Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109 results about "Hydrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen is the chemical element with the symbol H and atomic number 1. With a standard atomic weight of 1.008, hydrogen is the lightest element in the periodic table. Hydrogen is the most abundant chemical substance in the Universe, constituting roughly 75% of all baryonic mass. Non-remnant stars are mainly composed of hydrogen in the plasma state. The most common isotope of hydrogen, termed protium (name rarely used, symbol ¹H), has one proton and no neutrons.

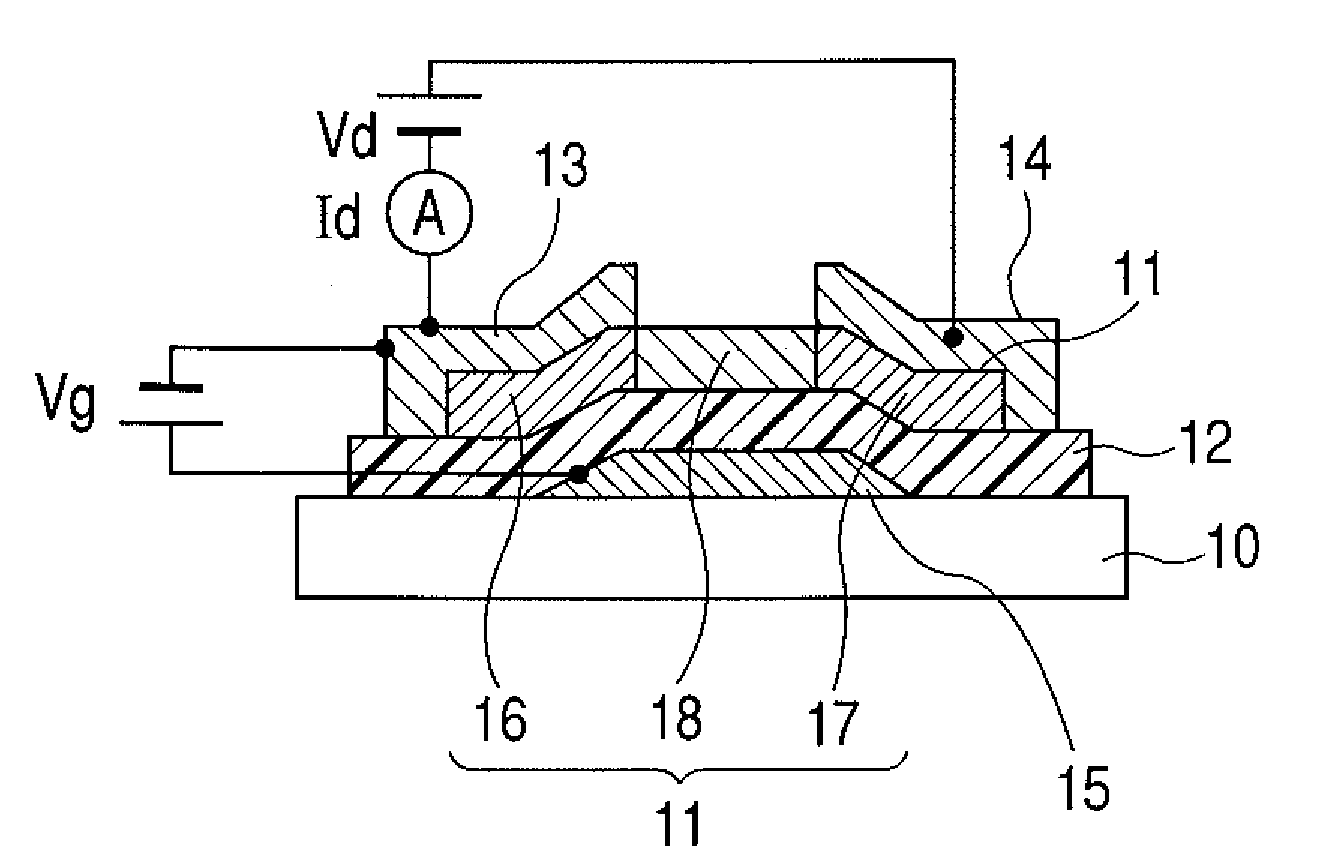

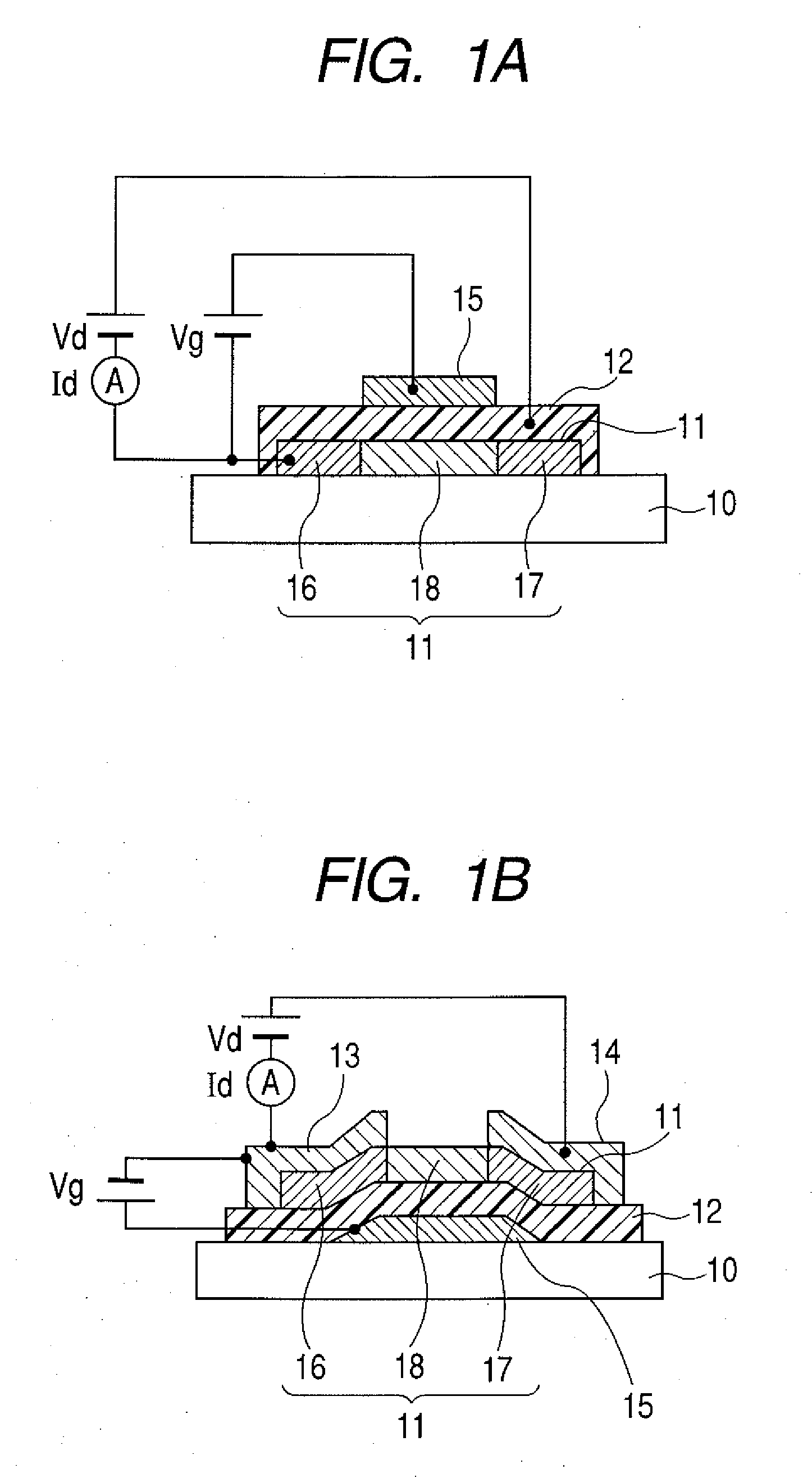

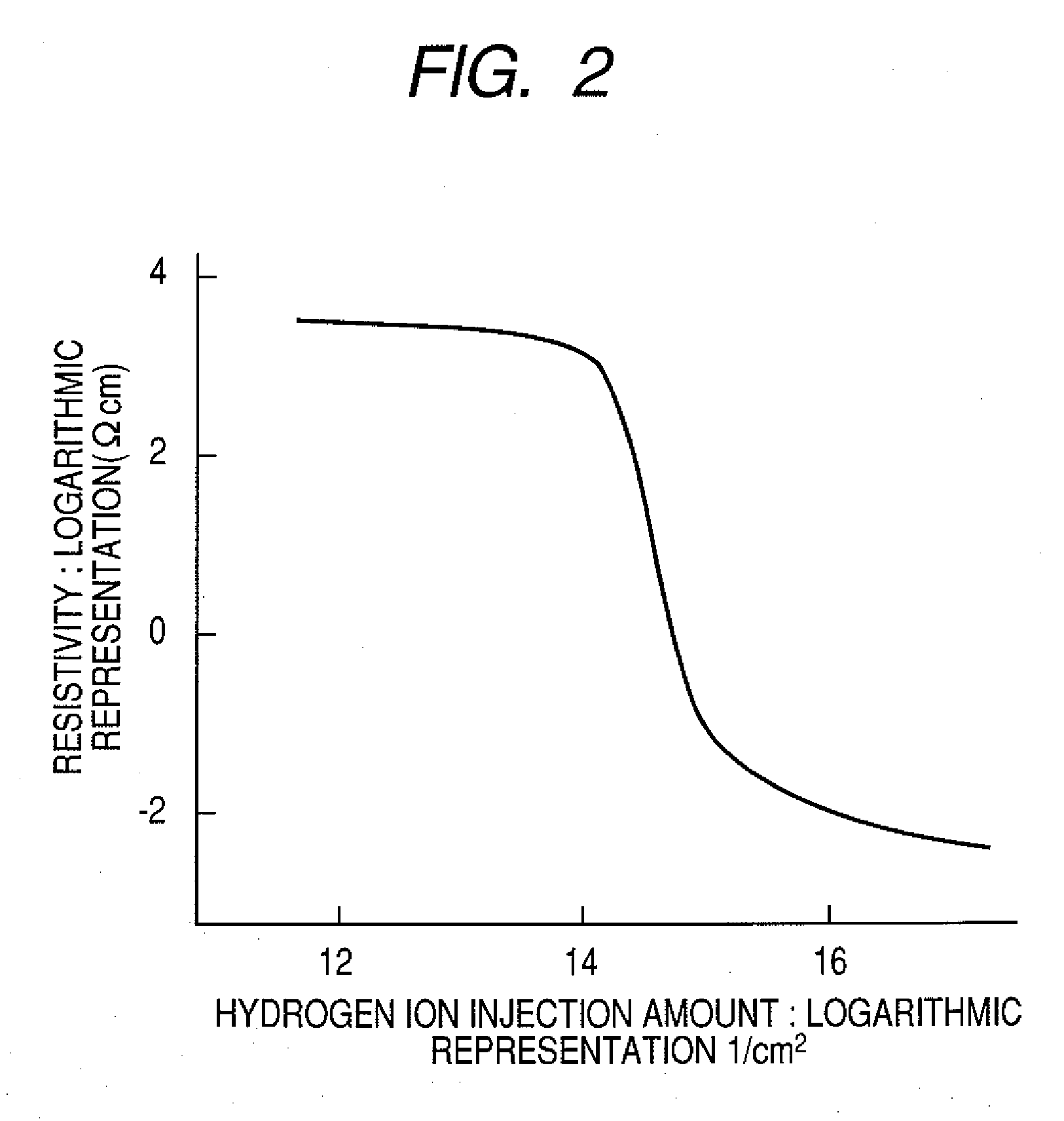

Field effect transistor using oxide film for channel and method of manufacturing the same

ActiveUS20090065771A1Reduce variationImprove accuracyTransistorSemiconductor/solid-state device manufacturingHydrogenField-effect transistor

Owner:CANON KK

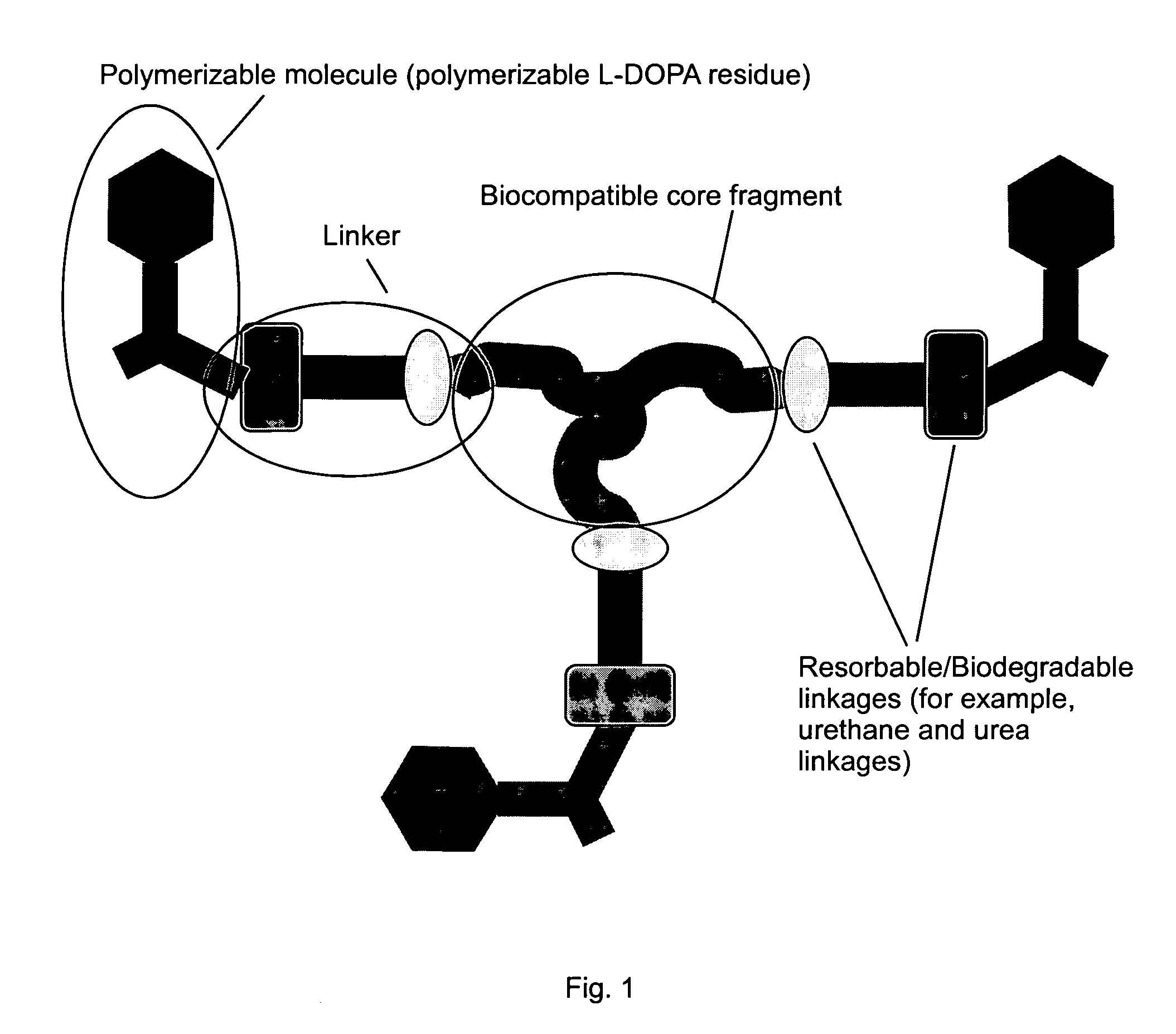

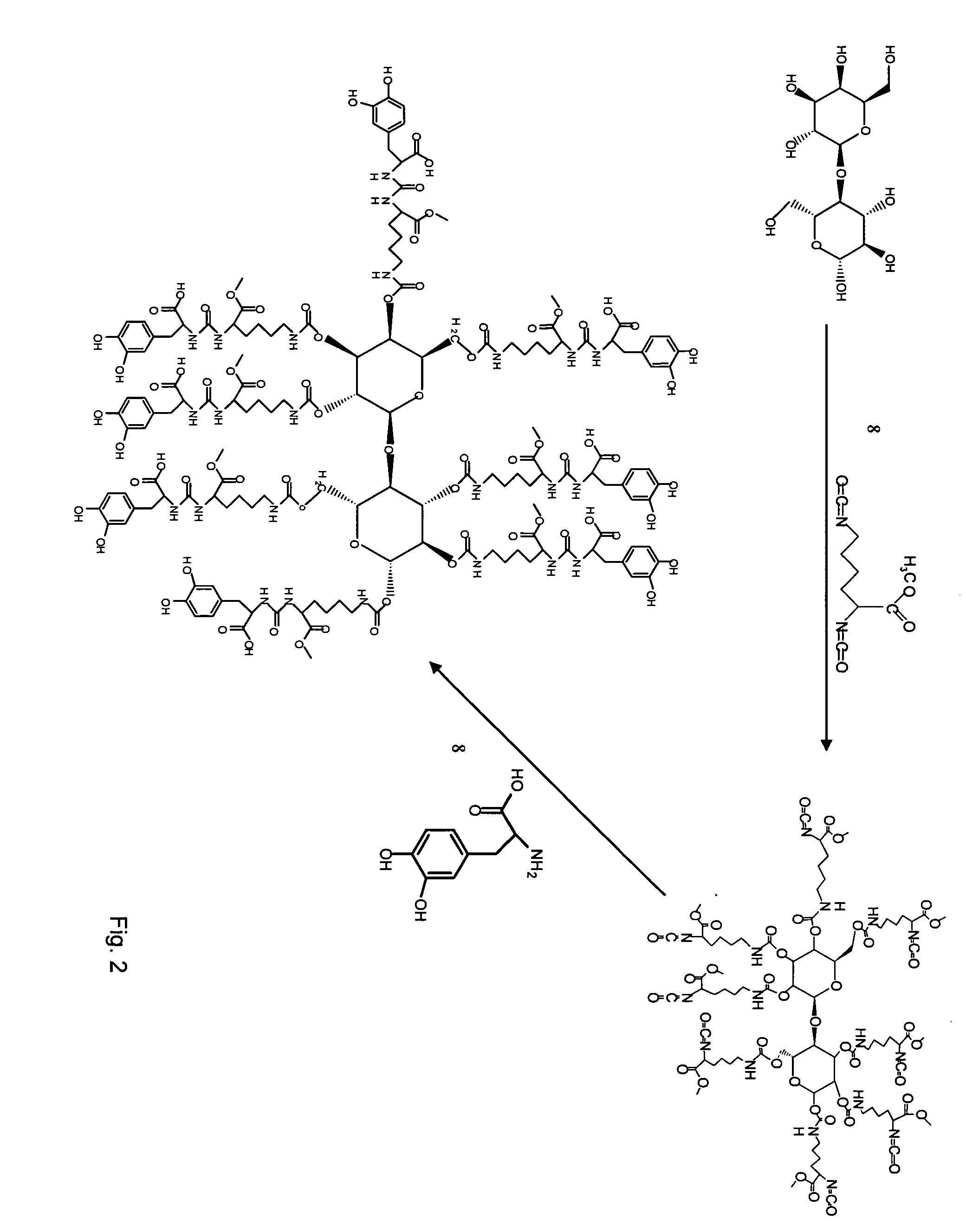

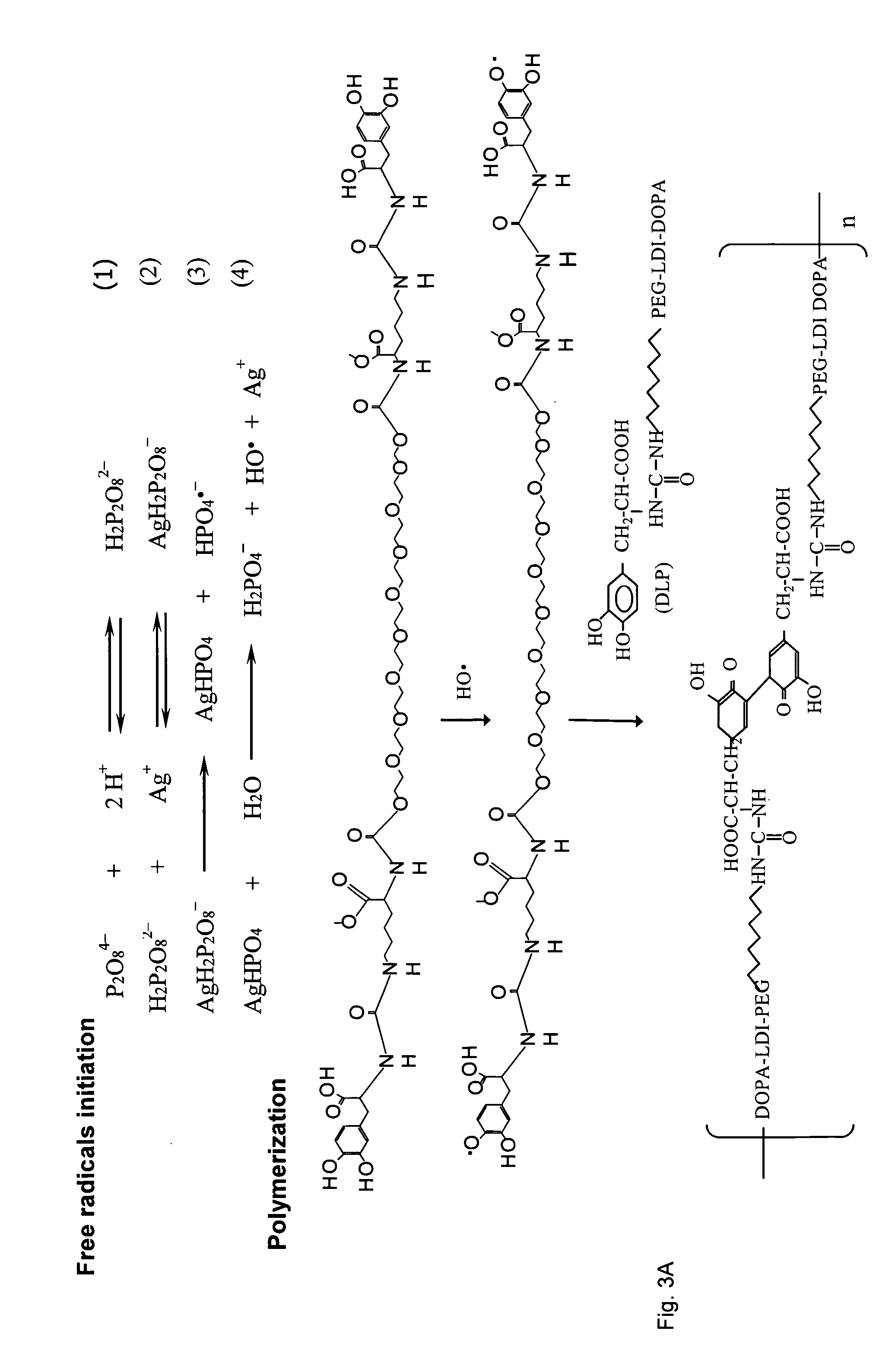

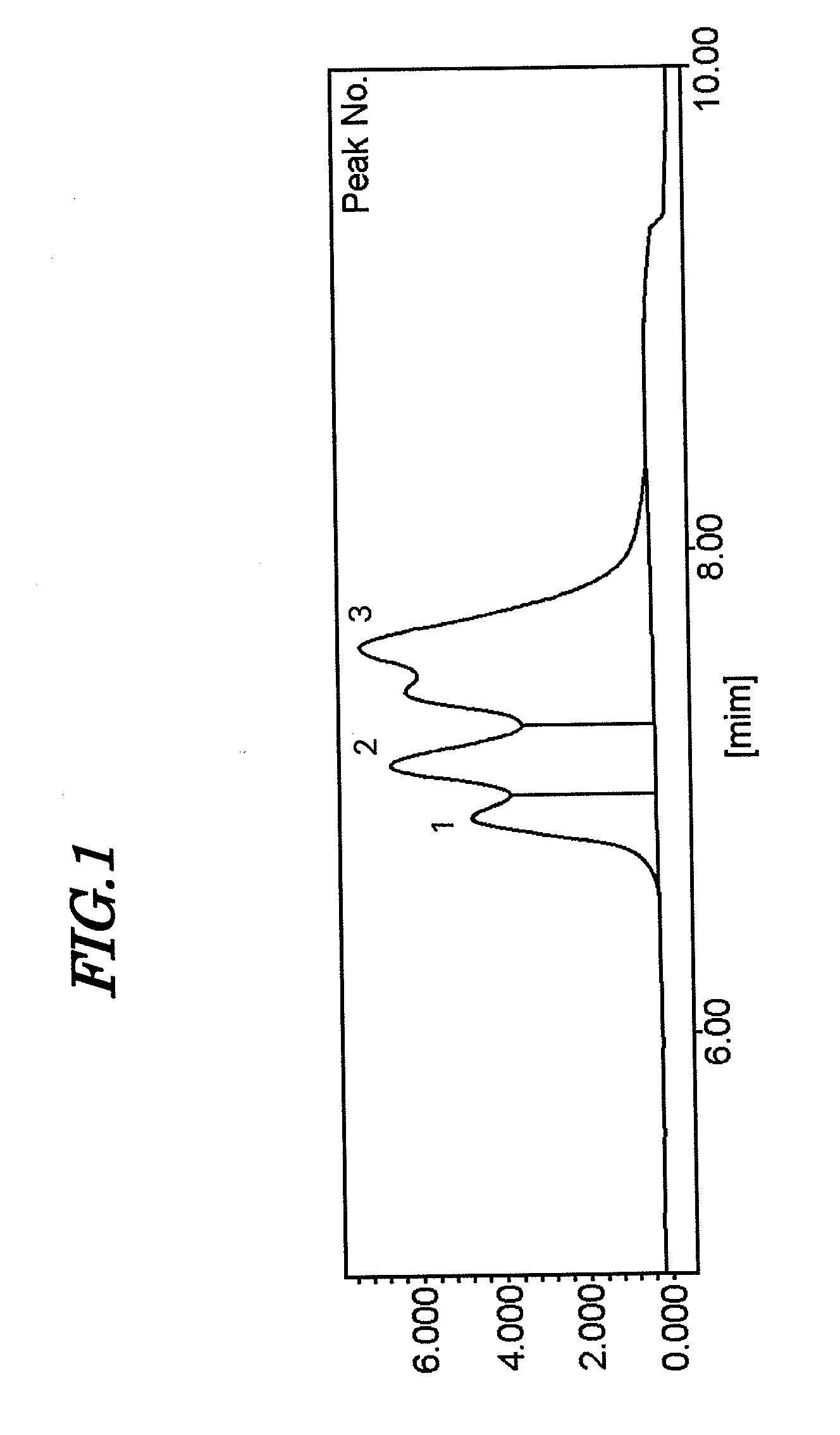

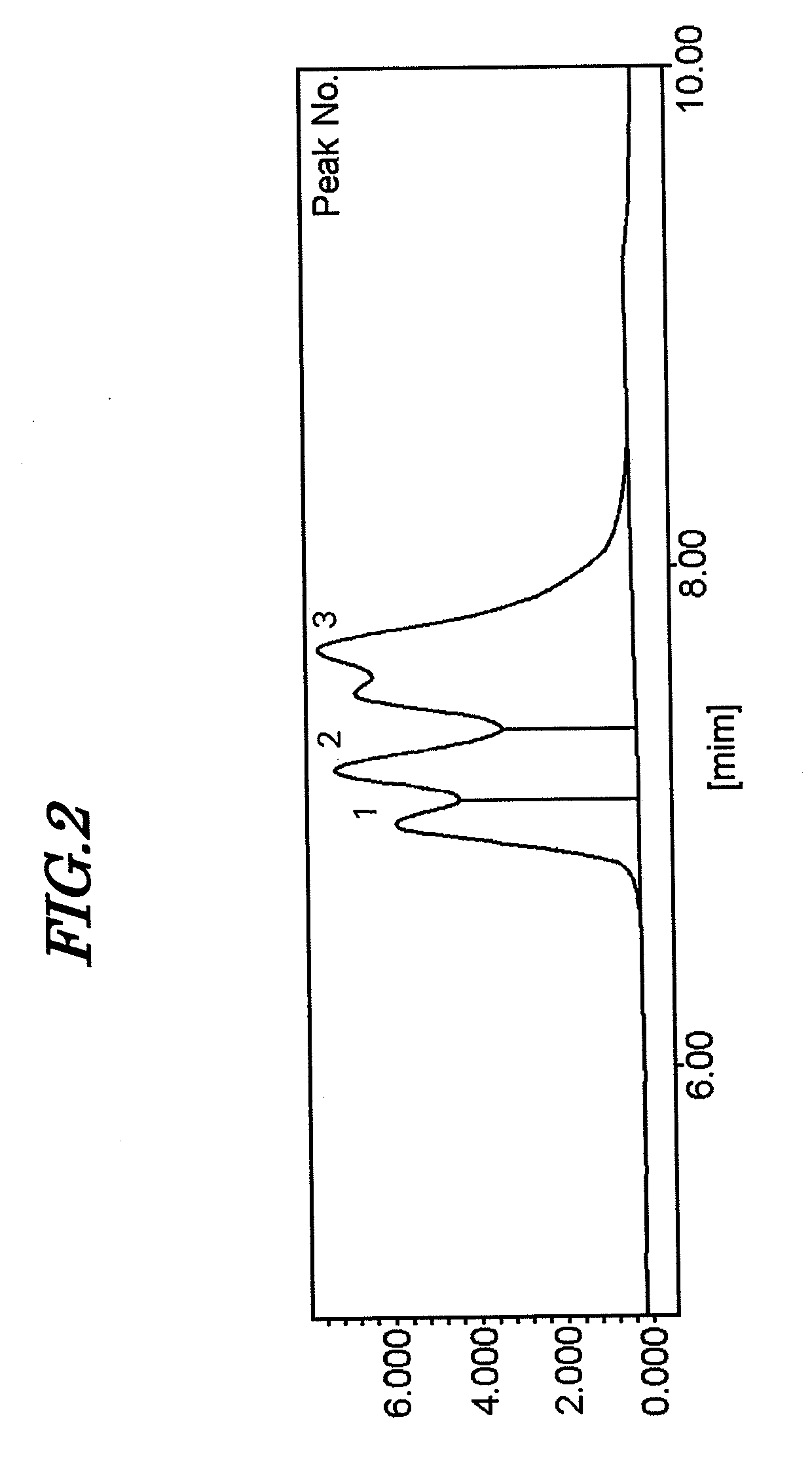

Wound healing polymeric networks

Owner:UNIVERSITY OF PITTSBURGH

Conjugated diene polymer, method for producing conjugated diene polymer, and conjugated diene polymer composition

Owner:SUMITOMO CHEM CO LTD

Integrally Molded Body of Silicone Resin and Silicone Rubber, Method of Manufacture, and Curable Silicone Resin Composition

Owner:DOW CORNING TORAY CO LTD

Method for recovering a natural gas contaminated with high levels of co2

Owner:SHELL OIL CO

Method for preparing diamond-like composite coating on surface of piston ring

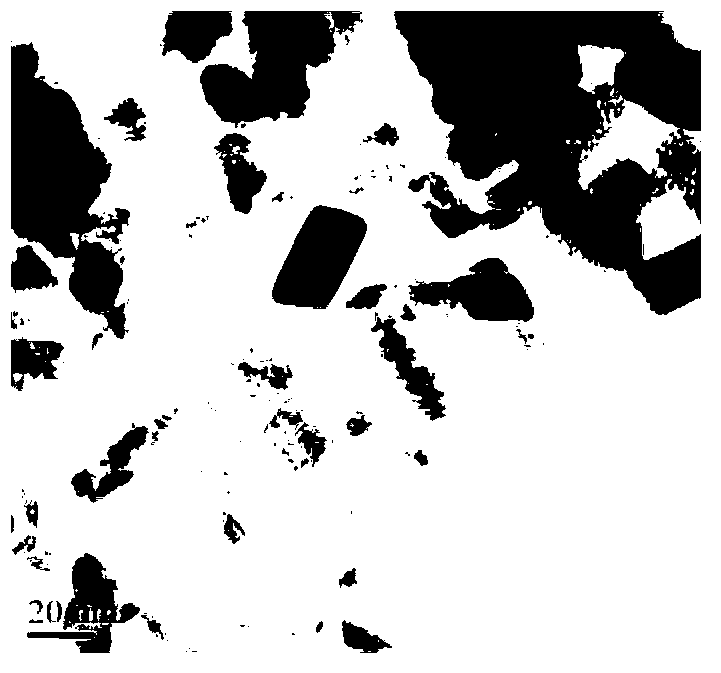

InactiveCN101665940AImprove wear resistanceImprove the lubrication effectVacuum evaporation coatingSputtering coatingLow temperature plasmaMagnetic filtration

The invention relates to a method for preparing a diamond-like composite coating with high hardness and good abrasion proof and self lubricating properties on the surface of a piston ring. In the method, a nitriding layer with high bonding strength, high hardness and good abrasion resistance is formed on the surface of the piston ring by the low-temperature plasma nitriding treatment, a non-hydrogen diamond-like surface layer with solid lubricating property is deposited by the combination of magnetic filtration cathode arc and magnetic control sputtering, and finally the nitriding / diamond-likecomposite coating, which is dense and smooth and possesses excellent abrasion proof and self-lubricating properties, is obtained on the surface of the piston ring. Compared with the durionising piston ring or CrN plating piston ring, the coating of the piston ring of the invention has higher comprehensive performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

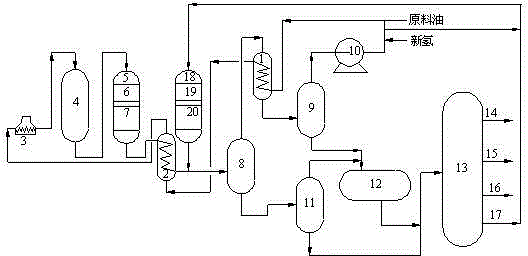

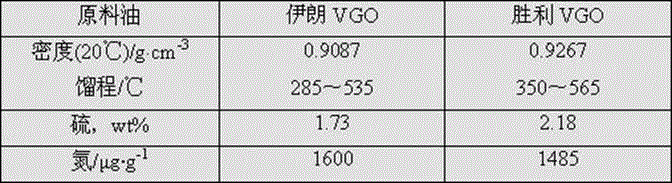

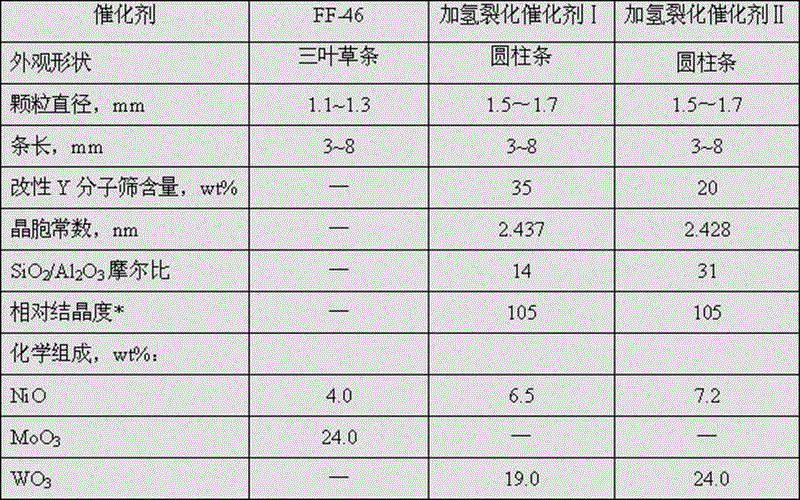

Hydrocracking method of low-energy-consumption, productive and high-quality jet fuel

ActiveCN105018137AReduce engineering investmentReduce operating energy consumptionTreatment with plural serial stages onlyMolecular sieveHydrogen

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ZnWO4 nanorod photocatalysis material

InactiveCN102935360APhotocatalyticWith photocatalytic effectMetal/metal-oxides/metal-hydroxide catalystsTungsten compoundsHeat treatedNanorod

Owner:SHAANXI UNIV OF SCI & TECH

Small pore diameter silicone rubber sponge and preparation method thereof

The invention discloses small pore diameter silicone rubber sponge and a preparation method thereof and relates to the field of processing of high polymer materials. The small pore diameter silicone rubber sponge comprises the following components in parts by weight: a component A: 100 parts of liquid organic silicone rubber; a component B: 3-8 parts of hydrogen-containing silicone oil; a component C: 0.5-10 parts of an emulsifier; a component D: 2-4 parts of a catalyst; a component E: 1-2 parts of an inhibitor; and a component F: 0-35 parts of a silicon resin. An emulsion dispersion mode is adopted, the dispersion phase size is small, and the silicone rubber sponge prepared by the method has the characteristics of bubble dispersion uniformity, small pore diameter and controllable density; and moreover, water serves as a foaming agent, and the sponge has the advantage of environment friendliness. The silicone rubber sponge material prepared by the method can serve as shock absorption, insulating, sound insulation and heat insulation materials.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

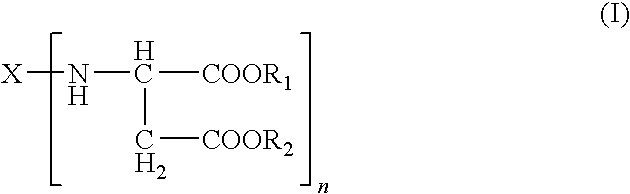

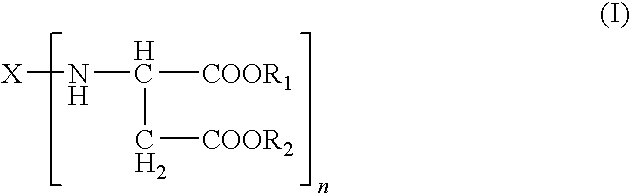

Adhesive systems containing polyisocyanate prepolymers and aspartate-ester curing agents, processes for preparing the same, medical uses therefor and dispensing systems for the same

InactiveUS20090191145A1Broaden applicationSurgical adhesivesPolyureas/polyurethane adhesivesPolyolHydrogen

Owner:BAYER MATERIALSCIENCE AG

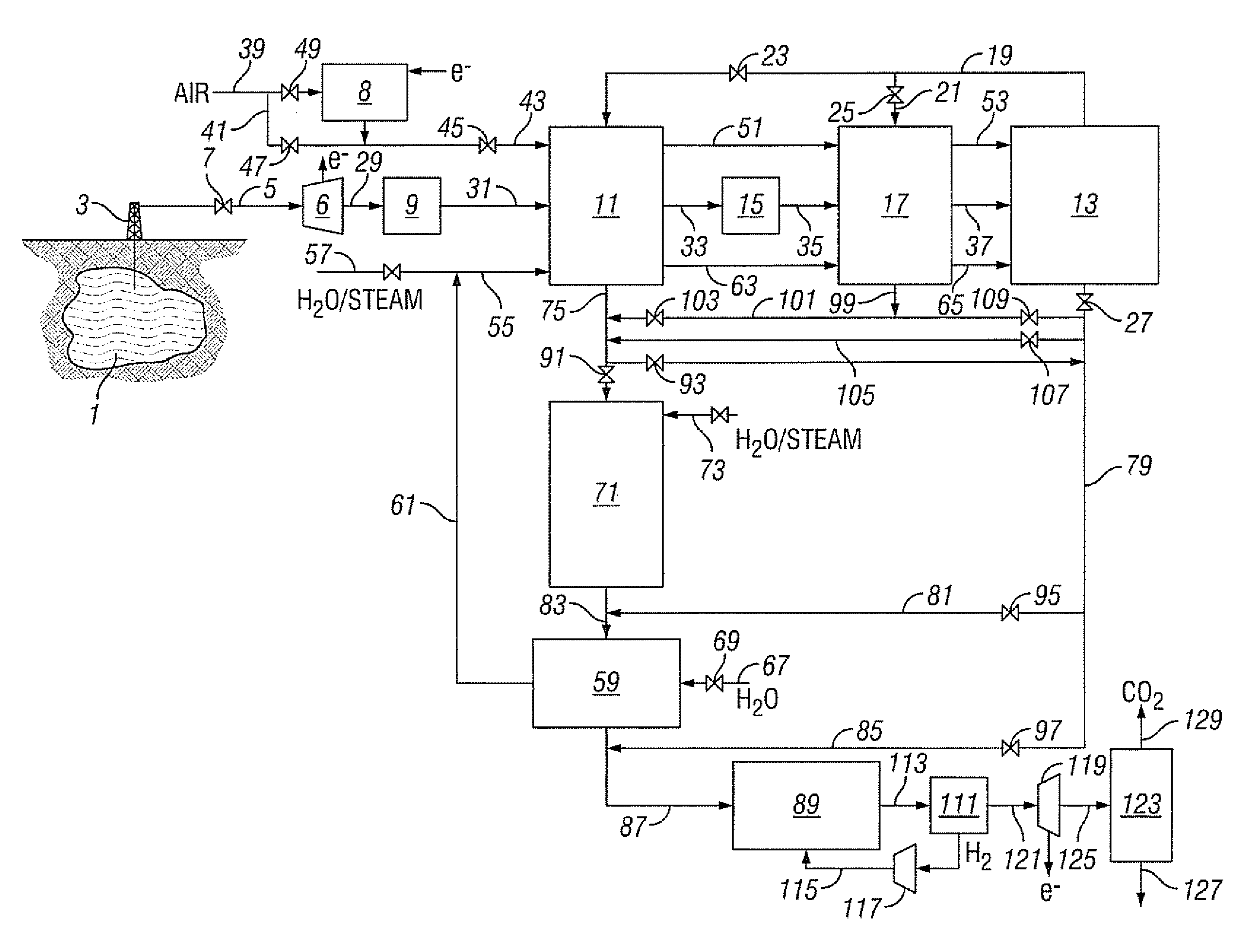

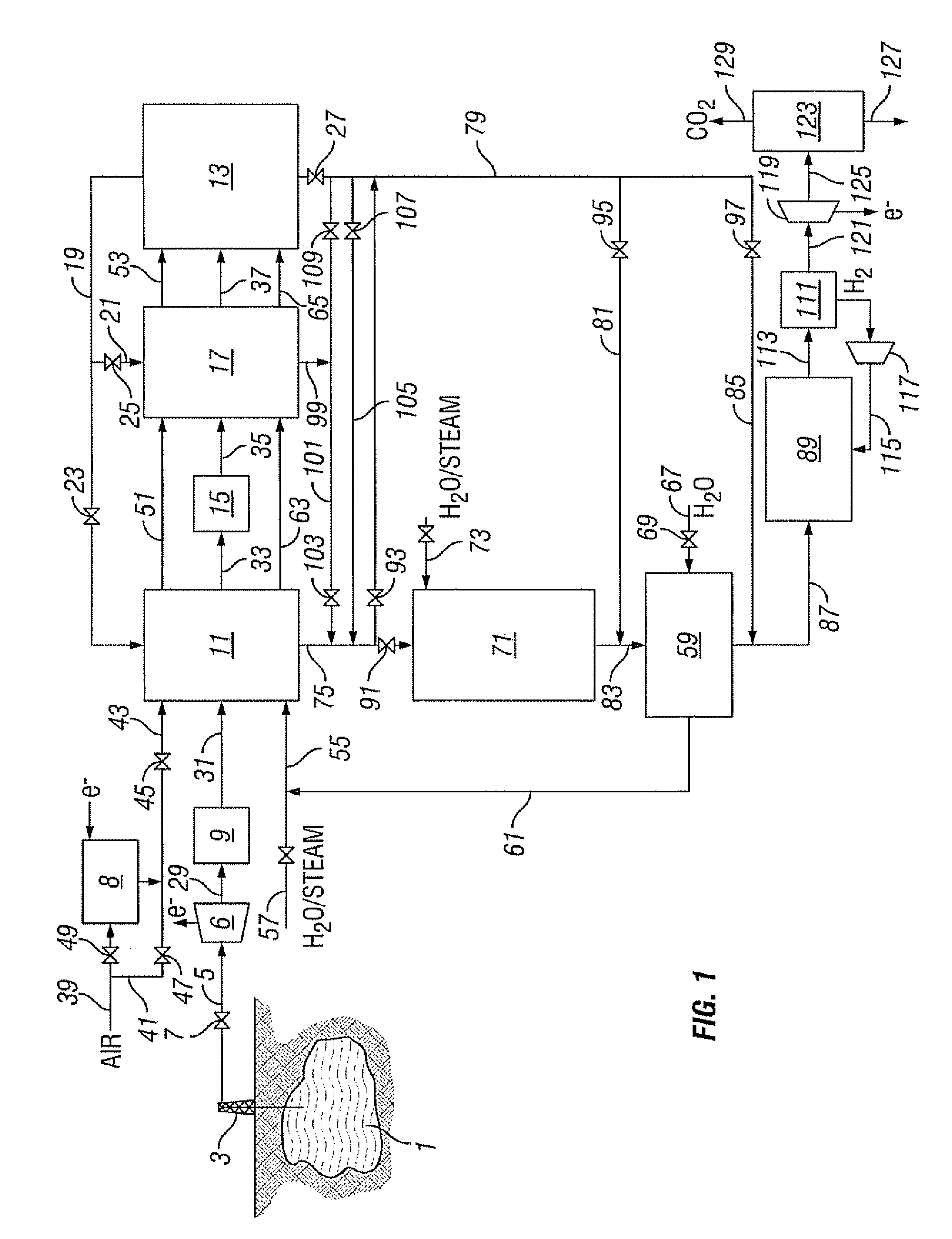

Hydrogen on demand electrolysis fuel cell system

InactiveUS20140262819A1Improve fuel economyEmission reductionCellsPhotography auxillary processesElectrolysisHydrogen

A hydrogen and oxygen (HHO) gas on-demand electrolysis fuel cell system for use with internal combustion engines is disclosed. This hydrogen on-demand (HOD) system integrates with the engine control module (ECM) or other control system that regulates the operation of an internal combustion engine in order to supply HHO to the engine and improve the engine's overall fuel efficiency. This system includes an electrolyte fluid reservoir outfitted with level, pressure and temperature sensors; a pump and heat exchanger; a uniquely-configured electrolyzer; and a filter. The combined engine and HOD system is controlled and regulated by an electronic control system (ECS) and a combustion control module (CCM). The CCM is installed on the engine such that it actively intercepts the electronic signals from the engine manufacturer's ECM to continuously coordinate the functions and operations of the HOD system and the engine.

Owner:NRG LOGISTICS

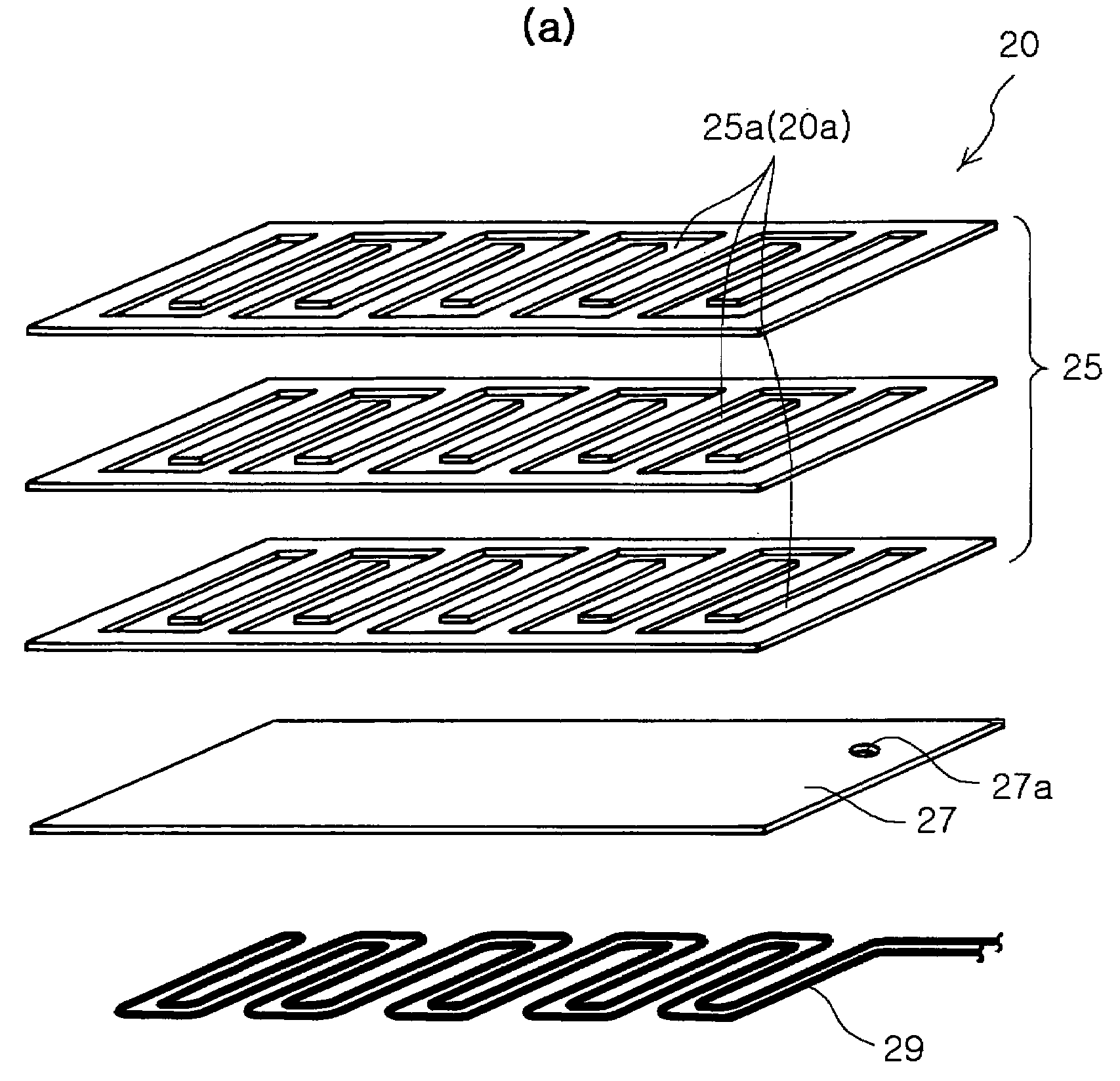

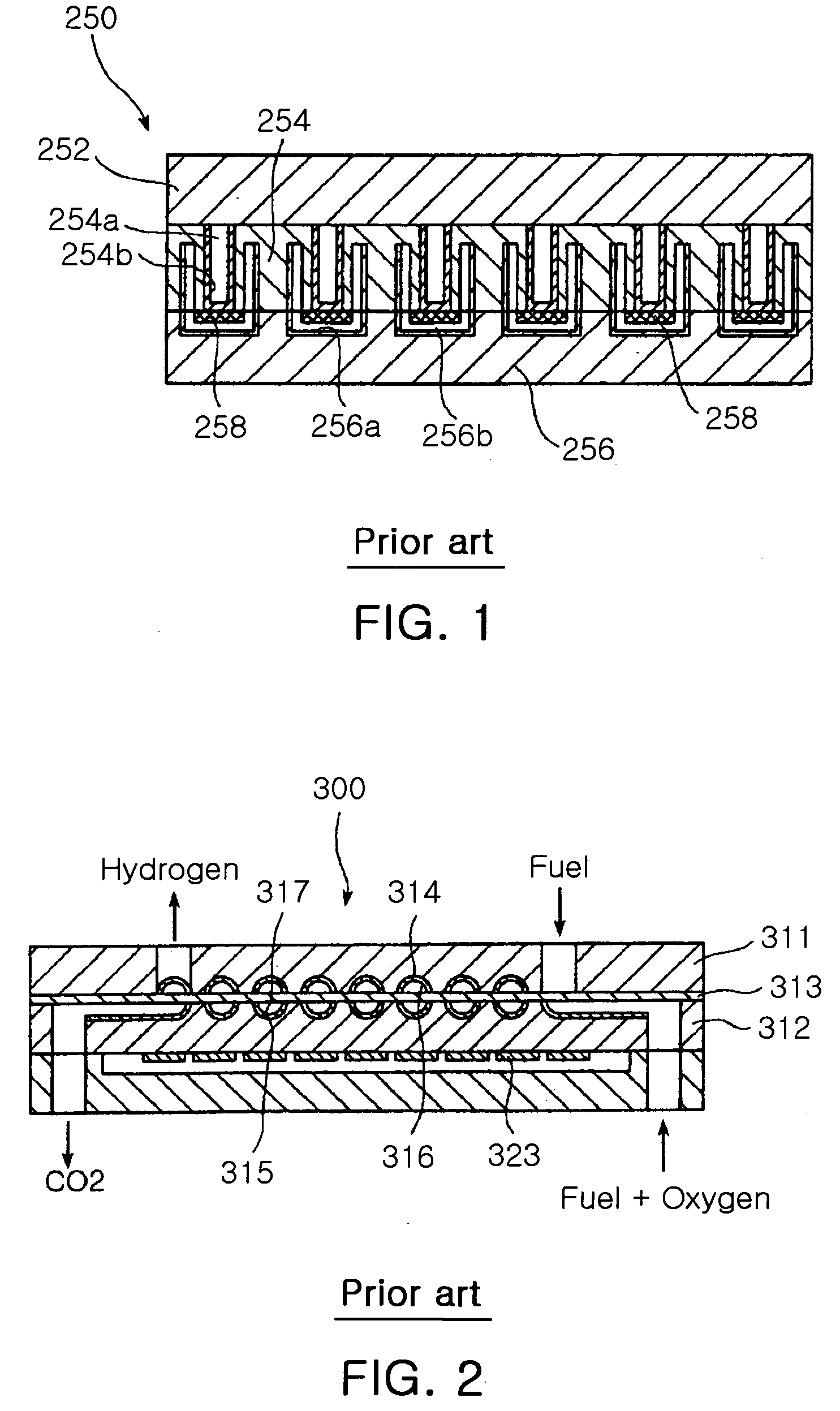

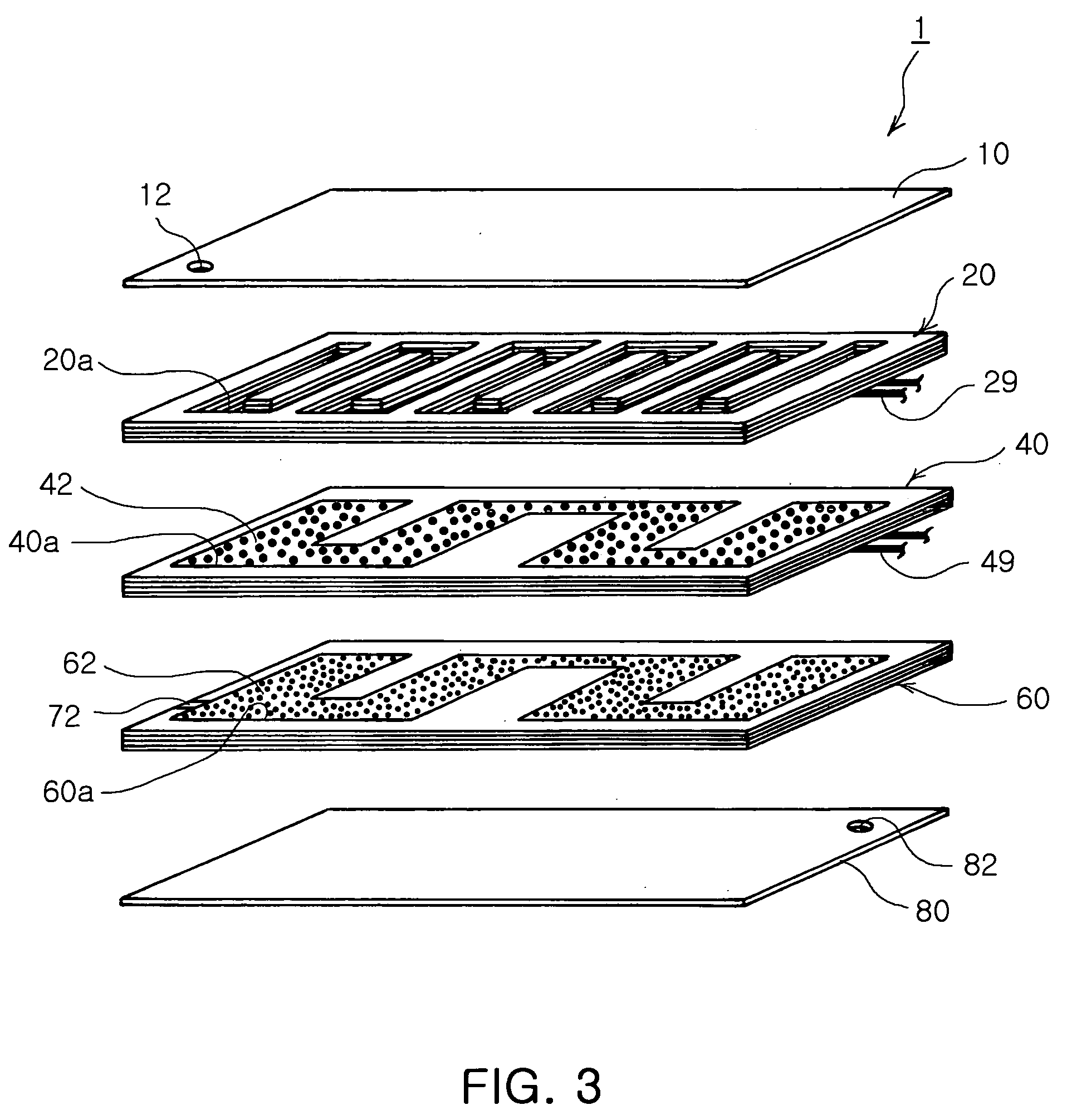

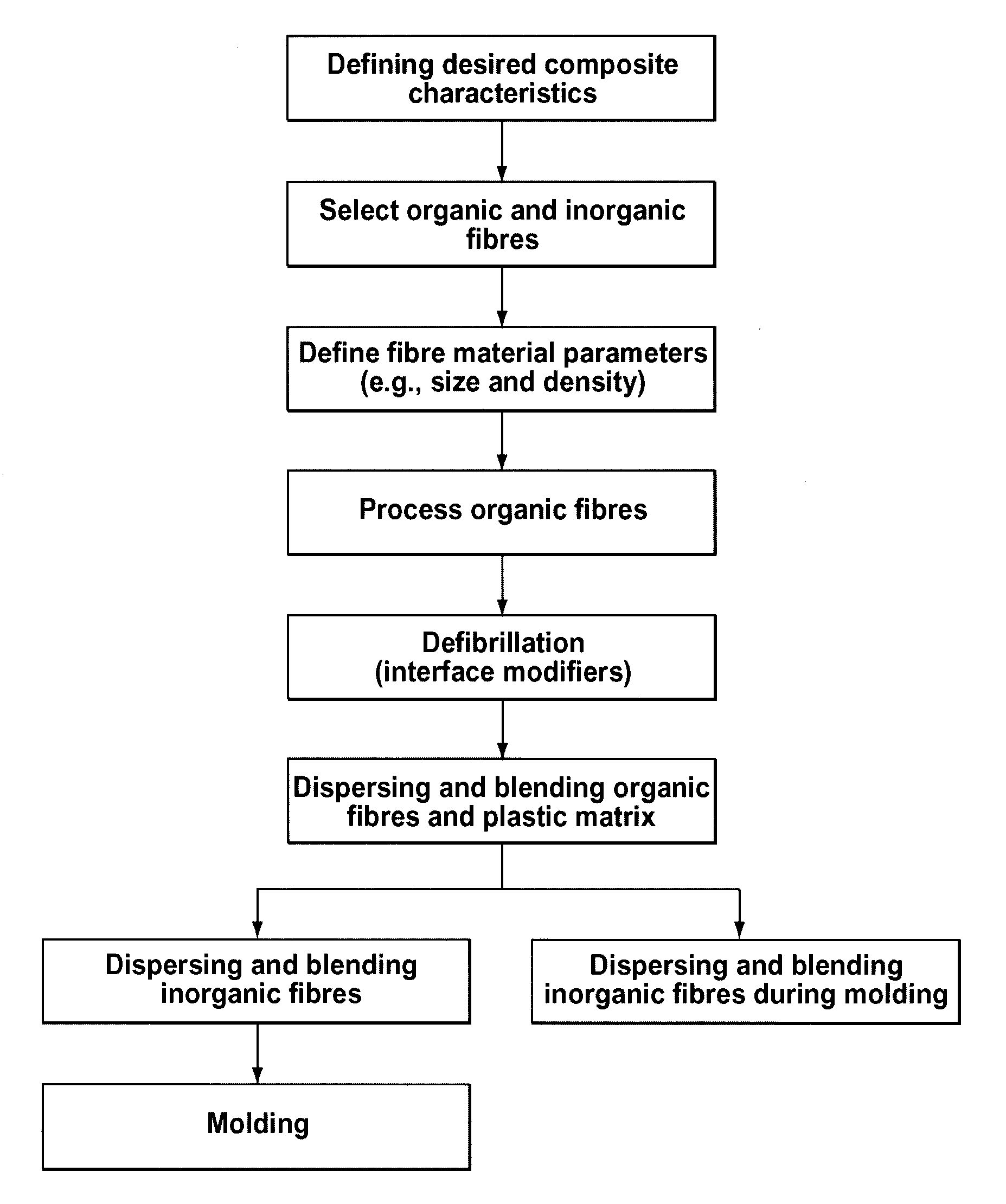

Multi-layer ceramic substrate reforming apparatus and manufacturing method therefor

InactiveUS20070154367A1Guaranteed uptimeSmall and thin and light-weight structureHydrogenChemical/physical/physico-chemical microreactorsHydrogenEngineering

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Catalyst for oxidative dehydrogenation of raw materials containing CO (carbon monoxide) gas

InactiveCN102649055ACarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsLoss rateAdditive ingredient

The invention relates to a catalyst for oxidative dehydrogenation of raw materials containing CO (carbon monoxide) gas, which mainly solves the technical problems in the prior art that the hydrogen removal rate is low, and the loss rate of CO is high. The catalyst comprises a carrier, an active component and an accessory ingredient in percentage by weight: (a) the active component which is selected from at least one of platinum metals, and has the dosage being 0.003-2 percent of the weight of the catalyst in a metering manner of a simple substance; (b) the accessory ingredient which is selected from at least one of Pr, Nd, Cs and Ba, and has the dosage being 0.005-15 percent of the weight of the catalyst in a metering manner of a simple substance; and (c) 84-99.5 percent of carrier, wherein the carrier is selected from a compound type carrier of aluminum oxide and silicon oxide, and the weight ratio of the aluminum oxide to the silicon oxide is 0.01-100:1. According to the technical scheme, the problems are better solved, and the catalyst can be applied in industrial production of oxidative dehydrogenation of raw materials containing the CO gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

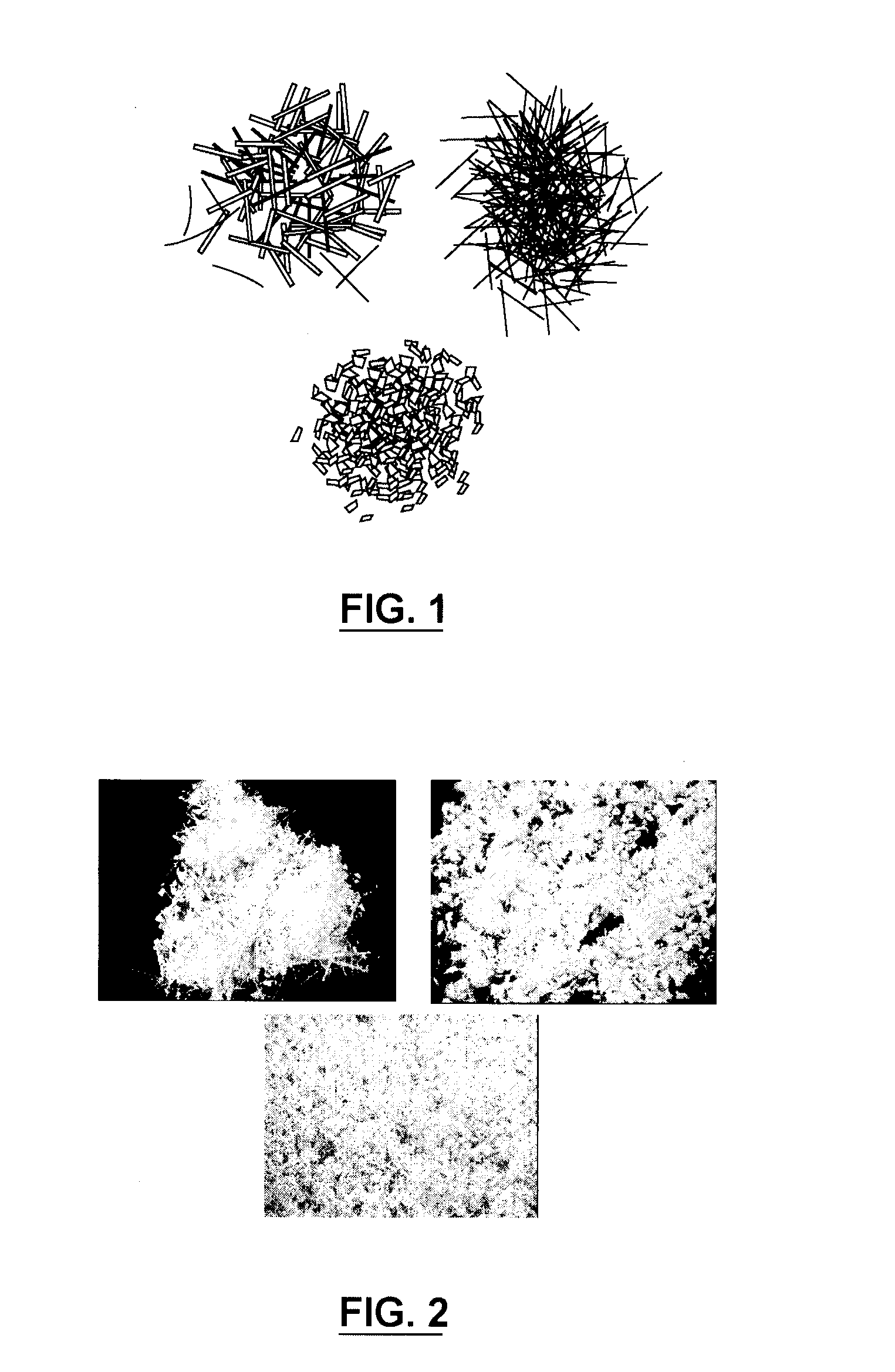

Manufacturing process for hybrid organic and inorganic fibre-filled composite materials

Owner:SAIN MOHINI M +2

Ferrierite molecular sieve, preparation method thereof and application

ActiveCN107010636AGood choiceImprove stabilityHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationCrystallinity

The invention provides a ferrierite molecular sieve, a preparation method thereof and an application. The preparation method includes the steps: mixing silicon sources, alkalinity conditioning agents, aluminum sources, template agents and water to form uniform sol; controlling the molar ratio of SiO2, Al2O3, R, Na2O to H2O to be 1.0:(0.005-0.10):(0.05-1.2):(0.03-0.50):(5.0-100.0), and enabling a pH (potential of hydrogen) value to be lower than 12.8; performing pre-crystallization, crystallization, drying and calcination to obtain molecular sieve raw powder; performing acid treatment on the obtained molecular sieve raw powder; mixing the molecular sieve raw powder, the template agents and the water or further mixing the molecular sieve raw powder, the template agents, the water and the silicon sources to form water solution; performing water-heat treatment, drying and calcination to obtain the ferrierite molecular sieve. R is the template agents. The prepared ferrierite molecular sieve is high in relative crystallinity and silica alumina ratio, large in specific surface area and crystal particle and adjustable in acidity and has excellent selectivity and stability when being applied to linear-chain olefin skeletal isomerization reaction.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method for high-purity rhenium powder

Owner:湖南元极新材料有限公司

Intelligent label for indicating freshness of aquatic products and preparation method of intelligent label

PendingCN107290335AFreshness real-time monitoringImprove securityMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsBromocresol greenHydrogen

The invention relates to an intelligent freshness label. The intelligent freshness label is characterized in that a bromocresol green pH (Potential of Hydrogen) sensitive dyestuff is utilized and an anodic aluminum oxide film is used as an adsorption carrier of the dyestuff. The anodic aluminum oxide film has a pore diameter less than 200nm, is vertical to the surface and has the pore density of 10<9> pores / cm<2> to 10<10> pores / cm<2>. The intelligent label provided by the invention is a visualized label which can be used for accurately characterizing the freshness of foods and directly feeding food freshness information back to consumers. According to the intelligent freshness label provided by the invention, the quality change of foods in packages can be directly characterized according to changes of environment parameters including temperature, time and the like of the foods.

Owner:GUANGDONG OCEAN UNIVERSITY +1

Novel imidazolidinedione derivatives and use thereof as drugs

Owner:SENJU PHARMA CO LTD

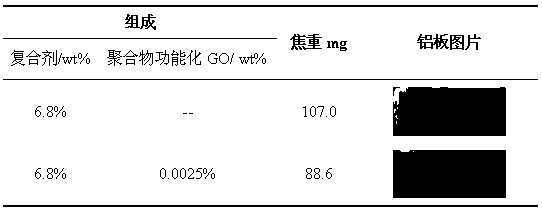

Polymer functional graphene and preparation method and application thereof

Owner:江西福安路润滑材料有限公司 +1

NiCoP nanoparticles grown on surface of g-C3N4 in situ as well as preparation method and application of NiCoP nanoparticles

InactiveCN107617443ASimple and fast manufacturing methodEasy to operatePhysical/chemical process catalystsHydrogen productionHydrogenNanoparticle

The invention provides NiCoP nanoparticles grown on the surface of g-C3N4 in situ as well as a preparation method and application of the NiCoP nanoparticles to production of hydrogen by photocatalytically decomposing water, and belongs to the technical field of photocatalytic decomposition of the water to prepare the hydrogen. The preparation method comprises the following steps: firstly, preparing g-C3N4powder particles; then adding 10mL to 30mL of secondary distilled water into 200mg to 400mg of the g-C3N4 powder particles; after carrying out ultrasonic treatment for 1h to 3h, stirring for 1h to 3h; then adding 10mg to 150mg of a nickel source and 10mg to 150mg of a cobalt source; after carrying out the ultrasonic treatment for 5min to 20min, stirring for 5min to 20min; then adding 50mgto 600mg of a phosphorous source; after carrying out the ultrasonic treatment for 1h to 3h, stirring for 1h to 3h; then drying under the condition that the temperature is 50 DEG C to 80 DEG C; after the water is completely volatilized, sufficiently grinding a product; then calcining for 1h to 3h in a nitrogen atmosphere under the condition that the temperature is 200 DEG C to 400 DEG C; finally, centrifuging and washing by utilizing the secondary distilled water and ethanol; drying a centrifugal product for 10h to 20h under a vacuum condition, so as to obtain the NiCoP nanoparticles grown on the surface of the g-C3N4 in situ.

Owner:JILIN UNIV

Ultrathin heat conductive silicon sheet and preparation method thereof

Owner:SUZHOU TIANMAI THERMAL TECH

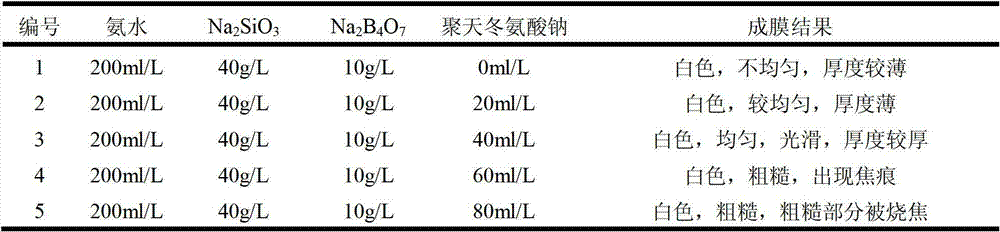

Electrolyte used for magnesium alloy anode oxidation treatment and treatment method

ActiveCN102828218AImprove corrosion resistanceStable temperatureAnodisationElectrolytic agentOxidative treatment

Owner:戚威臣

Method and equipment thereof for synthesizing methyl isobuthl ketone with acetone two-step method

ActiveCN108002995AReduce the problem of high DAA contentReduce generationOrganic compound preparationEnergy inputHydrogenMethyl isobutyl ketone

The invention discloses a method and equipment thereof for synthesizing methyl isobuthl ketone with an acetone two-step method. The method includes the steps that a, DAA and MSO are generated by condensation and dehydration of the raw material of acetone in a catalytic distillation column, products rich in MSO and water are side taken off from the catalytic distillation column; b, a material containing DAA is side taken off from the catalytic distillation column, and put into a DAA decomposition reactor, DAA in the material is transformed into acetone and MSO, the products are separated by flash evaporation to obtain a gas phase rich in acetone and a liquid phase rich in MSO and water, the gas phase and the liquid phase are respectively circulated back to the column; c, the liquid phase products in the step a are cooled and divided into phases, an organic phase rich in MSO and a water phase containing small amounts of organic matter are obtained, the water phase enters into a recoverytower to recycle organic matter; d, MIBK is generated by the hydrogenation of the organic phase in the step c, after hydrogen gas is recycled by flash evaporation, then enters into an MIBK refining tower, and a MIBK product is side taken off. The total conversion rate of acetone is 99.0%, and the product MIBK purify is up to 99.5%.

Owner:CHANGCHENG NEW ENERGY CO LTD +1

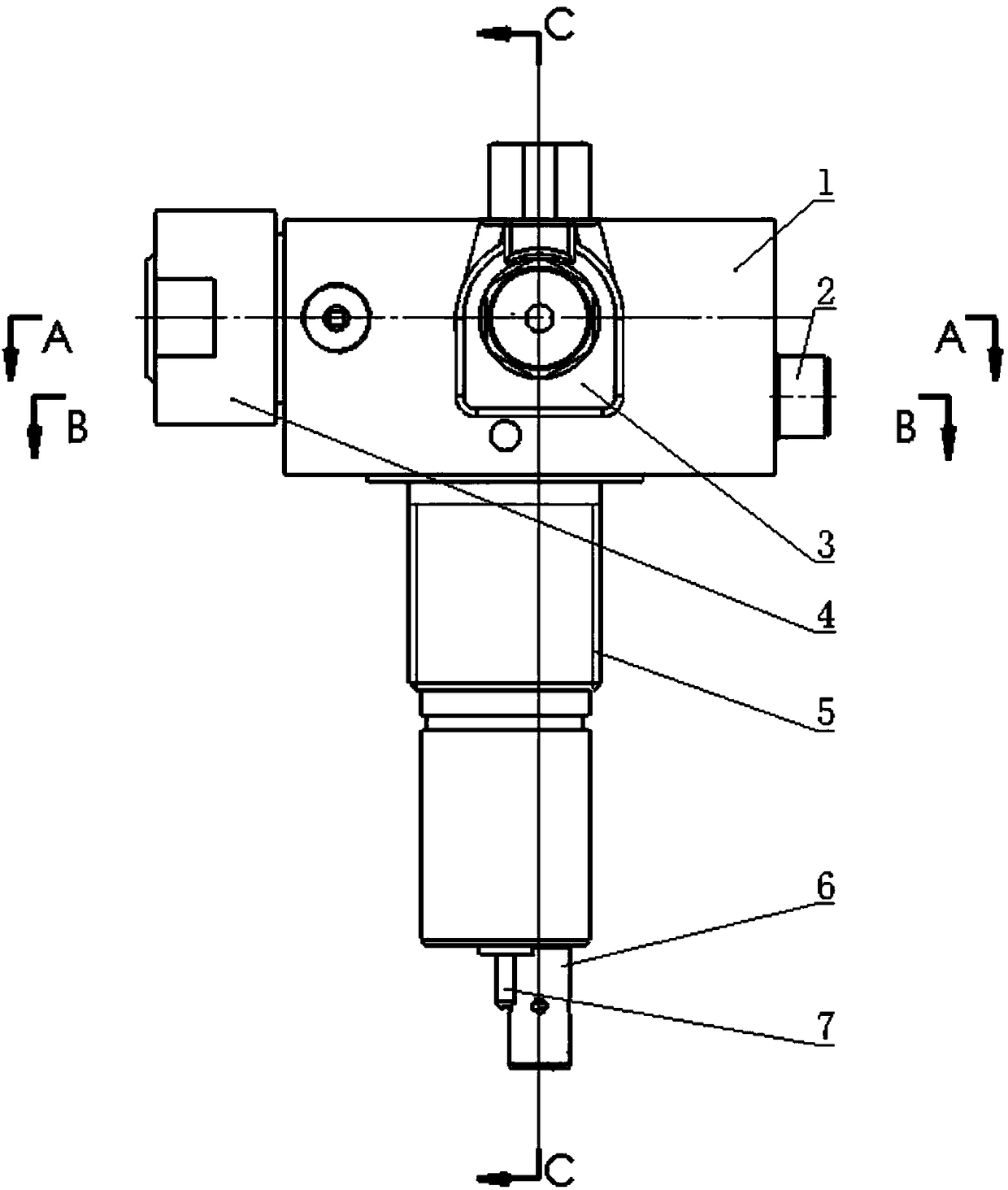

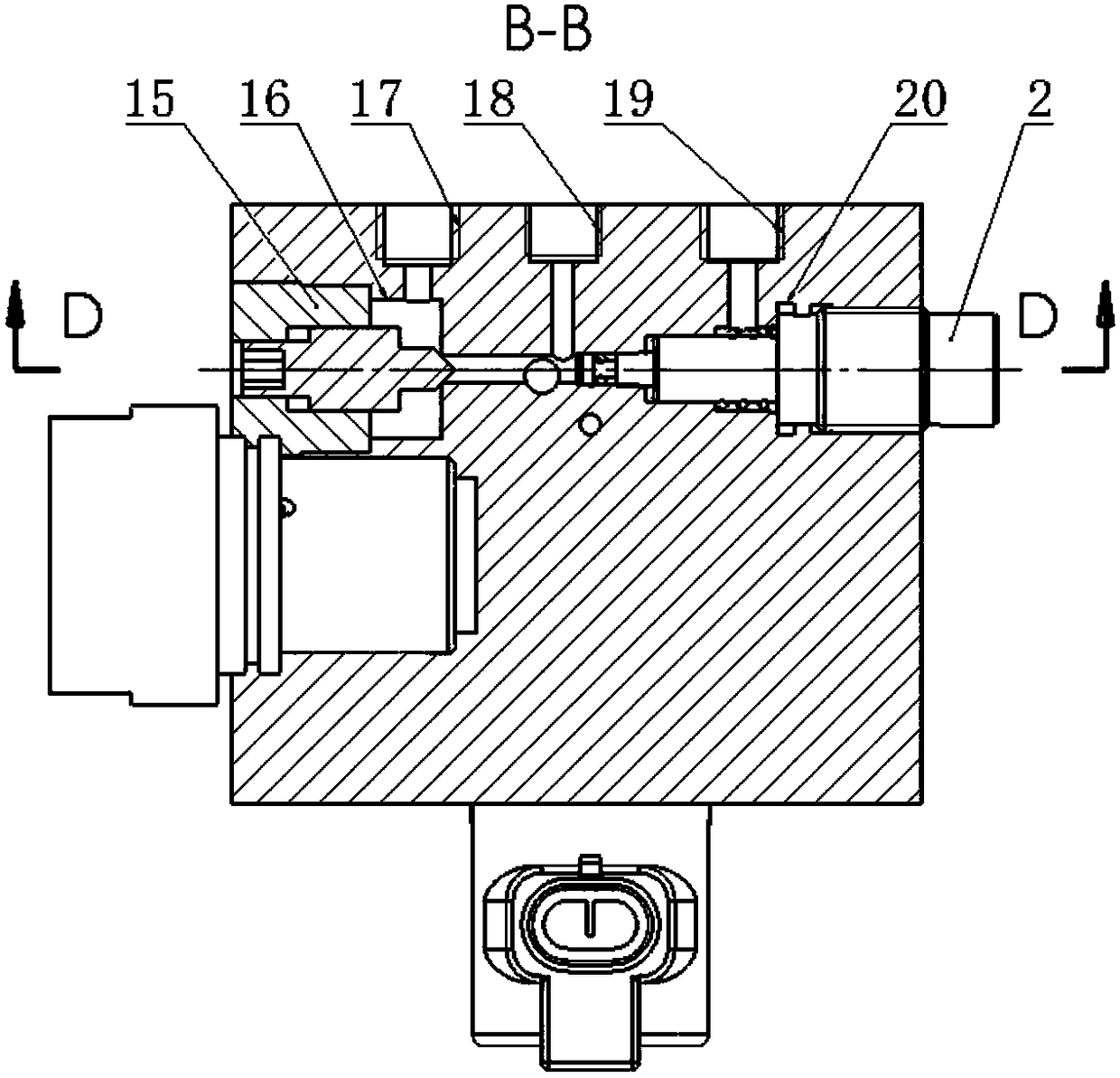

Ultrahigh-pressure hydrogen electromagnetic valve having pressure relief function and applied to vehicle

PendingCN108278395AExtended service lifeGuaranteed stabilityOperating means/releasing devices for valvesEqualizing valvesHydrogenUltra high pressure

Owner:DANYANG FEILUN GAS VALVE

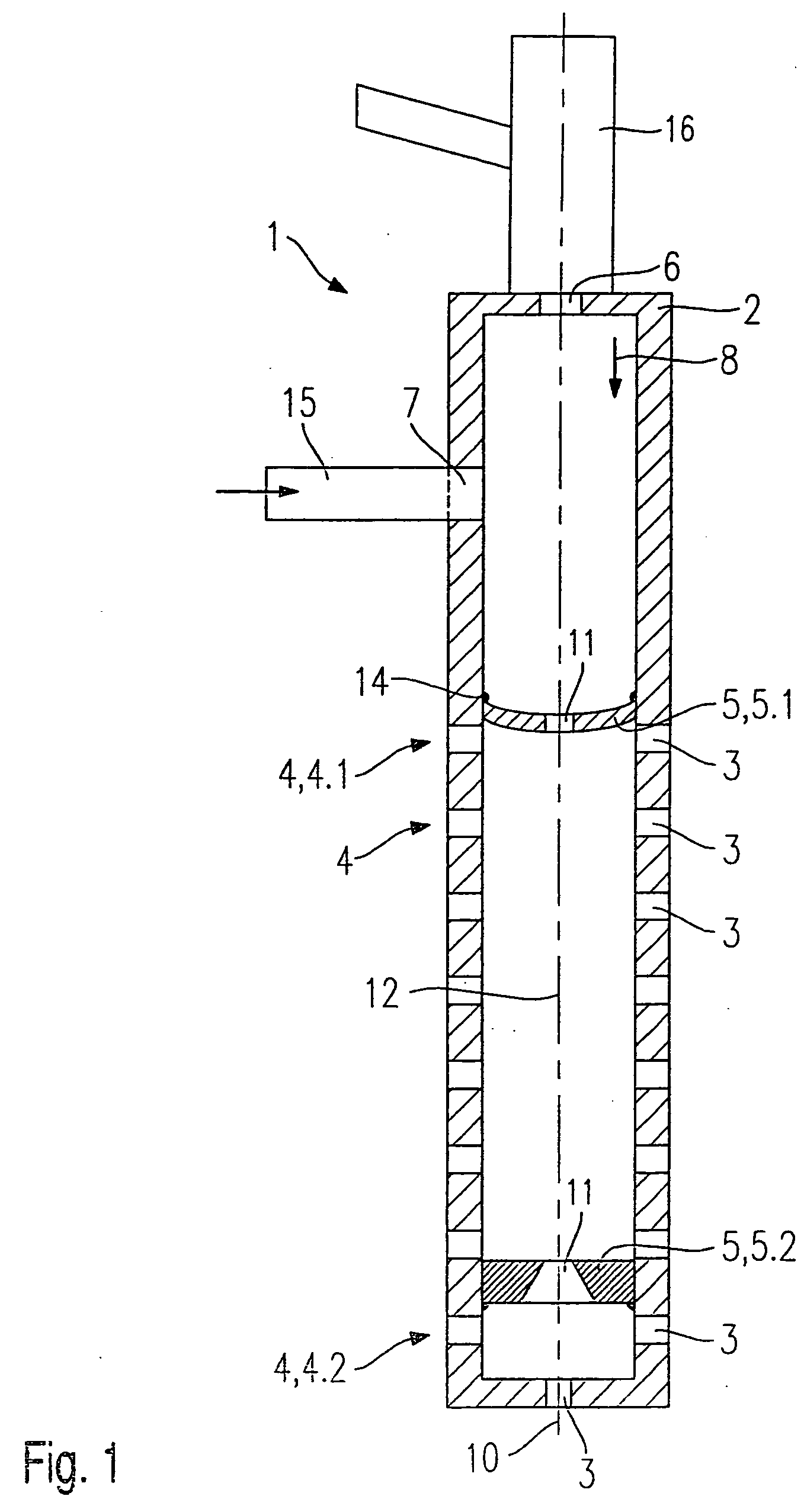

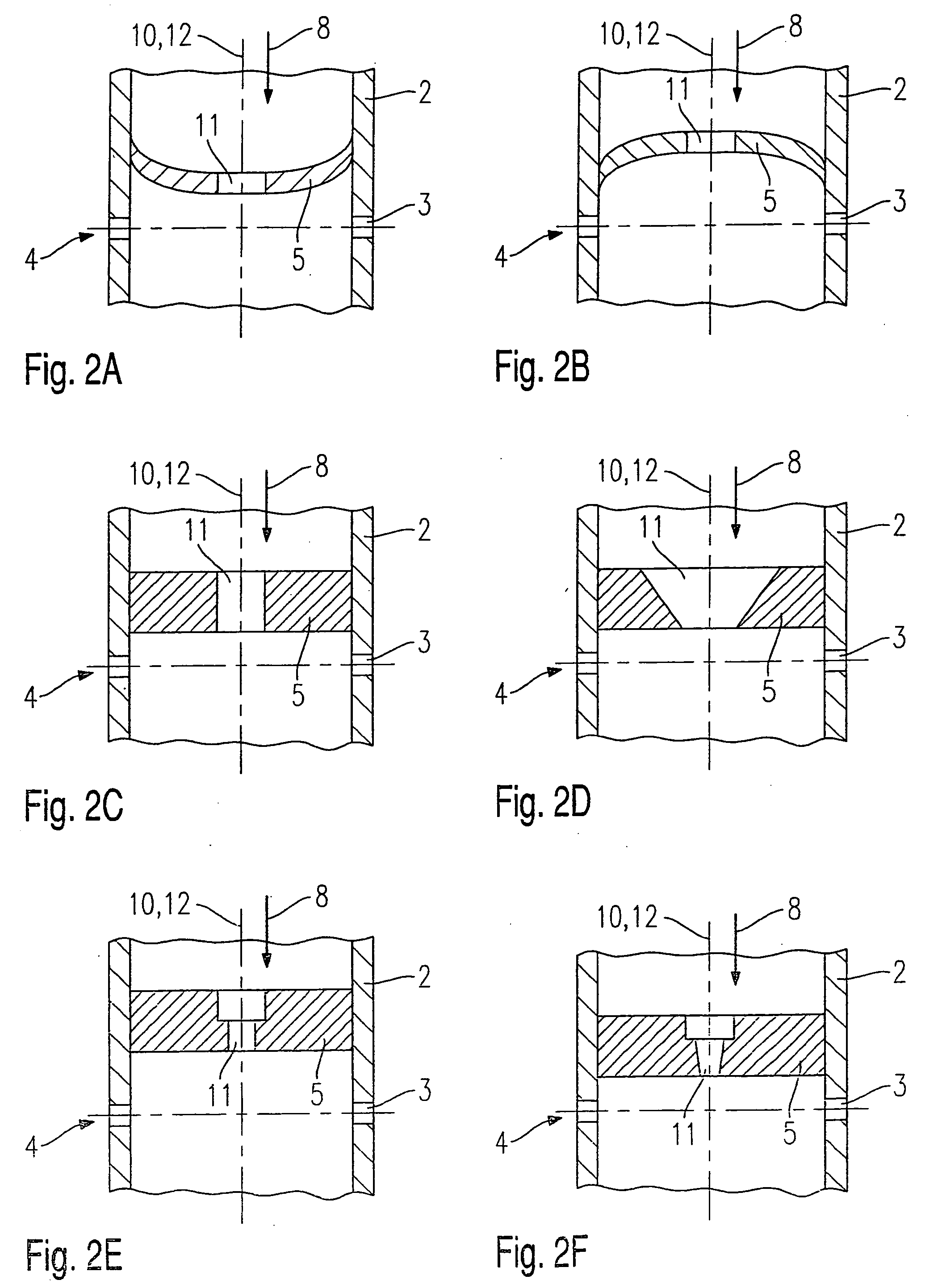

Atomising nozzle

InactiveUS20060144966A1Simple processImprove business performanceBurnersSpray nozzlesHydrogenAtomizer nozzle

Owner:ROBERT BOSCH GMBH

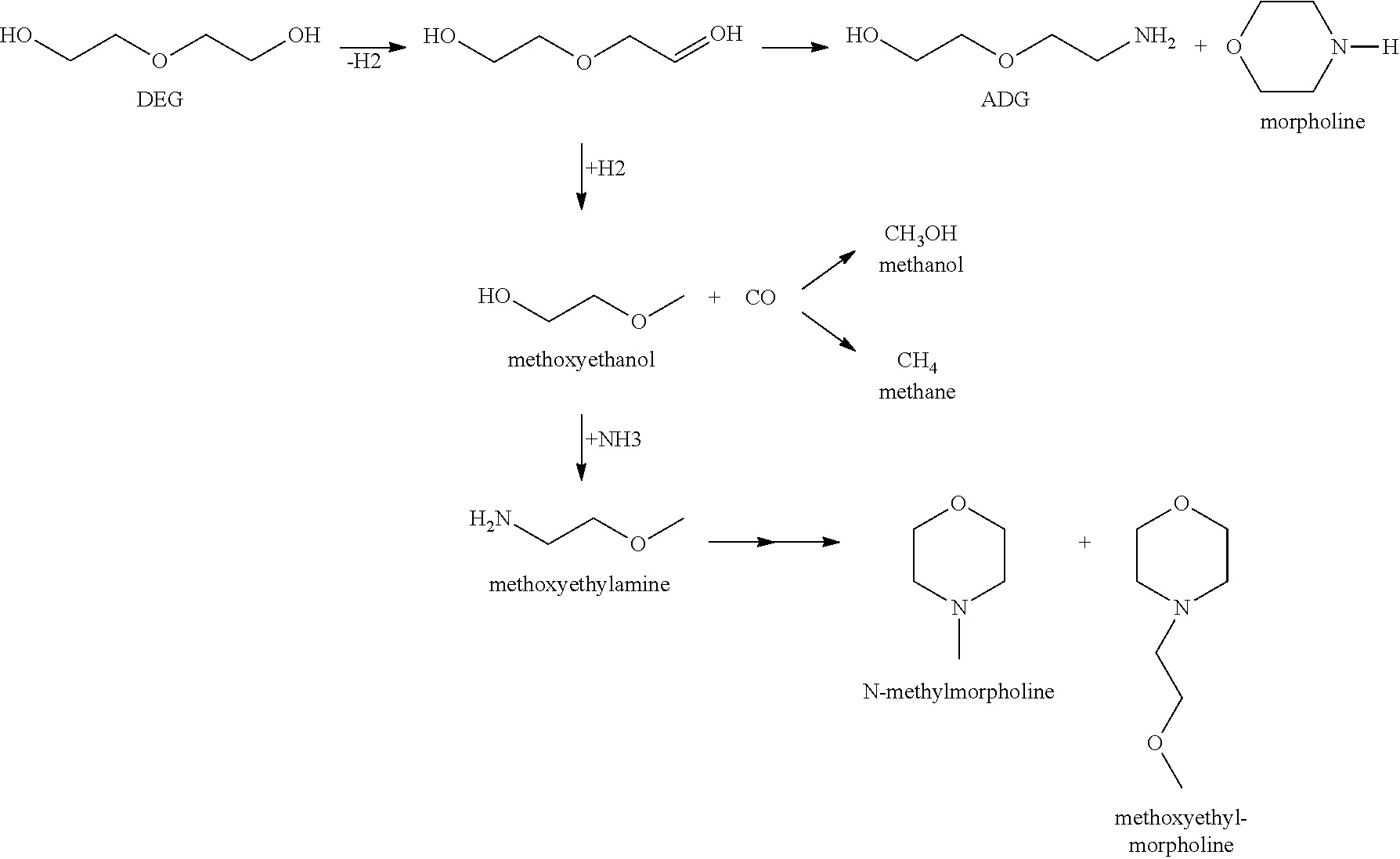

Catalyst and process for preparing an amine

ActiveUS8318982B2Enhances their economic viabilitySpeed up the conversion processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCeriumKetone

Owner:BASF AG

Furfural catalytic hydrogenation method under supercritical carbon dioxide and method for preparing catalysts

InactiveCN104059035AAchieve conversionNo carbon depositsOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPalladium on carbonLiquid product

Owner:ZHEJIANG UNIV

Bi-component polyurethane coating

InactiveCN104987819AReduces pungent odorsIncrease crosslink densityPolyurea/polyurethane coatingsHydrogenToluene diisocyanate

The invention provides a bi-component polyurethane coating, and relates to the field of coating. The bi-component polyurethane coating is composed of a component A and a component B. The component A comprises, by weight, 5-10 parts of acrylic resin dispersoid, 4-6 parts of glycol ether acetate, 5-9 parts of resin containing active hydrogen, 12-15 parts of padding, 8-10 parts of chitin derivative formaldehyde removal additives, 1-4 parts of anti-settling agents, 1-3 parts of defoaming agents and 2-3 parts of dryer. The component comprises, by weight, 7-13 parts of isocyanate and 10-12 parts of toluene diisocyanate capable. The bi-component polyurethane coating can reduce harm to the environment and the human body effectively and is suitable for being widely popularized.

Owner:SICHUAN ZHENFUTANG TRADING CO LTD

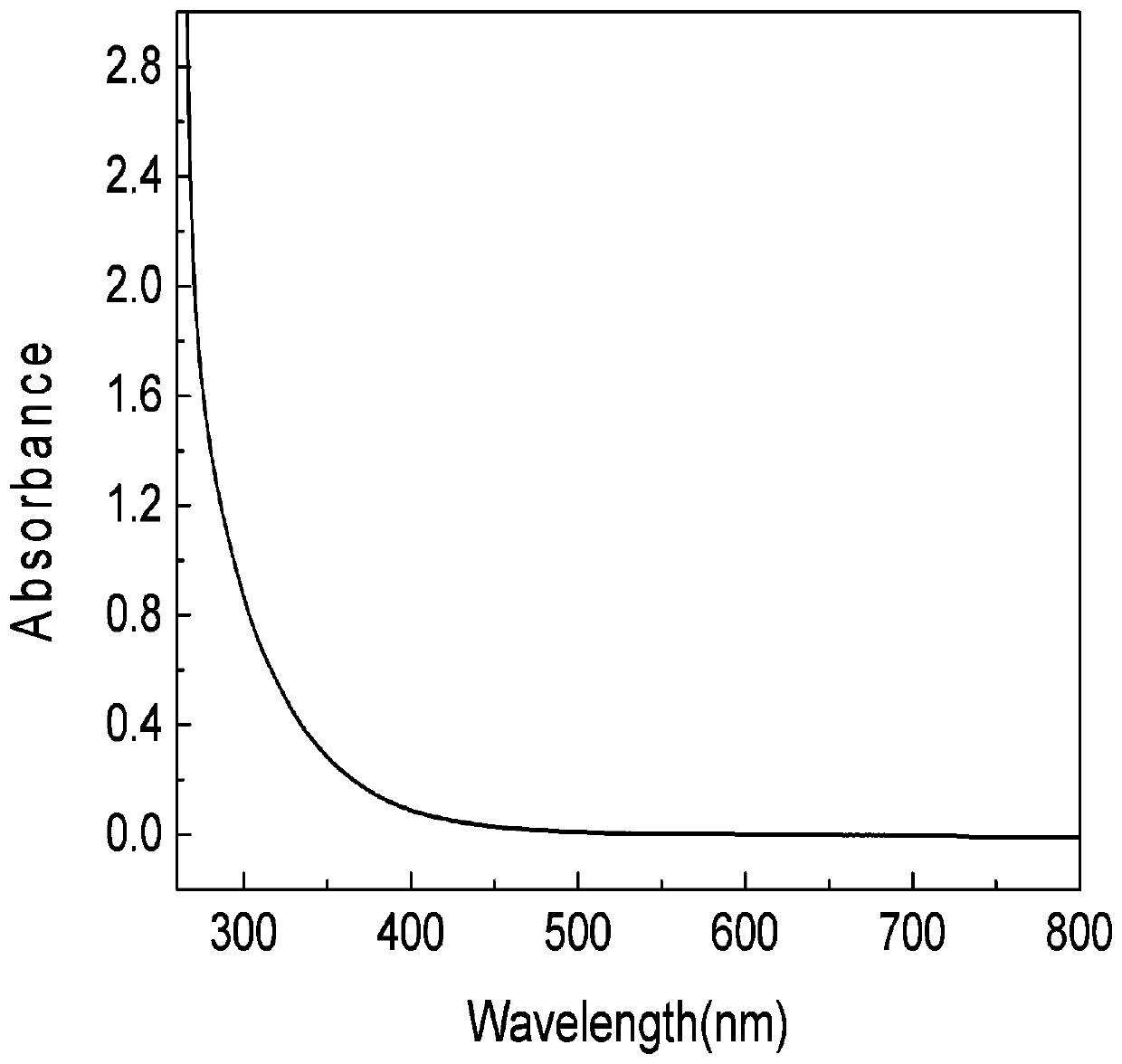

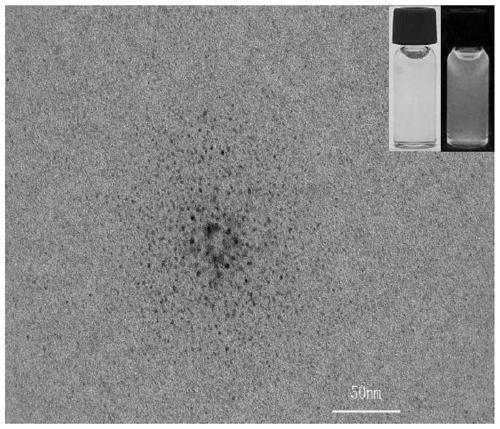

Method for synthesizing red fluorogold nano-clusters through photoinduction and application

ActiveCN110144207AThe synthesis method is simpleMaterial nanotechnologyFluorescence/phosphorescenceFluorescenceSynthesis methods

Owner:YUNNAN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap