Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11 results about "Polydimethylsiloxane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

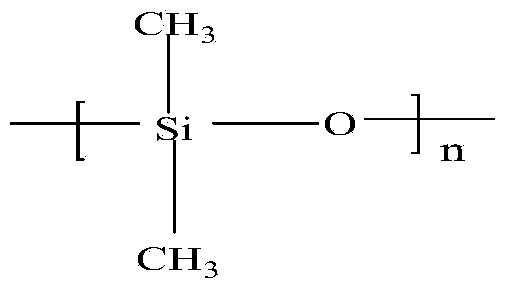

Polydimethylsiloxane (PDMS), also known as dimethylpolysiloxane or dimethicone, belongs to a group of polymeric organosilicon compounds that are commonly referred to as silicones. PDMS is the most widely used silicon-based organic polymer, and is particularly known for its unusual rheological (or flow) properties. PDMS is optically clear, and, in general, inert, non-toxic, and non-flammable. It is one of several types of silicone oil (polymerized siloxane). Its applications range from contact lenses and medical devices to elastomers; it is also present in shampoos (as dimethicone makes hair shiny and slippery), food (antifoaming agent), caulking, lubricants and heat-resistant tiles.

Method and device for electrolytic machining of massive array tiny pits through wedge-shaped runner

ActiveCN103600144APrevent inflowConsistent strengthMachining electrodesElectrical-based machining electrodesElectrolysisEngineering

The invention discloses a method and a device for electrolytic machining of massive array tiny pits through a wedge-shaped runner, and belongs to the technical field of electrolytic machining. The method includes processing the surface of a mask plate to enable the surface to fit with the surface of a workpiece anode; fixing a wedge-shaped tool cathode above the mask plate to enable the wedge-shaped runner to be formed between the wedge-shaped tool cathode and the mask plate; connecting the workpiece anode and the wedge-shaped tool cathode with an anode and a cathode of a power source respectively; feeding an electrolyte into the wedge-shaped runner, wherein the electrolyte reaches the surface of the workpiece anode through penetrating group holes in the mask plate; switching on the power source for electrolytic machining. The runner is arranged to be wedge-shaped, so that electric field intensity and electrolyte flowing speed are enabled to be progressively increased along the direction of the runner, both corrosion strength and speed of a workpiece are enabled to tend to be uniform, and uniformity and machining accuracy of electrolytic machining are improved. A PDMS (polydimethylsiloxane) template is taken as the mask plate, bonding strength of the mask plate and the workpiece anode can be guaranteed, stray corrosion, of the electrolyte, to places around a machining area can be effectively reduced, and locality and uniformity of electrolytic machining can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method of Treating Paper Forming Wire Surface

ActiveUS20120043040A1Non-fibrous pulp additionFats/resins/pitch/waxes removal in pulpPolymer sciencePolyethylene glycol

A method for inhibiting resinous and sticky substances from filling or forming deposits on or within papermaking forming wire, by applying to said wire an effective inhibiting amount of a composition comprising at least one cationic agent selected from the group consisting of (a) cationic polyureas, (b) hydrophobically modified cationic polymers, (c) alkylammonium or / and alkylimidazolium salts, and optionally at least one nonionic amphiphilic copolymer selected from (i) hydrophobically modified polyethylene glycols], (ii) hydrophobically modified cellulose ethers, (iii) copolymers of vinyl alcohol and vinyl alkonate, (iv) polyoxyalkylene block copolymers, and (v) hydrophilically modified polydimethylsiloxanes.

Owner:SOLENIS TECH CAYMAN

Hydrophobicity-enhanced heat-vulcanized silicone rubber and preparation method thereof

InactiveCN107286671AEnhance internal bondingImprove mechanical propertiesVulcanizationPolymer science

The invention provides hydrophobicity-enhanced heat-vulcanized silicone rubber and a preparation method thereof. The specific preparation method of the silicone rubber comprises steps as follows: divinyltetramethyldisiloxane is mixed with a mixed solution of concentrated hydrochloric acid, deionized water and ethanol, the mixture is mechanically stirred, ethyl orthosilicate is dropwise added, the mixture is subjected to hydrolytic condensation, methylbenzene is added for extraction and layering, methyl vinyl silicone resin is obtained, crosslinked polyethylene particles are added to the methyl vinyl silicone resin, the mixture is stirred uniformly and subjected to molding curing and vacuum heat treatment, and the polyethylene particle crosslinked methyl vinyl silicone resin is obtained; nano-montmorillonite, amorphous alumina and titanium dioxide are added to a polydimethylsiloxane prepolymer, the mixture is mixed and subjected to crosslinking and curing, and a reinforced material coated with organic silicone rubber is obtained; the polyethylene particle crosslinked methyl vinyl silicone resin, the reinforced material coated with organic silicone rubber, 2,4-dichlorobenzoyl peroxide, diphenyl silanediol and octamethylcyclotetrasiloxane are mixed uniformly, left to stand, subjected to open milling and secondary vulcanization, and the hydrophobicity-enhanced heat-vulcanized silicone rubber is obtained.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Environment-friendly ceramic coating material for water faucet

InactiveCN106189561ACorrosion resistantWear-resistantAnti-corrosive paintsCarbon fibersPolybutylene terephthalate

Owner:朱燕华

Preparation method of mosquito compound eye-imitating hydrophobic surface material

InactiveCN105045037AEasy to operateReduce manufacturing costPhotomechanical apparatusPolymer scienceSoft lithography

The invention relates to a preparation method of a mosquito compound eye-imitating hydrophobic surface material, and belongs to the field of preparation of hydrophobic materials. According to the method, colloidal crystal patterning is carried out on the surface of a polydimethylsiloxane template by soft lithography; hemispheric bumps on the surface of the template are collapsed when pressurized and tightly contact the colloidal surface; when the pressure is removed, the template restores into the original shape due to good elasticity, so that the mosquito compound eye-imitating hydrophobic surface material is obtained. The preparation process of the material is simple and easy to operate; the prepared template can be repeatedly utilized, so that the production cost is reduced; the material prepared by the bionic technology can relatively well adapt to various different natural conditions; and the performance of the product is relatively excellent.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

Gas-liquid converting stable borehole liquid for well drilling as well as preparation method thereof

ActiveCN104312556AAvoid falling blocksPrevent collapseDrilling compositionWell drillingSurface-active agents

Owner:CHENGDU DEDAO IND

Novel moisture-curing flame-retardant polyurethane hot melt adhesive and preparation method thereof

InactiveCN109679562AImprove performanceImprove flame retardant performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterMethacrylate

Owner:SHUNDE POLYTECHNIC

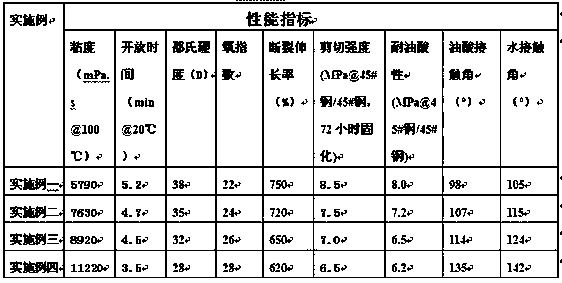

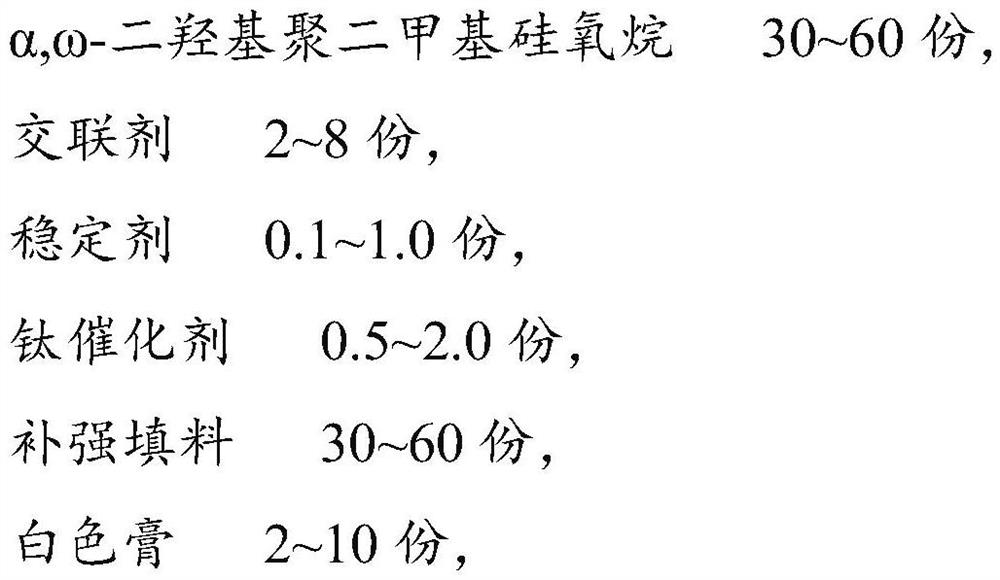

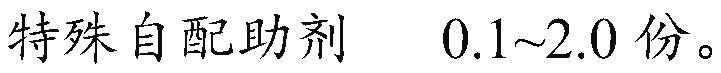

Panel lamp adhesive and comprehensive performance evaluation method thereof

ActiveCN112300750AImprove compatibilityHigh temperature and high humidity resistanceNon-macromolecular adhesive additivesPtru catalystHigh humidity

Owner:GUANGZHOU GLORYSTAR CHEM

Preparation method of 12 [mu]m battery aluminum foil

PendingCN113444921AGuaranteed mechanical propertiesElectrode carriers/collectorsMetal rolling arrangementsAl powderFerrosilicon

Owner:山东德利铝业科技有限公司

Preparation method of color fixing agent for mercerized wool deep green dyeing

InactiveCN109267401AHigh color fastnessAvoid fading and other phenomenaDyeing processColour fastnessPolypropylene glycol

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

Anti-yellowing leather finishing emulsion

InactiveCN111004556AEfficient captureAvoid oxidation reactionsCoatingsPolymer sciencePolypropylene glycol

The invention discloses an anti-yellowing leather finishing emulsion, which is prepared from the following raw materials in parts by weight: 65 to 80 parts of a modified polyacrylate resin, 1 to 3 parts of polydimethylsiloxane, 0.5 to 1.5 parts of an antifoaming agent, 0.5 to 1.5 parts of a leveling agent, 1.5 to 3 parts of silicon dioxide, 5 to 8 parts of polypropylene glycol and 10 to 20 parts of deionized water. According to the invention, the polyacrylate resin is modified, and the anti-yellowing modifier is prepared, is introduced into the polyacrylate resin in a cross-linking manner, andis firmly connected into the resin in a chemical bond manner, so that the polymers in a leather coating are effectively protected from an oxidation reaction, the good scrubbing resistance is achieved, and leather can resist yellowing for a long time.

Owner:王磊

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap