Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

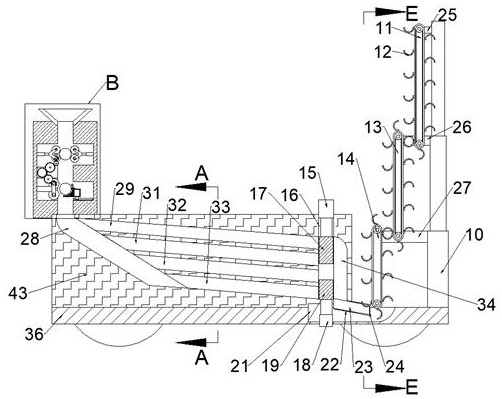

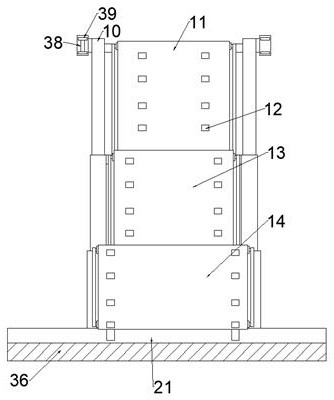

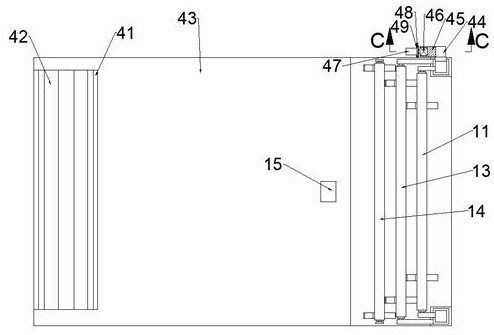

Jacking pipe cutting protective structure for building remains and construction method thereof

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +2

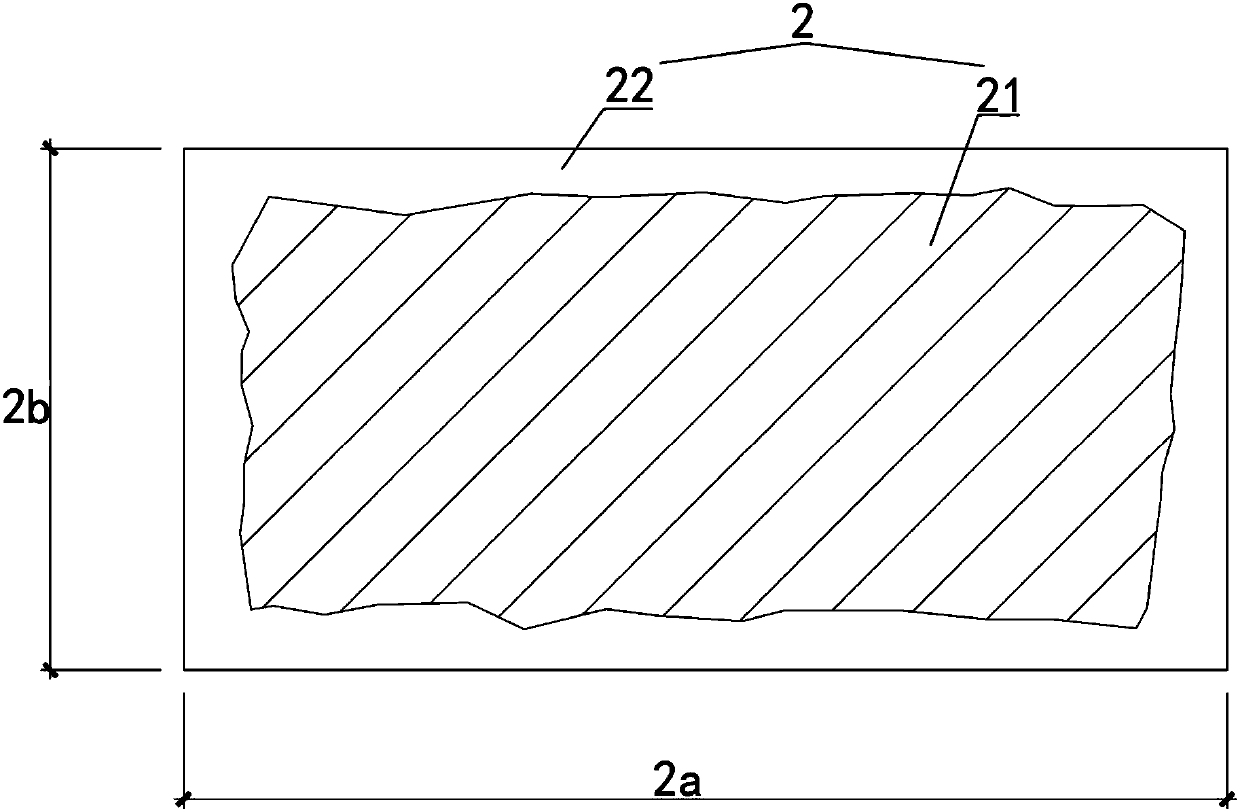

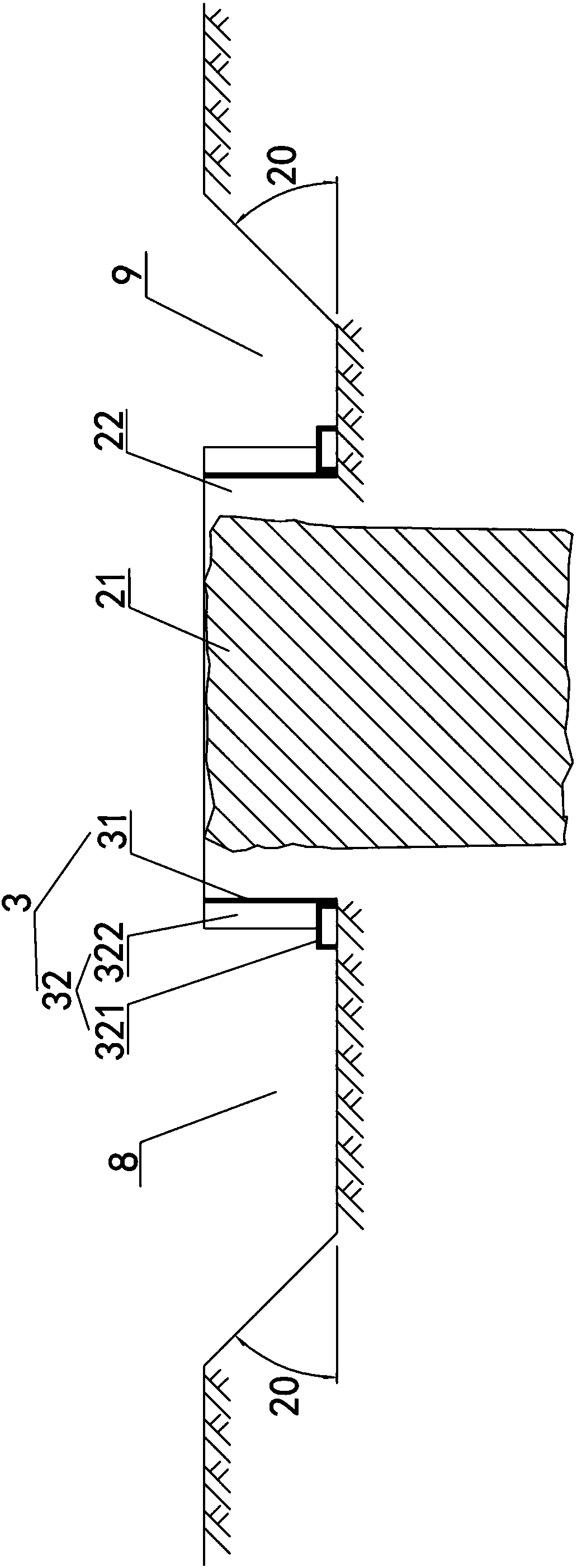

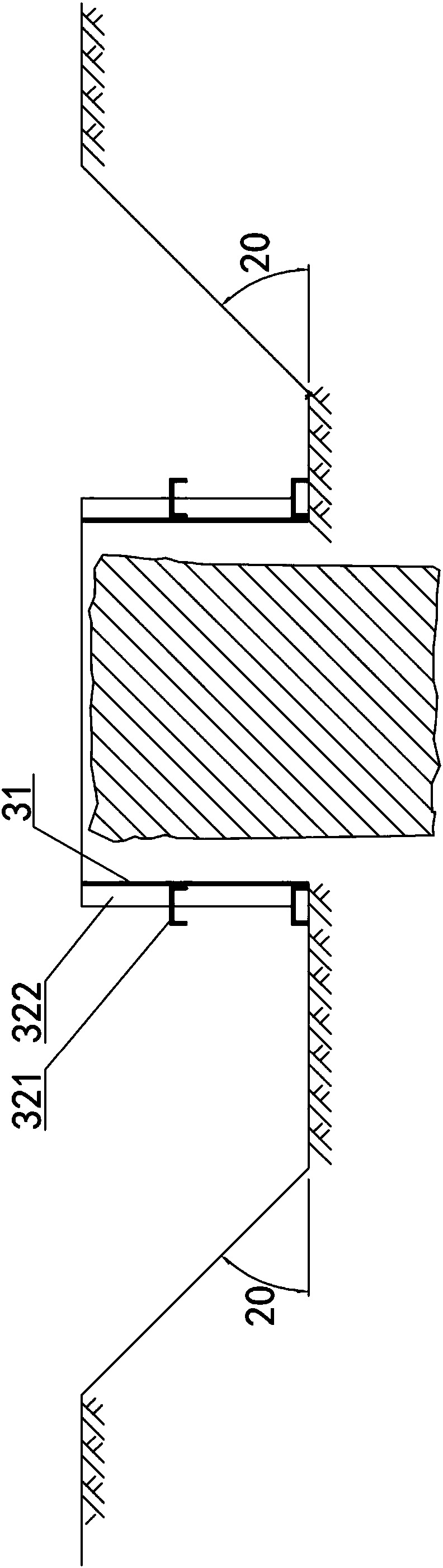

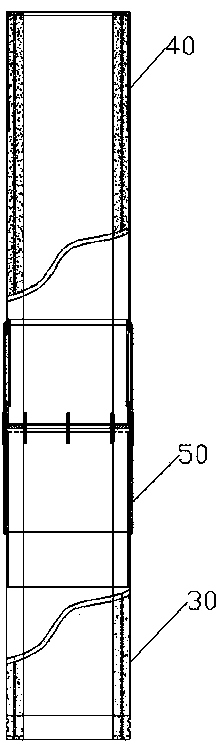

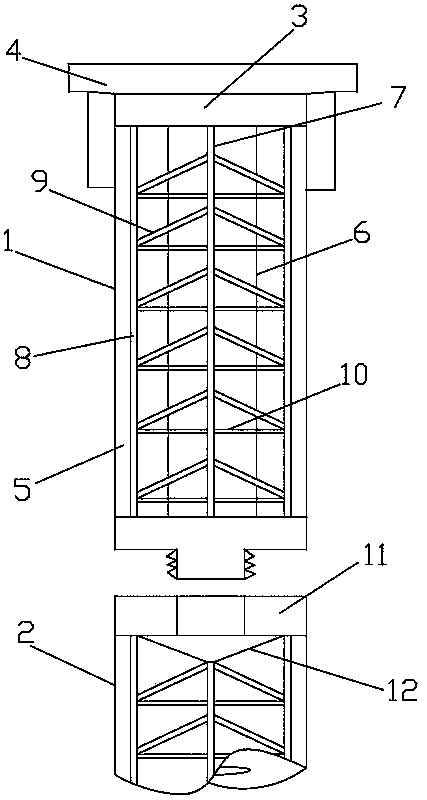

Combined splicing tubular pile and pile splicing method

Owner:国鼎(南通)管桩有限公司

Method for construction of pipe sinking cast-in-place pile in pebble bed, gravel layer and sand layer

A method for the construction of a pipe sinking cast-in-place pile in a pebble bed, a gravel layer and a sand layer, wherein firstly, a hole is drilled in a pile position and mud or coal ash slurry is simultaneously injected into the hole; and then the construction of the pipe sinking cast-in-place pile is performed through a process of hammering double sleeves; therefore, the purposes of no sediment at the bottom end of the pile and high bearing capacity of single pile are achieved. The method has the characteristics of high construction speed, no pollution on the spot, ensured quality, low construction cost, and ensured designed pile diameter and pile length.

Owner:刘清洁

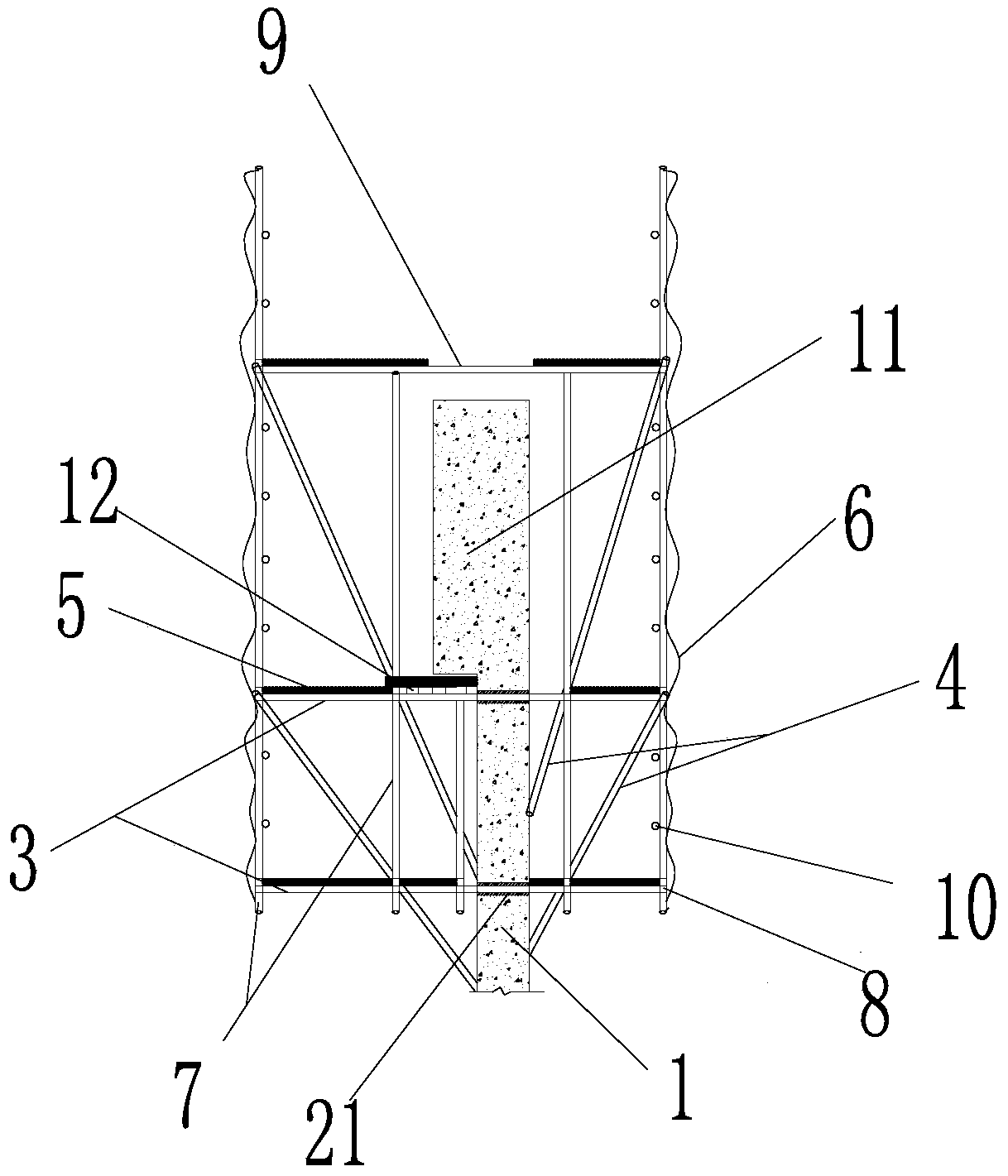

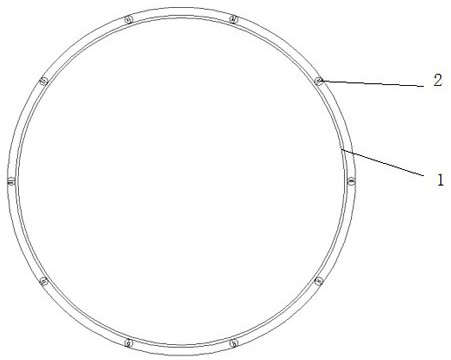

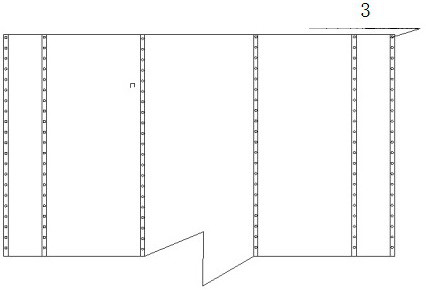

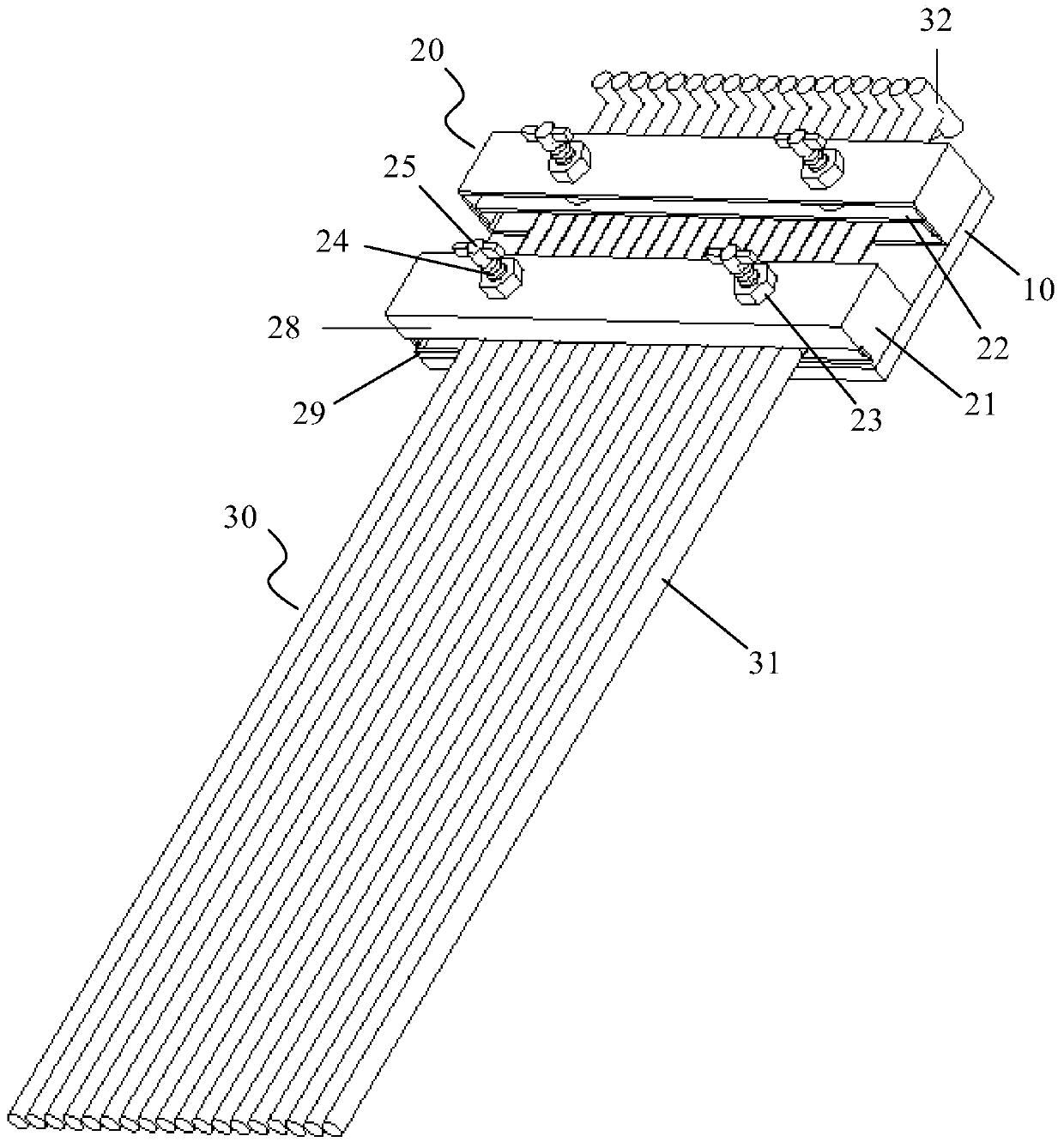

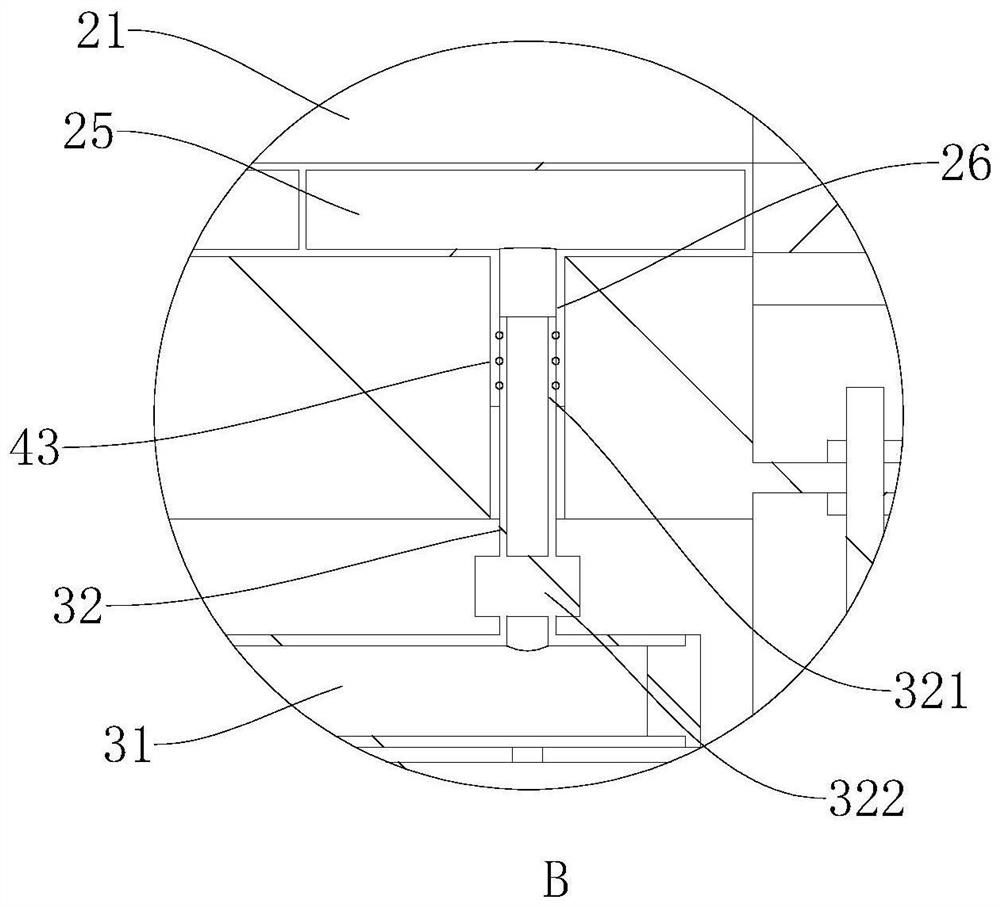

Erecting structure and erecting method for top ring beam construction platform of concrete silo

InactiveCN110725597ALess materialSimple structureBulk storage containerBuilding support scaffoldsArchitectural engineeringPipe layer

Owner:CHINA 19TH METALLURGICAL CORP

Method for grouting and wall protection of a soft stratum pile foundation through steel casing

Owner:THE 5TH CONSTR COMPANY LTD OF CHINA RAILWAY 15TH BUREAU GRP +1

Separating device for pouring different strengths of concrete for beam and column joints

PendingCN111173285AGood separation effectNo flow problemsBuilding material handlingClassical mechanicsStructural engineering

Owner:CHINA RAILWAY CONSTR ENG GROUP

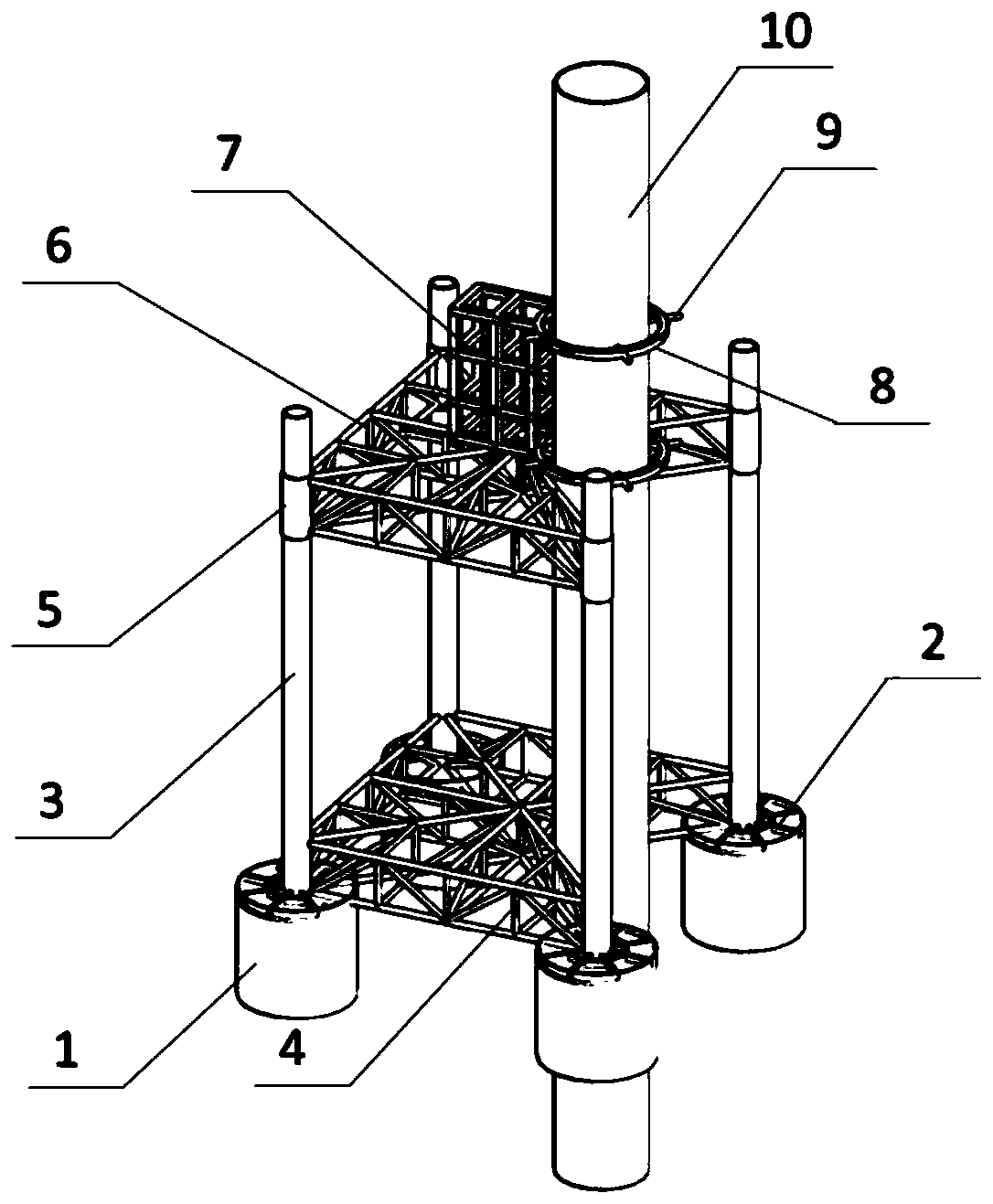

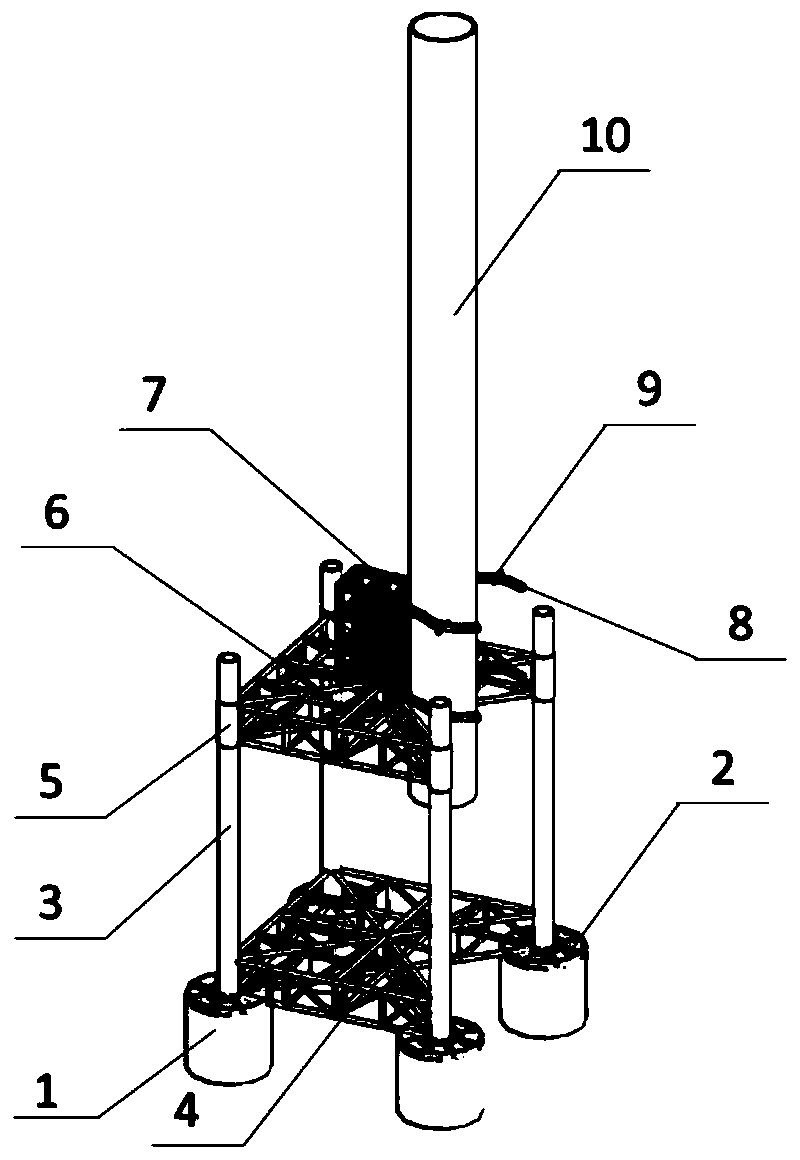

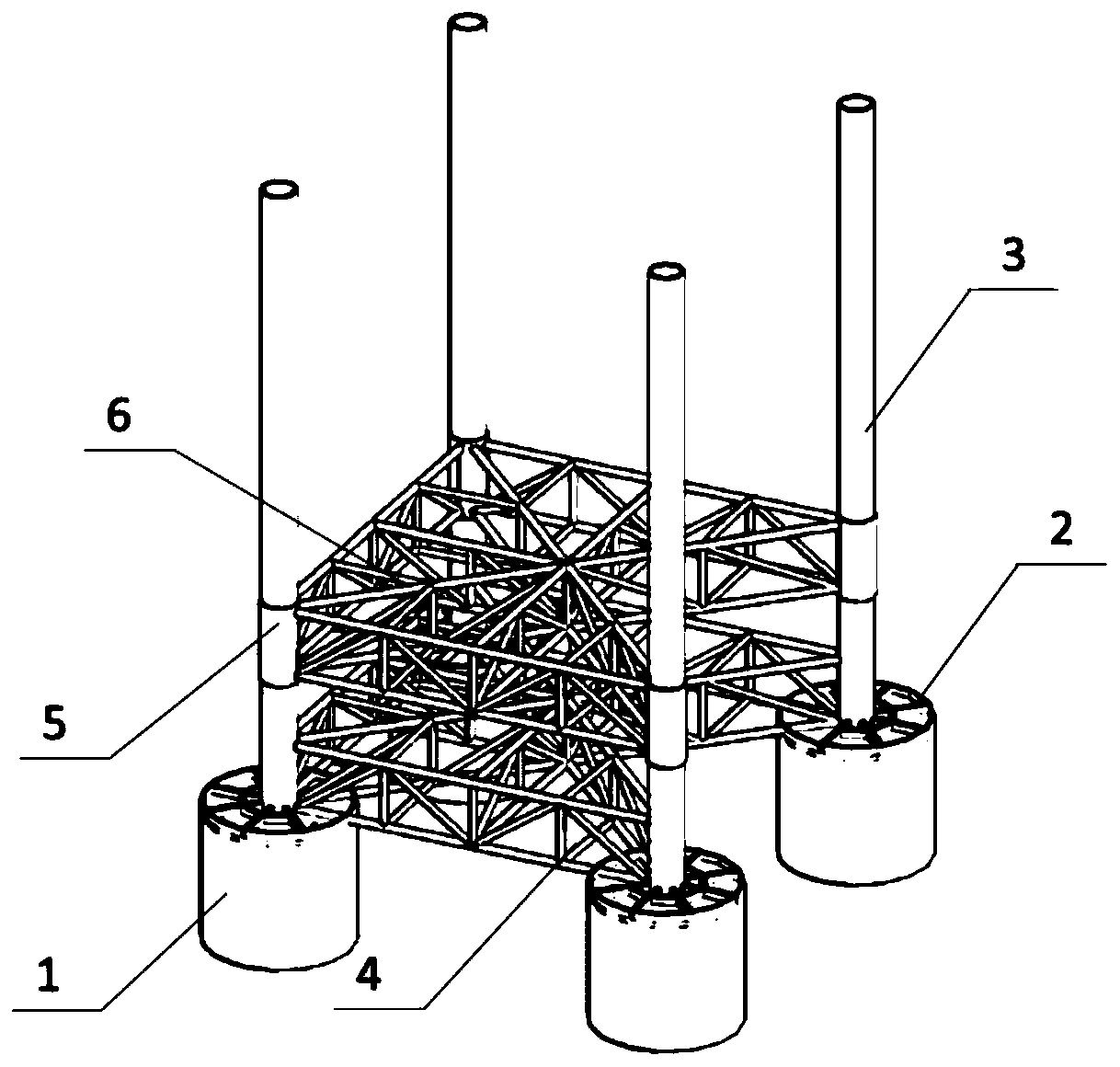

Construction method based on box-drum-type pile stabilizing platform

PendingCN110644487ASimple structureImprove horizontal bearing capacityArtificial islandsUnderwater structuresStable statusArchitectural engineering

Owner:天津港航工程有限公司

Multi-caliber pipe bending device for steel pipe machining

InactiveCN112024663AAvoid bendingImprove general performanceMetal-working feeding devicesPositioning devicesPipeScrew thread

Owner:合肥巨步机械科技有限公司

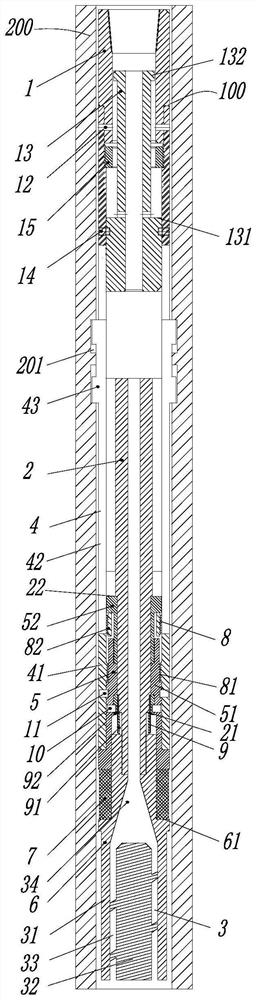

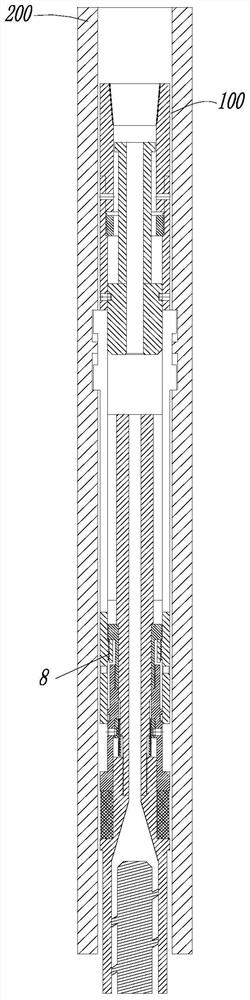

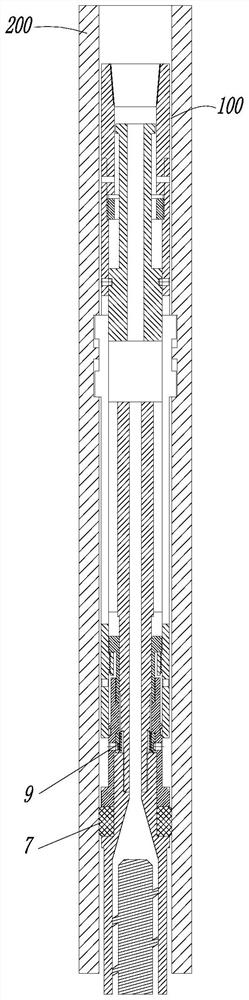

Underground drainage gas production device and pipe column

InactiveCN112302615ARelieve pressureReduce liquidityDrilling rodsFluid removalUpper jointStructural engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydraulic permeation increasing process for large-dip-angle low-permeability coal seam

PendingCN113756775AIncrease concentrationEasy extractionSurveyFluid removalHydraulic fracturingWater leak

The invention relates to the technical field of coal seam hydraulic permeation enhancement, and discloses a hydraulic permeation increasing process for a large-dip-angle low-permeability coal seam which comprises the following steps: step (1), drilling: drilling a coal seam to form a fracturing hole; step (2), a hole sealing process is determined, placing two packers in each fracturing hole, wherein the two packers are distributed in a spaced mode, a plurality of branch holes communicated with the fracturing hole are formed in one side of the fracturing hole, the intersection point between the branch holes and the fracturing hole is a branch point, a fracturing pipe is inserted into the fracturing hole, and a screen pipe section of the fracturing pipe is put into the position of the branch hole needed to be fractured; step (3), fracturing parameter design, including pump injection pressure parameter and injection liquid quantity parameter design; step (4), type selection of fracturing equipment; and (5) fracturing: after the fracturing hole is sealed through a hole sealing material, after the hole sealing material is solidified for 12-48 h, connecting a pipeline and equipment, and starting a pump for water injection fracturing. The phenomenon of water leakage caused by poor hole sealing effect in the hydraulic fracturing process can be avoided.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Concrete pipe pile

Owner:广水市浍洋科技有限公司

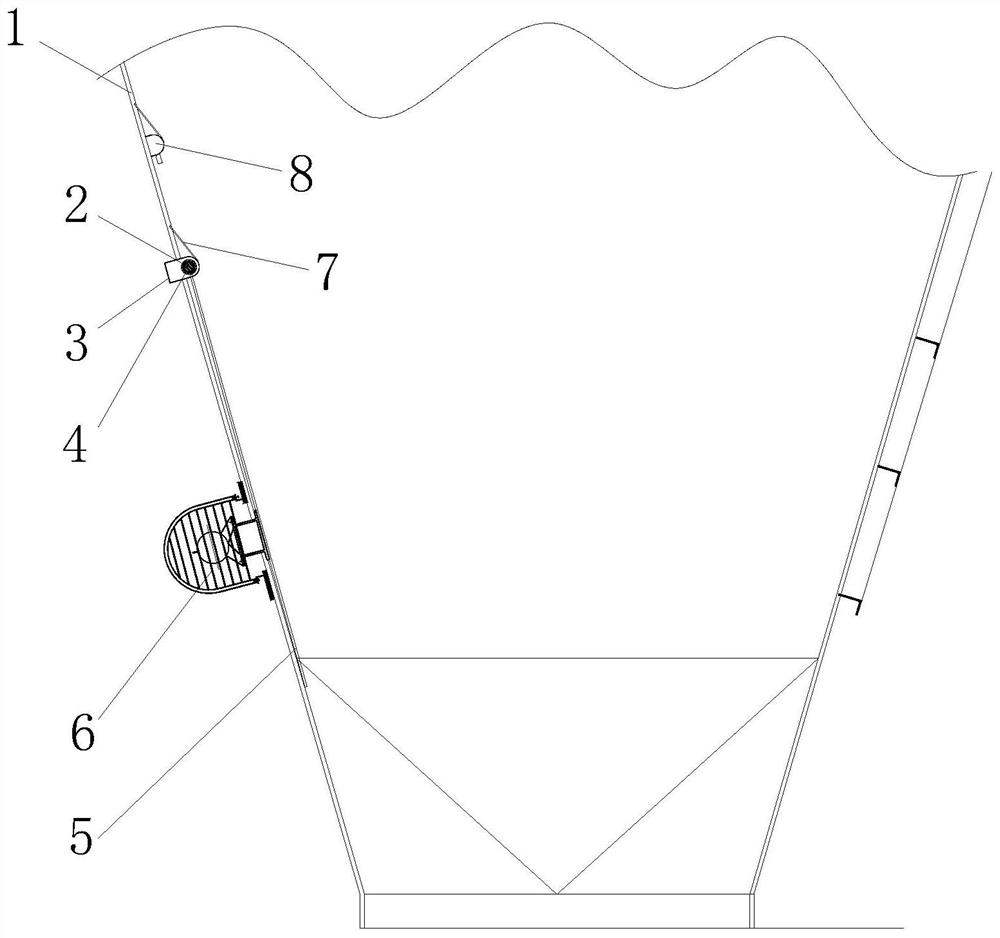

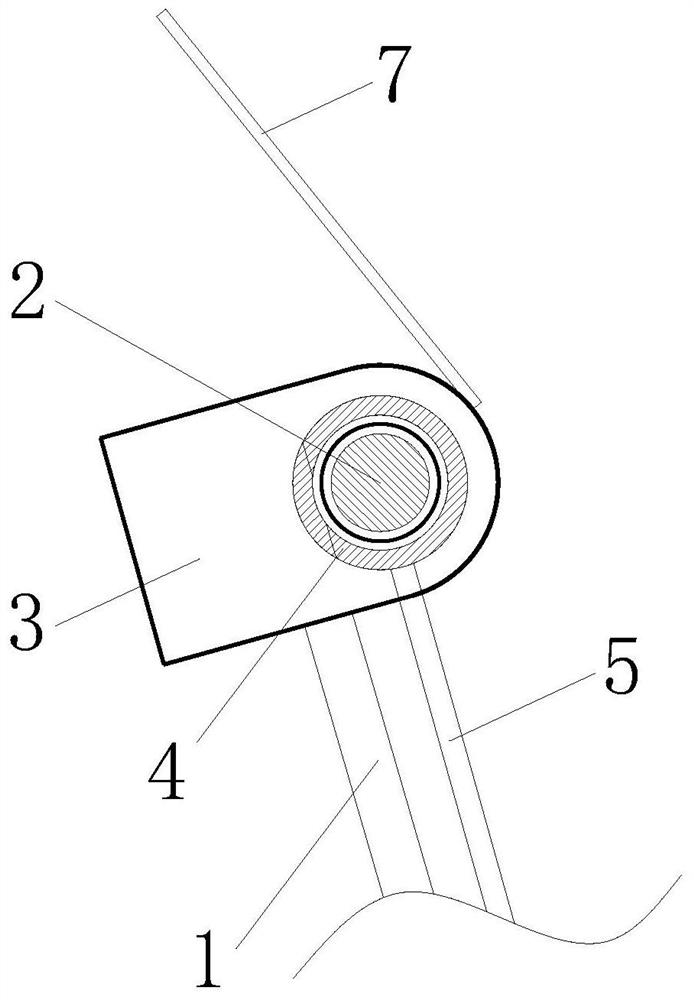

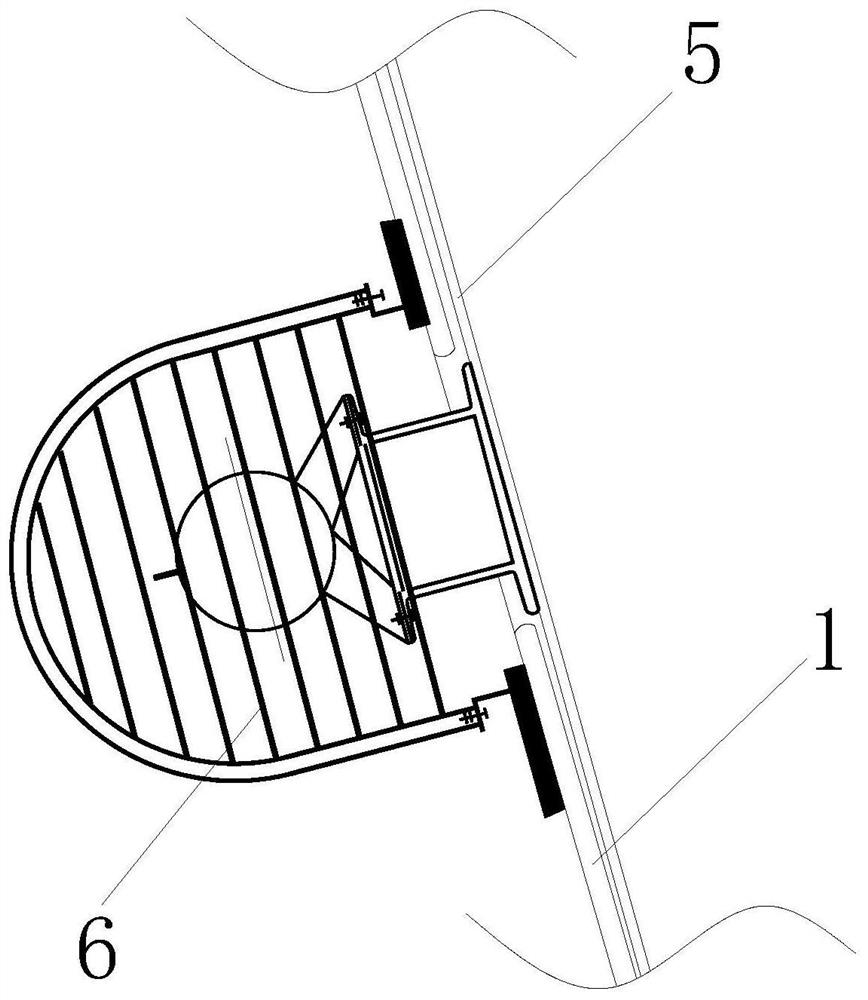

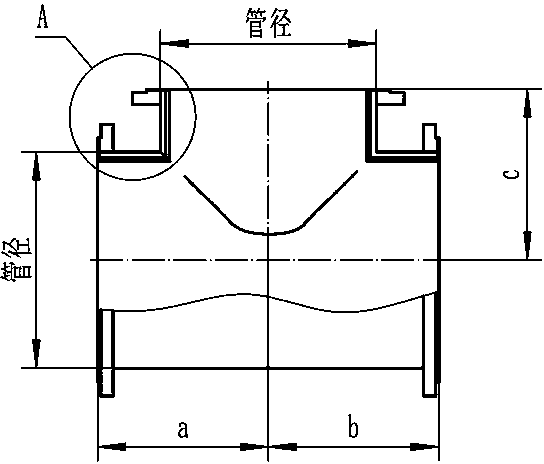

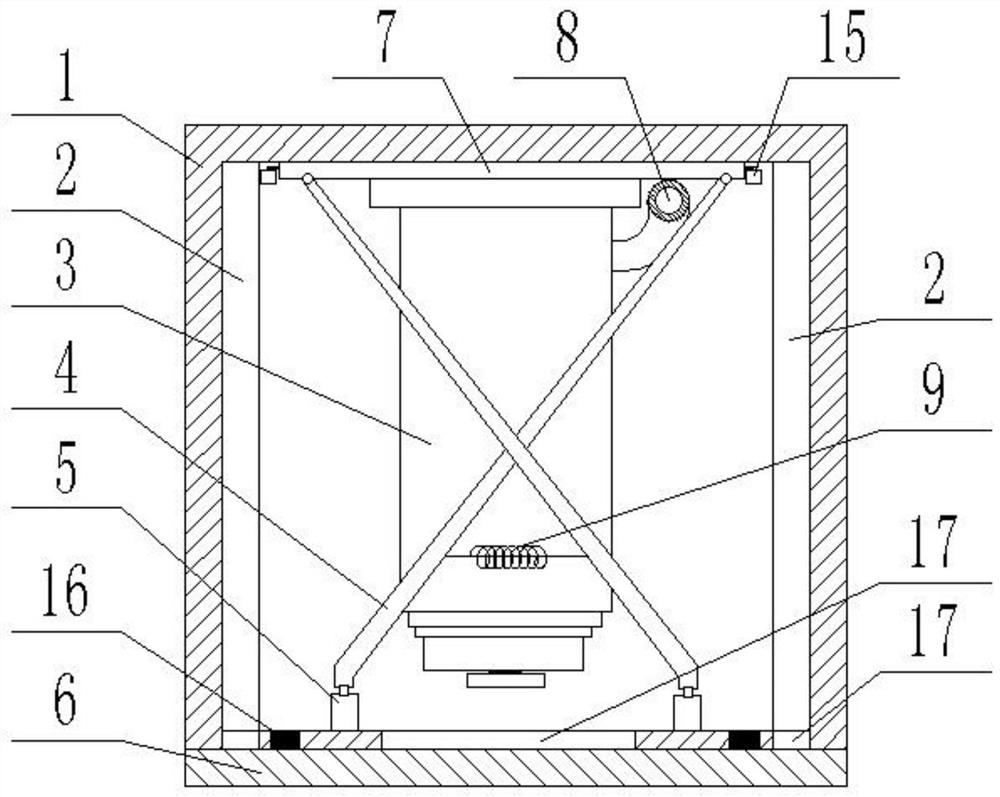

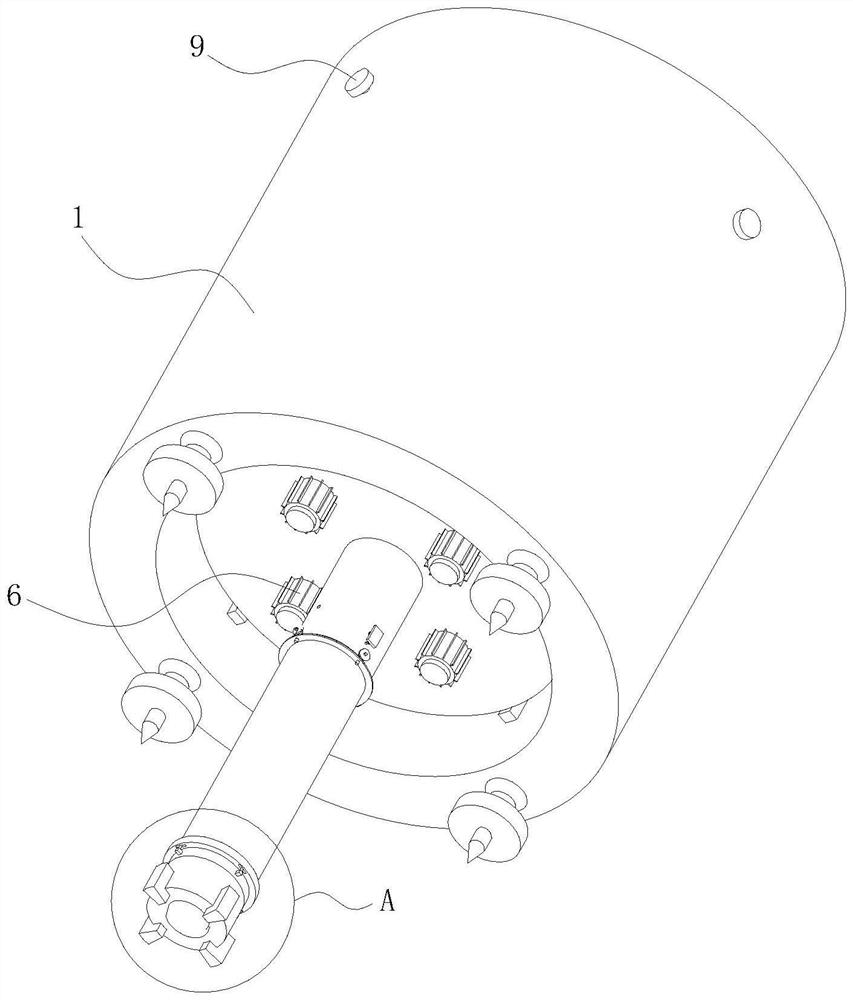

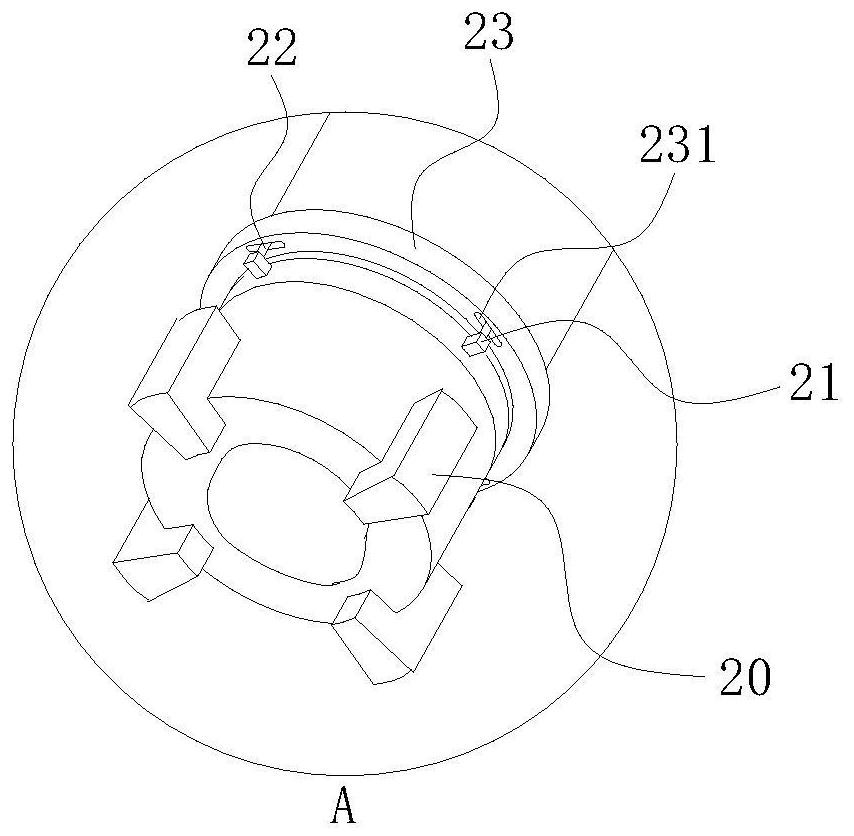

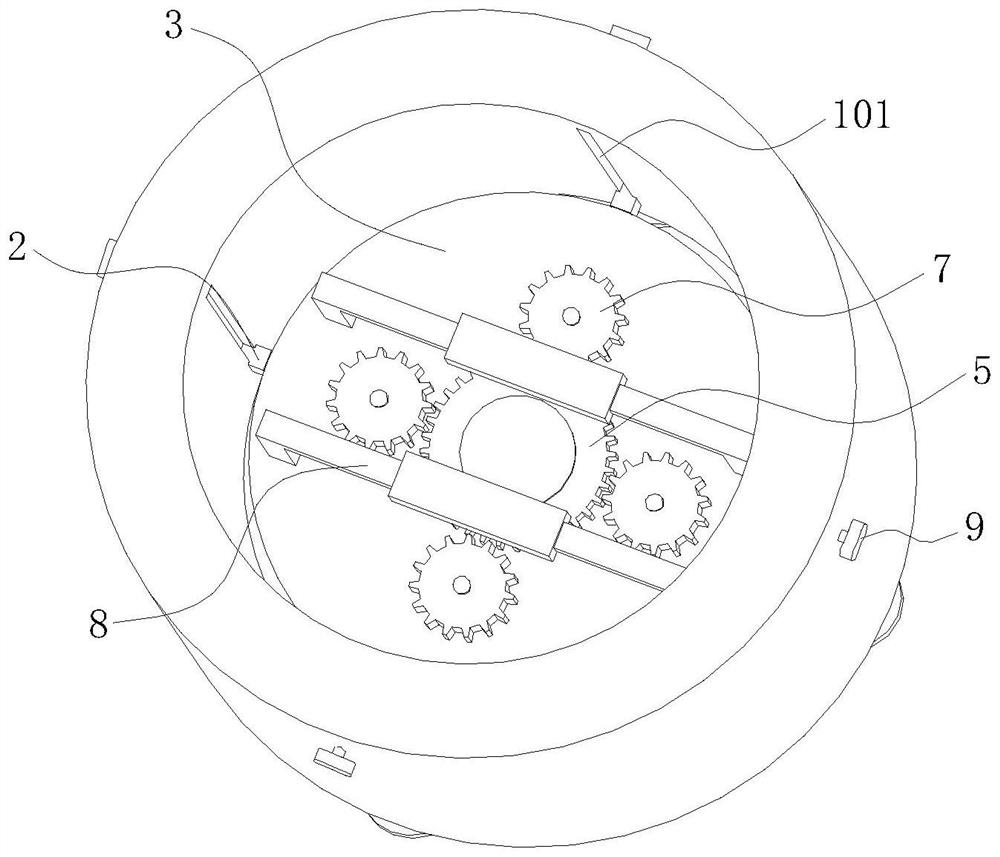

Storage bin wall vibrating device

PendingCN112678351ASolve the sticky problemShorten the timeLarge containersTank wagonsElectric machineStructural engineering

Owner:HUATIAN ENG & TECH CORP MCC

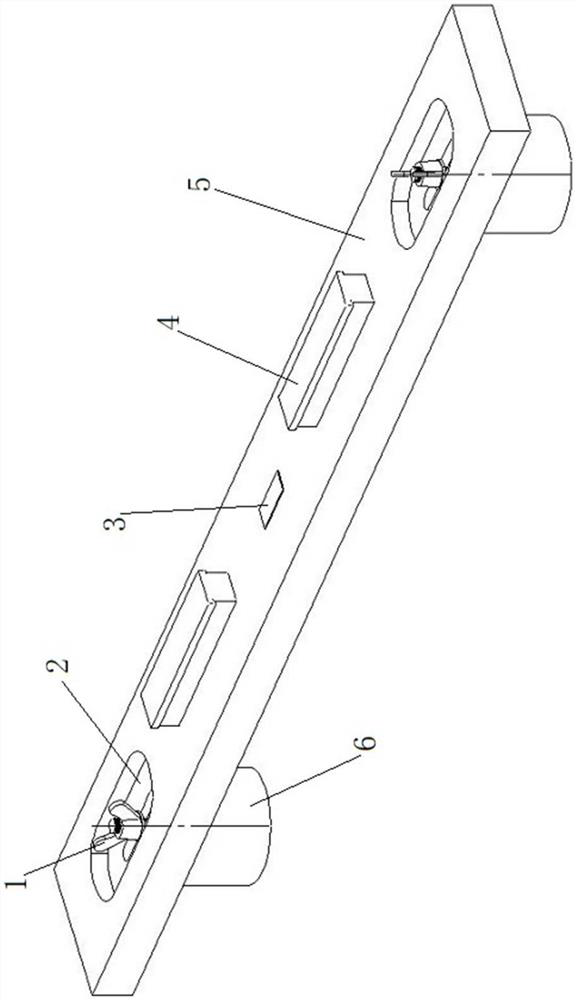

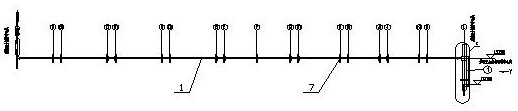

Pipe arranging machine

PendingCN113716308ARealize row assemblyAvoid the situation where the arrangement direction is inconsistentControl devices for conveyorsChutesEngineeringStructural engineering

The invention discloses a pipe arranging machine. The pipe arranging machine comprises a conveying mechanism, a discharging mechanism, a collecting mechanism and a pipe arranging correcting mechanism. The discharging mechanism comprises a discharging groove set inclining downwards, and the conveying mechanism is used for providing materials for the upper end of the discharging groove set. The collecting mechanism comprises a first collecting groove and a second collecting groove, the first collecting groove is in butt joint with the bottom end of the discharging groove set, and the second collecting groove is located on the side, away from the discharging groove set, of the first collecting groove. The pipe arranging correcting mechanism comprises correcting needles corresponding to the discharging groove set, the ends of the correcting needles incline upwards, the correcting needles can move to the position above the second collecting groove or be in butt joint with the bottom of the discharging groove set, and when the correcting needles are located above the second collecting groove, the correcting needles correspond to the second collecting groove, and the correcting needles can rotate till the ends incline downwards. According to the pipe arranging machine, arrangement of pipe bodies can be achieved, and the situation that the arrangement directions of the pipe bodies are inconsistent during arrangement can be effectively avoided.

Owner:GUIZHOU PANJIANG CIVIL EXPLOSIVE

Manufacturing method for large-caliber abrasion-resistant corrosion-resistant ternary composite pipe accessory

InactiveCN103411071ASolve labor-consumingTime consuming to solveBranching pipesCoatingsCeramic compositeInorganic particle

Owner:FUDAN UNIV

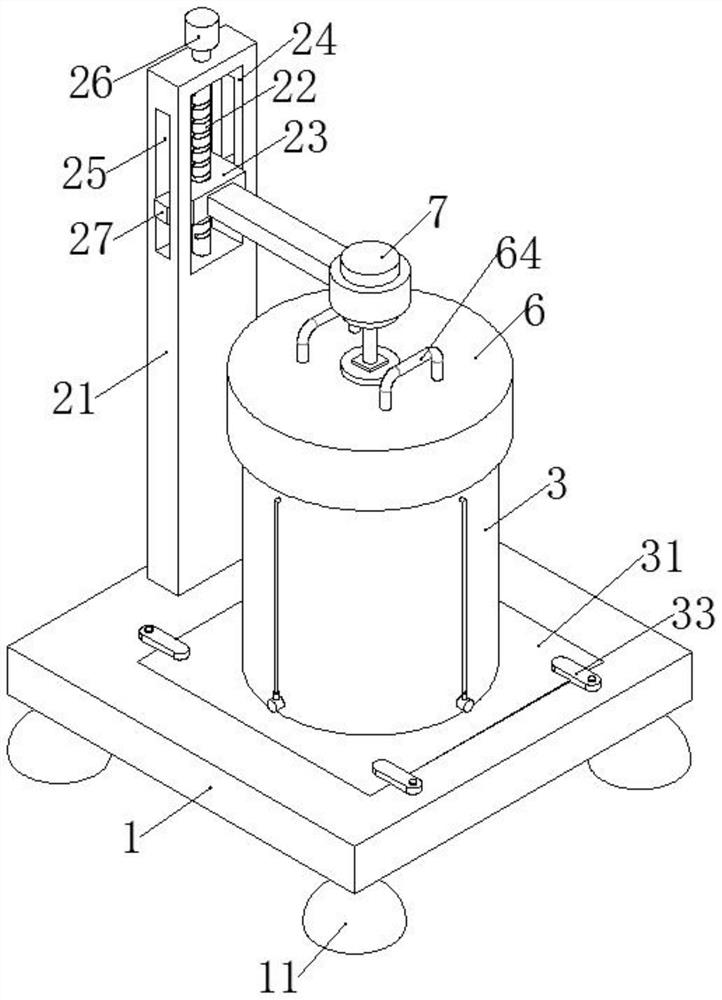

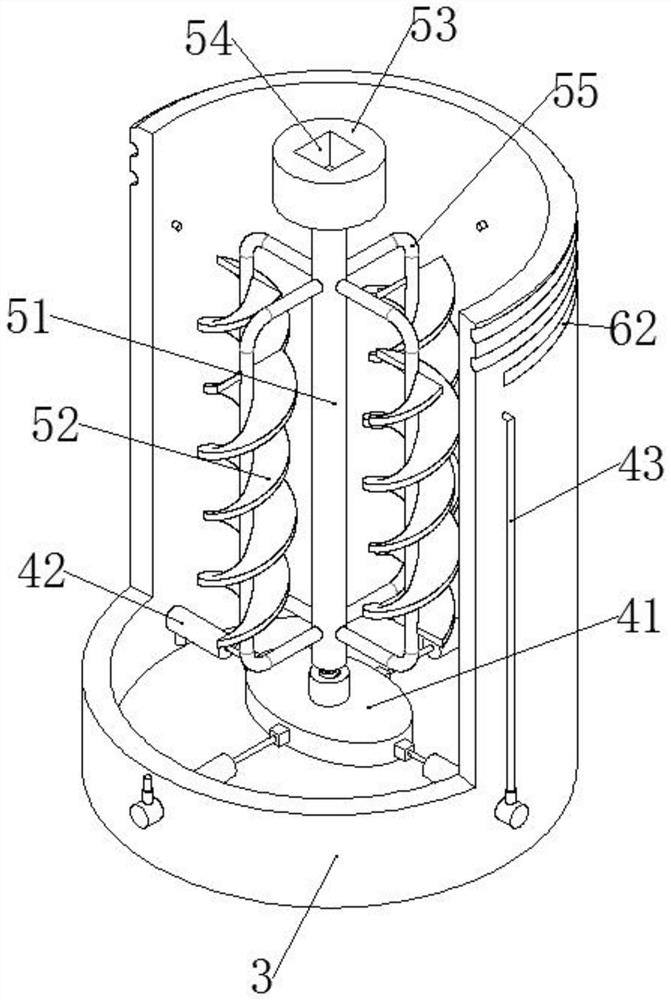

Checking and homogenizing device

PendingCN113522082AEasy to assemble and disassemblePrevent sinkingFlow mixersRotary stirring mixersBLENDER/MIXERElectric machine

Owner:中国人民解放军总医院第八医学中心

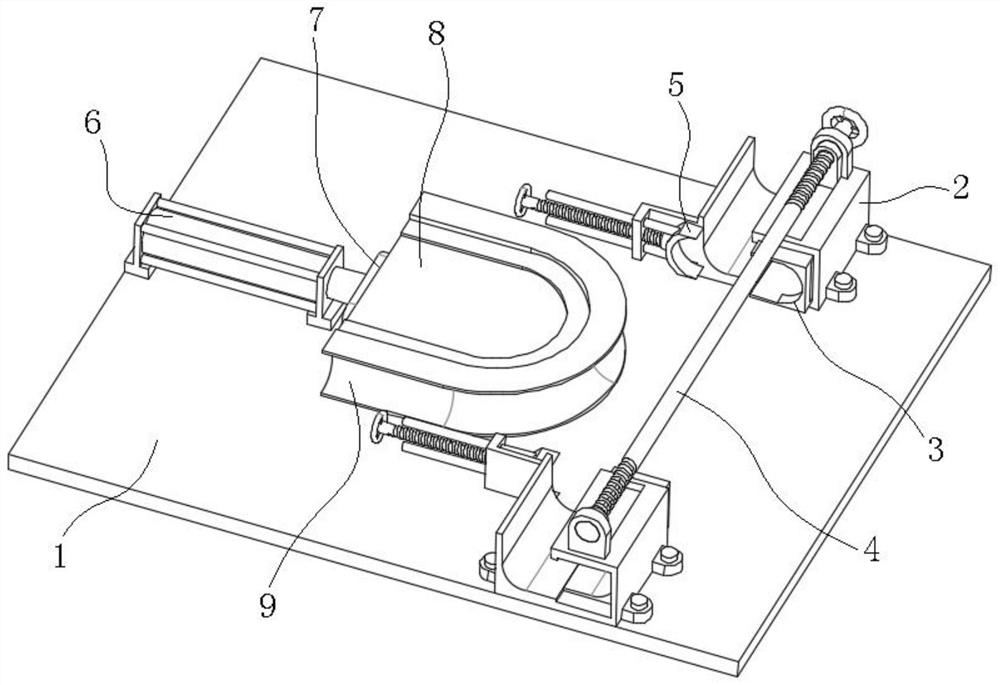

Grinding and polishing device and process

InactiveCN112621558AReduce processImprove processing efficiencyLapping machinesLapping toolsLiquid storage tankProcess engineering

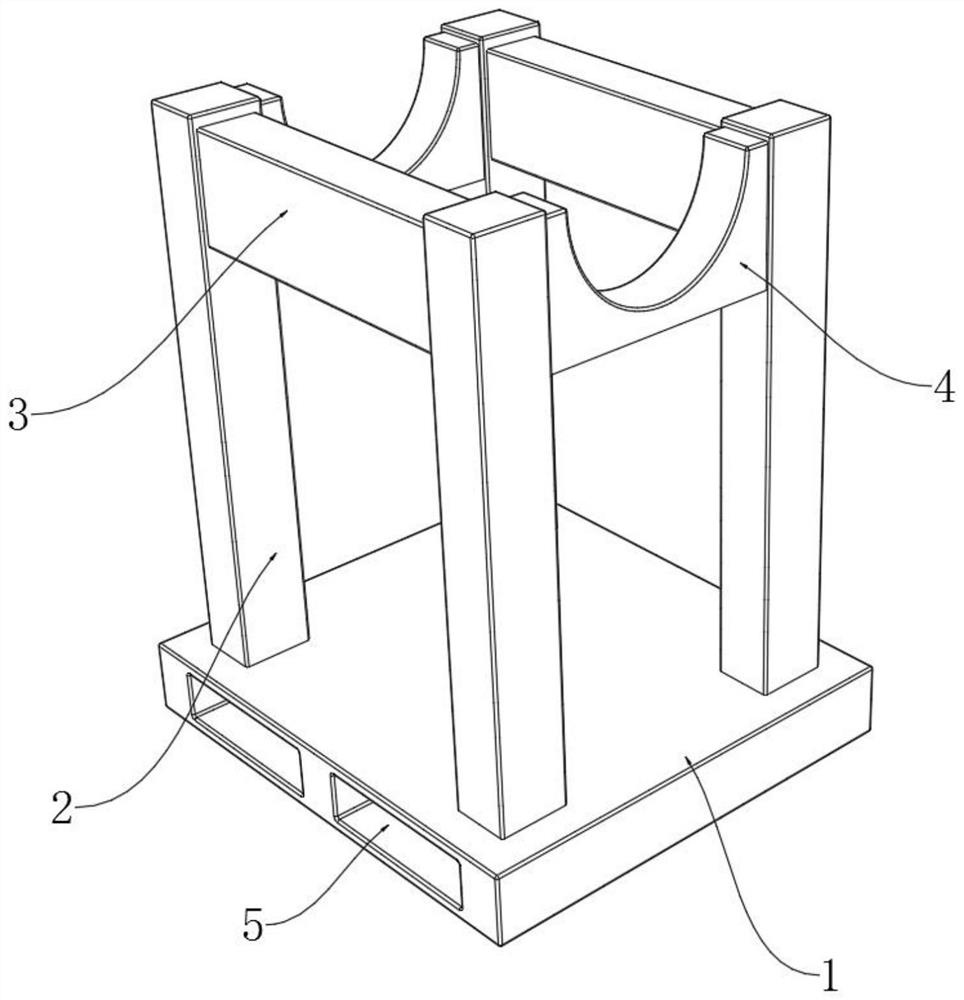

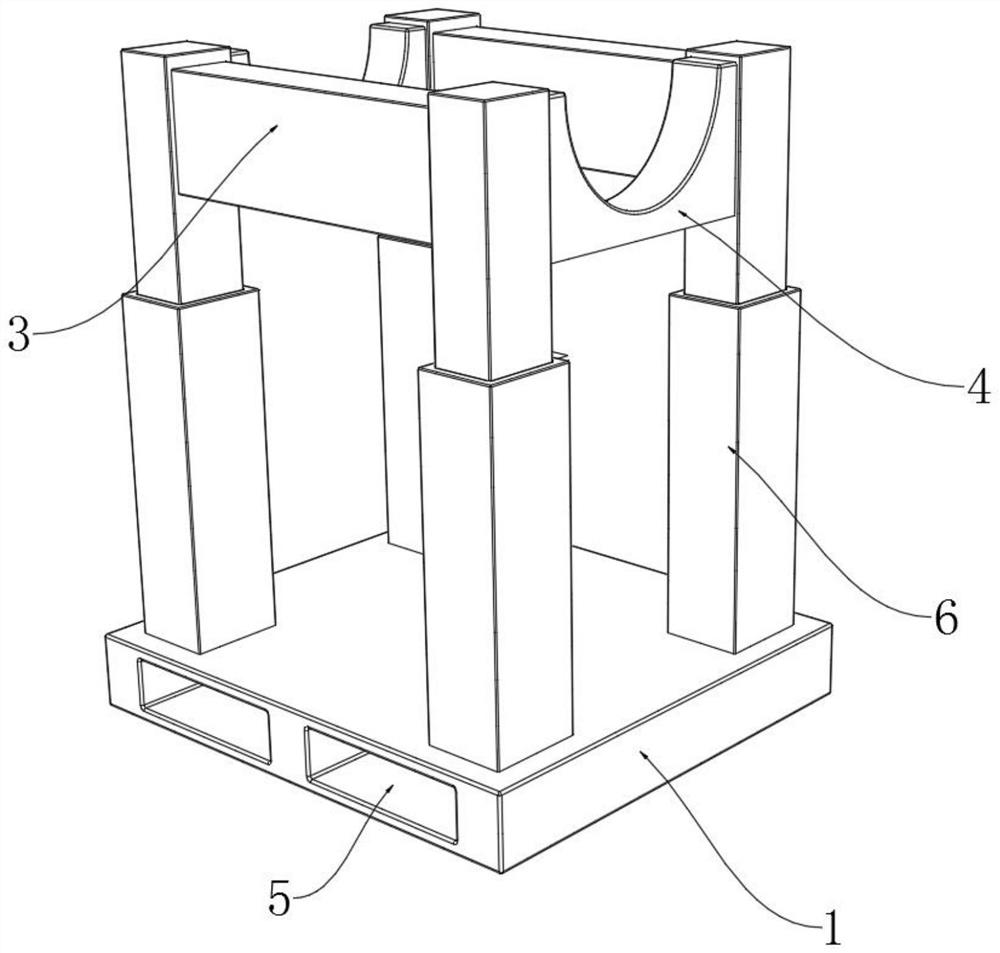

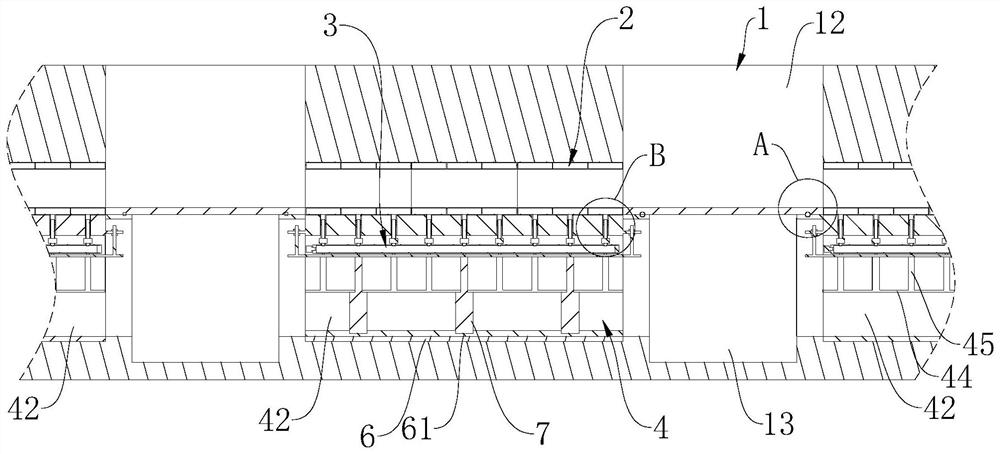

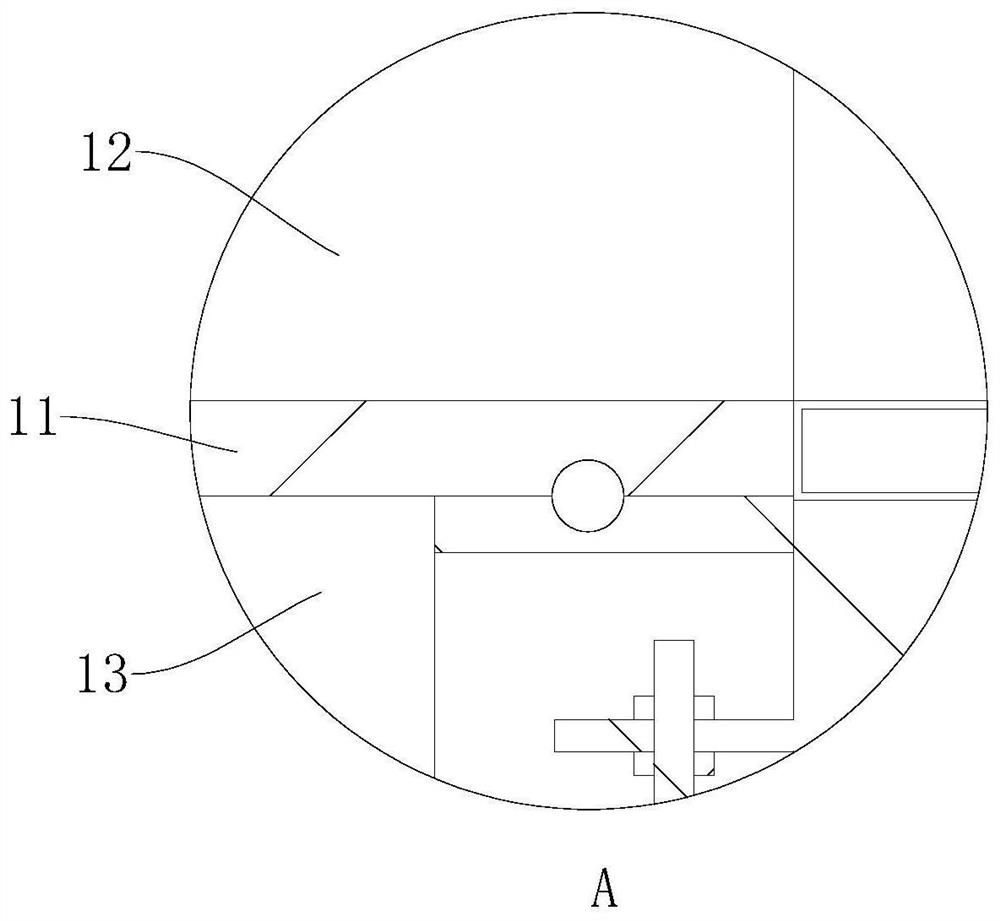

The invention discloses a grinding and polishing device and process, and relates to the technical field of grinding and polishing. The grinding and polishing device comprises a U-shaped frame and a bottom plate, a transverse rod is fixedly connected to one side of the middle of the U-shaped frame, a top plate is slidably connected to the top of the transverse rod, a collecting pool is fixedly connected to the middle of the top of the bottom plate through a supporting column, and the bottom of the collecting pool is fixedly connected with a collecting pipe. By arranging the top plate, raw materials do not need to be moved when the raw materials are processed, a grinding head and a liquid outlet pipe can be used for processing the raw materials at different working procedure time by moving the top plate, and therefore the purposes of saving the working procedures and improving the processing efficiency are achieved; and by arranging the collecting pipe, when polishing is carried out, polishing liquid in the collecting pool can be discharged, the polishing liquid enters a liquid storage tank again to be recycled, then the polishing liquid is pumped out again through a submersible pump, and therefore the purpose of reutilization is achieved.

Owner:寻瀚之

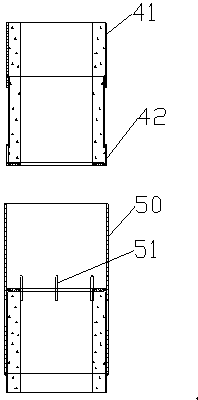

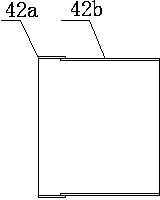

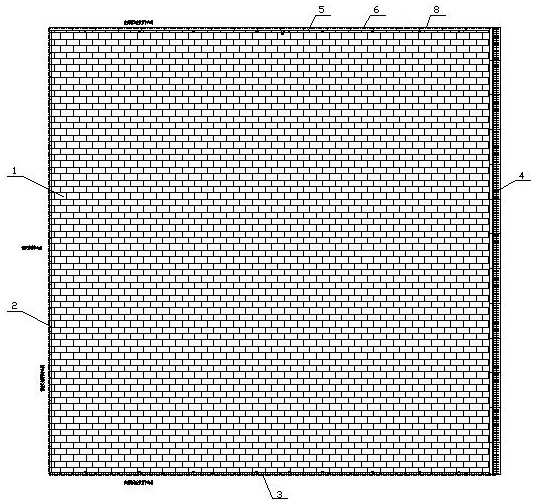

Pipe gallery segment installation construction system and method

InactiveCN113482046AImprove transport efficiencyImprove installation and construction efficiencyArtificial islandsTemporary pavingsArchitectural engineeringStructural engineering

The invention provides a pipe gallery segment installation construction system and method. The pipe gallery segment installation construction system comprises a foundation pit, first roads and second roads, wherein the first roads are arranged on the two sides of the foundation pit in the length direction of the foundation pit and used for supporting walking gallery lifting machines, the second roads are arranged on the sides, away from the foundation pit, of the first roads, the second roads are arranged in the length direction of the foundation pit and used for supporting walking gallery conveying vehicles, a third road is arranged between the two first roads, and the third road is arranged in the direction perpendicular to the length direction of the foundation pit and connected with the second roads. According to the pipe gallery segment installation construction system, conveying of the gallery conveying vehicles on the second roads is achieved, gallery lifting and transferring are conducted on the third road in cooperation with movement of the gallery lifting machines on the first roads, the position of the third road can be dismantled and then laid according to actual needs, the transferring and installing construction efficiency of a pipe gallery is improved, and the construction period is shortened.

Owner:NO 6 ENG CO LTD CCCC SECOND HIGHWAY ENG +1

Pipe shed for reinforcing rock-soil layer

ActiveCN113863269AControl altitudeControl increase heightProtective foundationSoil preservationSoil scienceStructural engineering

Owner:铁科院(深圳)研究设计院有限公司

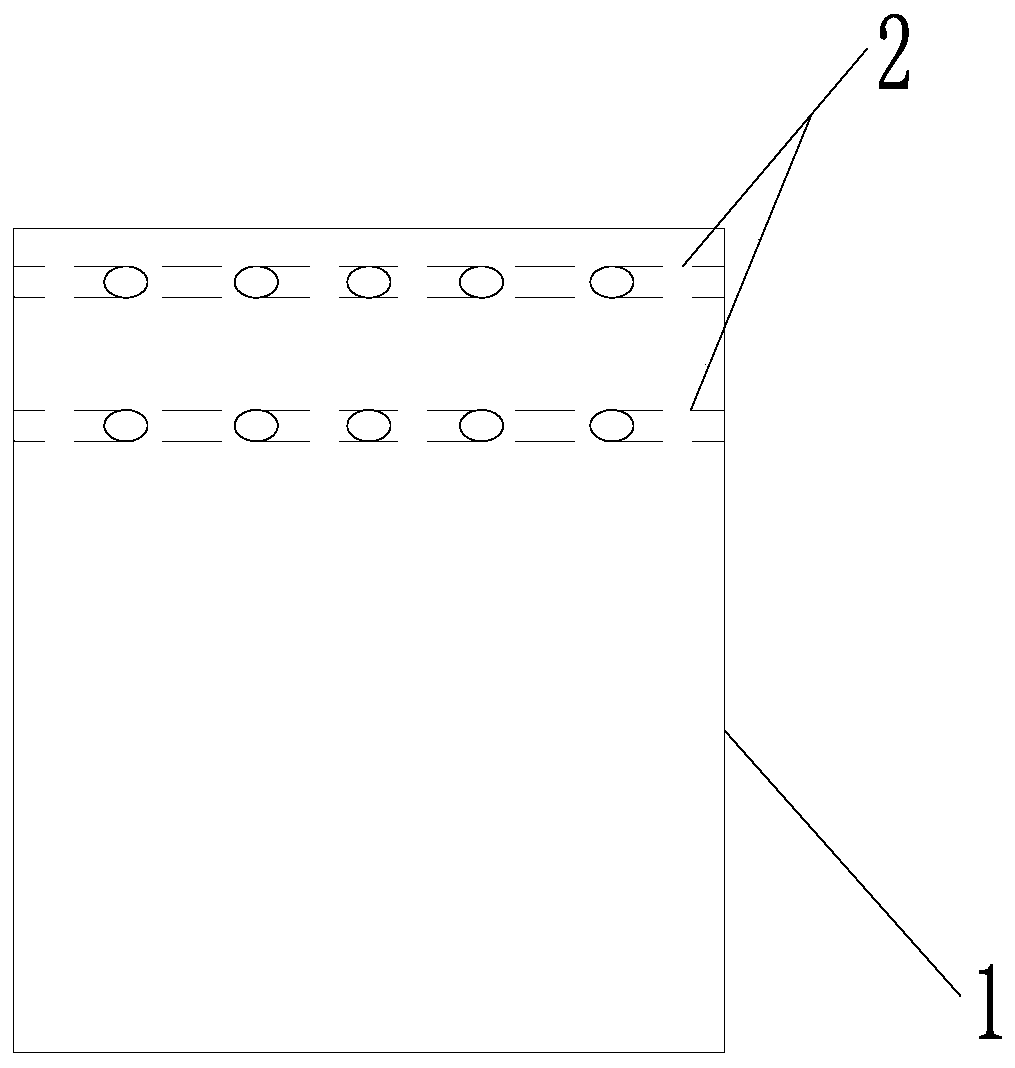

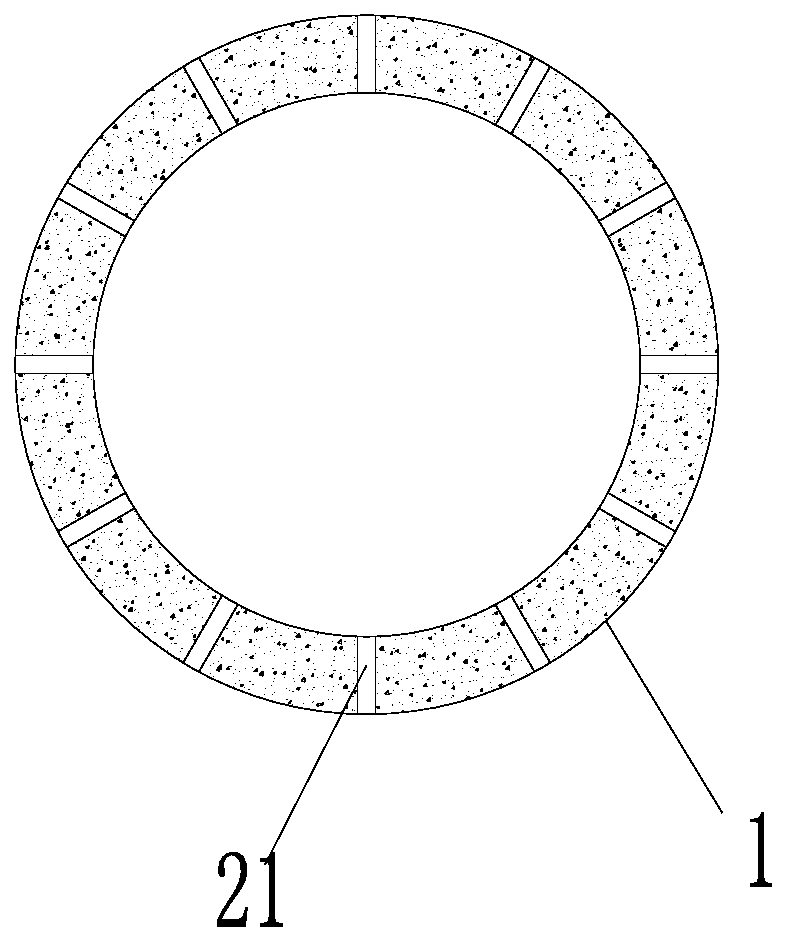

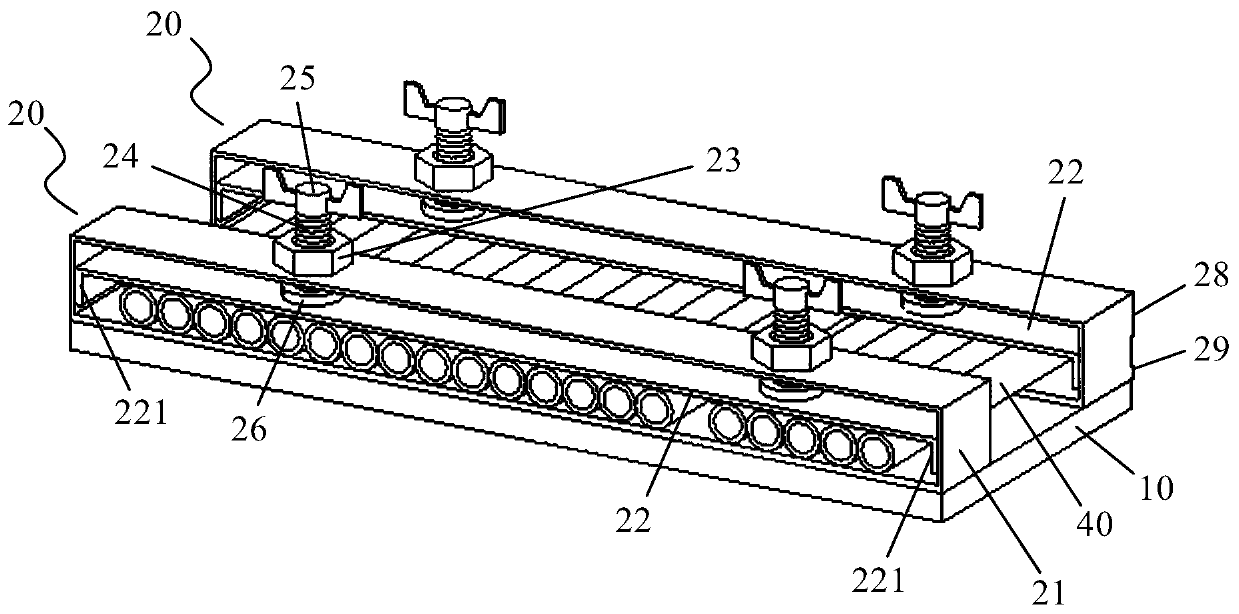

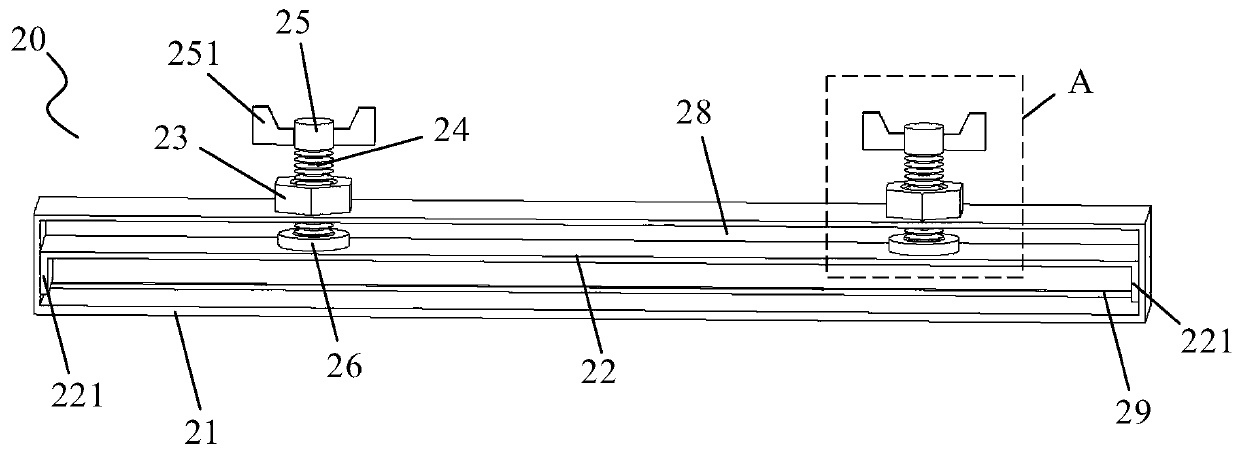

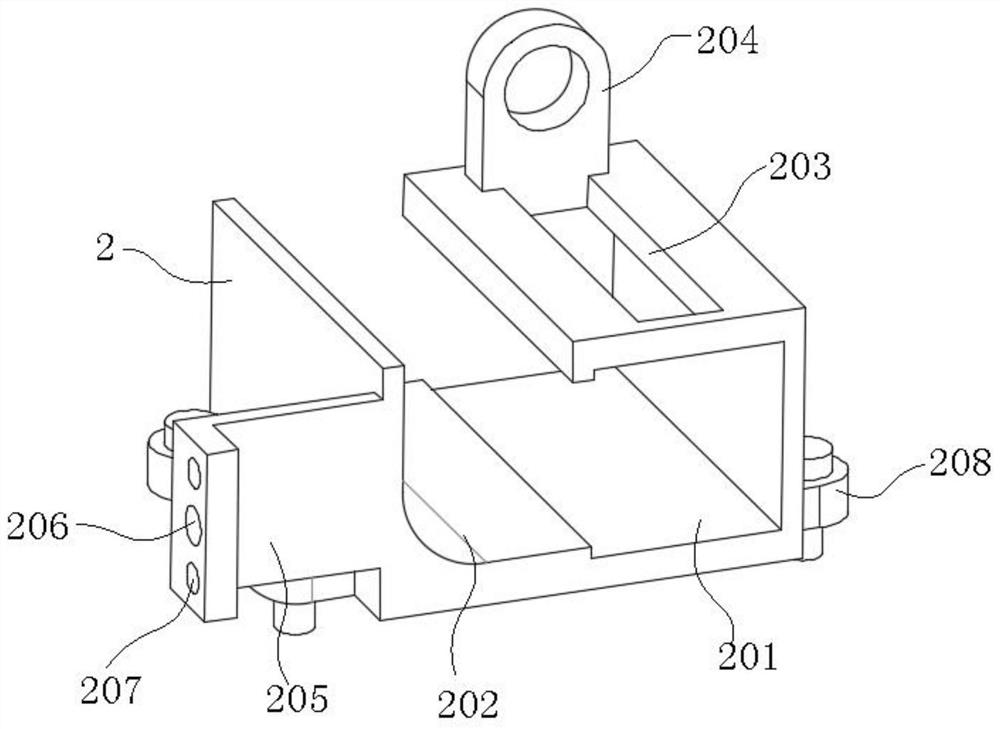

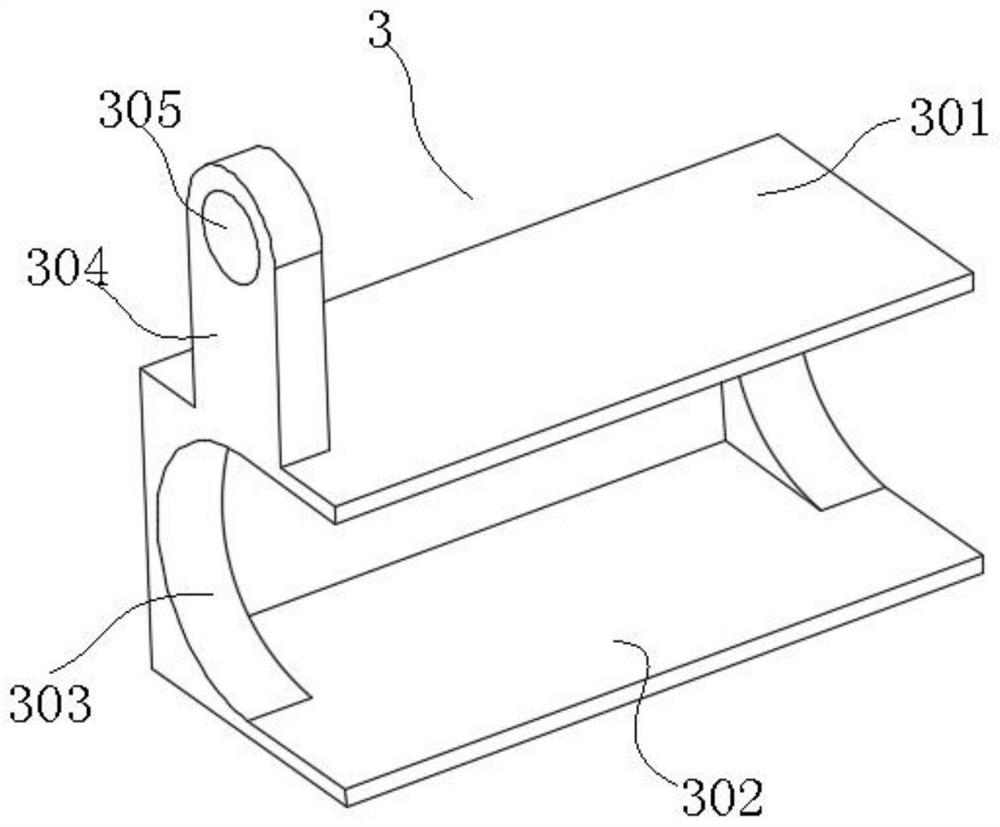

Assembly system and assembly method of horizontal vacuum tunnel detection model

ActiveCN114260847AUniform pressureAvoid the impact of different forcesWork holdersRailway transportPipeHydraulic pressure

The invention relates to the field of high-speed rail tunnel detection equipment, in particular to an assembling system and an assembling method of a horizontal vacuum tunnel detection model. The objective of the invention is to solve the problem of high segment installation difficulty in horizontal vacuum tunnel detection equipment in the prior art. The segment limiting device comprises a regular polygonal segment installation support, each side length forms an independent segment limiting unit, connecting original parts are arranged between the side lengths, and each segment limiting unit comprises support structural steel and a hydraulic supporting mechanism installed on the support structural steel. The other end of the hydraulic supporting mechanism is provided with a patch which is consistent with the outer wall of the duct piece in size, shape and position; a supporting frame and a sliding rail for installing a supporting table are further arranged at the bottom of the installation support, and a lifting mechanism matched with the top segment is arranged on the supporting table. The device has the advantages that the pipe pieces can be used for simulating the vacuum tunnel to be quickly and accurately mounted, and the formed simulated pipeline is good in sealing performance.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Anti-corrosion construction method for natural gas conveying pipeline

PendingCN113236908AAvoid erosionImprove corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationDry soilPipe

Owner:东方工建集团有限公司

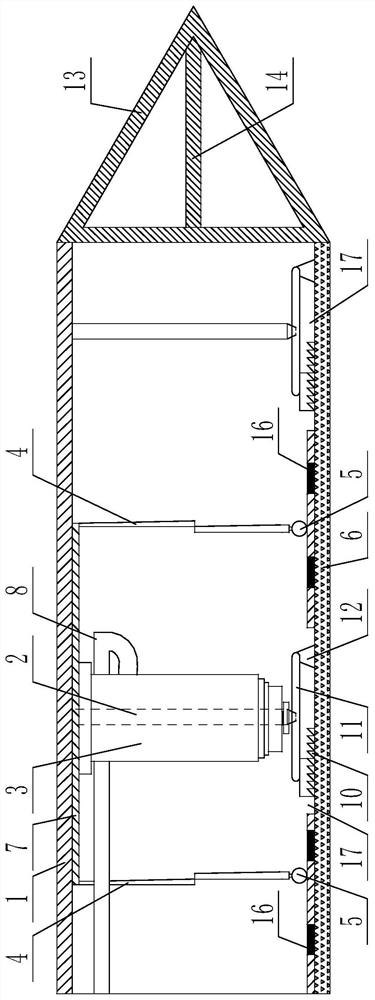

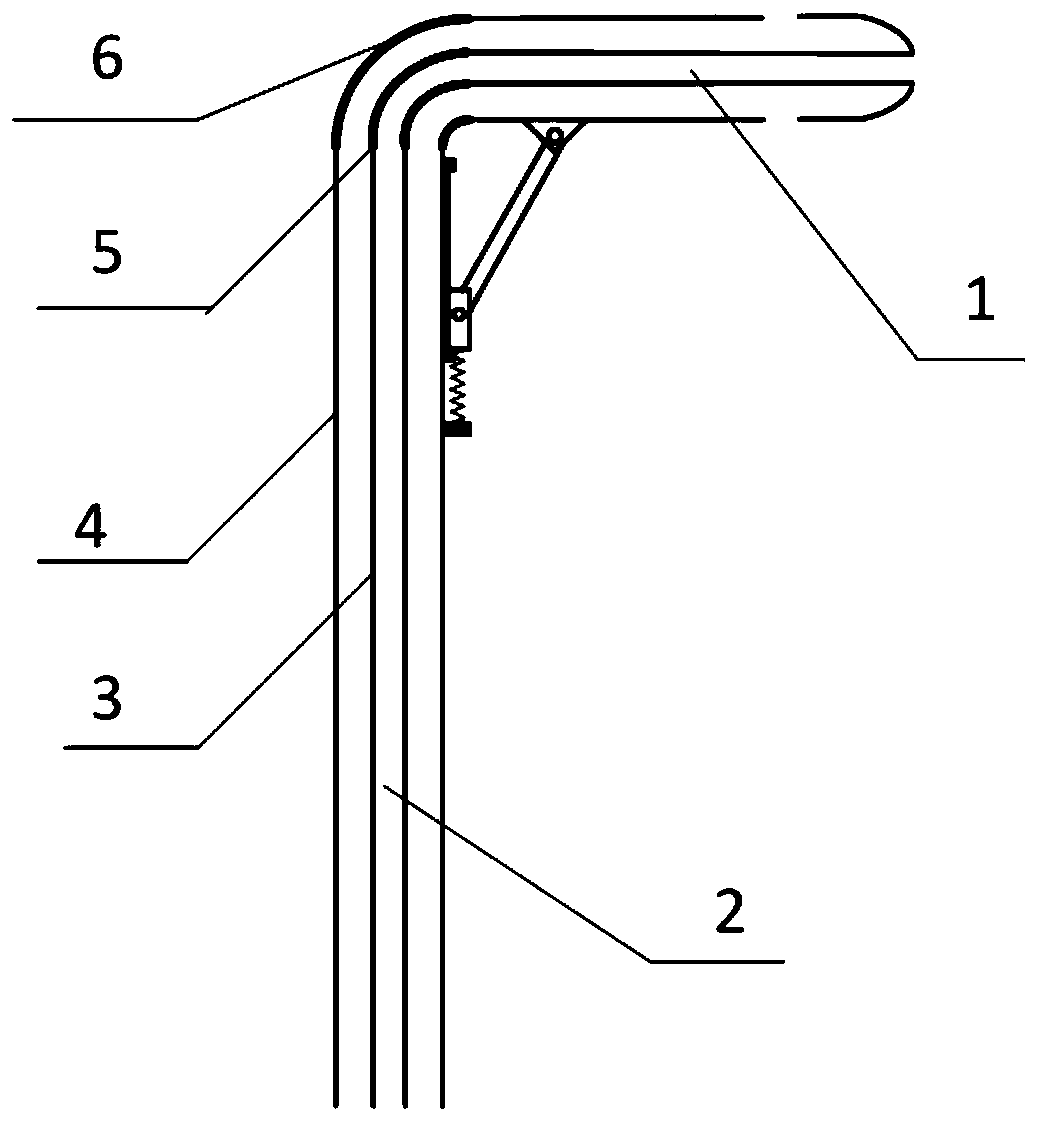

L-shaped pitot tube capable of being straightened

PendingCN111487436ASolve the problem that the flow rate cannot be measured by inserting the measuring hand hole into the pipeFluid speed measurementVertical tubeEngineering

Owner:HUANENG CLEAN ENERGY RES INST +1

Geological exploration equipment for geological exploration

PendingCN114017018AEasy to take outNot free fallBorehole/well accessoriesClassical mechanicsGeological survey

Owner:浙江省电力有限公司宁波供电公司

High-temperature pressure fusion manufacturing method of composite pipe internally coated with stainless steel

Owner:山东胜利长龙管道科技有限公司 +1

Bearing steel pipe inspection quality control method for cold rolling and expanding bearing

ActiveCN113088639AQuality improvementExtended service lifeFurnace typesTesting metalsBrinellingCarbide

The invention discloses a bearing steel pipe inspection quality control method for a cold rolling and expanding bearing. In the production process of a bearing steel pipe, pipe blank factory inspection, spheroidizing annealing state capillary pipe inspection and stress relief annealing state finished pipe inspection are sequentially carried out; stress relief annealing state finished pipe inspection includes hardness inspection, microscopic structure inspection, carbide non-uniformity inspection and decarburized layer inspection; during hardness inspection, the Brinell hardness is 179-190 HBW, and the grade is 2-3 according to the fifth grade diagram evaluation in the appendix A of GB / T 18254-2016 during microscopic structure inspection. The bearing steel pipe is subjected to quality control through the method, the surface of the bearing produced through cold rolling and expansion is free of cracks, the structure uniformity is high, thus the quality of the bearing is improved, and the service life of the bearing is prolonged.

Owner:JIANGXI HONGRUIMA STEEL PIPE

Double-sprue positioning device for casting

Owner:SHANGHAI HULIN HEAVY IND

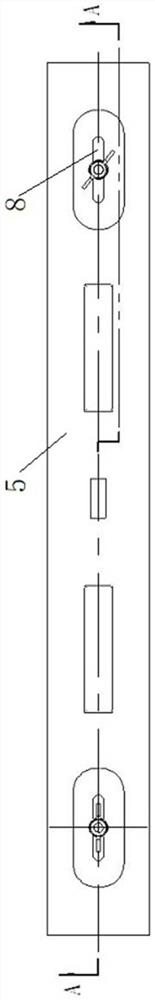

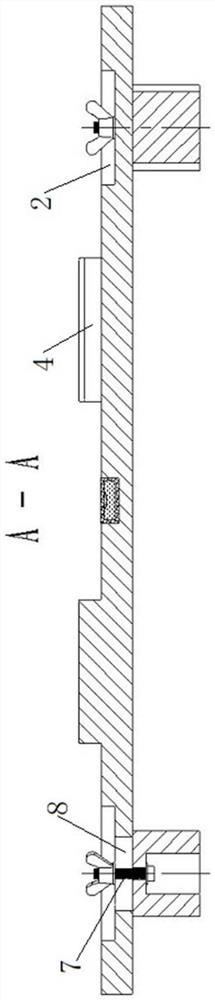

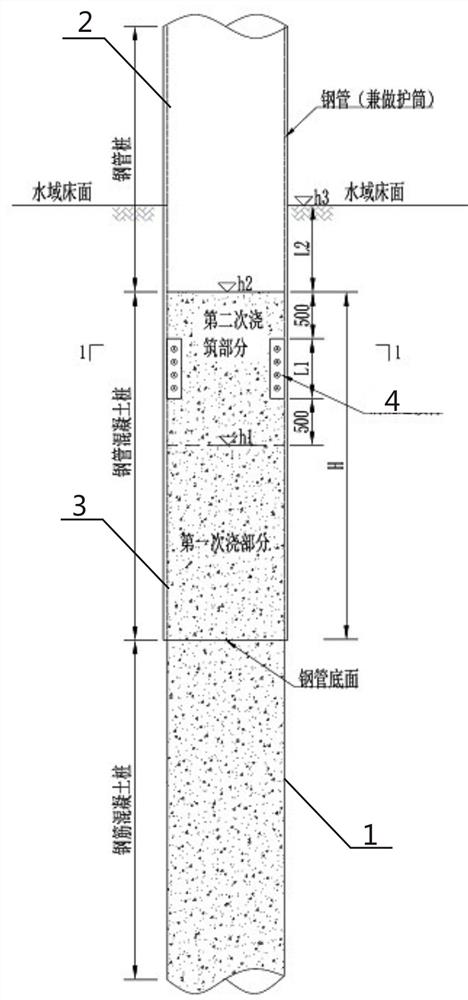

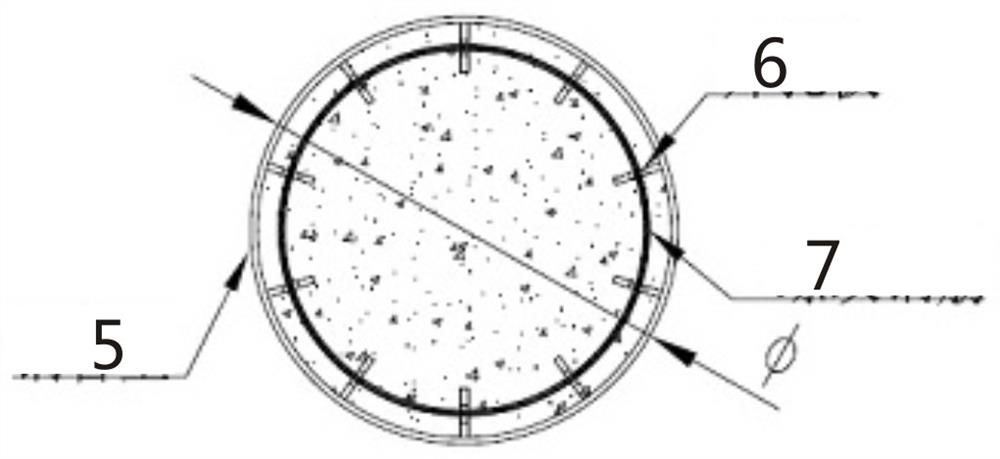

Steel pipe-reinforced concrete combined pile

PendingCN113882361AReduce the impactImprove horizontal bearing capacityBulkheads/pilesReinforced concreteRebar

Owner:四川路桥华东建设有限责任公司 +1

Auxiliary tool capable of removing supporting steel pipe at high distance

Owner:CHINA RAILWAY SIXTH GROUP

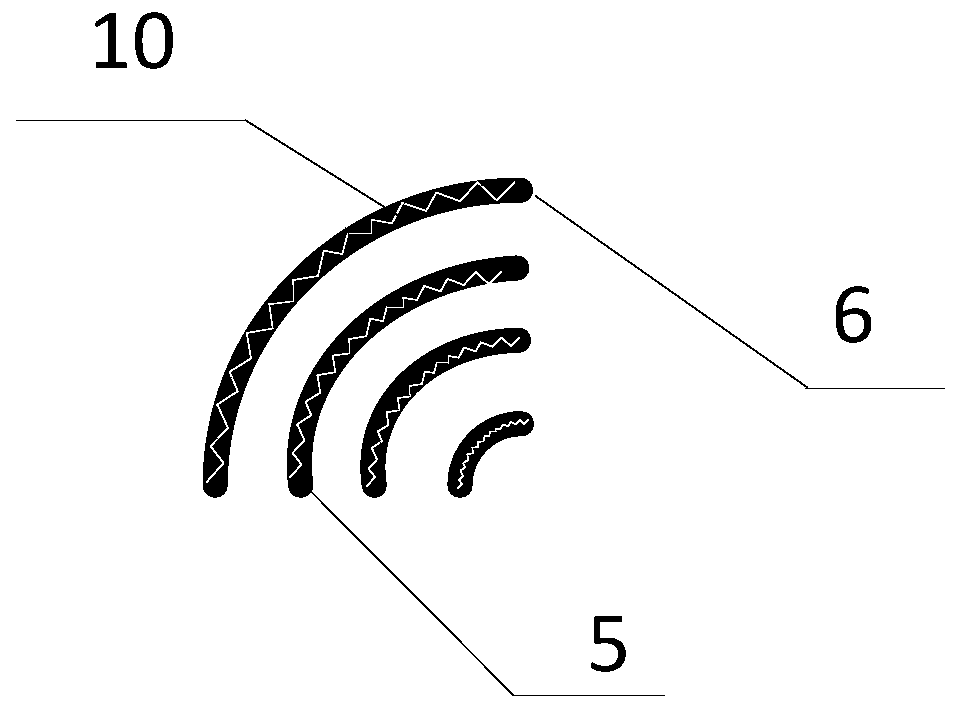

Drainage pipeline system, construction method and leakage detection method

ActiveCN111677087AEasy to detectImprove repair effectMeasurement of fluid loss/gain rateSewer pipelinesStructural engineeringDrainage tubes

Owner:宁波市北仑精诚设备安装有限公司

Novel million-tower boiler top sealing structure and mounting method thereof

PendingCN112503563AReduce design and manufacturing costsImprove the operating environmentCasings/liningsThermodynamicsBoiler furnace

Owner:华能陇东能源有限责任公司 +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap