Single-component epoxy structure adhesive for waterproof sealing and preparation method thereof

A structural adhesive, waterproof and sealing technology, applied in the direction of epoxy resin glue, adhesive, adhesive additive, etc., can solve the problems of insufficient high temperature and high humidity resistance, easy degumming, etc., to achieve good bonding strength and high body strength , the effect of good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

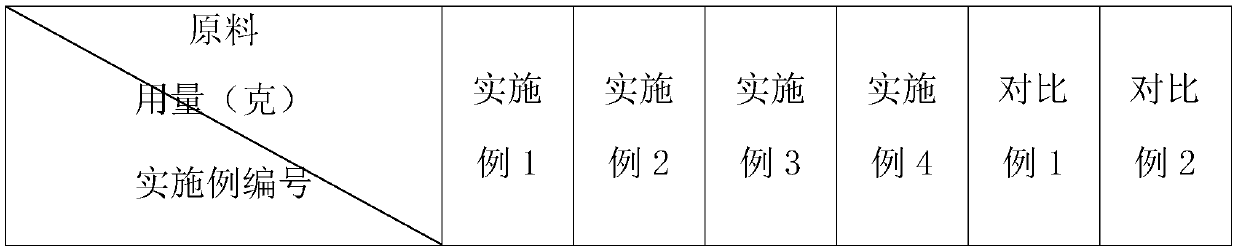

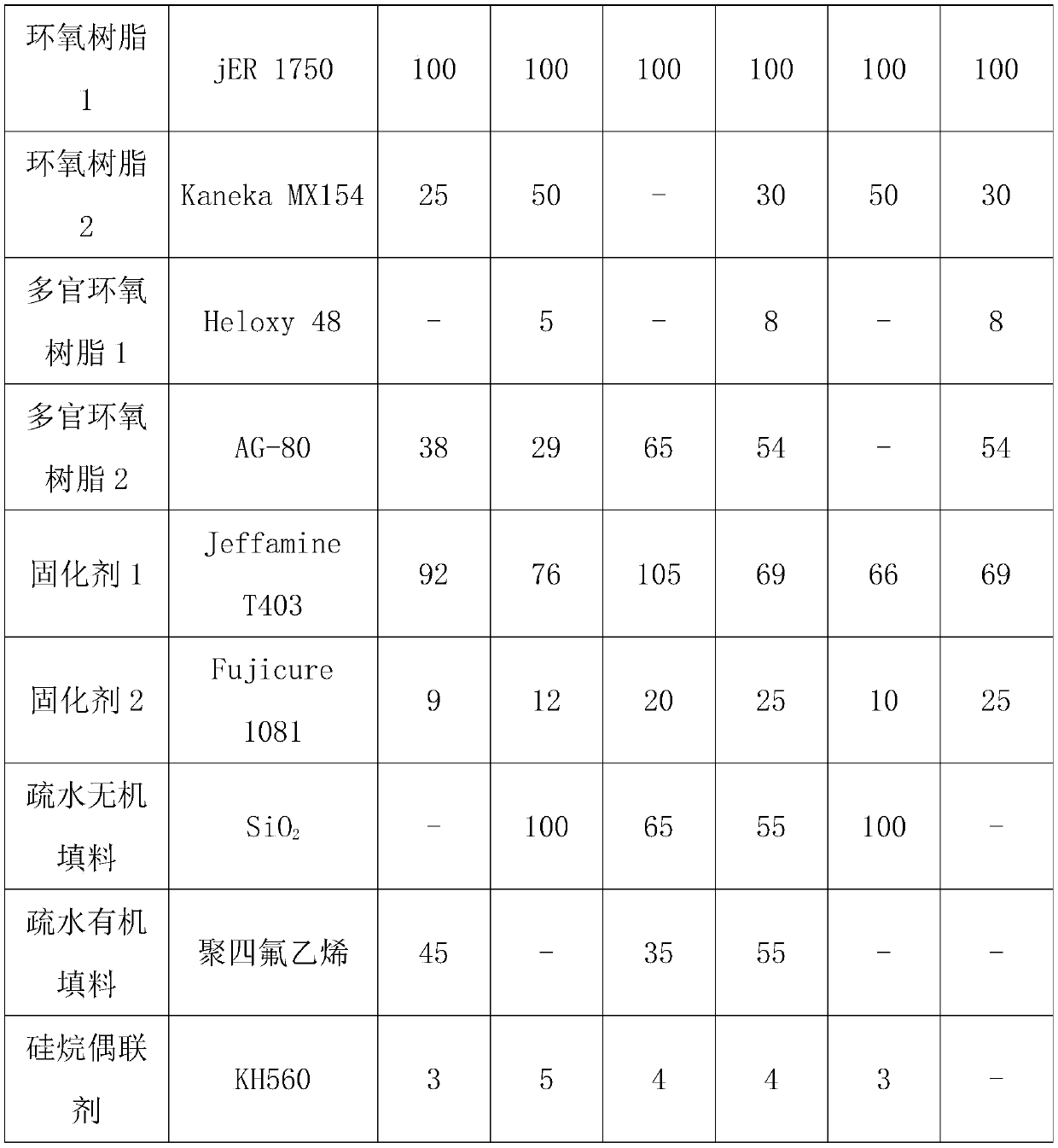

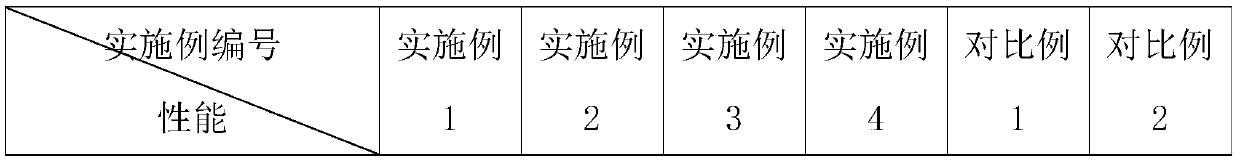

Embodiment 1

[0032] Weigh epoxy resin 1, epoxy resin 2 and polyfunctional epoxy resin 2 according to the mass given in table 1, mix with mechanical mixer, stirring rate is 1000 rev / min, time 30 minutes;

[0033] Then add the hydrophobic organic filler and continue to stir for 30 minutes;

[0034] After the mixture is cooled to room temperature, add curing agent 1 and curing agent 2, mechanically stir for 5 minutes, then transfer the mixture to a high-speed shear mixer for mixing, the mixing speed is 2000 rpm, the time is 30 seconds, repeat at high speed The mixing process in the shear mixer was performed three times to obtain a uniformly mixed jelly, which was the one-component epoxy structural adhesive for waterproof sealing.

Embodiment 2

[0036] Weigh epoxy resin 1, epoxy resin 2, polyfunctional epoxy resin 1, and polyfunctional epoxy resin 2 according to the mass given in Table 1, and mix them with a mechanical mixer at a stirring rate of 1000 rpm for 30 minutes ;

[0037] Then add the hydrophobic inorganic filler and continue to stir for 30 minutes;

[0038] After the mixture is cooled to room temperature, add curing agent 1 and curing agent 2, mechanically stir for 5 minutes, then transfer the mixture to a high-speed shear mixer for mixing, the mixing speed is 2000 rpm, the time is 30 seconds, repeat at high speed The mixing process in the shear mixer was performed three times to obtain a uniformly mixed jelly, which was the one-component epoxy structural adhesive for waterproof sealing.

Embodiment 3

[0040] Weigh epoxy resin 1 and polyfunctional epoxy resin 2 according to the mass given in table 1, mix with mechanical mixer, stirring rate is 1000 rev / min, time 30 minutes;

[0041] Then add hydrophobic inorganic filler and hydrophobic organic filler, continue to stir for 30 minutes;

[0042] After the mixture is cooled to room temperature, add curing agent 1 and curing agent 2, mechanically stir for 5 minutes, then transfer the mixture to a high-speed shear mixer for mixing, the mixing speed is 2000 rpm, the time is 30 seconds, repeat at high speed The mixing process in the shear mixer was performed three times to obtain a uniformly mixed jelly, which was the one-component epoxy structural adhesive for waterproof sealing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap