Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120 results about "Thermal insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal insulation is the reduction of heat transfer (i.e., the transfer of thermal energy between objects of differing temperature) between objects in thermal contact or in range of radiative influence. Thermal insulation can be achieved with specially engineered methods or processes, as well as with suitable object shapes and materials.

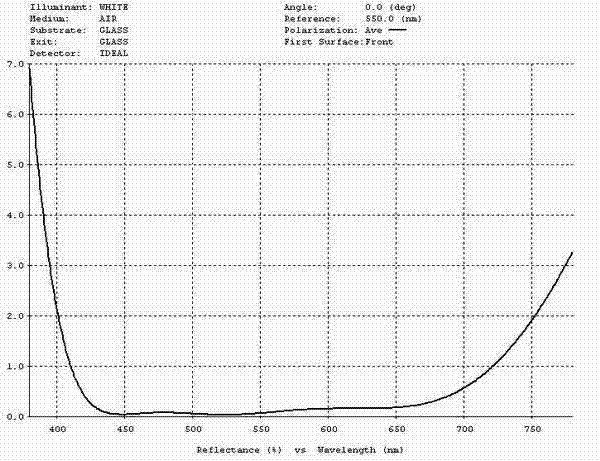

Transparent thermal insulation coating material system for glass substrate

InactiveCN102942841AInstant cureReduce energy consumptionPolyurea/polyurethane coatingsEpoxy resin coatingsThermal insulationUltraviolet lights

The present invention discloses a transparent thermal insulation coating material system for a glass substrate. The coating material system is a double layer coating material system formed by a separately-prepared primary coating and a separately-prepared surface coating, wherein the surface coating is coated on the primary coating, the primary coating comprises the following components, by mass, 0.05-3 parts of a silicane coupling agent or a titanate coupling agent, 0.2-5 parts of a hydrolysis catalyst, and 95-99 parts of a solvent, and the surface coating comprises the following components, by mass, 50-80 parts of a light curable resin, 5-35 parts of an active diluent, 1-8 parts of a photoinitiator, 5-35 parts of an antimony tin oxide nanometer thermal insulation powder slurry or an indium tin oxide nanometer thermal insulation powder slurry, 100-140 parts of an inert diluent, and 0.01-0.15 part of a leveling agent. With the coating material system, a film can be formed through a conventional film forming method, and the film layer can be cured within a few seconds after ultraviolet light irradiation. In addition, the coating material system has characteristics of high hardness, excellent adhesion and excellent water resistance.

Owner:刘志钊 +1

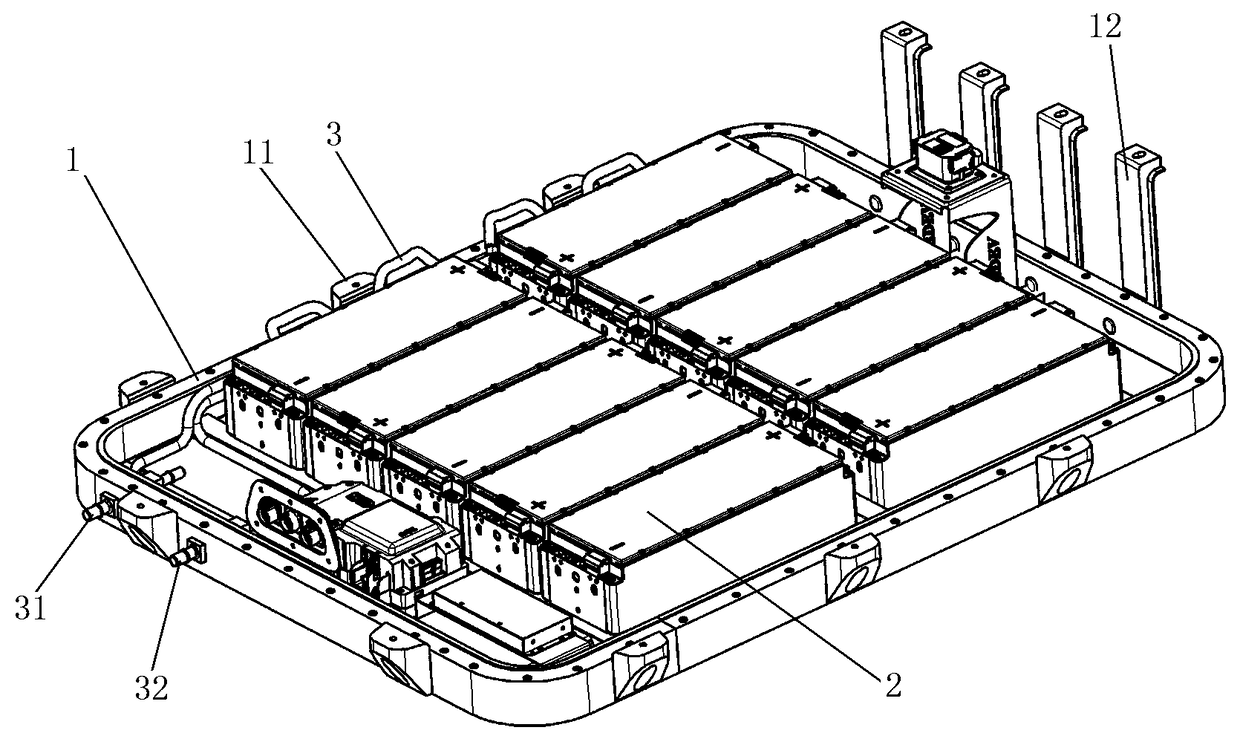

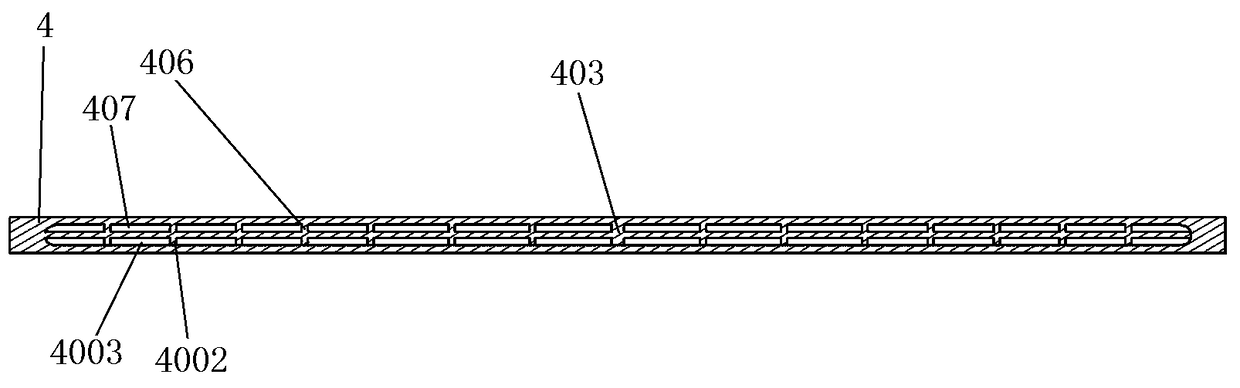

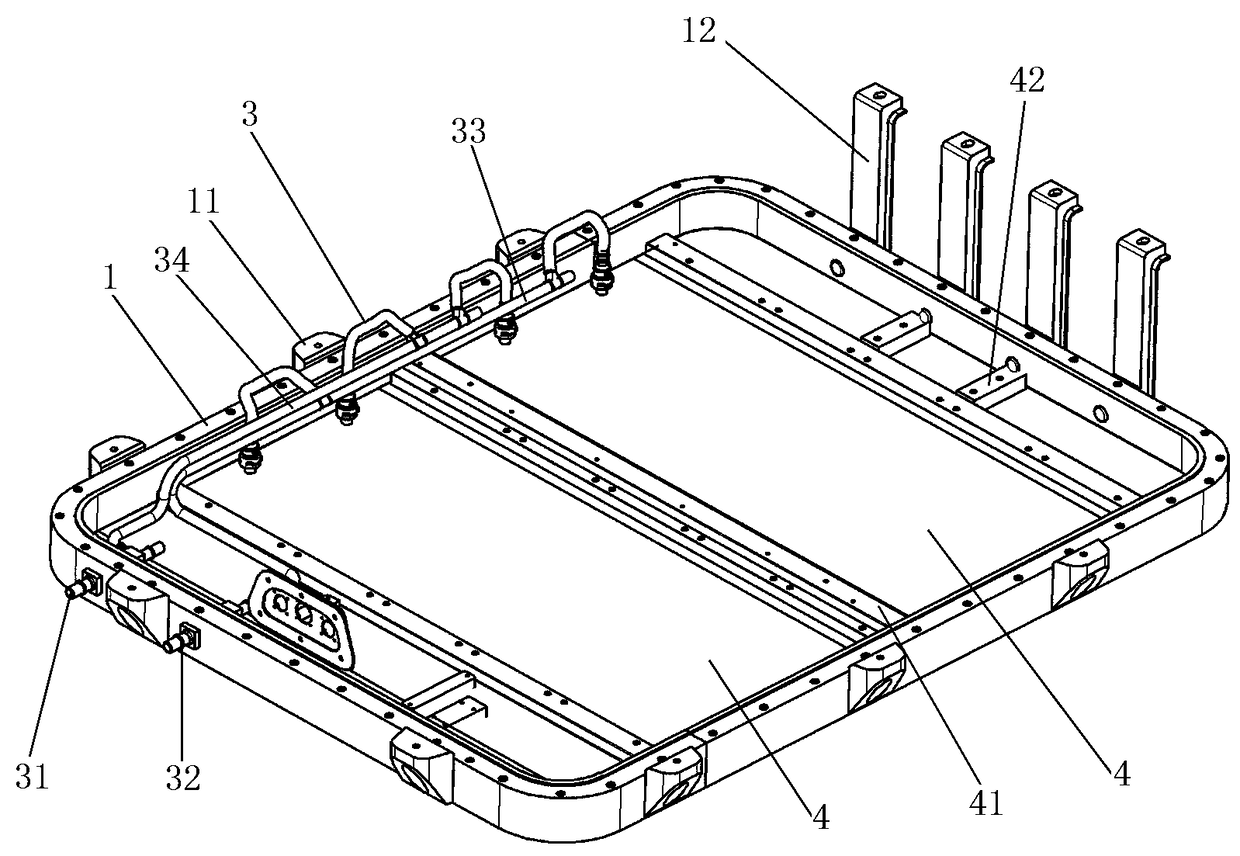

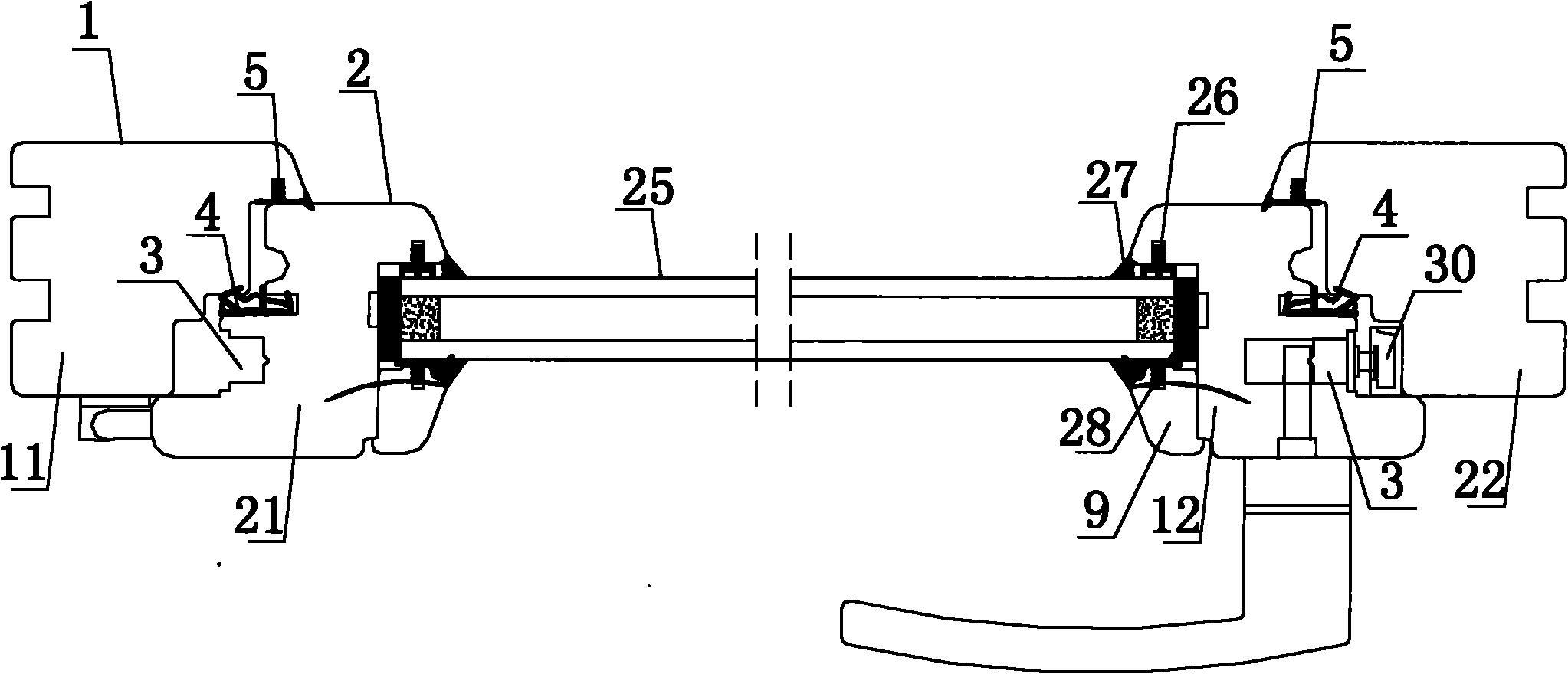

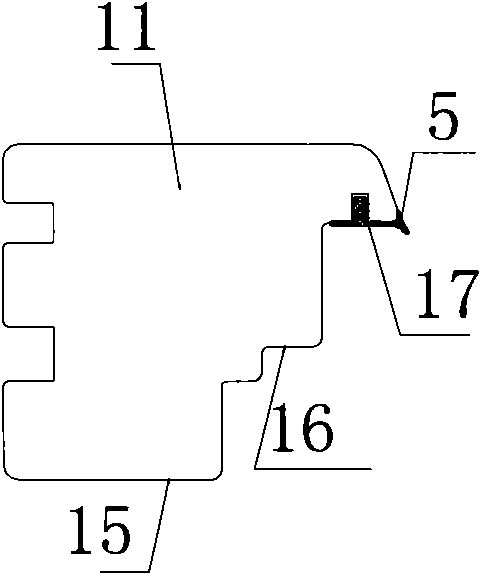

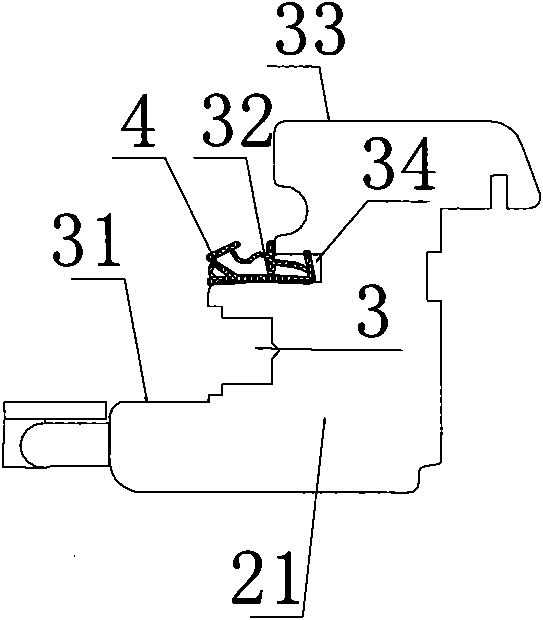

Electric vehicle, battery box body thereof, and battery box

Owner:HENAN SUDA ELECTRIC AUTOMOBILE TECH

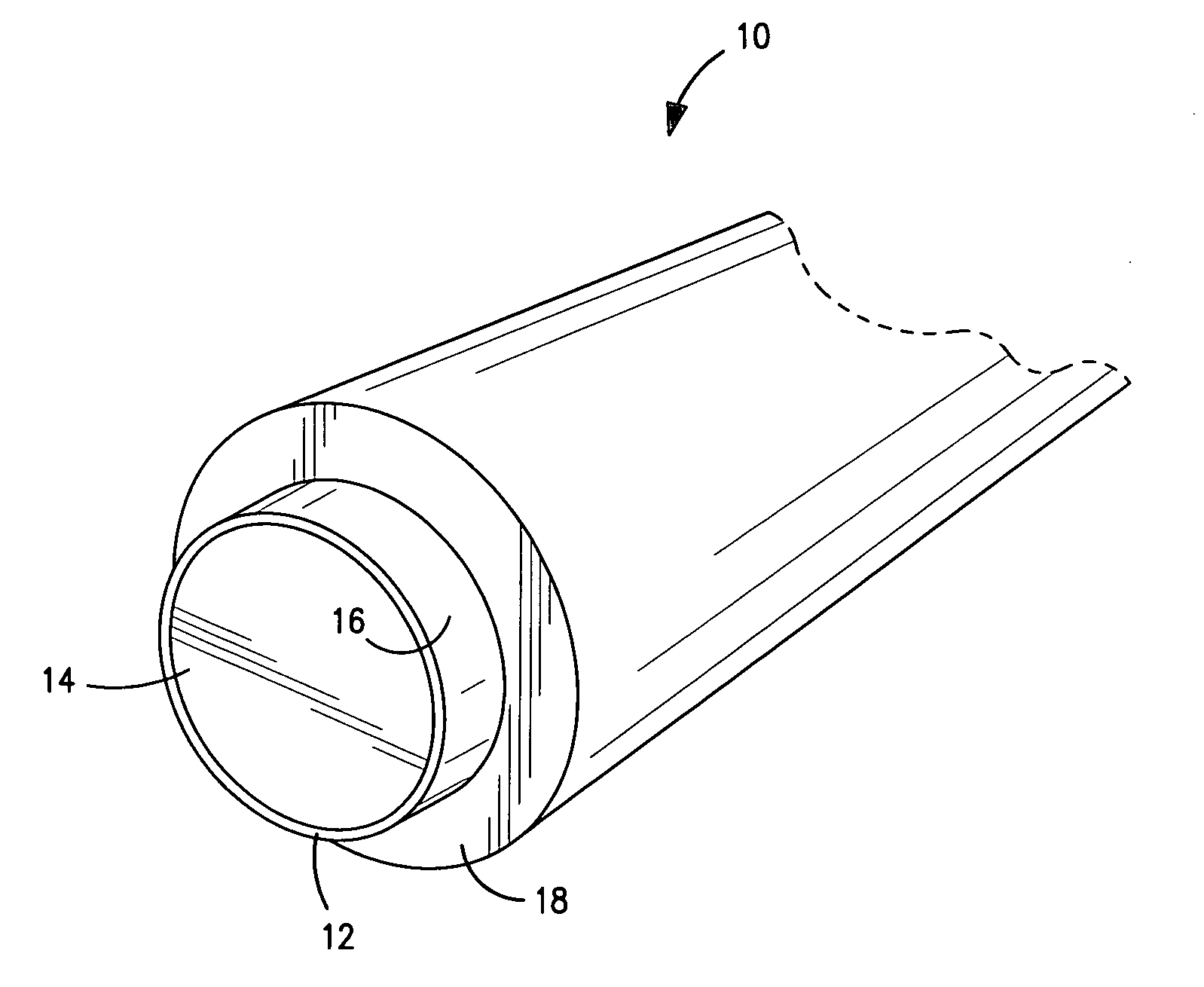

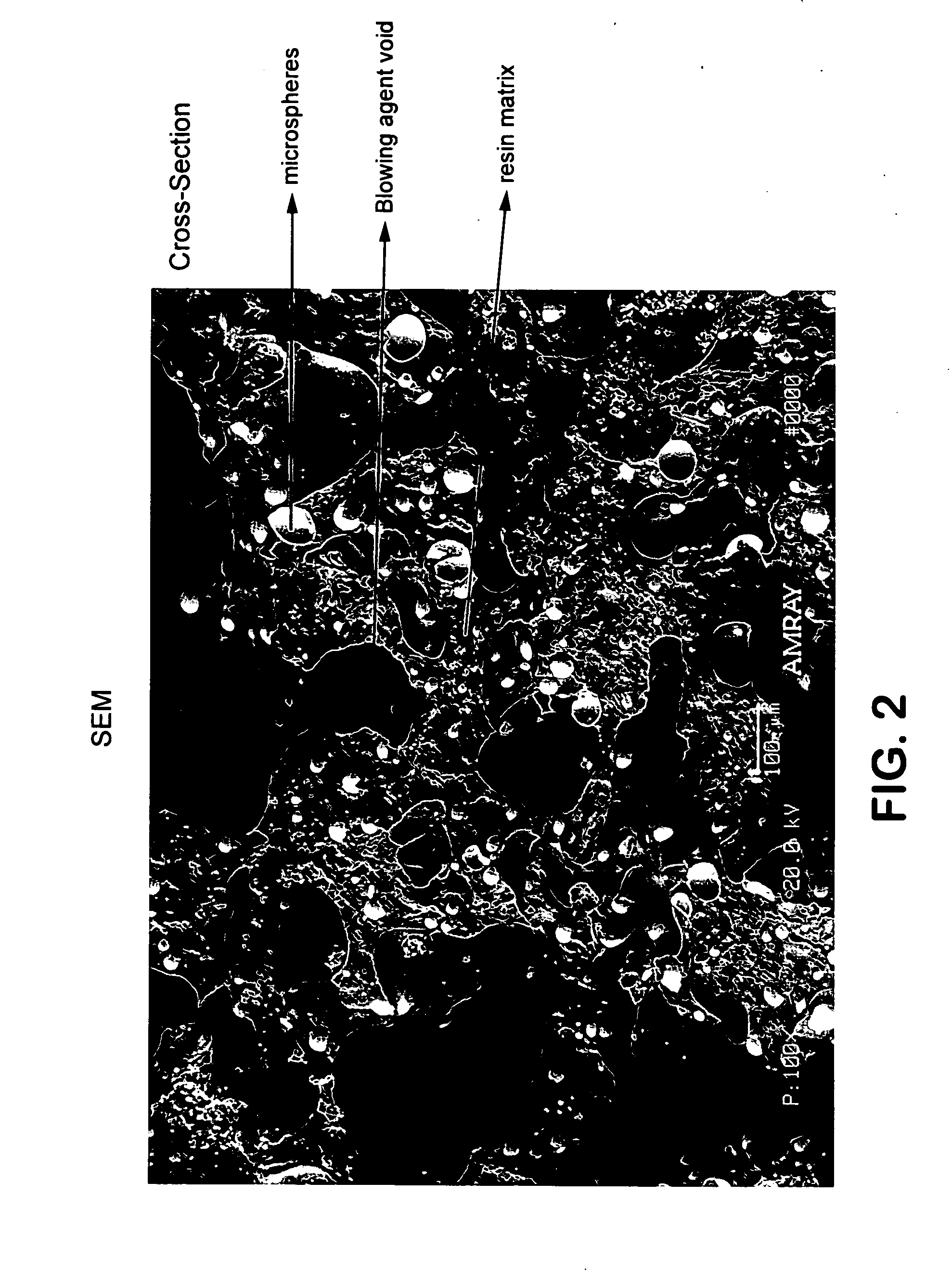

Syntactic Foam Compositions, Pipelines Insulated with Same, and Method

InactiveUS20110017340A1Improve thermal insulation propertiesIncrease buoyancyThermal insulationSolid waste managementEpoxyFoaming agent

Owner:CABOT CORP

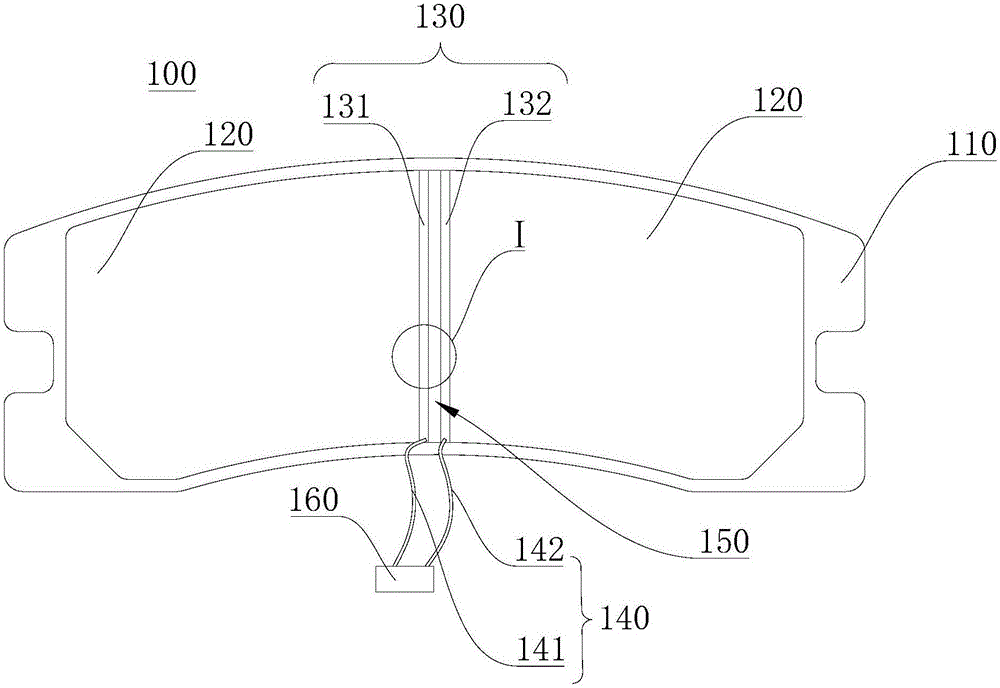

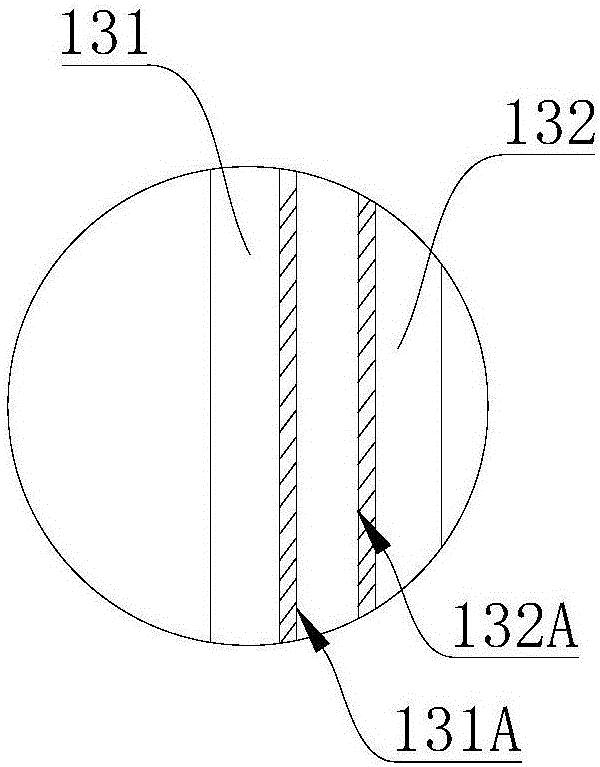

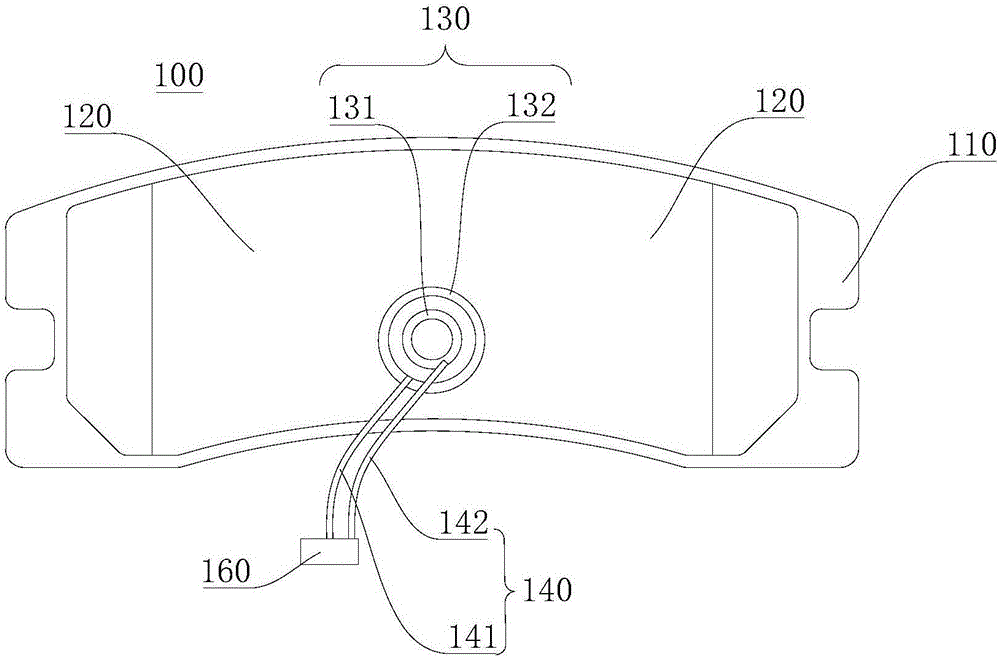

Brake pad and thickness detection method

InactiveCN106556336ABraking membersElectrical/magnetic thickness measurementsThermal insulationCapacitance

Owner:TONGREN UNIV

Copper/cerium-containing antimicrobial stainless steel and preparation method thereof

The invention discloses a copper / cerium-containing antimicrobial stainless steel and a preparation method thereof. The copper / cerium-containing antimicrobial stainless steel comprises the following chemical components in percentage by weight: at most 0.08% of C, at most 1% of Si, at most 2.00% of Mn, less than 0.045% of P, less than 0.030% of S, 17.5-20.0% of Cr, 8-11% of Ni, 0.5-2.8% of Cu, 0.01-0.45% of Ce, and the balance of Fe and inevitable impurities. The stainless steel is molten in an induction furnace after smelting, and is subjected to aging high-temperature diffusion heat treatment composed of 20-minute 1180 DEG C solid solution and 1-hour 685 DEG C thermal insulation so as to precipitate the antimicrobial phase epsilon-Cu and Ce, thereby endowing the stainless steel with antimicrobial property. The steel grade has stainless steel performance and broad-spectrum antibacterial property; the corrosion resistance, wear resistance, strength, toughness, oxidation resistance and other comprehensive properties of the stainless steel are improved; and the production technique is simple, has great utilization value in industry, and is suitable for industrial production.

Owner:SHANGHAI UNIV

Plating method for anti-reflection film with high transmittance and low reflectivity

ActiveCN102732830AFully oxidizedOrganizational stabilityVacuum evaporation coatingSputtering coatingThermal insulationEngineering

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

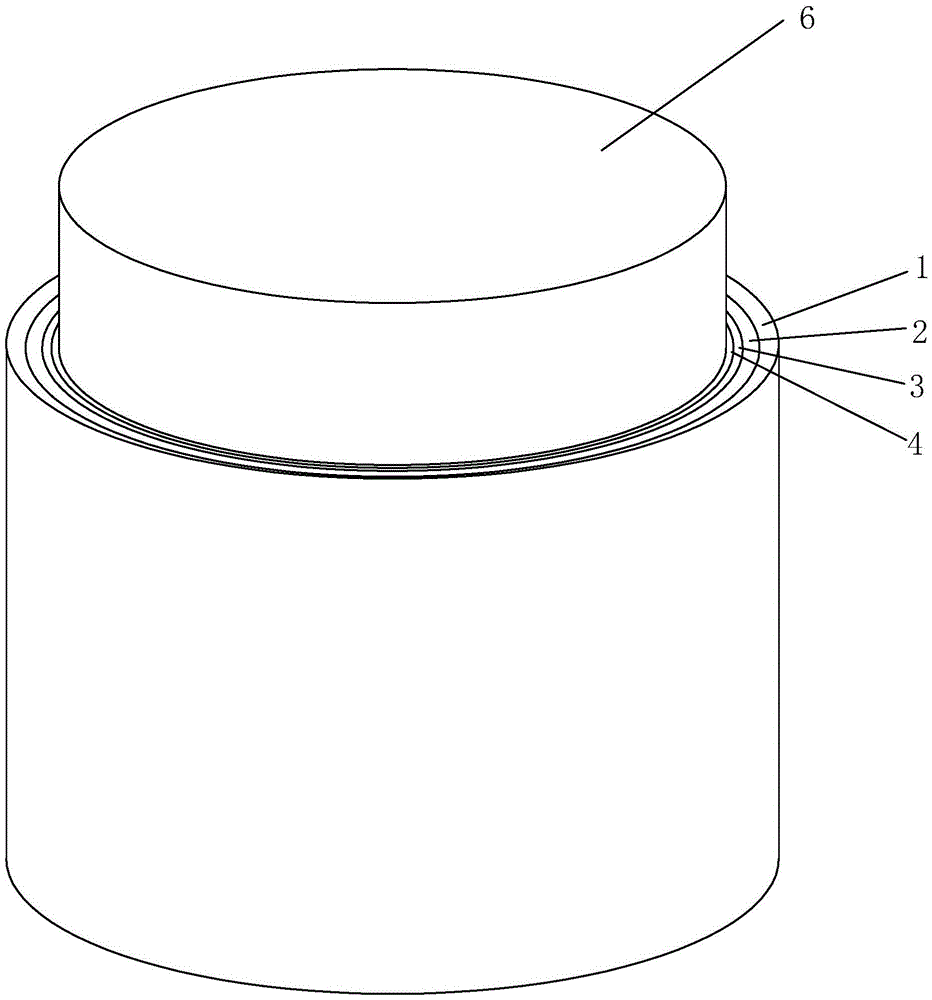

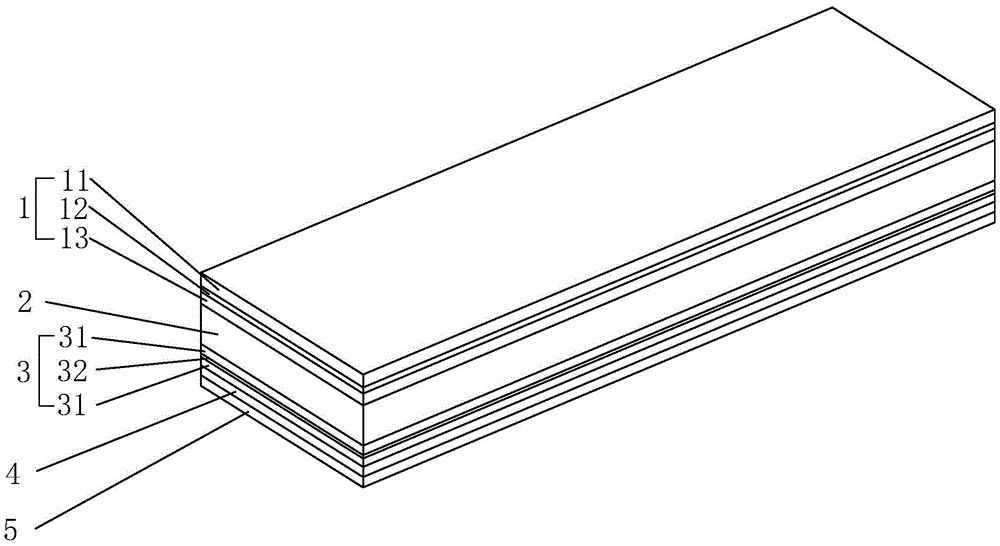

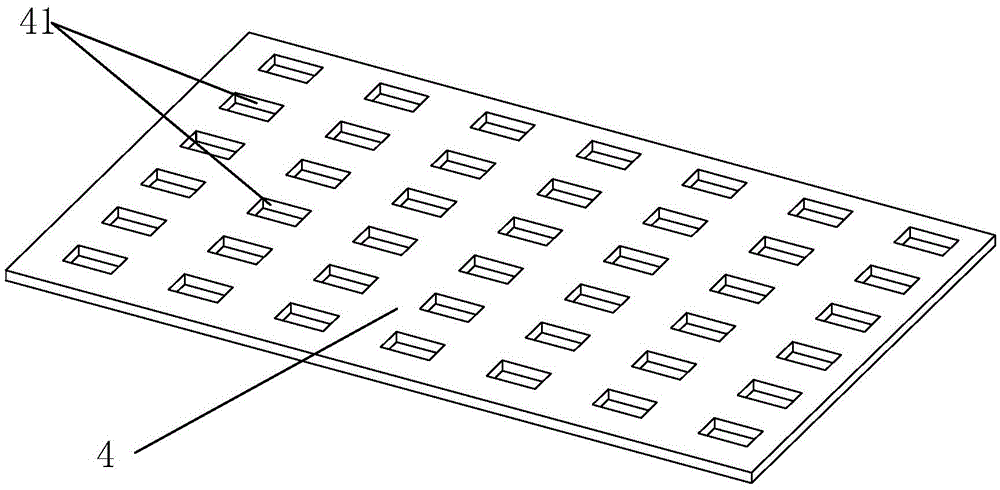

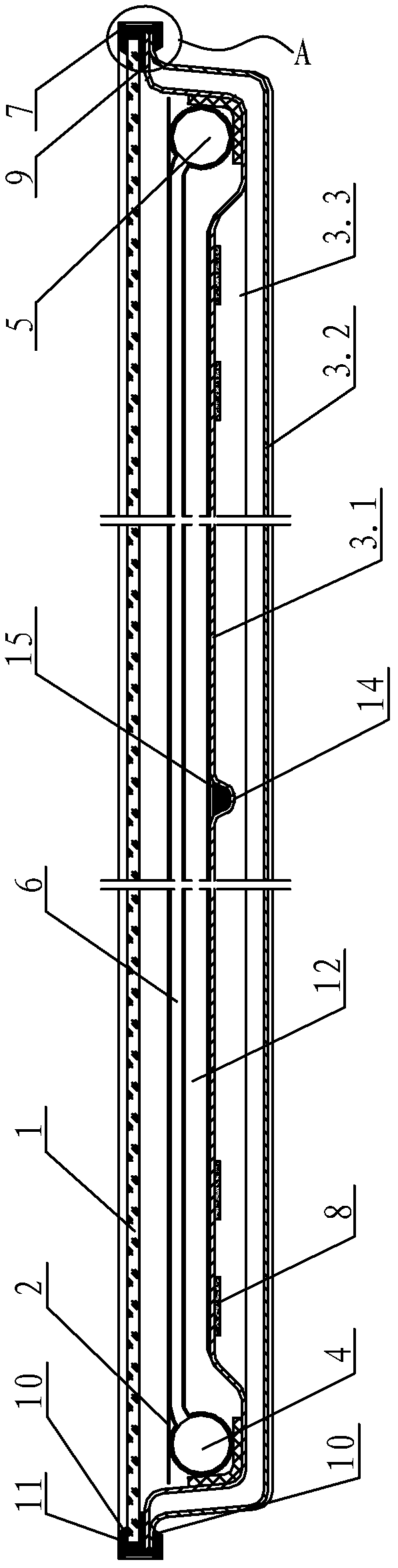

Solar film battery assembly for architecture

InactiveCN101510567AStable working environmentStrong penetrating powerGlass/slag layered productsCoatingsThermal insulationEngineering

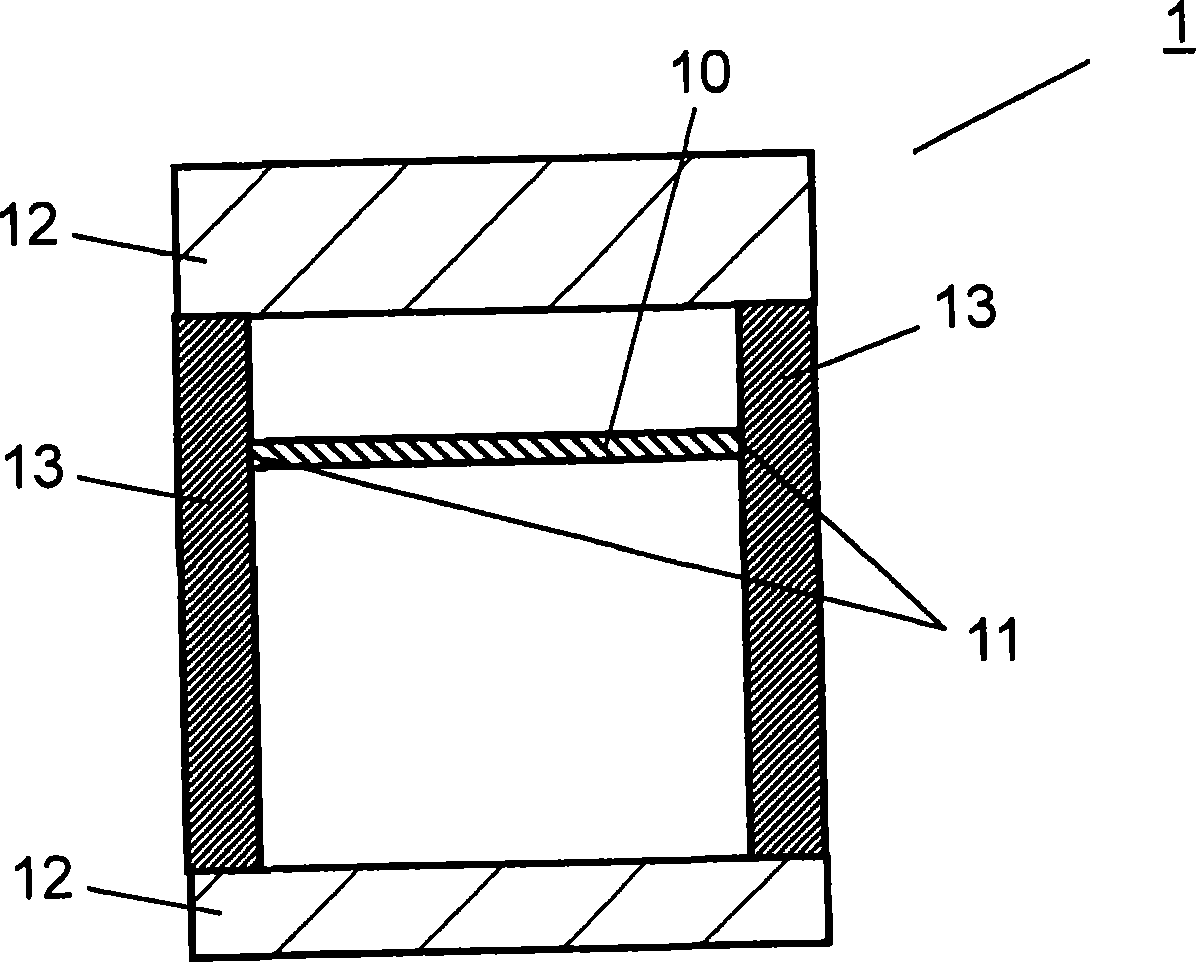

The invention relates to a solar energy thin-film battery component applied to architecture; the solar energy thin-film battery component consists of a conducting-film glass layer, a thin-film battery layer, an aluminum-film layer, an EVA layer, a float glass layer and a hollow glass layer in sequence from top to bottom; spacing bars are arranged at two ends between the float glass layer and the hollow glass layer and separate the float glass layer from the hollow glass layer to form a hollow cavity; a LOW-E film layer is arranged at either of the upper side and the lower side of the hollow cavity; from the external side of one spacing bar to the lateral side of the float glass layer, a junction box with diodes is arranged; and an electrode is led out respectively from the conducting-film glass layer and the aluminum-film layer, then the two electrodes are connected with the circuit inside the junction box. Compared with the prior art, the solar energy thin-film battery component is combined with the architecture and provided with an energy-saving coated film, a hollow structure and the junction box convenient for building installation, and has the advantages of environmentally-friendly power generation with solar energy, energy conservation and heat insulation of buildings, thermal insulation, sound insulation and no deposition of dew and frost.

Owner:HIMIN CLEAN ENERGY HLDG

Liquid heating vessel and controller thereof

The invention discloses a liquid heating vessel comprising an electronic controller executing one or more items of a group including boiling temperature or sub boiling temperature detection and / or control; volume / horizontal plane detection; ultrasonic water scale detection and / or suppression; determination of use efficiency level; self descaling; and light control. differert benefical illuminating devices are arranged. Halogen lamps are used as thermal insulation heater. Multiple halogen lamps are controlled such that different heating and illuminating are provided.

Owner:OTTER CONTROLS HUIZHOU LTD

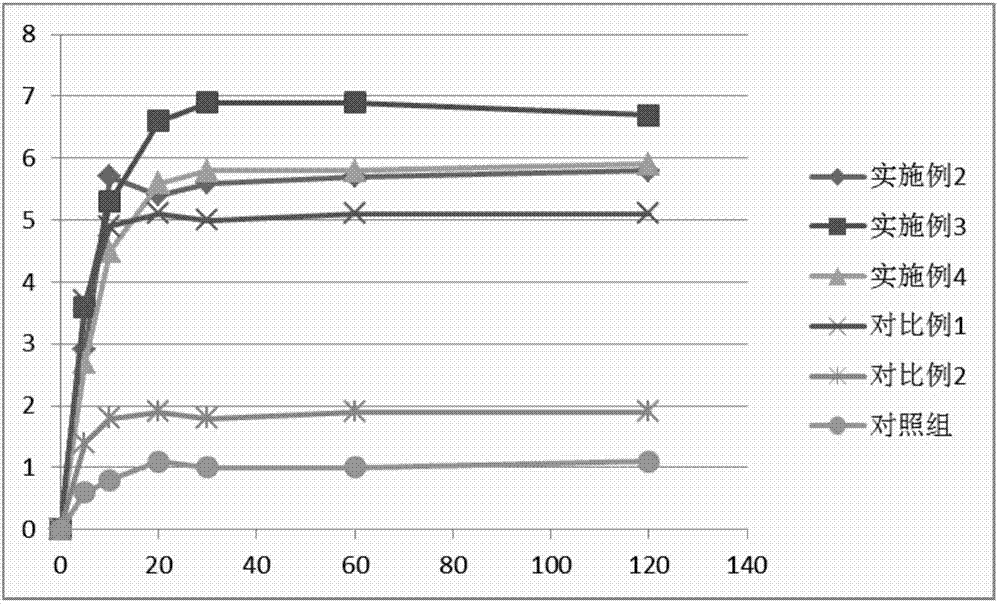

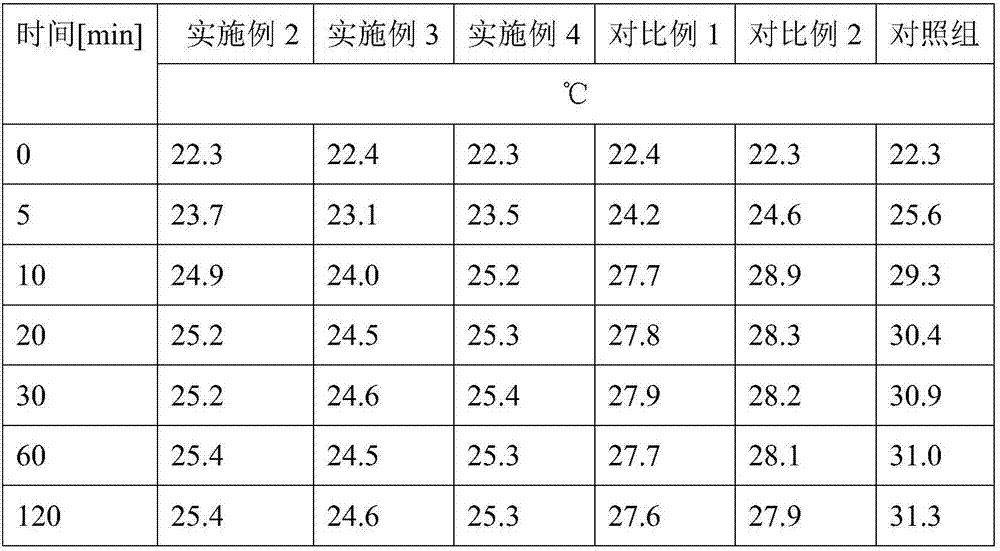

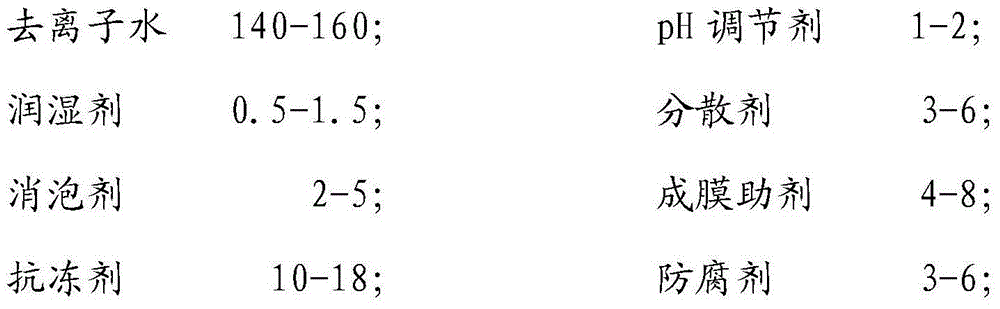

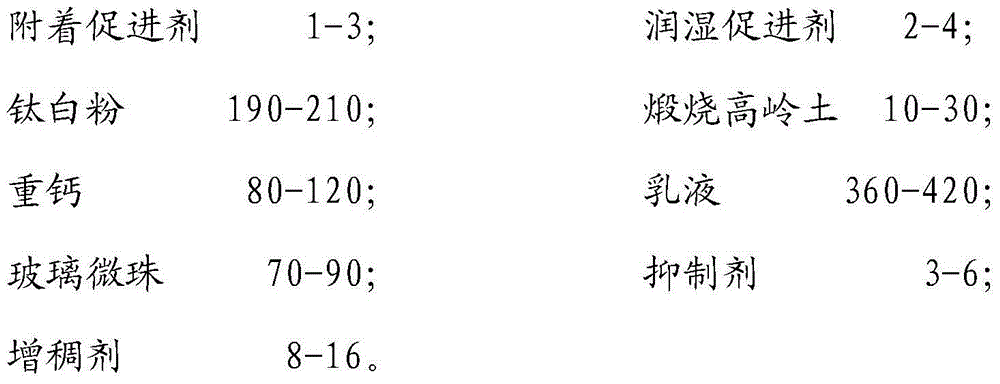

High infrared shielding rate thermal insulation paint and preparation method thereof

InactiveCN107880672AEffective insulationEven and stable insulationPolyurea/polyurethane coatingsIndiumMicrosphere

Owner:GUANGDONG VALSPAR CHEM IND

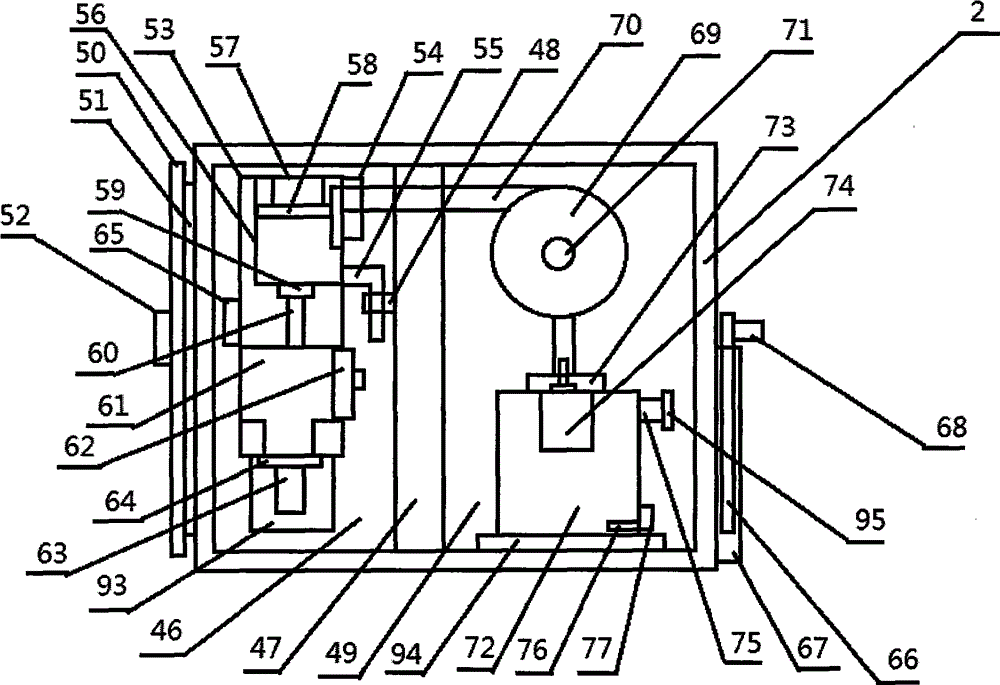

Equivalent thermal resistance and thermal conductivity coefficient detecting device for thermal insulation coating for building

Owner:成都市科创节能材料有限公司

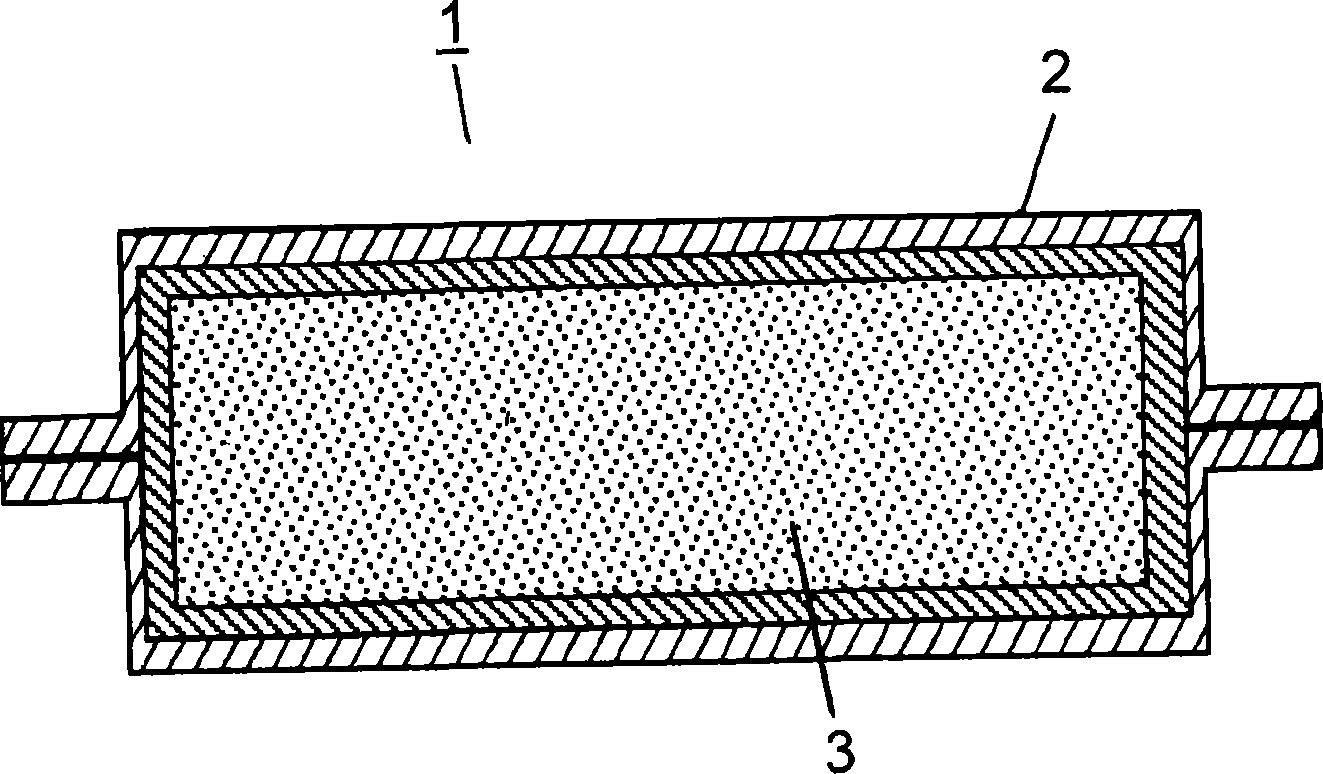

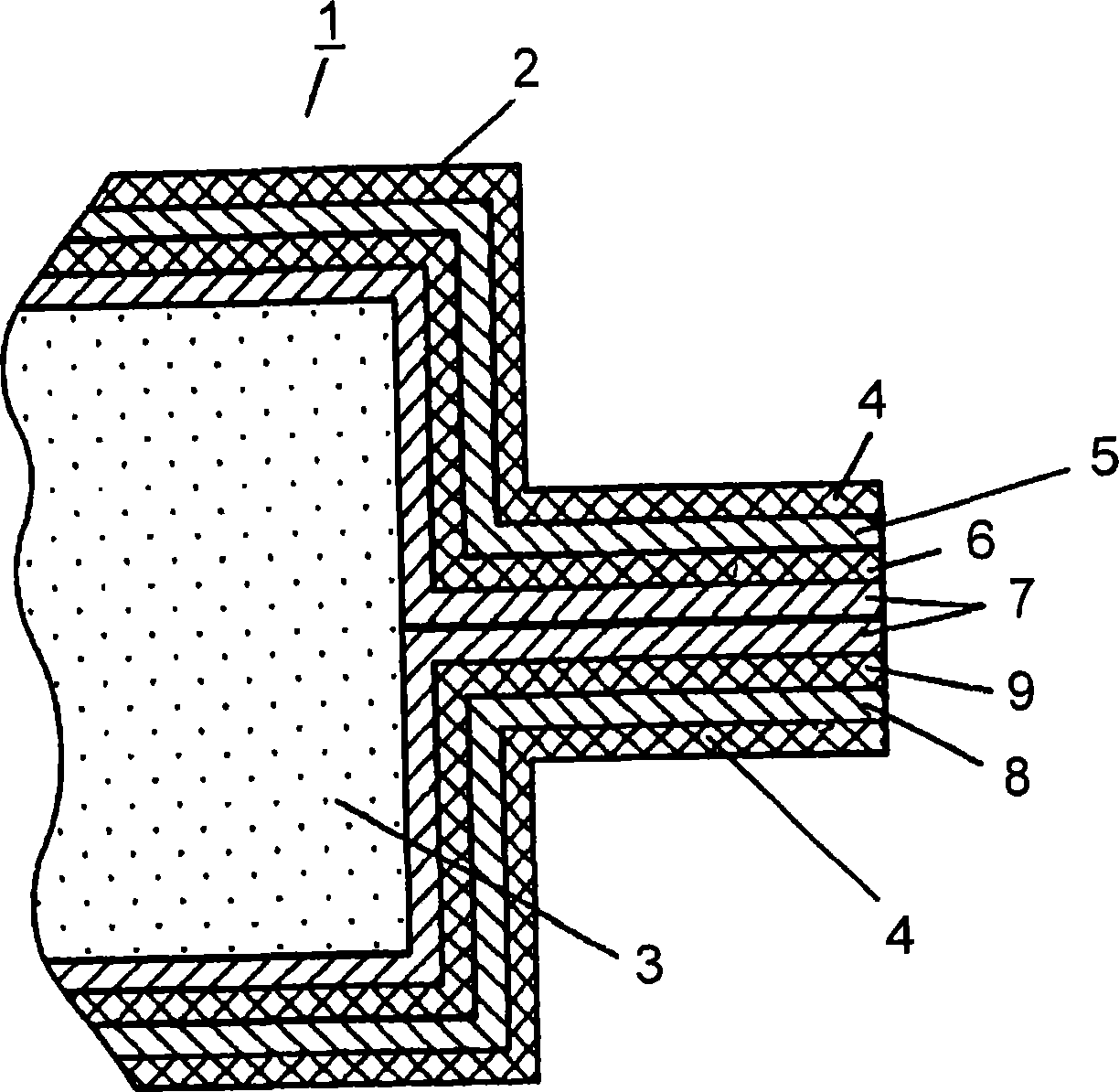

Vacuum thermal insulation material, thermal insulation apparatus using the material, and refrigerator-freezer

ActiveCN1860326AThermal insulationInsulation for cooling apparatusThermal insulationRefrigerated temperature

Owner:PANASONIC CORP

Thermal insulation material and preparation method thereof

InactiveCN107721451AEvenly dispersedEffective control of cell stabilityConstruction materialCeramicwareFoaming agentPolymer science

The invention discloses a thermal insulation material and a preparation method thereof. The thermal insulation material comprises a cement-based block skeleton and graphene modified polystyrene, wherein the cement-based block skeleton comprises multiple cavities; the multiple cavities are filled with graphene modified polystyrene; and graphene modified polystyrene is formed by performing melt extrusion on graphene and polystyrene resin according to a weight ratio of 1:(1-5) in the multiple cavities in the presence of an alkane foaming agent. According to the thermal insulation material disclosed by the invention, the strength and thermal insulation property are further improved.

Owner:ZHONGJING ECO IND CO LTD

Metal roof coating and preparation method thereof

Owner:厦门防水博士新材料有限公司

Calcium carbonate compound type flame-retardant foaming agent

Owner:新建特阔漂整(南通)有限公司

Novel winter plant protection system and use method thereof

Owner:JIANGSU PIPA LANDSCAPE

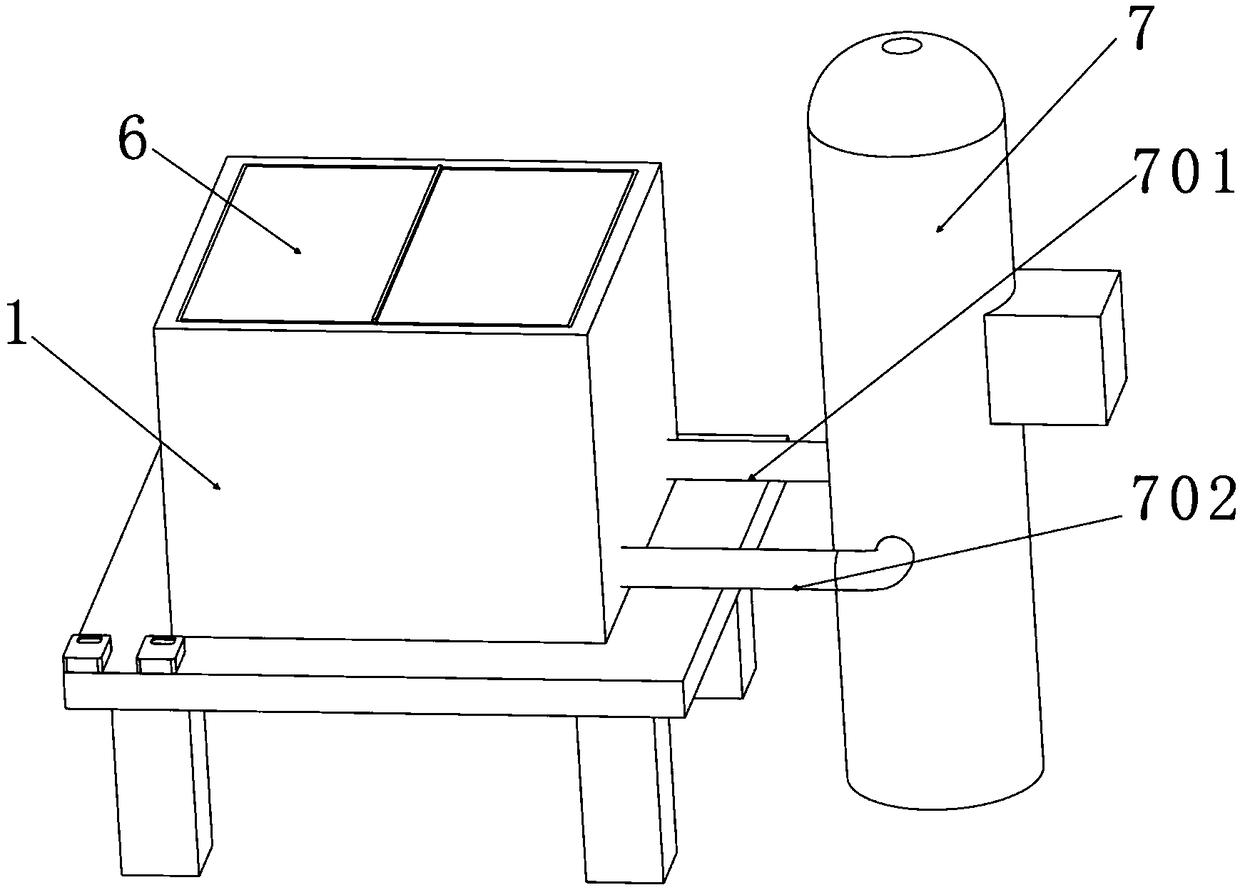

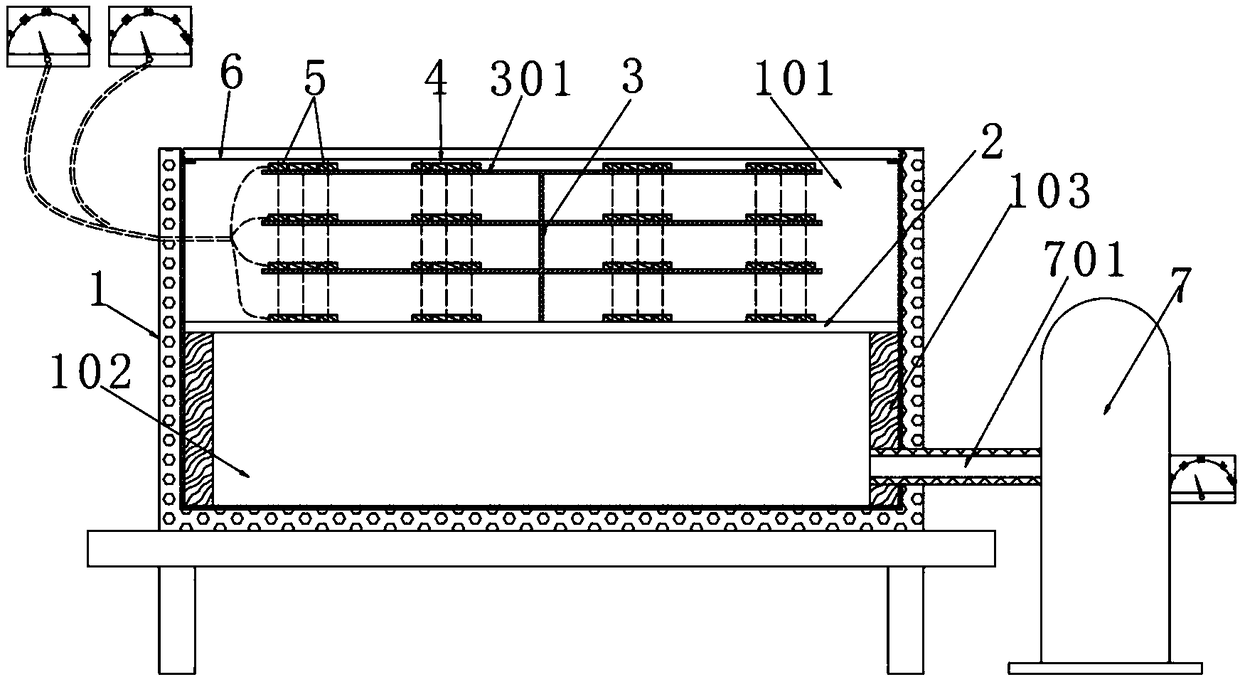

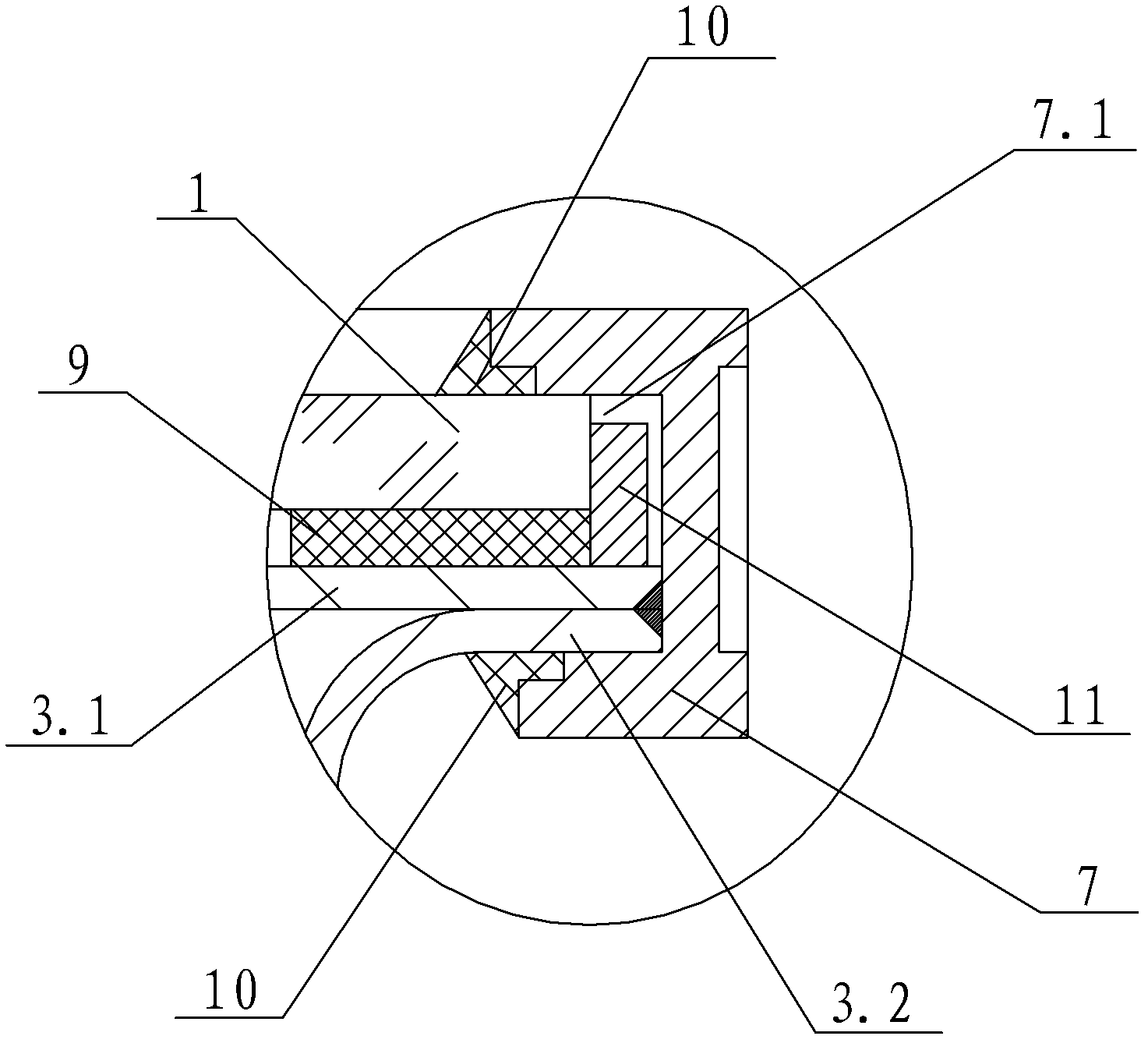

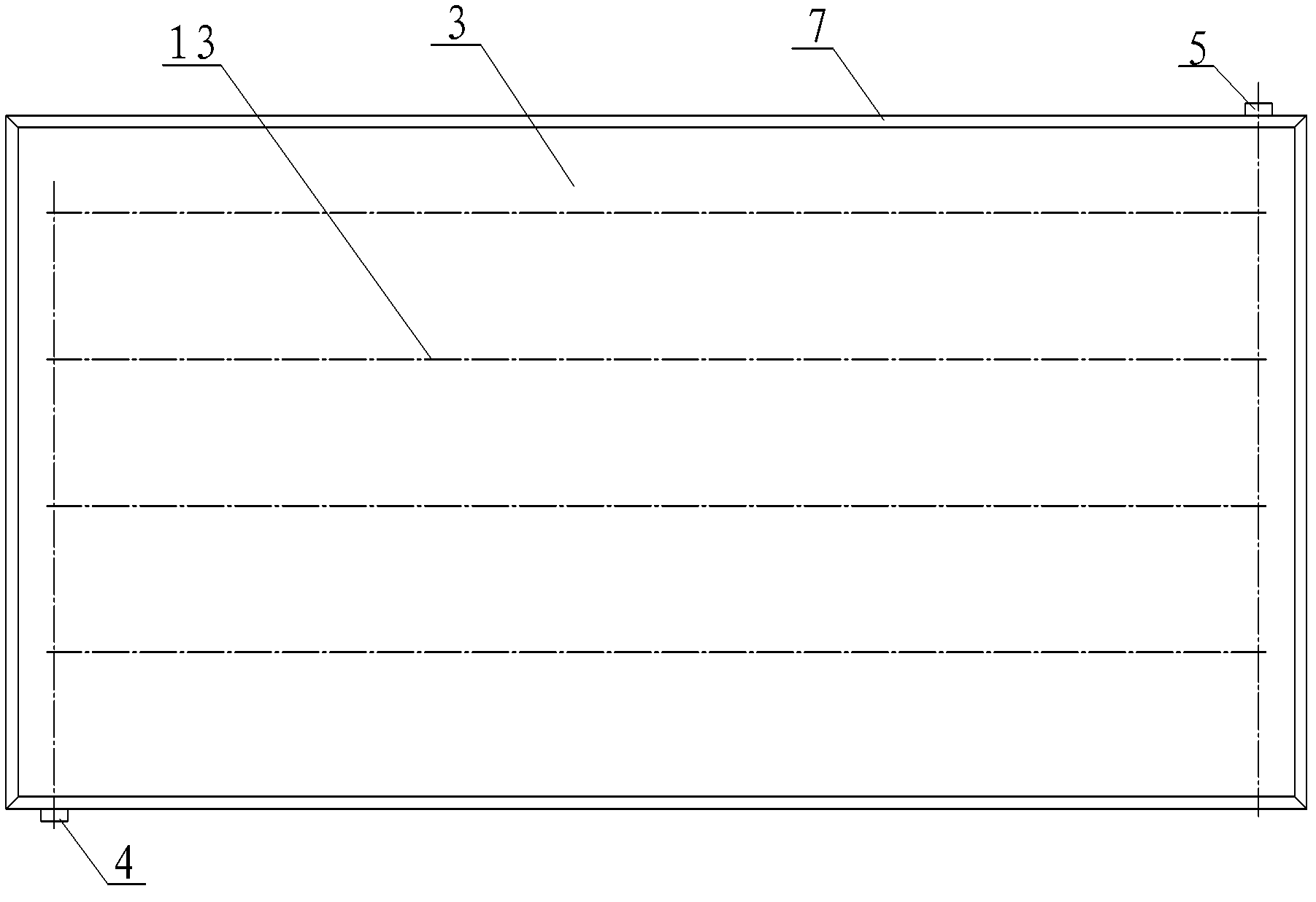

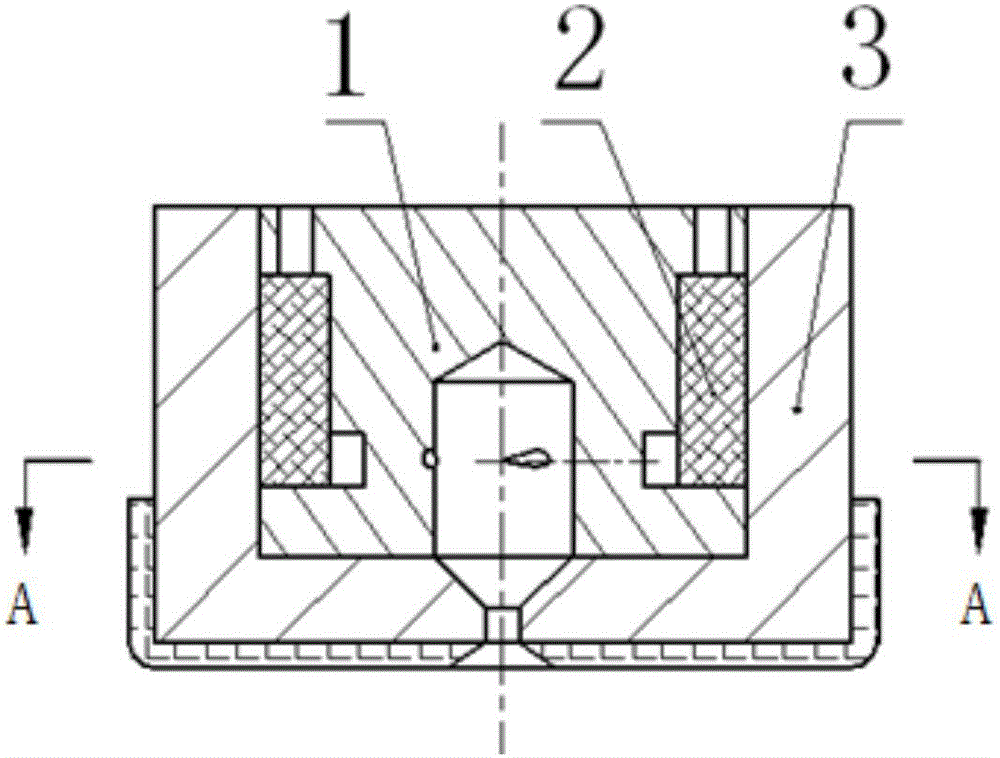

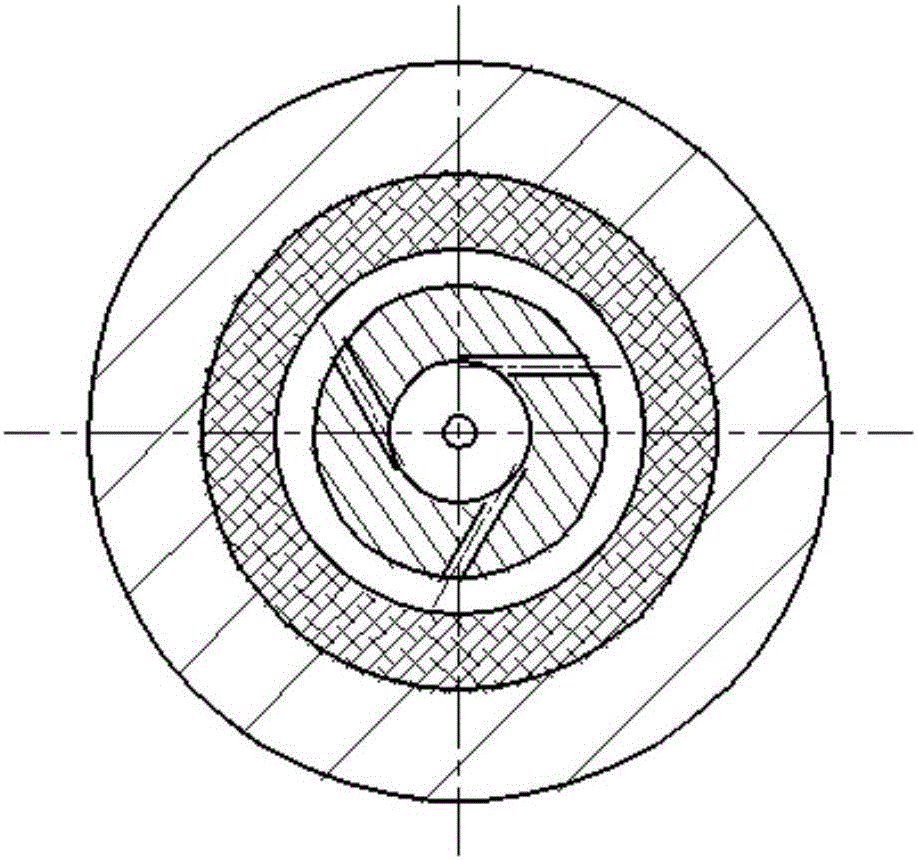

Panel solar thermal collector

InactiveCN102538235AImprove insulation effectIncrease profitSolar heating energySolar heat devicesThermal insulationCollector device

Owner:湖北贵族真空科技股份有限公司

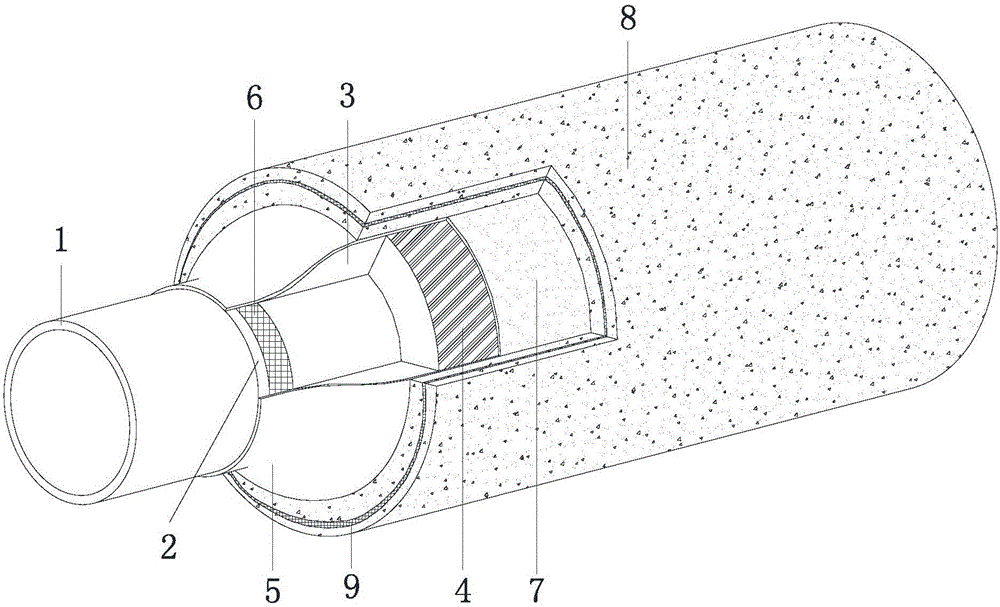

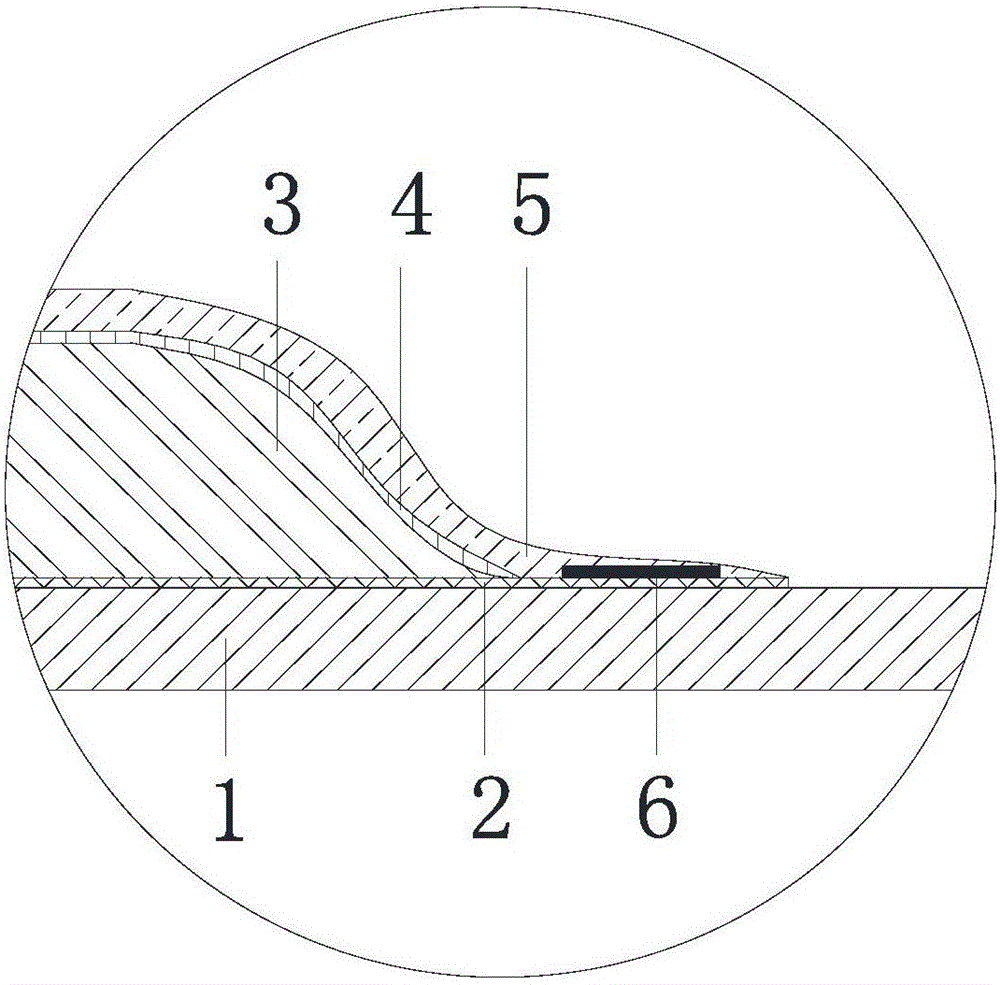

Anti-backfire nozzle for rocket engine

ActiveCN106762225AStop the spreadAnti-tempering functionRocket engine plantsCombustionThermal insulation

Owner:SHANGHAI INST OF SPACE PROPULSION

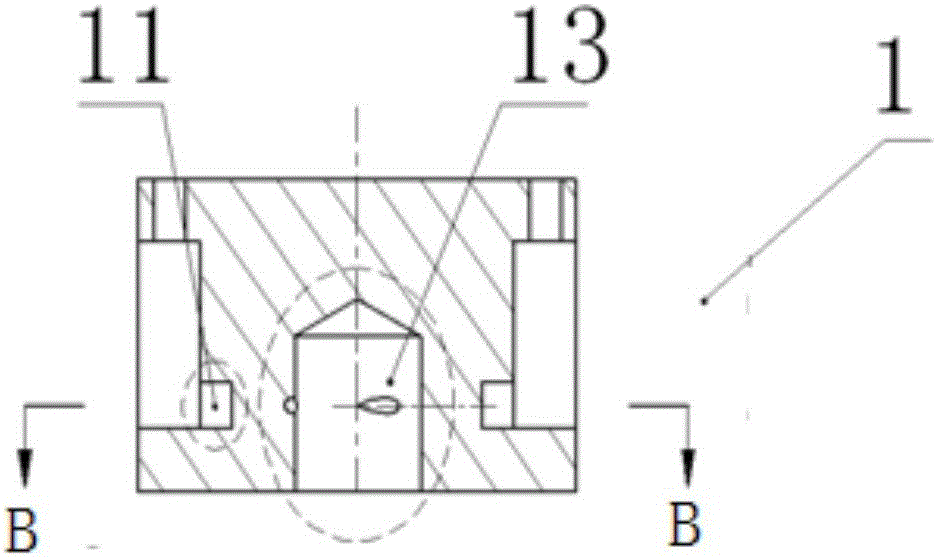

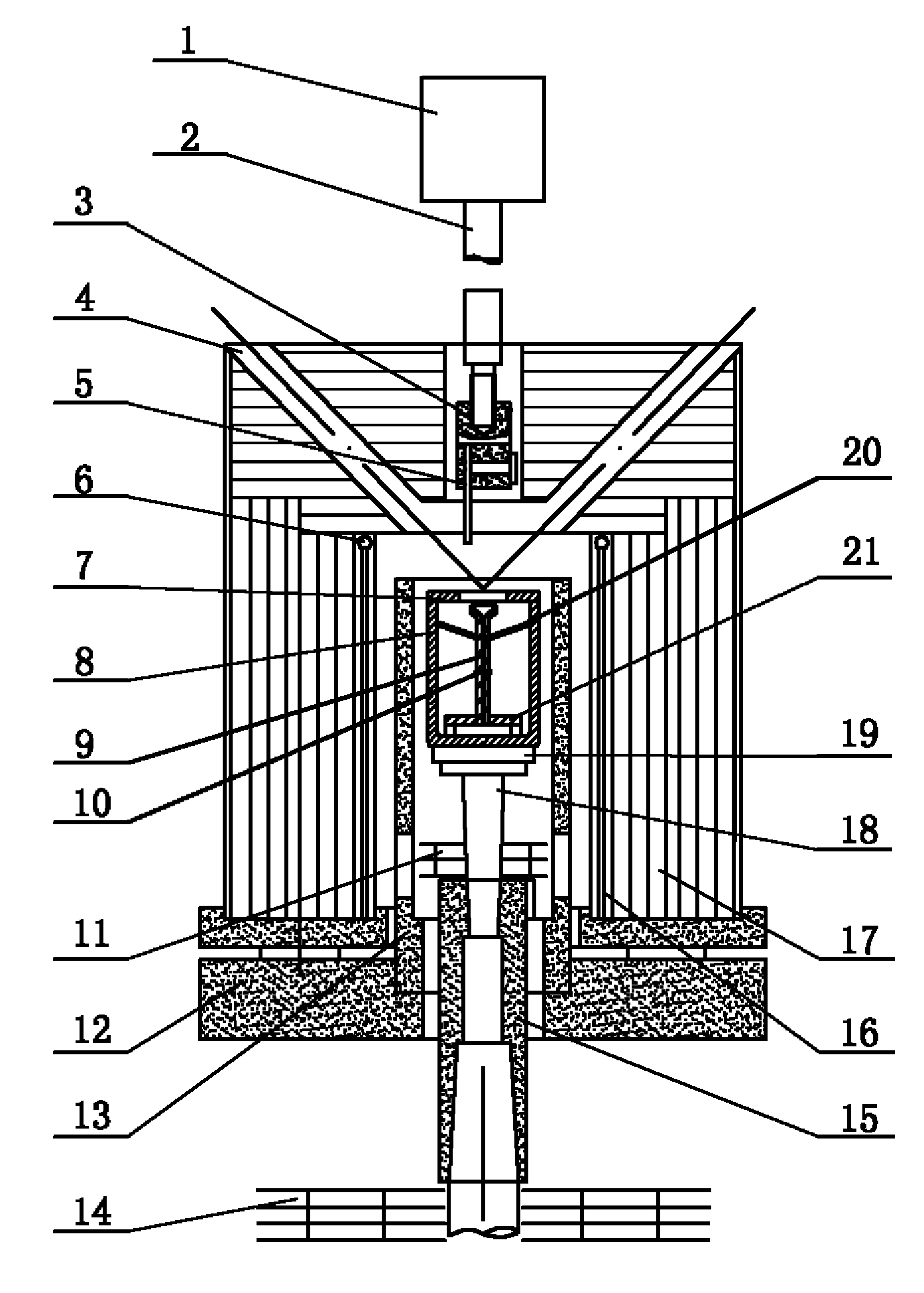

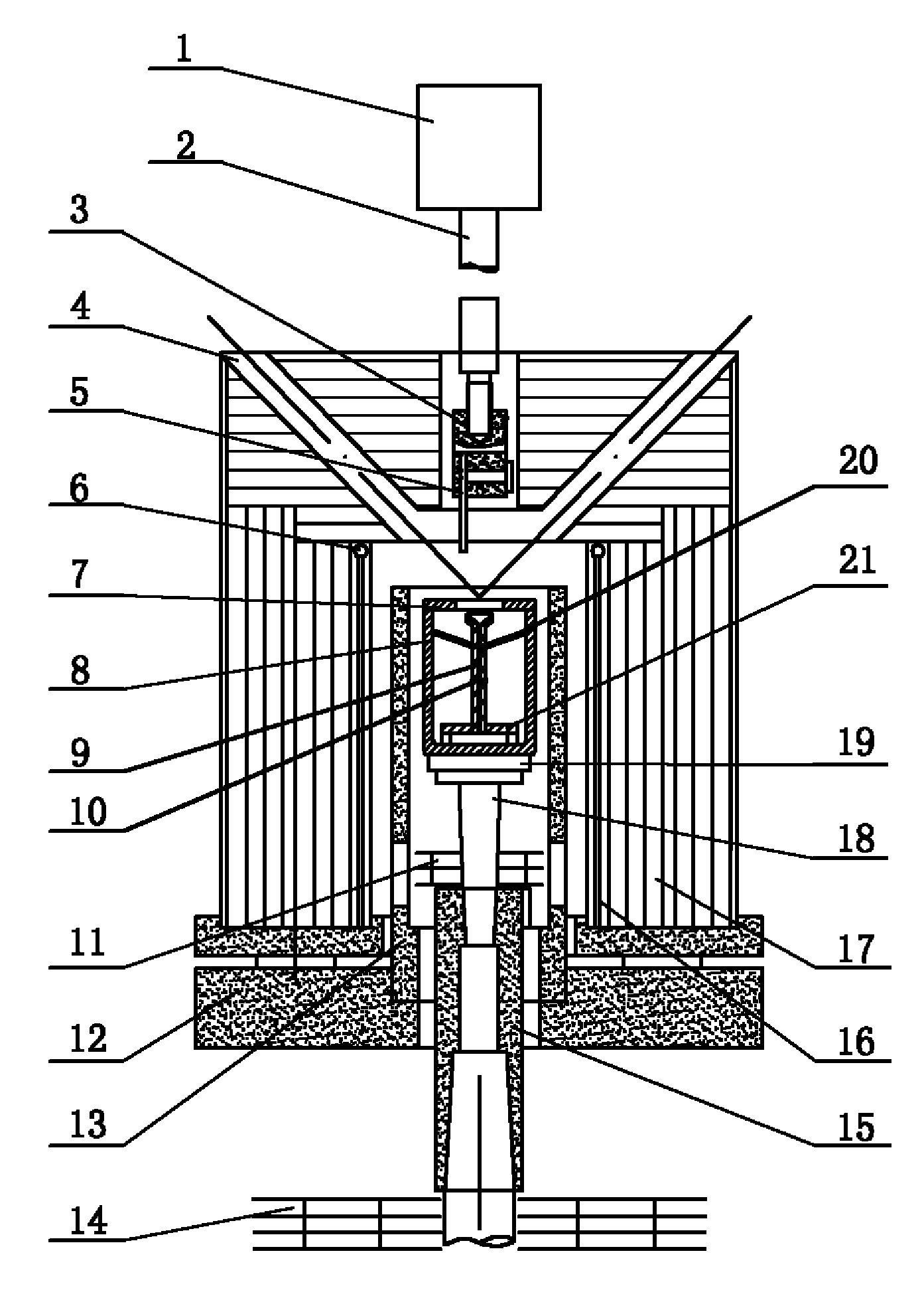

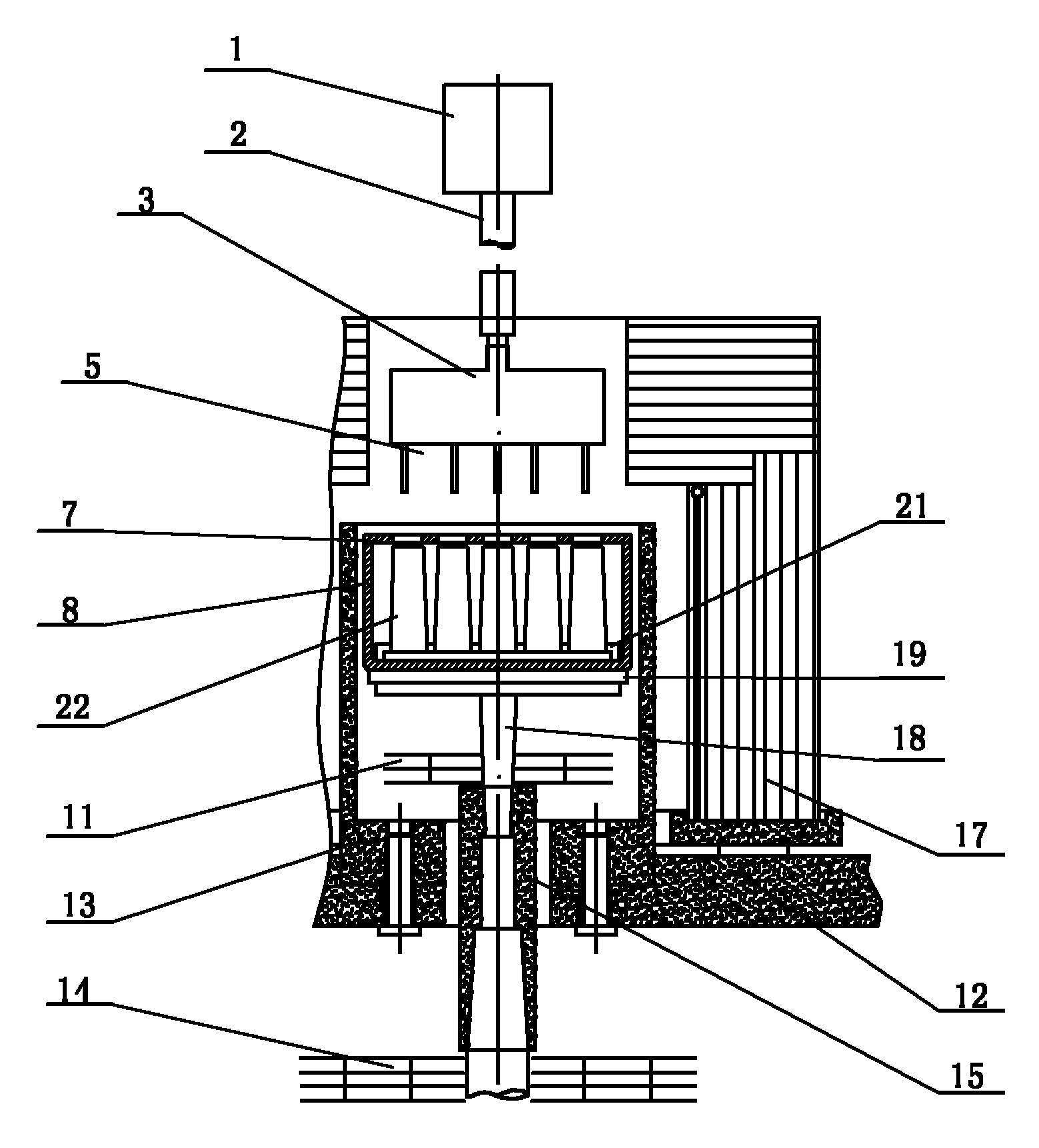

Guide die structure for growing extra-thick monocrystal alumina wafer

InactiveCN101899705APolycrystalline material growthBy pulling from meltThermal insulationSeed crystal

Owner:无锡金岩光电晶体科技有限公司

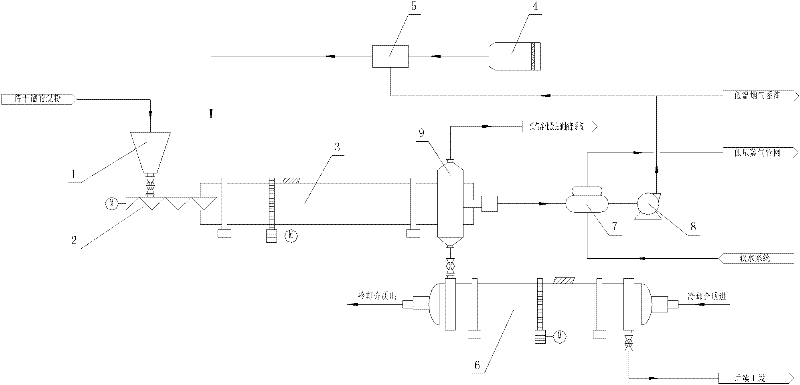

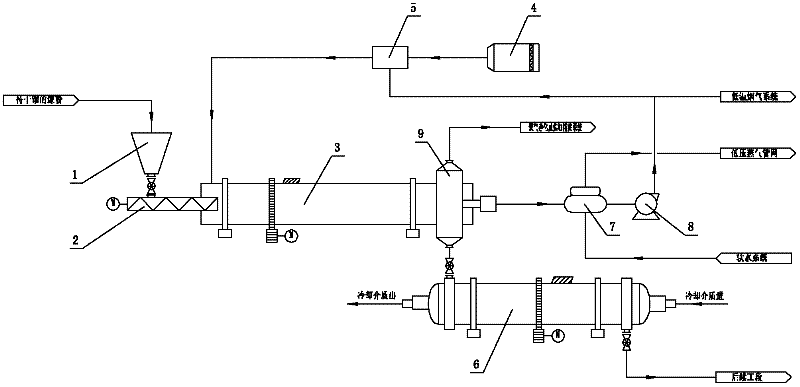

Multi-pipe revolving low-temperature dry distillation technology of fine coal

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

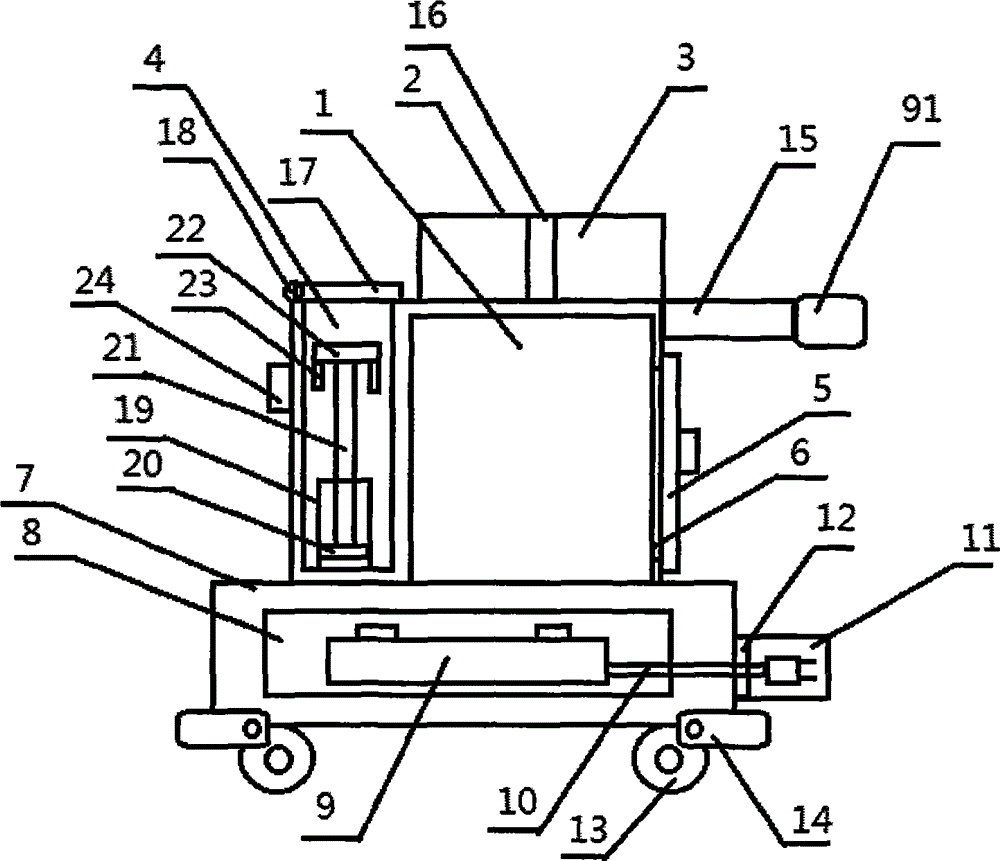

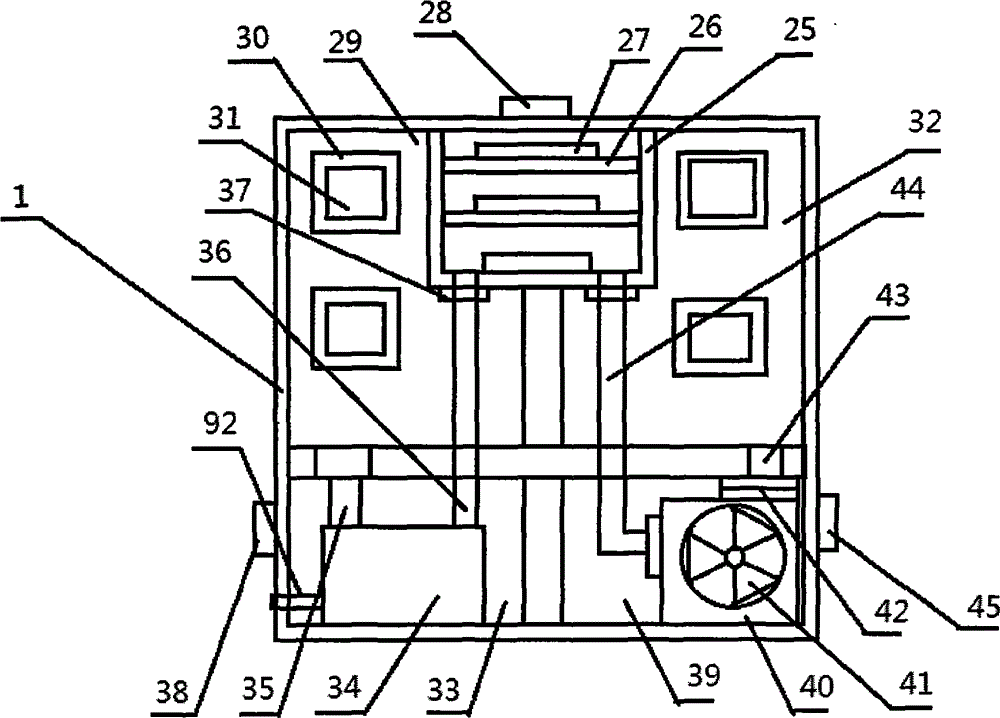

Combined medical device for internal medical nursing

InactiveCN104644363AReduce the burden onVersatileNursing accommodationThermal insulationEmergency medicine

Owner:高淑珍

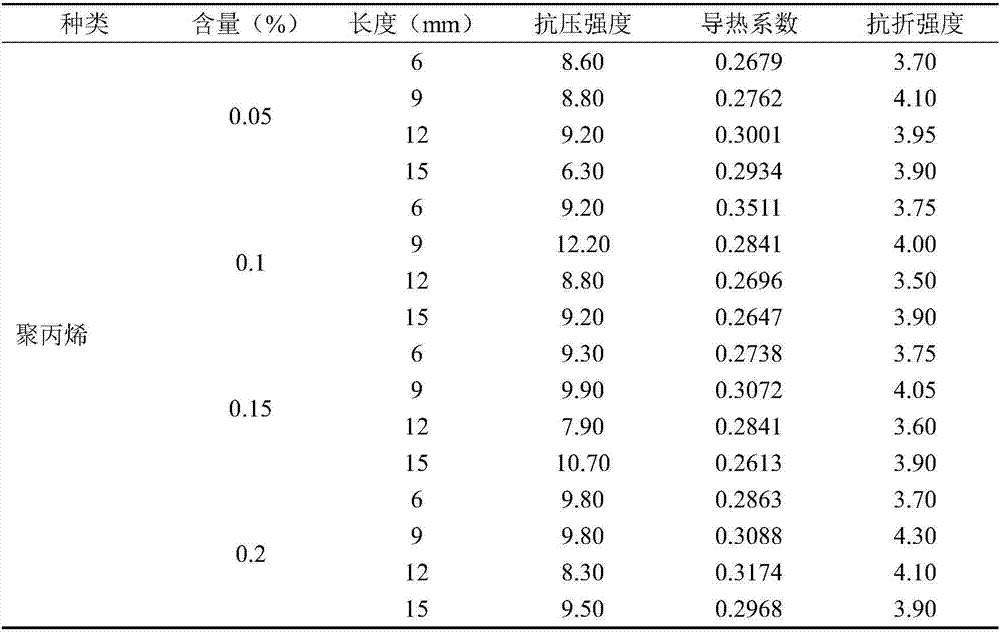

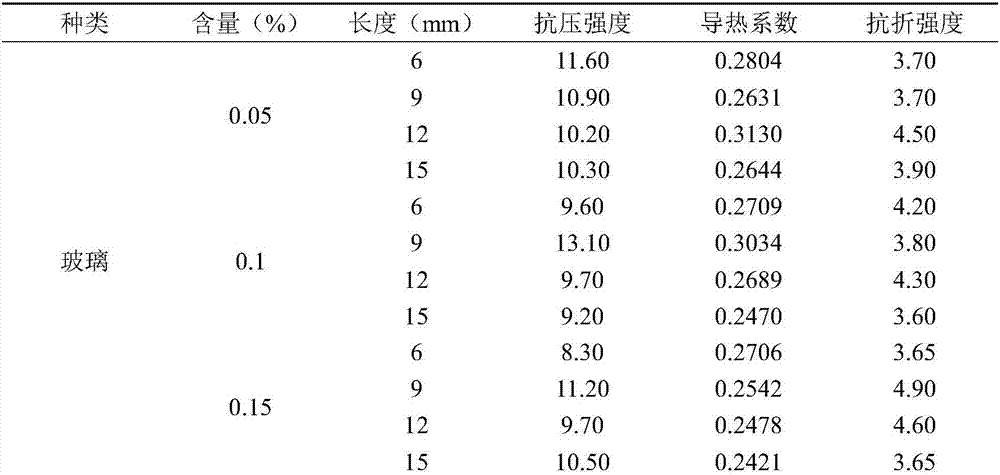

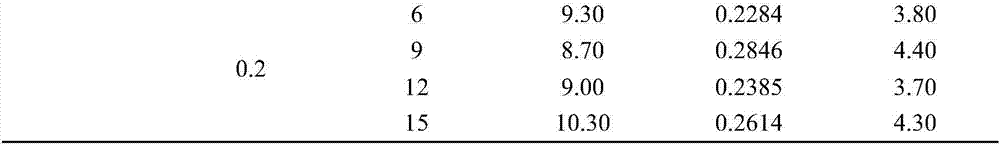

Fiber foamed concrete and preparation method thereof

ActiveCN106866177AIncrease the degree of mixingHigh compressive strengthCeramicwareThermal insulationSubgrade

The invention discloses a fiber foamed concrete and a preparation method thereof. The fiber foamed concrete comprises the following raw materials in parts by weight: 5290 parts of cement, 4965 parts of water, 1.361 part of foaming solution, 1.2964 part of fly ash and 10 parts of fiber. The preparation method comprises the following steps: proportionally weighing the components; sequentially adding the cement and fly ash into a stirrer, proportionally weighing the water, uniformly stirring the mixture by the stirrer, and adding the fiber; preparing and adding the foaming solution; gradually adding the foam into the mixture, and continuously stirring until all the components are uniformly mixed; pouring the mixture into a mold on which lubricating oil is brushed, and curing in a curing chamber; after 24 hours, removing the mold; and respectively curing for 3 days, 7 days and 28 days for experimental detection. The fiber foamed concrete has the advantages of favorable thermal insulation property, favorable compression resistance and favorable bending resistance, and is applicable to a railway bed strengthening layer.

Owner:SHIJIAZHUANG TIEDAO UNIV

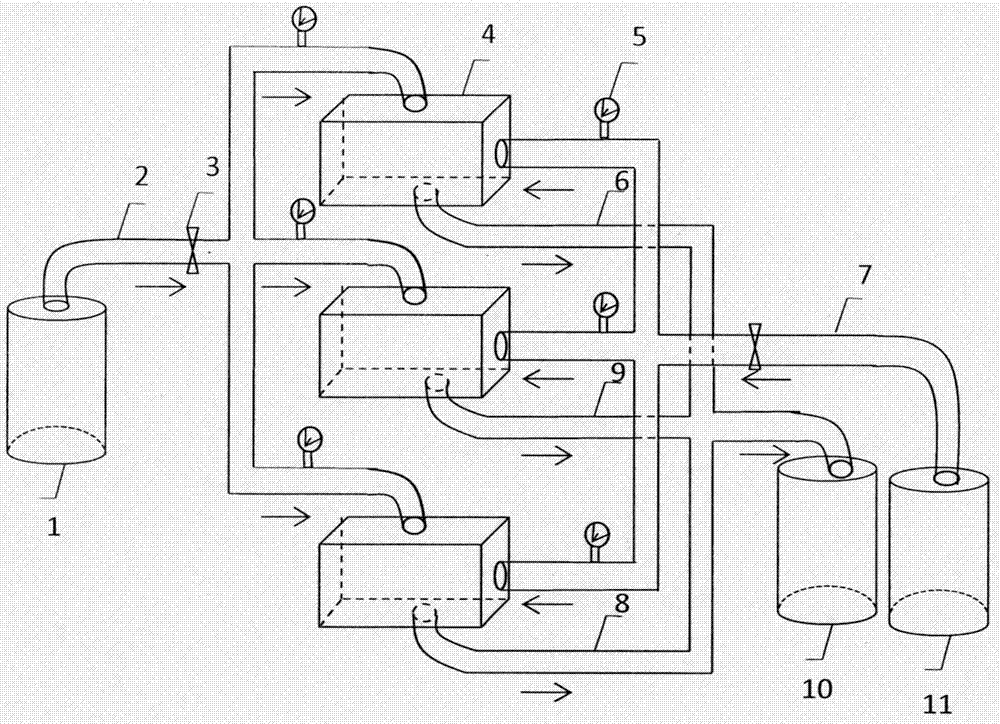

Pure wood internally-opening and energy-saving window and door system

Owner:浙江瑞明节能门窗技术有限公司

Decorative and thermal-insulation integrated novel lightweight walling material made from polishing brick waste

Owner:ZIBO YONGXU REFRACTORY MATERIALS

Anti-flaming thermal-insulation environmentally-friendly polymeric foaming material and method for producing the same

InactiveCN102516710ALow thermal conductivityImprove insulation effectPolymer sciencePolyvinyl alcohol

The invention discloses an anti-flaming thermal-insulation environmentally friendly polymeric foaming material and a method for producing the material. The method comprises the following steps: preparing a urea resin foam adhesive by successively adding 37 % of formaldehyde, polyvinyl alcohol and glycerin in a reaction kettle and stirring to heat up and then adding urea, hexamethylene tetramine, stabilizer and thiourea, preparing a foaming agent by firstly adding water in a stirring tank, successively adding nekal and nonylphenol polyoxylethylene ether with stirring, heating up for completely dissolving, and then adding phosphoric acid, glycerin and sodium phosphate, uniformly stirring until completely dissolving, and discharging and packaging, and preparing a foamed product by taking the urea resin adhesive, urea and the foaming agent, mixing and stirring uniformly, putting in a foaming machine to foam, and carrying out foaming, extrusion molding, drying and packaging. The invention can be widely applied in thermal insulation of building facilities, thermal insulation of venue decoration, shock absorption, replacement of benzene plate flexible package without anti-flaming property, and the like.

Owner:王喆

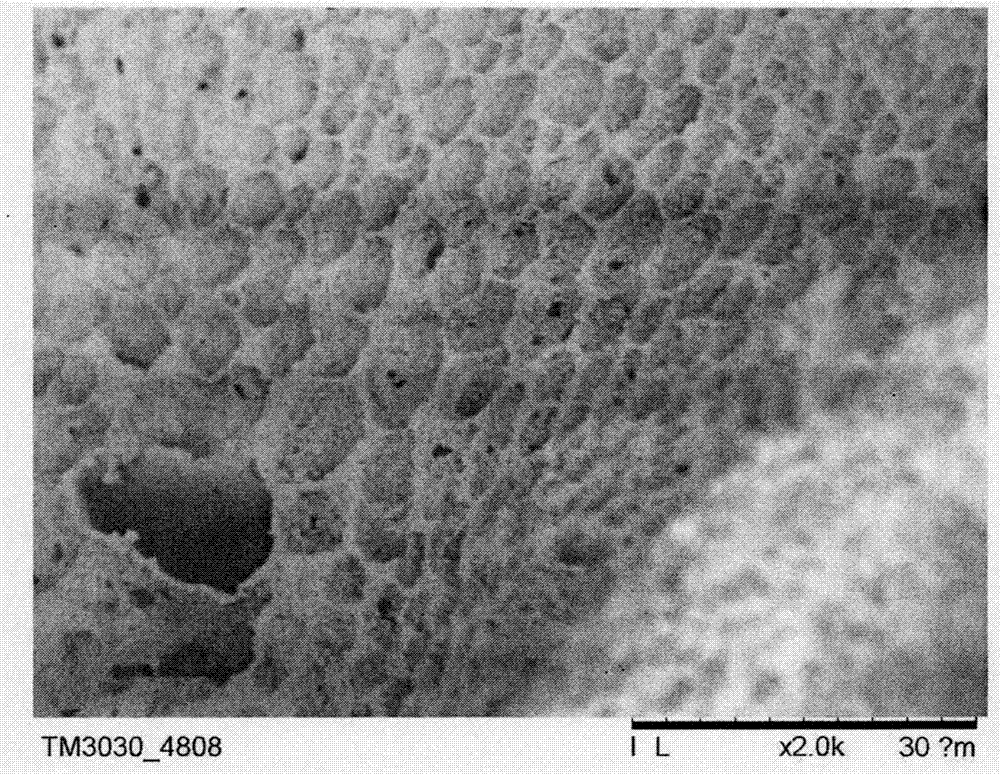

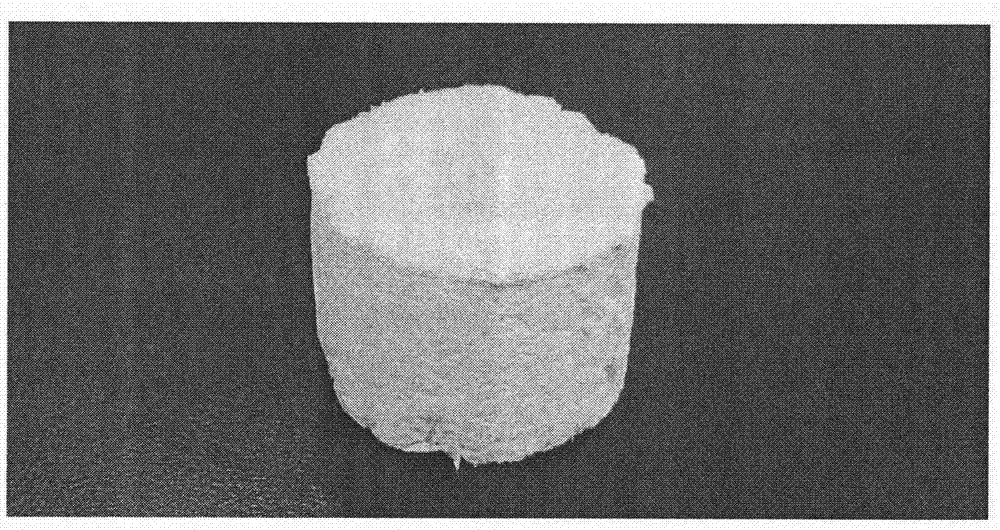

Preparation method for preparing nylon porous material on large scale

ActiveCN107353634ALarge specific surface areaWith insulationOther chemical processesWater/sewage treatment by sorptionPorositySodium bicarbonate

Owner:TIANJIN POLYTECHNIC UNIV

Thermal-insulation coating

Owner:SHANGHAI JUNXIONG INVESTMENT

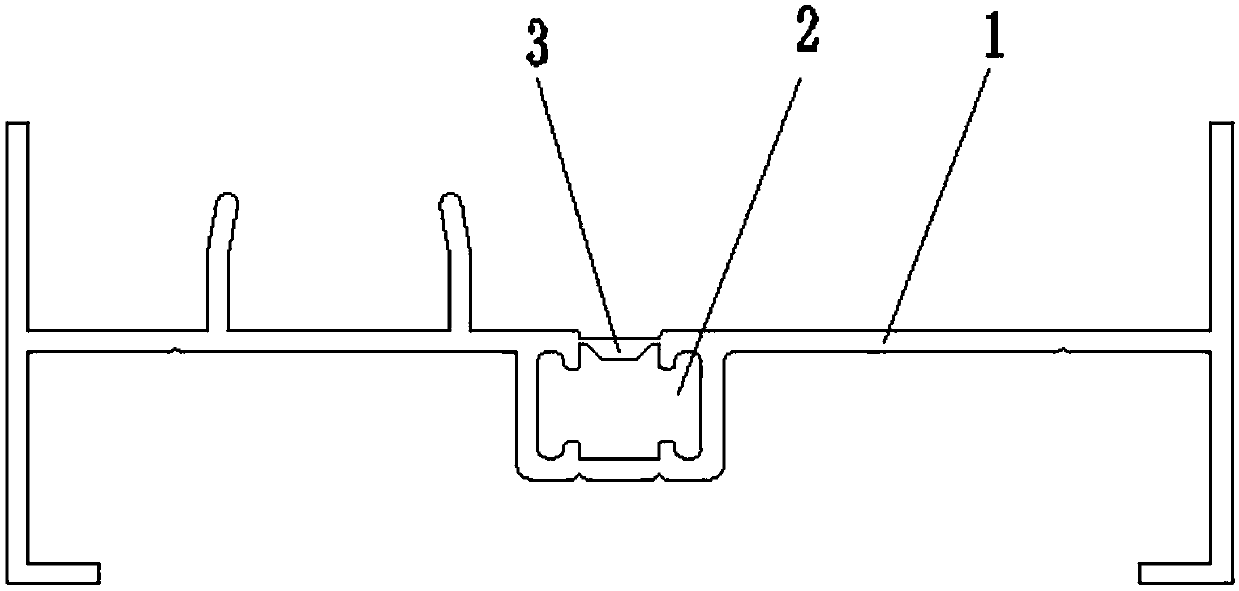

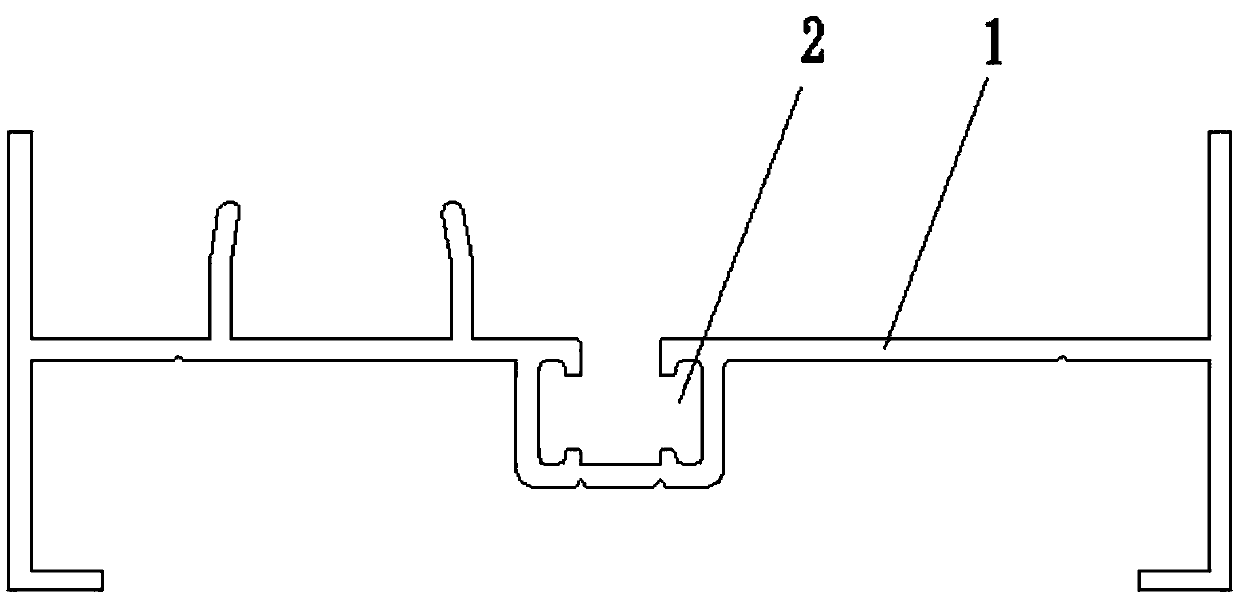

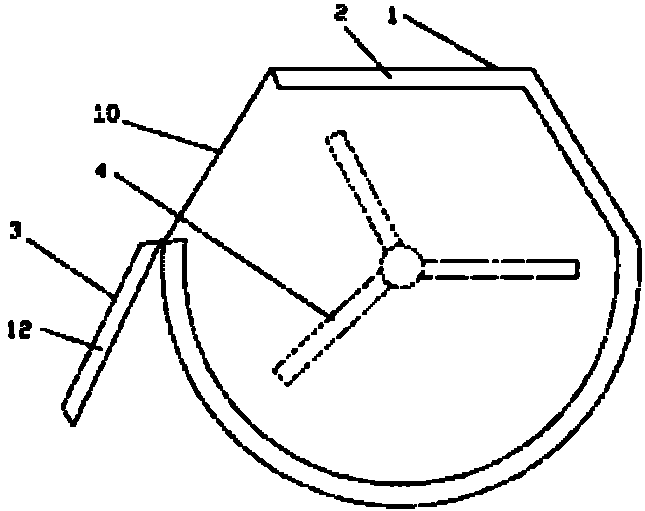

Production process of novel heat insulation cast electrophoresis aluminium section structure

Owner:WANBANGDE PHARM HLD GRP CO LTD

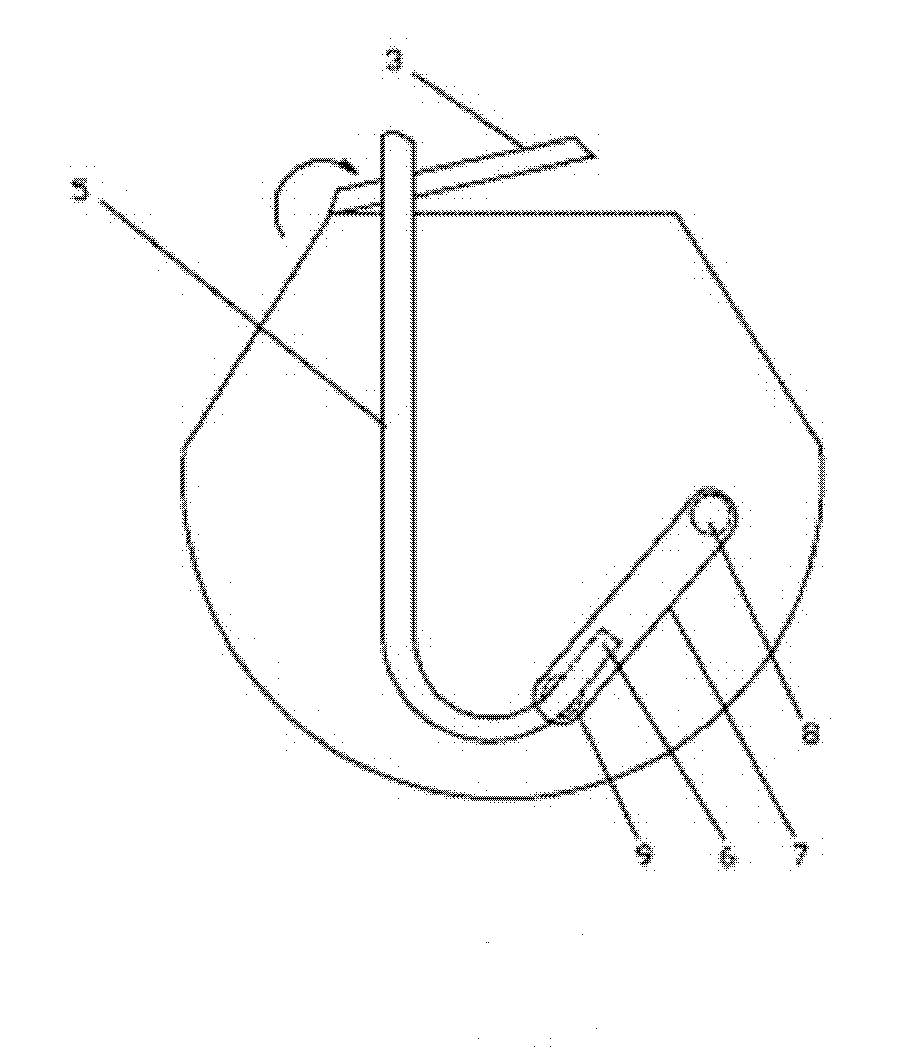

Fur dyeing kettle

Owner:TONGXIANG NEW ERA FUR

Bismaleimide resin/silicone rubber ablation-resistant thermal insulation composite material and preparation method thereof

Owner:湖北三江航天江北机械工程有限公司

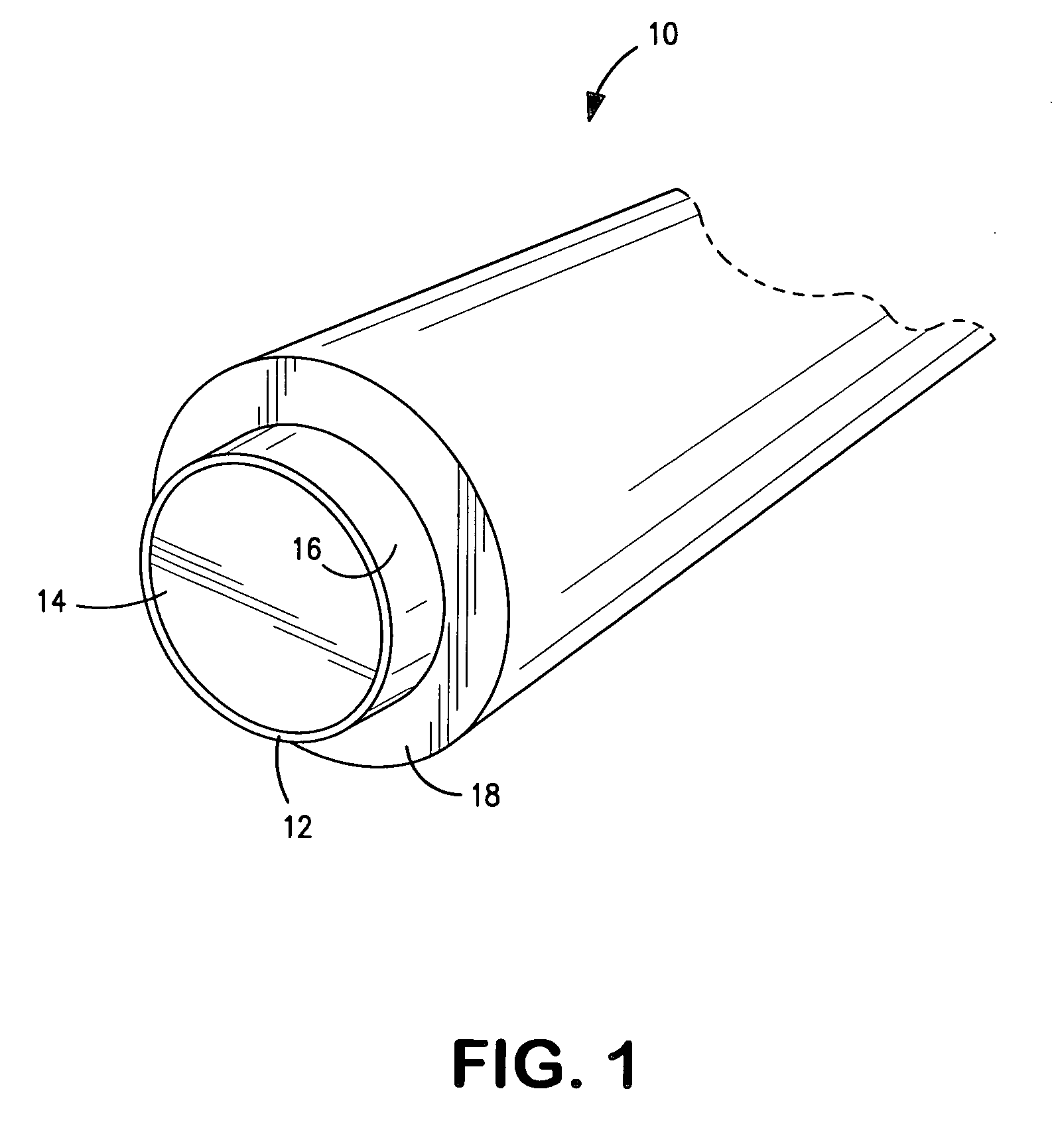

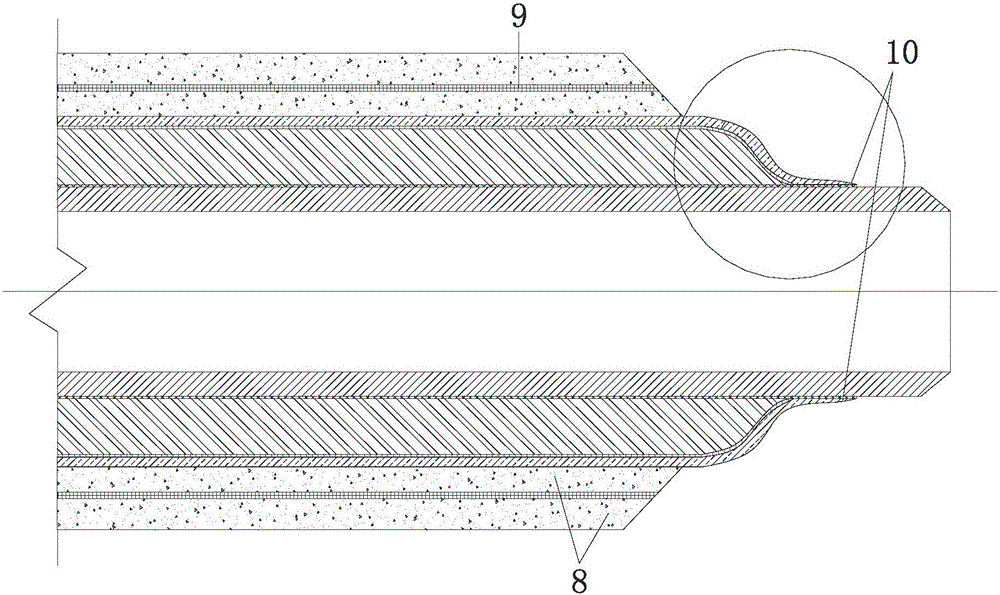

Marine polyurethane spraying prefabricated thermal insulation balance weight pipe and preparation method thereof

InactiveCN105909883AEnsure consistencyAvoid your own flawsThermal insulationPipe protection by thermal insulationPolyolefinAdhesive

Owner:CHINA NAT OFFSHORE OIL CORP +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap