Suspended adsorption type automatic adhering device for indicating gratings

An indicator grating and automatic bonding technology, which is applied in the direction of connecting components, mechanical equipment, etc., can solve the problems of inability to accurately control the three-dimensional adjustment of the indicator grating, poor bonding consistency, and low measurement accuracy, and achieve simple and convenient structure and bonding Reliability and the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

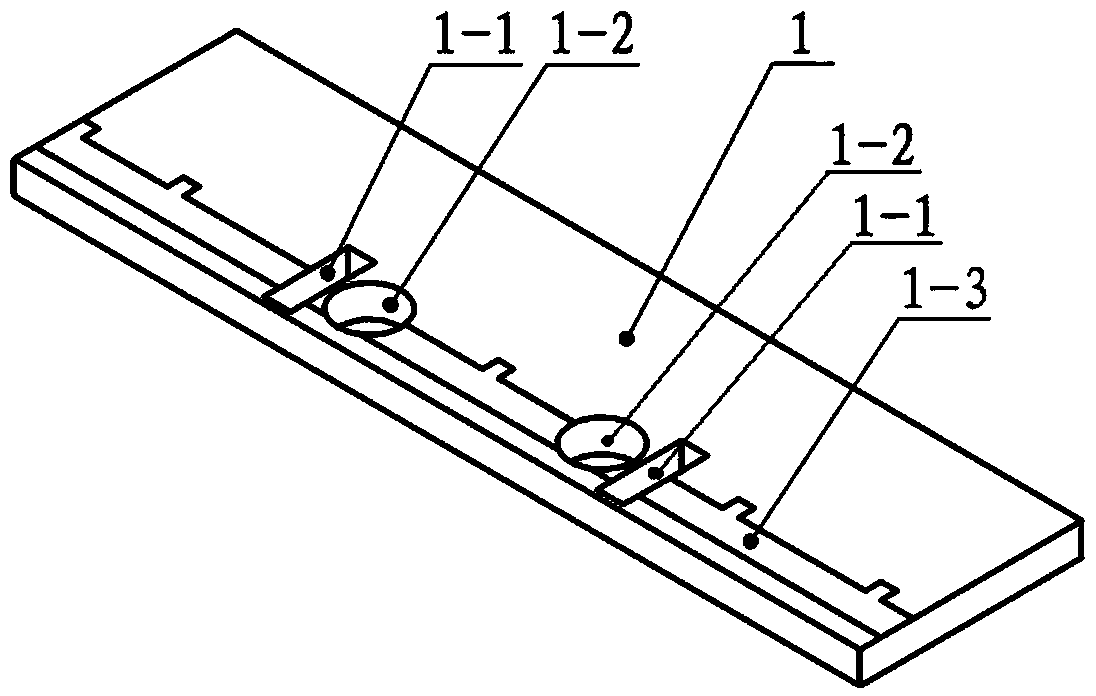

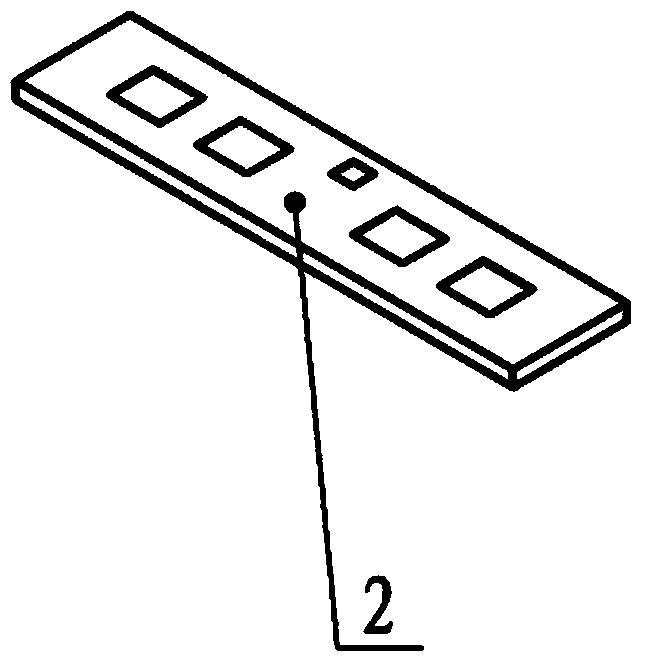

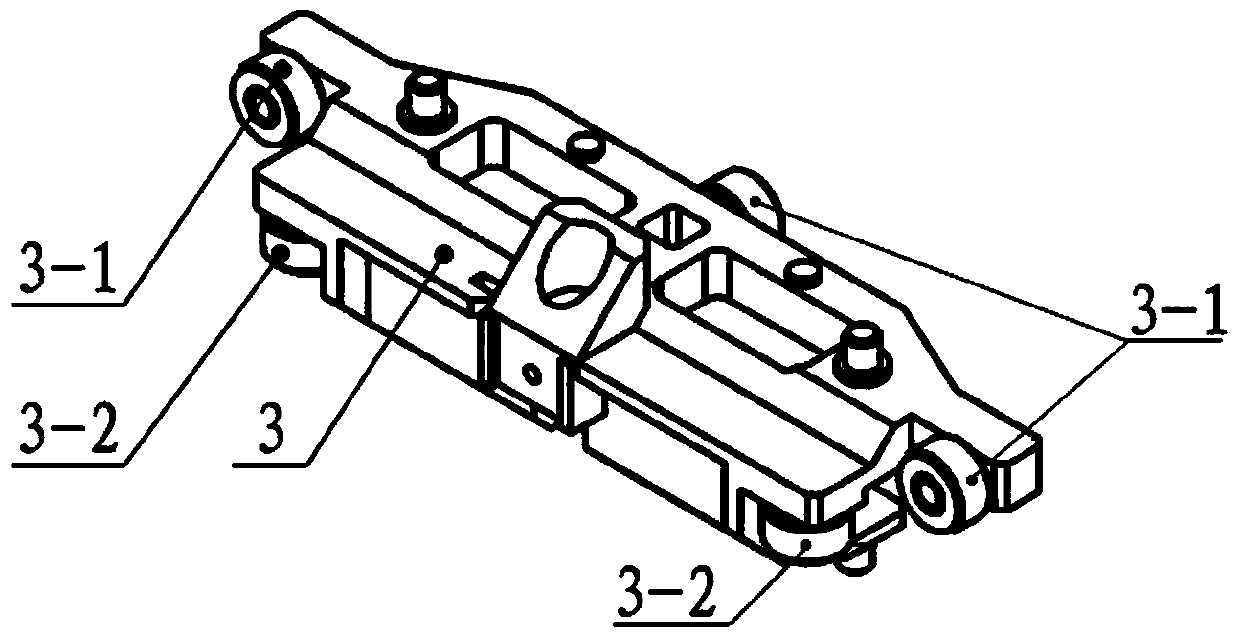

[0036] The suspended adsorption type indicating grating automatic bonding device of the present invention is mainly used to automatically bond the indicating grating 2 to the carriage 3 according to the technical index requirements, such as Image 6 As shown, the automatic bonding device of the suspended adsorption type indicating grating of the present invention consists of a main grating 1, an indicating grating 2, a carriage 3, a suspended adsorption structure, an electric rotating table 6, a hollow turntable 7, a grating picking assembly 8, and a carriage positioning assembly 9. It consists of a dispensing and curing assembly 10 , a two-speed zoom lens 11 , a tray 12 , a base 25 and an adjustment seat 26 .

[0037] The base 25 is located at the inner lower end of the hollow turntable 7 but is not connected with the hollow turntable 7 in any way. A plurality o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap