Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

199 results about "Adhesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adhesive, also known as glue, cement, mucilage, or paste, is any non metallic substance applied to one or both surfaces of two separate items that binds them together and resists their separation. The use of adhesives offers many advantages over binding techniques such as sewing, mechanical fastening, thermal bonding, etc. These include the ability to bind different materials together, to distribute stress more efficiently across the joint, the cost effectiveness of an easily mechanized process, an improvement in aesthetic design, and increased design flexibility. Disadvantages of adhesive use include decreased stability at high temperatures, relative weakness in bonding large objects with a small bonding surface area, and greater difficulty in separating objects during testing. Adhesives are typically organized by the method of adhesion. These are then organized into reactive and non-reactive adhesives, which refers to whether the adhesive chemically reacts in order to harden. Alternatively they can be organized by whether the raw stock is of natural or synthetic origin, or by their starting physical phase.

Electronics module having high density interconnect structures incorporating an improved dielectric lamination adhesive

InactiveUS6294741B1Improve electrical performanceAdequate processing propertyInsulating substrate metal adhesion improvementPrinted electric component incorporationComposite filmHigh density

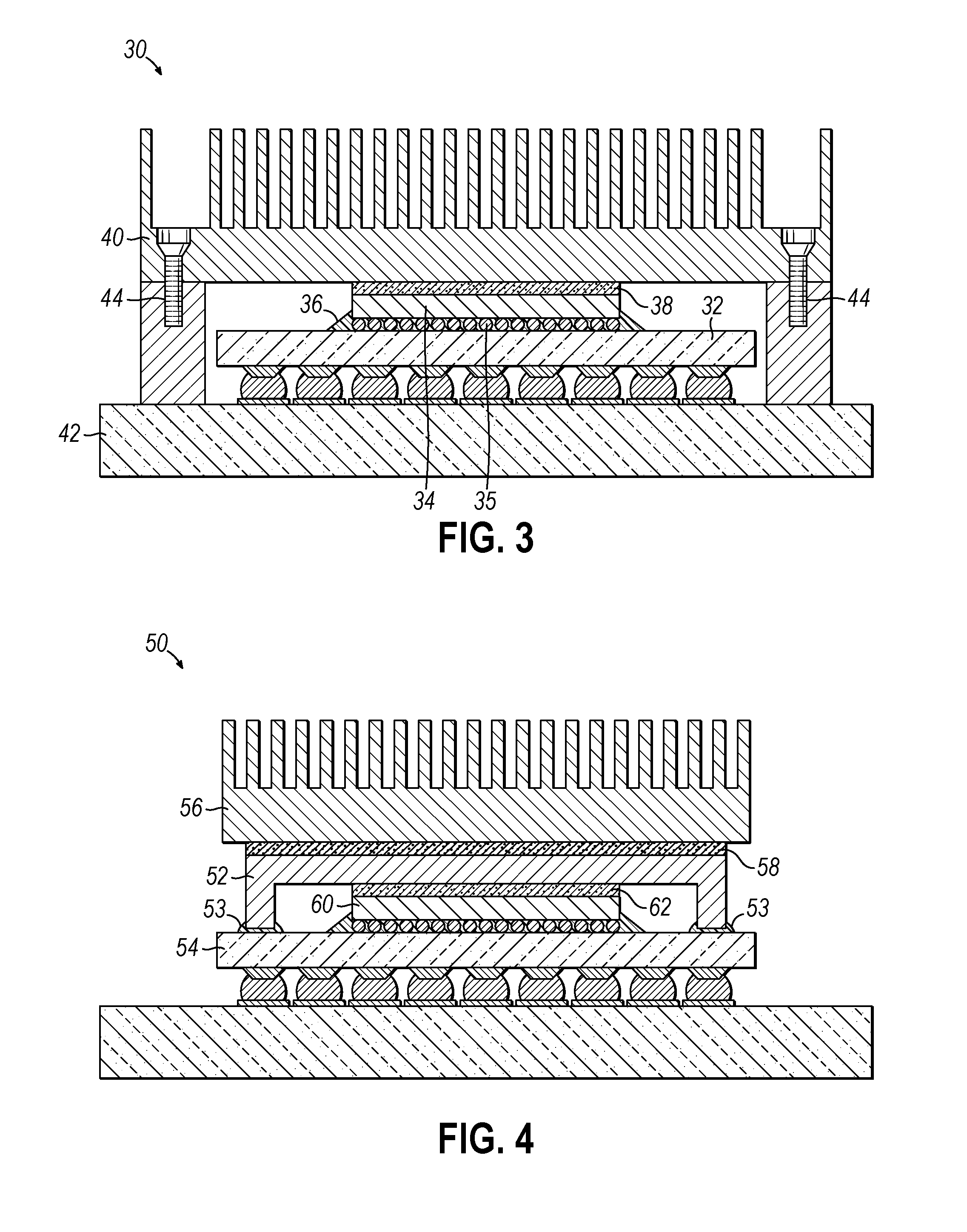

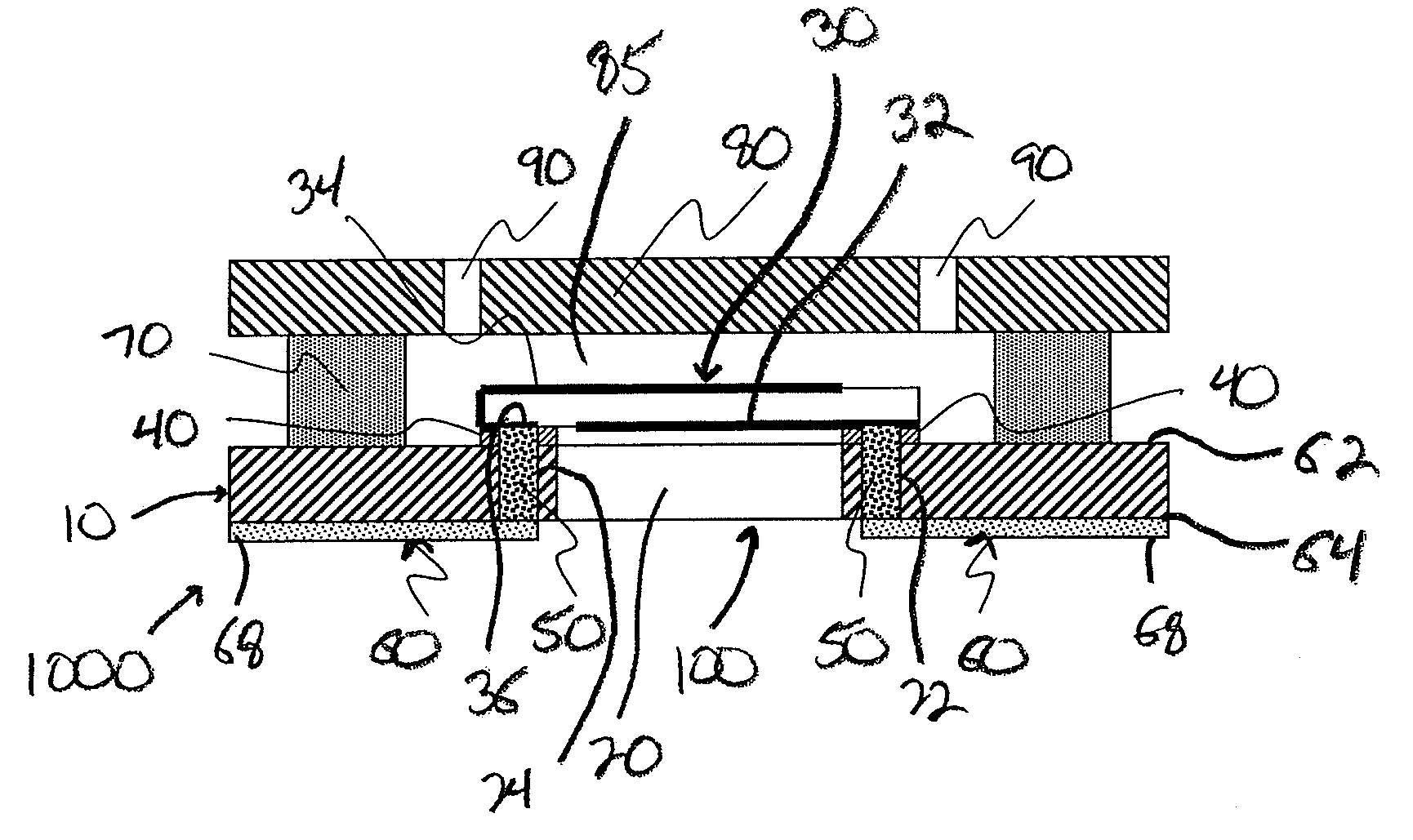

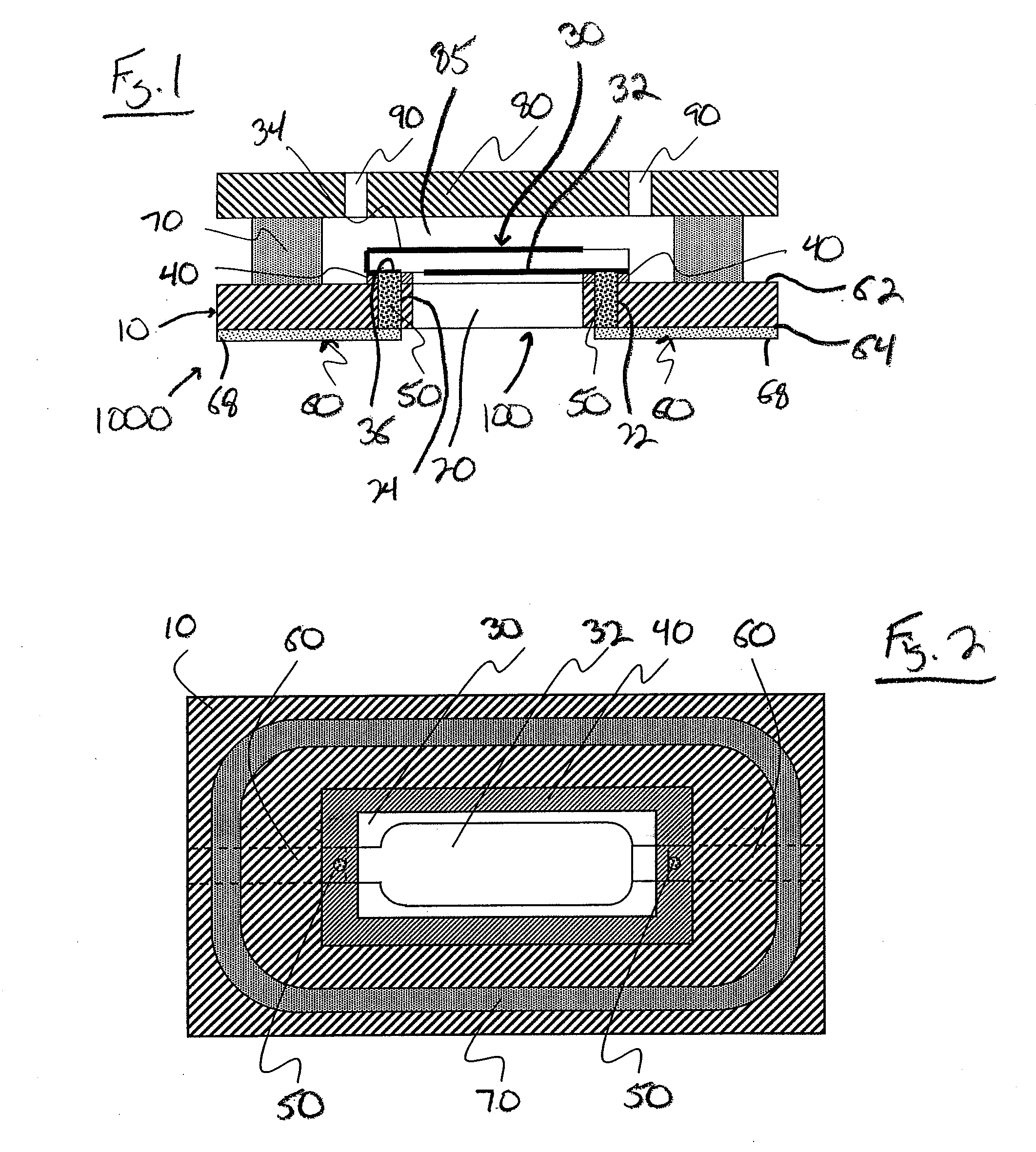

A multi-chip electronics module is provided which utilizes benzocyclobutene as a laminate adhesive for bonding the upper dielectric films in a high density interconnect structure. The benzocyclobutene thermosetting polymer is spin coated on a polyimide film, and baked at low temperature to remove any solvent to leave a B-staged coating on the polyimide film. The composite film can be laminated to an underlying electrical structure using a vacuum laminator and heat. As the heat is applied, the BCB layer softens, flows and then cures to bond the polyimide film to the underlying electrical structure.

Owner:LOCKHEED MARTIN CORP

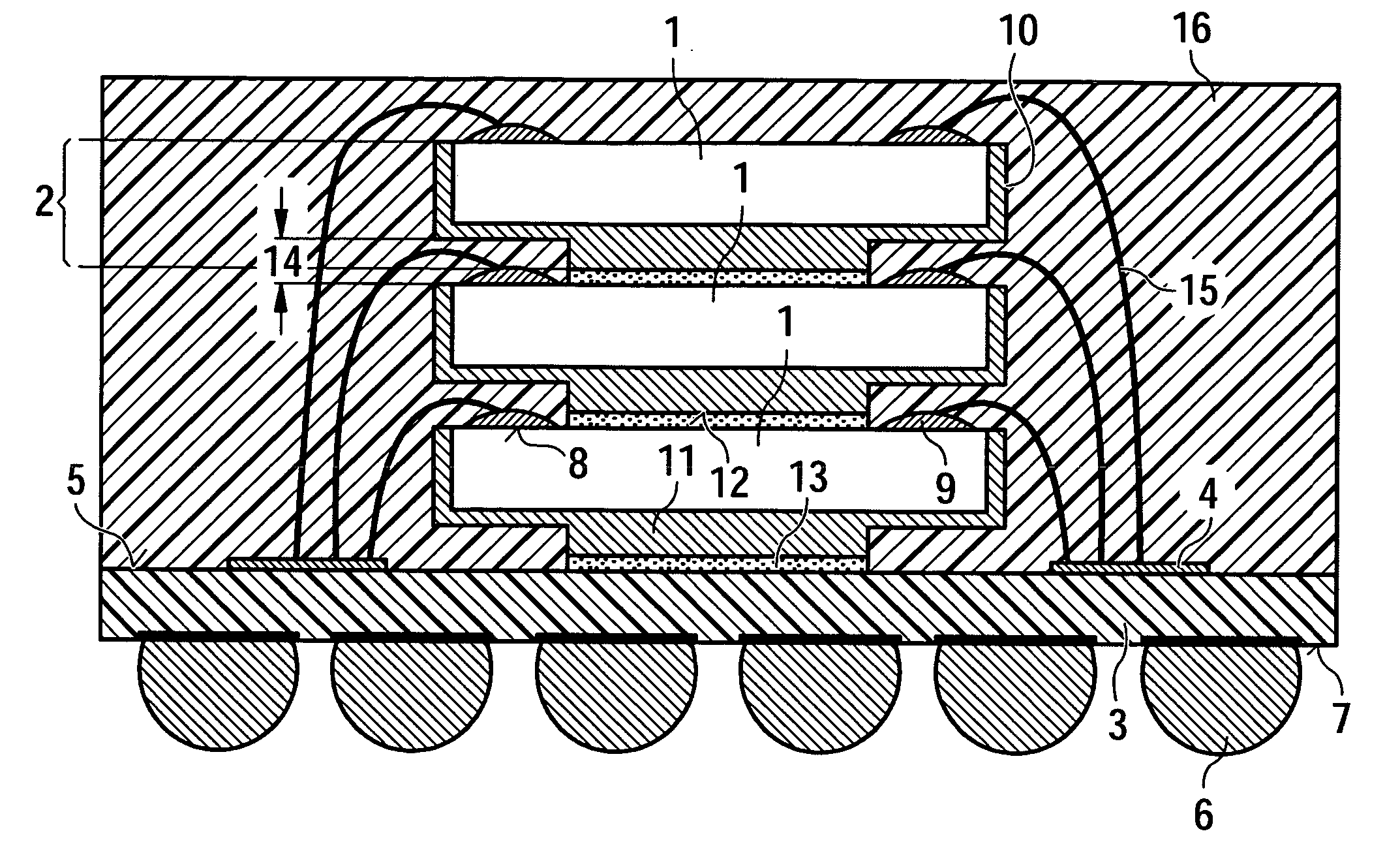

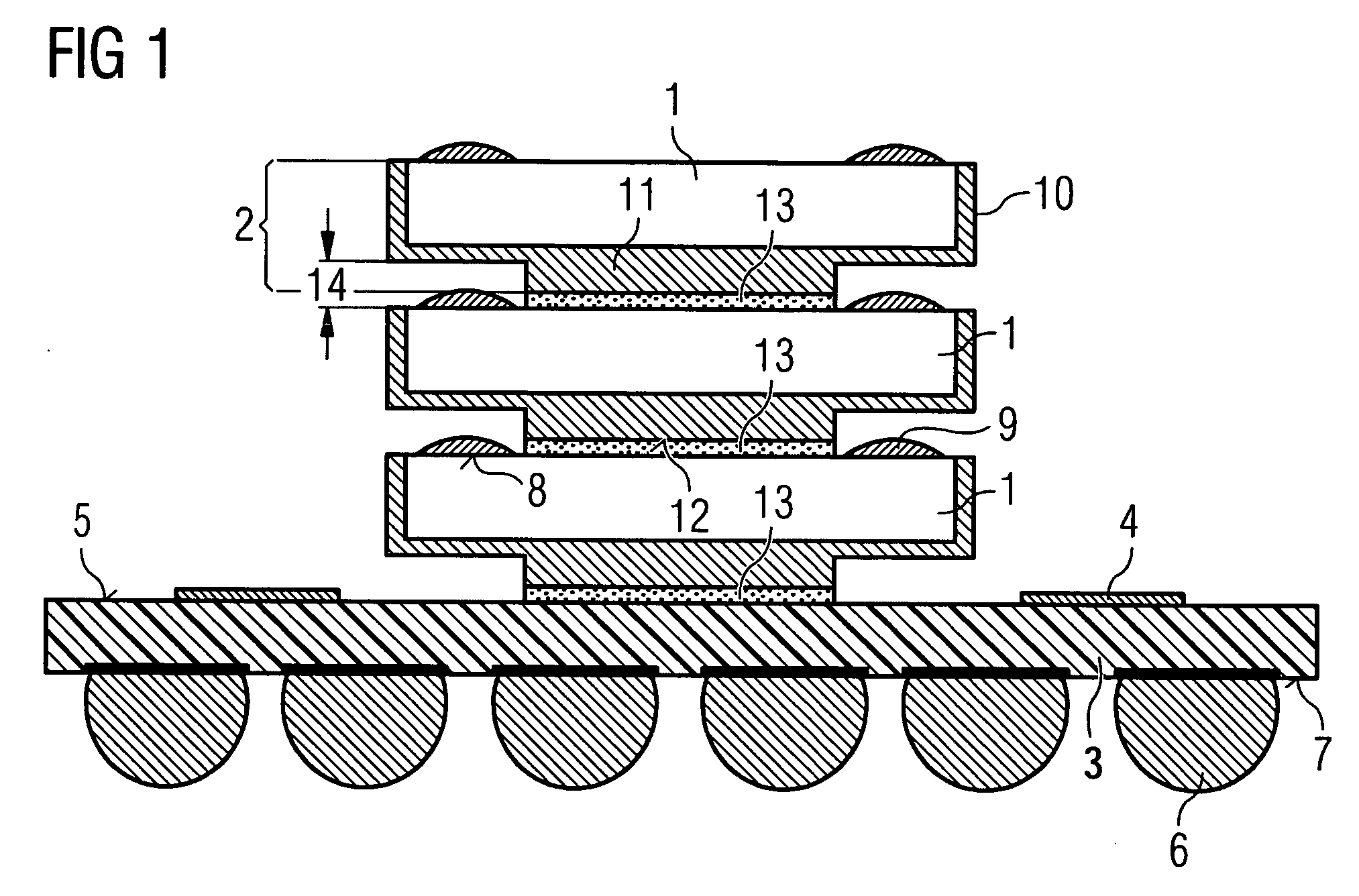

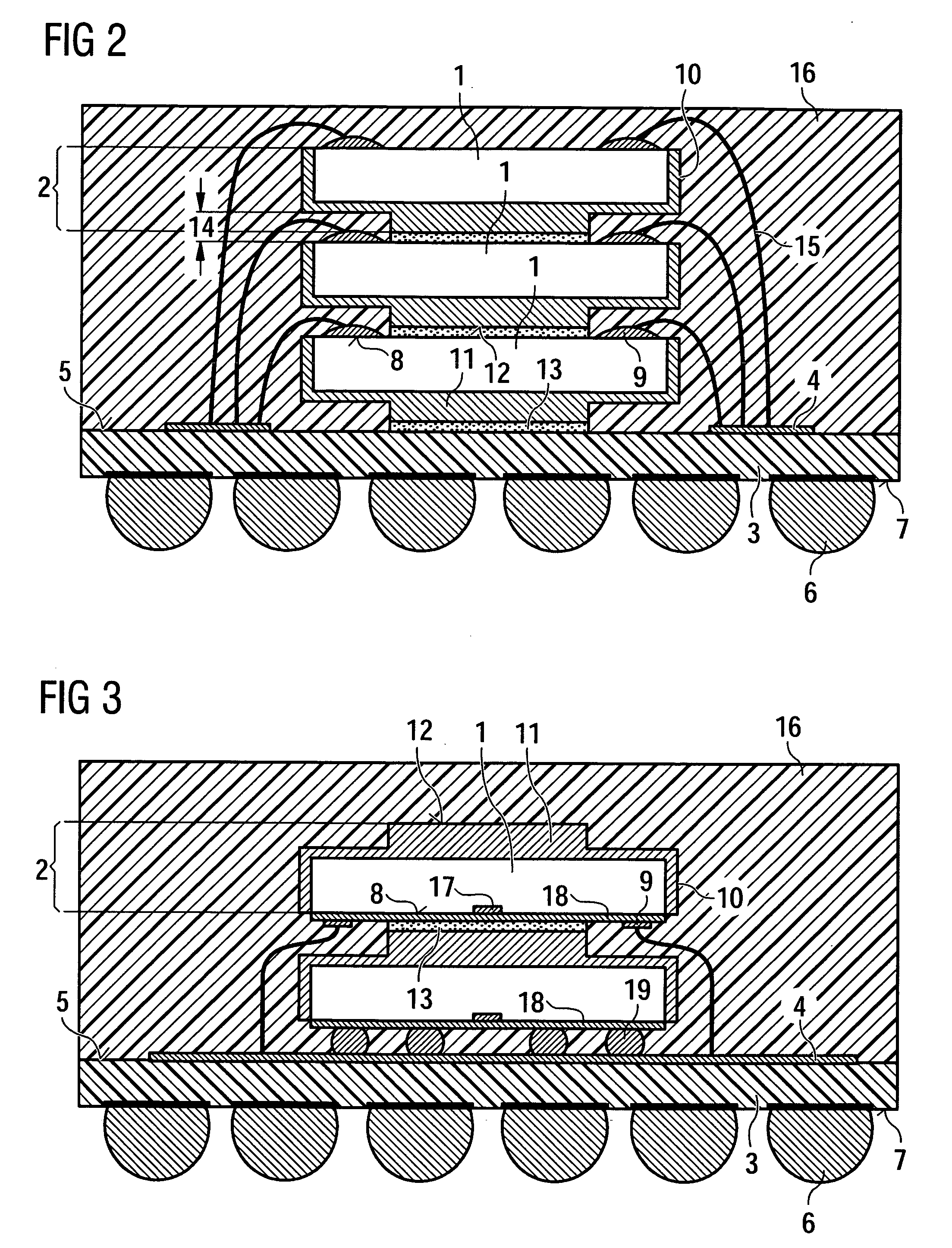

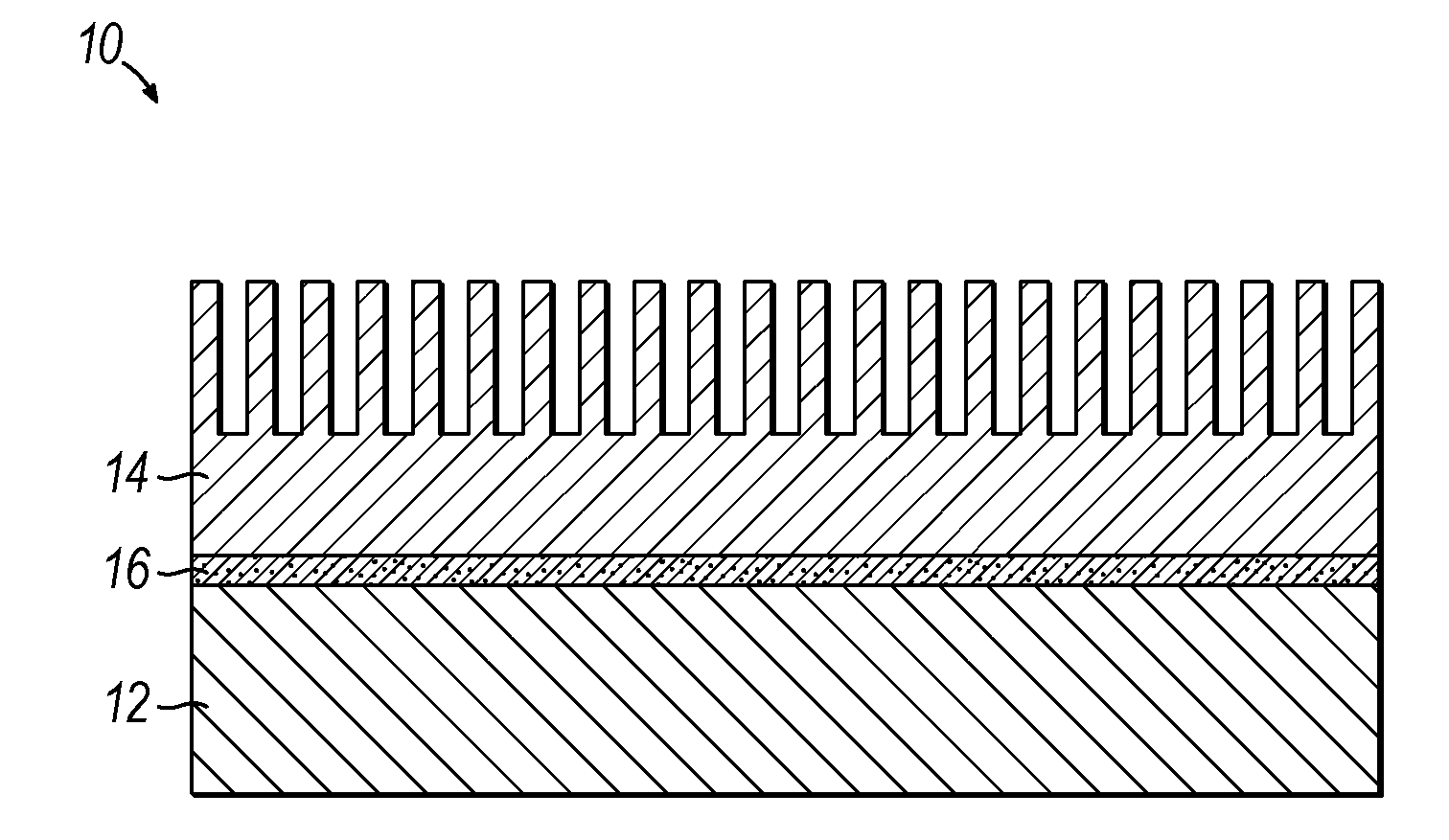

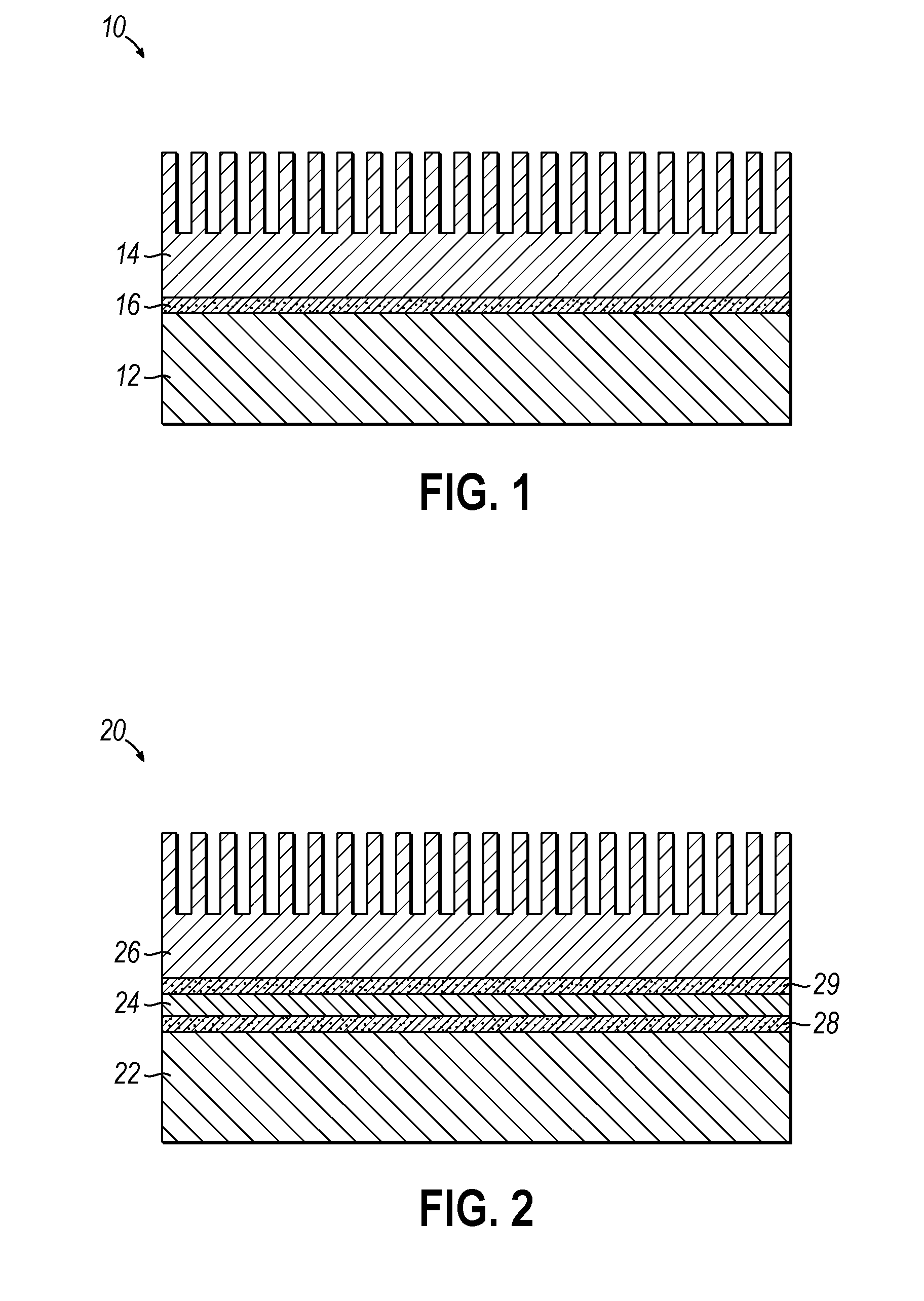

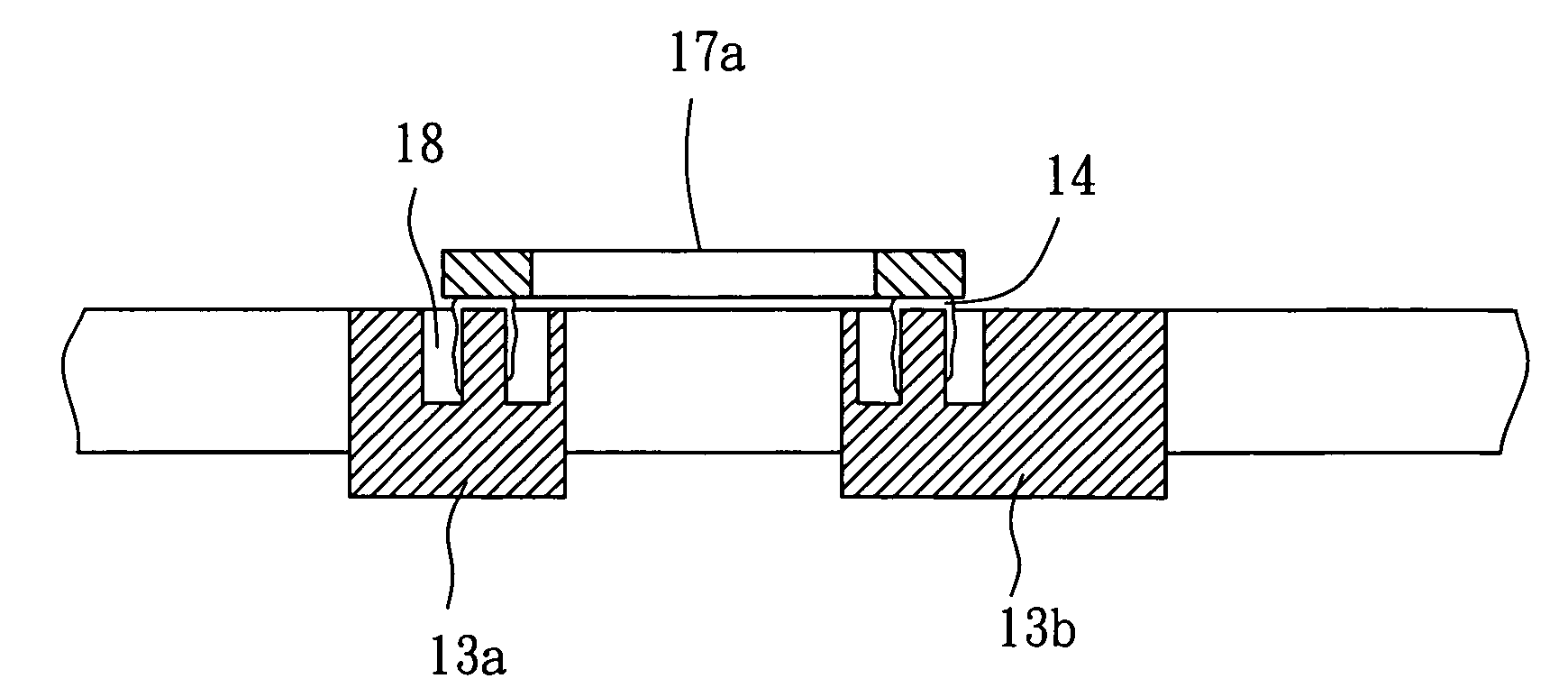

Stack of semiconductor chips

InactiveUS20070176275A1Improve adhesionIncrease surface areaSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorAdhesive

Owner:POLARIS INNOVATIONS

Apparatus and method for plasma treating and dispensing an adhesive/sealant onto a part

InactiveUS20060172081A1Minimal timeLow costMovable spraying apparatusPretreated surfacesAdhesiveSealant

Owner:NORDSON CORP

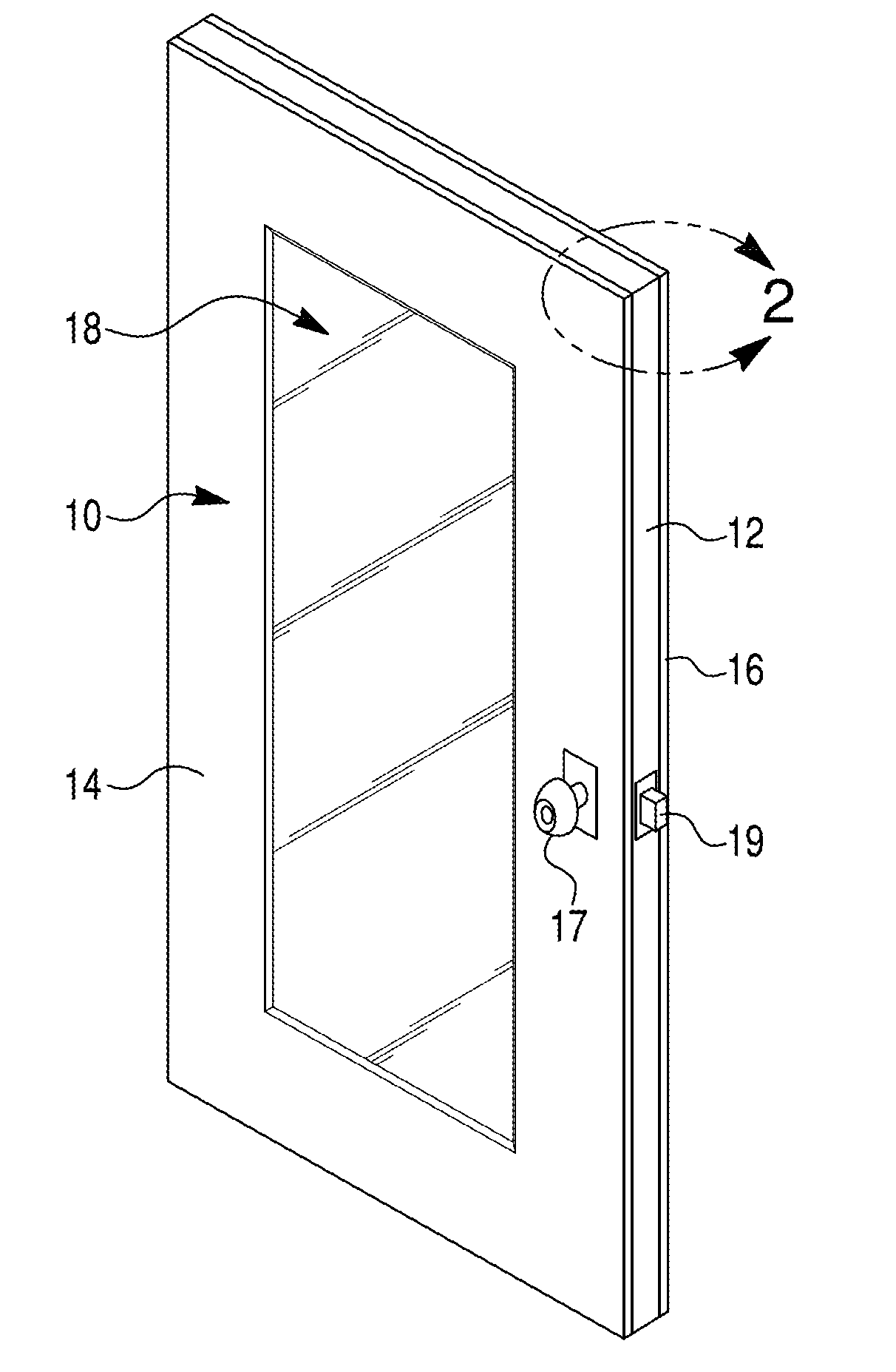

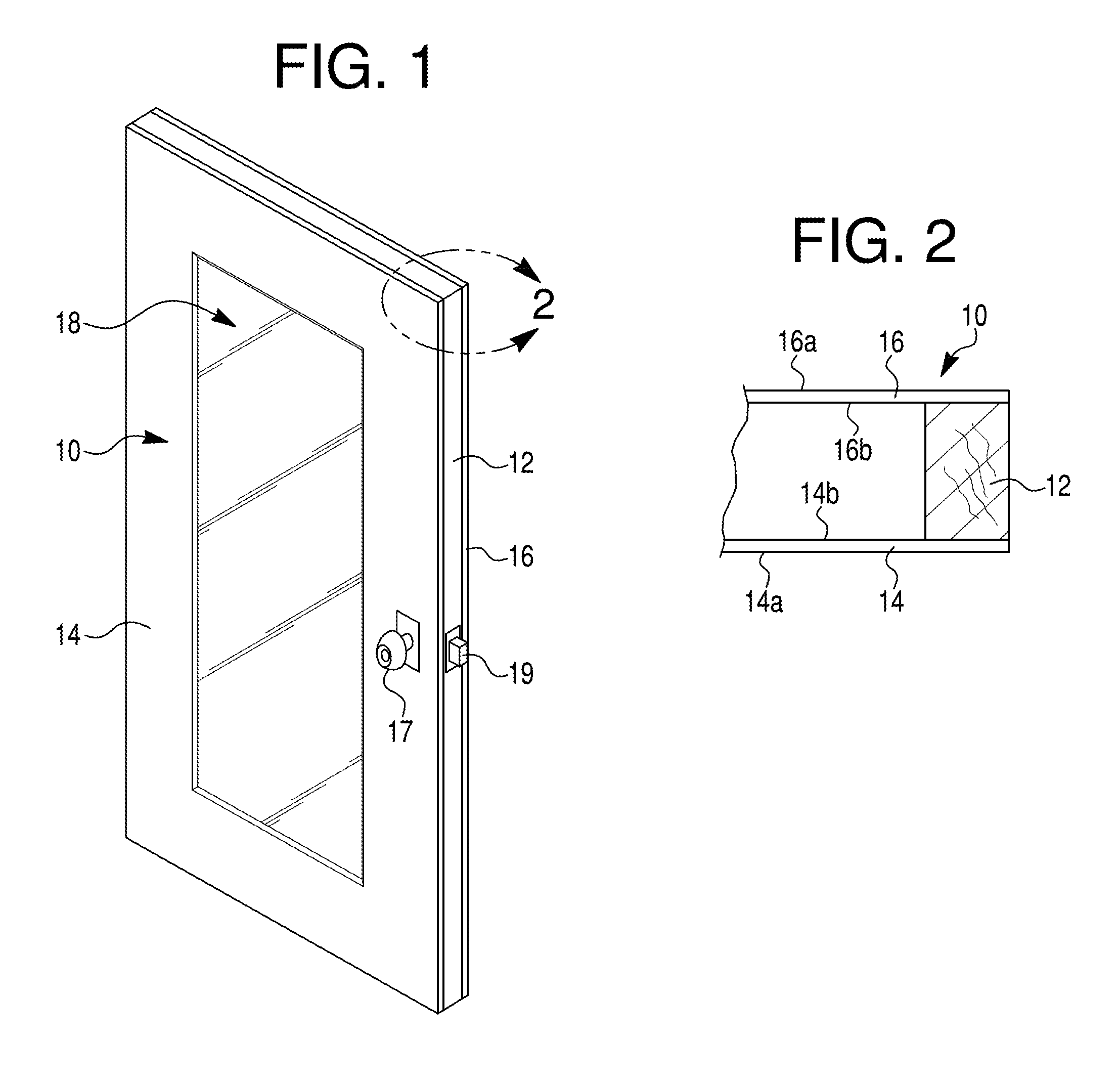

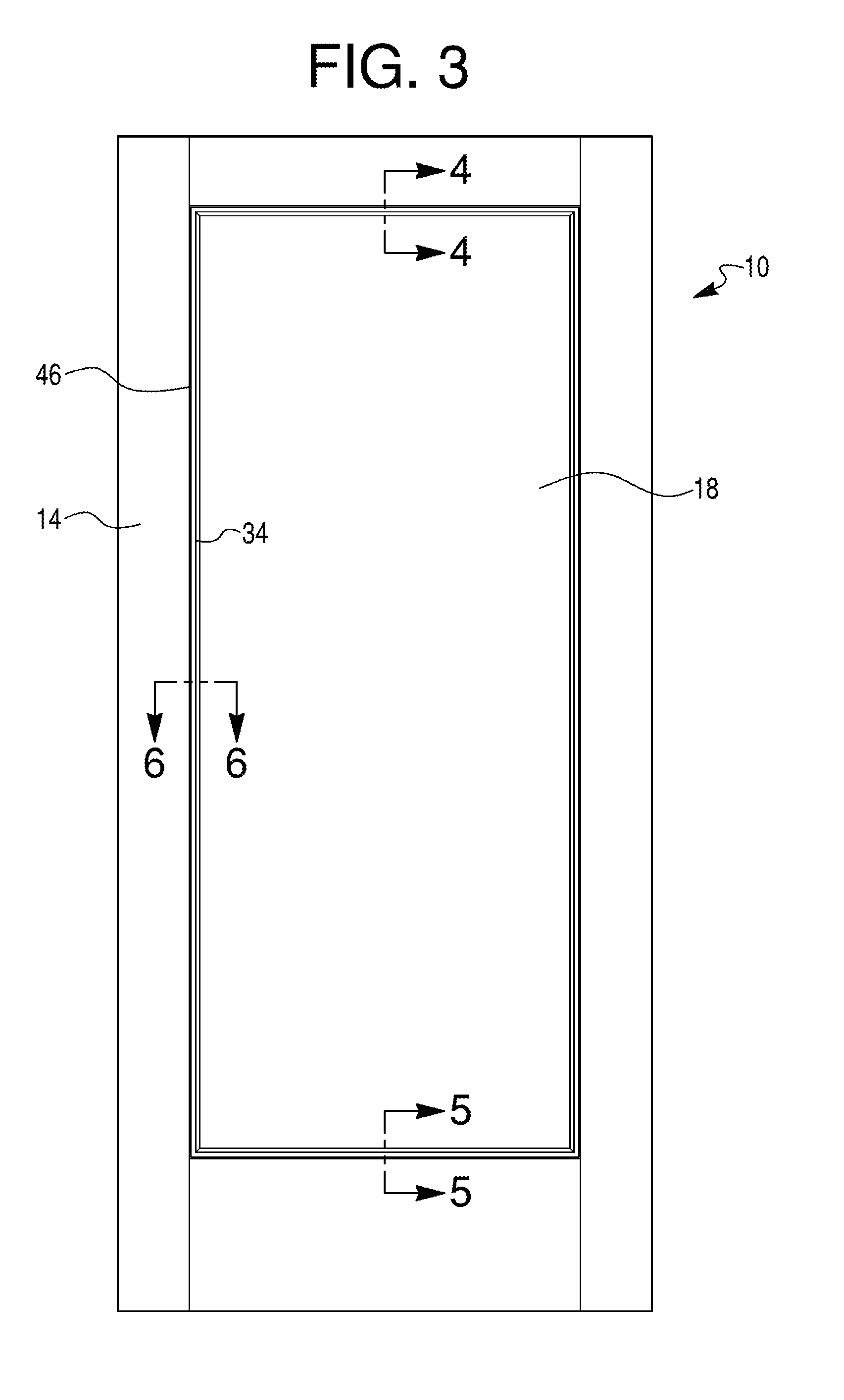

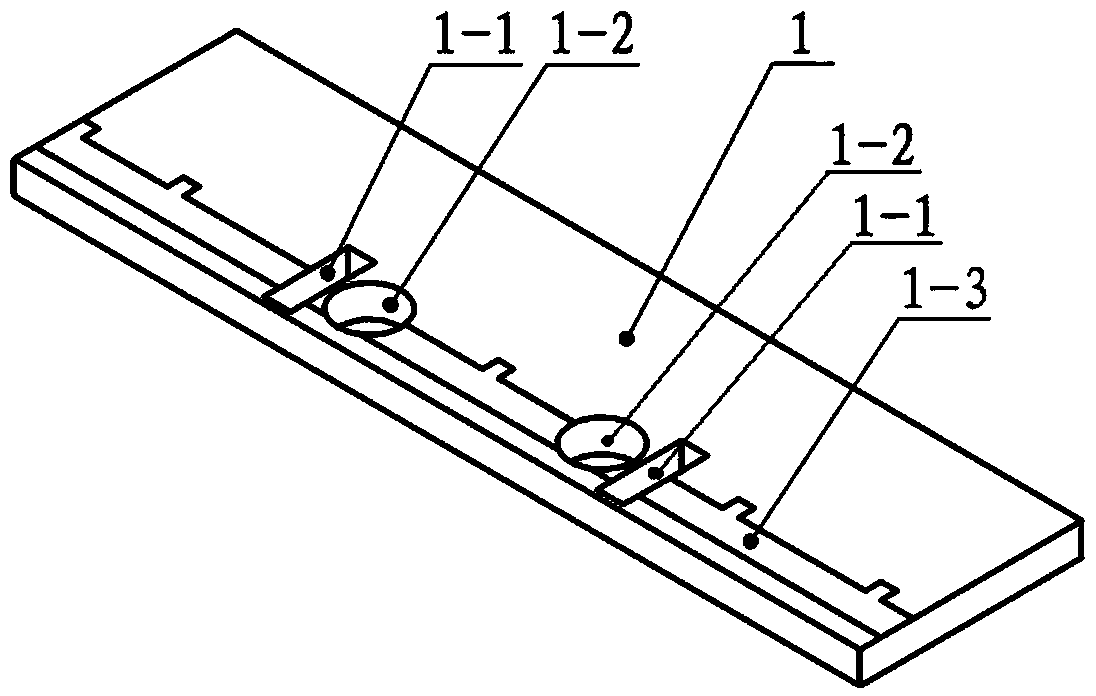

Door with frameless glazed unit, and related kit and methods

Owner:MASONITE CORP

Reversibly adhesive thermal interface material

Owner:IBM CORP

Dry Side Sensor Mounting for Sensor Chip Assembly

ActiveUS20090133470A1Good reproducibilityReduce vibrationVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesQuartz crystal resonatorAdhesive

Owner:BRUKER DALTONIK GMBH & CO KG

Activatable Adhesive, Labels, and Related Methods

InactiveUS20120216951A1Improve securityEasy to operateStampsNon-macromolecular adhesive additivesAdhesivePlasticizer

Owner:AVERY DENNISON CORP

Multilayer Printed Wiring Board And Manufacturing Method For Same

InactiveUS20080121416A1Prevented from short circuitingLine/current collector detailsPrinted circuit detailsConductive pasteAdhesive

In a case of multilayer circuit boards where a plurality of conventional films are used as insulating layers, the films are connected with each other using an adhesive, and therefore, the adhesive sometimes negatively affects reduction in thickness. Therefore, a plurality of two-sided boards with films used therein are pasted together with a paste connection layer interposed therebetween, the paste connection layer being configured such that through holes formed in a prepreg are filled in with a conductive paste which is then cured, and second wires are electrically connected with each other through the conductive paste with which the through holes formed in the paste connection layer in advance are filled in, and thus, a multilayer board can be provided without using an adhesive, and the entirety of the multilayer circuit board can be reduced in thickness.

Owner:PANASONIC CORP

Preparation method and application of water-soluble carbon fiber sizing agent

InactiveCN104975508AImprove protectionImprove smoothnessFibre treatmentFibre chemical featuresFiberCarbon fibers

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

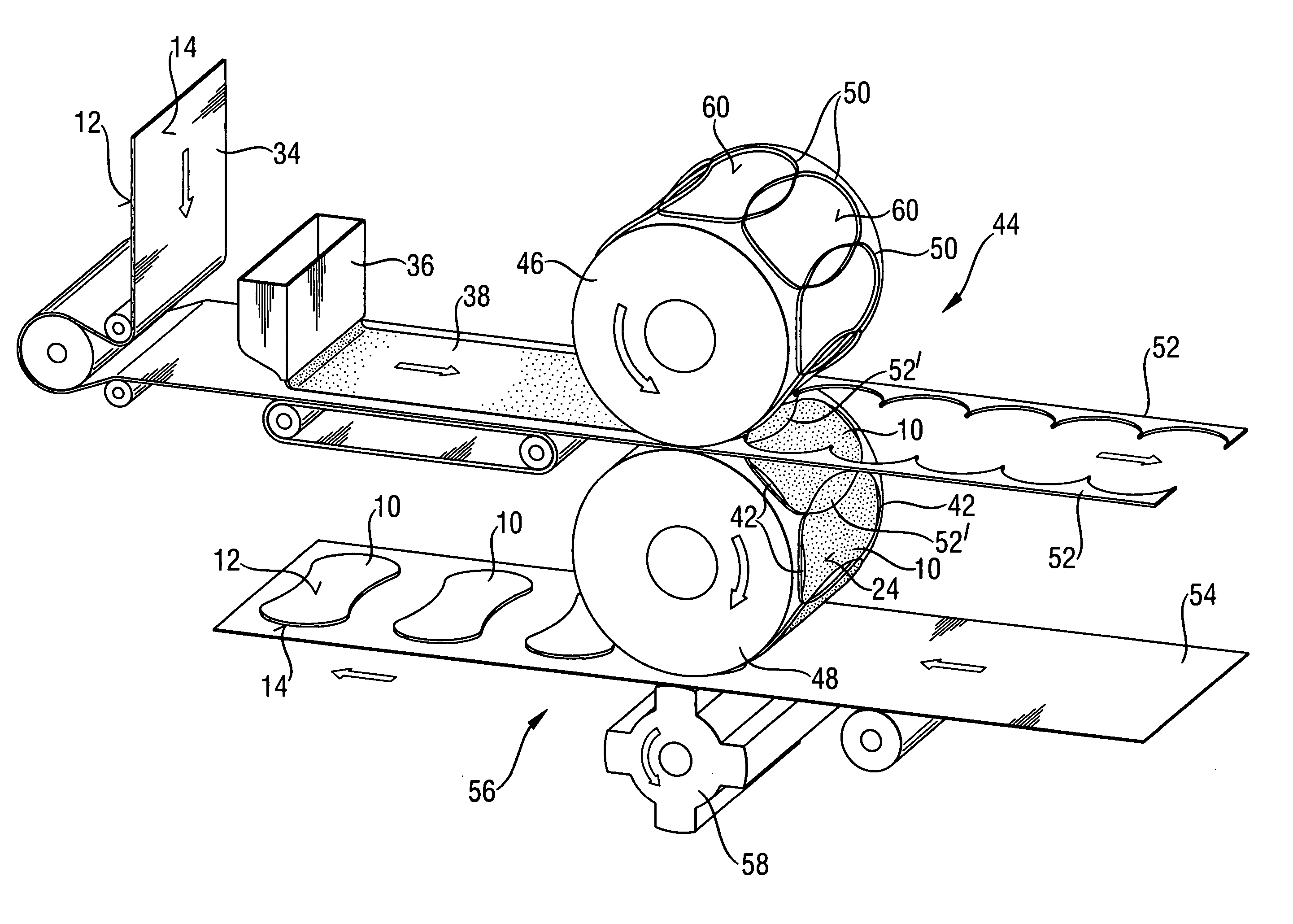

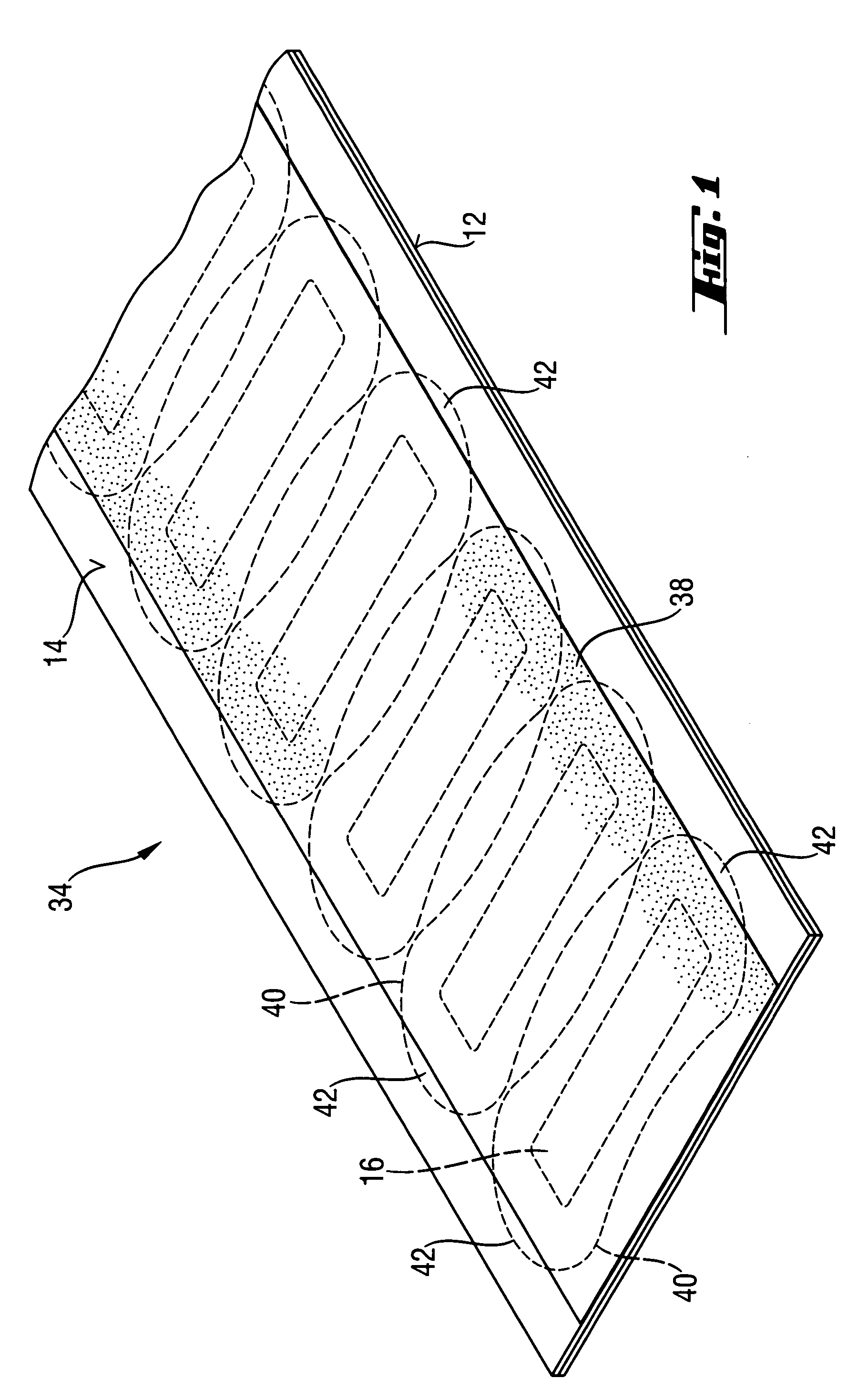

Process and apparatus for making individually packaged disposable absorbent articles

InactiveUS20050198931A1Lamination ancillary operationsWrapper folding/bending apparatusLayered structureAdhesive

Owner:THE PROCTER & GAMBLE COMPANY

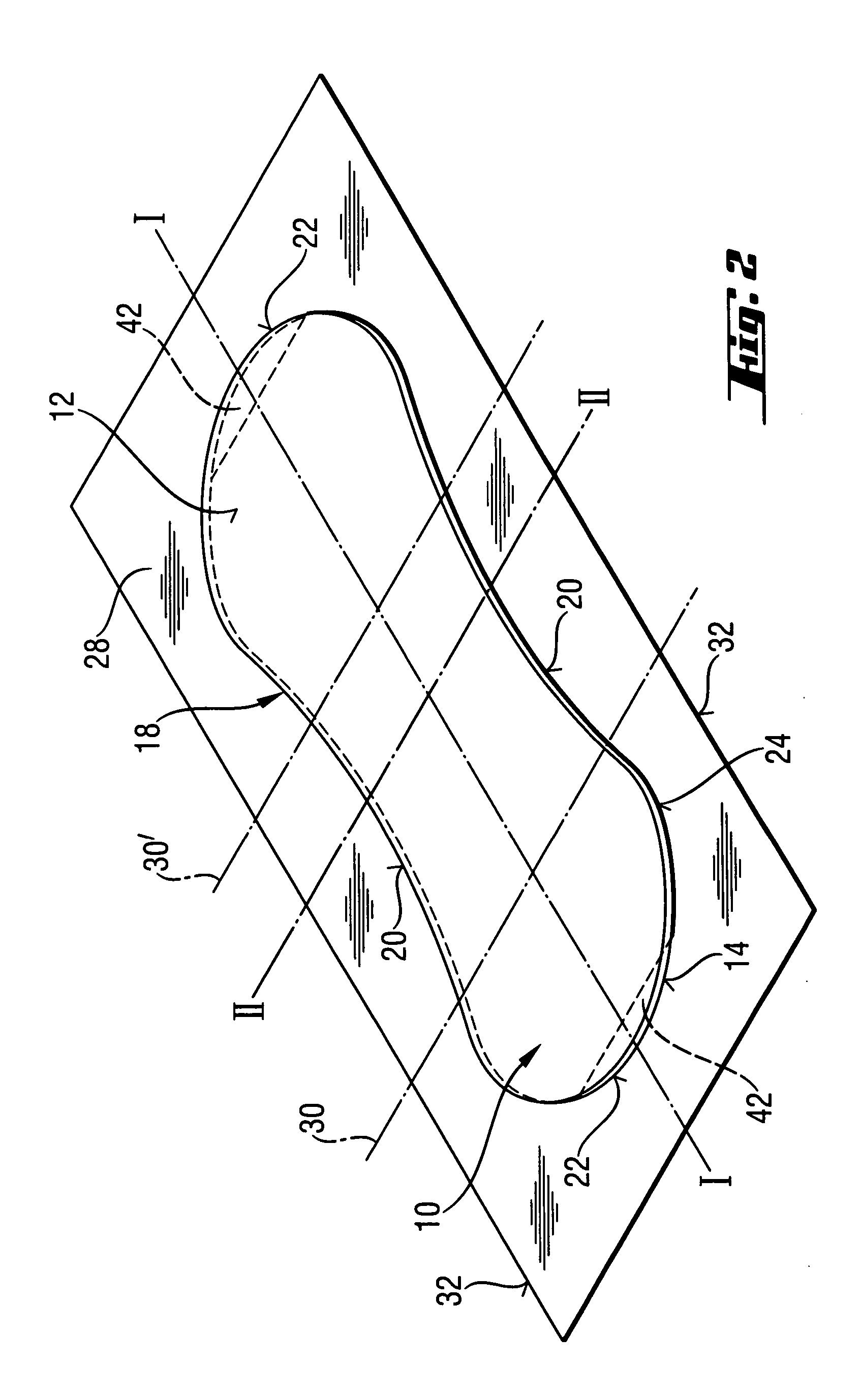

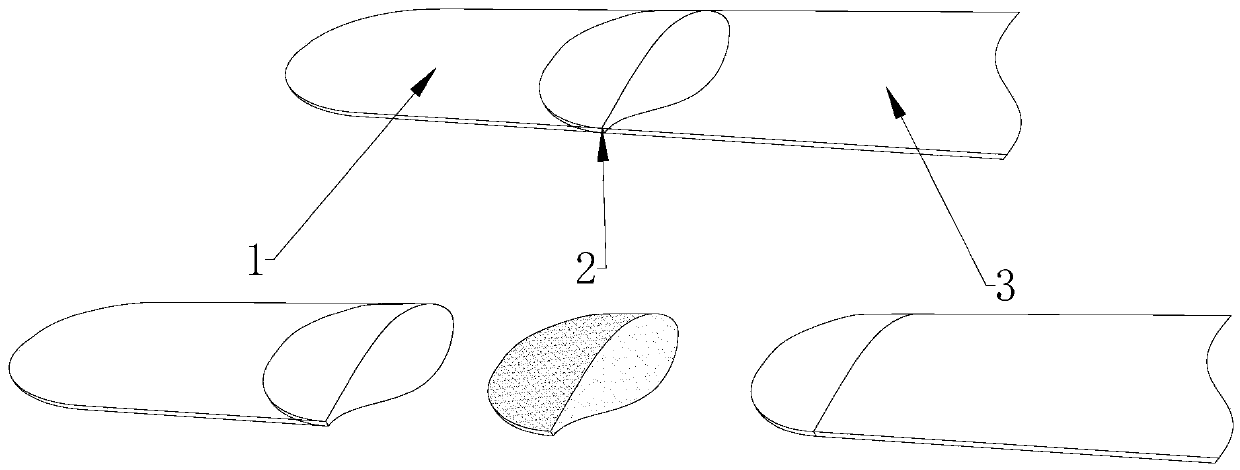

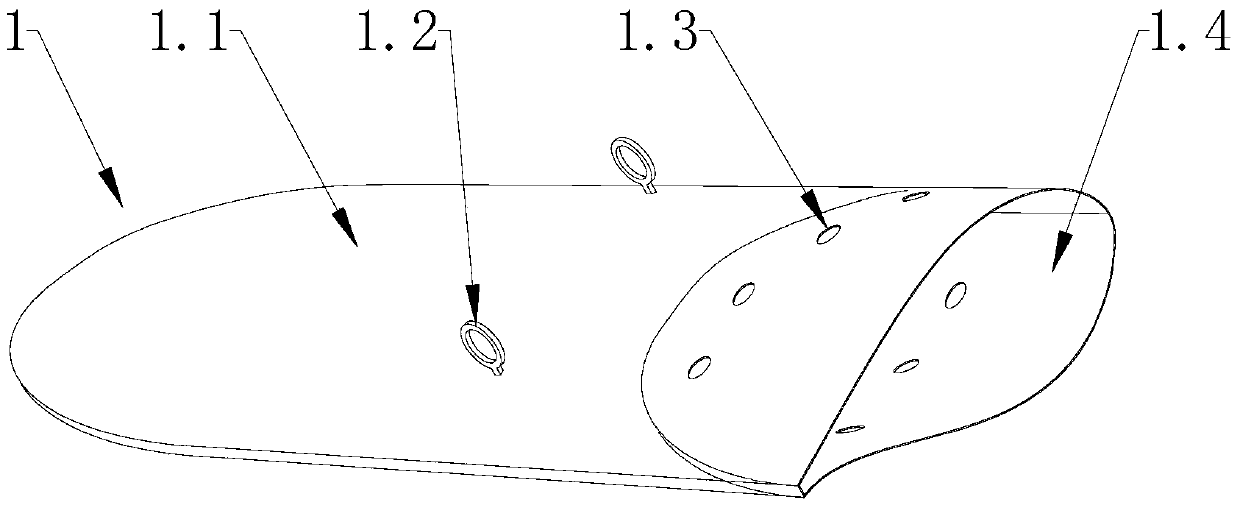

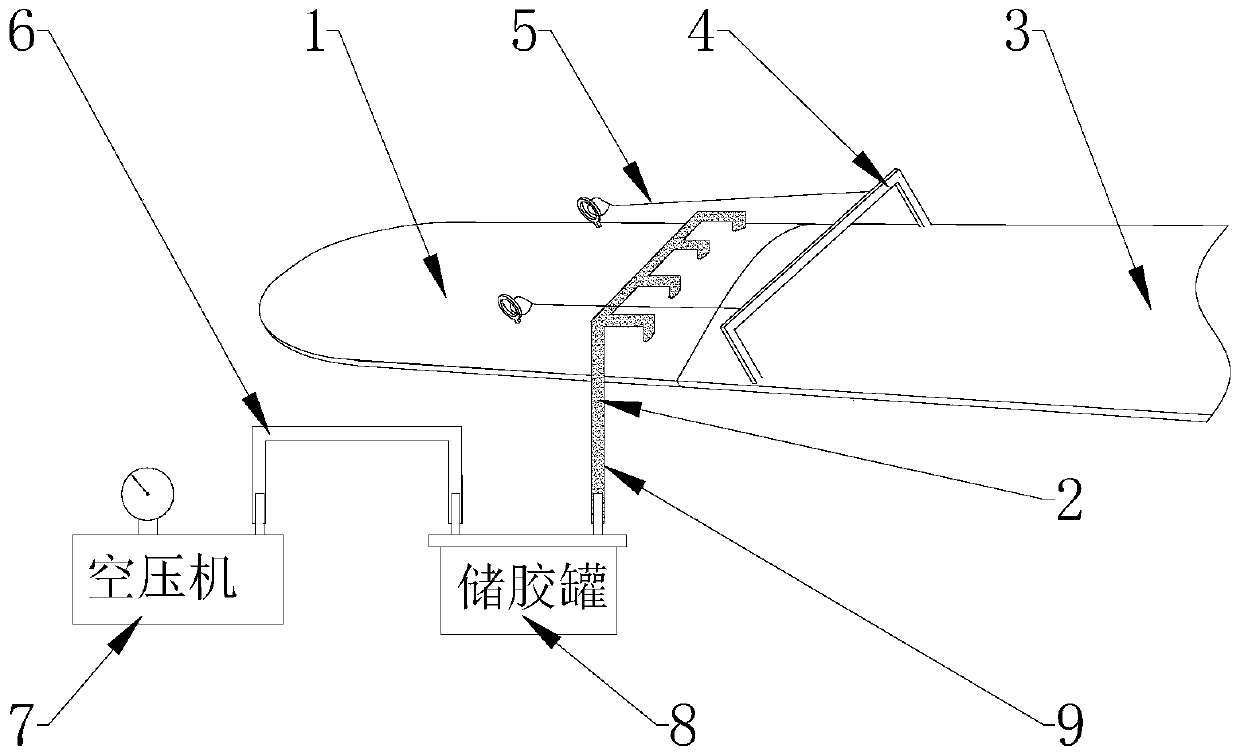

Wind power blade tip lengthening method

InactiveCN105500696AIncrease the lengthHigh bonding strengthEngine manufactureFinal product manufactureElectricityAdhesive

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

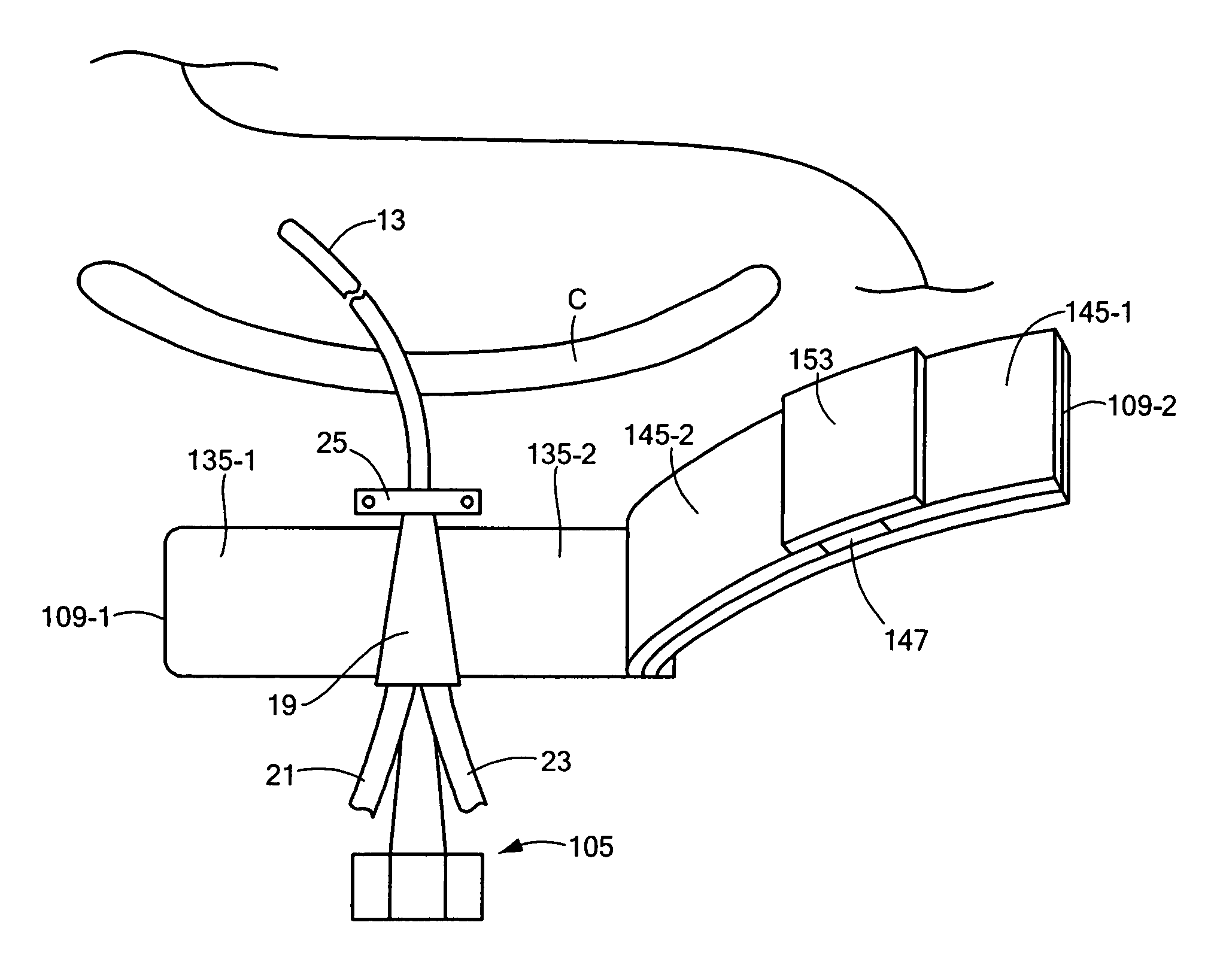

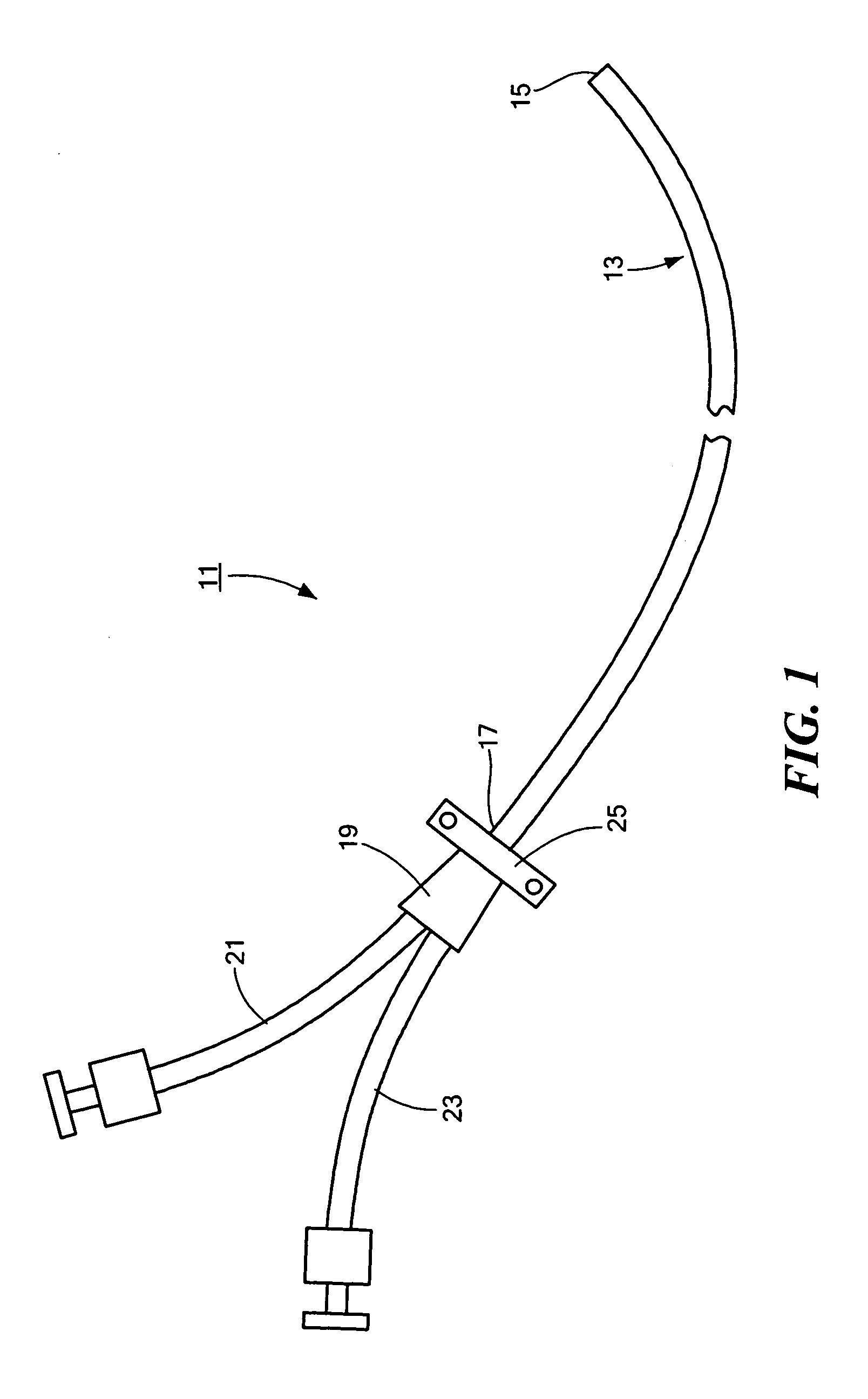

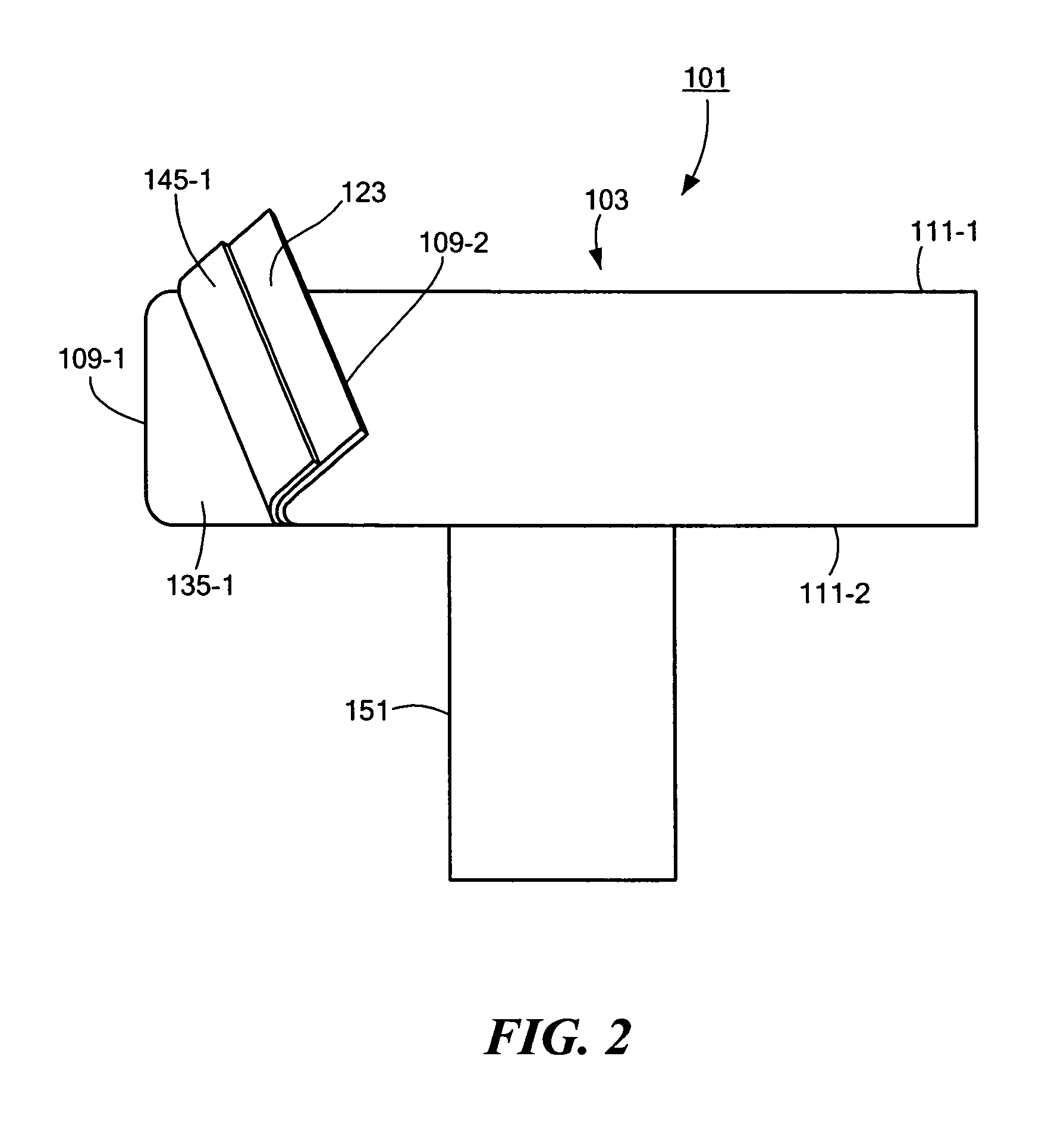

Medical appliance securing device and method of using the same

Owner:M C JOHNSON

Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

ActiveCN102030857AGood adhesionImprove water resistanceMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsCross-linkPolymer science

The invention relates to a vinyl acetate-ethylene copolymer emulsion as an electrostatic spinning adhesive and a synthesis method thereof. Organic peroxides and zinc formaldehyde sulfate are taken as an initiator; vinyl acetate, ethylene, acrylic ester monomers and cross-linking monomer N-hydroxymethyl acrylamide are taken as comonomers; a nonionic emulsifier, and the synthetic emulsion and the protective colloid of an amphoteric emulsifier are matched to be taken as an emulsification system; and the copolymer emulsion is prepared through emulsion polymerization. Compared with the VAE (vinyl acetate-ethylene) emulsion prepared by the conventional preparation method, the product in the invention has the advantages of good water resistance, strong adhesion on low-surface-energy materials (polyethylene, polypropylene and the like), fine grain and the like. The vinyl acetate-ethylene copolymer emulsion is suitable for being as the adhesive to be applied to the field of the electrostatic spinning in textile industry and the fields of waterproofing and packaging.

Owner:CHINA PETROCHEMICAL CORP +1

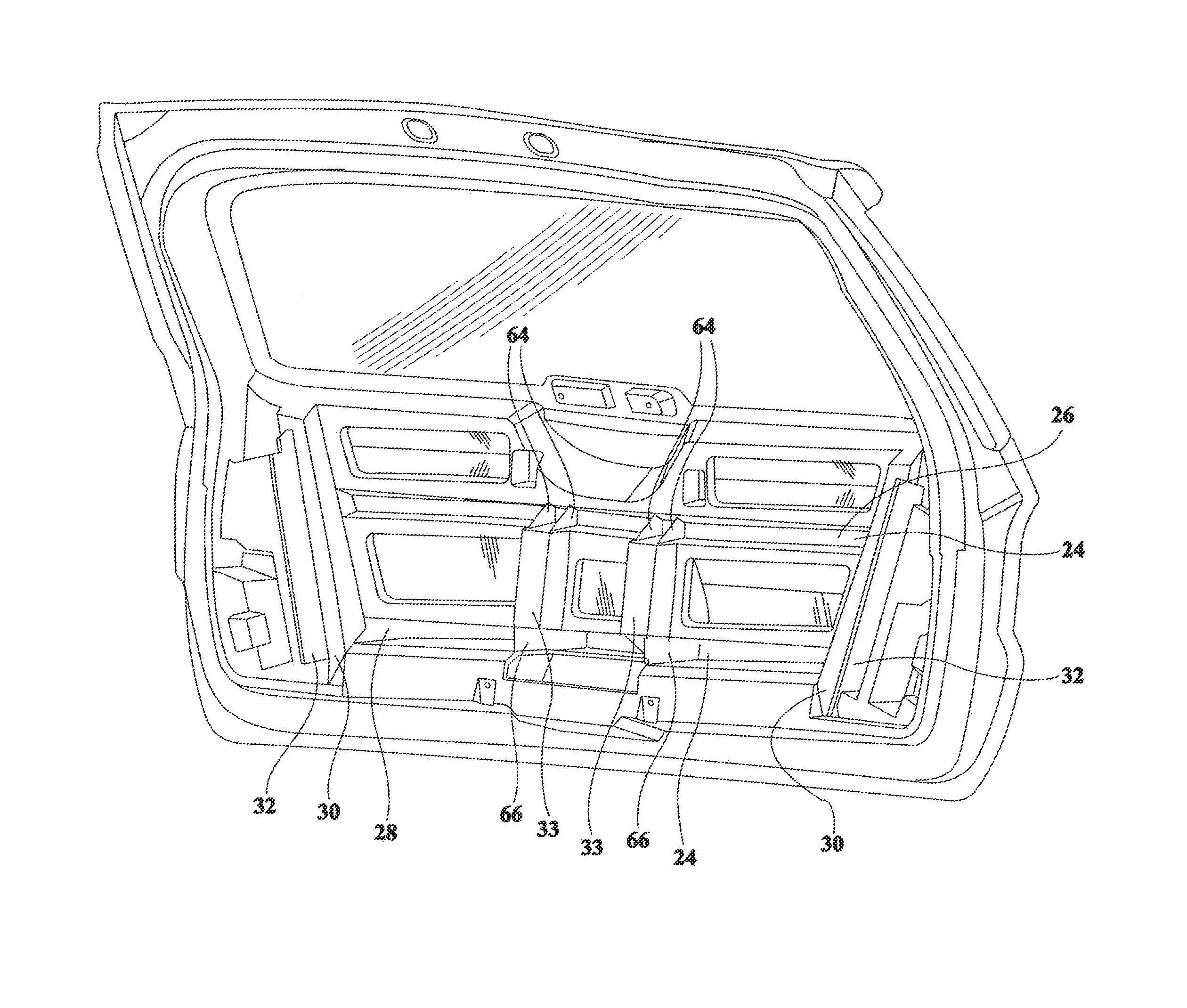

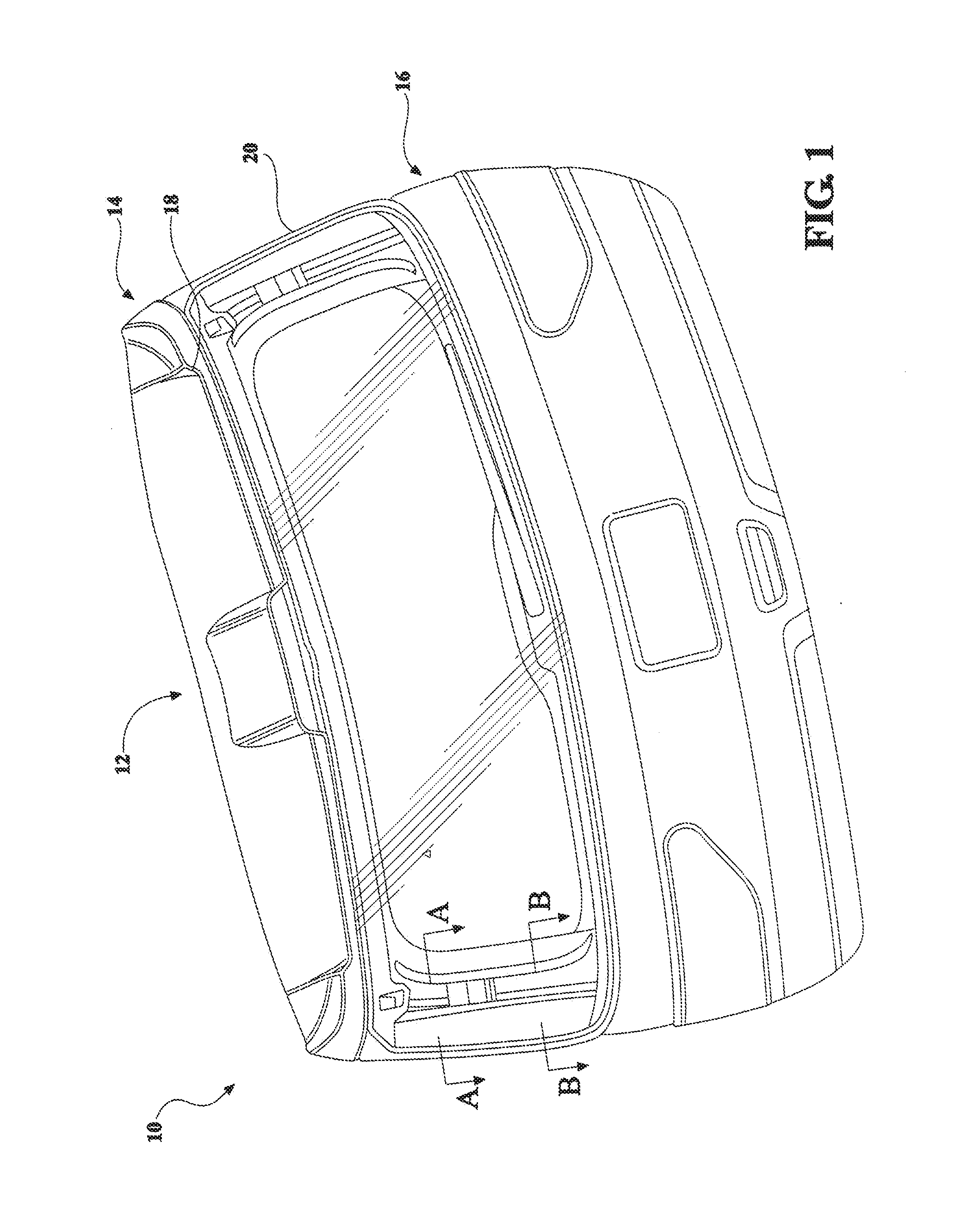

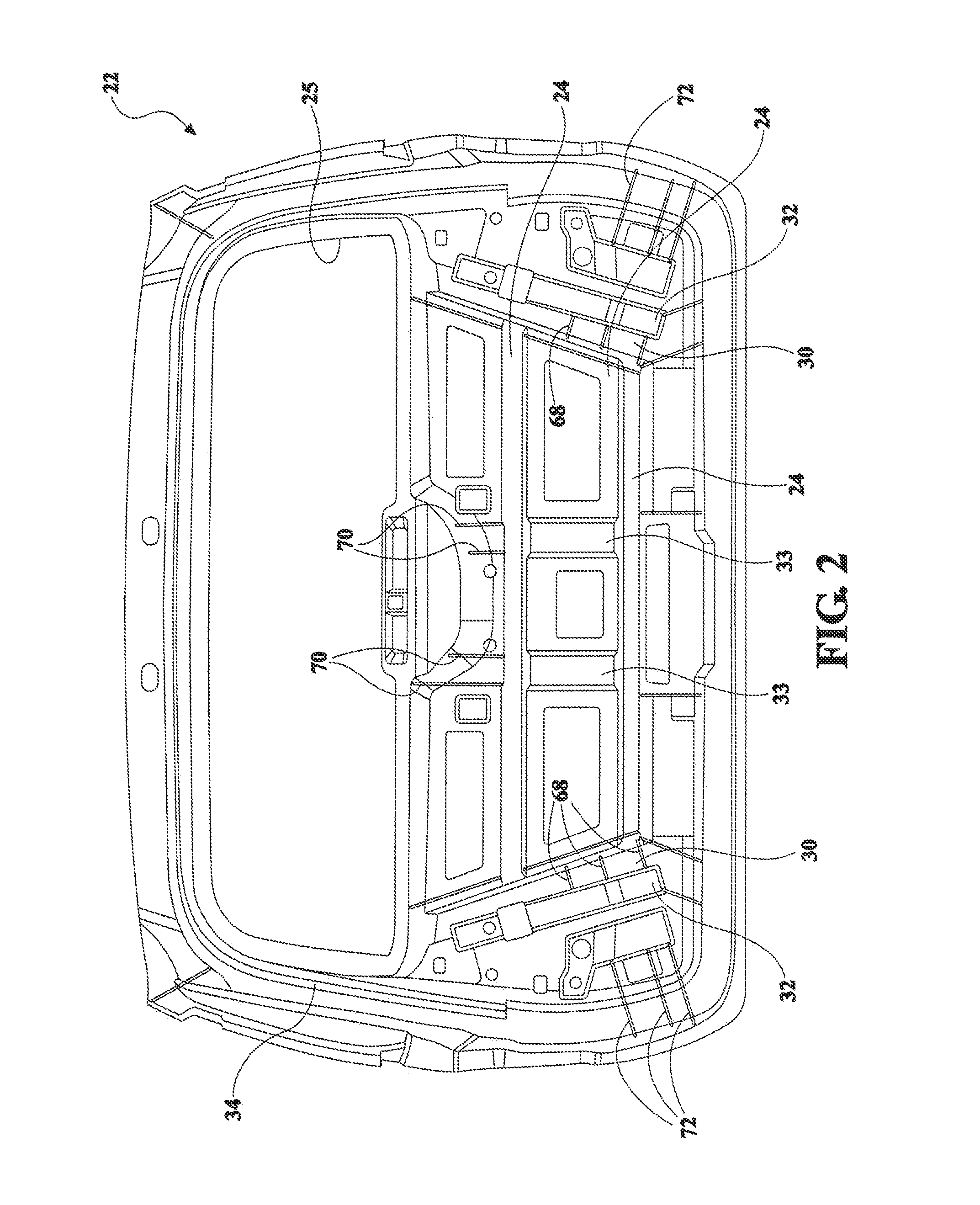

Composite liftgate

ActiveUS20160347155A1Minimized in sizeHigh strengthAerodynamics improvementDoorsAdhesiveUltimate tensile strength

Owner:MAGNA EXTERIORS INC

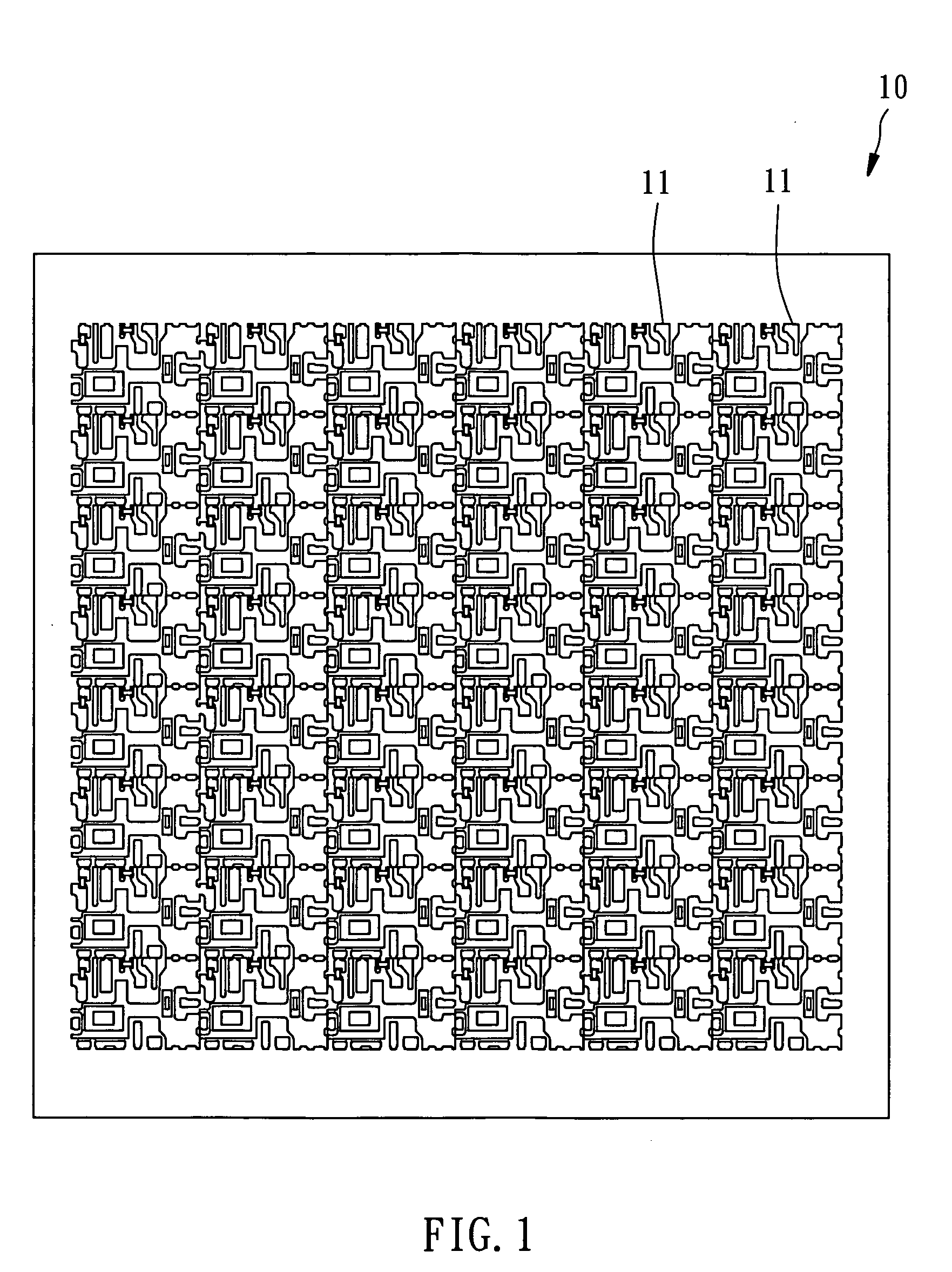

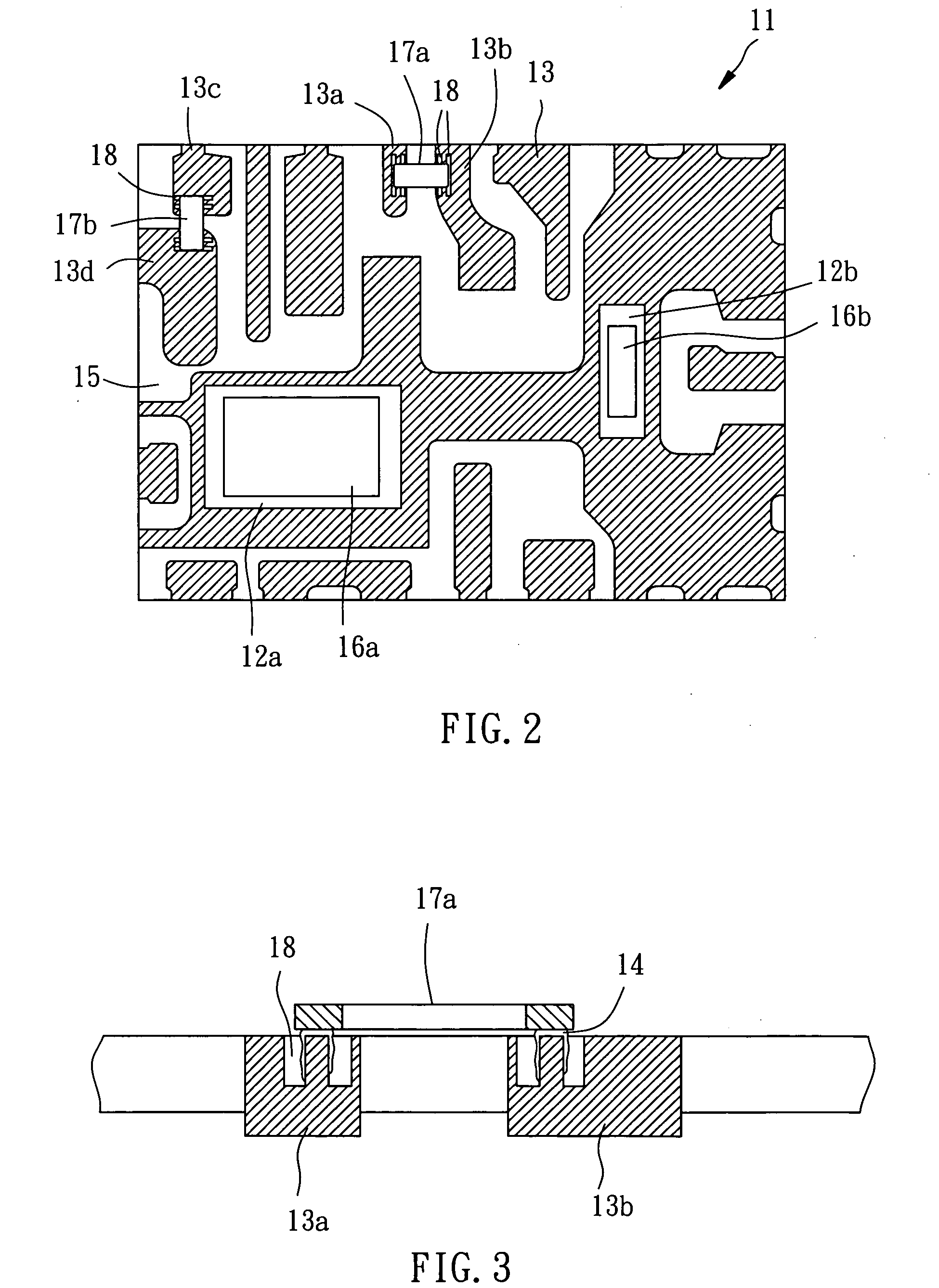

Packaging substrate having adhesive-overflowing prevention structure

InactiveUS20060221586A1Prevent a short circuit happenedPrevent overflowPrinted circuit assemblingPrinted electric component incorporationEngineeringAdhesive

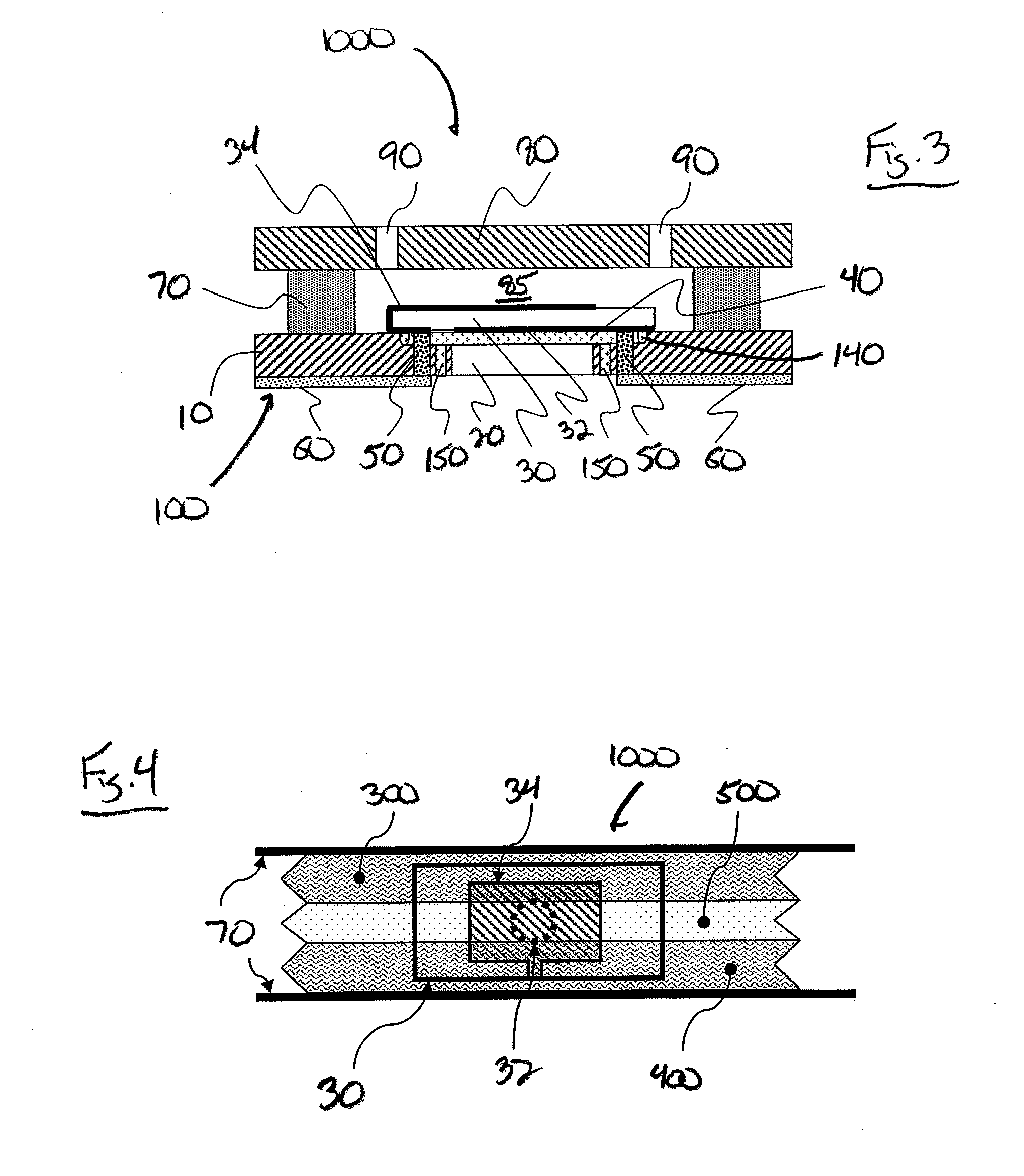

A packaging substrate includes an array of packaging units. Each packaging unit has a chip pad carrying a chip, a plurality of pins arranged around the chip pad and spaced from one another and the chip pad by an open space, an insulative member filling up the open space, passive components each connected between two pins, a bonding adhesive applied to the pins to which the passive components is connected to affix the connection between the passive components and the respective pins, and a plurality of overflow-preventive grooves respectively provided around the bonding adhesive at each of the pins to which the passive components are connected to prevent overflow of the bonding adhesive.

Owner:LINGSEN PRECISION INDS

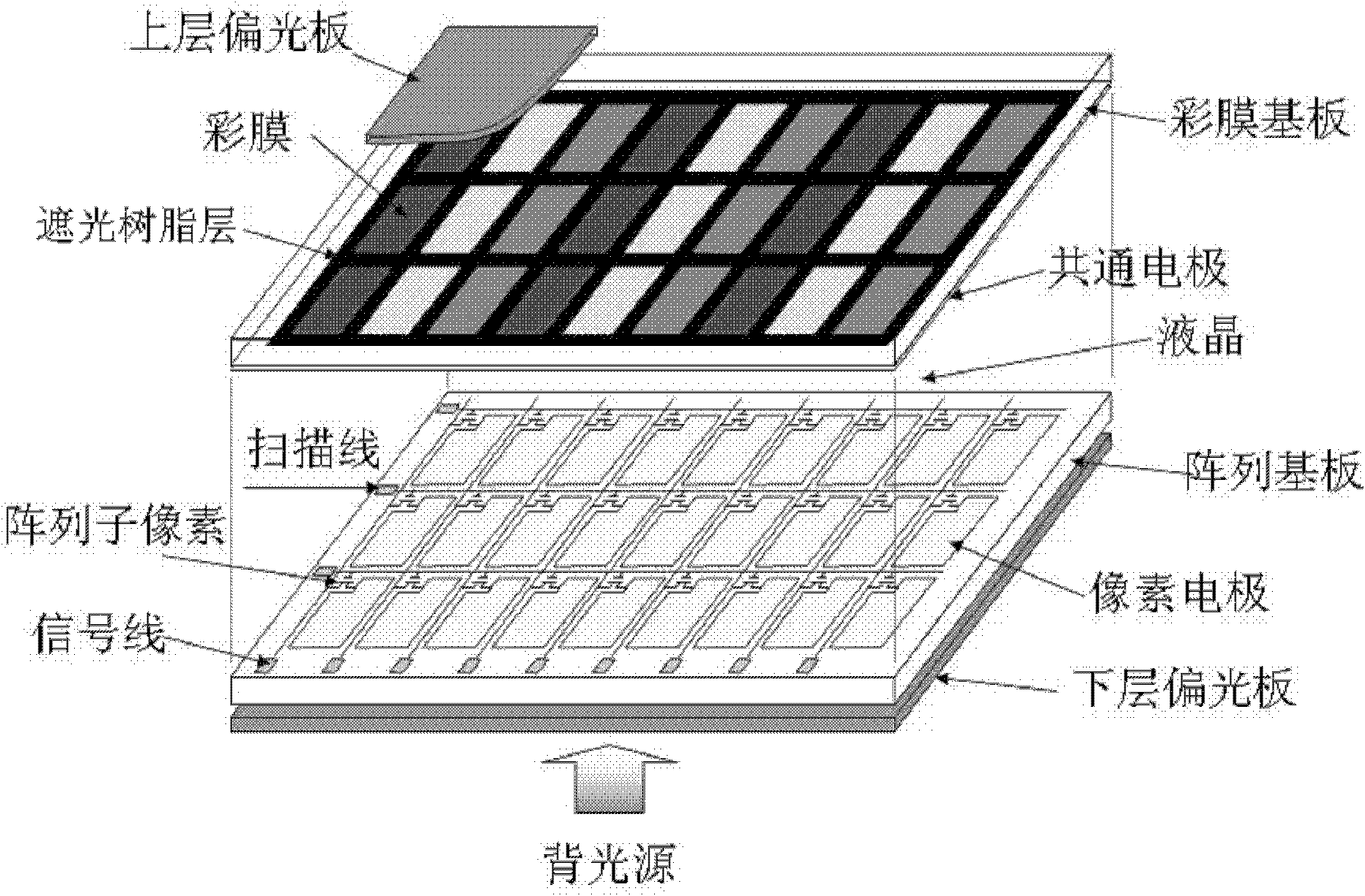

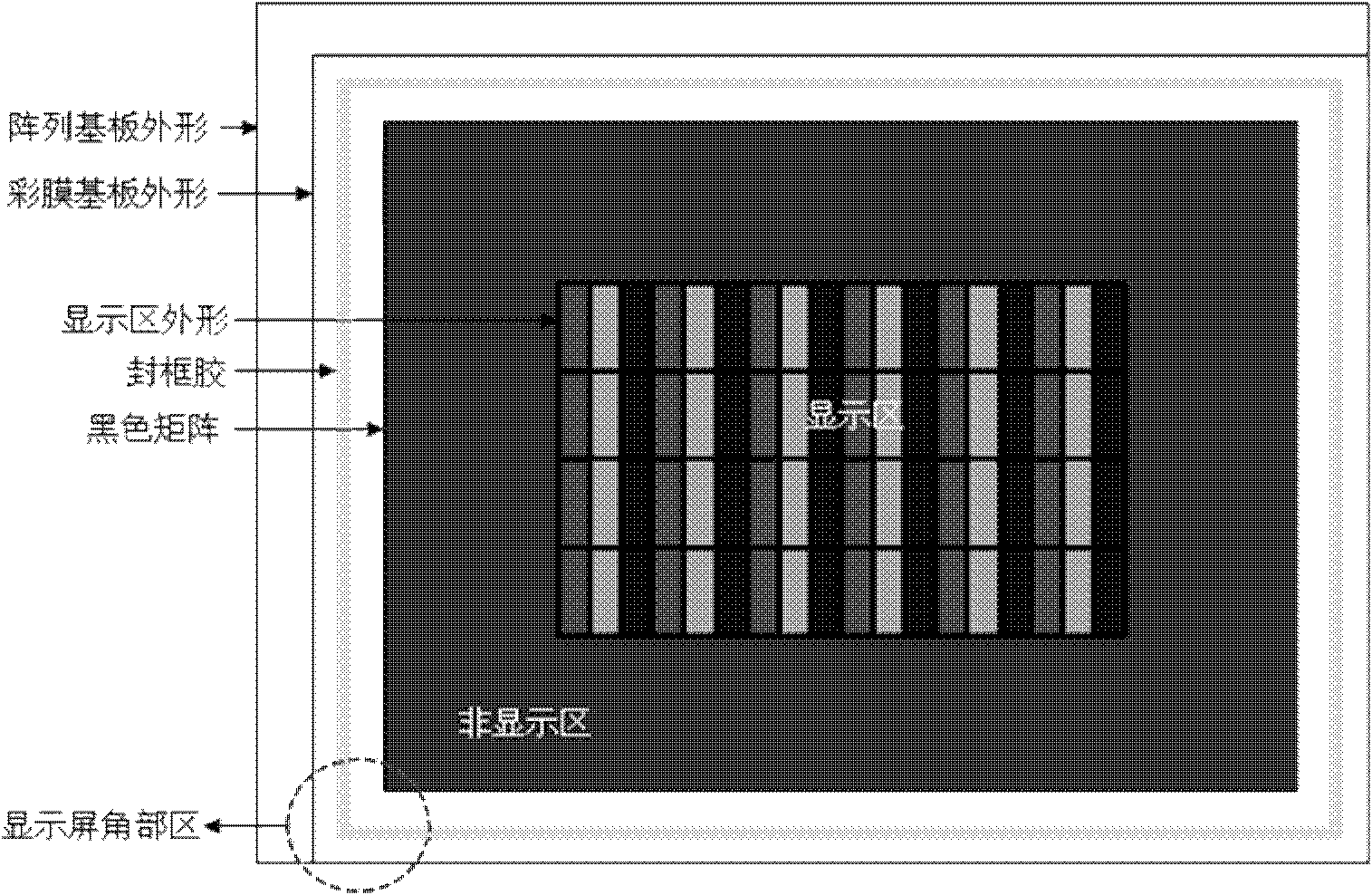

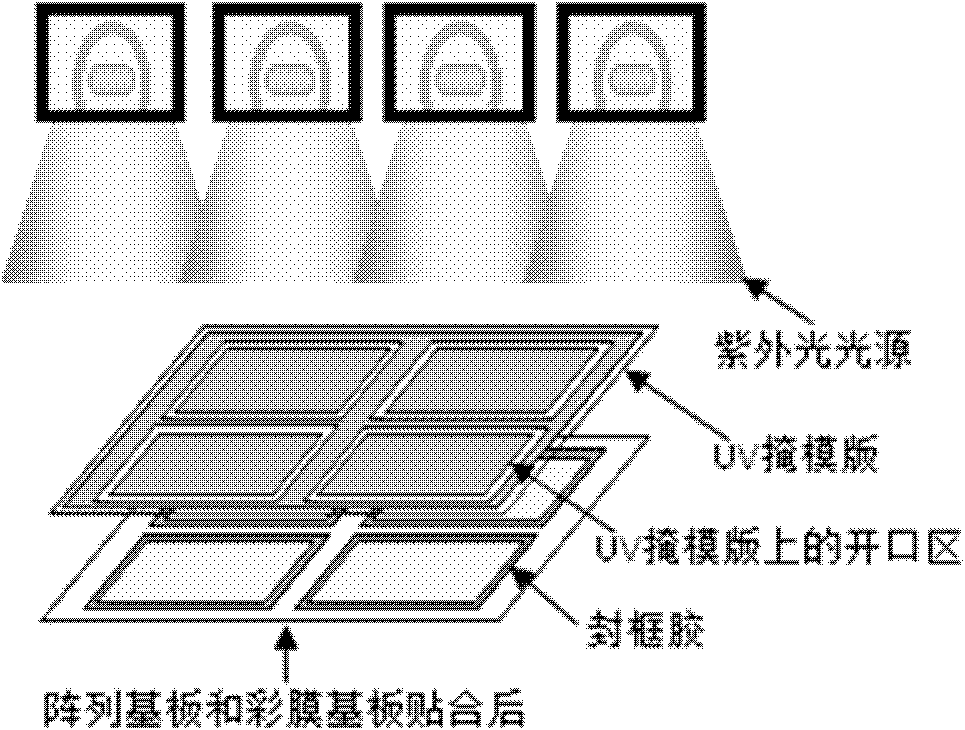

Liquid crystal display device

InactiveCN102566152AAvoid pollutionReduce poor display problems such as afterimagesNon-linear opticsLiquid-crystal displayAdhesive

Owner:NANJING CEC PANDA LCD TECH

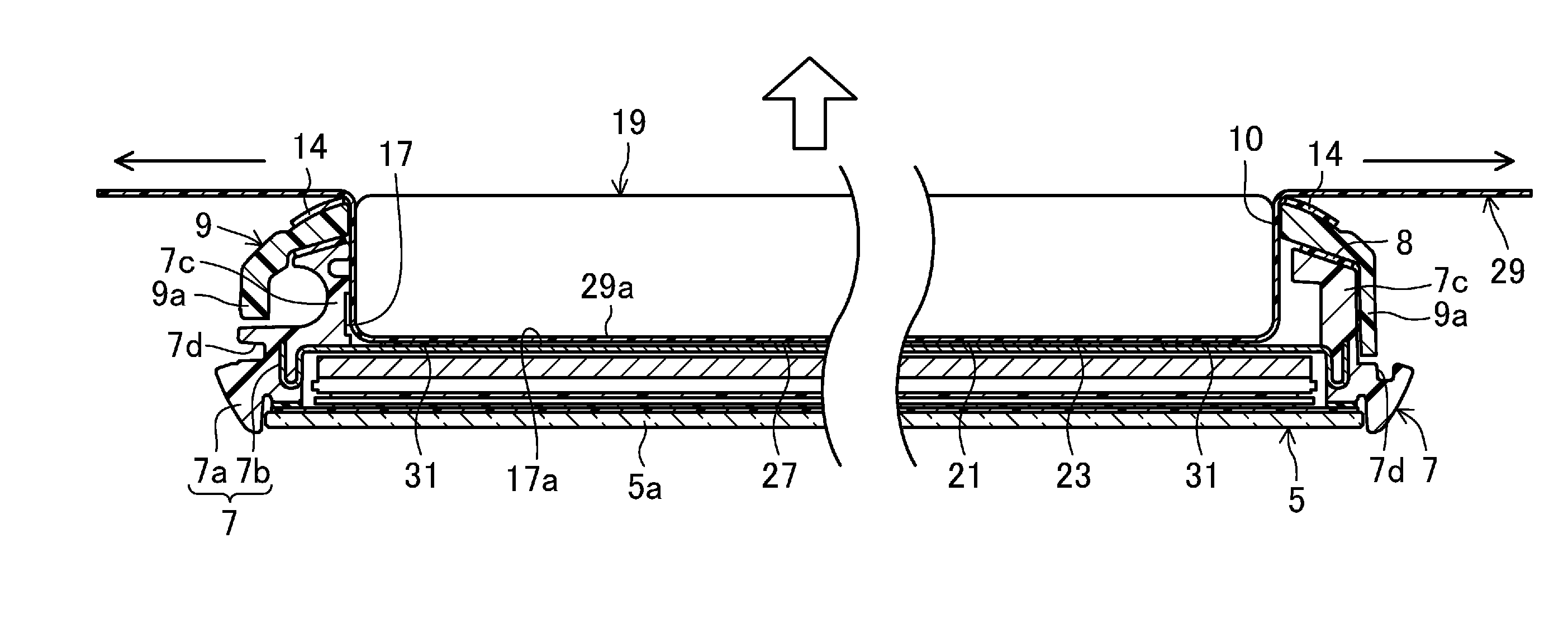

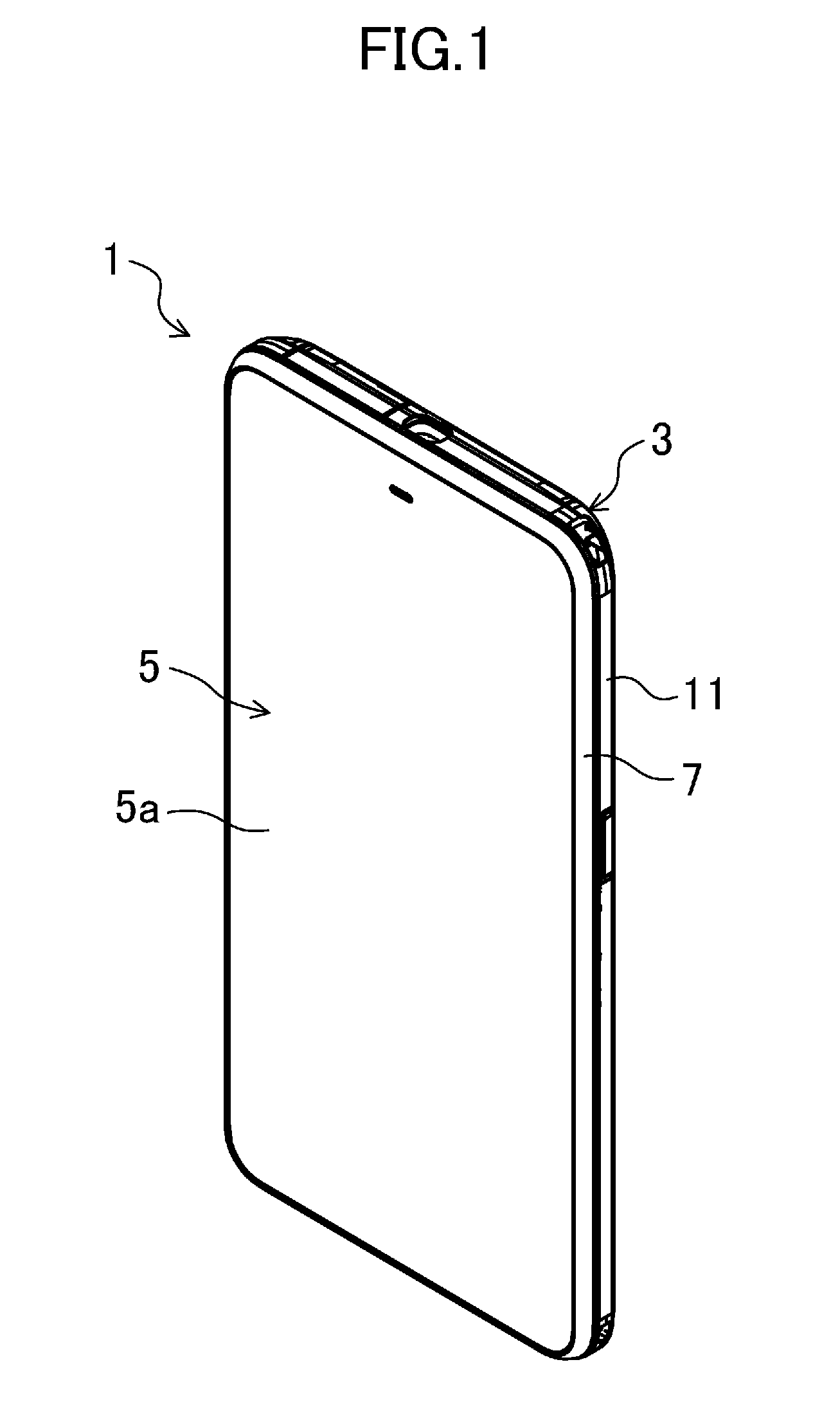

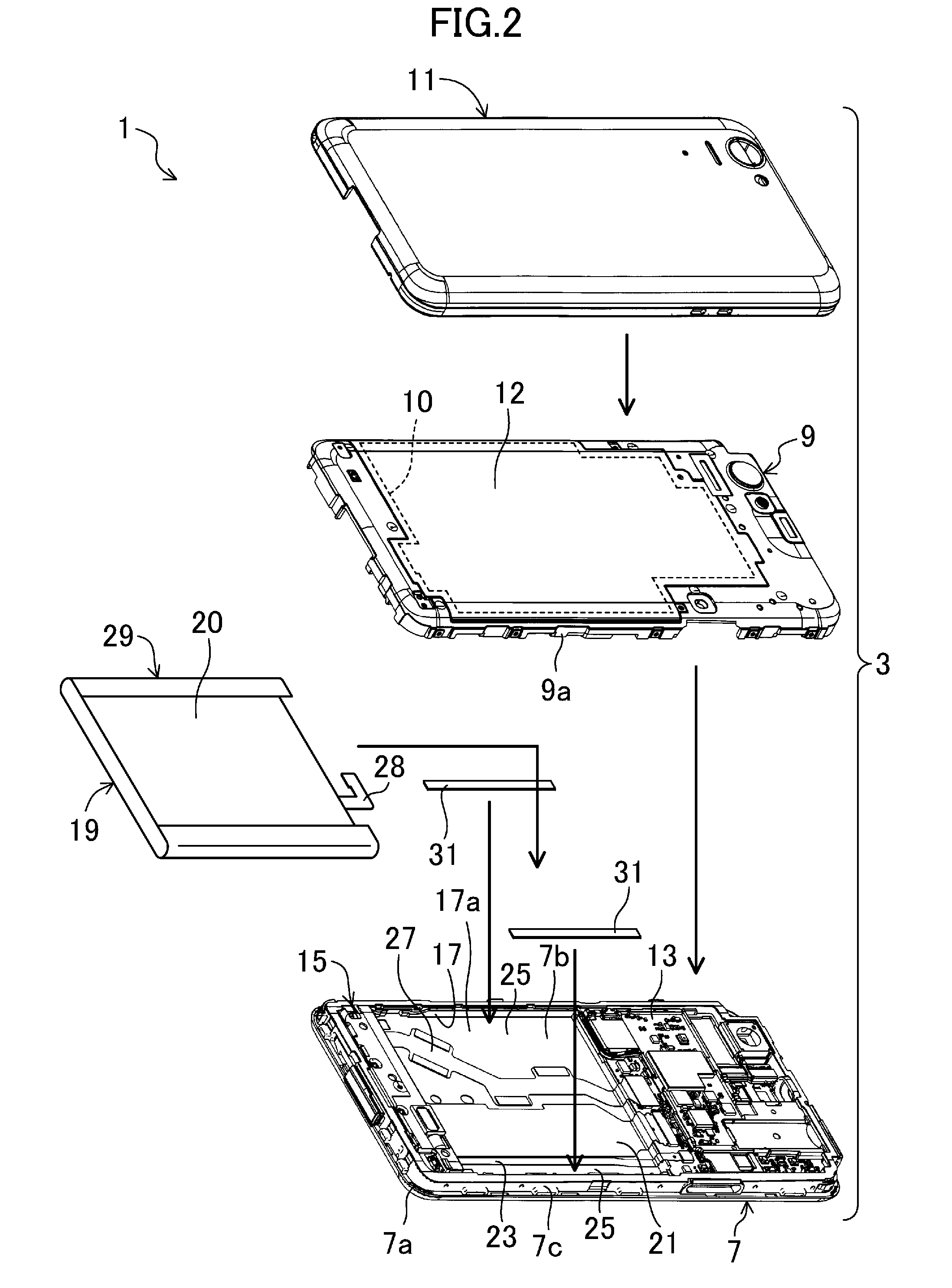

Mobile device

Owner:SHARP KK

Method for producing coating ultra-sense paper

InactiveCN101250835AProcessing into excellent performanceEasy to processSpecial visual effect coatingsCoatings with pigmentsFiberBenzene

The invention relates to a method for preparing a coating hypersensitive paper, which comprises the following steps: firstly, adopting fiber 100% as raw material, beating, dispensing, drawing the vibrator for fixation, modeling, drying, gluing and drying to produce the hypersensitive base stock which is provided with natural and native texture. The hypersensitive base stock is coated and manufactured through a 1760mm coater which velocity is 150 / min and the coating quantity area is 15g / m2. The coating paint comprises dye and latex adhesive, wherein the dye is selected from specially processed titanium oxide and kaolin, the particle size of titanium oxide and kaolin is less than 2 mum. The latex adhesive adopts benzene latex and starch to blend together. The hypersensitive base stock surface of the invention forms a natural and native texture dull base stock on the net without pressing, polishing and dressing. The prepared coating hypersensitive paper has the advantages of reducing manufacturing procedure, increasing natural and native texture of the paper and stereo aesthetics, reducing reflection light, which is non-excited in eyes, soft and comfortable in scene, easy in preparation and low in preparation cost.

Owner:SHANDONG KAILI SPECIAL PAPER

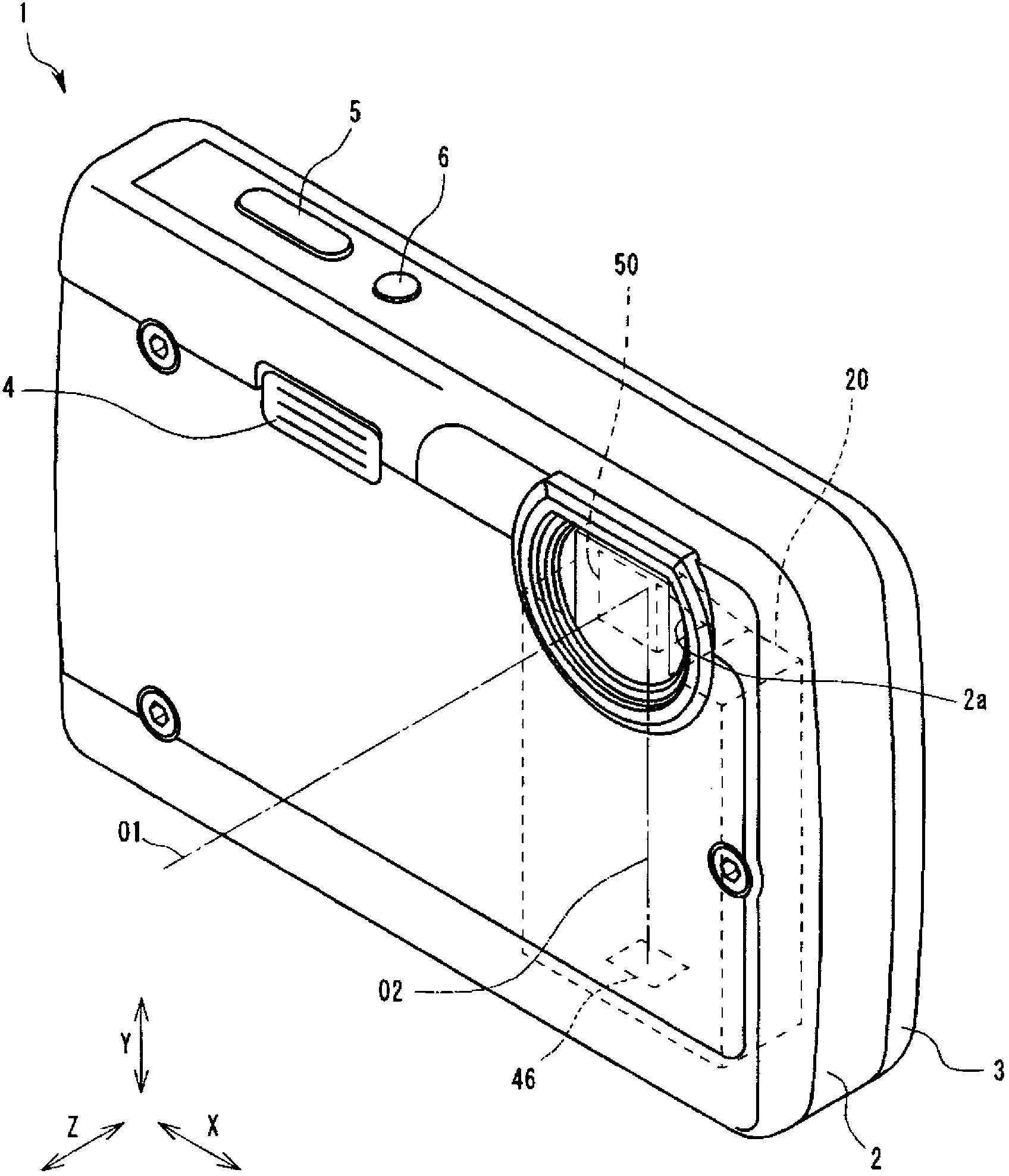

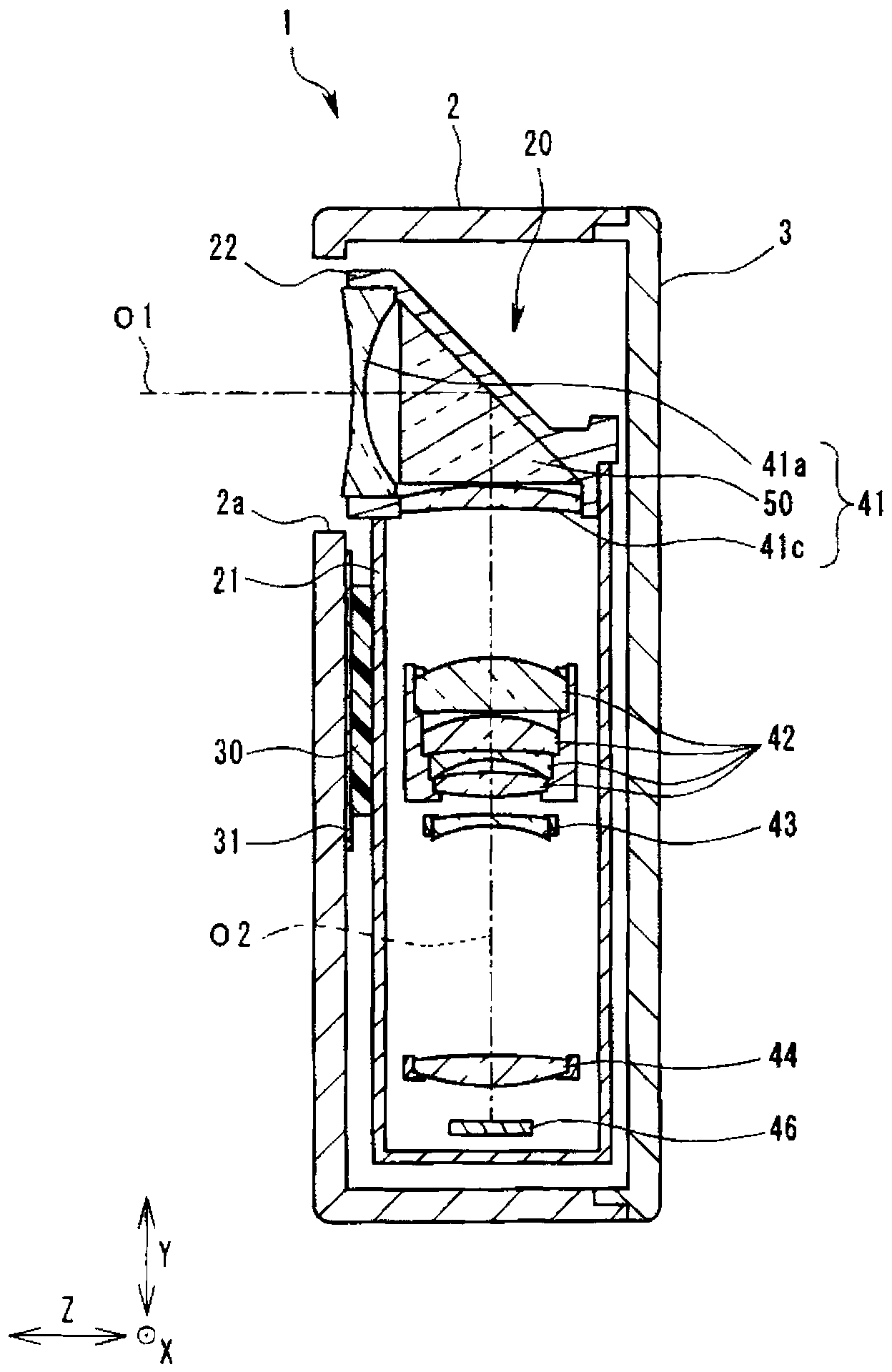

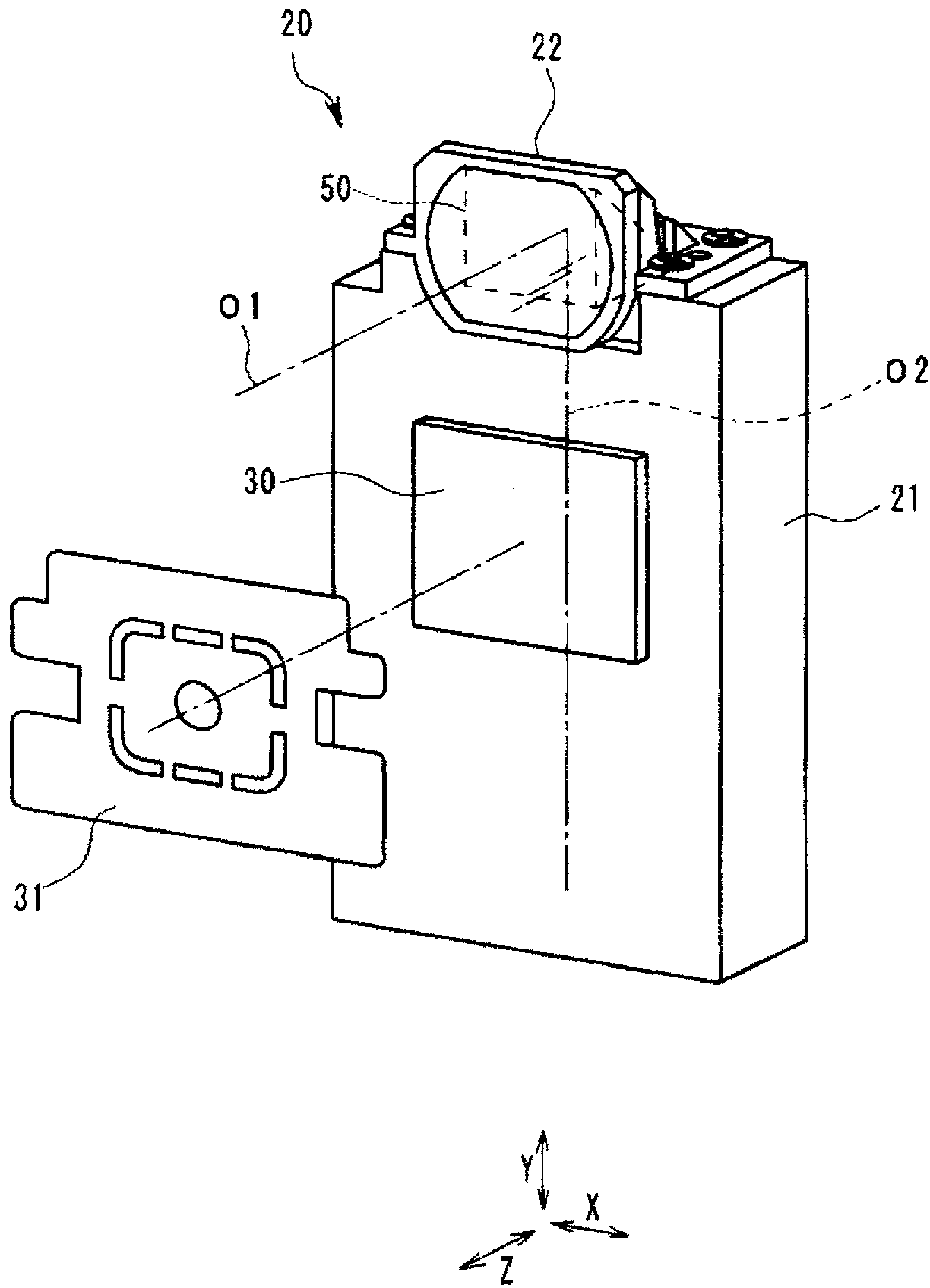

Photographic device

ActiveCN103257427AEasy to fixWill not be enlargedTelevision system detailsColor television detailsCamera lensAdhesive

Owner:OM DIGITAL SOLUTIONS CORP

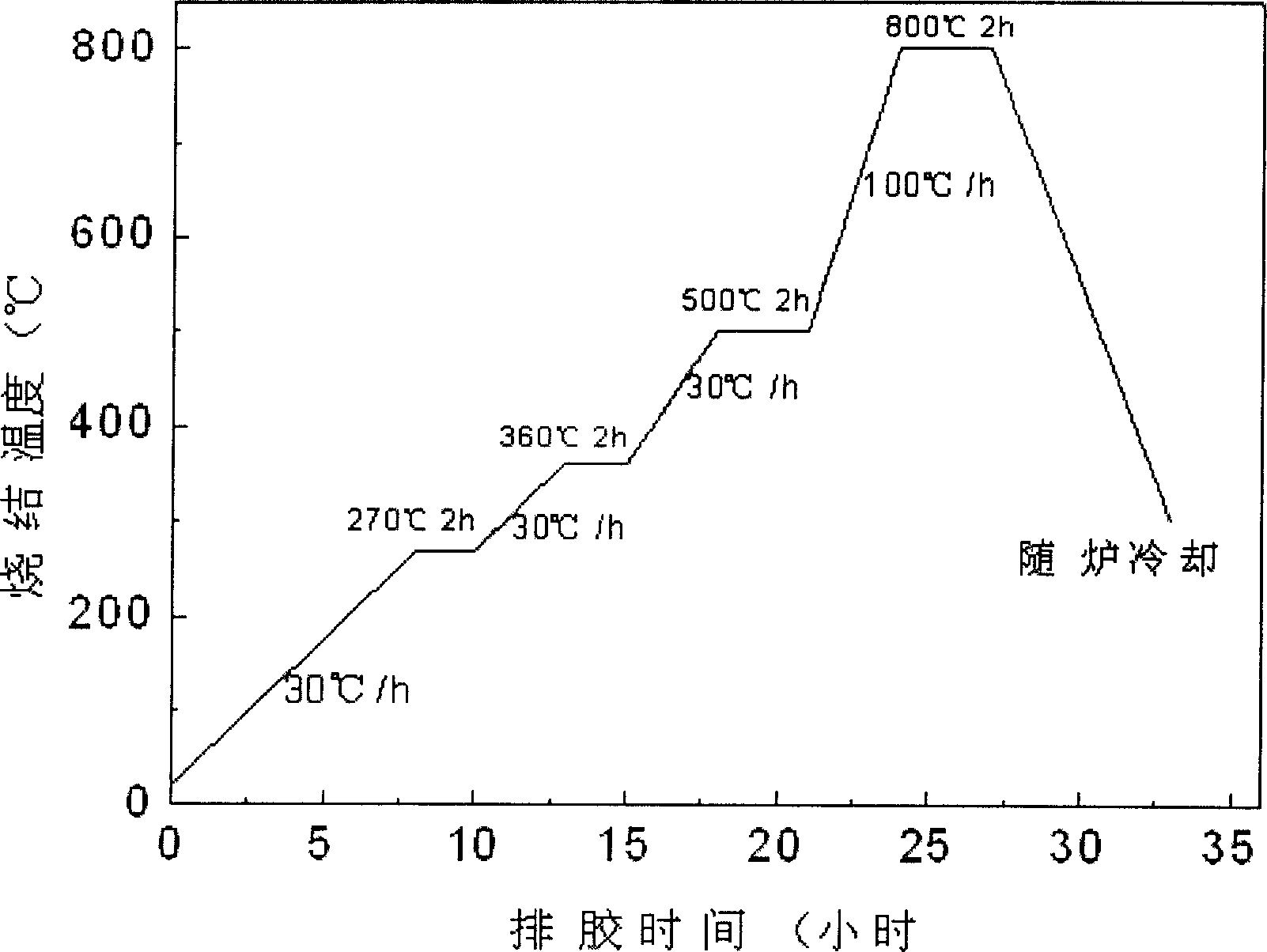

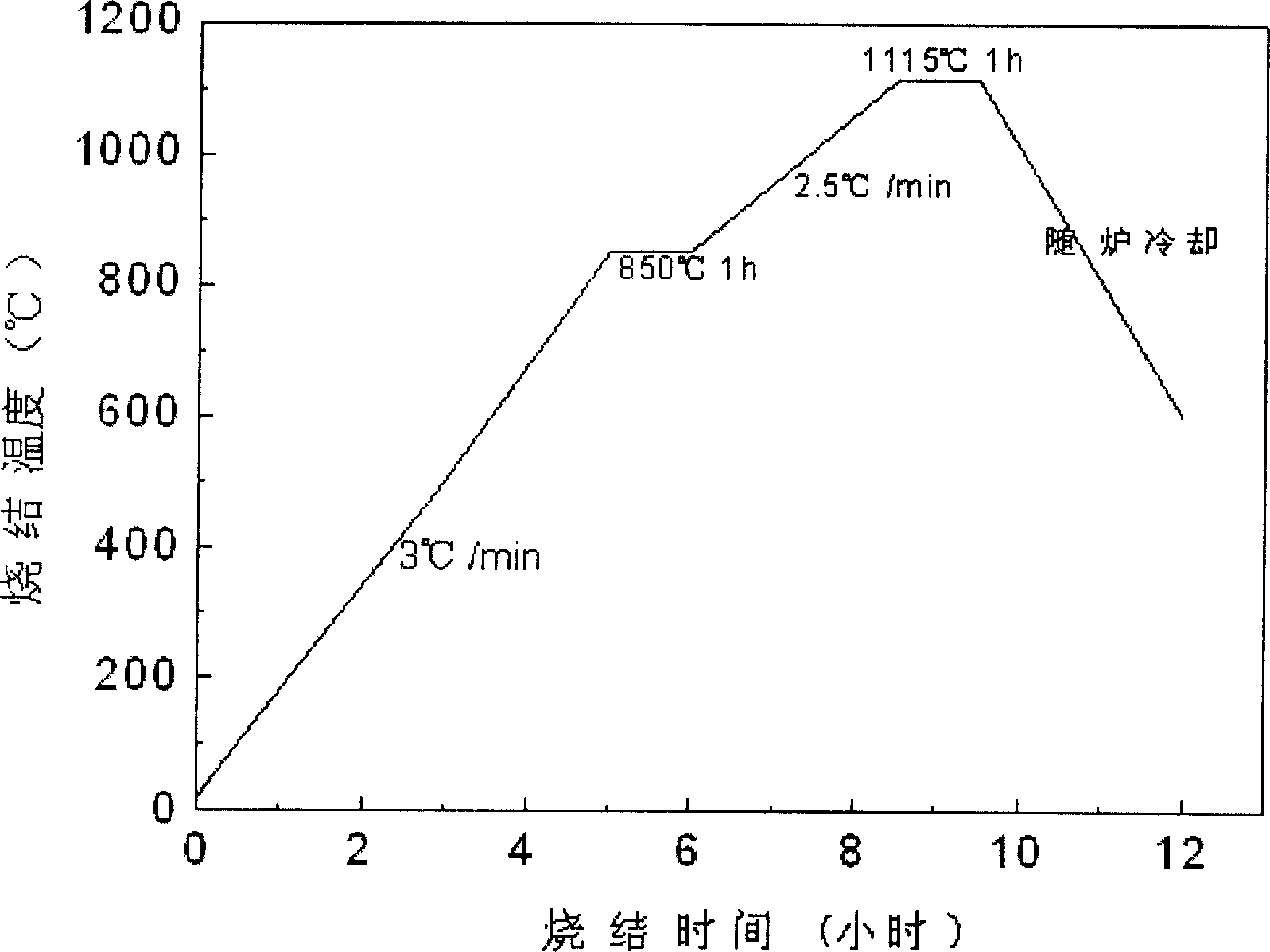

Bismuth sodium titanate-barium titanate base piezoelectric ceramic and its prepn process

InactiveCN1673178ALower coercive fieldLow resistivityPiezoelectric/electrostrictive/magnetostrictive devicesBarium titanateAdhesive

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Terminal structure and glass plate with terminal for vehicles

Disclosed is a terminal structure which has a high degree of freedom in selecting the mounting position. A terminal part (18) is affixed to a glass plate (11) with an adhesive (27). A conductive member (19) extends from the terminal part (18) too an object of power supply. The conductive member (19) is flexible.

Owner:NIPPON SHEET GLASS CO LTD

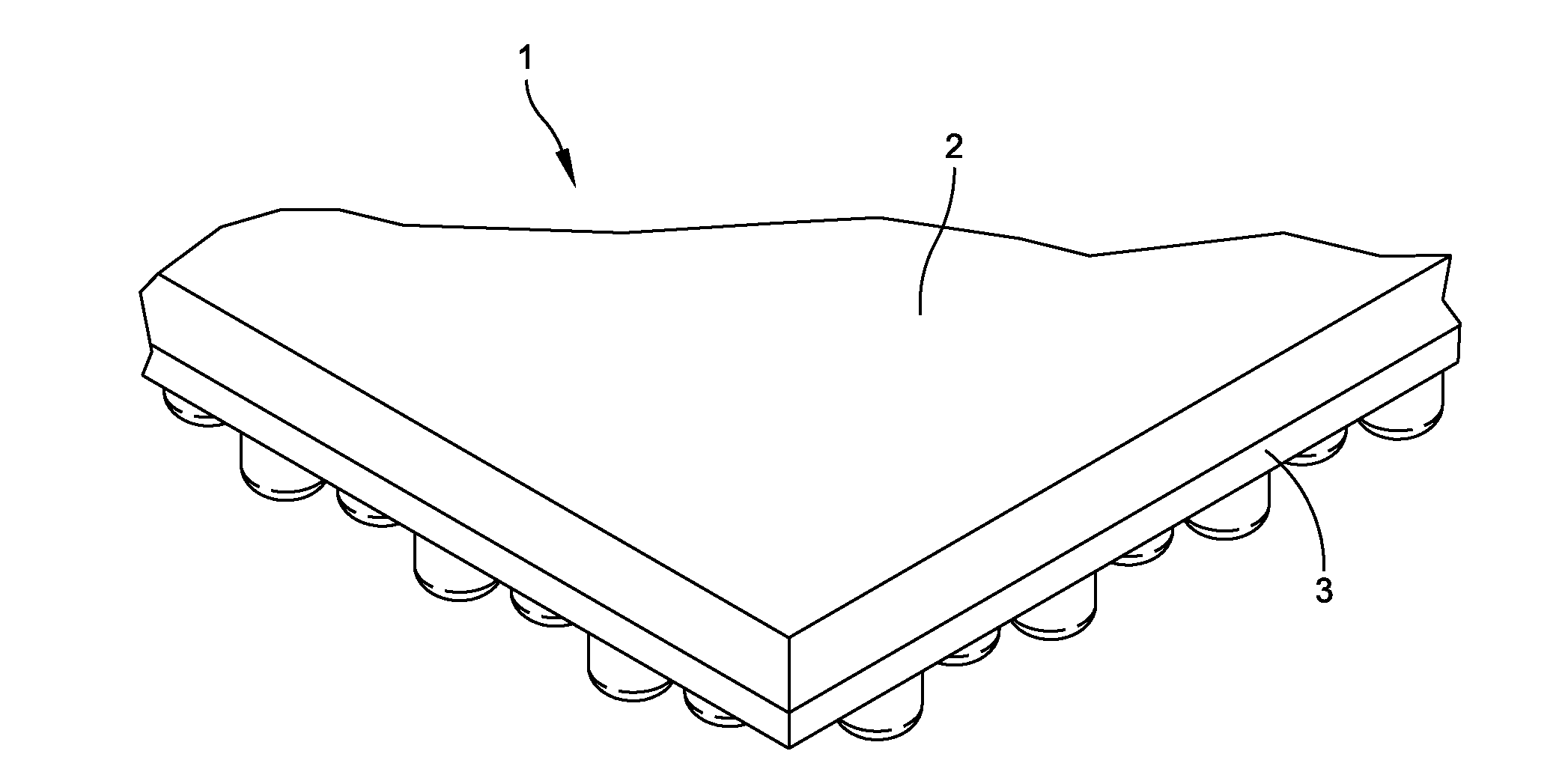

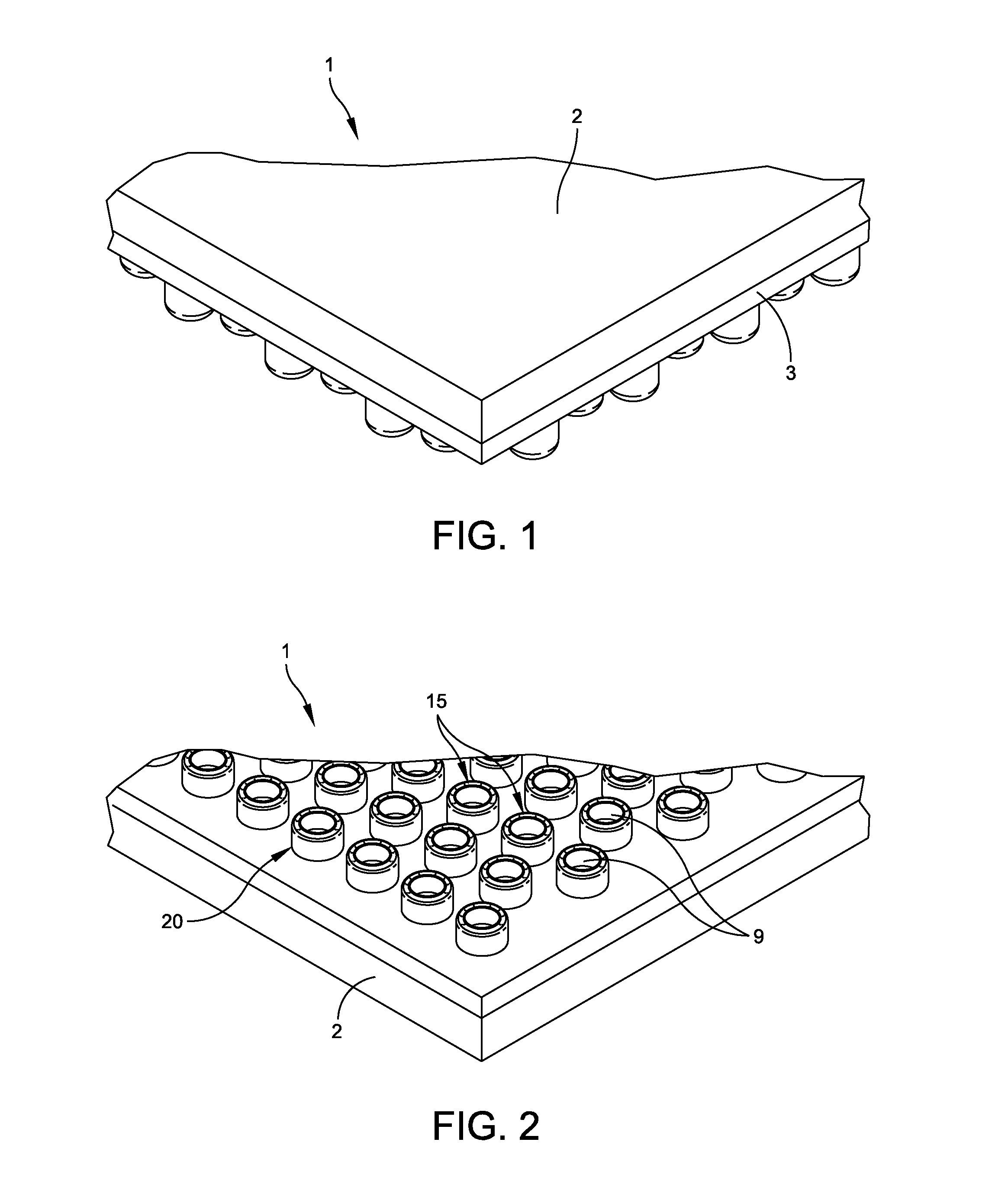

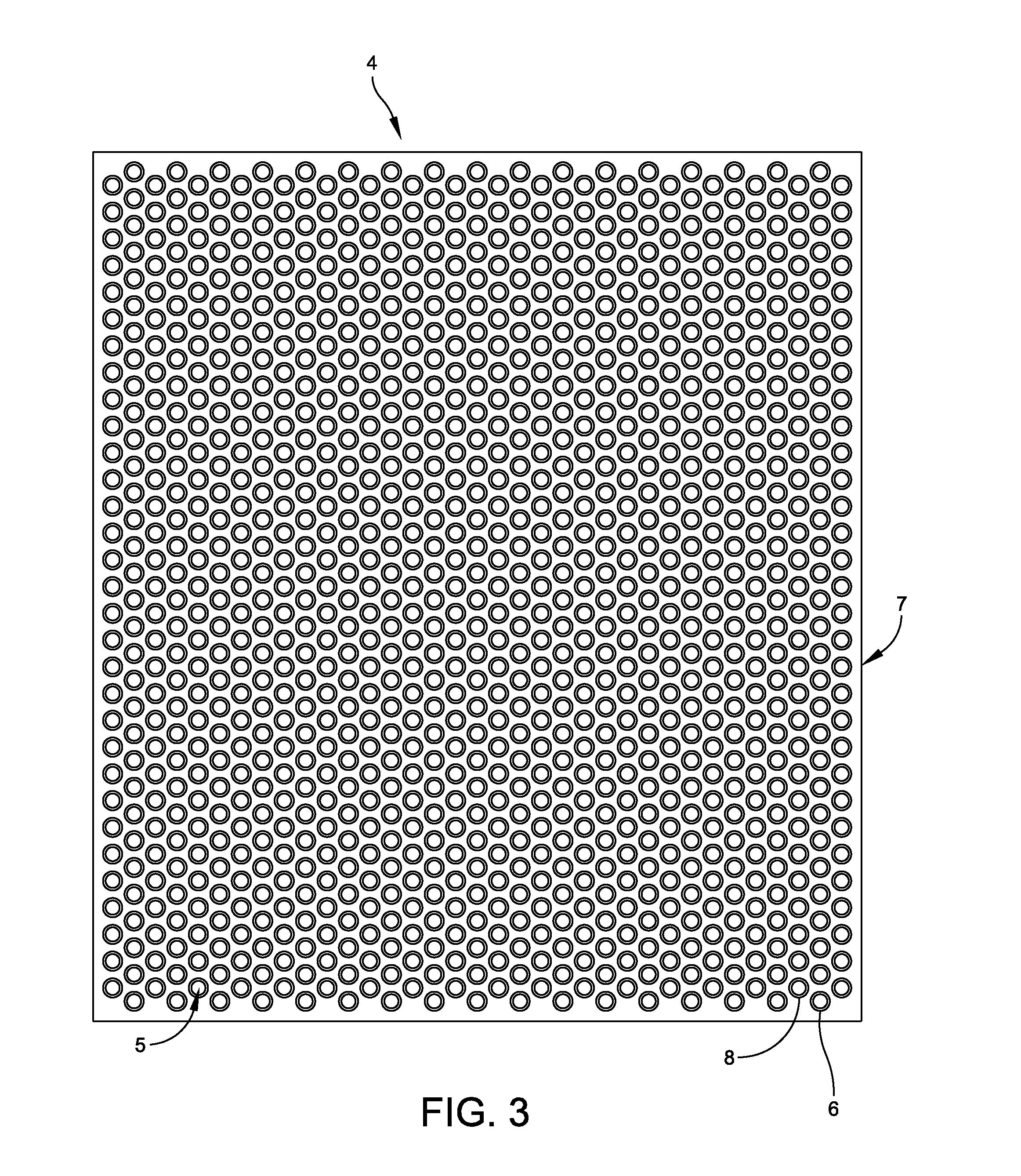

Adhesiveless decorative floor tile

InactiveUS20120324805A1Increase frictional resistanceFloorsFoundation engineeringAdhesiveSurface cover

Owner:GROWLIFE INC

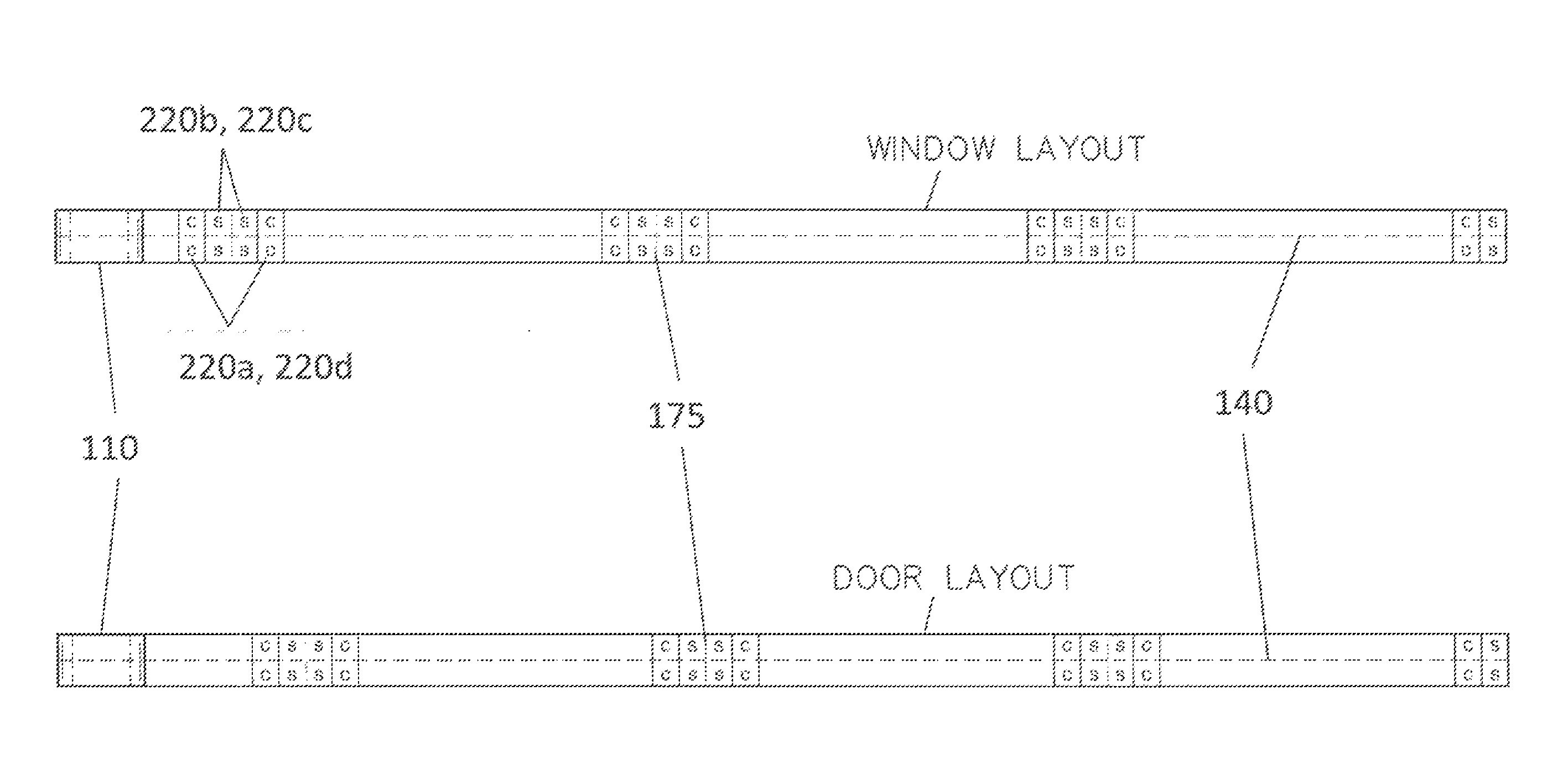

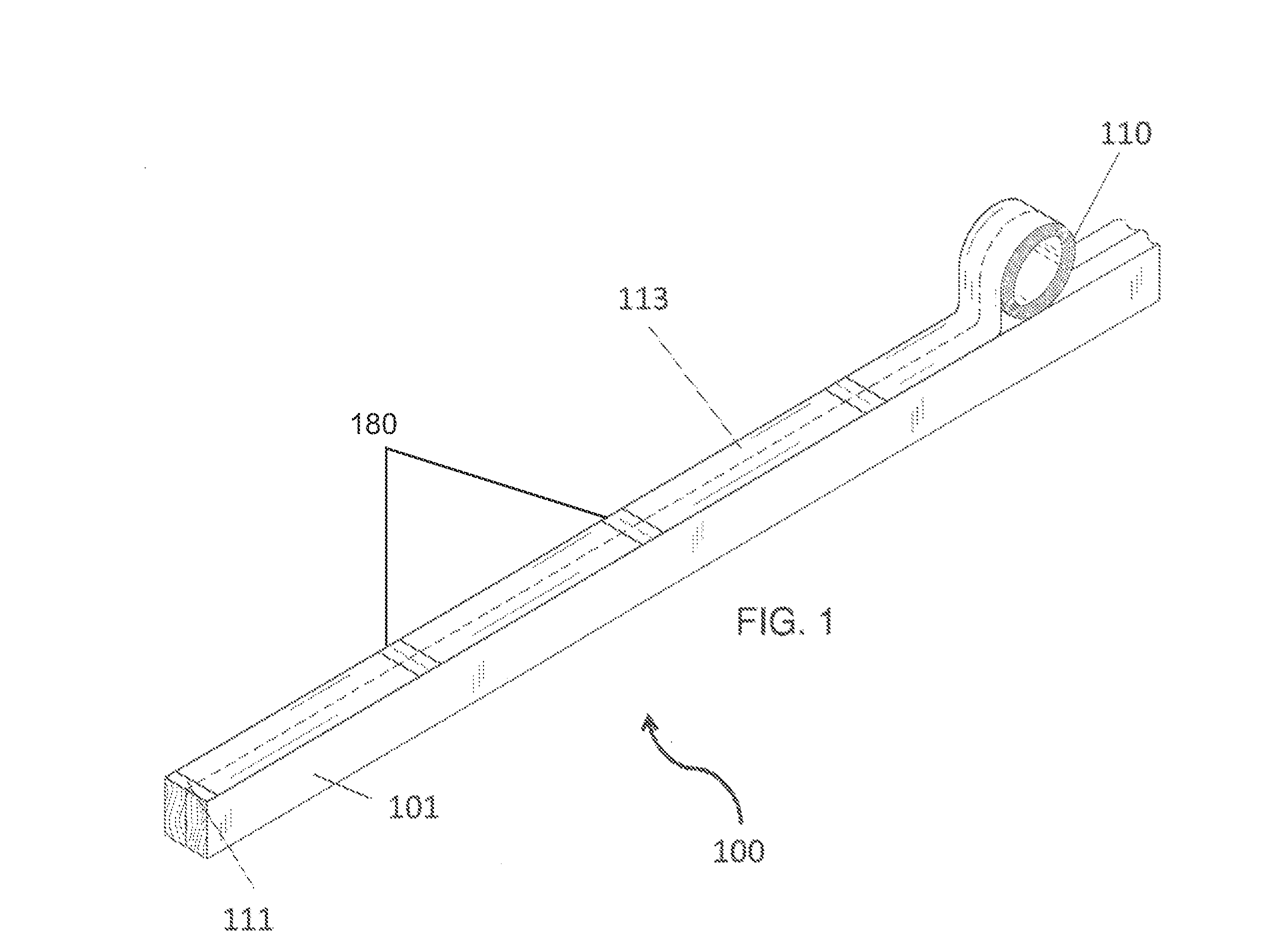

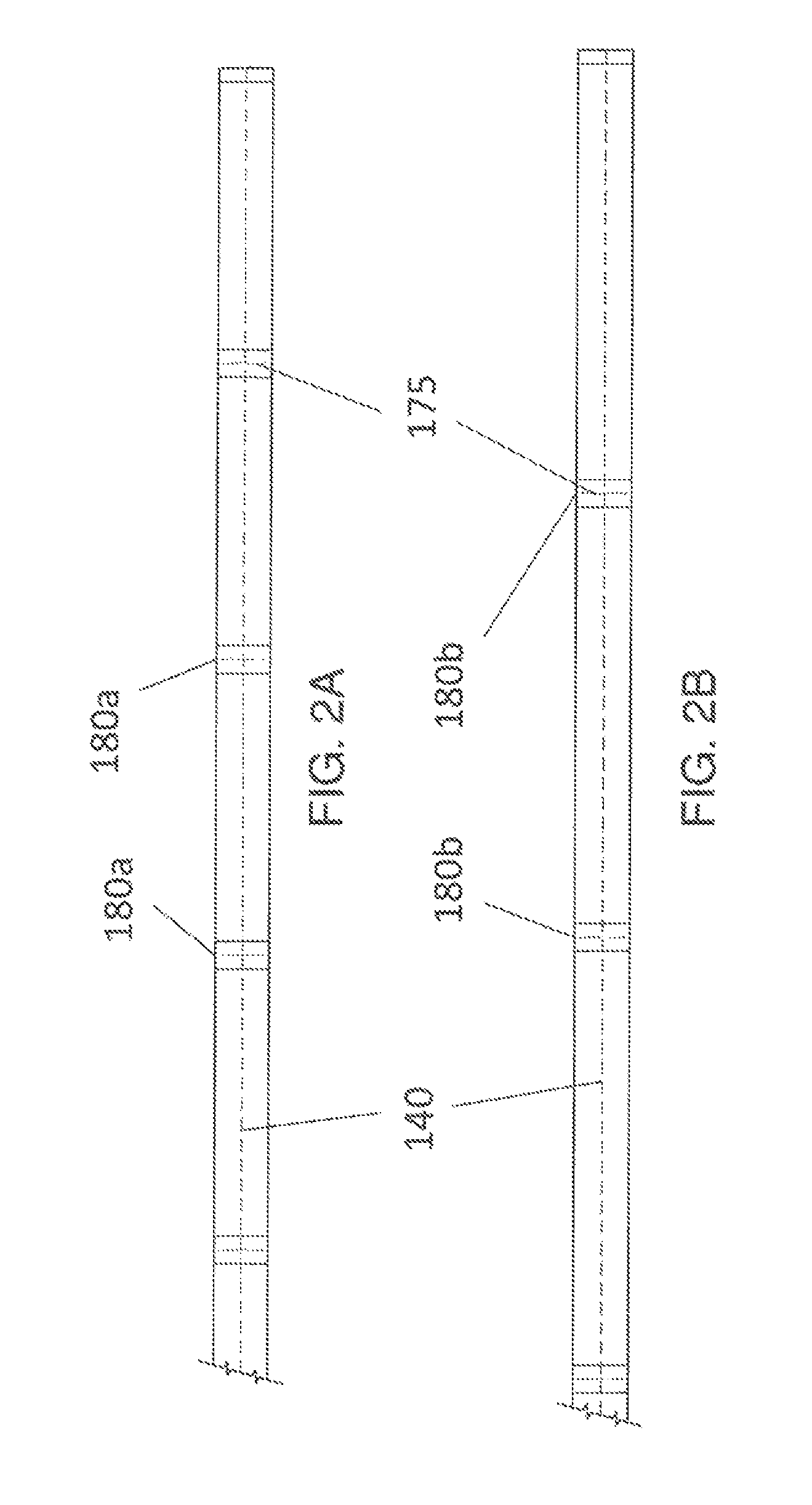

Tape system for framing

Owner:MOONEY DARRELL R

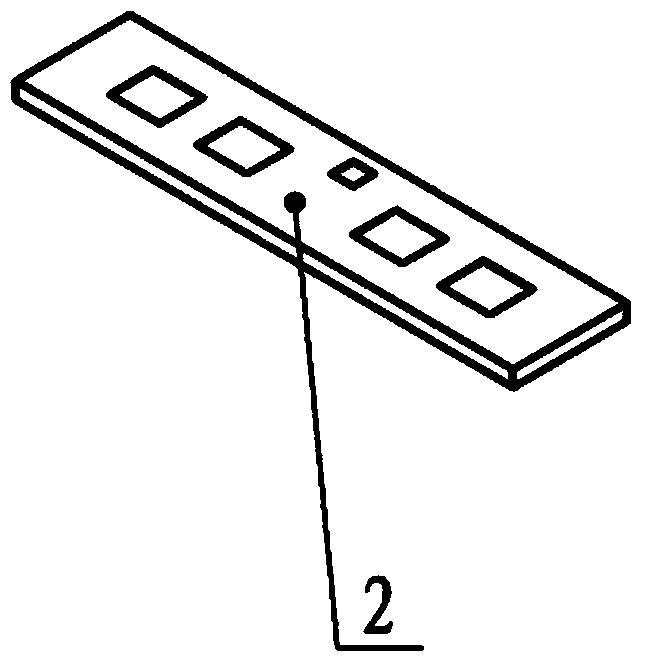

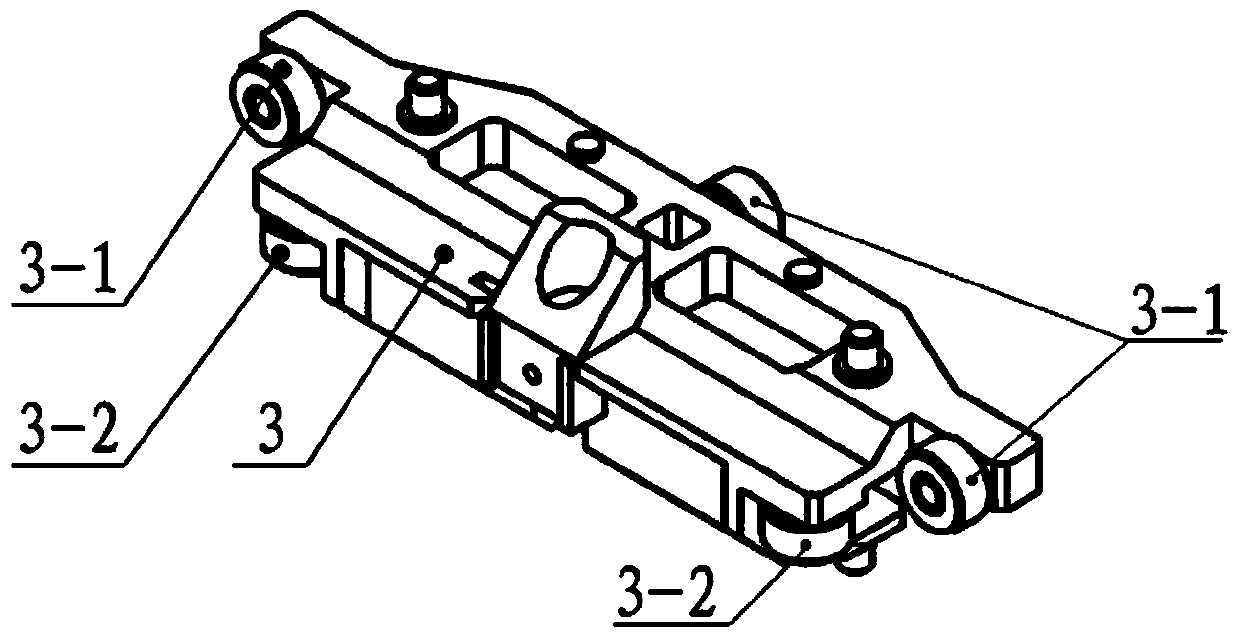

Suspended adsorption type automatic adhering device for indicating gratings

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Controlled release potash fertilizer and preparation method thereof

ActiveCN102653484AIncrease profitSolve the problem of insufficient supplyFertilizer mixturesSodium BentoniteControl release

Owner:张希纯 +1

Weather-resistant type coating material of acrylic acid-polyester powder modified by inorganic nano composite material, and its prepn. method

InactiveCN1462784AImprove anti-aging propertiesIncreased weather resistance indexPowdery paintsPolyester coatingsAcrylic resinAdhesive

Owner:SICHUAN UNIV +1

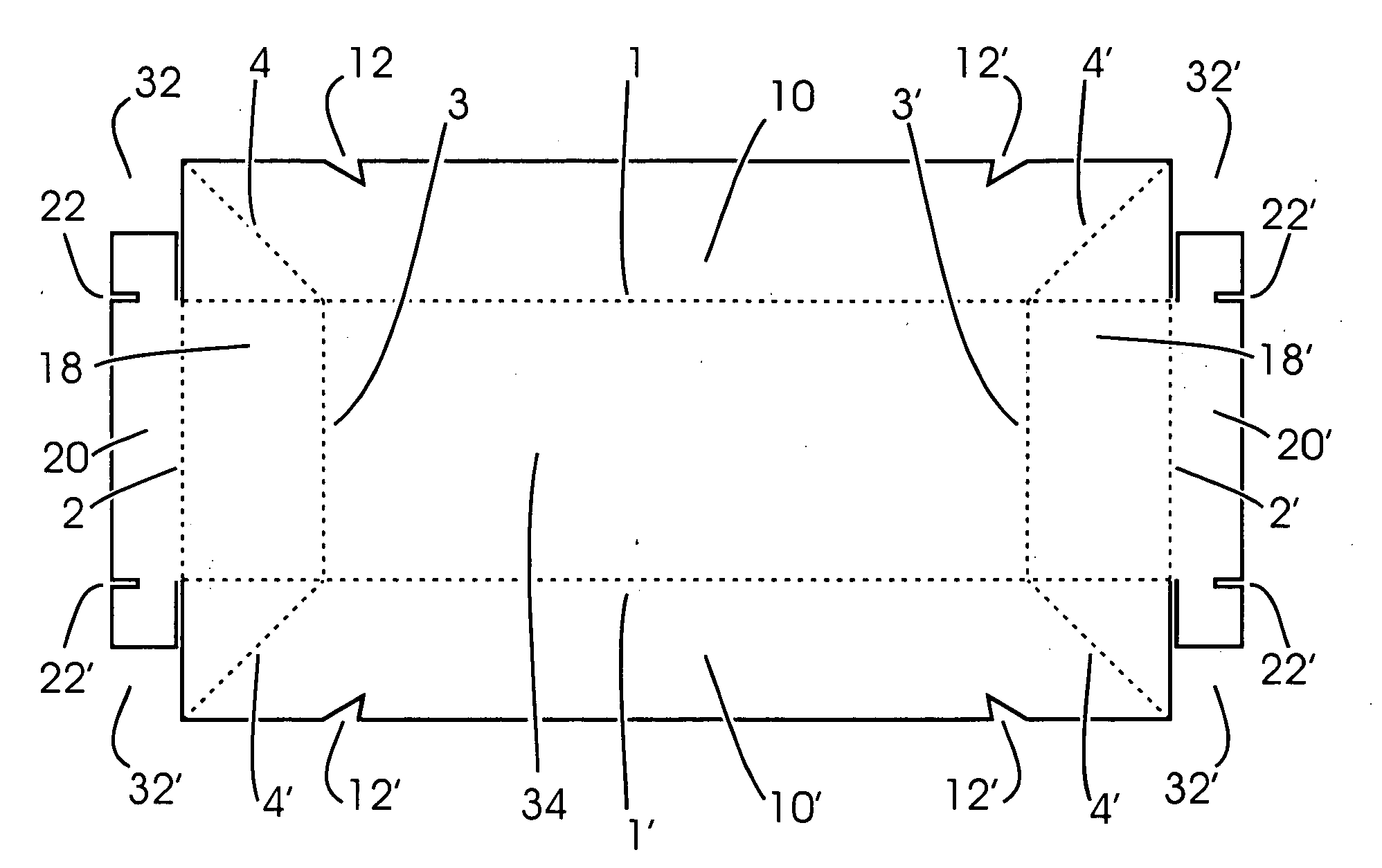

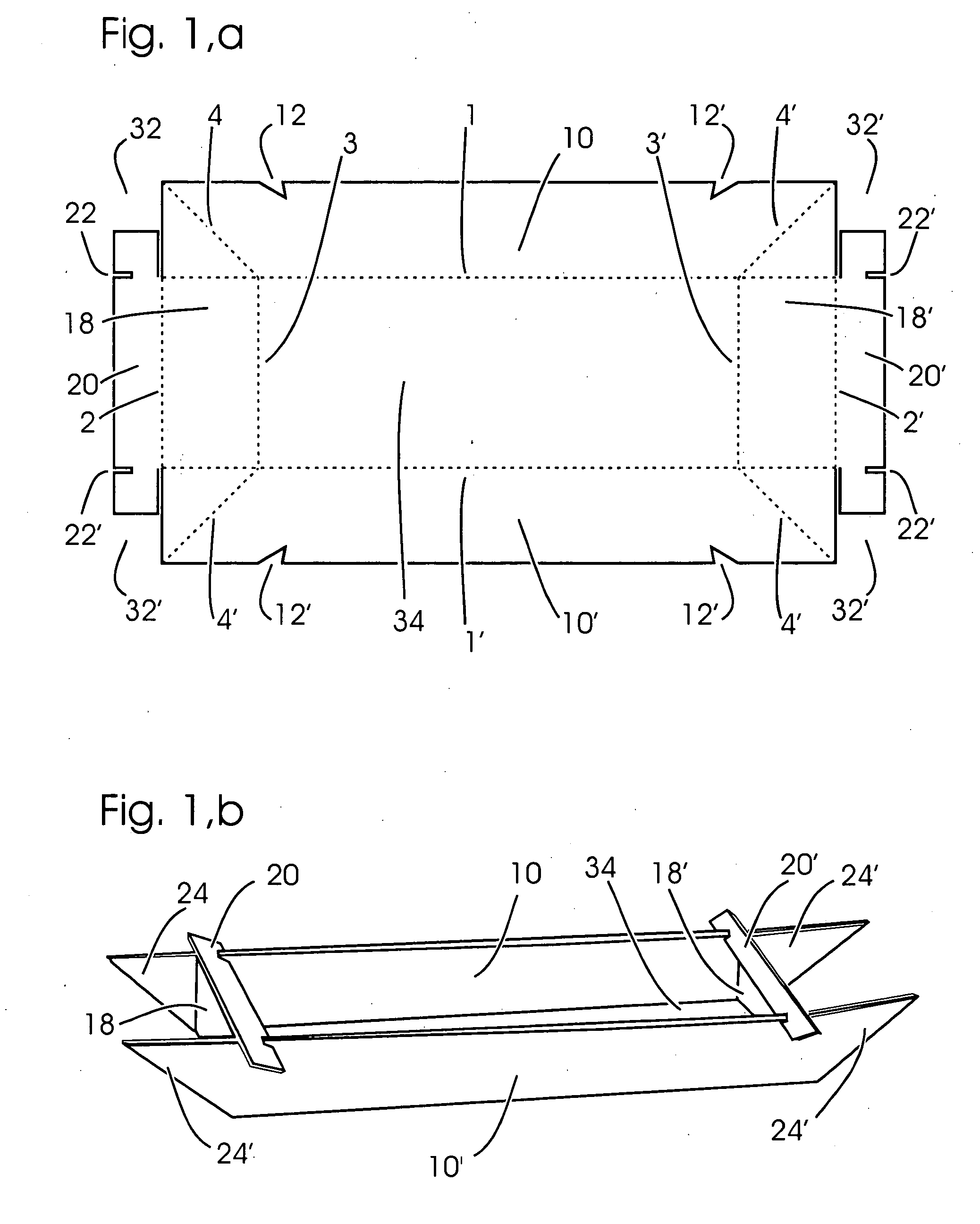

Leak proof self securing container from single sheet

InactiveUS20090044743A1Cost-effective manufacturingQuick assemblyMetal working apparatusRigid containersHuman useFlute

Owner:WAGENKNECHT CHARLES MAXWELL +2

Light diffusing layer, light diffusing film, and light diffusing adhesive sheet

Owner:TOMOEGAWA PAPER CO LTD

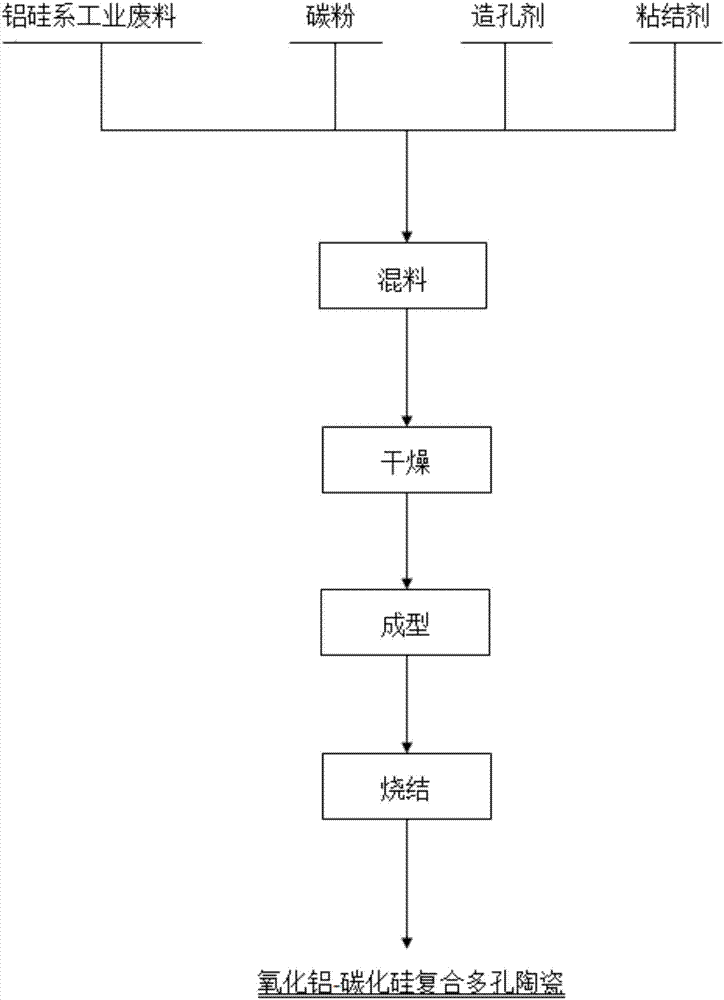

Method of preparing aluminum oxide-silicon carbide compound porous ceramic by aluminum-silicon industrial waste residues

ActiveCN107399988AModerate porosityExcellent strengthCeramic materials productionCeramicwareIndustrial wasteAdhesive

The invention discloses a method of preparing aluminum oxide-silicon carbide compound porous ceramic by aluminum-silicon industrial waste residues. The primary raw materials comprise industrial waste residues, carbon powder, a pore forming substance and an adhesive. The aluminum oxide-silicon carbide compound porous ceramic is prepared by the following steps of mixing, drying, forming and sintering to obtain a final product. Treatment and high additional value utilization of the industrial waste residues are achieved. The prepared porous ceramic is remarkable in performance, and can be applied to the fields of filtration, sound isolation, heat isolation, fire fighting and the like. The method is simple in process flow and convenient for industrialized promotion; and the cost is good to control and the method has extreme economical value.

Owner:NORTHEASTERN UNIV

Method for reinforcing titanium concentrate pellet prereduction

The invention belongs to the field of titanium concentrate smelting titanium slag, in particular to a method for reinforcing titanium concentrate pellet prereduction. The method for reinforcing the titanium concentrate pellet prereduction solves the technical problems of low titanium concentrate pellet metallization ratio and high later smelting electricity consumption of the prior prereduction. According to a scheme for solving the technical problems, the method for reinforcing the titanium concentrate pellet prereduction includes steps that a, pellet pressing, to be specific, mixing titanium concentrate, adhesives and water for 30 minutes, and conveying to a roller sheet pellet press machine to press to form the pellet; b, pellet drying, to be specific, drying the pressed pellet for 60 minutes at 200 degrees centigrade; c, pre-oxidation, to be specific, roasting and pre-oxidizing the dry pellet for 10 to 20 minutes at 950 to 1050 degrees centigrade, wherein the pre-oxidation atmosphere is air; d, prereduction, to be specific, roasting and pre-reducing for 25 to 30 minutes at 1250 to 1350 degrees centigrade after uniformly mixing the oxidized and roasted pellet with pulverized coal under nitrogen protection. The method for reinforcing the titanium concentrate pellet prereduction realizes the fine grained titanium concentrate use of Panzhihua, effectively lowers the later smelting electricity consumption and improves the smelting furnace conditions; devices needed for the method are broad in source, and the operation is convenient to perform.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap