Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Alkyd" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An alkyd is a polyester modified by the addition of fatty acids and other components. They are derived from polyols and a dicarboxylic acid or carboxylic acid anhydride. The term alkyd is a modification of the original name "alcid", reflecting the fact that they are derived from alcohol and organic acids. The inclusion of the fatty acid confers a tendency to form flexible coating. Alkyds are used in paints and in moulds for casting. They are the dominant resin or "binder" in most commercial "oil-based" coatings. Approximately 200,000 tons of alkyd resins are produced each year. The original alkyds were compounds of glycerol and phthalic acid sold under the name Glyptal. These were sold as substitutes for the darker-colored Copal resins, thus creating alkyd varnishes which were much paler in colour. From these, the alkyds we know today were developed.

Good-weather and water resistance water-based alkyd resin

Owner:深圳海德新材料科技有限公司

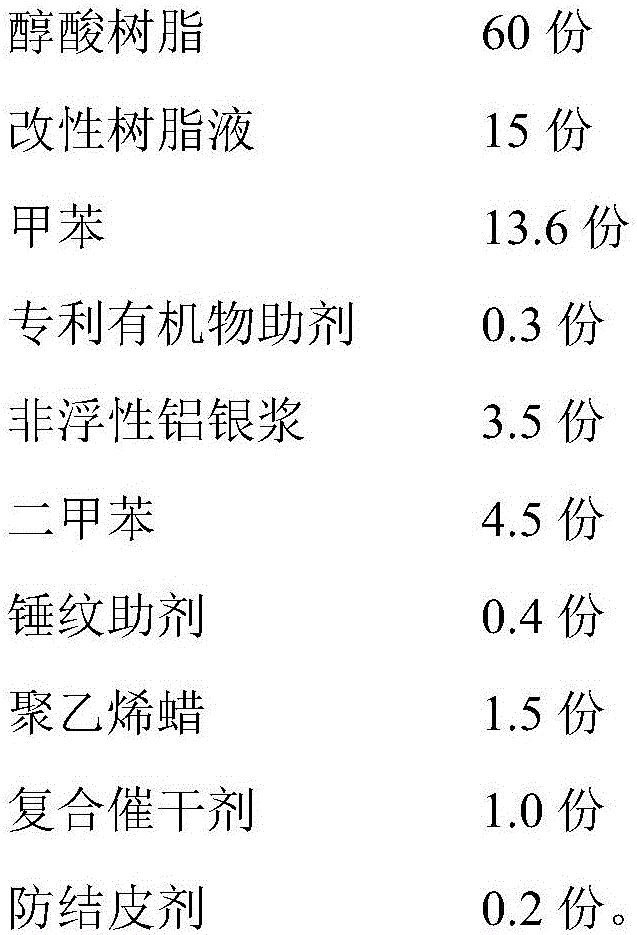

Water-based alkyd-acrylate dispersion as well as preparation method and application thereof

ActiveCN111138603AImprove compactnessImprove the level ofAnti-corrosive paintsPolymer sciencePtru catalyst

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Environment-friendly plastic material and preparation method thereof

The invention discloses an environment-friendly plastic material and a preparation method thereof. The preparation method comprises the following steps that 1, ball milling is performed on calcium sulfate and magnesium oxide through a ball mill, the ball milling time is 3-5 h, and the ratio of grinding media to the materials is 20:1-30:1; 2, 12-20 parts of polyamide-1010, 5-10 parts of polycarbonate, 4-9 parts of alkyd resin, 4-8 parts of polyvinyl alcohol, 3-8 parts of calcium sulfate, 4-10 parts of magnesium oxide, 2-6 parts of polytrimethylene terephthalate, 3-8 parts of tetrafluoroethylene-hexafluoropropylene copolymer, 2-6 parts of polybutyl methacrylate and 4-10 parts of polyparahydroxybenzoic acid are weighed by weight, all the components are extruded inside a double-screw extruder, and the extruded components are the environment-friendly plastic material. The obtained plastic material effectively overcomes the defects that the tensile strength and the elongation at break of the conventional plastic material are low, and the mechanical performance of the plastic material is improved.

Owner:SUZHOU SHURUI ENVIRONMENTAL PROTECTION TECH CO LTD

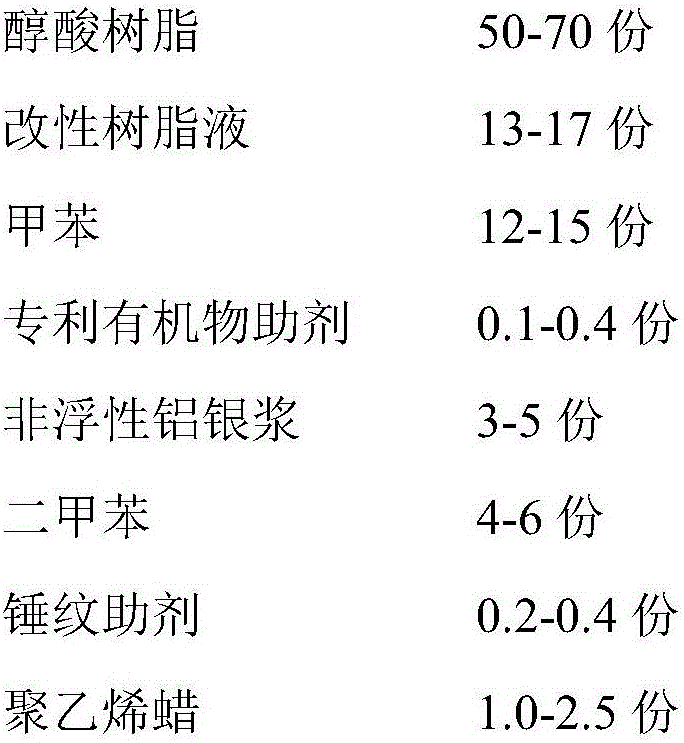

One-step forming solvent type single-component quick drying hammer finish and preparation method

InactiveCN105925156AClear patternStrong sense of hammeringPolyester coatingsAgricultural engineeringSolvent

Owner:WUXI HUHUANG PAINT

Fireproof preparation method of alkyd resin varnish

InactiveCN113600121AInject moreImprove the mixing effectChemical/physical/physico-chemical moving reactorsPolymer sciencePolymer chemistry

The invention relates to the field of fireproof preparation of alkyd resin varnish, and discloses a fireproof preparation method of alkyd resin varnish, the fireproof preparation method of alkyd resin varnish uses fireproof preparation method equipment of alkyd resin varnish, the fireproof preparation equipment of alkyd resin varnish comprises a rolling base, a bearing rolling cavity is formed in the rolling base, bearing balls are arranged in the bearing rolling cavity in a rolling mode, a rolling cavity is formed in the rolling base in a rolling mode, the rolling cavity rolls on the bearing balls, and a discharging port is formed in one side of the rolling base and communicated with the rolling cavity. And the problem that fire hazards are easily generated due to overheating and the like caused by the problems of feeding and the like in the preparation process of the alkyd resin varnish is avoided.

Owner:GUIZHOU HONGLIN MASCH TECH CO LTD

Motorcycle pedal and processing technology thereof

ActiveCN112175492AGood compatibilityImprove wear resistanceSpecial surfacesFoot-restsOxide ceramicMonoglyceride

The invention relates to the field of motorcycle accessories, and discloses a motorcycle pedal and a processing technology thereof. According to the motorcycle pedal, the surface of the pedal is treated by a surface treating agent, and the surface treating agent comprises the following raw materials in parts by weight: 50-60 parts of alkyd resin, 10-15 parts of amino resin, 5-8 parts of nano magnesium oxide, 3-4 parts of alumina ceramic, 5-6 parts of a monoglyceride maleate acidified product, 1-2 parts of dimethylolpropionic acid, and 1-2 parts of a cross-linking agent. The processing technology comprises the steps of phosphating treatment, surface treating agent preparation and pedal spray processing. The invention has the following advantages and effects: the mixed product of alkyd resinand amino resin and the addition of alumina ceramic and nano magnesium oxide enhance the wear resistance, the aluminum oxide ceramic and the monoglyceride maleate are mixed, so that the compatibilityamong the components is improved, the bonding strength of the surface treating agent and the pedal plate is improved, and the crosslinking compounding of the monoglyceride maleate acidified substanceand dimethylolpropionic acid can enhance the crosslinking density and enhance the wear resistance of the pedal.

Owner:WENZHOU OUHAI QUXI MOTORCYCLE FITTINGS FACTORY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap