Multi-pipe revolving low-temperature dry distillation technology of fine coal

A process method and technology of dry distillation, which is applied in the field of multi-tube rotary low-temperature dry distillation of pulverized coal, can solve the problems of high thermal insulation requirements for the cylinder body, difficulty in cloth distribution of multi-tube rotary dry distillation machines, etc., and achieve small gas processing capacity and simple and easy cloth distribution , to maximize the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

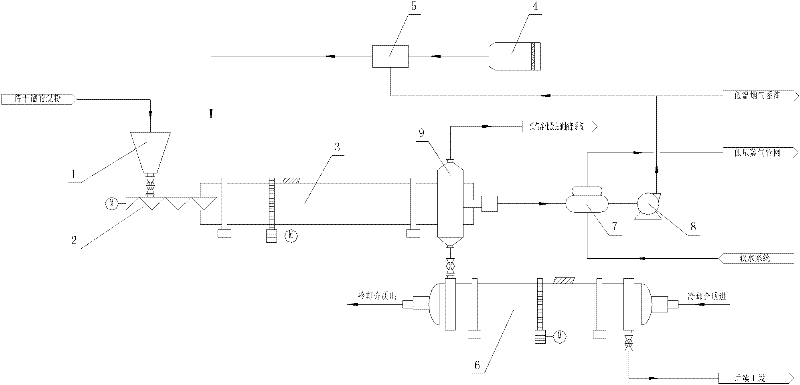

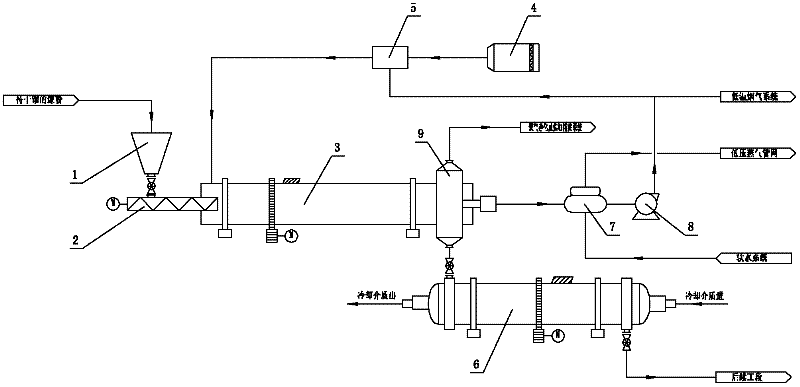

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] Such as figure 1 As shown, the process method of the present invention is divided into two parts: material flow and flue gas flow.

[0034] Material flow: the coal powder to be retorted enters the coal bunker 1, and is sent into the barrel of the multi-tube rotary retort 3 through the screw conveyor 2 or other conveying equipment. A plurality of heat exchange tubes are arranged in the barrel of the multi-tube rotary dry distillation machine. With the rotation of the barrel of the multi-tube rotary retort machine, the coal powder is lifted and sprinkled by the heat exchange tubes, fully contacts the built-in heat exchange tubes for heat exchange, and moves along the axis of the barrel. During the heating process, the pulverized coal is pyrolyzed to generate hot semi-coke and retort gas (coal gas, tar vapor, pyrolysis water, etc.). The discharge te

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap