Atomising nozzle

a technology of atomizing nozzles and nozzles, which is applied in the direction of burners, fuel cells, lighting and heating apparatus, etc., can solve the problems of increasing the cost of production, so as to improve the efficiency and efficiency of vaporization process, improve the operating performance, and improve the effect of vaporization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following, exemplary embodiments of the invention are described by way of example.

[0026] The exemplary embodiments described below of atomizer nozzles designed according to the present invention allow for simple metering and atomization in a hot atmosphere, while providing a robust construction, application in different spatial constellations and the use of standard low-pressure fuel injectors.

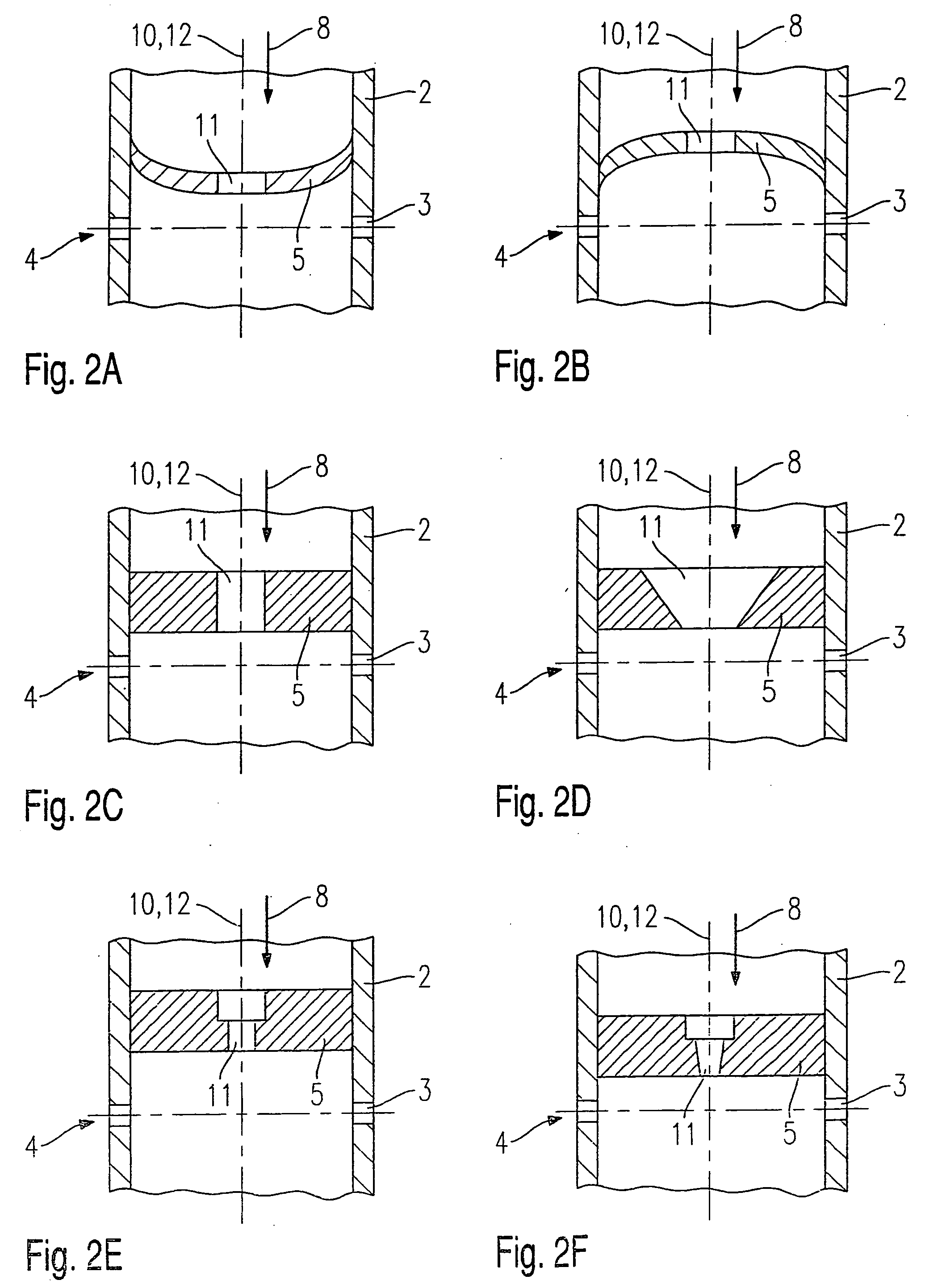

[0027] Identical parts are provided with the same reference numerals in all of the figures. The arrows represent the respective fuel and gas flows.

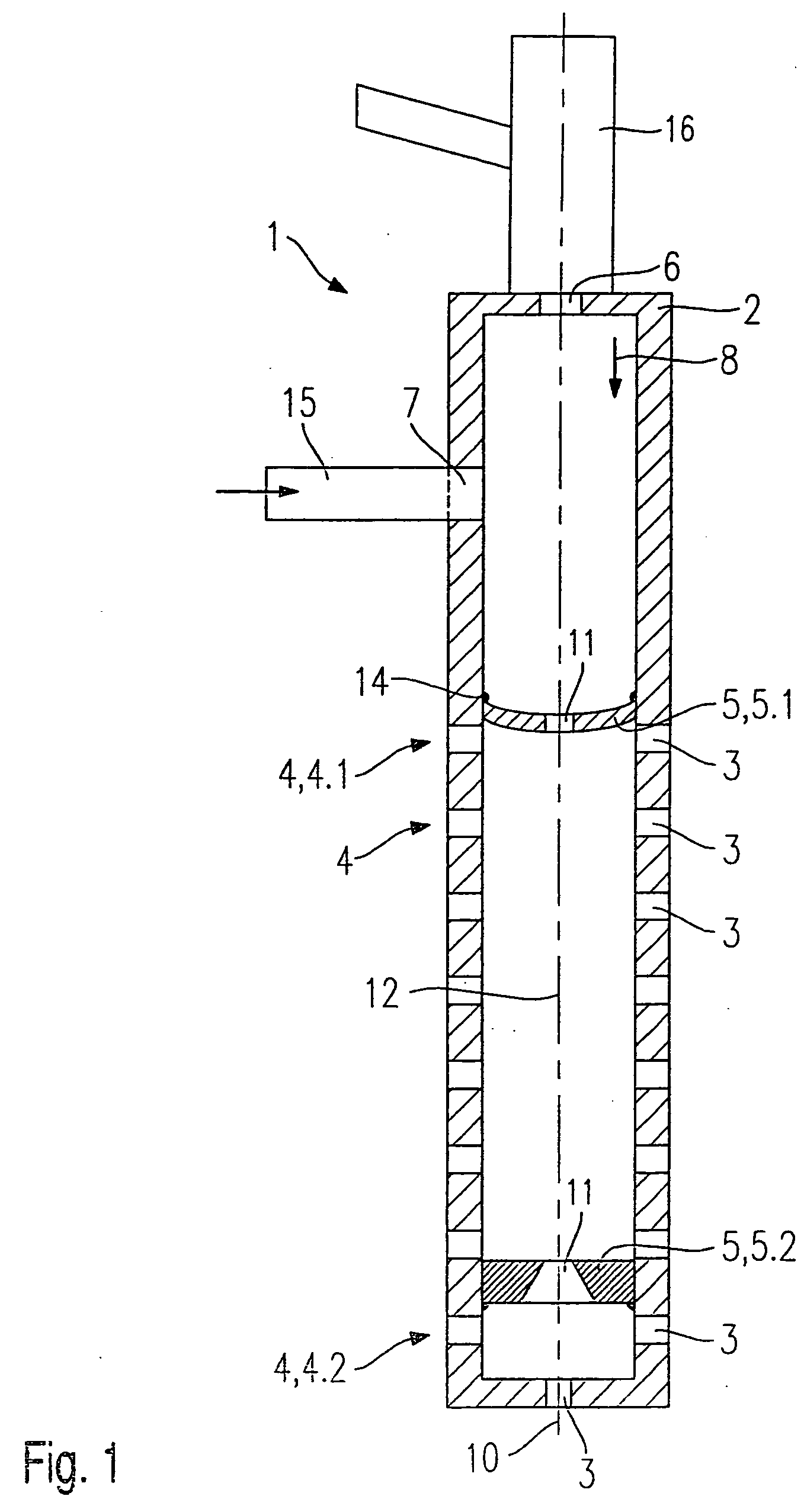

[0028] A first exemplary embodiment, schematically represented in FIG. 1, of an atomizer nozzle 1 according to the present invention is in the form of an atomizer nozzle 1 for the use of low-pressure fuel injectors 16. Atomizer nozzle 1 is particularly suitable for charging and atomizing fuel into a chemical reformer (not shown) for obtaining hydrogen.

[0029] In this exemplary embodiment, atomizer nozzle 1 features a nozzle body 2 in t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap