Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

154 results about "Organic solvent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic solvents are a chemical class of compounds that are used routinely in commercial industries. They share a common structure (at least 1 carbon atom and 1 hydrogen atom), low molecular weight, lipophilicity, and volatility, and they exist in liquid form at room temperature.

Conductive composite fiber and preparation method thereof

The invention relates to a conductive composite fiber and a preparation method thereof. The conductive composite fiber comprises a skin core structure including conductive particles and organic fibers, wherein the mass percentage composition of the conductive particles is 0.5-10%, and the mass percentage composition of the organic fibers is 90-99.5%. The preparation method comprises the following steps: (1) pre-treating the organic fibers in pretreatment liquid, and blowing; (2) soaking the fibers into water dispersion liquid of the conductive particles, ultrasonically assisting the conductive particles to outer layers of the fibers in ice water bath, soaking, drying, and soaking, cleaning and drying through hydrochloric acid solution to obtain the conductive composite fiber. According to the invention, the conductive composite fiber has the advantages of no organic solvent in preparation, greenness and environmental friendliness, simple process, low cost, continuous large-scale production, high conductivity of a product, difficulty in falling conductive components, durable conductive performance, soft hand feel and capability of being knitted; and the conductive composite fiber is used as an antistatic and electromagnetic shield material and an energy storage electrode material.

Owner:DONGHUA UNIV

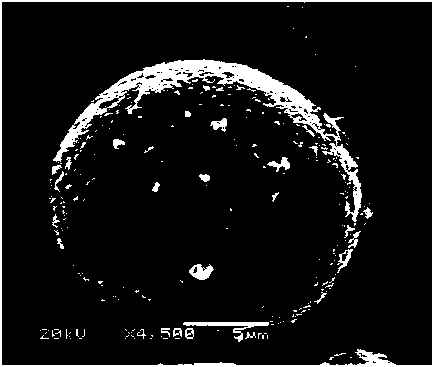

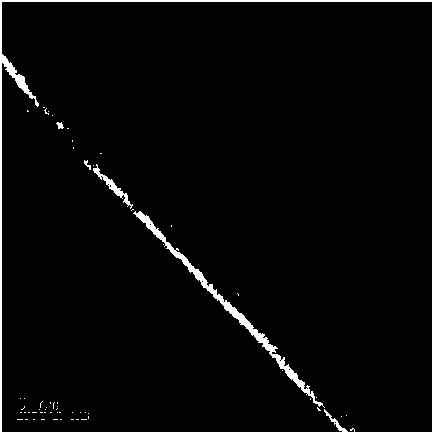

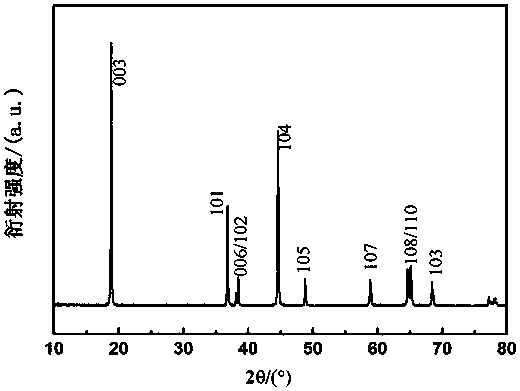

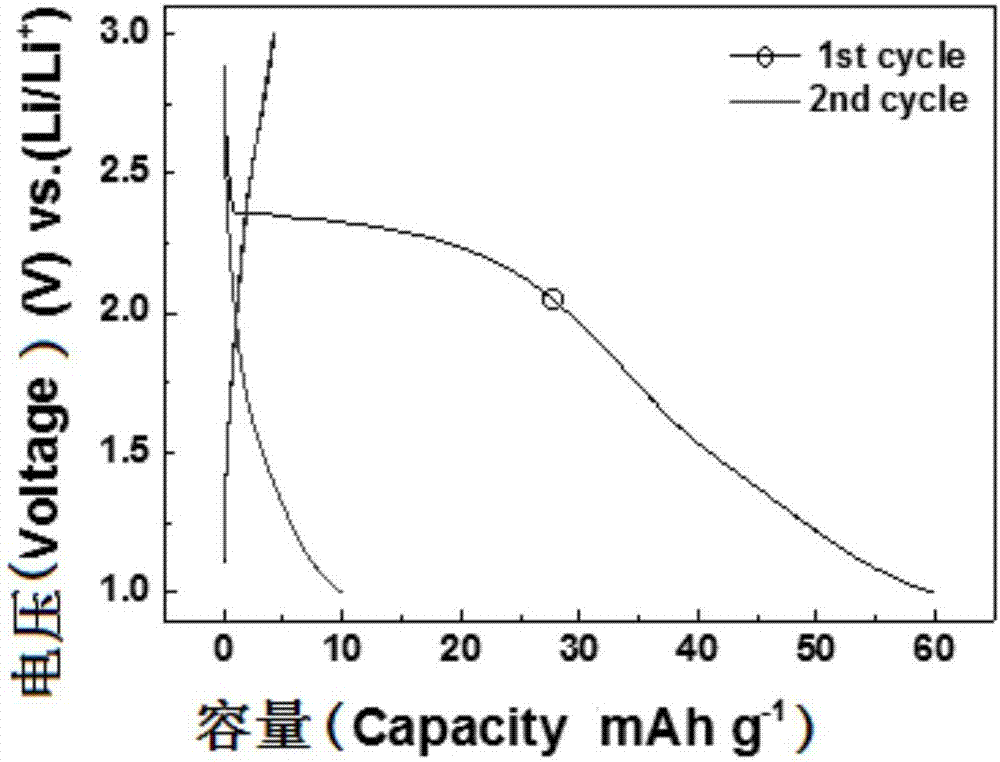

Lithium silicate-coated Ni-Co lithium aluminate positive electrode material and preparation method thereof

InactiveCN107910539AImprove cycle stabilityImprove high rate discharge performanceCell electrodesSecondary cellsLithium aluminateSilicon dioxide

Owner:CENT SOUTH UNIV

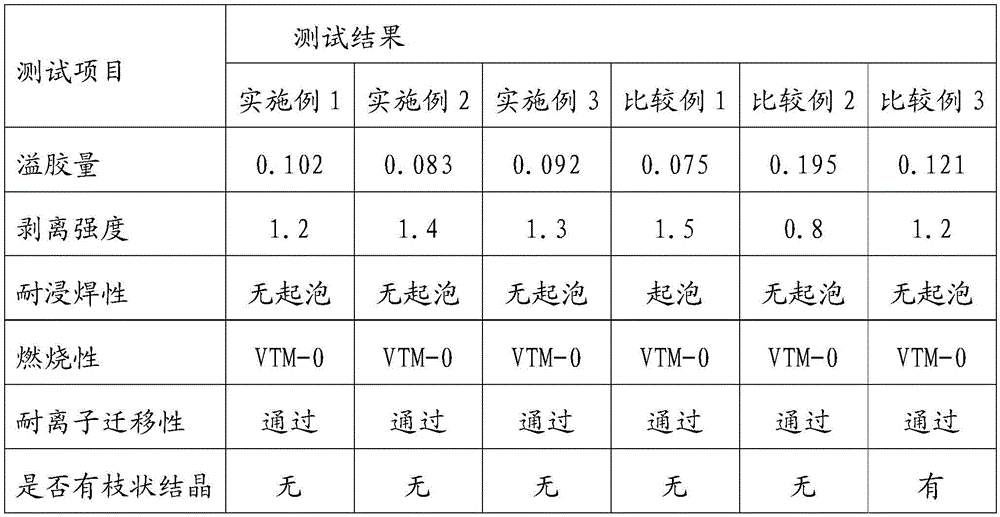

Halogen-free resin composition and cover film prepared from the same

InactiveCN105482442AExcellent resistance to ion migrationGood flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPolyester

Owner:GUANGDONG SHENGYI SCI TECH

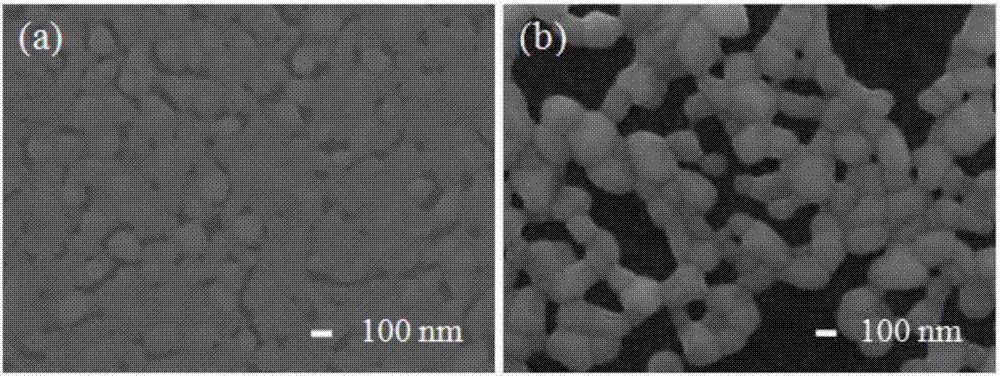

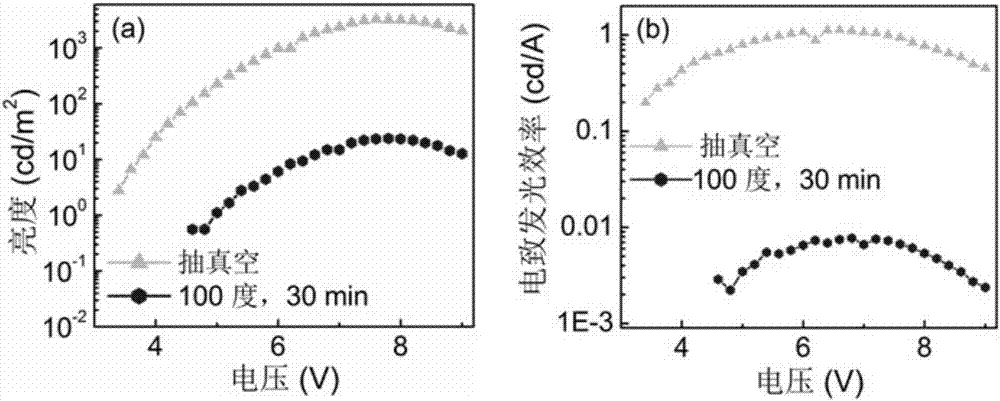

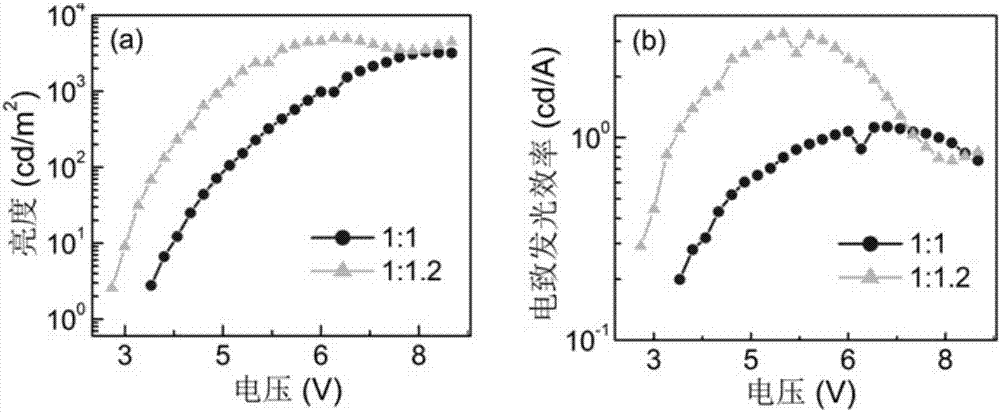

Method for preparing all-Inorganic perovskite film

InactiveCN107221612AEasy to prepareEasy to operateSolid-state devicesSemiconductor/solid-state device manufacturingTemperature controlOrganic solvent

Owner:SOUTHWEST UNIVERSITY

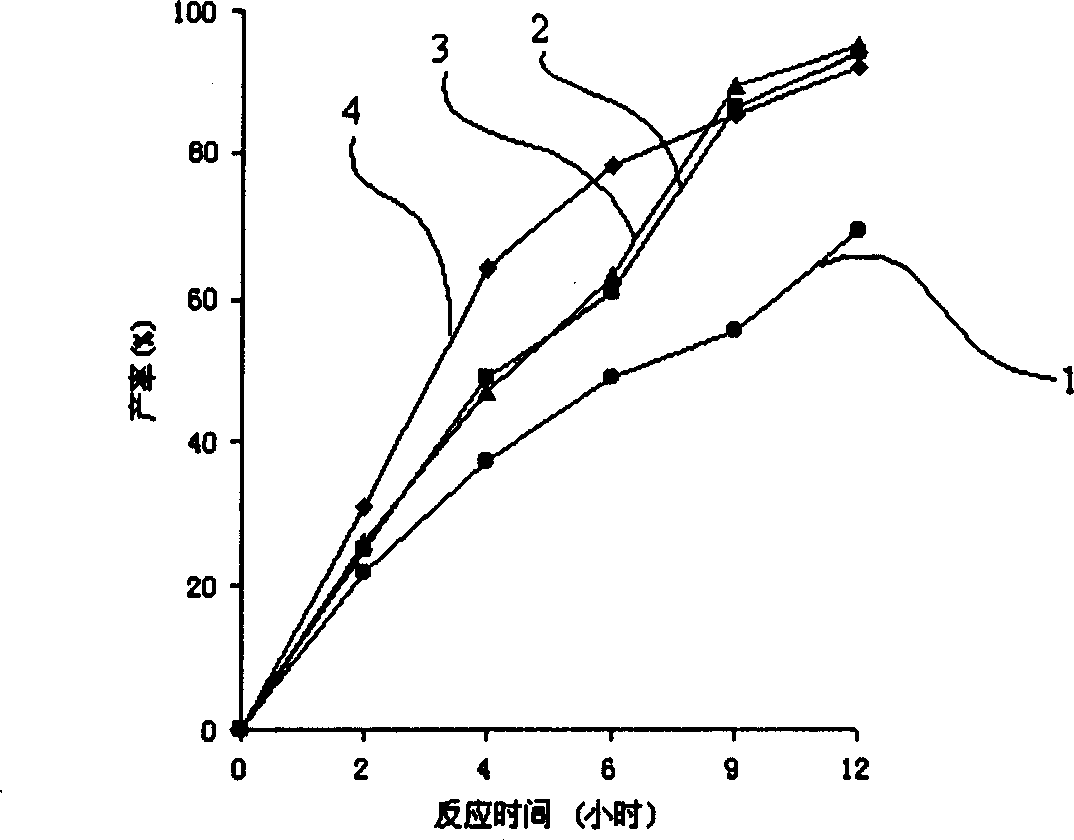

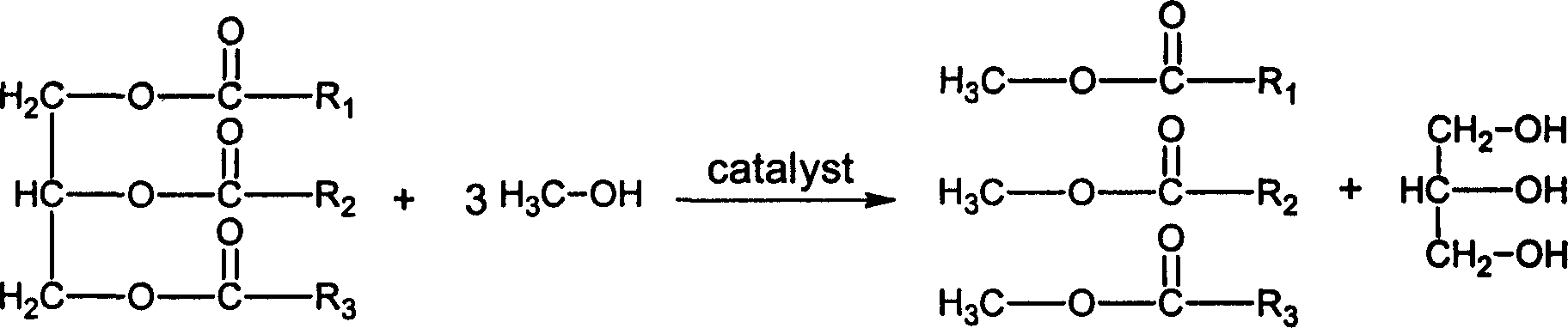

Organic solvent slow-releasing system and its preparation and application for catalyzing reaction of enzyme thereof

InactiveCN1793355AInexpensiveConducive to large-scale industrial productionFermentationOn/in inorganic carrierBiodieselVegetable oil

Owner:EAST CHINA UNIV OF SCI & TECH

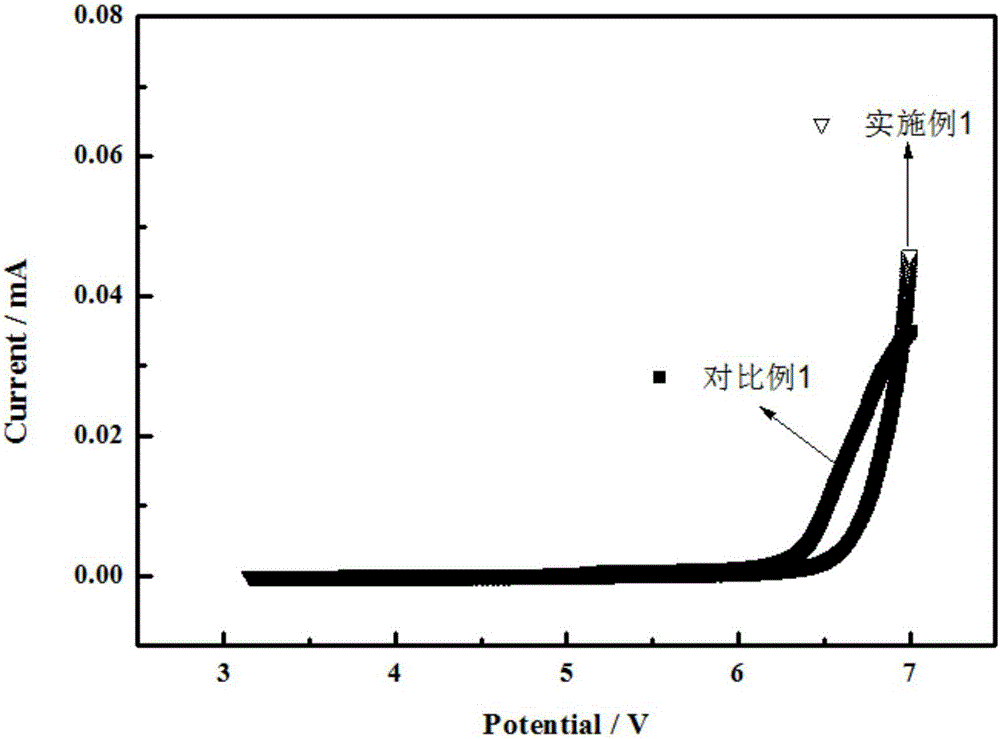

Electrolyte for ternary cathode material lithium ion battery and ternary cathode material lithium ion battery

InactiveCN106356562ASuppress generationPrevent agingSecondary cellsOrganic electrolytesOrganic solventInternal resistance

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

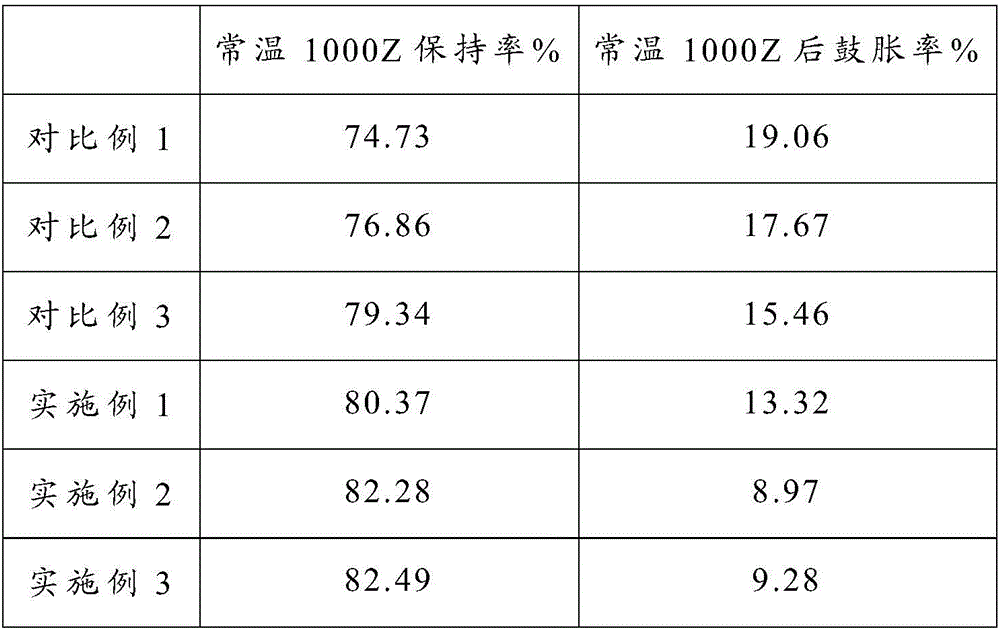

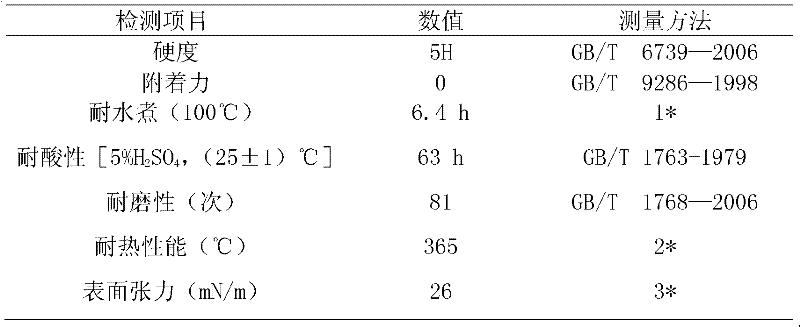

Preparation method of hyperbranched polyester modified organic silicon resin and coating comprising resin

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

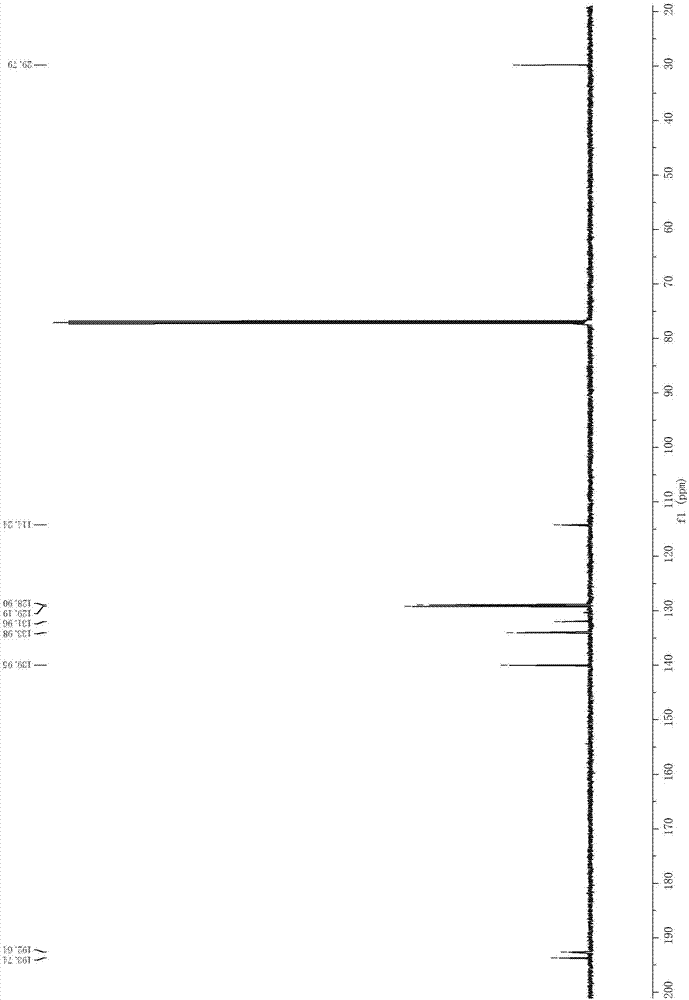

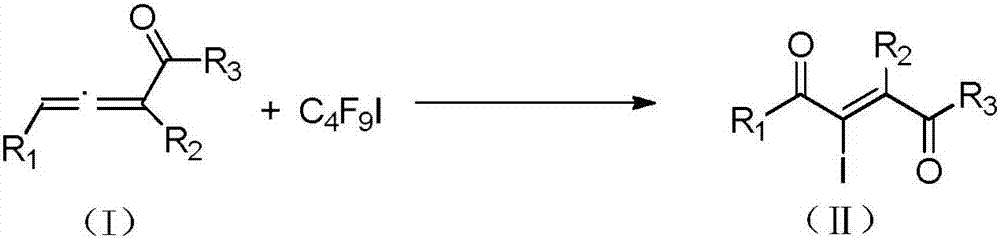

Method for preparing 2-iodine amyl -2-ene-1,4-diketone derivative by adopting visible light catalysis

ActiveCN107011145AMild reaction conditionsEasy to operateOrganic compound preparationCarboxylic acid esters preparationIodidePollution

Owner:ZHEJIANG UNIV OF TECH

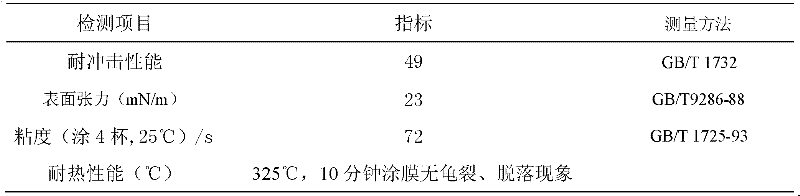

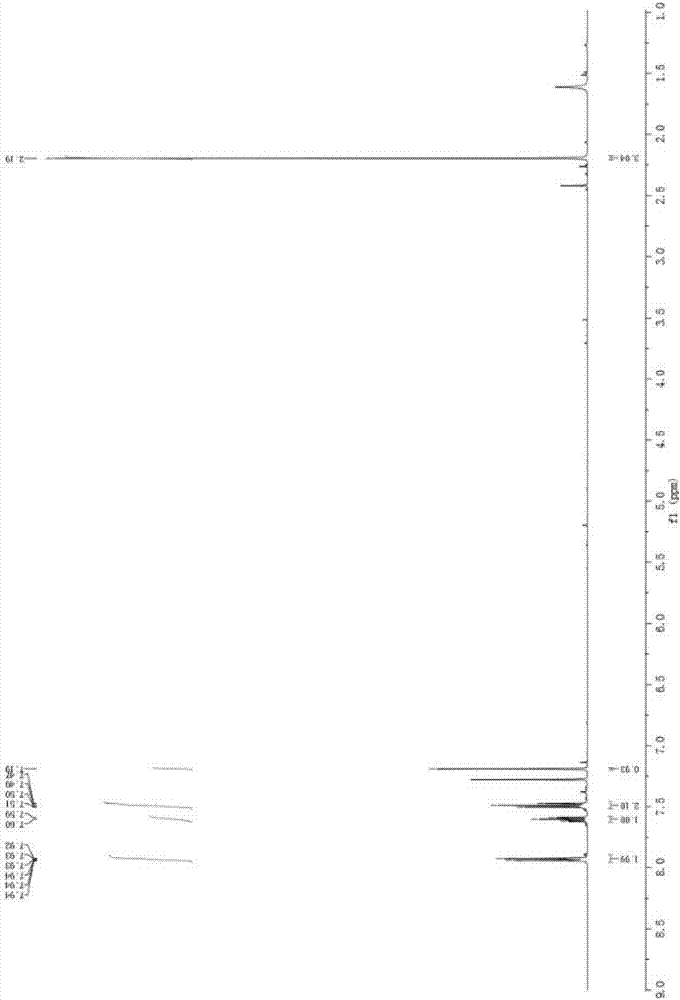

Heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane and functionalized derivates thereof

The invention provides a preparation method for heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane and functionalized derivates thereof. The preparation method comprises the steps as follows: adding tridecafluorooctylpropyl trimethoxy silane into an organic solvent, adding de-ionized water and NaOH, heating, stirring, reacting under reflux condition, washing by a washing solvent, and drying to obtain trisilanol sodium salt of heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane; and adding trisilanol sodium salt into an organic reagent, dropwise adding hydrochloric acid, triethylamine and a silane coupling agent, stirring a mixture at normal temperature for reaction, removing generated deposit, carrying out rotary evaporation, removing the solvent, obtaining white crystals, dissolving the crystals in methanol, filtering for collecting insoluble parts, and carrying out vacuum drying to obtain a T8-type monofunctional tridecafluorooctylpropyl POSS (polyhedral oligomeric silsesquioxane) monomer. The preparation method can obtain long branch chain type active fluorine-containing POSS, is simple and easy in process, low in cost, high in yield and higher in product purity, and is suitable for large-scale industrial production.

Owner:HOHAI UNIV

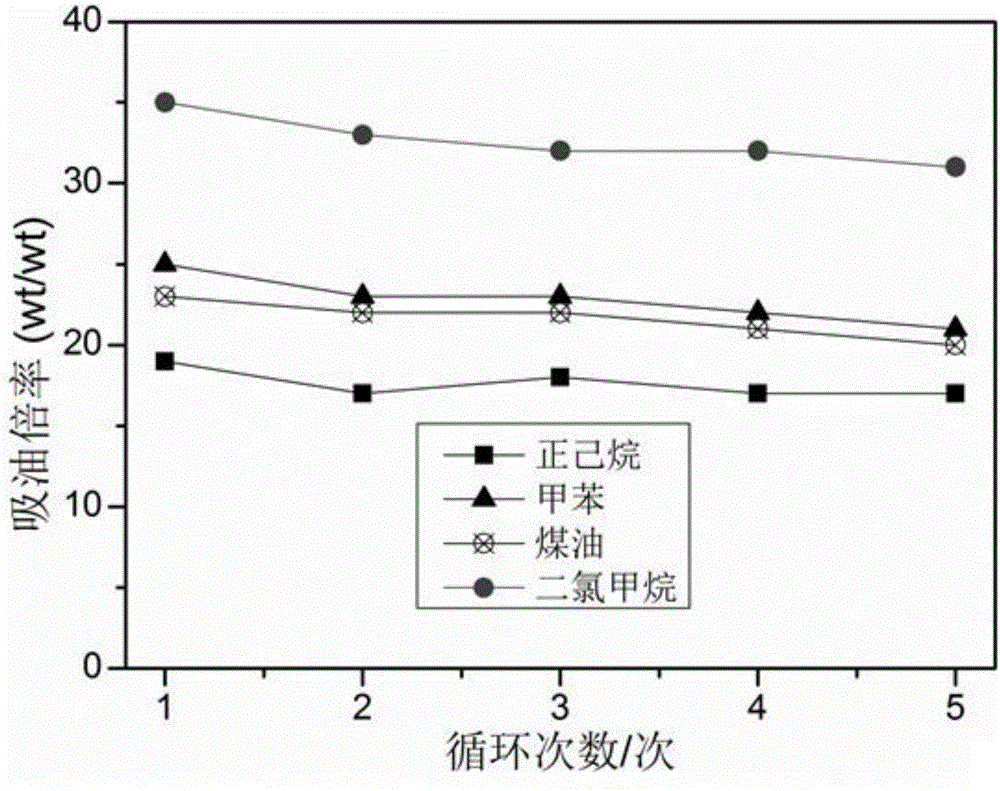

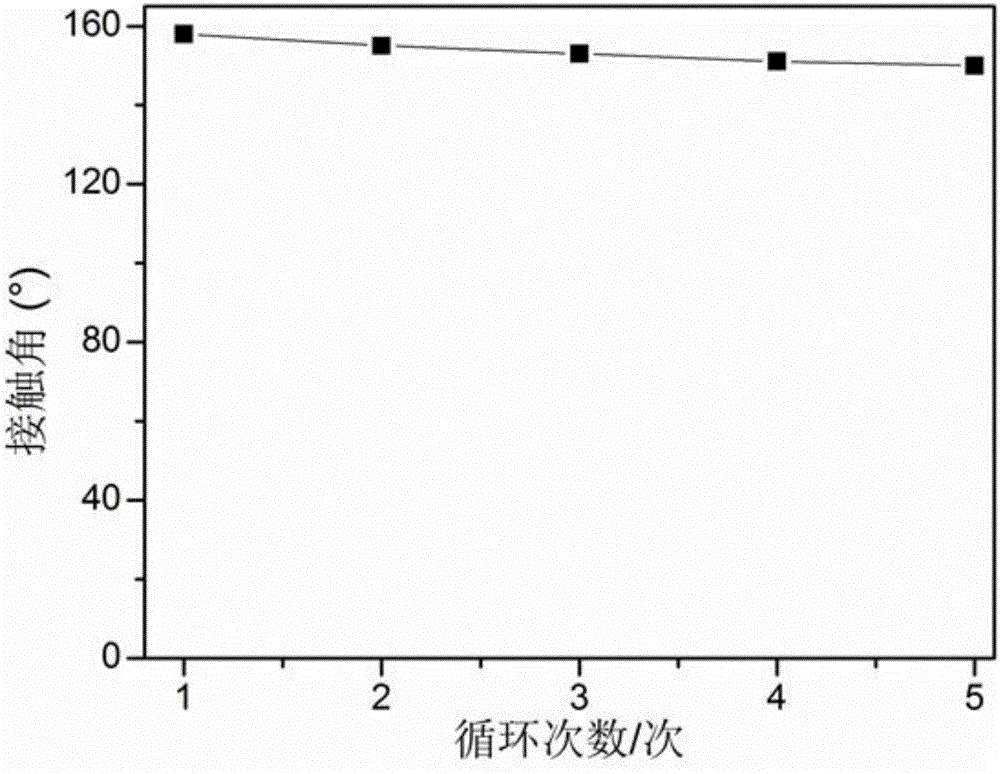

Preparation method for super-hydrophobic/super-oleophylic loofah sponge fiber and application thereof

InactiveCN106732463AEasy to degradeEasy to prepareOther chemical processesLiquid separationFiberPolymer science

Owner:FOSHAN UNIVERSITY

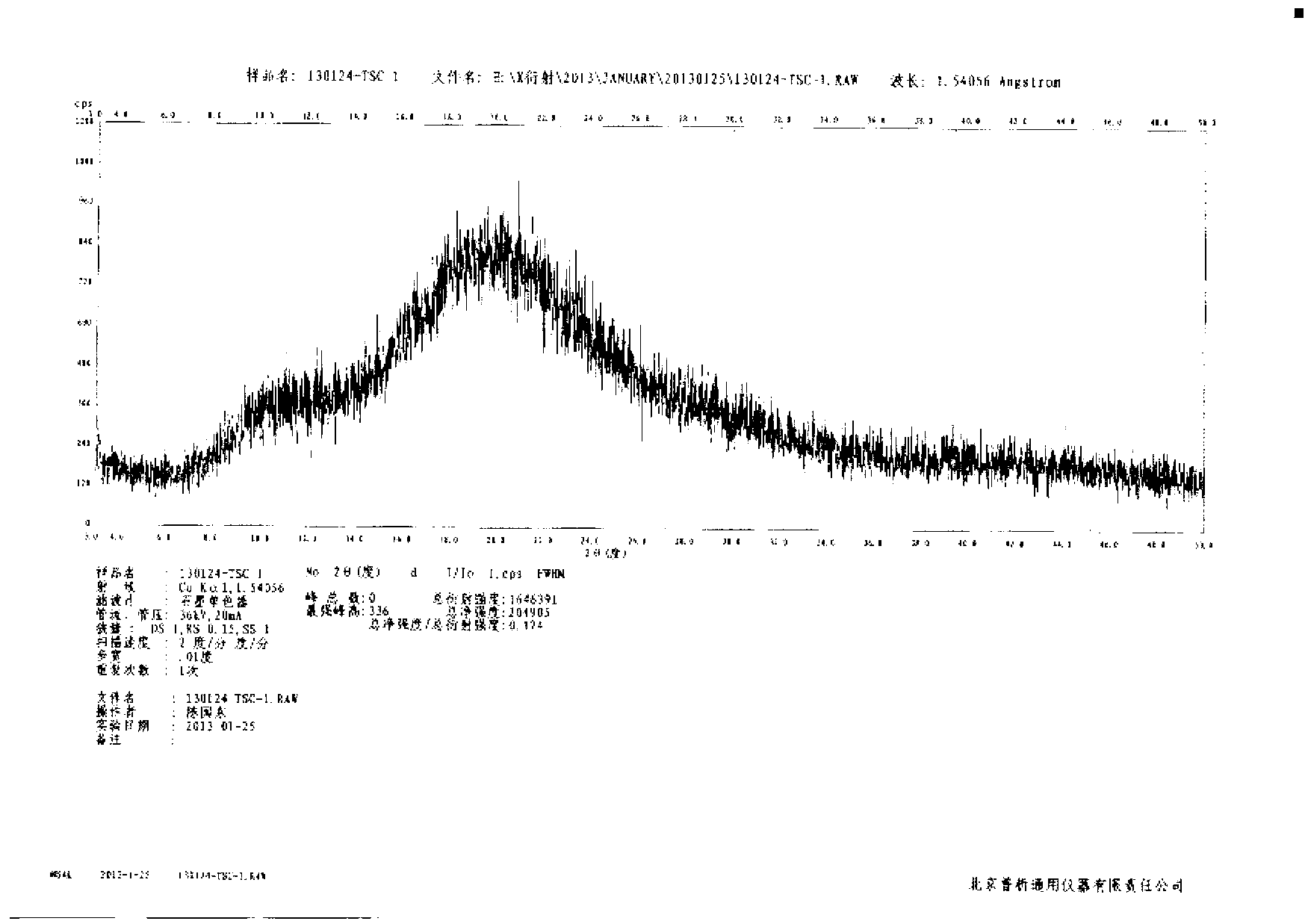

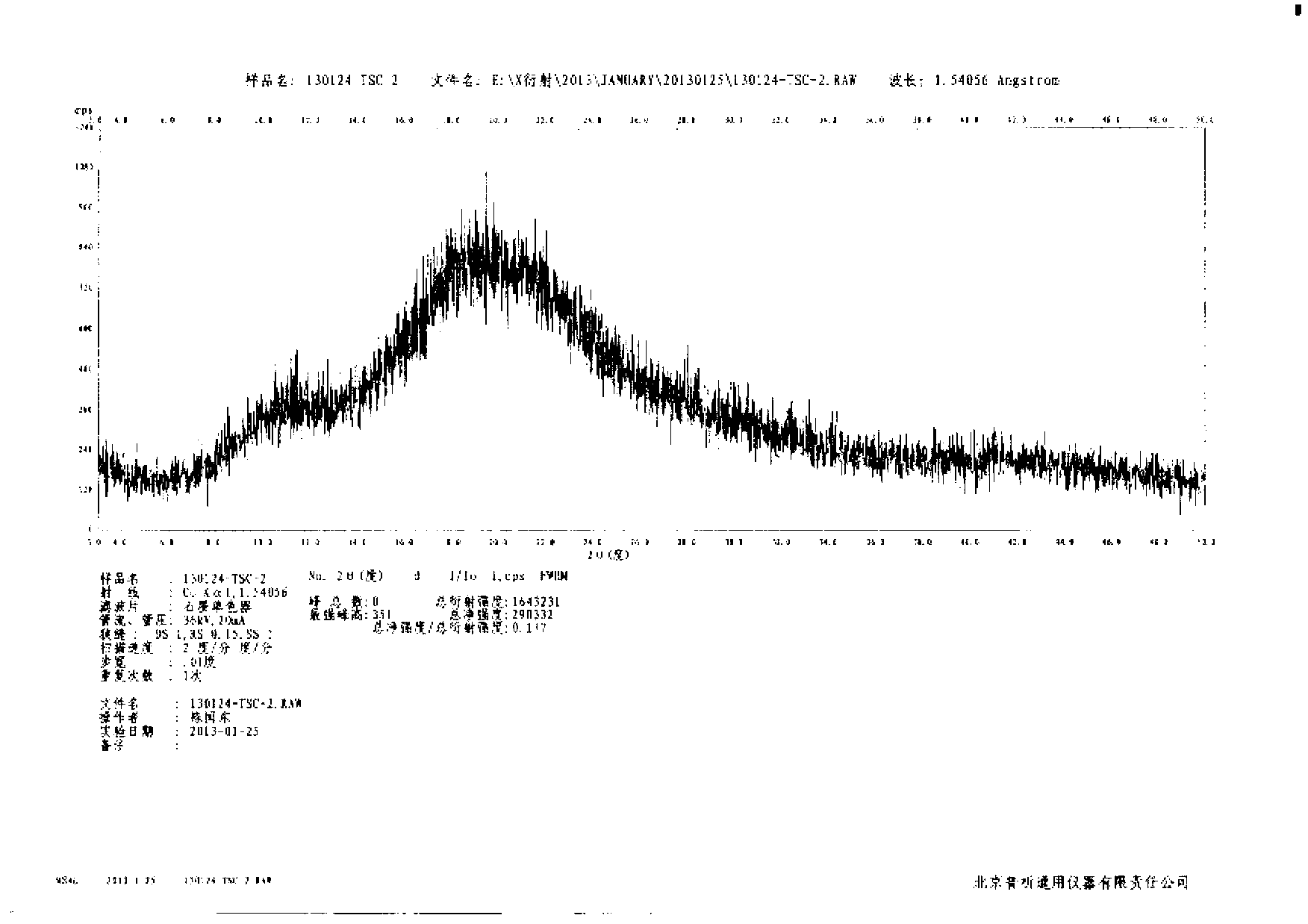

Preparation method for amorphous tofacitinib citrate

InactiveCN103073552AImprove solubilityImprove stabilityOrganic chemistryOrganic solventTOFACITINIB CITRATE

Owner:BEIJING PHARMA GRP CO LTD

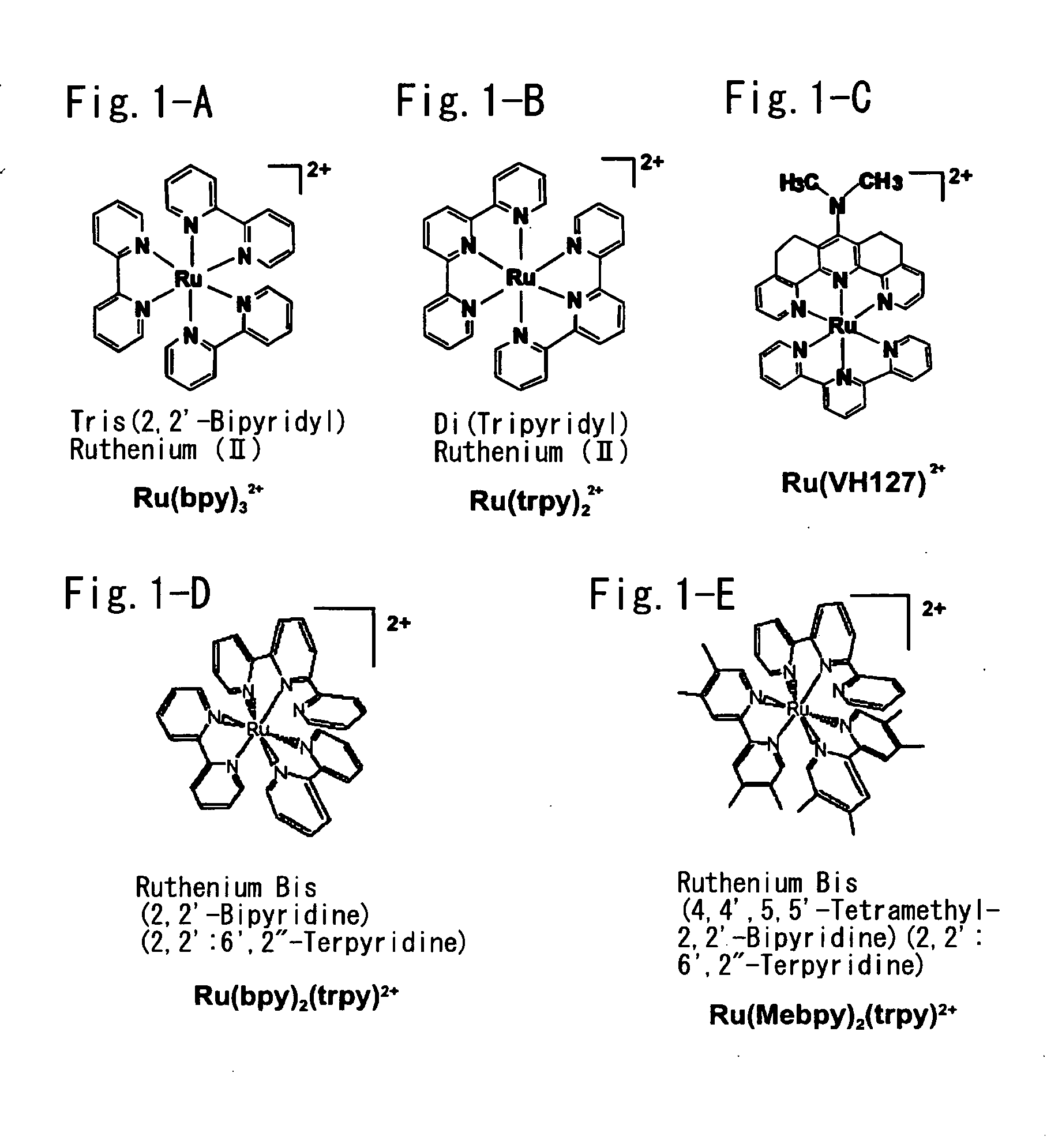

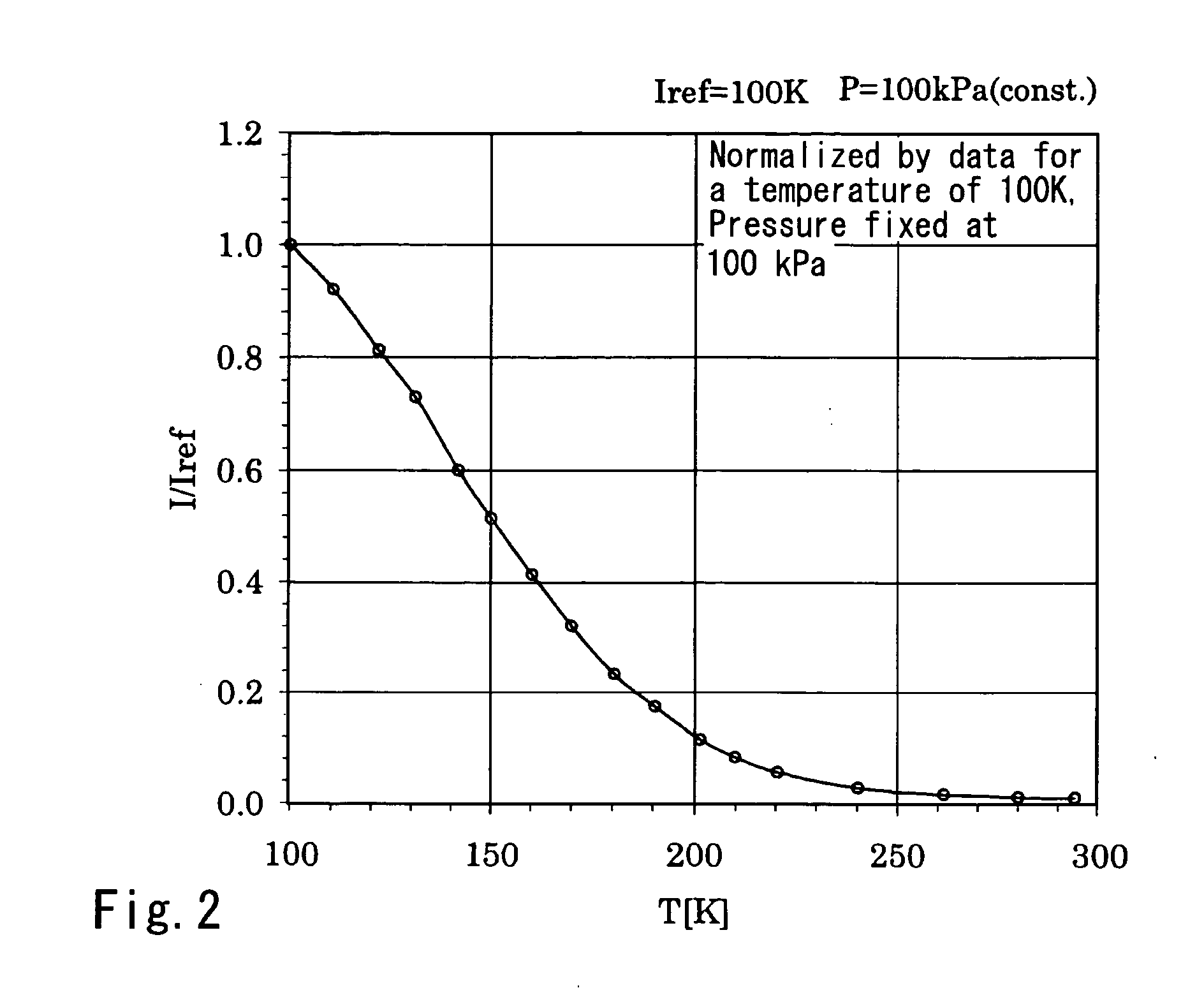

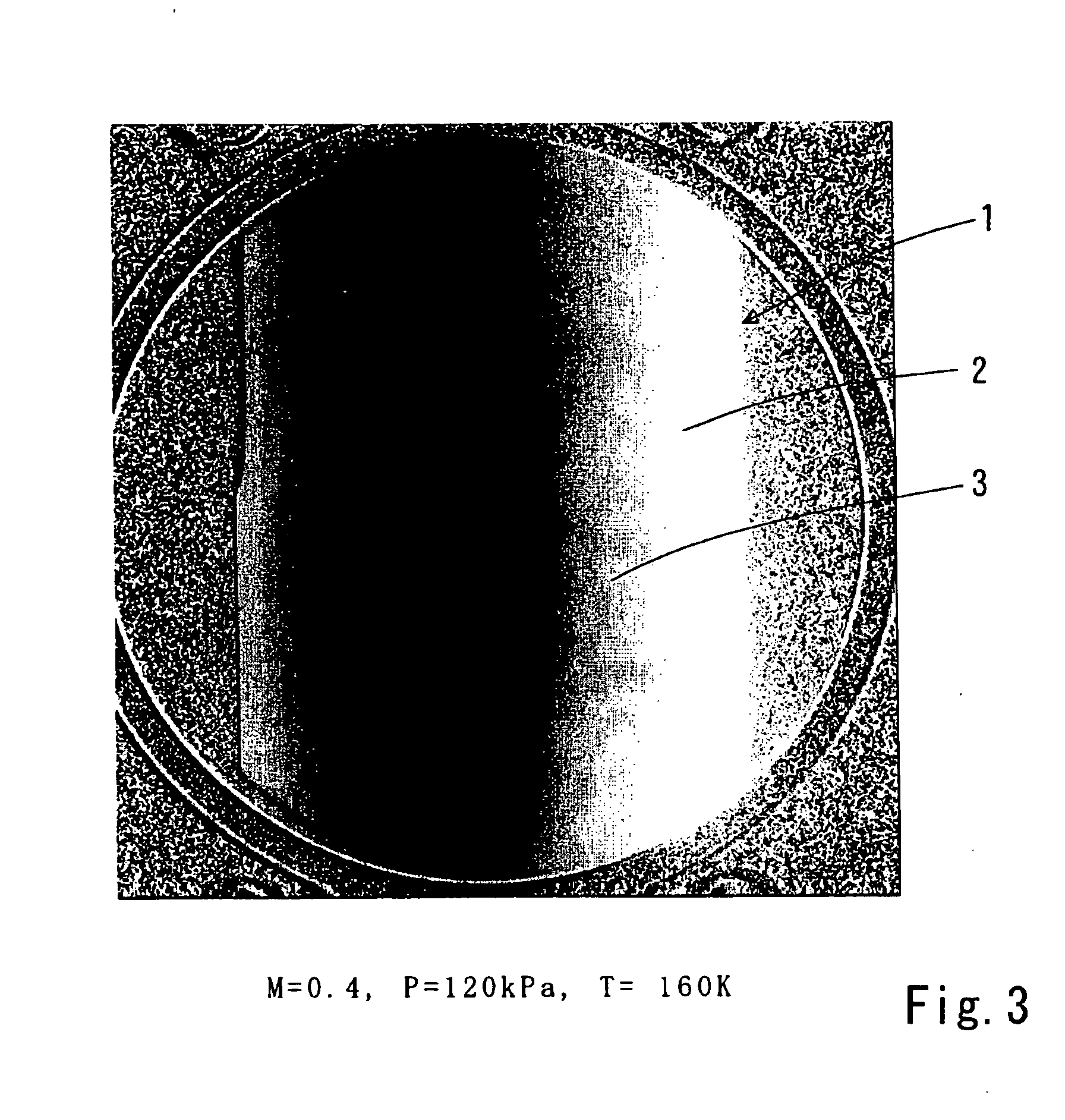

Temperature sensitive paint for low-temperature use

InactiveUS20050040368A1High luminous intensityLarge variation in light emission intensityAnalysis using chemical indicatorsLuminescent paintsSolubilityLuminous intensity

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

1,4-di(2,4-diamino phenoxy) benzenoid form high-temperature epoxy adhesive and preparation method thereof

InactiveCN103122231AGood adhesionGood viscosity controllabilityEpoxynovolac adhesivesBenzeneOrganic solvent

Owner:DONGHUA UNIV +1

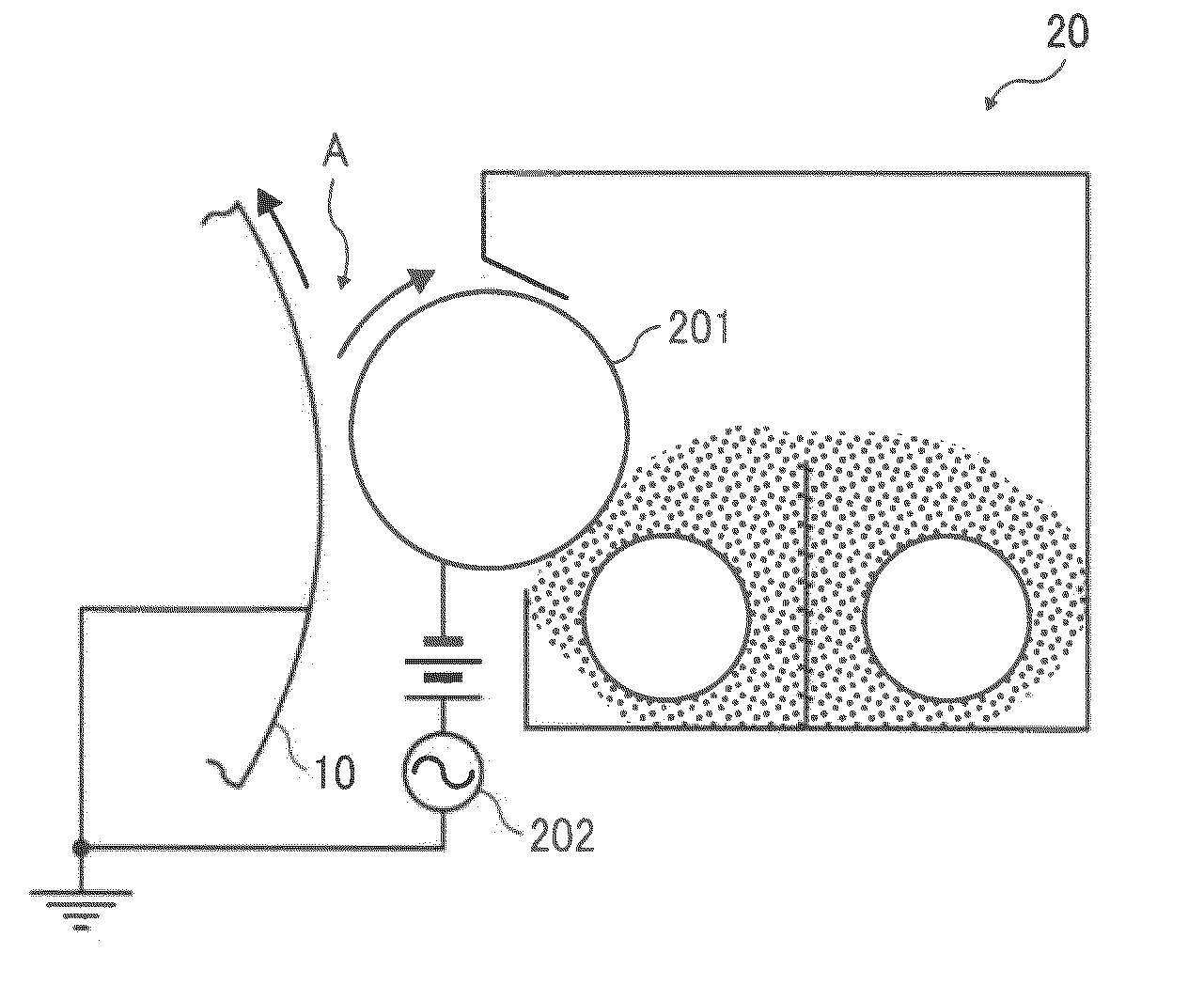

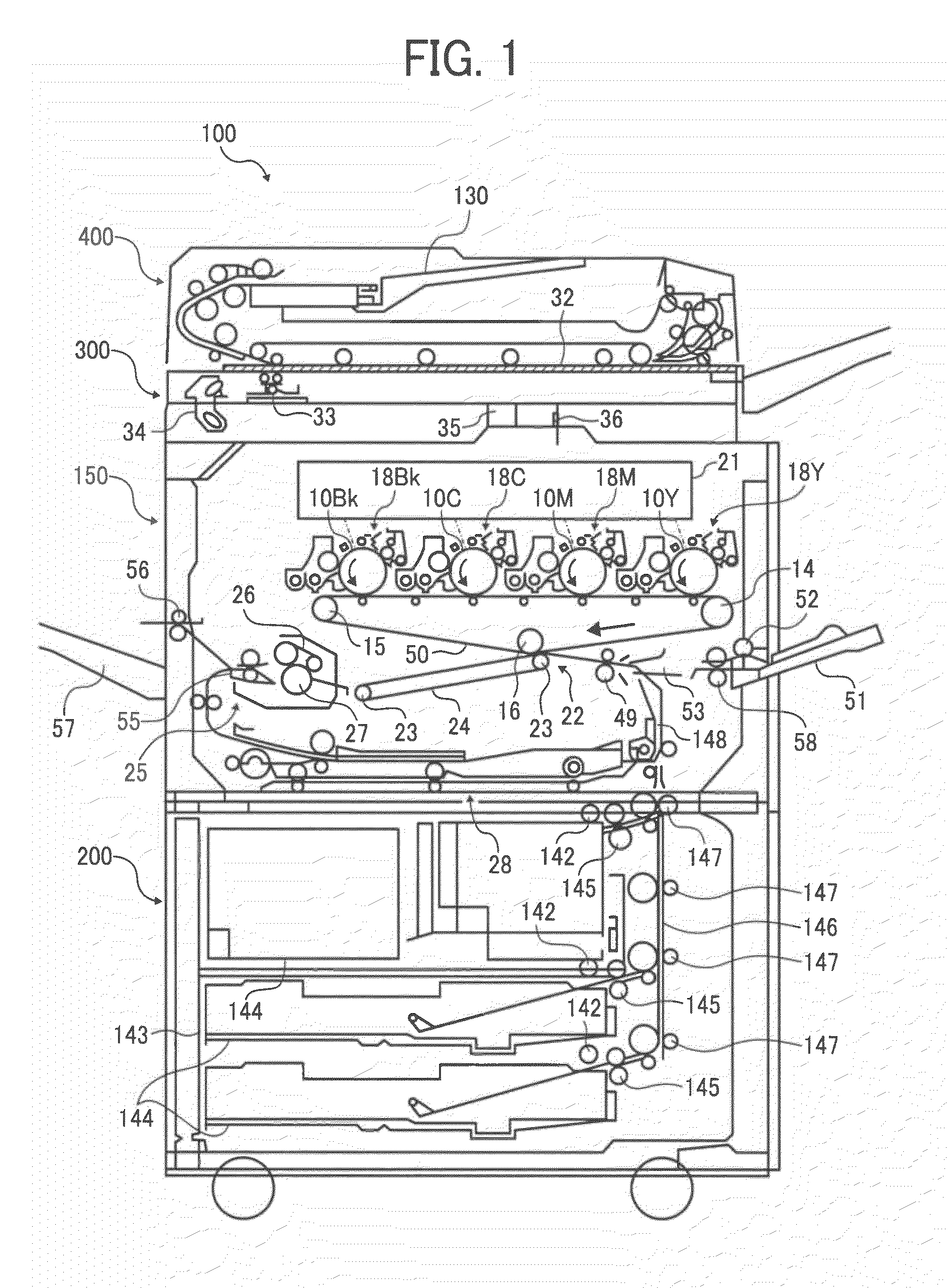

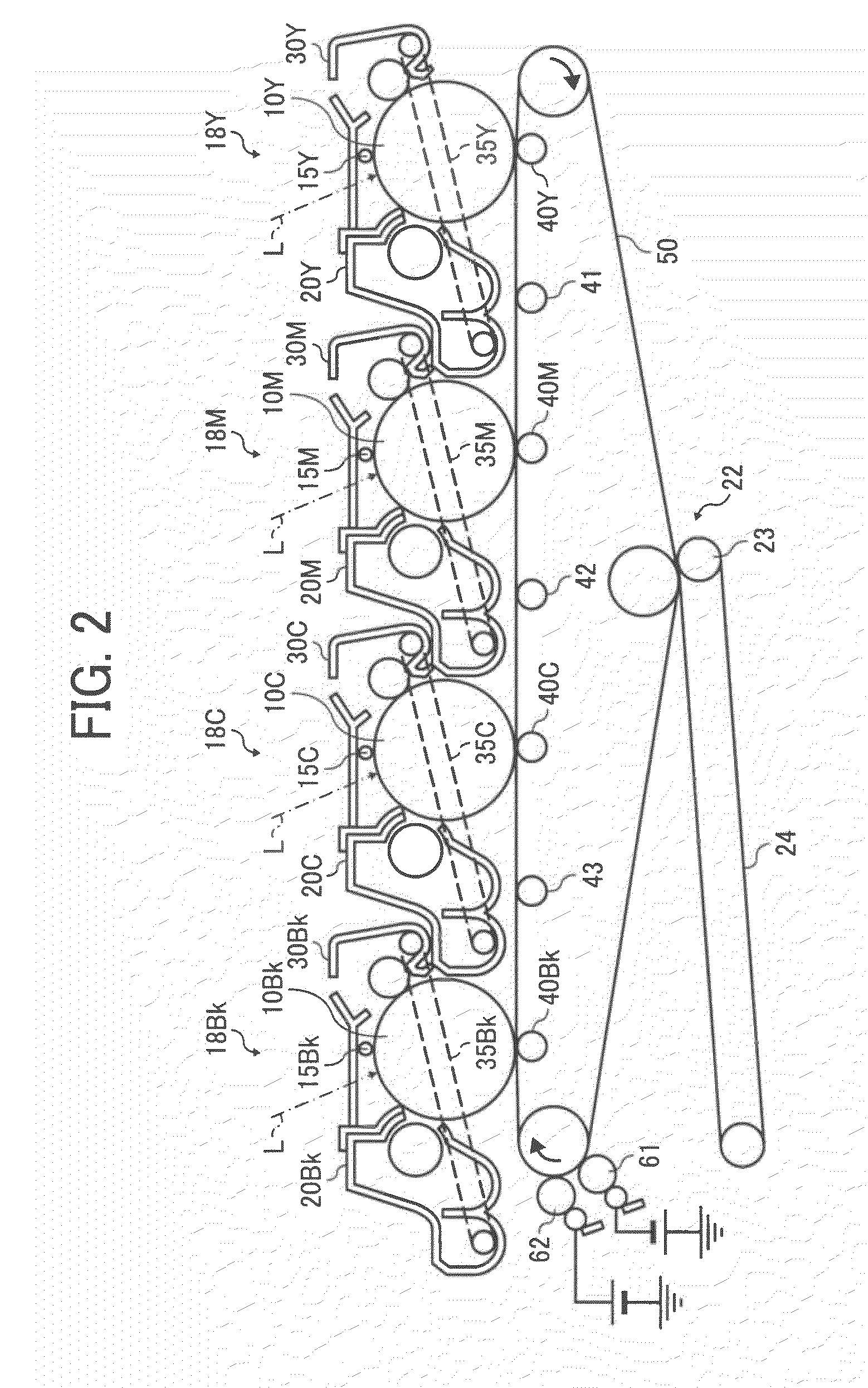

Toner, method of manufacturing toner, developer, and image forming method

InactiveUS20110086305A1Improve chargeabilityIncreased durabilityDevelopersElectrographic process apparatusCarbon ionOrganic solvent

Owner:RICOH KK

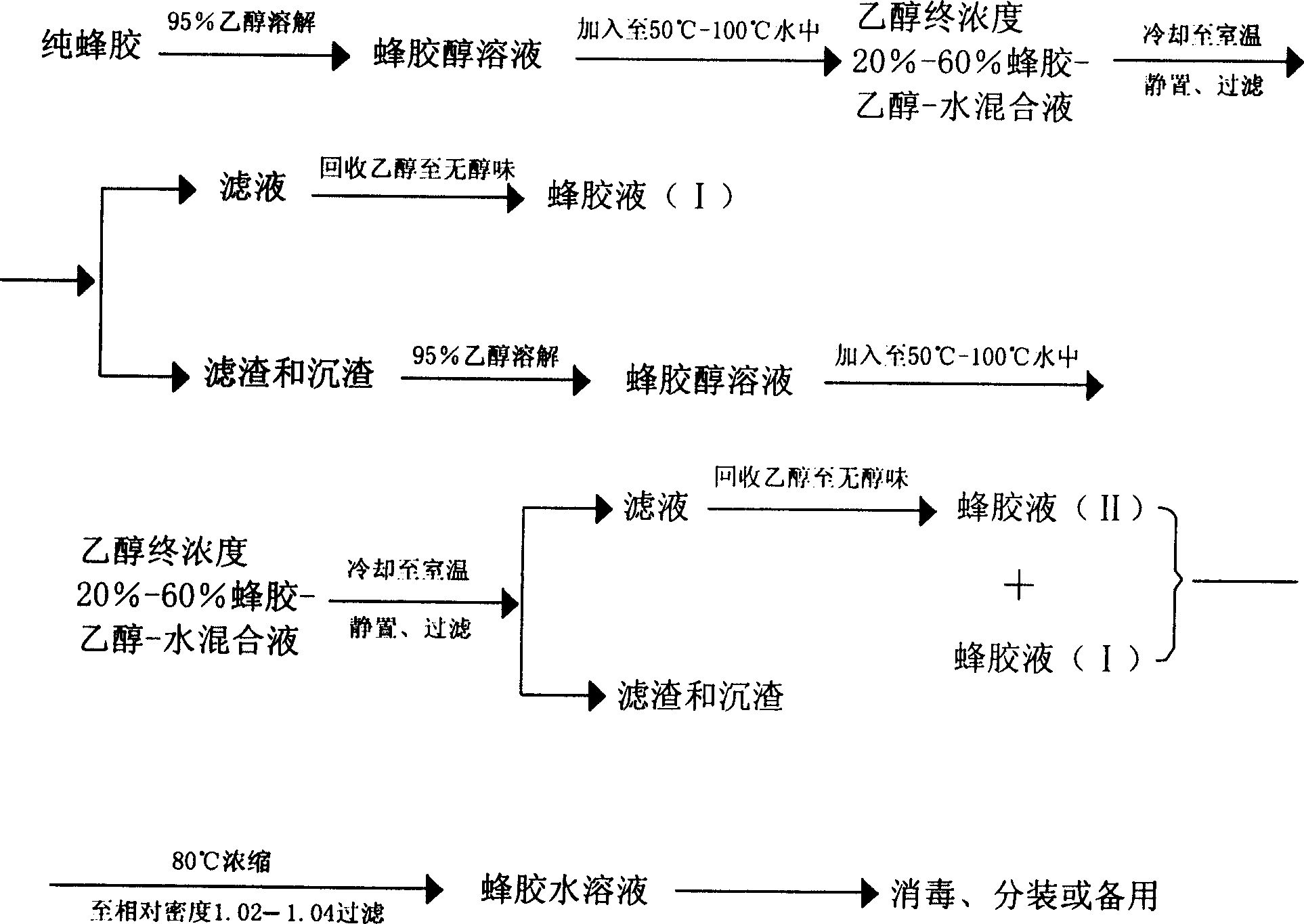

Process for preparing bee glue water solution and use

InactiveCN1682770ASimple processHigh in flavonoidsAnthropod material medical ingredientsMetabolism disorderAlcohol contentPropolis

Owner:ZHEJIANG ACAD OF TRADITIONAL CHINESE MEDICINE

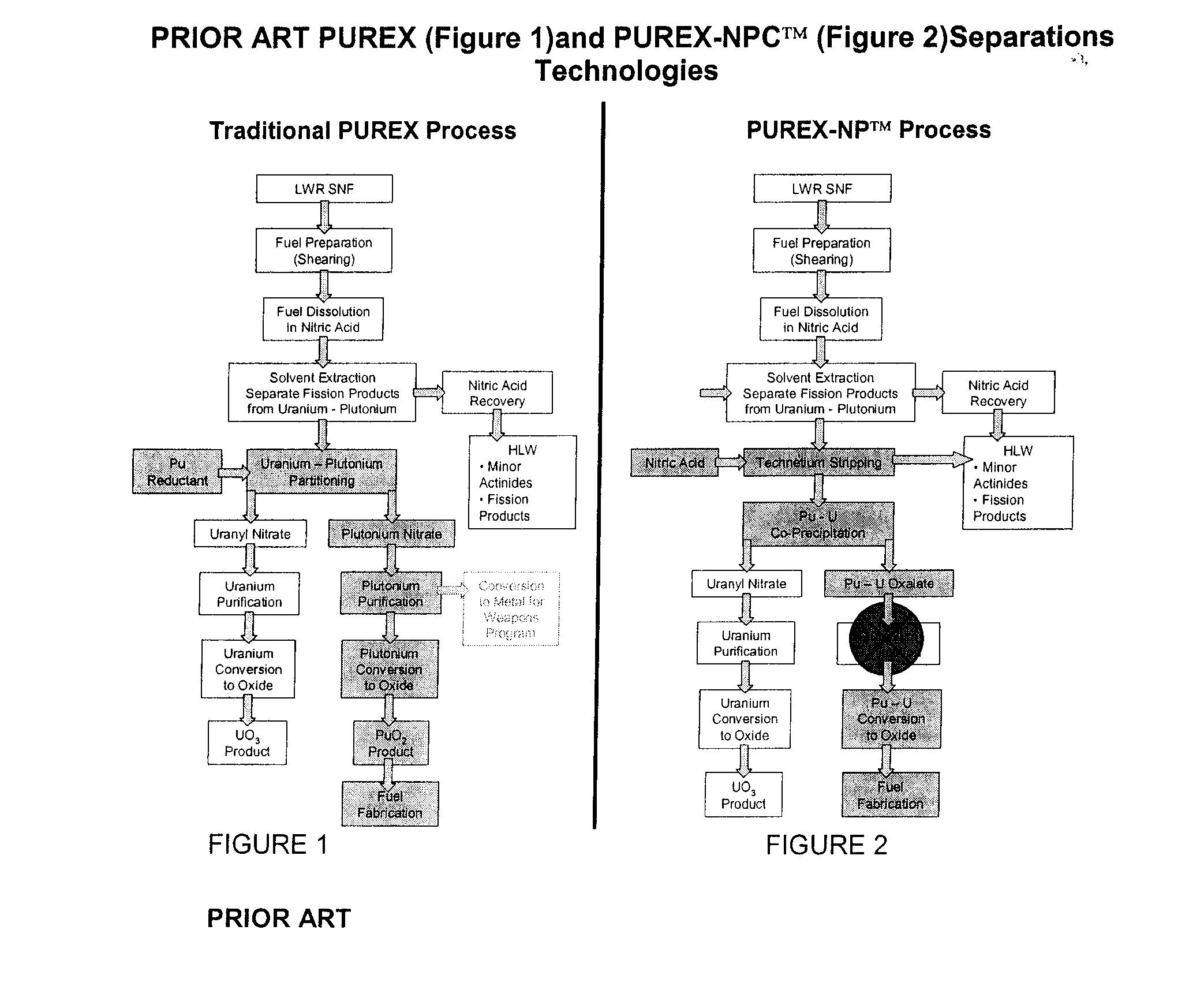

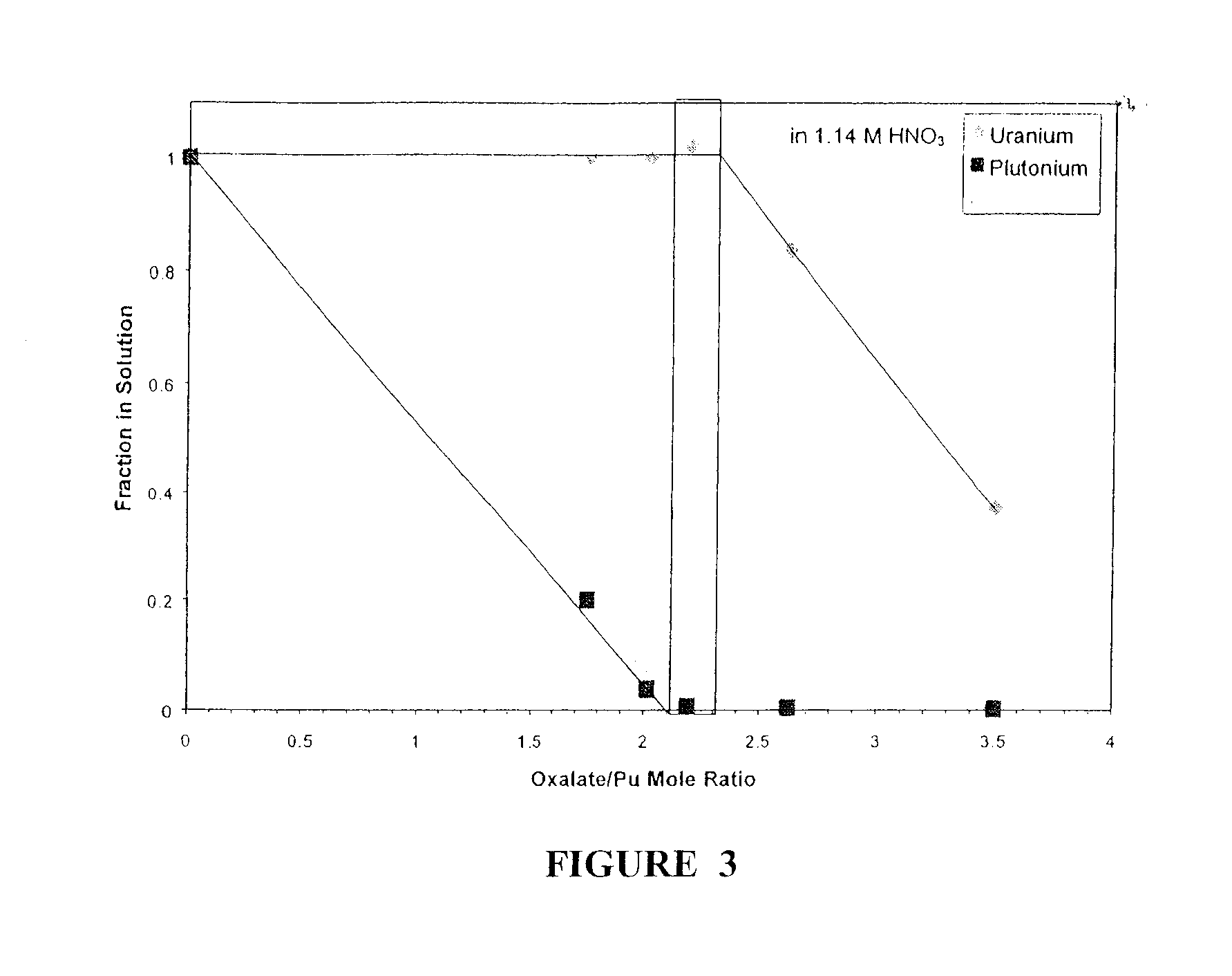

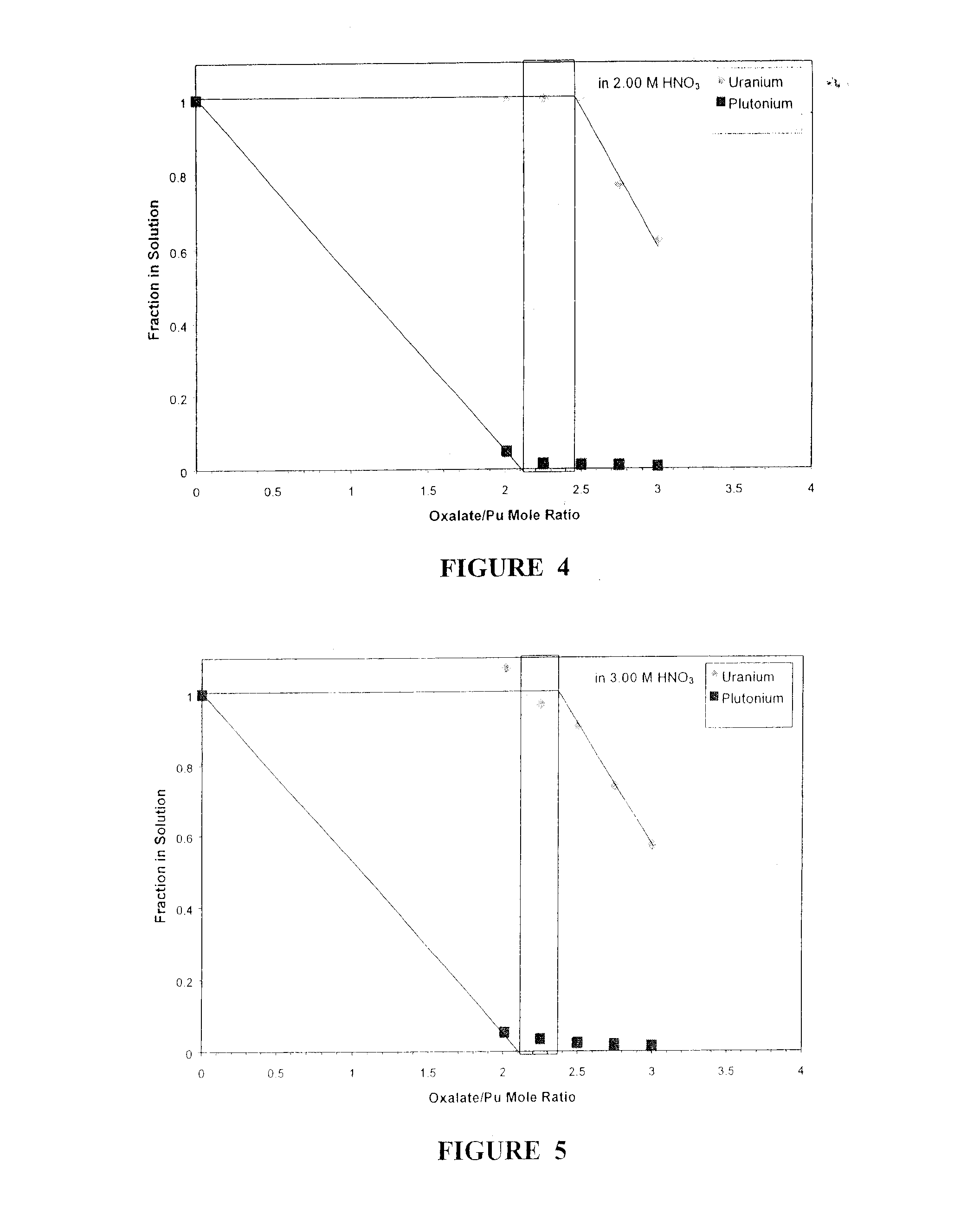

Process for Treating Spent Nuclear Fuel

InactiveUS20100301287A1Other chemical processesNuclear energy generationOrganic solventCarboxylic acid

Owner:CH2M HILL

Quaternary ammonium salt concrete anti-mud agent, and preparation method and application thereof

ActiveCN108545978AImprove securityThe production process is simpleOrganic compound preparationAmino compound preparationDistillationOrganic solvent

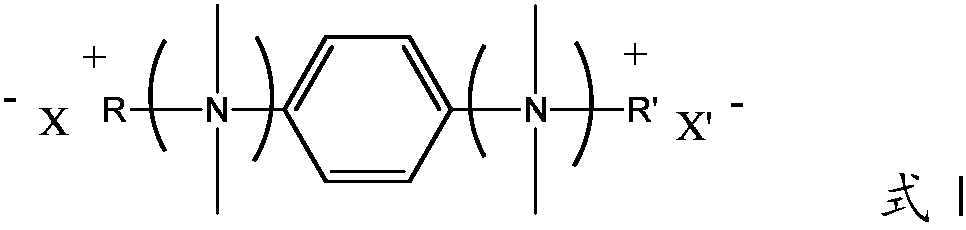

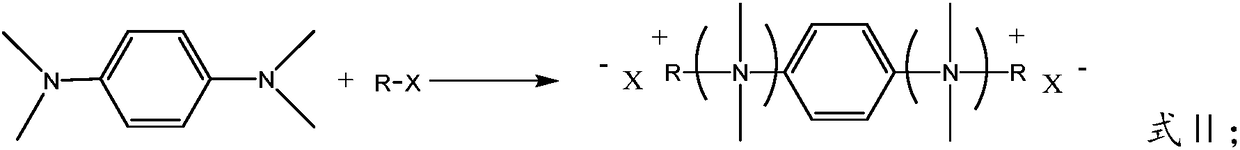

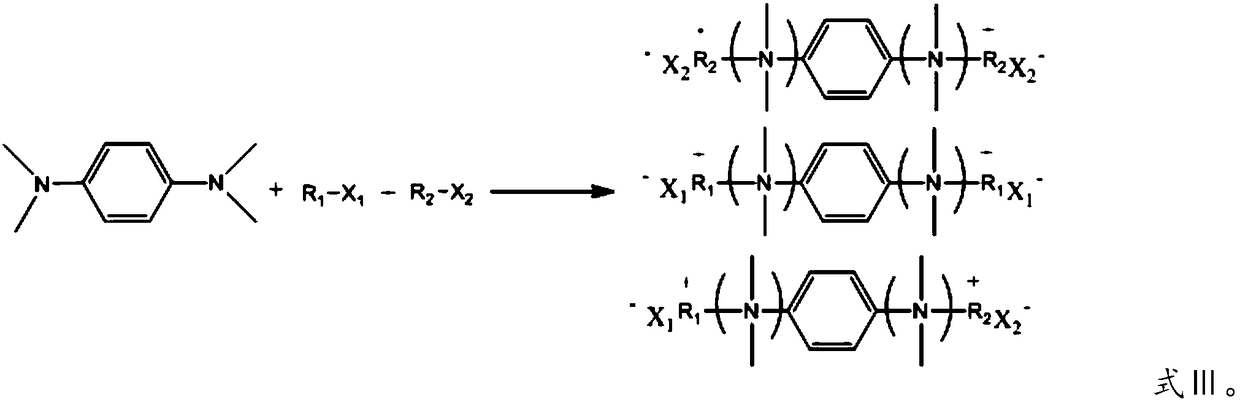

The invention provides a quaternary ammonium salt concrete anti-mud agent, and belongs to the technical field of building materials. The molecular structure of the quaternary ammonium salt concrete anti-mud agent is as shown in formula I, wherein R or R' is a hydrocarbyl group with a molecular weight of 200 or below, or a derivative of the hydrocarbyl group, and X or X' is selected from Cl, Br andI. The invention also provides a preparation method of the anti-mud agent. The preparation method comprises the following steps: 1) dissolving N,N,N,N-tetramethyl-1,4-phenylenediamine and a halogenated hydrocarbon into an inert organic solvent at an inert atmosphere; 2) controlling the temperature of the system, carrying out stirring, and carrying out reflux condensation; and 3) carrying out reduced pressure distillation to remove the organic solvent, adding distilled water to obtain an aqueous solution of the quaternary ammonium salt type concrete anti-mud agent. According to the anti-mud agent provided by the invention, epoxy monomers are not used as raw materials, the safety is high, and the production process is simple and convenient. When the usage amount of the anti-mud agent provided by the invention accounts for 0.05-0.25 wt% of the total mass of the concrete glue material, the addition amount of a water reducing agent of high-mud-containing mechanism sand concrete can be reduced by 0.5% or more, and the newly mixed concrete has no fluidity loss in 3 hours.

Owner:广西中建西部建设有限公司 +3

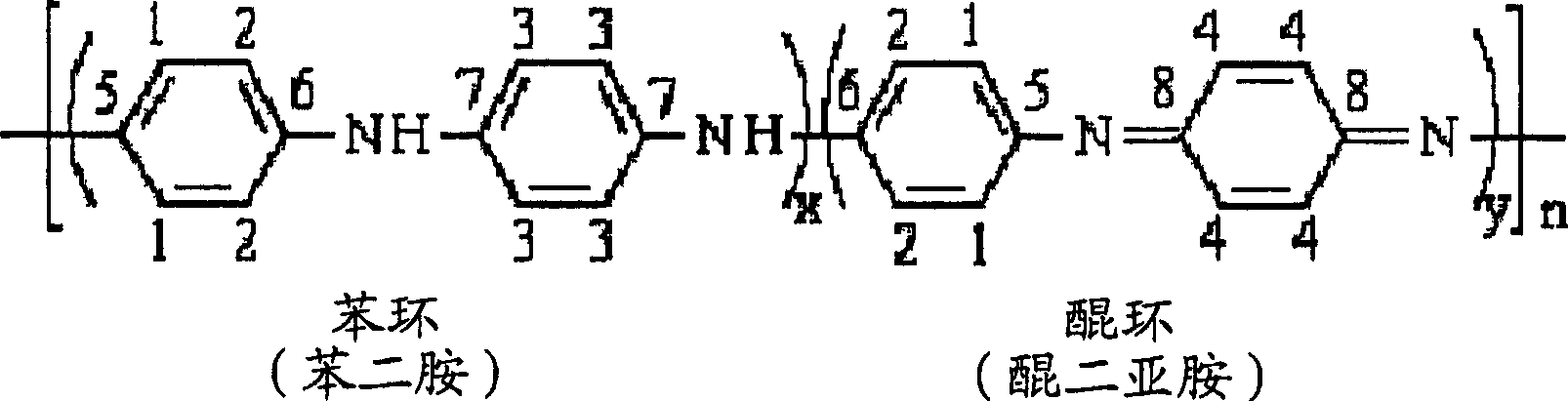

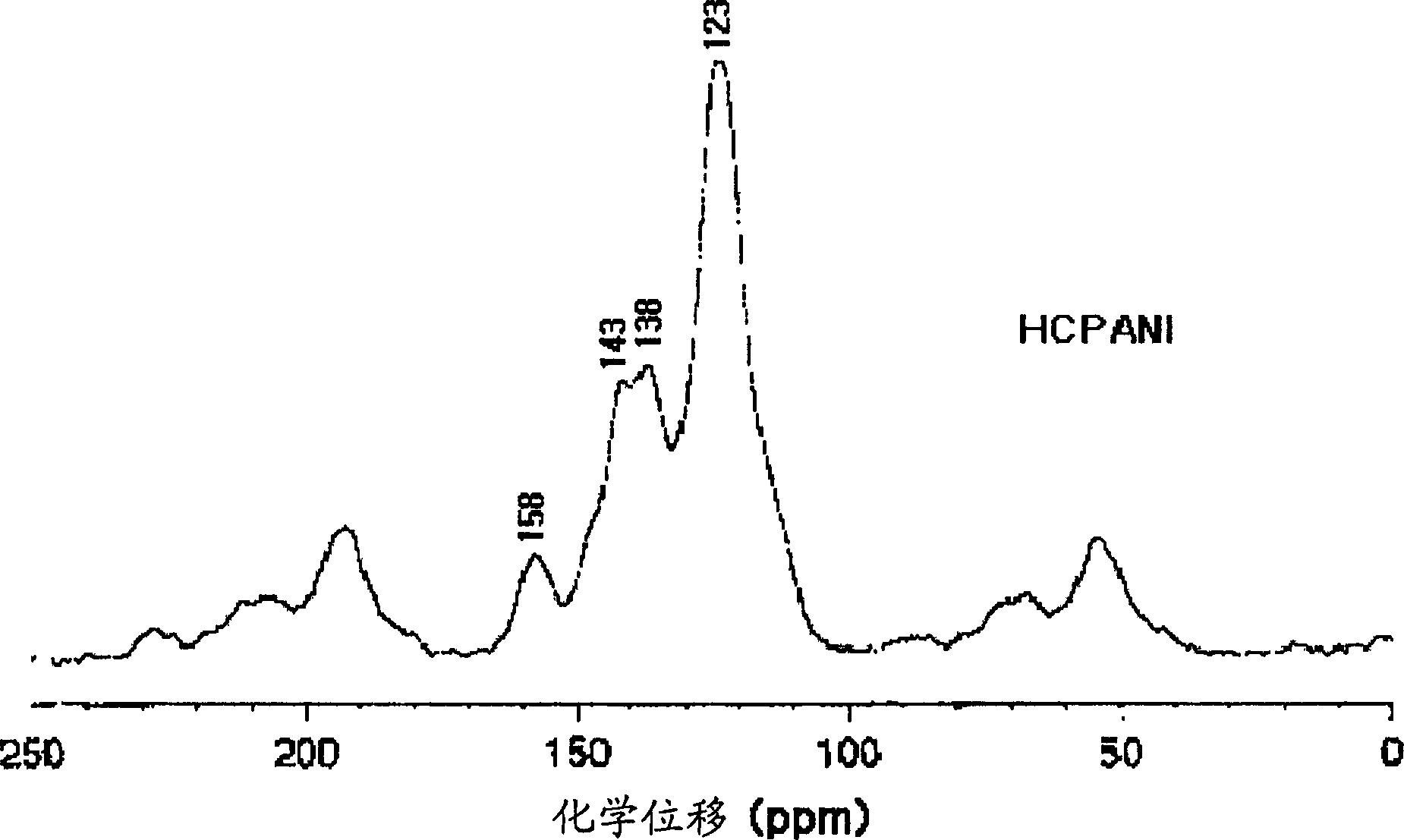

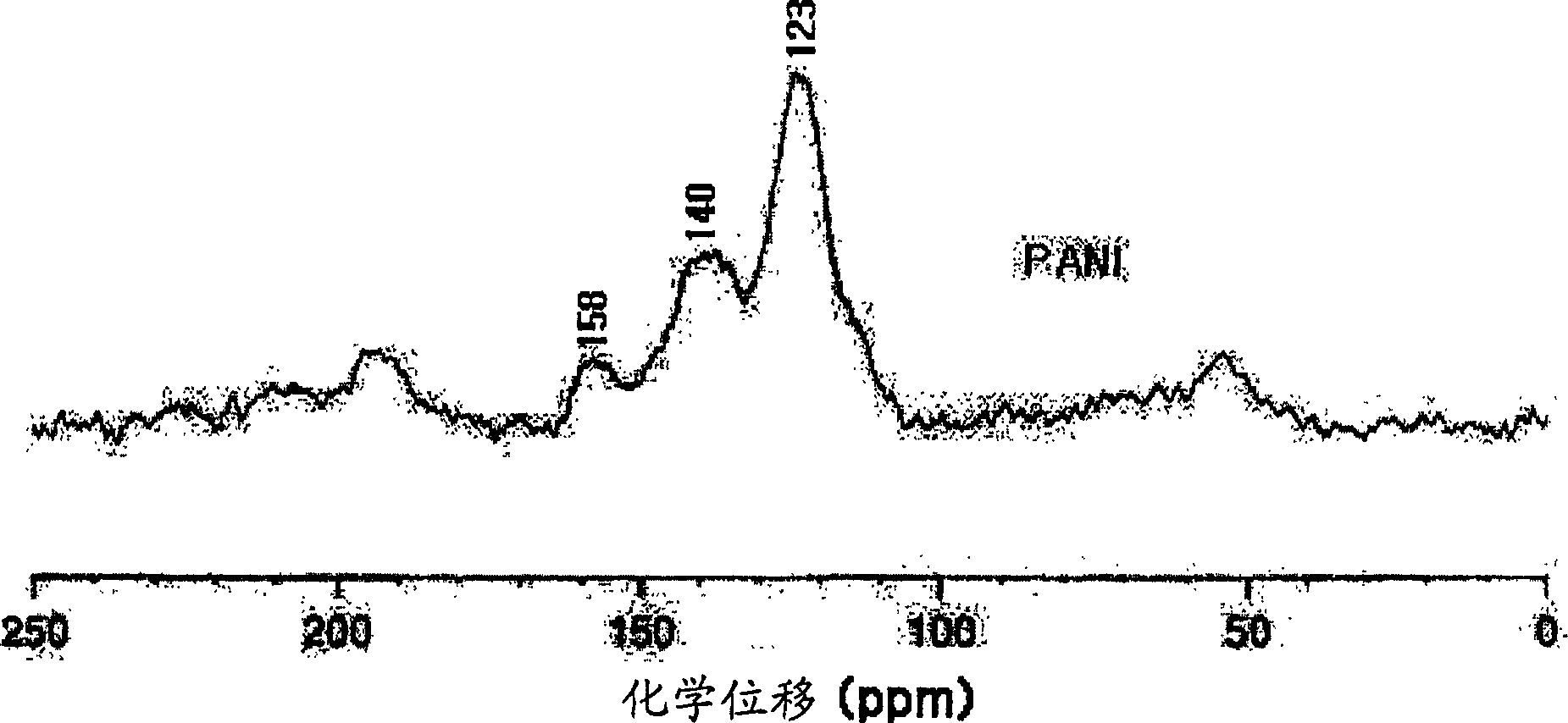

Conductive polymers having highly enhanced solubility in organic solvent and synthesizing process thereof

Owner:尹虎声 +1

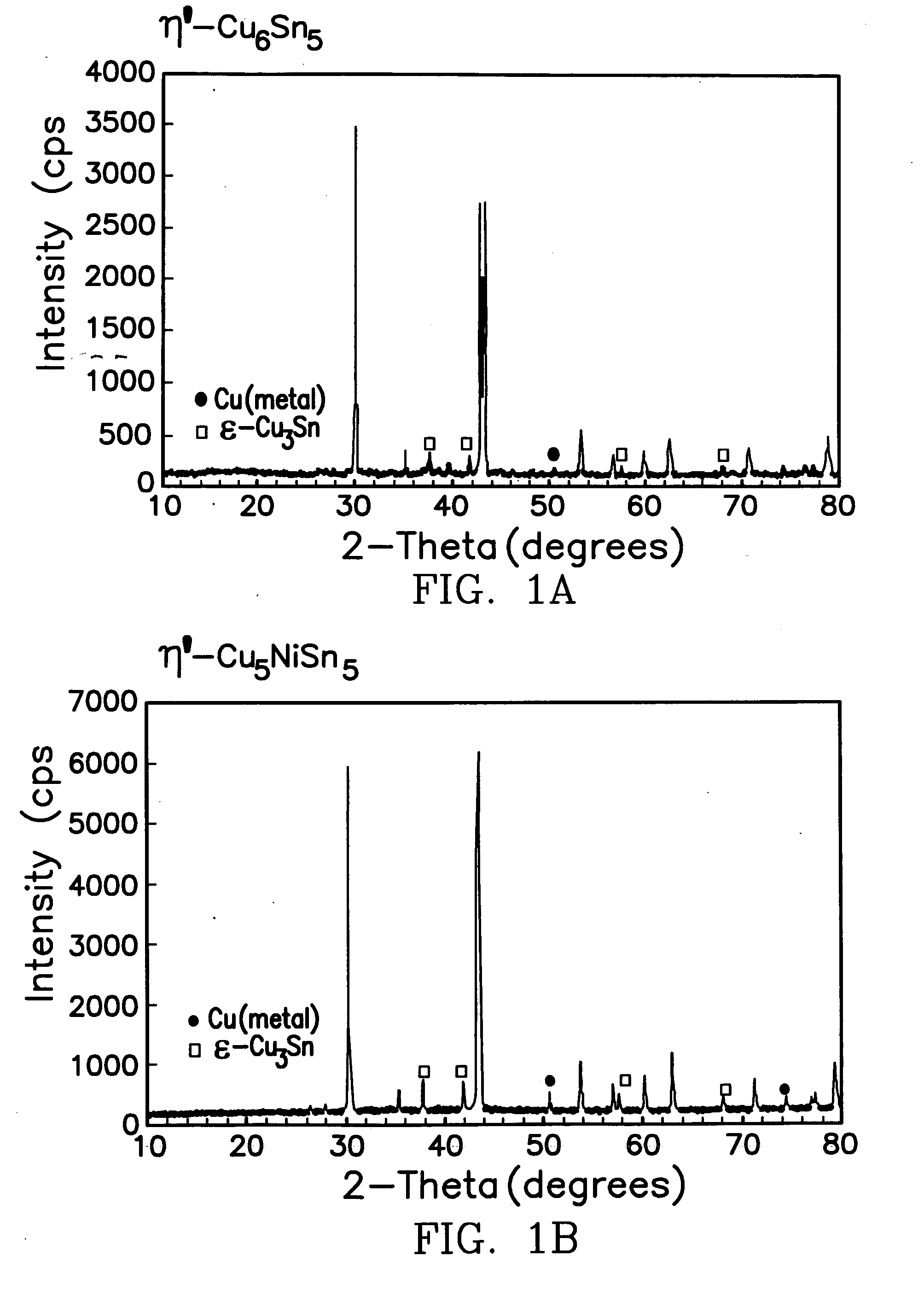

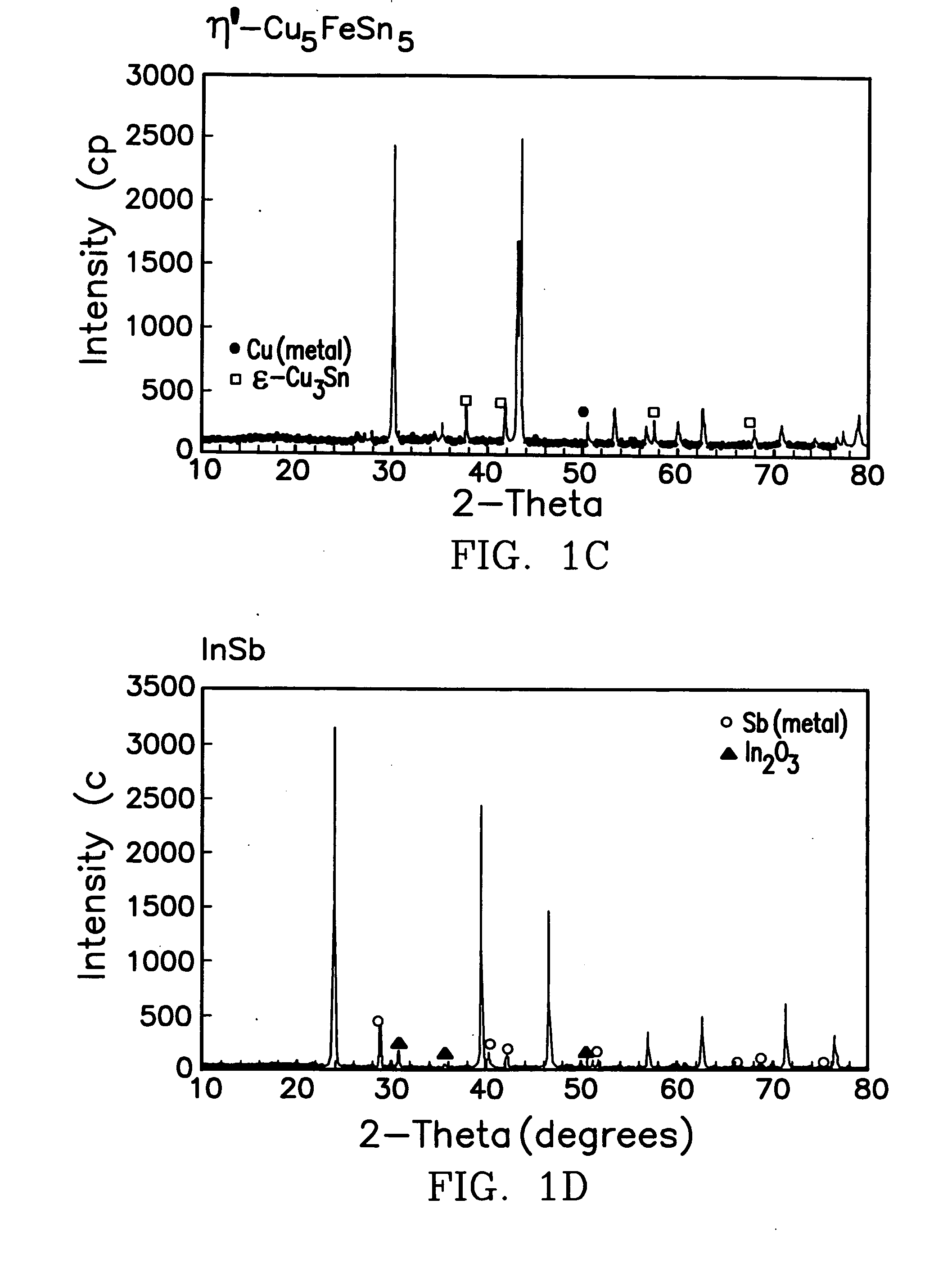

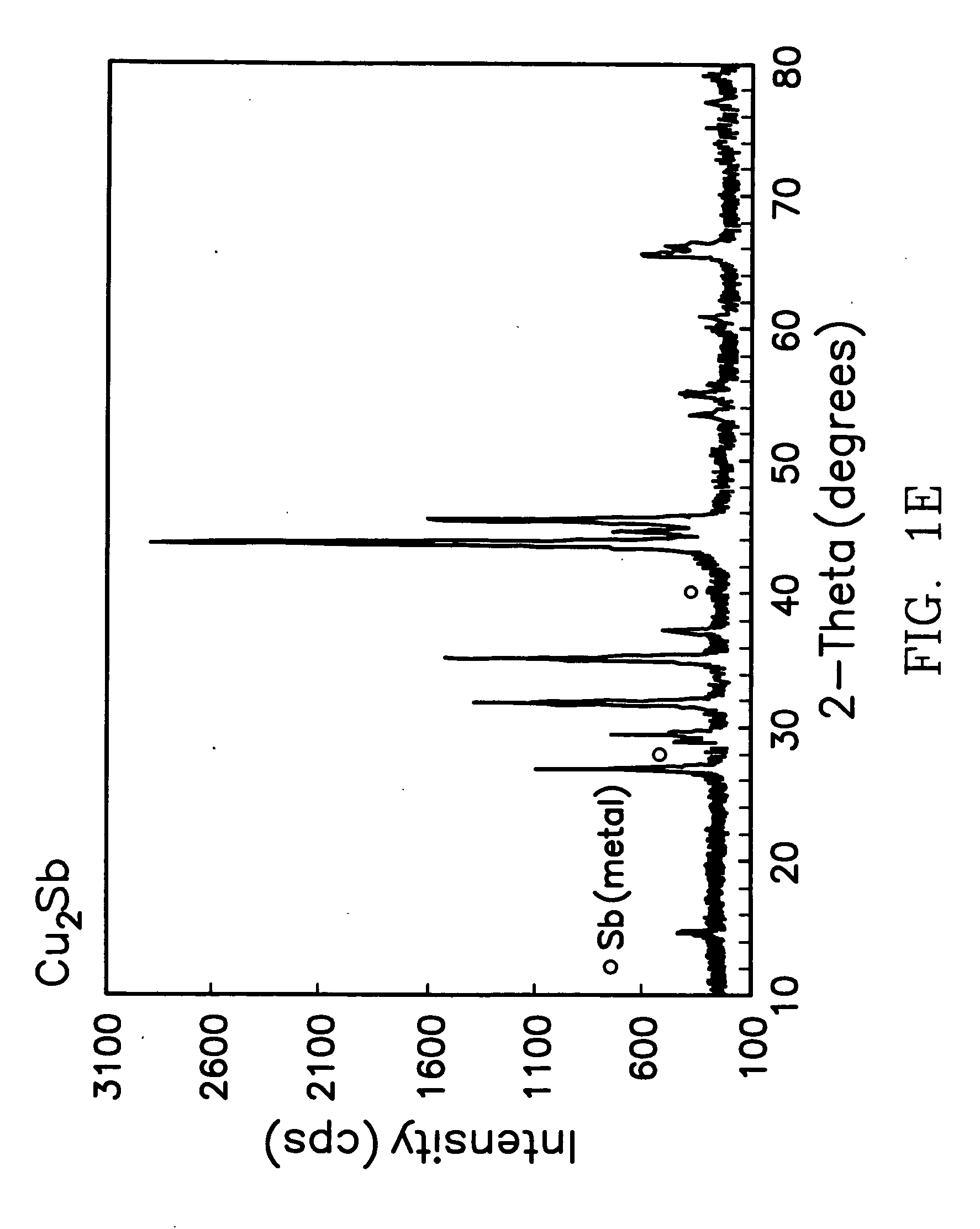

Synthesis of intermetallic negative electrodes for lithium cells and batteries

InactiveUS20070111094A1Primary cell to battery groupingLi-accumulatorsElectrochemical cellOrganic solvent

Owner:UCHICAGO ARGONNE LLC

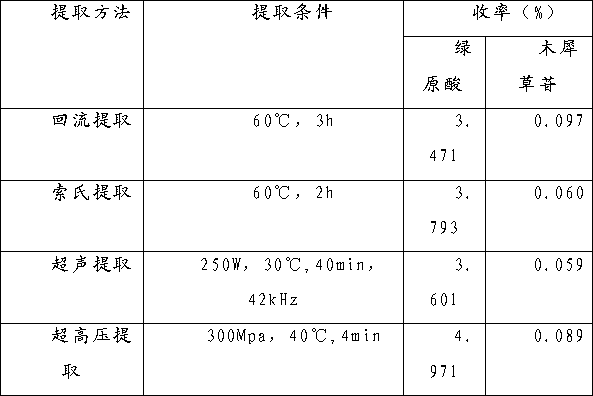

Chlorogenic acid and galuteolin in honeysuckle flower superhigh pressure extraction method and HPLC quantitative analysis method

Owner:SUZHOU UNIV

Low-temperature electrolyte for lithium iron phosphate battery

InactiveCN106129472AImprove low temperature conductivityReduced solvation radiusSecondary cellsElectrolytesLithium vanadium phosphate batteryTetrafluoroborate

Owner:DONGFENG COMML VEHICLE CO LTD

On-line cleaning device for heat exchanger with oily dirt

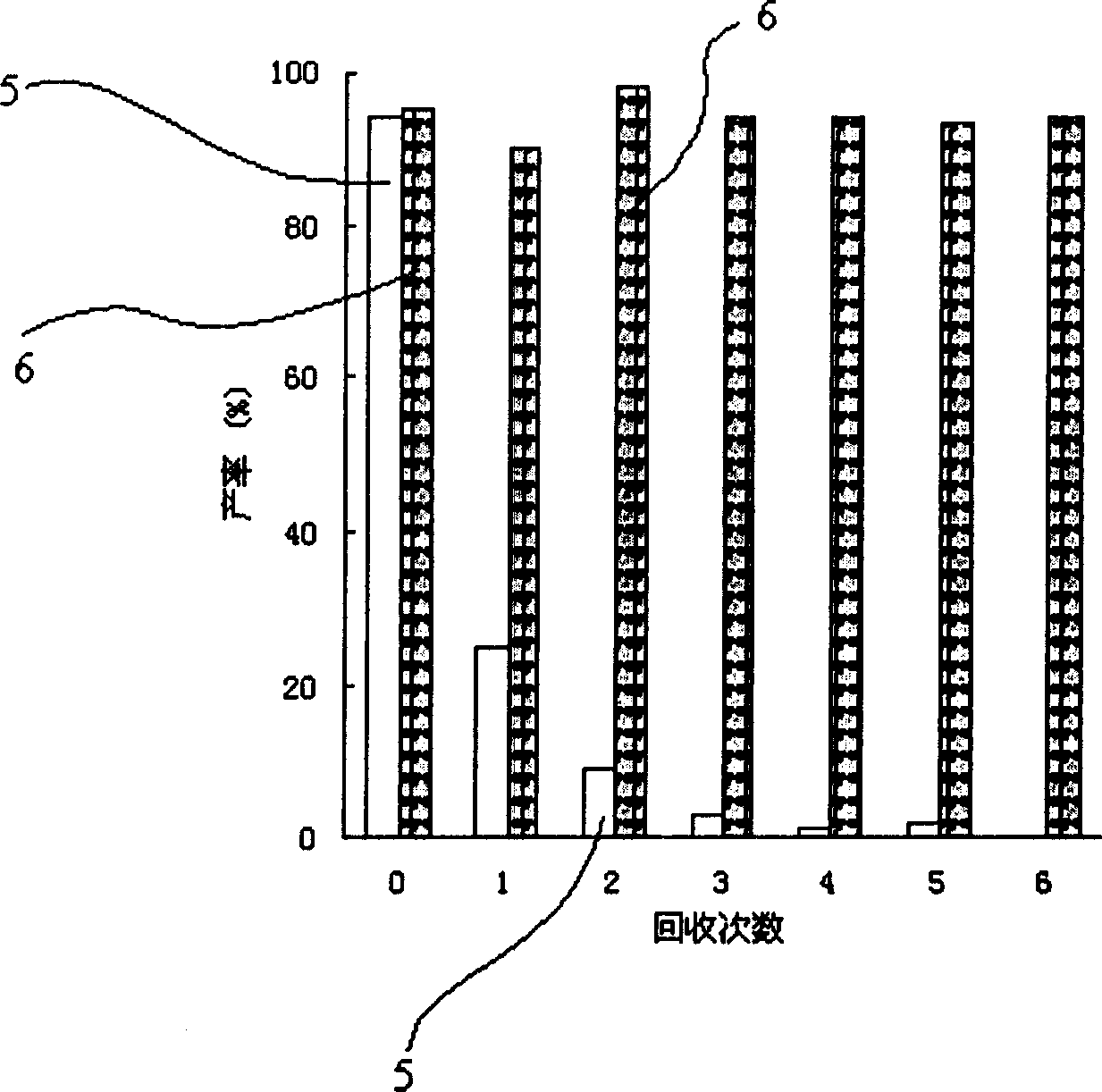

An online cleaning device for a heat exchanger with oily dirt, mainly composed of a cleaning agent storage tank (1), a hot oil pump a (2), a hot oil pump b (3), a cleaning agent heating device (4), and a steel wire pressurized hose (5) and heat exchanger (6), the components of the above-mentioned main structure pass through flange joints (11), tee joints (12), ball valves (13), reducing joints (14) and steel wire pressurized hoses (5) and other components are connected into a cleaning device capable of stable operation and recycling, wherein the cleaning agent heating device (4) is a welded box structure, and is provided with a steam heating coil (41), a filter plate (42), Sewage cleaning hole (43), sewage pipe (44) and removable transparent case cover (47). The invention has simple and practical structure, low cost, avoids the disassembly and transportation of the heat exchanger, can be cleaned at the production site, and multiple devices can be cleaned at the same time in a cycle loop, convenient and flexible to use, and easy to clean oil-soluble dirt The main component of the agent is an organic solvent, which can be reused after being circulated and filtered. It has good energy saving benefits, no pollution to the environment, and has broad market prospects.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

Method for forming ultrathin-wall porous metal pipe fitting

Owner:UNIV OF SCI & TECH BEIJING

High-performance water-based bicomponent epoxy zinc rich primer and preparation method thereof

ActiveCN107573816AReduce usageImprove protectionAnti-corrosive paintsEpoxy resin coatingsEpoxyCollocation

The invention relates to a high-performance water-based bicomponent epoxy zinc rich primer and a preparation method thereof. A water-based bicomponent epoxy zinc rich coating A in the high-performancewater-based bicomponent epoxy zinc rich primer comprises a water-based epoxy curing agent, an additive A, a complex solubilizer, zinc powder, zinc and an anti-settling agent; a water-based bicomponent epoxy zinc rich coating B comprises a water-based epoxy emulsion and an additive B; the weight ratio of the coating A to the coating B is at 100 to (10-30). The preparation method comprises the following steps: (1) uniformly mixing the components in the coating A at ratio and using a 100-mesh screen for filtering; (2) uniformly mixing the components in the coating B at ratio; and uniformly mixing the coating A with the coating B at the weight ratio in a use process and regulating the construction viscosity. When the high-performance water-based bicomponent epoxy zinc rich primer is used, water is taken as a solvent, so that the use of the organic solvent is greatly reduced and the environmental protection is benefited. The collocation of the anti-settling agent is utilized to solve the problems of storage and construction.

Owner:SHANDONG QIWEI NEW MATERIALS CO LTD

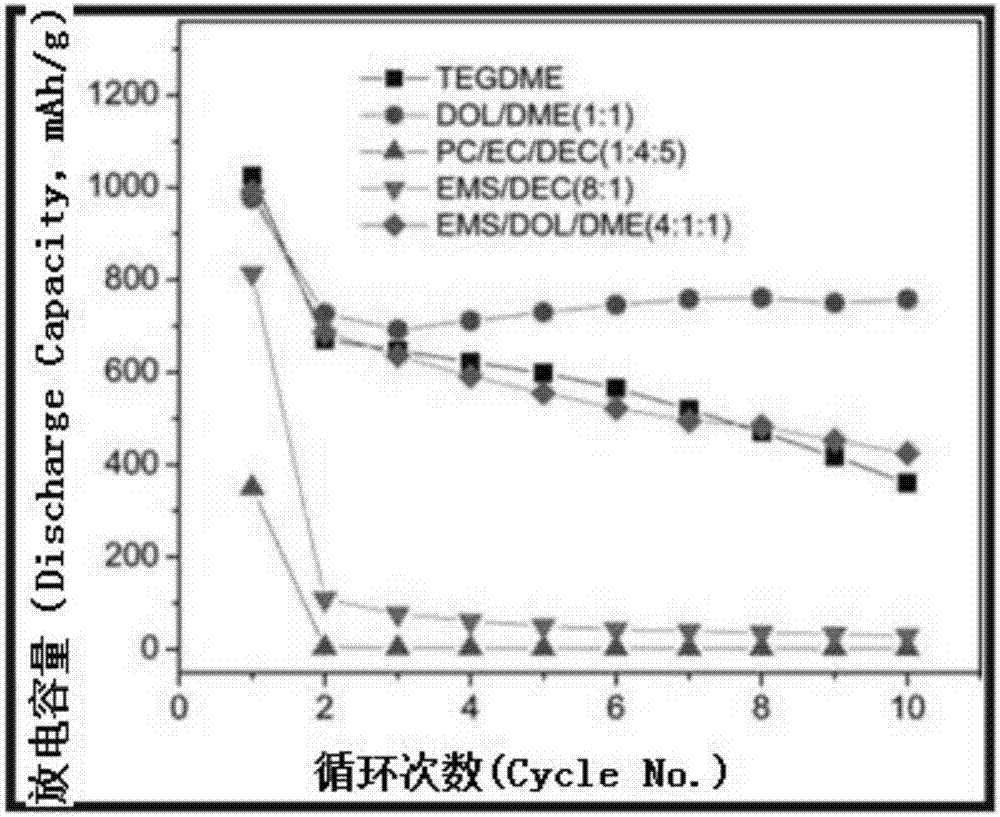

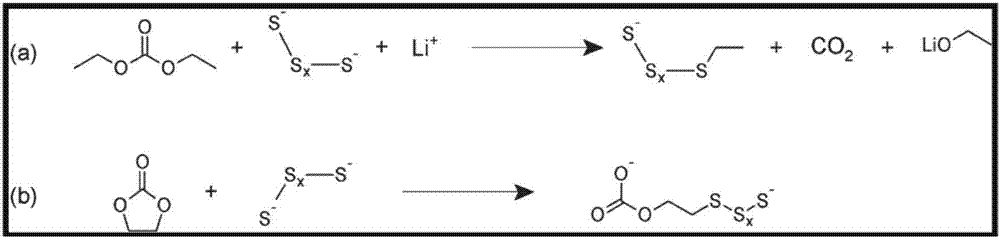

Lithium-sulfur battery electrolyte and lithium-sulfur battery adopting same

Owner:SHANDONG UNIV

Method for extracting unsaturated fatty acids from eucalyptus leaves

InactiveCN102604735ALow costSimple extraction methodFatty-oils/fats refiningFatty-oils/fats productionCholesterolDissolution

Owner:CHINA EUCALYPT RES CENT

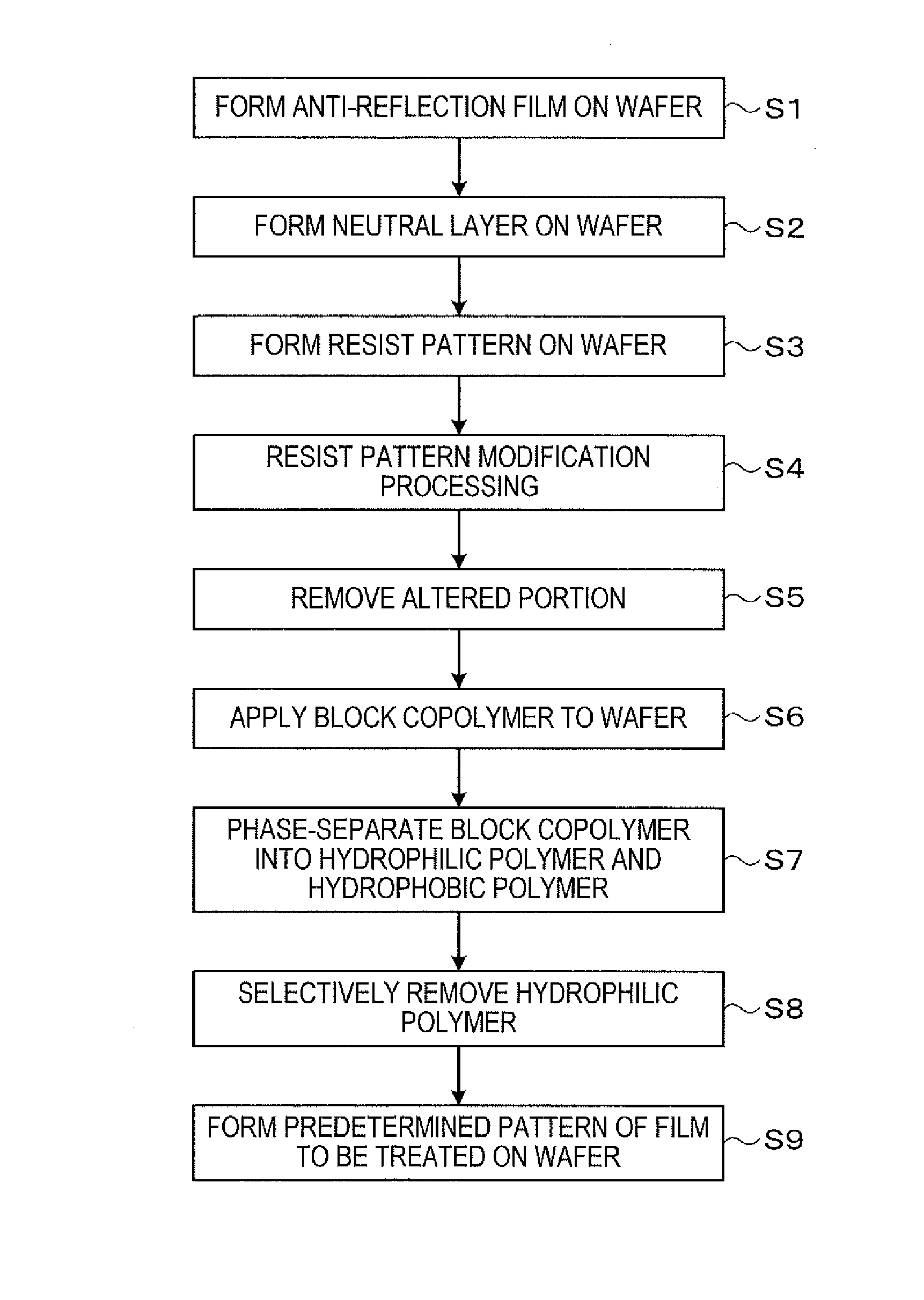

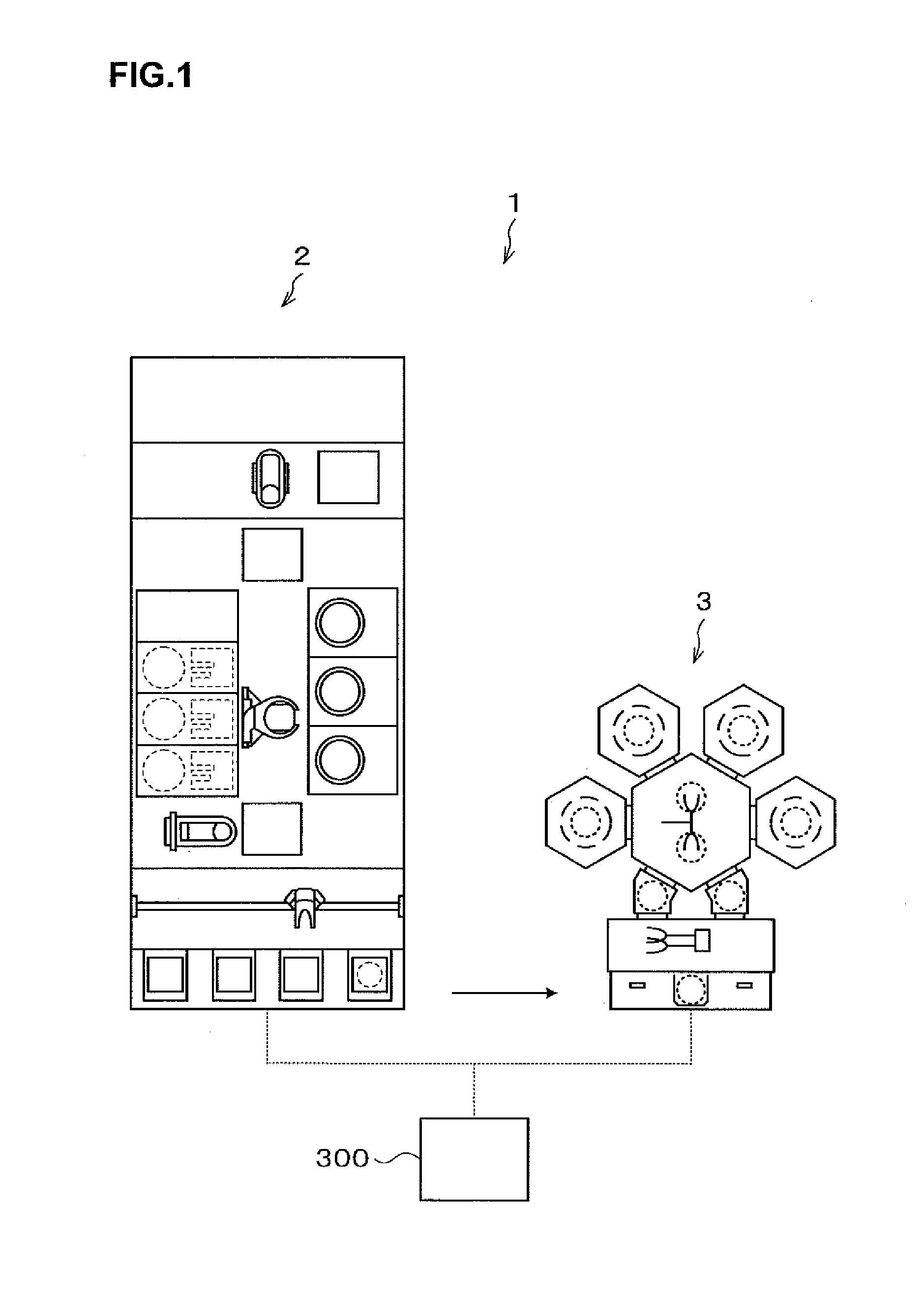

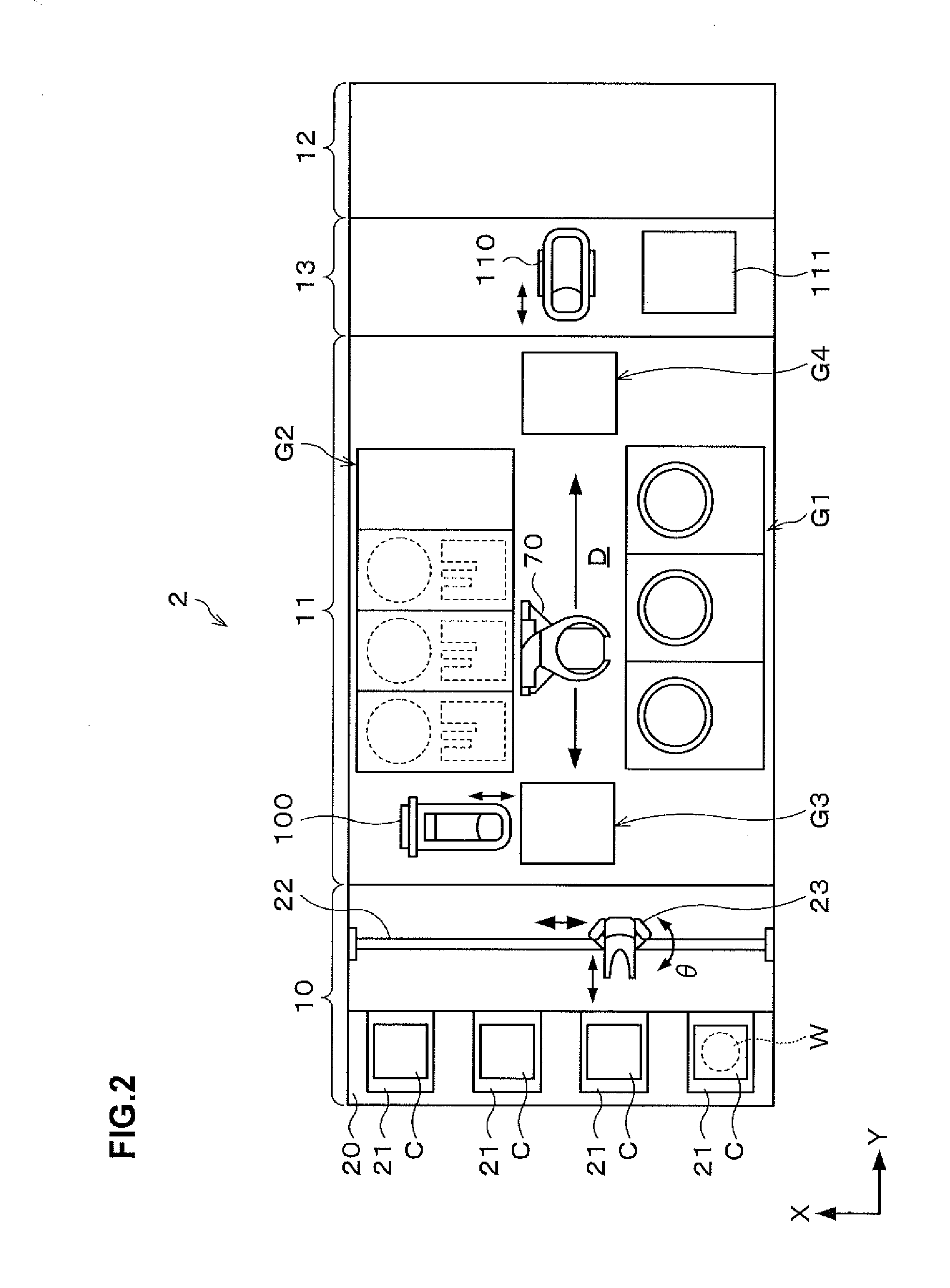

Substrate treatment method, computer storage medium, and substrate treatment system

ActiveUS20150255271A1Electric discharge tubesSemiconductor/solid-state device manufacturingResistHydrophilic polymers

Owner:TOKYO ELECTRON LTD

Method for producing microbial grease by fermenting inulin serving as raw material

InactiveCN102417915AExpand sourceLow costBiofuelsMicroorganism based processesBiodiesel feedstockBiodiesel

Owner:HENAN UNIV OF SCI & TECH

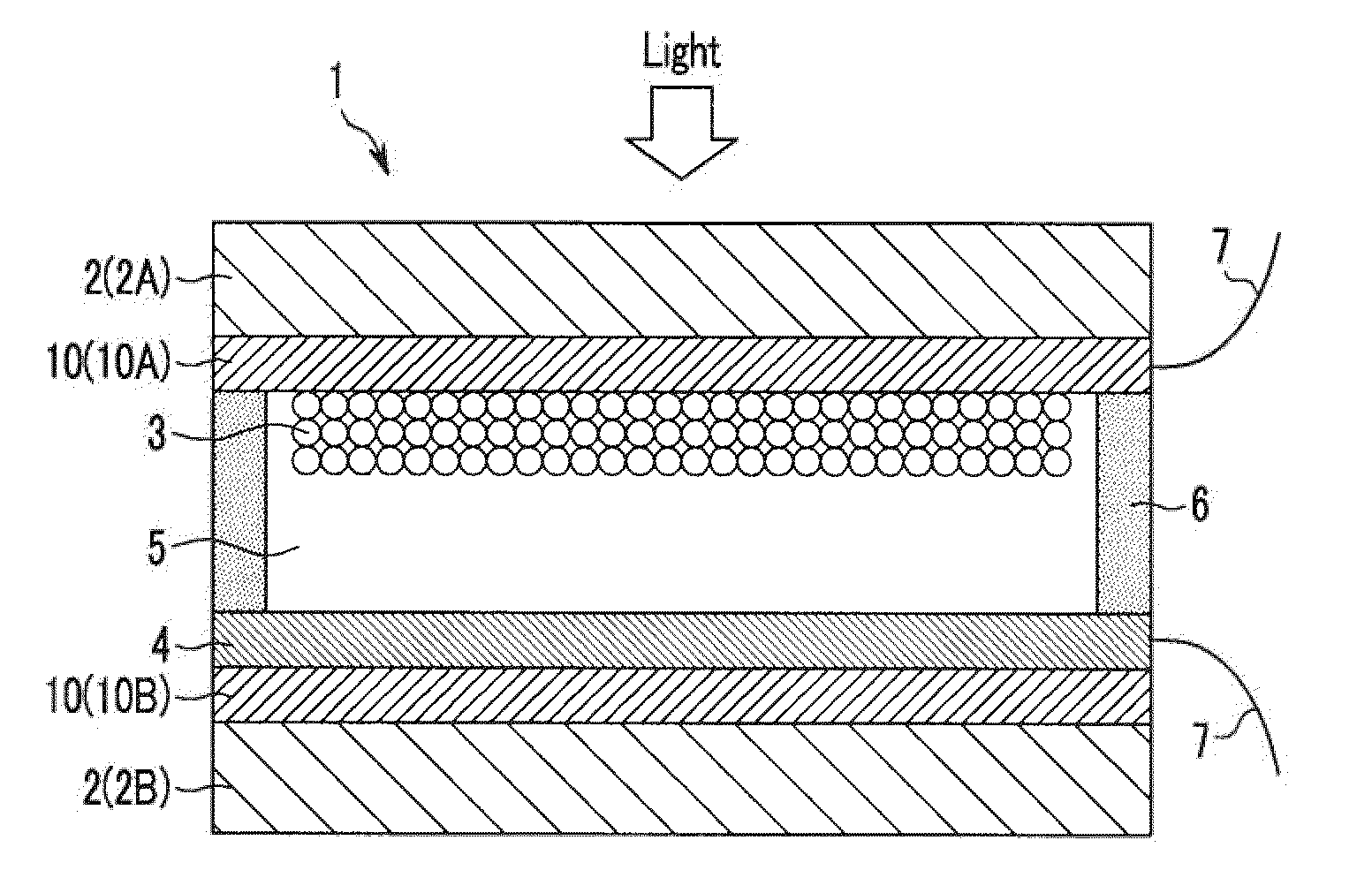

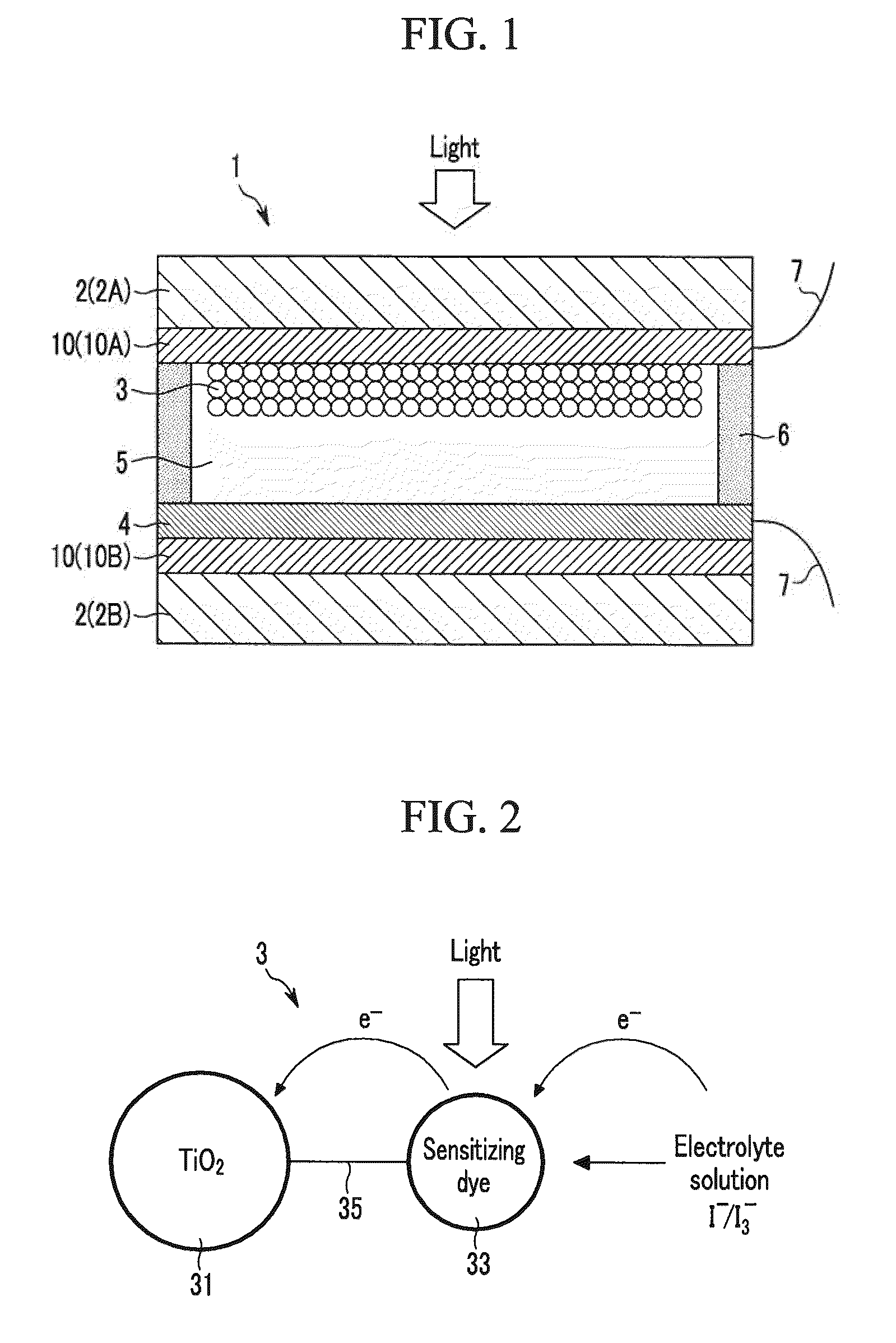

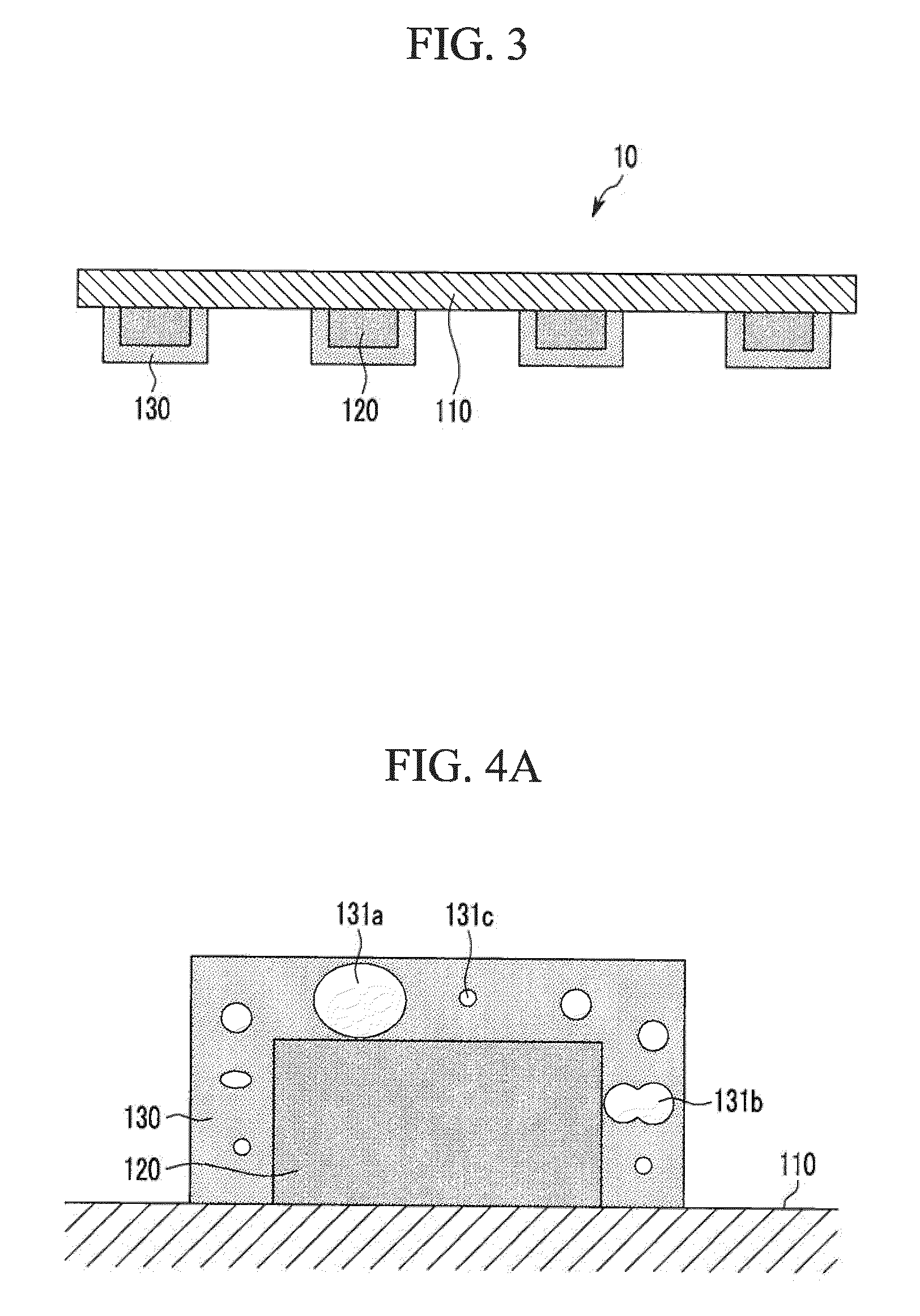

Glass paste composition, electrode substrate prepared using same, method of preparing electrode substrate, and dye sensitized solar cell including electrode substrate

InactiveUS20110088758A1Generation of cracking can be suppressed and preventedGood electrolyte solution resistanceElectrolytic capacitorsSolid-state devicesOrganic solventFrit

Owner:SAMSUNG SDI CO LTD

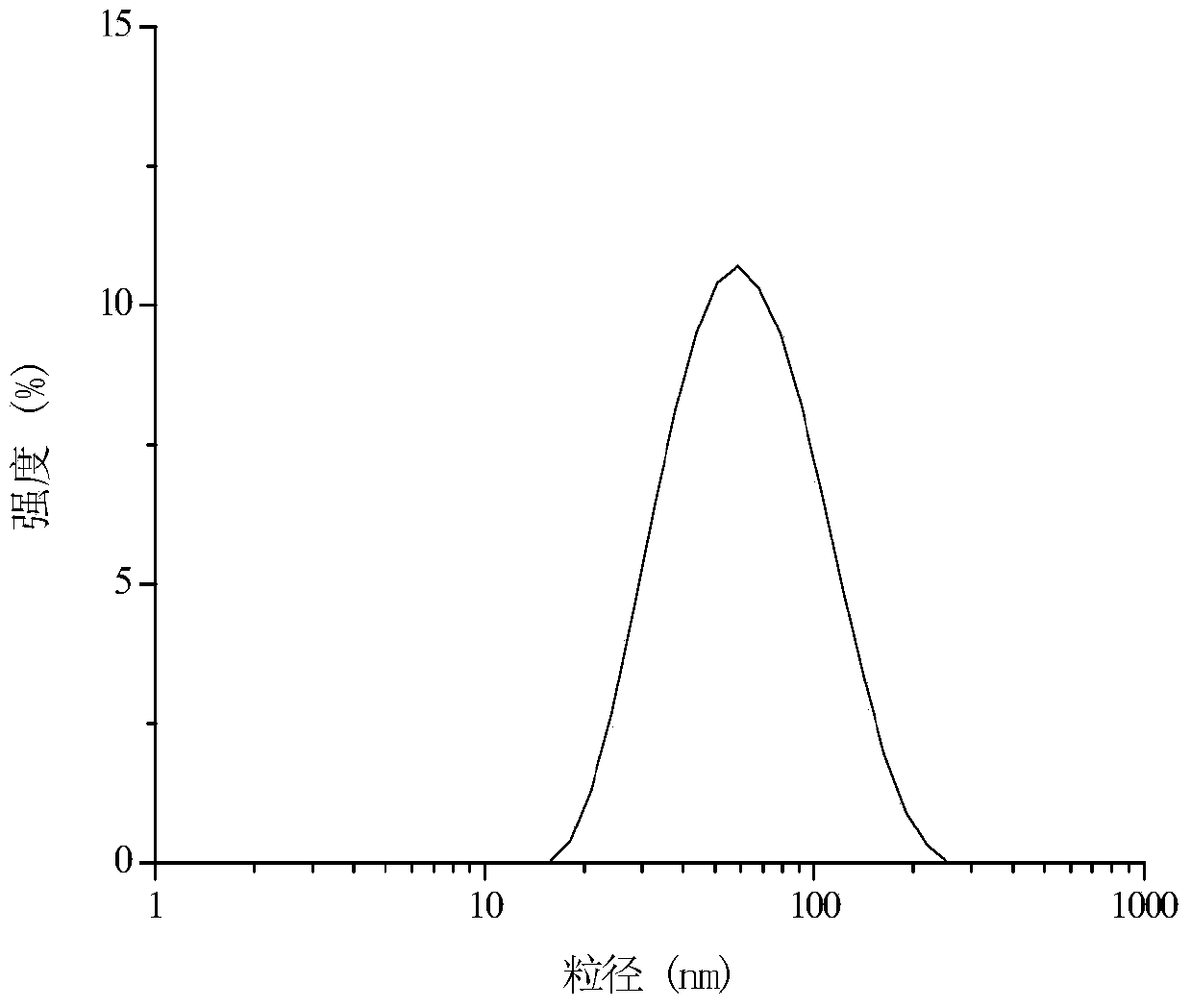

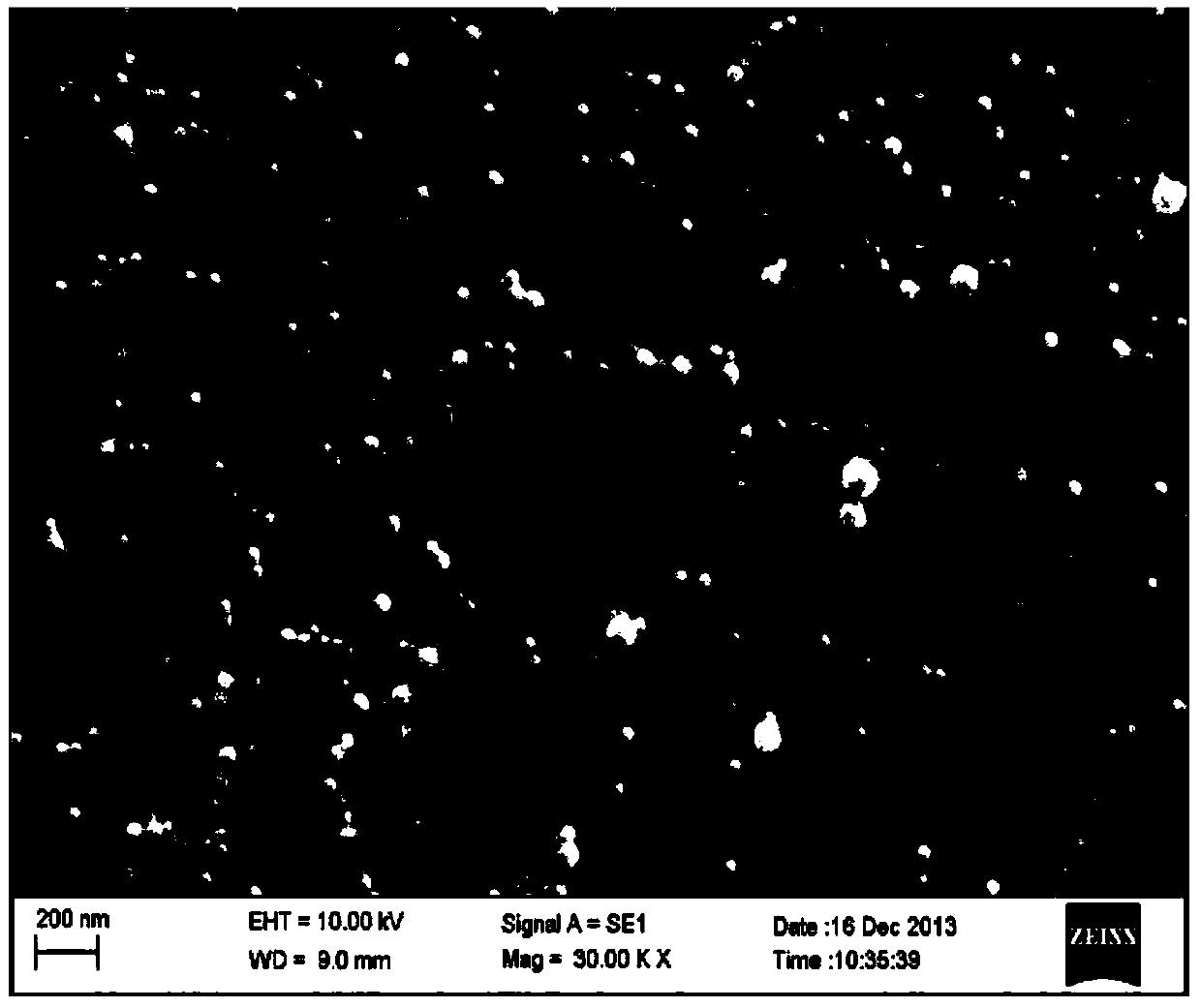

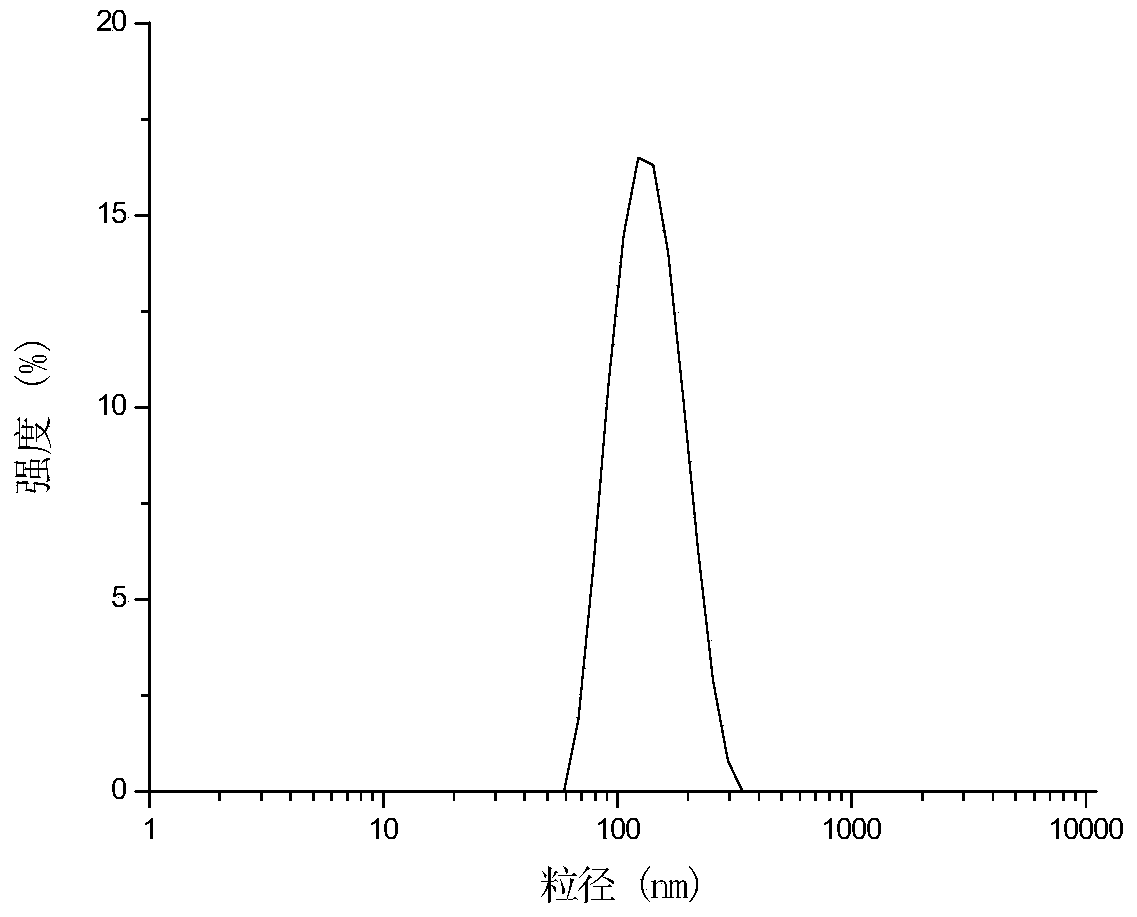

Self-assembly starch nanoparticle and preparation method thereof

Owner:SOUTH CHINA UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap