Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about "Non-macromolecular adhesive additives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance acidic transparent silicone sealant

ActiveCN101982516ANon-macromolecular adhesive additivesOther chemical processesChemistryDibutyl tin dilaurate

Owner:ZHEJIANG TIME NEW MATERIAL

Activatable Adhesive, Labels, and Related Methods

InactiveUS20120216951A1Improve securityEasy to operateStampsNon-macromolecular adhesive additivesAdhesivePlasticizer

Owner:AVERY DENNISON CORP

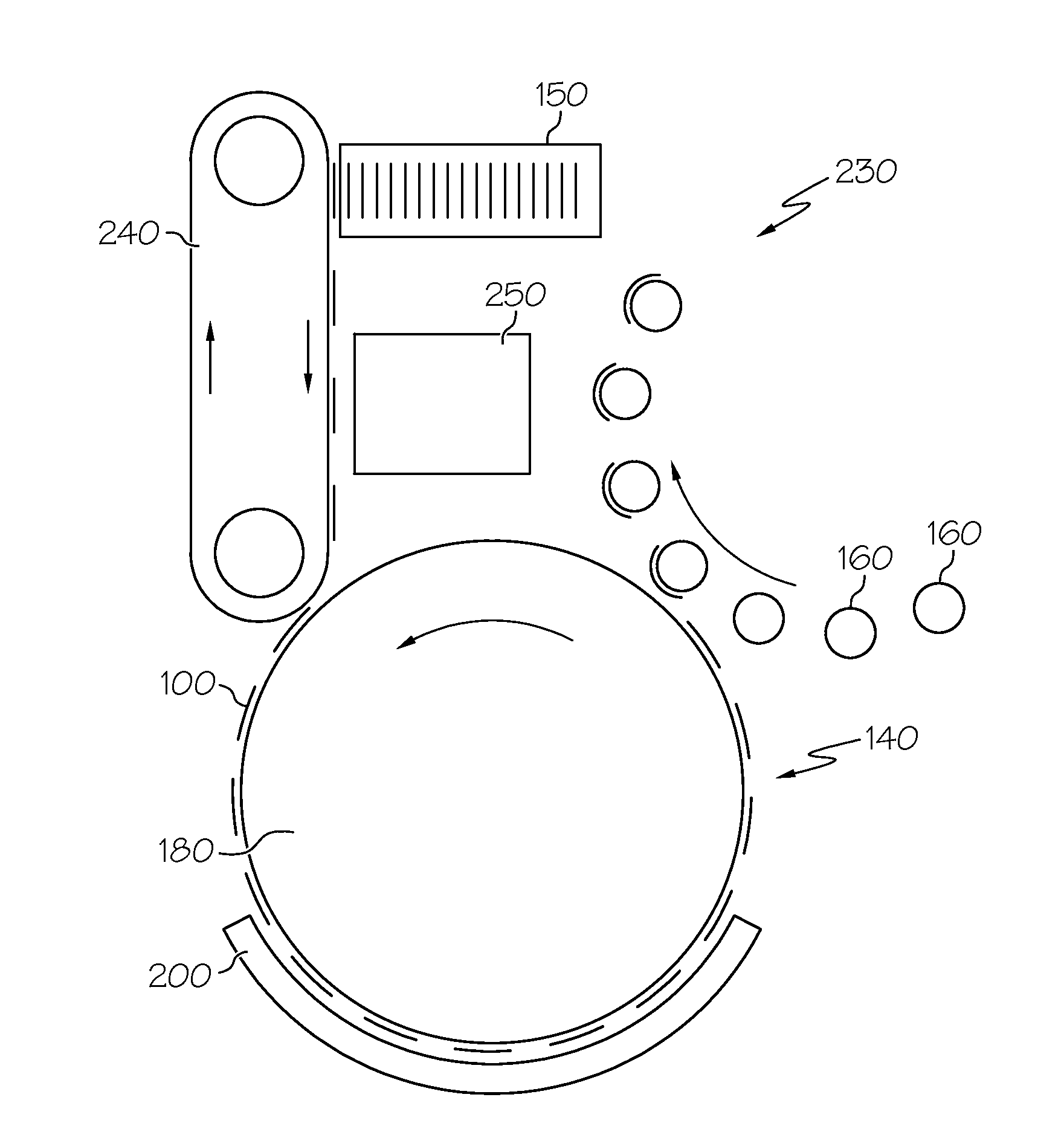

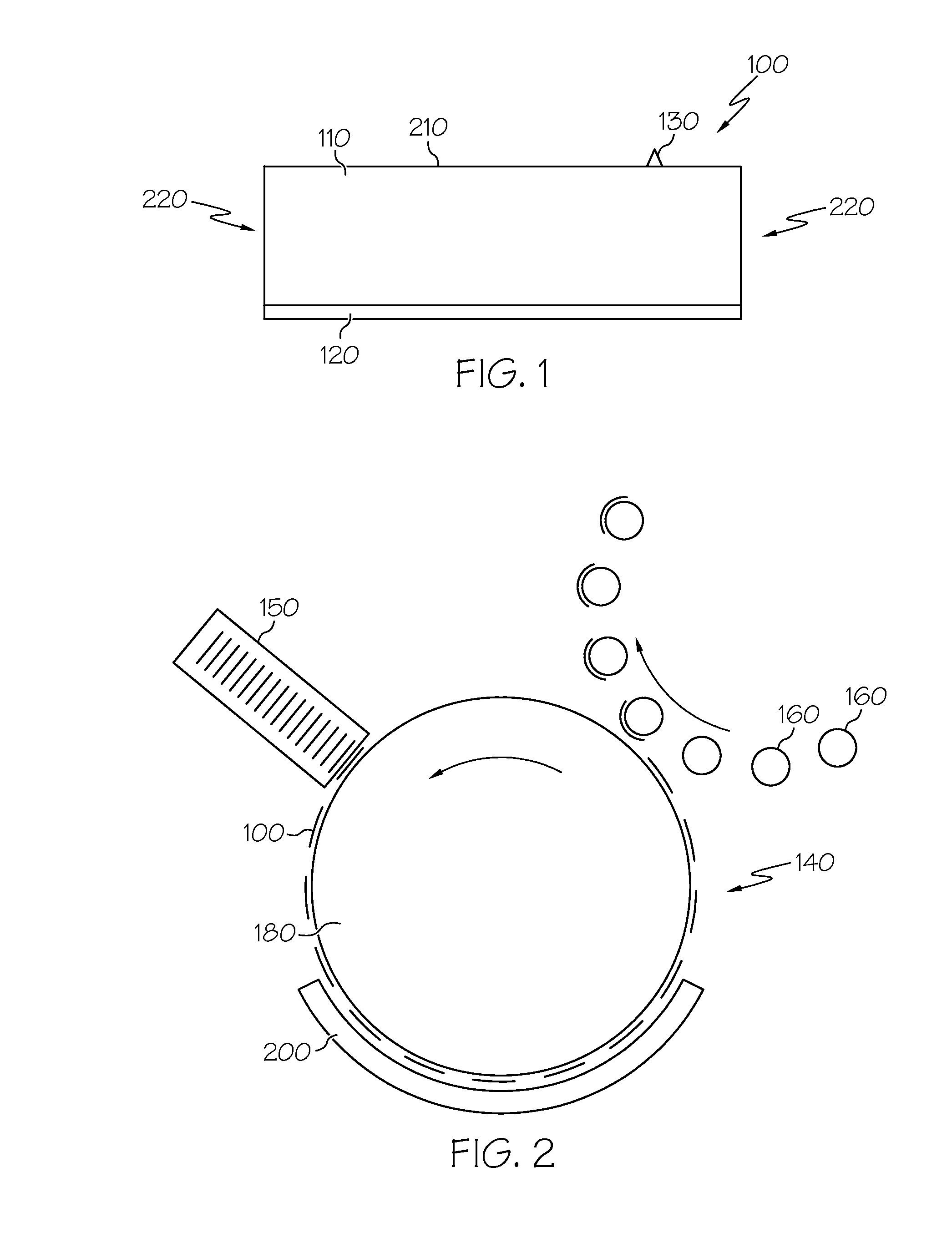

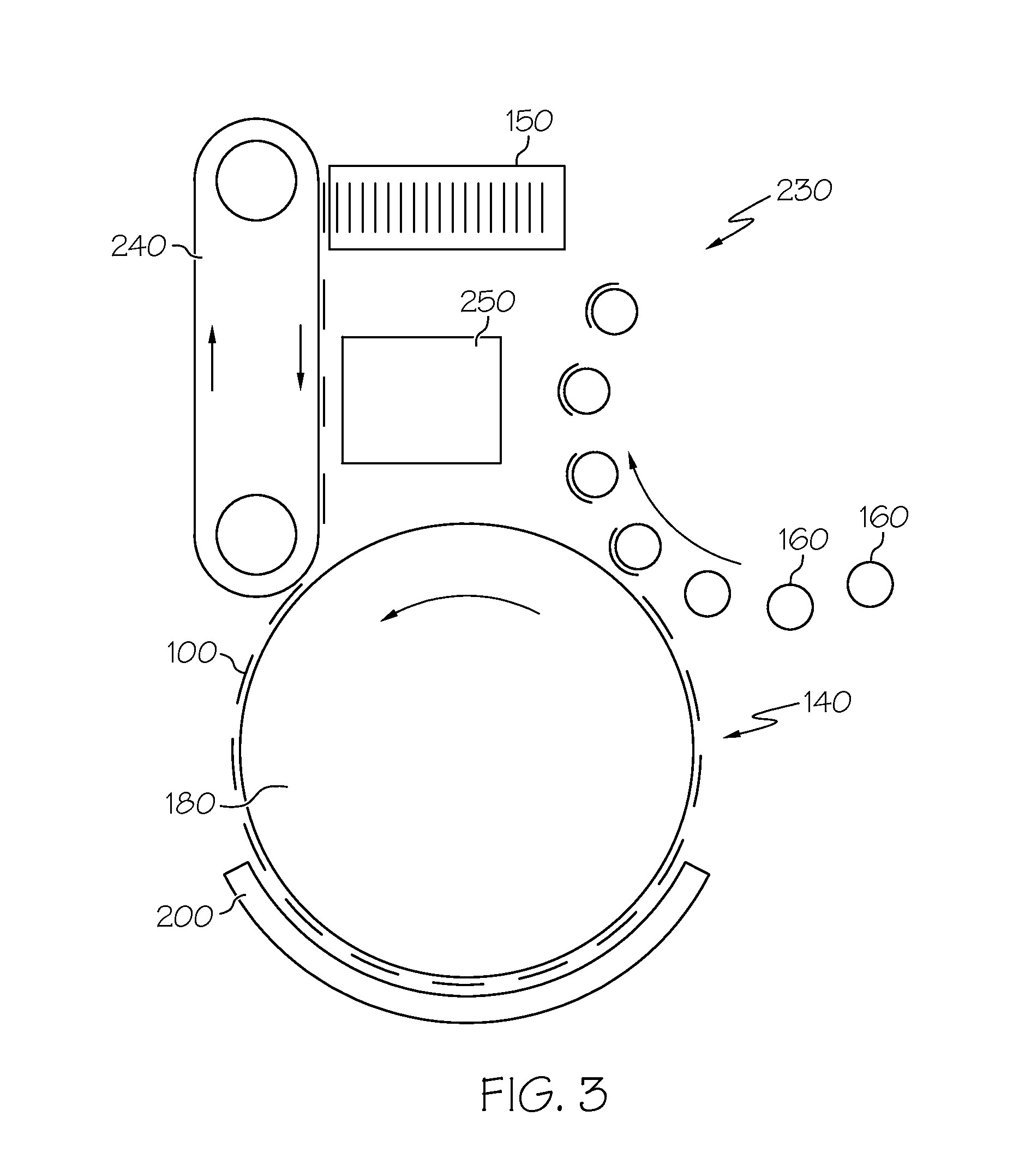

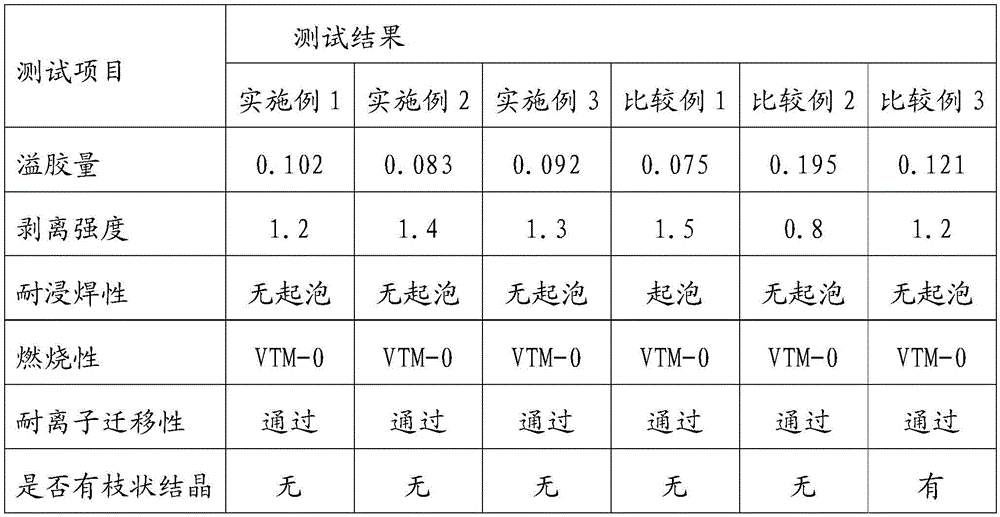

Halogen-free resin composition and cover film prepared from the same

InactiveCN105482442AExcellent resistance to ion migrationGood flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPolyester

Owner:GUANGDONG SHENGYI SCI TECH

Mildew-resistant and antibacterial nano-silver decorative laminated board

ActiveCN103862988AAdequate defense against invasionImprove adhesionNon-macromolecular adhesive additivesSpecial ornamental structuresPolymer sciencePolyolefin

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

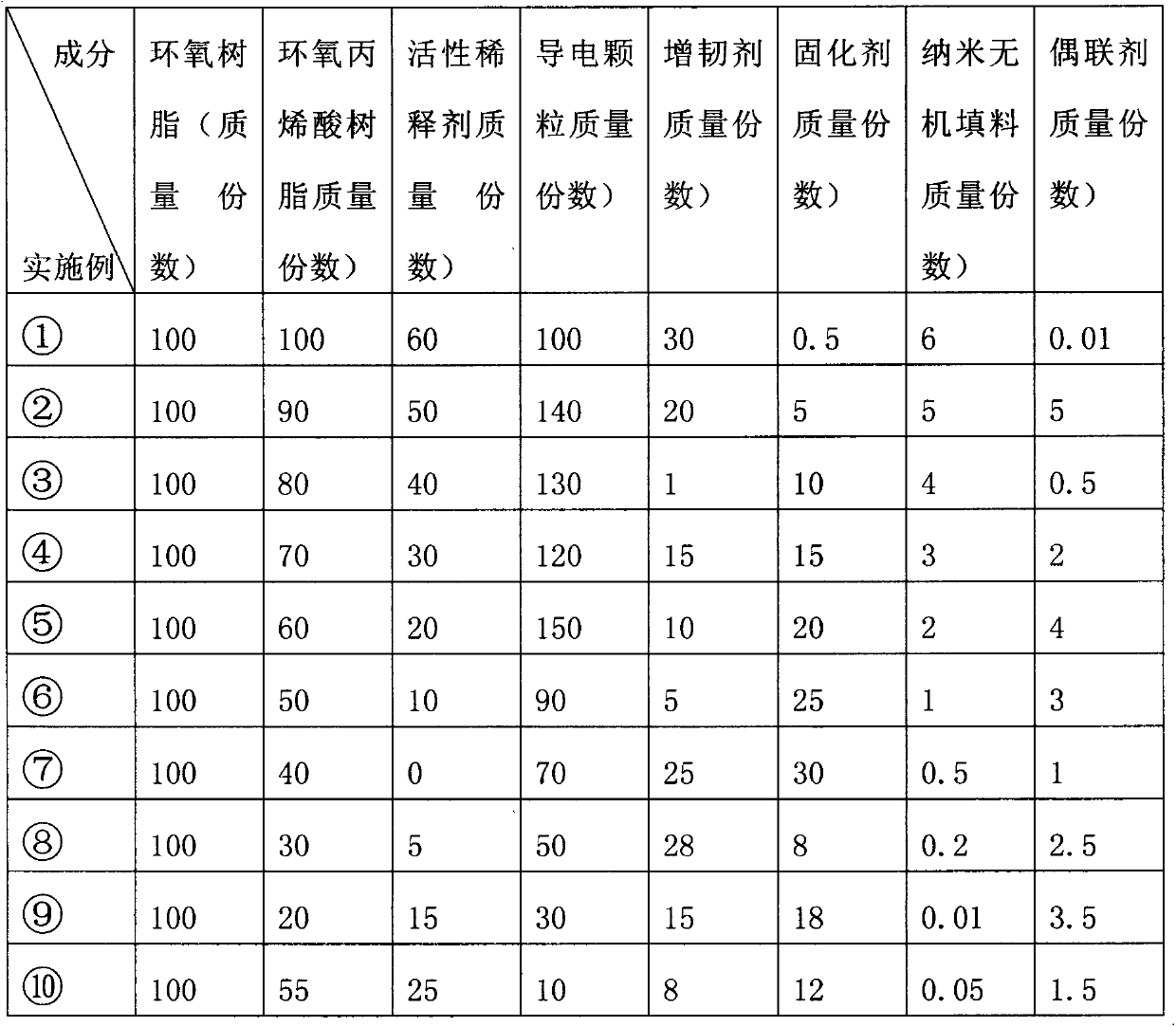

Rapidly solidified anisotropic conducting resin and preparation method thereof

InactiveCN103740311AFast curingImprove reliabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAcrylic resin

Owner:昆山西微美晶电子新材料科技有限公司

Production process of polyester water-resistant emery cloth with high adhesive power

InactiveCN107139087AImprove waterproof performanceLower surface energyNon-macromolecular adhesive additivesLiquid surface applicatorsEpoxyRubber material

The invention discloses a production process of high-adhesion polyester water-resistant abrasive cloth, which adopts water-resistant sandpaper as a cloth base for production; after scraping the sand-planted surface of the cloth base, corona treatment is performed on the sand-planted surface of the cloth base; Squeegee coating material, base rubber material and re-adhesive compound are all added with heat-dissipating materials and heat-conducting materials; the abrasive used for sand planting is diamond abrasive grain; the diamond abrasive grain layer (3) is coated with a re-adhesive layer (4) , the substrate (1) is a non-woven material; by mass percentage, the components of the primer layer (2) and the contents of each component are: 50% to 75% of epoxy modified phenolic resin, 15% to 15% of softening agent 35%, thickening lubricant 2%~5%, tackifier 8%~15%, the sum of the mass percentages of the above-mentioned components is 100%; by mass percentage, the components and The content of each component is: 60%-75% of water-based epoxy resin, 2%-10% of internal mixed antistatic agent, 15%-35% of auxiliary materials, and the sum of the mass percentages of the above-mentioned components is 100%.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Solvent-free unfoamed polyurethane structured adhesive and preparation method thereof

InactiveCN106433546ANon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolventPolyphenyl isocyanate

Owner:YANTAI DARBOND TECH

High-strength environment-friendly composite board and preparation method thereof

InactiveCN104690805AHigh strengthImprove toughnessNon-macromolecular adhesive additivesProtein adhesivesEnvironmental resistanceFiber

Owner:安徽忠盛新型装饰材料有限公司

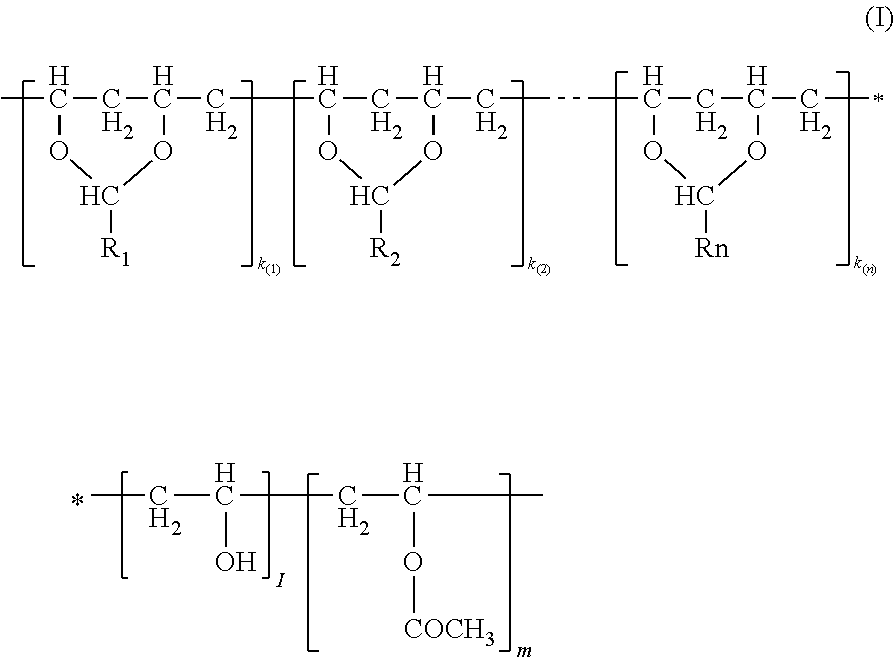

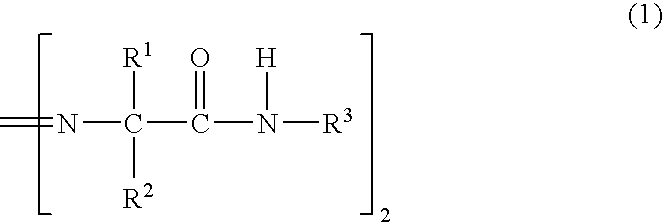

Thermoplastic polymer composition and molded article

InactiveUS20130122289A1Excellent in flexibility propertyImprove mechanical propertiesNon-fibrous pulp additionNon-macromolecular adhesive additivesPolyvinyl alcoholGlass transition

Owner:KURARAY CO LTD

Modified polyurethane acrylic resin and preparation method thereof

InactiveCN107353865ANot yellowingGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAdhesive

The invention discloses a modified polyurethane acrylic resin, which is prepared by polymerization among hydroxyl acrylate, diisocyanate, alkylated 4,4'-dicyclohexanol, and polyester / polyether glycol. The invention provides a method of preparing the modified polyurethane acrylic resin at the same time. The provided modified polyurethane acrylic resin does not contain active functional group such as phenyl ring, amino group, or the like, so the modified polyurethane acrylic resin will not become yellow even if the modified polyurethane acrylic resin is irradiated by light, and the weatherability is good. The resin can be applied to an adhesive, and has a good waterproof performance, good anti-falling performance, good drug resistant property, and excellent thermal stability.

Owner:SHENZHEN BAILICHU GLUE IND CO LTD

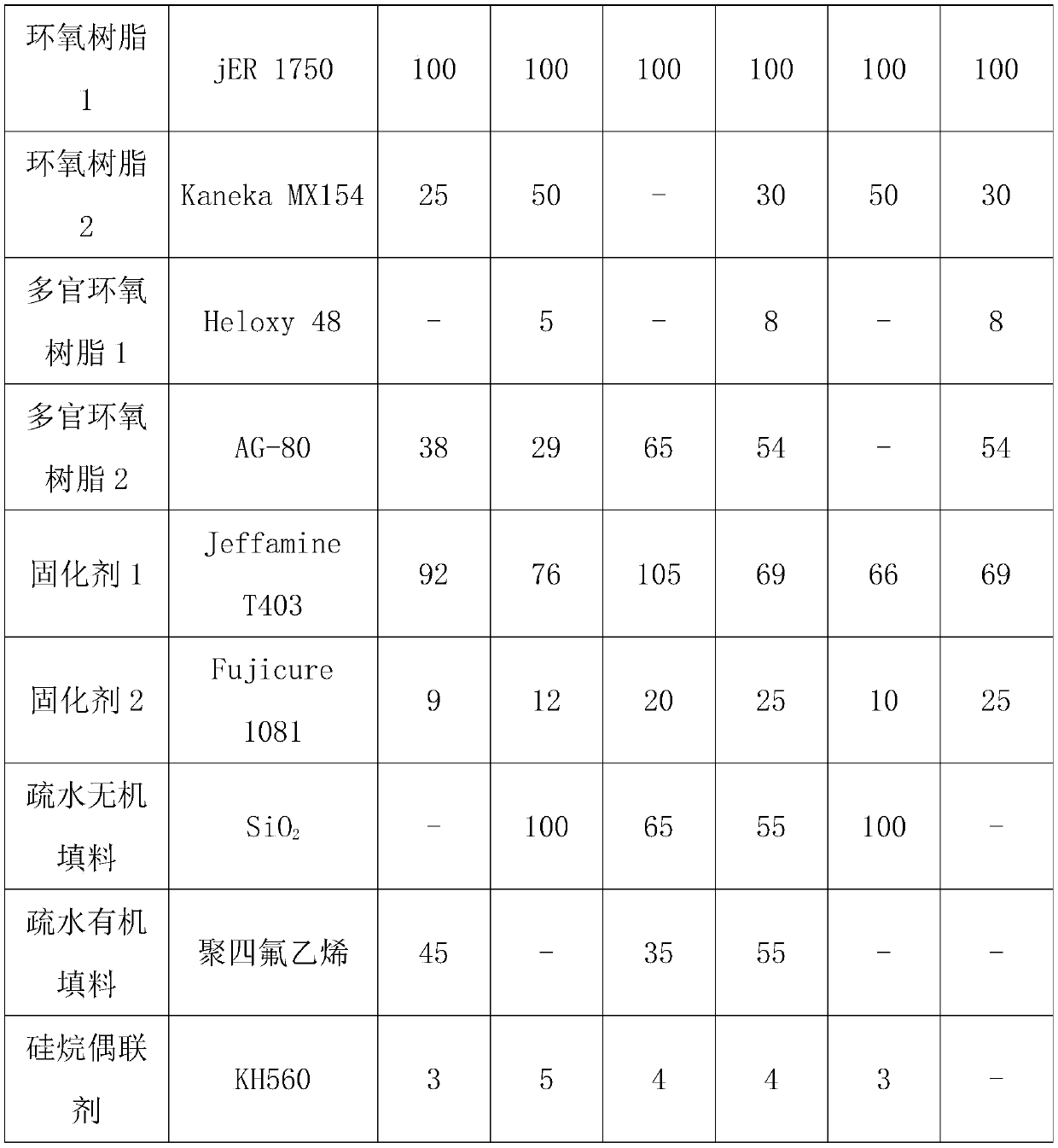

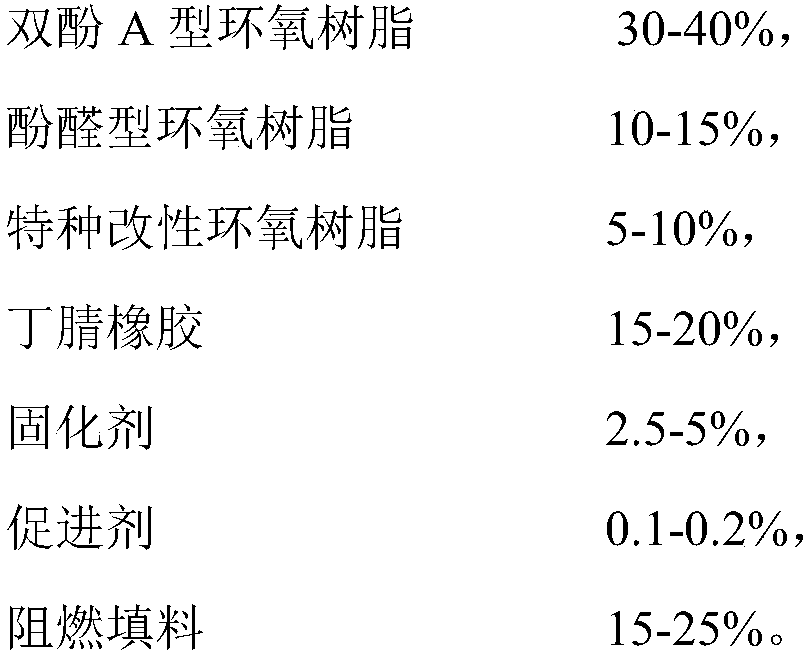

Single-component epoxy structure adhesive for waterproof sealing and preparation method thereof

InactiveCN110564347AHigh strengthHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyHigh humidity

Owner:上海汉司实业有限公司

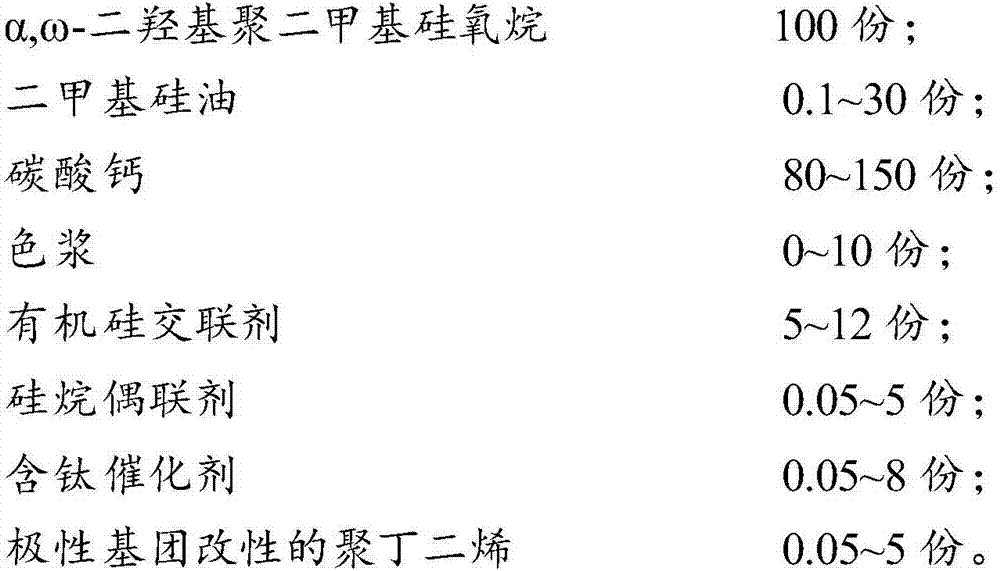

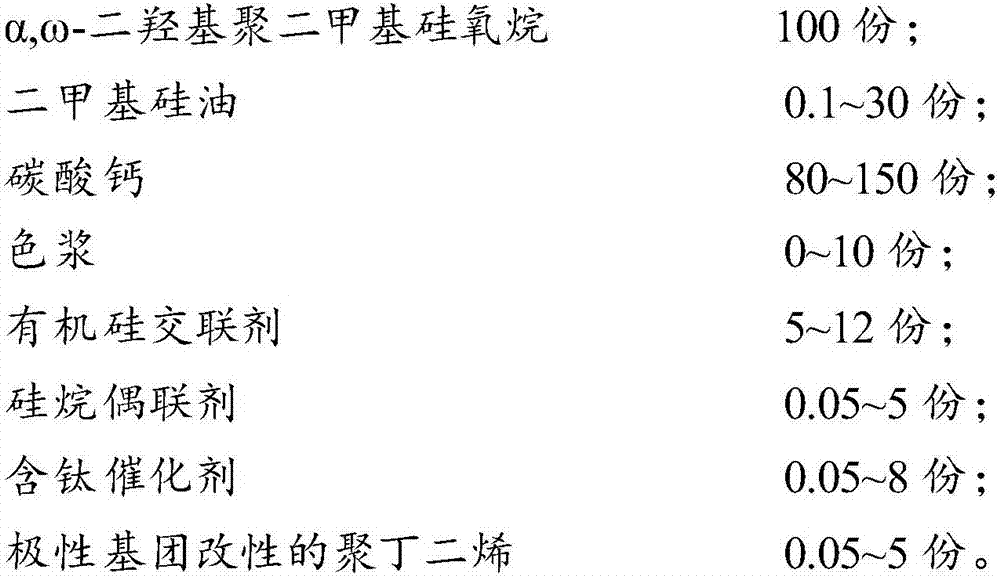

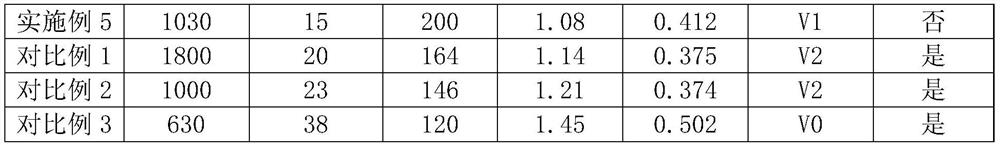

Dealcoholized silicone rubber sealant

ActiveCN106957631AGood flexibilityGood mechanical propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilicone sealantMoisture

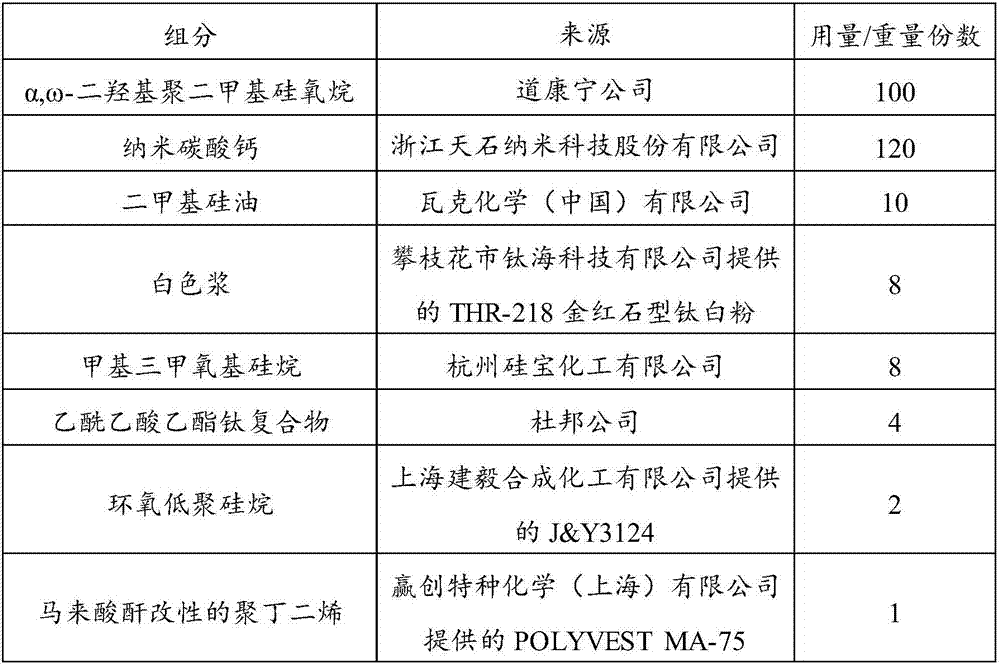

The invention provides a dealcoholized silicone rubber sealant, which is prepared from the following components in parts by weight: 100 parts of alpha, omega-dyhydroxyl polydimethylsiloxane, 0.1 to 30 parts of simethicone, 80 to 150 parts of calcium carbonate, 0 to 10 parts of mill base, 5 to 12 parts of silicone cross-linking agent, 0.05 to 5 parts of silane coupling agent, 0.05 to 8 parts of titanium-containing catalyst, and 0.05 to 5 parts of polar group modified polybutadiene. According to the dealcoholized silicone rubber sealant provided by the invention, the polar group modified polybutadiene is adopted, and a polar group is contained, so that the moisture introduction in air is increased, and the initial curing speed and the initial strength of the sealant are improved. According to the dealcoholized silicone rubber sealant provided by the invention, through reasonably controlling the components in the sealant and adjusting the content of each component, so that the sealant has the advantages of fast initial curing speed, high shearing strength, and excellent cohesiveness under the combined action of the components.

Owner:HANGZHOU ZHIJIANG SILICONE CHEM +1

Seam binding agent with modified fatty amine as epoxy curing agent resin

ActiveCN102816501AFast shapingEasy constructionNon-macromolecular adhesive additivesEpoxy resin adhesivesCalcium silicateFiber

The invention relates to a seam binding agent with modified fatty amine as epoxy curing agent resin. The agent is suitable for easy-cracking positions in indoor and outdoor decorations. The agent is filled into seams of same or different materials such as wood, brick and stone, gypsum board, calcium silicate, and the like, for providing an excellent anti-cracking effect. The agent can also be used as a binding agent for roof leakage repairing, wood, and plastic. The agent can be used in crack sealing and water proofing of various grouting projects, bridges, and tunnels. According to the invention, a novel nano fiber binding technology is adopted. When the product is cured, nano fibers in the product form a high-molecular high-density net-shaped film at a seam position, wherein the physical density of the film is close to that of wood board or gypsum board. The film can expand or contract synchronically with the board when weather is changed, and has good cracking resistance, adhesive force, and flexibility. The seam binding agent is advantaged in fast shaping, easy construction, and low sagging.

Owner:SKSHU PAINT

Coating Composition, Optical Film, Anti-reflection Film, Polarizing Plate, and Display Unit Using Them

ActiveUS20070289497A1Reducing drying unevennessReducing unevenness windNon-macromolecular adhesive additivesPretreated surfacesChemistryRepeat unit

A coating composition comprises: a fluoro-aliphatic group-containing copolymer comprising a repeating unit A corresponding to a fluoro-aliphatic group-containing monomer, and a repeating unit B corresponding to at least one monomer, wherein each of the I / O values of said at least one monomer constituting the repeating unit B is 1.0 or less.

Owner:FUJIFILM CORP

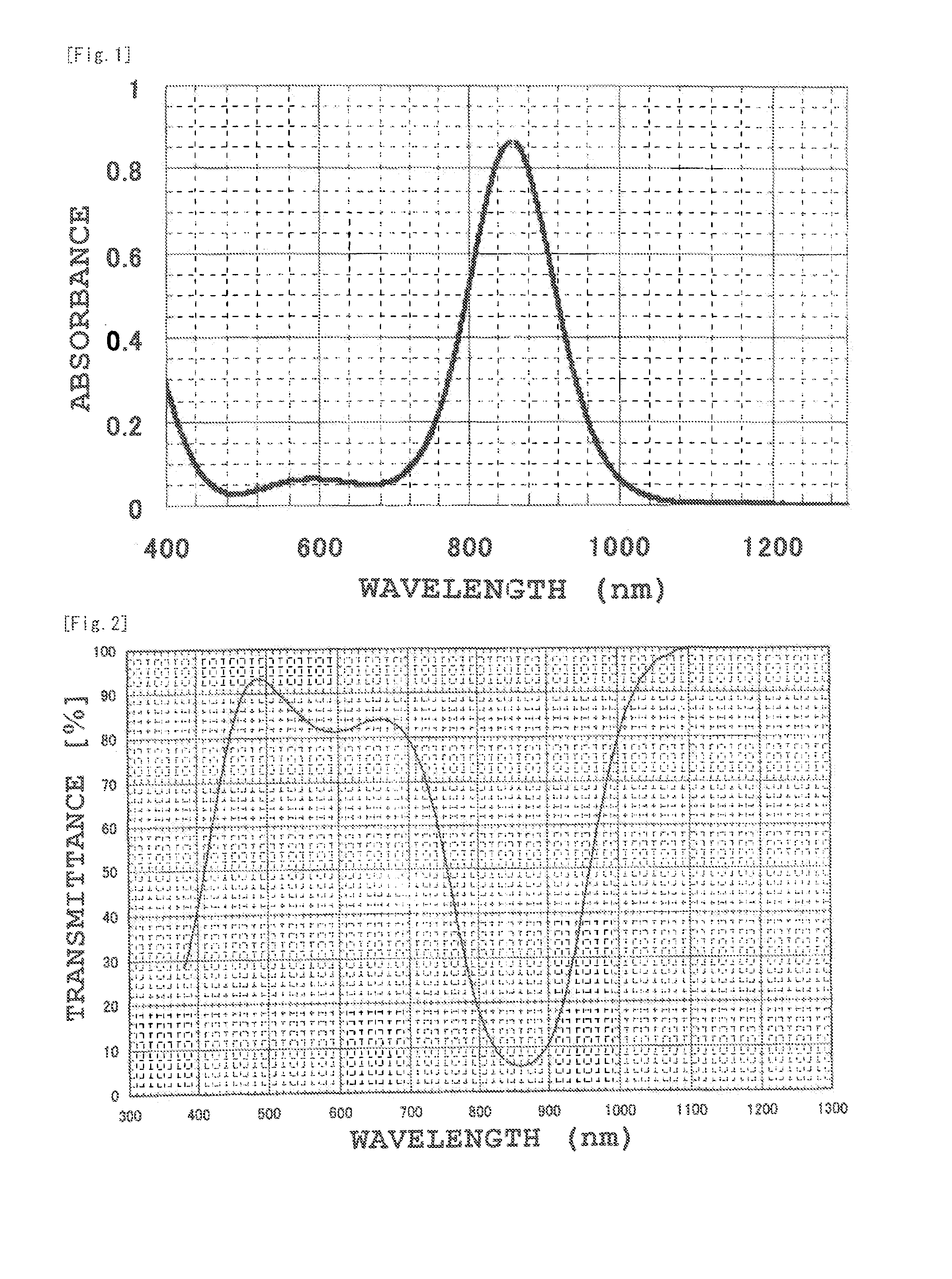

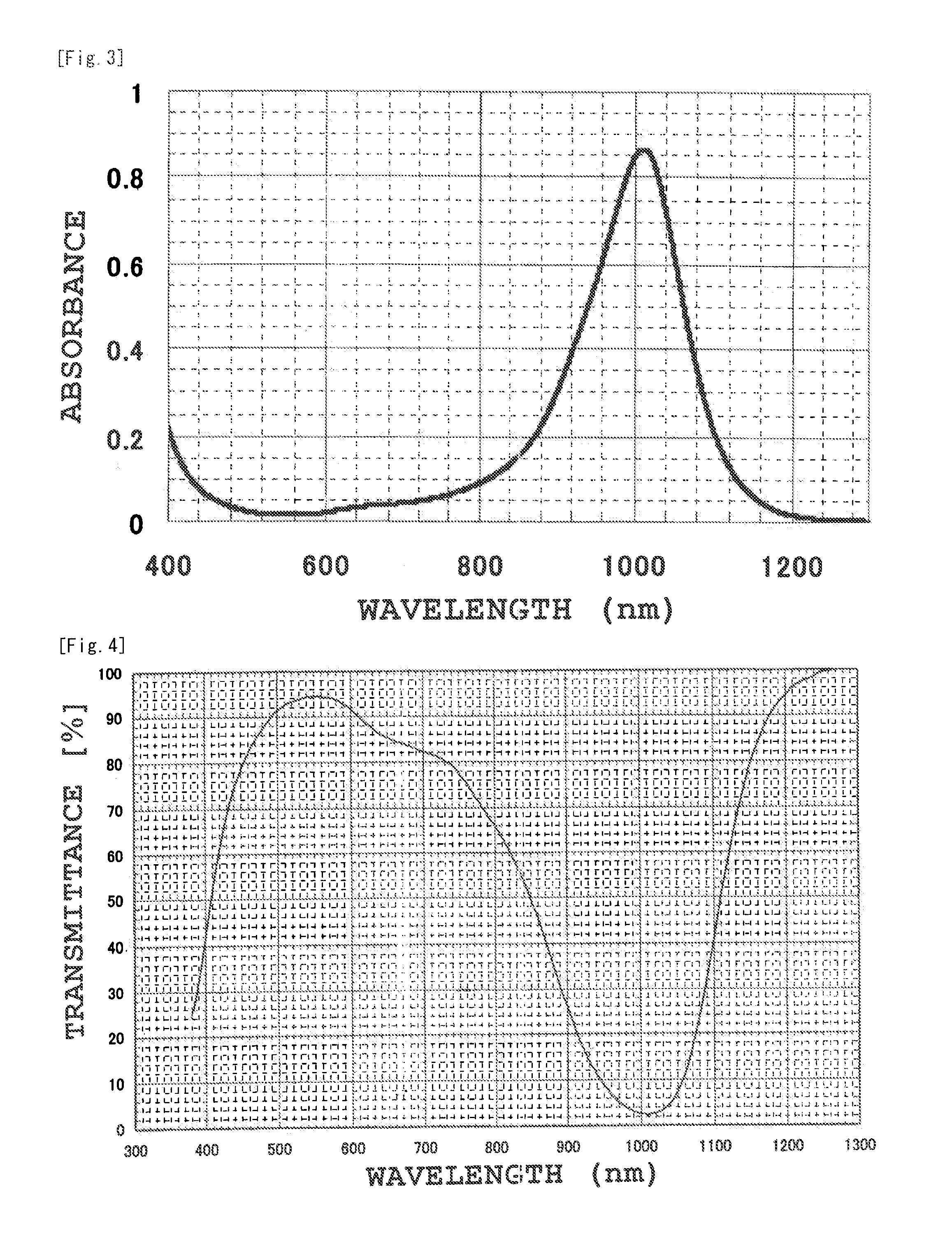

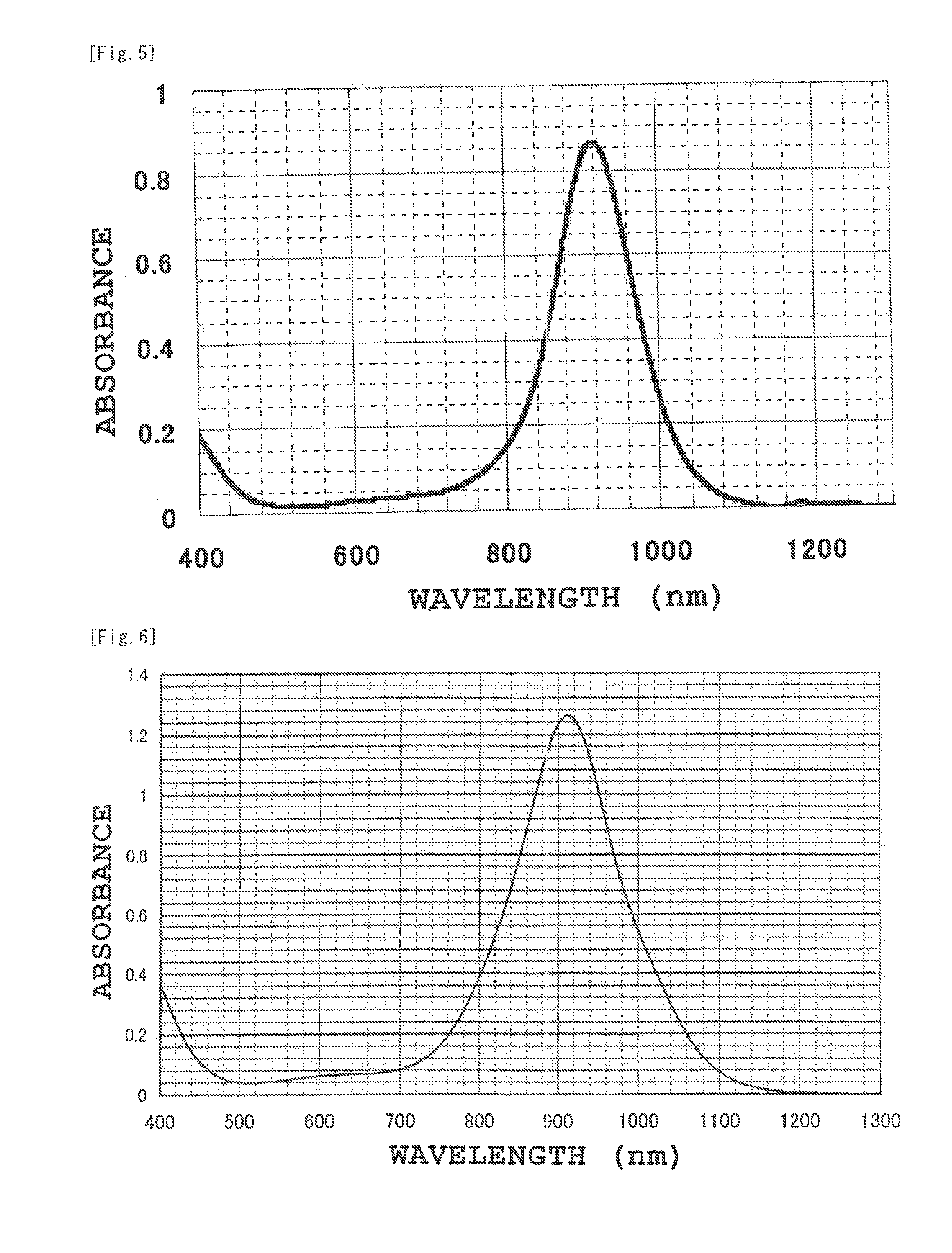

Near infrared ray-absorbable dye composition, and near infrared ray-absorbable filter and adhesive agent both comprising the composition

InactiveUS20100019212A1Improve light resistanceHigh visible light transmittanceNon-macromolecular adhesive additivesAzo dyesInfraredAryl

Owner:API CORP (JP)

Formaldehyde-free composite board special for flame retardant wooden house and preparing method of board

ActiveCN106514800AImprove bearing capacityTightly boundNon-macromolecular adhesive additivesStarch adhesivesPerliteParaffin oils

The invention relates to a formaldehyde-free composite board special for a flame retardant wooden house and a preparing method of the board. Plant fibers are adopted to be smashed, and the plant fibers and a phase change material are jointly machined into the board special for the wooden house. The board comprises a core layer with the flame retardant waterproof phase change energy storage function and a solid wood layer composited on the core layer through pressure; the core layer is prepared by raw materials including, by weight, 30 parts to 80 parts of expanded perlite or sepiolite, 30 parts to 40 parts of any phase change material in paraffin, n-octadecane, octadecanol, cetanol, tetradecyl alcohol, dodecanol, n-decanol, stearic acid, glyceryl stearate, palmitic acid, myristic acid, lauric acid, n-caprylic acid and stearic acid butyrin, 5 parts to 10 parts of Schiff alkaline gel factor, 10 parts to 20 parts of graphite, 20 parts to 40 parts of silica sol solutions, 20 parts to 40 parts of plant fibers, 10 parts to 20 parts of starch, 0.5 part to 5 parts of hydrogen peroxide, 5 parts to 10 parts of glass fibers, 2 parts to 10 parts of calcium carbonate, 0.5 part to 5 parts of a penetrating agent, 8 parts to 35 parts of a flame retardant agent, and 2 parts to 8 parts of a waterproof agent. The beneficial effects of saving a large amount of wood and adjusting the indoor temperature are achieved.

Owner:郑州一安水性高分子材料有限公司

Preparation method of special coating resin composition for polyethylene

ActiveCN102863670AImprove melt strengthLow shrinkageNon-macromolecular adhesive additivesFilm/foil adhesivesLow-density polyethylenePeroxide

Owner:PETROCHINA CO LTD

Ultraviolet-curing composition for LED packaging

InactiveCN104031591AImprove bonding performanceGood high and low temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerLed packaging

The invention relates to the technical field of LED packaging, and particularly relates to an ultraviolet-curing composition for LED packaging. The ultraviolet-curing composition comprises the following components: a polyurethane-acrylate-epoxy resin photosensitive prepolymer, epoxy resin acrylate, a light initiator, a flatting agent and an active diluent. According to the ultraviolet-curing composition for LED packaging disclosed by the invention, a certain amount of epoxy resin acrylate is added in the composition, so that the adhesive property of the composition after being cured is effectively improved; the adhesive has the advantages of excellent high and low-temperature resistance, high aging resistance and transparency, good formability, good bonding property, mild curing conditions, and the like.

Owner:江苏华程光电科技有限公司

Novel acrylic pressure-sensitive adhesive

ActiveCN108192019AWide range of bondingGood adhesionNon-macromolecular adhesive additivesAmide/imide polymer adhesivesFiberPolyester

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

Uv-curable resin composition for use in touchscreen, and bonding method and article using said uv-curable resin

Owner:NIPPON KAYAKU CO LTD

Halogen-free flame retardant polyamide hot-melt adhesive and preparation method thereof

Owner:CHANGYUAN ELECTRONICS DONGGUAN +4

Adhesive substance, adhesive product, and connected structure

InactiveUS20050054758A1Easy to peelAdhesive processesNon-macromolecular adhesive additivesIrradiationPhotochemistry

Owner:SEKISUI CHEM CO LTD

Near infrared blocking membrane and preparation method thereof

ActiveCN104327757AReduce light transmittanceGood light transmissionNon-macromolecular adhesive additivesFilm/foil adhesivesInfraredFilm coating

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

Heat conduction adhesive tape and heat conduction double-side adhesive tape

ActiveCN106189913AUniform heat conductionImprove thermal conductivityNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesiveGraphite

Owner:HUNAN PROVINCE PURUIDA INTERIOR MATERIAL CO LTD

Special unsaturated polyester resin adhesive for quartz stone sheet material

InactiveCN106753148AImprove impact toughnessHigh bonding strengthNon-macromolecular adhesive additivesGas phasePhosphine oxide

The invention discloses a special unsaturated polyester resin adhesive for a quartz stone sheet material. The special unsaturated polyester resin adhesive is prepared from the following raw materials: unsaturated polyester resin, acrylic acid-2-hydroxyethyl ester, pentaerythritol triacrylate, 2-methyl-1-(4-methylthiophenyl)-2-morpholinyl-1-acetone, biphenyl-(2,4,6-trimethylbenzoyl)phosphine oxide, a flatting agent, a de-foaming agent, a silane coupling agent, gas-phase silicon dioxide, glass microsphere and modified aluminum hydroxide. The special unsaturated polyester resin adhesive for the quartz stone sheet material, provided by the invention, has high binding performance, good impacting toughness and excellent flame-retarding performance.

Owner:ANHUI AIDIBEI BIOLOGICAL CO LTD

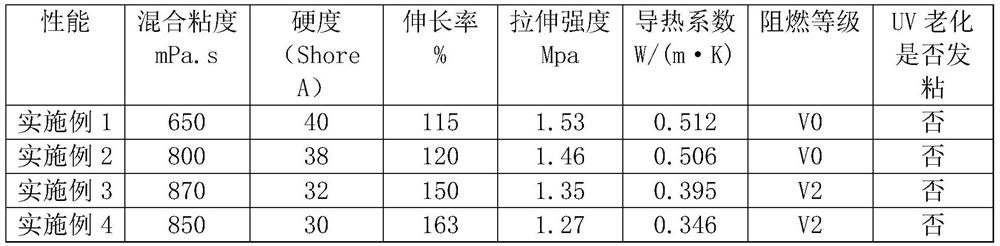

Organic silicon electronic potting adhesive for PCB circuit board with stable dielectric insulation performance

InactiveCN106634810AHigh tensile strengthHigh hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesDielectricAdhesive

The invention discloses an organic silicon electronic potting adhesive for a PCB circuit board with stable dielectric insulation performance. The organic silicon electronic potting adhesive is prepared from the following raw materials in parts by weight: 40 to 50 parts of vinyl-terminated silicone oil-1, 50 to 60 parts of vinyl-terminated silicone oil-2, 0.38 to 0.5 part of 12% of a platinum catalyst, 0.02 to 0.04 part of acetenyl cyclohexanol, 25 to 30 parts of vinyl silicon resin, 14.8 to 16.8 parts of 1-allyloxy-2,3-epoxypropane, 23 to 25 parts of 1,3,5,7-tetramethyl cyclotetrasiloxane, 2.7 to 3.6 parts of a silane coupling agent A171, an appropriate amount of silicon-containing silicon oil, 2.6 to 3 parts of mica powder, 1.8 to 3 parts of porcelain powder, 0.2 to 0.3 part of dimethyl silicone polymer, 4.6 to 5 parts of carboxylated latex, 1.1 to 1.6 parts of polyvinyl alcohol and an appropriate amount of deionized water. The potting adhesive disclosed by the invention has high heat conduction, dielectric insulation, impact resistance and adhesive performance, is high in fluidity, and is extremely suitable for potting electronic products.

Owner:TONGLING ONBOLE PCB CO LTD

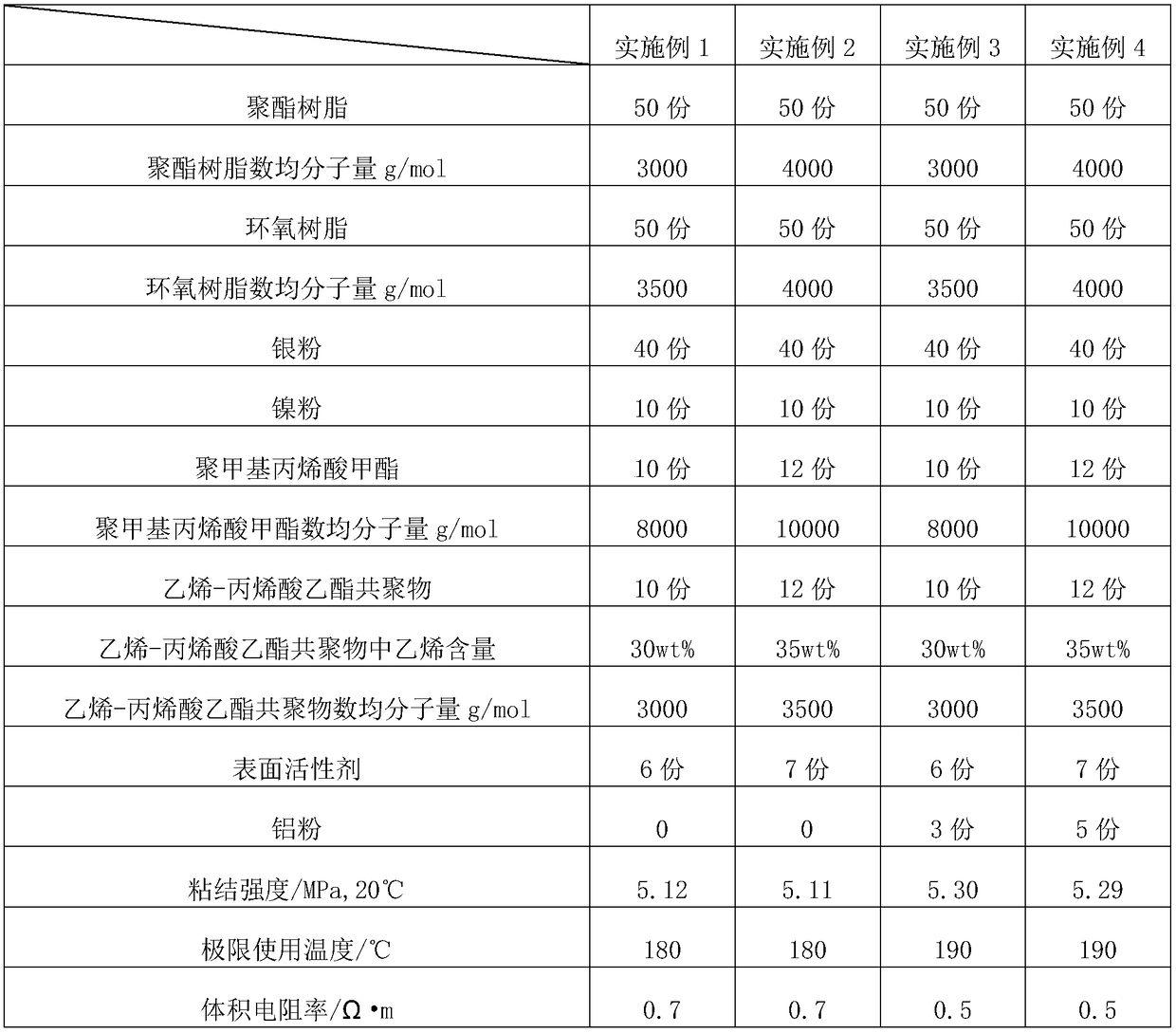

High-temperature-resistant conductive silver adhesive used for production of LED

InactiveCN108130032ANon-macromolecular adhesive additivesMacromolecular adhesive additivesMetallic NickelPolyresin

Owner:SUZHOU JIAYIDA ELECTRICAL APPLIANCES

FPC film for LED lamp strip and preparation method thereof

InactiveCN109251694AReduce manufacturing costExcellent adhesionNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyHot melt

Owner:广东新时代新材料科技有限公司

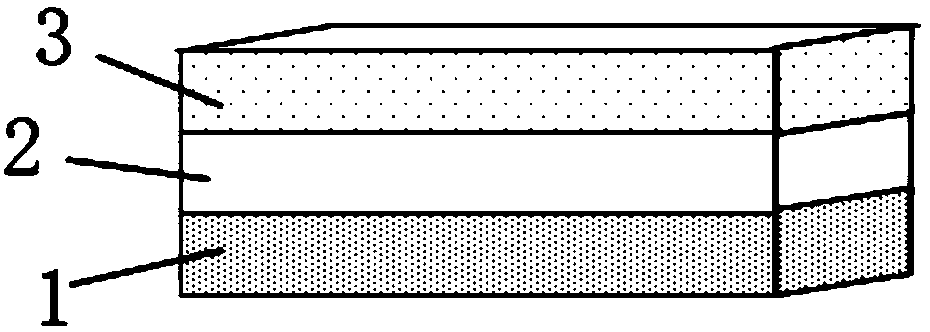

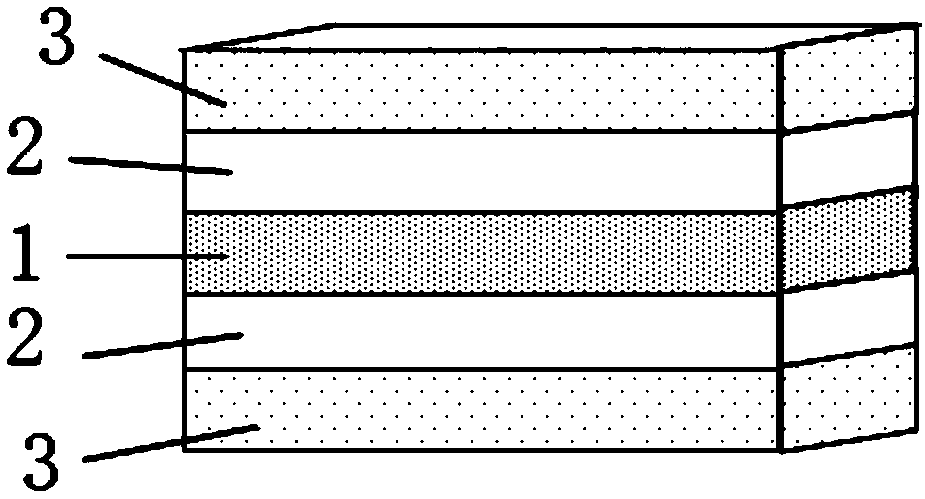

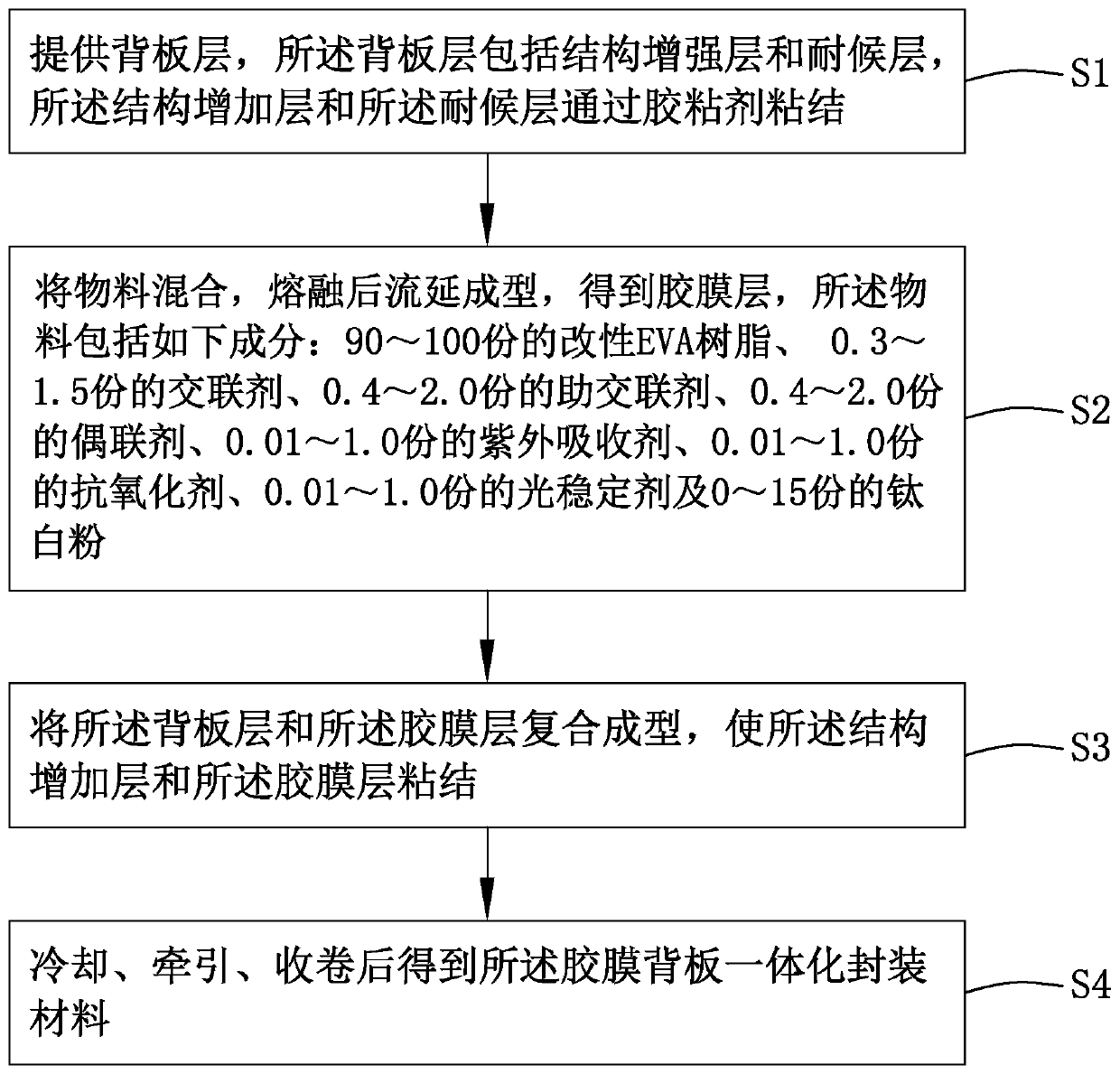

Adhesive film backboard integrated packaging material and processing technology thereof

InactiveCN111303790ANon-macromolecular adhesive additivesFilm/foil adhesivesUv absorbanceAdhesive cement

Owner:广东保均应用材料有限公司

Organic silicon pouring sealant and preparation method thereof

ActiveCN112080246ANon-macromolecular adhesive additivesPhotovoltaic energy generationDisiloxaneOrganosilicon

Owner:广州硅芯材料科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap