Halogen-free resin composition and cover film prepared from the same

A resin composition and covering film technology, applied in the field of flexible circuit boards, can solve problems such as dendrite growth, and achieve the effects of high adhesion, excellent ion migration resistance, flexibility and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

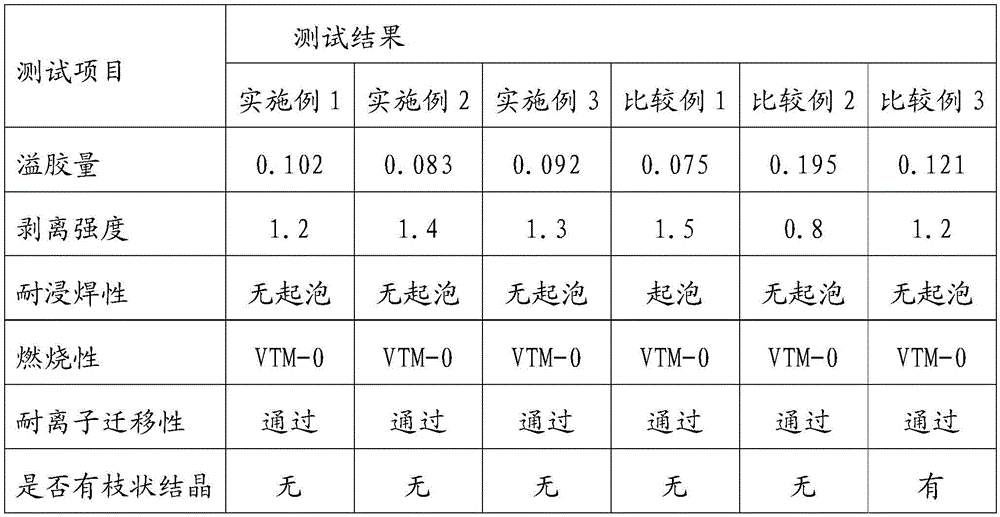

Examples

Embodiment 1

[0024] Halogen-free resin composition, by weight, comprising: polyester type polyurethane resin (UR-3500, solid content 40%, acid value 35KOHmg / g) 40 solid weight parts, biphenyl type epoxy resin (NC-3000H, epoxy equivalent 285±20g / eq, solid content 100%) 15 parts, phosphorus-containing phenolic resin (LC-950PM60, solid content 60%) 10 solid parts by weight, 2-ethyl-4-methylimidazole 0.1 part, containing 15 parts of phosphorus flame retardant (OP-935) and an appropriate amount of solvent butanone;

[0025] Preparation of halogen-free resin composition (resin glue): weigh the above components according to the formula, dissolve biphenyl type epoxy resin and 2-ethyl-4-methylimidazole with methyl ethyl ketone in advance, and then mix them with other components. Partially mixed to make resin glue, so that its solid content is 40%;

[0026] Preparation of cover film for flexible circuit boards: use a coating machine to coat the resin glue on a polyimide film with a thickness of 12

Embodiment 2

[0028] Halogen-free resin composition, by weight, comprising polyester polyurethane resin (UR-3500, acid value 35KOHmg / g, solid content 40%) solid weight 60 parts, biphenyl epoxy resin (NC-3000H, ring Oxygen equivalent 285±20g / eq, solid content 100%) 25 parts, phosphorus-containing phenolic resin (LC-950PM60, solid content 60%) 20 solid weight parts, 2-ethyl-4-methylimidazole 0.3 parts; phosphorus-containing 25 parts of flame retardant (OP-935) and appropriate amount of solvent butanone;

[0029] Preparation of halogen-free resin composition (resin glue): weigh the above components according to the formula, dissolve biphenyl type epoxy resin and 2-ethyl-4-methylimidazole with methyl ethyl ketone in advance, and then mix them with other components. Partially mixed to make resin glue, so that its solid content is 40%;

[0030] Preparation of cover film for flexible circuit boards: use a coating machine to coat the resin glue on a polyimide film with a thickness of 12.5 μm, con

Embodiment 3

[0032]Halogen-free resin composition, by weight, comprising polyester type polyurethane resin (UR-3500, acid value 35KOHmg / g, solid content 40%) 50 solid weight parts, biphenyl type epoxy resin (NC-3000H, cyclic Oxygen equivalent 285±20g / eq, solid content 100%) 20 parts, phosphorus-containing phenolic resin (LC-950PM60, solid content 60%) 15 solid weight parts, 2-ethyl-4-methylimidazole 0.2 parts, phosphorus-containing 20 parts of flame retardant (OP-935) and appropriate amount of solvent;

[0033] Preparation of halogen-free resin composition (resin glue): weigh the above components according to the formula, dissolve biphenyl type epoxy resin and 2-ethyl-4-methylimidazole with methyl ethyl ketone in advance, and then mix them with other components. Partially mixed to make resin glue, so that its solid content is 40%;

[0034] Preparation of cover film for flexible circuit boards: use a coating machine to coat the resin glue on a polyimide film with a thickness of 12.5 μm, c

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap