Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73 results about "Plasticizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasticizers (UK: plasticisers) or dispersants are additives that increase the plasticity or decrease the viscosity of a material. These are the substances which are added in order to alter their physical properties. These are either liquids with low volatility or solids. They decrease the attraction between polymer chains to make them more flexible. Over the last 60 years more than 30,000 different substances have been evaluated for their plasticizing properties. Of these, only a small number – approximately 50 – are today in commercial use. The dominant applications are for plastics, especially polyvinyl chloride (PVC). The properties of other materials may also be modified when blended with plasticizers including concrete, clays, and related products. According to 2014 data, the total global market for plasticizers was 8.4 million metric tonnes including 1.3 million metric tonnes in Europe.

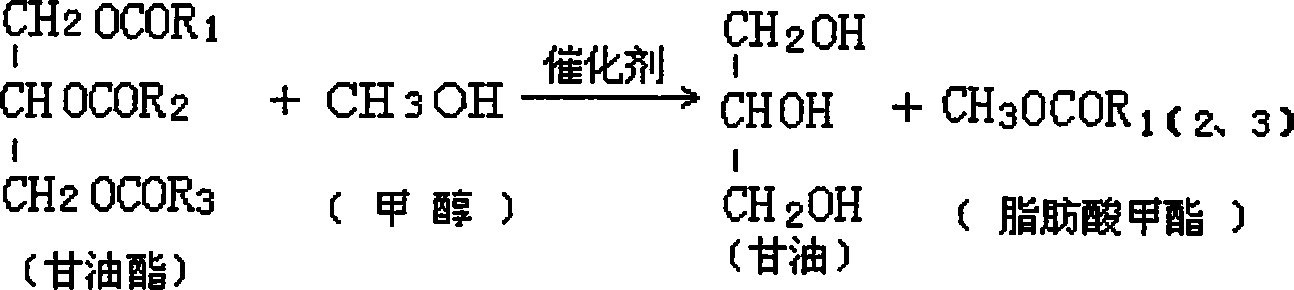

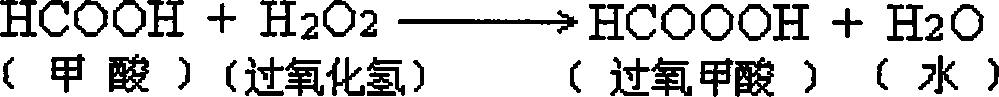

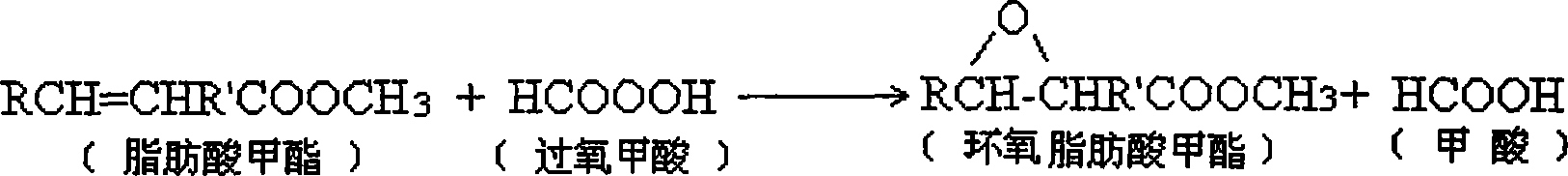

Method for producing epoxy plasticizer using waste grease

InactiveCN101070510AHarm reductionReduce dosageFatty oils/acids recovery from wasteFatty acid esterificationEpoxyDistillation

Owner:江苏向阳科技有限公司

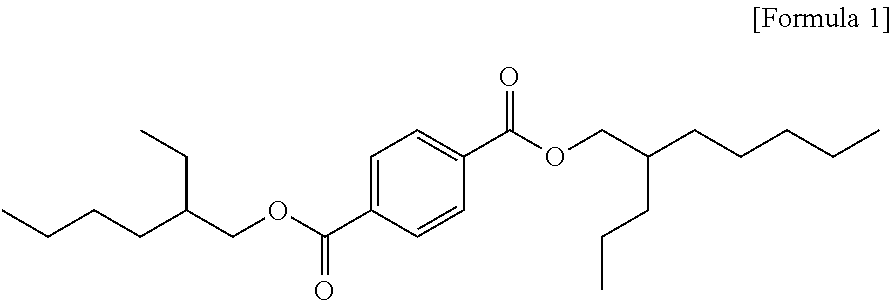

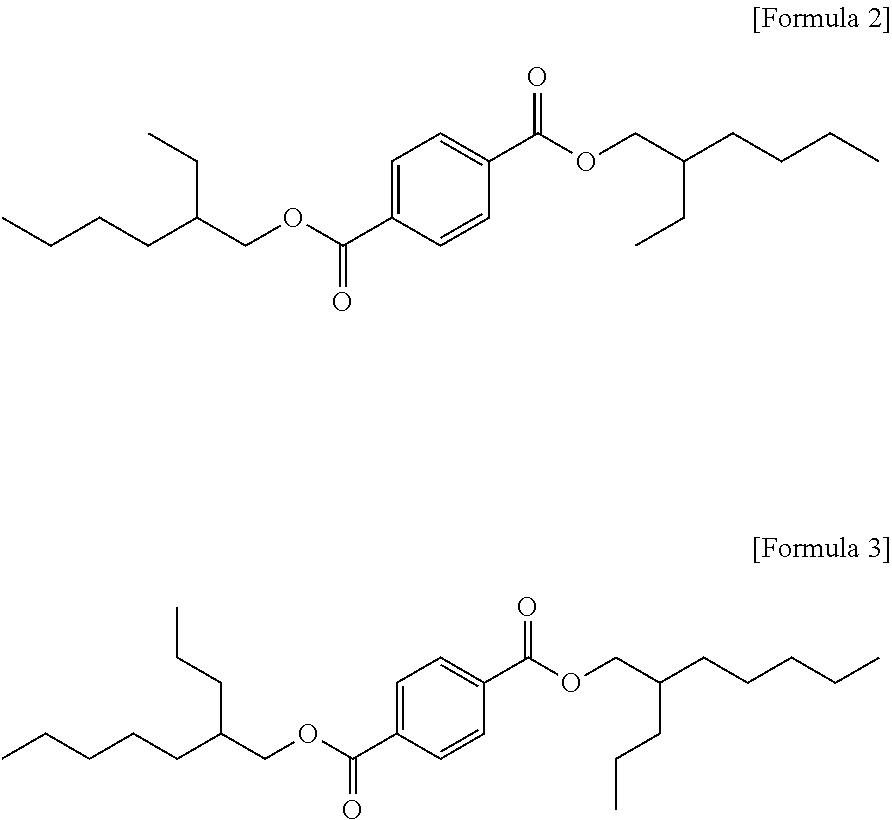

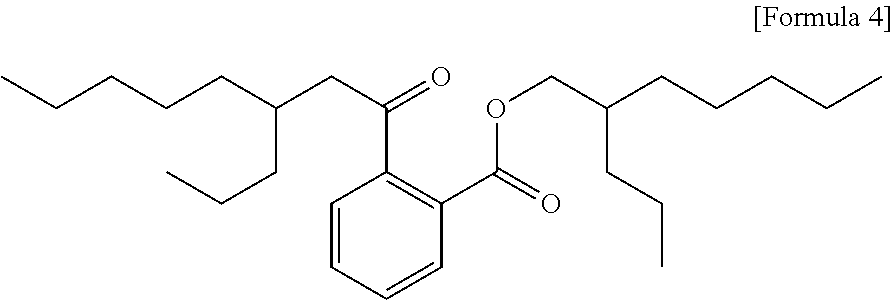

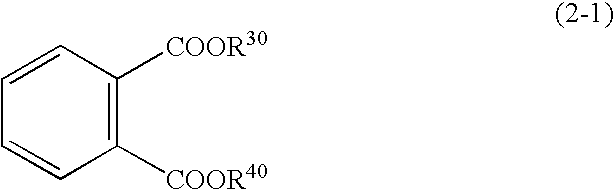

Plasticizer, plasticizer composition, heat-resistant resin composition and method for preparing the same

ActiveUS20140096703A1Improves elongation retentionImprove aging resistanceOrganic chemistryPlasticizerAging resistance

Owner:LG CHEM LTD

Plasticizers Derived From Renewable Feedstock

Owner:GALATA CHEM LLC

Activatable Adhesive, Labels, and Related Methods

InactiveUS20120216951A1Improve securityEasy to operateStampsNon-macromolecular adhesive additivesAdhesivePlasticizer

Owner:AVERY DENNISON CORP

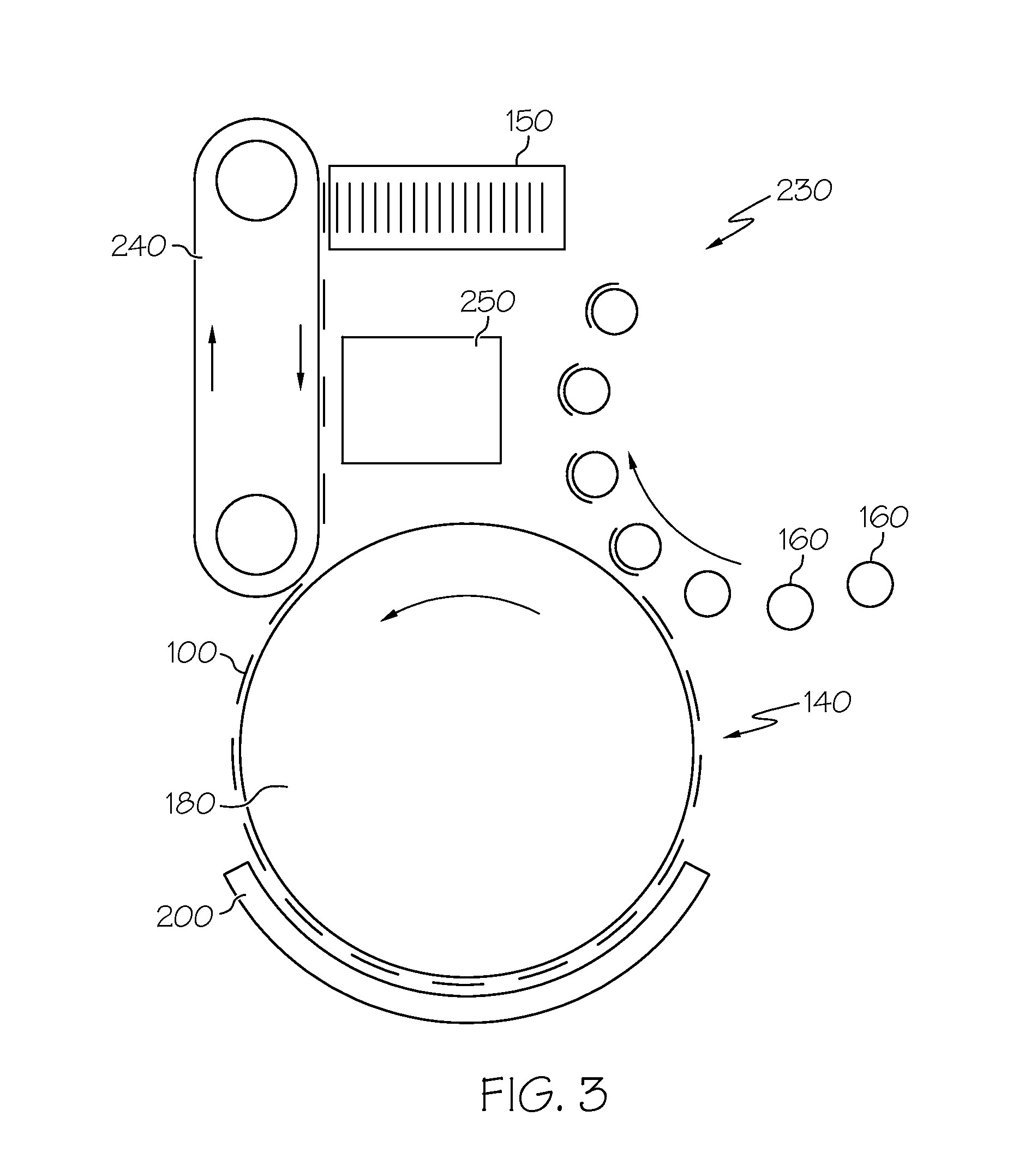

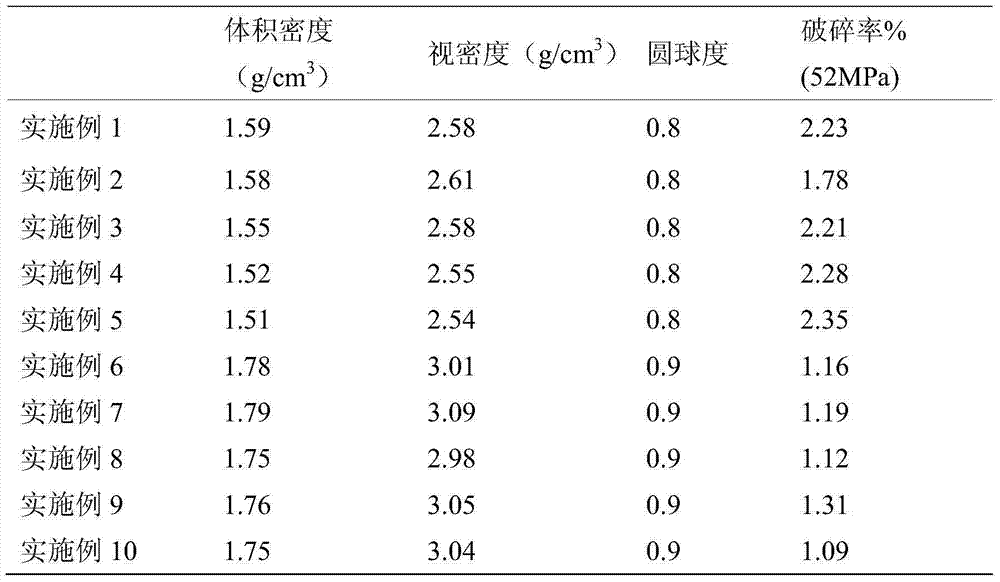

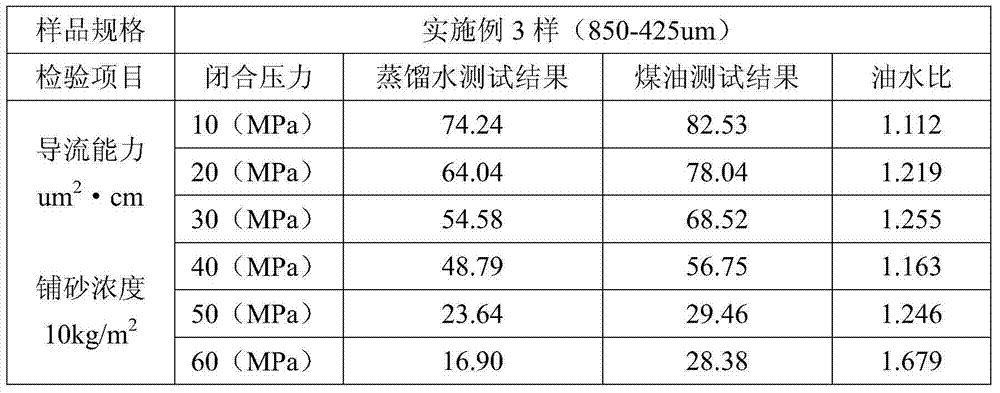

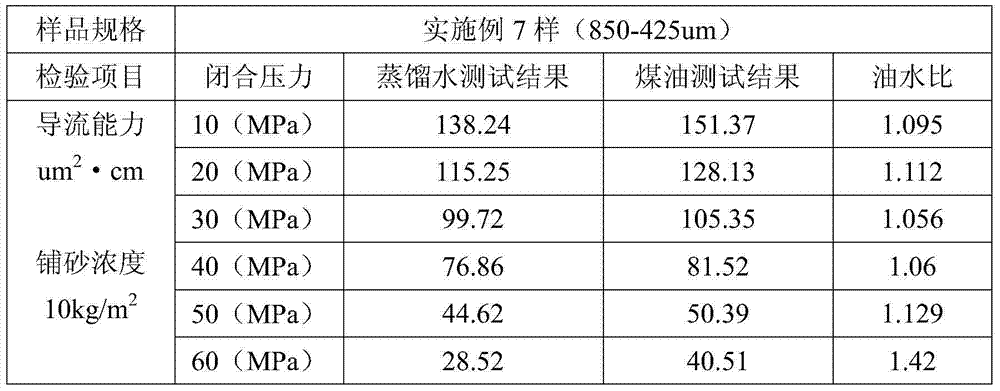

Preparation method of oleophilic hydrophobic coated proppant

InactiveCN104277821AIncrease oil outputIncrease productionFluid removalDrilling compositionProduction ratePlasticizer

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

High-thixotropic poly(vinyl chloride) plastic sol

Owner:上海理日化工新材料有限公司

Multi-purpose strippable acrylate adhesive microporous material and preparation method thereof

ActiveCN102925084AEasy to peelIncrease elasticityFilm/foil adhesivesEster polymer adhesivesPolymer scienceFoaming agent

Owner:HARBIN INST OF TECH

Preparation method of environment-friendly type alpha-cyanoacrylate

InactiveCN104402763AOrganic compound preparationCarboxylic acid nitrile purification/separationParaformaldehydePlasticizer

Owner:SHANDONG YUWANG IND

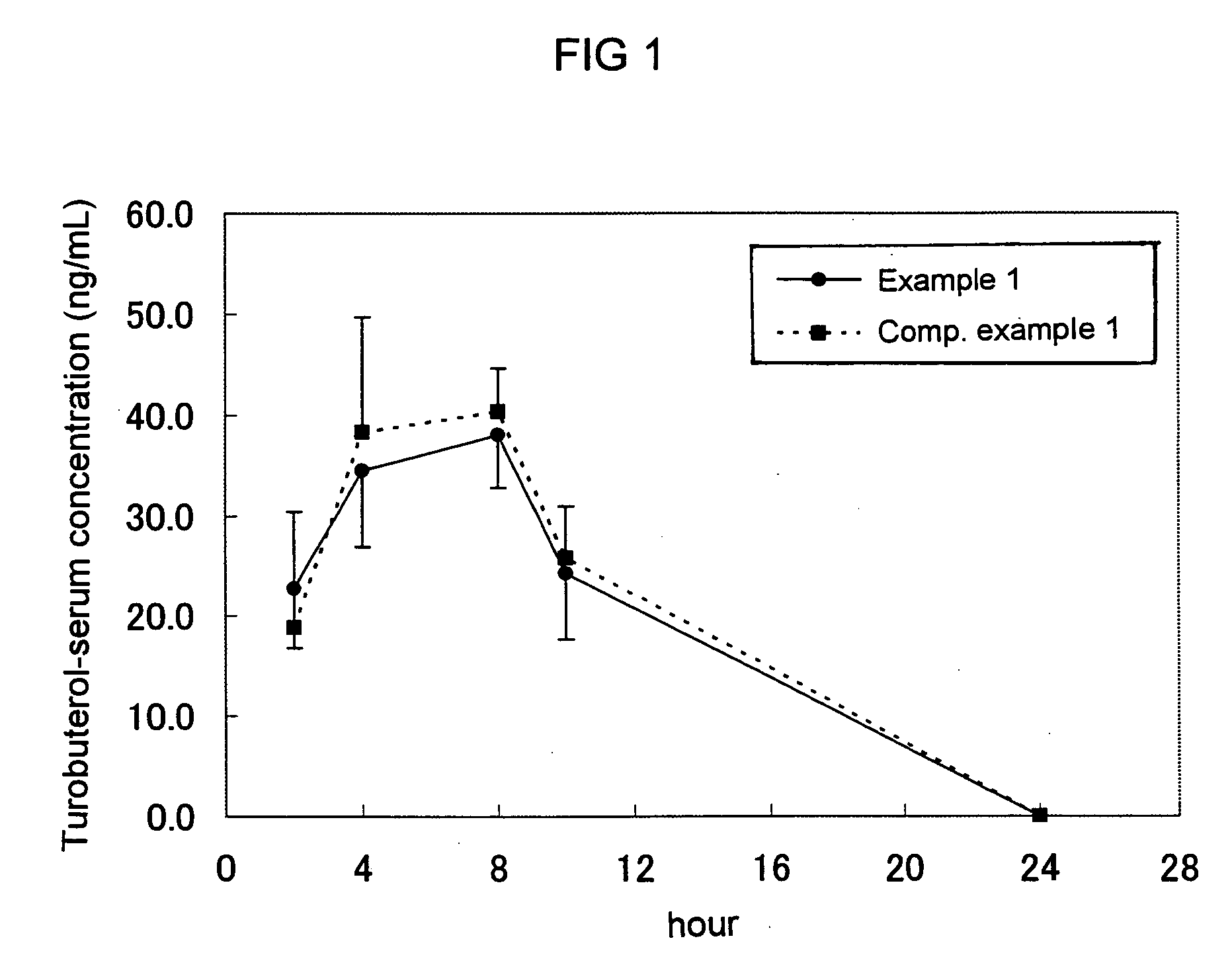

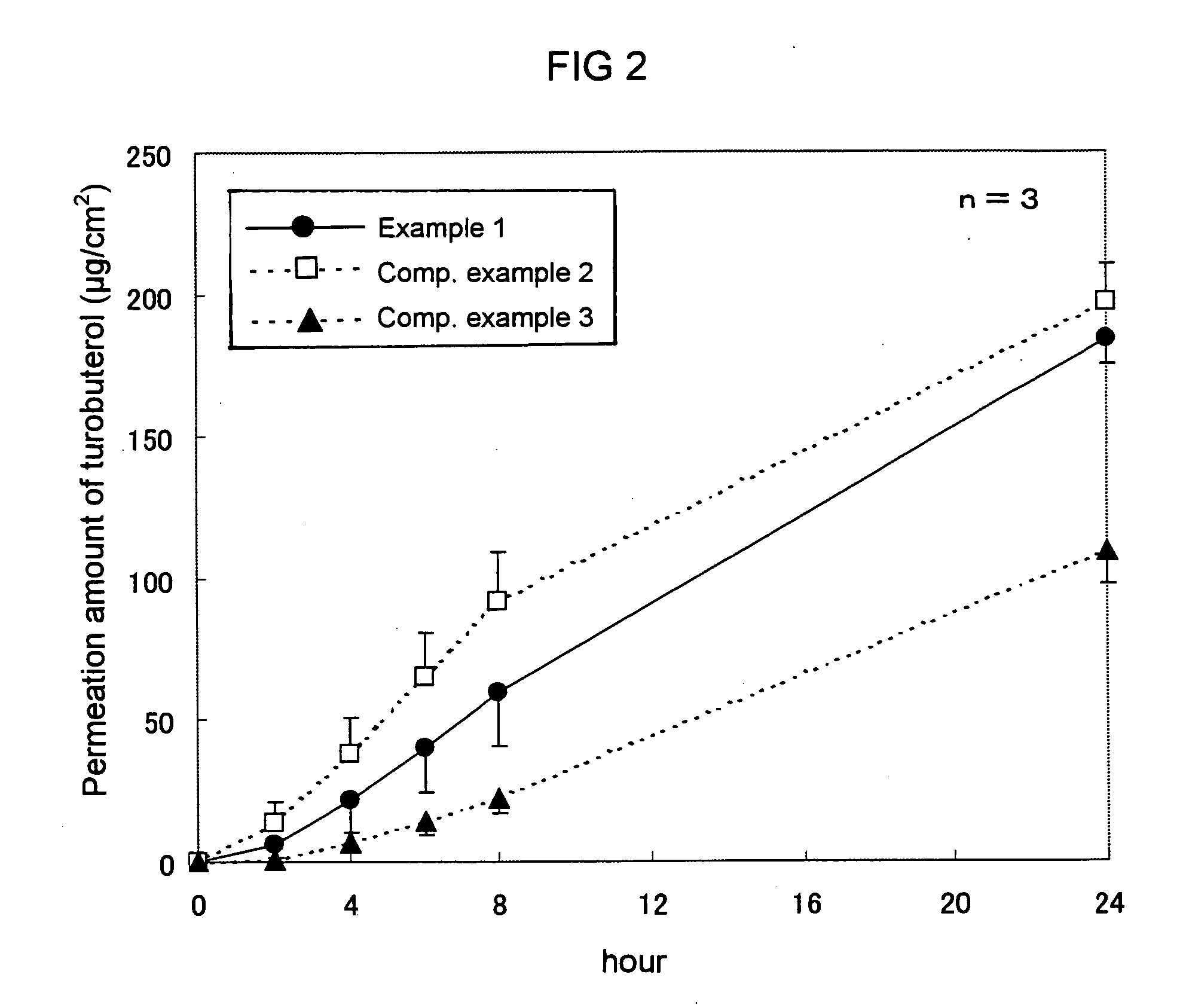

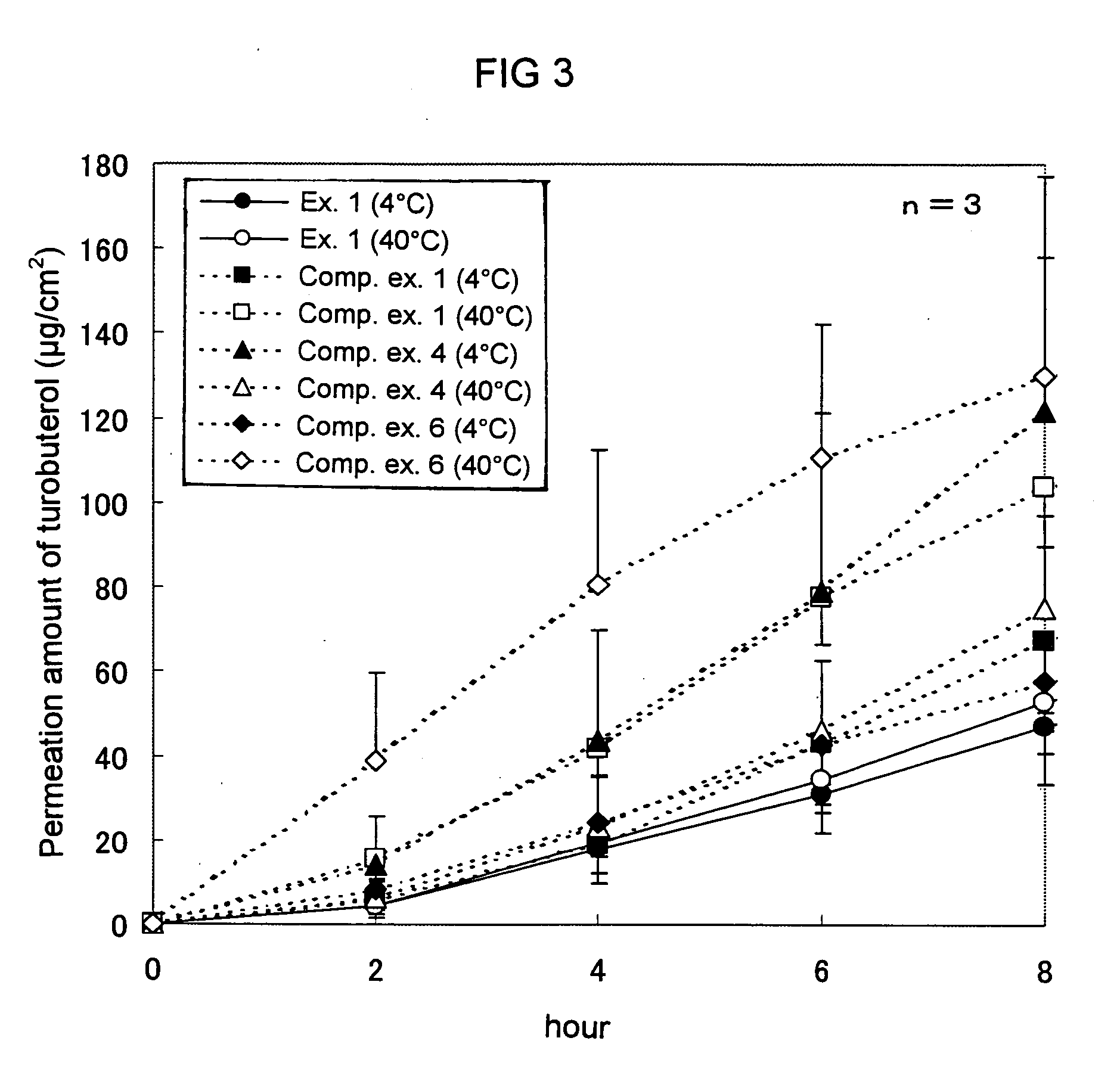

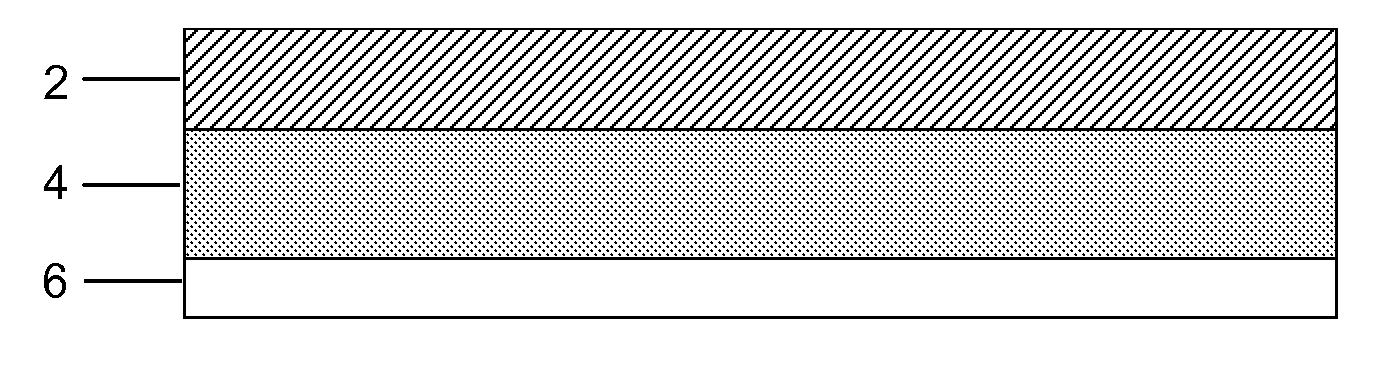

Adhesive patch containing tulobuterol

ActiveUS20050220852A1Easy to controlSimple processOrganic active ingredientsAdhesive dressingsChemistryPlasticizer

Owner:TEIKOKU SEIYAKU KK TEIKOKU SEIYAKU CO LTD

Waterproofing Membrane

InactiveUS20100196648A1Improve adhesionGood anti-sag performanceAdhesive articlesCoatingsLow-density polyethylenePolymer science

Owner:GCP APPL TECH INC

Flash rust-proof acrylic roof waterproof coating and preparation method thereof

InactiveCN109796825AAnti-rust and waterproof effect lasts for a long timeImprove UV protection effectAnti-corrosive paintsCelluloseUltraviolet

The invention relates to the field of water proofing of metal roofs and particularly discloses a flash rust-proof acrylic roof waterproof coating which is prepared from, by weight, the following raw materials: 30-50 parts of an acrylic emulsion, 25-60 parts of antirust slurry, 1-5 parts of a plasticizer, 0.3-5 parts of a dispersing agent, 0.1-1 part of a defoaming agent, 0.1-1 part of a base material wetting agent, 0.1-2 parts of an anti-flash rust additive, 1-4 parts of a film forming assistant, 3-10 parts of water, 0.01-0.5 part of cellulose ether, 0.1-0.5 part of a bactericide, 0.01-0.5 part of a coupling agent and 0.01-0.5 part of a pH adjusting agent. The flash rust-proof waterproof effect of the roof waterproof coating with a flash rust-proof function is longer lasting than that of acommon metal roof waterproof coating, the anti-ultraviolet effect is good, and the service life of a base material is prolonged. The waterproof coating has high elongation rate, good elasticity, strong base layer deformation resistance, the capability of shielding cracks, water proofing and breathability.

Owner:KESHUN WATERPROOF TECH CO LTD

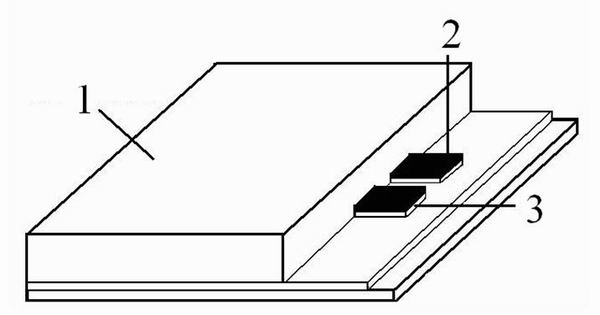

Method for directly preparing two-layer electrode by one-time silk-screen printing and used slurry thereof

InactiveCN102044395ASimple processLow costSustain/scan electrodesAlternating current plasma display panelsPhotoinitiatorPlasticizer

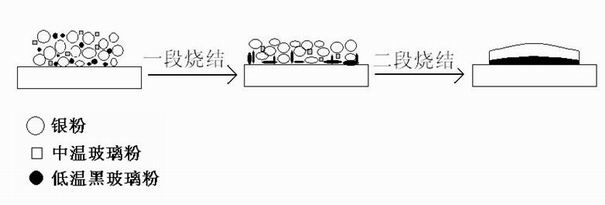

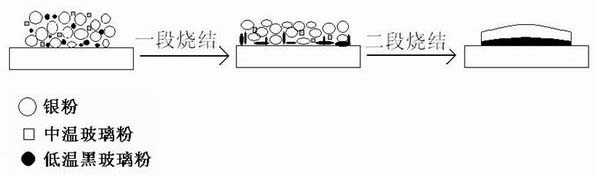

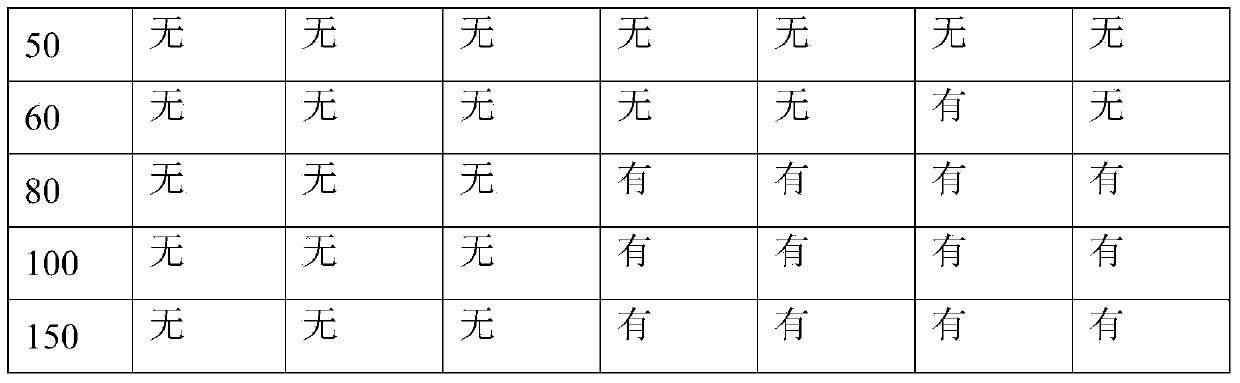

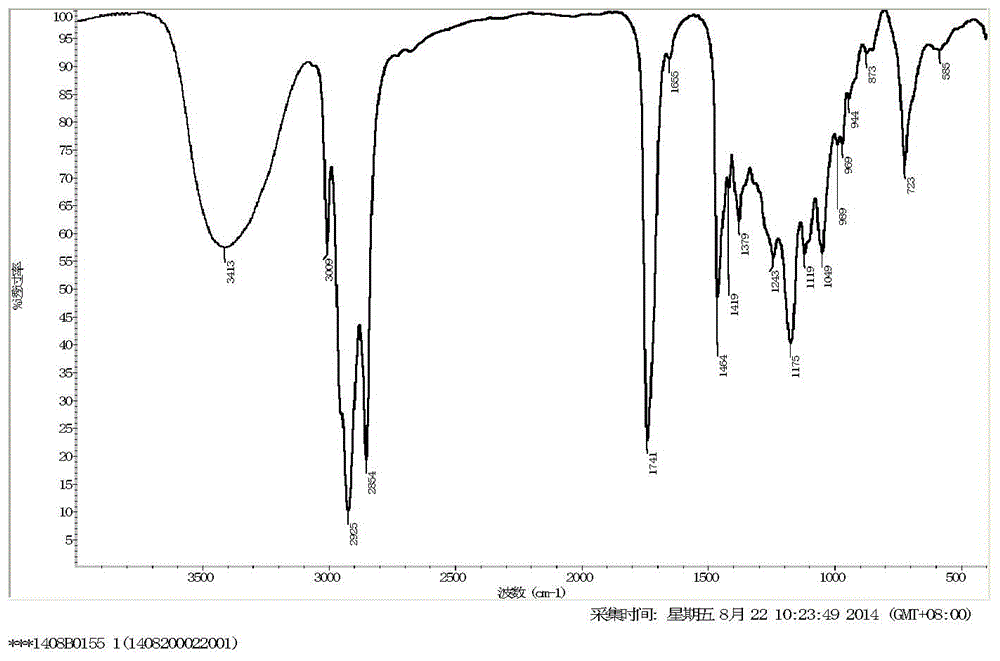

The invention discloses a method for directly preparing a two-layer electrode by one-time silk-screen printing and used slurry thereof. The slurry is composed of low-temperature black glass powder, medium-temperature lead-free glass powder, photosensitive monomer, photoinitiator, organic carrier and the balance of sliver powder, wherein the organic carrier is composed of plasticizer, coupling agent, resin and the balance of organic solvent; and the low-temperature black glass powder is obtained by the following steps: adding the lead-free glass powder with a low melting point to a black pigment, melting the mixture, then pouring the molten glass into cold water for water quenching, ball milling the obtained product until the grain diameter is less than or equal to 3mu m, and drying. The method comprises the following steps: evenly dispersing and mixing all components and rolling by three rollers; testing the fineness and viscosity of the slurry; printing the prepared slurry silk screen on a substrate, drying, exposing and developing; and sintering, wherein the peak temperature during first-stage sintering is higher than the melting temperature of the low-temperature black glass powder, and the peak temperature during second-stage sintering is higher than the melting temperature of the medium-temperature lead-free glass powder to obtain the two-layer electrode. The method provided by the invention can obtain the graph of the two-layer electrode only by one-time printing, exposing, developing, two-stage sintering and drying.

Owner:SOUTHEAST UNIV

Pitaya peel-based edible packaging film and preparation method thereof

ActiveCN105419370AFull edible medicinal valueAvoid pollutionWrappersFlexible coversCellulosePolymer science

The invention provides a preparation method for a pitaya peel-based edible packaging film. The preparation method is characterized by comprising the following steps: (1) washing and stripping and slicing pitaya peels; (2) performing blanching treatment; (3) adding water and pulping to obtain pitaya peel pulp, wherein the mass ratio of matter obtained in the step (2) to the water is (15 to 45):100; (4) adding a thickening agent and a plasticizer into the pitaya peel pulp, wherein the mass ratio of the thickening agent to the pitaya peel pulp is (0 to 0.4):100, and the mass ratio of the plasticizer to the pitaya peel pulp is (0 to 0.3):100; the thickening agent is sodium alginate or sodium carboxymethylcellulose, and the plasticizer is glycerinum or sorbitol; (5) performing homogenization treatment at a treatment rate of 15000 to 20000 r / min for 5 to 8min; then, performing degassing treatment and standing to obtain shaped pulp; (6) casting and drying, and then performing film uncovering to obtain the pitaya peel-based edible packaging film. The invention also provides the packaging film prepared by the preparation method.

Owner:SICHUAN AGRI UNIV

Diepoxide vegetable oil acid acetyl glyceride and synthesis method and application thereof

Owner:NANTONG HAIERMA TECH CO LTD

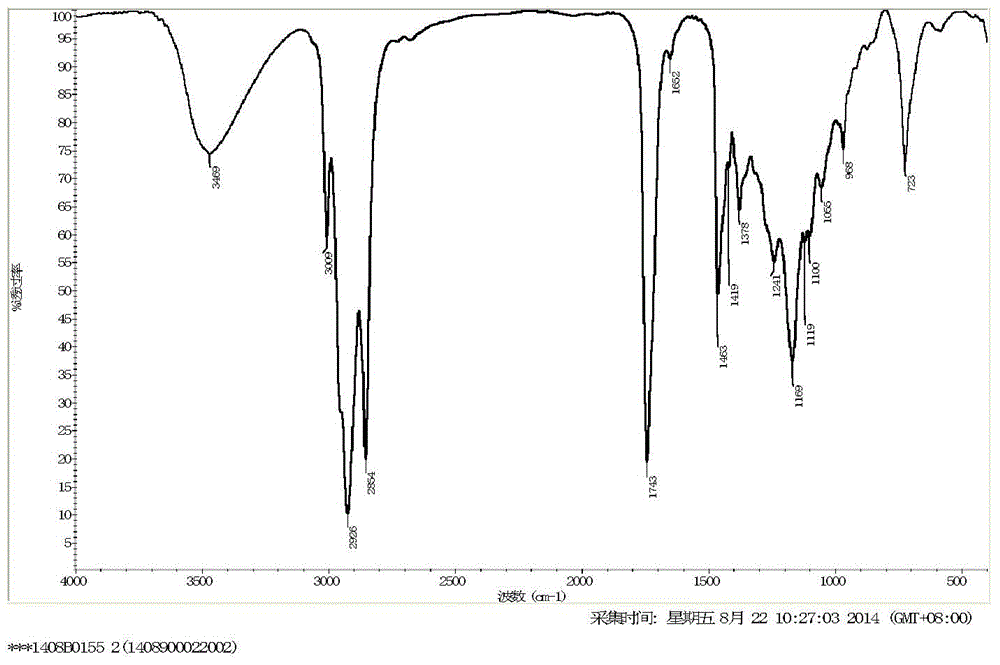

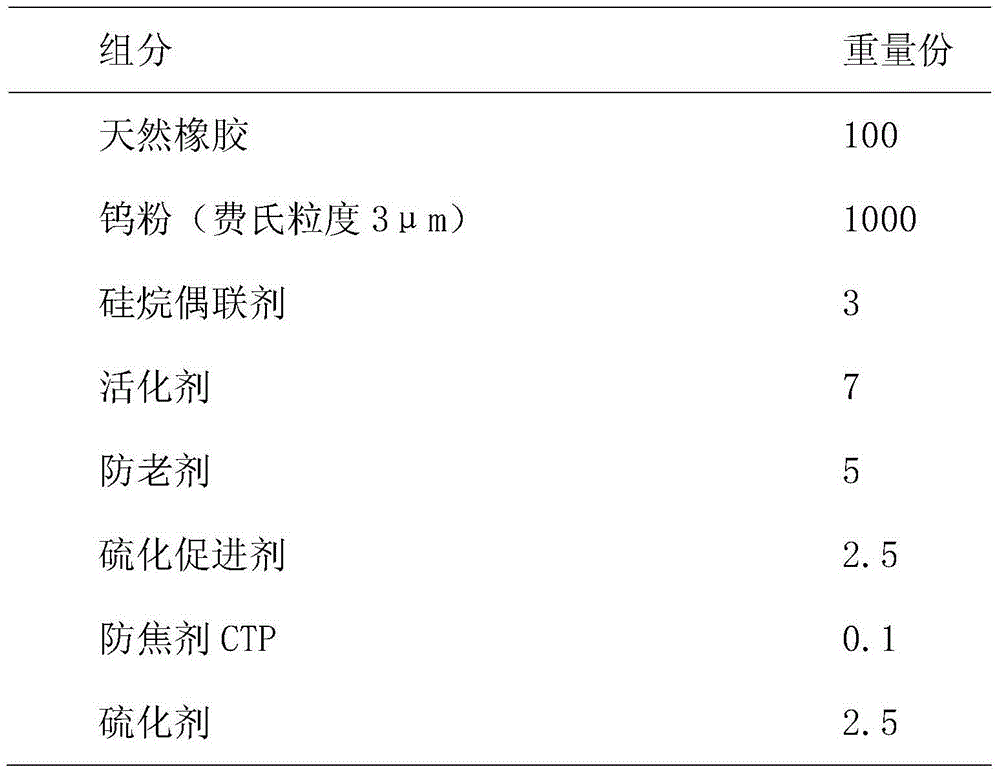

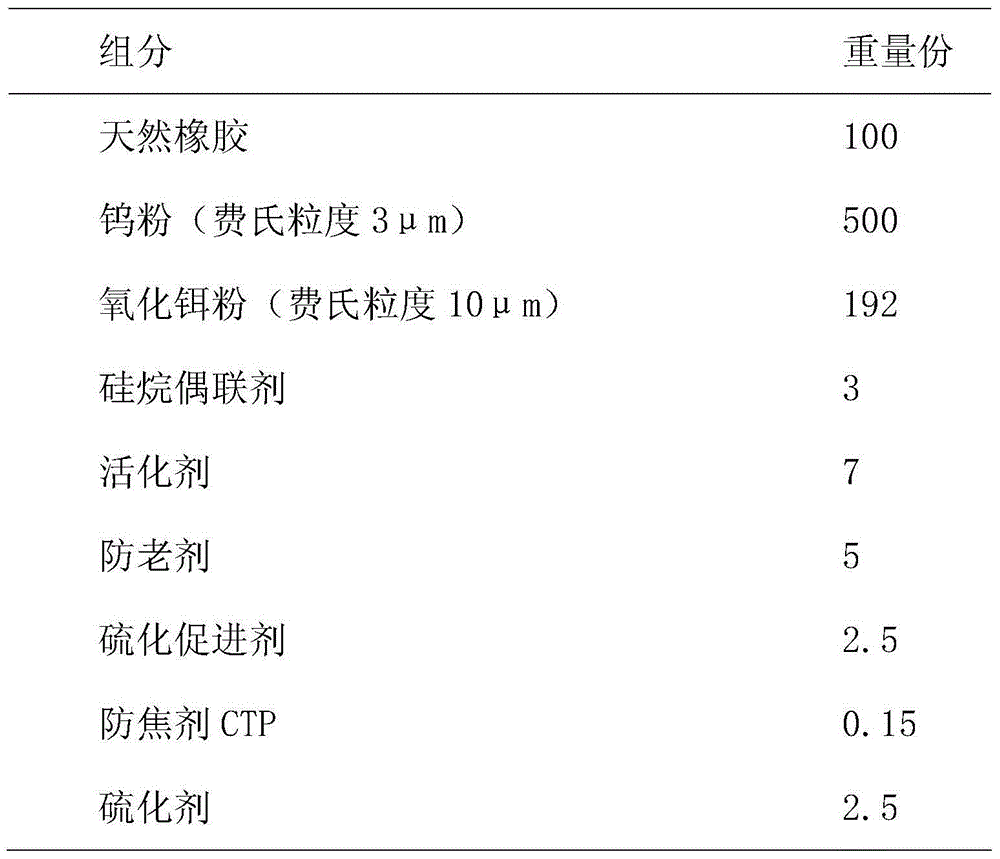

Tungsten-base composite material applied to ray shielding and preparation method thereof

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

Edible oil plasticizer removing method

InactiveCN104705419AEasy to handleAppearance has no effectEdible oils/fats ingredientsBiotechnologyPlasticizer

The present invention discloses an edible oil plasticizer removing method which belongs to the technical field of edible oil processing and food safety. The plasticizer removing method uses methanol as solvent, conducts liquid-liquid extraction for the edible oil and separates the methanol and the edible oil after extraction. The plasticizer removing method has high removal efficiency and no plasticizer compositions are detected in the treated edible oils. The plasticizer removing method almost has no effect on other ingredients in the edible oils and the appearance, color, and physical and chemical properties of the treated edible oils are not changed. Besides, the removing method has fast-rate processing and low cost.

Owner:HENAN YALINJIE BIOLOGICAL TECH

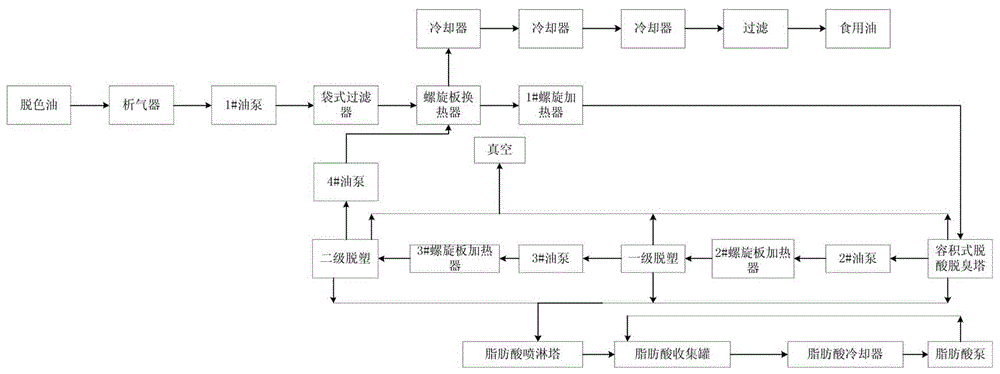

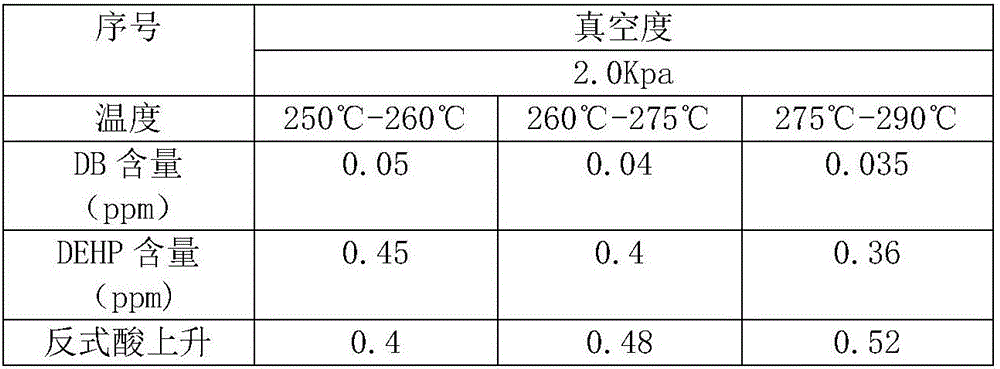

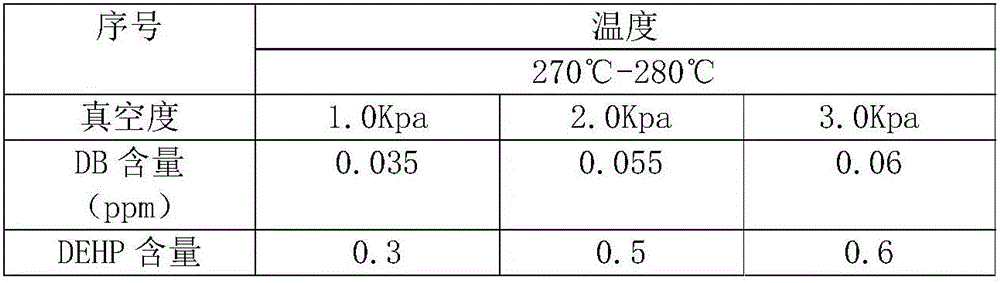

Edible-oil processing technology for decreasing content of trans-fatty acid and removing plasticizer

ActiveCN105925371AEfficient removalSolve the problem of serious exceeding the standardFatty-oils/fats refiningPlasticizerNational standard

Owner:HEBEI JIAFENG PLANT OILS

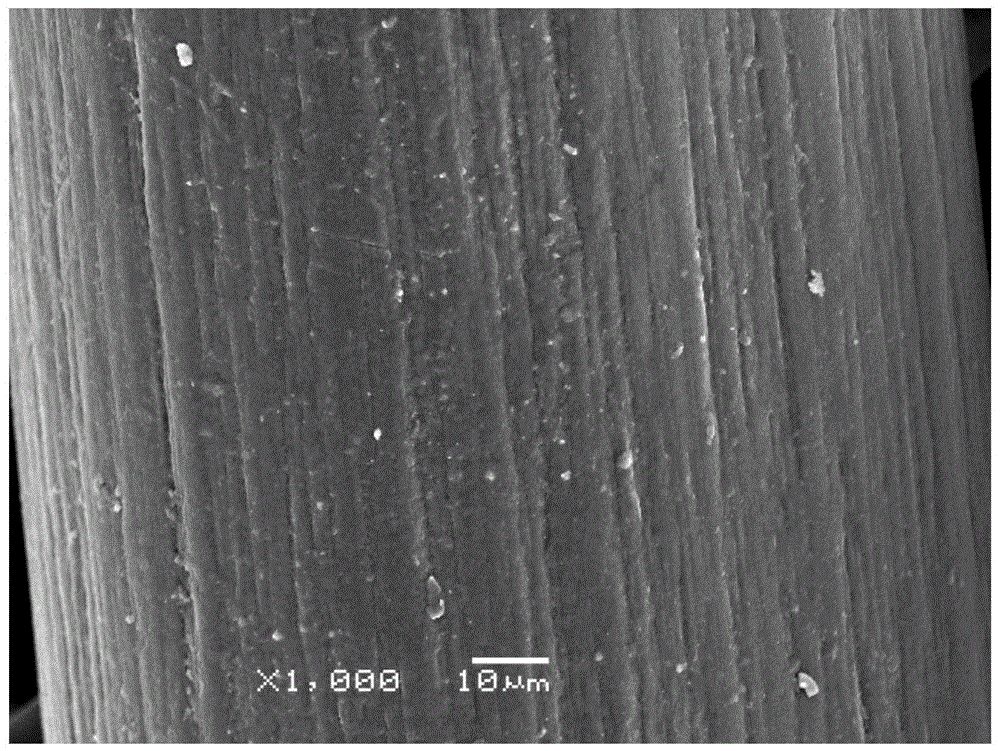

Polyvinyl Chloride Fiber and Process for Production Thereof

Owner:KANEKA CORP

Matrix dispersion solid phase extraction method for detection of plasticizer in animal and vegetable oil samples

InactiveCN102620978ASimplify the experimental stepsExperimental steps save timePreparing sample for investigationVegetable oilGas chromatography–mass spectrometry

The invention relates to a matrix dispersion solid phase extraction method for detection of plasticizer in animal and vegetable oil samples. The method comprises the following steps: (1) packing an extraction glass centrifuge tube: weighing 0.1-5g of solid phase extraction filler in a glass centrifuge tube with a stopper to obtain an extraction glass centrifuge tube; (2) weighing, dissolving and extracting: weighing 0.1-5g of an animal or vegetable oil sample, dissolving with 1-10ml acetonitrile saturated n-hexane, extracting with 1-10ml n-hexane saturated acetonitrile twice, centrifuging, combining acetonitrile layers as to-be-purified liquid; and (3) purifying: transferring the to-be-purified liquid into the extraction glass centrifuge tube, sufficiently shaking, centrifuging at a rotation speed of 1,000-10,000 r / min, collecting supernatant, analyzing with GC-MS (gas chromatography-mass spectrometry), establishing a standard curve with a standard sample, and carrying out quantitative and qualitative analysis. The method provided by the invention is especially suitable for rapid detection of phthalates in animal and vegetable oil samples.

Owner:TIANJIN CHUNFA BIO TECH GRP

Novel acrylic pressure-sensitive adhesive

ActiveCN108192019AWide range of bondingGood adhesionNon-macromolecular adhesive additivesAmide/imide polymer adhesivesFiberPolyester

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

Polyvinyl Chloride Resin Composition for Automotive Electric Wire, and Ultrathin-Wall Low-Voltage Electric Wire for Automobile

ActiveUS20150240104A1High hardnessPlastic/resin/waxes insulatorsInsulated cablesChemistryPlasticizer

Owner:YAZAKI CORP

Production method for preparing polyvinyl chloride fibers for hair by melting method

ActiveCN104611781ALow shrinkageSmall shrinkageWigsMonocomponent halogenated hydrocarbon artificial filamentPlasticizerBoiling point

Owner:邵阳美丽来发制品有限公司

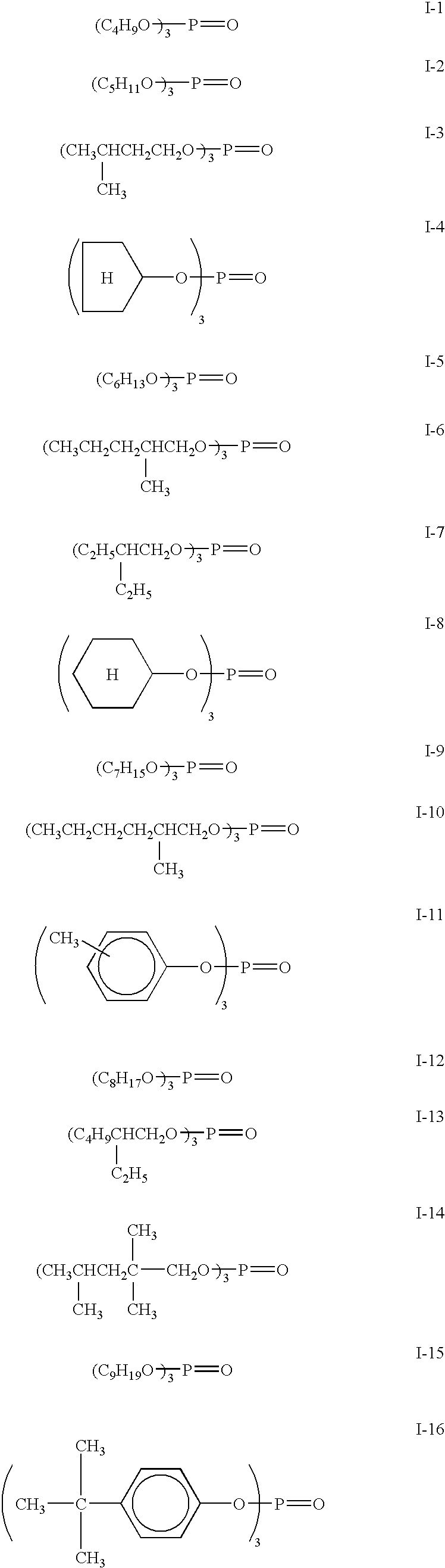

Ink composition

InactiveUS20060213391A1Shrinkage factorPromote wettingDuplicating/marking methodsInksPlasticizerPhosphate

Owner:FUJIFILM CORP +1

Aging-resistant polyvinyl chloride plastic

Owner:湖南凯誉电气科技有限公司

Method for preparing wear-resistant plastic particles by using waste polystyrene

InactiveCN110760138AImprove wear resistanceSolve the defect of poor wear resistanceCyclohexanoneSilicic acid

The invention discloses a method for preparing wear-resistant plastic particles by using waste polystyrene. The method specifically includes the following steps that (1) the waste polystyrene and liquid paraffin are put into a reactor for heat treatment under the nitrogen environment, then cobalt powder is added for natural cooling, and pretreated polystyrene is obtained; (2) tetraethyl orthosilicate is added into a chitosan solution, hydrochloric acid is added and then placed in a water bath, glutaraldehyde is added, and chitosan / silica particles are obtained by reaction; (3) the pretreated polystyrene is added into cyclohexanone after being cut into granules and dried, and polyvinyl pyrrolidone is added, stirred and dissolved, and then dried particles are added to obtain a coating solution; and (4) after the coating solution is treated, a film is scraped on a substrate, removed after phase transfer, and melted and extruded with a plasticizer and a lubricant through a twin-screw extruder. According to the method, by increasing the bond strength between the polystyrene and silicon dioxide, significant improvement of the wear resistance of the polystyrene is realized, and the methodis suitable for large-scale and industrial production.

Owner:ANHUI GUANHONG PLASTIC IND

Polyvinyl alcohol water-based architectural paint

Owner:苏州市超邦涂料有限公司

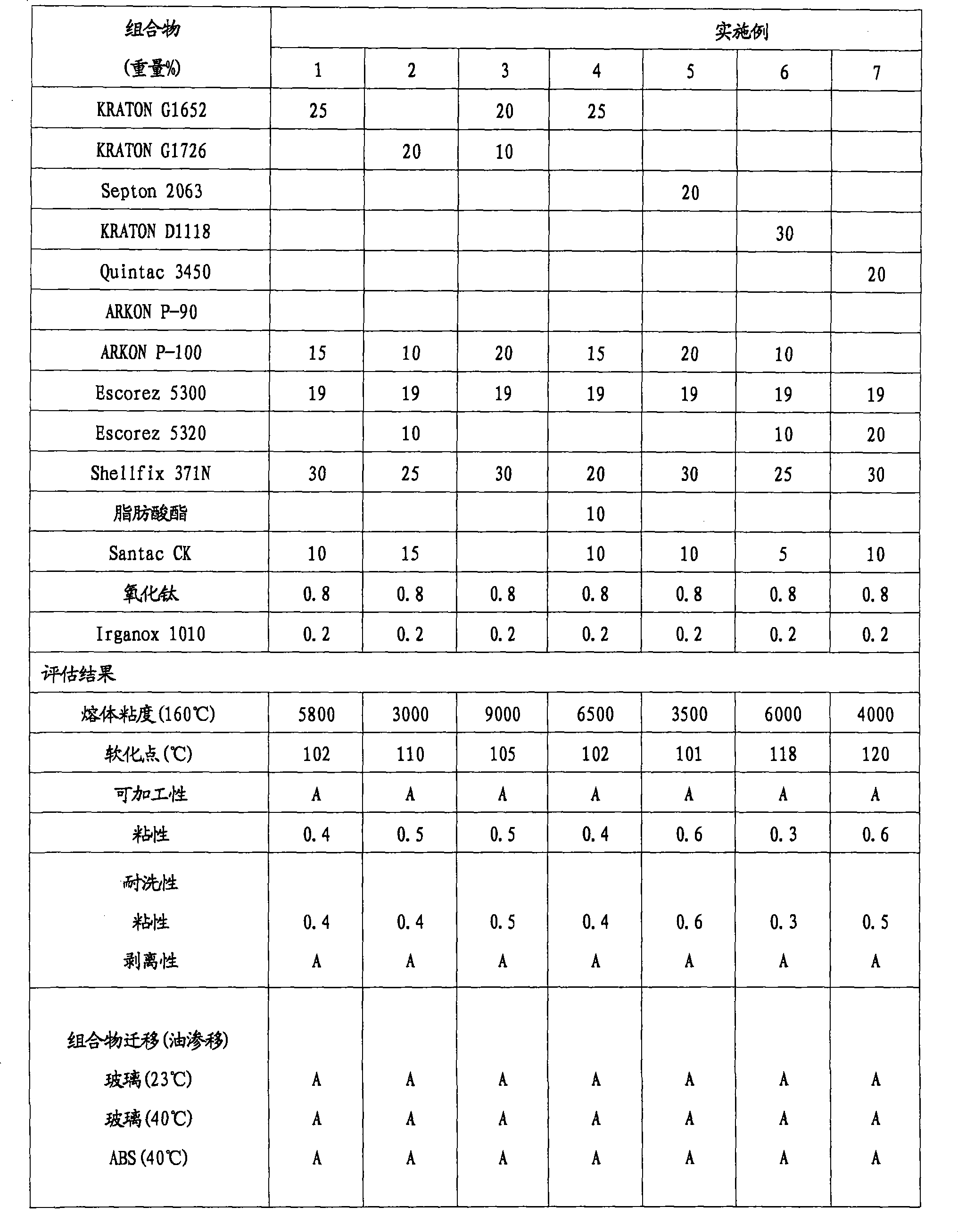

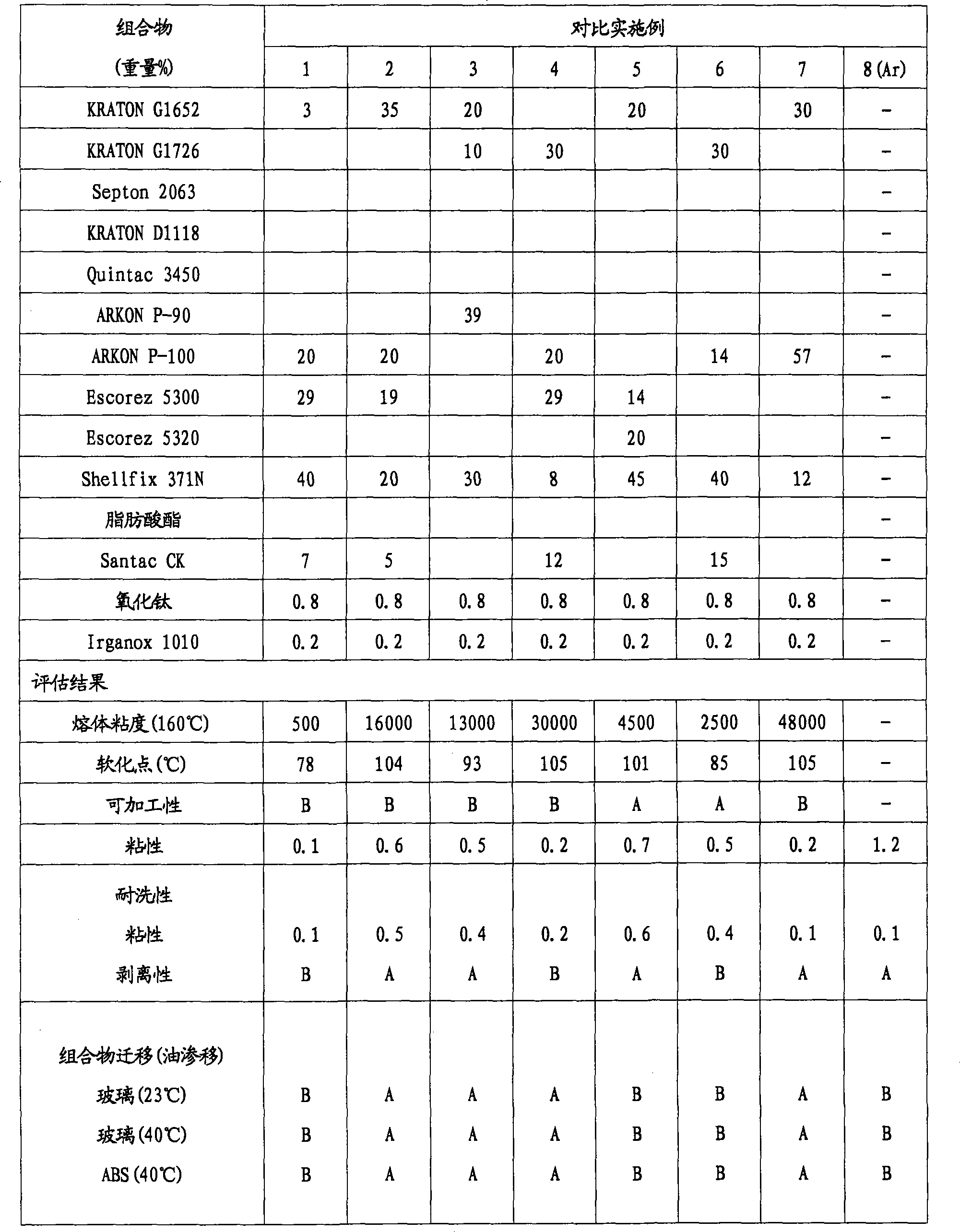

Hot melt composition for toilet seat sheet and toilet seat sheet

InactiveCN101381588AReduce manufacturing costIncrease productionBathroom coversAdhesivesPolyolefinEngineering

Owner:NISSHIN CHEM IND CO LTD

Mouth care membrane and preparation method thereof

InactiveCN109432067AExpand the scope of actionEasy to cleanDigestive systemInorganic non-active ingredientsAdditive ingredientFiller Excipient

The invention discloses a mouth care membrane and a preparation method thereof and belongs to the technical field of mouth care. The mouth care membrane is prepared from the following ingredients in parts by weight: 16 to 24 parts of medical activator, 40 to 50 parts of a film forming material, 8 to 10 parts of grinding particles, 6 to 8 parts of carbon dioxide, 10 to 20 parts of a filling agent and 3 to 5 parts of a plasticizer, wherein the medical activator is chosen from an antibacterial agent, a disinfectant, a tooth brightening agent, vitamin medicine and breath refreshing medicine. The preparation method comprises the steps: preparing the film forming material, the plasticizer, a part of medical activator and a part of filling agent into two pieces of membrane materials; then mixingthe grinding particles, the residual medical activator and the residual filling agent under the high-pressure carbon dioxide environment to be stirred and preparing nursing powder after cooling and depressurizing; finally, putting the nursing powder between the two pieces of membrane materials and preparing the mouth care membrane after film pressing. The mouth care membrane disclosed by the invention has a better nursing effect; a provided film pressing device is convenient to regulate and suitable for volume production.

Owner:杜娟

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap