Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "High bonding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Emulsified acrylic acid modified asphalt cement group waterproof coating material and method for producing the same

InactiveCN101220233AGood alkali resistanceAvoid demulsificationAntifouling/underwater paintsPaints with biocidesEmulsionAsphalt

The invention relates to an acrylic acid modified asphalt cement-based and water-proof coating and a preparation method. The emulsified acrylic acid modified asphalt cement-based and water-proof coating consists of component A and component B; wherein, the mixture ratio of the component A to the component B is from 1 : 0.5 to 1.5 (in weight); wherein, the raw materials of component A and the weight percentage thereof are respectively as follows: acrylic emulsion or amphetamine emulsion accounting for 40 to 70 percent, emulsified asphalt accounting for 10 to 50 percent, filler accounting for 8 to 20 percent, accessory ingredient accounting for 0.1 to 3 percent and water accounting for 1 to 19.0 percent; the raw materials of component B and the weight percentage thereof are as follows respectively: cement accounting for 70 to 100 percent and filler accounting for 0 to 30 percent. The acrylic acid modified asphalt cement-based and water-proof coating has the advantages of strong binding power with the base, high tensile strength, large unit extension, low cost and environment protection.

Owner:WUHAN YANGGUANG CONSTR NEW MATERIAL

Vehicular suspension arm

InactiveUS20090295113A1High strengthStrengthTractor-trailer combinationsResilient suspensionsSingle plateStructural engineering

A vehicular suspension arm is provided in which an arm main body (1) includes a main plate (2) press-formed as a main part of the arm main body and having a short cylindrical part (EB) provided integrally with one end by flanging, and a reinforcing plate (H) superimposed on one of upper and lower faces of the main plate (2) and reinforcing the main plate (2). The reinforcing plate (H) has an eye-shaped head part (Ha) formed in an annular shape and arranged coaxially with the short cylindrical part (EB), and a tail part (Hb) extending integrally from the eye-shaped head part (Ha) along the longitudinal direction of the main plate (2), is formed from a single plate material that is thicker than the main plate (2), and has at least the tail part (Hb) welded to the main plate (2). A bush press-fit portion (P1) is formed from an inner peripheral face of the eye-shaped head part (Ha) and an inner peripheral face of the short cylindrical part (EB). This ensures that the cross-sectional shape of a transition section from the bush press-fit portion to the plate-type arm main body is adequate, thus enabling the rigidity and strength required for the transition section to be easily guaranteed and, furthermore, it becomes possible to meet a requirement for increasing the strength of the arm without specially increasing the space around the outer periphery of the bush press-fit portion.

Owner:F TECH INC +1

Method and device for electrolytic machining of massive array tiny pits through wedge-shaped runner

ActiveCN103600144APrevent inflowConsistent strengthMachining electrodesElectrical-based machining electrodesElectrolysisEngineering

The invention discloses a method and a device for electrolytic machining of massive array tiny pits through a wedge-shaped runner, and belongs to the technical field of electrolytic machining. The method includes processing the surface of a mask plate to enable the surface to fit with the surface of a workpiece anode; fixing a wedge-shaped tool cathode above the mask plate to enable the wedge-shaped runner to be formed between the wedge-shaped tool cathode and the mask plate; connecting the workpiece anode and the wedge-shaped tool cathode with an anode and a cathode of a power source respectively; feeding an electrolyte into the wedge-shaped runner, wherein the electrolyte reaches the surface of the workpiece anode through penetrating group holes in the mask plate; switching on the power source for electrolytic machining. The runner is arranged to be wedge-shaped, so that electric field intensity and electrolyte flowing speed are enabled to be progressively increased along the direction of the runner, both corrosion strength and speed of a workpiece are enabled to tend to be uniform, and uniformity and machining accuracy of electrolytic machining are improved. A PDMS (polydimethylsiloxane) template is taken as the mask plate, bonding strength of the mask plate and the workpiece anode can be guaranteed, stray corrosion, of the electrolyte, to places around a machining area can be effectively reduced, and locality and uniformity of electrolytic machining can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

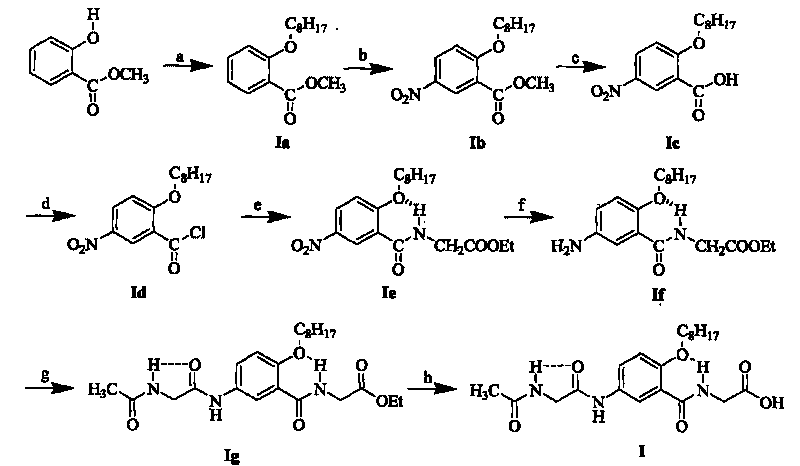

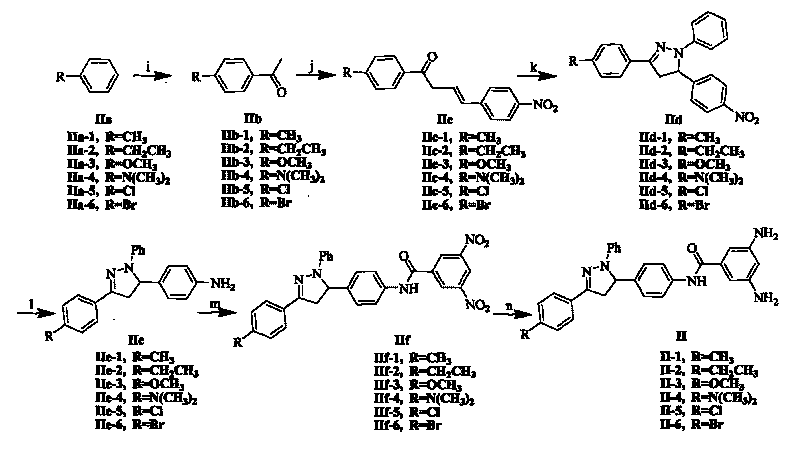

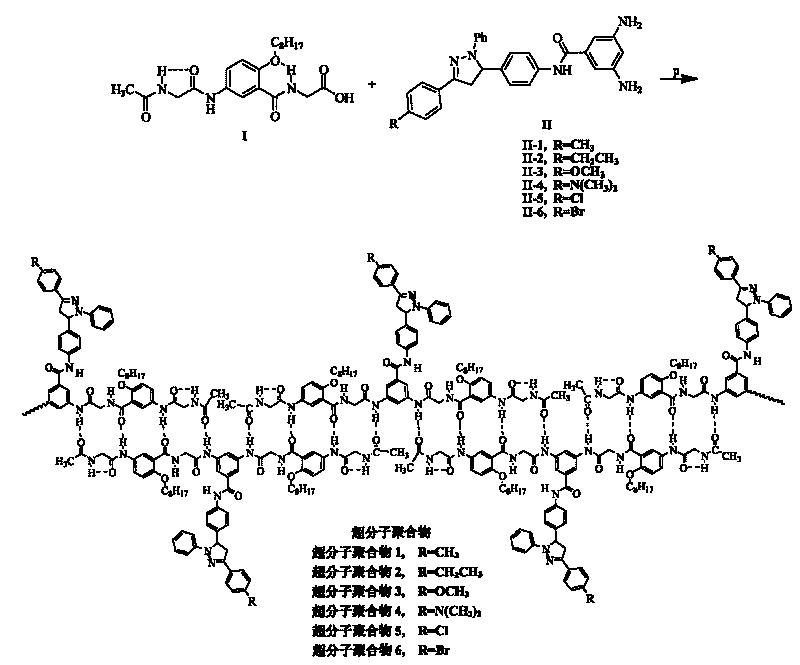

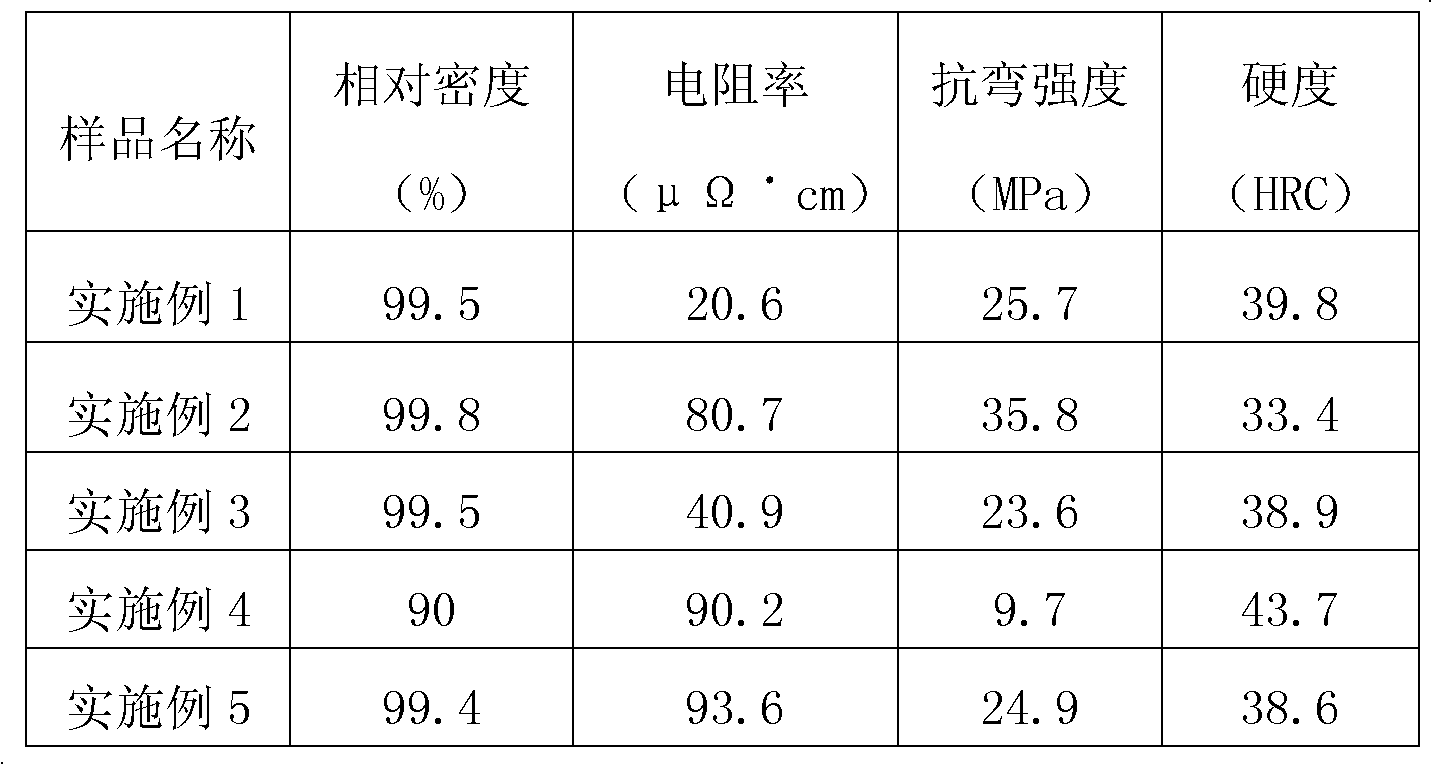

Hydrogen-bond self-assembly super-molecular blue-fluorescence polymer and symmetric method thereof

InactiveCN101693763ANo secondary repulsionImprove bindingOrganic compound preparationCarboxylic acid amides preparationChemistryRepulsion force

The invention relates to a pyrazoline-type hydrogen-bond self-assembly super-molecular polymer with blue-fluorescence property. The invention adopts an oligo-polyamide strip without secondary repulsion force as a hydrogen-bond bonding part and increases the number of hydrogen-bond donors and hydrogen-bond receptors to 8 from 4 so as to greatly improve the connection strength of the polymer. In addition, a pyrazoline derivative is introduced in a super-molecular polymer monomer as a blue-fluorescence unit to obtain a super-molecular blue-fluorescence polymer with a higher fluorescence quantum yield. The obtained six novel super-molecular polymer blue-fluorescence materials can emit pure-blue fluorescence in a solution state and have emission wavelengths of 440-455nm, semi-peak widths of 61-70nm and better color purity and can emit pure-blue fluorescence in a solid state and have emission wavelengths of 451-474nm, semi-peak widths of 71-79nm and better color purity.

Owner:SICHUAN UNIV

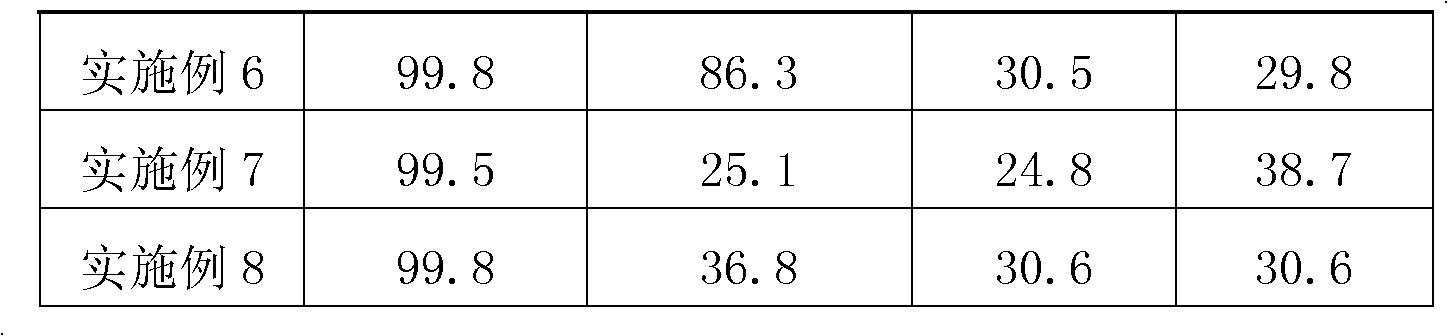

High-modulus carbon fiber used as thermoplastic resin-based composite reinforcement body and preparation method thereof

InactiveCN110528264AGood heat resistanceHigh bonding strengthCarbon fibresPhysical treatmentAmmoniumAtmosphere

Owner:BEIJING UNIV OF CHEM TECH

Self-cleaning antibacterial coating and preparation method thereof

ActiveCN114836070AHigh bonding strengthImprove adhesion durabilityAntifouling/underwater paintsPaints with biocidesAerogelAnti bacterial

Owner:广东卡百利新材料科技有限公司

High-strength TPU composite thermal insulation fabric and preparation method thereof

ActiveCN110861363AGood tensile propertiesHigh bonding strengthClothingsFibre treatment to obtain bast fibreBonding strengthFiber

Owner:厦门市北顶纺织科技有限公司

Formaldehyde-free composite board special for flame retardant wooden house and preparing method of board

ActiveCN106514800AImprove bearing capacityTightly boundNon-macromolecular adhesive additivesStarch adhesivesPerliteParaffin oils

The invention relates to a formaldehyde-free composite board special for a flame retardant wooden house and a preparing method of the board. Plant fibers are adopted to be smashed, and the plant fibers and a phase change material are jointly machined into the board special for the wooden house. The board comprises a core layer with the flame retardant waterproof phase change energy storage function and a solid wood layer composited on the core layer through pressure; the core layer is prepared by raw materials including, by weight, 30 parts to 80 parts of expanded perlite or sepiolite, 30 parts to 40 parts of any phase change material in paraffin, n-octadecane, octadecanol, cetanol, tetradecyl alcohol, dodecanol, n-decanol, stearic acid, glyceryl stearate, palmitic acid, myristic acid, lauric acid, n-caprylic acid and stearic acid butyrin, 5 parts to 10 parts of Schiff alkaline gel factor, 10 parts to 20 parts of graphite, 20 parts to 40 parts of silica sol solutions, 20 parts to 40 parts of plant fibers, 10 parts to 20 parts of starch, 0.5 part to 5 parts of hydrogen peroxide, 5 parts to 10 parts of glass fibers, 2 parts to 10 parts of calcium carbonate, 0.5 part to 5 parts of a penetrating agent, 8 parts to 35 parts of a flame retardant agent, and 2 parts to 8 parts of a waterproof agent. The beneficial effects of saving a large amount of wood and adjusting the indoor temperature are achieved.

Owner:郑州一安水性高分子材料有限公司

Natural granite marble and multiple-artificial material composite high-strength adhesive

InactiveCN111763489AGood bonding strengthHigh bonding strengthGraft polymer adhesivesMacromolecular adhesive additivesAdhesiveBonding strength

Owner:ANHUI LAO SHI REN STONE IND CO LTD

Ti2SnC-based electrical contact material as well as preparation method and application thereof

InactiveCN102320835AGood welding resistanceHigh bonding strengthCable/conductor manufactureNon-conductive material with dispersed conductive materialAlloyElectrical contacts

Owner:PANZHIHUA UNIV

Rubberized fabric material with polyester cotton lining and capable of preventing chemical penetration

ActiveCN109501415AHigh bonding strengthThe physical and mechanical properties have not declinedSynthetic resin layered productsClothingsPolyesterVulcanization

The invention discloses a rubberized fabric material with a polyester cotton lining and capable of preventing chemical penetration. The rubberized fabric comprises base cloth, wherein two side surfaces of the base cloth are respectively coated with a fluororubber layer and a chlorobutyl rubber layer; polyester cotton cloth is compounded outside the fluororubber layer. According to the rubberized fabric material, the polyester cotton cloth is laminated to the fluororubber layer, so that the bonding strength of the rubberized fabric is improved; the two surfaces of the base cloth are respectively coated with fluororubber and chlorobutyl rubber; the one layer of polyester cotton cloth is laminated to the fluororubber layer; after drum type primary vulcanization, secondary vulcanization is performed in a vulcanizing tank, and thereby a finished product is obtained. Compared with the prior art in China, the rubberized fabric material has the advantages that the bonding strength of the rubberized fabric is improved while physical and mechanical properties, medium resistance and protecting performance are prevented from being reduced.

Owner:SHANXI XINHUA CHEM

Steel strip reinforced polyethylene helically corrugated tube and production method thereof

InactiveCN103697250AIncrease contact surfaceHigh bonding strengthRigid pipesBack stressCompression molding

The invention relates to a steel strip reinforced polyethylene helically corrugated tube and a production method thereof. A steel screen is welded at the feet of a V-shaped steel strip, a polyethylene layer is wound and coated with the bent steel strip, and the outer part of the steel strip is coated with the polyethylene layer. The production method comprises the steps of (1) molding of an inner layer, (2) compression molding of the steel strip, (3) welding of the steel screen through the steel strip, (4) bending and winding of the steel strip with a steel wire screen, and (5) molding of an outer layer. The steel strip reinforced polyethylene helically corrugated tube has the beneficial effects that the steel strip has certain spring-back stress in the compression process, so that after the steel screen is welded to the steel strip, the contact area of the steel strip and the outer side of a polyethylene tube is increased, the adhesion strength is improved, the product yield is improved, the shape and quality of a product are stabilized, and the safety of the product is ensured.

Owner:TIANJIN SHENGXIANG PLASTIC PIPE IND

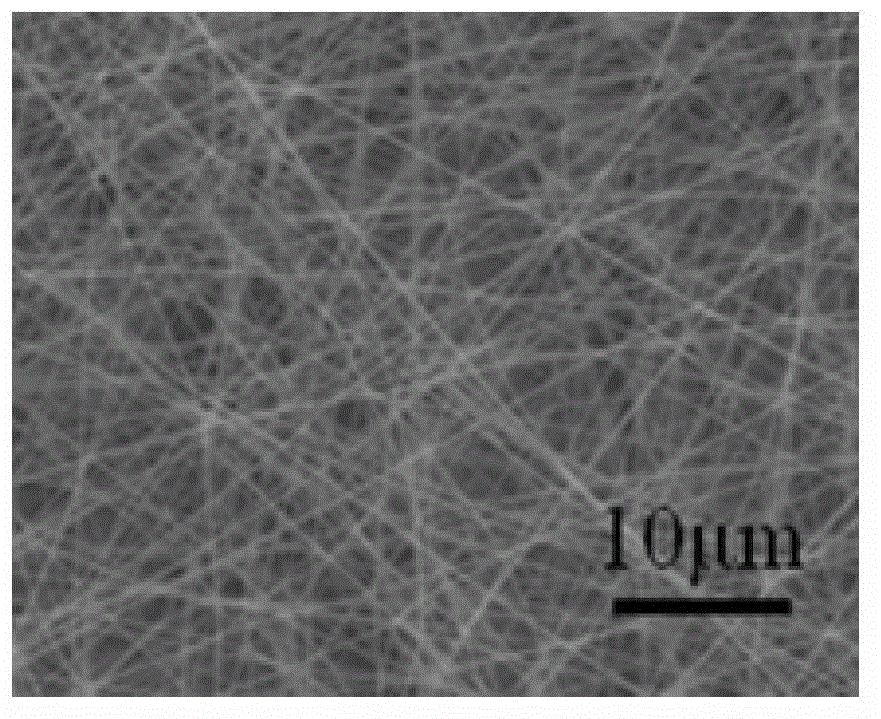

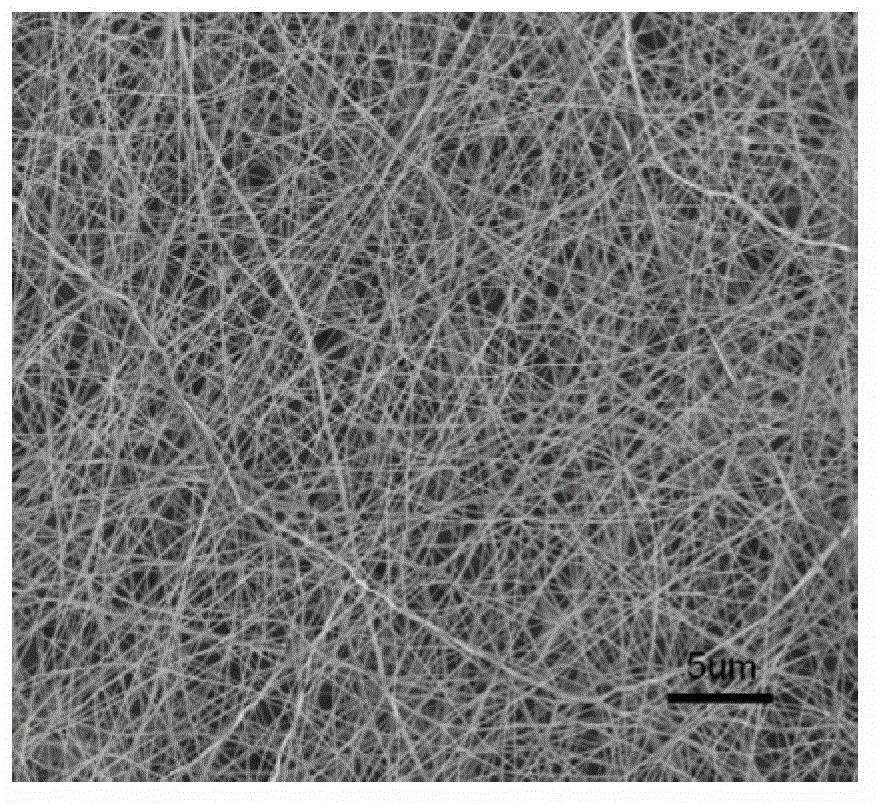

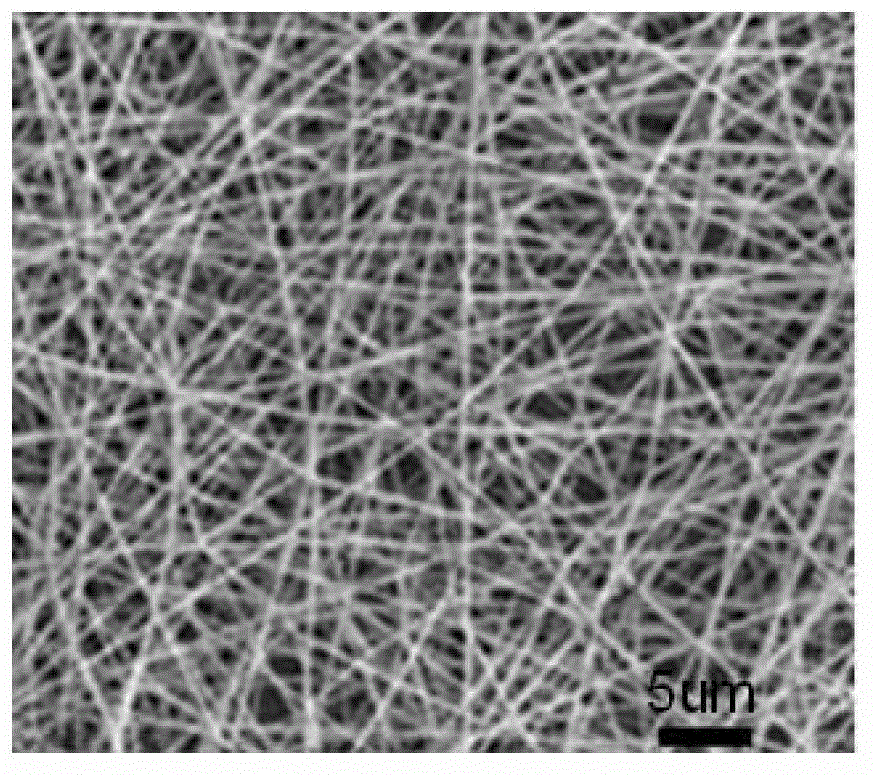

ITO (indium tin oxid) nanofiber/cadmium sulfide (CdS) quantum dot solar cell and preparing method thereof

InactiveCN102723212AHigh bonding strengthLow costLight-sensitive devicesBonding strengthCadmium sulfide

Owner:TIANJIN UNIV

Whole plasma vacuum plating process for car ornament

InactiveCN105671511AGuaranteed appearance and finishHigh bonding strengthIon implantation coatingSputtering coatingAnti-corrosionArgon

Owner:WUHAN CHAMPION ELECTRONICS

Method for preparing wear-resistant plastic particles by using waste polystyrene

InactiveCN110760138AImprove wear resistanceSolve the defect of poor wear resistanceCyclohexanoneSilicic acid

The invention discloses a method for preparing wear-resistant plastic particles by using waste polystyrene. The method specifically includes the following steps that (1) the waste polystyrene and liquid paraffin are put into a reactor for heat treatment under the nitrogen environment, then cobalt powder is added for natural cooling, and pretreated polystyrene is obtained; (2) tetraethyl orthosilicate is added into a chitosan solution, hydrochloric acid is added and then placed in a water bath, glutaraldehyde is added, and chitosan / silica particles are obtained by reaction; (3) the pretreated polystyrene is added into cyclohexanone after being cut into granules and dried, and polyvinyl pyrrolidone is added, stirred and dissolved, and then dried particles are added to obtain a coating solution; and (4) after the coating solution is treated, a film is scraped on a substrate, removed after phase transfer, and melted and extruded with a plasticizer and a lubricant through a twin-screw extruder. According to the method, by increasing the bond strength between the polystyrene and silicon dioxide, significant improvement of the wear resistance of the polystyrene is realized, and the methodis suitable for large-scale and industrial production.

Owner:ANHUI GUANHONG PLASTIC IND

Water-proof roof glue

InactiveCN101225288AImprove waterproof and thermal insulation performanceGood weather resistanceBituminous material adhesivesHydrocarbon polymer adhesivesAdhesivePolystyrene

The invention relates to a building waterproof material, in particular to a waterproof roof adhesive, which aims to solve the problems in prior roof waterproof material of poor weatherability, easy bubbling and peeling, and poor permeability and air permeability, comprising asphalt, coal tar, waste polystyrene foam, lime and sawdust. Firstly, the waste polystyrene foam is ground to particles; secondly, the coal tar is added into a vessel and heated to 650 to 700 degrees; and the asphalt is added into the vessel, and then the former mixture is agitated homogeneously and keep on warming up to 750 degrees, after the asphalt is dissolved, the mixture is cooled to 400 to 500 degrees; at last, waste polystyrene foam, lime and sawdust are added into mixture successively, the mixture is agitated homogeneously and cooled to a paste shape, and then the finished product is obtained. The building waterproof material has the advantages that: the building waterproof material integrates the advantages of waterproof, heat preservation and heat insulation and has admirable waterproof and heat preservation effect, good weatherability, no fluid and cracks, high adhesive strength; meanwhile, the material meet the national specified standard; more importantly, the aim of waste reuse, pollution treatment, environment protection and cost saving are realized by using the waste polystyrene foam.

Owner:亢吉田

Special unsaturated polyester resin adhesive for quartz stone sheet material

InactiveCN106753148AImprove impact toughnessHigh bonding strengthNon-macromolecular adhesive additivesGas phasePhosphine oxide

The invention discloses a special unsaturated polyester resin adhesive for a quartz stone sheet material. The special unsaturated polyester resin adhesive is prepared from the following raw materials: unsaturated polyester resin, acrylic acid-2-hydroxyethyl ester, pentaerythritol triacrylate, 2-methyl-1-(4-methylthiophenyl)-2-morpholinyl-1-acetone, biphenyl-(2,4,6-trimethylbenzoyl)phosphine oxide, a flatting agent, a de-foaming agent, a silane coupling agent, gas-phase silicon dioxide, glass microsphere and modified aluminum hydroxide. The special unsaturated polyester resin adhesive for the quartz stone sheet material, provided by the invention, has high binding performance, good impacting toughness and excellent flame-retarding performance.

Owner:ANHUI AIDIBEI BIOLOGICAL CO LTD

Polymer bonding mortar and preparation method thereof

The invention discloses a polymer bonding mortar and a preparation method of the polymer bonding mortar. The bonding mortar uses a modified redispersible powder to replace the traditional sizing material, the redispersible powder modified by paraffin and micron sized silica aerogel is better in water resistance and dispersibility, the bonding strength between the redispersible powder and an aggregate is stronger, in addition, a certain amount of aramid pulp and activated carbon powder are added as the aggregate, the degree of compacting of the mortar and the internal permeability of the mortar are improved, the bonding speed of the mortar is accelerated, the uneven hydration is avoided, the solidified mortar is excellent in anti-permeability, an introduced water retention particle is a long-acting reversible product, the water retaining property of the mortar is effectively improved, and the comprehensive performance of the mortar are further improved. The prepared bonding mortar is green and environmentally friendly, is economical and efficient, and has a prominent application advantage in an external wall insulation system.

Owner:HEFEI SHENZHOU CONSTR GRP CO LTD

Method for preventing landslides induced by inappropriate liquid injection intensity in in-situ leaching mining

ActiveCN105132675AAvoid wastingHigh bonding strengthProcess efficiency improvementCement slurryIn situ leach

Owner:四川共拓岩土科技股份有限公司 +1

Flame-retardant modified silane polyether adhesive

InactiveCN107974229AHigh bonding strengthImprove flame retardant performanceNon-macromolecular adhesive additivesPolyether adhesivesPolymer sciencePlasticizer

The invention provides a flame-retardant modified silane polyether adhesive. The flame-retardant modified silane polyether adhesive disclosed by the invention is prepared from the following raw materials calculated in parts by weight: 10 to 30 parts of modified silane polyether resin 30000 T, 1 to 5 parts of fumed silica, 1 to 5 parts of a silane coupling agent, 1 to 10 parts of a flame-retardantcomplex additive, 60 to 70 parts of powder, 0.1 to 0.5 part of a light stabilizer, 10 to 20 parts of a plasticizer, 0.1 to 0.3 part of a catalyst, and 0.1 to 0.5 part of an oxidant. The flame-retardant modified silane polyether adhesive disclosed by the invention is high in bond strength, and better in elongation and tensile strength and good in flame retardancy, wherein the bond strength is morethan 1.4 MPa, the elongation is more than 550%, the tensile strength is more than 3.6 MPa, and the flame retardancy can reach the levels V-1 and V-0.

Owner:SUZHOU QIYUE NEW MATERIAL TECH CO LTD

Electrostatic spraying slushing oil

InactiveCN104611109AImprove adhesionImprove thermal stabilityLubricant compositionPolyesterPhosphate

The invention discloses electrostatic spraying slushing oil. The electrostatic spraying slushing oil is composed of the following raw materials in parts by weight: 0.4-1 part of p-nitrophenyl phosphate sodium, 60-70 parts of #25 transformer oil, 1-2 parts of polyisobutene, 3-5 parts of microcrystalline wax, 2-3 parts of hosho oil, 2-4 parts of phthalate polyester, 4-6 parts of petroleum sodium sulfonate, 2-3 parts of fumed silica, 1-3 parts of triethanolamine oleic soap, 1-2 parts of diphenyl silandiol, 0.5-1 part of monopotassium phosphate, 0.4-1 part of inositol hexaphosphoric acid, 0.3-0.5 part of zinc acetylacetonate, 2-3 parts of oleic acid and 3-5 parts of wear resistant machine oil. A molecular directional adsorption film can be formed on the surface of the metal by adding the wear resistant machine oil into the slushing oil, so that the friction can be reduced; the modified terpene resin has a good cohesive property and strong thermal stability so that the compatibility between the materials can be promoted and the adhesive force of the film can be enhanced; the zinc dihydrogen phosphate is used as a common metal surfactant which has a good rust removal preservative effect; the rare earth lanthanum ion and the OH<-> generated on the surface of the metal material during the oxygen absorption corrosion process can generate an insoluble complex which can slow down the corrosion of the electrode reaction and has a good slow-release effect.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Energy-saving and environment-friendly thermal insulation material and preparation method thereof

The invention provides an energy-saving and environment-friendly thermal insulation material and a preparation method thereof. The energy-saving and environment-friendly thermal insulation material comprises the following components in parts by weight: 60 to 80 parts of polystyrene, 2 to 6 parts of nanometer titania, 2 to 4 parts of nano-aluminium hydroxide, 10 to 14 parts of cross-linking agent, 20 to 30 parts of PPF fiber, 15 to 22 parts of mineral waste residue, 10 to 14 parts of epoxy resin, 8 to 16 parts of foaming agent, and 45 to 60 parts of water. The preparation method comprises the steps of uniformly mixing the components, injecting into a mold, extruding in a spacing way, and maintaining for 8 to 12h under sustained pressure. The thermal insulation material has a higher flame retardant property, a lower heat conductivity coefficient and higher breaking strength.

Owner:HEFEI GUANGNENG NEW MATERIAL TECH CO LTD

Automobile seat connecting rod mechanism with high endurance fatigue strength

InactiveCN111993962APlay a lubricating roleConvenient for centralized processingMovable seatsEngine lubricationCar seatChemical plating

The invention belongs to the technical field of seat connecting rod mechanisms and especially relates to an automobile seat connecting rod mechanism with high endurance fatigue strength. The mechanismcomprises a right supporting plate, a left supporting plate, a first connecting rod, a second connecting rod and a connecting rod piece. Toothed plates are connected to the left side end and the right side end of the first connecting rod; the connecting rod piece internally comprises a first oil inlet groove, a first oil outlet groove, a first oil groove, a second oil inlet groove, a second oil outlet groove, a second oil groove, a first rivet groove and a second rivet groove. Oil in the oil groove can be pumped out through the oil outlet groove; centralized treatment of lubricating oil is convenient, recycling is achieved, both a first rivet and a second rivet adopt a quenching and tempering treatment process; first chemical plating layers are arranged on the surfaces of the first rivetand the second rivet; and the surface roughness of the first rivet and the second rivet is smaller than Ra0.8 micrometer, an ENP coating on the surface of the rivet is high in uniformity, bonding strength, abrasion resistance and corrosion resistance, the durability and a fatigue life of the rivet are improved, the service life of the connecting rod mechanism is prolonged, and meanwhile the wholemechanism is more stable and reliable in operation.

Owner:YANCHENG TONGHUAN ELECTROMECHANICAL TECH CO LTD

Soft magnet core material with high saturation magnetic flux transmission performance

InactiveCN105761863AEvenly dispersedImprove performanceInorganic material magnetismTransformers/inductances detailsIonMagnetic core

The invention discloses a soft magnet core material with high saturation magnetic flux transmission performance. The soft magnet core material is prepared from the following raw materials in parts by weight: 25-26 parts of nickel oxide, 58-62 parts of ferric oxide, 21-23 parts of zinc oxide, 6-8 parts of silicon dioxide, 0.3-0.5 part of propolis, 0.2-0.3 part of diphenyl silanediol, 0.8-1.1 parts of guanidine carbonate, 0.2-0.4 part of propylene glycol alginate, 0.7-0.9 part of stearic acid, 2.6-3 parts of a silane coupling agent kh550, 0.7-0.9 part of barium titanate, 2.6-3 parts of polyamide resin, 2-2.6 parts of sodium silicate, 1-1.4 parts of silica sol, 1-1.3 parts of polyvinyl alcohol, 0.5-0.6 part of nano dysprosium, 1.3-2 parts of magnetic carbon powder, 1.1-2 parts of nano lanthanum oxide and a proper amount of deionized water. The prepared core material is excellent in transmission performance, simple in production process, high in production efficiency and high in mechanical strength, and is more suitable for durably working in a high-temperature environment.

Owner:TIANCHANG TIANHAO REFRIGERATION EQUIP FACTORY

Preparation method of high bonding type salt storage asphalt pavement material

The invention relates to a preparation method of a high bonding type salt storage asphalt pavement material and belongs to the technical field of building materials. According to the technical scheme,heavy saline-alkali soil is adopted as a raw material, and subjected to high-temperature calcining and wire drawing in fusion; by a high-concentration saline-alkali material in the saline-alkali soil, wires are drawn and fibers are collected, and by full bonding with resin particles, the bonding property between the material and resin is effectively improved; by excellent bonding property betweenmixed resin and asphalt, the bonding strength of the material is further improved; in the technical scheme, the saline-alkali soil is adopted as a modifying raw material, organic matters carbonized by high temperature are mostly decomposed, a small part of the organic matters form porous carbide and are loaded to the surface of a fiber material, and by excellent structural property of the surfaceof the carbide, the bonding strength between the material and the resin is improved, so that the bonding property and the mechanical strength of the compound asphalt material are further improved.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

Co-Mn-Si-Fe nanometer welding layer for welding and preparation method

InactiveCN104889597AImprove performanceExtended service lifeArc welding apparatusWelding/cutting media/materialsUltimate tensile strengthWear resistance

The invention relates to a Co-Mn-Si-Fe nanometer welding layer for welding and a preparation method. The Co-Mn-Si-Fe nanometer welding layer for welding comprises the following components in percentage by mass: 46-63% of Co, 29-37% of Mn, 7-9% of Si, 7-9% of Fe, 2-3% of Al2O3, and 0.5-1.5% of additive. The additive is Ni60A. The method comprises the following steps: Co, Mn, Si, Fe and Al2O3 are prepared to nanometer balls by an atomization method; the nanometer balls are uniformly mixed with grinded Ni60A to prepare nanometer welding rods; and finally, the nanometer welding rods are welded on the surface of a part to form the nanometer welding layer. The prepared nanometer welding layer has such advantages as high bonding strength, wear resistance and good corrosion resistance, realizes the repairing of the part, improves the service performance of the part, and prolongs the service life of the part.

Owner:WUHU DINGHAN REMFR TECH

Packaging box adhesive and preparation method thereof

InactiveCN109517561AImprove stress resistanceImprove moisture resistanceEpoxy resin adhesivesRosin adhesivesWaxChemistry

The invention discloses a packaging box adhesive. The packaging box adhesive contains the following components in parts by weight: 30-50 parts of epoxy resin, 30-50 parts of maleic resin, 30-50 partsof 2-imidazolidone, 30-50 parts of an ethylene-acetate copolymer, 10-20 parts of butyl rubber, 20-40 parts of epoxidized soybean oil, 15-30 parts of a castor oil hydrogenated mixture, 10-20 parts of boiled wood oil, 8-12 parts of tripropargyl trimellitate, 8-12 parts of a water-soluble polyethylene acetylene alcohol wax, 8-12 parts of isopropanol, 8-12 parts of silicon resin, 0.8-1.2 parts of an antioxidant, 1-3 parts of a tackifier and 2-20 parts of deionized water. By utilizing the epoxy resin, the high temperature resistance and adhesion property of the adhesive can be improved, meanwhile,the prepared adhesive is non-toxic and harmless, and a water-glue separation phenomenon is unlikely to occur; and the preparation method is simple, low in process condition and stable in product quality, a paper board obtained through adhesion is high in compressive resistance and strong in puncture resistance, and the quality of a product packaging box can be guaranteed. The packaging box adhesive has the characteristics of strong adhesion force, compressive resistance, moisture resistance and high temperature resistance.

Owner:贵州众旺包装有限公司

Anti-wear electrical ternary fluororubber nonmetal compensator and preparation method thereof

InactiveCN106566140AHigh bonding strengthImprove heat resistancePipeline expansion-compensationYarnPolymer science

The invention discloses a wear-resistant electrical ternary fluororubber nonmetal compensator, which is prepared from the following raw materials in parts by weight: a proper amount of ternary fluorubber, 100-110 of alkali-free bulked yarn fiberglass fabric, 50-55 of vinylidene fluoride-hexafluoropropylene copolymer, 200-220 of acetone, 2-2.5 of TEBA, 80-85 of 5-5.5 wt% potassium hydroxide aqueous solution, 110-120 of 30-31 wt% hydrogen peroxide aqueous solution, a proper amount of 36-38 wt% hydrochloric acid aqueous solution, 3-3.5 of zinc oxide crystal whiskers, 0.5-0.7 of zirconium oxychloride, 2.5-3 of PPS micron powder, and 0.3-0.5 of trifluoroethyl acrylate. According to the technical scheme of the invention, the compatibility and the heat resistance of PPS micron powder and rubber are improved. Meanwhile, the PPS micron powder can improve the toughness and the wear resistance of the rubber. Therefore, the toughness and the wear resistance of the compensator are improved.

Owner:DANGTU JINLONGFENG TECH CO LTD

Damping material for dust collector motor

The invention discloses a damping material for a dust collector motor. The damping material is made of the following raw materials in parts by weight: 30-70 parts of butadiene styrene rubber, 30-70 parts of ethylene-propylene-diene-terpolymer rubber, 20-60 parts of styrene-butadiene-styrene segmented copolymer, 15-60 parts of a polypropylene thermal-plastic elastomer, 10-50 parts of a polyurethane elastomer, 10-60 parts of acrylic ester, 2-20 parts of nano silicon carbide powder, 1-20 parts of phosphate, 1-20 parts of nano magnesia powder, 2-20 parts of nano zirconium dioxide powder, 1-15 parts of carbon fiber powder, 1-15 parts of boron fiber powder, 1-15 parts of wollastonite powder, 1-25 parts of glass beads, 10-40 parts of methyl silicone oil, 5-40 parts of carboxymethyl starch, 5-40 parts of polyethylene wax, 5-30 parts of a coupling agent, 2-25 parts of a promoter, 2-25 parts of an initiator and 1-20 parts of an anti-aging agent. The damping material for the dust collector motor, which is disclosed by the invention, is excellent in damping property and wearing resistance.

Owner:SUZHOU HAIGE ELECTRICAL TECH CO LTD

Copper plating process

Owner:李振萍

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap