Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Dissolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

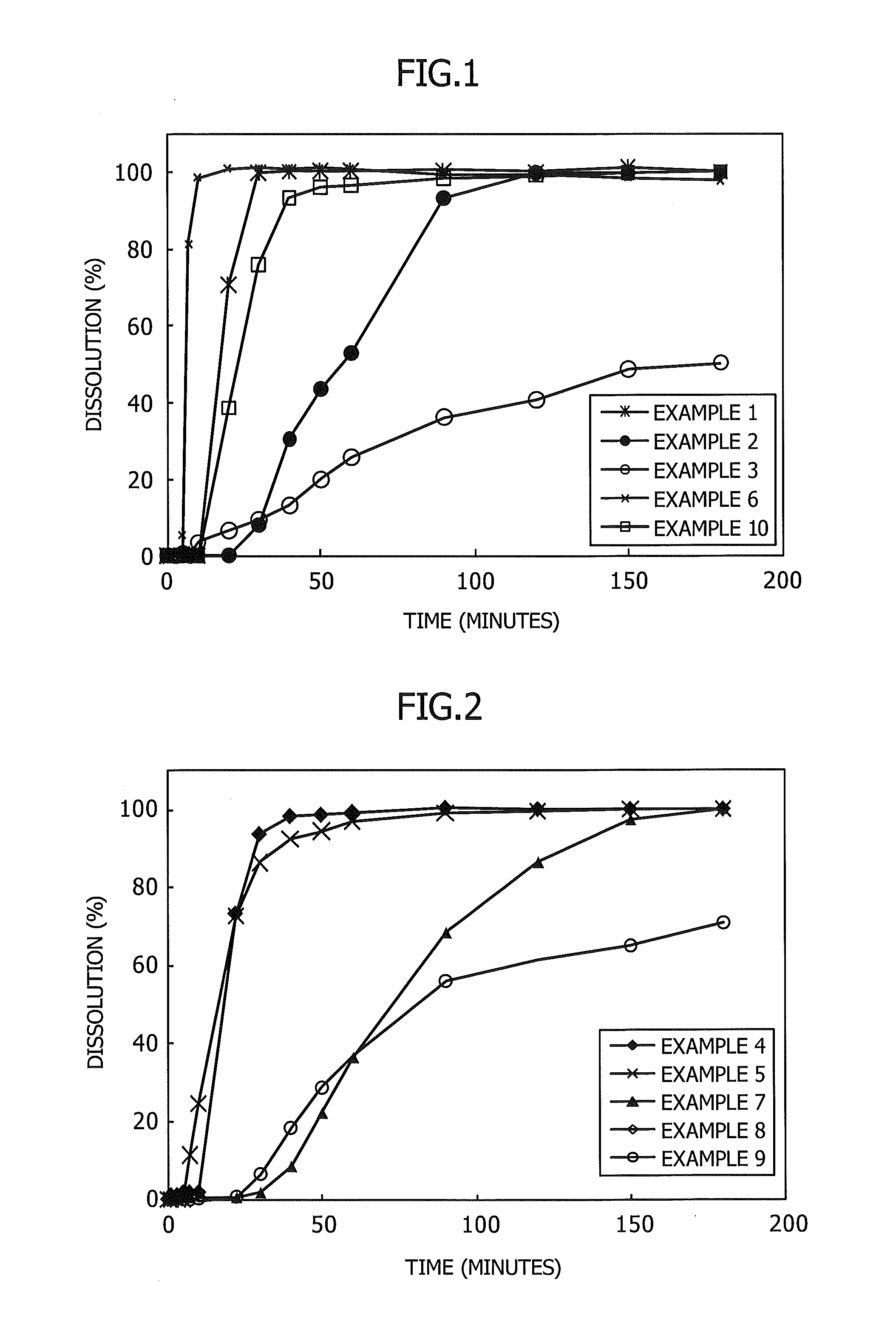

Dissolution is the process by which a solute forms a solution in a solvent. The solute, in the case of solids, has its crystalline structure disintegrated as separate ions, atoms, and molecules form. For liquids and gases, the molecules must be adaptable with those of the solvent for a solution to form. The outcome of the process of dissolution is governed by the thermodynamic energies involved, such as the heat of solution and entropy of solution, but the dissolution itself is not. Overall the free energy must be negative for net dissolution to occur. In turn, those energies are controlled by the way in which different chemical bond types interact with those in the solvent. Solid solutions occur in metal alloys and their formation and description is governed by the relevant phase diagram. Dissolution process is of fundamental importance to the description of numerous natural processes on earth, and it is commonly utilized by humans. Dissolution testing is widely used in the pharmaceutical industry for optimization of formulation and quality control.

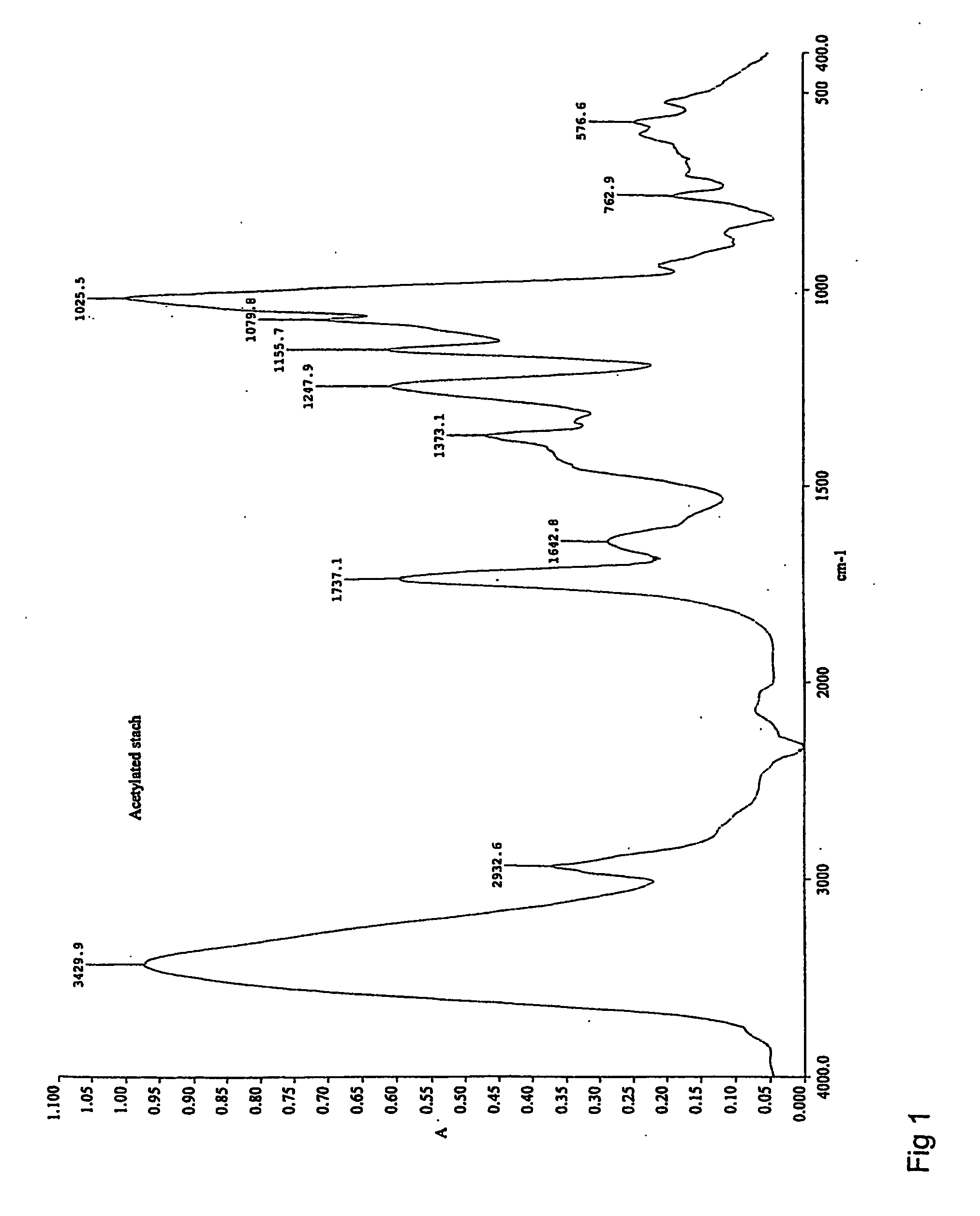

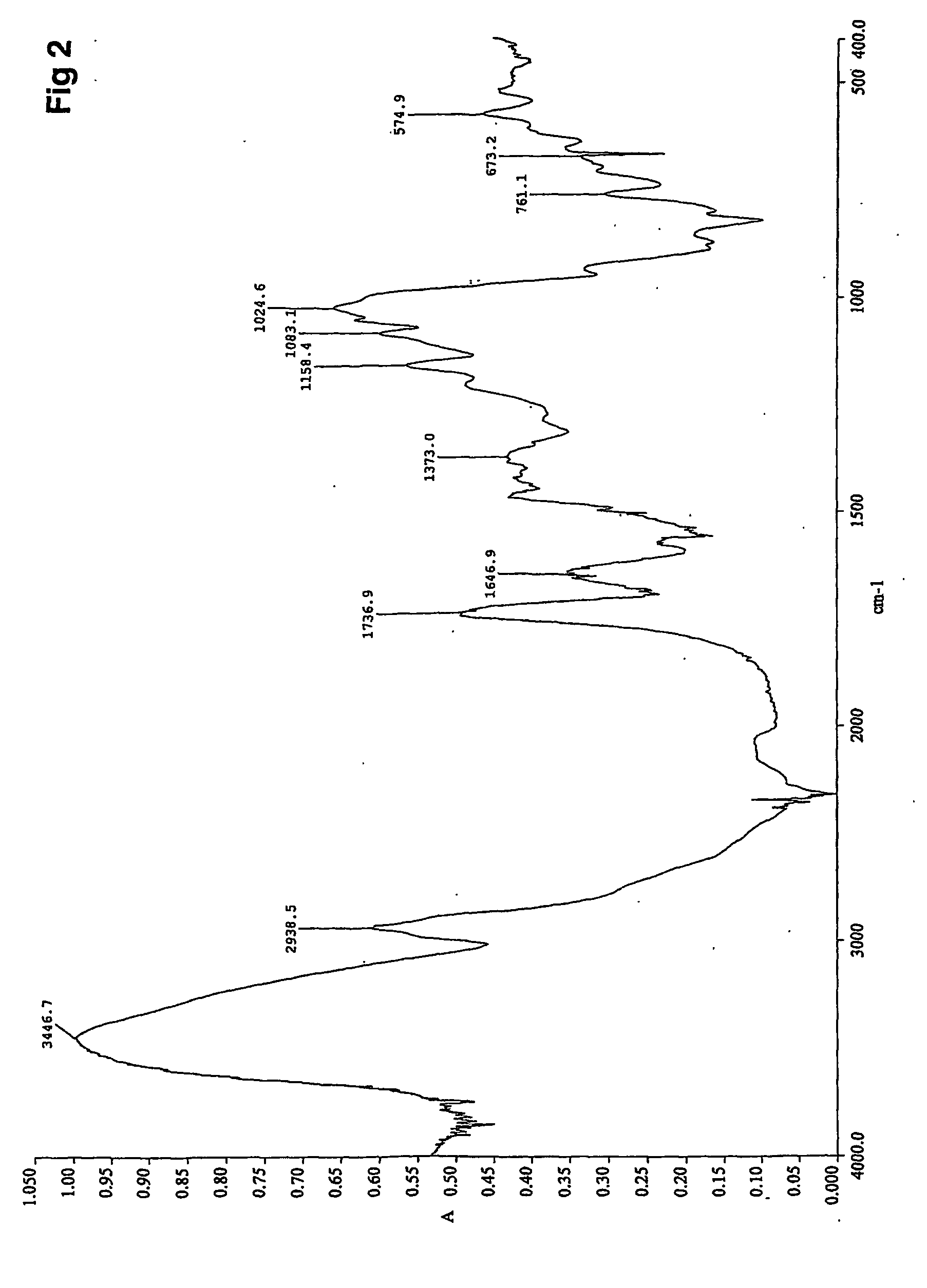

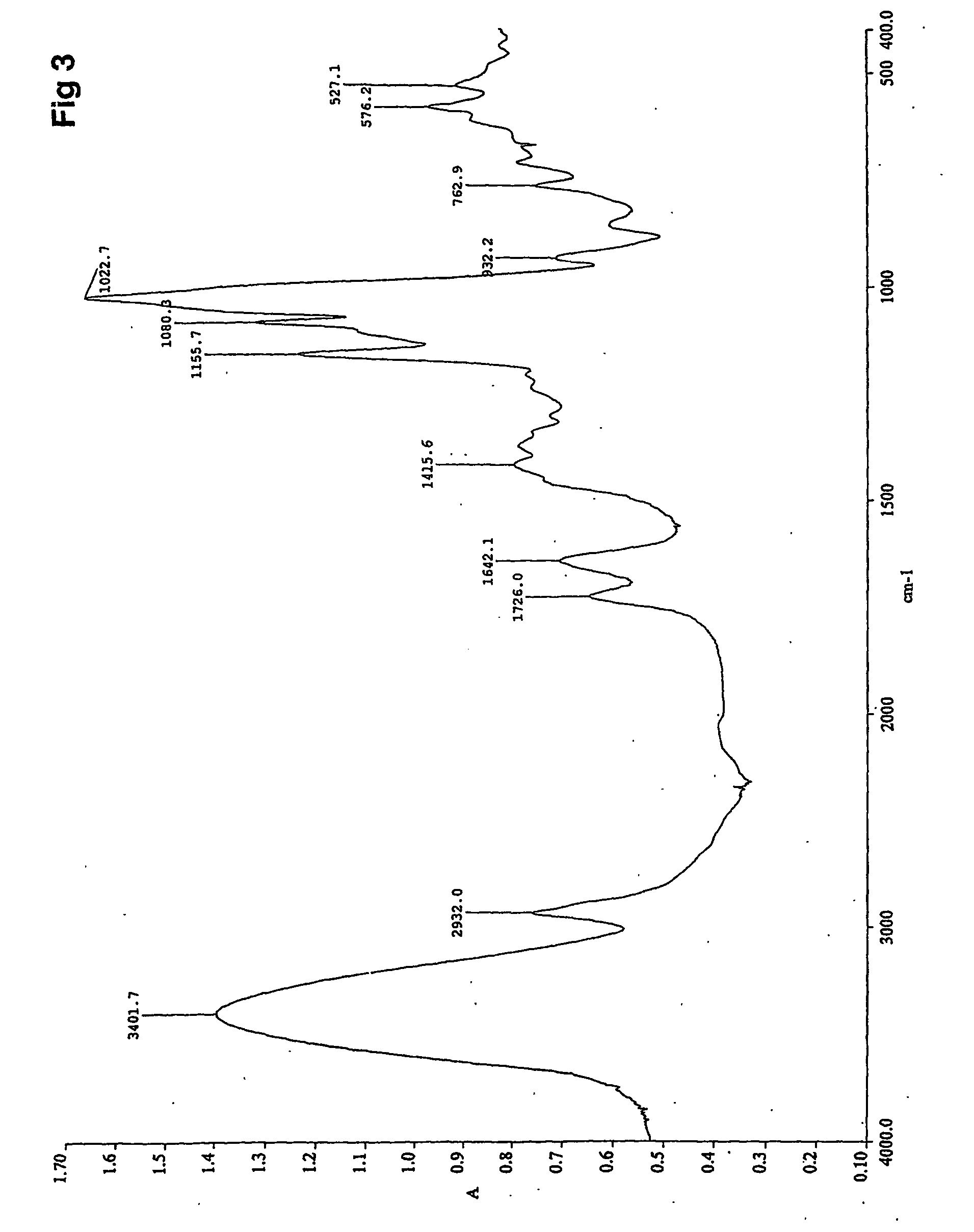

Starch esterification method

InactiveUS20070073051A1Efficient and gentle and environmentally benign preparationSimple and economical separationBulk chemical productionDissolutionSolvent

Owner:VESA MYLLYMAKI +1

Preparation method and application of water-soluble carbon fiber sizing agent

InactiveCN104975508AImprove protectionImprove smoothnessFibre treatmentFibre chemical featuresFiberCarbon fibers

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Method for analyzing quicklime composition

InactiveCN101109738AEasy to operateAccurate analysisWeighing by removing componentChemical analysis using combustionDissolutionWater mass

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

Method for extracting unsaturated fatty acids from eucalyptus leaves

InactiveCN102604735ALow costSimple extraction methodFatty-oils/fats refiningFatty-oils/fats productionCholesterolDissolution

Owner:CHINA EUCALYPT RES CENT

Characterization method for ionic liquid dissolvability

InactiveCN101470063AImprove solubilityReliable dataWeighing by absorbing componentSolubilityDissolution

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

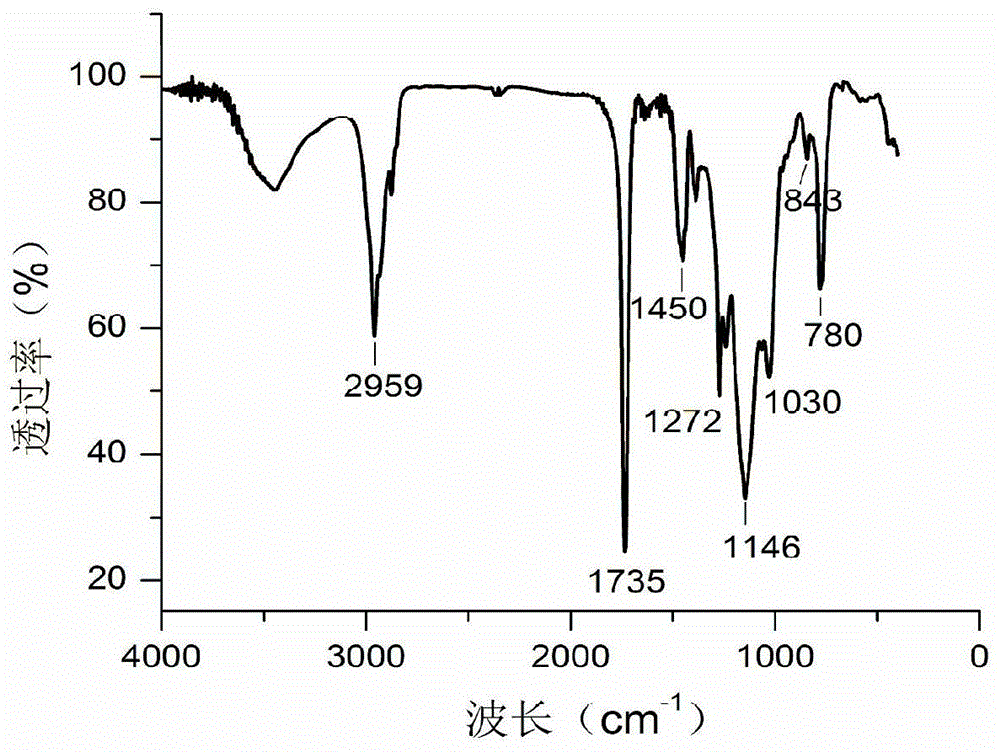

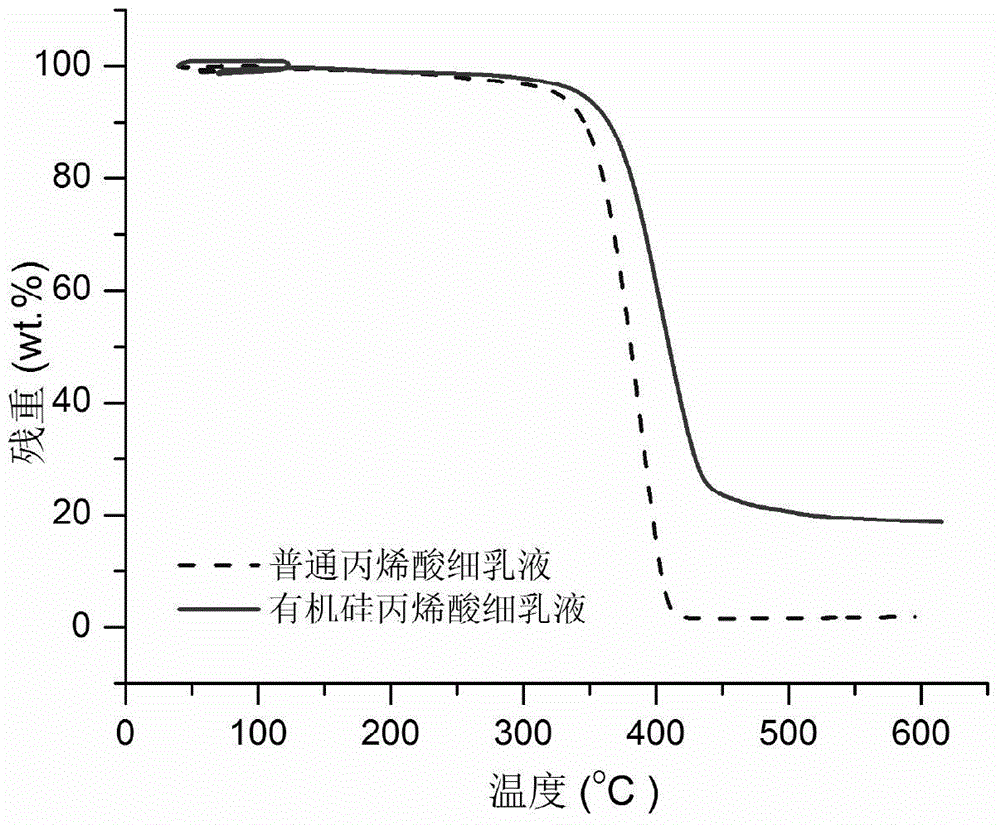

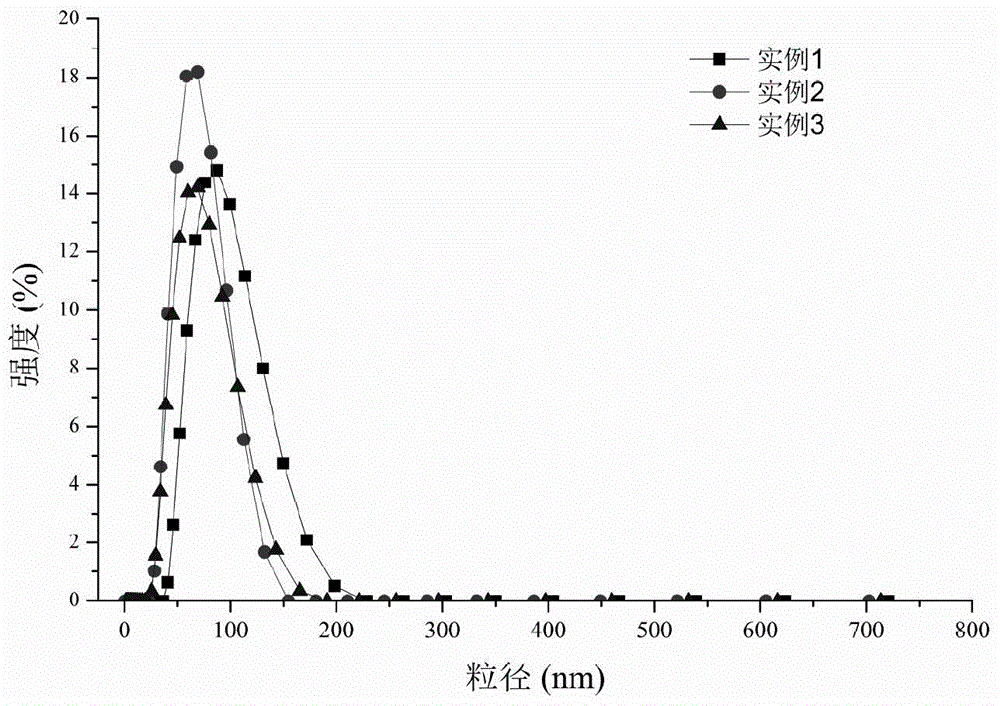

Preparation method for silicone-acrylic miniemulsion

Owner:ZHEJIANG UNIV

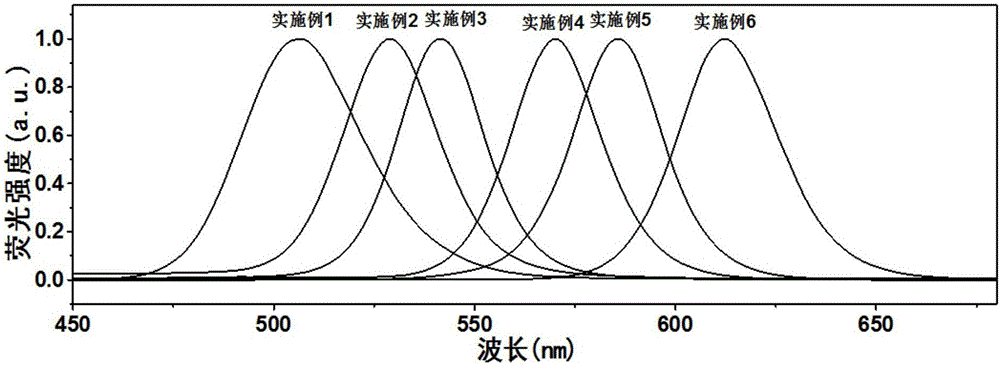

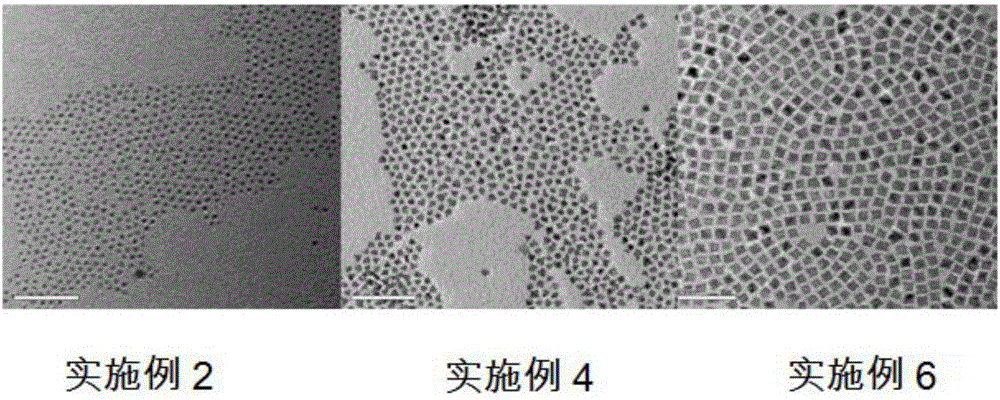

Preparation method of ZnCdSe/ZnS quantum dots

InactiveCN105885824AUniform and controllable sizeUniform and controllable shapeLuminescent compositionsQuantum yieldShielding gas

Owner:WUHAN JIAYUAN QUANTUM DOT TECHCAL DEV CO LTD

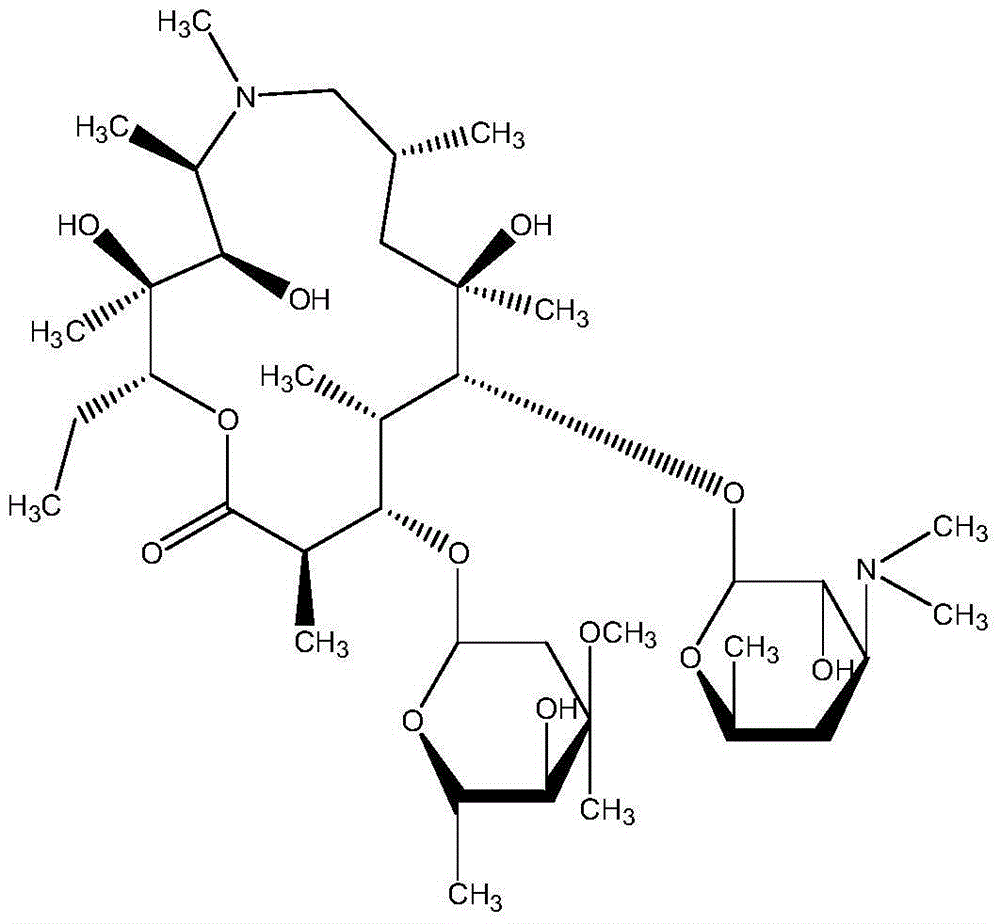

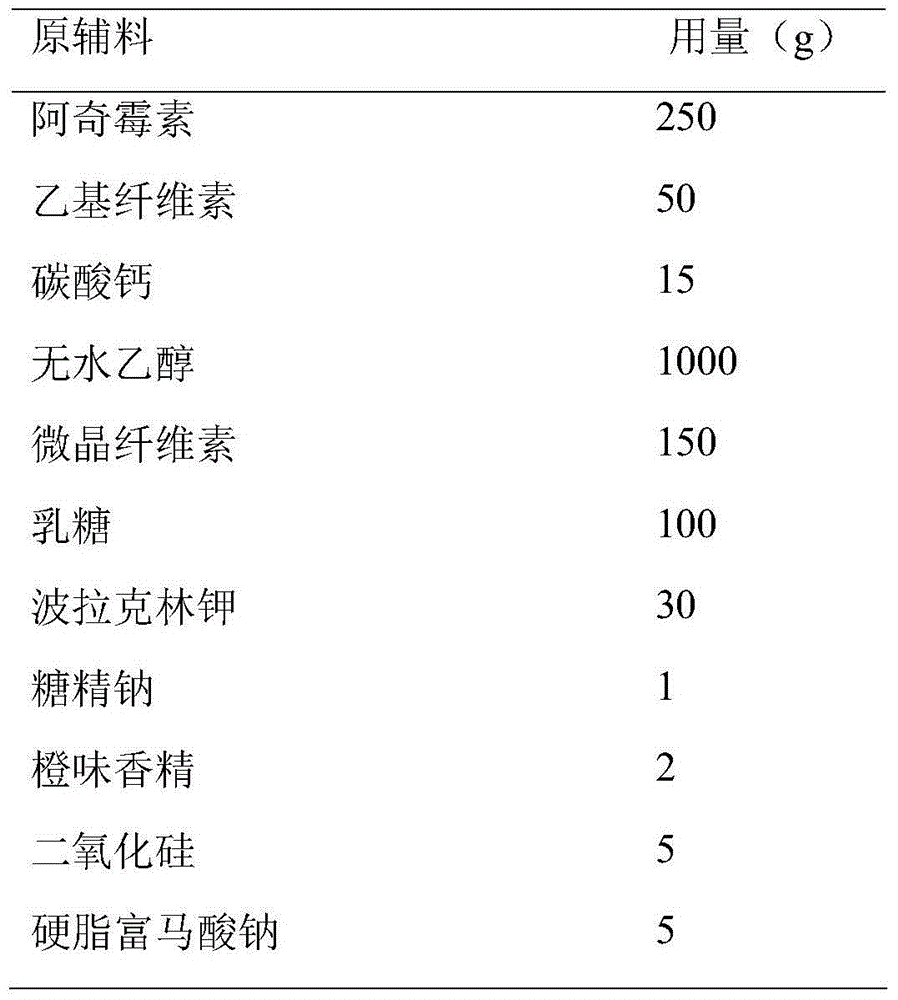

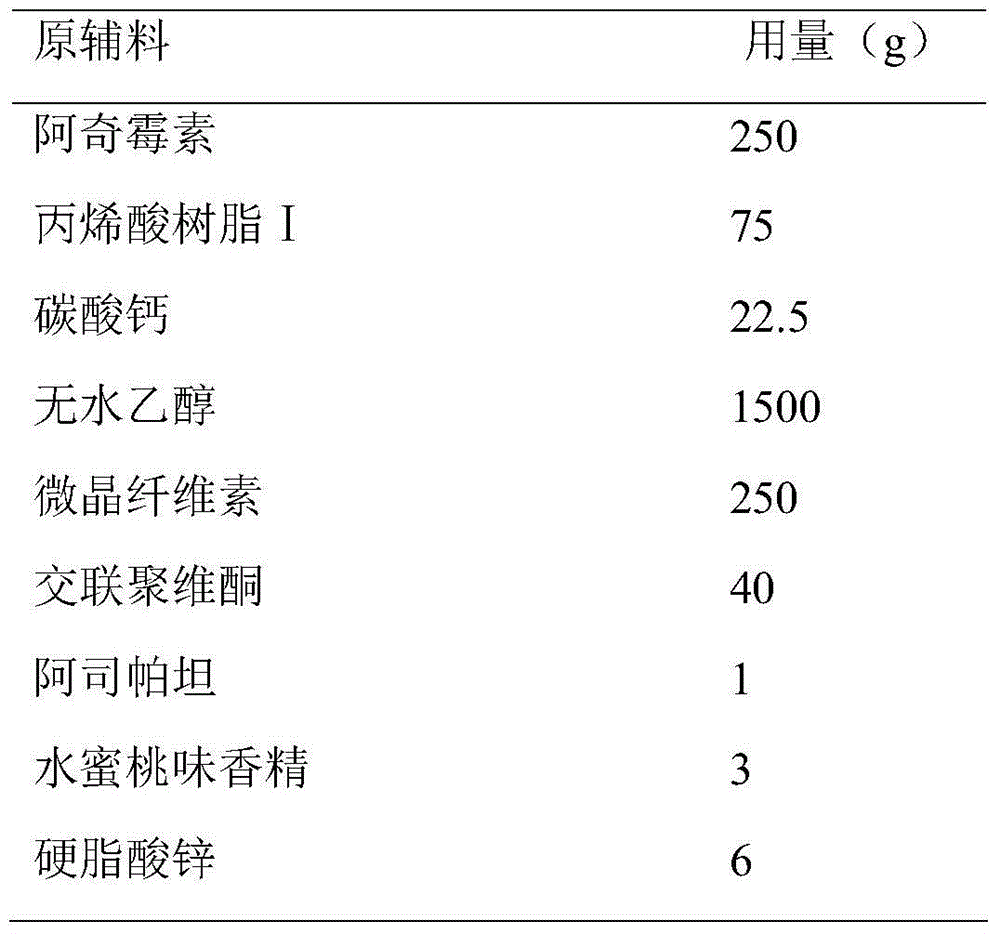

Azithromycin dispersible tablet

Owner:LUNAN BETTER PHARMA

Applicator and method for transferring dispersion liquid

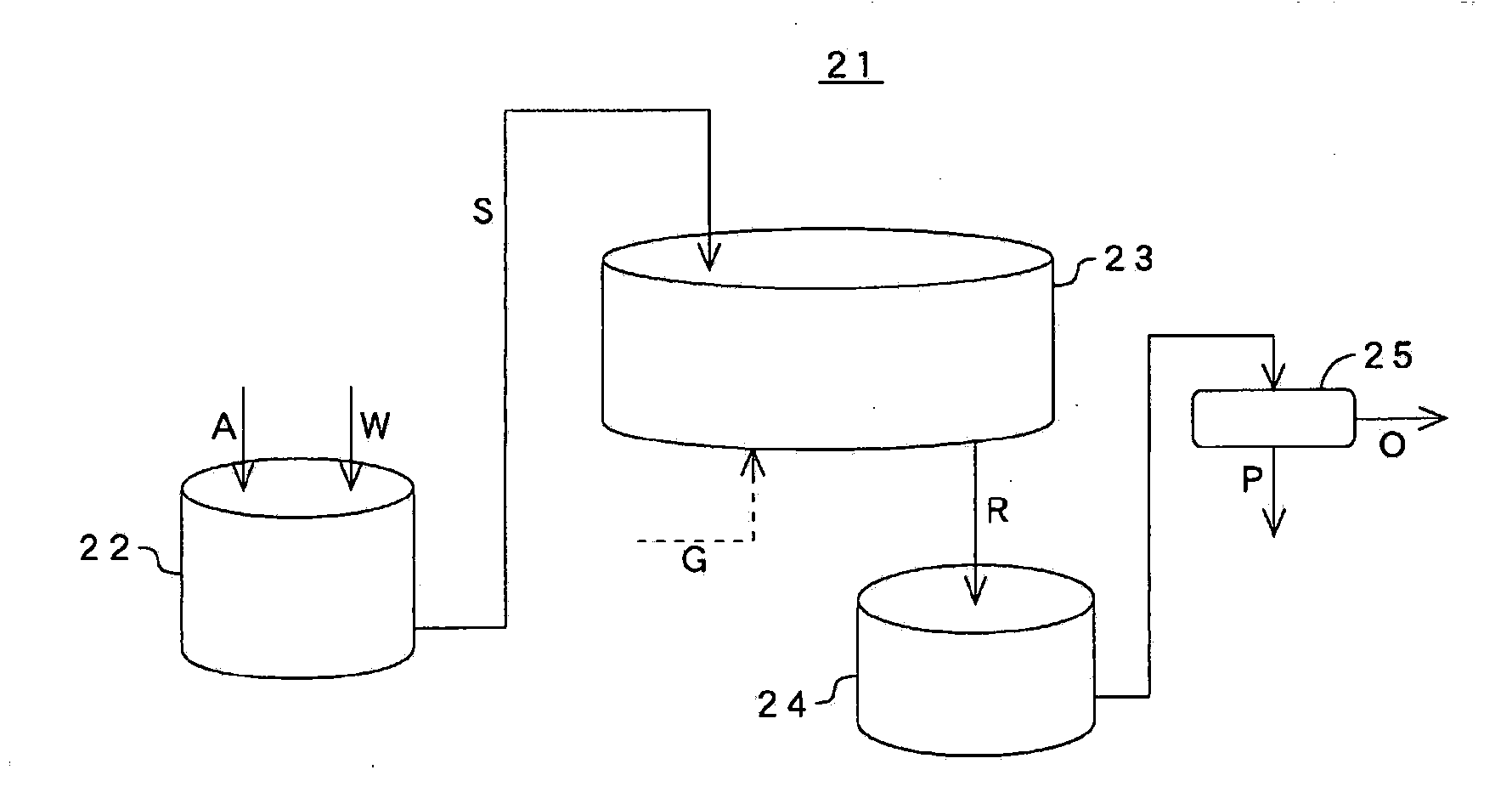

ActiveUS20080210160A1Bubble generating areReduce solubilityLiquid degasificationPressure pumpsBuffer tankDissolution

The present invention provides applicators reducing generating bubble. Dispersion liquid is supplied while the pressure of a circulation tank on the delivery side is lower than the atmospheric pressure but higher than the pressure of the space in buffer tanks. The dispersion liquid in the discharge chambers is recovered while the pressure in a circulation tank serving as recovery destination is lower than the atmospheric pressure. Gas dissolution can be reduced because the dispersion liquid does not come into contact with gases at pressures higher than the atmospheric pressure and engulffing gas or deformation of solid microparticles can be avoided because no pump is used.

Owner:ULVAC INC

Graphene coated carbon-sulfur composite material

InactiveCN104201354AImprove adsorption capacityBound to dissolveCell electrodesSecondary cellsEnvironmental resistanceCompound a

Owner:NANJING ZHONGCHU NEW ENERGY

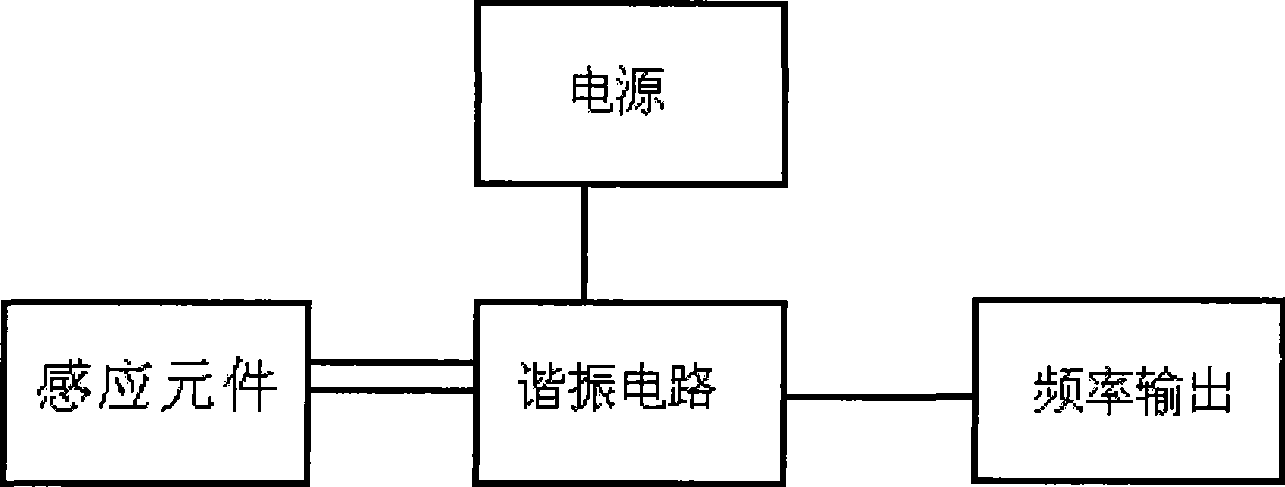

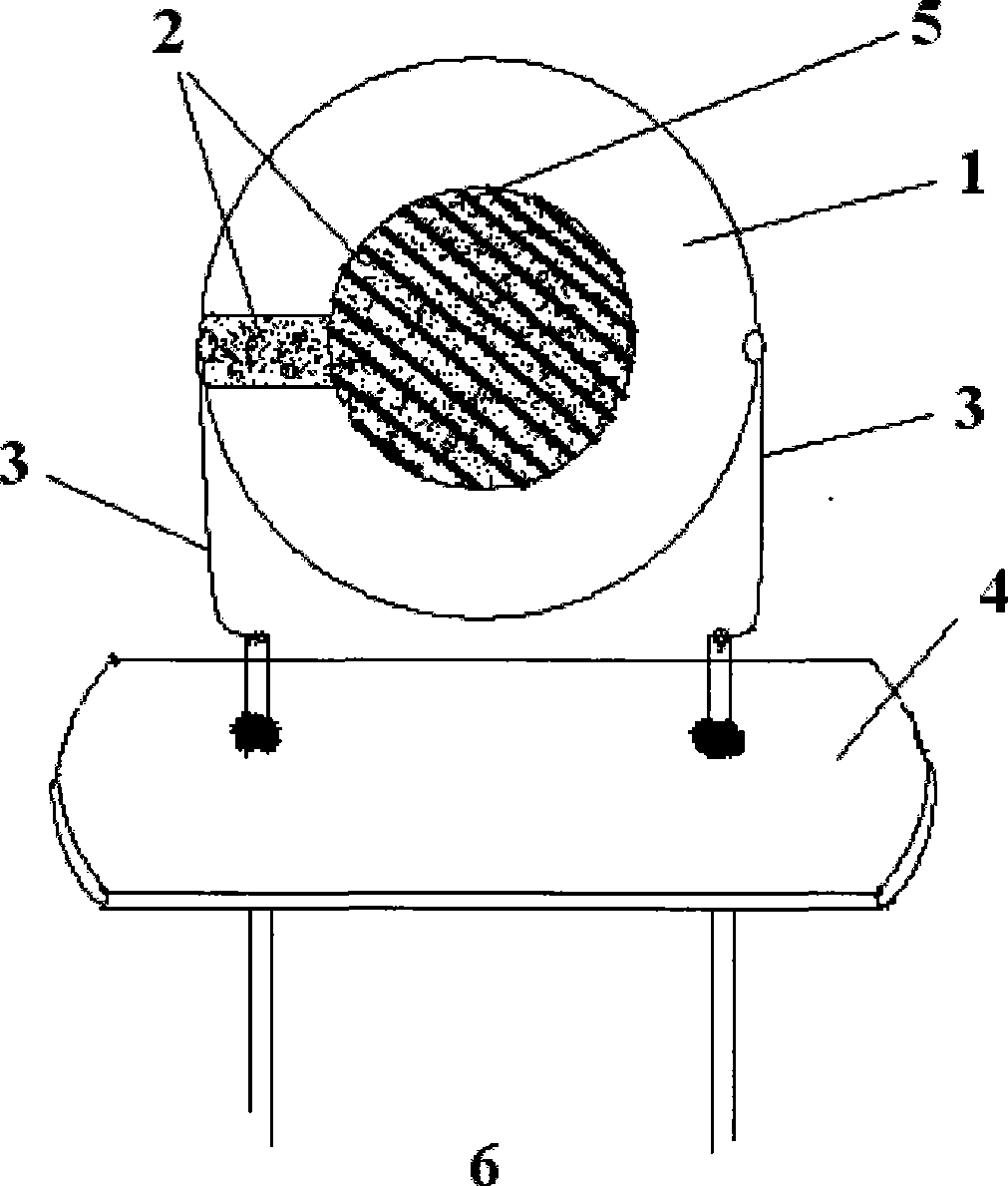

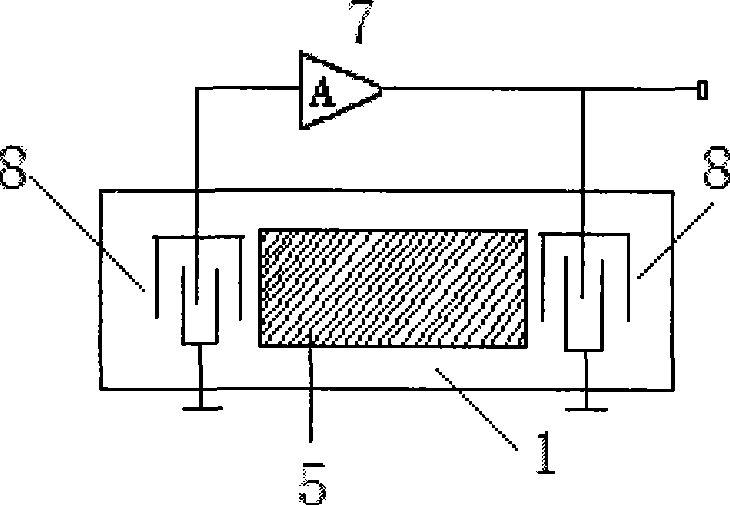

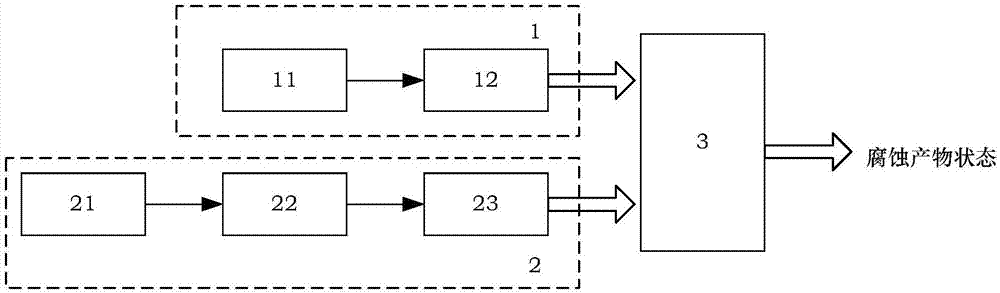

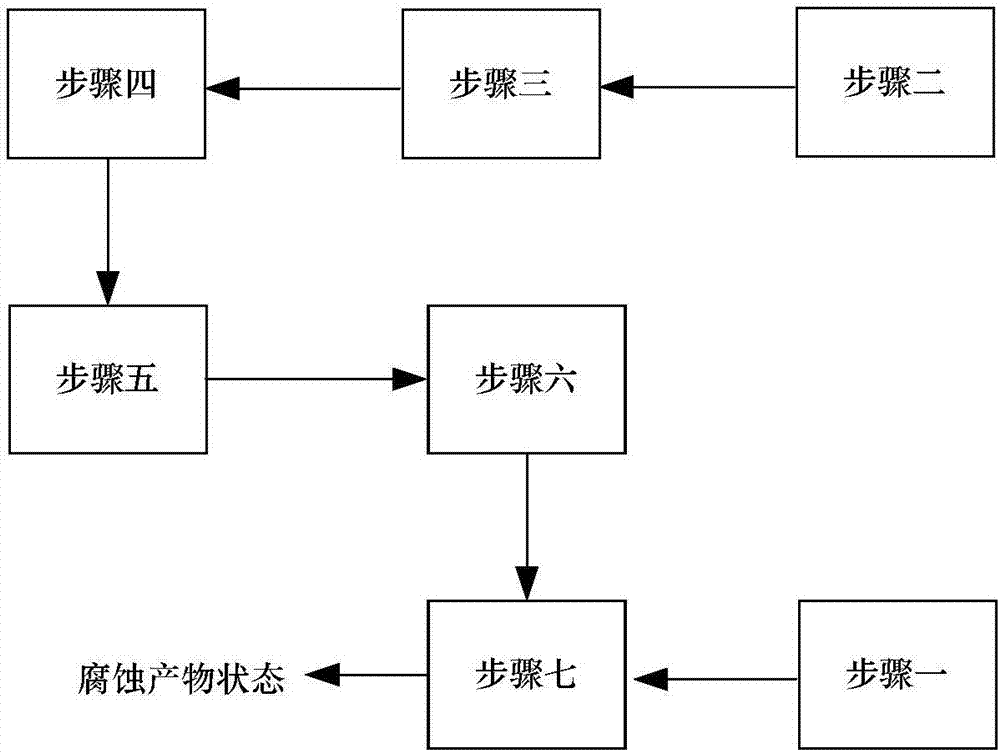

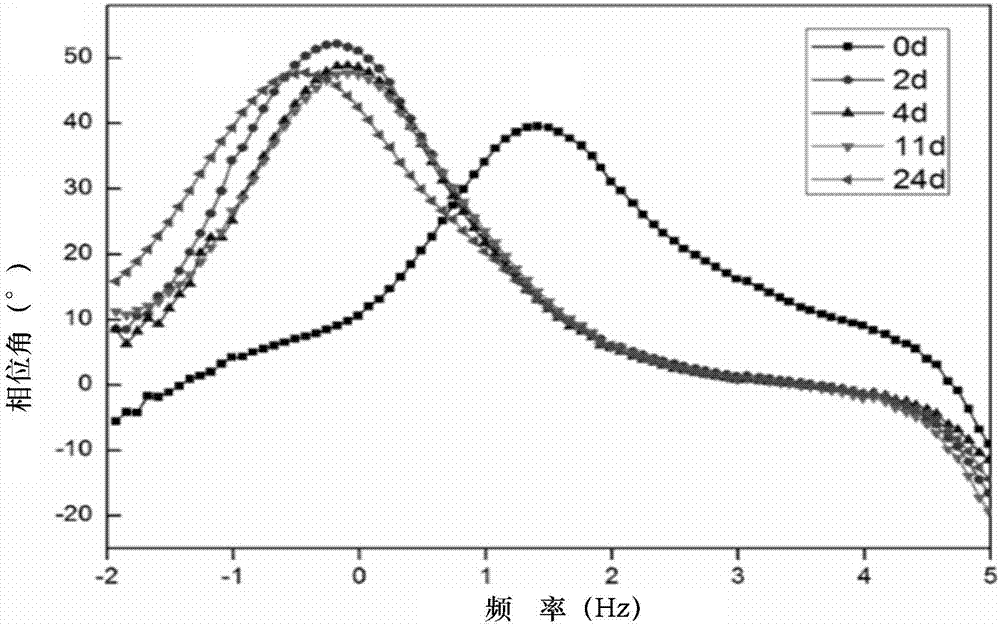

Nondestructive detection system for state of crude oil tank bottom plate corrosion product

ActiveCN107422005AJudge the situationReduce economic lossMaterial analysis using acoustic emission techniquesMaterial electrochemical variablesAcquisition timeAcoustic emission

Owner:BEIHANG UNIV

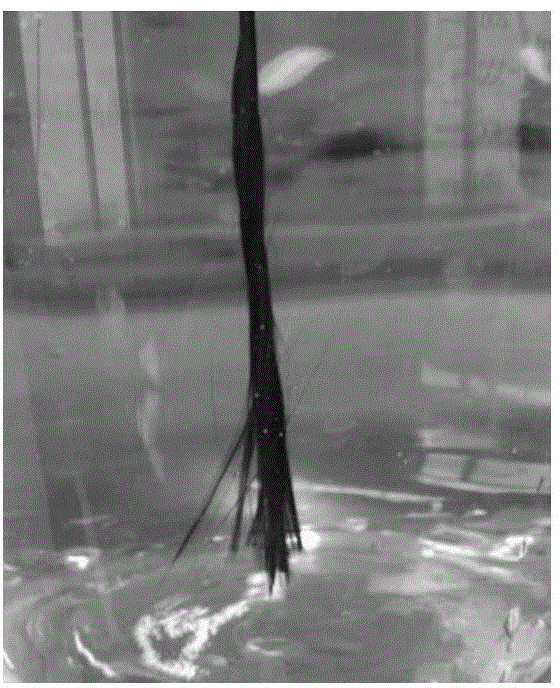

Nanometer antibacterial viscose fiber

InactiveCN103614798AImprove utilizationProtectiveArtificial filaments from viscoseArtifical filament manufactureDissolutionViscose fiber

Owner:CHANGSHU JINYU FIBER PROD

Activation system and method for enhancing metal recovery during atmospheric leaching of metal sulfides

ActiveUS20170356063A1Simple processPromotes rapid metal dissolutionSolvent extractionSulfur preparation/purificationMetallic sulfideDissolution

A method of improving metal leach kinetics and recovery during atmospheric or substantially atmospheric leaching of a metal sulfide is disclosed. In some embodiments, the method may comprise the step of processing a metal sulfide concentrate in a reductive activation circuit 220 that operates at a first redox potential, to produce a reductively-activated metal sulfide concentrate. The method may further comprise the step of subsequently processing the activated metal sulfide concentrate in an oxidative leach circuit 240 to extract metal values. In some disclosed embodiments, reductive activation steps and / or oxidative dissolution steps may employ mechano-chemical and / or physico-chemical processing of particles or agglomerates thereof. Reductive activation may be made prior to heap leaching or bio-leaching operations to improve metal extraction. Systems for practicing the aforementioned methods are also disclosed.

Owner:F L SMIDTH & CO AS

Method for dyeing carboxymethyl chitosan silicon-modified cotton fabric with natural dyes

Owner:ZHEJIANG SCI-TECH UNIV

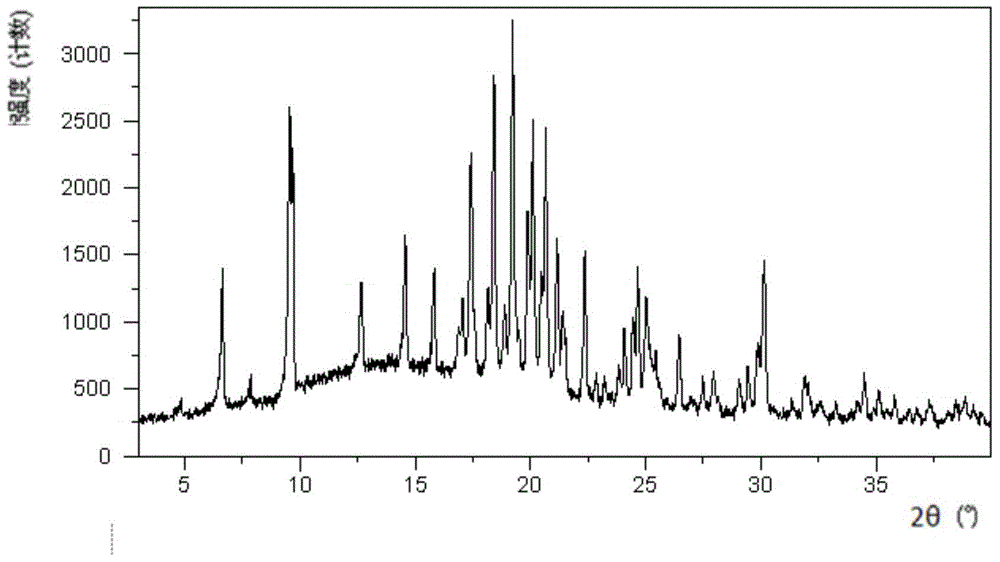

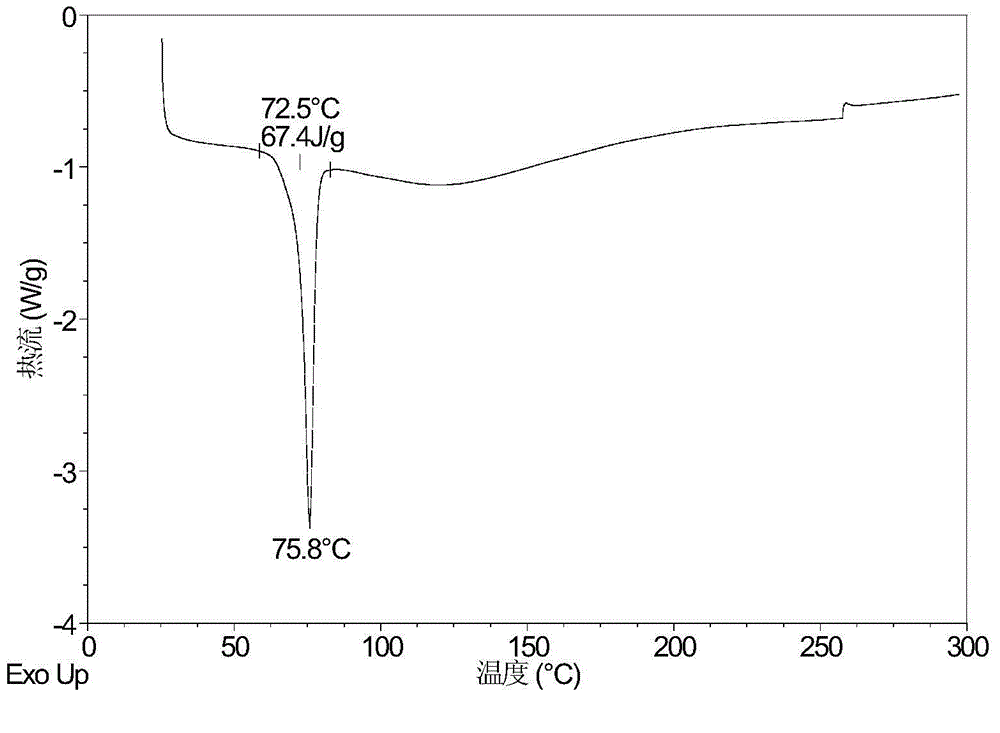

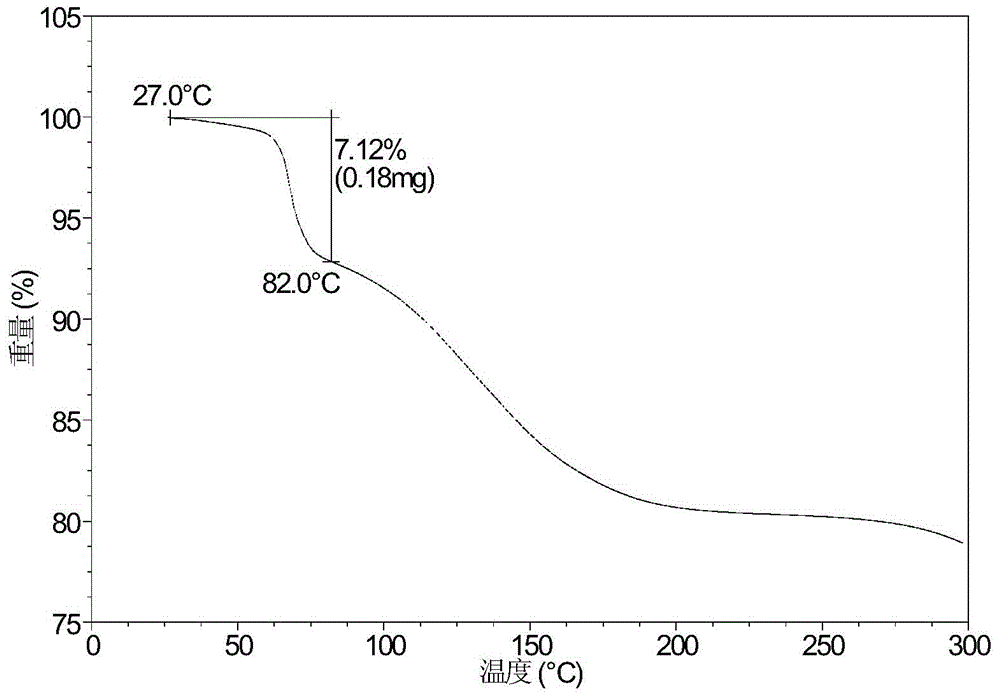

Crystal form E and crystal form F of canagliflozin and preparation method thereof

ActiveCN104974146AGood physical and chemical stabilityFine and evenly dispersedOrganic chemistry methodsSolubilityDissolution

Owner:CRYSTAL PHARMATECH CO LTD

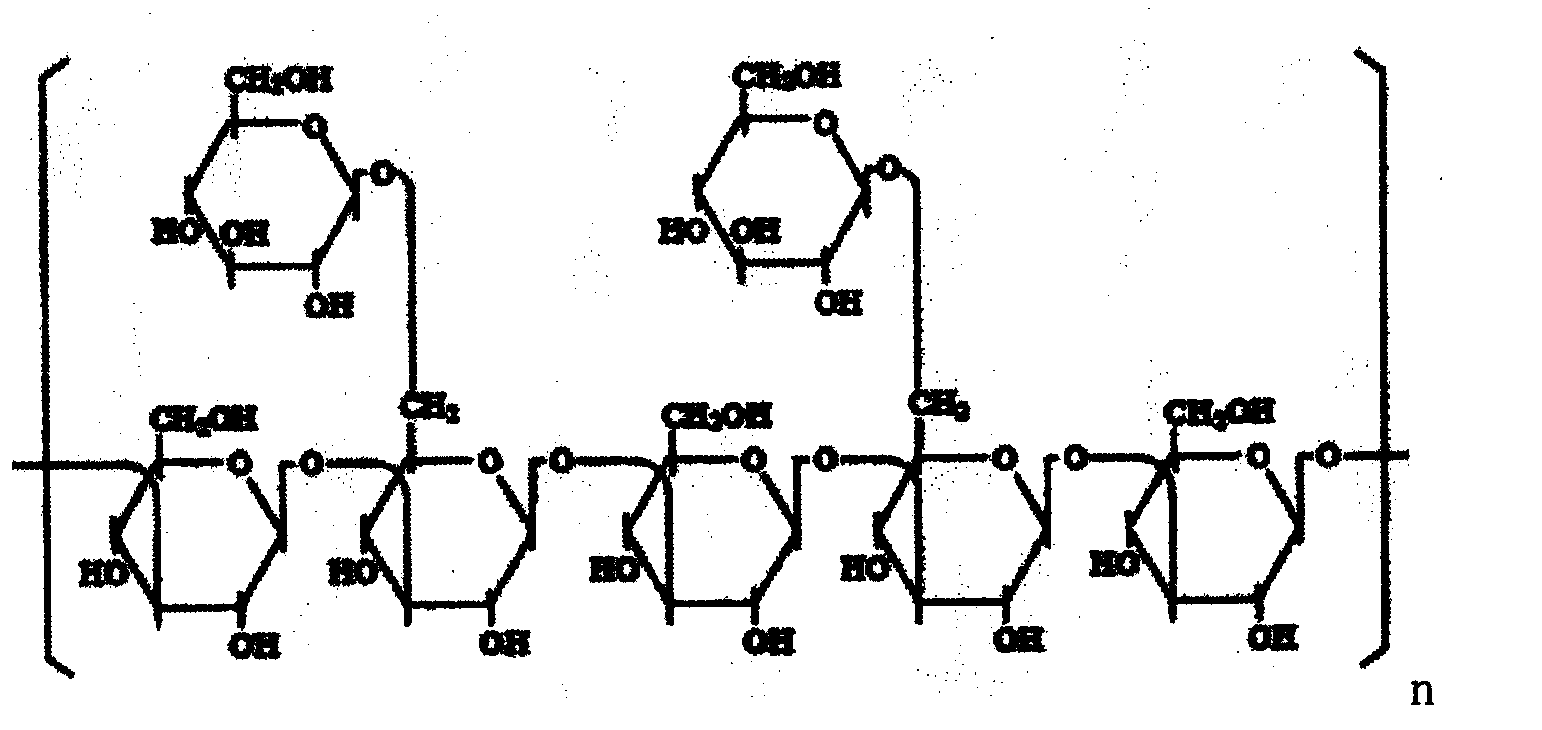

Physical oxidative carboxymethyl composite modified starch and preparation method thereof

InactiveCN104592404AHigh degree of substitutionWill not swell and dissolveSodium chloroacetateDissolution

The present invention relates to technical field of modified starch and provides physical oxidative carboxymethyl composite modified starch and a preparation method thereof. The modified starch is prepared from the following raw materials: raw starch, alcohol, inorganic alkali, sodium chloroacetate, hydrochloric acid and hydrogen peroxide. According to the carboxymethyl composite modified starch provided by the invention, the process steps of firstly mechanically activating the raw starch, etherifying the carboxymethyl and then carrying out hydrogen peroxide oxidation are adopted; therefore, the proportion of alcohol and water in a carboxymethylation reaction segment system can be favorably controlled to avoid expansion and dissolution of starch granules, so as to ensure high substitution ratio of the prepared product; in addition, due to the process operation of first etherification and then oxidation, the product viscosity can be controlled more accurately. The preparation method of the carboxymethyl composite modified starch provided by the invention can be used for preparing carboxymethyl starch with high substitution ratio and low viscosity by using mechanically activated corn, cassava and waxy maize starch as raw materials, the operation is convenient, the process flexibility is strong, the continuity is good, the utilization rate of equipment is high and the production efficiency is high.

Owner:HENAN HENGRUI STARCH TECH CO LTD

Preparation method of phosphatization liquid for steel pipe cold-rolling processing pre-treatment

InactiveCN104250740ARealization of continuous cold rolling processingSimple compositionMetallic material coating processesPhosphoric acidMonocalcium phosphate

Owner:WUXI LUOSHE TECH VENTURE

Coating Composition, Solid Preparation Coated Therewith, and Method for Preparing Solid Preparation

Owner:SHIN ETSU CHEM IND CO LTD

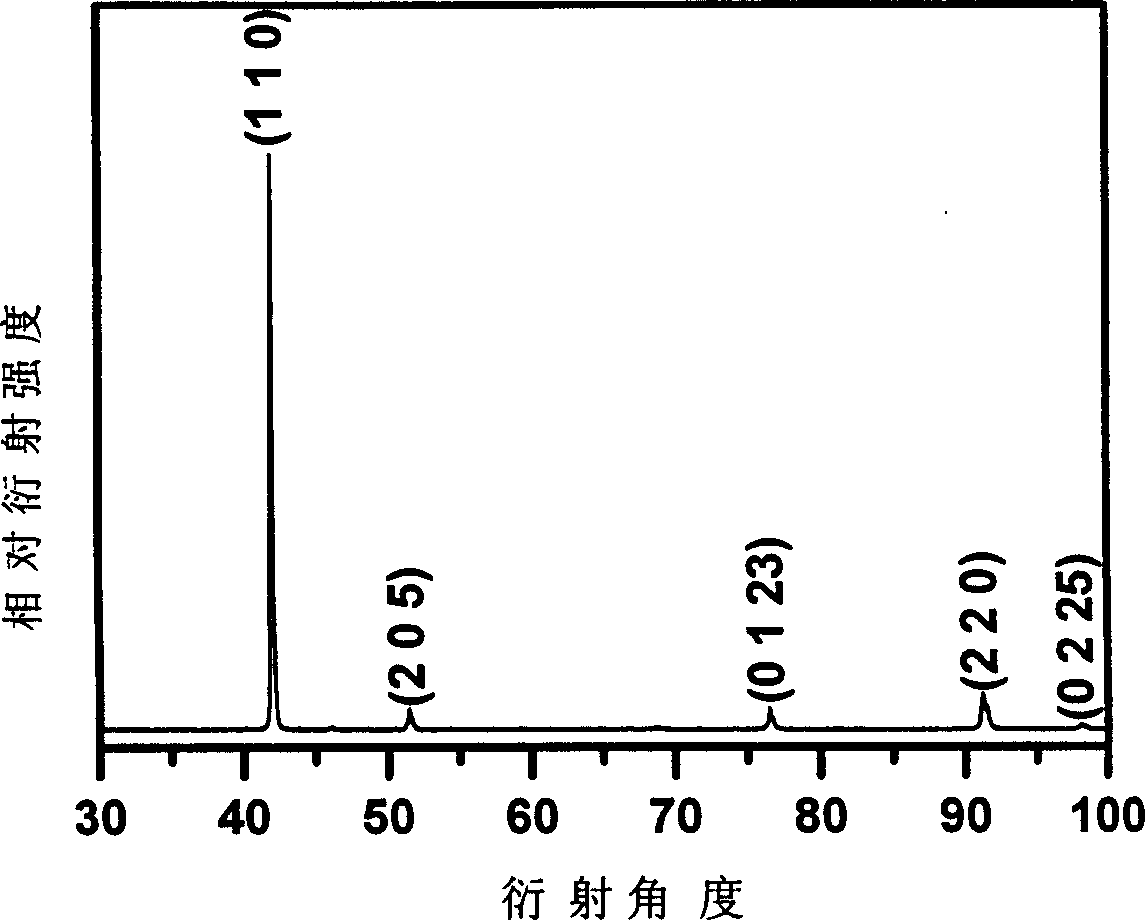

Sb2Te3 monocrystalline nanometer line ordered array and its preparation method

InactiveCN1769539ASolve easy hydrolysisAddress effectivenessPolycrystalline material growthElectrolytic organic material coatingNanowireAuxiliary electrode

Owner:UNIV OF SCI & TECH OF CHINA

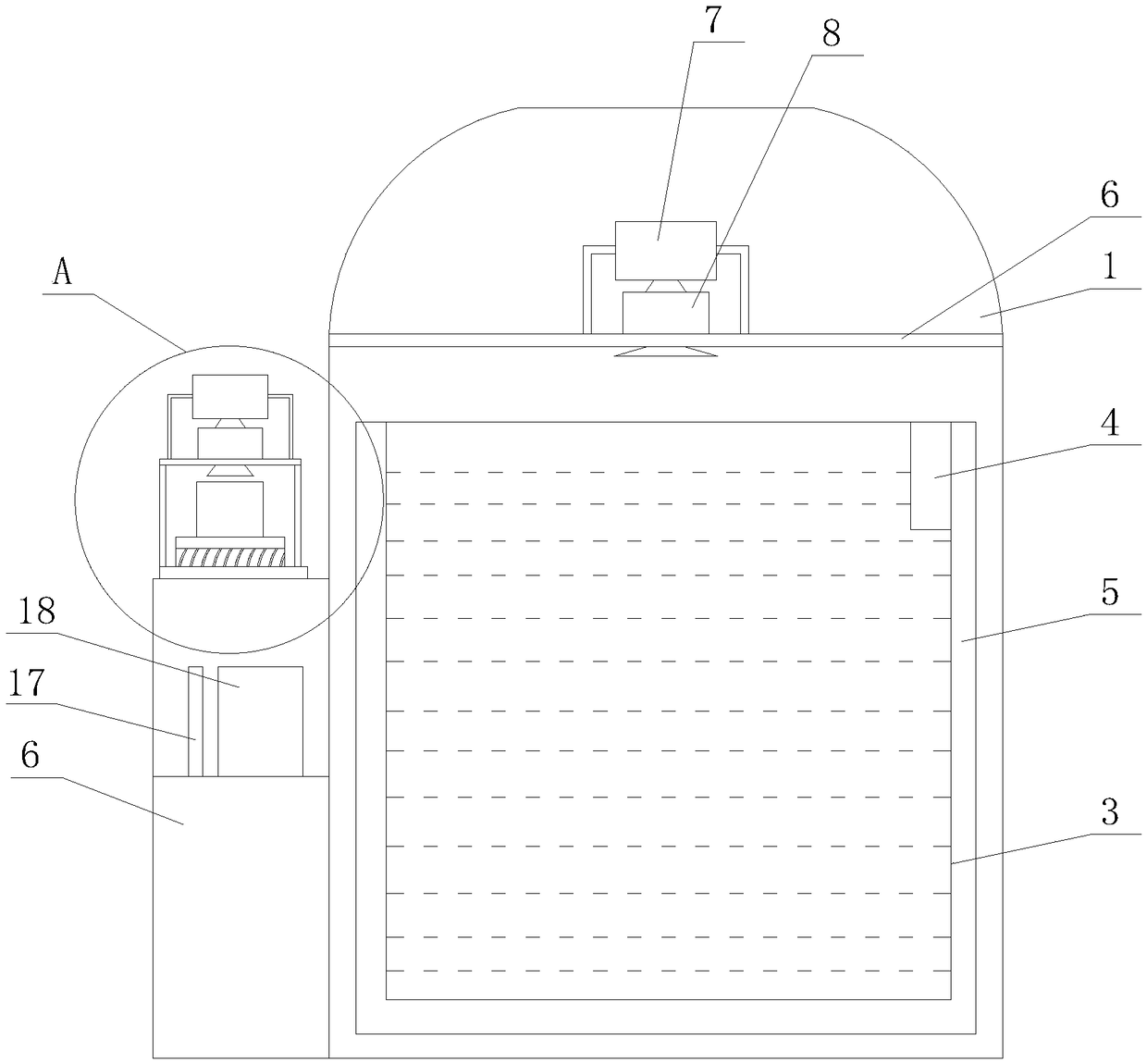

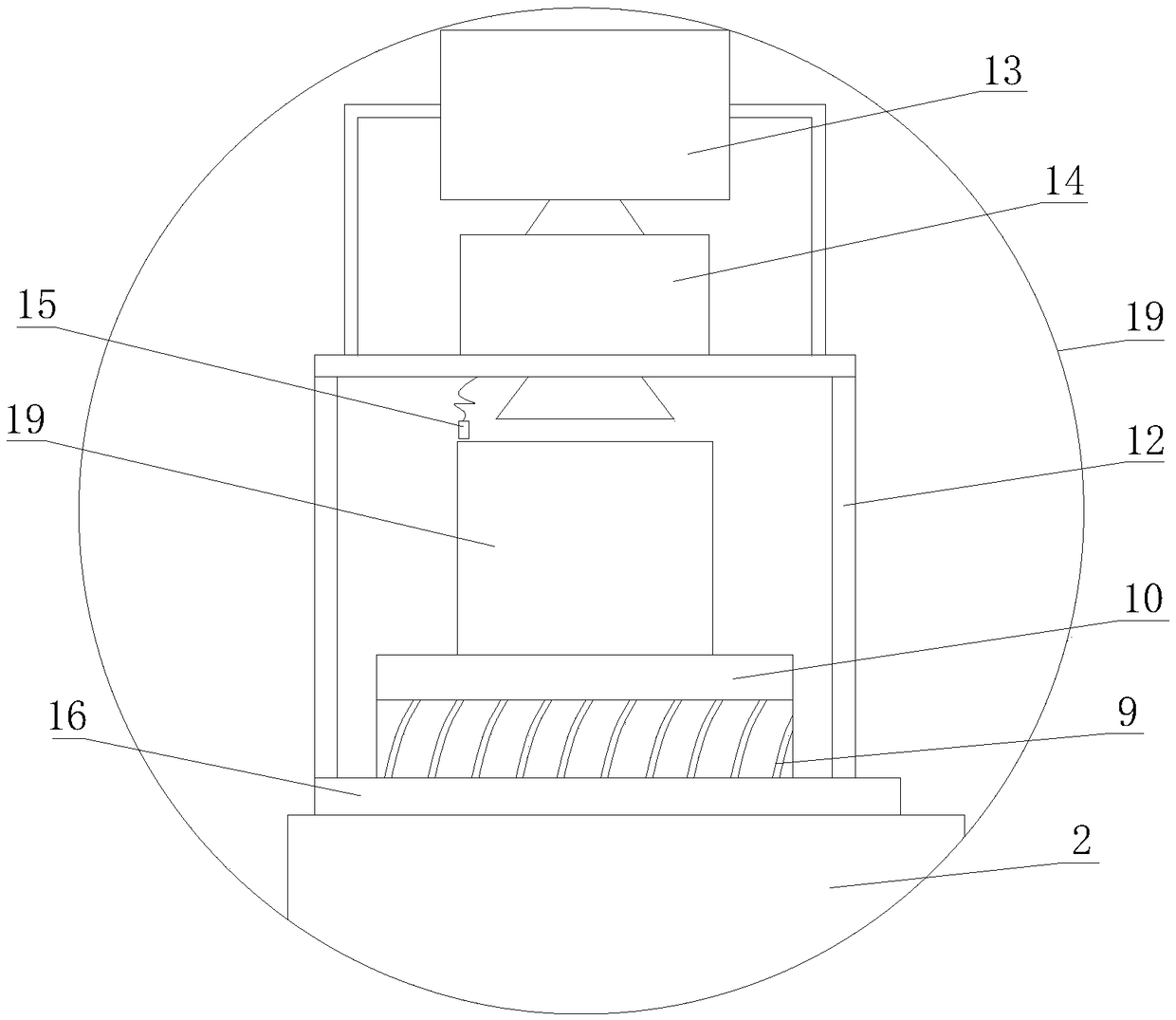

Ultrasonic improved fabric dyeing device and process thereof

InactiveCN108914457AImprove dye uptakeEnhance stirringTextile treatment machine partsVibration treatmentWater bathsLongitudinal wave

Owner:南通东屹高新纤维科技有限公司

Crystallization method for preparing high-purity monodisperse I crystal form atorvastatin calcium in single kettle

The invention relates to a crystallization method for preparing high-purity monodisperse I crystal form atorvastatin calcium in a single kettle. The method is as follows: adding a mixed solvent consisting of a good solvent and an antisolvent of atorvastatin calcium into a crystallizer, adding crystalline powder of crystal form I atorvastatin calcium into the crystallizer, keeping the temperature of the solution at normal temperature, dispersing crystal particles by using ultrasound, and then raising the temperature to the temperature of the dissolution process; adding two solutions of the anti-solvent and the good solvent for dissolving the atorvastatin calcium into seed crystal suspension at the same time, and keeping the solvent composition in the seed crystal suspension in the process basically unchanged; adding the antisolvent into the crystallizer continuously, and then keeping temperature and suspending; reducing the temperature of the solution to normal temperature, and then filtering the solution, washing by pure water and drying to obtain crystal the form I crystalline atorvastatin calcium powder. The crystal particles of the powder are long rod-shaped, and the longitudinal dimension of the powder is not more than 30mu m, and the cross-sectional dimension is not more than 5mu m. The production cycle is short, the cost of the solvent is low, the operation is simple, andthe method is suitable for industrial production.

Owner:TIANJIN UNIV +1

Liquid propolis and preparation method thereof

InactiveCN101647825AOrganic active ingredientsAnthropod material medical ingredientsStable statePropolis

The invention relates to a liquid propolis and a preparation method thereof. The liquid propolis mainly comprises the following materials in percentage by weight: 40-95% of capryl mono glyceride, 3-60% of propolis extractum and 0-2% of fat soluble vitamins. The preparation method comprises the following steps: adding crushed propolis to capryl mono glyceride solution, stirring, heating to the temperature of 80-90 DEG C, cooling to the temperature of 35-45 DEG C after complete dissolution, filtering with a 150-200 mesh filter screen, and filling to obtain a finished product. The liquid propolisis obviously characterized by stable state, good dissolvability, strong dispersibility, edible safety, enhancing effect on antibacterial action of propolis and the like.

Owner:SHAANXI OLD BEEKEEPER BIOTECHNOLOGY CO LTD

Ecological jelly based on bean curd and bean curd jelly and preparing method thereof

InactiveCN106417649AInhibition of dissolutionHigh nutritional valueCheese manufactureFood scienceNutritive valuesDissolution

Owner:淮南市农康生态农业有限公司

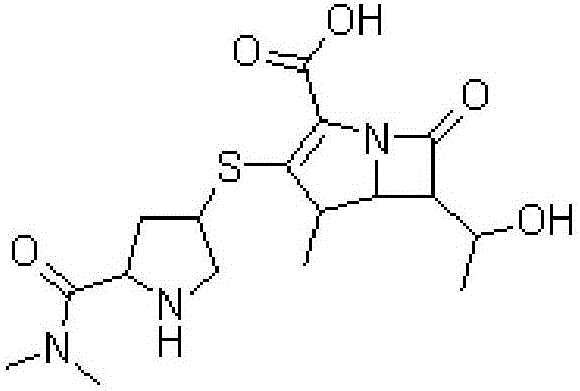

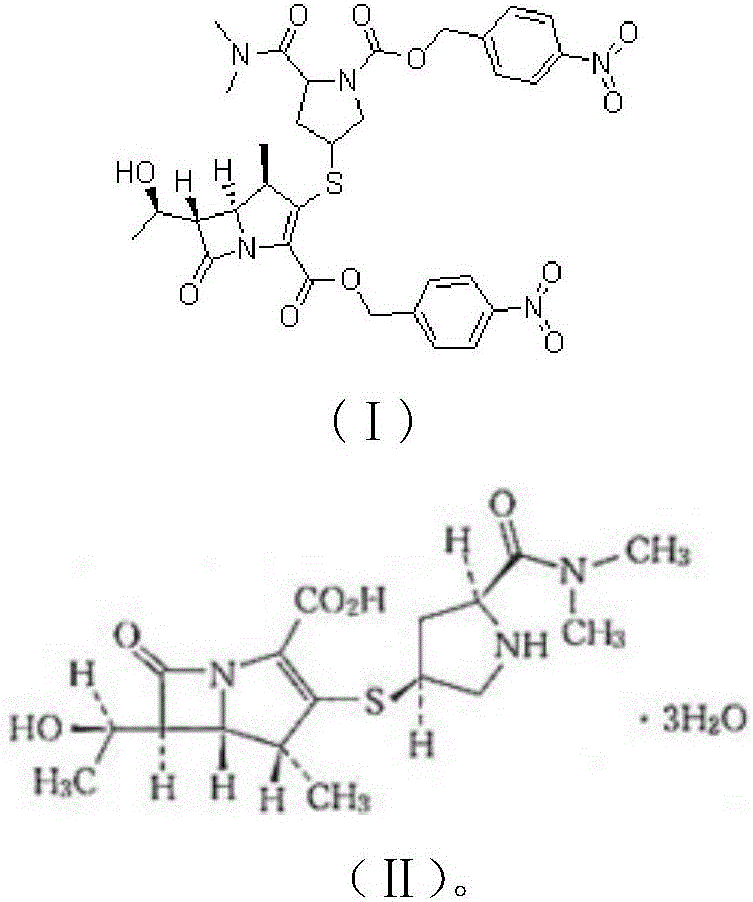

Method for synthesizing meropenem trihydrate

Owner:YIYUAN XINQUAN CHEM

Method for extracting caffeine by low temperature crystallization

Owner:芜湖天远生物科技有限公司

Pharmaceutical composition containing glucosamine and having weight reducing function

ActiveCN105520947AImprove solubilityImprove bioavailabilityOrganic active ingredientsMetabolism disorderOrlistatSide effect

The invention belongs to the field of medicine, and in particular, relates to a pharmaceutical composition containing glucosamine and having a weight reducing function. According to the pharmaceutical composition containing glucosamine and having the weight reducing function, tests find out that glucosamine can significantly increase the orlistat dissolution degree, and greatly improves the orlistat bioavailability. At the same time, the pharmaceutical composition containing glucosamine and having the weight reducing function has a significant weight reducing effect on obesity sensitive type rats; after drug discontinuance, a weight rebound phenomenon does not appear, moreover, diarrhea or loose stools or other side effects do not appear during drug taking, and the pharmaceutical composition is a healthy weight reducing drug having a significant weight reducing effect.

Owner:GUANGDONG PHARMA UNIV

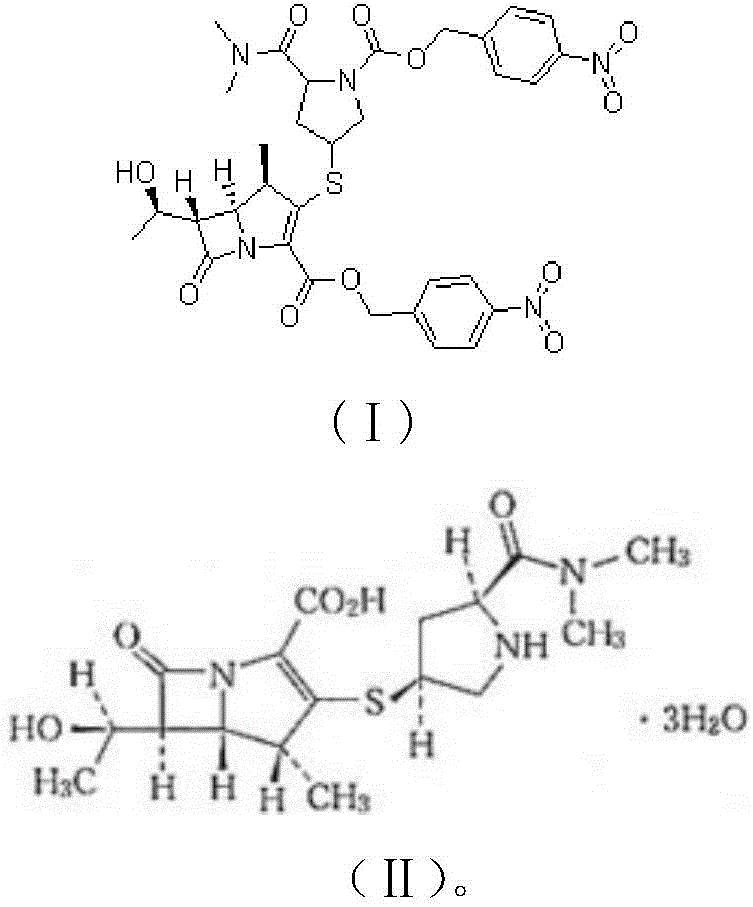

Continuous gas reaction device, and continuous dissolved gas reaction device

InactiveCN104203398AImprove processing efficiencyProhibition of useSolid waste disposalTransportation and packagingDissolutionSlurry

Owner:TAIHEIYO CEMENT CORP

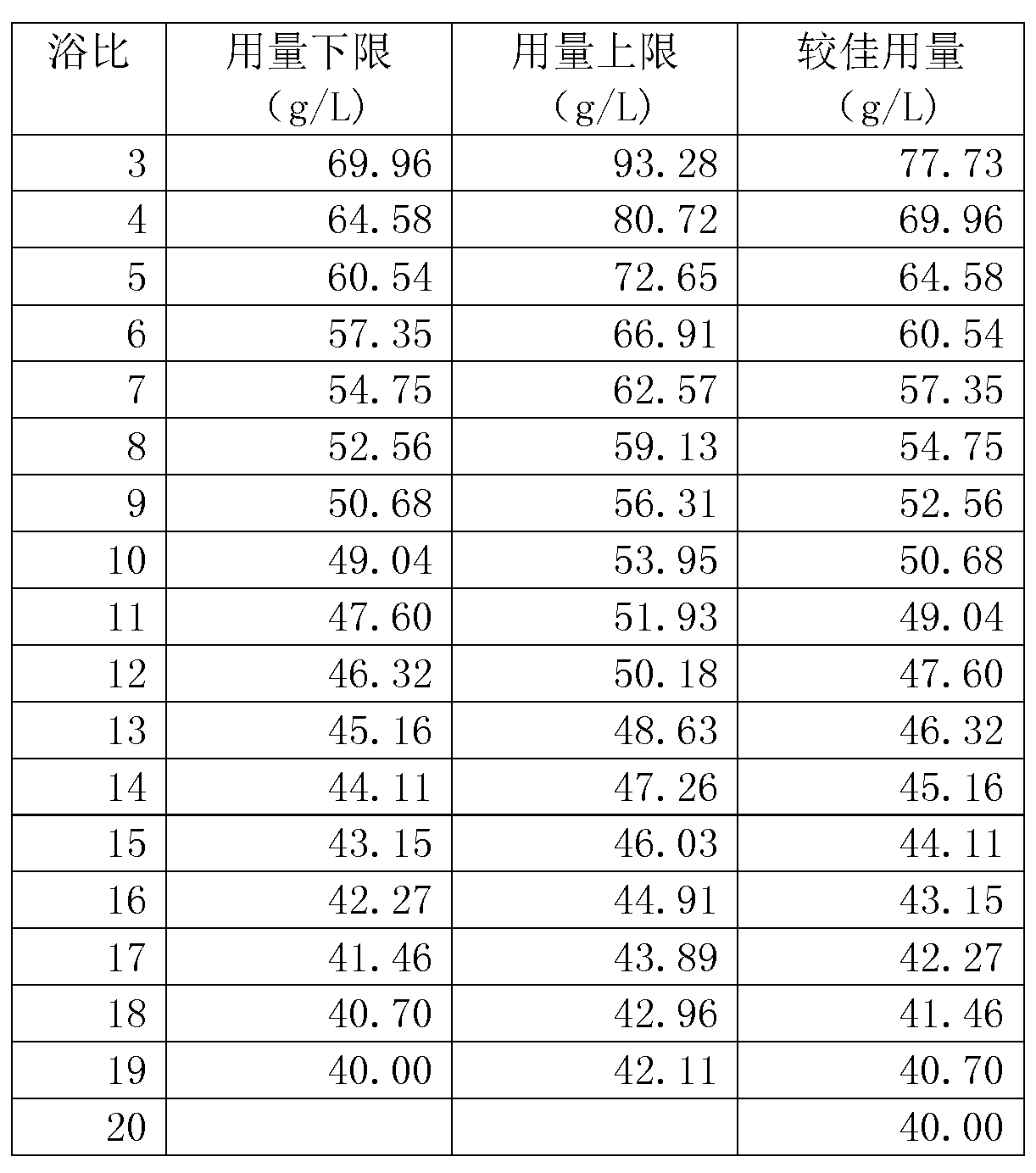

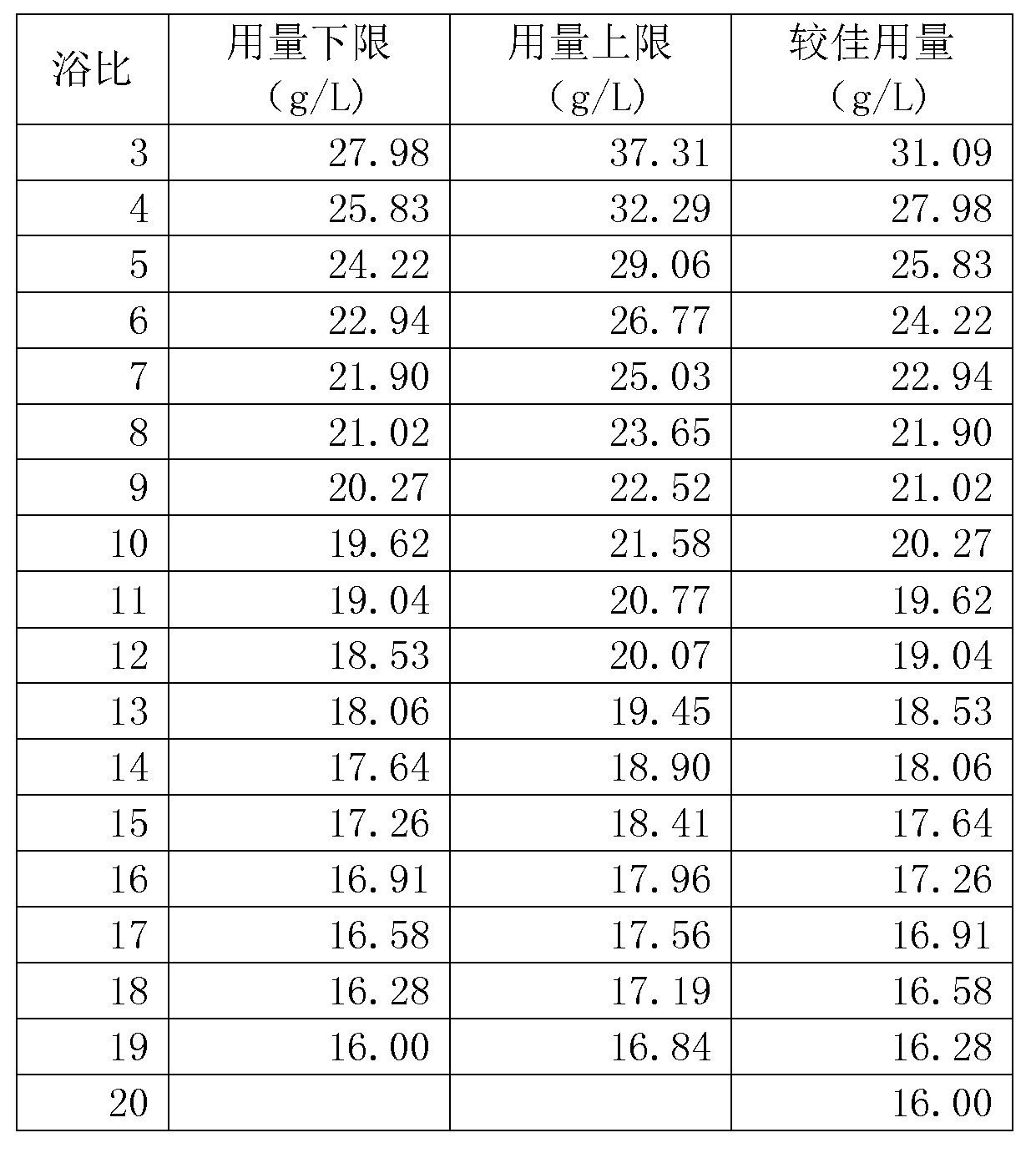

Method for converting traditional bath ratio reactive dye dyeing prescription into small bath ratio reactive dye dyeing prescription

ActiveCN102797169AEasy and fast conversion methodDyeing depth conforms toDyeing processLower limitDissolution

Owner:ZHEJIANG YIDE CHEM

Novel method for purifying arsenic chelating type immune complex

Owner:广东腾湃医疗股份有限公司

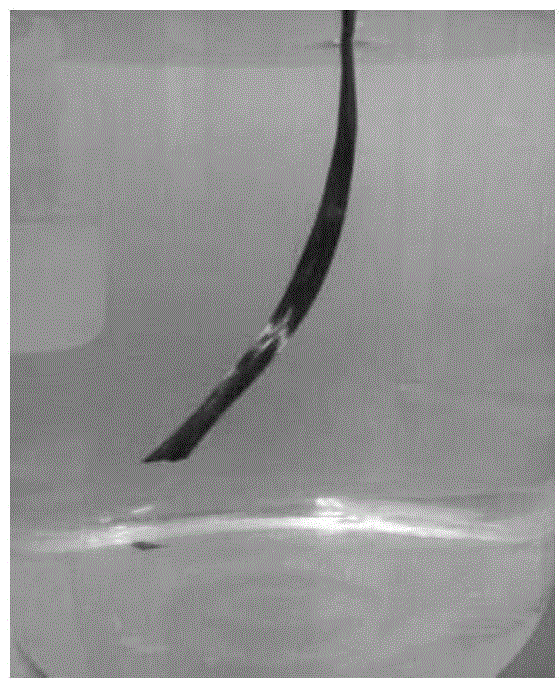

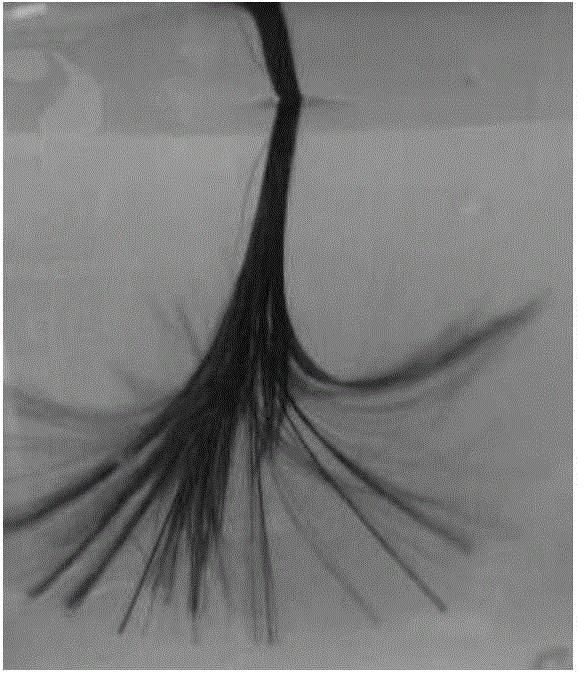

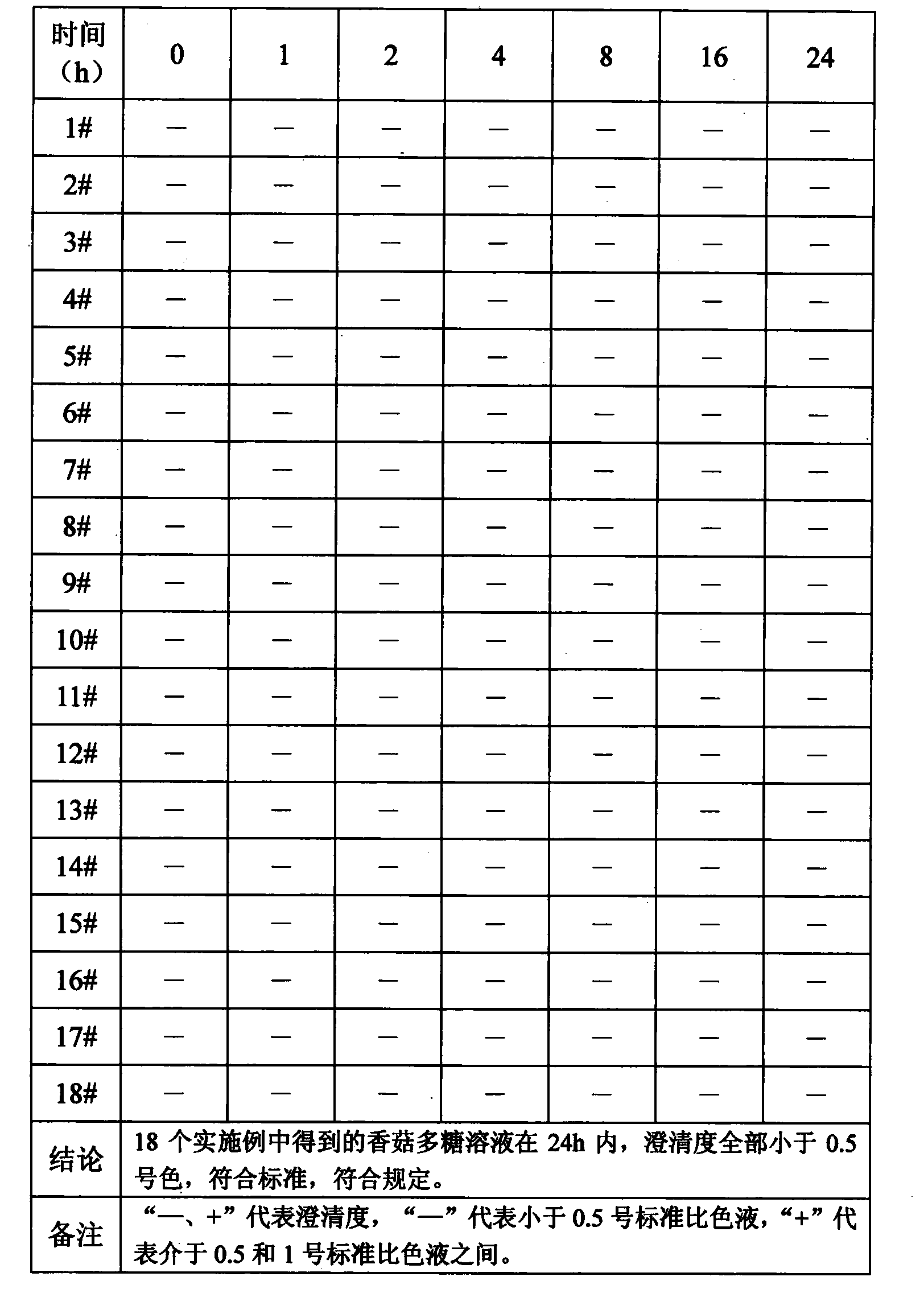

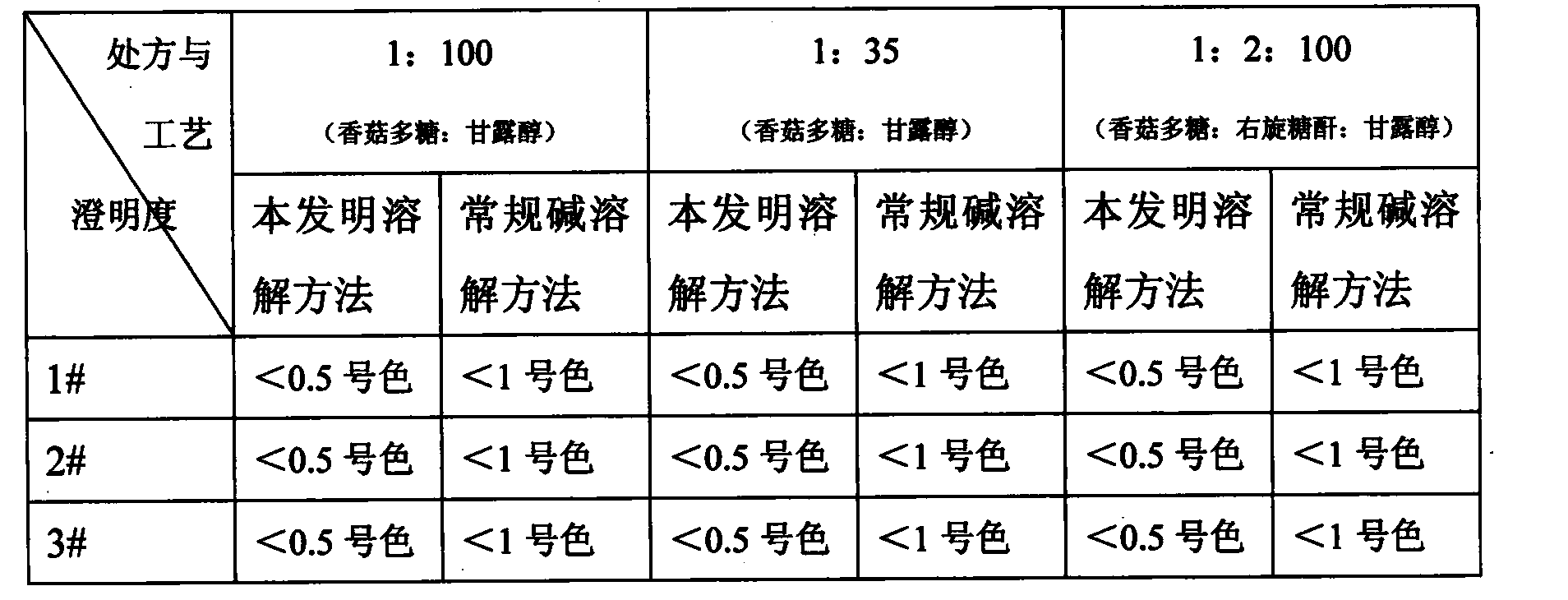

Method for dissolving lentinan solid powder

The invention provides a method for dissolving lentinan solid powder. The method is characterized by comprising the following concrete steps: adding the lentinan solid powder to water; shearing by using a shearing machine at the rotating speed of 500-30000rpm for 0-30 minutes, so as to obtain evenly dispersed liquid; pouring the obtained evenly dispersed liquid into the feeding hole of a homogenizer; homogenizing for 0-3 times by adopting secondary pressure at 30-300bar, and then adjusting the pressure to 300-2000bar by adopting a first-stage homogenizing valve or first-stage and second-stage homogenizing valves, and homogenizing 2-7 times, so as to obtain a lentinan solution of which the concentration is 0.1-3.0mg / ml. By adopting the method, dissolution of the lentinan under a non-alkali condition is achieved, stable lentinan is ensured, the toxic and side effects are reduced, and the use safety of the medicine is improved; meanwhile, the method is a simple and feasible drug dissolution method.

Owner:上海慈瑞医药科技股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap