Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

207 results about "Gear wheel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

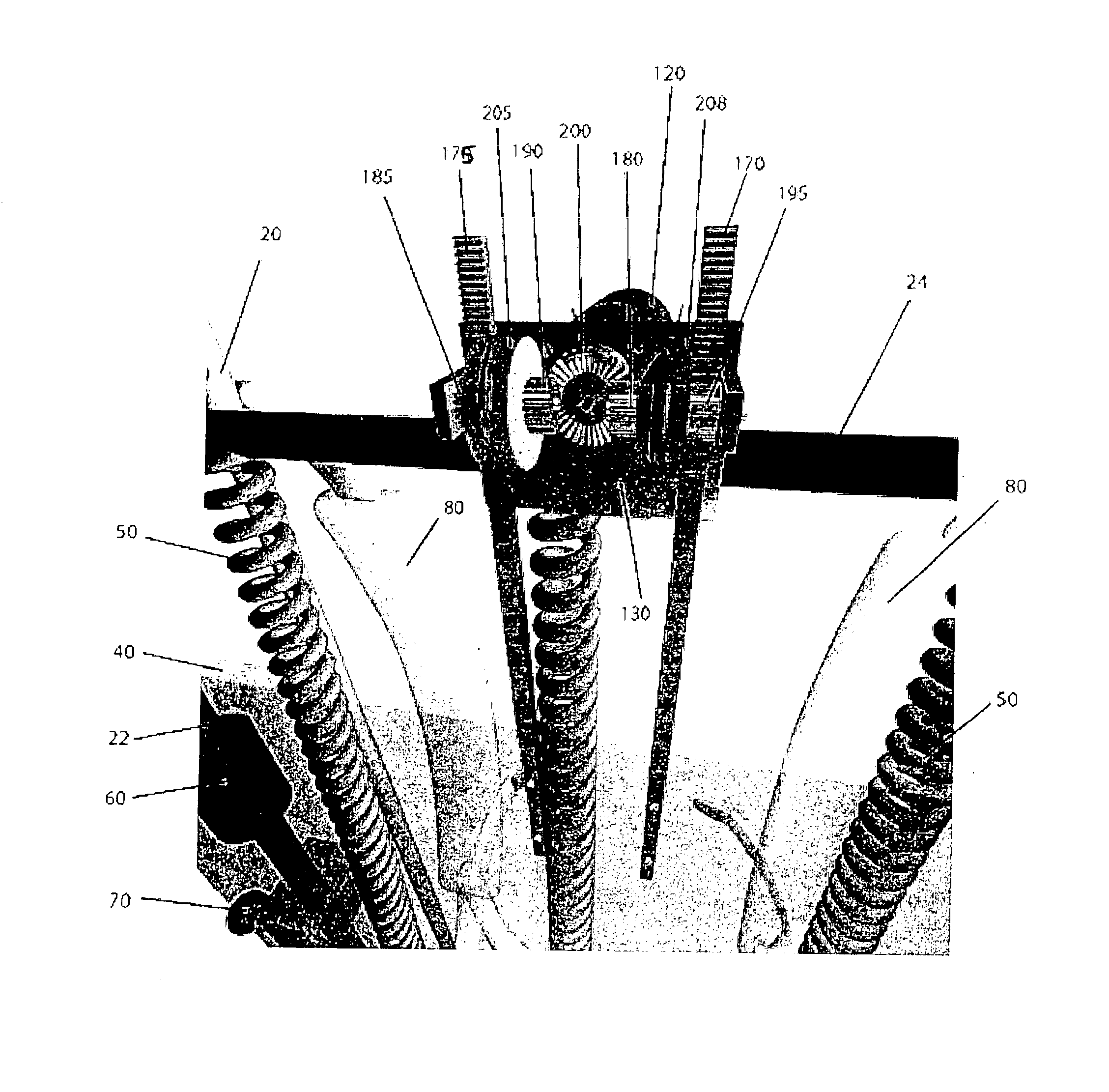

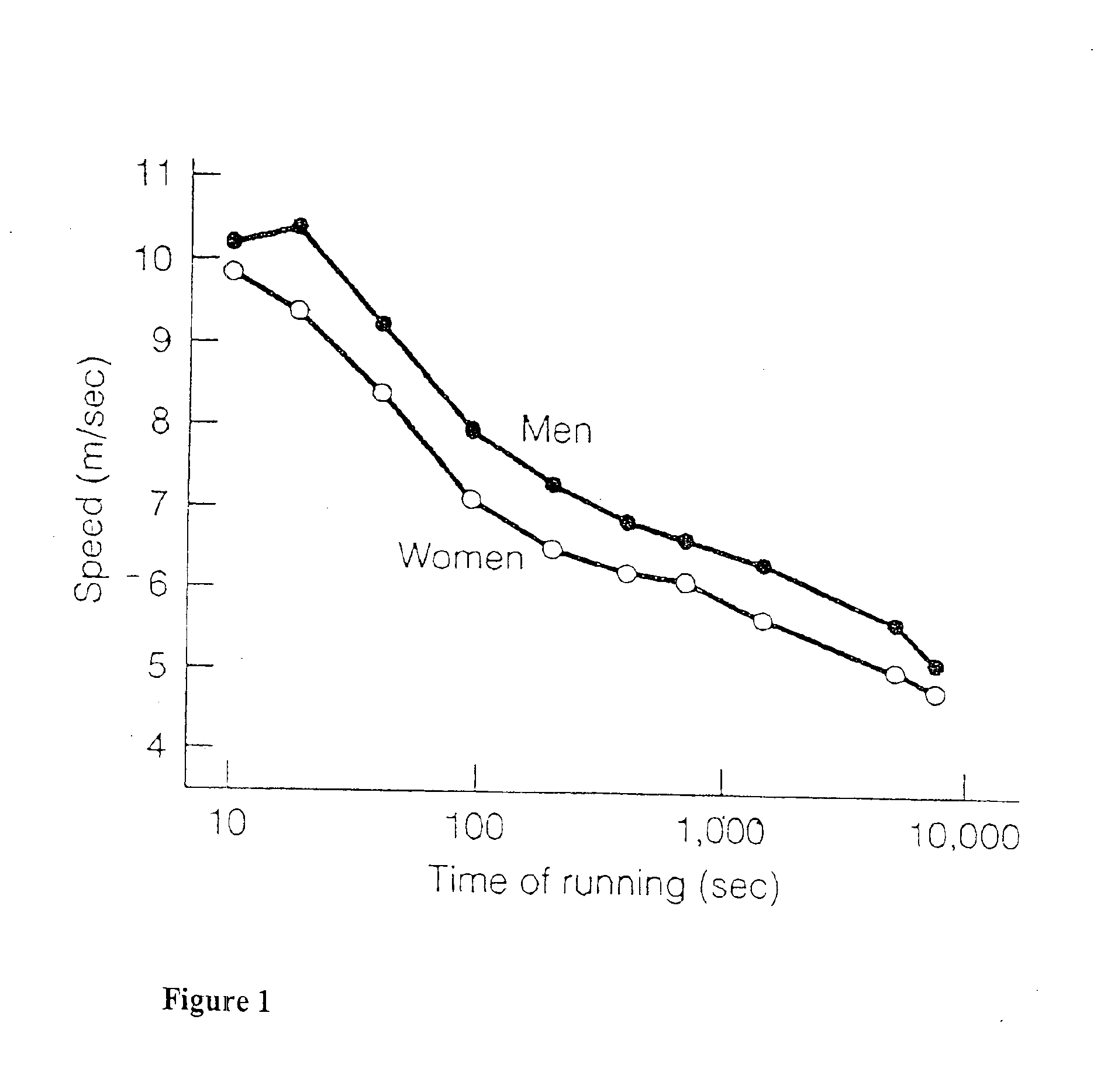

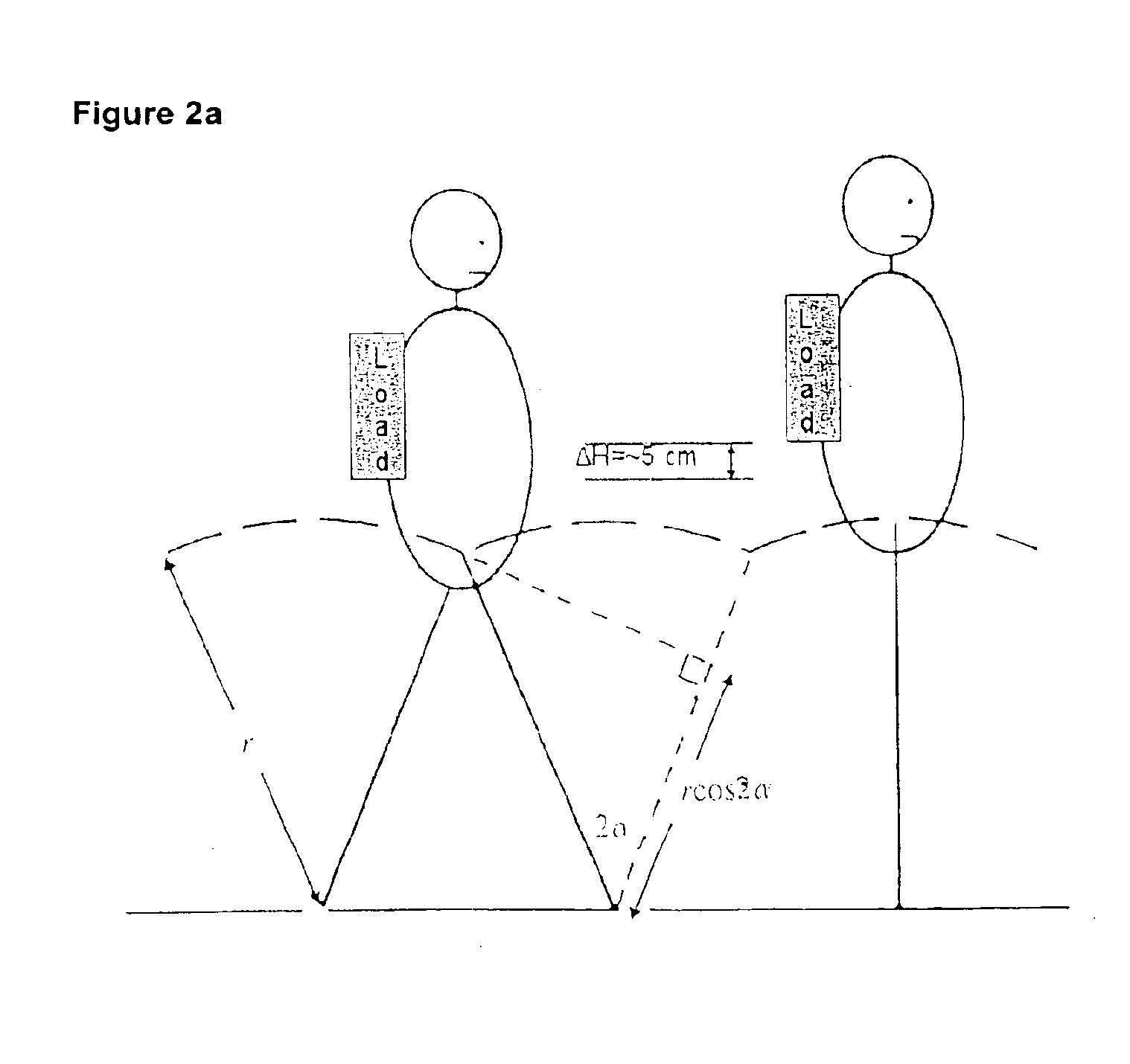

Backpack for harvesting electrical energy during walking and for minimizing shoulder strain

ActiveUS6982497B2Large movementReduce absolute vertical motionTravelling sacksPiezoelectric/electrostriction/magnetostriction machinesGear wheelShoulder strain

Owner:LIGHTNING PACKS

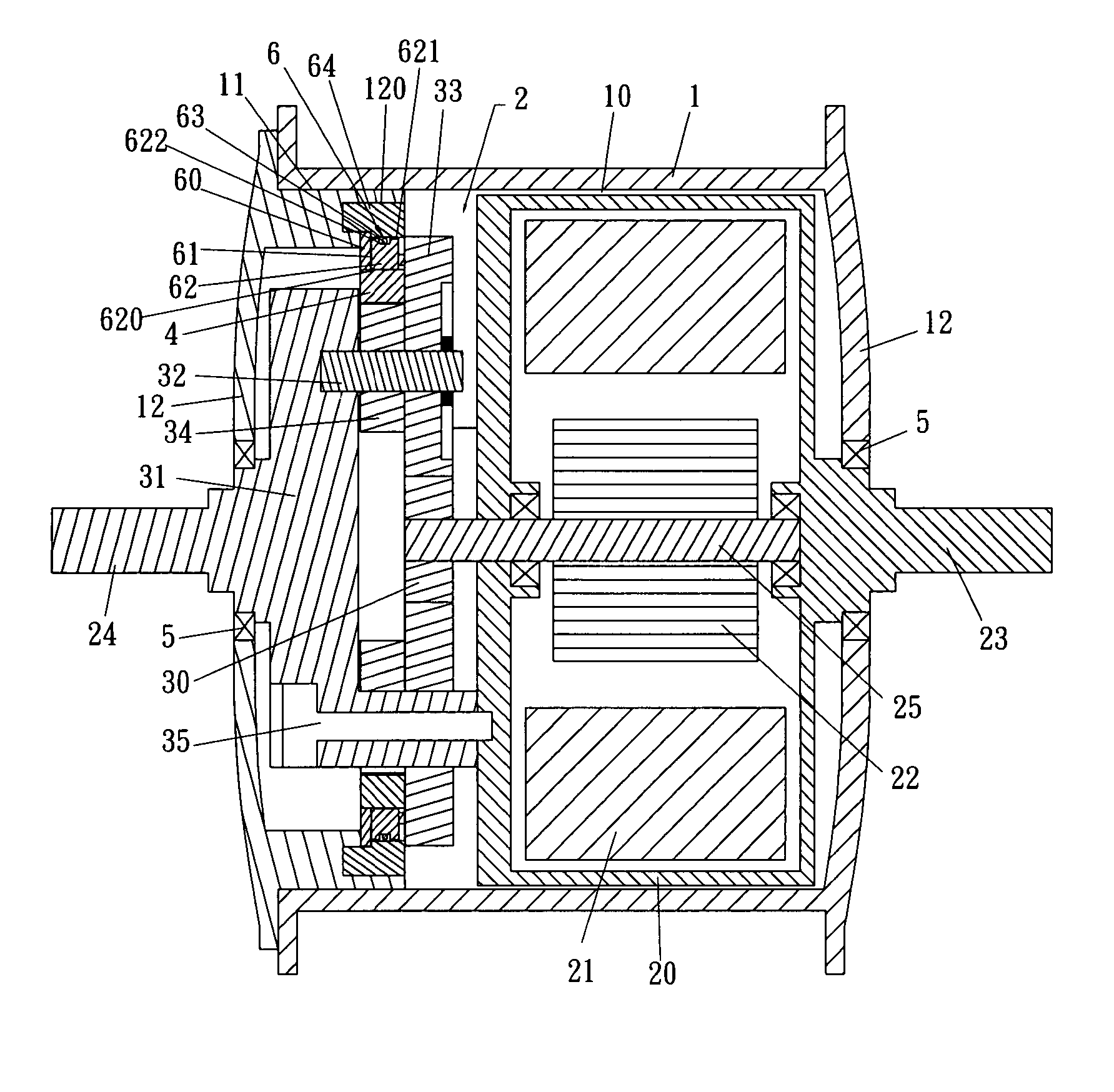

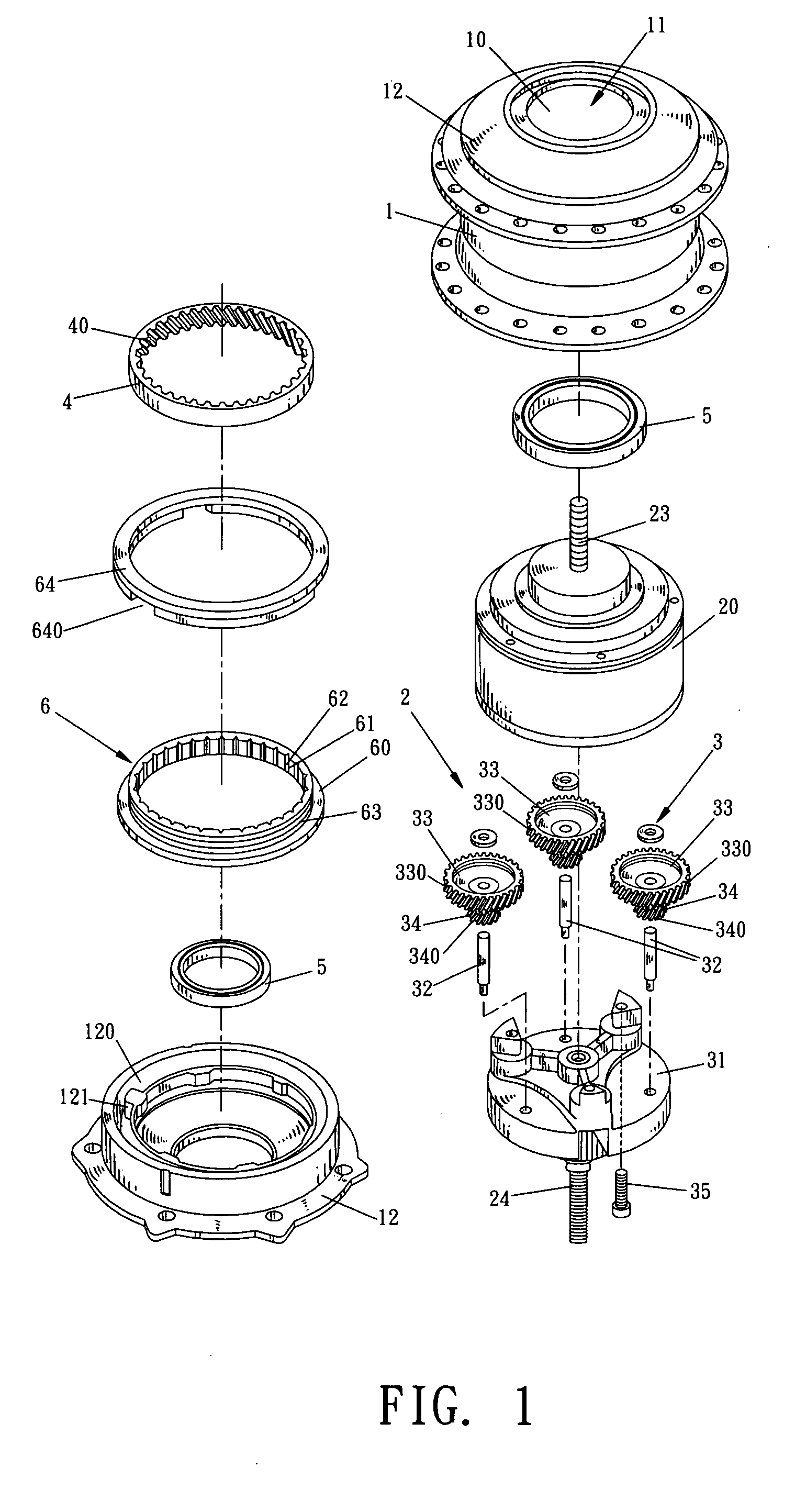

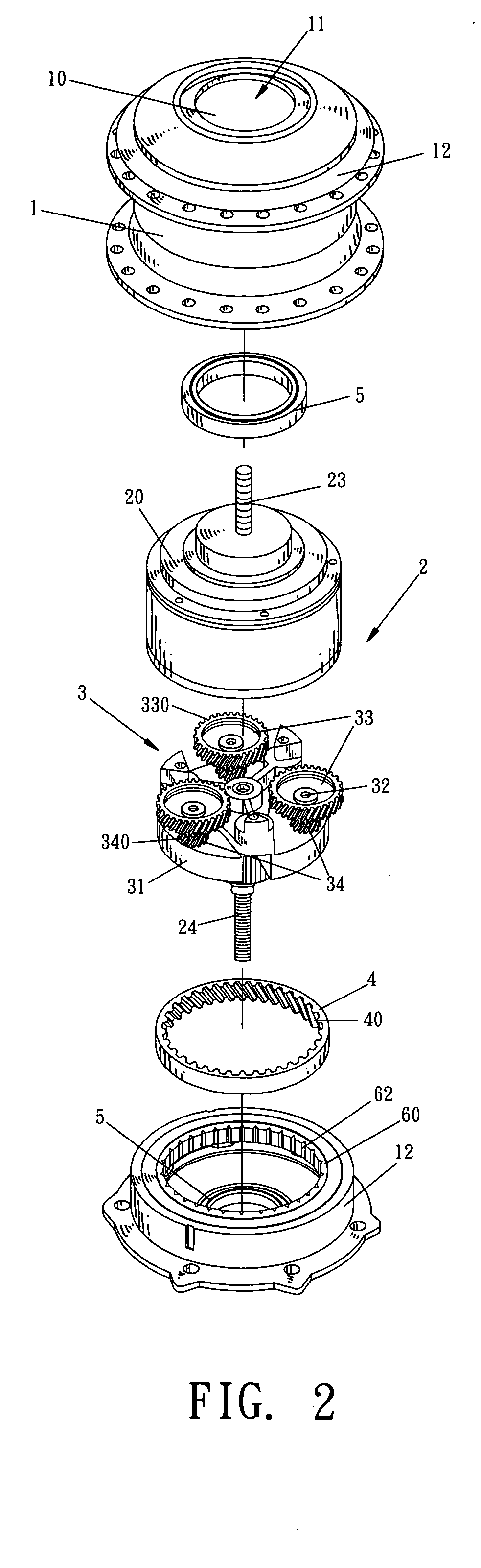

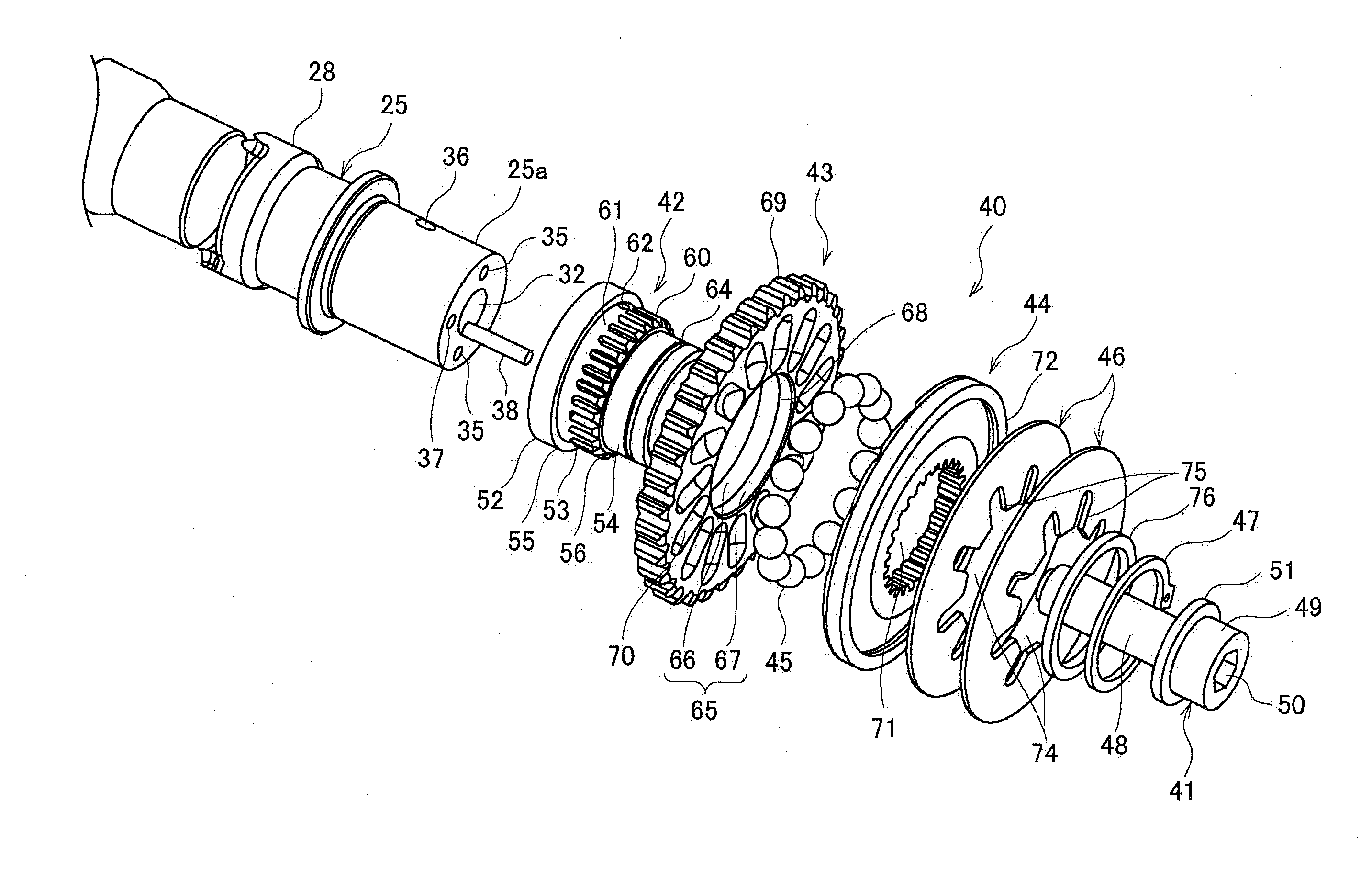

Hub motor mechanism

An electrically driven hub includes an electrical mechanism including an electrical motor and a planetary gear system connected to the electrical mechanism. A first fixed shaft is connected to the stator of the electrical motor and a second fixed shaft is connected to a second end of the stator of the electrical motor. The first and second fixed shafts are connected to the vehicle frame. A one-way clutch is connected between a cover of the hub and the planetary gear system so that the hub is rotated when the planetary gear system is activated by the motor.

Owner:LO CHIU HSIANG

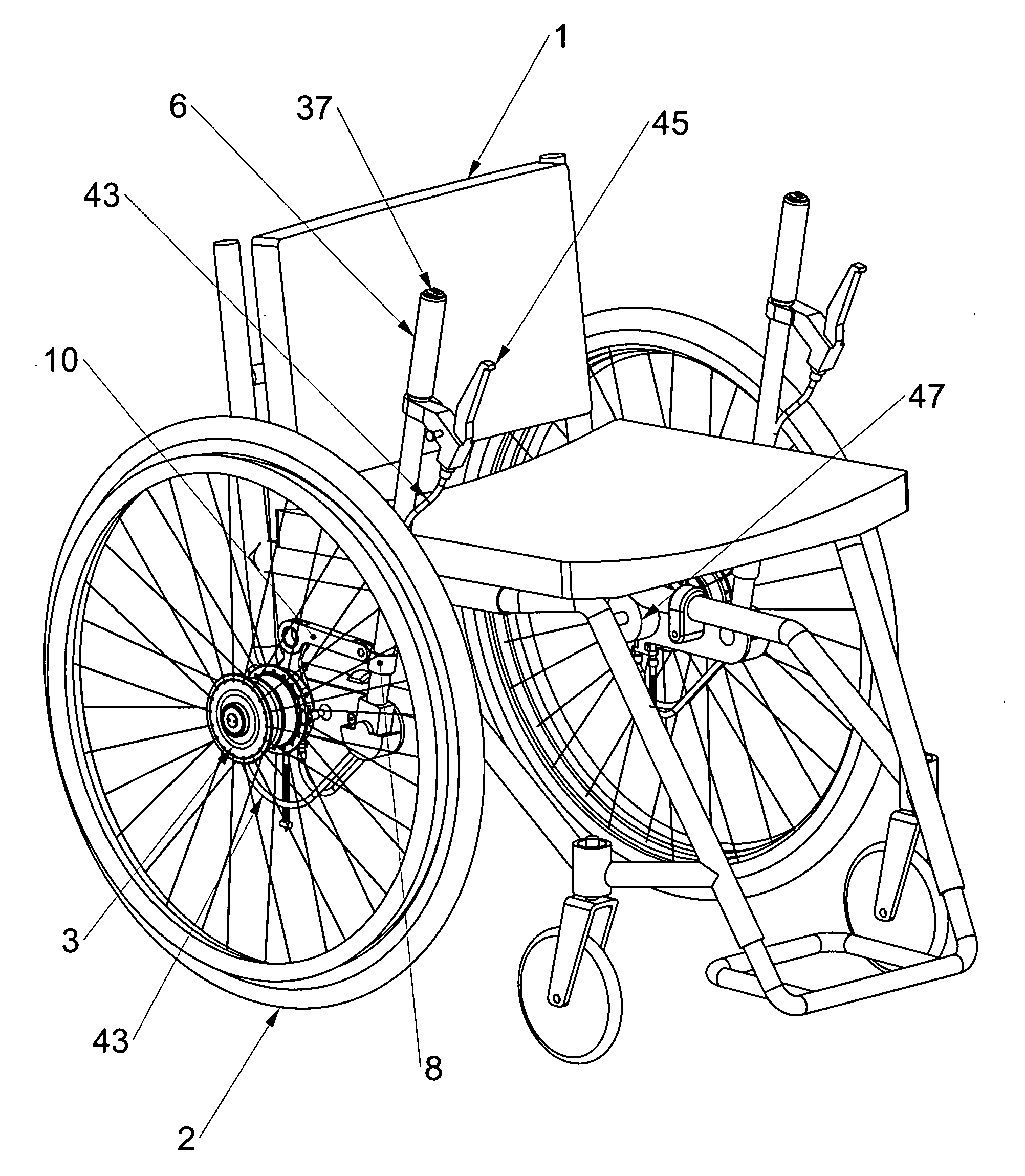

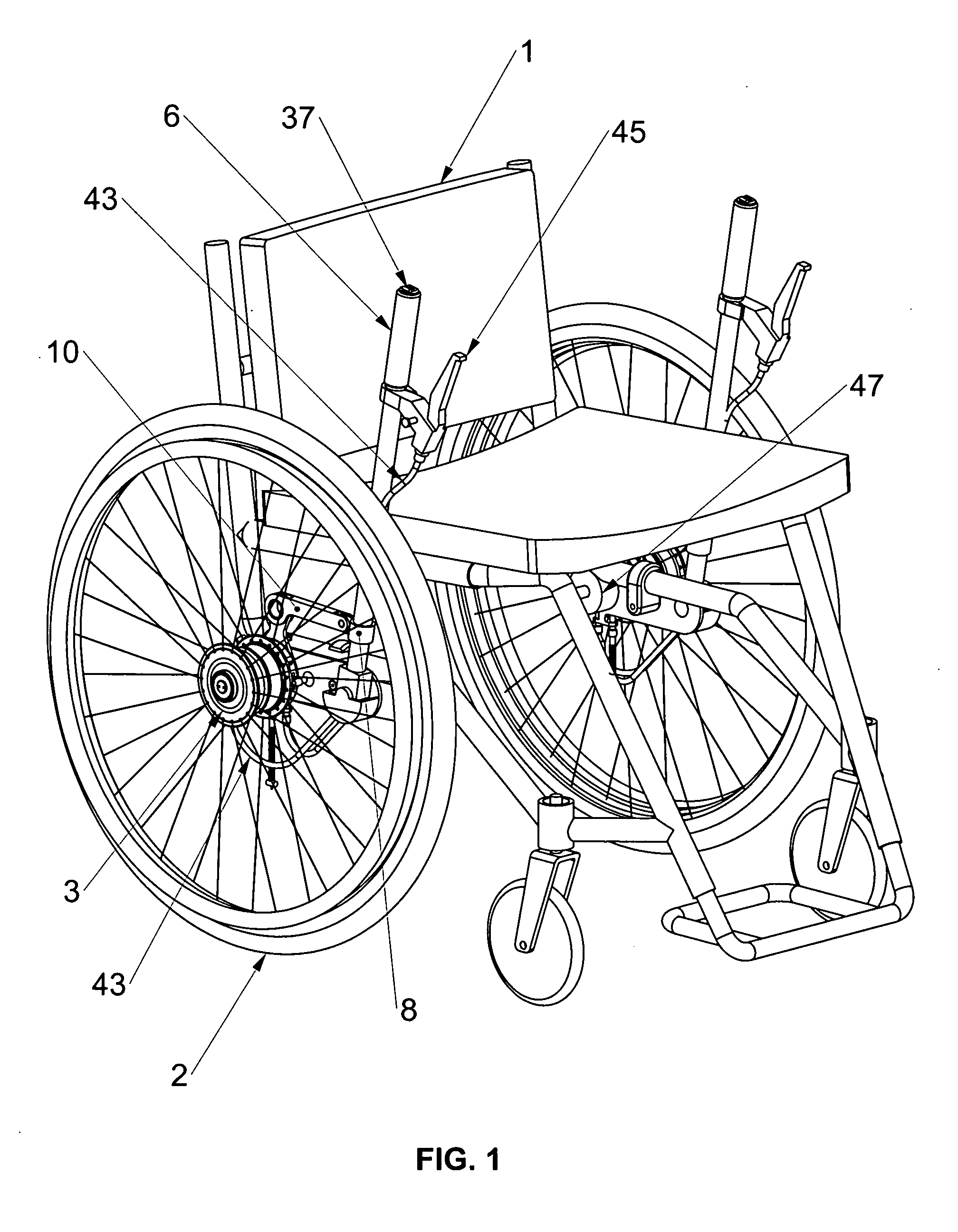

Wheelchair drive system with lever propulsion and a hub-contained transmission

InactiveUS20080238022A1Shifted quickly and remotelyEasy to disassembleWheelchairs/patient conveyanceRider propulsionWheelchairGear wheel

Owner:DAEDALUS WINGS

Blade driving mechanism for a table saw

InactiveUS20060191393A1Simple structureEasy to adjustMetal sawing devicesShearing machinesTransverse axisGear wheel

The present invention provides a blade driving mechanism for a table saw, wherein the table saw comprises a main frame and a saw blade mounted to and driven by the blade driving mechanism, and the blade driving mechanism comprises an electrical motor mounted to the main frame, with the motor being capable of sliding with respect to the main frame; a belt driving system for transferring the rotation of an output shaft of the motor to the saw blade; a center-distance setting means connected between the motor and the saw blade, for adjustably setting the center-to-center distance between the motor and the saw blade; and a saw-blade height adjusting device being operable to adjust the height of the of the saw blade. saw-blade height adjusting device comprises a transverse shaft being capable of rotating about a horizontal axis; a handwheel fixed to the outer end of the transverse shaft for driving the transverse shaft to rotate; a vertical screw shaft coupled with the transverse shaft by a set of bevel gears and is driven by the transverse shaft to rotate about a vertical axis; a nut mounted on and engaged with the screw shaft and being capable of moving along the screw shaft by the rotation of the screw shaft; and a guide connected to the nut and supporting the saw blade.

Owner:QINGDAO D& D ELECTRO MECHANICAL TECH

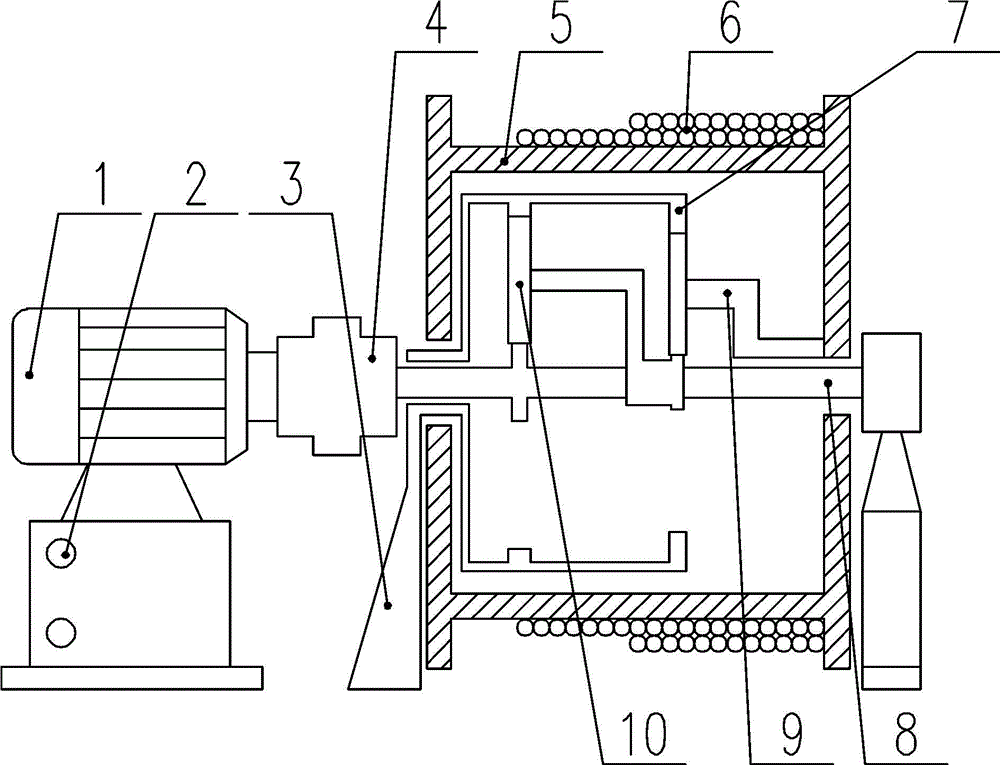

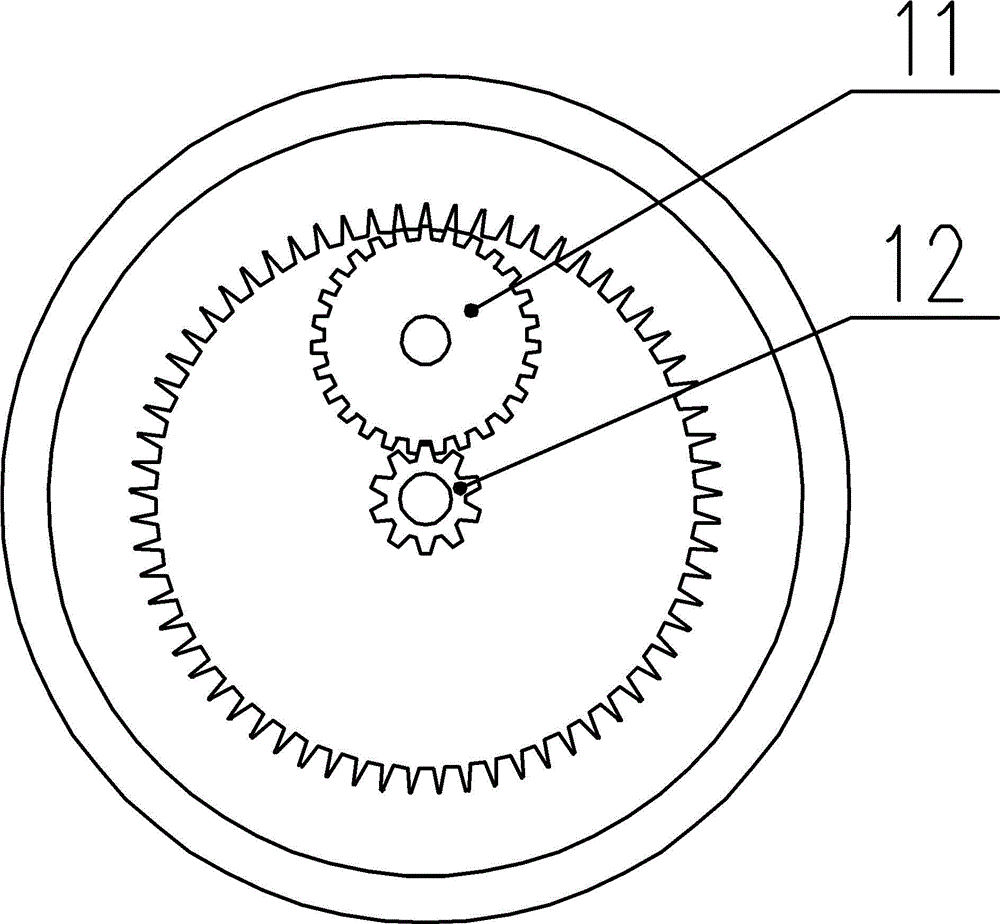

Gear reduction unit

InactiveUS20050028627A1Easy to useHigh contact ratioToothed gearingsTransmission elementsGear wheelEngineering

Owner:FLEYTMAN YAKOV

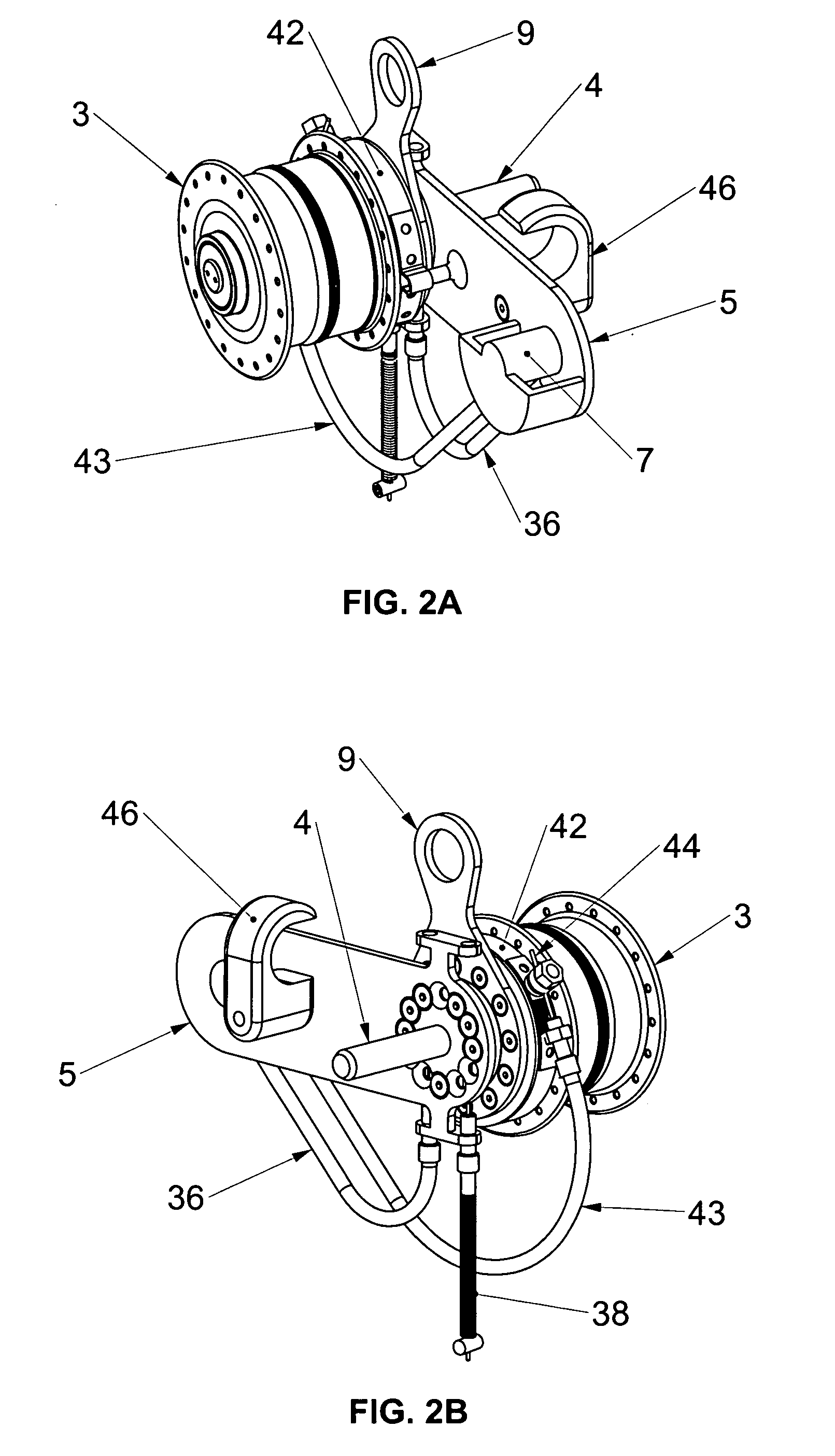

Lifting equipment

Owner:WUHU HENGHAO MACHINERY MFG

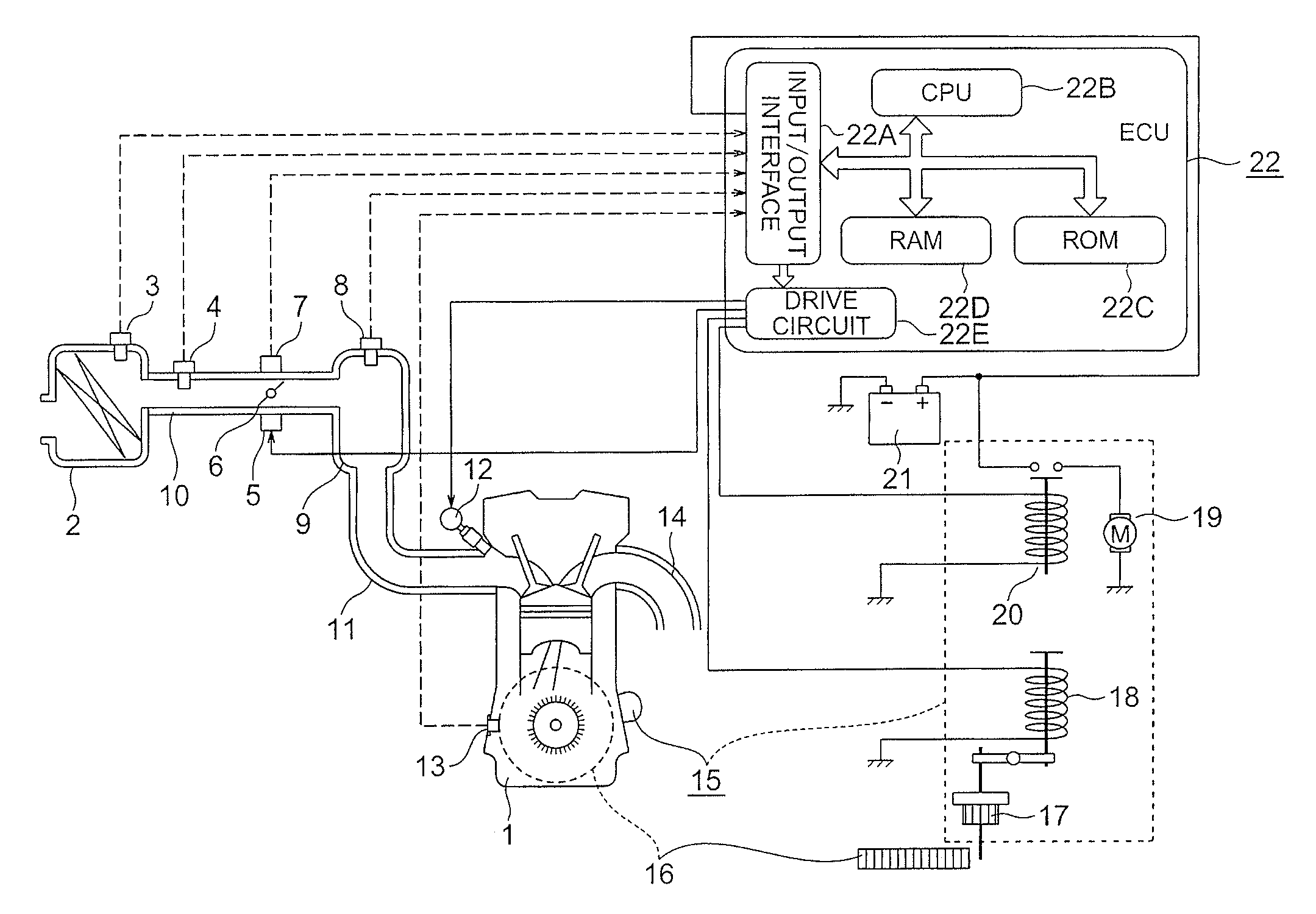

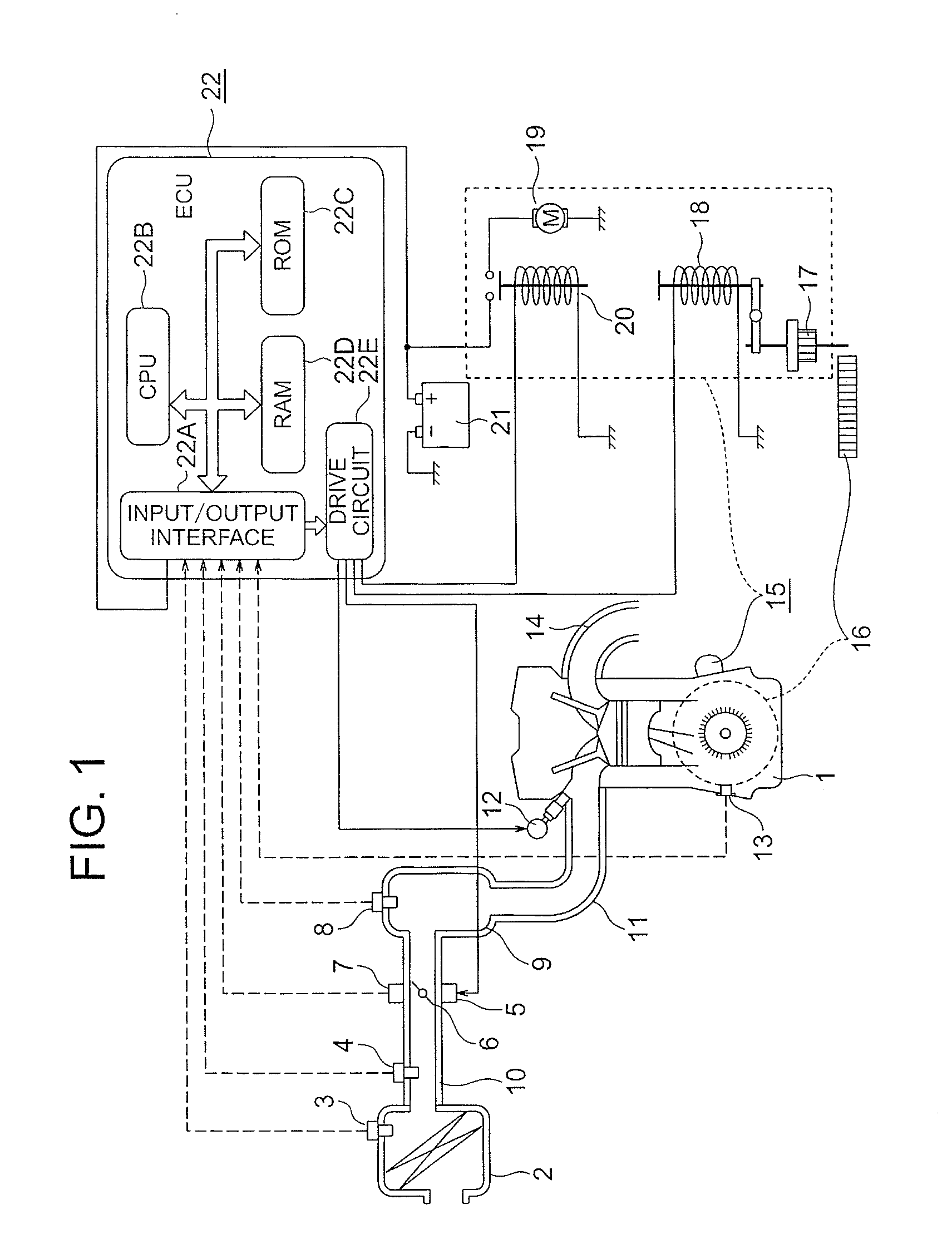

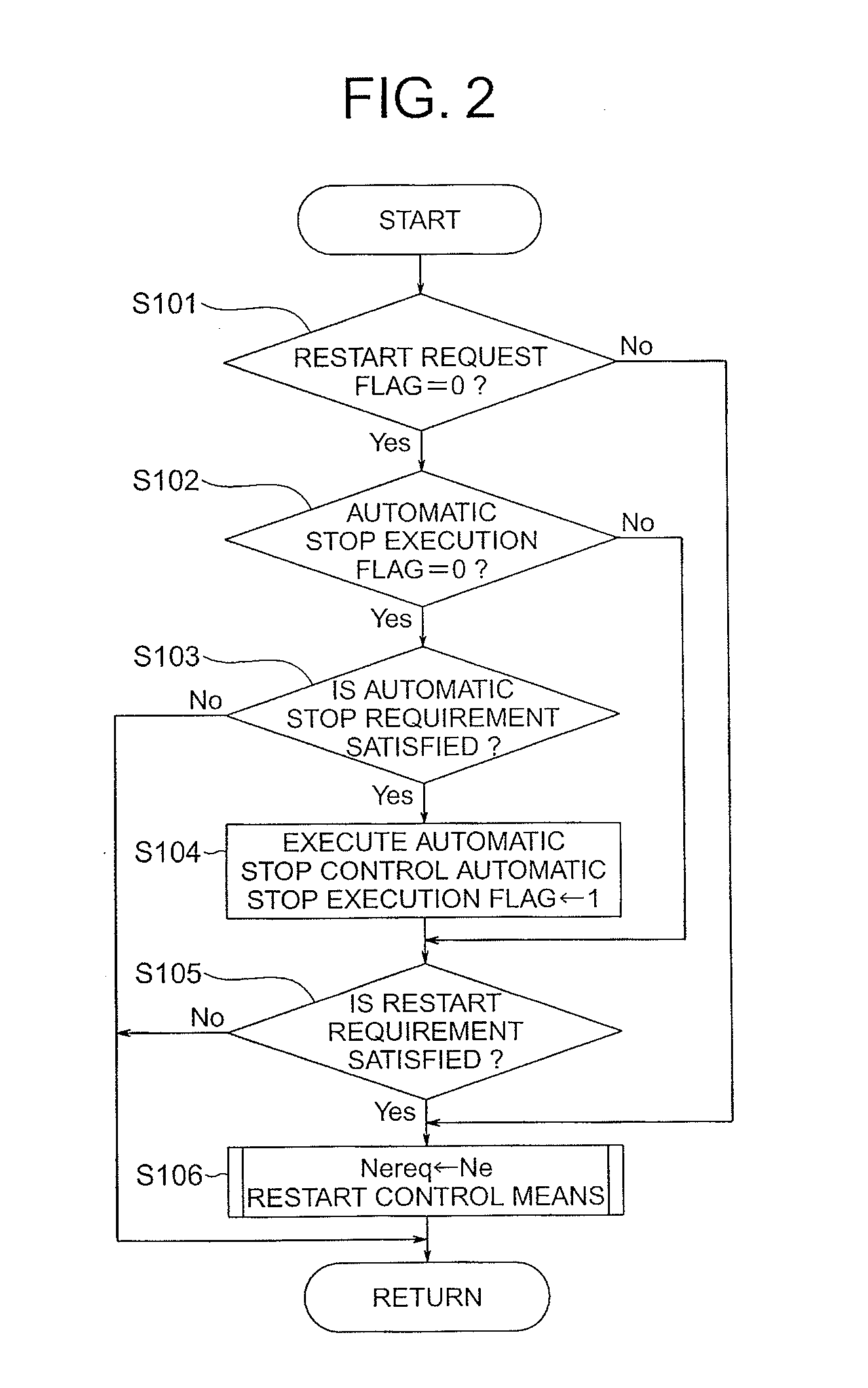

Automatic stop/restart device for internal combustion engine

ActiveUS20120290194A1Reliable engagementLow costElectrical controlDigital data processing detailsGear wheelExternal combustion engine

Owner:MITSUBISHI ELECTRIC CORP

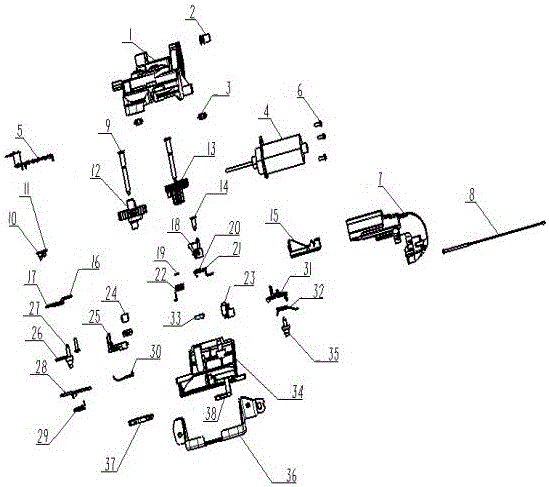

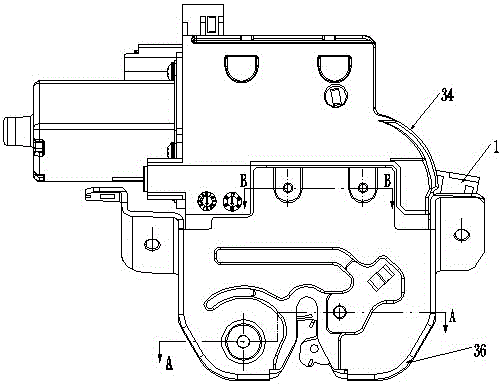

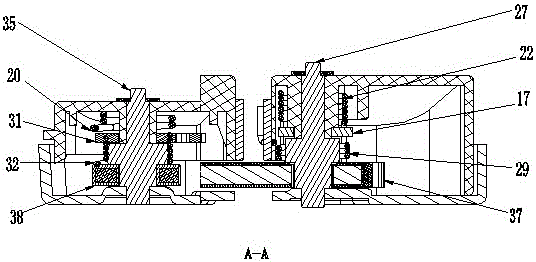

Self-suction tail door lock assembly

ActiveCN106014020ARealize self-priming functionElectrical locking circuitsElectrical locking actuatorsMotor driveGear wheel

Owner:靖江市汇聚汽车配件有限公司

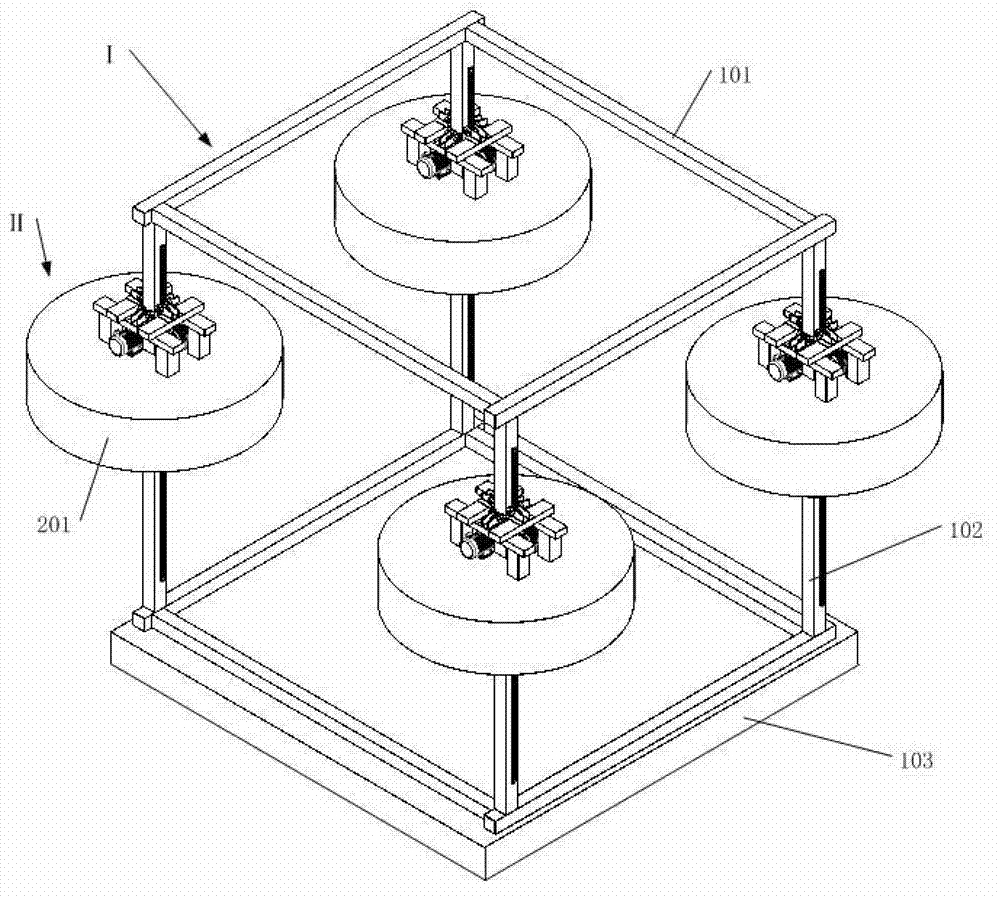

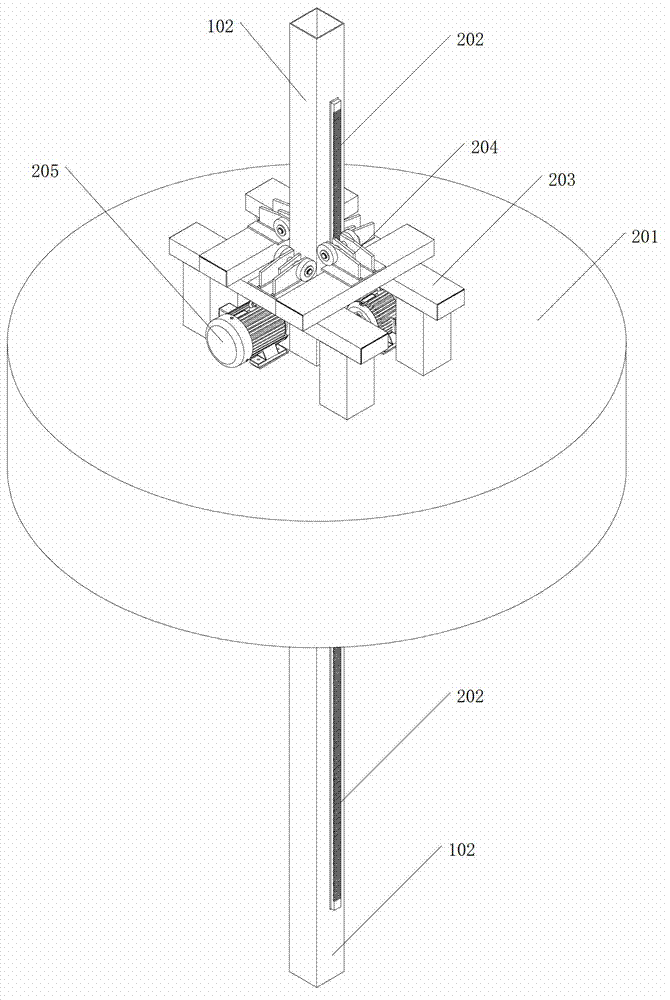

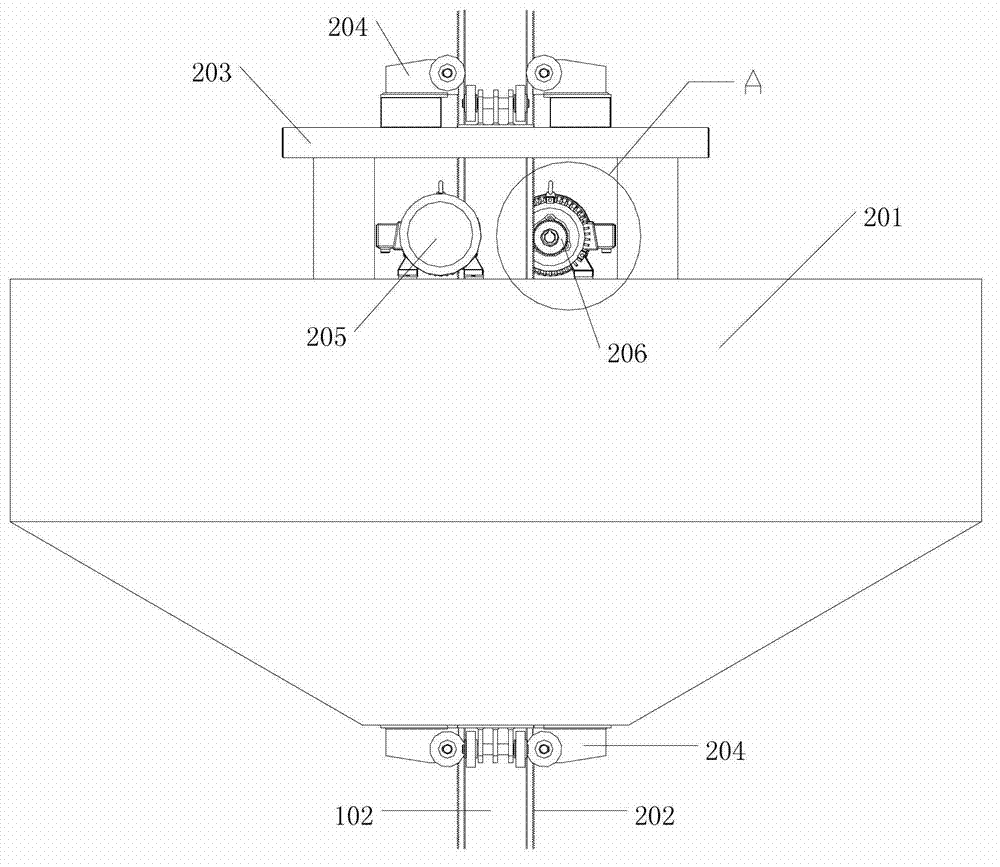

Mechanical combination type oscillating floater wave energy power generation device

InactiveCN103114958AHigh utilization rate of wave energyNot affected by tidal rangeMachines/enginesEngine componentsFixed frameGear wheel

Owner:OCEAN UNIV OF CHINA +1

Basketball cleaning device for sports

Owner:义乌市裕晨科技有限公司

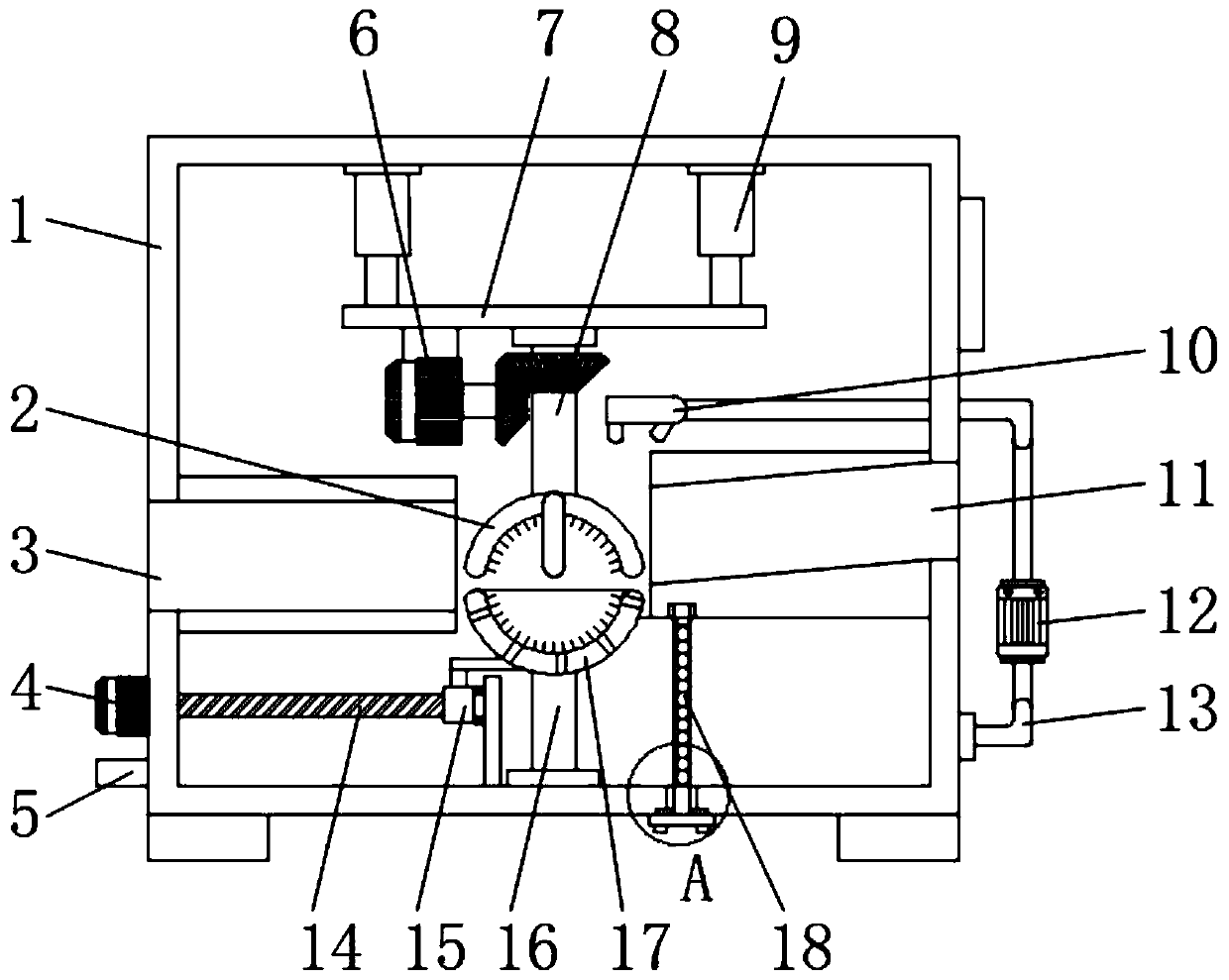

Vacuum panel sucking and hoisting crane

ActiveCN104016216AEnsure damage-free handlingReduce heavy laborTravelling cranesLoad-engaging elementsGear wheelEngineering

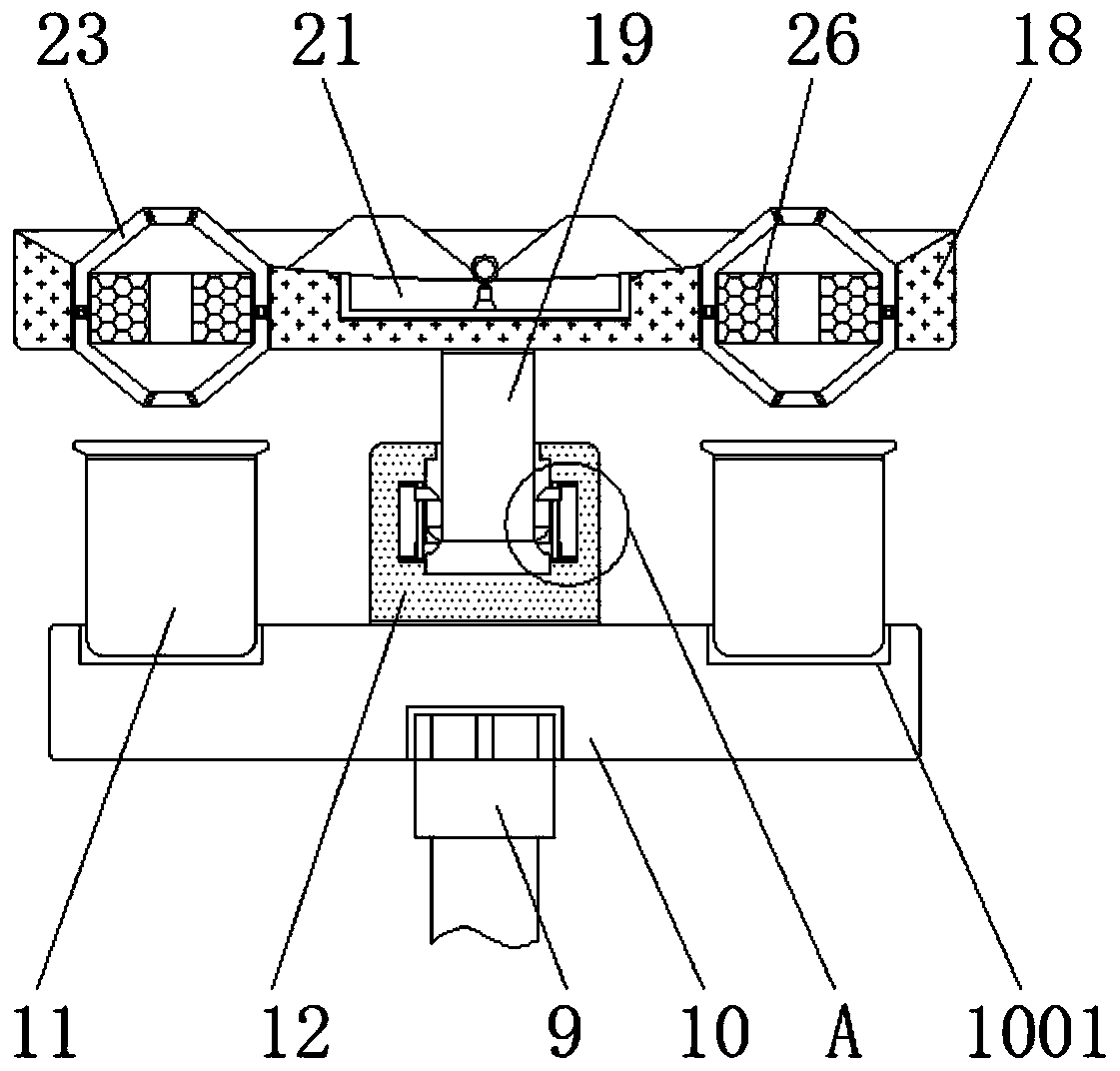

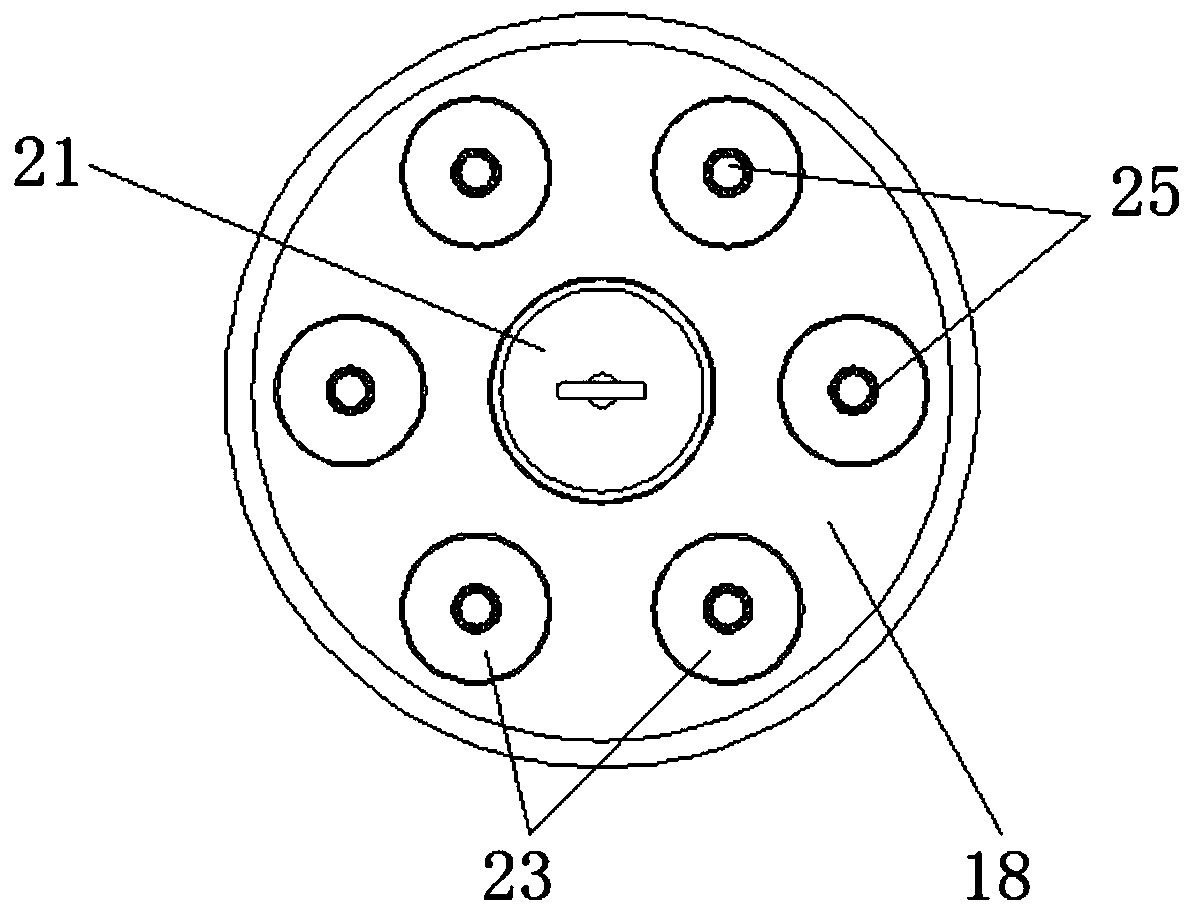

The invention relates to a vacuum panel sucking and hoisting crane. The vacuum panel sucking and hoisting crane comprises a rack, a walking mechanism, a hoisting mechanism and a vacuum chuck group, wherein the walking mechanism comprises a linear guide rail and a movable machine head, the linear guide rail is horizontally arranged on the rack, the movable machine head is capable of linearly reciprocating on the linear guide rail through a gear and a rack, the hoisting mechanism is arranged in the movable machine head and is capable of moving up and down relative to the movable machine head, a cross beam is arranged at the lower part of the hoisting mechanism, a panel detection sensing probe is connected to the cross beam through a detection rod, and a plurality of vacuum chucks are arranged on the cross beam. The vacuum panel sucking and hoisting crane provided by the invention is especially suitable for sucking and hoisting of stainless steel, and can be applied to feeding of a veneer reeling machine, thereby reducing heavy labor of manual carrying, and ensuring undamaged carrying of panels; meanwhile, through transmission of signals between upstream equipment and downstream equipment, unattended operation can be realized, and the labor is maximally saved; the vacuum sucking and hoisting crane has the characteristics of high efficiency, safety, rapidness, and labor saving.

Owner:JIANGSU CHANGCHENG ARCHIVES EQUIP

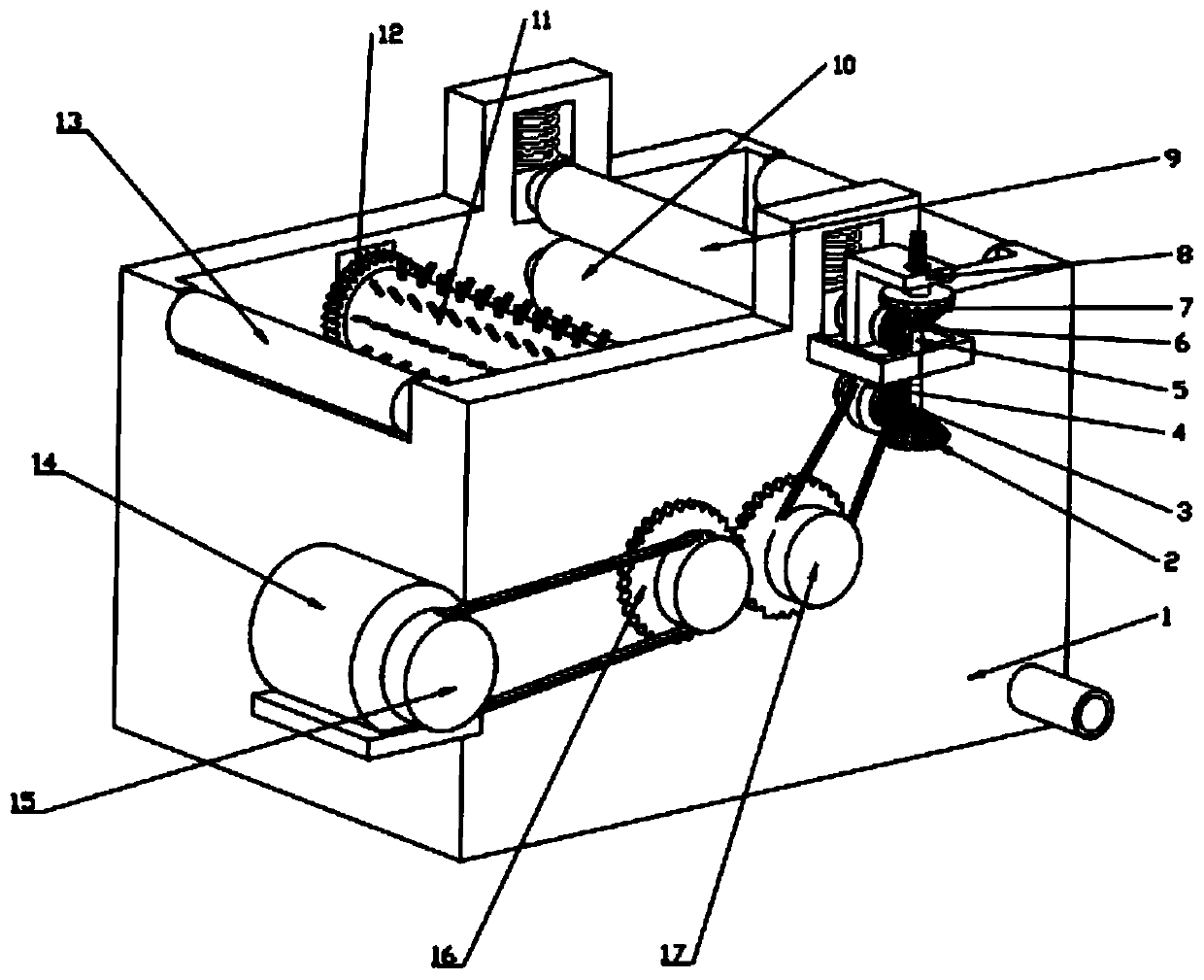

Double-crushing type civil paper shredder

InactiveCN108654779AReduce the number of installationsImprove confidentialityGrain treatmentsGear wheelPulp and paper industry

The invention discloses a double-crushing type civil paper shredder. The double-crushing type civil paper shredder comprises a paper shredder body, a paper inlet is formed in the top end of the papershredder body, two rubber roller shafts are movably arranged in the positions, located at the lower end of the paper inlet, in the paper shredder body, two paper shredding hobs are movably arranged atthe lower ends of the two rubber roller shafts correspondingly, a center shaft of one paper shredding hob is fixedly connected with the driving end of a motor, a driving gear is fixedly arranged on the outer side of the driving end of the motor, and a transmission gear is movably meshed on the driving gear. According to the double-crushing type civil paper shredder, waste paper is preliminarily crushed by the two paper shredding hobs which roll oppositely, one paper shredding hob is driven by the motor, the other paper shredding hob can freely rotate, furthermore, one rubber roller shaft is driven to rotate through a gear transmission structure, and the other rubber roller shaft can freely rotate, so that the number of the motors to be installed is reduced; and when the waste paper crushed by the paper shredding hobs enters a secondary crushing box, secondary crushing is carried out on preliminarily crushed paper strips by a high-speed rotating crushing device.

Owner:MINNAN INST OF SCI & TECH

Finger base joint transmission mechanism of dexterous robot hand with adjustable pre-tightening and transmission inter space

InactiveCN101327594AReasonable force balance effectSimple structureGripping headsRobot handGear wheel

Owner:HARBIN INST OF TECH

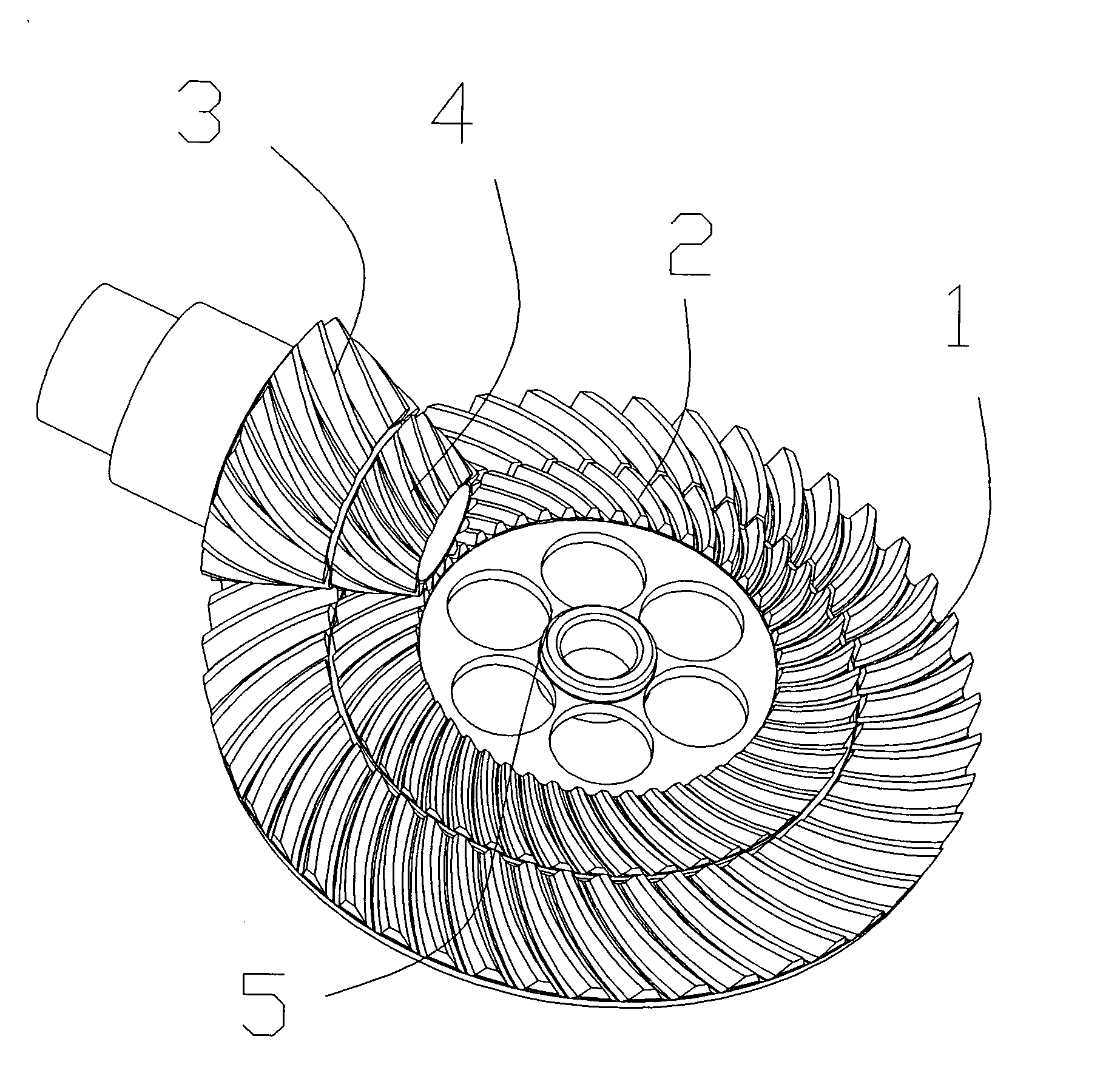

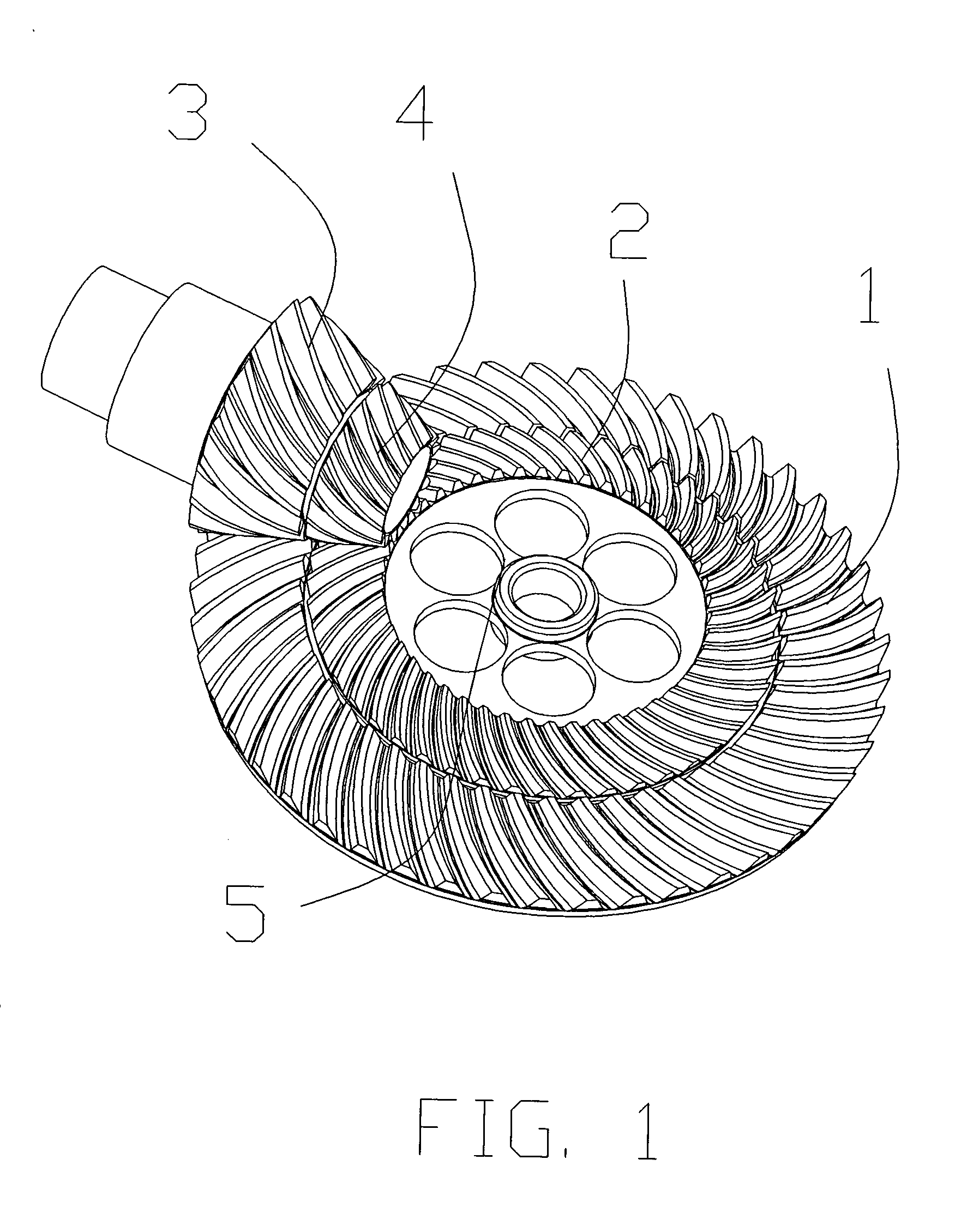

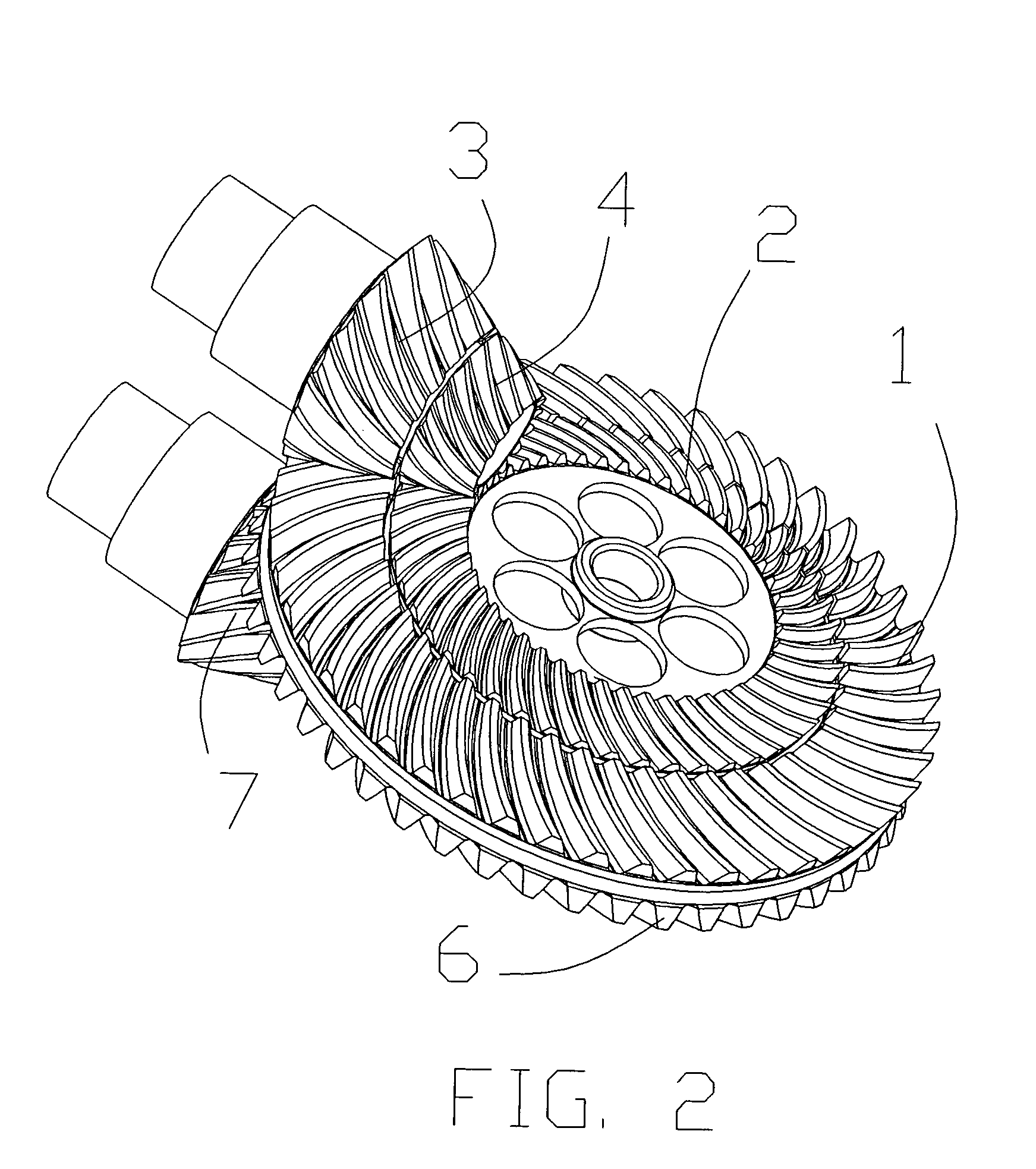

Gear configuration operable in various angles

A gear configuration allows force (torque) coming from a drive shaft to be transmitted to a driven shaft through two hemispherical gears that are placed at the end of the shafts and touch each other in variable, but constantly equal distance from the poles. This constant equal distance from the poles can be maintained through synchronization gears that are positioned against each other on both sides of U-shaped elements. These U-shaped elements also keep the shafts in position, where each U-shaped element on each of the shafts are connected by a ring formed hinge element, consequently keeping the hemispheres in connection

Owner:URGENC HASAN GOZDER

Energy Generation Method and Apparatus by the Harnessing of Centrifugal Force

An energy generation apparatus uses centrifugal force to generate energy in a controlled manner. The apparatus includes a dual function input shaft and output shaft rotatably attached to opposite sides of a housing defining an axis of orbit, an output gear fixed upon the output shaft, an input sprocket rotatably mounted on the output shaft, and at least two frame gear assemblies, each having a frame gear and at least two weight gears. The frame gears rotate about their centres and also orbit around the output gear in response to an input from the input sprocket.

Owner:LEVINY GEOFFREY WILLIAM GOOD

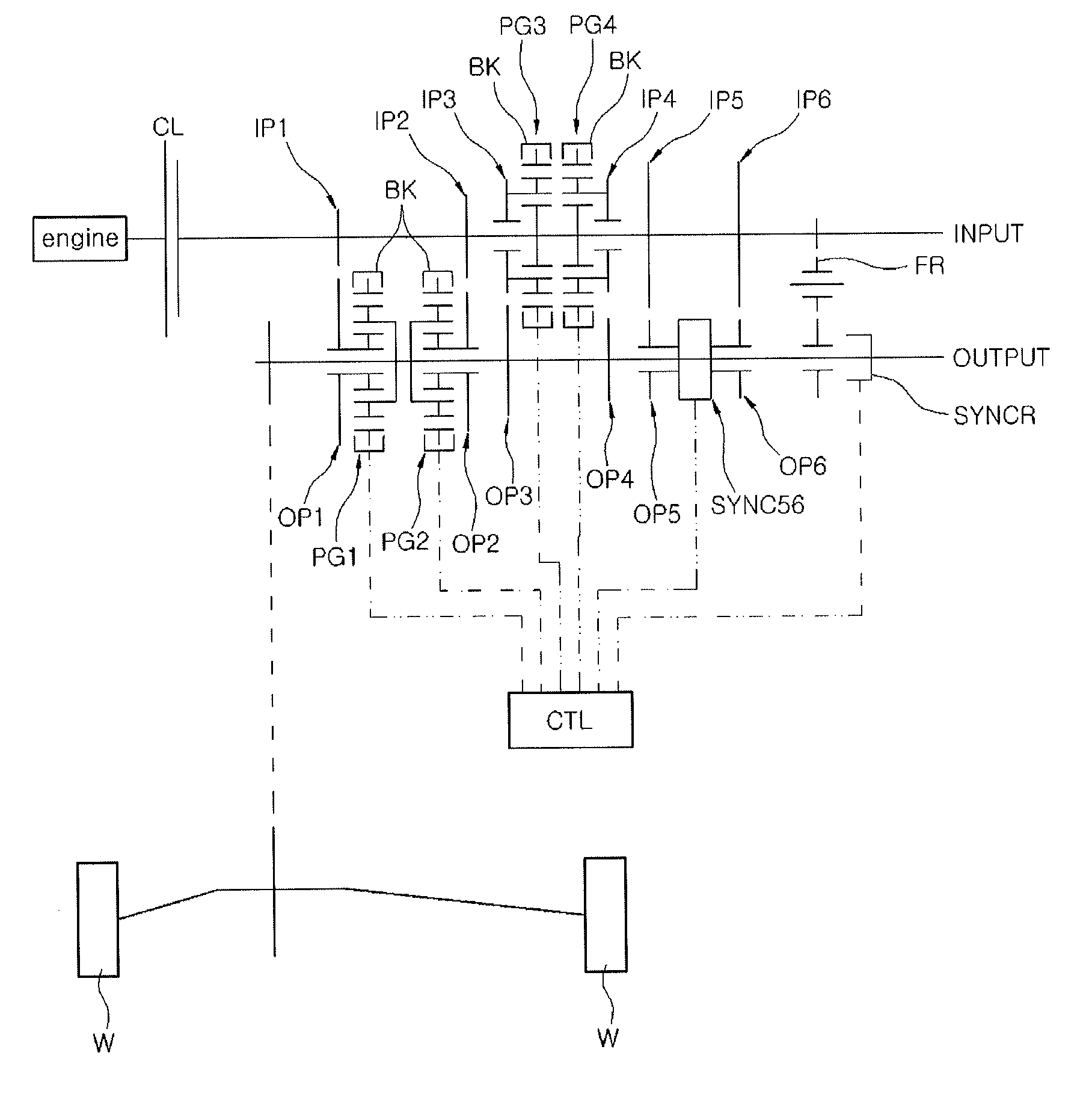

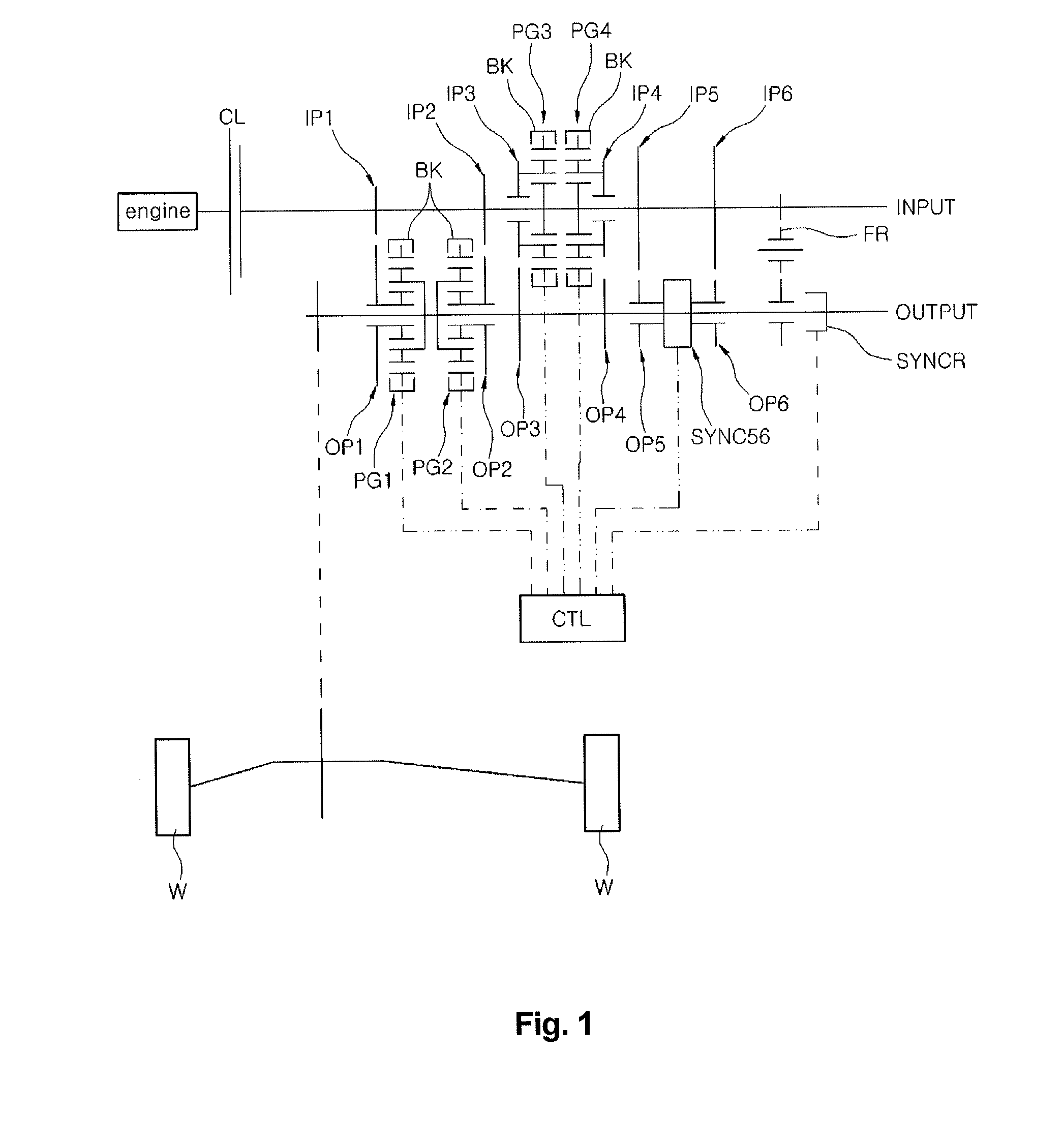

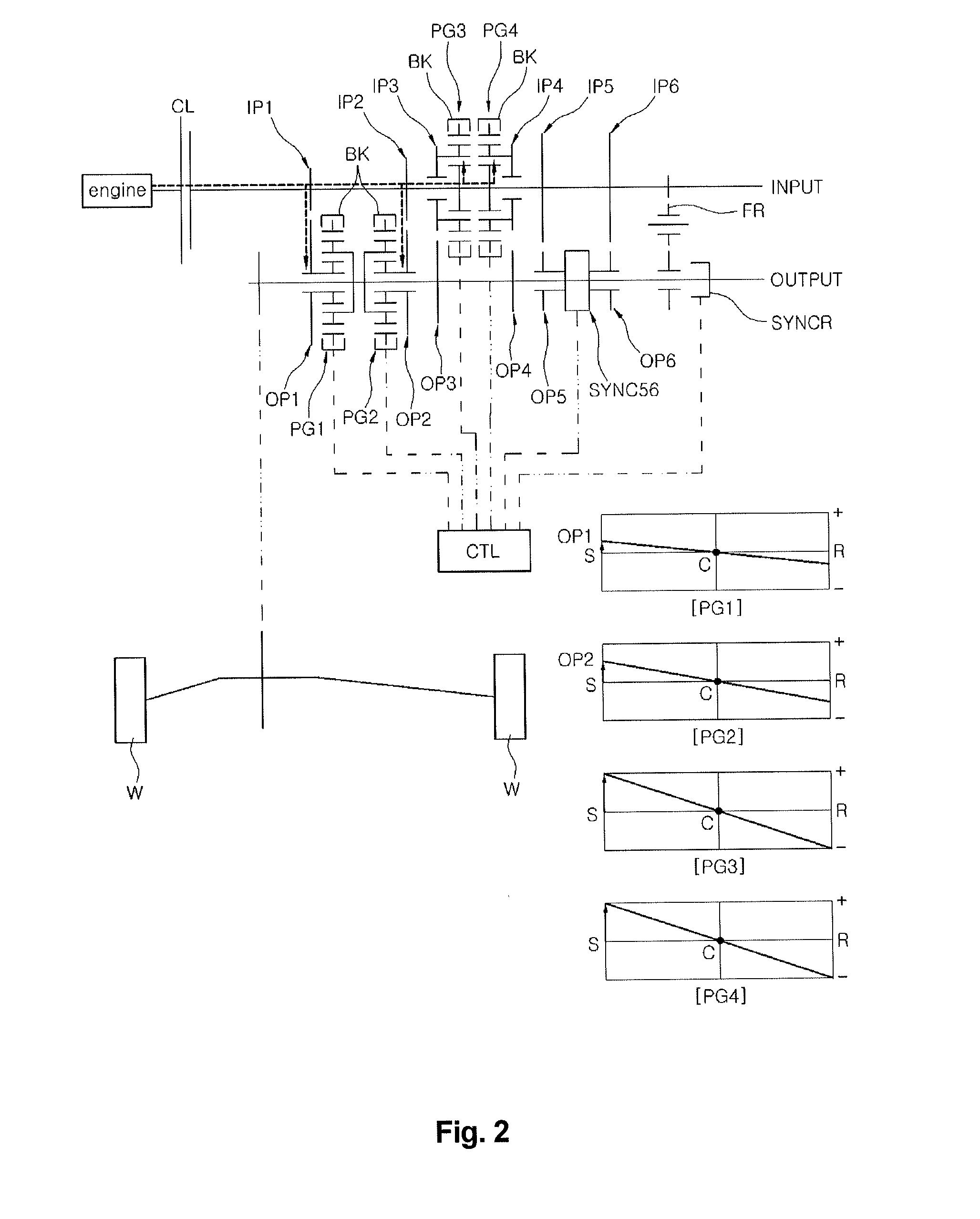

Automated manual transmission for vehicle

ActiveUS20140371022A1Smooth and reliable gear shift sensationImprove marketabilityToothed gearingsGearing controlGear wheelEngineering

Owner:HYUNDAI MOTOR CO LTD

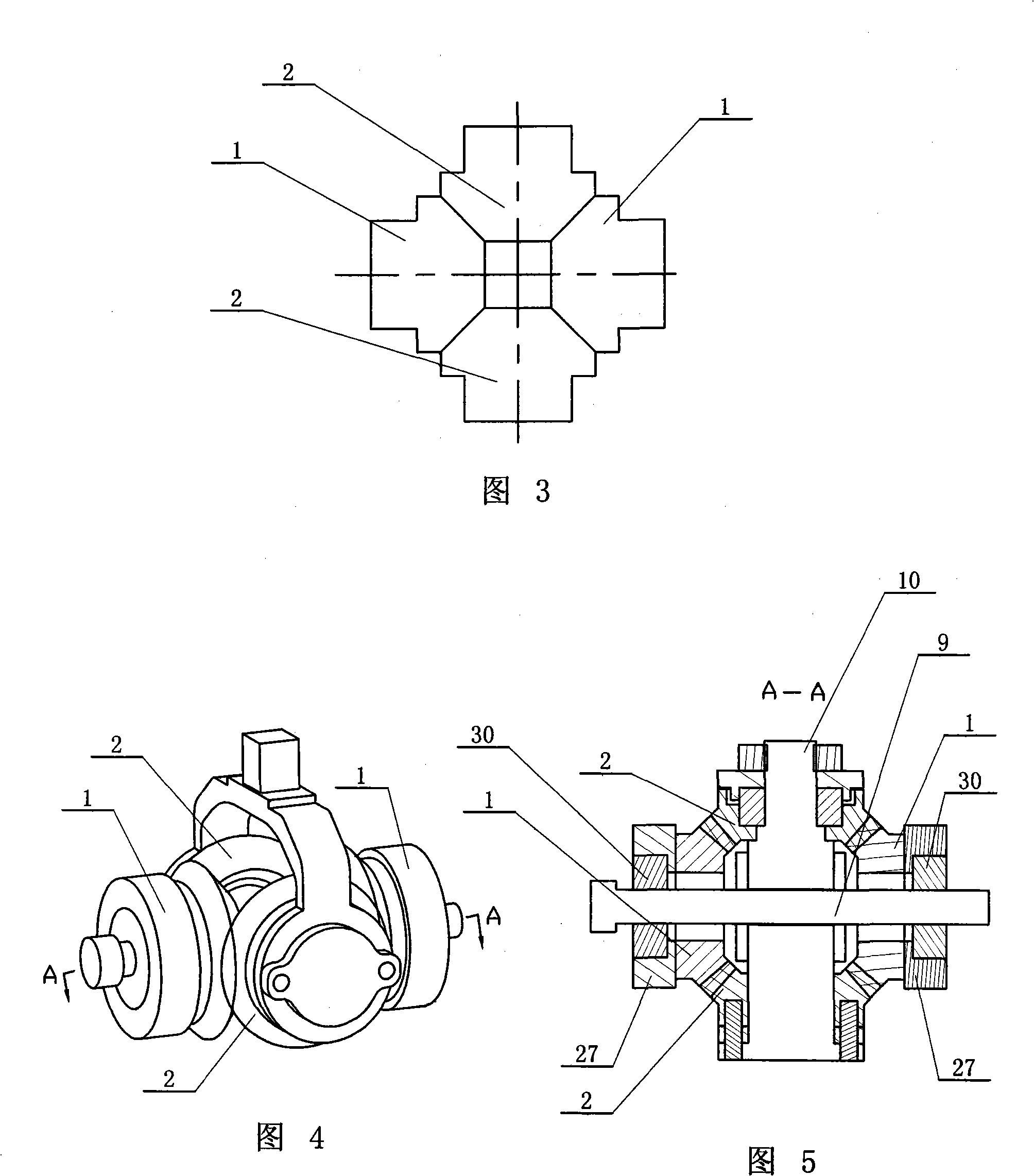

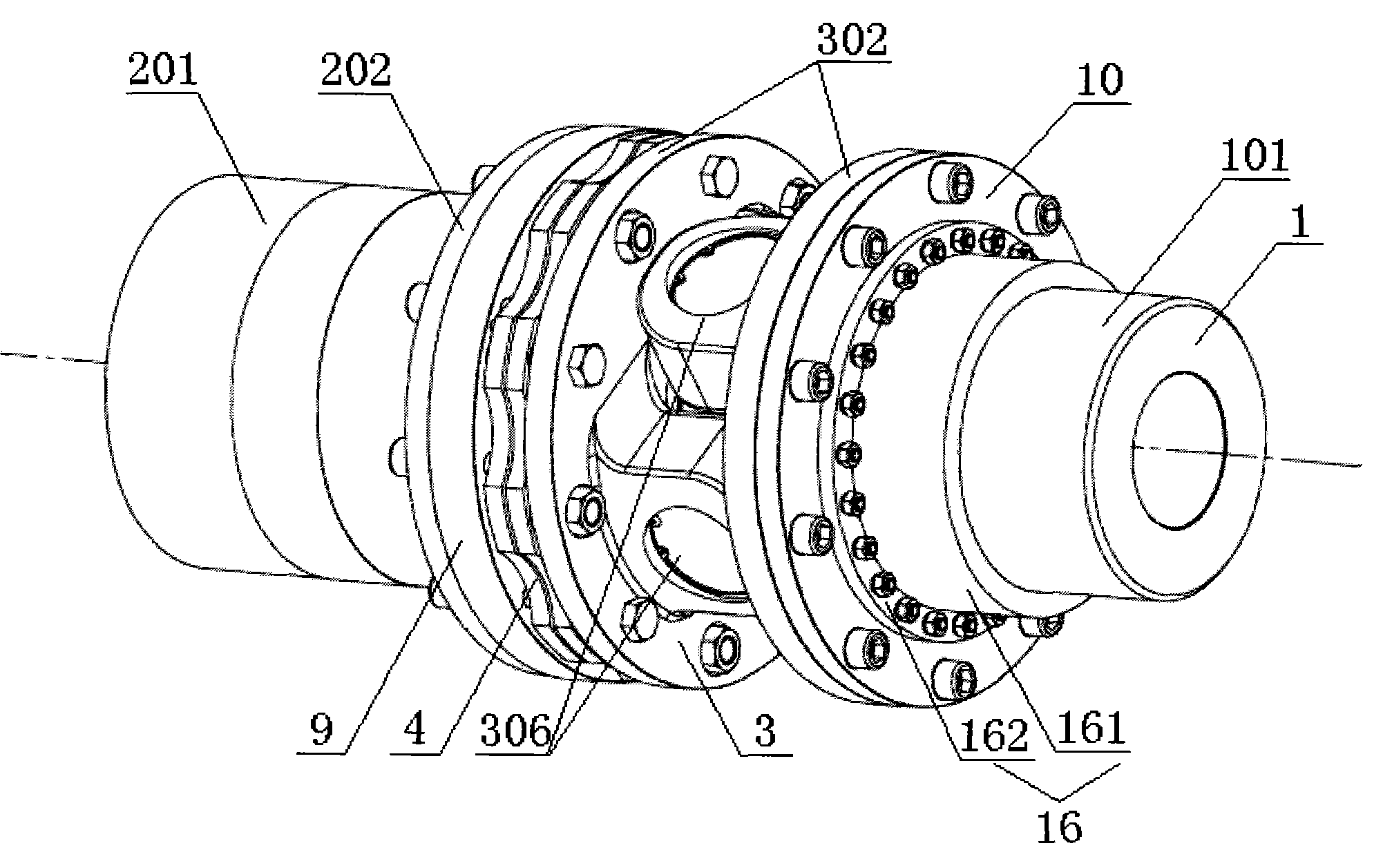

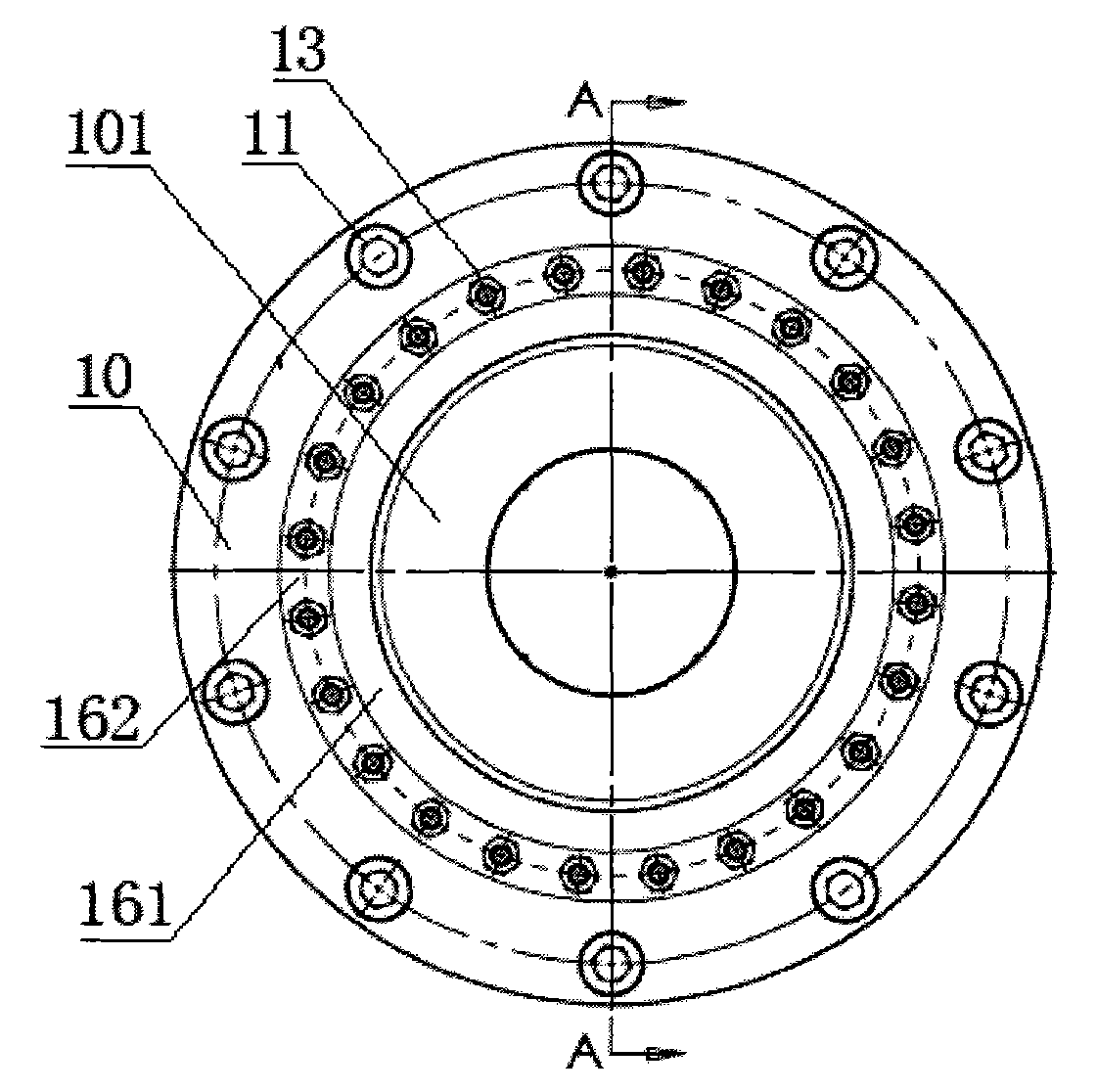

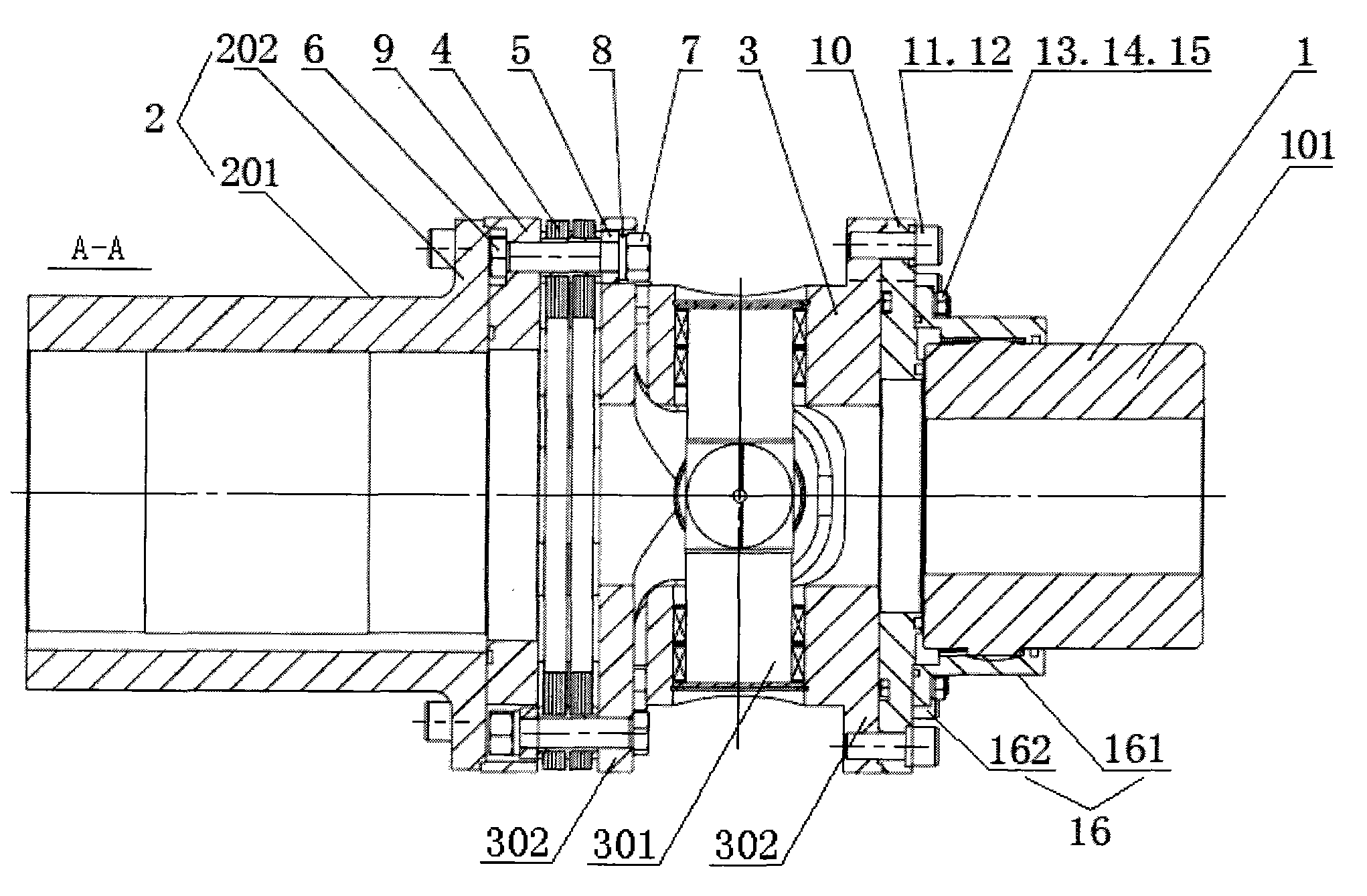

Drum-gear angular flexible coupling

InactiveCN102162491AExtended service lifeGuaranteed uptimeYielding couplingBearing componentsGear wheelCoupling

Owner:李文聪

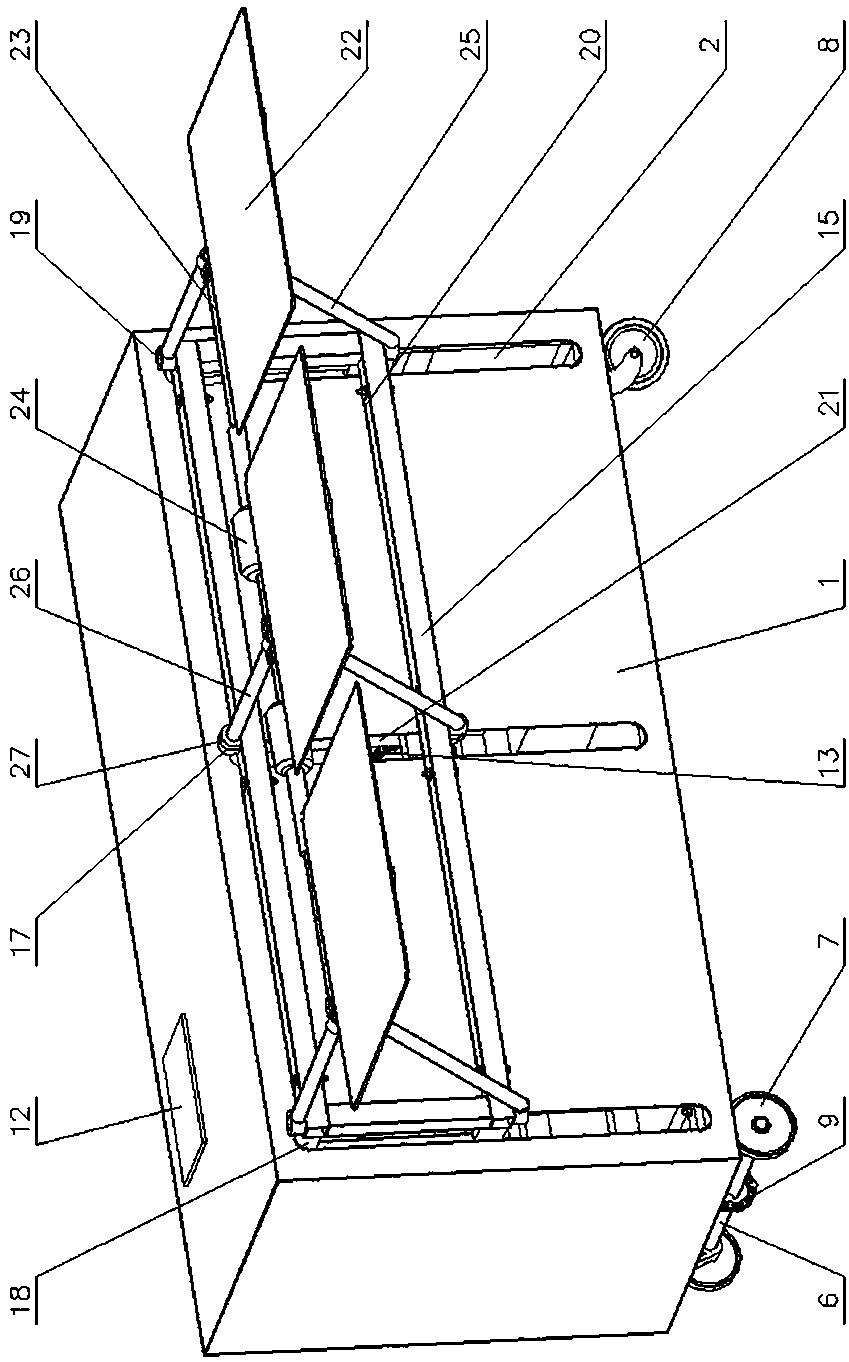

Turnover transport vehicle with limiting mechanism

InactiveCN111661120AShorten the timeImprove turnover efficiencyHand carts with multiple axesHand cart accessoriesPush and pullElectric machine

Owner:何红侠

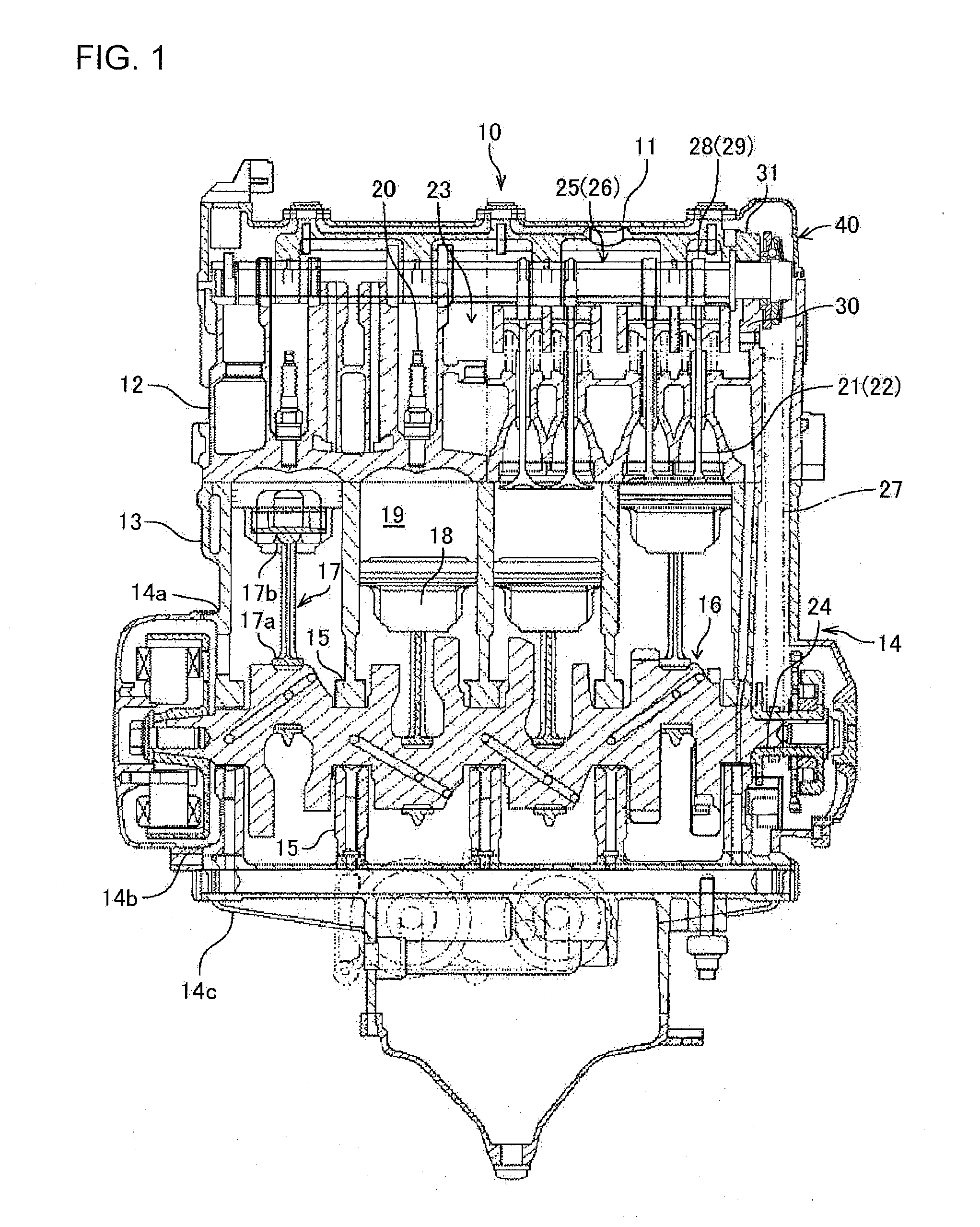

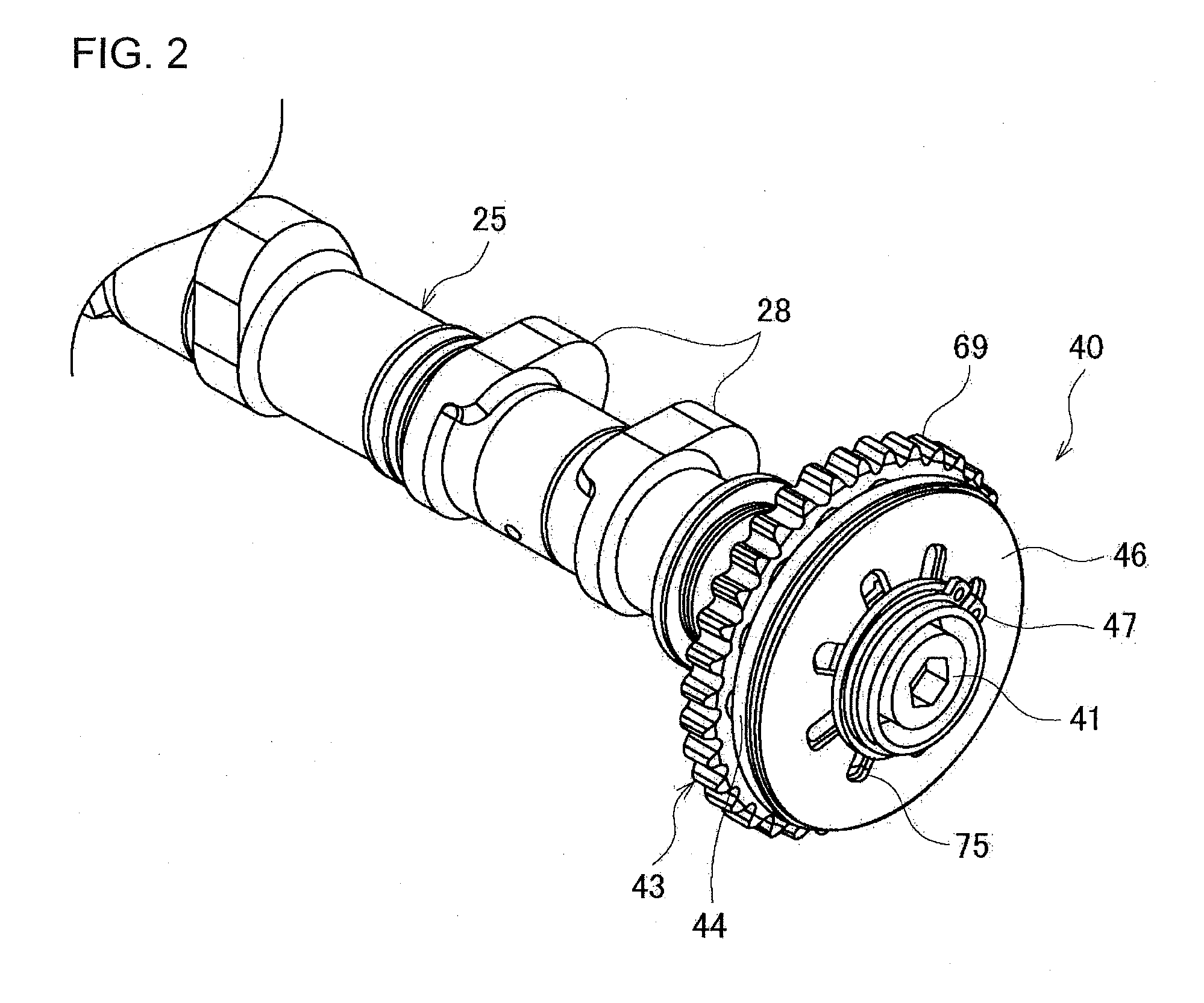

Valve gear for engine

ActiveUS20160010517A1Excellent abrasion resistanceEasy to replaceValve camshaftsMachines/enginesGear wheelEngineering

Owner:SUZUKI MOTOR CORP

Wheelchair device with assistant function

ActiveCN101816604ASmooth downDifficult to disperseWheelchairs/patient conveyanceGear wheelWheelchair device

The invention relates to a wheelchair device with an assistant function. The wheelchair device comprises a side frame group containing two side frames, two stand pipes, a console group containing two consoles, a deployment mechanism, at least one driving gear group and at least one transmission gear, wherein a front cross rod is pivoted between the two side frames, each side frame is provided with a wheel set; the two stand pipes are separately arranged in sleeves, each stand pipe contains a rack division; the two consoles are arranged above the side frame group, the front end of the console group is pivoted with the side frame group, a back cross rod is pivoted between the two consoles; the two ends of the deployment mechanism are separately connected with the front and back cross rods in a transmission manner; the driving gear group is arranged on the front of the side frames and linked with the front cross rod; and the transmission gear is pivoted on the front end of the side frames. By using the wheelchair device of the invention, when two lifting arms move up, the two stand pipes can move down so that the applied force on the stand pipes can not be easy to disperse in the driving process, the two stand pipes can move down smoothly and the safety of the wheelchair device with the assistant function can be increased.

Owner:LLOYD LINDEN INC

Mechanical arm of shooting videos automatically

InactiveCN111730610AAchieve the purpose of photographyEasy to useStands/trestlesCamera body detailsRobotic armElectric machine

The invention discloses a mechanical arm of shooting videos automatically. The mechanical arm primarily comprises a base, wherein a first through hole is formed in on side of the top end of the outersurface of the base; a second through hole is formed in the side, far away from the bottom end of the outer surface of the first through hole, of the base, and a first motor is fixedly connected to the bottom end of the outer surface of the base. A gear bank is used to drive a rotating box to rotate, so that the device can achieve a purpose of shooting at 360 degrees. A lead screw nut in the rotating box is used to drive a mounting plate to move up and down to achieve a purpose of shooting articles at different heights. Meanwhile, a motor is used to drive a camera mounting box to rotate so asto achieve a purpose of rotating the shooting direction of a camera. The mechanical arm is simple in integral structure and relatively small in moving range, can achieve a purpose of shooting within arelatively small space, and is conveniently used by a user, so that the mechanical arm solves the problem that the mechanical arm is inconveniently used by the user as the mechanical arm is complex in structure and large in moving space.

Owner:ZHENGZHOU SHANGHANG TECH CO LTD

Lifting type bedridden patient transfer robot

Owner:淄博科创医疗仪器有限公司

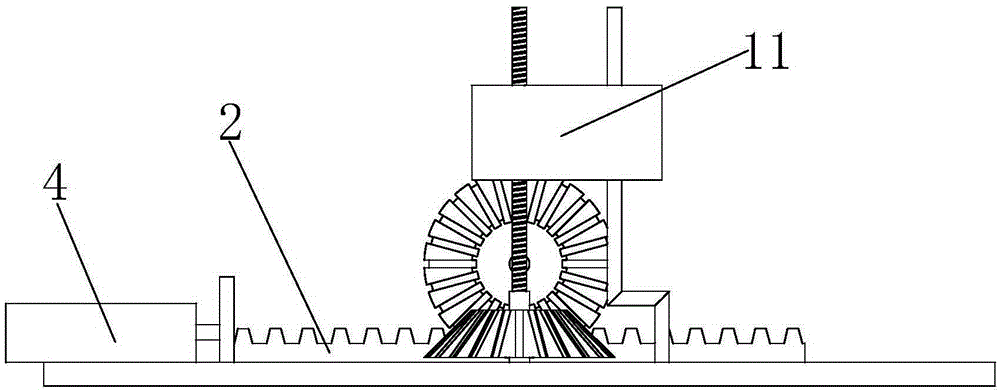

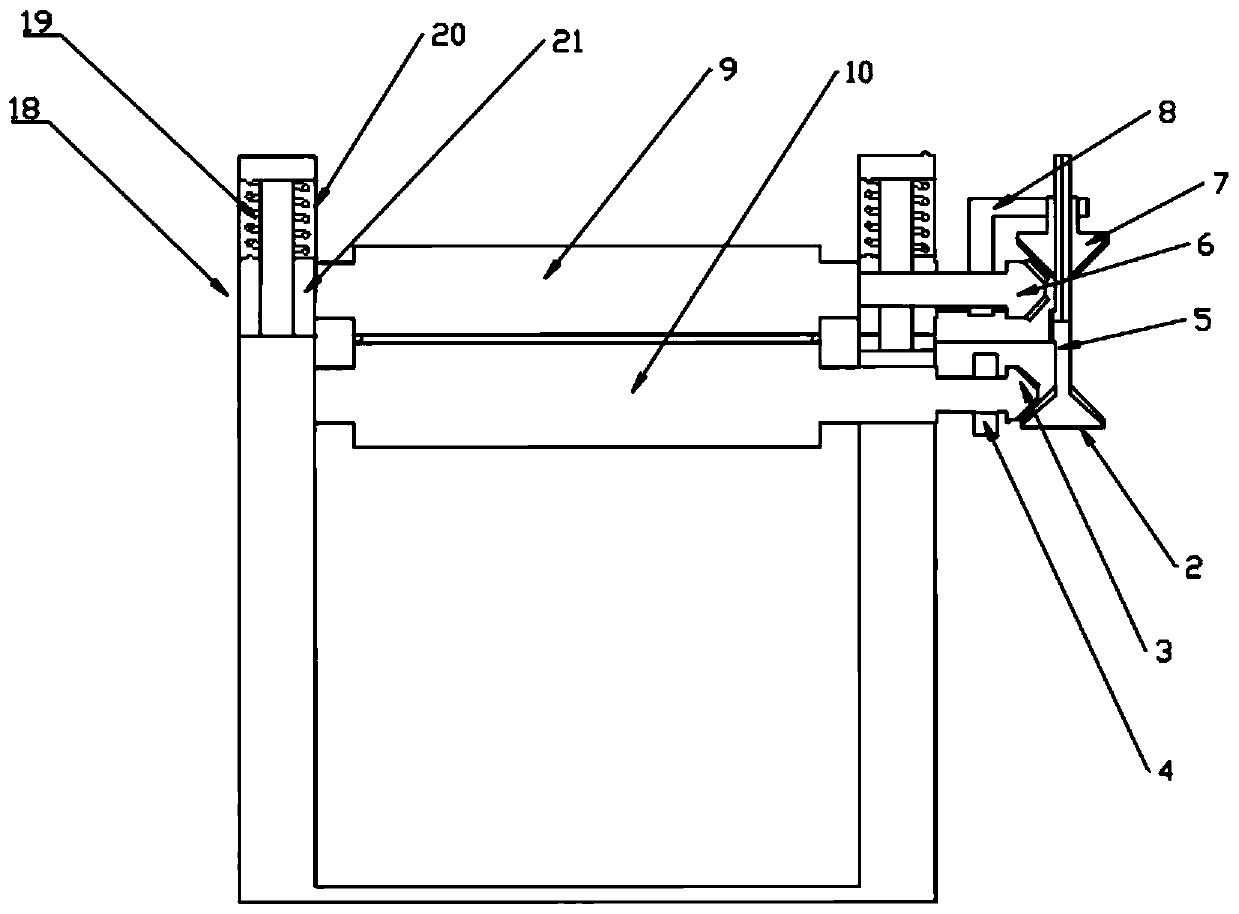

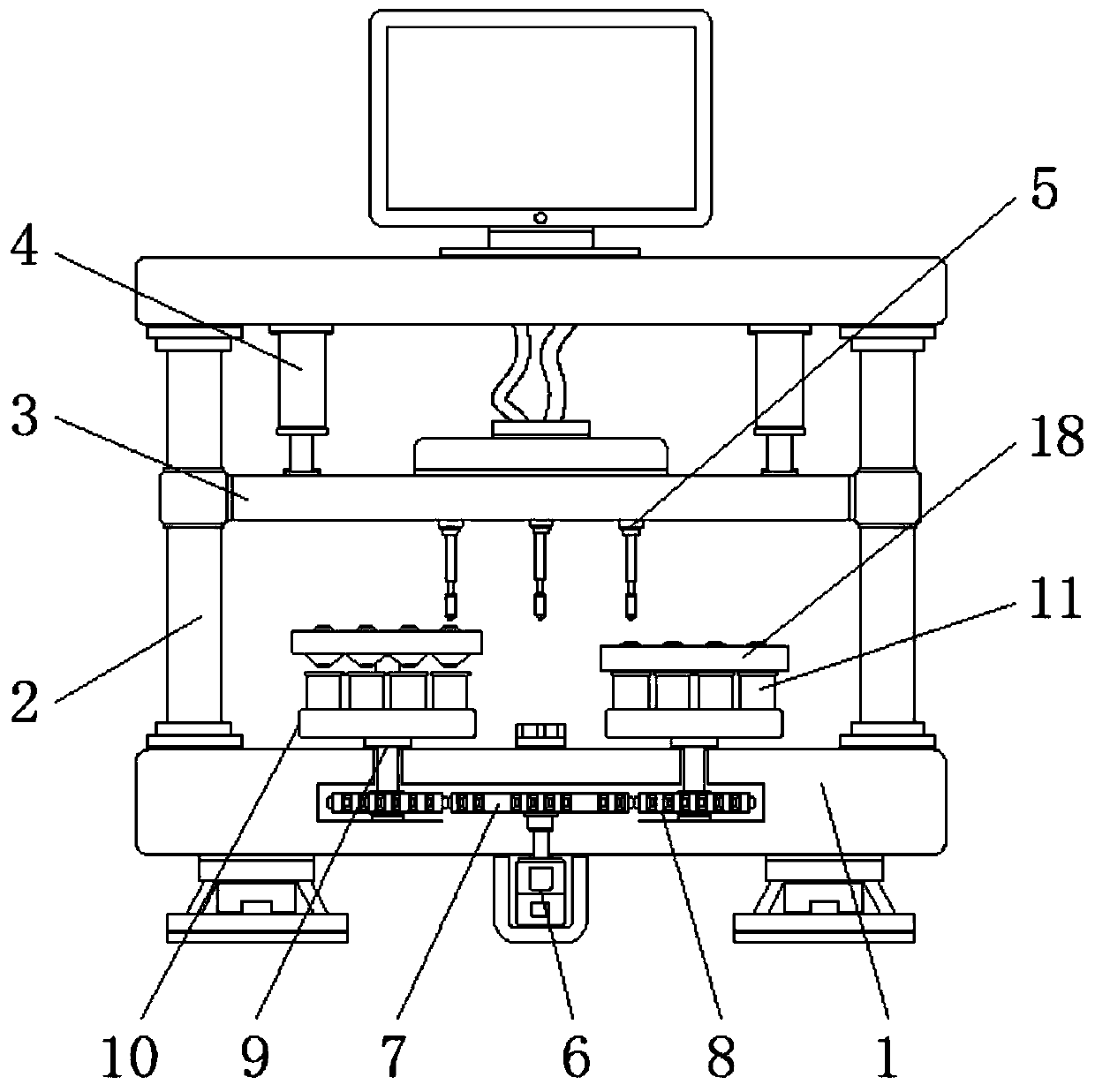

Supporting plate feeding system of numerical-control scraping rolling machine

InactiveCN112476011AAssisted movementReduce the impact of movementFeeding apparatusMaintainance and safety accessoriesGear wheelControl engineering

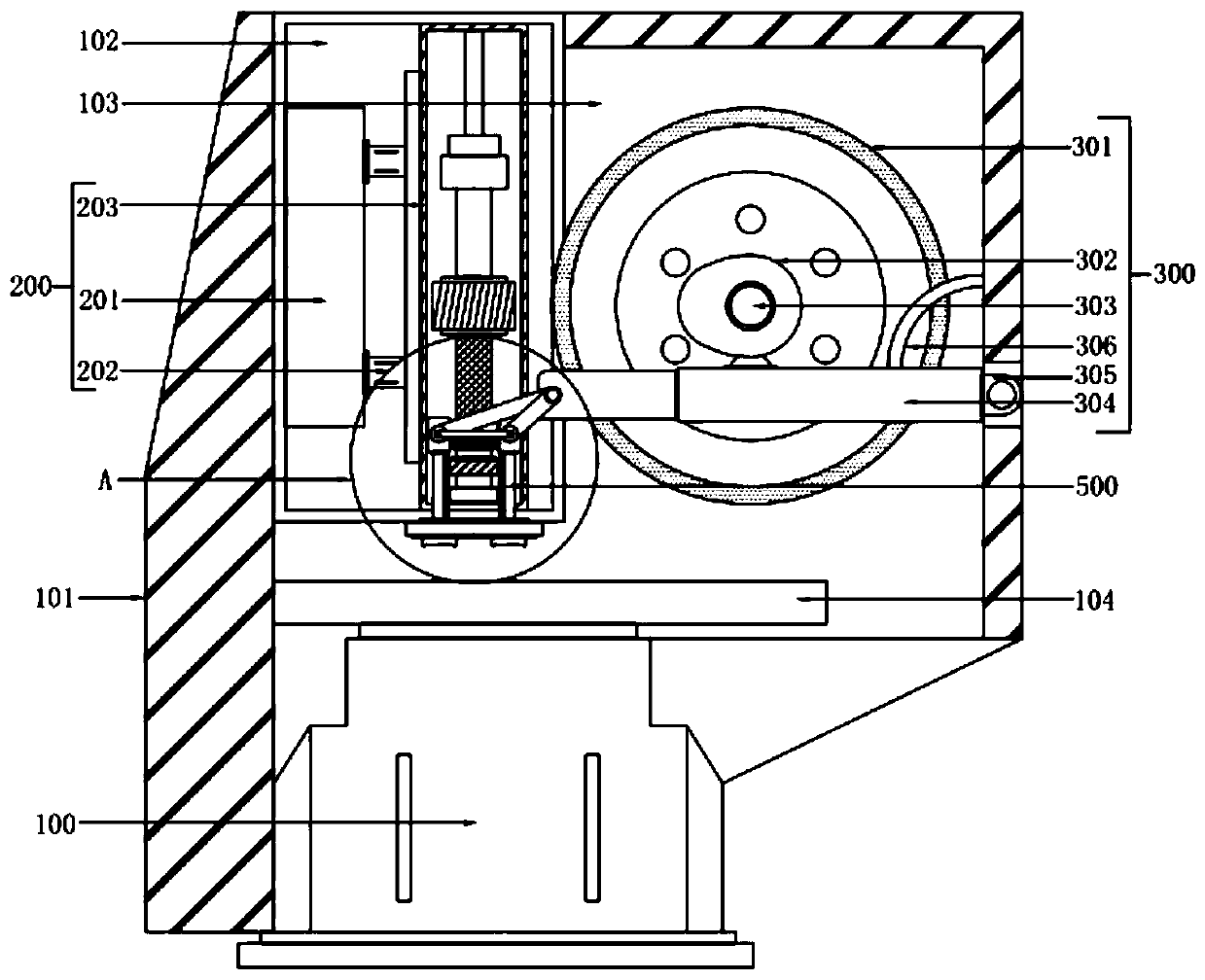

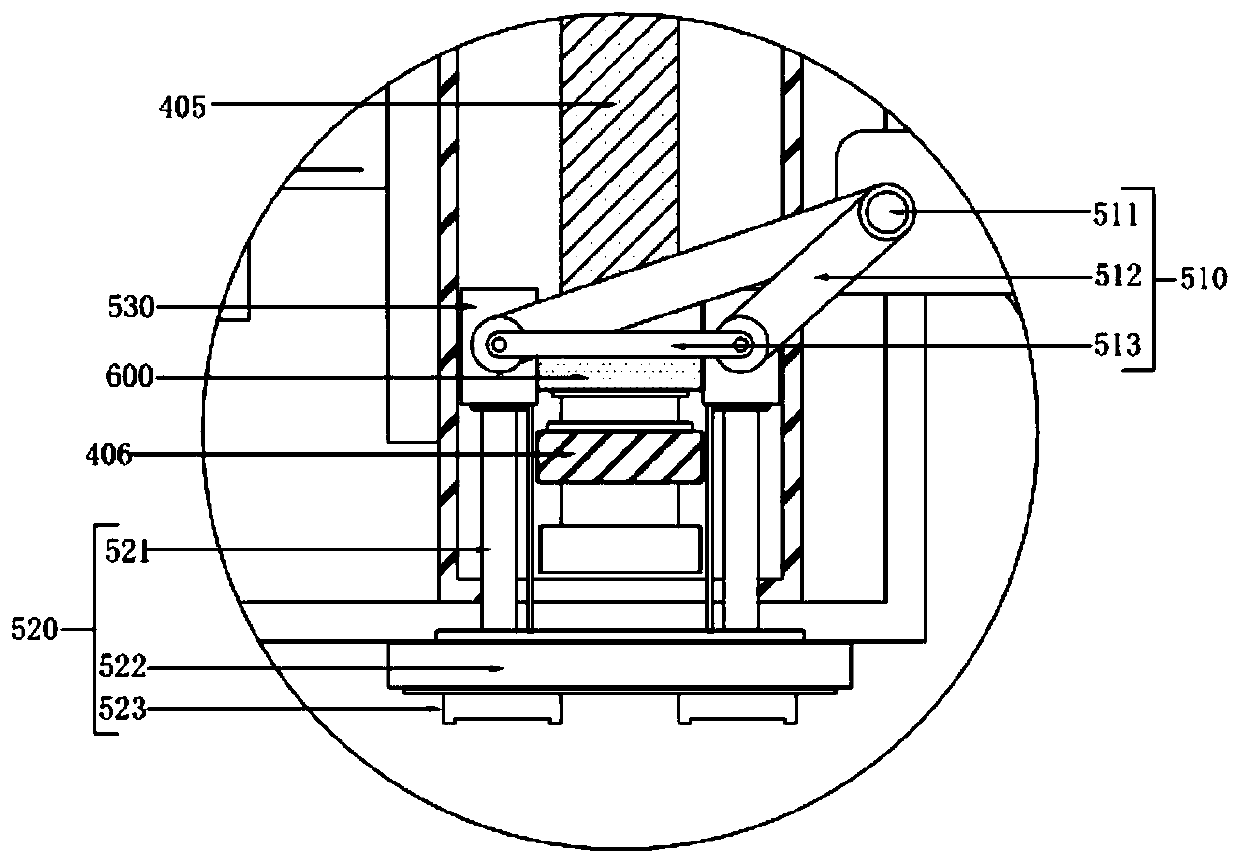

The invention relates to the technical field of oil cylinder machining, and discloses a supporting plate feeding system of a numerical-control scraping rolling machine. The supporting plate feeding system comprises a rack, wherein guide rails are fixedly mounted on the left side and the right side of the top end of the rack, fixed frames are movably mounted at the top ends of the guide rails, andracks are fixedly mounted at the ends, close to each other, of the two guide rails; and fixed seats are fixedly mounted on sides of the back surfaces of the fixed frames. According to the supporting plate feeding system of the numerical-control scraping rolling machine disclosed by the invention, the bottom ends of the output shafts of servo motors are fixedly sleeved with the gears, the racks arearranged on the side surfaces of the guide rails and connected to the gears in a meshed mode; and when the fixed frames need to be moved, the gears at the bottom ends of the servo motors can be driven to rotate at the moment by starting the servo motors; the gears can be driven by the racks to move relative to the guide rails and drive the fixed frames to move relative to the guide rails, so thatthe influence of sliding friction on movement of the fixed frames is reduced, and therefore, the advantage of assisting movement of the fixed frames is achieved.

Owner:LOUDI DINGLI HYDRAULIC TECH CO LTD

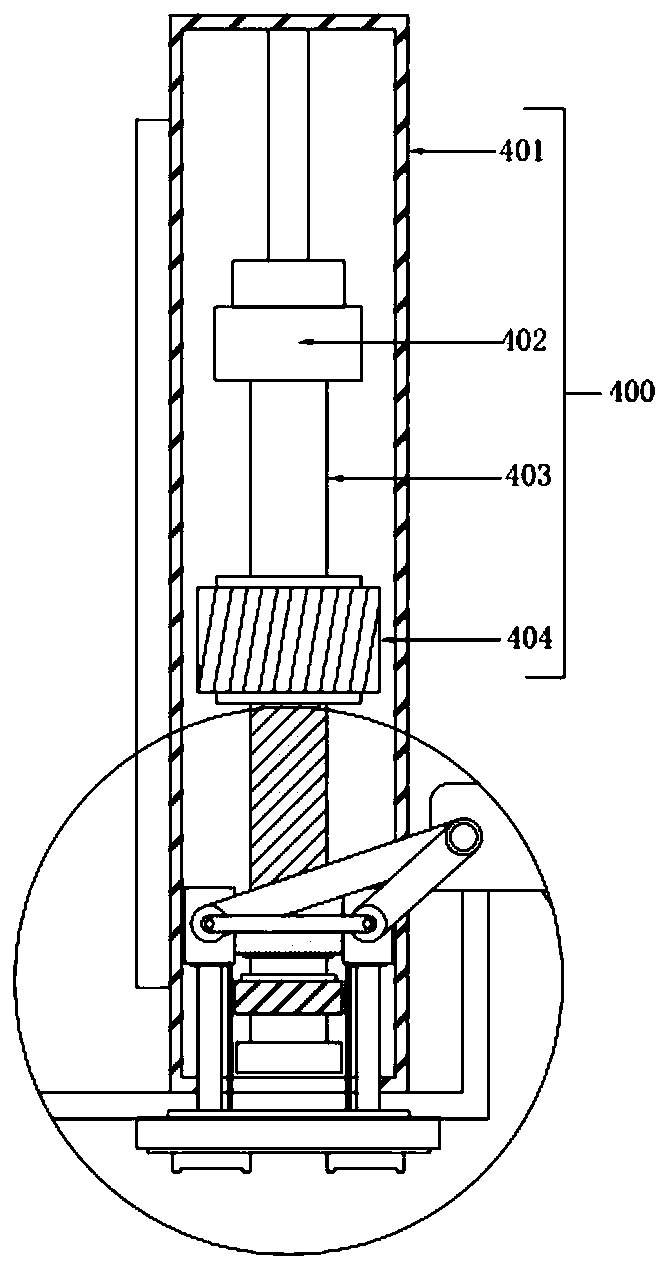

Planetary gear train built-in construction winch device

Owner:ANHUI KUDZUVINE ROOT PRODUCTIVITY PROMOTION CENT CO LTD

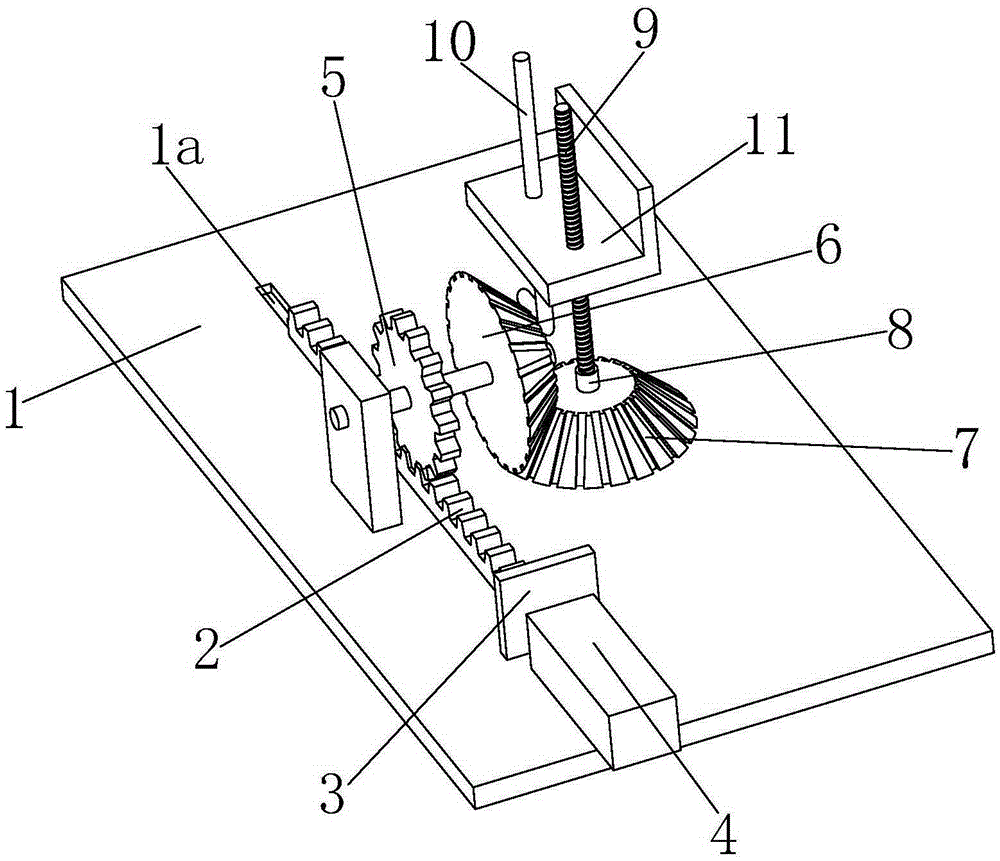

Cloth feeding mechanism for eyelet button hole sewing machine

ActiveCN106436045AEnsure safetyGuaranteed stabilityWork-feeding meansSewing-machine control devicesGear wheelPinion

The invention relates to a cloth feeding mechanism for an eyelet button hole sewing machine. The cloth feeding mechanism for the eyelet button hole sewing machine comprises an electric motor (1), a pinion (2), a gear wheel (3), a gear shaft (4) and a cloth feeding table (5); an output shaft of the electric motor (1) is fixedly connected with the pinion (2); the gear wheel (3) is in engaged transmission connection with the pinion (2); engaging teeth which can be in engaged transmission connection with the engaging teeth of the gear wheel (3) are formed on the gear shaft (4); the engaging teeth on the gear shaft (4) are in engaged transmission connection with the engaging teeth on the gear wheel (3) to drive the gear shaft (4) to move; one end of the gear shaft (4) is connected with the cloth feeding table (5). According to the cloth feeding mechanism provided by the invention, the cloth feeding table is driven to move and perform a cloth feeding operation by adopting the engaged transmission between the pinion and the gear wheel and the mode of driving the gear shaft to move; the service life is greatly prolonged; the cloth feeding mechanism is durable in use.

Owner:闫瑞东

Multi-lock two-unlocking locking device and equipment

The invention discloses a multi-lock two-unlocking locking device and equipment. The locking device comprises an input gear, an output gear, N lock bodies, N x (N-1) / 2 first clutch gears, N x (N-1) / 2 second clutch gears, a first clutch group, a second clutch group and a lock body driving group. The input gear is connected with the input shaft. The output gear is connected with an output shaft. The lock bodies are connected with the first clutch gears and the second clutch gears through N-1 driving parts. And the first clutch gears and the second clutch gears are correspondingly arranged on N * (N-1) / 2 clutch shafts. And the first clutch gears and the second clutch gears are correspondingly provided with a separation position and a meshing position on the clutch shaft. When the lock bodies are in the closed state, the first clutch gears or the second clutch gears connected with the lock bodies move to the separation position. When the lock bodies are in the open state, the first clutch gears and the second clutch gears which are connected with the lock bodies move to the meshing position. Therefore, the locking device can be opened as long as any two locks are opened.

Owner:NANJING EASTHOUSE ELECTRIC CO LTD

Screw rubber extruder for cable production

InactiveCN112026134AImprove practicalityAvoid the impact of product qualityDomestic articlesReciprocating motionSpiral blade

The invention relates to the technical field of cable production, and discloses a screw rubber extruder for cable production; the screw rubber extruder comprises a bottom plate; universal wheels are fixedly connected to the lower surface of the bottom plate; first brackets are fixedly connected to the left and right sides of the upper surface of the bottom plate; and conveying cylinders are fixedly connected to the inner walls of the first brackets. According to the screw rubber extruder for cable production, a heating wire, a stirring motor, a first cross rod, a second rotating shaft, a second cross rod and a third rotating shaft are arranged, so that a first gear can conveniently and effectively do reciprocating motion by taking the circle center of a first circular shaft as the center,a second gear can conveniently and effectively drive a second circular shaft and a stirring roller to do reciprocating motion to stir the material, heat is concentrated, the material is stirred to enable the material to be more uniformly and finely, the influence on the product quality due to the fact that the materials are adhered to the conveying cylinder and a spiral blade in the working process is avoided, and the practicability of the extruder is greatly improved.

Owner:HENGYANG SOUTH CHINA ELECTRIC WIRE CO LTD

Medicine detection device facilitating classified arrangement of medicines

PendingCN111458469AEasy to sortPlay a limiting roleTesting medicinal preparationsGear wheelElectric machinery

Owner:青海省药品检验检测院

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap