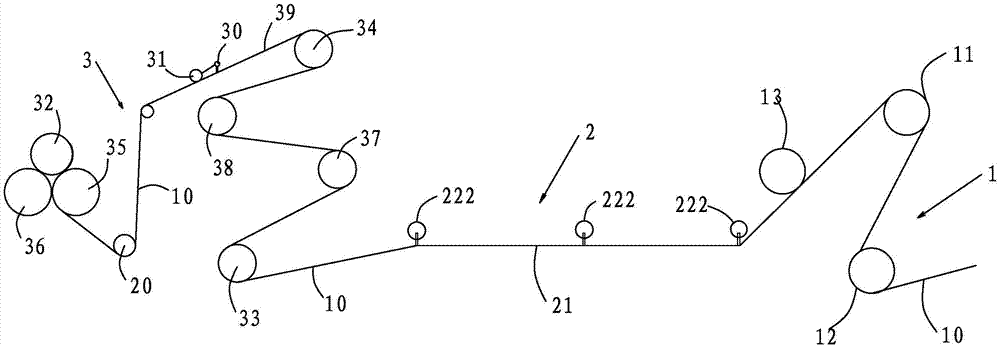

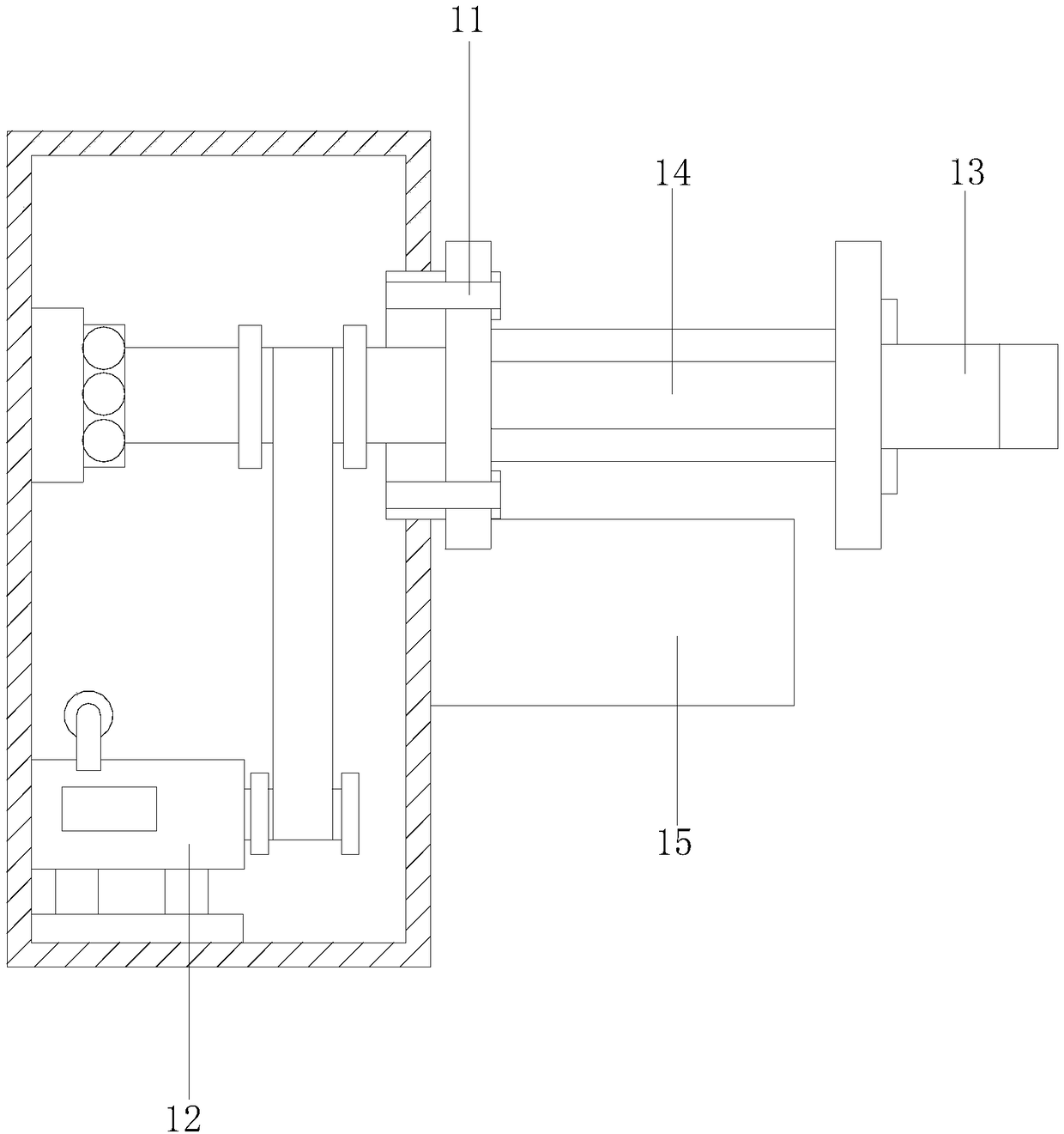

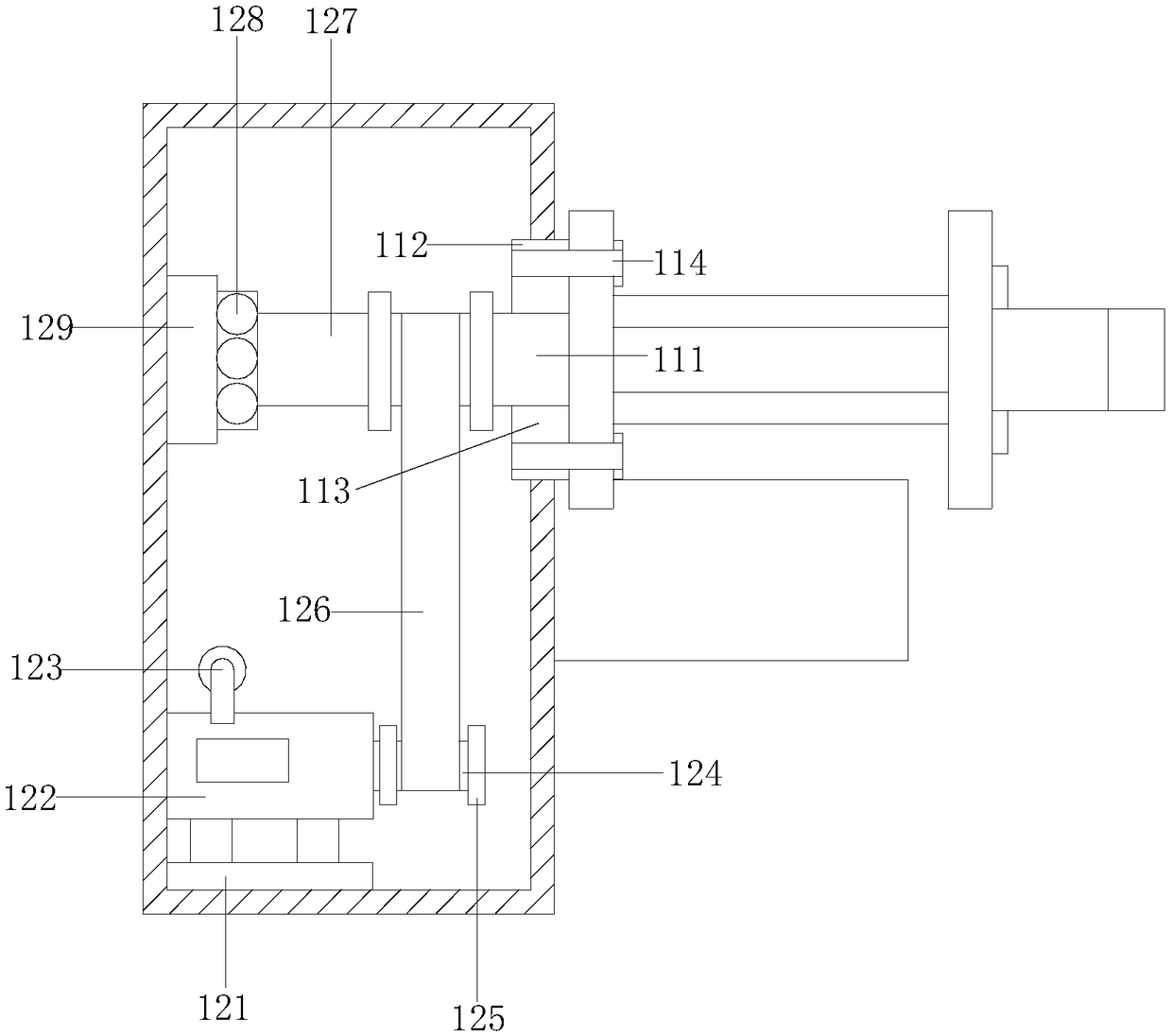

The invention relates to a production system for a soft foam die-cutting piece with large foaming holes. The system comprises an auxiliary protective film discharging roller (11), a handle release film discharging roller (12), a first pre-punching attaching unit, a first punching die-cutting machine (3), a second pre-punching attaching unit, a second punching die-cutting machine (5), a finished product attaching unit and a die-cutting piece collecting roller (71). Compared with the prior art, the production system has the advantages that poor stripping is prevented, and the reject ratio of products can be reduced to almost zero.

Owner:SHANGHAI HAOBAI ZHIZAO PRECISION ELECTRONICS CO LTD

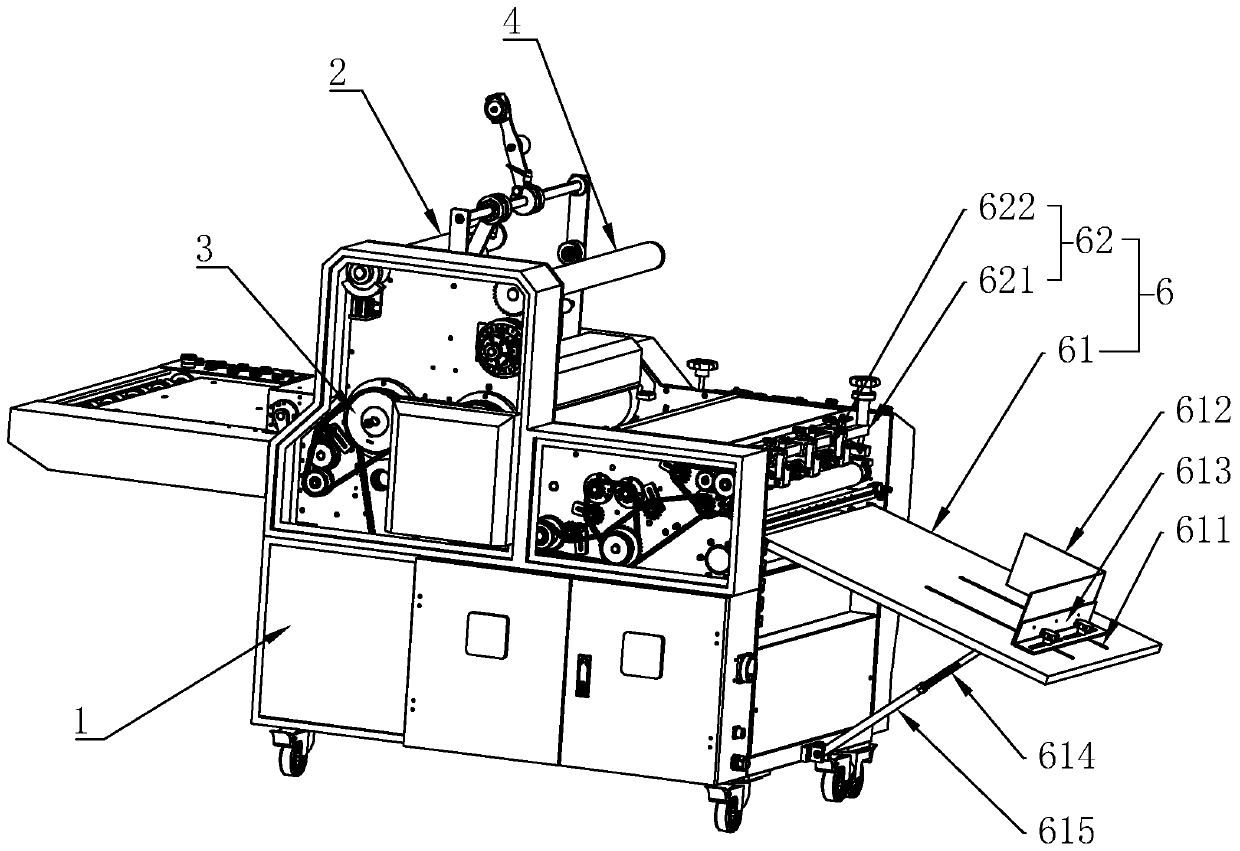

Cloth inspecting machine

Owner:佛山市三水三强塑胶有限公司

Multi-joint cotton packaging film connection equipment and application thereof

Owner:山东莱芜新甫冠龙塑料机械有限公司

Tension-free towel slitting machine

Owner:苏州大喆智能科技有限公司

Flexible material discharging platform capable of realizing waste separation treatment

PendingCN107571321AImprove collection efficiencyMetal working apparatusArticle deliveryEngineeringWaste management

Owner:YANCHENG XIONGYING PRECISION MACHINERY

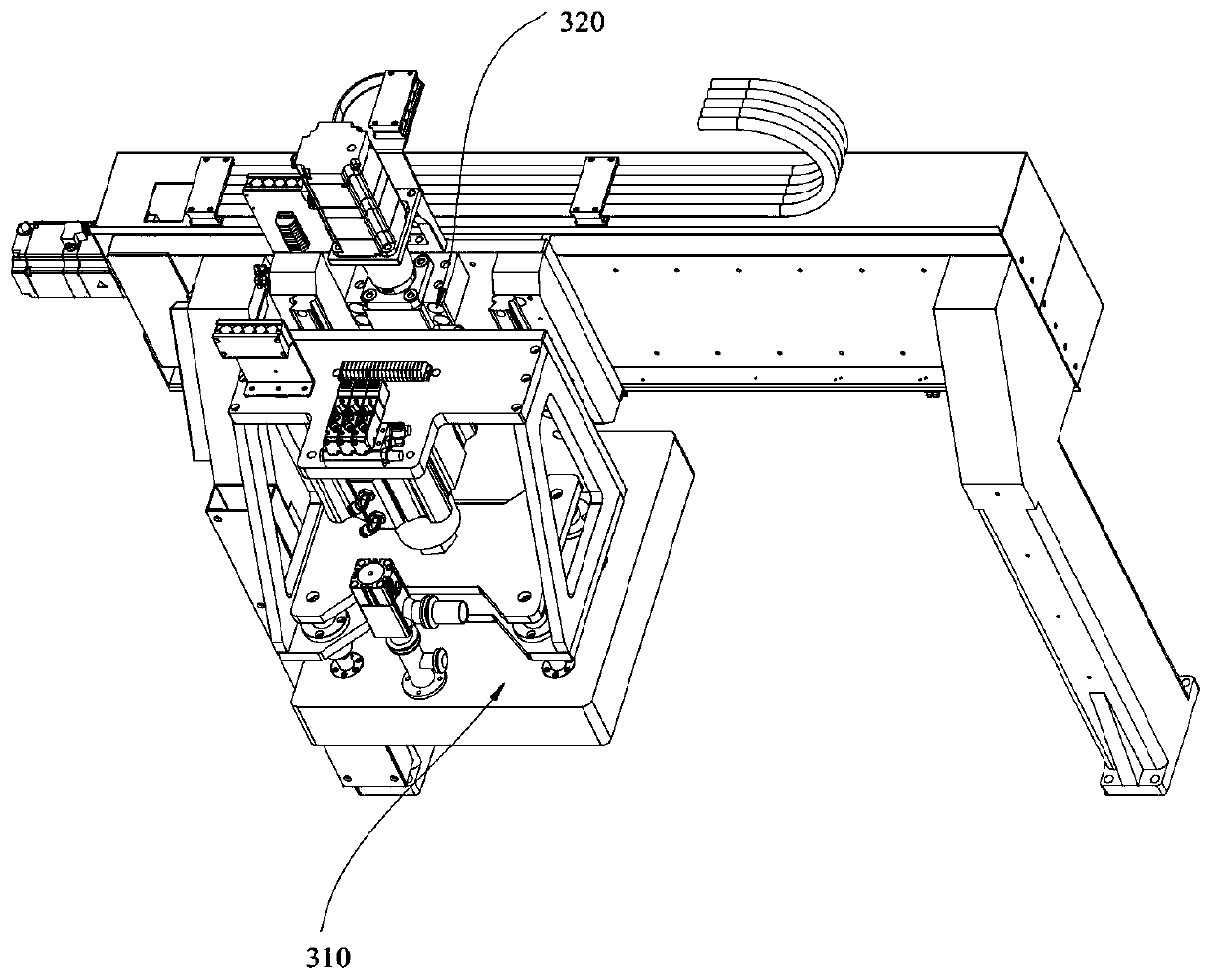

Deviation rectifying system and method for cutting and stacking all-in-one machine

ActiveCN112875379AHigh accuracy of deviation correctionReduce offsetAssembling battery machinesFinal product manufactureStructural engineeringMachine

Owner:中山科瑞自动化技术有限公司

Automatic feeding device for film bag-making machine

Owner:西安市洁美塑业有限责任公司

Outer film coating supply device and film coating machine

ActiveCN112208846AWrapping material feeding apparatusWrappingMechanical engineeringFilm-coated tablet

Owner:福融新材料股份有限公司 +1

End conveying device for transfer film

Owner:海盐三湾塑业有限公司

Base material tightening device for high-speed coiling machine

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Packaging bag waste collection machine

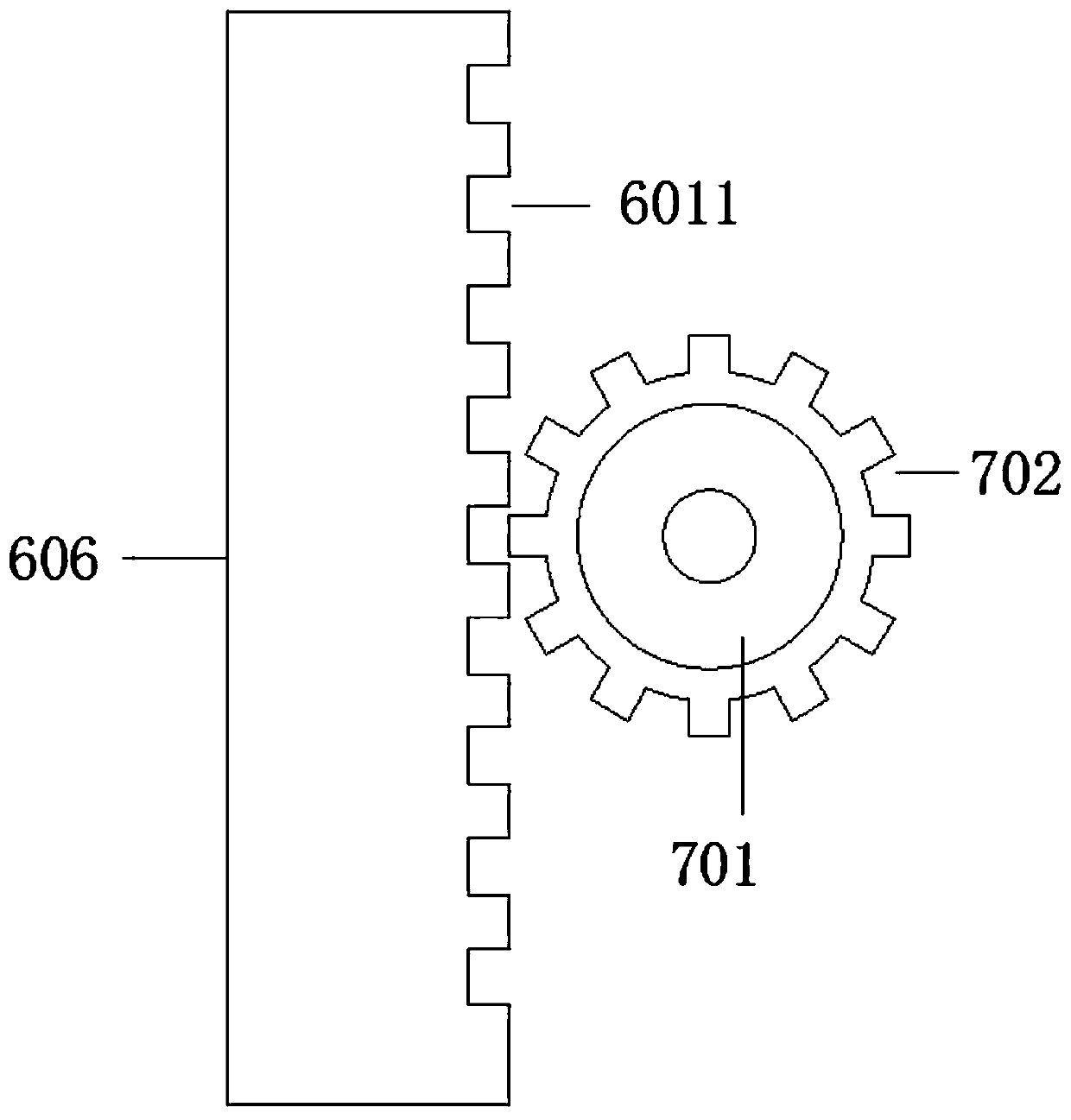

The invention discloses a packaging bag waste collection machine. The packaging bag waste collection machine comprises a collecting assembly and a guide assembly; the collecting assembly comprises a barrel seat, a charging barrel, a collecting rotation shaft, a barrel cover and a collecting motor; the charging barrel is located on the barrel seat; the collecting rotation shaft is rotationally arranged at the bottom of the charging barrel in a penetrating mode and stretches into the barrel seat, and the position, located in the barrel seat, of the collecting rotation shaft is sleeved with a first gear; the collection motor is arranged in the barrel seat; an output shaft of the collection motor is provided with a second gear, and the second gear is engaged with the first gear; the barrel cover is movably arranged at the top of the charging barrel; the guide assembly comprises a moving frame, a connection rod, a screw rod, a screw rod nut and a driving motor; the barrel wall is verticallyprovided with a long notch; and the positions, located at the long notch, of the barrel wall are provided with a first slide groove and a second slide groove. According to the packaging bag waste collection machine provided by the invention, packaging bag waste does not need to be manually collected any longer, the problems that the manual collecting efficiency is low, and time and labor are wasted are solved, and accordingly, the production cost is reduced.

Owner:HUNAN HENGSEN AGRI TECH CO LTD

Textile mechanical winding device for preventing cloths from falling

Owner:HUZHOU NANXUN ZHONGLI TEXTILE CO LTD

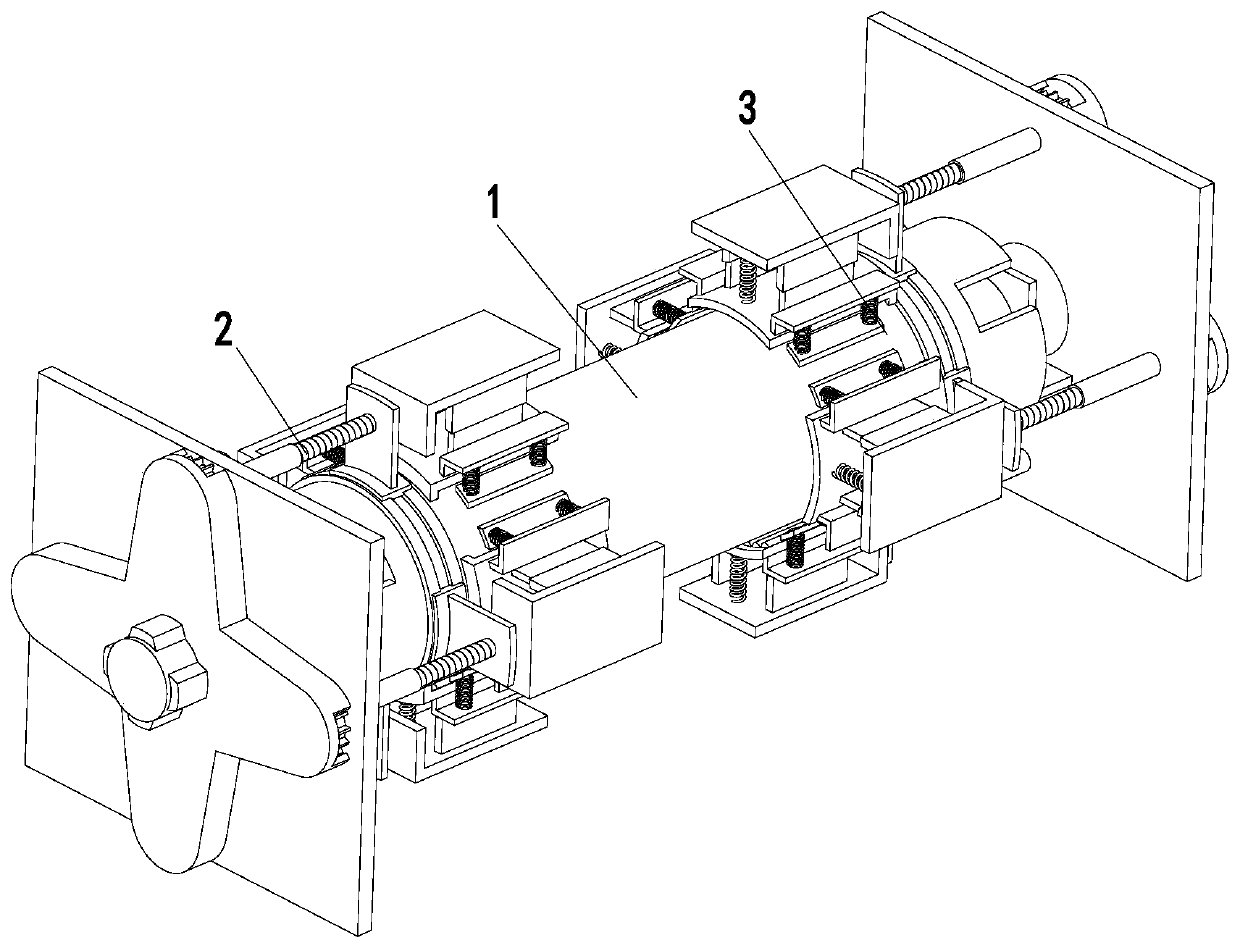

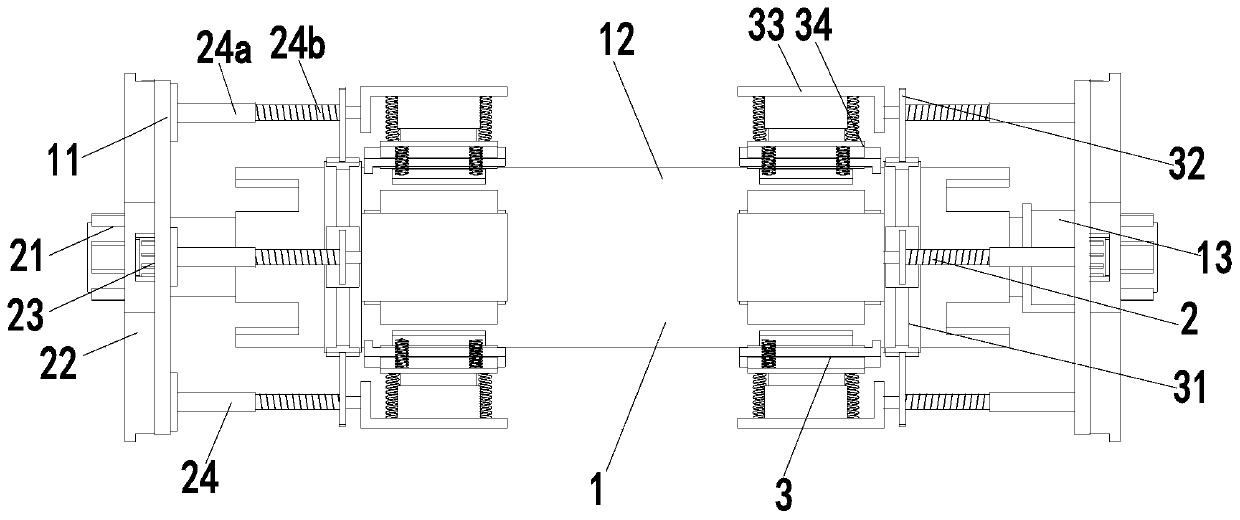

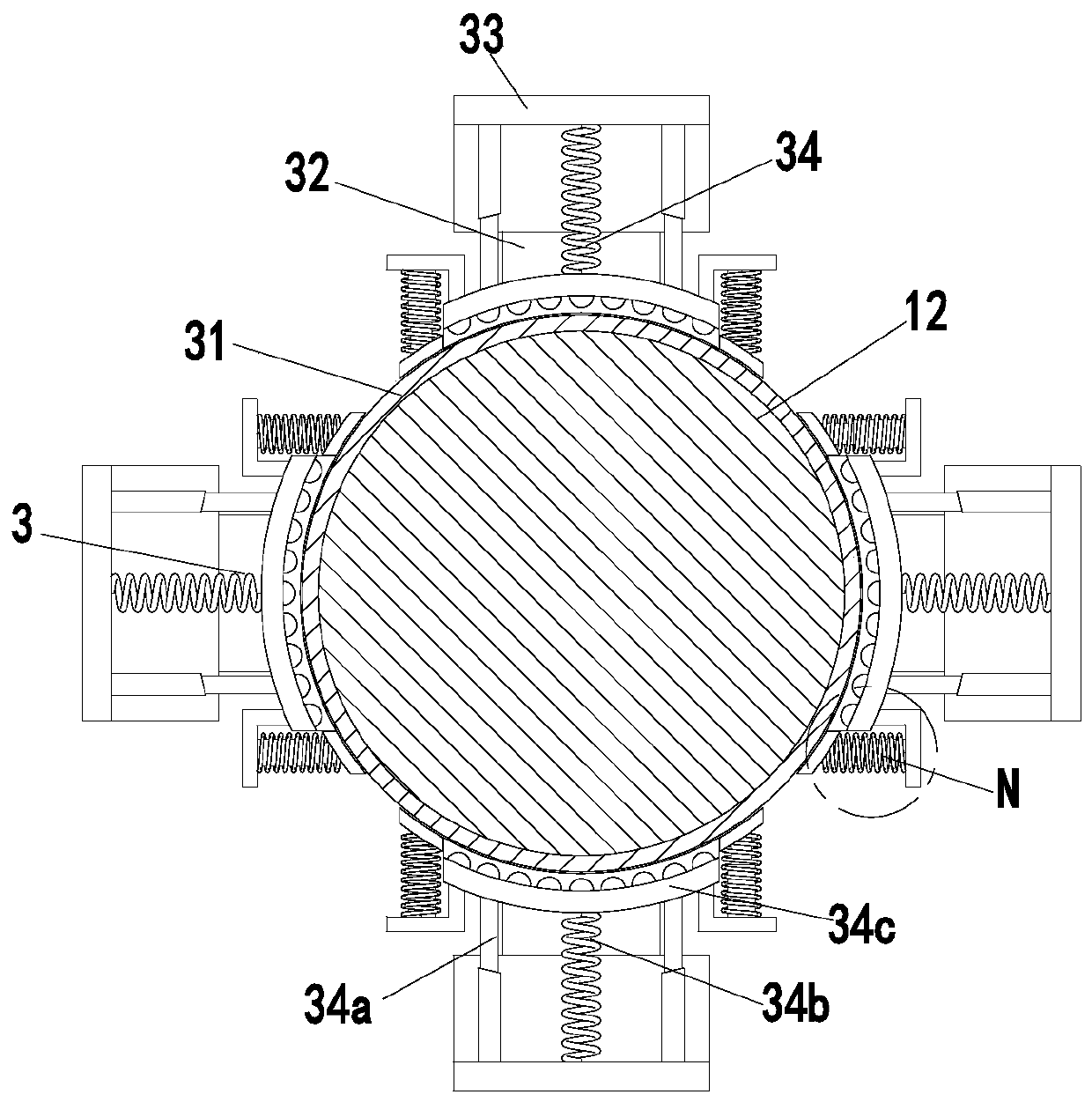

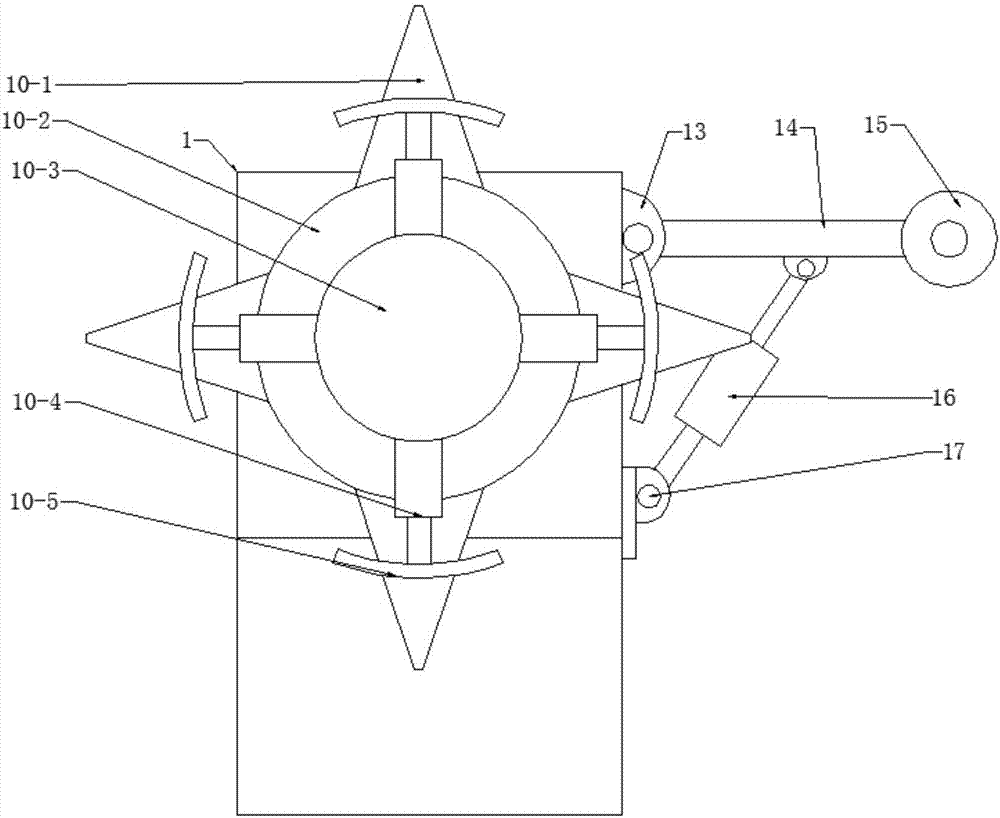

Rewinding machine with surface drive function

InactiveCN106006146AGuaranteed bulkinessIncrease intake pressureWebs handlingElectric machineEngineering

The invention discloses a rewinding machine with a surface drive function, and belongs to the technical field of printing machinery. According to the rewinding machine, a paper rewinding tension detection device is arranged on a paper output channel behind a traction unit; the paper rewinding tension detection device comprises a second swinging rod; one end of the second swinging rod is connected with a floating roll, and a second sensor for detecting a rotating position of the second swinging rod is arranged at the other end of the second swinging rod; a rewinding roll driven through a second variable-frequency motor behind the paper rewinding tension detection device is arranged, and the second variable-frequency motor is connected with the second sensor through a controller; an inflatable shaft for installing a paper reel in a penetrating manner is arranged above the rewinding roll, and in transmission connection with a lifting cylinder controlled by a proportional electromagnetic valve; and the proportional electromagnetic valve is connected with a third sensor for detecting a lifting position of the inflatable shaft through the controller. According to the rewinding machine disclosed by the invention, the problems that an original bulkiness of a printing stock cannot be recovered due to a too high tension during rewinding of an existing rewinding machine, and material reels are tight outside and loose inside due to dead weights can be solved.

Owner:王金根 +1

Winding device for alkali-resistant glass fiber grid cloth

Owner:合肥神舟建筑集团有限公司

Rim-material-free production device for paper gasket of compressor and using method thereof

Owner:杭州瀚真电器制造有限公司

Processing device and technology for towel production

Owner:安徽省伊贝雅纺织股份有限公司

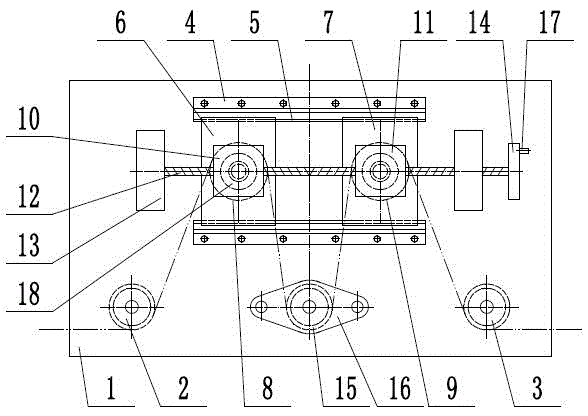

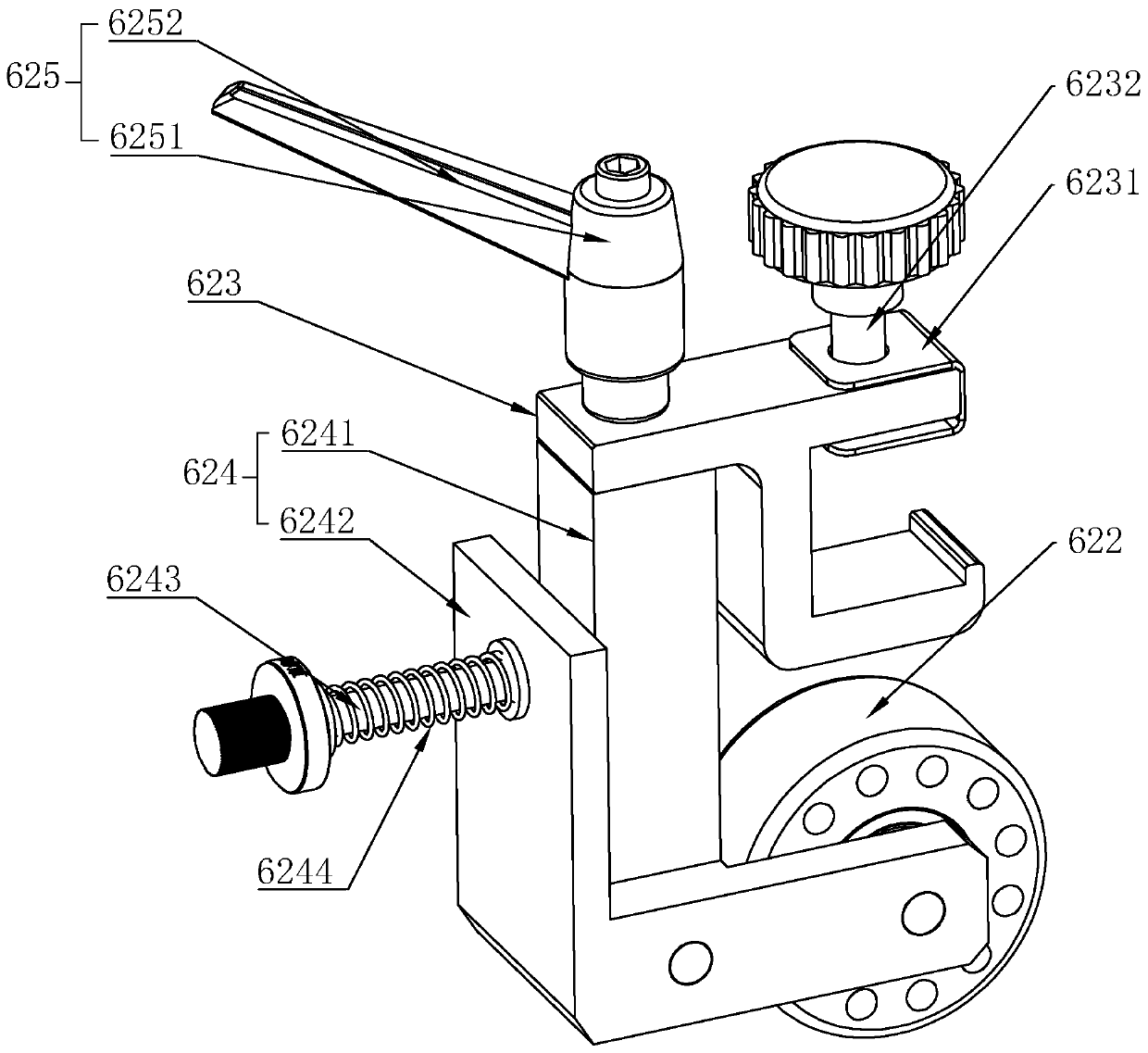

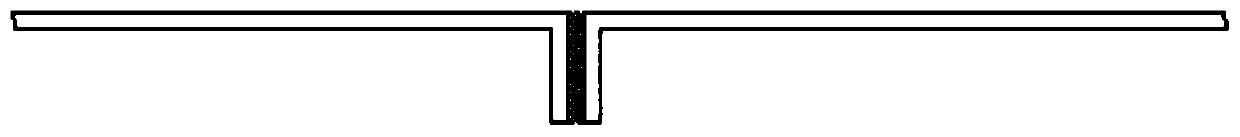

Tension control device of flexographic printing press

The invention provides a tension control device of a flexographic printing press. The tension control device comprises a first supporting roller and a second supporting roller, and also comprises a shaft base, an adjusting roller, a sliding base, a compression spring, an anti-breaking mechanism and a fixed base, wherein the shaft base is slidably arranged on a main frame; the adjusting roller is rotationally arranged on the shaft base; a printing substrate is sequentially wound on the first supporting roller, the adjusting roller and the second supporting roller; the sliding base is slidably arranged on the main frame; the compression spring is arranged between the sliding base and the shaft base; the anti-breaking mechanism is used for preventing the printing substrate from breaking due to excessive instantaneous tension; the anti-breaking mechanism comprises a moving base, a propping block, an impact rod and a linkage assembly; the moving base is slidably arranged on the main frame;the impact rod is telescopically arranged on the moving base; the propping block is movably arranged on the front side of the moving base through the linkage assembly; the propping block abuts againstthe tail end of the sliding base; the fixed base is fixedly arranged on the main frame; the fixed base is connected with an adjusting knob; and a screw rod of the adjusting knob abuts against the moving base. The tension control device of the flexographic printing press provided by the invention can effectively avoid the breakage of the printing substrate due to excessive instantaneous tension.

Owner:HENAN HUAGANG PRINTING

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap