Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

323 results about "Polymer chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer chemistry is a sub-discipline of chemistry that focuses on the chemical synthesis, structure, chemical and physical properties of polymers and macromolecules. The principles and methods used within polymer chemistry are also applicable through a wide range of other chemistry sub-disciplines like organic chemistry, analytical chemistry, and physical chemistry Many materials have polymeric structures, from fully inorganic metals and ceramics to DNA and other biological molecules, however, polymer chemistry is typically referred to in the context of synthetic, organic compositions. Synthetic polymers are ubiquitous in commercial materials and products in everyday use, commonly referred to as plastics, and rubbers, and are major components of composite materials. Polymer chemistry can also be included in the broader fields of polymer science or even nanotechnology, both of which can be described as encompassing polymer physics and polymer engineering.

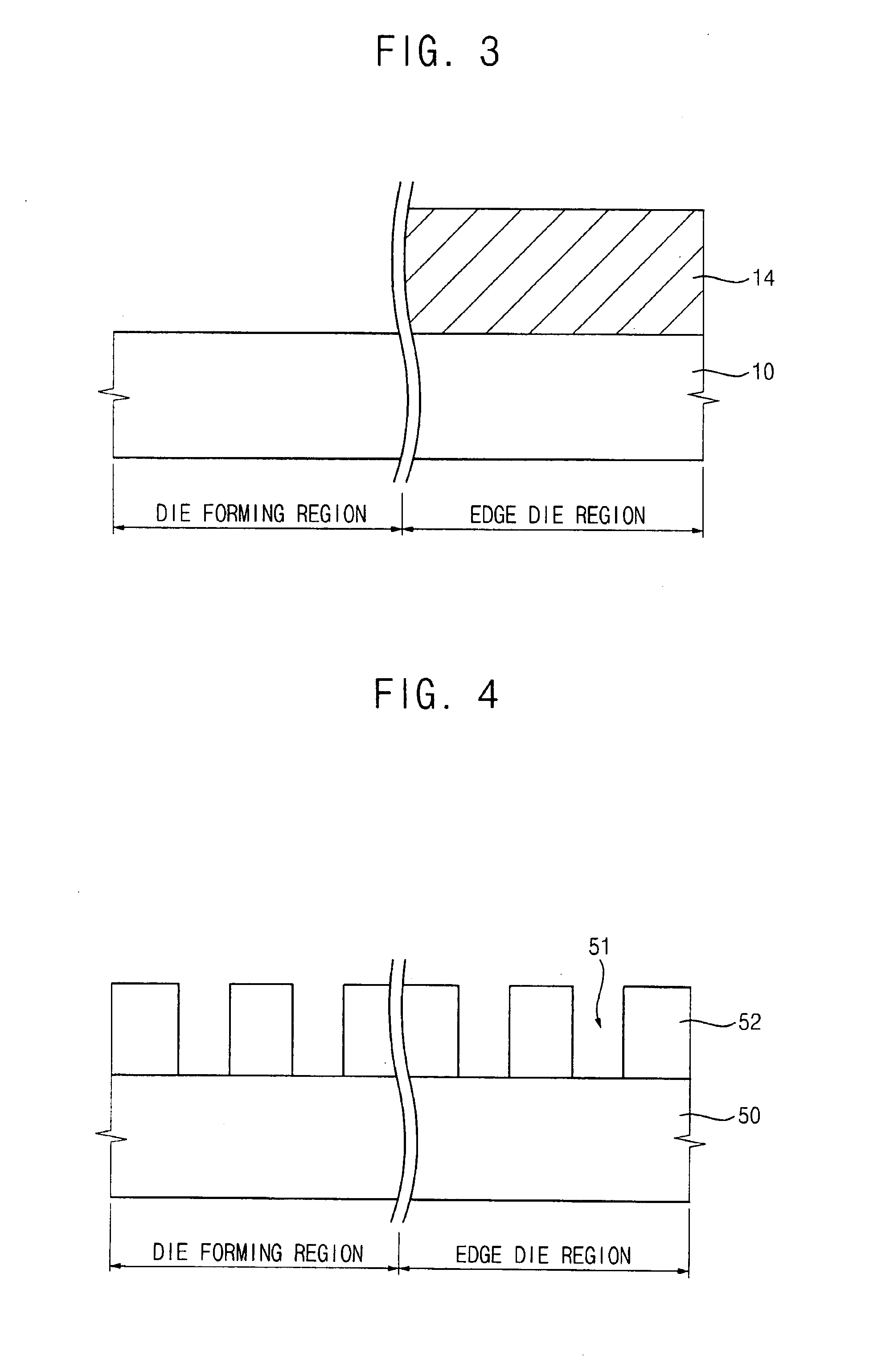

Method for depositing silicon-free carbon-containing film as gap-fill layer by pulse plasma-assisted deposition

ActiveUS20200013612A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingPolymer scienceWafering

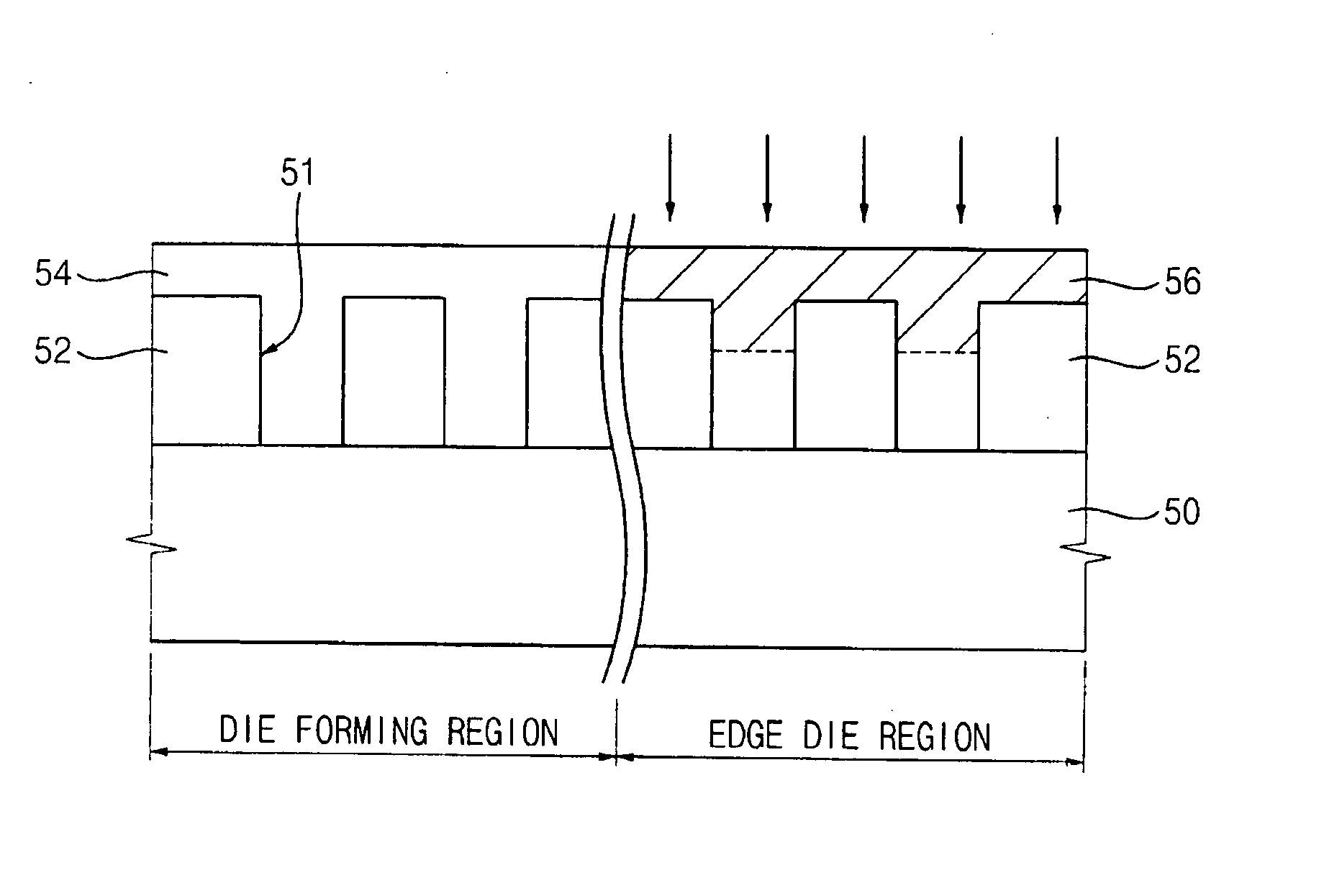

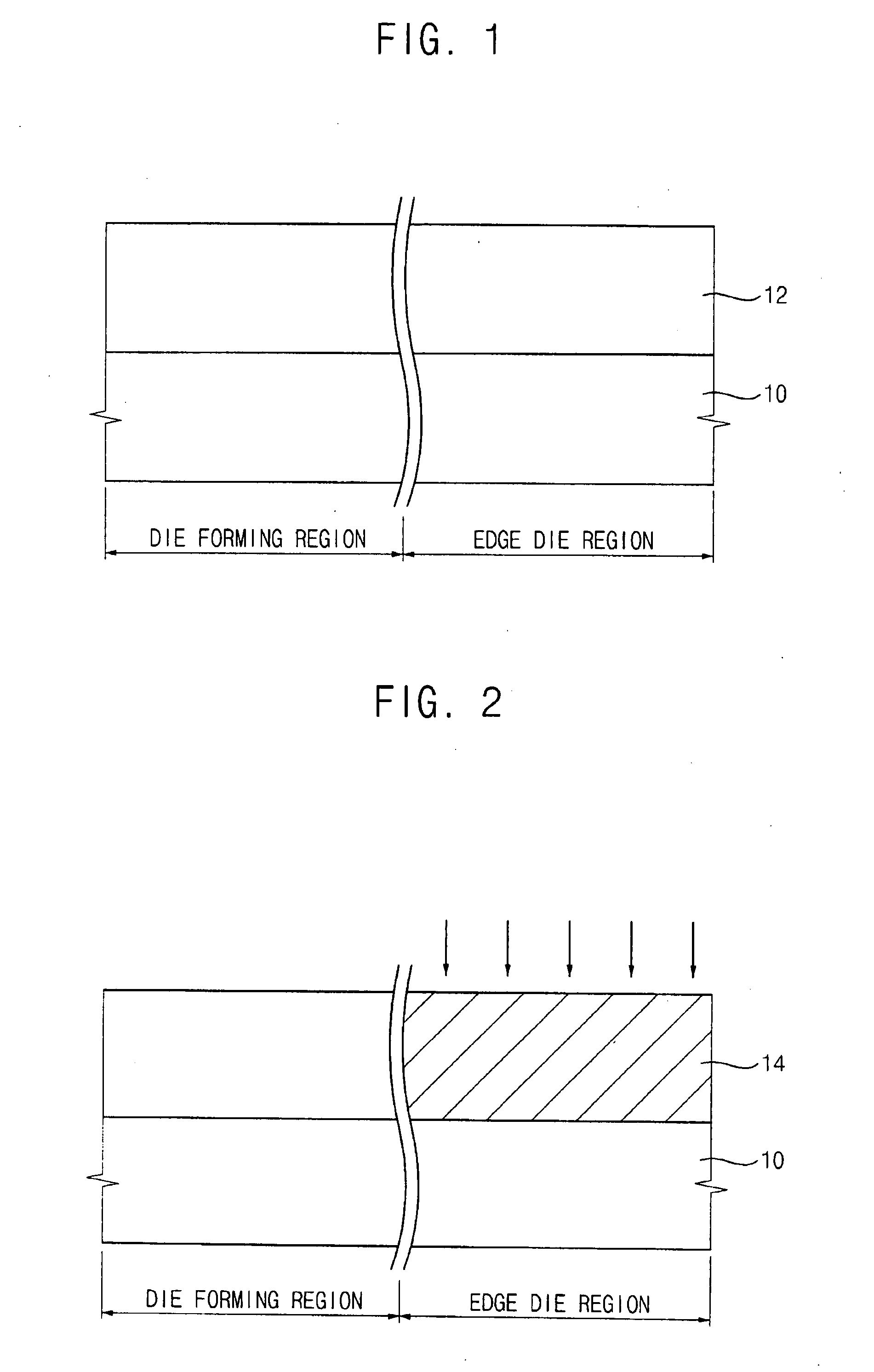

A film having filling capability is deposited by forming a viscous polymer in a gas phase by striking an Ar, He, or N2 plasma in a chamber filled with a volatile hydrocarbon precursor that can be polymerized within certain parameter ranges which define mainly partial pressure of precursor during a plasma strike, and wafer temperature.

Owner:ASM IP HLDG BV

Ink jet ink containing polyurethane dispersant

InactiveUS6136890AResistance to agglomerationResistance to flocculationDuplicating/marking methodsInksPolymer chemistryPigment

Owner:3M INNOVATIVE PROPERTIES CO

Medical devices having biodegradable polymeric regions

Owner:BOSTON SCI SCIMED INC

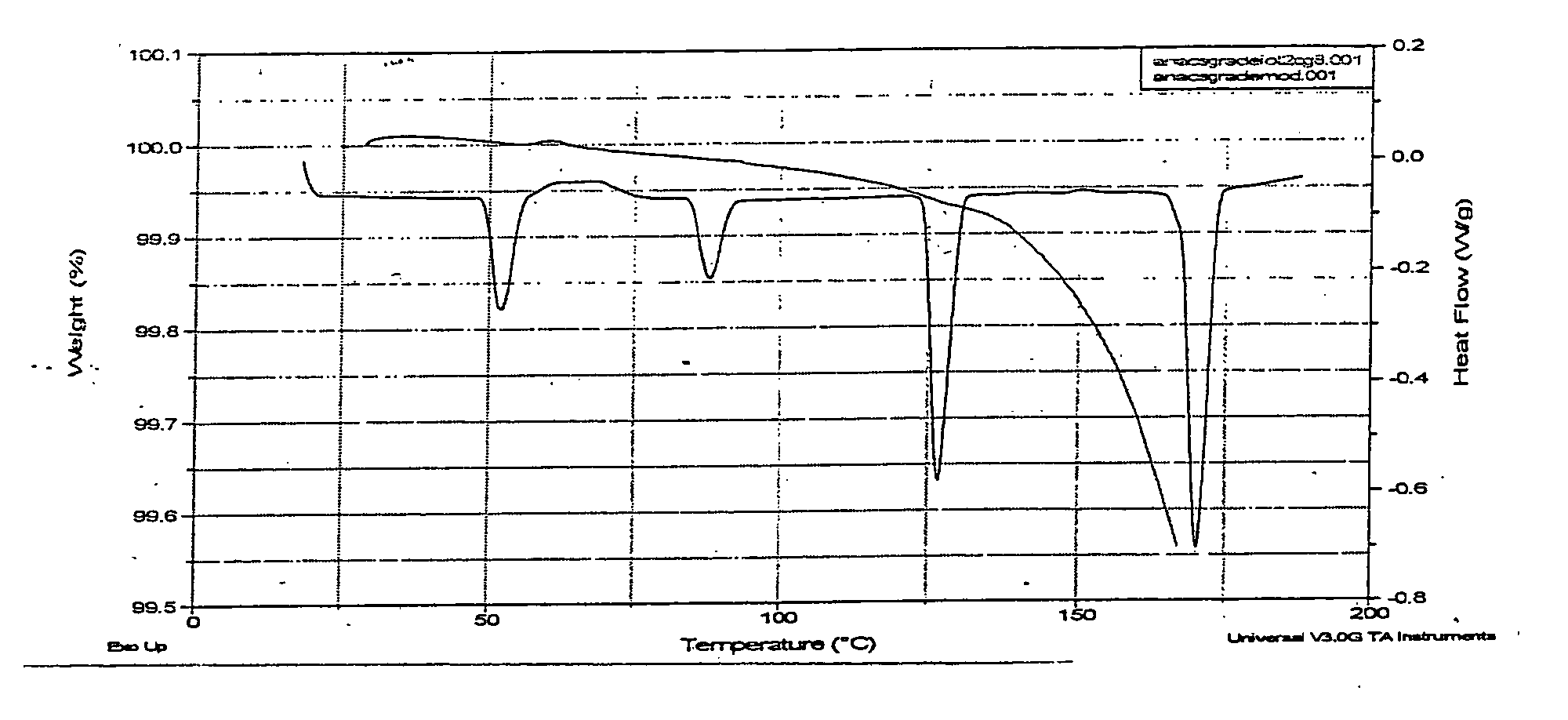

Roofing Products Containing Phase Change Materials

InactiveUS20080008858A1Improve the immunityAttractive appearanceRoof covering using tiles/slatesHeat storage plantsDegree CelsiusPhase change

Owner:CERTAINTEED CORP

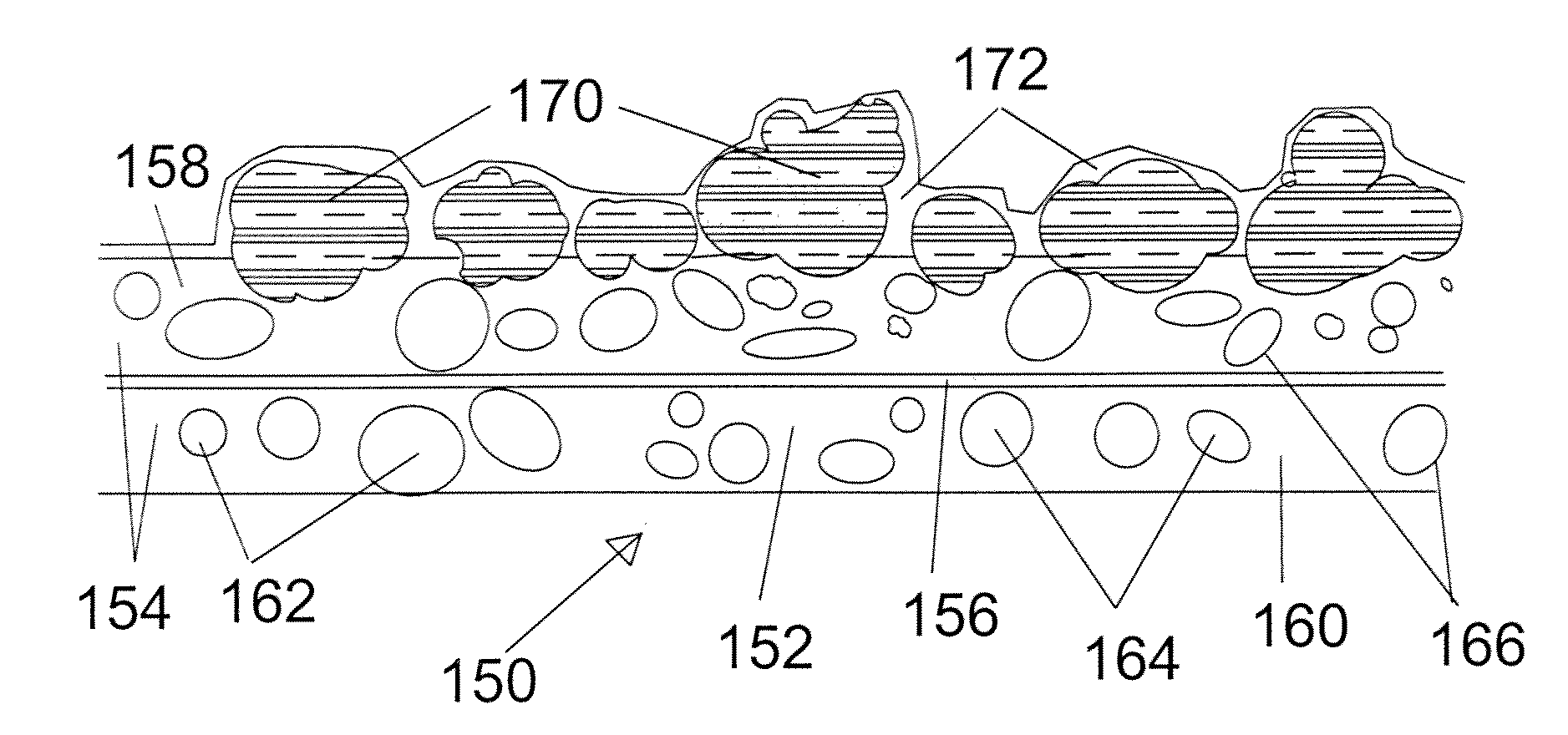

Comfortable and dry absorbent article

Acquisition members having 20 to 40 weight percent of a latex binder and 60 to 80 weight percent of polyester fibers are useful in absorbent articles such as diapers and sanitary napkins. The polyester fibers may further include 20 to 80 weight percent of a first type of fiber, and 20 to 80 weight percent of a second type of fiber, wherein the second type of fiber has spiral-crimped fibers.

Owner:PROCTER & GAMBLE CO

Polymer resin composition, related method for forming a pattern, and related method for fabricating a capacitor

InactiveUS20070249117A1Reduce in quantityReduce processing timeSolid-state devicesSemiconductor/solid-state device manufacturingCross-link(Hydroxyethyl)methacrylate

Owner:SAMSUNG ELECTRONICS CO LTD

Electrically controlled solid propellant

Owner:DIGITAL SOLID STATE PROPULSION

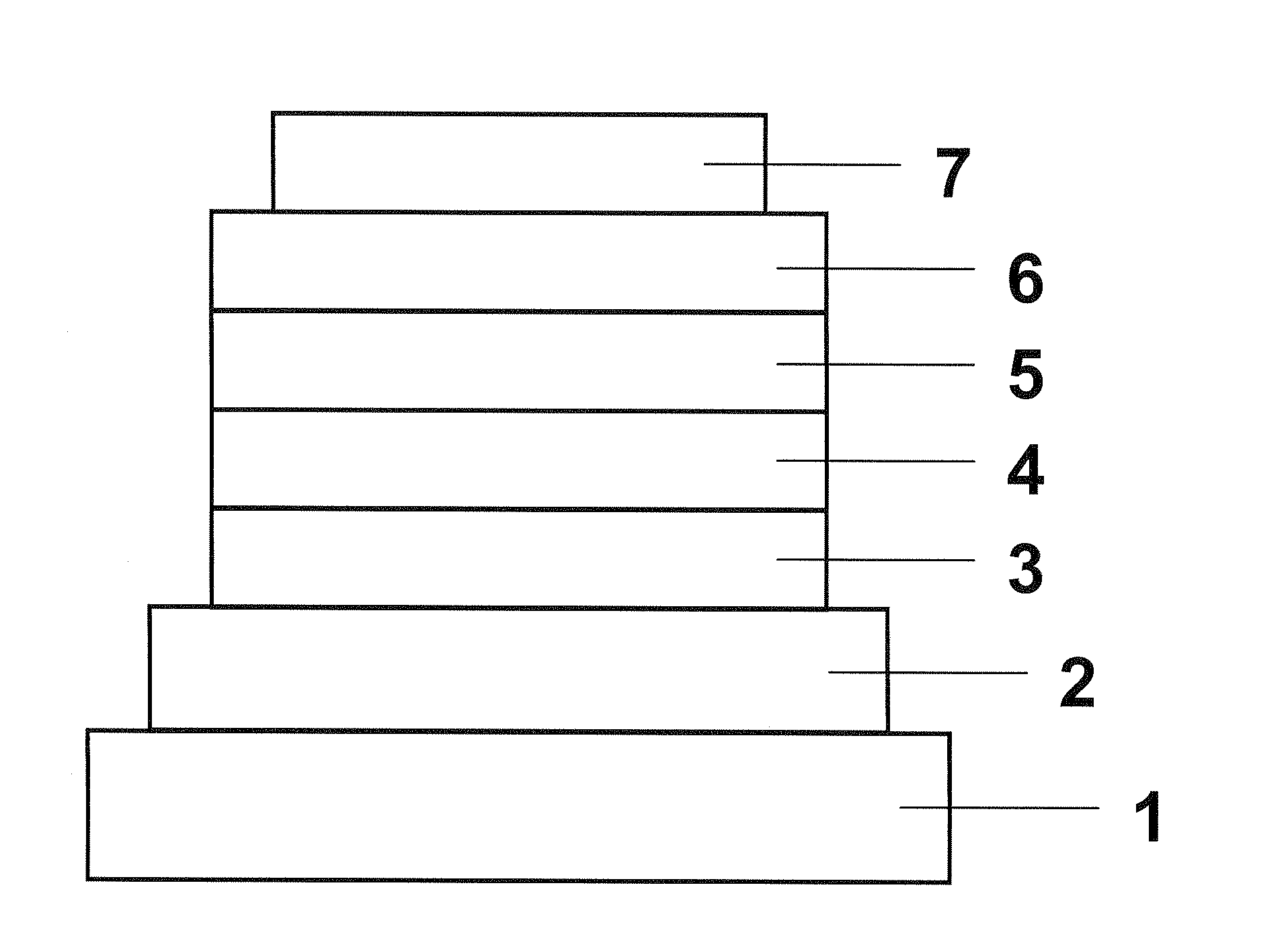

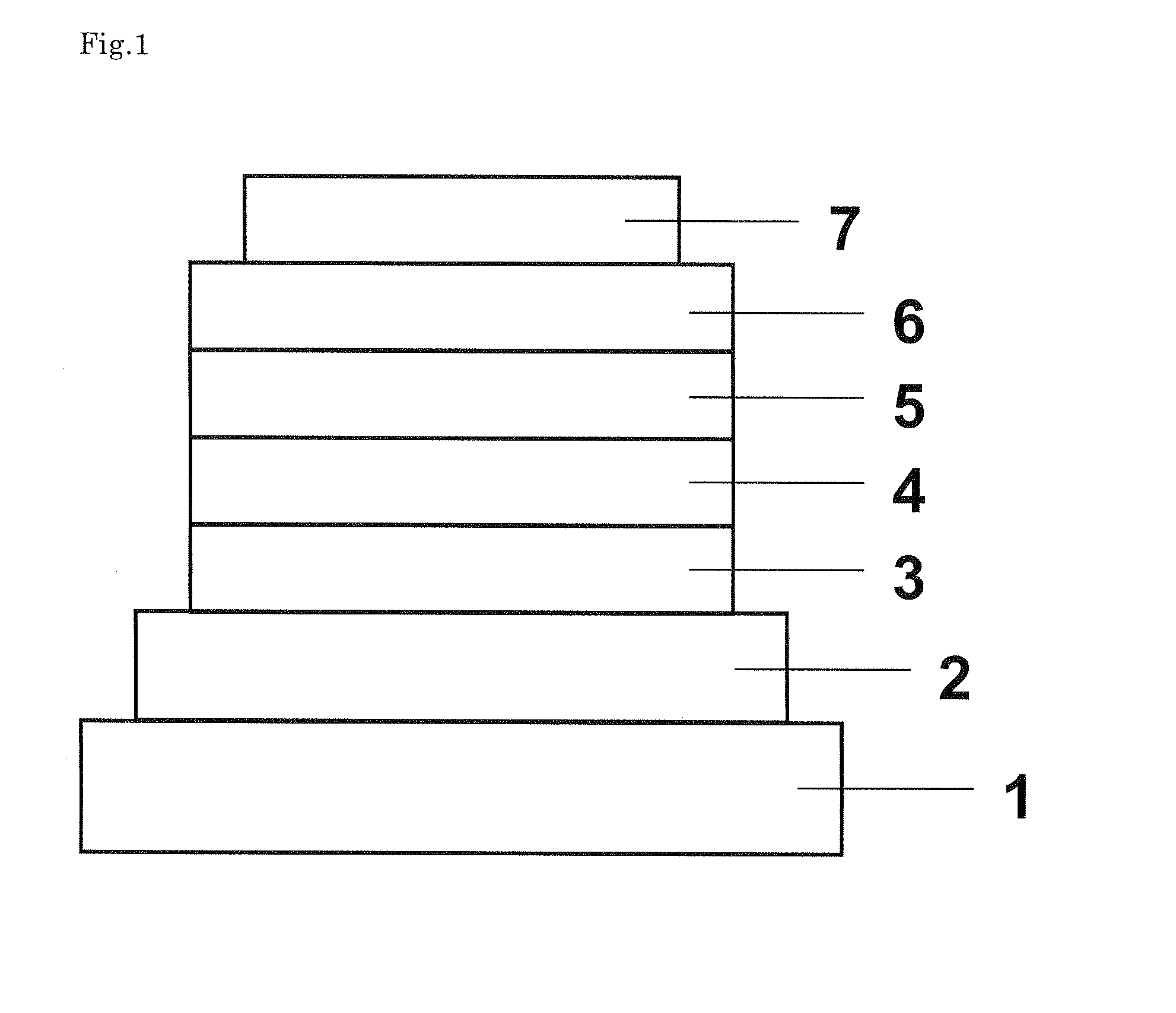

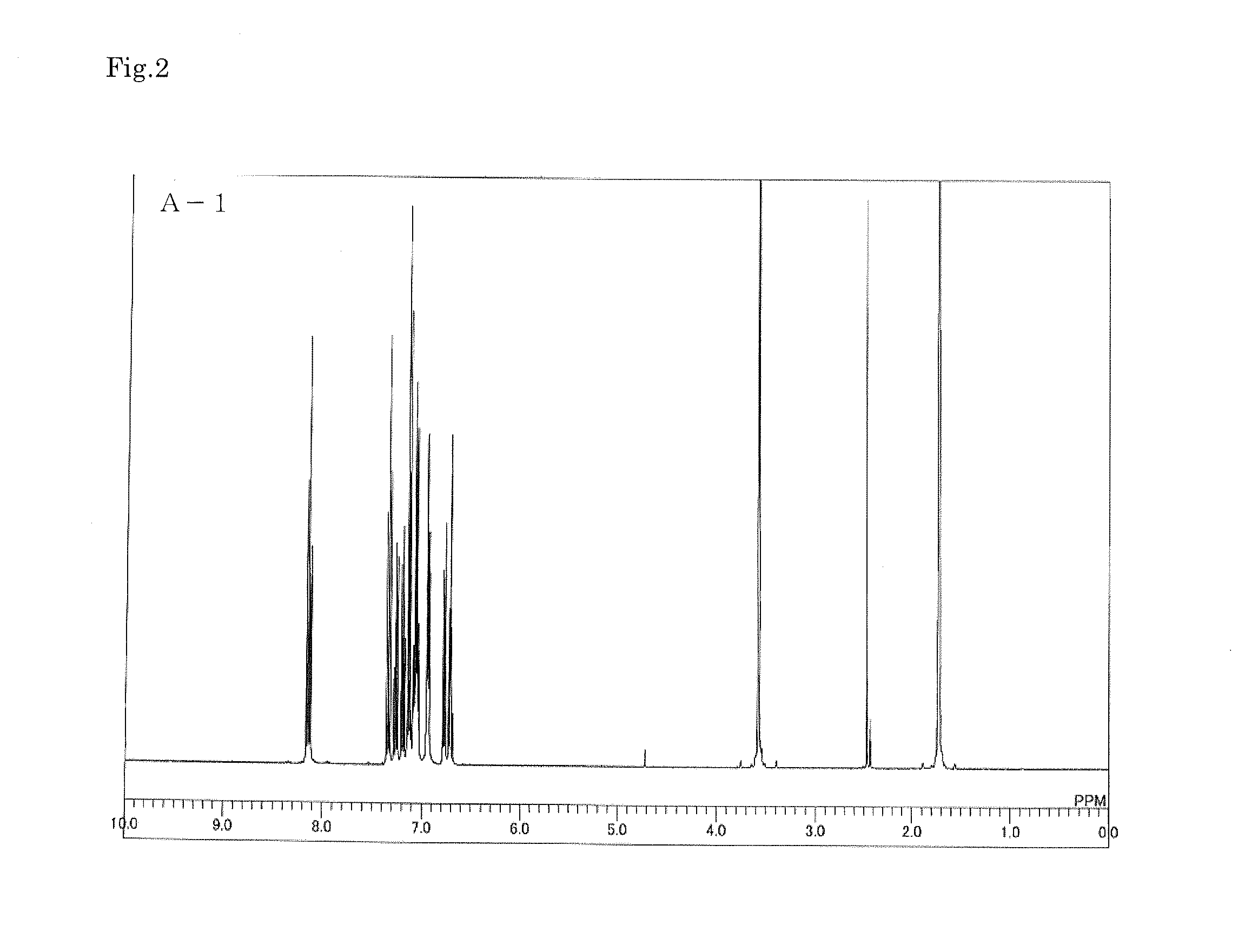

Organic electroluminescent device

ActiveUS20120319095A1Improve stabilityImprove featuresOrganic chemistrySolid-state devicesArylDopant

Owner:NIPPON STEEL CHEMICAL CO LTD

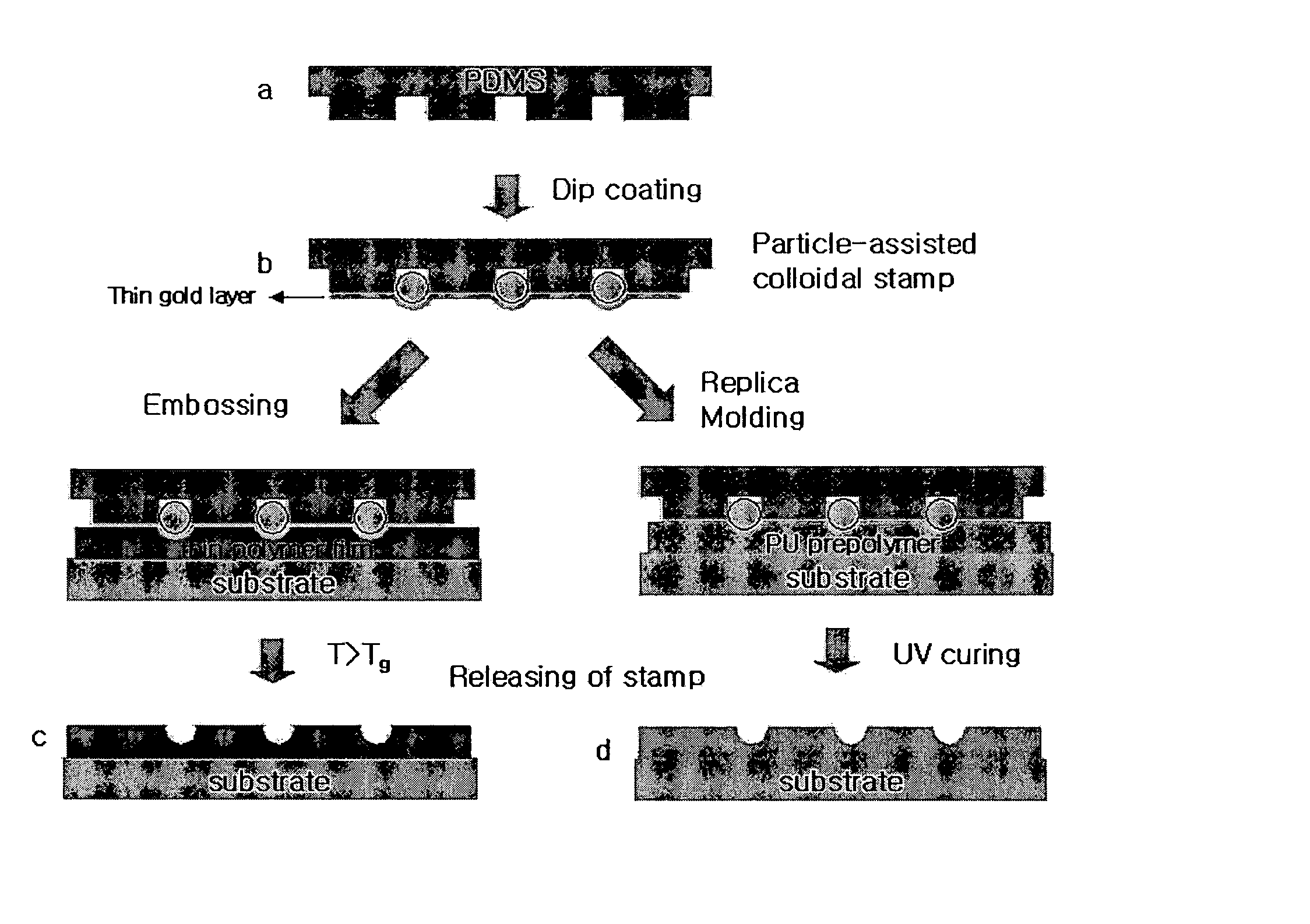

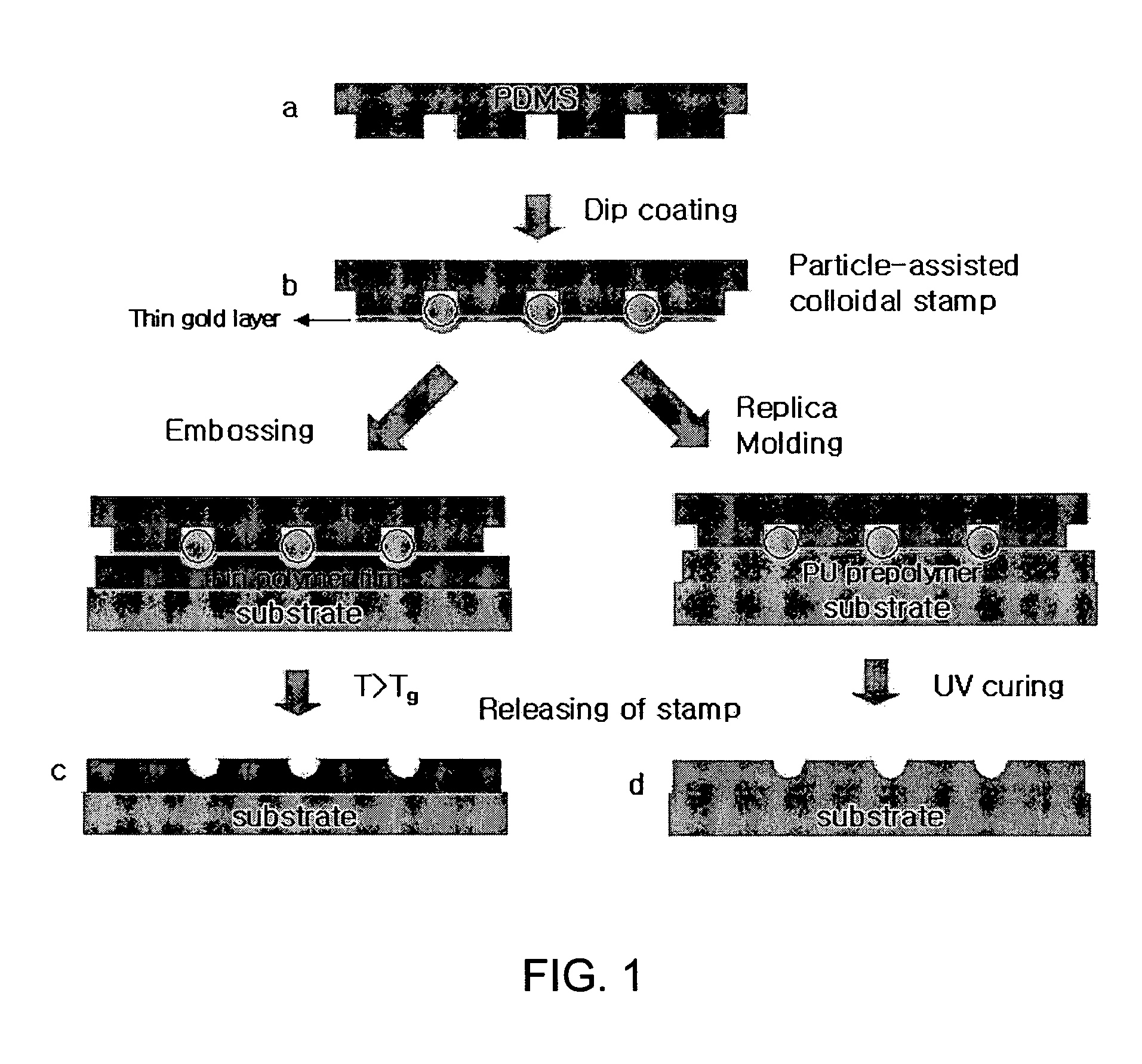

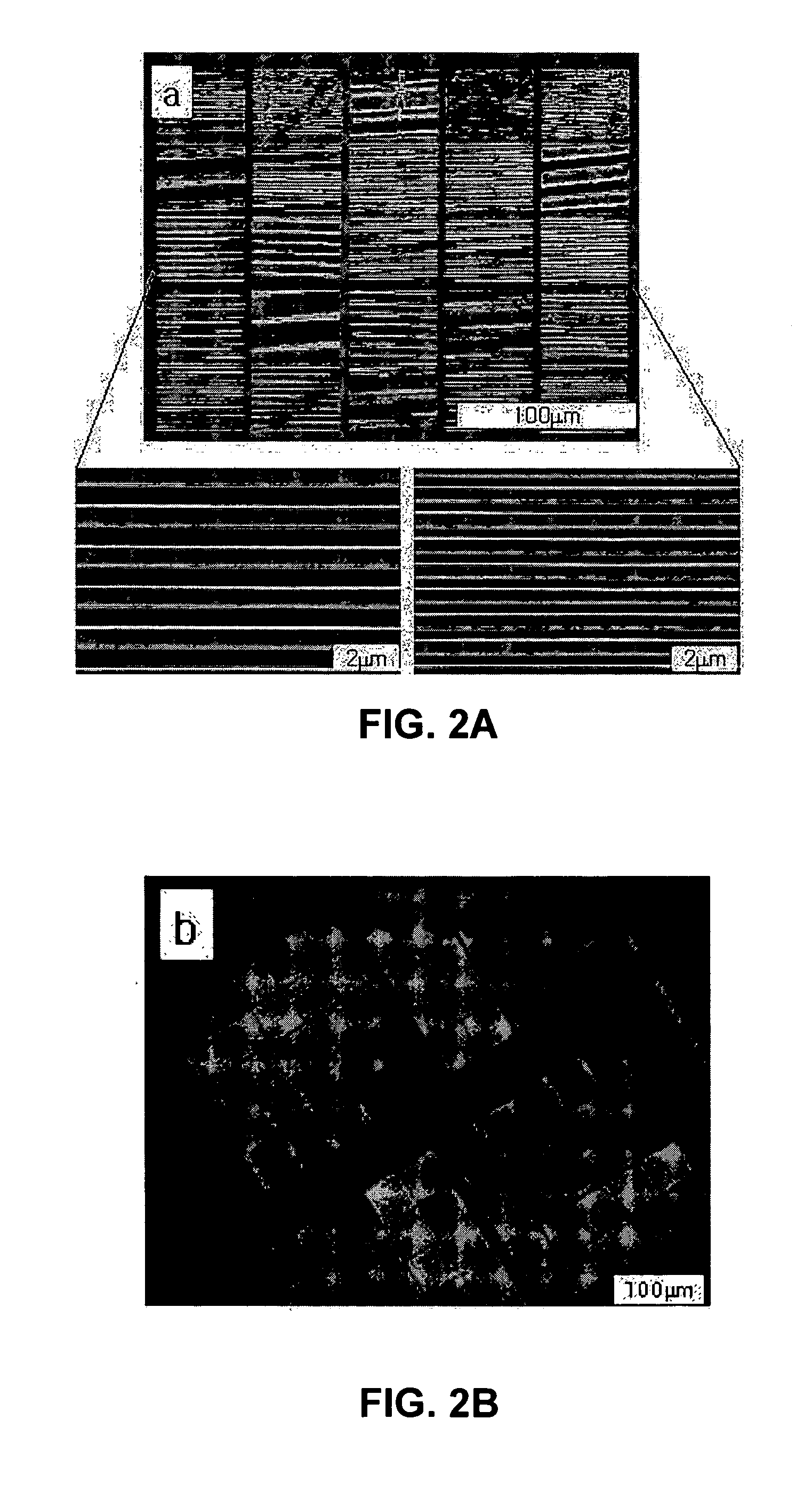

Method of fabricating patterned polymer film with nanometer scale

Owner:KOREA ADVANCED INST OF SCI & TECH

Superhigh melt index polypropene and preparing process thereof

Owner:DONGHUA UNIV

Ink set for ink-jet recording, ink-jet recording method and ink-jet recording apparatus

InactiveUS20050012796A1Measurement apparatus componentsDuplicating/marking methodsWater solubleSolvent

Owner:FUJIFILM BUSINESS INNOVATION CORP

Conjugated diene polymer, method for producing conjugated diene polymer, and conjugated diene polymer composition

Owner:SUMITOMO CHEM CO LTD

Active Energy Ray-Curable Organopolysiloxane Resin Composition, Optical Transmission Component, And Manufacturing Method Thereof

ActiveUS20080032061A1Good adhesionHigh optical transmittanceCladded optical fibreFibre mechanical structuresChemistrySilorane Resins

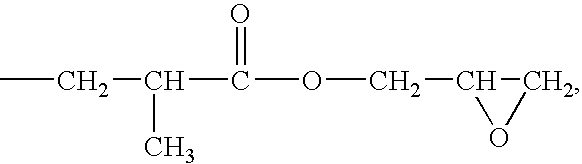

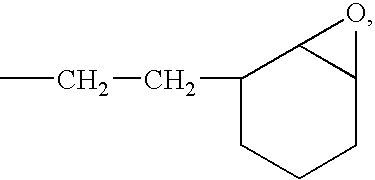

An active energy ray (e.g. UV rays)-curable organopolysiloxane resin composition comprises (A) 100 parts by weight of an organopolysiloxane resin containing epoxy groups and aromatic hydrocarbon groups, (B) 0.05 to 20 parts by weight of a photo acid generator, (C) 0.01 to 20 parts by weight of a photosensitizer or photo-radical generator, and (D) 0 to 5,000 parts by weight of an organic solvent. An optical transmission component made of the above-mentioned composition cured by irradiation with active energy rays (for example, UV rays). A method for manufacturing an optical transmission component by irradiating the above-mentioned composition with active energy rays (for example, UV rays).

Owner:DOW TORAY CO LTD +1

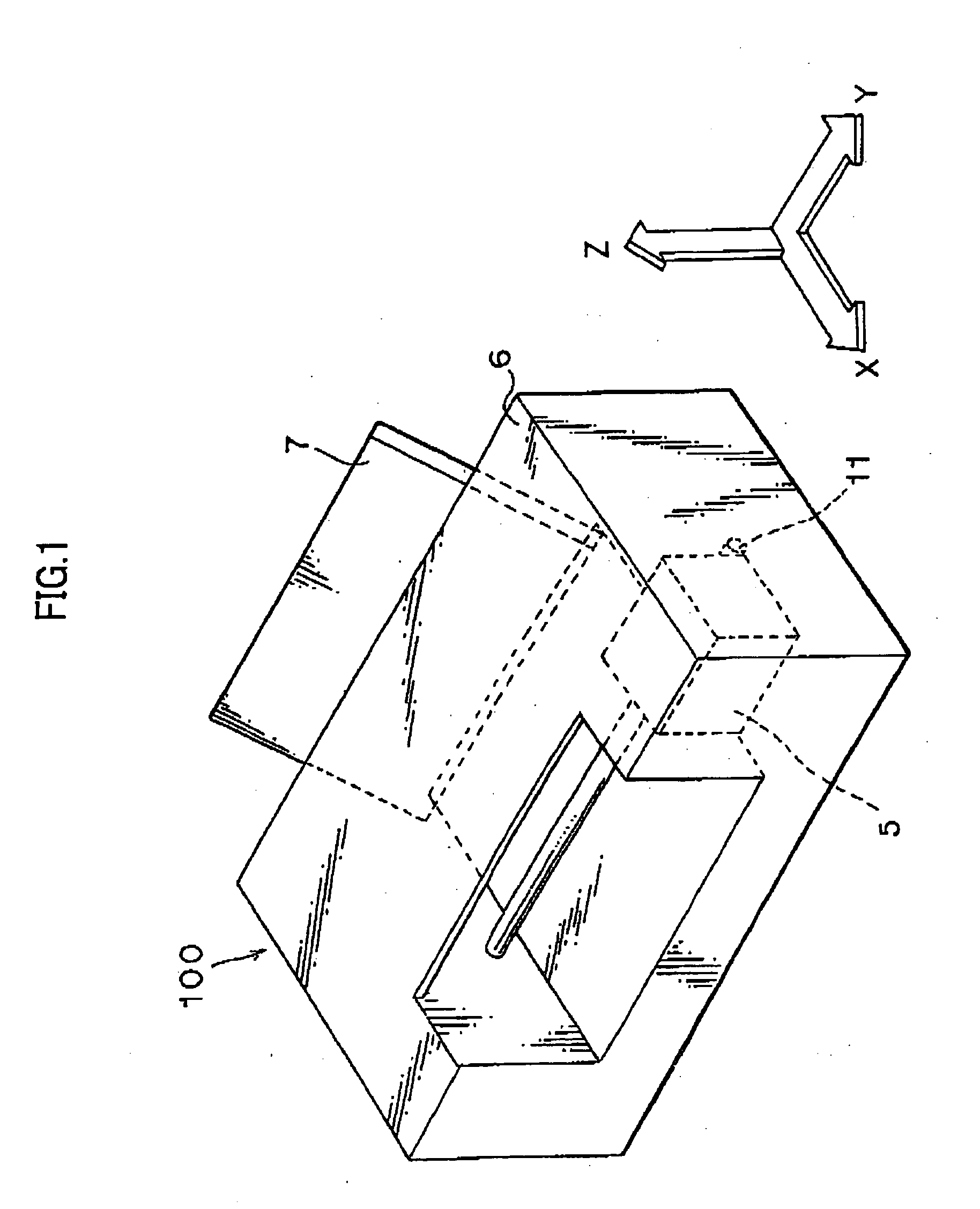

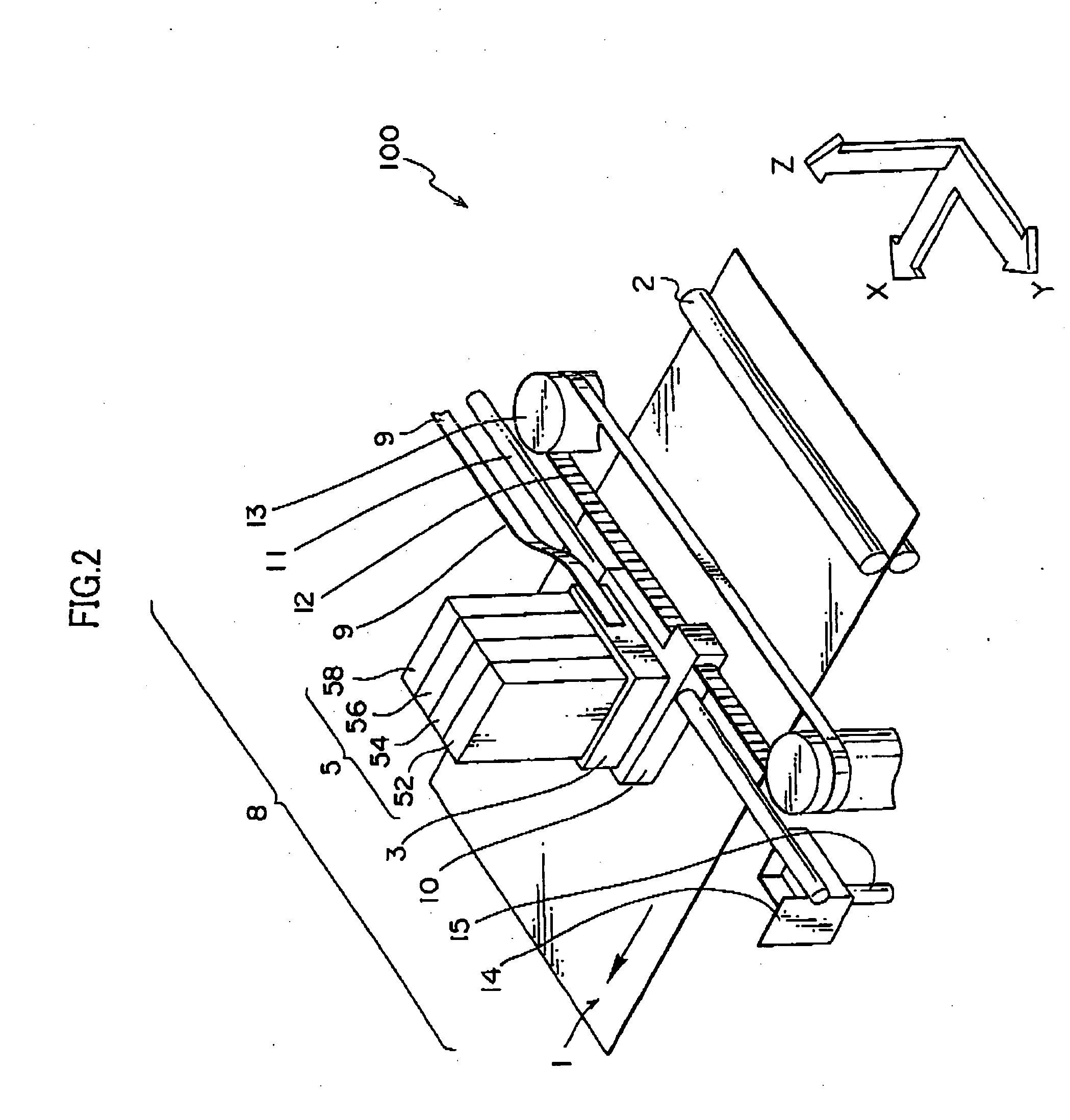

Microrelief structural body, decorative sheet, decorative resin molded body, method for producing microrelief structural body, and method for producing decorative resin molded body

ActiveUS20160052227A1Increase flexibilityGood stretchabilitySynthetic resin layered productsRecord information storagePolymer sciencePolymer chemistry

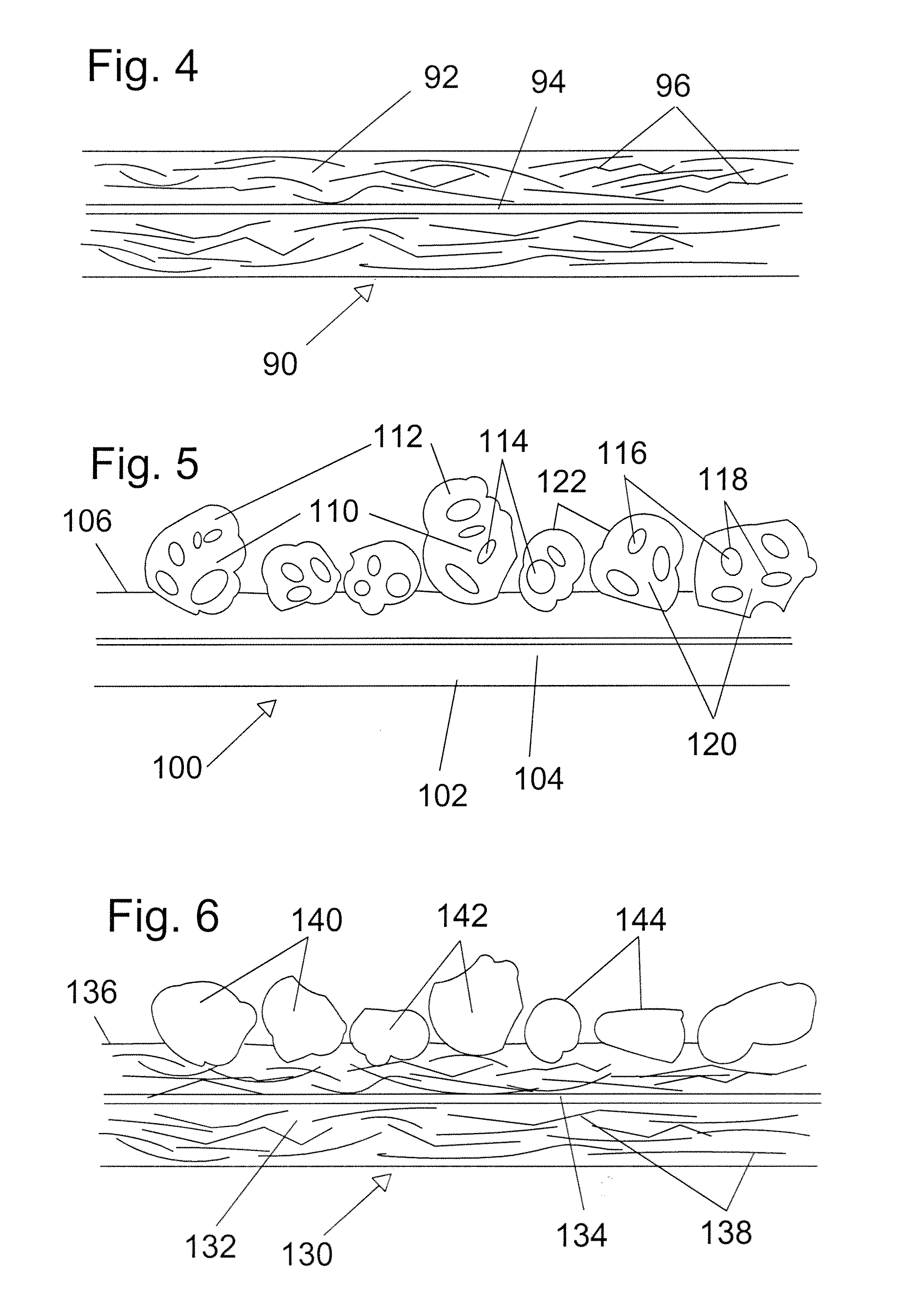

A structural body which comprises a base and a microrelief structure layer having a microrelief structure. The microrelief structure layer is laminated on the base so as to form the surface layer of this structural body, and the microrelief structure layer has at least one physical property selected from the group consisting of (A) and (B) described below. (A) The elastic modulus at 25° C. is 50 MPa or more, and the elastic modulus at 80° C. is 30 MPa or less. (B) The tensile elongation at break at 80° C. is from 20% to 100% (inclusive).

Owner:MITSUBISHI CHEM CORP

Artificial marble, cured resin containing mica flake and/or glass flakes, and polymerizable composition containing mica flakes and/or glass flakes

Owner:MITSUBISHI CHEM CORP

Water-Based Ink Set For Ink-Jet Recording

ActiveUS20070186812A1Improves not recovery performanceImprove the problemDuplicating/marking methodsInksWater basedMagenta

Owner:BROTHER KOGYO KK

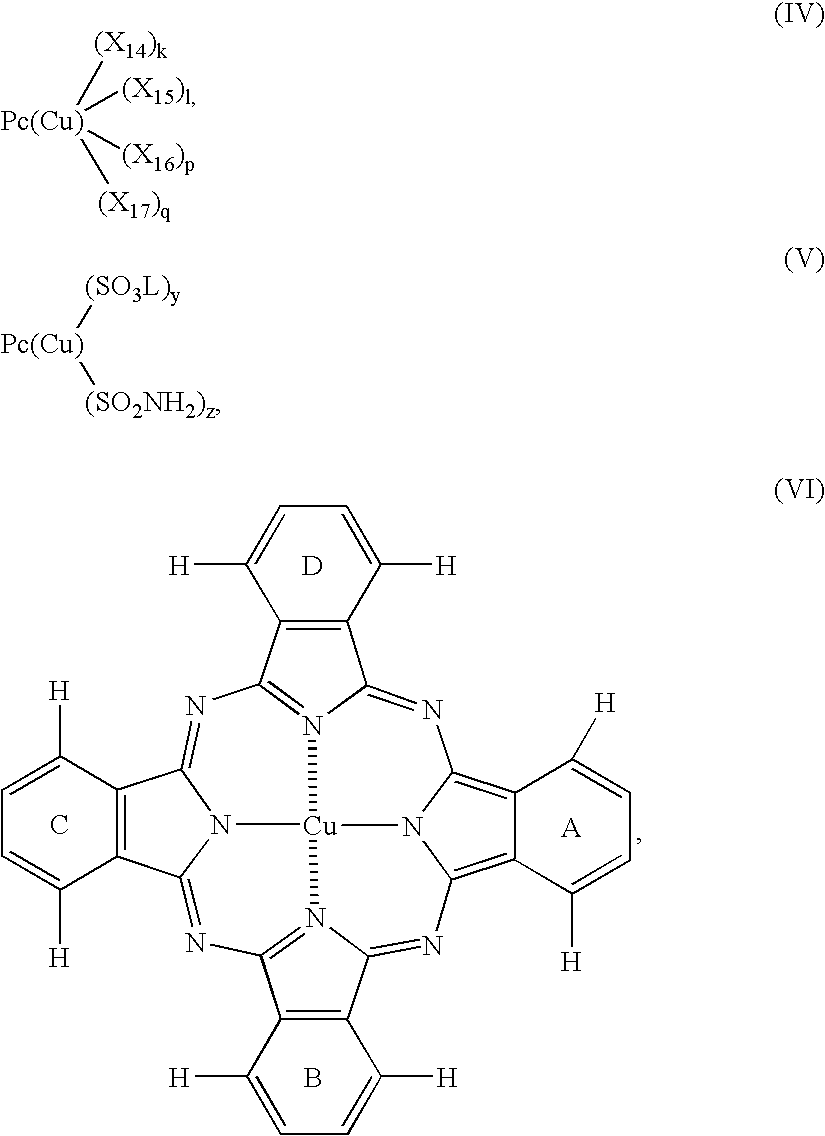

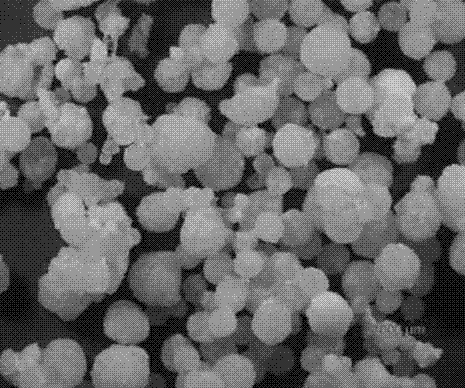

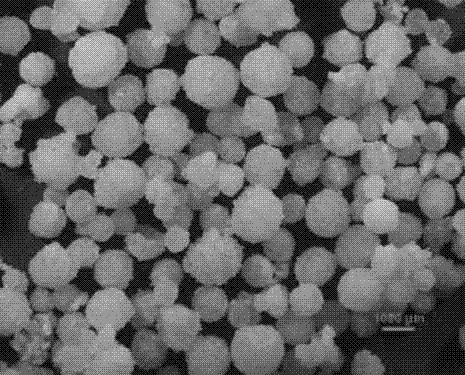

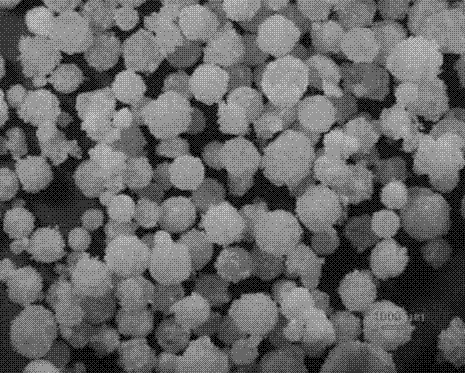

Spherical polybutylene-1 with high isotacticity and preparation method thereof

ActiveCN103288993AThe polymerization method is simpleSolve the difficulty of simultaneously controlling the isotacticity of polybuteneButenePolymer science

Owner:QINGDAO UNIV OF SCI & TECH

Method for raising fluidity of thermoplastic cross-linked rubber

Owner:SHANDONG DAWN POLYMER CO LTD

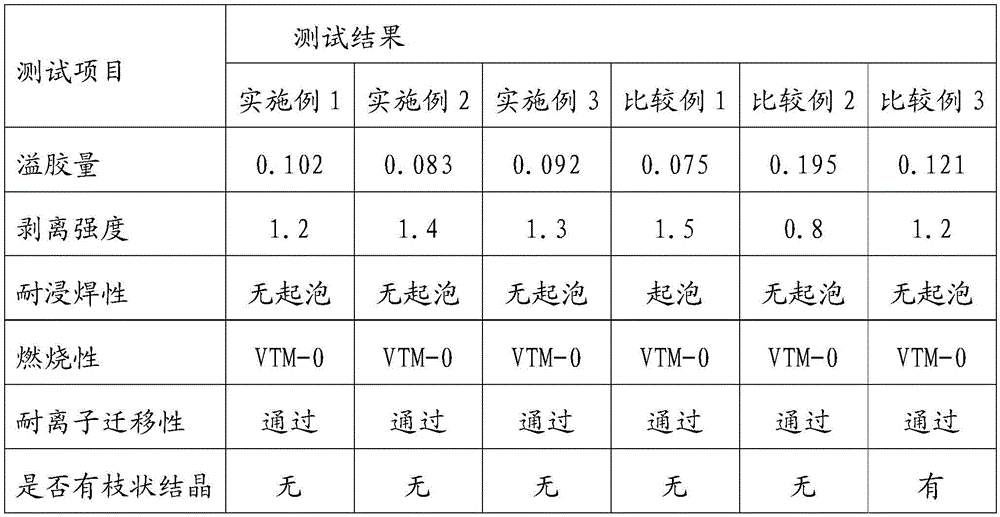

Halogen-free resin composition and cover film prepared from the same

InactiveCN105482442AExcellent resistance to ion migrationGood flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPolyester

Owner:GUANGDONG SHENGYI SCI TECH

Integrally Molded Body of Silicone Resin and Silicone Rubber, Method of Manufacture, and Curable Silicone Resin Composition

Owner:DOW CORNING TORAY CO LTD

Method for compression moulding reinforced thermoplastic article

A method for manufacturing a polymeric article having an integrated reinforcing element. A thermoplastic material is introduced into a mould, after which reinforcing elements are inserted into the mould cavity. A second layer of the thermoplastic material is introduced into the mould, after which the mould is closed, pressing and heating the mould to melt the thermoplastic material and form the article. The thermoplastic layers may be provided in powder, sheet, or pellet form. The reinforcing elements may comprise reinforcing fibres or reinforcing fabrics. A polymeric track for a vehicle may be produced from this method.

Owner:POLARIS IND INC +1

Process for preparing halogen-free atrp products

The present invention relates to the in situ removal of terminal halogen atoms from polymer chains which have been prepared by means of atom transfer radical polymerization, and to the simultaneous removal of transition metals from polymer solutions.

Owner:EVONIK ROEHM GMBH

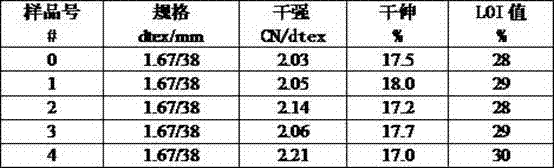

Composite silicon-based flame-retardant viscose fiber and production method thereof

ActiveCN102409420AImprove adhesionIncrease contact surfaceMonocomponent cellulose artificial filamentSpinning solutions preparationPolymer scienceSpinning

Owner:YIBIN GRACE +2

Terpene resin and preparation method thereof

InactiveCN102633919AEliminate quality impactEliminate the effects ofFood preparationTrimethylsilyl chloridePolymer science

The invention discloses a terpene resin and a preparation method thereof. The preparation method comprises steps as follows: terpene substances are used as a raw material, AlCl3 in the presence of an aromatic solvent is used as a main catalyst, and a cocatalyst is used in the reaction; polymerization is carried out at low temperature to prepare the crude terpene resin product; and the crude terpene resin product is washed and distilled under reduced pressure to obtain the terpene resin product. The cocatalyst is trimethylchlorosilane, triethylchlorosilane, tripropylchlorosilane or tributylchlorosilane, and accounts for 1-5% of the total mass of the terpene substance raw material; the main catalyst AlCl3 accounts for 4-12% of the total mass of the terpene substance raw material; the elemental chlorine content in the prepared terpene resin product is less than 100mg / kg, and the metallic aluminum content is less than 10mg / kg; the terpene resin product does not contain metallic antimony; and the residue level of the volatile solvent is less than 25mg / kg. The product reaches to the food level.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

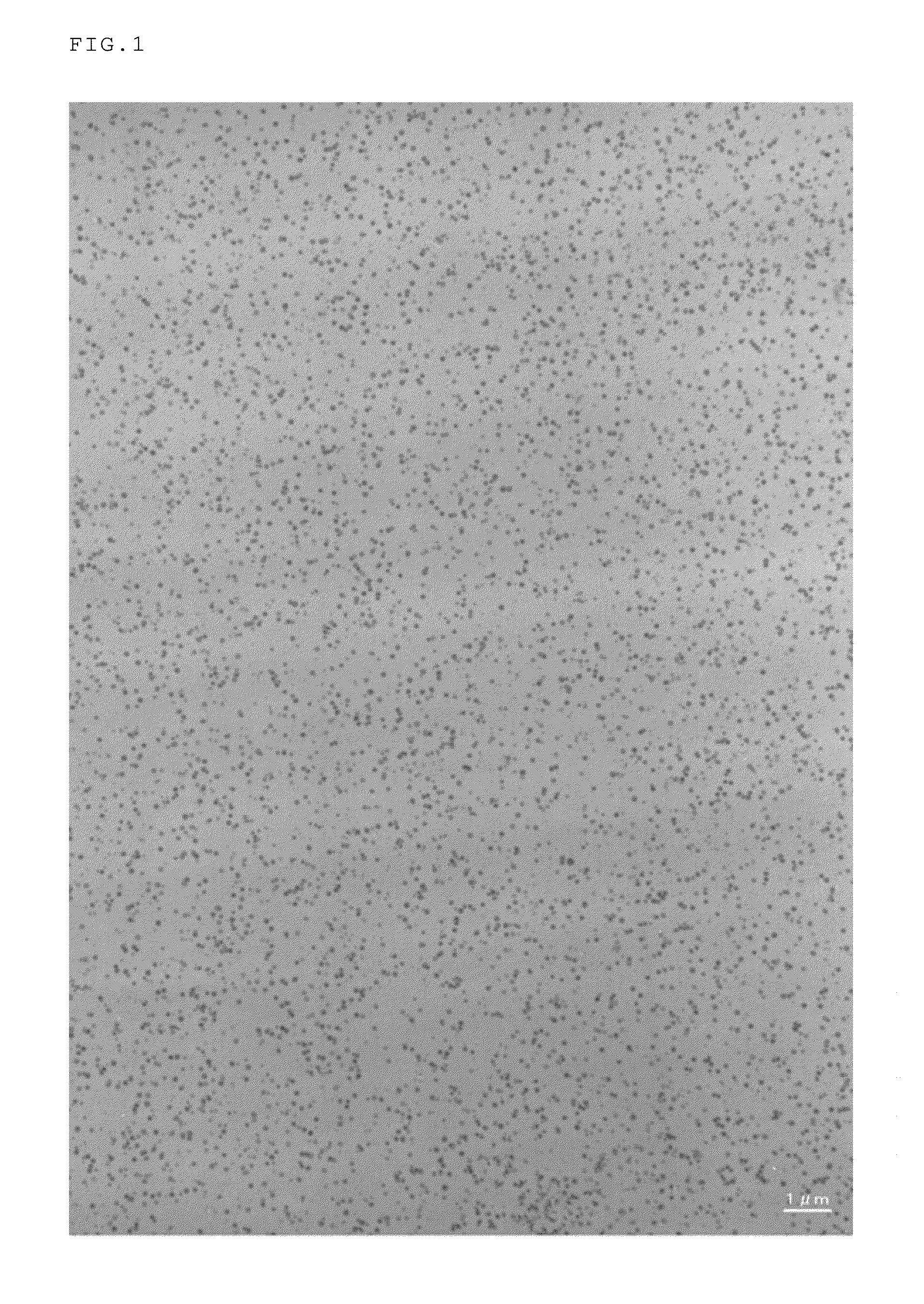

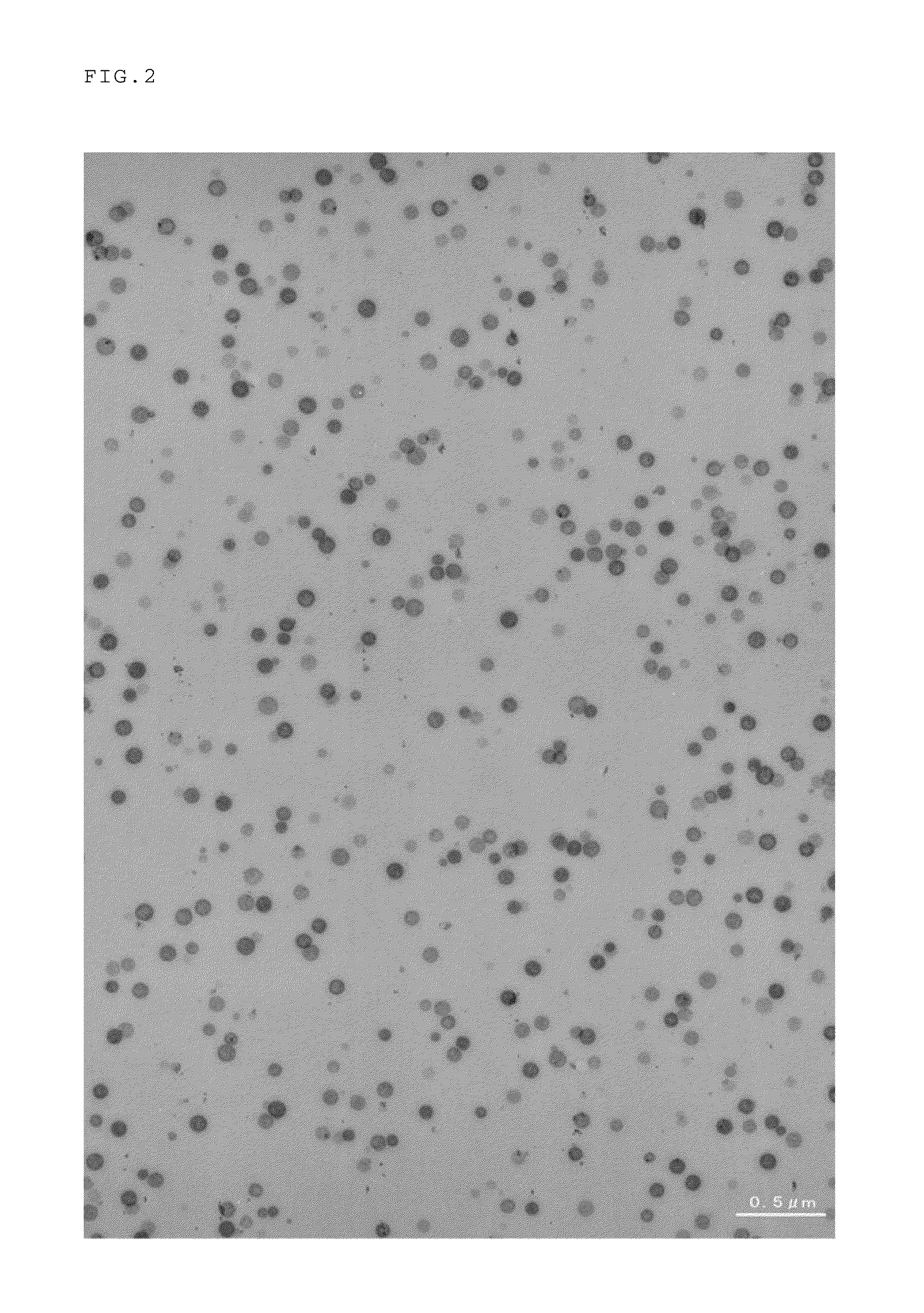

Curable resin composition containing polymer microparticles

Owner:KANEKA NORTH AMERICA +1

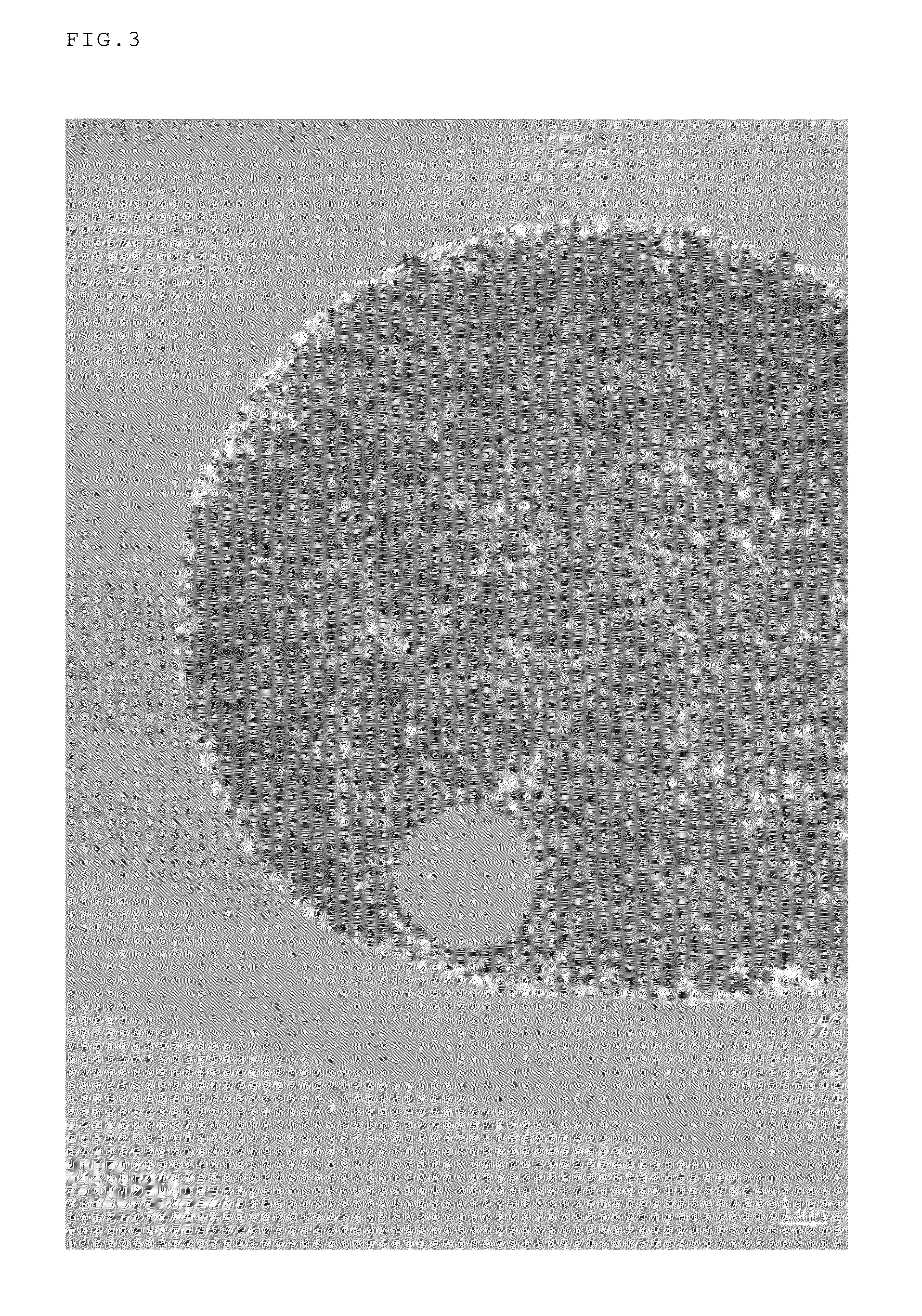

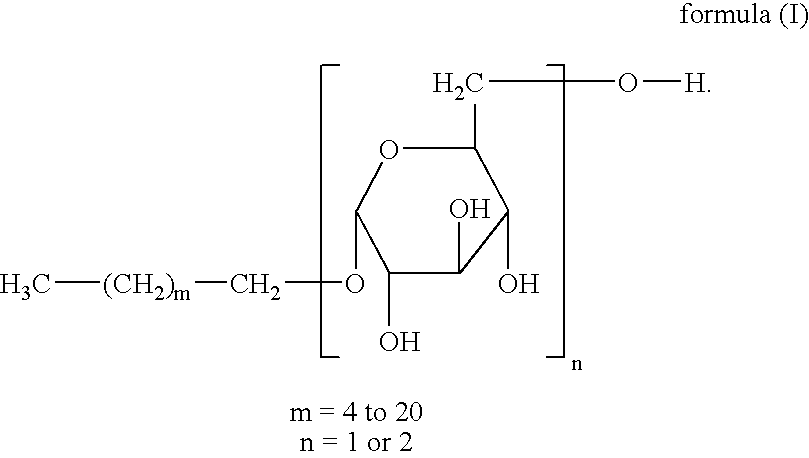

Alkylpolyglycosides useful as stabilizers for pur foams

InactiveUS20080070999A1Additional hydrophilicizationImprove stabilitySugar derivativesGlycosidesPolyurethane dispersionWound dressing

Owner:BAYER MATERIALSCIENCE AG

Polyetrafluoroethylene micropowder compositions

InactiveUS20070100077A1Improve performanceSpecial tyresPigment pastesTetrafluoroethylenePolymer science

A micropowder composition containing a granular PTFE micropowder, a fine powder PTFE micropowder, and a fine powder molding resin provides mixtures with fluoroelastomers containing copolymerized and alternating units of tetrafluoroethylene and propylene that provide molded articles having improved surface smoothness characteristics and tear resistance on molding. Processes for mixing additives with fluoroelastomers by adding or mixing the fluoroelastomer with the additives in the presence of micropowder PTFE compositions.

Owner:AGC CHEM AMERICAS INC

Textile with flame retardancy and water repellency, and production method thereof

The invention discloses a textile with flame retardancy and water repellency, and a production method thereof. The textile with flame retardancy and water repellency contains flame-retardant polyester fibers. Bromine element content of the textile with flame retardancy and water repellency is less than or equal to 5 micrograms per gram. Fluorine element content of the textile with flame retardancy and water repellency is less than or equal to 5 micrograms per gram. One or more non-halogen flame-retardant treating agents and one or more non-fluorine water-repellent treating agents are prepared into the textile with flame retardancy and water repellency through functional finishing. The textile with flame retardancy and water repellency is safe and environmentally friendly. After the textile with flame retardancy and water repellency is washed 5 times, the necessary frequency of exposure under flame for burning is great than or equal to 3 and the water repellency reaches or exceeds a second level. The textile with flame retardancy and water repellency can be utilized for preparation of shower curtains, tents, window curtains, outdoor gym suits and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Highly effective antistatic agglomerate for biaxial tension polypropylene and its preparation method

InactiveCN1765970AAdd lessLong-term stabilityAntistatic agentBiaxial tension

The invention relates to a highly effective antistatic agglomerate for biaxial tension polypropylene and its preparation method, wherein the agglomerate comprises raw materials of the following constituents (by weight proportion): polypropylene 70-90%, antistatic agent 8-30%, grinding agent 0.1-1%, dispersing agent 0.1-2%, anti-oxidant 0.1-1%, inhibiting agent 0.1-0.5%, anti-ageing 0.1-0.5%.

Owner:SHANGHAI SUNNY

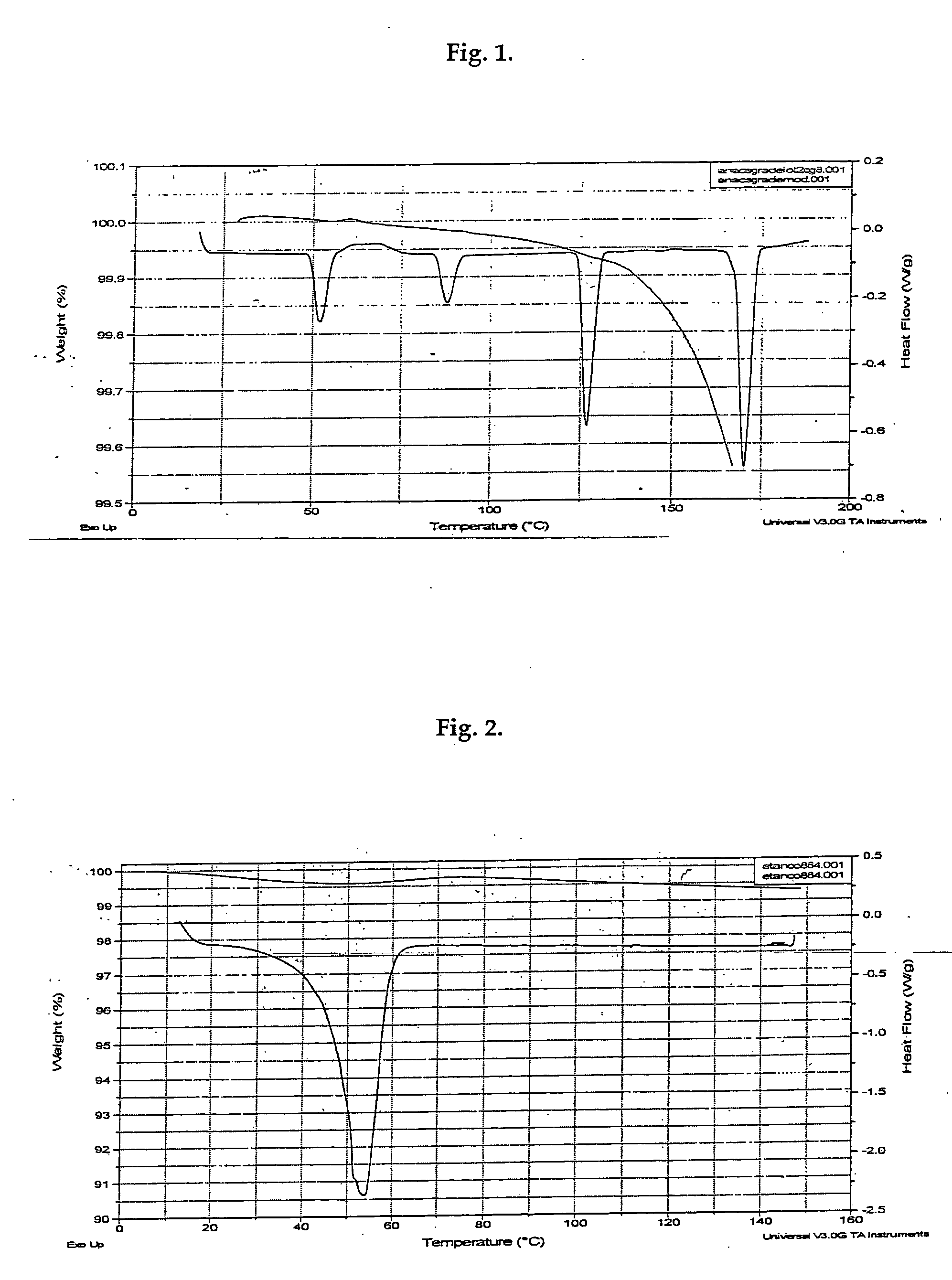

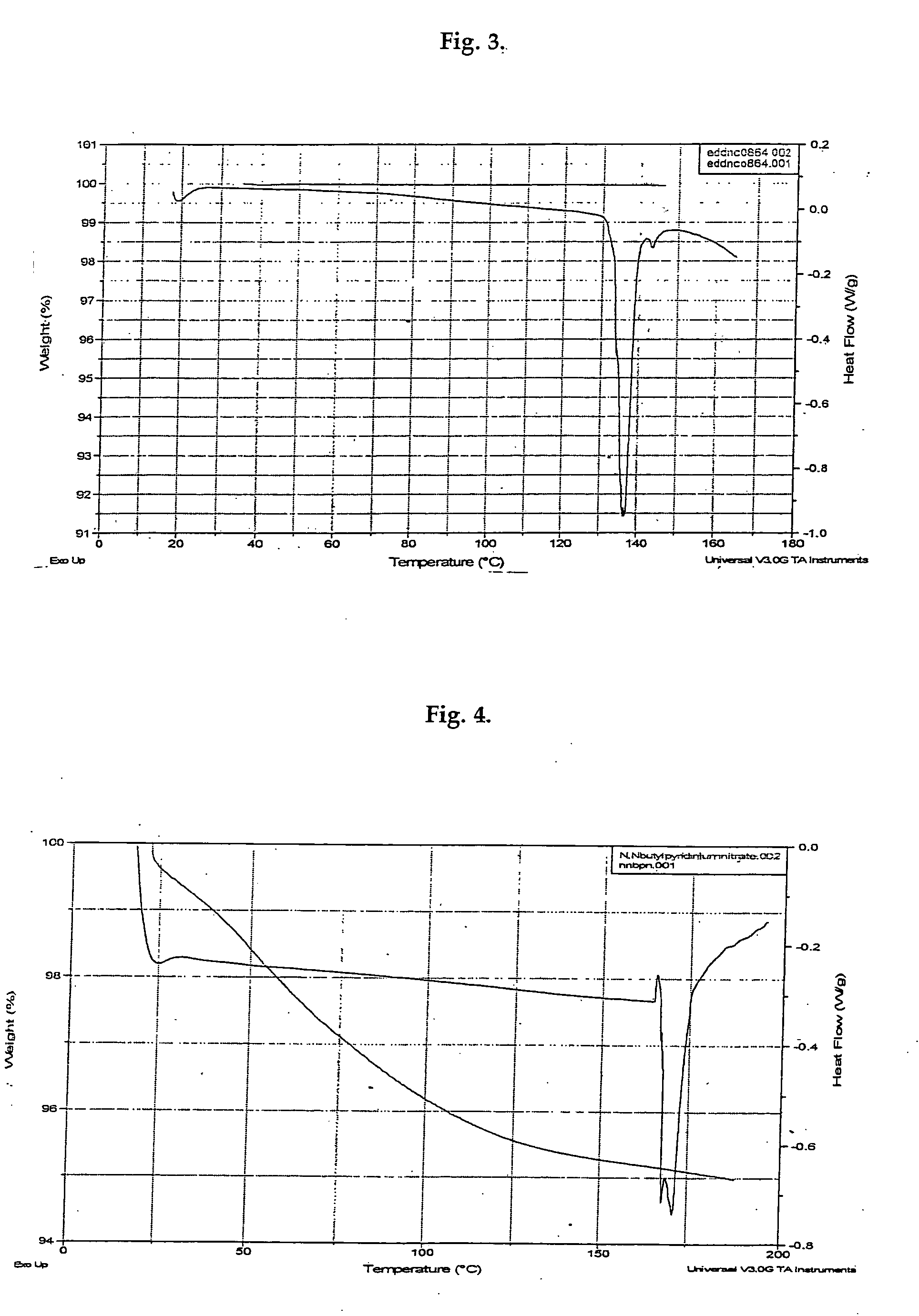

Mucosal Bioadhesive SLow Release Carrier for Delivering Active Principles

A mucosal bioadhesive slow release carrier comprising an active principle and devoid of starch, lactose, which can release the active principal for a duration of longer than 20 hours. This bioadhesive carrier contains a diluent, an alkali metal alkylsulfate, a binding agent, at least one bioadhesive polymer and at least one sustained release polymer, as well as a method for its preparation.

Owner:ONXEO SA

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap