Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Good adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic bonding and embossing of an absorbent product

InactiveUS20050136224A1Easily and effectively madeEnhanced structural integrity and performanceMechanical working/deformationSynthetic resin layered productsEngineeringUltrasonic bonding

Ultrasonically bonded laminated absorbent products comprising a liquid permeable top sheet, a liquid impermeable back sheet, an absorbent core positioned between the liquid permeable top sheet and the liquid impermeable back sheet, and an adhesive composition are disclosed. The laminated structure further comprising an embossed pattern stamped onto the liquid permeable top sheet, the liquid impermeable back sheet, the absorbent core, or any combination thereof. The adhesive composition comprises a mixture of atactic and isotactic polymers such that it has melt and flow characteristics similar to those of the topsheet and backsheet.

Owner:KIMBERLY CLARK WORLDWIDE INC

Active Energy Ray-Curable Organopolysiloxane Resin Composition, Optical Transmission Component, And Manufacturing Method Thereof

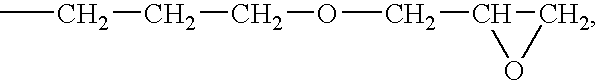

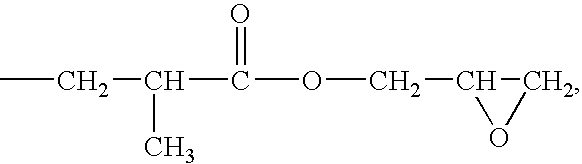

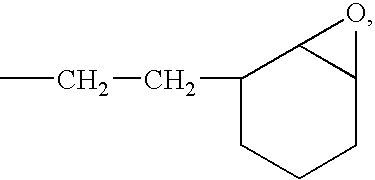

ActiveUS20080032061A1Good adhesionHigh optical transmittanceCladded optical fibreFibre mechanical structuresChemistrySilorane Resins

An active energy ray (e.g. UV rays)-curable organopolysiloxane resin composition comprises (A) 100 parts by weight of an organopolysiloxane resin containing epoxy groups and aromatic hydrocarbon groups, (B) 0.05 to 20 parts by weight of a photo acid generator, (C) 0.01 to 20 parts by weight of a photosensitizer or photo-radical generator, and (D) 0 to 5,000 parts by weight of an organic solvent. An optical transmission component made of the above-mentioned composition cured by irradiation with active energy rays (for example, UV rays). A method for manufacturing an optical transmission component by irradiating the above-mentioned composition with active energy rays (for example, UV rays).

Owner:DOW TORAY CO LTD +1

Coating compositions having improved "direct to metal" adhesion and method therefore

InactiveUS20040071887A1Good adhesionImprove corrosion resistanceMetallic material coating processesPolyester coatingsCorrosionMetallic substrate

Owner:BASF CORP

Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

ActiveCN102030857AGood adhesionImprove water resistanceMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsCross-linkPolymer science

The invention relates to a vinyl acetate-ethylene copolymer emulsion as an electrostatic spinning adhesive and a synthesis method thereof. Organic peroxides and zinc formaldehyde sulfate are taken as an initiator; vinyl acetate, ethylene, acrylic ester monomers and cross-linking monomer N-hydroxymethyl acrylamide are taken as comonomers; a nonionic emulsifier, and the synthetic emulsion and the protective colloid of an amphoteric emulsifier are matched to be taken as an emulsification system; and the copolymer emulsion is prepared through emulsion polymerization. Compared with the VAE (vinyl acetate-ethylene) emulsion prepared by the conventional preparation method, the product in the invention has the advantages of good water resistance, strong adhesion on low-surface-energy materials (polyethylene, polypropylene and the like), fine grain and the like. The vinyl acetate-ethylene copolymer emulsion is suitable for being as the adhesive to be applied to the field of the electrostatic spinning in textile industry and the fields of waterproofing and packaging.

Owner:CHINA PETROCHEMICAL CORP +1

Full-automatic patch pocket machine

InactiveCN104499187AEasy to disassemble and replaceIncrease the level of automationWork-feeding meansPressersMechanical engineering

A full-automatic patch pocket machine comprises a frame, a nose, a sewing former mechanism, a feeding mechanism and a collecting mechanism. The feeding mechanism comprises a pressing device, a feeding and supporting device and a feeding cylinder; the feeding and supporting device is fixed to the side of the frame; the pressing device is disposed over the feeding and supporting device; the feeding cylinder is disposed at the bottom of the supporting device and connected with the pressing device. A supporting block is disposed at the tail of the nose. Y-directional guide rails are disposed at the bottoms of supporting plates on two sides of the supporting block. A fly-rack is disposed under the supporting block. An X-directional guide rail is disposed at the front end of the fly-rack. A moving plate fitting the X-directional guide rail is disposed at the front end of the fly-rack. The sewing former mechanism is disposed on the moving plate and comprises an inner pressing plate and an outer pressing frame. The full-automatic patch pocket machine has the advantages such as reasonable structure, compact structure, operational convenience, running stability, convenience in maintenance and adjustment, low manufacturing cost and high efficiency.

Owner:SHENZHEN DEYE AUTOMATION TECH

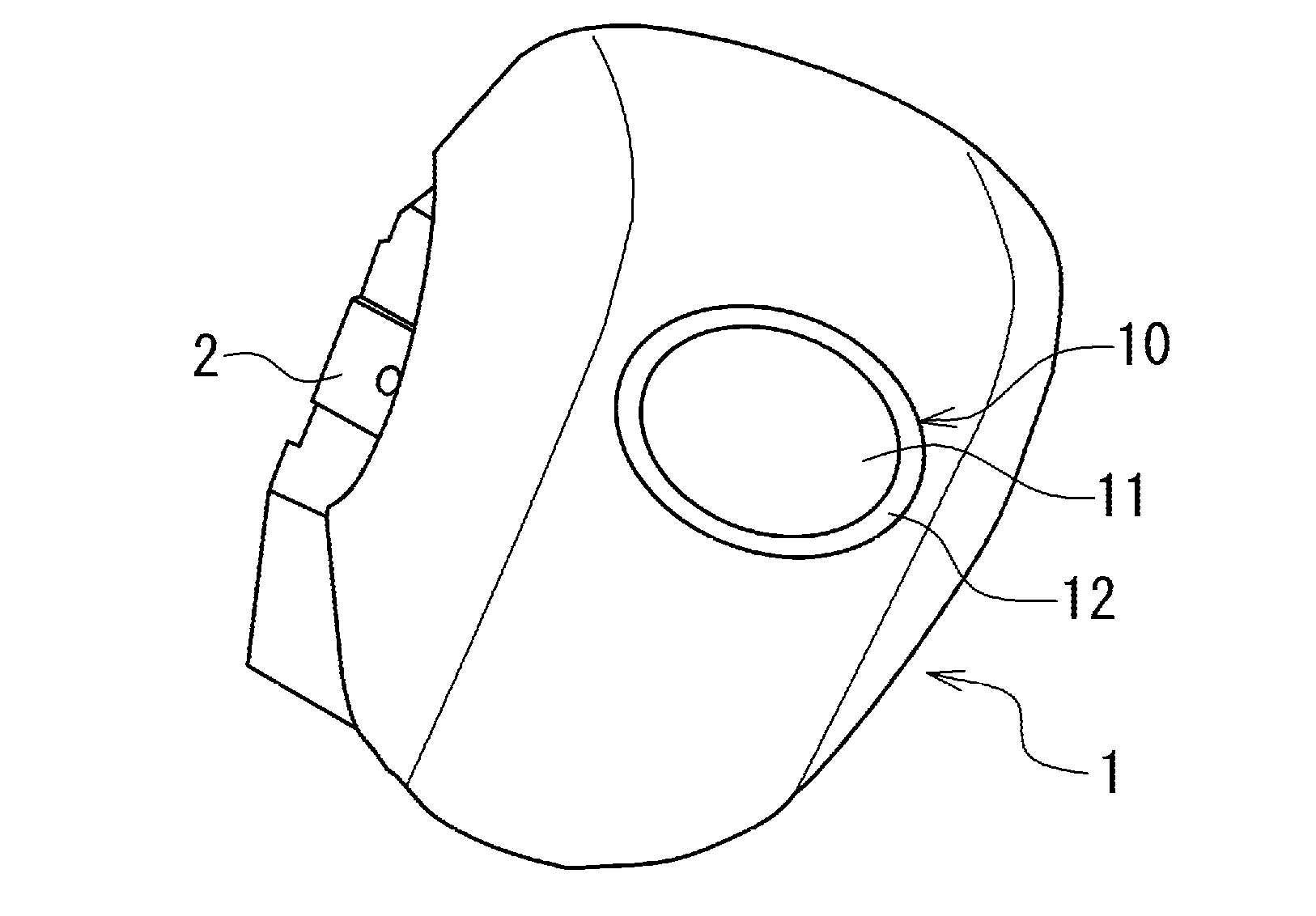

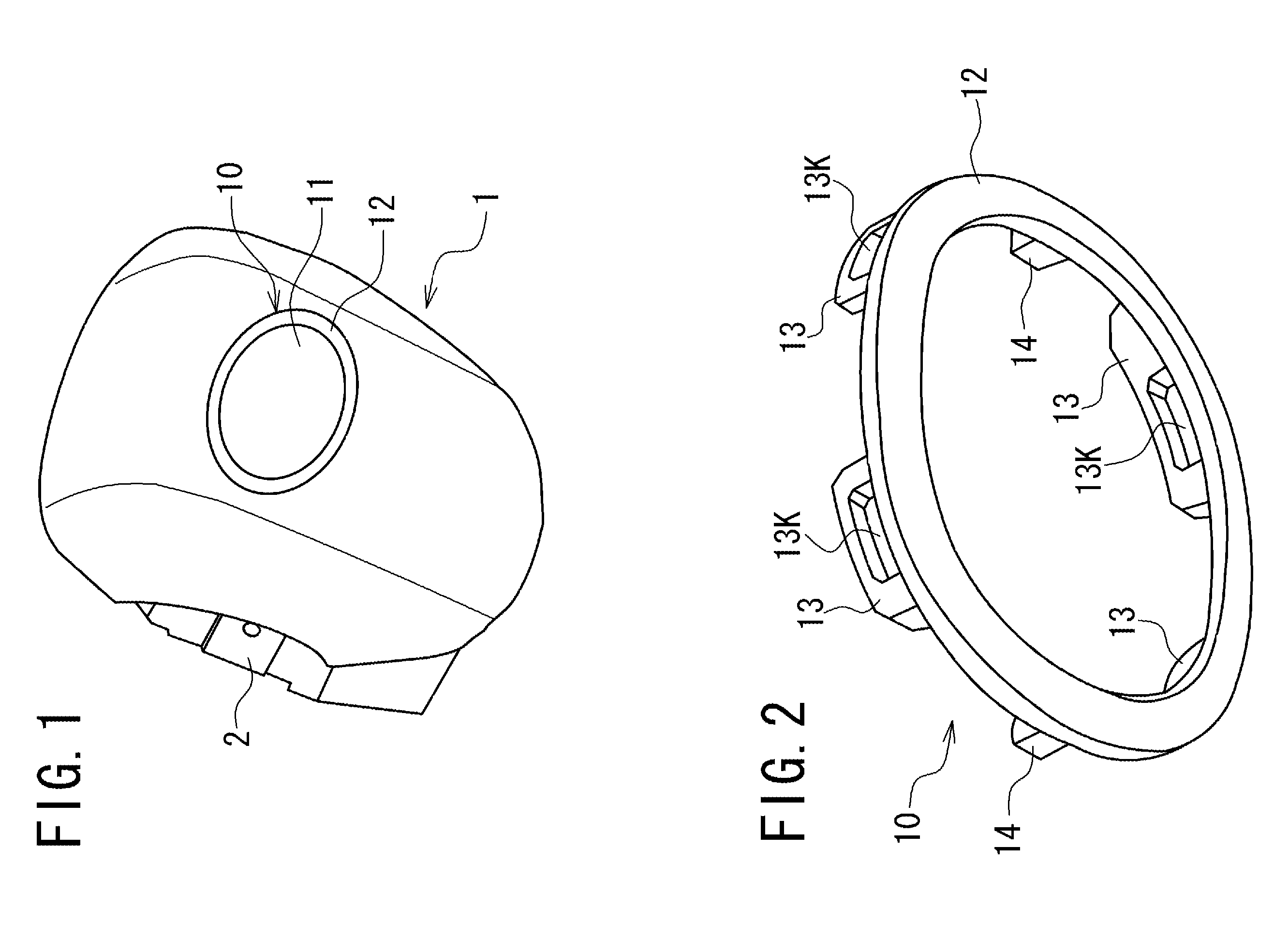

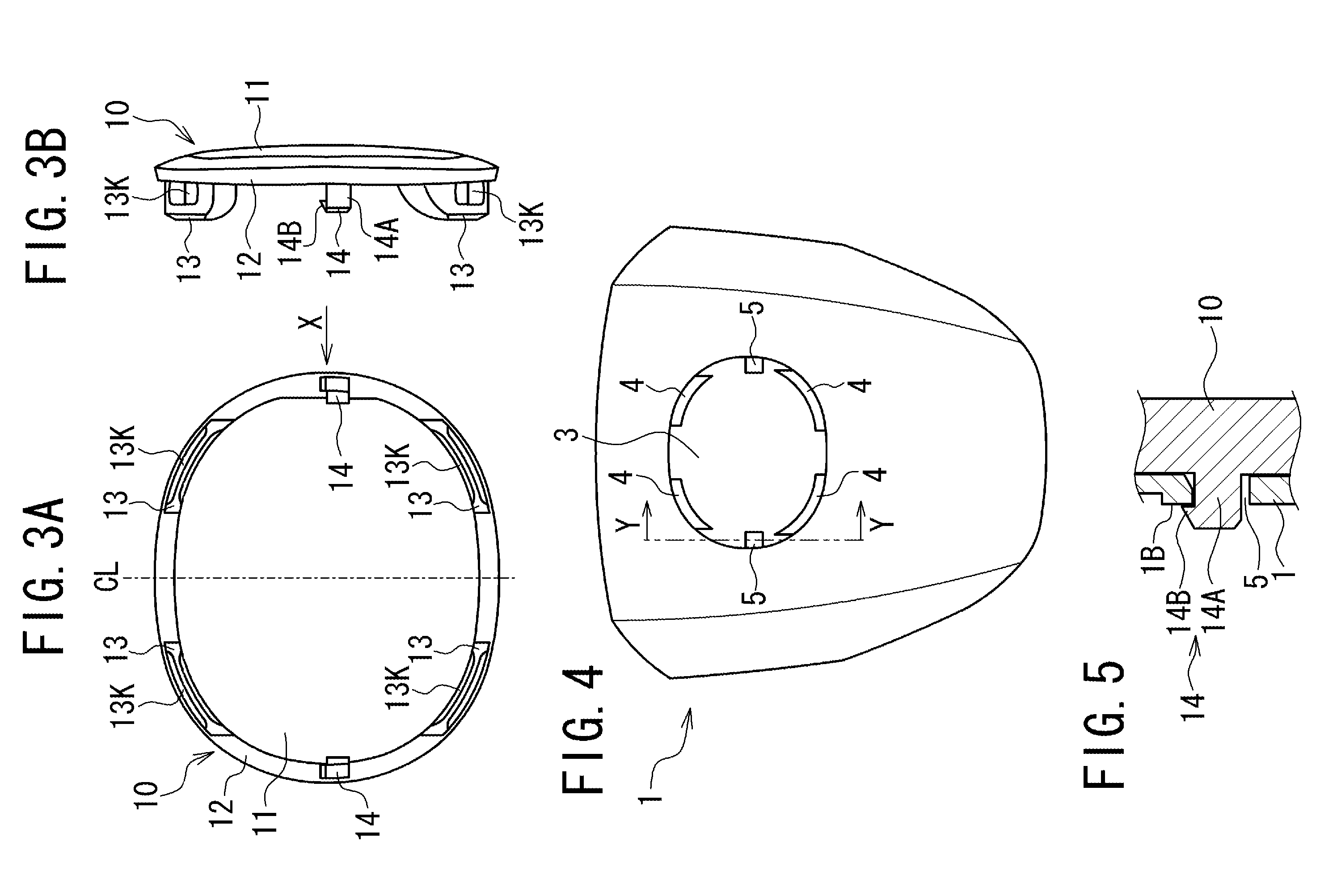

Airbag cover and airbag device

Owner:ASHIMORI INDS

Plastic hot stamping foil and production method thereof

ActiveCN105172407AEasy to transport and storeGood adhesionAldehyde/ketone condensation polymer adhesivesDuplicating/marking methodsAcrylic resinBoPET

Owner:ZHEJIANG HENGFENG PACKING

Nylon fuel oil pipe coated with polyurethane sheath and preparation method thereof

InactiveCN103629454AExcellent zinc chloride corrosion resistanceGood adhesionFlexible pipesPipe protection against damage/wearBinding propertiesBlocking layer

Owner:TIANJIN PENGYI GRP CO LTD

High-temperature-resistant water-based paint

Owner:TIANCHANG JULONG TRAVEL PAINT

Zirconium-manganese-vanadium passive film treating agent for die cast aluminium alloy and treatment method thereof

ActiveCN106048580AGood adhesionGood film uniformityMetallic material coating processes5052 aluminium alloyAluminium alloy

Owner:广东东明新材科技有限公司

Anticorrosive treatment method based on flange and anticorrosive sealing structure

The invention discloses an anticorrosive treatment method based on a flange and an anticorrosive sealing structure and mainly aims at solving the problems of poor durability and stability and the like of flange anticorrosive treatment in the prior art. According to the anticorrosive treatment method based on the flange, three unit structures (an anticorrosive sealant, an anticorrosive adhesive tape and an outer protecting band) are organically integrated to form an anticorrosive structure; the anticorrosive sealant is adopted to seal a center joint of the flange, and is never cured and does not flow at high temperatures; on the basis of the anticorrosive sealant, the anticorrosive adhesive tape is wound around a disc surface of the flange with the center joint filled with the anticorrosive sealant by at least one turn, and has excellent adhesion and leakproofness to a steel surface and thus is capable of thoroughly preventing water vapor permeation; subsequently, the outer protecting band is wound around a surface of the anticorrosive adhesive tape to protect the anticorrosive sealant and the anticorrosive adhesive tape, and therefore, an anticorrosive sealing effect is effective guaranteed on one hand, and on the other hand, the firmness and durability of the anticorrosive sealing structure is guaranteed.

Owner:SICHUAN DEYUAN PETROLEUM & GAS CO LTD

Preparation method for low-temperature-cured electrode slurry

ActiveCN105913896AGood adhesionGood solderabilityNon-conductive material with dispersed conductive materialCuring timeDefoaming Agents

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

Snorkel clip

InactiveUS20060112957A1Good adhesionEasy detachmentSnap fastenersBreathing masksPliabilityEngineering

A snorkel clip made up of two substantially rigid elements, which are designed to wrap at least half way around a snorkel tube, overmolded with a substantially flexible element to create a simple, aesthetically pleasing device. The snorkel clip also includes a hinge region created as part of the substantially flexible element. This hinge region allows the snorkel clip to flex or bend so that one of the rigid elements may be disengaged and pulled away from the riser tube of the snorkel, so that a mask strap may be attached to and removed from the snorkel, while the other rigid element remains attached to the riser tube in a generally secure manner. The substantially flexible portion may also include several cut out sections to provide visual and tactile access to portions of the substantially rigid elements for utility and aesthetic design.

Owner:JOHNSON MARK

Fireproof coating with black mica powder

ActiveCN103773170AGood adhesionGood fire and heat insulationFireproof paintsLignin material coatingsAcrylic resinAluminium oxides

Owner:ANHUI WILLY PAINT SCI & TECH LTD

High-tenacity polyester flame-retardant finishing adhesive and preparation method thereof

Owner:DONGHUA UNIV +1

SiC fiber reinforced polyurethane series skid-resistant coating and preparation method thereof

InactiveCN104710926AGood adhesionGood anti-corrosion performanceAnti-corrosive paintsPolyurea/polyurethane coatingsDefoaming AgentsEpoxy

Owner:NAT UNIV OF DEFENSE TECH

Ultra-thin anti-skid wear material based on steel slag aggregate and application of ultra-thin anti-skid wear material

PendingCN113582587AExtended service lifeGood adhesionIn situ pavingsSolid waste managementAggregate (composite)Asphalt pavement

Owner:SOUTHEAST UNIV

Antirust coating layer for heater cooling fin and preparation method thereof

InactiveCN108467634AGood adhesionGood high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsCorrosion inhibitorDefoaming Agents

Owner:浙江飞哲工贸有限公司

Thermoplastic resin adhesive film

InactiveCN102942878AExtended service lifeImprove long-term stabilityFilm/foil adhesivesPrinted circuit detailsVitrificationDielectric loss

The invention relates to a thermoplastic resin adhesive film and application thereof. The adhesive film comprises symmetrical polyphenylene ether molecules, is not sticky and has low dielectric constant and dielectric loss, and a high-frequency multilayer printed circuit board prepared by the adhesive film has high glass transition temperature, excellent heat resistance and flame resistance and an environmental protection function. The adhesive film serves as a thermally conductive and insulating layer of the high-frequency printed circuit board, so that the printed circuit board has the advantages of high thermal conductivity, quick signal transmission, low loss and the like.

Owner:彭代信

Waterproof coil and preparation method thereof

InactiveCN107938953AGood adhesionGood compatibilityBituminous coatingsRoof covering using flexible materialsAsphaltGlass fiber

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

Surface treatment method of car part of inert material

The invention relates to a surface treatment method of a car part of inert material. The surface treatment method comprises the following steps of: firstly, putting a working piece in a closed hollow cavity so that the surface of the working piece to be processed is fully exposed in the hollow cavity; then, pumping air in the hollow cavity; injecting fluorinated gases in the hollow cavity so that the fluorinated volume of the gases in the hollow cavity is 10-20 percent; keeping gas pressure in the hollow cavity as 380-420 mbar so that molecular replacement is carried out between fluorine atoms in the gases and fluorine atoms on the surface of the working piece, and C-F keys are formed on the surface of the working piece; and finally, removing residual fluorinated gases in the hollow cavity and taking out the working piece from the hollow cavity. After the working piece is processed, the surface adhesion is improved, and the surface wettability of the working piece is improved by a coating. Because the C-F keys have high key energy, the working piece has excellent heat stability and chemical inertia and good anti-leakage performance. The invention does not damage the working piece material by even treatment and has high qualified product rate, high production efficiency and low production cost.

Owner:DONGGUAN HIROSAWA AUTOMOTIVE TRIM

Protective coating applied to surface of solar panel bracket and preparation method thereof

InactiveCN109467987AImprove adhesionStrong acid and alkali resistanceEpoxy resin coatingsPolyester coatingsSolventStrong acids

The invention discloses a protective coating applied to the surface of a solar panel bracket. The protective coating applied to the surface of the solar panel bracket is prepared from the following raw materials in parts by weight: 20 to 30 parts of thermosetting fluorocarbon resin, 13 to 18 parts of glycerin alkyd resin, 17 to 26 parts of acrylic resin, 15 to 25 parts of modified epoxy resin, 6 to 13 parts of modified sepiolite, 2 to 4 parts of nano-titania, 1 to 3 parts of petroleum sodium sulphonate, 2 to 5 parts of modified mica powder, 0.3 to 0.8 part of multi-walled carbon nano-tubes, 1to 2 parts of an antioxidant, 2 to 4 parts of a light stabilizer and 30 to 50 parts of a solvent. According to the protective coating applied to the surface of the solar panel bracket provided by theinvention, the prepared coating has good adhesion force, strong acid resistance and alkaline resistance, and excellent anti-aging performance by controlling the types and the proportions of the raw materials.

Owner:安徽兆拓新能源科技有限公司

High-impact-resistance high-flowability ABS resin and preparation method thereof

InactiveCN108329646ASolve the problem of low impact strengthLiquidPolymer scienceBulk polymerization

The invention specifically relates to a preparation method for a high-impact-resistance high-flowability ABS resin, belonging to the technical field of high-molecular materials. The preparation methodcomprises the following steps: preparing ABS resin with high impact strength by using a DOW continuous bulk polymerization process, adding bulk ABS resin, SAN resin, a plasticizer, a lubricant and acompatibilizer in a certain mass ratio into a mixer for thorough mixing so as to obtain a mixed material; and then feeding the obtained mixed material into a twin-screw extruder for mixing, extruding,drawing, cooling and pelletizing so as to obtain the high-impact-resistance high-flowability ABS resin. The ABS resin prepared in the invention has superior impact performance; at the same time, thecompatibilizer is added during blending, so the compatibility between the ABS resin and the SAN resin is improved, the adhesion between the two polymers is increased, and a more stable structure is formed.

Owner:NORTH HUAJIN CHEM IND CO LTD

Polyurethane structural adhesive used for bonding automobile spoiler and preparation method and application of polyurethane structural adhesive

ActiveCN108276947AImprove toughnessGood adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyolAdhesive

The invention discloses a polyurethane structural adhesive used for bonding an automobile spoiler and a preparation method and application of the polyurethane structural adhesive used for bonding theautomobile spoiler. The polyurethane structural adhesive comprises raw materials of a first component and a second component in a feed mass ratio of 1: (0.75 to 1.5), wherein the second component comprises polyisocyanate; the first component comprises polyether polyol having the number average molecular weight from 2000 to 4000 and being more than difunctionality, polyether polyol having the number average molecular weight from 300 to 500 and being more than tri-functionality, polyether polyol having the number average molecular weight from 90 to 400 and castor oil in a feed mass ratio of (7 to 33): (0.6 to 5): 1 to (2 to 13); the preparation of the polyurethane structural adhesive used for bonding the automobile spoiler comprises the following steps: respectively mixing various componentsin the first component and the second component through a physical mixing method and then blending to obtain the polyurethane structural adhesive; the application of the polyurethane structural adhesive used for bonding the automobile spoiler is that the first component and the second component of the polyurethane structural adhesive are separately sprayed on the bonding part of the spoiler on anautomobile, and the automobile spoiler is bonded to realize bonding; and by adopting the polyurethane structural adhesive used for bonding the automobile spoiler, all performances in various aspectsat room temperature and high and low temperature are excellent.

Owner:CHINA BUILDING MATERIAL TEST & CERTIFICATION GRP SUZHOU

Self-disinfection intelligent pet excrement collector system

The invention relates to a self-disinfection intelligent pet excrement collector system, which comprises a box, a control processor, an isolation mesh layer and a disinfection module. One side of thebox is provided with an access port covered by an electric door, and the electric door is connected with the control processor. The isolation mesh layer is made of hard meshes and horizontally arranged in the box and comprises a pressure sensor connected with the control processor. The pressure sensor detects pressure applied to the isolation mesh layer, converts the pressure into pressure valuesand outputs the pressure values to the control processor, and the pressure sensor continuously detects and outputs the pressure values to the control processor. The disinfection module comprises an ultraviolet disinfection unit which is connected with the control processor.

Owner:SUZHOU LINGHUI ELECTRONIC TECH CO LTD

Glaze with low surface attaching force after drying for chinaware

Owner:ANHUI QINGHUAFANG FINE BONE PORCELAIN

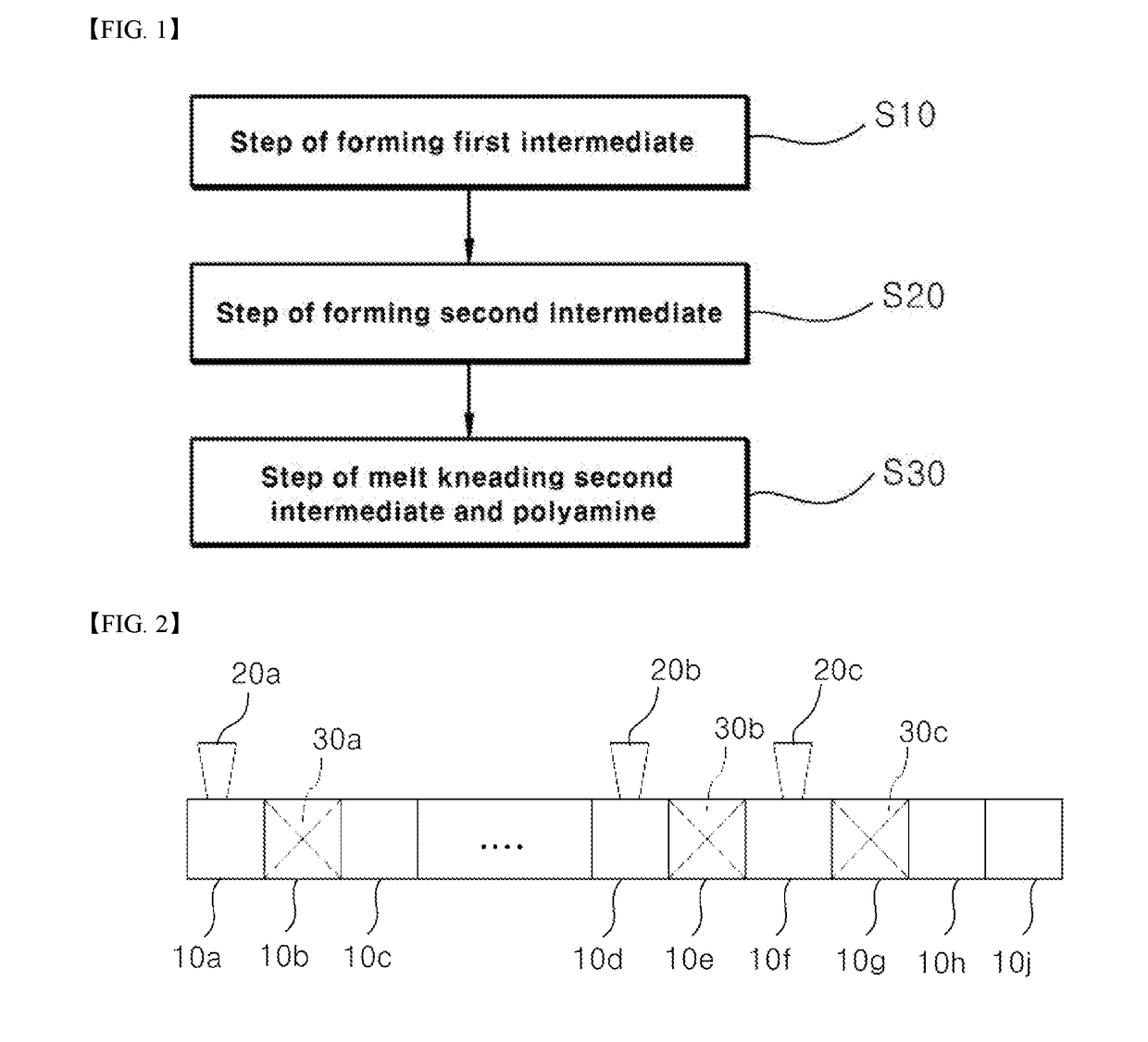

Polyamide/Polyphenylene Ether Resin Composition, and Vehicle Molded Product Prepared Therefrom

Owner:LOTTE ADVANCED MATERIALS CO LTD

Simulated aircraft self-adhered skin emergency door and preparation method thereof

The invention discloses a simulated aircraft self-adhered skin emergency door which is prepared from the following raw materials in percentage by weight: 50-66% of polyether, 0.30-0.40% of A-33, 0.02-0.06% of A-1, 0.4-0.8% of silicone oil, 4-8% of a foaming agent, 4-8% of ethylene glycol and 20-40% of modified MDI, totaling 100%. The framework and self-adhered skin of the simulated aircraft self-adhered skin emergency door disclosed by the invention are processed at a time, and the two are firmly adhered. The self-adhered skin belongs to one kind of polyurethane, has excellent wear resistanceand rebound resilience, avoids the problems of crack, deformation and the like during repeated use, and is high in corrosion resistance and oxidation resistance, long in service life, light in weightand low in production cost.

Owner:杨凌平安汽车座椅有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap